Patents

Literature

190results about How to "Affect the treatment effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Full-natural extruded coprinus slices and production method thereof

The invention relates to full-natural extruded coprinus slices and a production method thereof, belonging to the technical field of agricultural product deep processing. The production method comprises the following the steps that: after slicing and color protection processing, coprinus is put in an air dry oven until the water content of the corpinus is 65-70% of the water content of fresh unopened coprinus; and coprinus slices are placed in a vacuum microwave drying machine to be processed for 3-4min, and then, are returned to be at one air pressure. In the invention, by adopting ozonated water color protection, vacuum microwave drying extrusion, and other technical research and application, during the production process, no any additive is added, processed extruded coprinus slices have beautiful appearances and crisp taste, and are less in nutrition loss, the quality of the product is good, and the full-natural extruded coprinus slices have a wide market development prospect. According to the invention, the defects of fry extrusion and differential pressure extrusion are overcome, and the quick, low-temperature and non-fried extrusion processing of the coprinus slices are realized.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

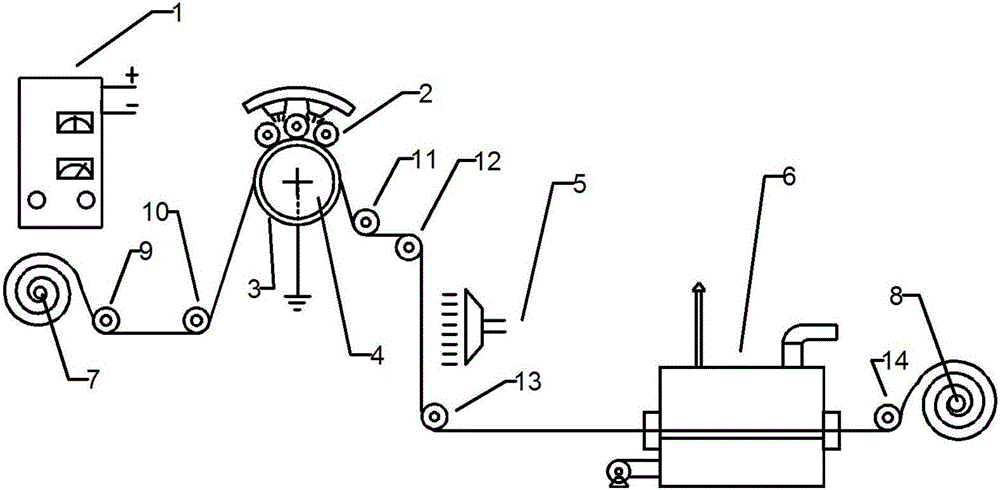

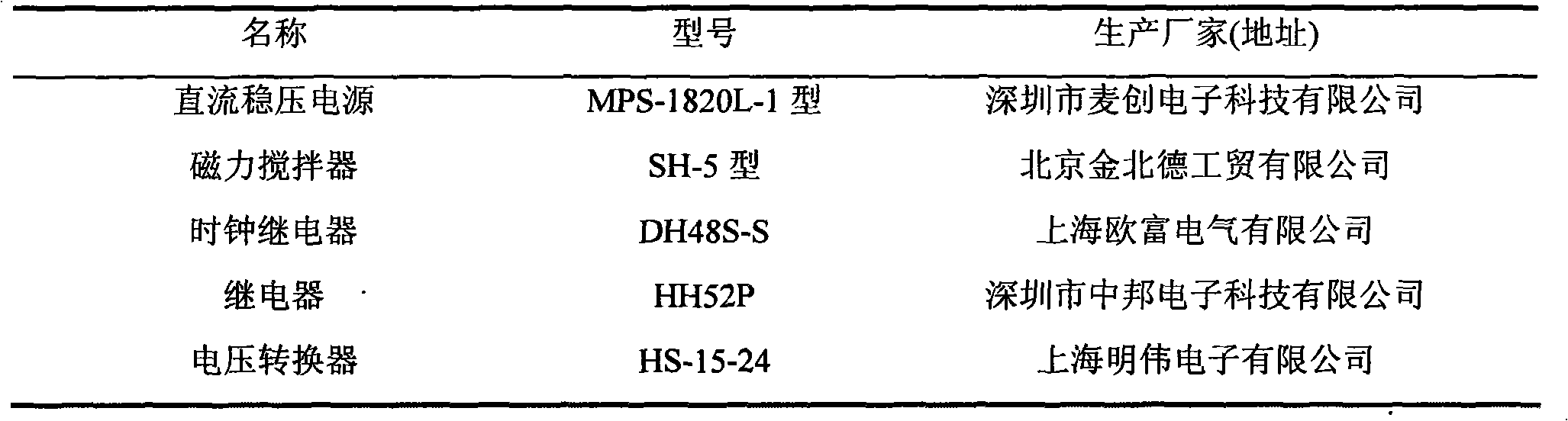

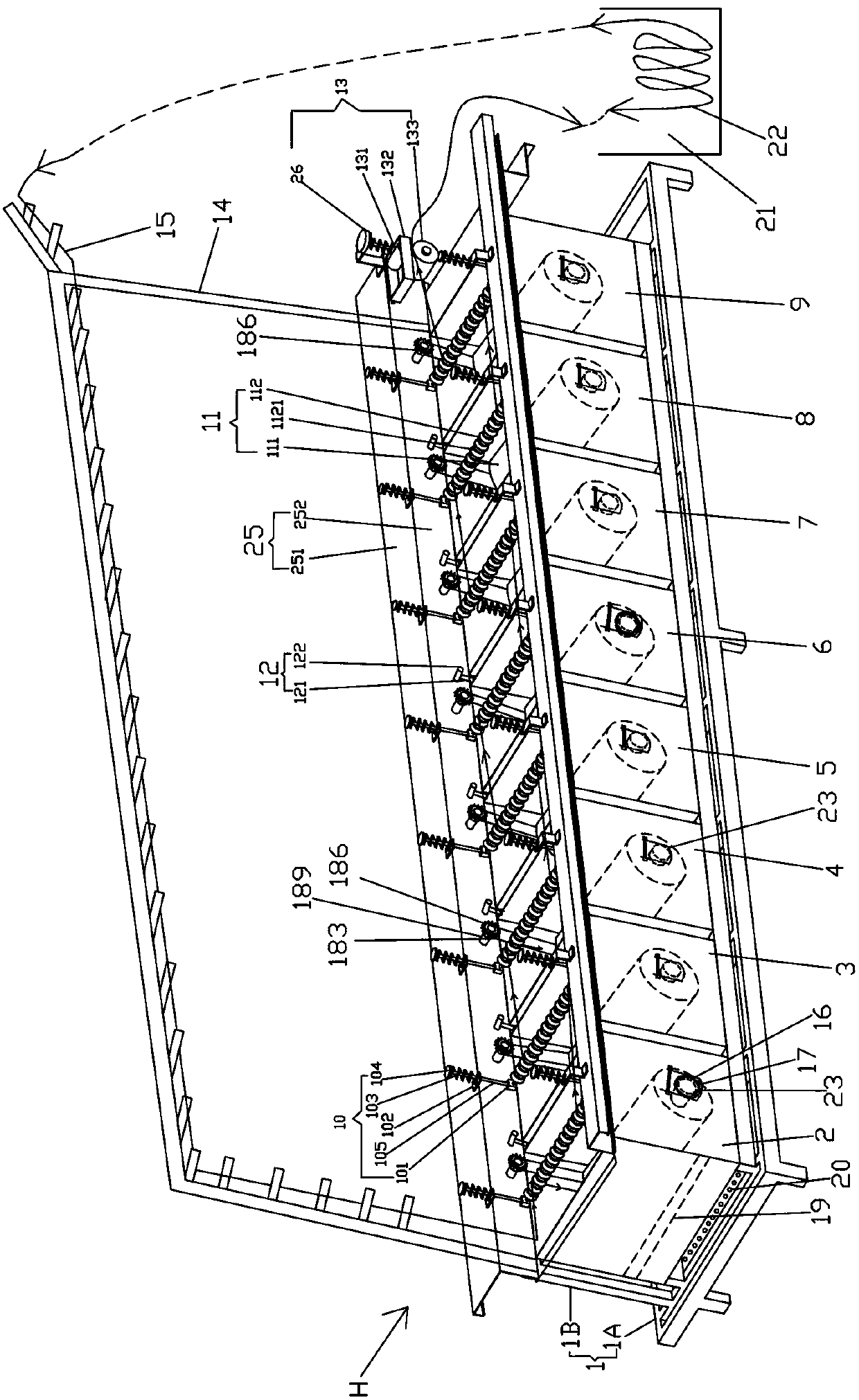

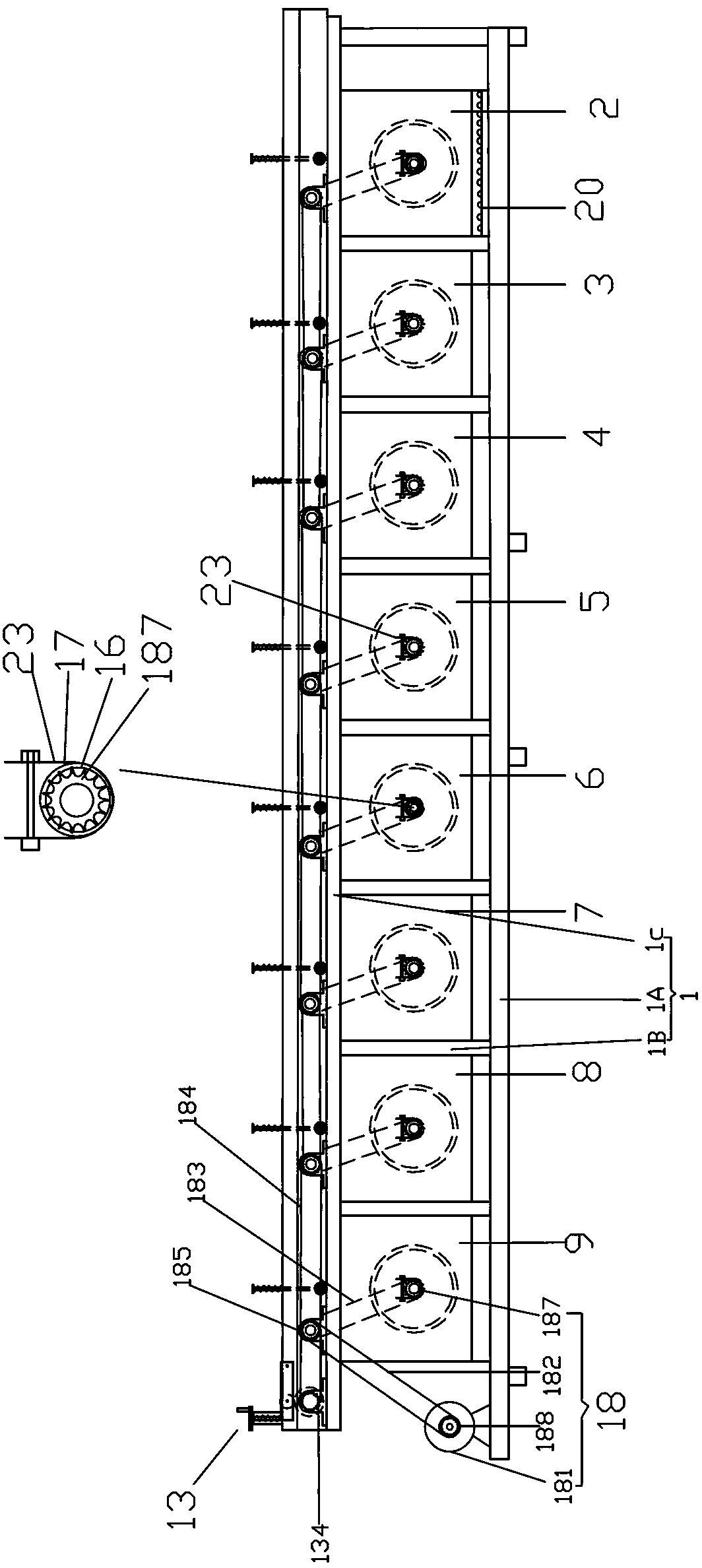

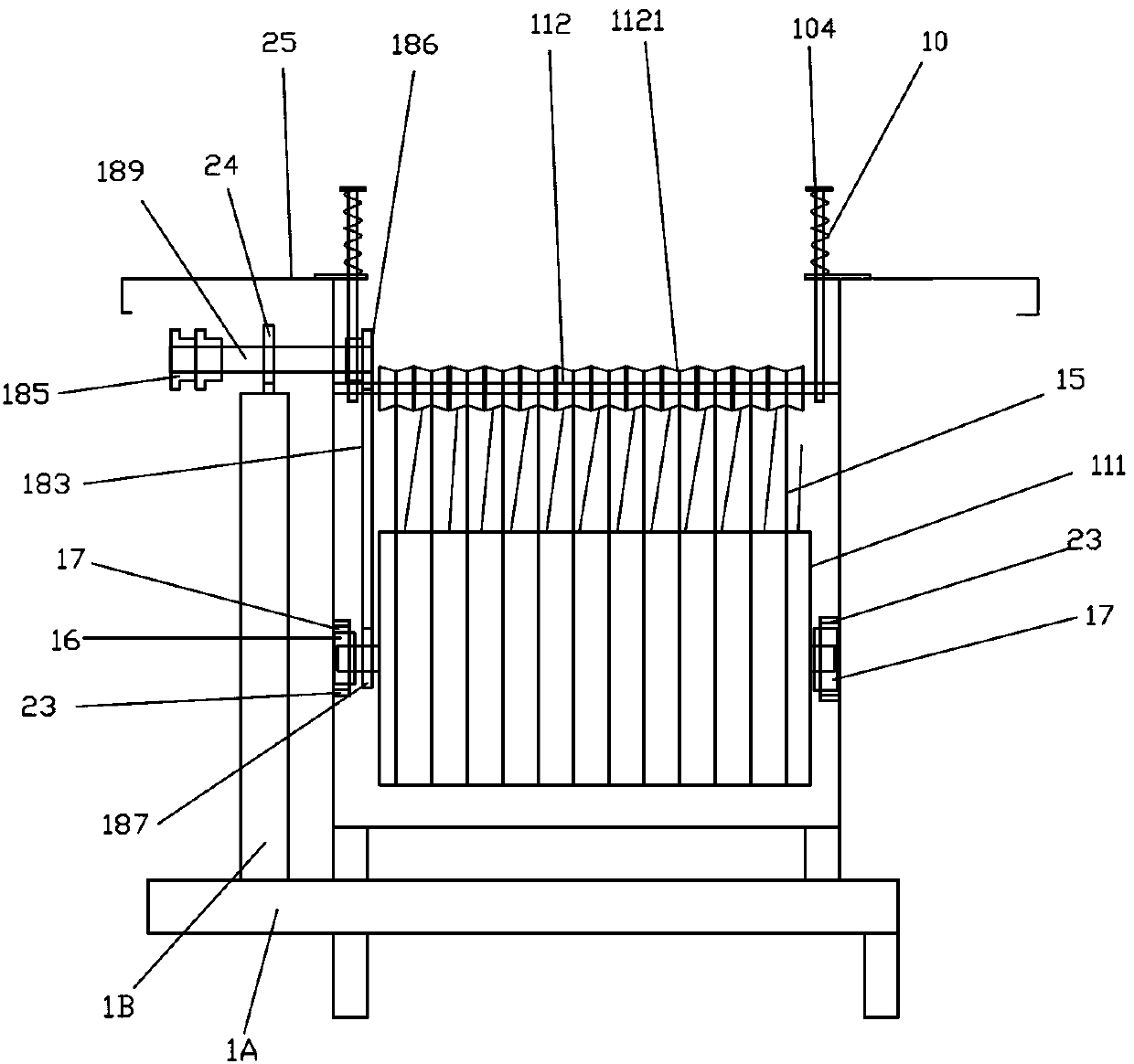

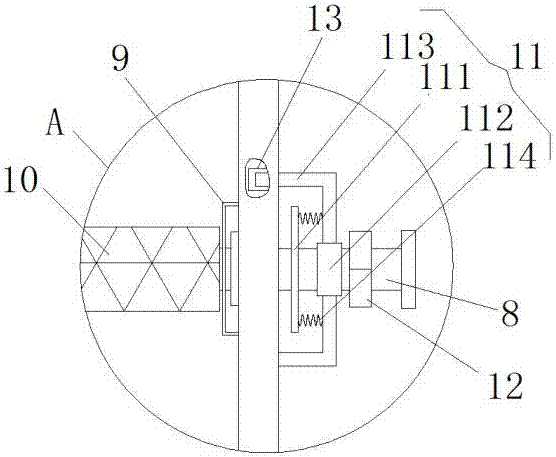

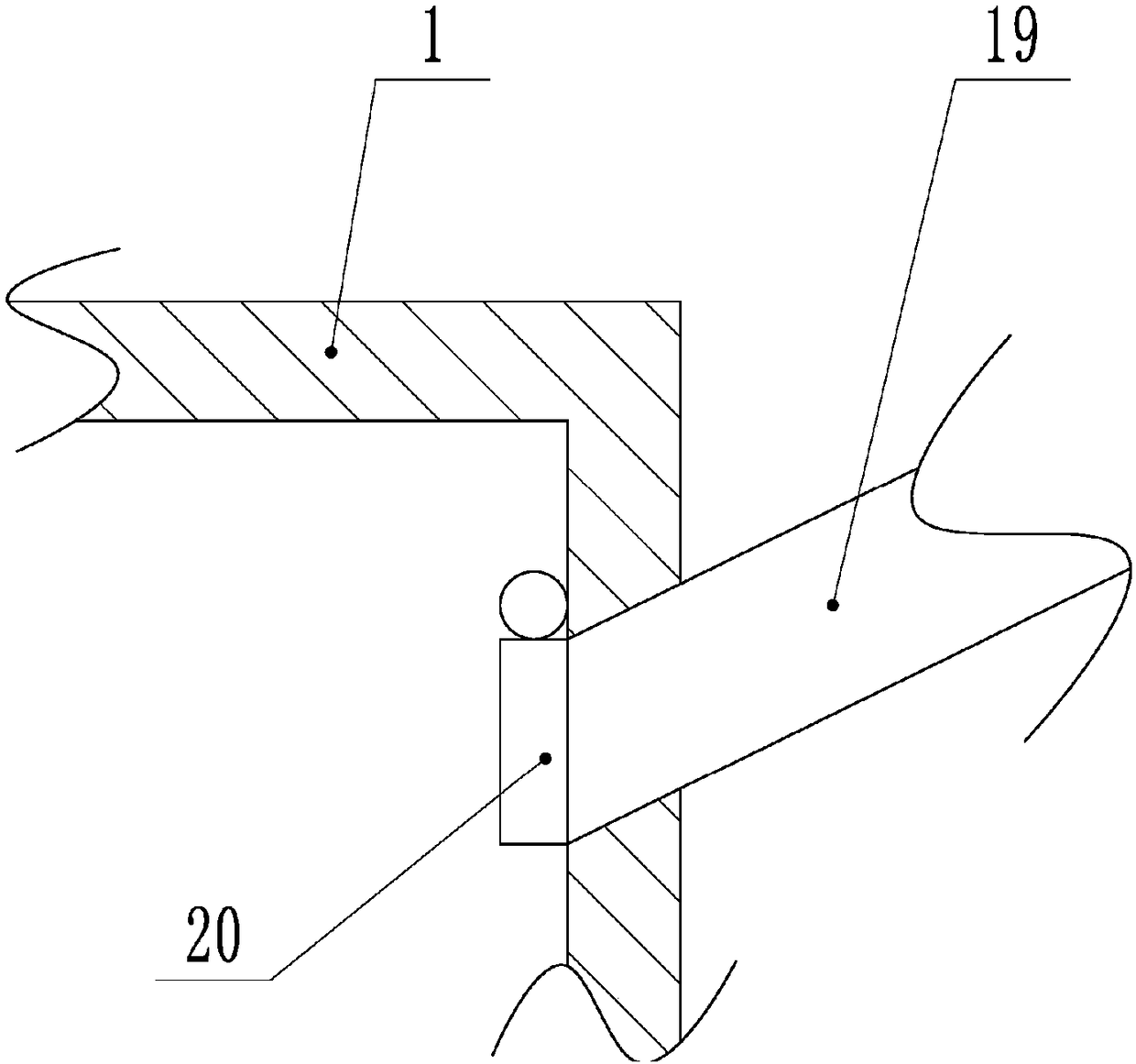

Skin-affinity and anti-static finishing device for single-side wool fabric and finishing method

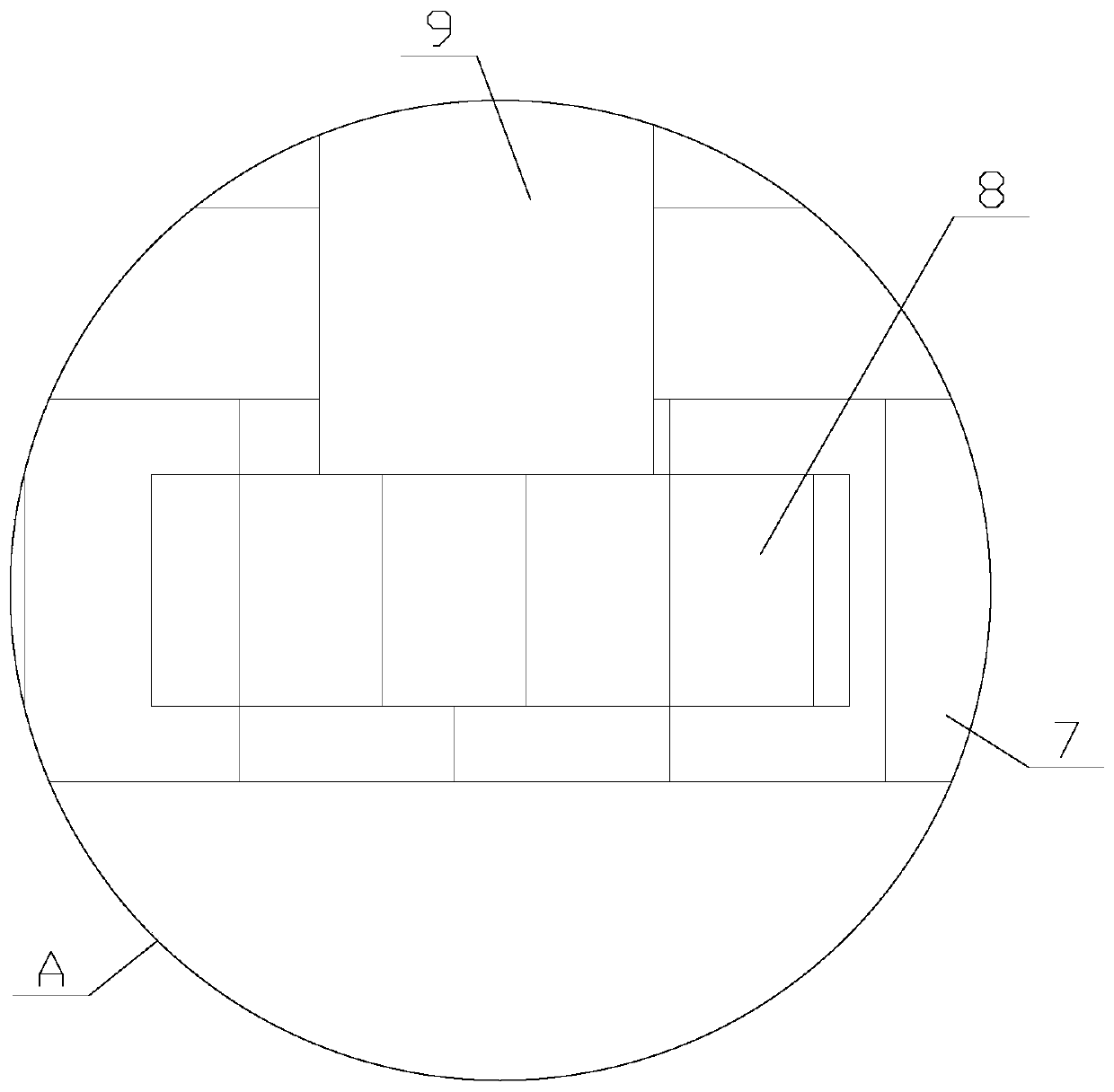

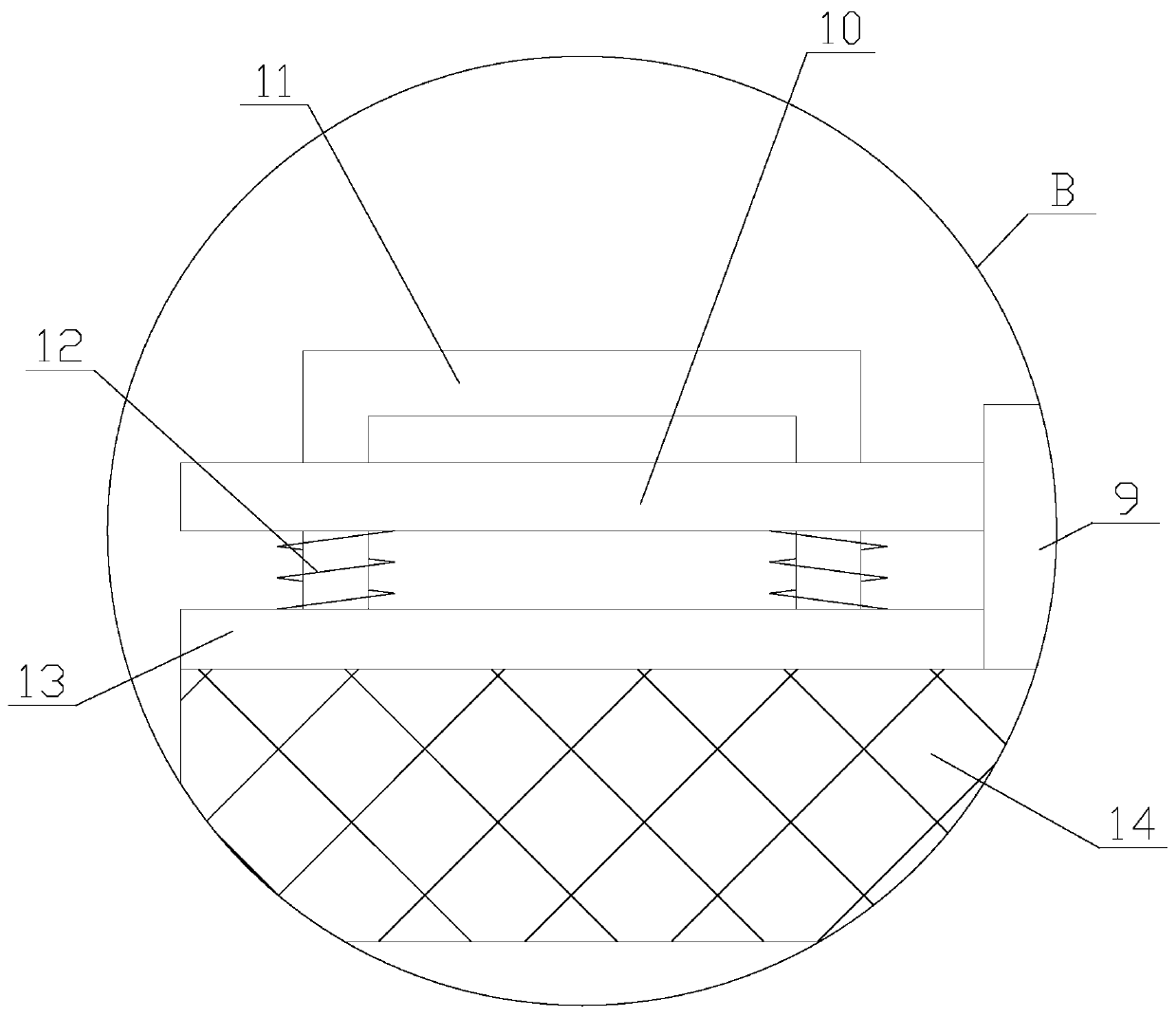

ActiveCN106120200AAffect the treatment effectIncreased durabilityLiquid/gas/vapor removalUltrasonic/sonic fibre treatmentWoolEngineering

The invention relates to a skin-affinity and anti-static finishing device for single-side wool fabric and a finishing method, pertaining to the textile technical field. The finishing device is composed of a high-voltage generator, an electrode group, a processing roll, a skin-affinity finishing agent sprayer, a drying device, a cloth-conveying roll and a cloth-receiving roll. The device utilizes the principle of glow-like discharge under barometric pressure and adopts a glow-like discharge region under barometric pressure and combine with the skin-affinity finishing agent sprayer and a drying structure to be used for skin-affinity modification of the single-side wool fabric so that mist discharge can be uniformly generated. Therefore, the signal surface of the wool fabric is uniformly processed by voltage. The fabric is not penetrated by voltage and the back side of a processing surface is not affected. At the same time, the skin-affinity finishing agent sprayer is vertical to the cloth surface of the wool fabric for signal-surface spraying treatment. The modified wool fabric is one with skin-affinity and anti-static functions. The invention discloses the skin-affinity and anti-static finishing device and method at low cost and high efficiency and with lasting performance.

Owner:安徽迪惠新材料科技有限公司

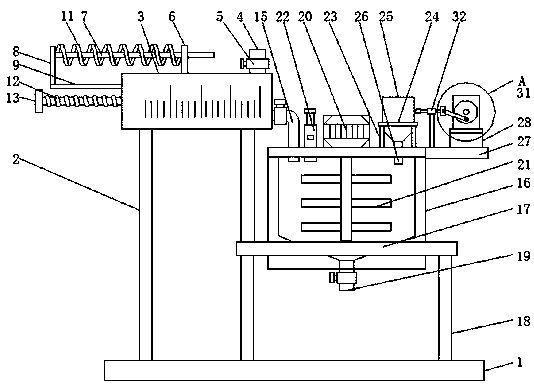

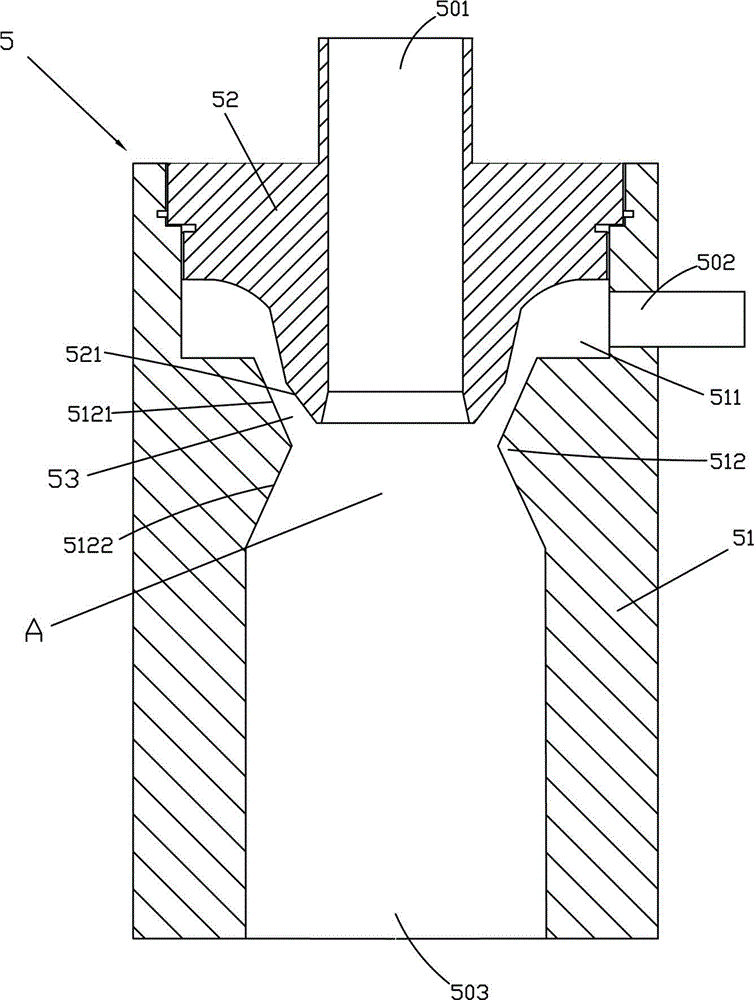

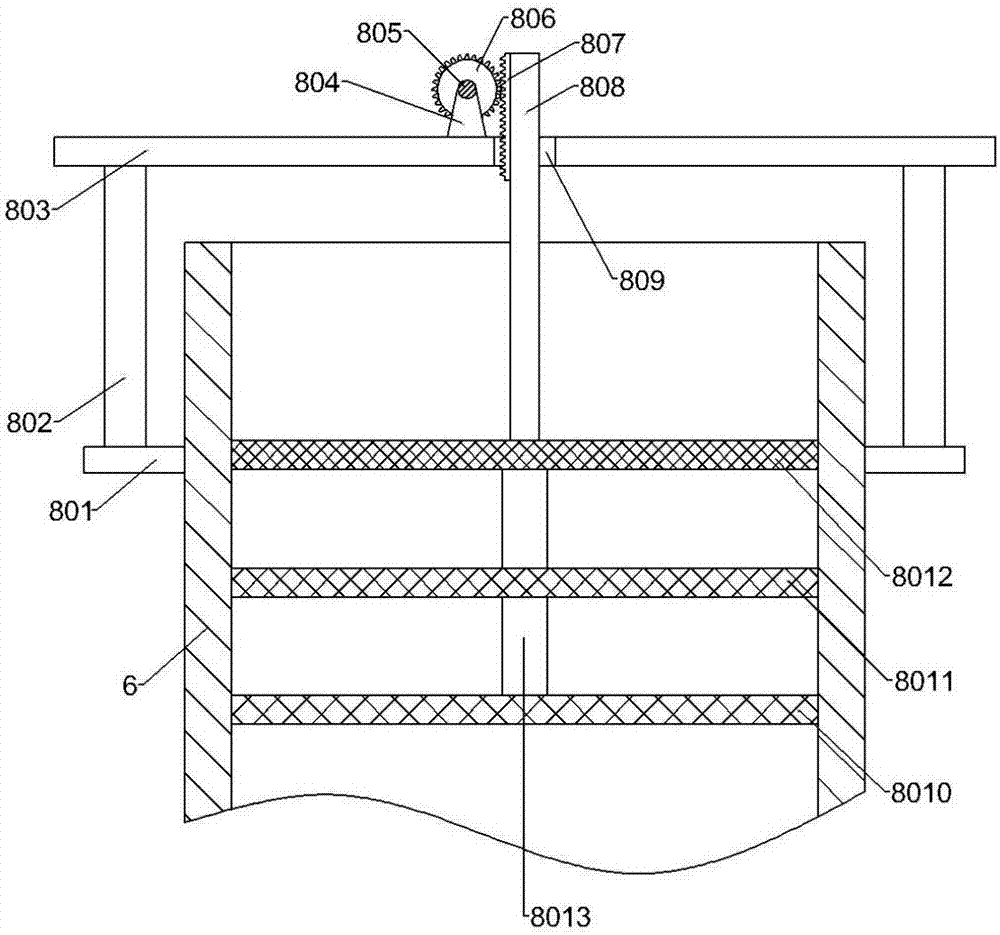

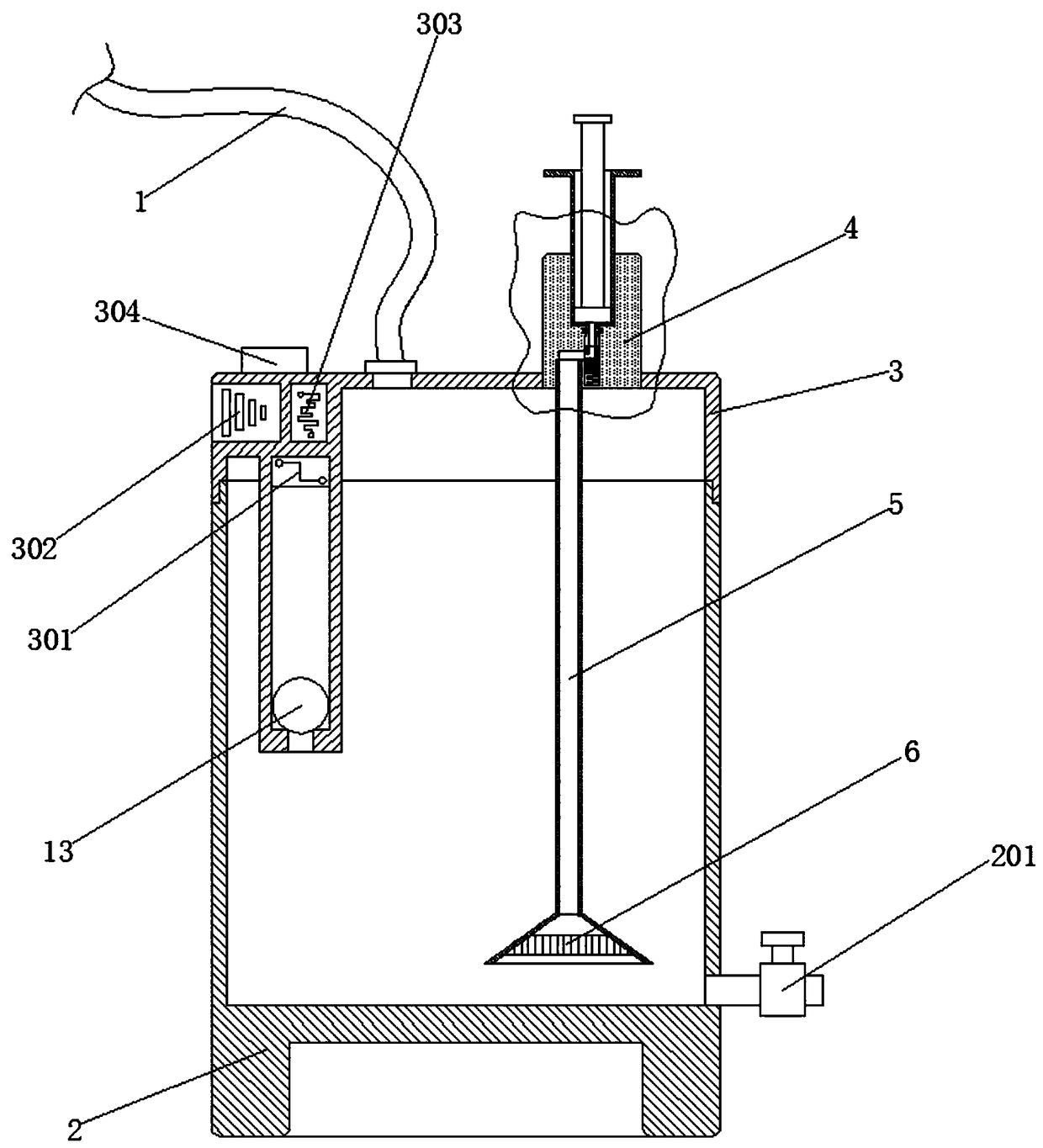

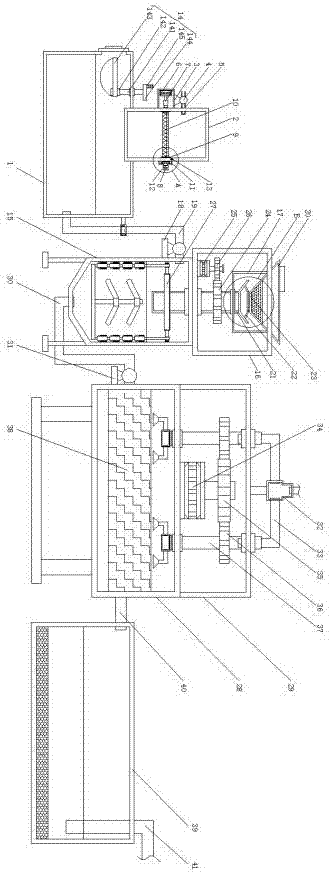

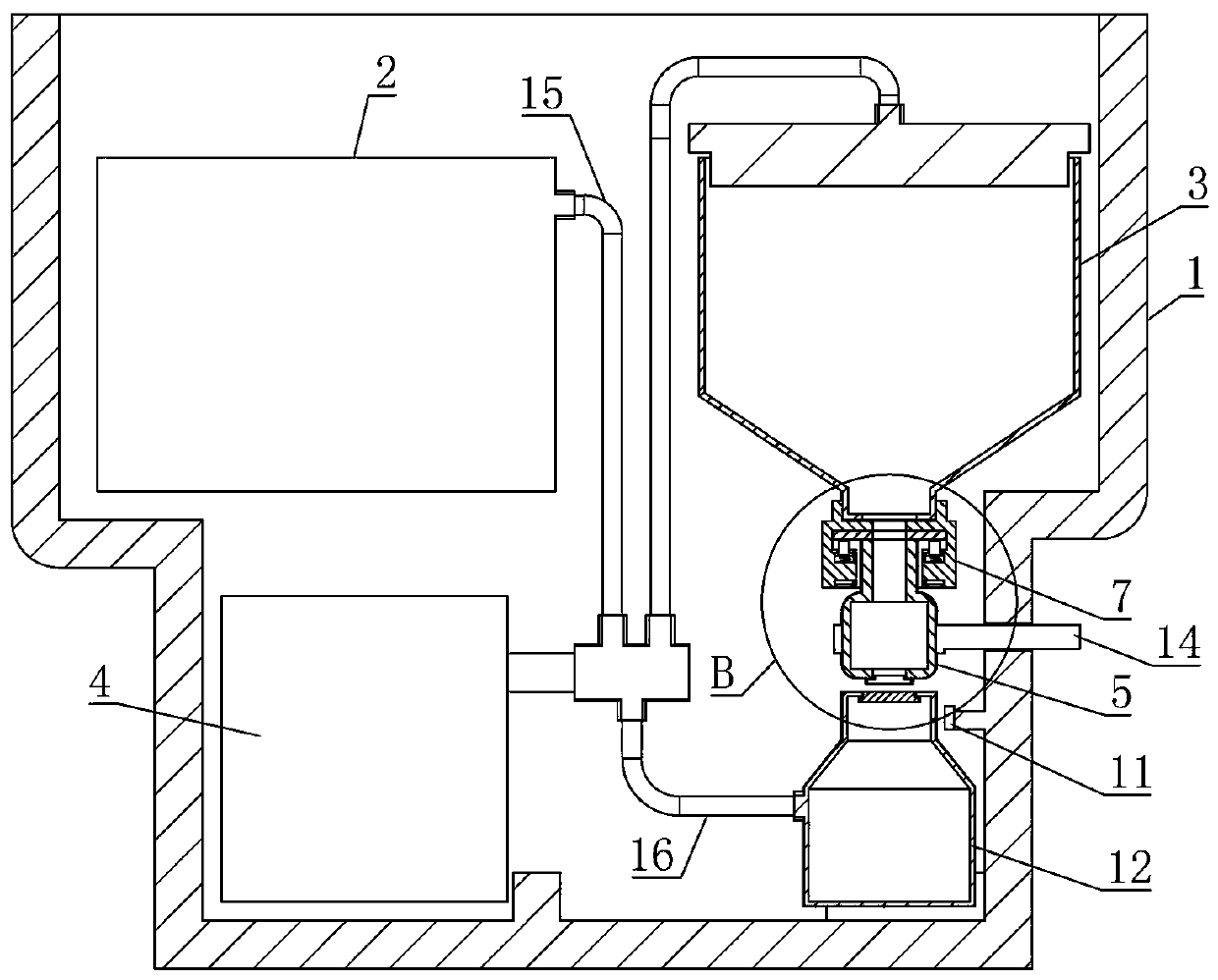

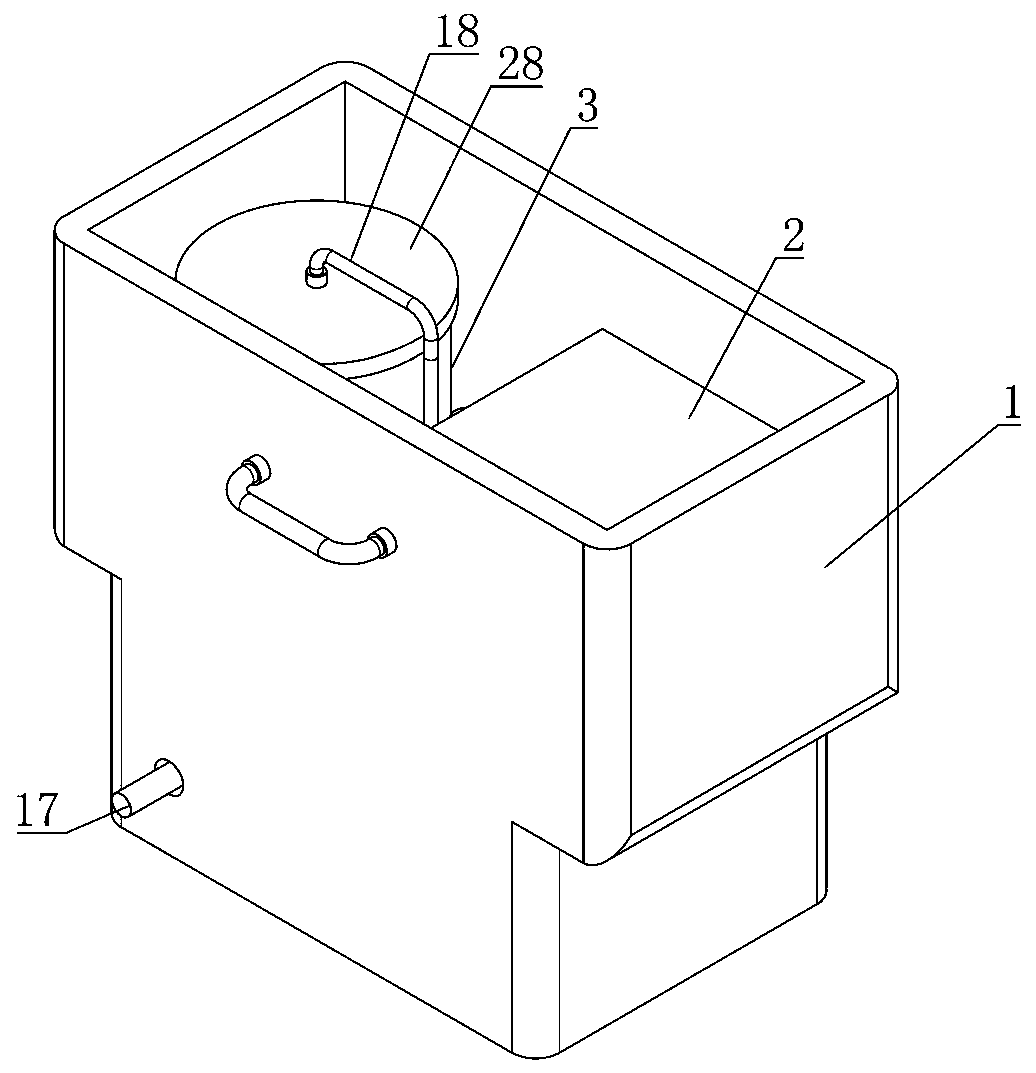

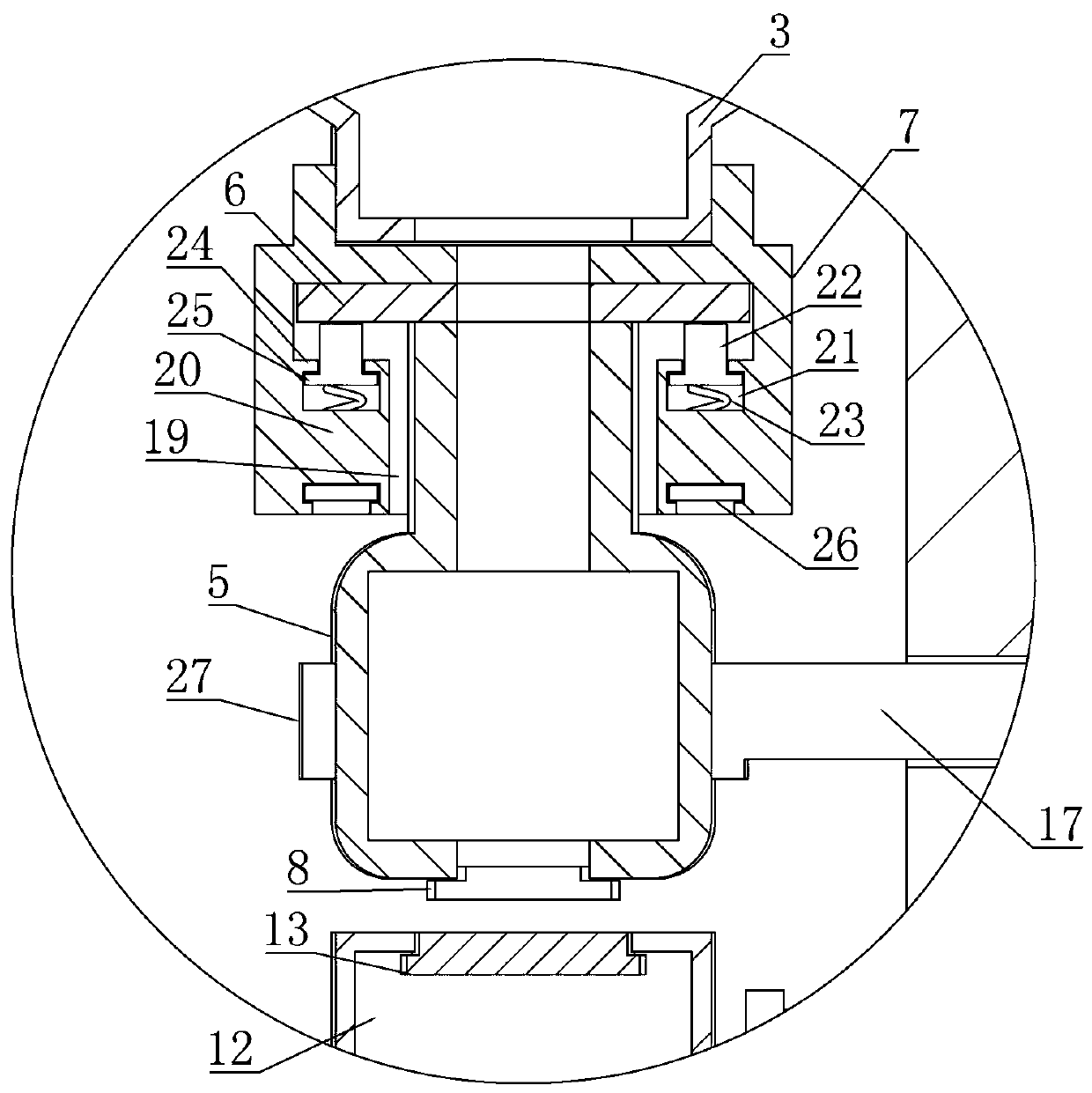

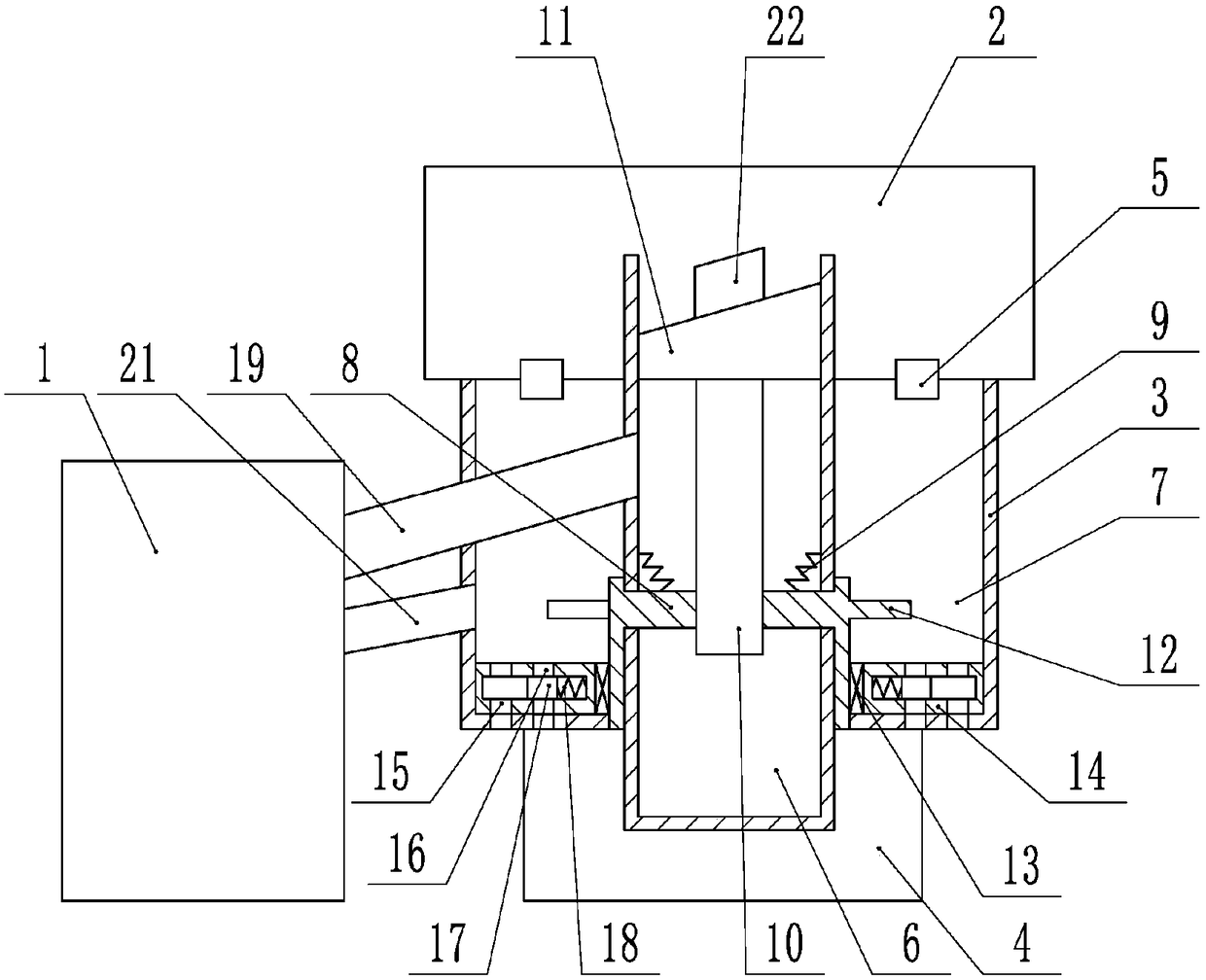

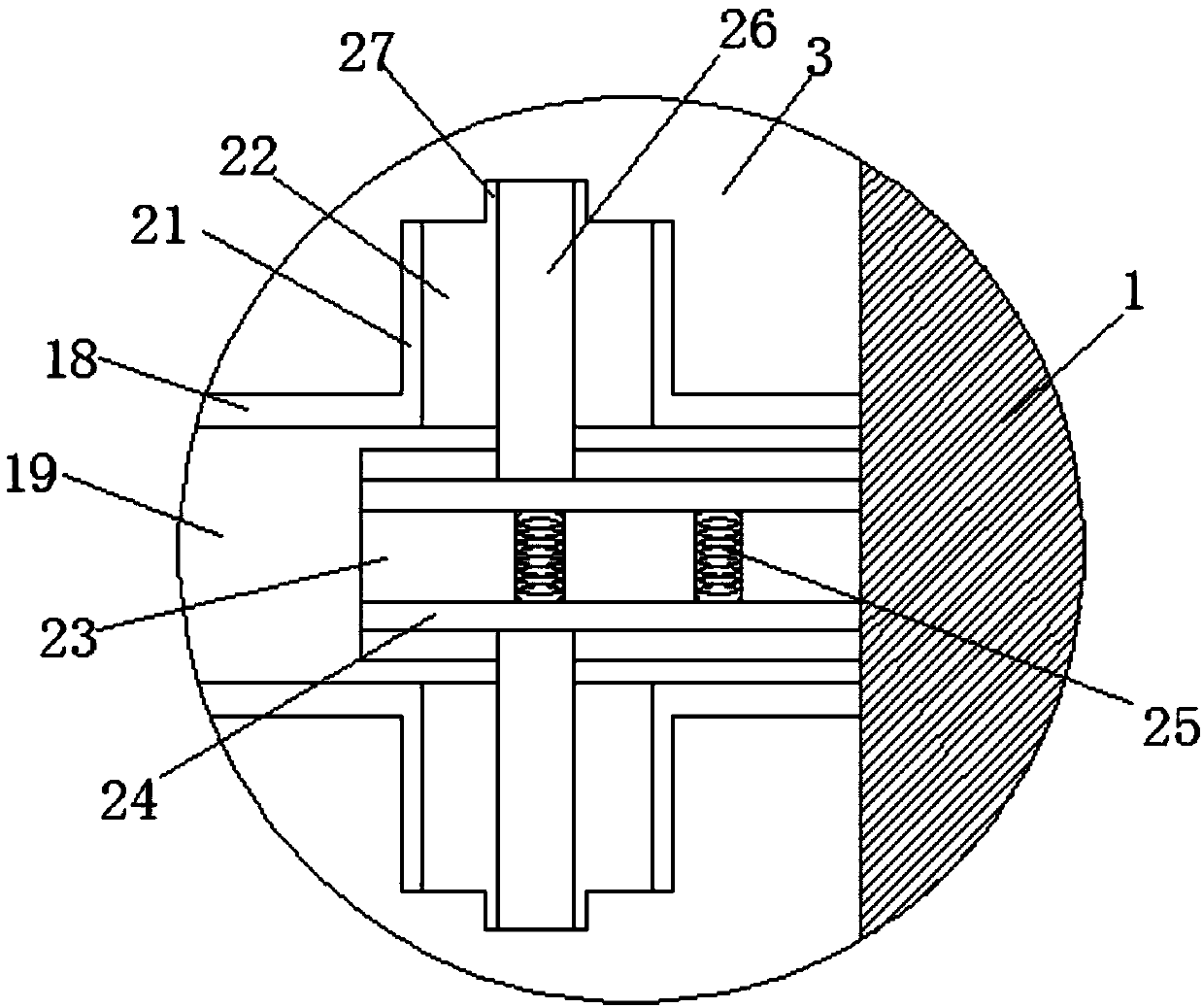

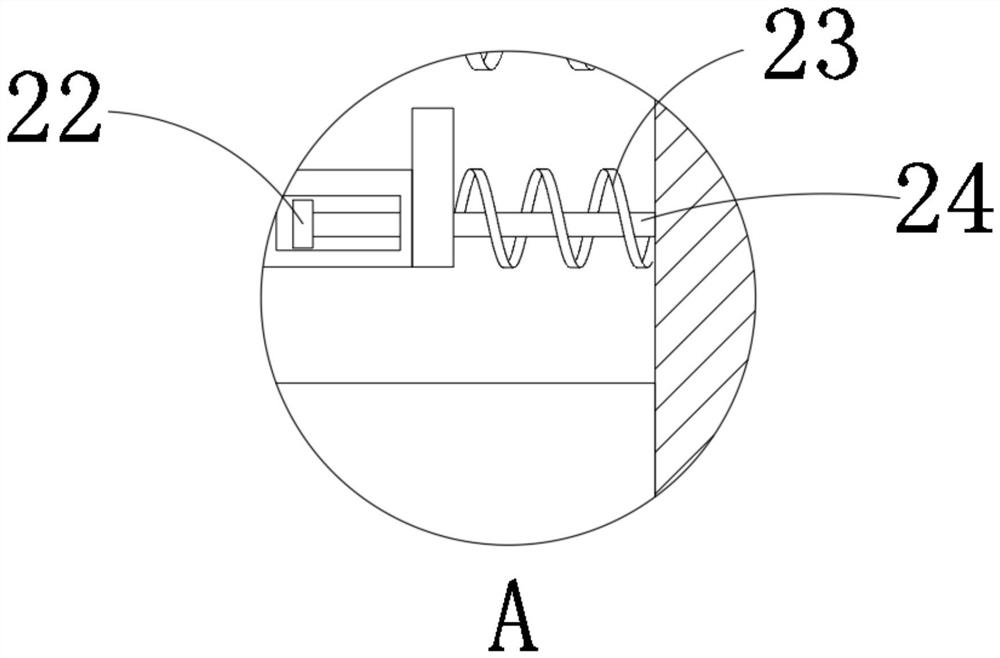

Dialysate preparing device for nephrology department

InactiveCN108283737AAffect the treatment effectPrecise proportionRotary stirring mixersTransportation and packagingEngineeringTherapeutic effect

The inventio relates to the field of medical devices, and discloses a dialysate preparing device for the nephrology department. The dialysate preparing device comprises a base, wherein support rods are fixedly mounted on the side face of the top of the base, four support rods are available, for the four support rods, each two support rods form one group, the support rods are symmetrically distributed on the base, the top ends of the four support rods are fixedly connected with a liquid guide box, and a water inlet pipe fixedly sleeves one side of the top of the liquid guide box. For the dialysate preparing device for the nephrology department provided by the invention, dialysate preparing dry powder is added into a feeding box and enters a stirring box through a material guide pipe, a threaded rod drives a baffle to move, in match with scale lines on the liquid guide box, the water amount needing to be added is controlled, through extruding of a piston, water enters the stirring box tobe mixed with the dry powder, thus the ratio of water to the dry powder is accurate, so that the problem that during artificial preparation, the water adding amount has errors, consequently, the concentration of the dialysate is not accurate, and the treatment effect of the dialysate is influenced, is solved.

Owner:鄢海军

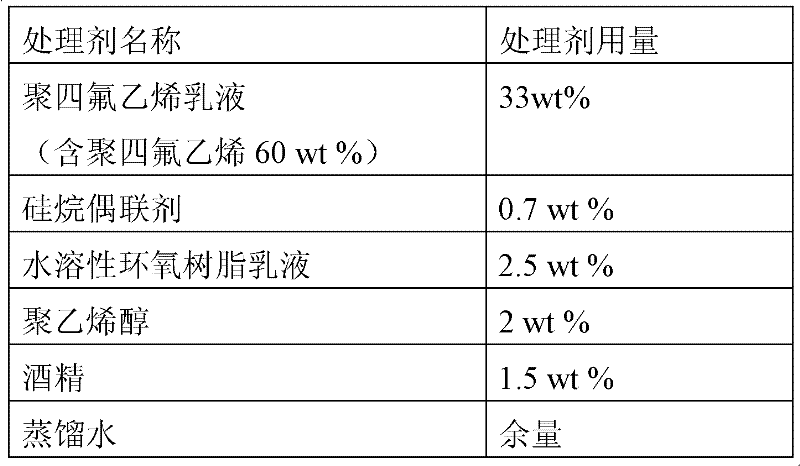

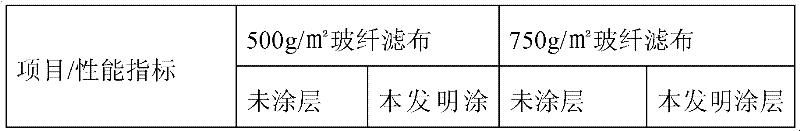

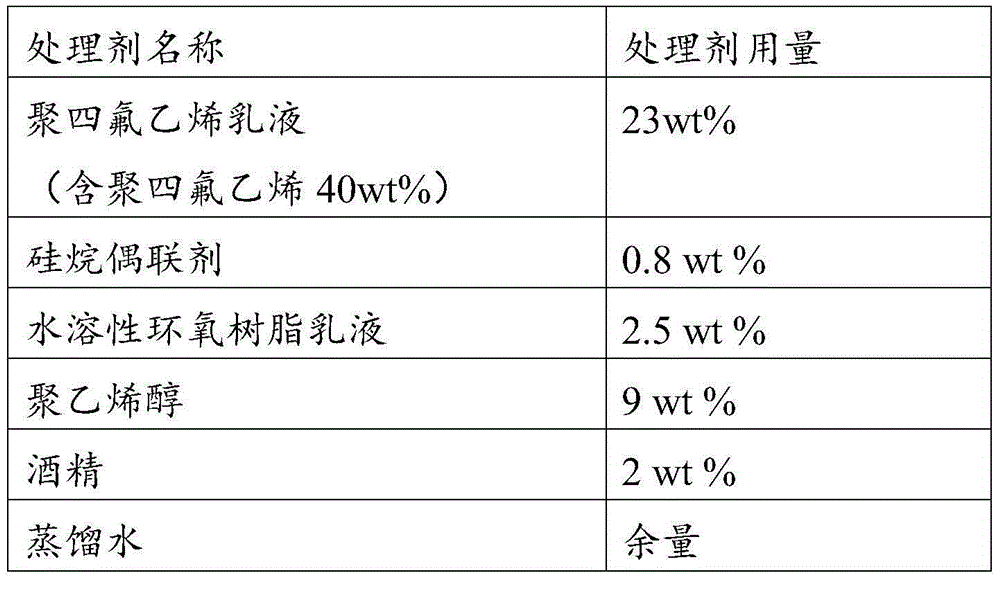

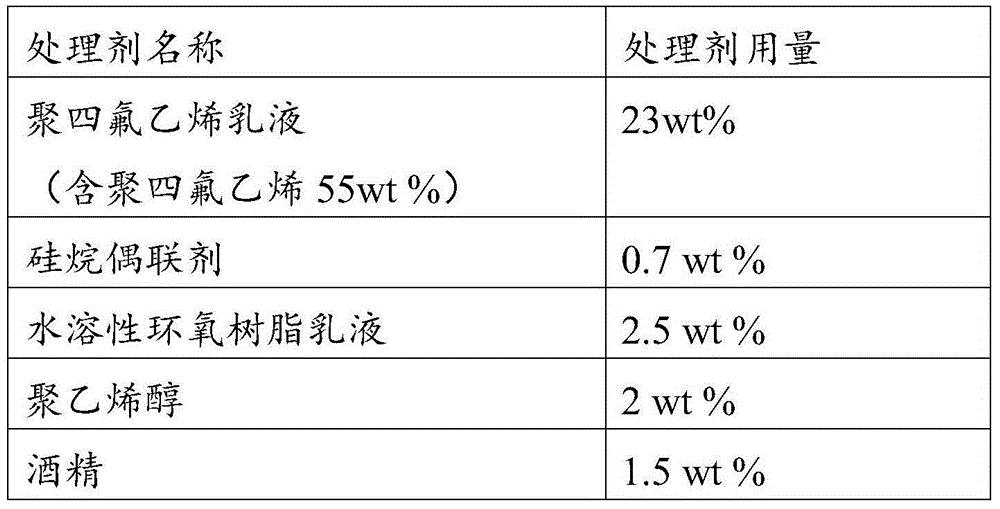

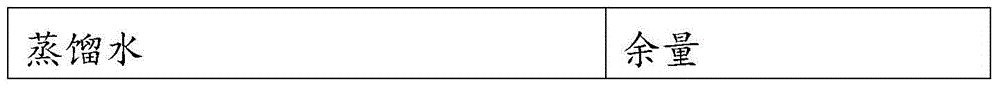

Manufacturing method for high-accuracy coating filter material

InactiveCN102512877AGood acid and alkali resistanceImprove water resistanceSynthetic resin layered productsGlass/slag layered productsFiberLoss strength

The invention provides a manufacturing method for a high-accuracy coating filter material, which has the advantages of good binding effect between the filter material and PTFE (Polytetrafluoroethylene) and capability of improving the performance of the filter material. The method comprises the following steps of: (1) thermal cleaning treatment, performing the thermal cleaning treatment on the filter material and removing various auxiliary agents on the surface of the filter material through high temperature; (2) dipping treatment, performing PTFE dipping treatment on the filter material which is subjected to the thermal cleaning treatment; (3) sequentially performing baking, drying and thermal forming treatment on the filter material which is subjected to the dipping treatment; (4) performing coating treatment on the filter material which is subjected to thermal forming; and (5) sequentially performing volatile treatment, baking treatment, sintering treatment and thermal forming treatment on the filter material which is subjected to the coating treatment. In the manufacturing method for the high-accuracy coating filter material, the thermal cleaning treatment is performed before the filter material is subjected to the dipping treatment, so that a wire drawing impregnating agent remained on the surfaces of fibers can be effectively removed, meanwhile, no loss strength of a textile is guaranteed; and the acid and alkali resistance, water resistance, oxidation resistance, wear resistance and folding resistance of the filter material are effectively improved, and the service life of the filter material is prolonged.

Owner:辽宁鸿顺环保新材料有限公司

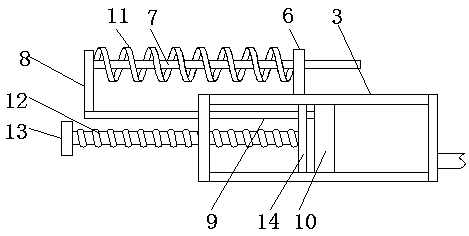

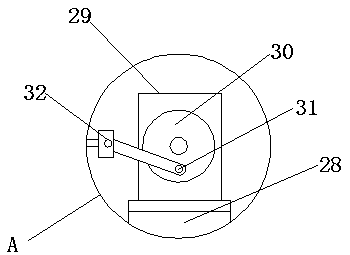

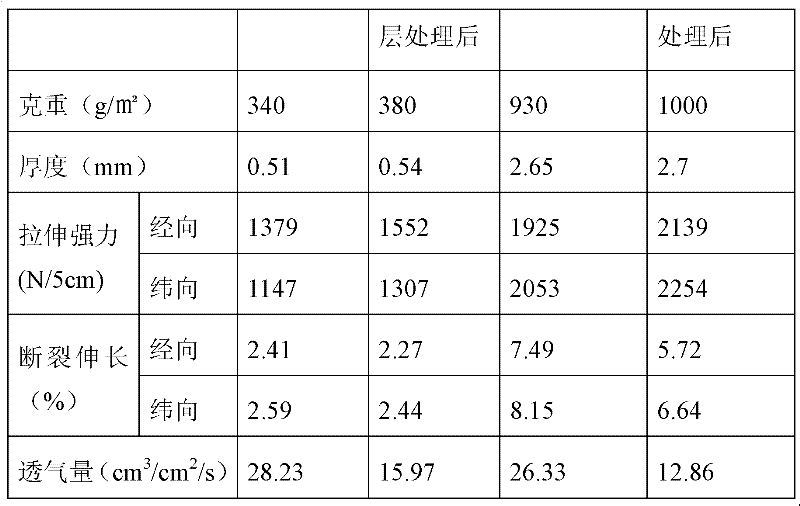

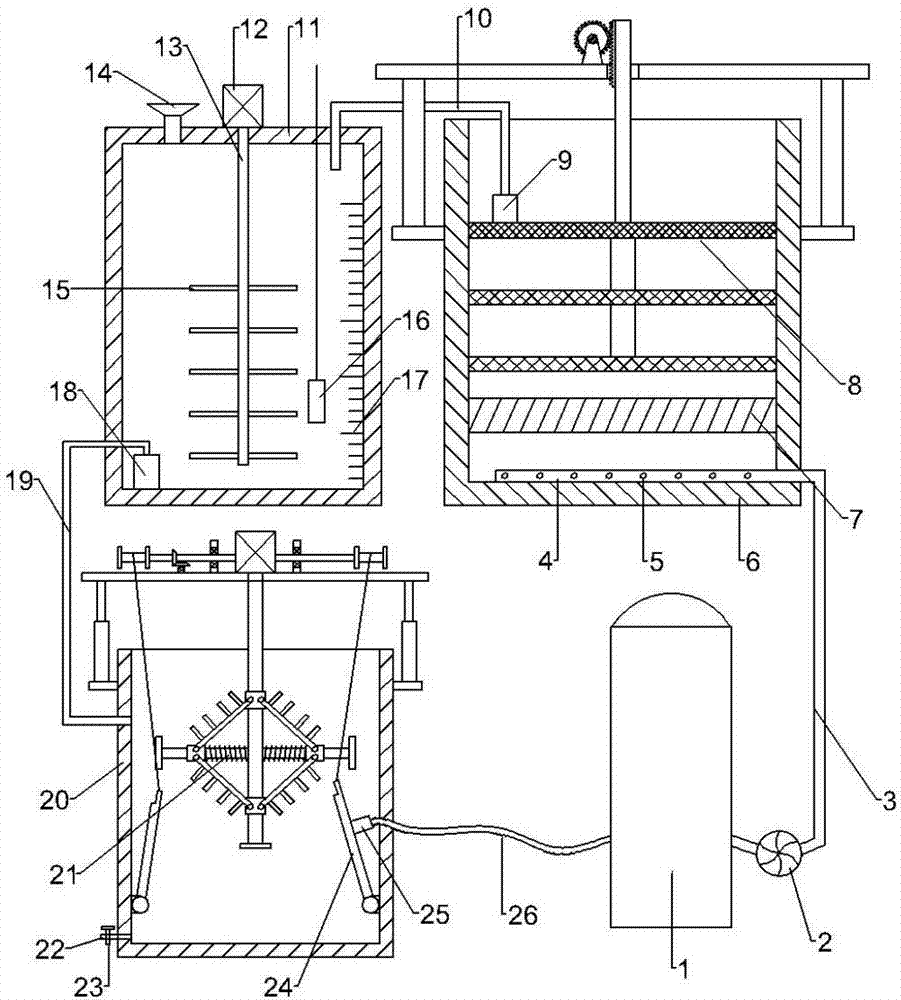

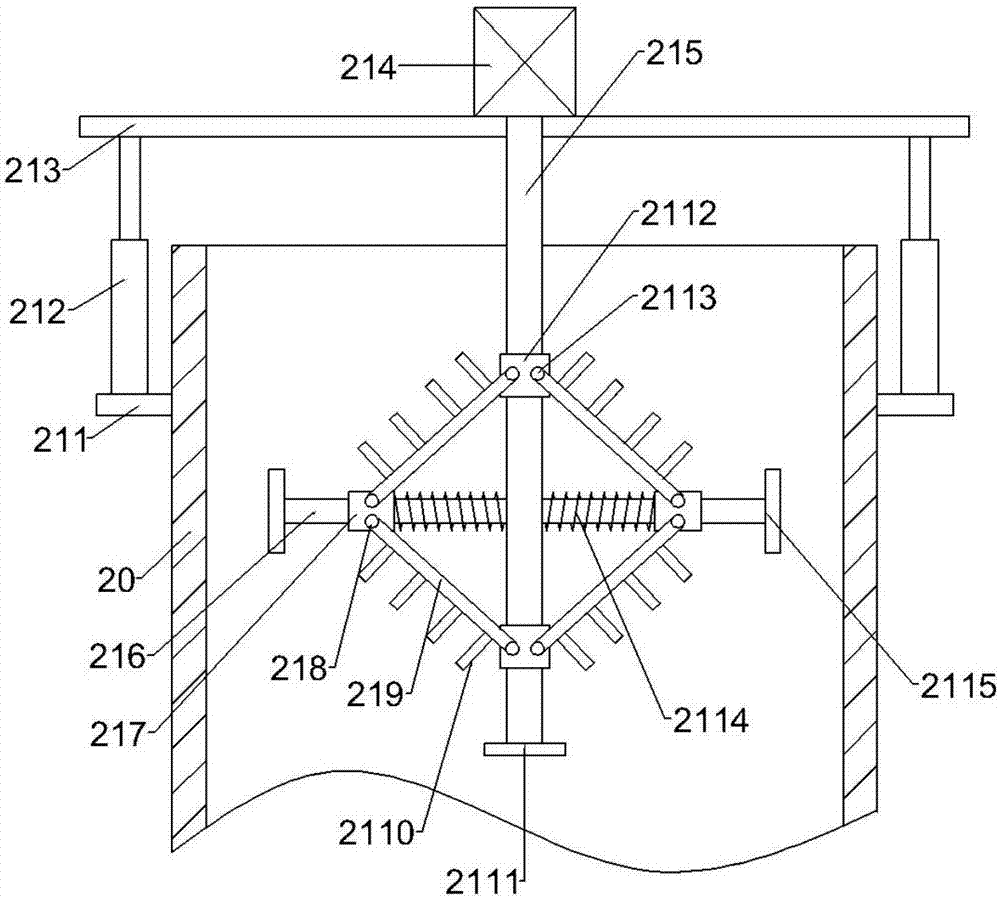

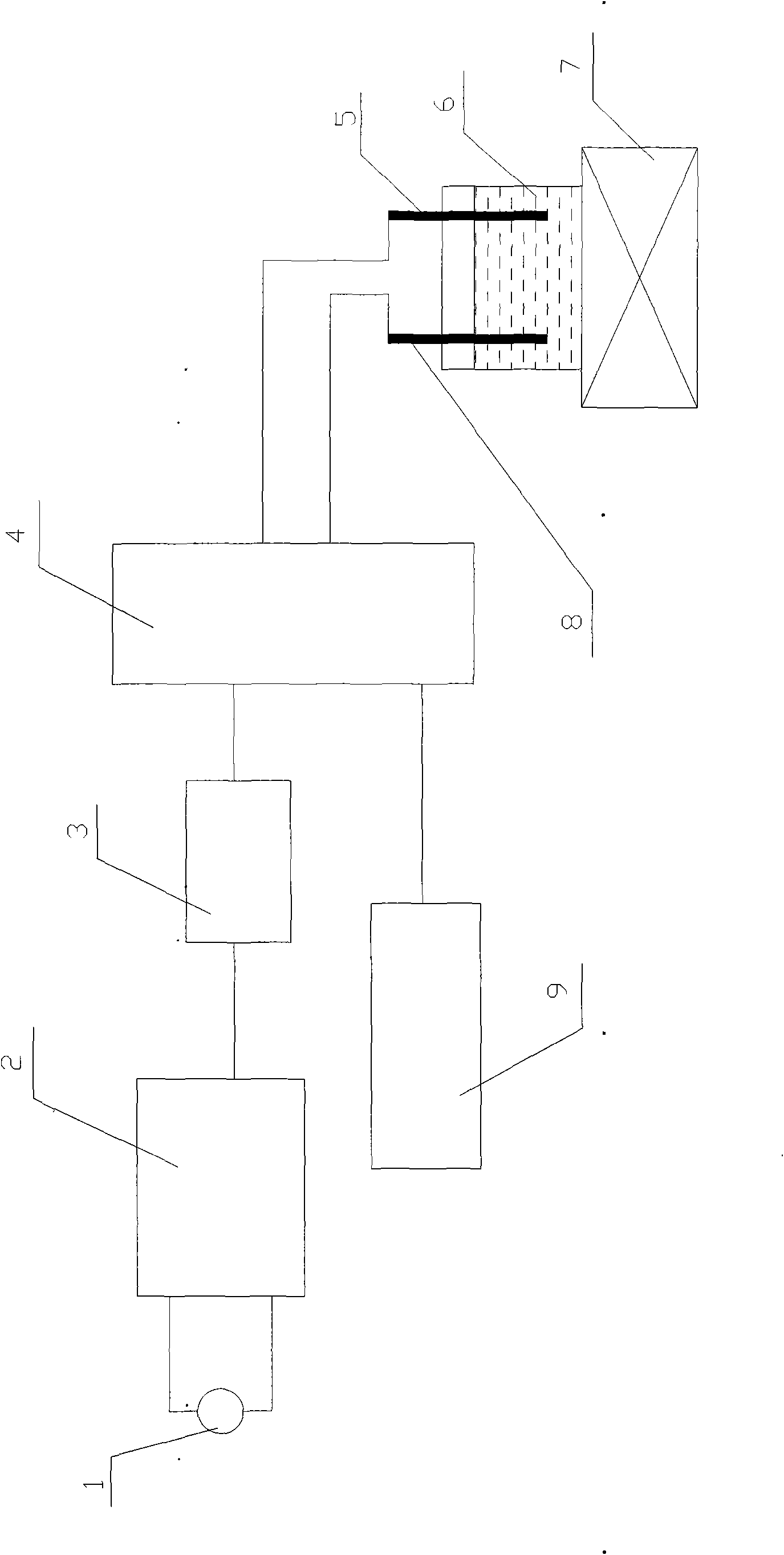

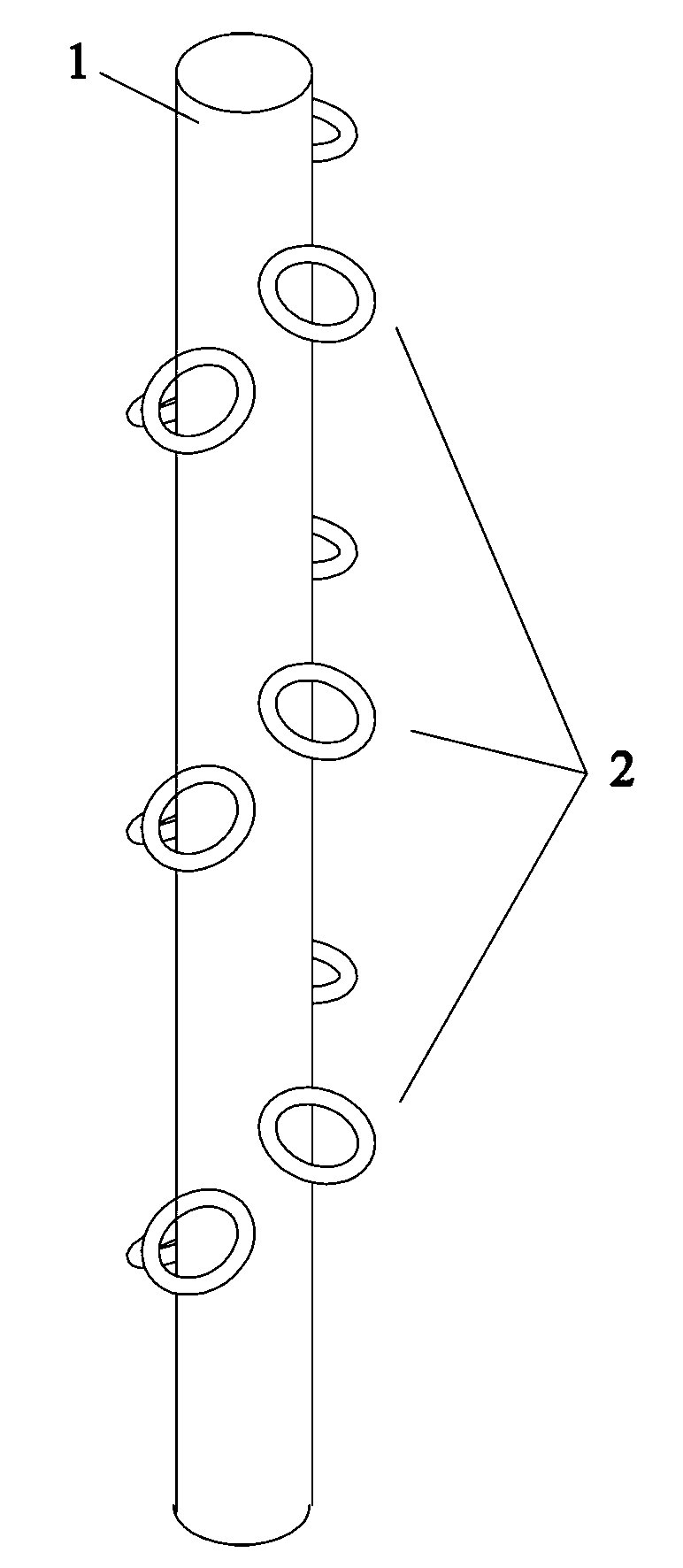

Automatic preparation device and method for flocculant solution

ActiveCN105152292AAvoid clumpingFully madeWater/sewage treatment by flocculation/precipitationAutomatic controlTreatment effect

The invention discloses an automatic preparation device and a method for flocculant solution. The automatic preparation device comprises a powder silo, a screw powder supply mechanism, a measuring pocket, a mixer, a first dissolving tank, a second dissolving tank and a controller in sequence. The preparation method includes: delivering flocculant powder stored in the powder silo to the measuring pocket through the screw powder supply mechanism, feeding the powder into the mixer under the action of compressed air to enable the powder to be uniformly mixed with water under the pressure of 0.12-0.2MPa, allowing obtained mixed materials to sequentially enter the first and second dissolving tanks, and stirring to obtain the flocculant solution with mass concentration being 3-5%o. The automatic preparation device and method for the flocculant solution have the advantages that automatic control can be realized, thorough mixing and dissolving of flocculant in water can be guaranteed, the prepared flocculant solution can be directly fed to each dosing point through dosing pumps to guarantee the flocculant solution against deterioration failure caused by long-term storage, and accordingly influences on wastewater treatment effects are avoided.

Owner:BAOSHAN IRON & STEEL CO LTD

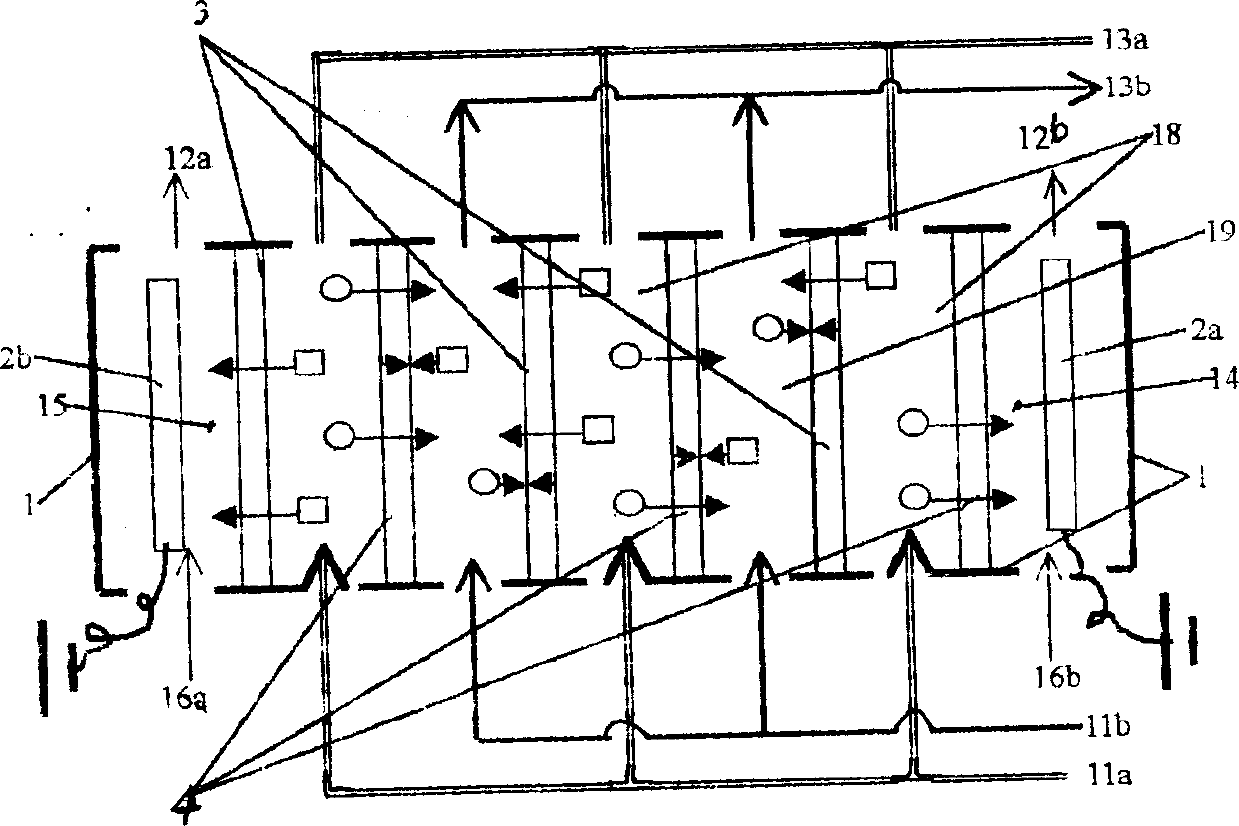

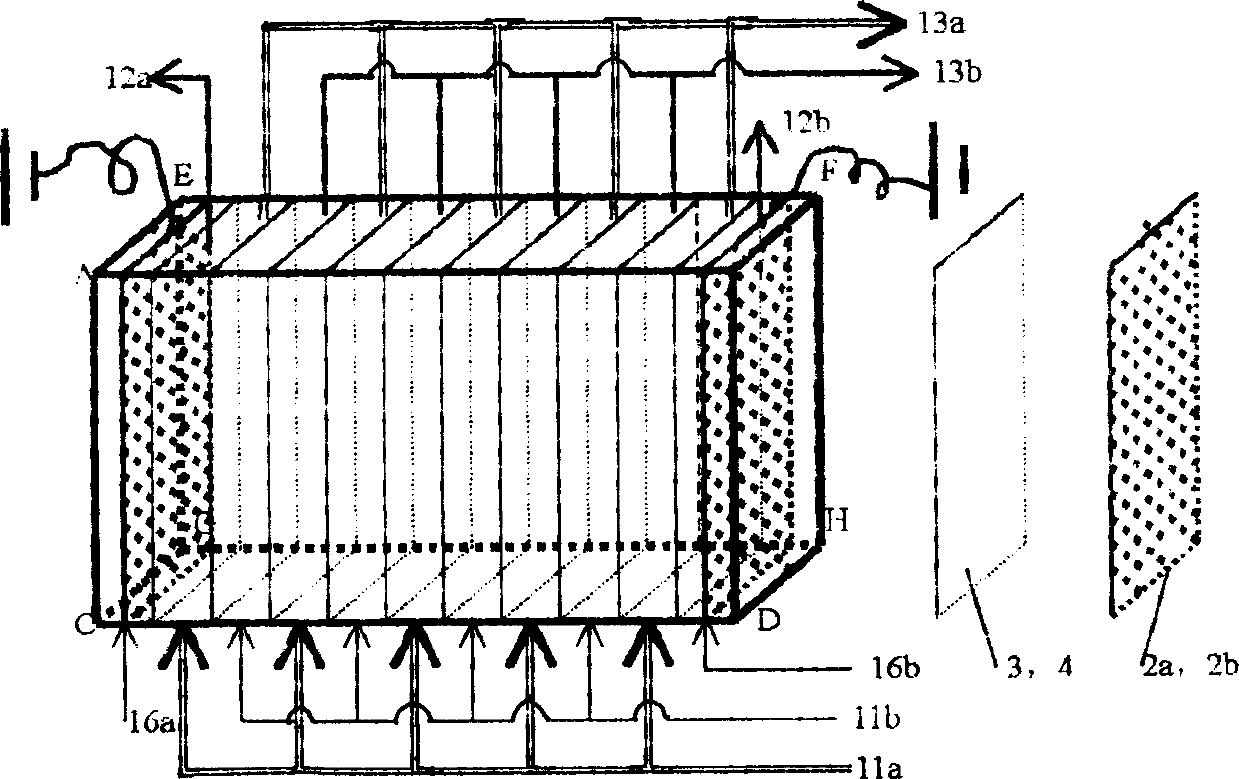

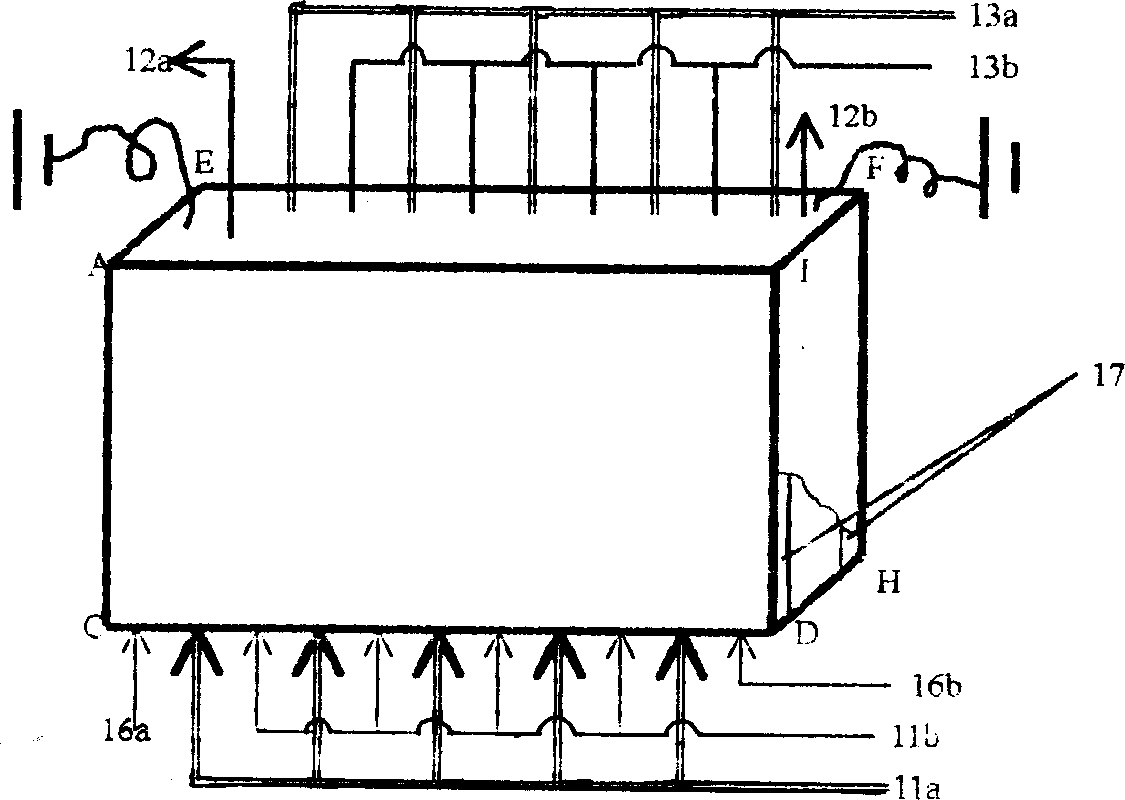

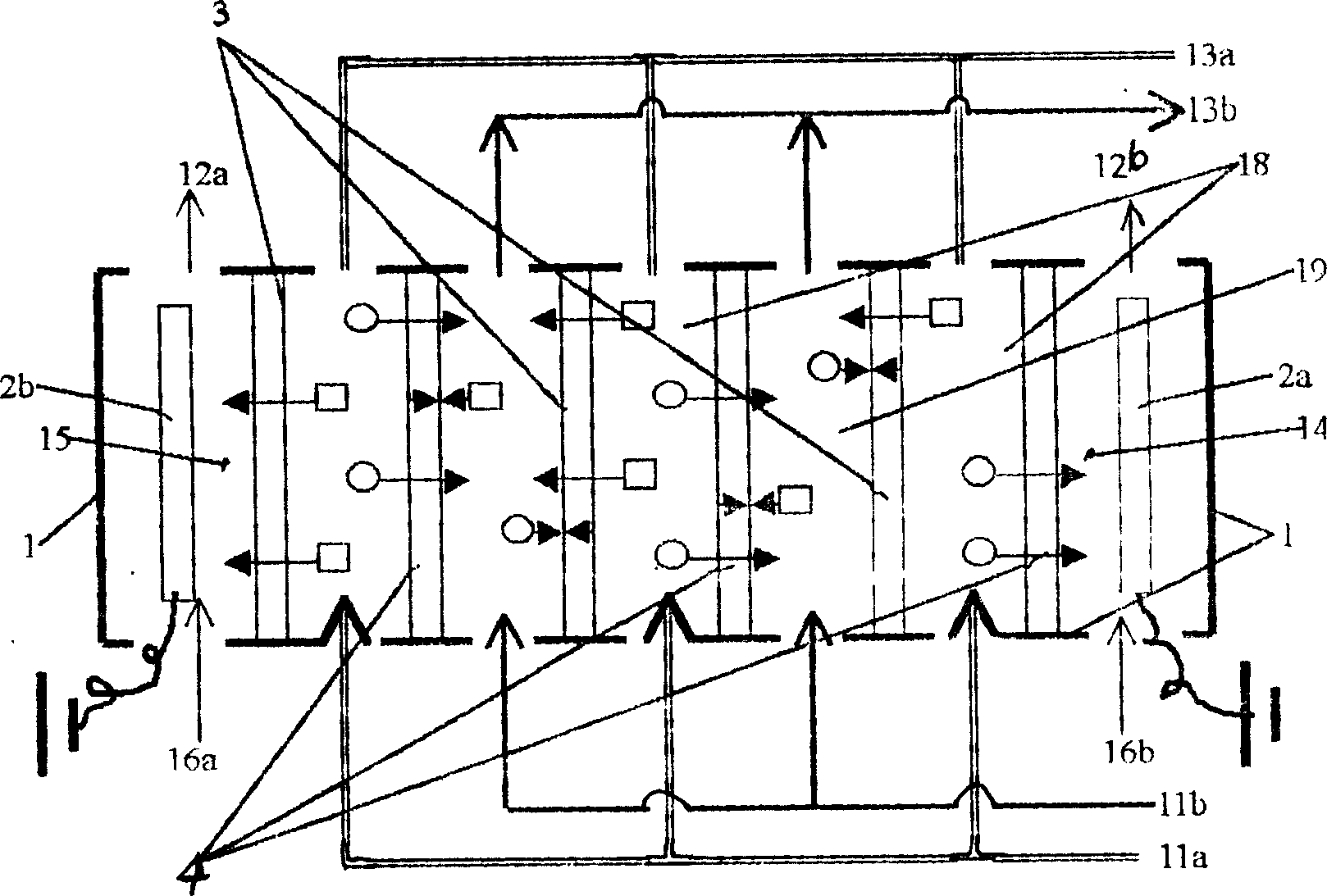

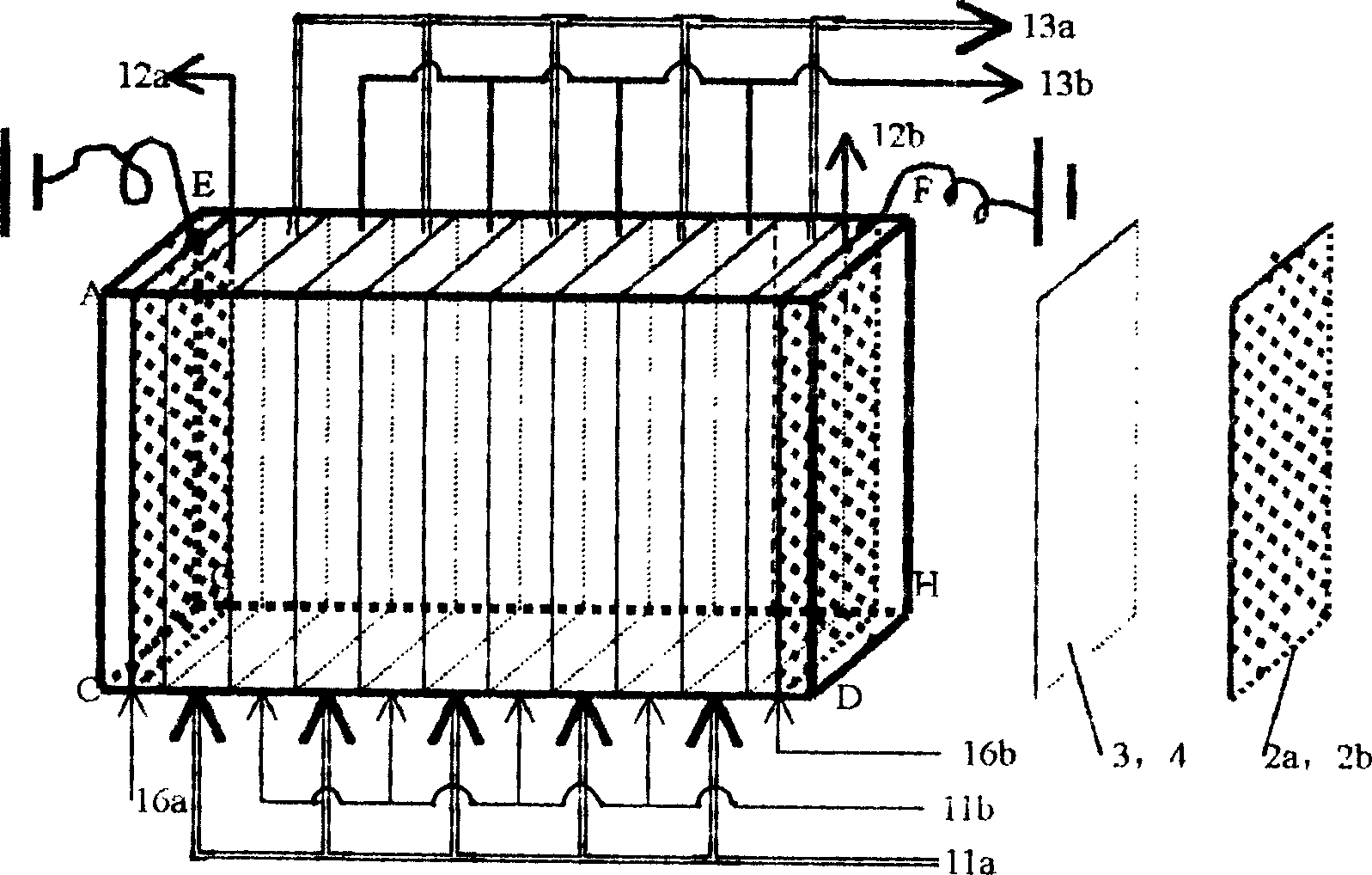

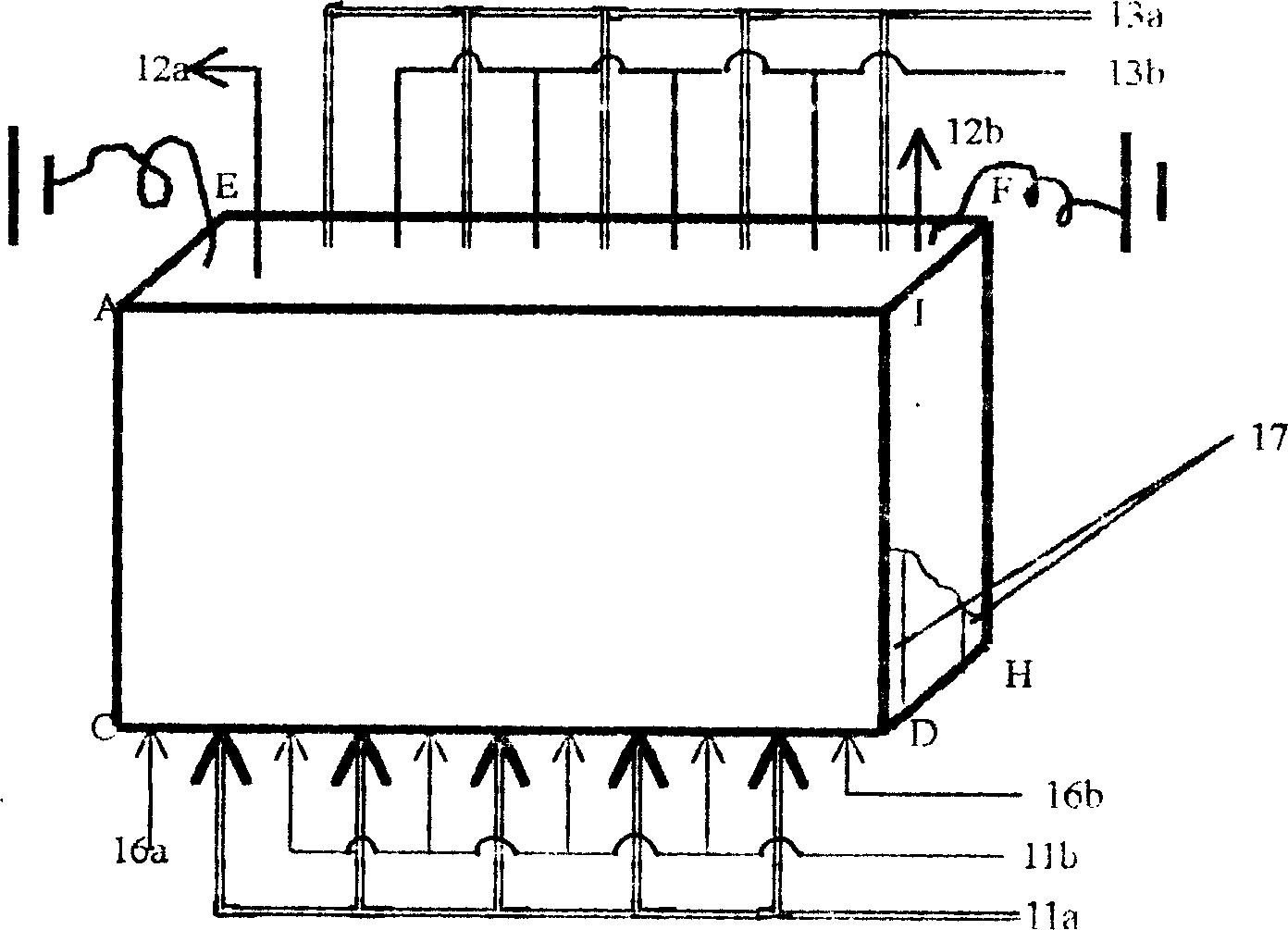

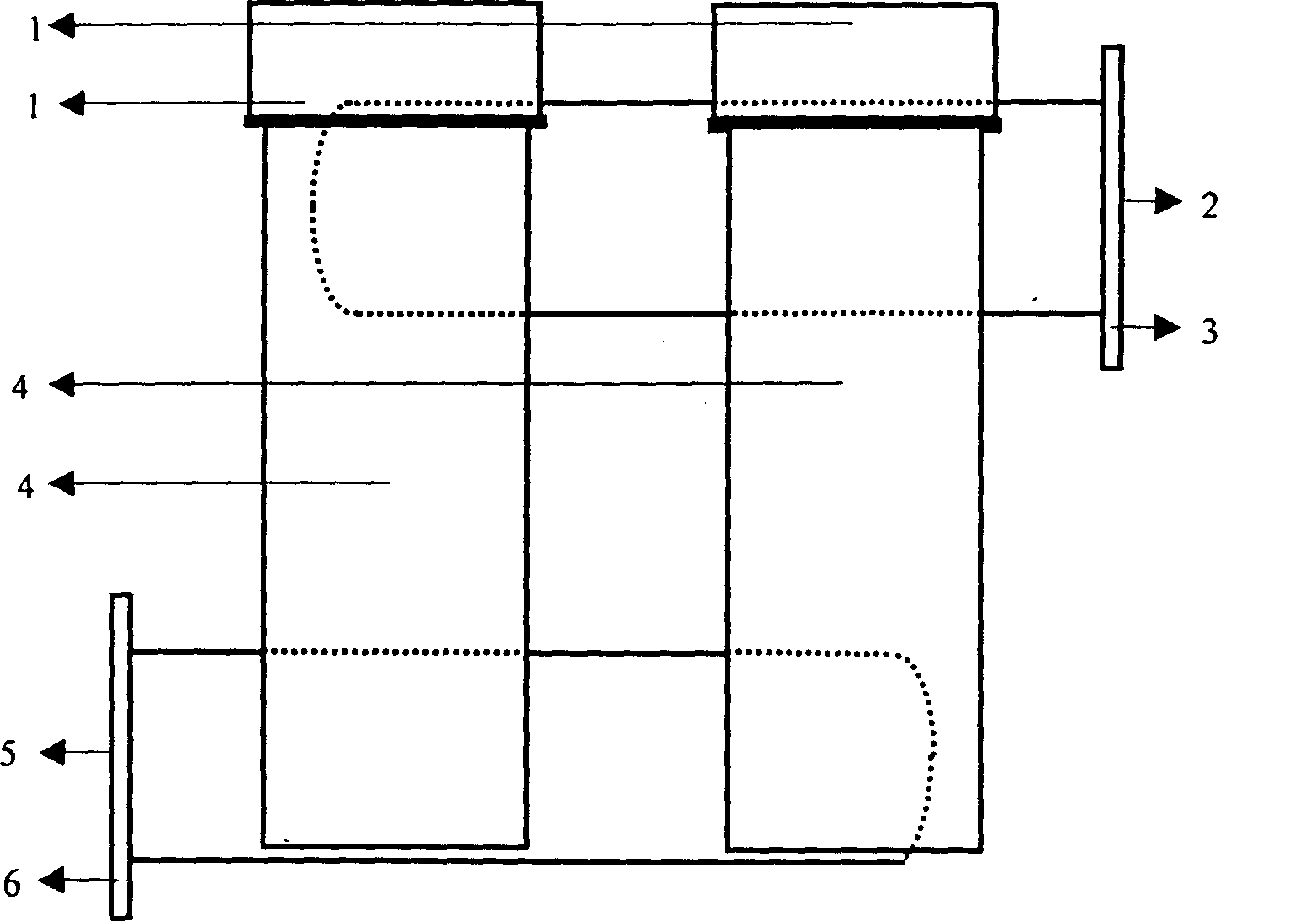

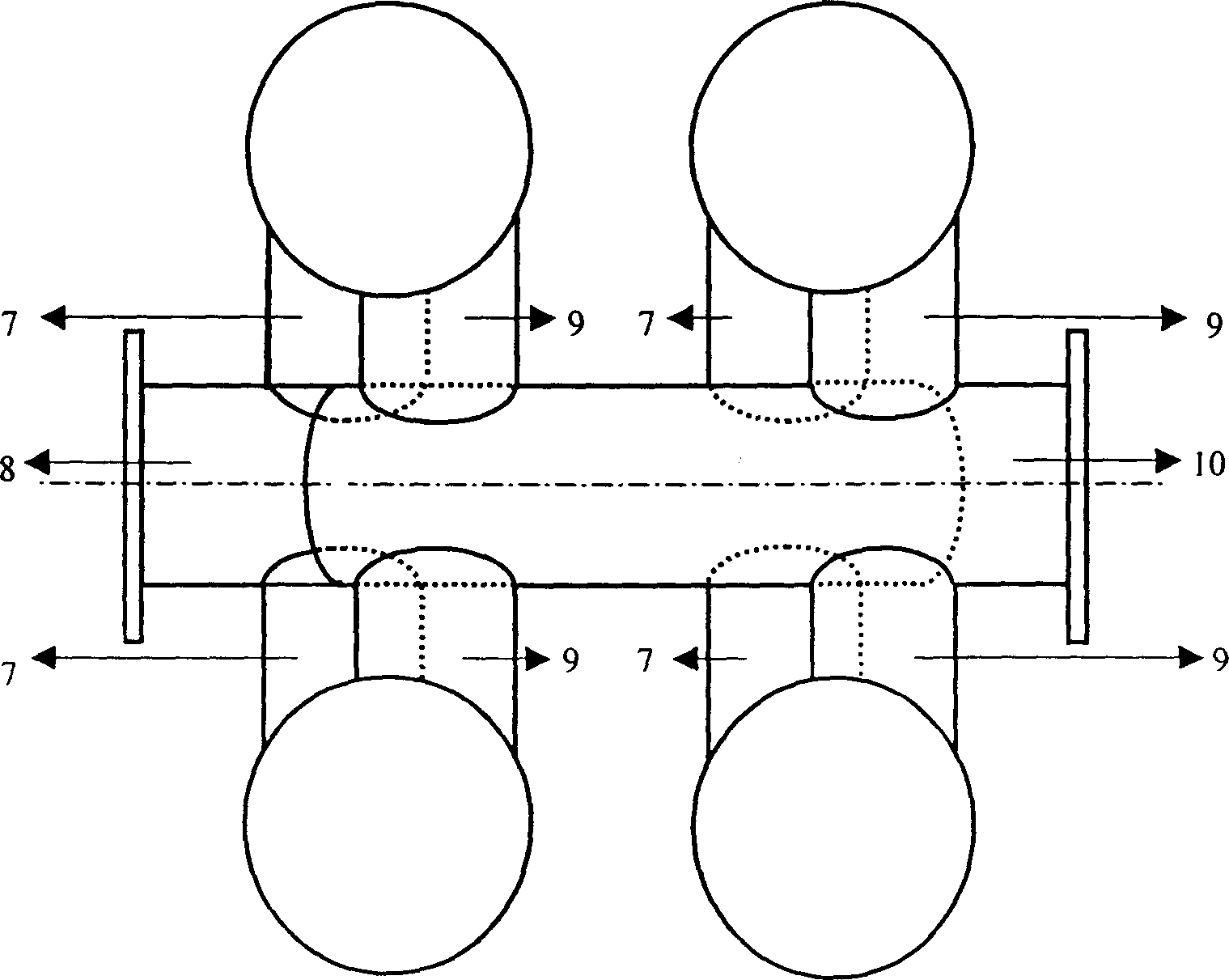

Process and apparatus for treating water by magneto-electric dialysis

InactiveCN1359857AImprove processing efficiencyIncrease directional forceGeneral water supply conservationDispersed particle separationMagnetic tension forceElectric consumption

A magneto-electric dialysis process for desalinating seawater, preparing salt from seawater and desalting industrial water is characterized by that on the basis is existing electric dialysis equipment, a static magnetic field is additionally used to directionally shift the cations and anions in flowing solution. Its apparatus is composed of a casing with different water inlets and outlets and electrodes, a group of cationic exchange membranes and anionic exchange membranes, which are alternatively arranged between anode and cathode, and a permanent magnet attached to each wall of the casing. Its advantages are high throughput, less electric consumption and not scaling.

Owner:陈树庆 +1

Water treating magnetoelectric dialysis process

InactiveCN1526654AEasy to handleImprove processing efficiencyGeneral water supply conservationDispersed particle separationWater desalinationSeawater

The water treating magnetoelectric dialysis process may be used in sea water desalting, salted water desalting, sea water concentration to produce salt, desalting industrial water, etc. Ion exchange membrane with selective penetration is utilized in establishing a water processing electric dialysis space, where electrolyte ion is made to migrate directionally in the DC electric field. The present invention features that in the electric dialysis space, one static magnetic field is applied, which has magnetic force line direction perpendicular to the water flow direction and the current direction to strengthen the directional migration of anion and cation in the flowing solution. The present invention is superior to available electric dialyser with small water processing amount, great power consumption, easy scaling and other demerits. The present invention is realized simply through applying two permanent magnets onto two opposite walls of the electric dialyser casing.

Owner:陈树庆 +1

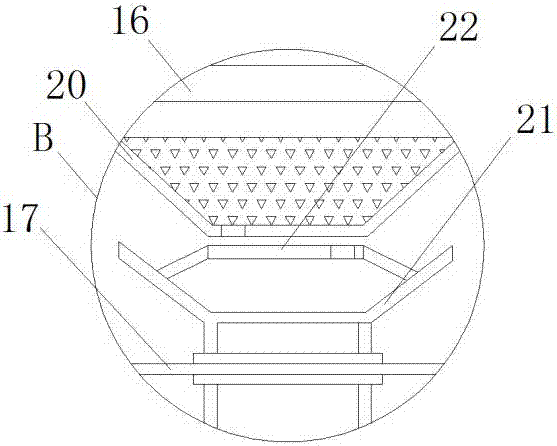

Energy-saving environmentally-friendly type circulating water system for wet flue gas desulfurization process

ActiveCN107200420ASmall diameterPrecipitation as soon as possibleTreatment involving filtrationWaste water treatment from gaseous effluentsFlocculationWastewater

The invention provides an energy-saving environmentally-friendly type circulating water system for a wet flue gas desulfurization process. The energy-saving environmentally-friendly type circulating water system for the wet flue gas desulfurization process comprises a desulfurization tower; a waste water outlet of the desulfurization tower is connected with a filtering pool through a first pipeline; a first pump body is arranged on the first pipeline; a water outlet pipeline is arranged at the inner bottom of the filtering pool; a plurality of water outlet holes are formed in the water outlet pipeline; the right end of the water outlet pipeline is communicated with the first pipeline; a honeycomb-like inclined pipe is arranged in the filtering pool above the water outlet pipeline; a filter screen device is arranged above the honeycomb-like inclined pipe; a second pump body is arranged in the filtering pool. The energy-saving environmentally-friendly type circulating water system for the wet flue gas desulfurization process has the following beneficial effects: 1, a first filter screen, a second filter screen and a third filter screen on a filter screen device are used for performing precipitation effect on impurities in the waste water, so that the granular impurities in the waste water can be precipitated as soon as possible; 2, the uniform mixing range is changed by a uniform mixing device, so that the flocculation effect of a flocculating agent and the waste water is more excellent and the flocculating effect is effectively improved.

Owner:唐山迪牧化工有限公司

Multifunctional sewage purification device

ActiveCN107973476AImpact treatmentFlow impactFatty/oily/floating substances removal devicesSpecific water treatment objectivesWater dischargeFuel tank

The invention belongs to the technical field of multistage treatment of sewage, and particularly relates to a multifunctional sewage purification device. The multifunctional sewage purification devicecomprises a stand and a cleaning barrel, wherein a water feeding pipe and a water discharging pipe are arranged on the cleaning barrel; a first valve is arranged on the water feeding pipe; a filter plate is arranged in the cleaning barrel; a piston cylinder is further fixedly arranged on the side wall of the cleaning barrel; a piece of oil filter cloth is arranged at a connection joint of the water discharging pipe and the cleaning barrel; a resistance wire is arranged in the oil filter cloth; a flexible oil discharging pipe is arranged below the oil filter cloth, and is connected with an oiltank; a second valve is arranged on the flexible oil discharging pipe; a first spring is connected between the oil tank and the stand; a first switch, a second switch and a third switch are arrangedon the stand; the oil tank is connected with the oil discharging pipe; a third valve is arranged on the oil discharging pipe; the inner wall of the water discharging pipe is connected with a turbine in a rotatable manner; one side of the turbine is connected with a swing rod in a rotatable manner; the other side of the turbine is connected with a cam. The multifunctional sewage purification devicecan perform multistage treatment on the sewage; furthermore, in a treatment process, blockage of the water feeding pipe by sediment is avoided; the multifunctional sewage purification device is mostly applied to treatment of the sewage.

Owner:宁波清智环保科技有限公司

Method and device for treating dye wastewater employing periodic reverse electrocoagulation

InactiveCN101638257AReduce passivationReduce lossWater/sewage treatmentWaste water treatment from textile industryAutomatic controlSystem maintenance

A method and a device for treating dye wastewater employing periodic reverse electrocoagulation, the reaction electrodes of the device electrolytic cell are aluminum plate and iron plate, and a periodic reverse power supply is used for power supply. The method for treating dye wastewater comprises the following steps: introducing dye wastewater in the electrolytic cell, adding electrolyte in the electrolytic cell to ensure that the concentration of electrolyte is 0.008-0.015mol / L, starting a stirrer, controlling the mixing speed to 750-1250rpm, the electrode voltage to 8-13V and the current commutation cycle to 6-20 seconds, adjusting the pH value of the wastewater to 5-9, electrolyzing for 30-50min, and then discharging the treated water. The system of the invention has compact structure,small floor space and simple operation management and system maintenance, and is easy to realize automatic control. By using the method of the invention to treat dye wastewater, the chroma removal rate can reach above 96% and COD in the treated wastewater can reach the requirement of the grade A discharge standard of The Integrated Wastewater Discharge Standard (GB8978-1996).

Owner:NORTHEASTERN UNIV

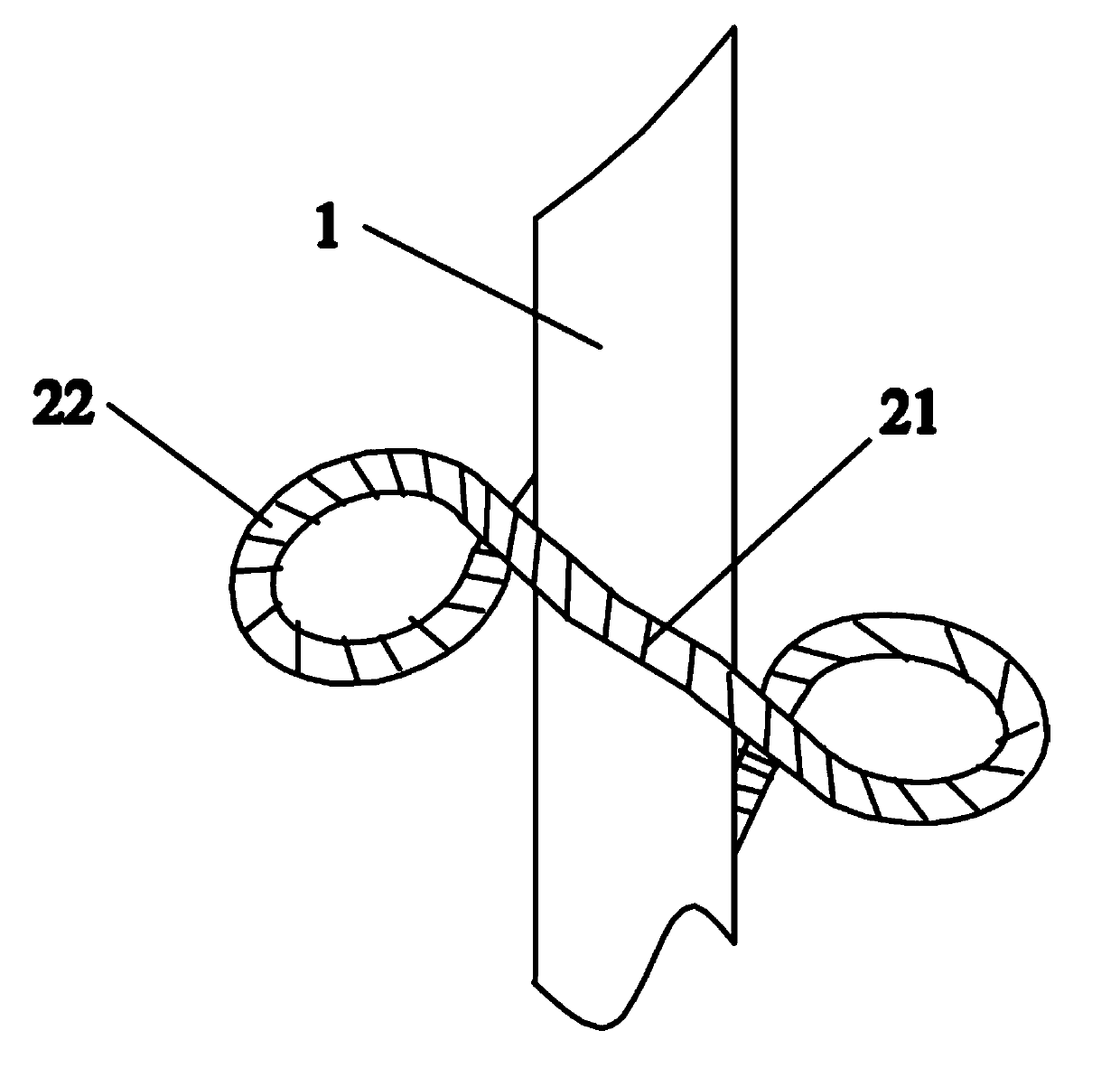

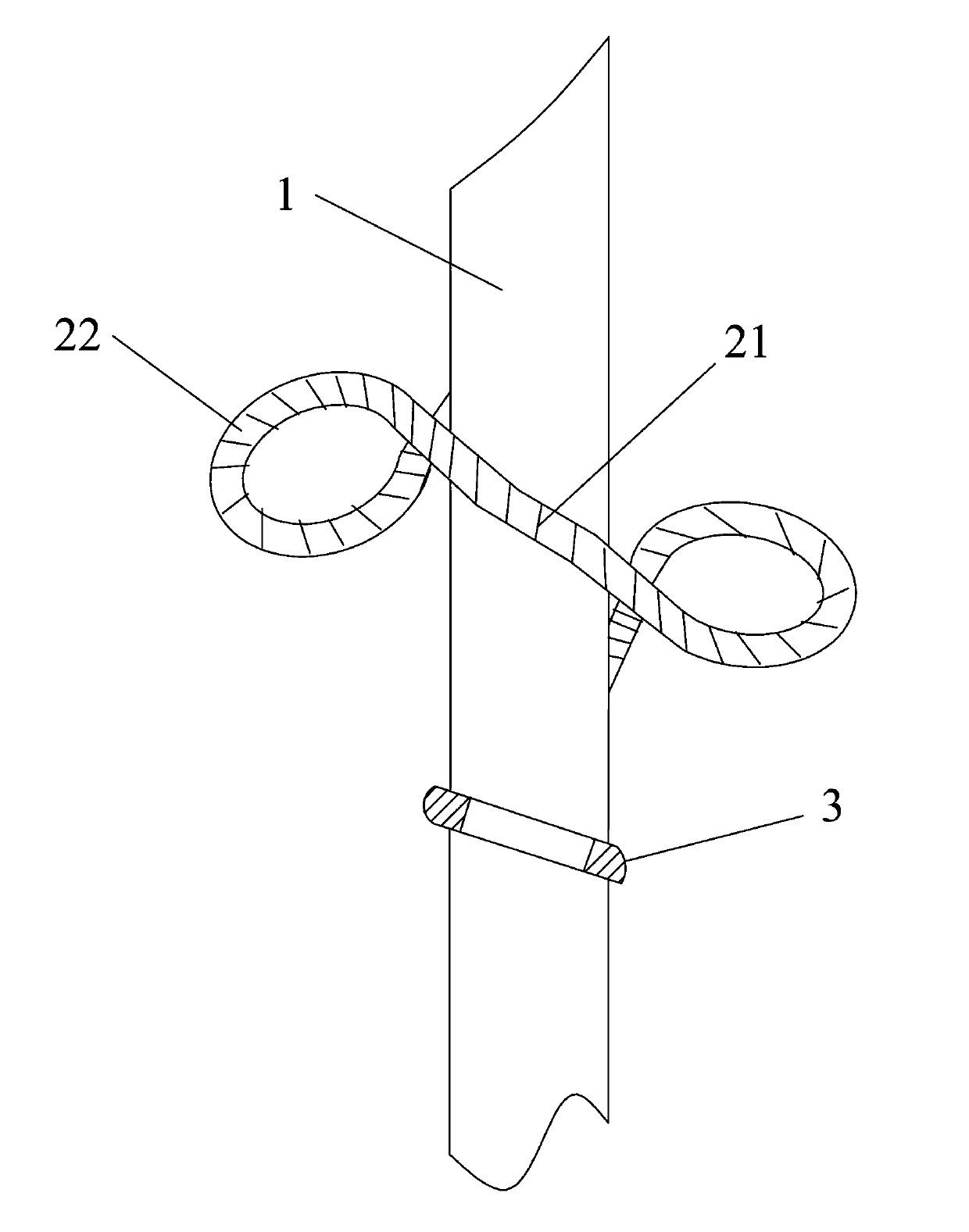

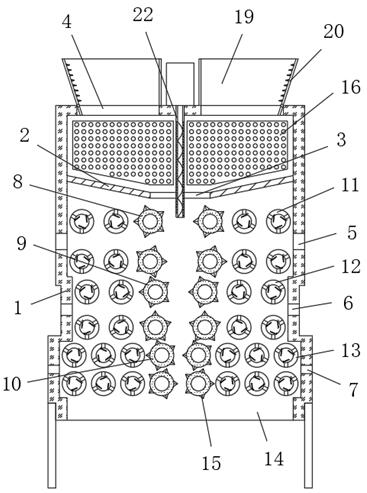

Bionic type water treatment filler

ActiveCN102992475AHigh specific surface areaImproved water and air distributionSustainable biological treatmentBiological water/sewage treatmentTreatment effectFiller metal

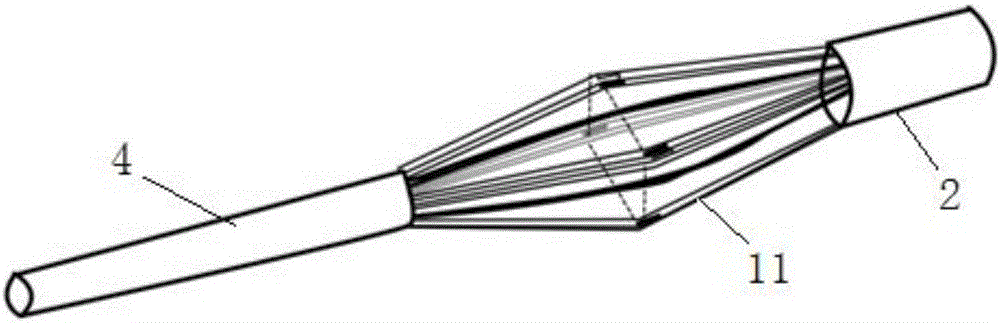

The invention relates to a bionic type water treatment filler, in particular to a bionic type water treatment filler applied in waste water generated in ready orgthe banism treatment. The bionic type water treatment filler comprises a middle rope, and a filler rope wound on the middle rope, the filler rope comprises a plurality of spiral filler units which are connected end to end, each filler unit comprises a filler unit first part penetrating in the middle rope, and a filler unit second part penetrating out of the middle rope, the filler unit first part and the filler unit second part are connected, and the filler unit second part is approximately annular. Through the improvement of structure and selection of filler materials, the bionic type water treatment filler has the advantages of being not easy to plug, stable in the quality of effluent water, good in treatment effect and long in service life.

Owner:JIANGSU SUJING GROUP +1

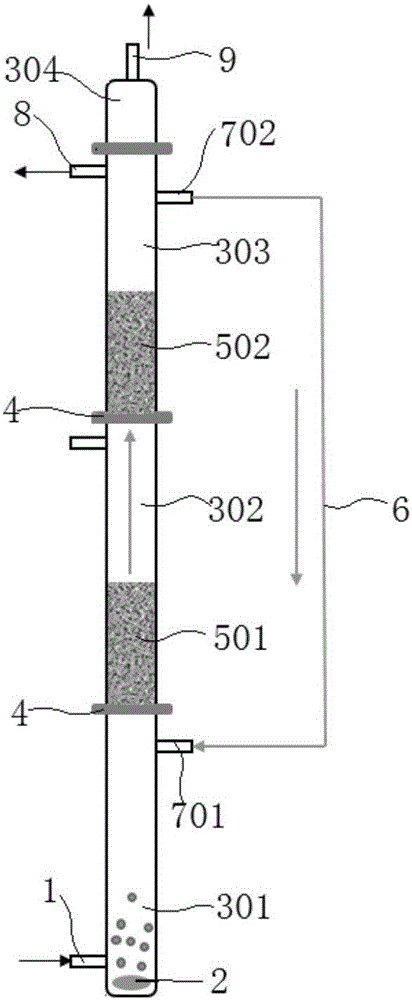

Integrated fluidized bed device for gradient ozone catalyzing and application of integrated fluidized bed device

PendingCN106630110AEasy to handleGuaranteed treatment effectWater treatment compoundsWater contaminantsRefluxFluidized bed

The invention discloses an integrated fluidized bed device for gradient ozone catalyzing and application of the integrated fluidized bed device. The integrated fluidized bed device comprises a primary reactor, a secondary reactor, a tertiary reactor and a quaternary reactor from bottom to top, a water inlet and an ozone aerating apparatus are arranged at the bottom of the primary reactor, a recycling water inlet is arranged on an upper portion of the primary reactor, a catalyzer layer and a second catalyzer layer are respectively arranged in the secondary reactor and the tertiary reactor, a water outlet and a recycling water outlet are arranged on an upper portion of the tertiary reactor, the recycling water inlet is connected with the recycling water outlet through a reflux pump and a circulating tube, and an upper cut angle is reserved between the recycling water inlet and a main reactor body. The integrated fluidized bed device for gradient ozone catalyzing has the advantages that a usage rate and a catalytic oxidation efficiency of ozone are increased, a catalytic oxidation reaction is more efficient and more thorough, a compact reaction mechanism is adopted to enable the reaction to be finished in one device, and small floor area is occupied.

Owner:NANJING UNIV +1

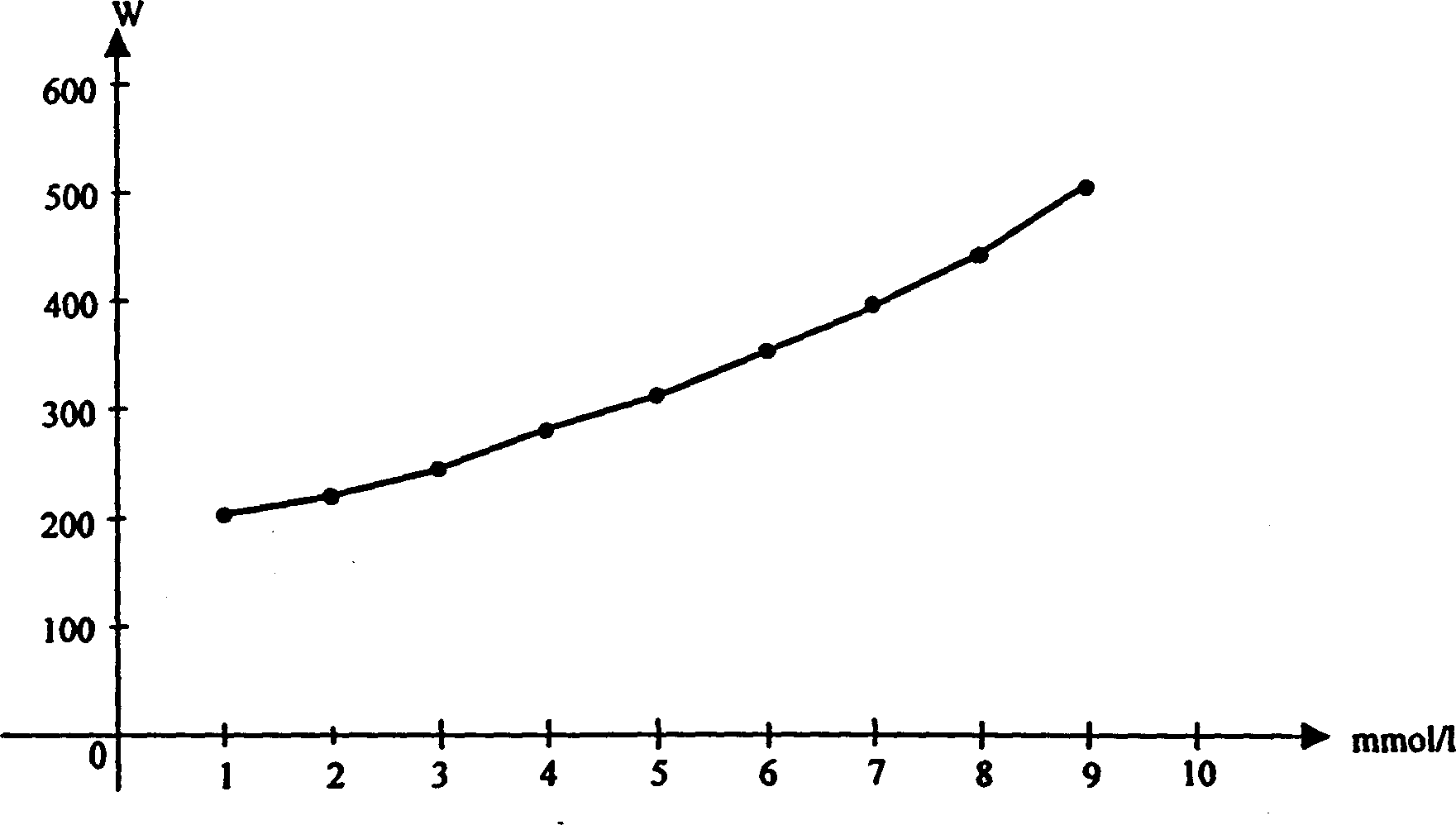

Electronic equipment in high frequency for descaling, and blocking scaling

InactiveCN1872718AEasy to handleImprove water treatment effectWater/sewage treatment by magnetic/electric fieldsHigh frequency powerHardness

This invention relates to a water treatment device. The device comprises a high frequency power, a feedback conducting wire, a high frequency electric field water treatment device, valves, water pipes, and connecting flanges. The high frequency electric field water treatment device comprises at least two water treatment units, which are connected with the other water treatment units by pipes. The power of the high frequency electric field is not less than (50n+150)V, wherein n is the hardness of the water to be treated (mmol / L), and V is the flux of the water to be treated 100m3 / h.

Owner:兰州盛源科技有限公司

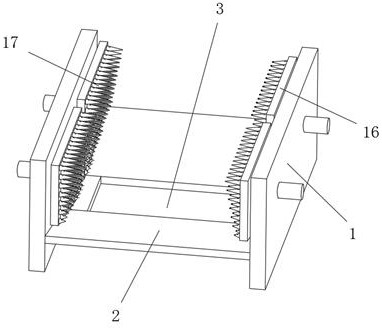

Metal zipper polishing device and method for polishing metal zipper through utilizing same

The invention provides a metal zipper polishing device and a method for polishing a metal zipper through utilizing the same. The device comprises a rack and a tank body, wherein the tank body is arranged on the rack. The tank body comprises an electrolytic degreasing cavity, a first rinsing cavity, a weak acid etching cavity, a second rinsing cavity, an electrolytic polishing cavity, a third rinsing cavity, an anti-fading cavity and a fourth rinsing cavity which are sequentially arranged along the length direction of the rack, wherein an ultrasonic device is arranged on the bottom of the electrolytic degreasing cavity; and the metal zipper sequentially penetrates through the electrolytic degreasing cavity, the first rinsing cavity, the weak acid etching cavity, the second rinsing cavity, the electrolytic polishing cavity, the third rinsing cavity, the anti-fading cavity and the fourth rinsing cavity under the action of a zipper guide mechanism and a transmission mechanism, and is led out from a zipper leading-out mechanism to complete a whole polishing process. The device has the beneficial effects that the device is simple in structure, reasonable in design and low in manufacturing cost; moreover, the metal zipper has a good polishing effect, damage to environment and human bodies is effectively reduced, and the metal zipper can be continuously polished.

Owner:孙斌

Preparation method of high-precision coating filter material

ActiveCN104436861AImprove acid and alkali resistanceExtended service lifeSynthetic resin layered productsGlass/slag layered productsPolytetrafluoroethyleneFilter material

The invention provides a preparation method of a high-precision coating filter material. According to the preparation method, the filter material can be well combined with PTFE (Polytetrafluoroethylene), and the performances of the filter material can be improved. The method comprises the following steps: (1) carrying out heat cleaning treatment, namely, performing the heat cleaning treatment on the filter material and removing various assistants on the surface of the filter material at high temperature; (2) performing immersion treatment, that is, performing PTFE immersion treatment on the filter material after heat cleaning treatment; (3) baking, drying, and carrying out heat setting on the filter material after immersion treatment sequentially; (4) coating the filter material after heat setting; and (5) performing volatilization, drying, sintering and heat setting on the filter material after coating treatment sequentially. According to the preparation method of the high-precision coating filter material, the filter material is subjected to heat cleaning treatment before immersion treatment, thus, wiredrawing impregnating compound remained on the surface of the fiber can be effectively removed, and the fabric strength can be ensured not to be lost; the acidic and alkali resistances, the water resistance, the oxidation resistance and the abrasion and folding resistances of the filter material can be effectively improved, and the service life of the filter material can be prolonged.

Owner:辽宁新洪源环保材料有限公司

Pus drainage device with sampling function for patients with burns

ActiveCN108969816AEasy to operateConvenient sampling and testingMedical devicesIntravenous devicesDraining tubeEngineering

The invention discloses a pus drainage device with a sampling function for patients with burns, which comprises a drain tube, a housing, an upper cover, a support block, a guide tube, a filter net, aholding channel, a limiting channel, a slider, a spring, a flow hole, a receiving hole, and a floater. The pus drainage device is ingenious in structure, good in functionality, simple to operate and low in time and manpower consumption; a sampling mechanism enables medical personnel to conveniently carry out sampling detection on drained liquid during drainage therapy of a patient; the problem iseffectively avoided that a traditional sampling method is inconvenient to perform and high in time and manpower consumption; in addition, a drainage alarm mechanism helps effectively prevent untimelyemptying of the drained liquid in the housing from affecting the drainage therapy of the patient; operation is finally simplified for medical personnel, treatment and healing are benefited for the patient. The pus drainage device is suitable for clinical popularization and application.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

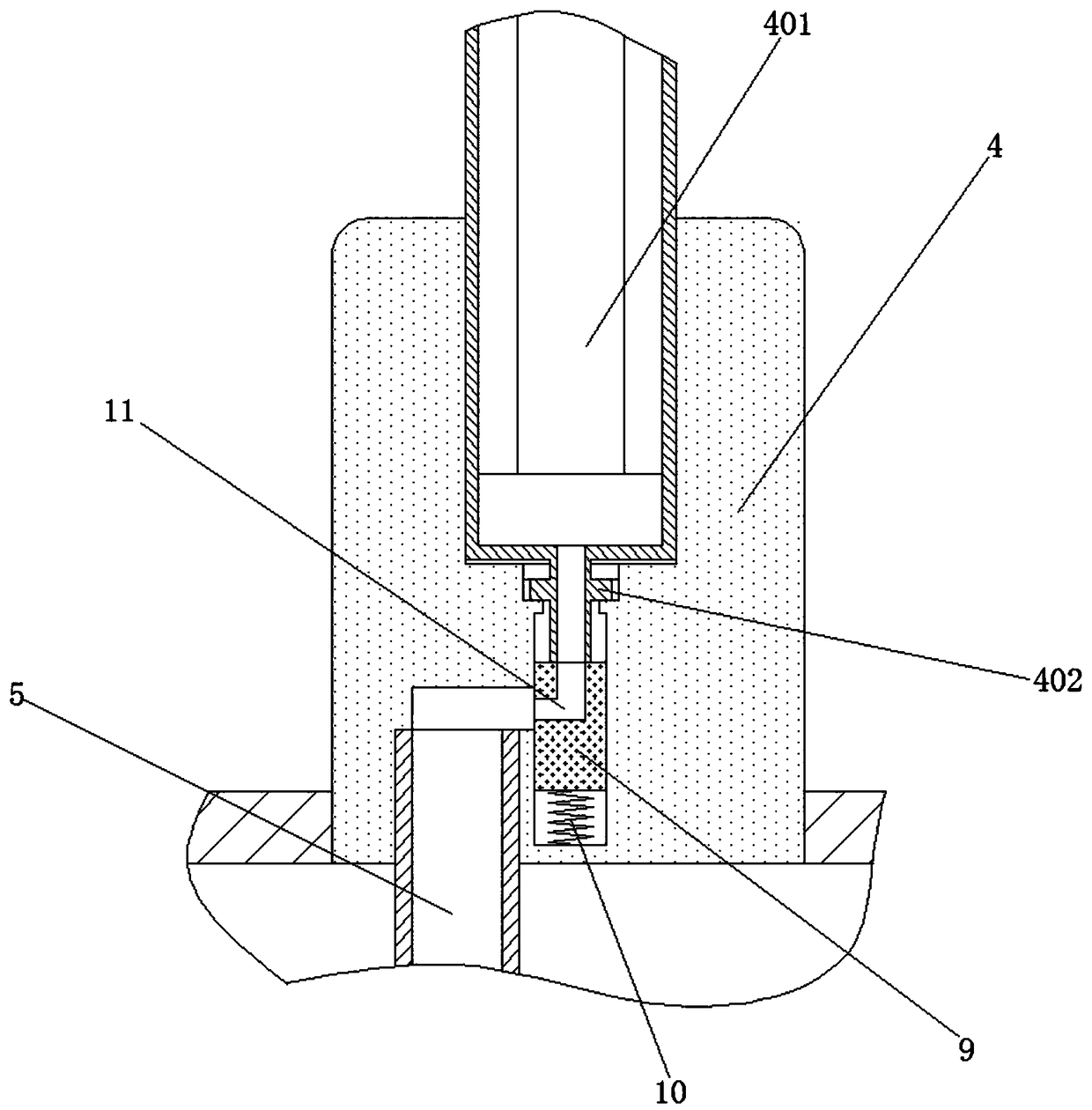

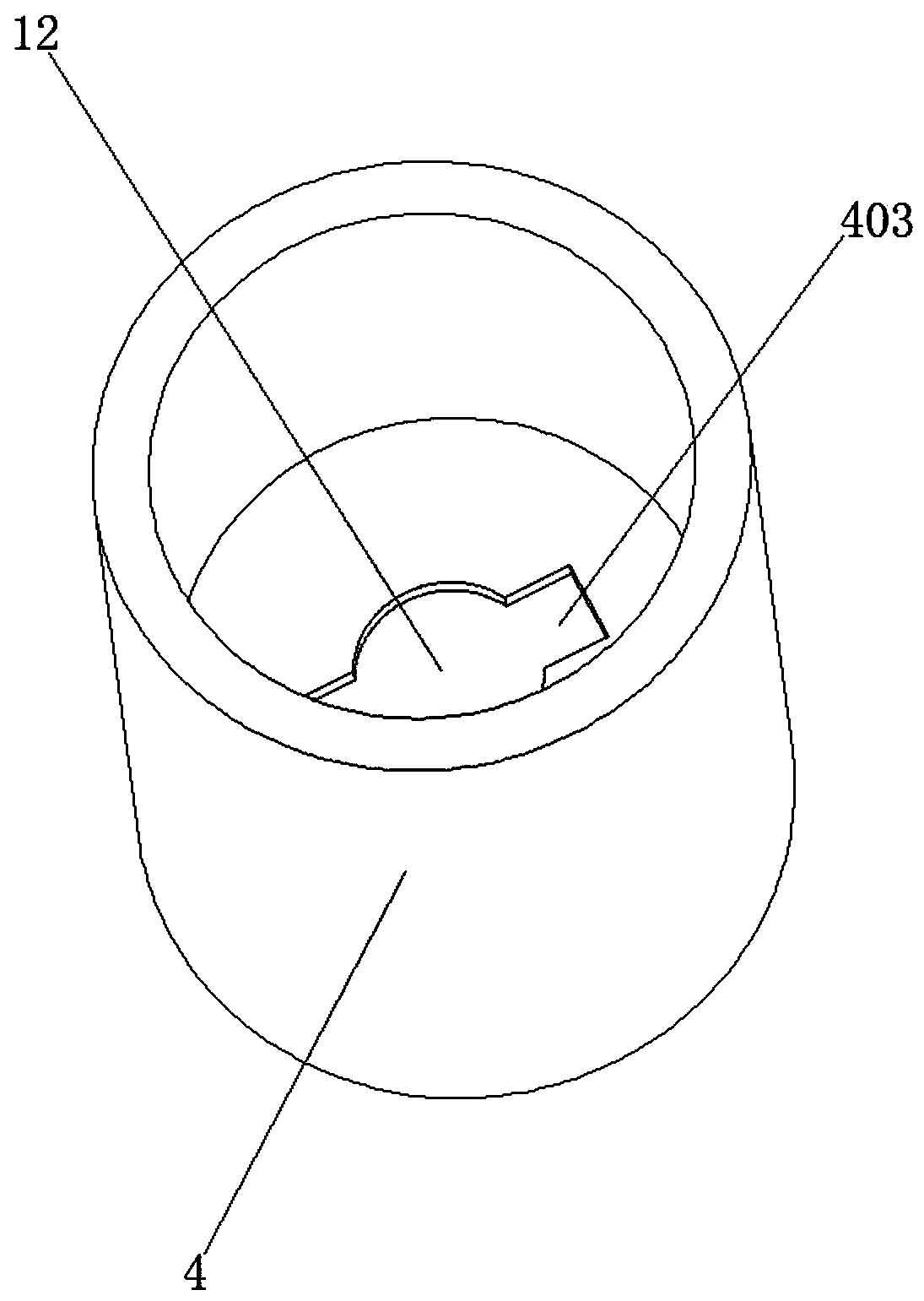

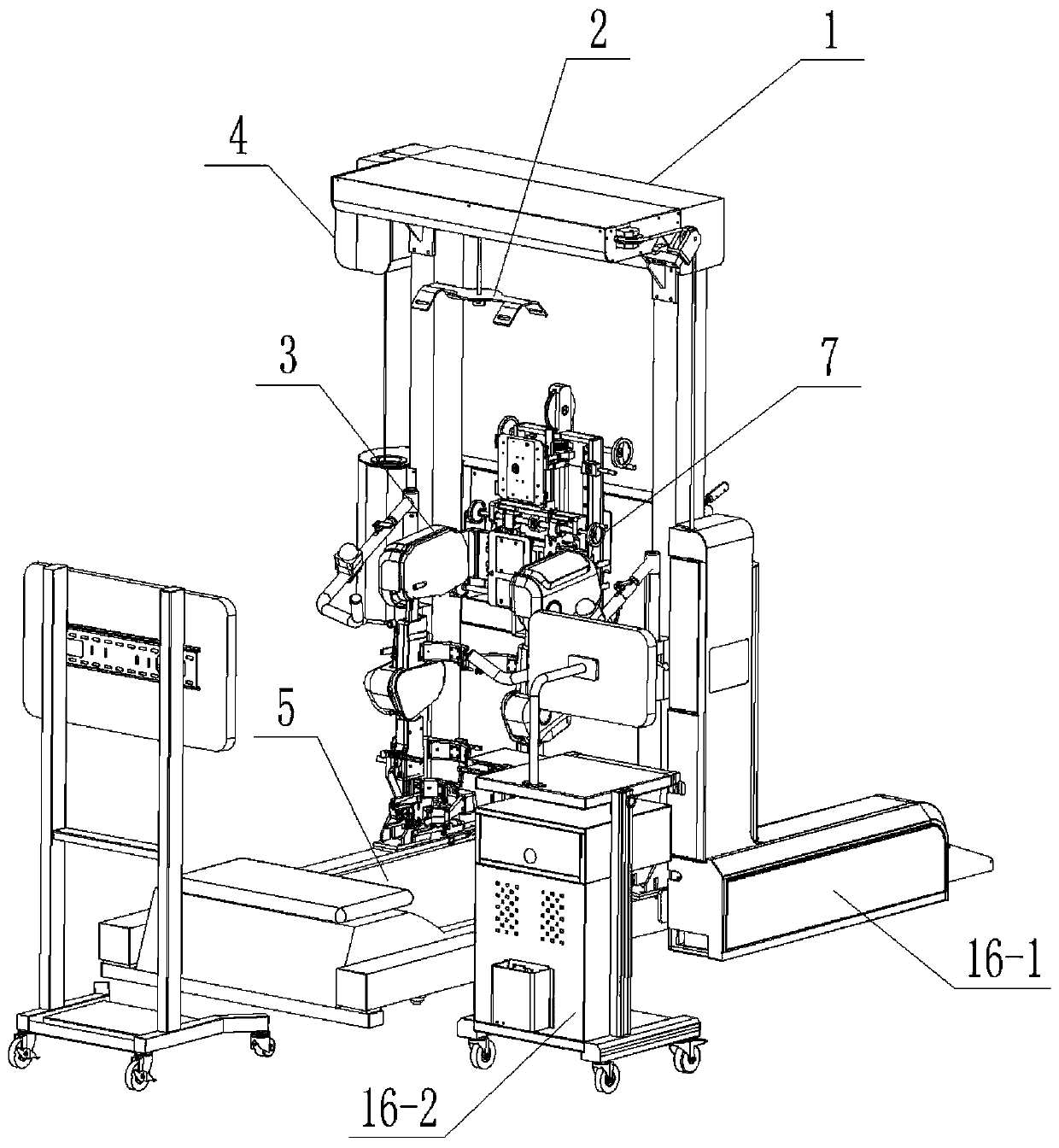

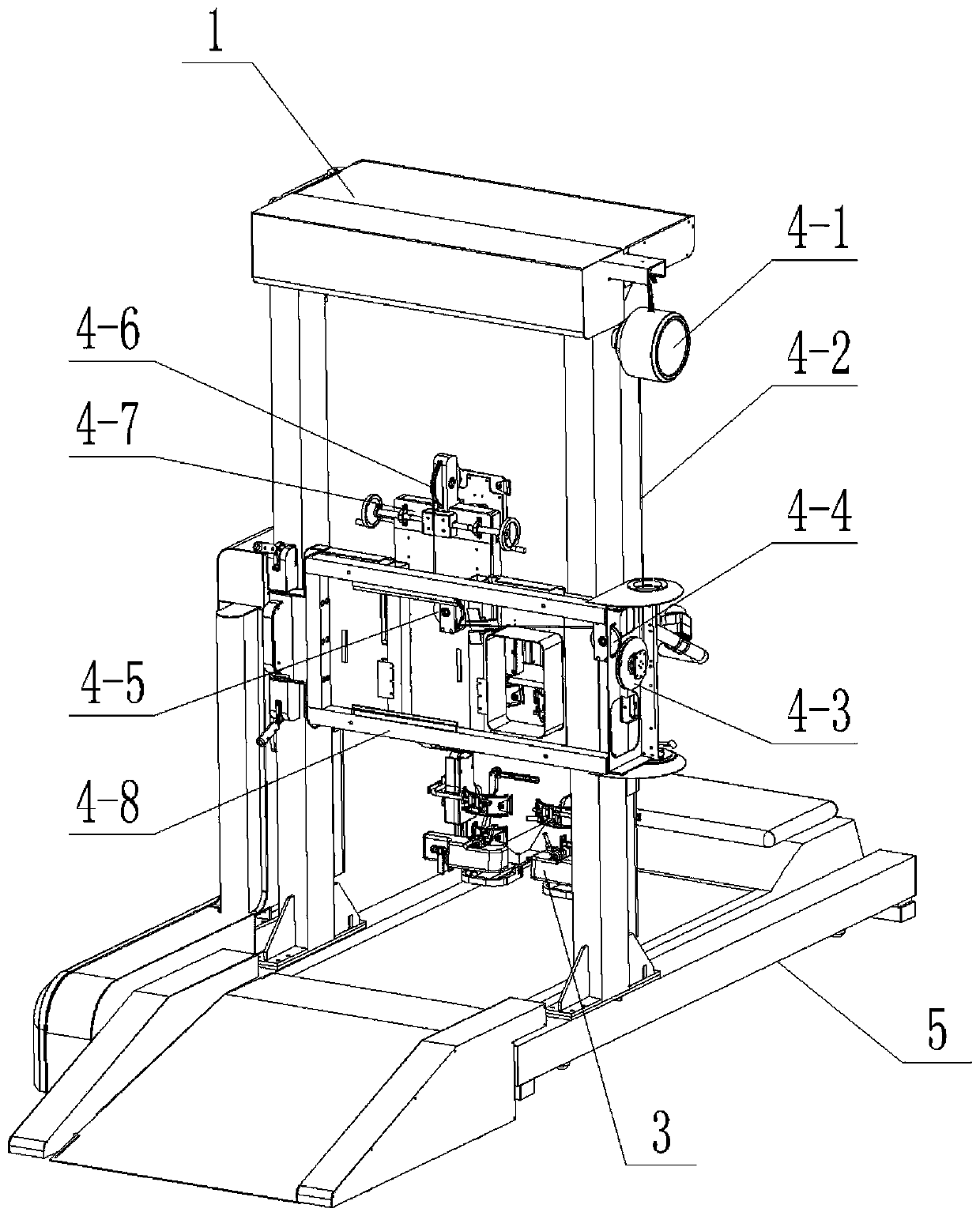

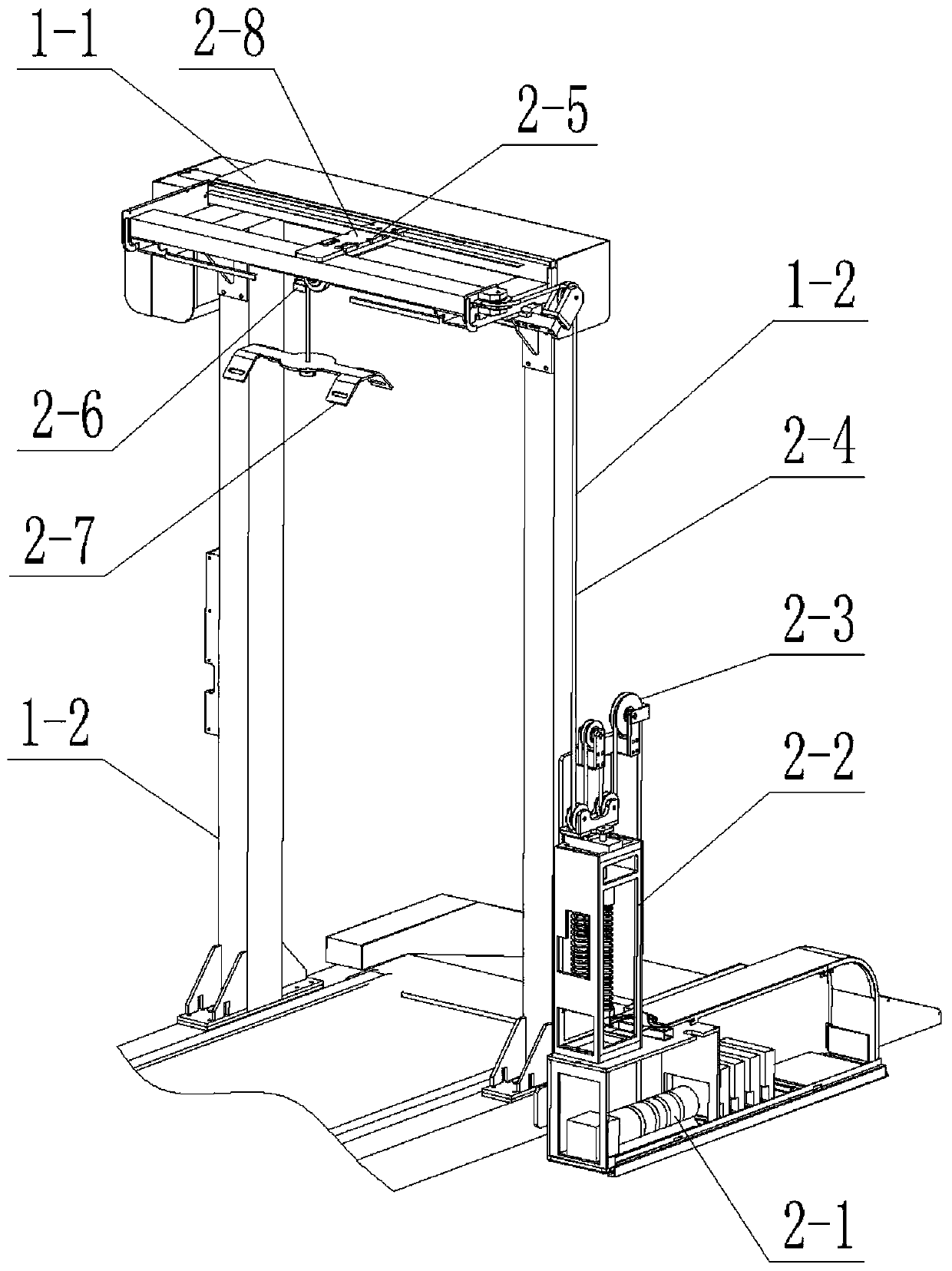

Intelligent rehabilitation robot for lower limb gait training

PendingCN111588595AEnsure safetyImprove rehabilitation effectChiropractic devicesEngineeringGravity center

The invention provides an intelligent rehabilitation robot for lower limb gait training. Most lower limb rehabilitation robots sold in the market are single in training mode, only two hip joints and knee joints move, ankle joint training is lacked, joint structures only do pure interrelated movement, no training function exists, gravity center changes during walking are not considered, and the training effect is affected. A rack comprises a cross beam and two stand columns, wherein the two stand columns are vertically arranged on a foot sole matching way side by side; a lower limb robot is arranged between the two stand columns and is close to the foot sole matching way; the cross beam is horizontally arranged between the two stand columns; a gravity compensation mechanism and a weight reduction lifting mechanism are arranged on the two stand columns respectively; the connecting end of the weight reduction lifting mechanism penetrates through the cross beam to be detachably connected with a rehabilitation person; the weight reduction lifting mechanism is connected with the lower limb robot; and the lower limb robot is matched with the hip joints, the knee joints and the ankle joints of the rehabilitation person. The intelligent rehabilitation robot is used for lower limb rehabilitation training.

Owner:深圳莱恩医学技术有限公司

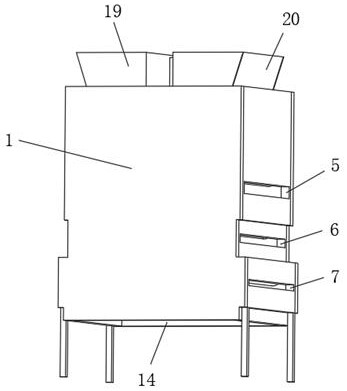

Efficient wet-method black magnetic powder sewage treatment equipment

InactiveCN107879546ALiquidity is hinderedSmooth rotationTreatment involving filtrationMultistage water/sewage treatmentBiochemical engineeringSewage

The invention relates to the technical field of sewage treatment equipment, and discloses a high-efficiency wet black magnetic powder sewage treatment equipment, including a transition pool, a filter chamber is provided on the top of the transition pool, and a motor compartment is provided on one side of the filter chamber A water pump is fixedly installed on the top of the motor compartment, and a water inlet pipe is fixedly set on the water pump, and one end of the water inlet pipe extends to the inner cavity of the filter chamber, and a first drive is fixedly installed on one side of the inner cavity of the filter chamber. In the motor, the output shaft of the first driving motor is fixedly sleeved with one end of the rotating shaft through the fixed sleeve. The high-efficiency wet black magnetic powder sewage treatment equipment, through the function of the fixed shaft sleeve, is convenient to drive the filter to rotate, and then separate the blockage on the filter from the filter, and use the garbage recovery device to pick it up to ensure the smoothness of the filter It avoids the blockage of sundries, the blockage of sewage flow, and the difficulty of cleaning process, which improves the convenience of decontamination.

Owner:鄢海军

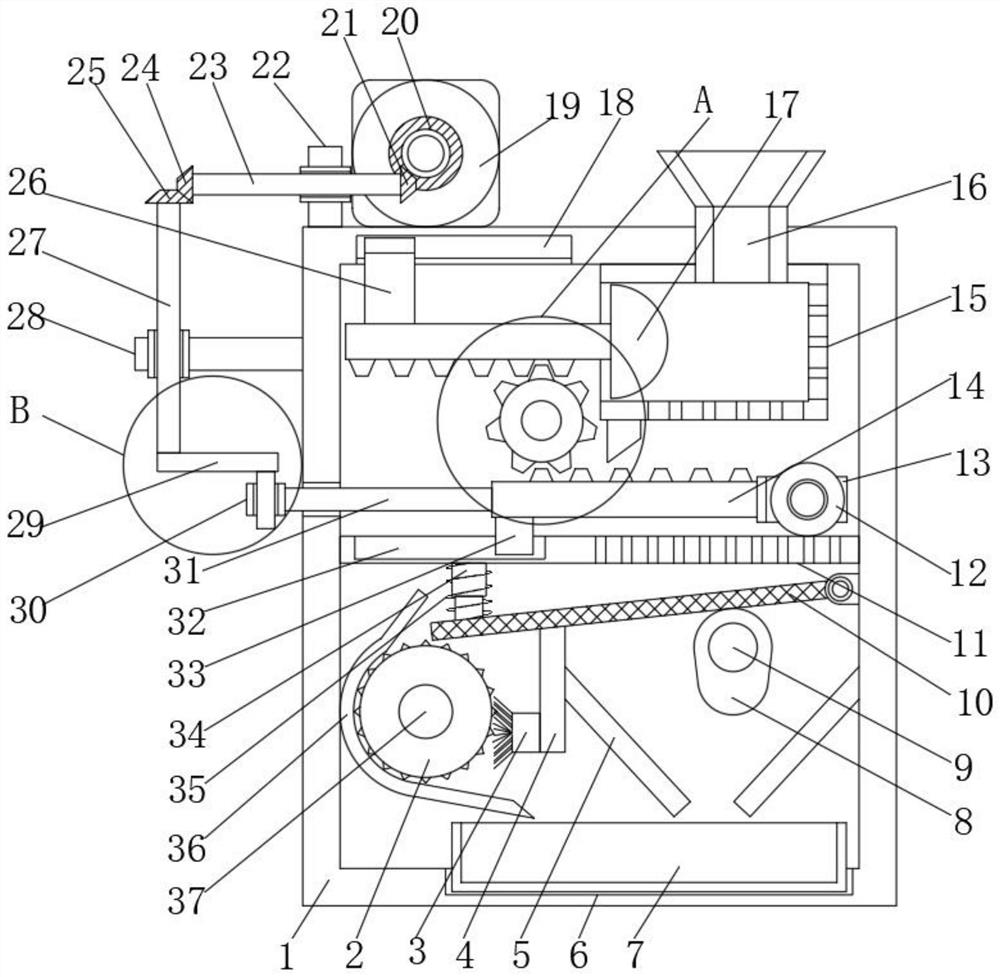

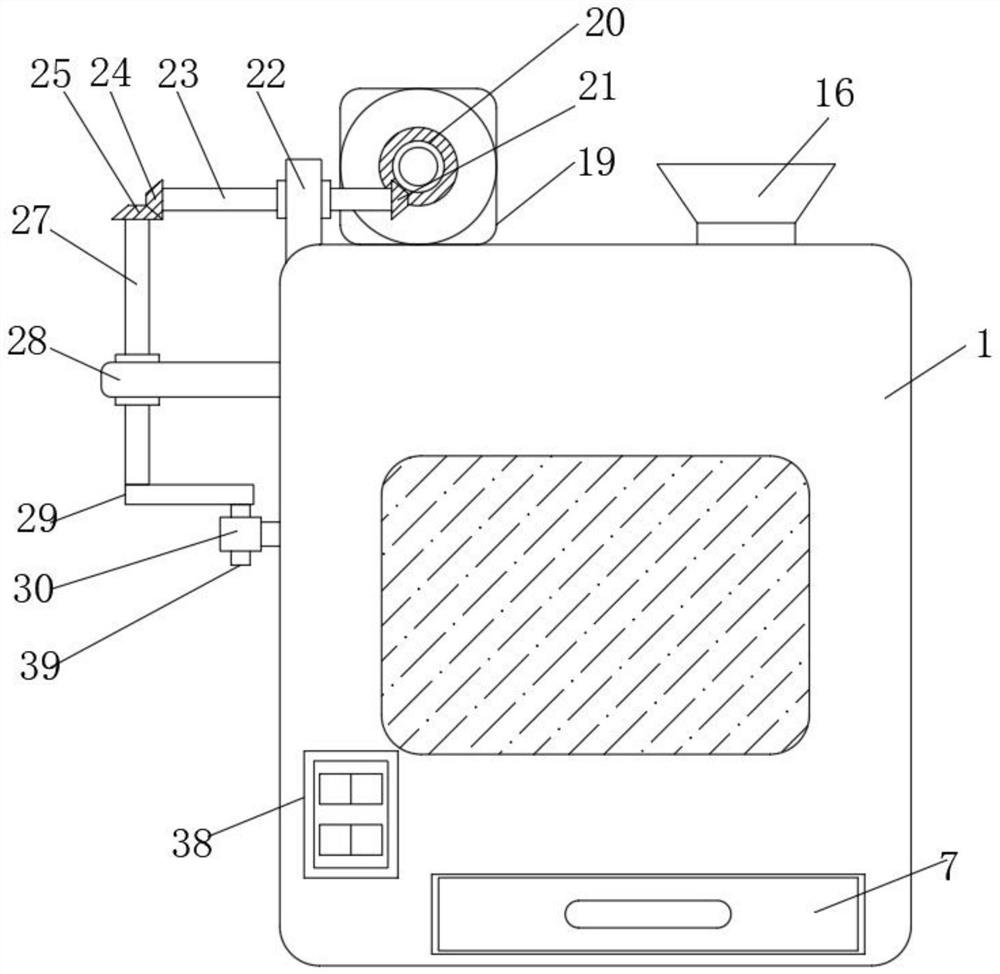

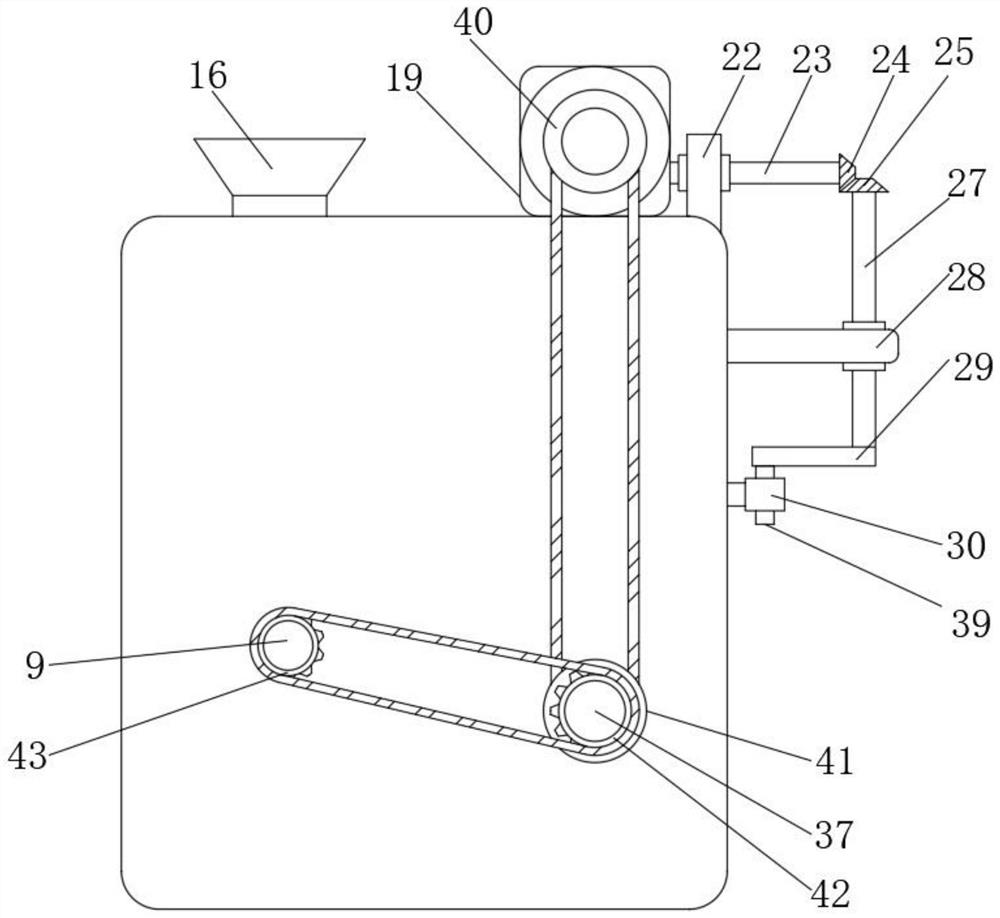

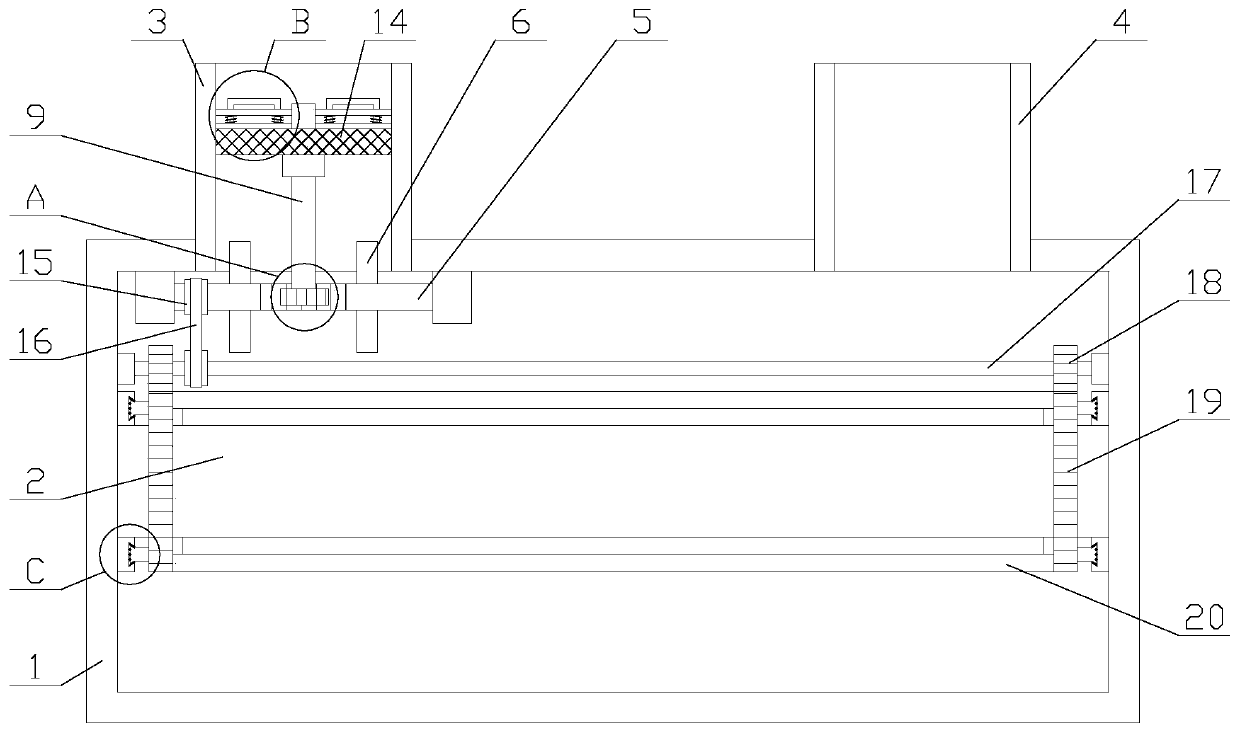

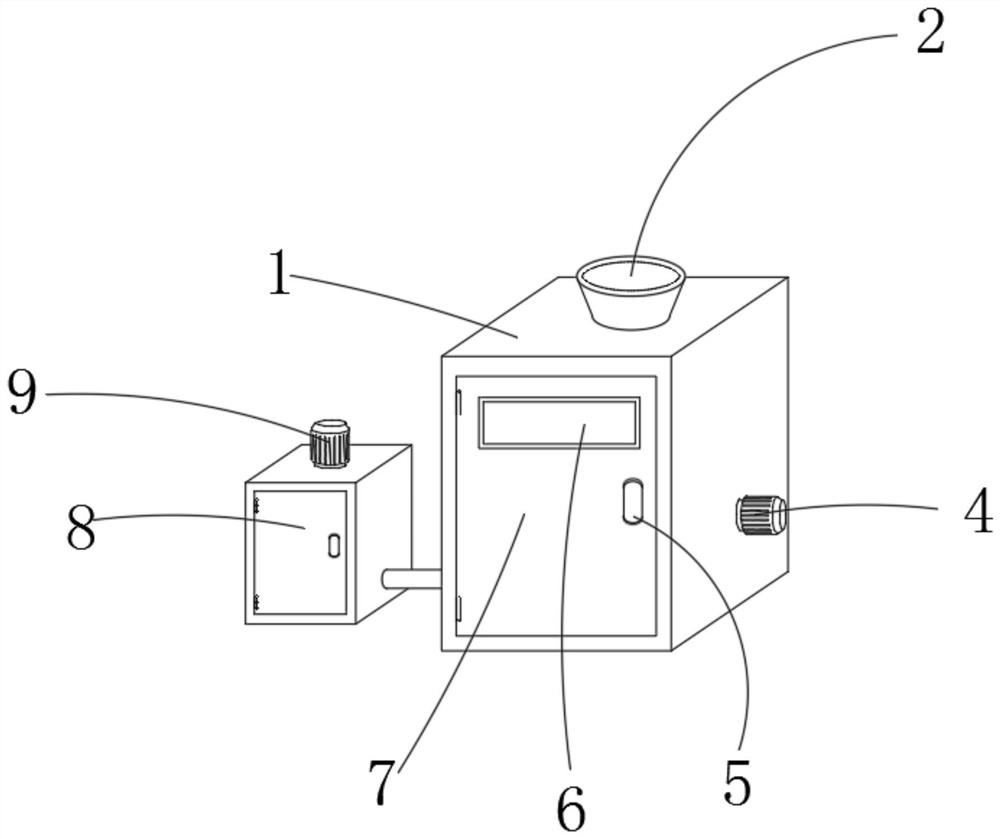

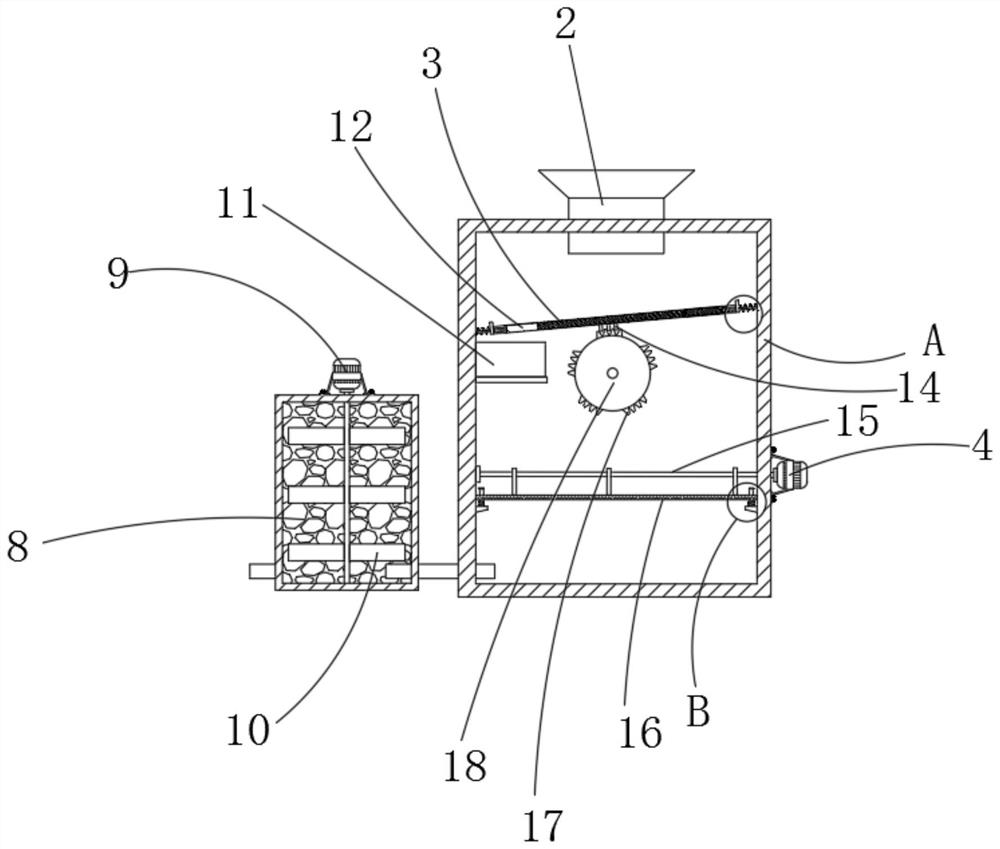

Tablet grinding device for medical nursing department

ActiveCN112871258AImprove grinding effectImprove grinding efficiencyGrain treatmentsMedical equipmentNursing care

The invention discloses a tablet grinding device for the medical nursing department, and relates to the technical field of medical equipment. The tablet grinding device for the medical nursing department comprises a box body, wherein a double-shaft motor is fixedly connected to the upper surface of the box body; a first bevel gear is fixedly connected to the front end of an output shaft on the front side of the double-shaft motor; and the first bevel gear is in meshed connection with a second bevel gear. According to the tablet grinding device for the medical nursing department, the double-shaft motor is controlled to work; when the double-shaft motor works, the output shaft on the front side of the double-shaft motor drives the second bevel gear and a second connecting shaft to rotate through the first bevel gear; and when the second connecting shaft rotates, a third connecting shaft and a first connecting rod are driven to rotate through a third bevel gear and a fourth bevel gear, so that the problems that most of existing tablet grinding devices are poor in grinding effect, large-particle tablets still exist after grinding, the feeding effect on patients is poor, a small amount of medicine powder adheres to the existing grinding devices in the grinding process, medicine powder is wasted, and meanwhile, the treatment effect on the patients is affected are solved.

Owner:济南高投园区运营管理有限公司

Ultraviolet water treatment equipment with impurity removal function

InactiveCN110668528AAffect the treatment effectAffect circulationWater/sewage treatment by irradiationSpecific water treatment objectivesUltraviolet lightsSewage

The invention relates to ultraviolet water treatment equipment with impurity removal function, which comprises a main body, an ultraviolet lamp, a water inlet pipe and a water outlet pipe, as well asan impurity removal mechanism and a cleaning mechanism, wherein the impurity removal mechanism comprises a filter screen, a worm, a connecting component, two impurity removal components and two rotating components; the impurity removal component comprises a connecting rod, a scraper, a rotating rod and two springs; and the cleaning mechanism comprises a transmission component, two cleaning plates,two circular rings and two limiting components. The ultraviolet water treatment equipment with the impurity removal function realizes the function of pre-impurity removal of sewage through the impurity removal mechanism, reduces the impurity content in the sewage, avoids excessive impurities in the sewage and affects the penetration of ultraviolet rays, thereby affecting the sewage treatment effect of the ultraviolet lamp; and through the cleaning mechanism, the periphery of the ultraviolet lamp can be cleaned, so that the impurities are prevented from adhering to the ultraviolet lamp and affecting the sewage treatment effect of the ultraviolet lamp.

Owner:葛军

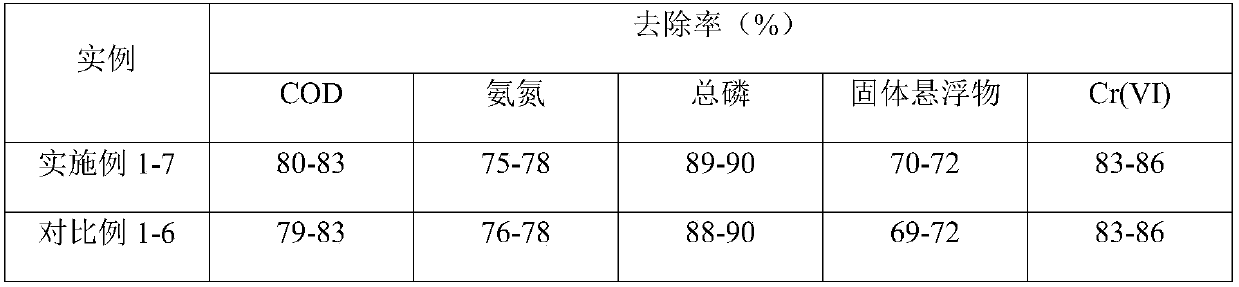

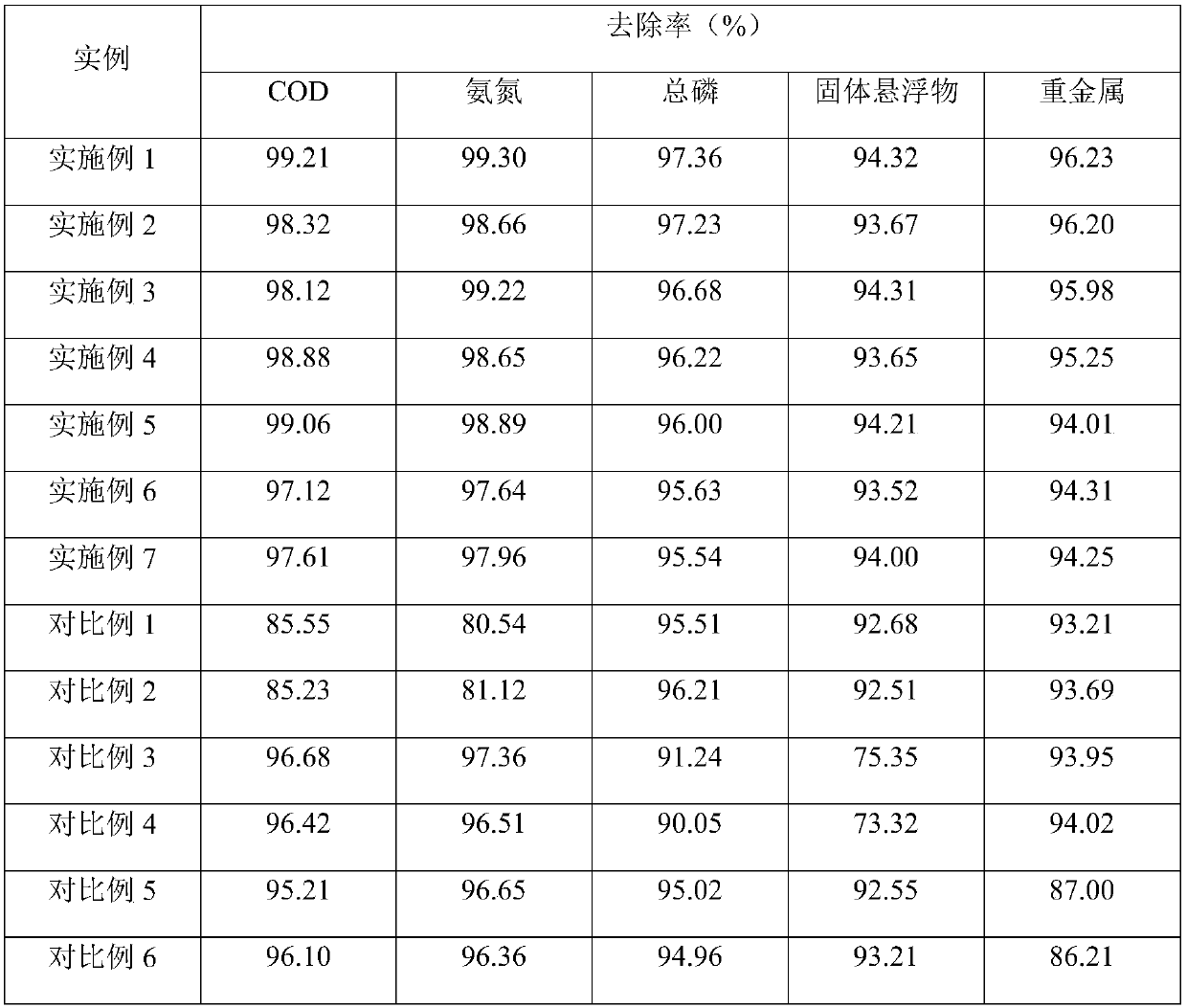

Leachate treatment agent and leachate treatment method

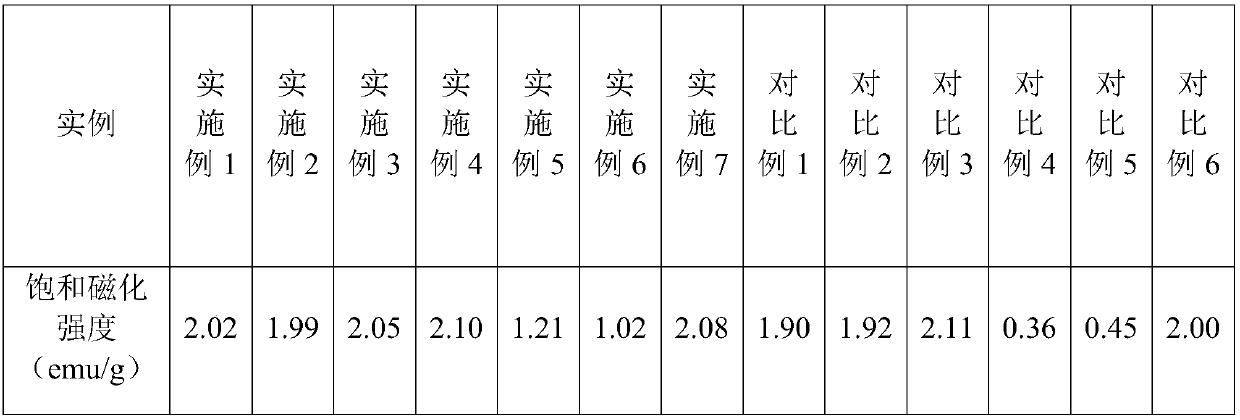

ActiveCN109626484AMagneticEasy to recycleWater contaminantsWater/sewage treatment by sorptionActivated carbonSuspended matter

The invention provides a leachate treatment agent and a leachate treatment method. A Fenton method is adopted for pretreating a garbage leachate, activated carbon is used as a carrier for loading magnesium oxide and an iron compound and used as the treatment agent for deeply treating the leachate, the removal rate of COD, ammonia nitrogen, total phosphorus, solid suspended solid, heavy metal and other substances in the leachate can be increased, the method is quick, economic and efficient, the problems such as secondary pollution cannot be caused, and the treatment agent has magnetism and is convenient to recycle.

Owner:湘潭城乡创新园林工程股份有限公司

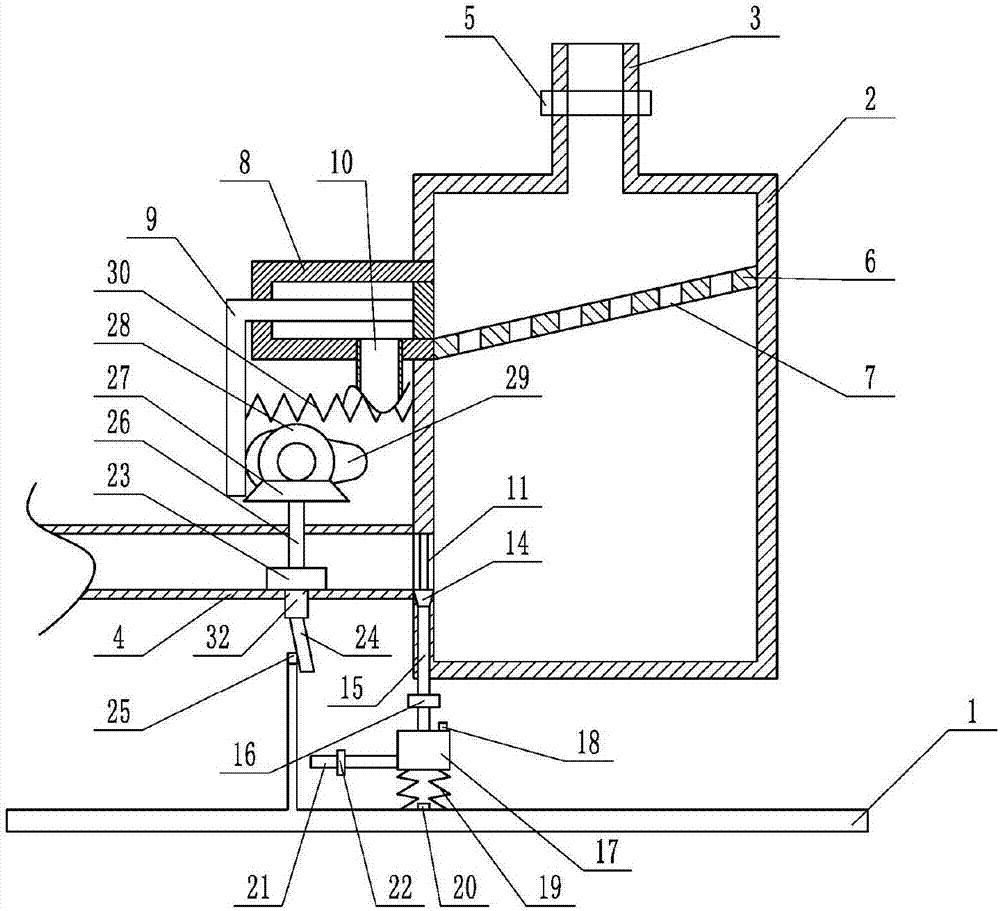

Medicine atomization device for ear-nose-throat nursing

ActiveCN110354346AAvoid wastingAffect the treatment effectPharmaceutical containersMedical devicesMedicineGear wheel

The invention relates to a medicine atomization device for ear-nose-throat nursing. A baffle is arranged at the upper end of a metering bottle, a guide base is fixed to the lower end of a medicine storage tank, and the baffle is slidingly connected with the guide base; a medicine outlet is formed in the bottom of the medicine storage tank, wherein the guide base runs through the medicine outlet, an inlet is formed in the top of the metering bottle, wherein the baffle runs through the inlet, and the metering bottle is slidingly connected with the guide base, so that the medicine outlet can be communicated with the inlet, and the baffle can seal the medicine outlet; the lower end of the metering bottle is rotatably connected with a metering door for sealing the outlet through a rotation shaft, and the rotation shaft is provided with a gear; a rack which is parallel to the sliding direction of the baffle and can be meshed with the gear is arranged in a shell, a sealing door for sealing anopening in a medicine mixing bottle is rotatably connected to the medicine mixing bottle, and the medicine mixing bottle is sealed when the sealing door is not subjected to downward application force. Medicine liquid can be used immediately after preparation, waste of the prepared medicine liquid is avoided, and the situation is avoided that the time delay caused by medicine liquid preparation influences the treatment effect for a patient; through gradual addition for the metering bottle, quantitative addition and proportioning are achieved, and the proportioning precision of the medicine liquid is improved.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

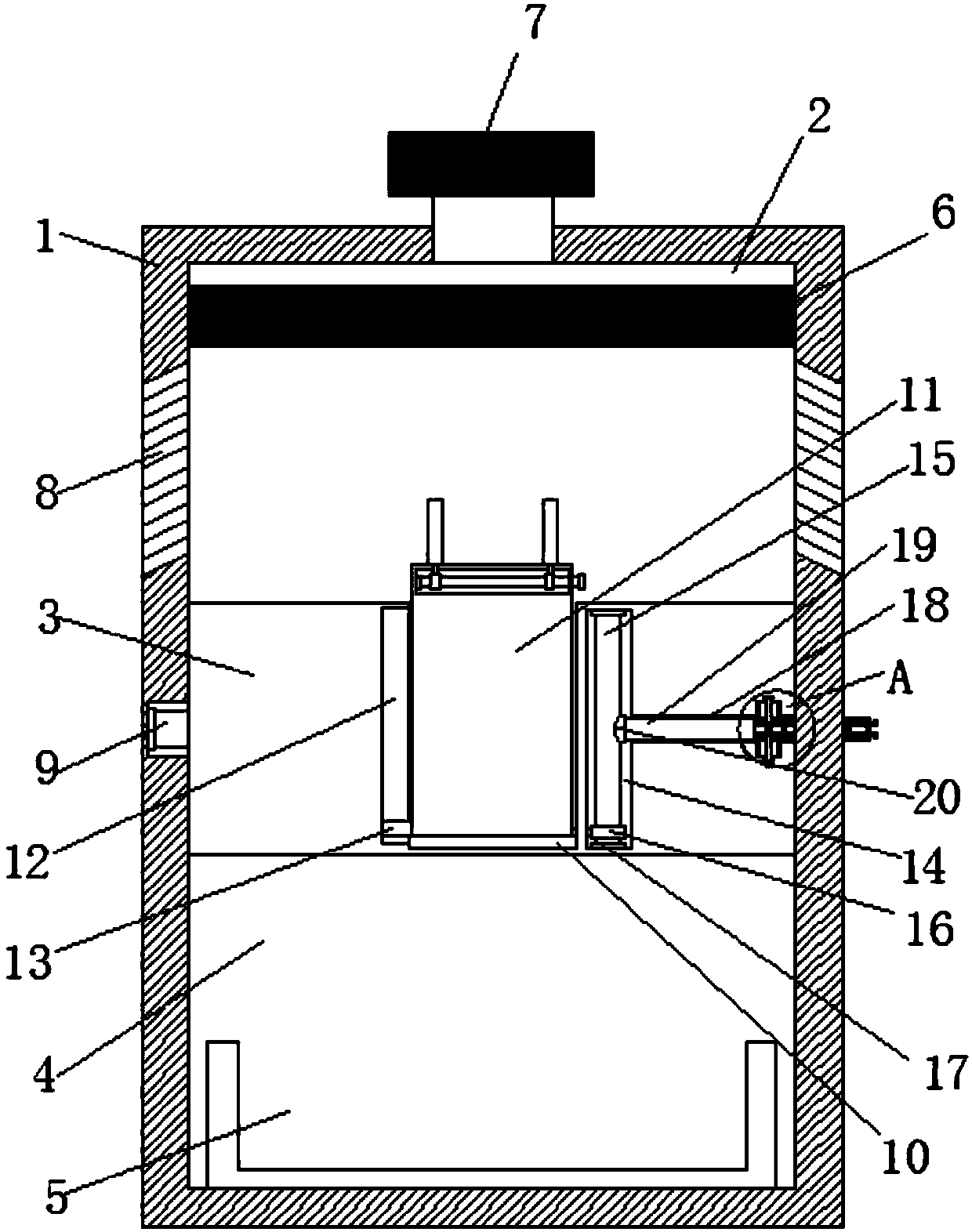

Automobile part quenching device

InactiveCN108330261ADrive mode is environmentally friendlyDrive mode energy savingQuenching devicesFlue gasSoot

The invention belongs to equipment for metal heat treatment and particularly relates to an automobile part quenching device. The automobile part quenching device comprises a quenching box, a heating box, an air feeding box and a flue gas processing box, wherein the heating box, the air feeding box and the flue gas processing box communicate with one another. The heating box is provided with valves. The air feeding box is internally provided with an air feeding channel and a sliding channel. The sliding channel is internally and rotatably connected with a rotary table, the rotary table is connected with a threaded rod in a threaded manner, and the threaded rod is fixedly connected with a workbench. The air feeding channel is internally and rotatably connected with a blade, first torsional springs are connected between the rotary table and the sliding channel. The rotary table is further rotatably connected with an air distribution disc, the air distribution disc is provided with an airinlet and an air outlet, and the air distribution disc is internally provided with a valve core for blocking the air inlet or the air outlet. The air feeding box is internally provided with a workpiece discharging slot, the workpiece discharging slot is formed between the sliding channel and the quenching box in a communicating manner, and the quenching box is further provided with a pipe communicating with the air feeding channel. By the adoption of the automobile part quenching device, the soot generated by oil quenching can be collected and processed, direct emission of the soot is reduced,and the automobile part quenching device is more environmentally friendly and is mostly used for oil quenching machining of automobile parts.

Owner:NINGBO HAIMAN AUTOMOTIVE TECH CO LTD

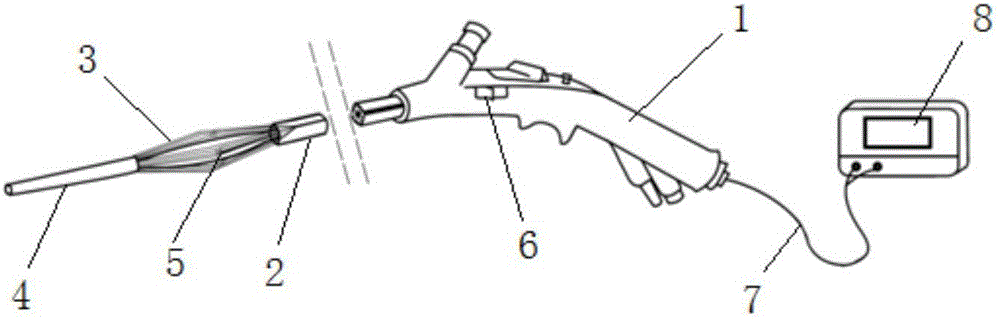

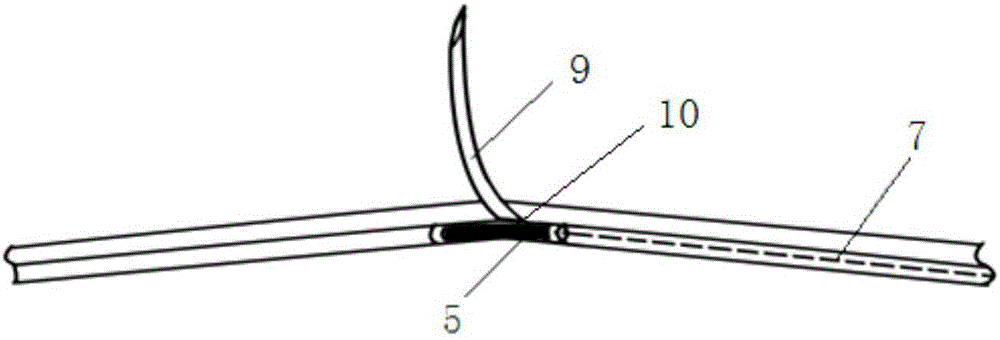

Radio-frequency ablation catheter for accurately positioning lower esophageal sphincter

PendingCN106420042APrecision therapyGood treatment effectCatheterDiagnostic recording/measuringOesophageal tubeSaccule

The invention discloses a radio-frequency ablation catheter for accurately positioning the lower esophageal sphincter (LES). The radio-frequency ablation catheter comprises a catheter handle and a catheter body, wherein the near end of the catheter body is connected with the catheter handle; a catheter part at the near end of a saccule part, a saccule part and a catheter part at the far end of the saccule part are sequentially arranged at the far end of the catheter body; and a pressure sensor is arranged on at least one of the saccule part, the catheter part at the far end of the saccule part and the catheter part at the near end of the saccule part. In the invention, a pressure measuring device is added to the radio-frequency ablation catheter and used for measuring the esophagus pressure in real time and accurately positioning the LES, then purposeful radio-frequency ablation treatment can be performed on the LES, the treatment effect is improved, adverse reactions of the treatment are reduced, and accurate treatment of reflux esophagopathy is possible.

Owner:SHANDONG UNIV QILU HOSPITAL

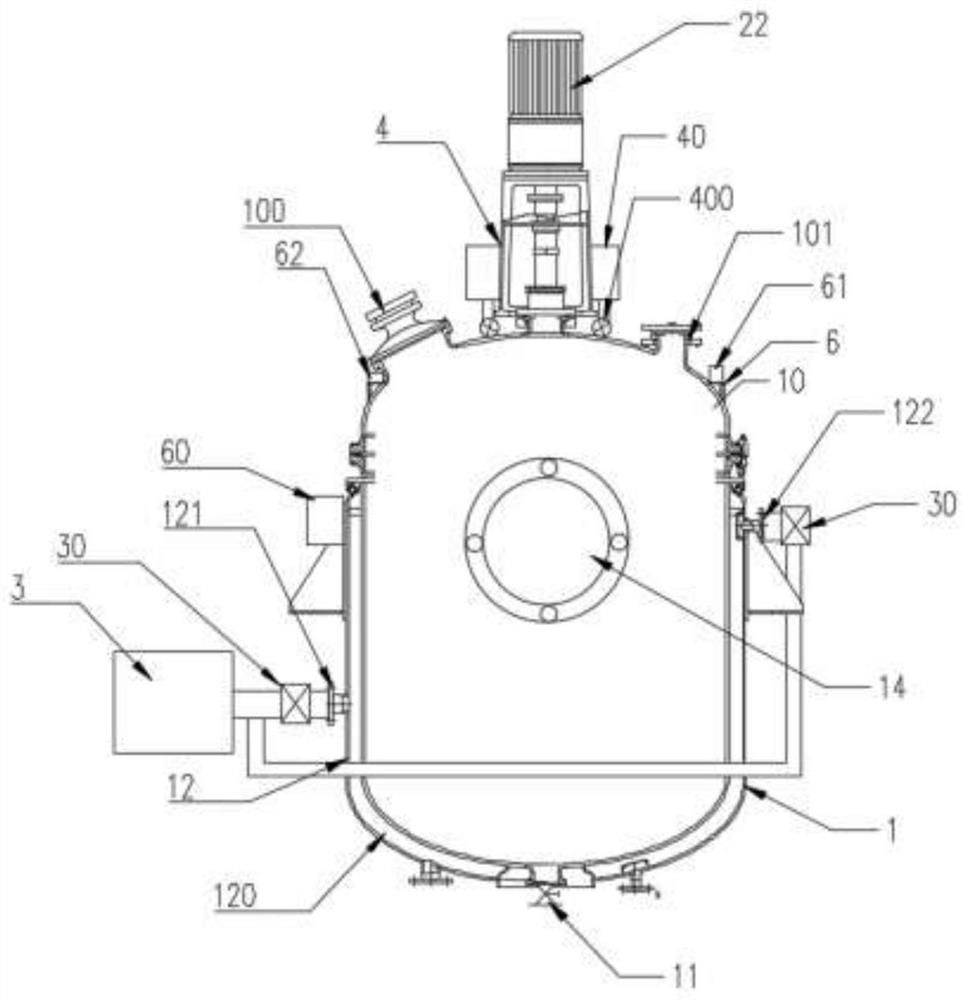

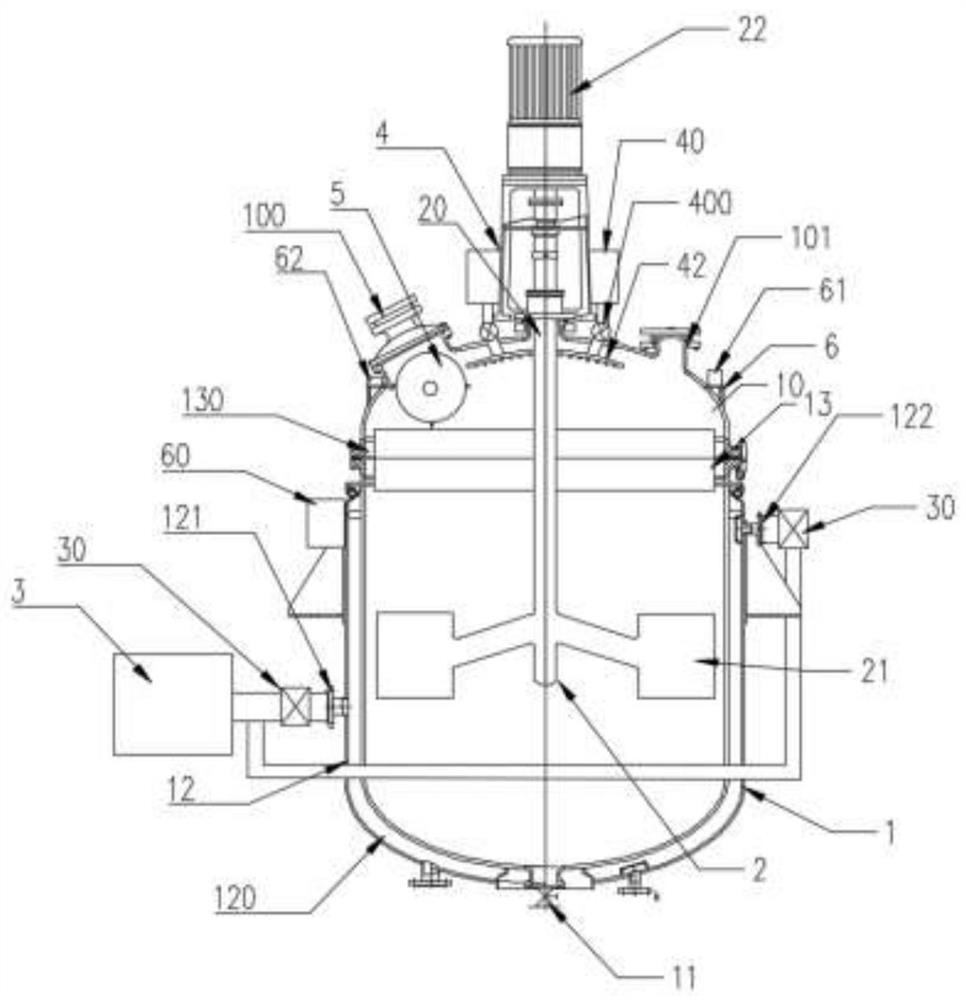

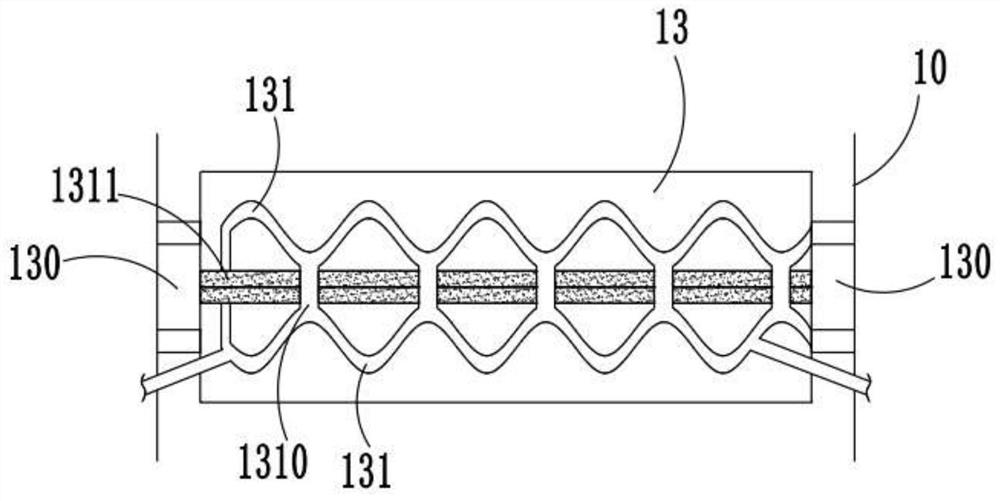

Cooling reactor having slag salvaging function and used for wastewater acid-base neutralization, and application of cooling reactor

PendingCN112456628AAdequate responseSolve the series of negative problems of heat releaseWater treatment parameter controlVapor condensationThermodynamicsSlag

The invention provides a cooling reactor having a slag salvaging function and used for wastewater acid-base neutralization, and application thereof. The cooling reactor comprises a tank body, a stirring and slag salvaging element, a cooling water tank, a mist cooling and collecting element, a quantity control adding element, an intelligent control element and a power supply. According to the invention, the reactor with the cooling function can be used for cooling a reaction medium, ensuring the safety of operation and regions, and quantitatively adding neutralizing agents in batches, so that the sufficient reaction of the neutralizing agents with waste acid and waste alkali can be ensured while the quantitative addition is met, and the treatment effect is improved; by arranging two annularseal strip plates which can be buckled with each other, the situation that acid and alkali in the tank body are splashed during stirring to corrode the sealing ring between the tank cover and the tank body so as to cause leakage to cause production accidents is avoided; and when the temperature in the tank body rises, the cooling channels also exist in the annular seal strip plates to cool the annular seal strip plates, so that the aging of the sealing ring due to local temperature rise can be avoided, and the service life of the device is shortened.

Owner:恩宜瑞(江苏)环境发展有限公司

Reinforced concrete waste treatment method

InactiveCN112657660APrevent crushingReduce sizeGrain treatmentsReinforced concreteArchitectural engineering

The invention belongs to the technical field of waste treatment, and particularly relates to a reinforced concrete waste treatment method. The reinforced concrete waste treatment method comprises the following steps that firstly, workers put the reinforced concrete into a treatment box from a feeding mechanism manually or by utilizing a feeding instrument; then a pre-crushing mechanism at the top of the treatment box pre-crushes the reinforced concrete waste fed from the feeding mechanism, the pre-crushed reinforced concrete falls down from a penetrating groove in the middle of a partition plate, a partition plate is fixedly arranged on the top between the inner walls of the two sides of the treatment box, the penetrating groove is formed in the middle of the partition plate, and the two sides of the outer wall of the top of the partition plate incline downwards towards one side close to the penetrating groove; and according to the reinforced concrete waste treatment method, waste materials sequentially enter a crushing cavity among a first crushing roller, a second crushing roller and a third crushing roller from the middle position, and reinforcing steel bars can be bent along spiral grooves in the outer walls of the crushing rollers and feeding rollers to be conveyed out of a discharging groove, or the reinforcing steel bars are bent and folded to be conveyed out of the discharging groove along with the spiral grooves in the outer wall of the feeding rollers.

Owner:安徽新红胜装饰工程有限公司

Complex forge piece oil immersion, oil pouring and blow drying integrated device

ActiveCN107930978AImprove processing efficiencyAffect the treatment effectPretreated surfacesCoatingsEngineeringAir blower

The invention discloses a complex forge piece oil immersion, oil pouring and blow drying integrated device which comprises a shell. The shell is of a hollow structure. A partition plate transversely arranged in the shell divides the shell into a blow drying chamber and an oil immersion chamber. The blow drying chamber is located above the oil immersion chamber. An oil storage groove is formed in the oil immersion chamber. The side wall of the upper end of the shell is provided with an air blower. The output end of the air blower is connected with the blow drying chamber. The side walls on thetwo sides of the shell are further provided with air outlets communicating with the blow drying chamber. The side wall on one side of the partition plate is rotationally connected with the inner wallof the shell through a rotating shaft. The partition plate is provided with an installation groove with an upward opening. An installation plate is arranged in the installation groove. The complex forge piece machining efficiency is improved, and the surfaces of complex forge pieces are prevented from being polluted when the complex forge pieces are transferred from one process to next process.

Owner:合肥海诺恒信息科技有限公司

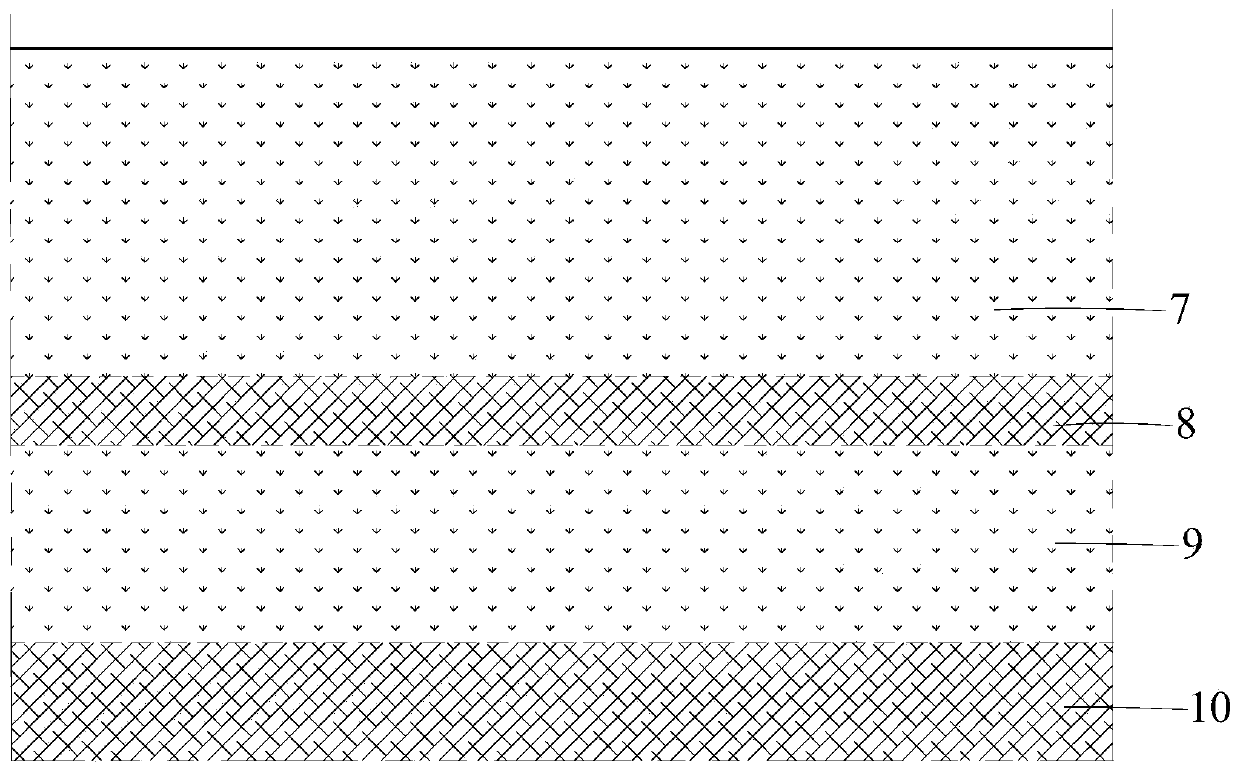

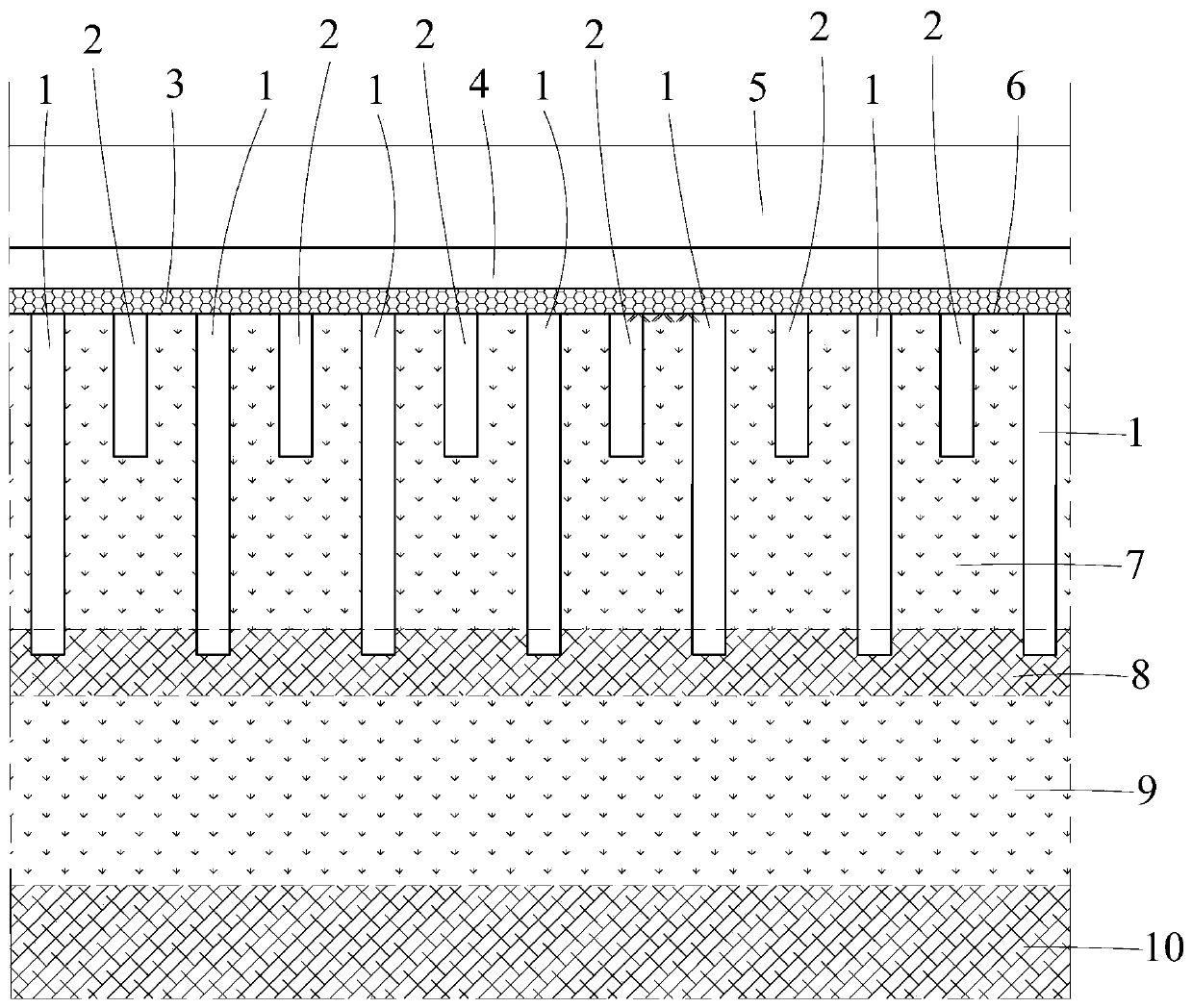

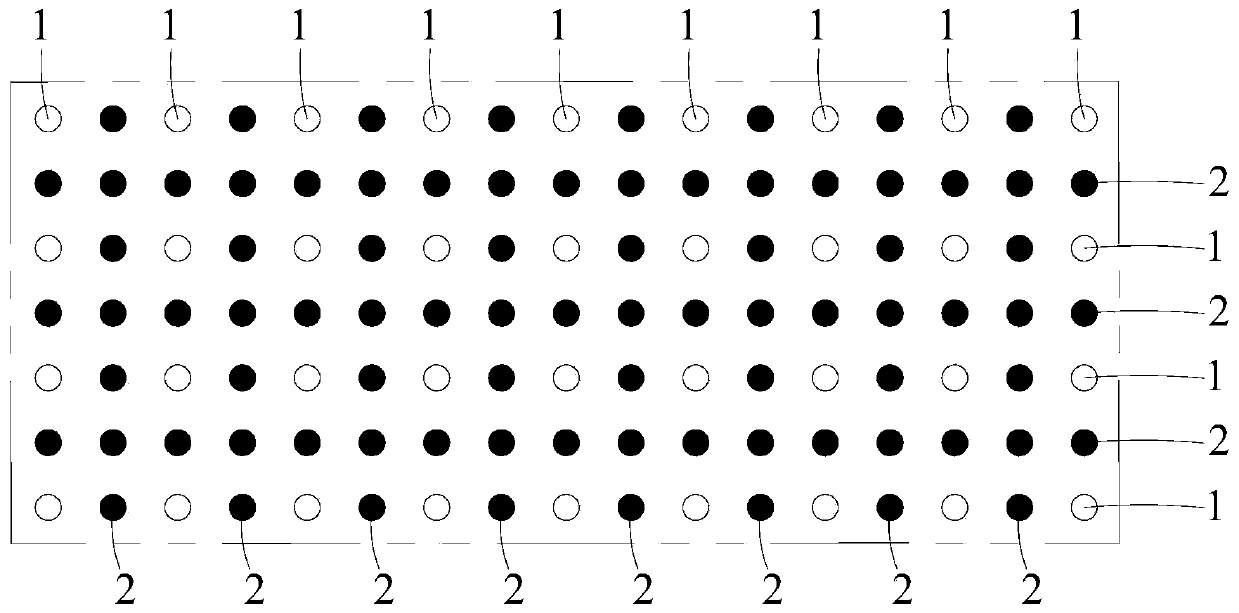

Foundation treatment structure suitable for deep soft foundation with sandwiched thin bearing stratum and construction method

PendingCN111321751ASave engineering investmentSolve the large settlementBulkheads/pilesPipeBearing capacity

The invention belongs to the field of geotechnical engineering, and particularly relates to a foundation treatment structure suitable for a deep soft foundation with a sandwiched thin bearing stratumand a construction method. The foundation treatment structure comprises a raft, a mattress layer, pipe piles and stirring piles, wherein the mattress layer is arranged at the bottom of the raft and located at the top of an upper soft soil foundation layer; the pipe piles are arranged at intervals and arranged at the bottom of the mattress layer, and the lower ends of the pipe piles are located ina middle bearing stratum; and the stirring piles are arranged at intervals and arranged at the bottom of the mattress layer and located in the upper soft soil foundation layer. According to the foundation treatment structure suitable for the deep soft foundation with the sandwiched thin bearing stratum, the engineering investment is saved; and settlement of a composite foundation is reduced, the bearing capacity of the composite foundation is improved, and the problems that the foundation settlement is large, the foundation bearing capacity is low and the pipe piles are prone to piercing the middle bearing stratum when the pipe piles are located in the middle bearing stratum are solved.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

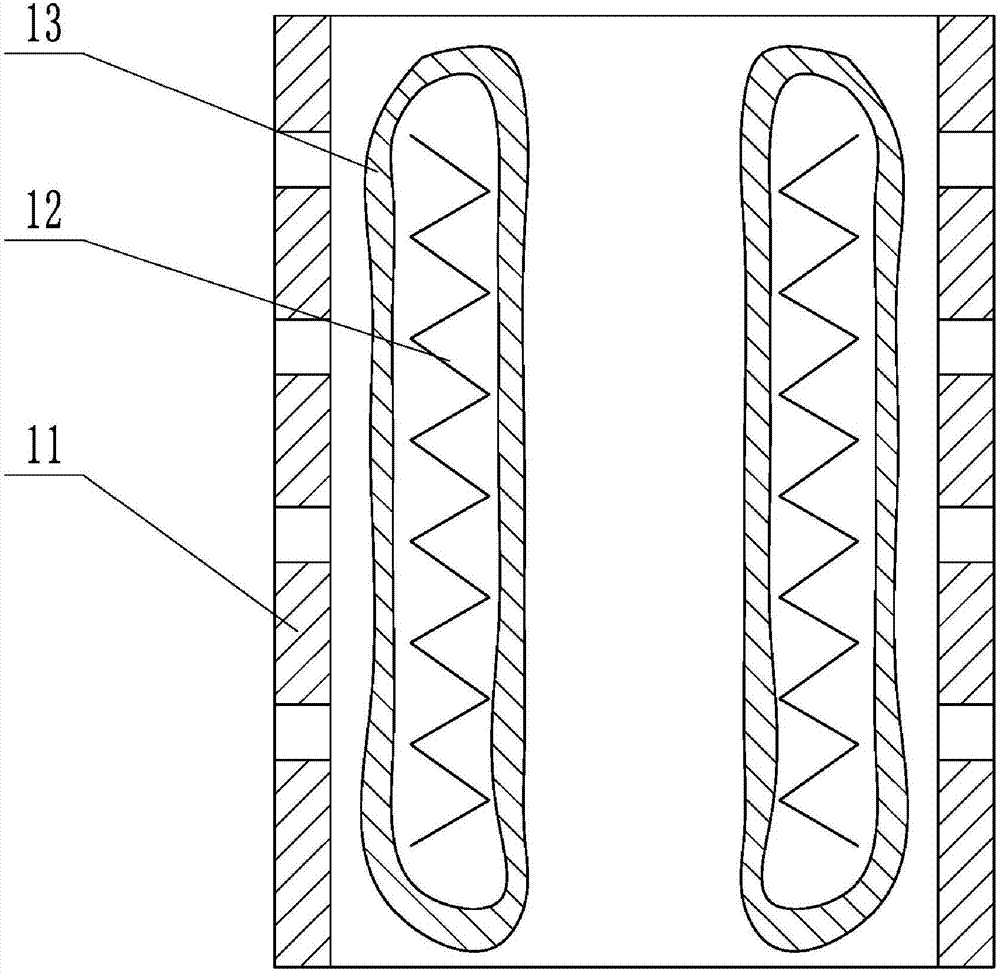

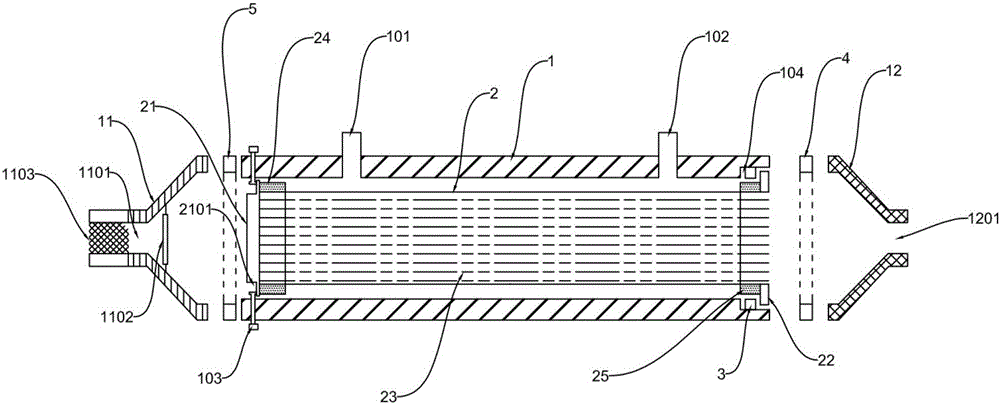

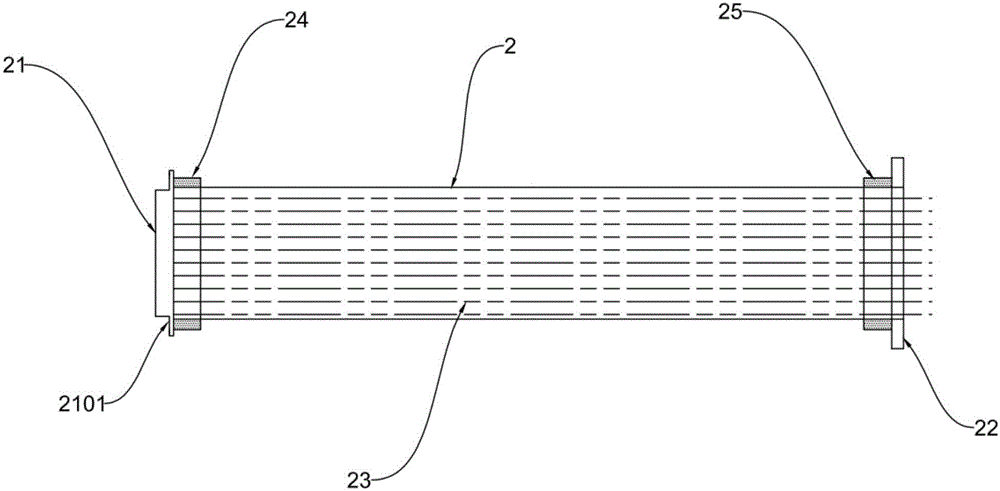

High-strength hollow fiber membrane module and preparation method thereof

PendingCN107174957AAvoid affecting service lifeAvoid damageMembranesSemi-permeable membranesEpoxyPolymer science

The invention relates to a high-strength hollow fiber membrane module and a preparation method thereof. The high-strength hollow fiber membrane module at least comprises an outer membrane cavity and an inner membrane core which is assembled inside the outer membrane cavity, wherein one end part of the inner membrane core is taken as an epoxy resin polystyrene sealing end, and the other end part of the inner membrane core is taken as an epoxy polystyrene resin casting end; two sides of the outer membrane cavity are provided with a left end part gland and a right end part gland respectively; the left end part gland is assembled on one side of the epoxy resin sealing end; an epoxy resin flexible glue protection layer is arranged beside the epoxy resin polystyrene sealing end; an outlet end epoxy resin flexible glue protection layer is cast beside the epoxy resin polystyrene casting end. By adopting the high-strength hollow fiber membrane module, hollow fiber membrane filaments beside the casting end can be effectively prevented from being damaged, and the service life of the hollow fiber membrane module is prolonged; the airtightness of the hollow fiber membrane module, particularly on sealing parts at two ends of the membrane filaments is enhanced, the requirement on separation at a high temperature is met, and the separation efficiency is increased. At the same time, the invention further provides a preparation method of the hollow fiber membrane module.

Owner:四川久润环保科技有限公司

Domestic sewage treatment device for environmental protection engineering

InactiveCN112892021AAffect the treatment effectReduce sheddingStationary filtering element filtersEngineeringStructural engineering

The invention discloses a domestic sewage treatment device for environmental protection engineering, and relates to the technical field of sewage treatment. The device comprises a treatment box, the upper surface of the treatment box is fixedly communicated with a liquid inlet hopper, limiting rods are fixedly connected to the inner walls of the two sides of the treatment box, a filter screen plate is arranged between the inner walls of the two sides of the treatment box, the limiting rods penetrate through the two side walls of the treatment box and are slidably connected with the treatment box, and the outer surfaces of the limiting rods are sleeved with reset springs; a plurality of uniformly distributed clamping blocks are fixedly connected to the lower surface of the filter screen plate, a rotating motor is fixedly mounted on the rear end face of the treatment box, a mounting rod is fixedly connected to the output end of the rotating motor through a coupler, a roller is fixedly mounted on the outer surface of the mounting rod, and a plurality of uniformly distributed tooth blocks are fixedly connected to the outer surface of the roller, and the clamping blocks are engaged with the tooth blocks. The problems that according to an existing sewage treatment device, a filter screen plate is difficult to shake, and impurities left on the filter screen plate are difficult to treat are solved.

Owner:江门高净环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com