Foundation treatment structure suitable for deep soft foundation with sandwiched thin bearing stratum and construction method

A construction method and bearing layer technology, which is applied in the direction of foundation structure engineering, building, sheet pile wall, etc., can solve the problems of large project investment and difficulty in controlling the depth of the bearing layer at the end of settlement piles, so as to reduce engineering investment and reduce the The effect of squeezing soil and saving engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

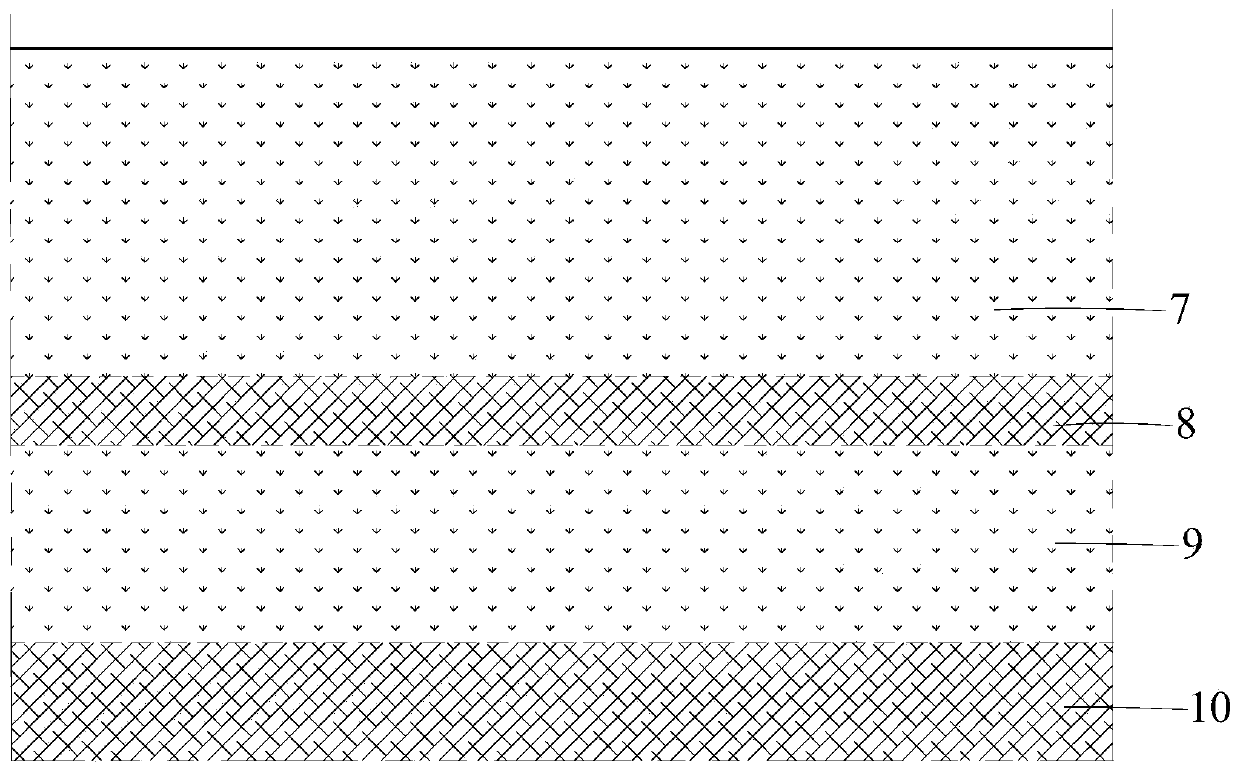

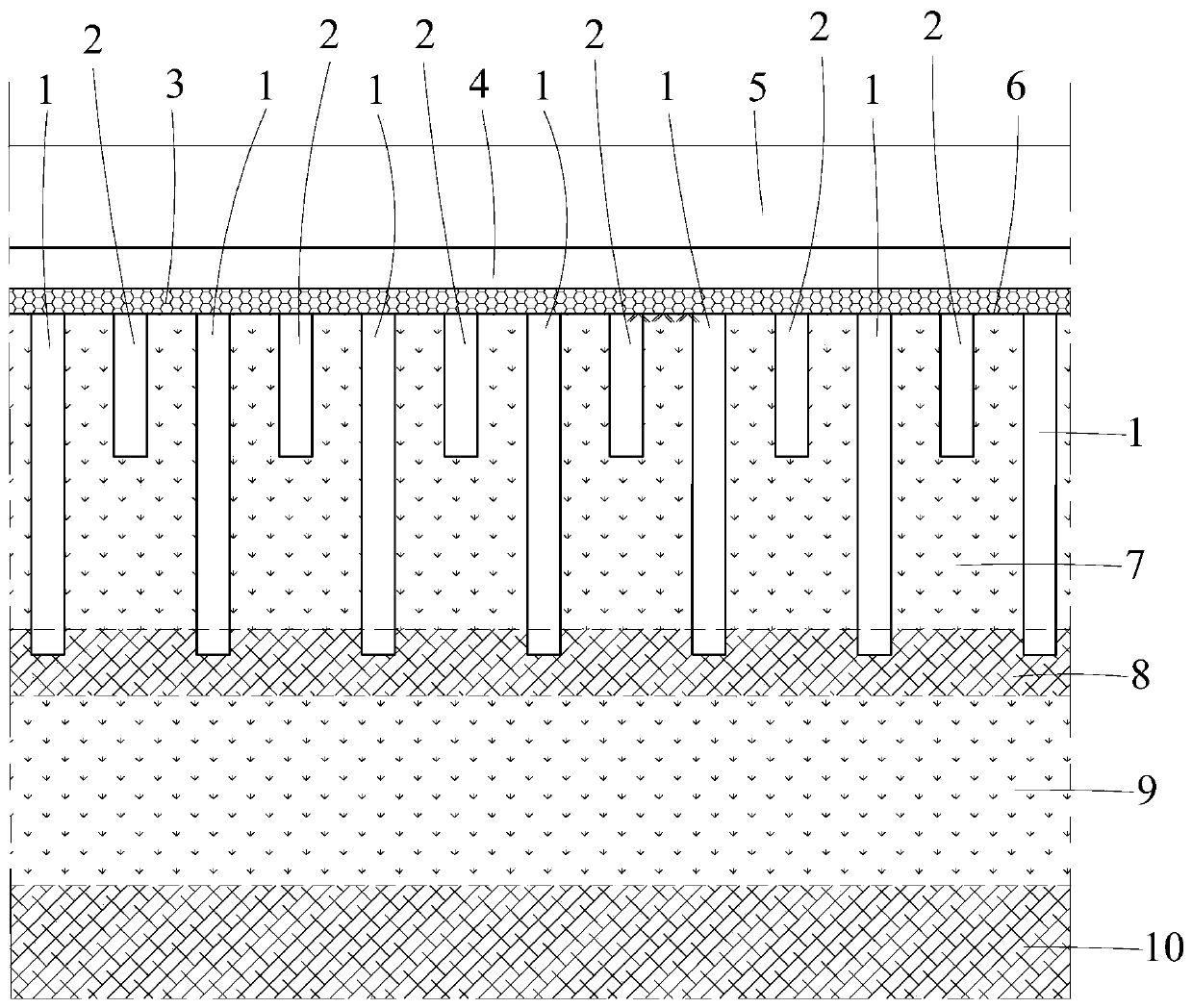

[0069] Such as Figure 2-3 As shown, a kind of deep and thick soft foundation treatment structure suitable for sandwiching a thin bearing layer described in this embodiment, the foundation conditions are as follows: the upper soft soil base is silt with a thickness of 20m, and the middle bearing layer is silty clay with a thickness of 3m. The upper soft soil base is 27m thick silt mixed with sand, the lower supporting layer is coarse sand, and the upper filling soil is 3m thick silty clay.

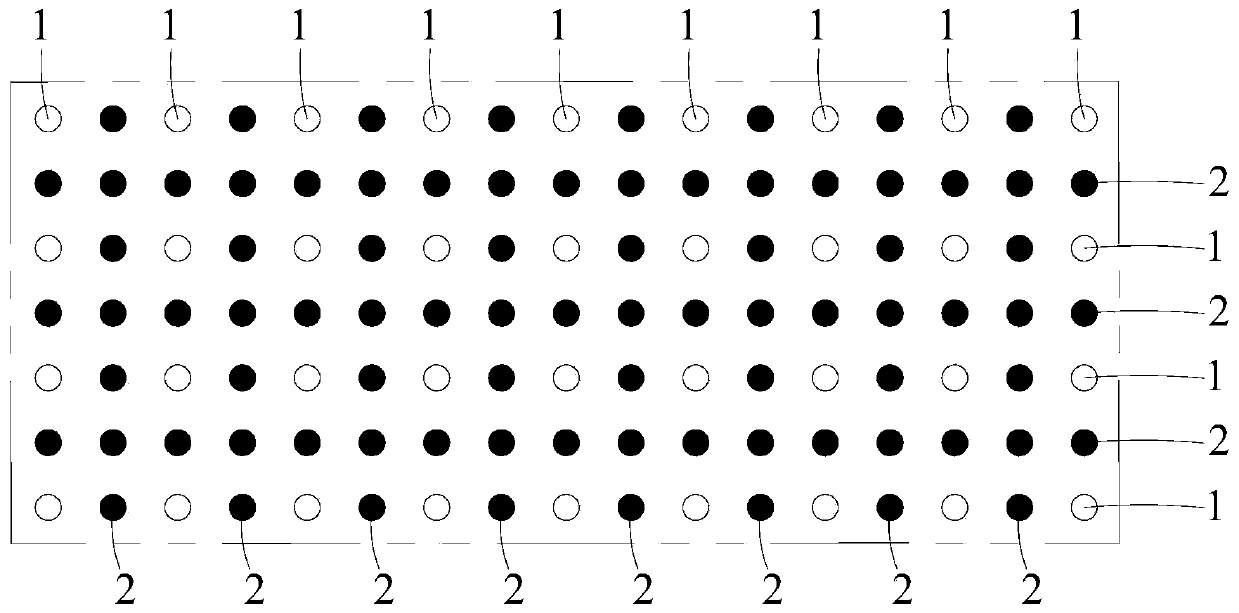

[0070] A deep and thick soft ground foundation treatment structure suitable for sandwiching thin bearing layers, comprising a raft 4, a cushion layer 3, pipe piles 1 and stirring piles 2. The raft 4 is arranged under the filling 5, the mattress layer 3 is arranged near the natural ground below the raft 4, the pipe piles 1 and the stirring piles 2 are arranged at intervals under the mattress layer and are in close contact with the bottom surface of the mattress layer 3, and the pipe piles ...

Embodiment 2

[0080] Such as Figure 2-5 As shown, a deep and thick soft ground foundation treatment structure suitable for sandwiching thin holding layers described in this embodiment,

[0081] 1: Level the site, measure and set out the line, and determine the position of each pipe pile 1 and mixing pile 2;

[0082] 2: Complete the construction of all the mixing piles 2 in sequence, and let them stand for a period of time, so that the mixing piles 2 have a certain strength.

[0083] 3: Complete the construction of all construction pipe piles 1, conduct quality inspection, and pass the inspection;

[0084] 4: fill the cushion layer 3 in layers and compact it, carry out quality inspection, after the inspection is qualified;

[0085] 5: Bind the reinforcement cage of the raft 4, cast the concrete of the raft 4 in the vertical formwork, and complete the construction of the raft 4;

[0086] 6: Fill the fill layer by layer 5 and compact it, and construct the superstructure.

[0087] Since th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com