Patents

Literature

77results about How to "Reduce the crowding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

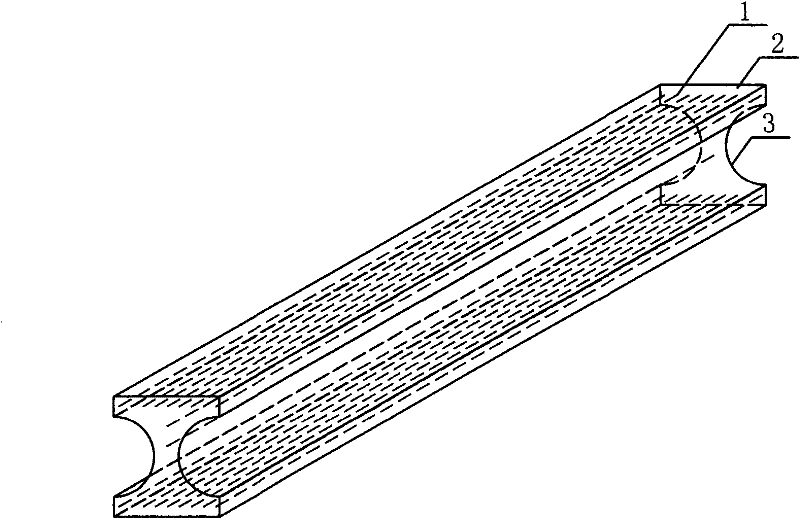

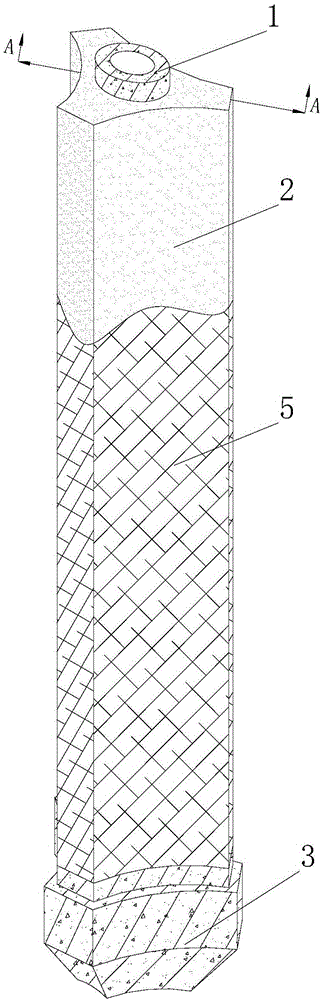

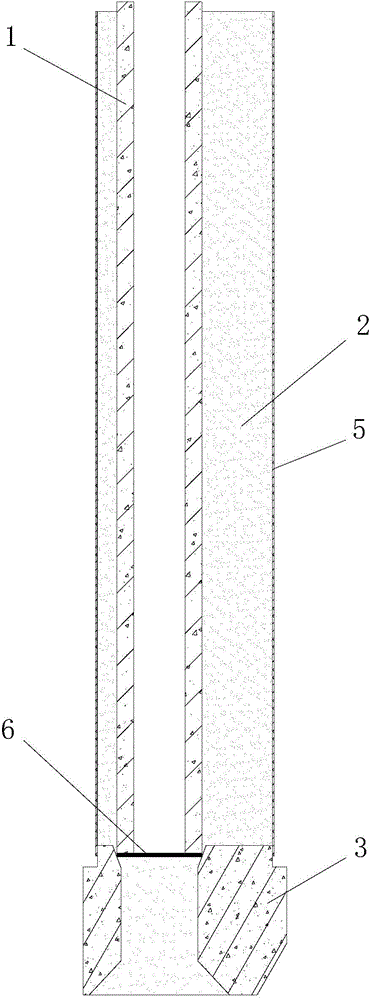

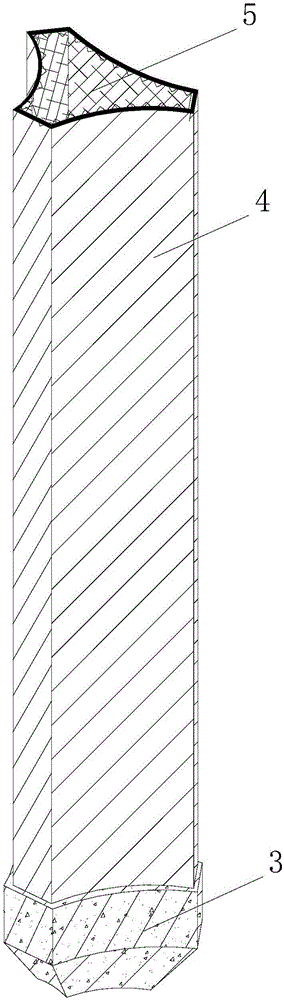

A kind of open high-strength concrete prefabricated pile and its pile form, centrifugal manufacturing method

InactiveCN102261065AImprove bearing capacityReduce the cross-sectional areaMouldsBulkheads/pilesHigh strength concreteCentrifugation

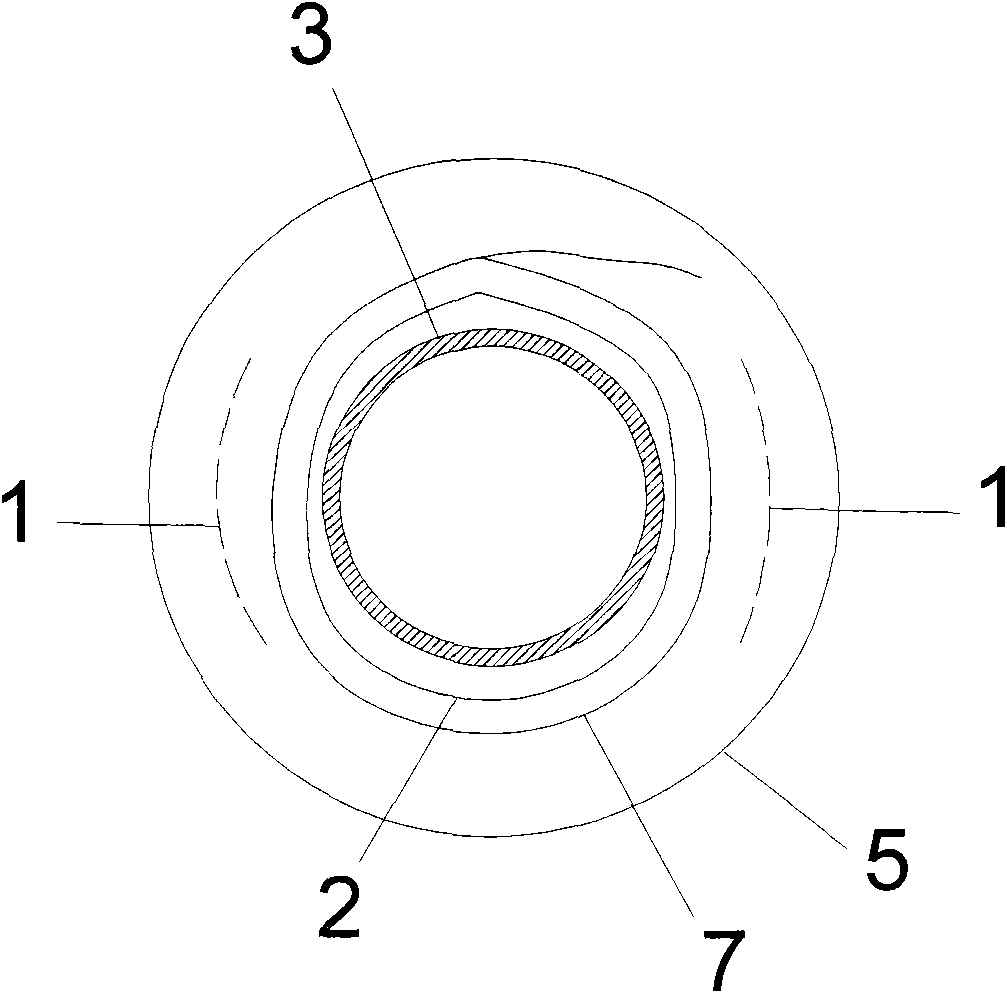

The invention relates to an open high-strength concrete prefabricated pile in the field of pile foundation engineering, a pile form thereof, and a centrifugal manufacturing method. 1) The outer high-strength concrete prefabricated pile body (2), and on the side of the high-strength concrete prefabricated pile body (2), there is a concave surface (3) with a centrifugally formed cross-section and an arc-shaped cross-section, depending on the shape of the cross-section. , proposed pile types such as H-type piles, groove piles, corner piles, open cylindrical piles, star piles, etc., and then put forward the pile mold and forming method of one-time centrifugal forming multi-section piles, and proposed open high-strength concrete precast piles and cement The structural composition and construction method of the PMW earth-retaining and water-stop pile combined with soil piles, the open high-strength concrete prefabricated pile of the present invention has high material strength, good flexural performance, small pile driving effect, and can greatly save the cost of pile foundation engineering. , the environmental protection benefits are outstanding.

Owner:张继红

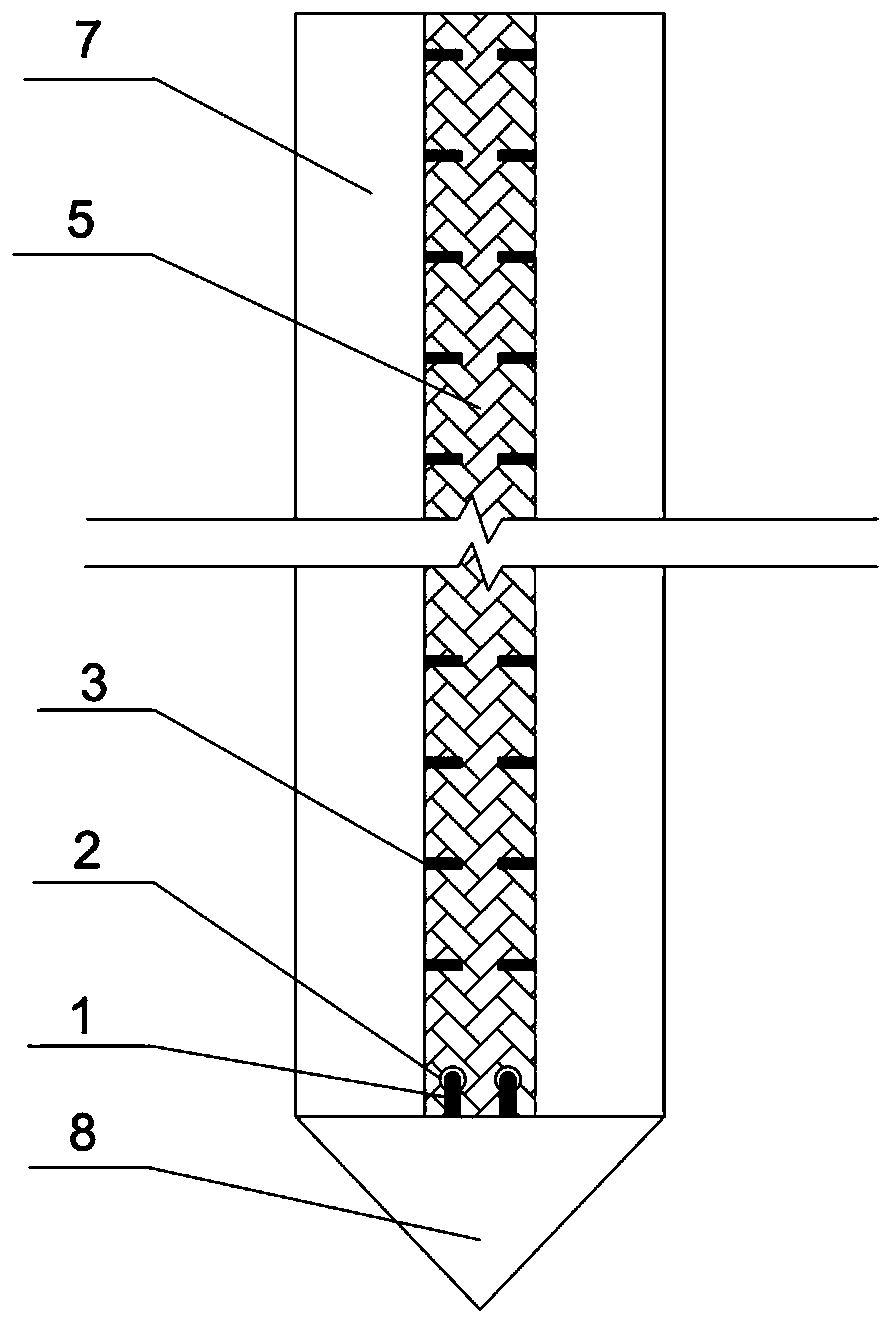

Original soft clay hollow cylinder sample manufacture method

InactiveCN101101241AReduce disturbanceReduce the crowding effectWithdrawing sample devicesPreparing sample for investigationStress conditionsSoft clay

The invention discloses a sampling method of status quo soft clay hollowness column sample. It includes the steps as follow: (1) fixing the core status quo soft clay hollowness column ample on the positioning board of cut core machine; (2) fixing the undisturbed sample between the drive dial and driven dial, cutting the outwall by drawknife. After the outwall forming, placing the fittings of block retaining ring,both steel model to fix sample;(3) Driving cut core machine drill pipe, cutting and fetching the core of sample by spiral bit and dismantle tool point slice; (4) every time when fetch the depth to 2cm, back out drill pipe, draw out overburden layer, and reset drill bit, fetching core repeat;(5) stop fetching core when the accumulation depth exceed standard depth 2cm;(6) unbolting the sample, shaving off the fluctuation end, finish preparation of sample. The invention can set the status quo soft clay hollowness column sample, the effect of perturbation and pile soil is small, providing the equipment bond guarantee for developing the experimental investigation of status quo soft clay under the complex stress condition.

Owner:ZHEJIANG UNIV

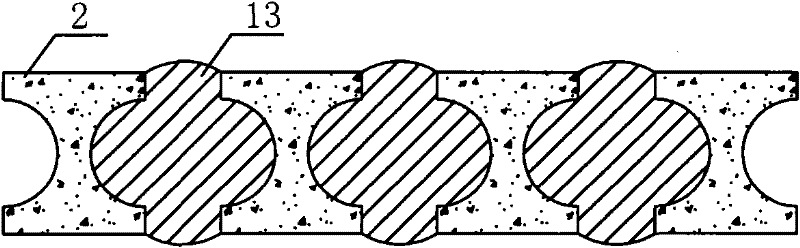

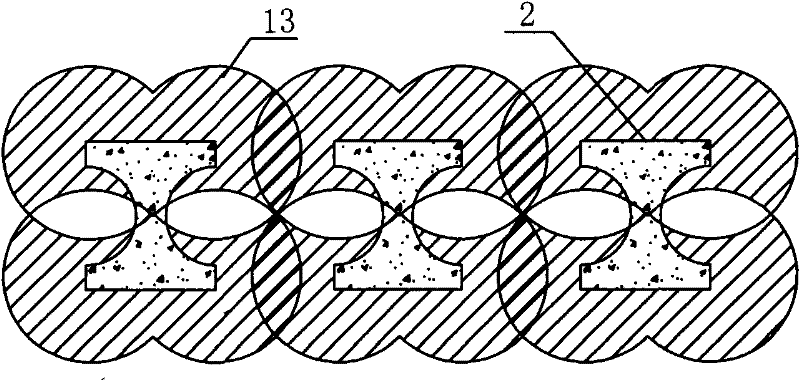

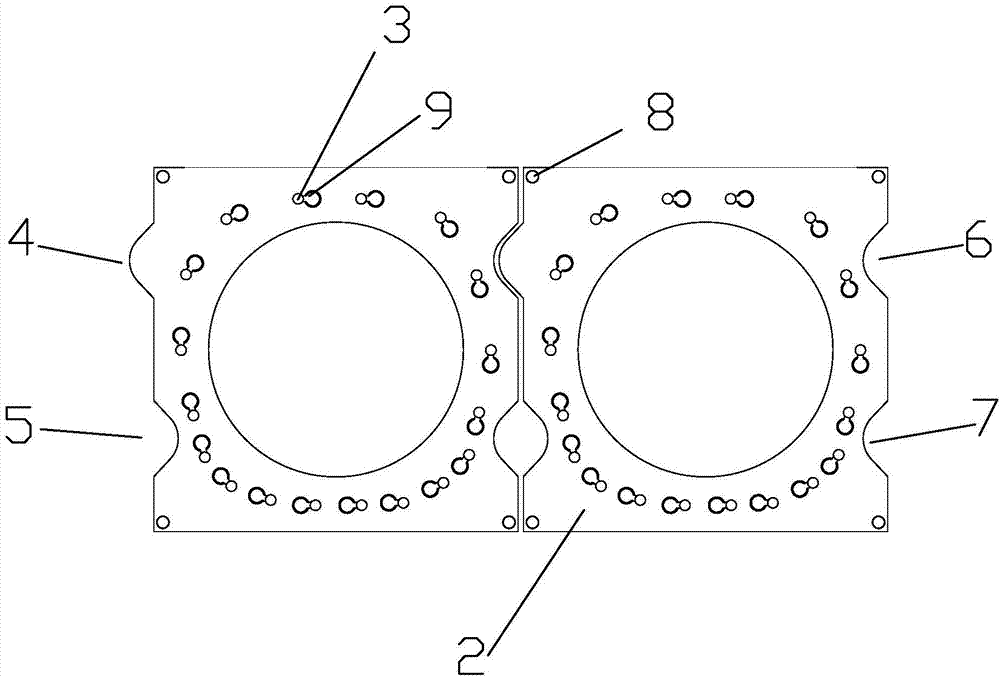

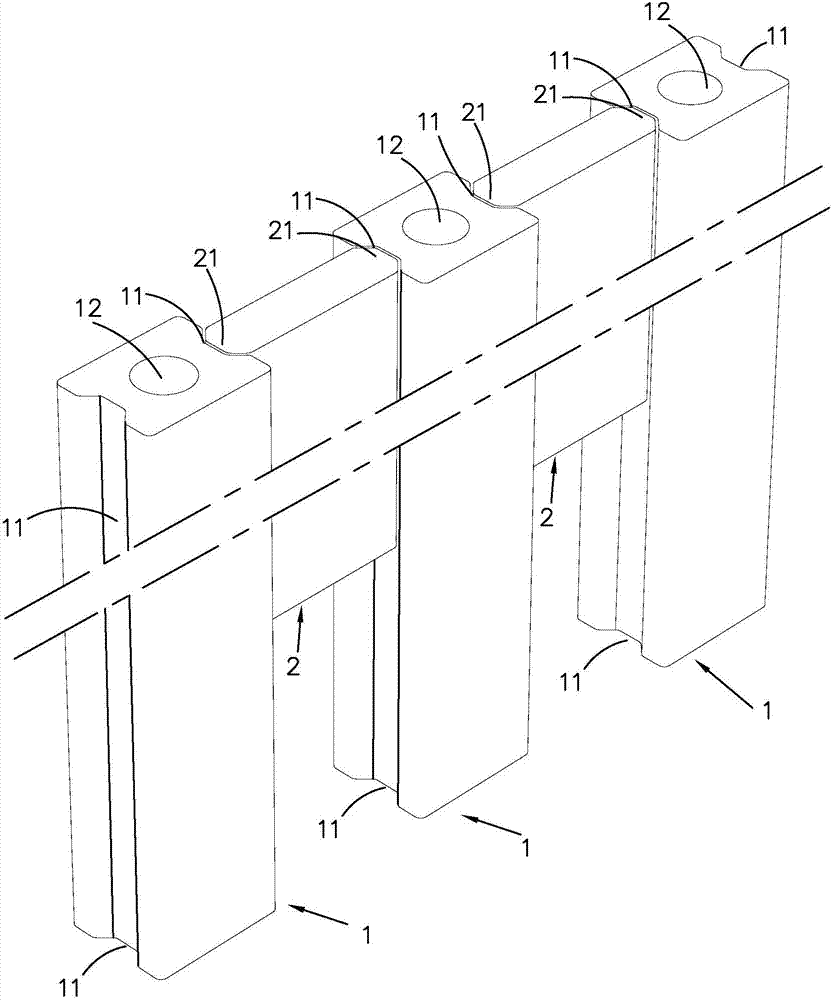

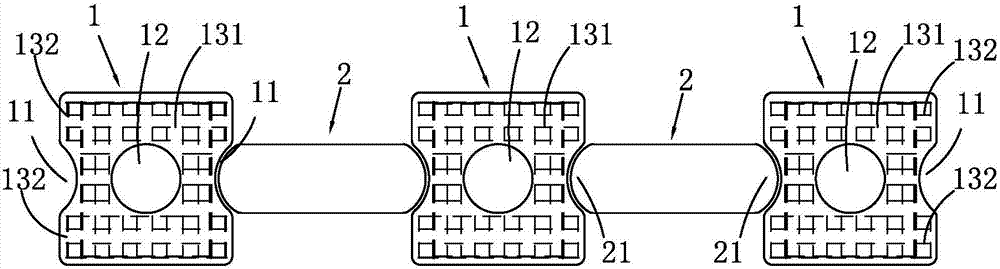

Prestressed concrete precast pile

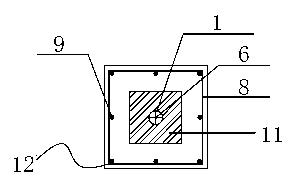

ActiveCN103572755ANot easy to tiltImprove bending abilityBulkheads/pilesSquare cross sectionPre stress

The invention discloses a prestressed concrete precast pile. The prestressed concrete precast pile comprises a precast pile body with a square cross section, wherein the precast pile body comprises two end plates, a pile body and prestressed reinforcements, the pile body is arranged between the two end plates, and the prestressed reinforcements are arranged in the pipe body and connected with the two end plates; bulge rib which longitudinally extends to an end and a first groove which longitudinally extends and penetrates through the end are arranged on an outer side surface of the precast pile body; and a second groove and a third groove which are corresponding to positions of the bulge rib and the first groove respectively, matched in shape and size and longitudinally extend and penetrate through an end of the precast pile body are formed in one outer side surface which is not adjacent to the outer side surface. According to the prestressed concrete precast pile, the construction is convenient, the engineering cost can be reduced, the water stopping effect is enhanced, and the prestressed concrete precast pile has good bending and shearing resistance.

Owner:宁波中淳高科股份有限公司

Slurry injection technique of double-valve sleeve valve tube of cloth bag

ActiveCN101644049ADissipate excess static pore water pressureDissipate water pressureBulkheads/pilesSoil preservationInjection pressureSleeve valve

The invention relates to a slurry injection technique of a double-valve sleeve valve tube of a cloth bag. For overcoming the defect of the slurry injection technique of a sleeve valve tube, a cloth bag made of geotextile is sleeved on a sleeve valve tube and is firmly bound on the sleeve valve tube at the interval of 1.5-2 m by plastic buckles; mechanical equipment is used for drilling holes to the design depth; the made double-valve sleeve valve tube of the cloth bag is installed; slurry is injected in segments from top to bottom; after each slurry injection segment reaches the designed slurry injection pressure, the plastic buckles can be automatically opened; and meanwhile, one to two plastic drainage plates are arranged outside the cloth bag, thereby eliminating partial water in slurryliquid, dissipating the super-static pore water pressure of injection slurry in a foundation and reducing the soil squeezing effect. The double-valve tube is used for directly injecting slurry, doesnot need sleeve shell material, is not easy to leak slurry and is easy to form a column body.

Owner:CRCC HARBOR & CHANNEL ENG BUREAU GRP

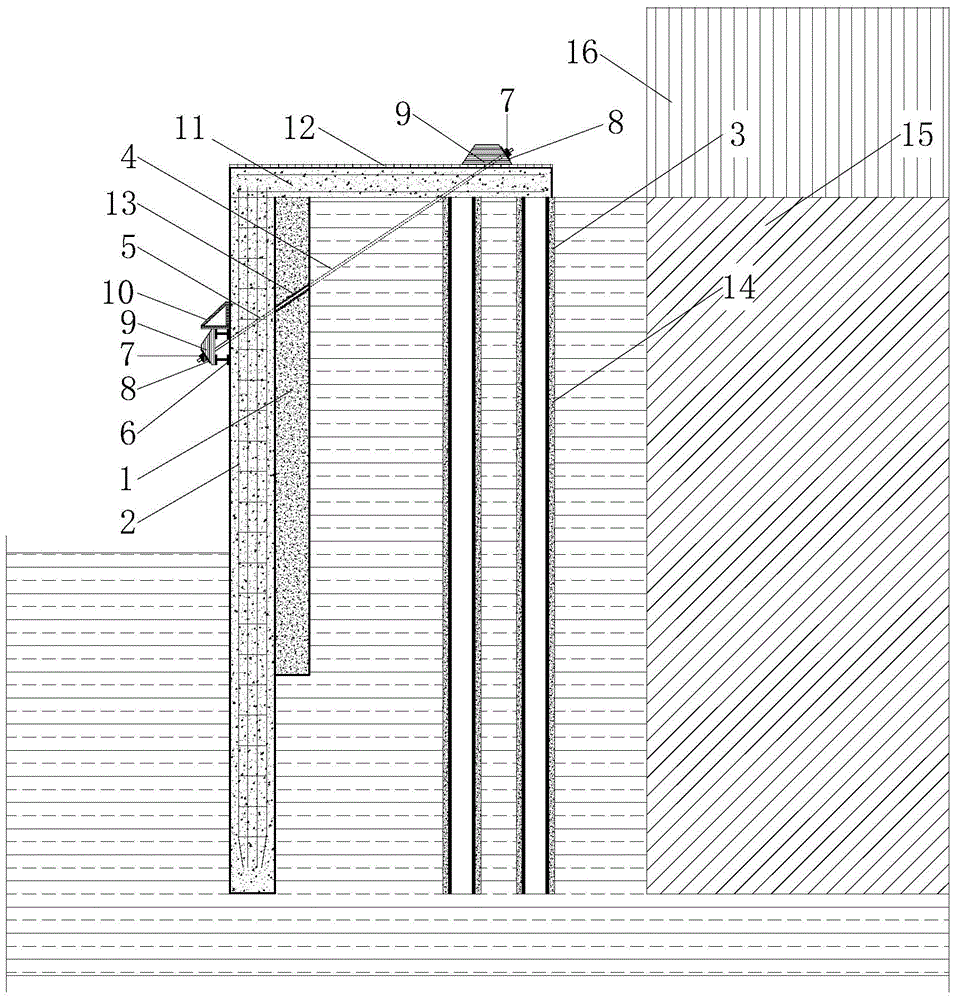

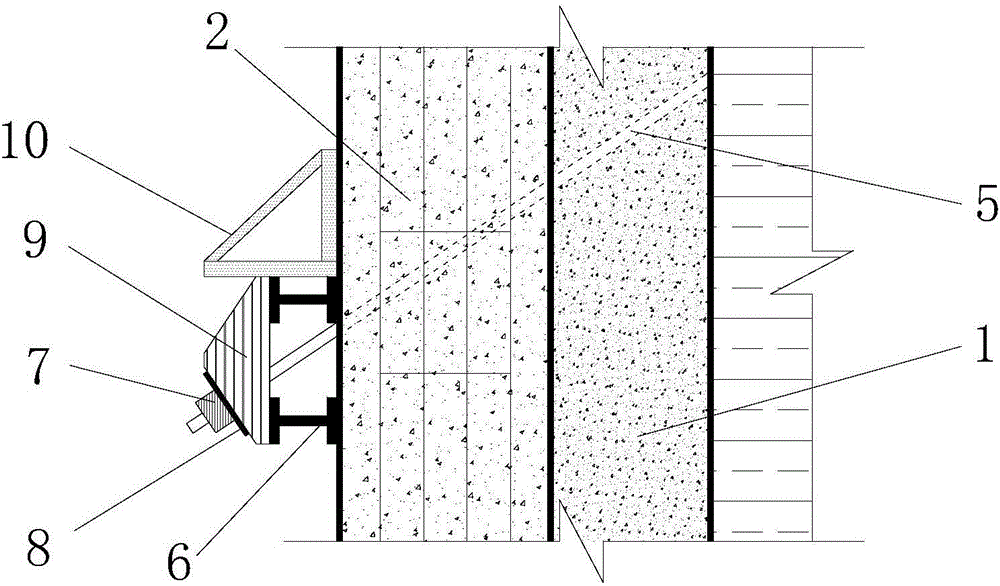

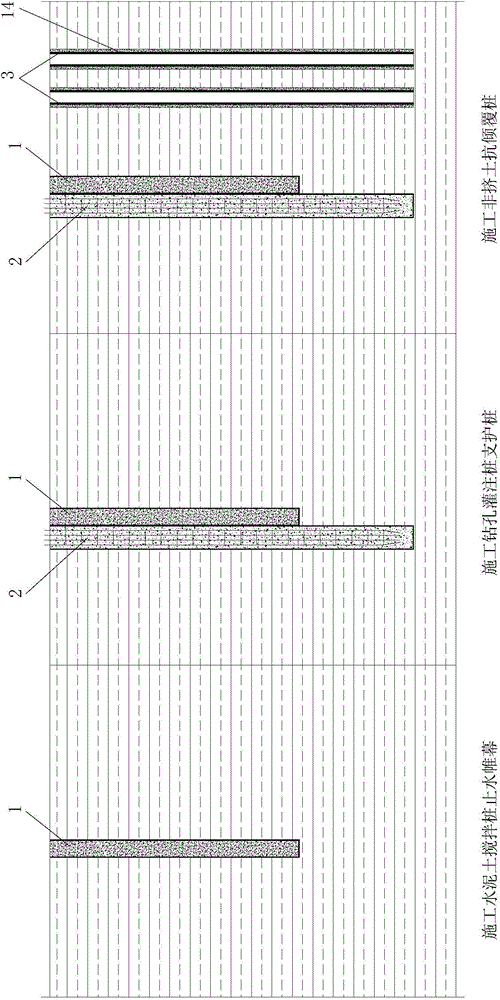

Maintenance structure for foundation pit next to existing building and construction method

ActiveCN104612160AEnsure safetyEnsure stabilityExcavationsArchitectural engineeringEconomic benefits

The invention relates to a maintenance structure for a foundation pit next to an existing building. The maintenance structure is characterized by mainly comprising a cement mixing pile water stop curtain, a cast-in-situ bored pile support pile, non-soil-squeezing anti-overturning piles and a slant pull rod, wherein the cast-in-situ bored pile support pile, the cement mixing pile water stop curtain and the non-soil-squeezing anti-overturning piles are sequentially arranged on the outer side of a foundation pit excavation side boundary from inside to outside; a raft plate is arranged in a pile body top area from the non-soil-squeezing anti-overturning piles to the cast-in-situ bored pile support pile, and a continuous perforated steel plate is arranged on the top of the raft plate; the upper portion of the slant pull rod is arranged on the continuous perforated steel plate on the tops of the non-soil-squeezing anti-overturning piles, the lower portion of the slant pull rod is arranged on the outer side of the cast-in-situ bored pile support pile, and the two ends of the slant pull rod are each fixed with an anchorage device, a base plate and a pedestal. The foundation pit maintenance structure effectively solves the technical problem that the foundation pit next to the existing building is hard to support, and has good technical and economical benefits.

Owner:ZHONGDA CONSTR

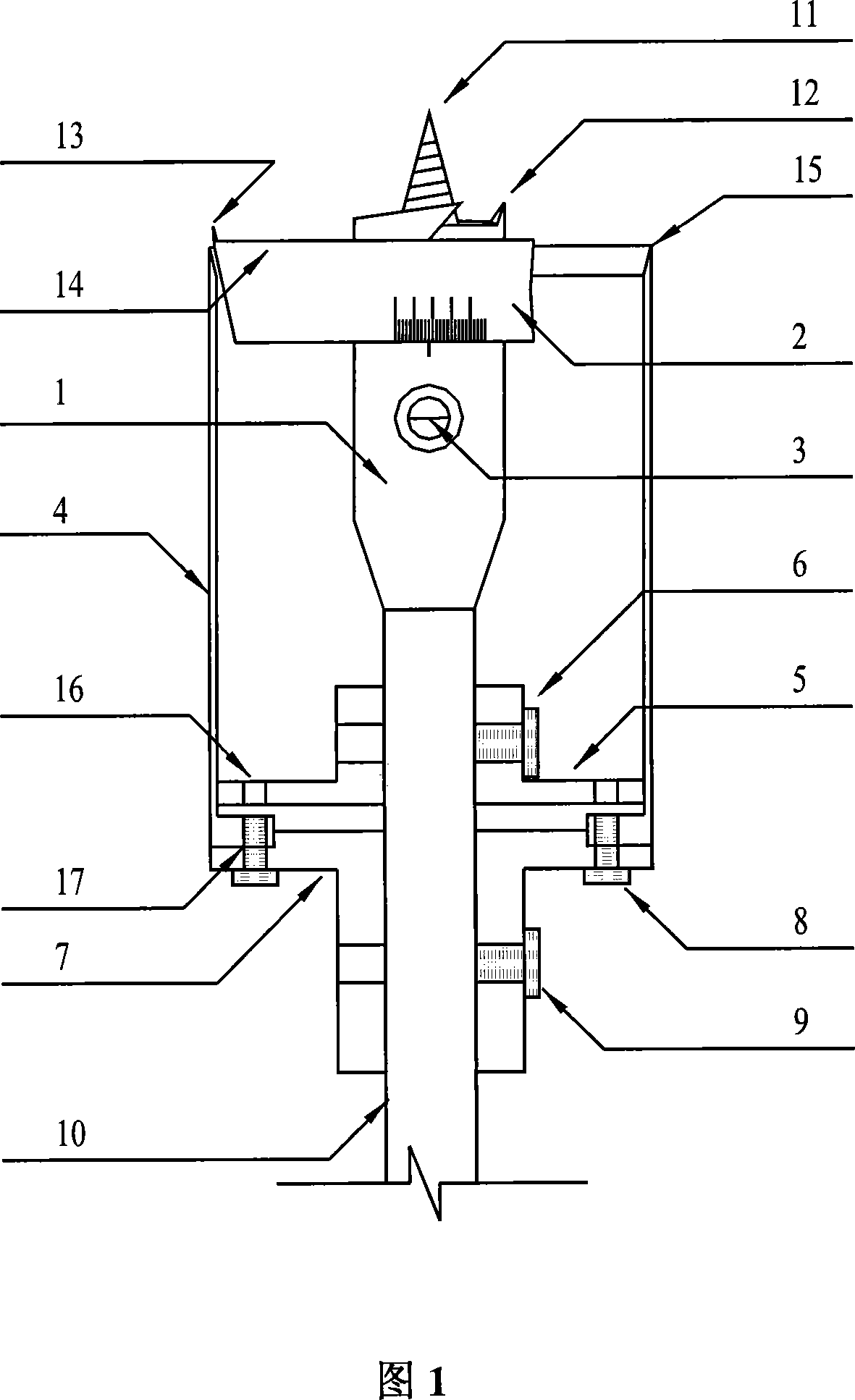

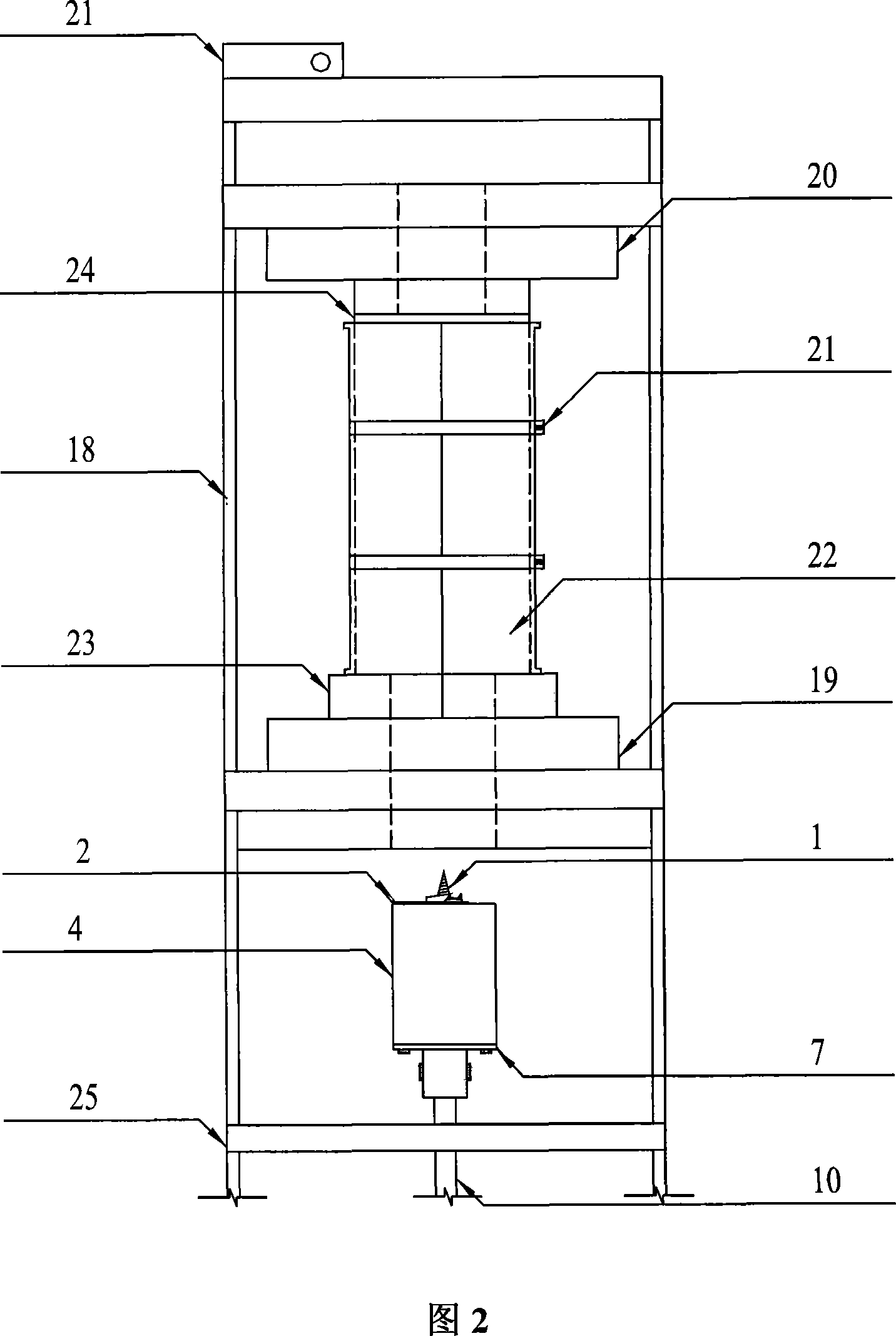

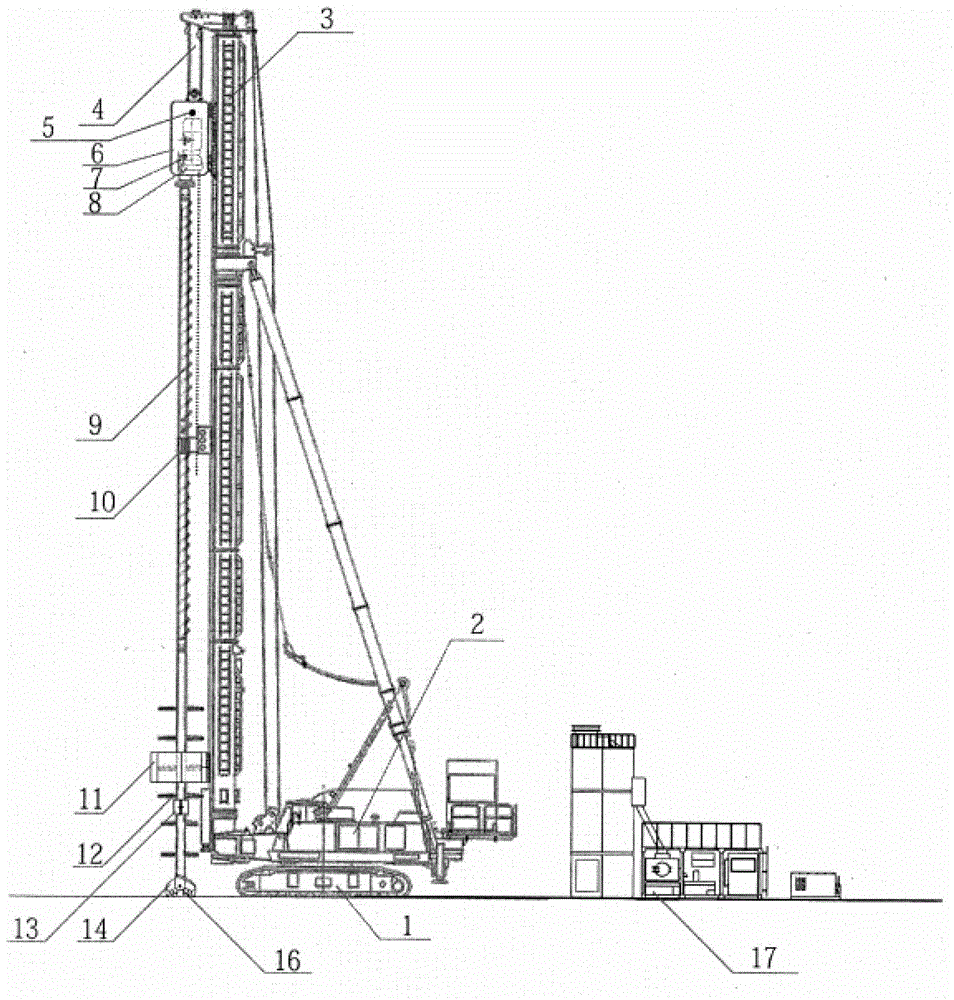

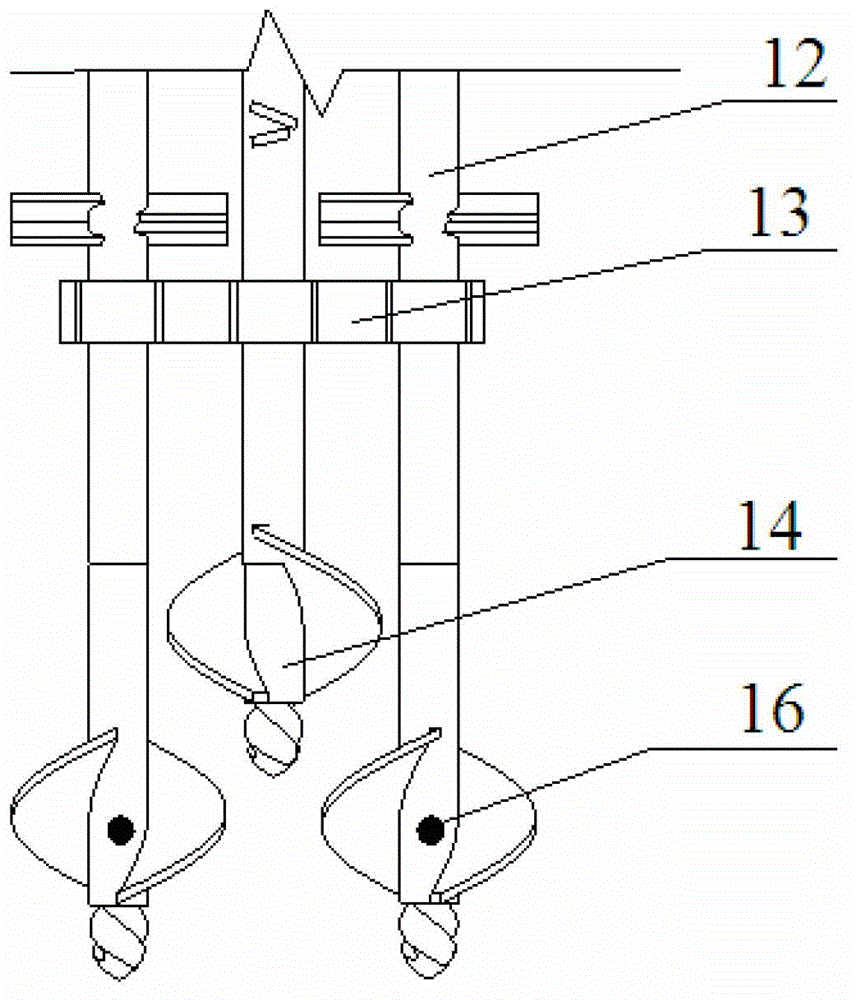

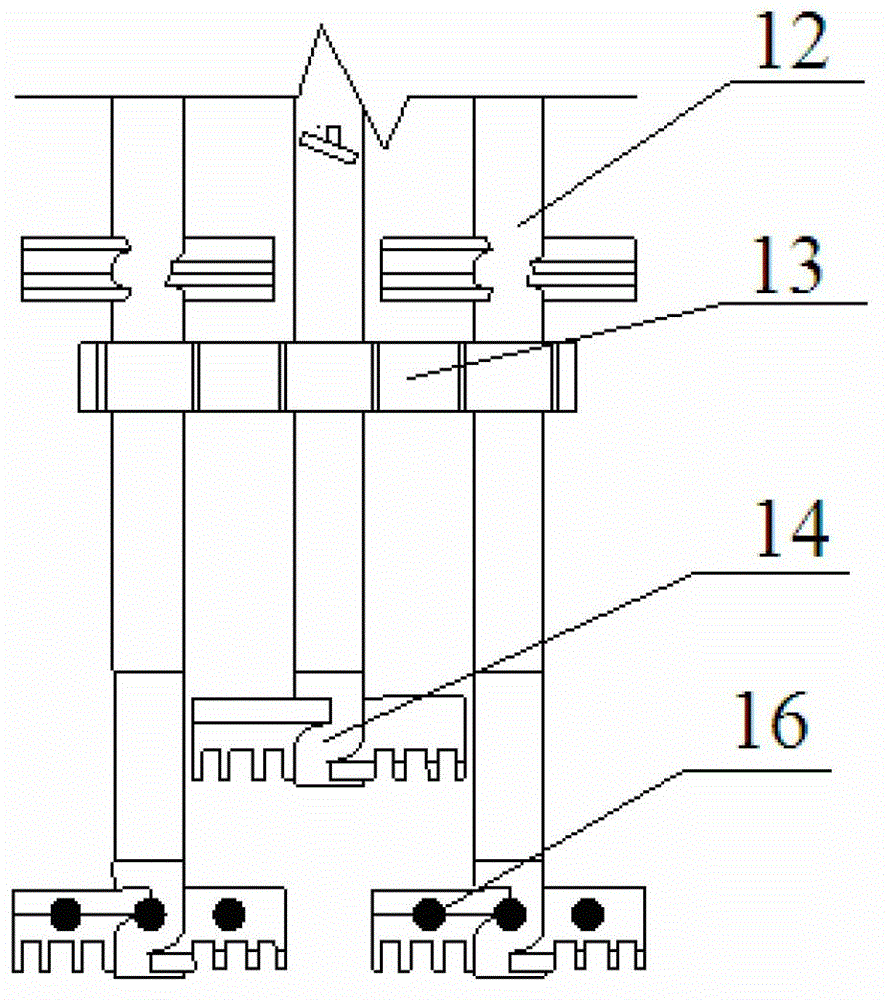

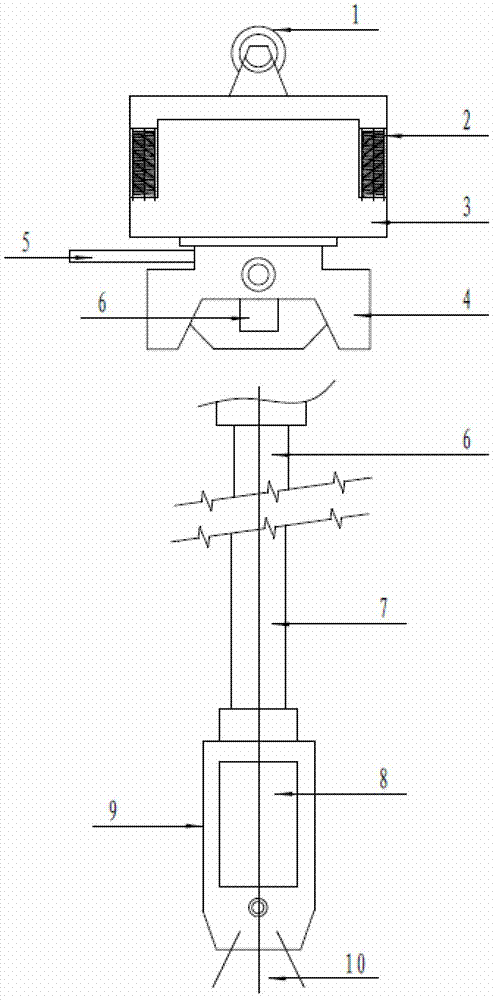

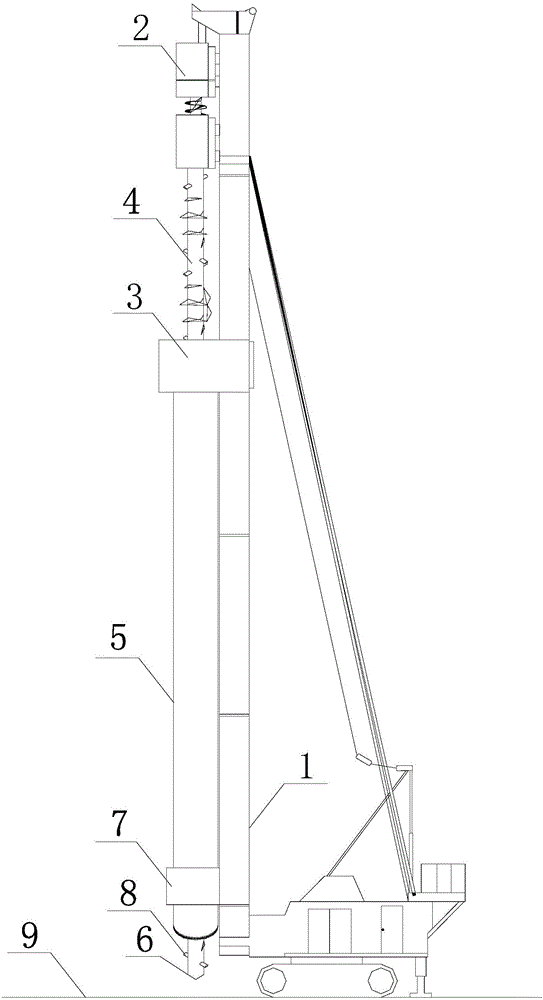

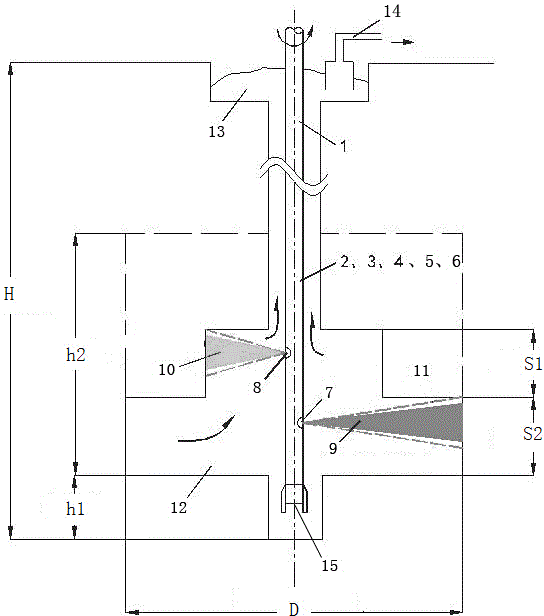

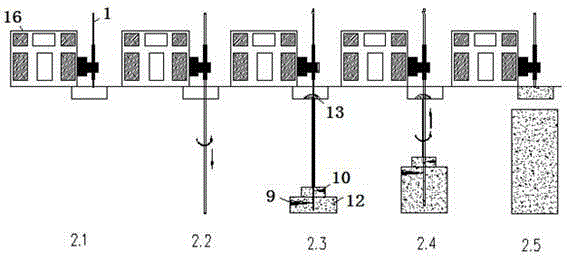

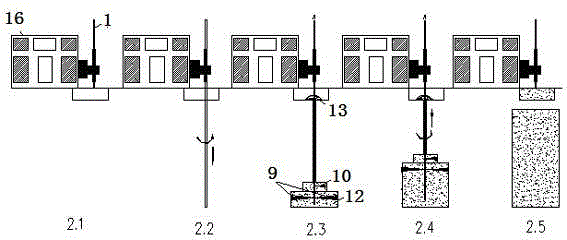

Multi-axial mixing pile device capable of reducing soil extrusion and application thereof

InactiveCN102943468AReduce the crowding effectGood drilling stabilityDrill bitsDerricks/mastsEngineeringReducer

The invention relates to a multi-axial mixing pile device capable of reducing soil extrusion and an application thereof. The device comprises a host, a hoist, a guide rod, a power head, a gearbox, a reducer and a drill pipe, wherein the hoist and the guide rod are fixed on the host; the power head, the gearbox and the reducer are arranged on the guide rod from top to bottom; the power head is connected with a pulley at the top of the guide rod through a steel wire rope which drives the power head to lift; the power head drives 1-9 drill pipes to rotate through the gearbox and the reducer sequentially, the rotation directions of the drill pipes are positive-reverse stagger, a grout inlet is arranged at the upper end of each drill pipe, the lower end of the drill pipe is connected with a winged drill pipe, the lower end of the winged drill pipe is connected with a multifunctional drill in a replaceable mode, and a grout nozzle and an air nozzle are arranged on the multifunctional drill. Compared with the prior art, the mixing pile device has the advantages of capable of reducing soil extrusion effect, better in drill forming, higher in cement use ratio, smaller in influence on surroundings and the like.

Owner:SHANGHAI CHENGDI CONSTR

Slurry injection technique of sleeve valve tube of cloth bag

ActiveCN101644048AConstrained diffusion spacePromote formationBulkheads/pilesSoil preservationSleeve valvePore water pressure

The invention relates to a slurry injection technique of a sleeve valve tube of a cloth bag, which is developed on the basis of a regular slurry injection technique for the sleeve valve tube and has the characteristics that the cloth bag having the same length as the sleeve valve tube is sleeved on the sleeve valve tube; one to two plastic drainage plates are fixed outside the cloth bag in the depth direction; sleeve shell material is injected into the cloth bag after the sleeve valve tube with the cloth bag and the plastic drainage plates is inserted into drilling holes and then constructingis carried out according to a regular slurry injection method of the sleeve valve tube. The technique can avoid slurry leaking and flowing phenomena and is beneficial to forming a column body. The plastic drainage plates are arranged, thereby quickly discharging partial water in slurry liquid, dissipating the super-static pore water pressure of injection slurry in a foundation, effectively reducing the soil squeezing effect and increasing the foundation soil strength.

Owner:CRCC HARBOR & CHANNEL ENG BUREAU GRP

Ecological landscape combination revetment

An ecological landscape combination revetment comprises stress piles and inserting sheet piles, wherein, the inserting sheet piles are used for being in fit connection with the stress piles and used for blocking soil and stopping water, the left and right sides of one of the stress piles and the inserting sheet piles are correspondingly provided with inserting slots extending in the longitudinal direction, and the left and right sides of the other one of the stress piles and the inserting sheet piles are correspondingly provided with inserting parts which extend in the longitudinal direction and are matched with the corresponding inserting slots in a mutual abutting mode. A new technical scheme of the ecological landscape combination revetment is provided, the ecological landscape combination revetment is mainly composed of the stress piles and the inserting sheet piles, every two stress piles are connected through one inserting sheet pile for blocking soil and stopping water, the stress piles and the inserting sheet piles adopt two specifications, and the requirements for revetment and supporting stress can be met; and the skipped piling construction method is adopted during construction, thus the soil-squeezing effect is weakened, the positioning accuracy is high, and the effect of the formed surface is good.

Owner:建华建材科技(江苏)有限公司 +1

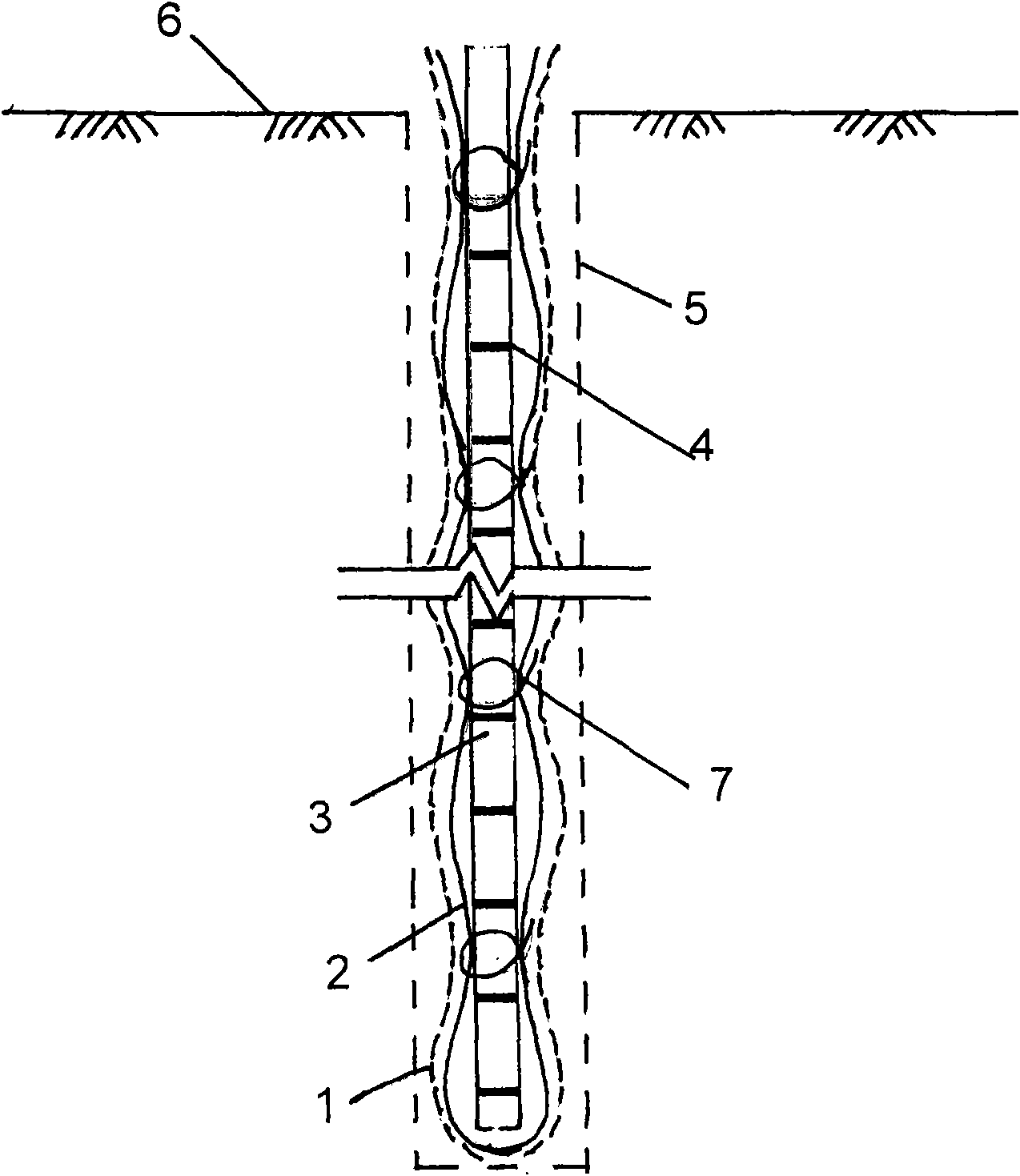

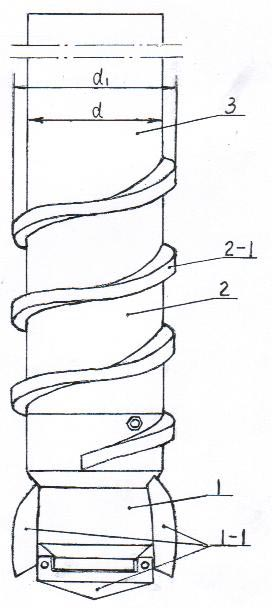

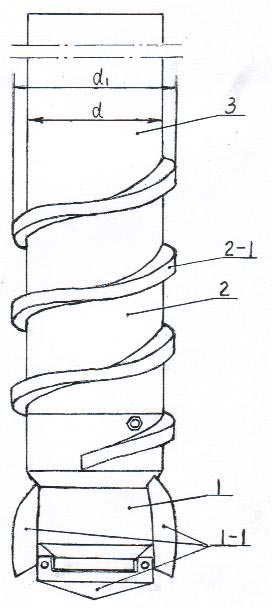

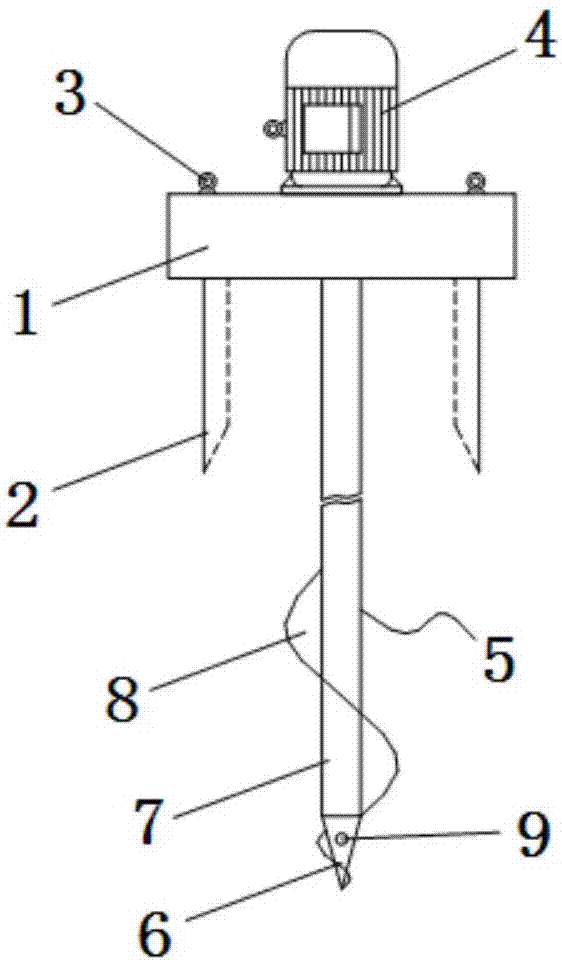

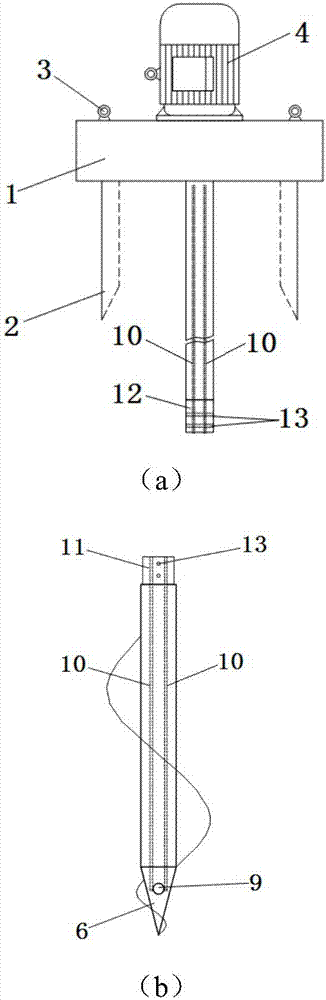

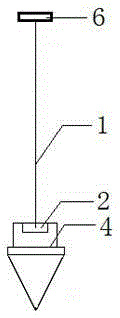

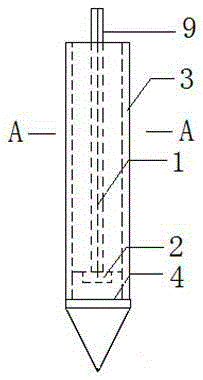

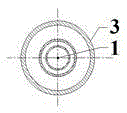

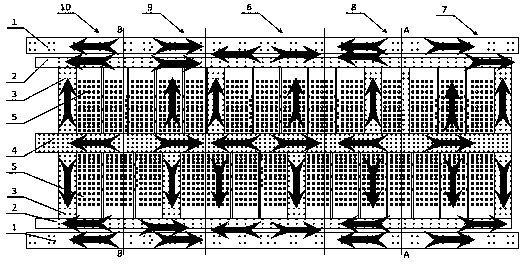

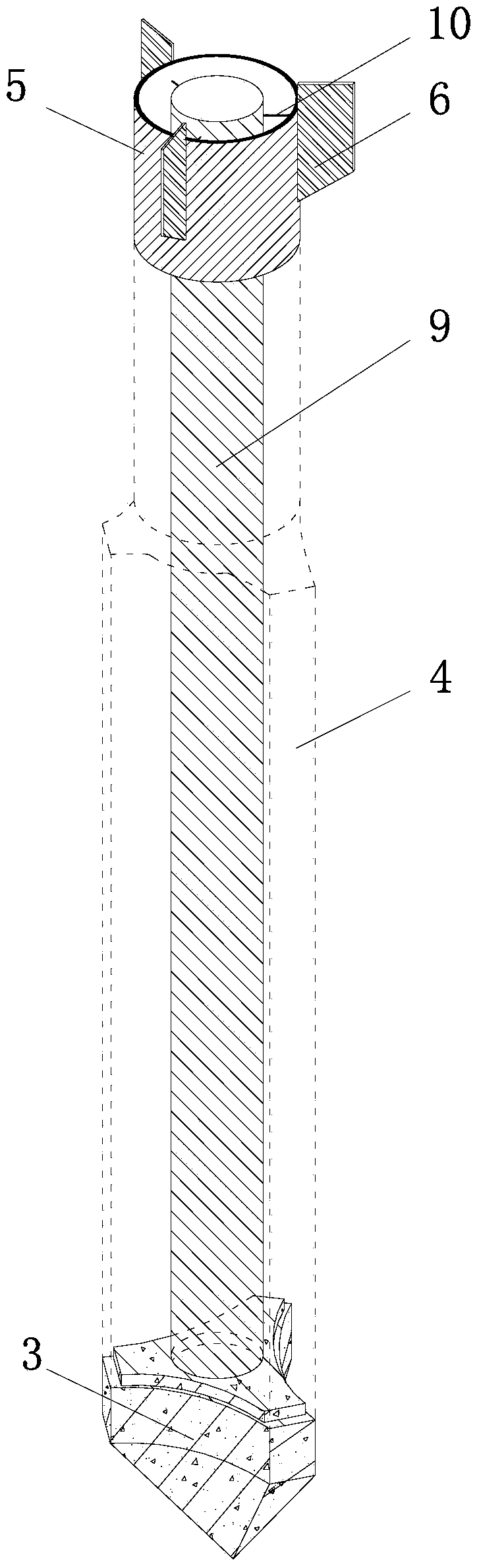

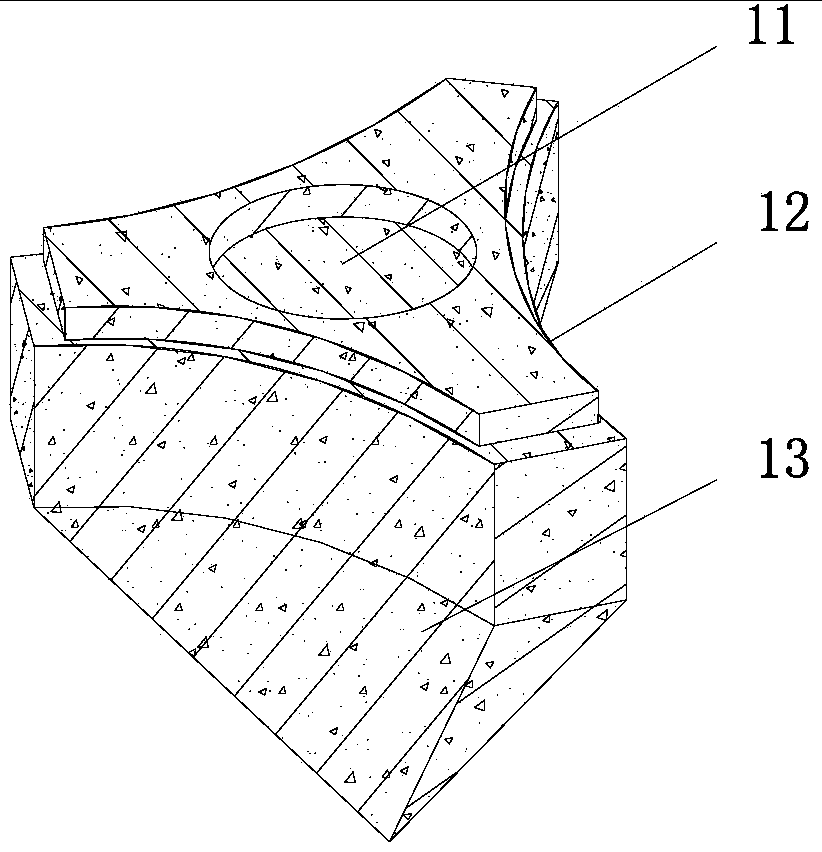

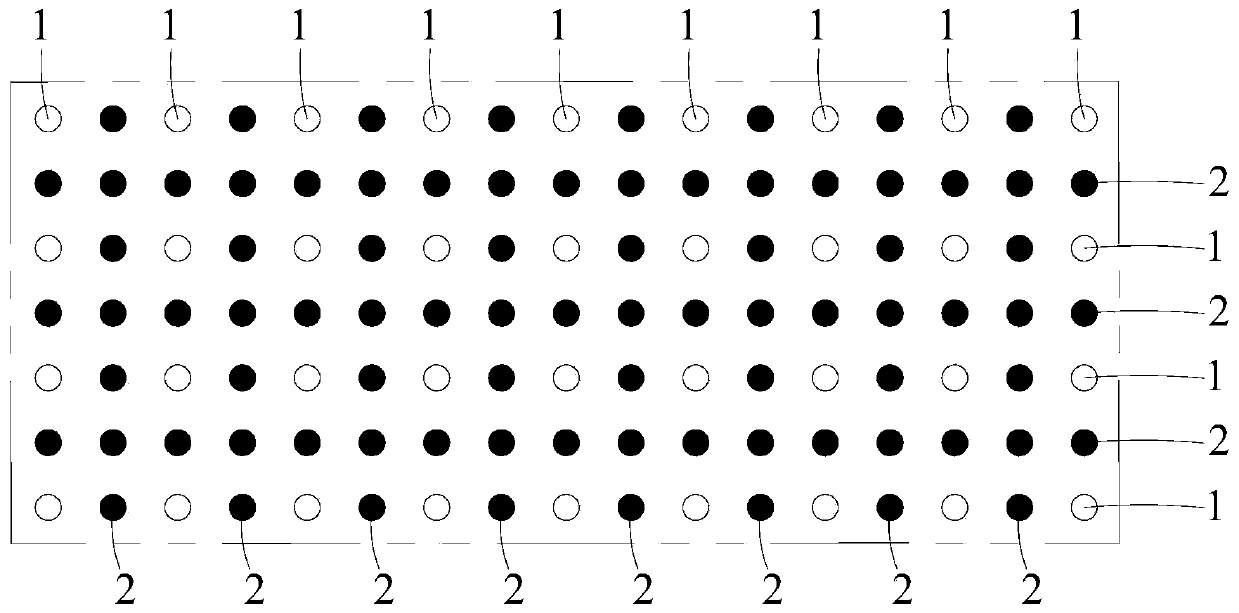

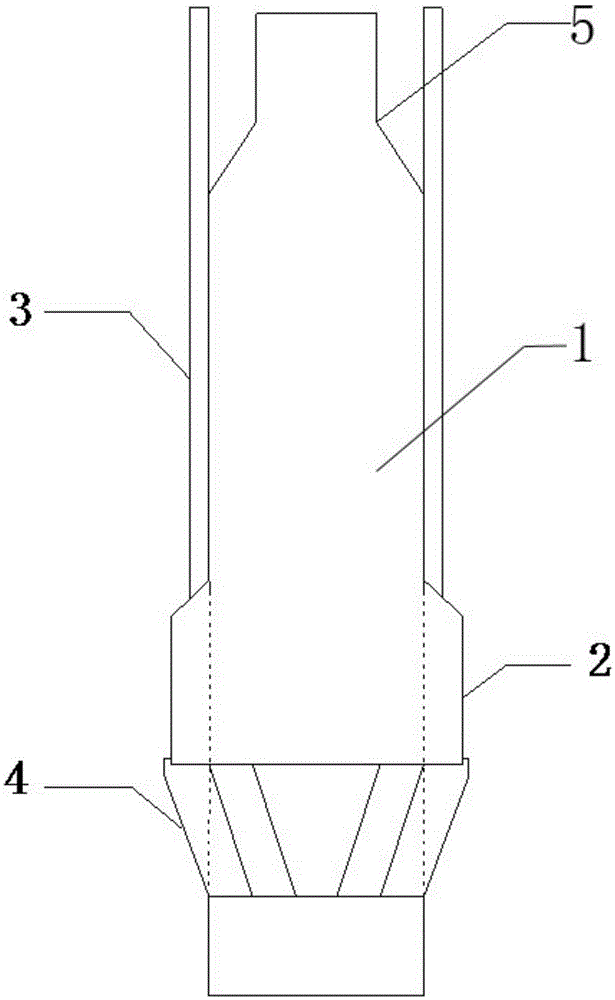

Half soil squeezing screw expansion pile forming method

InactiveCN102312427AStrong roughnessReduce torqueDrill bitsDrilling rodsScrew threadUltimate tensile strength

The invention belongs to a building construction method, and in particular relates to a half soil squeezing screw expansion pile forming method. The adopted combined drilling tool consists of a soil taking spiral drill bit (1) with at least two drill tips (1-1) and a soil squeezing threaded drill rod (2) connected with the spiral drill bit (1) or a polished rod (3) connected to the upper part of the spiral drill bit (1); the threaded drill rod has the characteristics that the diameter of the core rod is greater than that of a long spiral drilling tool, the blade is thick and the strength is higher; and according to the half soil squeezing screw expansion pile forming method, soil is taken by the drill bit part and squeezed by the threaded drill rod part, so that the torque is greatly reduced, the downward penetrating capacity is stronger, drilling is easy, pore forming or pile forming speed is increased, the soil squeezing effect is reduced, the penetrating capacity is enhanced, the torque is reduced, equipment faults are reduced, and the service life of the equipment is prolonged.

Owner:王庆伟

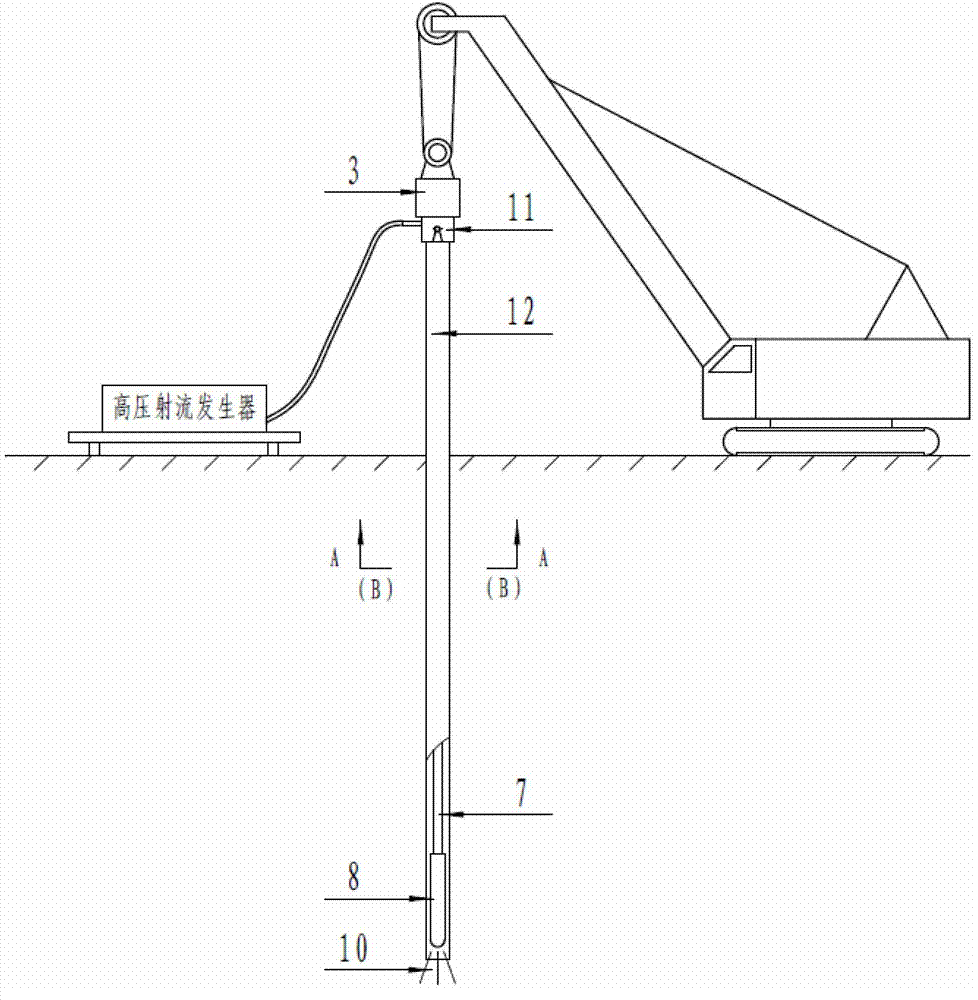

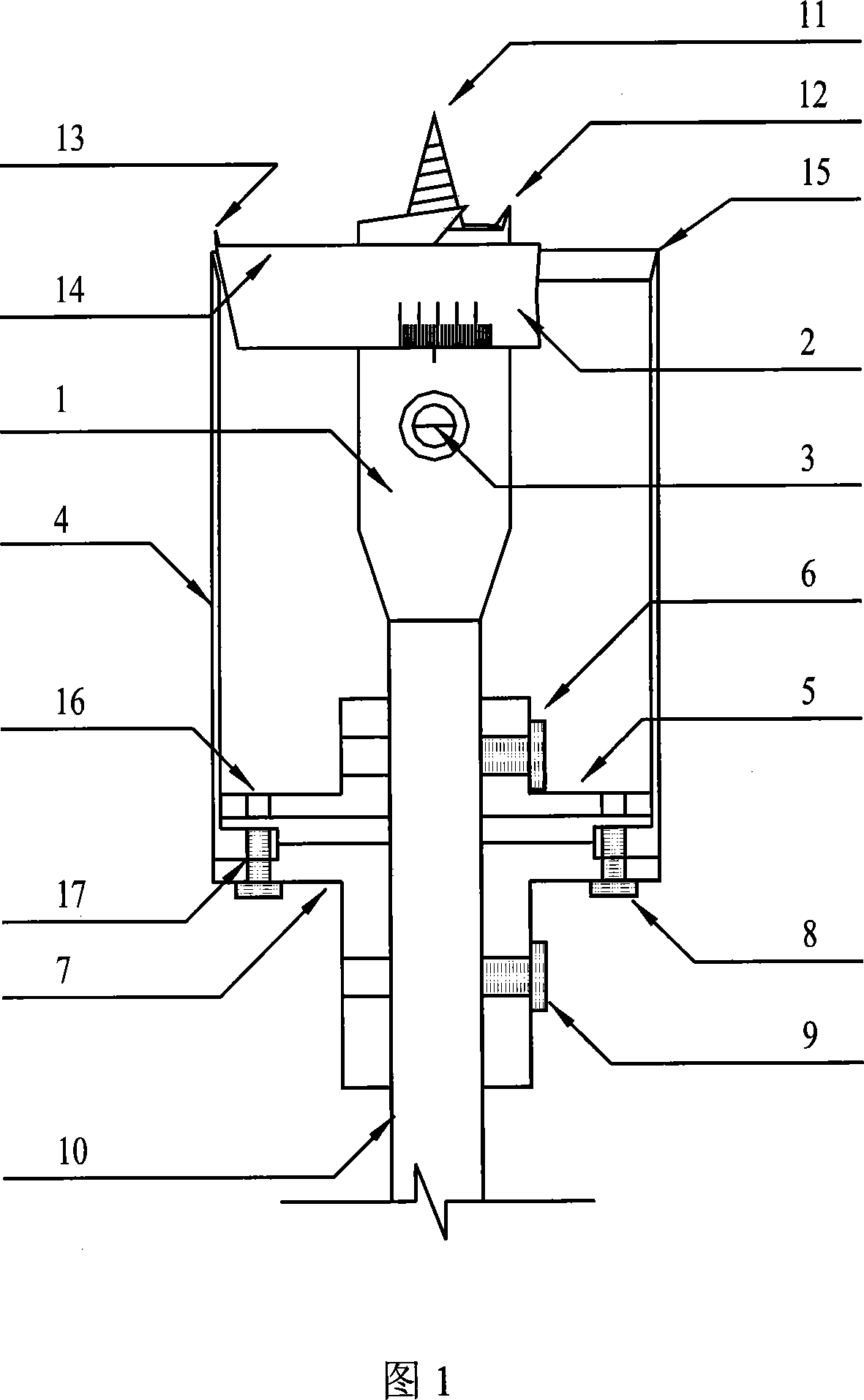

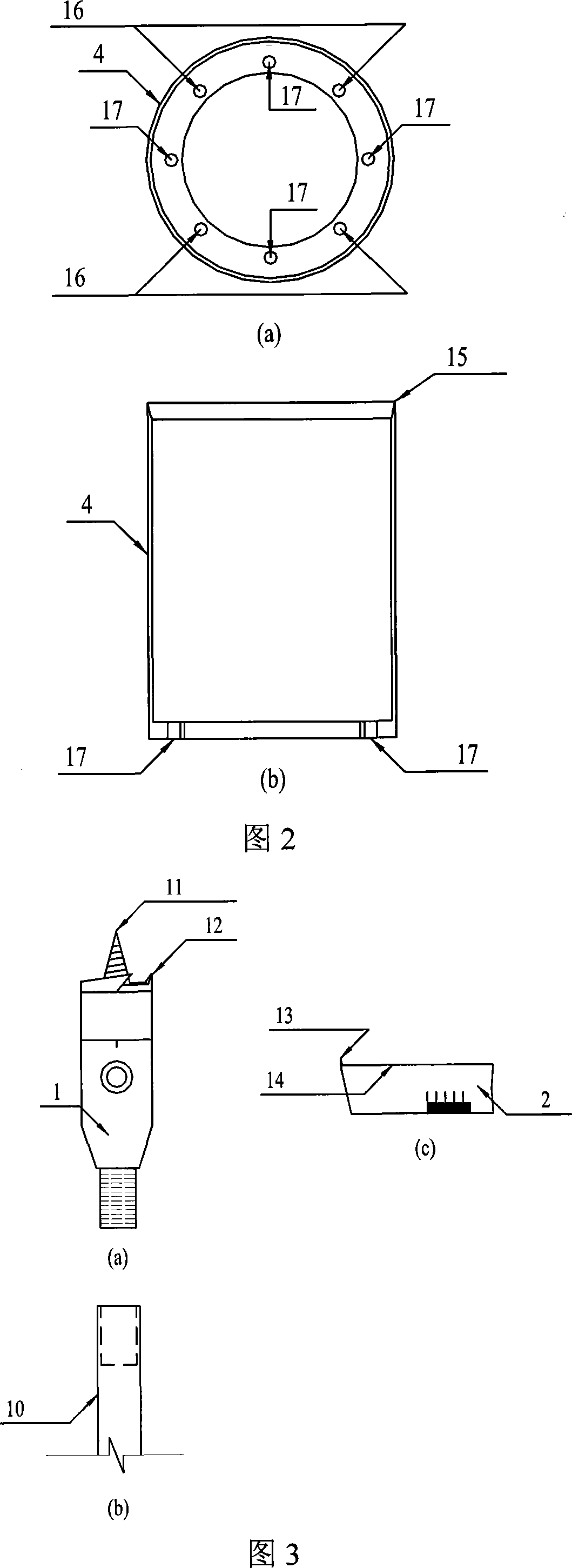

High-pressure spray pile vibrosinking device and process

The invention discloses a high-pressure spray pile vibrosinking device. Ground components comprise a vertical exciting force generator and a pile gripper which is connected with the vertical exciting force generator; the lower part of the vertical exciting force generator is connected with an outer high-pressure joint which is connected with a high-pressure spray generator; underground components comprise an inner joint which is connected with the lower end of the pile gripper and a spray pipe which is connected with the inner joint; the end of the spray pipe is provided with a high-pressure spray nozzle; a horizontal exciting force generator is arranged between the spray pipe and the high-pressure spray nozzle; and the high-pressure spray generator sprays to inject slurry or water, the sprayed liquid forms a high-pressure liquid column to cut, crush and liquefy soil, the horizontal exciting force generator generates vibratory force in a horizontal direction so as to vibrate the cut, crushed and liquefied soil, and a pile body is quickly pressed into a formation to reach a preset pile sinking depth, so that a technology for constructing difficult and different formations can be provided, and the construction benefit and quality can be greatly improved.

Owner:SHANGHAI ZHONGJI PILE IND

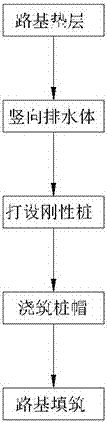

Construction method for combining composite foundations of rigid piles and soft-soil foundations of water-draining consolidation and reinforcement highways

InactiveCN107287999AReduce the crowding effectReduce car jumpingRoadwaysSoil preservationOn columnSubgrade

The invention relates to a highway-foundation construction method and particularly relates to a construction method for combining composite foundations of rigid piles and soft-soil foundations of water-draining consolidation and reinforcement highways. The construction method comprises the construction steps of paving a working cushion layer; adopting a bagged sand well as a vertical water-draining body, adopting vibratory tube sinking to lower the bagged sand well, carrying out vibratory tube pulling, and supplementing materials at an empty well section in the tube pulling process; driving rigid piles, carrying out vibratory tube pulling after filling up concrete into sleeves by a mode of vibratory tube sinking, wherein the tube pulling speed is less than 1.2m / minute, and the tubes cannot be inserted inversely in the process of vibratory tube pulling; and casting pile caps, and adopting an inverse excavation construction method to cast the pile caps in constructed working cushion layers or filled soil; and backfilling roadbeds, arranging a settlement plate on column tops and among columns, filling to the height of less than 5m and adopting a vibratory pressing machine for flattening. Compared with the construction method for composite foundations of pile supporting dikes and rigid piles, the construction method for combining the composite foundations of the rigid piles and the soft-soil foundations of the water-draining consolidation and reinforcement highways has the advantage that the cost can be respectively saved by 40% and 46%.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

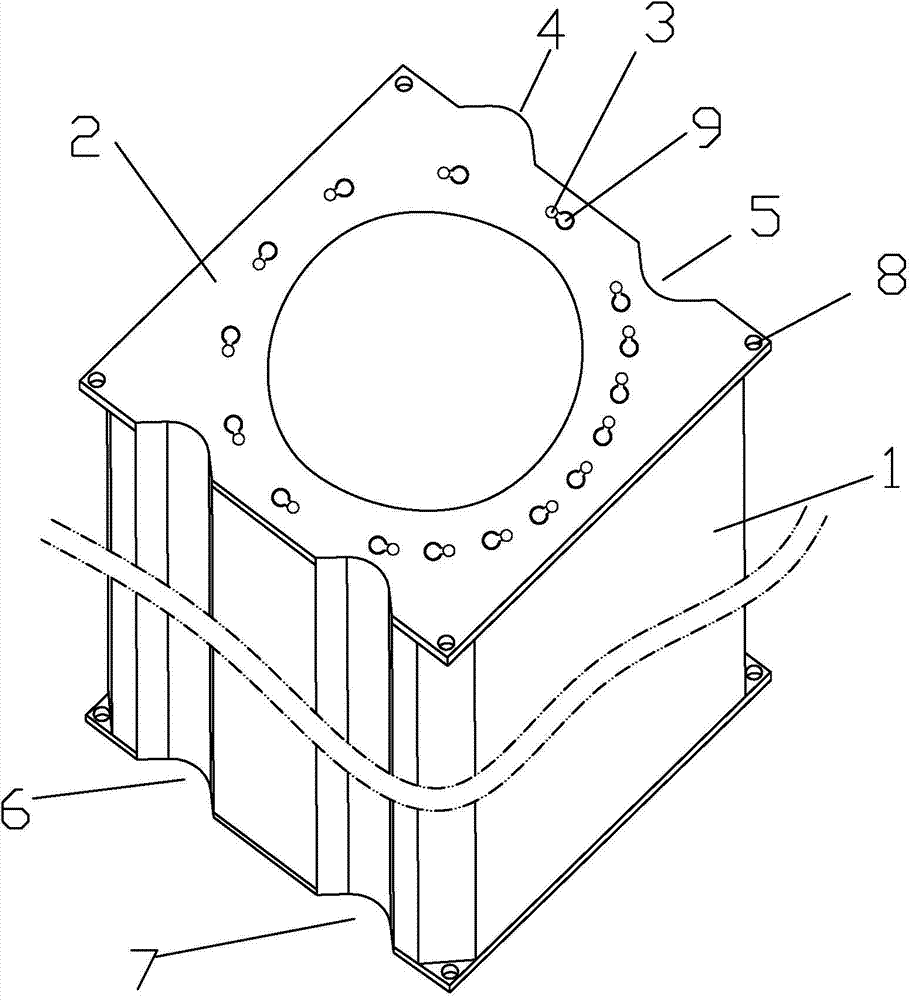

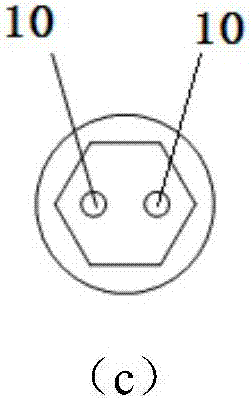

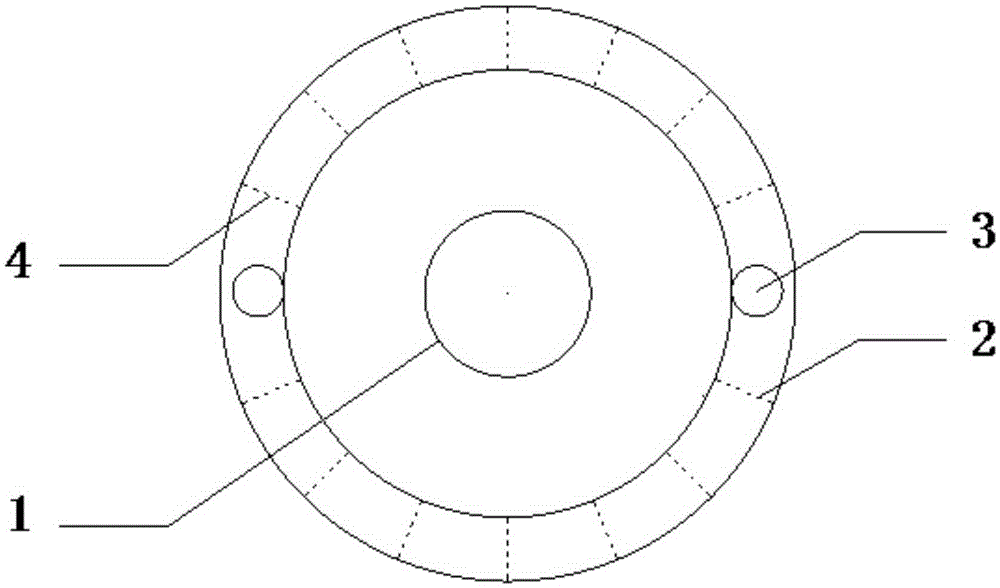

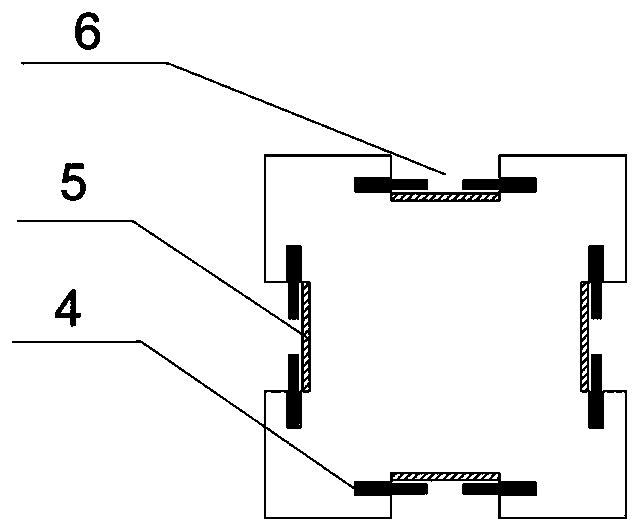

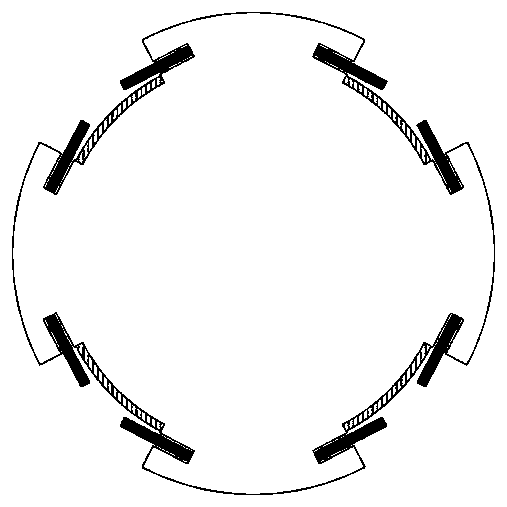

Original soft clay hollow cylinder sample inner core cutting device

InactiveCN101101242AAvoid secondary adhesionReduce propulsion resistanceWithdrawing sample devicesPreparing sample for investigationHollow coreHollow cylinder

The invention discloses a cut and get core machine of status quo soft clay hollowness column sample. It has pile casing, setting up the cutting edge on the superior extremity of pile casing, the inferior extremity of the pile casing connects with pallet of dismantle type pile casing by pile casing pallet hyphen pile casing fixed screw, fixing the dismantle type filling soil torr on the surface of the dismantle type pile casing pallet, fixing the pressure release hole on the dismantle type filling soil torr, fixing the direct bit in the middle of pile casing, the direct bit is made up of auger bit and inner margin blade, and connects with the drill pipe, the drill pipe traverses dismantle type filling soil torr, pallet of dismantle type pile casing, and is fixed by filling soil torr hyphen drill pipe fixed screw,pile casing hyphen drill pipe fixed screw, the dismantle type blade slice is made up of the inner margin blade,level blade, and connects stiffly with the direct bit by blade fixed screw. The pile casing is cylindrical form. The cut and get machine can prepare successfully status quo soft clay hollowness column sample, the disturbing of bringing in the process of cutting,the influence of hustle soil is small, providing the equipment bond guarantee for the experimental investigation of status quo soft clay under the complex stress condition.

Owner:ZHEJIANG UNIV

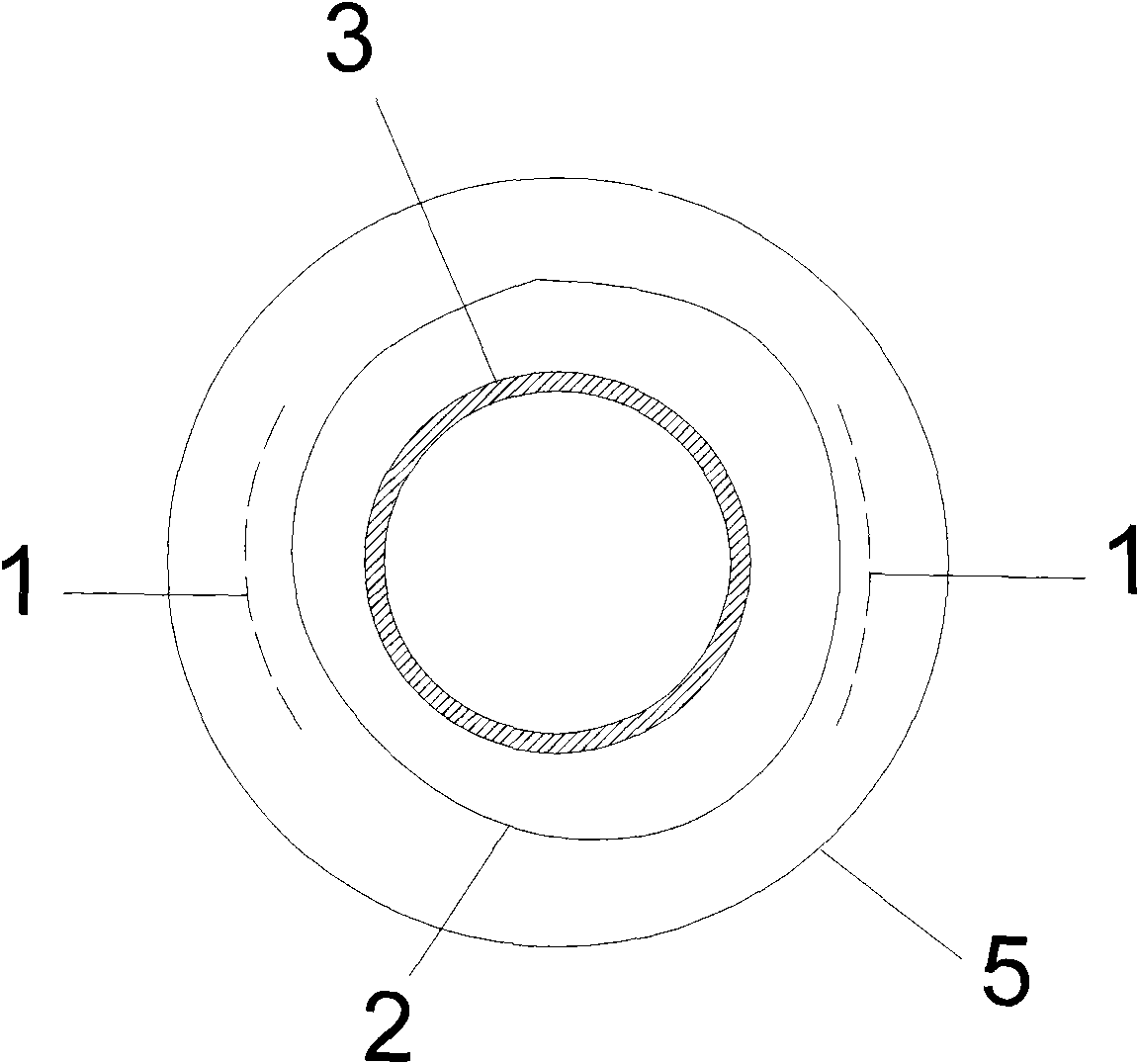

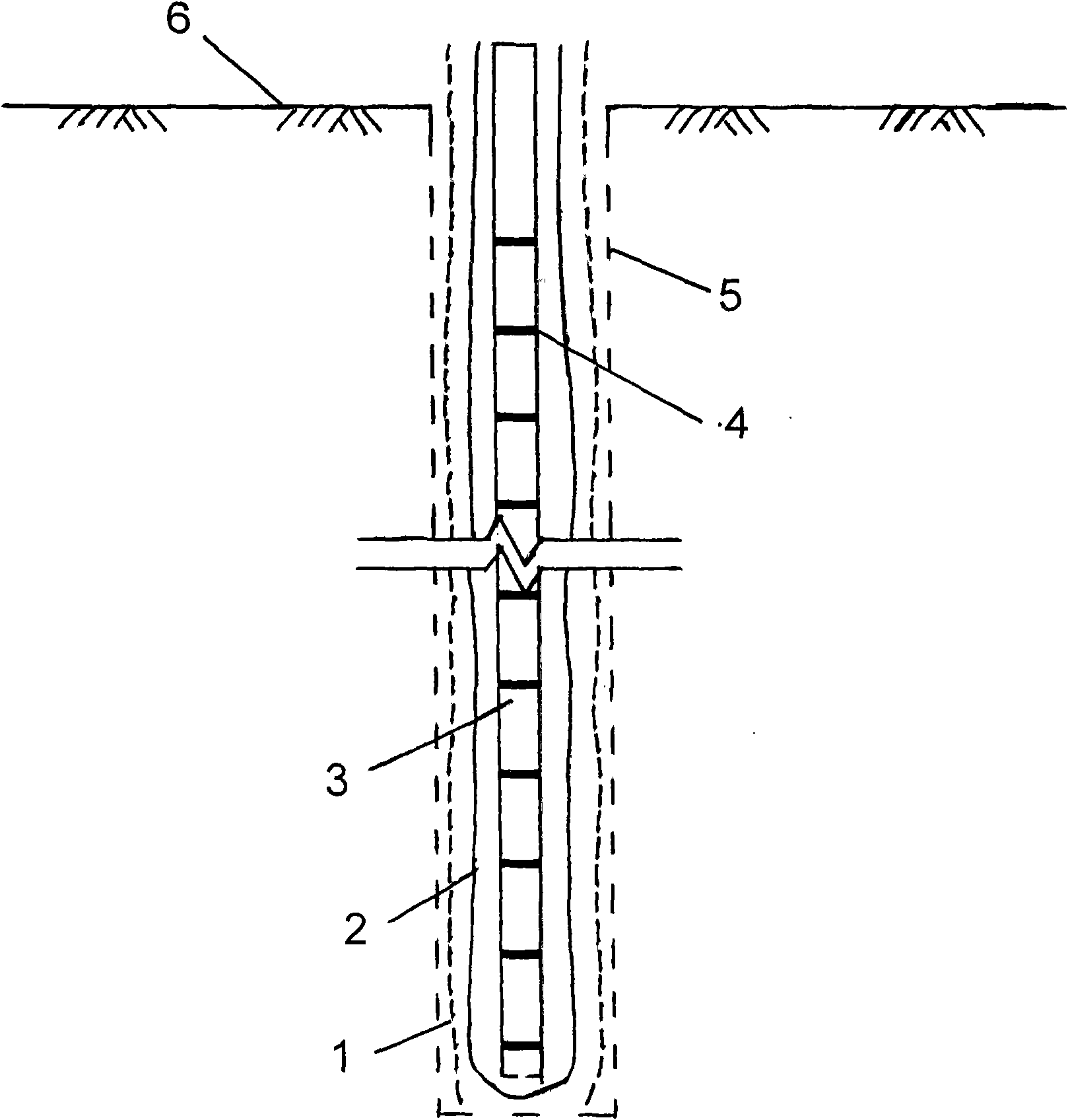

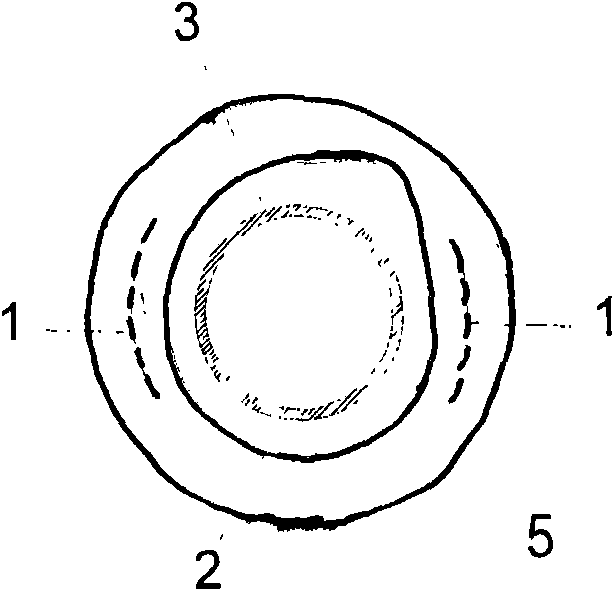

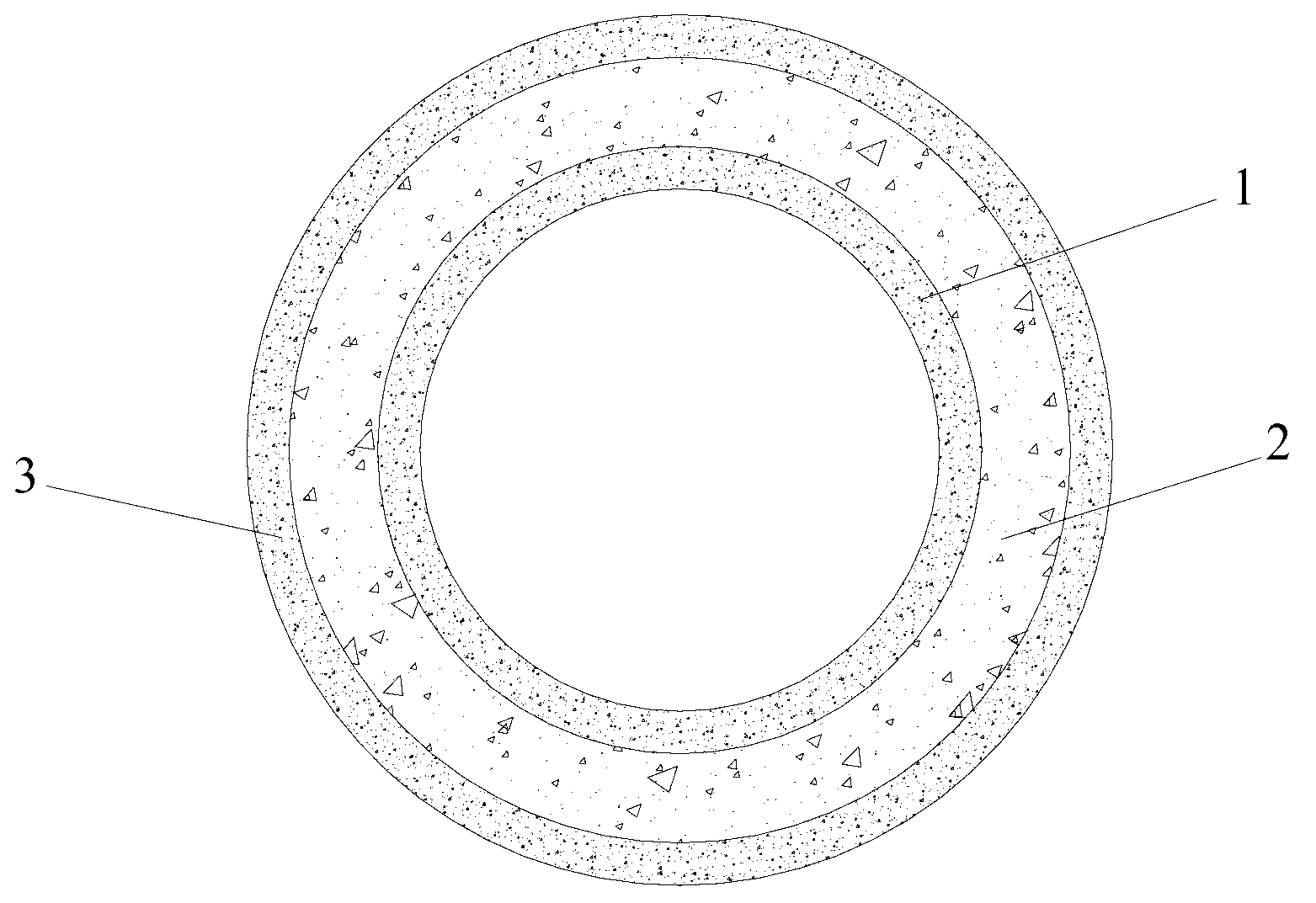

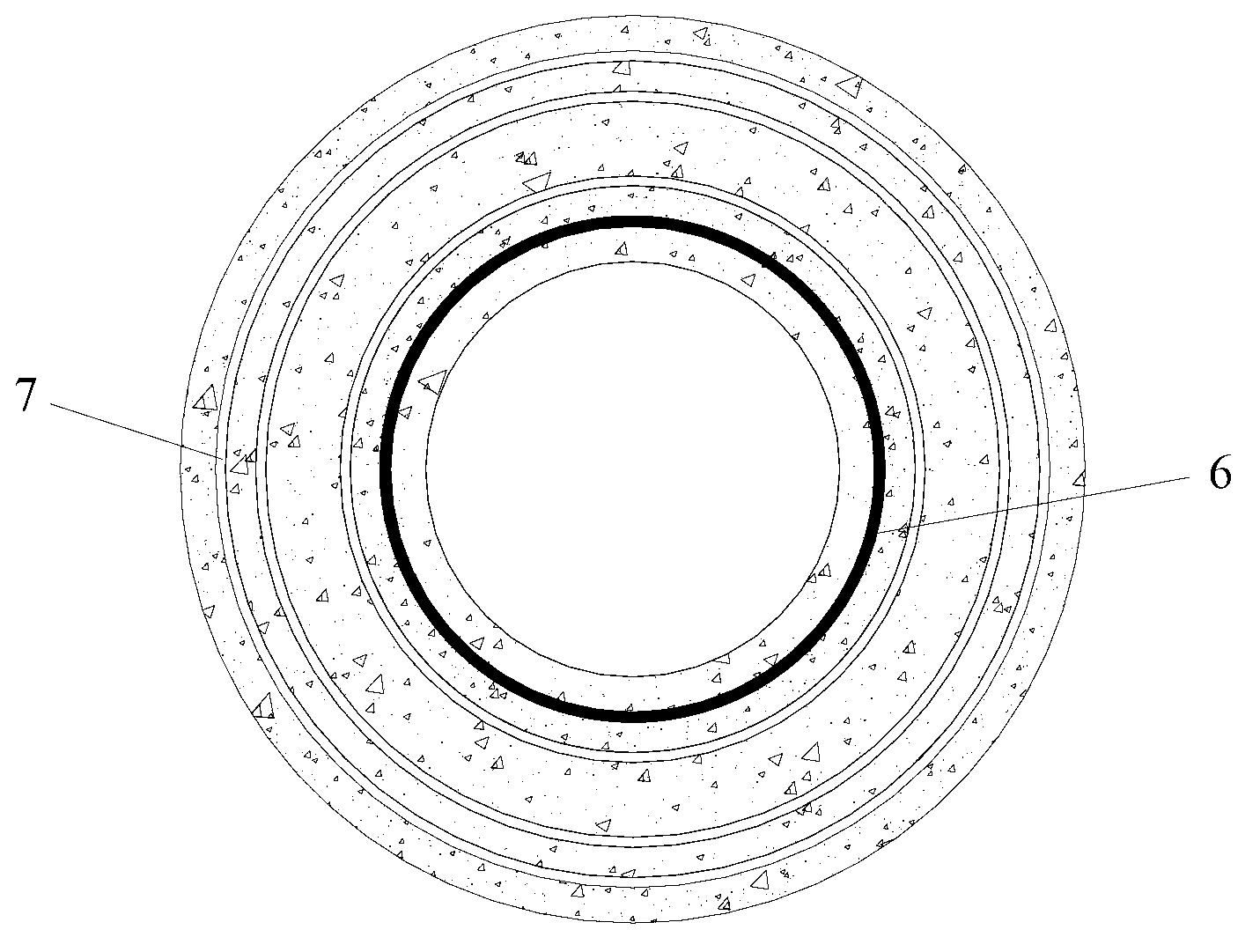

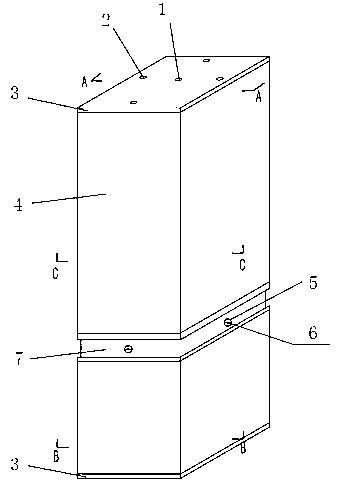

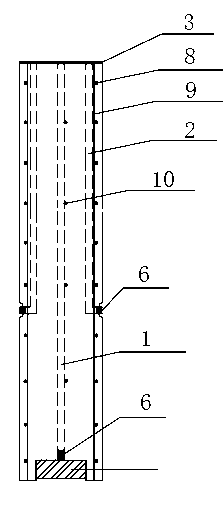

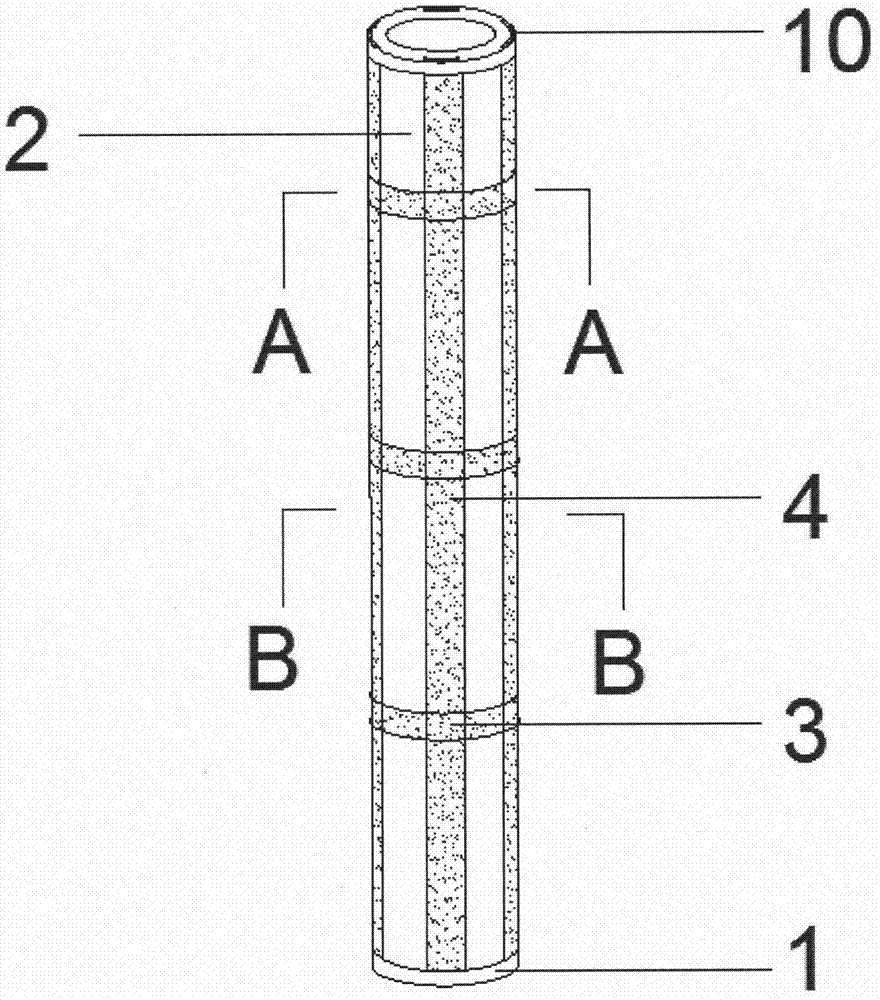

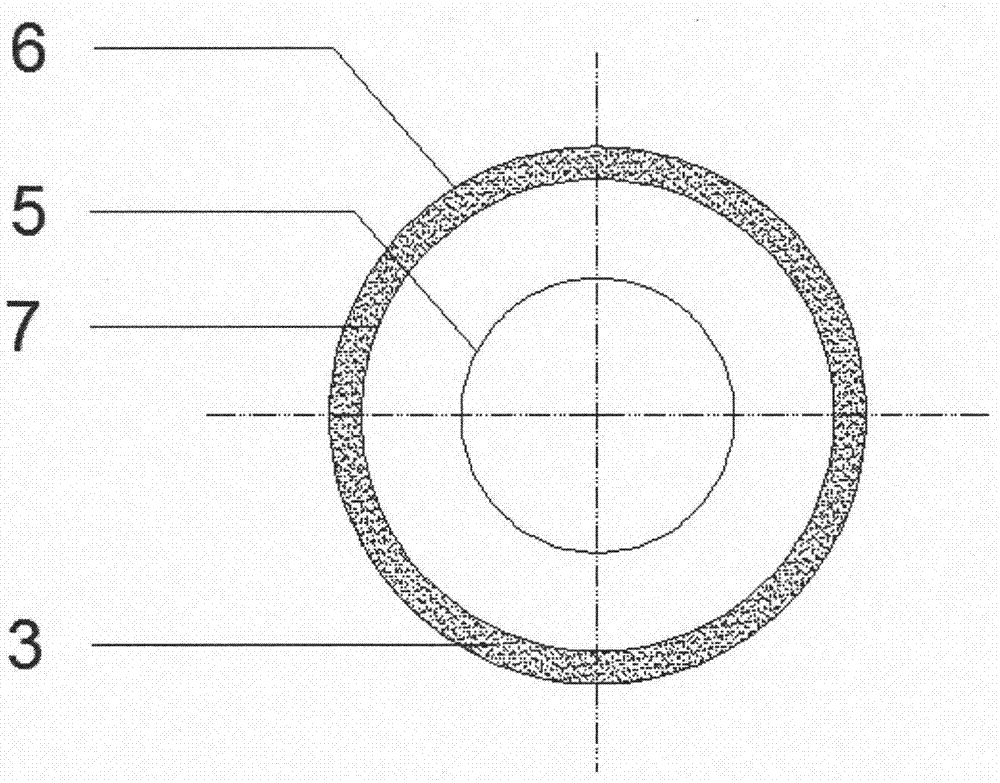

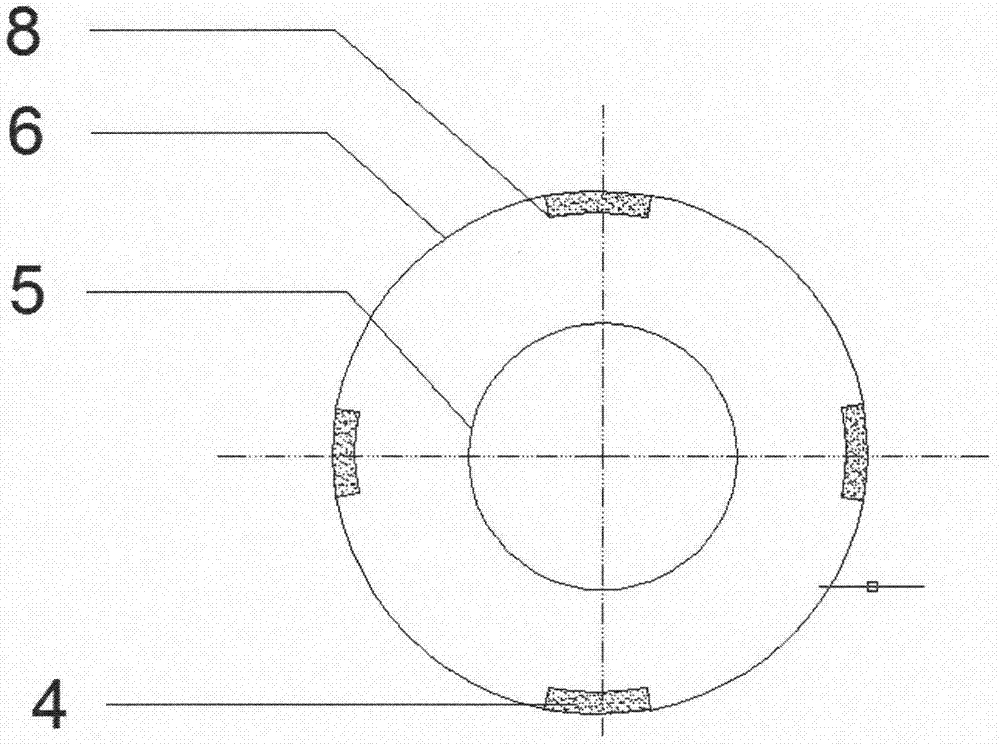

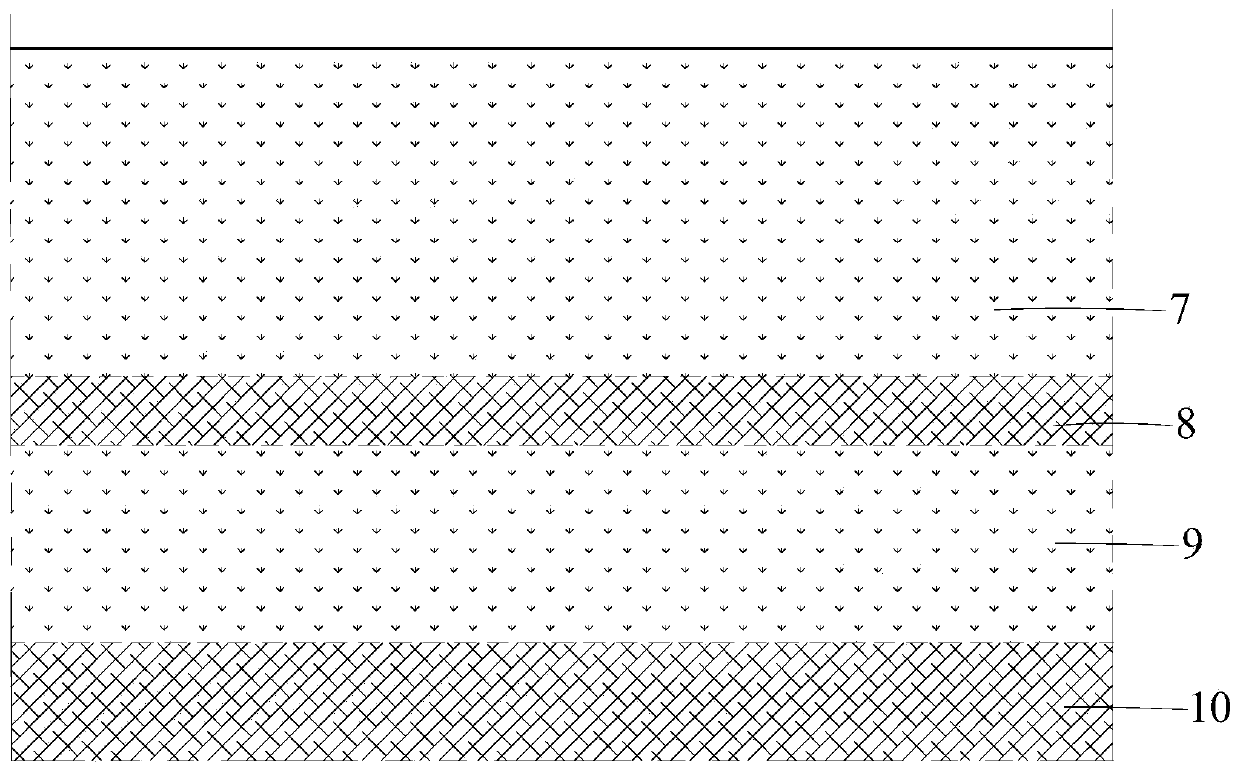

Integrally-arranged and externally-wrapped double-layered water discharging body and middle concrete combined pile and construction method

InactiveCN103061332ASuppression of squeeze effectAccelerated consolidationBulkheads/pilesSoil preservationReinforced concreteImmersed tube

The invention relates to an integrally-arranged and externally-wrapped double-layered water discharging body and middle concrete combined pile which is formed by a pile body inner side annular water discharging body, a cast-in-place concrete thin-walled pipe pile body, a pile body outer side annular water discharging body, a prefabricated pile tip and a prefabricated reinforced concrete cover plate; the prefabricated pile tip is arranged at the bottom of the combined pile; the top face of the pile tip is provided with four annular grooves for limiting the position of an immersed tube; the prefabricated reinforced concrete cover plate is arranged at the top of the combined pile; and a water discharging branch pipe is arranged inside the cover plate. According to the integrally-arranged and externally-wrapped double-layered water discharging body and middle concrete combined pile disclosed by the invention, the water discharging bodies with the uniform thickness are arranged on the inner side and the outer side of a concrete tubular pile, so that the consolidation of the soil body between the piles can be accelerated, the bearing capability of a soil foundation is improved, diseases of pile breaking and the like, caused by a soil squeezing effect, can be prevented when an adjacent pile is pegged, and the good technical economic benefit can be realized. The invention further provides a construction method of the combined pile.

Owner:XINYU CONSTR +1

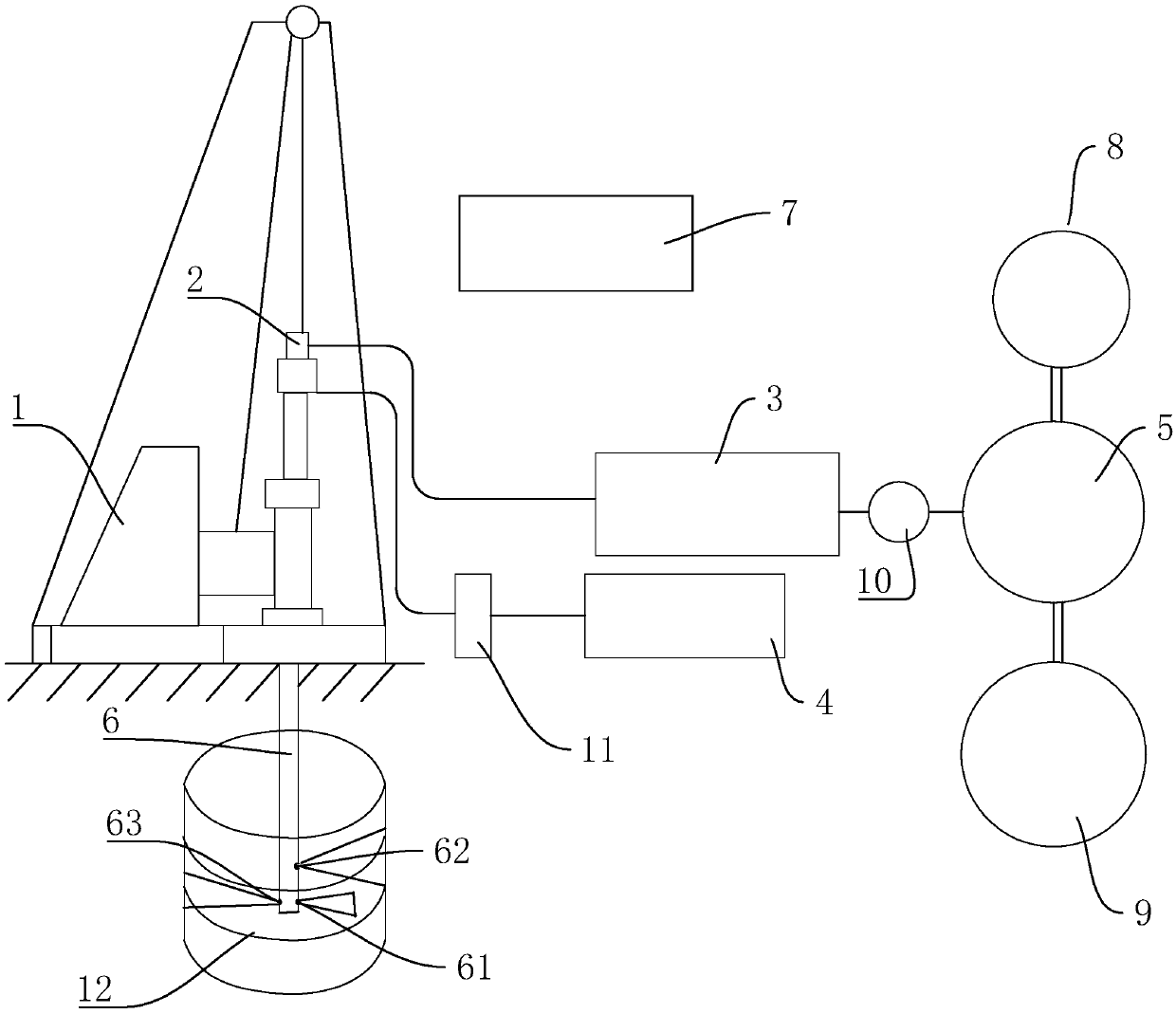

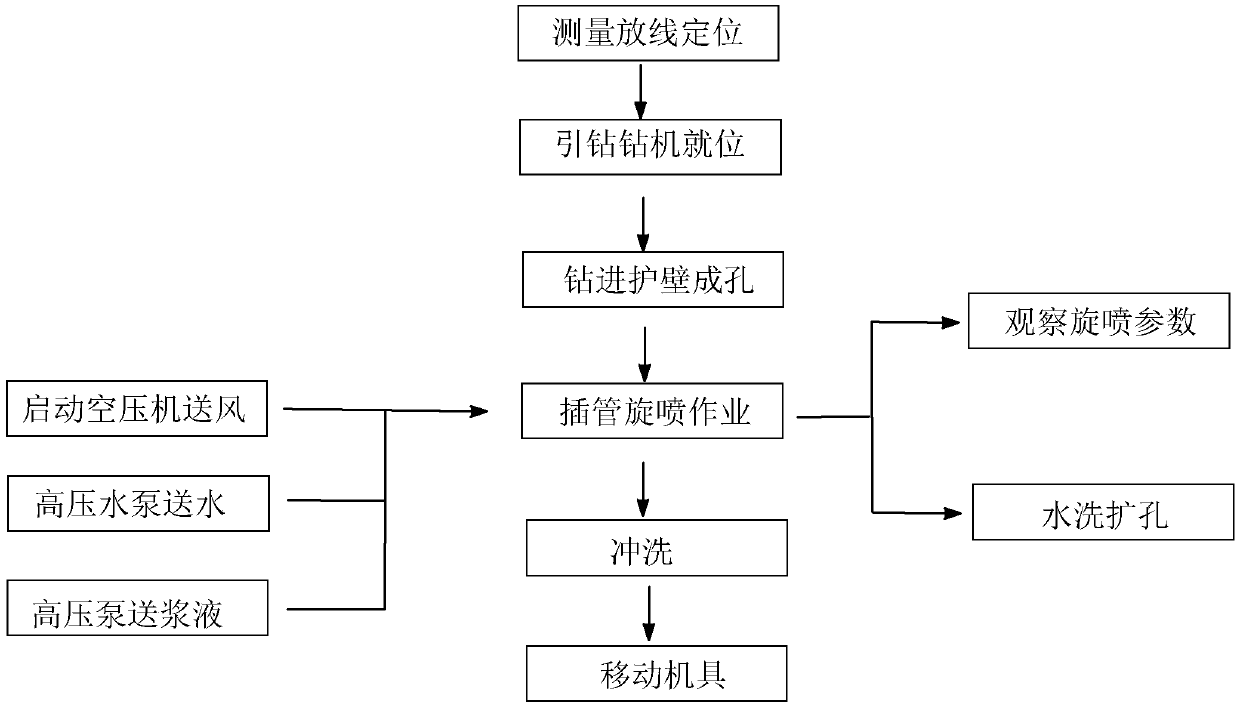

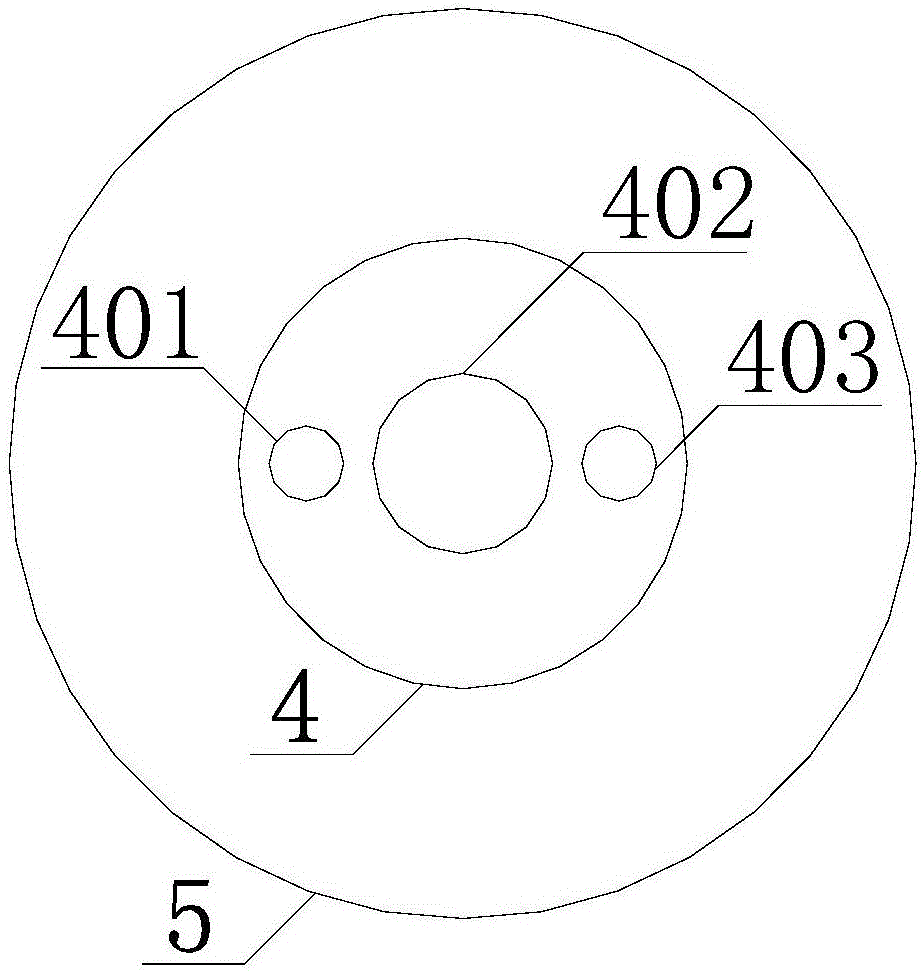

Tri-tube tri-high-pressure jet grouting pile construction method

InactiveCN110616709AEasy to monitorNormal constructionBulkheads/pilesArchitectural engineeringShop drawing

The invention relates to a tri-tube tri-high-pressure jet grouting pile construction method, and belongs to the field of constructional engineering. The tri-tube tri-high-pressure jet grouting pile construction method comprises the following steps: a first step of measuring, paying off and positioning, wherein measurement is performed according to a designed construction drawing, and a construction axis is paid off; a second step of guiding a drilling machine to be in place, wherein the drilling machine is mounted on a designed pile position, and a drill bit of the drilling machine is alignedto the center of the pile position; a third step of drilling, protecting walls and forming holes, wherein the drilling machine is used for drilling holes, and the walls are protected with mud until hole depth achieves designed elevation; a fourth step of separately forming a mud outlet, a water outlet and a gas outlet in the bottom end of a grouting rotary-jetting tube, wherein a pressure value ofair sprayed out by the gas outlet ranges from 1.6 MPa to 2.2 MPa, the water outlet is positioned above the mud outlet and the gas outlet, and the water outlet in the rotary-jetting grouting tube is drilled for washing and reaming while the jetting grouting tube carries out grouting; a fifth step of flushing; and a sixth step of moving the machine. A relatively great gap is formed between the grouting tube and the hole wall, so that pressure in holes is conveniently released, and high water pressure is reduced.

Owner:北京东地岩土工程有限公司

Pile forming operation method for protection barrel type cement soil mixing pile

The invention relates to a pile forming construction method for a protection barrel type cement soil mixing pile machine. The pile forming operation method is suitable for treatment of sludge, mucky soil and other soft soil foundations. The protection barrel type cement soil mixing machine is mainly composed of a crawler belt type mixing machine pile frame, a mixing machine power head, a protection barrel power head, a mixing shaft, a protection barrel, a drill bit, a supporting frame, mixing blades and the like. A slurry spraying pipe, a water spraying pipe and a material spraying pipe which are arranged in parallel are arranged in the protection barrel. When a cement soil mixing pile is formed, the protection barrel conducts cutting and drilling under the action of the protection barrel power head, the mixing machine power head carries a drill rod for rotary jet grouting following, and in the sinking mixing process of the mixing shaft, the slurry spraying pipe sprays slurry, the material spraying pipe sprays materials, and the water spraying pipe sprays water or slurry according to the stratum condition and the construction need. In the elevating mixing process of the mixing shaft, the protection barrel power head is closed, and the stirring shaft conducts mixing during slurry spraying to the preset slurry stopping face. The mixture and the slurry liquid are sufficiently mixed with an in-situ soil body in the closed protection barrel, the uniform degree and strength of a pile body are improved, and diffusion and flowing away of the slurry liquid of a curing agent are avoided.

Owner:ANHUI UNIV OF SCI & TECH

Porous pipe method large-diameter high-pressure jet grouting pile construction method

The invention relates to a porous pipe method large-diameter high-pressure jet grouting pile construction method. A high-pressure water conveying pipe, a high-pressure water compressed air conveying pipe and the like are arranged in a drill rod, the lower part of a drill bit is respectively provided with a high-pressure solidifying liquid and compressed air jet opening, a high-pressure water pipe jet opening and a compressed air water spraying opening, the positions of the high-pressure water pipe jet opening and the compressed air water spraying opening are positioned above the high-pressure solidifying liquid and compressed air jet opening, the bottom of the drill bit is provided with a high-pressure water jet opening, and the high-pressure water conveying pipe downwards jets water flow through the high-pressure water jet opening for cutting, so that the lower side of the drill pipe reaches the design pile bottom elevation, then, high-pressure water jet flow and compressed air jet flow are jetted from the high-pressure water pipe jet opening and the compressed air jet opening, high-pressure solidifying liquid and compressed air jet flow is jetted out from the high-pressure solidifying liquid and compressed air jet opening and is rotationally lifted along with the drill rod, and the peripheral soil bodies are subjected to secondary cutting, so that cement slurry and soil are stirred to be mixed into a pipe. Compared with an ordinary high-pressure jet grouting pile, the porous pipe method large-diameter high-pressure jet grouting pile has the advantage that the integral pile forming efficiency is improved by about 30 percent.

Owner:上海开普天岩土科技集团有限公司 +1

Inner drilling machine and construction method thereof

ActiveCN107386977ALow costSimple structureDrilling rodsConstructionsHelical bladeArchitectural engineering

The invention discloses an inner drilling machine and a construction method thereof. The inner drilling machine comprises a tunneling and drilling machine; the tunneling and drilling machine comprises a reducer, a fixture, a driving device and a drilling tool; the fixture is arranged on the reducer; a through hole is formed in the drilling tool, and an outlet of the through hole is formed in the bottom of the drilling tool; the drilling tool comprises a drill bit, a drilling rod and a helical blade; the drilling rod is connected with the reducer; the drilling rod is divided into a plurality of sections which are connected through drilling rod joints; and the drilling rod joints adopt male and female joints. According to the inner drilling machine and the construction method thereof, when the inner drilling machine is adopted in construction for precast hollow piles, simultaneous conducting of guiding holes and pressing piles can be achieved without changing original pile machine structure; and the inner drilling machine is low in cost, simple in structure, small in self-weight, convenient to construct, low in noise, low in vibration, friendly in environmental protecting and high in efficiency, and the problem of difficult construction of prefabricated hollow piles in dense sand layer geology can be effectively solved.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

Pipe pile-anchor rod composite foundation capable of bearing pulling and pressing bidirectional loads and construction technology

InactiveCN105350531AReduce the "crowding effect"Low costBulkheads/pilesStructural reliabilityErosion

The invention provides a pipe pile-anchor rod composite foundation capable of bearing pulling and pressing bidirectional loads and a construction technology of the pipe pile-anchor rod composite foundation. The pipe pile-anchor rod composite foundation comprises a pipe pile and an anchor rod. An anchoring hole is reserved in a foundation bottom plate of a building structure, and a stretching end anchorage device is pre-buried in the anchoring hole. The anchor rod is composed of an anchor cable and a prefabricated anchor head, and the prefabricated anchor head is buried in soil below the foundation bottom plate. The upper end of the anchor cable penetrates out of the pipe pile to stretch into the anchoring hole, and is locked by the stretching end anchorage device after being stretched. The pipe pile is supported between the foundation bottom plate and the prefabricated anchor head, and the lower end of the pipe pile is fixedly connected with the upper end of the prefabricated anchor head. In the pipe pile-anchor rod composite foundation, the prefabricated anchor head is additionally arranged at the lower end of the pipe pile so that the pressure resisting bearing capacity of the pipe pile can be improved; a waterproof curtain is formed by the pipe pile with the two closed ends, the erosion effect of underground water and the like on concrete and steel can be resisted, and the impermeability and durability of the anchor rod, the pipe pile and foundation bottom plate joints can be improved; and structural reliability and stress performance are ensured, meanwhile, project quality can be effectively improved, the construction period can be shortened, and the investment can be saved.

Owner:葛建

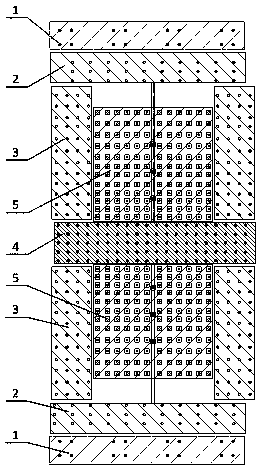

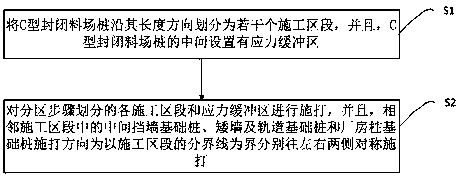

C-type closed material yard pile construction method

InactiveCN109653232AReduce breakage rateExpand the working areaCellarsBulkheads/pilesYardRetaining wall

The invention provides a C-type closed material yard pile construction method which includes the steps: partitioning, to be specific, dividing a C-type closed material yard pile into a plurality of construction sections along the length direction of the C-type closed material yard pile, and arranging a stress buffer area in the middle of the C-type closed material yard pile; piling, to be specific, piling the construction sections and the stress buffer area, and symmetrically piling middle retaining wall foundation piles, low wall and rail foundation piles and factory column foundation piles in adjacent construction sections towards the left side and the right side from boundaries of the construction sections. The C-type closed material yard pile is divided into a plurality of constructionsections by the aid of partitioning and sectioning principles, simultaneous piling is performed, and construction cycle is ensured. The middle retaining wall foundation piles, the low wall and rail foundation piles and the factory column foundation piles in the adjacent construction sections are piled towards the left side and the right side from the boundaries of the construction sections, piling directions are opposite to decrease squeezing effects, the problem of pile sinking difficulty is avoided, and piling quality is ensured.

Owner:CHINA MCC20 GRP CORP

Carbon fiber cloth bag cast-in-situ anti-arch curved surface combined irregular-shaped pile and construction method thereof

InactiveCN103741682AReduce pile side squeeze effectAccelerate soil consolidationBulkheads/pilesGeotechnical engineeringStructural engineering

The invention relates to a carbon fiber cloth bag cast-in-situ anti-arch curved surface combined irregular-shaped pile, which is characterized in that the upper part of the combined irregular-shaped pile is a round pile body while the lower part thereof is an anti-arch curved surface pile body, and the pile bottom is provided with an irregular-shaped prefabricated pile tip. A carbon fiber cloth bag wraps the outside of the pile body; a steel sleeve with a reinforcing plate is arranged on the top part of the combined irregular-shaped pile; a vertical drain body is filled in the cavity at the outer side of the round pile body; a vertical drain pipe communicated with the vertical drain body is preset in a cast-in-situ cover plate on the top part of the pile. The carbon fiber cloth bag arranged on the outer side of the pile body can reinforce the pile body, improve the stress performance of the pile body and enhance the integrity of the pile body; the section of the pile body on the lower part is an anti-arch curved surface which can prevent influence from excessive fullness of concrete of the pile body to the lateral friction of the pile; the section of the pile body on the upper part is round and can reduce the influence from the lateral negative friction of the pile to the performance of the pile body. The invention also discloses a construction method of the combined irregular-shaped pile.

Owner:JIANGSU ZHONGRUI ROAD & BRIDGE CONSTR

Precast concrete post grouting pile and grouting process

InactiveCN103015414ADimensions are easy to controlQuality controllableBulkheads/pilesCement pasteRebar

The invention discloses a precast concrete post grouting pile which comprises a post grouting pile body, a reinforcement cage framework, flanges, a post grouting tank, a post grouting pipe, a grouting hole and a pile bottom filler, wherein the reinforcement cage framework comprises longitudinal ribs and surrounding ribs; one end or two ends of the framework are welded with the flanges; at least one post grouting pipe runs through the center or the side edge position of the framework or the center and the side edge position of the framework; one end of the post grouting pipe is provided with the grouting hole; the grouting hole is positioned in the post grouting tank; and the post grouting tank is arranged on the post grouting pile body. In the constructing process, the post grouting pile is sunken and immediately, cement paste or powder paste with a specific surface area of 2,500 to 6,500kg / cm<2> is injected into the post grouting pile body by the grouting pipe, so that sufficient adhesion of the grouted paste and a soil layer around the pile is ensured. The precast concrete post grouting pile can realize improvement on rock and soil common resistance of soil and the pile so as to further play bearing capacity of the pile; and meanwhile, the number of the used piles can be reduced and engineering cost is reduced.

Owner:建华建材(四川)有限公司

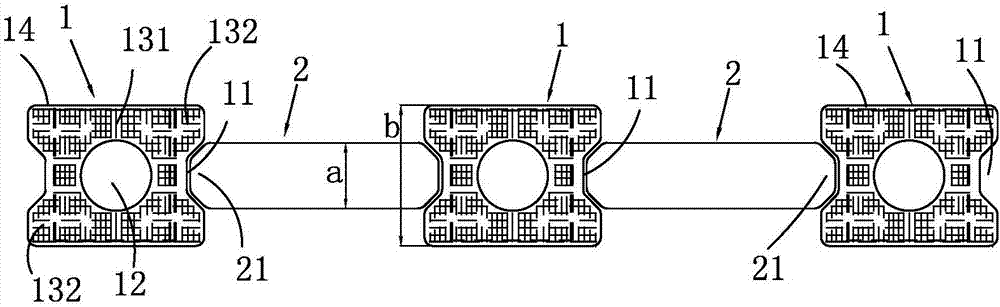

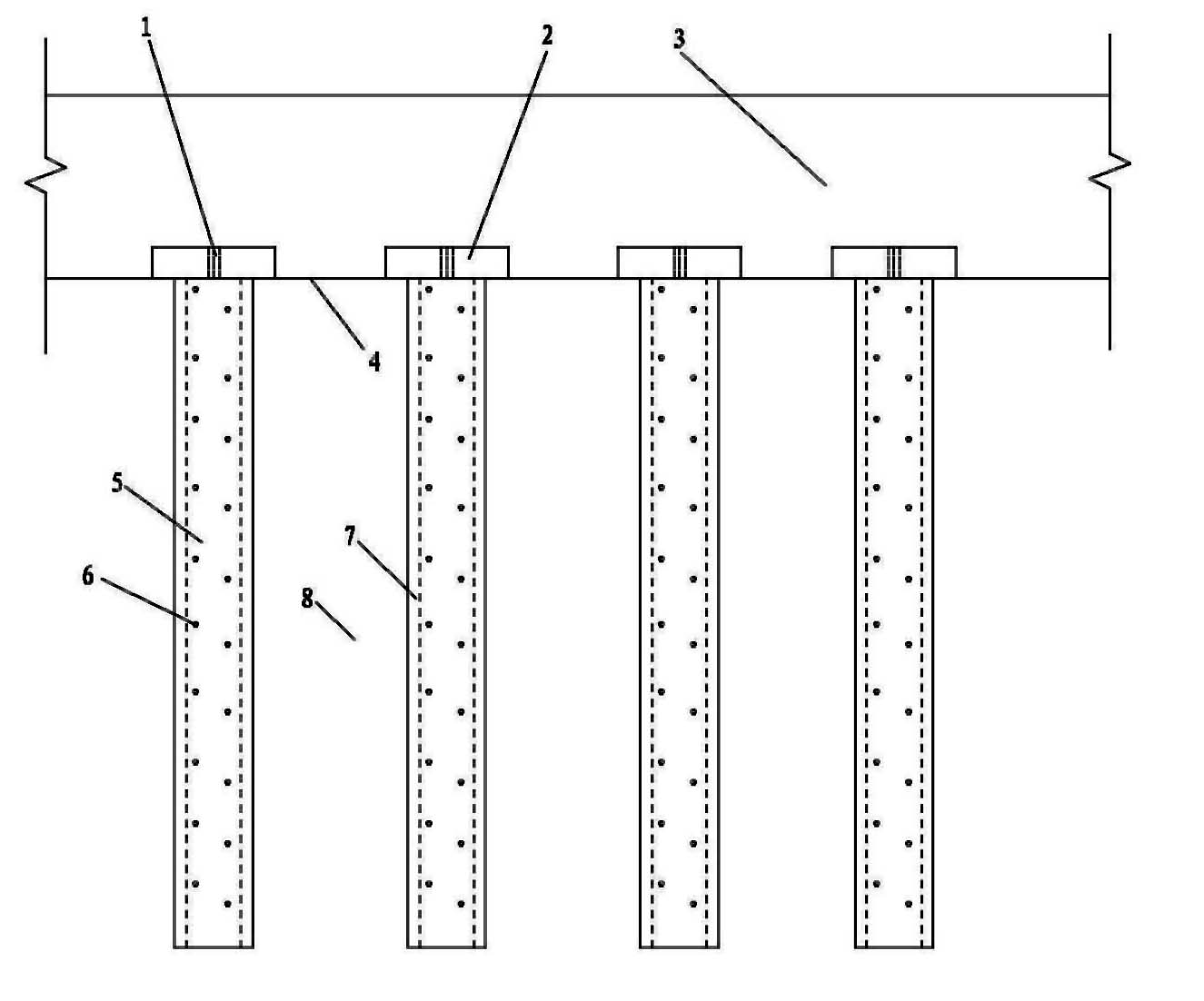

Novel precast drainable tube pile and preparing construction method thereof

InactiveCN107059854AAccelerated consolidationAccelerated dissipationShaping reinforcementsBulkheads/pilesSurface layerTransverse groove

The invention discloses a novel precast drainable tube pile and a preparing construction method thereof, which belong to the field of geotechnical engineering. The novel precast drainable tube pile comprises a precast tube pile body, longitudinal and transverse reserved grooves in the pile surface, a pervious concrete layer and corresponding tube pile end plates, etc. The longitudinal and transverse reserved grooves in the side wall of the pile body of the precast tube pile are filled with pervious concrete as drainage passages for pore water in a soil mass, and by performing inter-pile connection on the corresponding tube pile end plates designed by the present invention, smoothness of the drainage paths after pile connecting can be ensured. By applying the novel precast drainable tube pile, a soil compaction effect in a pile sinking process can be reduced, consolidation of the soil mass among the piles can be accelerated, a pile side friction can be increased, vertical and horizontal displacements of adjacent pile bodies can be effectively reduced, and a pile base bearing capacity can be increased; and a settling volume and a negative friction resistance of the pile side soil mass after construction can be reduced. The novel precast drainable tube pile is simple in structure, can be industrially produced and is high in construction efficiency and obvious in actual social and economic benefits.

Owner:NANJING UNIV OF TECH

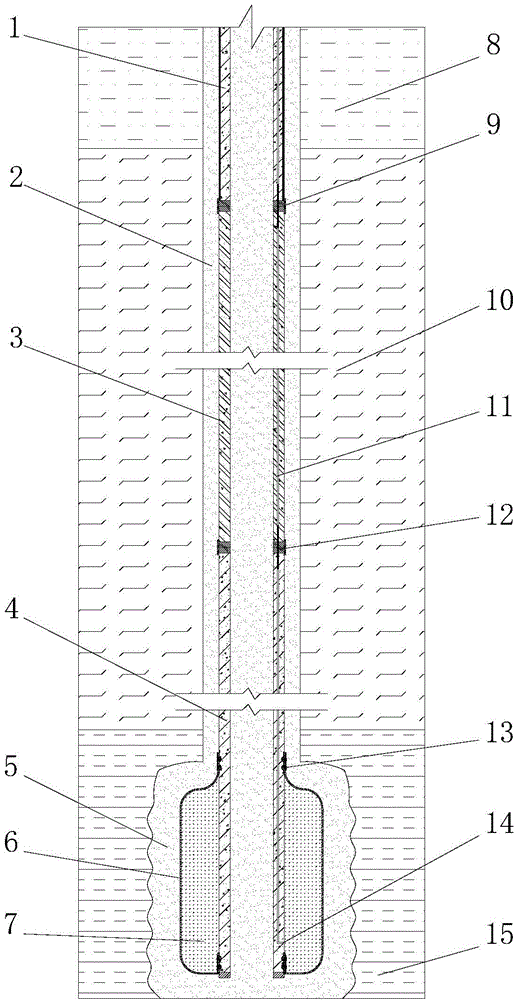

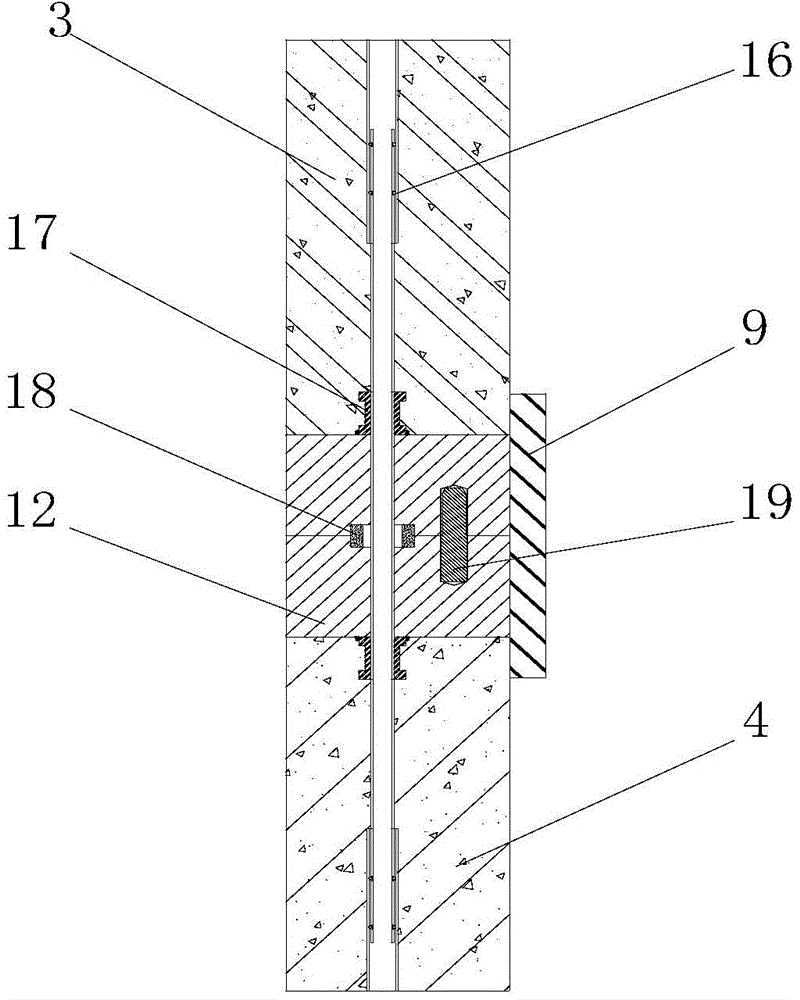

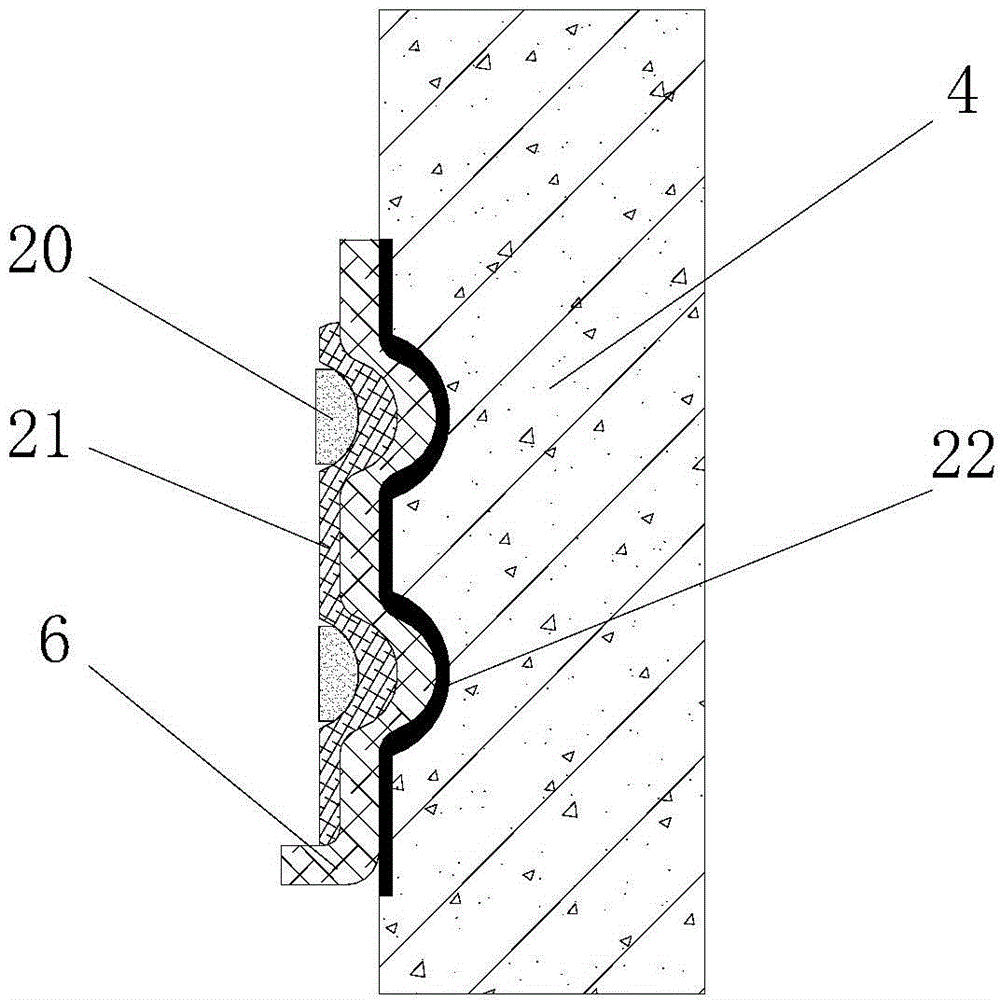

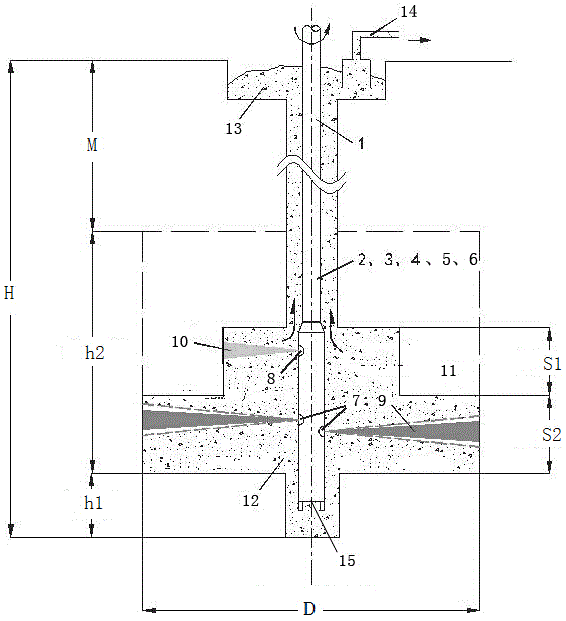

A kind of rigid-flexible combined pile with pocket expanded bottom and its construction method

ActiveCN103741683BGive full play to the horizontal load bearing performanceNot easy to damageBulkheads/pilesSoil cementPipe

The invention relates to a bag bottom expanding rigid-flexible combined pile. The bag bottom expanding rigid-flexible combined pile is formed by connecting the following prefabricated pipe piles including a TSC (prestress concrete thin wall concrete) pile, a PRC (prestress reinforcement concrete) pile and a PHC (prestress high-strength concrete) pile from top to bottom. The bottom end of the PHC pile is provided with a pile bottom expander packed by a bag; the inside of the prefabricated pipe piles is provided with a grouting duct; both ends of every pile is provided with perforated pipe pile joints, and the side wall of the pile at the bottom is provided with a grout outlet; the outside of the combined pile is packed by surrounding cemented soil. According to the bag bottom expanding rigid-flexible combined pile, based on the law of horizontal load bearing of the pile bodies inside soil, the prefabricated pipe piles with the anti-bending and anti-shearing performance gradually improved, which are connected in a combined mode, are sequentially planted inside the cemented soil, and the expanded is grouted after the bag with stable characteristics is set to improve the vertical bearing capacity of the piles, so that relatively higher technical and economical benefits can be obtained. The invention also discloses a construction method of the bag bottom expanding rigid-flexible combined pile.

Owner:ZHEJIANG TIANRUN CONSTR +4

Perforated pipe method super-deep, fast, and super-large diameter high pressure chemical churning pile construction method

InactiveCN104612137AReduce the crowding effectLarge pile diameterDrill bitsDrilling rodsWater pipeEngineering

The invention relates to a perforated pipe method super-deep, fast, and super-large diameter high pressure chemical churning pile construction method. Two high pressure curing liquid and compressed air injection openings and a high pressure water pipe injection opening and compressed air water injection nozzle are arranged on the lower side of a drill, the position of the high pressure water pipe injection opening and compressed air water injection nozzle is above the position of the high pressure curing liquid and compressed air injection openings, and the two pressure curing liquid and compressed air injection openings are in the symmetric positions of the same flat surface; the high pressure water pipe injection opening downward injects water to conduct cutting, the lower side of a drill stem is higher than a bottom label of a designed pile, then the high pressure water pipe injection opening and compressed air injection nozzle injects a high pressure water pipe injection flow and compressed air injection flow, and the high pressure curing liquid and compressed air injection openings inject high pressure curing liquid and compressed air injection flow. With the drill stem rotating and lifting, adjacent soil body is conducted a secondary cutting, and cement paste and soil are mixed to a pile. Compared with the prior high pressure chemical churning pile, the overall pile formation efficiency is increase by almost 48%.

Owner:上海开普天岩土科技集团有限公司 +1

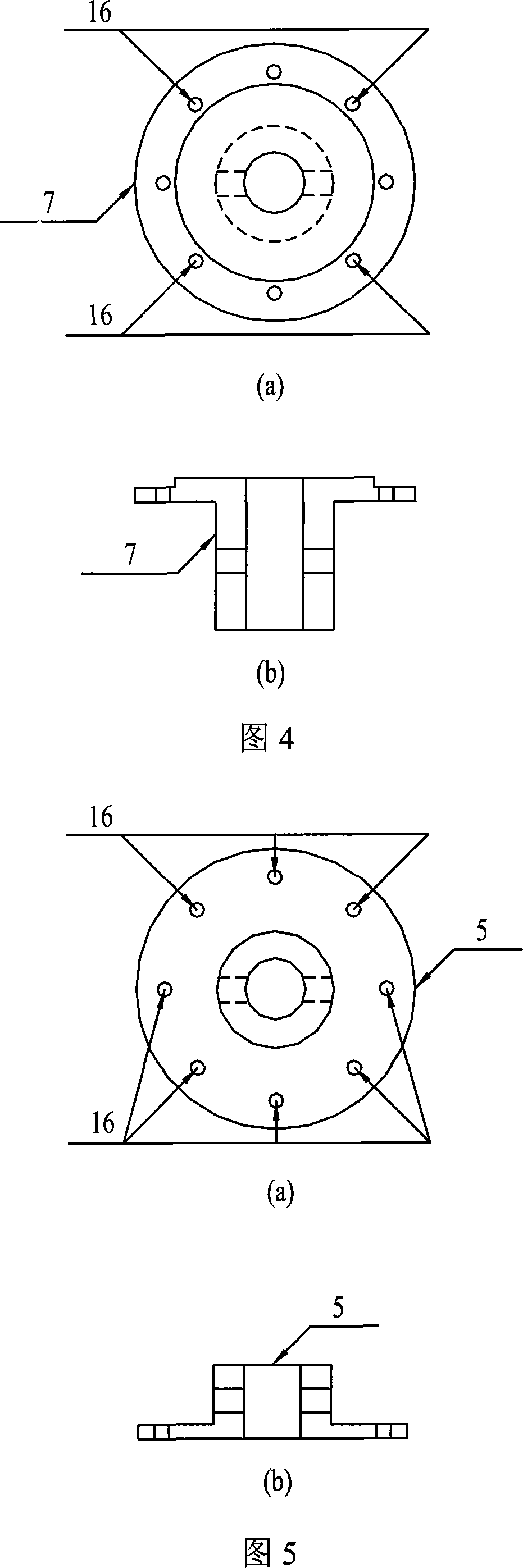

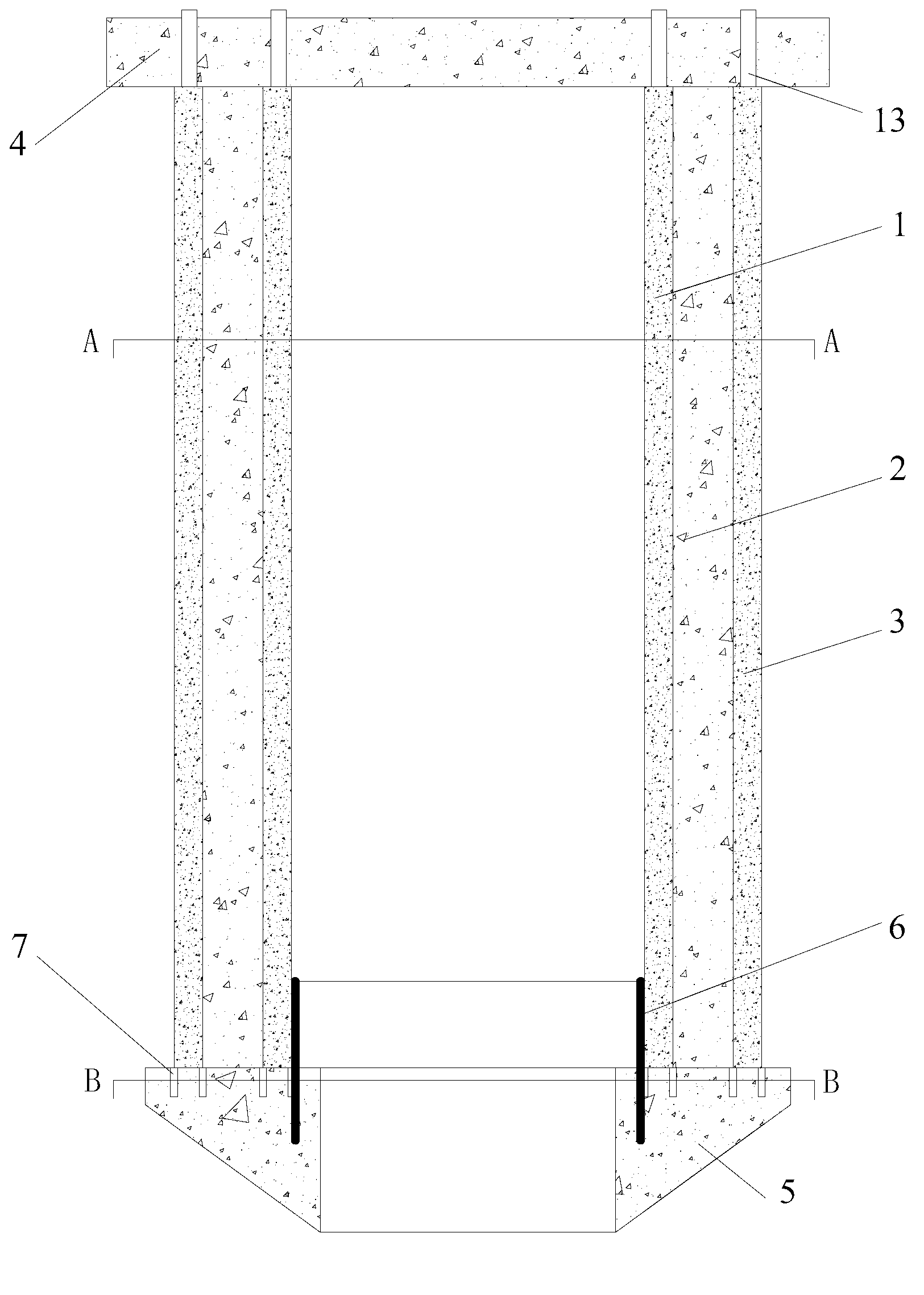

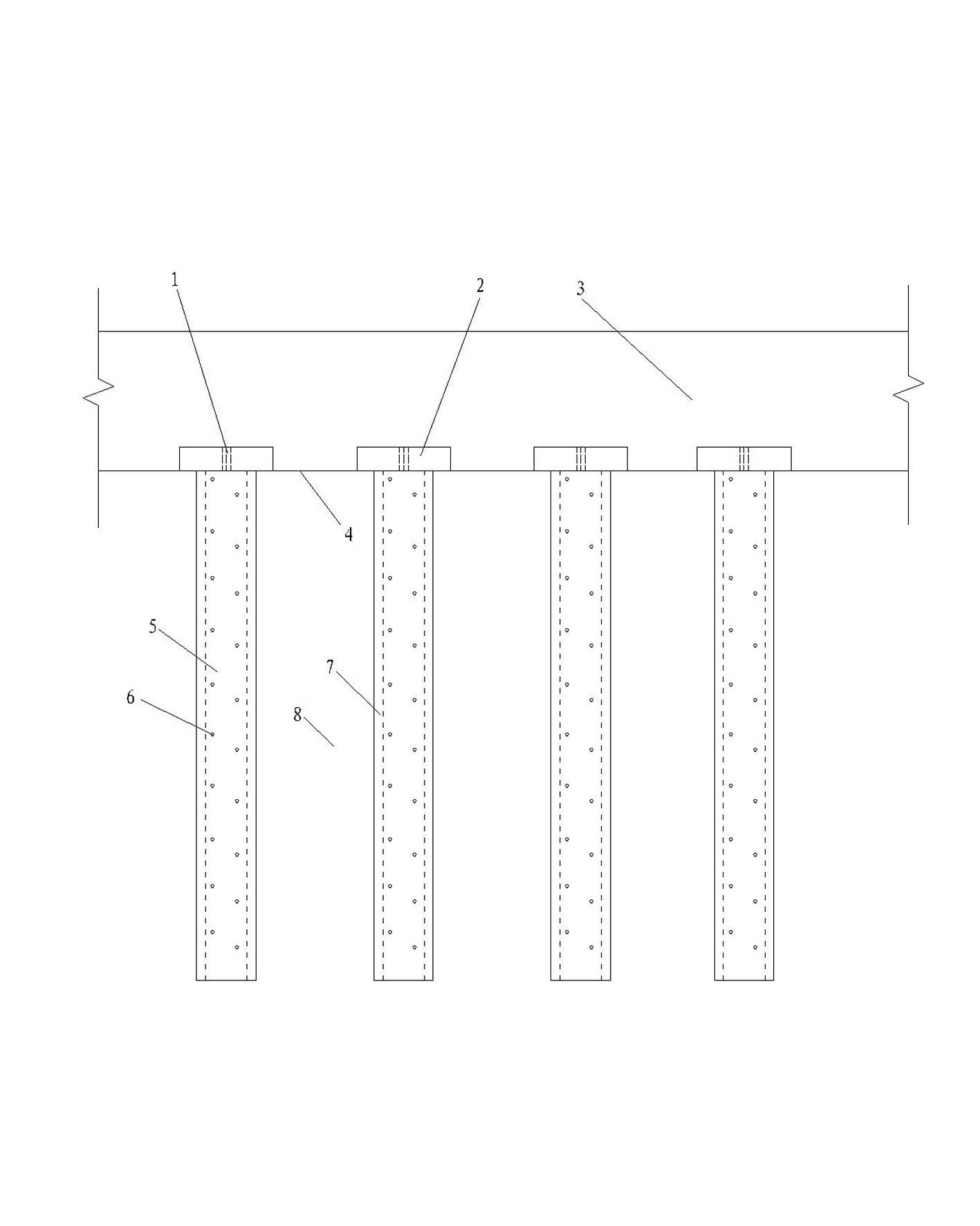

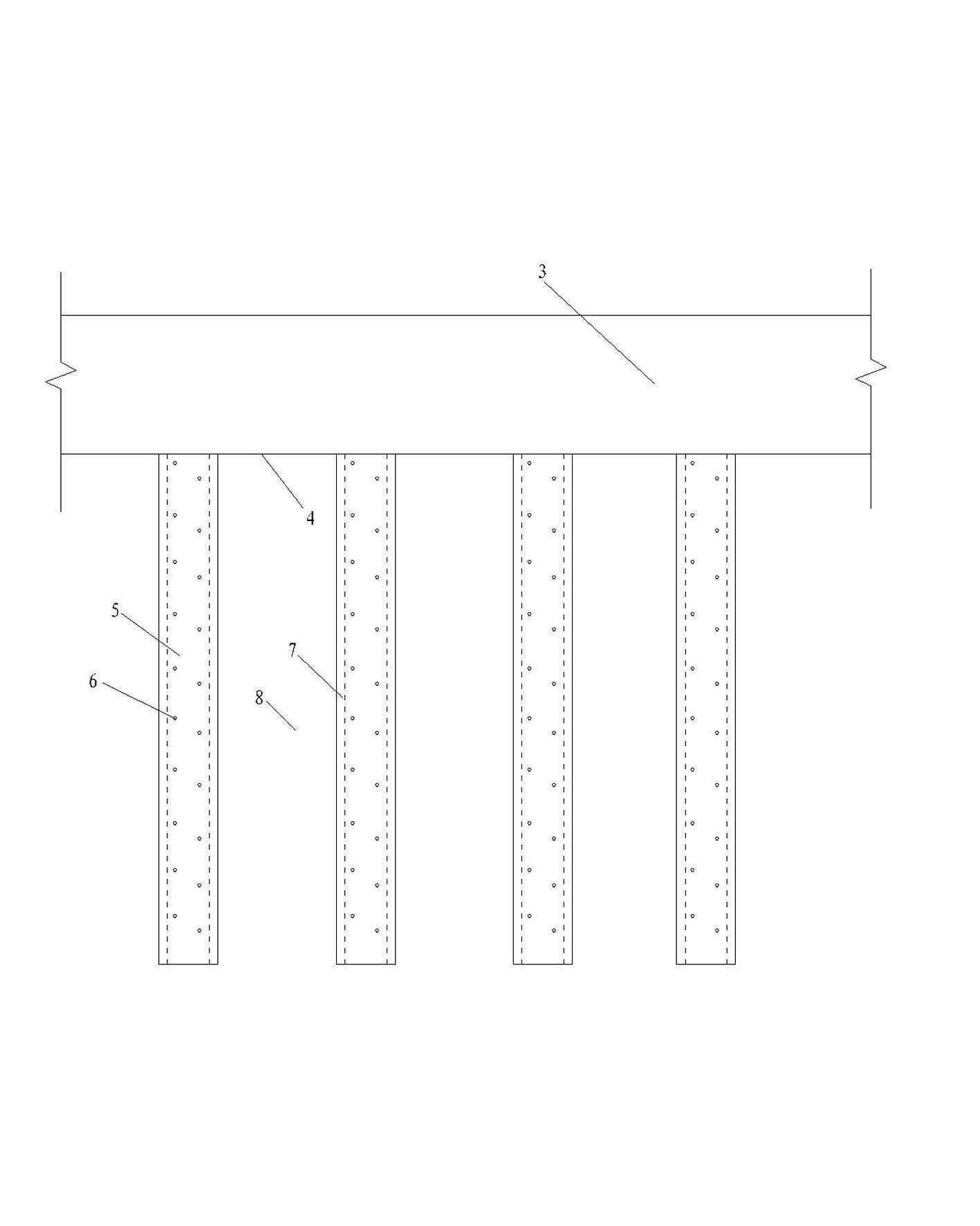

Extrusion formed precast pile stiffness core and cement soil combined Y-shaped pile and construction method thereof

InactiveCN104141304AStable formReduce the crowding effectBulkheads/pilesImmersed tubeAbnormal shaped

The invention relates to an extrusion formed precast pile stiffness core and cement soil combined Y-shaped pile. The Y-shaped pile is composed of an external cement soil cladding, a precast core pile and a precast end-open pile tip, wherein the cross section of the external cement soil cladding is Y-shaped and is formed through enclosing of a steel immersed tube in a constraint mode, the external cement soil cladding is coated with geotechnical cloth bags, and the precast core pile presses downwards perpendicularly along the center of the steel immersed tube and is embedded into a precast hollow pile tip. Back extrusion initial set type cement soil is shaped by means of the Y-shaped steel immersed tube, stability of forming of the Y-shaped pile is guaranteed, the precast core pile is inserted in the center, the advantages that the frictional resistance of the special-shaped pile side is large and the bearing capacity of the stiffness core composite pile is high are fully utilized, and technological and economical efficiency is high. The invention further discloses a construction method of the Y-shaped pile.

Owner:GUANLU CONSTR

Treatment method of drainage pipe pile composite foundation

InactiveCN102061695AUltra-clean pore water pressure dissipationReduce the crowding effectSoil preservationPile capSoft clay

The invention relates to a treatment method of a drainage pipe pile composite foundation. The treatment method comprises the following steps: arranging drainage pipe piles according to a certain distance in a soft clay foundation; arranging drainage cushion layers on the top surfaces of the drainage pipe piles or pile caps; when the pile caps are arranged on the top of the drainage pipe piles, arranging preformed holes on the pile caps so as to ensure that the pipe pile holes are communicated with the drainage cushion layers; and arranging a certain number of small holes penetrating through pipe walls on the pipe walls of the drainage pipe piles so that underground water in soil among the piles can flow into the pipe pile holes via the small holes and then is drained via the preformed holes and the drainage cushion layers on the pile caps. Therefore, by means of the treatment method of the drainage pipe pile composite foundation, the dissipation of excess pore water pressure in the soil among the piles can be enhanced, the soil compacting effect generated by pipe pile construction can be reduced, and the load carried by the soil among the piles or post-construction settlement caused by self weight of foundation soil can be reduced.

Owner:GUANGDONG PROVINCE HANGSHENG CONSTR GRP

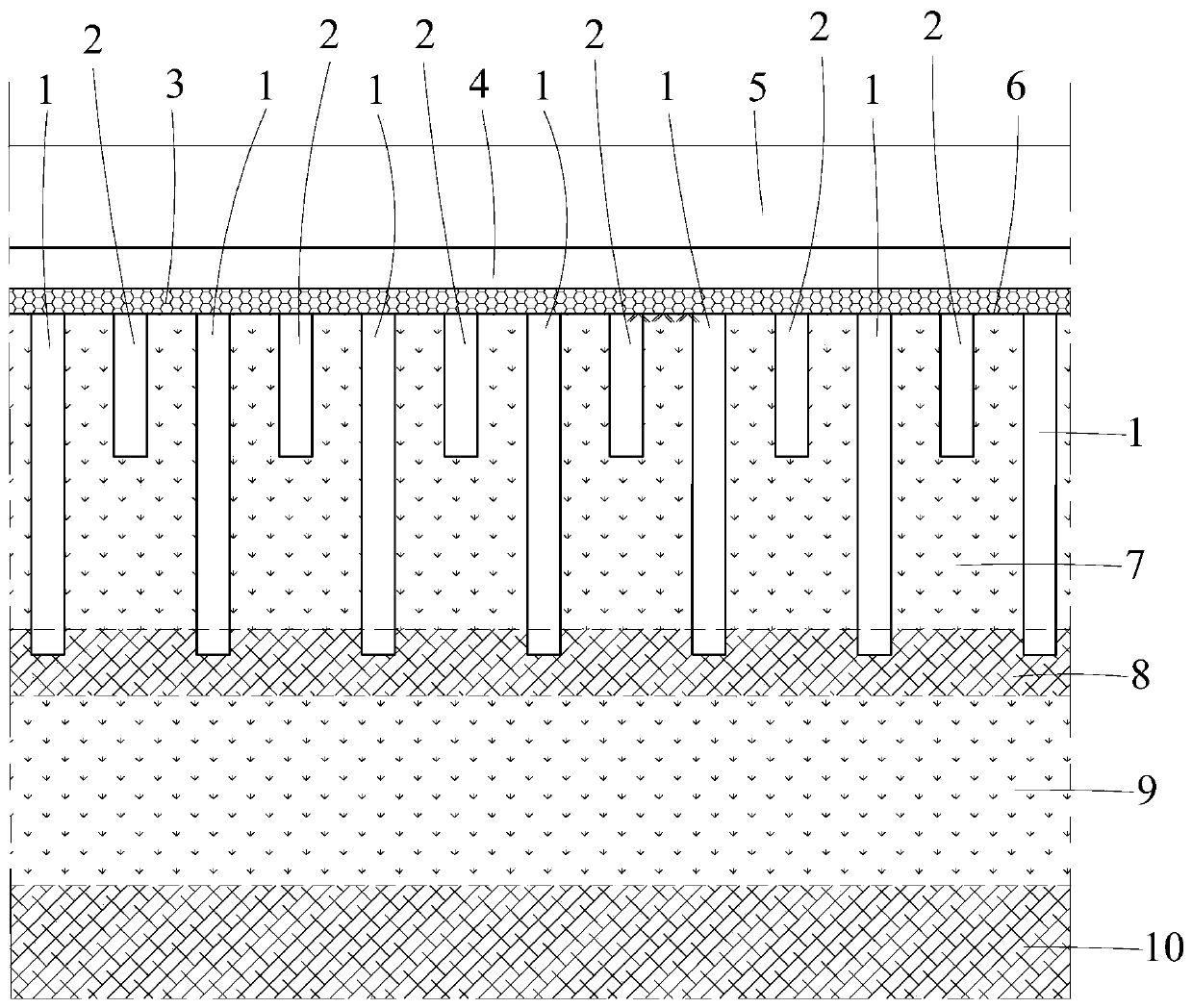

Foundation treatment structure suitable for deep soft foundation with sandwiched thin bearing stratum and construction method

PendingCN111321751ASave engineering investmentSolve the large settlementBulkheads/pilesPipeBearing capacity

The invention belongs to the field of geotechnical engineering, and particularly relates to a foundation treatment structure suitable for a deep soft foundation with a sandwiched thin bearing stratumand a construction method. The foundation treatment structure comprises a raft, a mattress layer, pipe piles and stirring piles, wherein the mattress layer is arranged at the bottom of the raft and located at the top of an upper soft soil foundation layer; the pipe piles are arranged at intervals and arranged at the bottom of the mattress layer, and the lower ends of the pipe piles are located ina middle bearing stratum; and the stirring piles are arranged at intervals and arranged at the bottom of the mattress layer and located in the upper soft soil foundation layer. According to the foundation treatment structure suitable for the deep soft foundation with the sandwiched thin bearing stratum, the engineering investment is saved; and settlement of a composite foundation is reduced, the bearing capacity of the composite foundation is improved, and the problems that the foundation settlement is large, the foundation bearing capacity is low and the pipe piles are prone to piercing the middle bearing stratum when the pipe piles are located in the middle bearing stratum are solved.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Cast-in-place large-diameter pipe pile casing pipe and construction method

The invention discloses a cast-in-place large-diameter pipe pile casing pipe which comprises a main casing pipe body, a lower-end outer casing pipe body, feeding pipes and a valve pile shoe. The main casing pipe body and the lower-end outer casing pipe body are concentric cylindrical barrels, the lower end of the outer side of the main casing pipe body is sleeved with the lower-end outer casing pipe body, and the lower-end outer casing pipe body is attached to the outer wall of the main casing pipe body to form a closed cavity. The lower end of the lower-end outer casing pipe body is connected with the valve pile shoe. The feeding pipes are arranged on the outer wall of the main casing pipe body, and the lower ends of the feeding pipes stretch in the closed cavity formed between the lower-end outer casing pipe body and the main casing pipe body. Pile-forming quality is effectively guaranteed, disturbance to soil and generation of a soil extrusion effect are reduced, and the phenomena of wall collapsing, wall shrinking, pile breaking and the like are avoided; pile subsoil is prevented from being brought upwards through the horn-shaped main casing pipe body at the upper end, and bearing capacity is increased; and the structure is simple, the principle is clear, the manufacturing cost is low, and wide application prospects and good economic and technological benefits are achieved.

Owner:HOHAI UNIV

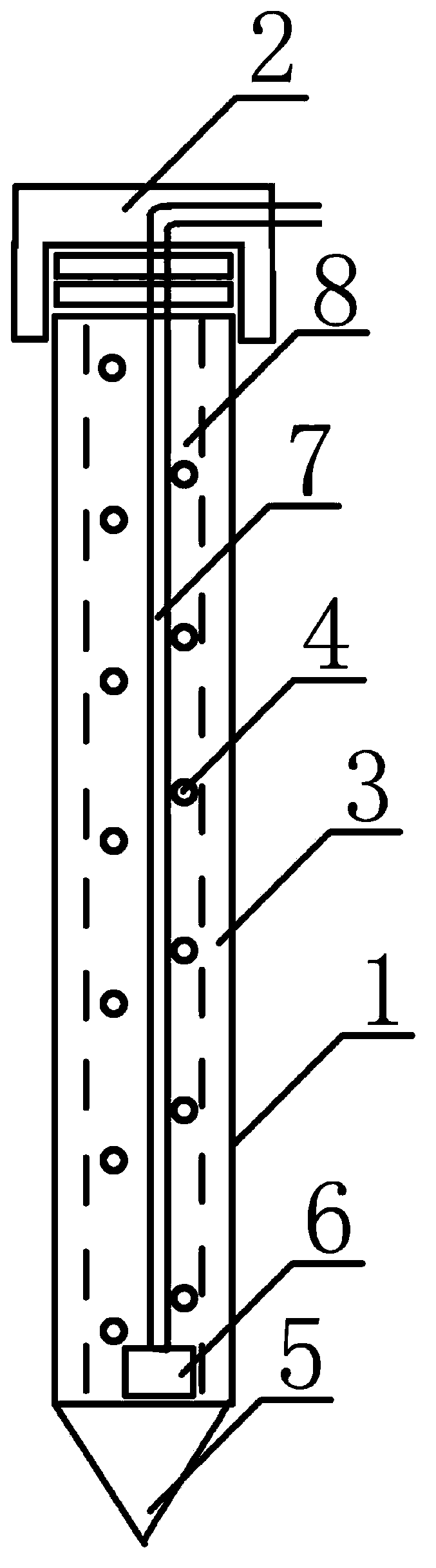

Novel decompression drainage precast pile and construction method

PendingCN109914384AEffectively fixedClosely connectedBulkheads/pilesSoil preservationReinforced concretePore water pressure

The invention discloses a novel decompression drainage precast pile. The novel decompression drainage precast pile comprises a novel reinforced concrete precast pile which is formed by a formwork pile-making method, and a groove is formed in the surface of the pile body in the axial direction of the pile body. A plastic drainage belt is laid in the groove and is fixed by steel bars, a connecting ring is arranged at the bottom end of a drainage belt of a first section of the pile body; hooks are arranged at the top of the tip of the precast pile and connected to the connecting ring in a hung mode and used for fixing the drainage belt and preventing the drainage belt from falling off in a pile pressing process. The novel precast pile can dissipate generated hyperstatic pore water pressure through drainage by the drainage belt in the pile pressing process and after pile pressing and accelerate consolidation of a foundation.

Owner:TIANJIN CHENGJIAN UNIV

Quick drainage tubular pile

The invention provides a quick drainage tubular pile which comprises a tubular pile body and a tubular pile alternating beating piece. The quick drainage tubular pile is characterized in that small holes with a certain number are formed in the pipe wall of the tubular pile body, the small holes penetrate through the pipe wall, underground water can directly enter a pile hole, the tubular pile is prevented from bearing super-static hole water pressure, lateral displacement or ground protrusions are avoided, and therefore pile breakage, pile body inclination and other engineering accidents can be avoided, the tubular pile alternating beating piece is arranged on the upper portion of the tubular pile body, a conical pile shoe is arranged on the lower portion of the tubular pile body, a water suction pump is arranged in the pile hole of the tubular pile body, a drainage pipe is arranged on the water suction pump, and the other end of the drainage pipe penetrates through the tubular pile alternating beating piece and stretches to the outer end of the tubular pile alternating beating piece. The water in the pile hole can be directly pumped out through the water suction pump, and therefore the super-static hole water pressure in a foundation is promoted to dissipate, the soil-squeezing effect and post-construction settlement are reduced, the tubular pile can be normally used, and the quick drainage tubular pile is simple in structure and convenient to operate.

Owner:TIANJIN YONGSHENG XINHE PILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com