Patents

Literature

56results about How to "Reduce propulsion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

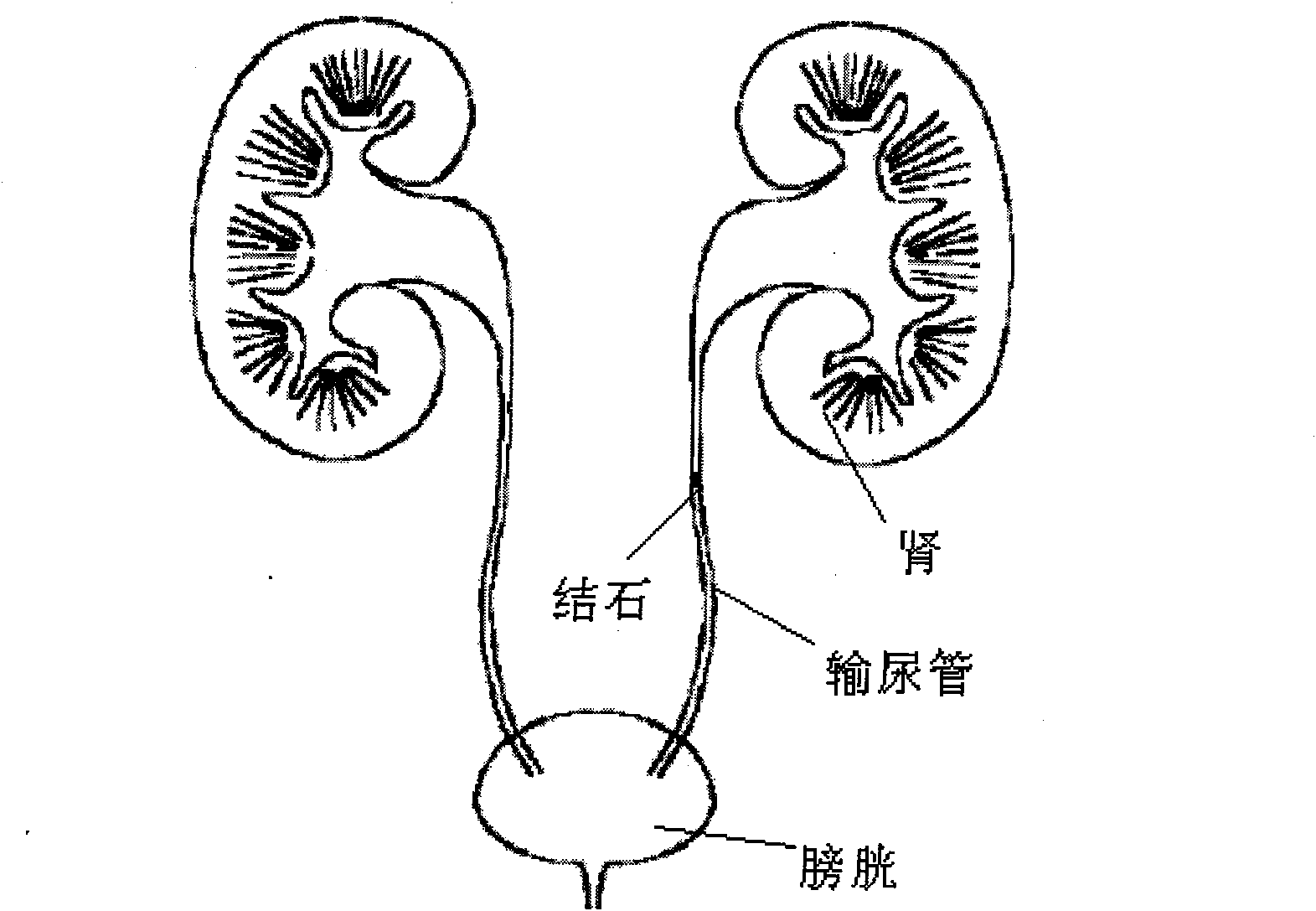

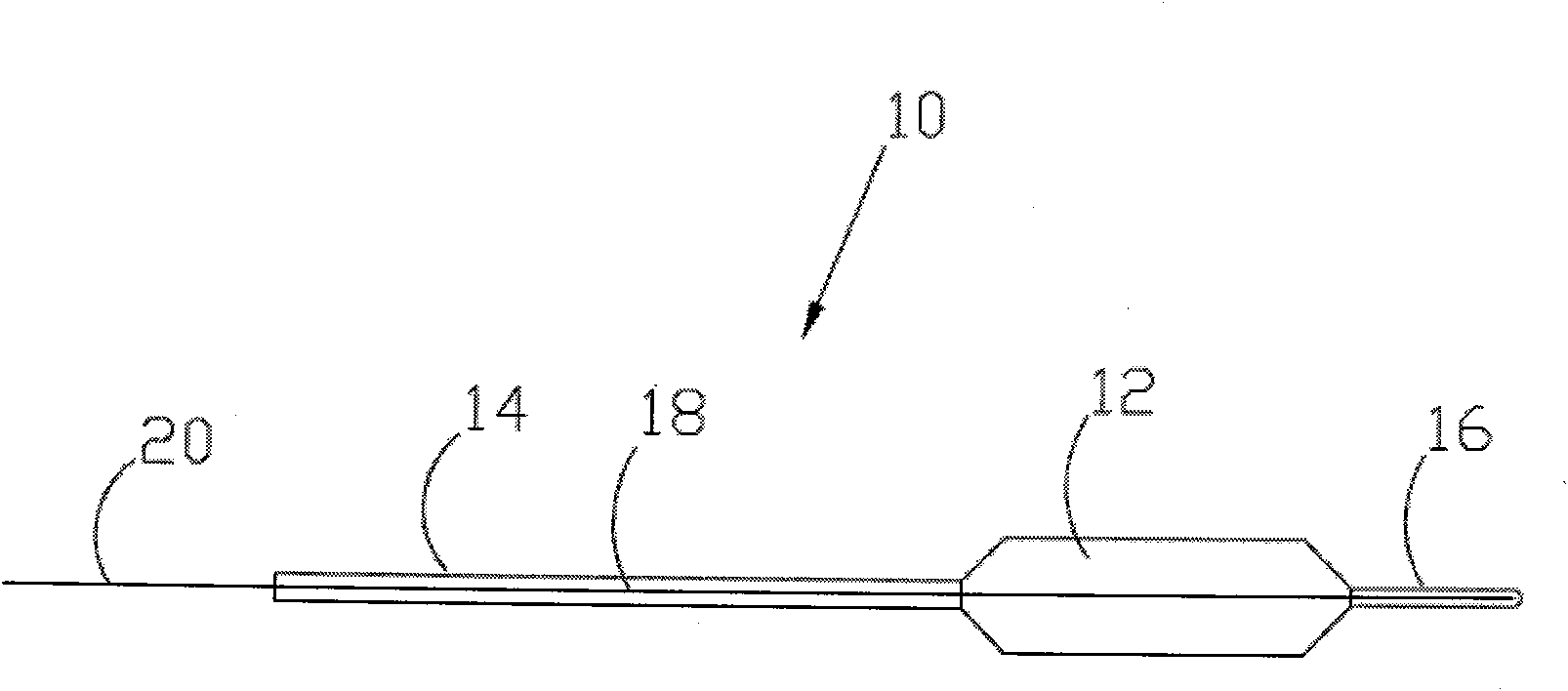

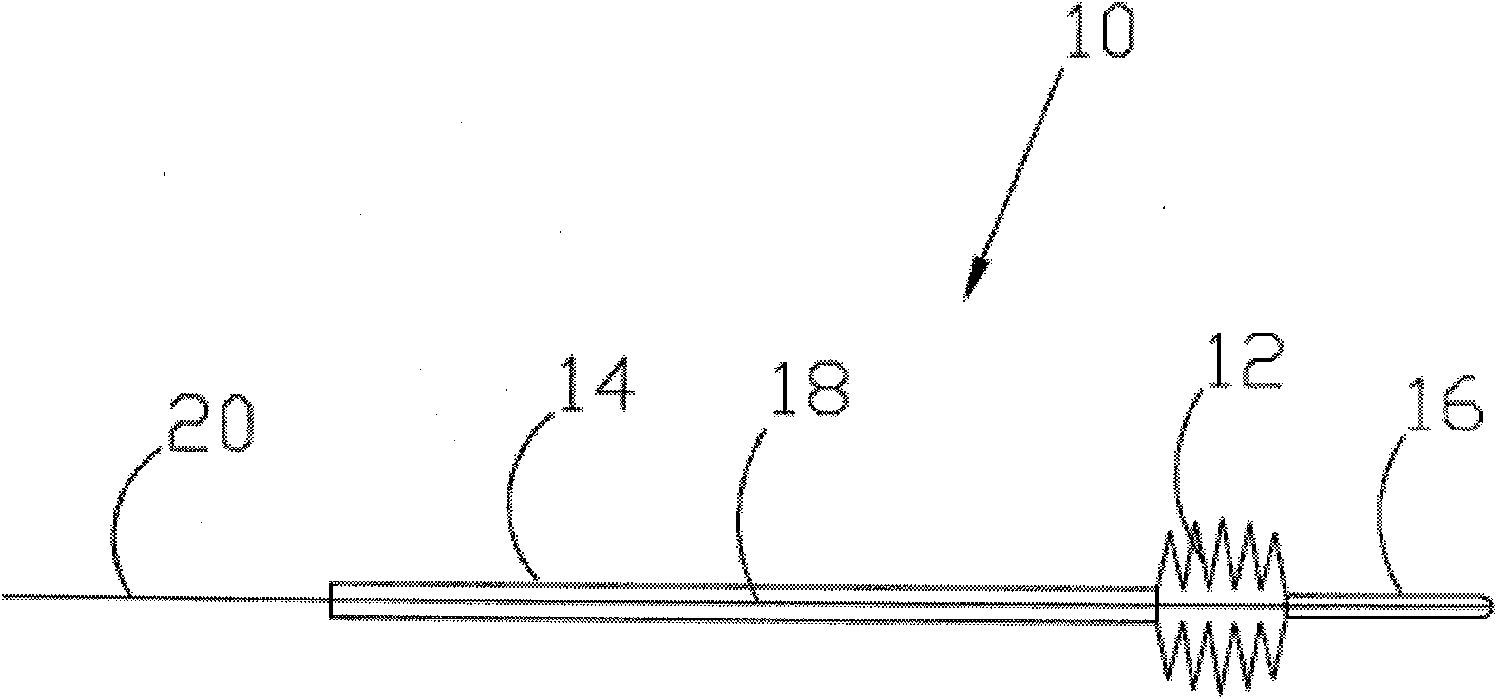

Method for blocking up obstacle in coelom and blocking device thereof

The invention discloses a method for blocking up obstacle in coelom and a blocking device thereof. The blocking device comprises a guide wire, a guide tube and a blocking substance; one end of the guide wire penetrates the guide tube and cavity of the blocking substance; a remote end of the blocking substance is fixed to the guide wire, so as to pull a near end of the guide wire, thereby axially compressing the spread blocking substance to form a plug-shaped blocking object. The method of using the blocking device for blocking up obstacles in coelom is that the blocking substance in the coelom blocking device penetrates the obstacles in coelom, a near end of the guide wire is pulled, and the spread blocking substance is axially compressed to form a plug-shaped blocking object to block up the obstacles. The method for blocking up obstacle in coelom of the invention sets up a special coelom blocking device to block up and fix obstacles, such as thrombus and stone in coelom, and removes the obstacles according to practical requirements. The method for blocking up obstacle in coelom has tiny structure, simple operation, convenient use and high efficiency.

Owner:INNOVEX MEDICAL CO LTD

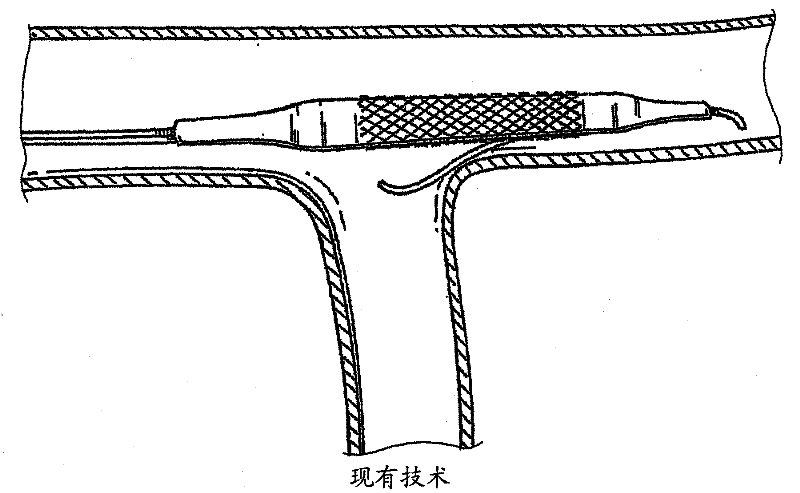

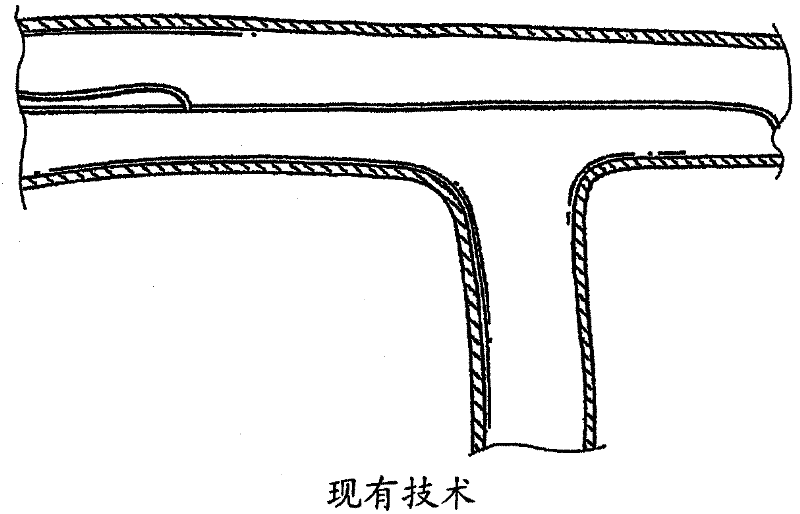

Navigation guide wire through an anatomical structure having branched ducts

InactiveCN102202717AEasy to operateQuick twist feedbackStentsGuide wiresAnatomical structuresDistal portion

A navigation guide wire (1 ) through an anatomical apparatus, for example a vascular system, unusually capable of being safely positioned proximate to bifurcations, comprises: - an elongated body (19) having a proximal end (21 ), a distal end (20), and a longitudinal extension along an axis (x-x) extending at least from said proximal end to said distal end; - at least one first proximal portion (4) having a predetermined first flexural rigidity (KfI ) capable of a first predetermined flexure in at least one plane comprising at least one portion of said longitudinal axis in order to allow a first curvature to said proximal portion when bending stressed, while ensuring a predetermined elastic return in a rectilinear position of the elongated body proximal portion when not subjected to stresses; - at least one second distal portion (3) having a predetermined second flexural rigidity (Kf2), the amount of which is equal to or higher than said first flexural rigidity of said at least one first proximal portion, capable of a predetermined flexibility of said second distal portion in order to obtain a second curvature when bending stressed in at least one plane comprising at least one portion of said longitudinal axis, while ensuring an elastic return to a rectilinear position of said distal portion of said elongated body when not subjected to stress; - at least one intermediate length (6), arranged between said first proximal portion and said second distal portion, having a third flexural rigidity (Kf3) essentially lower than said first flexural rigidity (KfI ) and said second flexural rigidity (Kf2), which allows a predetermined flexibility capable of a third curvature substantially more pronounced compared to said first curvature and second curvature, so as to allow a considerable direction change between said first proximal portion (4) and said second distal portion (3).

Owner:EVR MEDICAL S AR L

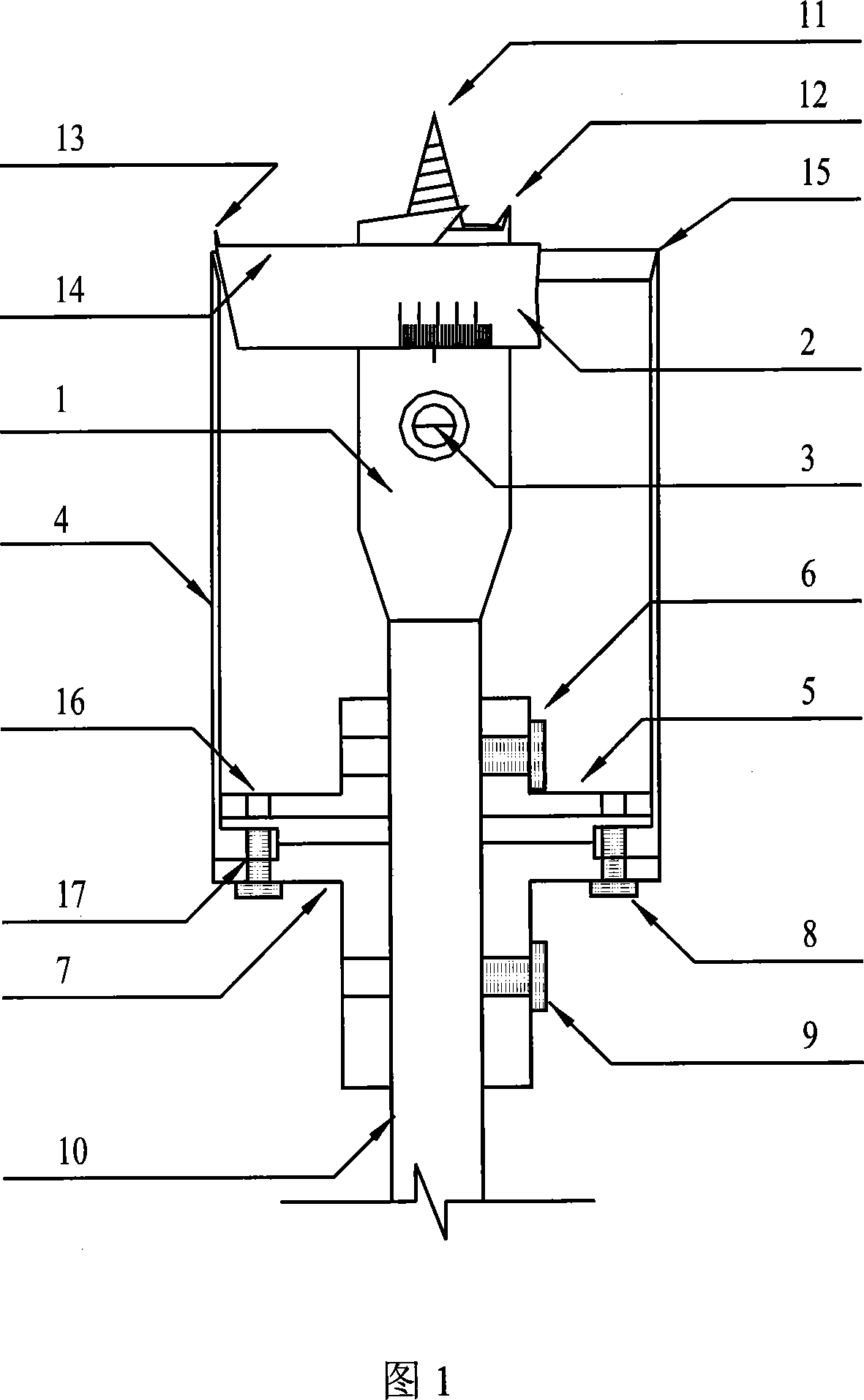

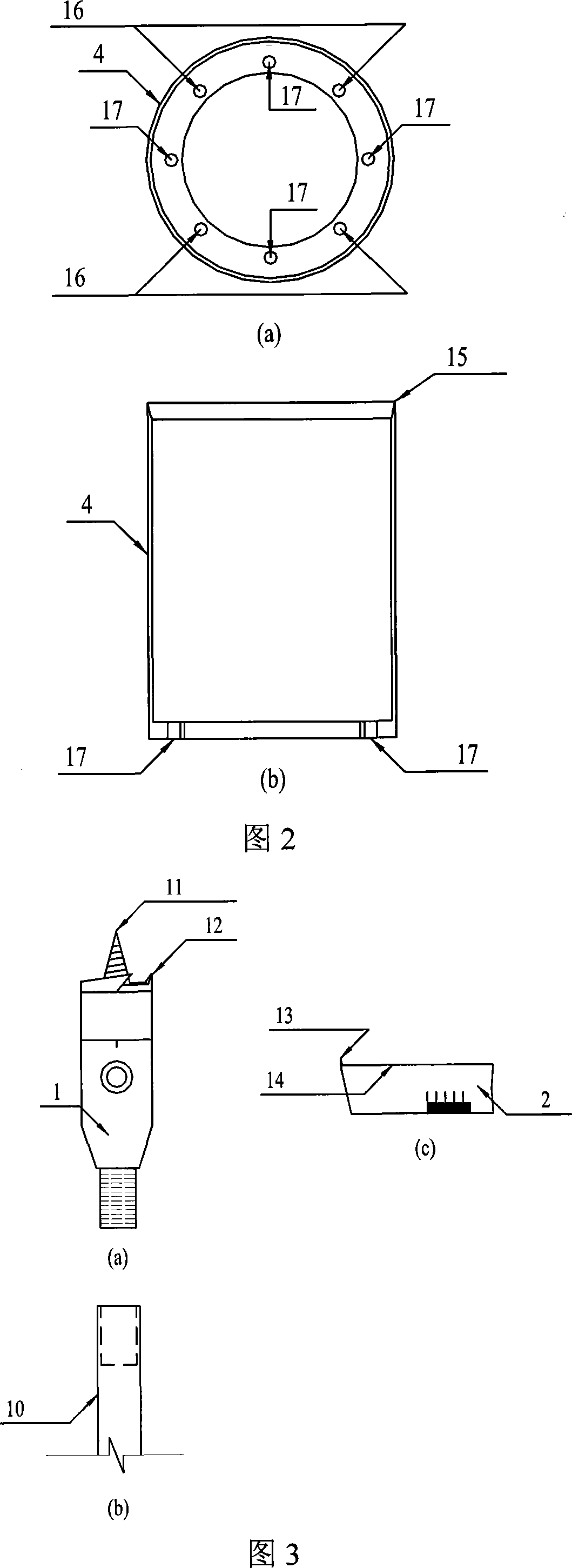

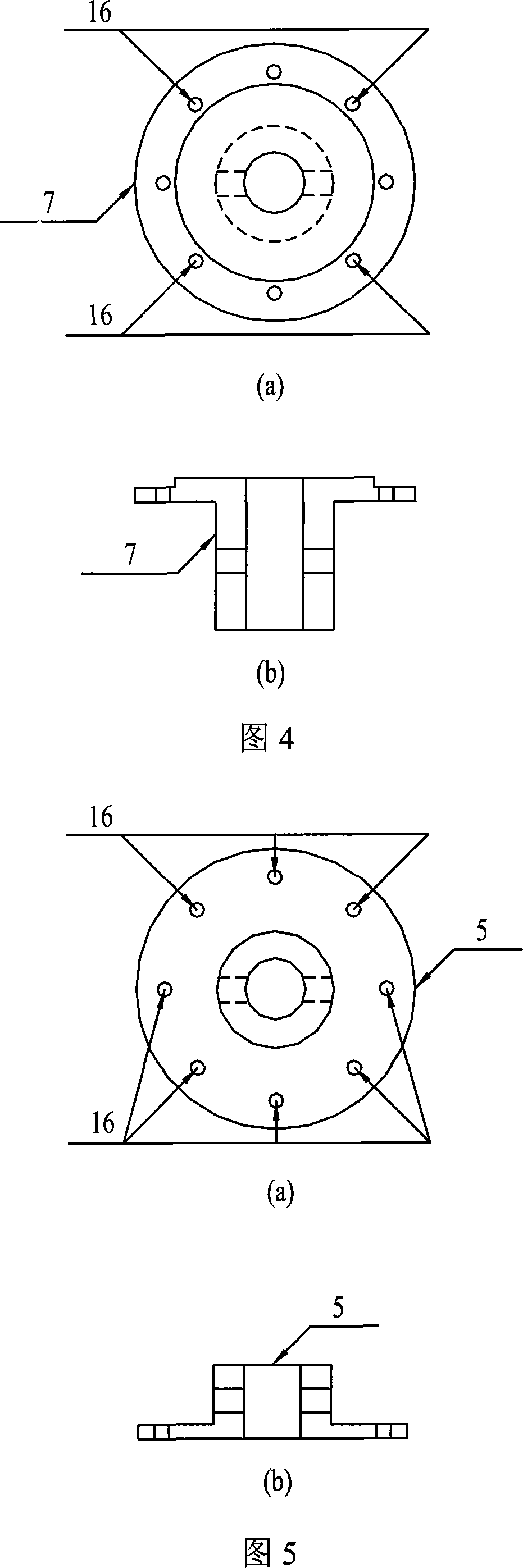

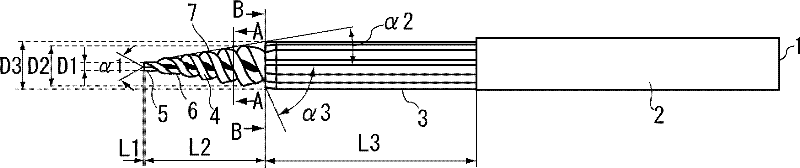

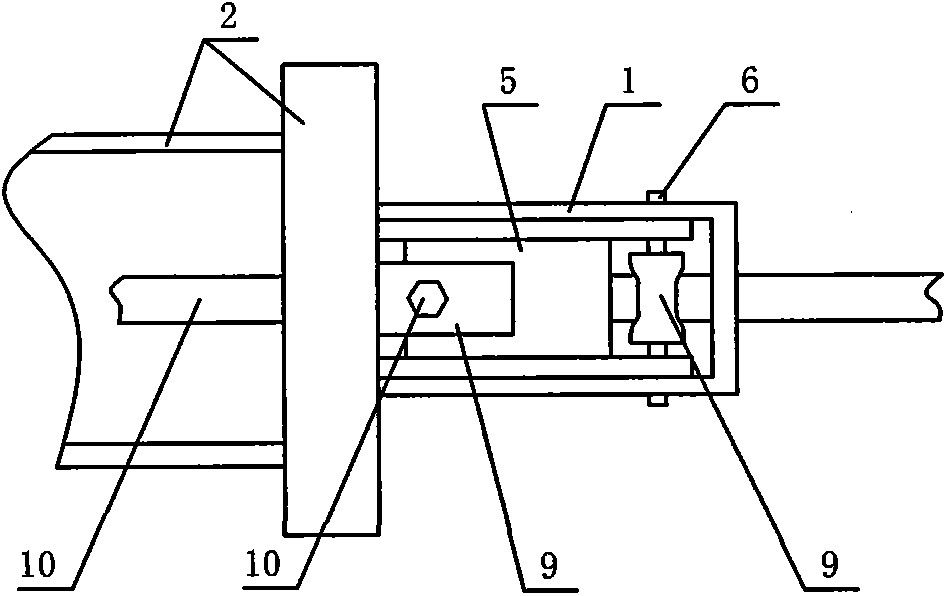

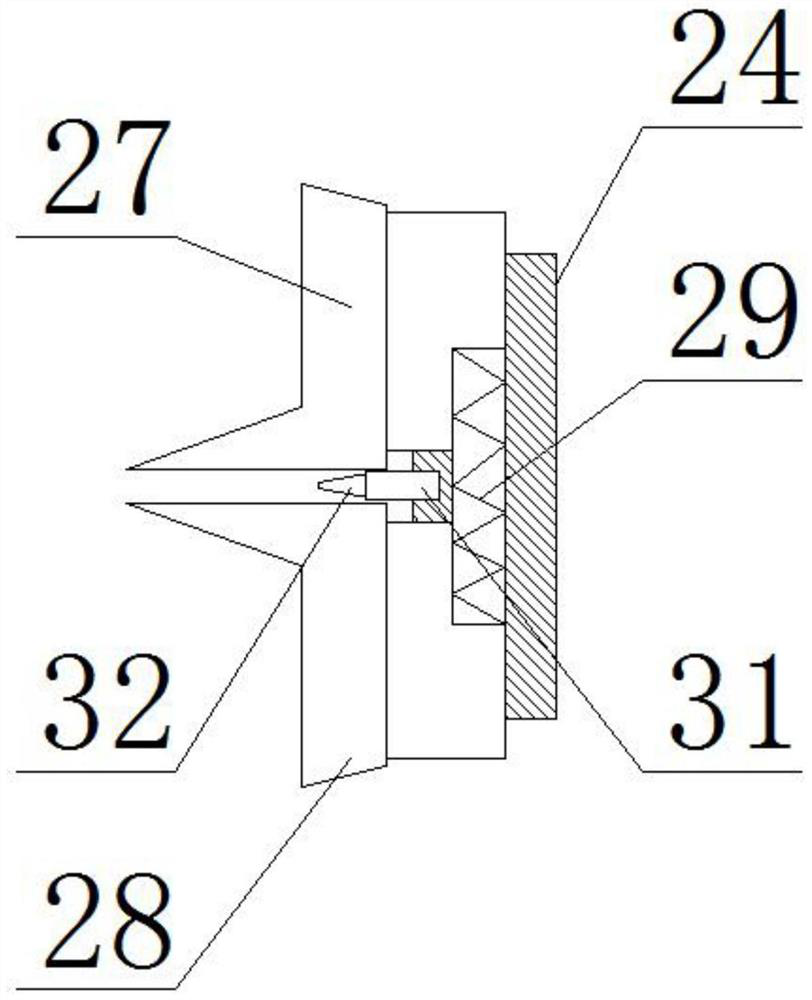

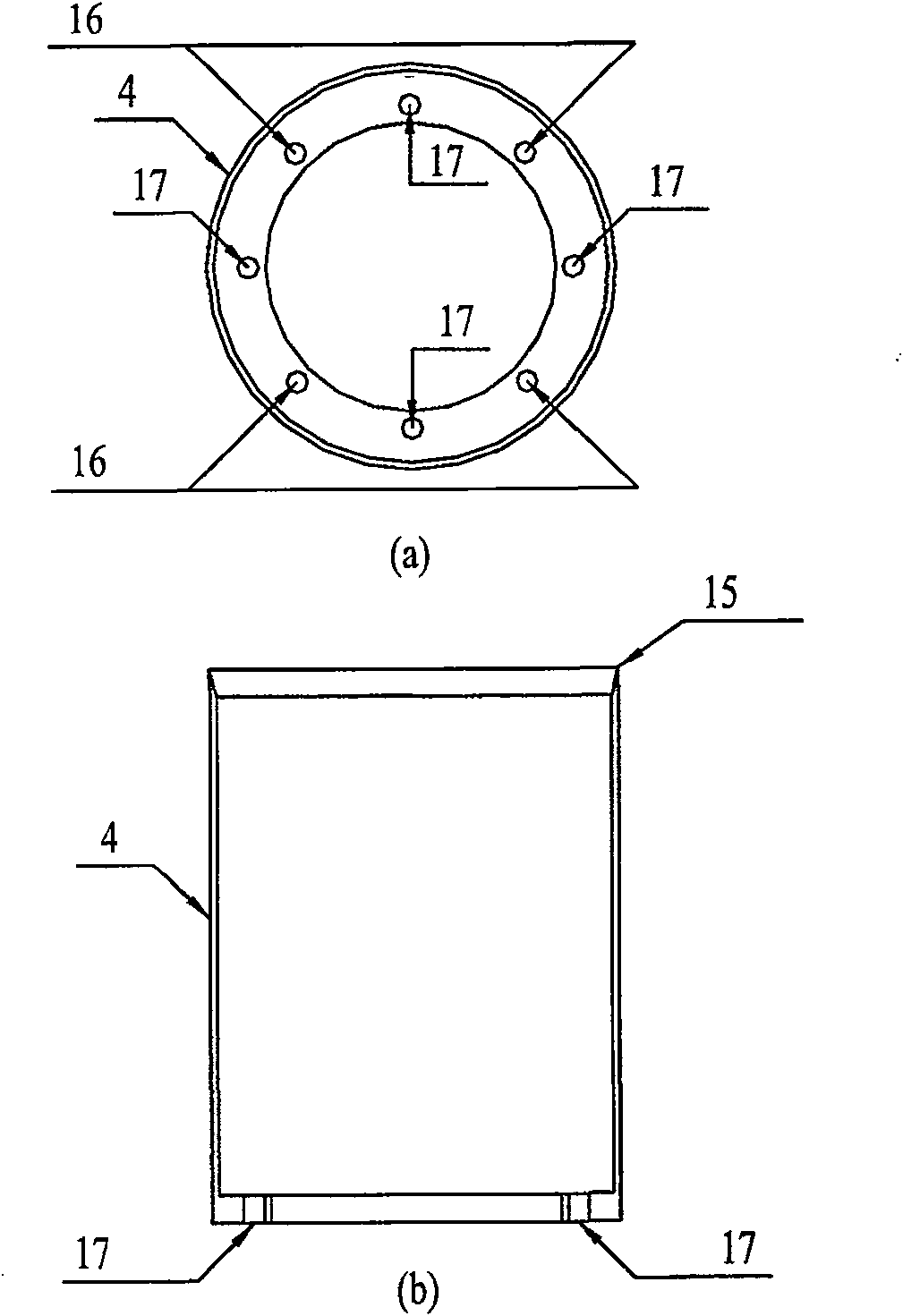

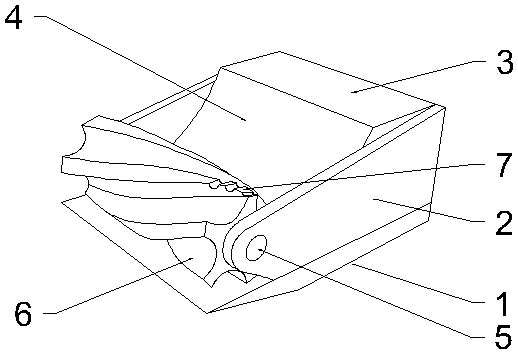

Original soft clay hollow cylinder sample inner core cutting device

InactiveCN101101242AAvoid secondary adhesionReduce propulsion resistanceWithdrawing sample devicesPreparing sample for investigationHollow coreHollow cylinder

The invention discloses a cut and get core machine of status quo soft clay hollowness column sample. It has pile casing, setting up the cutting edge on the superior extremity of pile casing, the inferior extremity of the pile casing connects with pallet of dismantle type pile casing by pile casing pallet hyphen pile casing fixed screw, fixing the dismantle type filling soil torr on the surface of the dismantle type pile casing pallet, fixing the pressure release hole on the dismantle type filling soil torr, fixing the direct bit in the middle of pile casing, the direct bit is made up of auger bit and inner margin blade, and connects with the drill pipe, the drill pipe traverses dismantle type filling soil torr, pallet of dismantle type pile casing, and is fixed by filling soil torr hyphen drill pipe fixed screw,pile casing hyphen drill pipe fixed screw, the dismantle type blade slice is made up of the inner margin blade,level blade, and connects stiffly with the direct bit by blade fixed screw. The pile casing is cylindrical form. The cut and get machine can prepare successfully status quo soft clay hollowness column sample, the disturbing of bringing in the process of cutting,the influence of hustle soil is small, providing the equipment bond guarantee for the experimental investigation of status quo soft clay under the complex stress condition.

Owner:ZHEJIANG UNIV

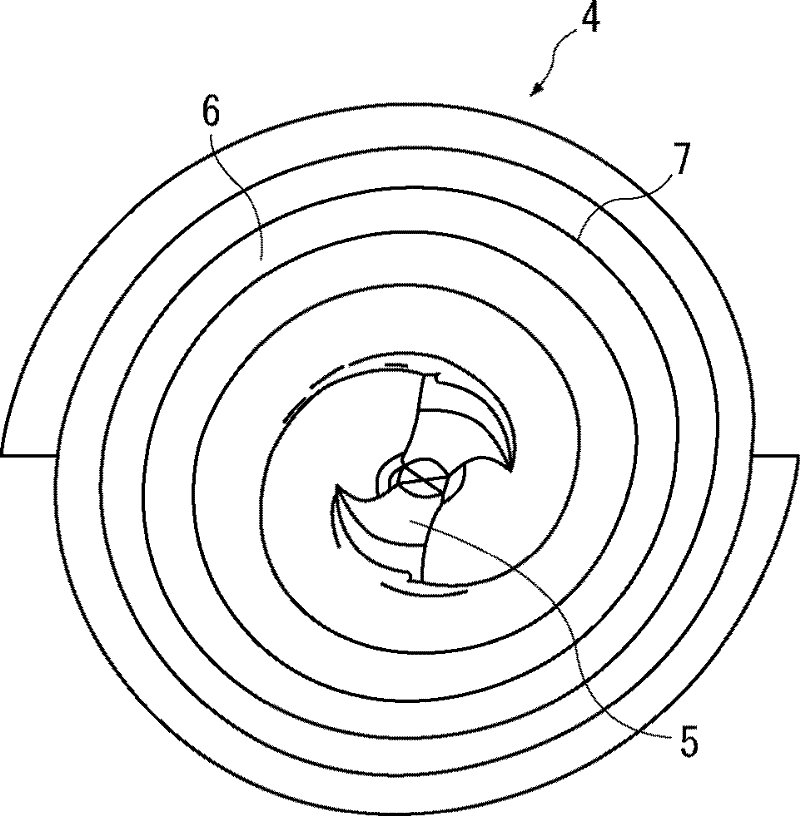

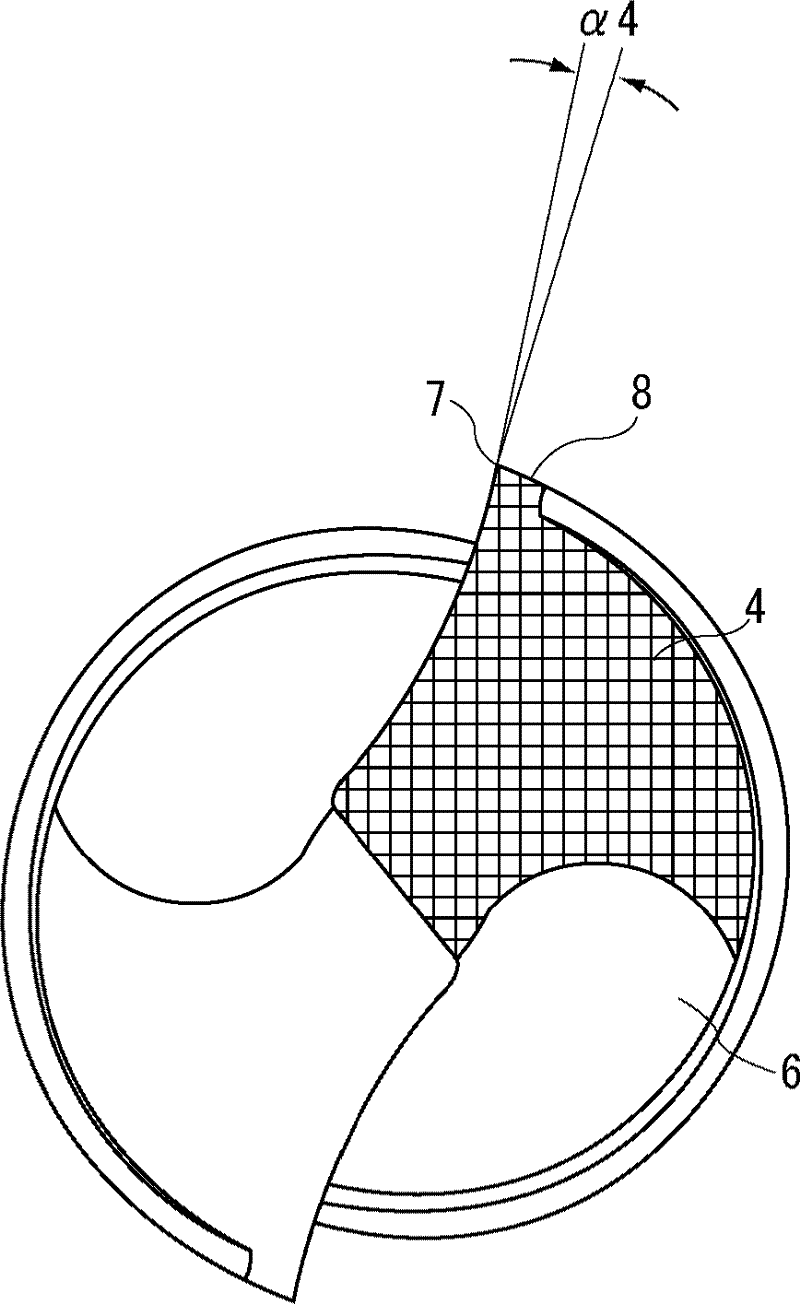

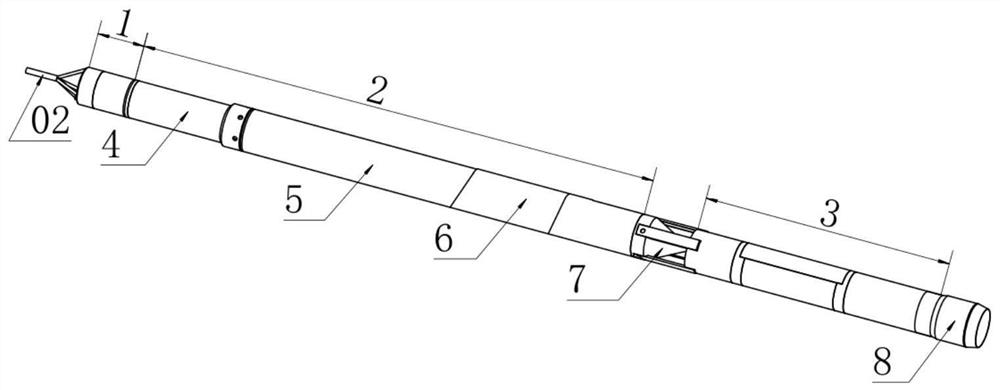

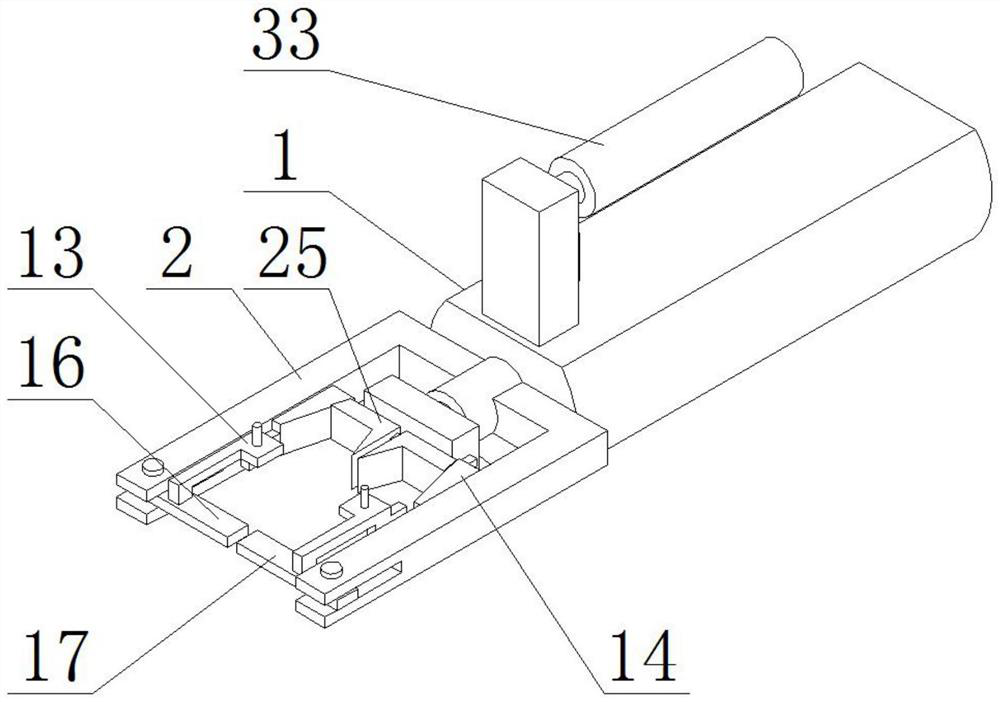

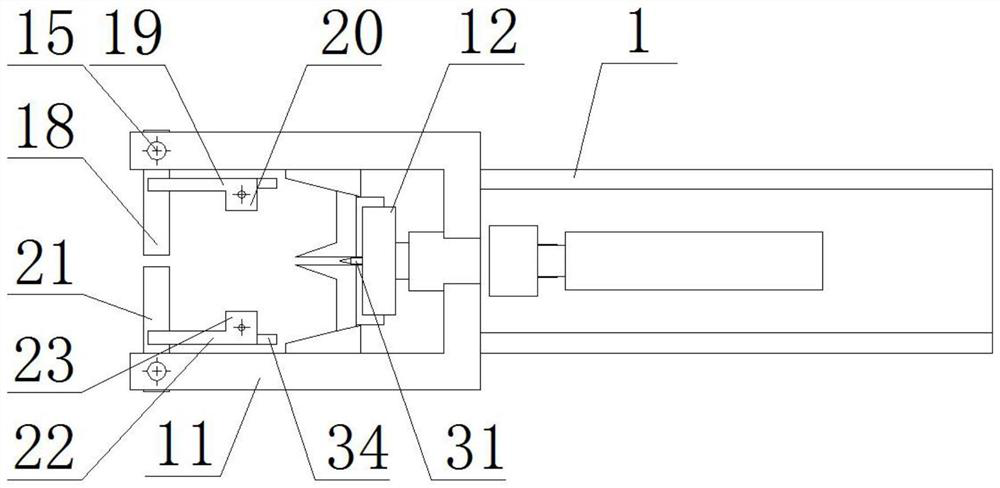

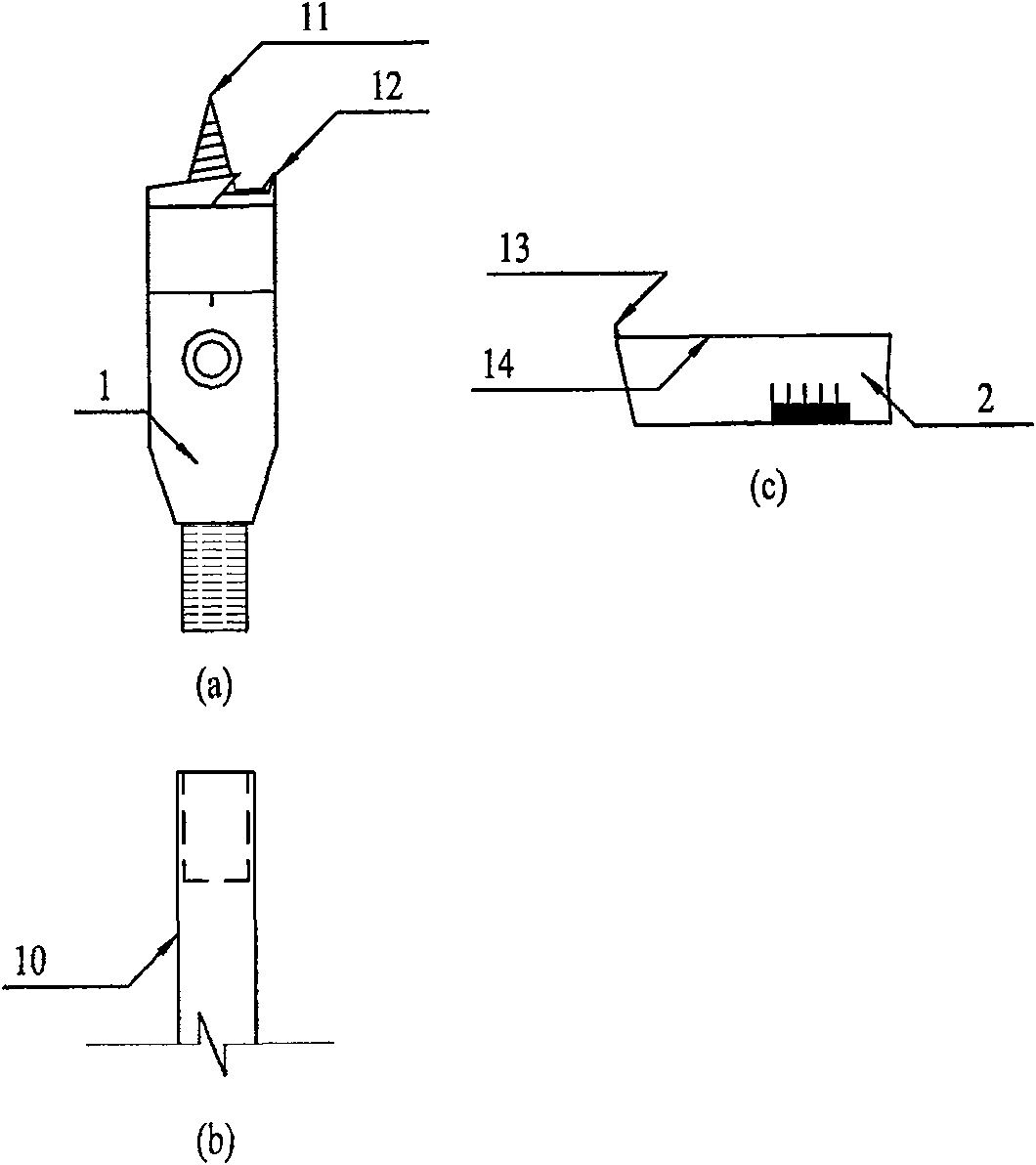

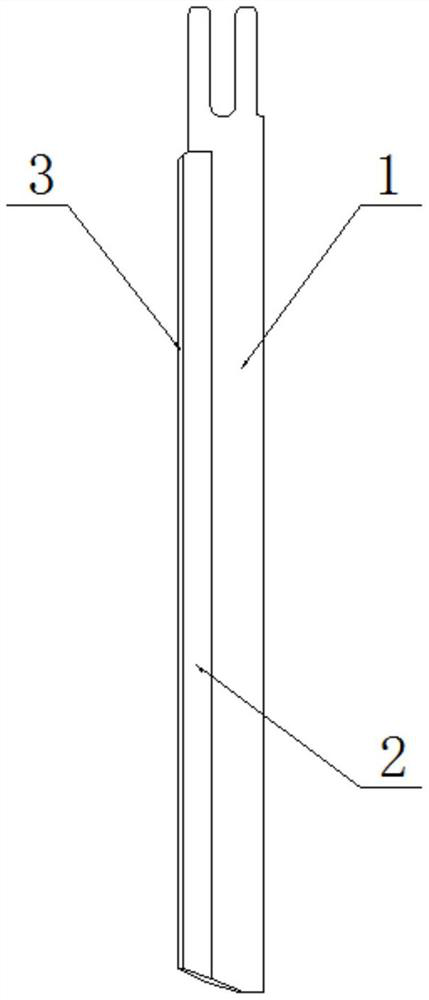

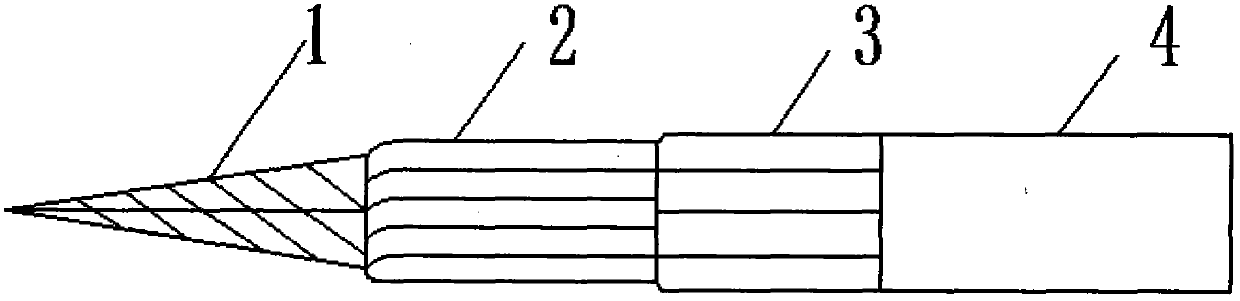

Drill for composite material as well as machining method using same and machining apparatus using same

InactiveCN102574219AReduce propulsion resistanceSmall peeling forceTransportation and packagingWorkpiecesEngineeringFiber-reinforced composite

Provided is a drill for composite material, this drill permitting a high quality boring operation wherein almost no burrs or delamination occurs during the boring of a member to be machined which at least partially contains fiber-reinforced composite material. The drill (1) for composite material comprises a tip section wherein a tip cutting edge (5) is formed; a tapered section (4) that is formed by being joined to the rear end portion of the tip section and is further formed into a tapered shape having a diameter difference equal to the difference between the rear end portion outside diameter and the tip portion outside diameter, the aforementioned rear end portion outside diameter being larger than the aforementioned tip portion outside diameter; and a straight section (3) that is formed by being joined to the rear end portion of the tapered section (4) and is further formed so as to have the same diameter throughout the straight section (3) in such a way that the member to be machined can be finished to a bored diameter which is larger than the outside diameter of the rear end portion of the tapered section (4). On the periphery of the tapered section (4), there are formed peripheral cutting edges (7) which are spirally twisted and are set in such a way that a bored diameter increases continuously.

Owner:FUKUI PREFECTURE

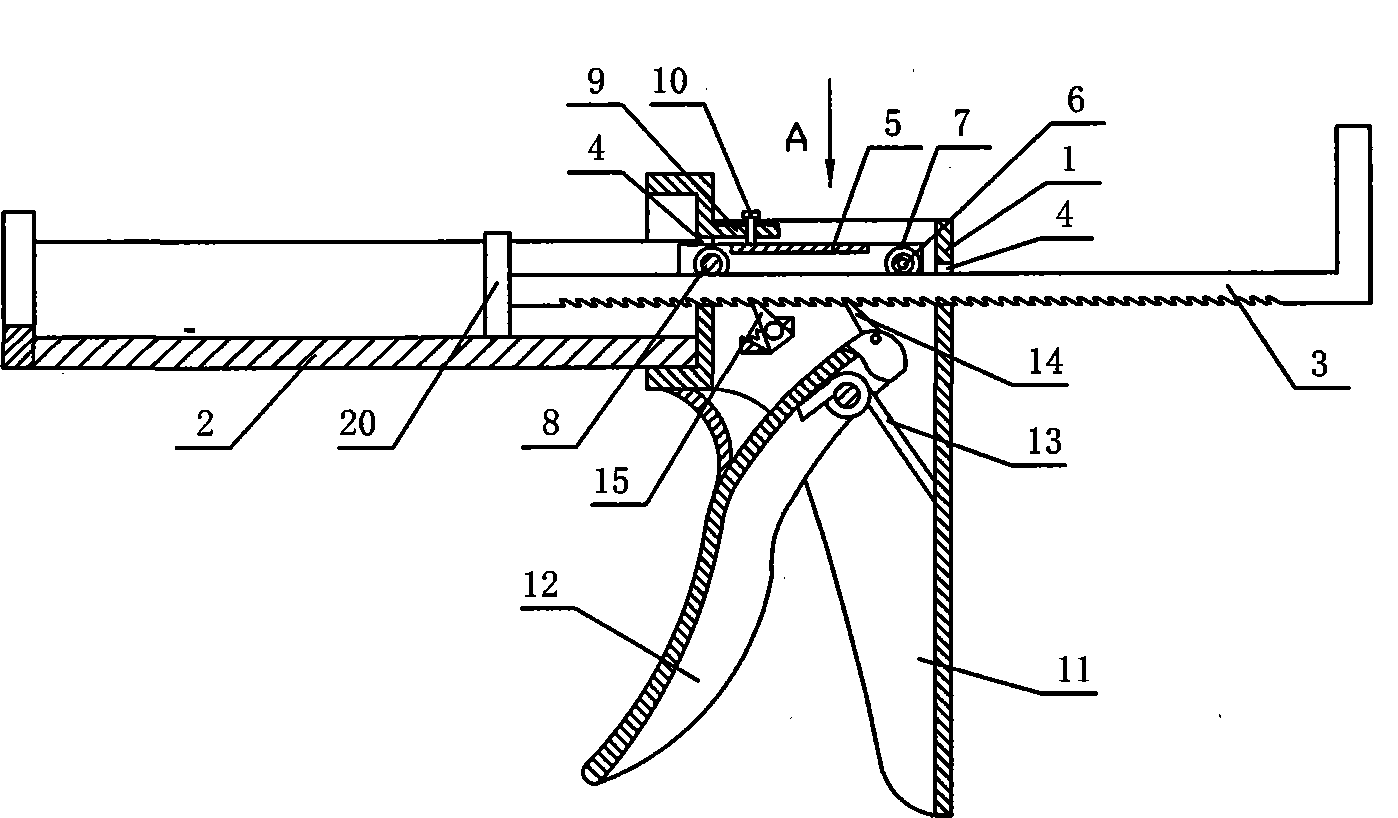

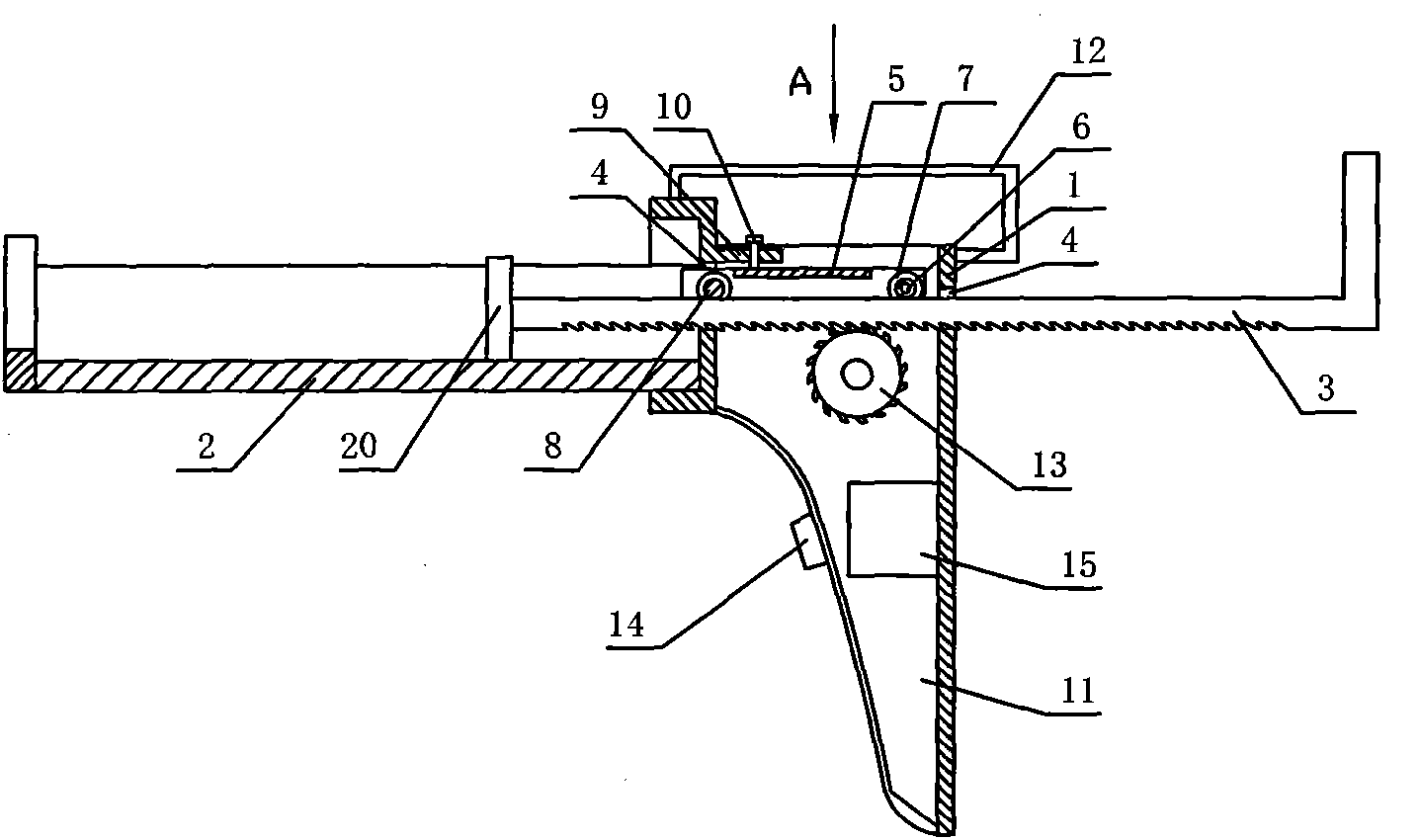

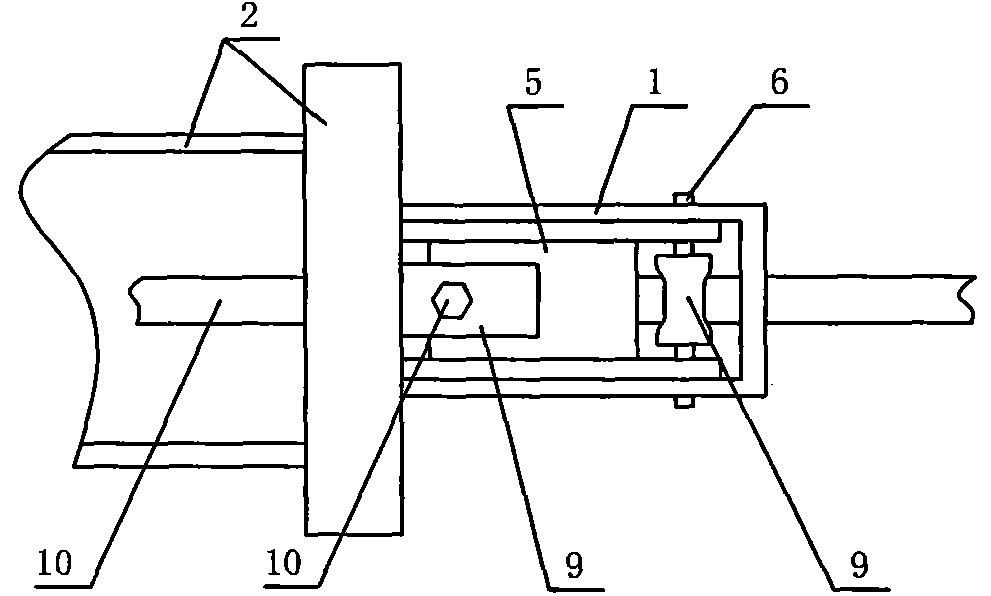

Rubber injection gun

InactiveCN103447211AAvoid warpingAvoid deformationLiquid surface applicatorsCoatingsIdler-wheelSupport plane

The invention discloses a rubber injection gun. The rubber injection gun comprises a support frame and a rubber tube bracket connected at the front end of the support frame, wherein through holes are correspondingly formed at the rear of the rubber tube bracket and the support frame; a push rod penetrates through the through holes; a propelling disc sliding along the rubber tube bracket is fixedly installed on the front of the push rod; the push rod is driven by a driving mechanism connected on the support frame; a guide frame is installed on the support frame; the rear of the guide frame is connected on the support frame via a hinge axis; a rear idler wheel pressing against the top of the push rod is installed on the hinge axis; the front of the guide frame penetrates through the rear end of the rubber tube bracket and is connected with a front idler wheel pressing against the push rod in a rotary manner; the front of the support frame or the rubber tube bracket is connected with a height limiting device for limiting the front height of the guide frame. The rubber injection gun has a simple structure and has the advantages that the rubber injection gun saves effort during pushing and can effectively prevent the push rod from tilting.

Owner:GAOMI ANNAI RUBBER

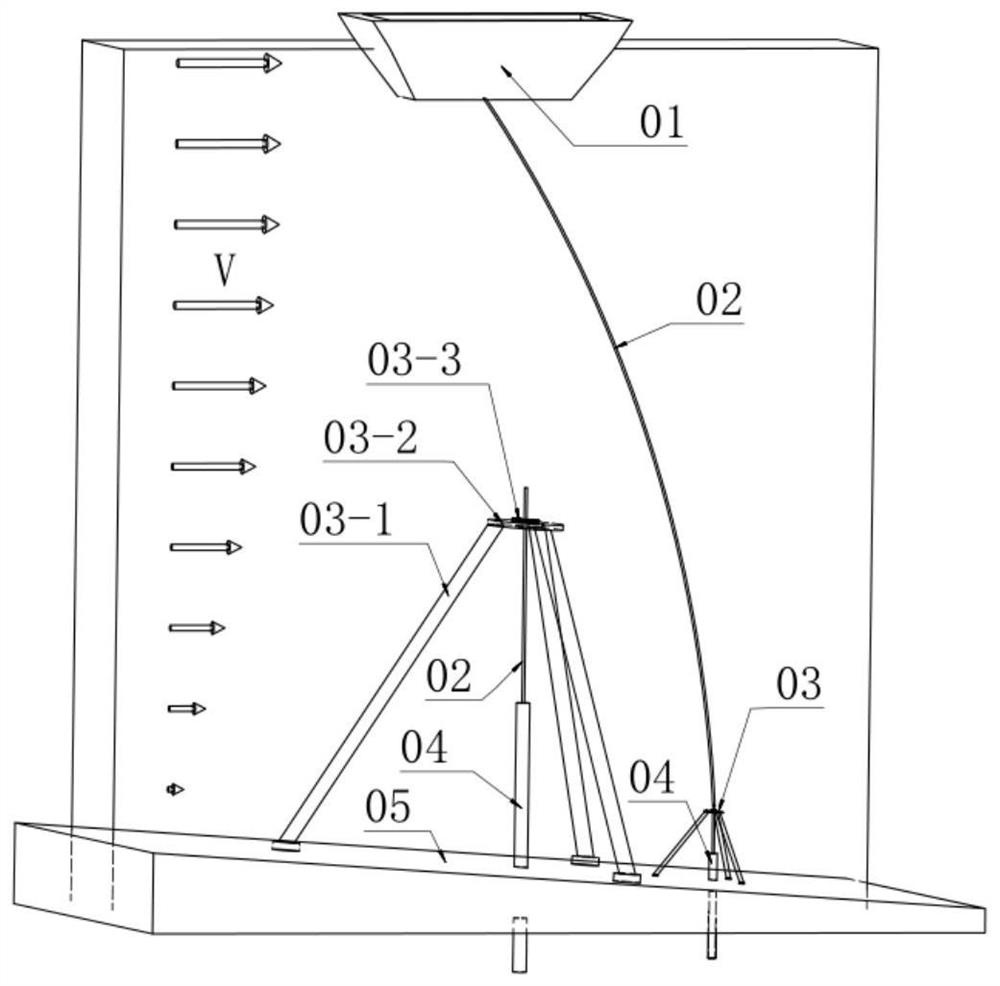

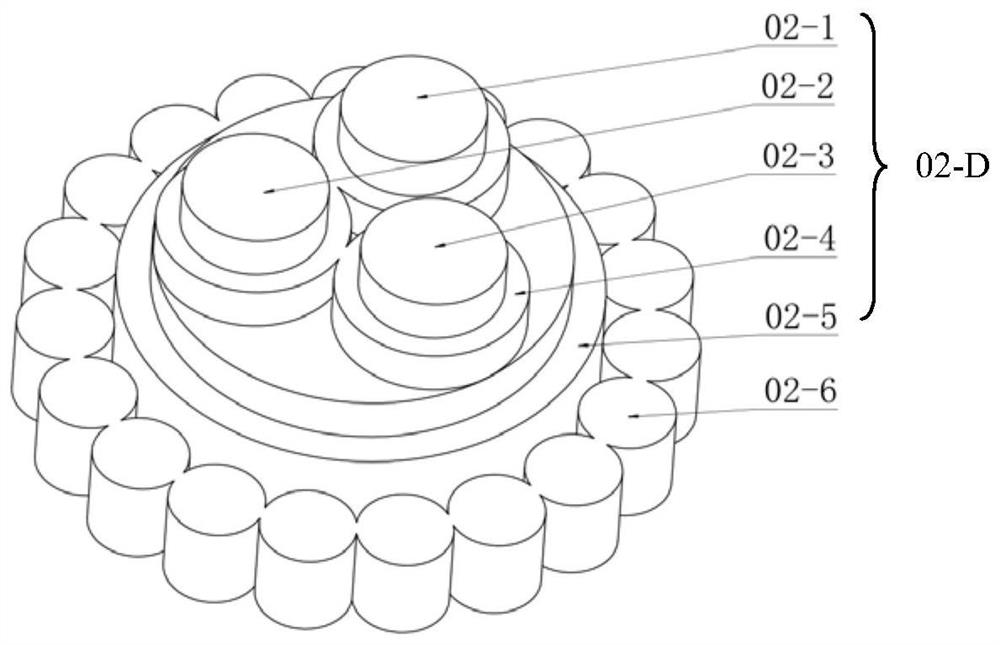

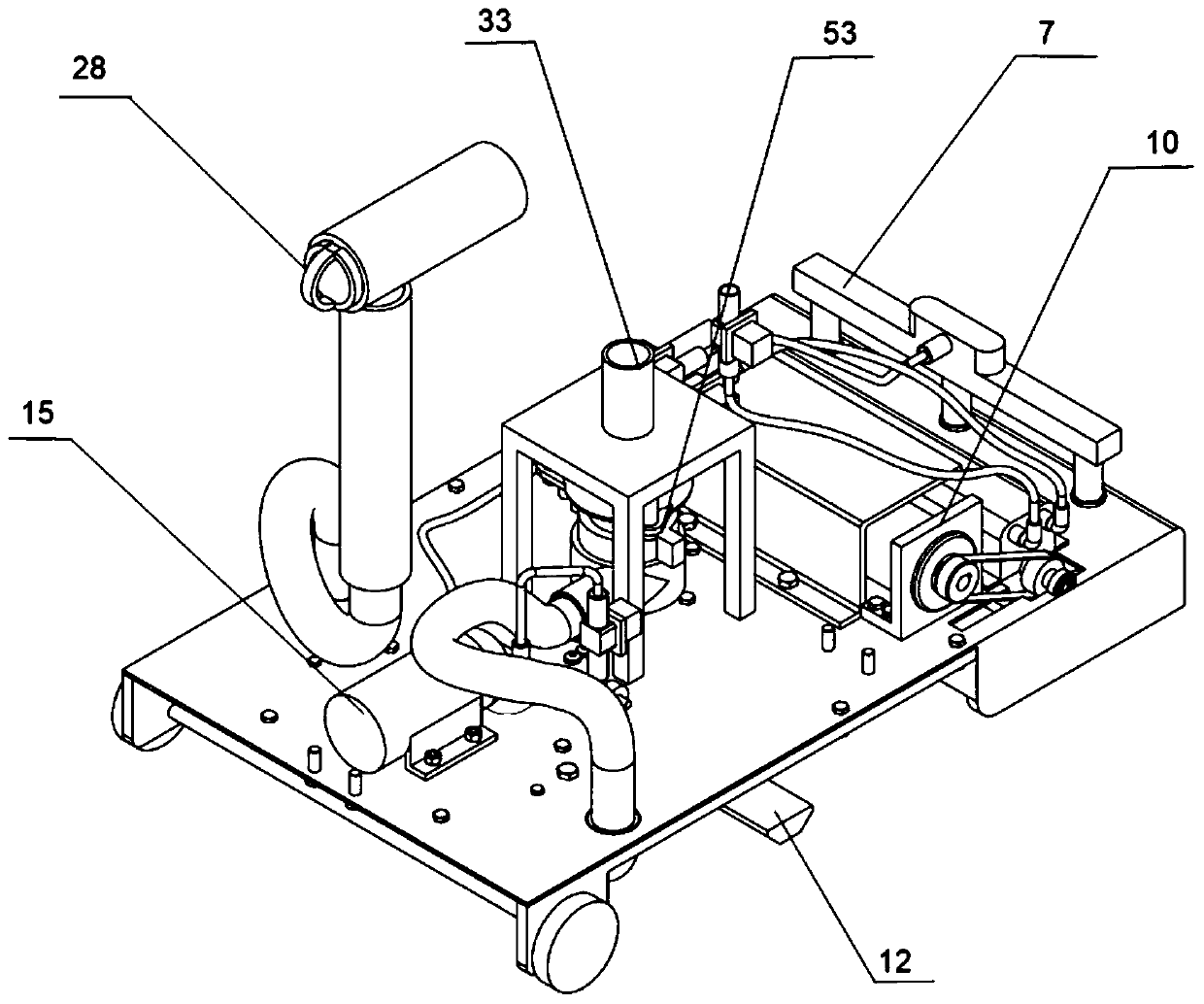

Unlimited depth self-propelled riverbed material sampling device

ActiveCN111624024ASmall driving forceUnlimited sampling depthWaterborne vesselsWithdrawing sample devicesEngineeringRiver bed

The invention relates to an unlimited depth self-propelled riverbed material sampling device. The sampling device comprises a working ship, a composite steel cable, a support frame and a sampler, thesampler comprises an information bin, a power bin, a sample bin, a sand discharging cone and a leakage-proof part. The sampler and the support frame sink together through the composite steel cable onthe working ship, and the water depth is not limited; the sampler can be vertically suspended and automatically and integrally pushed downwards when being close to the bed surface, and the sampling depth is not limited. The counter weight is pulled by the chain to roll along the cylinder wall in a three-point simple supporting mode and ascend and descend in the air, and it is guaranteed that resistance is small; the total length of the thin-wall pipe orifice and the sampler is relatively short so that the energy of push-down driving is relatively small; the extrusion deformation of the sand sample in the short pipe type sample bin is very small, and the bin cover is independently opened and closed to realize high fidelity of sampling; the leakage-proof part ensures that the sand sample does not slip and leak; and a water pressure gauge in the sampler detects the depth of the sampling point away from the bed surface. Sampling of the device is not limited by depth, and the riverbed material sample can be safely, reliably and accurately collected in a high-fidelity mode.

Owner:BEIJING JIANGYI TECH

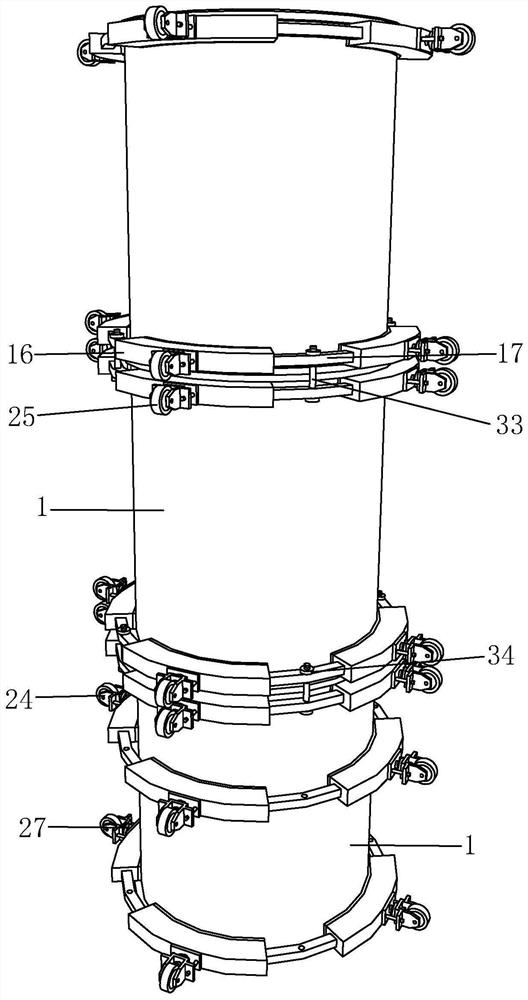

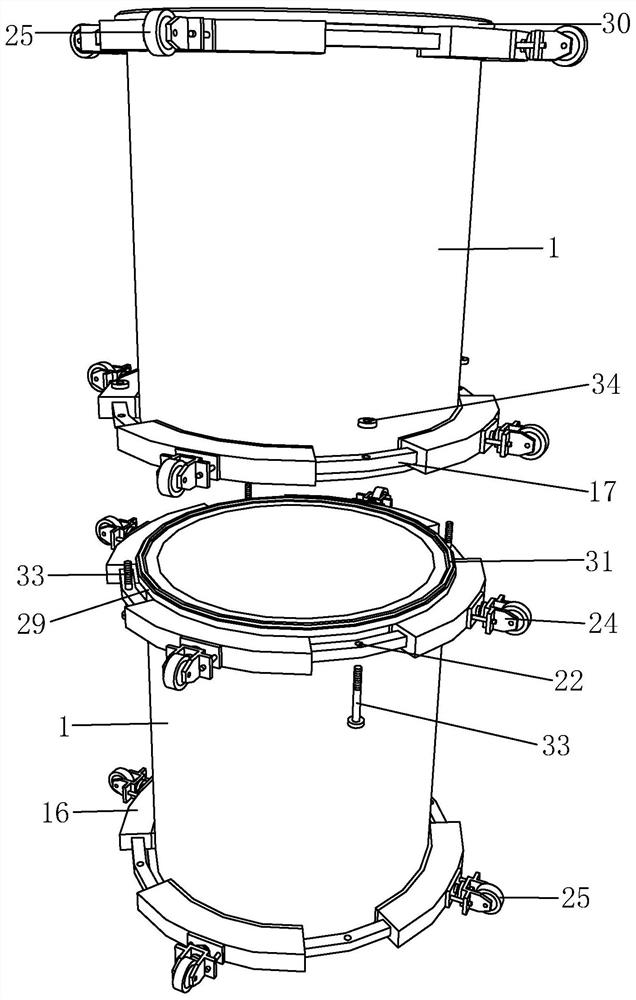

Construction method for internally penetrating steel pipes for top pipe of water diversion project

ActiveCN113339585AFlexible height changeStrong penetrating powerPipe laying and repairArchitectural engineeringWater diversion

The invention discloses a construction method for internally penetrating steel pipes for a top pipe of a water diversion project. The construction method comprises the following steps that (a) construction preparation is conducted; (b) the first steel pipe is in place; (c) the first steel pipe is positioned; and (d) the pipes are penetrated one by one. According to the construction method, the construction difficulty is low, the efficiency is high, flexibility and applicability are achieved, the front and back steps are orderly, control is convenient, the construction quality is ensured, steel pipe pushing is convenient and fast, the equipment input cost is low, the front steel pipe and the back steel pipe are connected firmly, the structure is stable, the sealing performance is high, and the service life is long.

Owner:ZHEJIANG JIANGNANCHUN CONSTR GRP

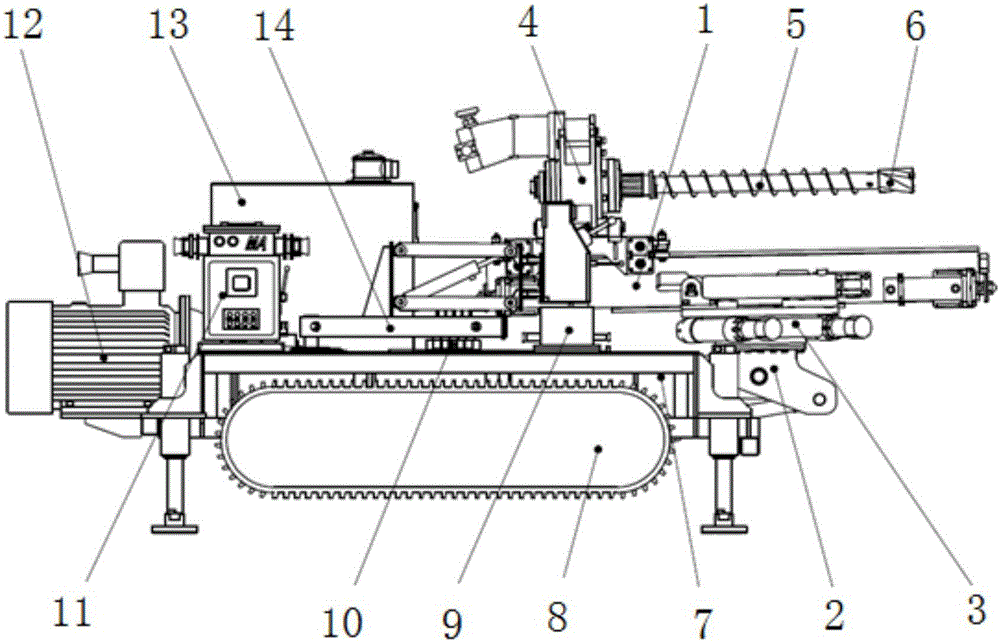

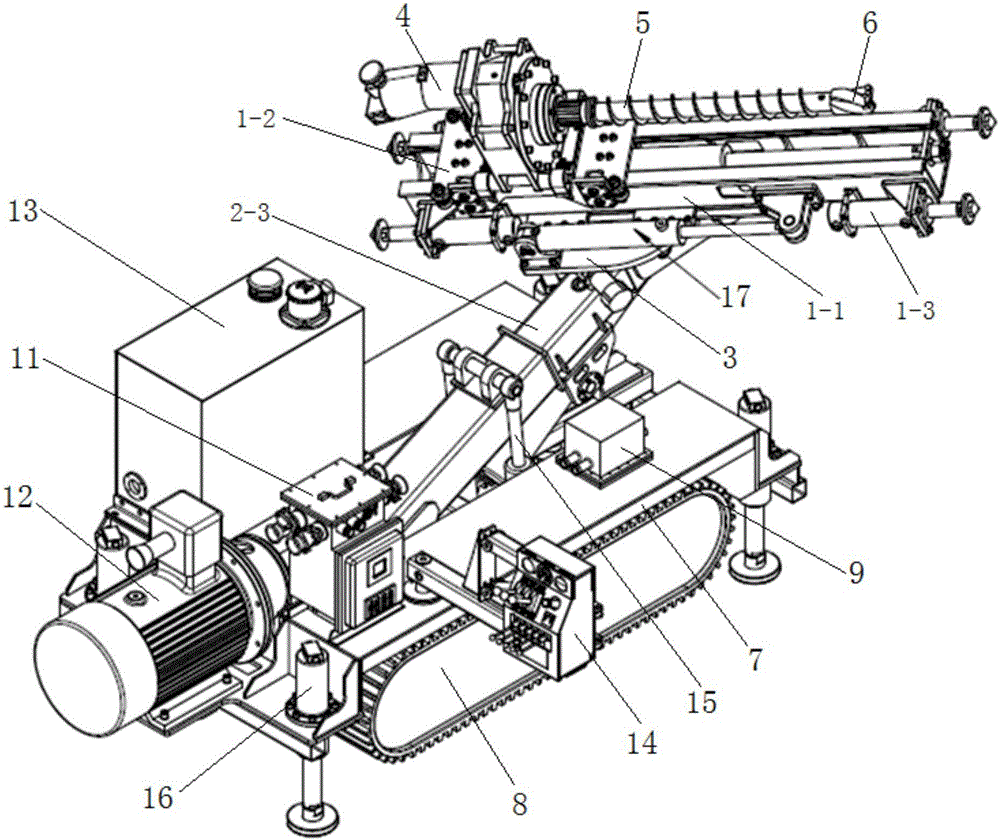

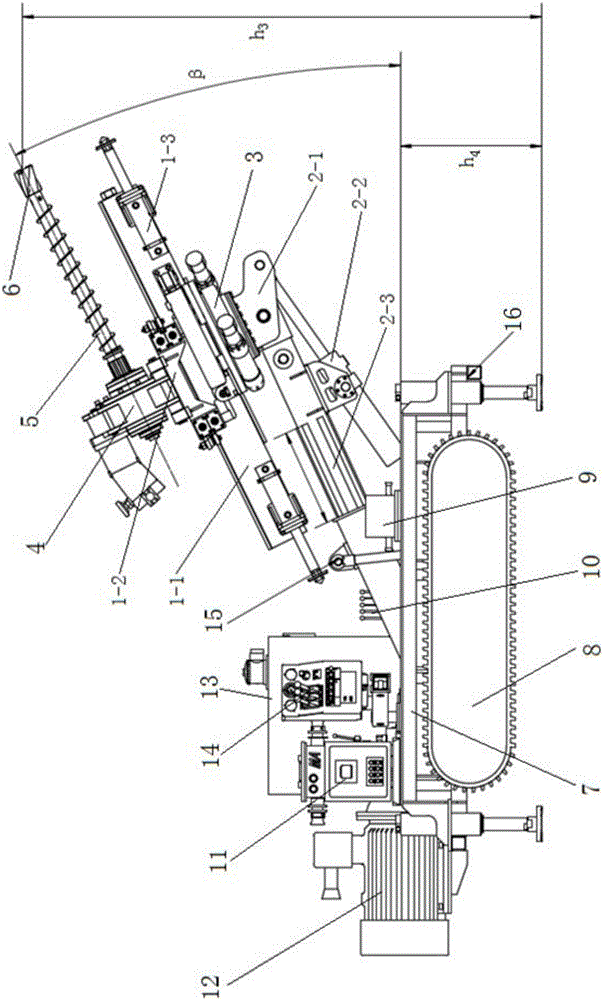

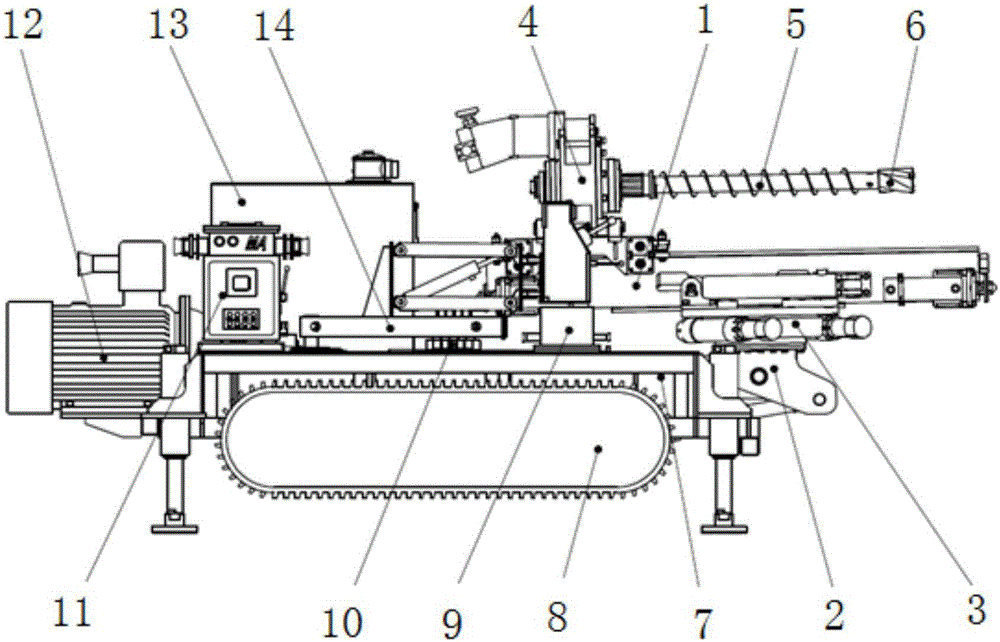

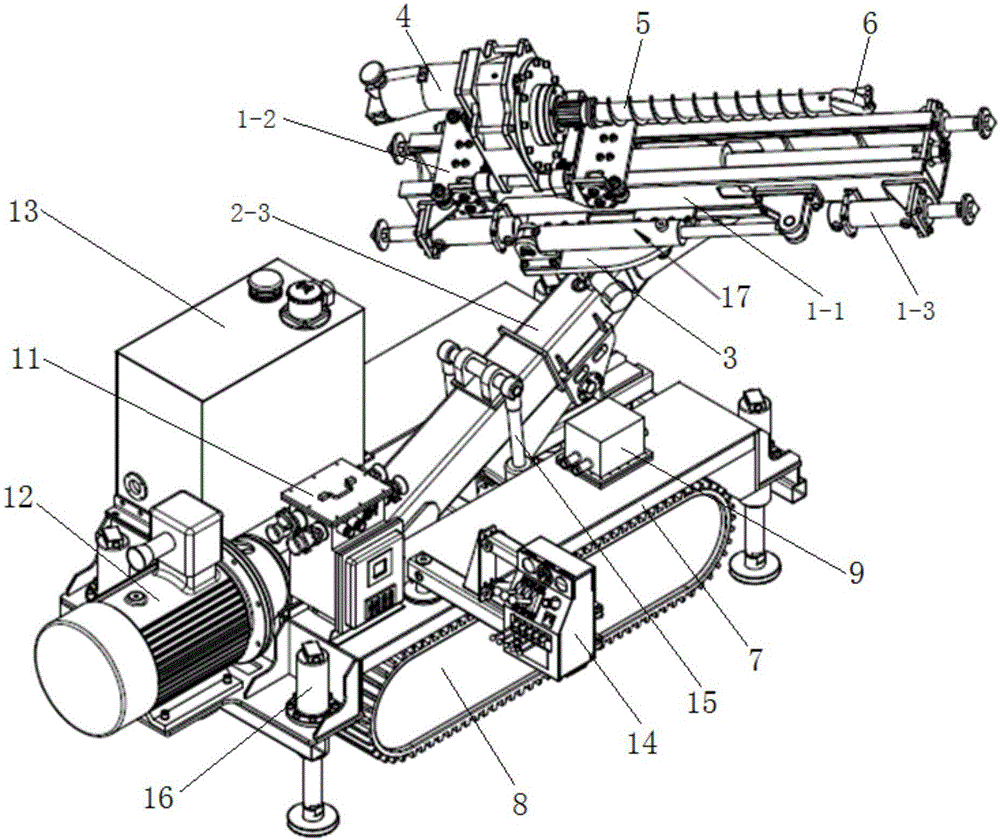

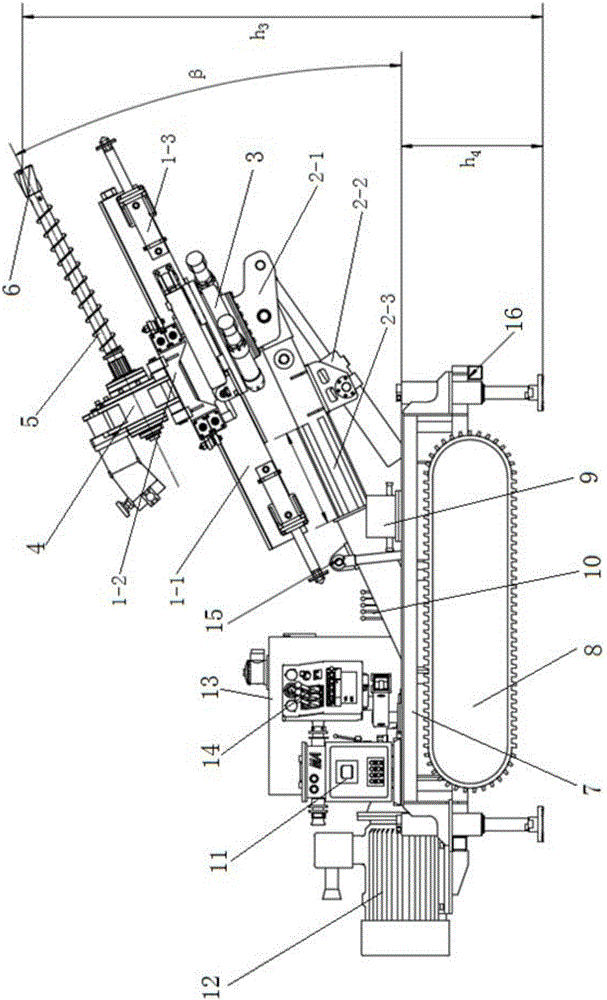

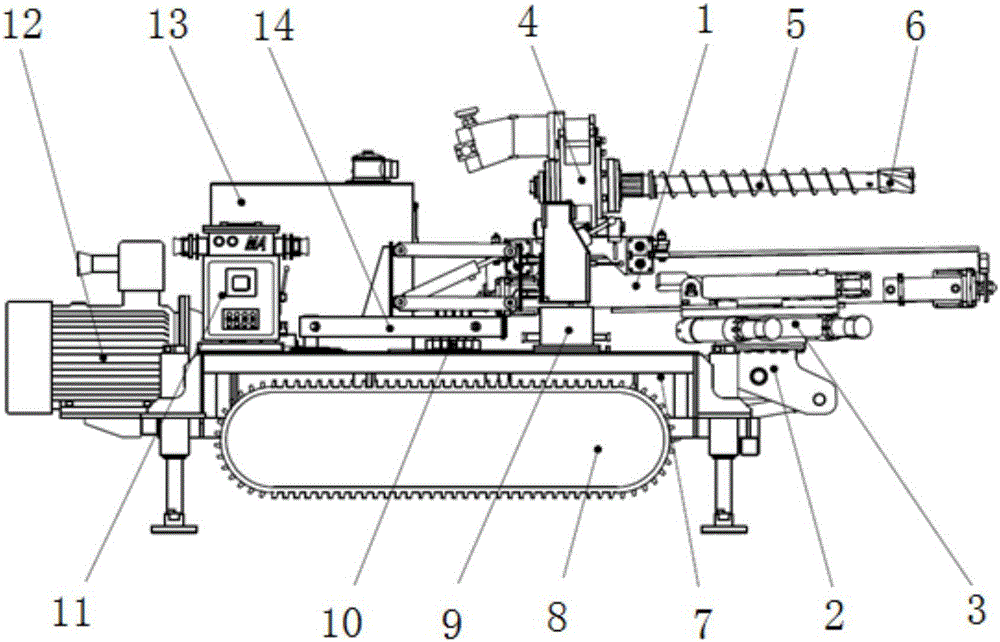

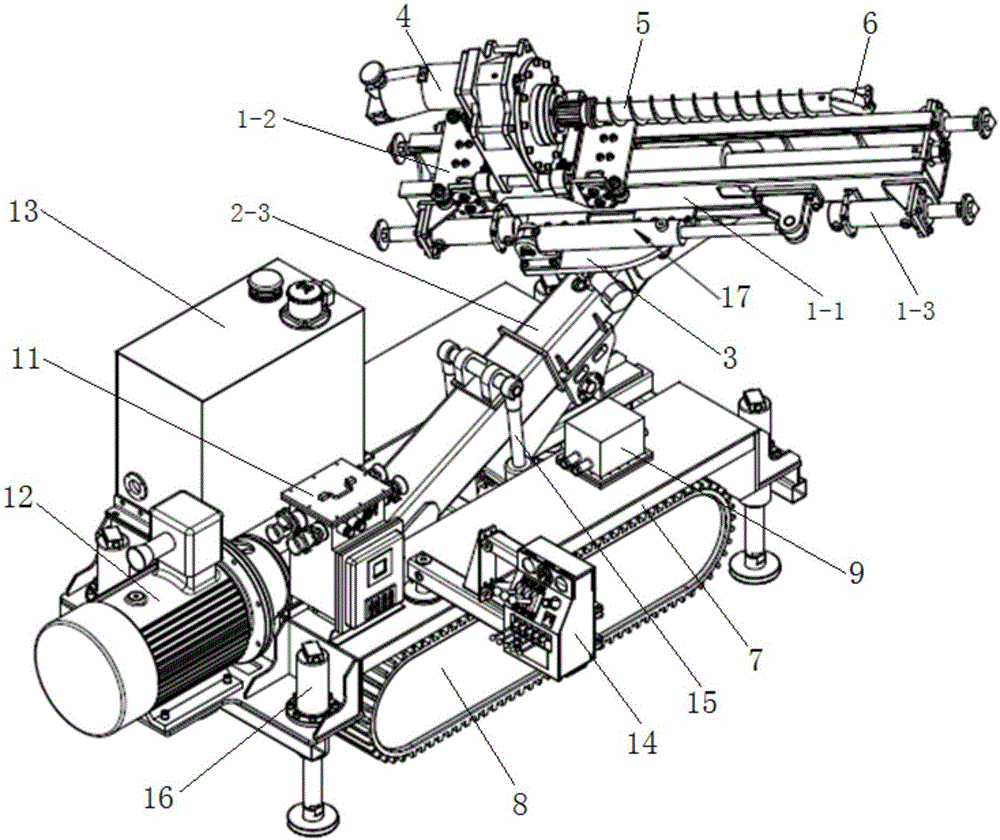

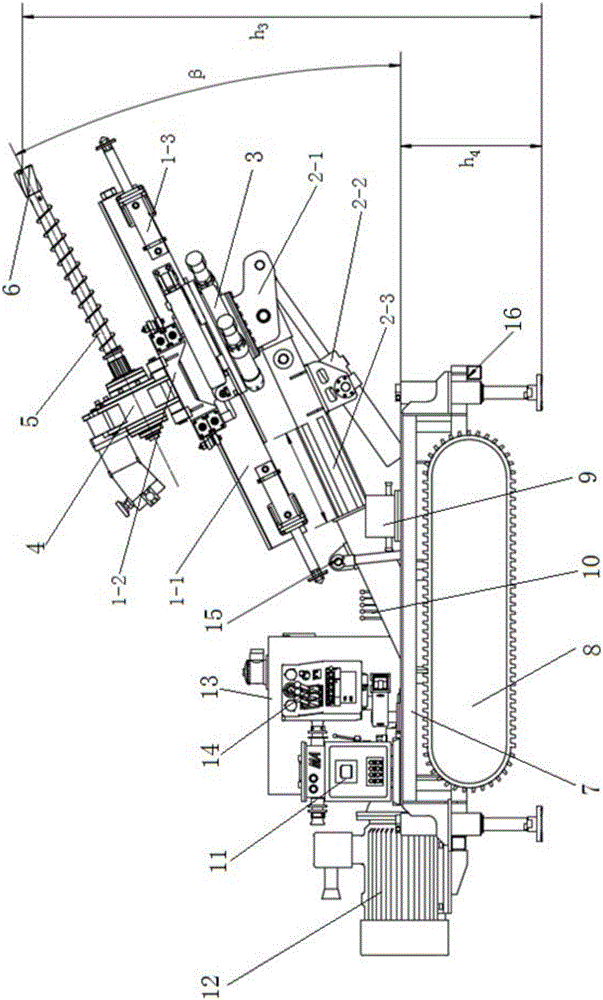

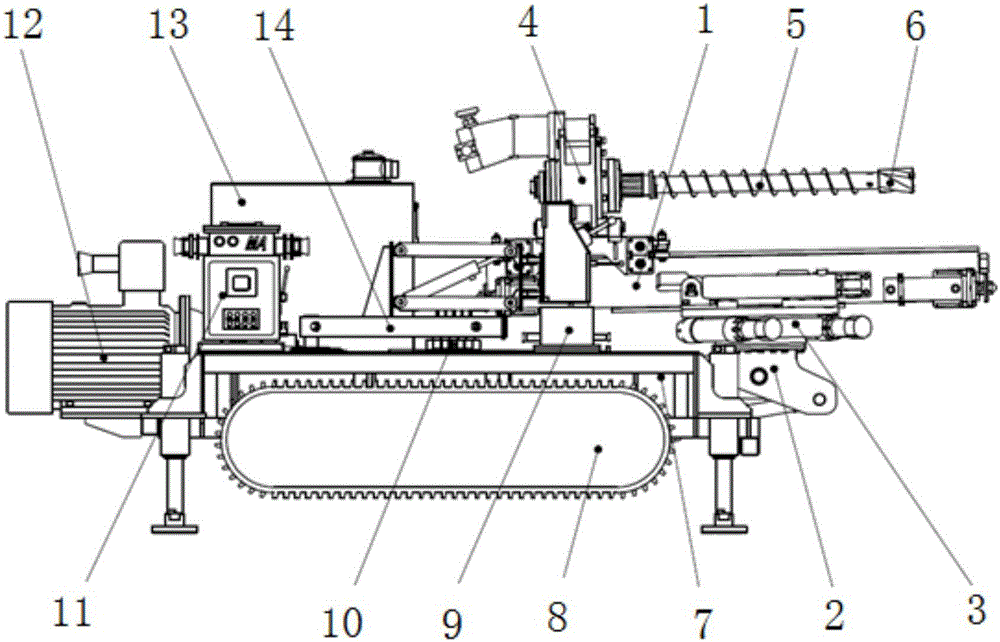

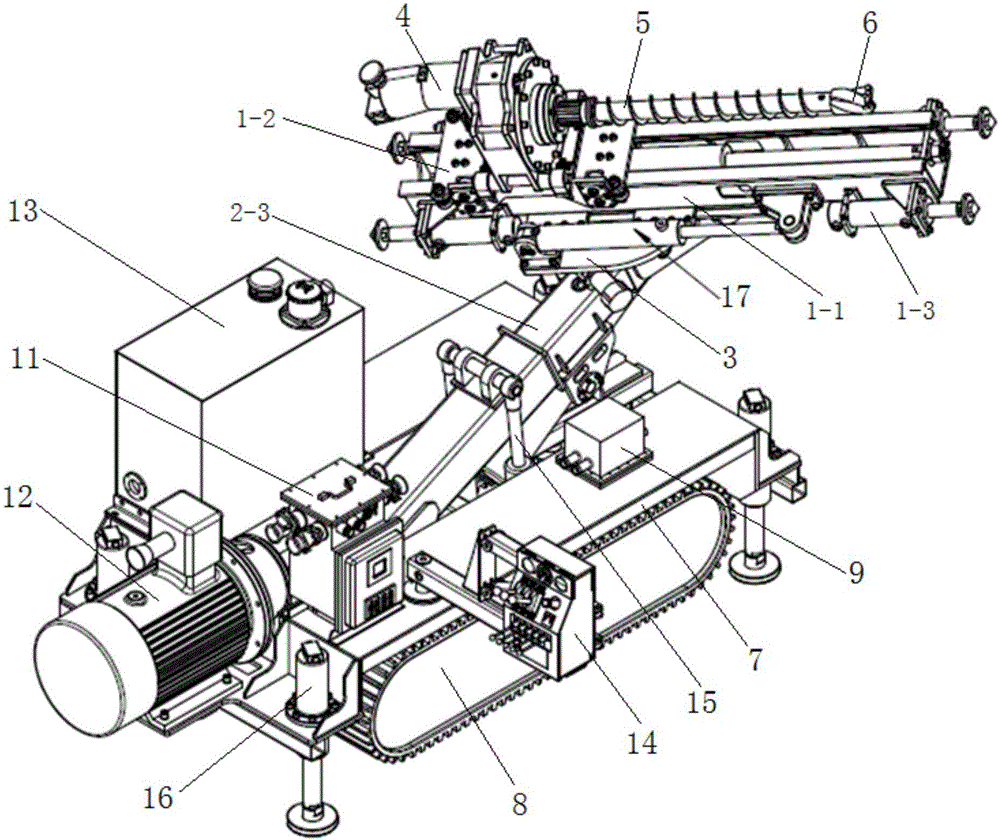

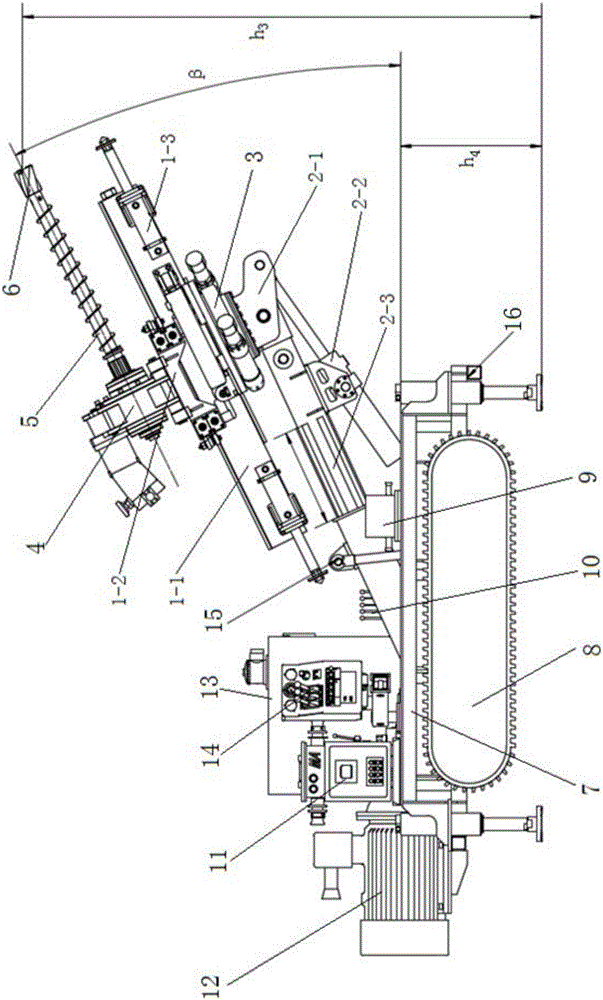

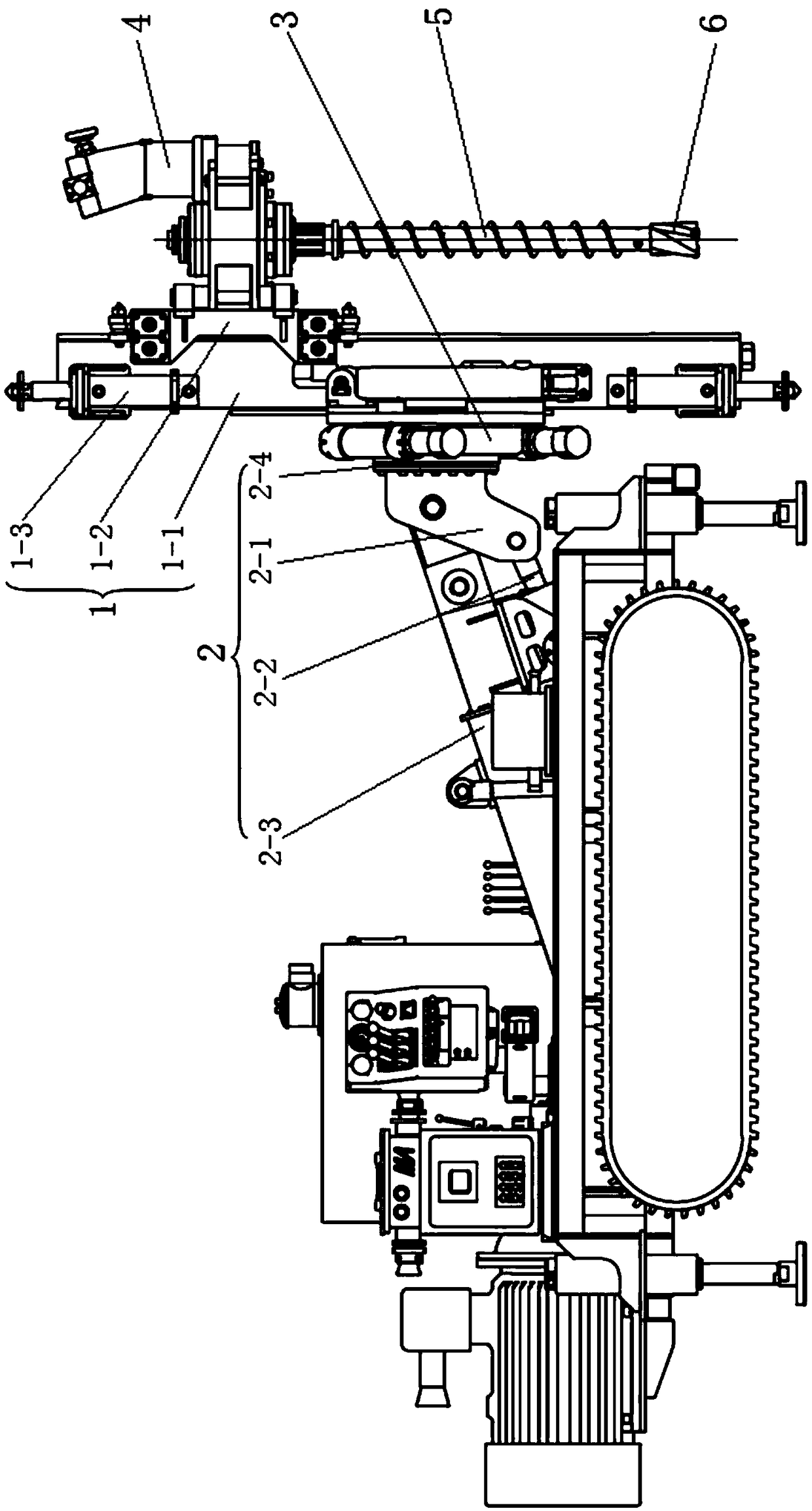

All-dimensional deep hole drilling machine

InactiveCN106437506AGuaranteed Support RangeAvoid damageDerricks/mastsDirectional drillingRolling resistanceHydraulic pump

The invention discloses an all-dimensional deep hole drilling machine. The all-dimensional deep hole drilling machine comprises a rack. A crawler belt and leg supporting oil cylinders are installed under the rack. A hydraulic pump, an oil tank and an operating component are installed on the rack. The rack is provided with an amplitude variation unit, a rolling friction unit and a drilling machine unit. A non-swing end of the amplitude variation unit is fixedly arranged on the rack. The swing end of the amplitude variation unit is provided with the rolling friction unit. The rolling friction unit is provided with the drilling machine unit. The rolling friction unit and the drilling machine unit can be adjusted to swing in the range of 0-105 degrees through the amplitude variation unit, and the rolling friction unit can drive the drilling machine unit to walk in a rolling mode in the axial direction of the rolling friction unit. According to the all-dimensional deep hole drilling machine, 0-26 degree inclined hole drilling operation can be achieved in the range of 800-3000 mm; and drilling operation of upward perpendicular holes, downward perpendicular holes and holes which form any angles with the perpendicular holes can be achieved by adjusting the drilling machine through an amplitude variation oil cylinder, the leg supporting oil cylinders and a rotary assembly.

Owner:SHAANXI STAR EXPLOSION SAFETY POLYTRON TECH INC

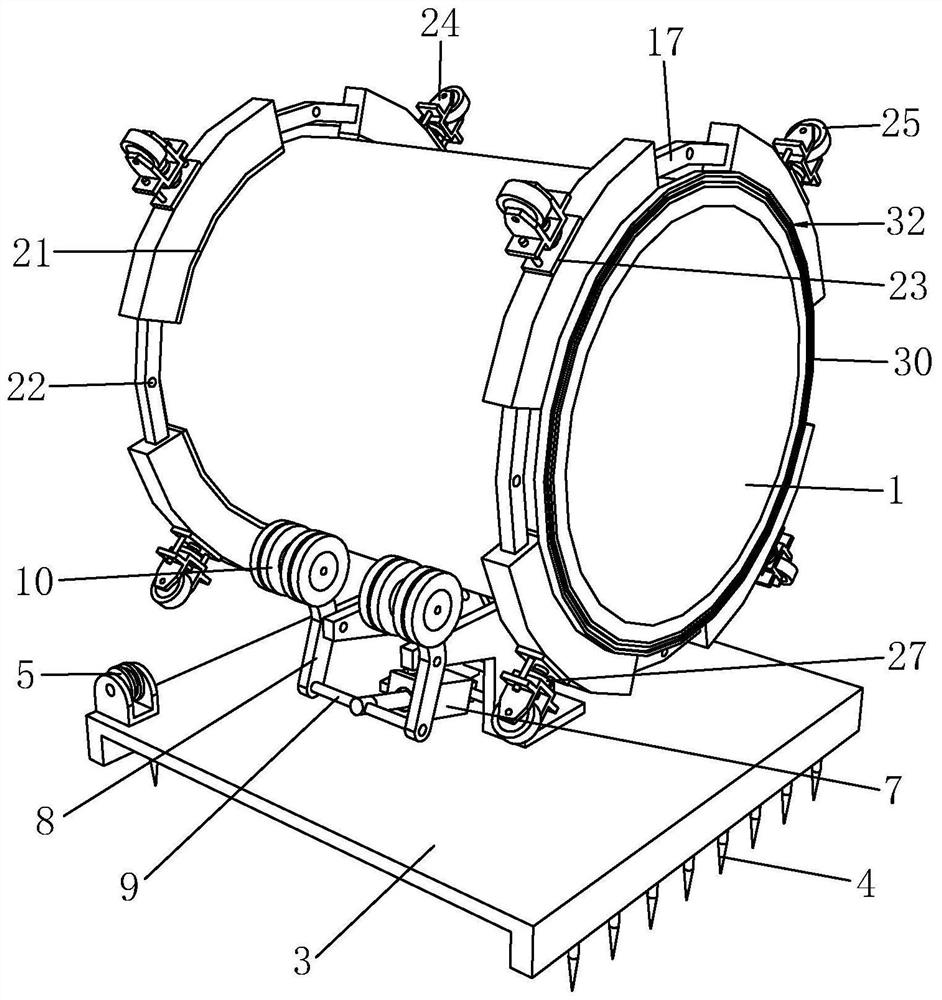

Omnibearing longhole drilling machine

InactiveCN106401469ACylinder diameter reductionReduce propulsion resistanceDerricks/mastsDrilling machines and methodsEngineeringFuel tank

The invention discloses an omnibearing longhole drilling machine. The omnibearing longhole drilling machine comprises a machine frame. Tracks and supporting leg oil cylinders are mounted under the machine frame. A hydraulic pump, an oil tank and a control part are mounted on the machine frame. An amplitude change unit, a rolling friction unit and a drilling machine unit are arranged on the machine frame. The non-swing end of the amplitude change unit is fixedly arranged on the machine frame. The rolling friction unit is arranged at the swing end of the amplitude change unit. The drilling machine unit is arranged on the rolling friction unit. The rolling friction unit and the drilling machine unit can be adjusted to swing within the range of 0-105 degrees through the amplitude change unit. The rolling friction unit can drive the drilling machine unit to walk in a rolling mode in the axial direction of the rolling friction unit. The omnibearing longhole drilling machine can complete oblique hole drilling operation with the inclination angle being 0-26 degrees within the range of 800-3000 mm; and the drilling machine can complete drilling operation of upward and downward vertical holes and drilling operation with any angles formed with the vertical holes through adjustment of an amplitude change oil cylinder, the supporting leg oil cylinders and a rotation assembly.

Owner:SHAANXI STAR EXPLOSION SAFETY POLYTRON TECH INC

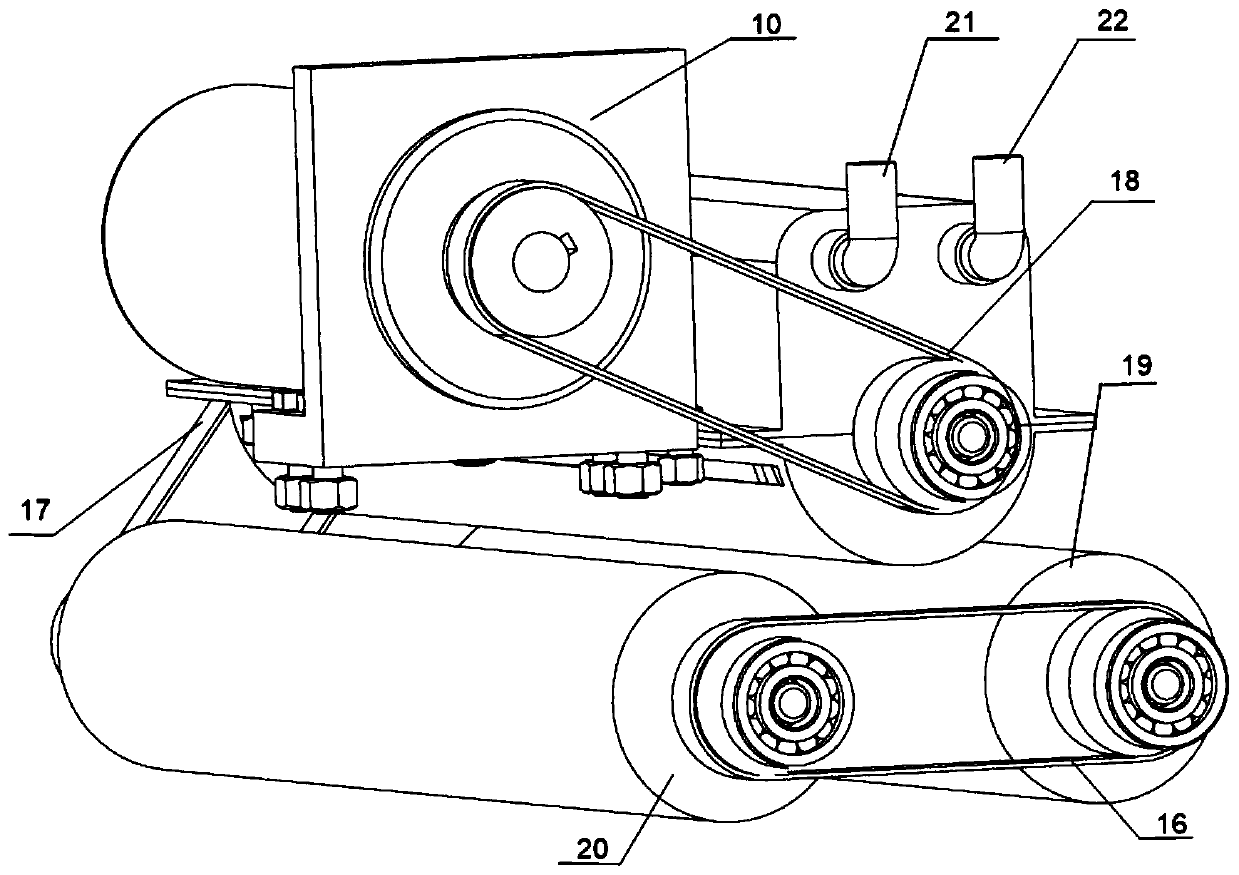

Full-automatic rubber injection gun

InactiveCN103447210AAvoid warpingSimple structureLiquid surface applicatorsCoatingsEngineeringIdler-wheel

The invention discloses a full-automatic rubber injection gun. The rubber injection gun is characterized in that a cylindrical push rod penetrates through a through hole; a propelling disc sliding along a rubber tube bracket is fixedly installed on the front of the push rod; a fixed handlebar is arranged at the lower part of the rear end of a support frame; a row of plane indentions arranged from front to rear are arranged on the surface of the push rod; a drive gear which is driven by a positive and negative rotation motor and is meshed with the plane indentions on the push rod is connected in the fixed handlebar in a rotary manner; an electric button for controlling rotation of the positive and negative rotation motor is installed on the fixed handlebar; a guide frame is installed on the support frame; the rear of the guide frame is connected on the support frame via a hinge axis; a rear idler wheel pressing against the top of the push rod is installed on the hinge axis; the front of the guide frame penetrates through the rear end of the rubber tube bracket and is connected with a front idler wheel pressing against the push rod in a rotary manner; the front of the support frame or the rubber tube bracket is connected with a height limiting device for limiting the front height of the guide frame. The full-automatic rubber injection gun has a simple structure and has the advantages that the full-automatic rubber injection gun saves effort during pushing and can effectively prevent the push rod from tilting.

Owner:GAOMI ANNAI RUBBER

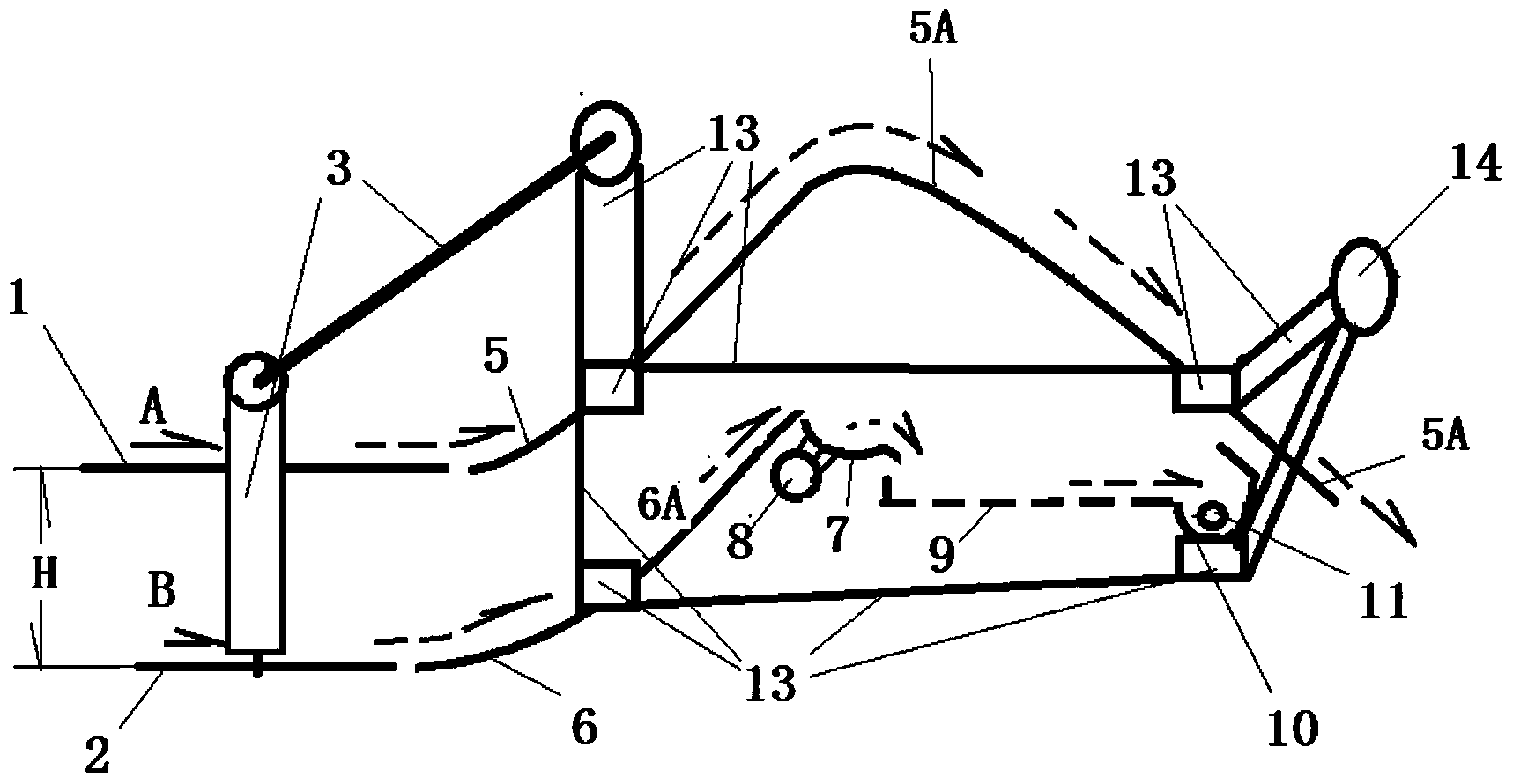

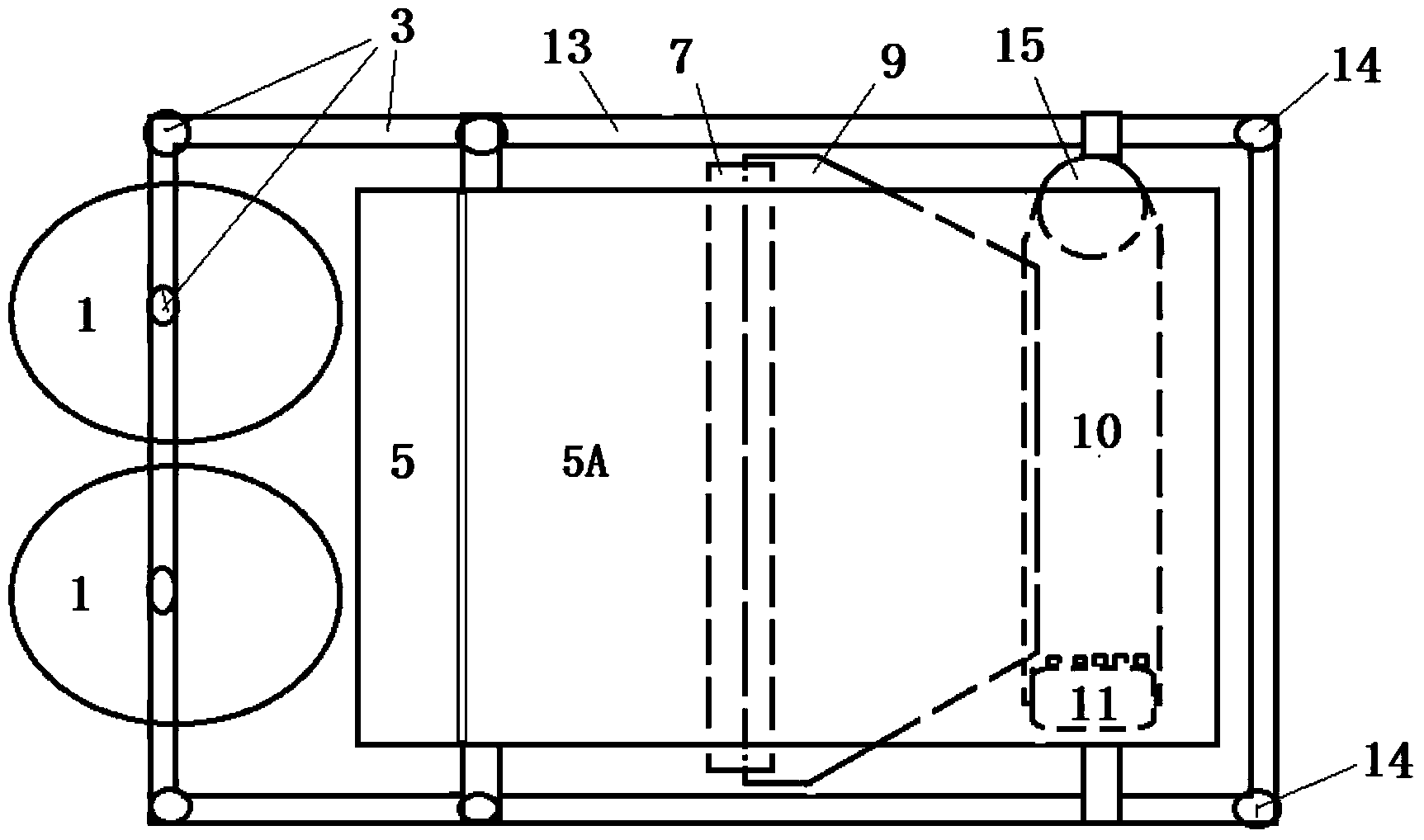

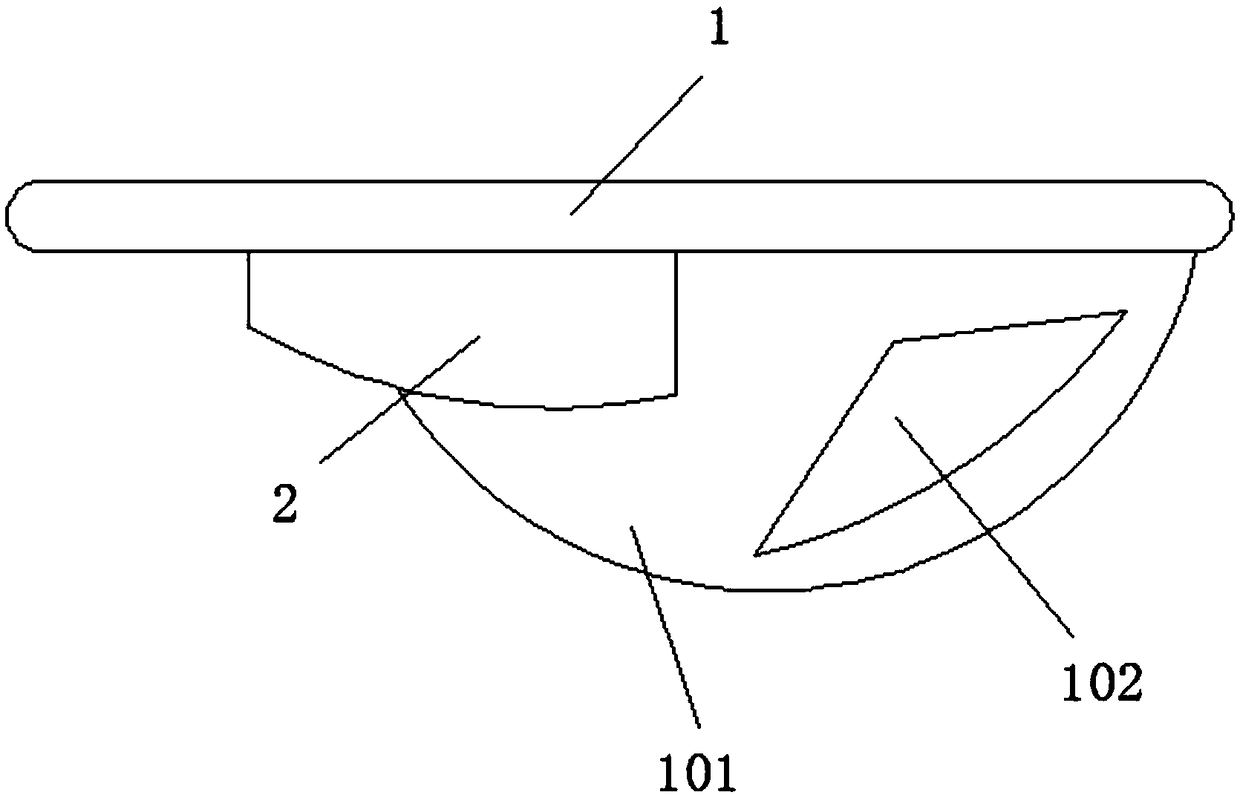

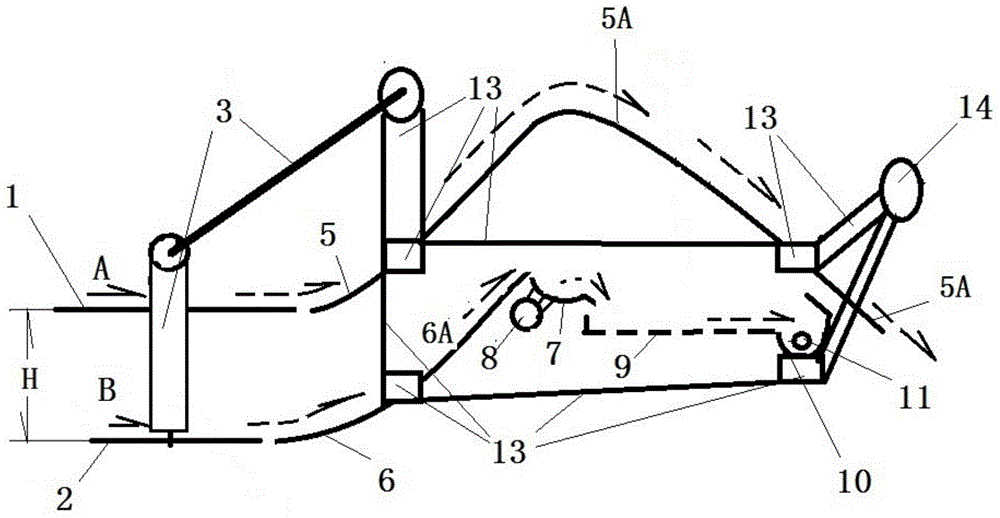

Disk rotary-cutting layering water chestnut excavation shovel

InactiveCN104221574ASolve the problem of limited power outputSmall horsepowerDiggersCircular discWater Chestnuts

The invention discloses a disk rotary-cutting layering water chestnut excavation shovel. The disk rotary-cutting layering water chestnut excavation shovel is characterized in that the excavation shovel is divided into an upper excavation shovel and a lower excavation shovel, wherein an upper excavation cutting wheel (1) formed by at least one disk saw is arranged at the front end of the upper excavation shovel; an upper excavation shovel way (5) matched with the upper excavation cutting wheel (1) is arranged behind the upper excavation cutting wheel (1); a passage (5A) is connected to the upper excavation shovel way (5); a lower excavation cutting wheel (2) formed by at least one disk saw is arranged at the front end of the lower excavation shovel; a lower excavation shovel way (6), a passage (6A), a screen-shaped bucket (7), a vibrating screen (9) and a collection tank (10) are sequentially arranged behind the lower excavation cutting wheel (2), and are matched with the lower excavation cutting wheel (2). The disk rotary-cutting layering water chestnut excavation shovel has the characteristics of simple structure, easiness in manufacturing, low cost, reliable performance, good effects and the like.

Owner:廖煜明

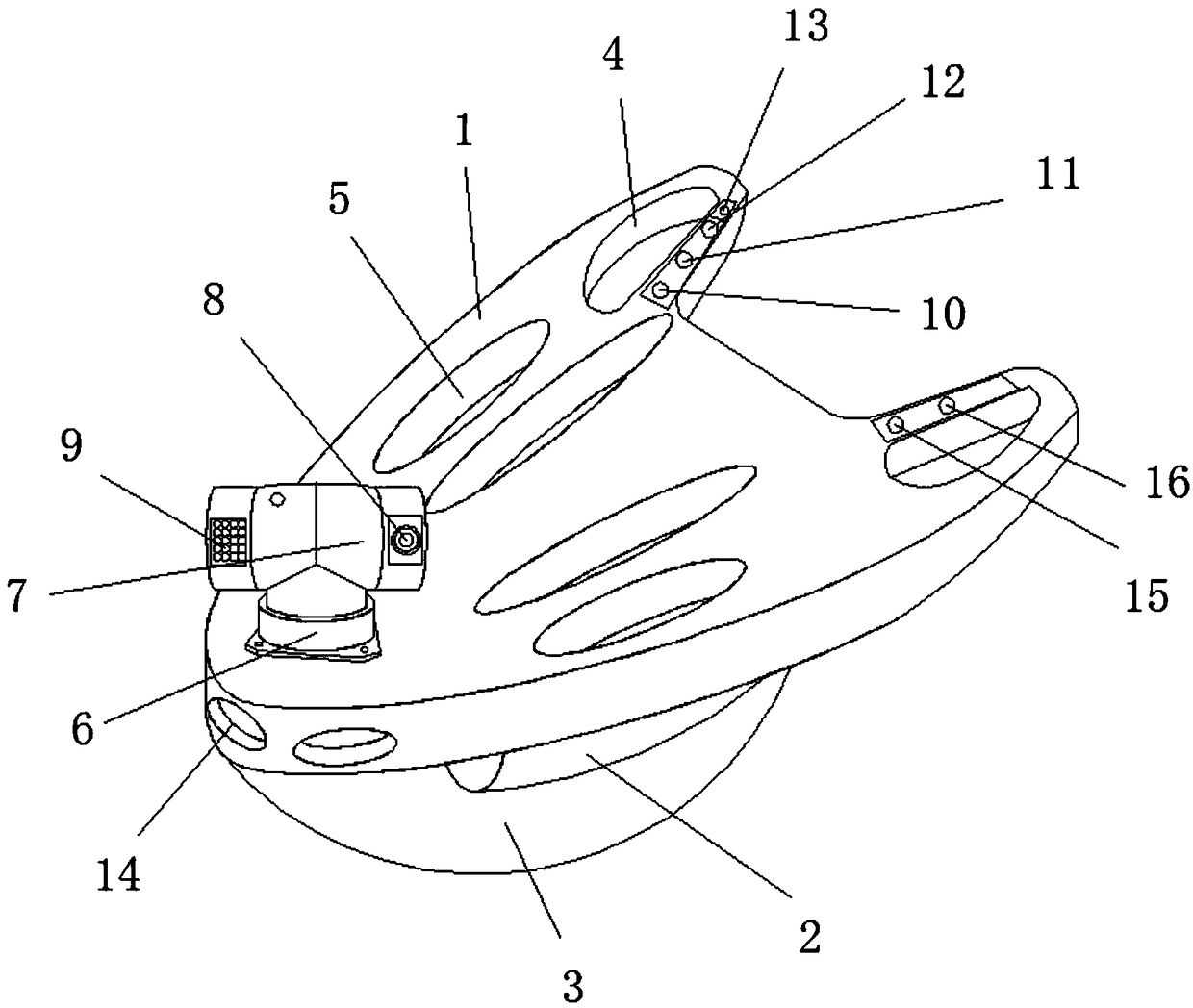

Hand-held diver propulsion vehicle with shooting function

InactiveCN108945353AReduce propulsion resistanceHandheld in various waysSwimming frameworkUnderwater equipmentPropellerEngineering

The invention provides a hand-held diver propulsion vehicle (DPV) with a shooting function. The hand-held DPV comprises a DPV body, a submersible motor and a propeller, wherein the DPV body is a plate-shaped isosceles triangle; base angles are provided with a pair of symmetrical elliptical ring handles; a compartment body is equipped with hollowed-out water-permeable holes; a waterproof shooting unit is mounted at a vertex angle of the compartment body; a searchlight is mounted at the front end of a compartment housing; a first speed reduction motor and a second speed reduction motor which areseparately arranged vertically and horizontally, a camera and a fill light are mounted in the waterproof shooting unit; and the first speed reduction motor, the second speed reduction motor, the camera and the fill light are electrically connected with waterproof and sealing capacitive touch-control buttons through a control chip in one-to-one correspondence. The hand-held DPV with the shooting function is small in propulsion resistance during underwater tour and use, various in hand-held modes, maneuverable and flexible in steering operation and labor-saving. While enjoying the scenery of marine animals and plants, a diver can take pictures or videos as mementos in a large angle range at any time. The hand-held DPV with the shooting function is suitable for promotion and use in diving entertainment places as diving equipment.

Owner:史长江

All-dimensional deep hole drilling machine

InactiveCN106401472ACylinder diameter reductionReduce propulsion resistanceDerricks/mastsDirectional drillingDrill holeHydraulic pump

The invention discloses an all-dimensional deep hole drilling machine. The all-dimensional deep hole drilling machine comprises a rack. A crawler belt and leg supporting oil cylinders are installed under the rack. A hydraulic pump, an oil tank and an operating component are installed on the rack. The rack is provided with an amplitude variation unit, a rolling friction unit and a drilling machine unit. A non-swing end of the amplitude variation unit is fixedly arranged on the rack. The swing end of the amplitude variation unit is provided with the rolling friction unit. The rolling friction unit is provided with the drilling machine unit. The rolling friction unit and the drilling machine unit can be adjusted to swing in the range of 0-105 degrees through the amplitude variation unit, and the rolling friction unit can drive the drilling machine unit to walk in a rolling mode in the axial direction of the rolling friction unit. According to the all-dimensional deep hole drilling machine, 0-26 degree inclined hole drilling operation can be achieved in the range of 800-3000 mm; and drilling operation of upward perpendicular holes, downward perpendicular holes and holes which form any angles with the perpendicular holes can be achieved by adjusting the drilling machine through an amplitude variation oil cylinder, the leg supporting oil cylinders and a rotary assembly.

Owner:SHAANXI STAR EXPLOSION SAFETY POLYTRON TECH INC

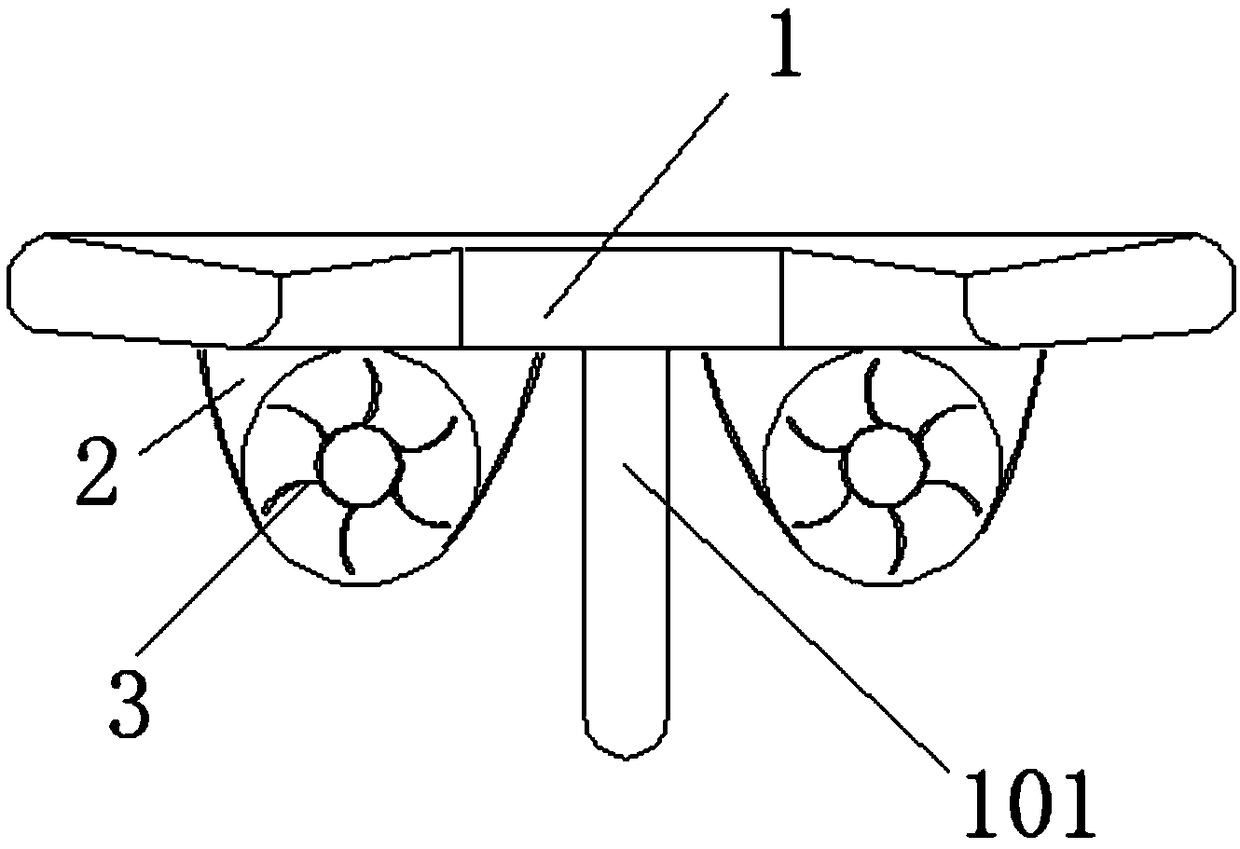

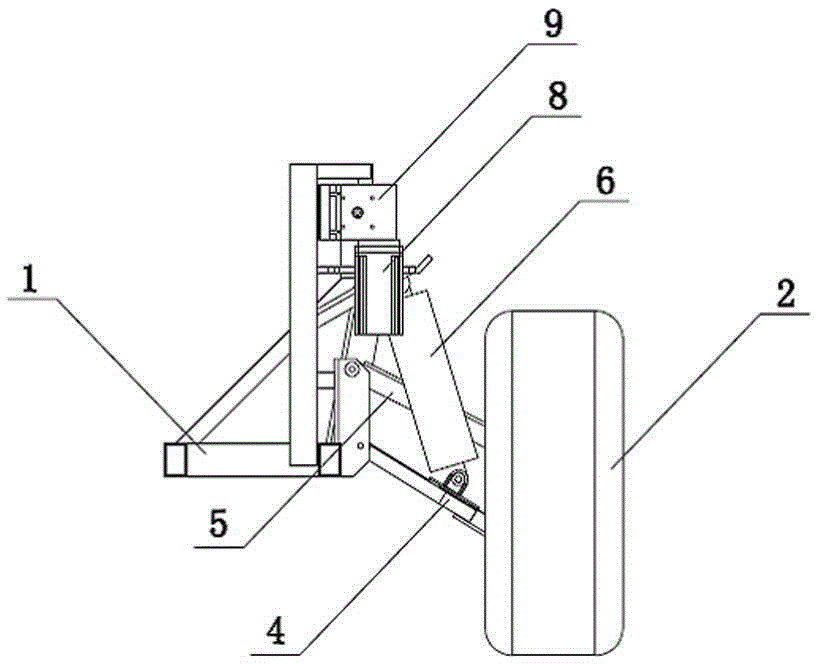

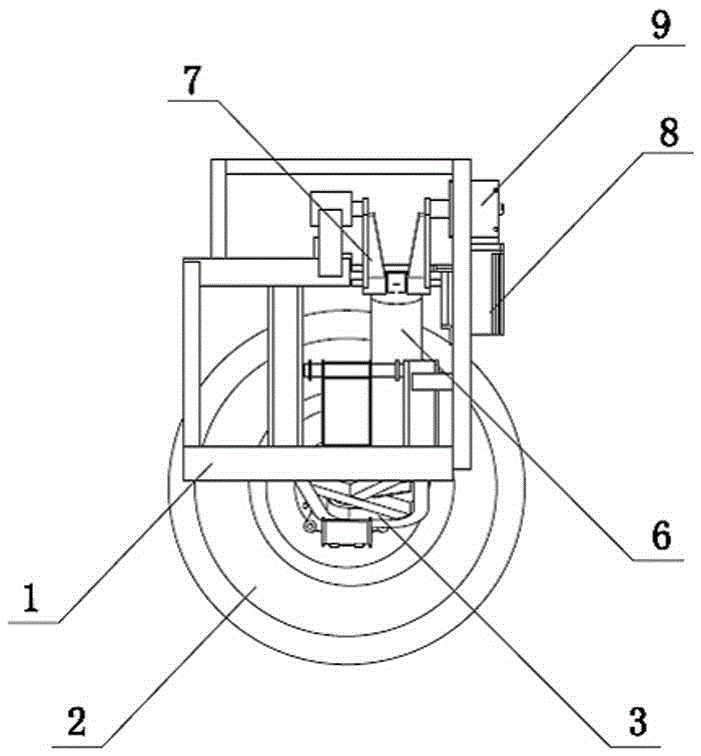

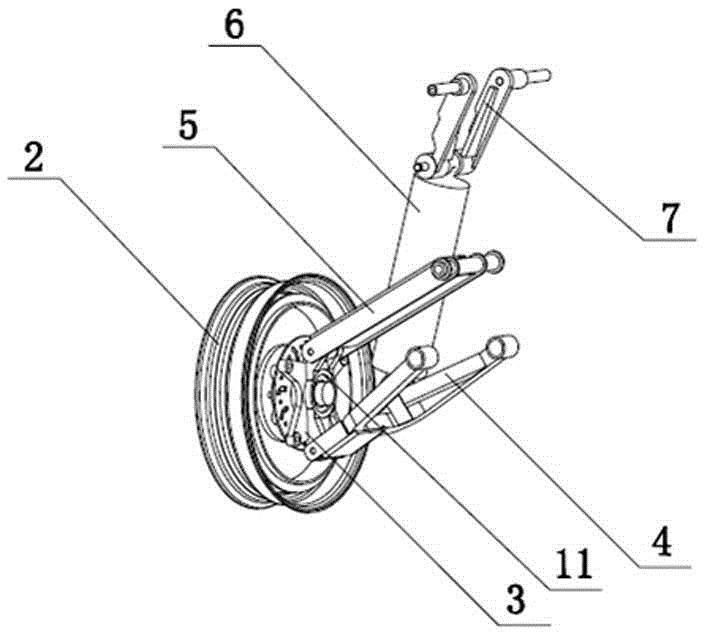

Waterborne propulsion resistance reduction device for all-terrain vehicle

ActiveCN105346344AReduce propulsion resistanceAdvance smoothlyAmphibious vehiclesWatercraft hull designVehicle frameThrust bearing

The invention discloses a waterborne propulsion resistance reduction device for an all-terrain vehicle. The waterborne propulsion resistance reduction device comprises a frame and tires. A thrust bearing is arranged in a steel ring axle hole of the tire and provided with a supporting base. An upper swing arm and a lower swing arm which are arranged in parallel are hinged to the longitudinal end face of the supporting base with one on the upper portion and the other one on the lower portion. The other free end of the upper swing arm and the other free end of the lower swing arm are both hinged to the frame. A shock absorption rod is hinged to one of the upper swing arm and the lower swing arm; the other free end of the shock absorption rod is hinged to a main journal of a crankshaft; the crankshaft is arranged on the frame; one crank arm on the crankshaft is connected with a speed reducer; and the speed reducer is connected with a drive motor. Great resistance is brought to propulsion when too many tires on the amphibious special vehicle sink into water together with a vehicle body, and therefore the tires can be designed into a lifting mechanism which can be lifted up, lifting is conducted during waterborne propulsion, the tires can not enter water, resistance to waterborne propulsion is greatly reduced, and it is ensured that the vehicle body can be smoothly propelled on water.

Owner:ZHEJIANG XIBEIHU SPECIAL VEHICLE

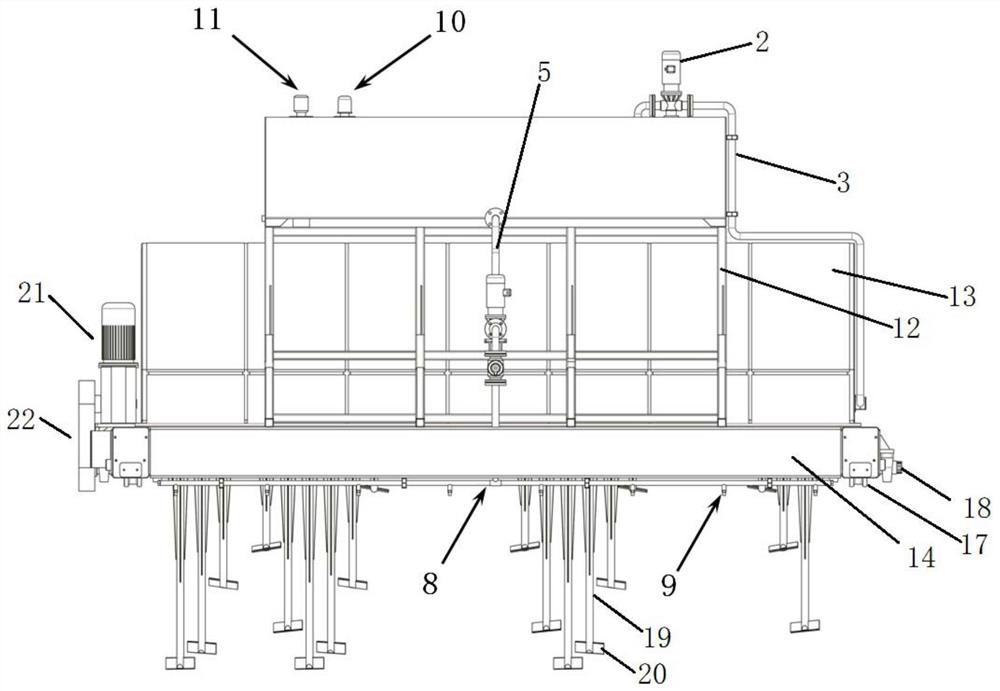

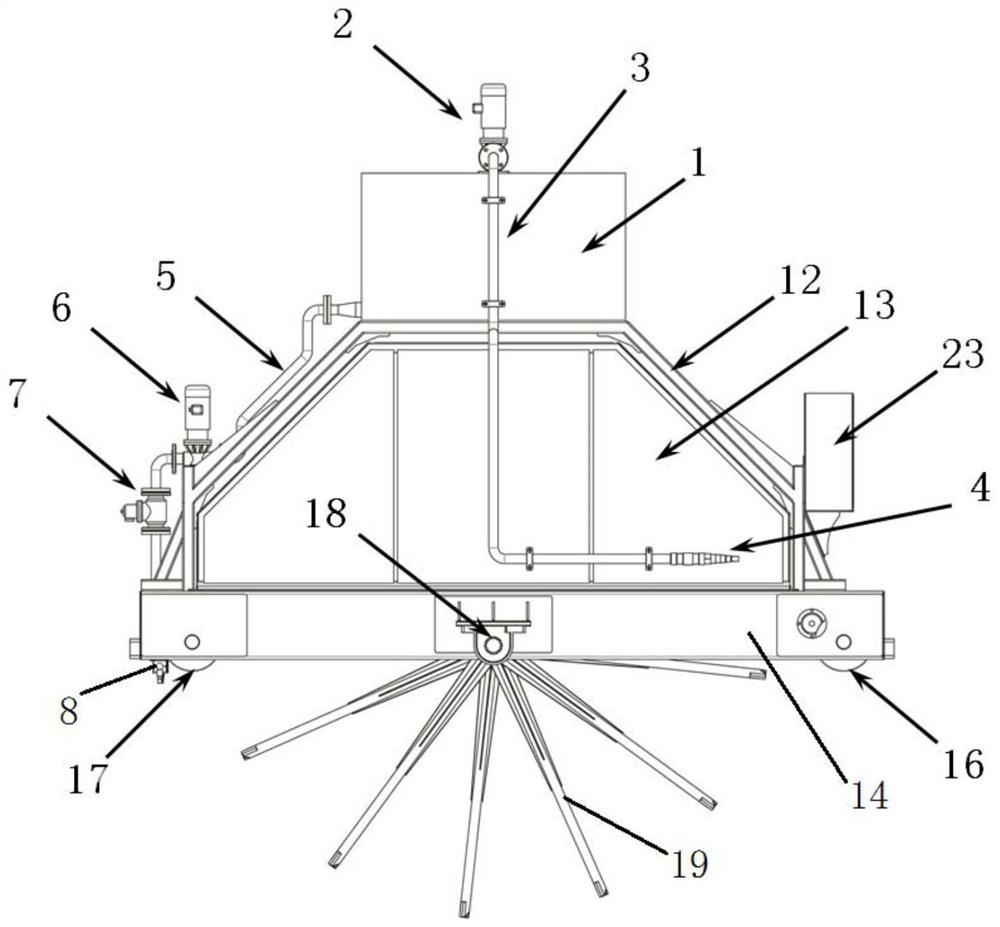

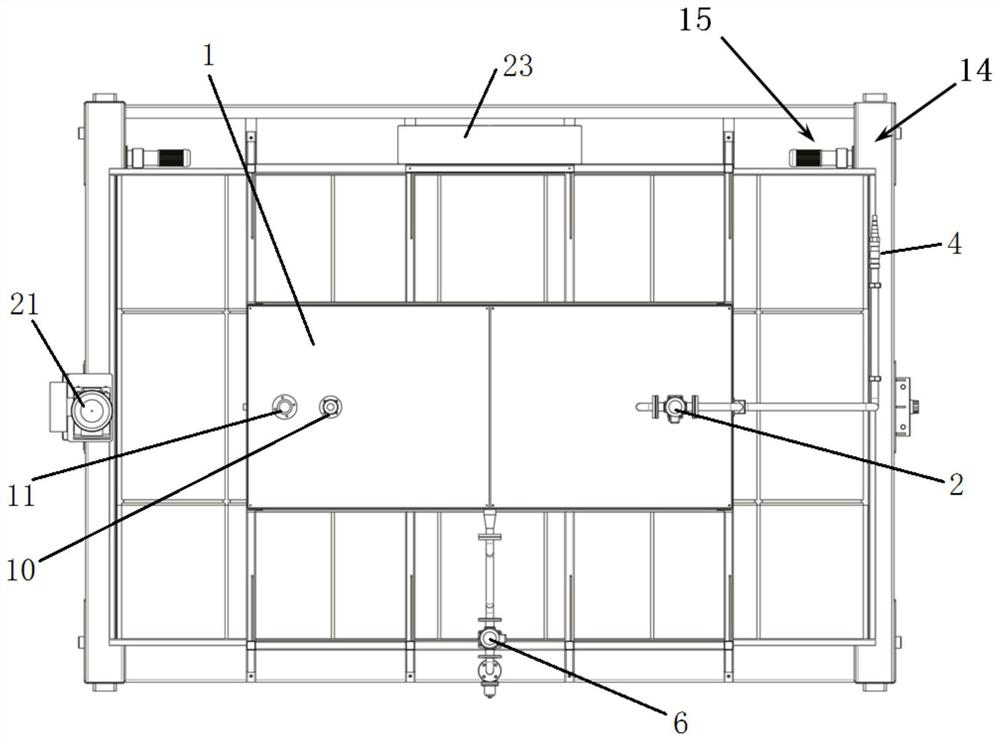

Material overturning vehicle for organic fertilizer production

PendingCN112500213ARealize unmanned operation on siteRealize unmanned operationBio-organic fraction processingFertiliser treatment controlVehicle frameAgricultural engineering

The invention relates to a material overturning vehicle for organic fertilizer production. The material overturning vehicle comprises a bacterium applying assembly, a vehicle frame assembly, an overturning and stirring assembly and a control assembly. The bacterium applying assembly comprises a bacterium liquid box (1) and a spraying assembly; and the frame assembly comprises a frame structural part (14) and a walking mechanism. The overturning and stirring assembly comprises a overturning and stirring main shaft (18) and paddle rods (19), and the paddle rods (19) are spirally arranged and mounted on the overturning and stirring main shaft (18); wherein the bacterium applying assembly and the overturning and stirring assembly are both mounted on a frame structural part (14), and the bacterium applying assembly, the walking mechanism and the overturning and stirring assembly are controlled by the control assembly. Compared with the prior art, the material overturning vehicle has the advantages of being small in material overturning resistance, capable of fully overturning and throwing material piles, low in energy consumption, capable of uniformly applying bacteria at the same timeand the like.

Owner:上海国茏环保科技有限公司

A hydraulic nut shredder

ActiveCN110919059BQuick cutReduce propulsion resistanceShearing machinesMetal working apparatusLaser transmitterHydraulic motor

The invention discloses a hydraulic nut shredder, which comprises a fuselage, a machine head and a control box. The fuselage includes a casing, a hydraulic motor, a hydraulic oil cylinder, a hydraulic oil tank, a storage battery and a current amplifier. There is a fixed sleeve, one end of the casing is provided with a rotary sleeve, the hydraulic cylinder is sleeved at one end of the fixed sleeve, and the hydraulic cylinder, hydraulic motor, hydraulic oil tank, battery and current amplifier are sleeved from left to right Located in the fixed casing, the machine head includes a crushing fixed frame, a combined pressing head and a self-locking discharge mechanism, and the crushing fixed frame is provided with a tapered guide rail and a rotary pin. The indenter of the cutting machine of the present invention adopts a docking type, with a built-in laser transmitter, which produces a shallow indentation by pressing the indenter on one side of the nut, and heats and softens the bottom of the indentation through the built-in laser irradiation, reducing the propulsion resistance of the hydraulic cylinder. This can quickly break the nut and prolong the service life of the hydraulic components.

Owner:NANJING YUZHI INTELLIGENT TECH CO LTD

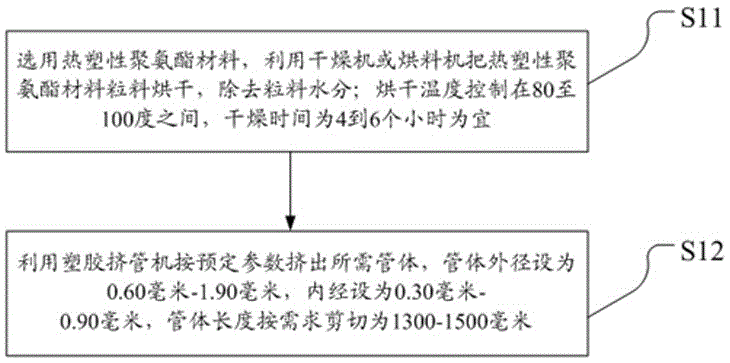

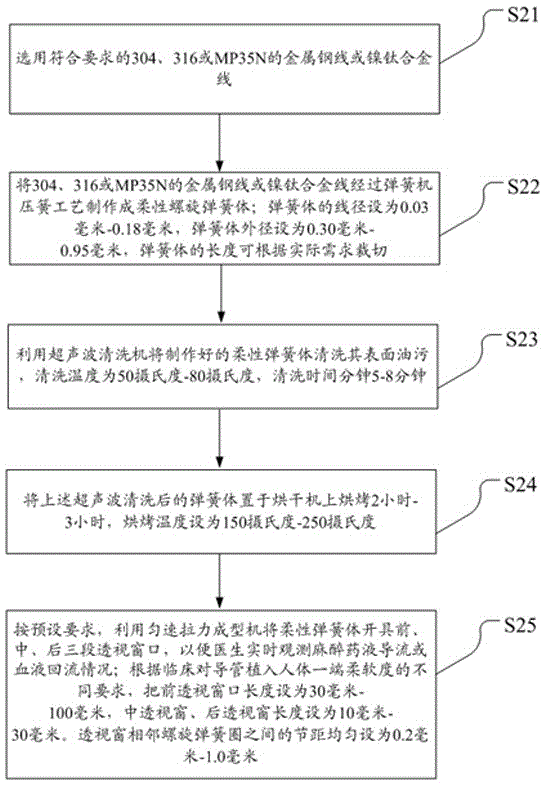

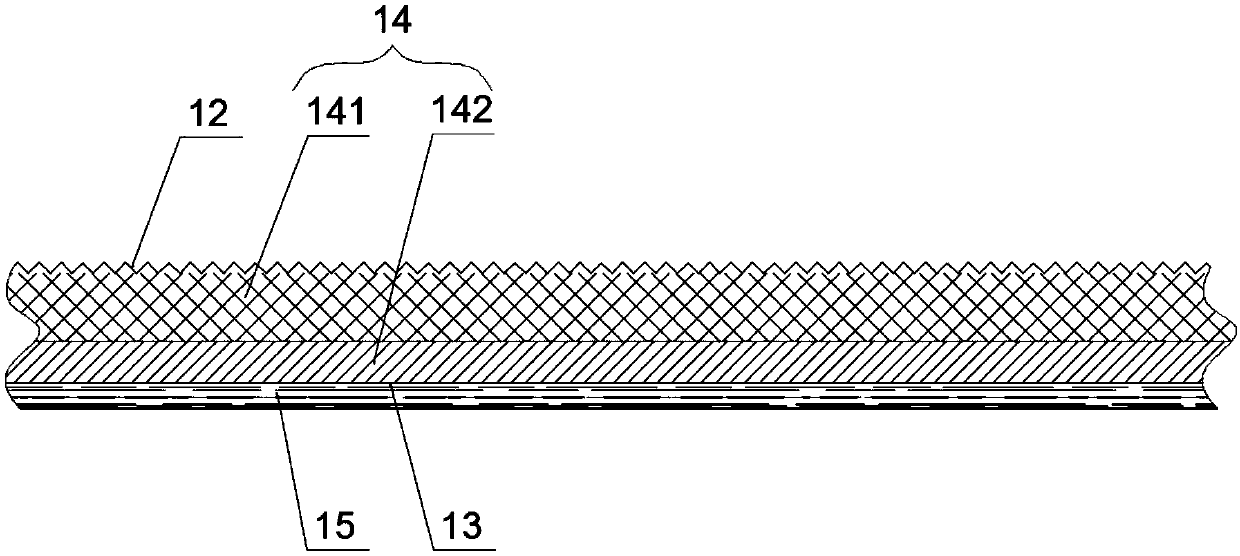

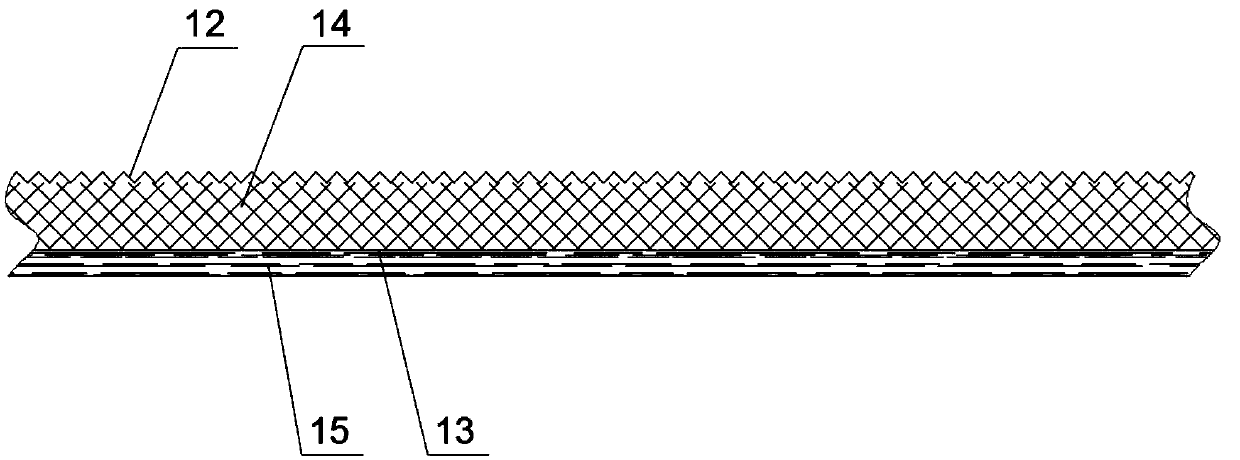

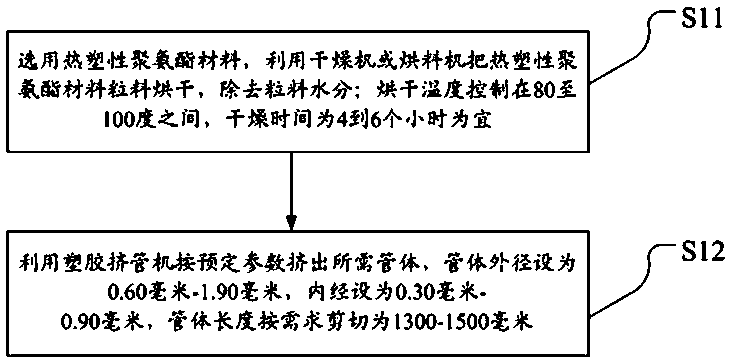

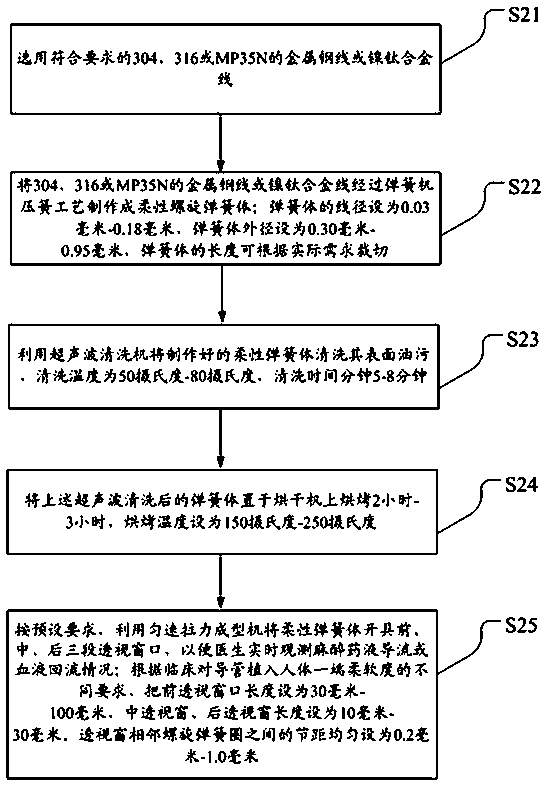

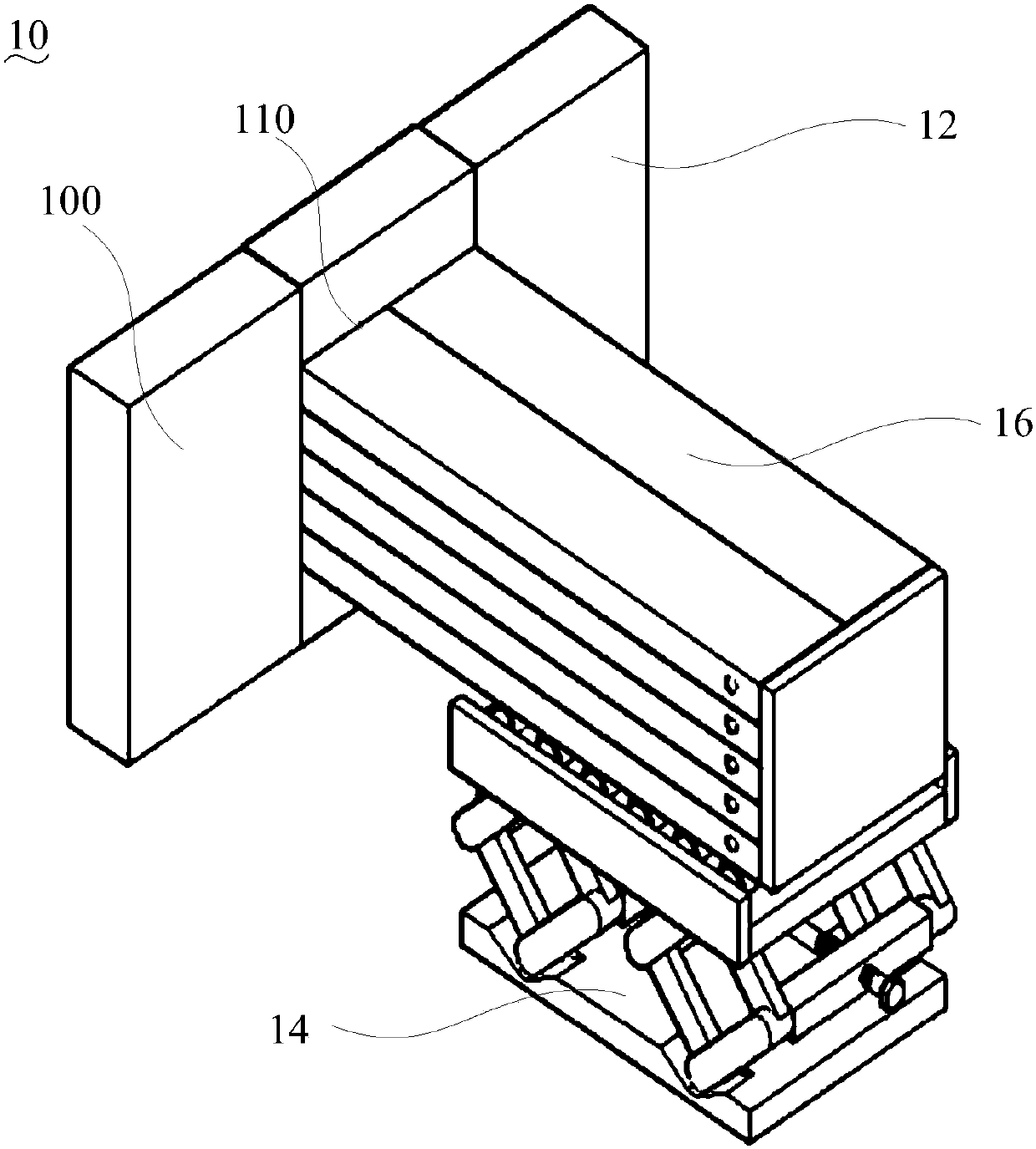

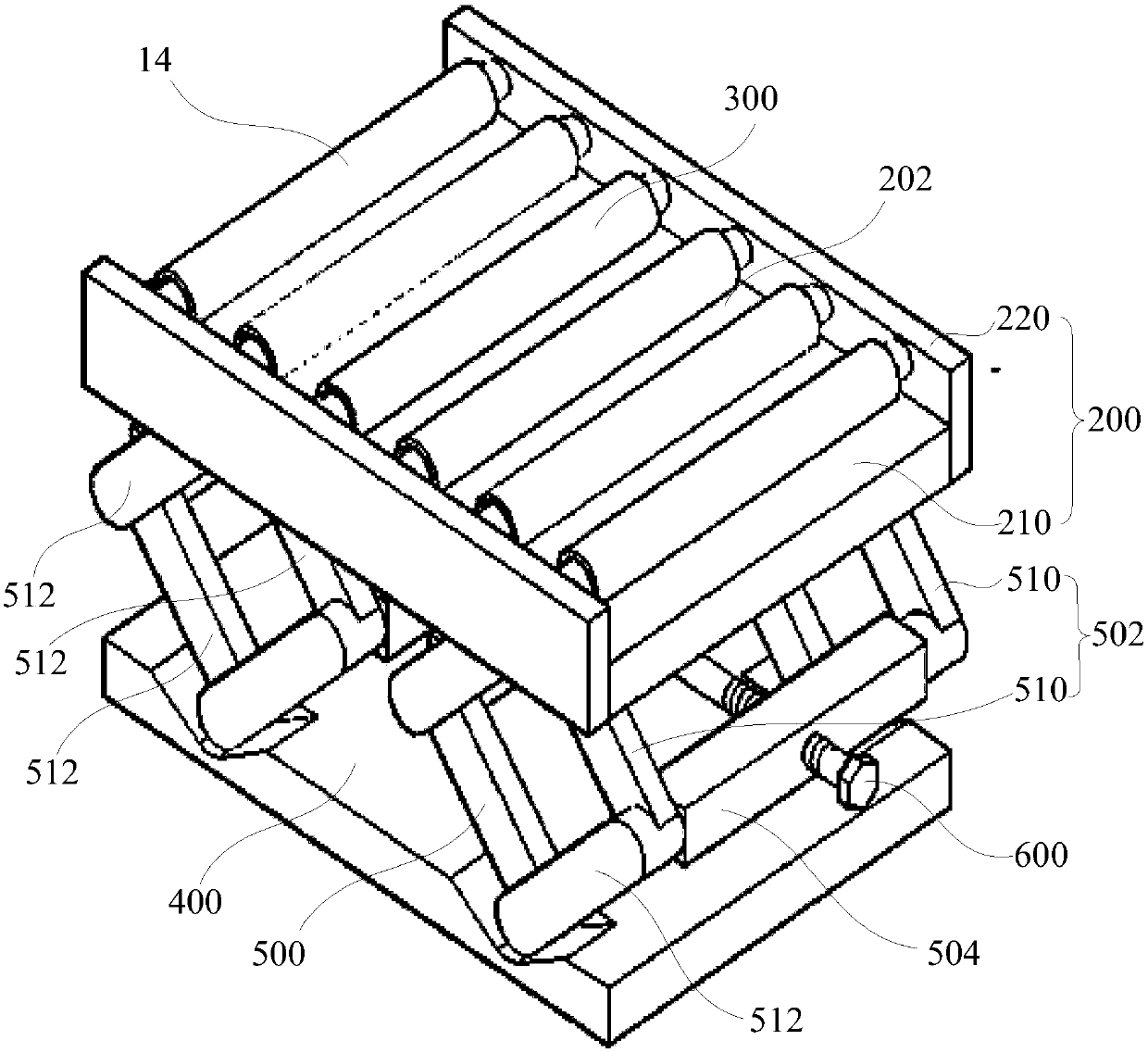

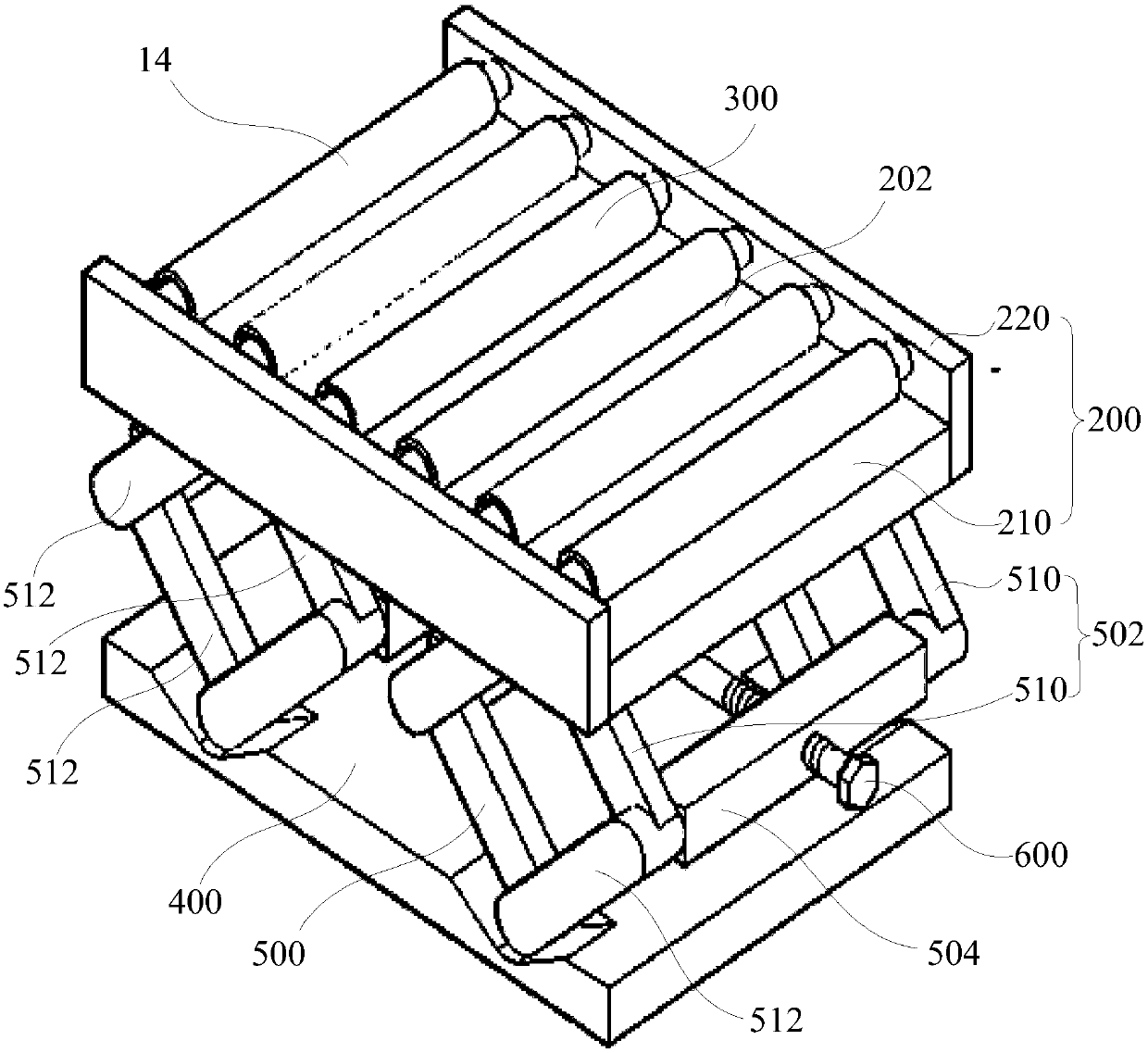

Flexible reinforced type segmental epidural catheter and manufacturing method thereof

ActiveCN106621005AReasonable workmanshipEasy to operateMulti-lumen catheterCoatingsOperabilityGuide tube

The invention discloses a flexible reinforced type segmental epidural catheter and a manufacturing method thereof. The flexible reinforced segmental epidural catheter comprises a catheter body for guiding liquid medicine for anaesthesia, a medicine inlet and a medicine outlet of the catheter body are communicated, a supporting spring body is arranged inside a catheter body cavity; one end of the catheter body is provided with a flexible tip section, the flexibility of the flexible tip section is superior to that of a main body section of the catheter body. The manufacturing method of the flexible reinforced type segmental epidural catheter is reasonable in technology, high in operability, safe and reliable and has the advantages of being simple in technology, easy to master, low in production cost, high in efficiency, reliable in quality and the like.

Owner:珠海金导医疗科技有限公司

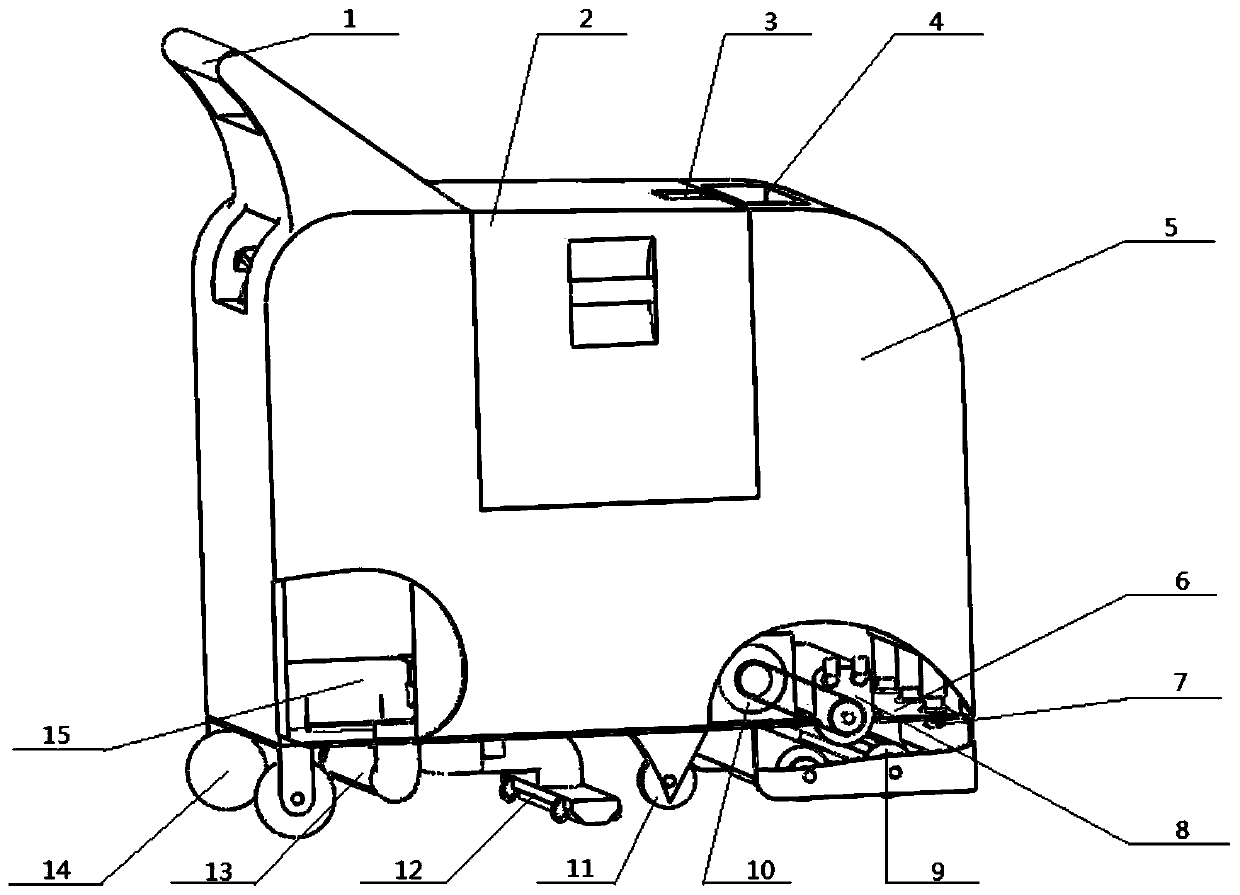

Multifunctional carpet cleaning machine

InactiveCN110292332AEasy to cleanReduce propulsion resistanceCarpet cleanersFloor cleanersDrive motorSewage

The invention discloses a multifunctional carpet cleaning machine. The multifunctional carpet cleaning machine is characterized by including a clean water tank for storing clean water, a cleaning fluid storage chamber for storing cleaning fluid, a water-spraying device for spraying the clean water on a to-be-cleaned carpet, a foaming device for mixing the cleaning liquid with the clean water and then foaming, a booster pump for conveying the clean water from the clean water tank to the water-spraying device or the foaming device, a scrubbing device for scrubbing the carpet, a drive motor for driving the foaming device and the scrubbing device, a water absorption rake for sucking liquid residues on the carpet, a slop tank for collecting sewage sucked by the water absorption rake, a drying device for drying the carpet and a wet or dry water absorption motor. According to the multifunctional carpet cleaning machine, the carpet cleaning machine with complete functions, easy-to-replace parts and the good cleaning effect is provided, the cleaning efficiency is high, the multiple functions of water spraying, foaming, cleaning, water absorption and drying are integrated in one, the machineis convenient to disassemble, assemble and clean, the size is moderate, and the cleaning effect is good.

Owner:DONGHUA UNIV

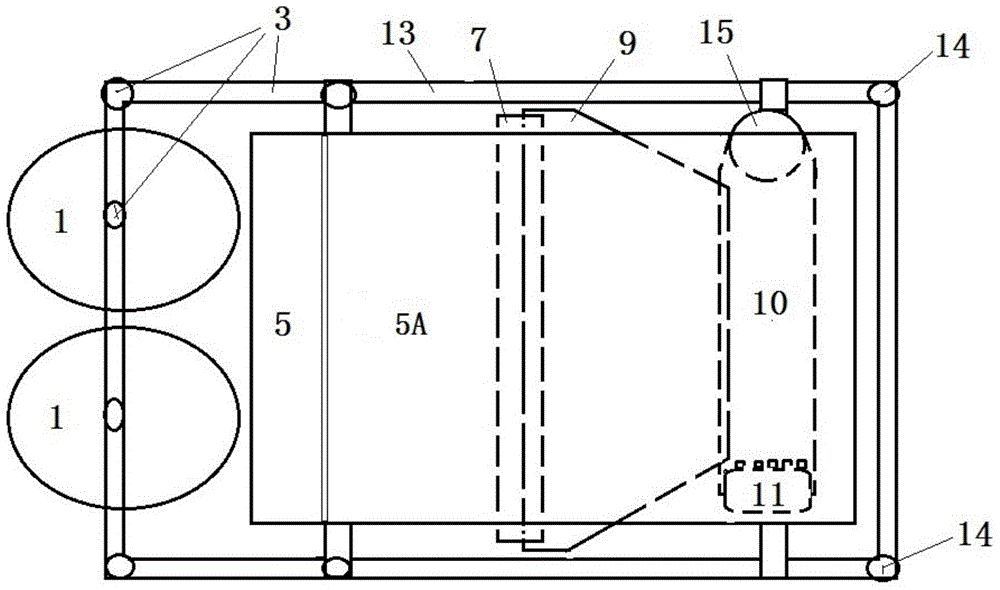

Disc rotary cutting stratifying excavation water chestnut machine

InactiveCN104145596ASolve the problem of limited power outputSmall horsepowerLiftersTopping machinesCircular discWater Chestnuts

The invention discloses a disc rotary cutting stratifying excavation water chestnut machine comprising an excavation shovel connected and combined with a power machine through a drive arm joint by the existing technology. The excavation shovel includes upper and lower shovel units, the front end of the upper shovel unit is provided with an upper excavation cutting wheel (1) composed of at least one disc saw, an upper excavation shovel channel (5) matched with the upper excavation cutting wheel (1) is arranged behind the upper excavation cutting wheel (1), and the upper excavation shovel channel (5) is connected to a channel (5A); the front end of the lower shovel unit is provided with a lower excavation cutting wheel (2) composed of at least one disc saw, a lower excavation shovel channel (6), a passage (6A), a meshed hopper (7), a vibration screen (9) and a collecting groove (10) which match with the lower excavation cutting wheel (2) are sequentially arranged behind the lower excavation cutting wheel (2). The machine has the advantages of simple structure, easiness for manufacture, low cost, reliable performance and fine effect.

Owner:廖煜明

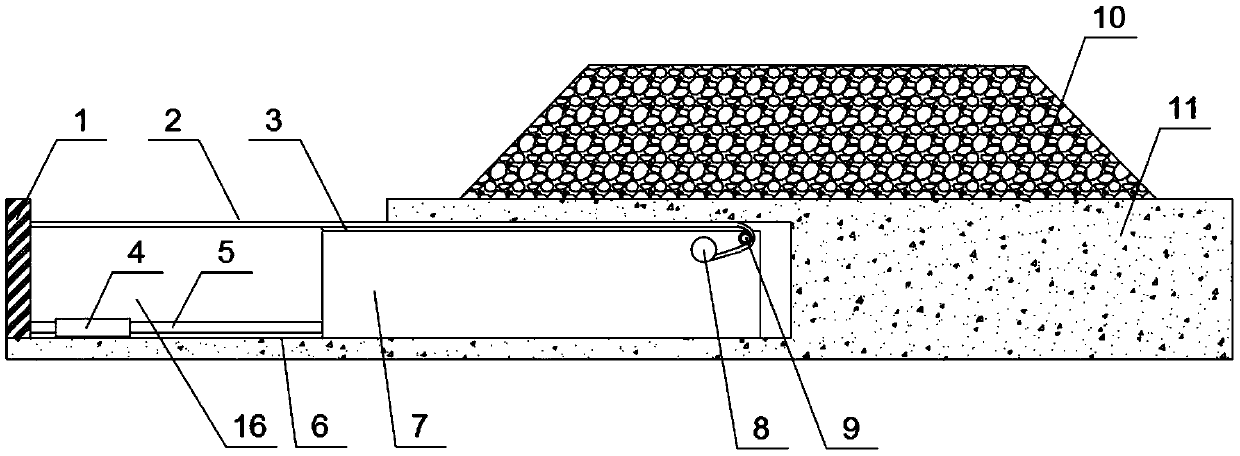

Sliding film, box culvert pushing system and construction method for reducing box culvert pushing disturbance

PendingCN109667588AReduce disturbanceReduce propulsion energy consumptionGround-workUnderground chambersEngineeringMechanical engineering

The invention belongs to the technical field of existing line culvert pushing construction, and discloses a sliding film, a box culvert pushing system and a construction method for reducing box culvert pushing disturbance. The sliding film for reducing the box culvert pushing disturbance comprises a bendable sliding film body with a rough face and a smooth face. The box culvert pushing system comprises the sliding film, a groove body perpendicular to the box culvert forward moving direction is arranged behind a blade corner at the front end of the outer wall of a box culvert, a roller is installed in the groove body, one end of the sliding film is fixed to a back wall, the other end of the sliding film is laid on the outer wall of the box culvert in the pushing forward moving direction ofthe box culvert and bypasses the roller, the sliding film portion not bypassing the roller is a laid sliding film portion, the rough face of the laid sliding film portion makes contact with a soil body outside the box culvert and cannot relatively slide, the smooth face of the laid sliding film portion makes contact with the outer wall of the box culvert and can relatively slide, and the sliding film portion bypassing the roller is an unlaid sliding film portion which is arranged inside the box culvert. The construction method adopts the box culvert pushing system for construction. By means ofthe technical scheme, disturbance to an existing road is little.

Owner:ZHUMADIAN CITY HIGHWAY ENG DEV CO LTD

A kind of manufacturing method of flexible reinforced epidural anesthesia catheter

ActiveCN106621005BReasonable workmanshipEasy to operateMulti-lumen catheterCoatingsOperabilityGuide tube

Owner:珠海金导医疗科技有限公司

Graphitic push pedal

InactiveCN101323534AReduce propulsion resistanceImprove thermal conductivityCharge manipulationFurnace typesHeat conductingAdhesive

The invention discloses a graphite push slab which consists of the following ingredients in proportion by weight: 82 percent to 88 percent of graphite, 10 percent to 15 percent of alundum powder and 2 percent to 3 percent of refractory mortar. The production method of the graphite push slab of the invention is that: the graphite, the alundum powder and the refractory mortar are selected and mixed at a mixture ratio, pressed into shapes and burned in a high temperature kiln at 1000 DEG C to 1200 DEG C. The push slab of the invention has small pushing resistance, good heat-conducting property, light weight and long service life and is high temperature resisting, non-adhesive, antiseptic and oxidation resisting.

Owner:HUAIAN DINGYU SCI & TECH

Glass melting furnace system and electrode brick supporting device thereof

InactiveCN109987821AReduce moving frictionReduce propulsion resistanceGlass furnace apparatusTank furnacesBrickRolling resistance

The invention relates to a glass melting furnace system and an electrode brick supporting device thereof. According to the electrode brick supporting device, the electrode brick supporting device is used for bearing electrode bricks, the electrode bricks can move on the electrode brick supporting device, and in the moving process, friction between the electrode bricks and the electrode brick supporting device is rolling friction. The electrode brick supporting device is used for bearing the electrode bricks, in the moving process of the electrode bricks on the electrode brick supporting device, the friction between the electrode bricks and the electrode brick supporting device is rolling friction, compared with a traditional mode that electrode bricks are supported through refractory bricks, the moving friction force of the electrode bricks on the electrode brick supporting device can be reduced, then the pushing resistance of the electrode bricks is reduced in the pushing process of the electrode bricks, and the problem that the electrode bricks are damaged or pool wall bricks move is effectively avoided.

Owner:QINGYUAN CSG NEW ENERGY SAVING MATERIALS CO LTD +1

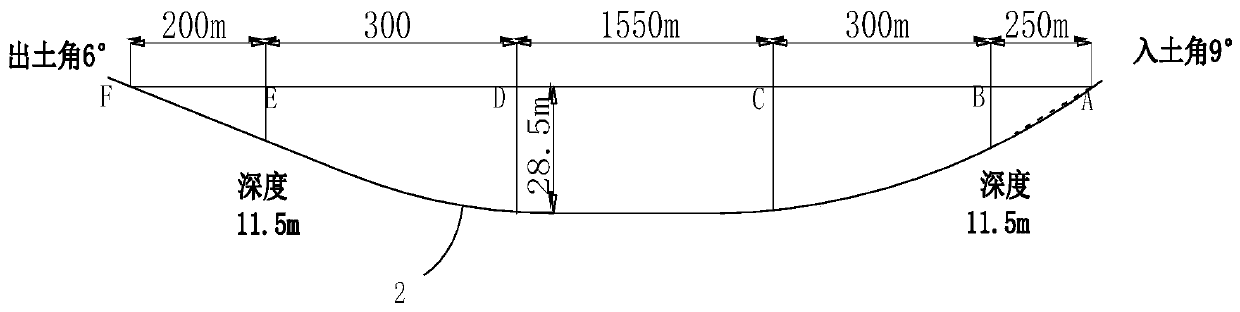

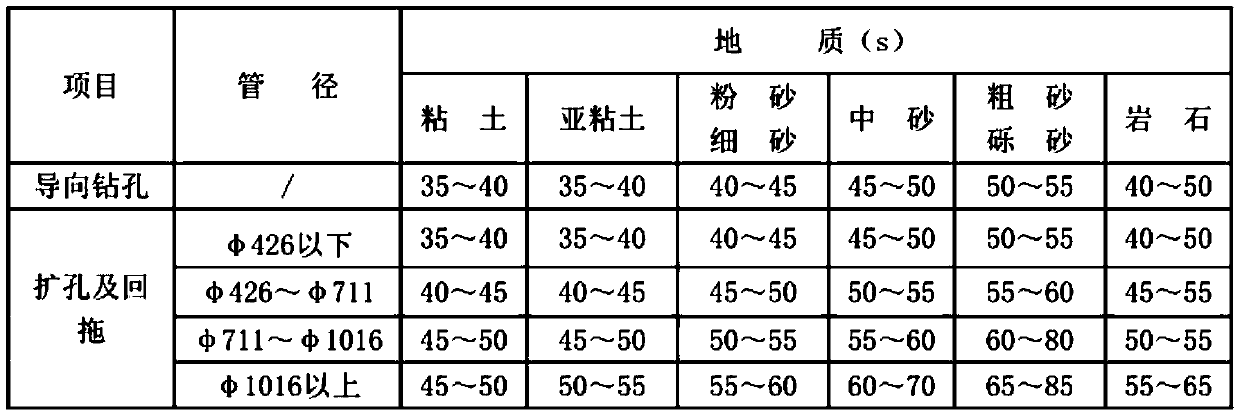

The method of using mud in the construction of directional drilling crossing the river

ActiveCN108086908BGood suspensionImprove liquidityDirectional drillingDrilling compositionSoil scienceRiver routing

The invention discloses a using method of slurry in crossing-with-directional-drilling of river construction. The method comprises the steps that the slurry is prepared according to formation conditions and diameter and length of crossing pipelines, and suitable slurry materials are selected; in a pipeline crossing process, time needed by the slurry and a drilling bit to reach different soil layers is calculated according advance speed of directional drilling, reaming, hold flushing and pipeline back-dragging in different soil layers and flow rate of the slurry, the slurry required by different soil layers is injected into a drill hole at preset times, the slurry returned from the drill hole is injected into a slurry circulation tank, and the slurry is returned to the drill hole and used after the slurry is processed. According to the method, effects of suspending, carrying, lubricating, hole fixing, leakage plugging and the like of the slurry are improved, and occurrences of phenomenons of hole collapse, formation leakage and the like are effectively avoided.

Owner:CHINA MCC 2 GRP CO LTD

Original soft clay hollow cylinder sample inner core cutting device

InactiveCN100570320CEasy to determineEasy to cleanWithdrawing sample devicesPreparing sample for investigationStress conditionsSoft clay

The invention discloses an inner core cutter of a hollow cylindrical sample of soft clay. It has a casing, the upper end of the casing is provided with a cutting edge, the lower end of the casing is connected with the detachable casing bottom bracket through the casing bottom bracket-casing positioning screw, and the detachable soil holding bracket is arranged above the detachable casing bottom bracket. There is a pressure relief hole on the detachable soil holder, and a main drill bit is arranged in the middle of the casing. The main drill bit is composed of a spiral drill bit and an inner edge blade, and is connected with a drill pipe. The drill pipe passes through the detachable soil holder and the bottom of the detachable casing. The brackets are respectively fixed by the soil support-drill pipe set screw and the casing bottom support-drill pipe set screw. The detachable blade is composed of an outer edge blade and a horizontal blade, and is rigidly connected to the main drill bit through the blade set screw. The casing is cylindrical. The cutter can successfully prepare the hollow cylindrical sample of undisturbed soft clay, and the disturbance and extrusion effect on the sample during the cutting process are small, which provides equipment guarantee for the experimental research of undisturbed soft clay under complex stress conditions.

Owner:ZHEJIANG UNIV

All-dimensional deep hole drilling machine

InactiveCN106437508AGuaranteed Support RangeAvoid damageDerricks/mastsDirectional drillingRolling resistanceHydraulic pump

The invention discloses an all-dimensional deep hole drilling machine. The all-dimensional deep hole drilling machine comprises a rack. A crawler belt and leg supporting oil cylinders are installed under the rack. A hydraulic pump, an oil tank and an operating component are installed on the rack. The rack is provided with an amplitude variation unit, a rolling friction unit and a drilling machine unit. A non-swing end of the amplitude variation unit is fixedly arranged on the rack. The swing end of the amplitude variation unit is provided with the rolling friction unit. The rolling friction unit is provided with the drilling machine unit. The rolling friction unit and the drilling machine unit can be adjusted to swing in the range of 0-105 degrees through the amplitude variation unit, and the rolling friction unit can drive the drilling machine unit to walk in a rolling mode in the axial direction of the rolling friction unit. According to the all-dimensional deep hole drilling machine, 0-26 degree inclined hole drilling operation can be achieved in the range of 800-3000 mm; and drilling operation of upward perpendicular holes, downward perpendicular holes and holes which form any angles with the perpendicular holes can be achieved by adjusting the drilling machine through an amplitude variation oil cylinder, the leg supporting oil cylinders and a rotary assembly.

Owner:SHAANXI STAR EXPLOSION SAFETY POLYTRON TECH INC

Spiral tool bit mechanism

The invention provides a spiral tool bit mechanism. The mechanism comprises a bottom plate, side plates and a shovel base, wherein the bottom plate is rectangular, an inclined guide surface is arranged at the bottom of one end of the bottom plate in the length direction, and the higher end of the guide surface is located at the end of the bottom plate; the two side plates are fixed to two sides ofthe top of the bottom plate respectively, and the shovel base is fixed at the other end of the bottom plate; the two sides of the shovel base are fixedly connected with the corresponding side plates,and the portion, on one side of the guide surface, of the shovel base inclines to the lower front portion and extends to form an arc-shaped shovel surface; a cutter shaft is movably hinged between the two side plates above the guide surface, one end of the cutter shaft penetrates through the side plates and is connected with a motor, and a spiral convex rib is arranged on the surface of the cutter shaft; a concave-convex cutting edge is formed in the surface of the convex rib, and a material shoveling channel is reserved between the cutting edge and the surface of the bottom plate; the lowestpart of the shovel surface extends into the material shoveling channel. According to the scheme, the structure is reasonable, and the meat stripping effect is good.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

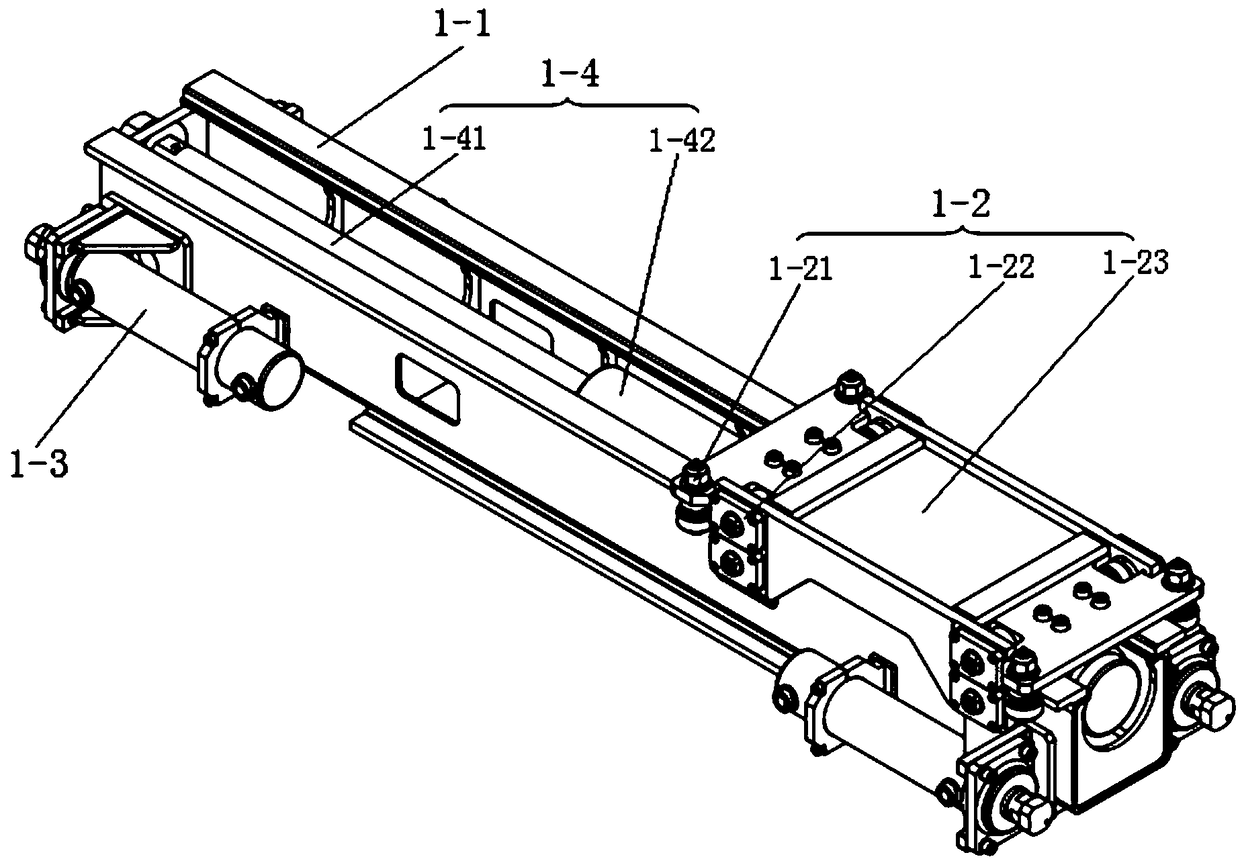

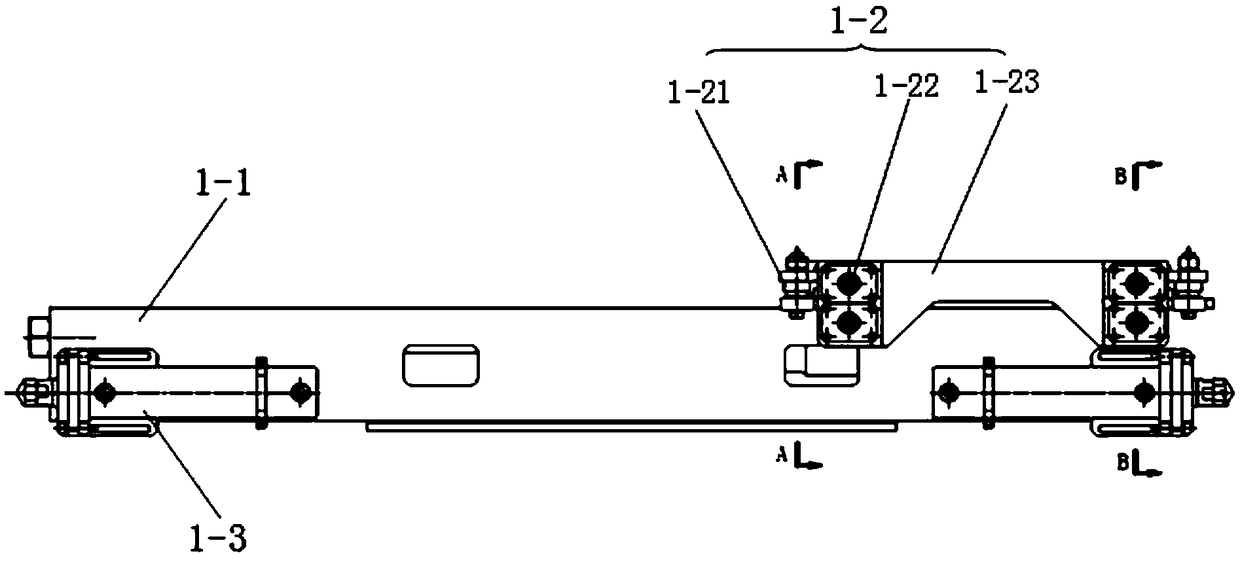

A luffing rolling friction drilling mechanism

ActiveCN106401471BAvoid damageEasy to cleanDerricks/mastsDrilling machines and methodsRolling resistanceDrilling machines

The invention discloses an amplitude variation rolling friction drilling machine component. The amplitude variation rolling friction drilling machine component comprises a drilling machine unit, an amplitude variation unit and a rolling friction unit. The amplitude variation unit comprises a cross beam which is a telescopic cross beam. The cross beam comprises a telescopic beam and a fixed beam which are sleeved with each other, and tracks are arranged on the telescopic beam in the length direction in a spaced mode. The fixed beam end of the amplitude variation unit is fixedly arranged on a drilling machine. The telescopic beam end of the amplitude variation unit is provided with the rolling friction unit. The rolling friction unit and the head of the drilling machine can be adjusted to swing in the range of 0-105 degrees through the amplitude variation unit, and the rolling friction unit can drive the head of the drilling machine to walk in a rolling mode in the axial direction of the rolling friction unit. The drilling machine unit comprises a drilling machine power head, a drilling rod and a drilling bit. The drilling machine power head is installed on the rolling friction unit. The drilling rod and the drilling bit are sequentially installed on the drilling machine power head.

Owner:SHAANXI STAR EXPLOSION SAFETY POLYTRON TECH INC

Drill for composite material, machining method and machining device using same

InactiveCN104785826BReduce propulsion resistanceSmall peeling forceTransportation and packagingWorkpiecesMachine partsMaterial Perforation

The invention discloses a drill bit used for a composite material and a machining method and device using the same. The drill bit comprises a drill bit body, a reaming part, a finish machining part and a drill rod which are sequentially connected from bottom to top. The front end of the drill bit body is provided with a cutting edge and a chip removal groove, a reaming edge is arranged at the connecting position of the reaming part and the drill bit body, the reaming part is provided with a drill lip and a chip groove, and the finish machining part comprises an external grinding beveled edge. As the drill bit body, the reaming part and the finish machining part are connected into a whole, while the conical part of the drill bit body can be used for restraining cutting resistance to be small, a lower hole is enlarged for perforation machining, flash is not prone to being generated on the machining part, and propelling resistance exerted on a machined part in the perforation machining direction can be reduced; the stripping force on the interface in the composite material is reduced, and therefore interlayer stripping is not prone to being caused.

Owner:JIYUAN VOCATIONAL & TECHN COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com