Drill for composite material as well as machining method using same and machining apparatus using same

A composite material and mechanical processing technology, which is applied in the direction of reaming devices, metal processing equipment, and cutting tools for lathes, etc., can solve the problems of flashing in the perforated part and increased cutting resistance, so that it is not easy to peel off layers, Effects of reduced cutting resistance and high-precision piercing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0041] Regarding the embodiment of the present invention, when the present invention is applied to a two-blade drill having two torsion grooves, as the first embodiment of the present invention, the linear portion is formed in the shape of a reamer, and as the second embodiment The method is to form the straight portion into a land drill shape, which will be described with reference to the drawings.

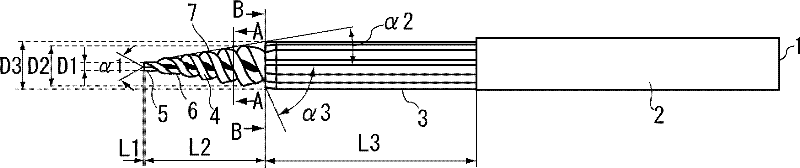

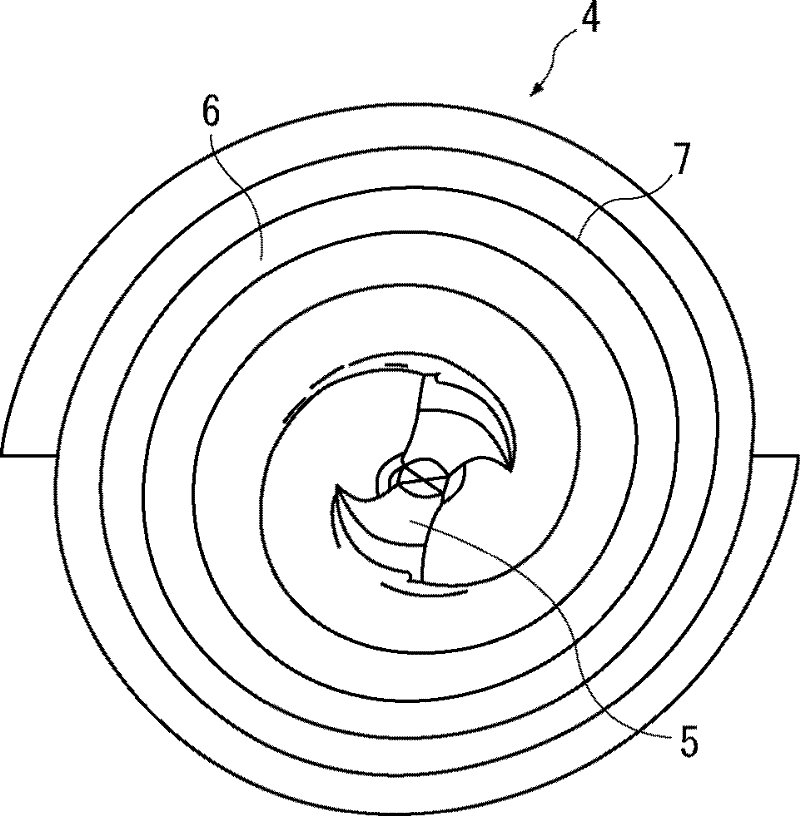

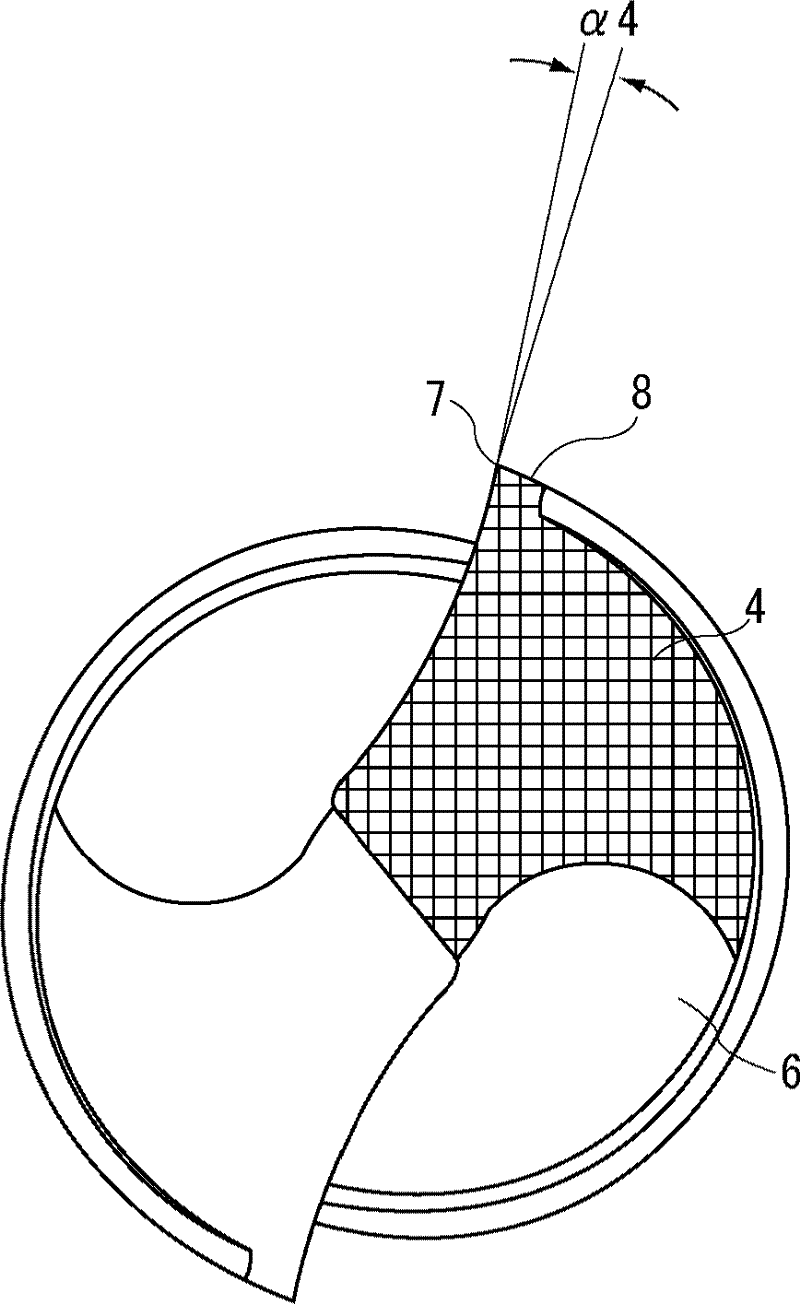

[0042] refer to Figure 1 ~ Figure 4 The first embodiment according to the present invention will be described. figure 1 It is a side view of the drill 1 of the first embodiment. figure 2 It is viewed from the front side toward the rear end side figure 1 The front view obtained from the tapered part. image 3 yes figure 1 A cross-sectional view of the A-A line. Figure 4 yes figure 1 The cross-sectional view of the B-B line.

[0043] The drill 1 according to the present embodiment is a two-blade drill formed by connecting a straight portion 3 forming a reamer to the front...

Embodiment 1

[0078] Such as Figure 5 As shown, a cutting test was performed on a drill including a tip portion having a tip cutting edge, a tapered portion formed with a peripheral cutting edge, and a straight portion, and the thrust resistance (force applied in the drill axial direction) was measured.

[0079] In the cutting test, the cutting edge with no margin on the peripheral cutting edge was used. Figure 5 The four types of drills shown and the three types of drills as comparative examples make a total of seven types of drills.

[0080] as Figure 5 For the drills shown, the following three drills A to C are used. That is, the base material of the drill is cemented carbide and diamond coating. The following are general specifications: the tip angle of the tip of the drill is β1 = 135°, and the overall length of the drill is 103 mm. , Taper angle β2 of the tapered part = 2°, outer diameter of the front end of the tapered part D4 = 3.0 mm, outer diameter of the rear end of the tape...

Embodiment 2

[0101] Next, the same cutting test was performed using the same seven types of drills as in Example 1, and the presence or absence of burrs in the vicinity of the through-hole of the workpiece (carbon fiber reinforced plastic) was visually observed.

[0102] Figure 14 It is a table showing the observation results when the machining numbers of 10 holes, 40 holes, 80 holes, and 120 holes are processed with respect to the presence or absence of burrs near the through-holes processed by seven types of drills.

[0103] As a result of observation, no burrs were generated when drilling 120 holes with the drills A and B of the examples. For drill C, breakage occurred when the 92nd hole was processed. The breakage of the drill C is considered to be caused by the superimposition of the reduction of the core diameter of the drill due to the increase of the twist angle as the angle of the chip discharge flute and the deterioration of the chip discharge performance. On the other hand, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com