Patents

Literature

59results about "Conical drills" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

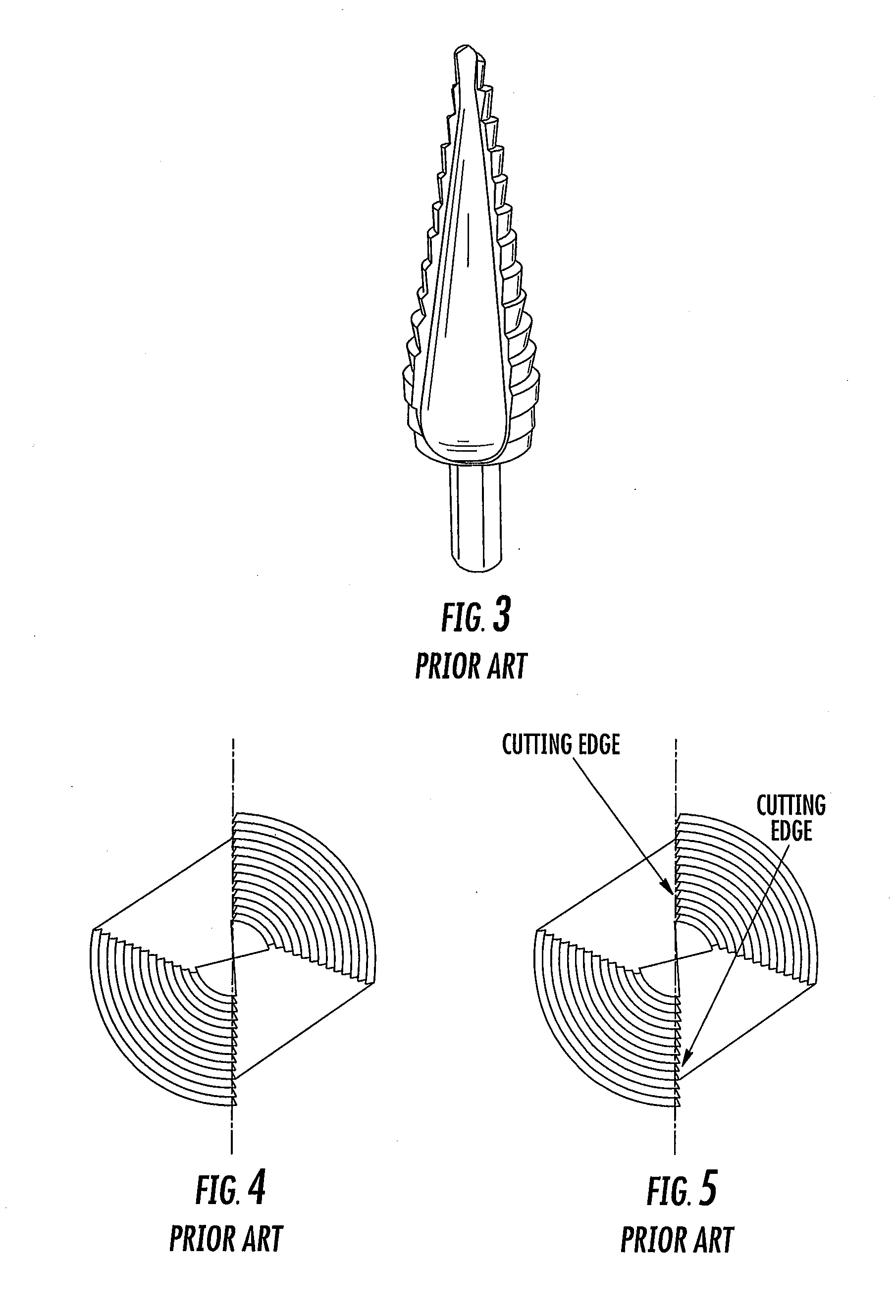

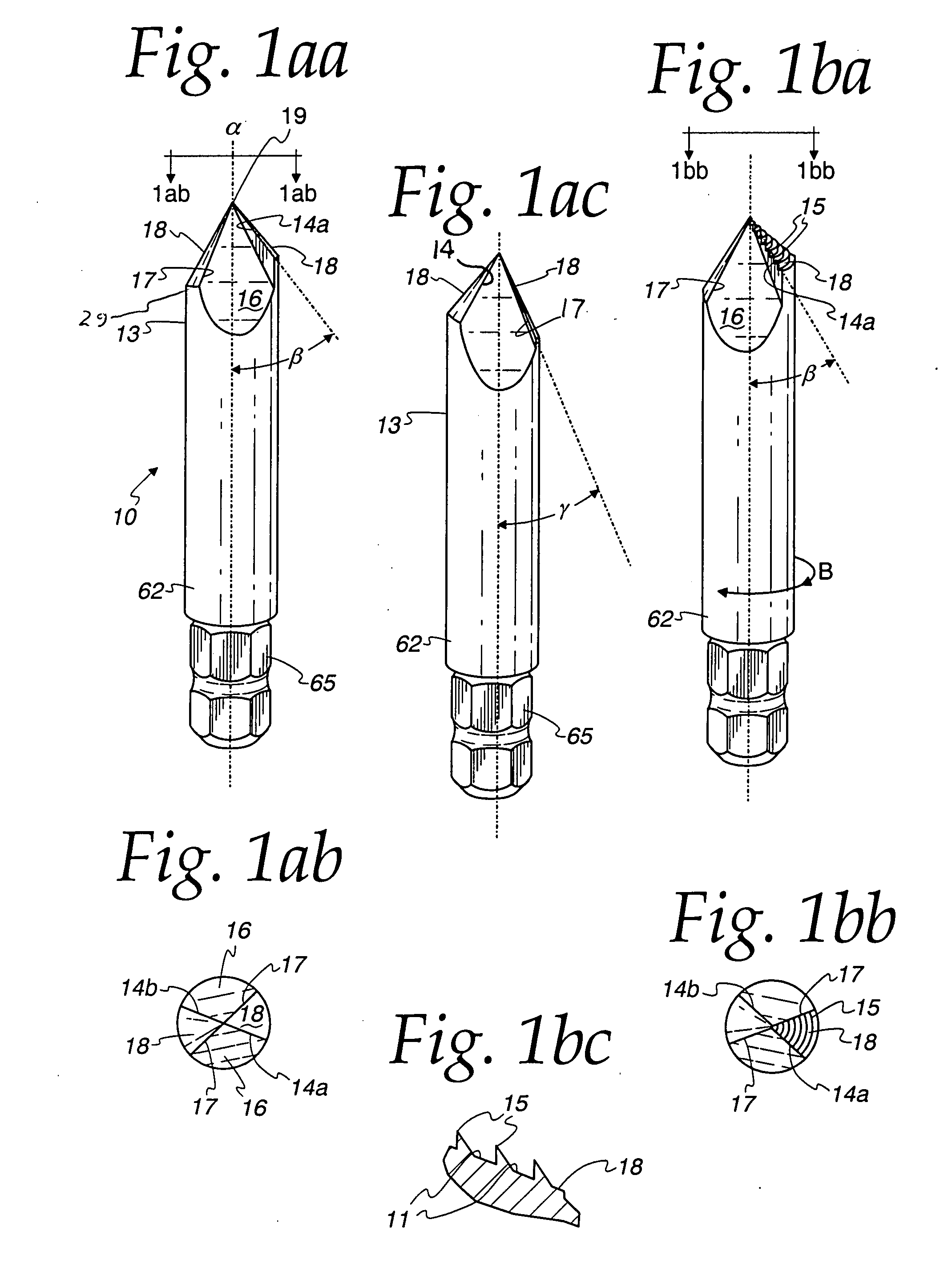

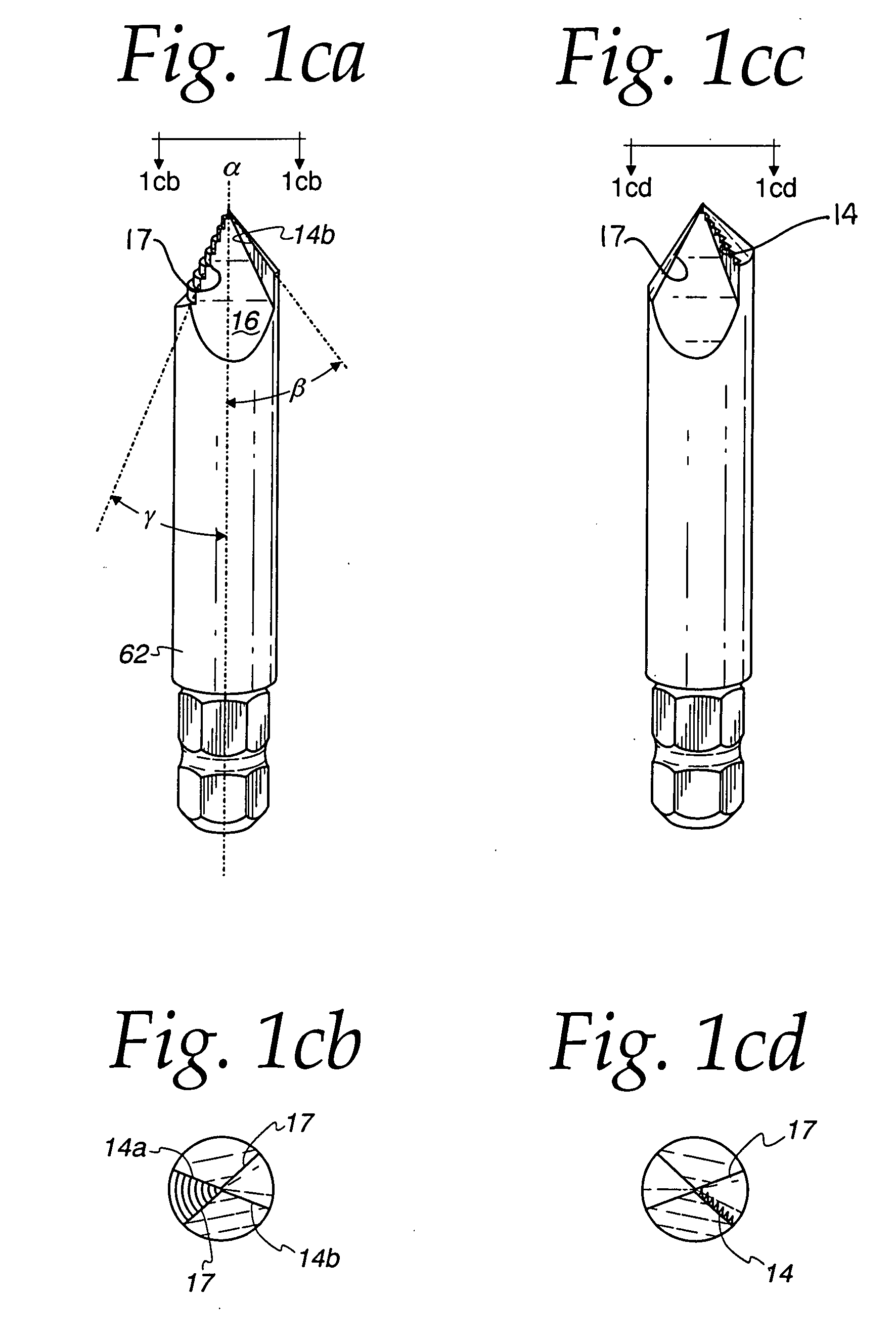

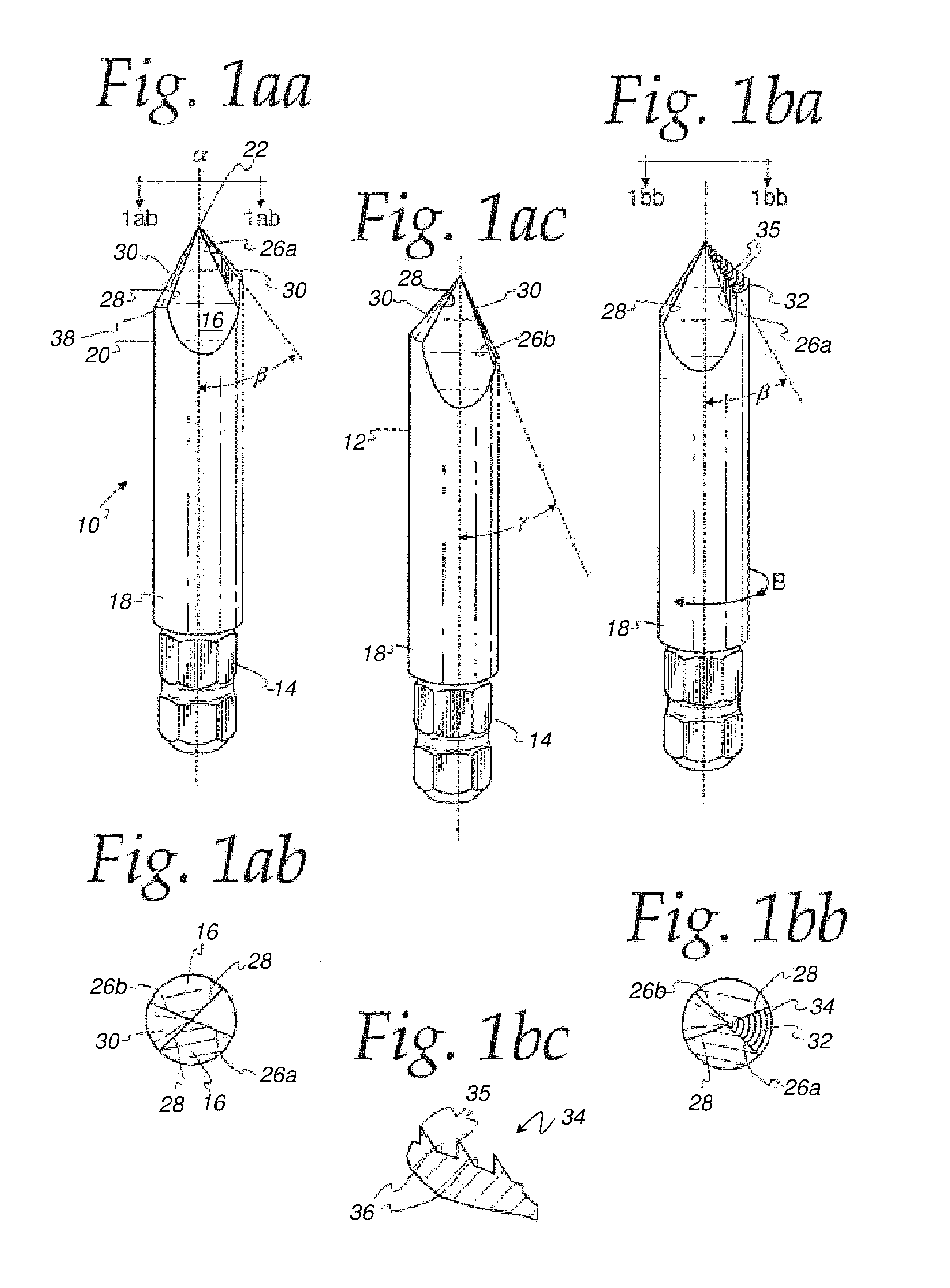

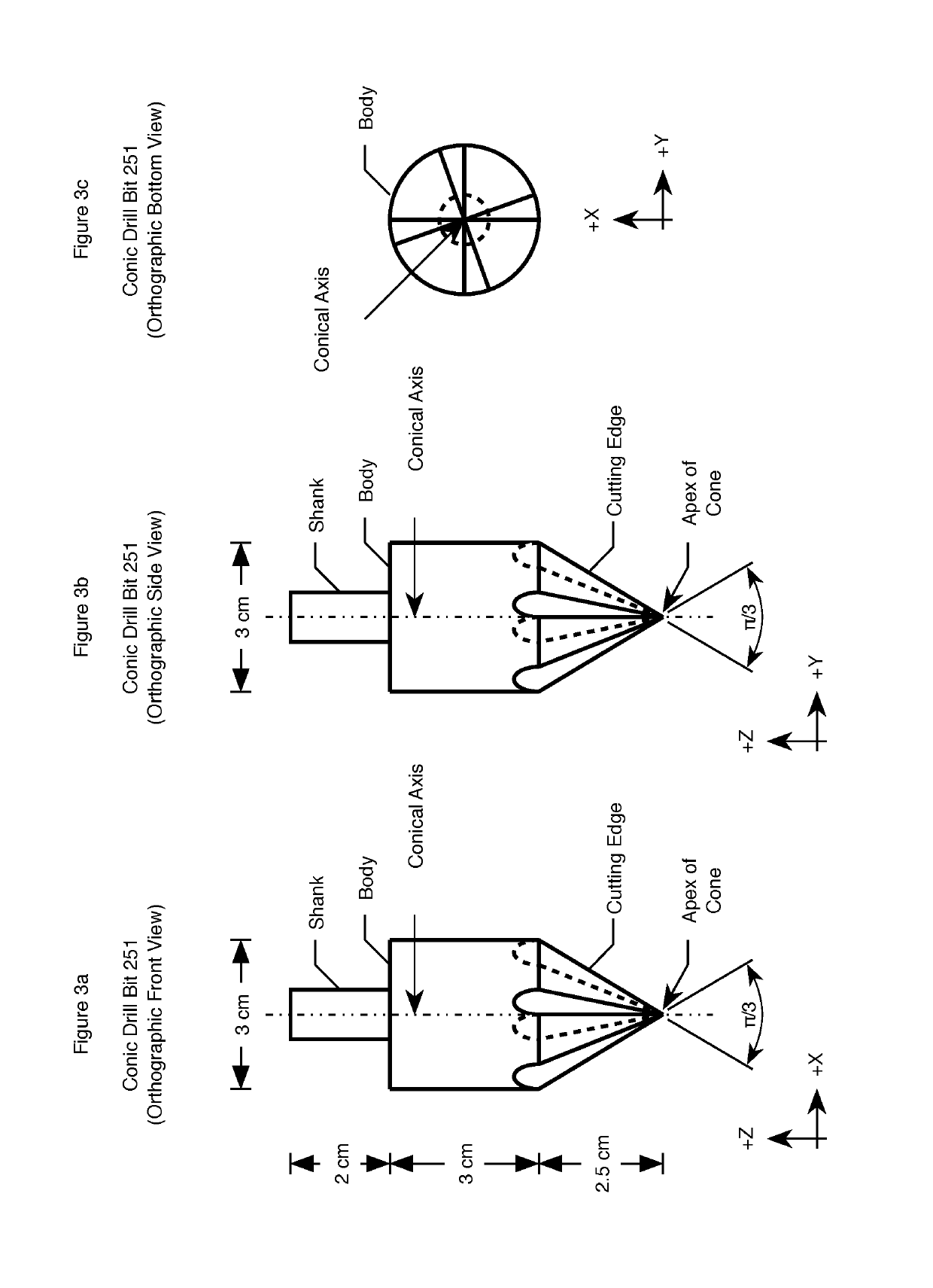

Drill bit

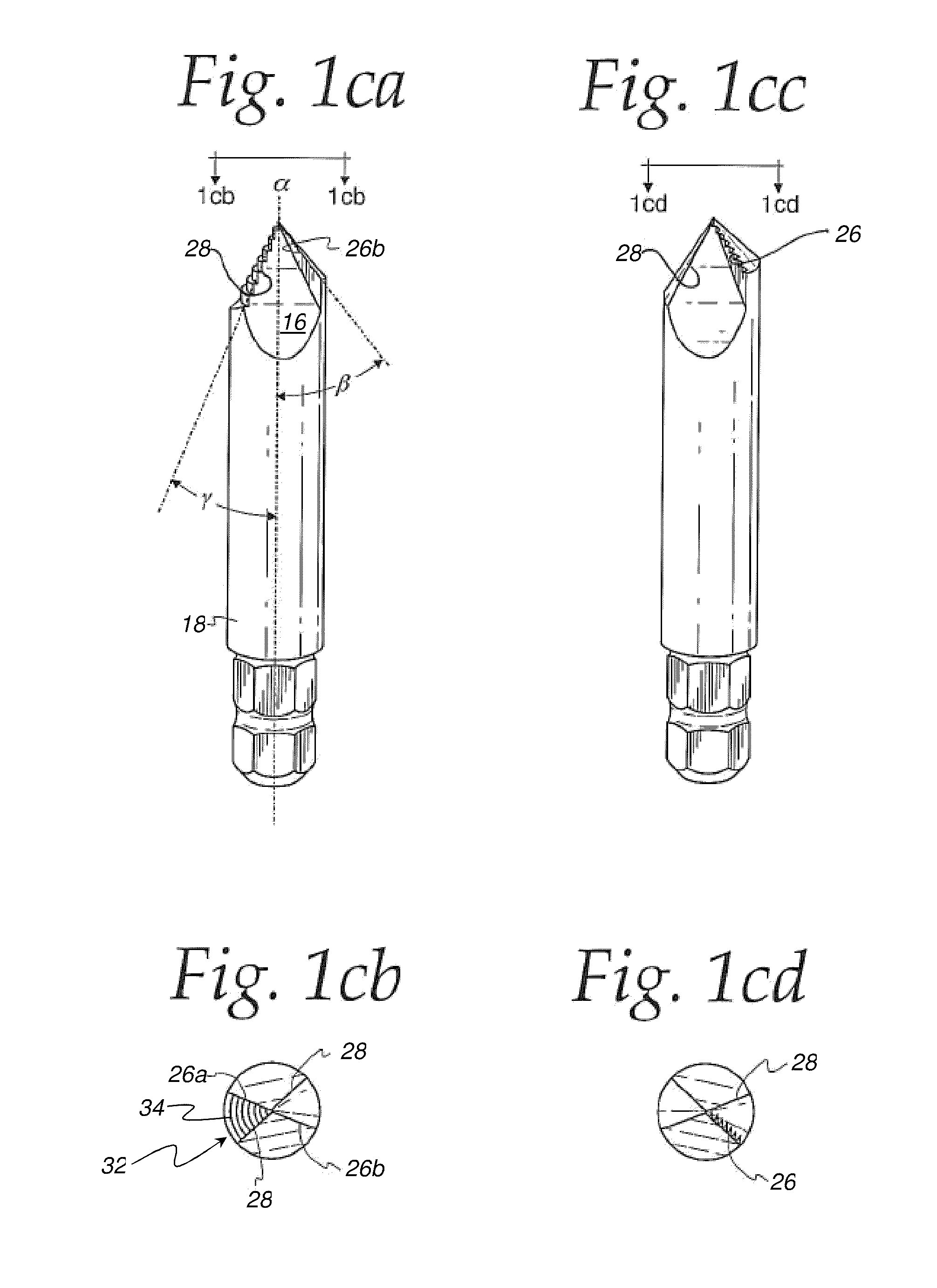

InactiveUS20120195704A1Addressing slow performanceGuaranteed uptimeWood turning toolsTransportation and packagingEngineeringMechanical engineering

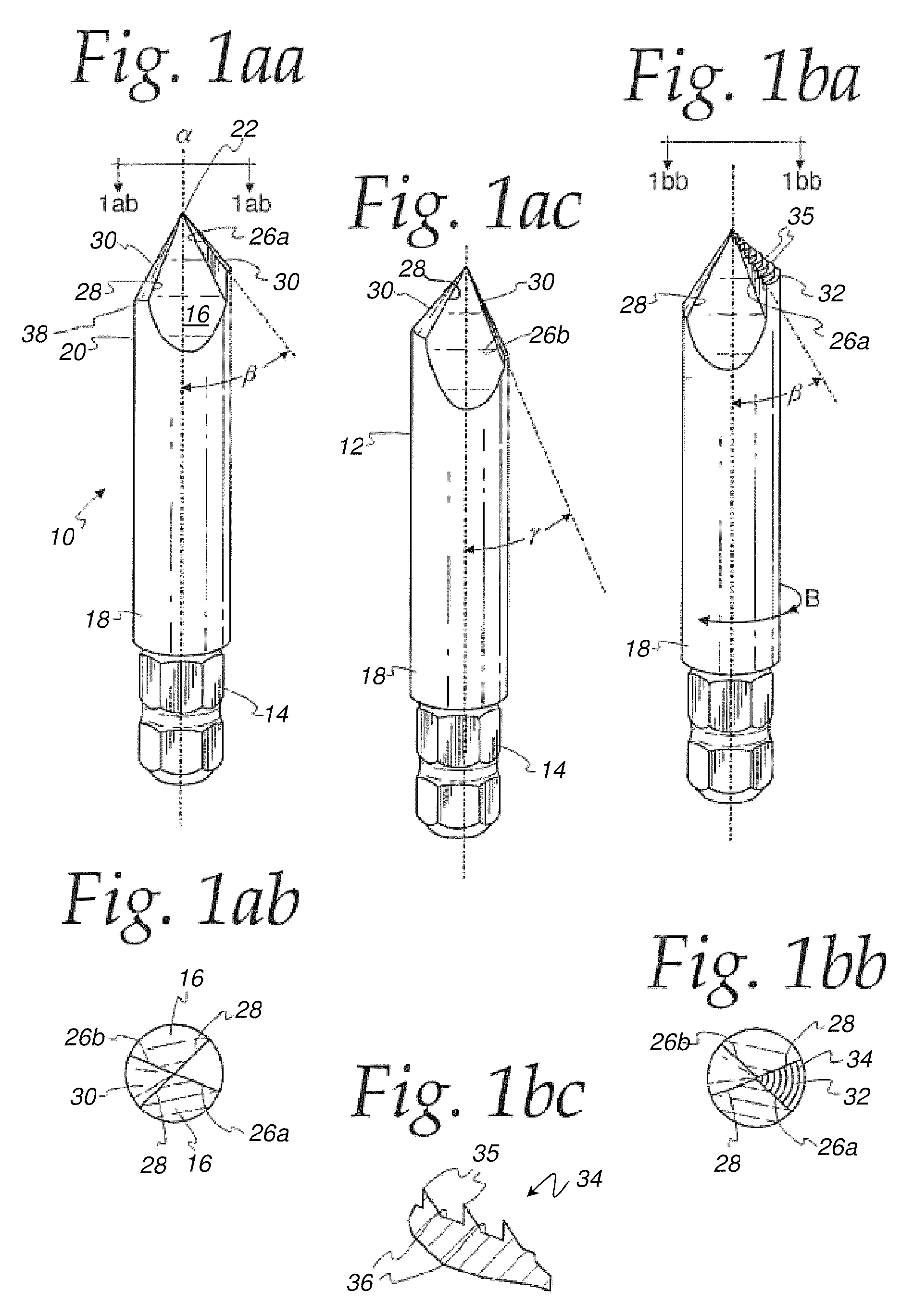

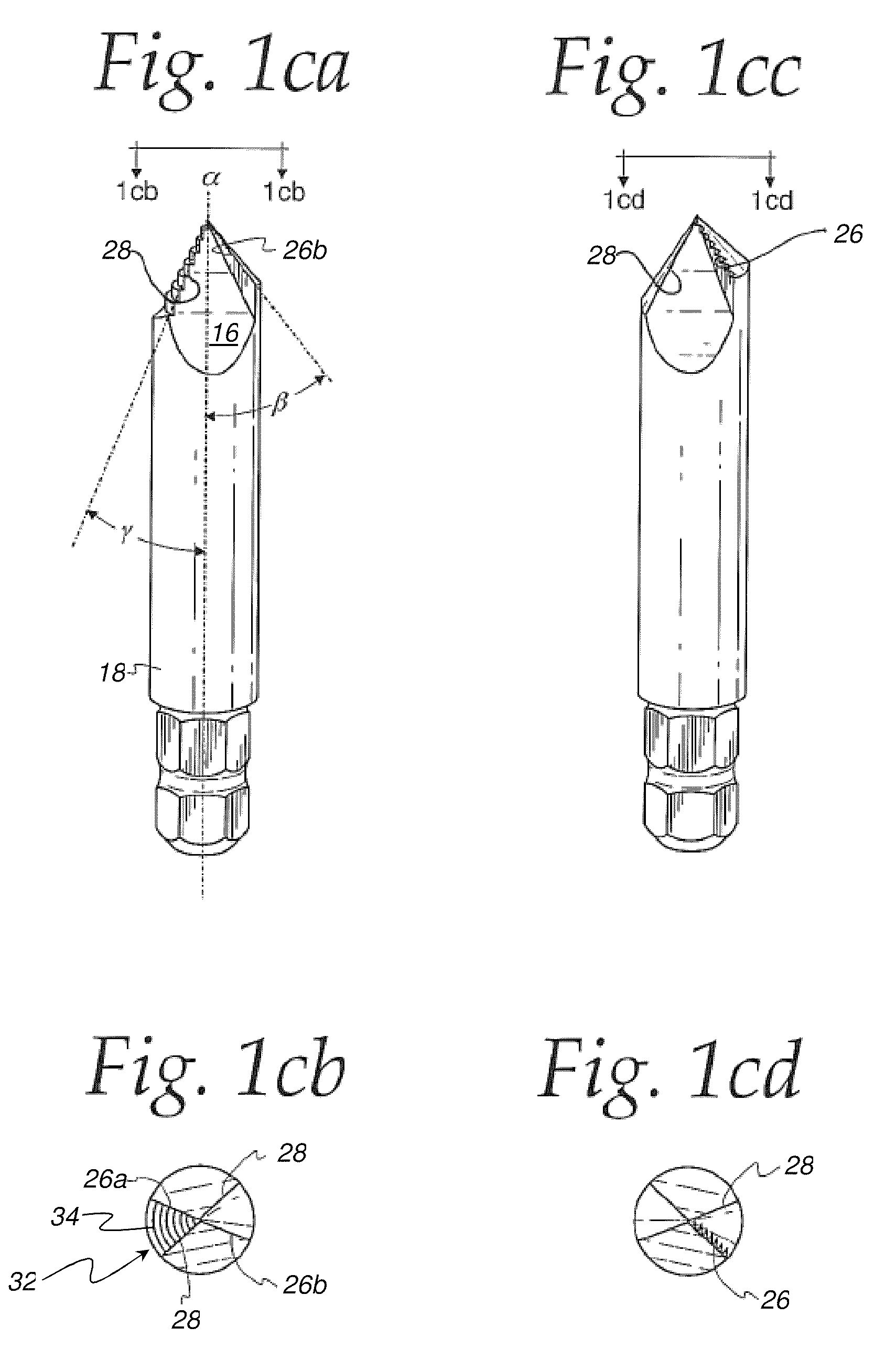

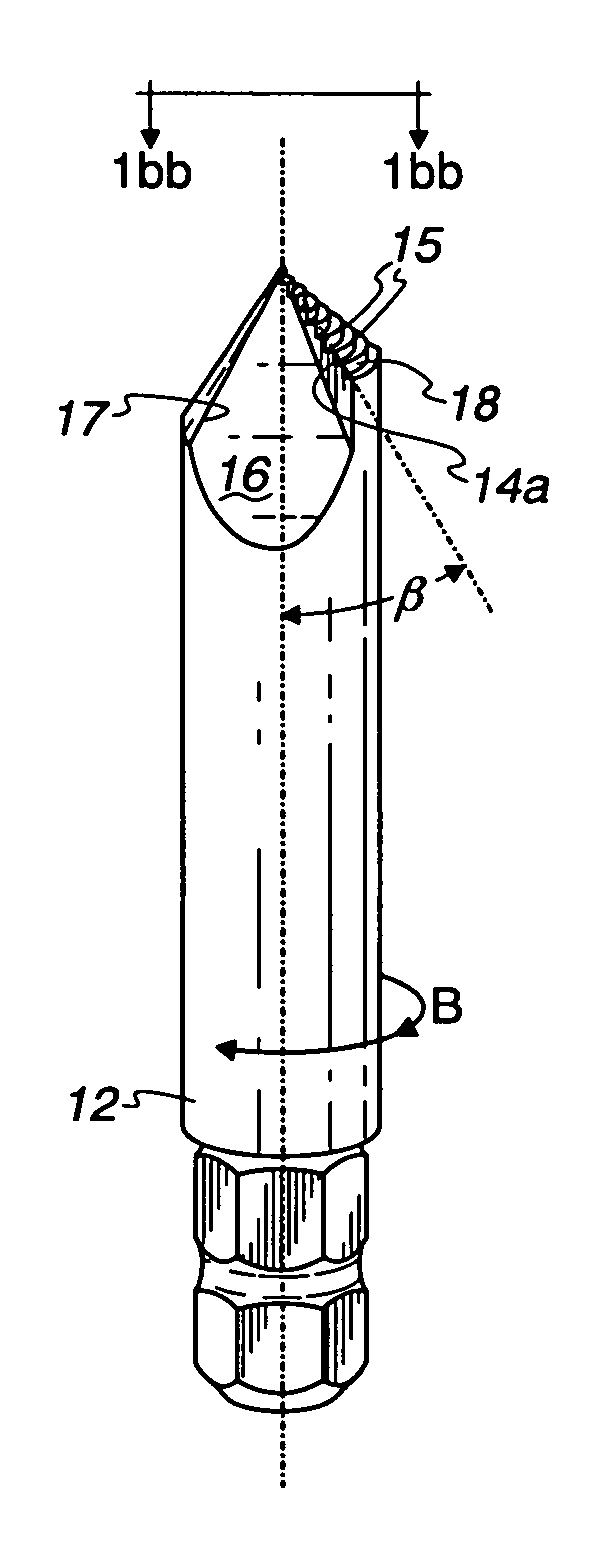

A drill bit for cutting successively larger holes in a substrate includes a conically-shaped body having first and second cutting flutes extending along the length of the body. The first cutting flute includes a first cutting edge and the second cutting flute includes a second cutting edge. The first and second cutting edges are offset relative to each other to create a cutting angle adapted to reduce chatter.

Owner:WHITE CHRISTOPHER L

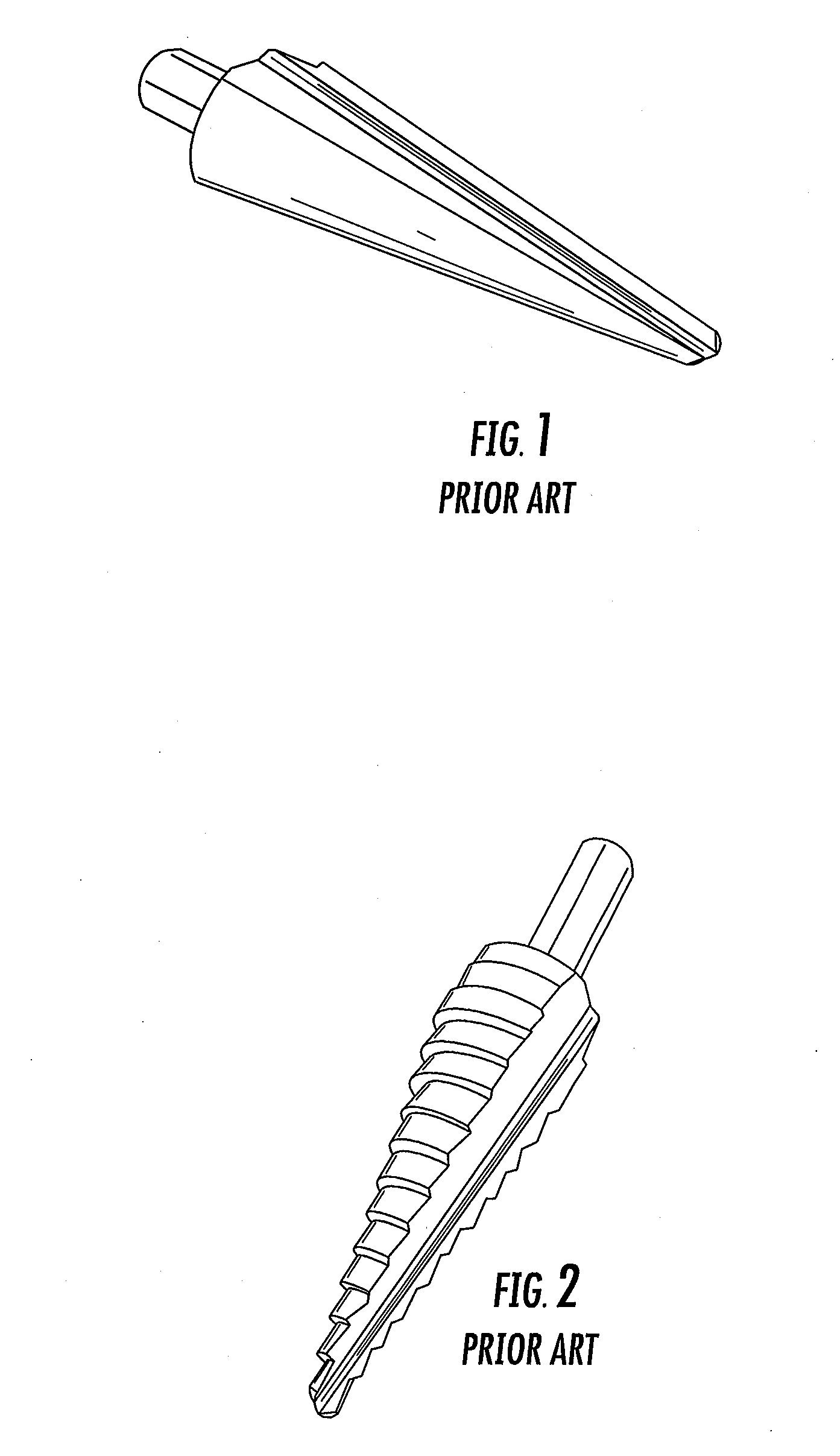

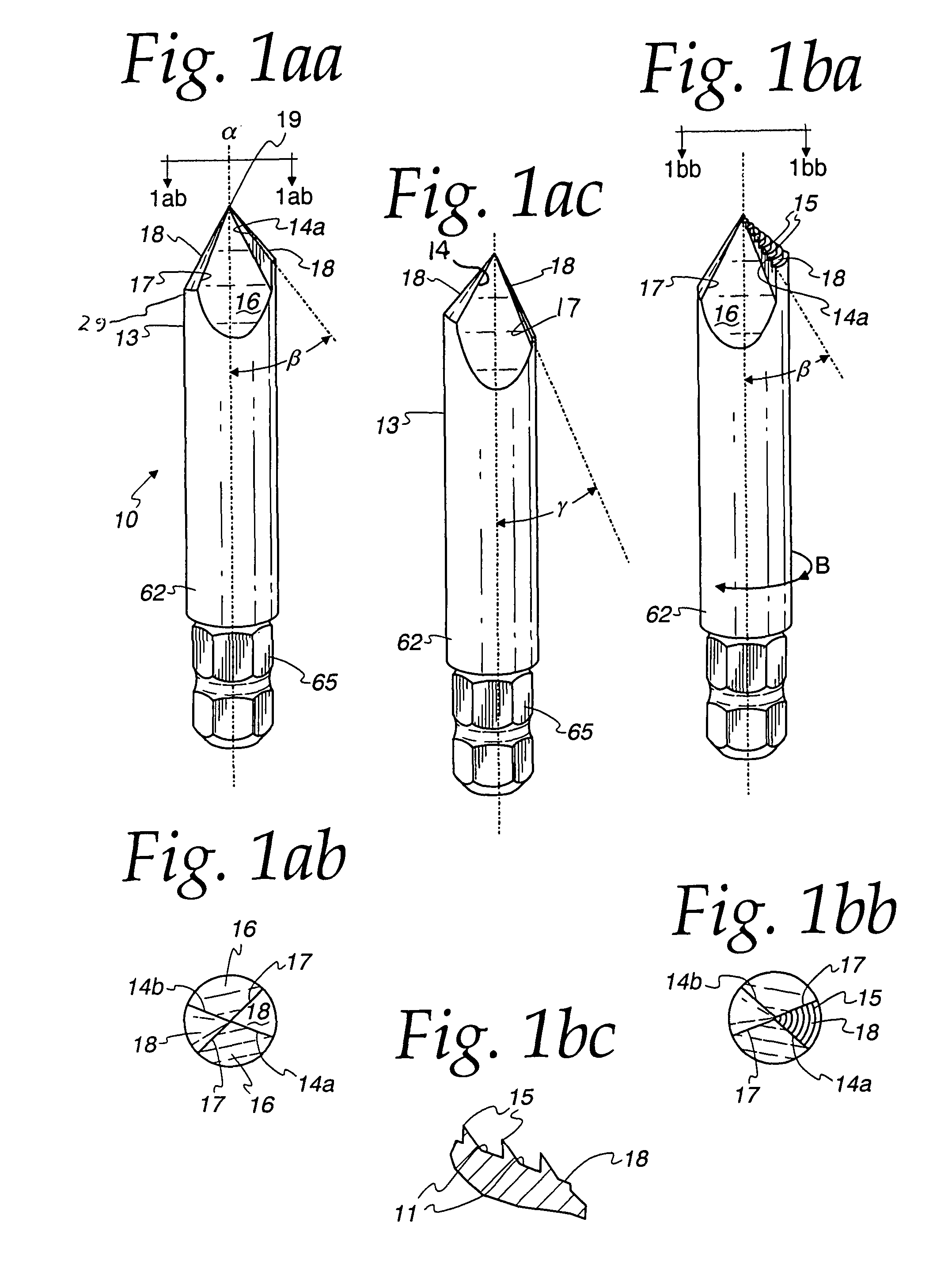

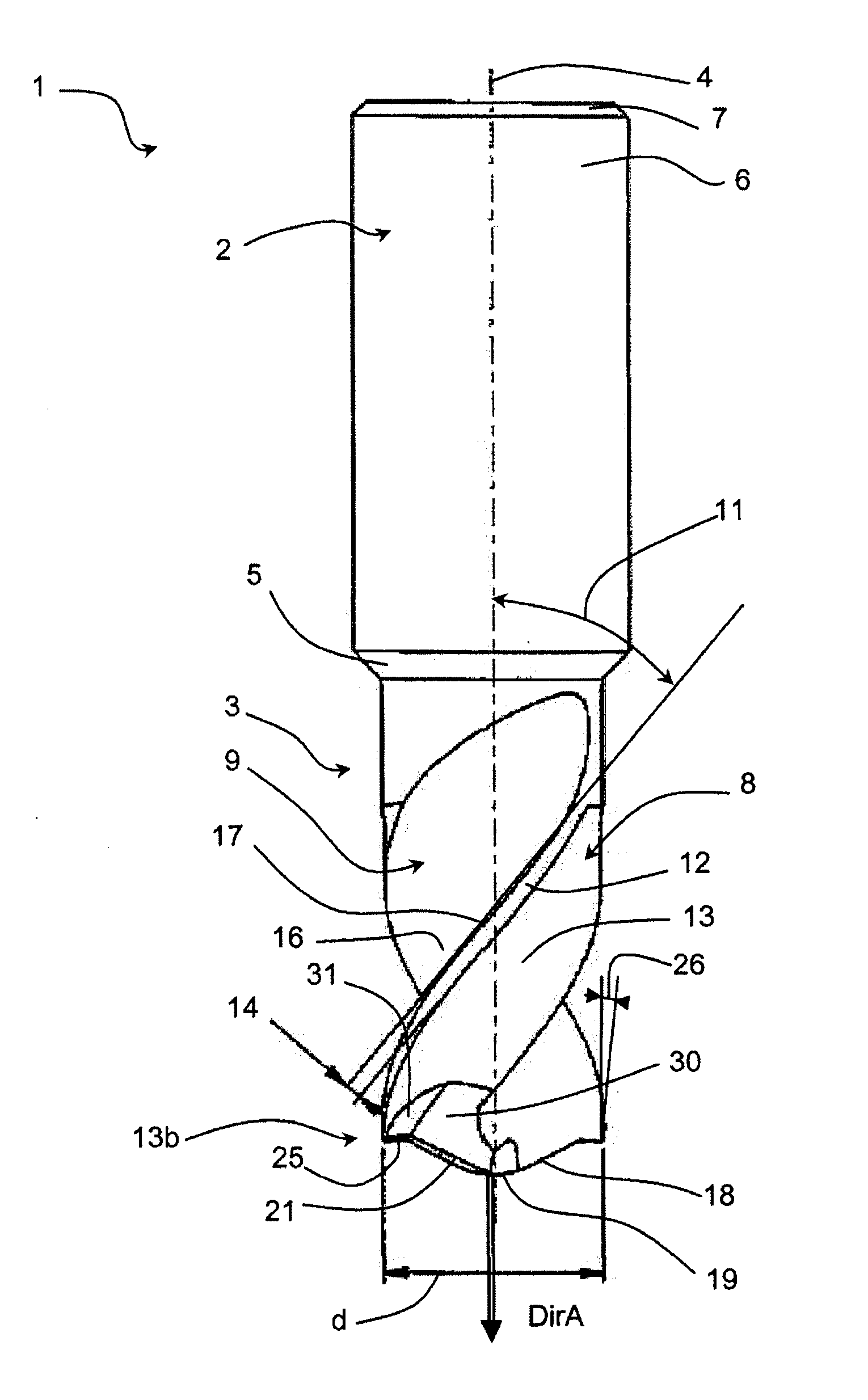

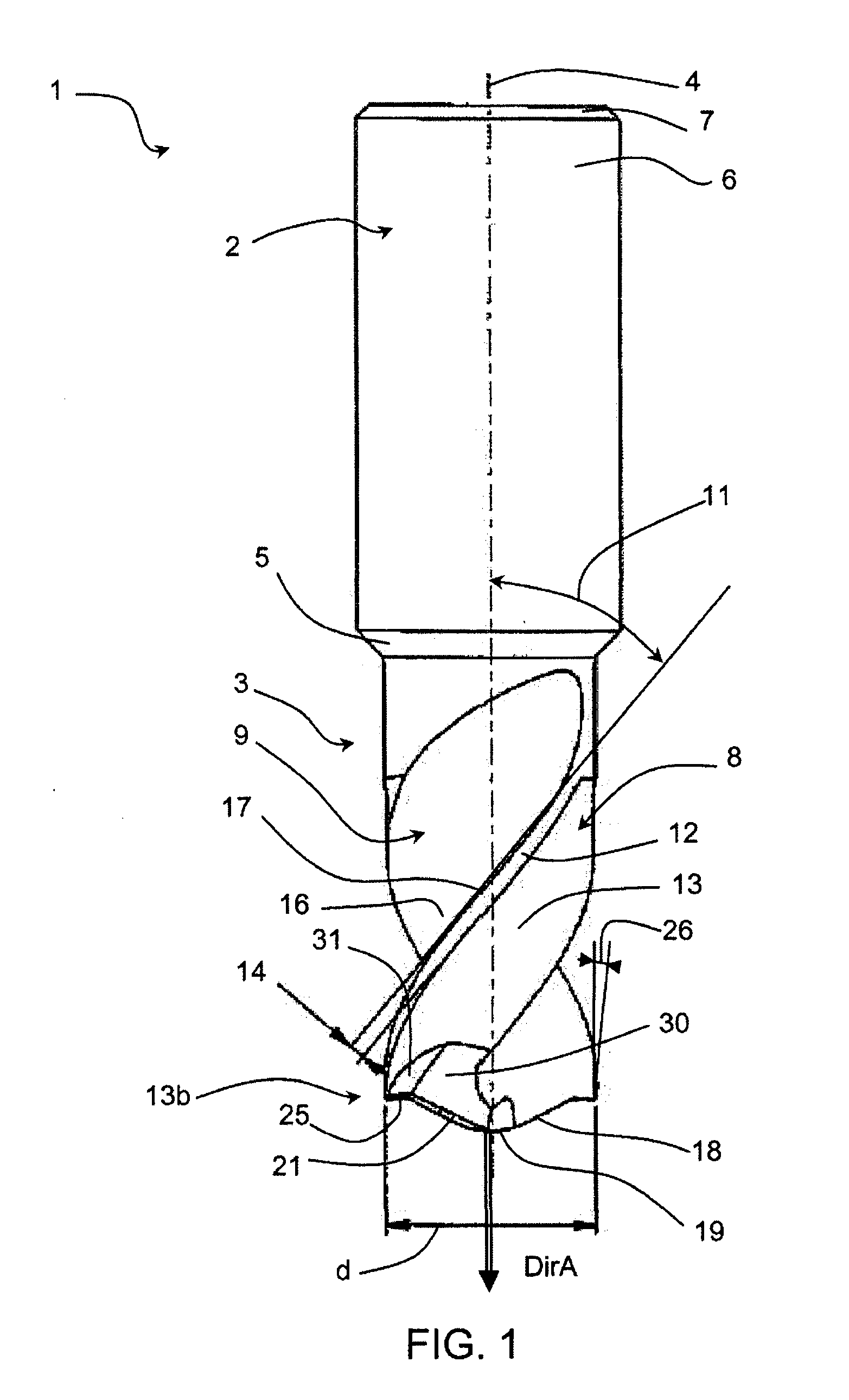

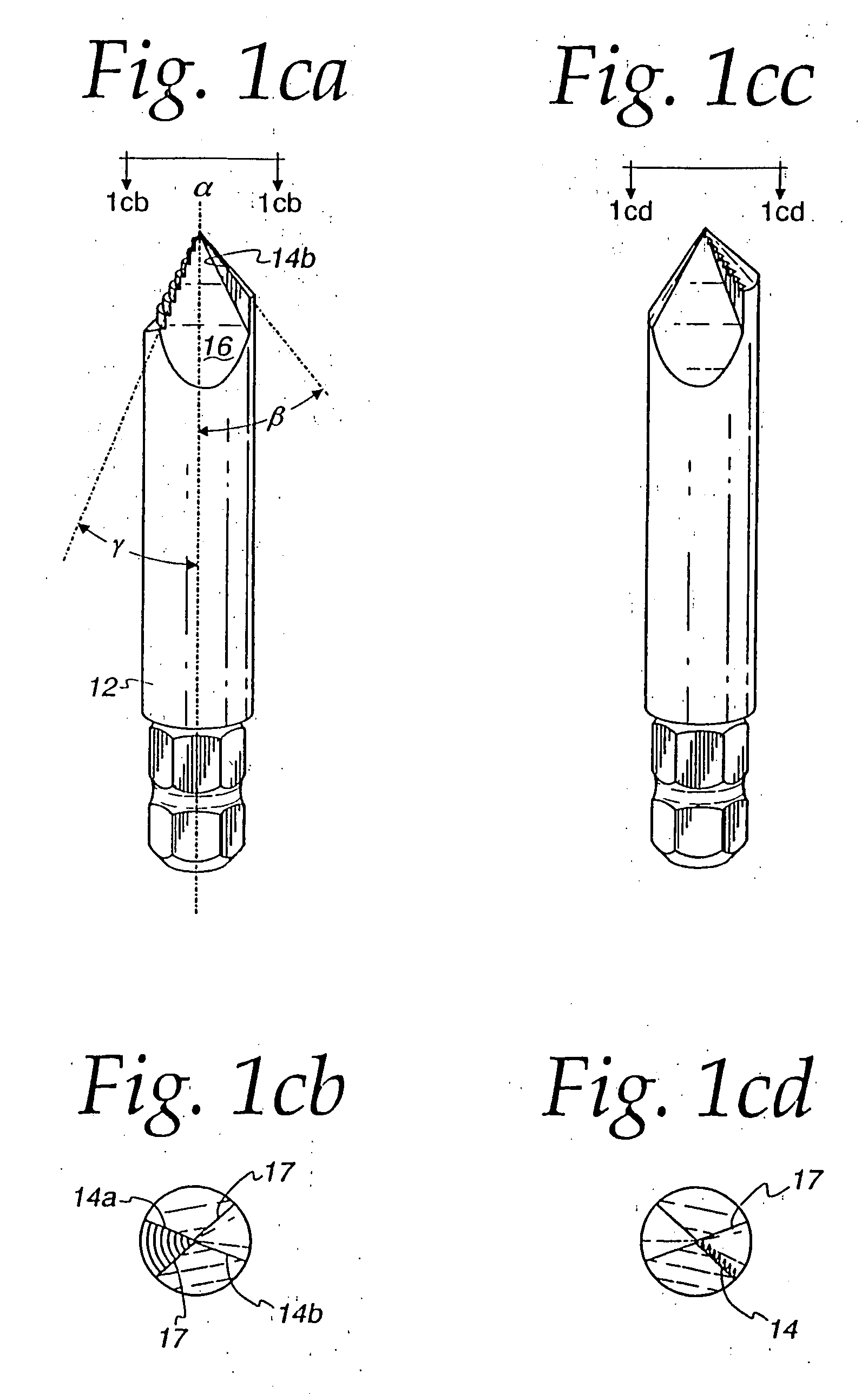

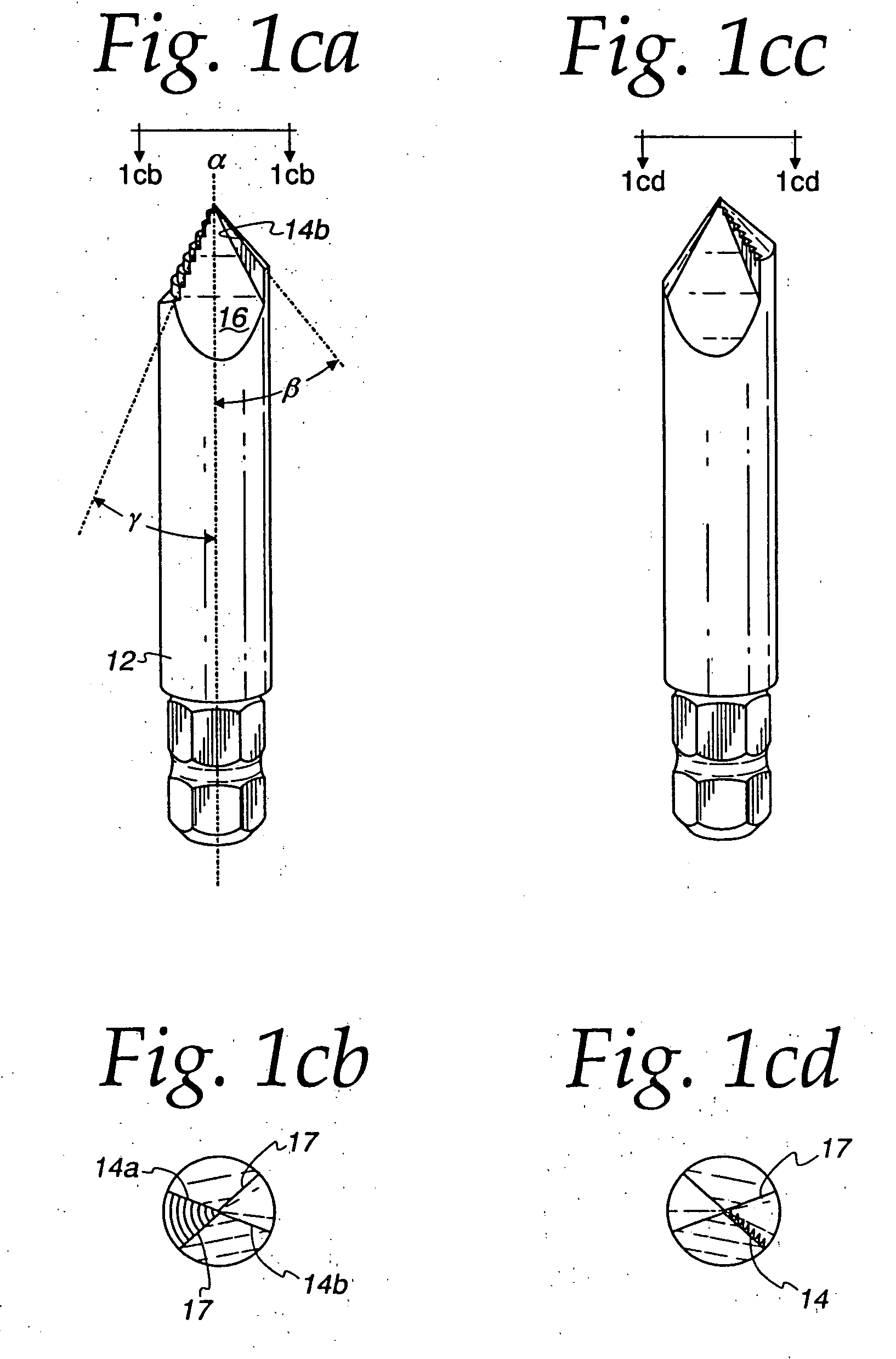

Ceramic bit for high speed drilling

ActiveUS20050135889A1Technically inexpensiveTechnically simpleWood turning toolsTransportation and packagingEngineeringHigh speed drilling

A ceramic drill bit comprising a cylindrical shank and a shaped portion extending axially in line with the shank and having a free end forming the tip of the bit, a relief face extending from each main cutting edge with a relief angle lying in the range 4° to 10° approximately relative to a plane perpendicular to the axis of rotation of the bit, and two notches forming two secondary cutting faces extending from the central edge with positive cutting angles lying in the range 10 to 70 approximately relative to the axis of rotation of the bit.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

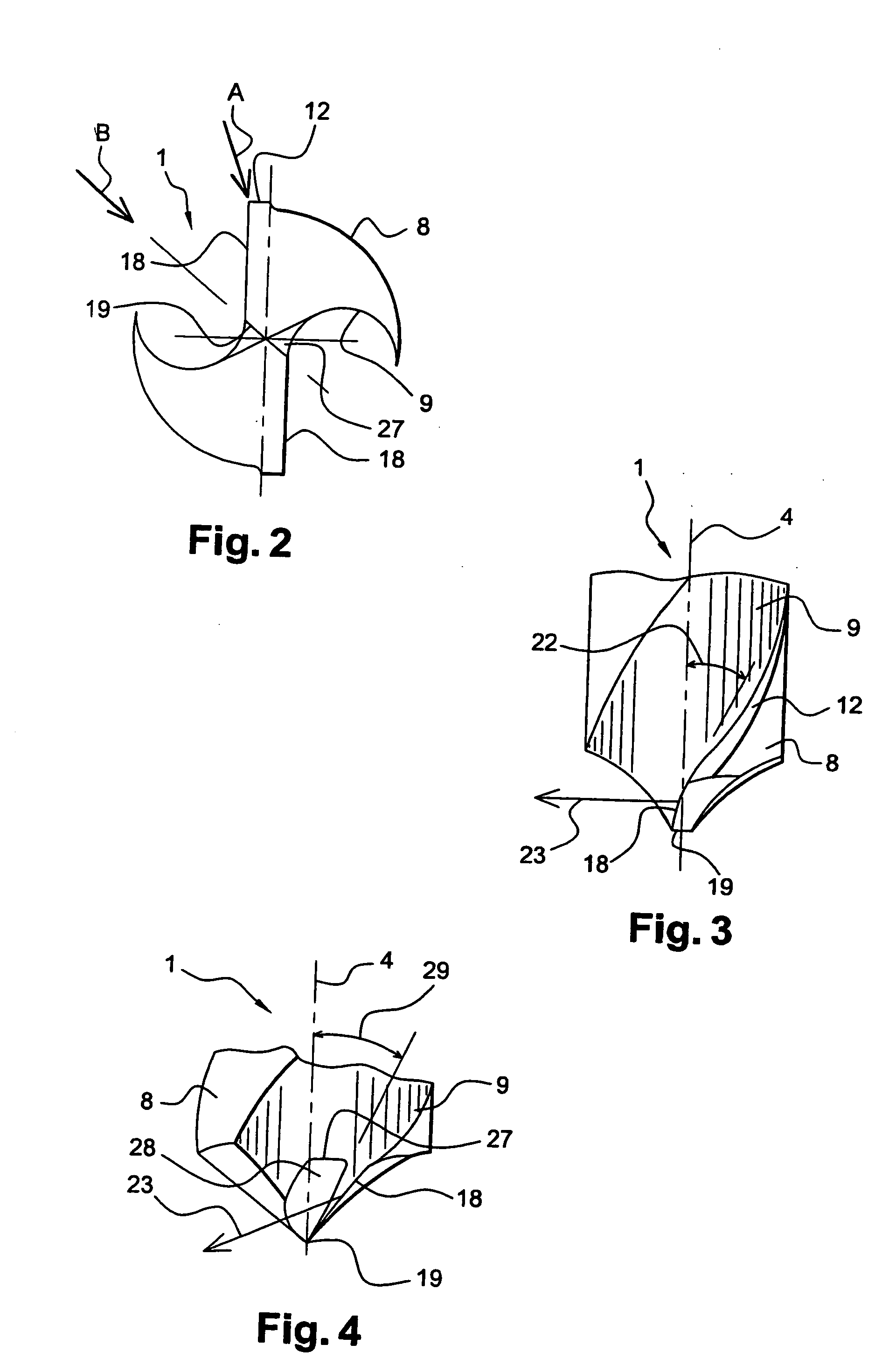

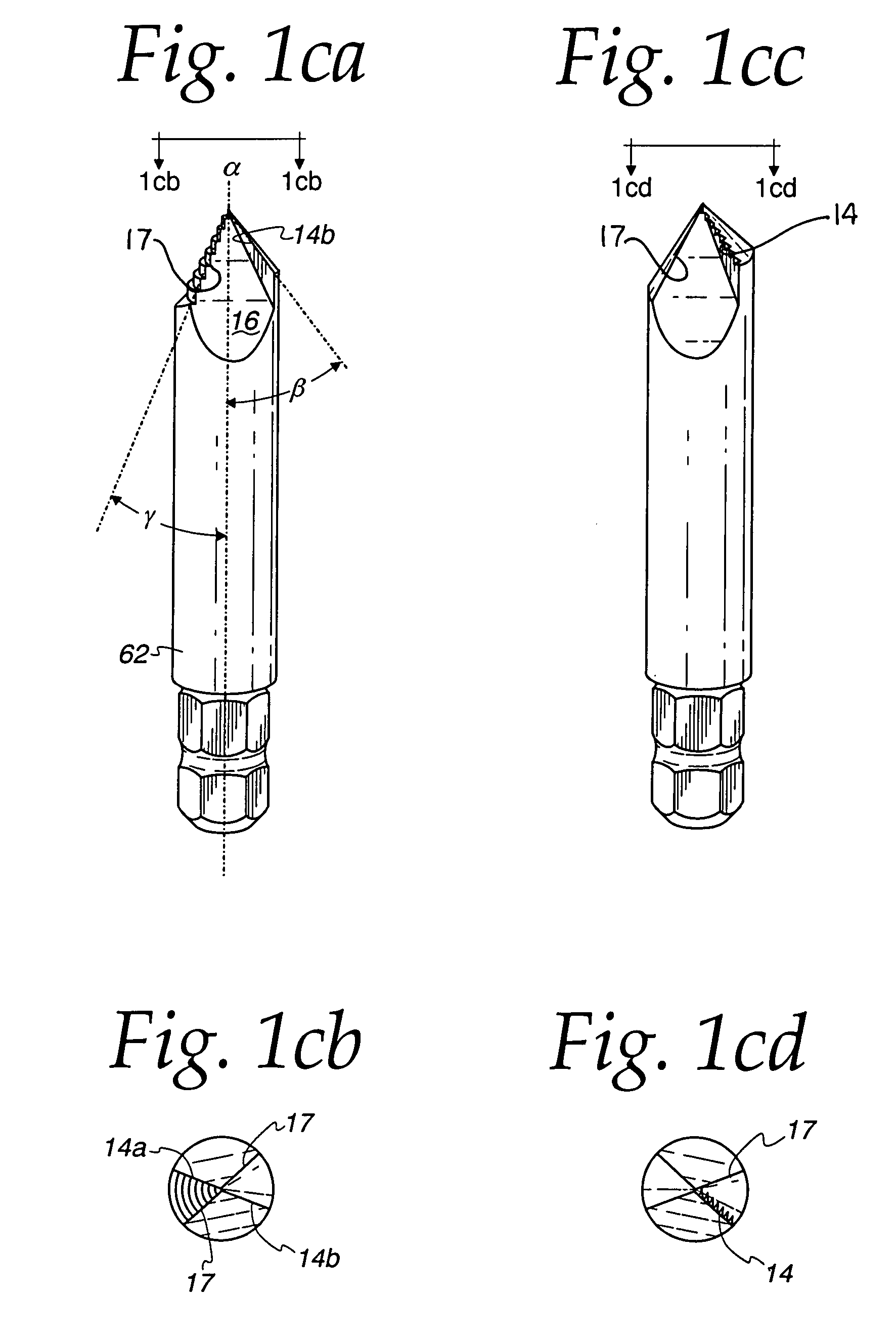

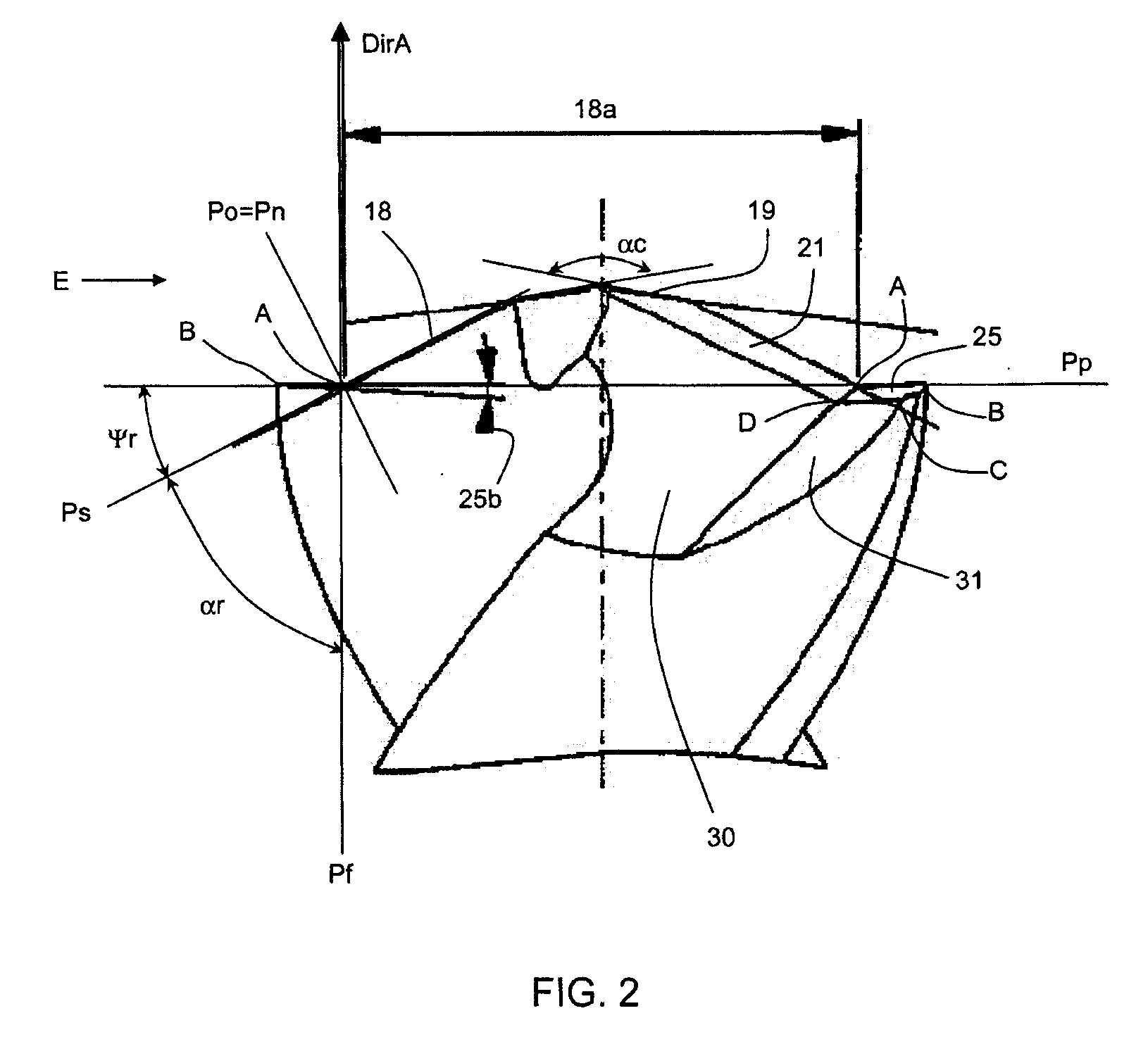

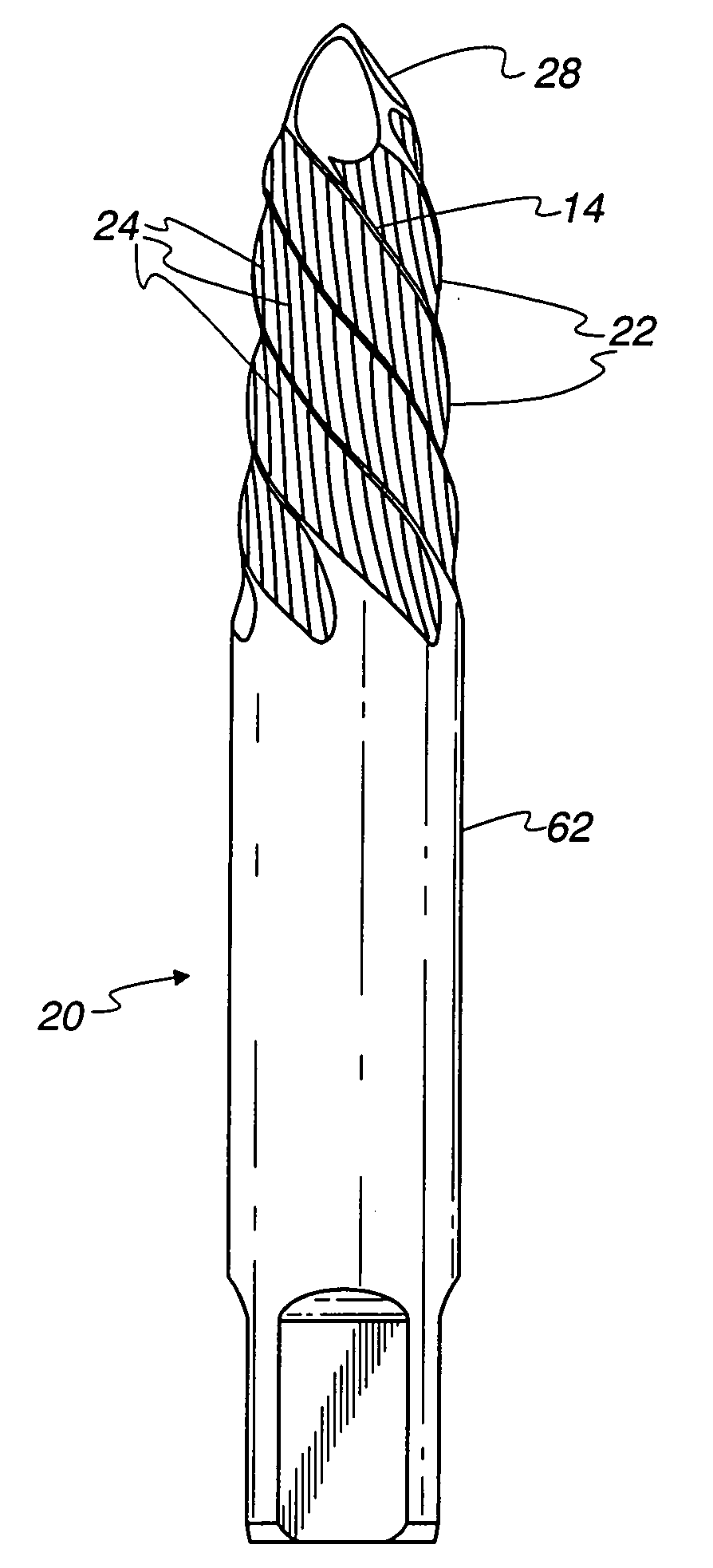

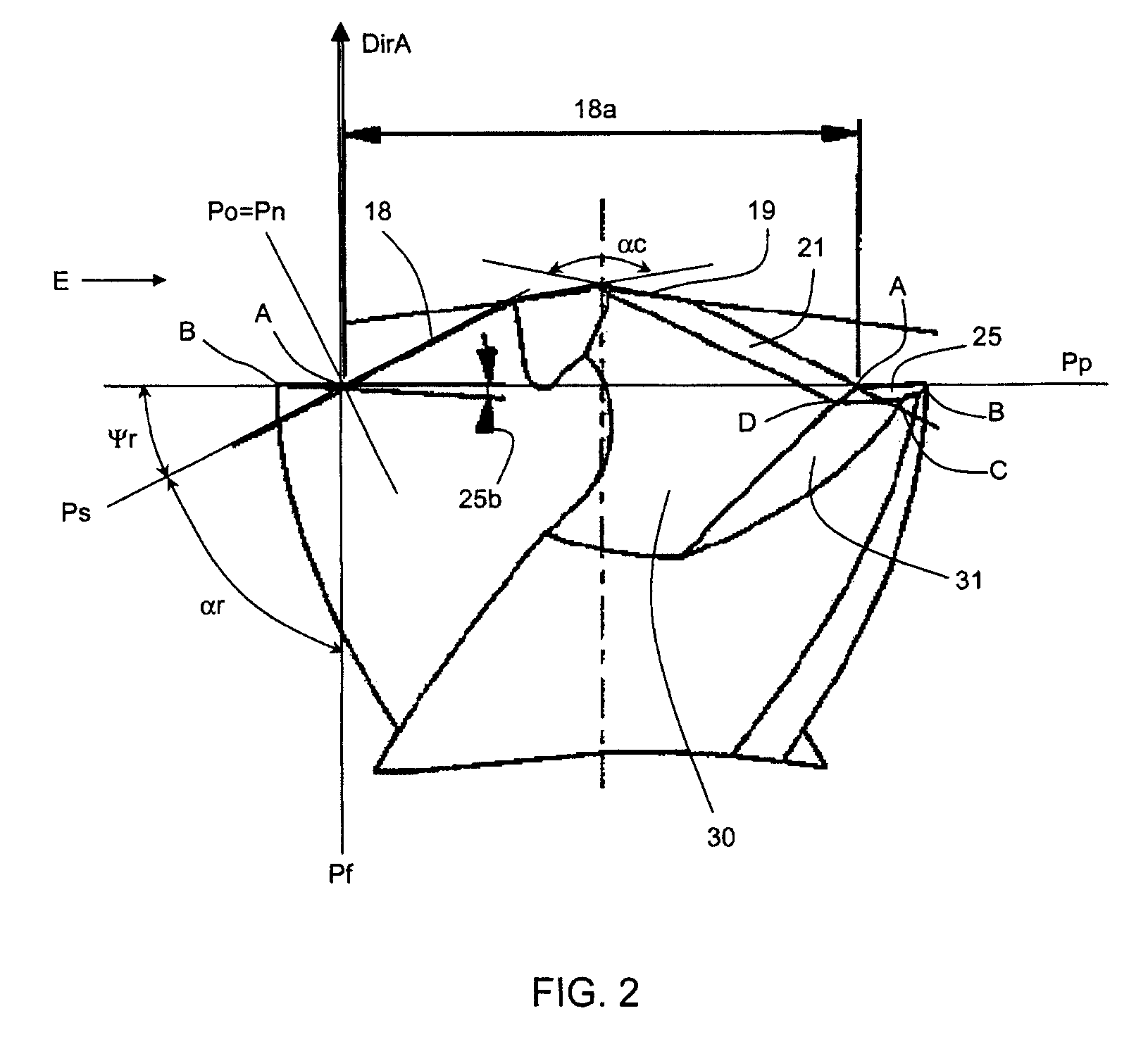

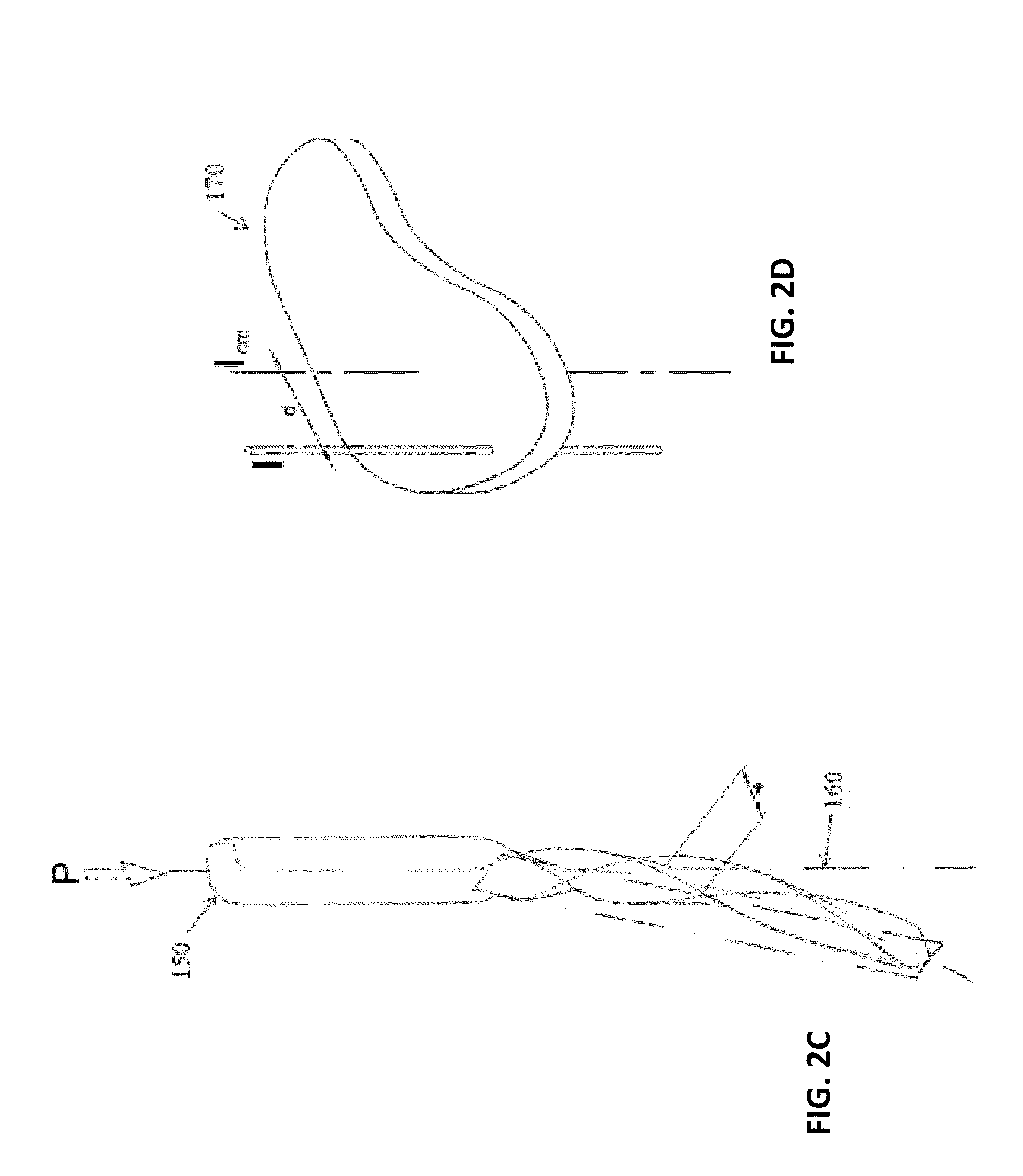

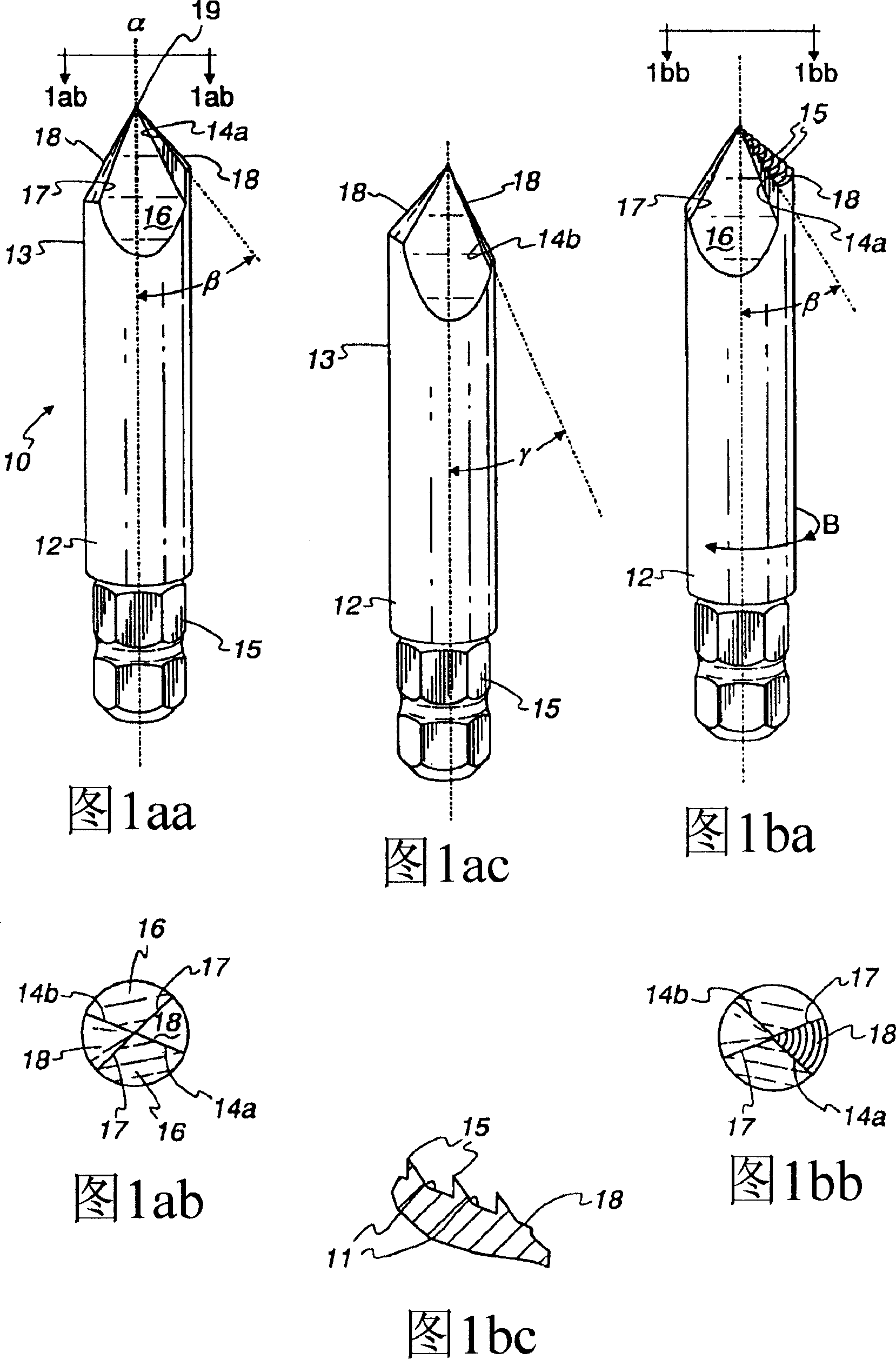

Precessional Drilling and Reaming

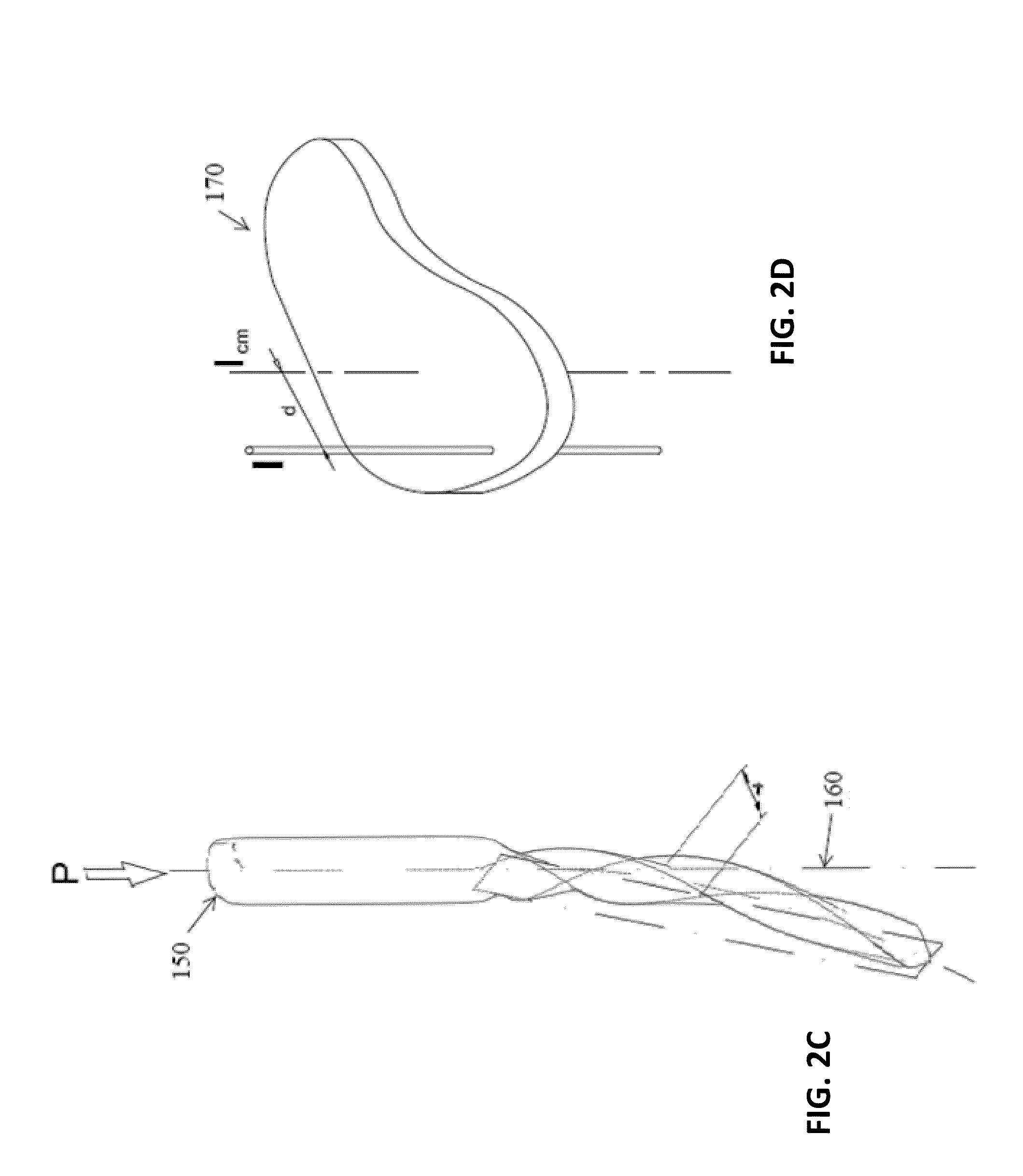

ActiveUS20150056032A1Small diameterAvoid and reduce and deformationThread cutting toolsTransportation and packagingMulti materialTitanium

This document provides novel drills and / or reamers that are well-suited for making holes in a variety of materials including, but not limited to, metals, ceramics, glass, wood, plasterboard, plastics, stone, composites, synthetics, silicon or multi-layered or hybridized substrates. In some embodiments, these drilling devices have some centers of mass that are offset from the axis of rotation. Accordingly, such drills and / or reamers may rotate and cut using a precessional pattern of motion. Precessional cutting devices may display a mechanical wave pattern in relationship to the longitudinal axis of the device. If the cutting device is fabricated from a flexible material, for example Nickel-Titanium, bodily deflection of the device may result during rotation.

Owner:SCIANAMBLO MICHAEL J

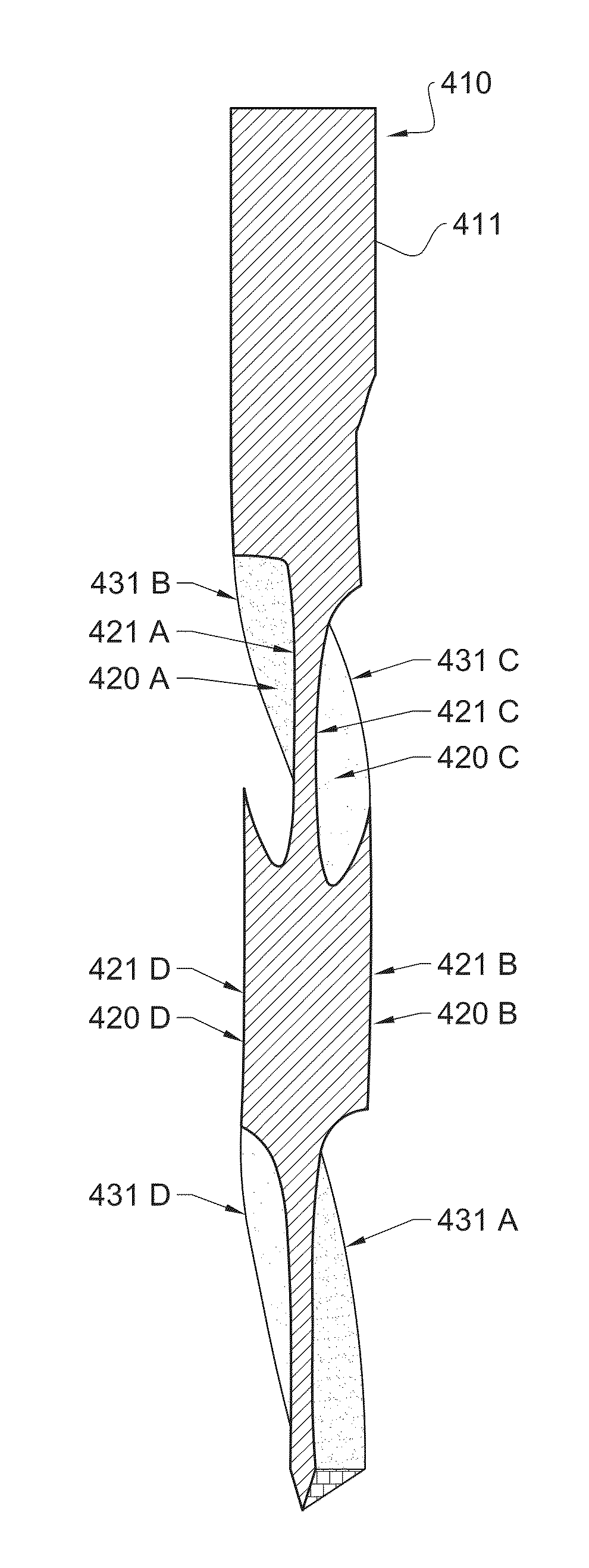

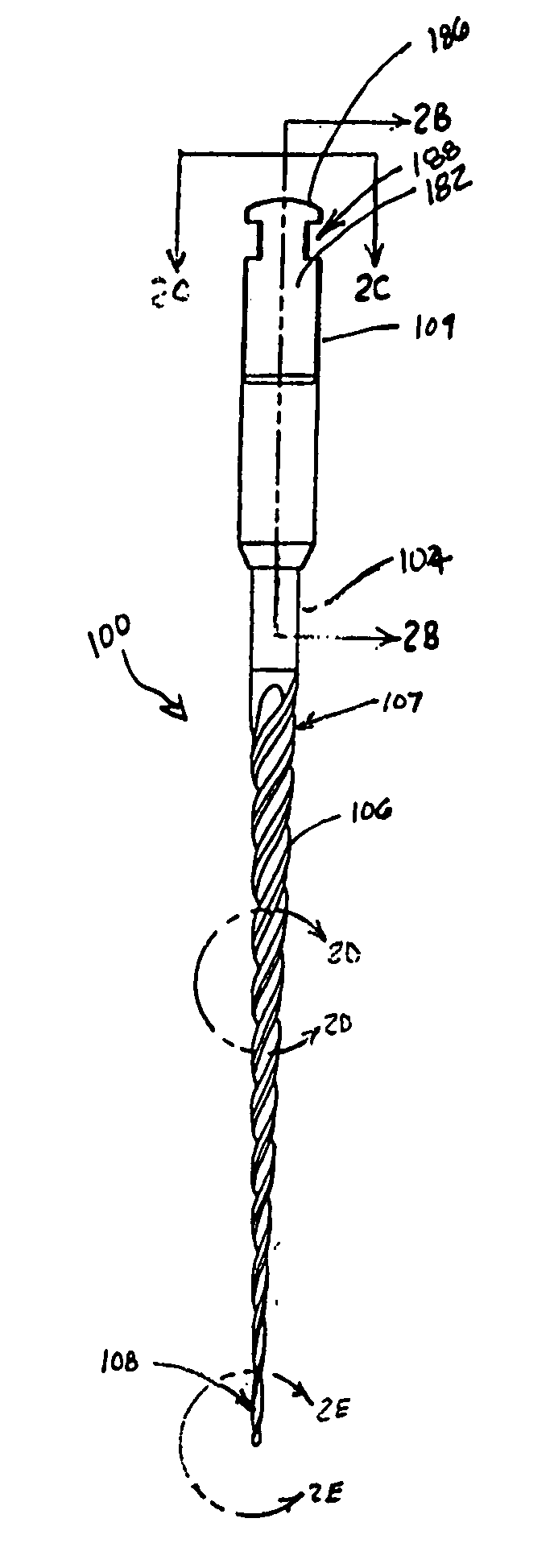

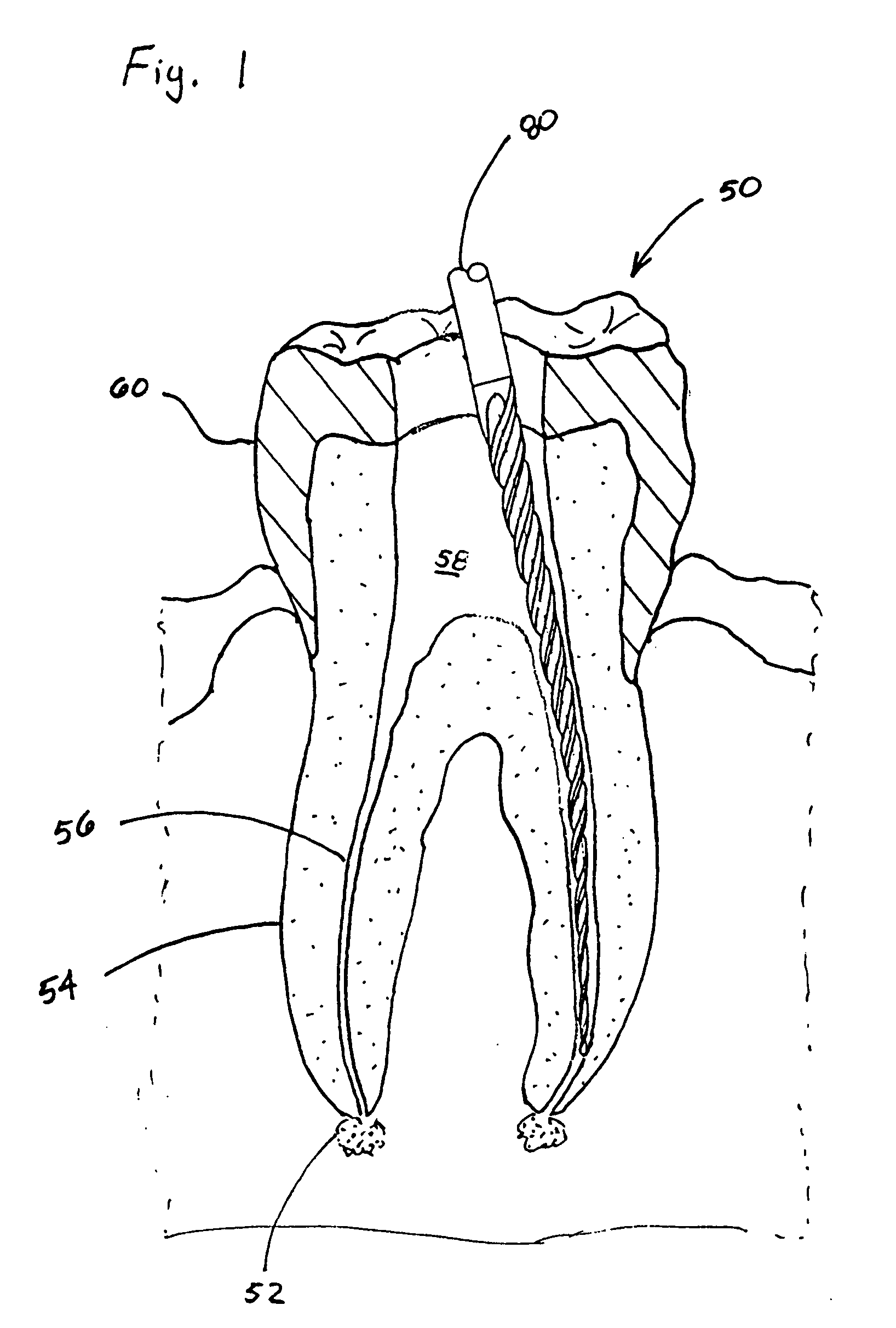

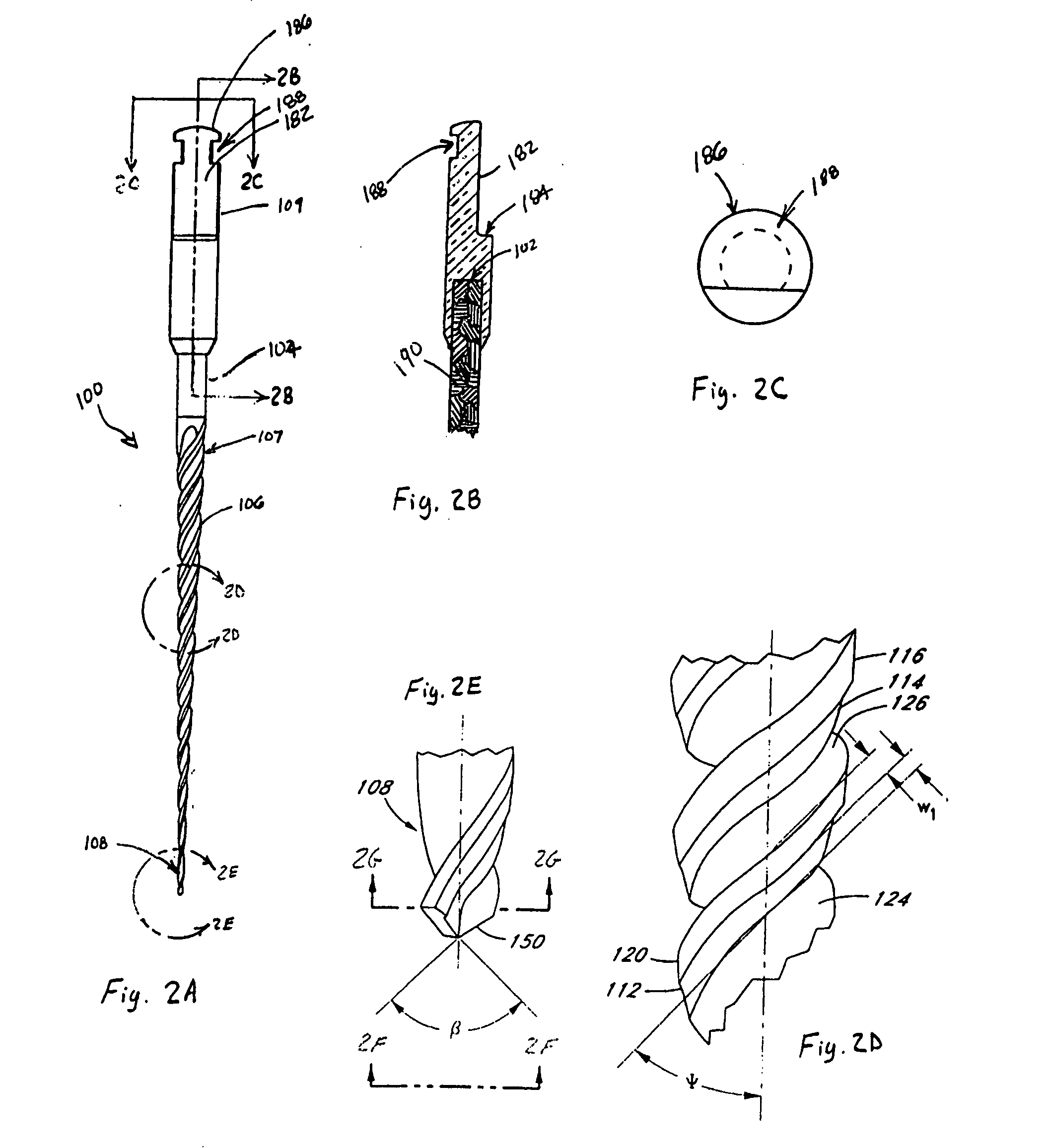

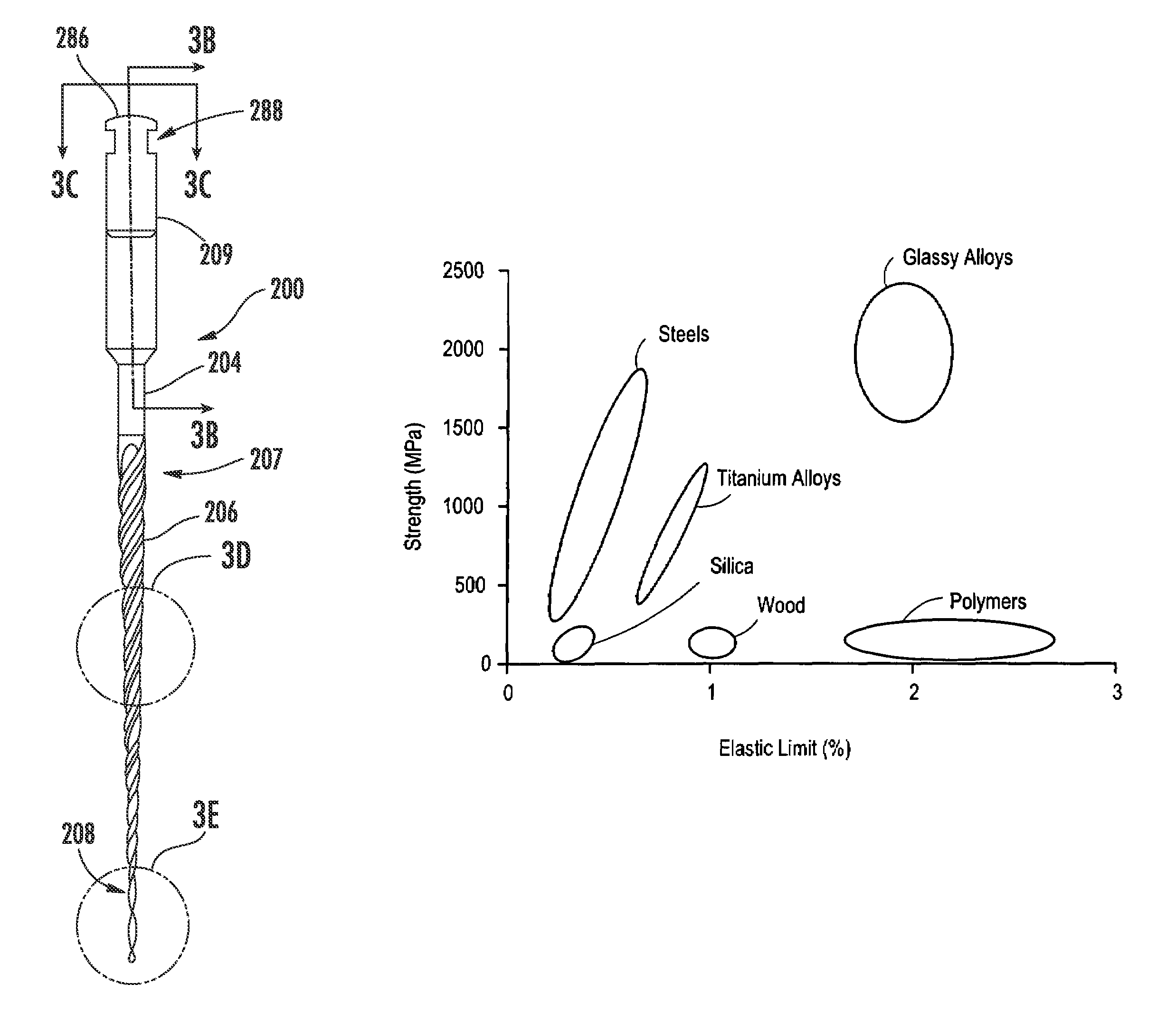

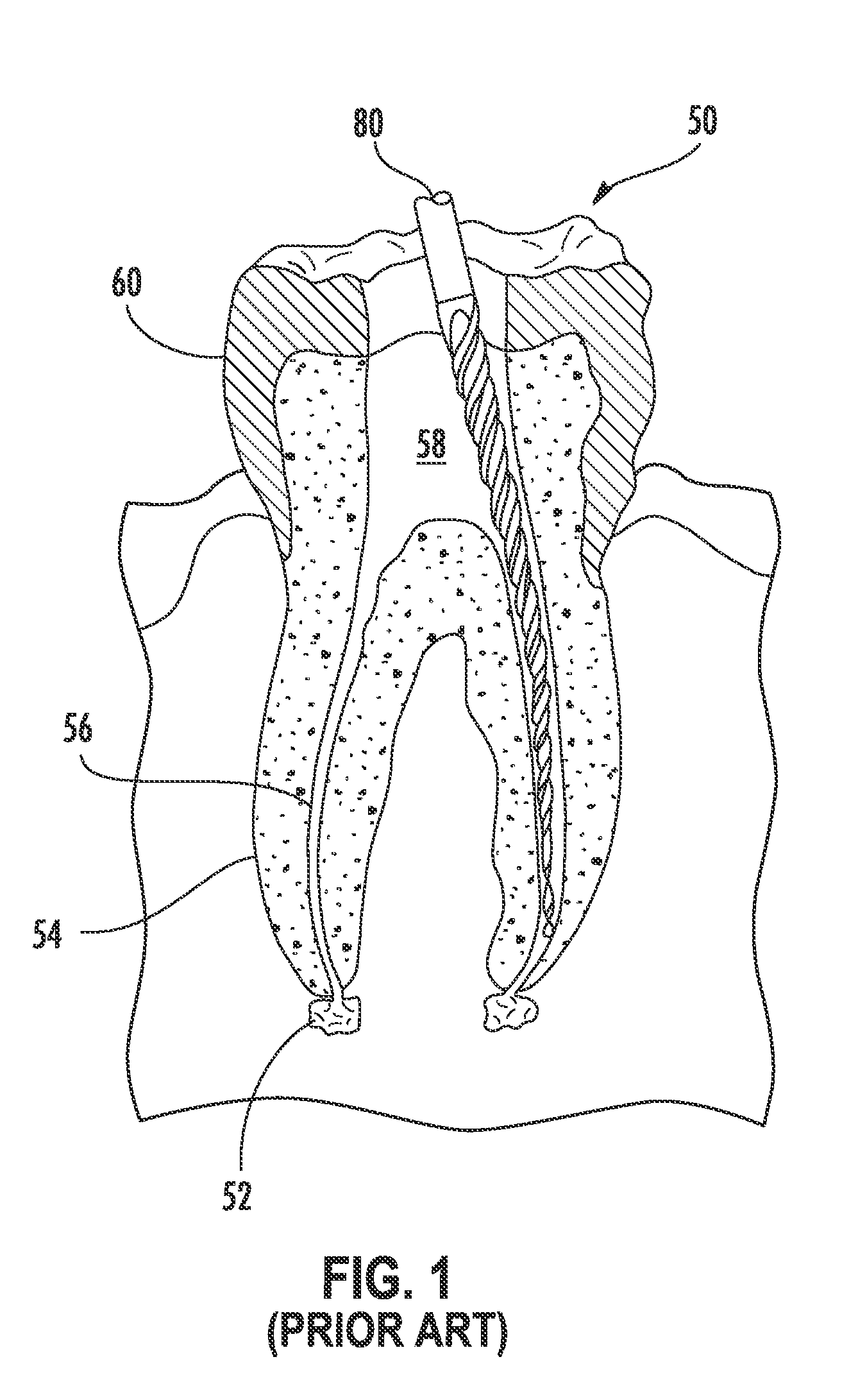

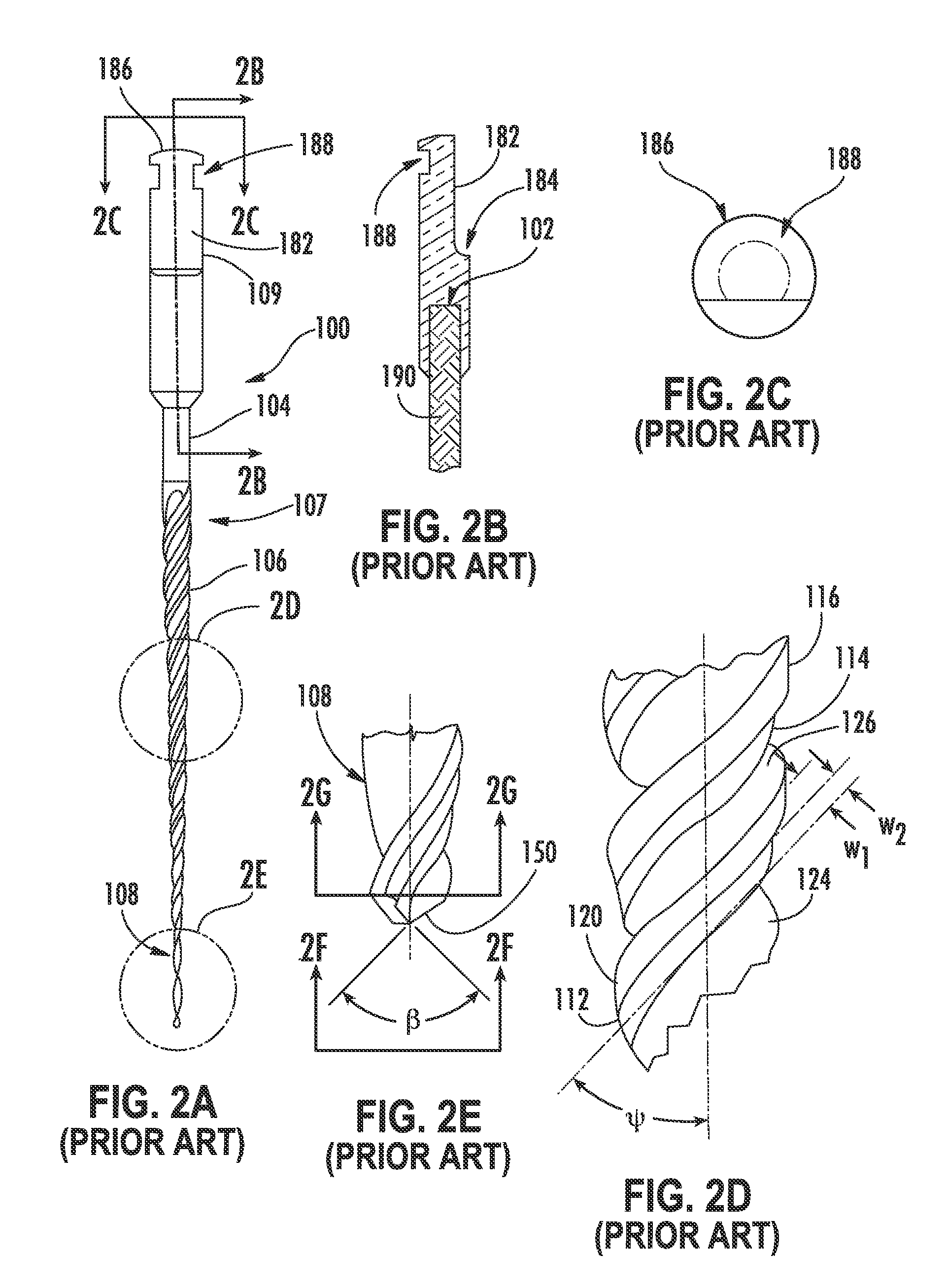

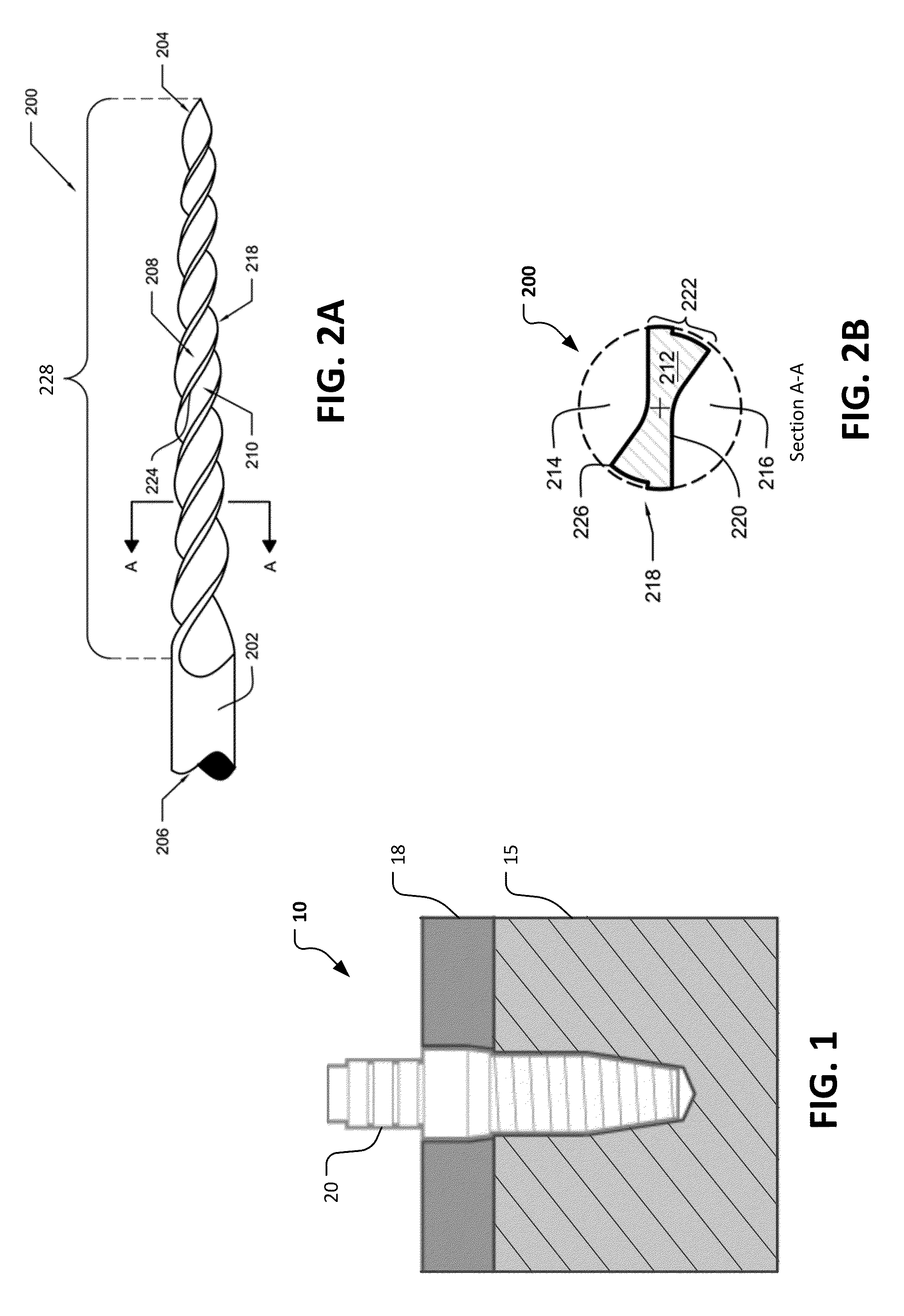

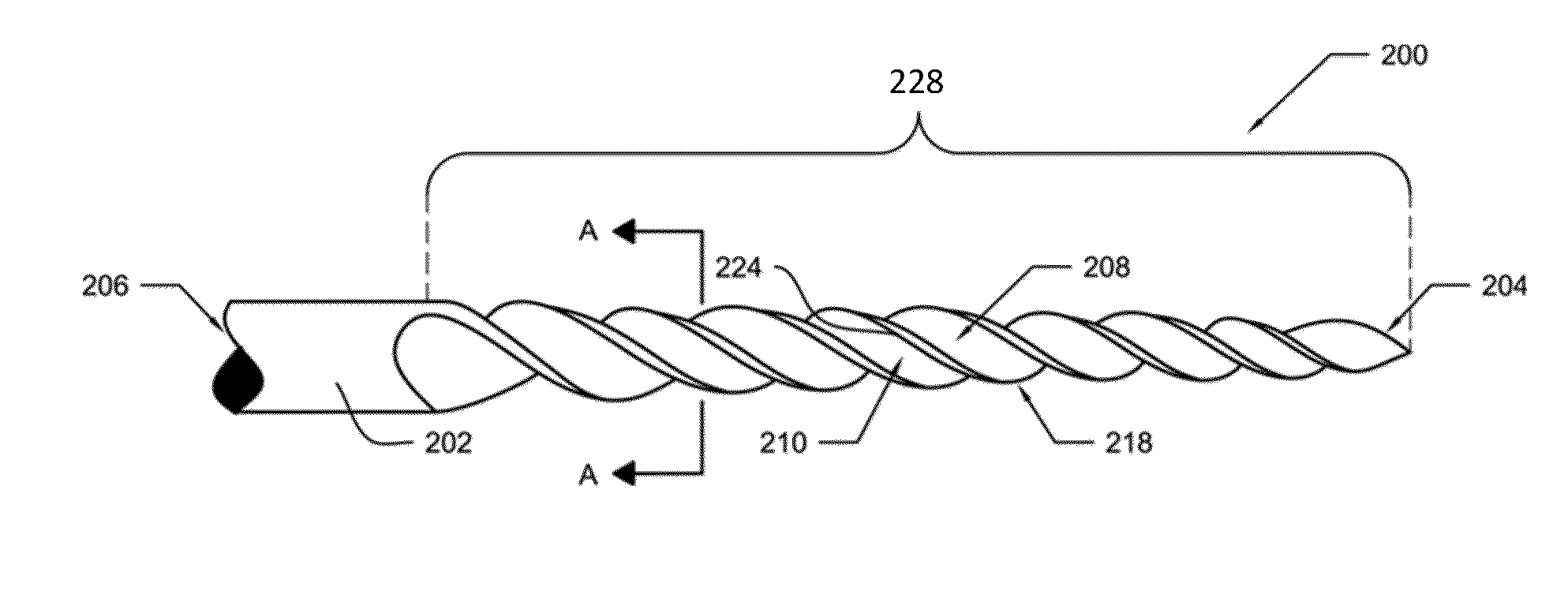

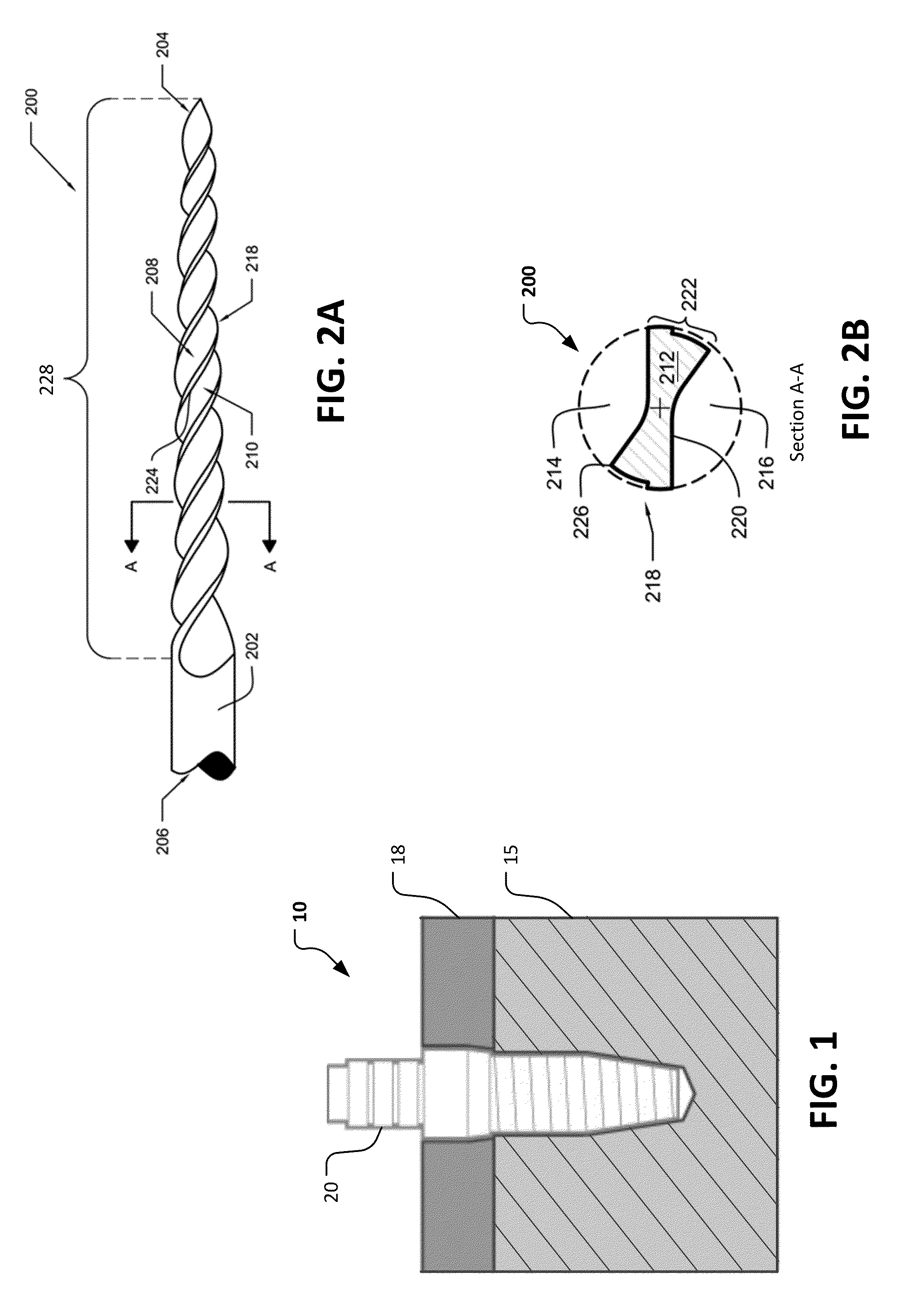

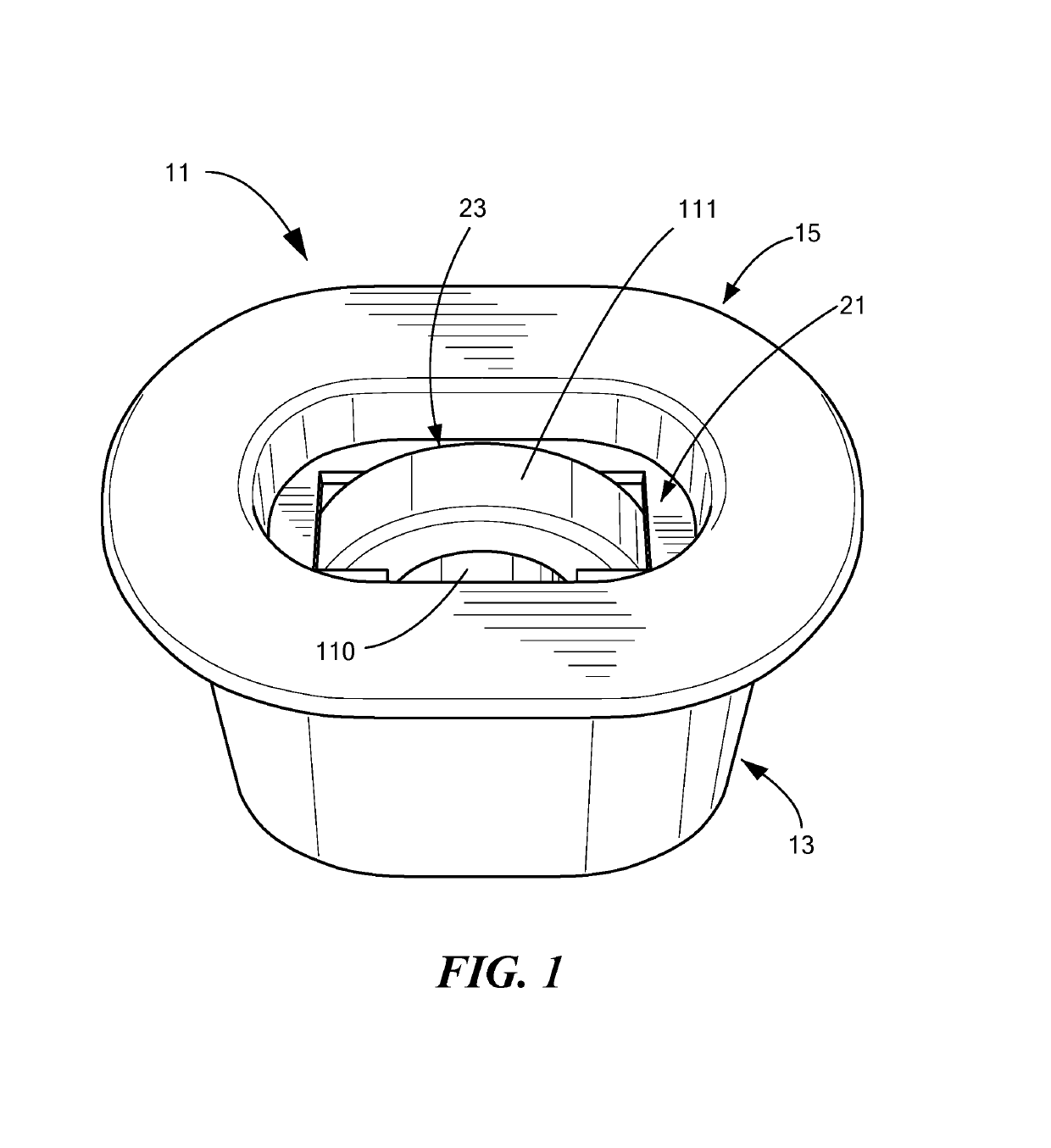

Precision cast dental instrument

InactiveUS20070184406A1Resistance to breakageResistance to wearTransportation and packagingWristbandsDental structureInstrumentation

An endodontic file (200) is provided particularly adapted for the removal of tooth structure, decayed or damaged nerve tissues or dentine material on the interior walls of a root canal or dentine and / or enamel from the external tooth wall. The endodontic instrument includes a shaft (202) having a shank portion (204) and a generally elongated working portion (206). The working portion preferably includes cutting or abrading features (232) adapted upon rotation and / or reciprocation of the instrument to cut, abrade or remove tissue from the interior walls of a root canal or dentine and / or enamel from the external tooth wall. The working portion extends from a proximal end (207) adjacent the shank portion to a distal end (208) terminating at a tip (250). The entire instrument and / or at least the working portion thereof is formed of an amorphous or essentially amorphous material having no or essentially no detectable crystalline structure and / or from a nanocrystalline material having an average crystalline grain size less than about 1 μm. The instrument may be formed by conventional grinding operations or by direct casting, forging or molding, in a manner producing an integral as-molded instrument having one or more sharp cutting edges. The instrument is inexpensive to manufacture and exhibits improved cutting-edge sharpness, wear resistance, lubriciousness and resistance to breakage.

Owner:CLOUDLAND INST

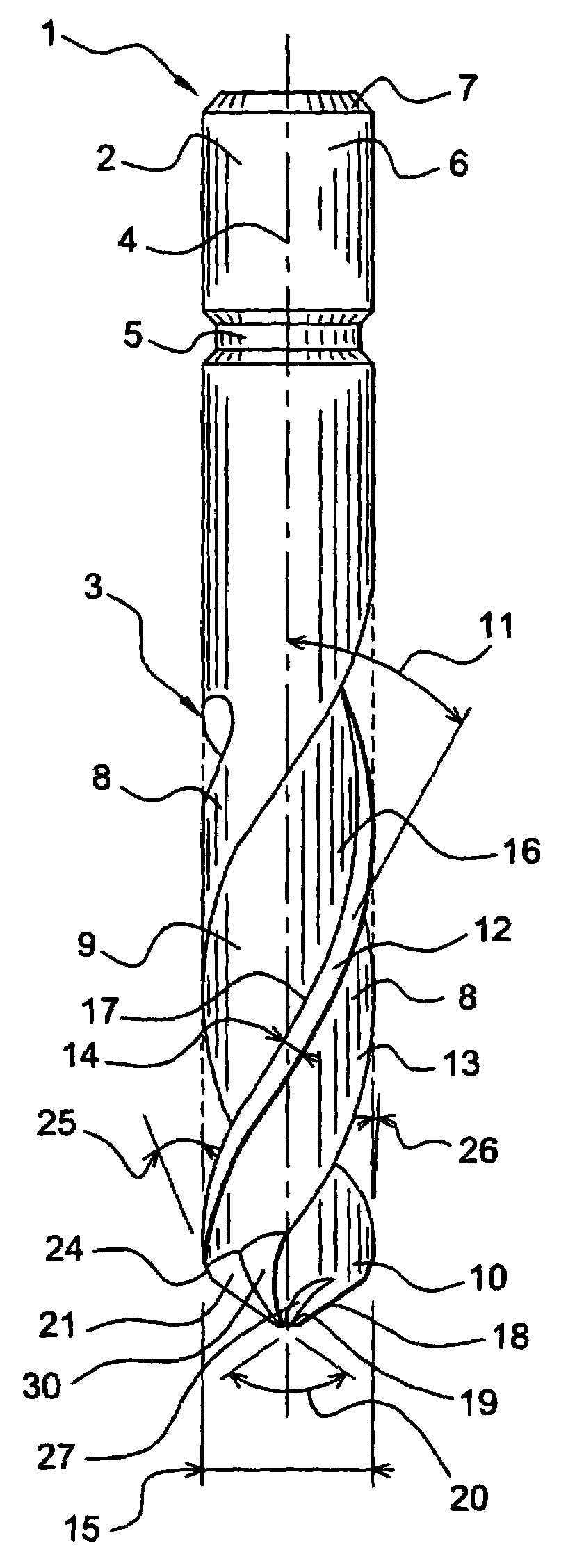

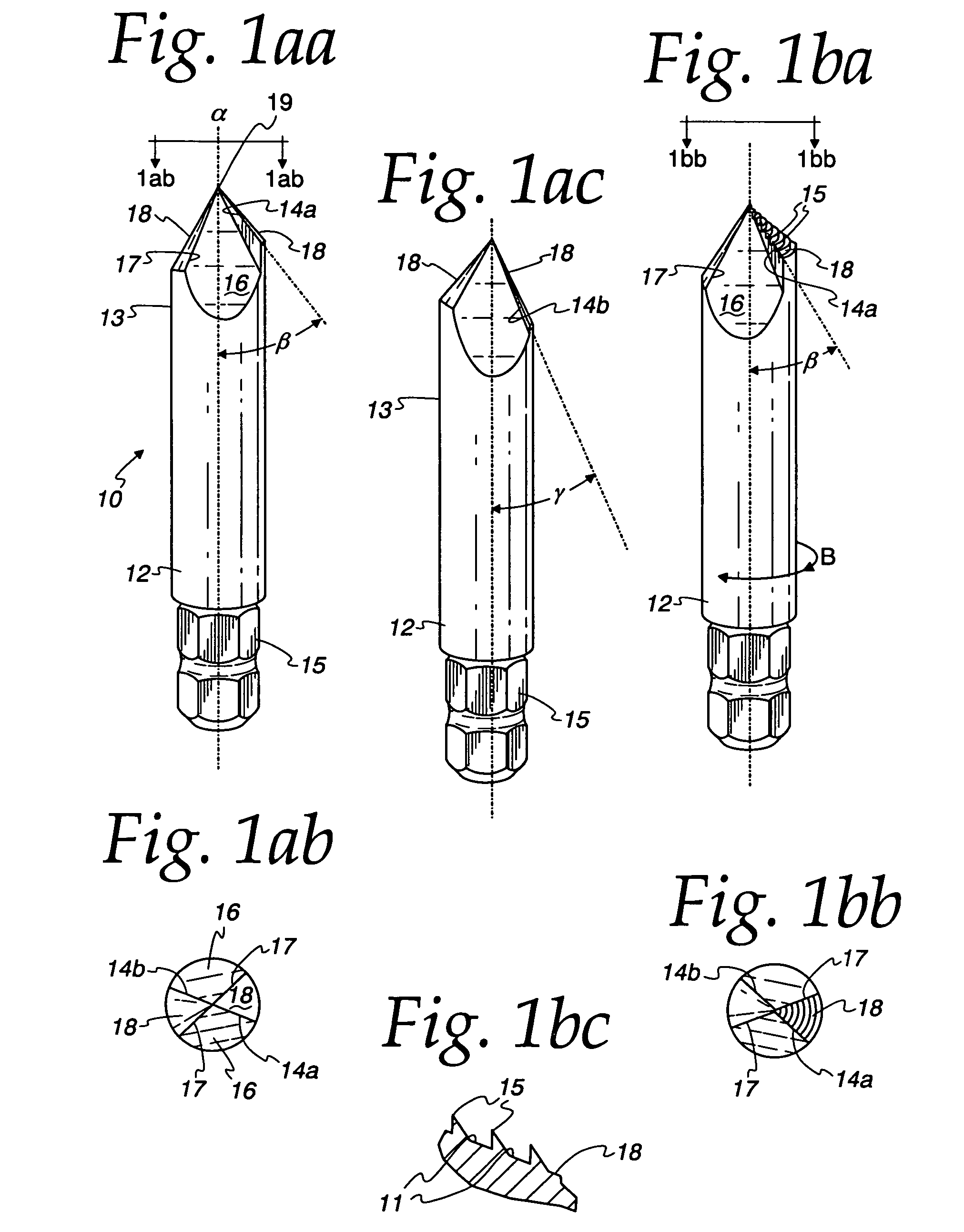

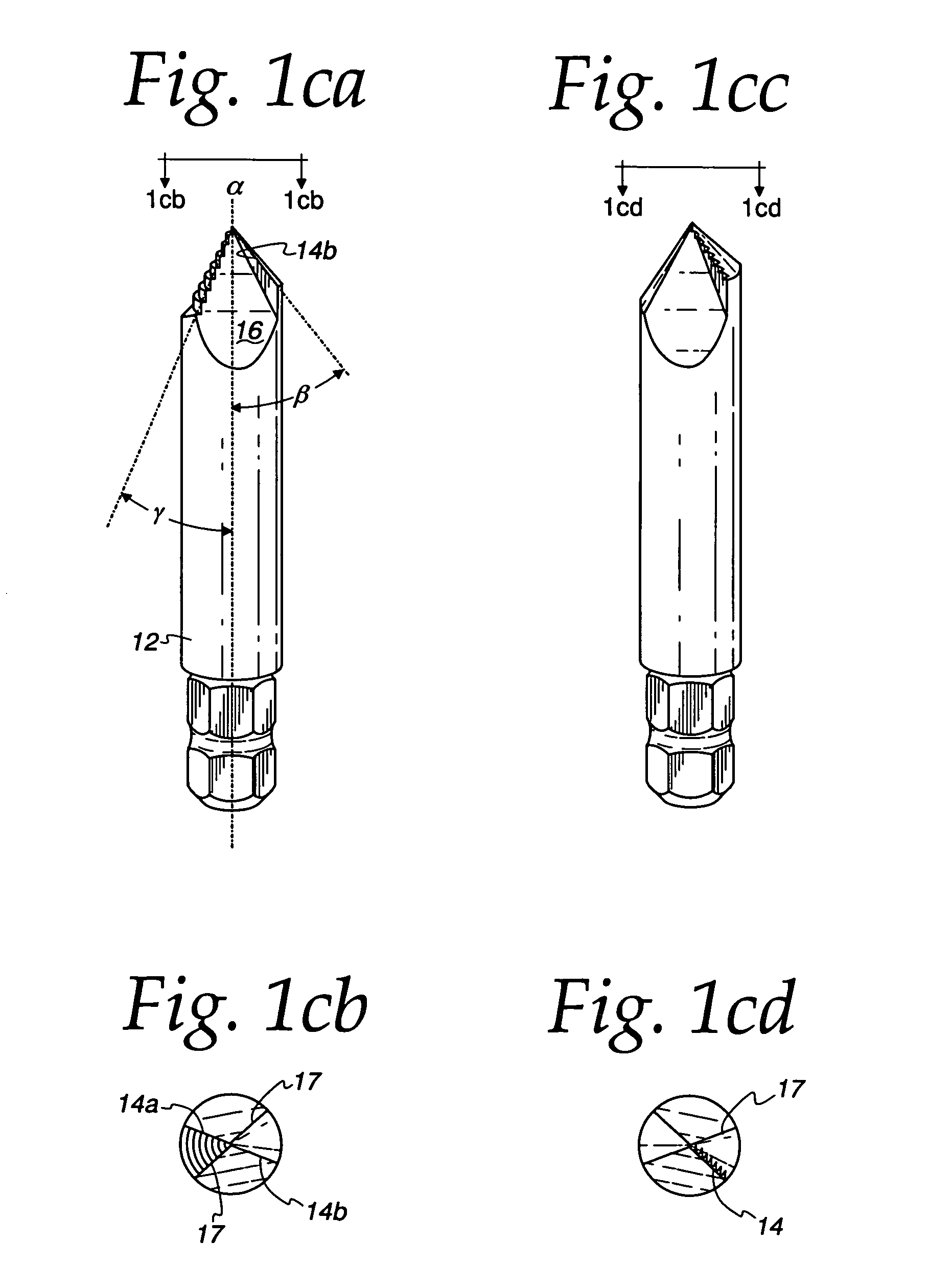

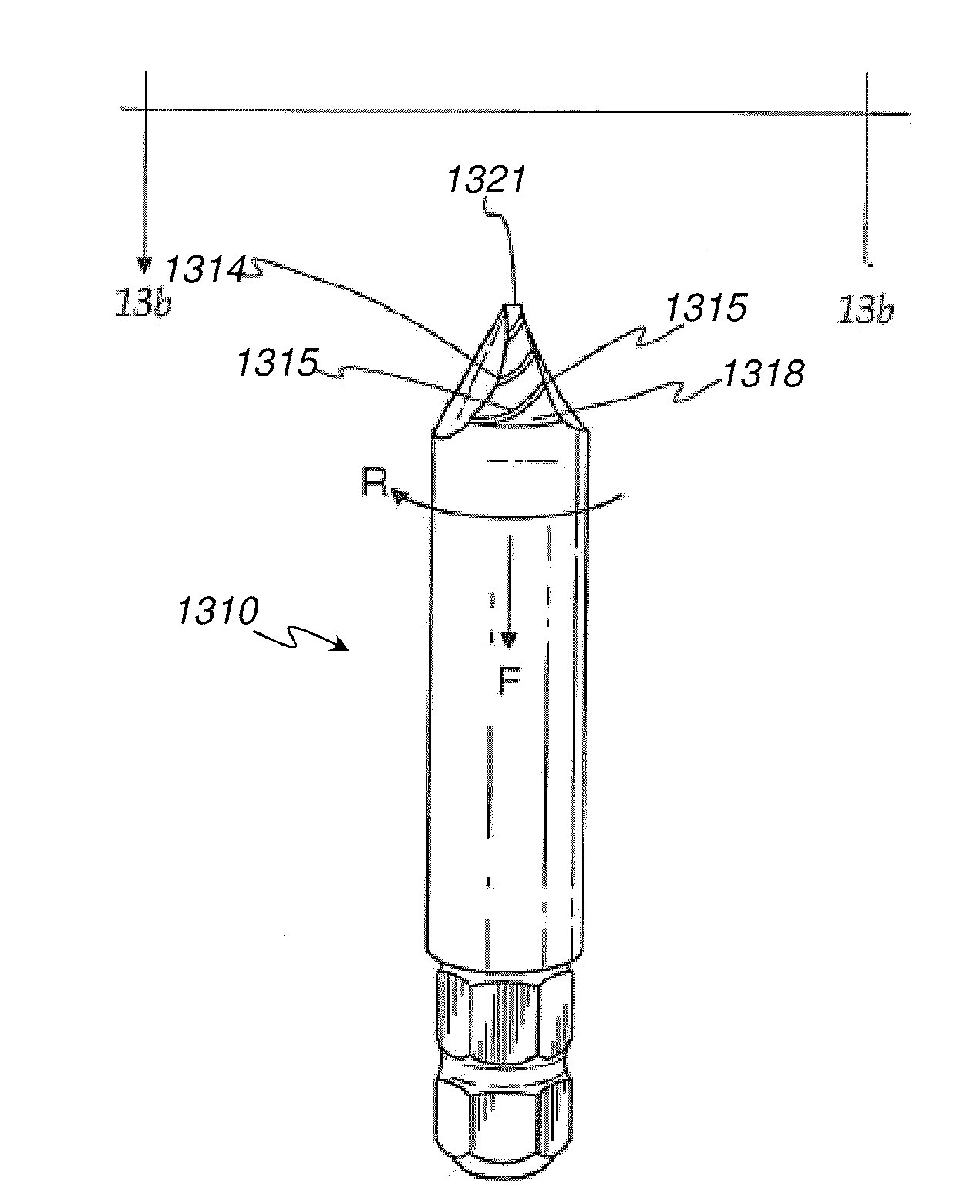

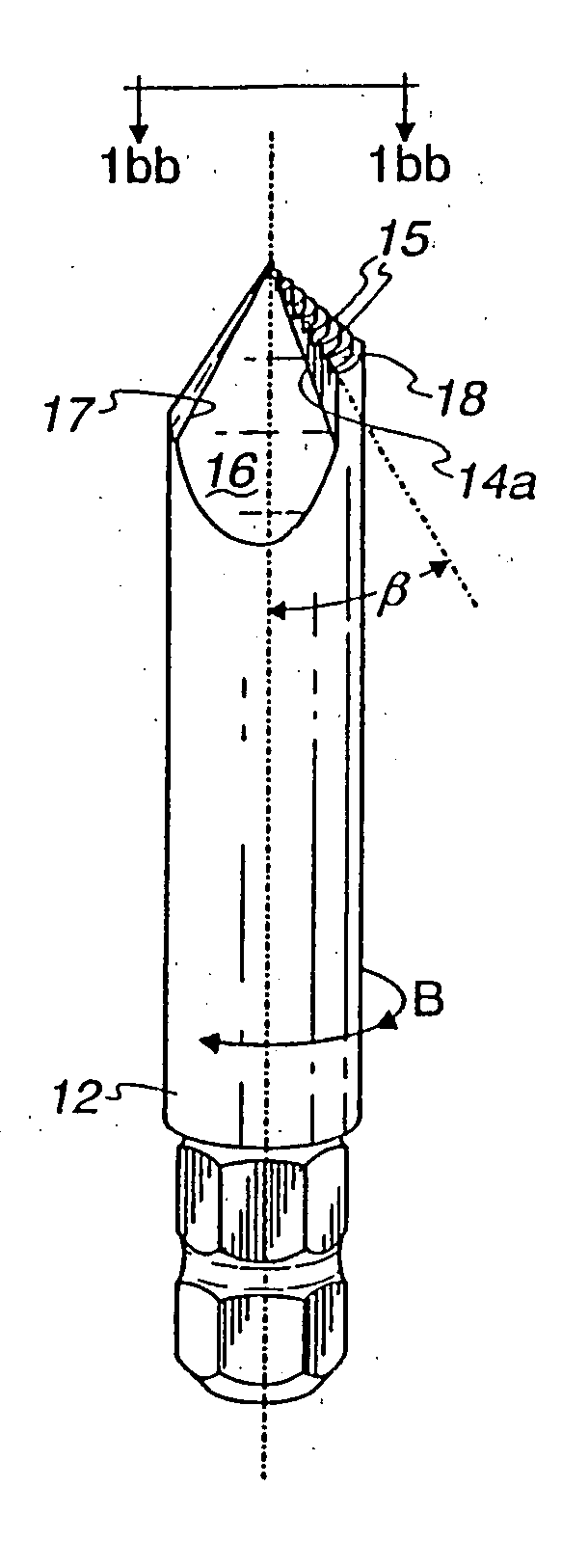

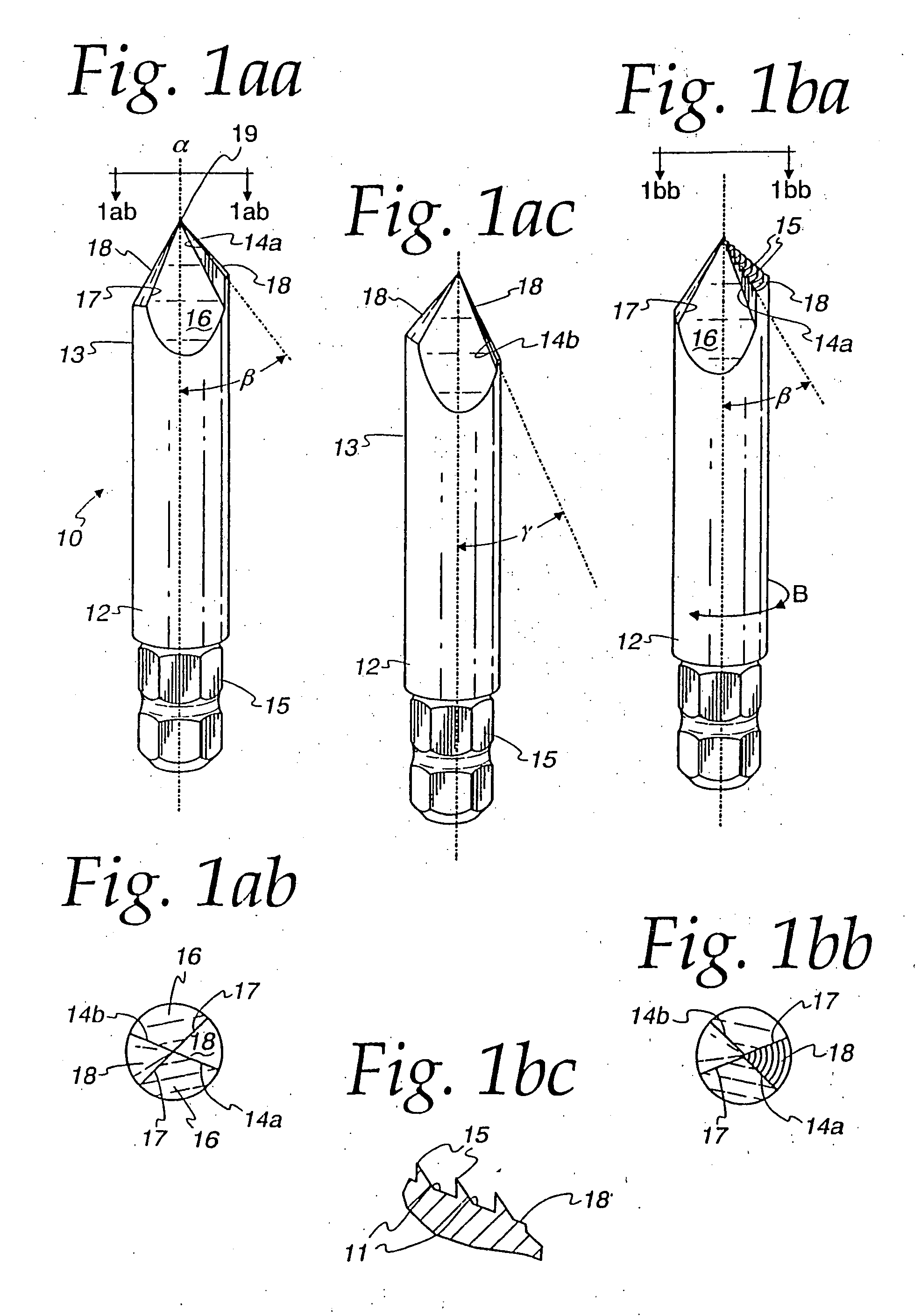

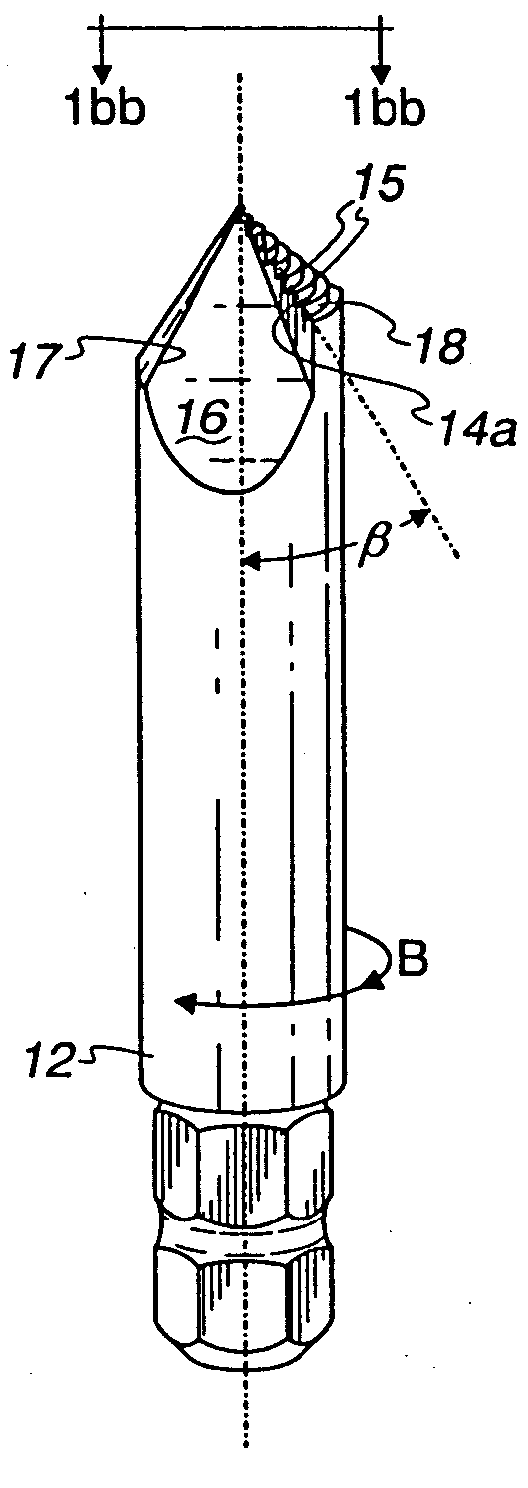

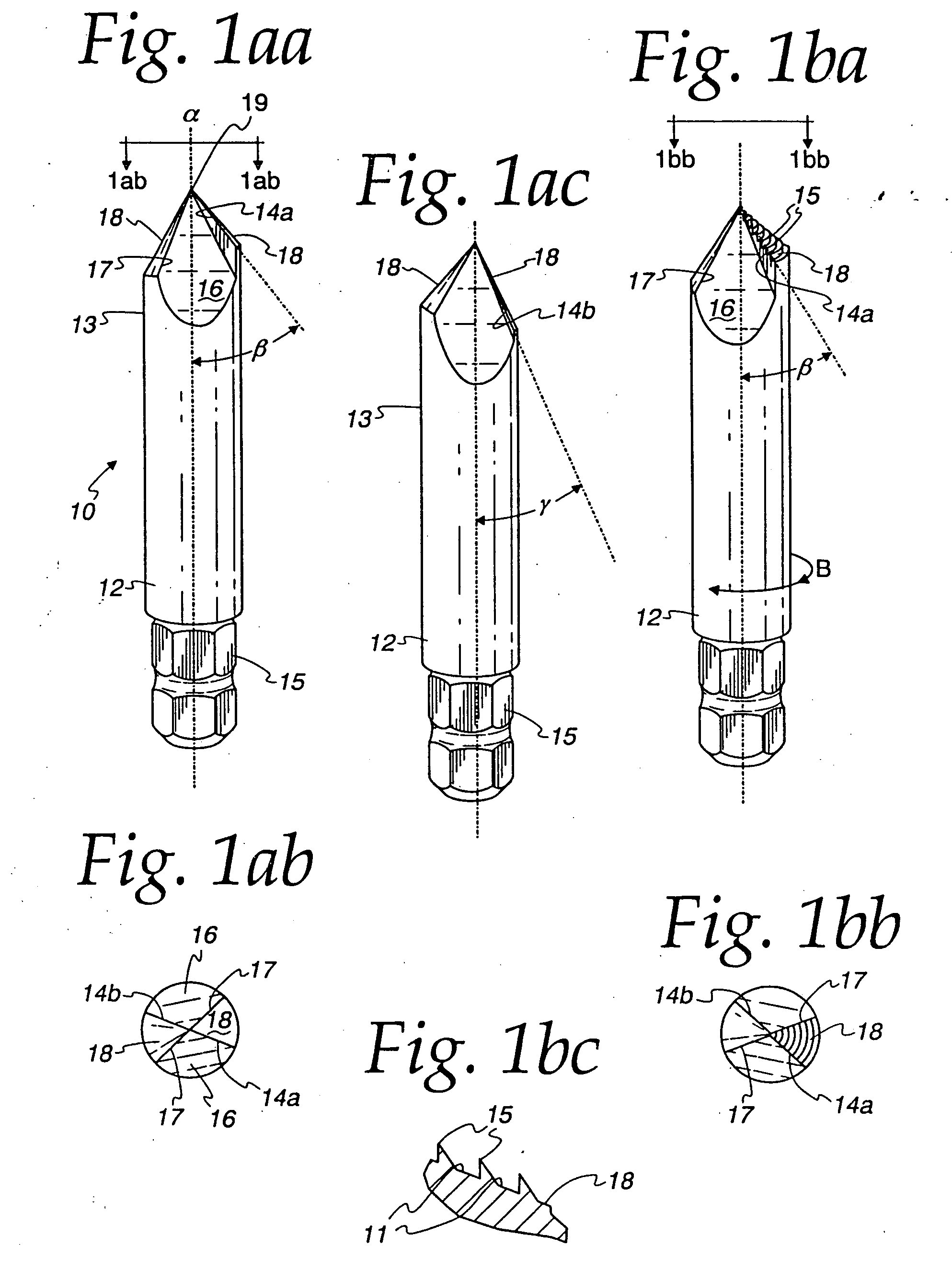

Damaged bolt and screw removing devices

A bit for removing a broken fastener comprises a tip from which extend two or more notches separated by traction or biting surfaces formed from two-sided frusto-conically-shaped regions. The surfaces are bounded on one side by a nonlinear cutting edge and on the other side by a non-cutting edge and are configured to cut into the fastener when the bit is rotated in a direction opposite to the fastener's direction of engagement. Specific embodiments include configurations where the cutting edges extend at different angles with respect to the bit axis, where the biting surfaces comprise a plurality of serrations, and where the cutting edges are separated by flutes which spiral along a longitudinally extending periphery of the bit.

Owner:COMBINED PRODS

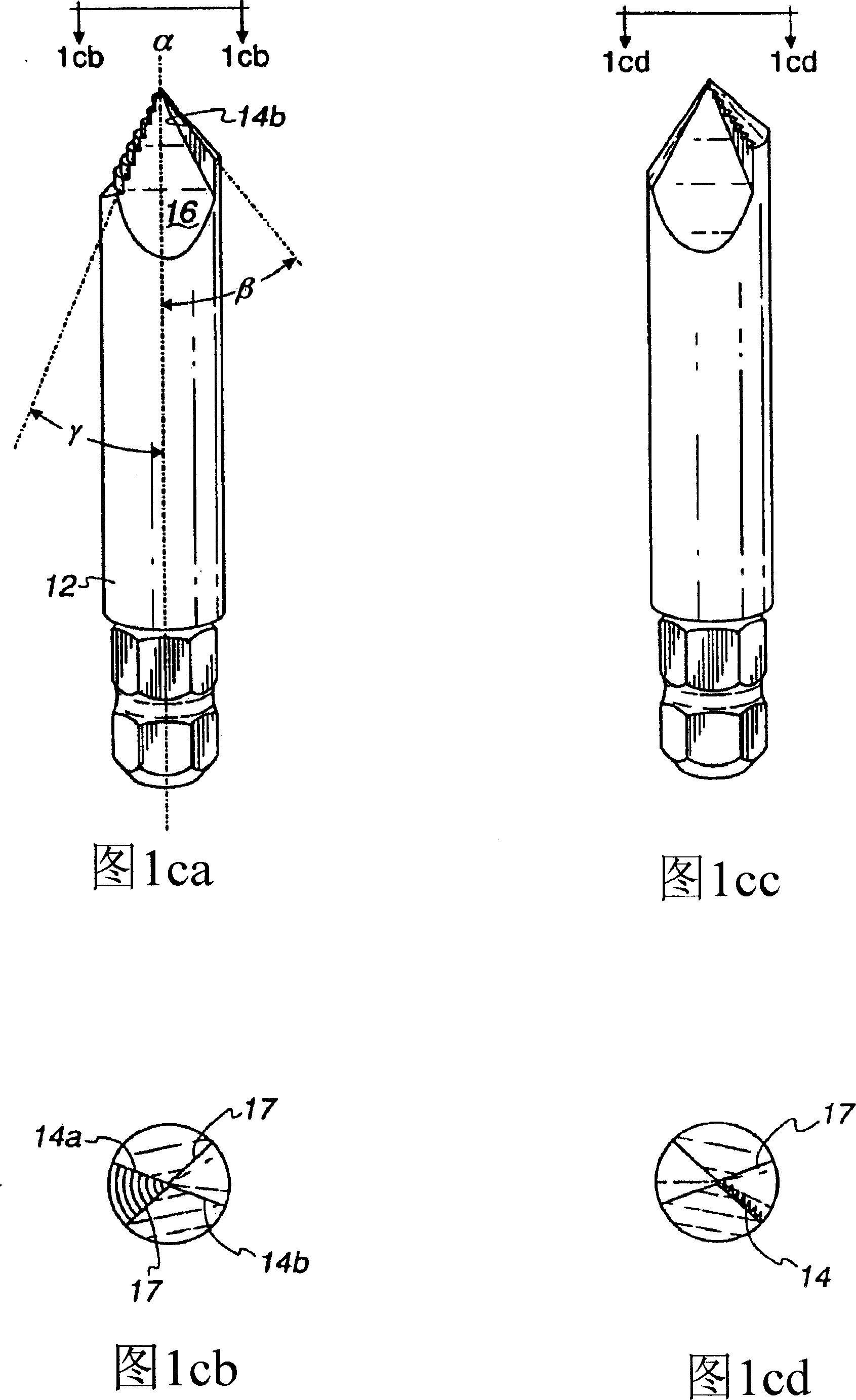

Ceramic bit for high speed drilling

ActiveUS7367758B2Technically inexpensiveTechnically simpleWood turning toolsTransportation and packagingStructural engineeringMechanical engineering

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

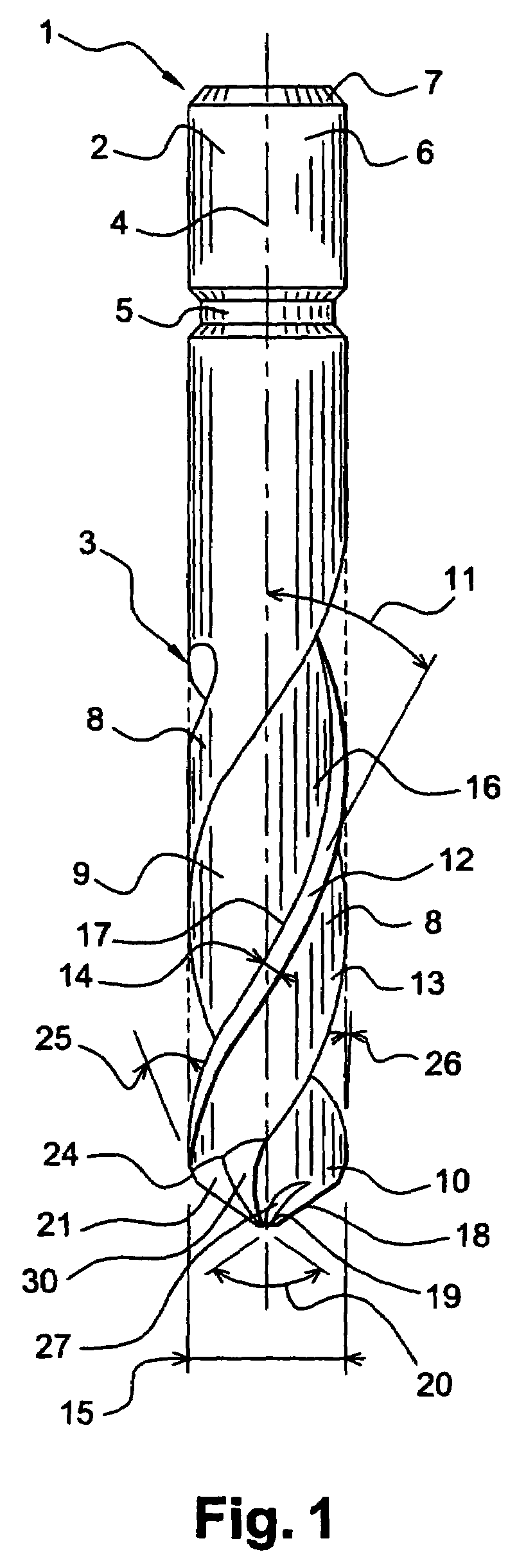

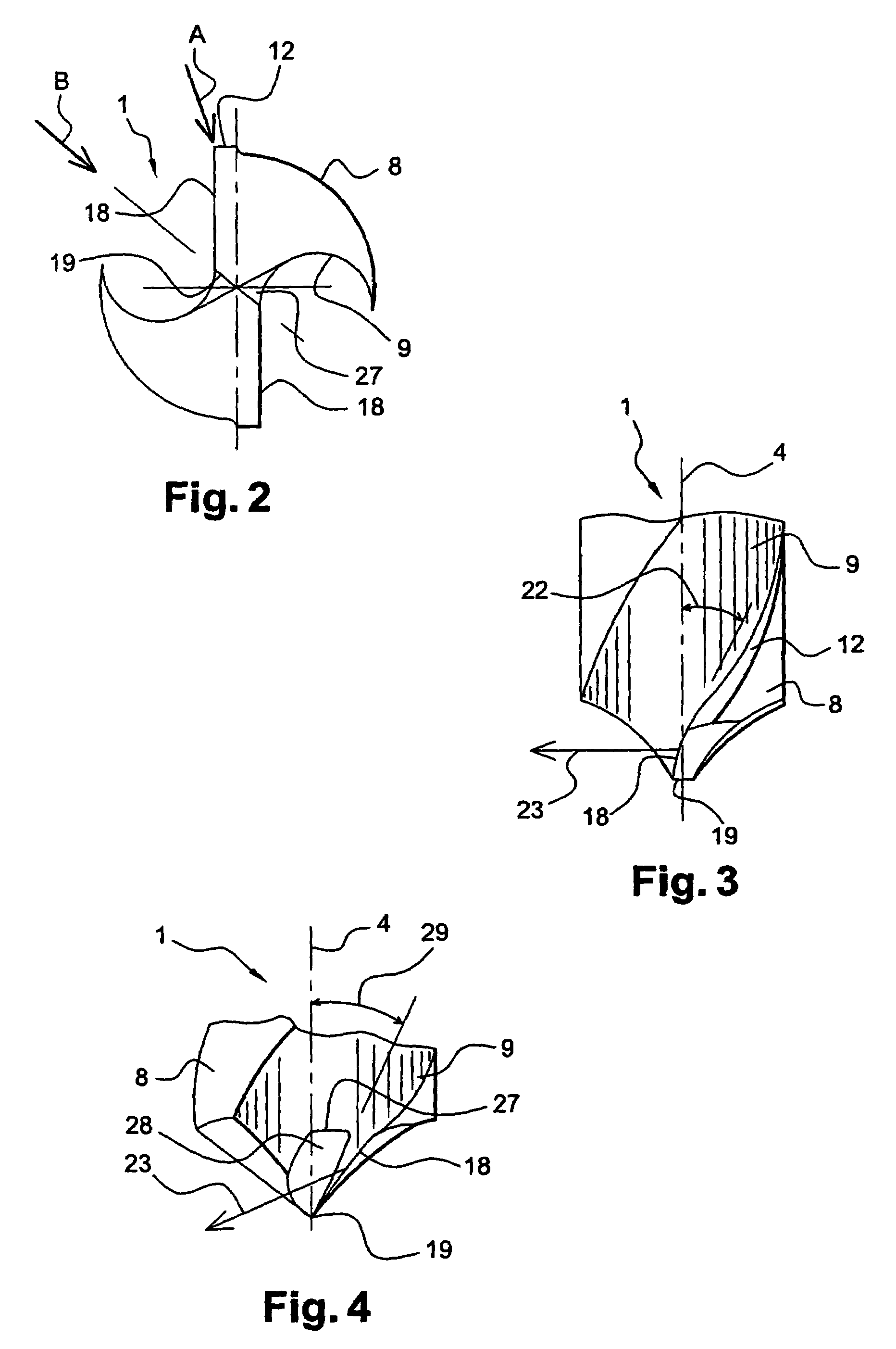

Ceramic drill bit for high-speed drilling of composites

The ceramic drill bit has a particular geometry and is very advantageously applicable to the very high-speed drilling of parts made of a composite, especially a carbon-fiber composite having an epoxy resin matrix. The invention also relates to a method for the high-speed drilling of composites.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Damaged bolt and screw removing devices

ActiveUS20090183603A1Lower levelImprove biteTransportation and packagingSpade drillsFluteEngineering

A bit for removing a broken fastener comprises a tip from which extend two or more notches separated by traction or biting surfaces formed from two-sided frusto-conically-shaped regions. The surfaces are bounded on one side by a nonlinear cutting edge and on the other side by a non-cutting edge and are configured to cut into the fastener when the bit is rotated in a direction opposite to the fastener's direction of engagement. Specific embodiments include configurations where the cutting edges extend at different angles with respect to the bit axis, where the biting surfaces comprise a plurality of serrations, and where the cutting edges are separated by flutes which spiral along a longitudinally extending periphery of the bit.

Owner:COMBINED PRODS

Damaged bolt and screw removing devices

ActiveUS8276482B2Improve biteEfficient extractionTransportation and packagingSpannersEngineeringDrill bit

Owner:COMBINED PRODS

Damaged bolt and screw removing devices

A bit for removing a broken fastener comprises a tip from which extend two or more notches separated by scraping surfaces formed from two-sided frusto-conically-shaped regions. The scraping surfaces are bounded on one side by a cutting edge and on the other side by a non-cutting edge and are configured to cut into the fastener when the bit is rotated in a direction opposite to the fastener's direction of engagement. Specific embodiments include configurations where the cutting edges extend at different angles with respect to the bit axis and where the scraping surfaces comprise a plurality of serrations.

Owner:COMBINED PRODS

Ceramic drill bit for high-speed drilling of composites

The ceramic drill bit has a particular geometry and is very advantageously applicable to the very high-speed drilling of parts made of a composite, especially a carbon-fiber composite having an epoxy resin matrix. The invention also relates to a method for the high-speed drilling of composites.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Precision cast dental instrument

InactiveUS7677296B2Resistance to breakageResistance to wearTransportation and packagingWristbandsInstrumentationPrecision casting

An endodontic file (200) is provided particularly adapted for the removal of tooth structure, decayed or damaged nerve tissues or dentine material on the interior walls of a root canal or dentine and / or enamel from the external tooth wall. The endodontic instrument includes a shaft (202) having a shank portion (204) and a generally elongated working portion (206). The working portion preferably includes cutting or abrading features (232) adapted upon rotation and / or reciprocation of the instrument to cut, abrade or remove tissue from the interior walls of a root canal or dentine and / or enamel from the external tooth wall. The working portion extends from a proximal end (207) adjacent the shank portion to a distal end (208) terminating at a tip (250). The entire instrument and / or at least the working portion thereof is formed of an amorphous or essentially amorphous material having no or essentially no detectable crystalline structure and / or from a nanocrystalline material having an average crystalline grain size less than about 1 μm. The instrument may be formed by conventional grinding operations or by direct casting, forging or molding, in a manner producing an integral as-molded instrument having one or more sharp cutting edges. The instrument is inexpensive to manufacture and exhibits improved cutting-edge sharpness, wear resistance, lubriciousness and resistance to breakage.

Owner:CLOUDLAND INST

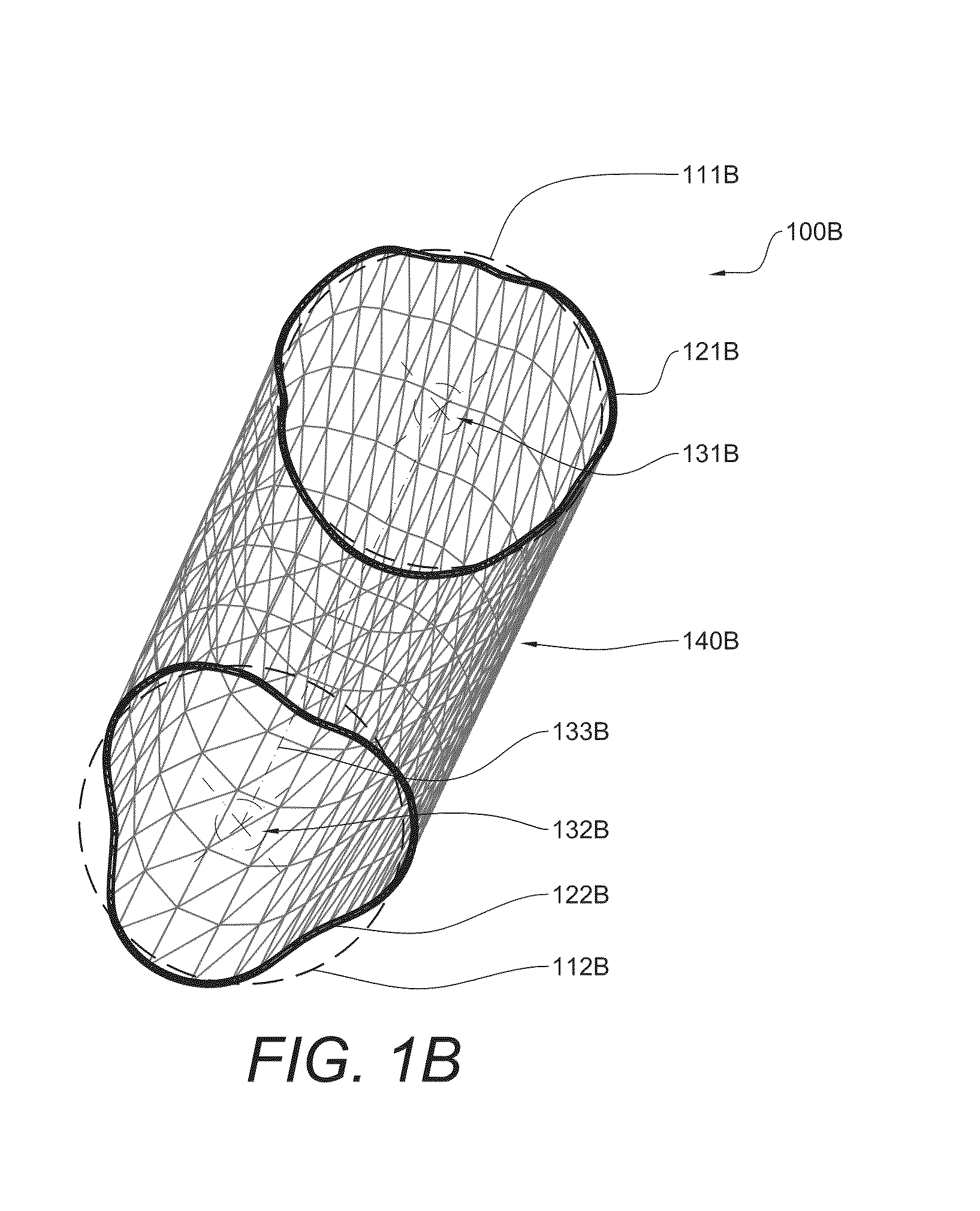

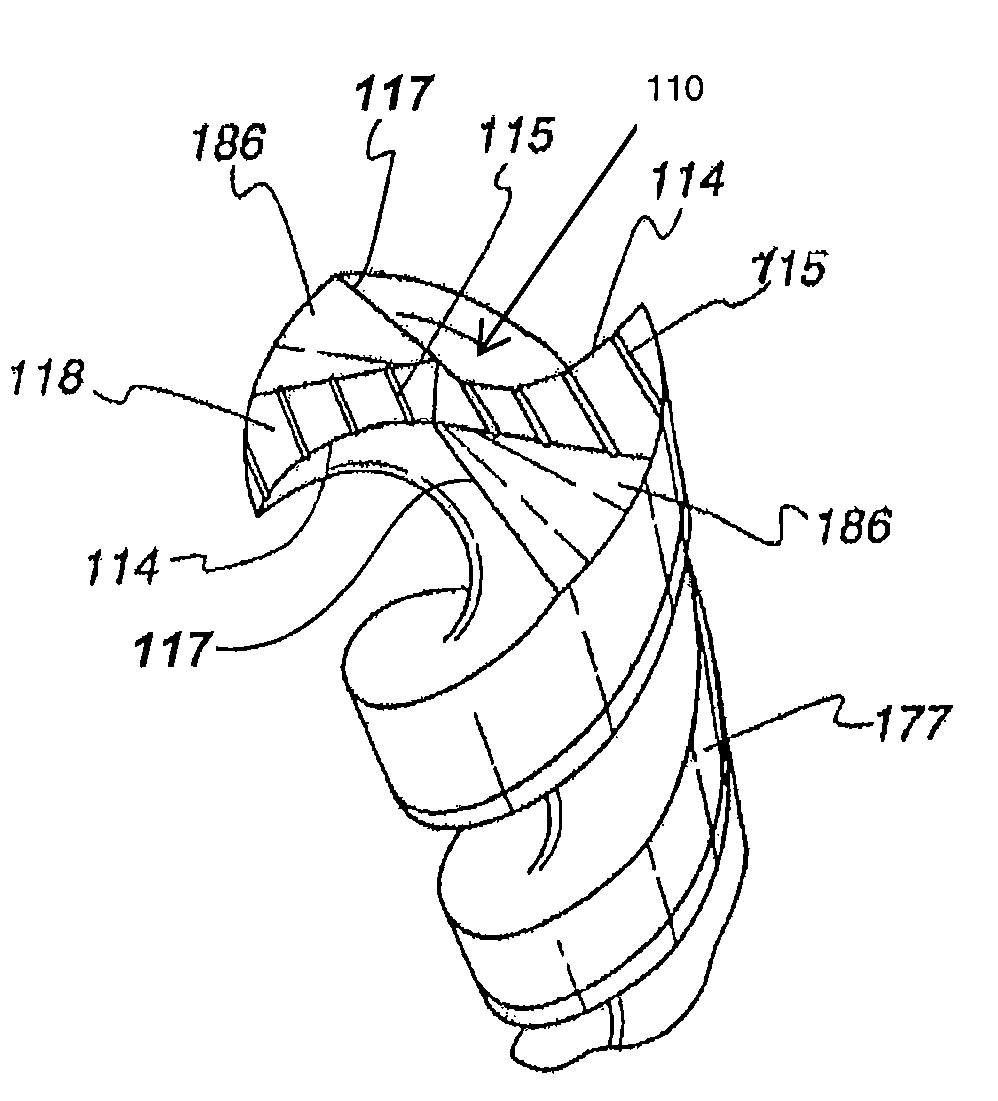

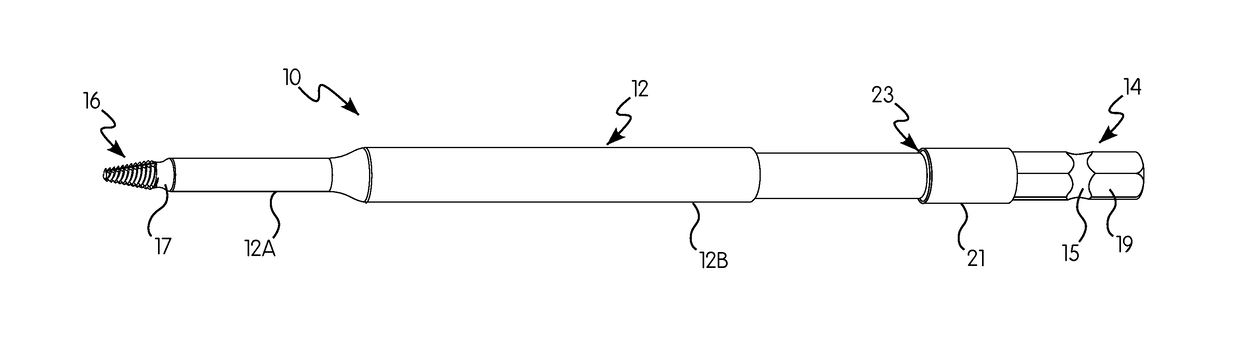

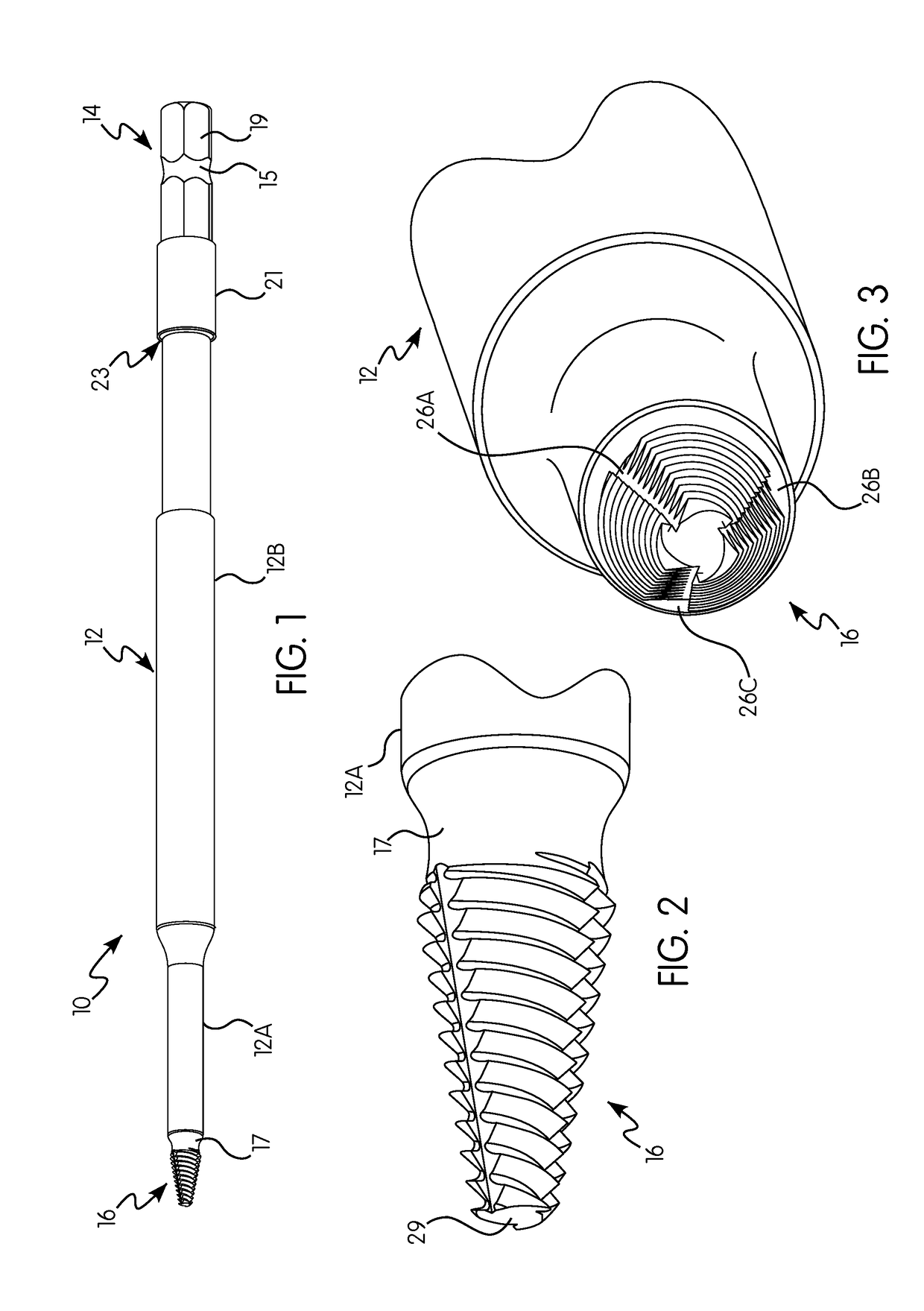

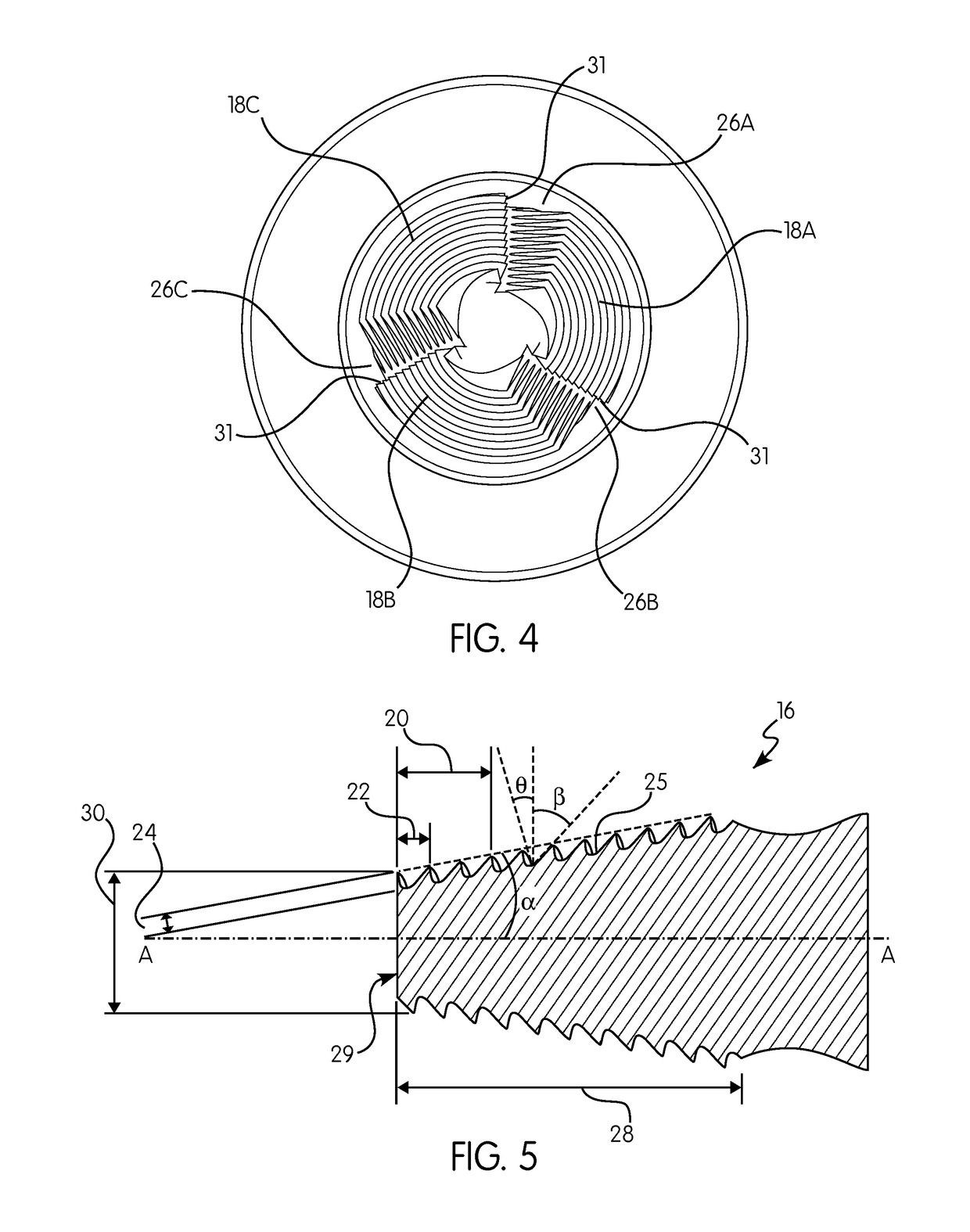

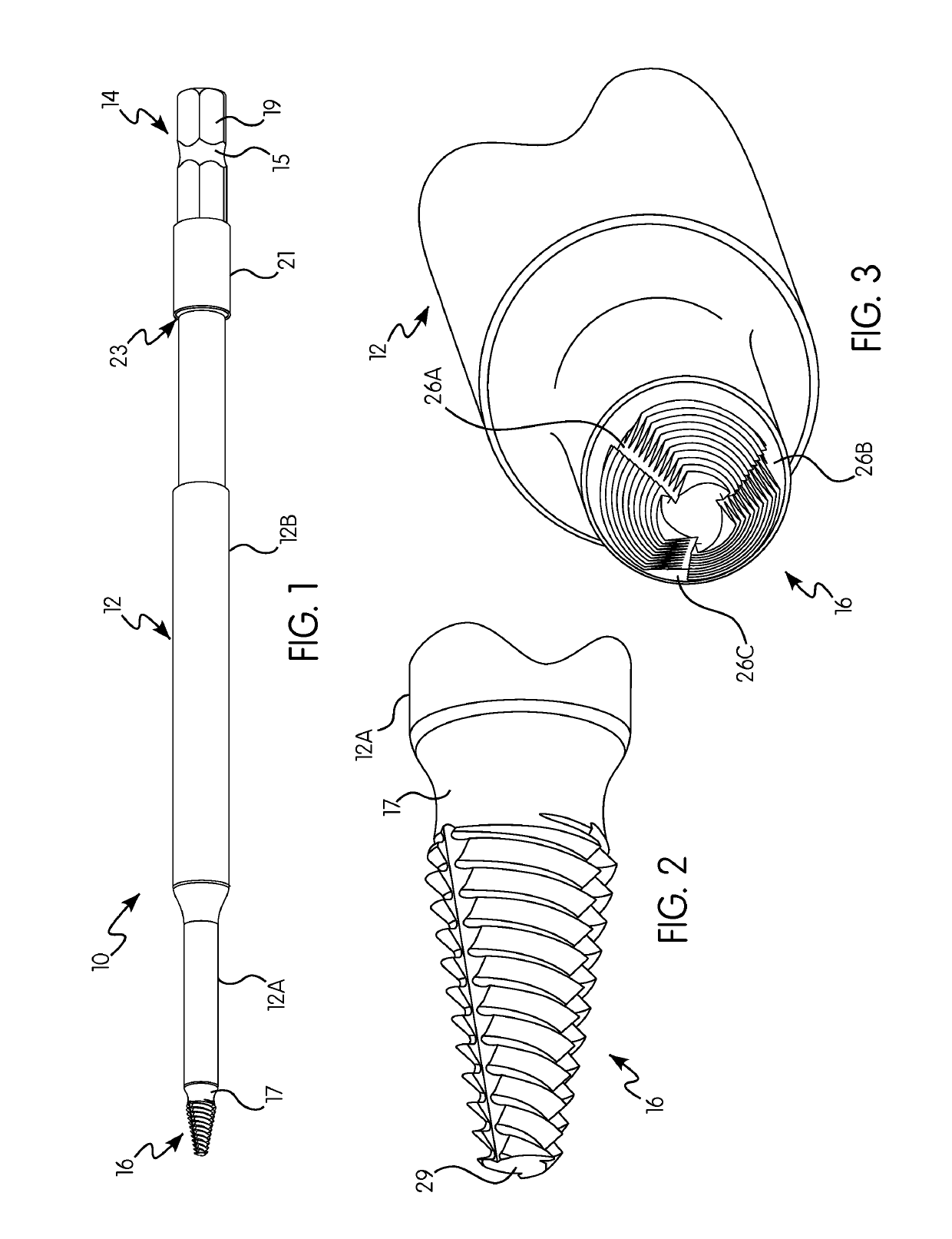

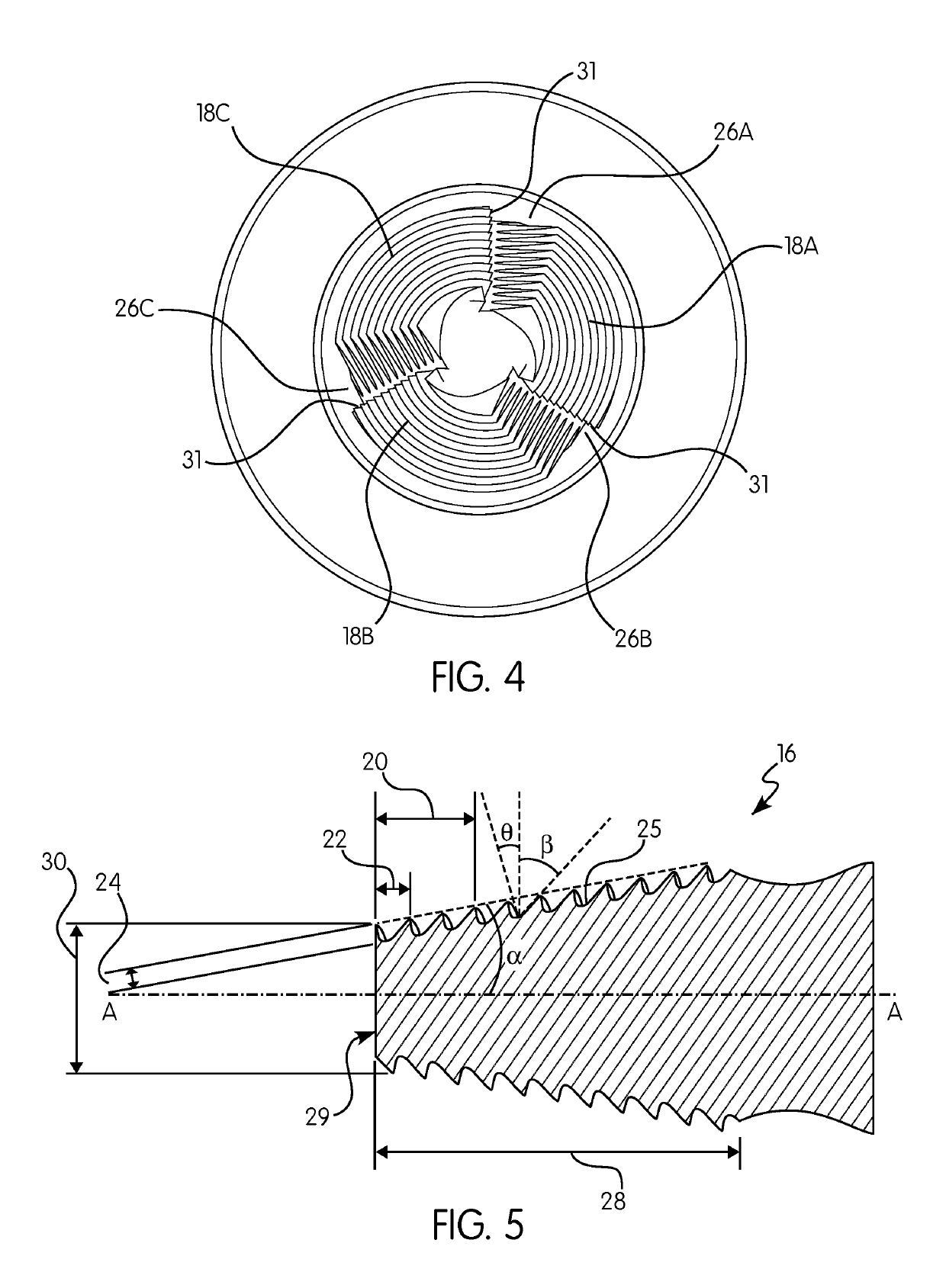

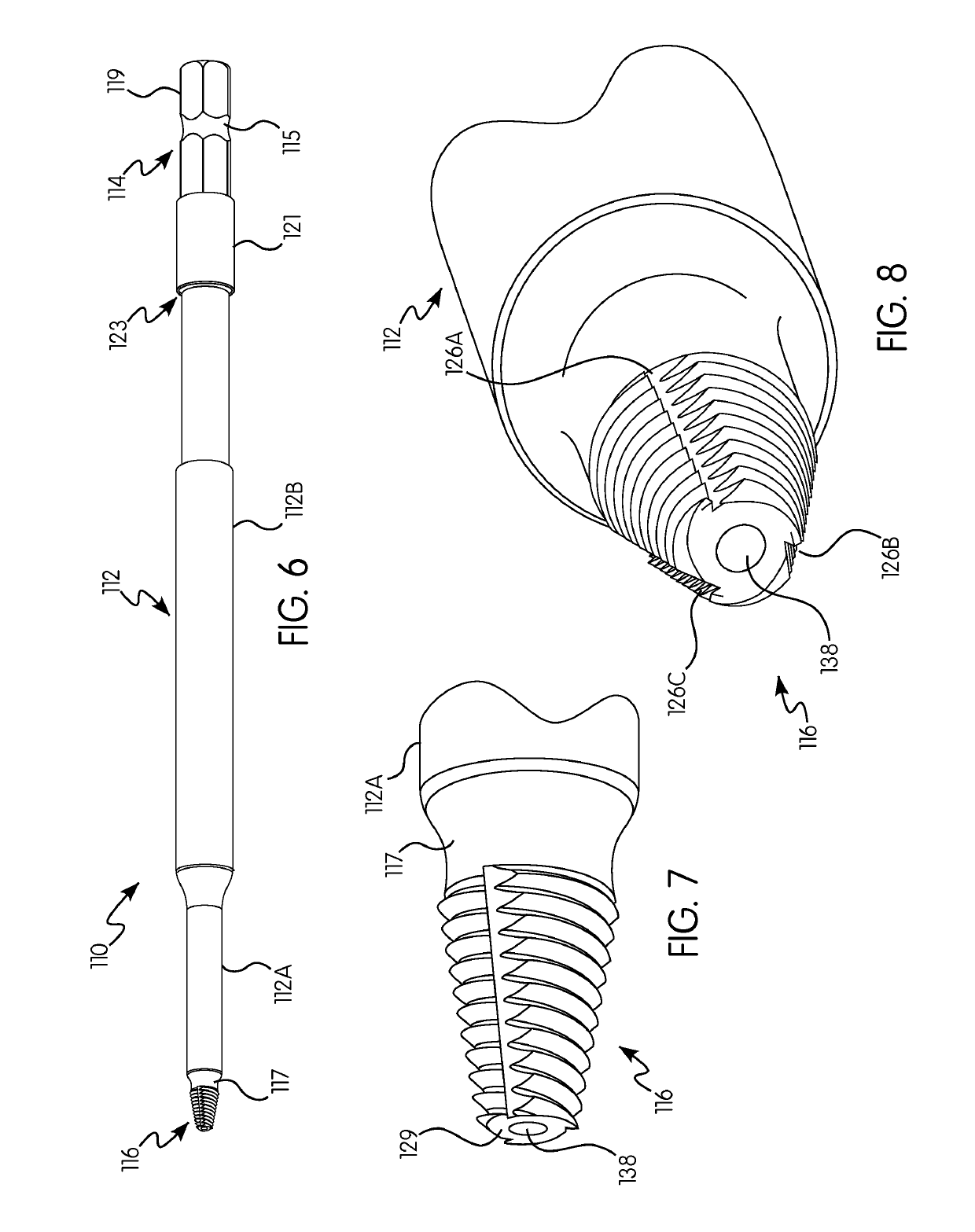

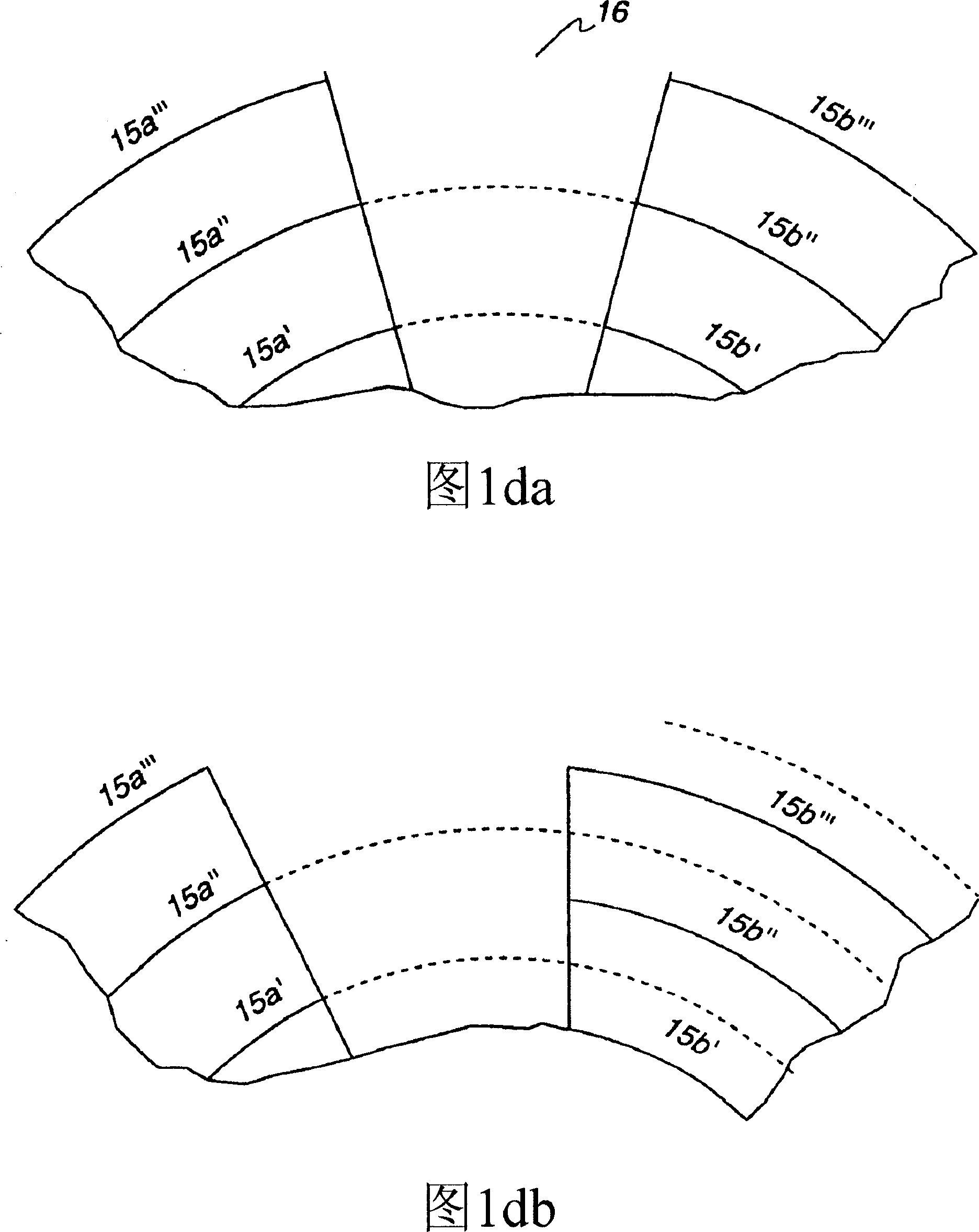

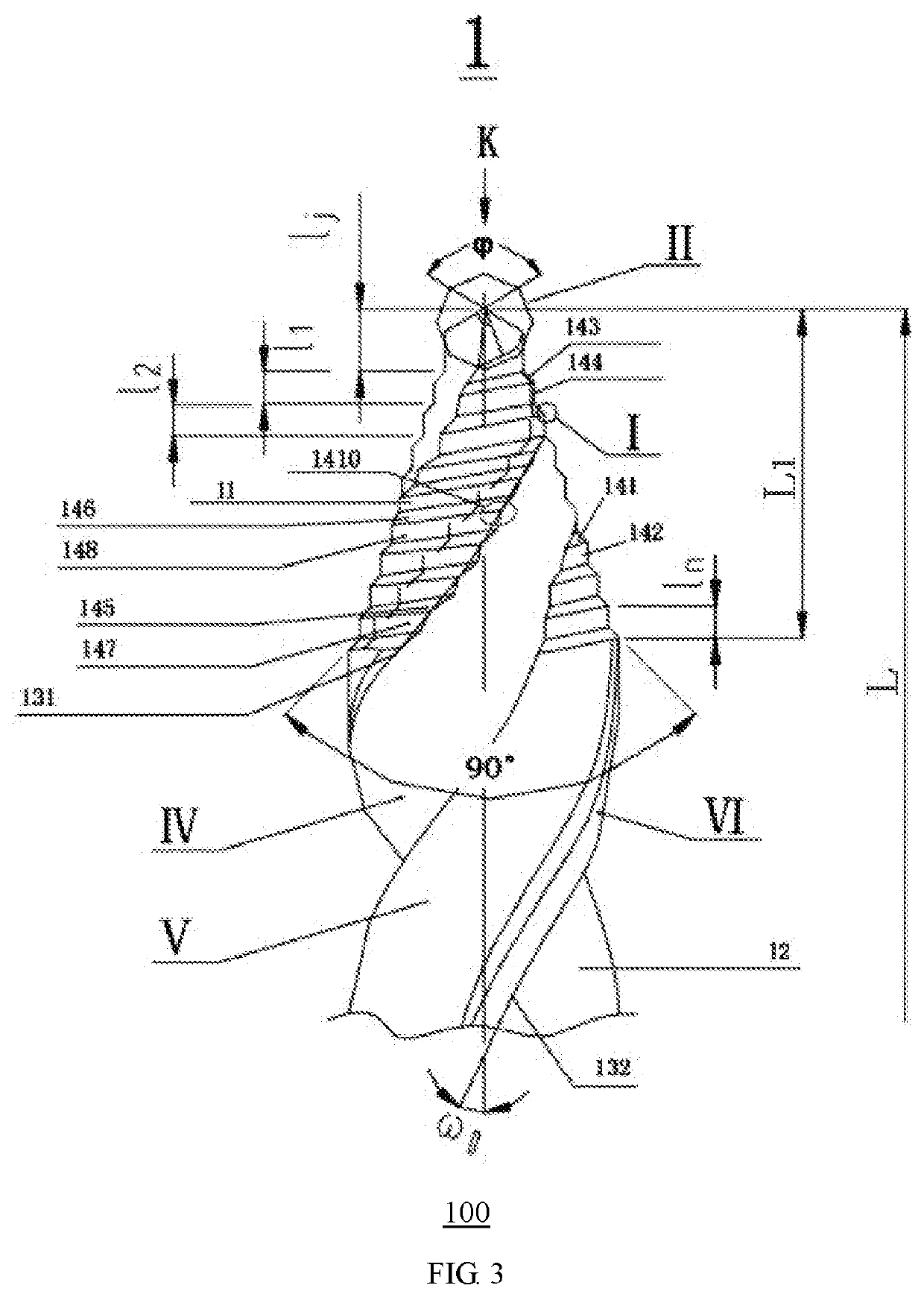

Precessional-motion bone and dental drilling tools and bone harvesting apparatus

ActiveUS9271740B2Wider clearance angleIncrease flexibilityTransportation and packagingSurgeryDistal portionChip formation

Owner:SCIANAMBLO MICHAEL J

Precessional-motion bone and dental drilling tools and bone harvesting apparatus

ActiveUS20150057664A1Efficient osteotomyPatient SafetyTransportation and packagingSurgeryDistal portionChip formation

This document provides orthopedic and dental devices and methods for their use. For example, novel bone drills and dental drills are described. The bone and dental drills have at least some centers of mass that are offset from the drills' axis of rotation. Accordingly, the bone and dental drills may rotate and cut using a precessional pattern of motion. The design facilitates bone cutting, chip formation and hauling capacity, irrigation and bone harvesting. In some embodiments, the bone chips are collected in a removable apparatus fixed to the distal portion of the drill, and the collected bone chips can be used for bone grafting.

Owner:SCIANAMBLO MICHAEL J

Damaged bolt and screw removing devices

ActiveUS20100037734A1Improve biteEfficient extractionTransportation and packagingSpannersEngineeringDrill bit

A bit for removing a broken security fastener having an elongated shaft with a longitudinal axis. The shaft has a first end and a second end. The first end terminates in a tip region having a recess for receipt of the post of the security fastener, the recess being disposed substantially along the longitudinal axis. The second end of the shaft is configured to be received by the chuck of a tool which provides rotational torque.

Owner:COMBINED PRODS

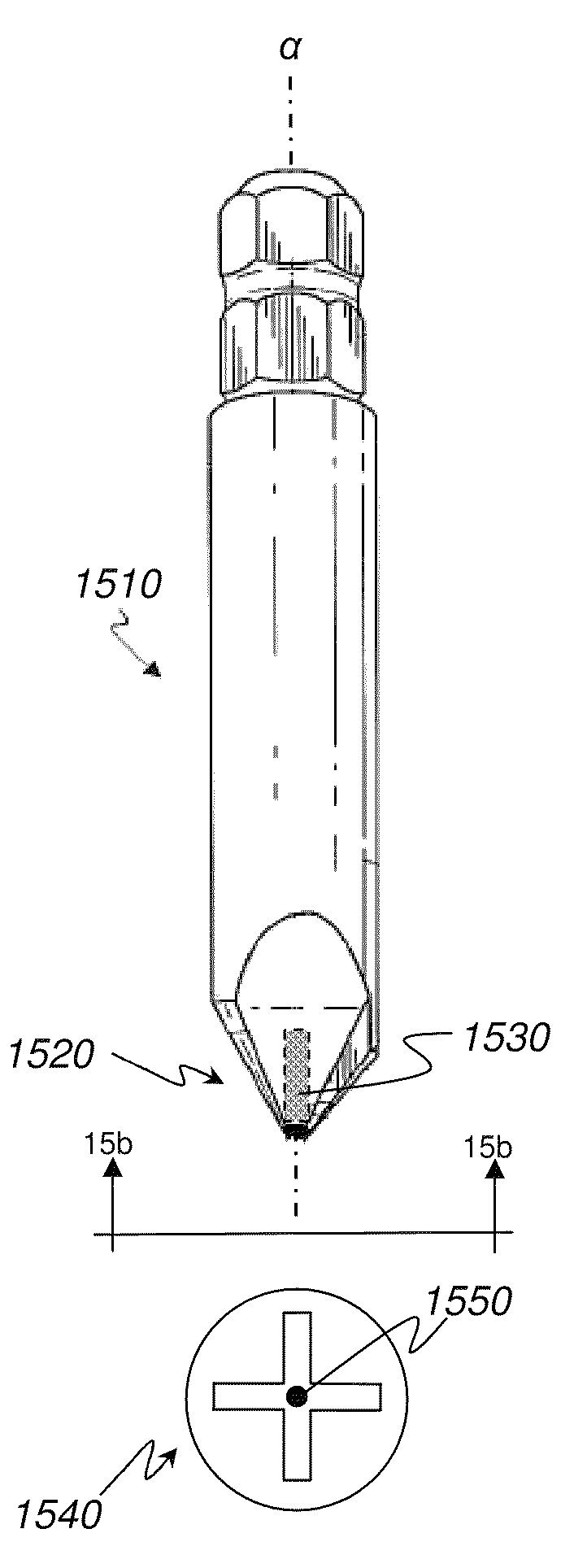

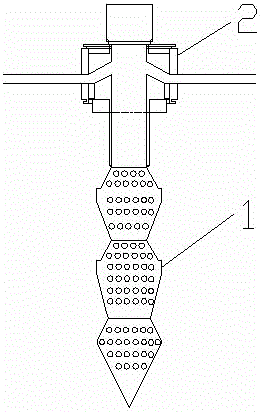

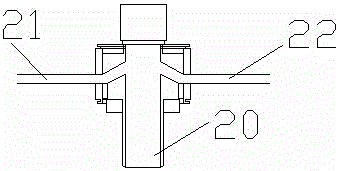

Self-cooling type drill bit

ActiveCN105710419AImprove drilling efficiencyReduce high temperatureTransportation and packagingConical drillsAir compressorPivot joint

The invention discloses a self-cooling type drill bit. A cavity is formed in the drill bit. The drill bit comprises a drill bit body at the top, a drill rod in the middle and a connecting portion with the tail pivoted to a drill bit seat. The drill bit body is in an inverted conical shape. The drill rod is in the shape formed by connecting at least two inverted circular truncated cones. The drill bit body and the drill rod are provided with multiple holes communicating with the cavity in the drill bit. A pivot joint segment body is connected with two pipes extending outwards, namely the grinding aid liquid pipe and the cooling gas pipe. The outer portion of the cooling gas pipe is connected with an air compressor. The outer portion of the grinding aid liquid pipe is connected with grinding aid equipment. The drill bit integrates drilling, lubricating and cooling, lubricating can be conducted while drilling, and no extra cooling and lubricating device needs to be designed for drilling equipment, so that the drill bit equipment is simplified. When the drill bit works, drilling and grinding efficiency can be improved through grinding aid, and the edges of drilled holes are smooth and not sharp and coarse.

Owner:惠州市中德纳微科技有限公司

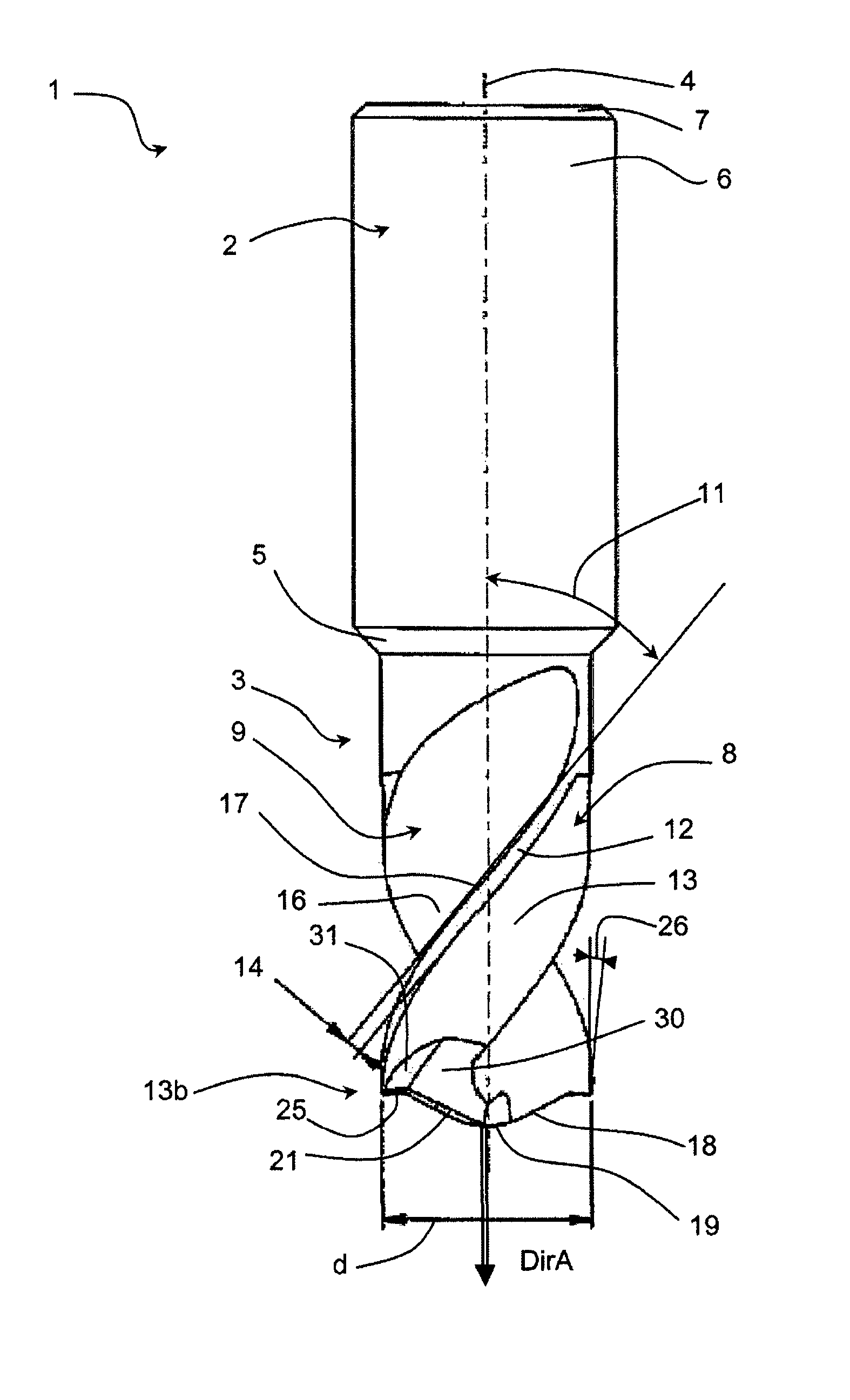

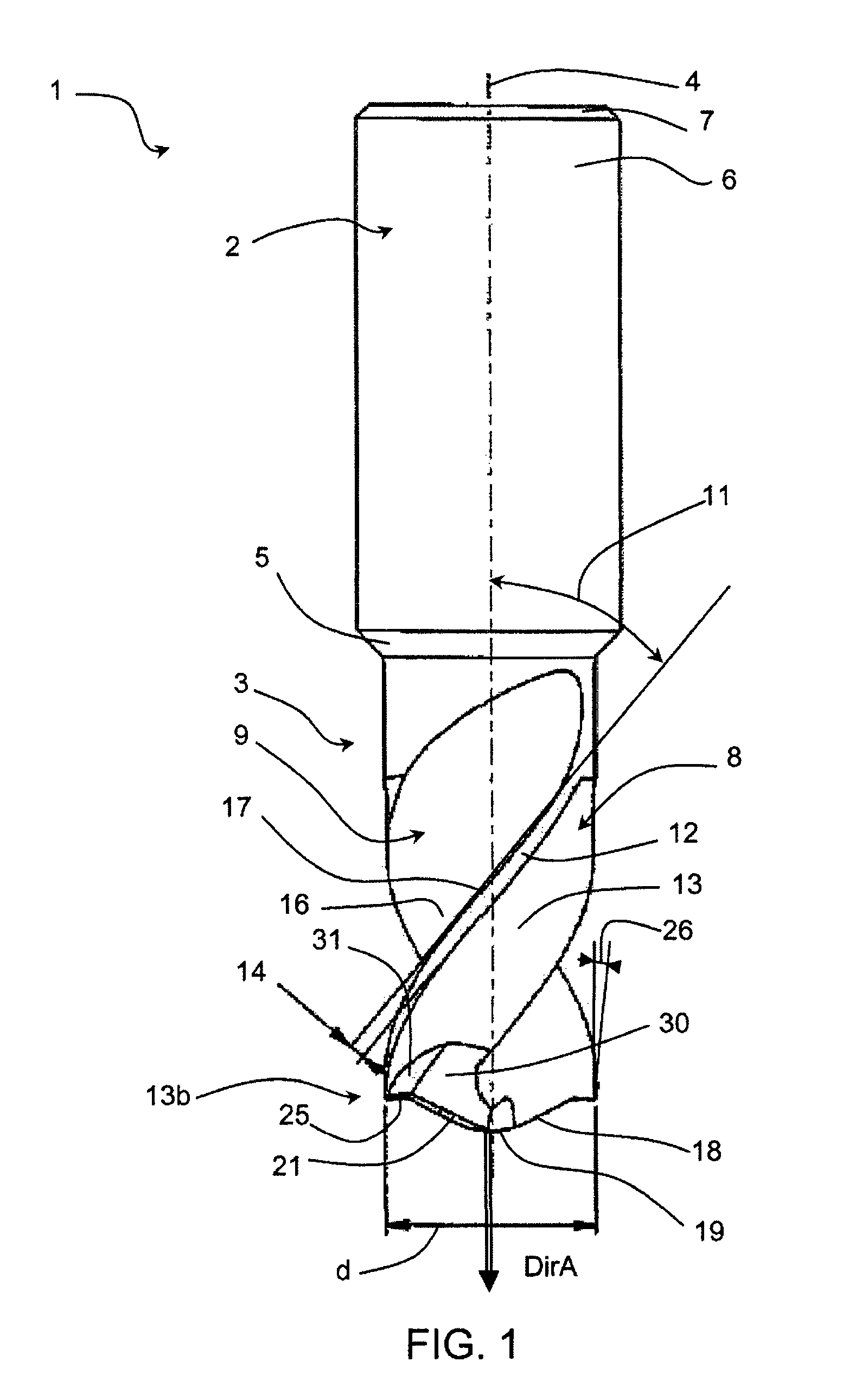

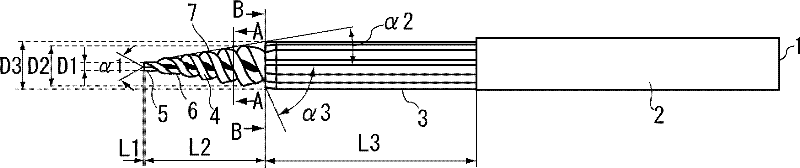

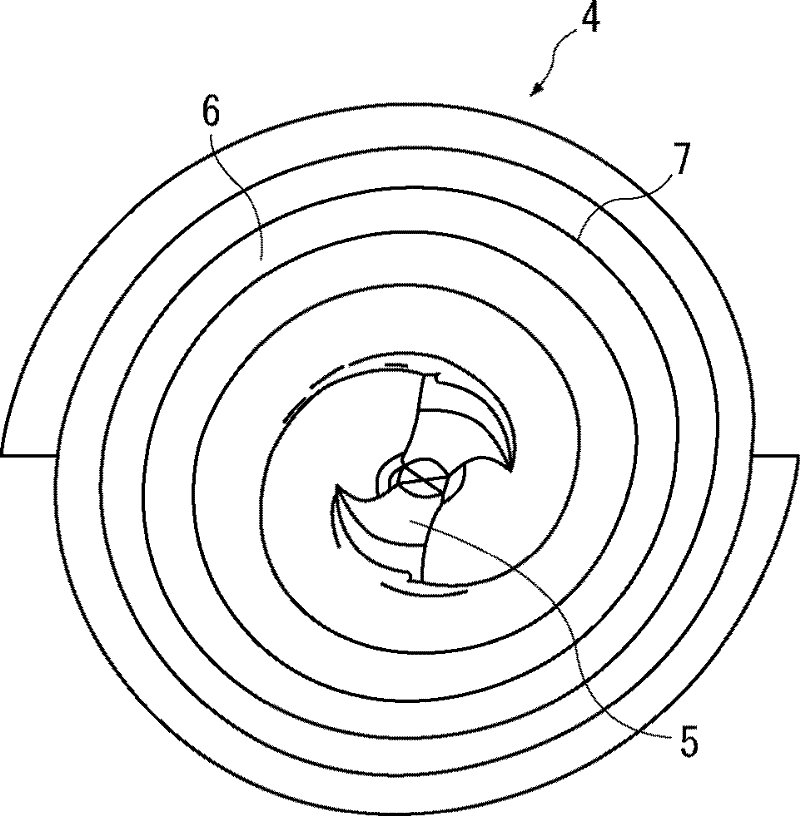

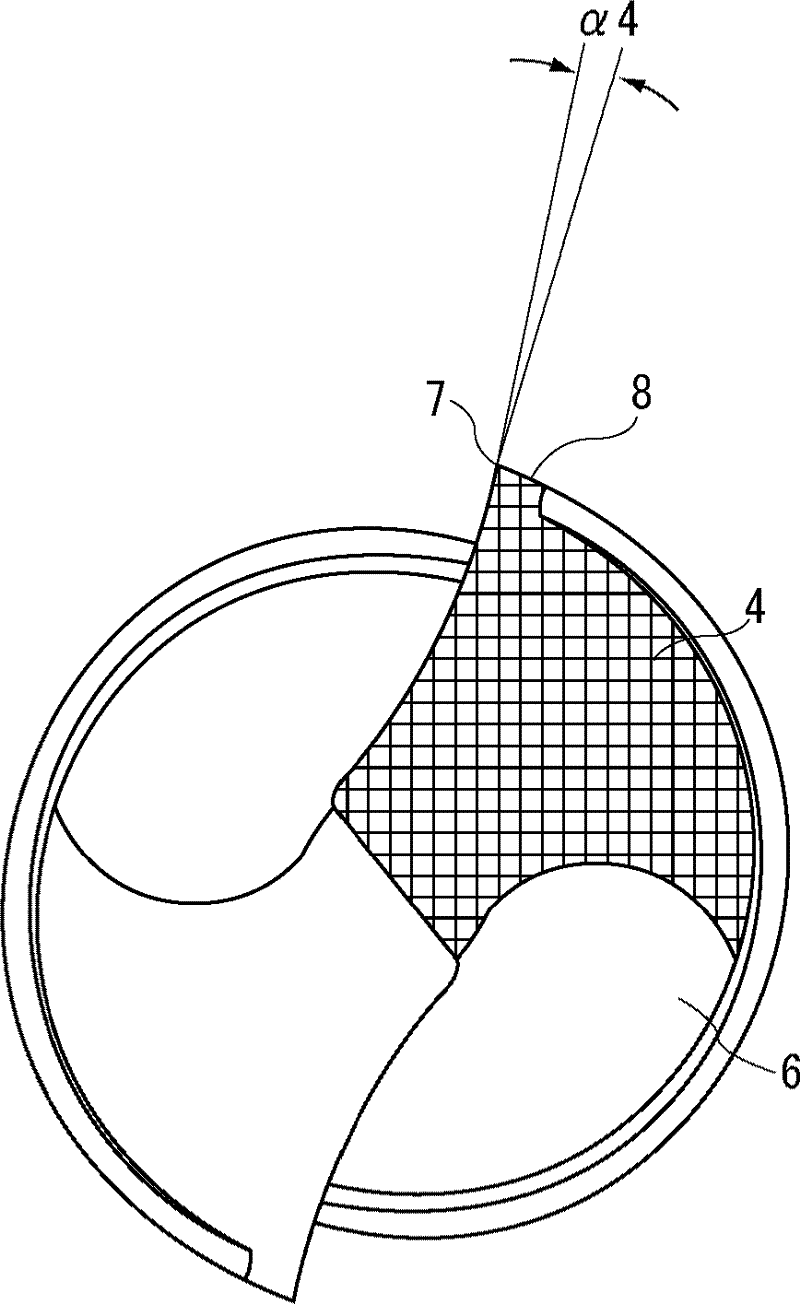

Drill for composite material as well as machining method using same and machining apparatus using same

InactiveCN102574219AReduce propulsion resistanceSmall peeling forceTransportation and packagingWorkpiecesEngineeringFiber-reinforced composite

Provided is a drill for composite material, this drill permitting a high quality boring operation wherein almost no burrs or delamination occurs during the boring of a member to be machined which at least partially contains fiber-reinforced composite material. The drill (1) for composite material comprises a tip section wherein a tip cutting edge (5) is formed; a tapered section (4) that is formed by being joined to the rear end portion of the tip section and is further formed into a tapered shape having a diameter difference equal to the difference between the rear end portion outside diameter and the tip portion outside diameter, the aforementioned rear end portion outside diameter being larger than the aforementioned tip portion outside diameter; and a straight section (3) that is formed by being joined to the rear end portion of the tapered section (4) and is further formed so as to have the same diameter throughout the straight section (3) in such a way that the member to be machined can be finished to a bored diameter which is larger than the outside diameter of the rear end portion of the tapered section (4). On the periphery of the tapered section (4), there are formed peripheral cutting edges (7) which are spirally twisted and are set in such a way that a bored diameter increases continuously.

Owner:FUKUI PREFECTURE

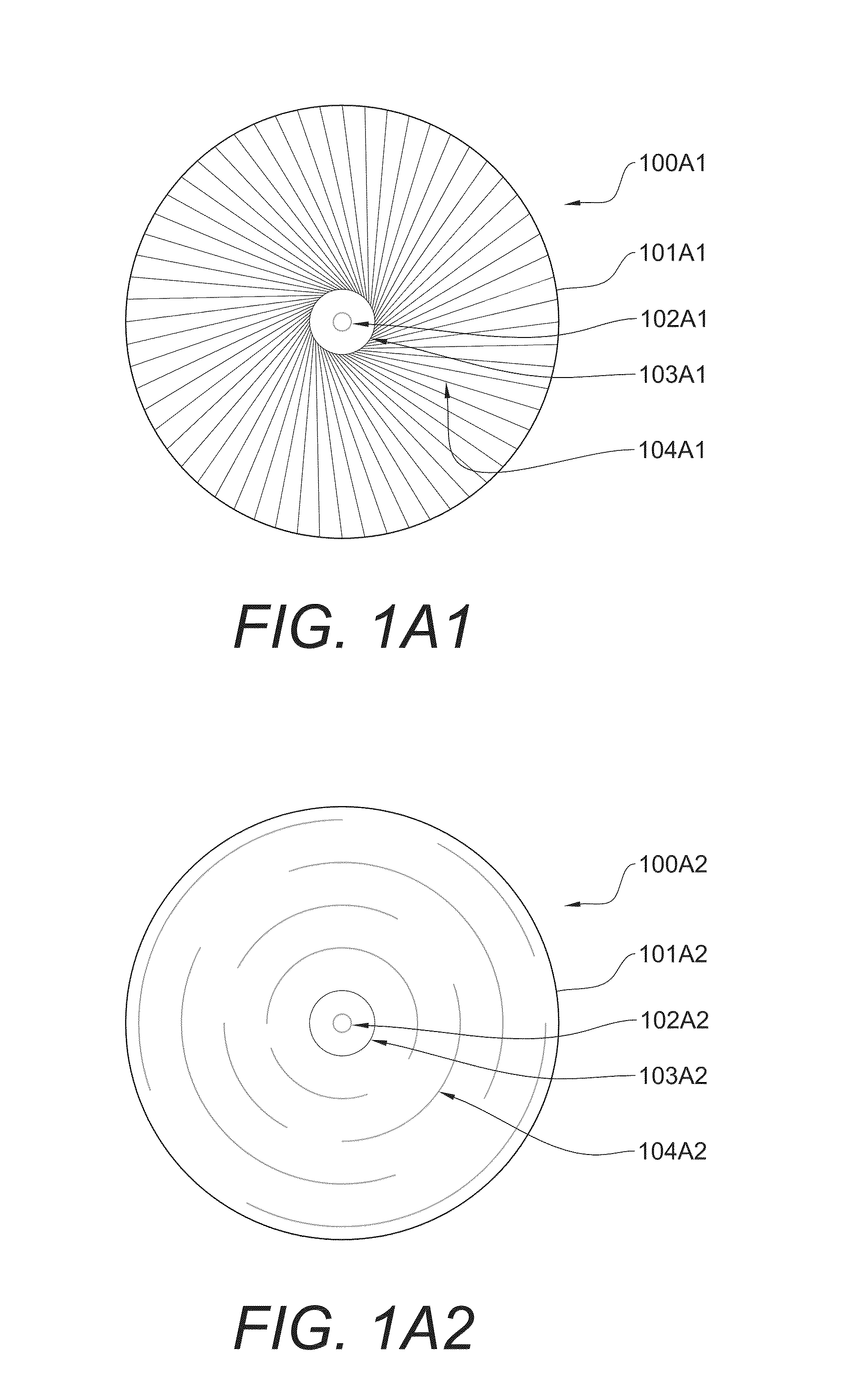

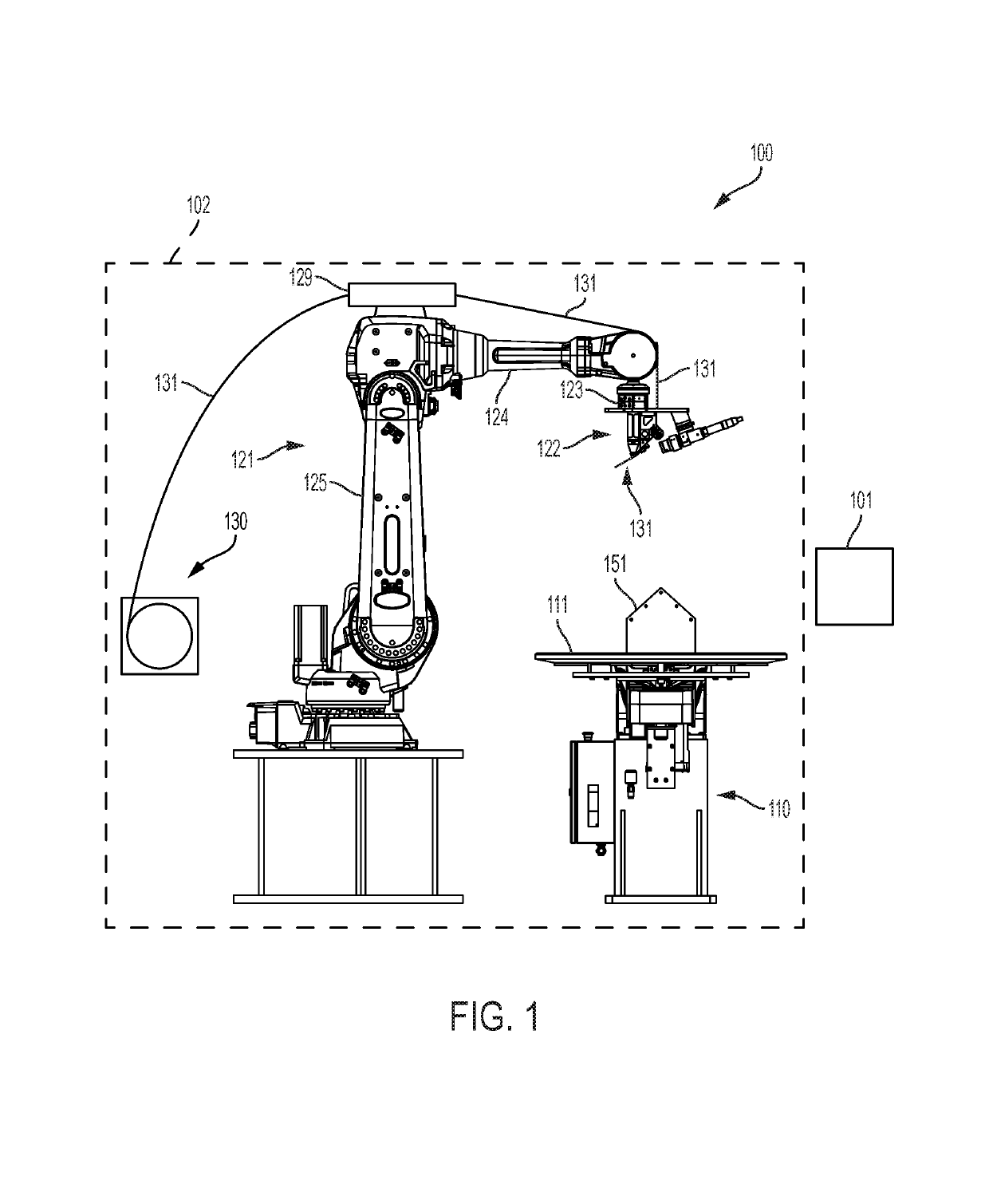

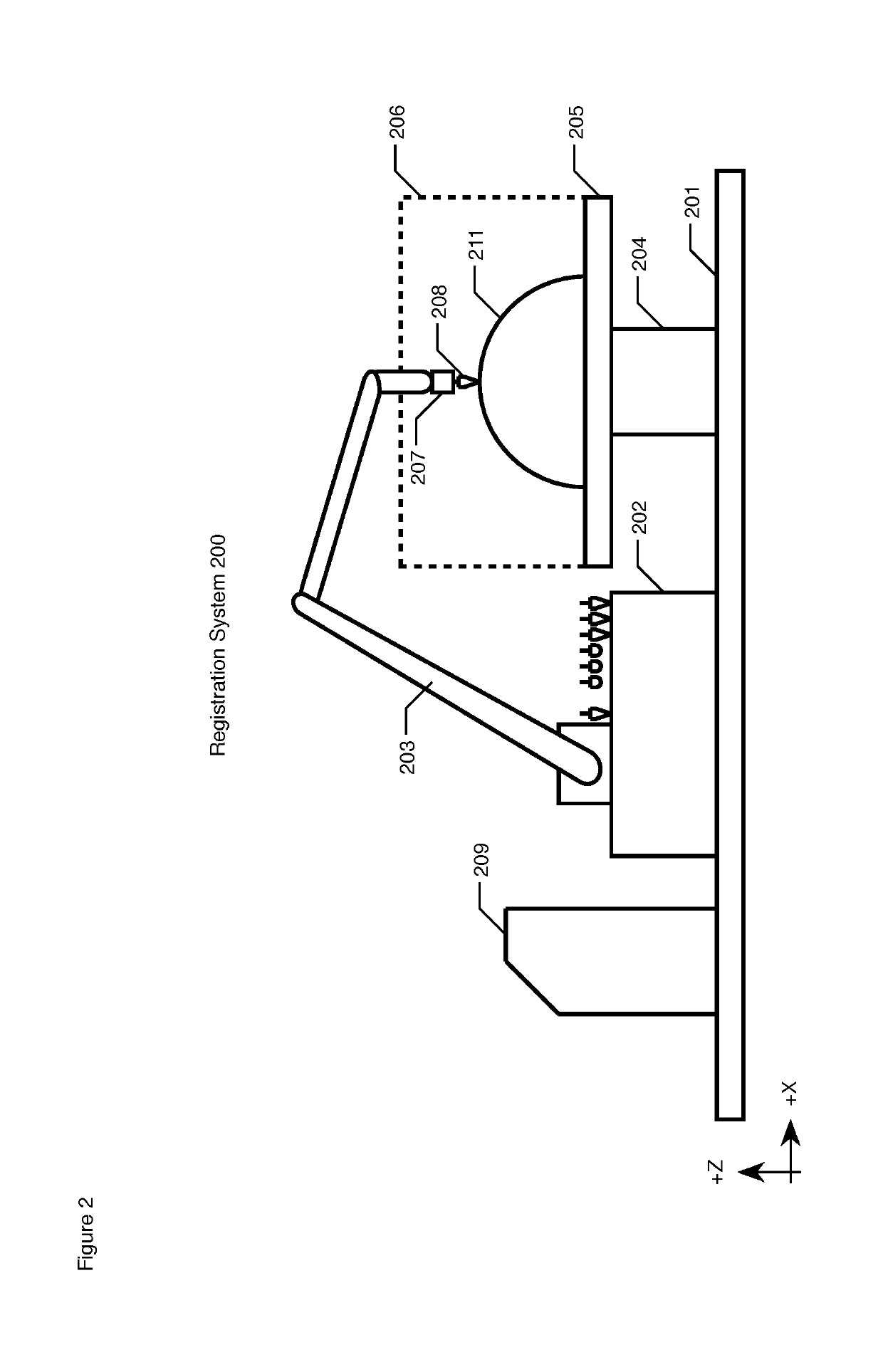

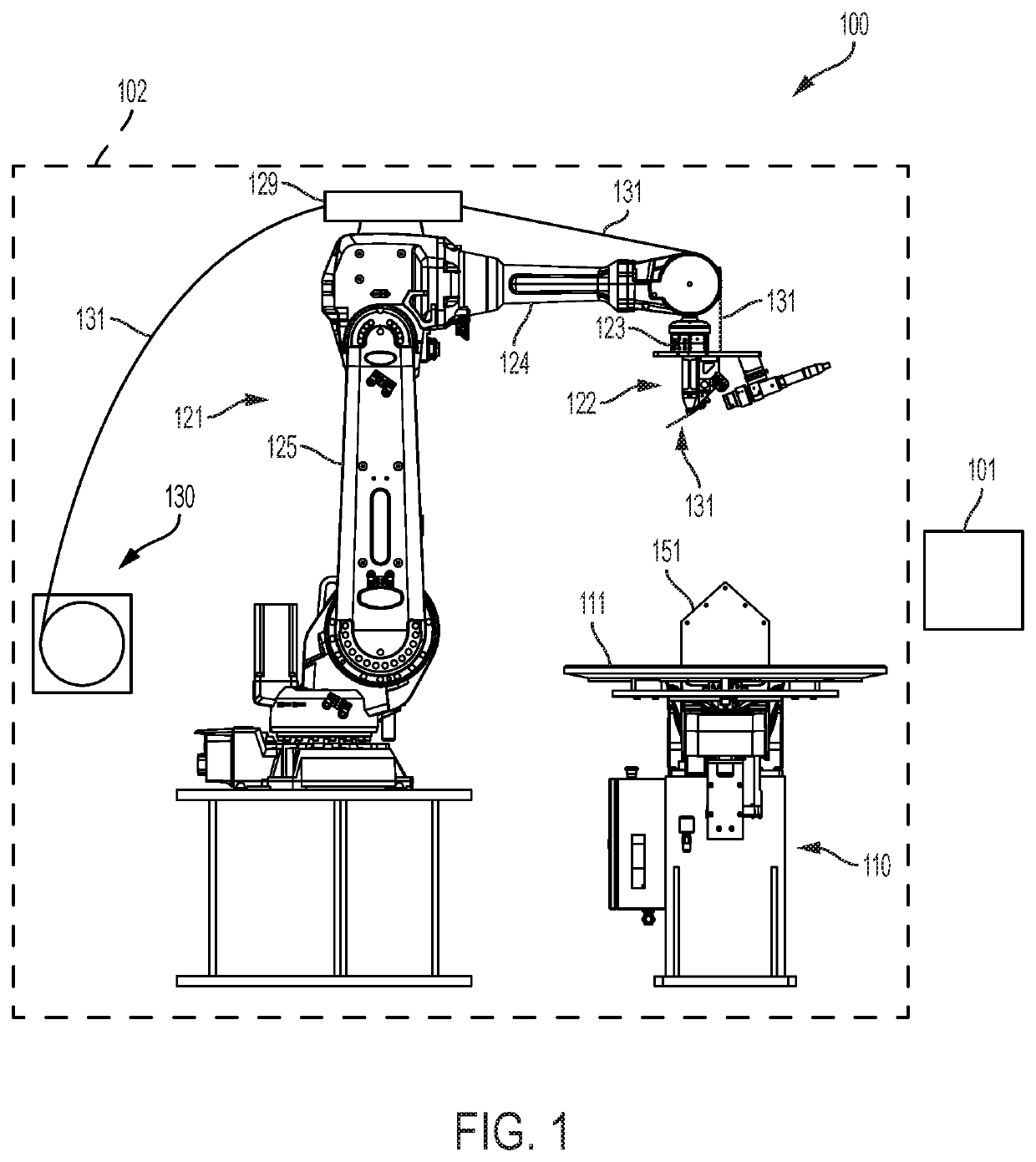

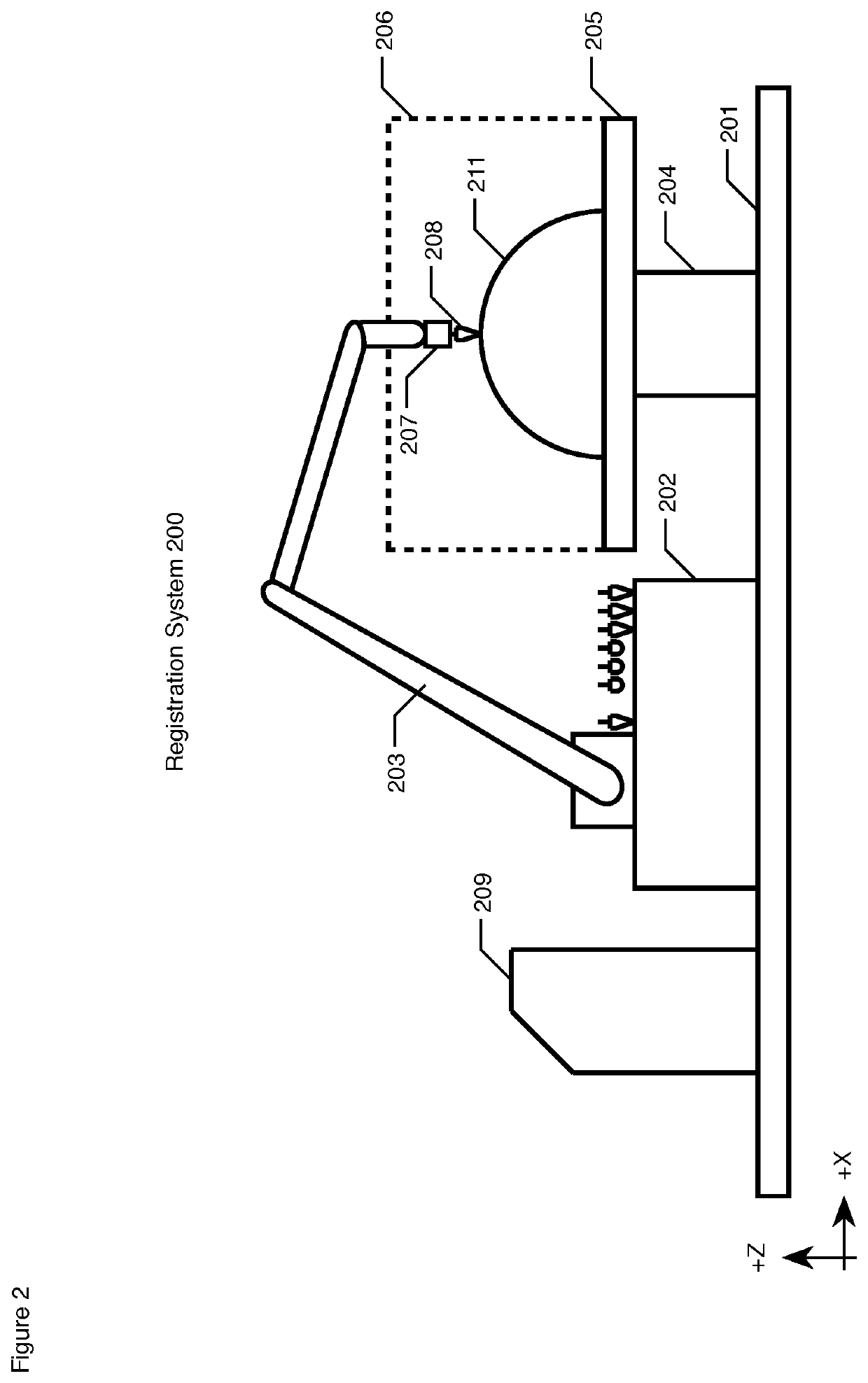

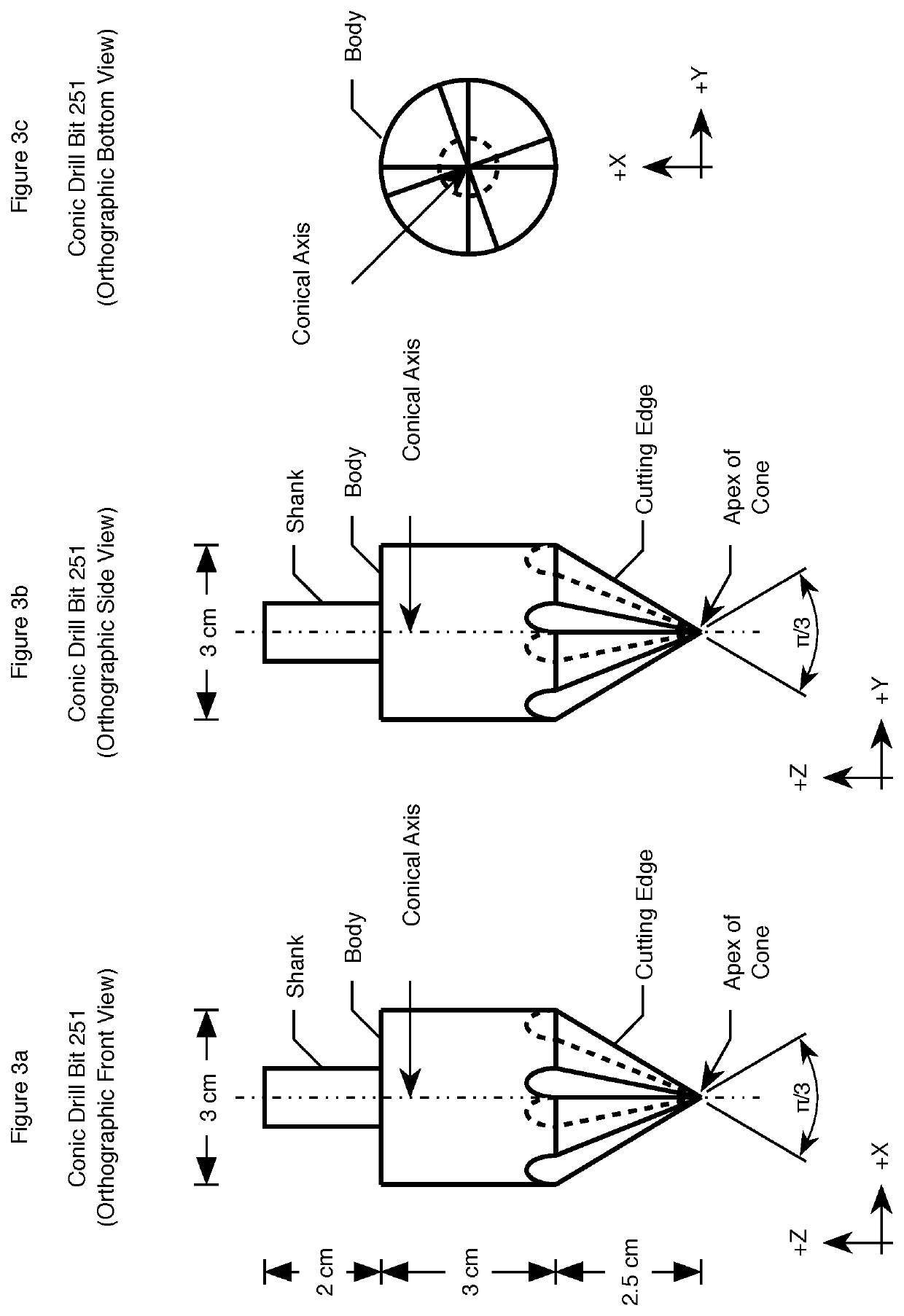

Fiducial marks for articles of manufacture with non-trivial dimensional variations

ActiveUS10252350B1Accurate locationProgramme-controlled manipulatorImage enhancementEngineeringSpherical form

The illustrative embodiment of the present invention uses a tangible three-dimensional structure as a fiducial mark, which structure is, at least partially, tolerant of dimensional variations in the article. The illustrative embodiment uses three such tangible three-dimensional structures: (1) a portion of a tangible conical surface, (2) a portion of a tangible spheroidal surface, and (3) a portion of a tangible pyramidal surface.

Owner:AREVO INC

Damaged bolt and screw removing devices

Owner:COMBINED PRODS

Orthopedic screw extractor

An orthopedic screw extractor device including a shaft, an end portion about a first end of the shaft for securing to a handle, and a screw extracting tip about a second end of the shaft opposite the first end. The screw extracting tip further includes a generally frustoconical shape having a side at an angle of about 5 to 15 degrees relative to a longitudinal axis of the screw extracting tip. The screw extracting tip further includes first, second and third screw threads and first, second and third flutes circumferentially spaced about the screw extracting tip and extending across an entire length of the screw extracting tip. Each of the screw threads has a lead of about 0.07 to 0.12 inches, a pitch of about 0.02 to 0.04 inches, a thread angle of about 40 to 50 degrees, and a depth of about 0.01 to 0.02 inches.

Owner:SHUKLA MEDICAL

Embedding Fiducial Marks into Articles of Manufacture with Non-Trivial Dimensional Variations

The illustrative embodiment of the present invention uses a tangible three-dimensional structure as a fiducial mark, which structure is, at least partially, tolerant of dimensional variations in the article. The illustrative embodiment uses three such tangible three-dimensional structures: (1) a portion of a tangible conical surface, (2) a portion of a tangible spheroidal surface, and (3) a portion of a tangible pyramidal surface.

Owner:STRATSYS INC

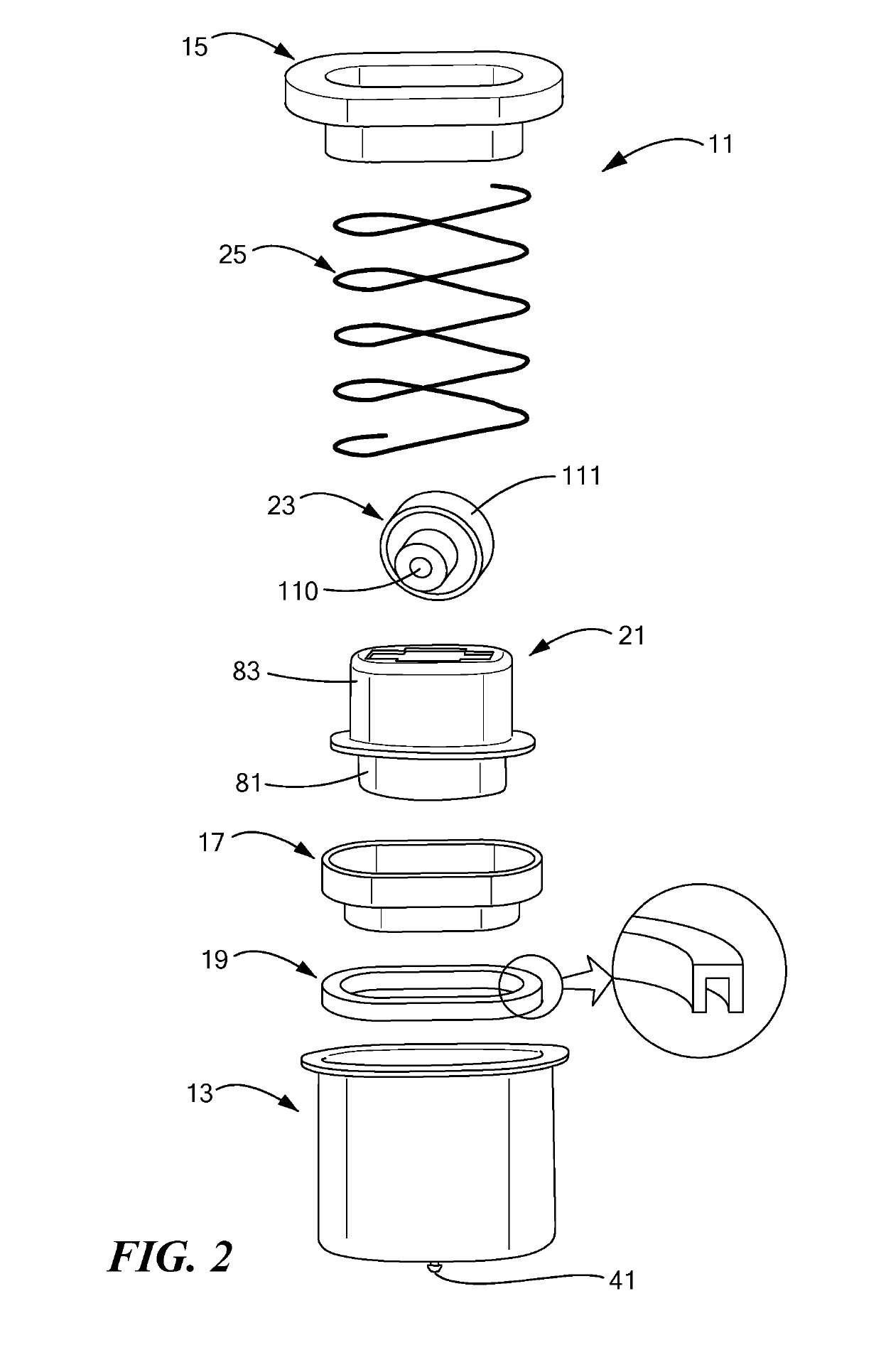

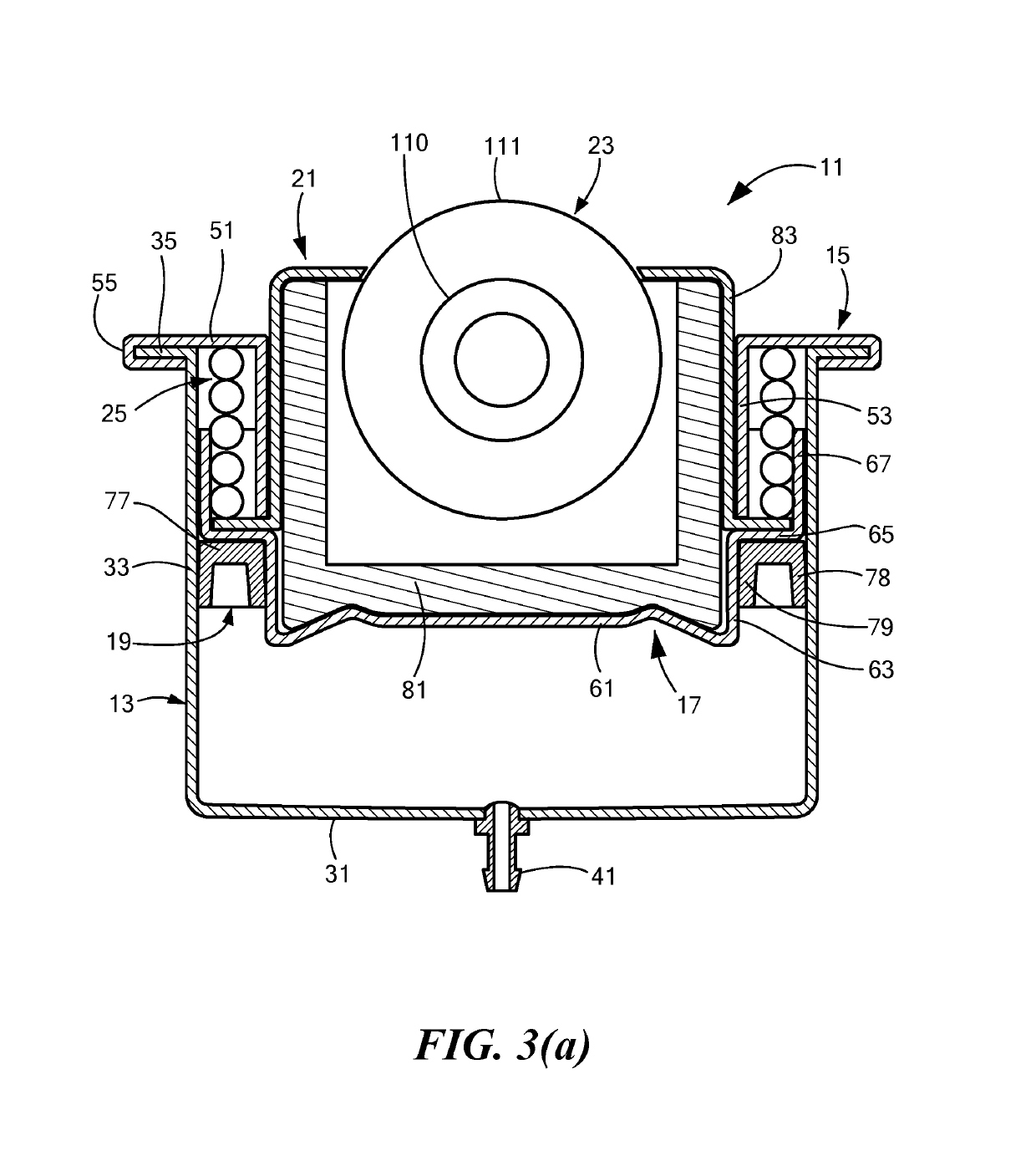

Pop-up wheel device for use in material handling equipment

ActiveUS10464753B2Easy to mass produceEasy to assembleLinear bearingsFluid-pressure actuatorsEngineeringMechanical engineering

A pop-up wheel device for use in material handling equipment. In one embodiment, the pop-up wheel device includes a housing, which is a can of generally track-shaped transverse cross-section. A nipple is mounted in the housing bottom to permit fluid under pressure to pass to and from the interior of the housing. A cap, which includes a central opening, is positioned over and is secured to the housing. A piston is slidably mounted within the housing between a lower position and an upper position. A seal is fitted around a lower portion of the piston and creates an air-tight chamber between the piston and the housing. A spring biases the piston towards the lower position. A wheel that is freely rotatable in one direction is coupled to the piston using a wheel mount. The wheel may be removed from the wheel mount without removing the cap from the housing.

Owner:OMTEC CORP

Damaged bolt and screw removing devices

InactiveUS20060101949A1Leaves intactImprove biteTransportation and packagingSpannersFluteEngineering

A bit for removing a broken fastener comprises a tip from which extend two or more notches separated by traction or biting surfaces formed from two-sided frusto-conically-shaped regions. The surfaces are bounded on one side by a nonlinear cutting edge and on the other side by a non-cutting edge and are configured to cut into the fastener when the bit is rotated in a direction opposite to the fastener's direction of engagement. Specific embodiments include configurations where the cutting edges extend at different angles with respect to the bit axis, where the biting surfaces comprise a plurality of serrations, and where the cutting edges are separated by flutes which spiral along a longitudinally extending periphery of the bit.

Owner:COMBINED PRODS

Orthopedic screw extractor

An orthopedic screw extractor device including a shaft, an end portion about a first end of the shaft for securing to a handle, and a screw extracting tip about a second end of the shaft opposite the first end. The screw extracting tip further includes a generally frustoconical shape having a side at an angle of about 5 to 15 degrees relative to a longitudinal axis of the screw extracting tip. The screw extracting tip further includes first, second and third screw threads and first, second and third flutes circumferentially spaced about the screw extracting tip and extending across an entire length of the screw extracting tip. Each of the screw threads has a lead of about 0.07 to 0.12 inches, a pitch of about 0.02 to 0.04 inches, a thread angle of about 40 to 50 degrees, and a depth of about 0.01 to 0.02 inches.

Owner:SHUKLA MEDICAL

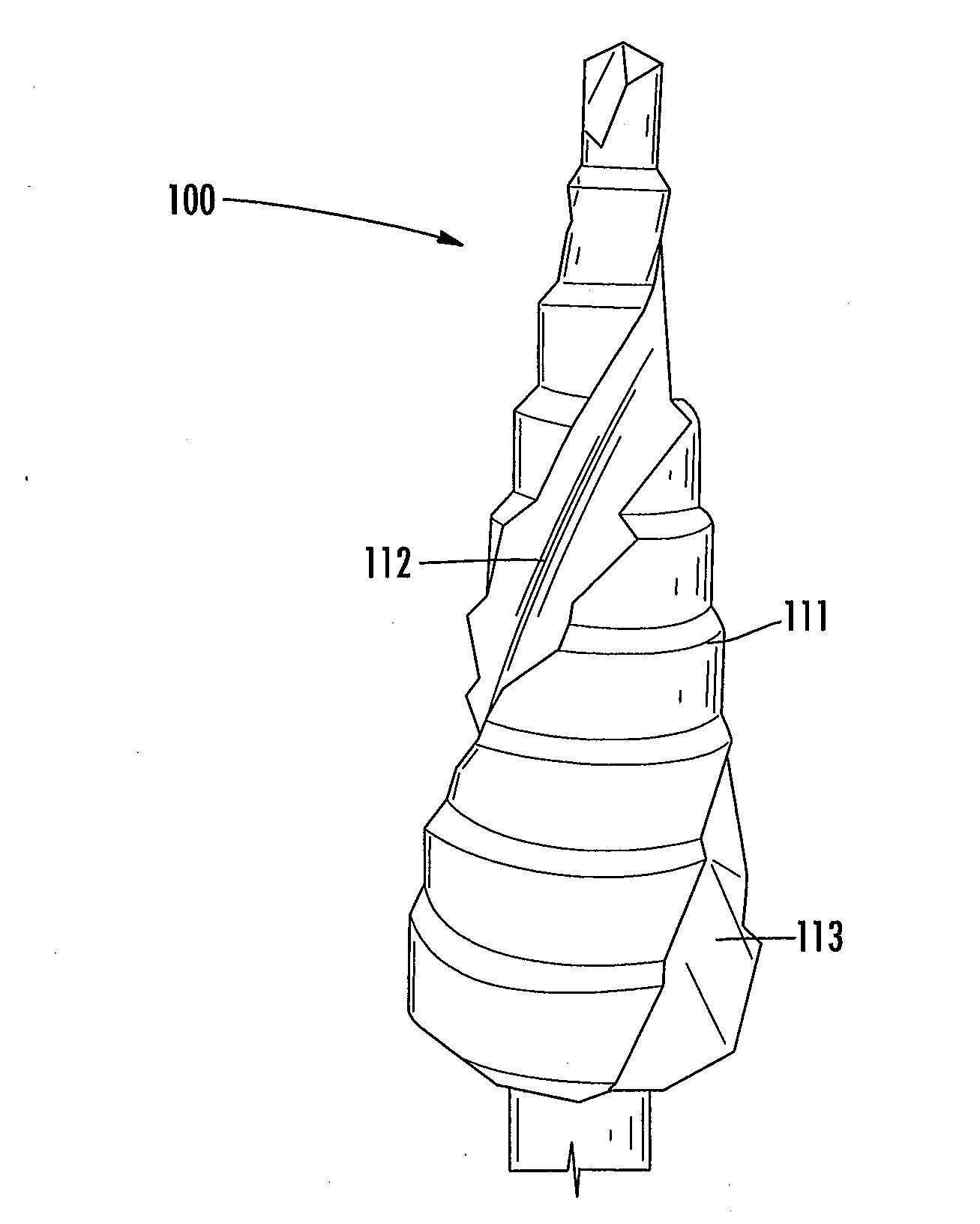

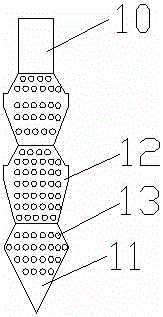

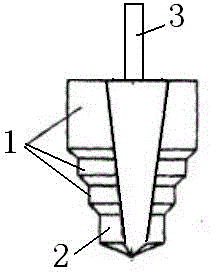

Tapered step drill

The invention discloses a tapered step drill which comprises a drill, a drill handle and a tapered main body, wherein the tapered main body comprises a plurality of step sections which are connected in sequence from top to bottom; each step section comprises cylindrical main bodies and an inverted truncated conical secondary body, the cylindrical main bodies are arranged in sequence from top to bottom, central axes of the inverted truncated conical secondary body and the cylindrical main bodies are on the same straight line, the top surface of the inverted truncated conical secondary body is connected with the bottom surfaces of the cylindrical main bodies, the areas of the top surface of the inverted truncated conical secondary body and the bottom surfaces of the cylindrical main bodies are equal, thread through holes along the central axes are formed in the step sections, a threaded hole is formed in the drill, one end of the drill handle is used for connecting a clamping device, threads are formed on the other end of the drill handle, one end, which is provided with the threads, of the drill handle penetrates through the plurality of step sections in sequence, and the end of the drill handle is screwed in the threaded hole. According to the tapered step drill, the drill, the drill handle and the tapered main body are not integrated, additionally, the tapered main body is composed of the plurality of step sections, and when partial step sections are damaged, only the corresponding part needs to be replaced, so that resources are saved.

Owner:滁州用朴合金工具有限公司

Damaged bolt and screw removing devices

InactiveCN1951637AImprove biteEfficient extractionTransportation and packagingSpannersEngineeringMechanical engineering

A bit for removing a broken fastener comprises a tip from which extend two or more notches separated by scraping surfaces formed from two-sided frusto-conically-shaped regions. The scraping surfaces are bounded on one side by a cutting edge and on the other side by a non-cutting edge and are configured to cut into the fastener when the bit is rotated in a direction opposite to the fastener's direction of engagement. Specific embodiments include configurations where the cutting edges extend at different angles with respect to the bit axis and where the scraping surfaces comprise a plurality ofserrations.

Owner:COMBINED PRODS

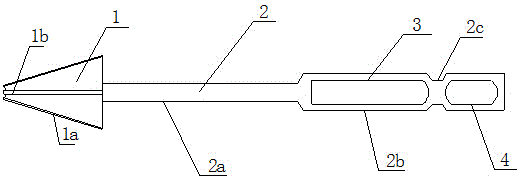

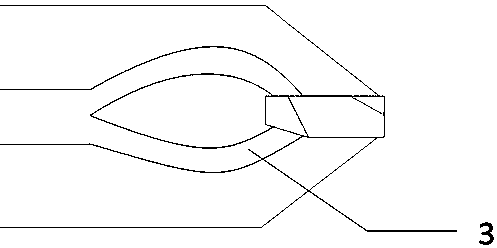

Drill bit capable of performing multichannel chip removal

InactiveCN104816016AEffective dredgingSolve the difficulty of chip removalTransportation and packagingConical drillsDrillDrill bit

The invention discloses a drill bit capable of performing multichannel chip removal. A main body is a drill bit body. The drill bit body is integrally formed by a drill bit and a drill body. The drill bit is characterized in that the drill bit is structurally a cone, a tip part of the drill bit is designed into a plane end with the length of 0.5-1.5 cm, the cone is provided with a spiral groove, and a through hole is formed in the center line of the drill bit in the axial direction. The drill body is a two-stage step type cylinder, a groove is formed in one stage of the cylinder in the circumferential direction to divide the cylinder into two sections, and each section is internally provided with a long hole. The multichannel chip removal is adopted by the drill bit, a conical spiral drill bit structure is combined; during the drilling through the drill bit, a chip removal channel is divided into a spiral chip removal mode and a straight channel chip removal mode, chip removal channels are effectively dredged, and the problem of difficulty in chip removal is solved.

Owner:启东市吕四科技创业中心有限公司

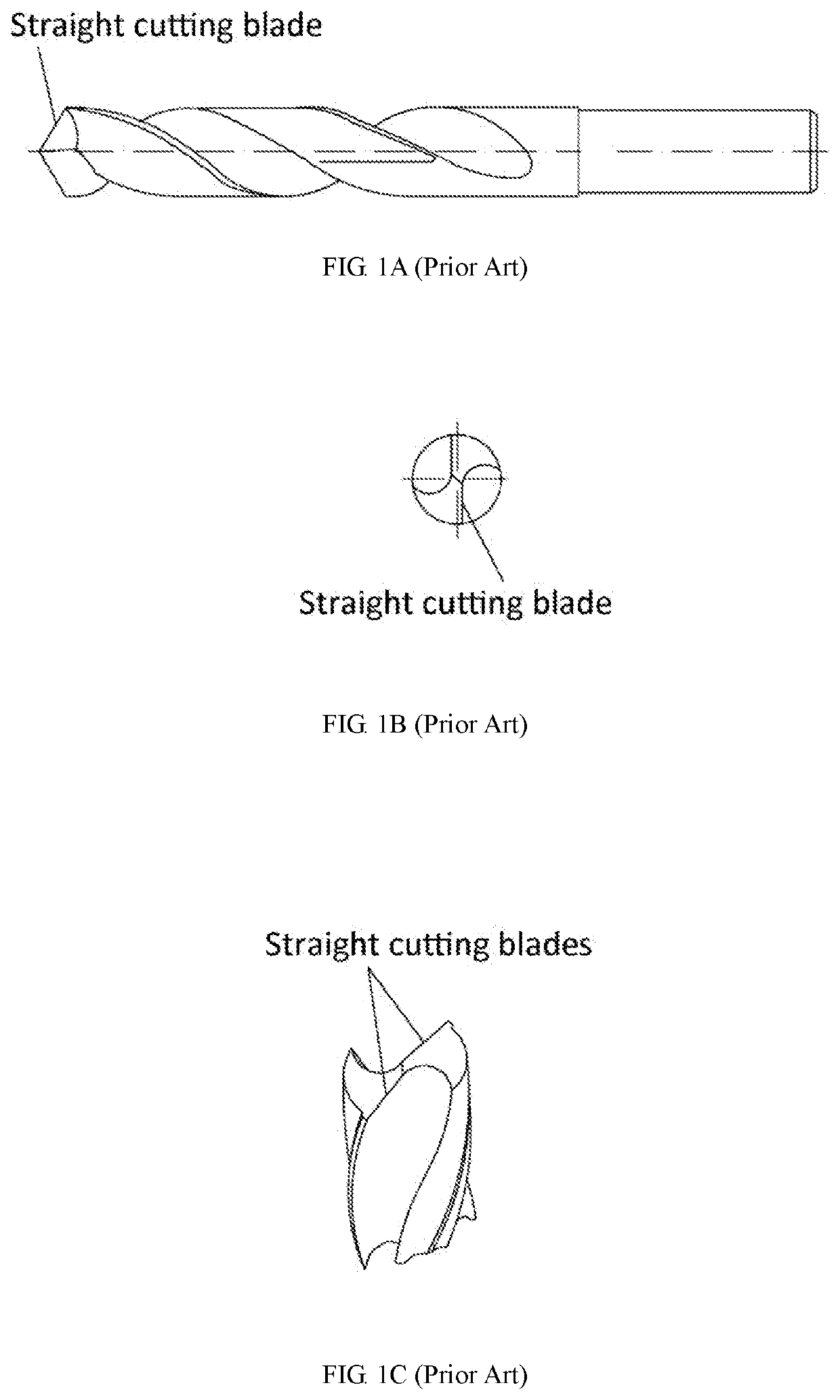

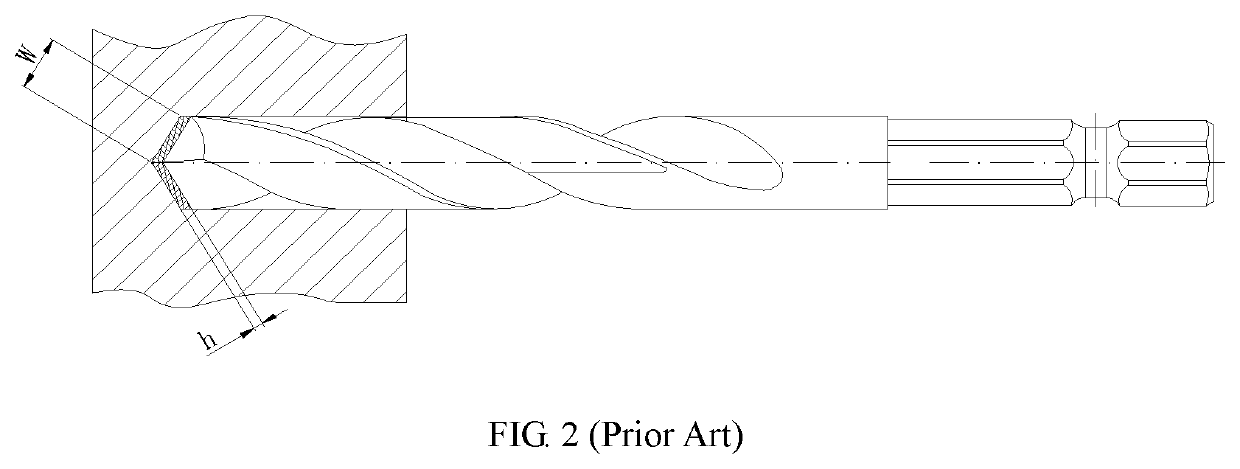

Twist drill

ActiveUS20200094331A1Smoother drilling processImprove drilling efficiencyConical drillsTwist drillsClassical mechanicsStructural engineering

The present invention provides a twist drill. A cone portion is provided at a front end of the operating portion, and an exterior surface of the operating portion is provided with a spiral flute for shunting cutting chips. The exterior surface of the cone portion is provided with a plurality of composite cutting blade groups which are sequentially enlarged in diameter from the front end to the rear end of the cone portion. The cone portion is provided with a top blade on the tip. In use, the top blade is used for positioning, and the cutting process is carried out by the top blade and the composite cutting blade groups.

Owner:WANG HONGJIA

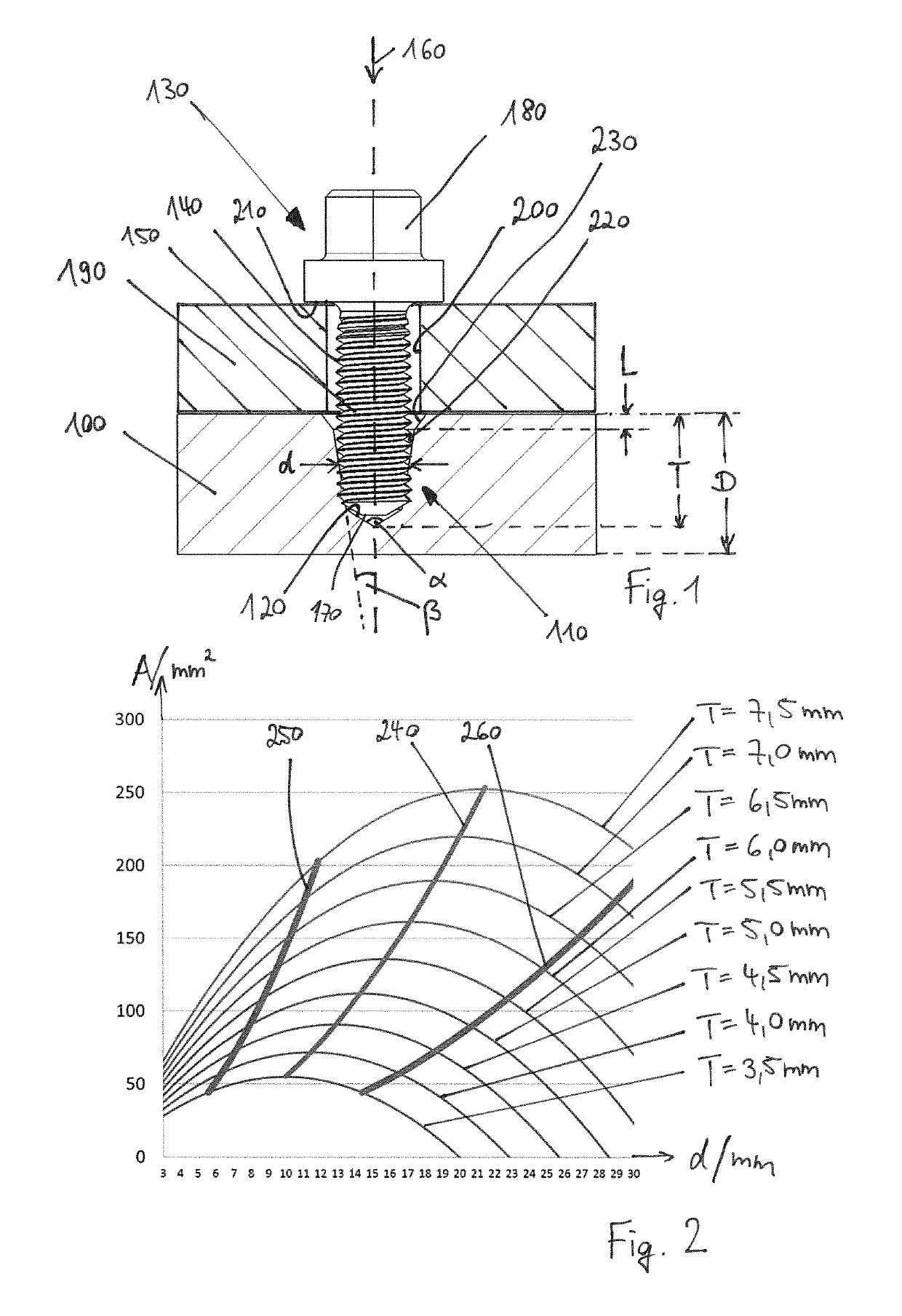

Fastening method

A method for fastening a component to a base element, in which method there is produced in the base element a blind bore which defines a depth direction and which has a force transmission surface which has a depth T in the depth direction, wherein the force transmission surface is of frustoconical form with a cone opening half-angle (β) and a mean diameter (d), wherein the blind bore has a conical blind bore base with a cone opening angle (α) and, at the edge thereof, a bevel which extends in the depth direction to a bevel depth L, wherein, in the method, a fastening element is anchored in the blind bore by way of the force transmission surface, and wherein the component is held by the fastening element.

Owner:HILTI AG

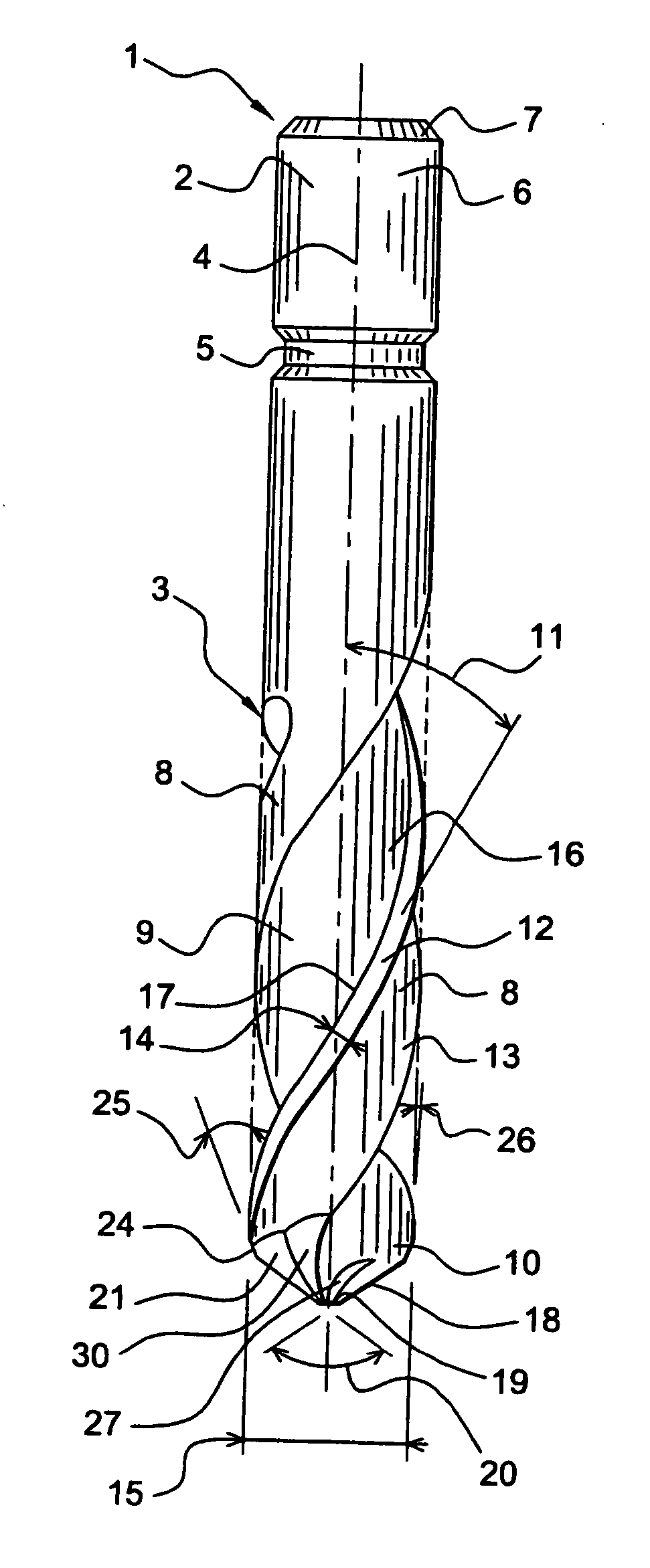

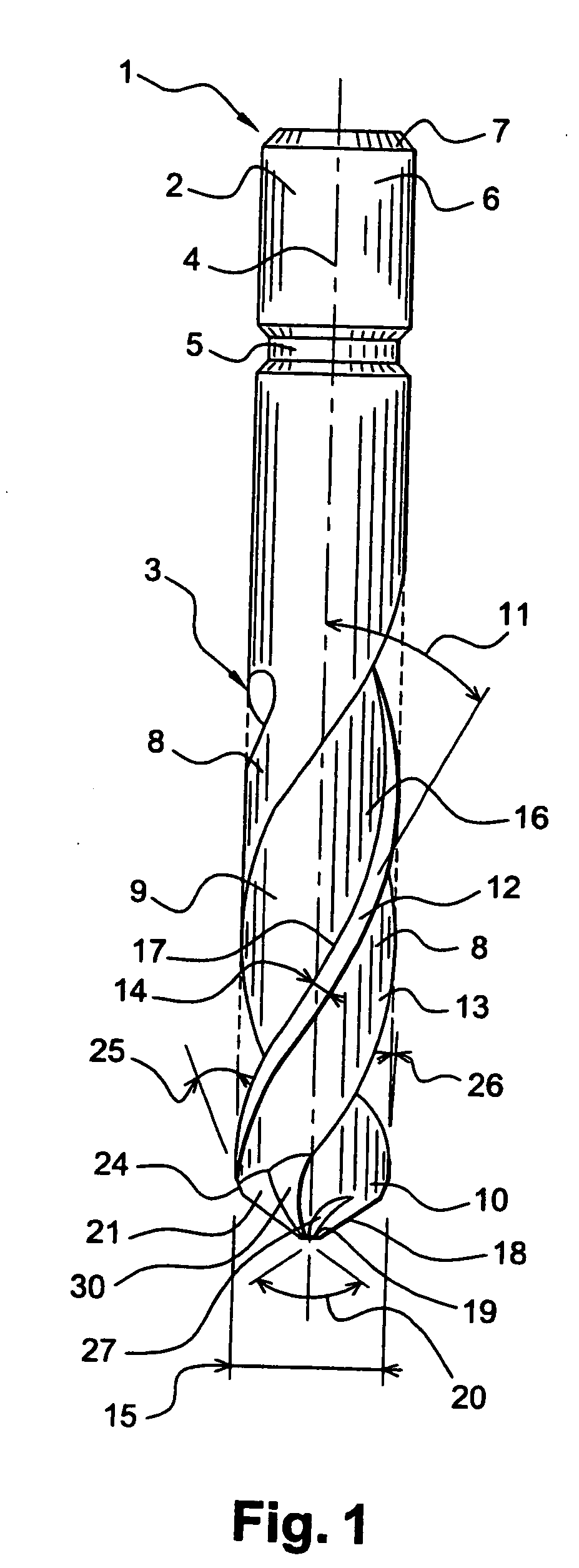

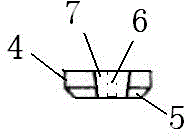

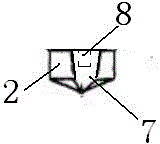

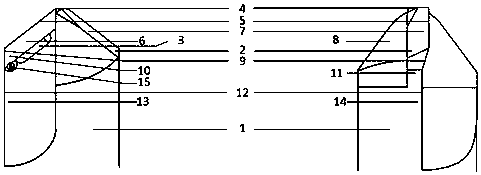

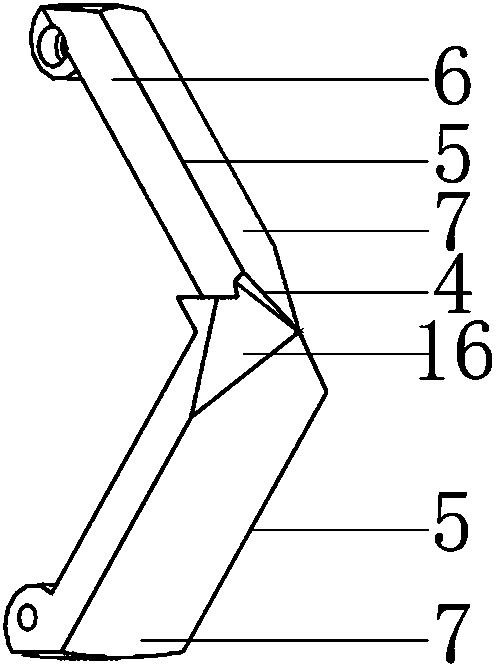

Air suction type drill bit with replaceable blades used in CFRP drilling

PendingCN108817482AImprove processing qualityReduce the temperatureTransportation and packagingConical drillsChiselKnife blades

The invention relates to a drill bit used in CFRP drilling to reduce the defects in the process of CFRP machining. The drill bit comprises 1-drill body, 2-blades, 3-air suction duct, 4-chisel edge, 5-main cutting edge, 6-main rake face, 7-first main flank face, 8-second main flank face, 9-first minor cutting edge, 10-first minor rake face, 11-first minor flank face, 12-second minor cutting edge, 13-second minor rake face, 14-second minor flank face, 15-screw and 16-cutting at chisel edge. The effects of tearing, burrs, delamination and thermal damage during machining can be achieved, and the machining cost can be reduced by the replaceable blades.

Owner:HARBIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com