Patents

Literature

64results about "Spade drills" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

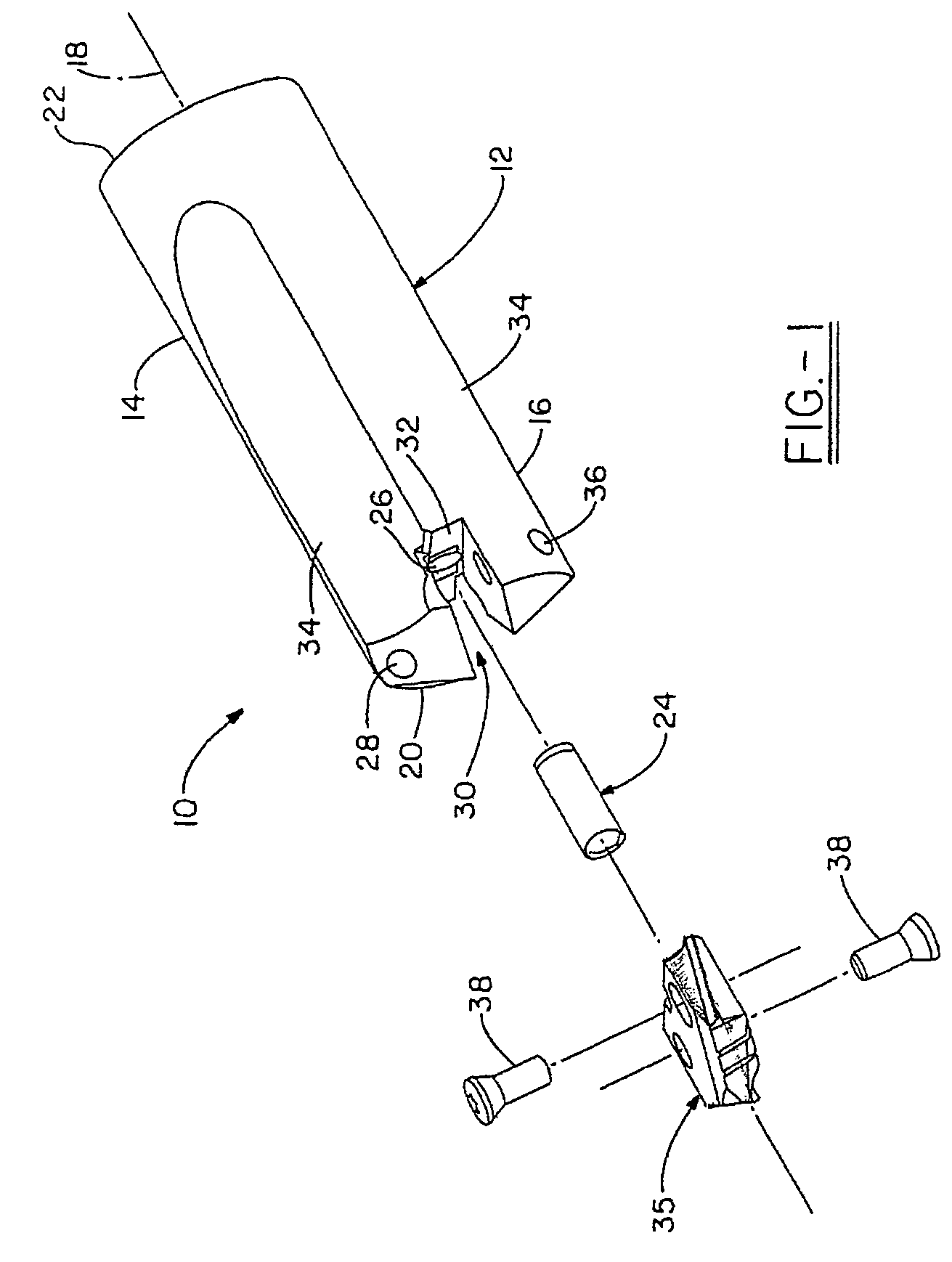

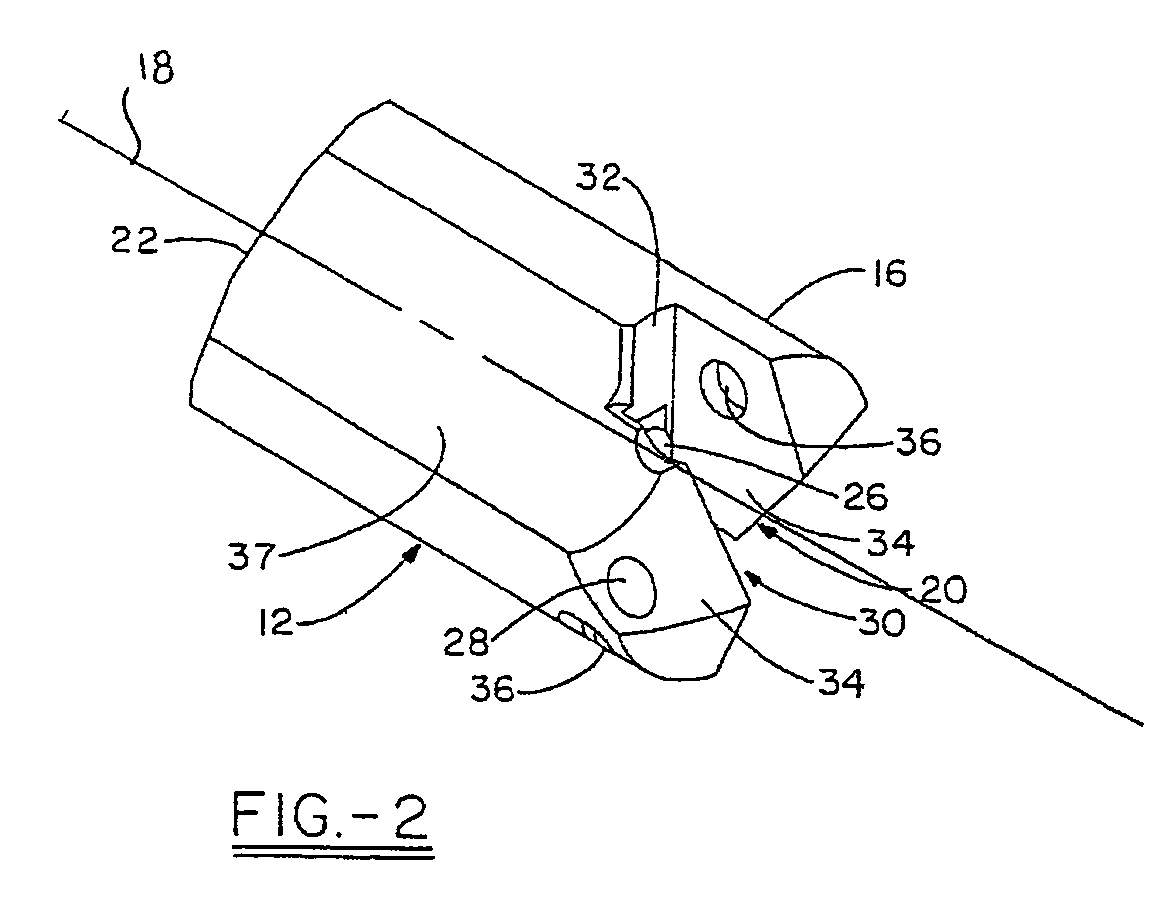

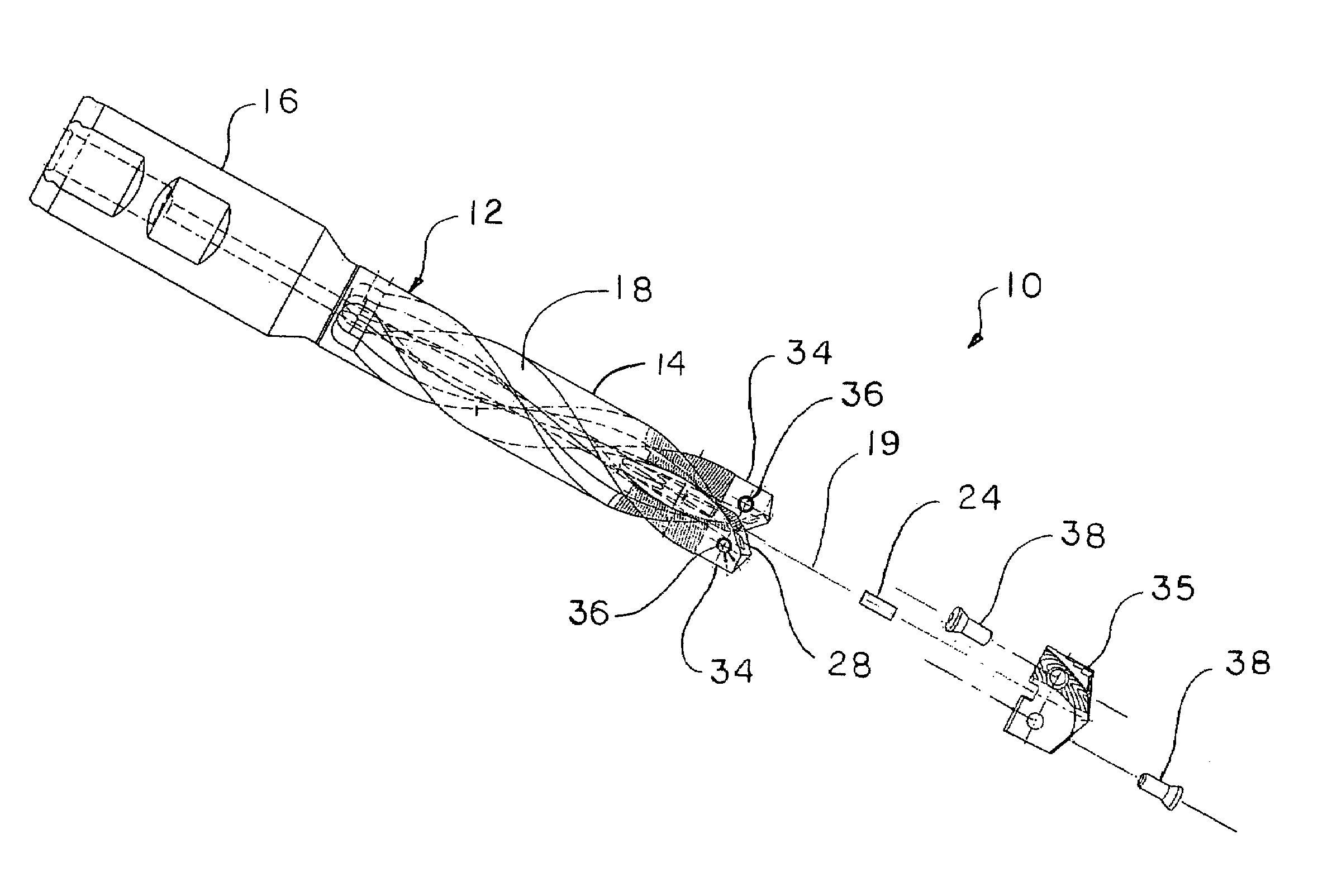

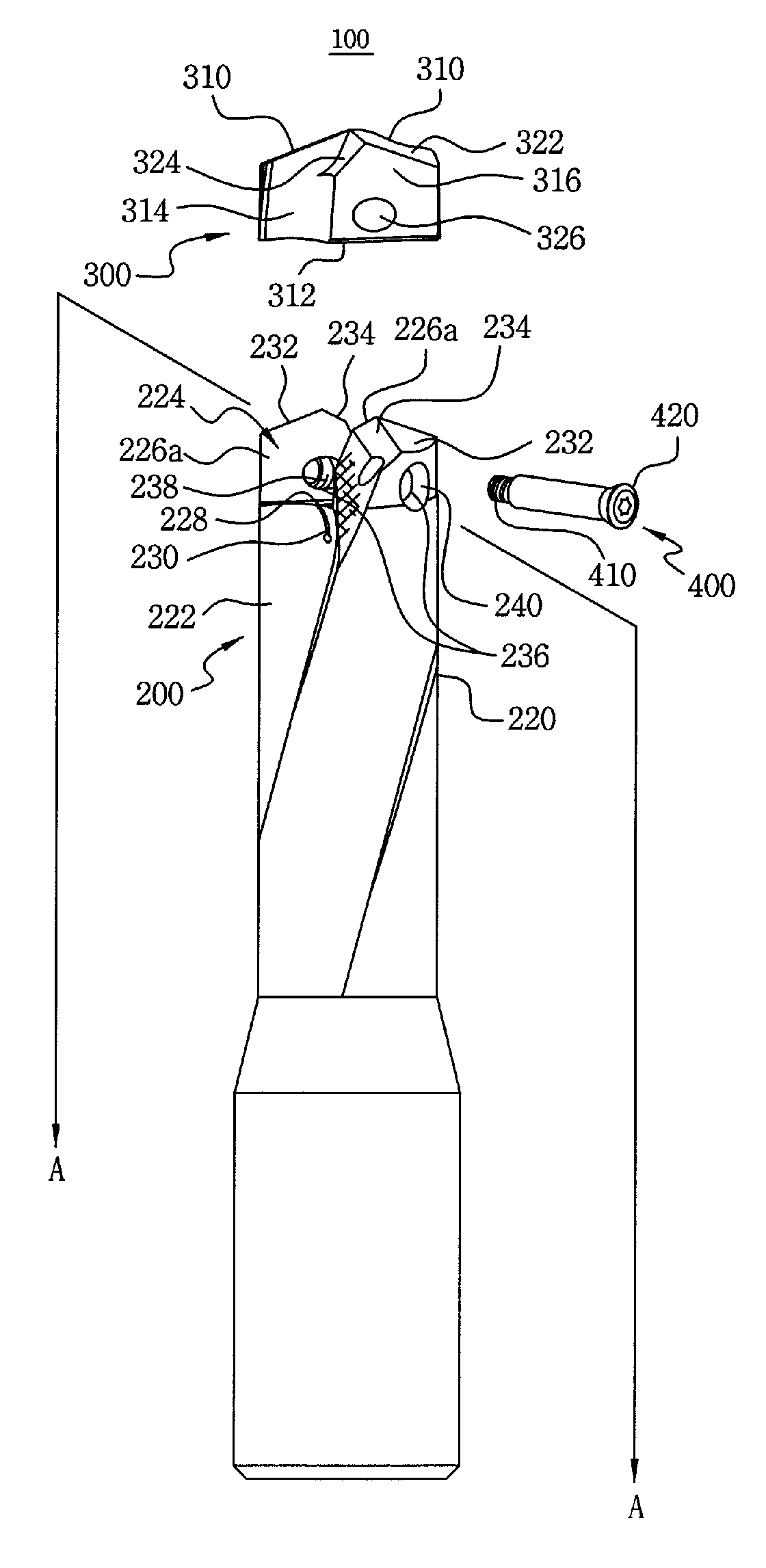

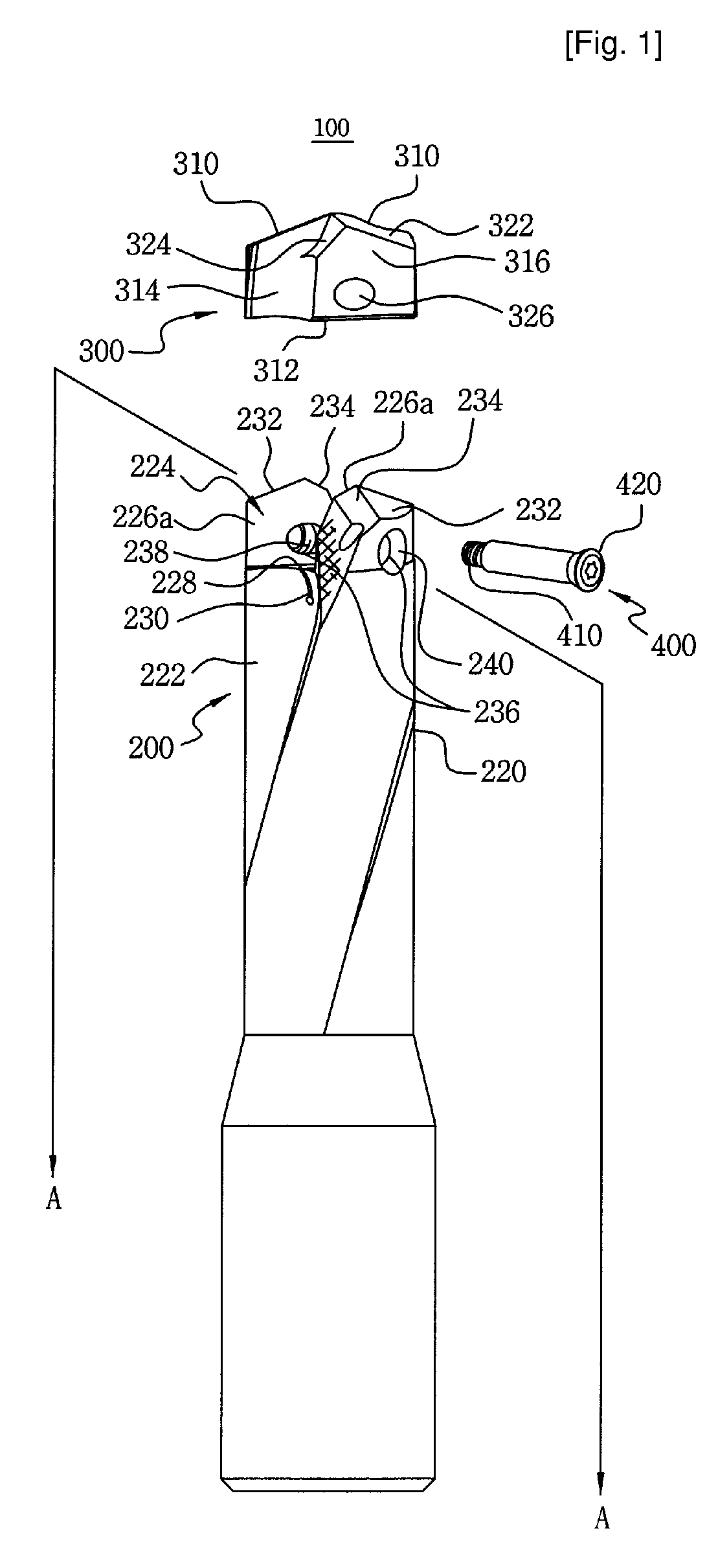

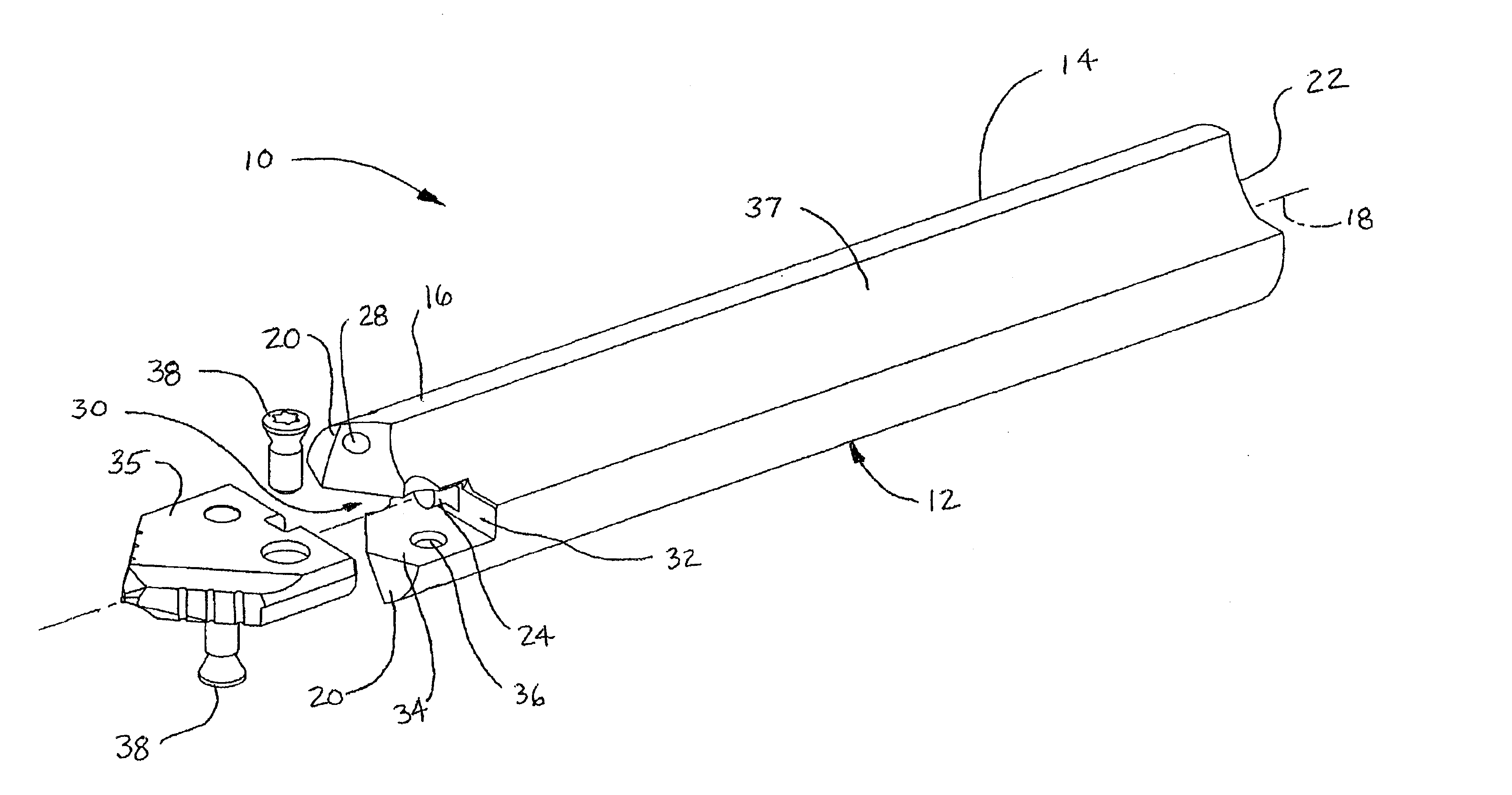

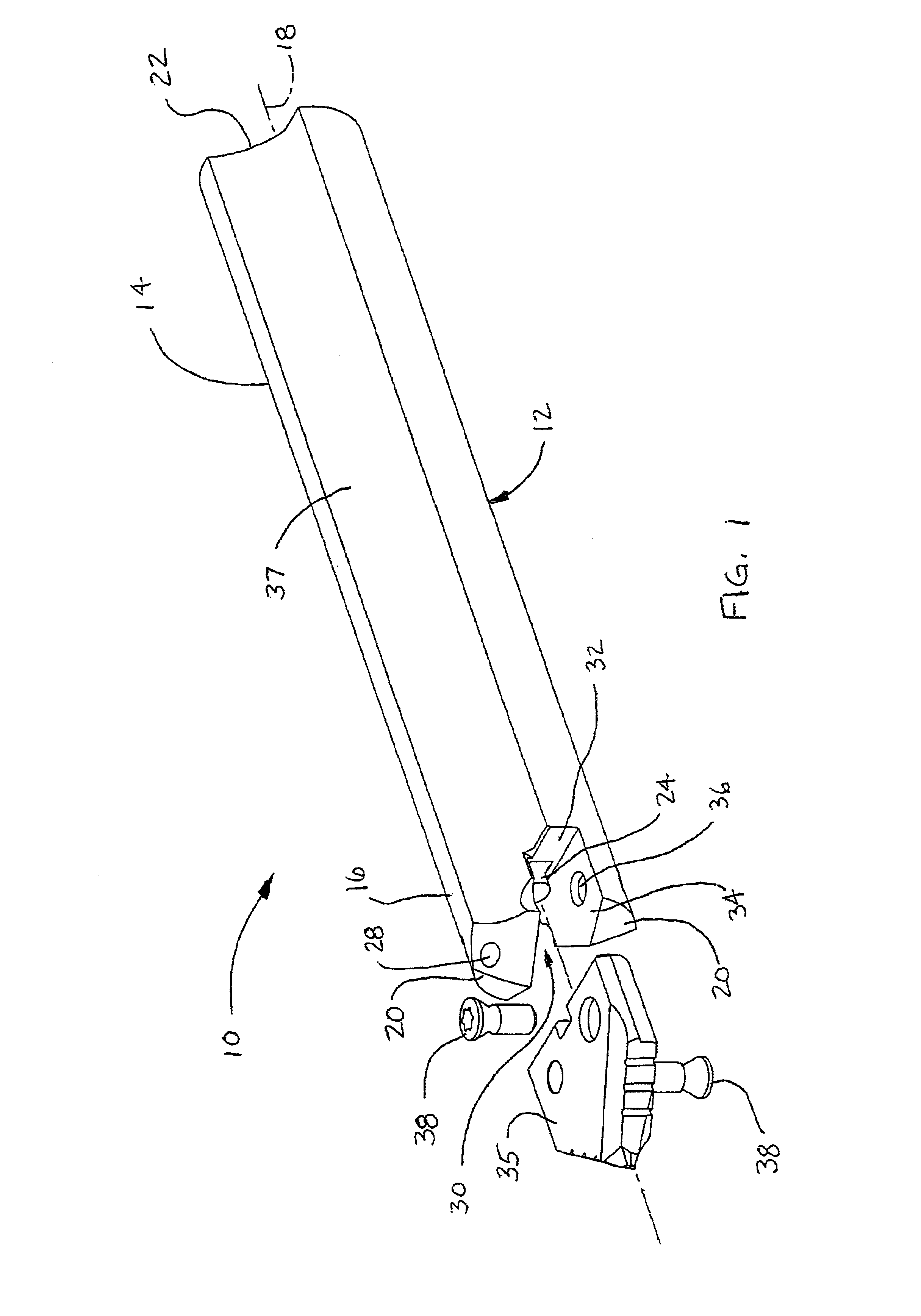

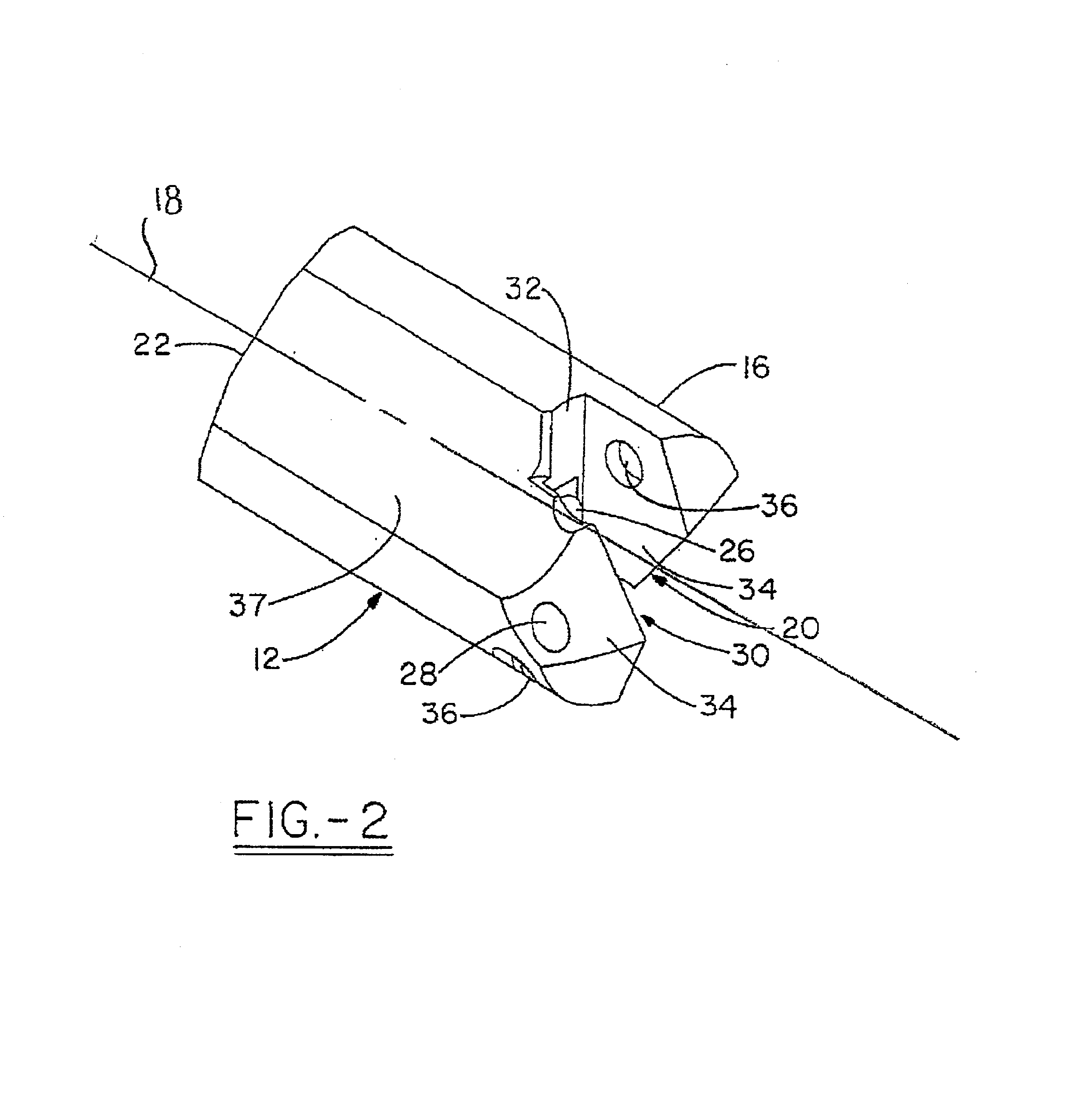

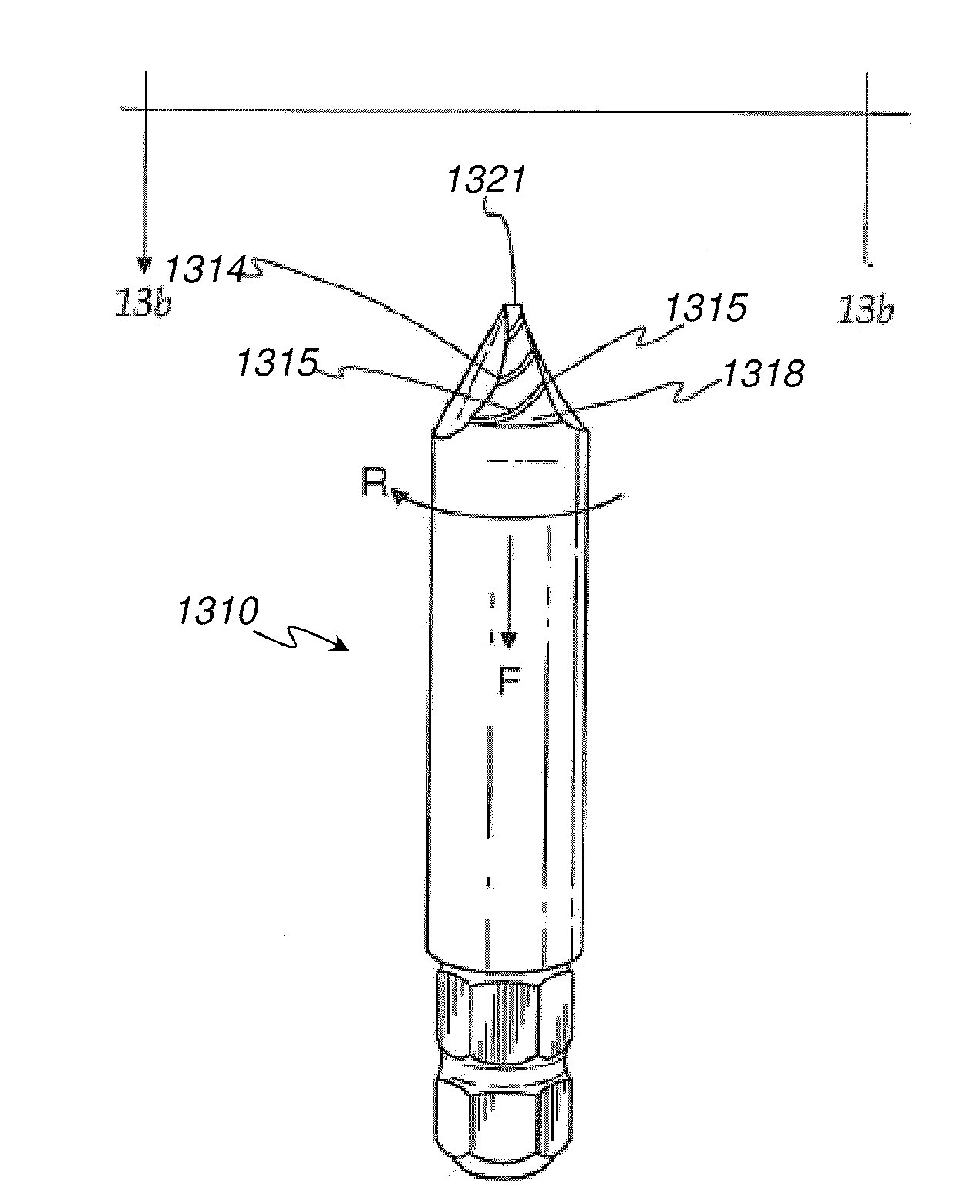

Multi-Piece Drill Head and Drill Including the Same

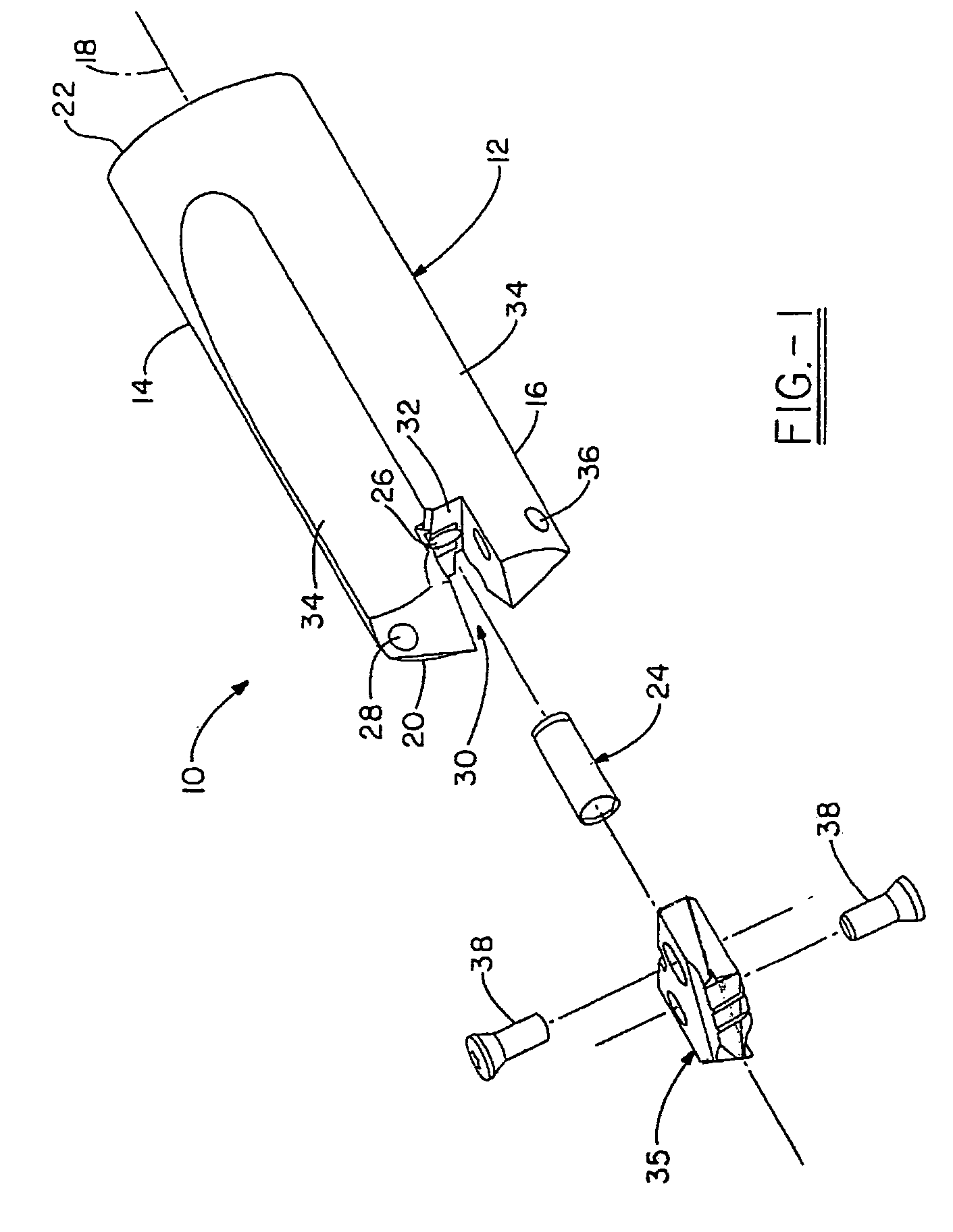

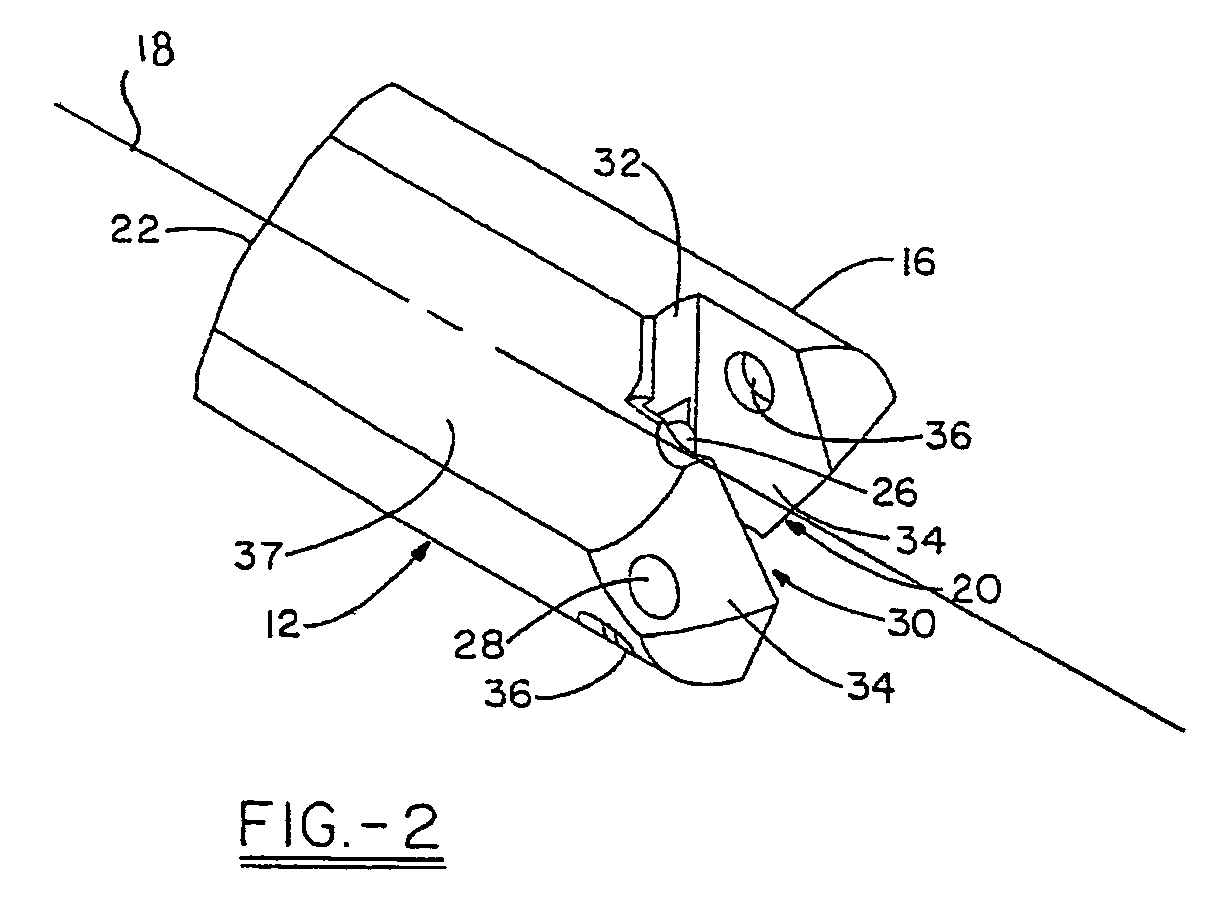

One non-limiting aspect of the present disclosure is directed to a multi-piece spade drill head for a spade drill, wherein the spade drill includes an elongate body portion and a cutting portion removably secured to an end of the body portion. The multi-piece spade drill head includes at least two insert pieces, each piece including a cutting edge. The at least two insert pieces are configured to be removably secured to the body portion of the spade drill adjacent one another and with the cutting edges of the insert pieces aligned to together form a cutting edge on an end of the spade drill.

Owner:KENNAMETAL INC

Indexable Type Cutting Tool

InactiveUS20080003072A1Improve cutting performanceSimply and quickly and precisely fastenedThread cutting toolsWood turning toolsFluteEngineering

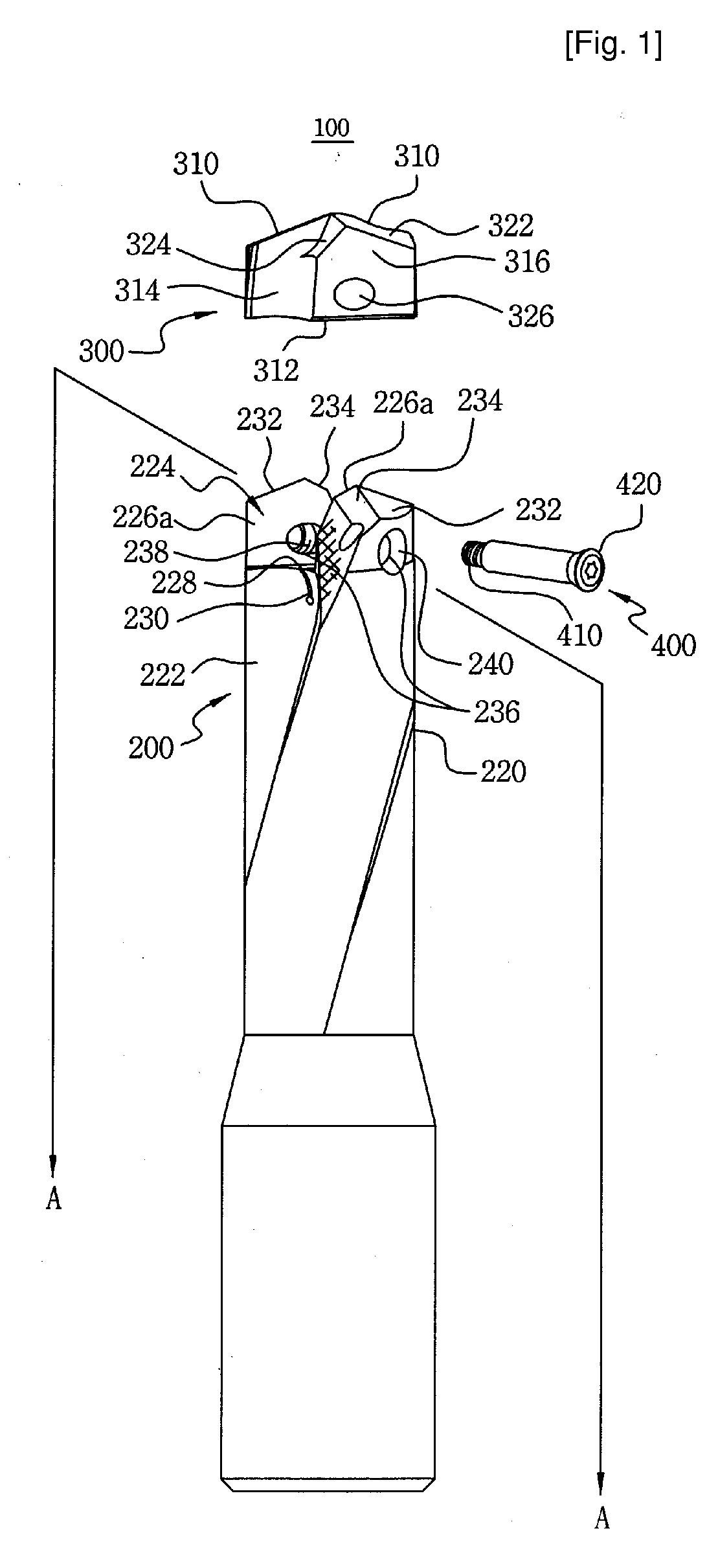

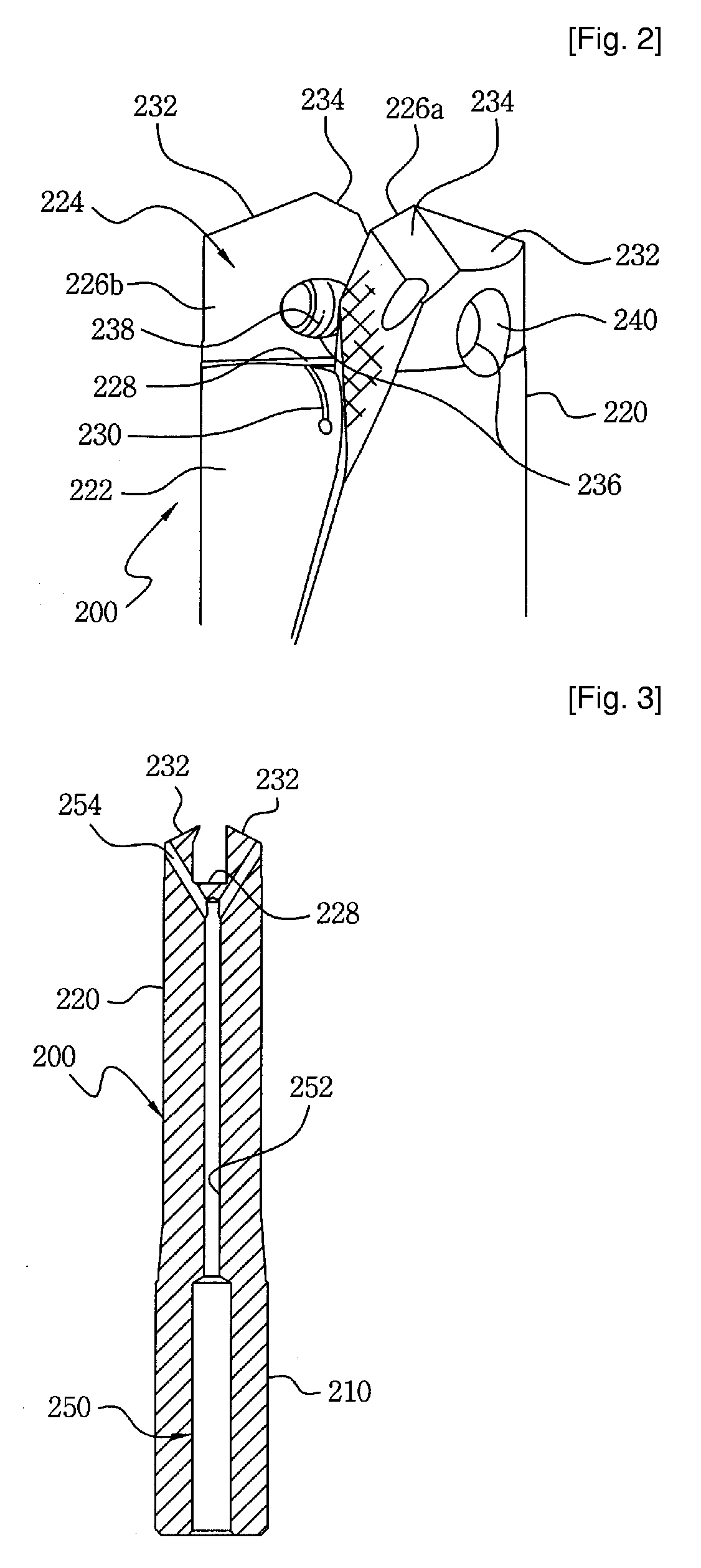

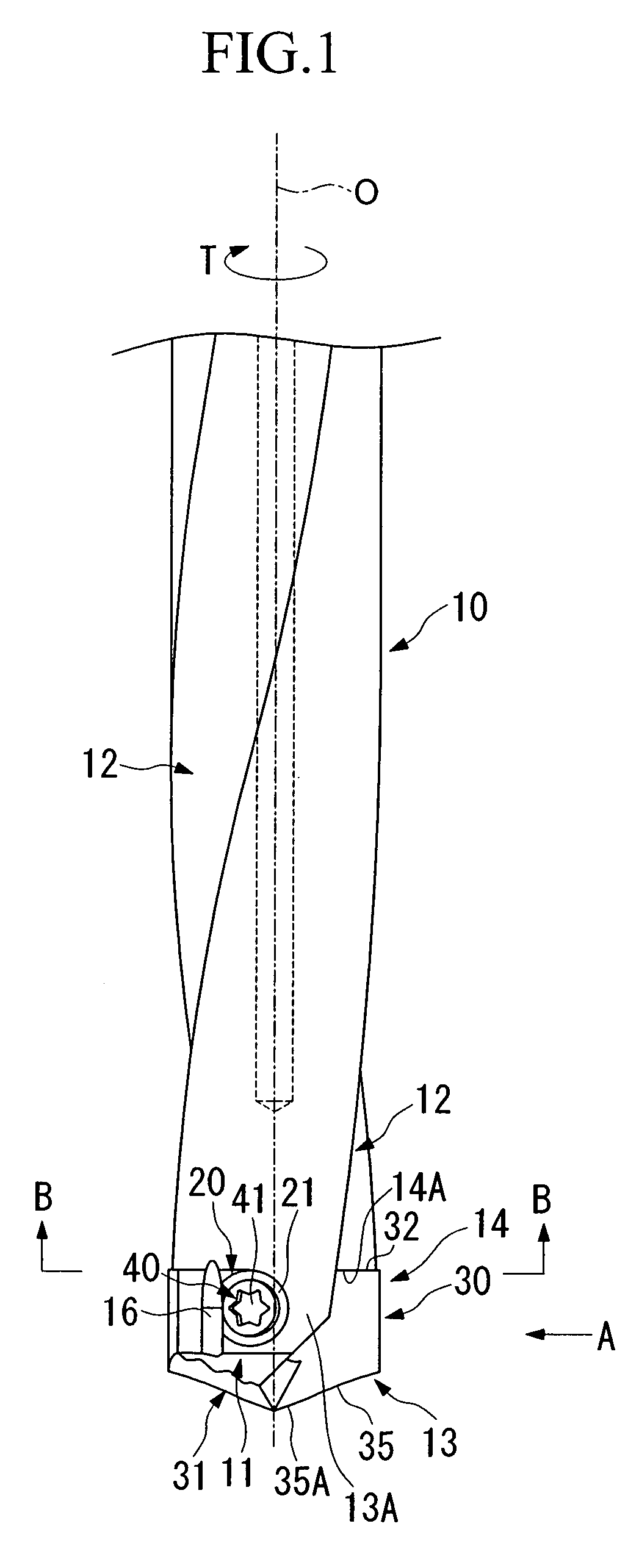

An indexable type cutting tool comprises a drill having a shank and a drill body which extends from the shank, the drill body being defined with body flutes, and being formed with an insert seat which has seat side surfaces and a seat bottom surface and body flank surfaces and body thinning surfaces; a drill insert fitted into the insert seat of the drill body, having cutting edges and an insert bottom surface which is brought into close contact with the seat bottom surface, formed with insert flutes and insert side surfaces which are brought into close contact with the seat side surfaces, and defined with a through-hole which passes through the insert side surfaces; and a fastening screw for fastening the drill insert fitted into the insert seat to the drill.

Owner:KORLOY

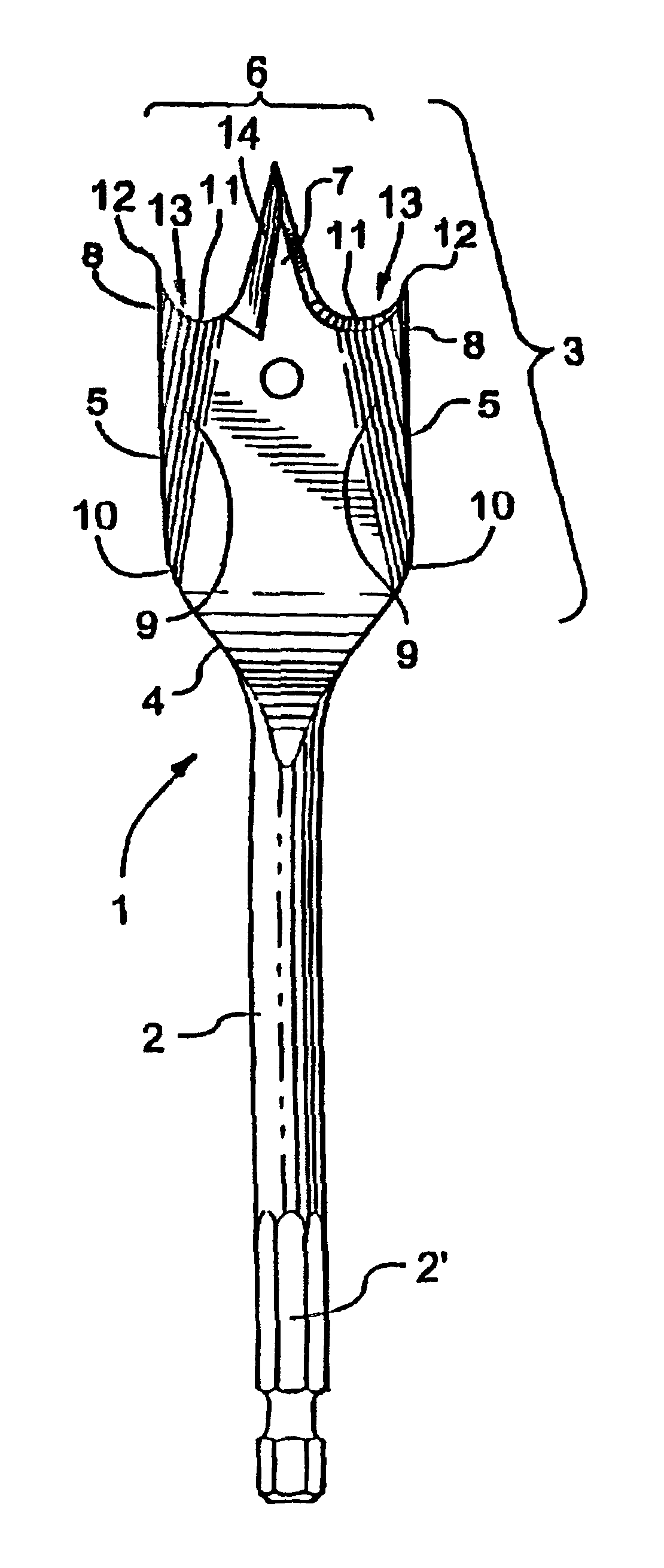

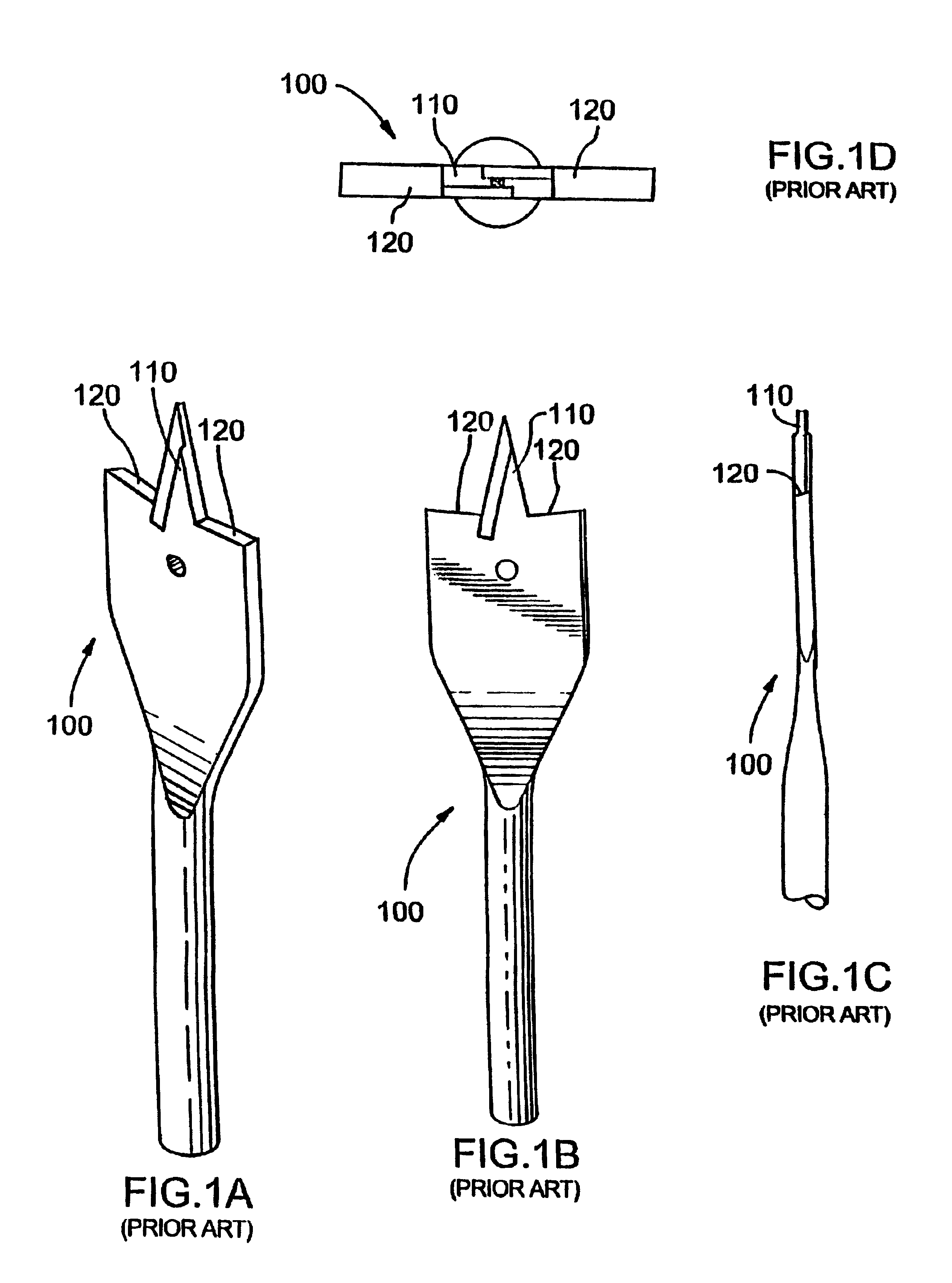

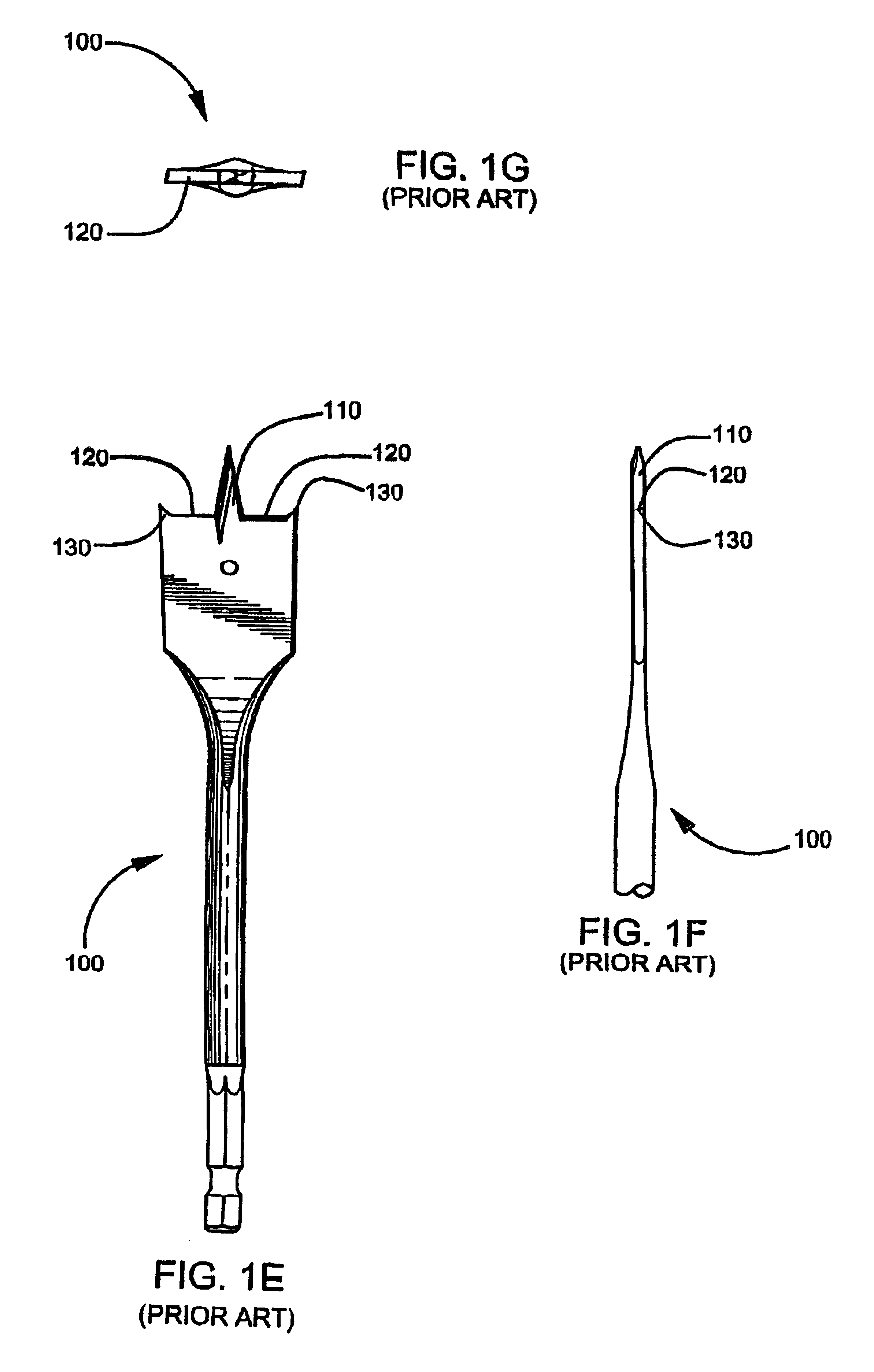

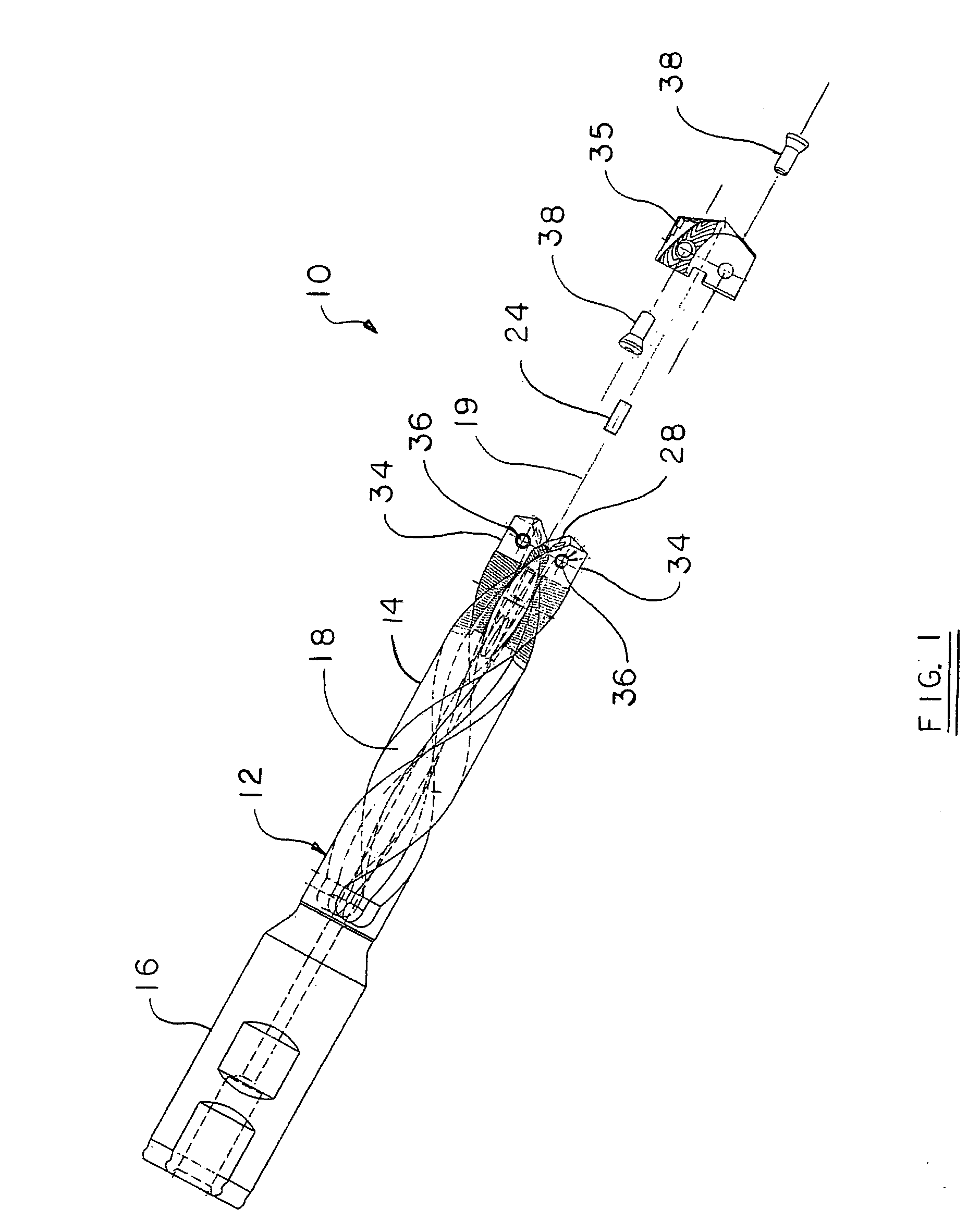

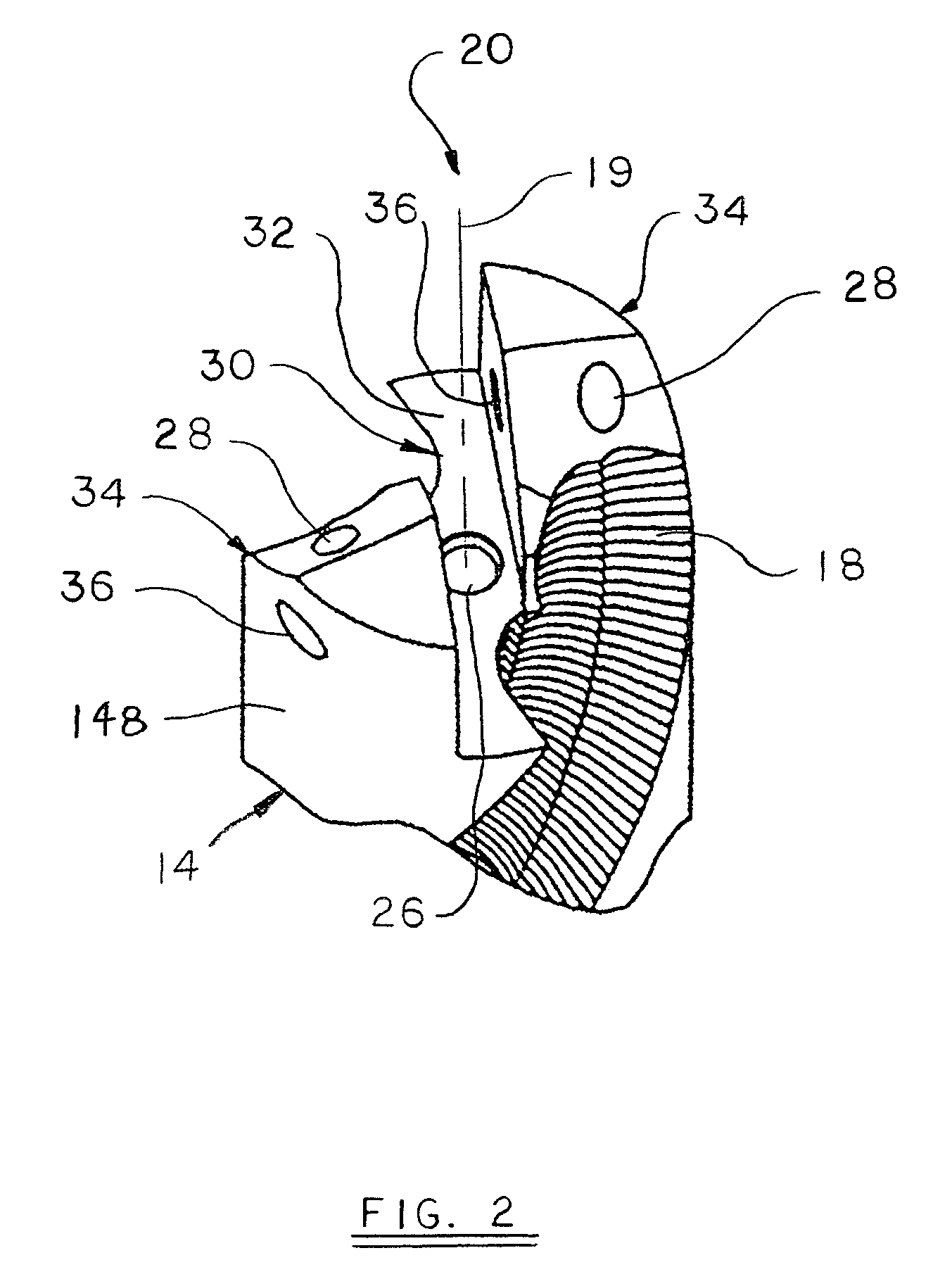

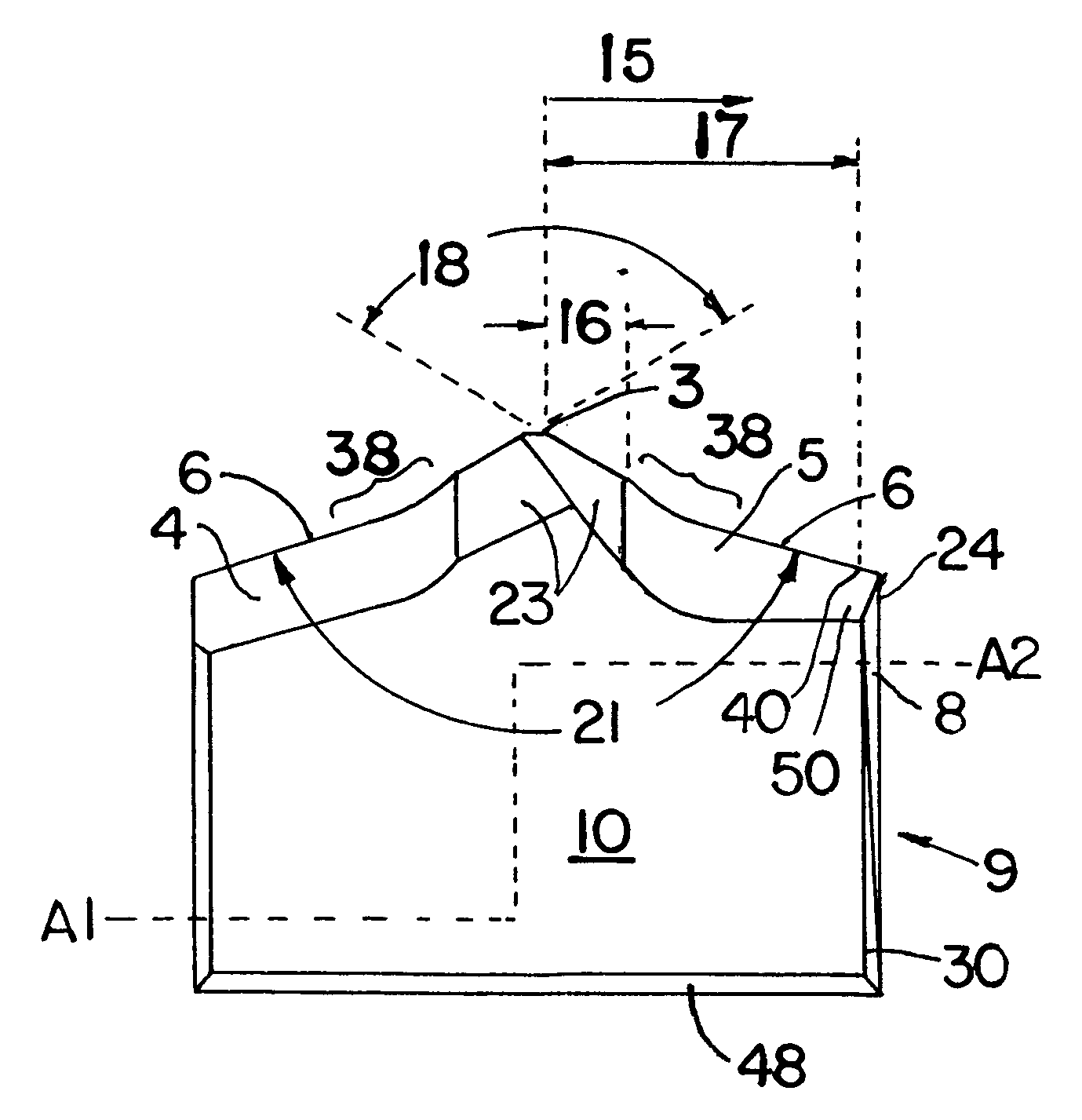

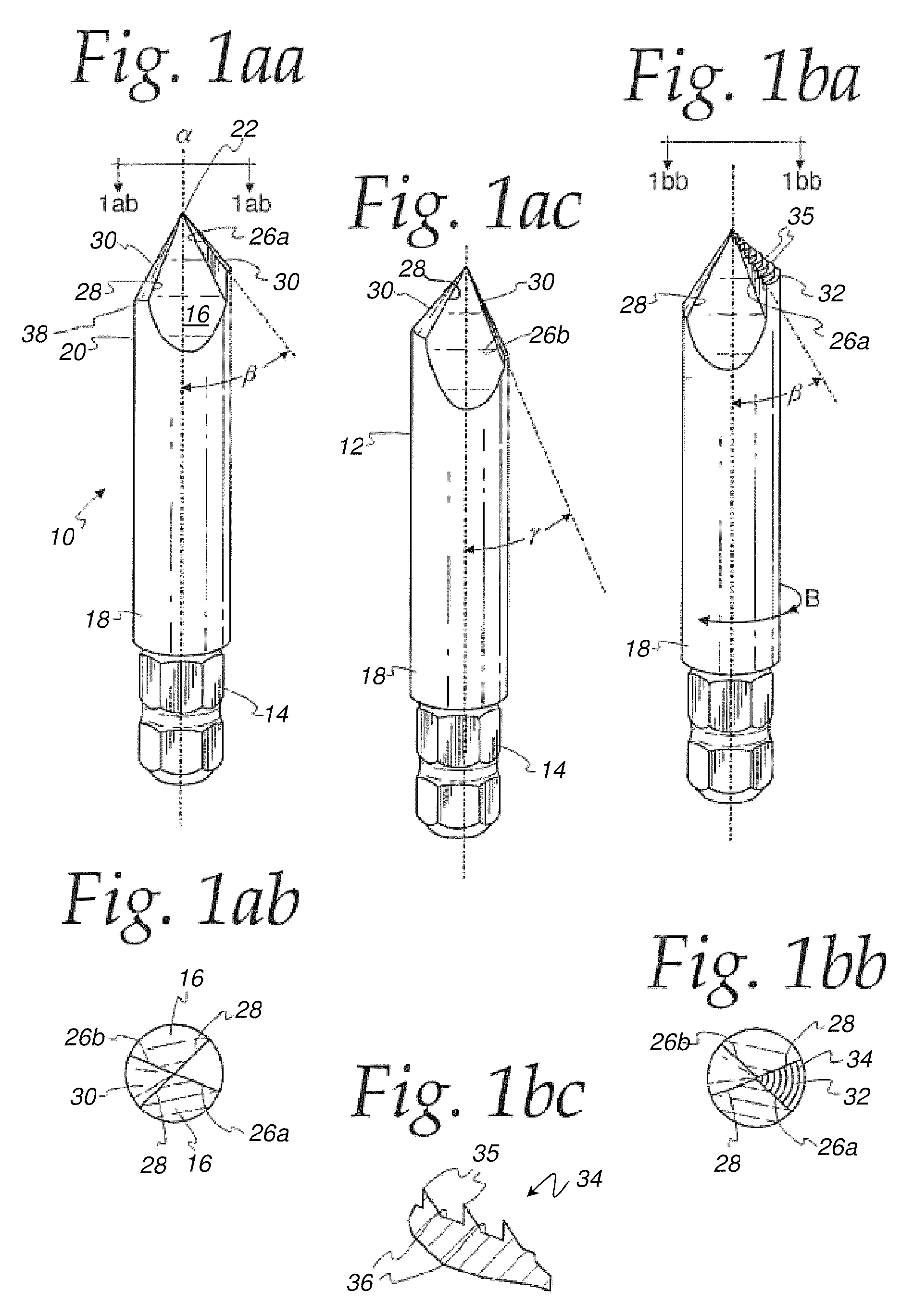

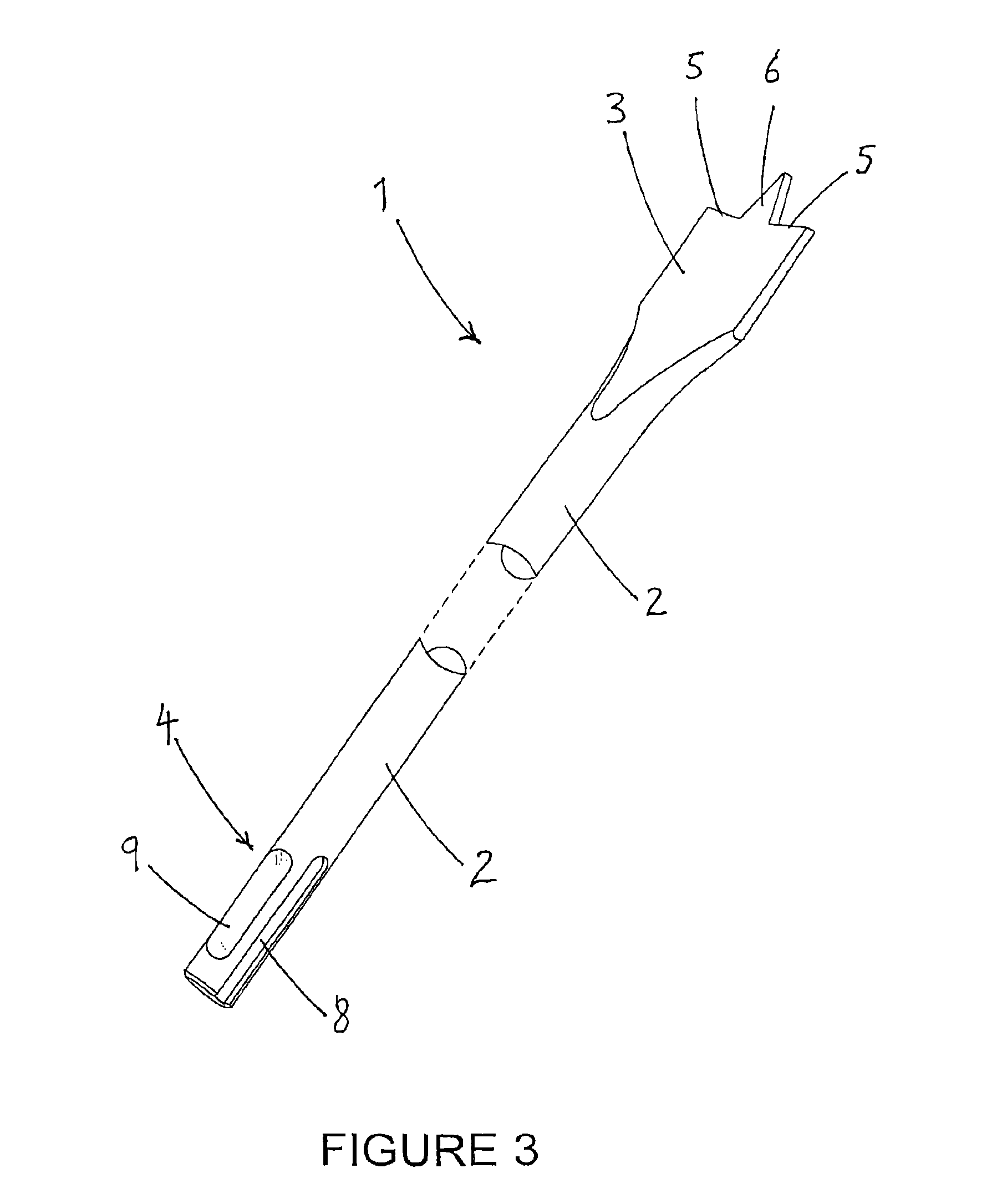

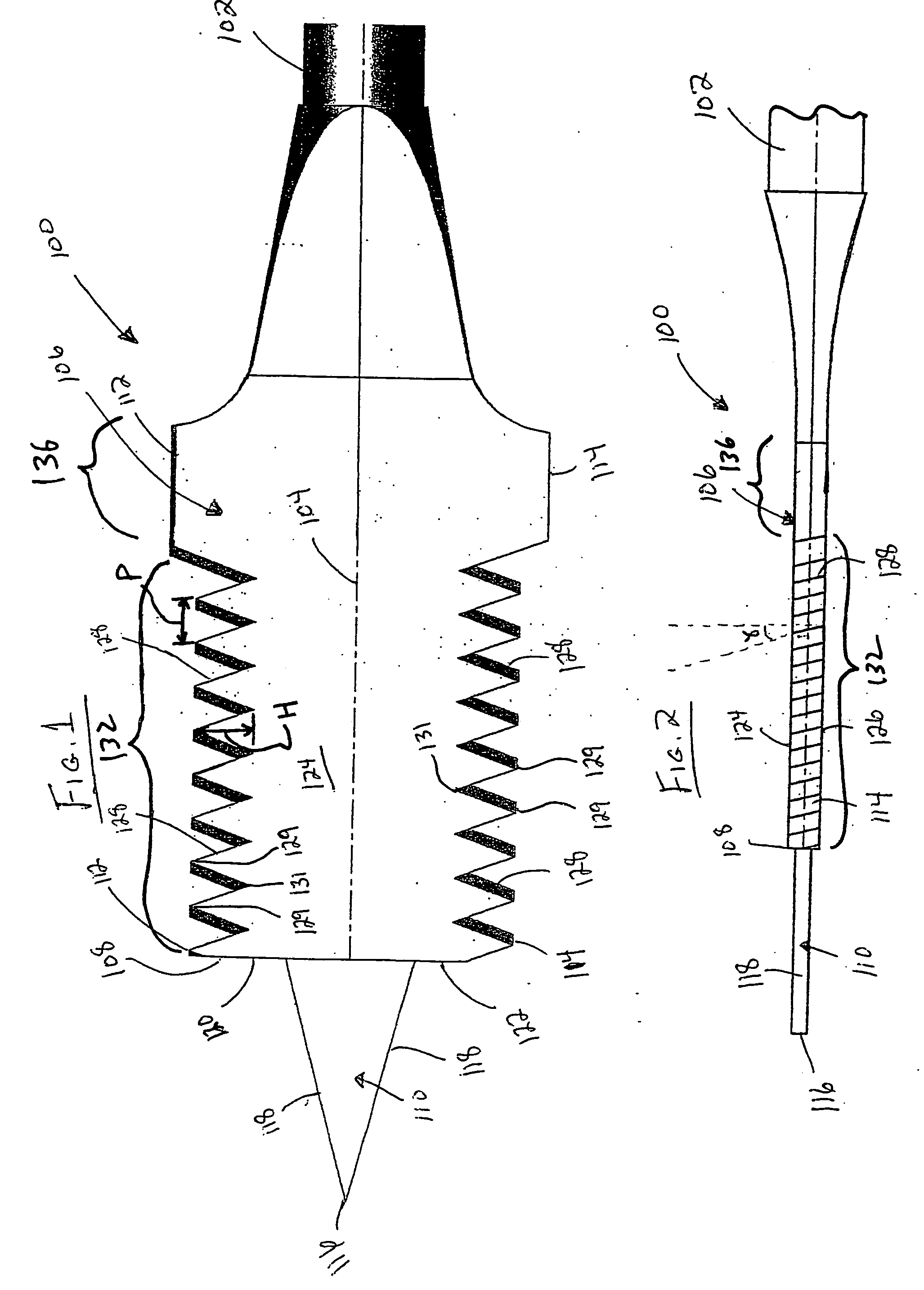

Spade bits with angled sides

InactiveUS6957937B2Improve Chip EvacuationDrawback mentionedWood turning toolsTransportation and packagingEngineeringMechanical engineering

A spade drill bit has a shaft and a spade head portion arranged on the shaft. The head portion has a rearward facing bottom edge, two longitudinal sides and a forward facing cutting edge. The cutting edge has a pointed, generally triangularly shaped tip and outer ends. The longitudinal sides of the head portion are bent along a bend in a direction of rotation of the drill bit during operation, so that the outer ends are bent forwards in the rotating direction. The bend runs from a first position at one of the longitudinal sides, closer to the bottom edge than to the cutting edge, and to a second position at the cutting edge between the outer end and the tip.

Owner:TEAM FAIR HLDG

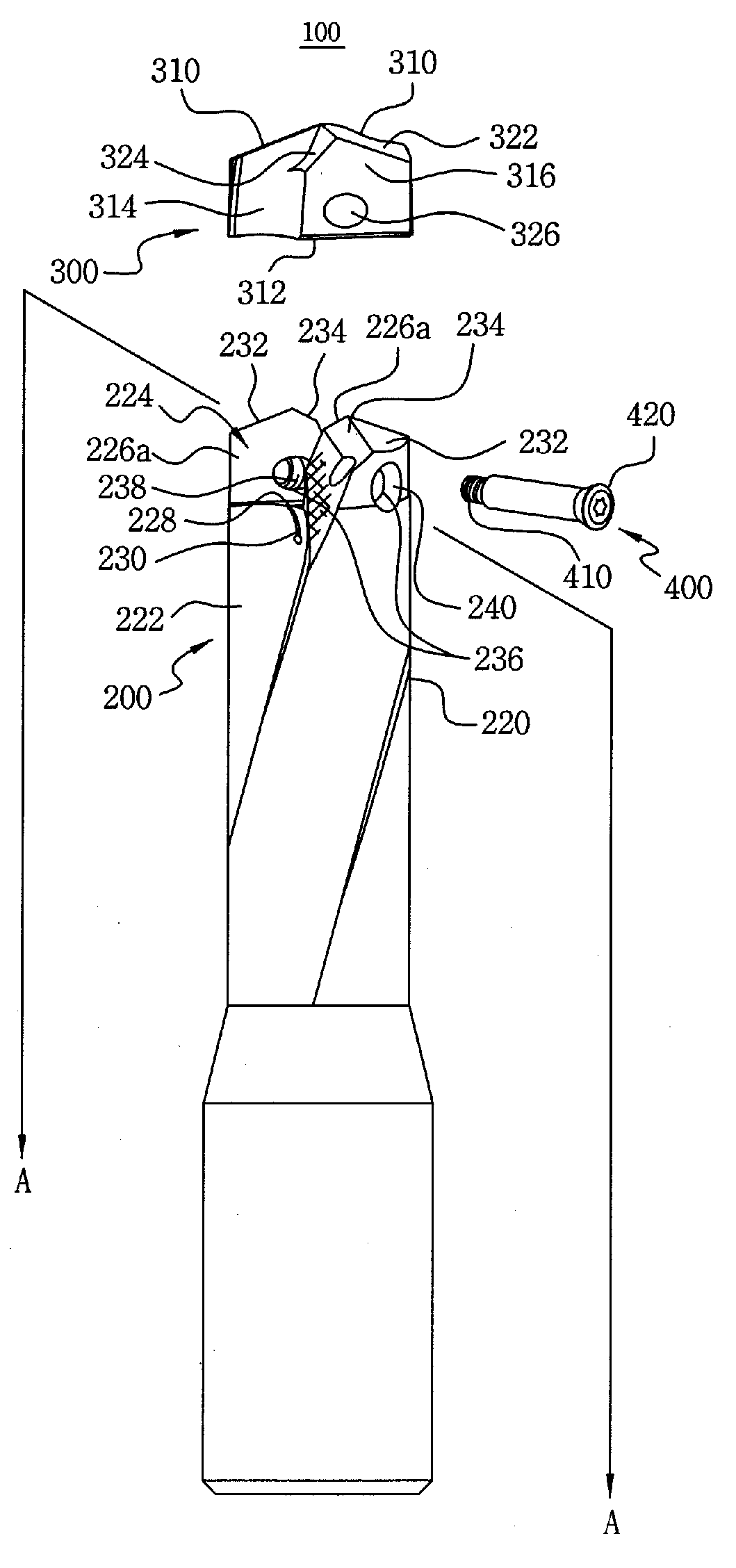

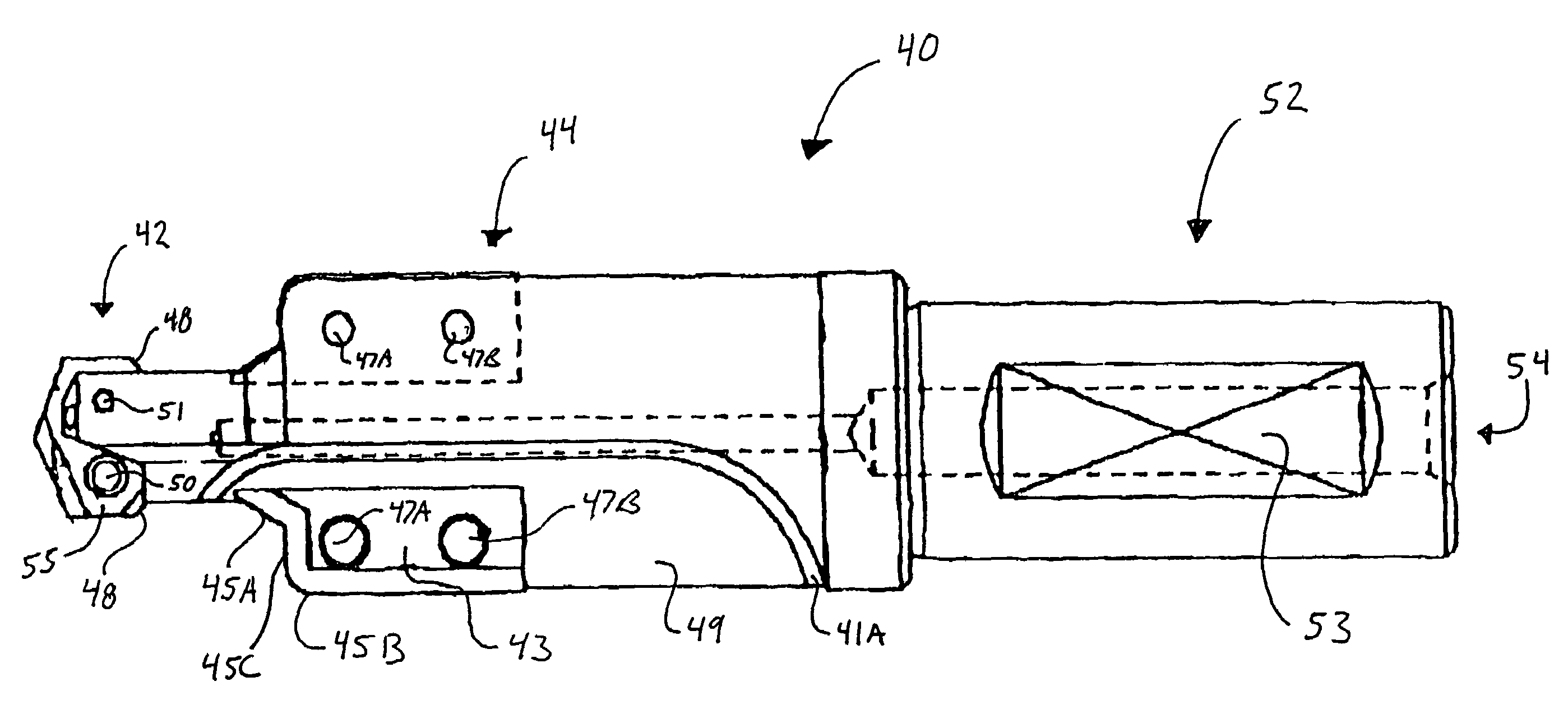

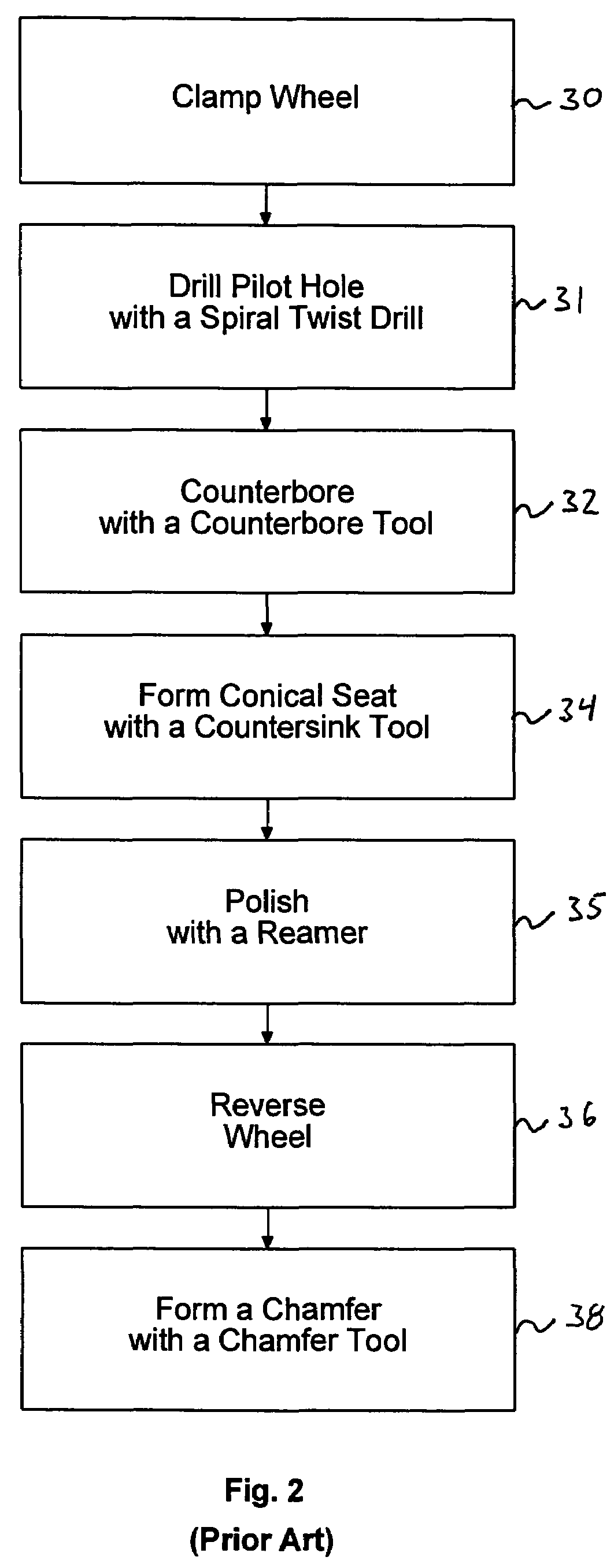

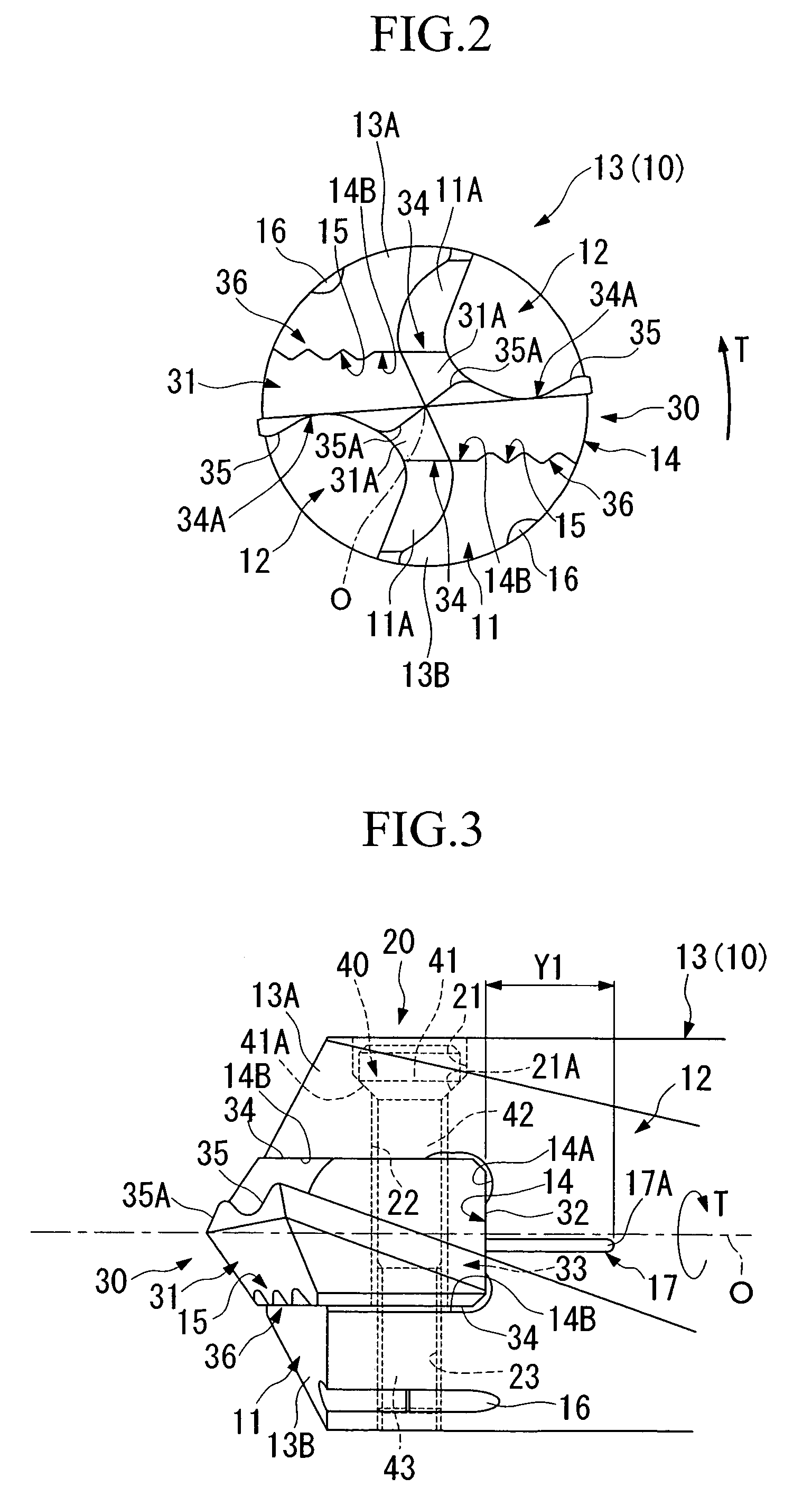

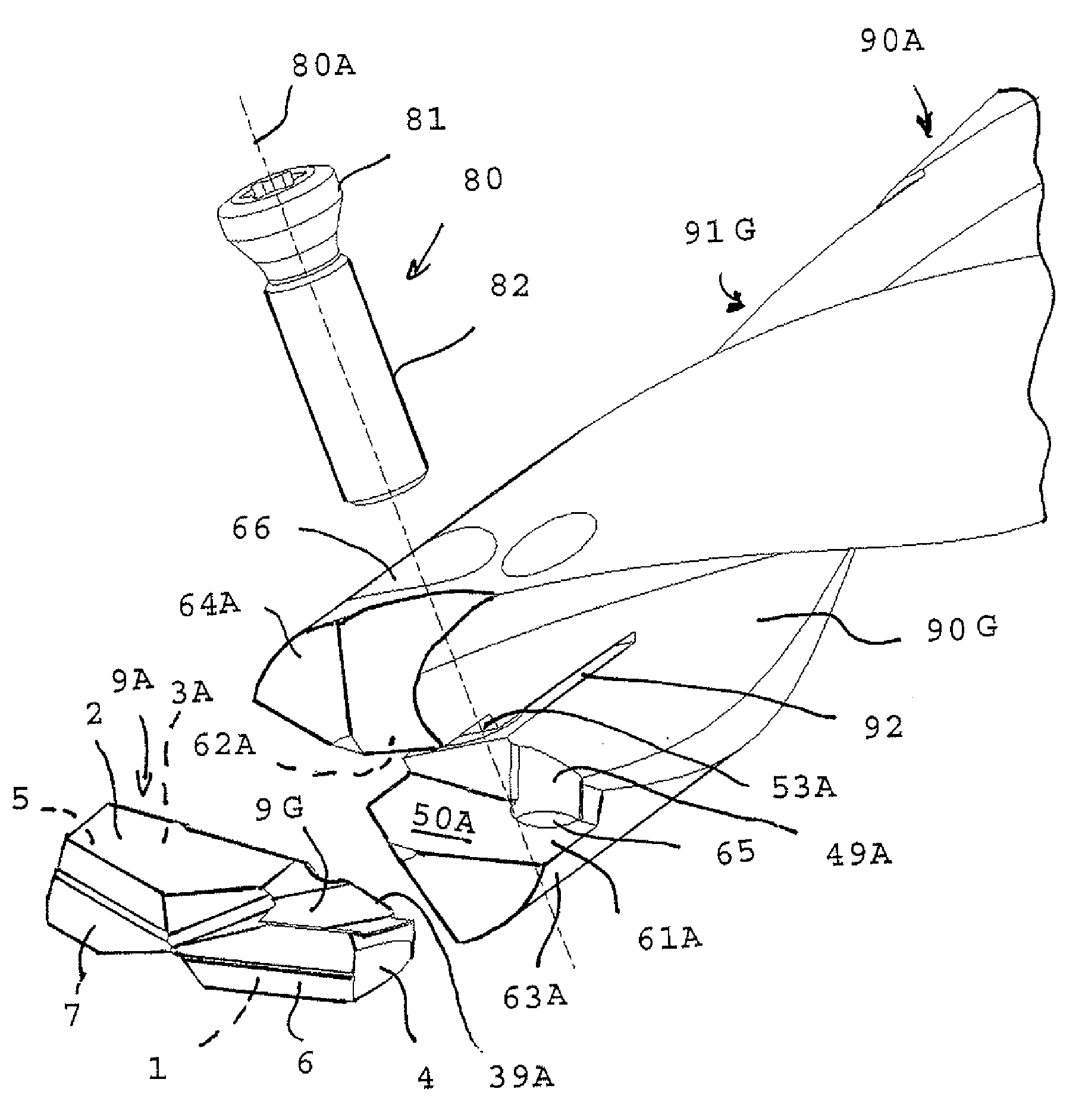

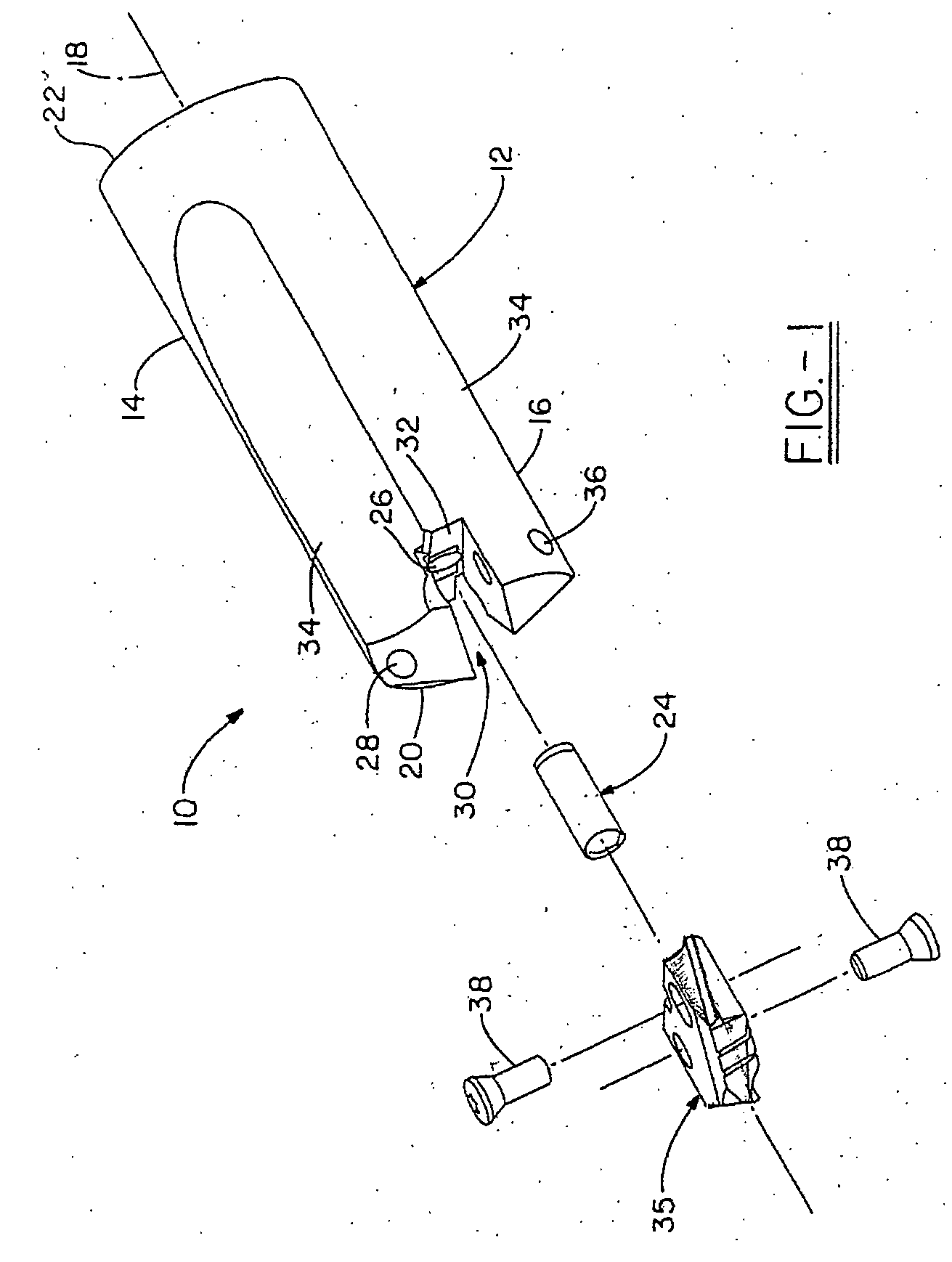

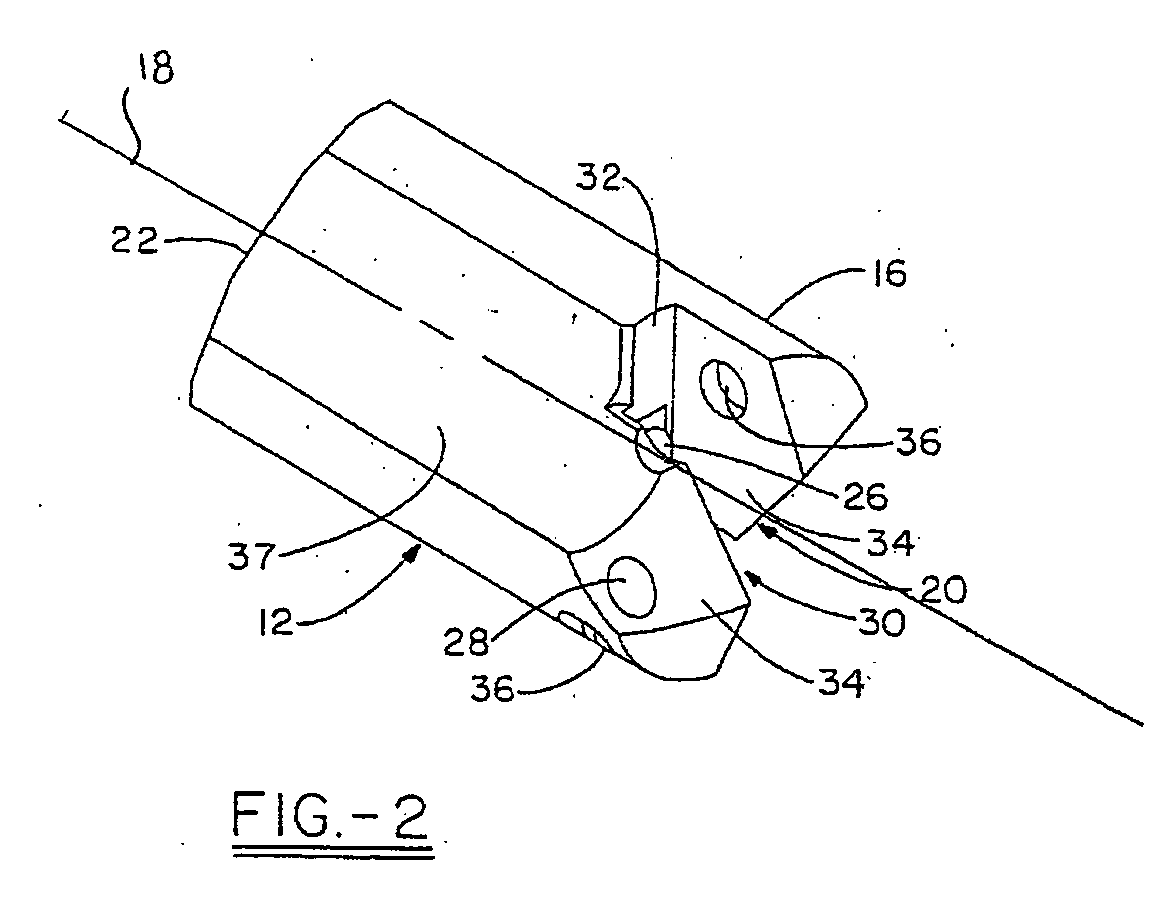

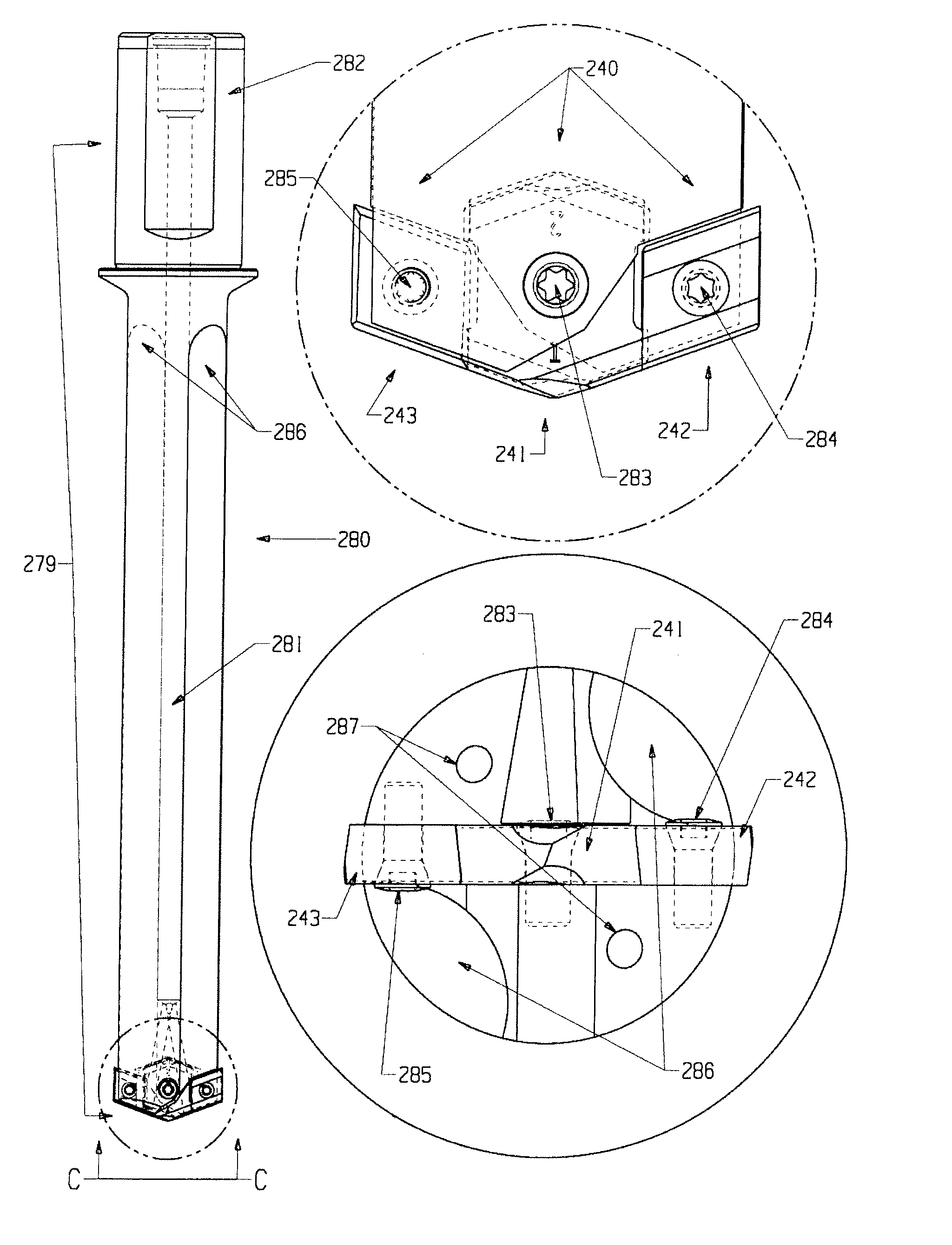

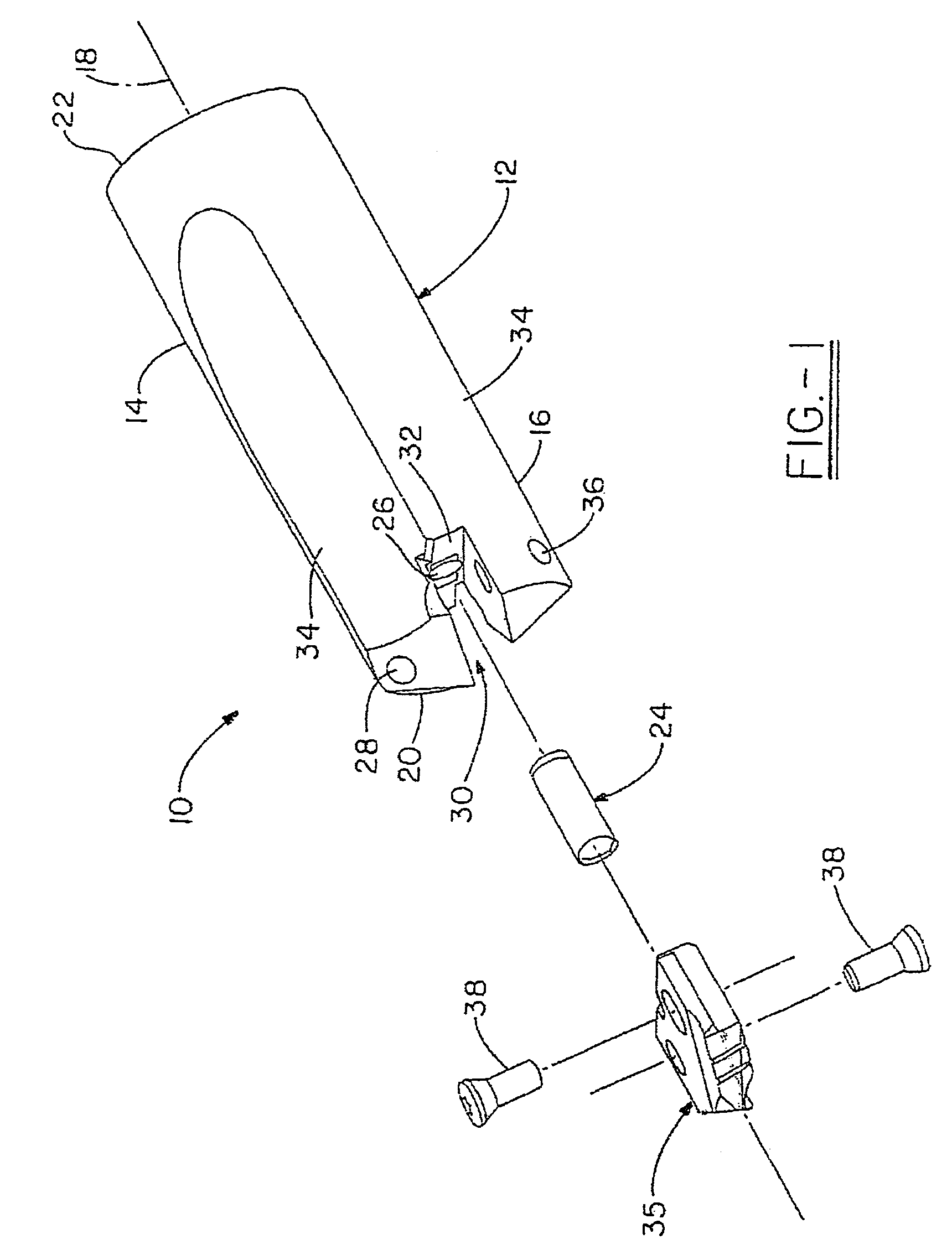

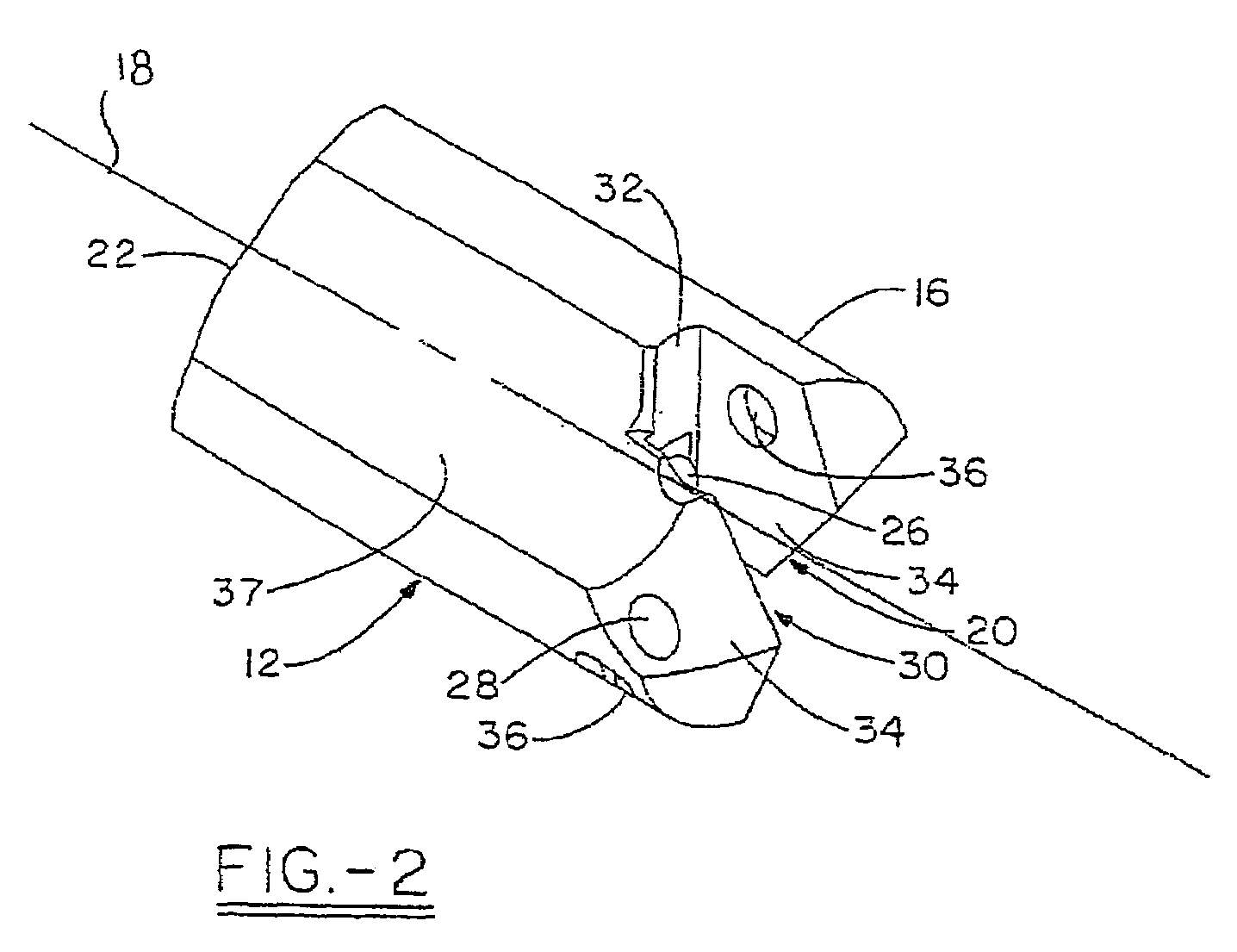

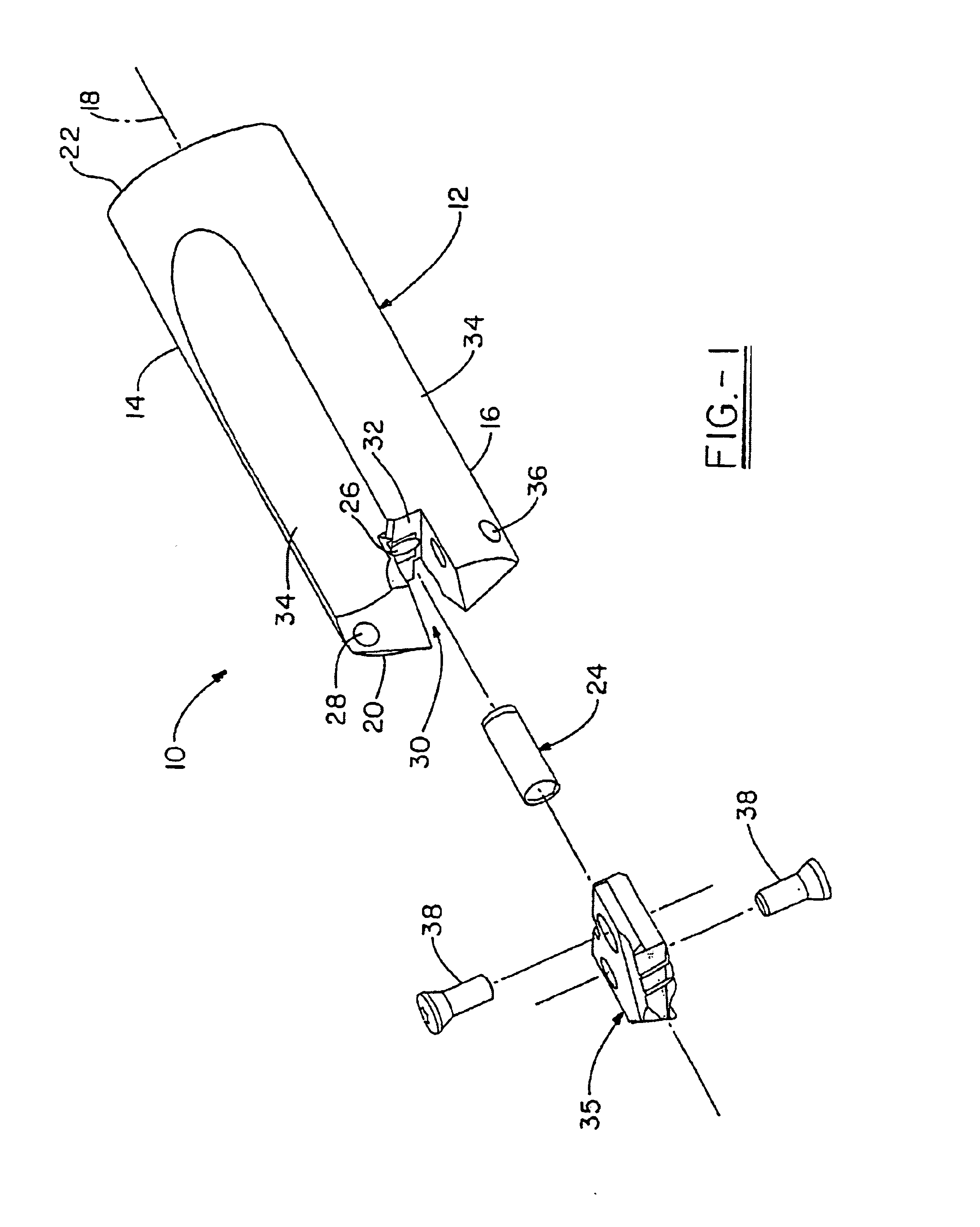

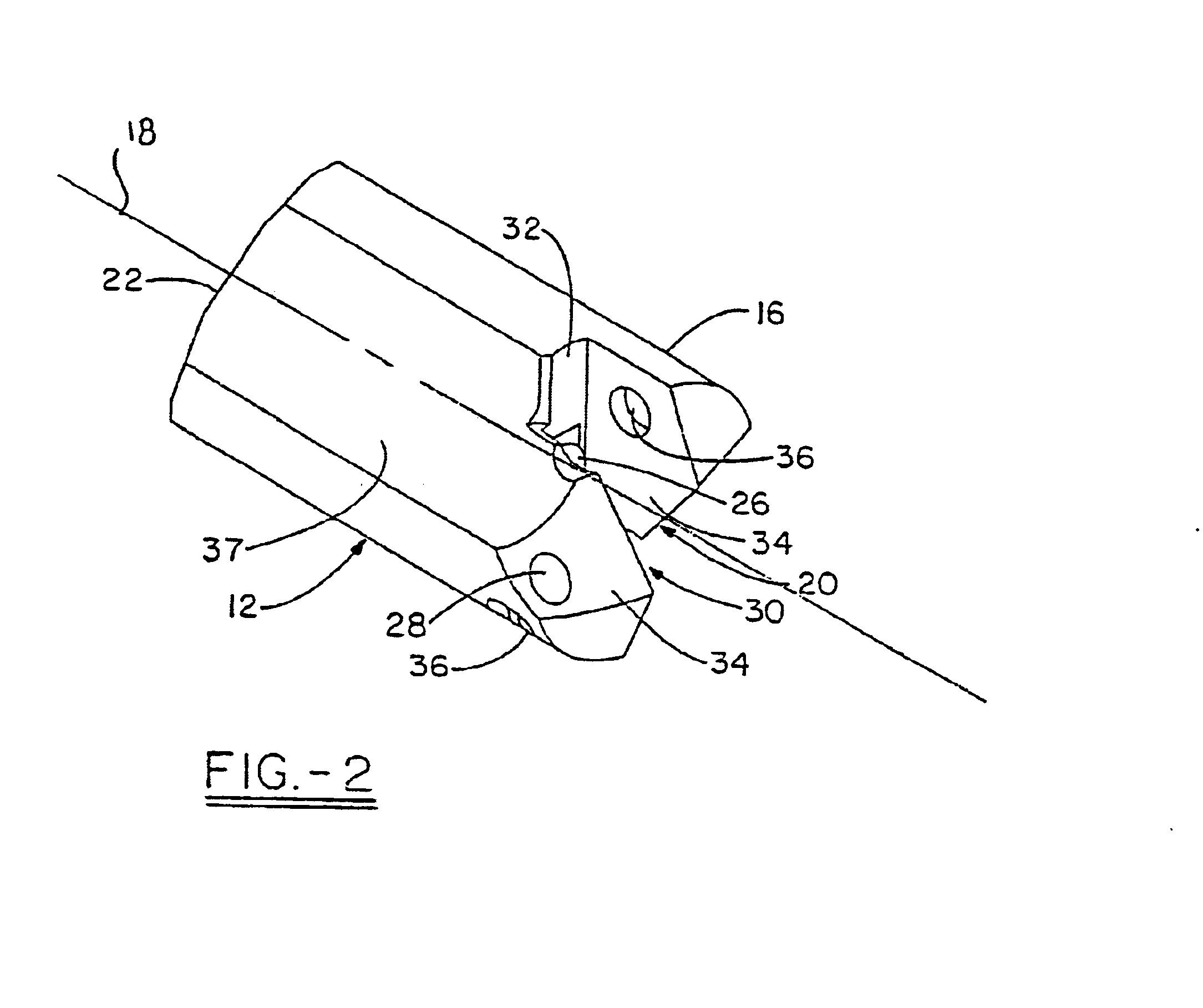

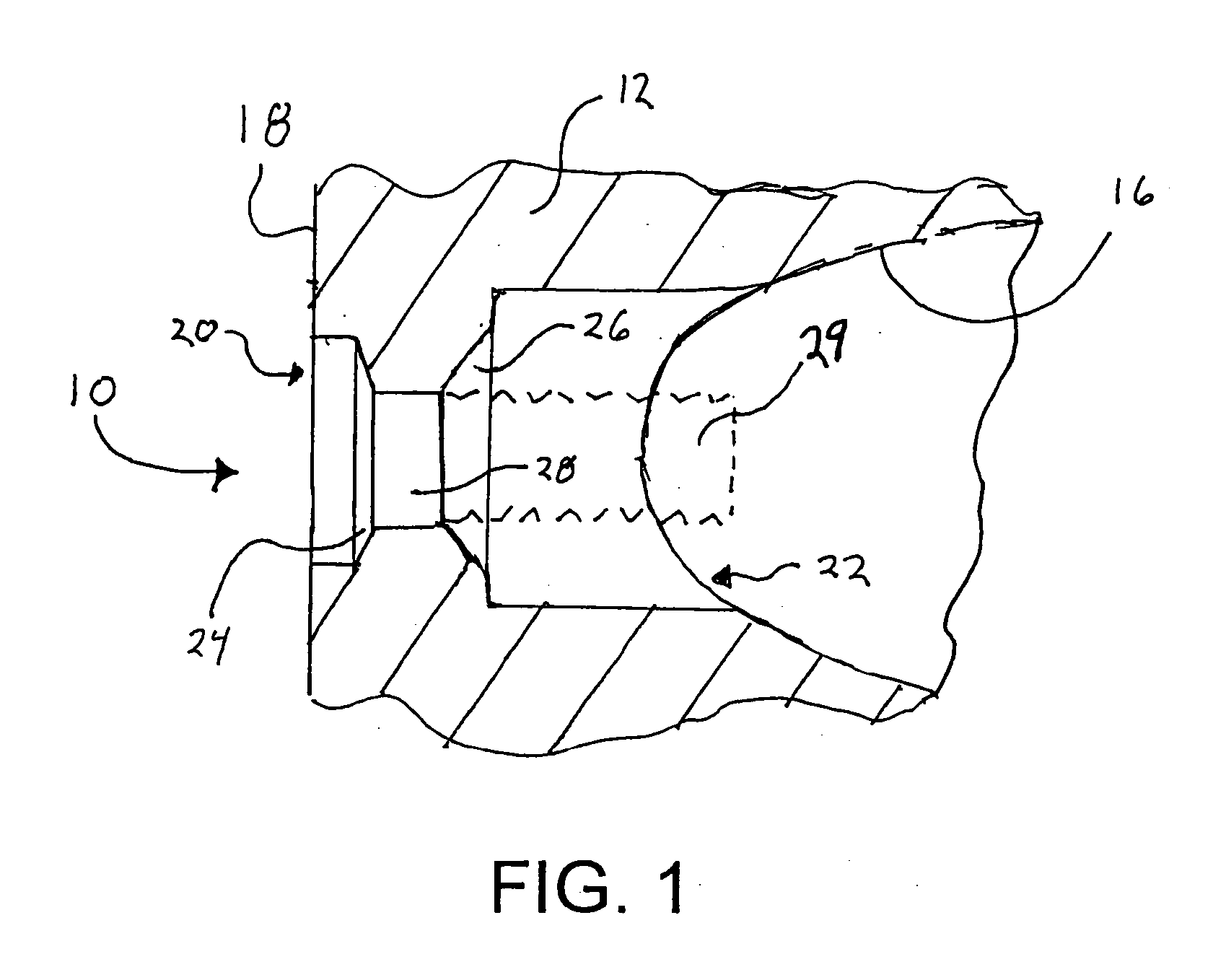

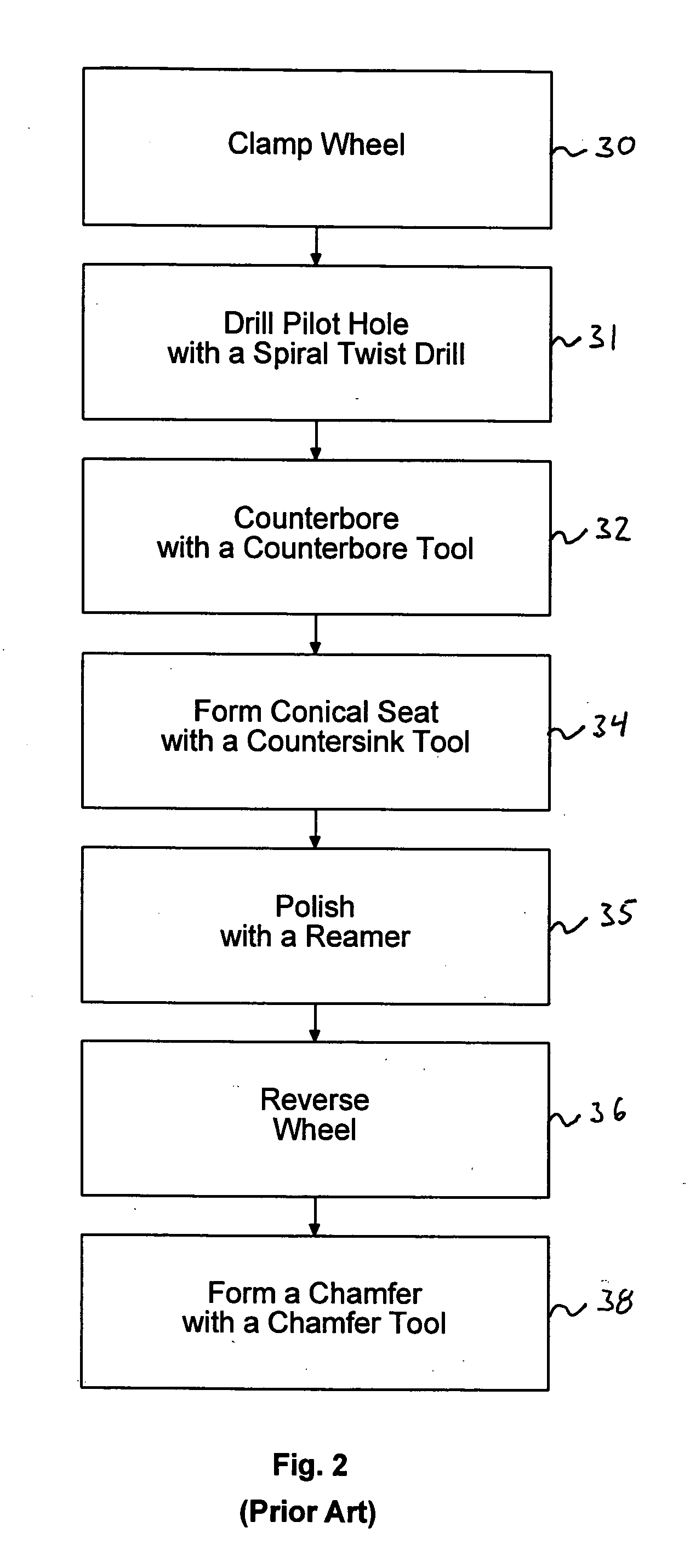

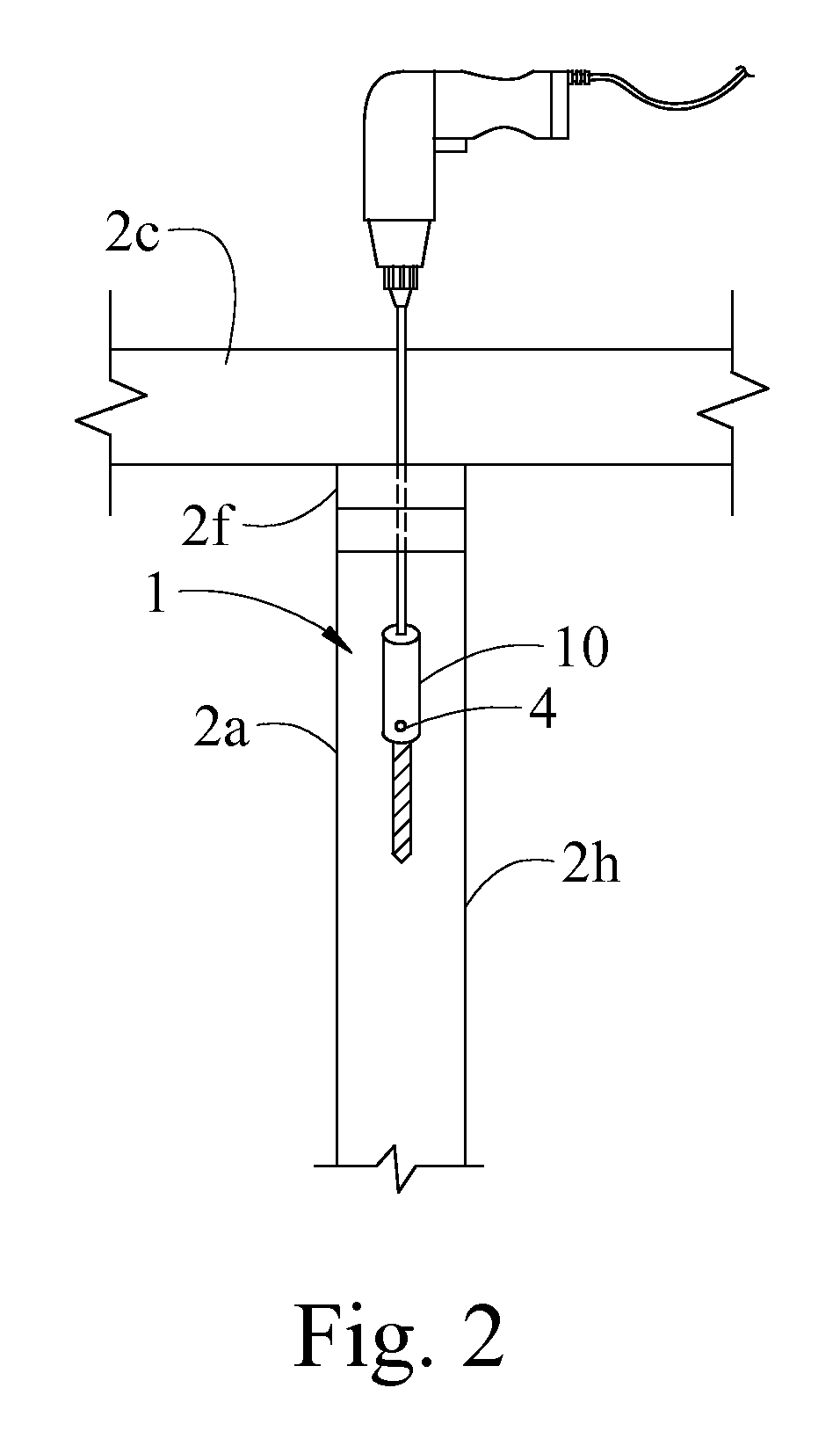

Tool and method for forming a lug hole

A single tool that provides multiple machining operations for forming a lug hole through a vehicle wheel hub includes an end portion having a first diameter and a mid-portion having a second diameter that is greater than the first diameter. A spade drill bit is mounted upon the end portion and a bore cutting tool is mounted upon the mid-portion.

Owner:HAYES LEMMERZ INT

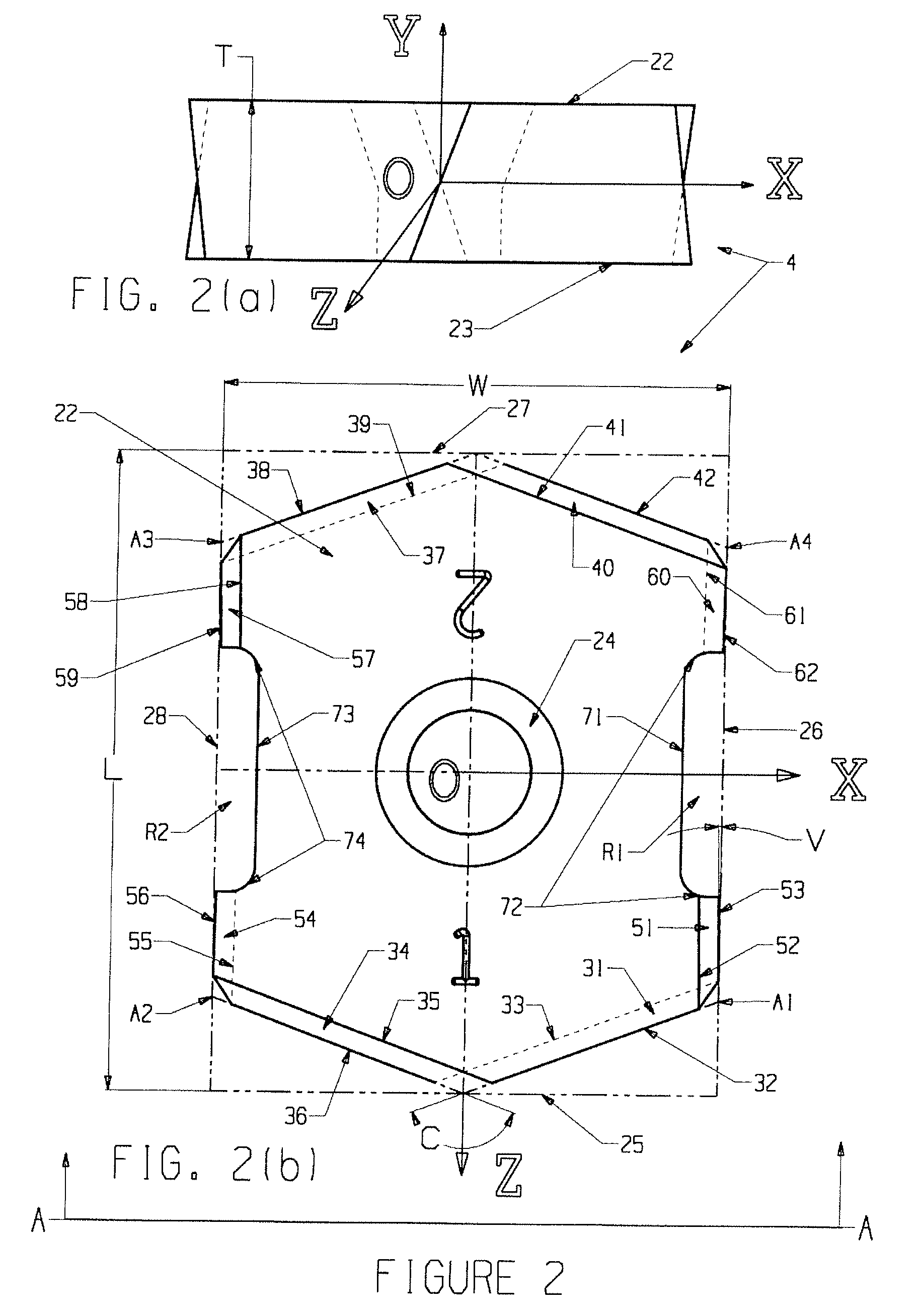

Spade drill insert having curved cutting edges

ActiveUS7018145B2Improved chip formationWood turning toolsTransportation and packagingEngineeringChip formation

Owner:ALLIED MASCH & ENG CORP

Cutting insert with helical geometry and holder therefor

Owner:ALLIED MASCH & ENG CORP

Indexable type cutting tool

InactiveUS7997836B2Reduce tooling costsReduce manufacturing costThread cutting toolsWood turning toolsFluteEngineering

Owner:KORLOY

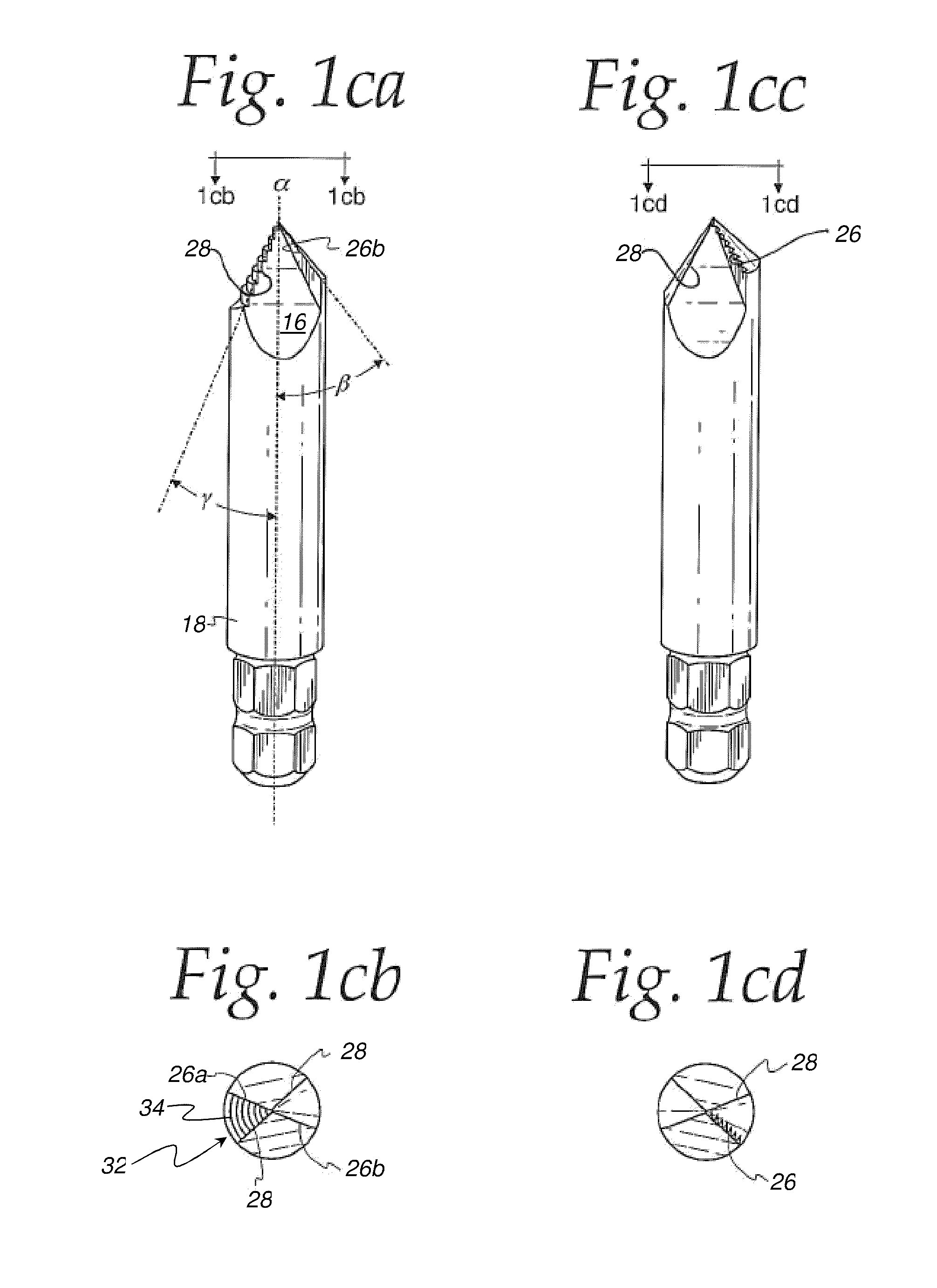

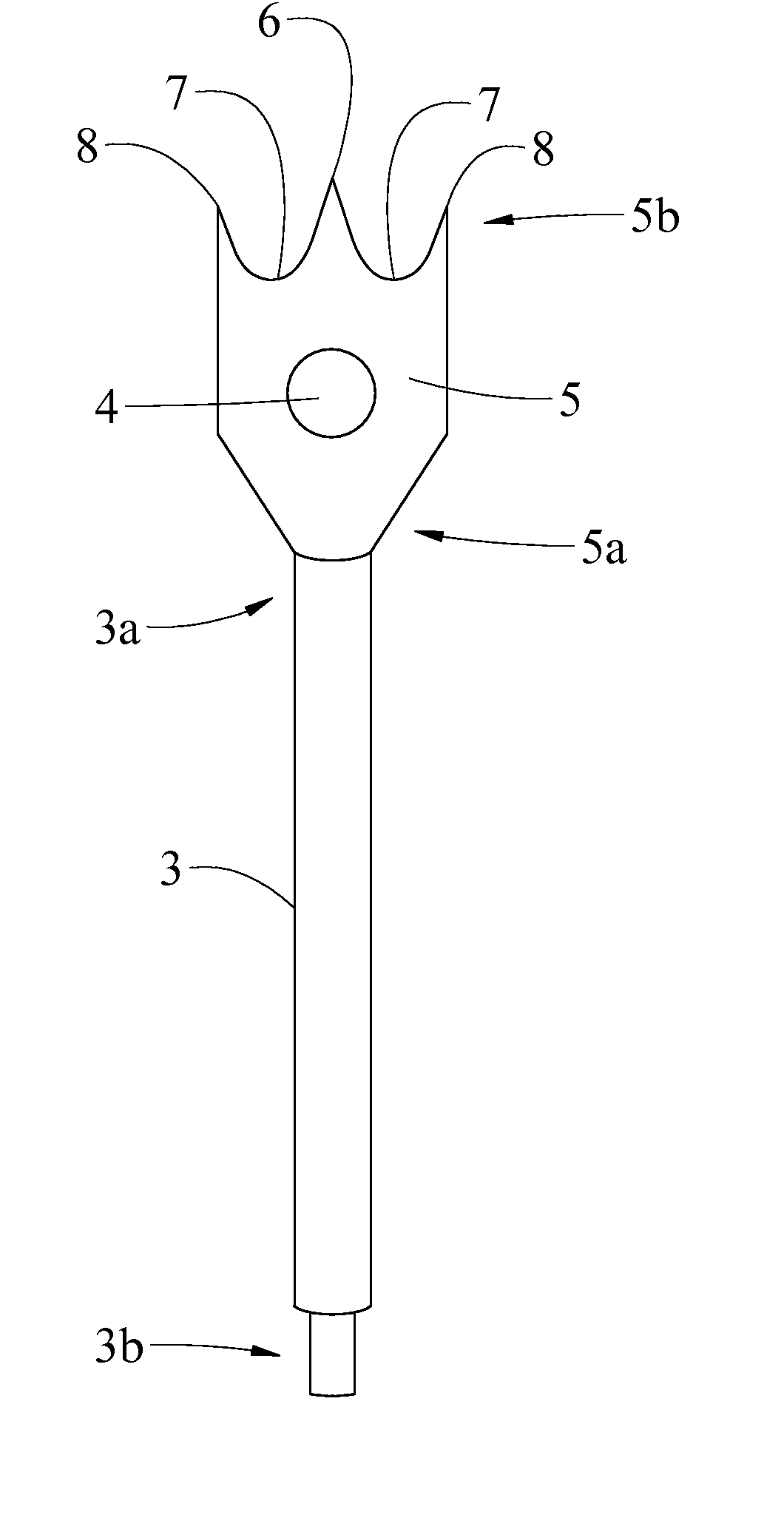

Hard metal drill bit for use on a drill

InactiveUS6629805B1Reduce wearReduce frictionWood turning toolsTransportation and packagingBreaking strengthHard metal

The invention concerns a hard-metal cutting tip for use on a drill, particularly on a rock or concrete drill, including a drill point (3) extending through an axis of rotation of the drill, primary cutting edges (6) that slope downwardly on both sides, each composed of a primary land (4) and a primary flank (5), the primary flank (5) forming at the primary cutting edge (6) a primary lip clearance angle (14) with a plane perpendicular to the axis of rotation. To provide a hard-metal cutting tip that possesses high cutting, feed, bending and breaking strength and wear resistance, especially at its outer regions subjected to high peripheral speeds, the hard-metal cutting tip is realized such that the primary lip clearance angle (14) formed at the primary cutting edge (6) decreases with increasing distance from the drill point (3).

Owner:EISCHEID KARL

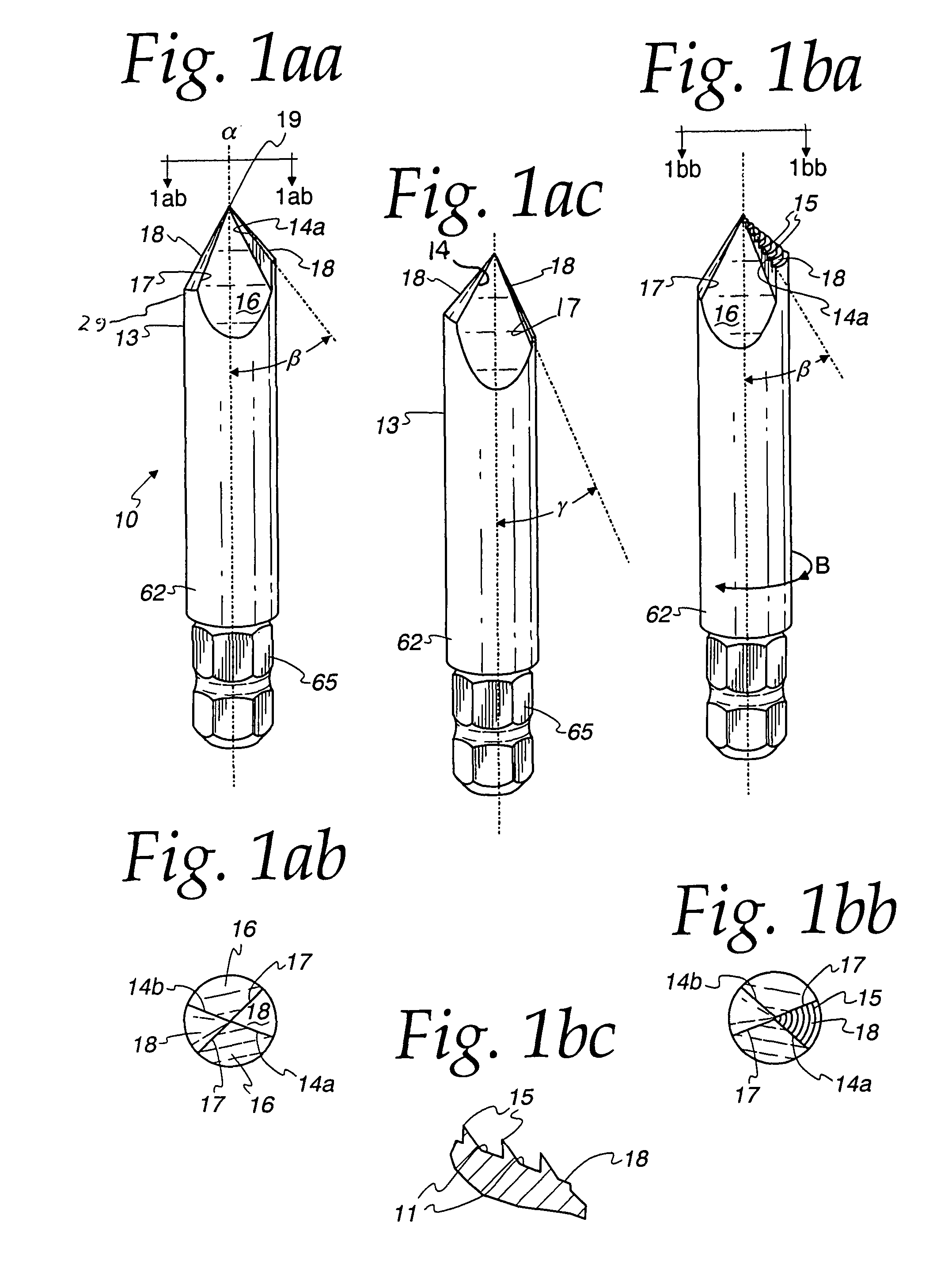

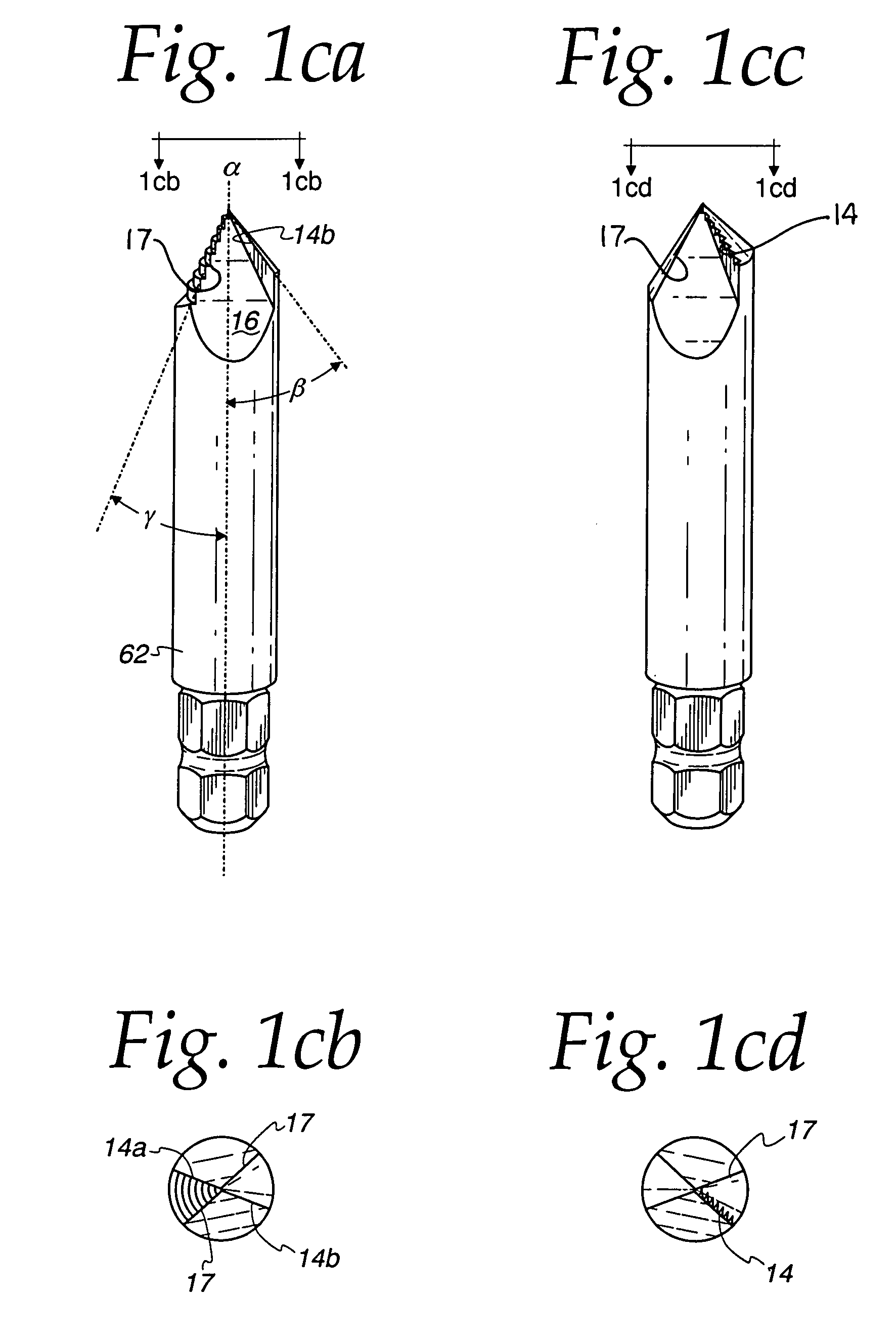

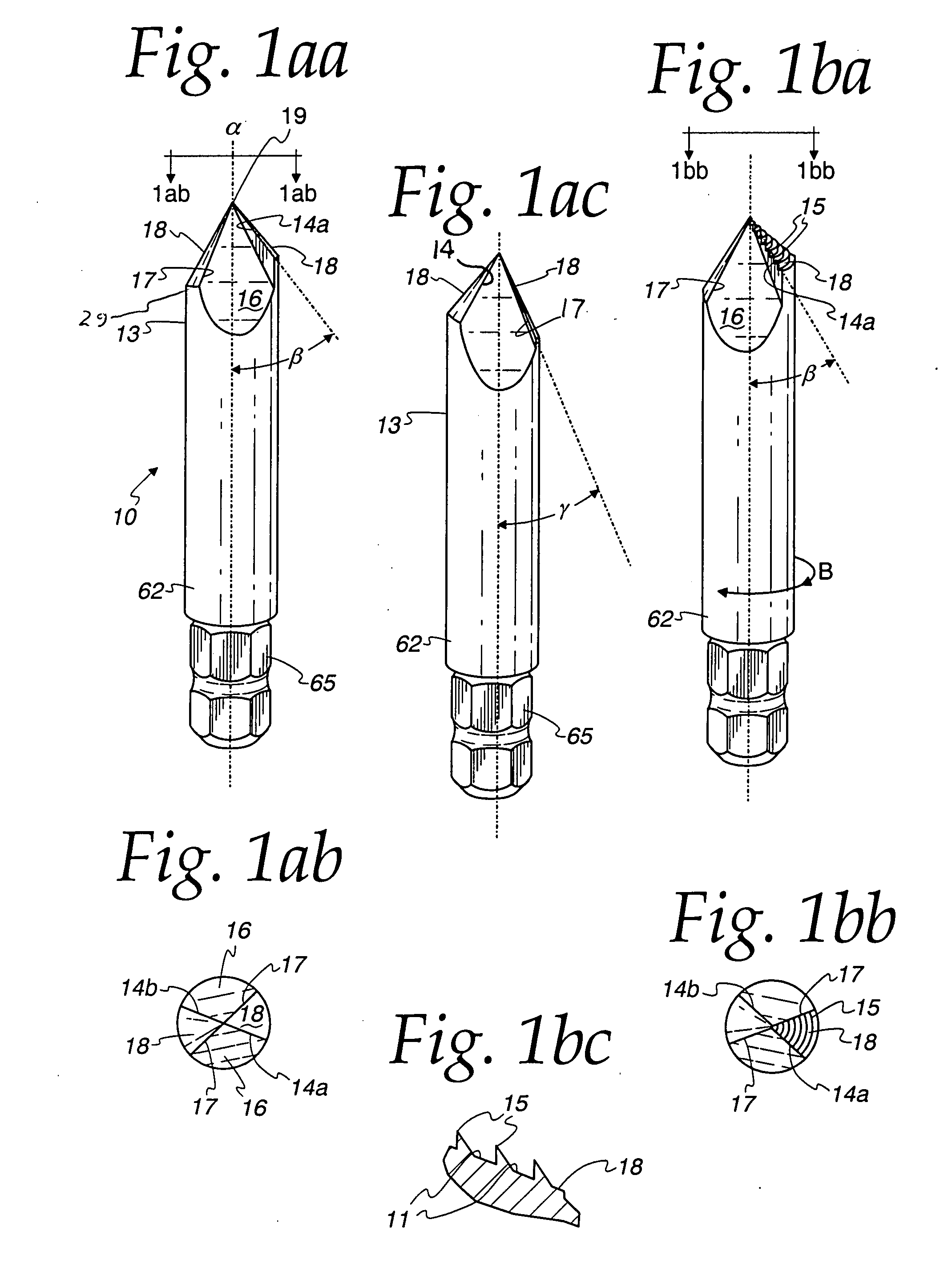

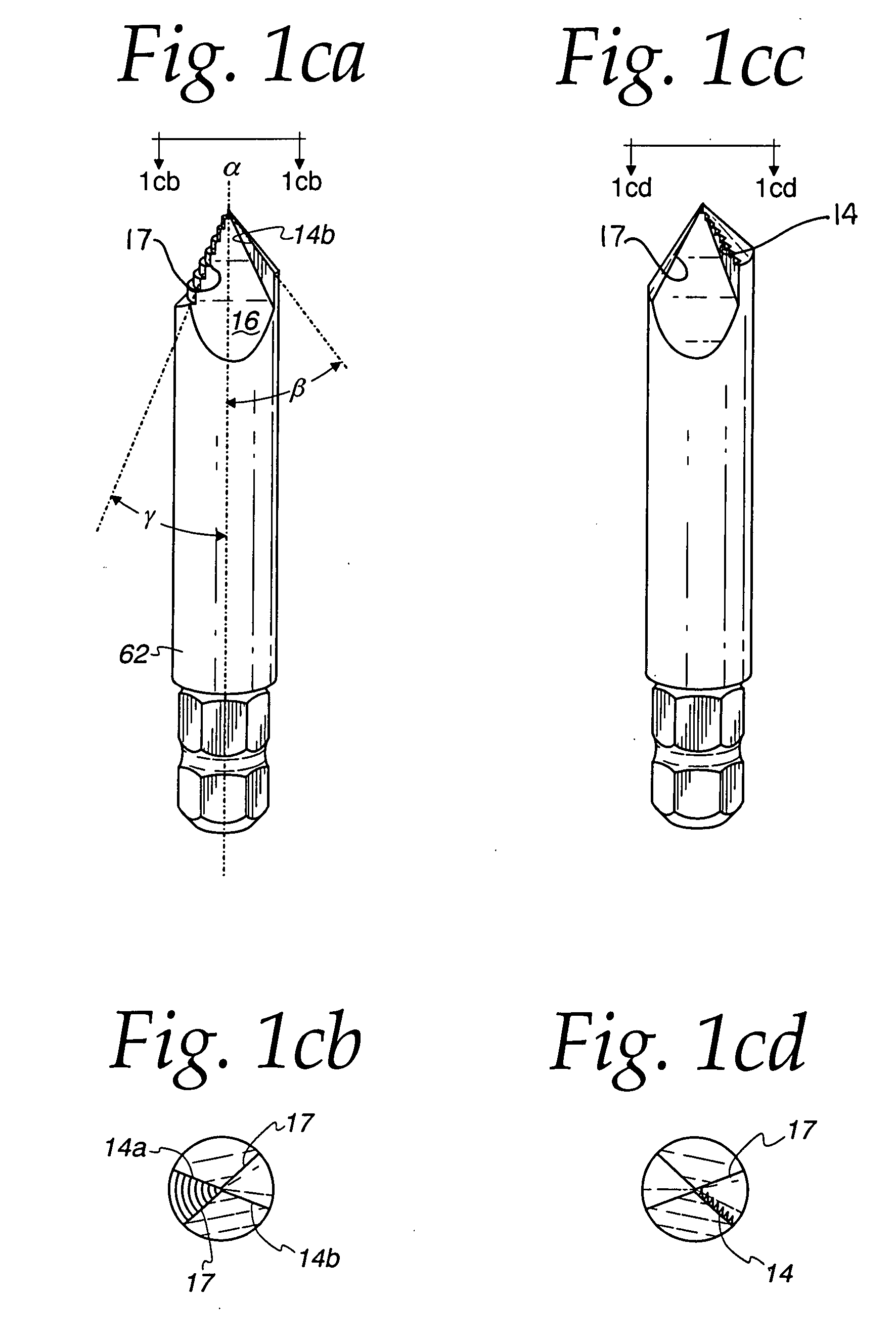

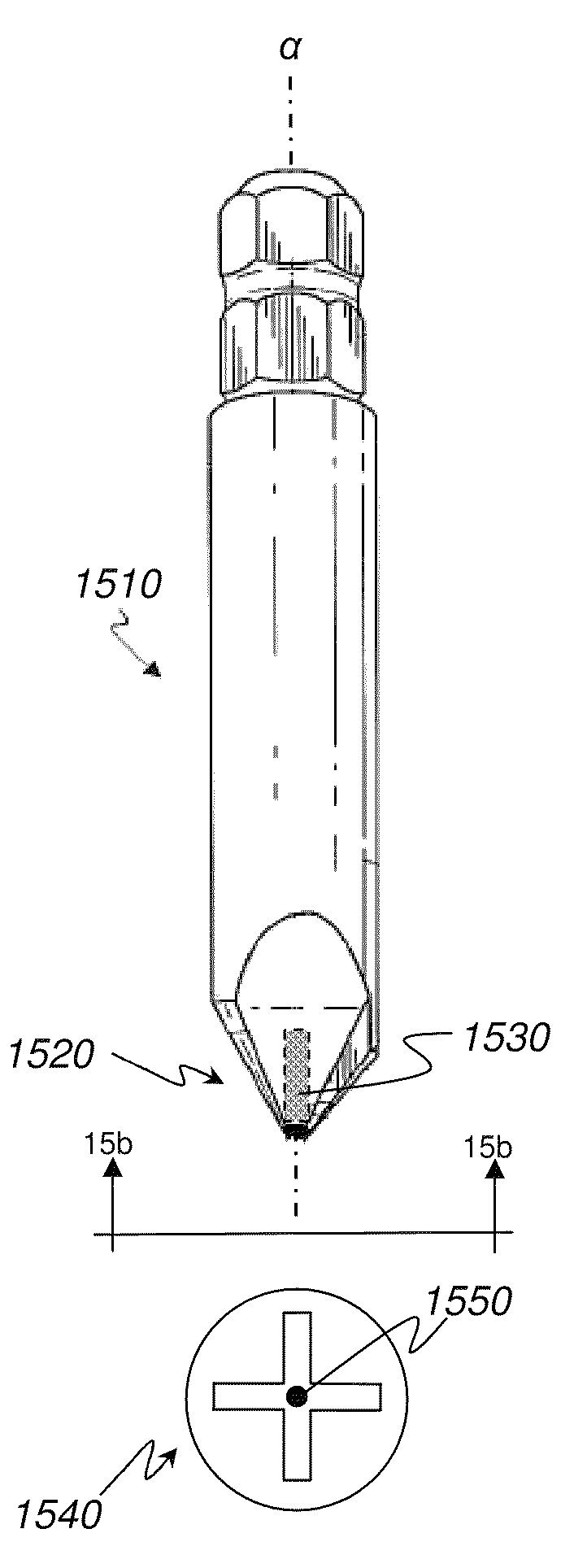

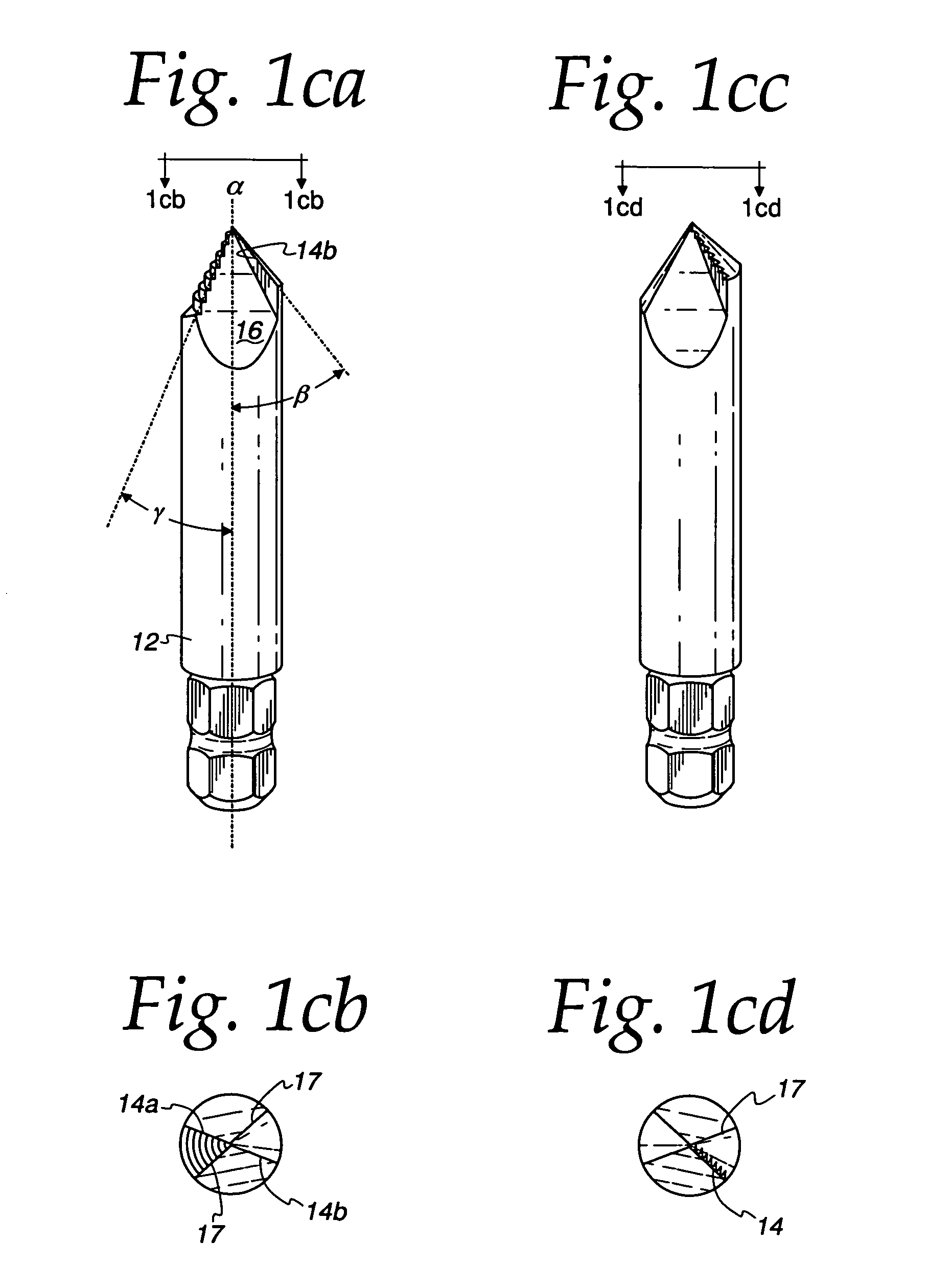

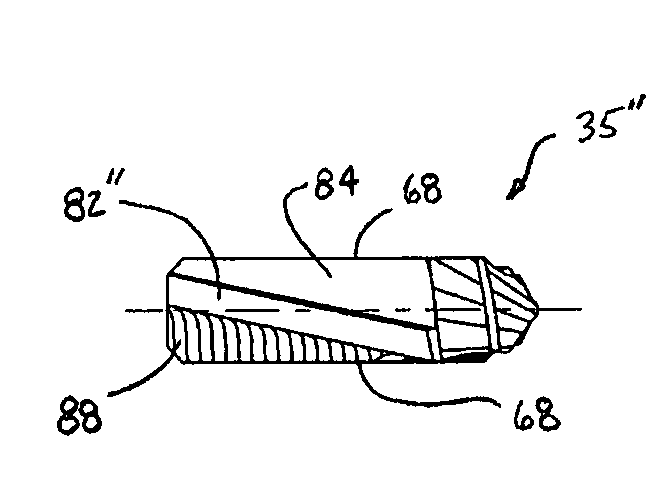

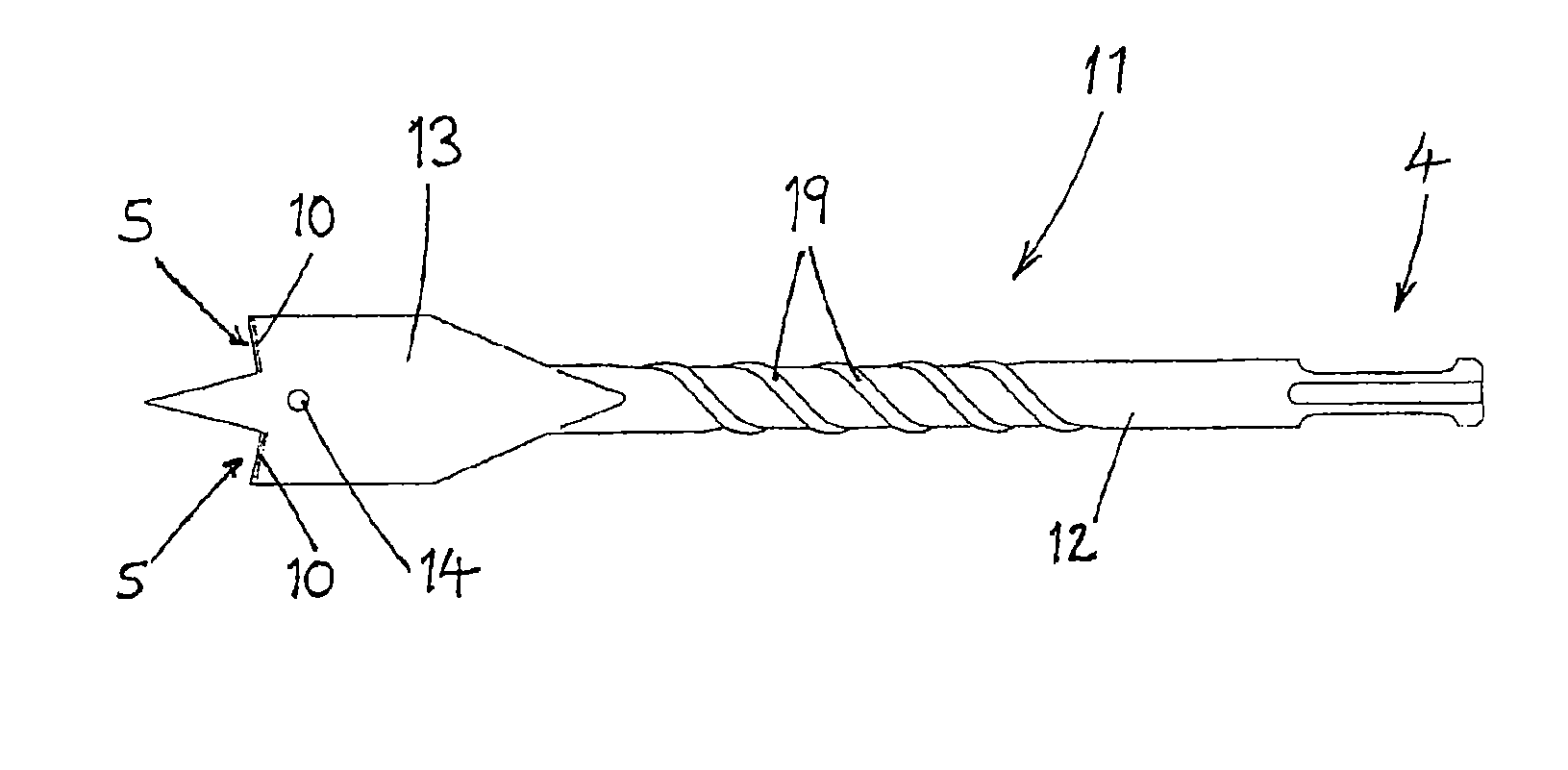

Damaged bolt and screw removing devices

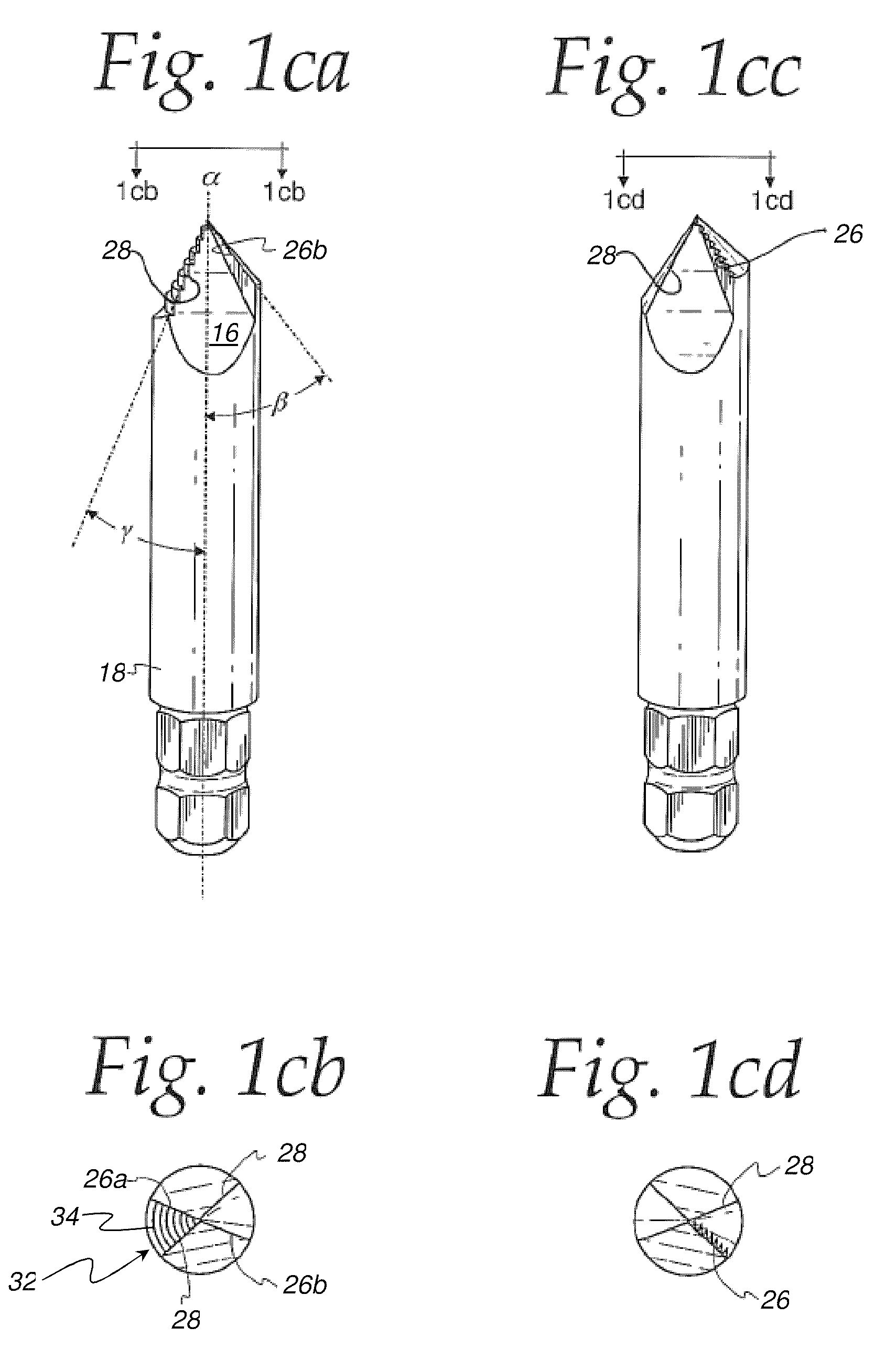

A bit for removing a broken fastener comprises a tip from which extend two or more notches separated by traction or biting surfaces formed from two-sided frusto-conically-shaped regions. The surfaces are bounded on one side by a nonlinear cutting edge and on the other side by a non-cutting edge and are configured to cut into the fastener when the bit is rotated in a direction opposite to the fastener's direction of engagement. Specific embodiments include configurations where the cutting edges extend at different angles with respect to the bit axis, where the biting surfaces comprise a plurality of serrations, and where the cutting edges are separated by flutes which spiral along a longitudinally extending periphery of the bit.

Owner:COMBINED PRODS

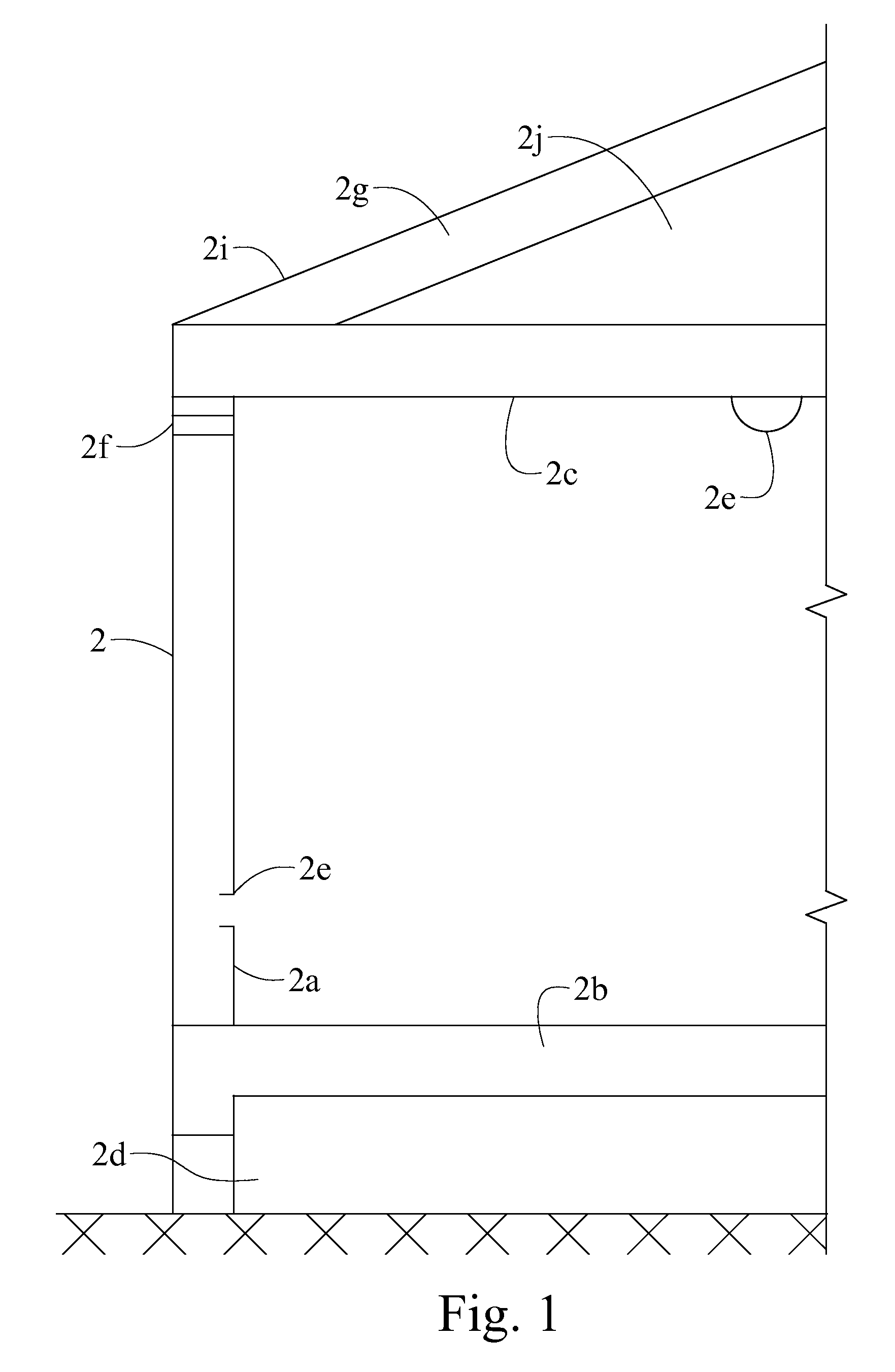

Tool for enlarging hole

A tool for enlarging the size of an existing bore to a selected enlarged size. The tool has a drill sized to define the enlarged bore, and a guide having a cylindrical body sized so that the guide can be rotated in the existing bore. The guide and drill including cooperating structures for releasably interconnecting the guide and the drill with the guide and drill coaxially aligned whereby, with the guide releasable secured to the drill, the guide can be located within the original hole to guide the cutting action of the drill as it enlarges the original hole.

Owner:NEWFREY

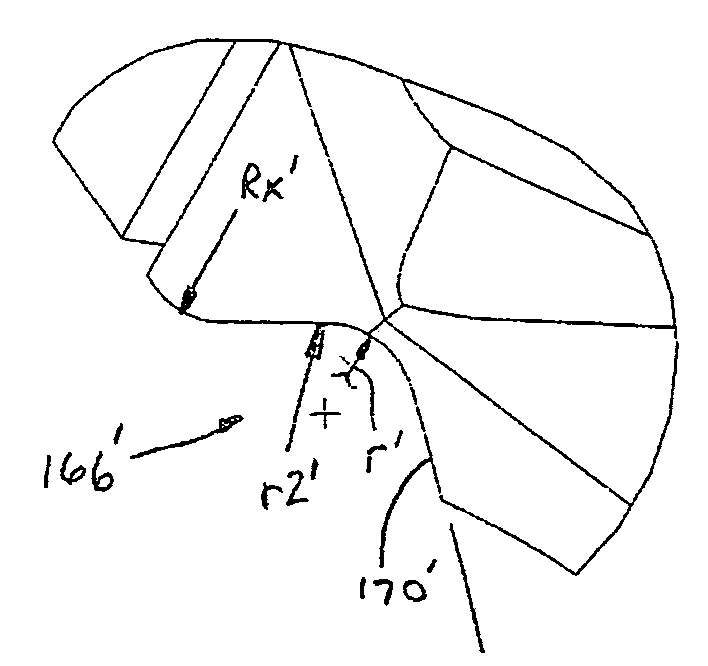

Damaged bolt and screw removing devices

ActiveUS20090183603A1Lower levelImprove biteTransportation and packagingSpade drillsFluteEngineering

A bit for removing a broken fastener comprises a tip from which extend two or more notches separated by traction or biting surfaces formed from two-sided frusto-conically-shaped regions. The surfaces are bounded on one side by a nonlinear cutting edge and on the other side by a non-cutting edge and are configured to cut into the fastener when the bit is rotated in a direction opposite to the fastener's direction of engagement. Specific embodiments include configurations where the cutting edges extend at different angles with respect to the bit axis, where the biting surfaces comprise a plurality of serrations, and where the cutting edges are separated by flutes which spiral along a longitudinally extending periphery of the bit.

Owner:COMBINED PRODS

Spot and chamfer drill insert

InactiveUS6848869B2Improved point geometryAccurate spot cutWood turning toolsTransportation and packagingDrill bitDrill hole

The present invention relates to a spot and chamfer drill insert which can be utilized to create accurately located spots for subsequent drilling operations while simultaneously providing a chamfer for the finished hole. The present invention utilizes web thin clearance surfaces that are formed at web thin clearance angles, wherein the web thin clearance angles are oriented with respect to a projected plane normal to a plane through the web thin cutting edge and parallel to the longitudinal axis of the insert, wherein the projected plane is tangent to the web thin cutting edge.

Owner:ALLIED MASCH & ENG CORP

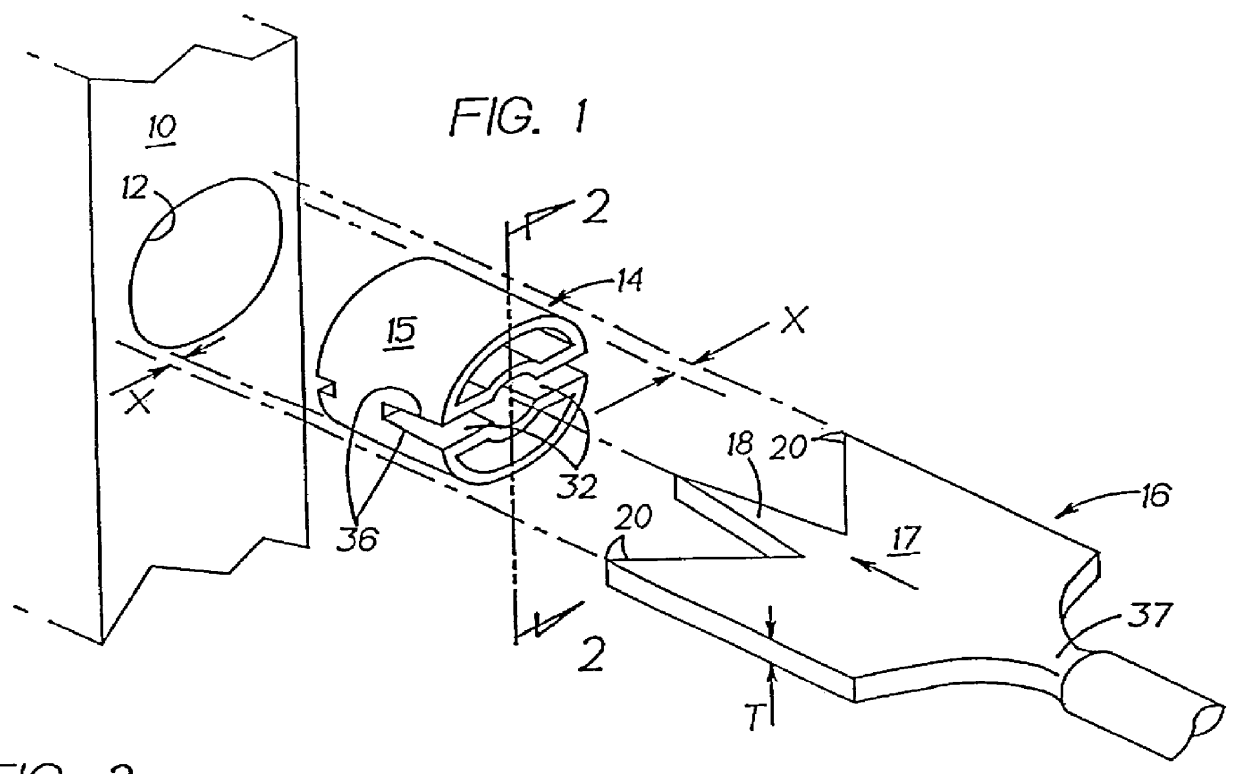

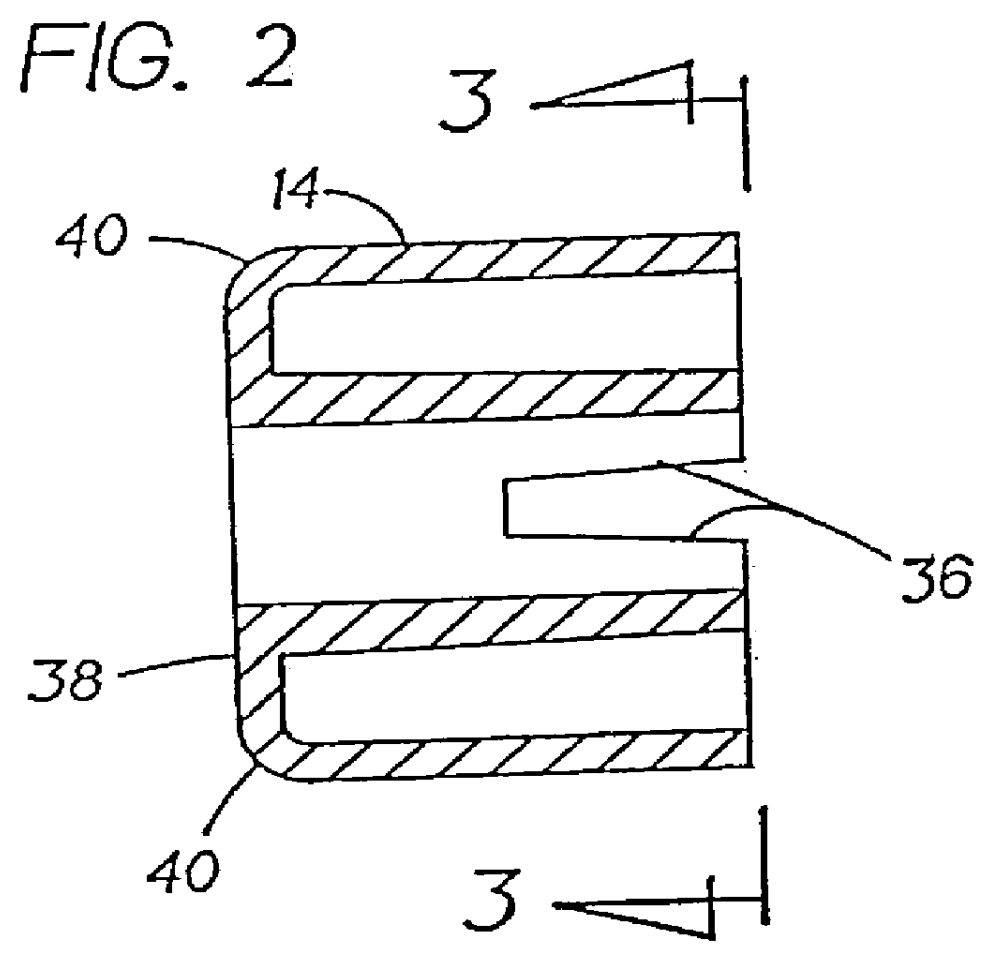

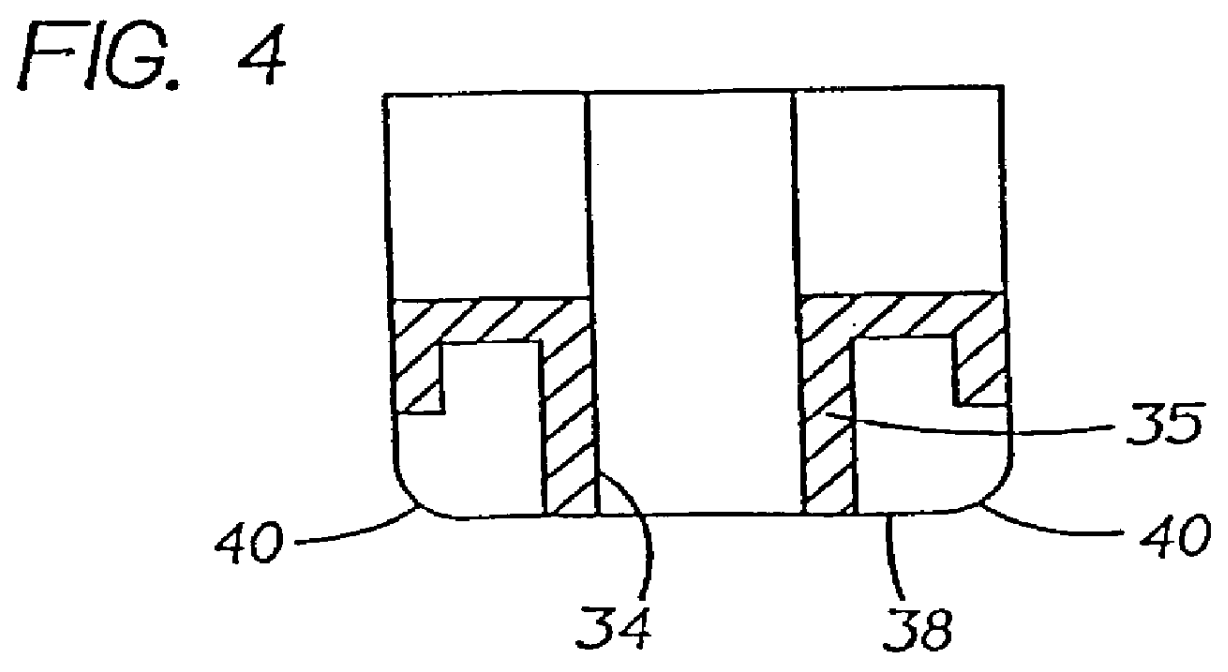

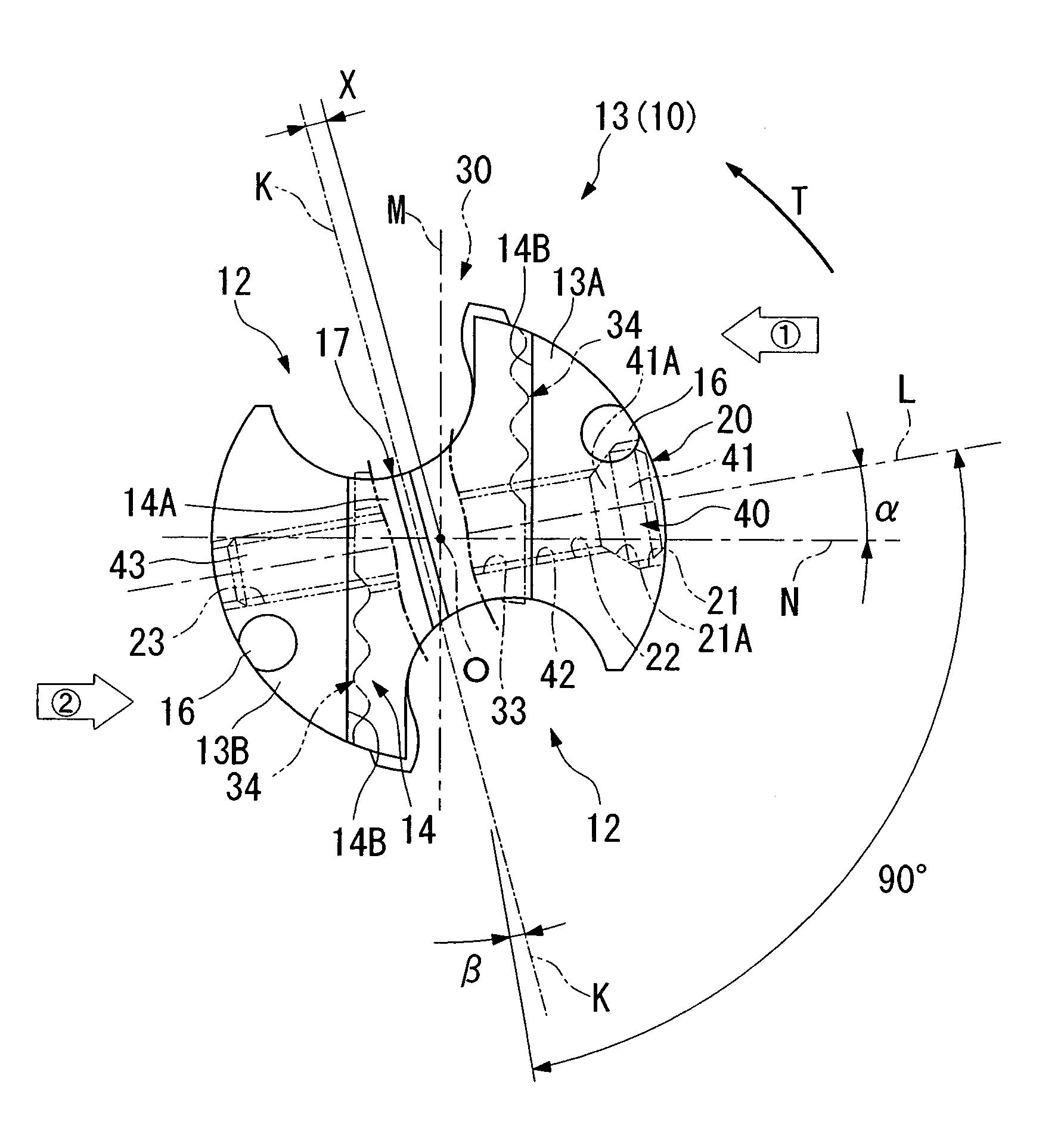

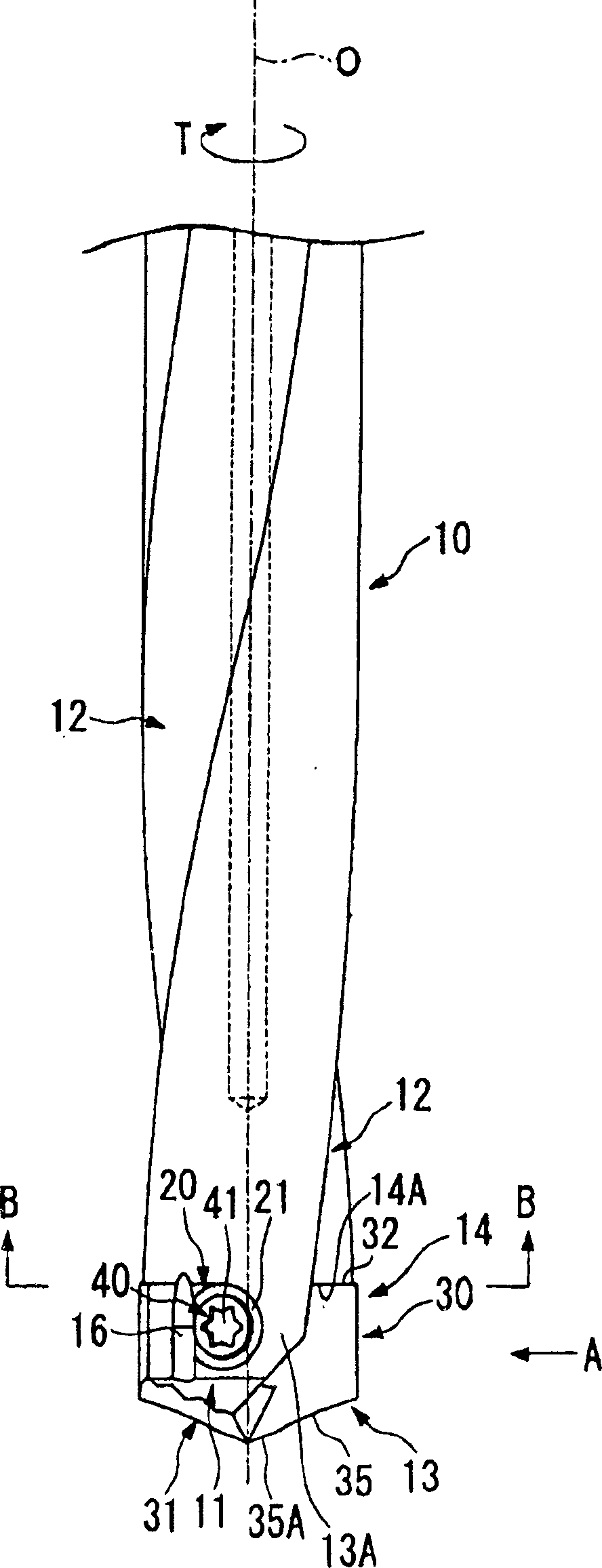

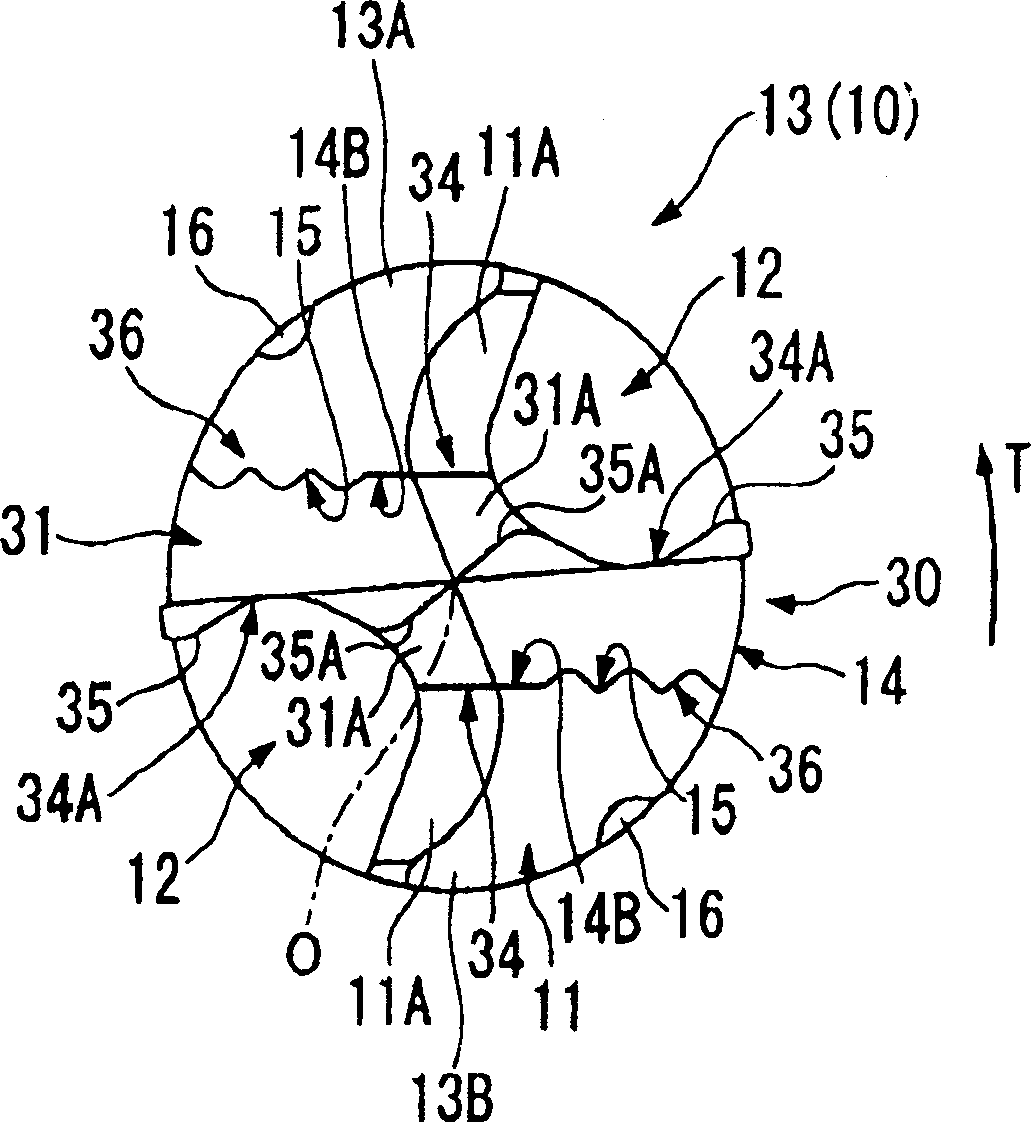

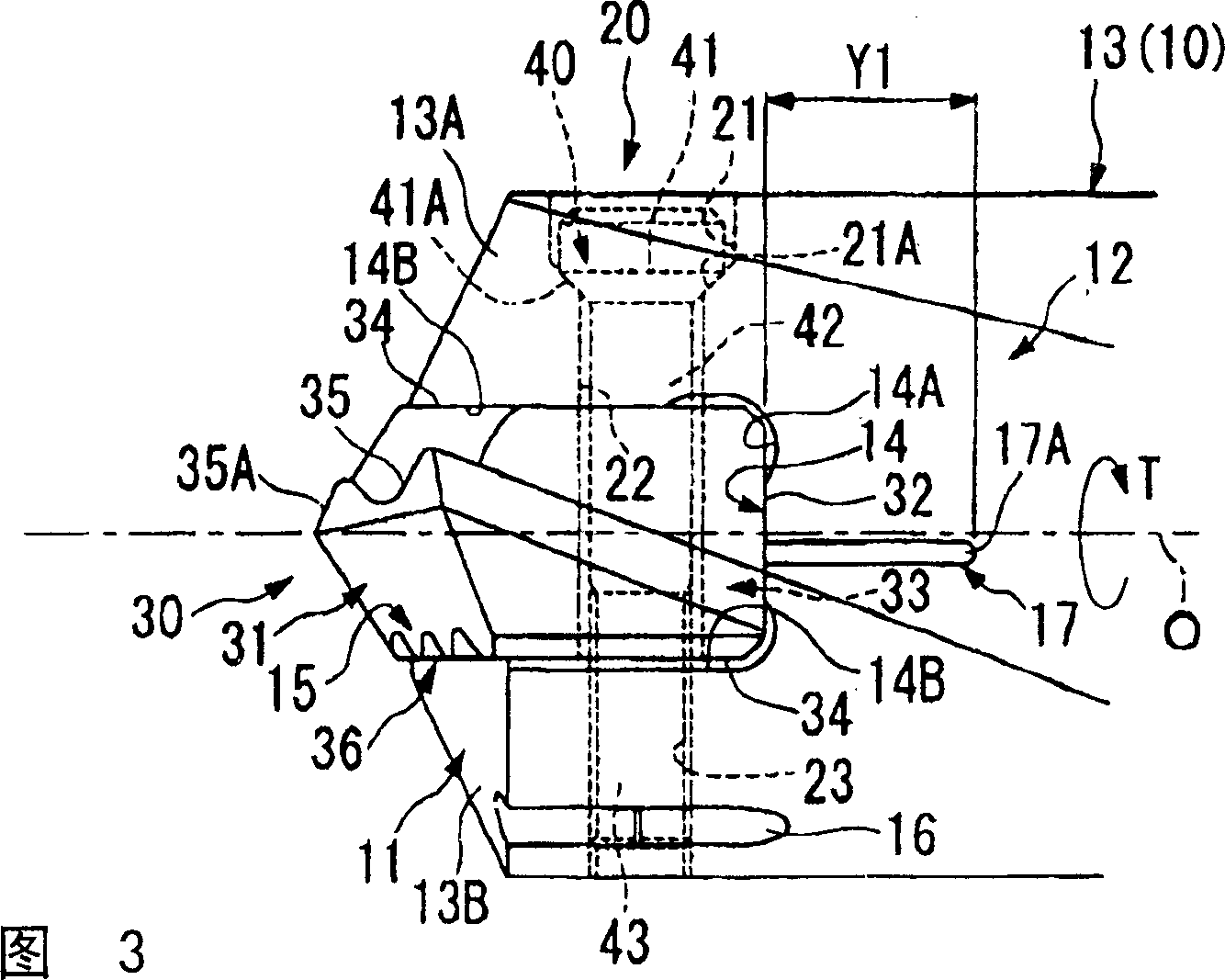

Throw-away tipped drill, throw-away tip, and drill main body

ActiveUS7168893B2Easily and reliably performEasy elastic deformationWood turning toolsTransportation and packagingEngineeringDrill bit

In a throw-away tipped drill, a slit is formed at the bottom surface of a tip attachment seat which faces towards the end of its axial line direction, with this slit extending towards the rear of the axial line direction. Furthermore, when seen from the end of the axial line direction, this slit is arranged as being displaced so as to be closer to a second end portion into which a shaft portion of a clamp bolt is threaded than to a first end portion which is pressed by a head portion of that clamp bolt. As a result, when, using the clamp bolt, the pair of outer side surfaces of the tip are pressed by the pair of internal side surfaces of the tip attachment seat, the pressing forces are mutually equal to one another.

Owner:MITSUBISHI MATERIALS CORP

Damaged bolt and screw removing devices

ActiveUS8276482B2Improve biteEfficient extractionTransportation and packagingSpannersEngineeringDrill bit

Owner:COMBINED PRODS

Tool holder and cutting insert with centering nose portion

InactiveUS20100303561A1Reduce riskLow costTransportation and packagingMilling cuttersNoseKnife blades

The cutting tip comprises a lateral face for aligned lateral positioning against a lateral alignment line with a tool holder housing, comprising an alignment snout with first and second lateral alignment surfaces that bear respectively against first and second lateral driving alignment surfaces and comprising, at some distance, a third lateral alignment surface for bearing against a third lateral driving alignment wall surface, two out of the first, second and third alignment surfaces being mutually inclined in such a way as to ensure alignment in a chosen position of travel with respect to the driving lateral wall surfaces opposite.

Owner:SAFETY SA

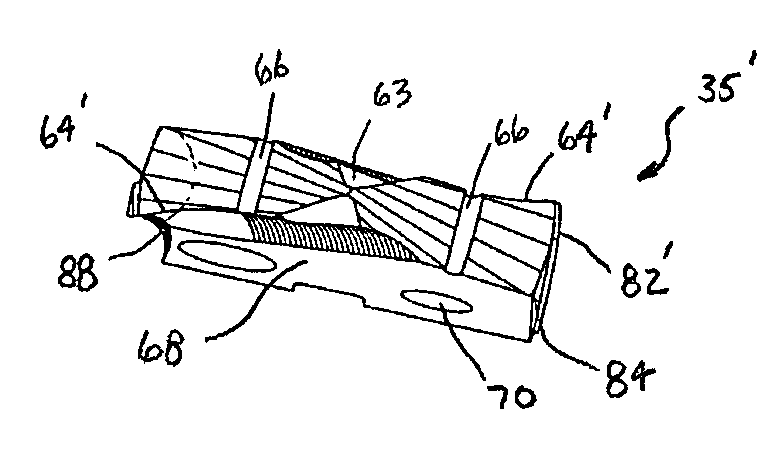

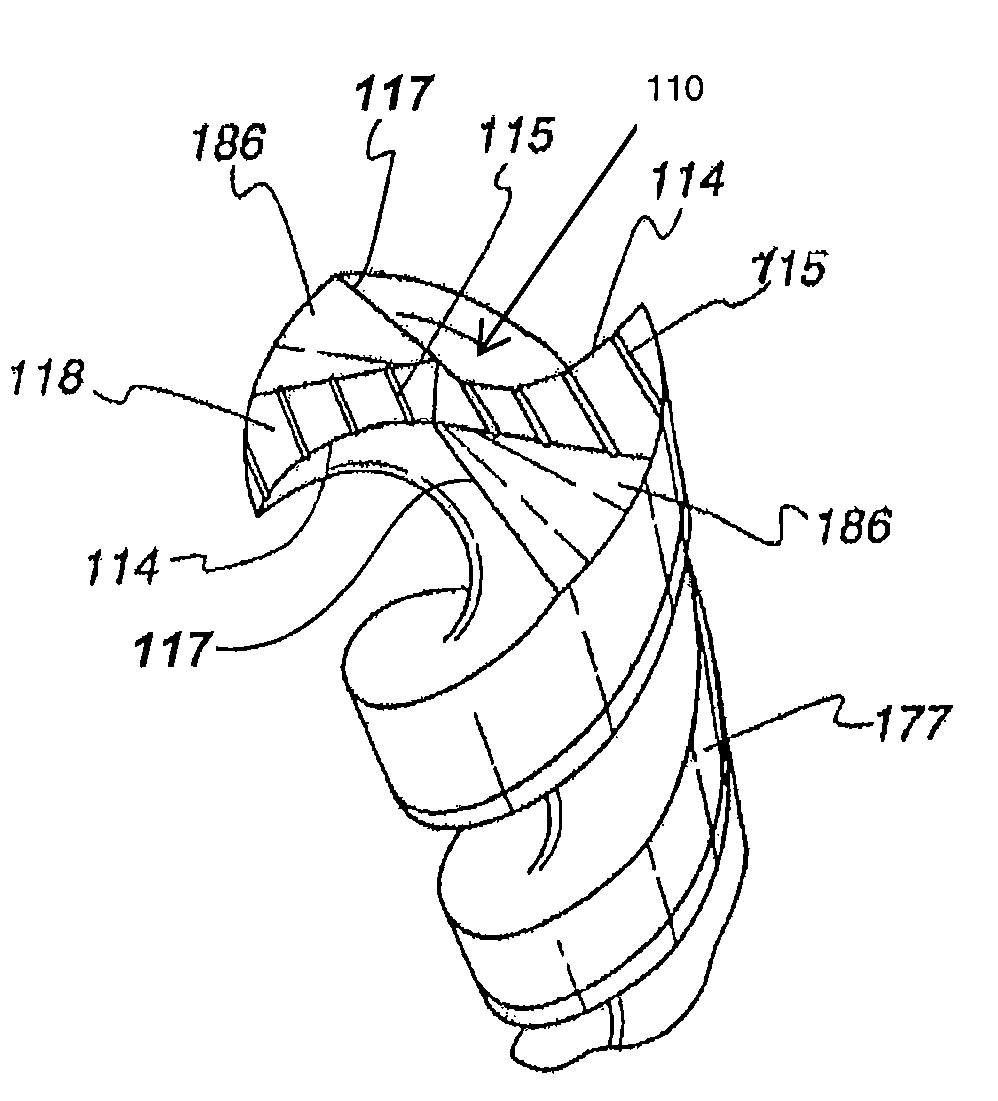

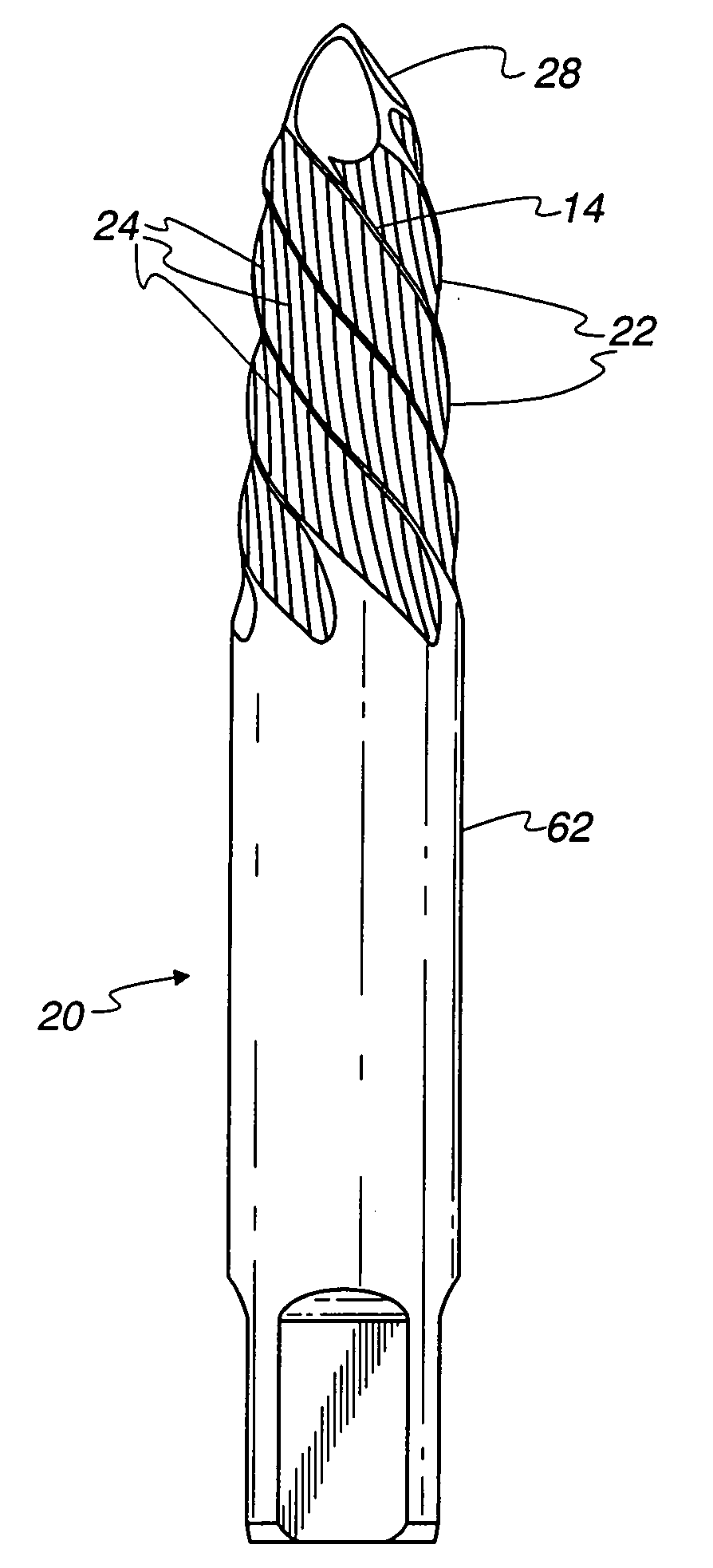

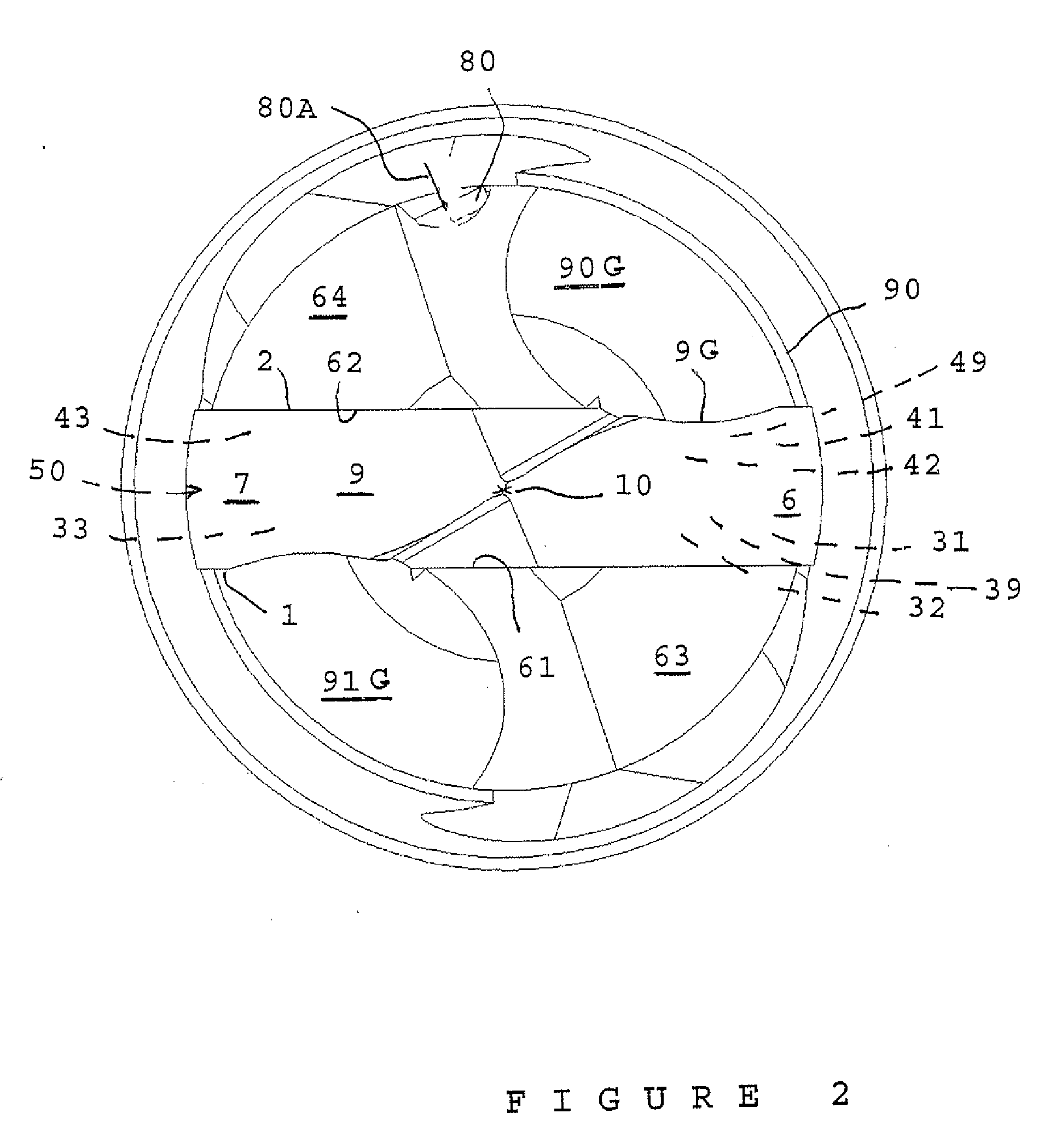

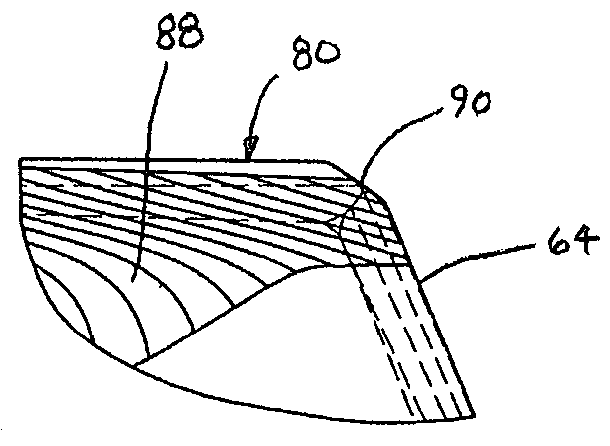

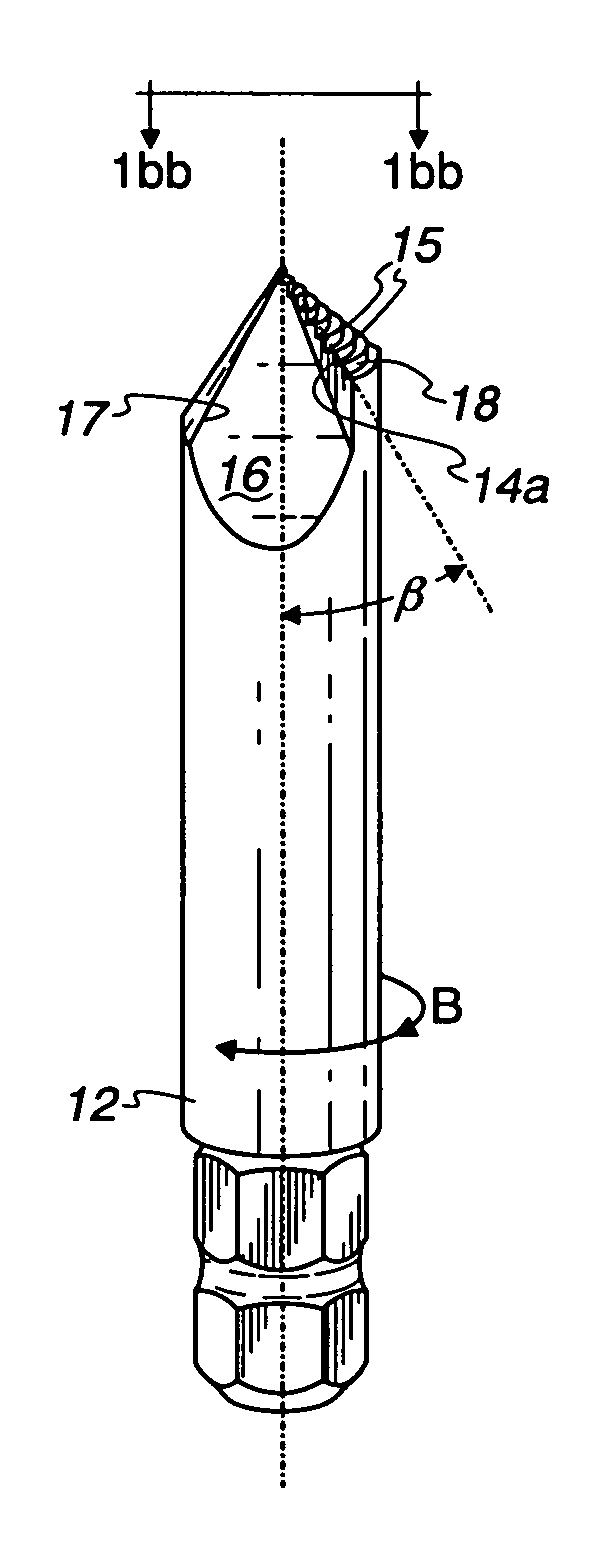

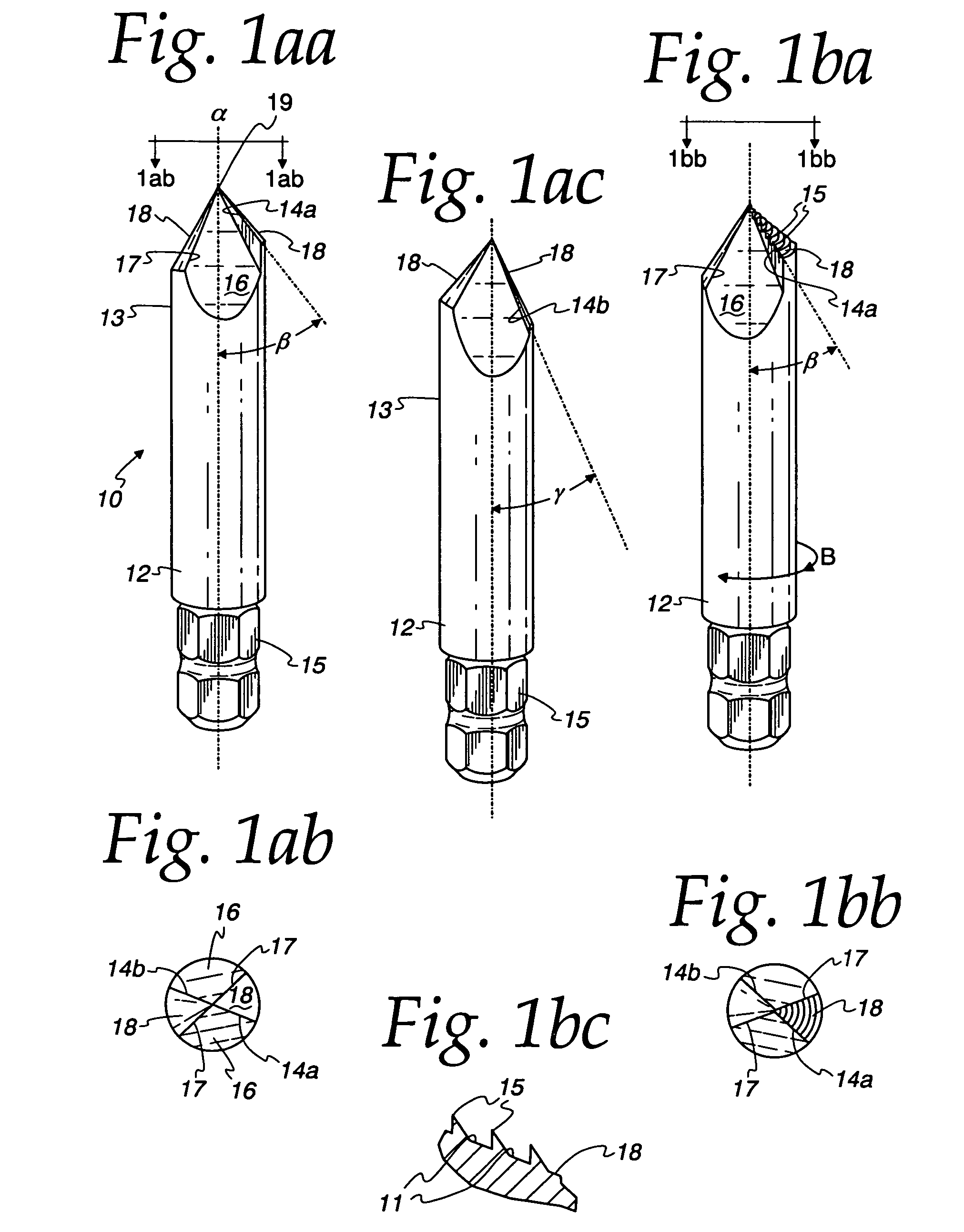

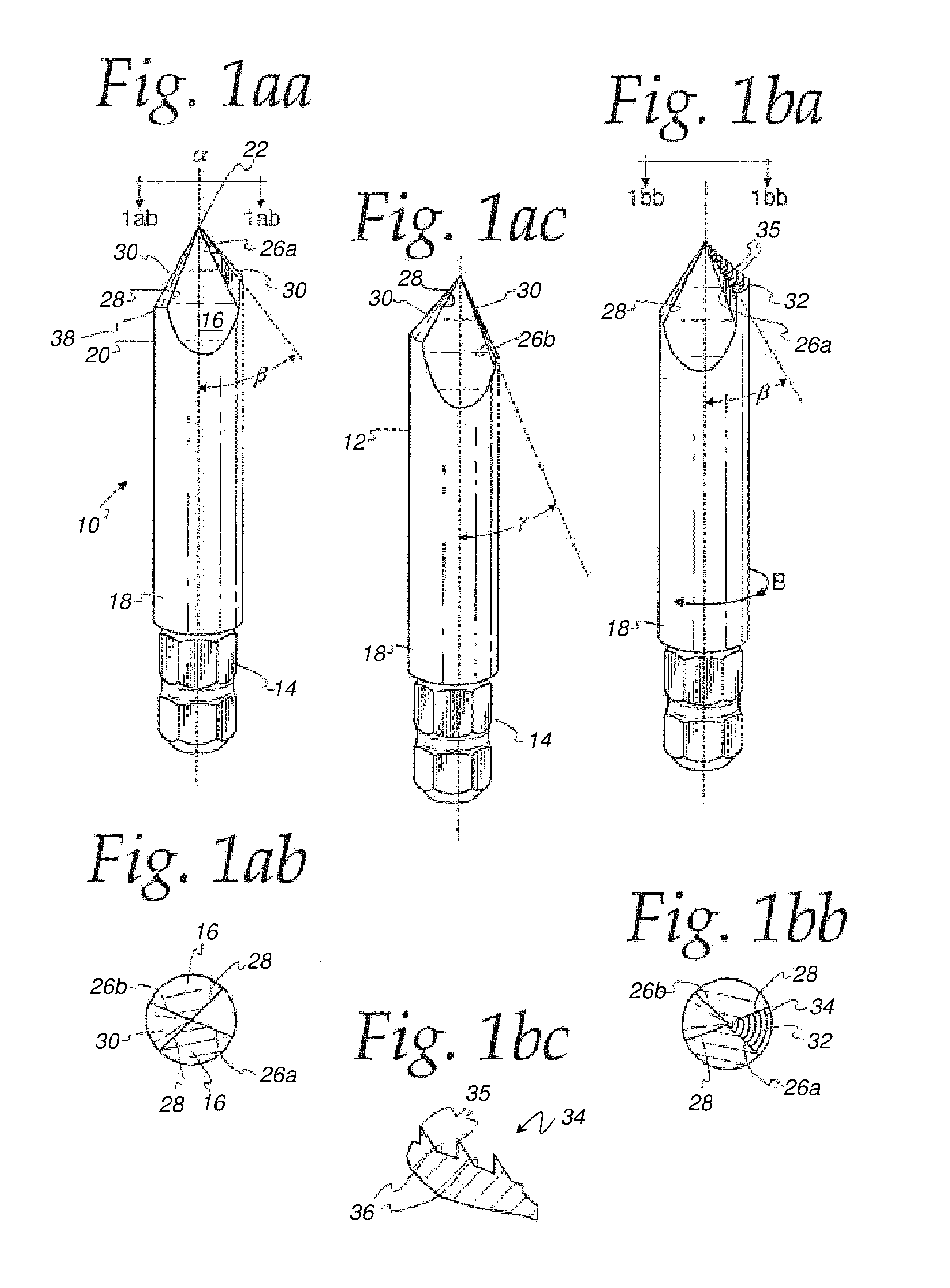

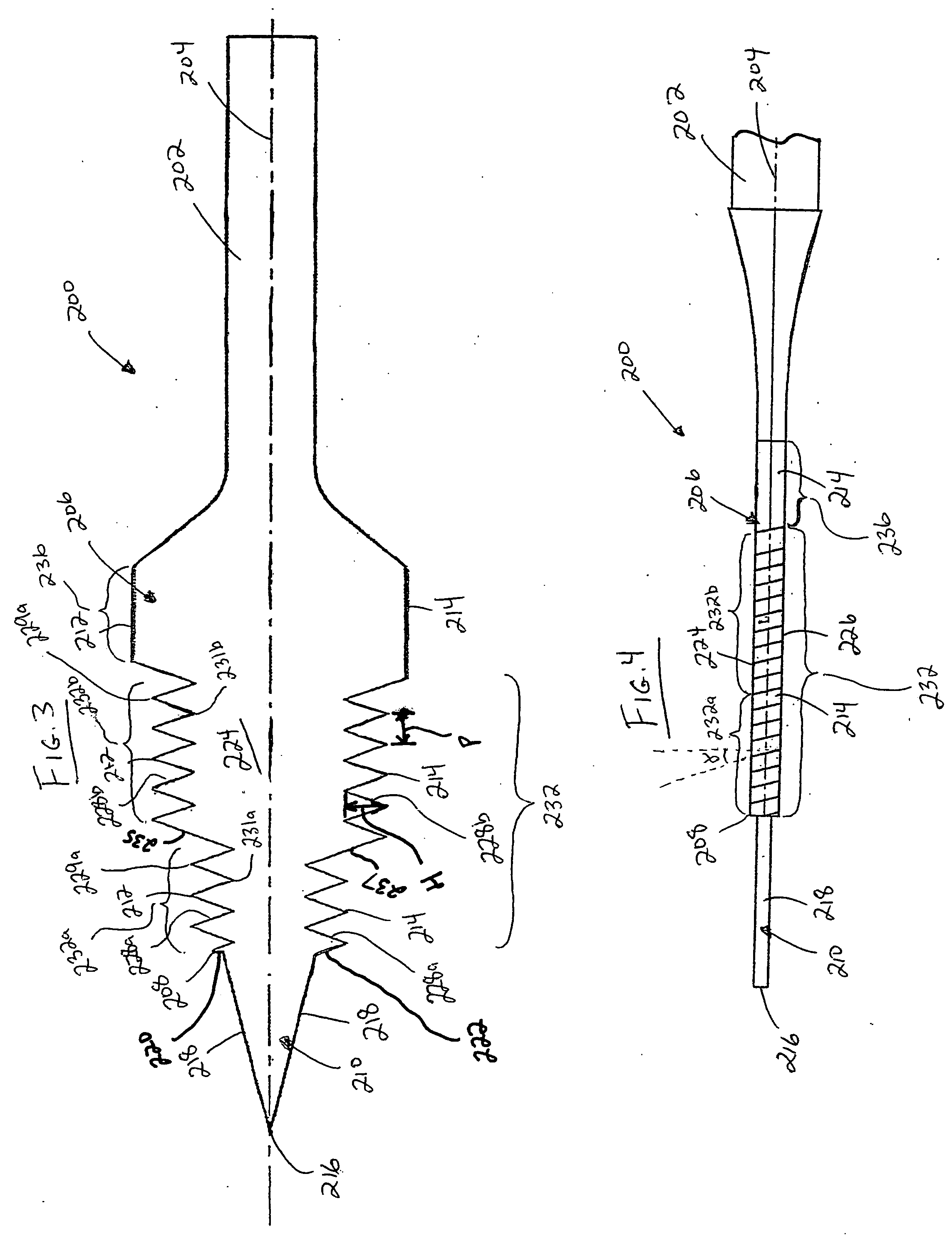

Spade drill insert having helical margins

ActiveUS20050100419A1Improve stabilityWood turning toolsTransportation and packagingFluteEngineering

A spade drill insert and drilling tool assembly is provided wherein the lands of the spade drill insert have helical margins which provide increased stability during cutting operations. The margin may have a helical trailing side or leading side, a parallel helical margin, or may also include a gullet or flute adjacent the helical margin.

Owner:ALLIED MASCH & ENG CORP

Spade drill insert having curved cutting edges

ActiveUS20050100420A1Improved chip formationWood turning toolsTransportation and packagingChip formationKnife blades

A spade drill insert and drilling tool assembly is provided wherein the spade drill insert body comprises curved cutting edges and a lip groove having a trough substantially parallel to a plane formed through each adjacent curved cutting edge, which provides a significant improvement in chip formation during cutting operations.

Owner:ALLIED MASCH & ENG CORP

Damaged bolt and screw removing devices

A bit for removing a broken fastener comprises a tip from which extend two or more notches separated by scraping surfaces formed from two-sided frusto-conically-shaped regions. The scraping surfaces are bounded on one side by a cutting edge and on the other side by a non-cutting edge and are configured to cut into the fastener when the bit is rotated in a direction opposite to the fastener's direction of engagement. Specific embodiments include configurations where the cutting edges extend at different angles with respect to the bit axis and where the scraping surfaces comprise a plurality of serrations.

Owner:COMBINED PRODS

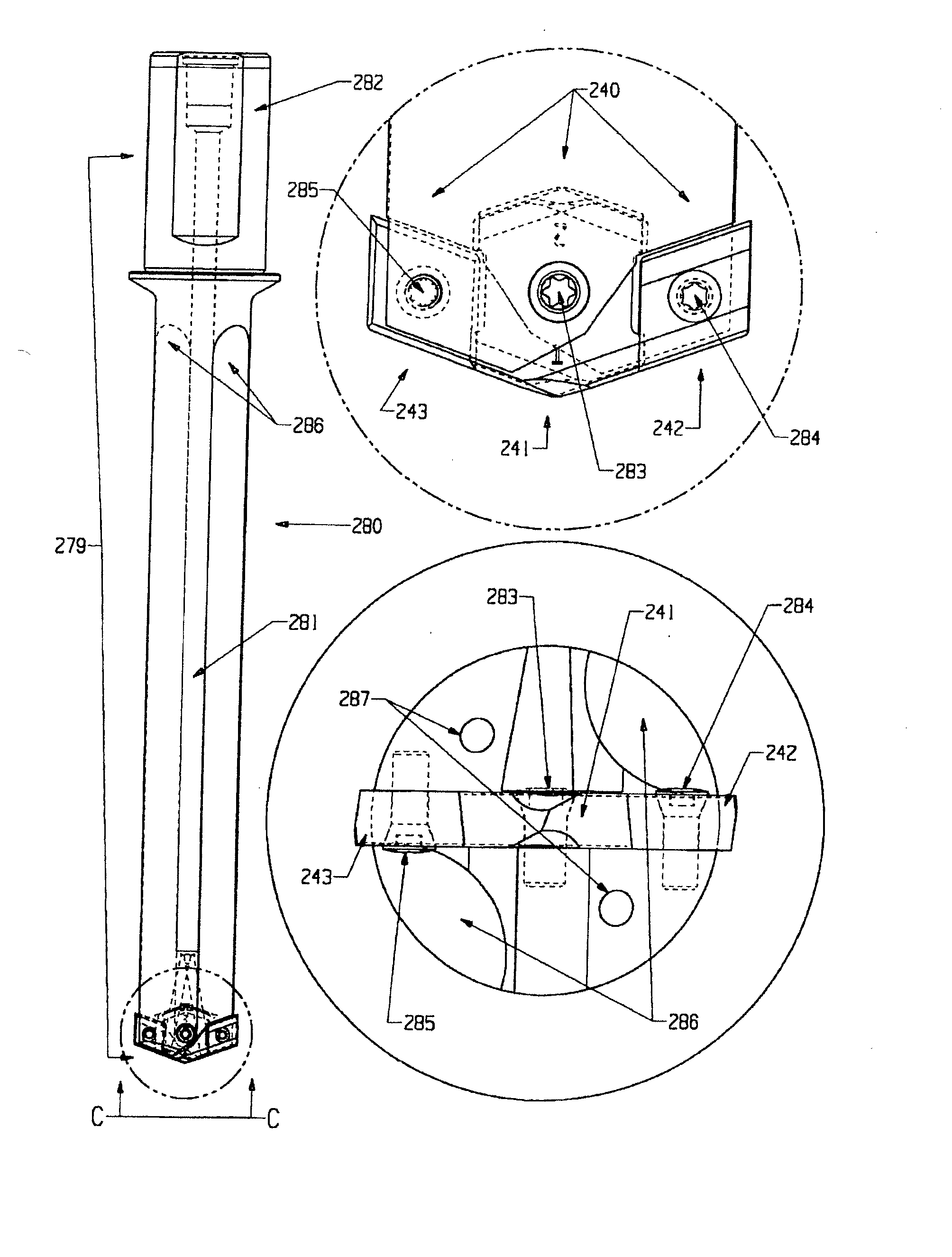

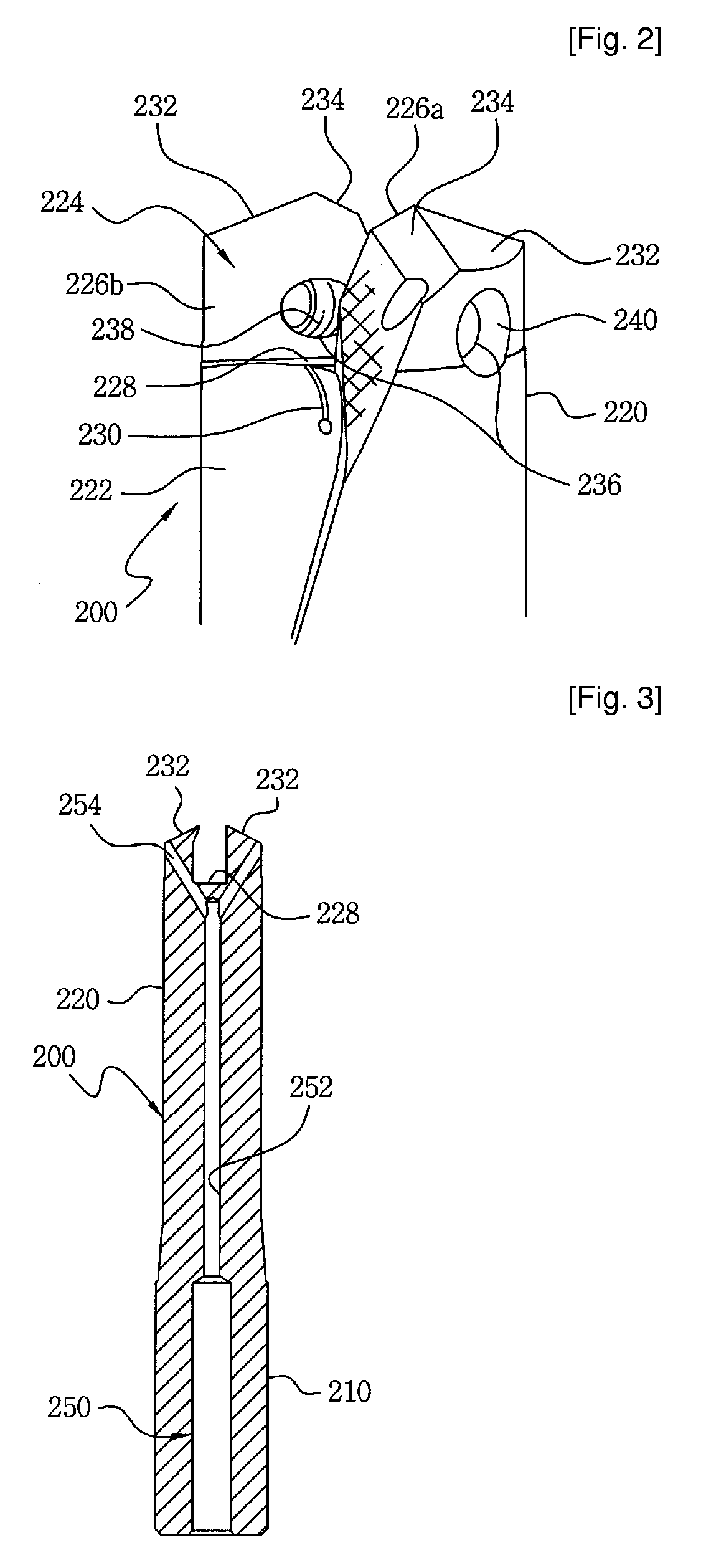

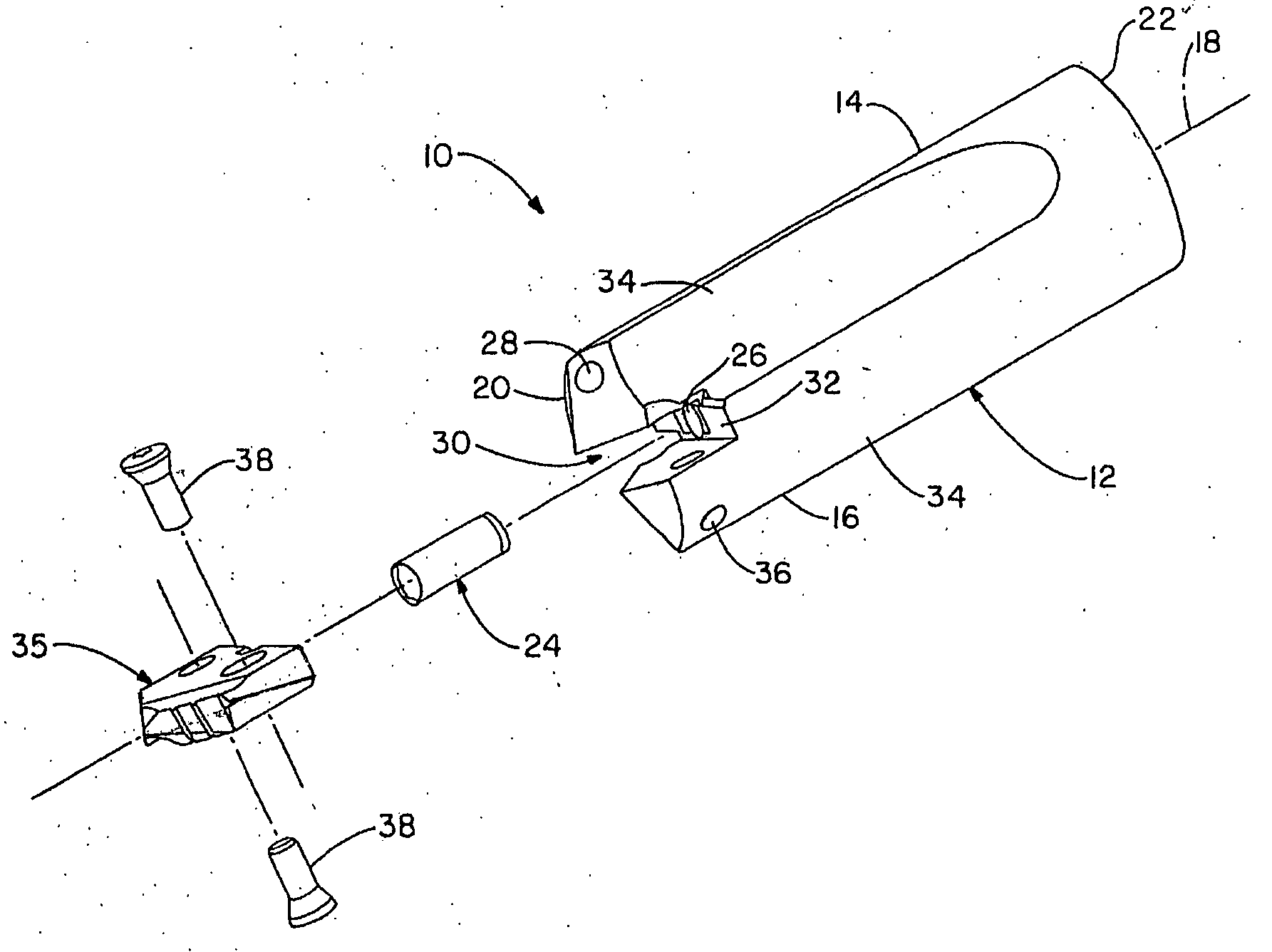

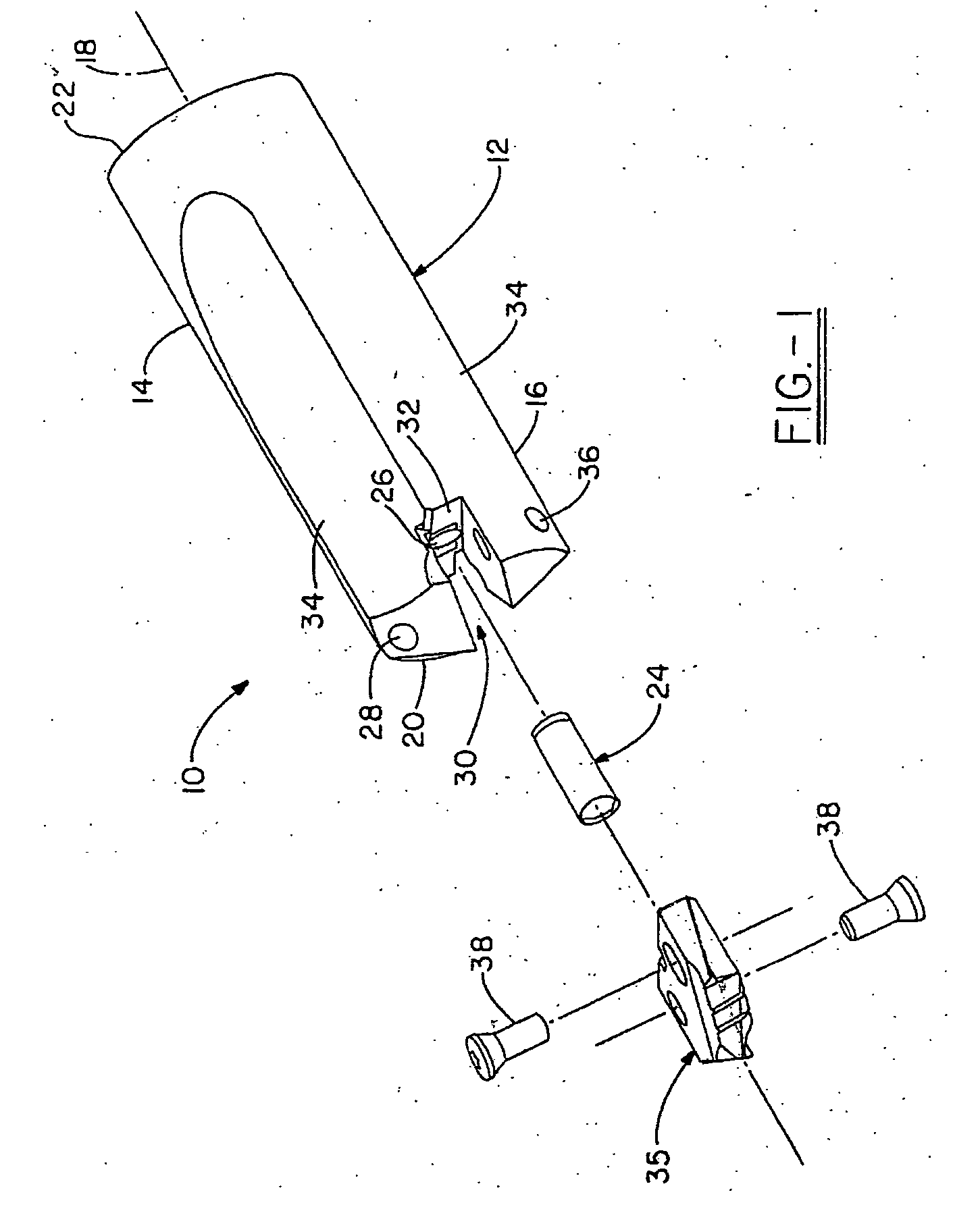

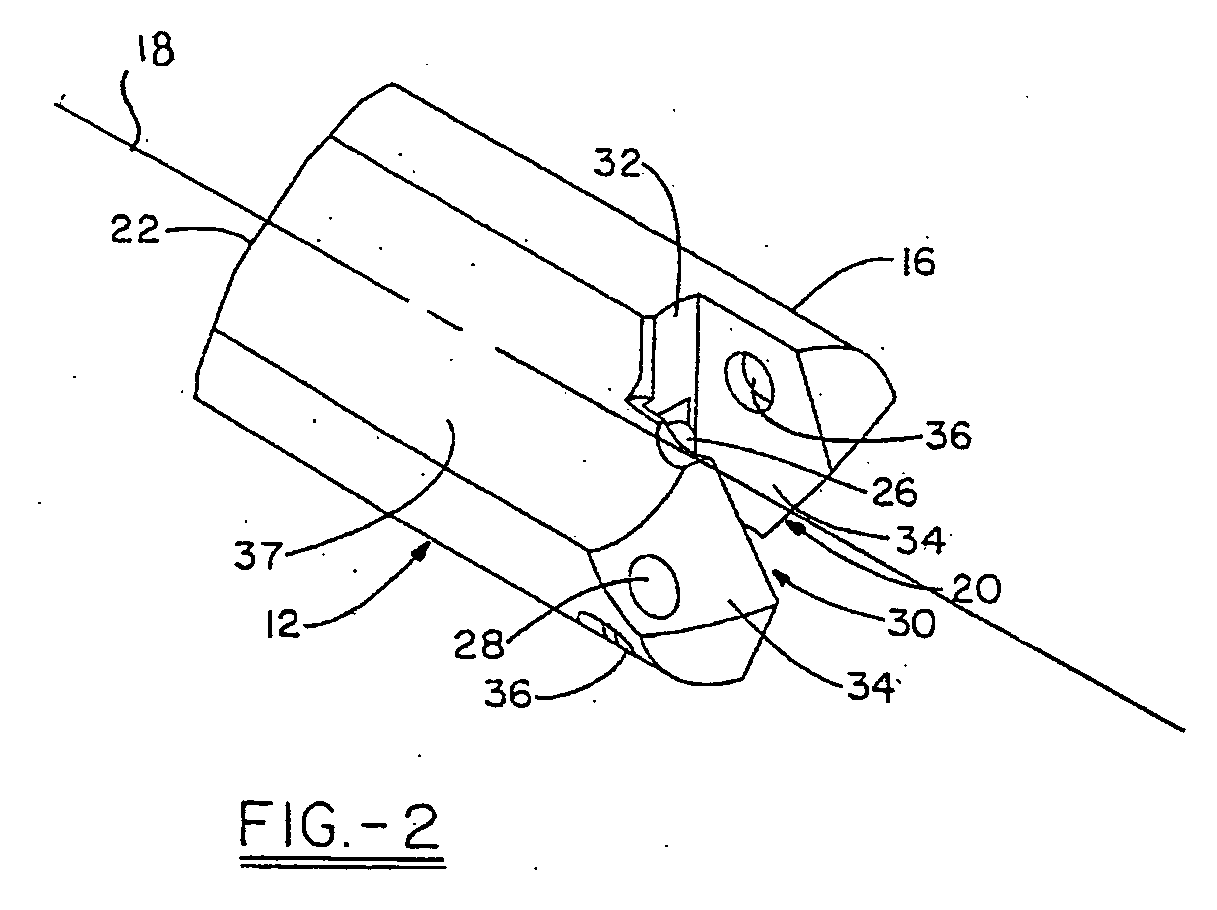

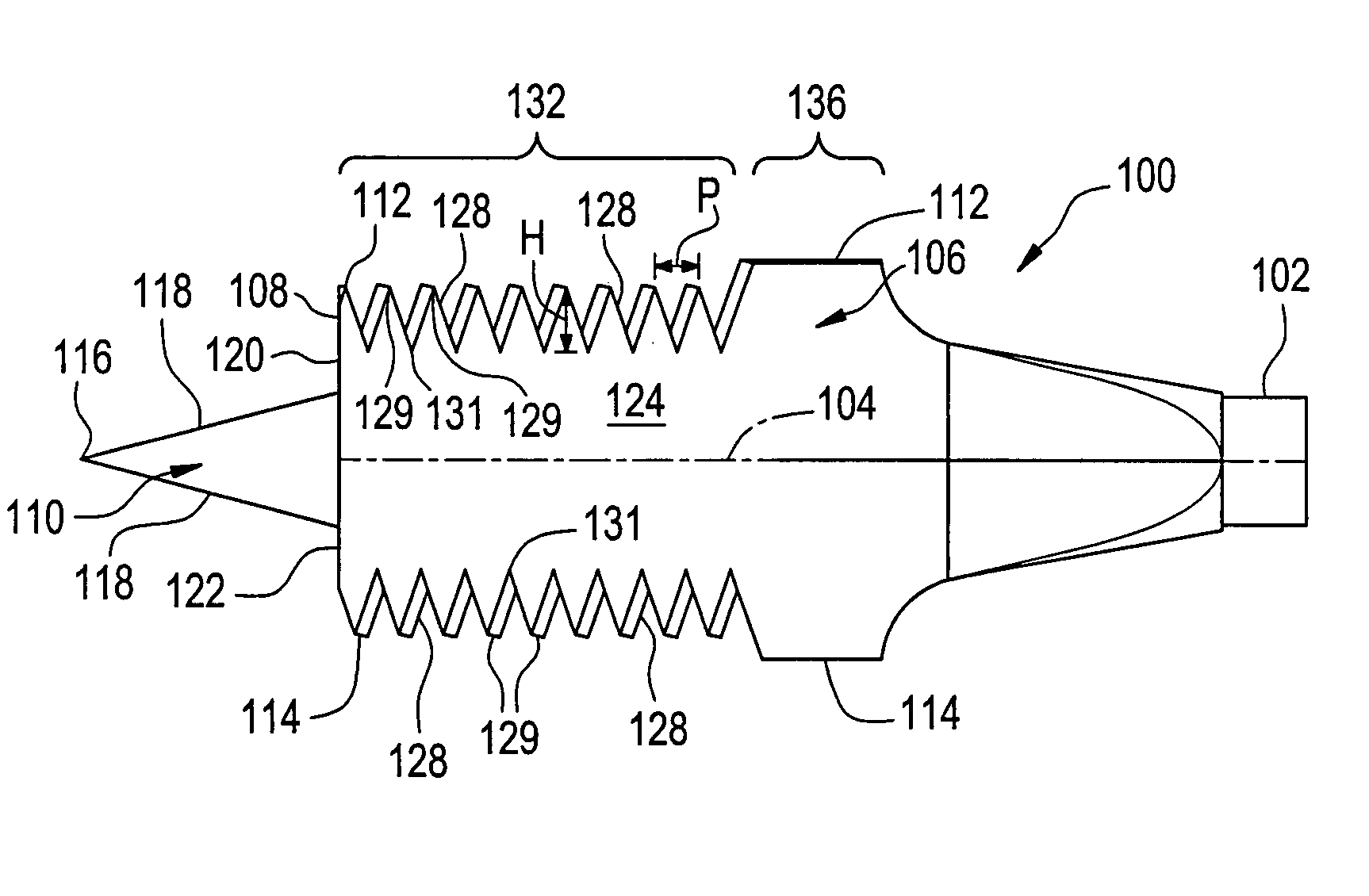

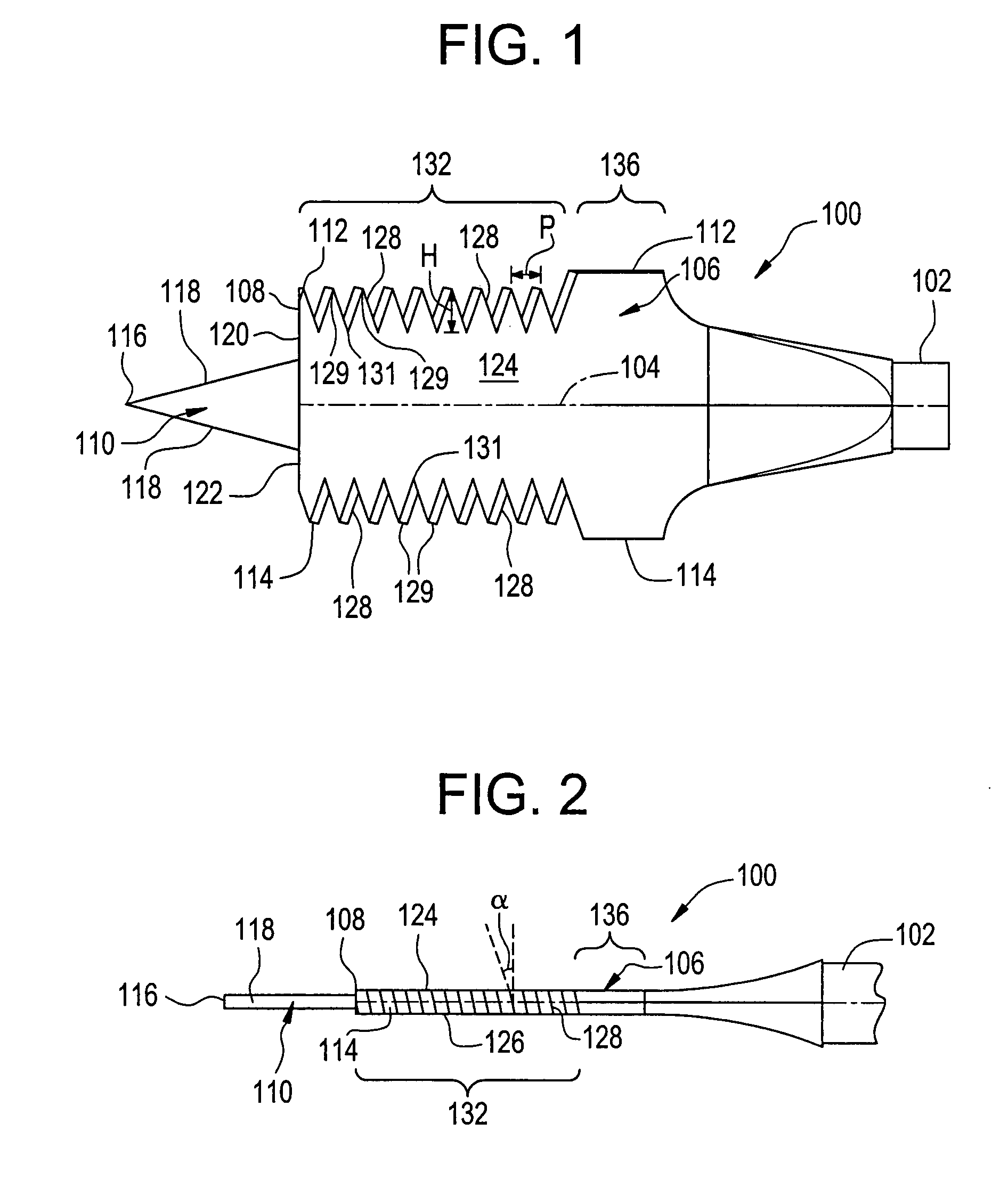

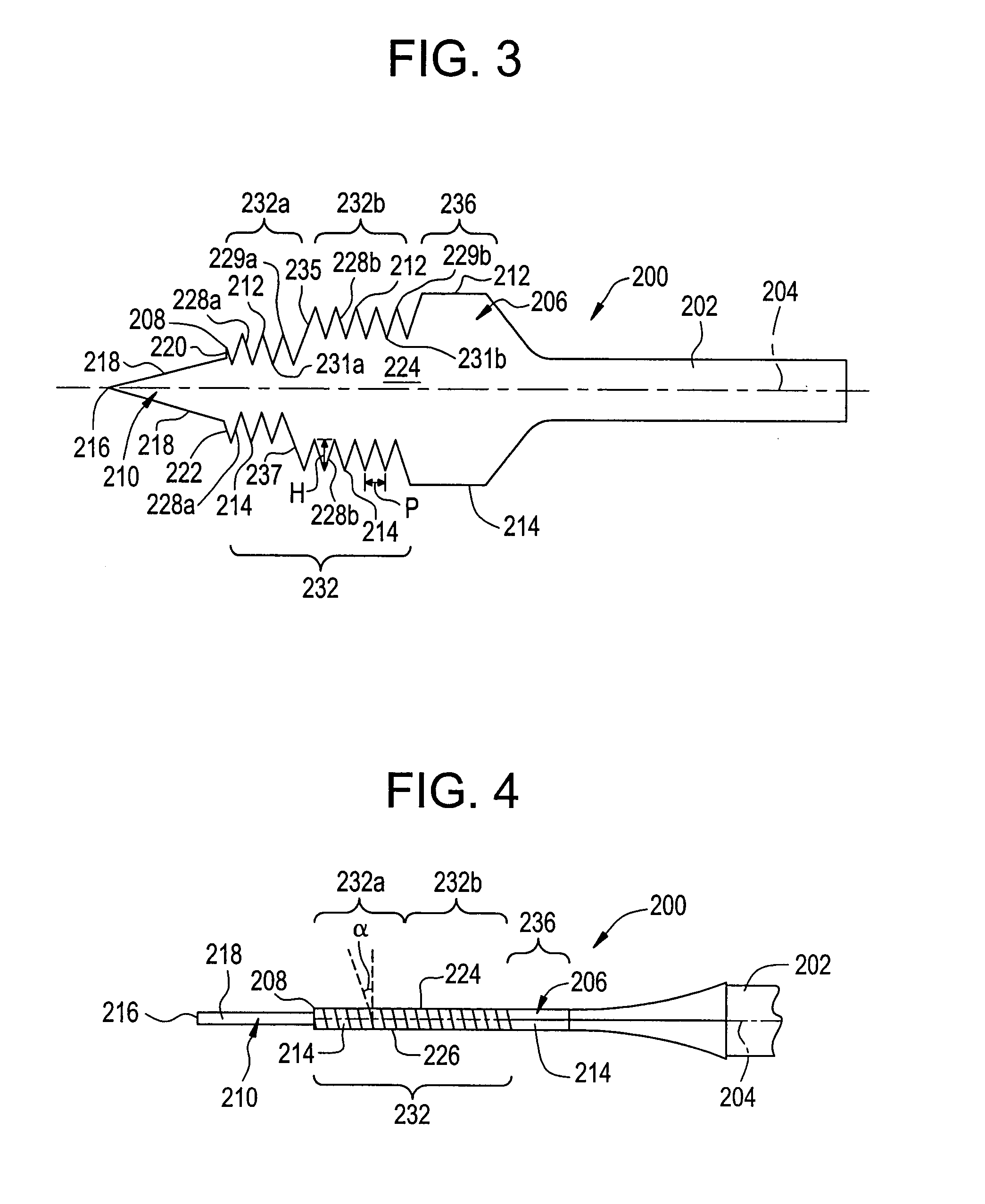

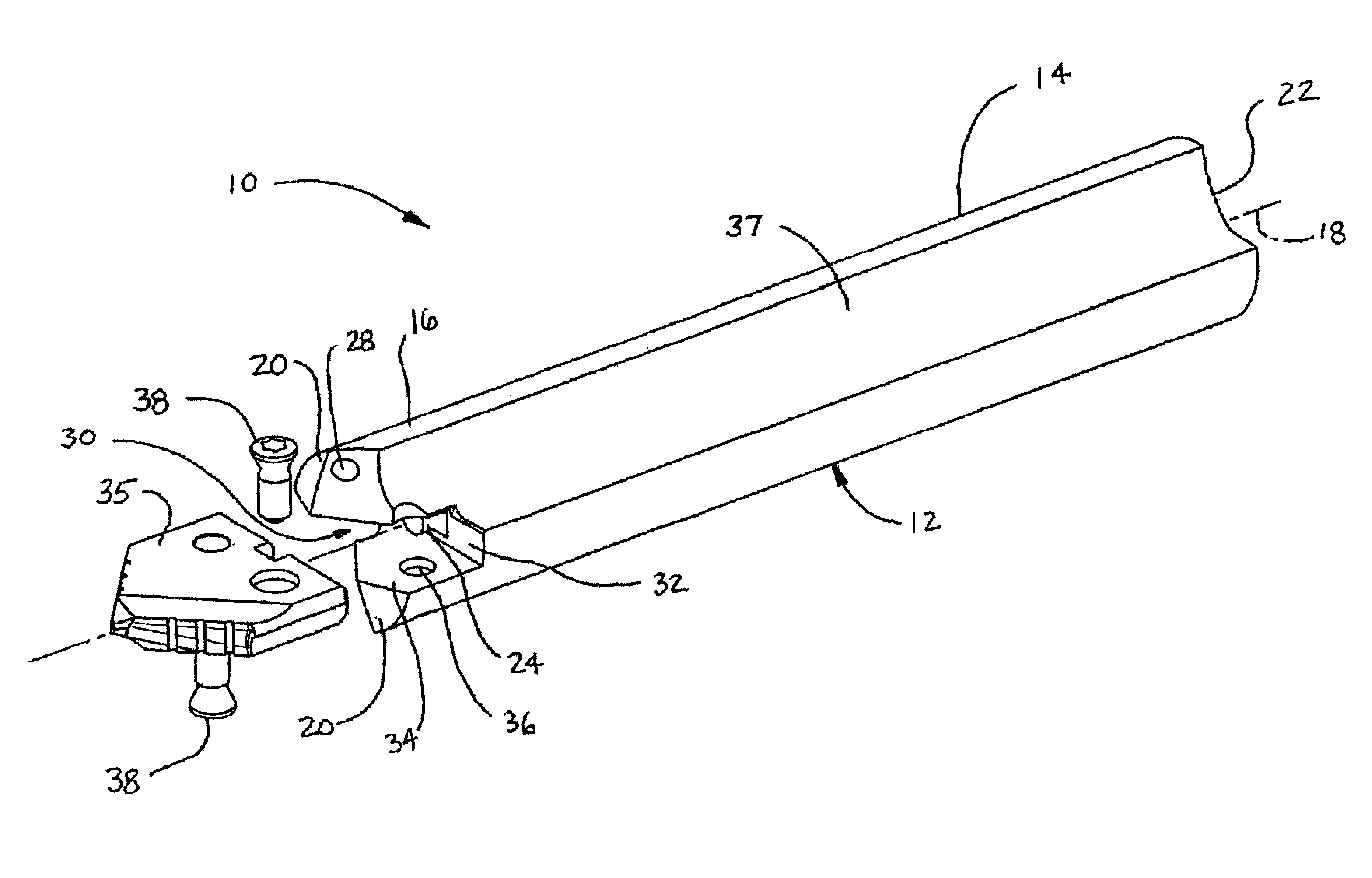

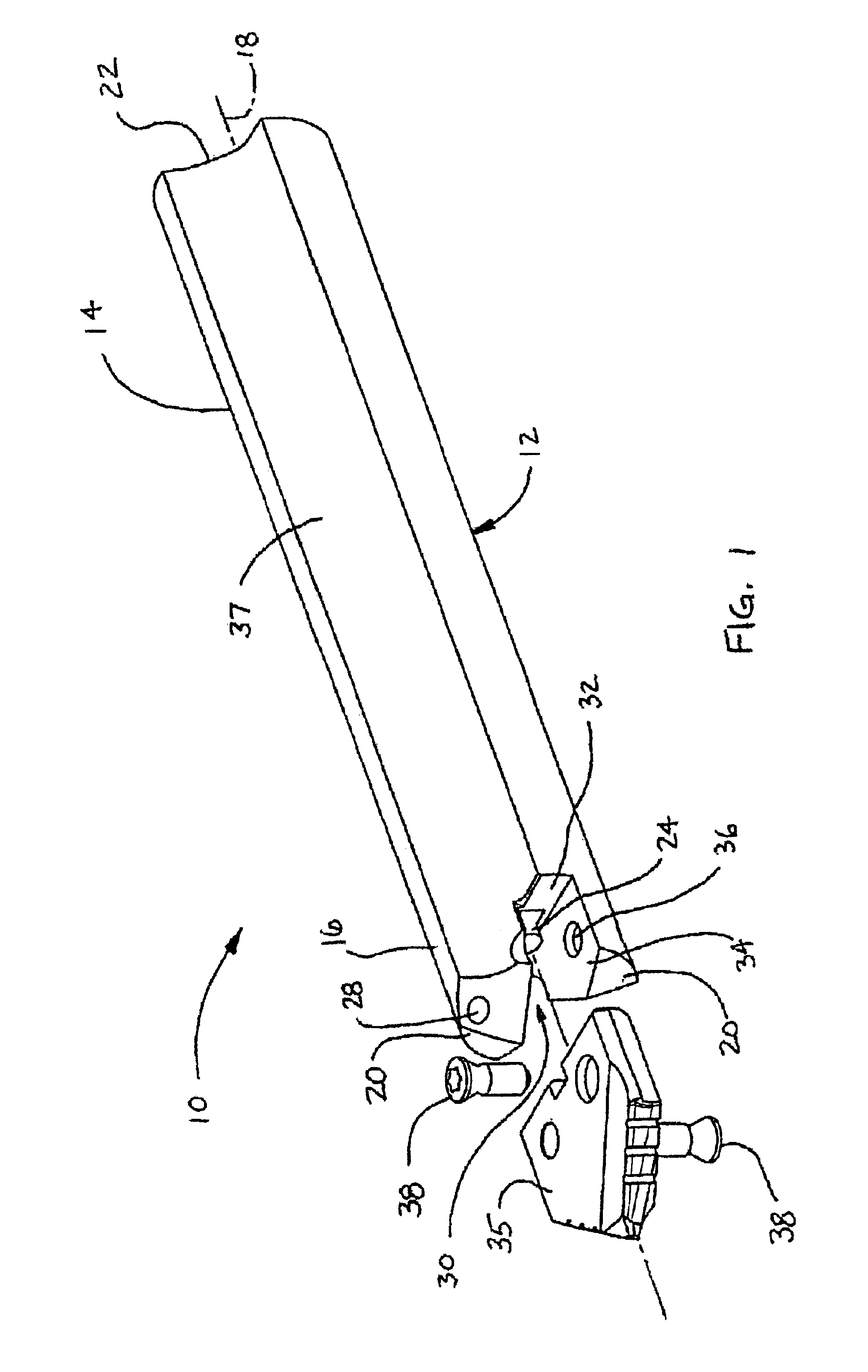

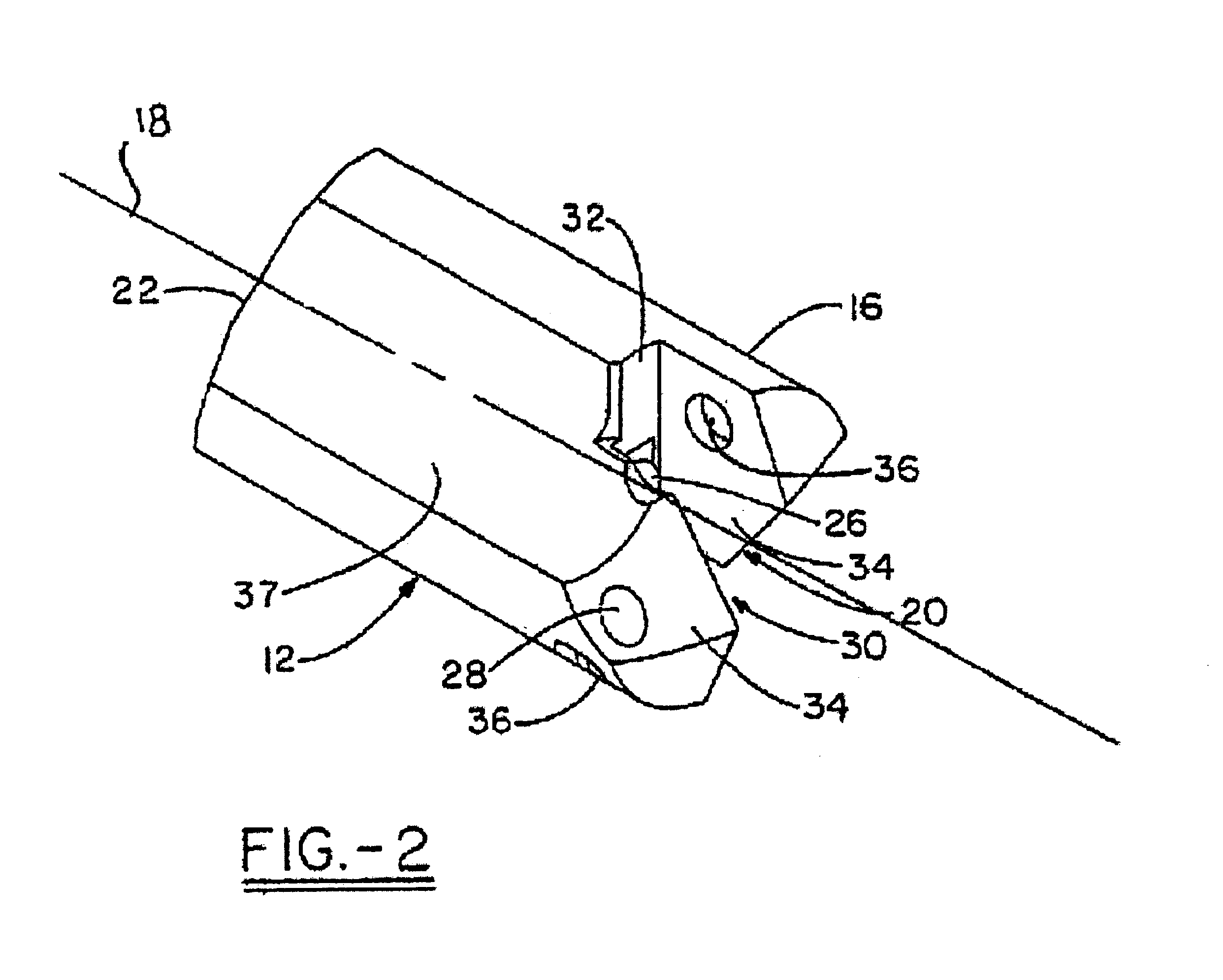

Multi-piece drill head and drill including the same

One non-limiting aspect of the present disclosure is directed to a multi-piece spade drill head for a spade drill, wherein the spade drill includes an elongate body portion and a cutting portion removably secured to an end of the body portion. The multi-piece spade drill head includes at least two insert pieces, each piece including a cutting edge. The at least two insert pieces are configured to be removably secured to the body portion of the spade drill adjacent one another and with the cutting edges of the insert pieces aligned to together form a cutting edge on an end of the spade drill.

Owner:KENNAMETAL INC

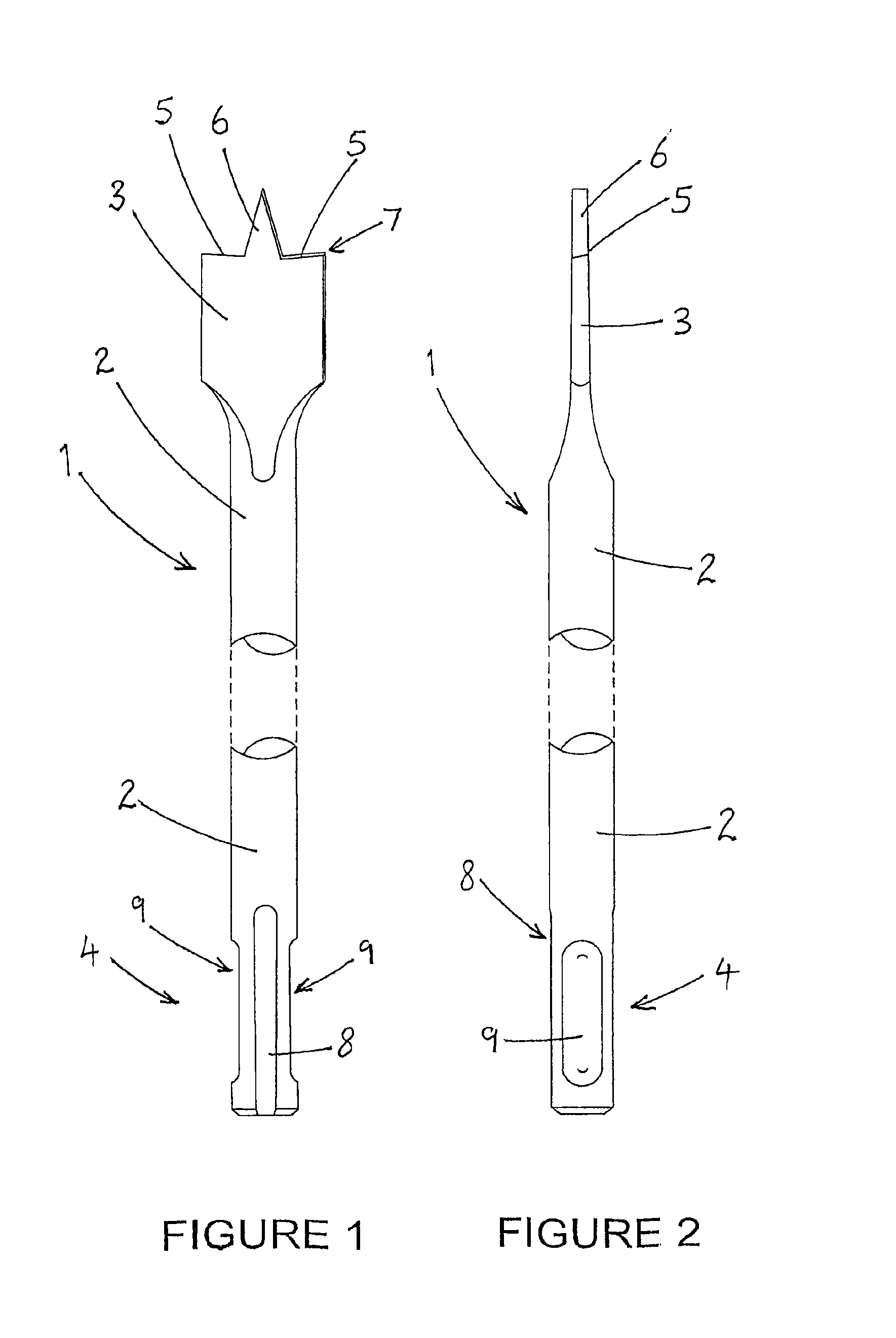

Spade bit

ActiveUS7246976B2Improve usabilityEasy to useWood turning toolsTransportation and packagingEngineeringTwo step

An embodiment of a spade bit has straight grooves at a lead angle of 4 to 8 degrees placed on flat edges of the spade bit. In an alternative embodiment, a spade bit has two steps of straight grooves at a lead angle of 4 to 8 degrees placed on flat edges of the spade bit. In other alternative embodiments, a spade bit has tapered flat edge which have straight grooves at a lead angle of 4 to 8 degrees placed thereon. The straight grooves on the flat edges of the spade bits allow the spade bit to pull itself through the workpiece with a minimal amount of penetration. The flat edges of the spade bit may also have cutting surfaces for cleaning the hole and permitting the easy removal of the spade bit from the hole after drilling.

Owner:GREENLEE TEXTRON

Spade drill insert having helical margins

A spade drill insert and drilling tool assembly is provided wherein the lands of the spade drill insert have helical margins which provide increased stability during cutting operations. The margin may have a helical trailing side or leading side, a parallel helical margin, or may also include a gullet or flute adjacent the helical margin.

Owner:ALLIED MASCH & ENG CORP

Drilling bit without resharpening, non-resharpening blade, and drilling bit main body

InactiveCN1526500AReliable holdEasy elastic deformationTransportation and packagingTurning toolsKnife bladesDrill bit

In a throw-away tipped drill, a slit (17) is formed at the bottom surface of a tip attachment seat (14) which faces towards the end of its axial line direction (O), with this slit (17) extending towards the rear of the axial line direction (O). Furthermore, when seen from the end of the axial line direction (O), this slit (17) is arranged as being displaced so as to be closer to a second end portion into which a shaft portion of a clamp bolt is threaded than to a first end portion which is pressed by a head portion of that clamp bolt. As a result, when, using the clamp bolt, the pair of outer side surfaces of the tip are pressed by the pair of internal side surfaces of the tip attachment seat (14), the pressing forces are mutually equal to one another.

Owner:MITSUBISHI MATERIALS CORP

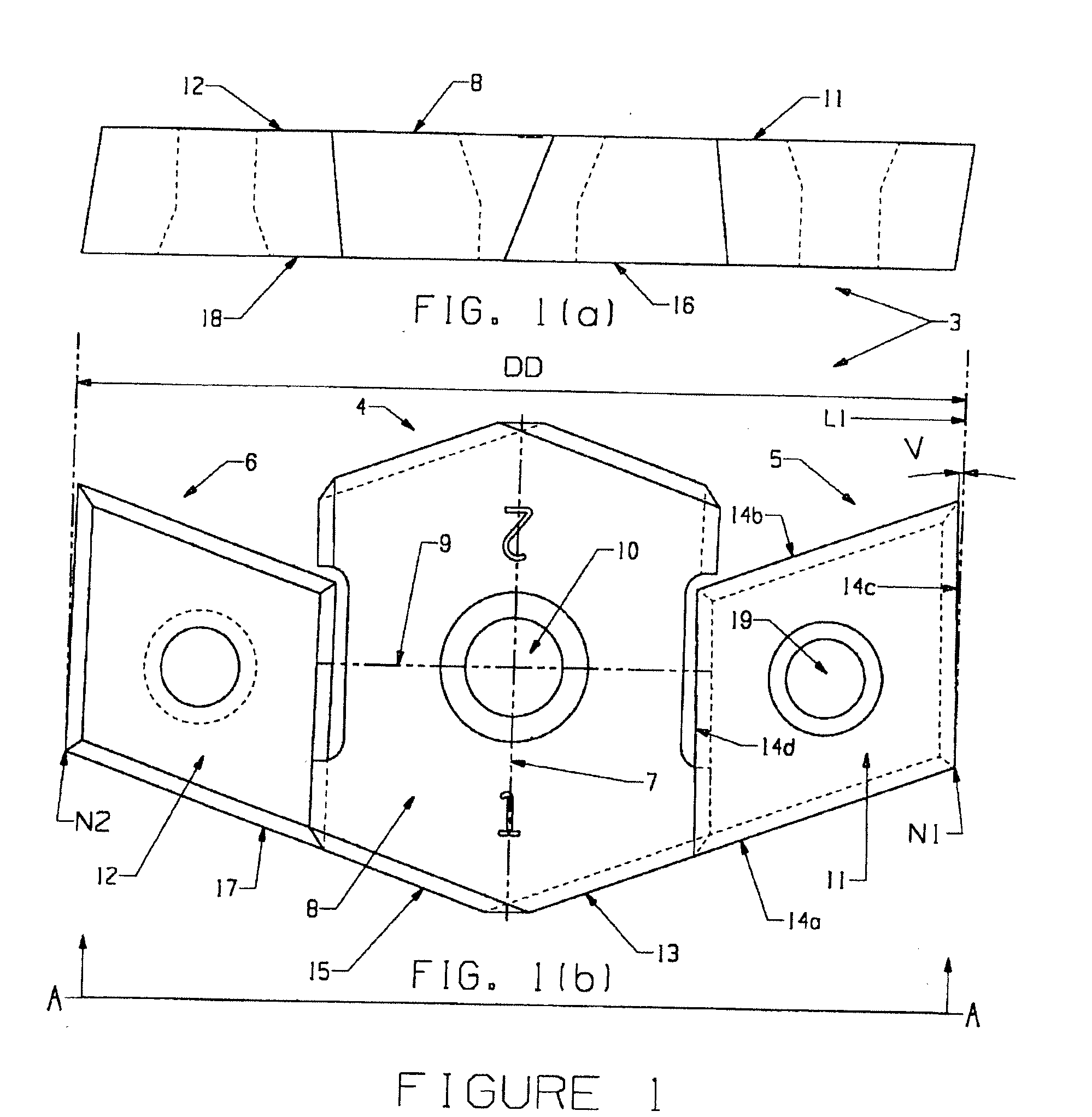

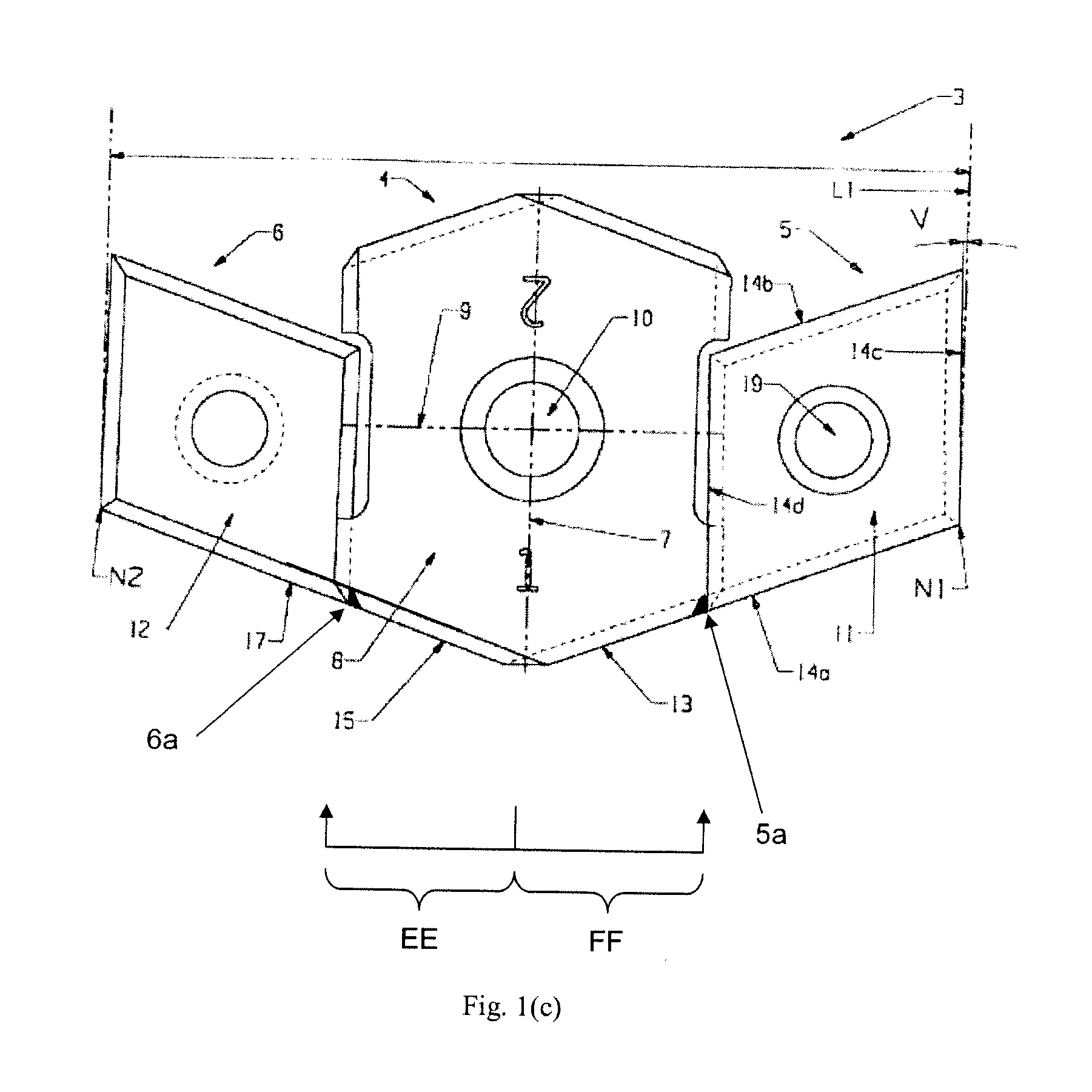

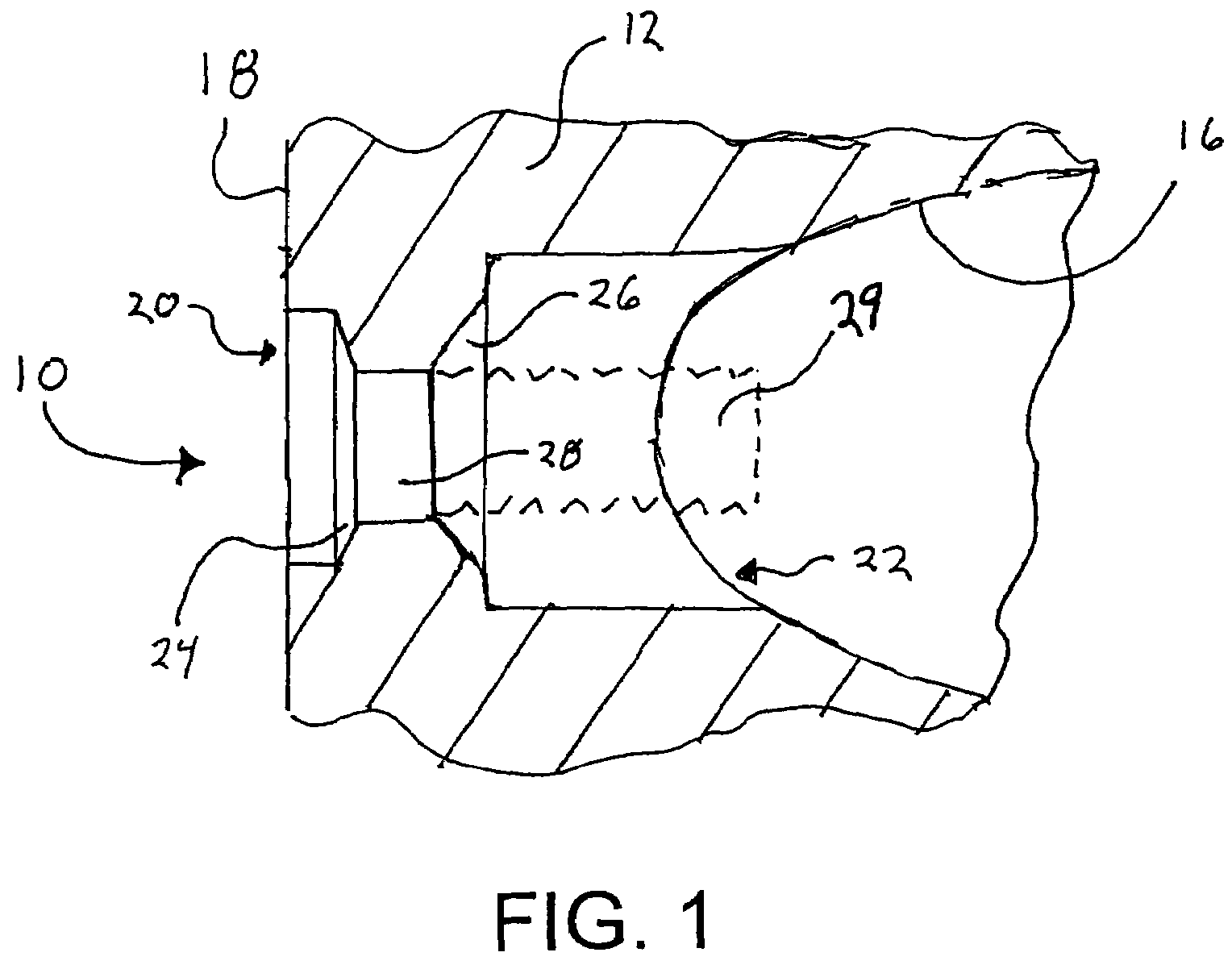

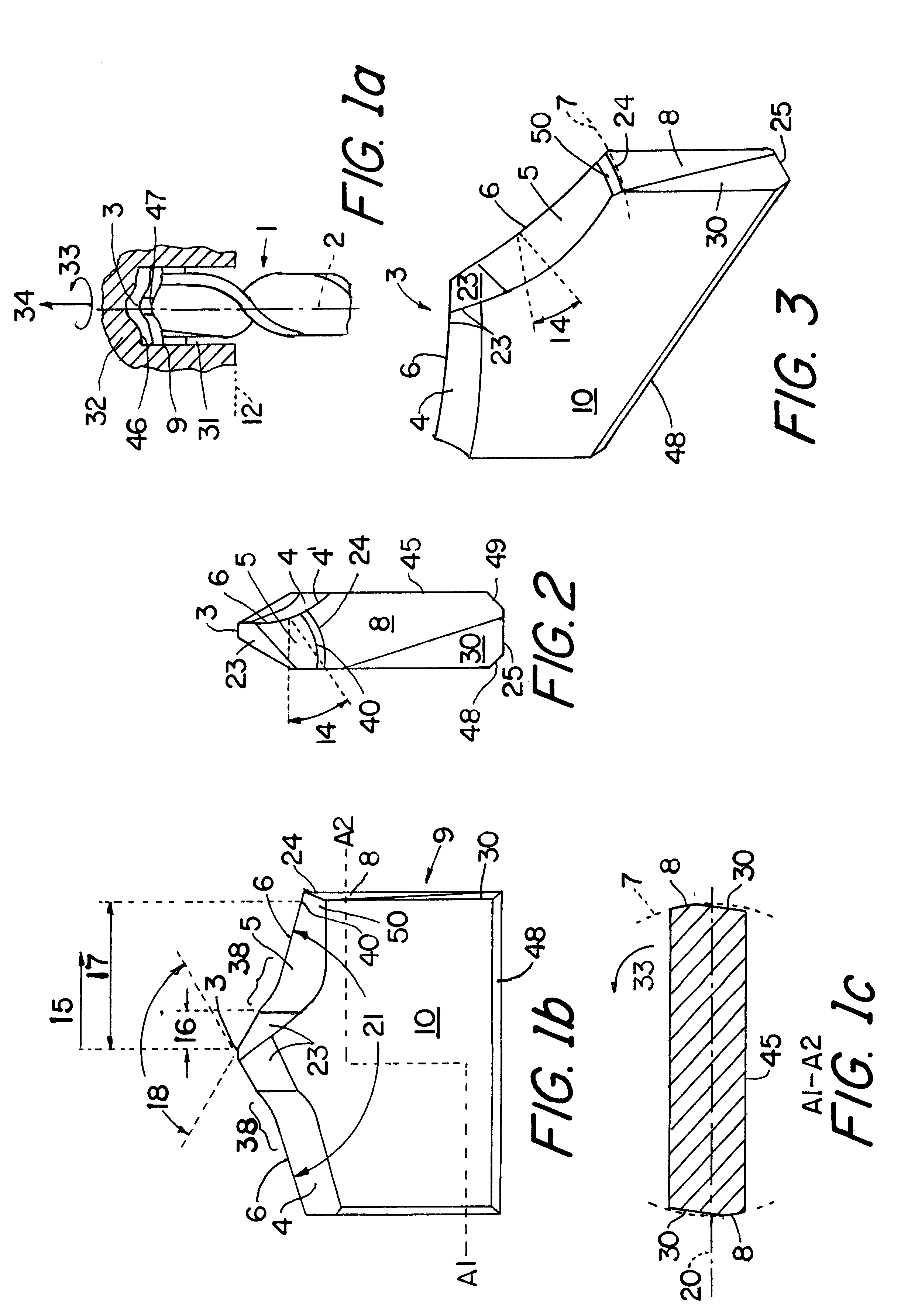

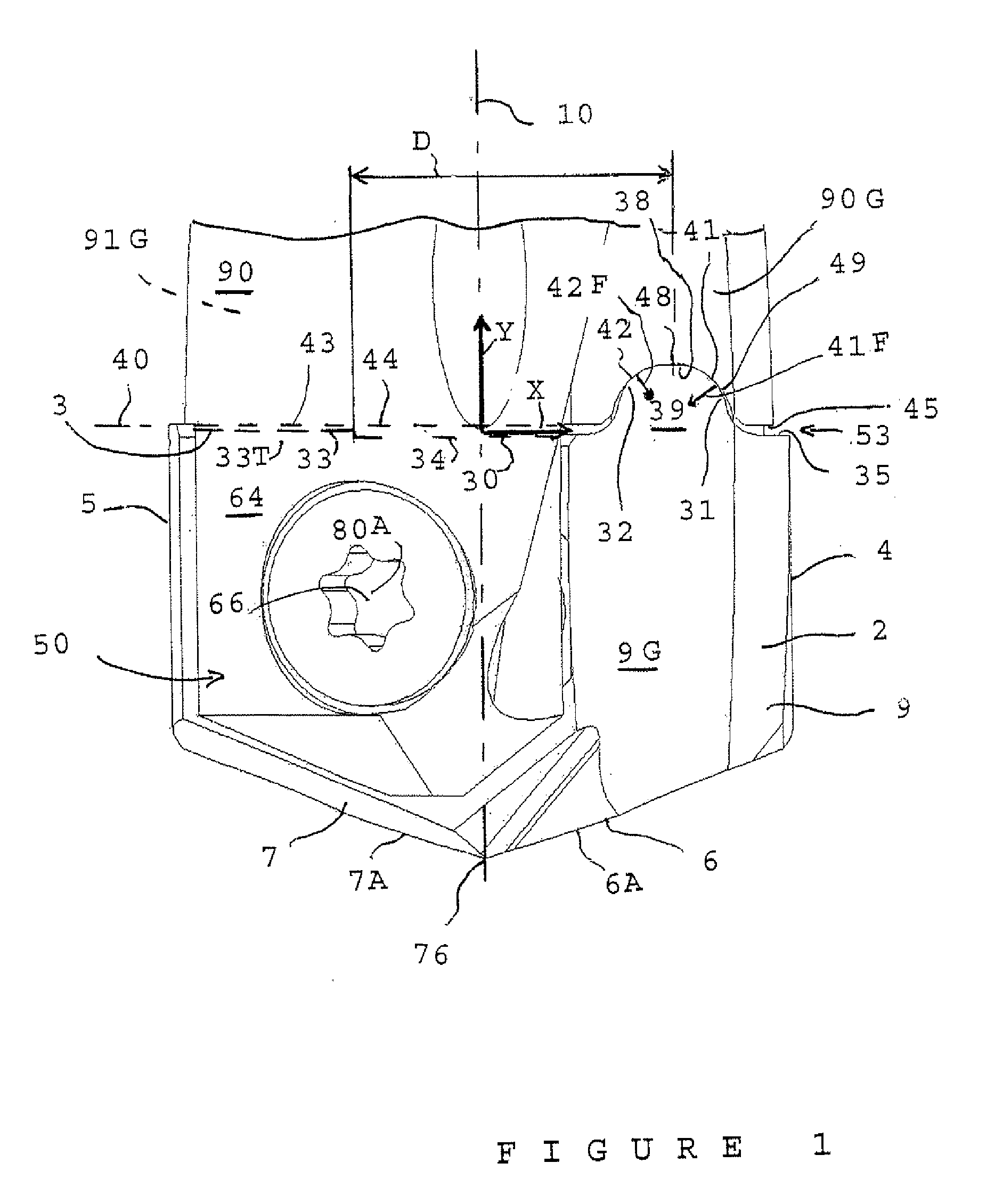

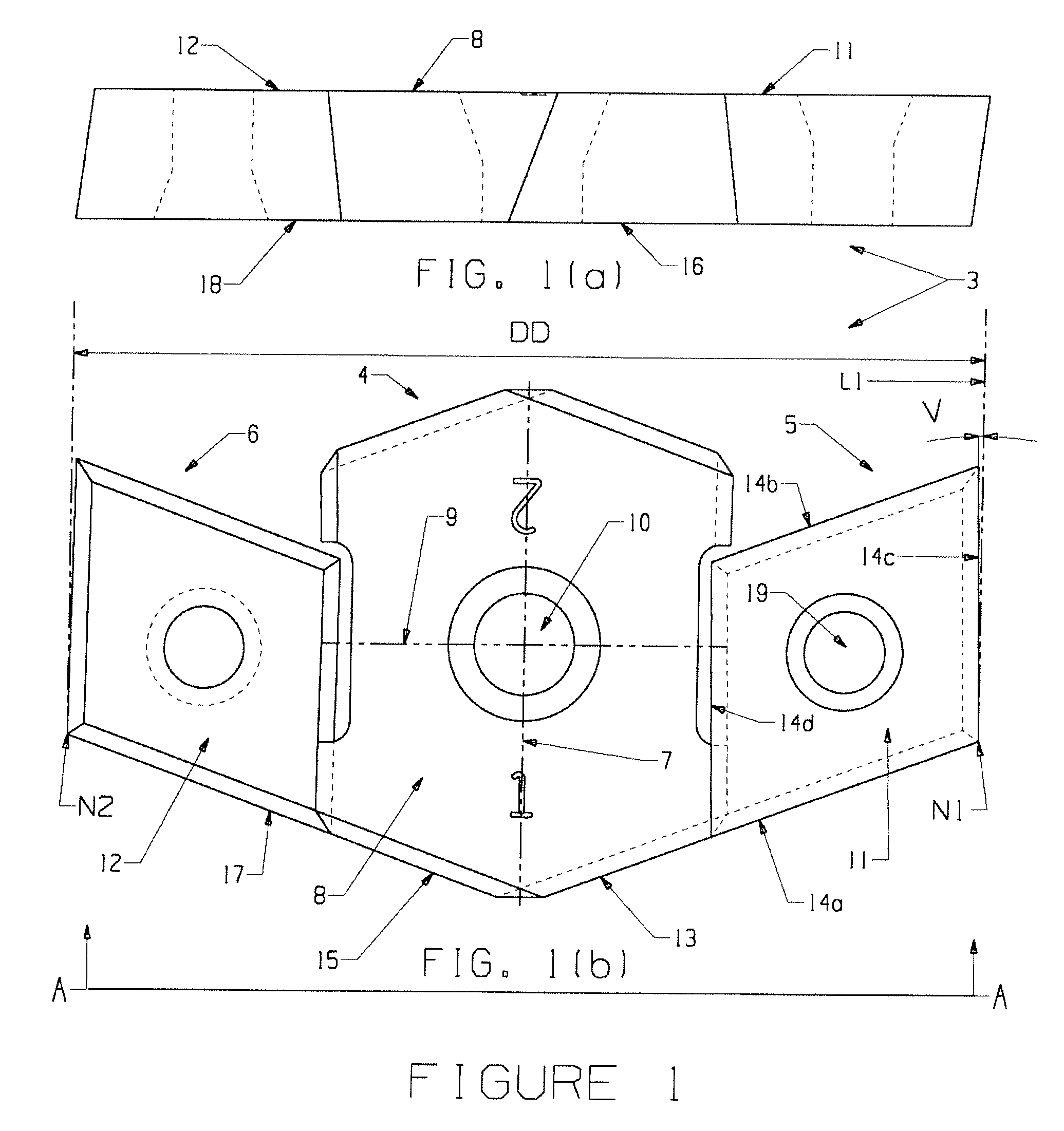

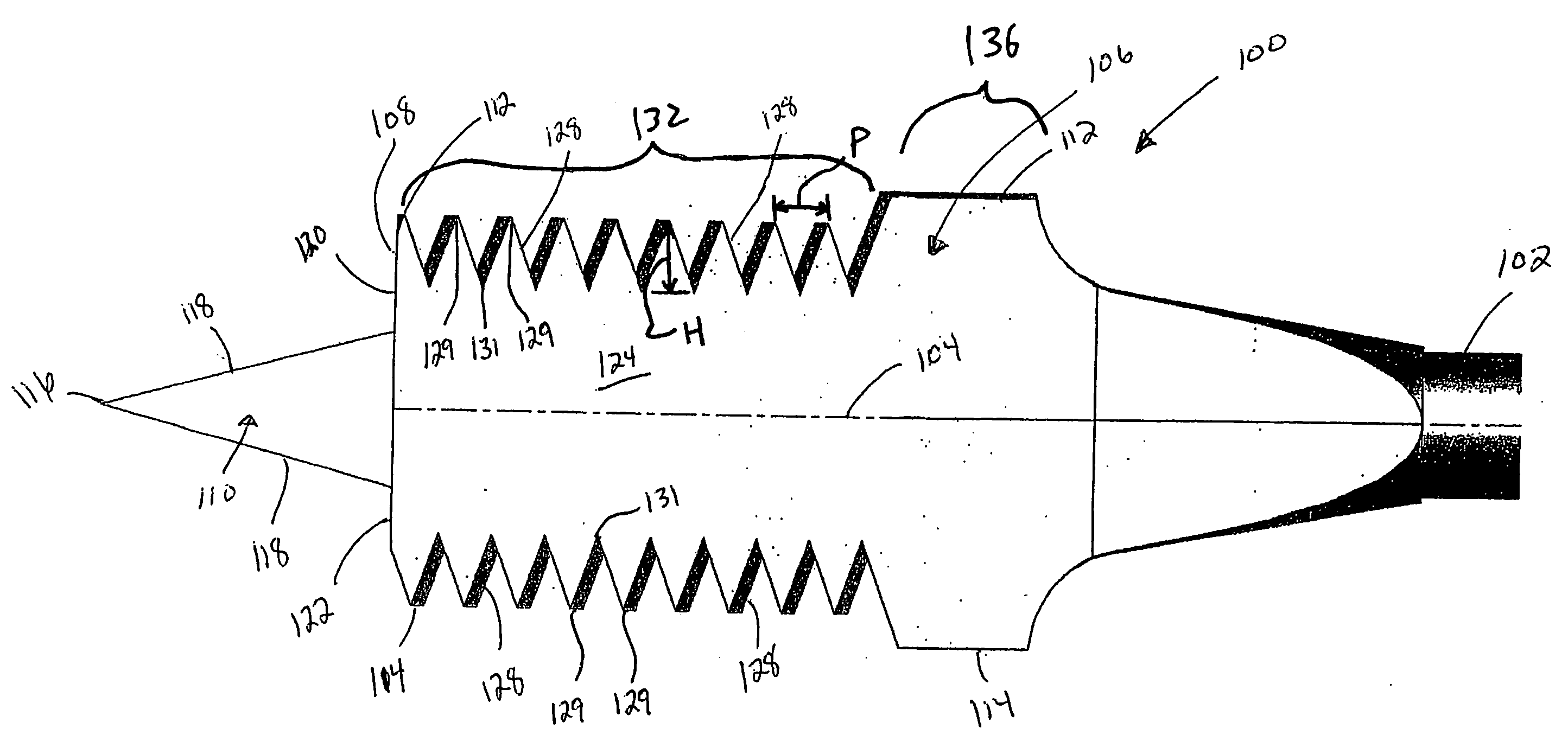

Drill insert geometry having V-notched web

InactiveUS7114893B2Great stability and feed rateIncrease heightWood turning toolsTransportation and packagingEngineeringNotching

The present invention relates to a V-notched web formed on a drill insert of a drill tool assembly. The V-notched web allows greater stability and feed rates, while decreasing the heat generated at the insert tip. The present invention is provided by a drill insert comprising a drill insert body having at least two cutting edges, a web between the two cutting edges, and a web thinning notch formed on either side of the web. Each web thinning notch forms a notch cutting edge having a positive rake angle.

Owner:ALLIED MASCH & ENG CORP

Drill insert geometry having V-notched web

InactiveUS6986628B2Improve stabilityGreat feed rateWood turning toolsTransportation and packagingNotchingRake angle

The present invention relates to a V-notched web formed on a drill insert of a drill tool assembly. The V-notched web allows greater stability and feed rates, while decreasing the heat generated at the insert tip. The present invention is provided by a drill insert comprising a drill insert body having at least two cutting edges, a web between the two cutting edges, and a web thinning notch formed on either side of the web. Each web thinning notch forms a notch cutting edge having a positive rake angle.

Owner:ALLIED MASCH & ENG CORP

Damaged bolt and screw removing devices

ActiveUS20100037734A1Improve biteEfficient extractionTransportation and packagingSpannersEngineeringDrill bit

A bit for removing a broken security fastener having an elongated shaft with a longitudinal axis. The shaft has a first end and a second end. The first end terminates in a tip region having a recess for receipt of the post of the security fastener, the recess being disposed substantially along the longitudinal axis. The second end of the shaft is configured to be received by the chuck of a tool which provides rotational torque.

Owner:COMBINED PRODS

Drill bit

InactiveUS8545140B2Inhibit sheddingEasy and speedy change-overWood turning toolsTransportation and packagingBiomedical engineeringDrill bit

A drill bit for drilling holes in wood or the like has a spade cutting element, a thick elongate shaft and a shank adapted to be inserted into an SDS drill chuck. In a preferred embodiment, the shaft is provided with one or more ridges extending helically along most of its length, to strengthen and stiffen the shaft and to direct drilling debris away from the cutting element. The shaft has a diameter greater than or equal to that of the shank. The drill bit may be installed in and removed from the drill chuck more rapidly than conventional wood bits, is more robust and is more convenient and reliable in use.

Owner:BURN STEVE

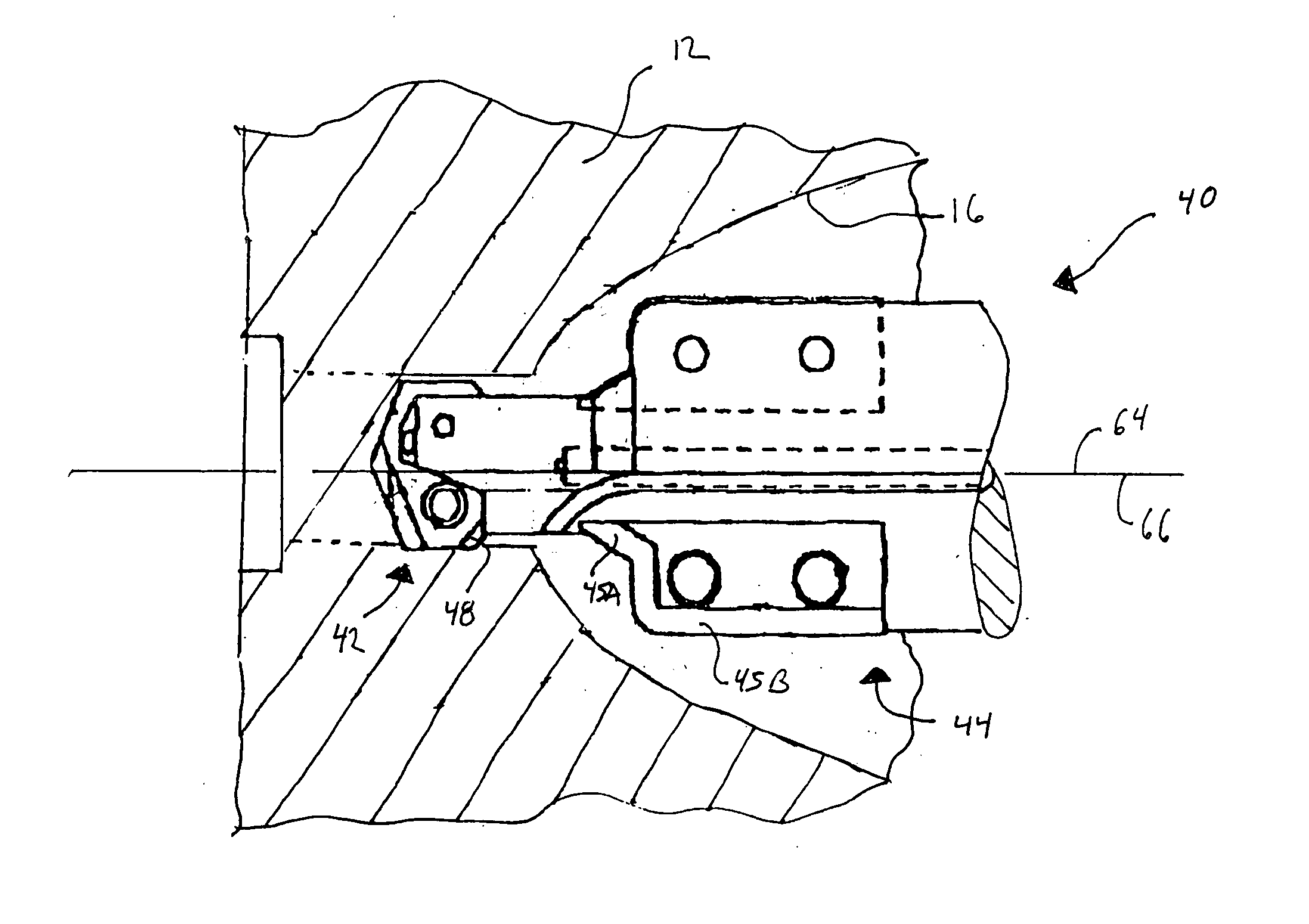

Tool and method for forming a lug hole

A single tool that provides multiple machining operations for forming a lug hole through a vehicle wheel hub includes an end portion having a first diameter and a mid-portion having a second diameter that is greater than the first diameter. A spade drill bit is mounted upon the end portion and a bore cutting tool is mounted upon the mid-portion.

Owner:HAYES LEMMERZ INT

Drill insert with controlled contact clearance

InactiveUS6902359B2Limit wearMore coolantWood turning toolsTransportation and packagingEngineeringDrill bit

A cutting tool insert having a controlled contact clearance behind the cutting edge which limits flank wear and allows more coolant near the cutting edge further allowing an increase in surface speed, feed rates, and tool life. The controlled contact clearance surface provides a first wear zone and a second wear zone, the first wear zone generated during operation of the drill insert allows the flank wear distance to grow from zero to the distance from the cutting edge to the controlled contact clearance surface, the second wear zone keeps the flank wear distance substantially constant until the controlled contact clearance surface is substantially worn away.

Owner:ALLIED MASCH & ENG CORP

Spade bit

ActiveUS20050084350A1Minimise amount of vibrationReduce chanceWood turning toolsTransportation and packagingEngineeringTwo step

An embodiment of a spade bit has straight grooves at a lead angle of 4 to 8 degrees placed on flat edges of the spade bit. In an alternative embodiment, a spade bit has two steps of straight grooves at a lead angle of 4 to 8 degrees placed on flat edges of the spade bit. In other alternative embodiments, a spade bit has tapered flat edge which have straight grooves at a lead angle of 4 to 8 degrees placed thereon. The straight grooves on the flat edges of the spade bits allow the spade bit to pull itself through the workpiece with a minimal amount of penetration. The flat edges of the spade bit may also have cutting surfaces for cleaning the hole and permitting the easy removal of the spade bit from the hole after drilling.

Owner:GREENLEE TEXTRON

Magnetized drill bit extension

InactiveUS20070127994A1Readily and efficiently manufactured and marketedReadily applied to renovation and repairWood turning toolsTransportation and packagingEngineeringDrill bit

The magnetized drill bit extension provides a socket that accepts bits of various diameters and indicates its location when concealed, as within a wall. The invention has a socket at the end of a drill bit extension with a strong magnet integrated into the socket. The socket accepts round, square, and square corner rounded shanks of bits. The magnet within the socket endures drilling through wood. The socket emanates a magnetic field from within a concealed location that deflects a compass, thus revealing the location of the extension within a wall. Alternatively, a magnet is joined to the spade of a drill bit to reveal its location when concealed.

Owner:WELKER ROBERT E

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com