Drilling bit without resharpening, non-resharpening blade, and drilling bit main body

A drill bit and blade technology, applied in drilling/drilling equipment, shovel drill, drill repair, etc., can solve the problems of insufficient alignment accuracy, difficulty in firmly holding the blade 5, and difficulty in adhering to it, and achieve the goal of maintaining the accuracy of shaft vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

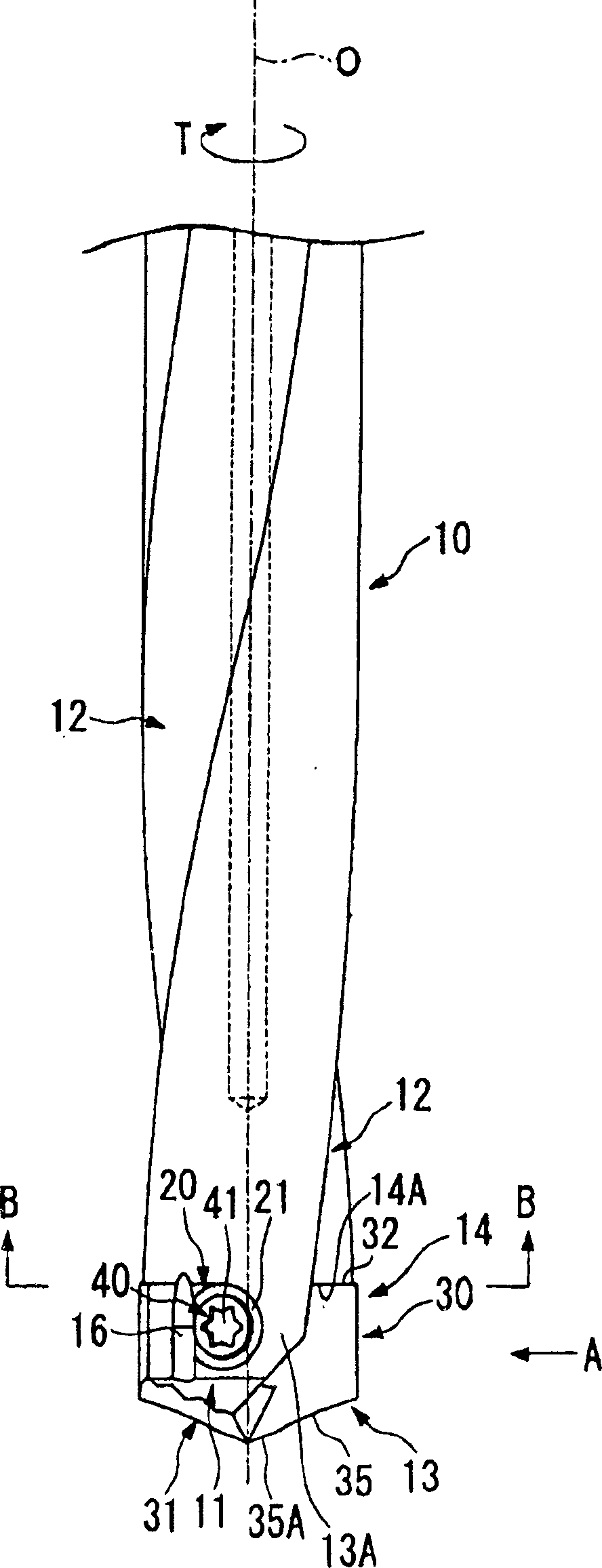

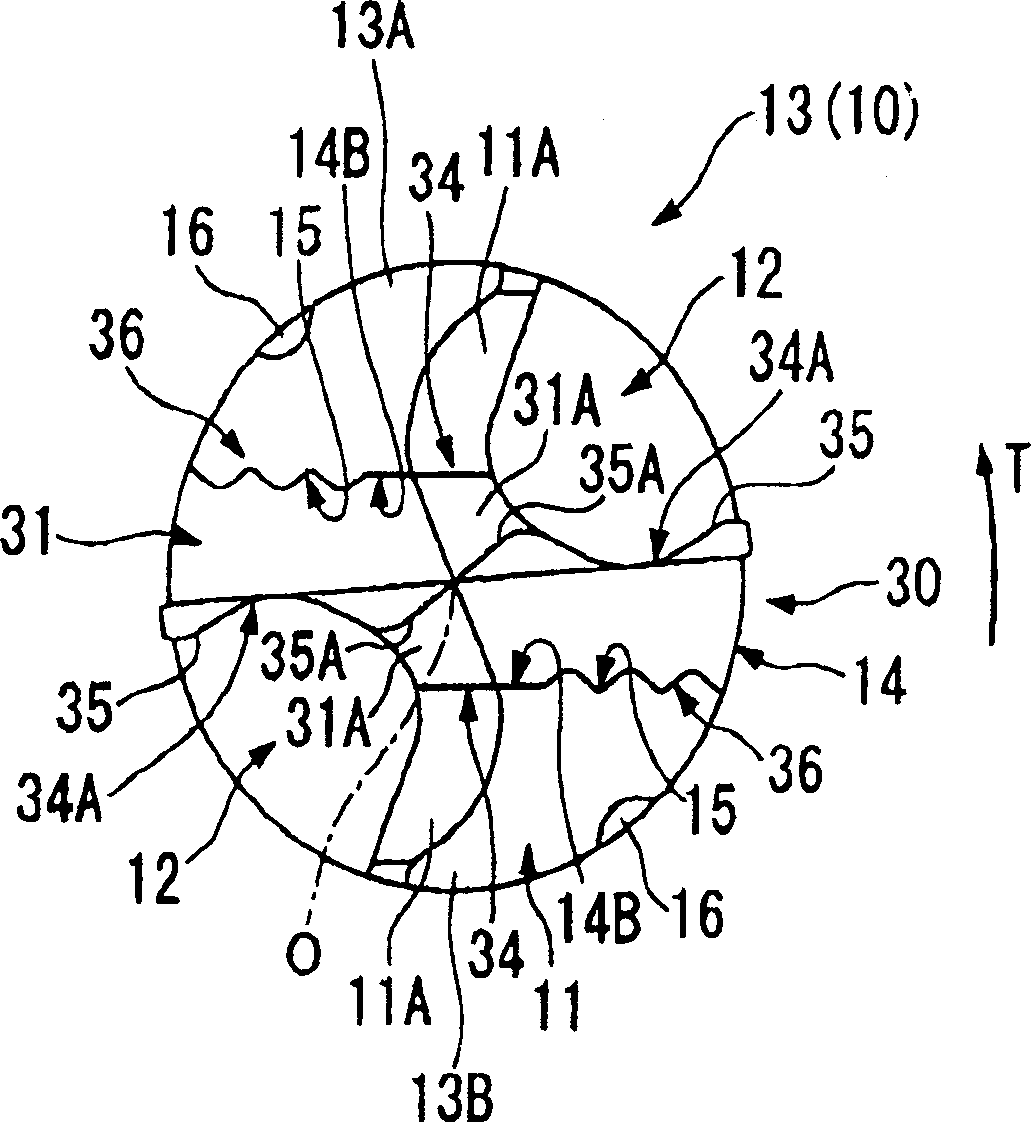

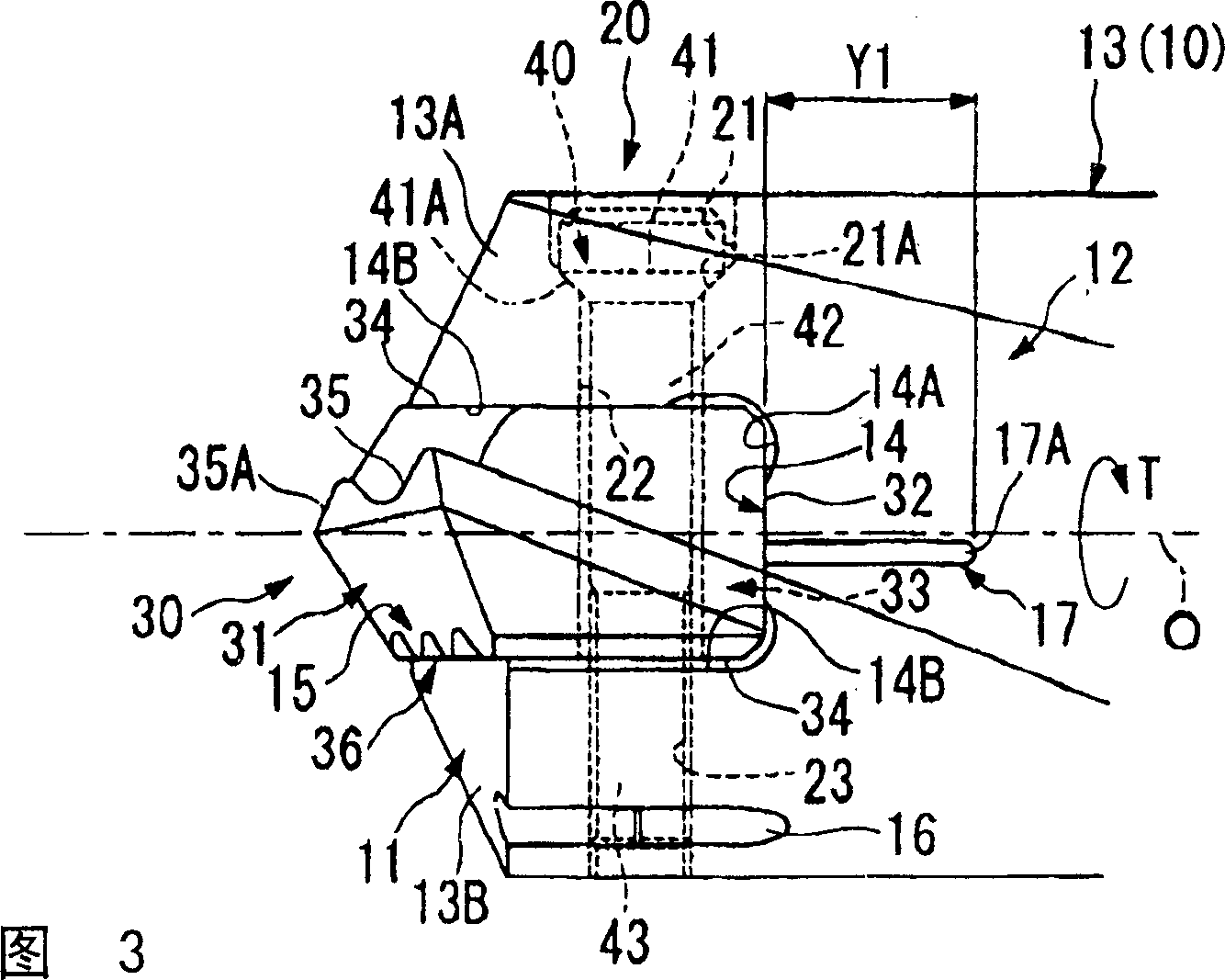

[0052] Embodiments of the present invention will be described below with reference to the drawings.

[0053] Figure 1 to Figure 5 It represents the first embodiment of the present invention.

[0054] The drill body 10 of the throwaway drill of this embodiment is reduced in diameter with respect to the drill pipe tail (not shown) integrally formed on its rear end side, and as a whole constitutes a drill body 10 that rotates around the axis O and rotates around the axis O. Centered multistage cylinder.

[0055] A pair of chip discharge grooves 12 opened on the front end surface 11 of the drill body 10 are formed on the outer periphery of the front end side portion of the drill body 10, and the discharge grooves 12 are on mutually opposite sides of the clamping axis O so as to move toward the axis O. The rear end side of the drill bit is twisted backward in the direction of rotation T of the drill to form a helical shape.

[0056] In addition, on the front end portion 13 of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com