Patents

Literature

45 results about "Screw extractor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A screw extractor is a tool for removing broken or seized screws. There are two types: one has a spiral flute structure, commonly called an easy out after the trademarked name EZ-Out; the other has a straight flute structure. Screw extractors are intentionally made of hard, brittle steel, and, if too much torque is applied, can break off inside the screw that is being removed. Since the extractor is an extremely hard material, and a typical home shop drill bit will not be able to drill into it, a larger element of difficulty is added to the original screw extraction project. One way to avoid this added difficulty is to drill a hole completely through the screw. Thus, if the fastener breaks, a punch can be used to drive out the easy out from the screw, via the back, or end, of the fastener.

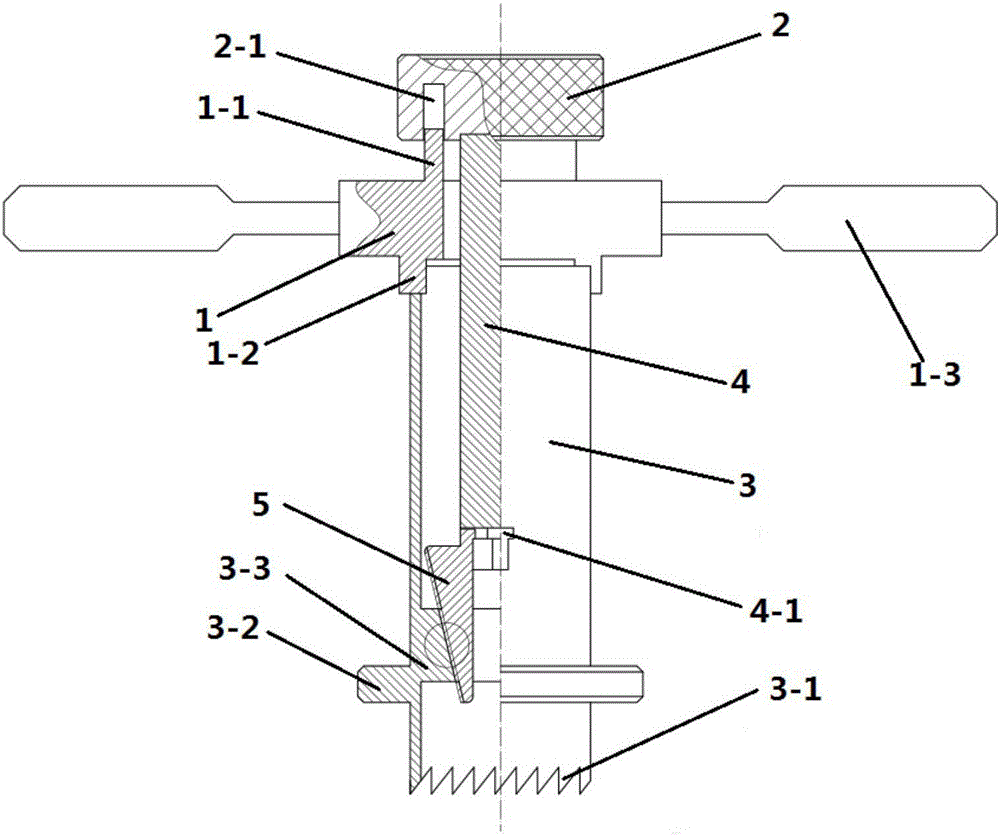

Clamping screw extractor

InactiveUS20040068269A1Prevent rotationSleeve/socket jointsDispensing apparatusScrew extractorScrew thread

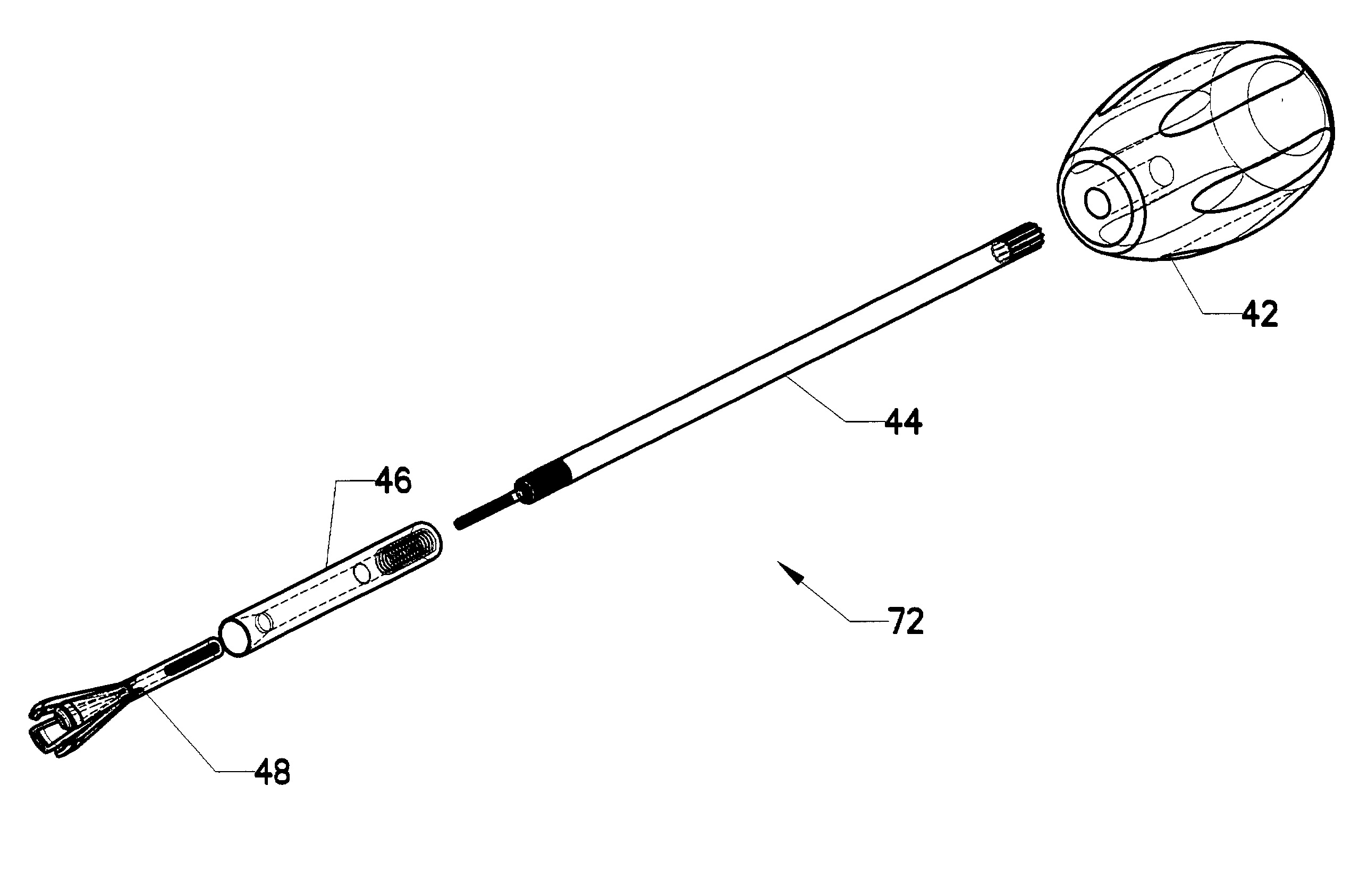

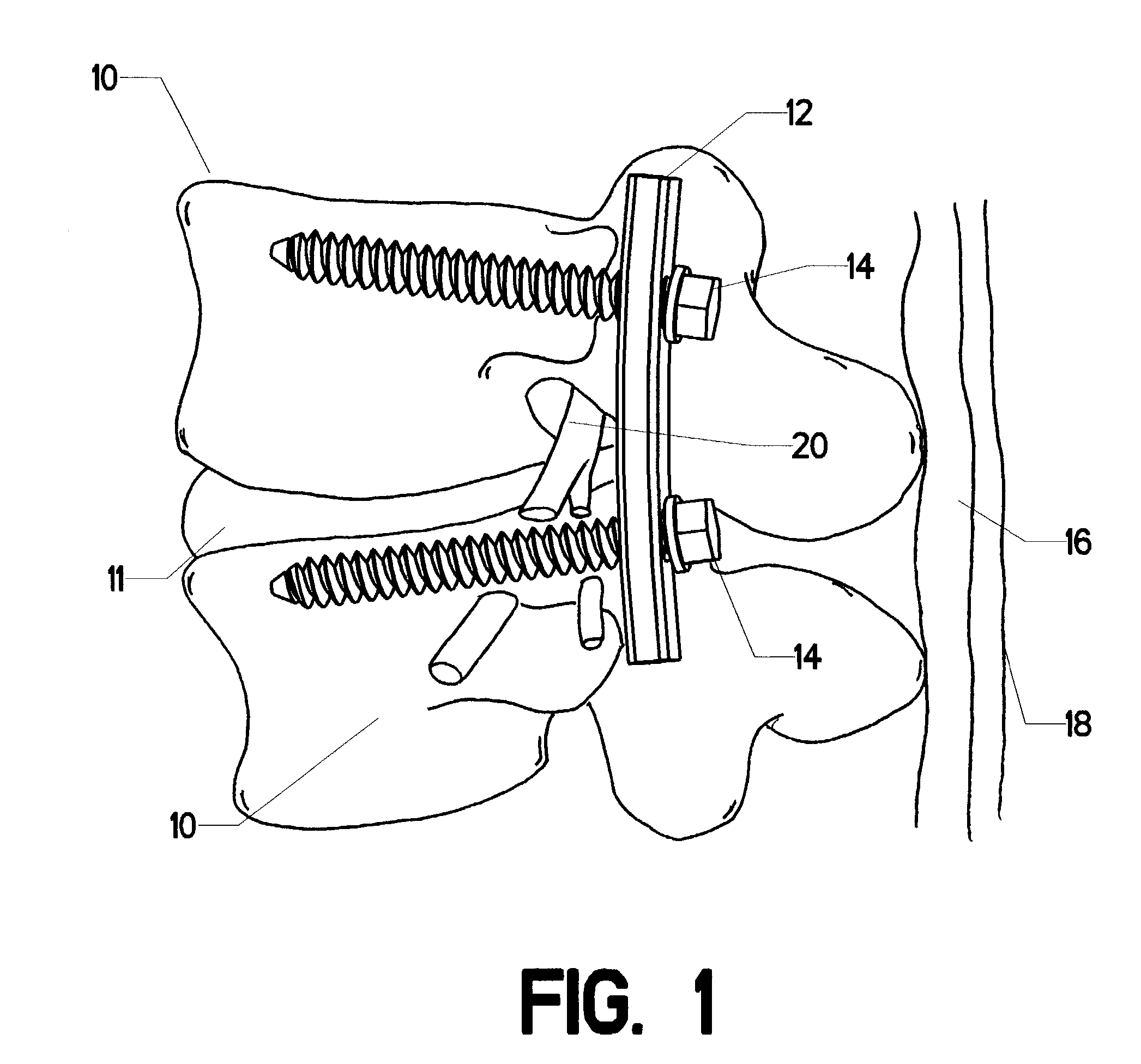

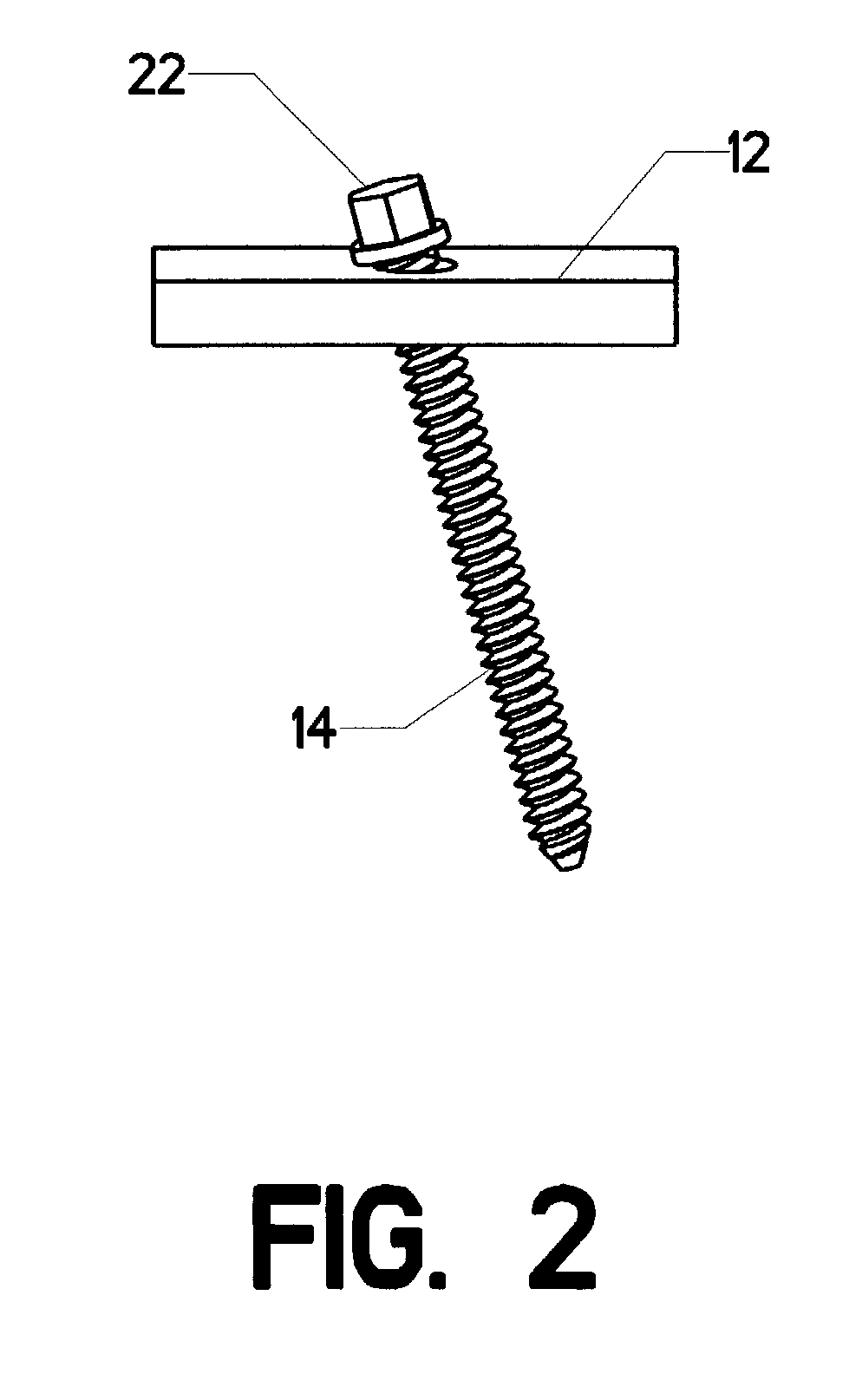

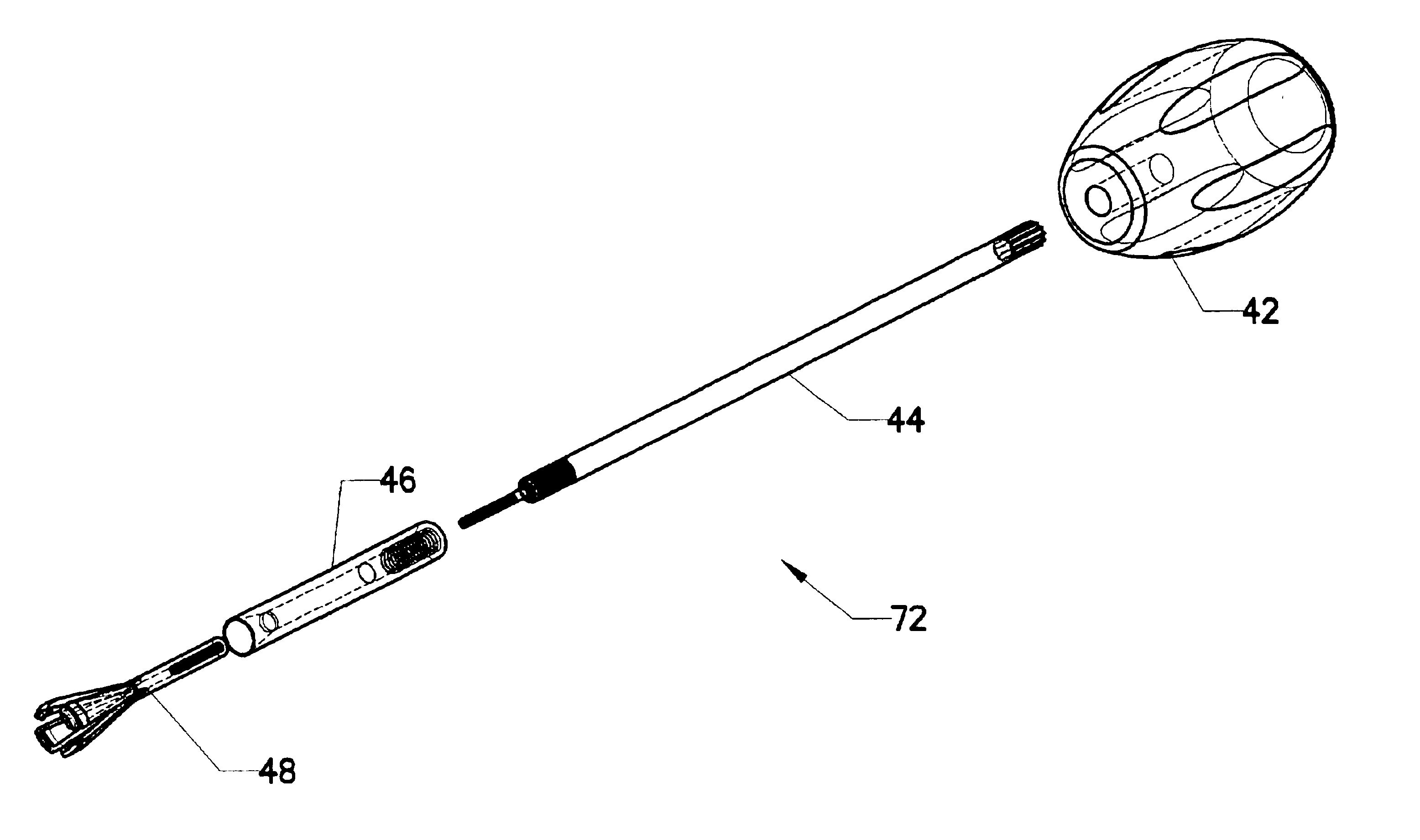

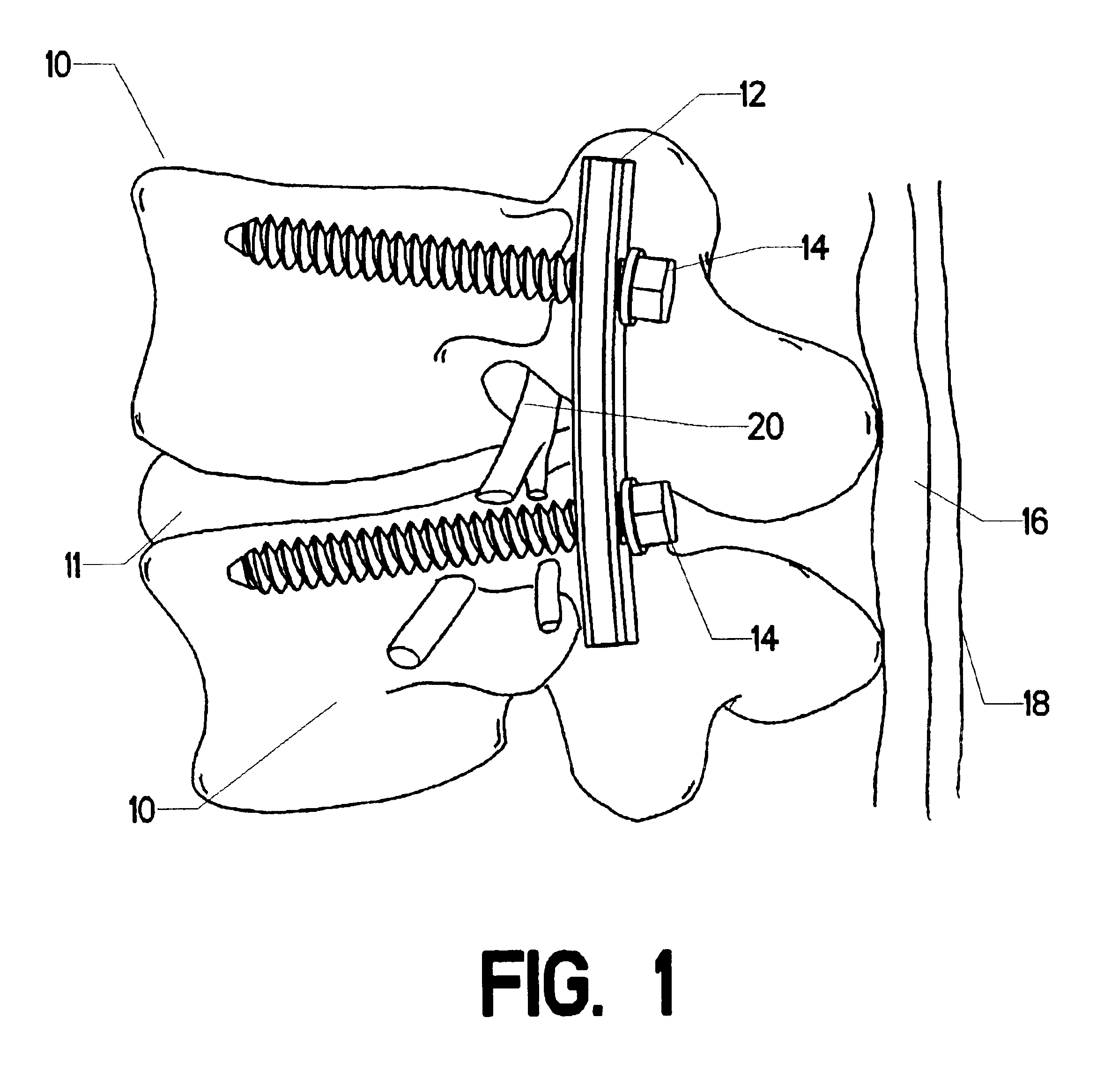

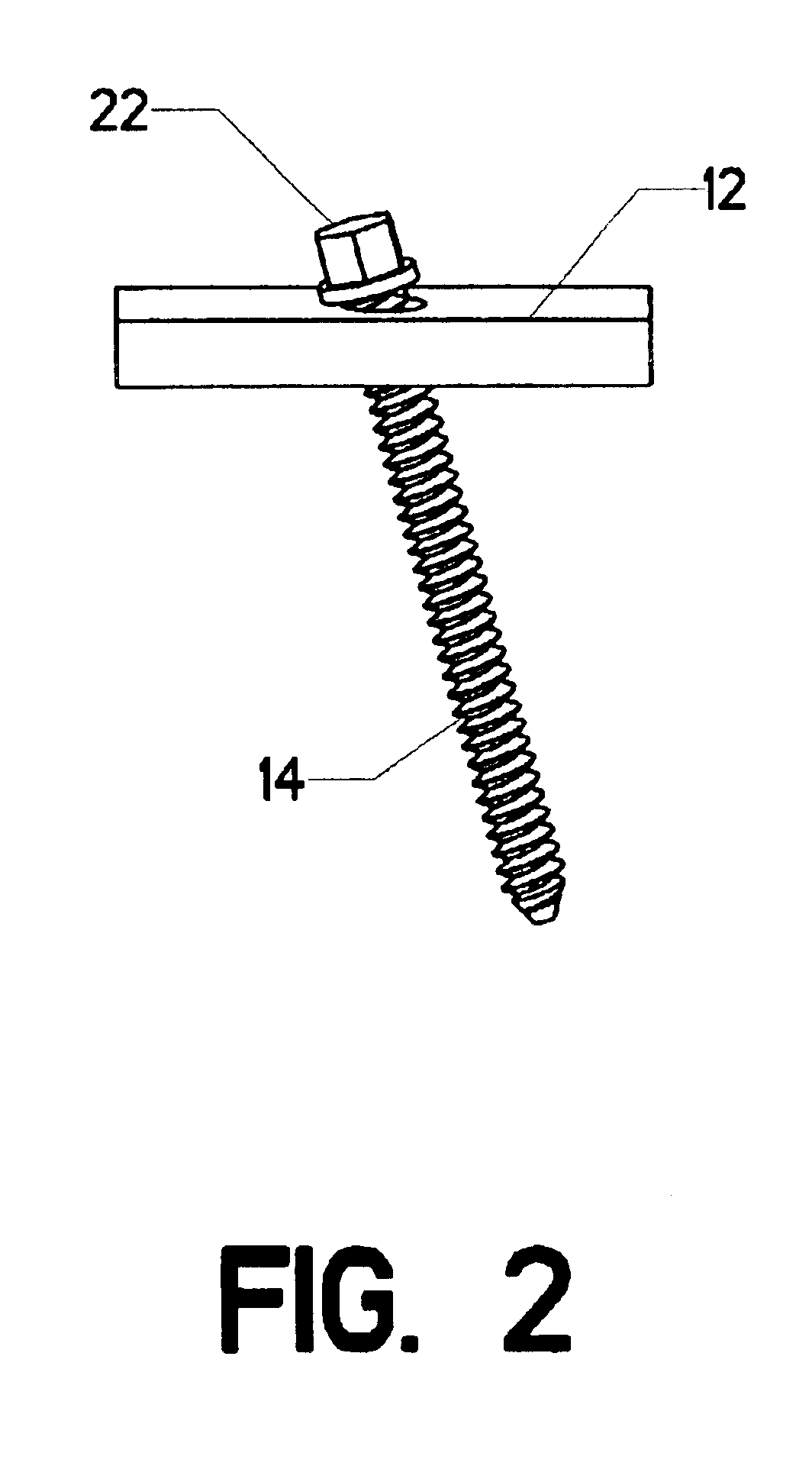

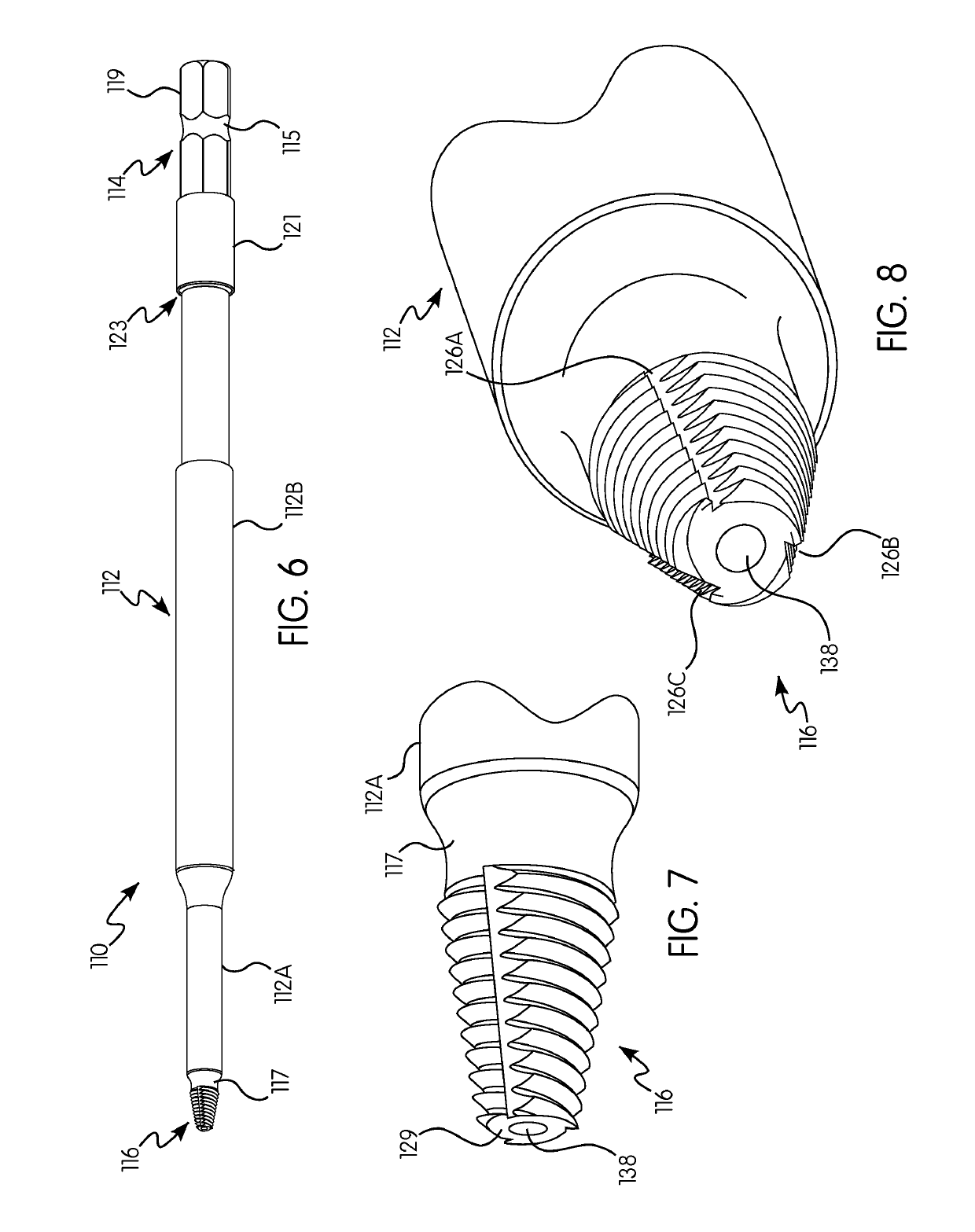

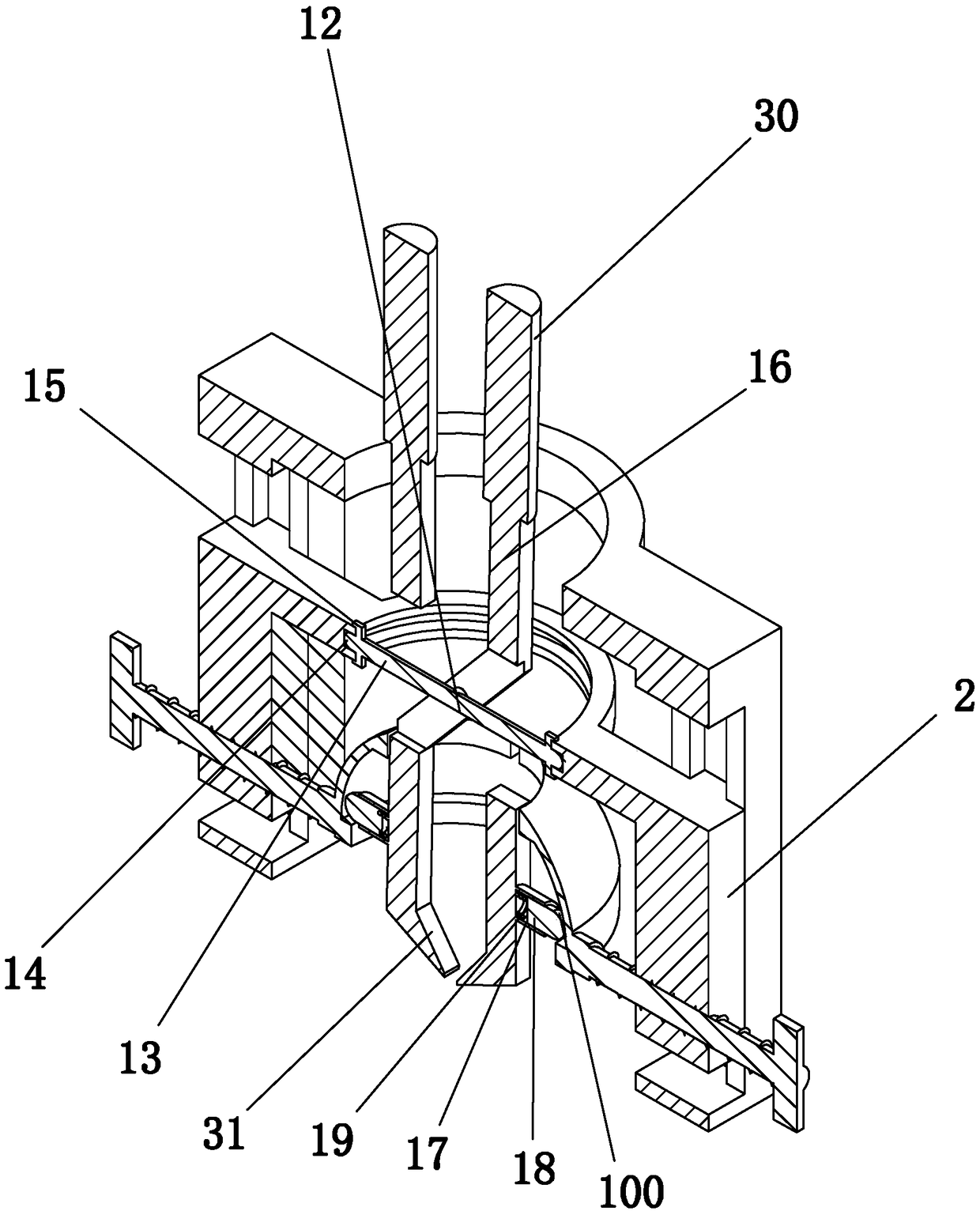

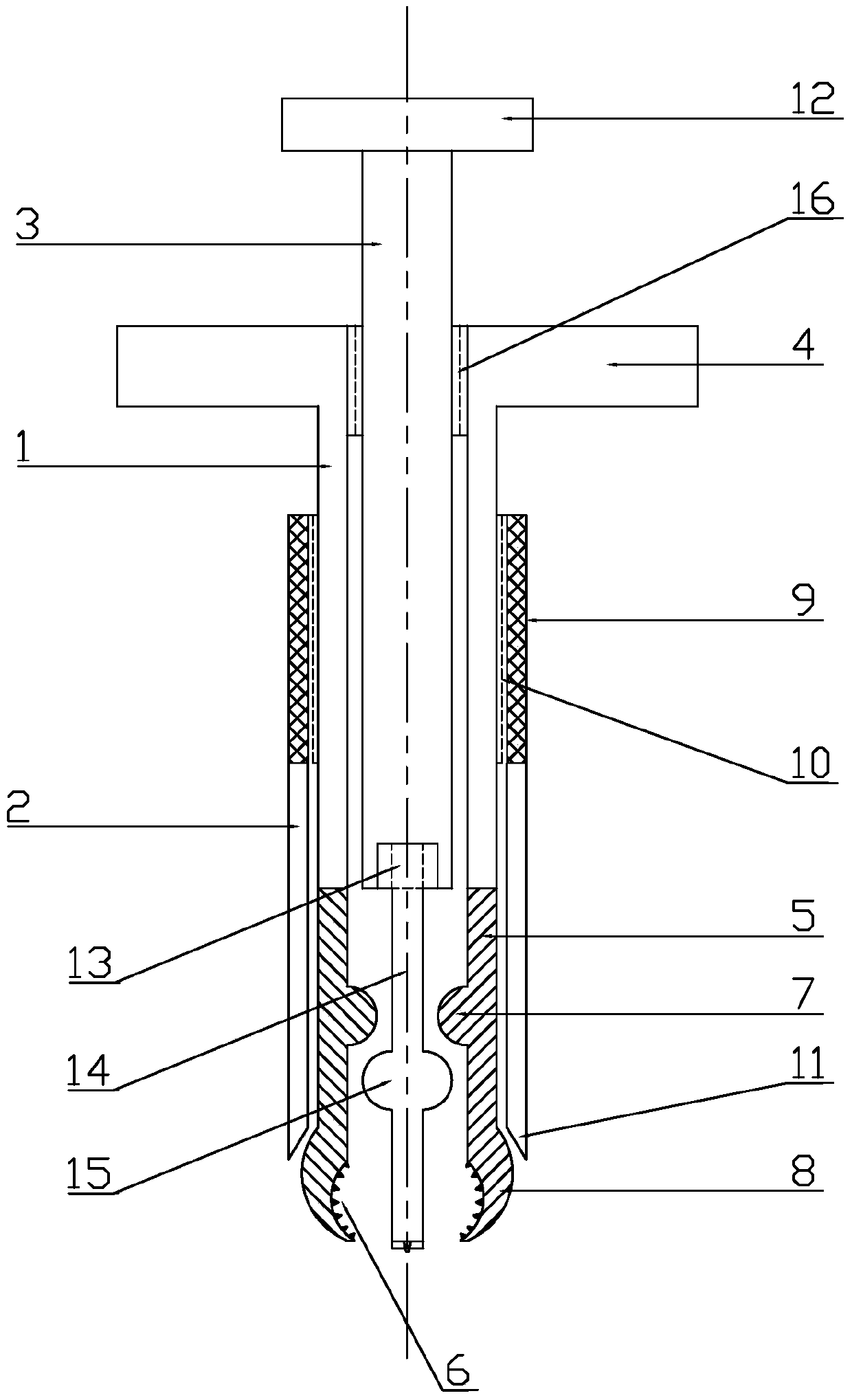

A tool for gripping and removing mechanical fasteners such as pedicle screws. With reference to FIG. 7, the device generally resembles a screwdriver, having a handle on one end, a long shaft in the middle, and fastener engaging means on the other end. The fastener engaging means comprises a set of two or more jaws having inward facing gripping surfaces positioned to grasp the external surfaces of a screw head. The jaws are formed as part of a collet slidably mounted within an outer thread sleeve. The thread sleeve is attached to the shaft. A tapered journal on the collet interacts with a tapered bore in the thread sleeve so that when the collet is pulled into the thread sleeve, the set of two or more jaws are squeezed together. The threaded engagements between the collet and the thread sleeve should be the reverse of the thread on the screw to be removed; i.e., if a right-hand screw is to be removed then the threaded engagement between the collet and the thread sleeve should be made with a left-hand thread. In operation, the jaws are placed over the screw head and the device is rotated in a counterclockwise direction (for removal of a screw with a right-hand thread). The inward facing surfaces on the jaws bear against the bolt head, thereby impeding the rotation of the collet relative to the thread sleeve. The left-hand threaded engagement between the collet and the thread sleeve therefore pulls the collet further into the thread sleeve, whereupon the tapered bore squeezes the jaws more tightly together. Thus, the reader will appreciate, applying torque to the device when it is in position on a screw head simultaneously torques the screw head and squeezes the jaws more tightly together. The inward facing surfaces are also provided with an undercut in order to accommodate axial misalignment between the jaws and the screw head.

Owner:MEDITRON DEVICES

Clamping screw extractor

A tool for gripping and removing mechanical fasteners such as pedicle screws. With reference to FIG. 7, the device generally resembles a screwdriver, having a handle on one end, a long shaft in the middle, and fastener engaging means on the other end. The fastener engaging means comprises a set of two or more jaws having inward facing gripping surfaces positioned to grasp the external surfaces of a screw head. The jaws are formed as part of a collet slidably mounted within an outer thread sleeve. The thread sleeve is attached to the shaft. A tapered journal on the collet interacts with a tapered bore in the thread sleeve so that when the collet is pulled into the thread sleeve, the set of two or more jaws are squeezed together. The threaded engagements between the collet and the thread sleeve should be the reverse of the thread on the screw to be removed; i.e., if a right-hand screw is to be removed then the threaded engagement between the collet and the thread sleeve should be made with a left-hand thread. In operation, the jaws are placed over the screw head and the device is rotated in a counterclockwise direction (for removal of a screw with a right-hand thread). The inward facing surfaces on the jaws bear against the bolt head, thereby impeding the rotation of the collet relative to the thread sleeve. The left-hand threaded engagement between the collet and the thread sleeve therefore pulls the collet further into the thread sleeve, whereupon the tapered bore squeezes the jaws more tightly together. Thus, the reader will appreciate, applying torque to the device when it is in position on a screw head simultaneously torques the screw head and squeezes the jaws more tightly together. The inward facing surfaces are also provided with an undercut in order to accommodate axial misalignment between the jaws and the screw head.

Owner:MEDITRON DEVICES

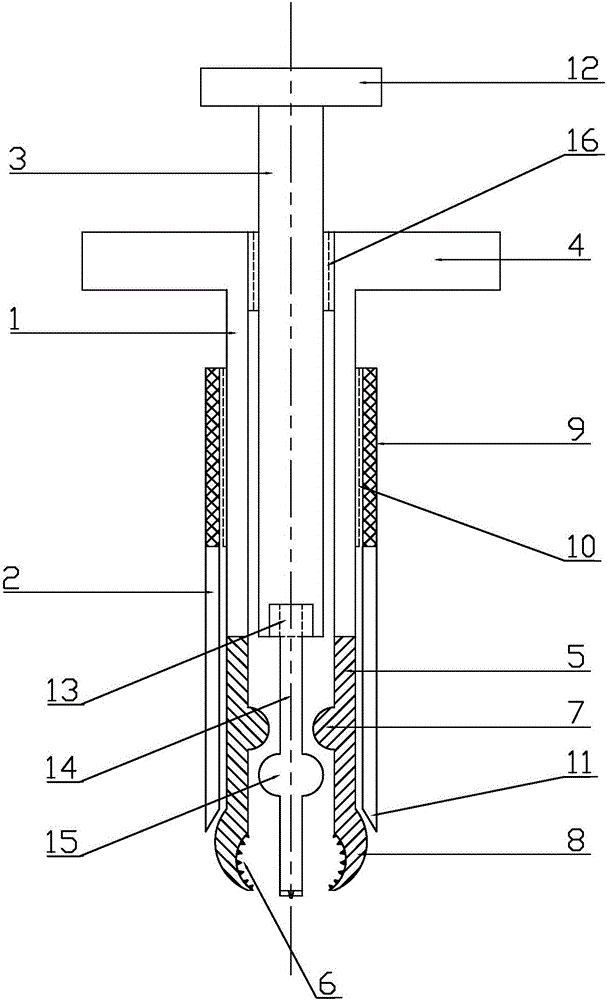

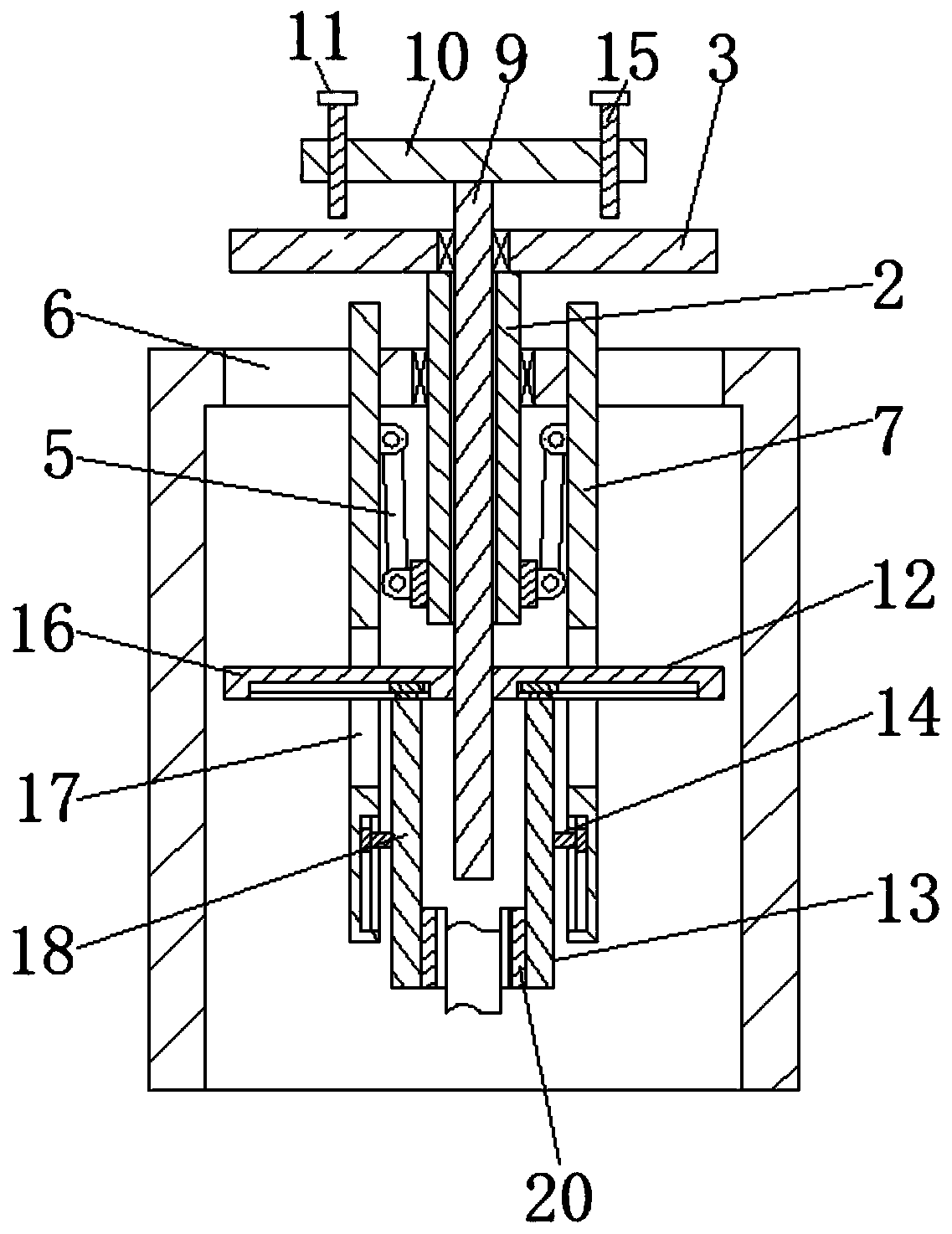

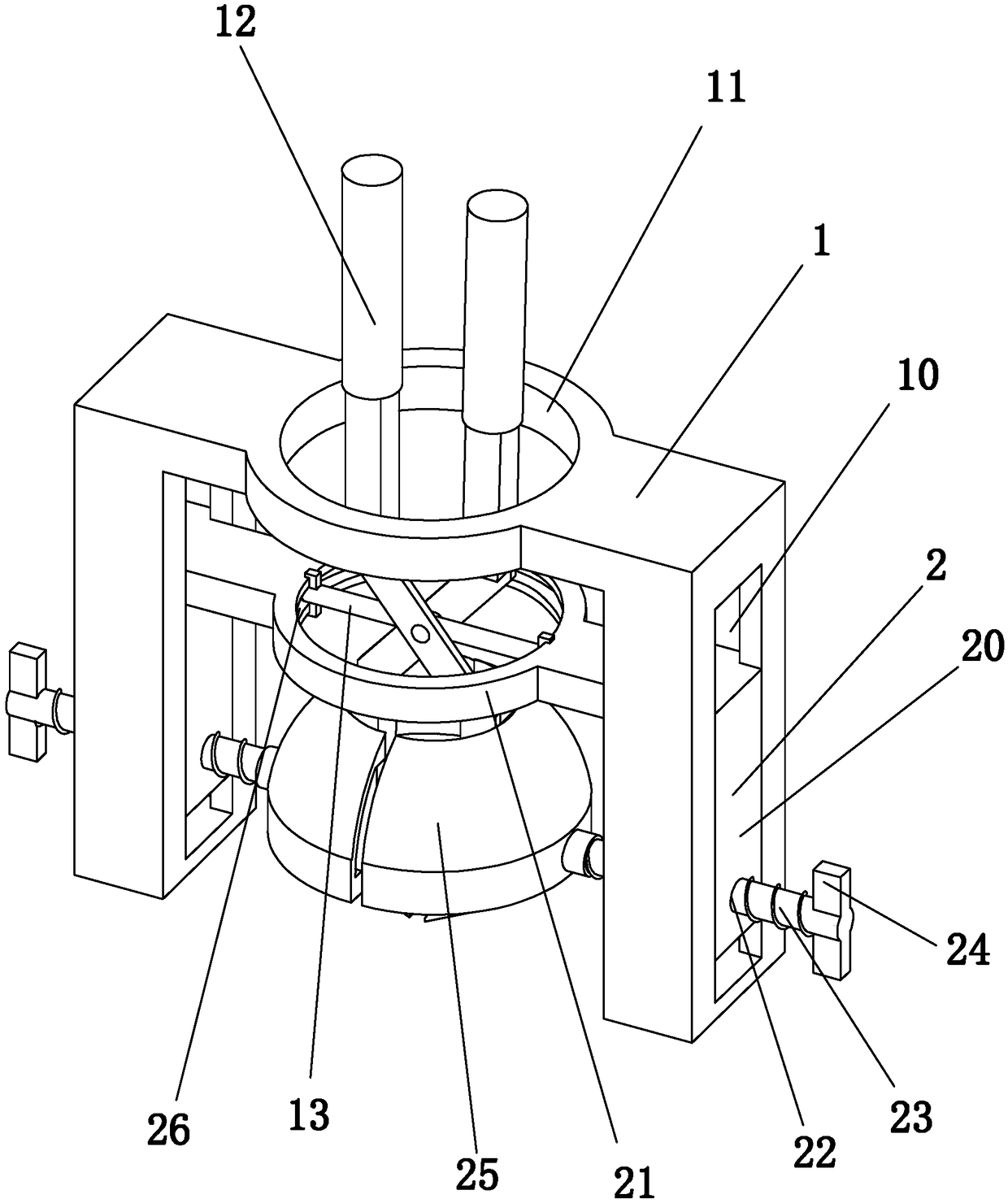

Screw extractor for orthopedic surgery

The invention discloses a screw extractor for an orthopedic surgery. The screw extractor comprises a screw extracting tube, holding tubes, a dilator, holding clamps, conical teeth, tooth clamp convex sections, arc-shaped chucks, a driver bar and a dilating ball joint, wherein the dilator is arranged in the screw extracting tube through limit threads in a screwing manner; the holding tubes are arranged at the outer part of the screw extracting tube through fastening threads; handles are arranged at the outer sides of the upper end of the screw extracting tube, and the limit threads are arranged at the inner side of the upper end of the screw extracting tube; a plurality of holding clamps and holding clamp grooves are arranged at and formed in the lower end of the screw extracting tube; the arc-shaped chucks and the conical teeth are arranged at the lower ends of the corresponding holding clamps; one tooth clamp convex section is arranged at the inner side of each holding clamp; the driver bar is arranged at the lower end of the dilator; the dilating ball joint is arranged in the middle of the dilator; the dilating ball joint is moved by the dilator through the limit threads; the dilating ball joint pushes away the tooth clamp convex sections and drives the holding clamps to dilate; a bone screw cap is clamped and fixed by the plurality of arc-shaped chucks. According to the screw extractor disclosed by the invention, the screw cap is fixed by the arc-shaped chucks and the conical teeth; screws can be quickly and conveniently taken out and are prevented from sliding out of the groove, so that pains of a patient are relieved, and the efficiency of the surgery is improved.

Owner:SUZHOU SUNAN ZIMMERED MEDICAL INSTR

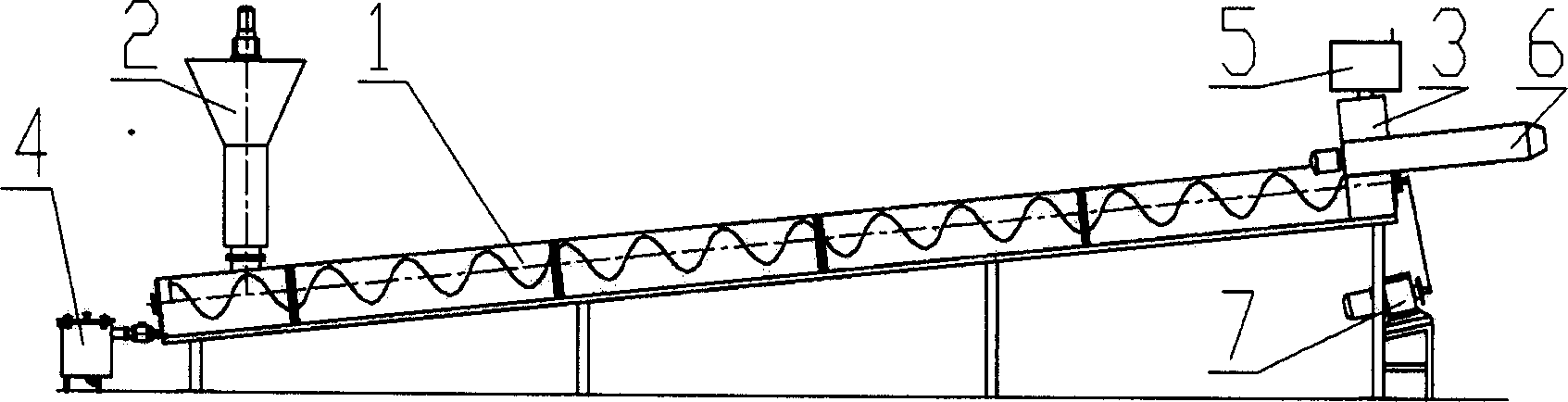

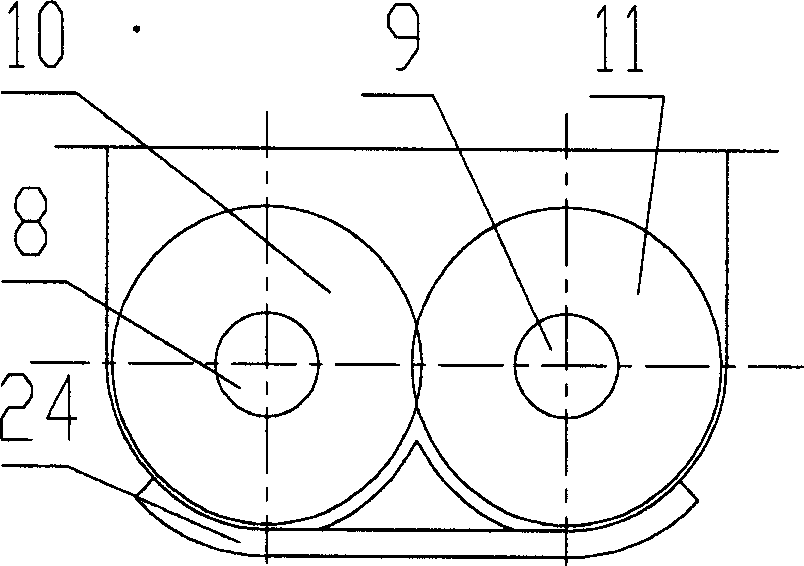

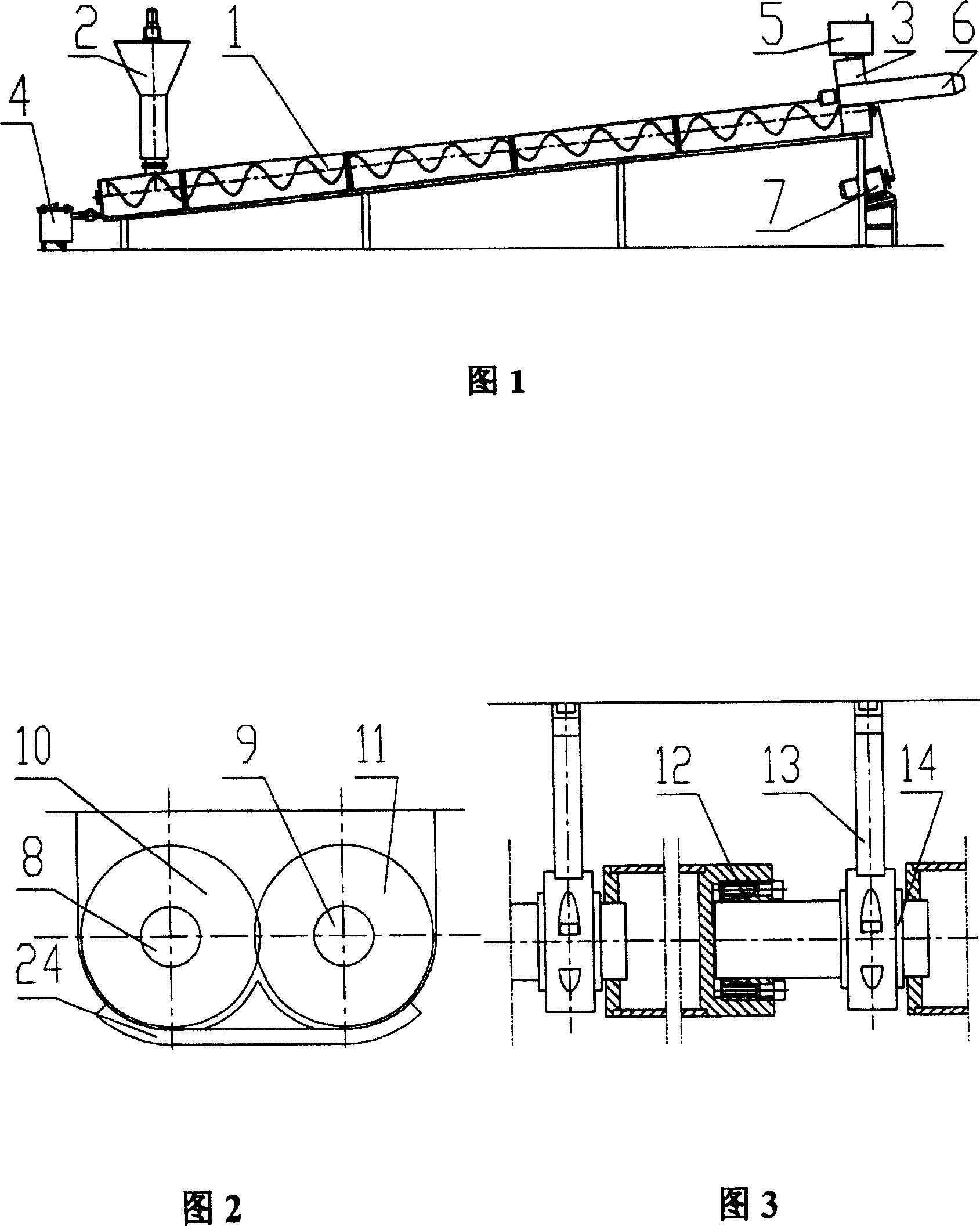

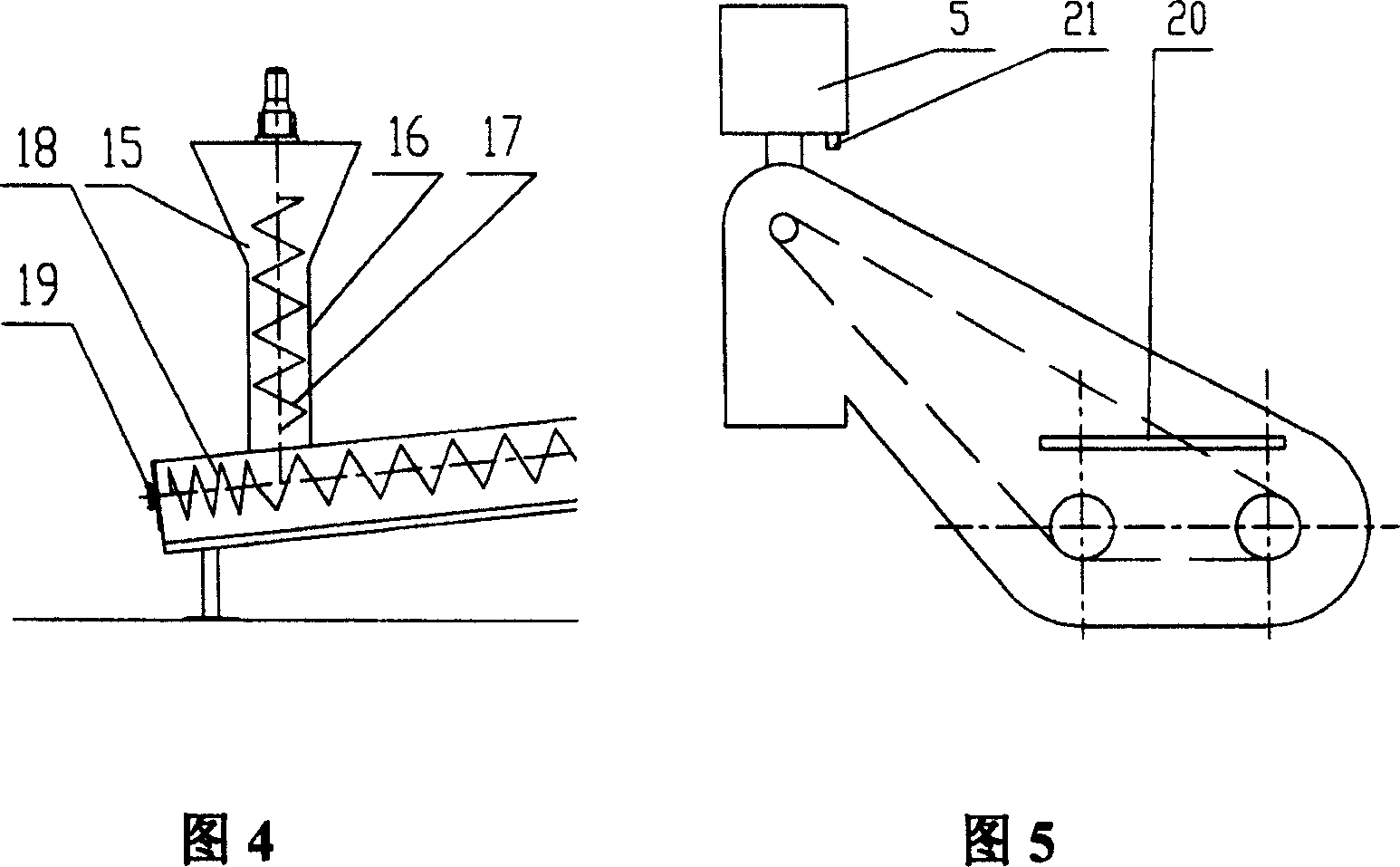

Double-spiral, continuous counter-flow extraction equipment

InactiveCN1792407AImprove work efficiencyIncrease effective volumeSolid solvent extractionScrew extractorCounter flow

A countercurrent-type continuous dual-screw extractor is composed of feeder, inclined extracting cabin, dregs discharger, filter, condenser, juice squeezer and power drive mechanism. It features that parallel two spiral axles, which consists of multiple segments and has continuous perforated spiral blade or discontinuous paddles, are rotating in different directions.

Owner:黑龙江省计算中心

Preparation method of modified ultrahigh molecular weight polyethylene powder direct extruded tubing

InactiveCN1807062AImprove mechanical propertiesSimple processTubular articlesScrew extractorGranulation procedure

The invention relates pipes manufacturing method, specially one-step method manufacturing pipe technique. The method comprises the following steps: mixing the LCP, UHMW-PE and special adjuvant, sending them into single screw extractor with 42-45Deg helix angle, compressing the powdery material, melting, plastifying, direct squeezing pipes, using die to form cast, cooling with water chamber, drawing with draw machine, cutting with cutting machine, and realizing the production of UHMW-PE. Due to cancel the granulation procedure ad directly squeeze pipes, the mechanics property of UHMW-PE in improved, the technology is simplified and the space is saved.

Owner:江苏星鑫工程管道有限公司

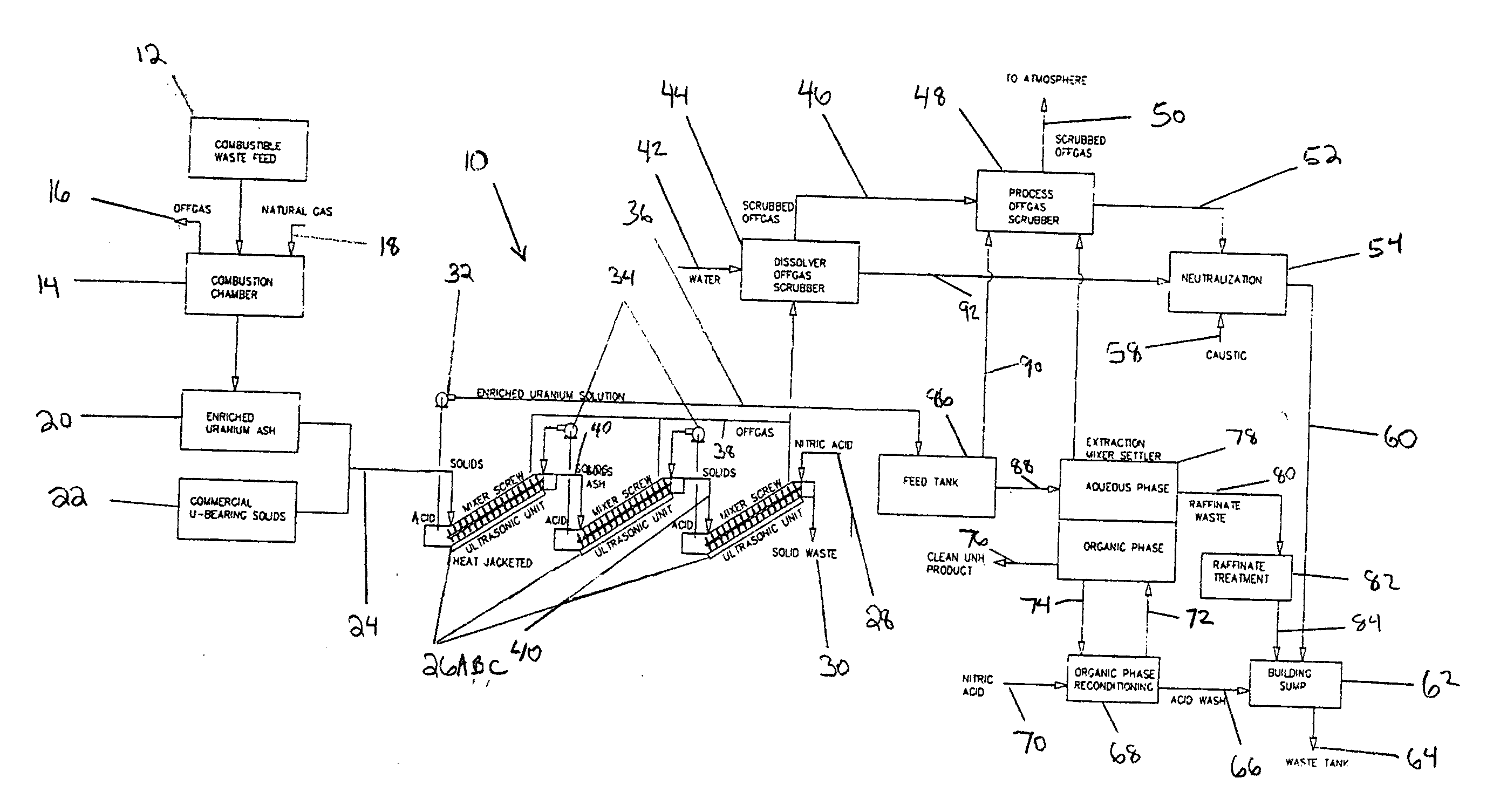

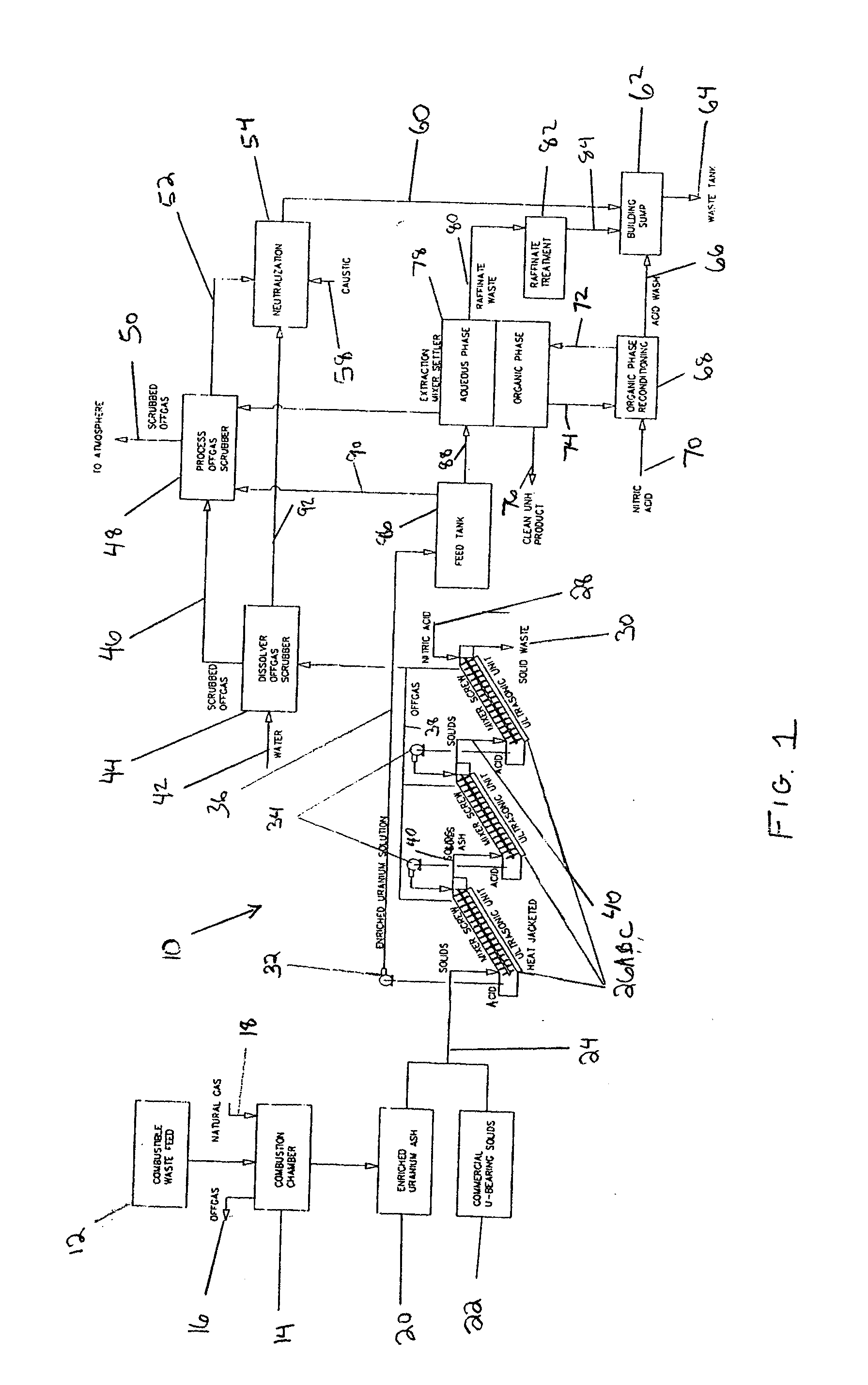

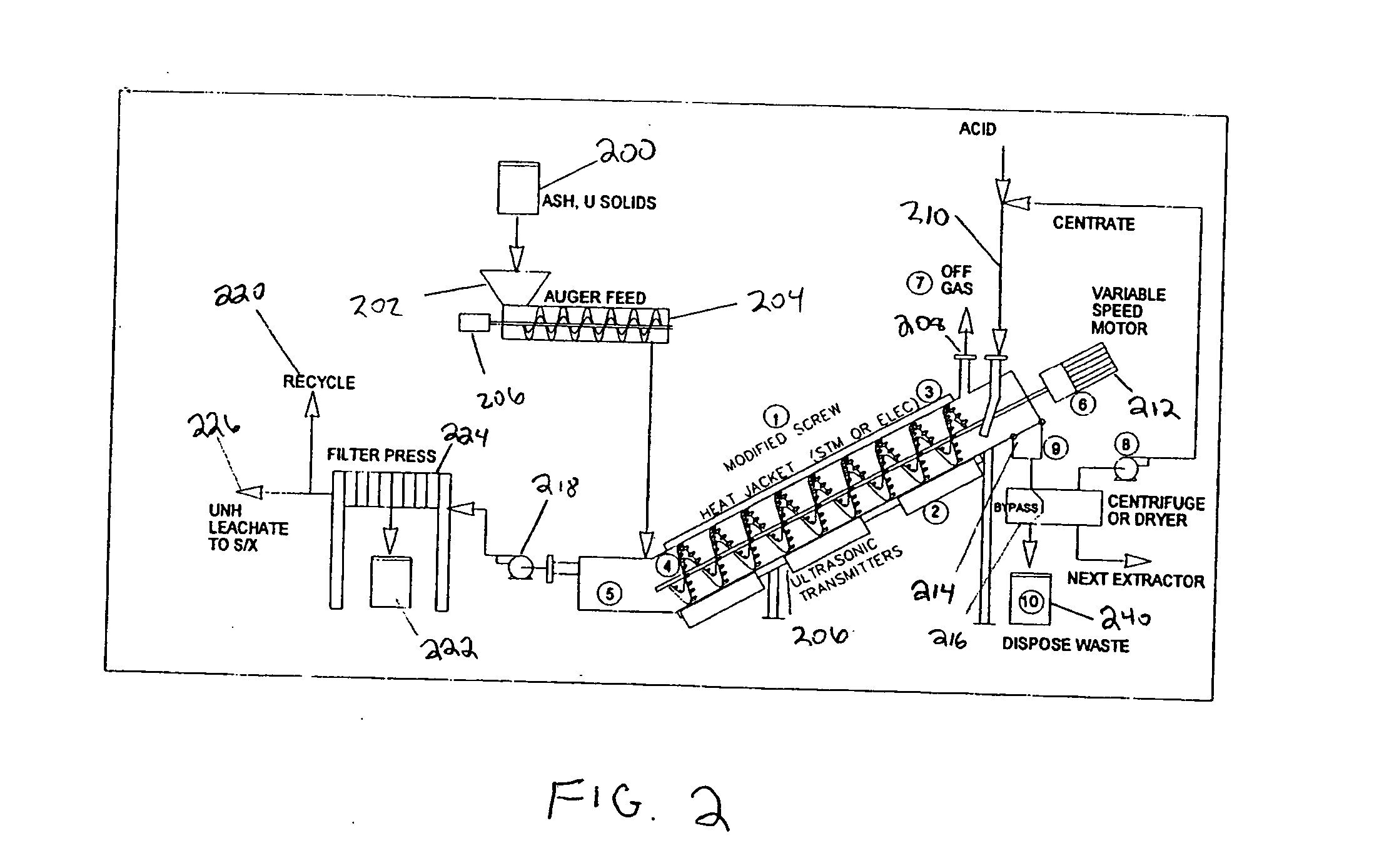

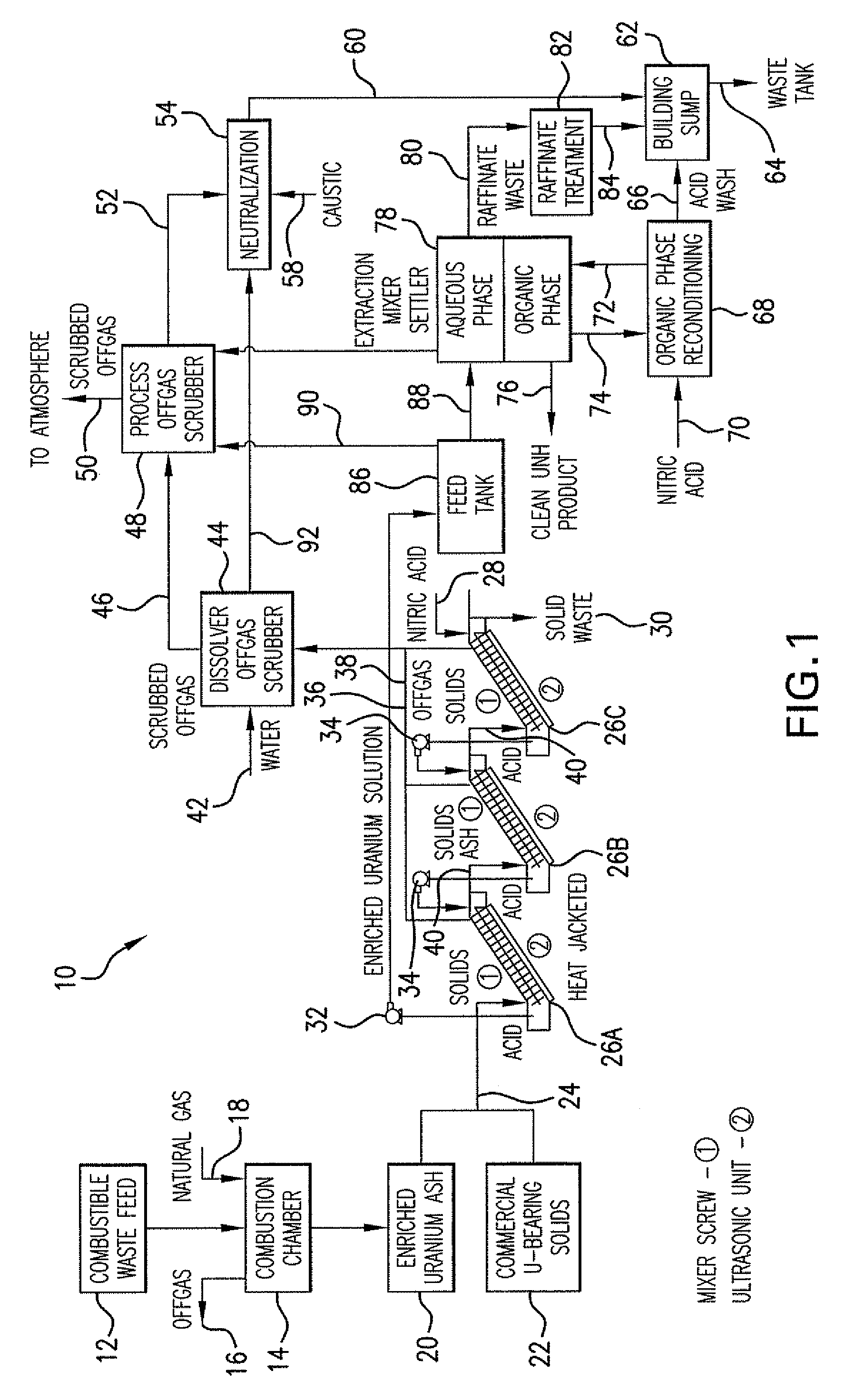

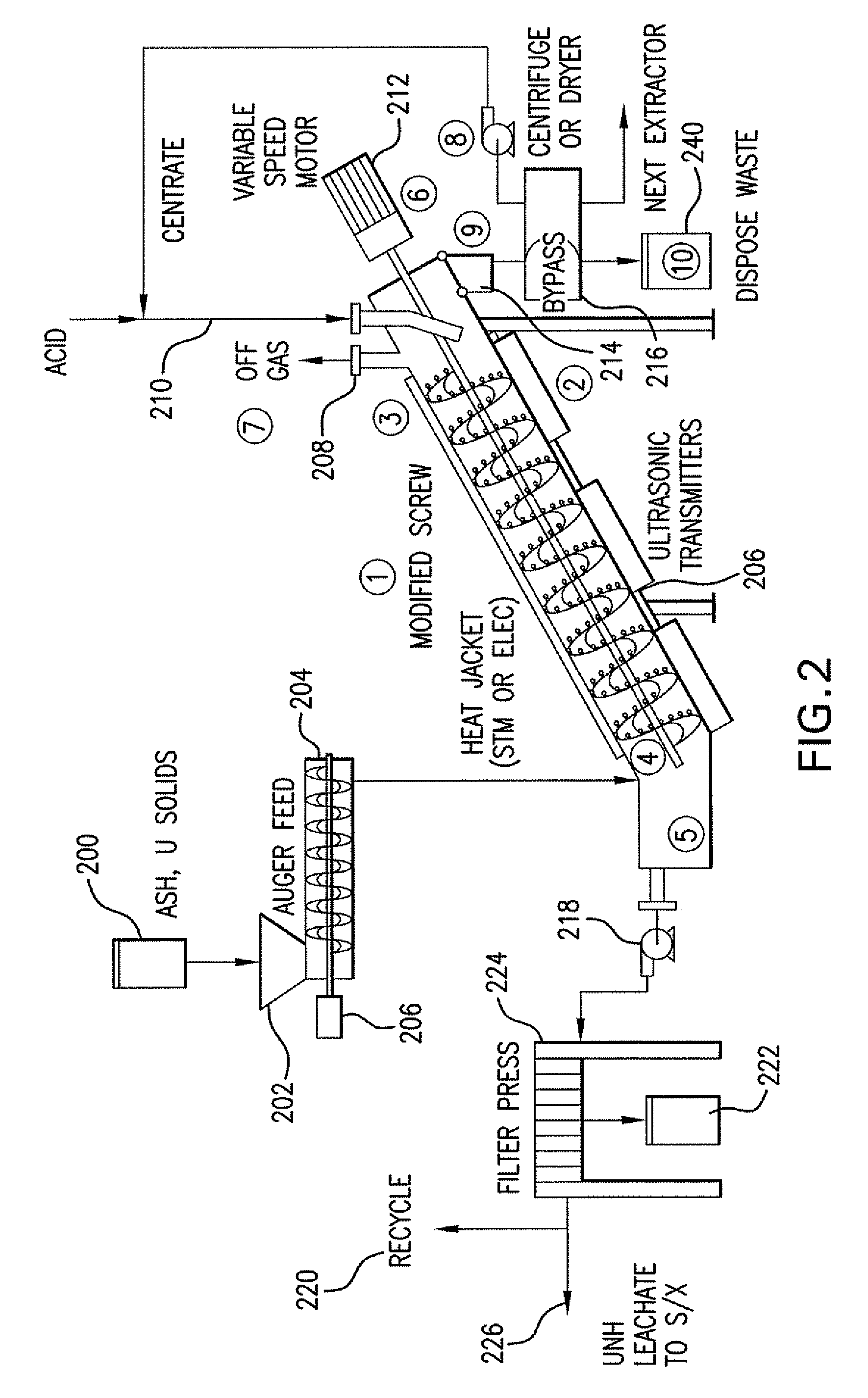

Ultrasonic counter-current screw extractor for uranium recovery

ActiveUS20060088457A1Improve efficiencySeparated economicallyShaking/oscillating/vibrating mixersTransuranic element compoundsScrew extractorMixer-settler

An apparatus and method to remove uranium from a body of material wherein the method includes the steps of depositing the body of solid material in an ultrasonic extractor and depositing an amount of acid in the ultrasonic extractor. The method also provides for the steps of heating a jacket of the ultrasonic extractor, transporting the body of solid material in the ultrasonic extractor and the amount of acid such that the body of solid material and the acid contact each other inside the heated ultrasonic extractor while the ultrasonic extractor provides ultrasonic energy to both the body of solid material and the amount of acid, wherein the amount of acid strips uranium from the body of solid material. The method further provides for collecting the amount of acid and the body of solid material in the ultrasonic extractor in different positions, transporting the amount of acid with the stripped uranium to an extraction mixer settler, and settling uranium product from the extraction mixer settler.

Owner:AREVA NP INC

Screw for juice extractor

Owner:乐美益

Bamboo powder-high density polyethylene composite materials and process for preparing same

The invention relates to a bamboo powder - high-density polyethylene composite and its process for preparing, which consists of granulating in the twin-screw extruder after kneading the raw material components comprising bamboo powder, high-density polyvinyl resin, polyethylene oxide and geoceric acid, then obtaining the product by squeezing the master batch in the single screw extractor. The external appearance of the invented bamboo powder - high-density polyethylene composite is close to the wood, and the invented product has good fire-retardancy. By changing different dies, complex-shaped products can be prepared and is capable of boring, digging and nailing. The product of this invention is of no release of formaldehyde, of nice appearance, good handle, no warp, excellent resistance to aging, and so it has a prodigious superiority outside, for example, it can be used as marine landscape materials such as corridor, sunshade, baluster and movable dwelling.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

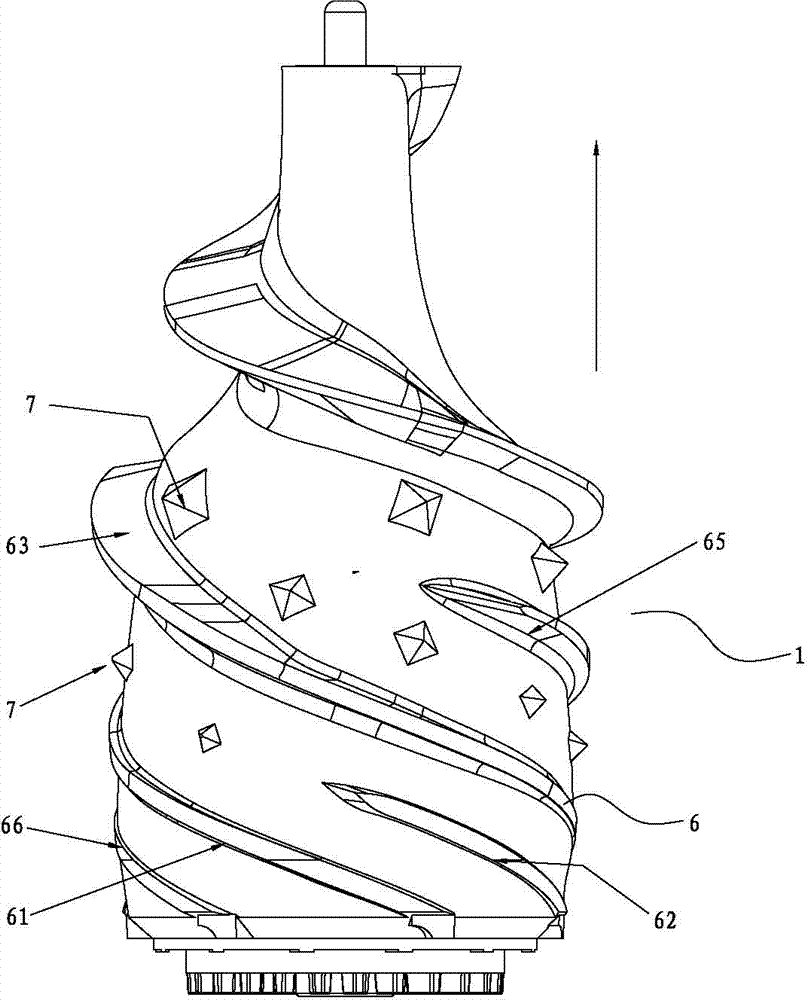

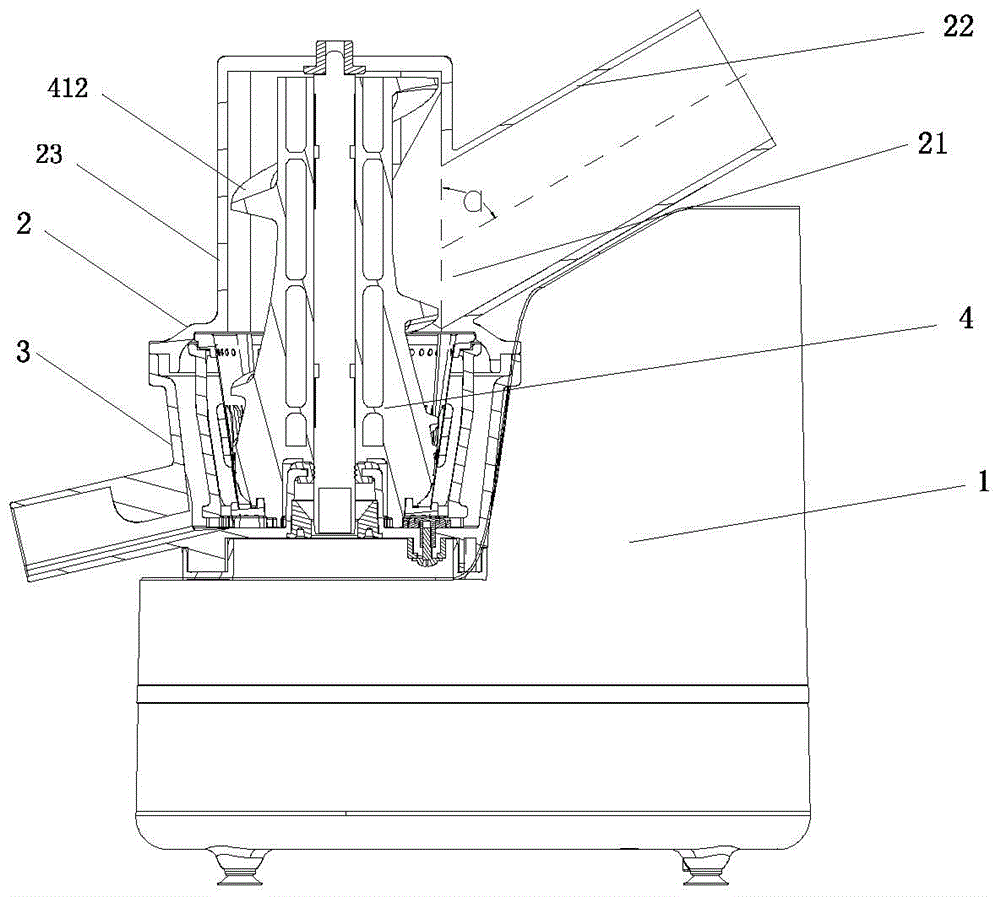

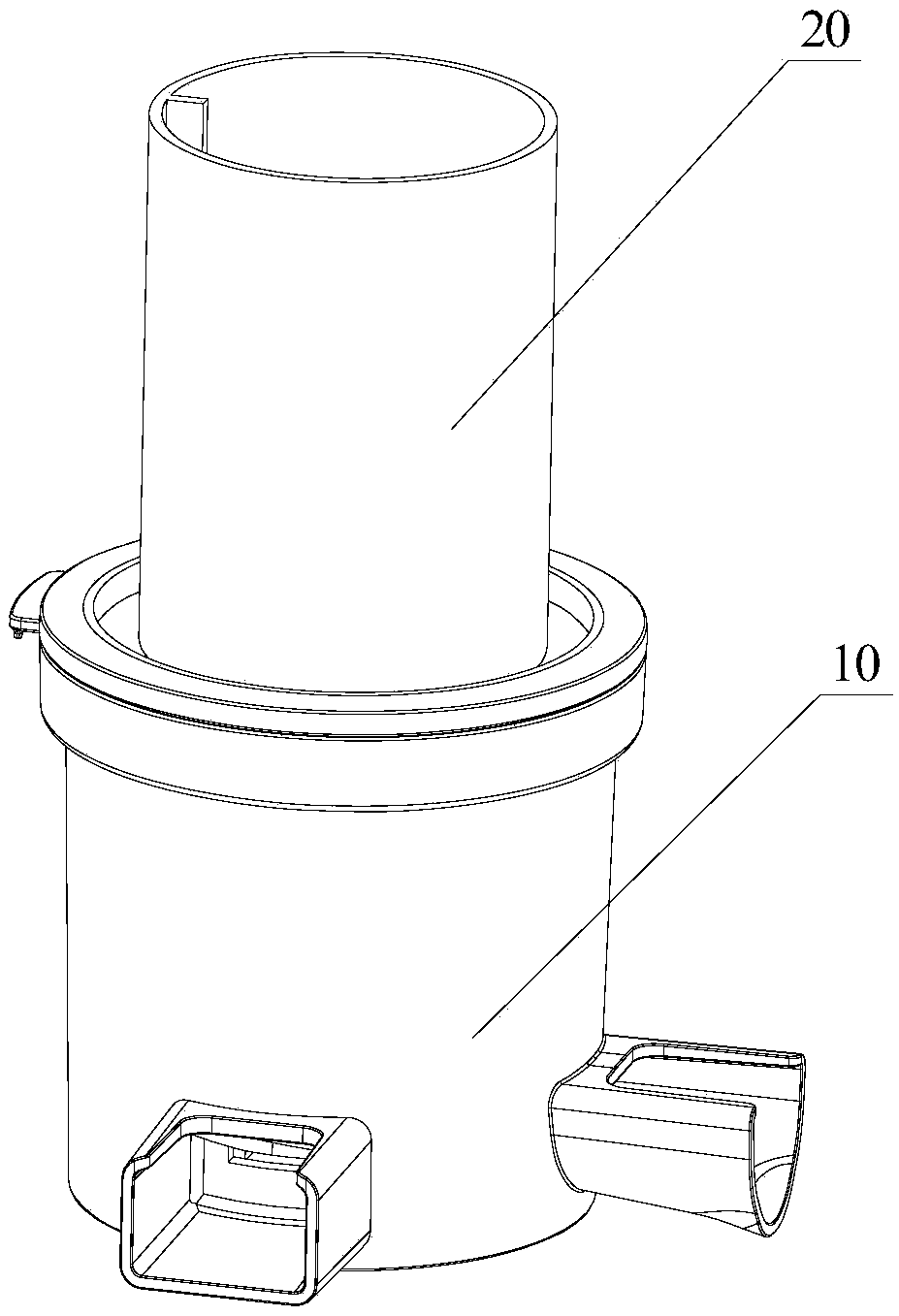

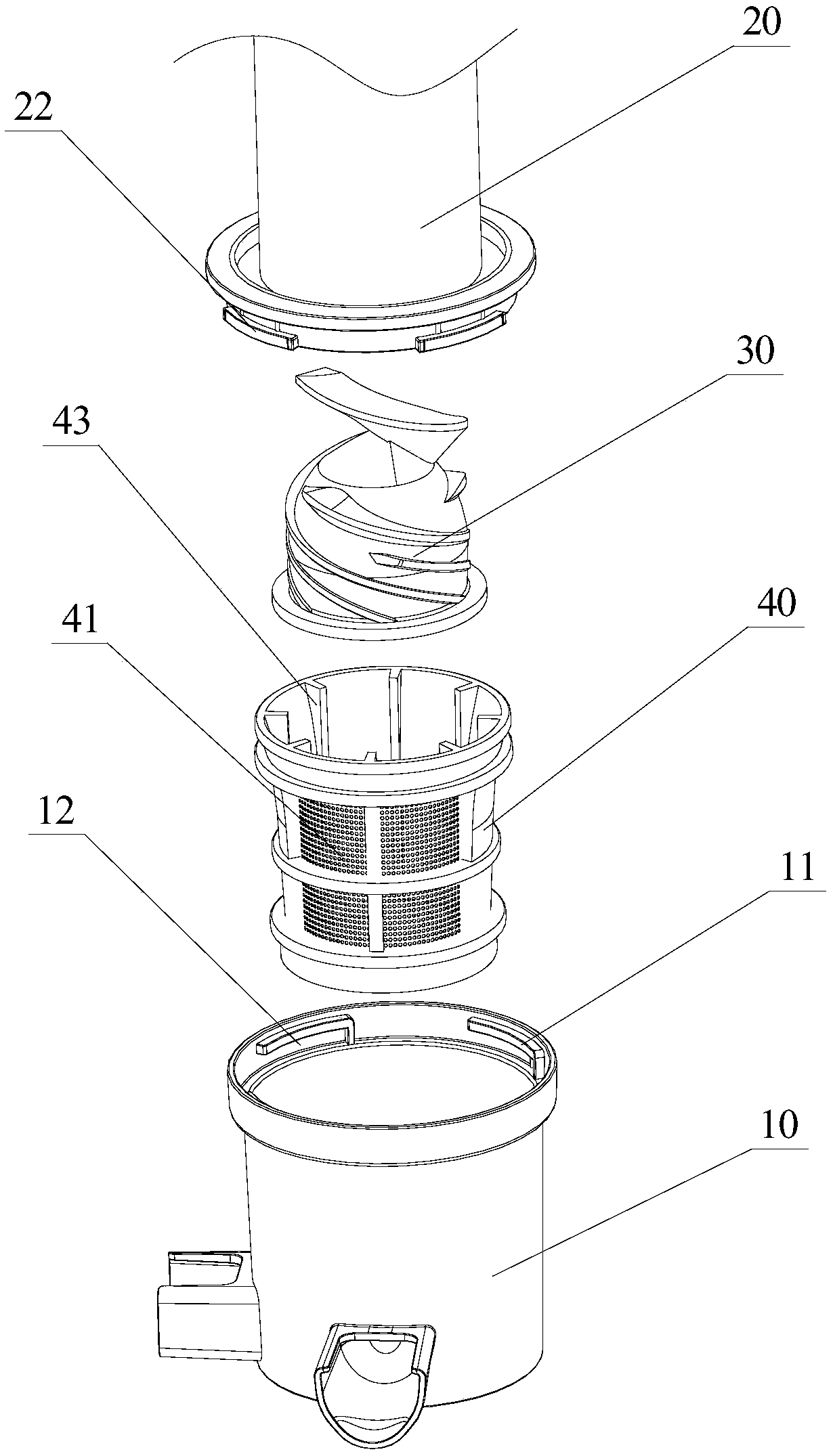

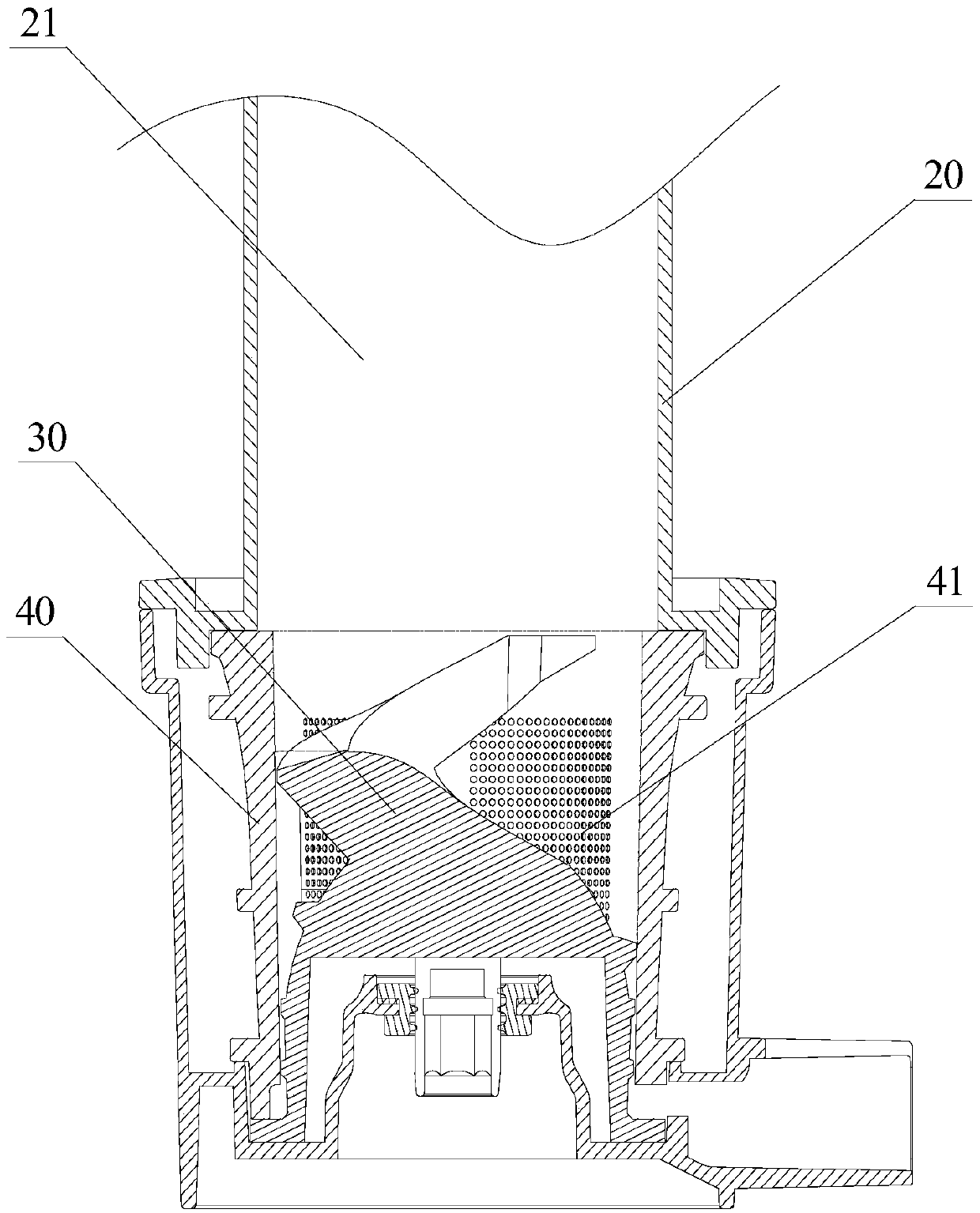

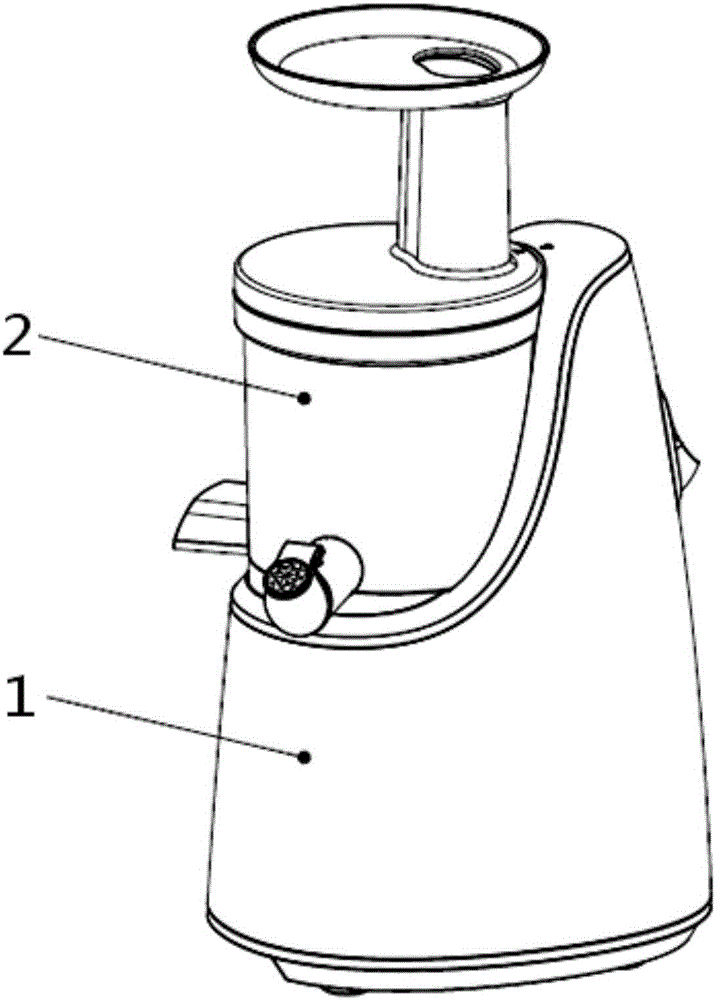

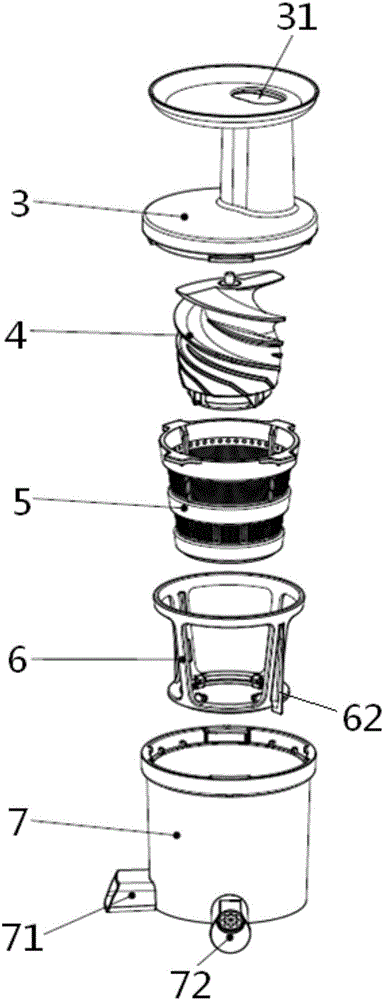

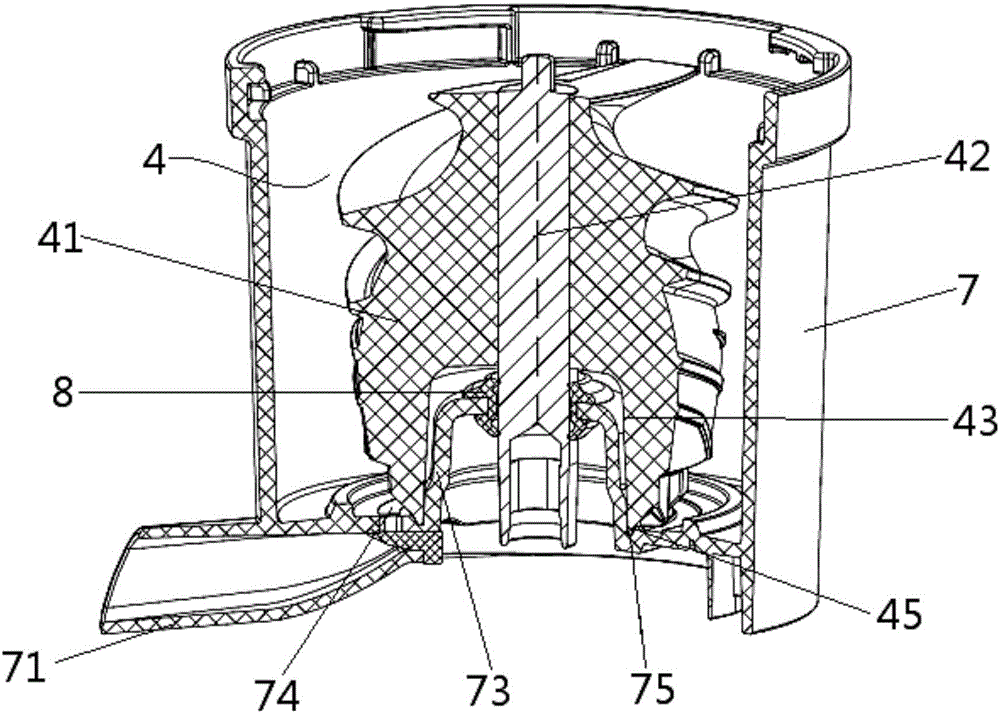

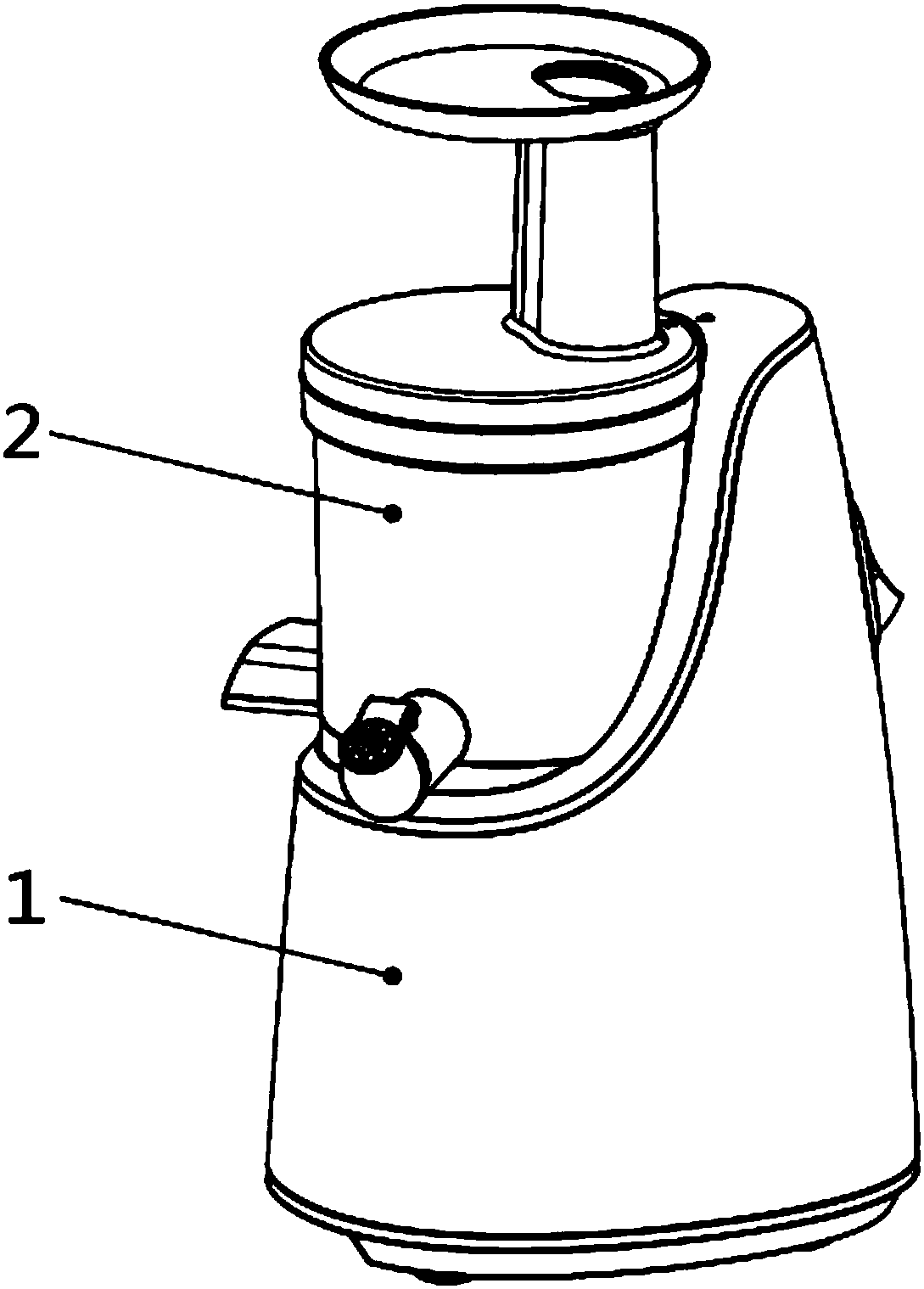

Vertical screw extruding juice extractor

The invention discloses a vertical screw extruding juice extractor, which comprises a machine base, a motor arranged in the machine base, an extrusion screw, a pressing chamber cooperating with the extrusion screw to extrude materials, and an upper cover installed above the pressing chamber , the pressing chamber is installed on the machine base, the extruding screw is installed in the pressing chamber, the upper cover is provided with an accommodating part protruding upwards and used to accommodate the upper part of the extruding screw, and the side wall of the accommodating part is set There is a feed port and a feed channel connected to the feed port, the angle between the geometric center of the two ports of the feed channel and the vertical plane is a, 30°≤a≤60°, so that the material depends on itself The gravity can quickly enter the accommodating part directly through the feeding channel, and is quickly brought into the extrusion grinding part of the extrusion screw and the pressing chamber formed by the downward guidance of the material propulsion part at the corresponding position of the feeding port. Squeeze in the juice gap, easy to realize fast automatic feeding.

Owner:JOYOUNG CO LTD

Trephine broken screw extractor

A ring saw broken nail remover, which is composed of a connecting seat, a handle, a clamping handle, a ring saw, a tapered notch, a connecting shaft, a T-shaped through groove, a clamping jaw, a T-shaped thread, etc., the upper part of the connecting seat is connected with the The clamping handle is connected, the left and right sides are connected with the handle, and the lower part is connected with the ring saw. The connecting shaft passes through the connecting seat from the middle and is connected with the jaws. The tapered groove There is a T-shaped thread groove on the mouth, which is used to cooperate with the T-shaped thread on the jaw. Since the thread is arranged in a tapered shape, it can also move radially when the jaw moves up and down, so that The clamping and loosening actions of the jaws are completed. The invention only needs to carry out very shallow drilling to take out the broken nail, and the operation does not need to repeatedly adjust the direction and position, and the operation is simple.

Owner:YANTAI NANSHAN UNIV

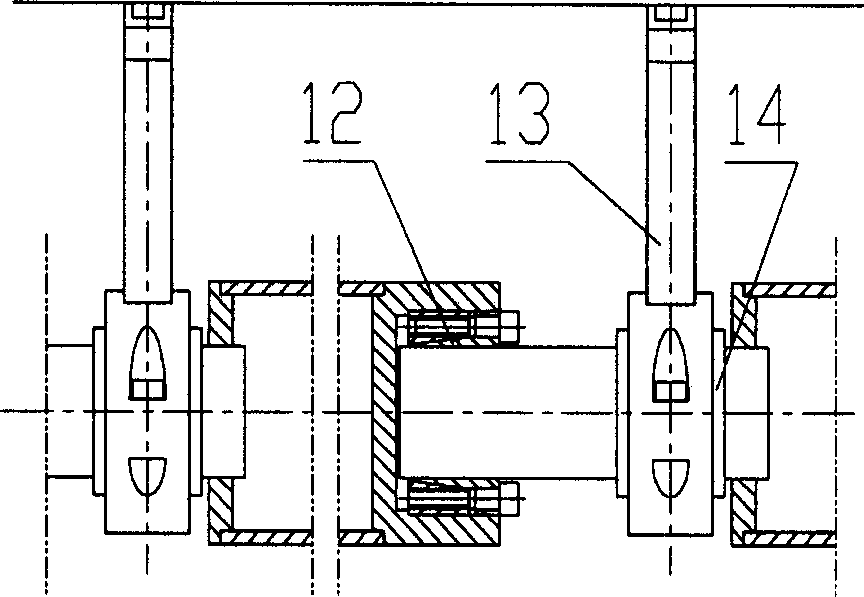

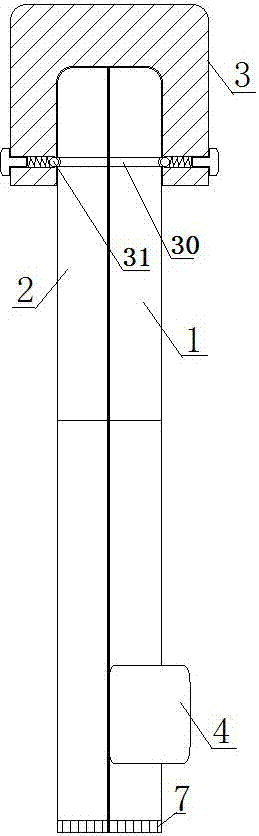

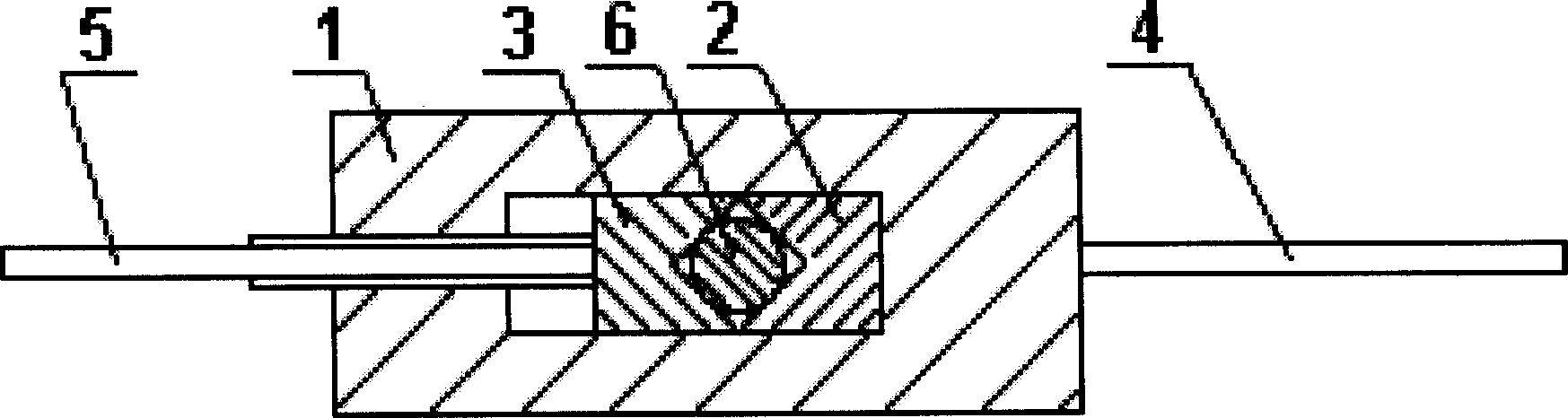

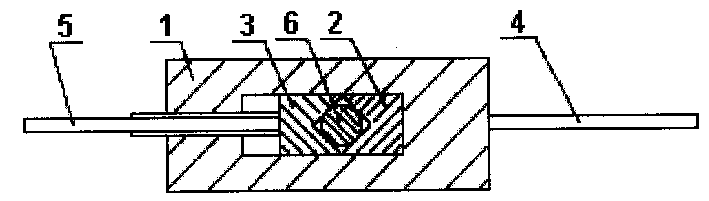

High frequency induction heating screw extractor

InactiveCN101829976AImprove pull performanceImprove work performanceMetal-working hand toolsScrew extractorInduction heater

The invention relates to a screw extractor, in particular to a high frequency induction heating screw extractor. The invention solves the problem that the existing screw extractor is hard to disassemble some shaft fastening pieces with tight fit. The high frequency induction heating screw extractor comprises a mandrel and a falcula connected with the mandrel and also comprises a group of high frequency induction heaters, wherein a magnet is arranged on one end of each high frequency induction heater. Compared with the traditional screw extractor, the heating device is added on the high frequency induction heating screw extractor of the invention; and the gaps between the parts to be disassembled can be increased by heating so as to greatly reduce the friction force between the parts to be disassembled, largely increase the drawing ability of the screw extractor and protect the parts to be disassembled and the personal safety of the site operation personnel.

Owner:TAIYUAN COAL GASIFICATION

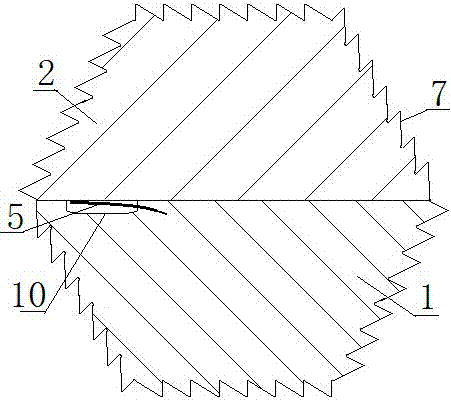

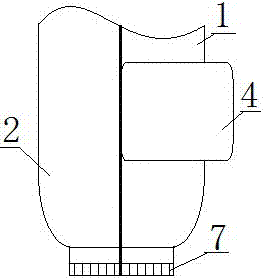

Orthopedic screw extractor

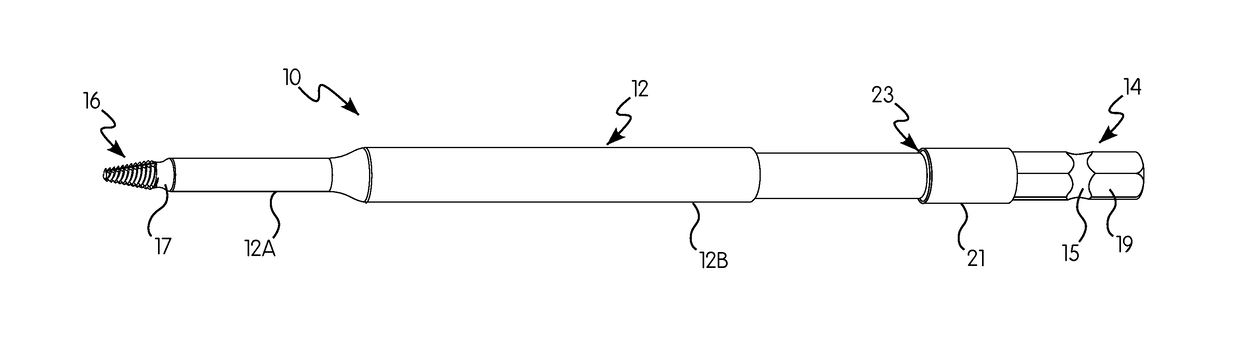

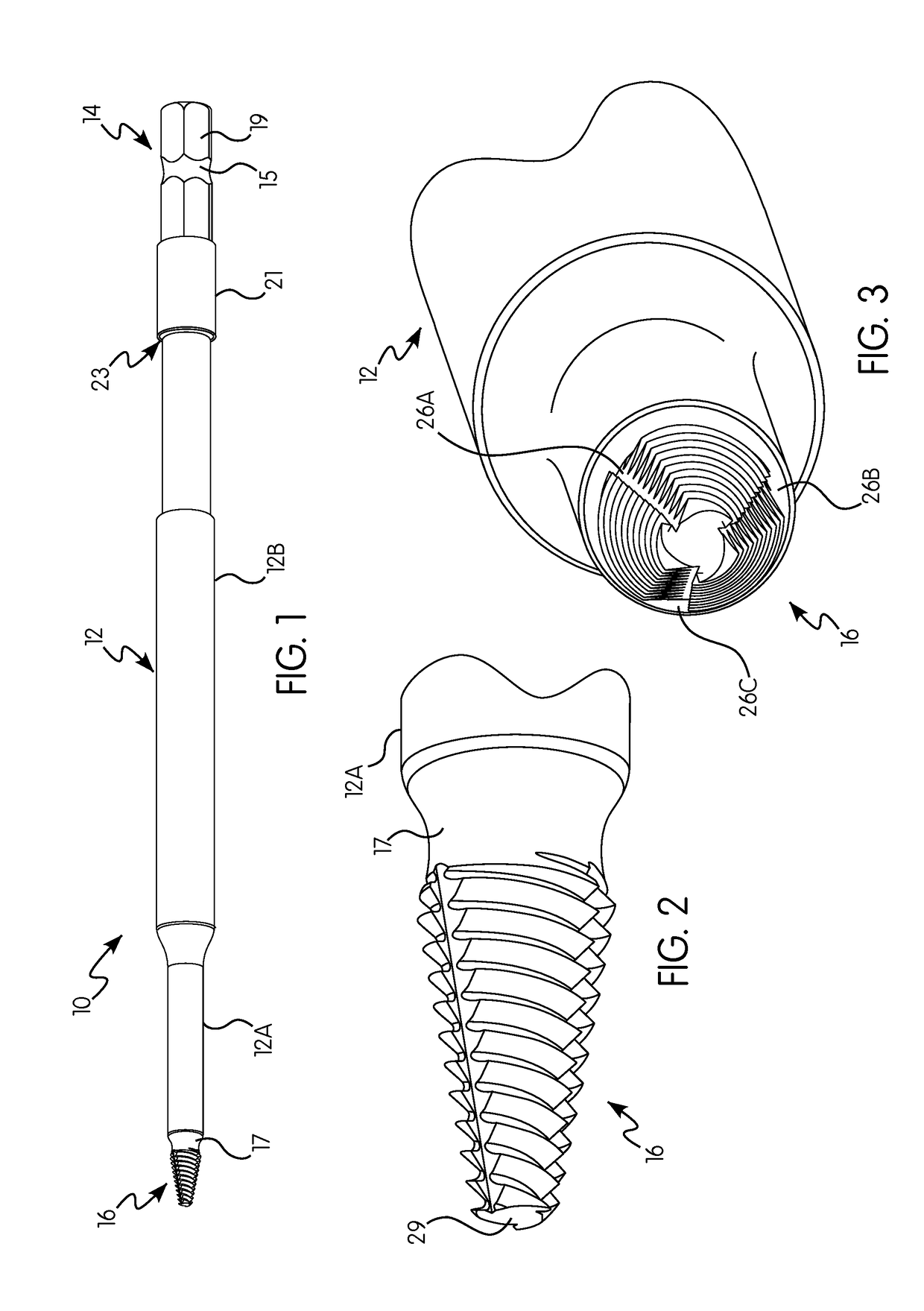

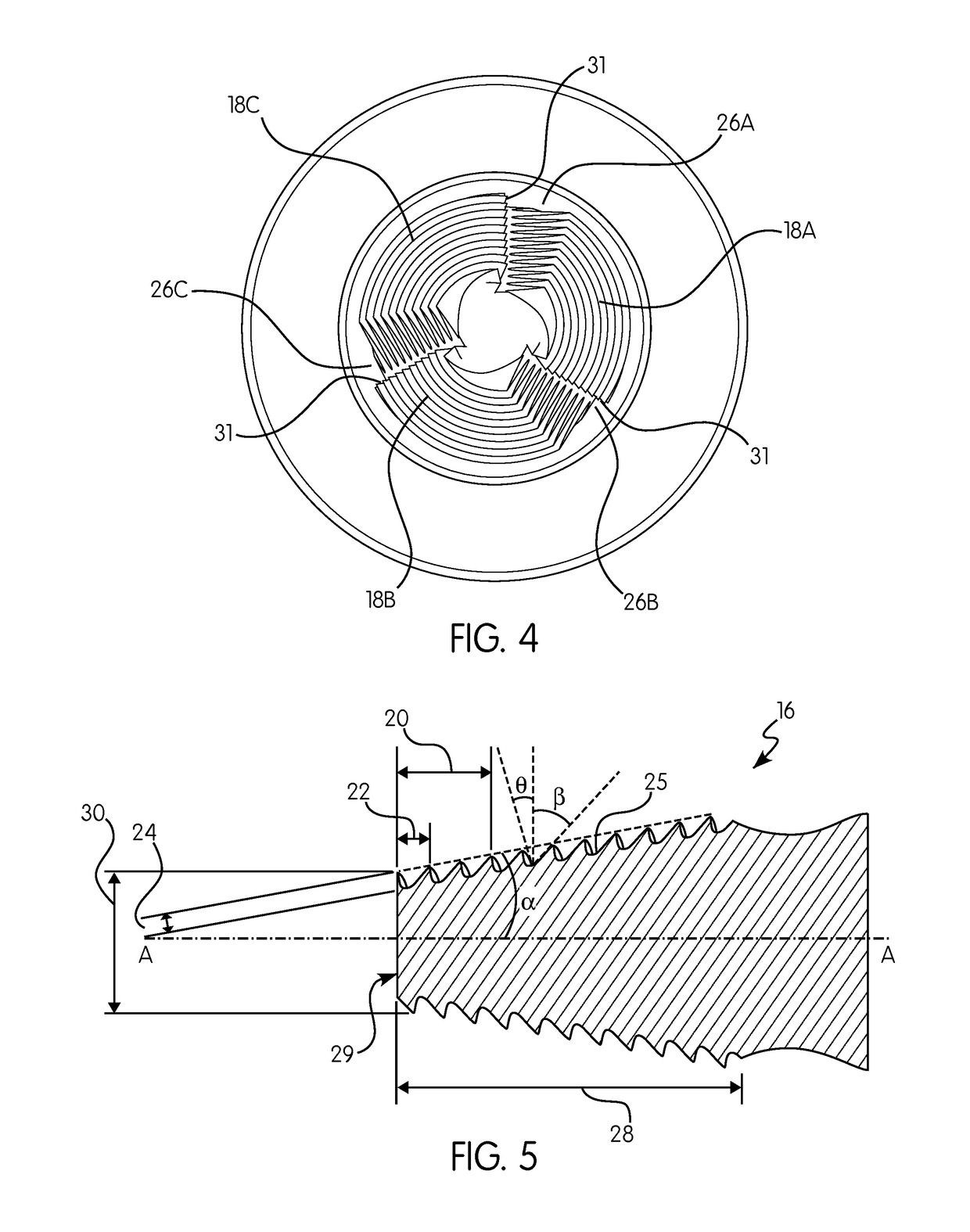

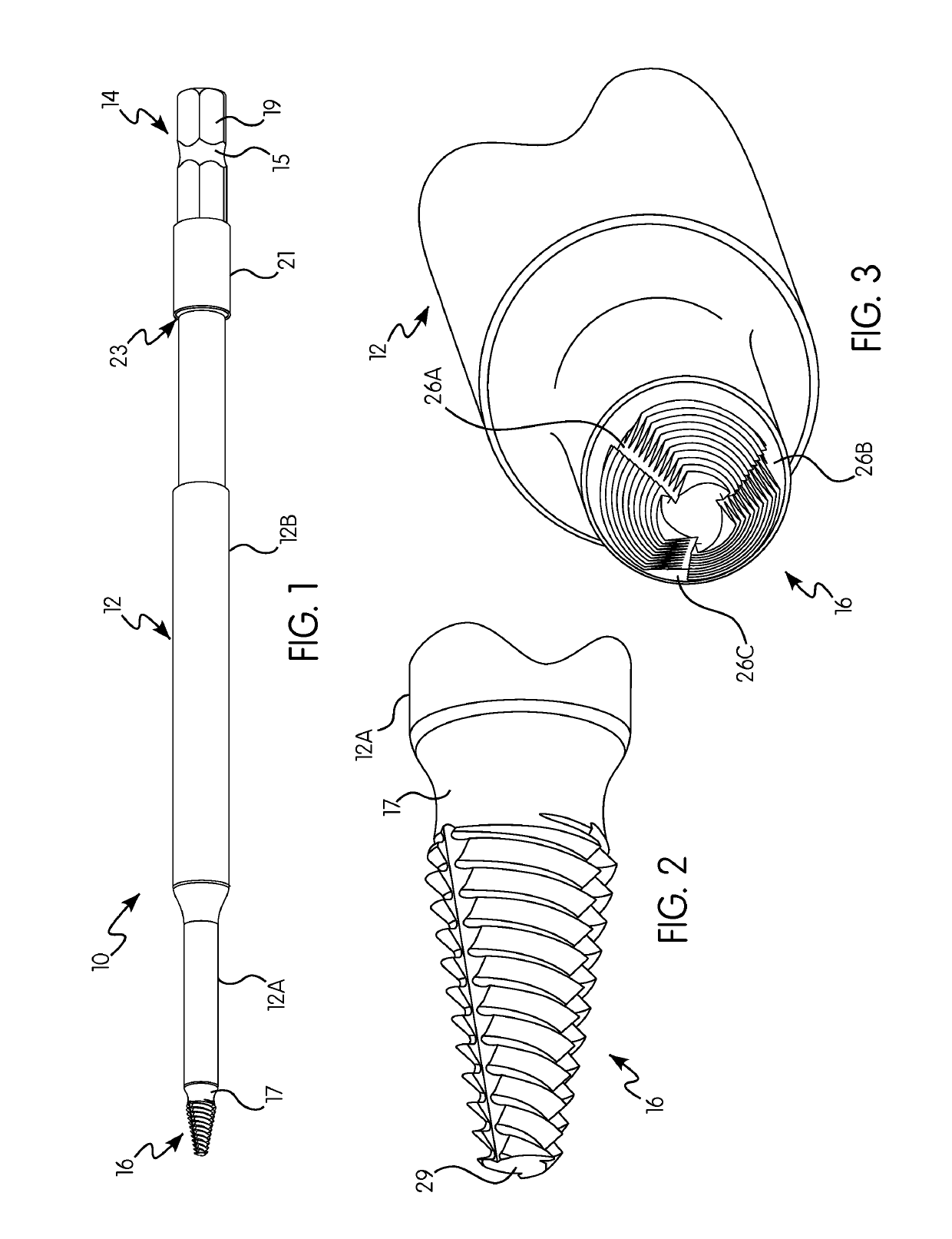

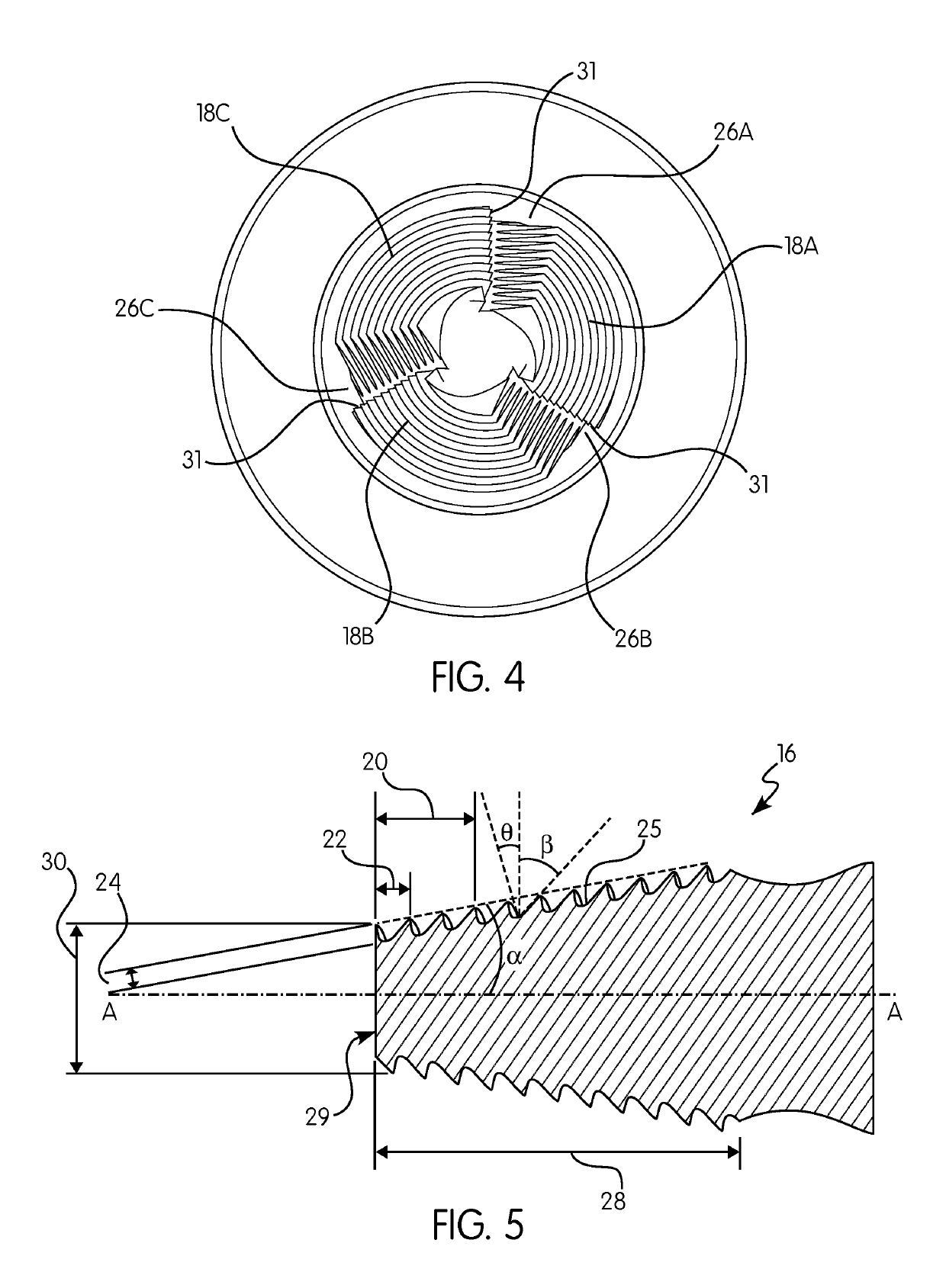

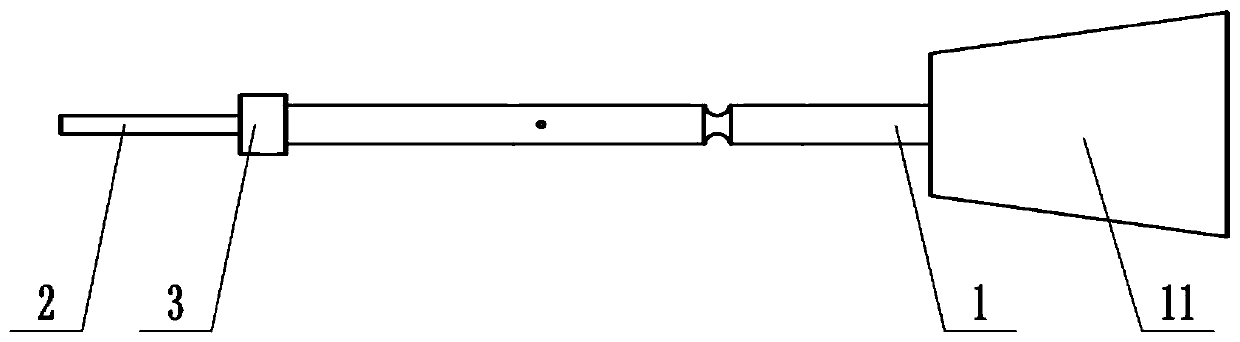

An orthopedic screw extractor device including a shaft, an end portion about a first end of the shaft for securing to a handle, and a screw extracting tip about a second end of the shaft opposite the first end. The screw extracting tip further includes a generally frustoconical shape having a side at an angle of about 5 to 15 degrees relative to a longitudinal axis of the screw extracting tip. The screw extracting tip further includes first, second and third screw threads and first, second and third flutes circumferentially spaced about the screw extracting tip and extending across an entire length of the screw extracting tip. Each of the screw threads has a lead of about 0.07 to 0.12 inches, a pitch of about 0.02 to 0.04 inches, a thread angle of about 40 to 50 degrees, and a depth of about 0.01 to 0.02 inches.

Owner:SHUKLA MEDICAL

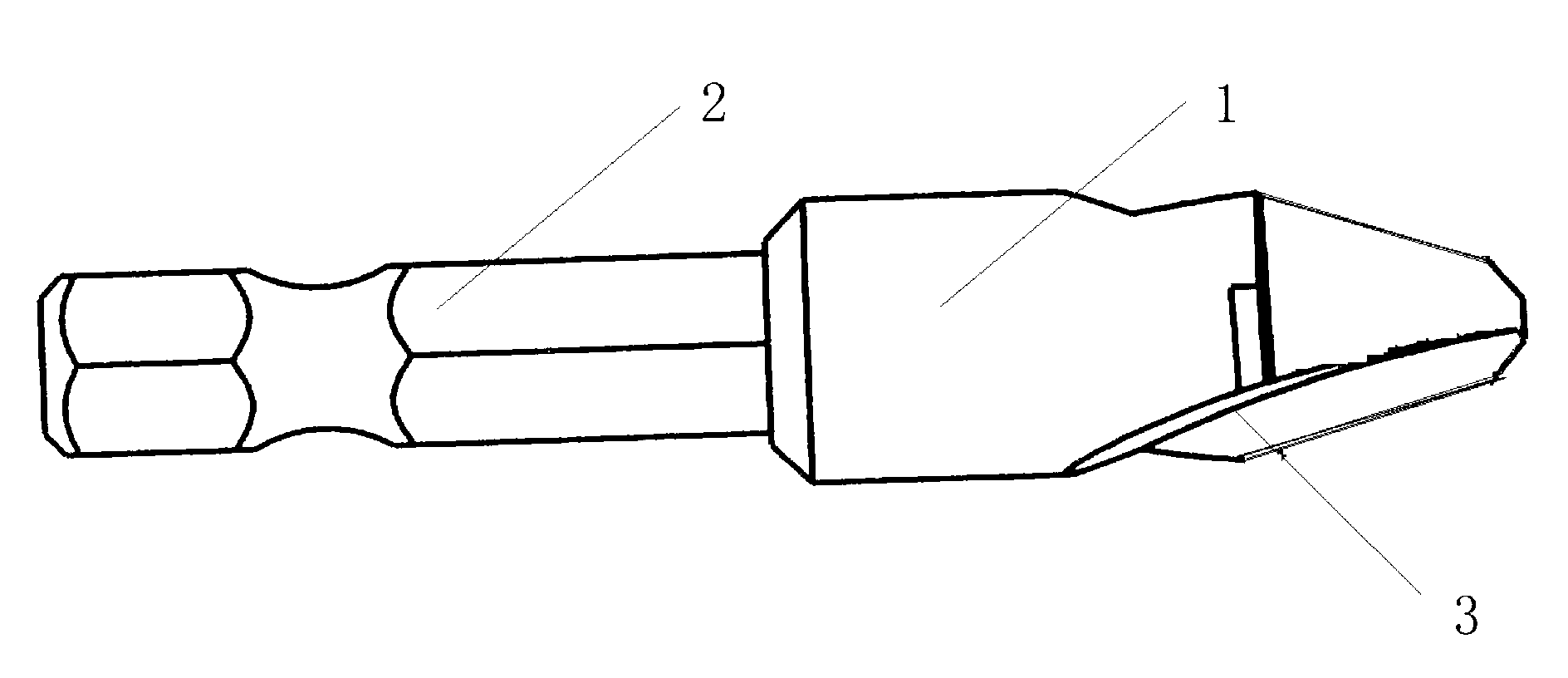

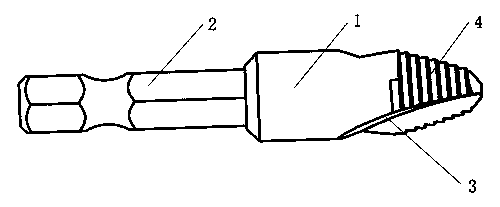

Screw extractor

The invention discloses a screw extractor which comprises a big head and a handle, wherein the handle is arranged at the rear end and connected with the big head into a whole, and the big head is conical and is provided with a cutting edge. The screw extractor disclosed by the invention has the advantages of providing a tool which is specially used for taking screws, especially broken screws which are difficult to remove inside objects, being simple in structure, capable of taking the screws out under the driving of forceful pulling just through wedging the cone at the front end into the screw so as to connect the cone and the screw into a whole, being practical and effective and convenient to use and providing convenience for production and daily use.

Owner:ZHENJIANG HUAPU ELECTRONICS EQUIP

Orthopedic screw extractor

An orthopedic screw extractor device including a shaft, an end portion about a first end of the shaft for securing to a handle, and a screw extracting tip about a second end of the shaft opposite the first end. The screw extracting tip further includes a generally frustoconical shape having a side at an angle of about 5 to 15 degrees relative to a longitudinal axis of the screw extracting tip. The screw extracting tip further includes first, second and third screw threads and first, second and third flutes circumferentially spaced about the screw extracting tip and extending across an entire length of the screw extracting tip. Each of the screw threads has a lead of about 0.07 to 0.12 inches, a pitch of about 0.02 to 0.04 inches, a thread angle of about 40 to 50 degrees, and a depth of about 0.01 to 0.02 inches.

Owner:SHUKLA MEDICAL

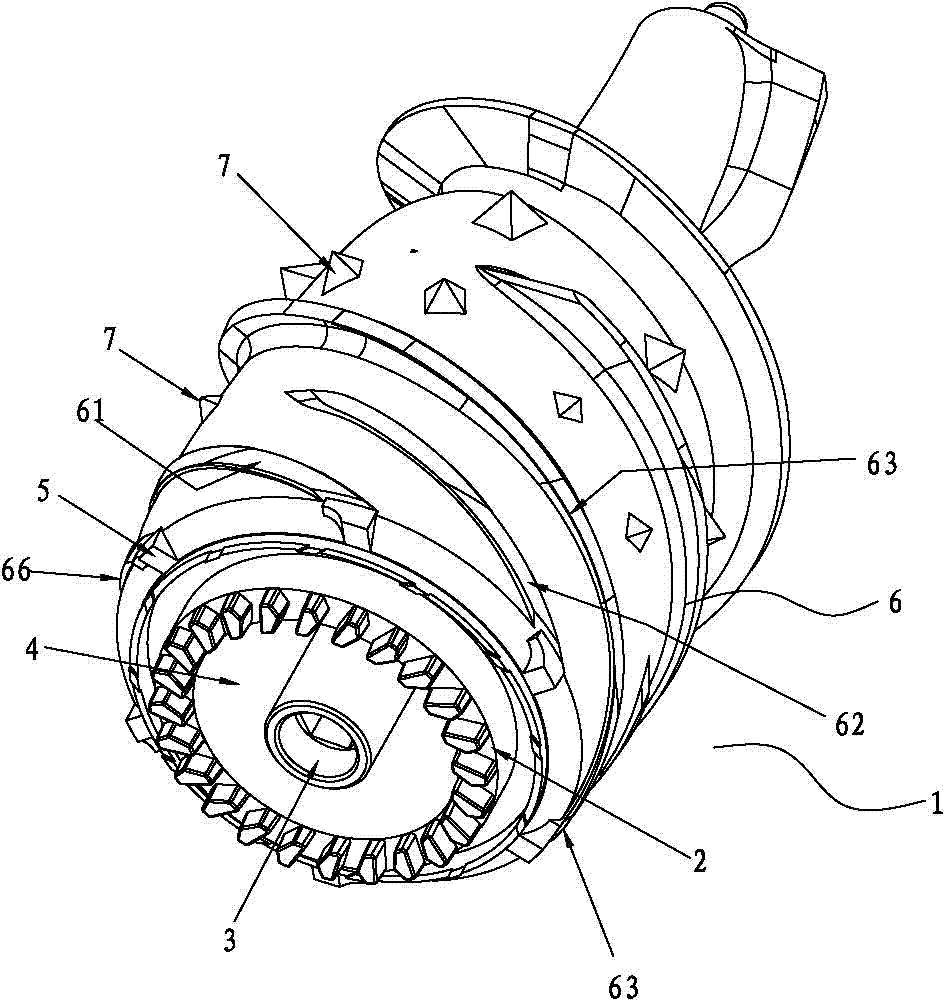

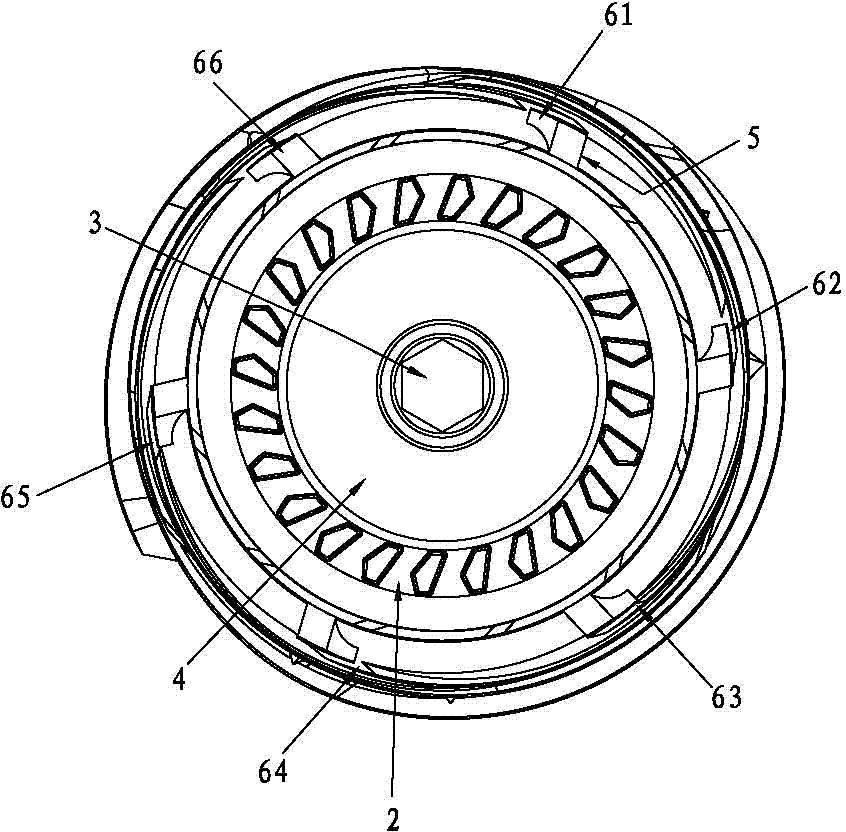

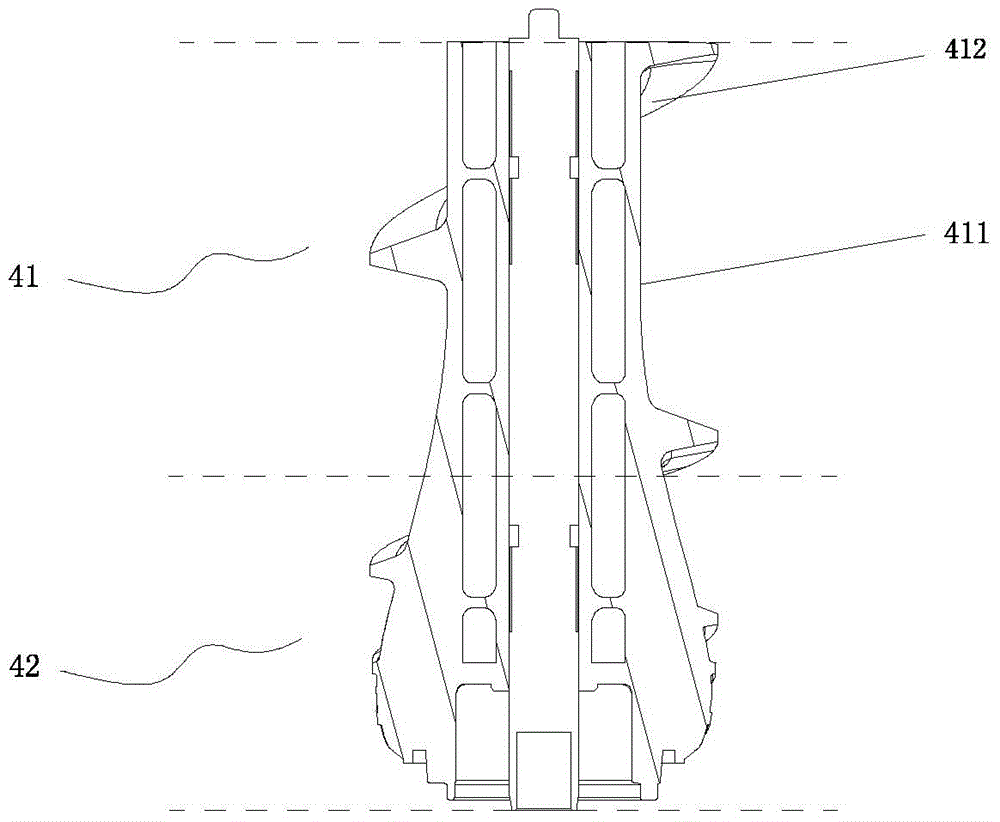

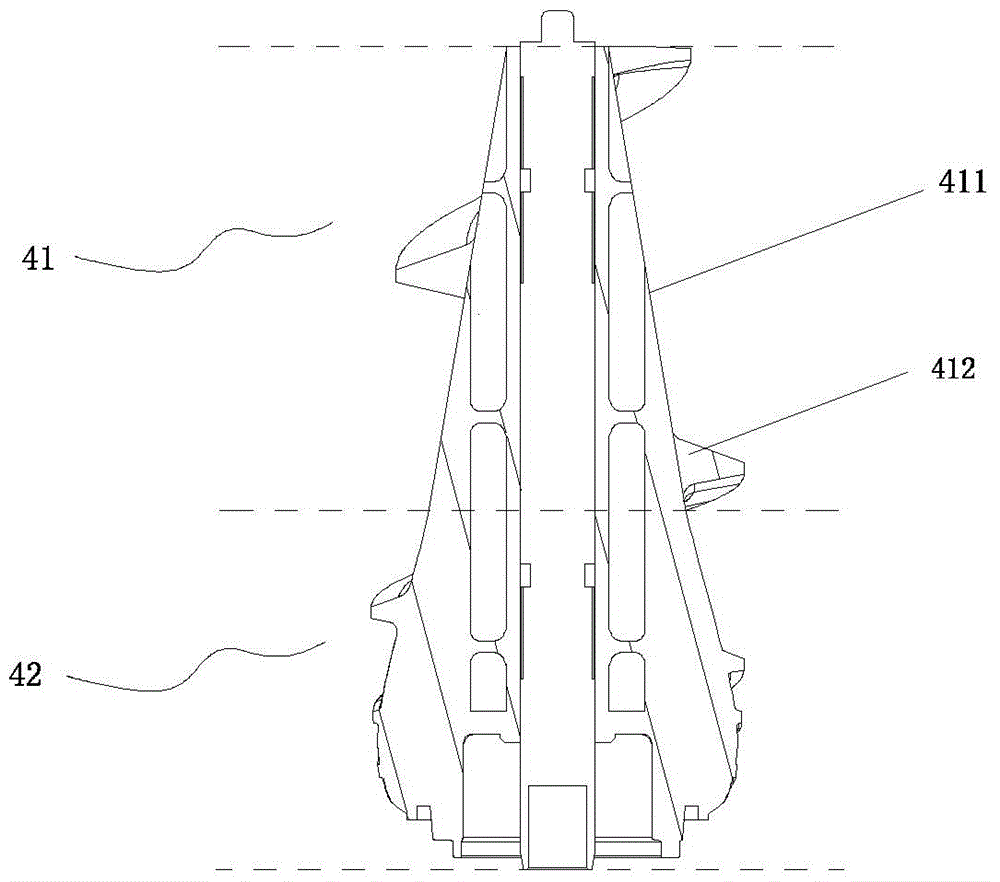

Juice extractor and spiral-extruded juicing screw thereof

The invention discloses a juice extractor and a spiral-extruded juicing screw thereof. An extrusion juicing part is formed at a spiral part of an outside surface of the spiral-extruded juicing screw;an upper part of the extrusion juicing part upwards extend in a spiral manner, and a holding cavity for enabling a rotary central axis of the screw to penetrate is formed between an inside surface andan inner wall of a filter module of the juice extractor; the food material with size exceeding the semi-diameter of the screw can be fed through the holding cavity, and the rotary central axis of thescrew is located in a horizontal projection plane of the holding cavity. The juice extractor is free from using a positioning shaft, a vertical size of the screw is reduced, then the volume of the juice extractor is reduced, and the material cost is reduced, so that the juice extractor is convenient to transport and store; and meanwhile, the top of the extrusion juicing part of the screw is eccentrically arranged, the rotary central axis is located at a discharge channel outlet and the horizontal projection plane of the holding cavity, the size of the holding cavity is increased so that the holding cavity can hold the food material with the size exceeding the semi-diameter of the filter module, and the juicing effect and the juicing efficiency are increased.

Owner:ISLOW ELECTRIC (SHEN ZHEN) CO LTD

Double-spiral, continuous counter-flow extraction equipment

A countercurrent-type continuous dual-screw extractor is composed of feeder, inclined extracting cabin, dregs discharger, filter, condenser, juice squeezer and power drive mechanism. It features that parallel two spiral axles, which consists of multiple segments and has continuous perforated spiral blade or discontinuous paddles, are rotating in different directions.

Owner:黑龙江省计算中心

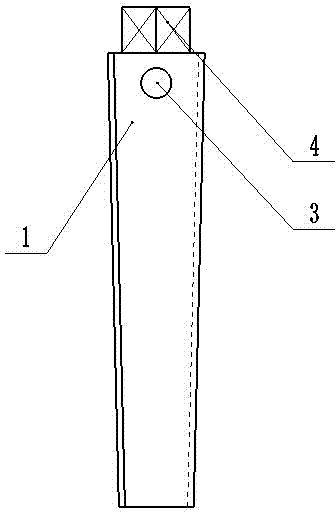

Broken screw extractor

The invention discloses a broken screw extractor, which relates to a manual tool which can be used for extracting a broken screw easily. The technical problem to be solved is to provide a broken screw extractor for extracting a broken screw without damaging screw threads. The broken screw extractor comprises a body and teeth, wherein the body gradually becomes thick from bottom to top; any cross section of the body is regularly polygonal; the edge of the body is provided the projecting teeth; the teeth are in the same direction; the upper part of the large head end of the body is provided with a hole; the end part of the large head end of the body is provided with a handle; and the handle has a rectangular or cylindrical structure of which the two faces are milled into planes. The broken screw extractor is convenient to use, is easy to operate, is suitable for any broken screw, and is prevented from damaging the screw thread.

Owner:杨锋刚

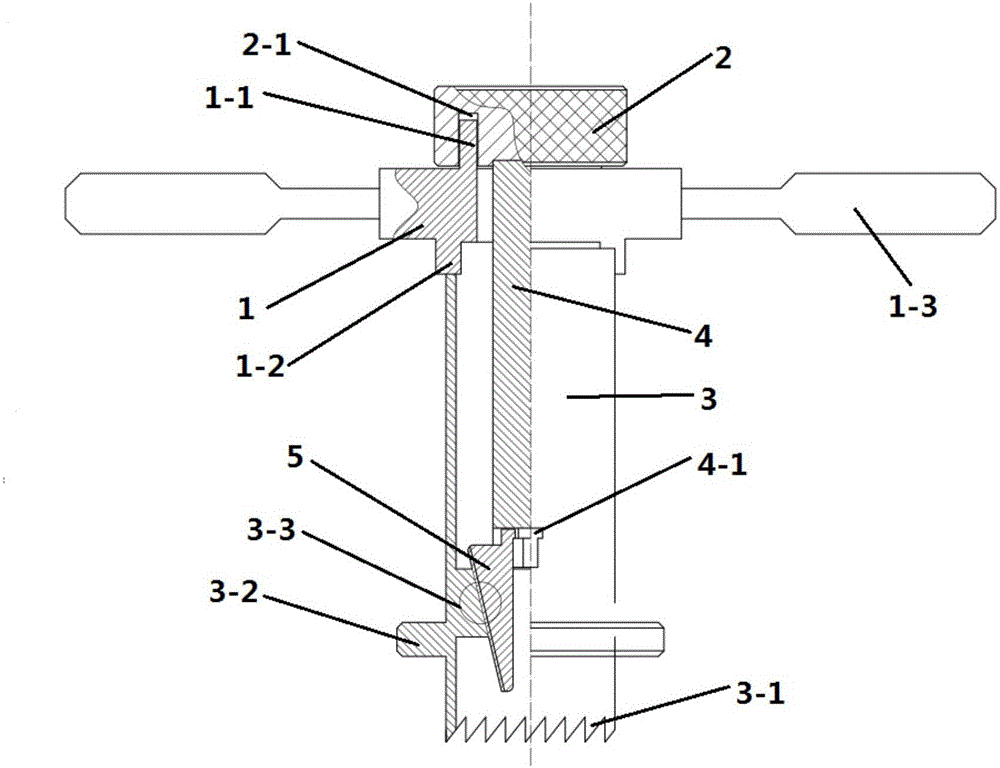

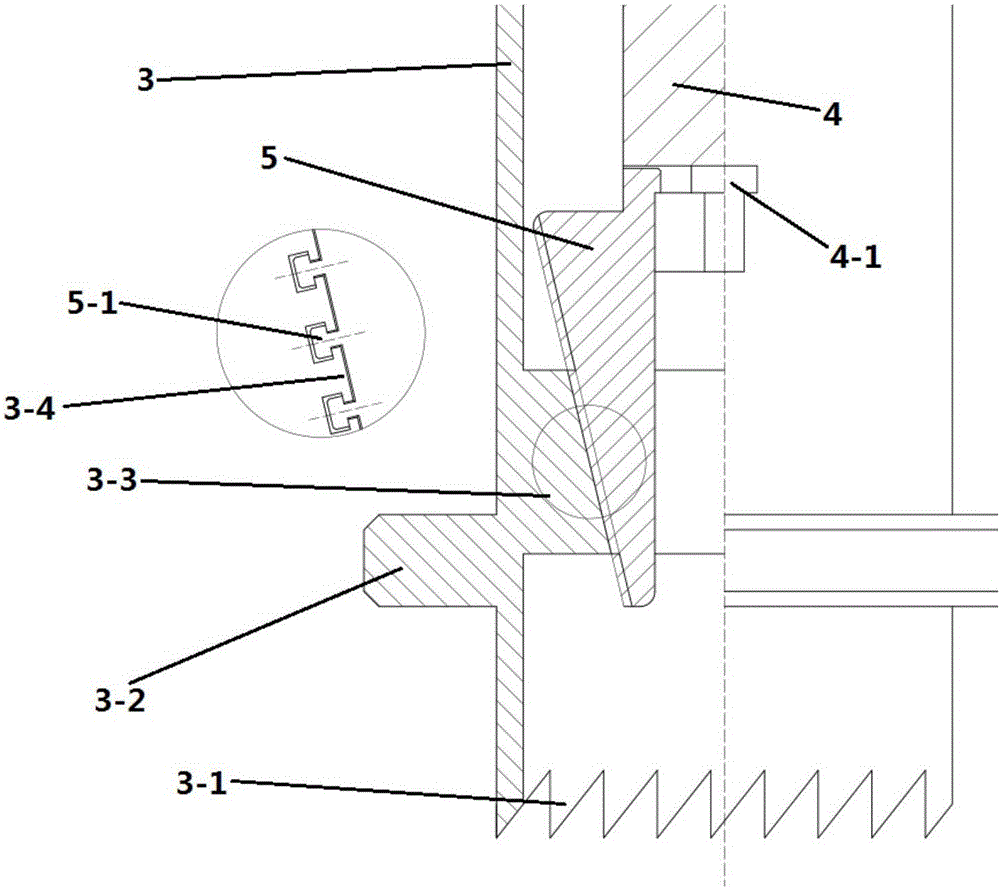

Inner fixing screw extractor in orthopedics department

InactiveCN107242900ATake out fitIncrease bite forceOsteosynthesis devicesScrew extractorOrthopedic department

The invention relates to an inner fixing screw extractor in the orthopedics department. In order to solve the problem that inner fixing screw is difficult to extract in the orthopedics department, tool steel is manufactured into an outer hexagonal prism or hexagram spanner cylinder composed of a left pedal and a right pedal, the upper portion and the lower portion of the cylinder are equal in thickness, or the portion above the lower end is thickened, the upper end of the cylinder is buckled by an upper end cap, or the upper end cap is hinged to the upper end of the cylinder; a sideway stretching handle for rotationally applying force is fixedly installed at the lower portion of the right pedal of the outer hexagonal prism or hexagram spanner cylinder, and a spring for outwards extruding the left pedal of the lower end of the outer hexagonal prism or hexagram spanner cylinder to face the inner end face is installed on the rear inner end face of the lower end of the right pedal of the spanner cylinder in the clockwise direction. Convex teeth obliquely stretching in the anticlockwise direction are manufactured on the periphery of the lower end of the outer hexagonal prism or hexagram spanner cylinder composed of the left pedal and the right pedal. The inner fixing screw extractor has the advantages of being capable of remarkably increasing occlusal force, simple, easy to use, high in anti-slipping performance, low in cost, high in safety, not prone to thread slipping and particularly suitable for extracting a slipping screw, and metal debris and heat are not generated.

Owner:武永刚

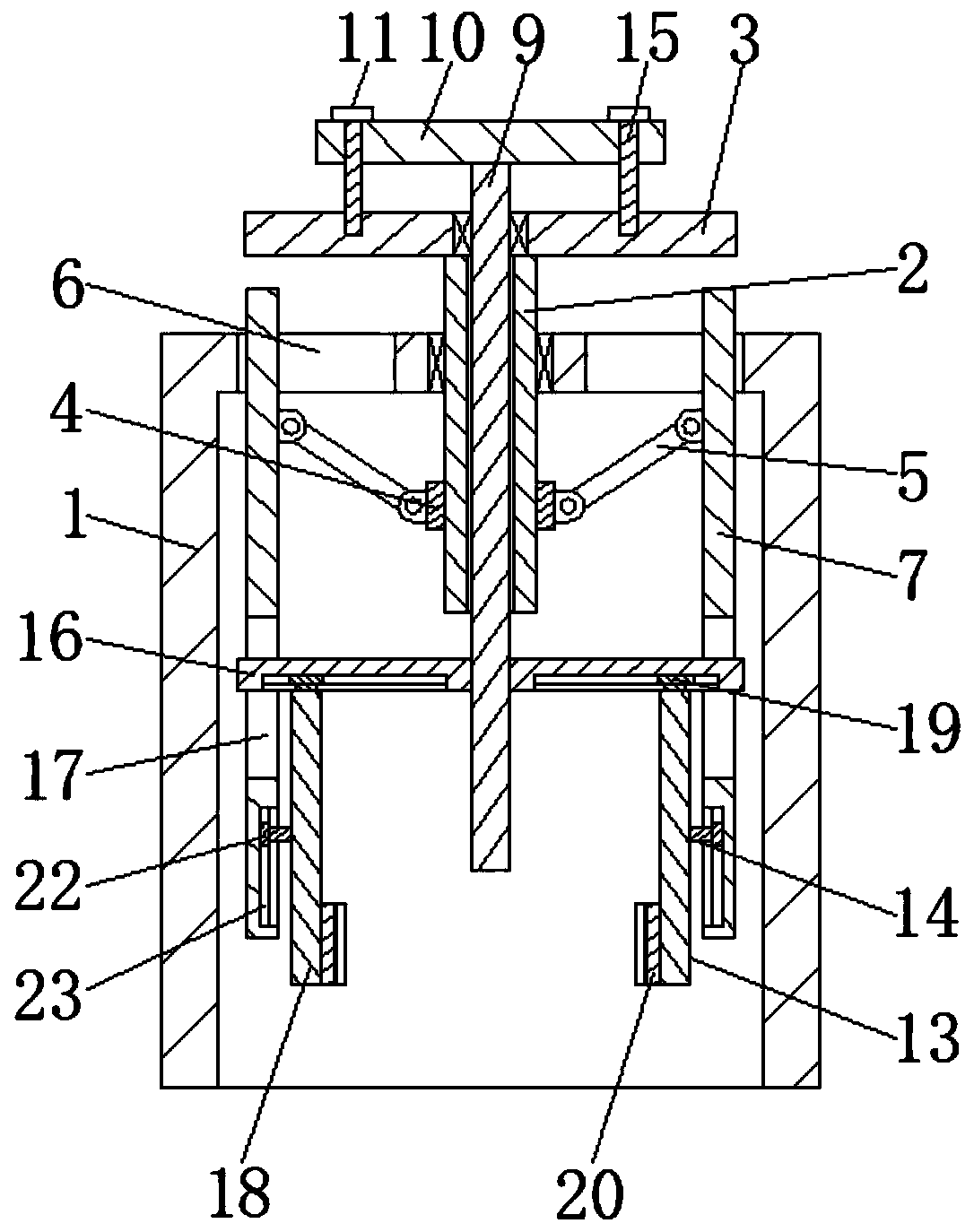

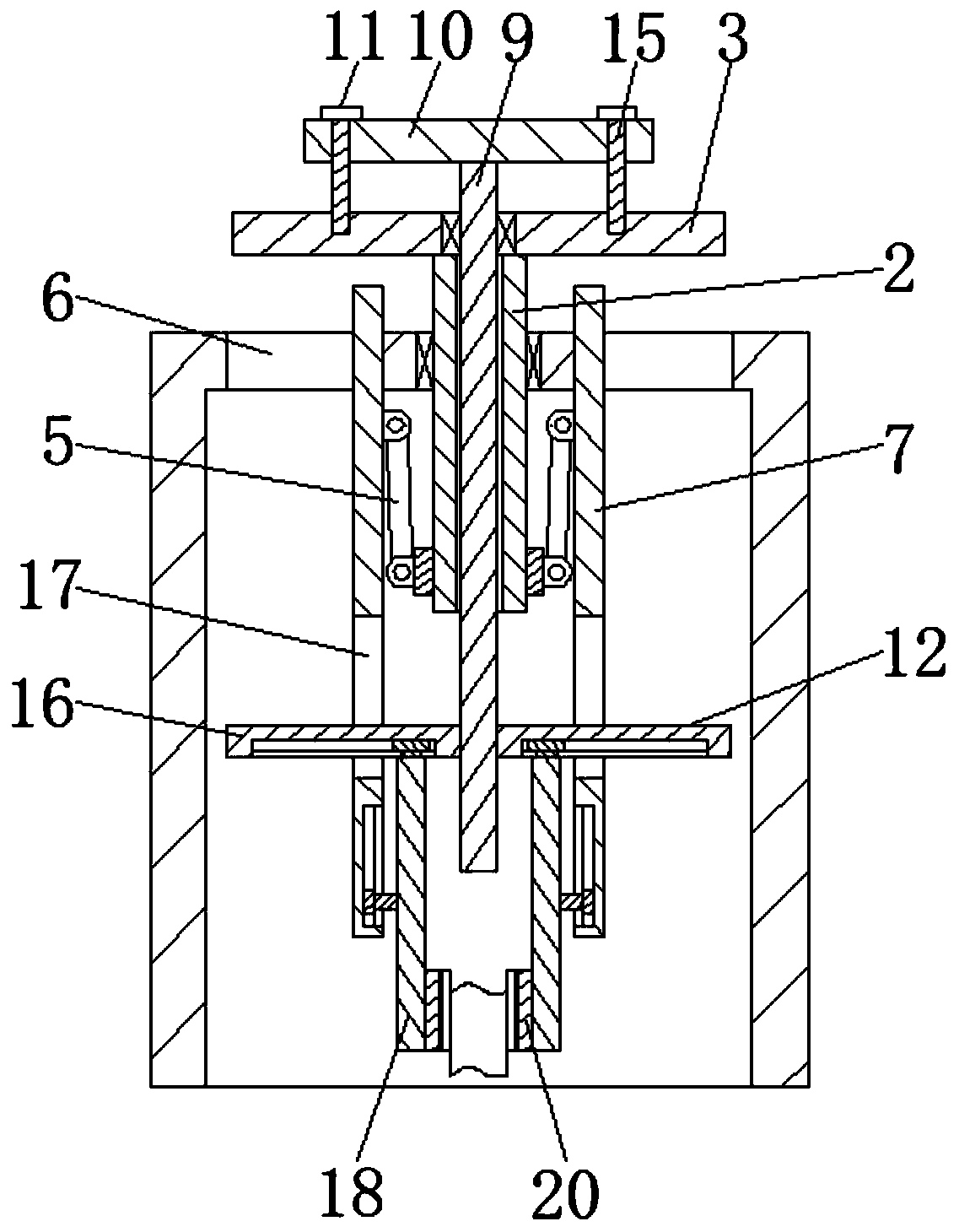

Broken screw extractor for orthopedics department clinic

InactiveCN110974393AImprove extraction efficiencyEasy to moveOsteosynthesis devicesScrew extractorOrthopedic department

The invention discloses a broken screw extractor for orthopedics department clinic. The broken screw extractor comprises a fixed cylinder with an open bottom end, the top of the inner wall of the fixed cylinder is rotationally connected with an outer threaded cylinder with the two ends open through bearings, connecting rods are hinged to the left side and the right side of a moving block through hinge seats, through grooves are formed in the tops, close to the left side and the right side, of the fixed cylinder, the top of a fixing disc is rotationally connected with a screw rod through a bearing, the surface, close to the bottom end, of the screw rod is in threaded connection with a moving part, and the opposite sides of the two clamping parts are in sliding connection with the opposite sides of two moving plates through sliding parts. Through cooperation of the structures, the broken screw extractor solves the problems that in the broken screw extracting process, the broken screw extractor is not ideal in broken screw clamping and fixing effect, broken screws are prone to disengagement in the pulling-out process, after the broken screw is clamped and fixed, the broken screw is pulled out in an upward lifting mode through a handle, labor is wasted, and the pulling-out efficiency is low.

Owner:付连冲

Ultrasonic counter-current screw extractor for uranium recovery and process therefore

ActiveUS7527772B2Improve efficiencySeparated economicallyShaking/oscillating/vibrating mixersSolvent extractionScrew extractorMixer-settler

An apparatus and method to remove uranium from a body of material wherein the method includes the steps of depositing the body of solid material in an ultrasonic extractor and depositing an amount of acid in the ultrasonic extractor. The method also provides for the steps of heating a jacket of the ultrasonic extractor, transporting the body of solid material in the ultrasonic extractor and the amount of acid such that the body of solid material and the acid contact each other inside the heated ultrasonic extractor while the ultrasonic extractor provides ultrasonic energy to both the body of solid material and the amount of acid, wherein the amount of acid strips uranium from the body of solid material. The method further provides for collecting the amount of acid and the body of solid material in the ultrasonic extractor in different positions, transporting the amount of acid with the stripped uranium to an extraction mixer settler, and settling uranium product from the extraction mixer settler.

Owner:AREVA NP INC

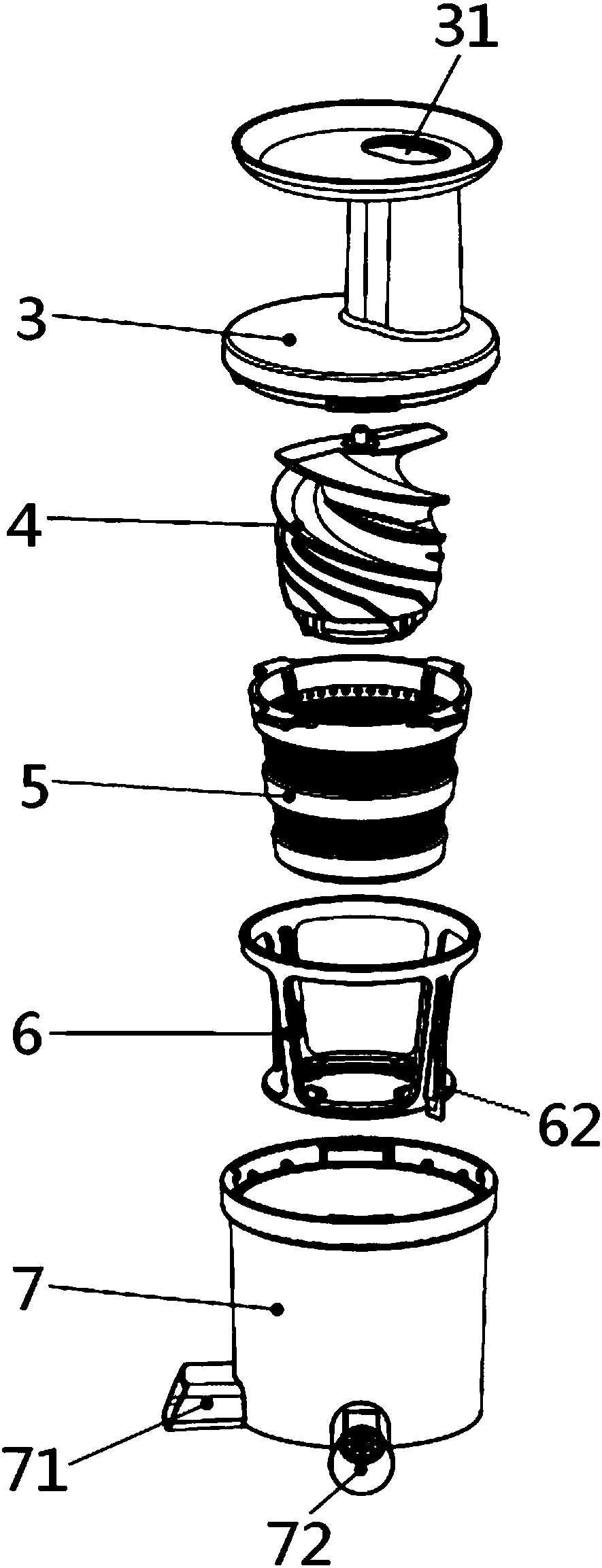

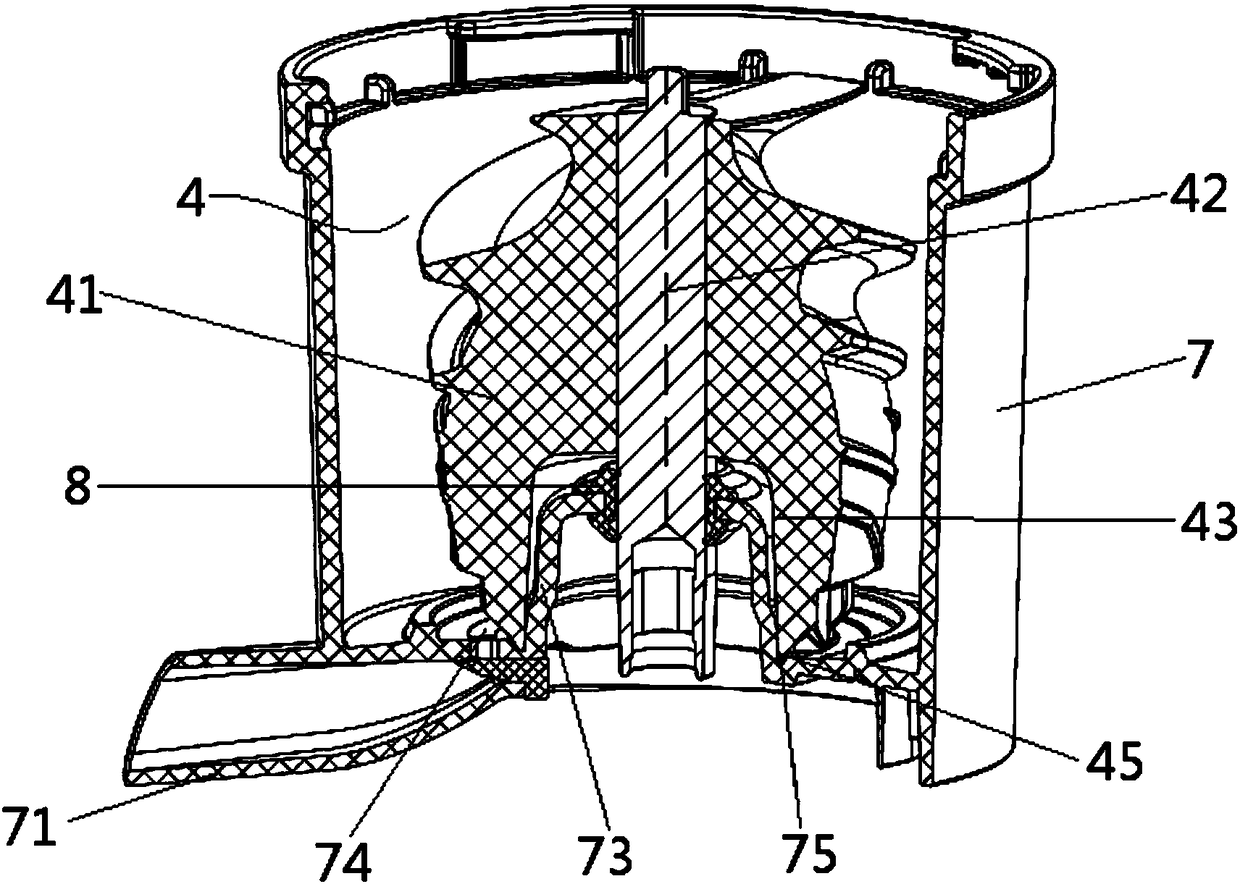

Screw juice extractor

ActiveCN106108589AImprove slagging effectIncrease the juice yieldStrainersScrew extractorEngineering

The invention relates to a screw juice extractor. The screw juice extractor comprises a screw (4) used for squeezing materials and a juice collecting cylinder (7) for accommodating the materials, and a sealing structure is arranged in a mutually matched position of the bottom surface of the screw (4) and the juice collecting cylinder (7) for preventing squeezed material residues from entering into an inner cavity of the screw (4) from the mutually matched position of the bottom surface of the screw (4) and the juice collecting cylinder (7). The screw juice extractor disclosed by the invention can prevent the squeezed material residues from entering into the inner cavity of the screw from the mutually matched position of the bottom surface of the screw and the juice collecting cylinder through the sealing structure, so that the residue discharging effect of the screw juice extractor can be optimized, and the juice yield is improved, furthermore, the material residues can be prevented from being accummulated in the inner cavity of the screw or flowing into the main machine body of the screw juice extractor to the greatest extent to reduce the cleaning workload of a user and optimize the experience effect of the user.

Owner:GREE ELECTRIC APPLIANCES INC

High-strength screw extractor

InactiveCN103406877AImprove connection strengthAvoid damageMetal-working hand toolsScrew extractorEngineering

The invention discloses a high-strength screw extractor. The high-strength screw extractor comprises a large head and a handle which is integrally connected with the rear end of the high-strength screw extractor, cutting edges are formed on the large head, and threads are formed on the surface of the large head. The high-strength screw extractor has the advantages that the threads are formed on the large head portion where the screw extractor acts on a screw so that more fastness are achieved when the high-strength screw extractor is connected with the screw, the connecting strength of the screw extractor is improved, meanwhile the acting force during striking can be reduced, the damage to the high-strength screw extractor can be reduced, the service life is prolonged, and more convenience and reliability during usage can be obtained.

Owner:DANYANG CITY EAGLE TOOLS

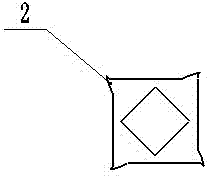

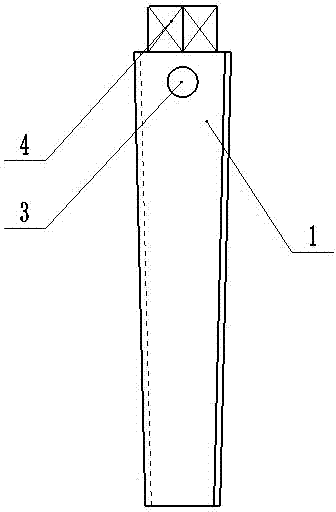

Screw extractor

InactiveCN105818098AEasy to replaceSimple structureMetal-working hand toolsScrew extractorEngineering

The invention relates to a screw extractor, and belongs to the technical field of mechanical assembly. The screw extractor comprises a screw extractor body. The top of the screw extractor body is connected with an extension rod through a connector. A square clamping block is arranged on the top of the extension rod. The top of the square clamping block is connected with a connecting handle. The connecting handle is provided with a clamping opening corresponding to the square clamping block. A screw extraction vessel is arranged on one side of an inner cavity of the connecting handle. One side of the screw extraction vessel is connected with a vessel cover through a movable rotating shaft. A handle is further arranged on one side of the vessel cover. A reverse thread is further arranged on the screw extractor body. A drill bit is arranged at the bottom of the screw extractor body. A detached screw or a screw needing to be installed can be stored through the screw extraction vessel. When the screw is needed or placed, the vessel cover can be pulled open directly through the handle. Meanwhile, a detachable structure is adopted in the connecting handle and the square clamping block, corresponding screw extractors can be conveniently selected for screws of different types, replacing is convenient, the structure is simple, and practicability is high.

Owner:ZAOZHUANG POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +1

Broken-end screw taking-out device

The invention relates to an end breaking screw extractor which comprises a clamping rack, a retaining clamping mould, a movable clamping mould, a fixed bar, a movable bar and a screw-threaded bar. Compared with the prior art, the invention keeps the threaded hole dimension on one hand, and realizes easiness in use and simplicity of operation on the other hand.

Owner:上海神模电气有限公司

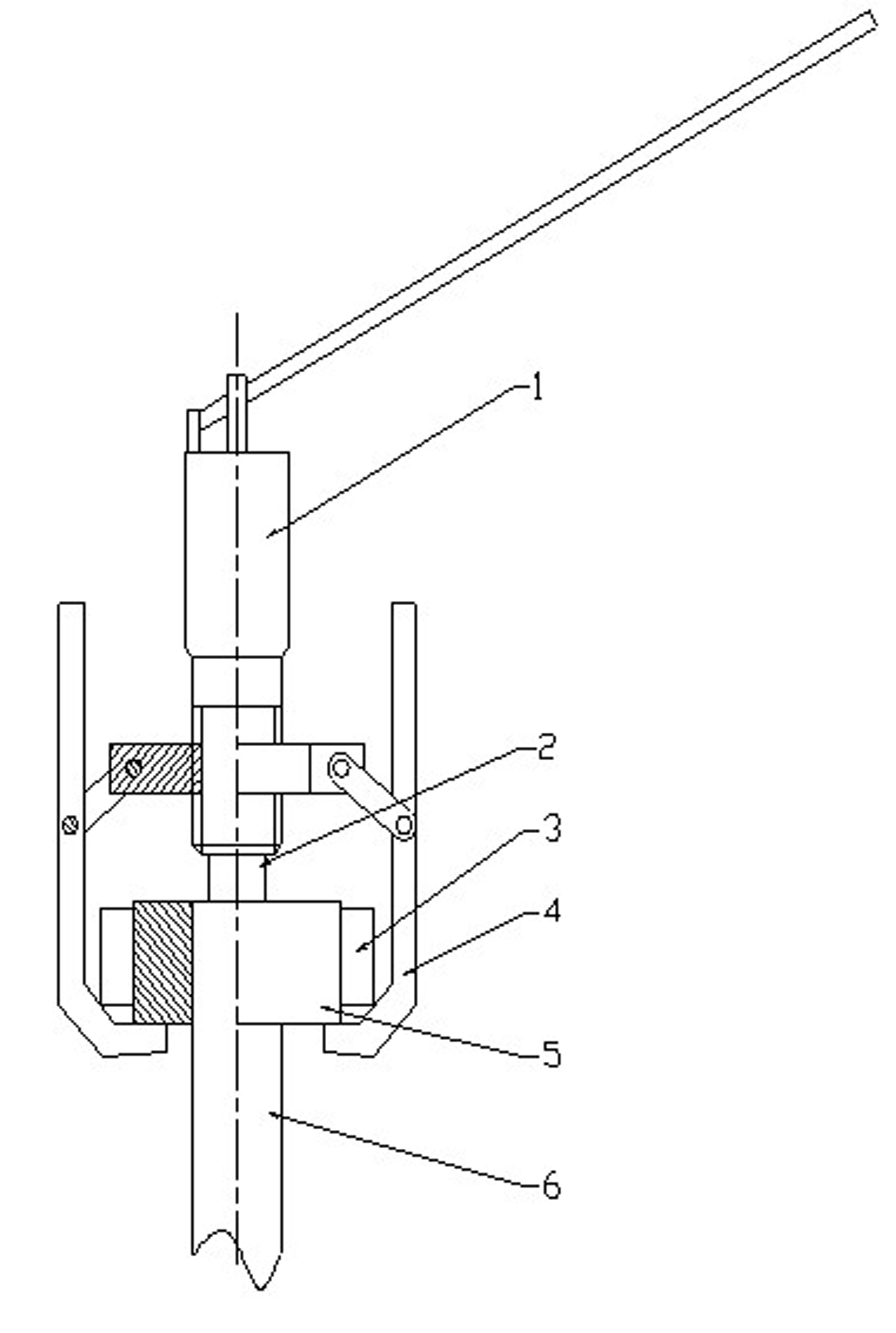

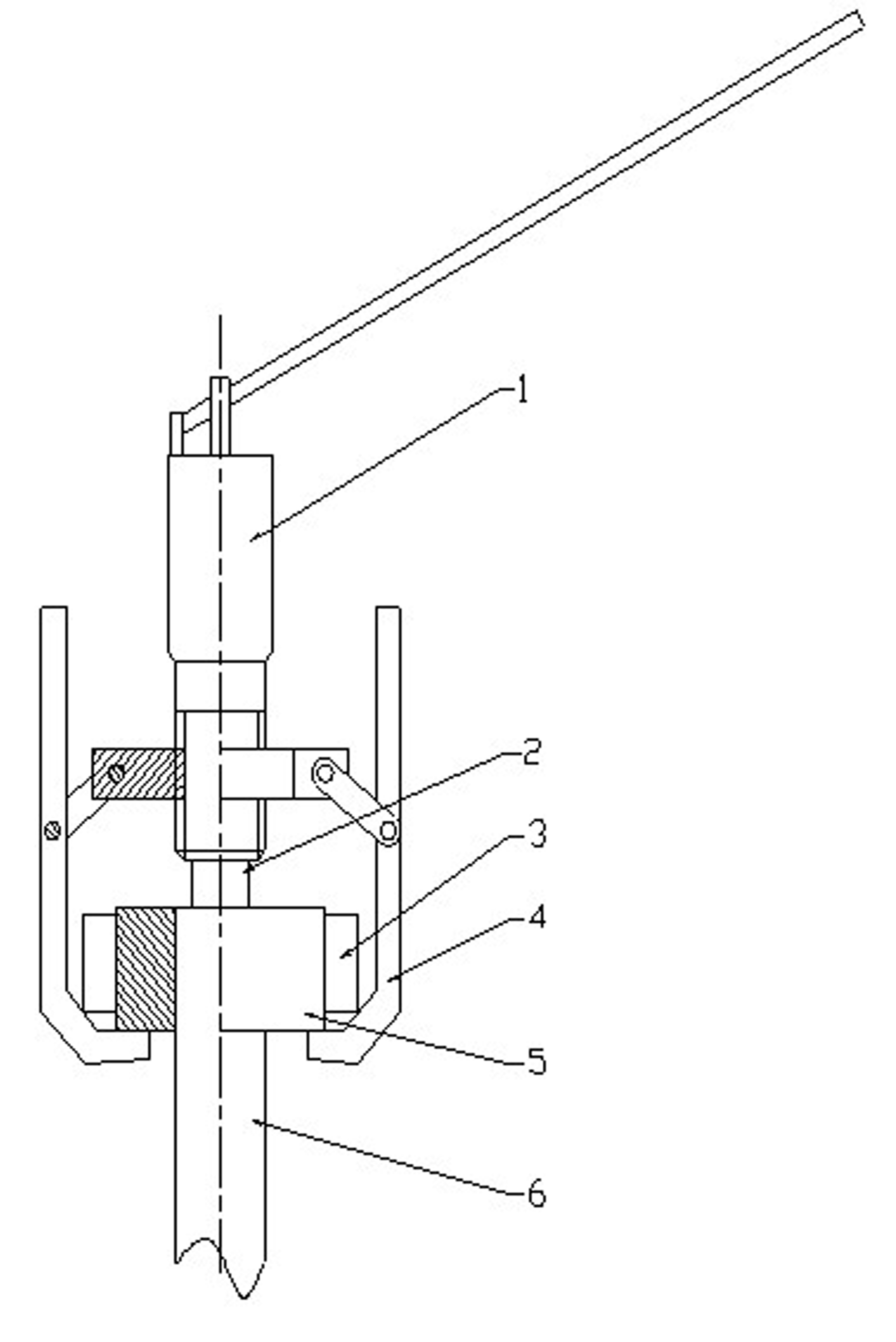

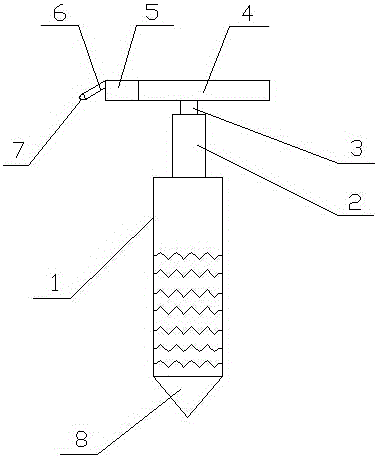

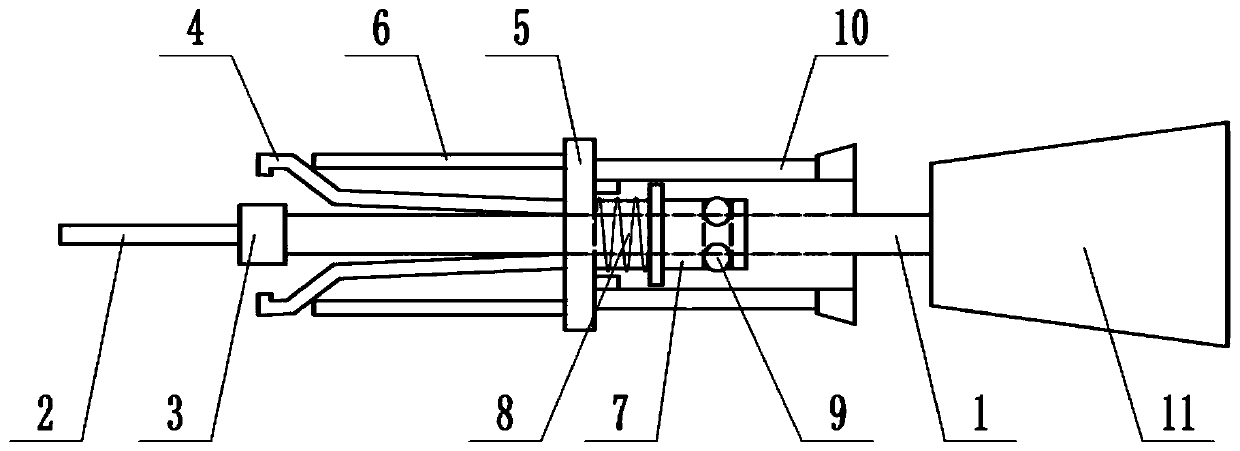

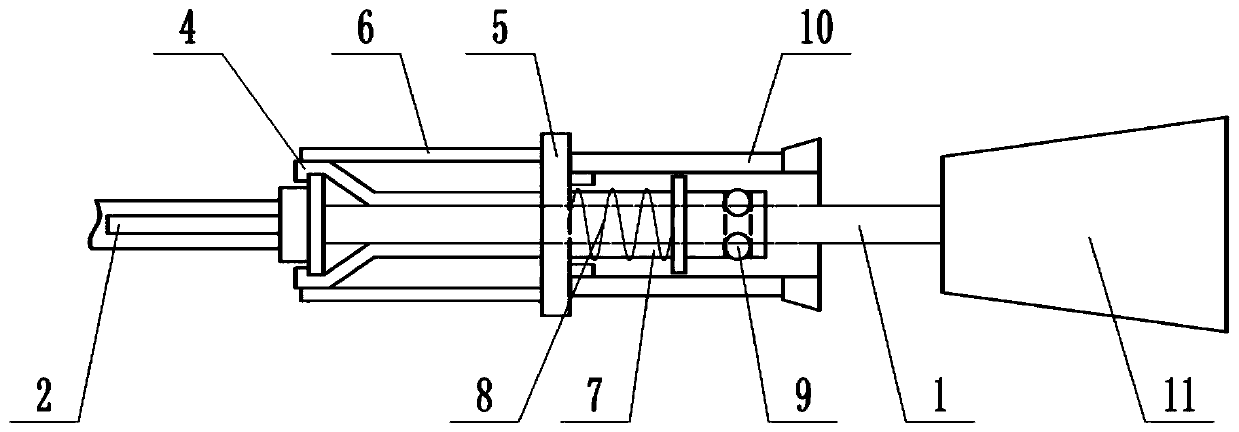

Minimally invasive centrally-mounted hollow screw extractor

The invention discloses a minimally invasive centrally-mounted hollow screw extractor, and relates to the related technical field of hollow screws for operations. An annular groove is arranged in themiddle of a polished rod; a guide rod is arranged at the front end of the polished rod and used for inserting a hollow nail; a clamping block is arranged at the joint of the polished rod and the guiderod; a clamping sleeve is arranged on the polished rod, and a buckle corresponding to the clamping block is arranged at the front end of the clamping sleeve; a push plate is movably arranged on the outer side of the polished rod; a sleeve is arranged at the front end of the push plate and used for controlling opening and closing of the buckle; a sliding block is movably arranged on the outer sideof the polished rod, and a ball hole communicated with the inner cavity is formed in the rear end of the sliding block; one end of a spring is connected with the polished rod, and the other end of the spring is connected with the rear end of the push plate; a ball is arranged in the ball hole of the sliding block; and a push sleeve is arranged on the outer side of the polished rod and the outer side of the sliding block and installed at the rear end of the push plate. The invention has the following beneficial effects that: when the clamping block and the clamping sleeve are combined, the endof the hollow nail can be fixed; then the hollow nail can be taken out through a grab handle; and the whole operation process is minimally invasive, convenient and rapid.

Owner:青岛山大齐鲁医院(山东大学齐鲁医院(青岛))

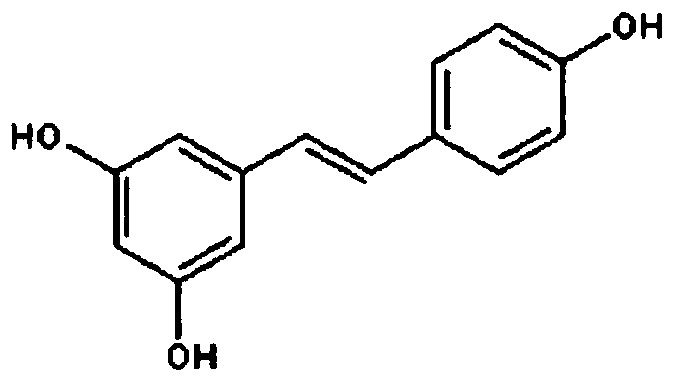

A method for extracting resveratrol from Polygonum cuspidatum

ActiveCN104946689BHigh yieldIncrease productivityOrganic chemistryOrganic compound preparationScrew extractorPOLYGONUM CUSPIDATUM

The invention discloses a method for extracting resveratrol from polygonum cuspidatum. The method comprises the operation steps of smashing, fermentation, extraction, primary concentration, secondary concentration, and drying and smashing. The temperature in the fermentation process is controlled between 30 DEG C and 40 DEG C, the fermentation lasts 4-6 days, extraction is conducted three times through a continuous type countercurrent screw extractor, further purification is conducted through the primary concentration and the secondary concentration, the yield of resveratrol is 0.9%, the purity is 99%, the fermentation time is greatly shortened, the production efficiency is improved, and the production process is simplified.

Owner:四川维尔仕生物科技有限公司

Screw loose screw extractor

The invention discloses a screw loose screw extractor. The screw loose screw extractor comprises a supporting frame and is characterized in that guide slots are symmetrically formed in the two sides of the supporting frame, wherein a through hole is formed in the upper part of the supporting frame; a pair of screw extracting pliers are arranged in the through hole; and a clamping mechanism which can guide, rotate and clamp the pair of screw extracting pliers, is movably arranged in the guide slots and is used for clamping the screw extracting pliers and orientating the rotation of the screw extracting pliers. The screw loose screw extractor is convenient for the labor-saving extraction of screws and is simple in structure and convenient to use.

Owner:GUANGDONG KNOWLEDGE CITY OPERATION SERVICES CO LTD

screw juicer

ActiveCN106108589BImprove slagging effectIncrease the juice yieldStrainersScrew extractorEngineering

The invention relates to a screw juice extractor. The screw juice extractor comprises a screw (4) used for squeezing materials and a juice collecting cylinder (7) for accommodating the materials, and a sealing structure is arranged in a mutually matched position of the bottom surface of the screw (4) and the juice collecting cylinder (7) for preventing squeezed material residues from entering into an inner cavity of the screw (4) from the mutually matched position of the bottom surface of the screw (4) and the juice collecting cylinder (7). The screw juice extractor disclosed by the invention can prevent the squeezed material residues from entering into the inner cavity of the screw from the mutually matched position of the bottom surface of the screw and the juice collecting cylinder through the sealing structure, so that the residue discharging effect of the screw juice extractor can be optimized, and the juice yield is improved, furthermore, the material residues can be prevented from being accummulated in the inner cavity of the screw or flowing into the main machine body of the screw juice extractor to the greatest extent to reduce the cleaning workload of a user and optimize the experience effect of the user.

Owner:GREE ELECTRIC APPLIANCES INC

Nail remover for orthopedic surgery

The invention discloses a screw extractor for an orthopedic surgery. The screw extractor comprises a screw extracting tube, holding tubes, a dilator, holding clamps, conical teeth, tooth clamp convex sections, arc-shaped chucks, a driver bar and a dilating ball joint, wherein the dilator is arranged in the screw extracting tube through limit threads in a screwing manner; the holding tubes are arranged at the outer part of the screw extracting tube through fastening threads; handles are arranged at the outer sides of the upper end of the screw extracting tube, and the limit threads are arranged at the inner side of the upper end of the screw extracting tube; a plurality of holding clamps and holding clamp grooves are arranged at and formed in the lower end of the screw extracting tube; the arc-shaped chucks and the conical teeth are arranged at the lower ends of the corresponding holding clamps; one tooth clamp convex section is arranged at the inner side of each holding clamp; the driver bar is arranged at the lower end of the dilator; the dilating ball joint is arranged in the middle of the dilator; the dilating ball joint is moved by the dilator through the limit threads; the dilating ball joint pushes away the tooth clamp convex sections and drives the holding clamps to dilate; a bone screw cap is clamped and fixed by the plurality of arc-shaped chucks. According to the screw extractor disclosed by the invention, the screw cap is fixed by the arc-shaped chucks and the conical teeth; screws can be quickly and conveniently taken out and are prevented from sliding out of the groove, so that pains of a patient are relieved, and the efficiency of the surgery is improved.

Owner:SUZHOU SUNAN ZIMMERED MEDICAL INSTR

Bamboo powder-high density polyethylene composite materials and process for preparing same

The invention relates to a bamboo powder - high-density polyethylene composite and its process for preparing, which consists of granulating in the twin-screw extruder after kneading the raw material components comprising bamboo powder, high-density polyvinyl resin, polyethylene oxide and geoceric acid, then obtaining the product by squeezing the master batch in the single screw extractor. The external appearance of the invented bamboo powder - high-density polyethylene composite is close to the wood, and the invented product has good fire-retardancy. By changing different dies, complex-shaped products can be prepared and is capable of boring, digging and nailing. The product of this invention is of no release of formaldehyde, of nice appearance, good handle, no warp, excellent resistance to aging, and so it has a prodigious superiority outside, for example, it can be used as marine landscape materials such as corridor, sunshade, baluster and movable dwelling.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com