Broken screw extractor

A technology for extractors and screws, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of easy breakage of screws, difficult screws, and damage to threads, etc., and achieves the effect of convenient use and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

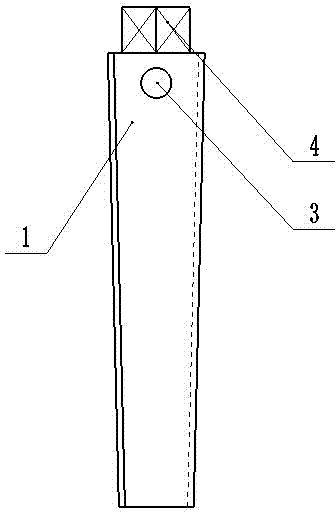

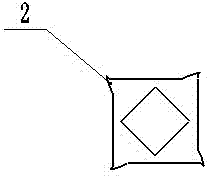

[0013] Such as figure 1 , figure 2 As shown in the present invention, the broken screw extractor includes a body 1 and a mouth 2, the body 1 gradually becomes thicker from bottom to top, the arbitrary cross section of the body 1 is a regular polygon, and the edge of the body 1 is provided with a protruding mouth 2 , the tooth opening 2 is in the same direction, the upper part of the big end of the body 1 is provided with a hole 3, and the end of the big end of the main body 1 is provided with a handle 4, and the handle 4 is either in the shape of a cuboid, or has two sides milled into a plane Cylindrical.

[0014] First drill a hole in the deadhead screw, and then use a hammer to hammer the lower end of the deadhead screw extractor into the pre-drilled deadhead screw, so that the tooth mouth 2 on the body 1 is embedded in the deadhead screw body, and in the upper hole 3 of the body 1 Insert any applicable metal cross bar, screw the cross bar, or screw the handle 4 at the en...

Embodiment 2

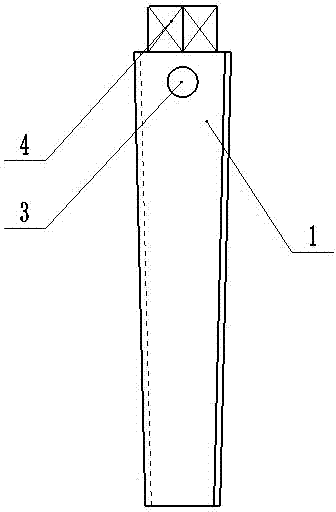

[0016] Such as image 3 , Figure 4 Shown the present invention, its structure except that the direction of tooth opening 2 is opposite to embodiment 1, and all the other structures are identical with embodiment 1, and are used for taking out the dead end screw whose thread direction is opposite to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com