Patents

Literature

99results about How to "Improve slagging effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Granular heat-preserving covering flux for hot metal in steelmaking

InactiveCN101787413AConducive to slag cleaning operationImprove adsorption capacityProcess efficiency improvementSteelmakingImpurity

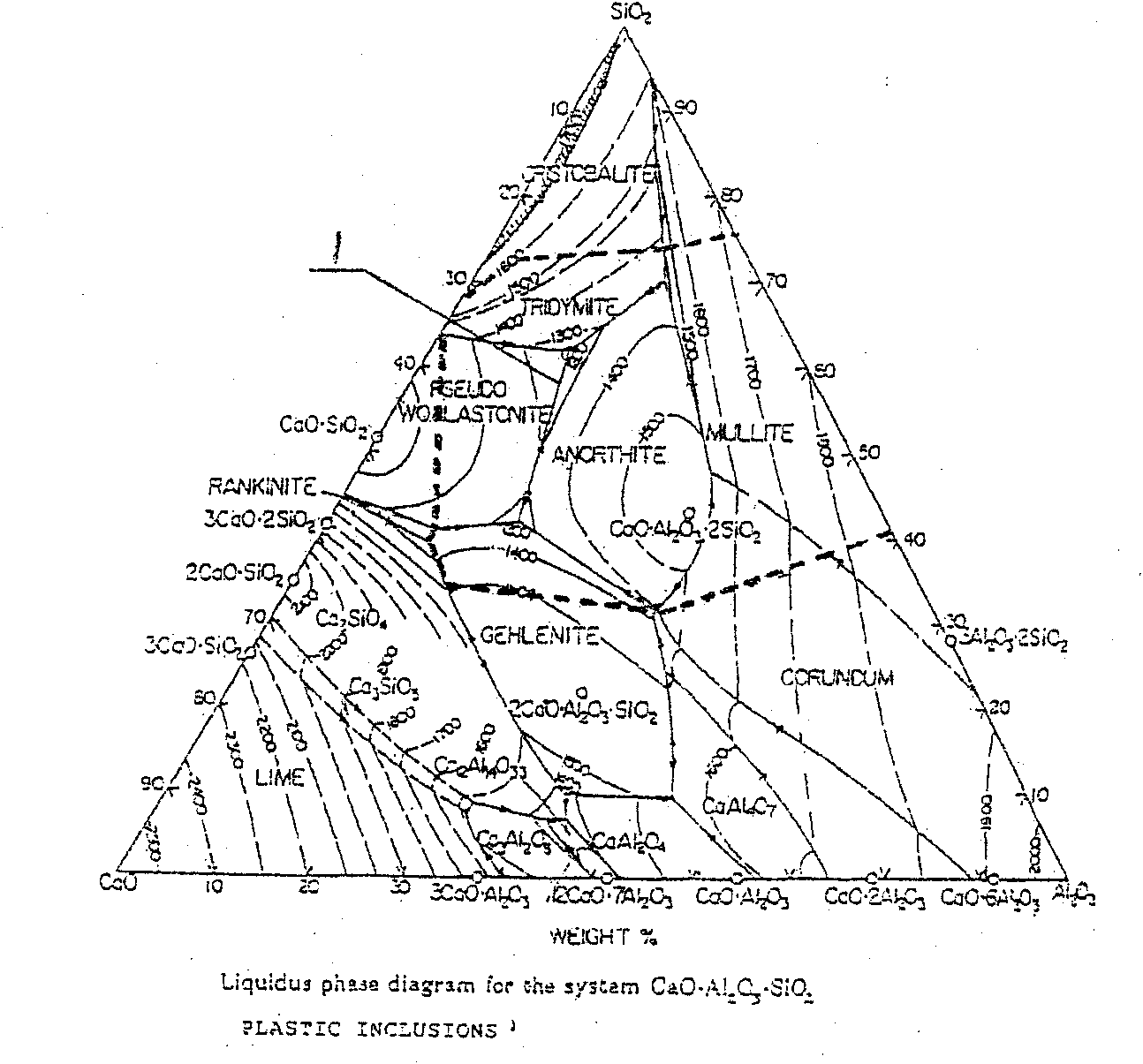

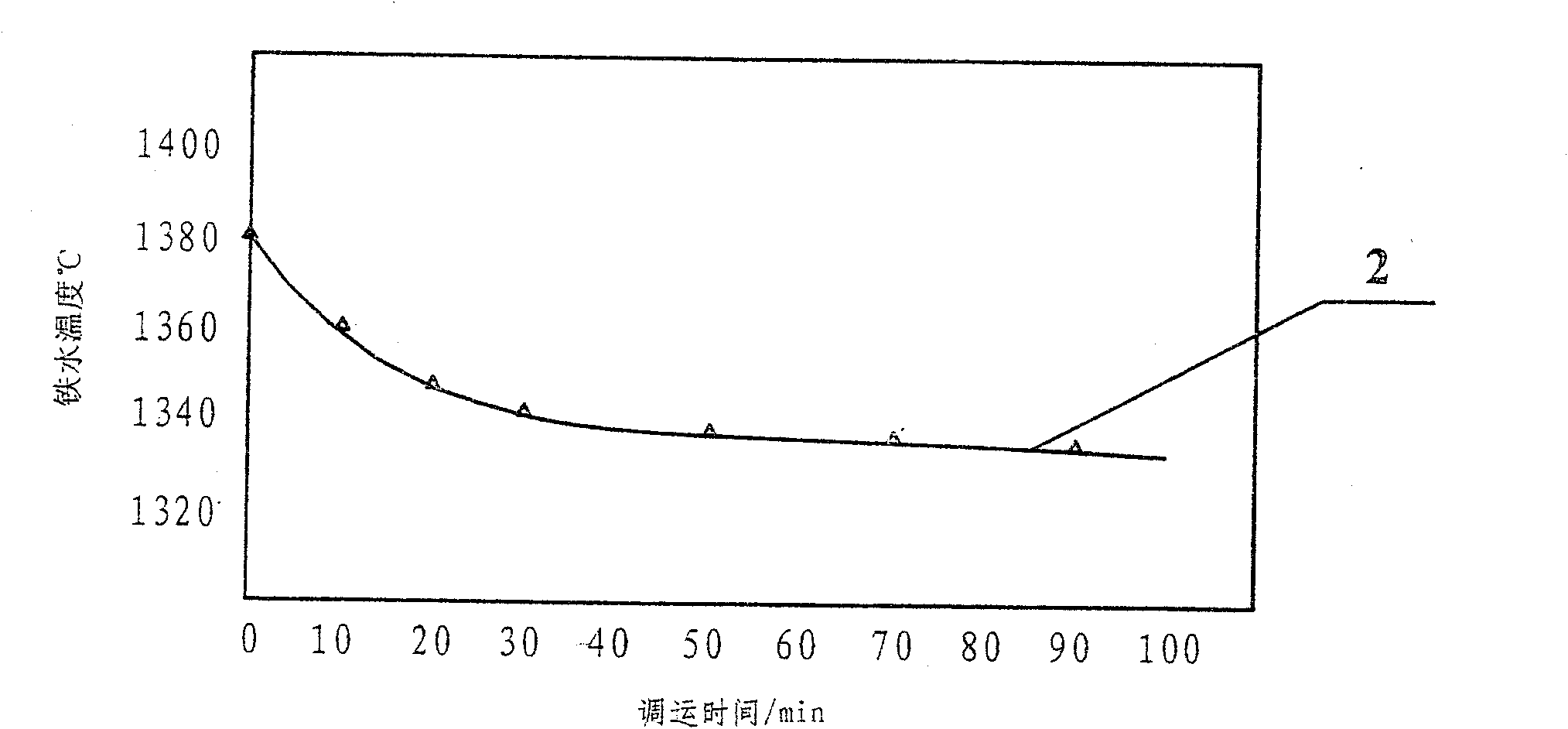

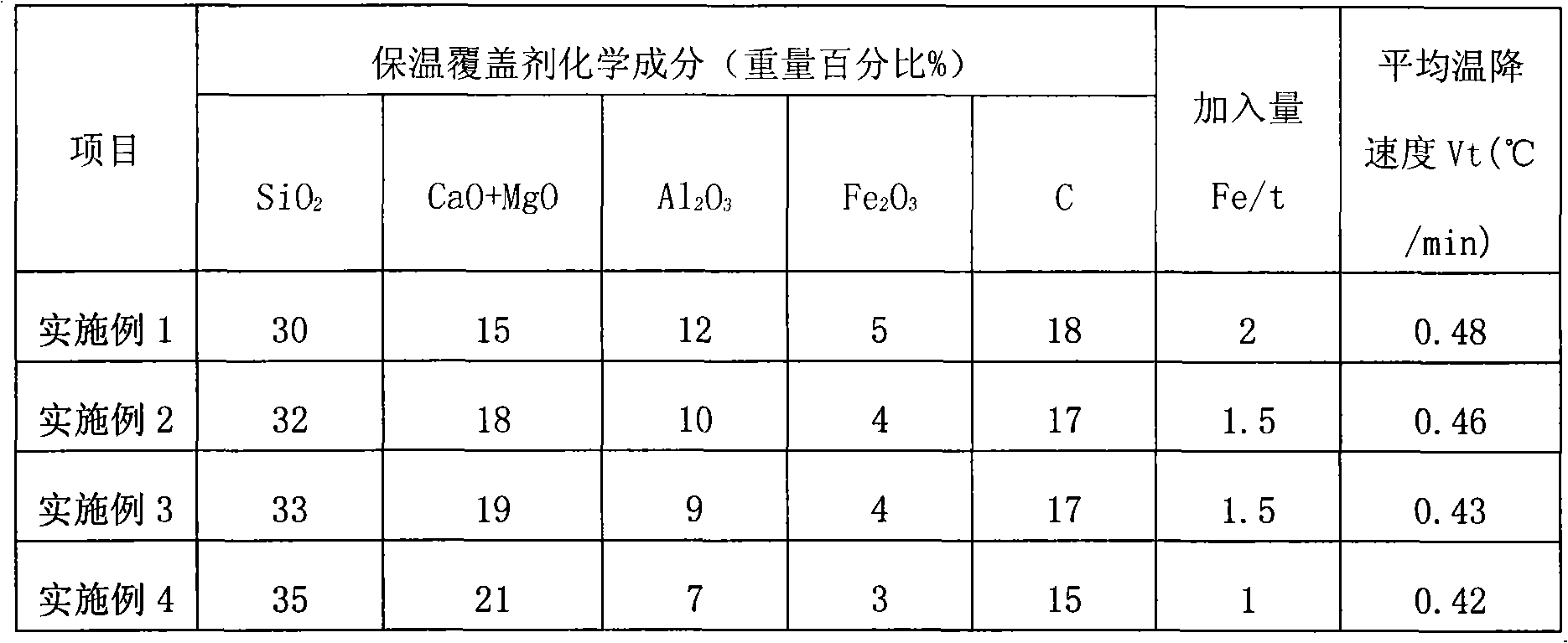

The invention discloses a granular heat-preserving covering flux for hot metal in steelmaking, and relates to a treatment agent added into a ladle for preserving heat on the surface of hot metal for steelmaking. The granular heat-preserving covering flux is characterized in that: the heat-preserving covering flux is prepared from expanded vermiculite, wollastonite, bauxite, iron ore concentrate and coke powder, and comprises the following components in percentage by weight: 30 to 35 percent of SiO2, 15 to 21 percent of (CaO+MgO), 7 to 12 percent of Al2O3, 3 to 5 percent of Fe2O3, 15 to 20 percent of C, and the balance of impurities; and the raw materials are ground, sieved, mixed, mixed and stirred, dried, cooled, and weighed and packaged at normal temperature and normal pressure. The granular heat-preserving covering flux has the advantages that: the granular heat-preserving covering flux has good slagability and spreadability, is conveniently adsorbed by inclusion, contains a heat-generating agent and an oxygen supplying agent so as to facilitate melting per se and reduce iron sticking and ladle sticking; the expanded vermiculite and the wollastonite regulate components of the heat-preserving covering flux, and have expanding and heat insulating functions, and good heat preservation property; the MgO regulates the alkalinity and reduces the adhesion of the heat-preserving covering flux with a ladle lining so as to facilitate cleaning slag in the ladle; and the heat-preserving covering flux is granular and greatly reduces dust pollution.

Owner:马鞍山中冶钢铁冶金高新技术有限公司

Method for utilizing sulfur-containing refining waste residue for refining slag

InactiveCN101717843AGive full play to the maximum utility valueImprove cleanlinessProcess efficiency improvementCalcium/strontium/barium oxides/hydroxidesCalcium hydroxideSlag

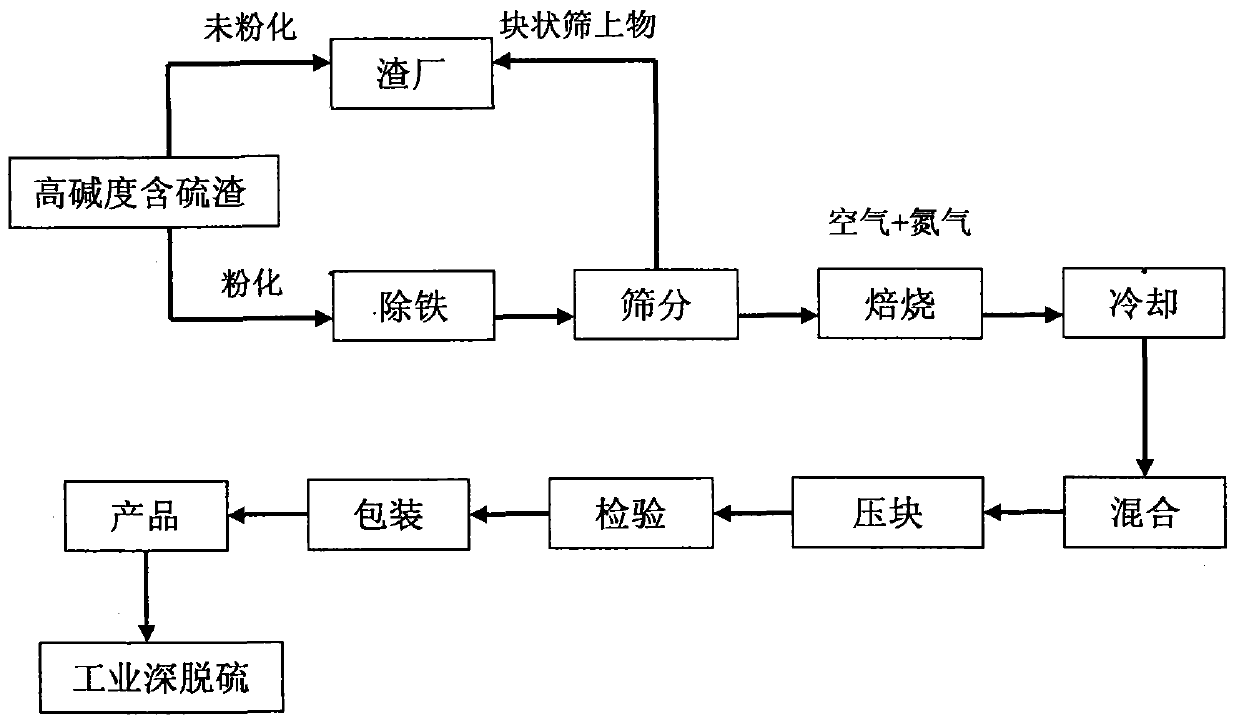

The invention relates to a method for recycling sulfur-containing refining waste residue generated in the process of liquid steel refining for refining slag, which is characterized by taking cooling pulverization pretreatment fine powders, roasting the sieving fine powders in the weak oxidizing atmosphere that an oxygen partial pressure is between 0.08 and 0.15atm at a temperature of more than or equal to 1100 DEG C to convert a harmful component CaS to an effective component CaO so as to remove sulfur impurities, and decomposing calcium hydroxide. In the method, the recycling of the sulfur-containing refining waste residue is directly used for reusing the refining slag with high utilization value, and the maximum utility value of the abandoned sulfur-containing refining slag is fully exerted. Compared with the conventional technology application, the invention can increase the value added for each ton of the abandoned sulfur-containing refining slag by more than 800 RMB. Moreover, the sulfur in the sulfur-containing refining waste residue is removed by a simple oxidizing and roasting process to guarantee the cleanliness of the recyling product, the liquid steel resulfurization can not be caused in the recycling process of carrying out the liquid steel desulfuration, the cumulative effect of the sulfur can not be generated in the metallurgy process, and a novel way of recycling the sulfur-containing refining slag is developed.

Owner:NORTHEASTERN UNIV +1

Low-density high manganese steel with high product of strength and elongation

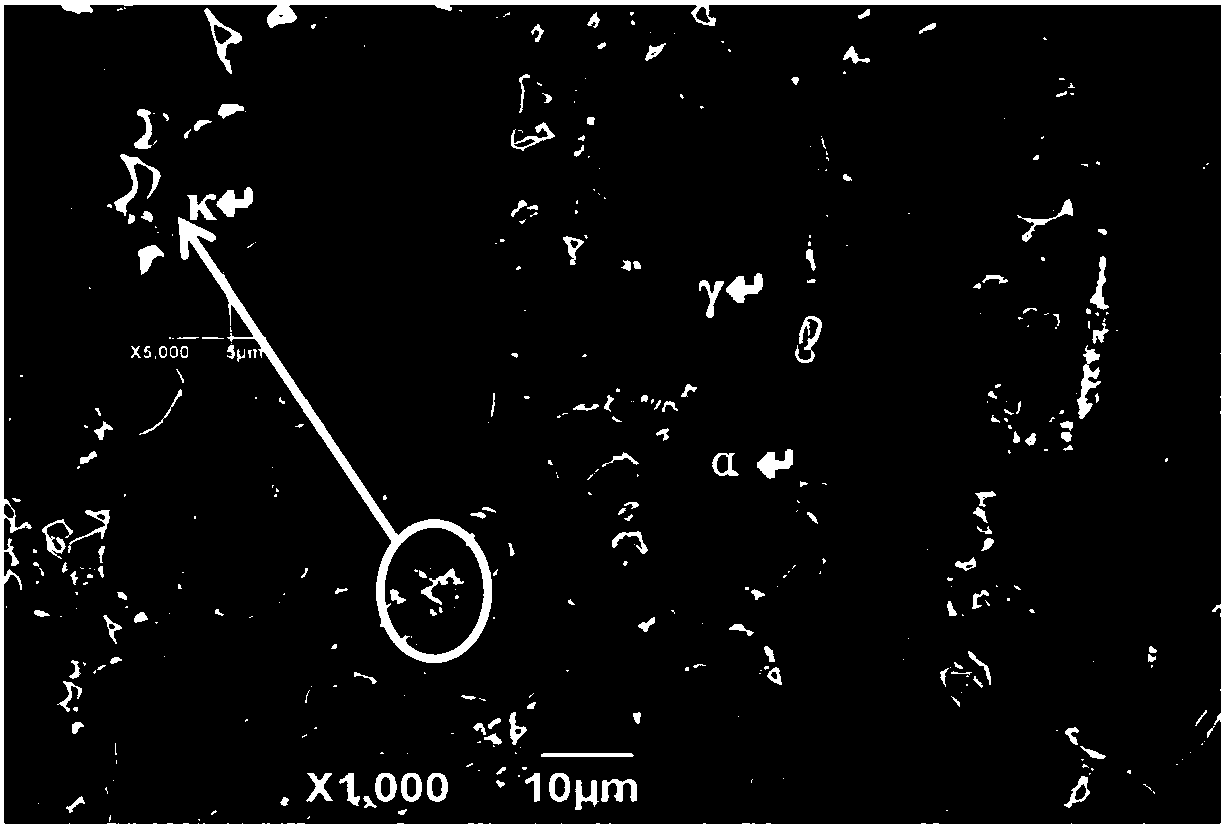

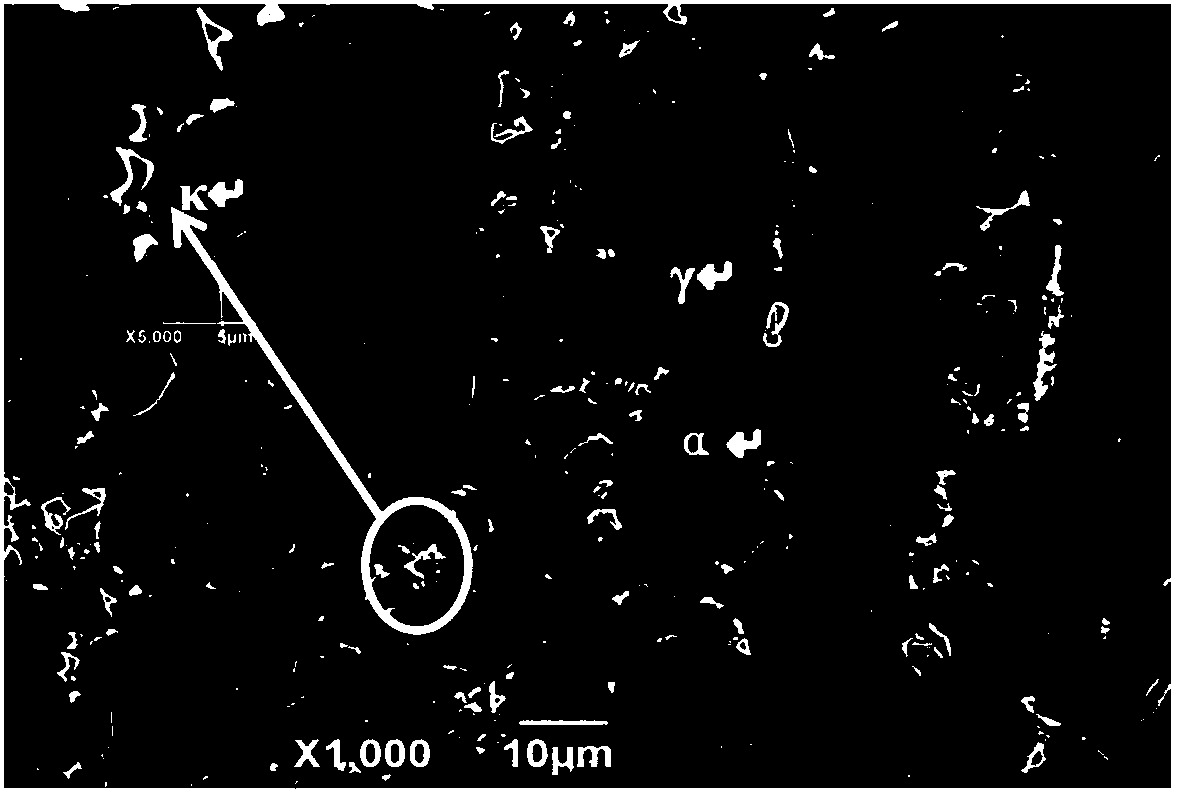

InactiveCN107641763AHigh strengthImprove plasticityProcess efficiency improvementSolution treatmentCarbide

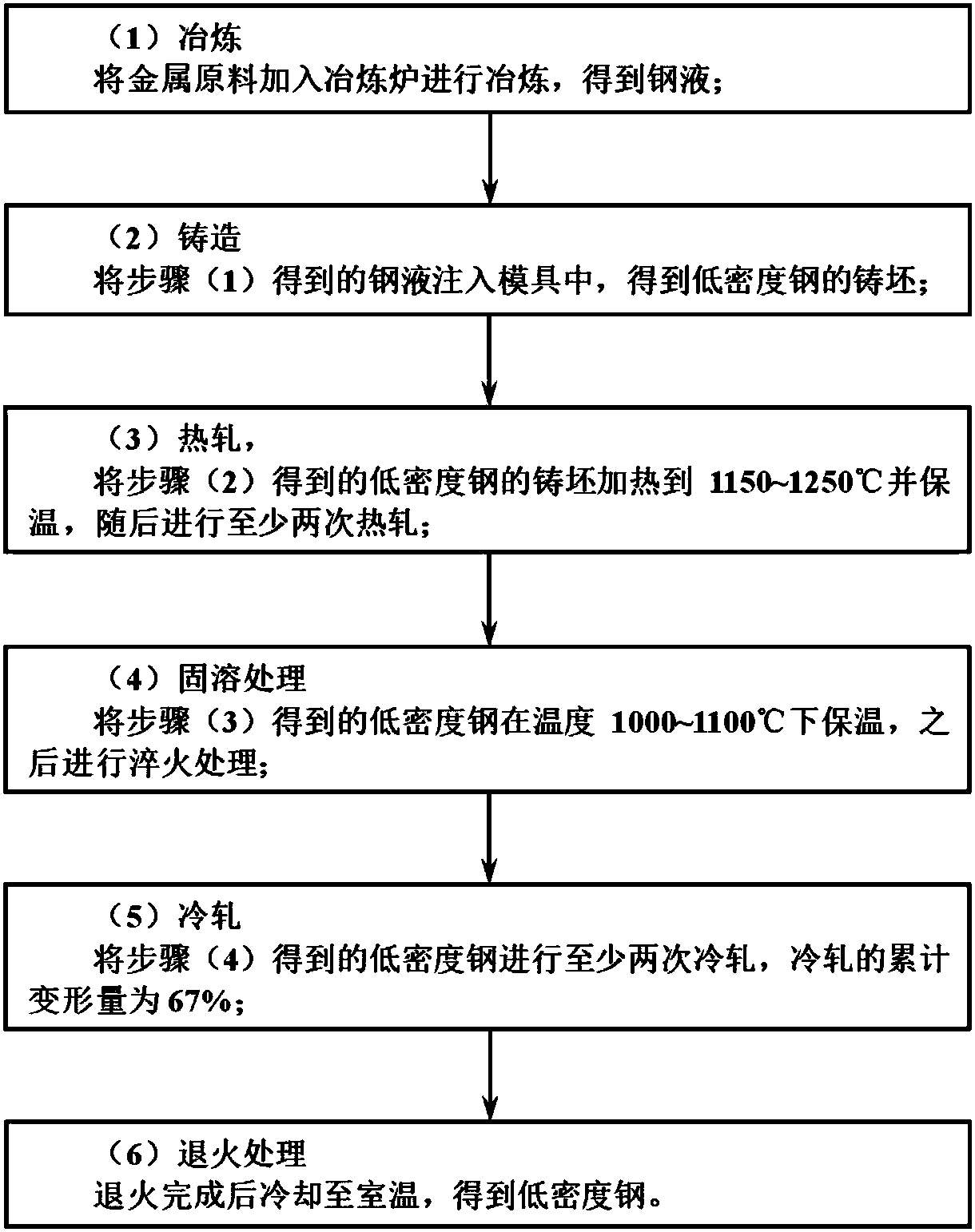

The invention provides low-density high manganese steel with high product of strength and elongation, and belongs to the field of low-density steel. The sum of the mass percents of Mn and Al in low-density steel exceeds 28%. The low-density high manganese steel is prepared through the following steps: smelting, namely, smelting on the basis of the alloy component system; casting; hot rolling, namely, heating a casting blank to be 1150-1250 DEG C; maintaining the temperature; then performing hot rolling at least twice; performing solution treatment, namely, maintaining the temperature of 1000-1100 DEG C of the casting blank, and then quenching; cold rolling, namely, performing cold rolling on the obtained low-density steel at least twice; annealing and then cooling to obtain the low-densitysteel. According to the low-density high manganese steel with high product of strength and elongation, a certain amount of Al is added to the steel, and the alloy component and the processing technology are adjusted, so as to obtain Fe-Mn-Al-C series low-density steel; the low-density steel is of an appearance of an austenite, ferrite and k carbide multi-phase structure, so that the low-density steel is high in strength and high in plasticity.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Continuous casting crystallizer casting powder special for bar plate stainless steel containing titanium and manufacturing technique thereof

The invention relates to an auxiliary product for metallurgy used for continuous casting of titanium-containing stainless steel in the metallurgy field, which is mainly applied in the mould powder technique of pre-melted crystallization mould of continuous casting for high titanium containing stainless steel. The materials of the invention comprise: specific used pre-melted base materials containing boron, flux materials, carbonaceous materials and additives; wherein, the flux materials comprise Li2CO3, Na2CO3, NaF, etc. The invention is characterized by good performance of accommodating and adsorbing titanium inclusion under the condition of meeting requirements for adding no carbon and reducing regrinding of traditional stainless steel; besides, after absorption of inclusion, the viscosity properties and solidification properties of the mould powder can be kept relatively stable, and compared with the import slag, the invention has the advantages of lower caking bleeding rate, casting billet with less surface defect, high anterograde of processing. Besides, the production of the invention has little slag strip; reaction in the crystallization mould is active; spreading property is good.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Preparation method for low-density steel with strength and elongation product larger than 50 GPa.%

The invention relates to a preparation method for low-density steel with the strength and elongation product larger than 50 GPa.%, and belongs to the field of low-density steel. The preparation methodincludes the following steps of smelting, specifically, raw materials are put into a smelting furnace for smelting; casting, specifically, obtained molten steel is poured into a mold, and low-densitysteel ingots are obtained after cooling; hot rolling, specifically, the obtained low-density steel ingots are heated to 1150-1250 DEG C, heat preservation is carried out, and then at least two timesof hot rolling are carried out; solution treatment, specifically, the obtained low-density steel is subjected to heat preservation at the temperature of 1000-1100 DEG C, and quenching treatment is carried out; cold rolling, specifically, the obtained low-density steel is subjected to at least two times of cold rolling; and cooling after annealing treatment. In this way, the low-density steel is obtained. Through regulation of alloy elements and the machining process, the Fe-Mn-Al-C system low-density steel is obtained, and the morphology of the low-density steel is of a multi-phase structure including austenite, ferrite and kappa carbide, so that the low-density steel has high strength and good plasticity, and the strength and elongation product is larger than 50 GPa.%.

Owner:马鞍山学院

High-breathability lost foam coating and preparing method thereof

ActiveCN105268911AGood high temperature breathabilityGood slagging abilityFoundry mouldsFoundry coresSurface-active agentsPolystyrene

The invention provides a high-breathability lost foam coating prepared through cast waste resin sand and a preparing method of the high-breathability lost foam coating. The high-breathability lost foam coating comprises the cast waste resin sand, aluminum silicon series refractory aggregate, crystalline flake graphite, polystyrene resin particles, aluminum powder, an oxidizing agent, fluoride, carbon fibers, a suspending agent, a bonding agent, a surface active agent, a defoaming agent and water. The high-breathability lost foam coating comprises 100 parts of cast waste resin sand, 60-100 parts of aluminum silicon series refractory aggregate, 5-25 parts of crystalline flake graphite, 2-6 parts of polystyrene resin particle, 1-3 parts of aluminum powder, 2-10 parts of oxidizing agent, 1-5 parts of fluoride, 1-5 parts of carbon fiber, 3-10 parts of suspending agent, 5-15 parts of bonding agent, 0.2-0.5 part of surface active agent, 0.5-1.5 parts of defoaming agent and 80-120 parts of water. The cast waste resin sand is used as the main refractory material of the lost foam coating, casting wastes are effectively utilized, the green casting and circulation sustainable principles are met, the problems of carbon defects and contraction defects of the waste resin sand lost foam coating are solved, and good application prospects are achieved.

Owner:GANSU KOCEL CHEM

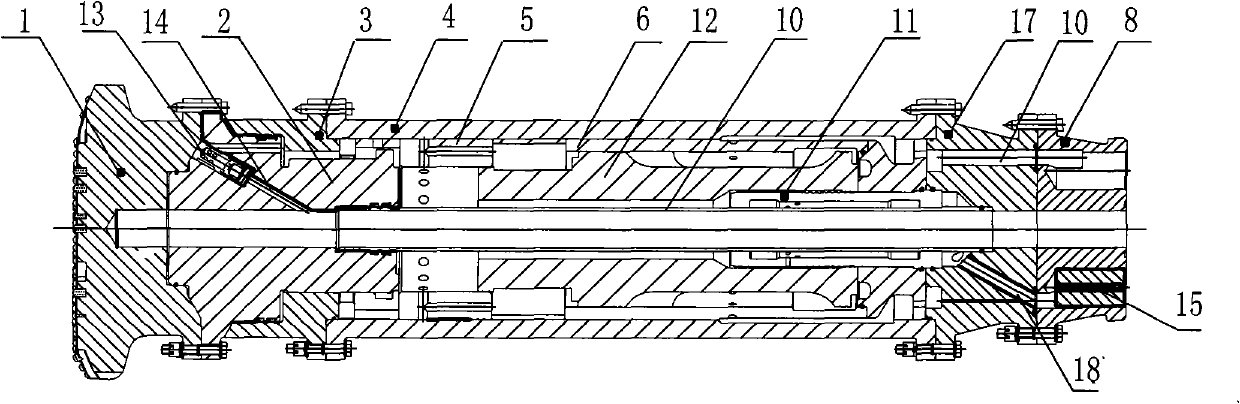

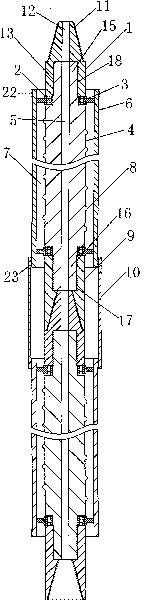

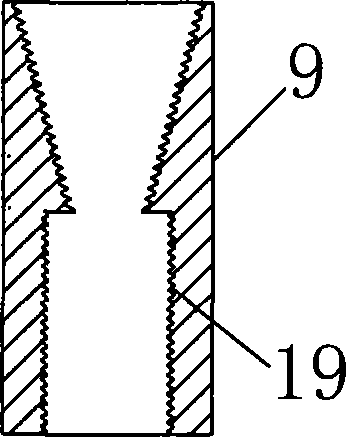

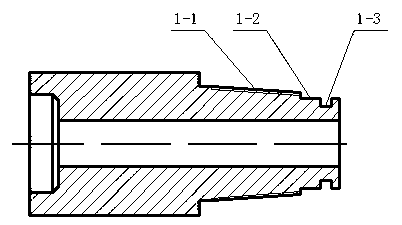

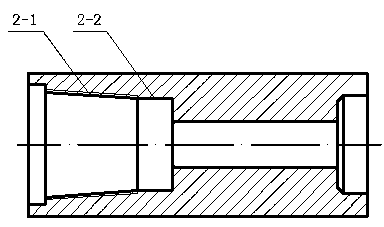

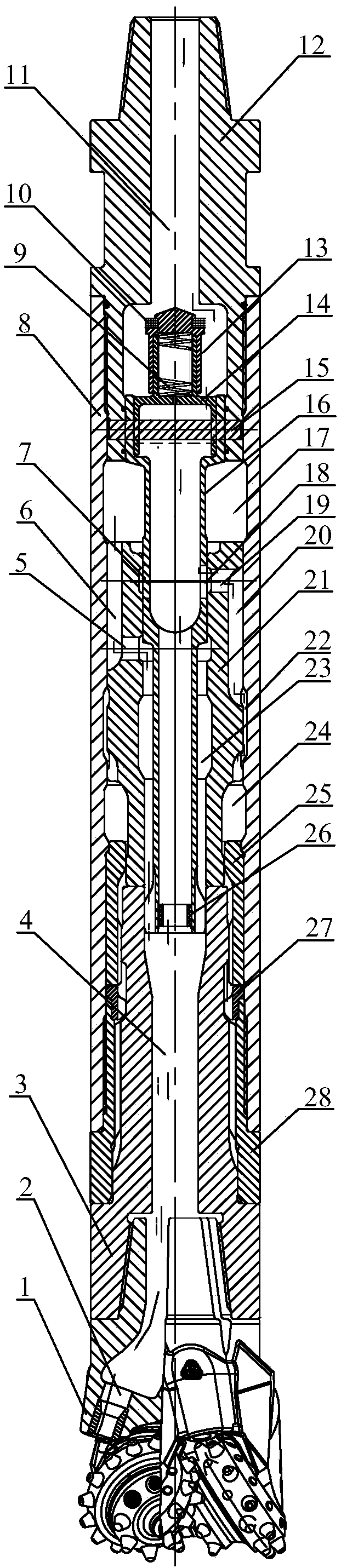

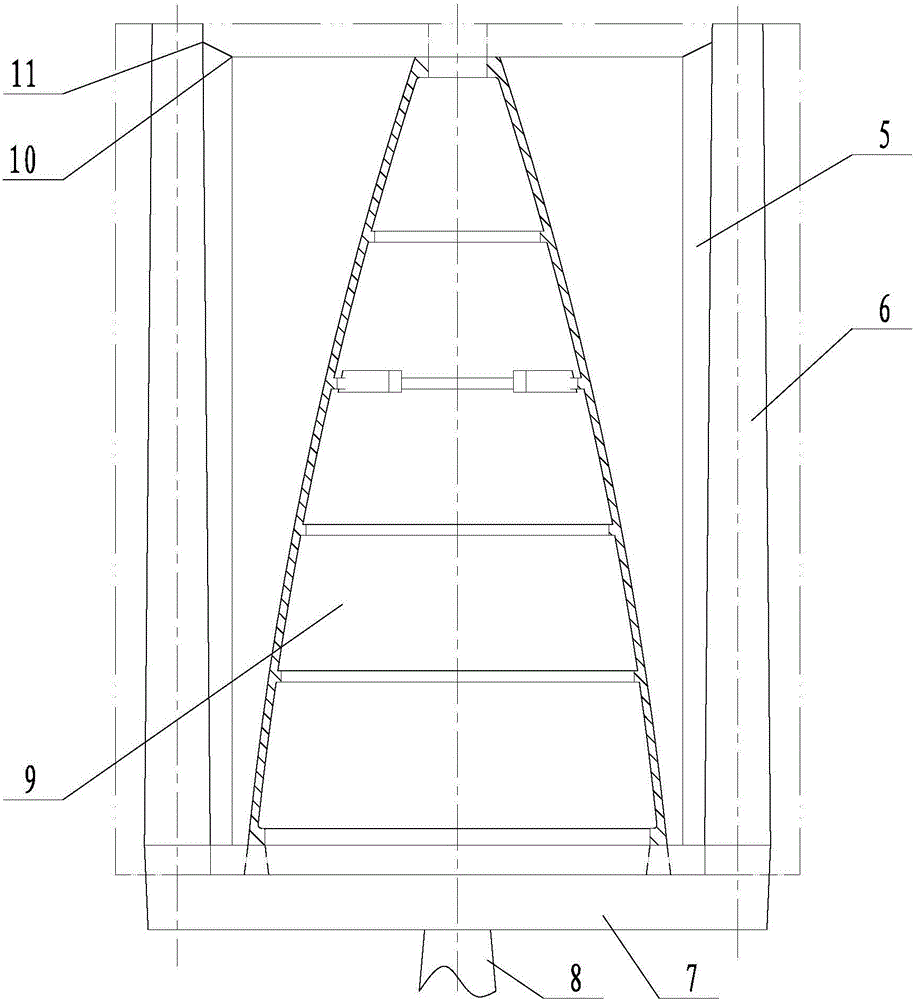

Single body large-diameter pneumatic down-the-hole hammer

ActiveCN102003139AAvoid abrasionsCompact and reasonable structureBorehole drivesStructural engineeringSlurry

The invention relates to a single body large-diameter pneumatic down-the-hole hammer. The single body large-diameter pneumatic down-the-hole hammer comprises a drill, a spline shaft, a spline sleeve, a cylinder body, a gas distribution sleeve, a bush, an upper flange, an intermediate flange, a piston and a central gas pipe which are coaxially connected with one another, wherein the central gas pipe is arranged in an inner hole of the piston and is a double-core pipe; a gas-guide annular groove is formed between an outer core pipe and an inner core pipe of the double-core pipe; an ejecting hole communicated with the inner core pipe is formed on the spline shaft connected with the drill; an exhaust check valve is arranged at an inlet of the ejecting hole; the intermediate flange is providedwith an exhaust channel and an intake channel; and an exhaust throttle valve is arranged in the exhaust channel. The single body large-diameter pneumatic down-the-hole hammer of the invention can achieve good gas lifting reverse circulation slag-absorbing and slag-discharging effects, effectively preventing the abrasion of parts caused by internal movement due to slurry recharge, is compact and reasonable in structure, light in weight and low in manufacturing cost, is convenient to assemble and maintain, and has high working efficiency.

Owner:GUIZHOU AEROSPACE TIANMA ELECTRICAL TECH

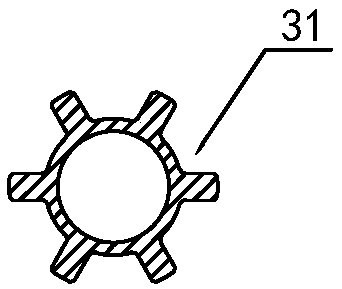

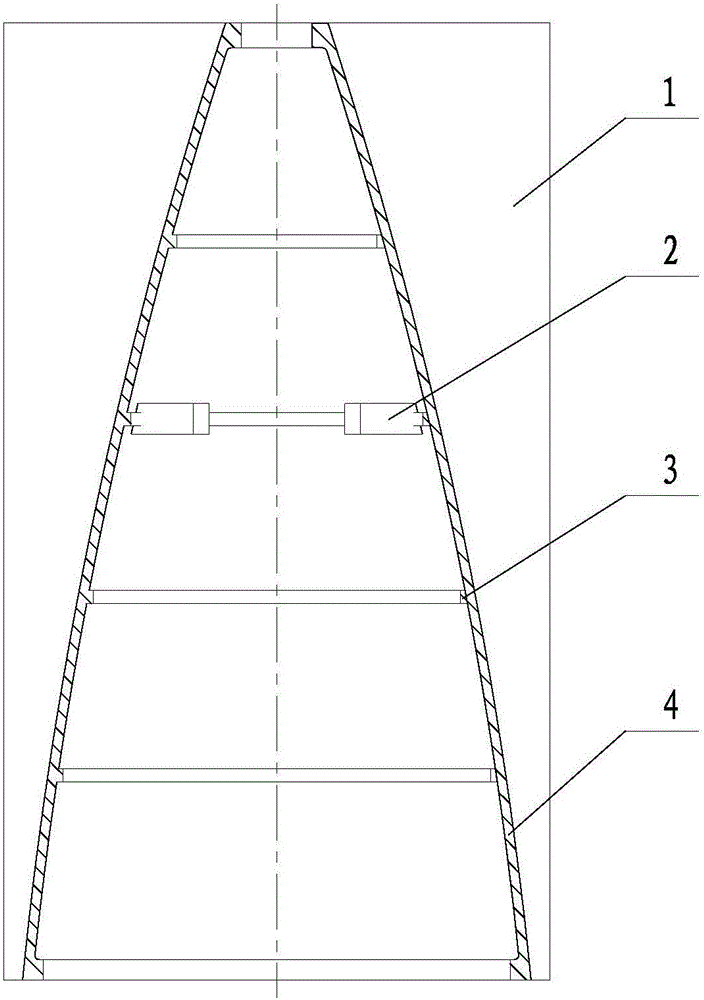

Deep well drilling waterpower deslagging device of floor anchor rod hole of tunnel

InactiveCN101749039AIncrease drilling speedAdd depthShaft equipmentAnchoring boltsInlet channelWell drilling

The invention relates to a deep well drilling waterpower deslagging device of a floor anchor rod hole of a tunnel, which effectively solves the difficulties that the deslagging effect in the drilling process of a floor anchor rod hole drilling device and the increase of the drilling rate of the anchor rod hole is restricted. The invention has the technical scheme that a drill pipe both ends of which extend out of a sleeve is arranged in the sleeve, the upper end of the drill pipe is connected with an upper connector connecting piece, the lower end of the drill pipe is connected with a lower connector connecting piece, the upper end and the lower end of the drill pipe and the sleeve are fixed together via a closed-type bearing and a bearing sleeve connecting piece to form a deslagging structure with a dewatering and deslagging channel, the periphery wall of the drill pipe is provided with a spirally wound annular rib, a water inlet channel is arranged in the drill pipe, and the deslagging structures are connected with each other via a sleeve connecting pipe. The invention has the advantages of simple structure, convenient operation and good deslagging effect, greatly increases the drill rate and hole forming depth of the floor anchor rod, and is innovative on a deslagging device.

Owner:HENAN POLYTECHNIC UNIV

High-pressure water seal dual-power auger stem

ActiveCN102839927ARealize dual power slag dischargeThe overall thickness is thinDrilling rodsDrilling casingsHelical bladeSlag

The invention relates to an auger stem which is used for drilling operation and hydraulic seam cutting in a soft coal seam, in particular to a high-pressure water seal dual power auger stem. A high-pressure water seal dual power auger stem body is formed by sequential connection of a male connector, a rod body and a female connector in a welding mode, and helical blades are welded on the periphery of the male connector, the rod body and the female connector. Dual-power combination of fluid slag discharge (wind power slag discharge or waterpower slag discharge) and mechanical slag discharge are used in the auger stem, the section of each helical blade is in a shape of a pentagon which is formed by the fact that one right angle of a rectangle is chamfered, grinding effect on coal particles of big size can be achieved when a hole is drilled, a sealing ring placed on a straight shaft section of the male connector is closely contacted with an shaft surface of a straight shaft hole section of the female connector of a next auger stem, and accordingly radial seal is achieved, high pressure water of 50 MPa can be borne due to combined action with a tightened taper thread, and leakage is avoided. The high-pressure water seal dual power auger stem is reasonable in design, simple in structure, easy to process, low in cost, safe and reliable, good in slag discharge effect, deep in drilling depth and high in working efficiency.

Owner:CHONGQING UNIV

Method for reducing solvent consumption under slag remaining condition of converter

ActiveCN104388625AMake sure to splash dryReduce consumptionManufacturing convertersProcess efficiency improvementSmelting processOxygen

The invention discloses a method for reducing solvent consumption under a slag remaining condition of a converter. The method comprises the following steps of (1) preparing two bins in a converter region before converter operation, wherein one of the bins is used as a raw dolomite bin, and the other bin is used as a limestone bin; (2) confirming the addition amount of the converter according to steel type and molten iron conditions, wherein the addition amount of raw dolomite in every ton of aluminum killed steel is less than or equal to 12kg, the addition amount of limestone in every ton of aluminum killed steel is less than or equal to 10kg, the addition amount of the raw dolomite in every ton of other kinds of silicon killed steel is less than or equal to 10kg, and the addition amount of the limestone in every ton of other kinds of silicon killed steel is less than or equal to 8kg; (3) adding the limestone along with the first batch of active lime at one step before beginning to blow in the smelting process; and adding the raw dolomite at one step when beginning to blow to the deslagging period; (4) sampling no slag specimen in first converter slag remaining operation during converter pouring for sampling once the blowing oxygen of the converter is up to 750S; and (5) keeping the tapping temperature at 1660-1700 DEG C during tapping. By using the method, the waste steel consumption of the converter can be effectively reduced, so that the cost of a converter solvent is reduced.

Owner:武汉钢铁有限公司

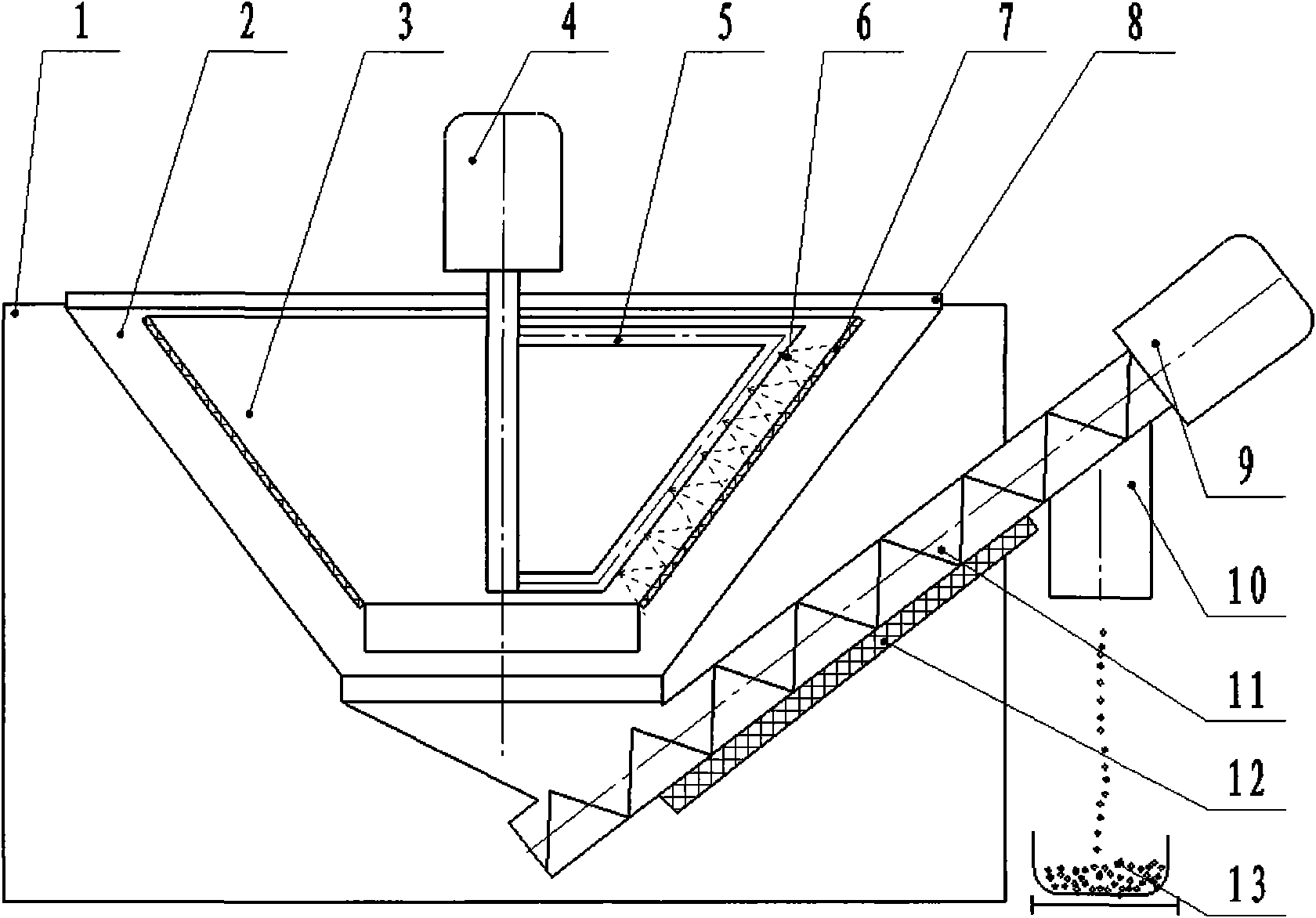

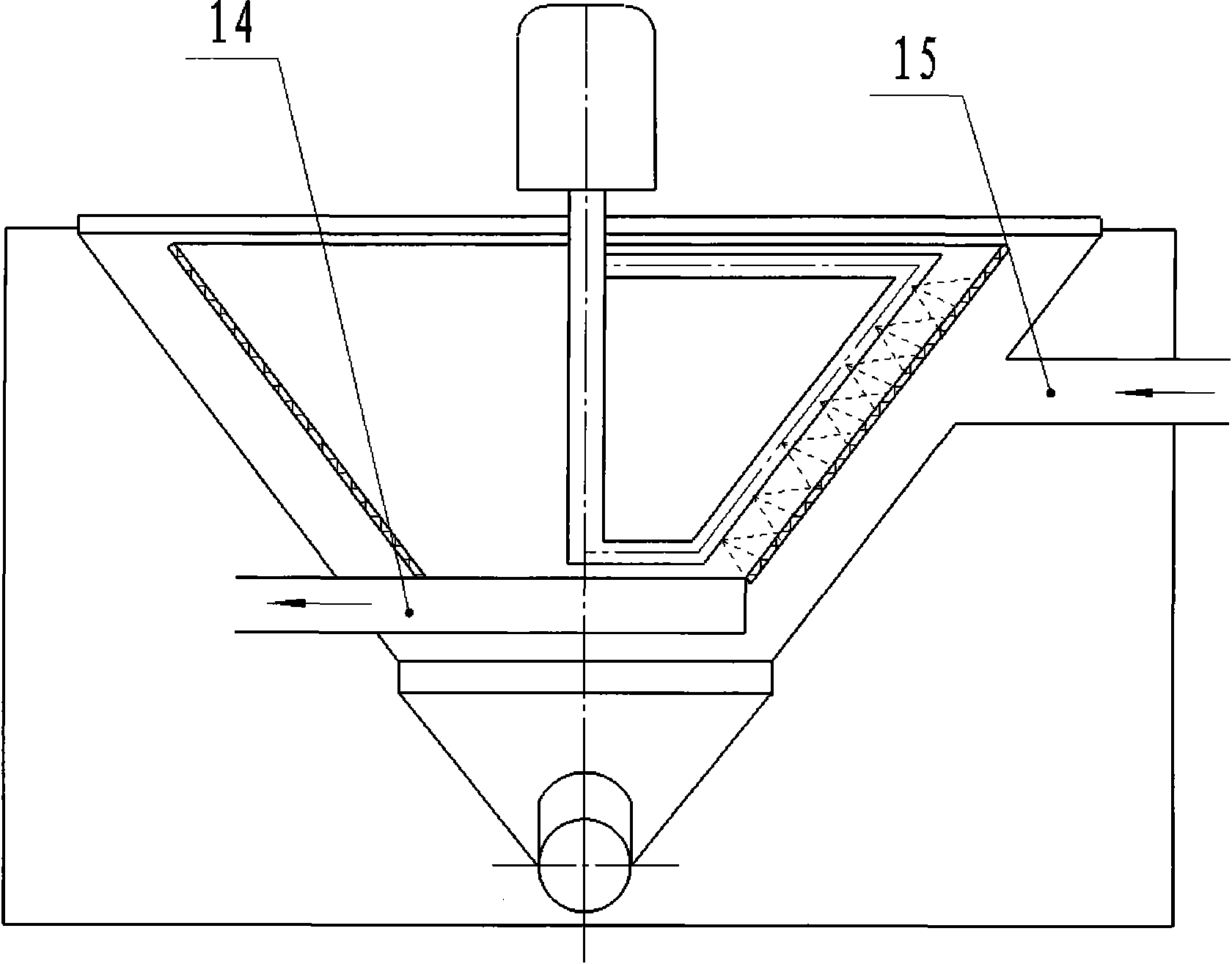

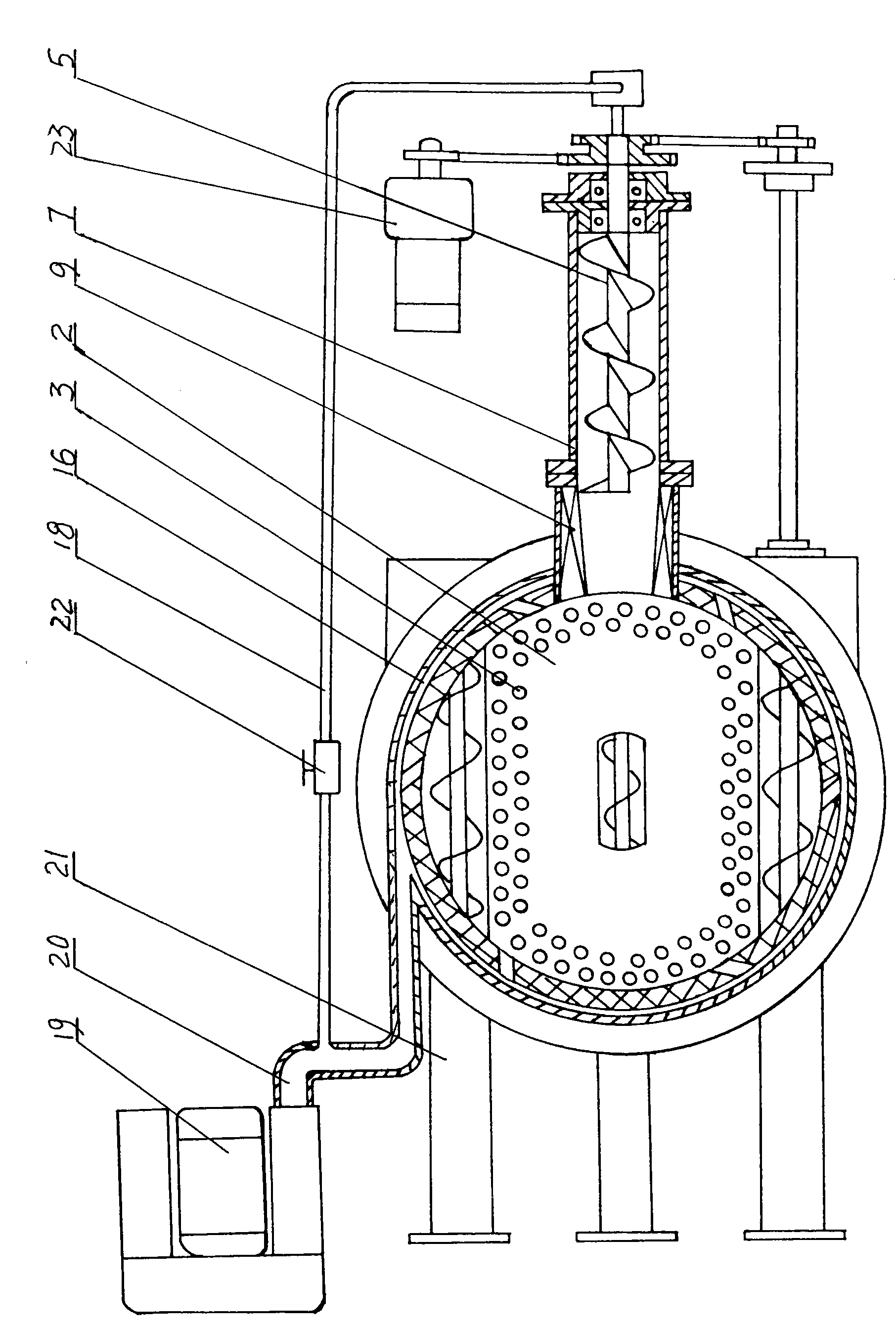

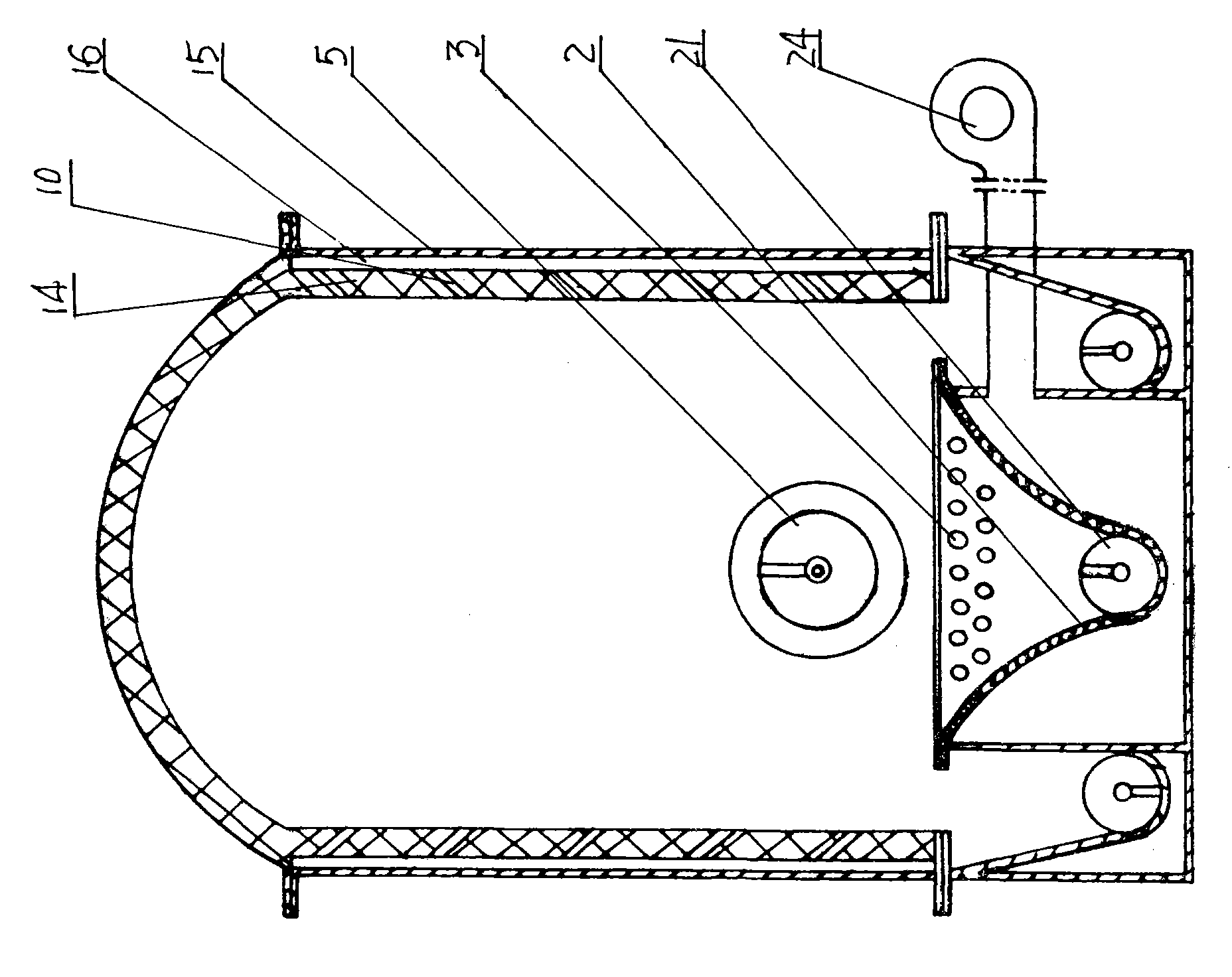

Back-wash filtering spiral deslagging machine

InactiveCN101648091APrevent the phenomenon of non-refluxCompact structureStationary filtering element filtersSlagBackflow

The invention relates to a back-wash filtering spiral deslagging machine, which comprises a clear water tank and a spiral deslagging machine, wherein a cleaning barrel is fixed in the clear water tankand internally provided with a filtering conical hopper, and the filtering conical hopper is fixed in the clear water tank through a mounting plate; the interior of the filtering conical hopper is communicated with the clear water tank; a back-wash spray pipe of a back-wash mechanism is connected with a reducing motor; the back-wash spray pipe is provided with a plurality of nozzles; the cleaningbarrel and the filtering conical hopper are of a hopper shape; the bottom of the cleaning barrel is communicated with the deslagging machine; and interior of the filtering conical hopper is communicated with the clear water tank. The invention can effectively prevent a phenomenon of no backflow of cleaning liquid because a filtering net is blocked by iron scraps through adopting back-wash filtering, has good deslagging effect because of adopting a magnetic conical deslagging mechanism, is particularly suitable for filtering cleaning liquid of a workpiece containing more iron scraps, and has high degree of automation because filtered iron scraps are automatically discharged from a deslagging port and fall into a slag trolley without manually cleaning the filtering net.

Owner:YICHANG ENHANCE ULTRASONIC ELECTRIC

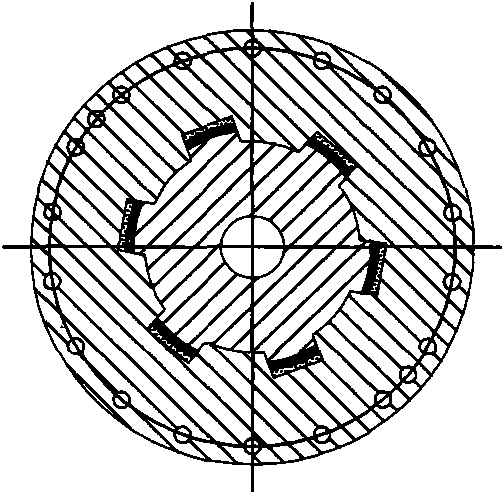

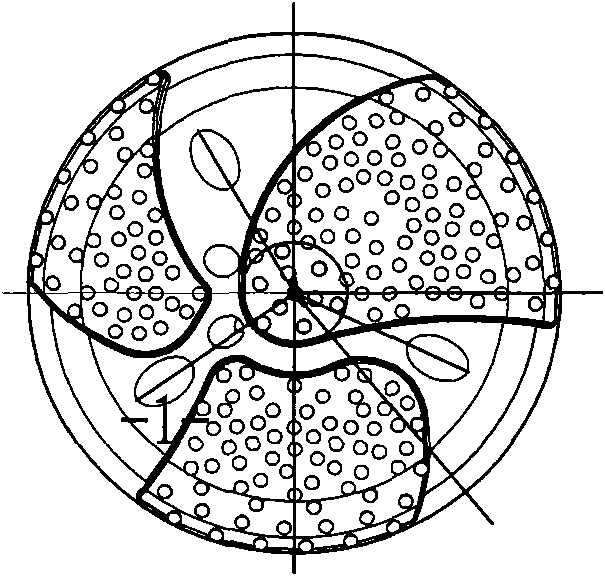

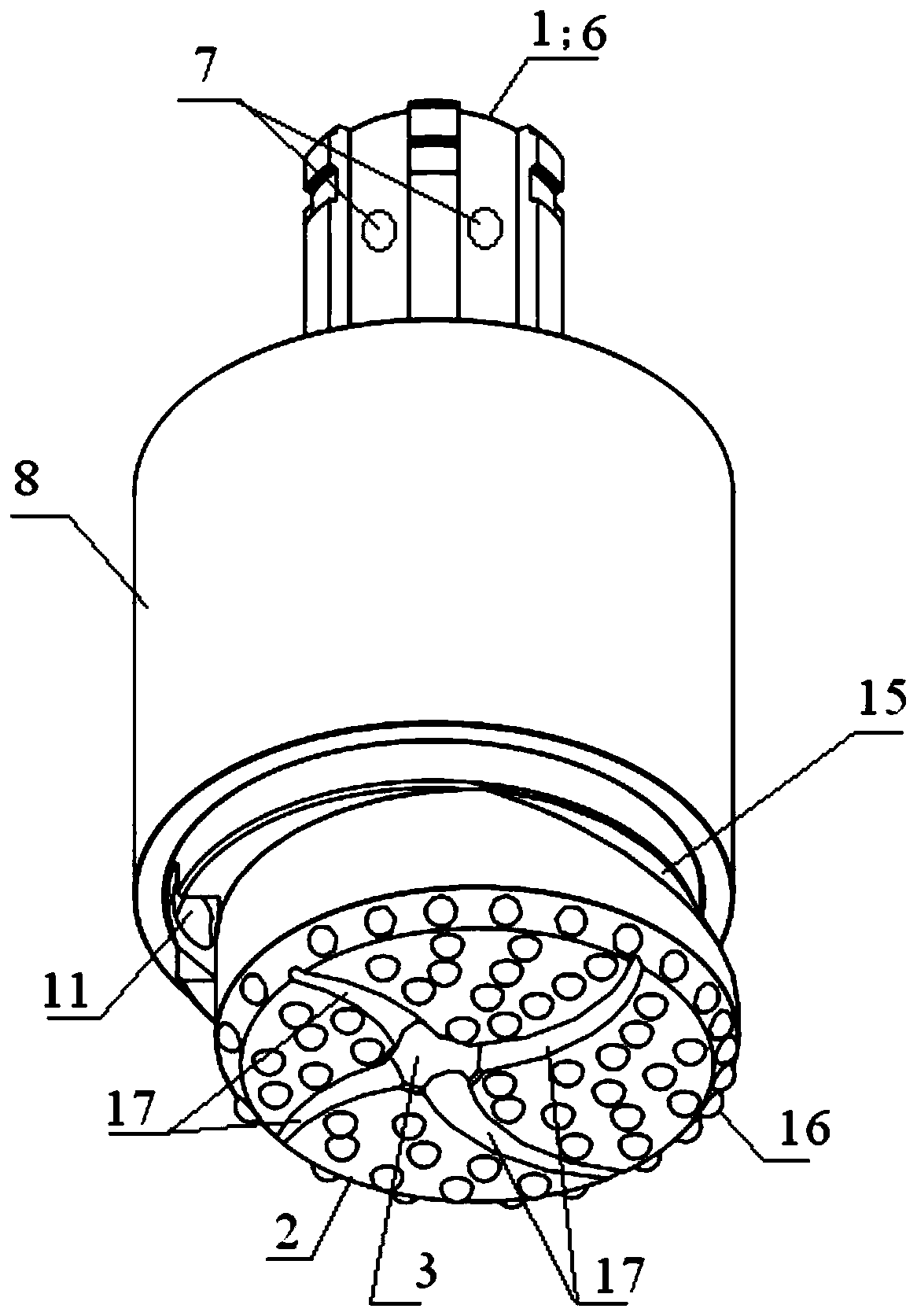

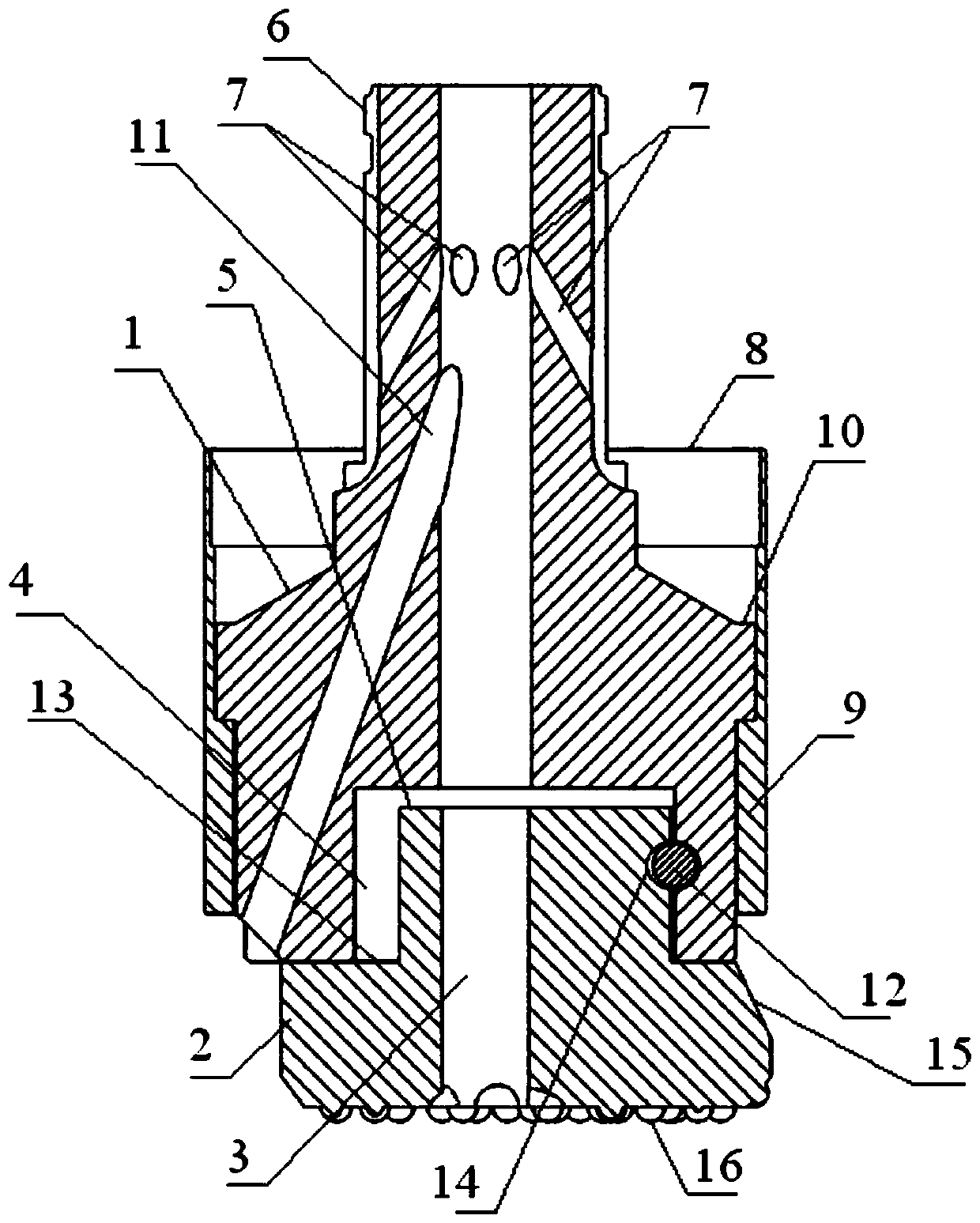

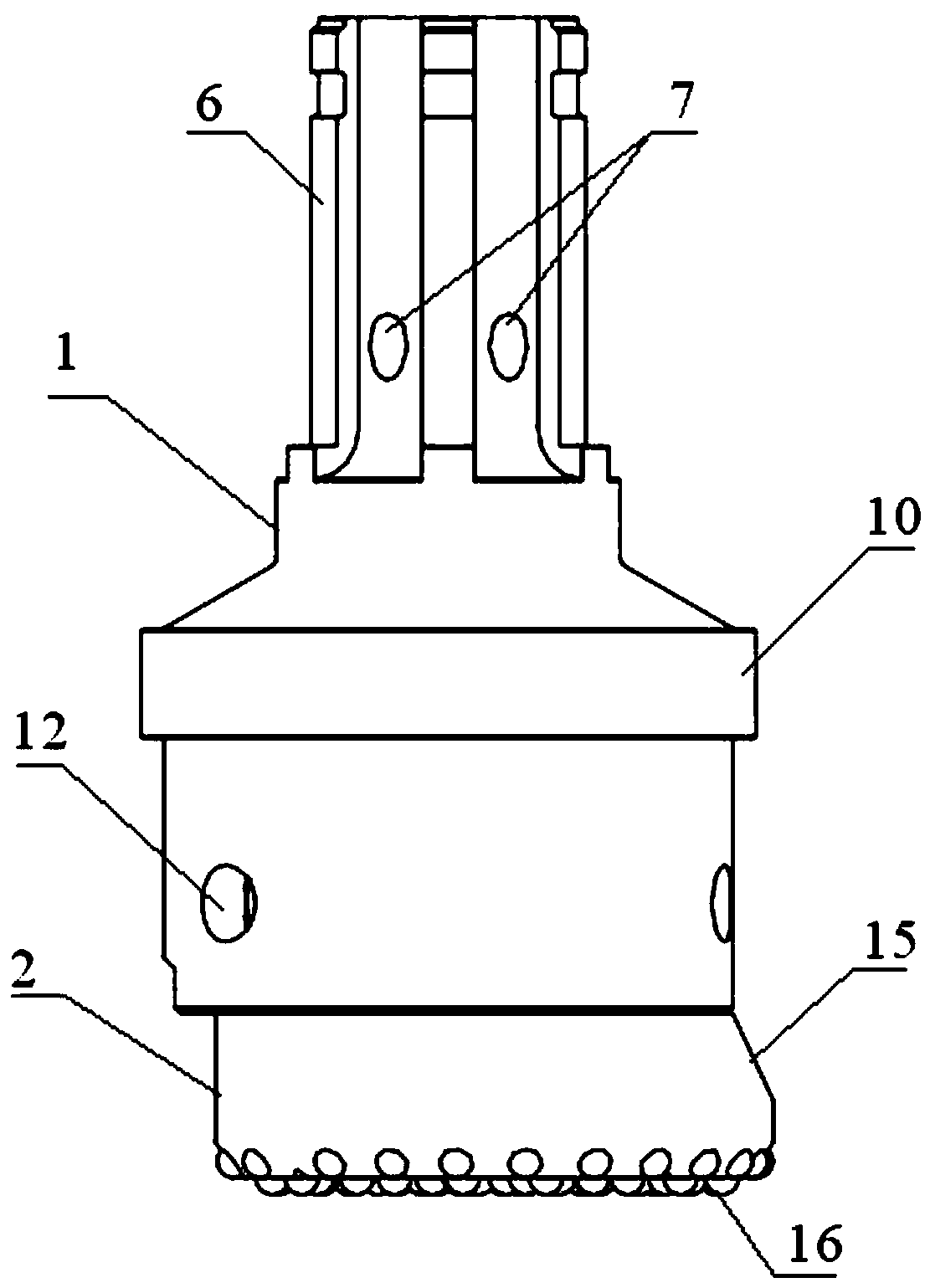

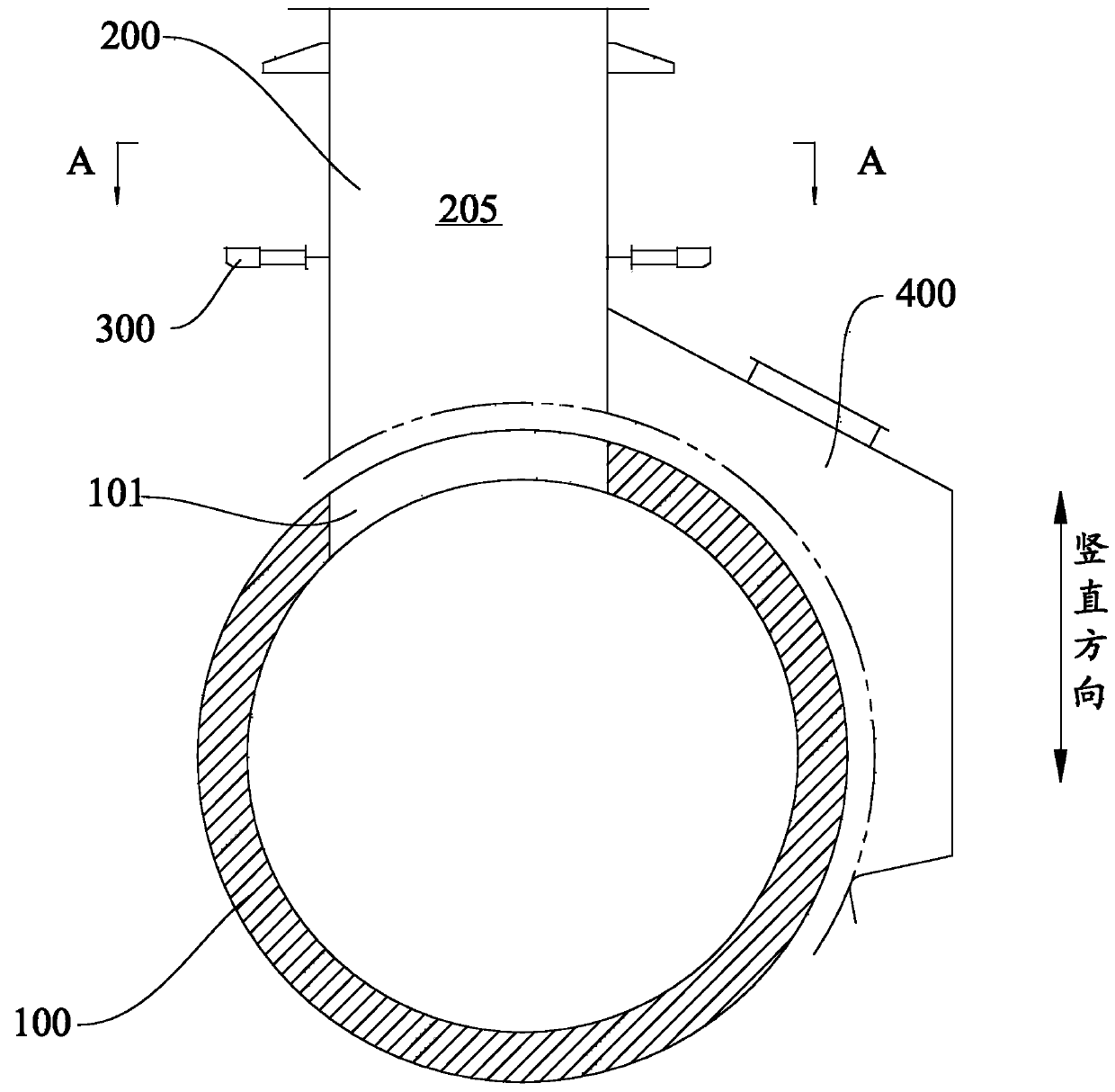

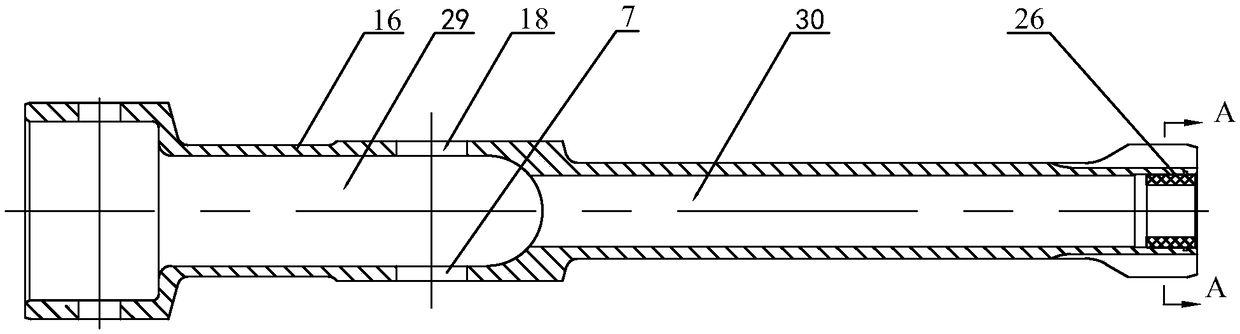

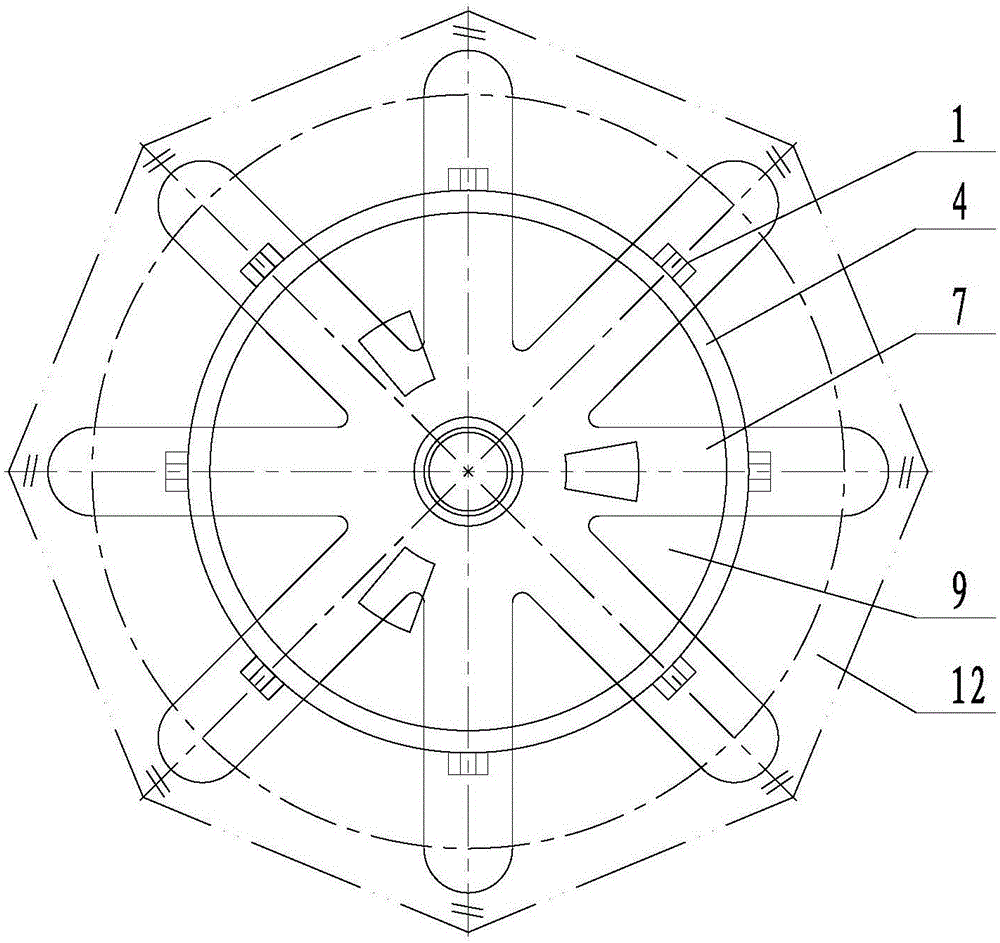

Down-the-hole hammer reverse circulation pipe-following drill bit suitable for large-diameter drilling

PendingCN111021964AImprove structural strengthImprove energy transfer efficiencyDrill bitsDrill holeMining engineering

The invention discloses a down-the-hole hammer reverse circulation pipe-following drill bit suitable for large-diameter drilling. The down-the-hole hammer reverse circulation pipe-following drill bitcomprises an upper drill bit body and a lower drill bit body, wherein the lower drill bit body is hung on the lower part of the upper drill bit body, central channels are formed in the middle part ofthe upper drill bit body and the middle part of the lower drill bit body, a groove is formed in the lower part of the upper drill bit body, a raised shaft is arranged at the top end of the lower drillbit body, the shape of the groove corresponds to the shape of the raised shaft, the raised shaft is inserted in the groove, the hole diameter of the groove is larger than the outer diameter of the raised shaft, the raised shaft can slide in the groove, and when the raised shaft slides and abuts against one end of the groove, the bottom of the lower drill bit body moves out of the outer edge of adrilling tool to realize reaming drilling. The down-the-hole hammer reverse circulation pipe-following drill bit has the beneficial effects that downhole double slag suction channels are arranged andmatched with involute type slagging guide grooves in the bottom surface of the drill bit, the reverse circulation efficiency is high, impact energy efficiency of a down-the-hole hammer is high, the slagging effect is good, meanwhile, ball teeth on the edge of the bottom surface of the drill bit are densely arranged, and the service life of the drill bit is effectively prolonged in combination withgood slagging conditions.

Owner:JILIN UNIV

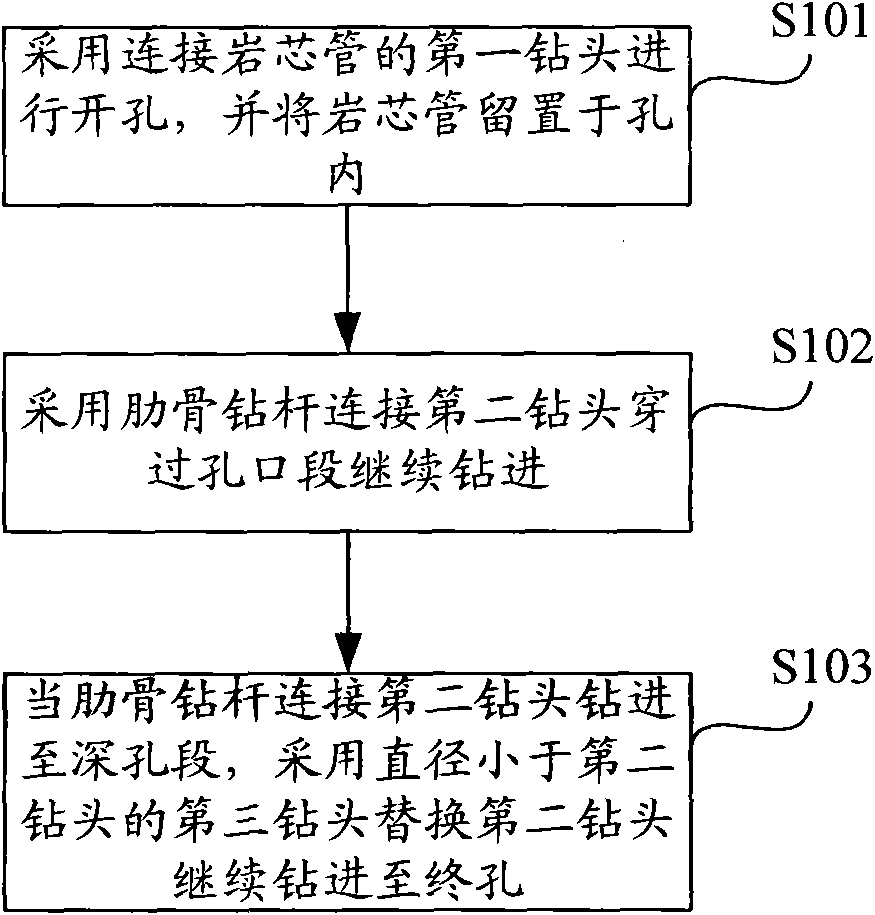

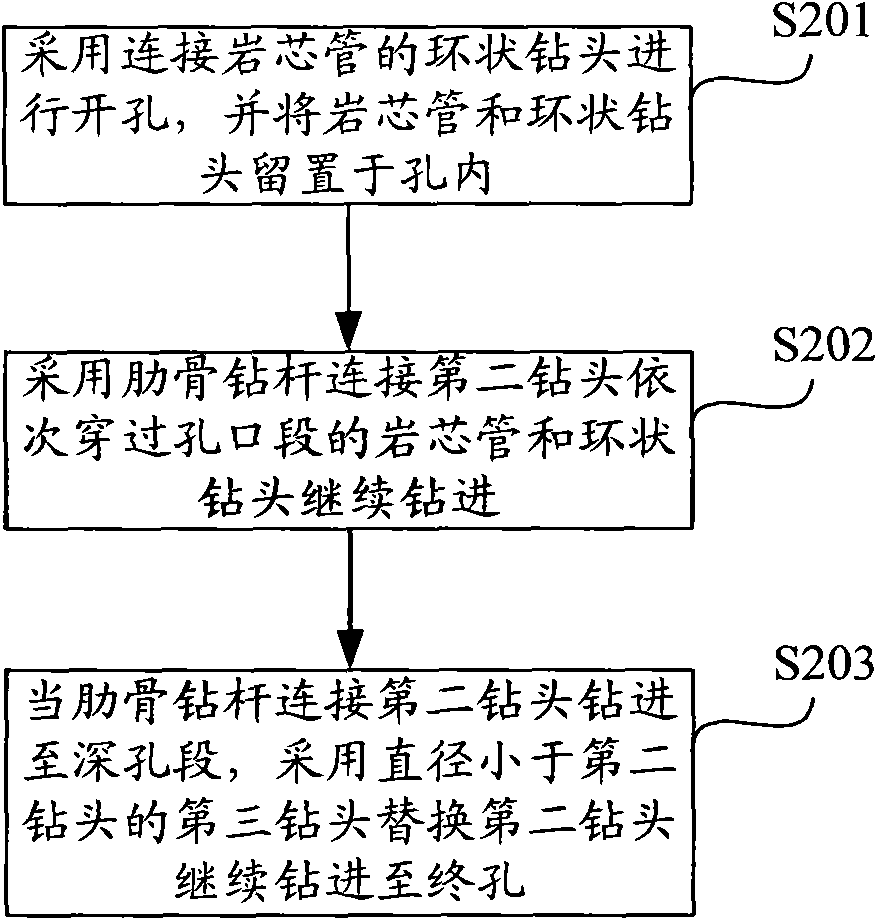

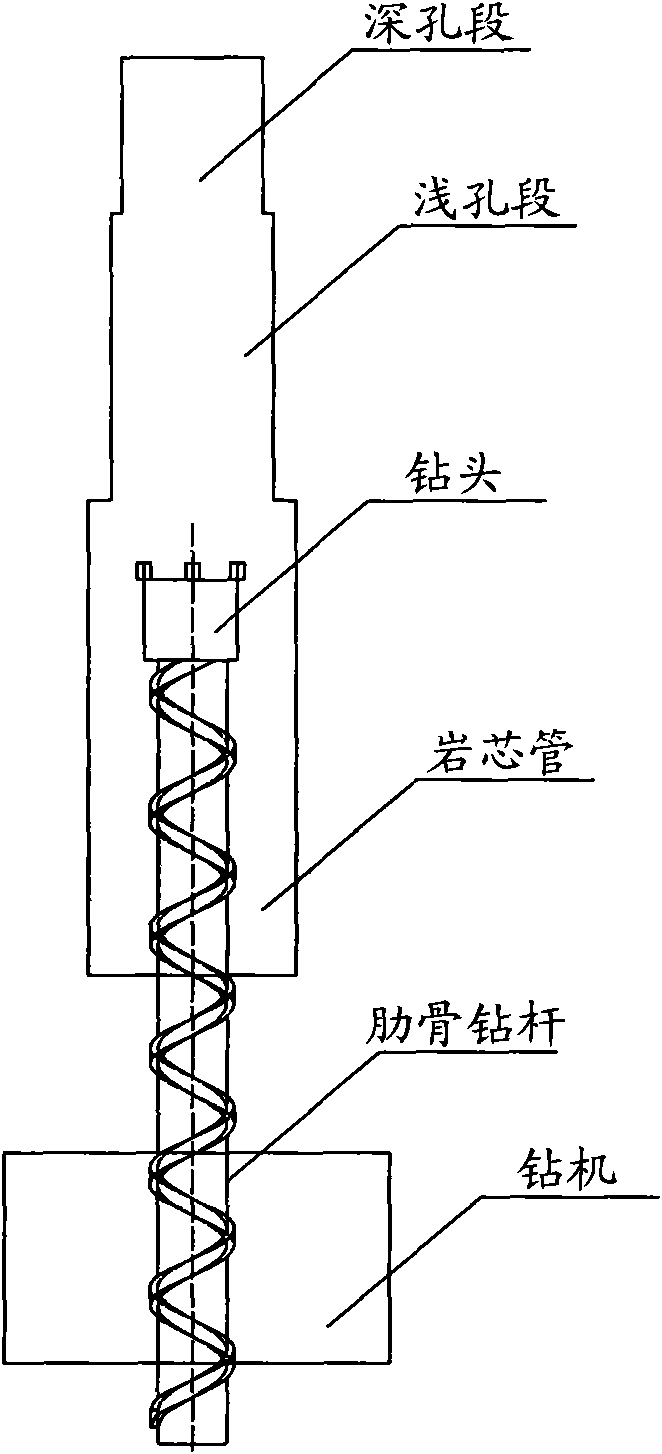

Coal mine underground over-broken abnormal zone drilling method

The invention provides a coal mine underground over-broken abnormal zone drilling method. The method comprises the following steps of: forming a hole by adopting a first drill bit connected with a core pipe, and reserving the core pipe in the hole; connecting a rib drill rod and a second drill bit, and making the rib drill rod pass through the hole section to perform continuous drilling; and whenthe rib drill rod connected with the second drill bit drills to the deep hole section, replacing the second drill bit by adopting a third drill bit, the diameter of which is smaller than that of the second drill bit, to perform continuous drilling till the final hole. The embodiment of the invention realizes hole formation and hole protection of the broken abnormal zone, reduces the resistance ofdrilling to the deep hole section, and improves the efficiency of drilling to the deep hole section.

Owner:HUAINAN MINING IND GRP

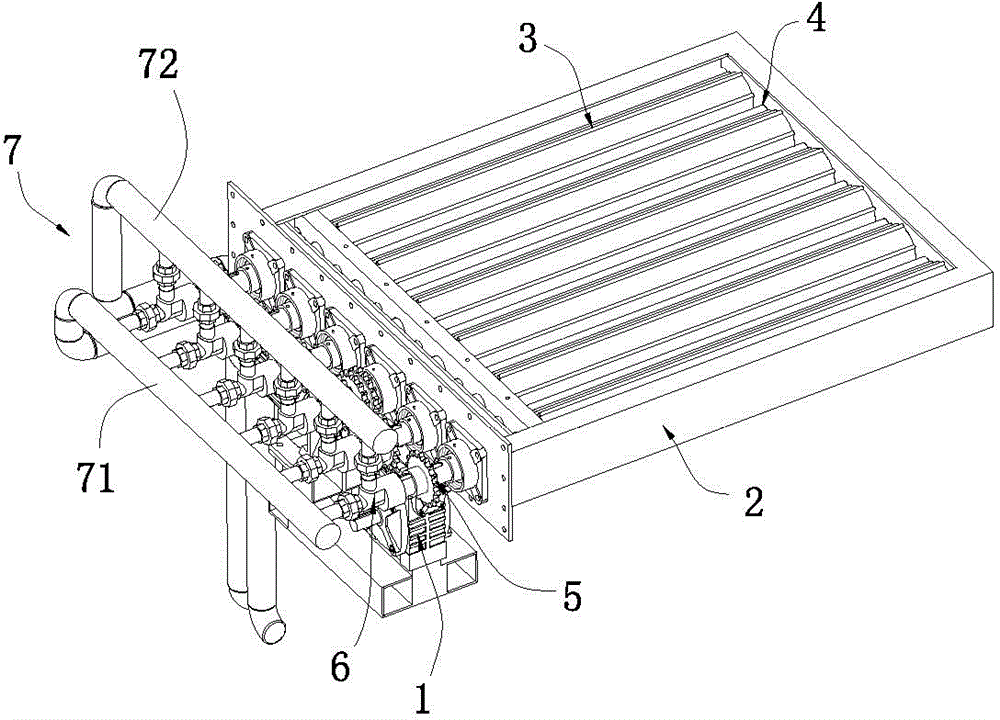

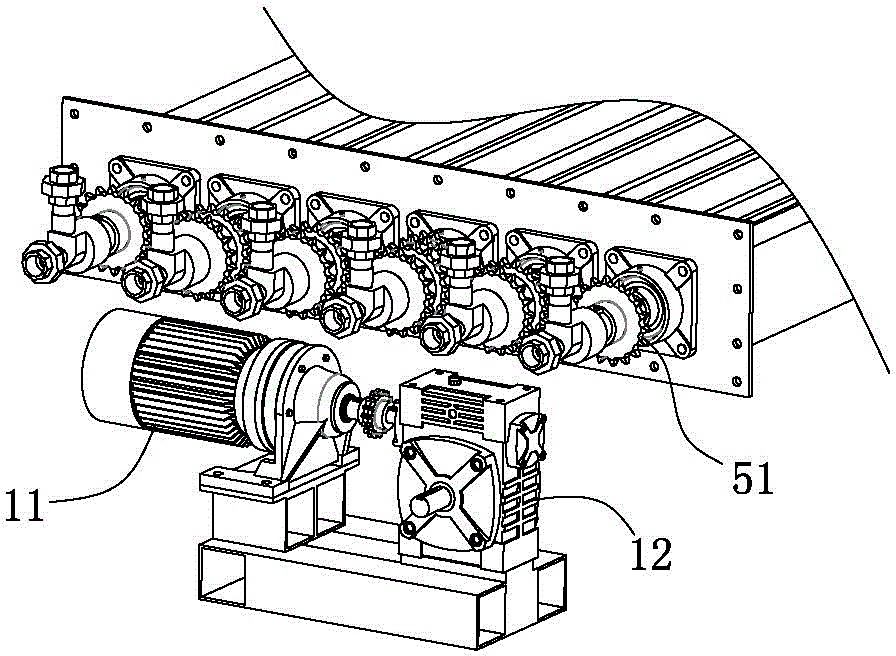

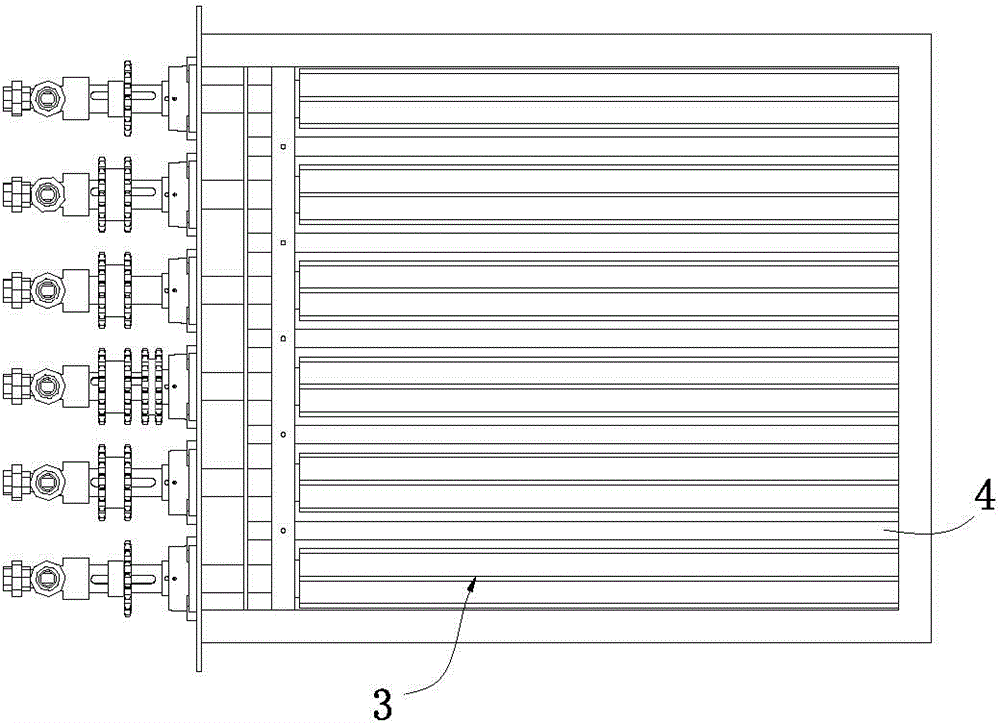

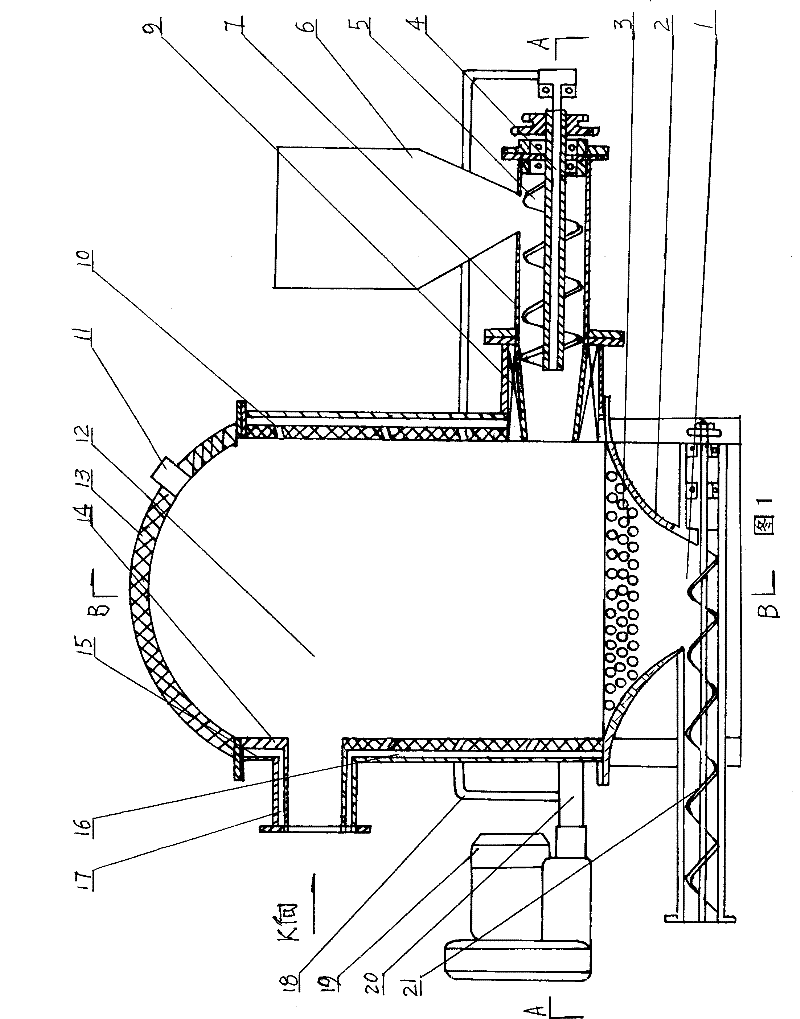

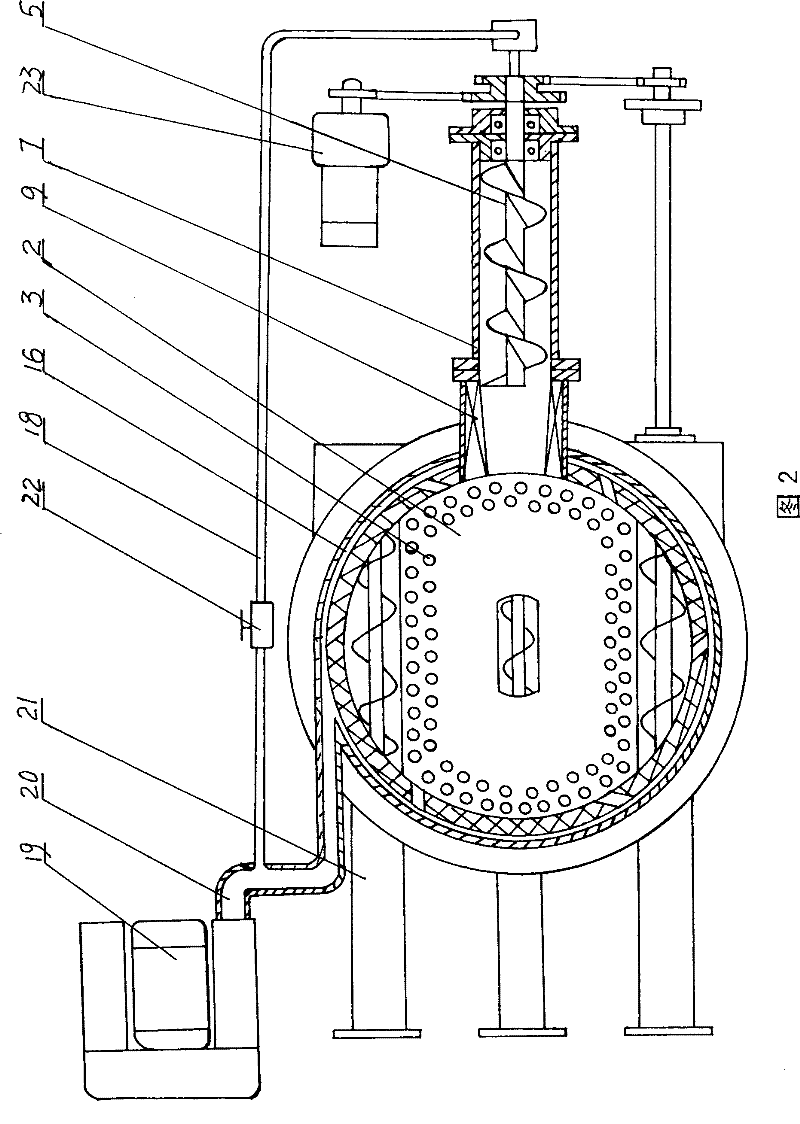

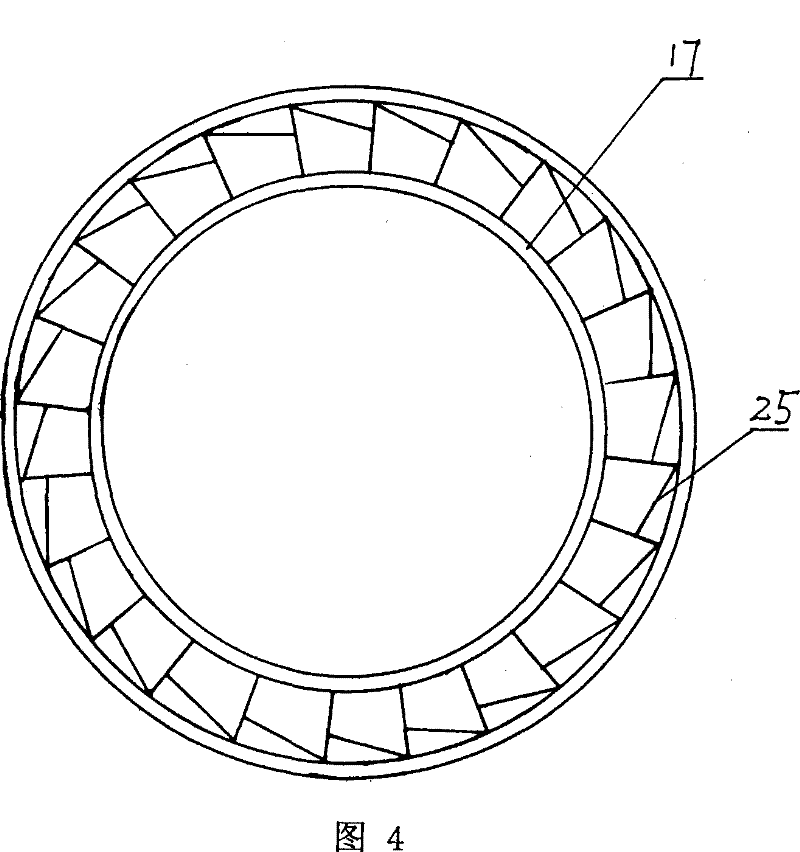

Rotary type water-cooled fire grate

InactiveCN103953935ABurn fullyWon't burn outRevolving grateRocking grateElectric machineThrough transmission

The invention discloses a rotary type water-cooled fire grate, which comprises a drive device, an installation frame, a plurality of large rotary discharge pipes and small fixed tier poles, wherein the large rotary discharge pipes are arranged on the installation frame in parallel at intervals; one small fixed tier pole is arranged between each two adjacent large rotary discharge pipes; the drive device is connected with all the large rotary discharge pipes through transmission components. The rotary type water-cooled fire grate is ingenious and reasonable in structural design; the large rotary discharge pipes are arranged in parallel at intervals, and one small fixed tier pole capable of forming a certain barrier is arranged between each two adjacent large rotary discharge pipes, so that air leakage can be prevented, fuel can be fully combusted, meanwhile, wind energy can be utilized maximally, the large rotary discharge pipes are linked synchronously, the deslagging effect is good, and the application range is wide; in addition, water cooling is adopted for protection, the service life is long, and the rotary speed and the working time of a motor can be controlled through a controller, so that the rotary type water-cooled fire grate can meet the work requirements under different conditions, is simple, easy and convenient to operate, is high in degree of automation, and is beneficial to be popularized and applied widely.

Owner:佛山市凯沃森环保科技有限公司

Straw gasification combustor

InactiveCN101660751AImprove combustion efficiencyBurn fullySolid fuel combustionSpecial form destructive distillationCombustion chamberCombustor

The invention discloses a straw gasification combustor, and relates to improvement on a straw combustor structure. The invention provides the straw gasification combustor more suitable for straw combustion and having high combustion efficiency. The straw gasification combustor comprises a furnace body; the inside of the furnace is provided with a combustion chamber; and the straw gasification combustor has structural key points that: the bottom of the combustion chamber is provided with a slag falling baffle with air holes; an outlet on the bottom of the slag falling baffle is provided with aslag outlet screw; a secondary air duct is arranged between a furnace wall with air holes of the combustion chamber and a shell of the furnace body; an outlet of the combustion chamber is a cyclone spout with spiral blades; a feeding hole of the combustion chamber is provided with an electric heater which is connected with a feed delivery pipe of which the inside is provided with a feeding screw and the upper part is provided with a fuel bin; and the inside of the feeding screw is provided with an ignition air duct.

Owner:C A S ZHONGLI SCI & TECH CO LTD

Dish washing machine

InactiveCN105615799AImprove washing effectImprove self-cleaning abilityTableware washing/rinsing machine detailsHome appliance efficiency improvementFilter systemEnergy consumption

The invention discloses a dish washing machine. The dish washing machine comprises a filtering system, a washing system, a residue shredding system and a drainage system and is characterized in that a residue shredding cavity, a washing pump cavity and a drainage pump cavity are formed in the dish washing machine, a residue shredding filtering net is arranged at a water inlet of the residue shredding cavity, residue shredding blades are arranged in the residue shredding cavity, a water inlet of the washing pump cavity is communicated with the residue shredding cavity, a washing filtering net is arranged at the water inlet of the washing pump cavity, a washing pump is arranged in the washing pump cavity, a water outlet of the washing pump cavity is connected with a spray device of the washing system, a drainage filtering net is arranged at a water outlet of the residue shredding cavity, a water outlet of the residue shredding cavity is connected with a water inlet of the drainage pump cavity, and a drainage pump is arranged in the drainage pump cavity. The dish washing machine comprises the drainage pump provided with cutting blades and filters out, collects, shreds and discharges food residues, so that water consumption and energy consumption of the dish washing machine are reduced, the cleaning rate of the dish washing machine is increased, the dish washing machine has the self-cleaning function, and manual washing of the filtering nets is avoided.

Owner:林贤华

Smoke outlet cover and rotary metallurgical furnace with same

ActiveCN103471382AFor quick maintenanceEasy maintenanceRotary drum furnacesIncrustation removal devicesRespiratorEngineering

The invention discloses a smoke outlet cover and a rotary metallurgical furnace with the same. The smoke outlet cover comprises a flue body, a flue hoop and a vibrator. The flue body comprises flue wall plates and cooling wall plates. The flue wall plates enclose a flue. The cooling wall plates are fixed to the outer faces of the flue wall plates and define a cooling passage with the flue wall plates. The flue clamp is connected with the flue body and clamped to the outer wall of the flue body. The vibrator is mounted on the flue clamp and used for vibrating the flue wall plates. The smoke outlet cover is simple in structure, convenient to assemble and disassemble, convenient to maintain, and long in service life.

Owner:CHINA ENFI ENGINEERING CORPORATION

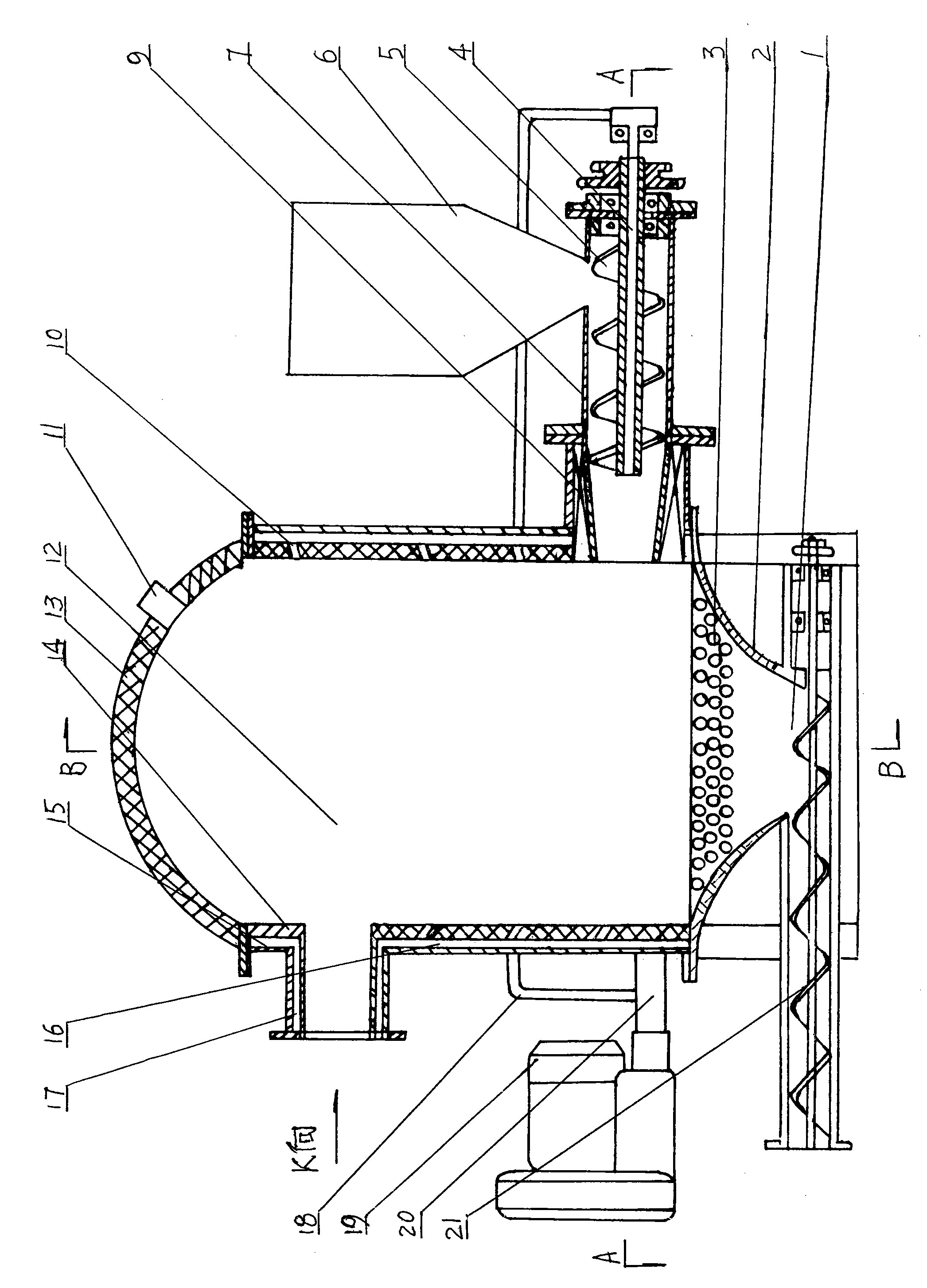

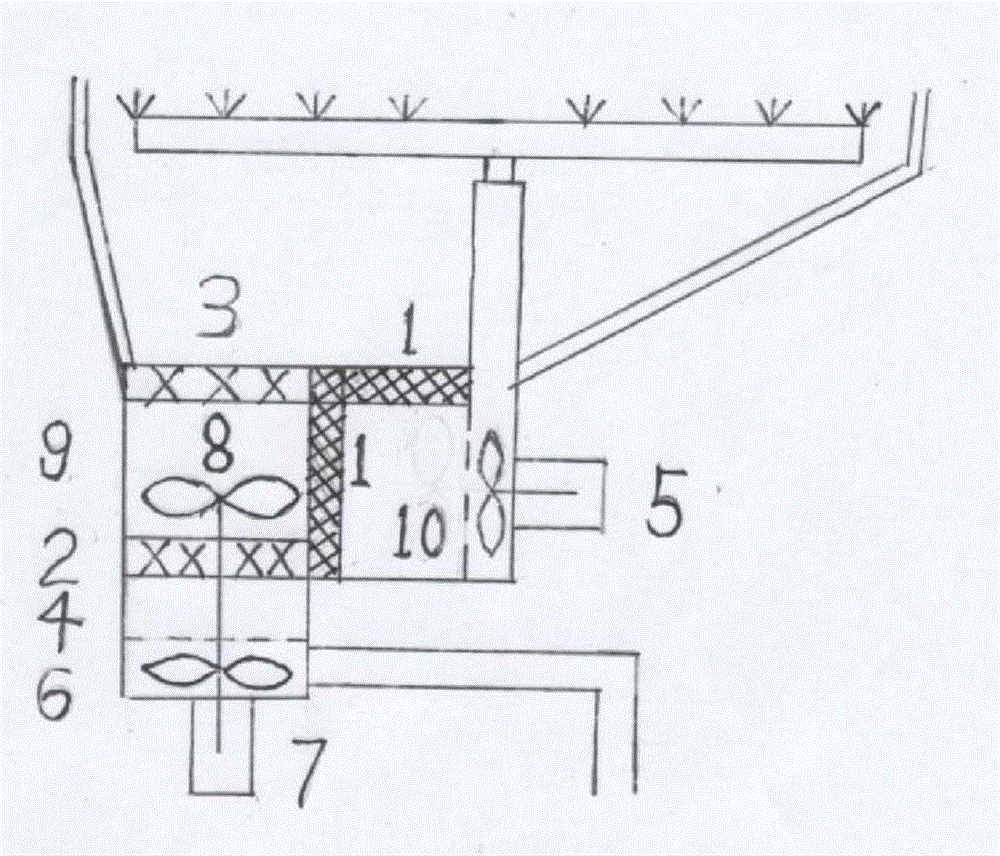

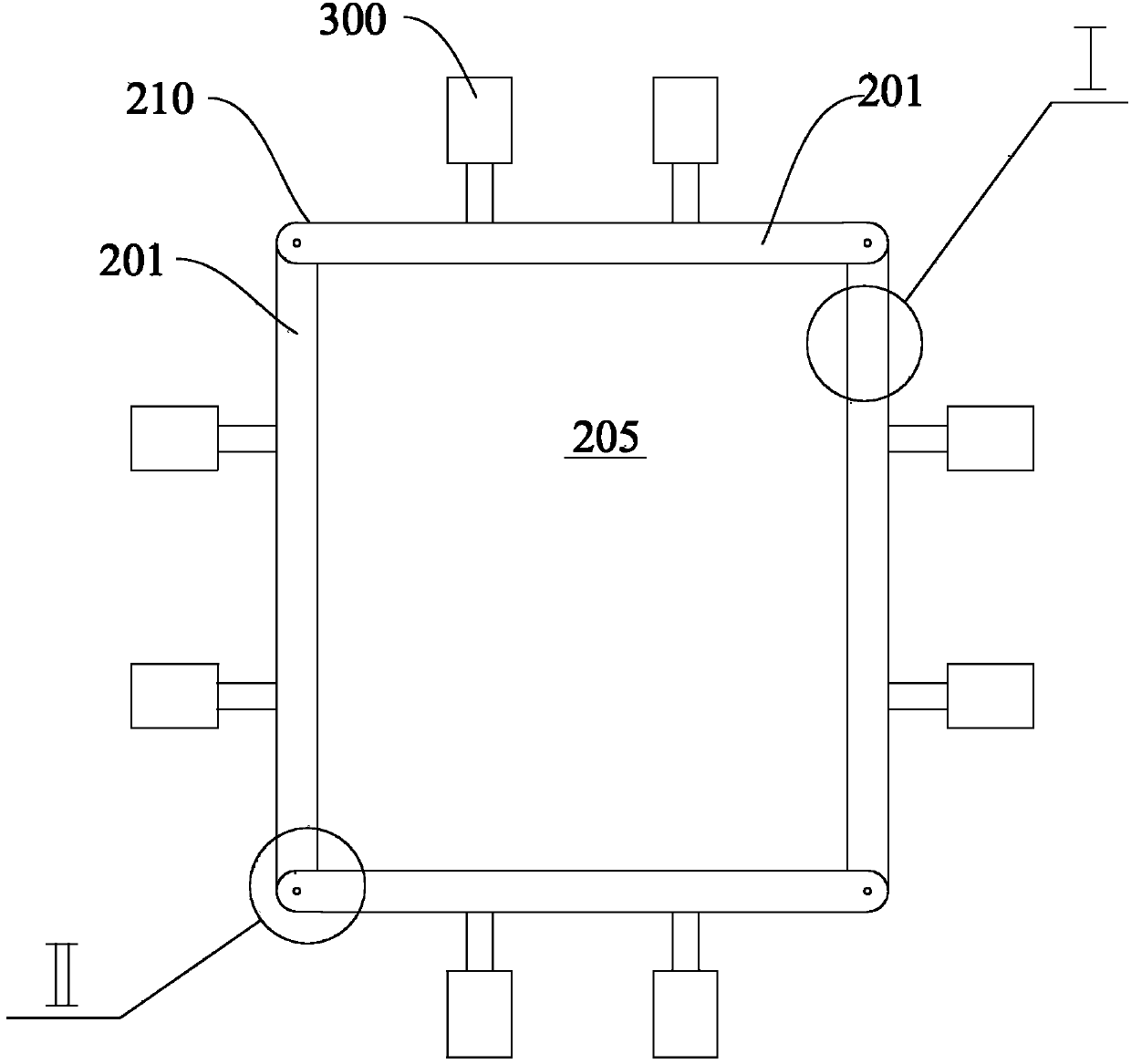

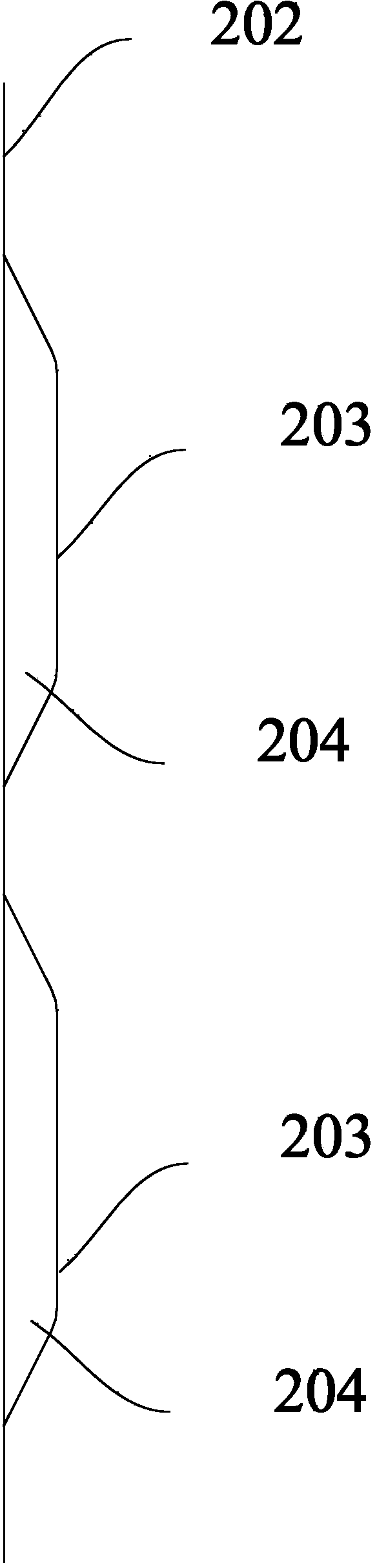

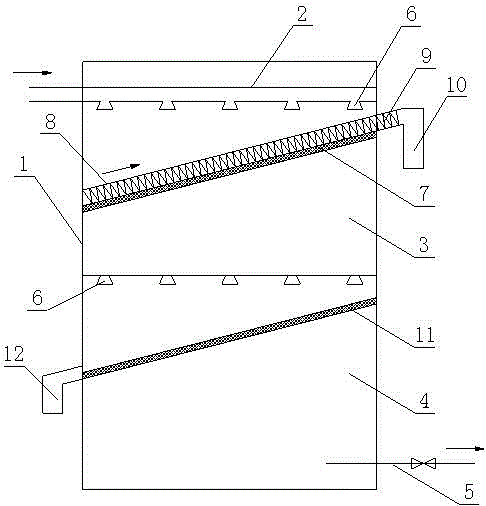

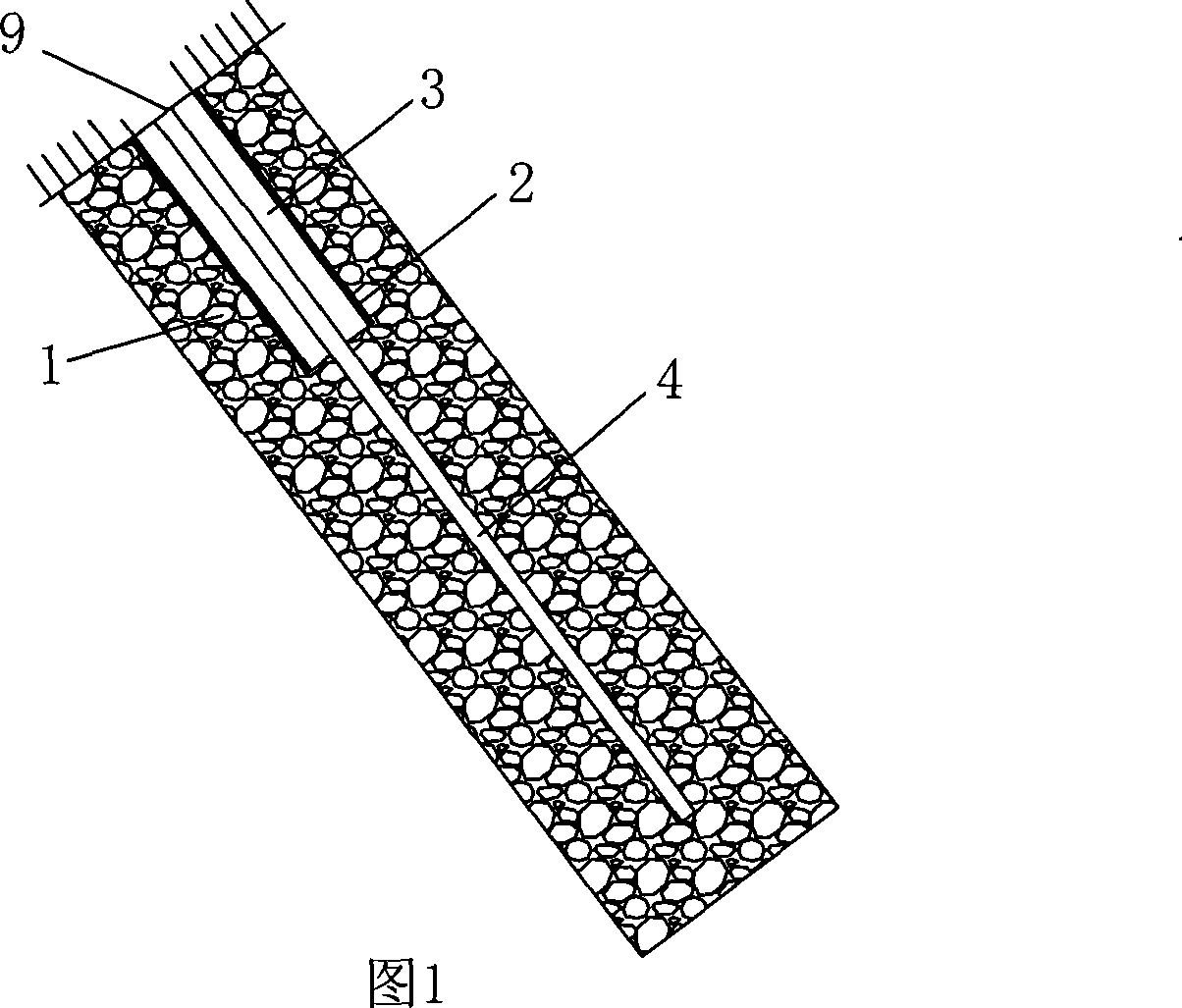

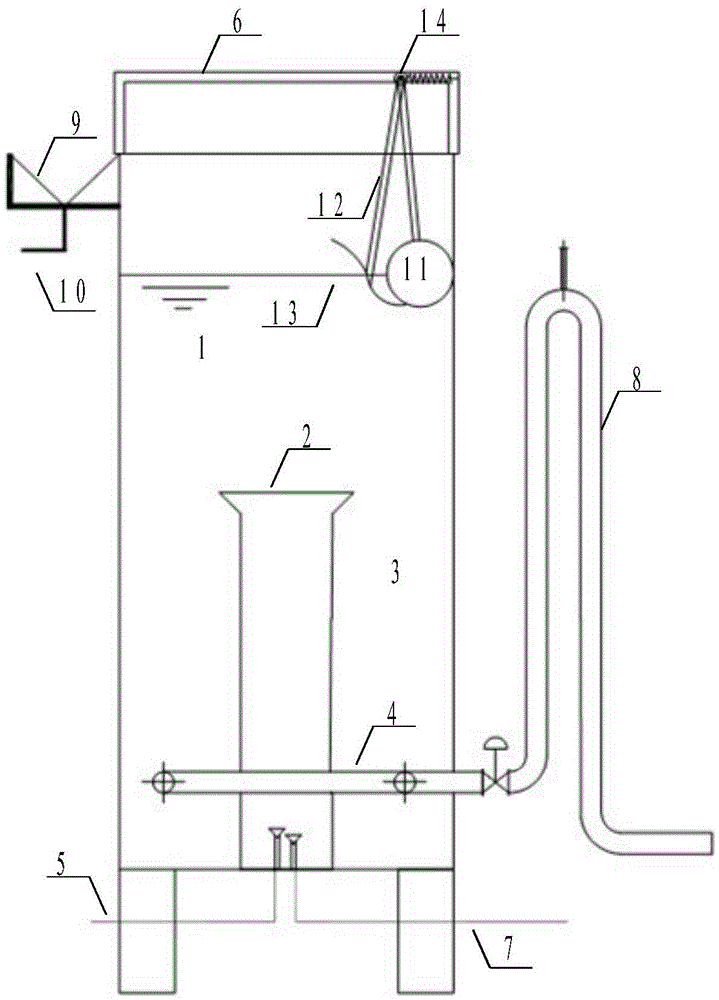

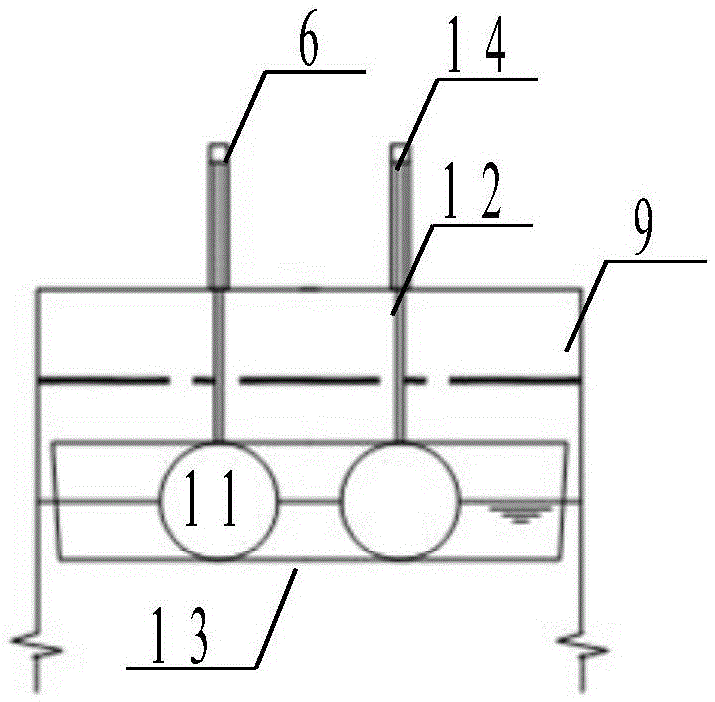

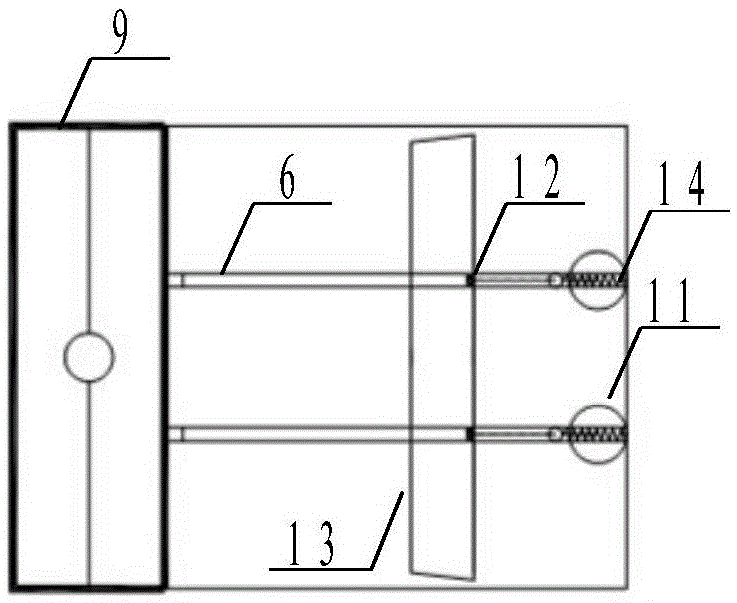

Softening-electrolysis integrated acidic electrolyzed oxidizing water reactor

ActiveCN104591446AEffective filteringImprove water qualityMultistage water/sewage treatmentDischarge efficiencyElectrolysis

The invention discloses a softening-electrolysis integrated acidic electrolyzed oxidizing water reactor which comprises a reactor body (1), wherein a cavity of the reactor body (1) is internally provided with a tap water inlet pipe (2), a first filter, a softening reaction area (3), a second filter and an electrolytic reaction area (4) sequentially from top to bottom; the water outlet of the tap water inlet pipe (2) is arranged above the first filter; the softening reaction area (3) is arranged below the first filter; the water outlet of the softening reaction area (3) is arranged above the second filter; the electrolytic reaction area (4) is arranged below the second filter; and an electrolyzed water discharge pipe (5) is arranged at the bottom of the electrolytic reaction area (4). According to the softening-electrolysis integrated acidic electrolyzed oxidizing water reactor, effluent water can come into sufficient contact with the filters by adopting the design of a plurality of atomizing water spray heads, so that relatively good filtering effect is achieved; and a spiral residue discharge device can be used for effectively discharging filter residues accumulated on an inclined filter screen and is simple in structure and high in discharge efficiency.

Owner:成都邦研科技有限公司

Method for removing boron impurity from industrial silicon by using titanium-containing compound

The invention provides a method for removing a boron impurity from industrial silicon by using a titanium-containing compound and belongs to the field of metallurgy. The method comprises the following steps of: mixing the industrial silicon and a slag forming constituent, adding the mixture into a graphite crucible and pre-heating the graphite crucible in a smelting furnace to the temperature of between 1,400 and 1,600 DEG C; vacuumizing the smelting furnace with a mechanical pump and a Roots pump in turn, heating the smelting furnace to the temperature of between 1,500 and 1,700 DEG C and controlling the frequency of a medium frequency power supply to between 80 and 120kW; and introducing gas into the smelting furnace, stirring, forming slag, pouring silicon liquid into a die after the slag is fully formed, and cutting impurities from the solidified silicon material to obtain the silicon material from which boron is removed. The slag forming constituent used in the method has a good effect; the distribution ratio can be over 5; and compared with the distribution ratio of a pure Ca slag forming constituent, the distribution ratio of the slag forming constituent is obviously improved. The content of the boron in the industrial silicon is obviously reduced. The method has a wide application prospect.

Owner:XIAMEN UNIV

Rapid dust removal method and device in tunnel

InactiveCN101387203AImprove dust removal rateQuick dustDust removalFire preventionEngineeringHigh pressure

The invention relates to a downhole quick dustfall method and a downhole quick dustfall device, which are characterized in that a drilling position of a heading is provided with a front-end hole by utilization of a drill; an annular area between a drill rod and the rock wall of the front-end hole is taken as a dustfall area in the front-end hole, and spray which is formed by inlet of compressed air and water together is led into the dustfall area; and the spray is maintained when the drill rod drills simultaneously. The downhole quick dustfall method and the downhole quick dustfall device can maintain using high-pressure blast to quicken normal drilling construction, and simultaneously effectively reduce the discharge capacity of downhole dust, thereby solving the problem of the hazard of the dust on the health of workers and the safety threat of the dust on mines.

Owner:HUAINAN MINING IND GRP

Automatic deslagging system for dish-washing machine

InactiveCN105581763AGuaranteed non-stickImprove self-cleaning abilityTableware washing/rinsing machine detailsHome appliance efficiency improvementAutomatic testingEnergy consumption

The invention provides an automatic deslagging system for a dish-washing machine. The automatic deslagging system is composed of a washing filtering net, a water draining filtering net, a slag cutting filtering net, a washing pump, and a water draining pump with cutting blades, and is characterized in that a slag cutting cavity, a washing pump cavity and a water draining pump cavity are arranged in the dish-washing machine, the slag cutting filtering net is arranged at a water inlet of the slag cutting cavity, the slag cutting cavity is communicated with the washing pump cavity through the washing filtering net, the washing pump is arranged in the washing pump cavity, the slag cutting cavity is communicated with the water draining pump cavity through the water draining filtering net, and blades for cutting food residue and mounted on an output shaft of a water draining pump motor are arranged in the slag cutting cavity. According to the automatic deslagging system, the food residue can be automatically cleaned without the manual operation, therefore, the self-cleaning capacity of the dish-washing machine is improved, the water consumption and energy consumption of the dish-washing machine are reduced, and the washing efficiency of the dish-washing machine is improved.

Owner:林贤华

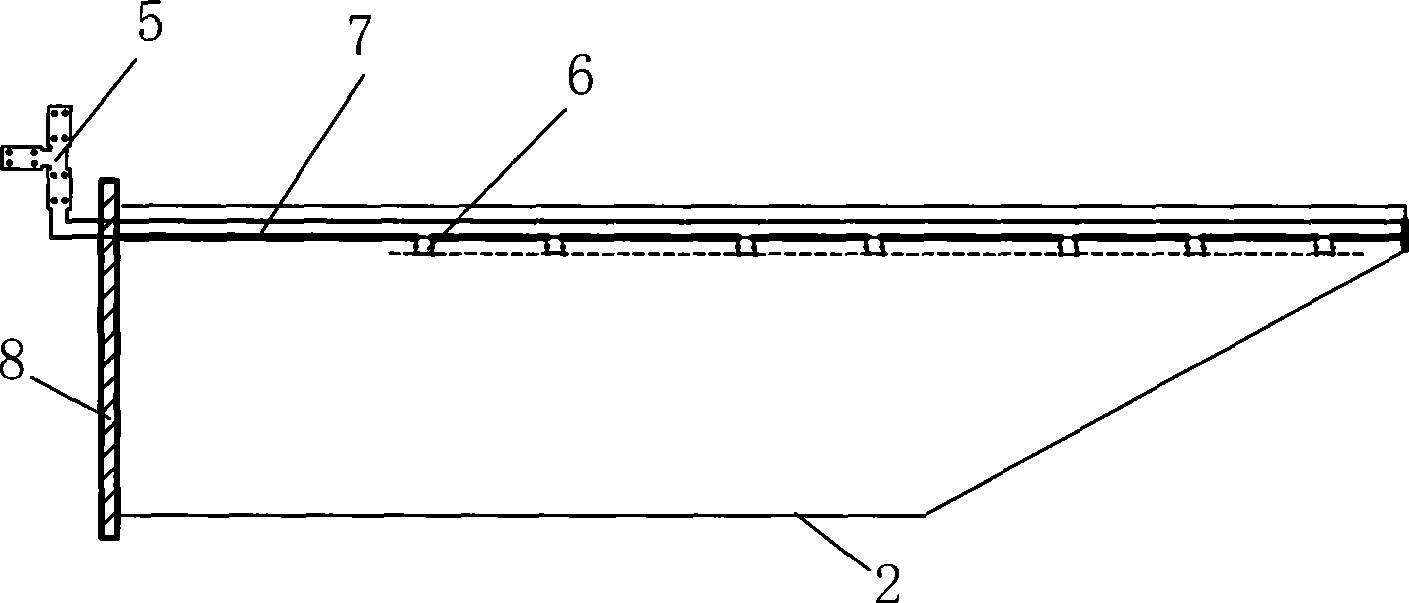

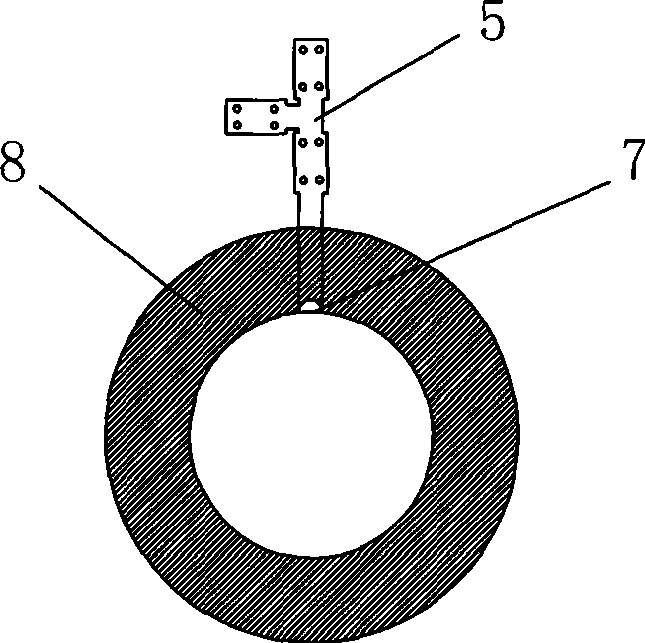

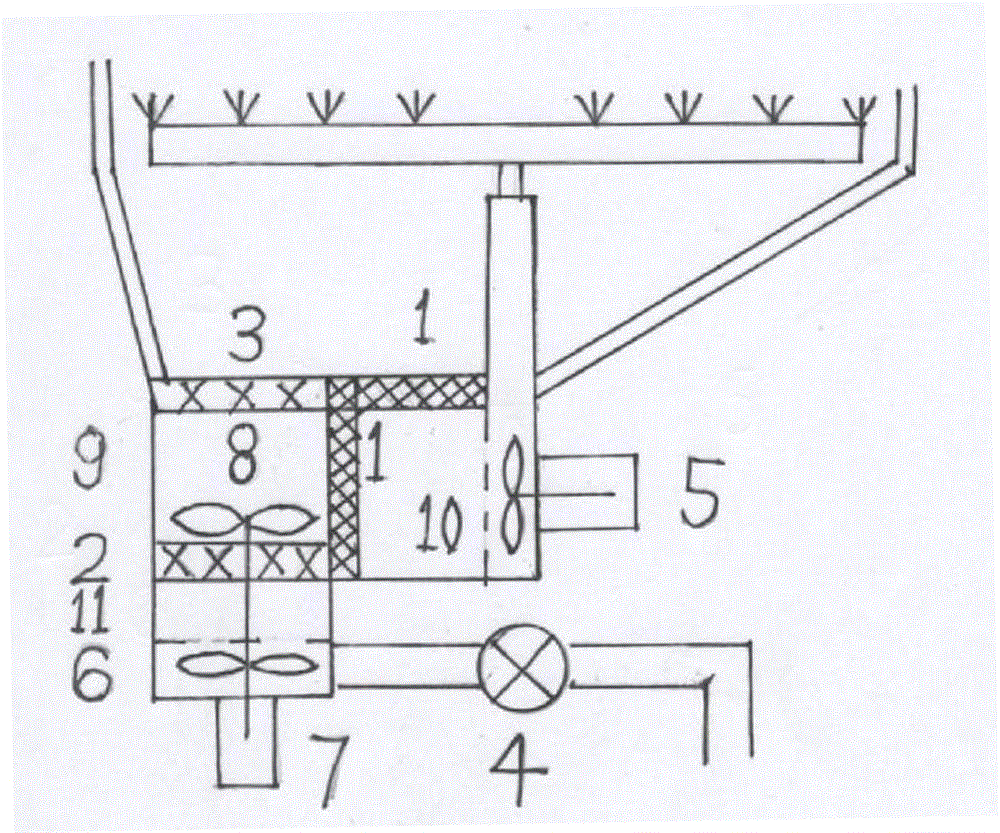

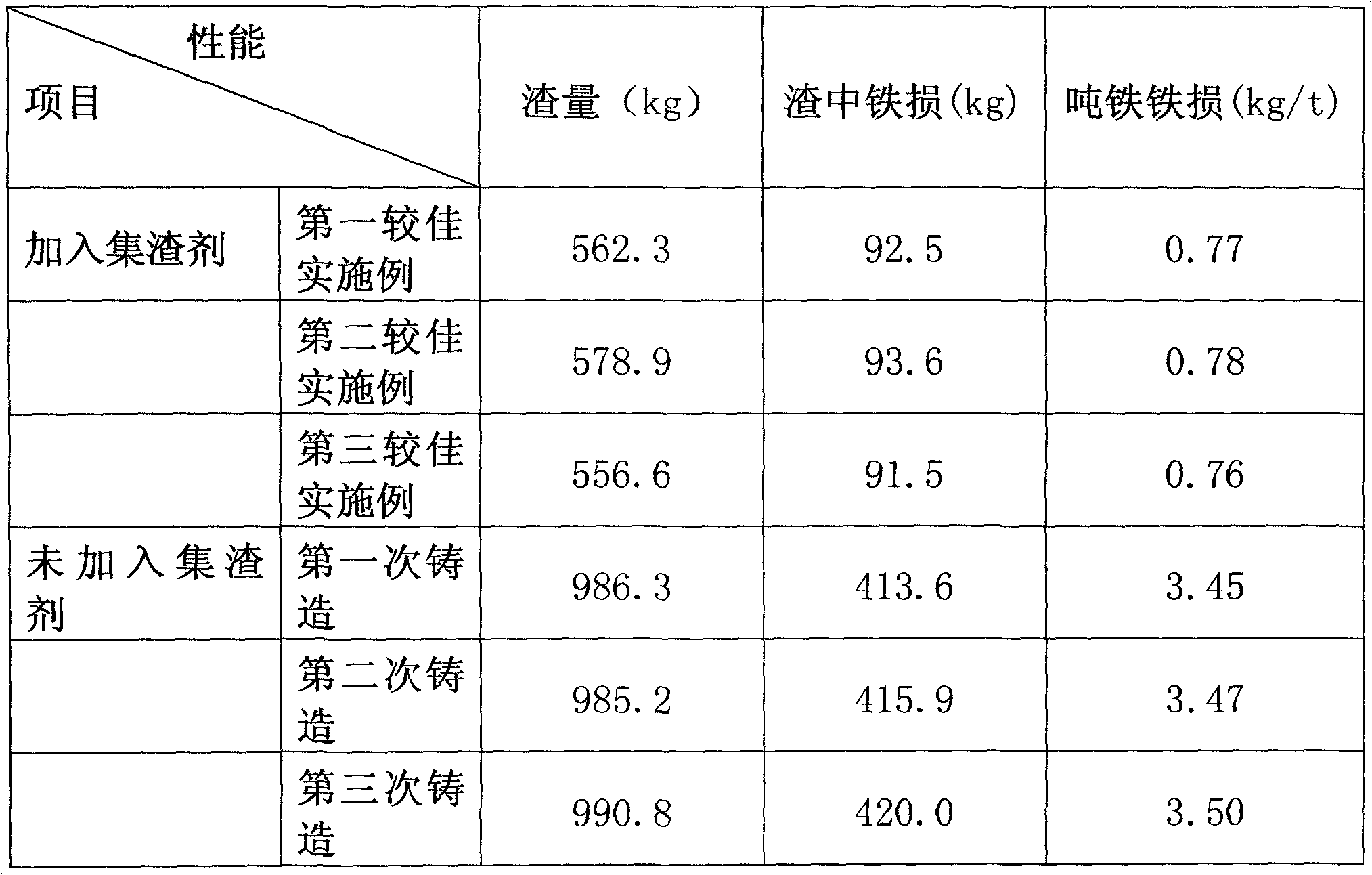

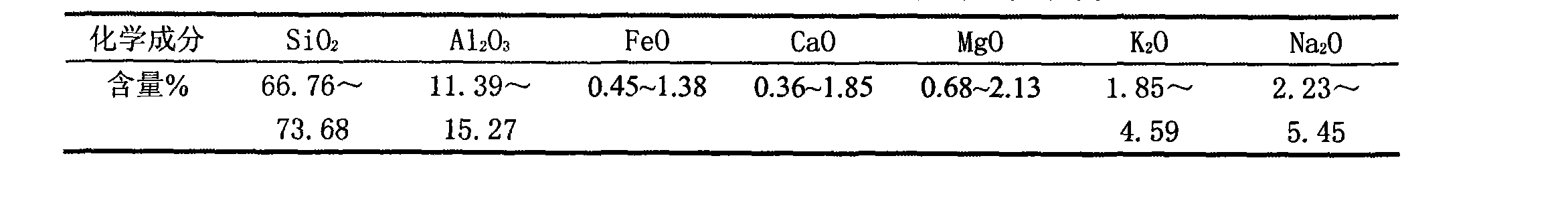

Slag collecting agent and preparation method thereof

The invention discloses a slag collecting agent, belongs to the technical field of cast iron metallurgy and solves the defects that in the prior art, the slag collecting agent has poor slag collecting effect and large iron loss. The slag collecting agent comprises the following components by mass percent: 74%-74.5% of SiO2, 12.7%-13.1% of Al2O3, 0.8%-1.2% of Fe2O3, 0.7%-0.9% of Ca, 0.08%-0.12% of Mg, 4.3%-4.7% of K2O, 3.0%-3.4% of Na2O and the balance of Fe and inevitable impurities. The invention also discloses a preparation method of the slag collecting agent. Compared with the existing slag collecting agent, the slag collecting agent disclosed by the invention has the following beneficial effects: (1) drossing time is short: after the slag collecting agent is added, slagging effect is good, furnace slag is of a large bulk shape, drossing is easy and complete, and drossing time is reduced by two thirds as compared with the drossing time without adding the slag collecting agent; (2) iron loss is small: after the slag collecting agent is added, the average iron loss of iron slag is reduced to less than 1kg / t from 3.5kg / t; and (3) in the use process, the slag collecting agent has no environment pollution, no toxicity, no dust, no odor, wide raw material sources and low cost.

Owner:宁波康发铸造有限公司

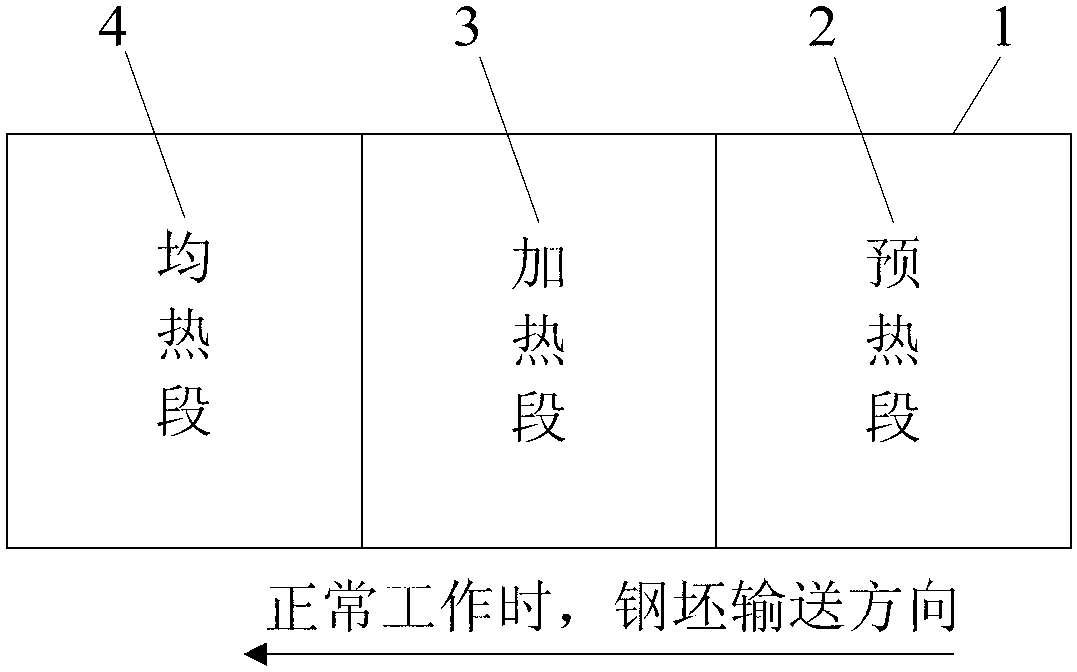

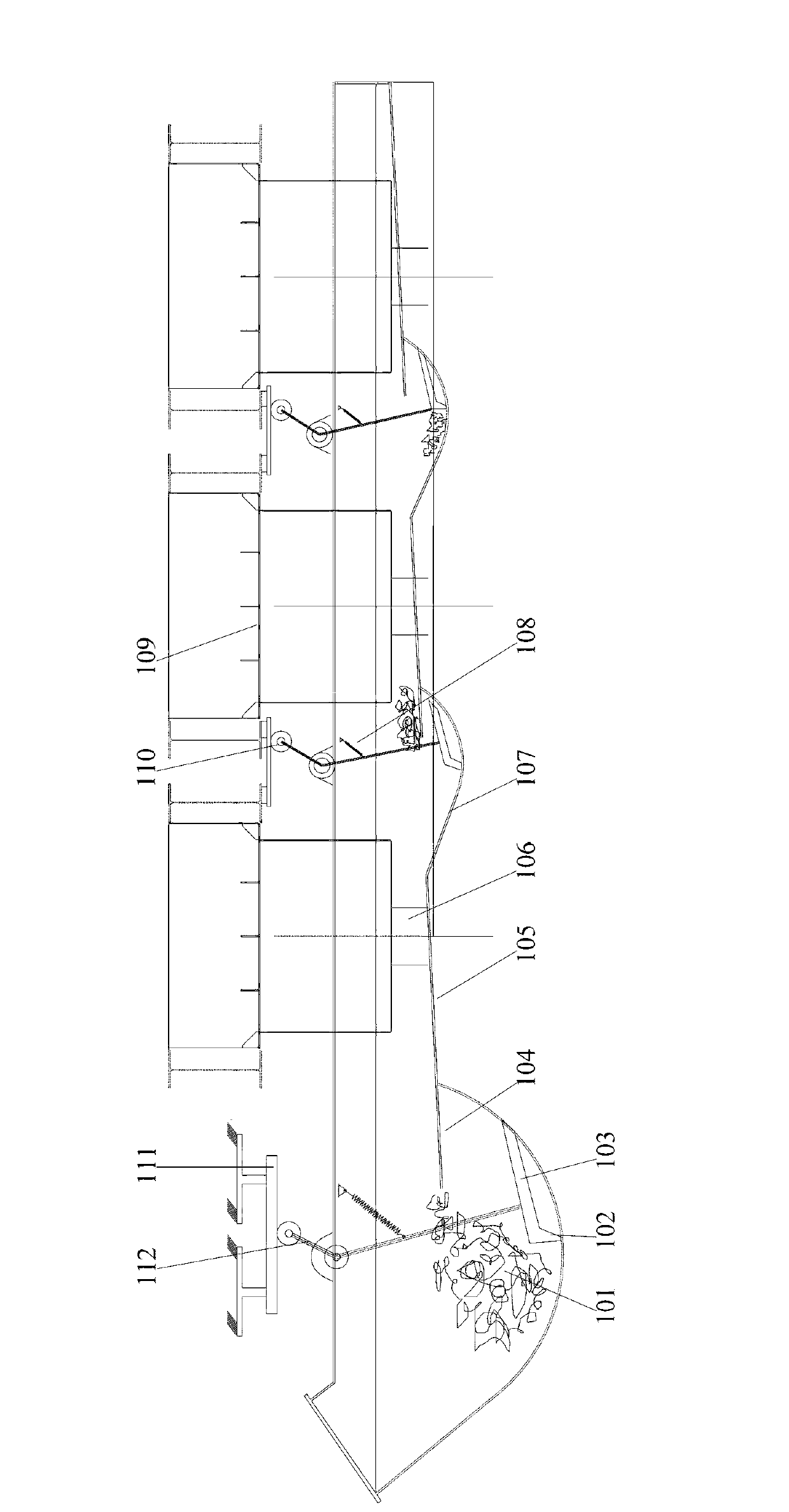

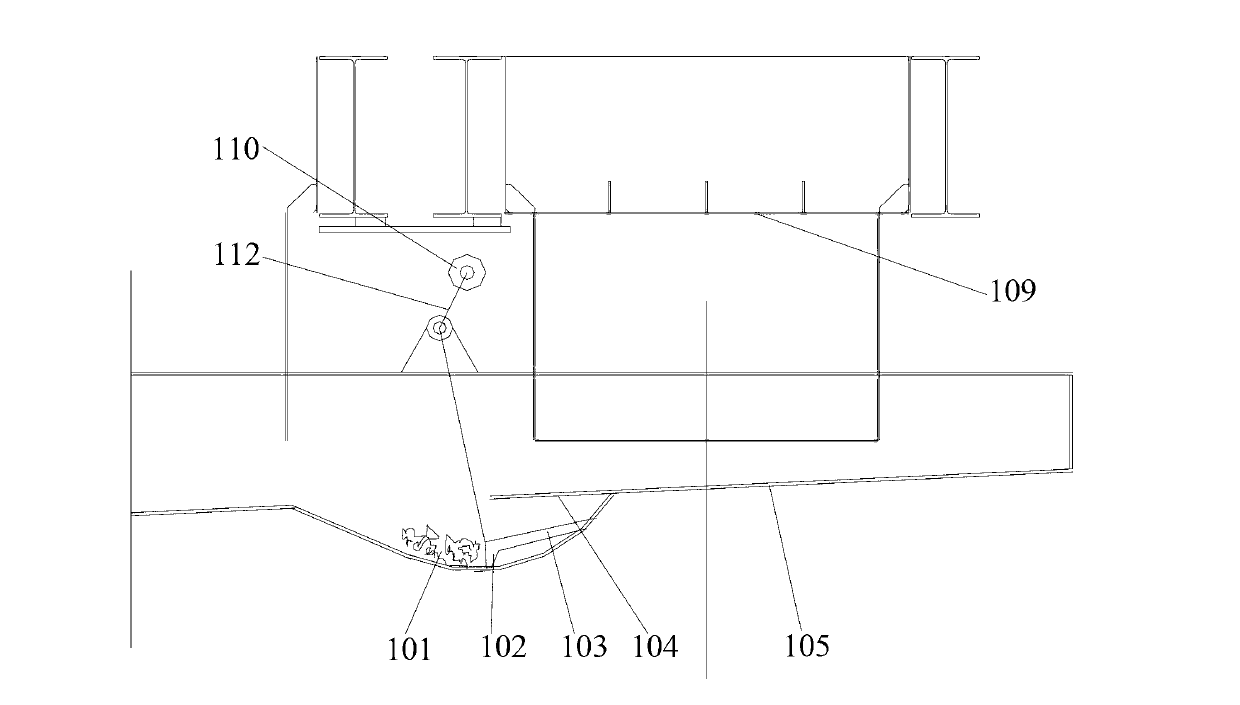

Walking beam reheating furnace

The invention discloses a walking beam reheating furnace. The walking beam reheating furnace comprises a furnace body, a water seal tank and seal boxes, wherein the plurality of seal boxes extending out of the furnace body are arranged at the bottom of the furnace body at intervals; the water seal tank is positioned below the furnace body; the lower ends of the seal boxes extend into the water seal tank; the bottom of the water seal tank, corresponding to the soaking section of the walking beam reheating furnace, is an inclined section from the preheating section of walking beam reheating furnace to the soaking section, and a plurality of arc sections are arranged on the inclined section; the walking beam reheating furnace further comprises a V-shaped swing stem hinged with the top of the water seal tank through the bending point, a pulley arranged at one end of the V-shaped swing stem and positioned close to the furnace body and slag pushing pieces fixed at the other end of the V-shaped swing stem and matched with the arc sections; and the opening of the V-shaped swing stem faces to the preheating section and has the angle range of 90 degrees to 180 degrees. By adopting the walking beam reheating furnace, ferric oxide slag at the bottom of the water seal tank, corresponding to the soaking section, can be discharged nearby, so that the slag removal effect is excellent.

Owner:LAIWU IRON & STEEL GRP

Down-the-hole holding-up hammer

PendingCN108756730AImprove perforation efficiencyExtended service lifeBorehole drivesEngineeringMaterial Perforation

A down-the-hole holding-up hammer comprises an outer casing pipe, a piston, an air distribution rod, an impact joint and a roller bit. An air inlet is formed in the upper end of the outer casing pipe,the lower end of the outer casing pipe is connected with the roller bit through the impact joint, and the impact joint is provided with a joint ventilating hole communicating with an inner hole spraying nozzle of the roller bit; the air distribution rod is fixedly arranged in the outer casing pipe, and the upper end outer wall of the air distribution rod and the inner wall of the outer casing pipe are fixed in a contact mode; the lower end of the air distribution rod extends into the joint ventilating hole in the impact joint, and the lower end outer wall of the air distribution rod is in contact fit with the inner wall of the joint ventilating hole in the impact joint; and the piston is arranged between the outer casing pipe and the air distribution rod, the piston can do up-down reciprocating impact movement in the axial direction of the outer casing pipe, and the bottom end face of the piston serves as an impact acting face acting on the impact joint. According to the down-the-holeholding-up hammer, the higher perforation efficiency and long service life are achieved under the pressure of 6-7.5 bar.

Owner:SHAREATE TOOLS

Ceramic slag separator and gel injection molding manufacturing process thereof

The invention discloses a ceramic slag separator and a gel injection molding manufacturing process thereof, and belongs to the technical field of slag separators. The ceramic slag separator is characterized in that a ceramic slag separator main body is made from aluminum oxide ceramic; the inner wall of the slag separator is 0.01 to 0.1mu m in roughness; the aluminum oxide ceramic is prepared from the following raw materials in percentage by mass: 54 to 60 percent of aluminum oxide, 0.8 to 1.2 percent of chitosan, 0.7 to 0.85 percent of acetic acid, 0.015 to 0.027 percent of glutaraldehyde, 0.2 to 0.35 percent of polyacrylamide and 37.985 to 43.873 percent of water. The manufacturing process comprises the following steps: adding the aluminum oxide, the chitosan and the polyacrylamide into a ball mill in batches to perform ball milling, adding the acetic acid and the glutaraldehyde into a vacuum conical stirrer, and injecting slurry into a chromium-plated steel mold for curing and molding; placing a cured and molded product into a kiln for sintering to obtain the ceramic slag separator. The inner wall of the ceramic slag separator has a mirror effect, so that the problem of loss of accepted stock is solved, the recovery rate of the accepted stock is improved, and the equipment running utilization rate is high.

Owner:山东倍辰新材料有限公司

Tail wing pouring system and tail wing manufacturing method for aluminum alloy underwater launching tube

The invention discloses a tail wing pouring system for an aluminum alloy underwater launching tube. According to the tail wing pouring system, a horizontal runner and a vertical runner are located on the bottoms of vertical cylinders and communicate with each other, and the horizontal runner communicates with the bottoms of the vertical cylinders; a tail wing casting of the underwater launching tube is located inside the cylindrical area defined by the vertical cylinders and is spaced from the outer side wall of each vertical cylinder by a gap, the top of each vertical cylinder communicates with the corresponding gap, a cavity of the tail wing casting of the underwater launching tube is formed by an inner sand core, and an outline and wings of the tail wing casting of the underwater launching tube, the vertical cylinders and the gaps are formed by outer sand cores. According to the system, the tail wings high in overall strength, water tightness, stability, earthquake resistance, corrosion resistance and dimensional accuracy can be provided; the method has the advantages that the process is simple, the operation is convenient and the manufacturing cost is low.

Owner:HUBEI SANJIANG AEROSPACE WANFENG TECH DEV

Low-energy-consumption buoyancy pushing type scum scraping device

ActiveCN105585062ASimple slag discharge equipmentGood slagging effectHollow article cleaningWater/sewage treatment by flotationTreatment effectEngineering

A low-energy-consumption buoyancy pushing type scum scraping device comprises a floating ball arranged in an ozone floatation column, the floating ball is connected to a rail bracket on the top of the ozone floatation column through an extending and contracting support which is of an inverted V-shaped structure, the extending and contracting support is formed by connecting two rods through a horizontal rotating shaft, the lower end of the rod located on the rear portion is connected with the floating ball, the lower end of the rod located on the front portion is connected with an arc-shaped scum scraping plate, the horizontal rotating shaft is arranged on the rail bracket in a slidable mode and is perpendicular to the rail direction, a spring for horizontally abutting against the rotating shaft is arranged on the rail bracket, and the arc-shaped scum scraping plate and the spring are located in front of and behind the floating ball respectively. Compared with a traditional closed scum extruding technology, by means of the low-energy-consumption buoyancy pushing type scum scraping device, the problems that the traditional technology is larger in energy consumption, and more equipment is used are solved; meanwhile, automatic operation is easy to conduct, the treatment effect is stable, and important significance in the field of advanced wastewater treatment is achieved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Straw gasification combustor

InactiveCN101660751BImprove combustion efficiencyBurn fullySolid fuel combustionSpecial form destructive distillationCombustorCombustion chamber

Owner:C A S ZHONGLI SCI & TECH CO LTD

Molten iron pretreatment slag collecting agent

InactiveCN101372722AThe desulfurization rate has no effect onNo pollutionCasting cleaning apparatusSlagPre treatment

The invention discloses a slag-collecting agent of pre-treatment for molten iron, containing the following raw materials by weight percentage: 60-80 parts of perlite, 5-15 parts of potassium-sodium feldspar and 10-20 parts of white sand. Compared with the traditional technique, the invention has the advantages as follows: 1 the time of slag-raking is short, after the slag-collecting agent is added, the process furnace is slagged totally with good effect of slagging, slag appears big block to rake easily and completely; the time of slag-raking is 1 / 3 times that of slag-raking without the slag-collecting agent, the slag is completely raked, the quantity of slag in the molten iron is decreased, thus efficiently improving the condition of the molten iron entering furnace; 2 iron loss is little, after the slag-collecting agent is added, the iron loss of the iron slag is reduced from average 6.25kg iron per ton to below 1kg iron per ton; 3 the desulfurization degree of the molten iron is not influenced; 4 As the agent causes no pollution to environment in used, and is of no toxicity, no dust, no smell, convenient operation, wide source of materials and low cost, the requirements of steel plants can be fully met.

Owner:凯蒂(信阳)新型材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com