Slag collecting agent and preparation method thereof

A technology of slag collecting agent and mass percentage, applied in the field of slag collecting agent and its preparation, can solve the problems of inability to meet the casting requirements of ductile iron, the effect is not significant, and the time of slag removal is reduced, and the slag forming effect is good and the iron loss is small. , the effect of short slag removal time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

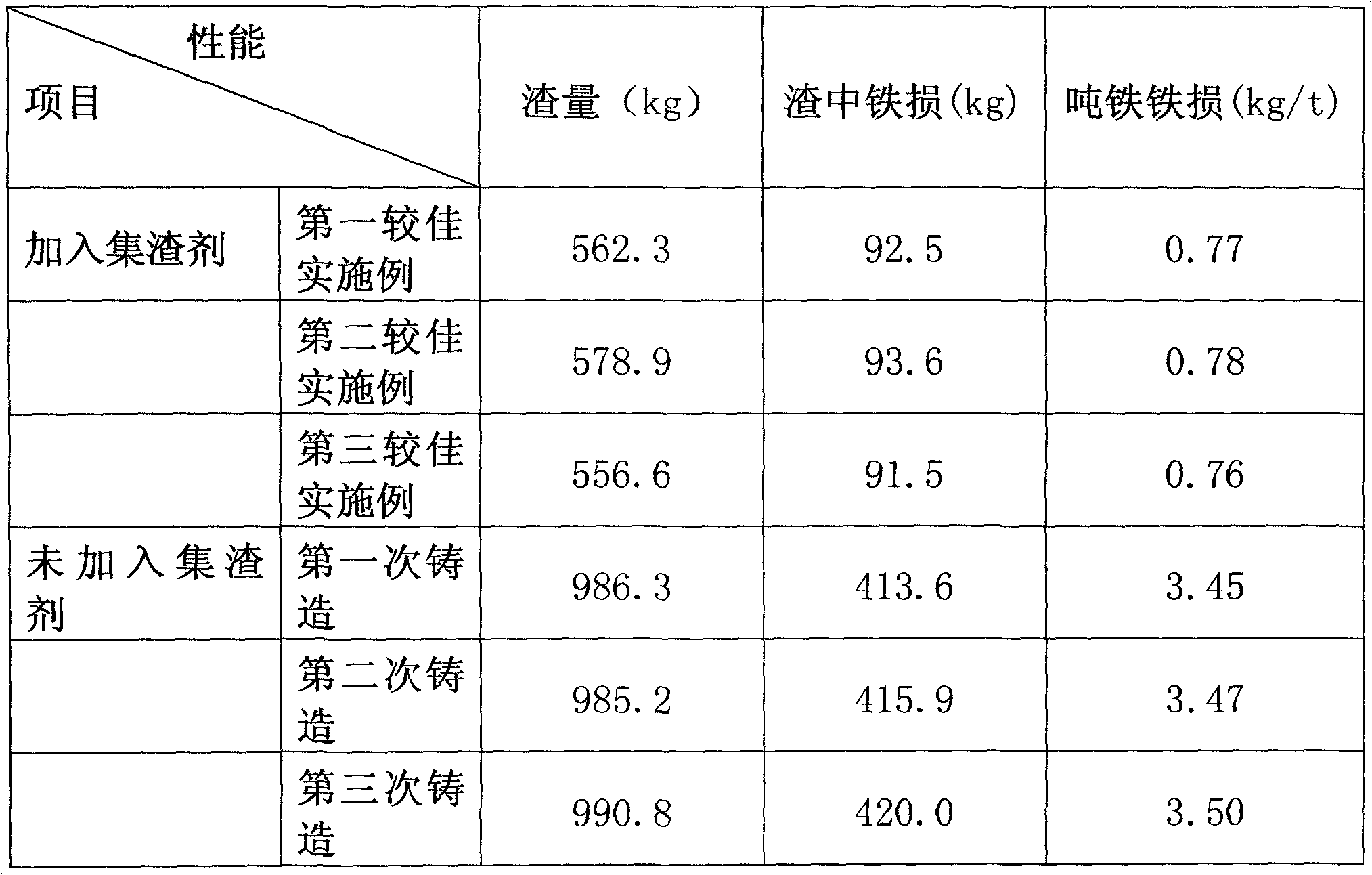

Examples

Embodiment Construction

[0013] The slag collecting agent mainly uses the neutral substance to expand or melt under the action of high temperature. After expansion, it forms low specific gravity, hollow air holes, and has certain cohesive properties after melting to gather the residue on the surface of the molten iron to form a residue block. Easy to clean up. Since the slag collector uses neutral substances as its main component, its chemical properties are stable and will not cause secondary pollution to molten iron.

[0014] In the first preferred embodiment of the present invention, the mass percent of the slagging agent is: SiO 2 : 74%, Al 2 o 3 : 12.7%, Fe 2 o 3 : 0.8%, Ca: 0.7%, Mg: 0.08%, K 2 O: 4.3%, Na 2 O: 3.0%, the balance is Fe and unavoidable impurities.

[0015] In the second preferred embodiment of the present invention, the mass percent of the slagging agent is: SiO 2 : 74.5%, Al 2 o 3 : 13%, Fe 2 o 3 : 1.0%, Ca: 0.8%, Mg: 0.10%, K 2 O: 4.5%, Na 2 O: 3.2%, the balance is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com