Down-the-hole hammer reverse circulation pipe-following drill bit suitable for large-diameter drilling

A down-the-hole hammer and reverse circulation technology, which is applied to drill bits, earthwork drilling, drilling equipment, etc., can solve the problems of difficult construction, frequent accidents, and low efficiency, and achieve good slag discharge effect, high structural strength, and reverse circulation high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

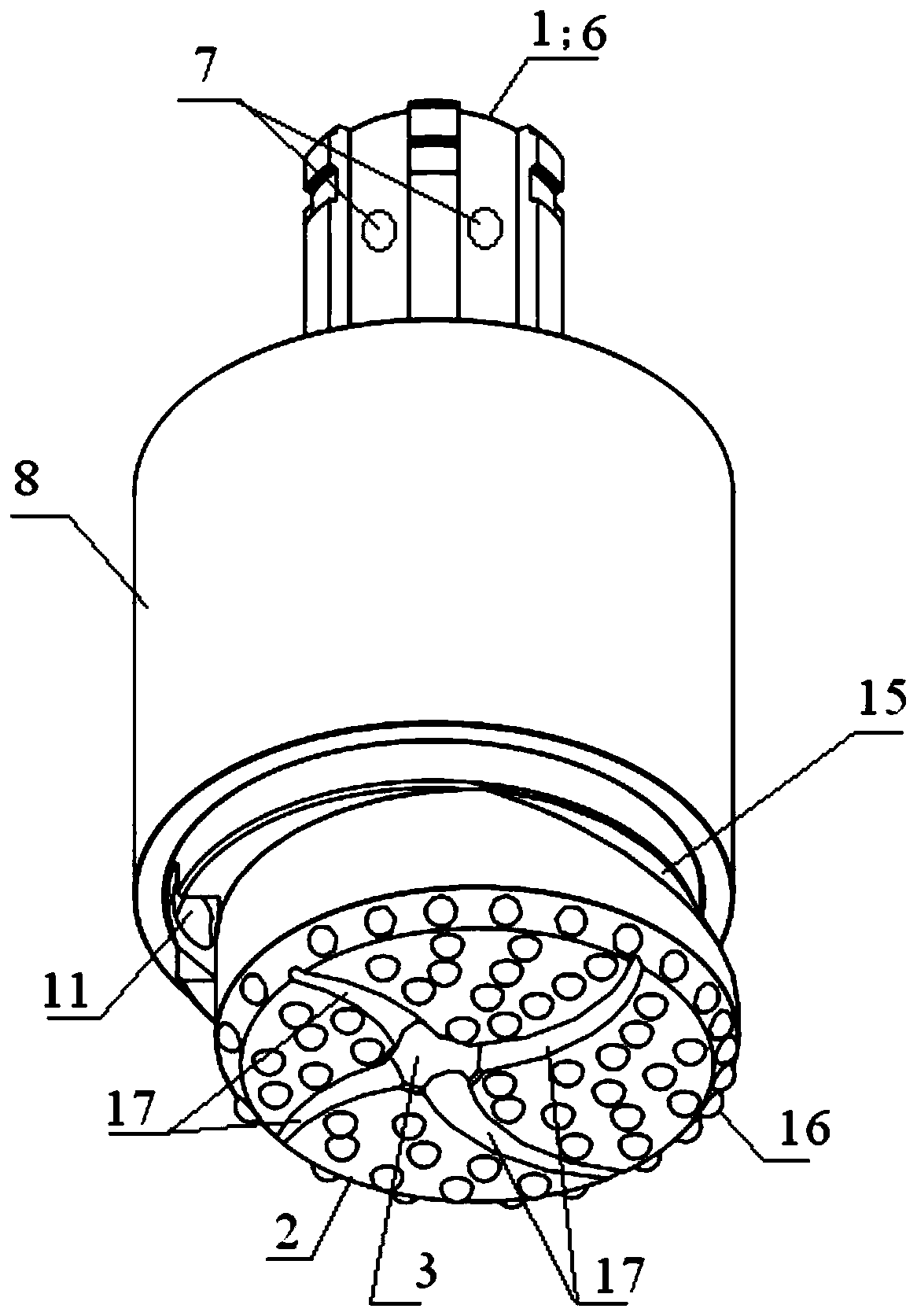

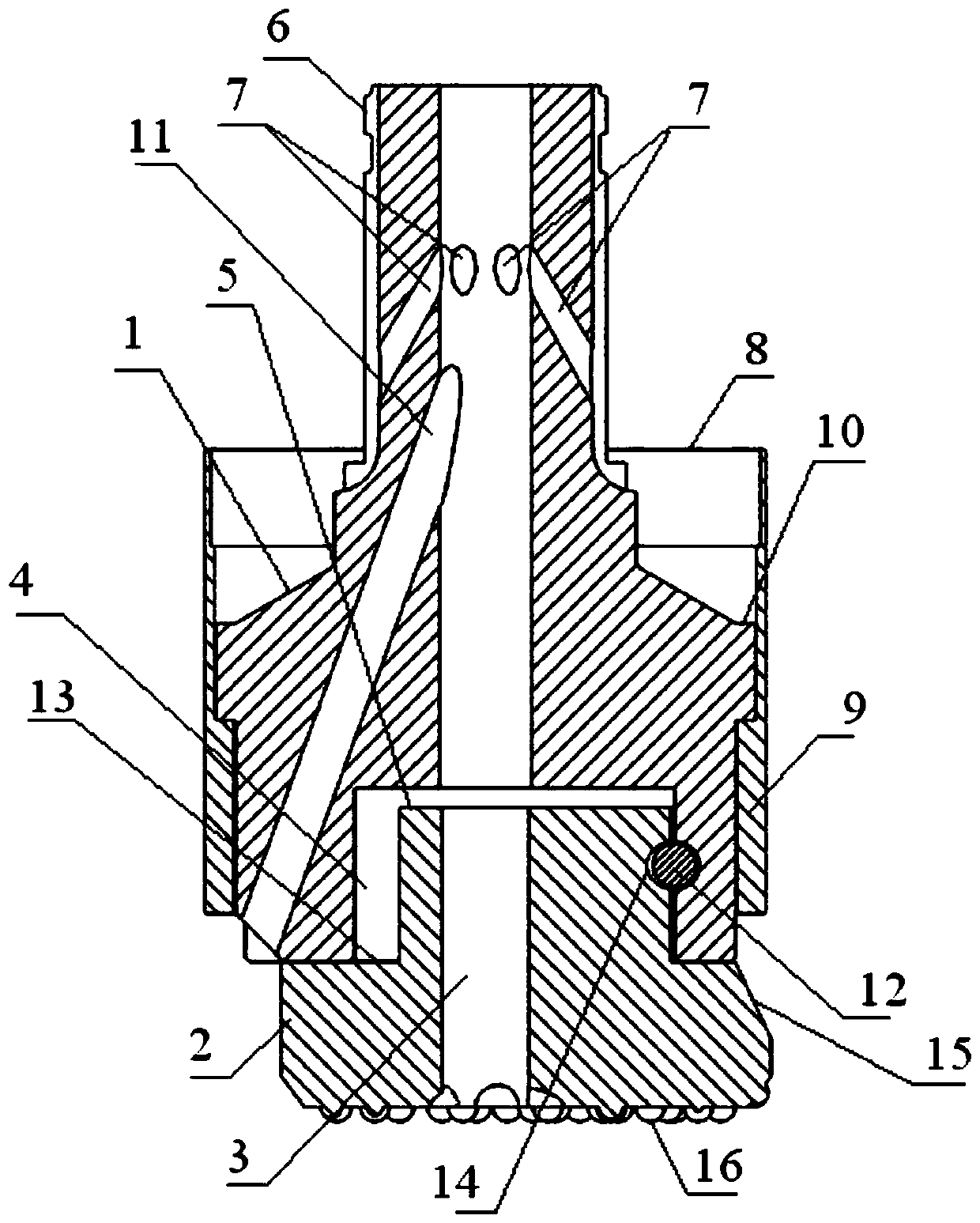

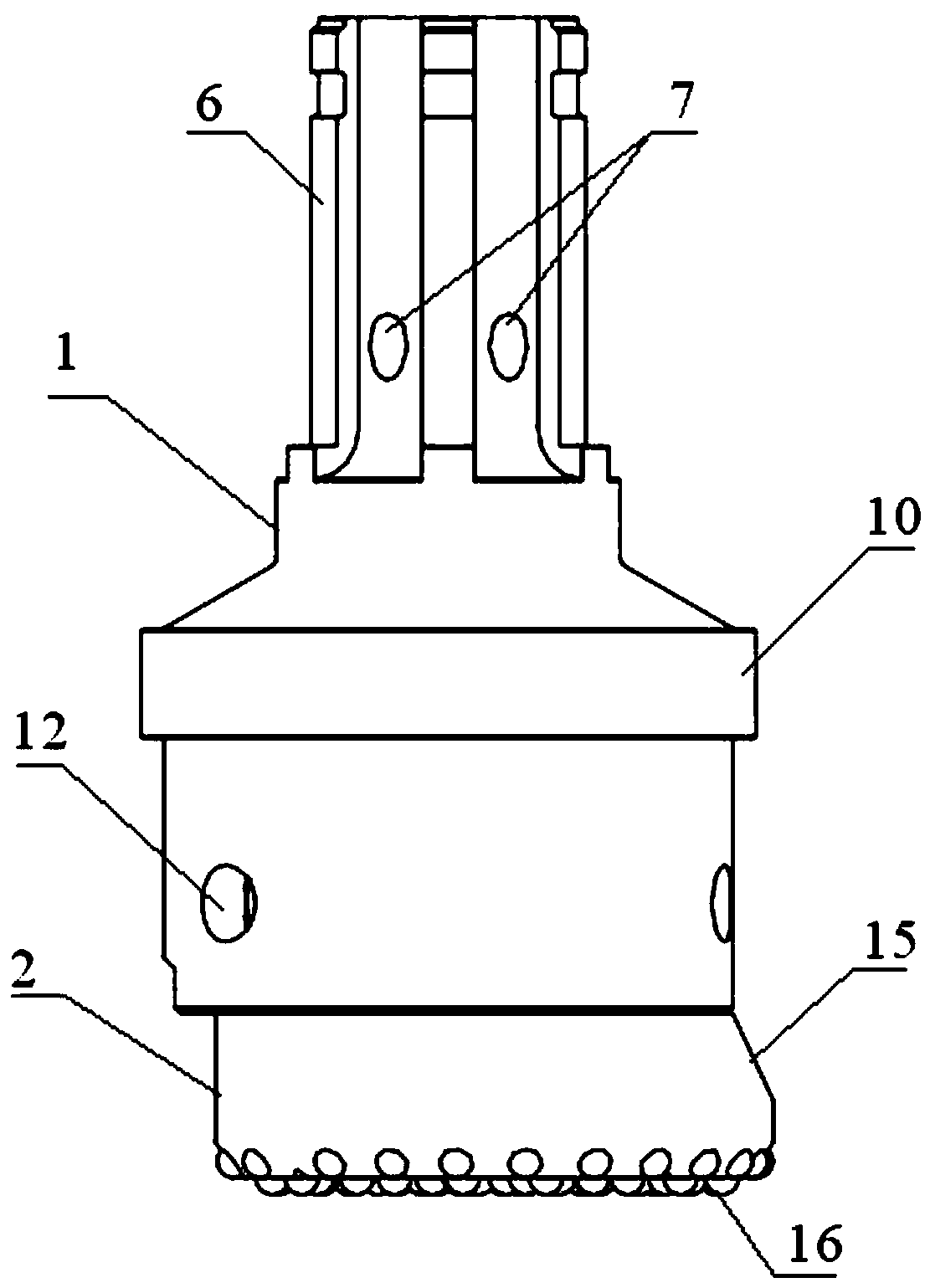

[0028] see Figure 1 to Figure 6 Shown:

[0029] The down-the-hole hammer reverse circulation pipe drill bit suitable for large-diameter drilling provided by the present invention includes an upper bit body 1 and a lower bit body 2, wherein the lower bit body 2 is hung on the lower part of the upper bit body 1, and the upper bit body 1 The central channel 3 is provided in the middle part of the lower drill body 2, the lower part of the upper drill body 1 is provided with a groove 4, and the top of the lower drill body 2 is provided with a convex shaft 5, and the groove 4 corresponds to the shape of the convex shaft 5. The protruding shaft 5 is inserted in the groove 4. The diameter of the groove 4 is larger than the outer diameter of the protruding shaft 5. The protruding shaft 5 can slide in the groove 4. When the protruding shaft 5 slides and abuts against one end of the groove 4 At this time, the bottom of the lower drill body 2 moves out of the outer edge of the drilling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com