Patents

Literature

187results about How to "Not easy to go off track" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

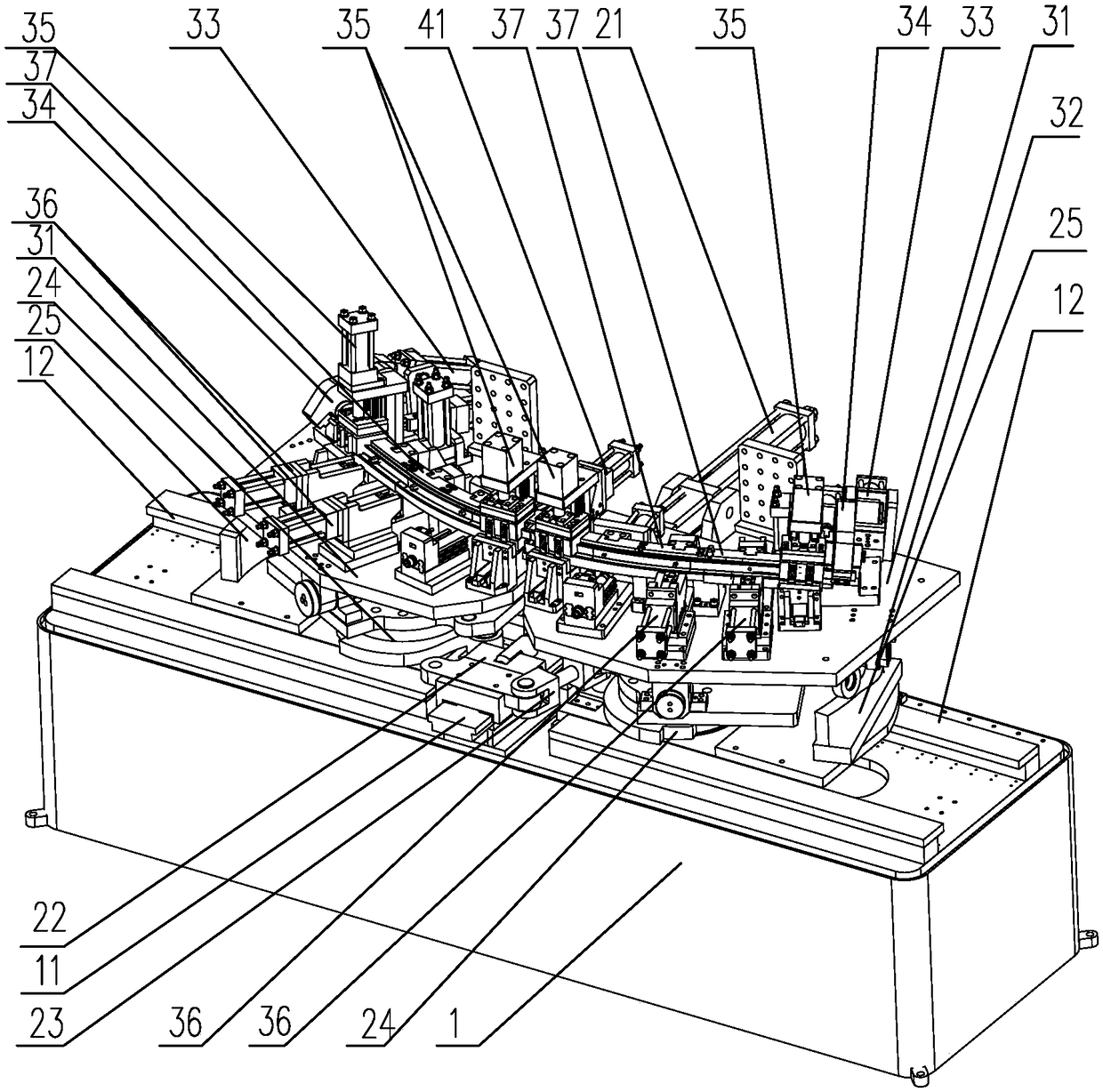

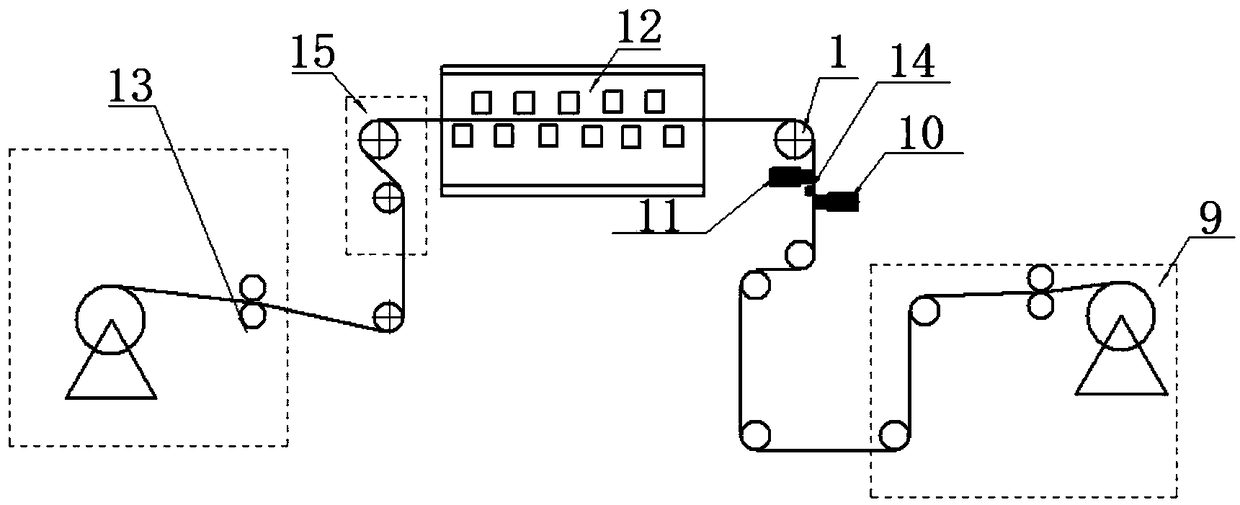

Automatic surface wiping and cleaning device and automatic cleaning machine

ActiveCN104624590AEliminate health hazardsIncrease frictionFlexible article cleaningEngineeringTouchscreen

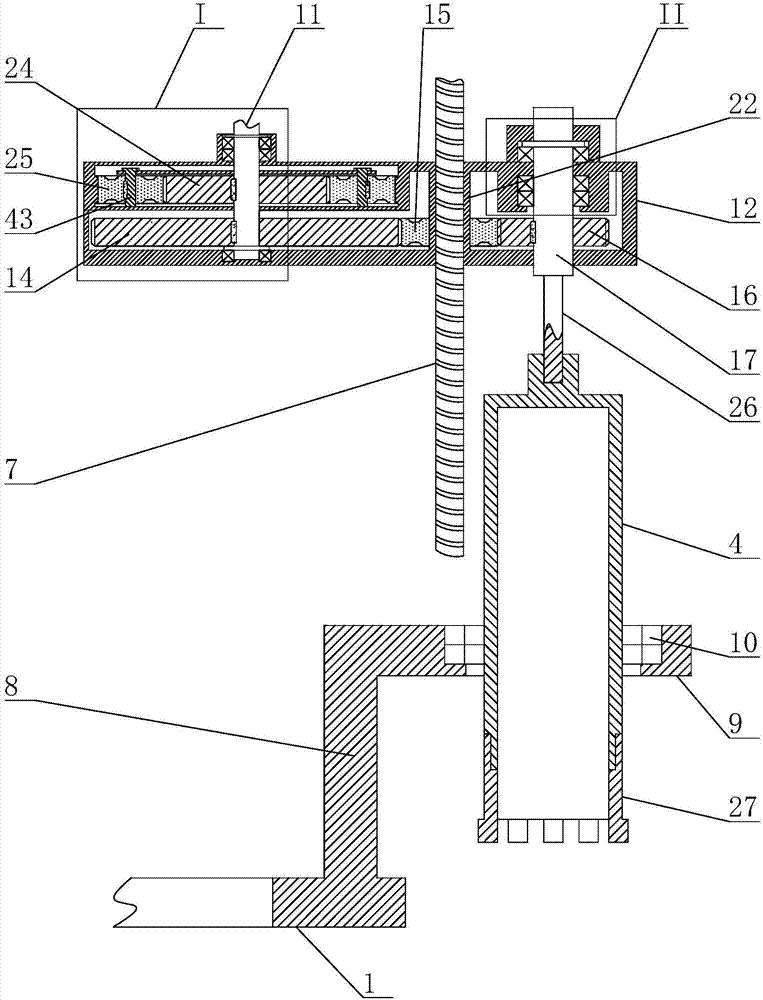

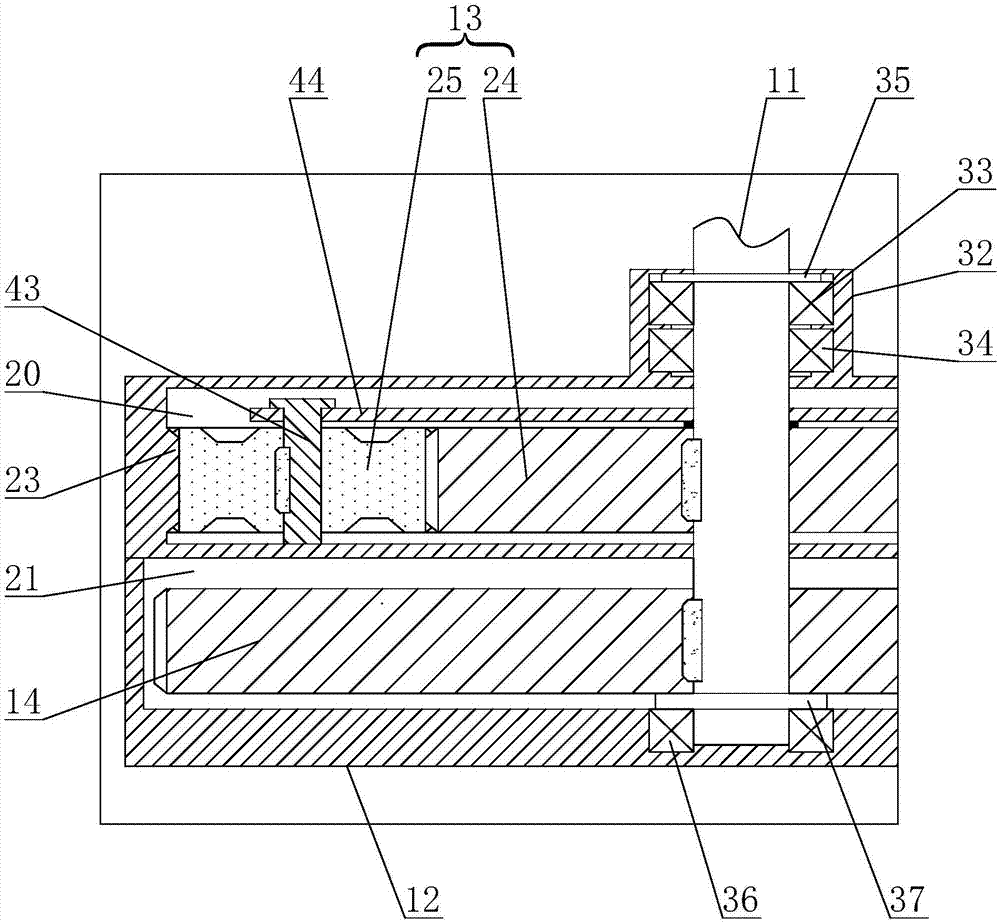

The invention relates to an automatic surface wiping and cleaning device and an automatic cleaning machine which are used for cleaning the surface of a touch screen of a mobile phone. A platform rotating mechanism is arranged at the center of a bottom plate of a power distribution cabinet, a feeding conveying line is arranged at the starting end of the cleaning machine, the feeding conveying line, a blowing conveying line, a feeding and discharging mechanical arm and a discharging conveying line are sequentially connected in a front-back mode and fixed to the front end of the bottom plate of the power distribution cabinet, the far end of the feeding and discharging mechanical arm is connected with the platform rotating mechanism, a first cleaning head mechanism and a second cleaning head mechanism are arranged beside the platform rotating mechanism, the cleaning head mechanisms are provided with cleaning press plates used for cleaning materials according to sine wave tracks, and the cleaning press plates are connected with ethyl alcohol spraying mechanisms. The automatic surface wiping and cleaning device and the automatic cleaning machine have the advantages of eliminating health hazards of manual operation and greatly improving cleaning work efficiency and cleaning quality.

Owner:GUANGZHOU LINKCORE AUTOMATIC EQUIP CO LTD

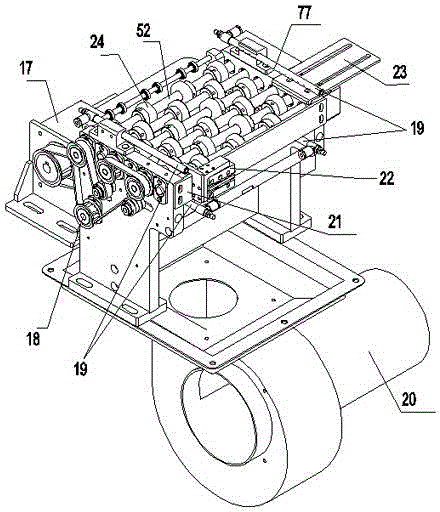

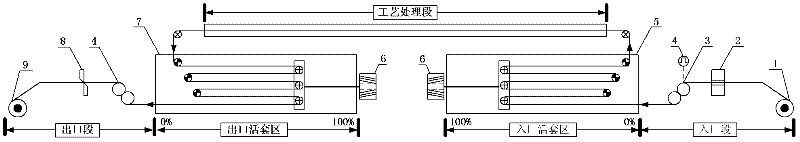

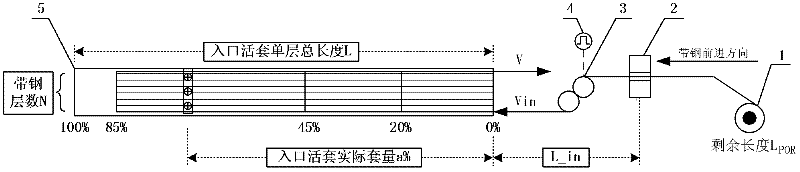

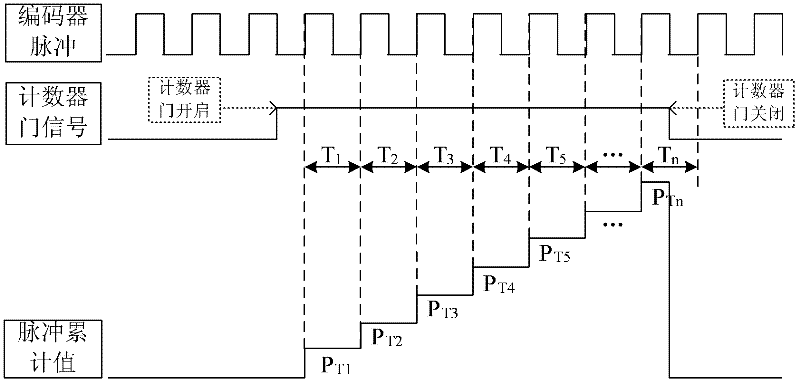

Automatic dynamic adjustment method for synchronous extension of loop of cold rolling continuous processing line

ActiveCN102553948AThere is no need to dynamically adjust the set value of synchronous setsPrevent deviationFlexible work arrangmentsMetal rolling arrangementsBreakage probabilityExtension set

The invention relates to an automatic dynamic adjustment method for synchronous extension of a loop of a cold rolling continuous processing line. The automatic dynamic adjustment method specifically comprises the following steps of: at a non-drift stage of an uncoiling machine, acquiring a pulse encoder signal on an inlet tension roller, calculating the actual traveling distance of strip steel and thereby judging the relative position of a weld joint and the loop, and automatically adjusting a synchronous extension set value of the loop; at a drift stage of the uncoiling machine, calculating length of strip steel to be replenished according to a target set value and a current actual value for the synchronous extension of the loop, comparing the length of the strip steel with that of the remaining strip steel on the inlet uncoiling machine, and automatically adjusting the synchronous extension set value of the loop; and finally, arranging a functional module in a cold rolling continuous processing line control system to realize an undisturbed automatic switching function of the synchronous extension set value of the loop. According to the automatic dynamic adjustment method, deviation of the strip steel in the loop can be prevented, and the strip breakage probability of the strip steel in the loop is reduced; the production efficiency of the processing line can be increased and the working intensity of operation personnel is reduced; and the disposal difficulty for strip breakage accidents in the loop can be reduced and the accident recovery time is shortened.

Owner:WISDRI WUHAN AUTOMATION

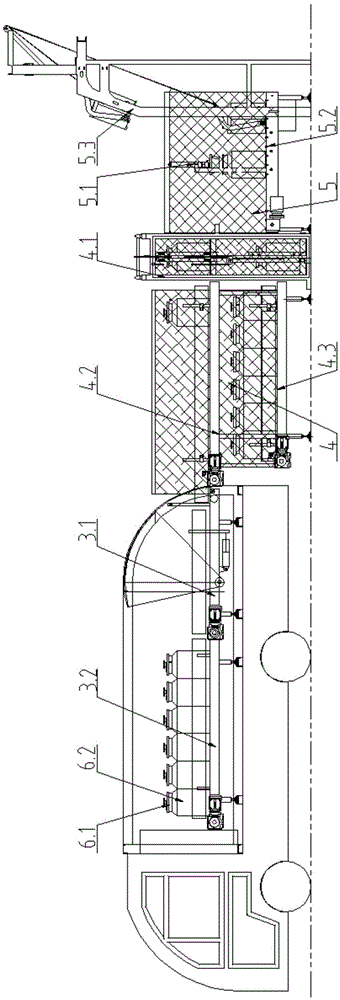

Sample barrel automatic transferring system

ActiveCN105600511AConvenient input and outputReduced Parking Position Accuracy RequirementsLoading/unloadingInformation leakageSample collection

The invention discloses a sample barrel automatic transferring system, which comprises a sample collector, a transferring vehicle, a vehicle loading conveying device, a vehicle unloading conveying device and an automatic discharging device, wherein the sample collector is an automatic inlet and outlet collector; a clamping mechanism takes out sample barrels from the collector; the conveying device transfers the sample barrels which are taken out to the vehicle loading conveying device; the vehicle loading conveying device and the vehicle unloading conveying device are inclined conveyors or vertical and horizontal conveyors or rotary conveyors; the sample barrels are transferred to the transferring vehicle from the sample collector; the automatic discharging device comprises a cover opening mechanism, a conveying machine and a discharging mechanism; sealing cover bodies are arranged above the conveying device of the sample collector, the outer side of the vehicle loading conveying device, above the transferring vehicle, the outer side of the vehicle unloading conveying device and above the conveying machine in the automatic discharging device. The sample barrel automatic transferring system has the advantages that sample collection, packaging and transferring are performed in the sealed environment; the sample accuracy is ensured; the sample information leakage is prevented.

Owner:SAIMO ELECTRIC

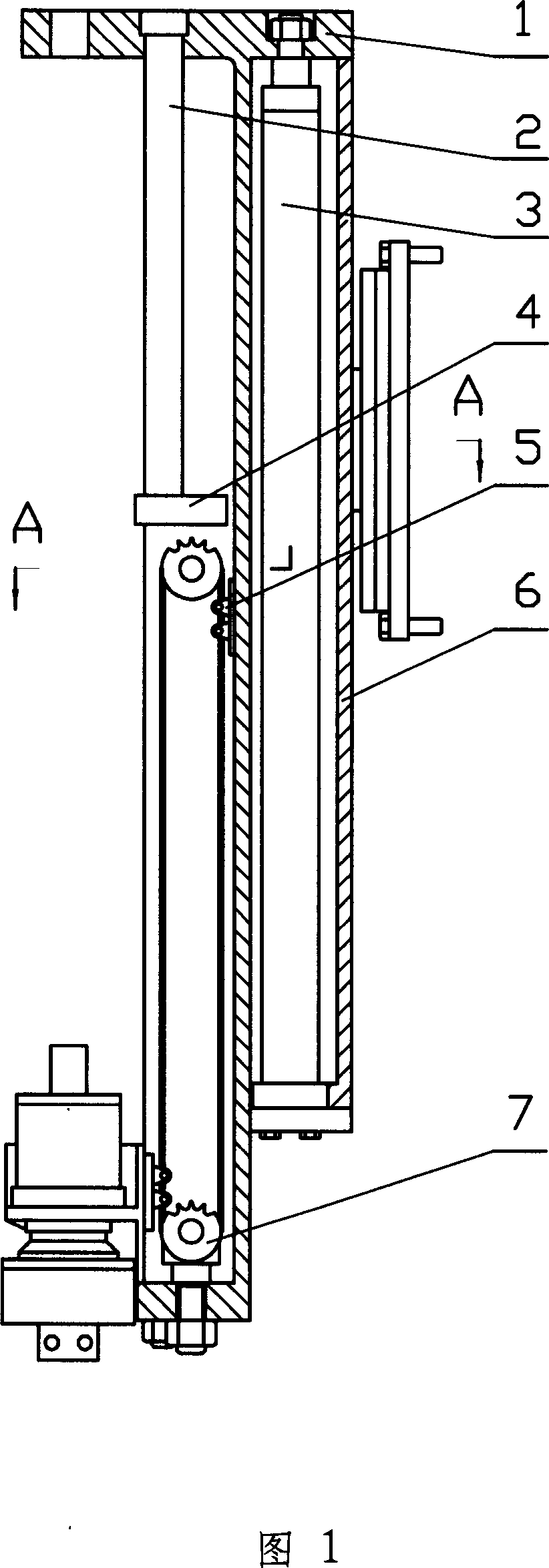

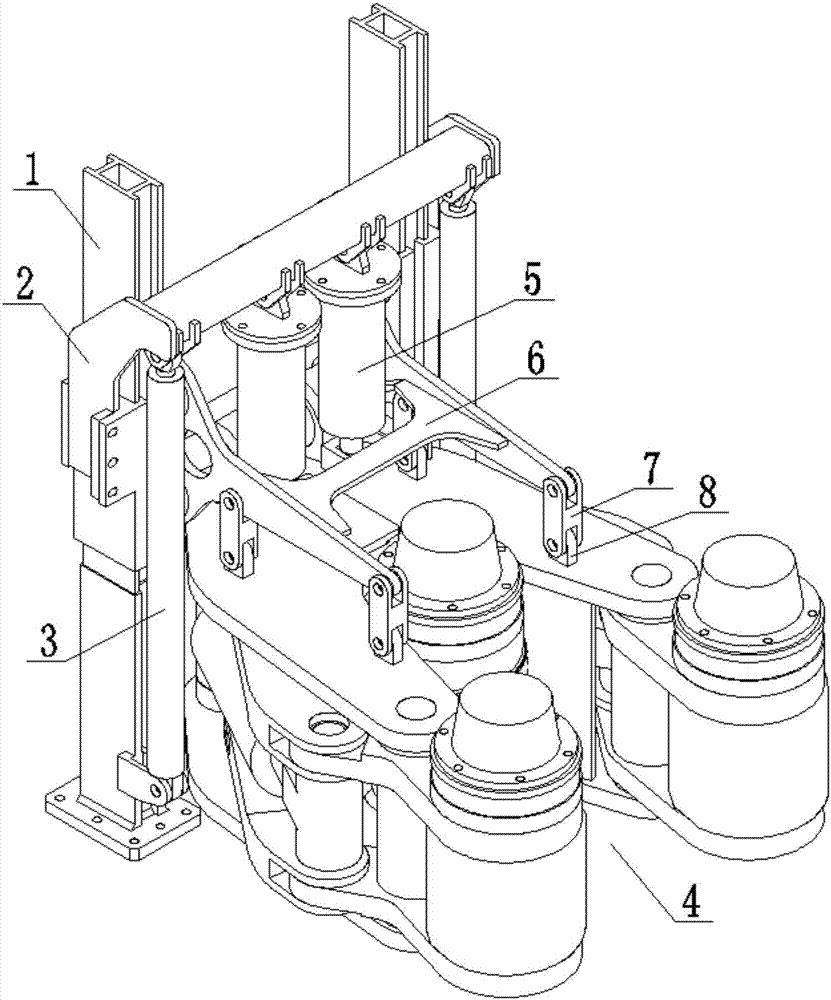

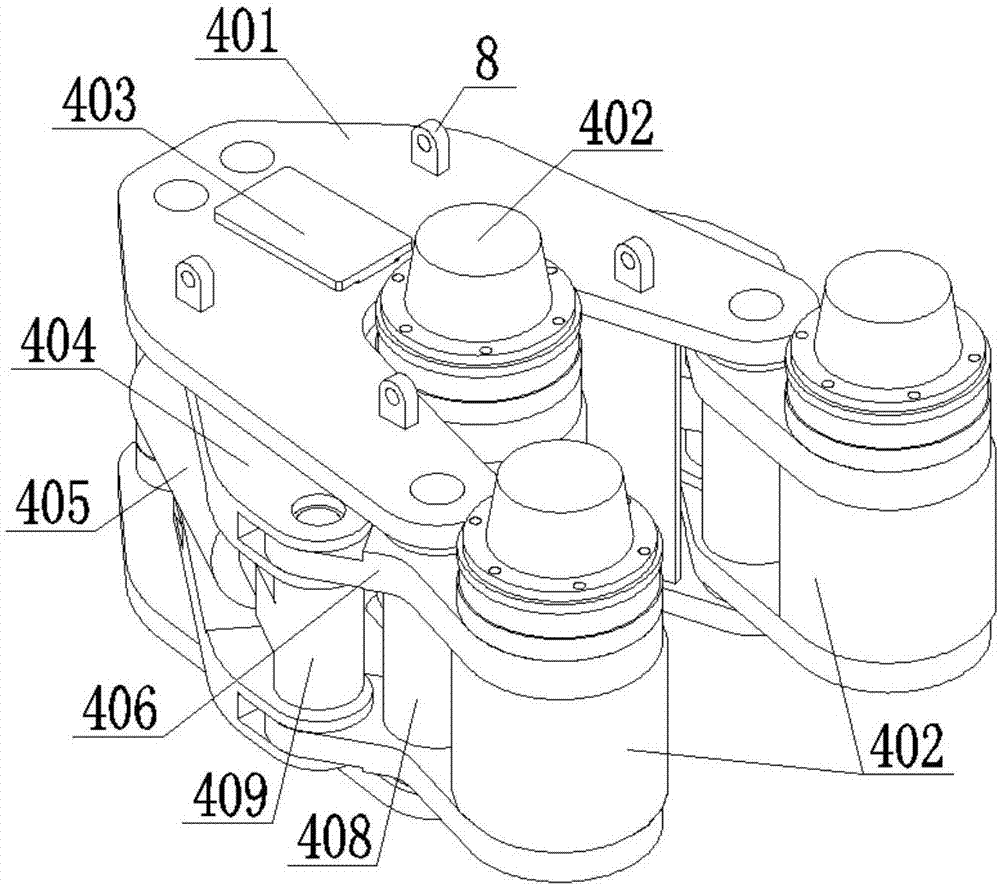

Airborne anchor rod drilling machine

InactiveCN1948696AControl vibrationReduce swingConstructionsRotary drillingHydraulic motorEngineering

This invention relates to a rig using for the tunnel anchor below the coal mine. This invention resolves the problem of the existing technology. It supplies an airborne anchor pole rig that can locate more precise and assurance the quality of anchor hole. It includes hydraulic motors, tanks, fixation agencies, supporting agencies, feed and drilling sector. The front bracket inserts the sliding chute of back bracket. The supporting guide pole installed in the front bearer penetrates the guide hole of the back bracket. The guide plate connecting to feed tank is installed feed guide pole of the front bracket. The guiding hole on the hydraulic motor bed is installed on the feed guiding pole. Thus, all expanding components move along the guide pillar and the sliding chute, so the locating is more precise, the anchor hole has the high quality.

Owner:SHANXI DONGHUA MACHINERY

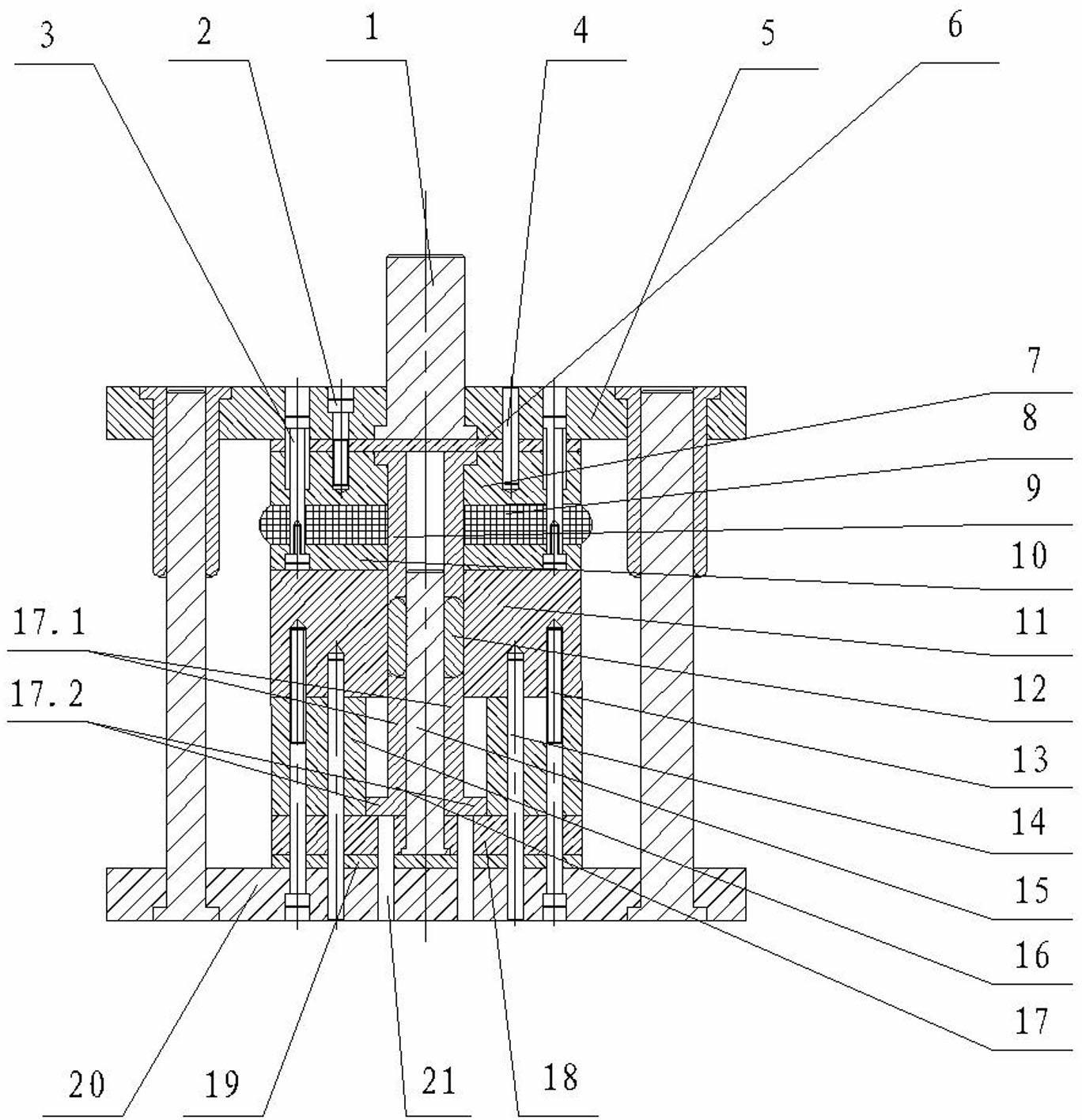

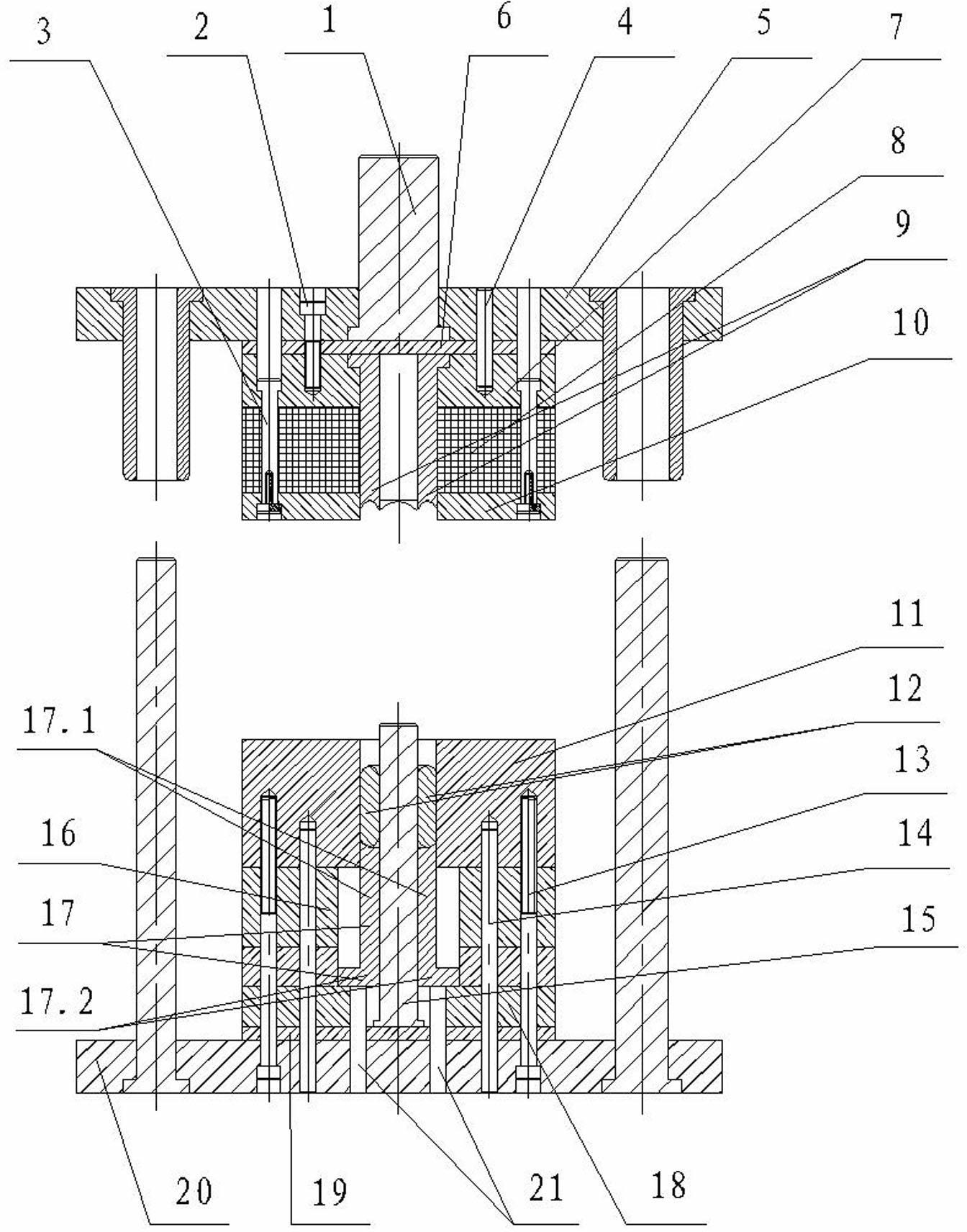

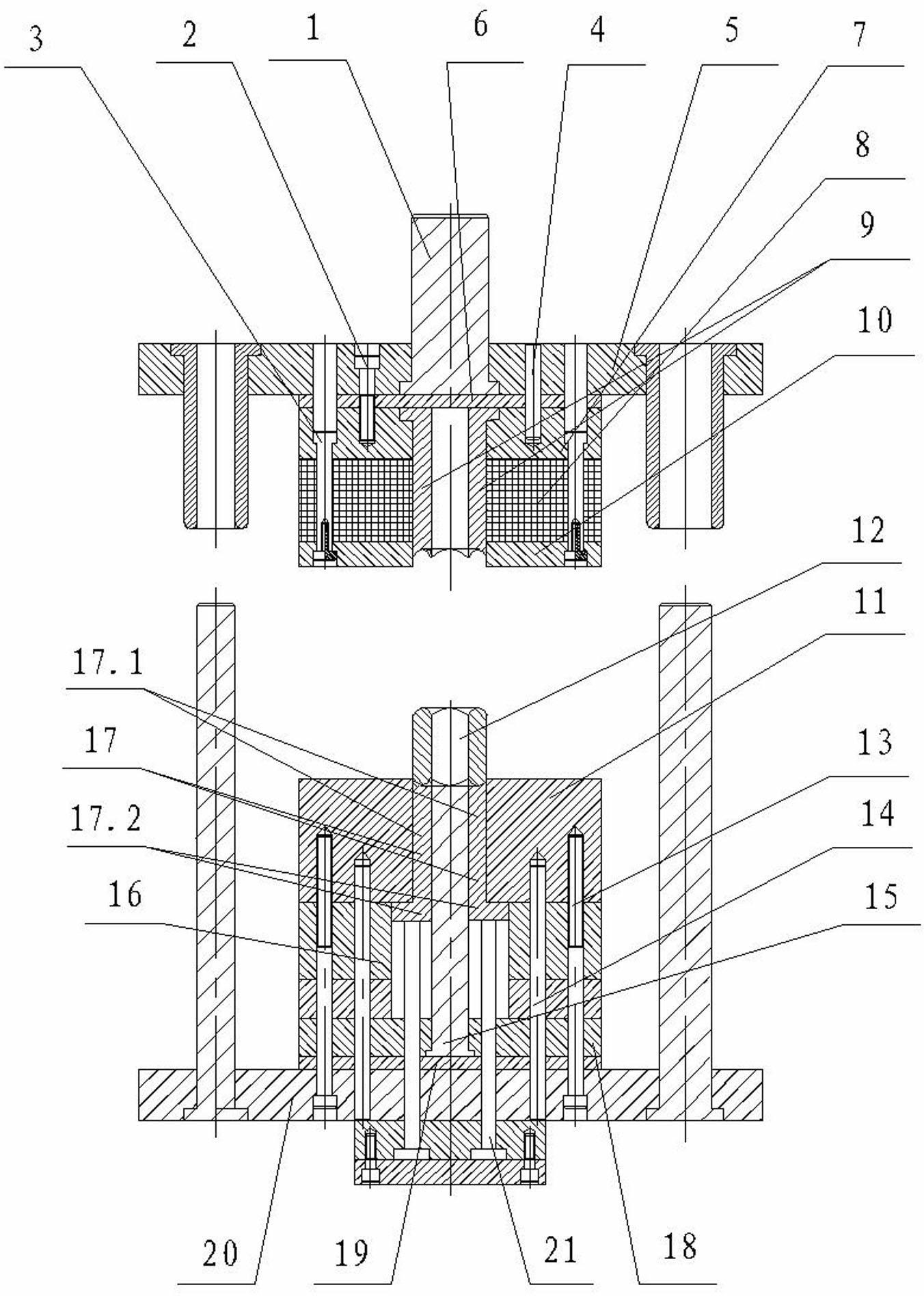

Hot stamping mould for nut

The invention discloses a hot stamping mould for a nut. The hot stamping mould comprises an upper mould frame, an upper mould base plate, a fixing plate, an elastomer and a stripper plate which are sequentially fixedly connected from top to bottom, a lower mould frame, a lower mould base plate, a lower mould fixing plate, a base plate and a lower female mould plate which are sequentially fixedly connected from bottom to top, and a mould shank, wherein the lower end of the mould shank is fixed on the upper mould frame; a hollow upper male mould is fixed in a stepped hole which is formed by the stripper plate, the elastomer and the fixing plate; a mould core and a lower moving mould matched in a sliding mode are arranged in a stepped hole which is formed by the lower female mould plate and the base plate; the cross sections of the upper male mould, the hole of the lower female mould plate and the upper part of the lower moving mould are hexagons; and a jacking mechanism is arranged at the bottom of the lower moving mould. Due to the hot stamping mould for the nut, the production process of the nut is simple, time consumption is low, materials are saved, and the strength of the nut can be increased.

Owner:NINGBO HAOBO IND & TRADE

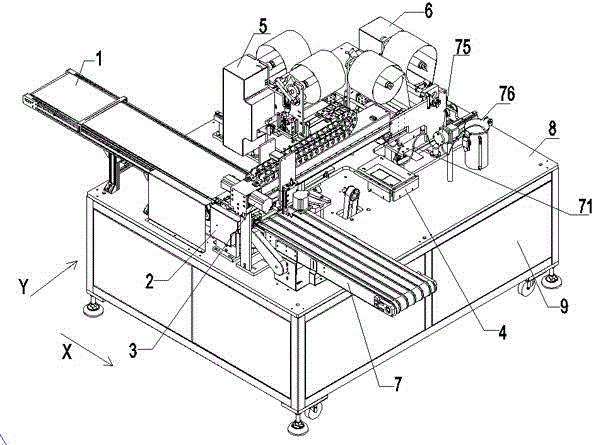

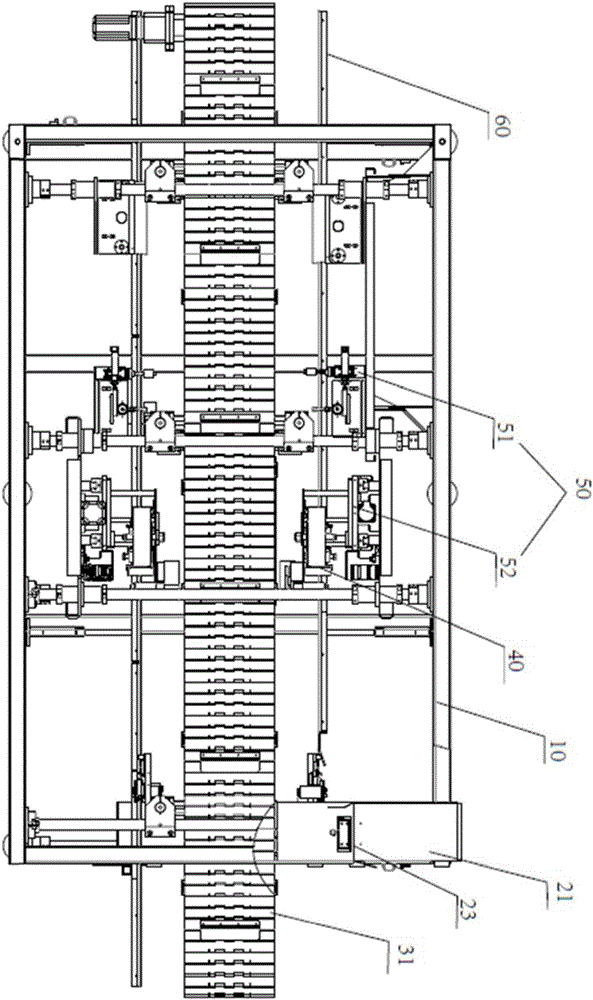

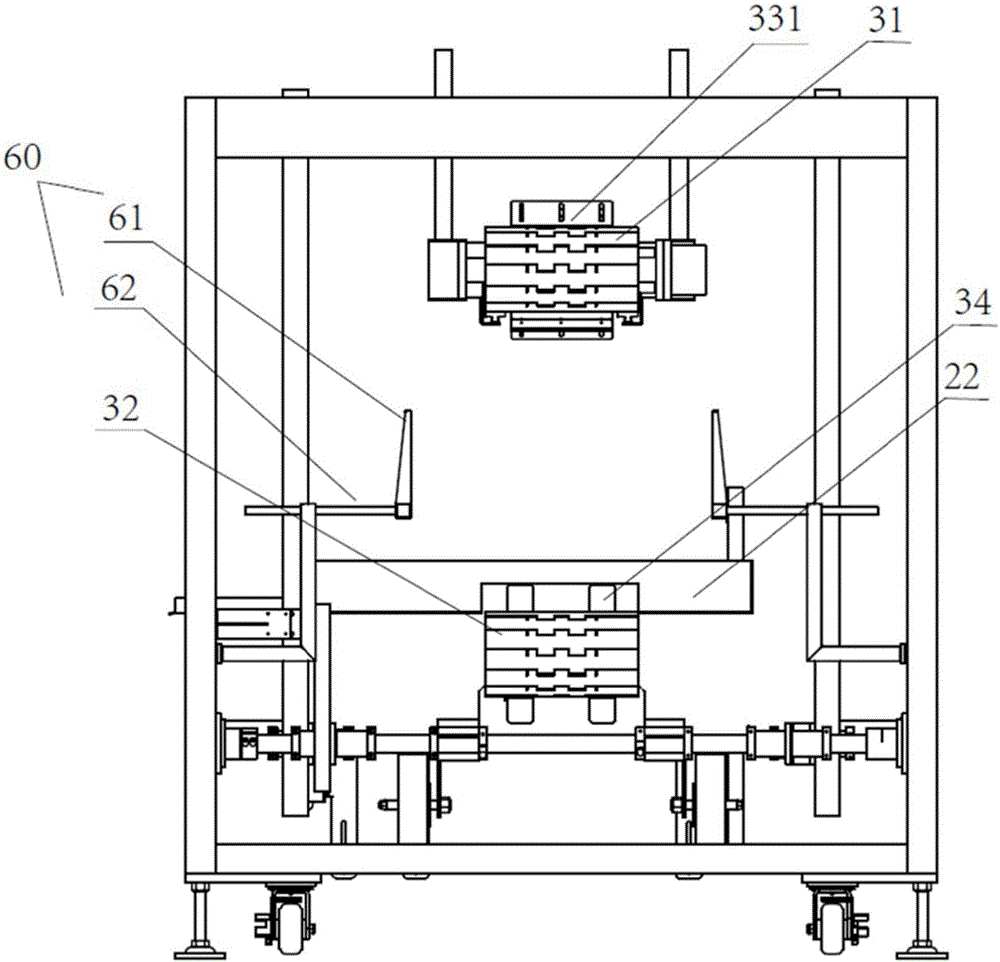

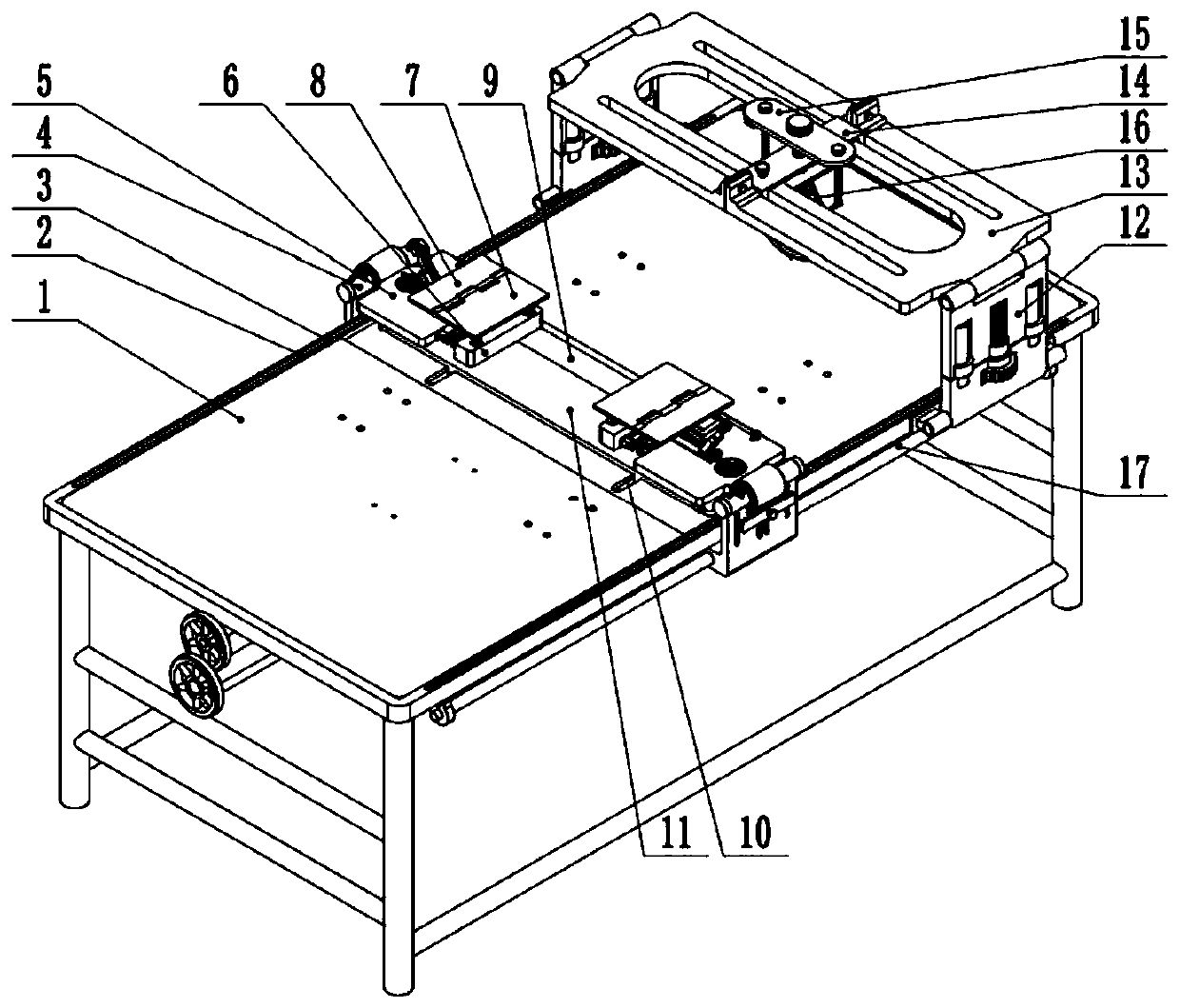

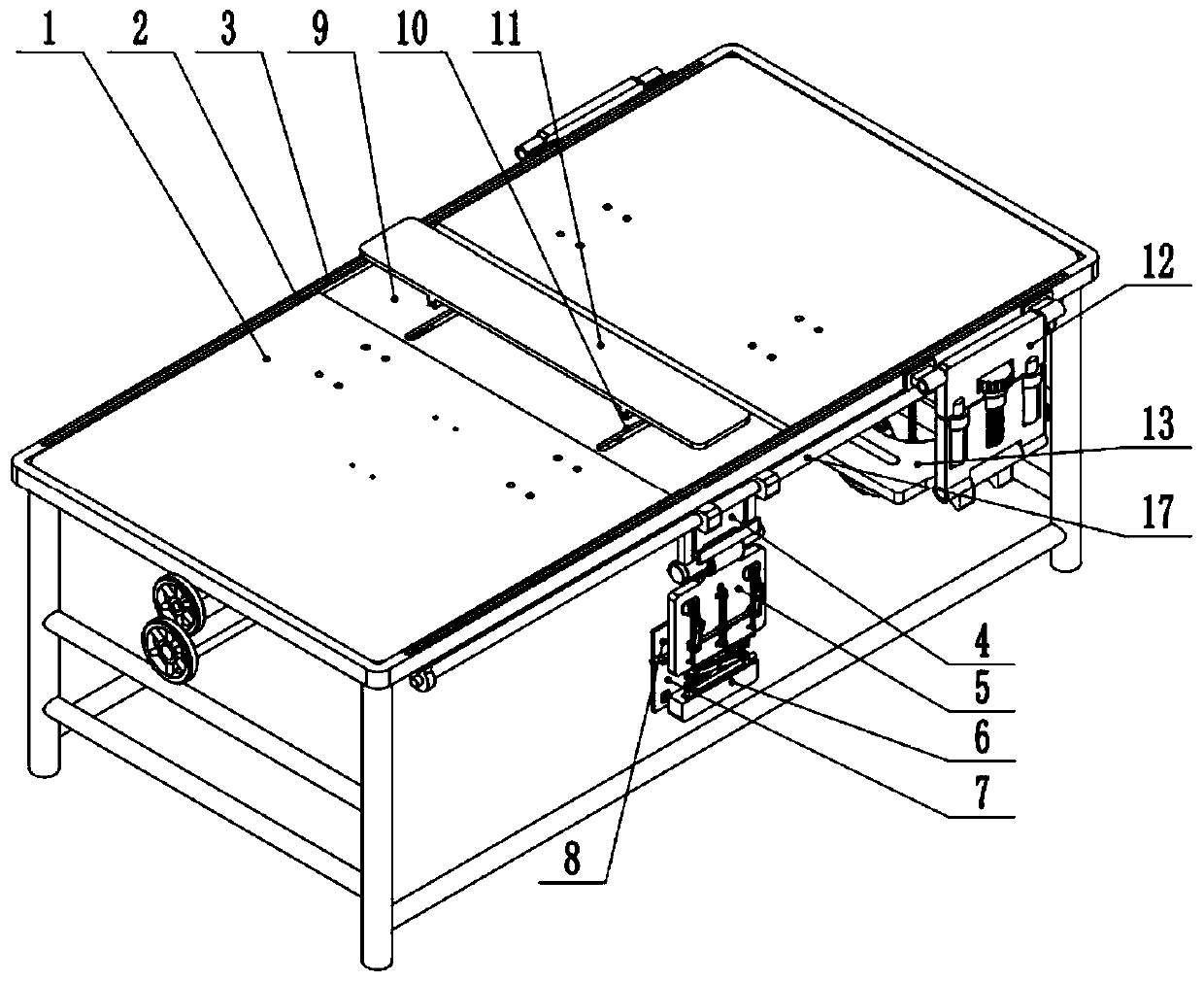

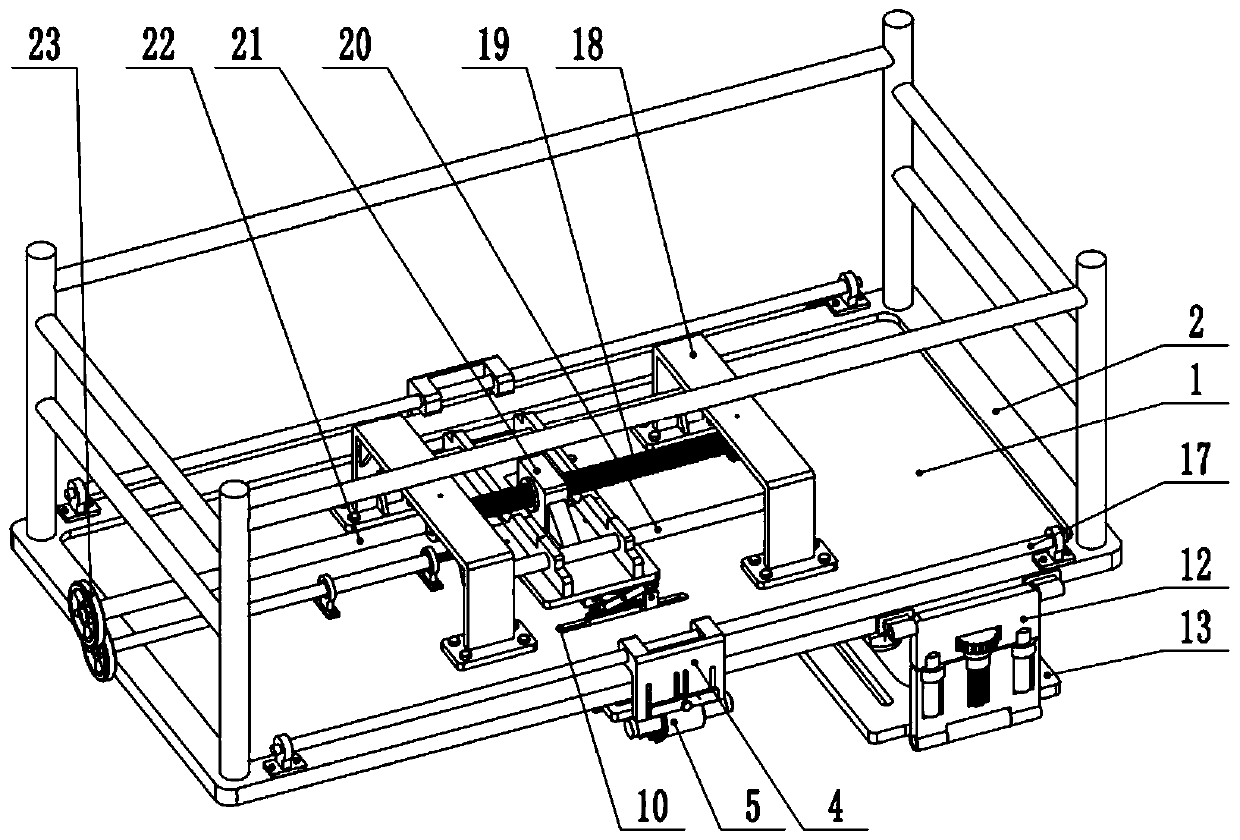

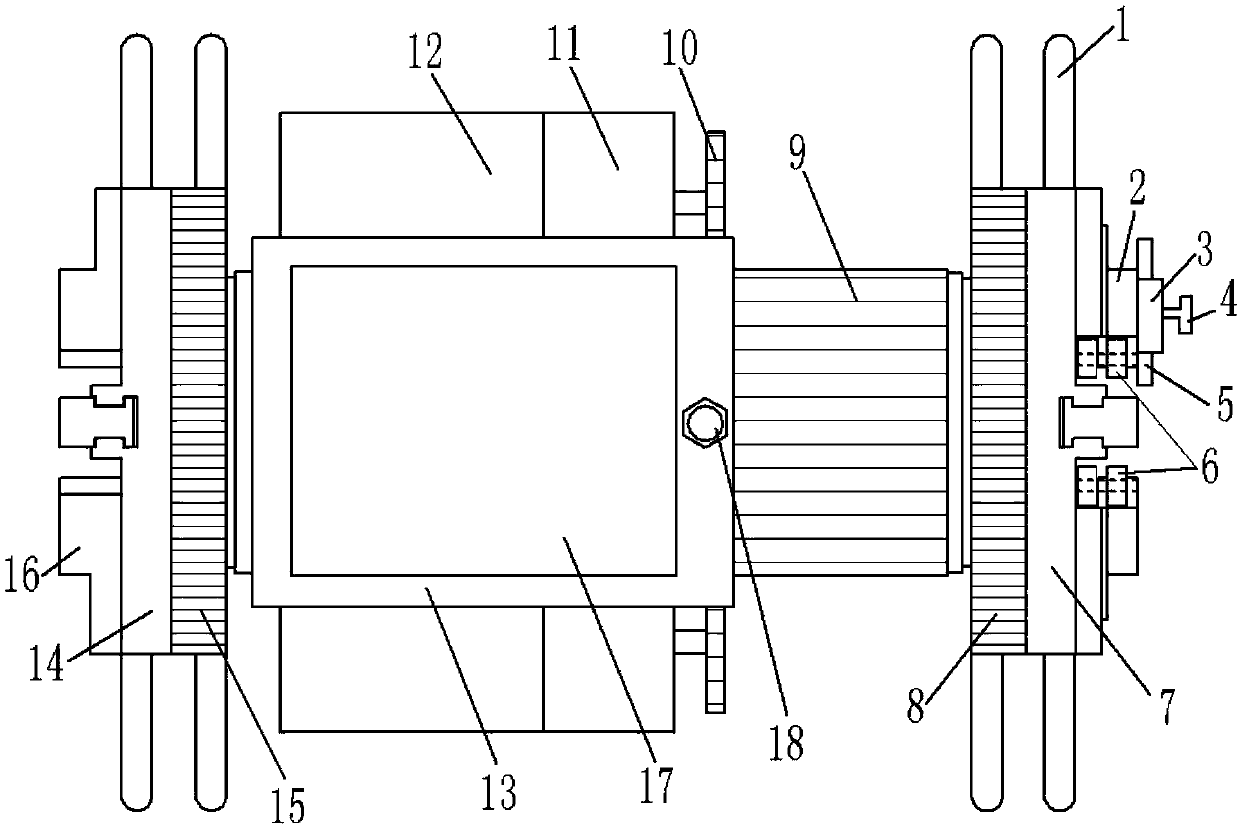

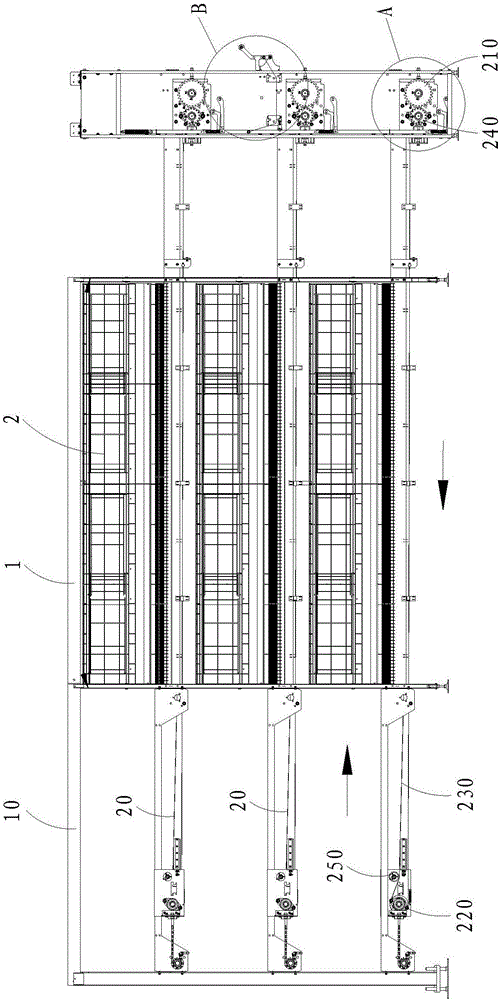

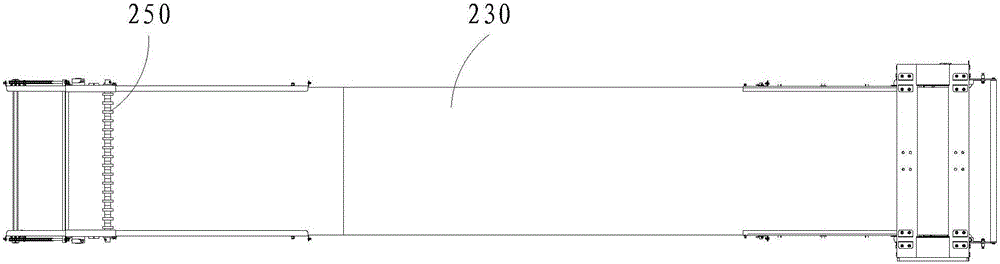

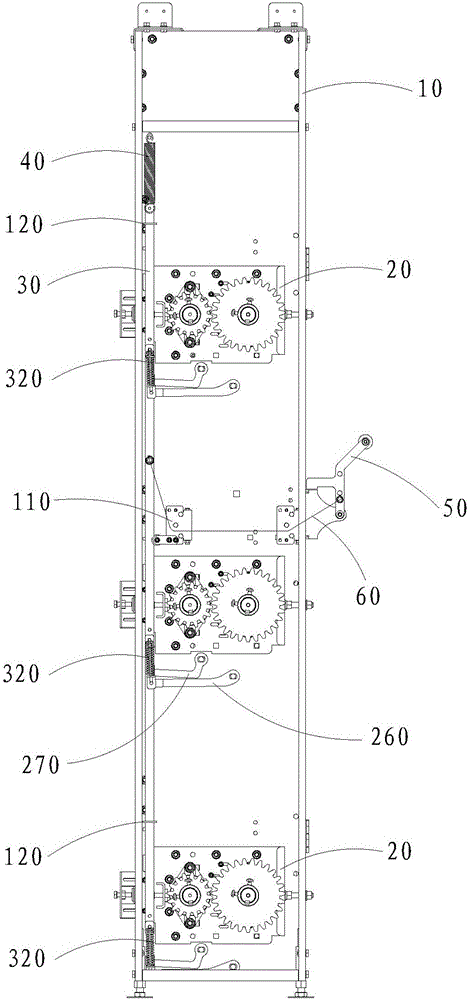

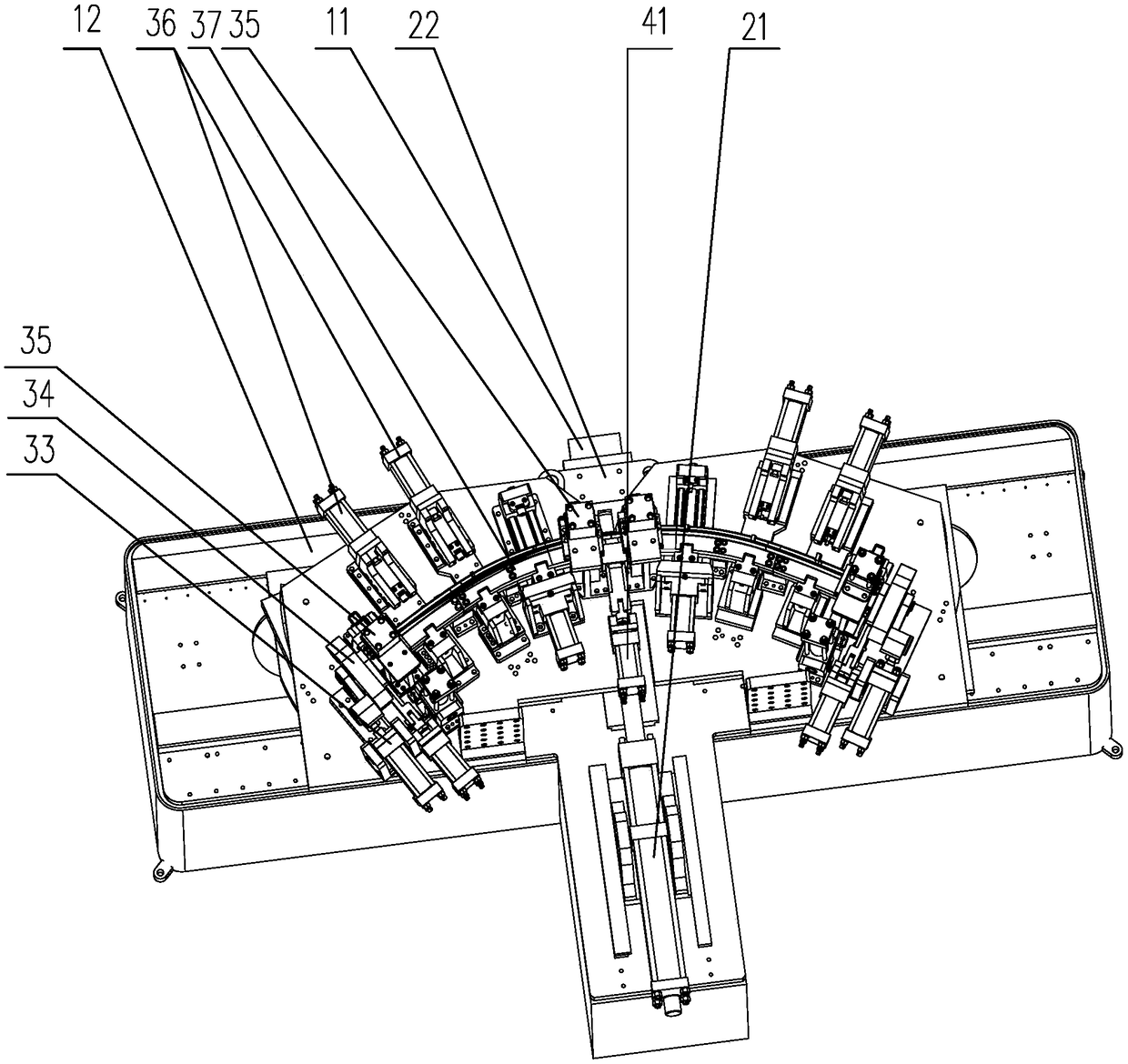

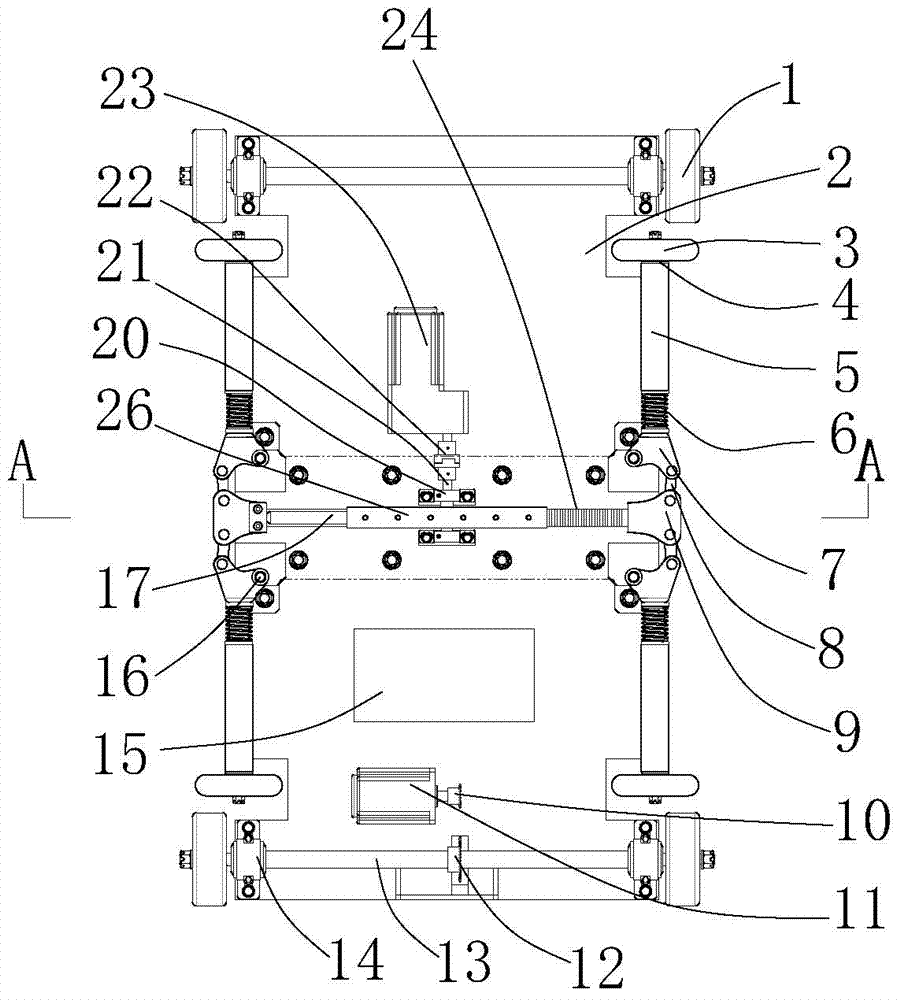

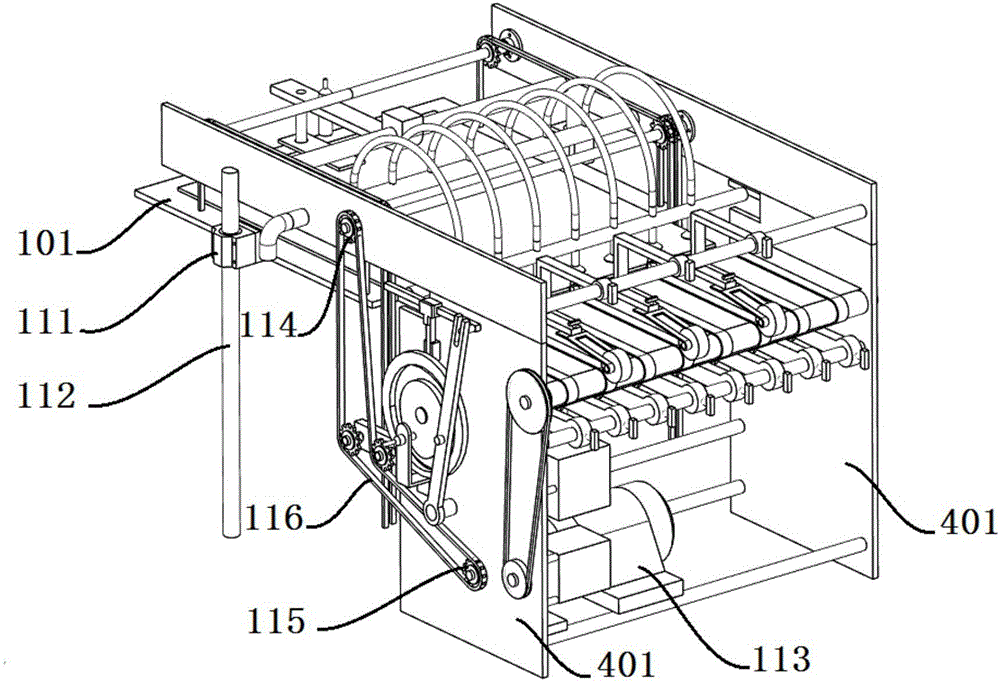

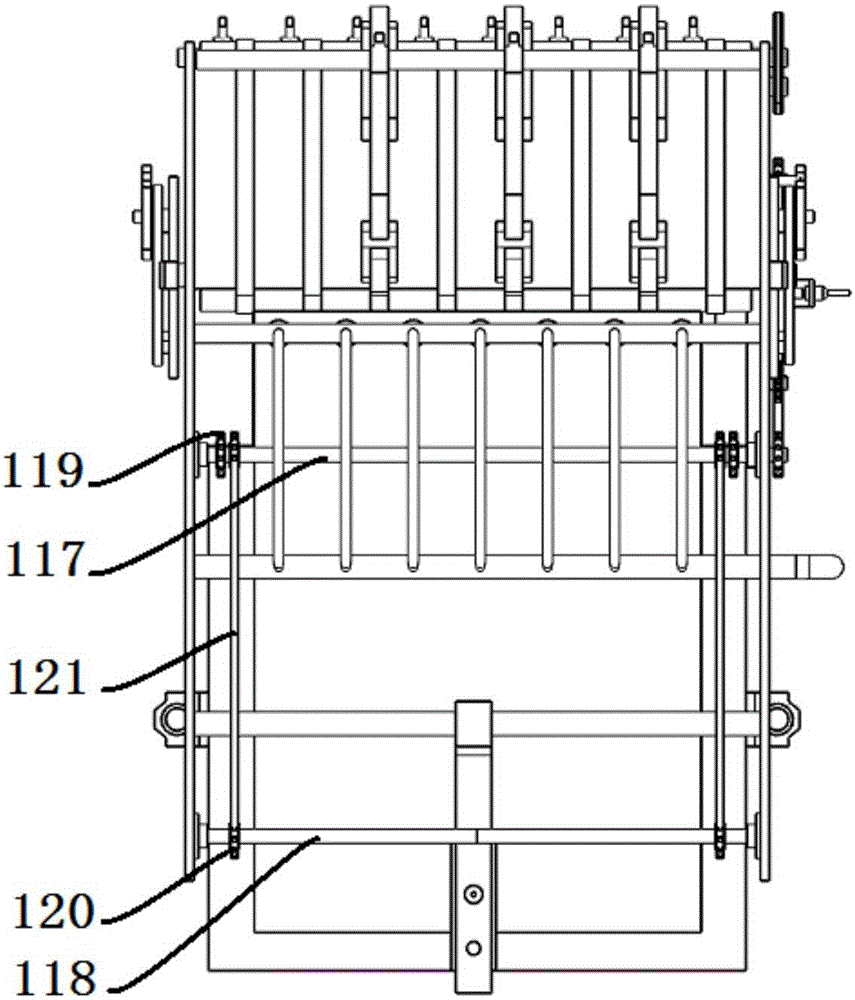

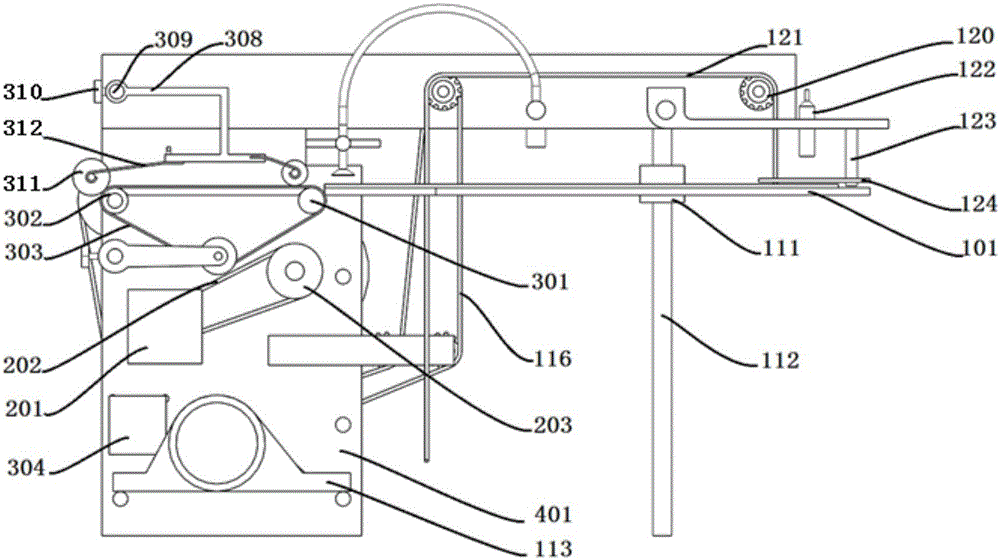

Four-corner case sealer

ActiveCN106218978ANot easy to go off trackNot easy to fallConveyorsWrapper twisting/gatheringEngineeringInductor

The invention discloses a four-corner case sealer. The four-corner case sealer comprises a frame body, a case feeding auxiliary mechanism, a conveying mechanism, a tape adhering mechanism and a brushing-flat mechanism, wherein the conveying mechanism is mounted on the frame body, the case feeding auxiliary mechanism is mounted at the inlet of the conveying mechanism, and the tape adhering mechanism and the brushing-flat mechanism which are mounted on the frame body are located on two sides of the conveying mechanism; the conveying mechanism comprises an upper conveyor belt and a lower conveyor belt; locating pieces are further arranged on the upper and lower conveyor belts; left and right fixing mechanisms are further arranged on two sides of the conveying mechanism. The case sealer conveys case bodies through upper and lower synchronous conveyor belts and fixes the case bodies through the locating pieces on the conveyor belts. In addition to automatic correction of an infrared inductor, a steady conveying environment is provided, so that the case bodies are unlikely to deviate and fall, and the tape adhering mechanism accurately adheres tapes to the four corners of the case bodies.

Owner:JIANGMEN KEYE ELECTRICAL & MECHANICAL MFG CO LTD

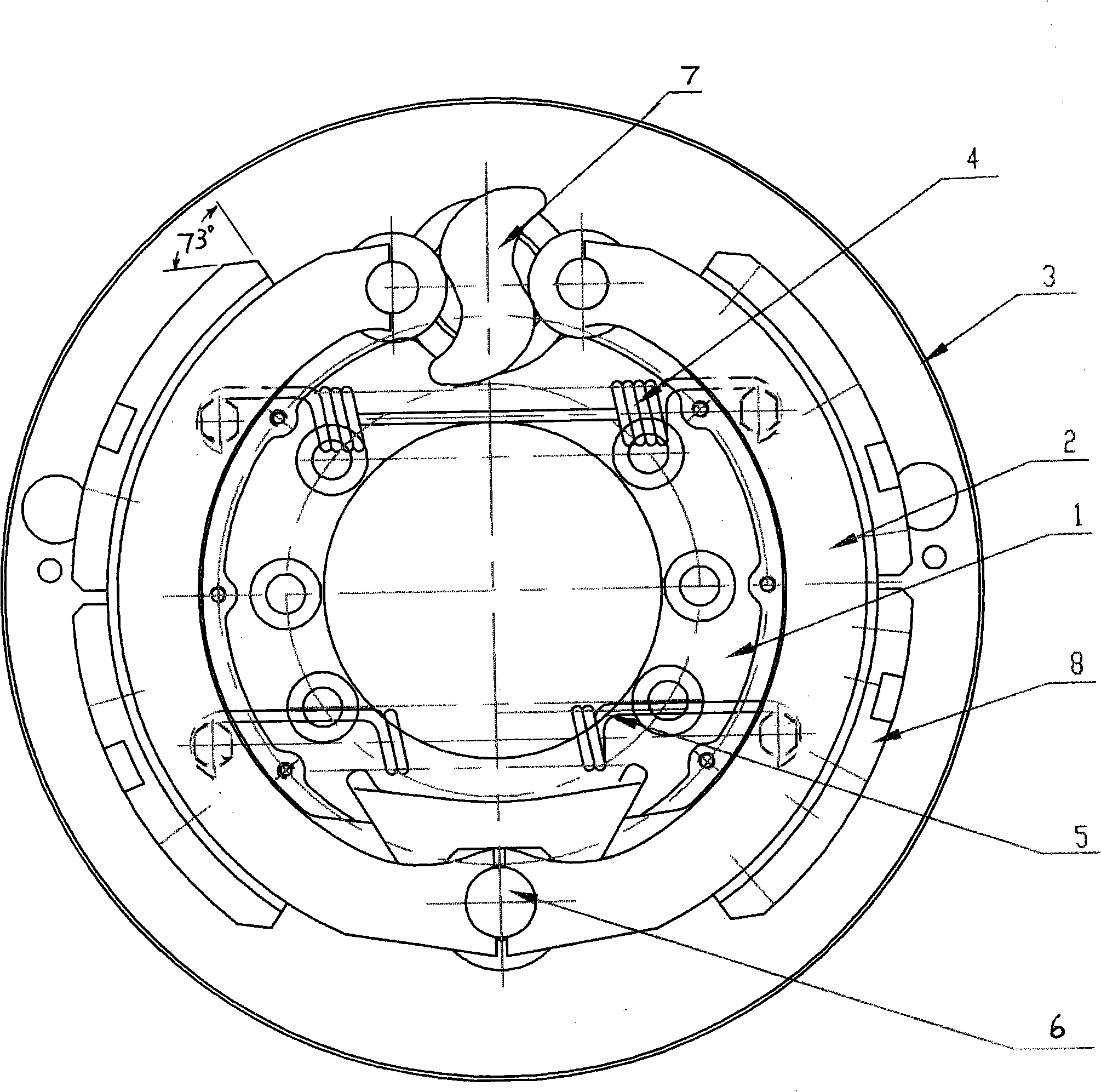

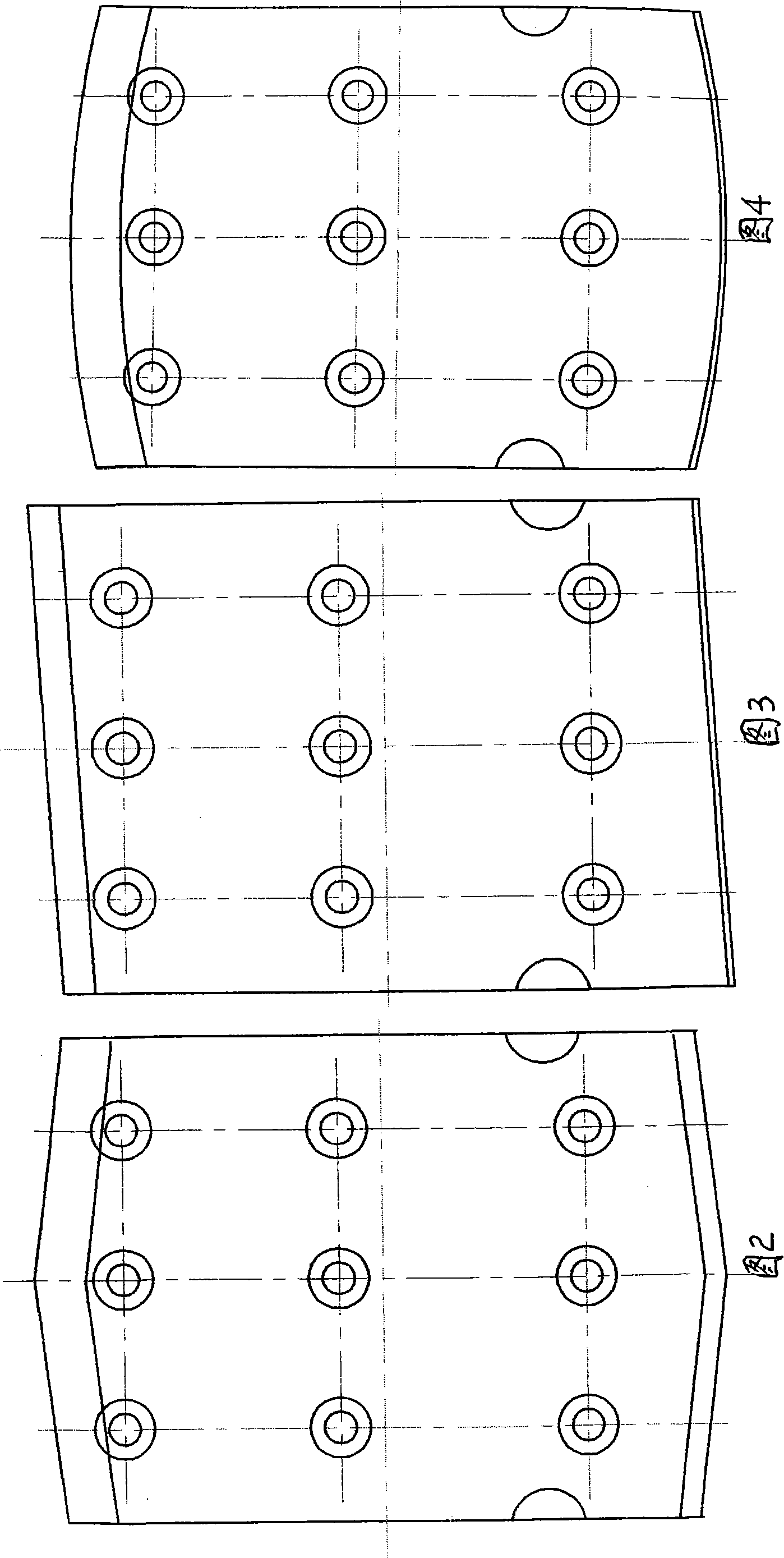

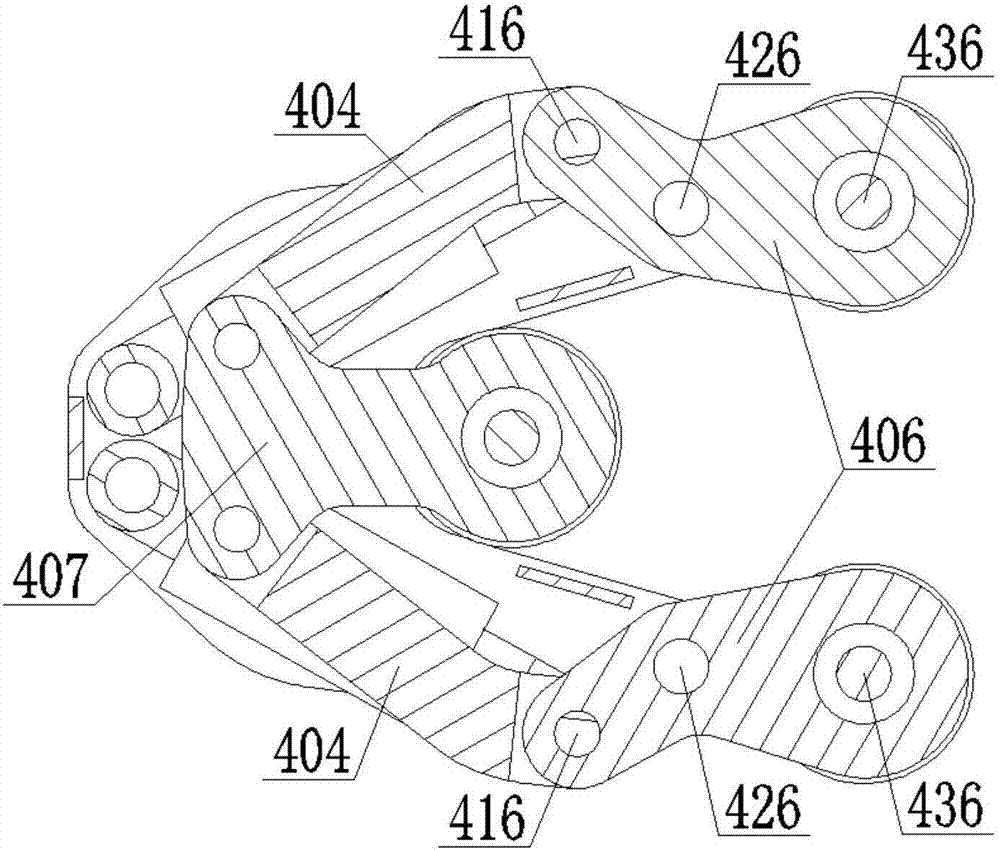

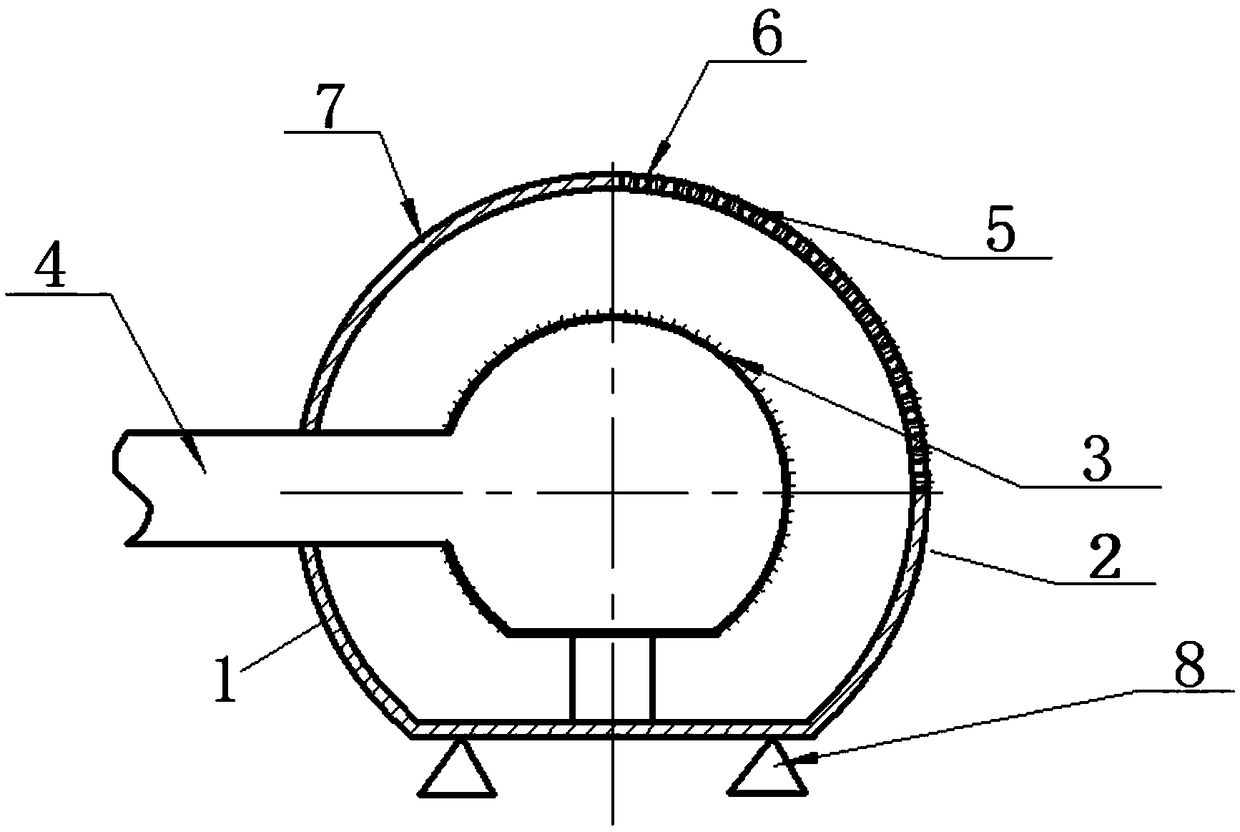

Single-anchor pin cam drum type brake

InactiveCN101493124AImprove performance factorReduce manufacturing costBraking membersMechanically actuated drum brakesHelical lineEngineering

A single rest pin cam drum brake mainly comprises a bottom plate of the brake, two brake shoes, a dust cover, a return spring, a fixed spring, a rest pin and a camshaft. The center of the rest pin is arranged on the extension line of the line of centers of the camshaft and the bottom plate of the brake. The supported end of the brake shoe adopts a double subplate riding tractor single rest pin structure. One end of the brake shoe is supported on the rest pin in a semicircle and nick way. The two brake shoes share one rest pin. The other end of the brake shoe is provided with a roller which is connected with the cam. The excircle of every brake shoe is fixed with two friction liners. The single rest pin drum brake has the advantages that the two brake shoes share one rest pin, which reduces the quantity of parts and the material weight of the bottom plate of the brake and the brake shoes and simplifies the processing technique of the bottom plate of the brake; in addition, the shape of the friction liners is optimized to cause the contact line of the friction liners and the cylindrical surface in the brake drum to be a cylindrical helix, thus brake being more stable and difficult to off tracking.

Owner:HUNAN YUNDA MACHINERY MFG

Auxiliary device for hip joint replacement operation

InactiveCN110141407ASolve the situationTo solve the doctor's need to change the body positionJoint implantsFemoral headsHip joint replacement operationButtocks

The invention relates to an auxiliary device for hip joint replacement operation. The device comprises a bedstead and a bed plate, wherein the middle part of the top end of the bedstead is provided with a buttocks-supporting plate which can move back and forth and lift; the left and right sides of the bedstead are respectively and slidably connected to sliding plates capable of sliding forwards and backwards, the top end of each sliding plate is hinged to a working plate, the bottom of each working plate is provided with leg supporting rods with adjustable height, the inner sides of the working plates are provided with jacking plates capable of moving leftwards and rightwards and inclining forwards and backwards, and the top end of each jacking plate is provided with a push plate and a folding plate which can independently adjust the inclination angle and are hinged to each other; and the left and right sides of the rear end of the bedstead are hinged to telescopic lifting plates, thetop ends of the lifting plates are hinged to bridge plates, the inner ends of the two bridge plates are movably connected and slidably connected to a moving plate, a rotating plate capable of horizontally rotating and moving up and down is arranged on the moving plate, and two leg lifting clamps hinged to each other are arranged at the bottom end of the rotating plate. The device effectively solves the problems that: the body position cannot be changed in the prior hip joint replacement operation, the body position of a patient cannot be firmly fixed in the operation, and the part to be operated cannot be fully exposed.

Owner:宋晓飞

Cable external-screen stripper

PendingCN107785816AHigh transmission precisionImprove stripping accuracyApparatus for removing/armouring cablesElectronic waste recyclingElectrical and Electronics engineeringElectric cables

Provided is a cable external-screen stripper. The cable external-screen stripper includes a shell, a transmission device, a cutter assembly, a movable stripping clamp disc and a fixed clamp disc; thefixed clamp disc is fixedly connected with one end of the shell; the transmission device is arranged at the other end of the shell and can rotate relative to the shell, and the movable stripping clampdisc is fixedly connected to the other end of the transmission device; the shell, the transmission device, the fixed clamp disc and the movable stripping clamp disc are arranged coaxially, and holesfor cables to penetrate through are formed in the shell, the transmission device, the fixed clamp disc and the movable stripping clamp disc respectively; the movable stripping clamp disc and the fixedclamp disc are further provided with cable clamping and positioning assemblies. Compared with the prior art, by tightly clamping the two end faces of each cable, the cable external-screen stripper does not easily deviate when cable external-screen stripping is carried out, the precision of cable external-screen stripping can be improved, the structure is simple, and the practicality is high.

Owner:张同义

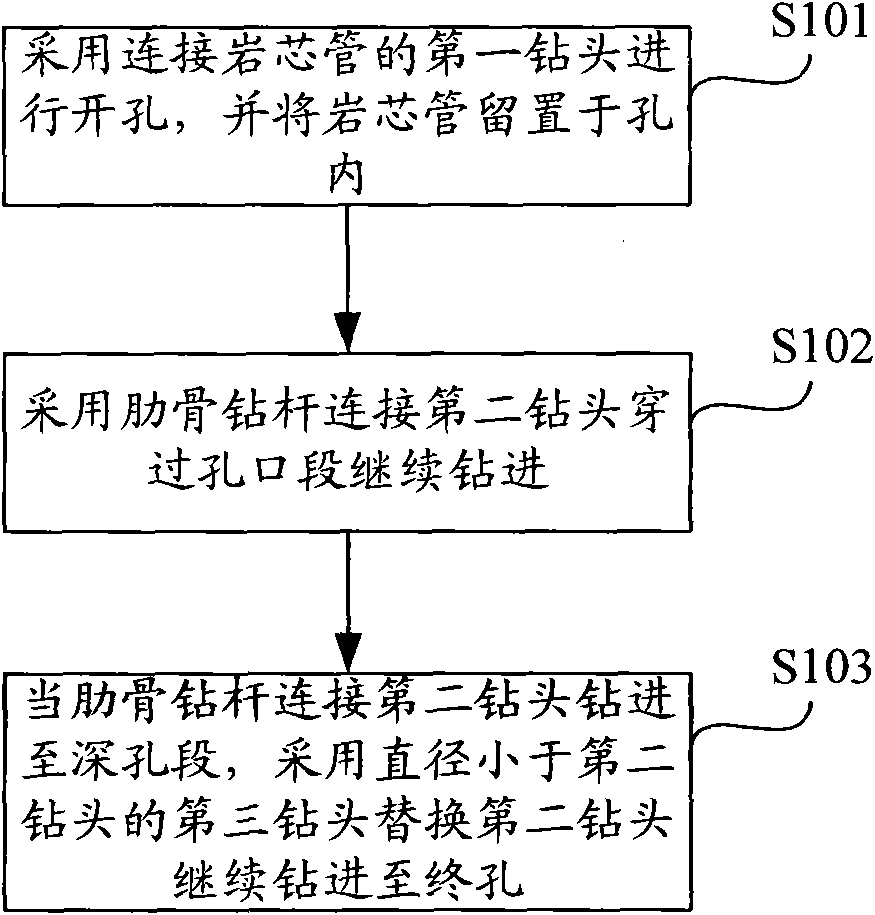

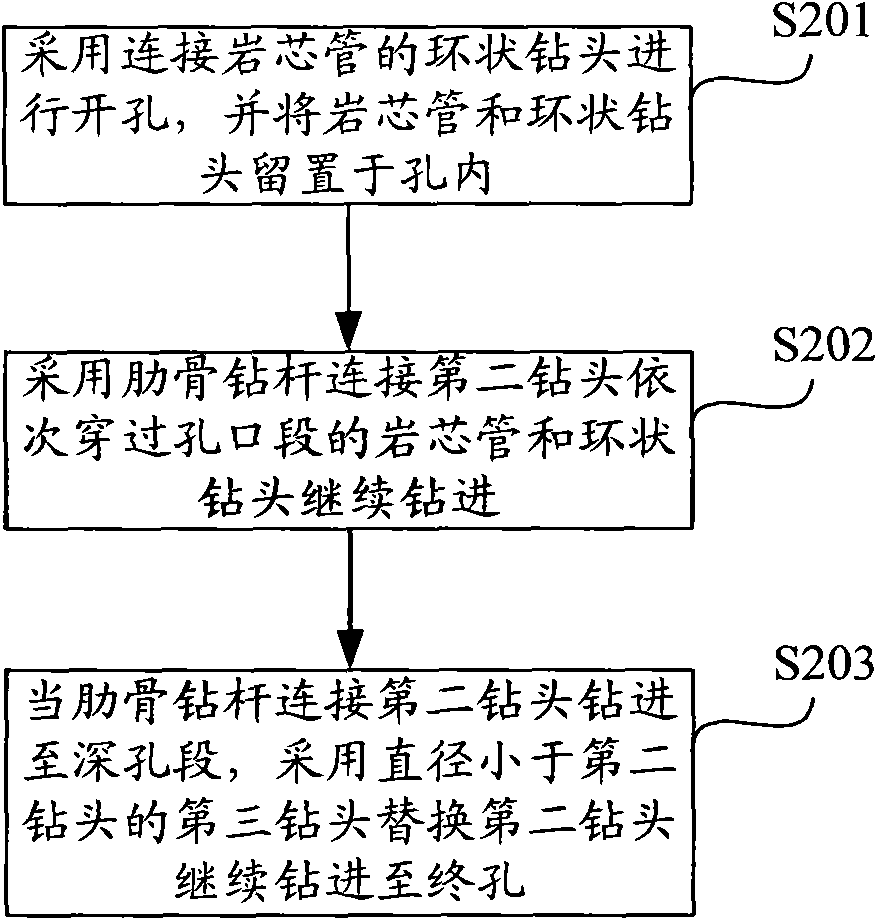

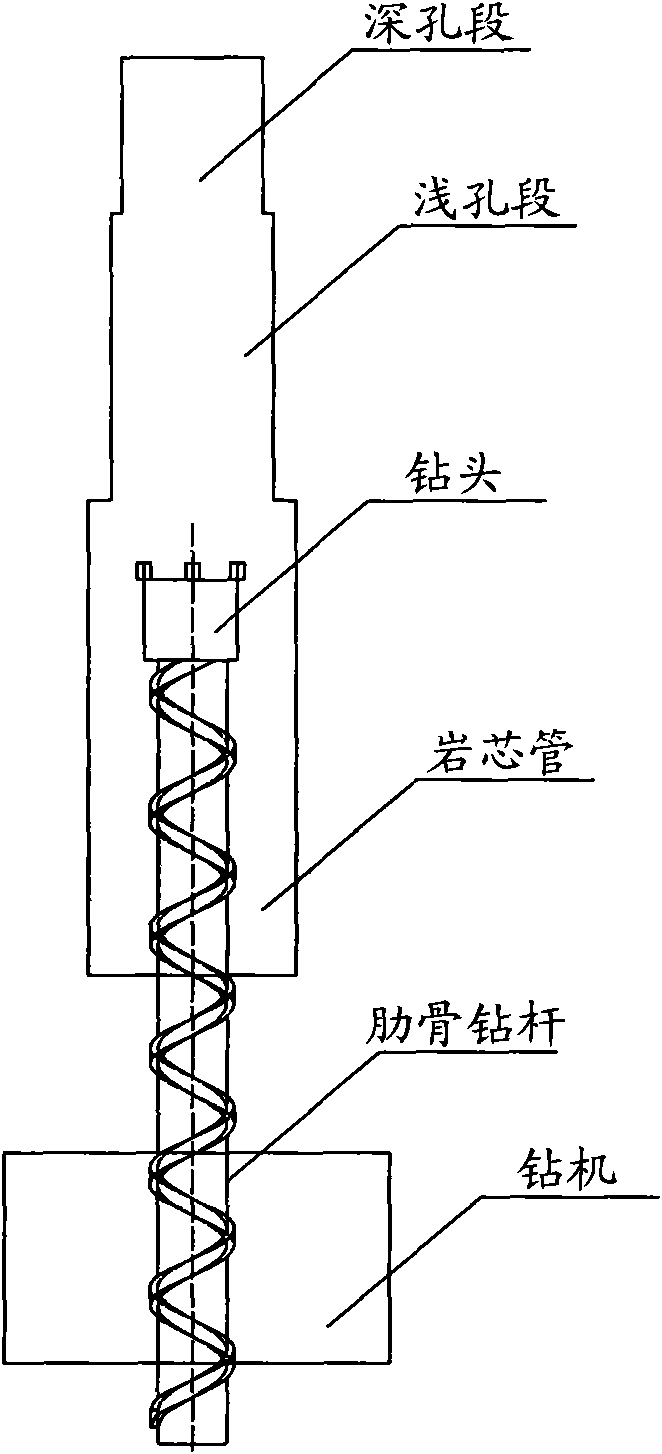

Coal mine underground over-broken abnormal zone drilling method

The invention provides a coal mine underground over-broken abnormal zone drilling method. The method comprises the following steps of: forming a hole by adopting a first drill bit connected with a core pipe, and reserving the core pipe in the hole; connecting a rib drill rod and a second drill bit, and making the rib drill rod pass through the hole section to perform continuous drilling; and whenthe rib drill rod connected with the second drill bit drills to the deep hole section, replacing the second drill bit by adopting a third drill bit, the diameter of which is smaller than that of the second drill bit, to perform continuous drilling till the final hole. The embodiment of the invention realizes hole formation and hole protection of the broken abnormal zone, reduces the resistance ofdrilling to the deep hole section, and improves the efficiency of drilling to the deep hole section.

Owner:HUAINAN MINING IND GRP

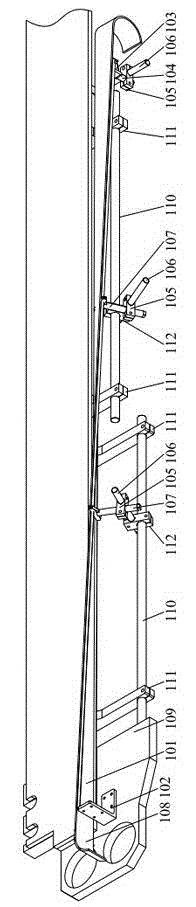

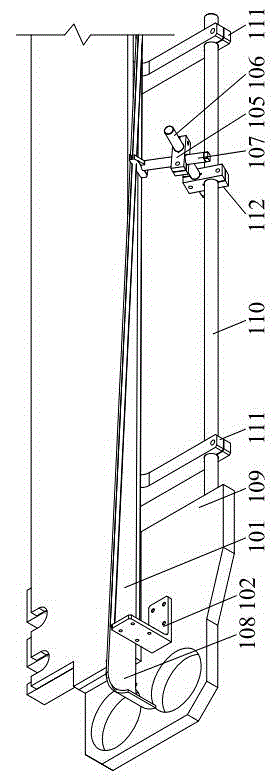

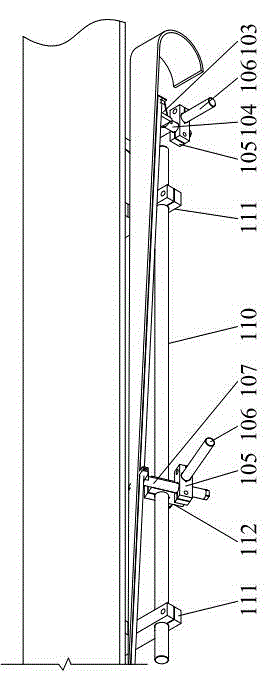

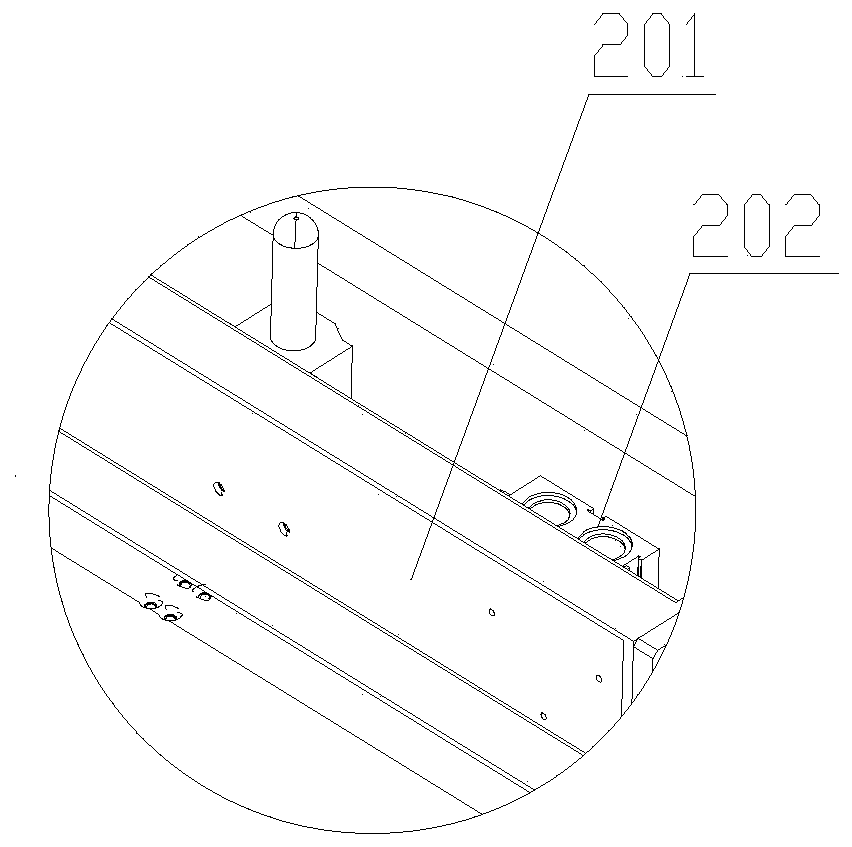

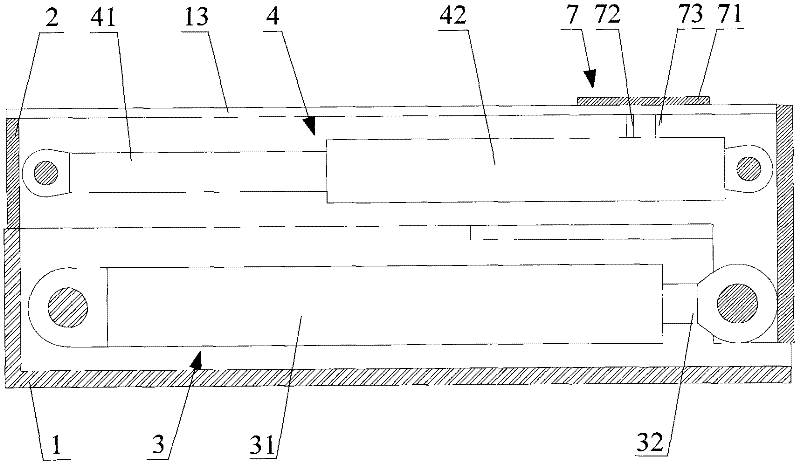

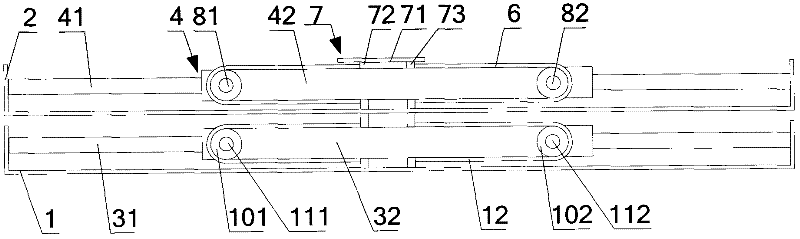

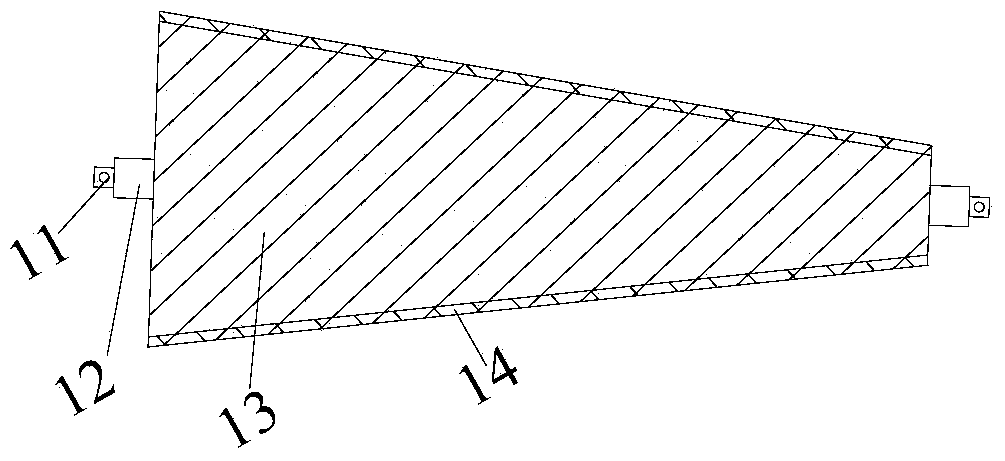

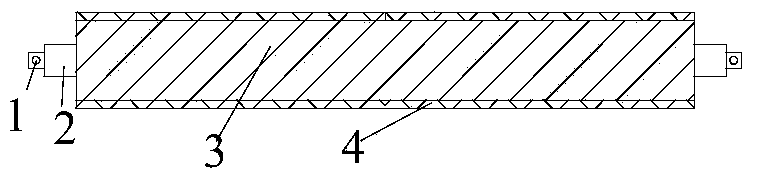

Novel folding belt locating and paperboard folding guide mechanism

ActiveCN104527130AAdapt to requirementsNot easy to go off trackContainer making machineryCardboardEngineering

The invention relates to the technical field of box covering machine, and in particular relates to a novel folding belt locating and paperboard folding guide mechanism. The novel folding belt locating and paperboard folding guide mechanism comprises a crossbeam, a rear rack and a front rack arranged at two ends of the crossbeam. The novel folding belt locating and paperboard folding guide mechanism further comprises a folding plate, an adjusting mechanism, a support mechanism and a folding belt arranged on the folding plate, two ends of the folding plate are respectively connected with the rear rack and the front rack, the support mechanism is fixed on the crossbeam, the middle adjusting mechanism is arranged between the support mechanism and the folding plate, the front adjusting mechanism is arranged between the front rack and the folding plate. The novel folding belt locating and paperboard folding guide mechanism guides the paperboard for folding according to the shape and angle of the folding plate, the folding belt works on the folding plate, the paperboard works on the folding belt, and the paperboard is folded according to the shape and angle of the folding plate. The relationship between the folding belt and the folding plate is surface contact, the folding plate adjusts the folding belt in a smooth state and the paperboard can be smoothly folded, and the folding belt is not easy to have line deflection.

Owner:GUANGDONG DONGFANG PRECISION SCI & TECH CO LTD

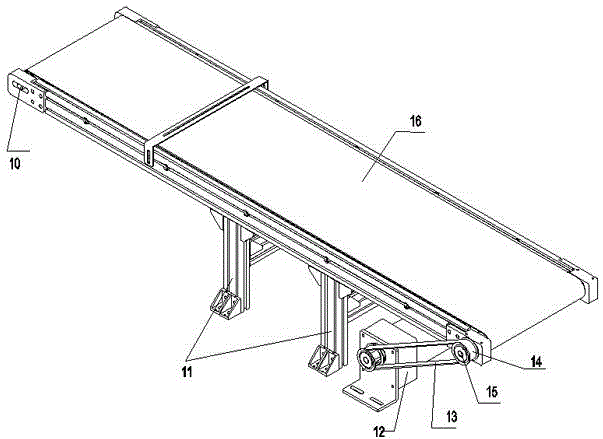

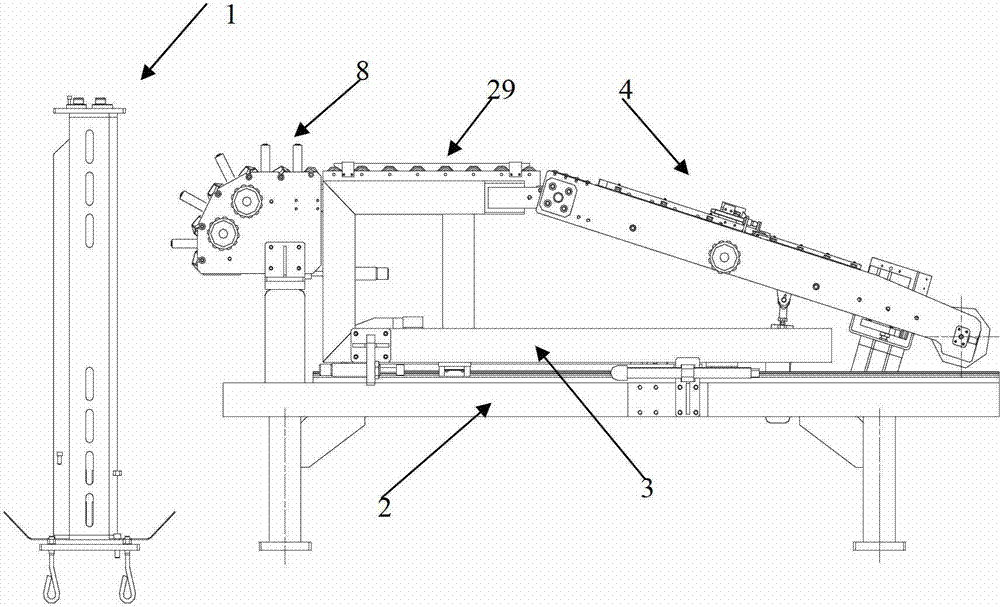

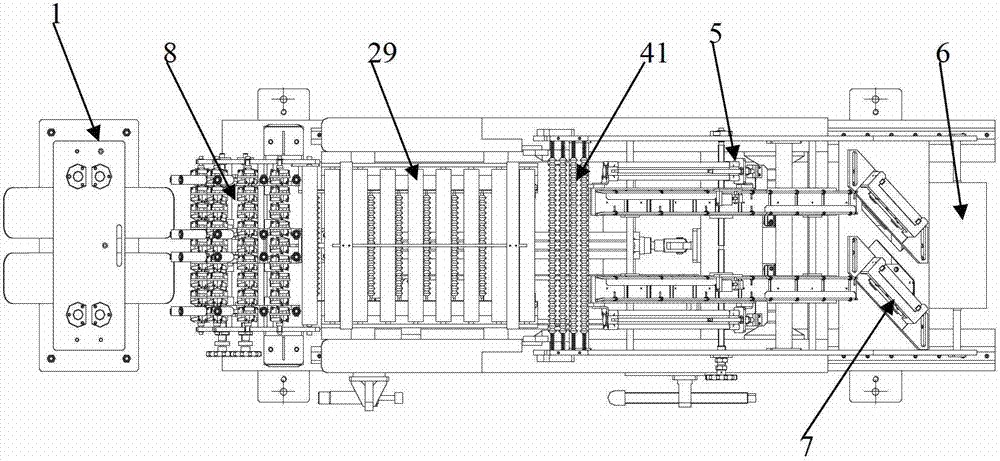

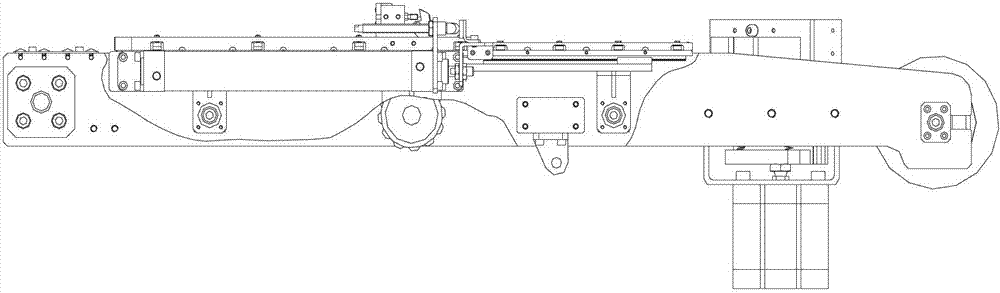

Feeding rack for zero-degree belted layers

The invention discloses a feeding rack for zero-degree belted layers. The feeding rack comprises a zero-degree belted layer guiding device, a tensing device for keeping the zero-degree belted layers with a pre-set tension force, a sliding bracket capable of slidably arranged on a bracket front and back, a feeding bracket with one end hinged with the sliding bracket and capable of being driven to swing, a feeding device arranged on the feeding bracket, a pressing roller arranged at the front end part of the feeding bracket, and a cutting device which is fixedly connected between the feeding device and the pressing roller and is fixedly connected with the feeding bracket. According to the feeding rack for the zero-degree belted layers provided by the invention, the two zero-degree belted layers can be respectively arranged at the both sides of the belted layer for automatic feeding, aligning, feeding and adhering without manual reference; the automatic degree is high; the labor force is saved; and the production efficiency is improved. Meanwhile, a drum set long-cutting manner is used; the alignment of the zero-degree belted layers is better; and the off-tracking is difficult. An air cylinder is used for clamping and feeding; and air cylinder is used for cutting after partial adhesion; the cutting joint has good quality; and the tire quality is improved.

Owner:TIANJIN SAIXIANG TECH

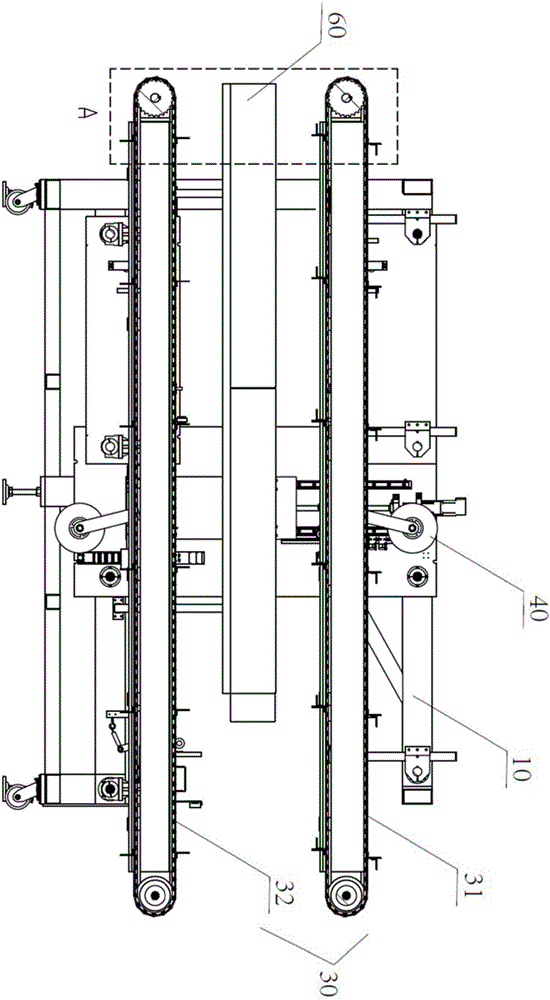

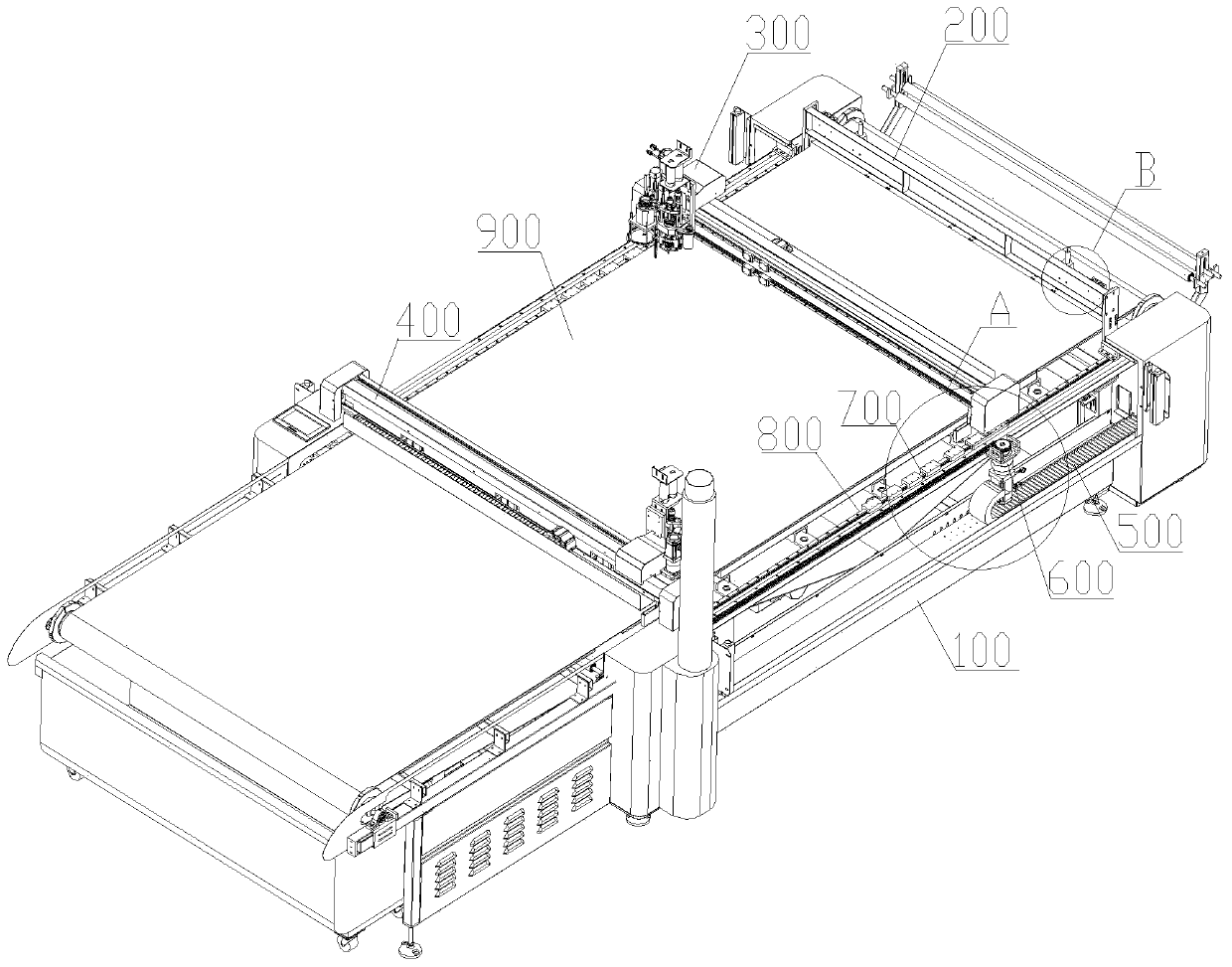

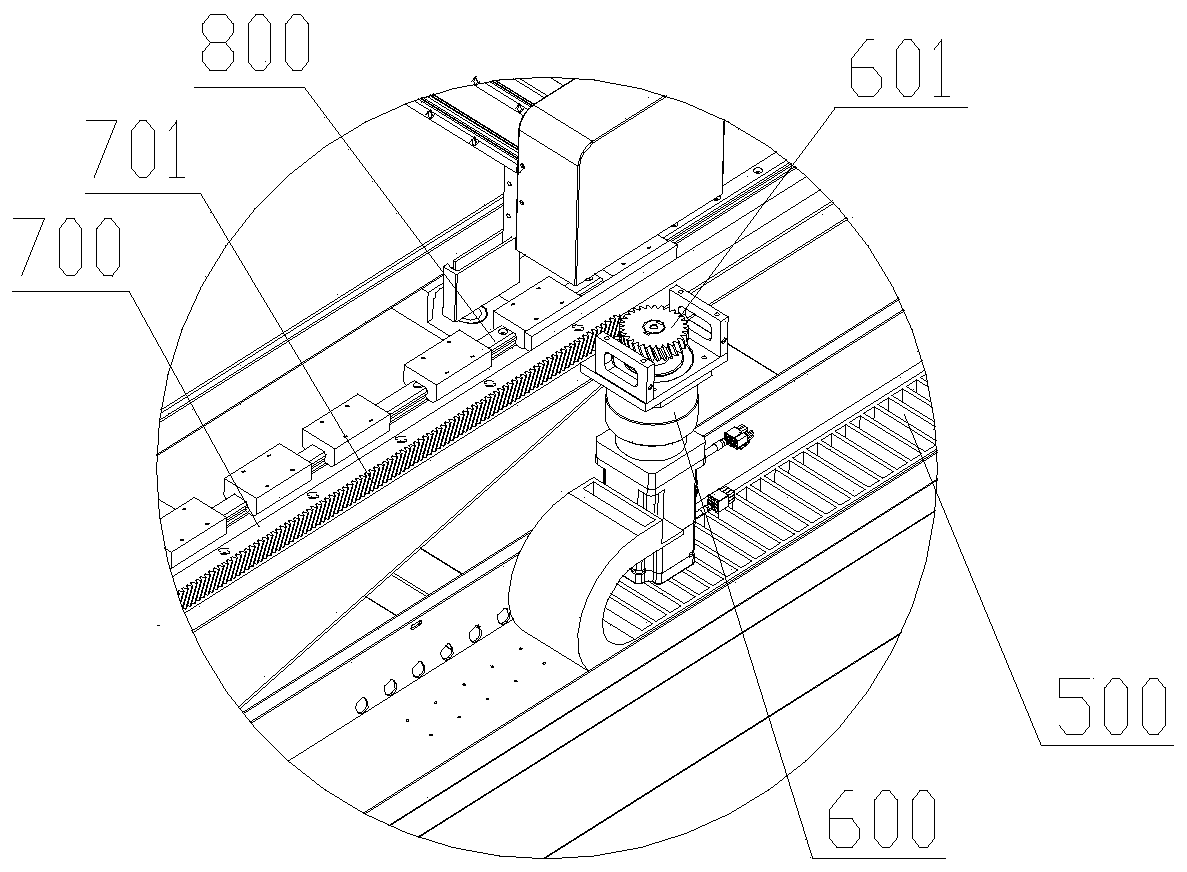

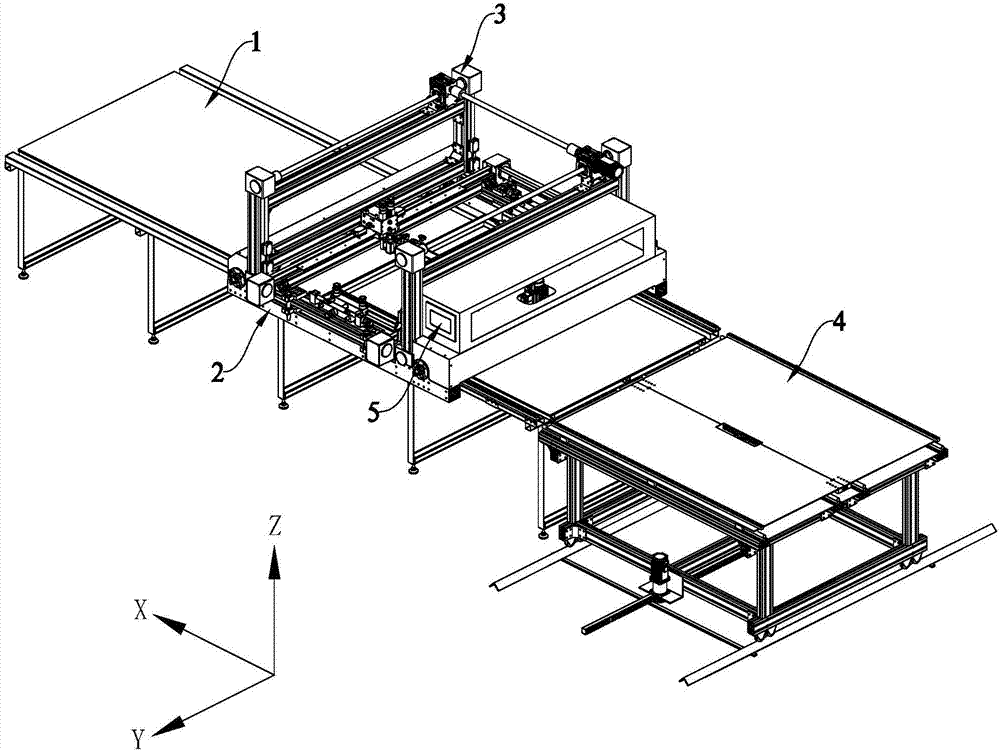

Cloth pulling and feeding mode of cutting machine and cloth pulling and feeding device of cutting machine

PendingCN110127415AIncrease the itineraryNot easy to go off trackSevering textilesUnfolding thin materialsEngineeringMachine

The invention discloses a cloth pulling and feeding mode of a cutting machine and a cloth pulling and feeding device of the cutting machine. According to the cloth pulling and feeding device, a firstpressing component and a second pressing component are arranged at the two ends of a rack correspondingly, a driving component is arranged on the side surface of the rack, a sliding rail is arranged on the rack, a sliding component is arranged on the sliding rail, the sliding component and a cloth pulling component are mutually fixed, the cloth pulling component is positioned between the first pressing component and the second pressing component, the driving component is in transmission connection with the sliding component, a tensioning roller is further arranged on the rack, the tensioning roller is used for tensioning the annular conveying belt, the annular conveying belt is positioned below the first pressing component, the cloth pulling component and the second pressing component, theannular conveying belt is made of a material capable of being magnetically attracted, an electromagnet is arranged at the bottom of the cloth pulling component, the first pressing component, the second pressing component, the driving component, the cloth pulling component and the electromagnet are electrically connected with a controller. The cutting machine has the advantages that the amount ofthe cloth distributed at one time is large and the cloth is not easy to deviate; moreover, the feeding structure is simple, the assembling is convenient, and the maintenance is convenient.

Owner:东莞市超音速智能切割科技有限公司

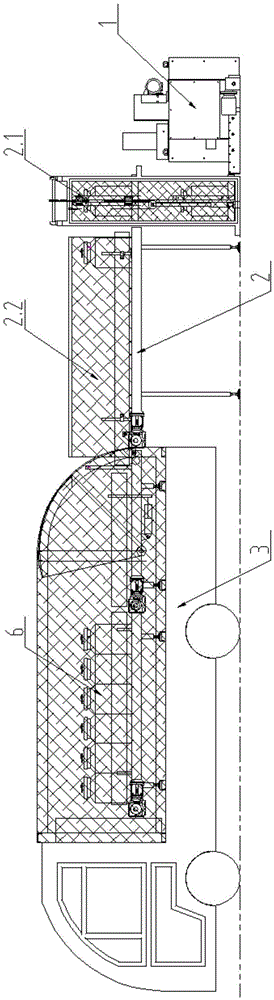

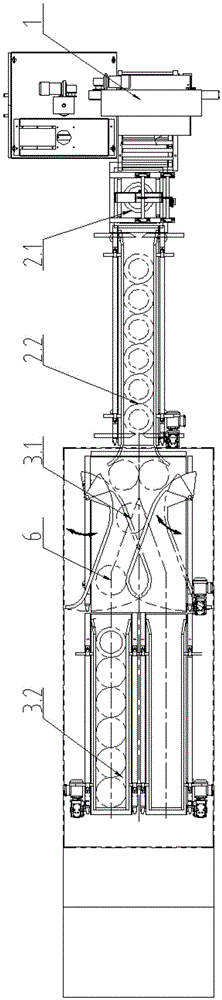

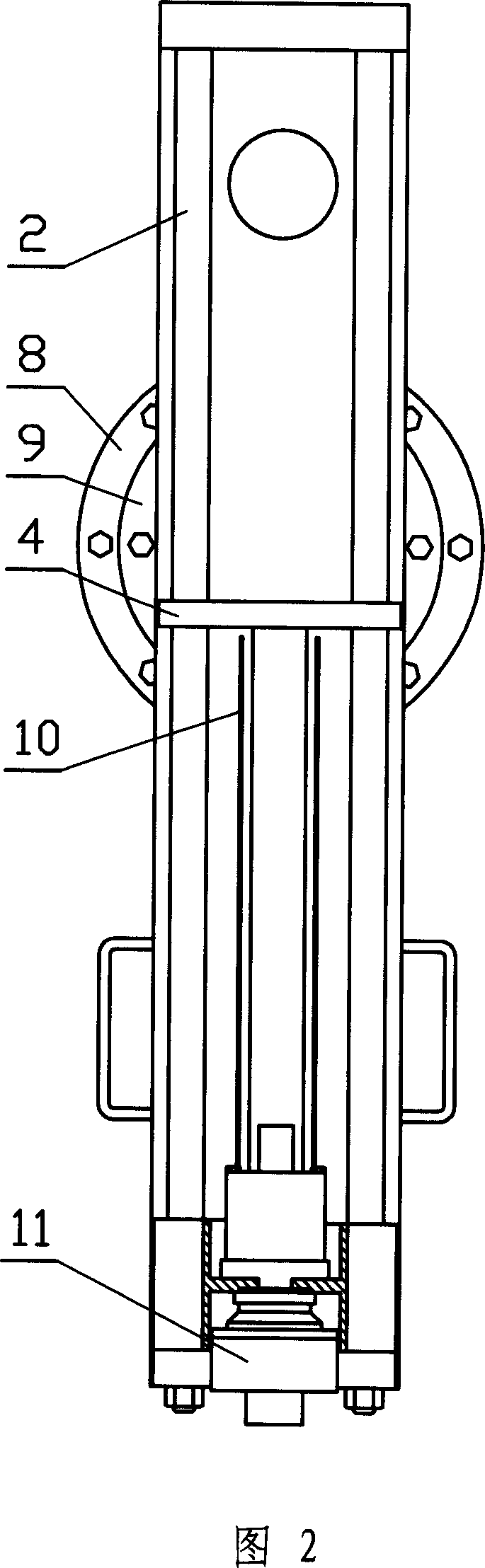

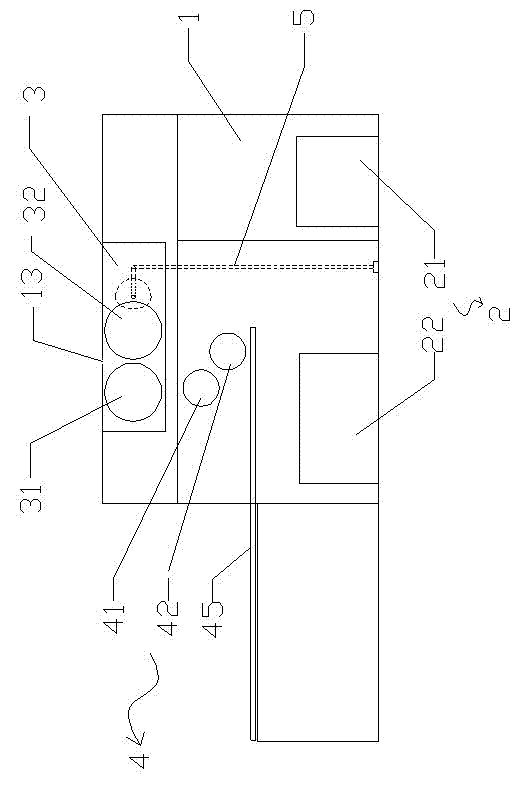

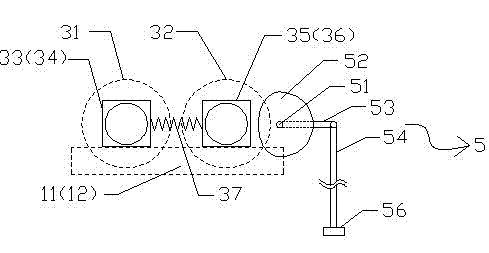

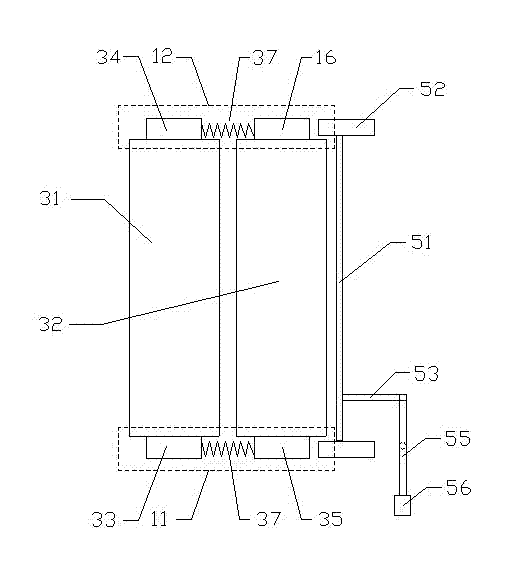

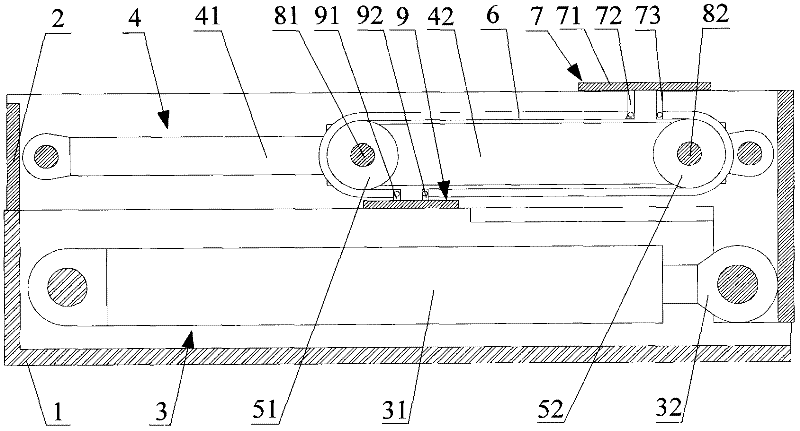

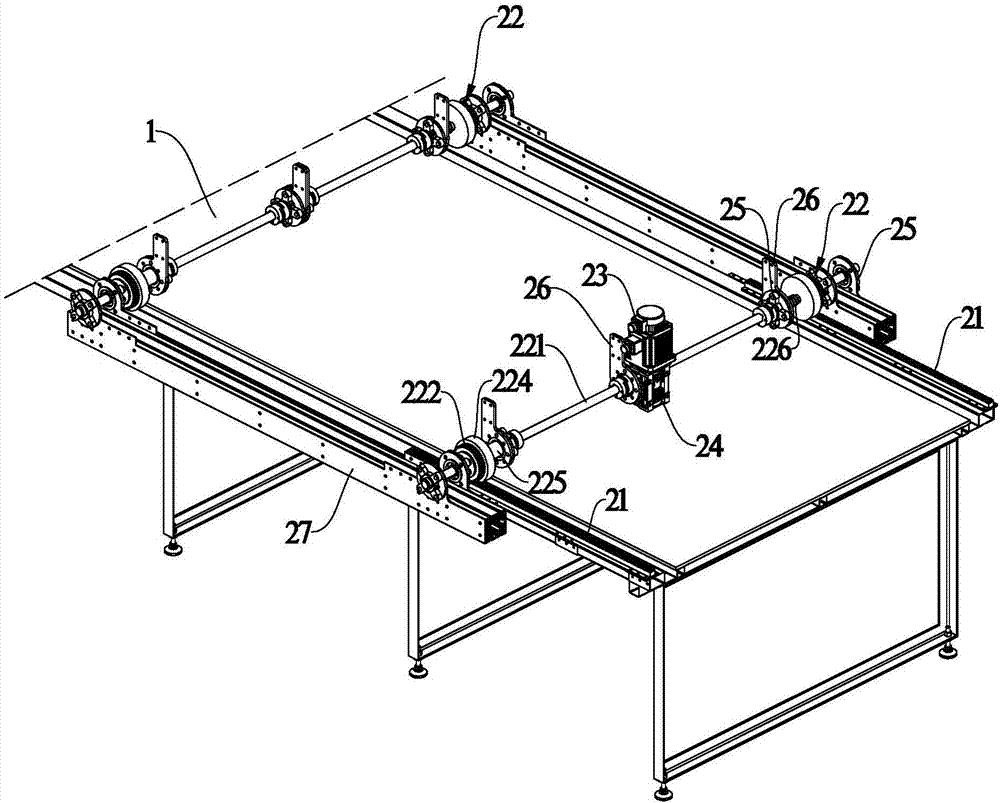

Peeler of aluminum-plastic plates

InactiveCN102815082AFully automatedNot easy to go off trackLamination ancillary operationsLaminationPulp and paper industryFault rate

The invention relates to a peeler of aluminum-plastic plates, comprising a frame (1), wherein a peeling mechanism (3) and a discharging mechanism (4) are arranged on the frame; the peeling mechanism (3) comprises a roller I (31) and a roller II (32) arranged left and right; a feed inlet (13) is arranged above the middle between the roller I (31) and the roller II (32); the discharging mechanism (4) comprises a roller III (41), a roller IV (42) and a discharging guide plate (45); the roller III (41) is arranged below the roller I (31); the roller IV (42) is arranged below right of the roller III (41); the discharging guide plate (45) is arranged transversely; and the discharging guide plate (45) leftwards extends below the roller IV (42) to left of the frame (1). The peeler provided by the invention has the advantages of higher production efficiency and lower failure rate.

Owner:周平

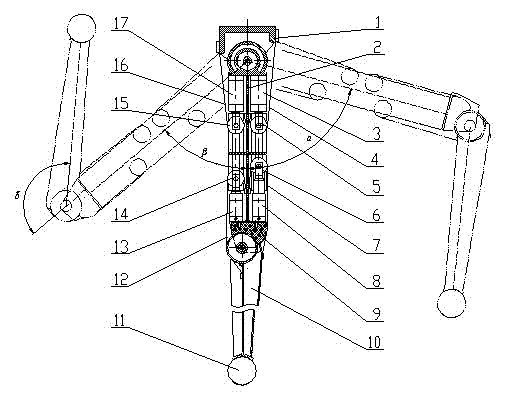

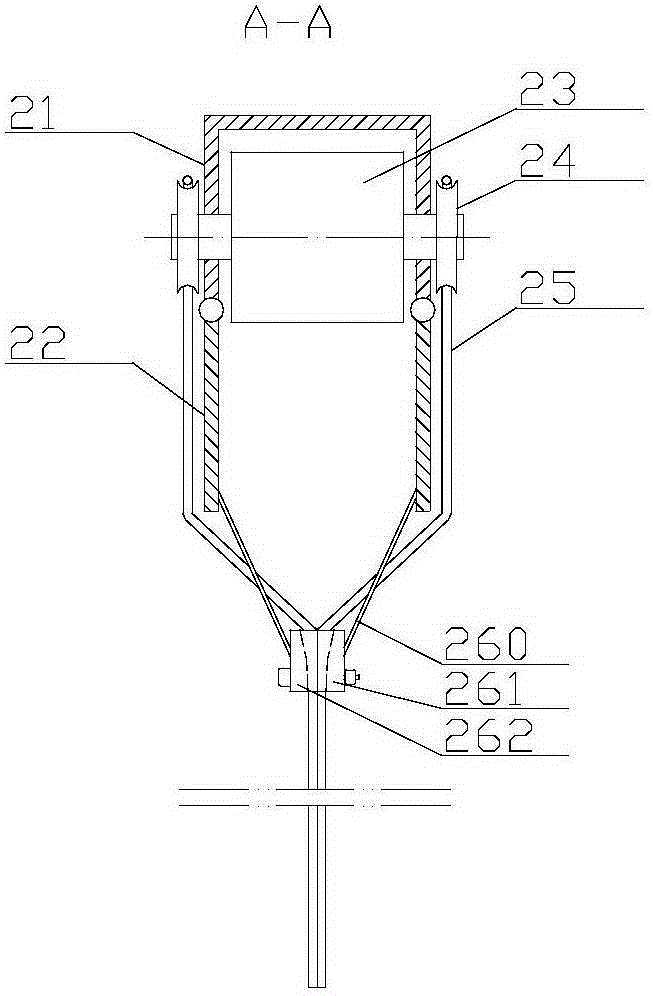

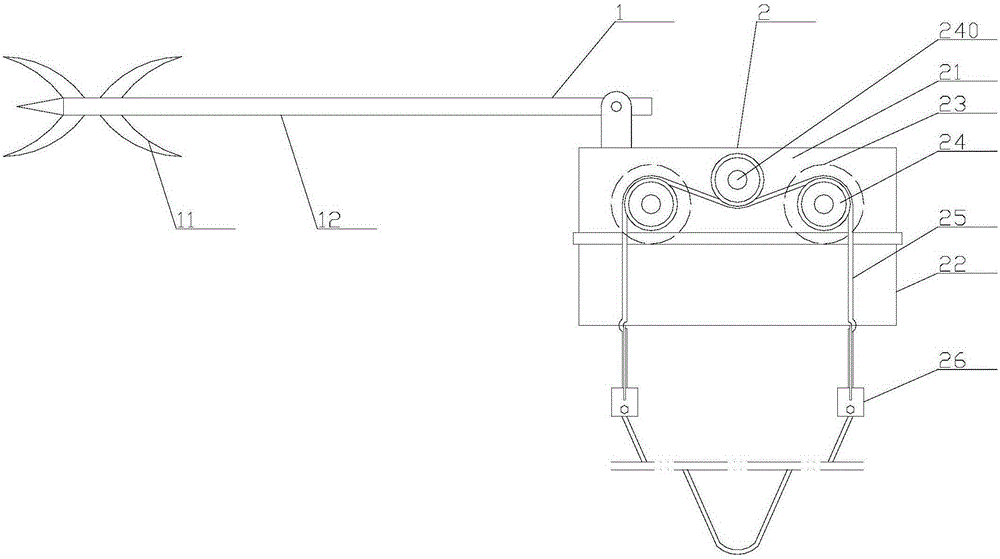

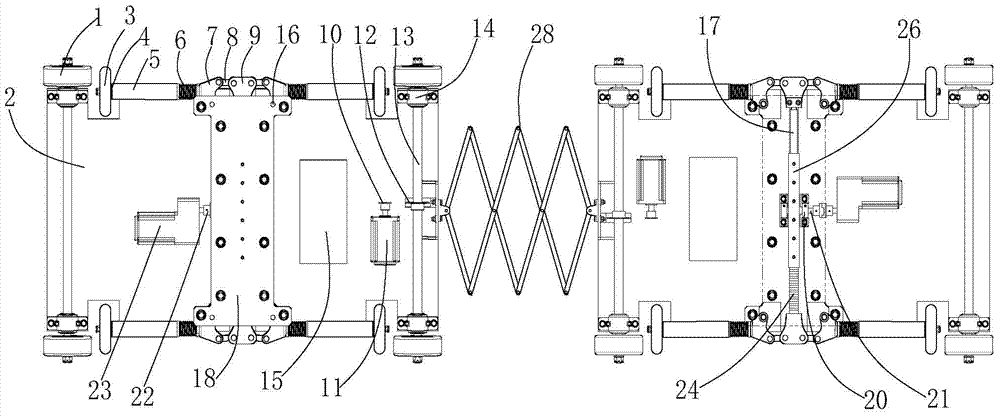

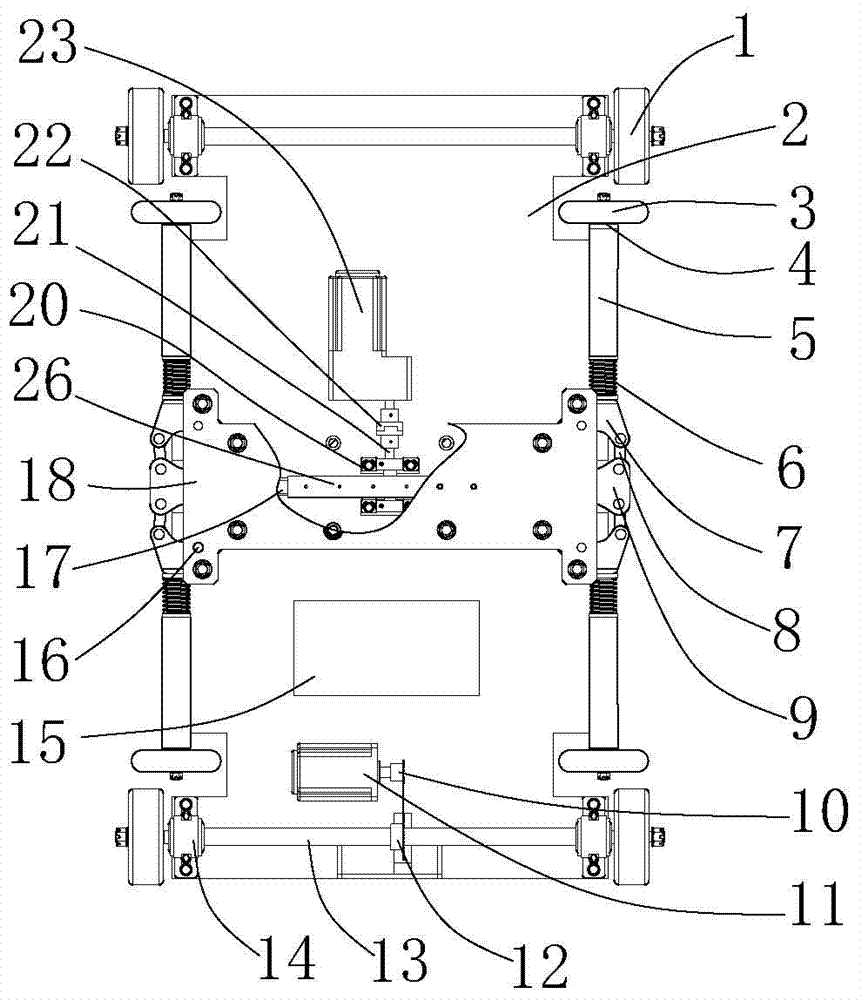

Driving leg mechanism for footed robot

The invention provides a driving leg mechanism for a footed robot, belonging to the technical field of footed robots. The driving leg mechanism comprises a leg support, a thighbone, a thigh forward swing cylinder, a thigh front stay cable, a thigh front pulley, a crus front pulley, a crus front stay cable, a crus forward swing cylinder, a joint mat, a focile, a ball-shaped foot, a crus rear stay cable, a crus backswing cylinder, a crus rear pulley, a thigh rear pulley, a thigh rear stay cable, a thigh backswing cylinder, a knee-joint pillar and a hip joint pillar, wherein the leg support is hinged with the hip joint pillar to form a hip joint, the upper end of the thighbone is fixedly connected with the hip joint pillar, the joint mat is arranged at the lower end of the thighbone and is hinged with the knee-joint pillar, a knee joint is composed of the thighbone, the joint mat and the knee-joint pillar, the upper end of the focile is fixedly connected with the knee-joint pillar, and the lower end of the focile is fixedly connected with the ball-shaped foot. The driving leg mechanism has the advantages of compact structure, light weight, low energy consumption, capability of realizing rapid joint movements, stable carrying capacity, large foot end movement space, good buffering performance and long service life.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

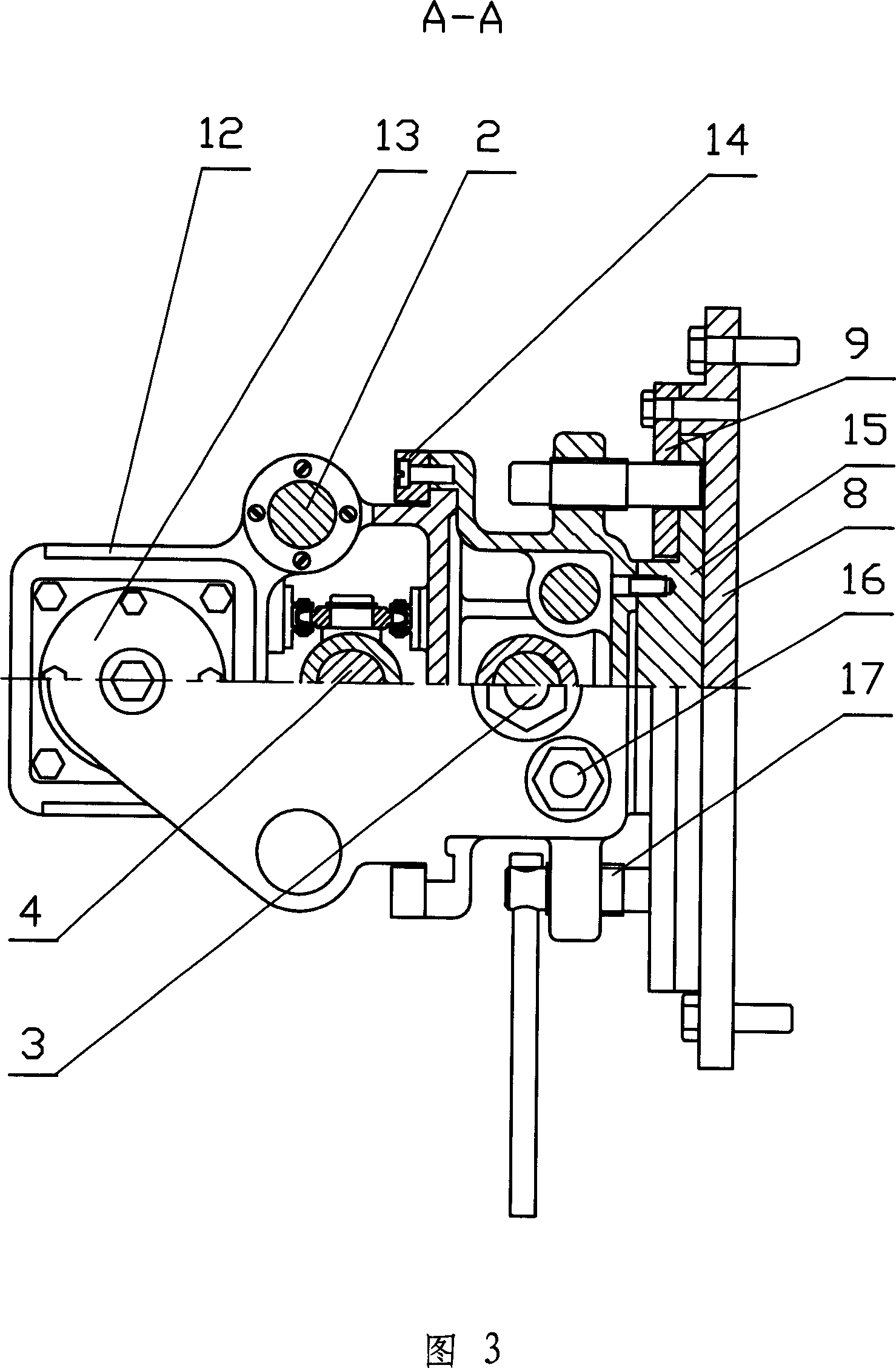

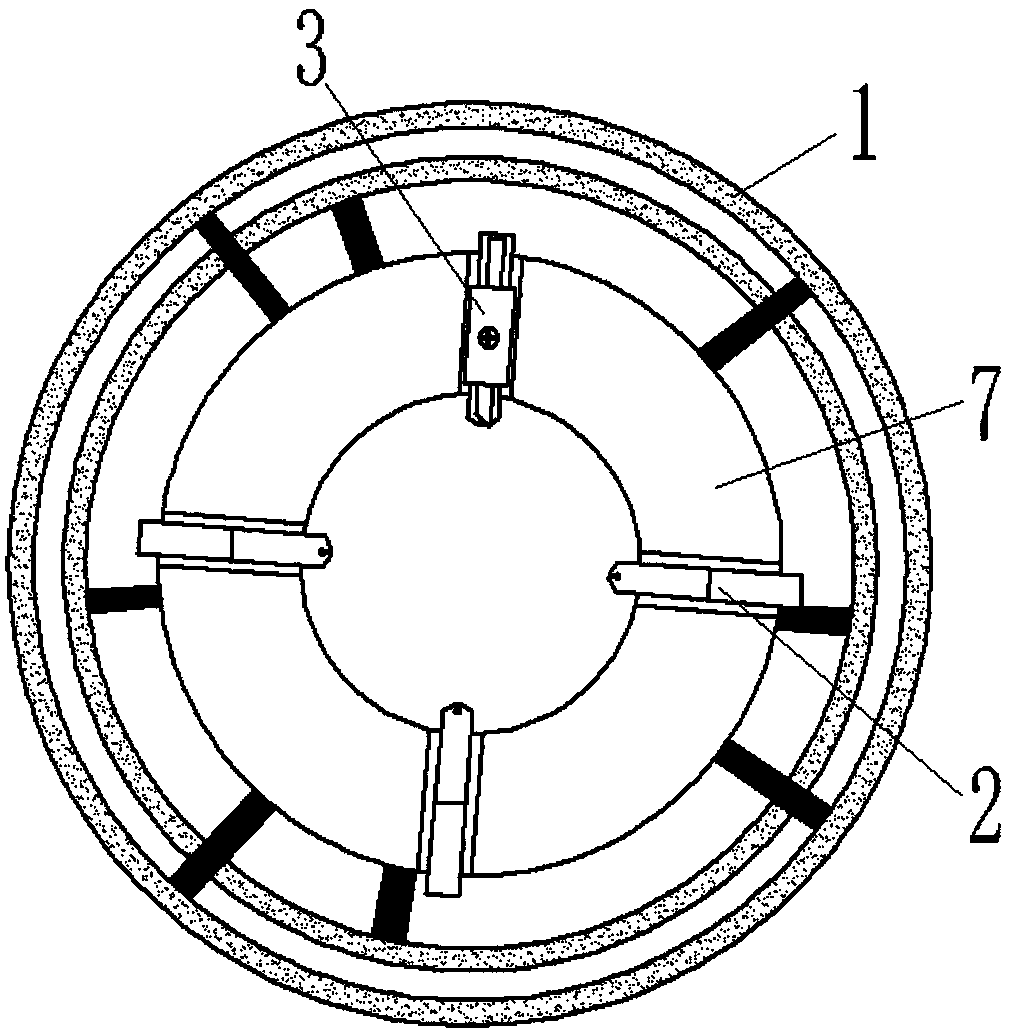

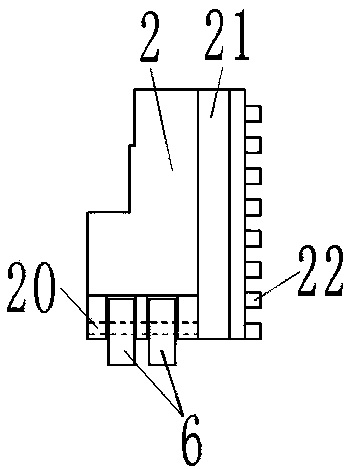

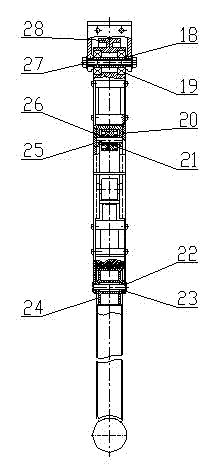

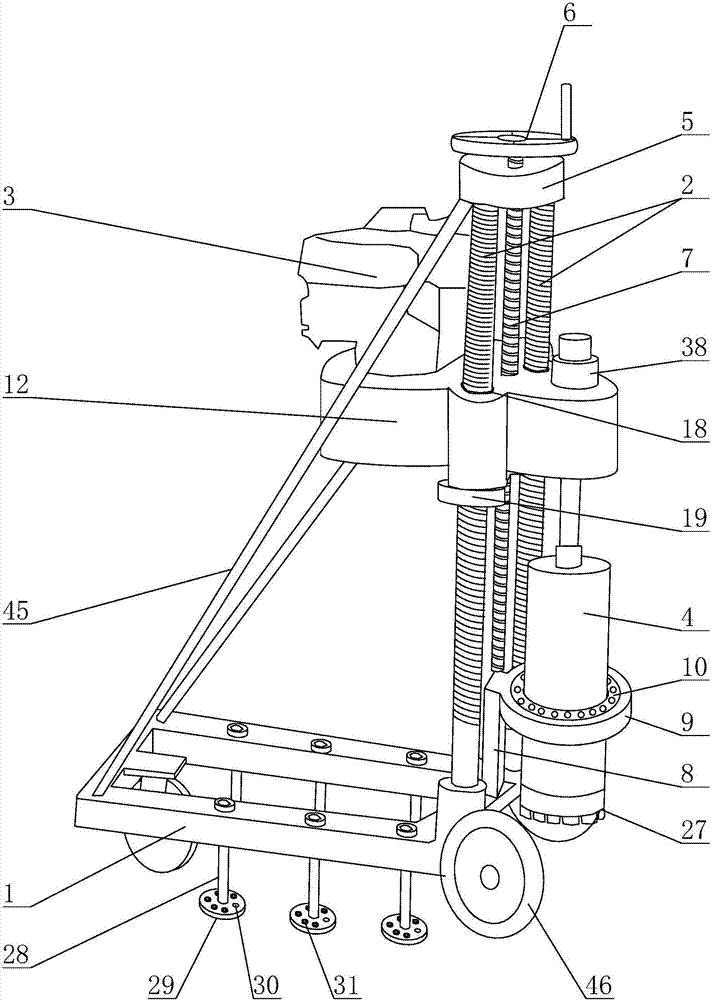

Precision core drilling machine

ActiveCN107191148ASmooth motionSmooth transmissionToothed gearingsCore removalDrive shaftEngineering

The invention discloses a precision core drilling machine. The machine includes a base, a threaded rod, an anti-deviation device, an actuator assembly, a vertical engine, a hollow drill, a top base, a rotating hand wheel and a leading screw, wherein the actuator assembly is composed of a driving shaft, an outer shell body, a planetary gear train, a big sun gear, a transition gear, a tail end gear and a driven shaft; the side wall of a planetary gear groove is provided with annular gears, and the planetary gear train includes a small sun gear and small planetary gears; the driving shaft is successively connected to the small sun gear and the big sun gear in a key joint mode; one end of the transition gear is meshed with the big sun gear, and the other end of the transition gear is meshed with the tail end gear; the leading screw is connected to the internal of a nut sleeve, the driven shaft is connected to the tail end gear in a key joint mode, and the bottom of the driven shaft is connected to the hollow drill. The precision core drilling machine has the advantages that a series of deficiencies in the adoption of belt transition are abandoned, and transmission is much stabler during drilling; the rotation of the hollow drill is much stabler, deviation does not occur easily, and obtained core samples are more precision and uniform.

Owner:杨婷

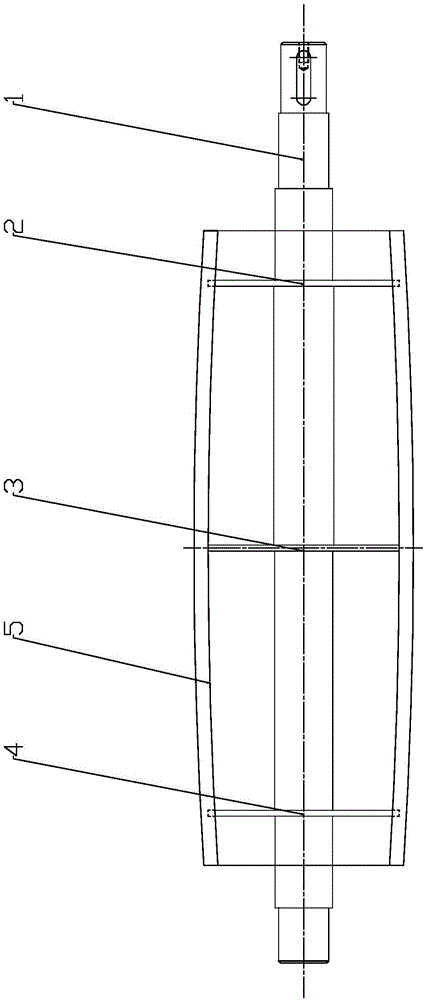

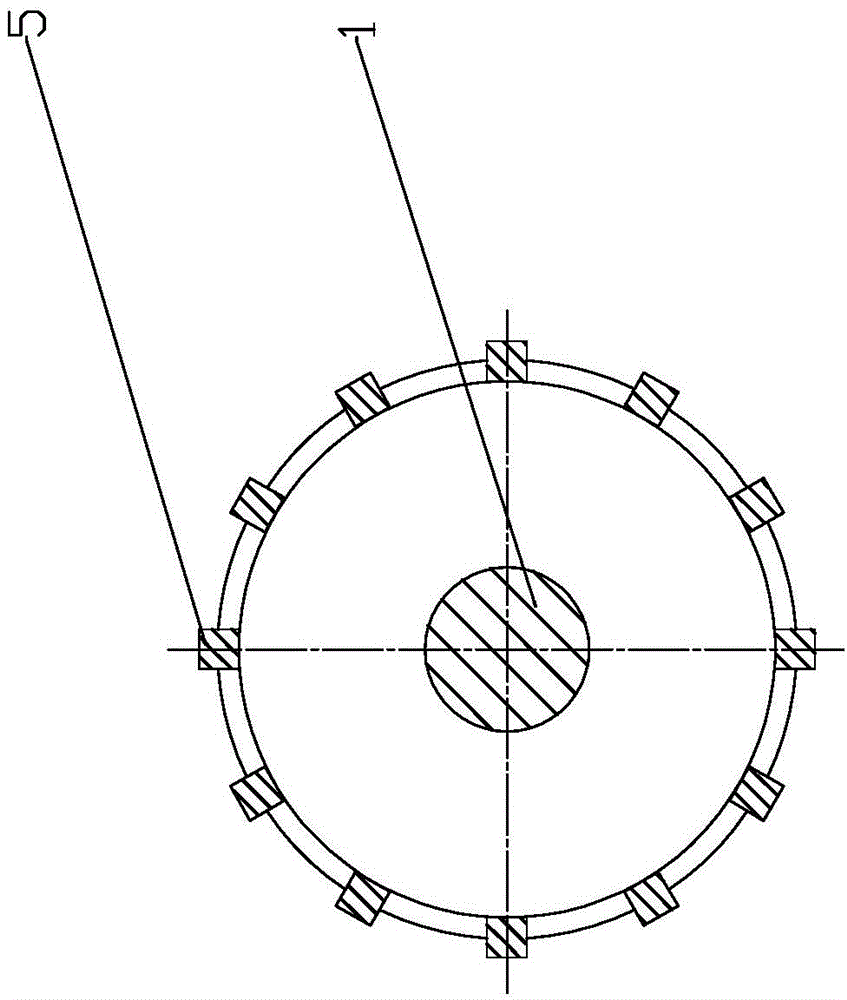

Conveying roller

Owner:WUXI HUAZHONG TECH

Belt dung cleaner and chicken house feeding apparatus

Owner:WENS FOOD GRP CO LTD +1

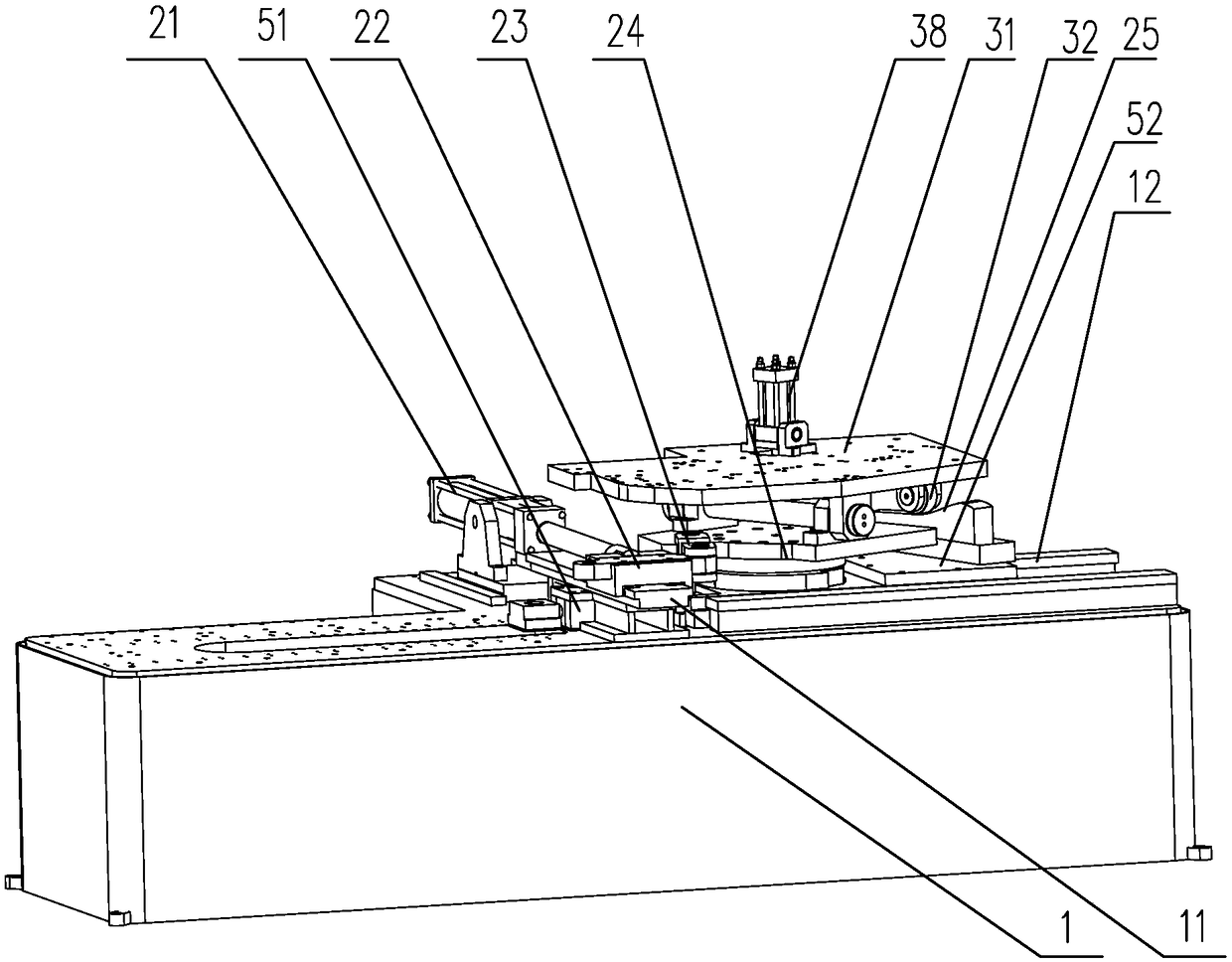

Car door sliding rail stretch bending machine

The invention discloses a car door sliding rail stretch bending machine. The car door sliding rail stretch bending machine comprises a support. Two stretch bending devices are arranged on the supportin a mirror image manner. Each stretch bending device comprises a movable platform and a drive mechanism, wherein the movable platform is arranged on the support and provided with an arc carrying track, and the movable platform is provided with a positioning device; and the drive mechanism comprises a steering disc, a lifting track and a steering drive piece, the position, corresponding to the movable platform, of the steering disc is rotationally arranged on the support, the steering disc is hinged to the movable platform, the lifting track is arranged on one side of the steering disc, the movable platform is provided with wheels, and the wheels and the lifting track are in sliding fit. A cropping device is arranged between the two stretch bending devices, and the support is further provided with an adjusting device for adjusting the distance between the two stretch bending devices. The improved structure of the car door sliding rail stretch bending machine is simple and reasonable, the whole machine structure is simple, stretch bending of a car door sliding rail in the vertical direction and the horizontal direction is effectively achieved, forming is fast, and the production efficiency is higher.

Owner:浙江创大汽车部件有限公司

Spinning wrench device acting or moving synchronously with spinner wheel

PendingCN107269237ANot easy to go off trackReduce distanceDrilling rodsDrilling casingsPhysicsWrench

The invention relates to a spinning wrench device acting or moving synchronously with a spinner wheel. The spinning wrench device comprises stand columns and a spinning wrench mounted on the stand columns. The spinning wrench comprises a rack, clamping oil cylinders, clamping arms and a rear spinning roller support, wherein two spinning assemblies are mounted on the clamping arms, and a spinning assembly is mounted on the rear spinning roller support; the rack is hinged to the middle of the clamping arms, the end portions of the clamping arms are hinged to one ends of connecting arms correspondingly, and the other ends of the connecting arms are hinged to the rear spinning roller support; one ends of the clamping oil cylinders are connected with hinged points of the clamping arms and the connecting arms correspondingly, and the other ends of the clamping oil cylinders are hinged to the rack; the connecting lines of the middles and the ends of the clamping arms are not collinear with the motion directions of the clamping oil cylinders; and a guide device is arranged between the rear spinning roller support and the rack. According to the spinning wrench device, all of the spinning assemblies can enclasp one another toward the center of a tube tool synchronously so that aligning of the tube tool is facilitated, and in the spinning process, all of the spinning assemblies are not prone to be off tracking through connective matching of the connecting arms, the clamping arms and the rear spinning roller support.

Owner:SICHUAN KUNLUN GASOLINEEUM EQUIP MFG

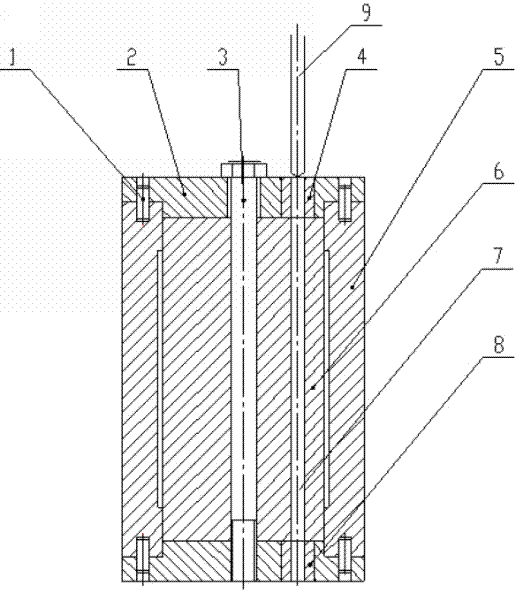

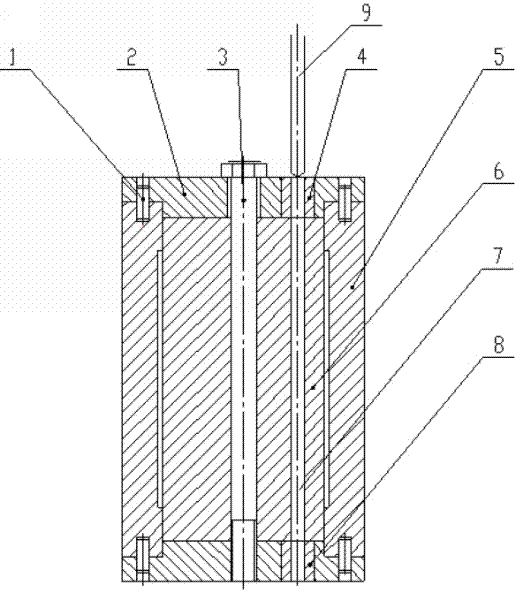

Deep-hole drilling jig

The invention discloses a deep-hole drilling jig for processing deep holes. Two drilling jig plates and a drilling jig body are positioned by positioning pins; a workpiece is arranged in the drilling jig body and between the two drilling jig plates and is pressed by a pressing screw; and the two drilling jig plates are internally and respectively provided with a drilling sleeve I and a drilling sleeve II which are concentric. The deep-hole drilling jig adopts a method of oppositely drilling at two ends to process the deep holes, and since holes concentrically drilled by the two drilling sleeves are not easy to deviate, are high in concentricity are not subjected to limitation of equipment, and the processing of the deep holes can be realized on any drilling machine; the drilling jig can be designed and manufactured according to the shape of the workpiece, and is simple in structure and low in cost; and a lengthened twist drill can not be adopted, chip removal is easy, the fracture of a drilling bit is effectively prevented, the processing cost is reduced and the hole drilling efficiency is high.

Owner:CRRC LUOYANG CO LTD

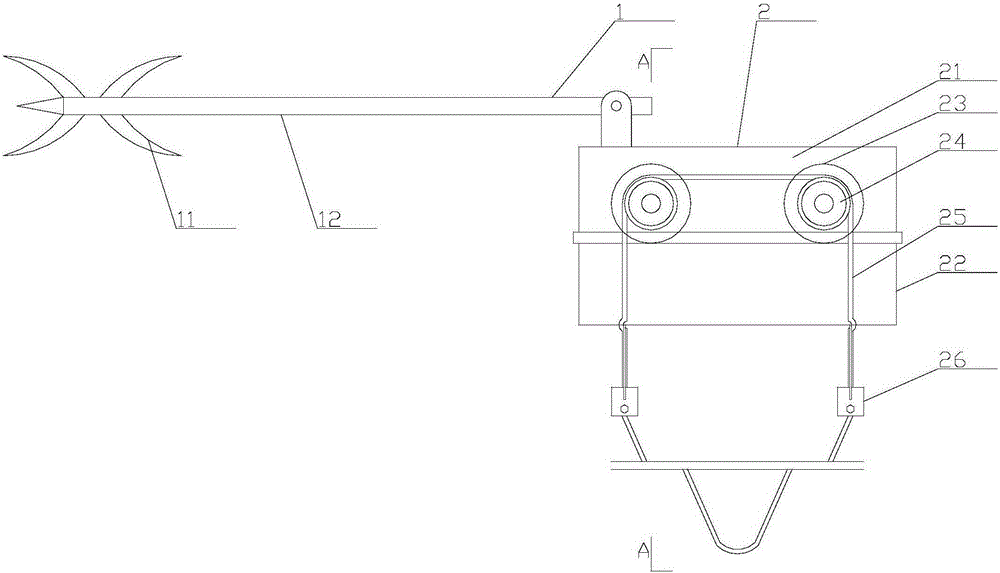

Cleaning device and cleaning method for foreign matters on different-layer overhead cable

InactiveCN105244803AEasy to moveMobile location is accurateApparatus for overhead lines/cablesForeign matterDrive wheel

The invention discloses a cleaning device and a cleaning method for foreign matters on a different-layer overhead cable, and relates to improvement of a high-voltage cable device and an operation method thereof. The cleaning device is delicate in structure, convenient to use and good in stability, can conveniently move on the cable in a reciprocating manner in use and can keep stable. The cleaning device comprises a cleaning component and a mobile component, wherein the mobile component comprises a body, a pair of clamping plates, at least one pulley, at least one pair of driving wheels, two driving ropes and two rope lacing devices, wherein the body is in a frame body with an opening in the bottom; the clamping plates are hinged to two sides of the bottom of the body; the pulley is hinged in the body; the driving wheels are fixed at one end far away from the pulley; the driving ropes are in a closed loop form and respectively wind the driving wheels; the cleaning component comprises a cleaning claw and a cleaning rod; the cleaning rod is connected to the body; and the cleaning claw is fixed at one end of the cleaning rod. The cleaning device is convenient to move, accurate in moving position, and extremely stable in movement. The stability in movement is greatly improved. The cleaning device is convenient to move, efficient, good in stability, high in foreign matter cleaning efficiency and good in cleaning effect.

Owner:YIZHENG POWER SUPPLY OF JIANGSU ELECTRIC POWER +2

Intelligent carrier cart for stereo garage

The invention discloses an intelligent carrier cart for a stereo garage. The intelligent carrier cart solves the problems that in an existing stereo garage, vehicle carrying efficiency is low, synchronization is poor, and reliability is low. The intelligent carrier cart comprises bearing main bodies, marching motors are arranged on the bearing main bodies, driving wheels are fixedly arranged on rotation shafts of the marching motors in a sleeved mode, and wheel main shafts are provided with driven wheels matched with the driving wheels through transmission; three connection ends are arranged on a rotation support, one connection end is connected with a clamping rod, one connection end is hinged to a corresponding bearing main body through a pin shaft, the other connection end is hinged to one end of a connection piece, and the other end of the connection piece is hinged to a connection push rod; a telescopic device is connected with the other end of the connection push rod. According to the intelligent carrier cart for the stereo garage, through cooperation of the bearing main bodies, the clamping rod, the connection push rod and the connection piece, the problems that in the existing stereo garage, vehicle carrying efficiency is low, synchronization is poor, and reliability is low are solved. The intelligent carrier cart has the advantages of being simple in structure, convenient to use, good in synchronization, high in reliability, and the like.

Owner:成都人工智能呼叫产业园管理有限公司

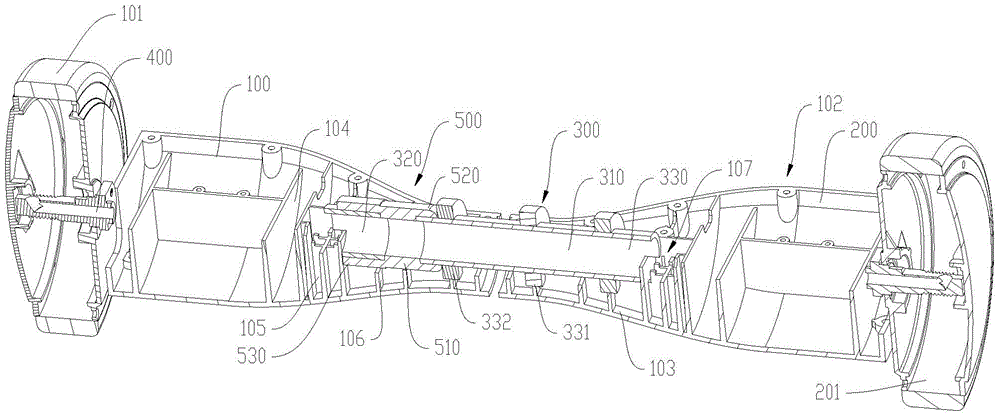

Segway adopting transverse foot-control steering

Owner:ZHEJIANG TOPSO TECH

Sliding device

InactiveCN102506276AMeet the use requirementsShorten the timeStands/trestlesFluid gearingsPetroleum engineering

Owner:JIKAI EQUIP MFG CO LTD

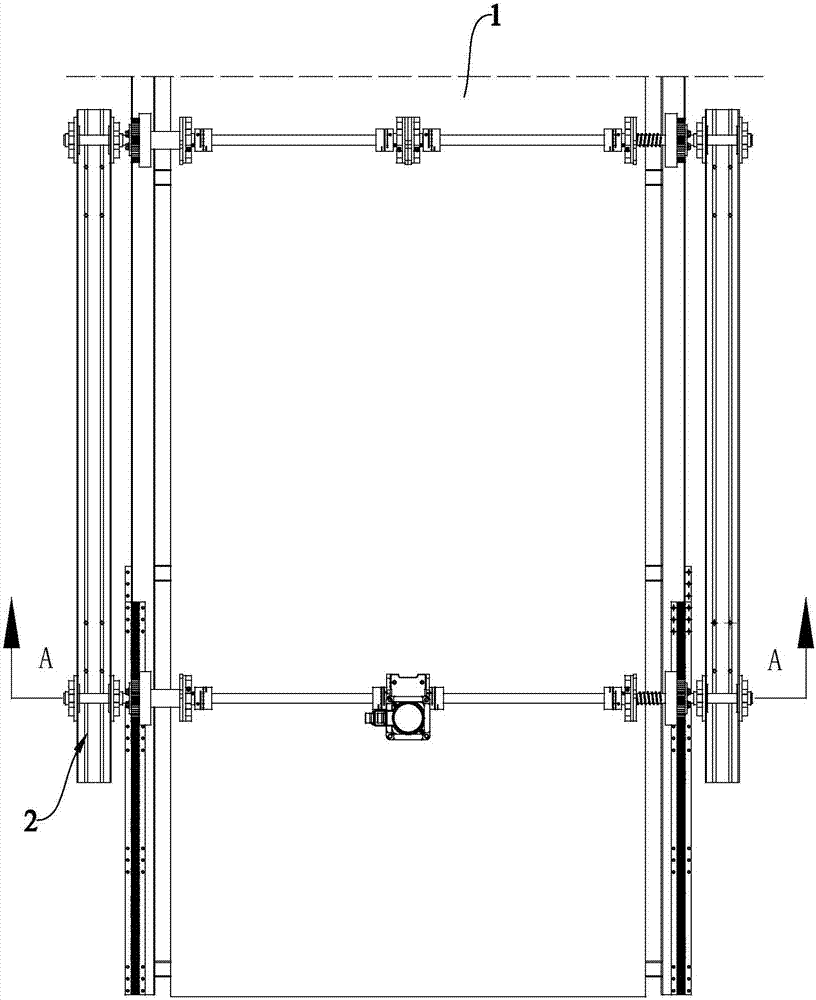

Printing component for high-precision treadmill printing machine

ActiveCN107187180AGuaranteed uptimeRun accuratelyScreen printersScreen printingMechanical engineeringTreadmill

The invention discloses a printing component for a high-precision treadmill printing machine. The printing component is characterized in that the printing component is arranged on a traveling component and comprises a longitudinal support, a transverse frame, a longitudinal driving assembly, a net plate, a net plate adjusting assembly, a scraper, a transverse driving assembly and a scraper mounting and adjusting assembly. The printing component has the advantages of being simple in structure, convenient to assemble, high in printing efficiency, smooth in traveling, accurate in positioning and relatively small in occupied area.

Owner:NINGBO TIANHONG POWER APPLIANCE

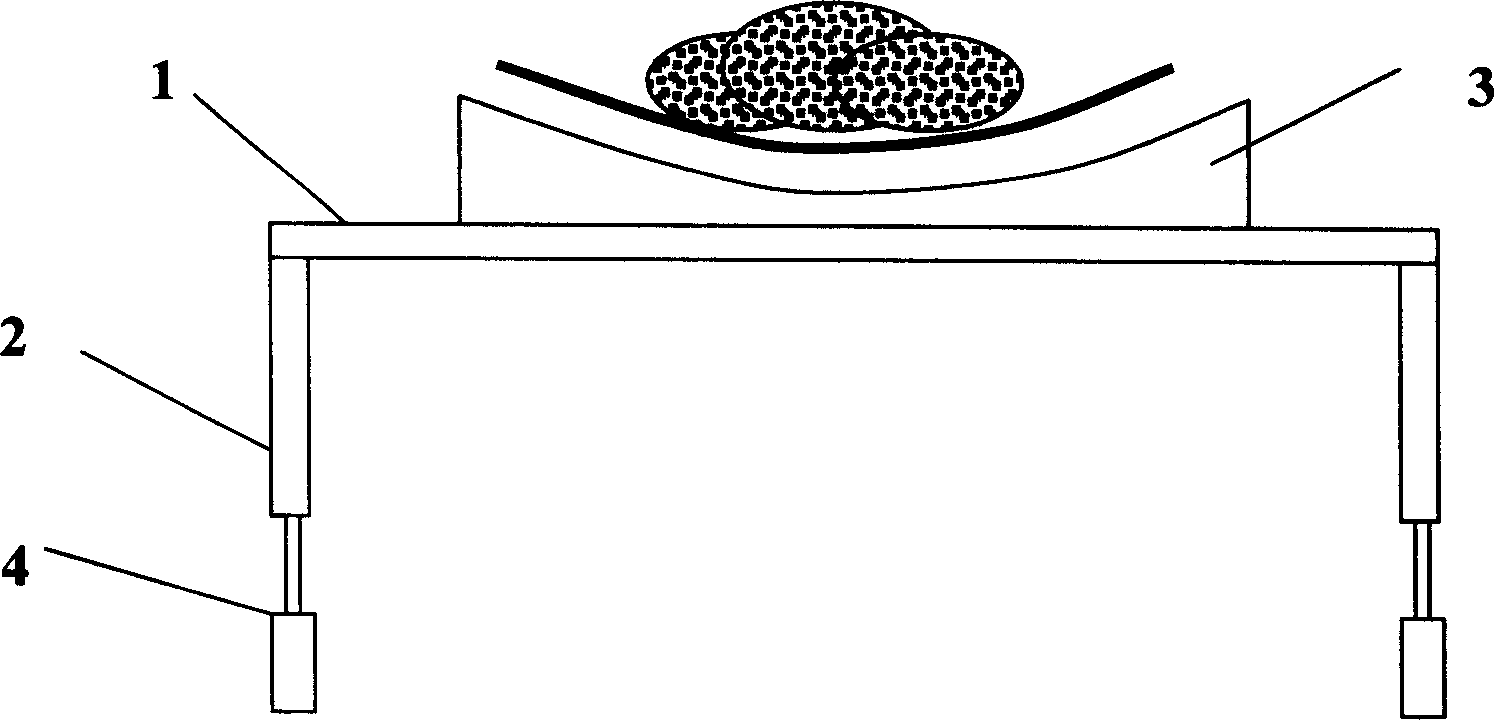

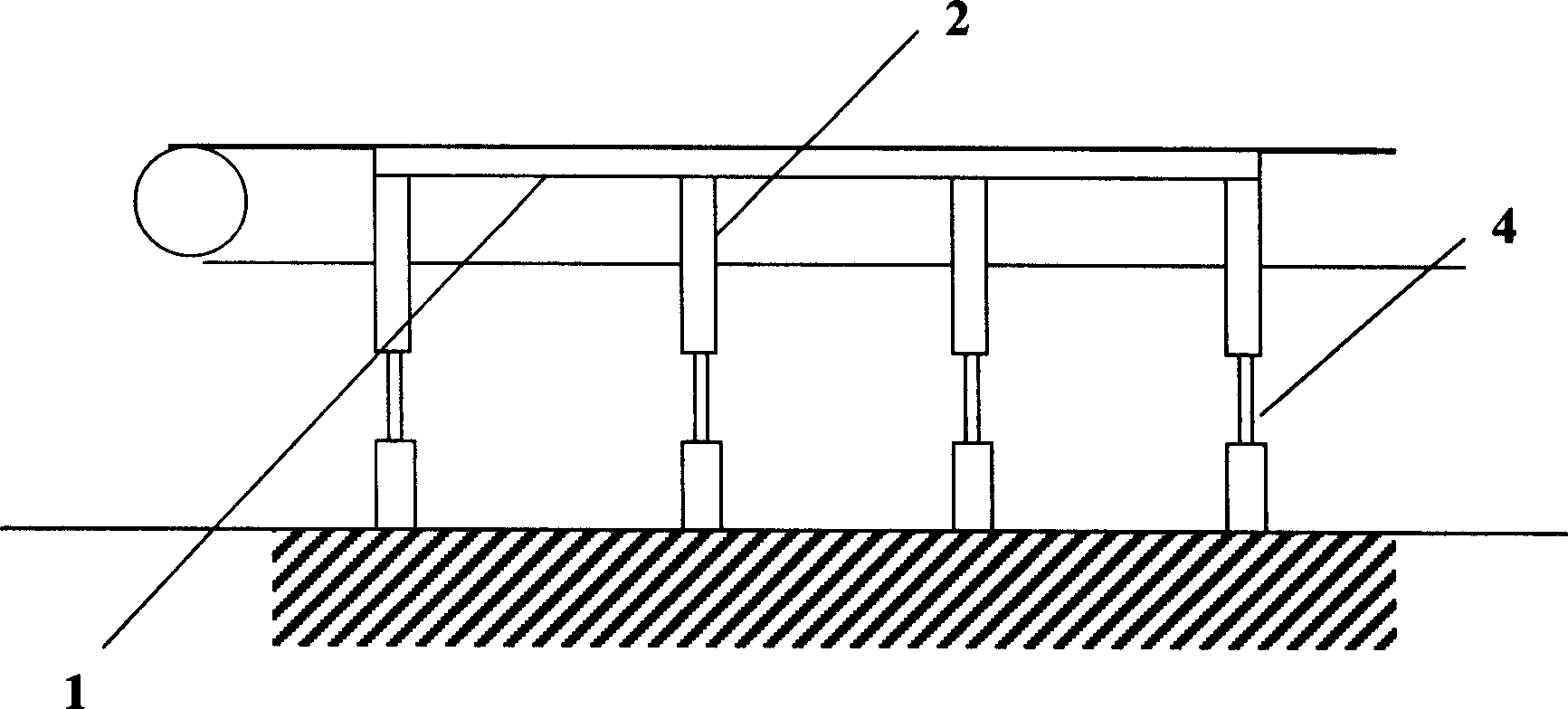

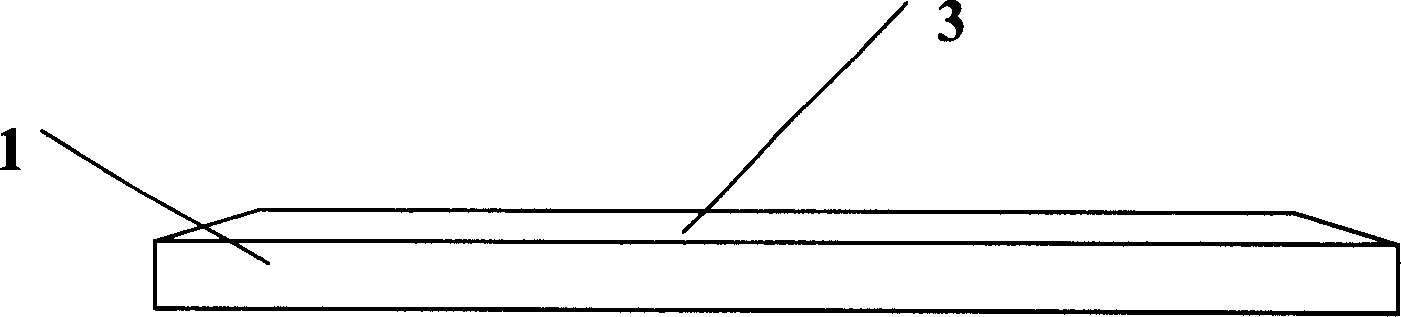

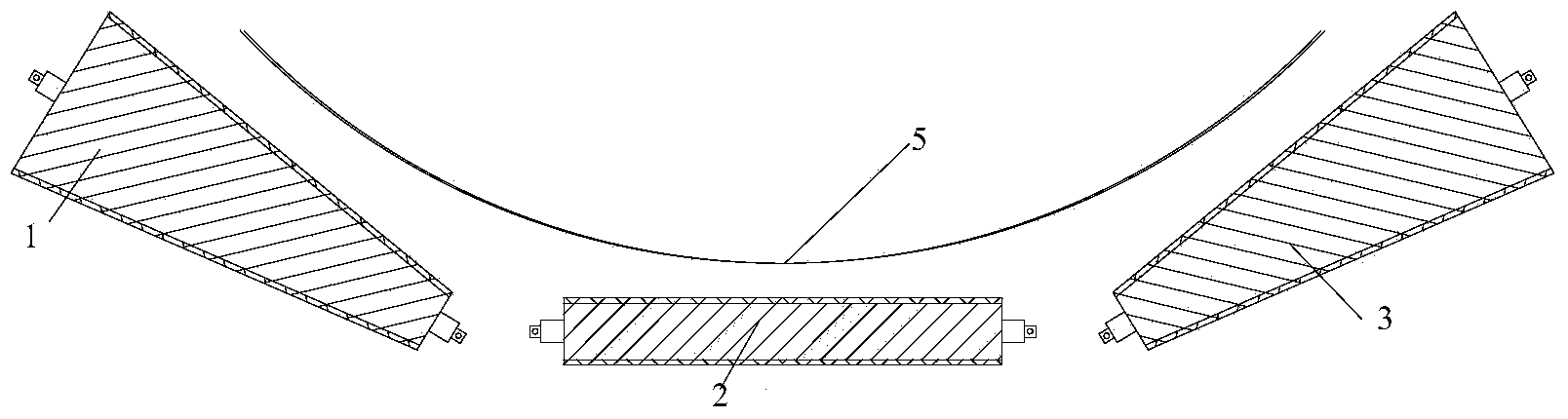

Supporting device for receiving hopper operation of conveyer belt

InactiveCN1836992AThe material receiving process is stableNot easy to go off trackConveyorsVertical vibrationDamping factor

The supporting unit for conveyer belt consists of support plate and support legs with elastic elements and below the support plate. The support plate has one continuous support surface layer of ceramic plates or GRP plates and in parabolic cross section. The supporting unit supports the conveyer belt, and the impact of the falling material and the vertical vibration of the carried material are absorbed by the elastic elements in the support legs. The continuous support surface layer in parabolic shape can avoid the early wear of its middle part to ensure smooth running of the conveyer belt, and the continuous support surface layer of ceramic plates or GRP plates has low damping coefficient, high friction resistance and fire retarding performance and is suitable for use in mine with gas.

Owner:SHANGHAI GORO CONVEYOR EQUIP CO LTD

Cylinder device of belt conveyer

The invention discloses a cylinder device of a belt conveyer. Compared with the prior art, the cylinder device is mainly characterized in that a middle cylinder body is cylindrical, a left cylinder body and a right cylinder body are of a circular truncated cone shape, a right shaft of the left cylinder body and a first joint bearing arranged on a left machine frame of the belt conveyer are rotatably connected, a left shaft of the right cylinder body and a second joint bearing arranged on a right machine frame of the belt conveyer are rotatably connected, the outer surface of the left cylinder body, the outer surface of the middle cylinder body and the outer surface of the right cylinder body are all rubber lining layers, and a plurality of grooves are formed in the surfaces of the rubber lining layers. The cylinder device can guarantee that a belt runs more stably and does not deviate in the work process of the belt conveyer, and adjustment is easy and convenient to achieve when the belt deviates.

Owner:SHANDONG UNIV OF SCI & TECH

Automatic paper conveying device

InactiveCN106697411AImprove general performanceGood compression effectWrapping material feeding apparatusPulp and paper industryPaper sheet

The invention provides an automatic paper conveying device comprising a paper supplying unit, a paper picking unit and a paper output unit. The two ends of the paper picking unit are connected with the paper supplying unit and the paper output unit correspondingly. The paper supplying unit conveys stacked paper to a picking station of the paper picking unit. The paper picking unit picks single piece of paper from the stacked paper on the picking station and conveys the single piece of paper to the inlet end of the paper output unit. The paper output unit conveys the single piece of paper from the device to outside. Compared with the prior art, the automatic paper conveying device has the beneficial effects that universality is strong, the automation degree is high, the paper pressing effect is good, the device is suitable for different thicknesses of paper, jamming or deviation of the paper is not liable to occur, and paper conveying is accurate.

Owner:襄阳欧昇机械科技有限公司

Dual-face coating machine

PendingCN108787338ANot easy to go off trackWon't hurtLiquid surface applicatorsCoatingsAir volumePulp and paper industry

The invention belongs to the technical field of coating machines, and particularly relates to a dual-face coating machine. The dual-face coating machine comprises an air flotation via roller. The airflotation via roller comprises a hollow roller body and an air volume rectifier. The air volume rectifier is fixed into the hollow roller body. An air inlet of the air volume rectifier communicates with an air pipe, and the air pipe is connected with the hollow roller body. The air volume rectifier is provided with multiple first through holes. Gas of the air volume rectifier enters an inner cavity of the hollow roller body through the multiple first through holes. Multiple second through holes are formed on the roller face of the hollow roller body and are evenly arranged in a staggered manner.

Owner:FOSHAN GOLD SILVER RIVER INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com