Deep-hole drilling jig

A technology of deep hole drilling and drilling dies, which is applied to the drilling dies for workpieces, etc., can solve the problems of long drilling time, difficult chip removal, stuck twist drills, etc., so as to reduce processing costs, high drilling efficiency, The effect of easy chip evacuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

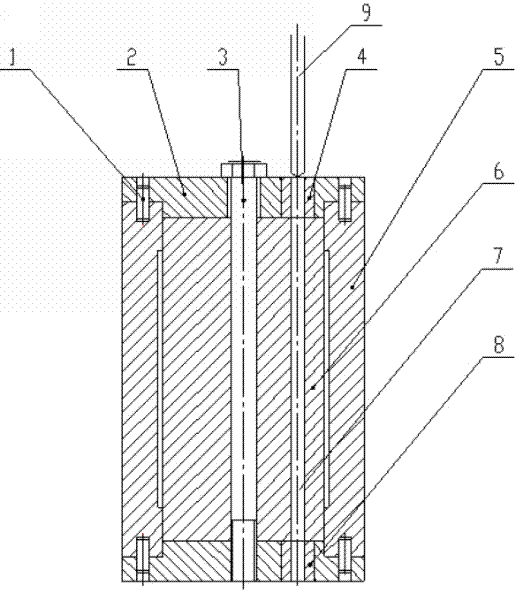

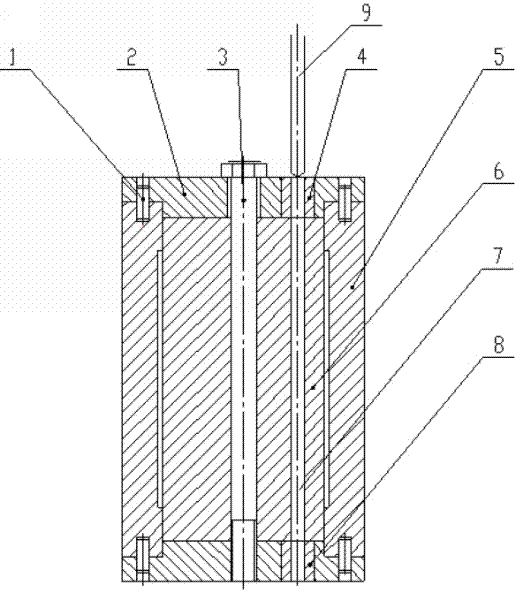

[0011] As shown in the accompanying drawings, the present invention is made up of four alignment pins 1, two drill templates 2, a compression screw 3, drill sleeve one 4, drill sleeve two 8, and drill template body 5. The two drill templates 2 are respectively inlaid with a drill sleeve 1 4 and a drill sleeve 2 8. The drill template 2 is positioned together with the drill template body 5 through four positioning pins 1. The workpiece 6 is installed in the drill template body 5. Between the templates 2, use the compression screw rod 3 to compress, and the first drill sleeve 4 is concentric with the second drill sleeve 8.

[0012] When drilling, the workpiece 6 is put into the template body 5, the template body 5 is clamped with two templates 2, four positioning pins 1 are inserted, the compression screw 3 is tightened, the template is placed on the drill press, Drill bushing 1 4 faces up, start the drilling machine, shake the handle to make the twist drill bit 9 feed downwards,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com