Printing component for high-precision treadmill printing machine

A technology for printing parts and printing machines, applied in printing, printing machines, screen printing, etc., can solve the problems of insufficient use of site area, affecting printing efficiency, large footprint, etc., to reduce the possibility of deviation, The effect of ensuring printing quality and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The following description is used to disclose the present invention so that those skilled in the art can implement the present invention. The preferred embodiments in the following description are only examples, and those skilled in the art can think of other obvious variations.

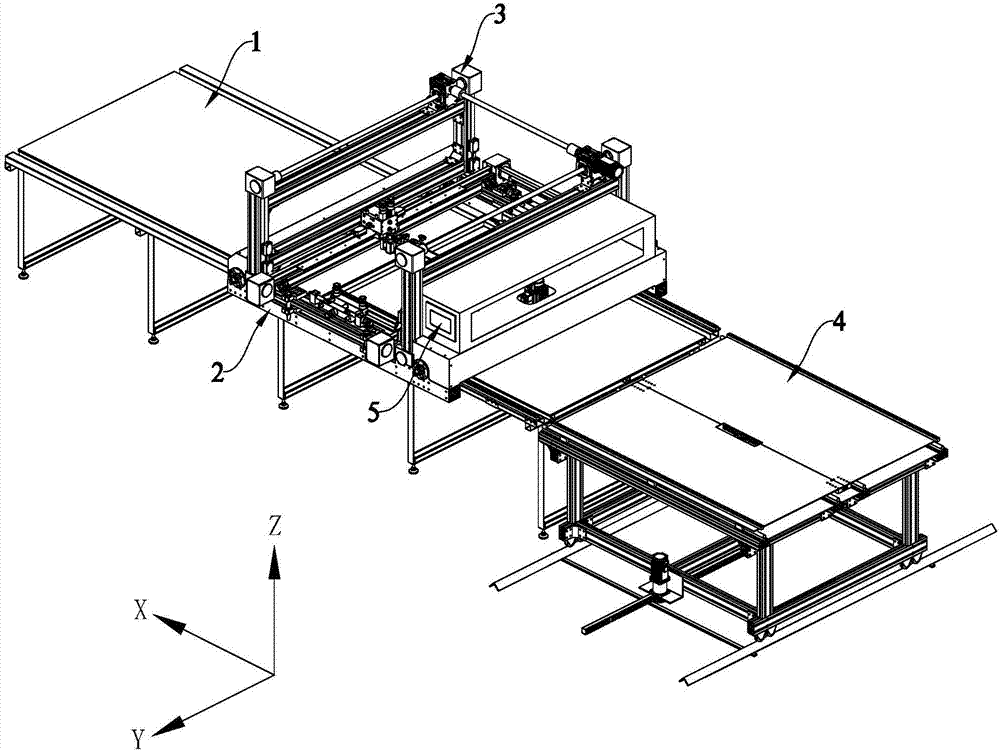

[0052] Such as Figure 1~25 As shown, it is a preferred embodiment of the present invention, which includes a workbench, a walking part, a printing part, a transfer part and a control part. specific:

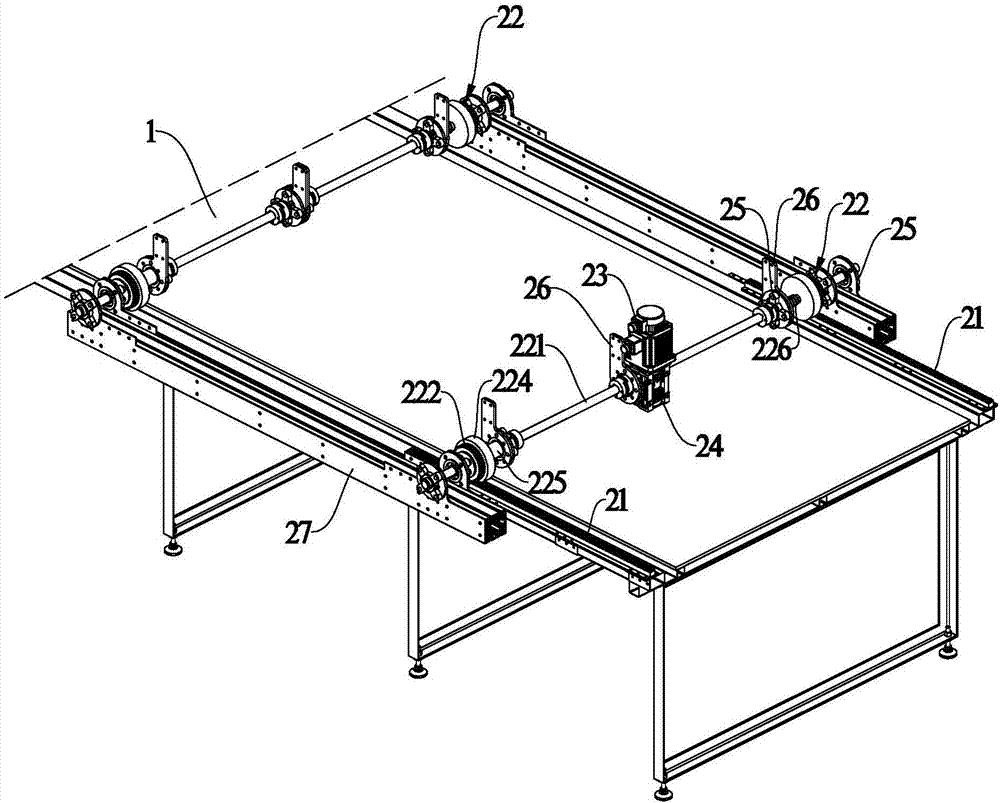

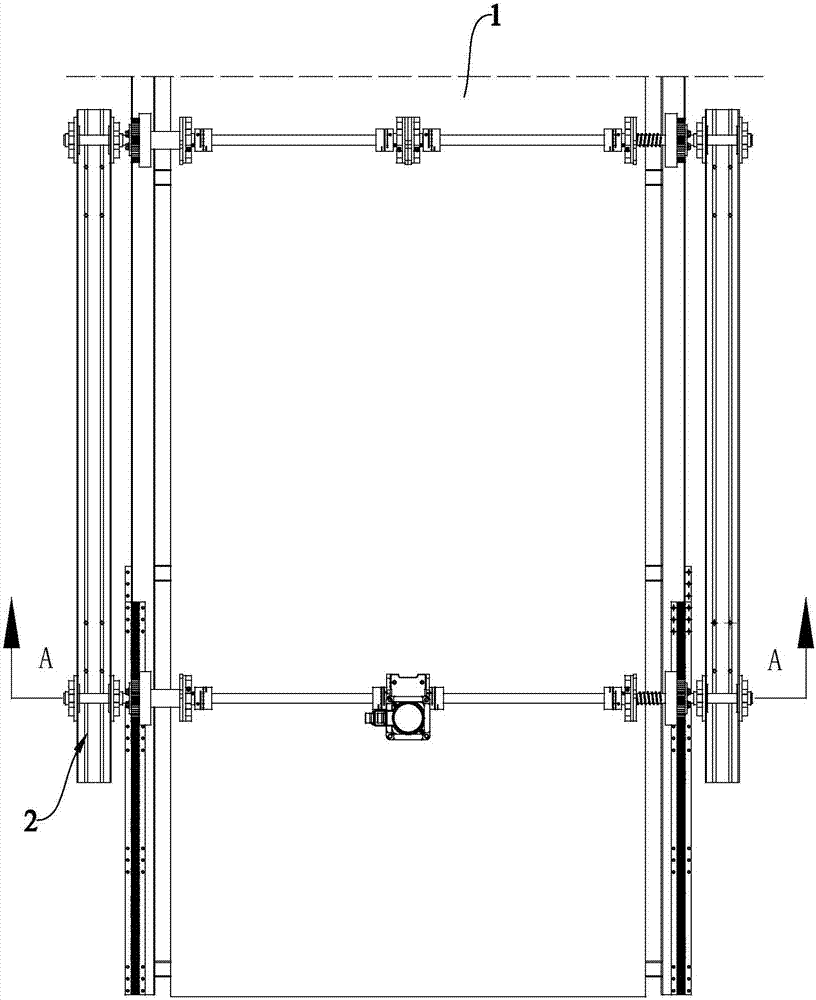

[0053] The workbench 1 has a linear structure and is used for placing printed matter. The length direction of the workbench 1 is the X axis, the width direction of the workbench is the Y axis, and the height direction of the workbench 1 is the Z axis.

[0054] The walking part 2 is arranged on the worktable 1 and is used for driving the printing part 3 to perform a linear reciprocating movement along the X axis on the worktable 1. The traveling component 2 includes a traveling rack 21, a traveling w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com