Single-anchor pin cam drum type brake

A technology for drum brakes and support pins, which is applied in the field of auto parts, can solve the problems of complex structures of two support pins, and achieve the effects of optimizing shape, not easy to run off, and reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing the specific embodiment of the present invention is described in detail as follows:

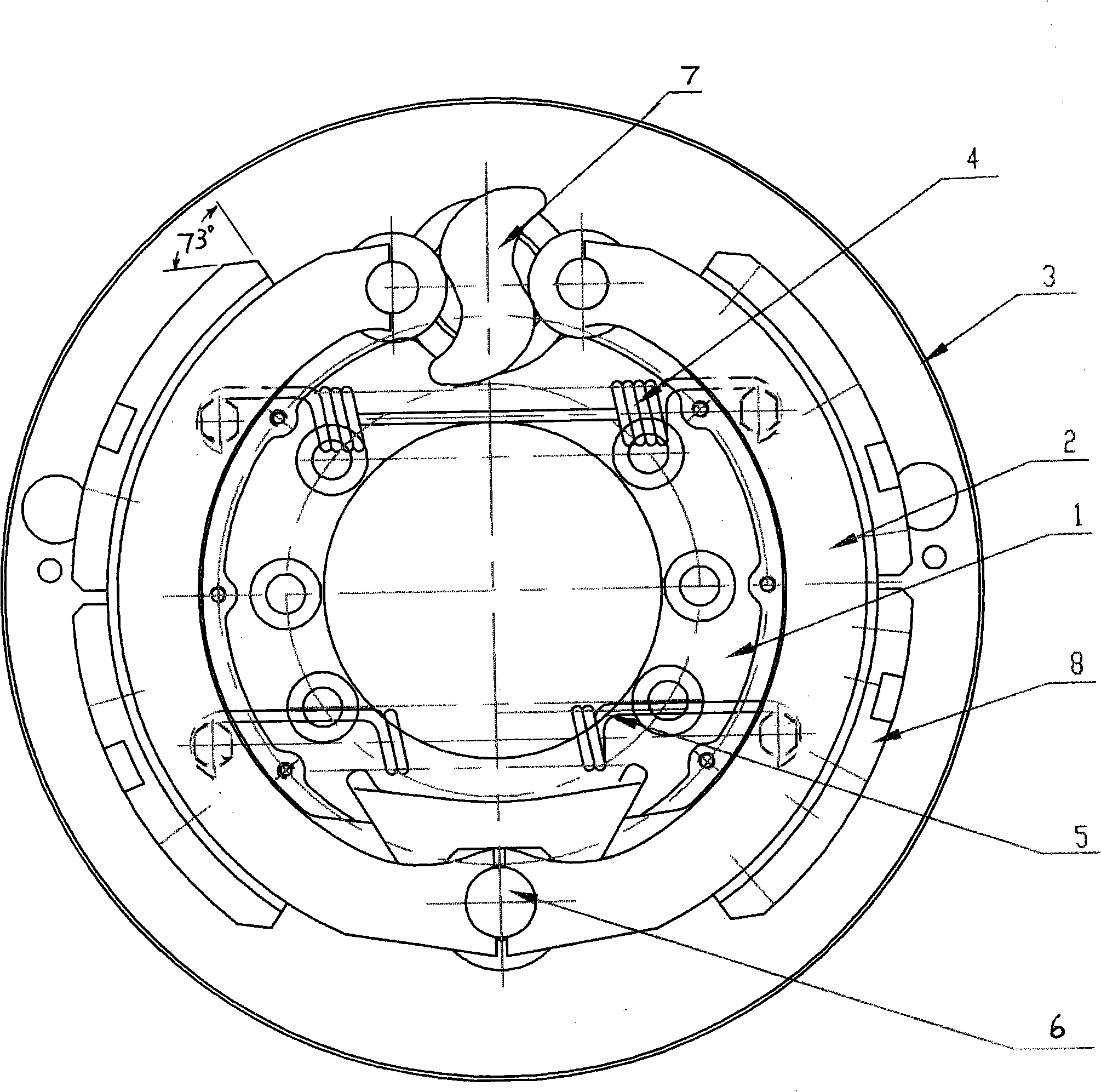

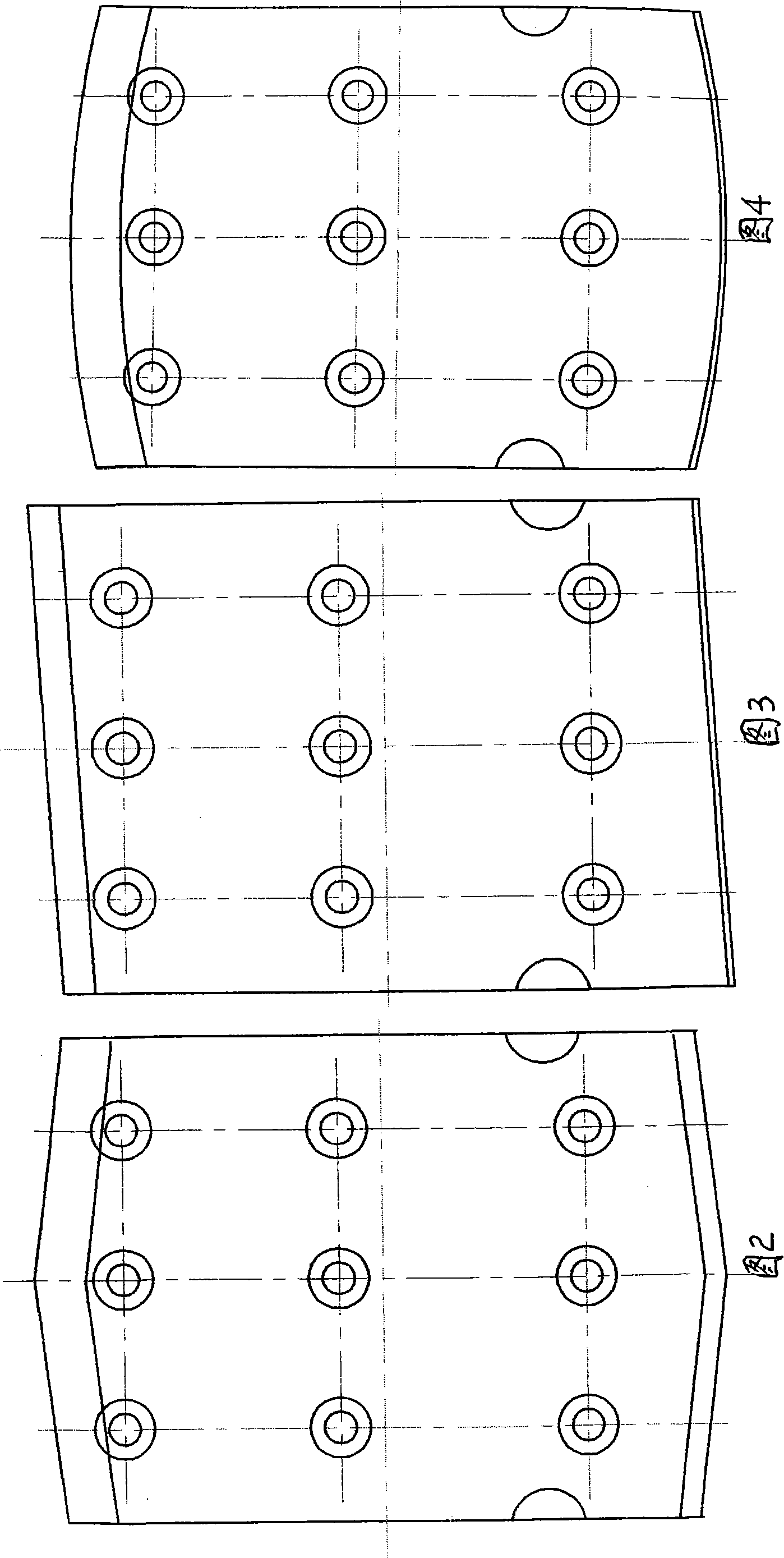

[0015] exist figure 1 Among them, the brake of the present invention includes a circular base plate 1, a dust cover 3 fixed on the circumference of the base plate 1, and a brake shoe 2. There are two brake shoes 2, which are semicircular and symmetrically arranged, and are fixed on the base plate 1. There is a support pin 6, and there is a semicircular notch at one end of the brake shoe 2, and the notch is stuck on the support pin 6, and the two brake shoes 2 share a support pin 6, and the other end of the brake shoe 2, that is, the movable end, passes through The pin holes are fixed with rollers, the bottom plate 1 in the middle of the rollers is fixed with a camshaft 7, the camshaft 7 is fixed with a cam, the cam contacts with the rollers, and a return spring 4 is installed between the two brake shoes 2 and the fixed spring 5, on the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com