Patents

Literature

535results about "Mechanically actuated drum brakes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

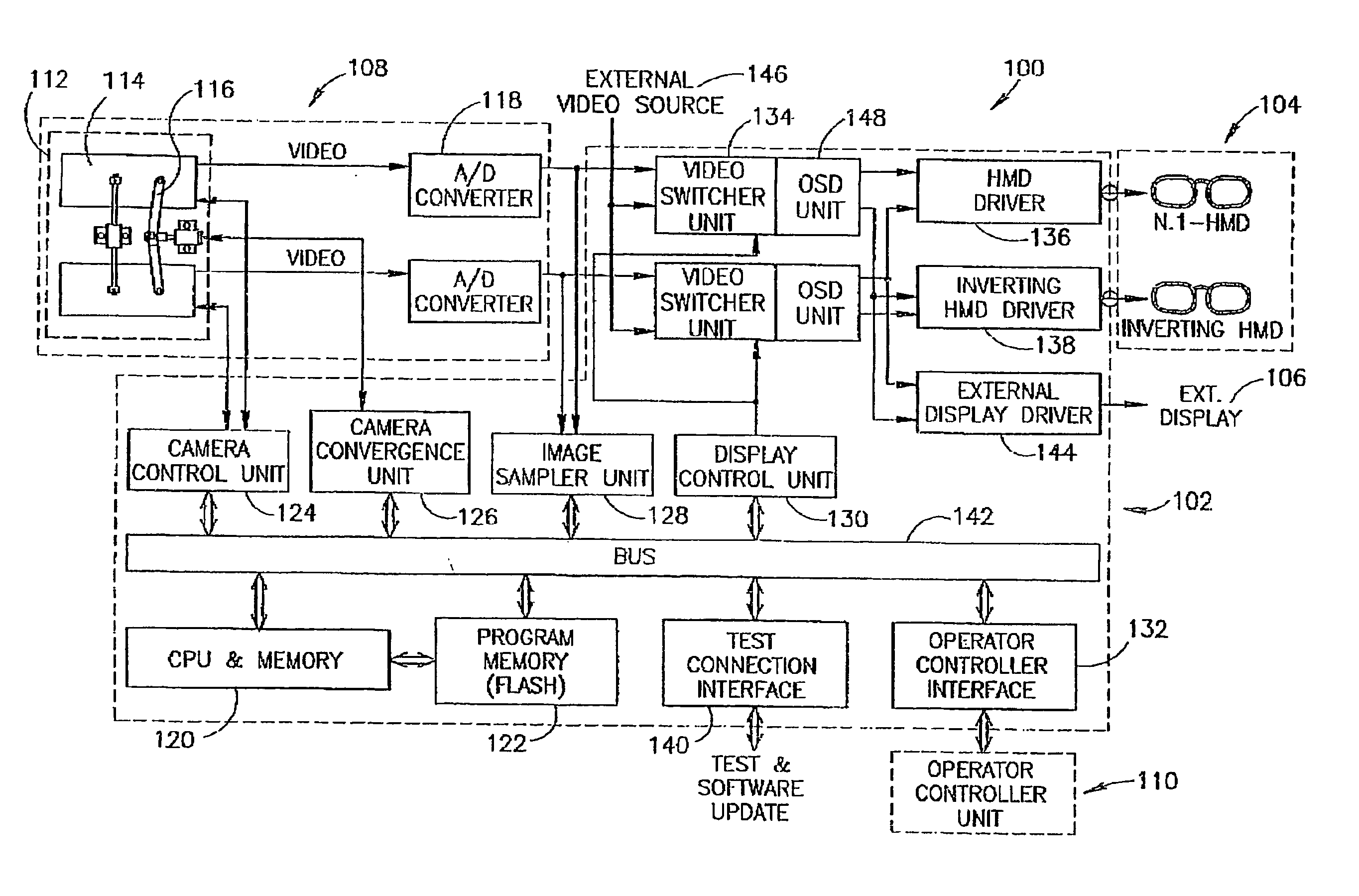

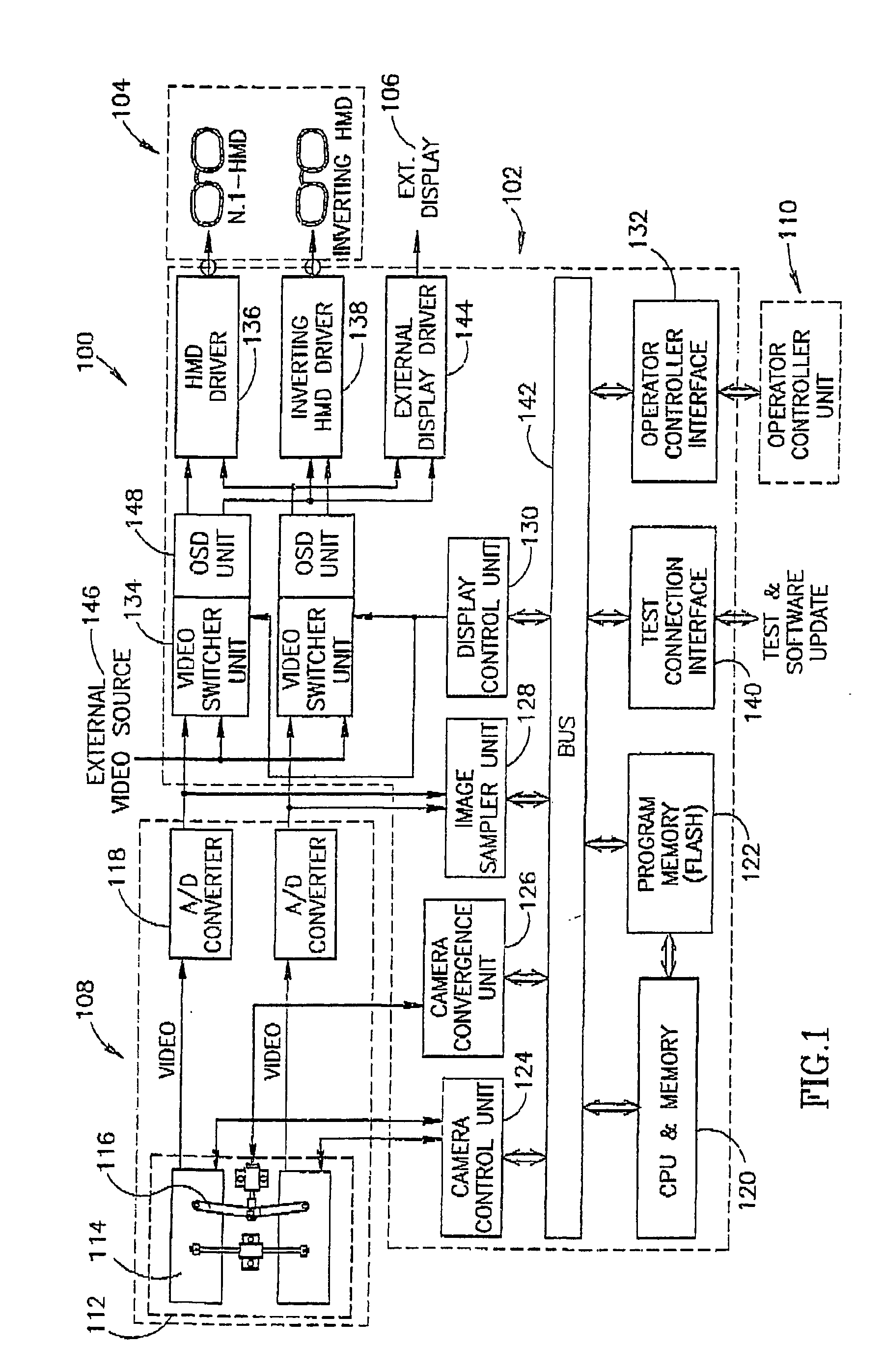

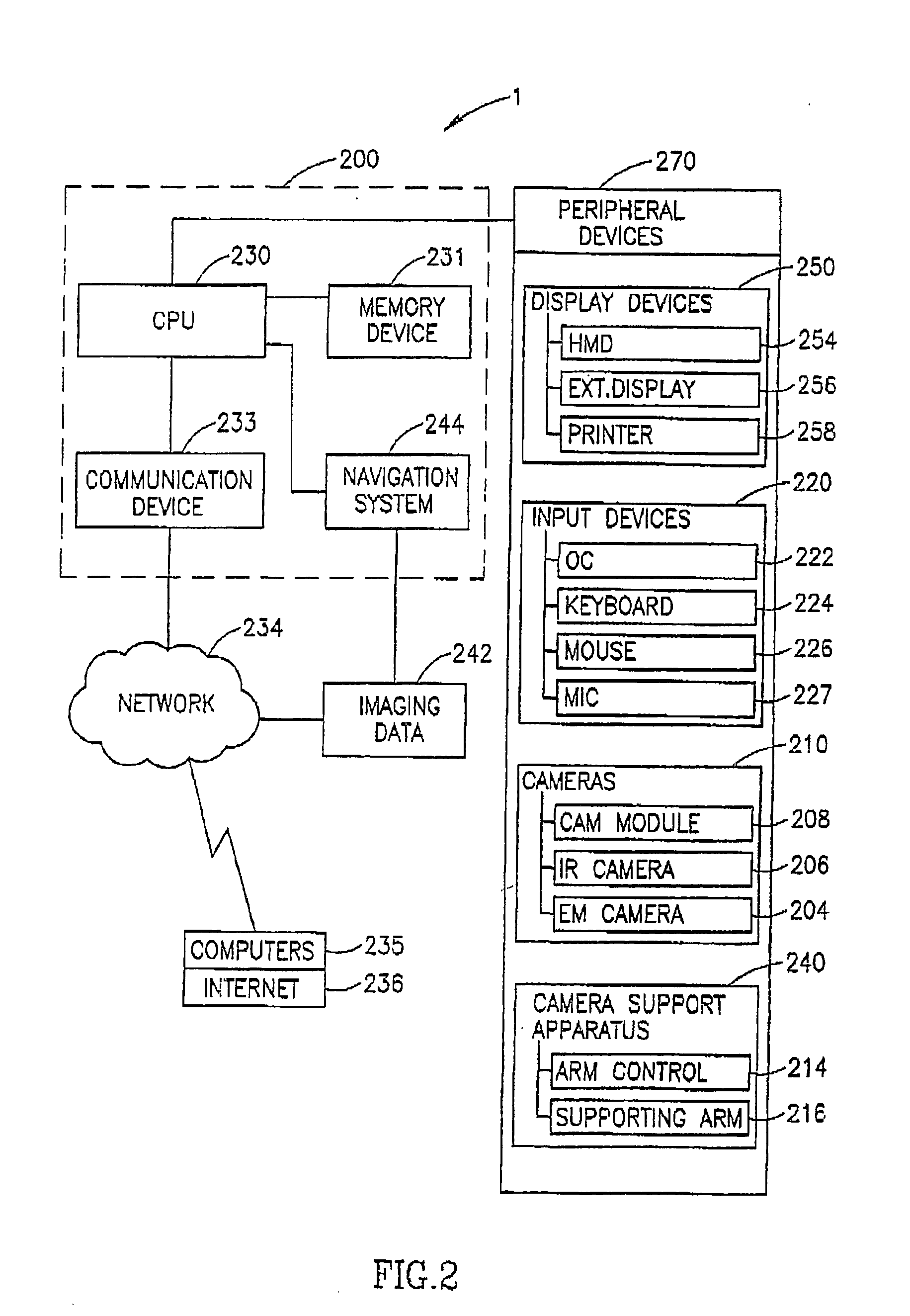

Stereoscopic video magnification and navigation system

InactiveUS20050090730A1Accurate informationImprove ergonomicsDiagnostic recording/measuringSensorsStereoscopic videoDisplay device

An apparatus and method for providing stereoscopic magnified observation enabling an operator to perform surgical procedures without having to remove his eyes from the operating field comprising a head mounted display for provding the operator with stereoscopic magnified images in an operating field, a camera module for providing stereoscopic magnified images, an operator controller unit for enabling an operator to control the operation of the apparatus; and an interface processing unit for processing and dynamically presenting the stereoscopic magnified images in an operating field.

Owner:FRENI BREMBO SPA

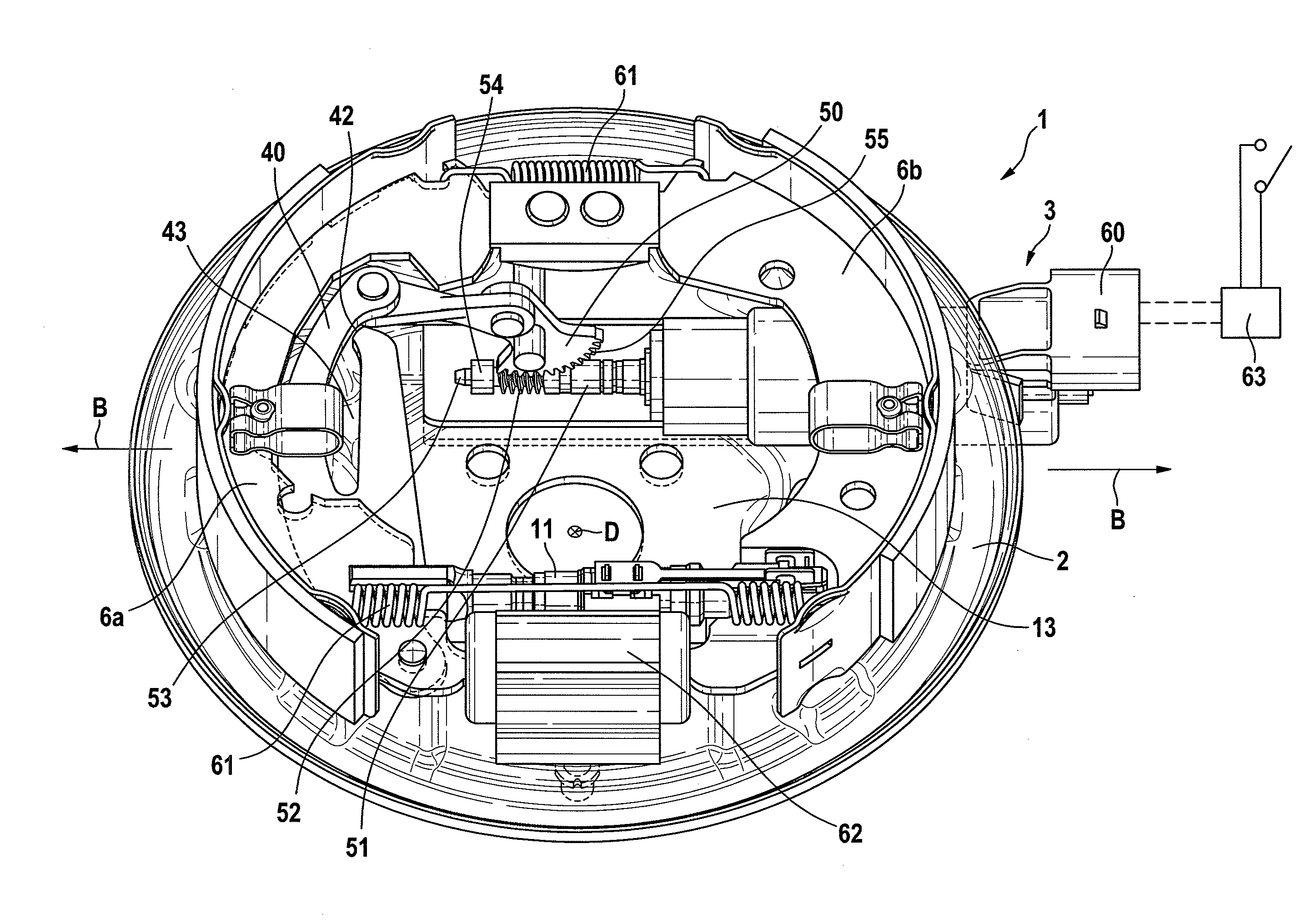

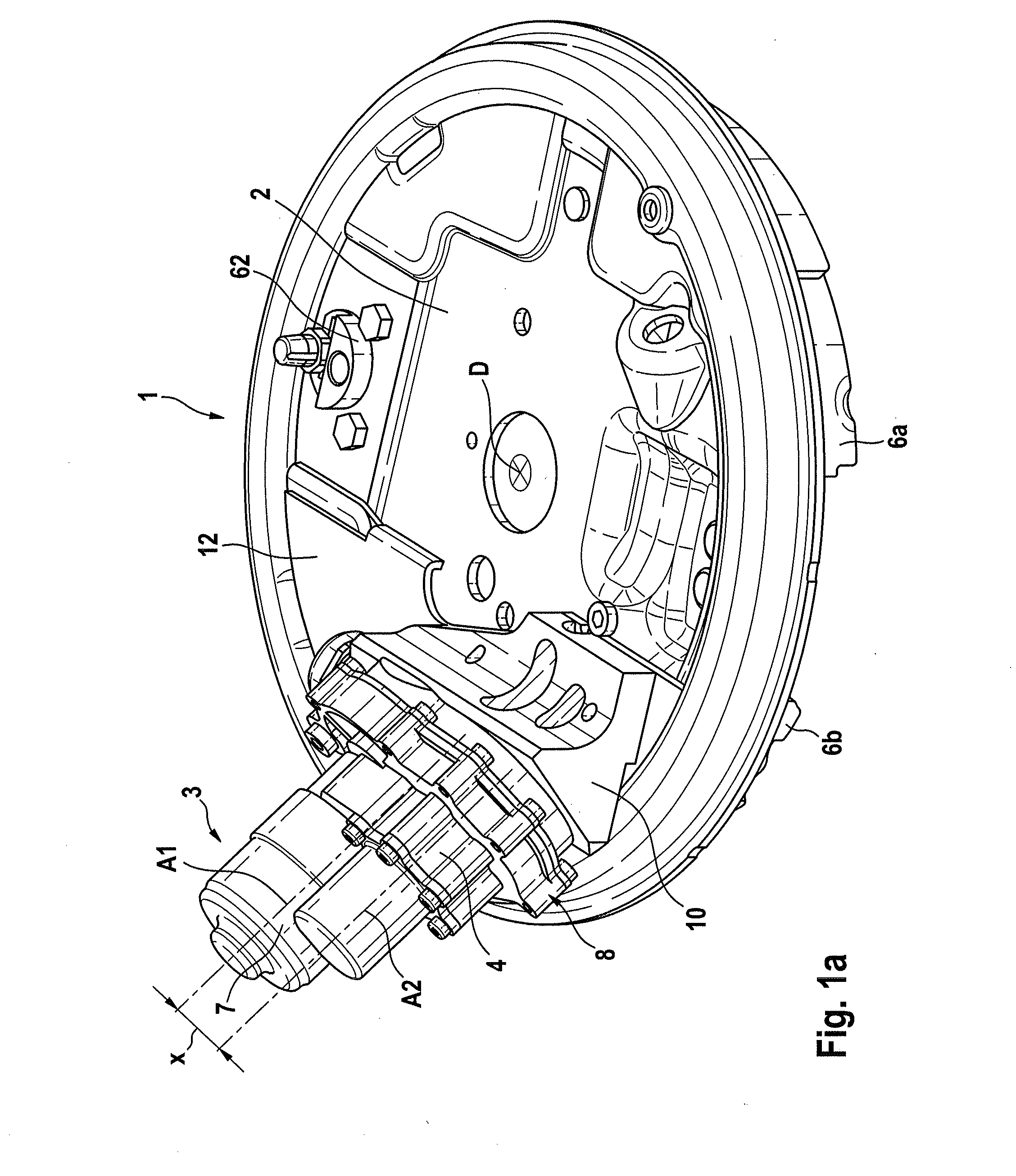

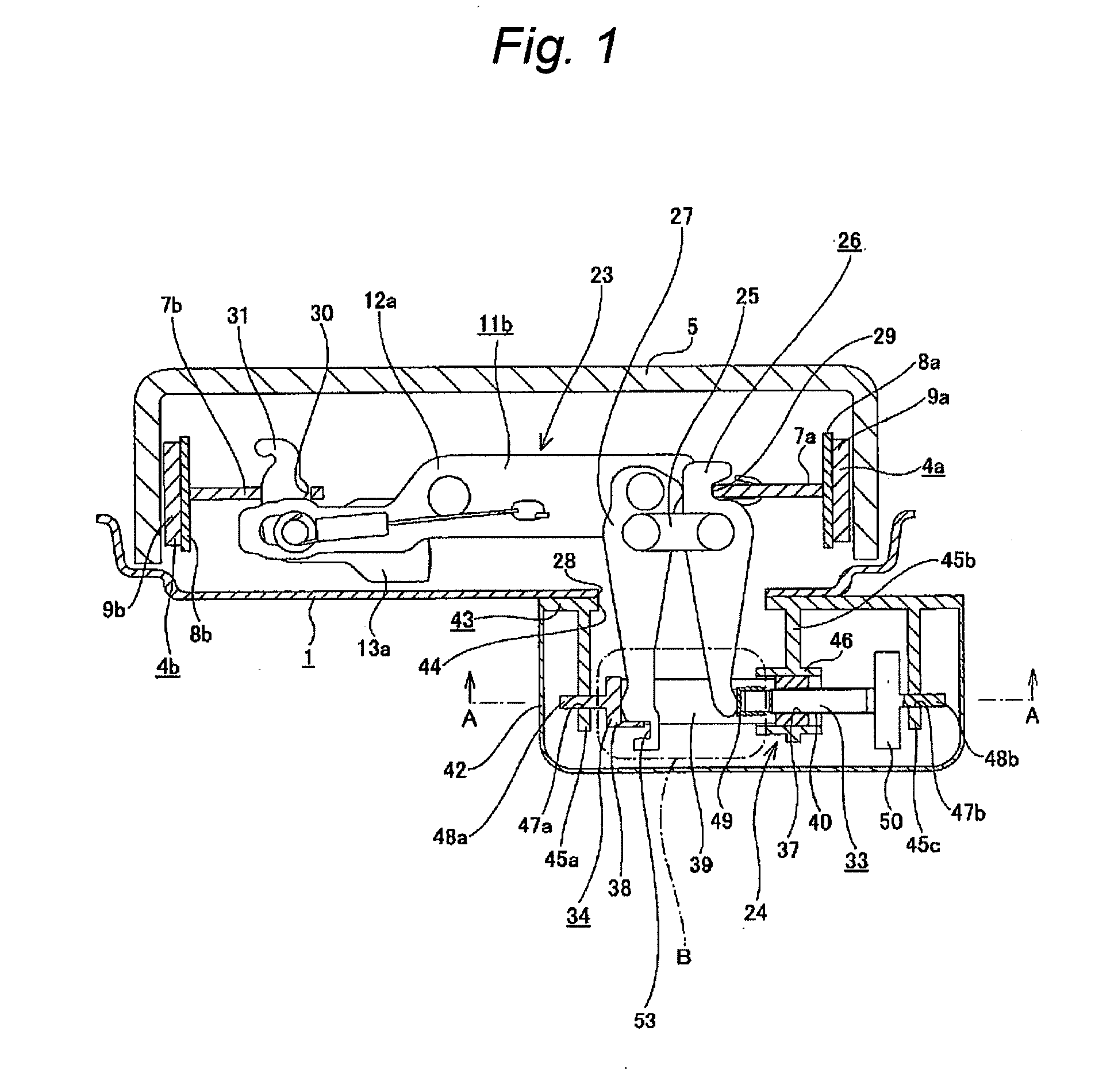

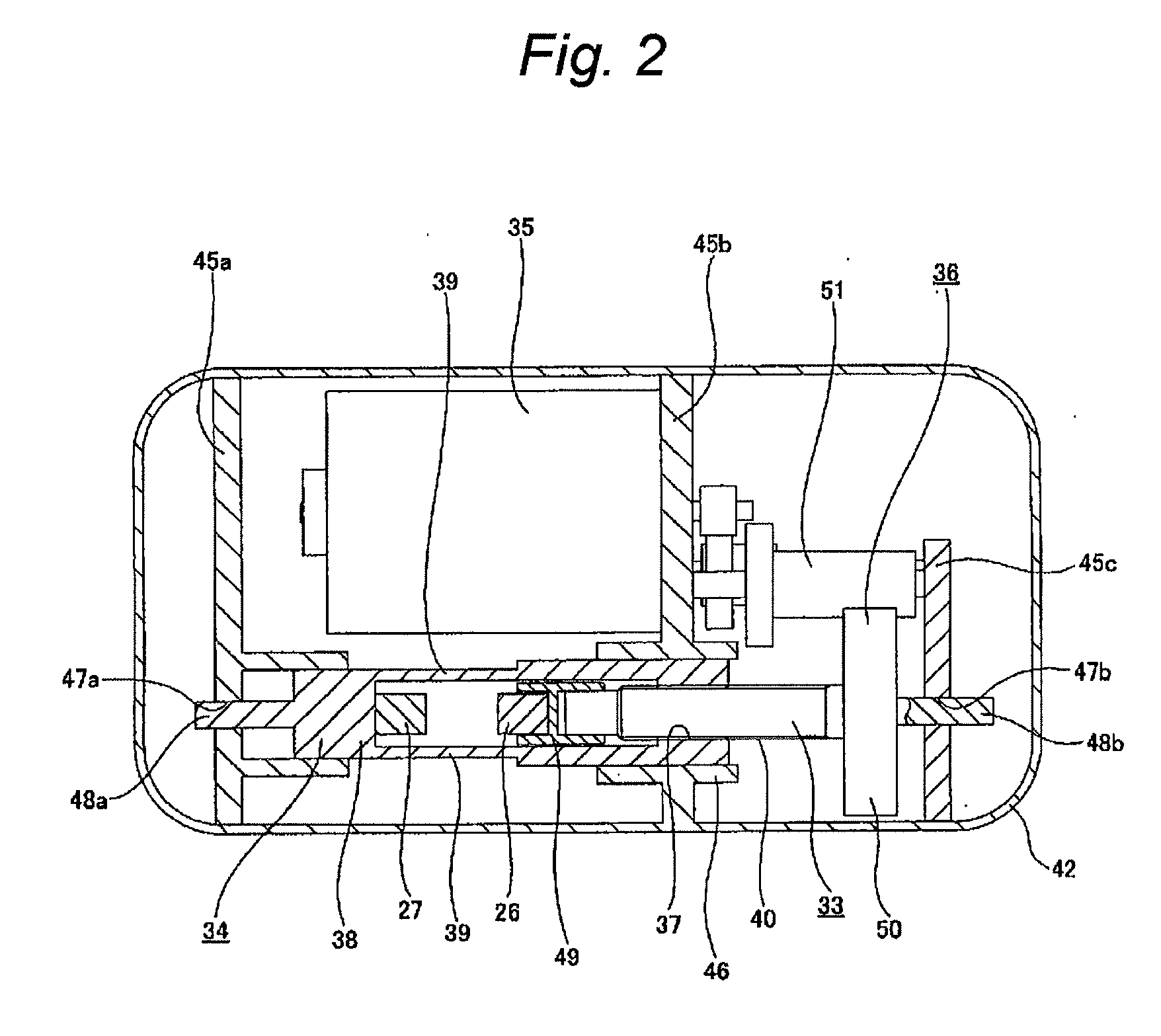

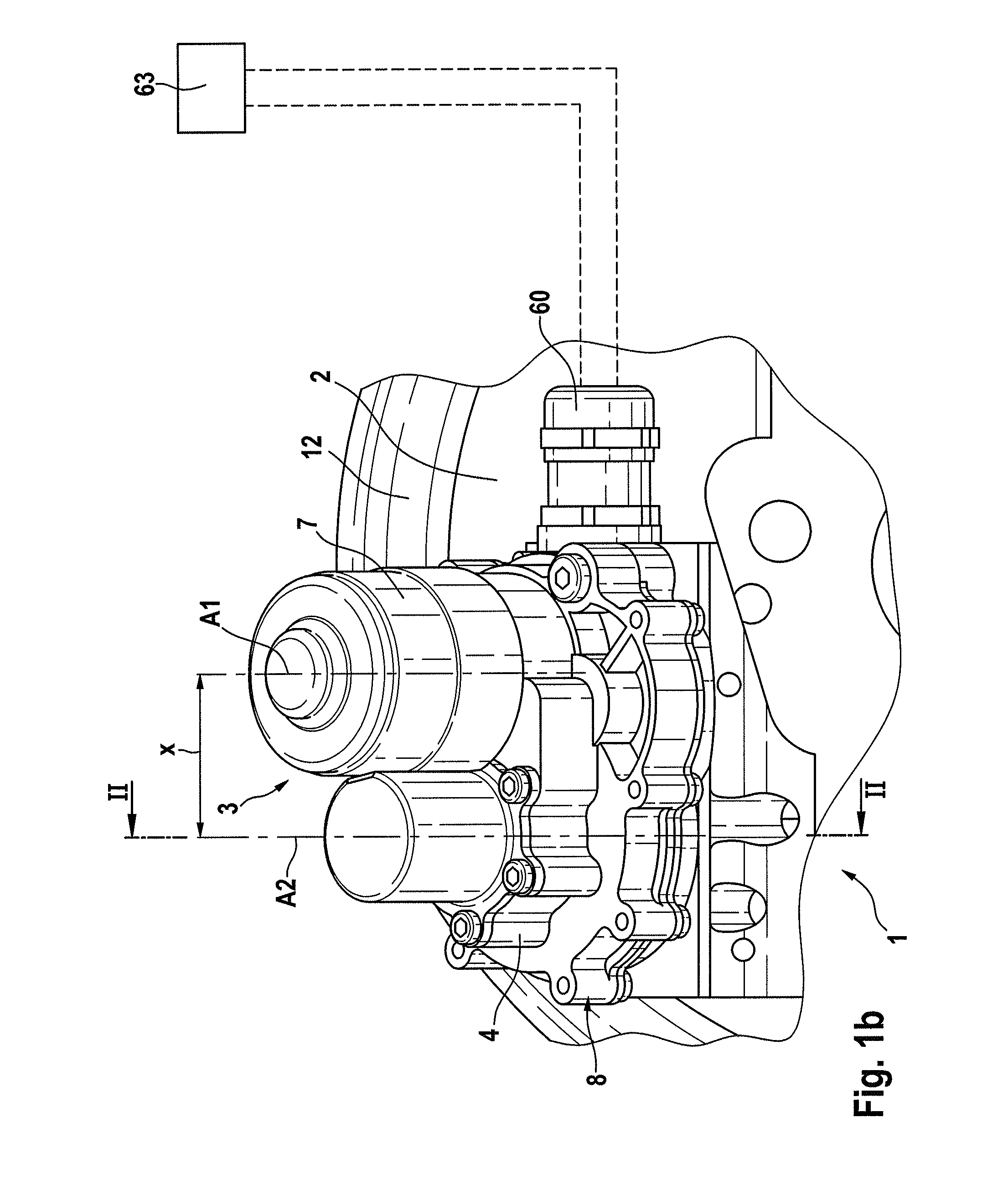

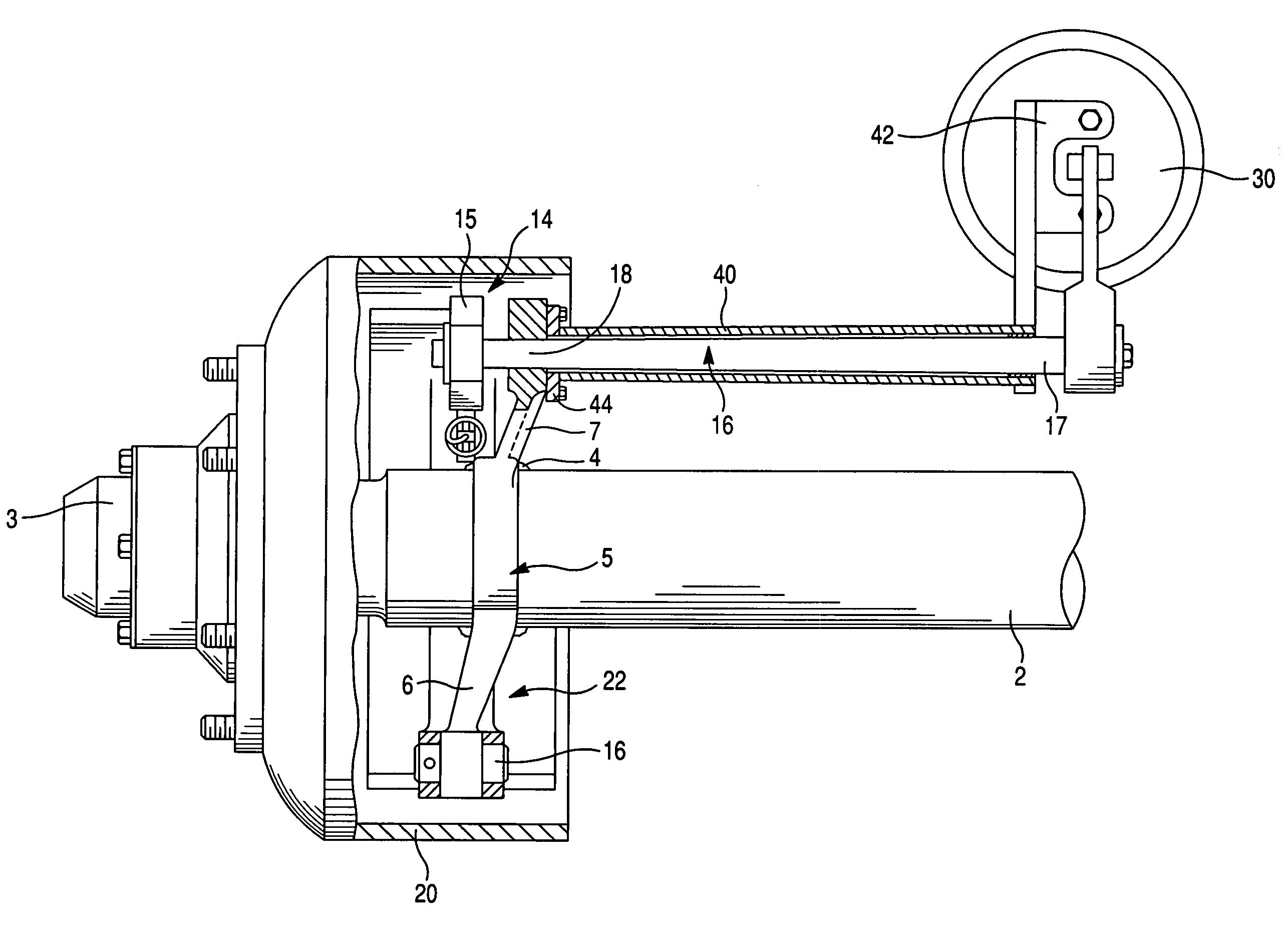

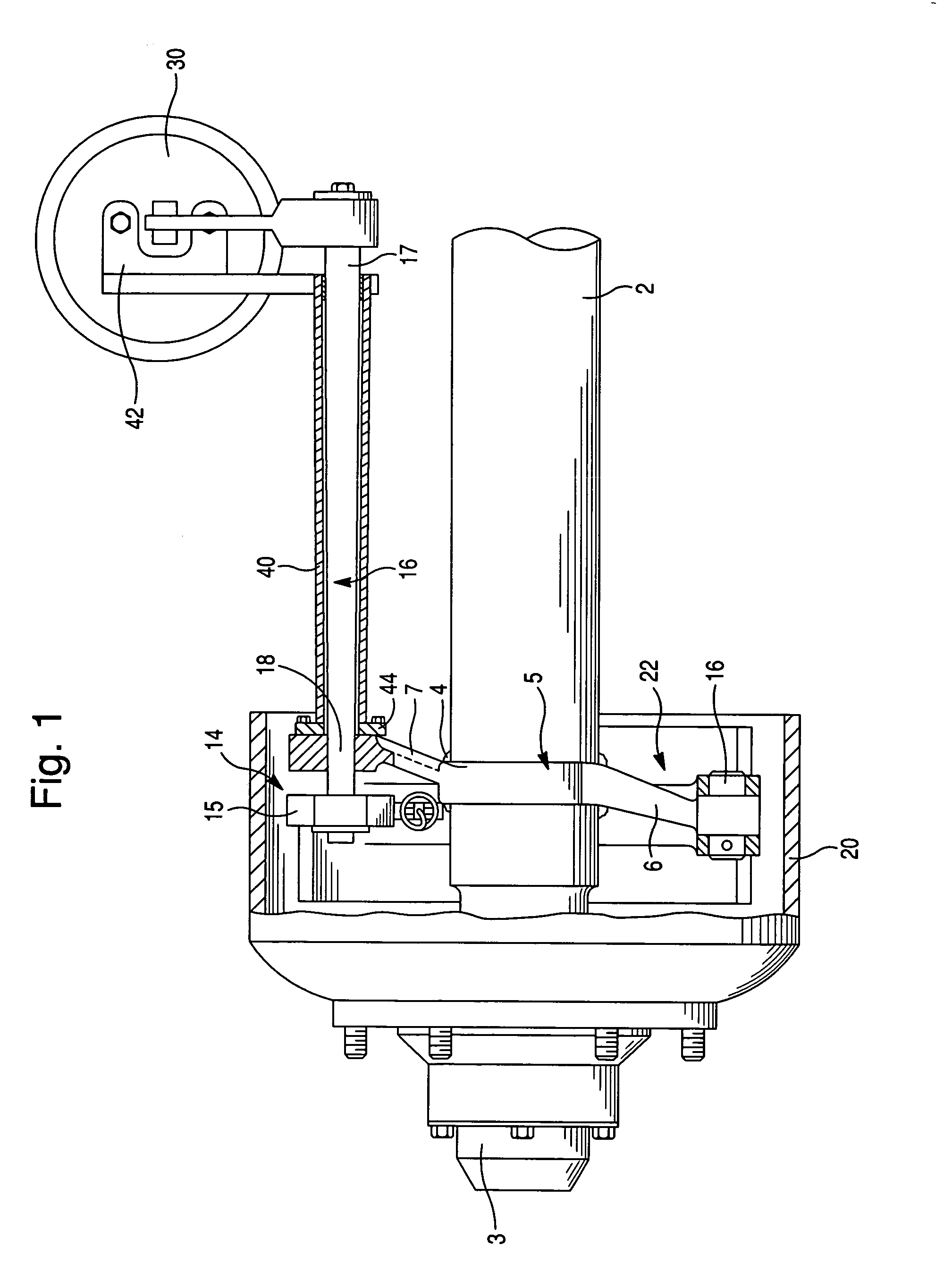

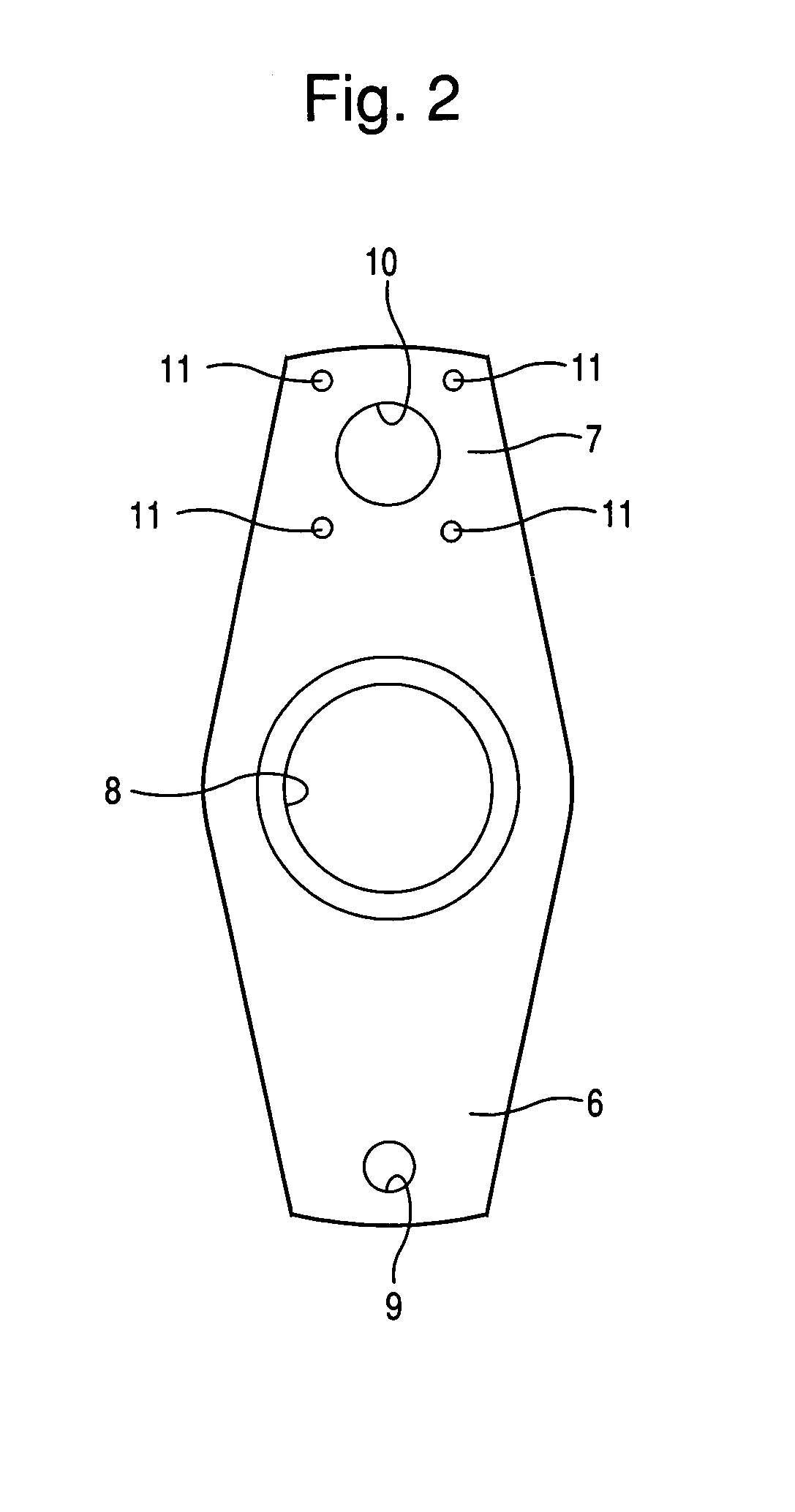

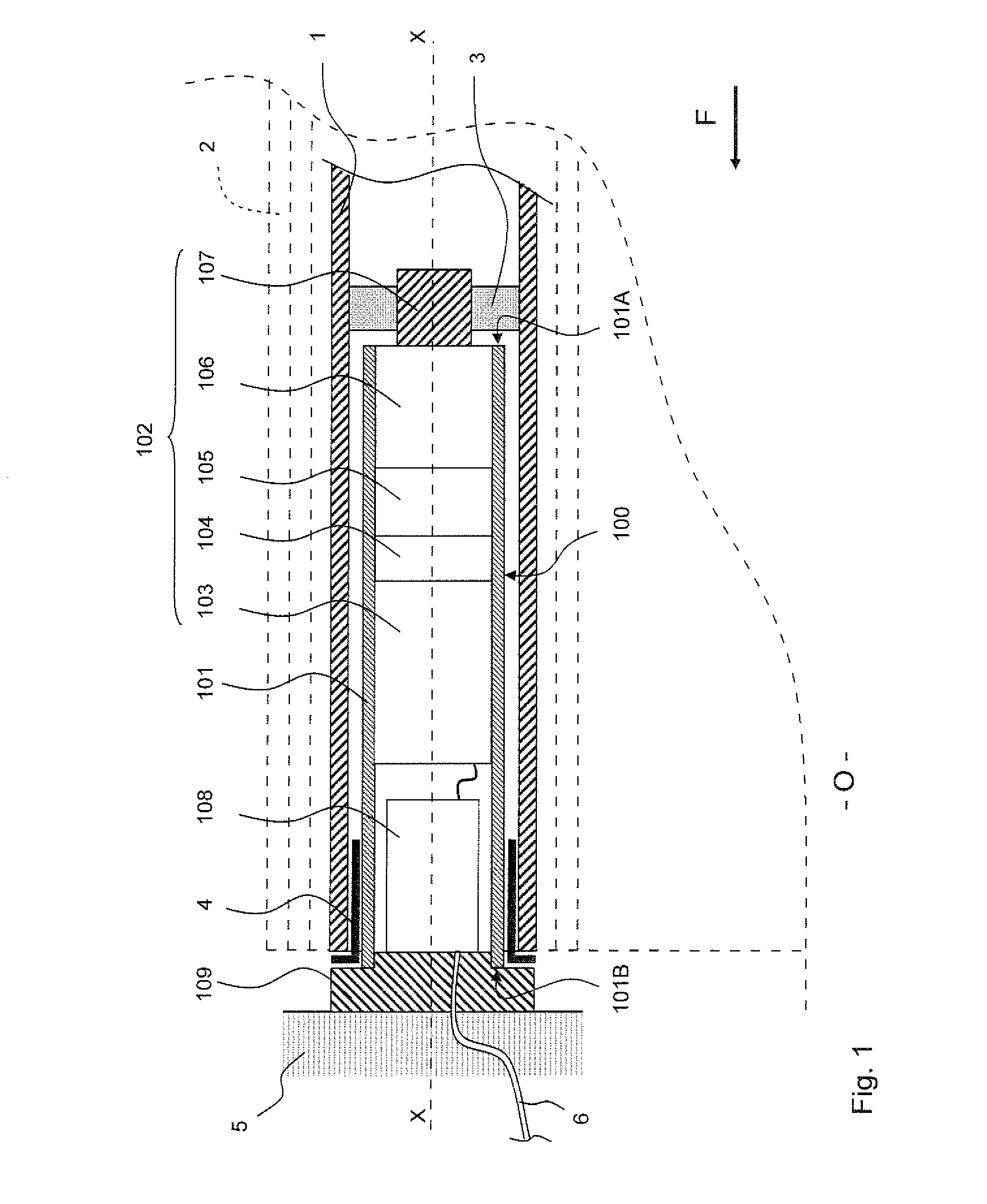

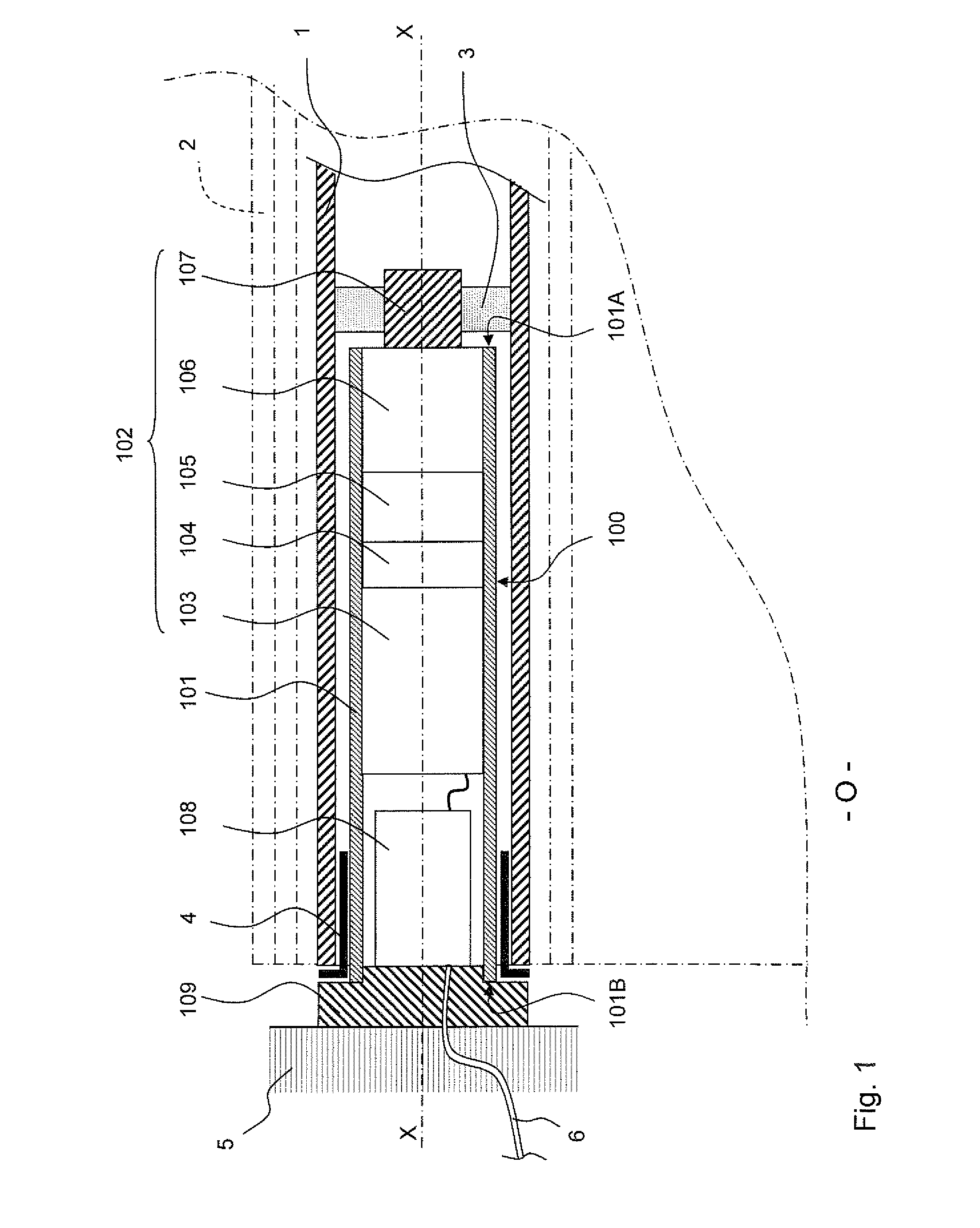

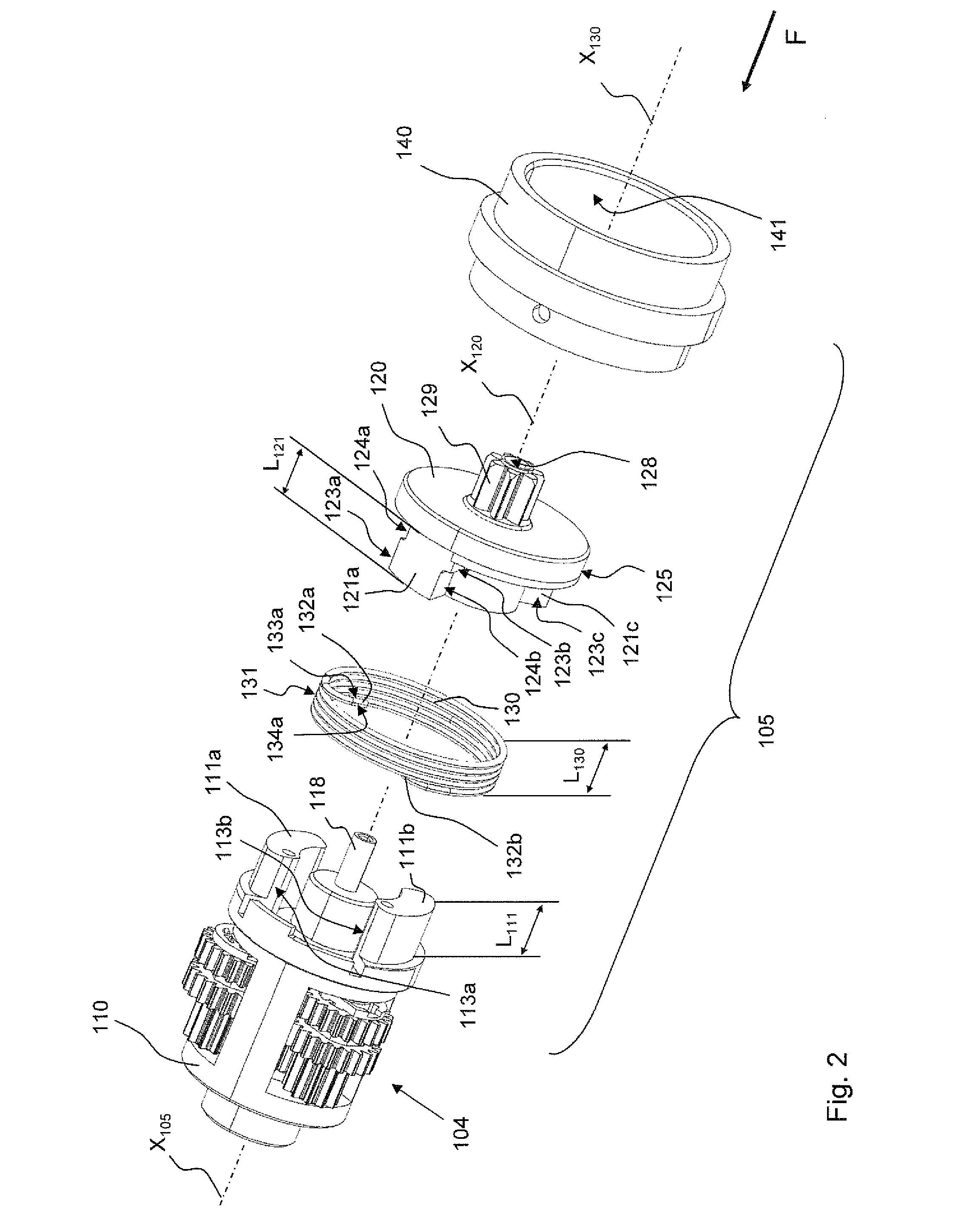

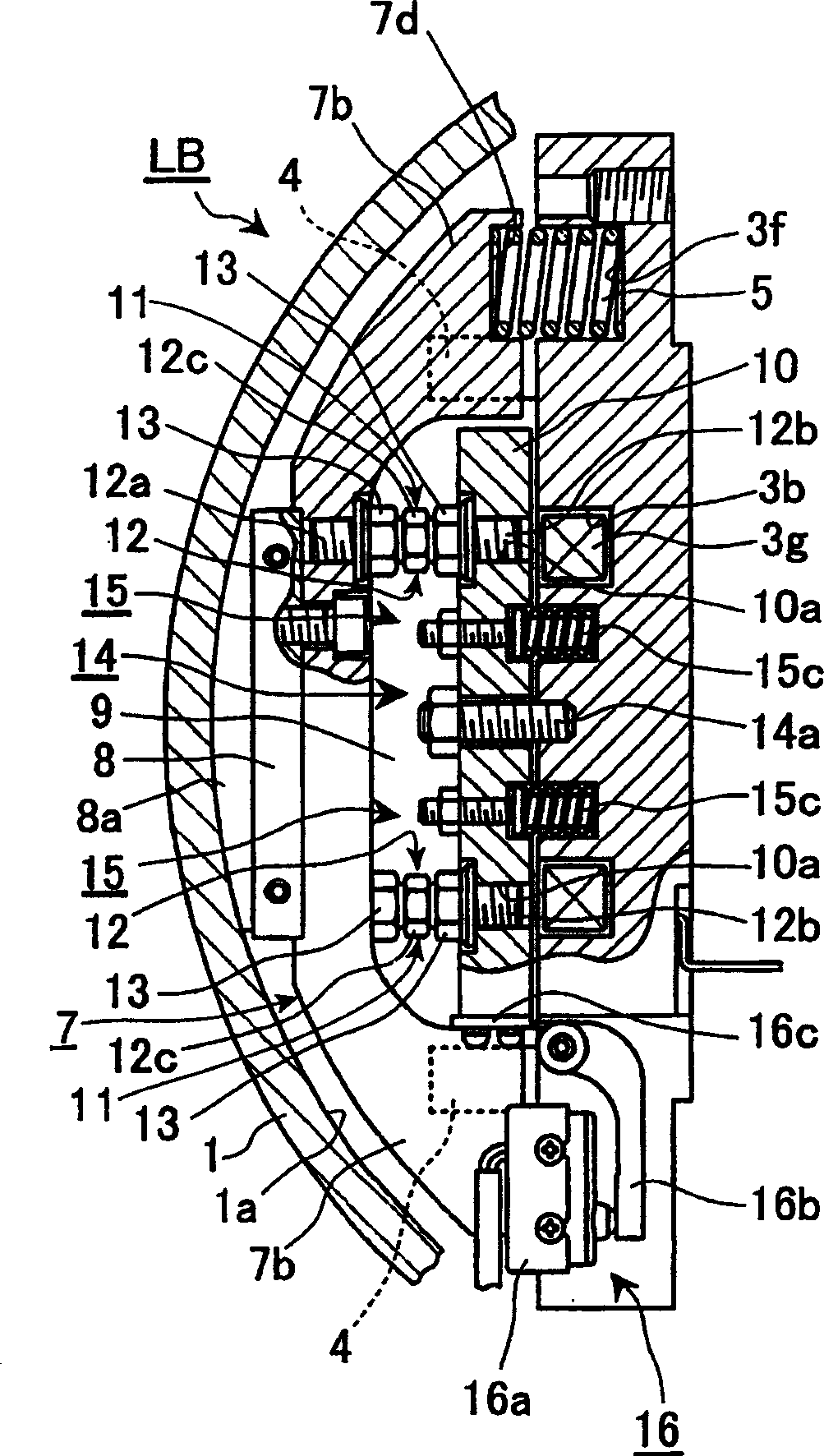

Drum brake module which can be operated by electric motor

ActiveUS20140020997A1Disadvantageous effect of contracting is avoidedAvoid distortionBrake actuating mechanismsMechanically actuated drum brakesEngineeringBiological activation

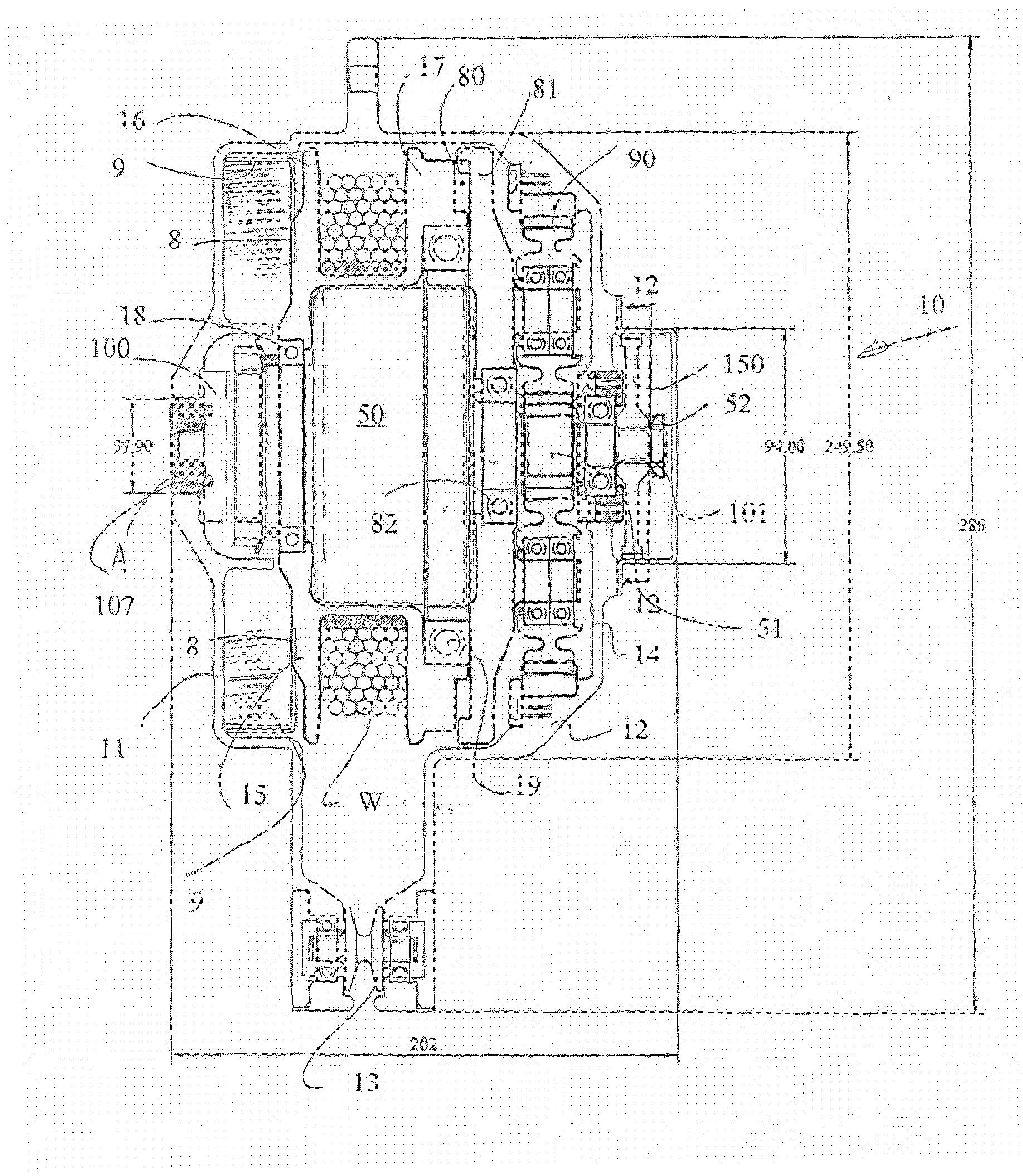

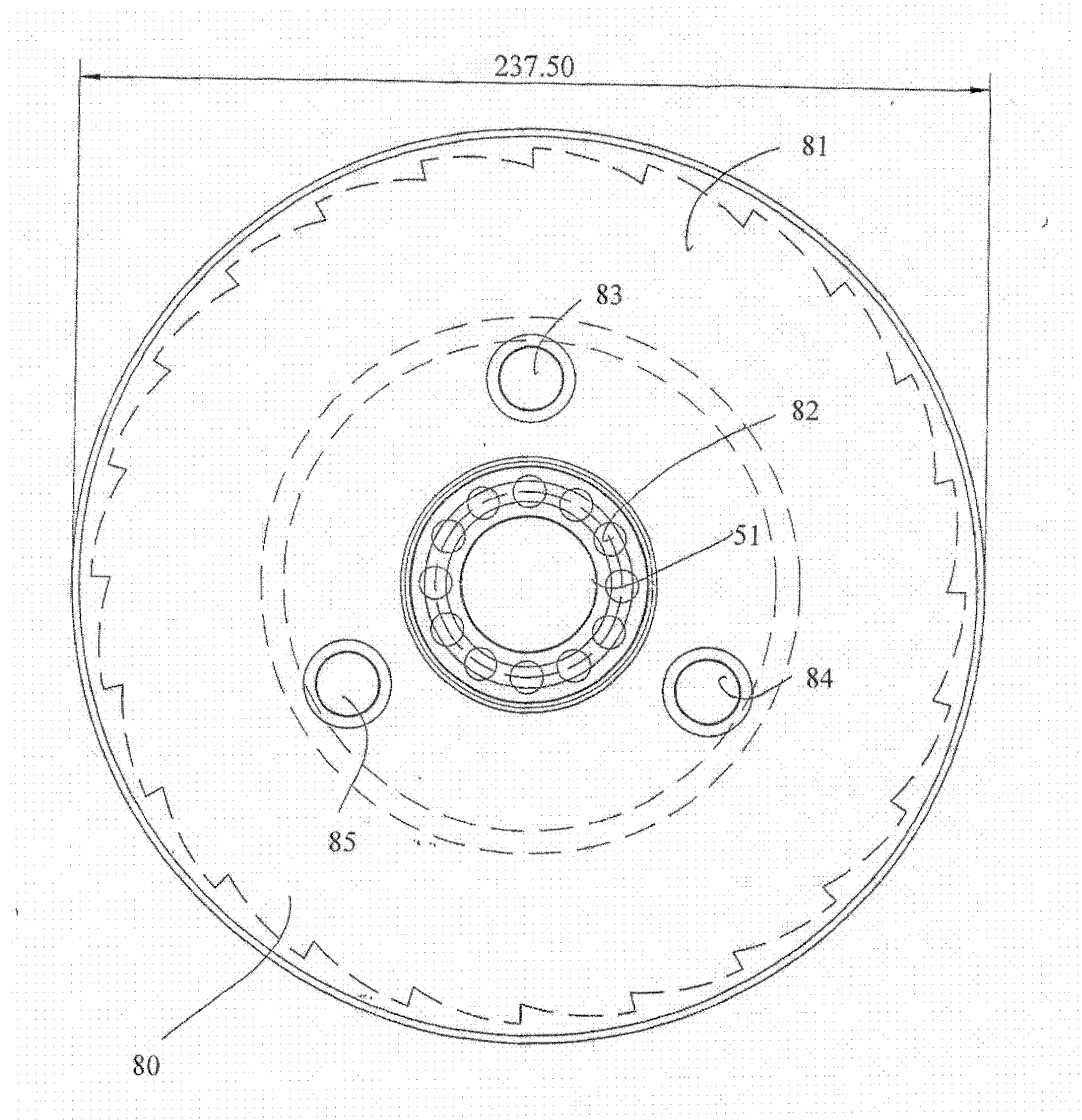

A drum brake module for motor vehicles operable by electric motor and performs at least one parking brake function, having an electromechanical actuator mounted on one side of the armature plate and a rotational-translational movement converter converting a rotational drive rotational movement into a translational activation movement of brake shoes arranged on a side of the armature plate facing away from the actuator in a brake drum, and including at least one supporting device between the brake shoes such that the latter can carry out an activation movement in the direction of the brake drum. A drive nut is supported by the rotational-translational movement converter in an axially secure and rotatable fashion on the armature plate to assist the braking force. The drive nut drives a spindle arrangement mounted in a rotationally fixed and axially displaceable fashion and engages with an activation cable on at least one brake shoe.

Owner:CONTINENTAL TEVES AG & CO OHG

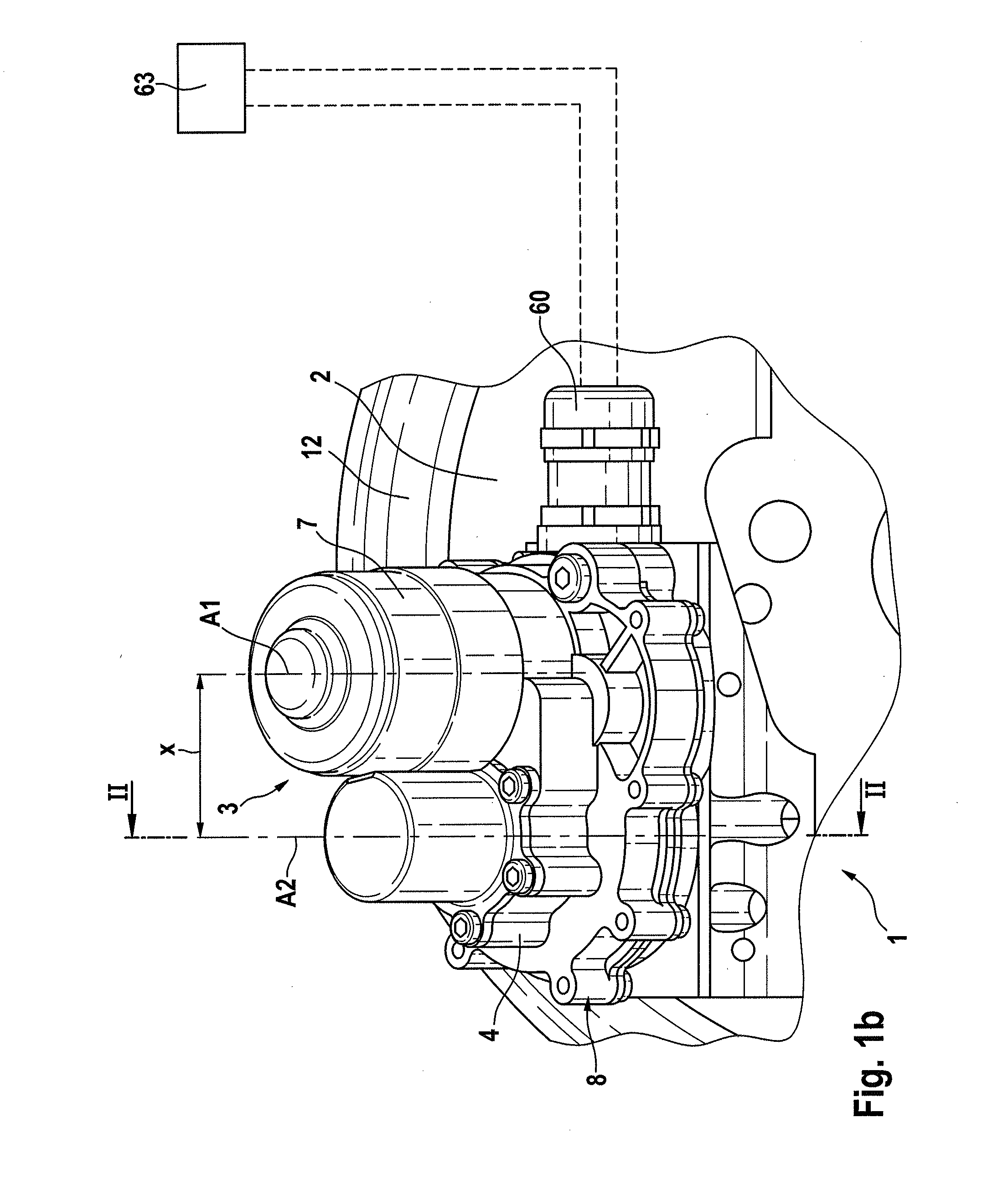

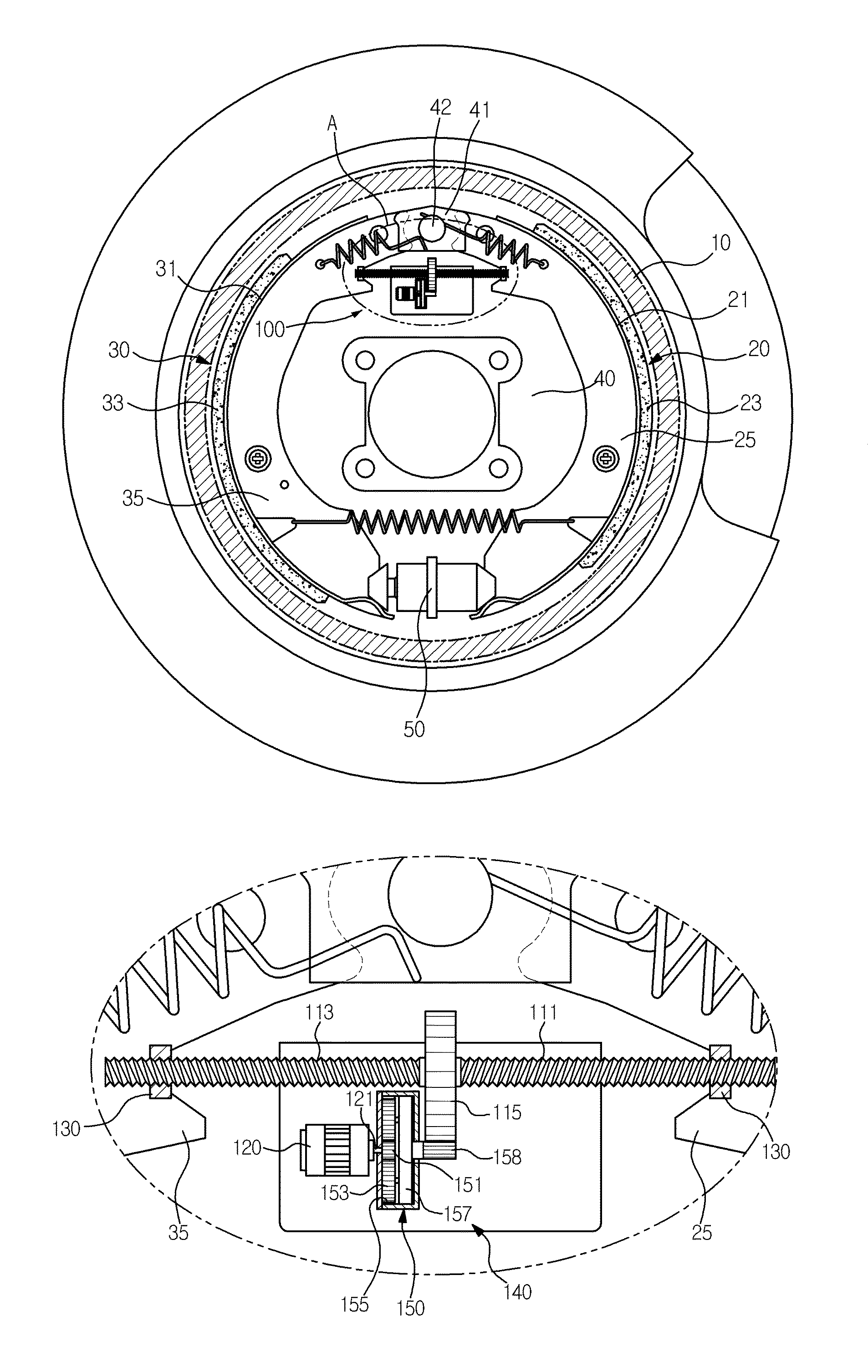

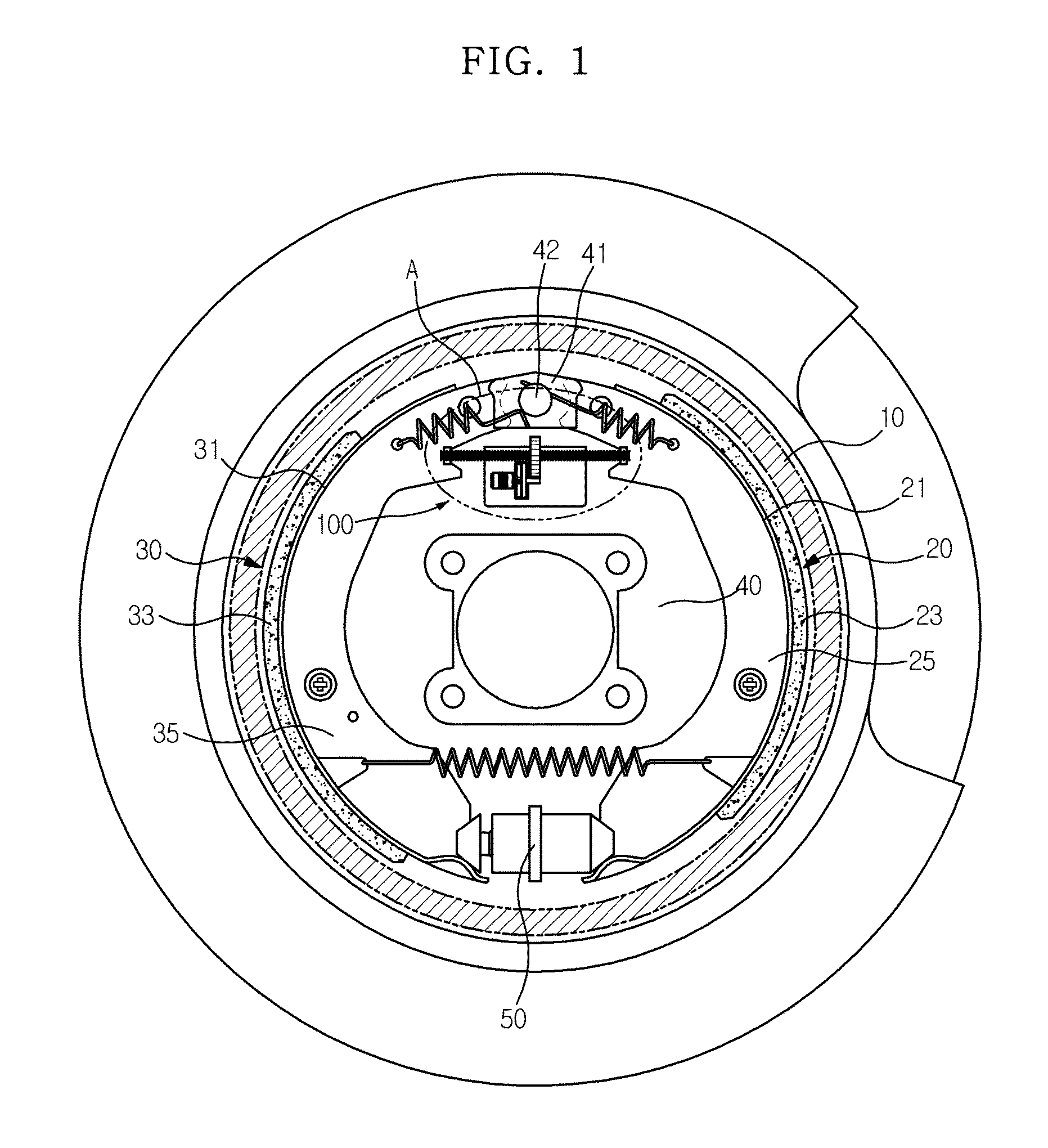

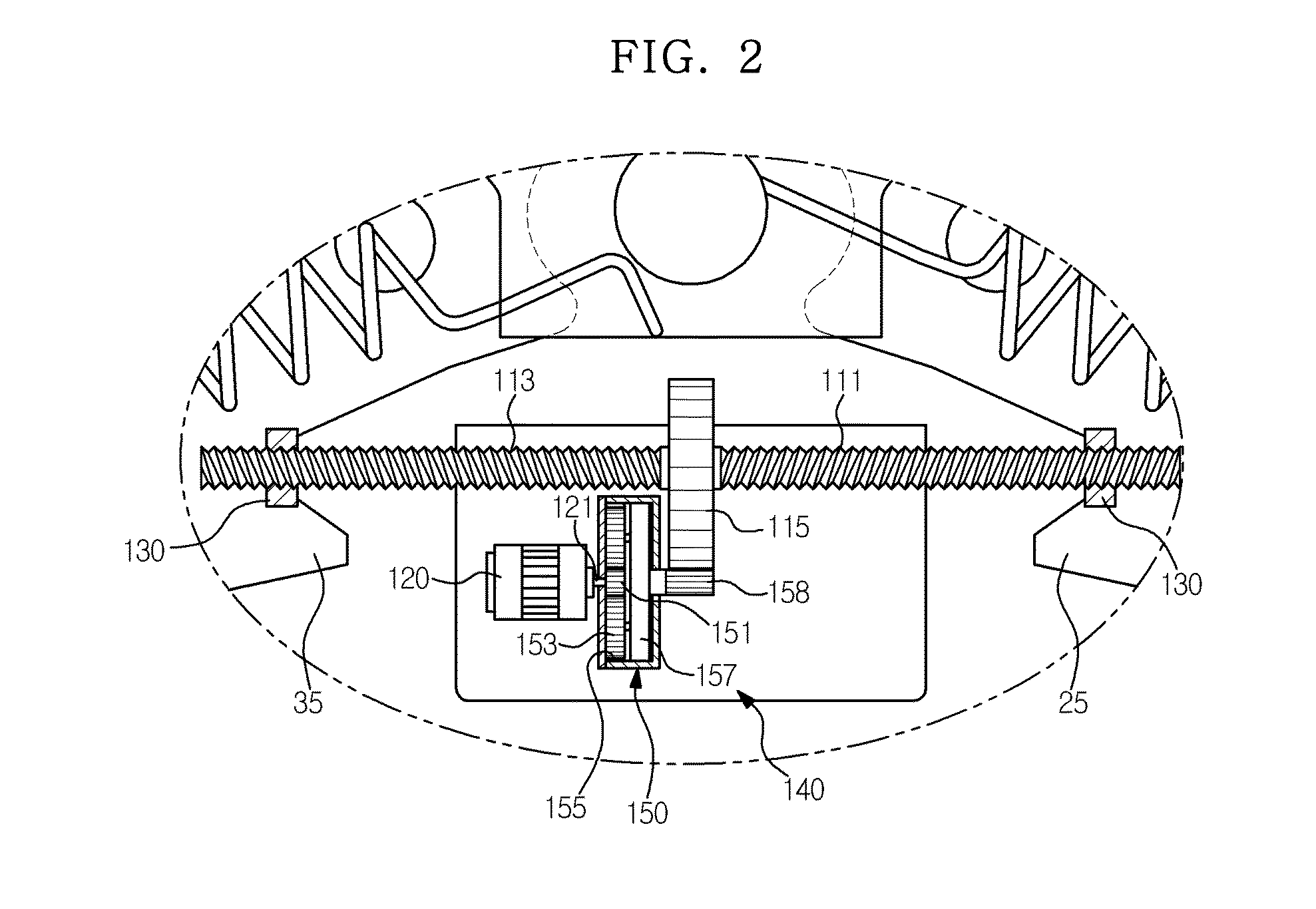

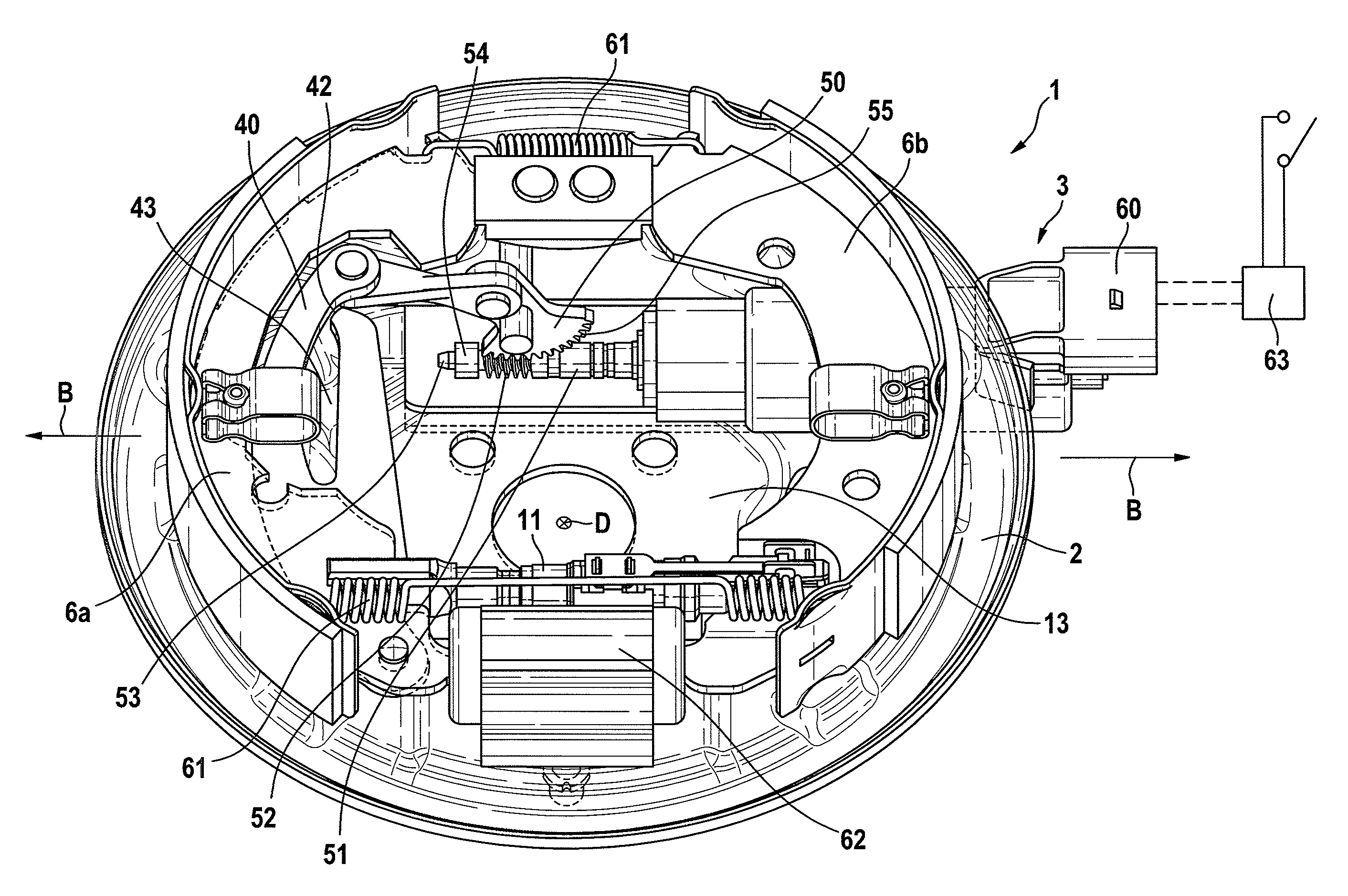

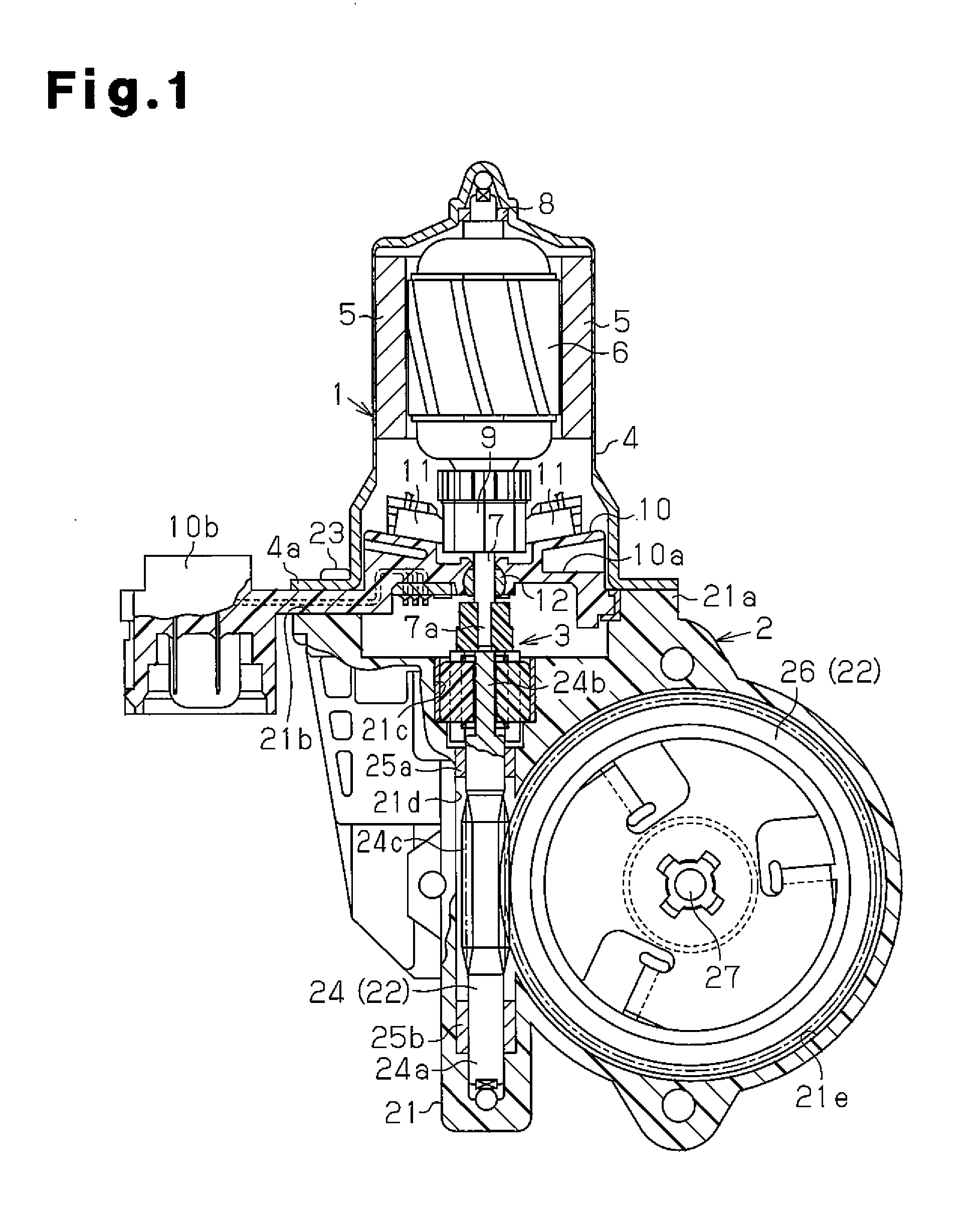

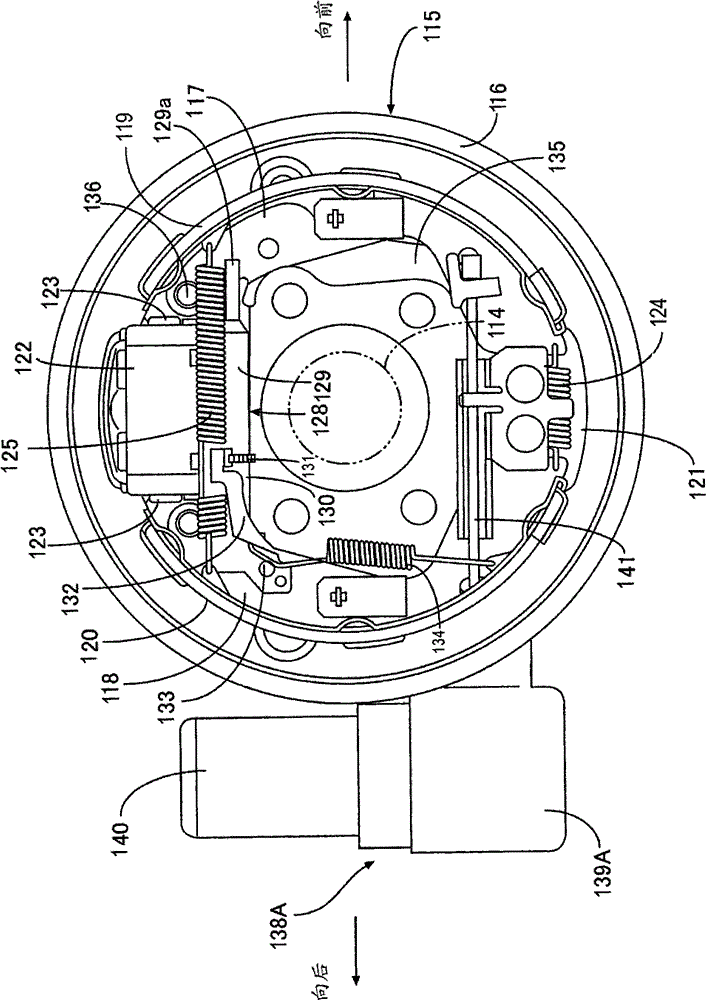

Electronic mechanical drum brake

ActiveUS20100096224A1Simple mechanical configurationLarge braking forceMechanically actuated brakesBraking membersDrive motorEngineering

Disclosed herein is an electronic mechanical drum brake. In the electronic mechanical drum brake including a drum rotated together with a wheel, a pair of brake shoes respectively including rims provided with linings, which rub against the inner circumferential surface of the drum and generate braking power, attached thereto and webs provided on the inner circumferential surfaces of the rims to reinforce rigidity of the rims, and an actuator provided between the webs of the pair of brake shoes, the actuator includes a screw shaft provided with a driven gear formed integrally therewith and a left-handed thread at one side thereof and a right-handed thread at the other side thereof, a driving motor to rotate the screw shaft in a regular direction and its reverse direction, a booster unit to increase rotary force of the driving motor and then to transmit the increased rotary force to the driven gear, and nuts screw-connected to both ends of the screw shaft and fixed to the webs. Thereby, the electronic mechanical drum brake has a large braking power and improved space efficiency.

Owner:HL MANDO CORP

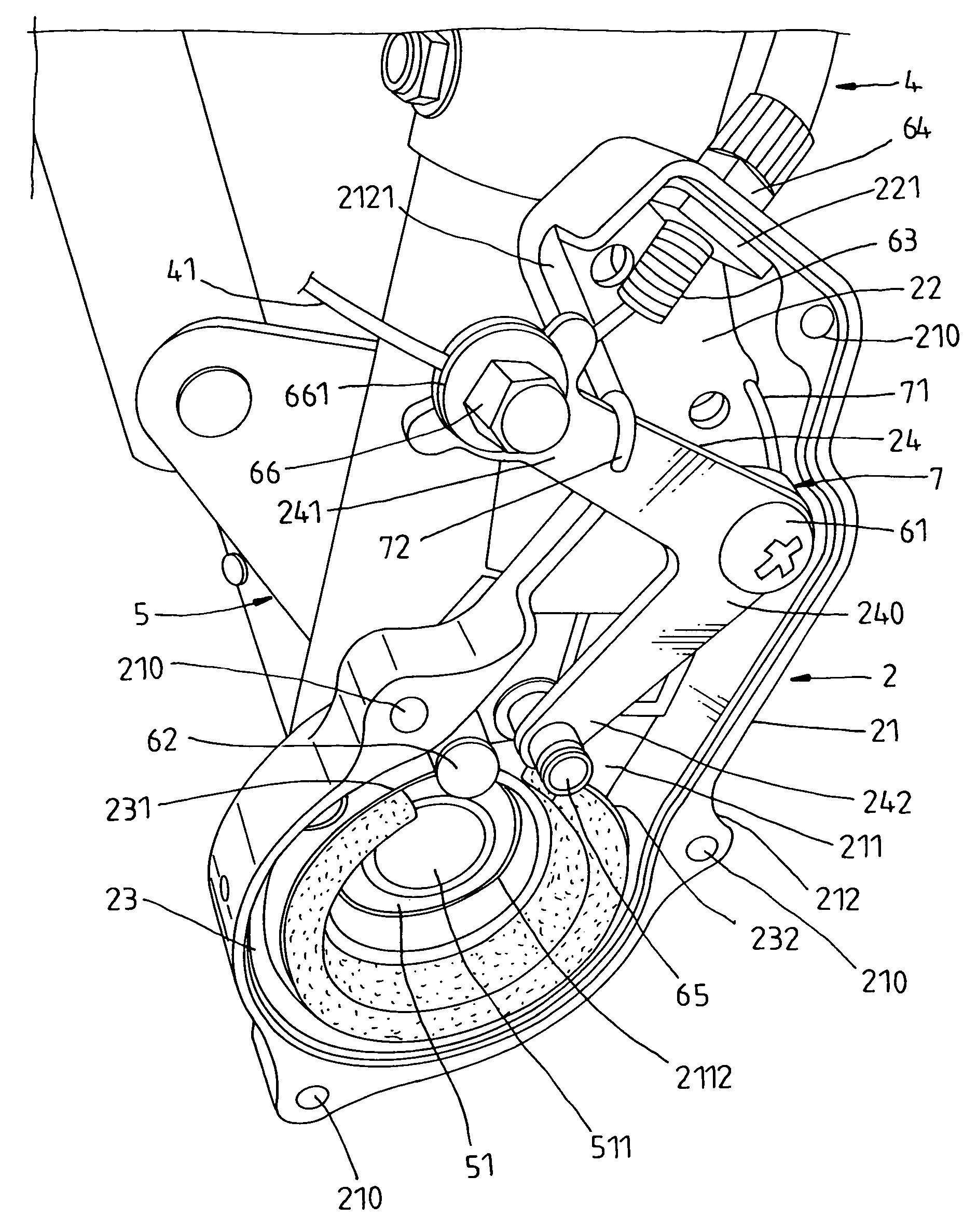

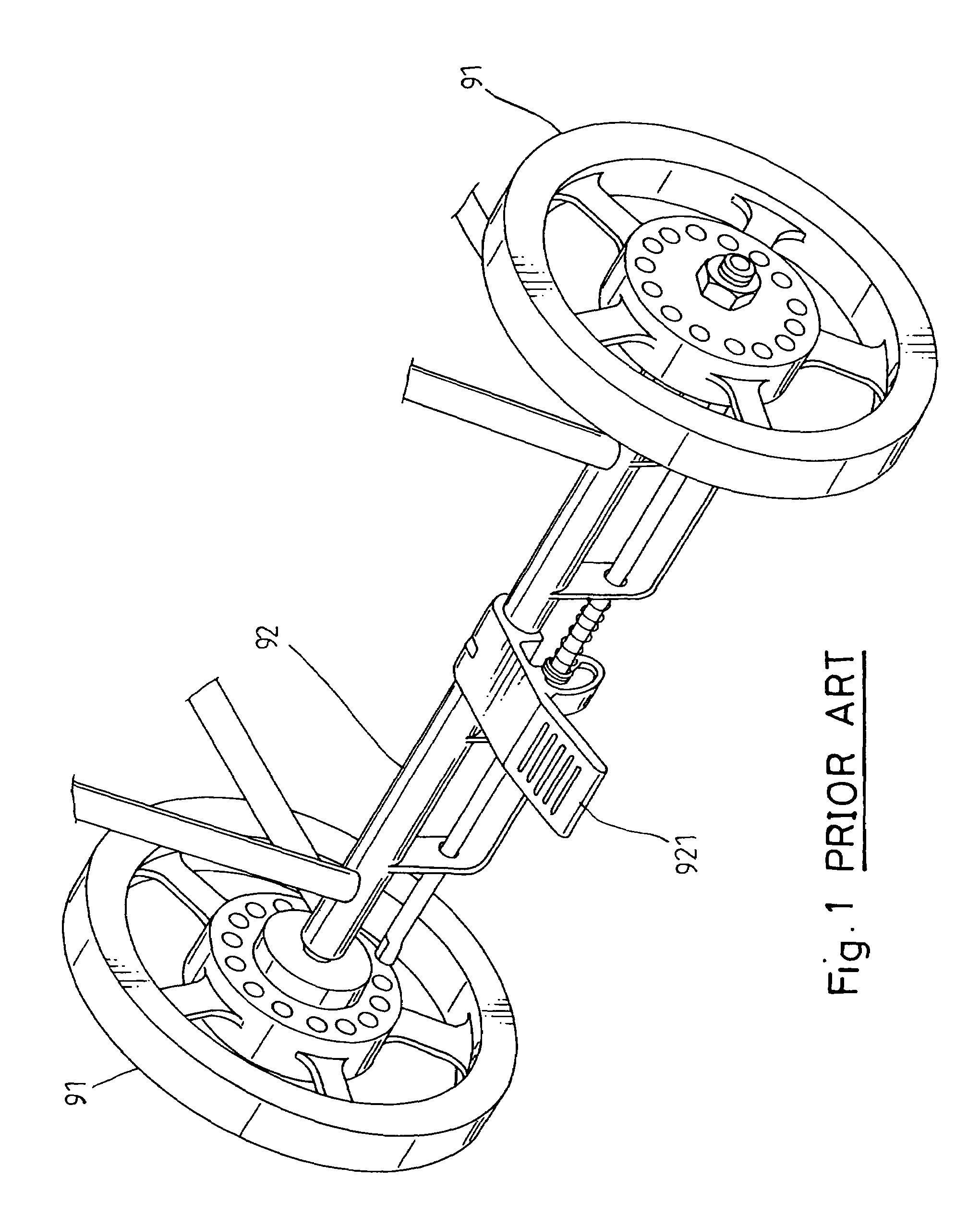

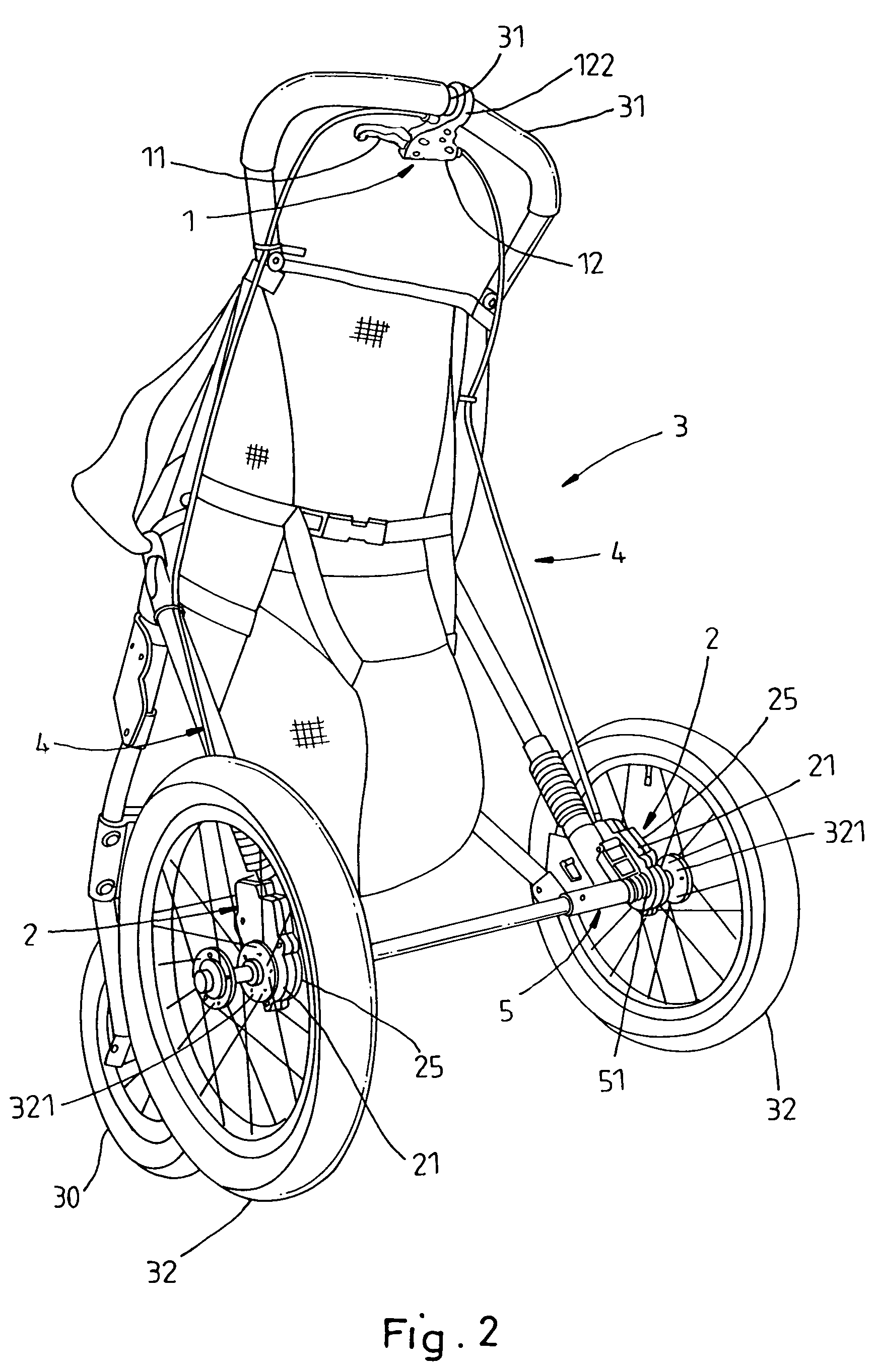

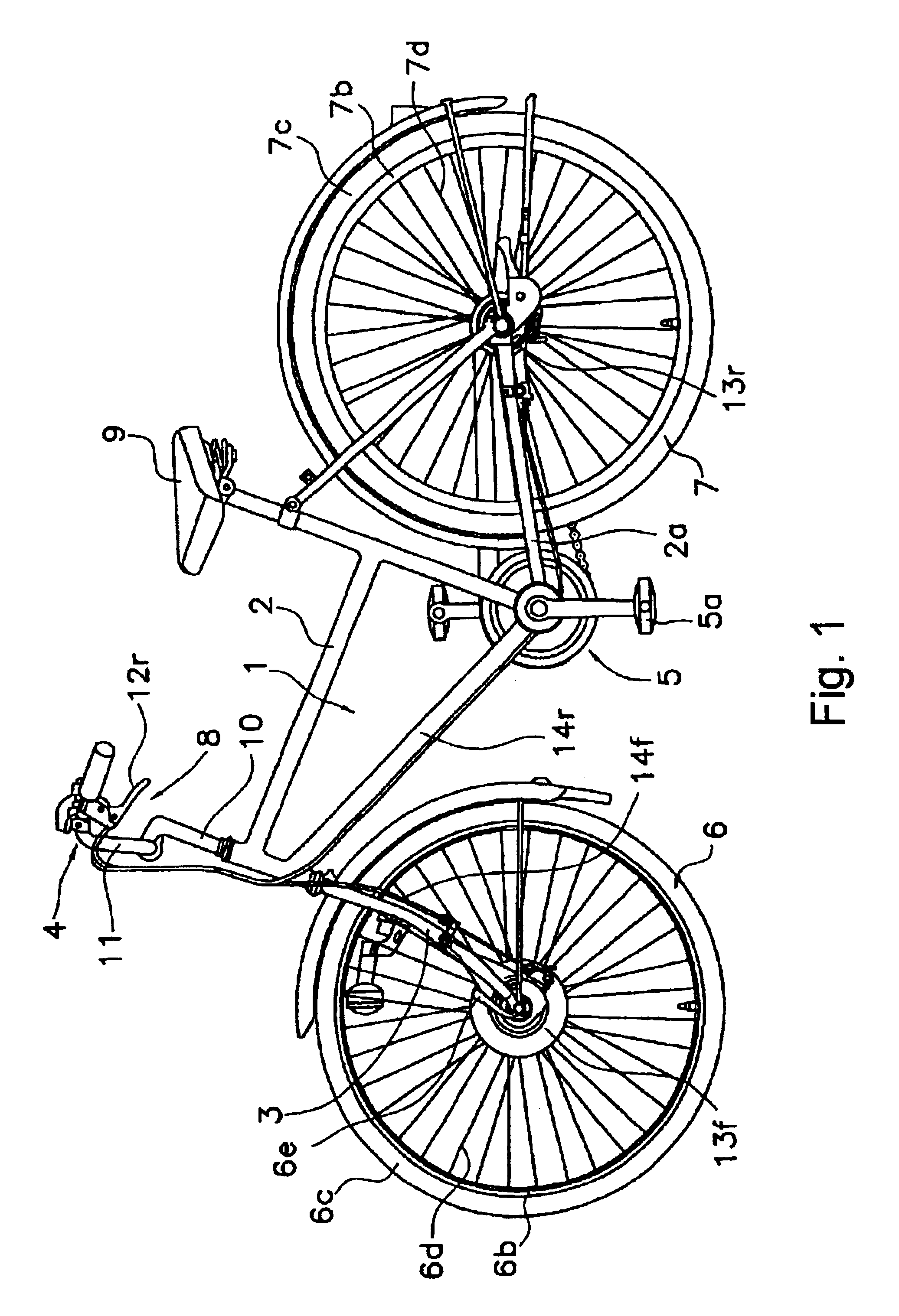

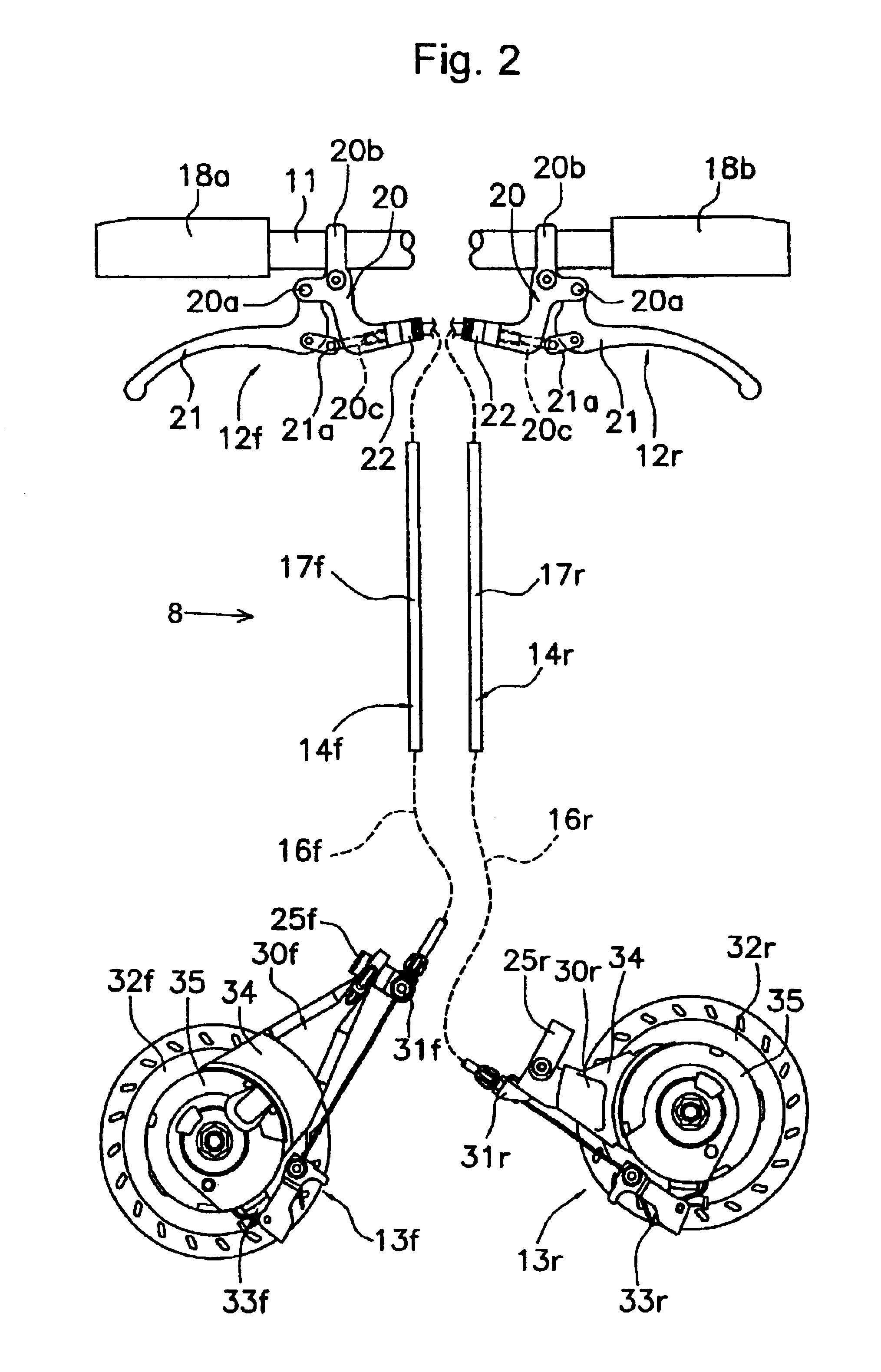

Rear wheel synchronous brake system for pushcart

InactiveUS7222874B1Easy to operateEasy to useBraking element arrangementsUnderstructuresBraking systemControl unit

A rear wheel synchronous brake system used in a pushcart such as a baby jogging stroller is disclosed to include two rear brakes respectively coupled to the two rear wheels of the baby jogging stroller, a hand control unit mounted on the handle of the baby jogging stroller at the top, and two brake lines coupled between the brake lever of the hand control unit and the two rear brakes for driving the rear brakes to brake the two rear wheels of the baby jogging stroller synchronously when the user pulling the brake lever.

Owner:LIU SSU LIU

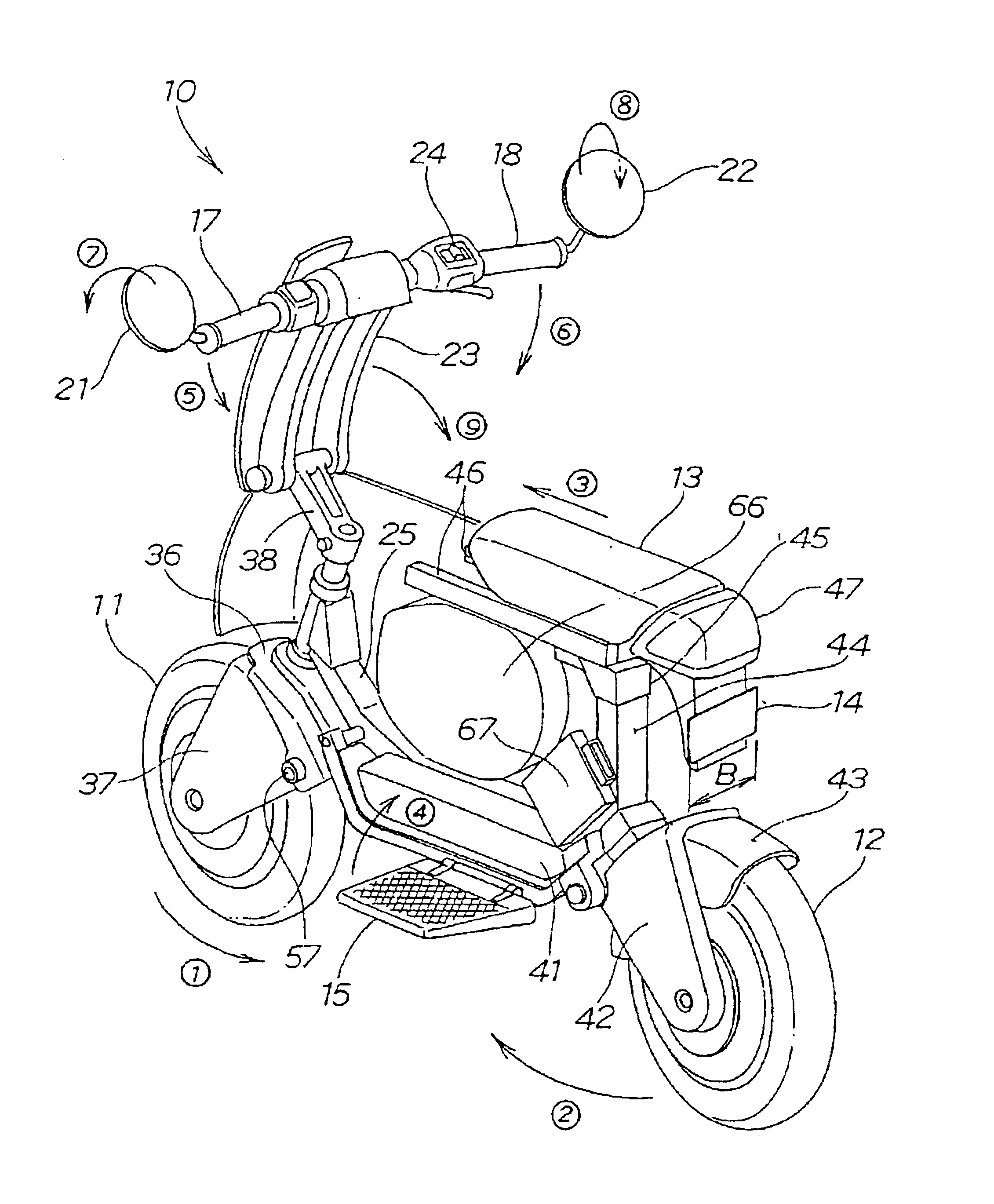

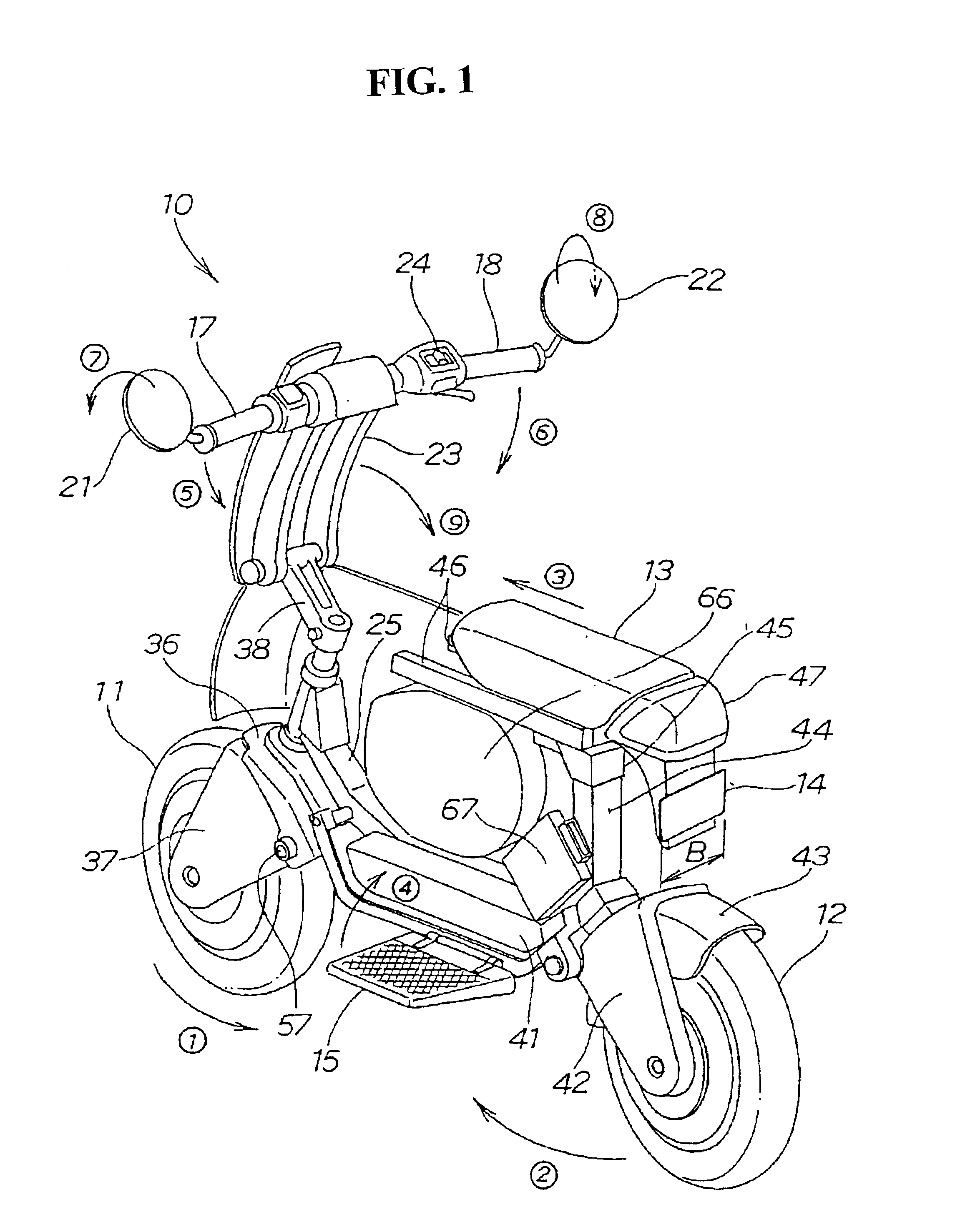

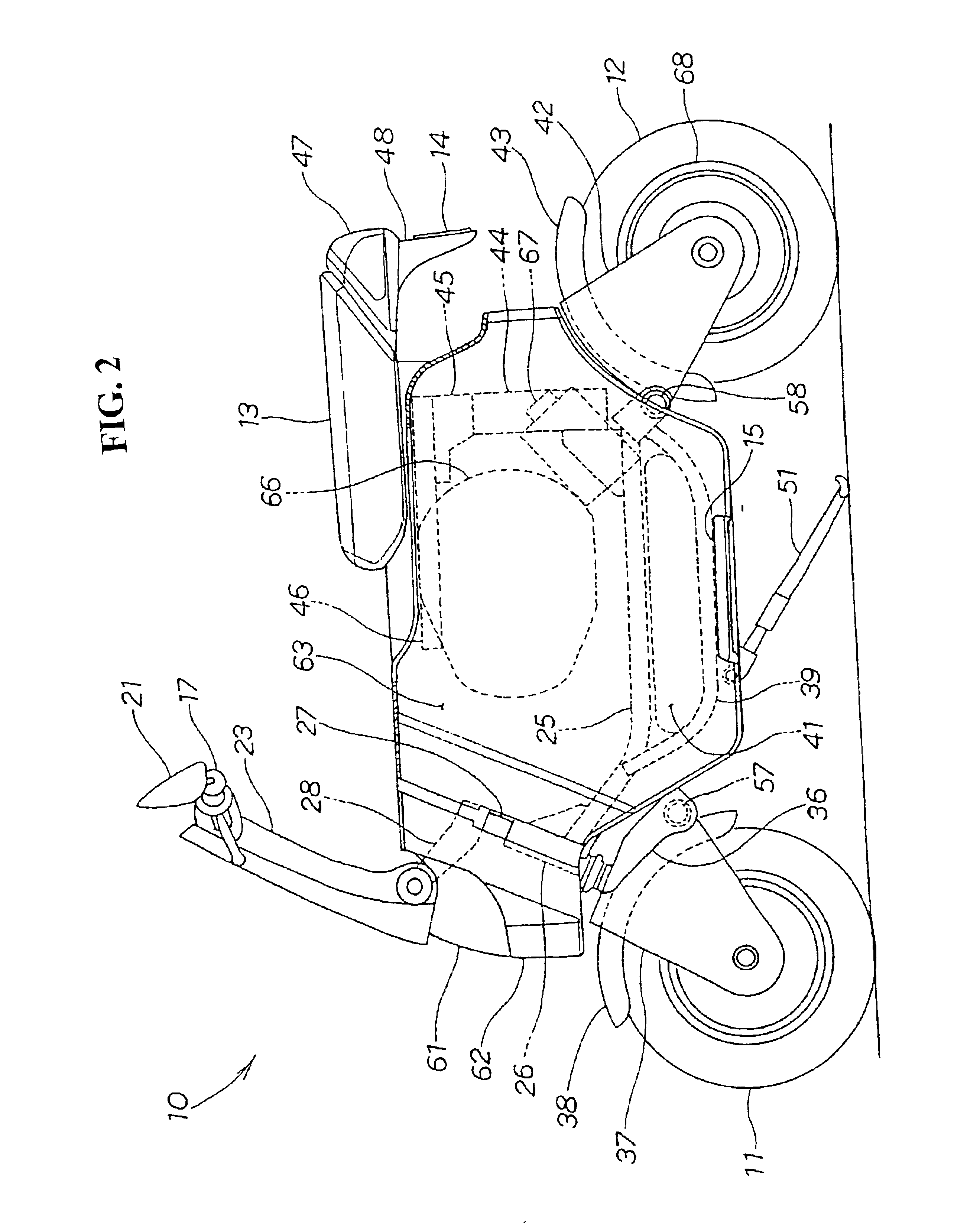

Vehicle wheel structure

InactiveCN1403310ASimple structureEasy to assembleBraking element arrangementsHubsEngineeringDrum brake

A drum brake for braking a wheel disposed on the inside in the radial direction of an electric motor. The drum of the drum brake and an electric motor are disposed separate from each other, and thus wear powders of a brake shoe do not adhere to a permanent magnet of the electric motor. As a result, the wear powders do not adversely influence the performance of the electric motor, and the performance of the electric motor is maintained. The electric motor and the drum brake are disposed concentrically, so that the width of the wheel is reduced. Thus, a small and compact wheel is realized.

Owner:HONDA MOTOR CO LTD

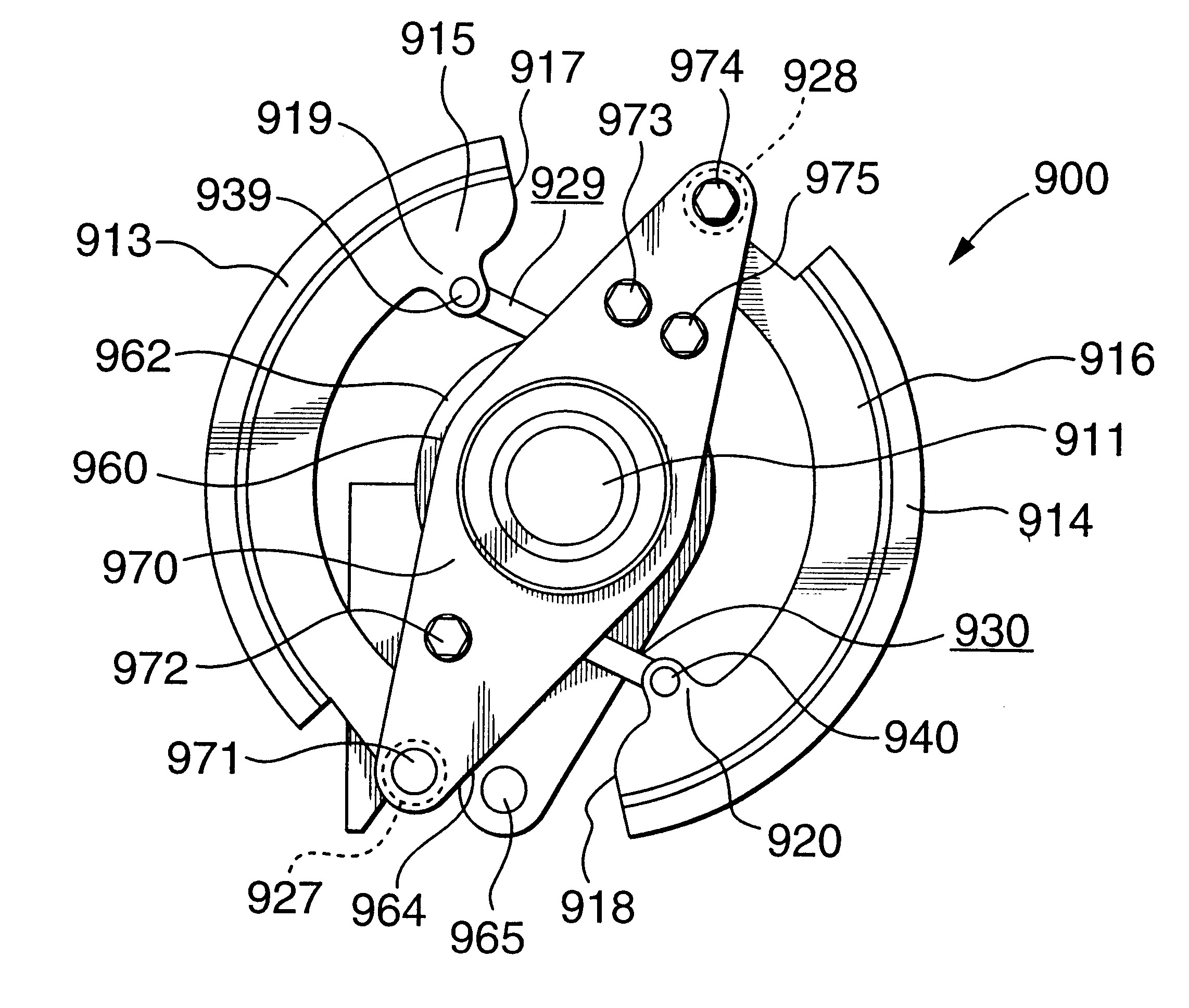

Drum brake type parking brake apparatus

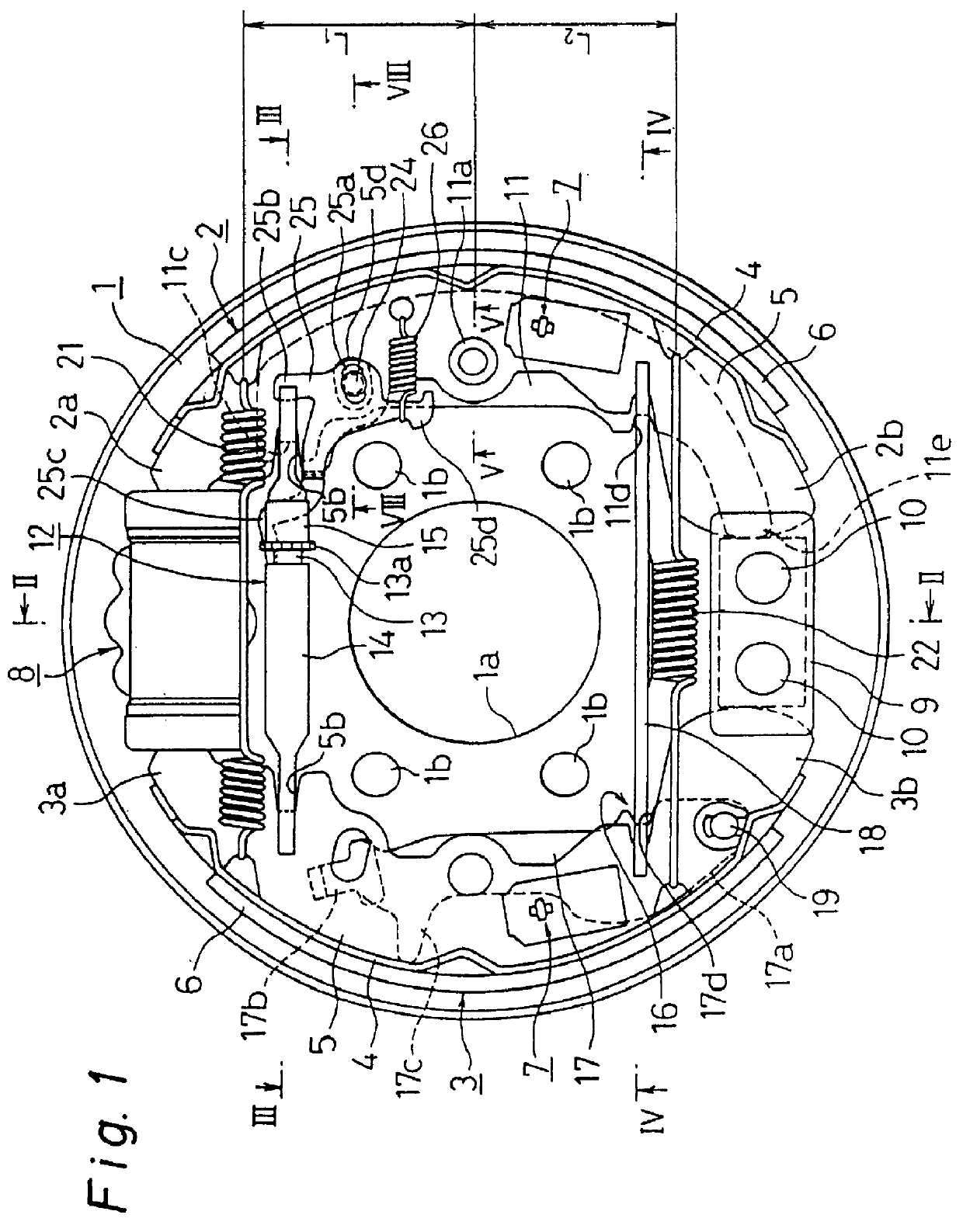

InactiveUS20120205209A1Braking element arrangementsBrake actuating mechanismsEngineeringParking brake

Owner:AKEBONO BRAKE IND CO LTD

Drum brake module which can be operated by electric motor

ActiveUS9175737B2Easy to assembleImprove efficiencyBraking drumsBrake actuating mechanismsEngineeringBiological activation

A drum brake module for motor vehicles operable by electric motor and performs at least one parking brake function, having an electromechanical actuator mounted on one side of the armature plate and a rotational-translational movement converter converting a rotational drive rotational movement into a translational activation movement of brake shoes arranged on a side of the armature plate facing away from the actuator in a brake drum, and including at least one supporting device between the brake shoes such that the latter can carry out an activation movement in the direction of the brake drum. A drive nut is supported by the rotational-translational movement converter in an axially secure and rotatable fashion on the armature plate to assist the braking force. The drive nut drives a spindle arrangement mounted in a rotationally fixed and axially displaceable fashion and engages with an activation cable on at least one brake shoe.

Owner:CONTINENTAL TEVES AG & CO OHG

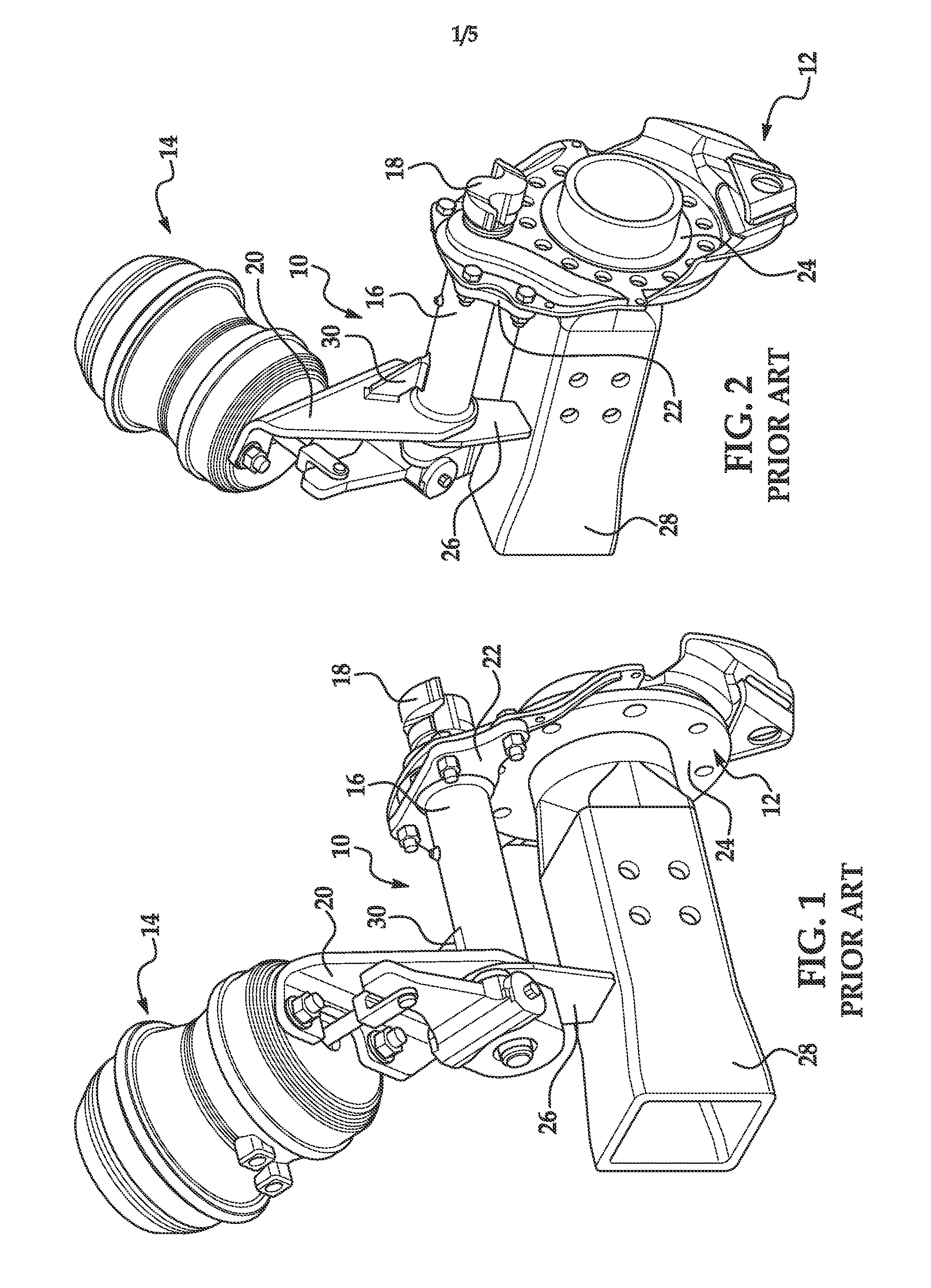

Vehicle axle beam and brake assembly

InactiveUS7055662B1Easy to assembleMore variationBraking membersBrake actuating mechanismsActuatorHeavy duty

An improved axle beam and self-contained drum brake assembly, particularly for heavy duty trucks, is disclosed. The assembly includes a brake spider and actuating members mounted thereto via a mounting assembly comprising a mounting sleeve attached to the brake spider by means of a second mounting bracket, and a first mounting bracket securing a pneumatic brake actuator cylinder to the mounting sleeve. A brake actuating camshaft is positioned and rotationally supported therewithin. The disclosed brake assembly allows for numerous variations of axle beam and suspension arrangements.

Owner:DANA CORP

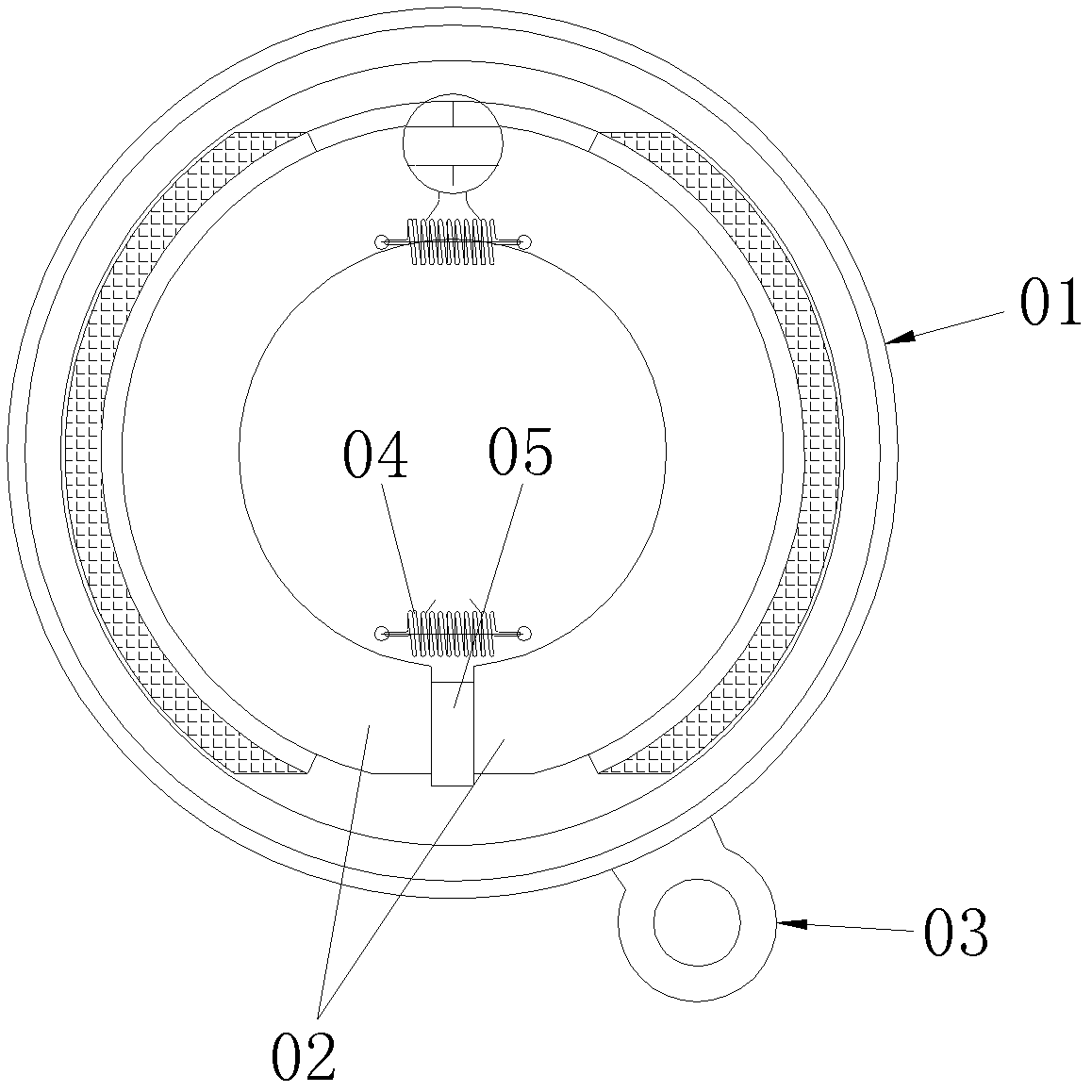

Novel anti-falling device for old people going upstairs and downstairs

ActiveCN111134431AReasonable structural designEasy to assembleWalking sticksMechanically actuated drum brakesOlder peoplePulley

Owner:TSINGHUA UNIV

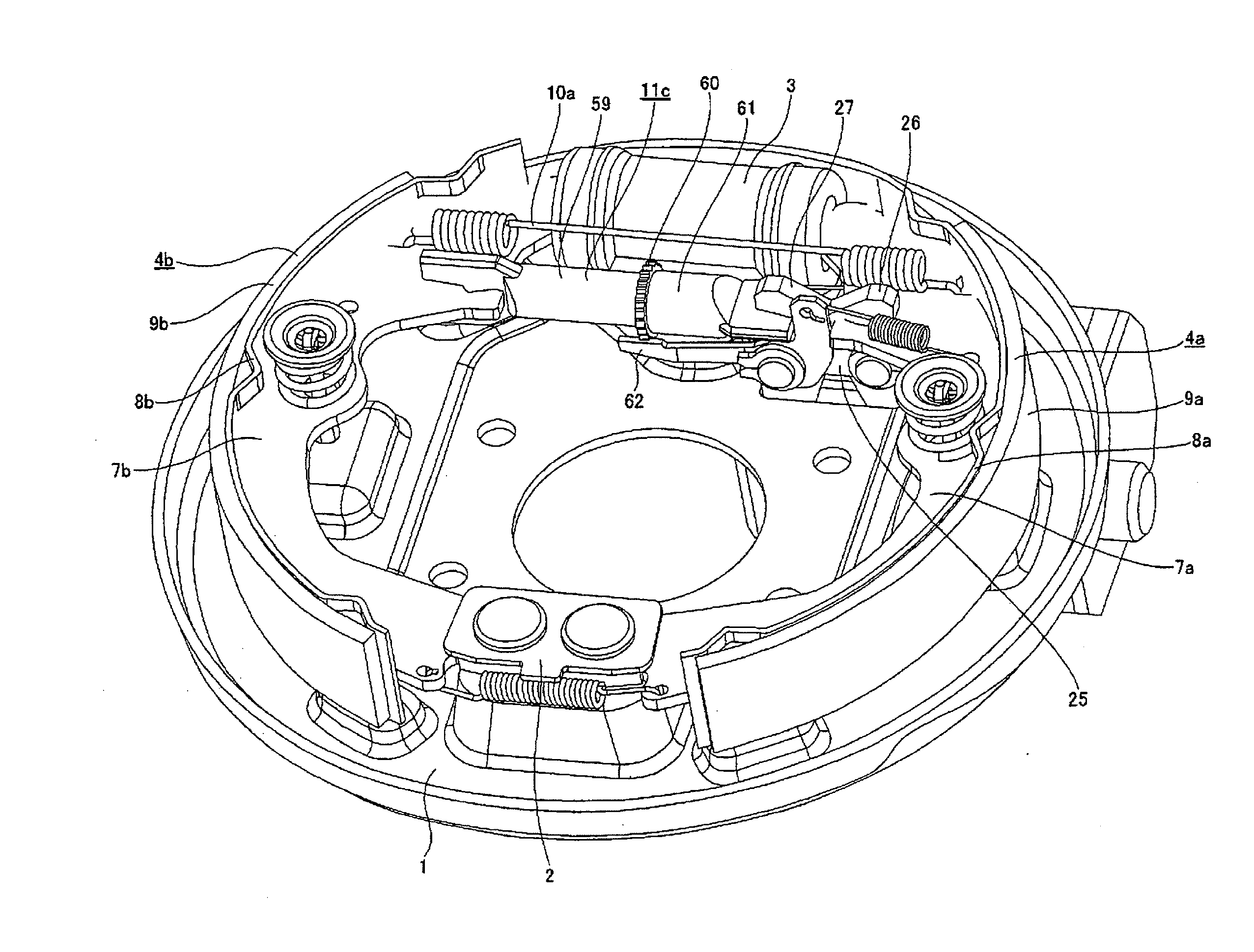

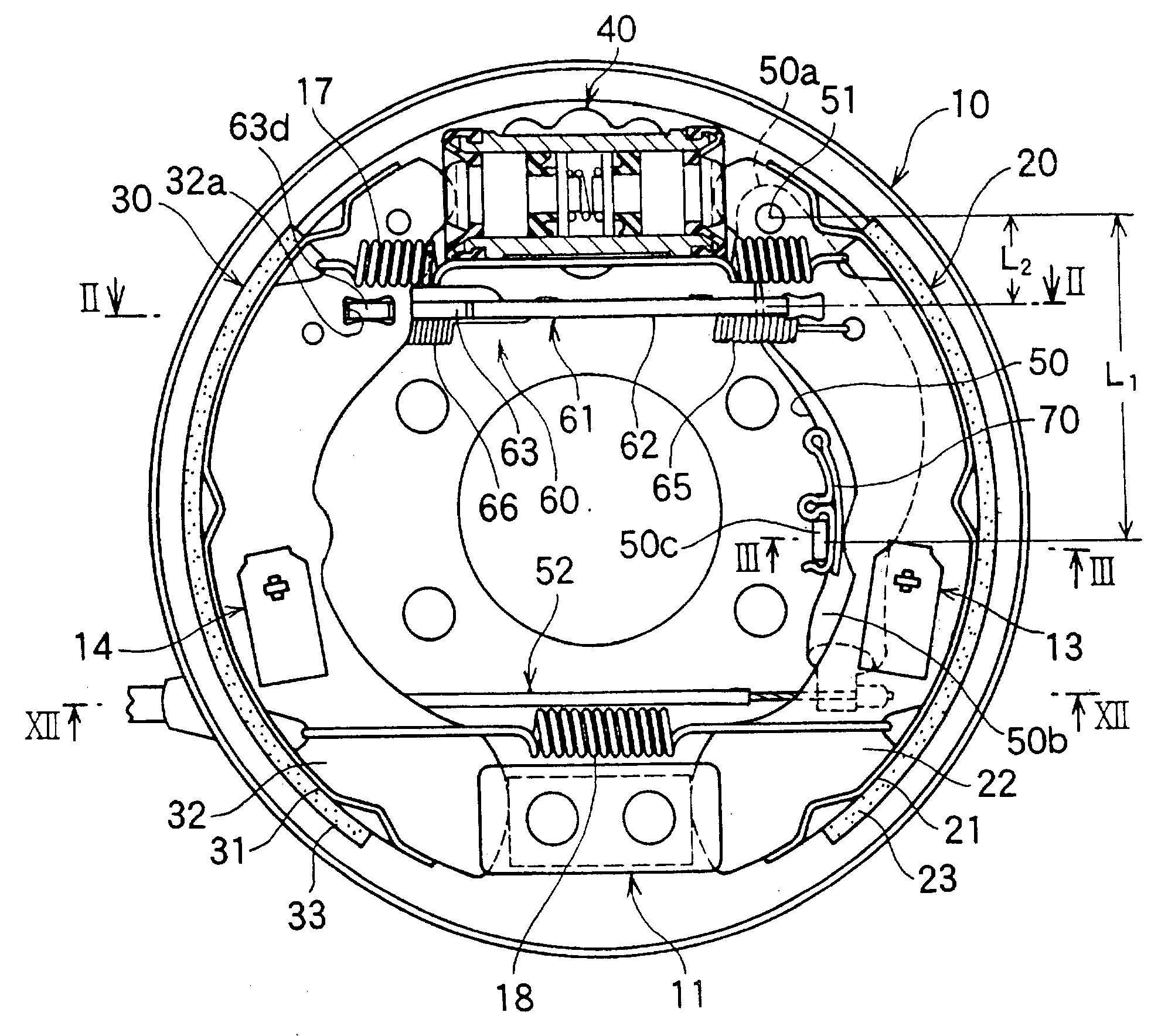

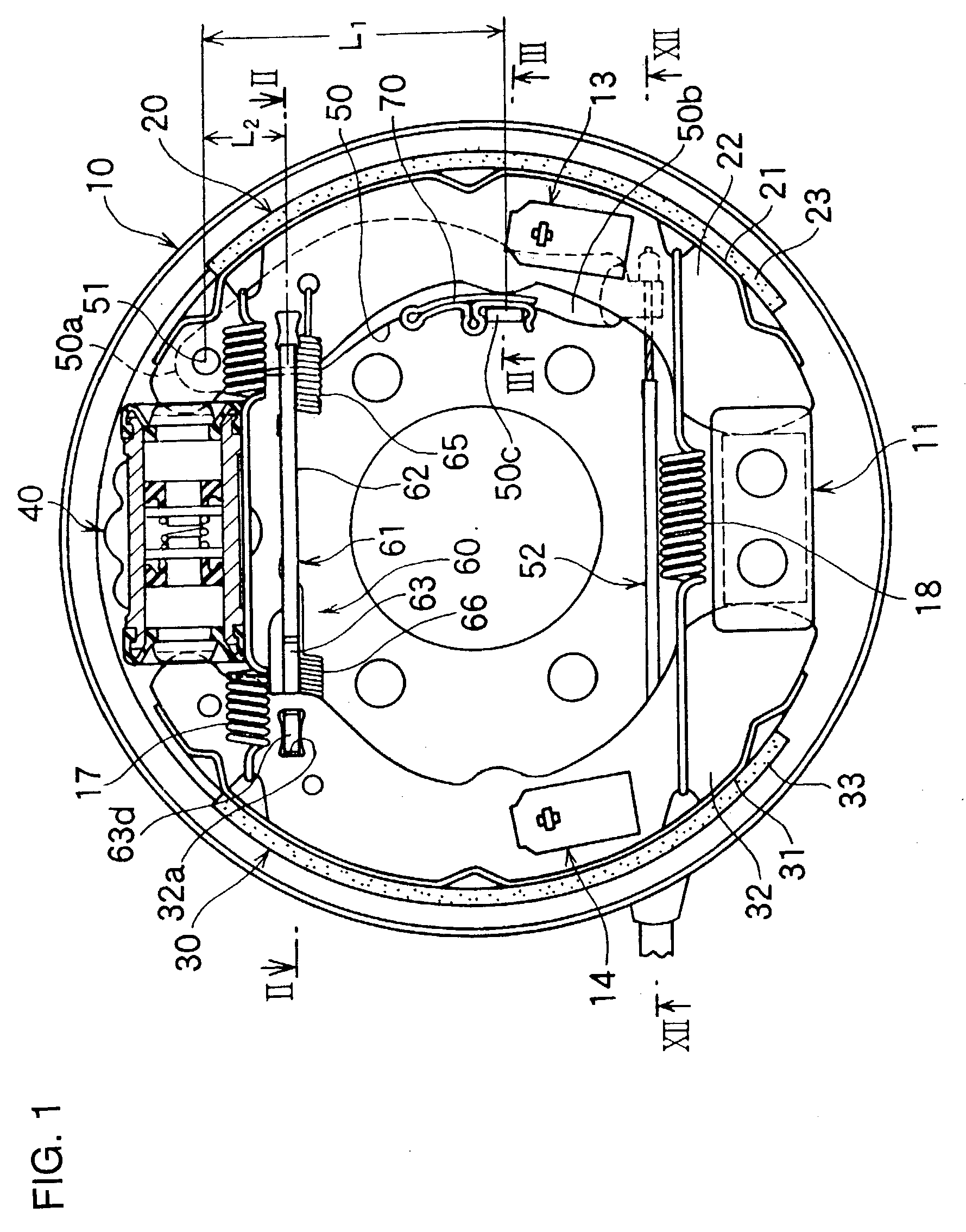

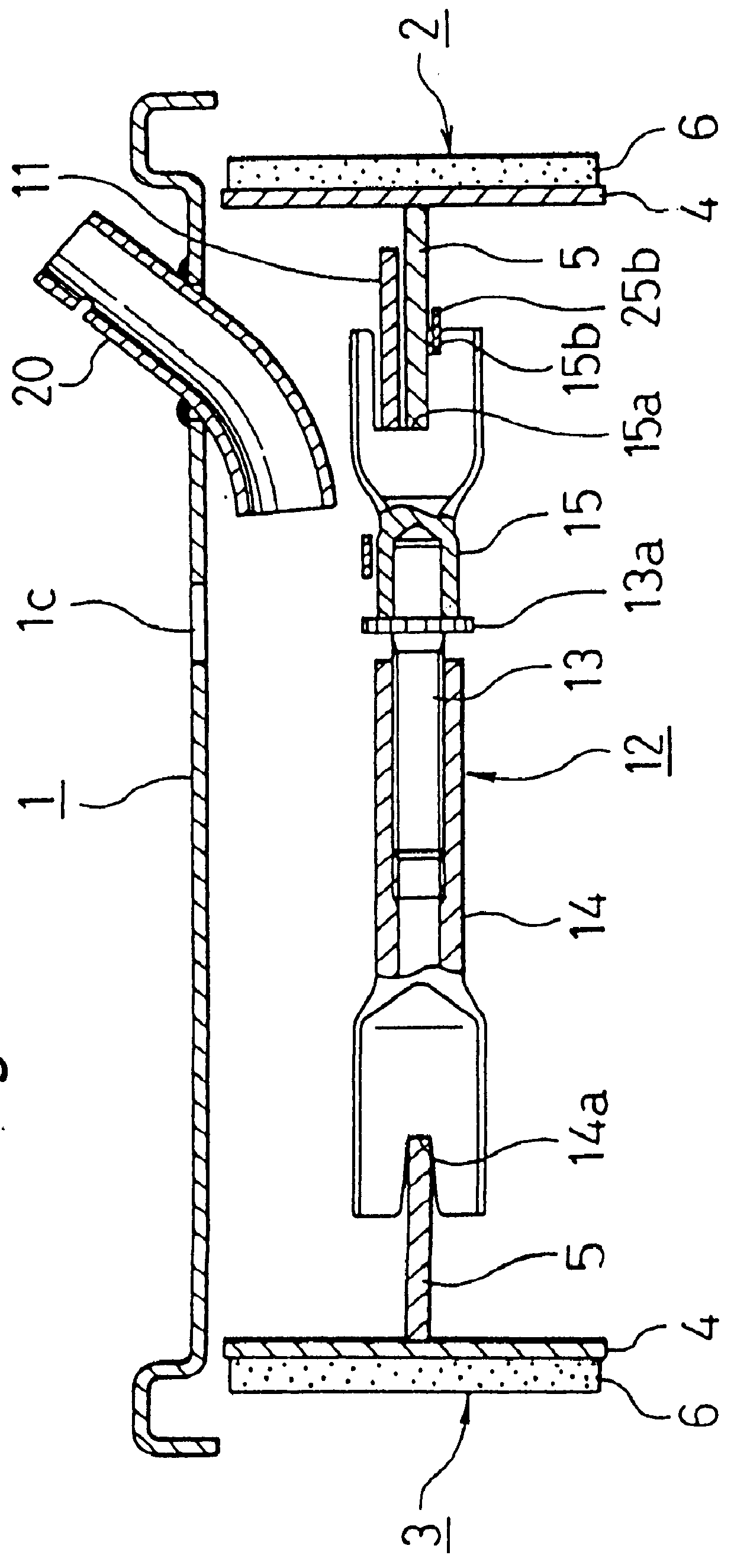

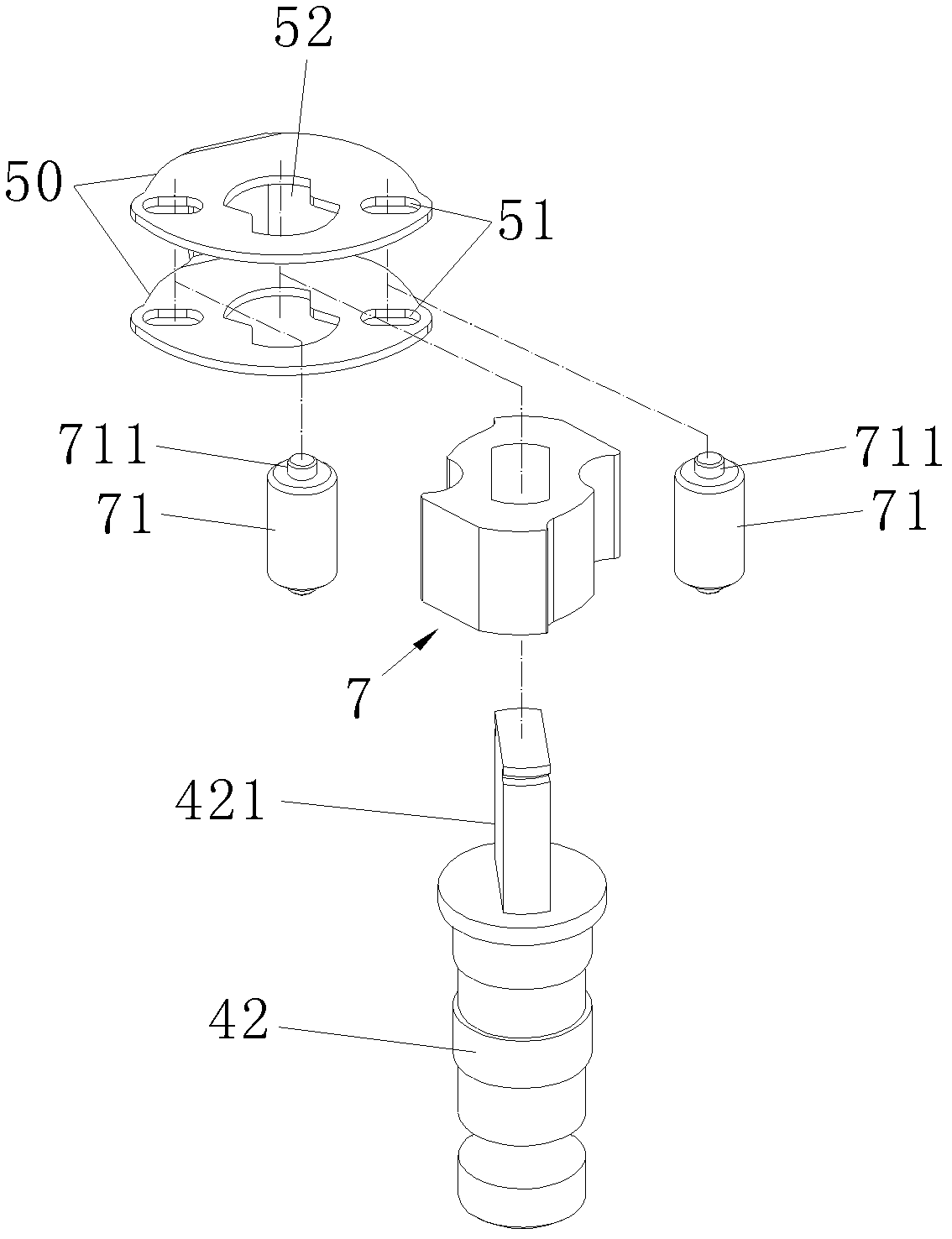

Drum brake device with an automatic shoe clearance adjustment apparatus

InactiveUS20030183465A1Small designMaterial minimizationSlack adjustersMechanically actuated drum brakesEngineeringMechanical engineering

A drum brake device prevents shoe clearance over-adjustment by means of a thermo-sensitive member with a lower leg opening force and provides a smaller thermo-sensitive member with a lower cost. A portion between both ends of the brake lever (50) in a direction of crossing the shoe return inhibitor (61) engages with one end of the shoe return inhibitor (61) automatically restricting the return position of the pair of brake shoes (20) and (30); the proximate portion (50a) of the brake lever (50) is pivotally supported on the brake shoe (20); and the free end (50b) side of the brake lever (50) is supported at the brake shoe (20) via the thermo-sensitive member (70).

Owner:NISSHINBO IND INC

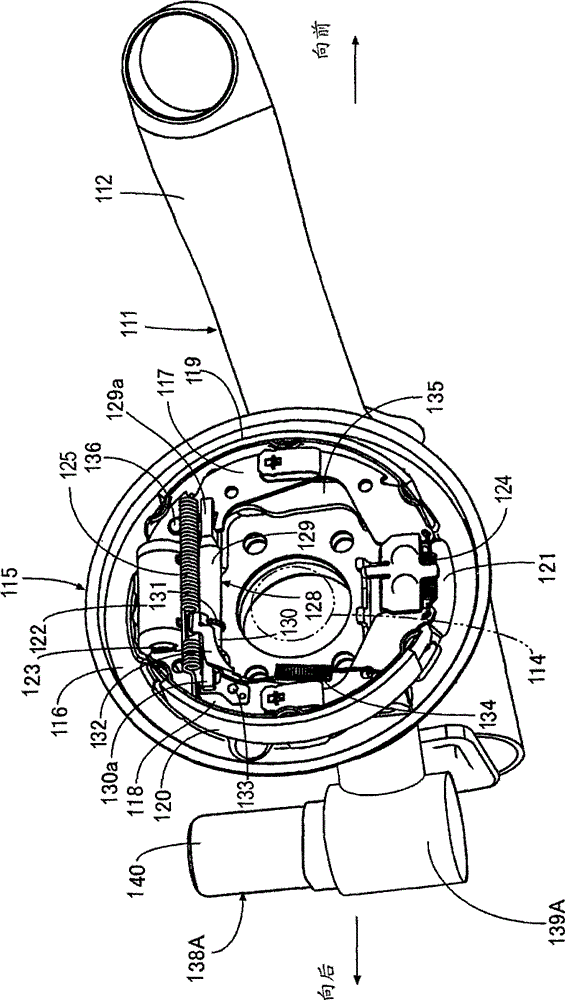

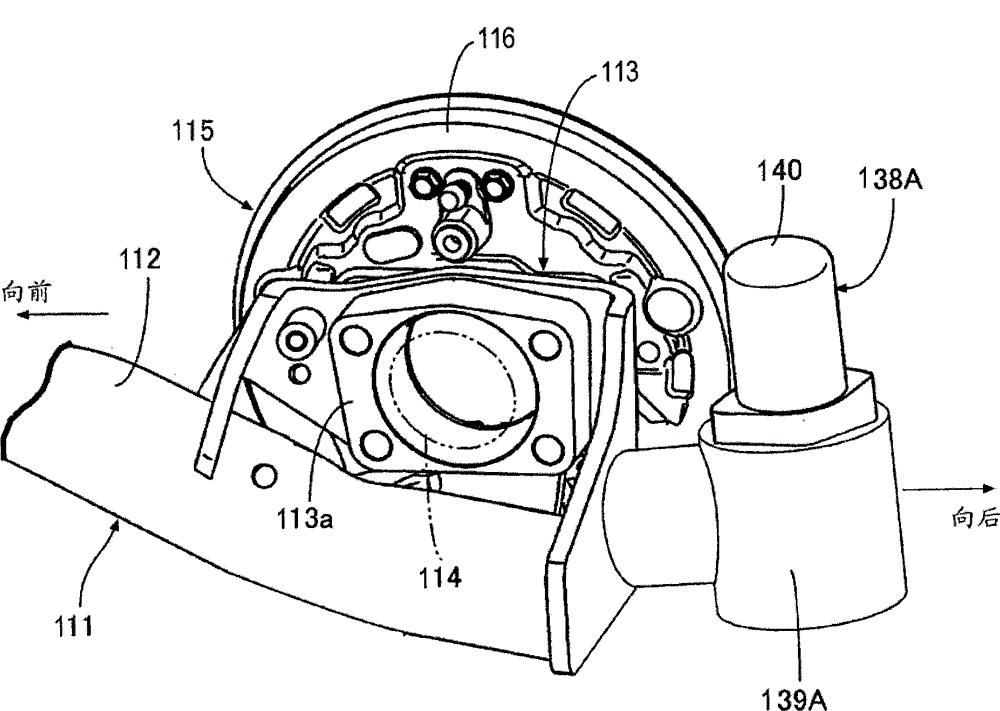

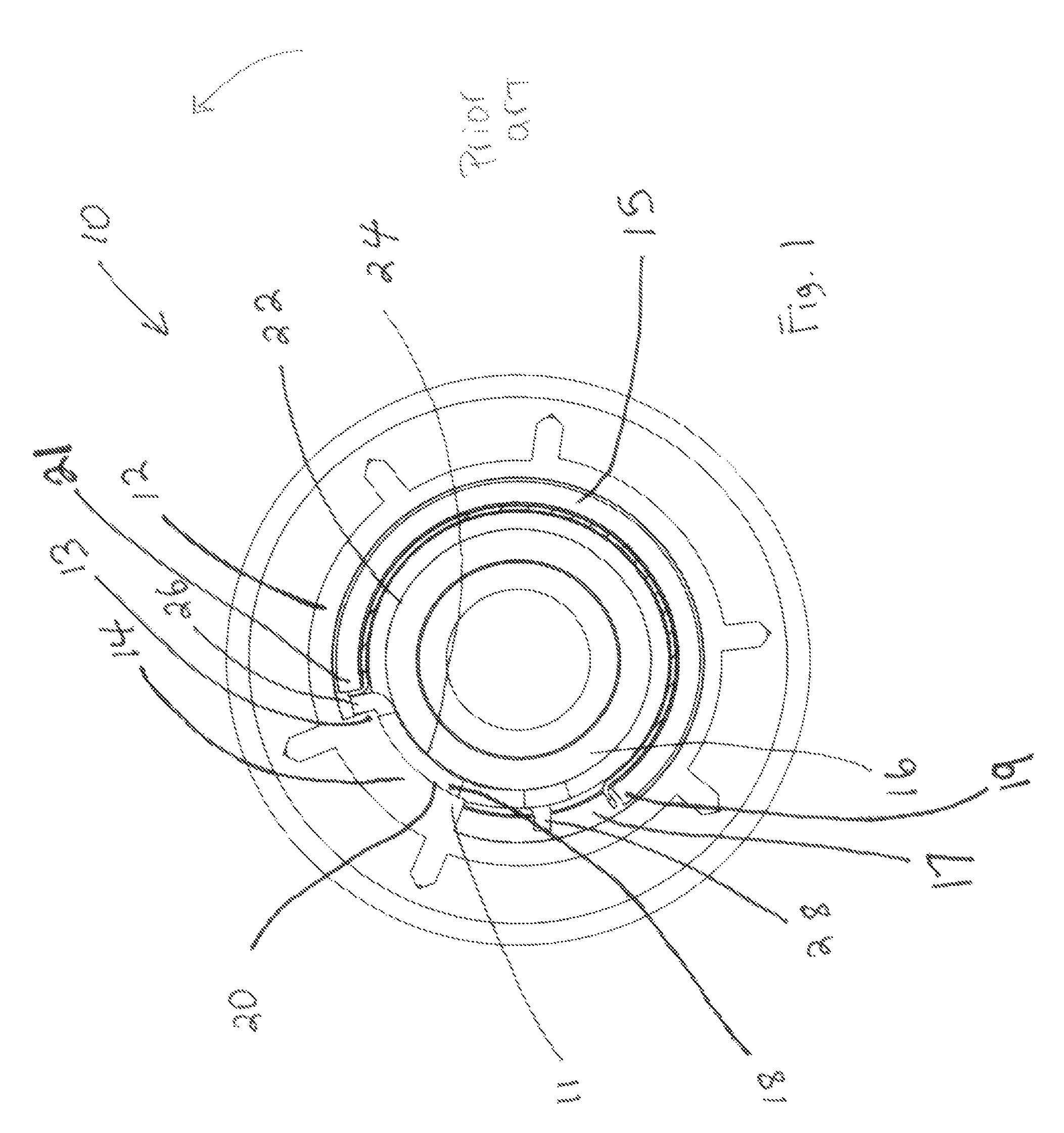

Clutch and motor

ActiveUS20120098367A1Prevent further rotationFluid couplingsMan-operated mechanismDrive shaftElectric machinery

A clutch including a drive shaft, drive side rotation body, driven shaft, driven side rotation body, clutch housing, and lock member is disclosed. During non-rotation of the drive side rotation body, when the driven side rotation body is rotated, the lock member is pushed by the driven side rotation body and moved outward in a radial direction thereby bringing the contact portion into contact with the inner circumferential surface of the clutch housing. During rotation of the drive side rotation body, the drive side rotation body pushes a drive side cam surface in the rotation direction, and the drive side cam surface acts to move the lock member inward in the radial direction and push the lock member against the driven side rotation body. Thus, the lock member is sandwiched between the drive side rotation body and the driven side rotation body thereby coupling the drive side rotation body and the driven side rotation body with the lock member to be integrally rotatable.

Owner:DENSO CORP

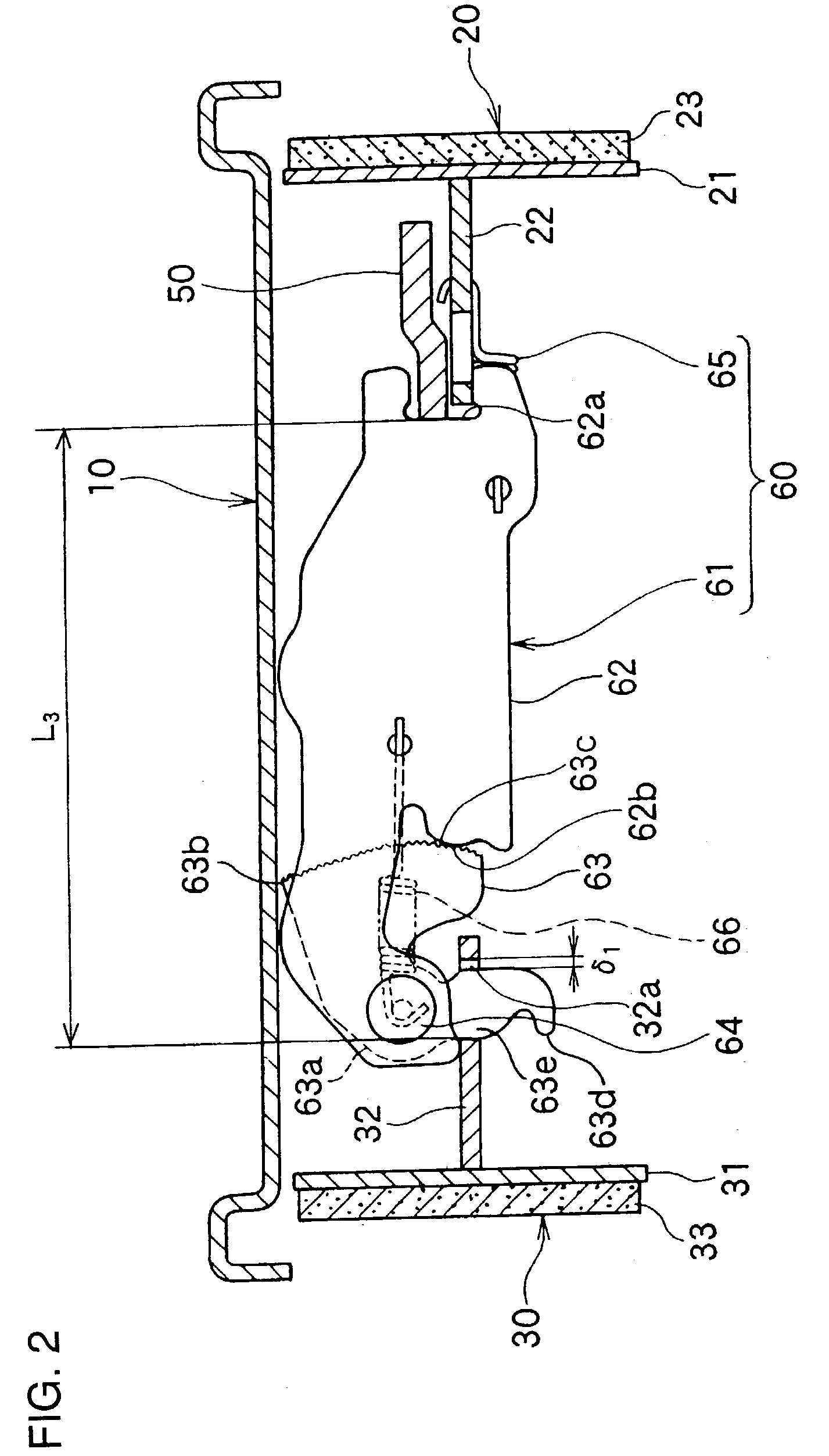

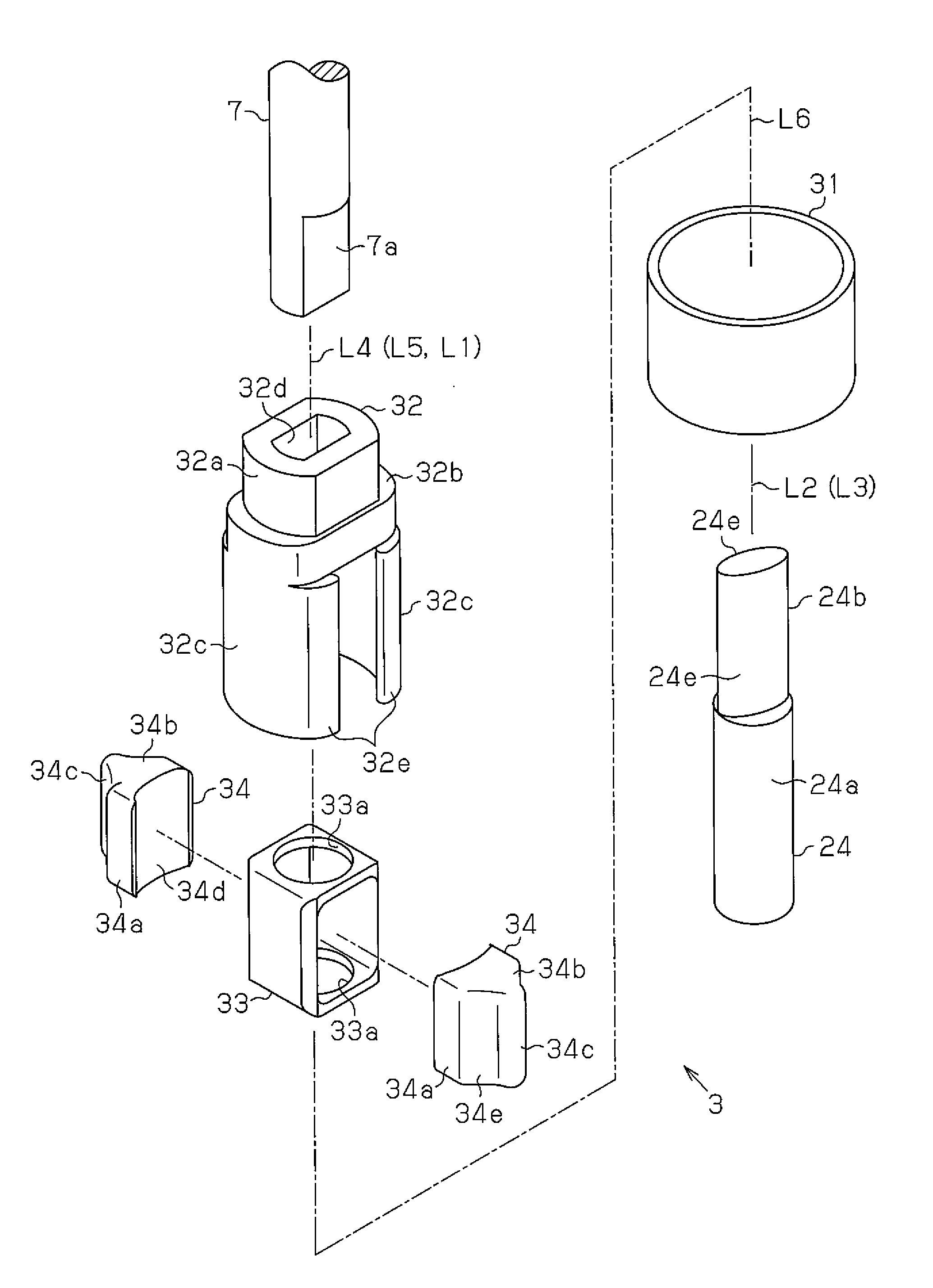

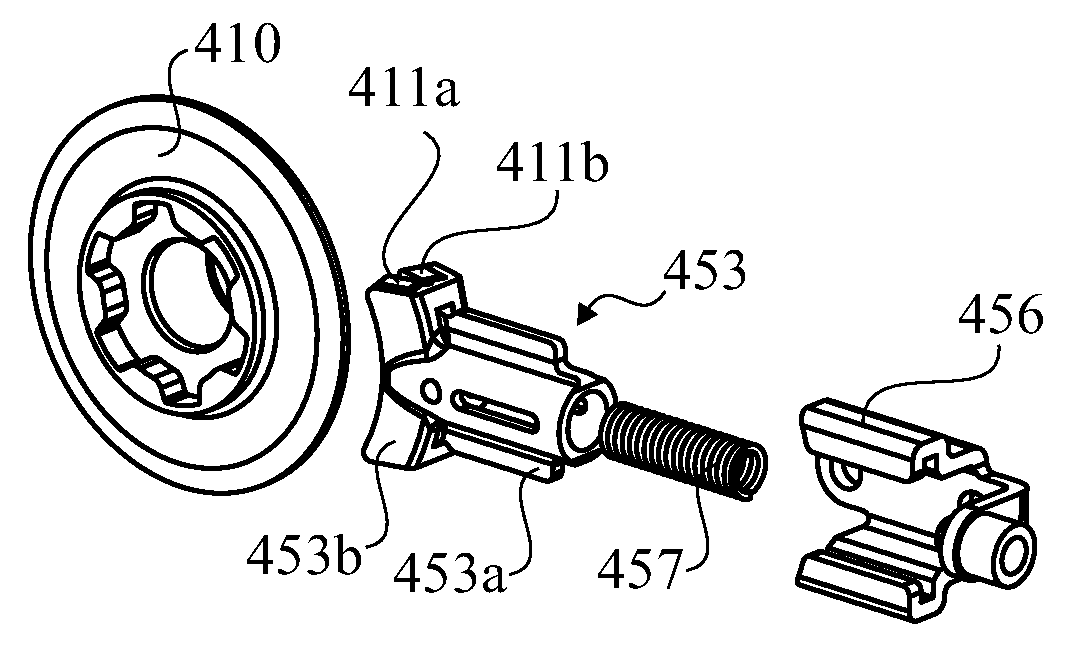

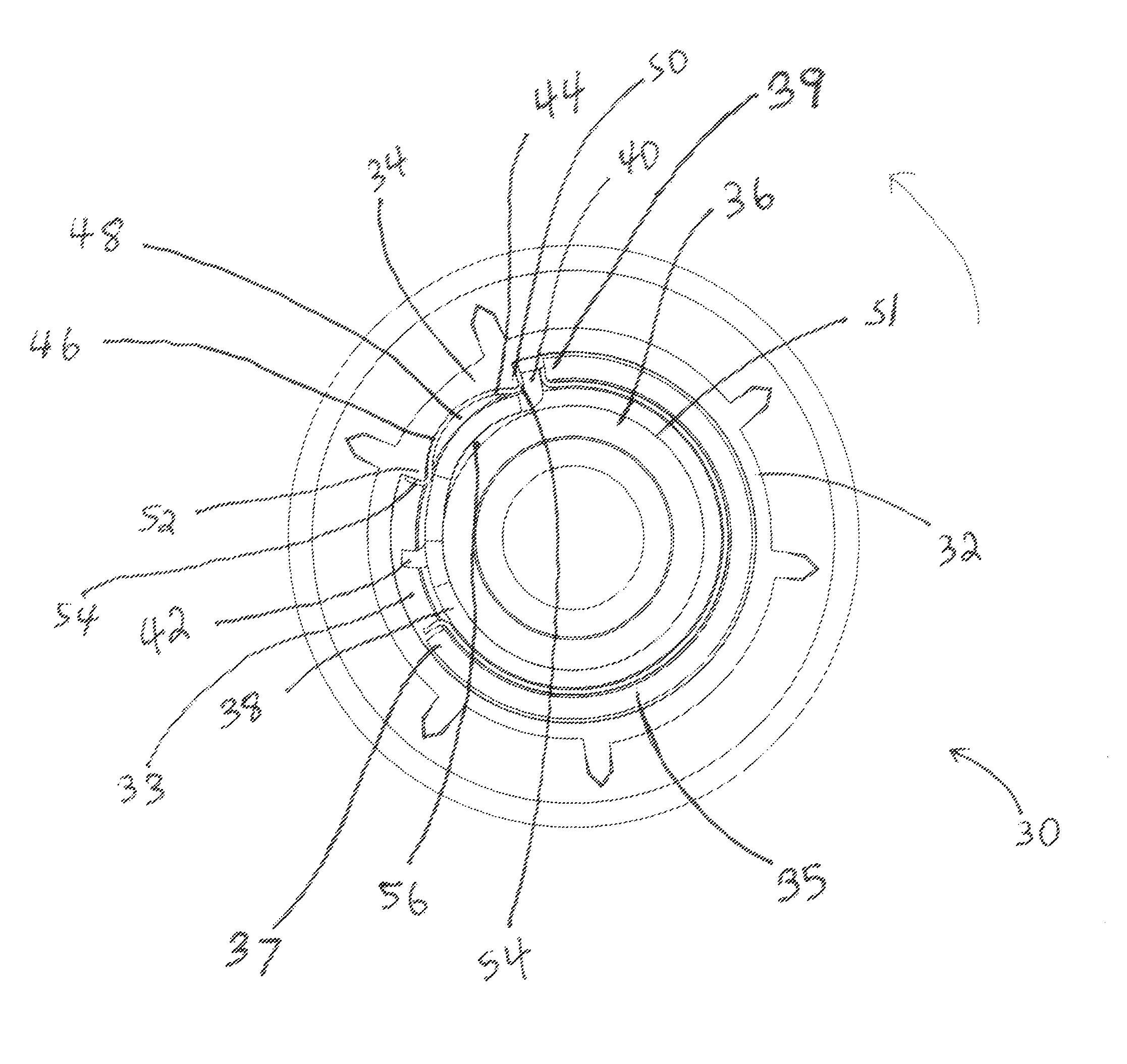

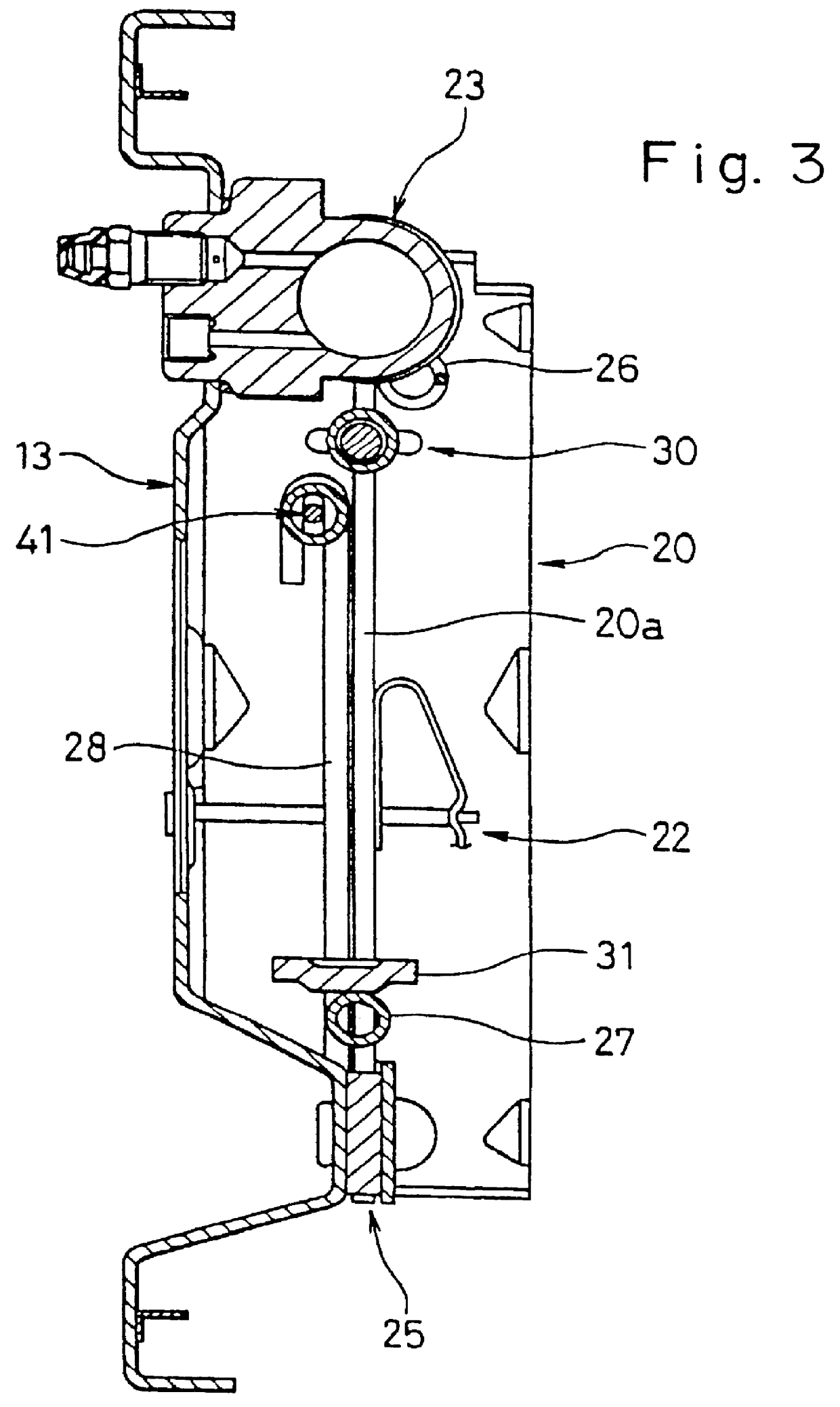

Brake cable connecting apparatus for drum brake

InactiveUS20040055833A1Reduced durabilityIntensive impact noiseMechanical braking transmissionBrake actuating mechanismsEngineeringMechanical engineering

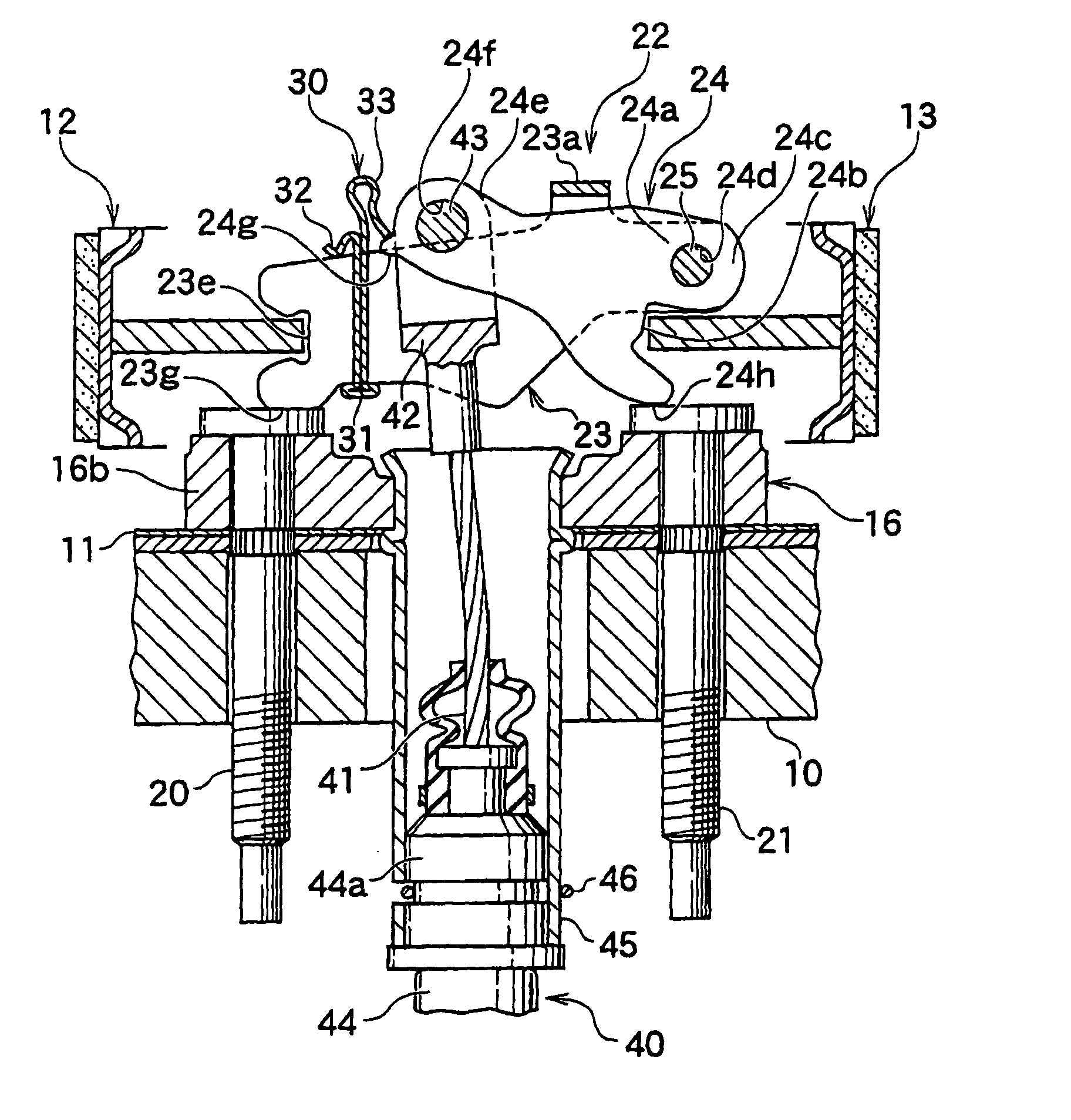

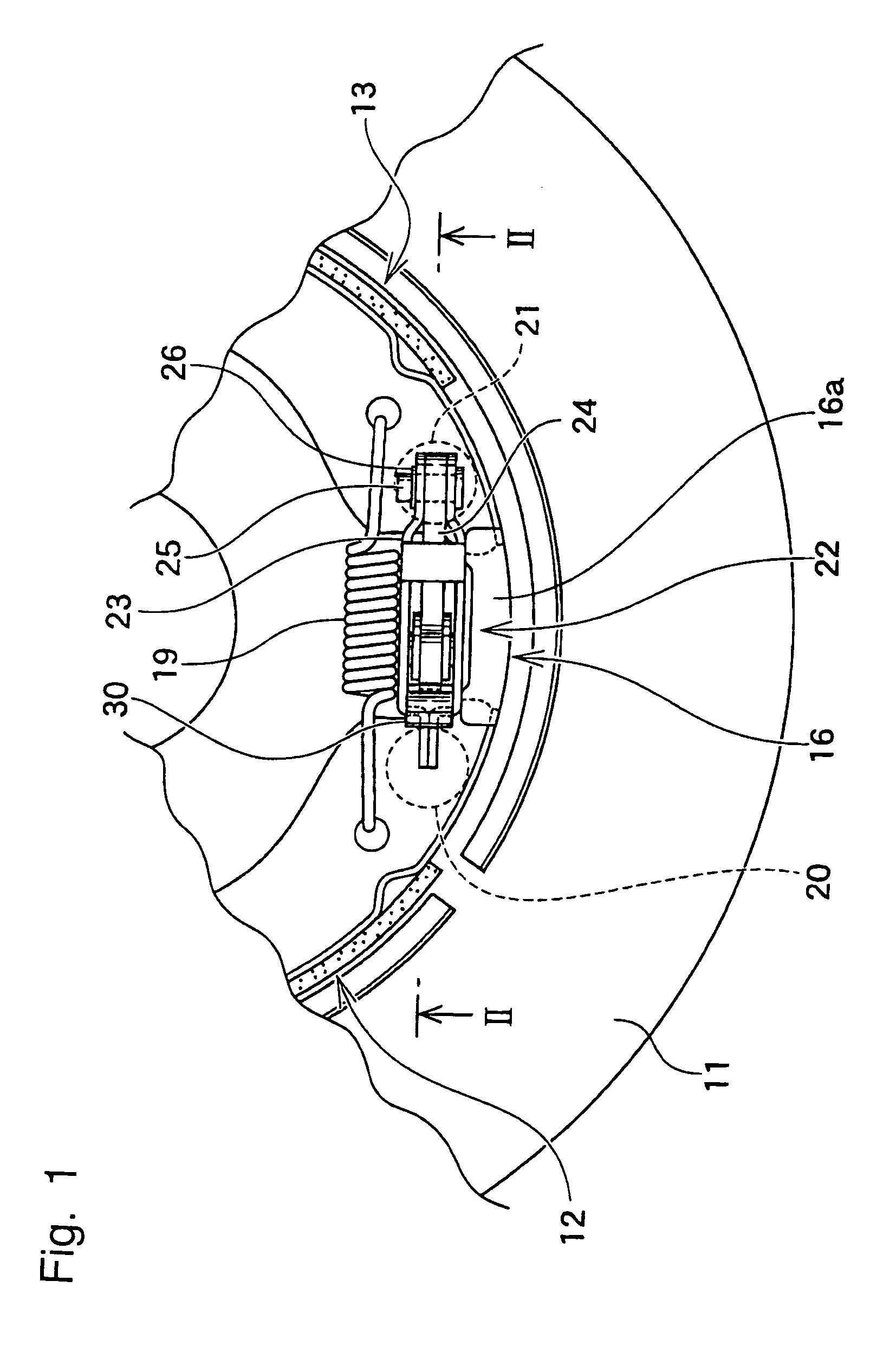

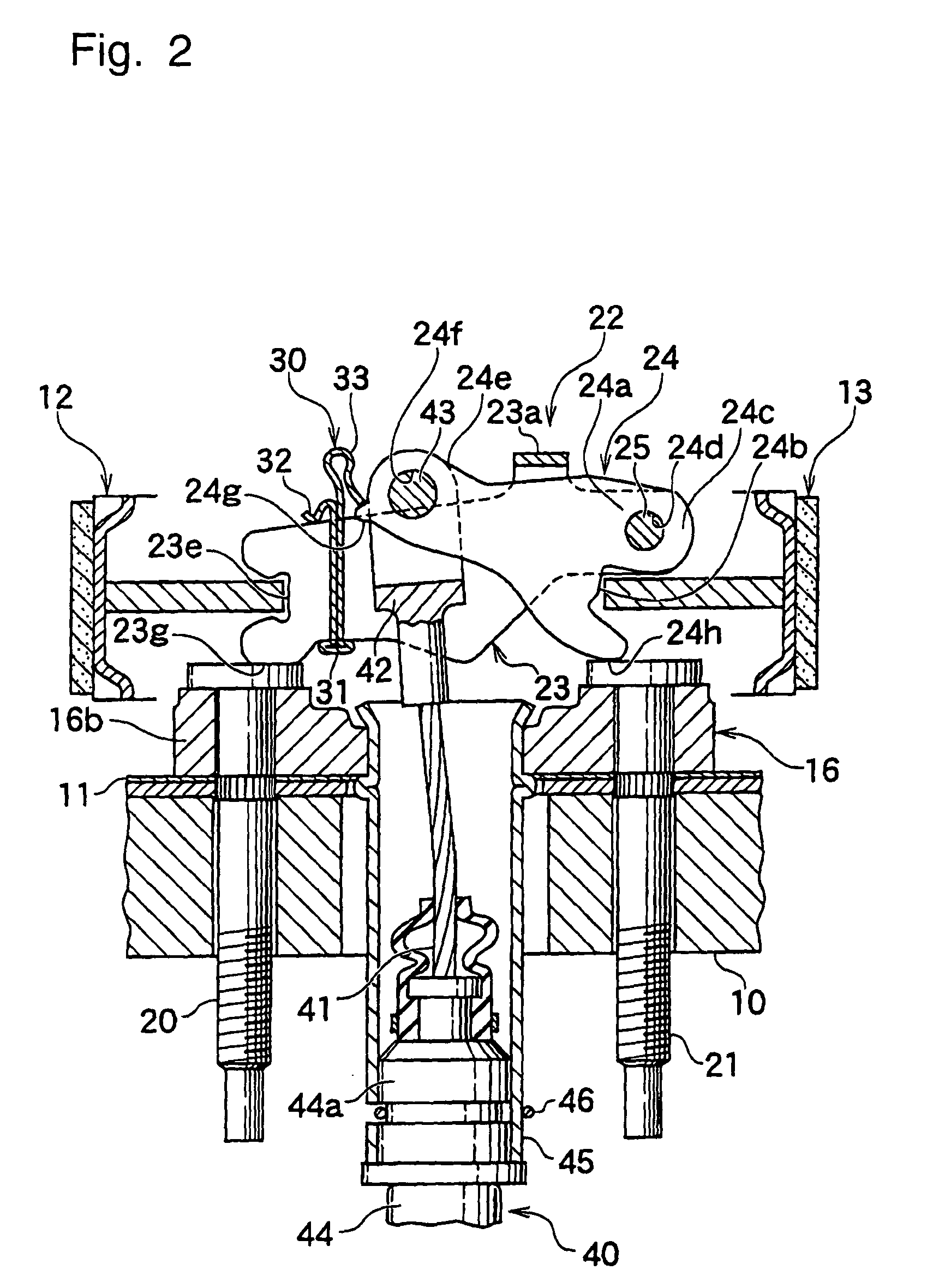

A brake cable connecting apparatus ensures prevention of brake cable disengagement by a simple structure that offers simple and accurate assemblability. The brake cable connecting apparatus comprises the strut 23 engaging with the brake shoe 12 and the plate-like brake lever engaging with the brake shoe 13. The proximal portion 24a of the brake lever 24 is pivotally positioned in the wider space 23c formed between the two facing surface walls of the strut 23. The cable end 42 of the brake cable 40 is connected with the free end 24e of the brake lever 24 by the connecting pin 43. The inner cable 41 is operated to effectuate braking, and the projection 24g of the free end 24e interferes with the resilient stopper 33 of the resilient member 30 mounted on the strut 23 and is positioned on the rotating trajection of the brake lever 24.

Owner:AH BRAKE CO LTD

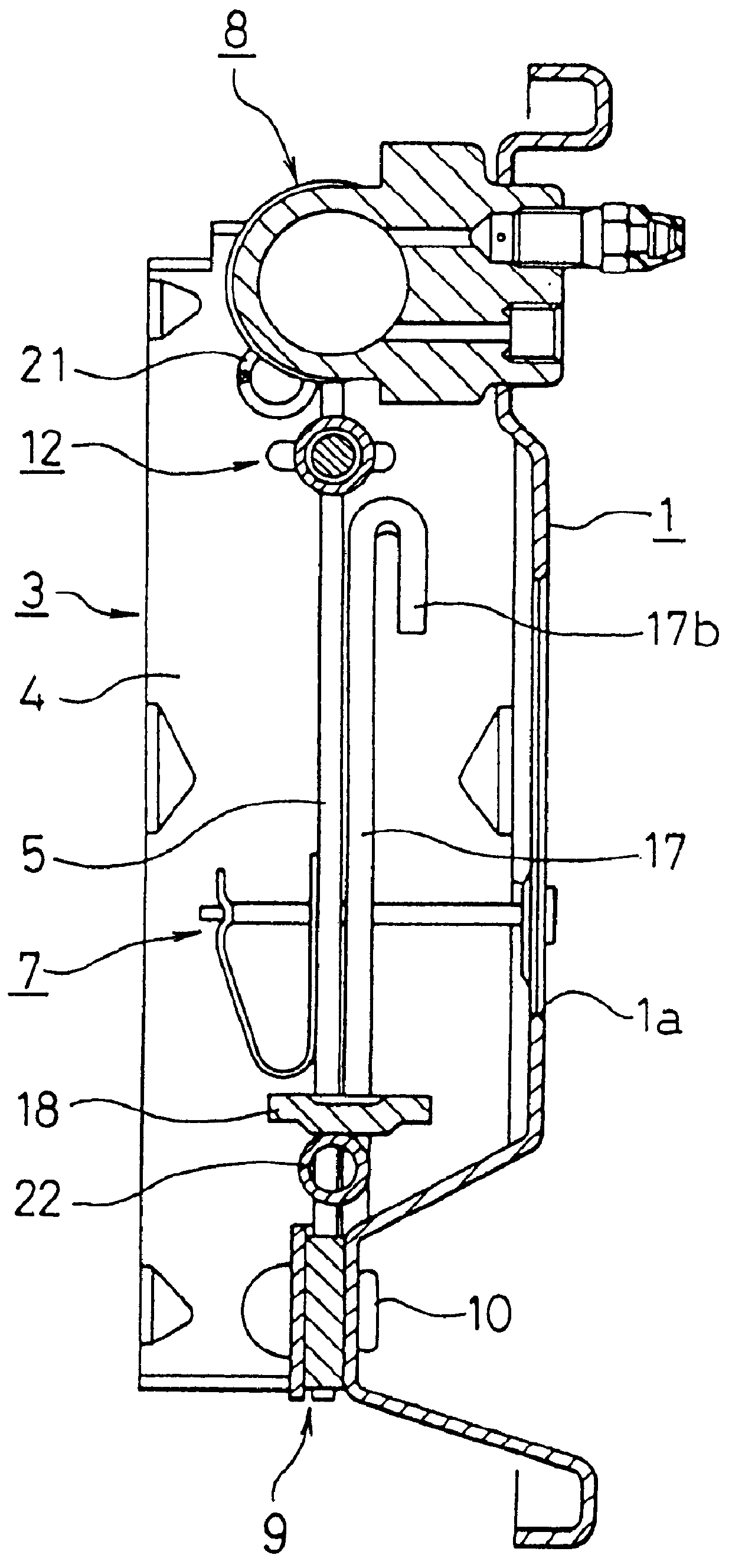

Drum brake device

InactiveUS6125976AEasy to observeEliminate discomfortBraking membersFluid actuated drum brakesEngineeringParking brake

A drum brake device that functions as a leading-trailing (LT) type when the service brake is applied, and as a duo-servo (DS) type when the parking brake is applied, in which the automatic shoe clearance adjustment mechanism functions precisely for a prolonged period, thereby generating no strange noise. This mechanism also eliminate any impact load applied to any of the components, thus enabling a lighter device. The middle segment of a long link 11 is pivotable in the middle of the one brake shoe 2.

Owner:NISSHINBO IND INC

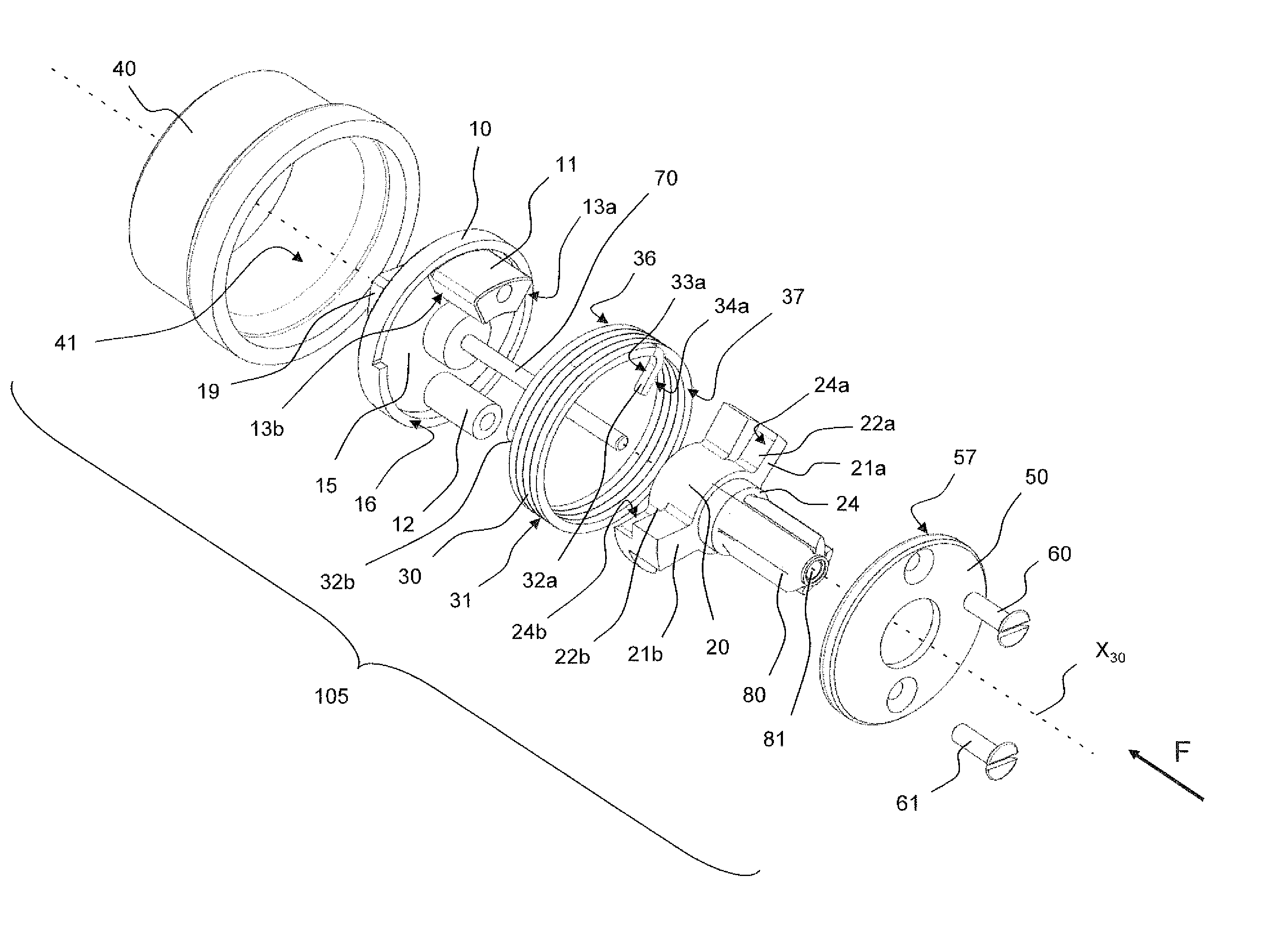

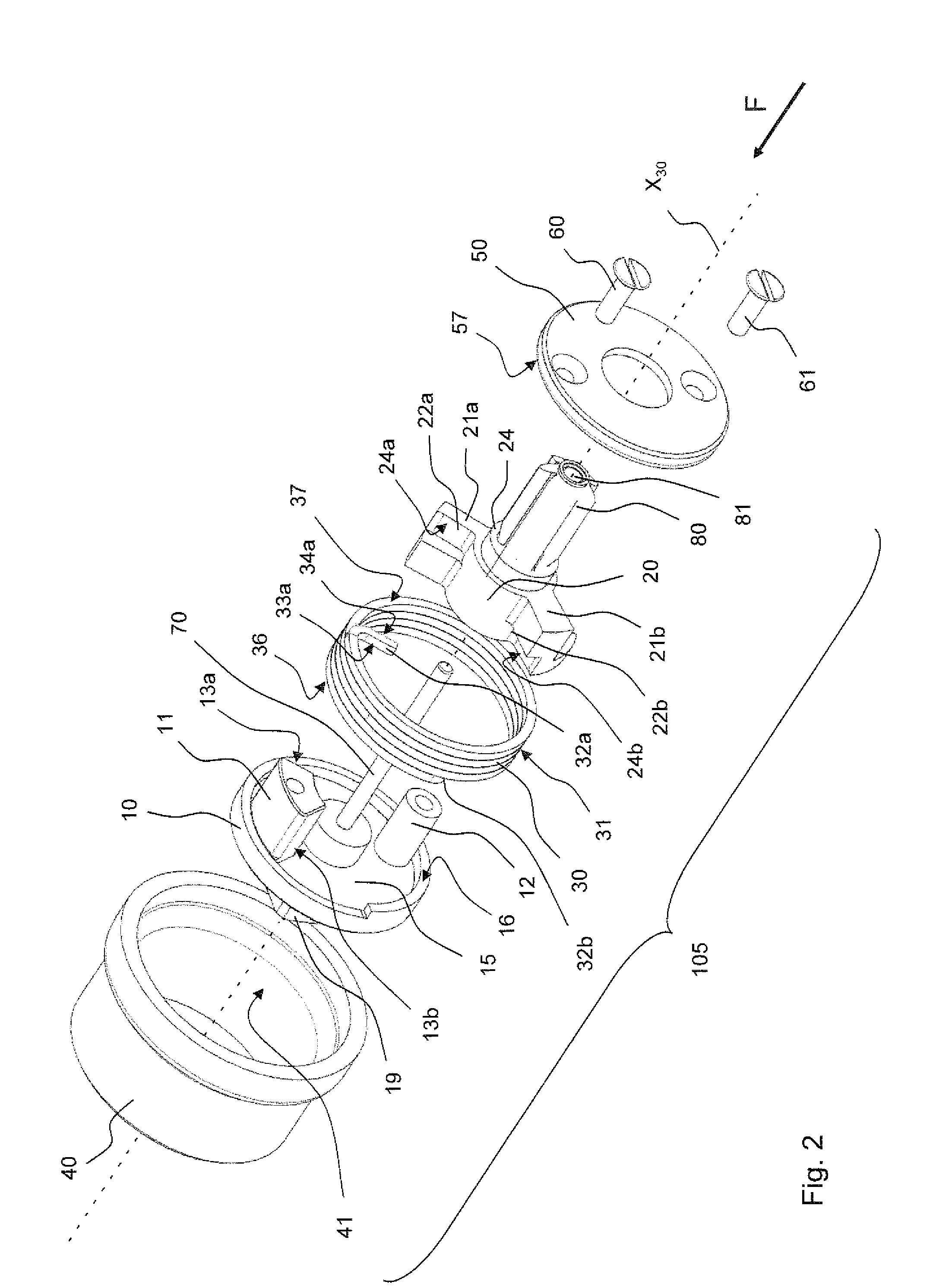

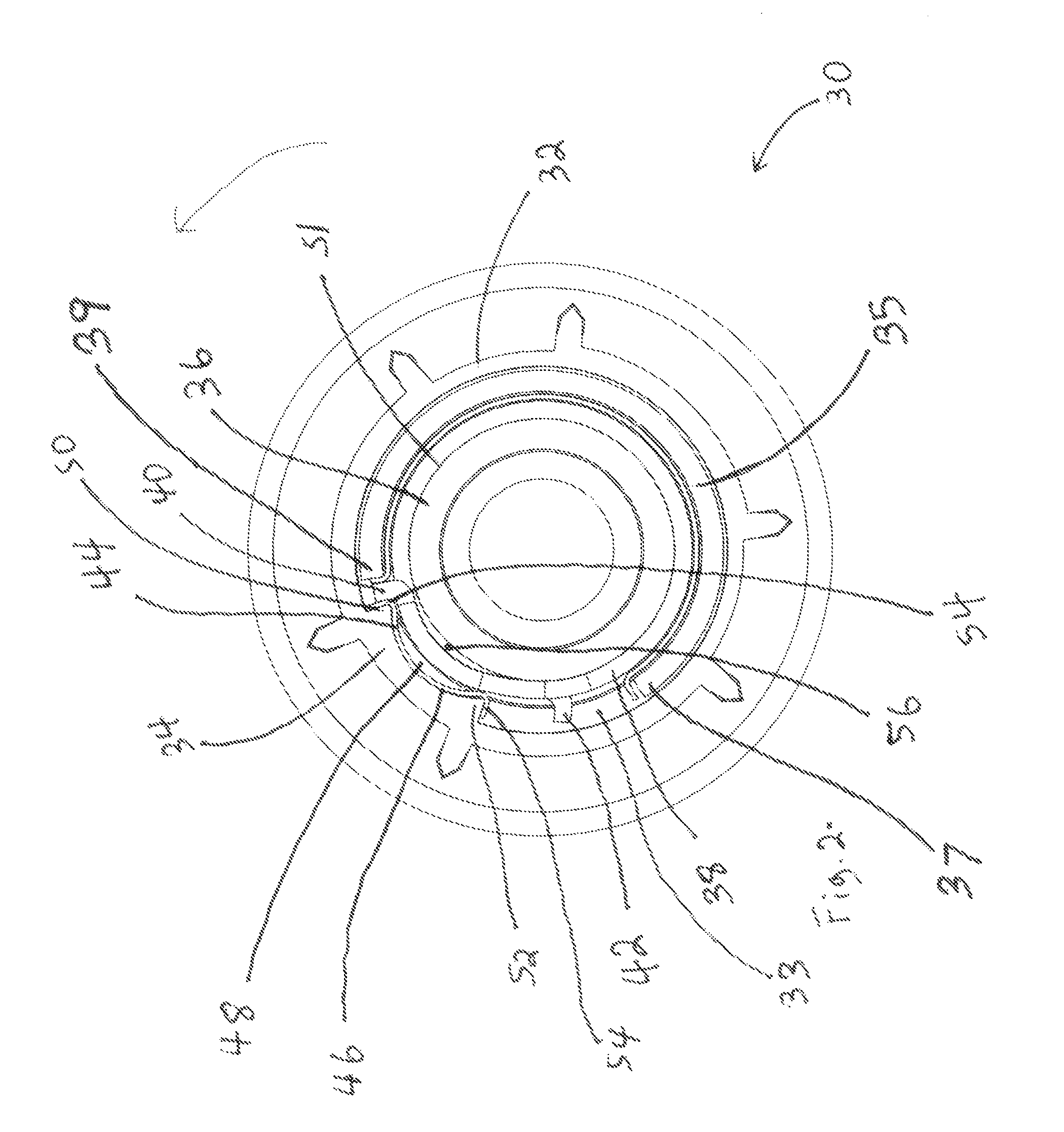

Spring-loaded brake for an actuator for driving a household screen and actuator equipped with such a brake

ActiveUS20100236891A1Little strengthDoor/window protective devicesCoupling-brake combinationCoil springEngineering

This spring-loaded brake (105) for an actuator for driving a household screen comprises a helical spring (30) each end of which forms a lug (32a, 32b) extending radially, a friction piece (40) comprising a friction surface (41) against which the helical spring (30) presses radially, an input piece (10) able to drive the rotation of the spring (30) about a central axis (X30) in one direction reducing the force of contact between the helical spring (30) and the friction surface, and an output piece (20) able to drive the rotation of the spring (30) about its axis in a direction increasing the force of contact between the helical spring and the friction surface. This brake (105) additionally comprises two pieces (10, 50) which always rotate as one about the axis (X30) of the spring and each of which forms an end stop (16, 57) to an axial movement of the helical spring (30). The end stop (16) formed by one of these pieces (10) is able to limit the axial movement of the spring in a first direction, whereas the end stop (57) formed by the other piece (50) is able to limit the axial movement of the spring in a second direction opposite to the first direction.

Owner:SOMFY ACTIVITES SA

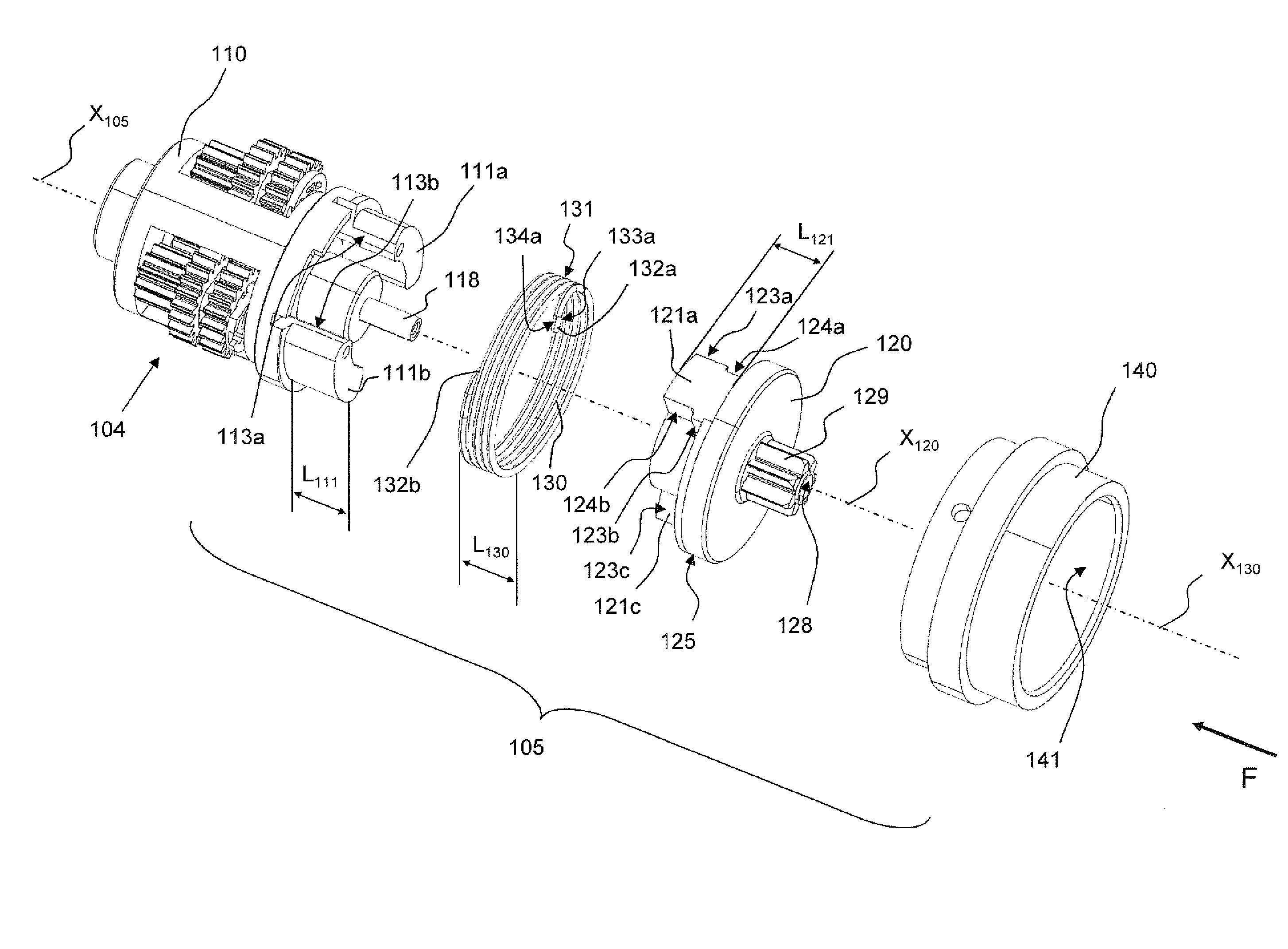

Electric actuator for driving a home-automation screen

ActiveUS20100320855A1Increase contact forceReduce contact forceDoor/window protective devicesMechanical energy handlingContact forceEngineering

Owner:SOMFY ACTIVITES SA

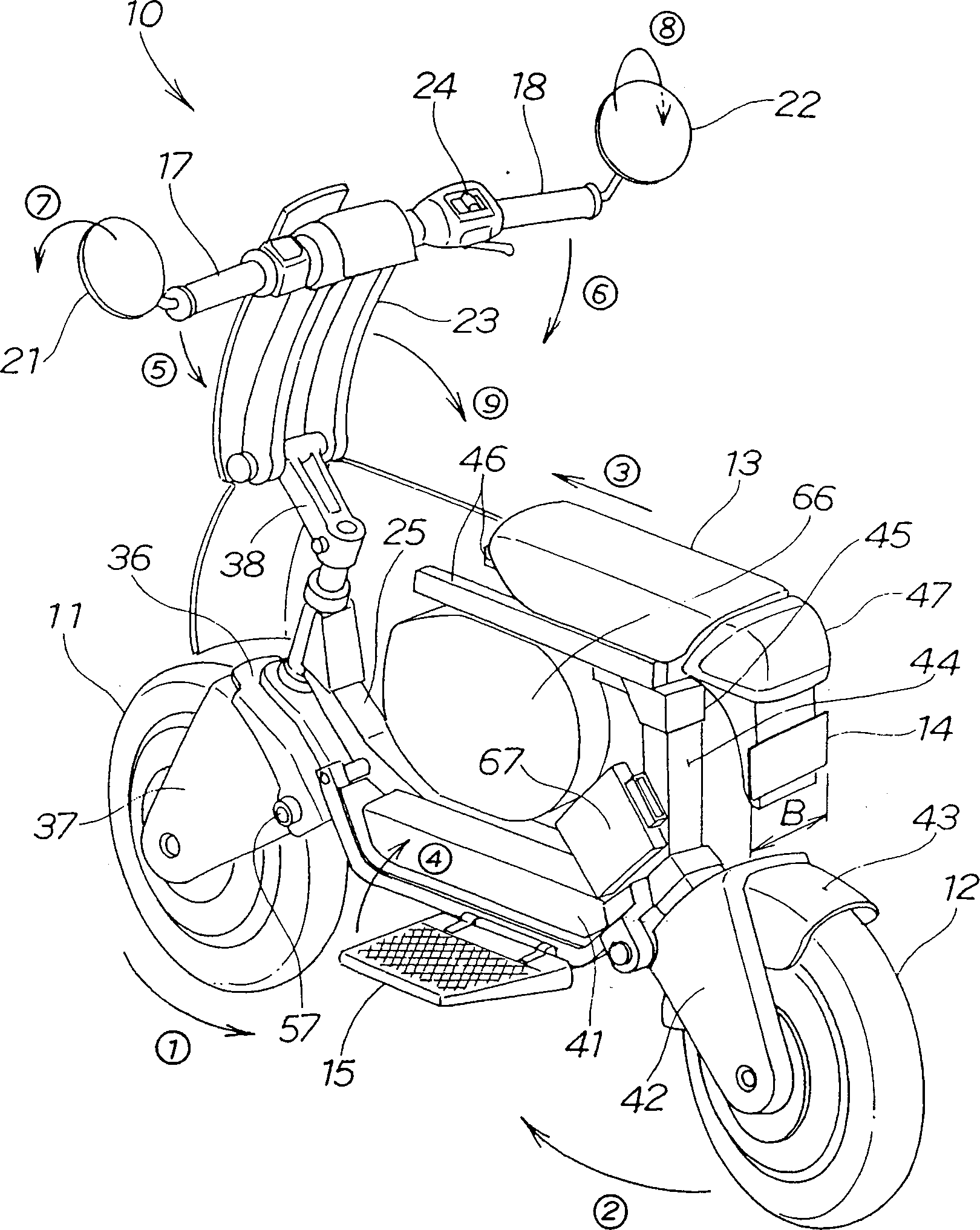

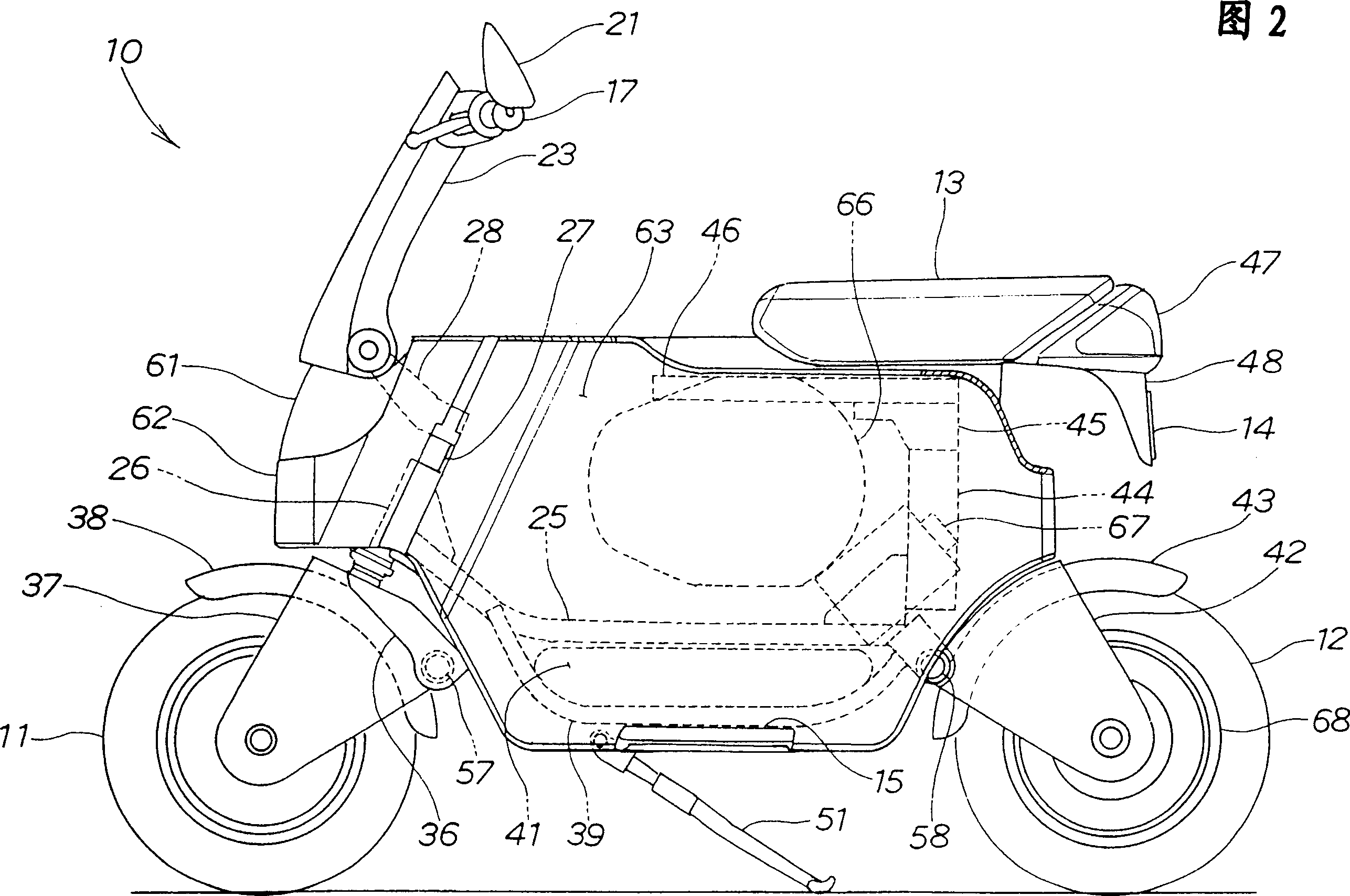

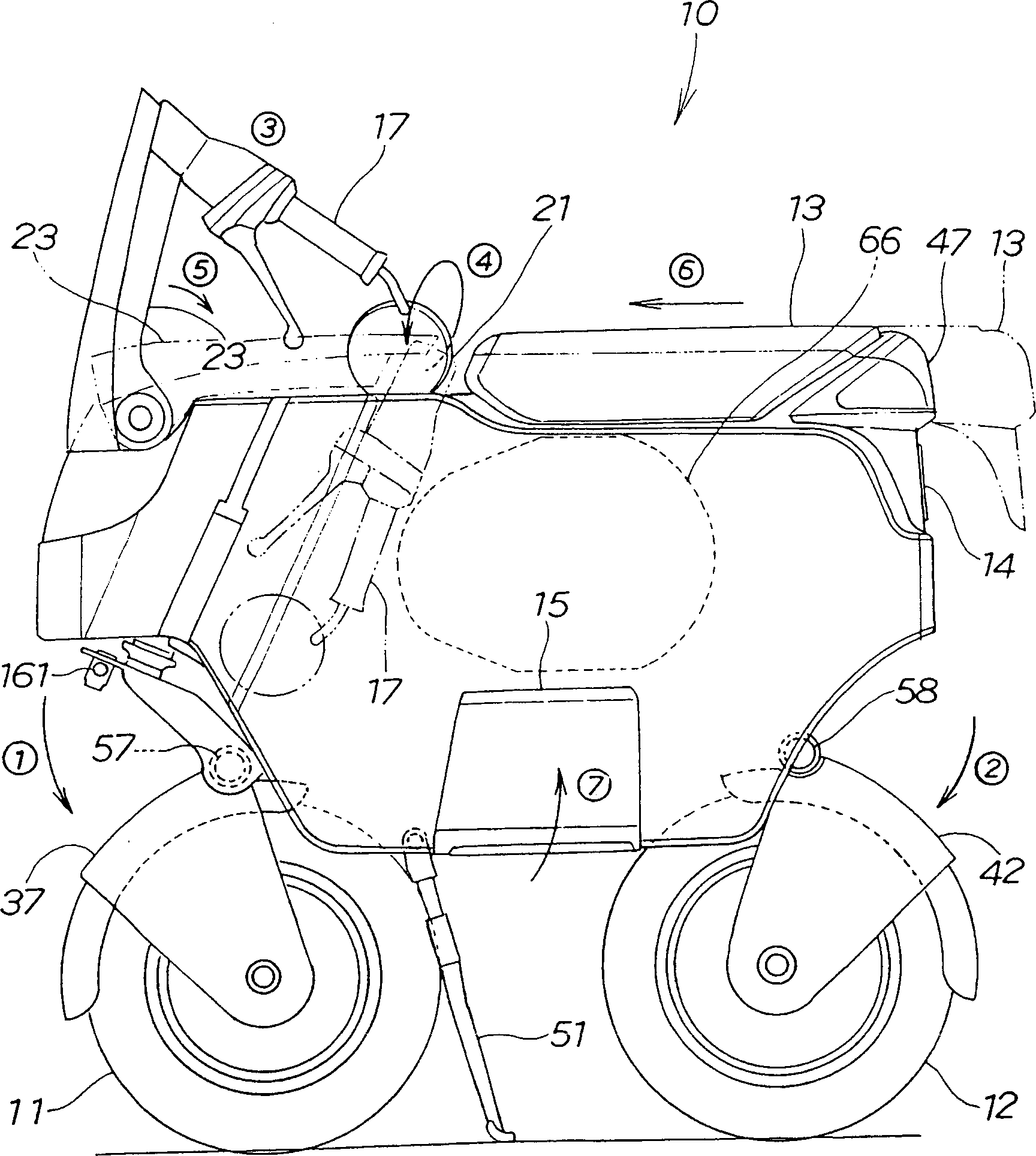

Wheel structure

InactiveUS6892841B2Reduce adverse effectsSimple structureBraking element arrangementsBraking drumsEngineeringDrum brake

A drum brake for braking a wheel disposed on the inside in the radial direction of an electric motor. The drum of the drum brake and an electric motor are disposed separate from each other, and thus wear powders of a brake shoe do not adhere to a permanent magnet of the electric motor. As a result, the wear powders do not adversely influence the performance of the electric motor, and the performance of the electric motor is maintained. The electric motor and the drum brake are disposed concentrically, so that the width of the wheel is reduced. Thus, a small and compact wheel is realized.

Owner:HONDA MOTOR CO LTD

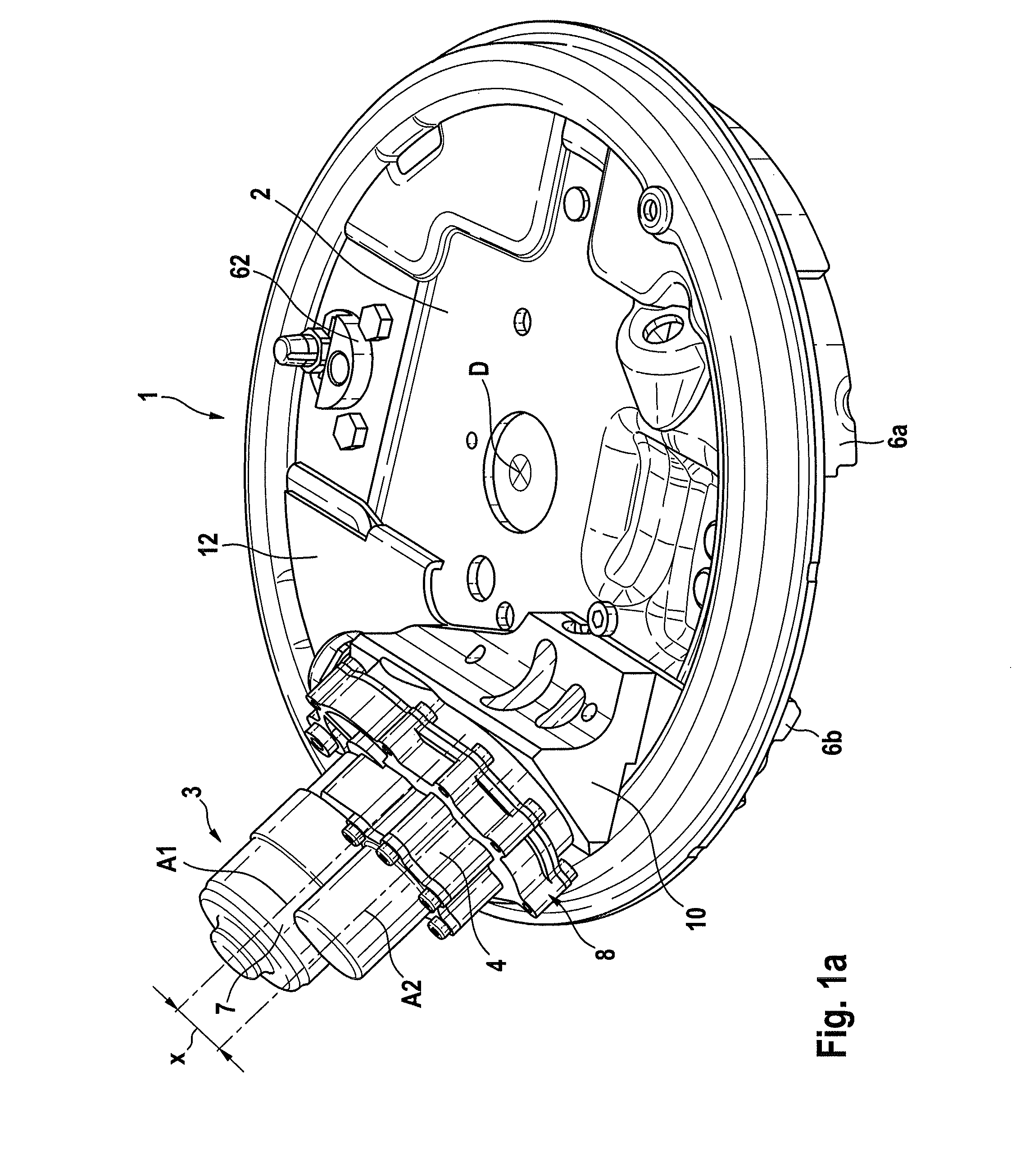

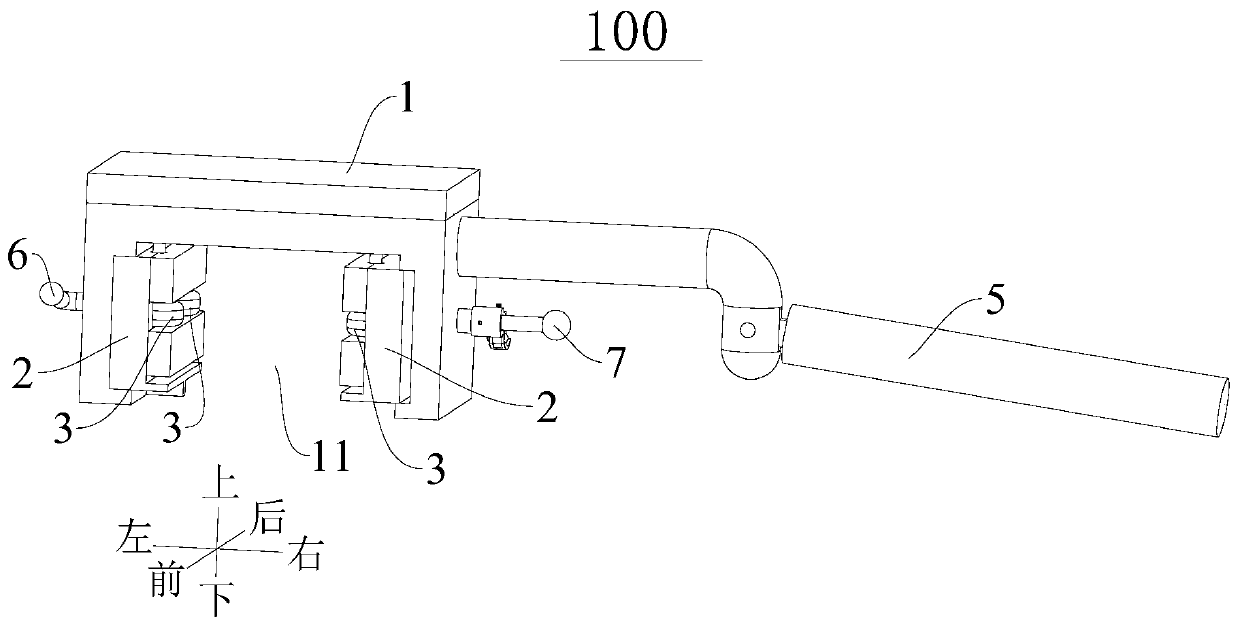

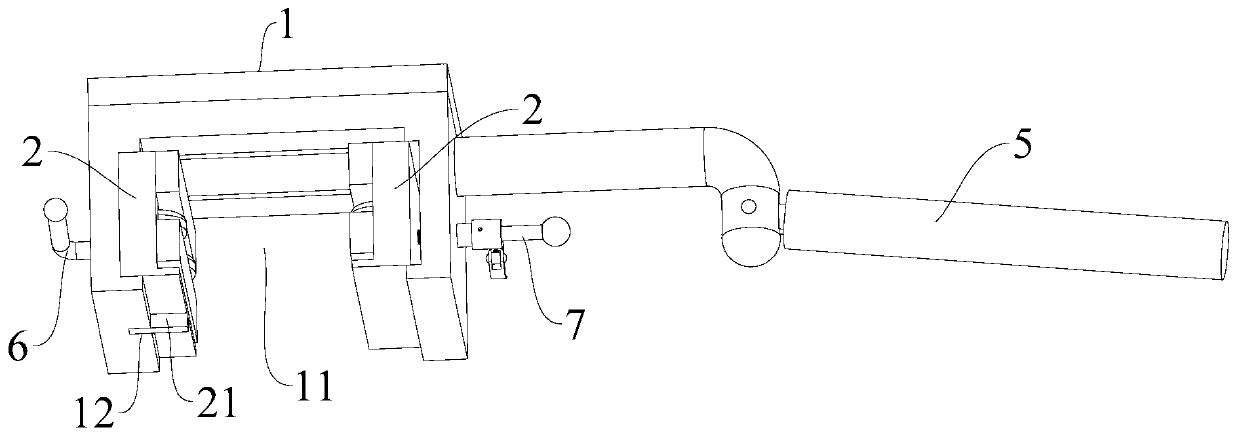

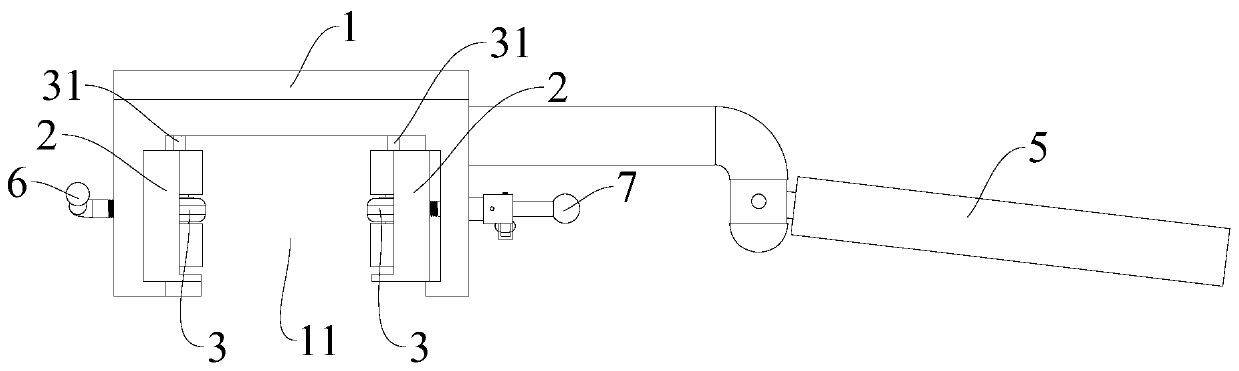

Drum brake module which can be operated by electric motor

ActiveCN103339401AImprove efficiencyReduce adverse effectsBrake actuating mechanismsMechanically actuated drum brakesBiological activationParking brake

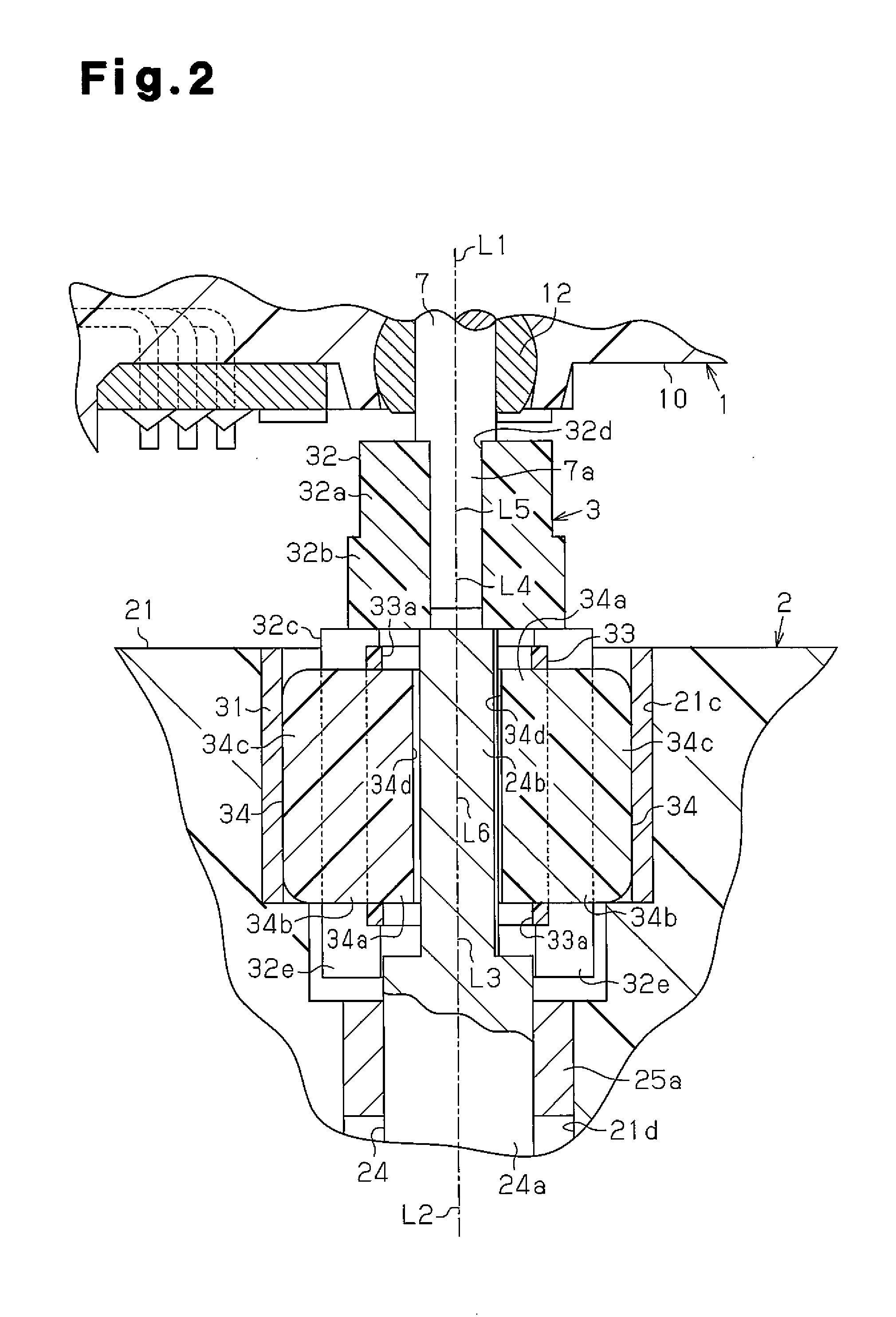

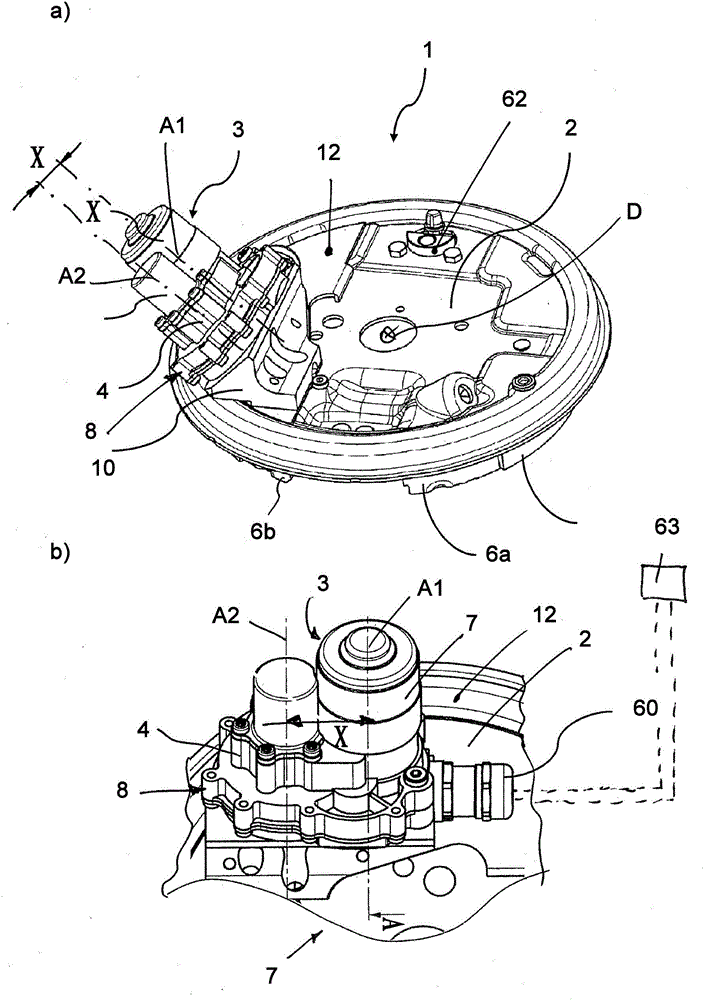

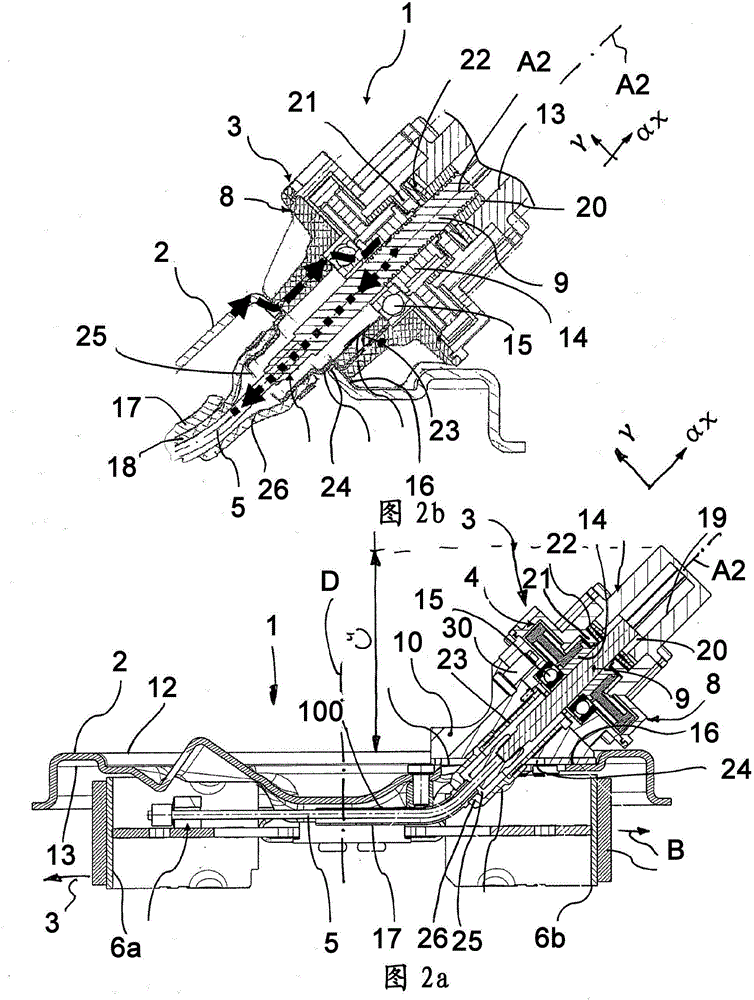

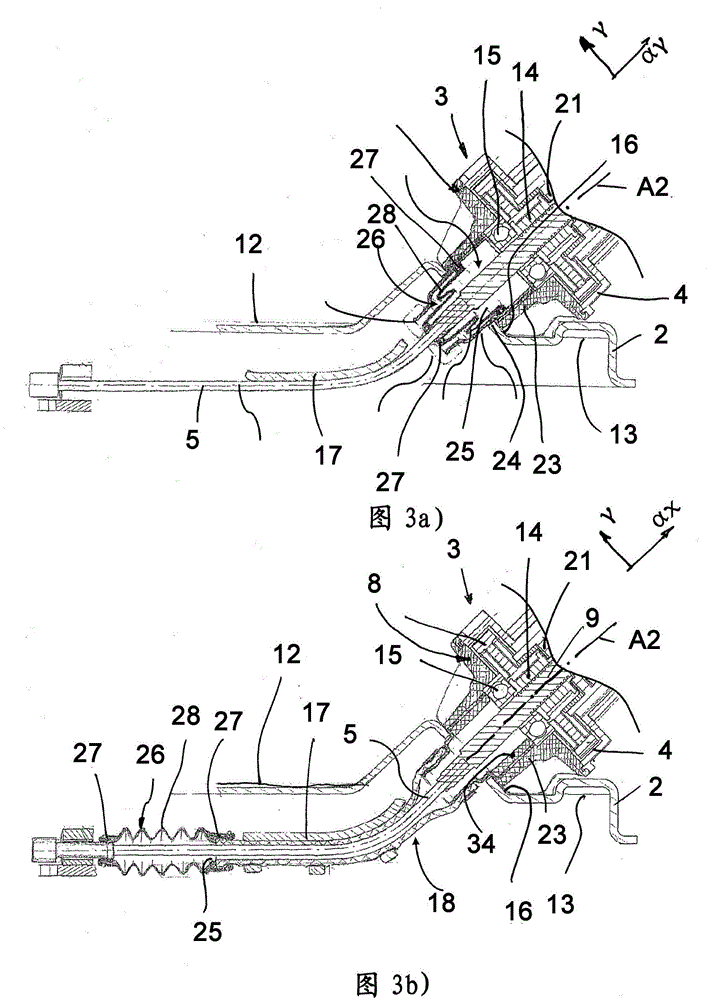

The invention relates to a drum brake module 1 for motor vehicles, which drum brake module 1 can be operated by electric motor and performs at least one parking brake function, comprising an electromechanical actuator 3 which is mounted on one side 12 of the armature plate 2, and comprising a rotational-translational movement converter for converting a rotational drive rotational movement into a translational activation movement of brake shoes 6a, b which are arranged on a side 13 of the armature plate 2 facing away from the actuator 3, in a brake drum, and comprising at least one supporting device between the brake shoes 6a, b, with the result that the latter can carry out an activation movement in the direction of the brake drum.; In order to provide a stable, space-saving drum brake module 1 which is economical to manufacture and can be mounted easily on an axle, it is proposed that a drive nut 14 be supported by the rotational-translational movement converter in an axially secure and rotatable fashion on the armature plate 2 in order to assist the braking force, and that the drive nut 2 drives a spindle arrangement 9 which is mounted in a rotationally fixed and axially displaceable fashion and engages with an activation cable 5 on at least one brake shoe.

Owner:CONTINENTAL AUTOMOTIVE TECH GMBH

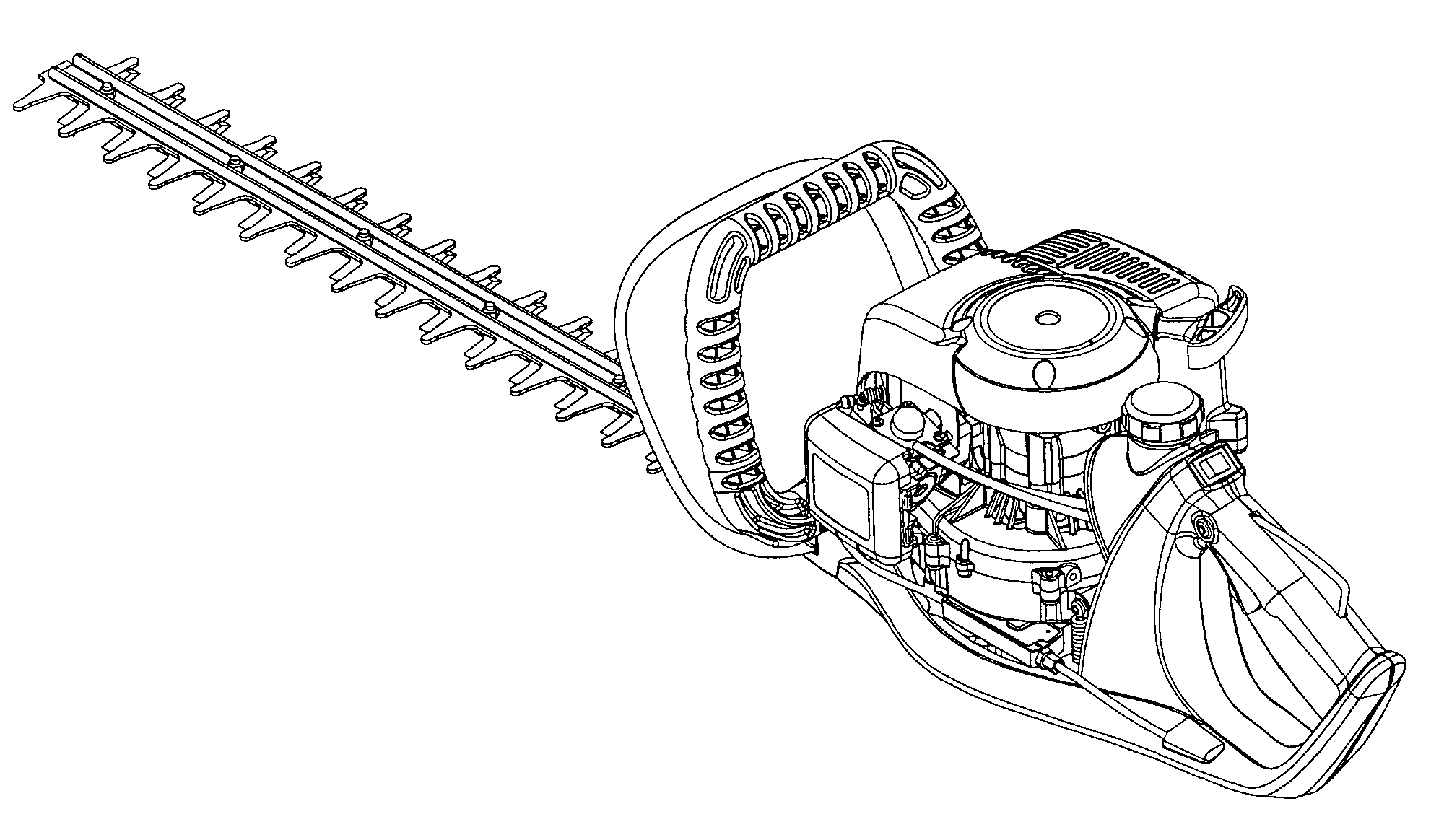

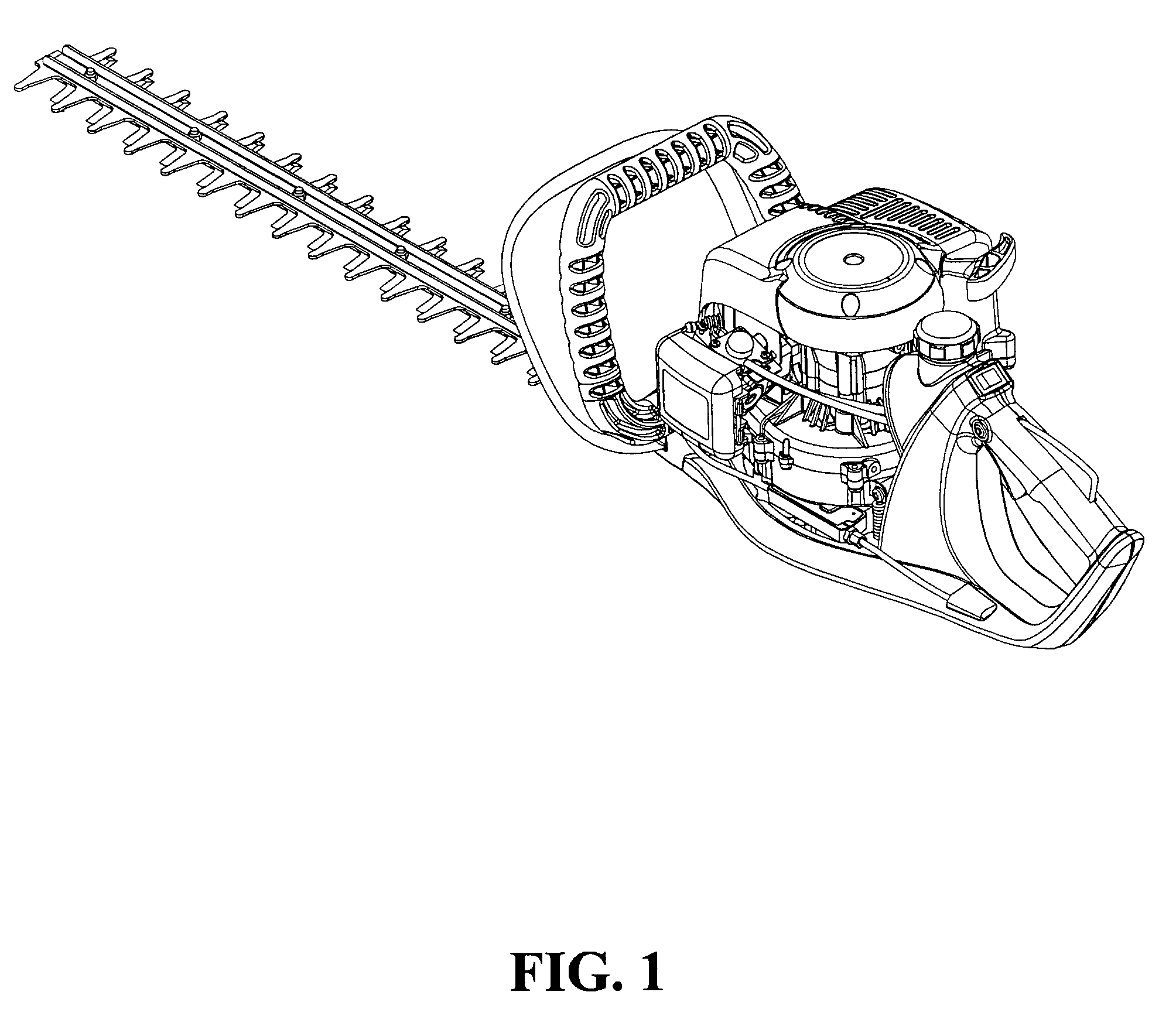

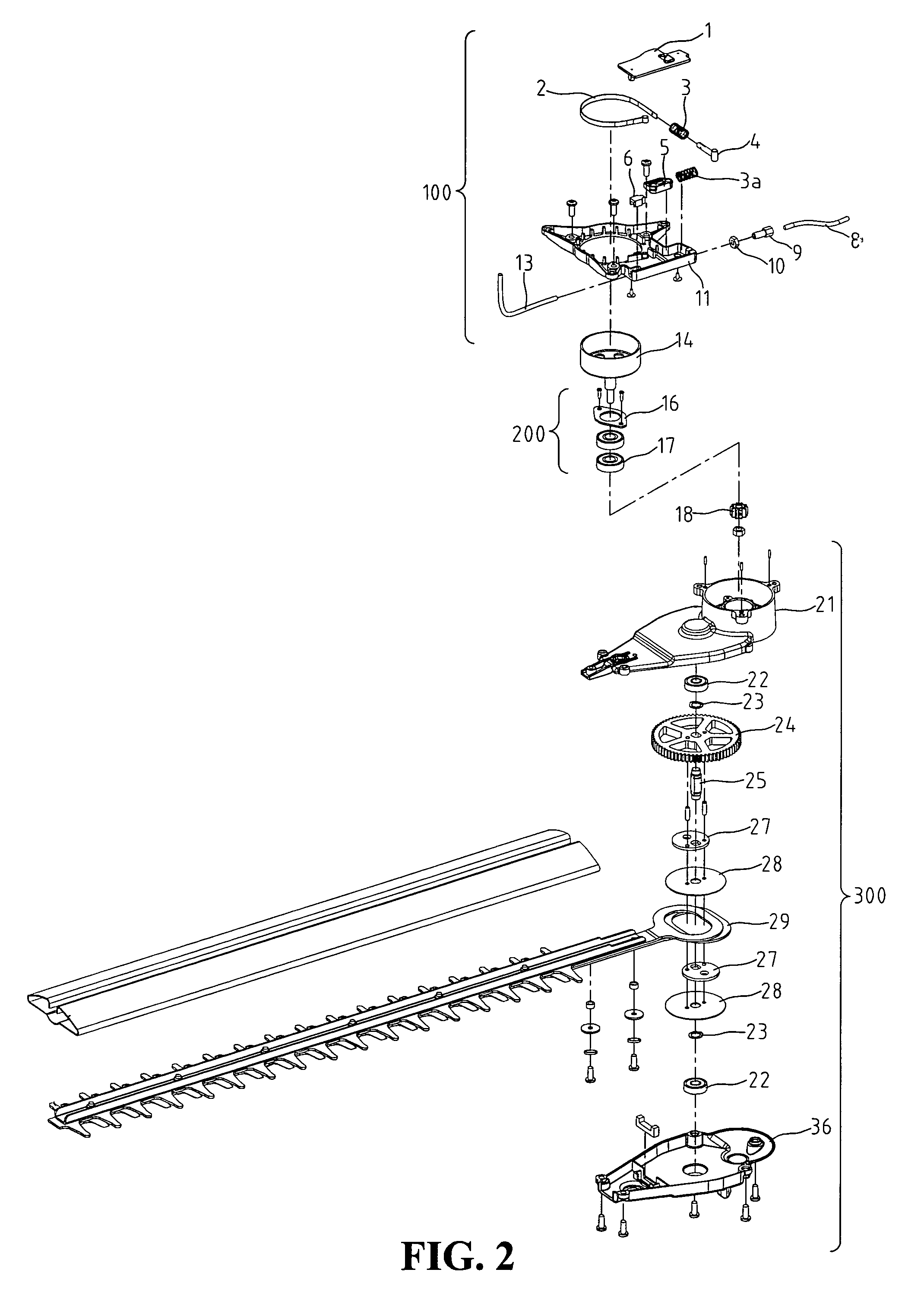

Brake device for power tool

InactiveUS7290641B2Simple structureNumber of the components,Metal sawing devicesCarriage/perambulator accessoriesSeparated statePower tool

A brake device for a power tool has a brake assembly, a bearing portion, a pinion and a gearbox. The brake assembly includes a brake base, a cover, a first throttle cable, a second throttle cable, a brake-activating block, a brake-guiding pillar, a brake band and a brake drum. The first throttle cable, the brake-activating block and the second throttle cable are linearly connected together in series. The brake-activating block is designed to abut against the brake-guiding pillar in a brake position and a release position, respectively. With the relative movement among the first throttle cable, the brake-activating block and the brake-guiding pillar, the abutting or separating state between the brake band and the brake drum can be easily controlled.

Owner:HUSQVARNA AB

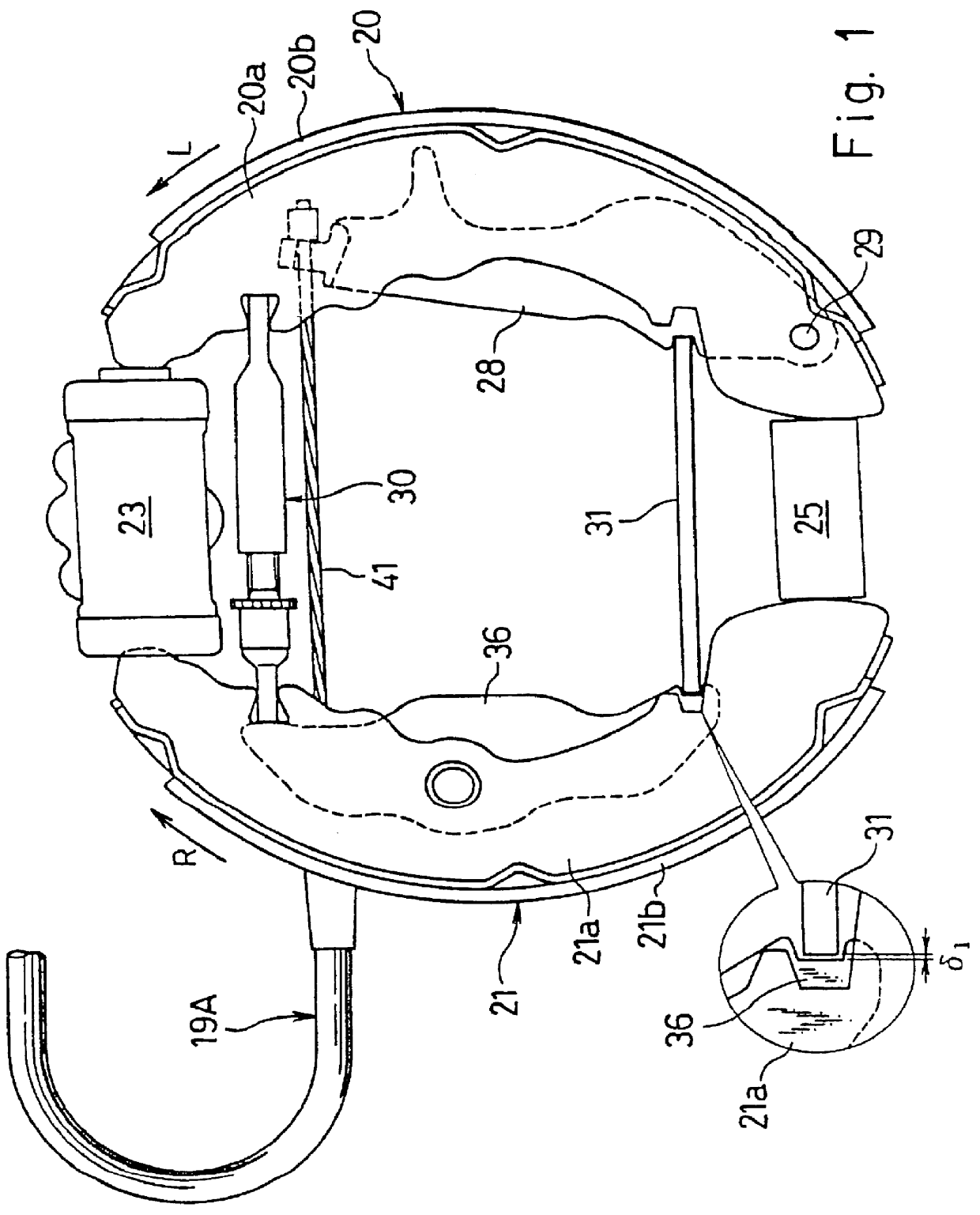

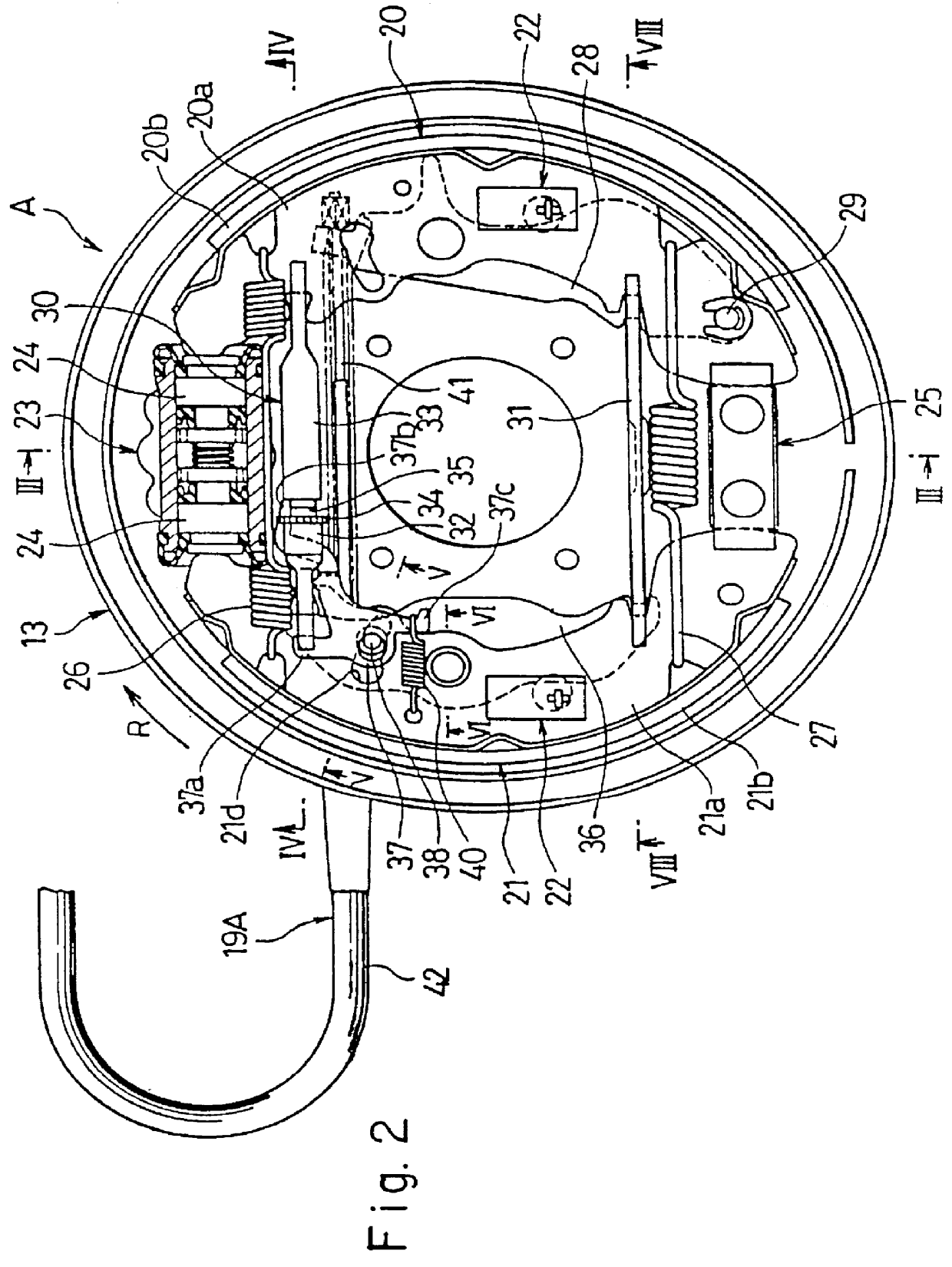

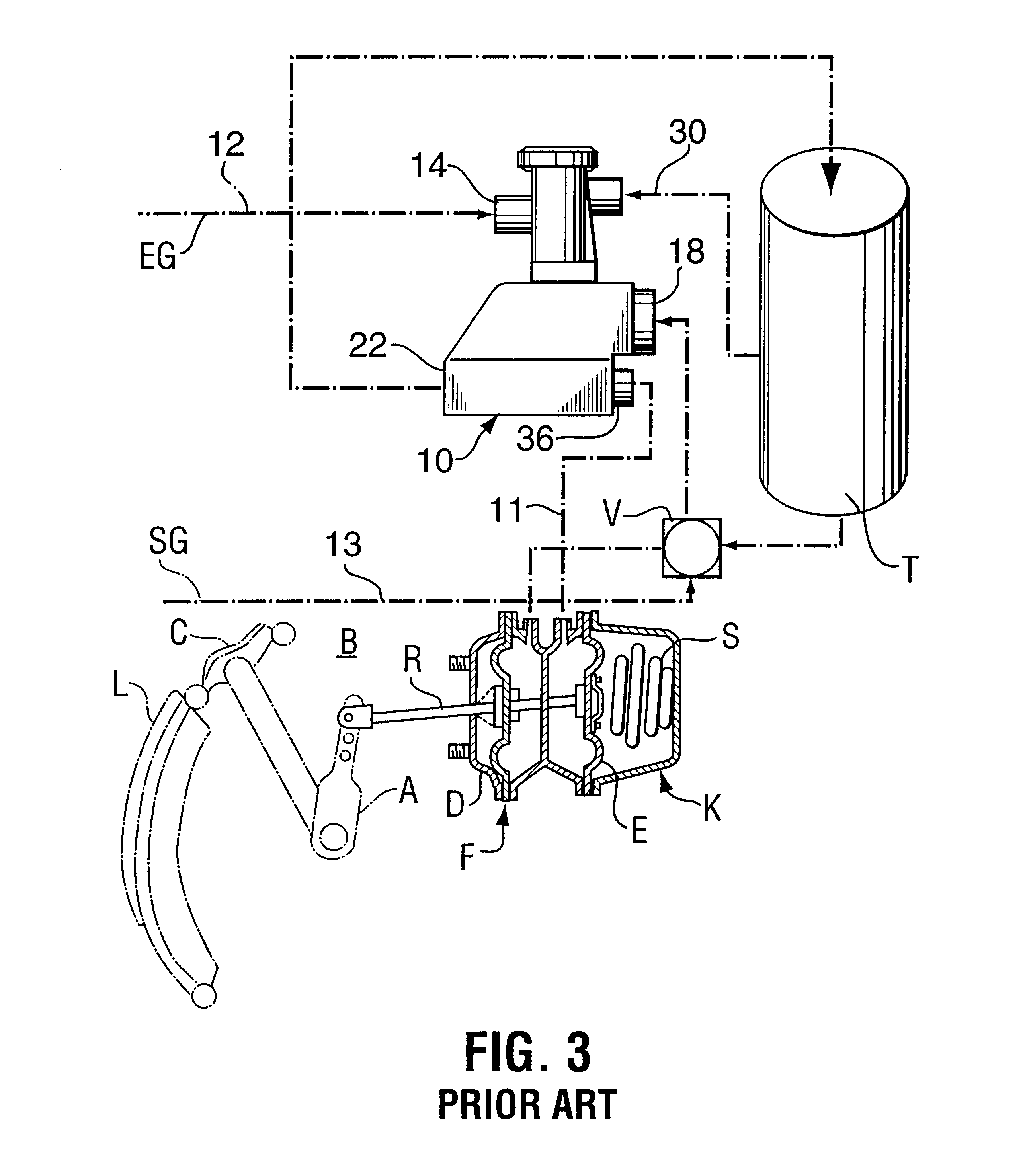

Vehicle brake apparatus

InactiveCN104912974AIncrease freedomImprove layout effectBraking element arrangementsFluid actuated drum brakesActuatorDrum brake

One embodiment provides a vehicle brake apparatus, including: an electric actuator; and a drum brake. The drum brake is attached to a wheel so as to be driven by power exhibited by the electric actuator. In a state of being mounted on a vehicle, the electric actuator is disposed and fixed further rearwards than an axle of the wheel.

Owner:NISSIN KOGYO CO LTD

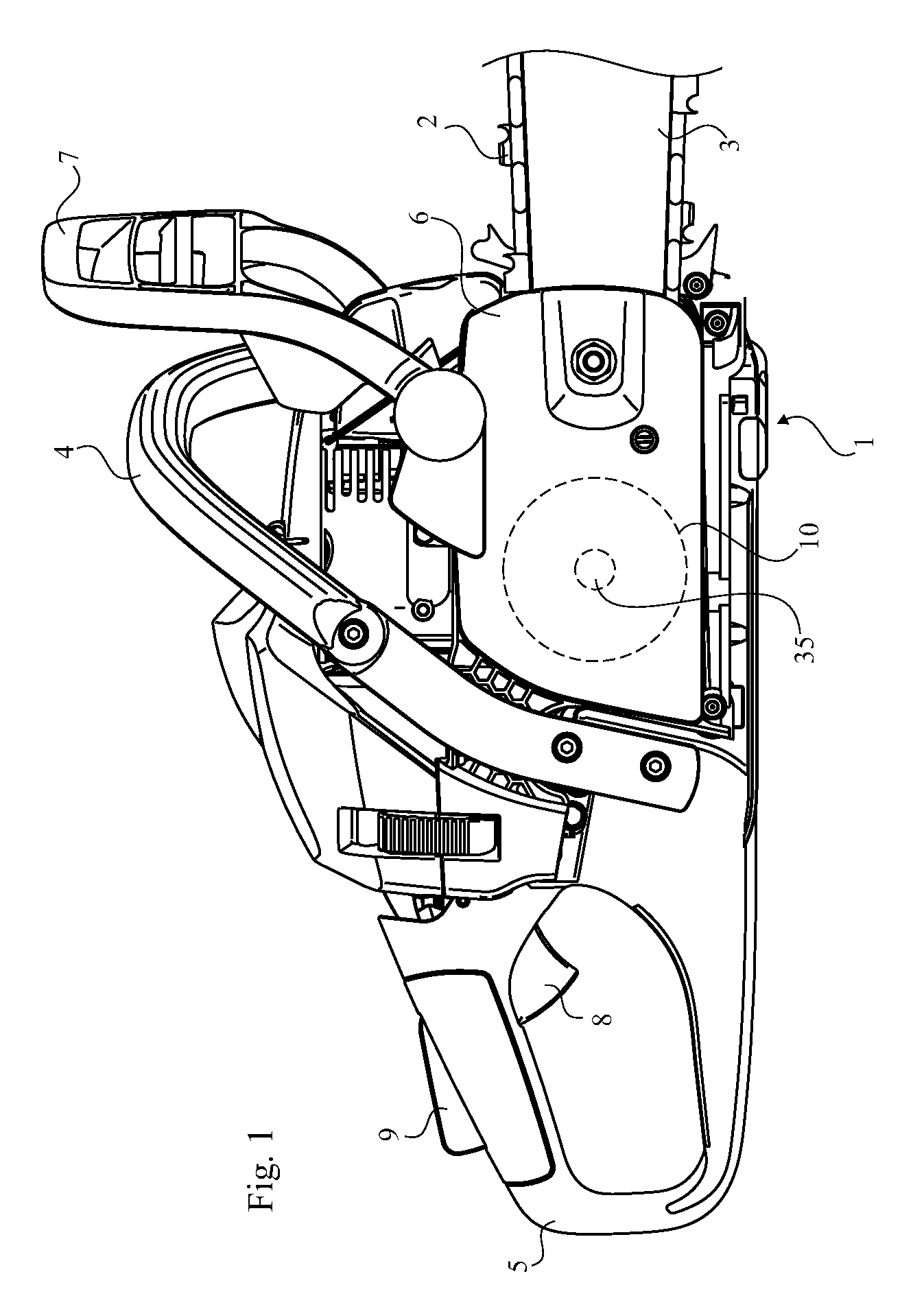

Coasting brake arrangement for a power tool

ActiveUS20110061246A1Different stopping timeMeet the regulationMetal sawing devicesMetal sawing accessoriesSprocketPower tool

A chainsaw having a brake arrangement comprising: a kickback brake drum (10) arranged to rotate together with a drive sprocket driving a saw chain of a chainsaw, a kickback brake for quickly stopping the saw chain if at least one kickback actuator (7) is actuated, the kick back brake including a kickback brake band (11) extending around the kickback brake drum (10) and means for tightening the kickback brake band (17-19, 22) around the kickback brake drum (10), and; a coasting brake weaker than the kickback brake being arranged to brake the saw chain (2) unless a coasting actuator of the chainsaw is actuated, the coasting brake includes a coasting brake band extending around a coasting brake drum (10) arranged to rotate together with the drive sprocket (37), and means for tightening the coasting brake band (20, 22, 23) around the coasting brake drum, wherein the coasting brake band is either at least one longitudinally slit portion (11b) of the kickback brake band or a separate brake band.

Owner:HUSQVARNA AB

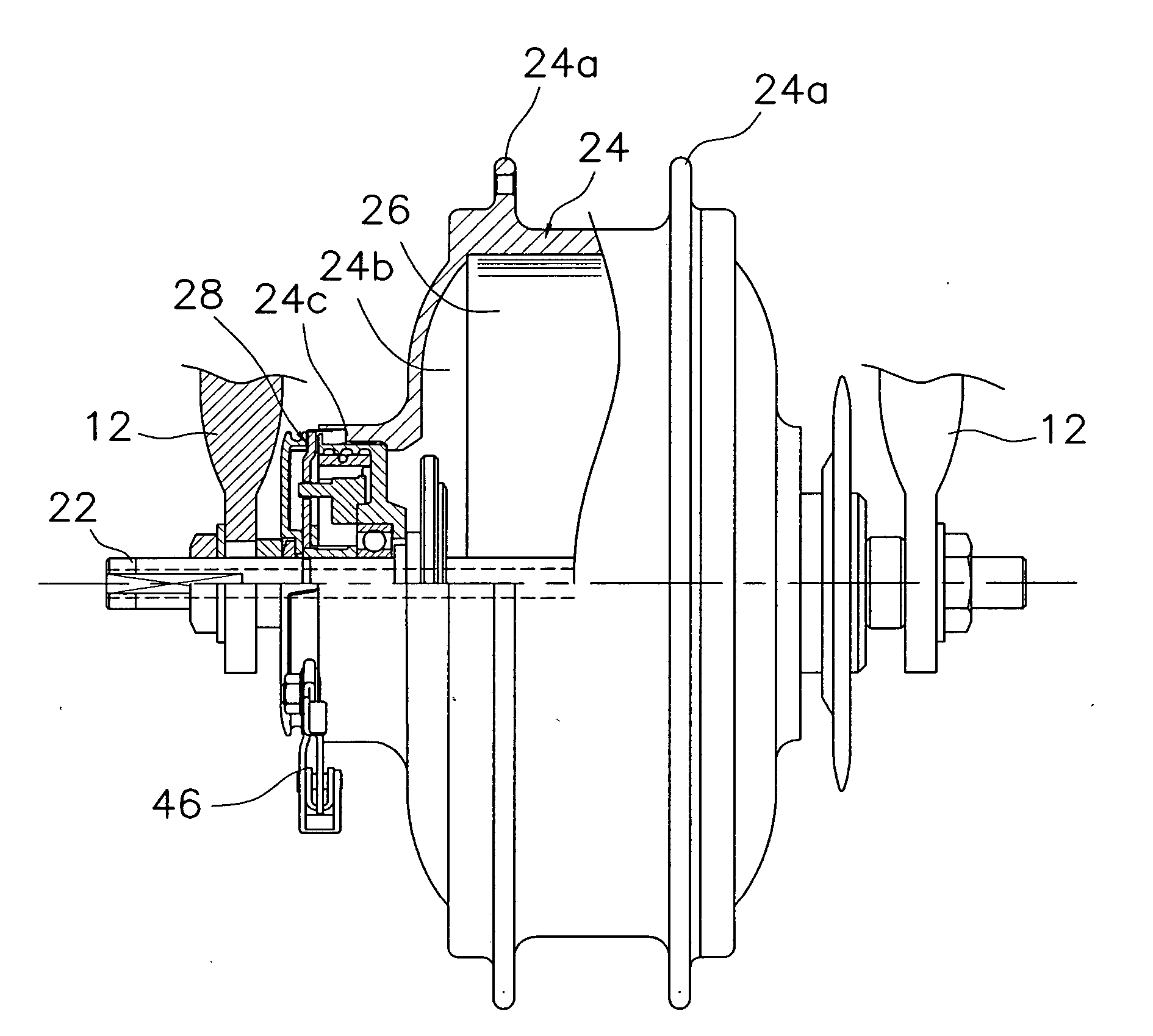

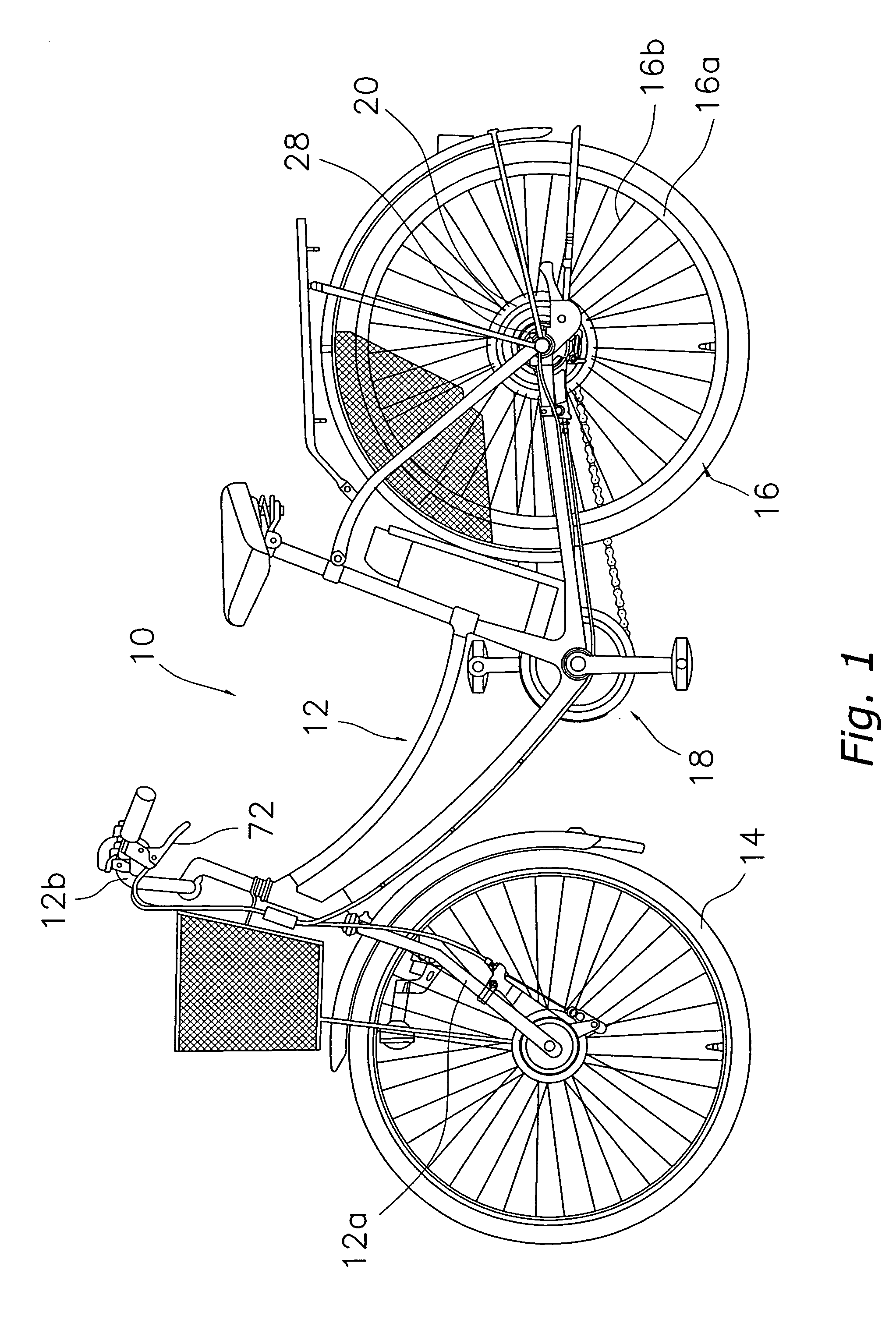

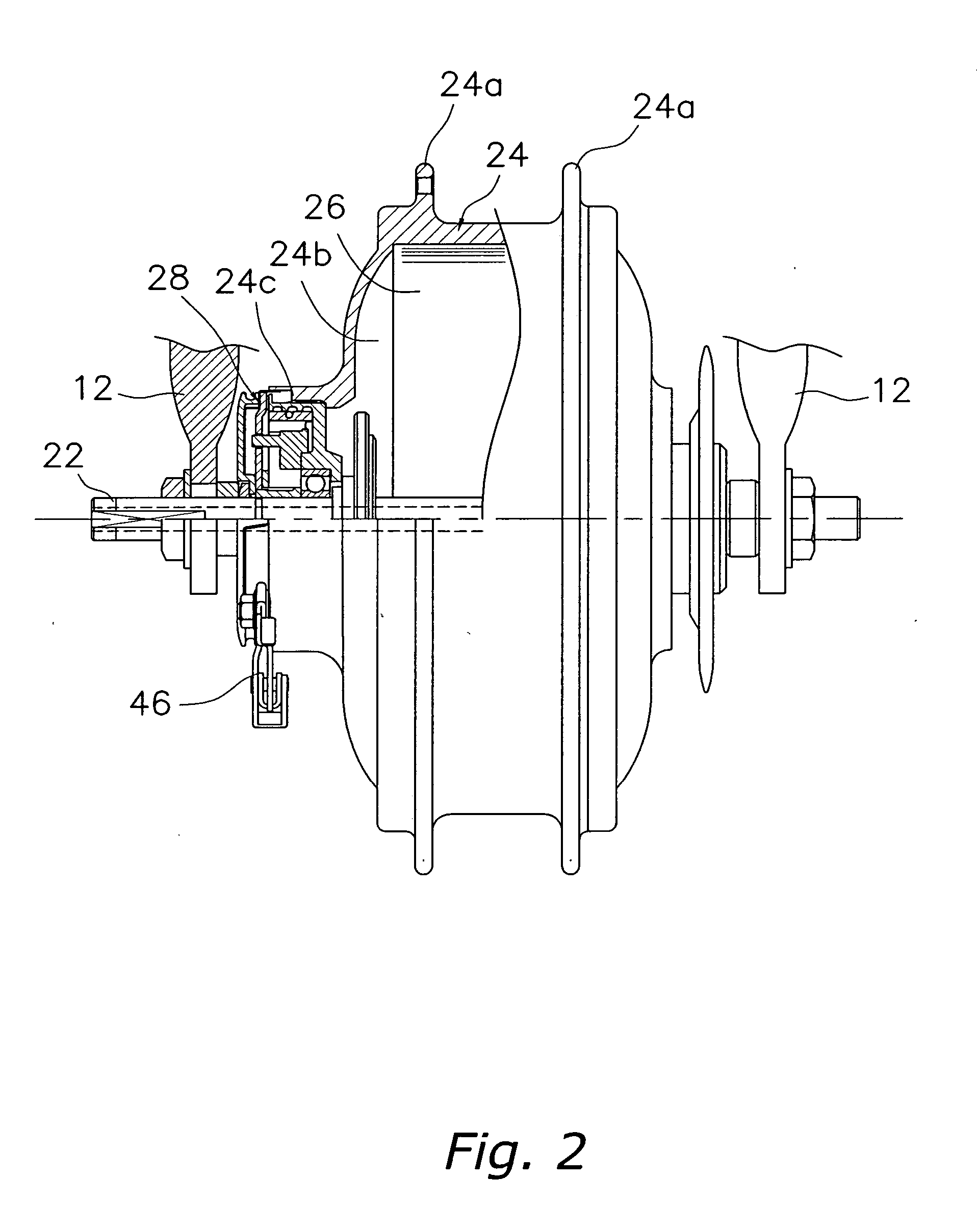

Bicycle wheel driving device

ActiveUS20060283644A1Solve insufficient braking forceSufficient forcePropulsion by batteries/cellsVehicle transmissionEngineeringMotor Drive Unit

A motor-equipped hub 20 is provided with a hub axle 22, a hub shell 24, a motor drive unit 26 and a roller brake device 28. The hub shell 24 is arranged around the outside of the hub axle 22, has a hub flange 24a on an outside circumference thereof, and has a housing space 24b on the inside thereof. The motor drive unit 26 is housed inside the housing space 24b and configured to rotate the hub shell 24 with respect to the hub axle 22. The roller brake device 28 is arranged within the hub shell 22 to the outside of the housing space 24b.

Owner:SHIMANO INC

Roller clutch assembly

An improved roller blind clutch assembly is disclosed for controlling the raising and lowering of a roller blind which permits the smooth raising and lowering of roller blinds even if the blinds are heavy. The improved roller blind clutch assembly includes a roller tube mount coaxially and rotatably mounted to a barrel. A clutch member is in turn coaxially and rotatably mounted to the barrel between the roller tube mount and the barrel. The clutch member has a window formed between a first and a second edge of the clutch member. A torsion locking spring is coaxially mounted to the barrel between the barrel and the clutch member. The torsion locking spring has opposite first and second ends which project into the window. The roller tube mount has an extension portion configured to extend into the window and dimensioned to fit between the first and second ends of the torsion locking spring. The extension has opposite first and second shoulders covered by a steel shim configured to fit between the extension and the torsion locking spring. The extension portion is also dimensioned and configured to maintain a gap between the extension and the torsion locking spring; thereby permitting the torsion locking spring from catching on the barrel as the clutch mechanism is used to raise and lower the blind. The extension portion has a concave face with a circular diameter less than the diameter of the torsion locking spring.

Owner:NG PHILIP +1

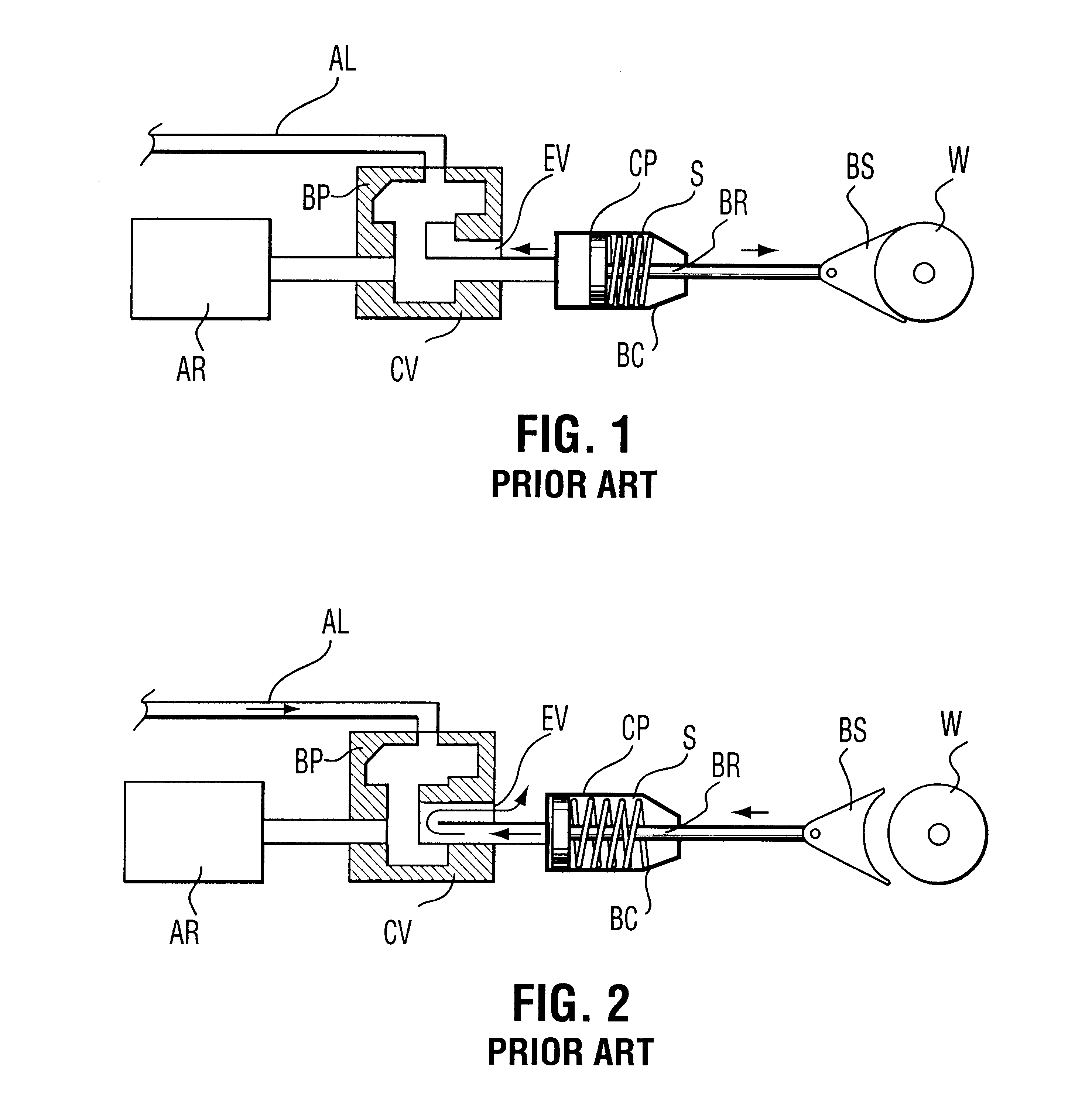

Drum brake system and device

InactiveUS6065571AFeel discomfortEliminate riskFluid actuated drum brakesBrake actuating mechanismsDriver/operatorSTI Outpatient

A drum brake device is provided in which a stroke before effectuating the parking brake effect of the brake shoes is restricted so that any disconcerting feeling to the driver and any delay in effectuating the parking brake when in an emergency situation are eliminated. The drum brake device includes a pair of the brake shoes 20, 21, a pivot lever 36 pivotally provided at one of the two brake shoes 21, a shoe clearance adjustment device provided between one end of the pivot lever 36 and one end of the brake shoe 20, and a strut provided between the other end of the pivot lever 36 and one end of the brake lever 28, wherein the braking force is transferable between the two brake shoes 20, 21 through the connection with the pivot lever 36. This produces a duo-servo type of brake device. The brake shoe 21 functions as a trailing shoe in which the lining wears slower when the service brake is in operation.

Owner:NISSHINBO IND INC

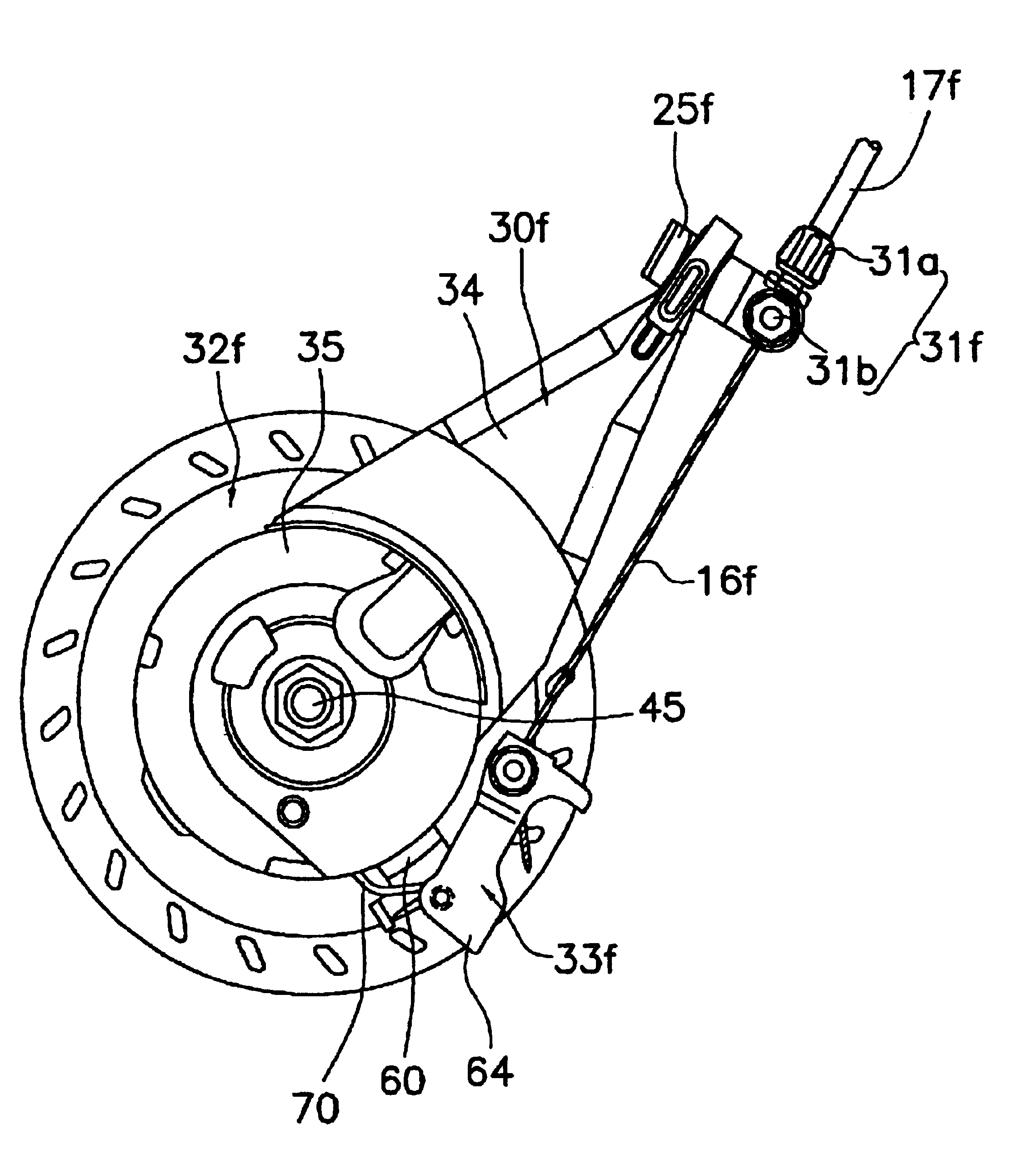

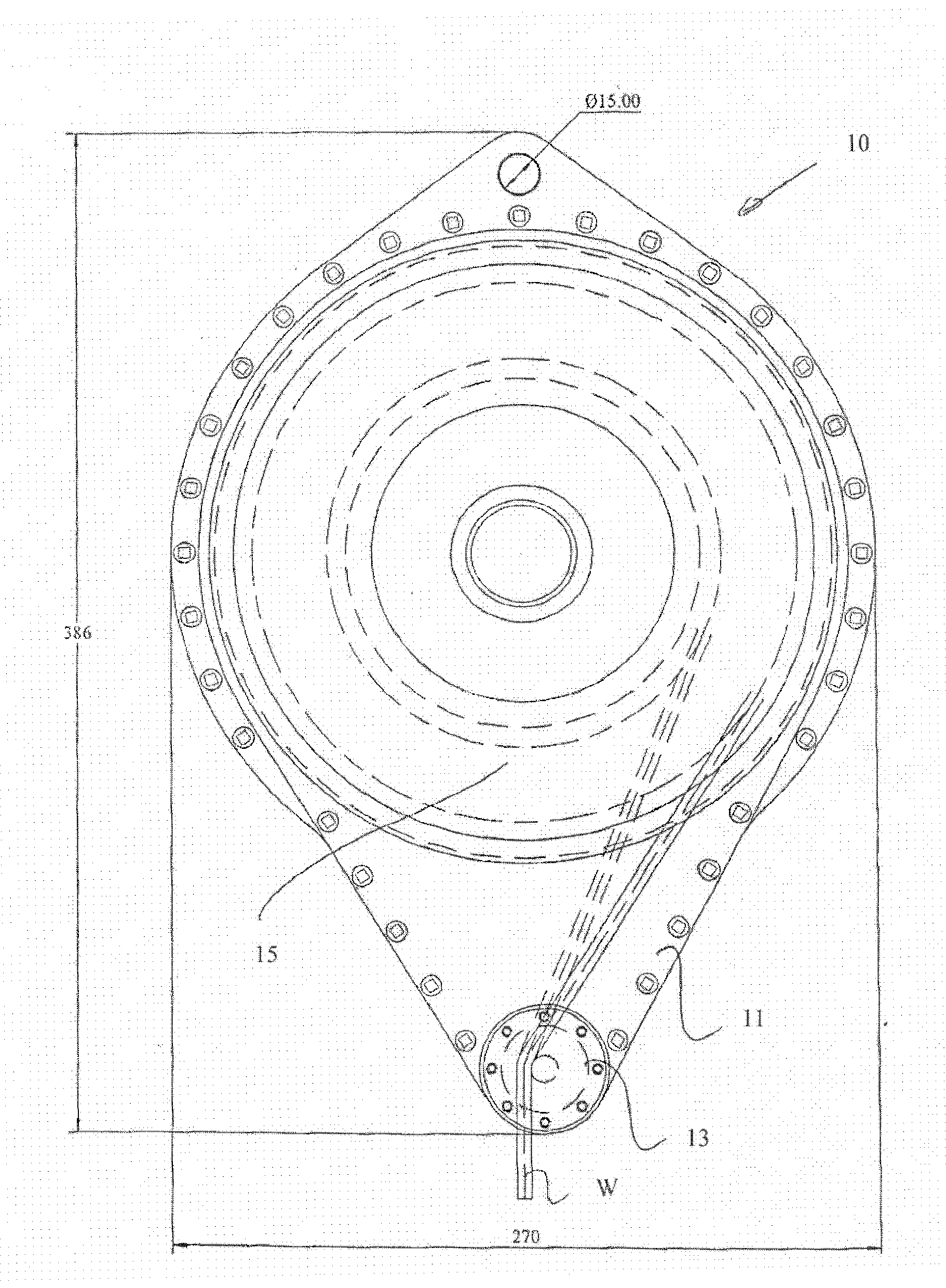

Apparatus for mounting a brake drum to a bicycle frame

A apparatus is provided for mounting a brake device to a bicycle frame, wherein the brake device brakes the hub of a wheel that rotates around a hub shaft. The apparatus comprises a fastening bracket, a bracket fastening member, and an insert member. The fastening bracket comprises a base portion adapted to receive the hub shaft therethrough; an arm portion that extends outwardly from the base portion; and a detaining portion having first and second side surfaces disposed on the arm portion for mounting the brake device to the bicycle frame. The bracket fastening member has a detaining space into which the detaining portion is inserted for detaining the fastening bracket to the bicycle frame, and the insert member has first and second contact portions that face the respective first and second side surfaces of the detaining portion when the insert member is disposed in the detaining space.

Owner:SHIMANO INC

Brake system

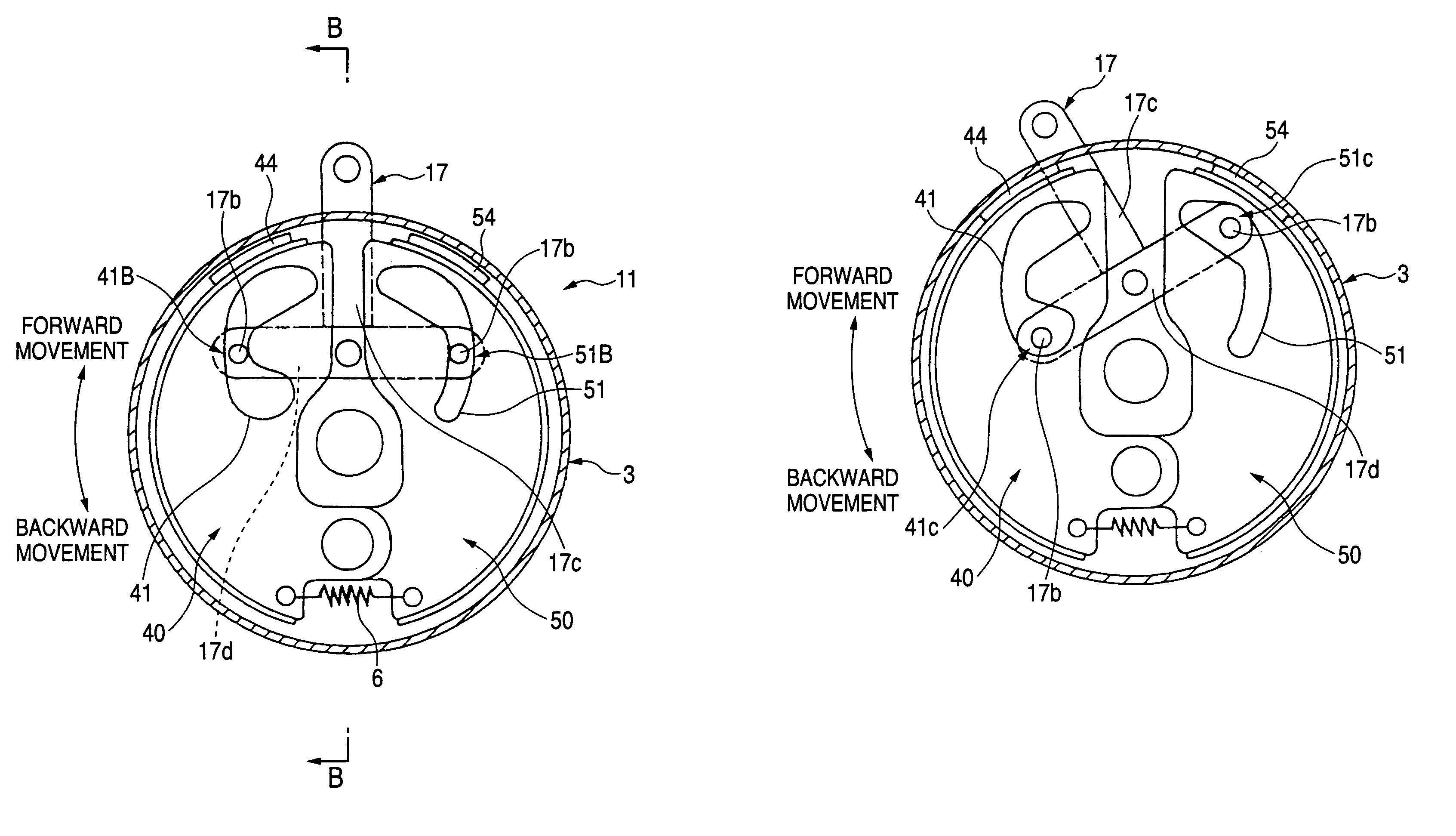

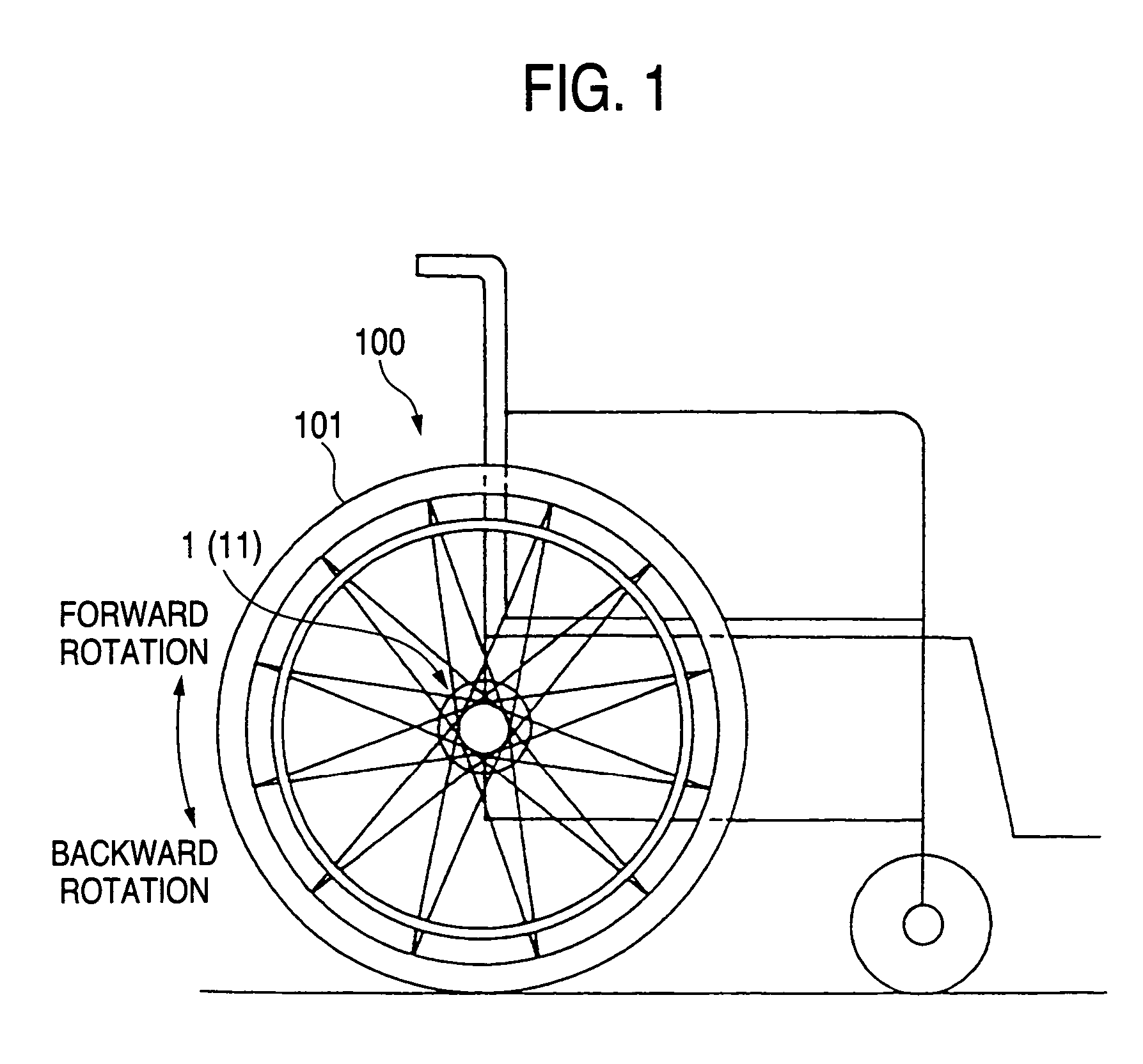

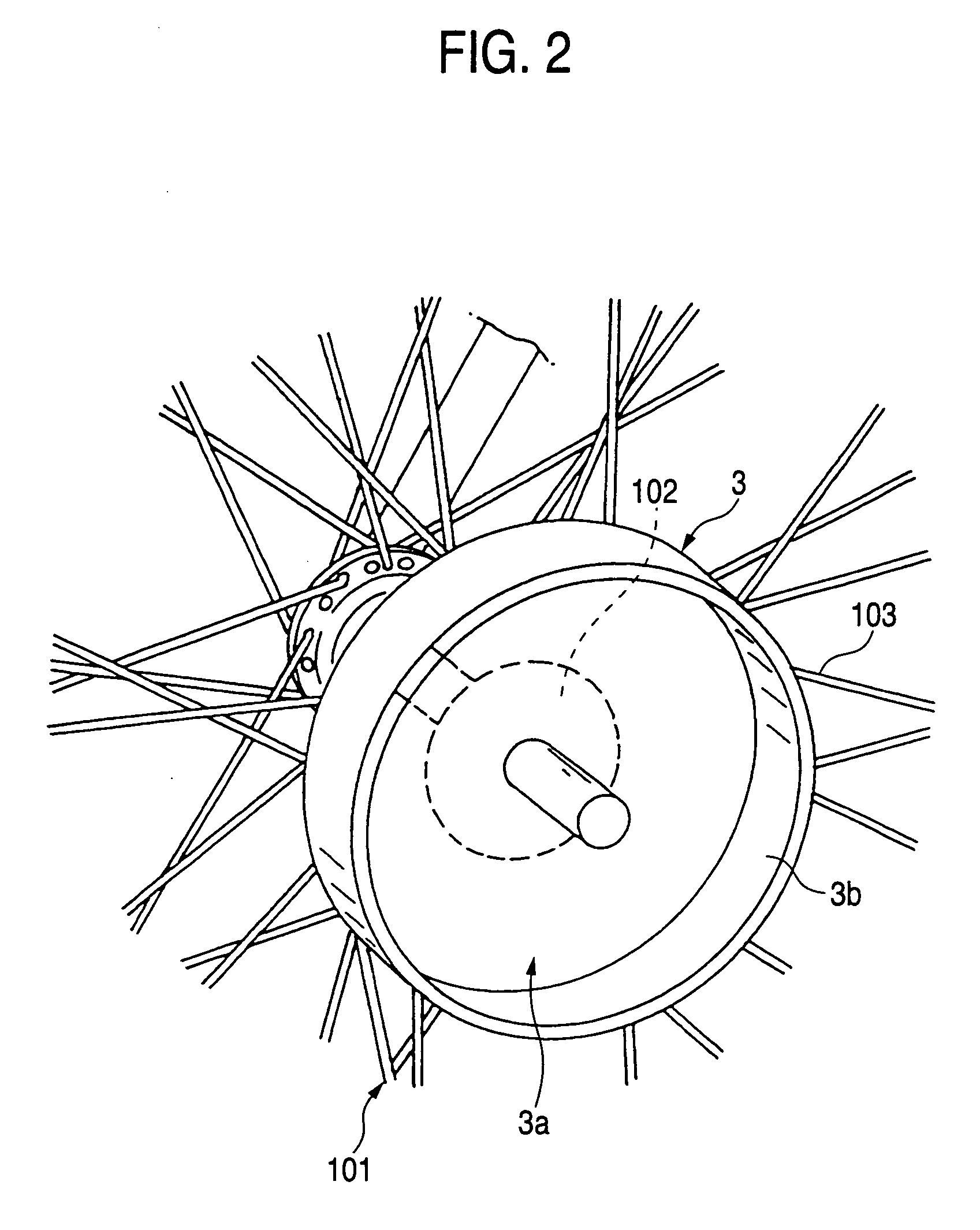

InactiveUS7124858B2Improve braking performanceSmall sizeWheelchairs/patient conveyanceAutomatic initiationsRotational axisBrake shoe

An object of the invention is to provide a brake apparatus which can facilitate slope starting and slope climbing and which can be produced small in size and light in weight. In addition, another object of the invention is to provide a brake apparatus which can obtain a stable brake force under any conditions including running in the rain.The invention provides a brake apparatus in which a restriction is imposed on the rotation of a wheel (101) via a brake drum (3) provided on a rotational shaft of the wheel (101) so as to rotate together with the rotational shaft, the brake apparatus being characterized by comprising a brake shoe (30) for imposing a restriction on the rotation of the brake drum (3) in a forward or backward direction through wedge engagement with an inner circumferential surface of the brake drum (3) when the brake drum (3) rotates either in the forward direction or in the backward.

Owner:AKEBONO BRAKE IND CO LTD

fall protection system

InactiveCN102281923AControl rotation speedReduce rotation speedLiquid resistance brakesSafety beltsFall protectionRotation velocity

A fall protection system comprising a line wound onto a rotatable pulley having a centrifugal clutch which activates a gearbox which in turn drives an input shaft of a hydraulic actuator whereby the hydraulic actuator controls the rate of rotation of the pulley, and a secondary brake which slows the rotational speed of the pulley should it exceed a predetermined speed, whereby in use, the line isattached to a user to restrain a fall and then the system facilitates unwinding of the line at a controlled speed to effect descent.

Owner:FALLSAFE TECH PTY LTD

Electromagnetic drum brake

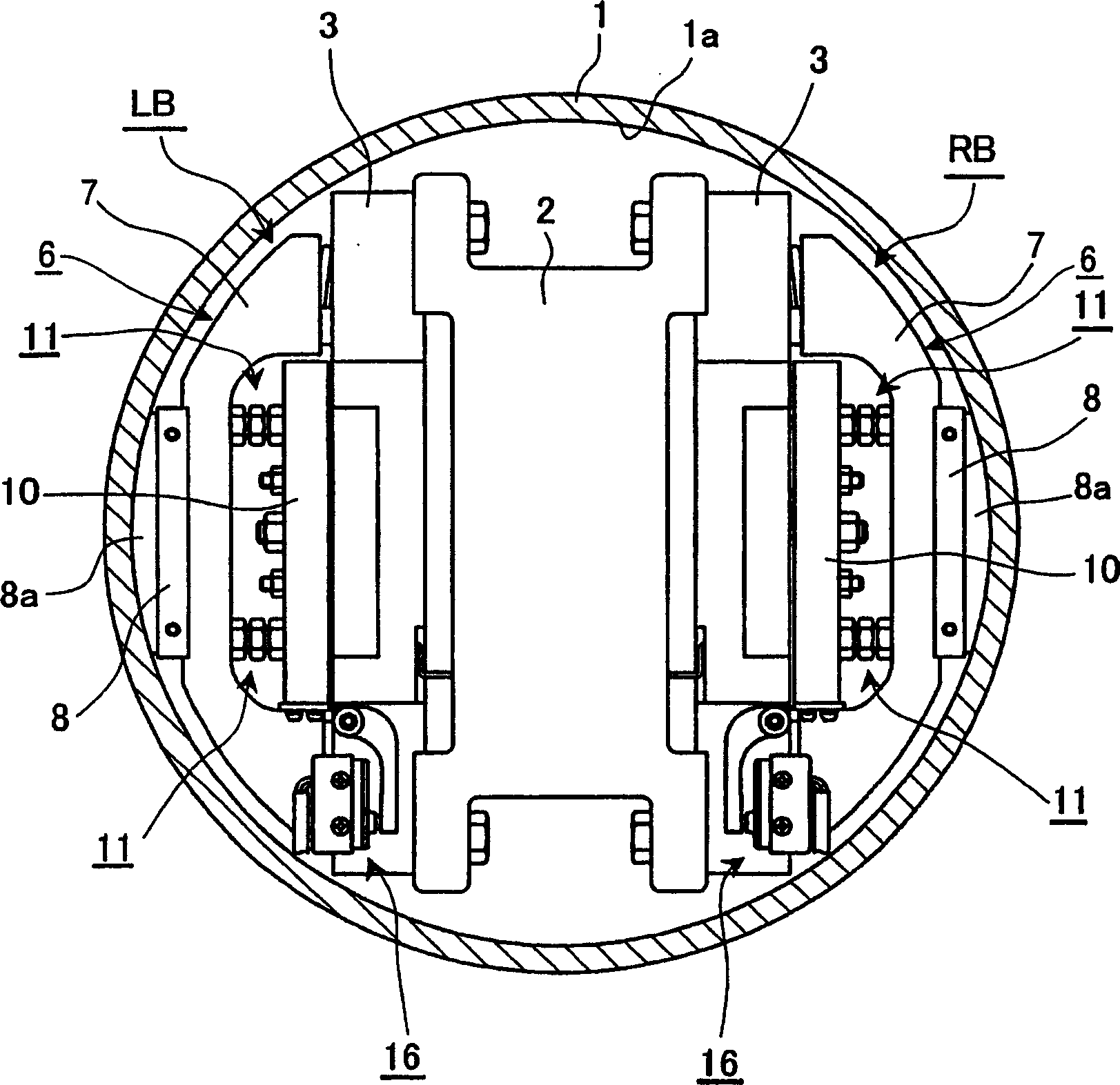

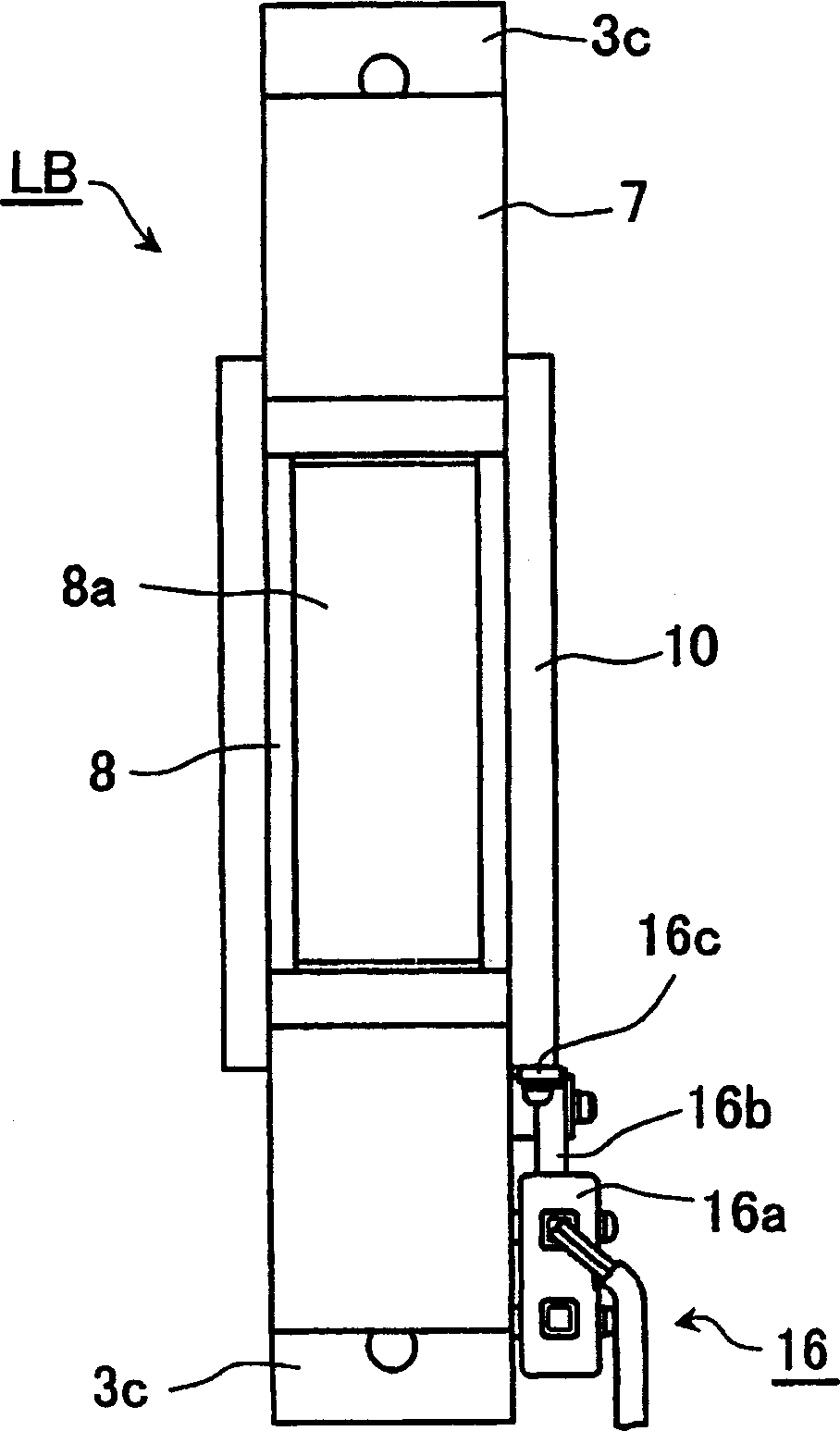

InactiveCN1646824ASuppresses reduction in braking forceEasy to adjustSelf acting brakesBrake actuating mechanismsMechanical engineeringDrum brake

An electromagnetic drum brake, comprising a field core (3) having support parts (3c) formed therein, brake shoes (6) having leg parts (7b) formed therein, armatures (10) stored between the brake shoes (6) and the field core (3) and connected to the brake shoes (6), and a plurality of braking springs (5) installed between the support part (3c) of the field core (3) and the end faces of the leg parts (7b) of the brake shoes (6), wherein the armatures (10) are connected to the brake shoes (6) with adjusting bolts (12) having right-hand threads (12a) formed on one sides thereof and left-hand threads (12b) formed on the other sides.

Owner:OGURA CLUTCH CO LTD

Air brakes for trucks

The present invention provides an improvement in an actuator system for use with a brake system of the type including a brake and a source of compressed air which is connected to an air chamber including a push rod for moving a transverse brake actuator bar between a brake applied position and a brake released position. The push rod operates the transverse brake actuator bar. The actuator system includes an asymmetric operator member which is relatively-rotatably-attached to a non-rotatable wheel support, and which is concentrically-disposed around an axle of a wheel. The asymmetric operator member includes an ear which is attached to the transverse brake actuator bar. A brake arm assembly includes a pair of diametrically-opposed arcuate brake arms, each brake arm including an inner arcuate channel member, one end of the arcuate channel member terminating in a hollow cylindrical bushing, the other end of the channel member terminating in a pair of transversely-spaced-apart ears having aligned apertures therethrough. An inner anchor plate and an outer anchor plate sandwich the asymmetric operator member therebetween and also are relatively-rotatably-attached to the non-rotatable wheel support which is concentrically-disposed around the axle of the wheel. The anchor plates are non-rotatably-secured to the asymmetric operator member. A first bifurcated link is rotatably-attached between the ears of a first channel member and the anchor plates, and a second bifurcated link is rotatably-attached between the ears of a second channel member and the anchor plates. A first hollow cylindrical bushing is rotatably-attached to the anchor plates opposite to the attachment of the second bifurcated link, and a second hollow cylindrical bushing is rotatably-attached to the anchor plates opposite to the attachment of the first bifurcated link. On activating the air pot, the push rod moves the transverse actuator bar to rotate the asymmetric operator member in a counter-clockwise direction, to urge the arcuate brake arm to move in a braking action radially-outwardly from an inactive position towards, and frictionally-engaging, radially-inwardly-facing brake pads, and on venting compressed air from the air pot, the push rod moves the transverse actuator bar to rotate the asymmetric operator member in a clockwise direction, to urge the arcuate brake arms to move in a brake releasing action radially-inwardly to inactive positions away from, and out of frictional engagement with, the radially-inwardly-facing brake pads.

Owner:HUNTER MARC

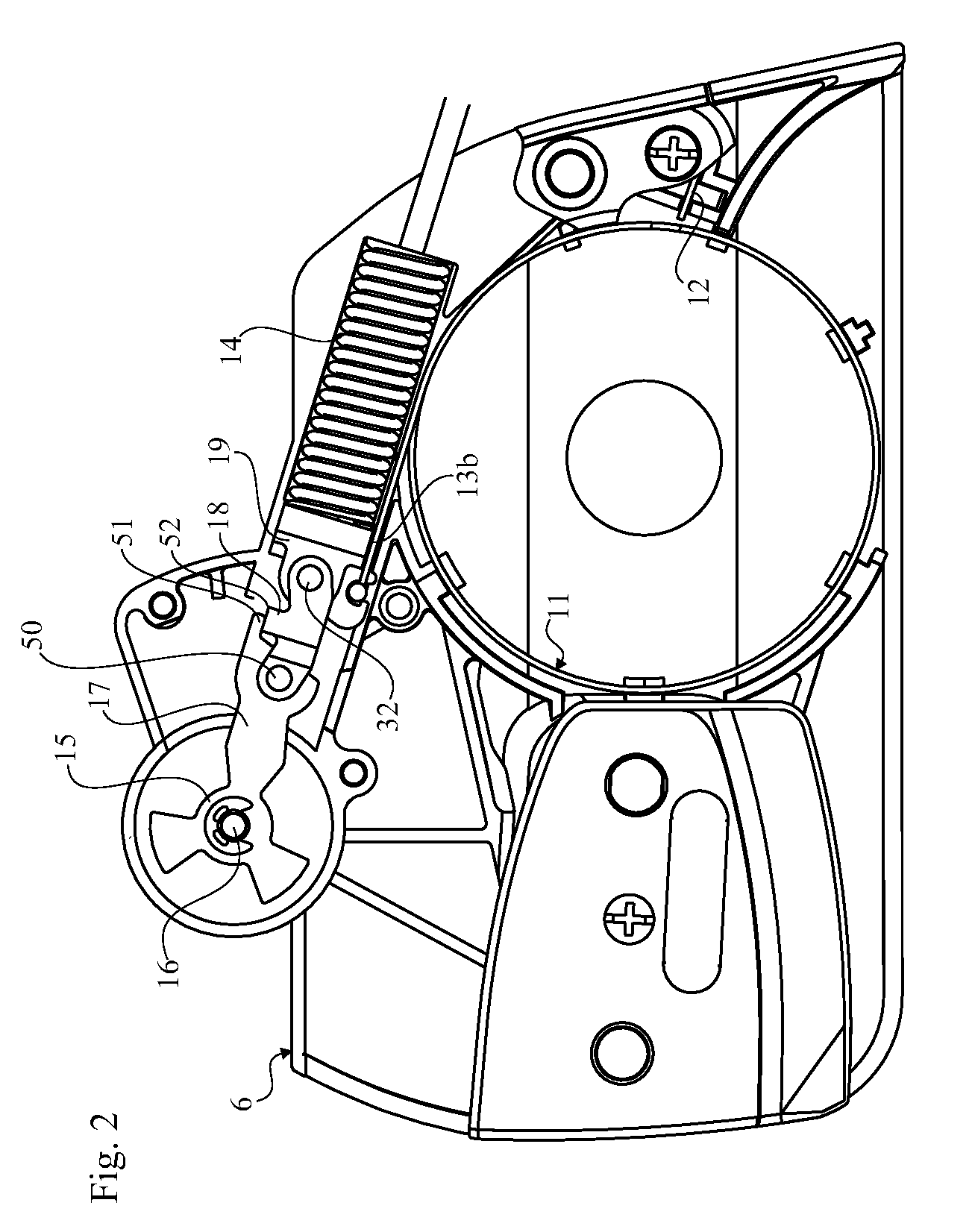

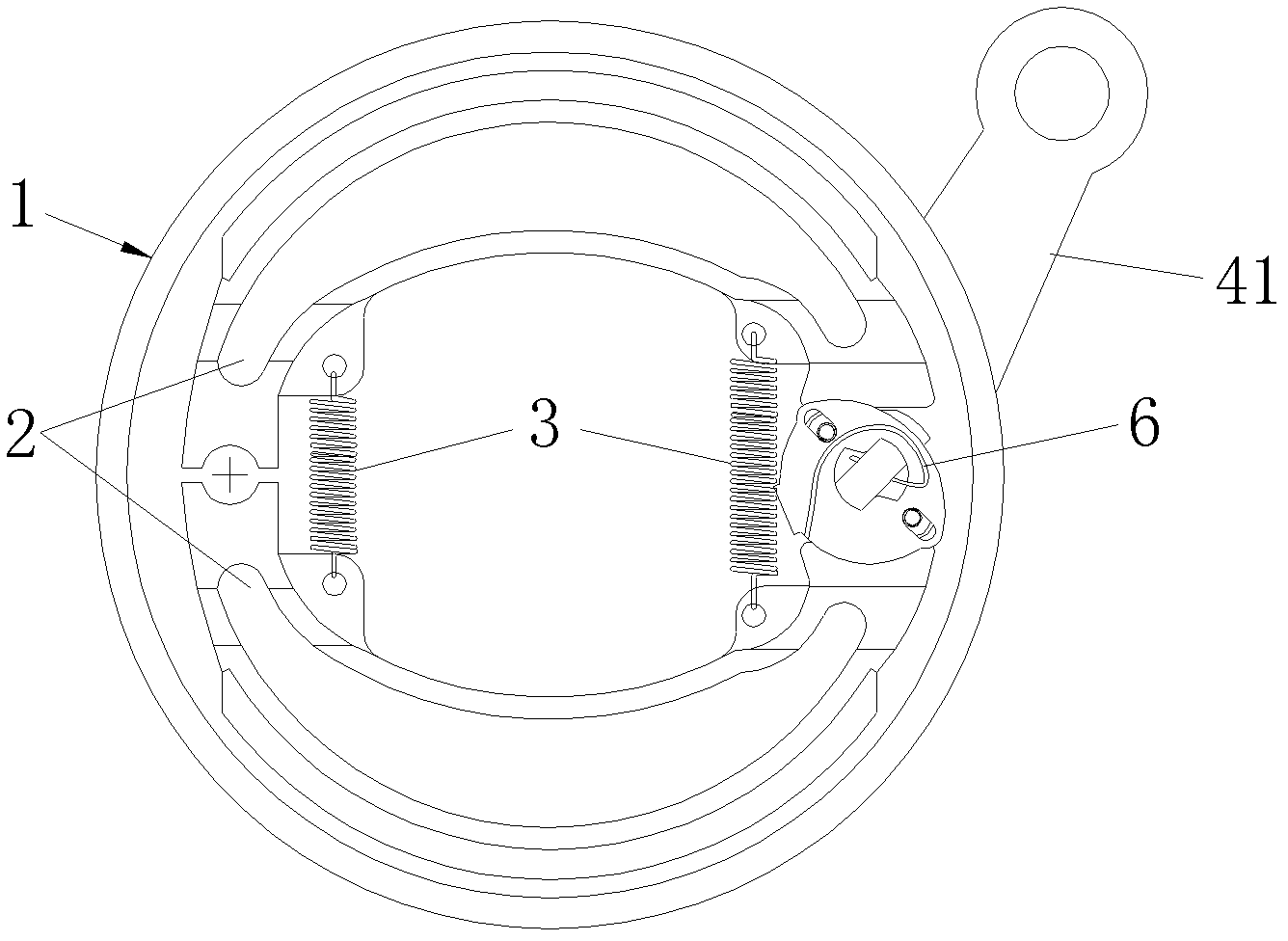

Improved drum brake structure

ActiveCN102305252AReduced service lifeExtended service lifeBrake actuating mechanismsMechanically actuated drum brakesEngineeringCam

The invention discloses an improved drum brake structure which comprises a shell, a pair of brake shoes arranged in the shell, a resetting element and a brake arm assembly, wherein the resetting element is connected with the pair of brake shoes; one end of each brake shoe is rotatably positioned in the shell, and a gap between the other ends of the brake shoes is provided with a brake wheel driven to rotate by the brake arm assembly; a pin roller is respectively abutted and connected between the brake wheel and the end surfaces of the brake shoes on two sides; locating plates are arranged on the two axial end surfaces of the brake wheel, and the pin roller is rotatably positioned between the two locating plates; the edge of the brake wheel is provided with a limiting edge face which is matched with the end surface of the brake shoes to be abutted with the pin roller; and a rolling meshing structure is arranged between the limiting edge face and the pin roller. According to the improved structure provided by the invention, the phenomenon that the original drum brake adopts the working mode of directly driving the brake shoes to expand by a cam is changed, and the shortages of poor brake effect and long vehicle brake sliding distance of the existing drum brake can be effectively improved.

Owner:CHANGXING HUAYI ELECTROMECHANICAL

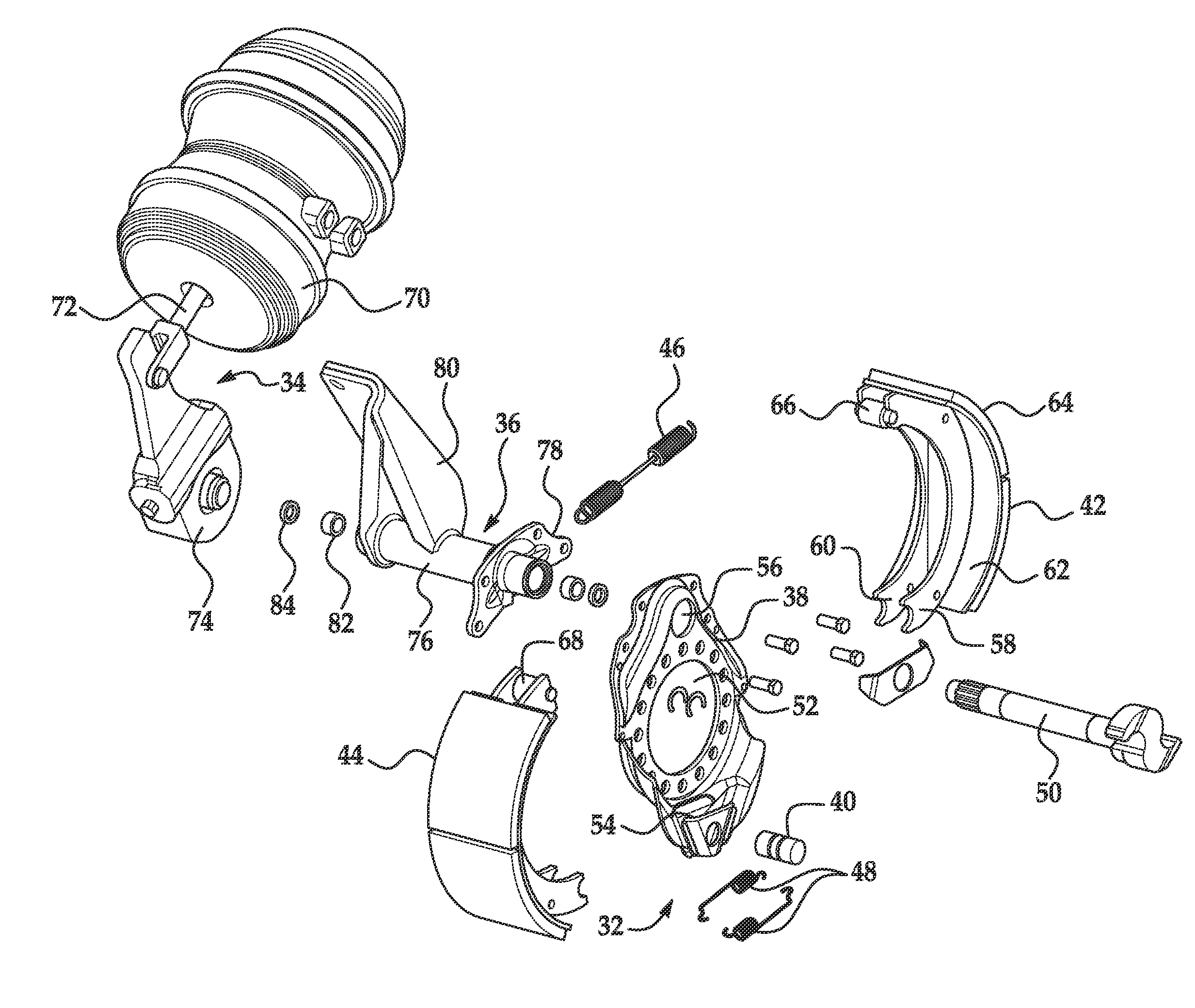

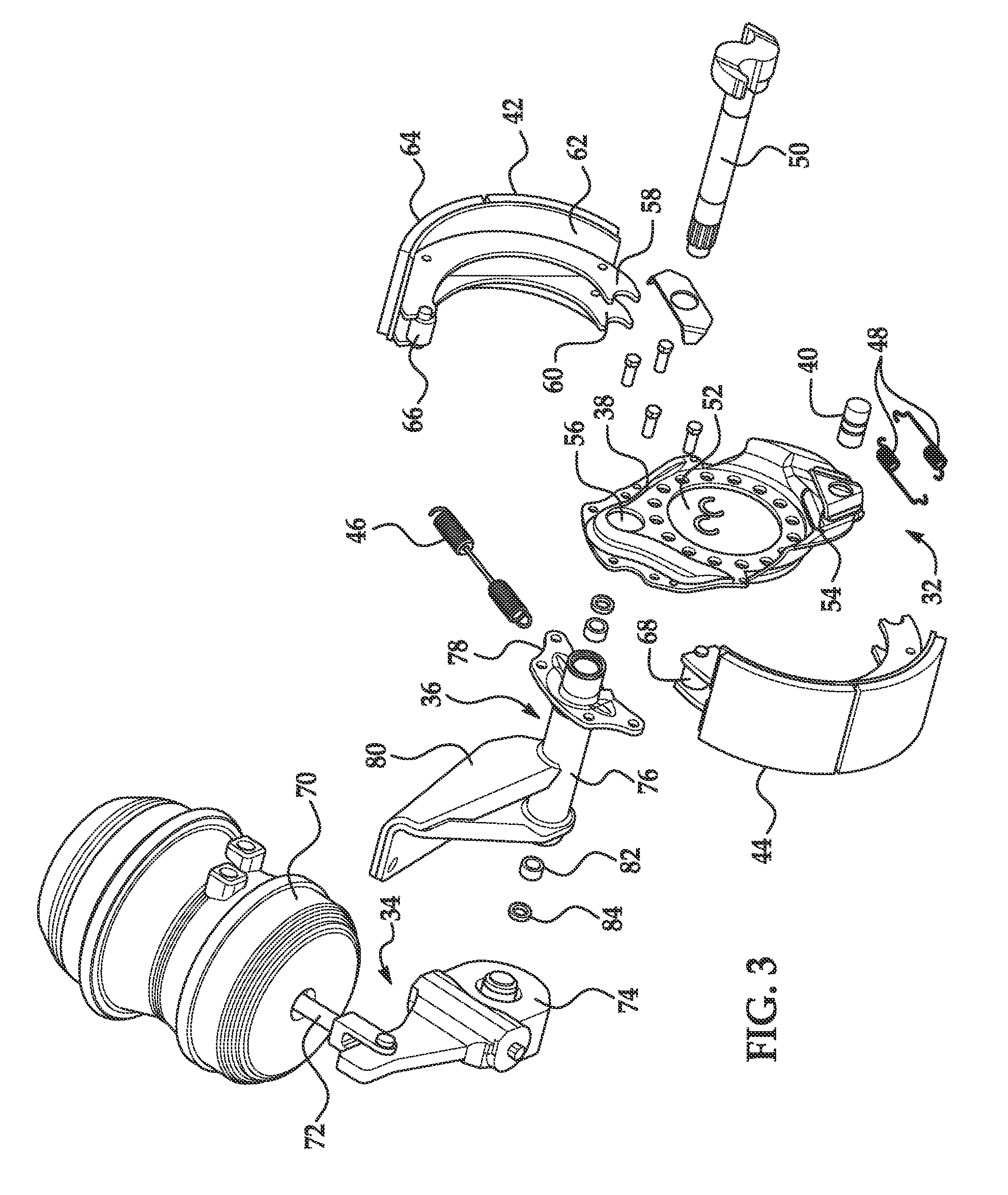

Rigid Bracket Assembly for Mounting a Brake Assembly and Brake Actuator

ActiveUS20170030422A1Withstand mechanical stressLess airMechanically actuated drum brakesSlack adjustersActuatorCamshaft

An improved bracket assembly for receiving a brake assembly and a brake actuator is provided. The bracket assembly includes a tube configured to receive a camshaft of the brake assembly. A brake spider mounting flange is disposed proximate a first end of the tube, defines an aperture configured to allow the tube to extend therethrough, and is configured to receive a brake spider of the brake assembly. An actuator mounting arm is disposed proximate a second end of the tube, is configured for coupling to the brake actuator, and has inboard and outboard members. Each of the inboard and outboard members has a body having a first end affixed to the tube and an actuator mounting flange extending from a second end of the body. The actuator mounting flanges define aligned bores configured to receive a fastener extending from the brake actuator.

Owner:BENDIKS SPAJSER FAUNDEJSHN BREJK LLK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com