Improved drum brake structure

A drum brake and elastic reset structure technology, applied in the direction of brake actuators, mechanically driven drum brakes, etc., can solve the problems of poor braking effect of drum brakes, large sliding distance of vehicle braking, etc., to achieve enhanced braking effect, Improved braking stability and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

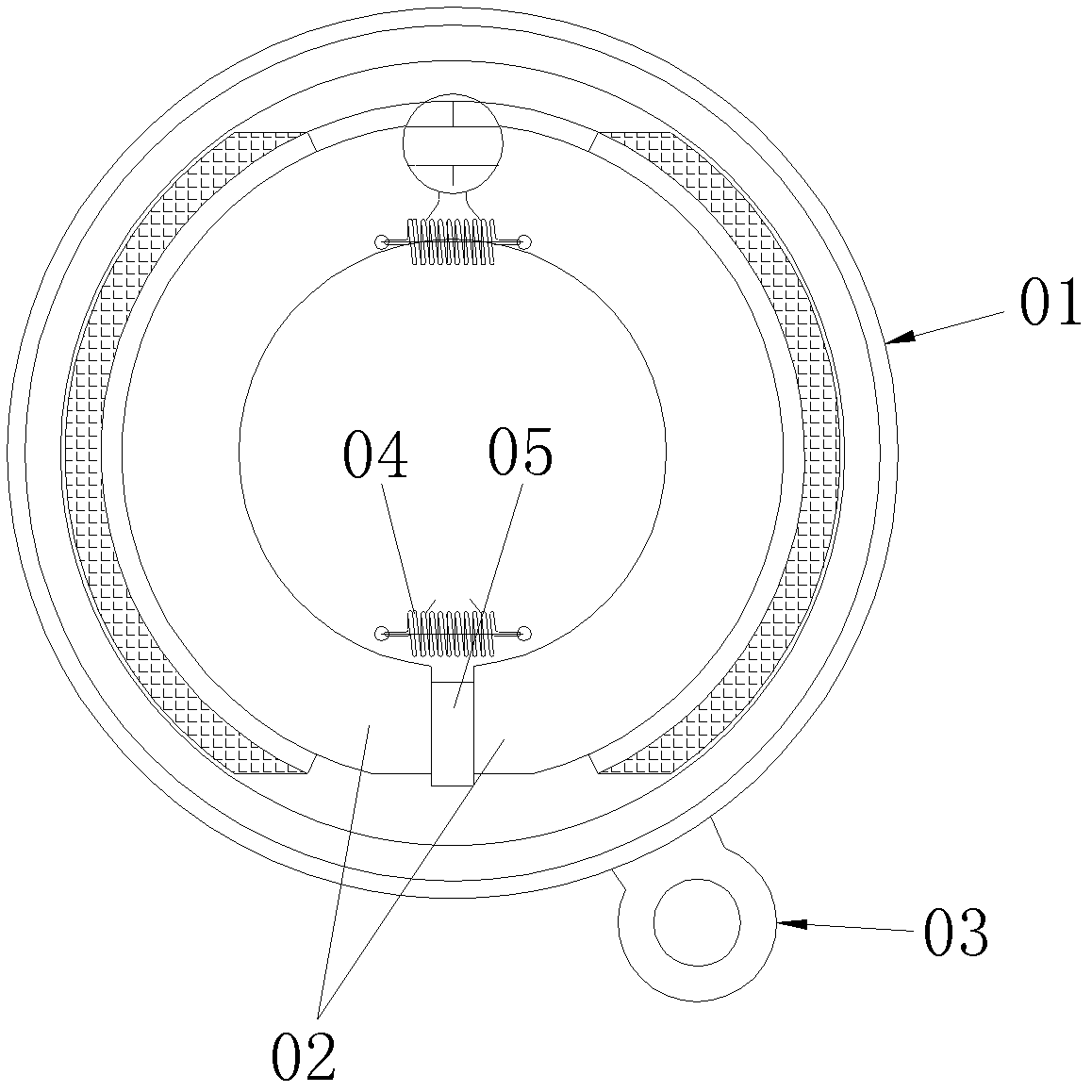

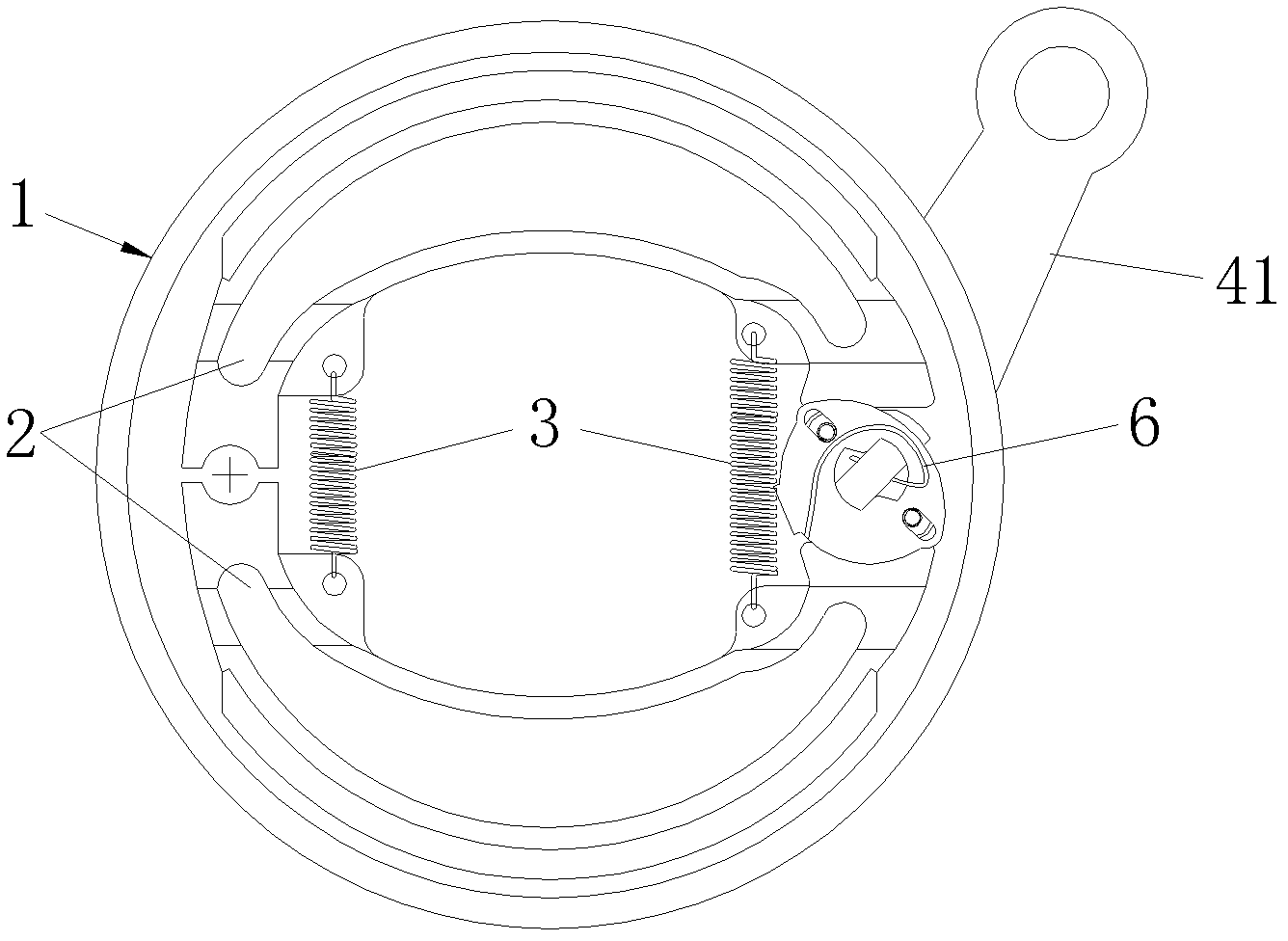

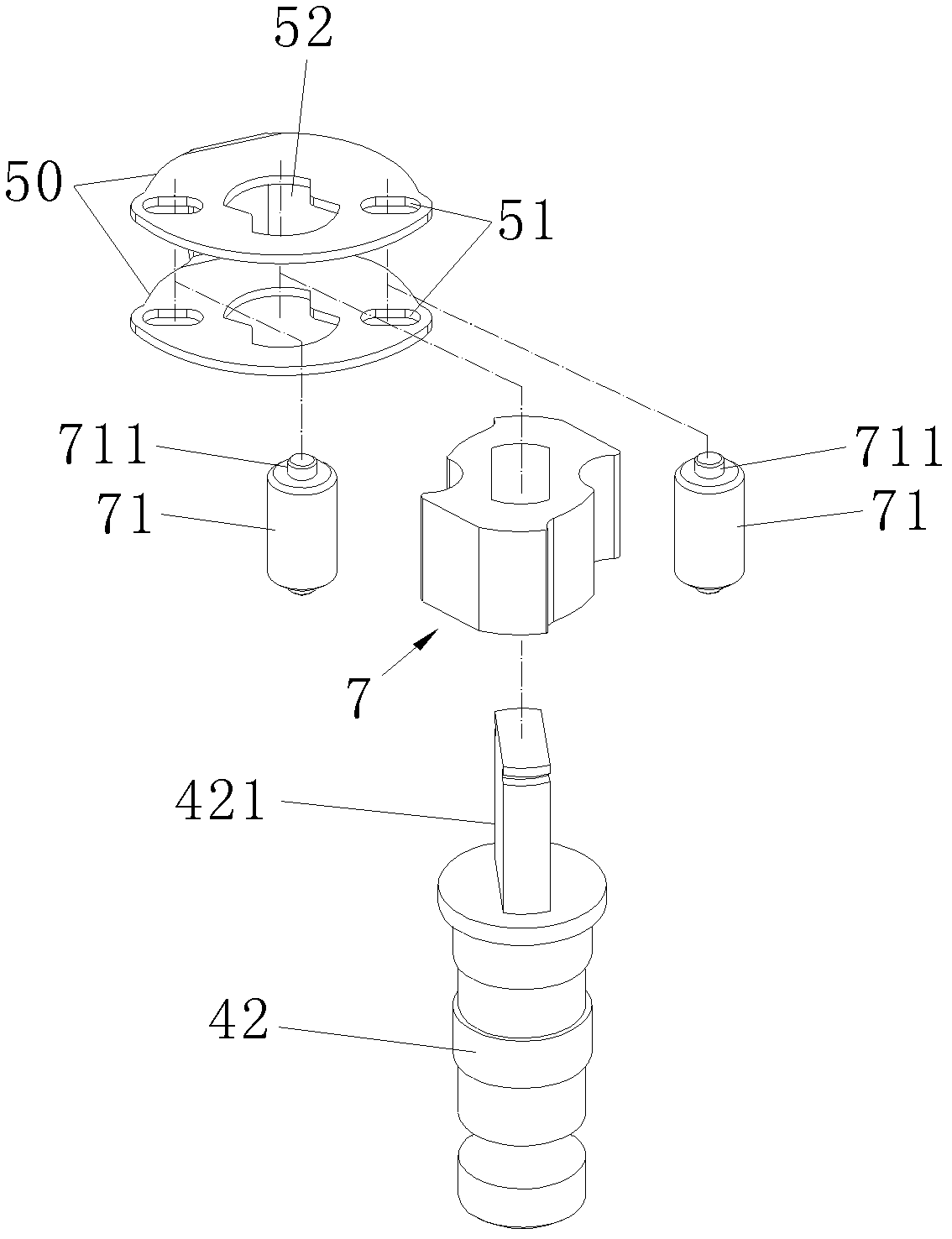

[0022] refer to Figure 2-3 , an improved drum brake structure, including a housing 1, a pair of brake shoes 2 arranged in the housing 1, a reset element 3 connected between the pair of brake shoes 2 and a brake arm assembly, the pair of brake shoes 2 One end of the pair of brake shoes 2 is rotated and positioned in the housing 1. A brake wheel 7 driven by the brake arm assembly is provided between the end gaps at the other end of the pair of brake shoes 2. The brake wheel 7 and the end surfaces of the brake shoes 2 on both sides are respectively There are rollers 71 abutted against, and positioning plates 50 are arranged on both ends of the brake wheel 7 in the axial direction, and the rollers 71 are rotatably positioned between the two positioning plates 50. The end face of the sheet 2 fits against the limiting edge surface of the roller 71, and the two ends of the roller 71 are provided with an axially protruding rotating pin 711, and the positioning plate 50 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com