Pressure cooker component

A pressure cooker and component technology, applied in pressure cooker, cooking utensils, household appliances, etc., can solve the problems of electrical safety hazards, difficult to achieve sealing, inconvenient operation, etc., to achieve convenient operation, quick pressure release and opening, and prevent electrical safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

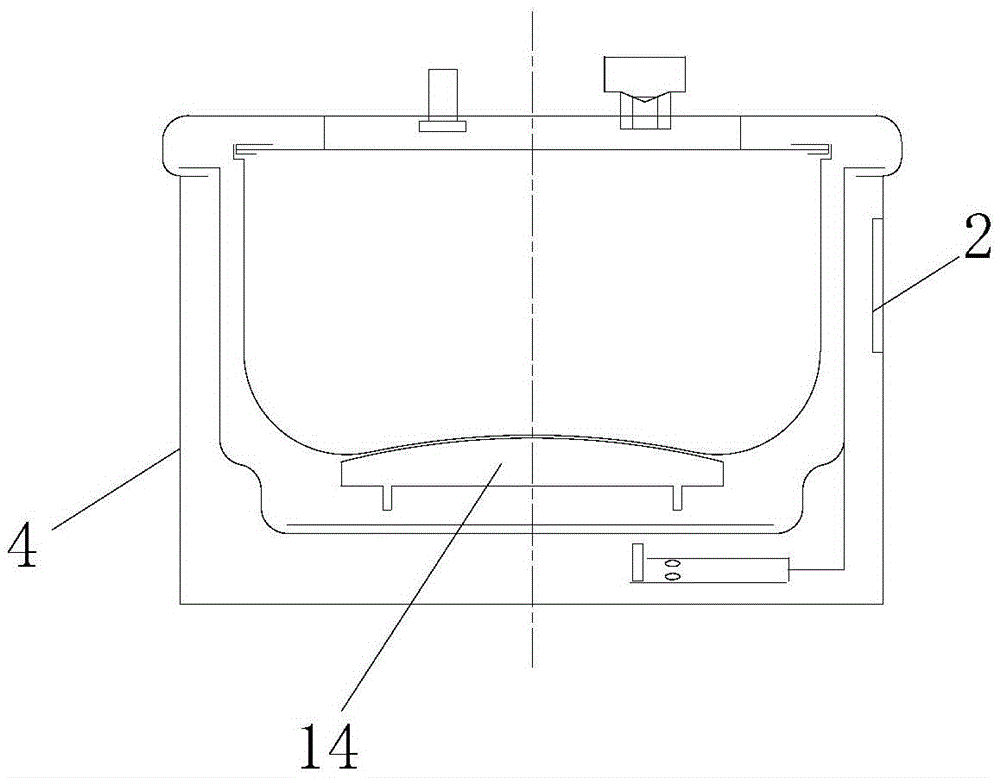

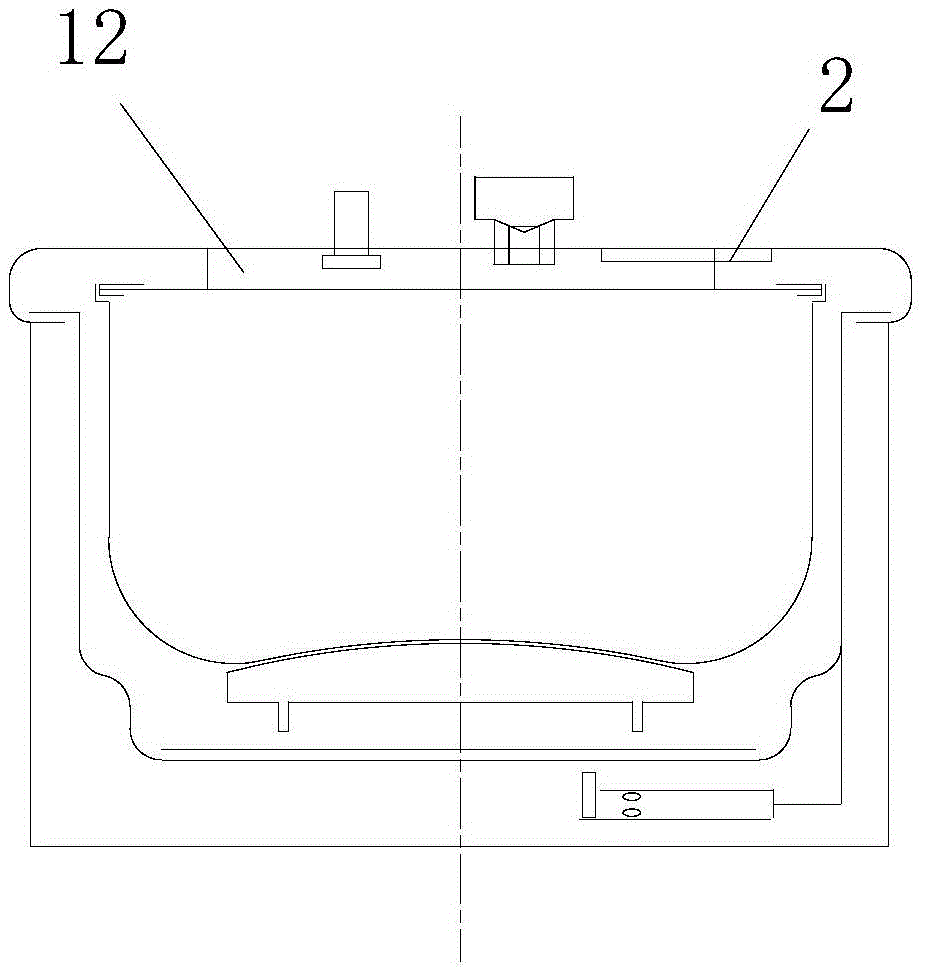

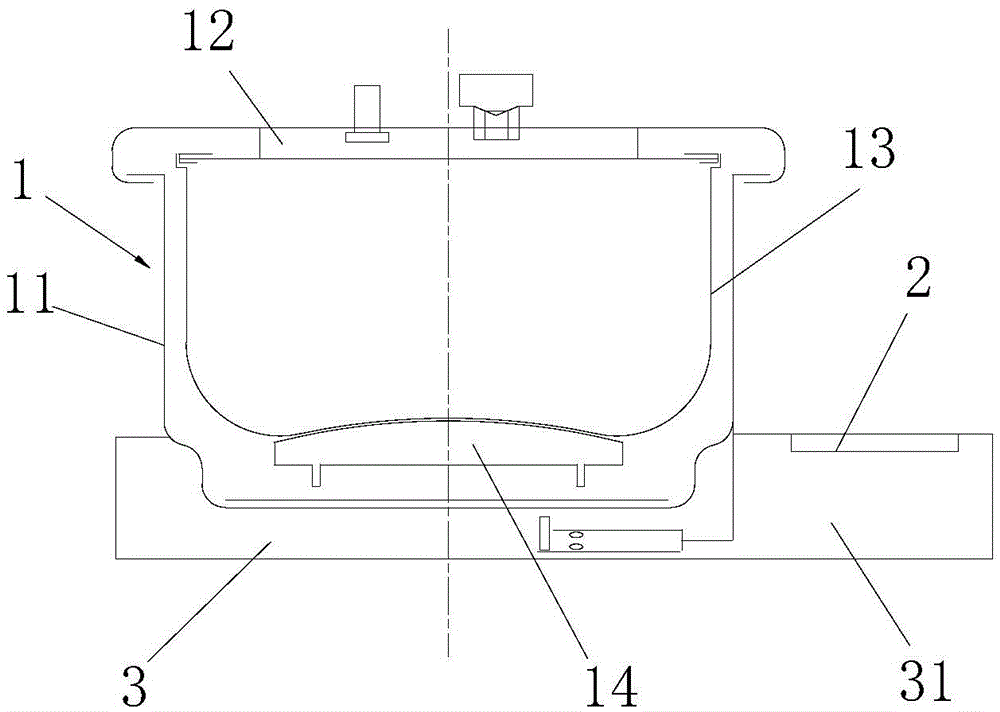

Embodiment approach 1

[0042]Since the display panel is not on the side, a semi-enclosed case can be used, such as image 3 , can save the raw materials of the outer pot, and can better realize artificial cooling. For example, wrapping the outer pot with a wet towel can make the pressure in the inner pot drop rapidly. Compared with exhaust and pressure relief, this pressure reduction method has no noise and can better retain the aroma of food. Electronic components generally have a temperature tolerance, and the bottom protruding part is installed with a control panel, and the controller is far away from the heat source (heating plate), so as to improve the temperature rise of electronic components and improve the service life of electronic vitality. The bottom display is adopted, so that the operation display panel faces upwards, which improves the convenience of side display operation and display reading. Since the control panel is far away from the inner pot, the water vapor in the inner pot can...

Embodiment approach 2

[0044] This display method can be combined with the traditional open flame pressure cooker, the lid of the pot is fastened with the inner pot, and the pressure limiting valve is used for pressure limiting control. After cooking, the inner pot can be taken out to cool down in water to realize quick pressure relief and opening of the lid. It not only has the convenience of electronic control operation, but also can continue cooking on an open fire in case of accidents such as power failure.

[0045] The above embodiment is that the present invention has the ability to keep the control device away from the heat source, thereby reducing the temperature rise of the control device, and preventing water vapor from entering the control device. At the same time, it also has the advantages of easy operation, display and reading.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com