Patents

Literature

102 results about "Volume analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

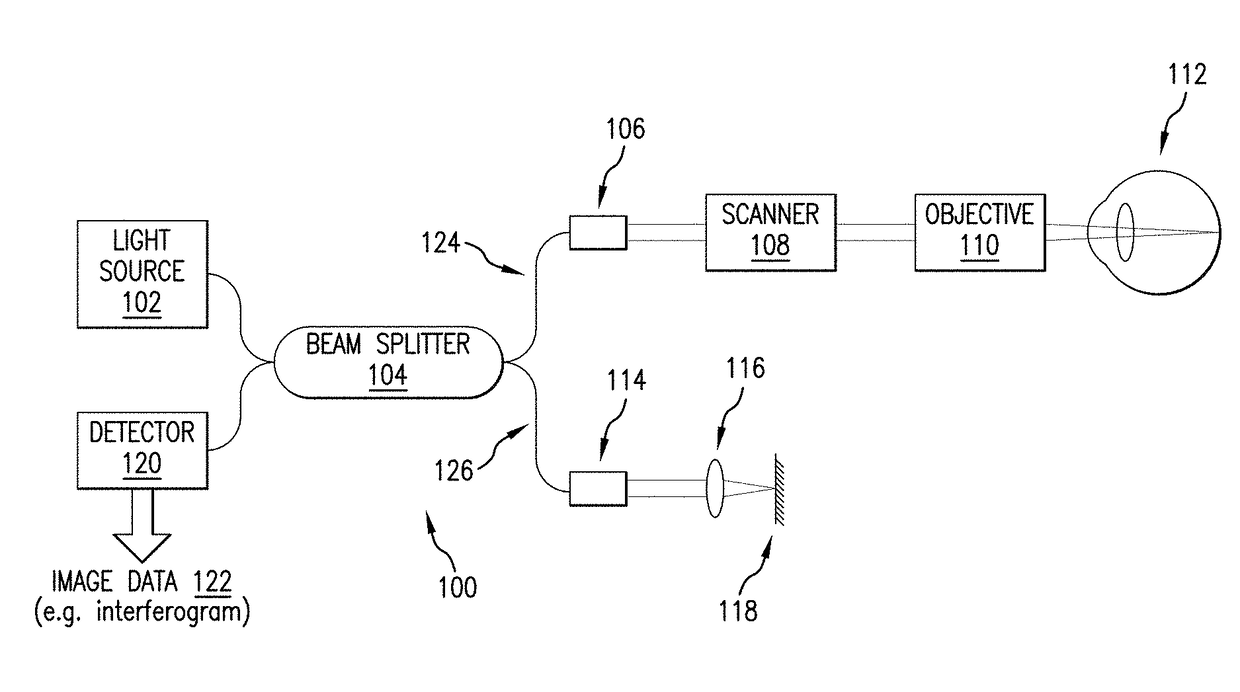

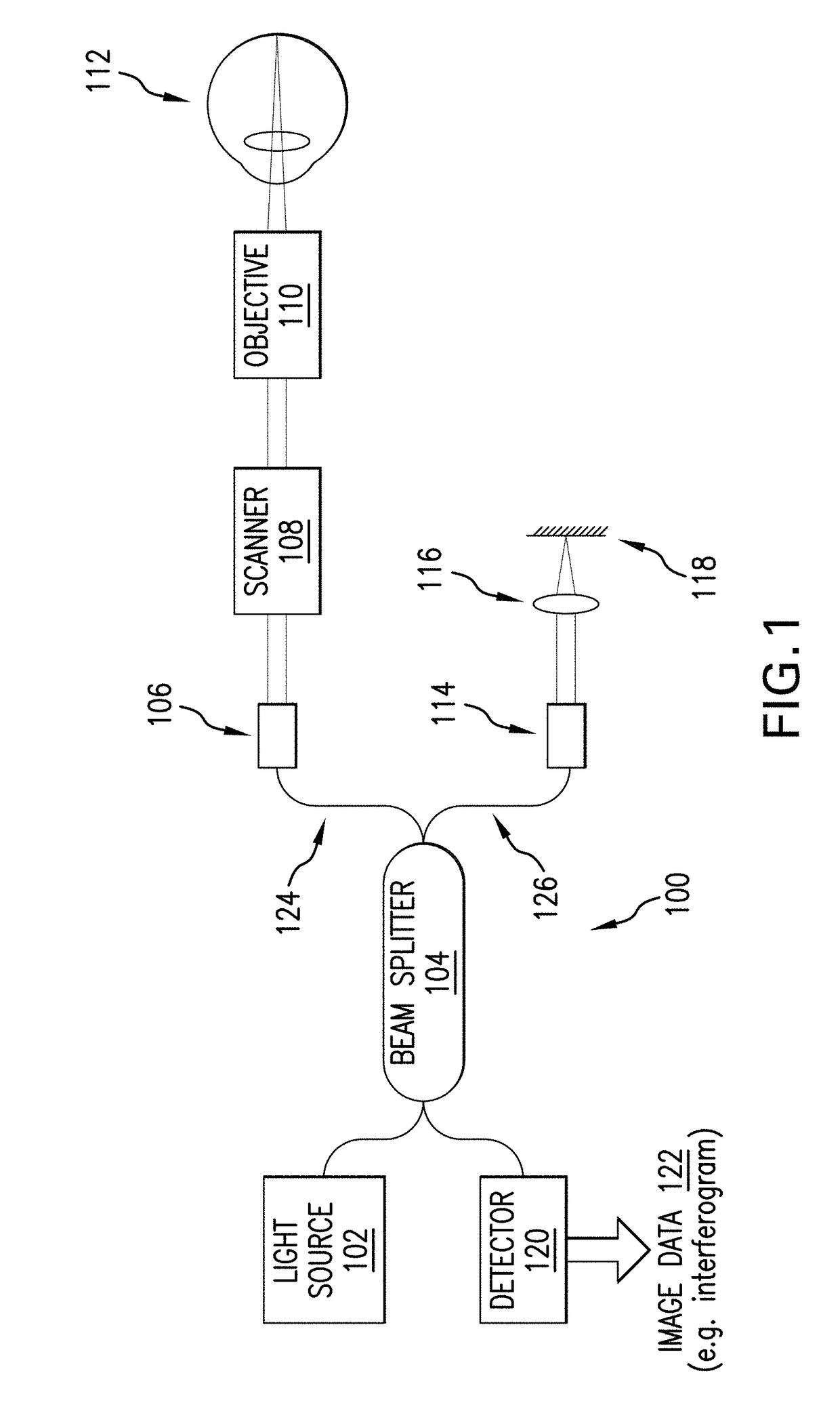

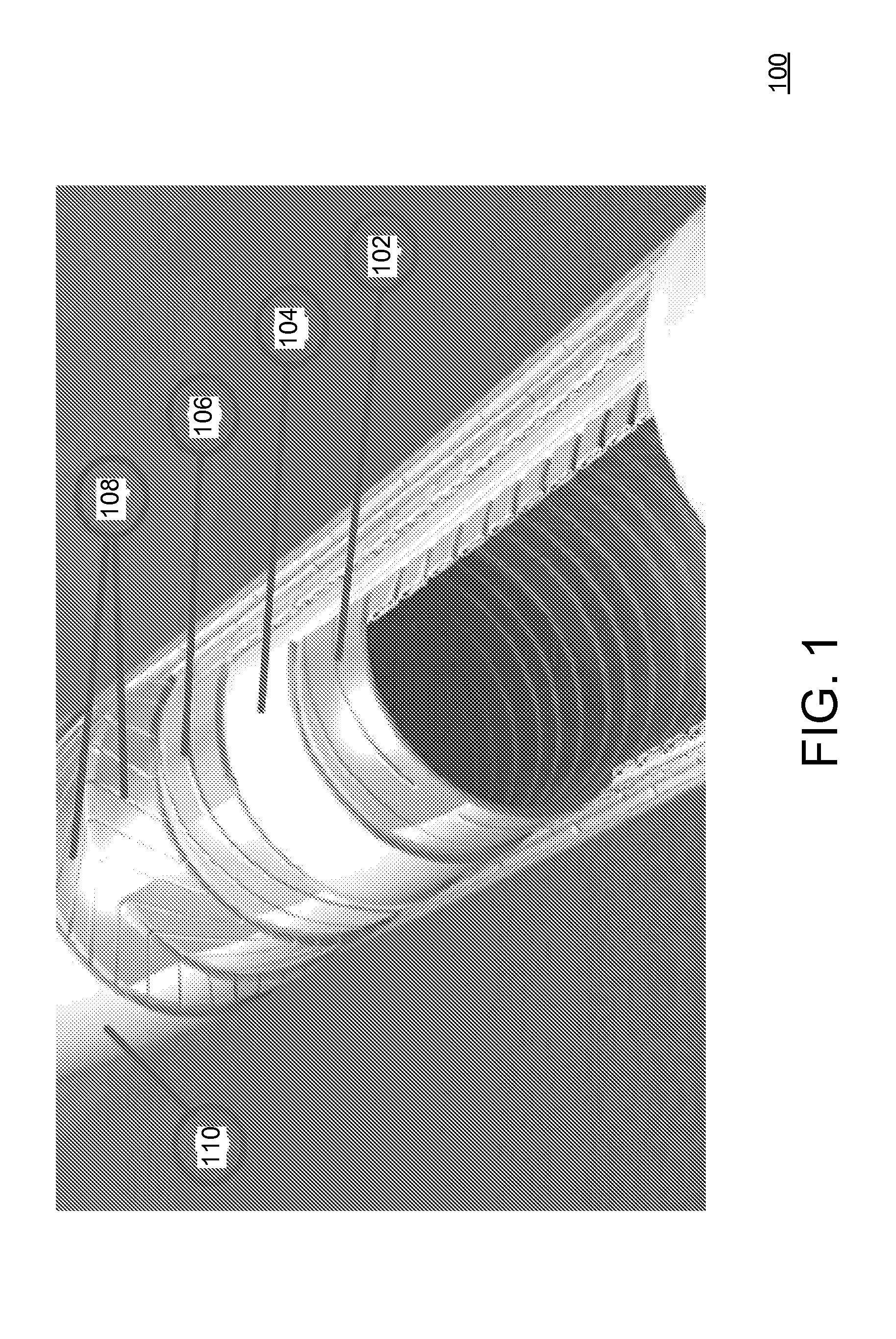

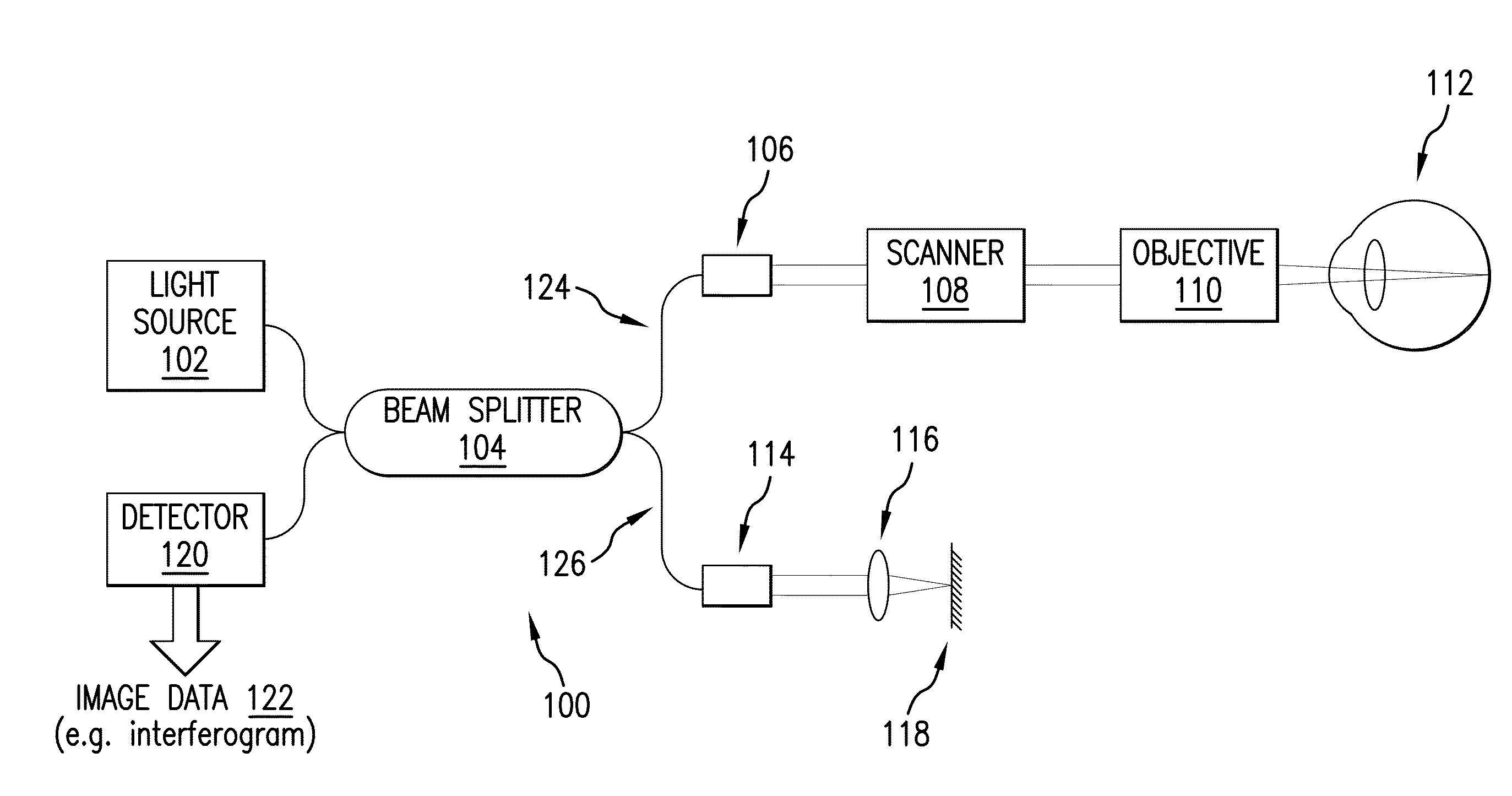

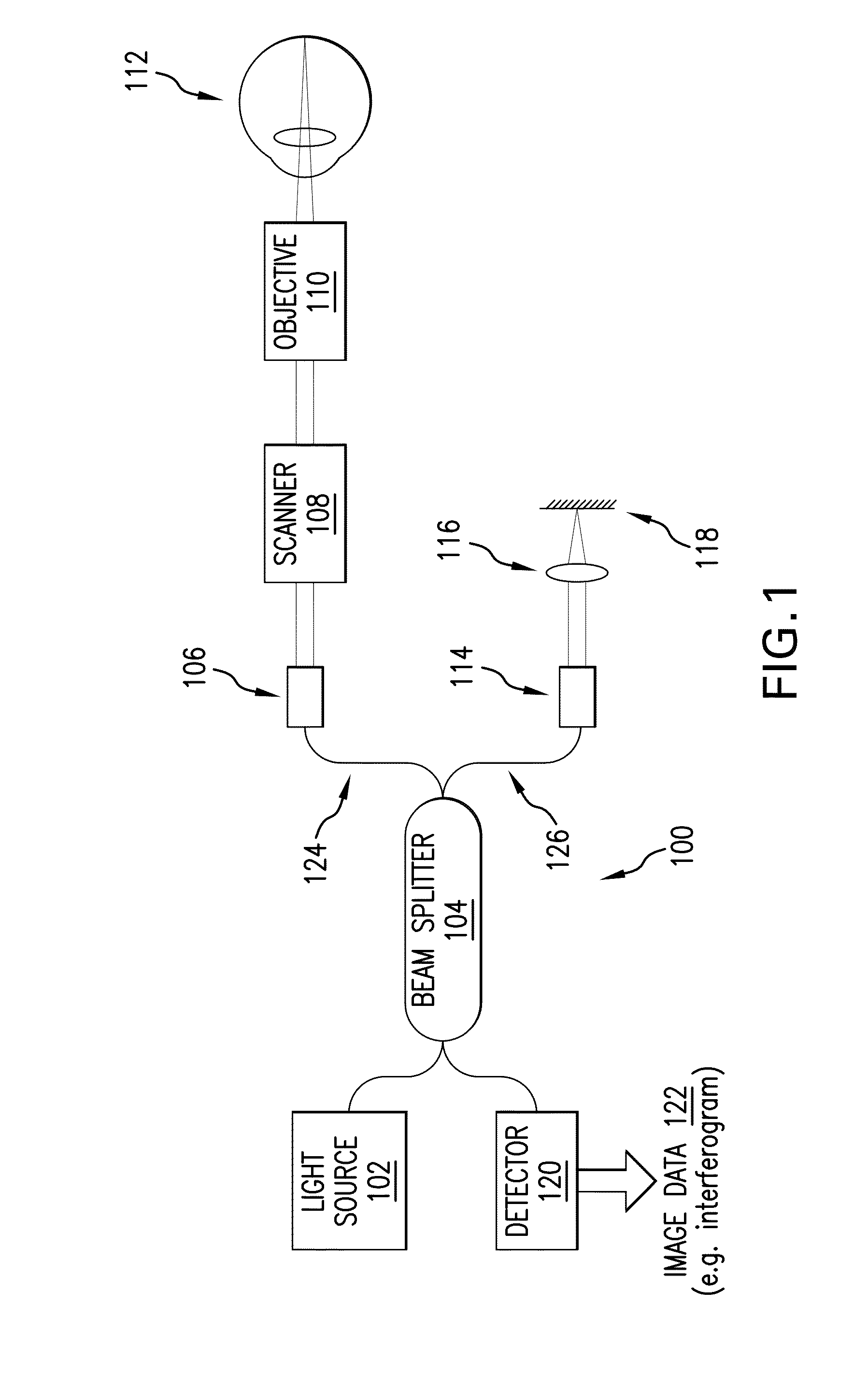

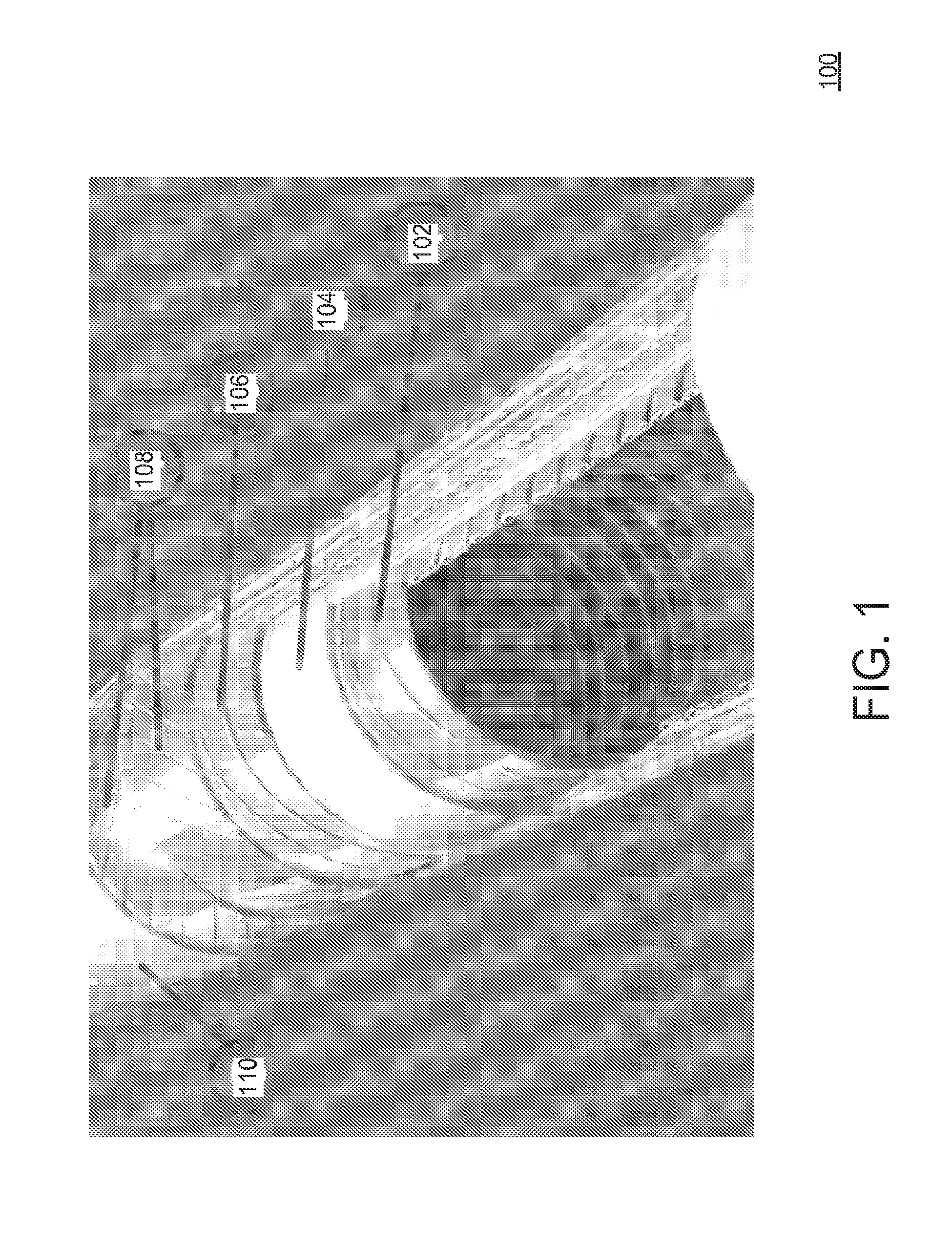

Volume analysis and display of information in optical coherence tomography angiography

ActiveUS9713424B2Solve the slow scanning speedHigh transparencyImage enhancementImage analysisVoxelData set

Computer aided visualization and diagnosis by volume analysis of optical coherence tomography (OCT) angiographic data. In one embodiment, such analysis comprises acquiring an OCT dataset using a processor in conjunction with an imaging system; evaluating the dataset, with the processor, for flow information using amplitude or phase information; generating a matrix of voxel values, with the processor, representing flow occurring in vessels in the volume of tissue; performing volume rendering of these values, the volume rendering comprising deriving three dimensional position and vector information of the vessels with the processor; displaying the volume rendering information on a computer monitor; and assessing the vascularity, vascular density, and vascular flow parameters as derived from the volume rendered images.

Owner:SPAIDE RICHARD F

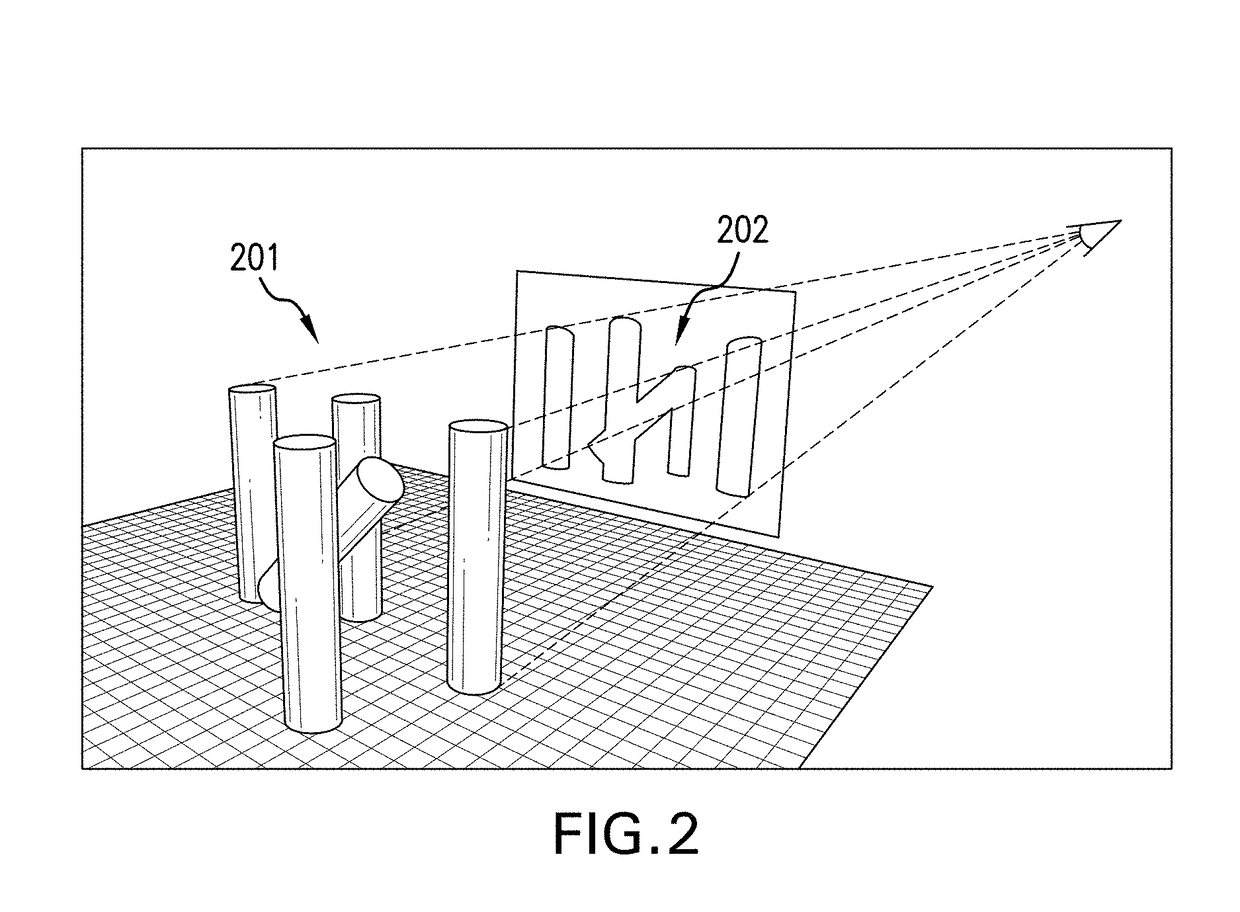

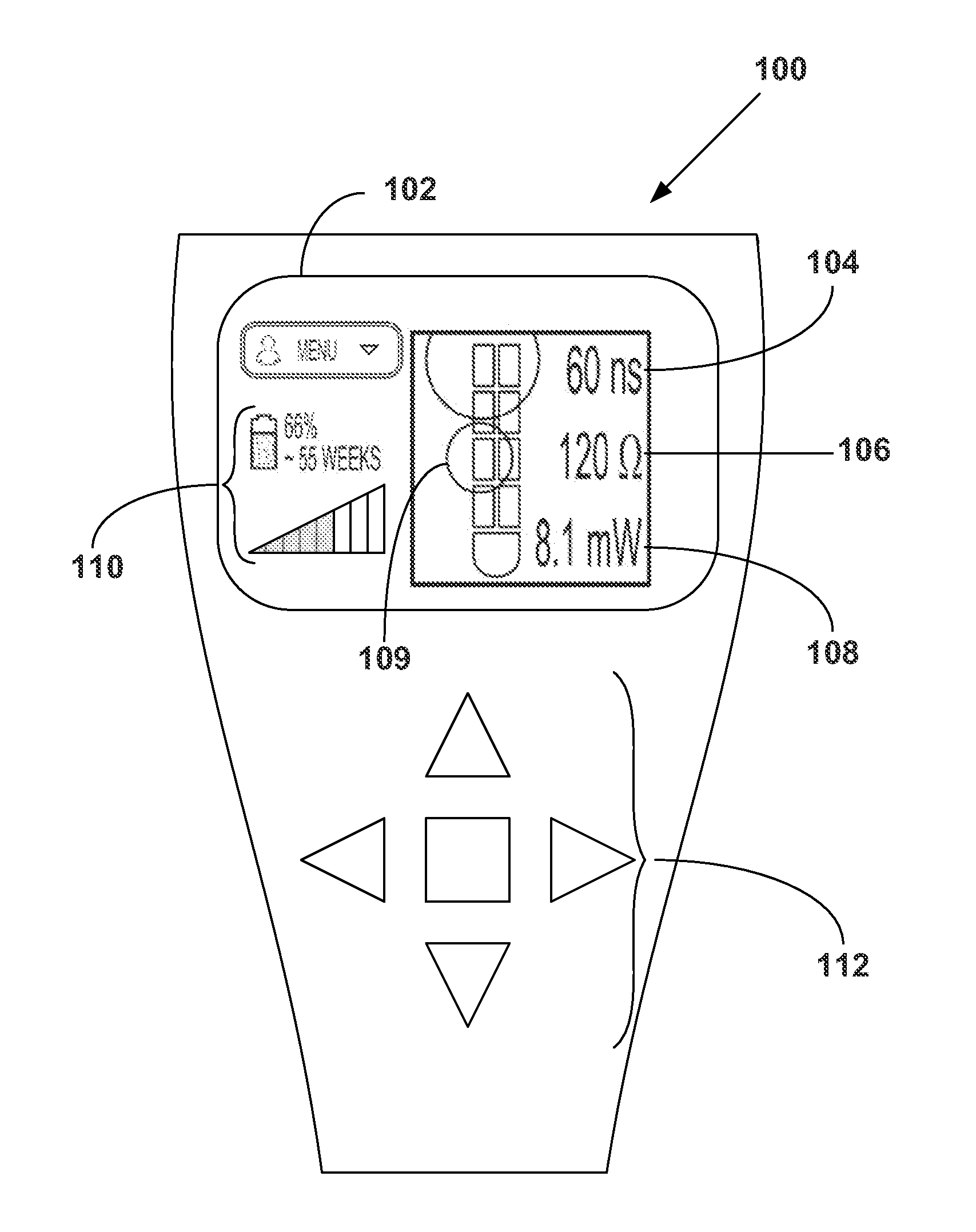

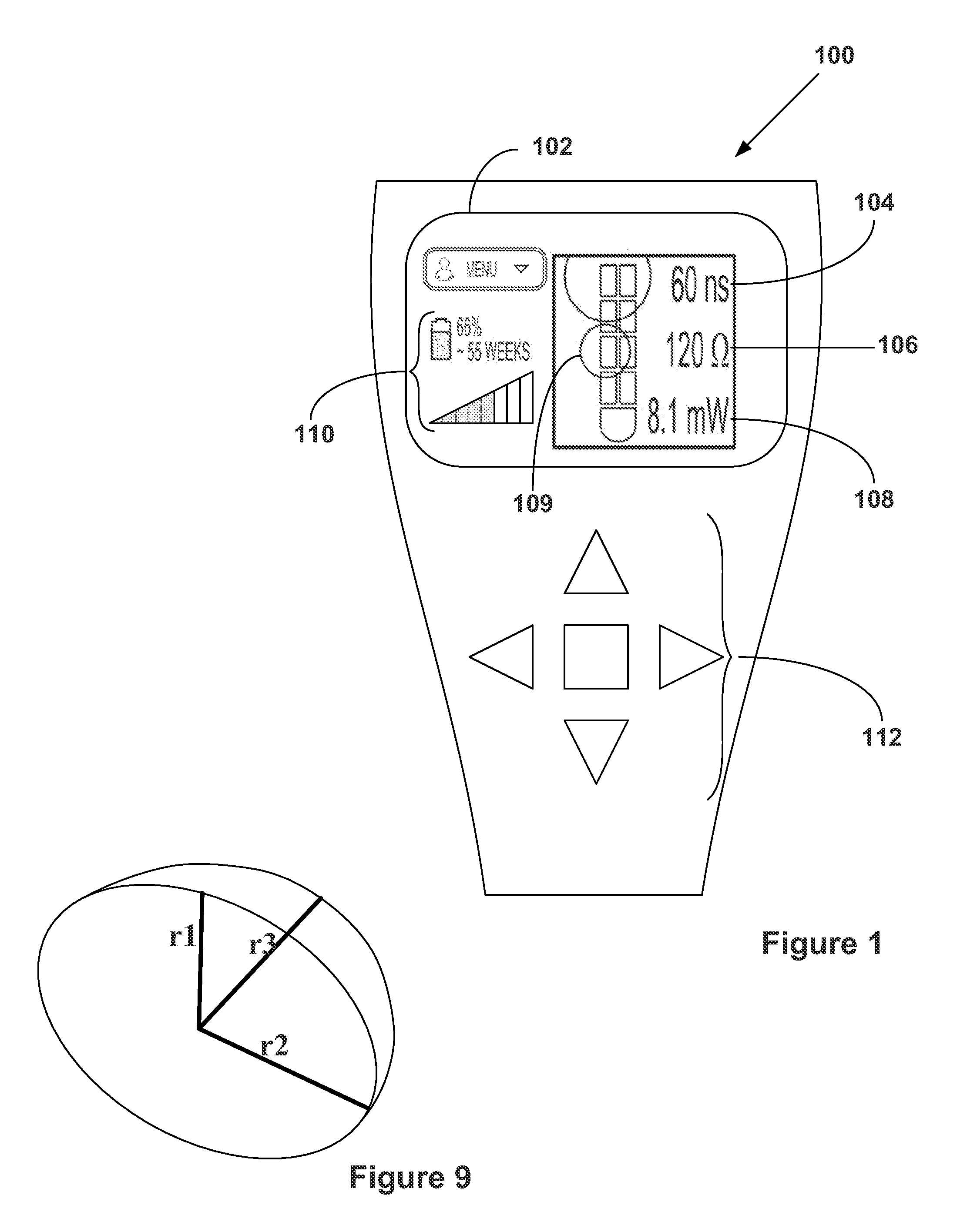

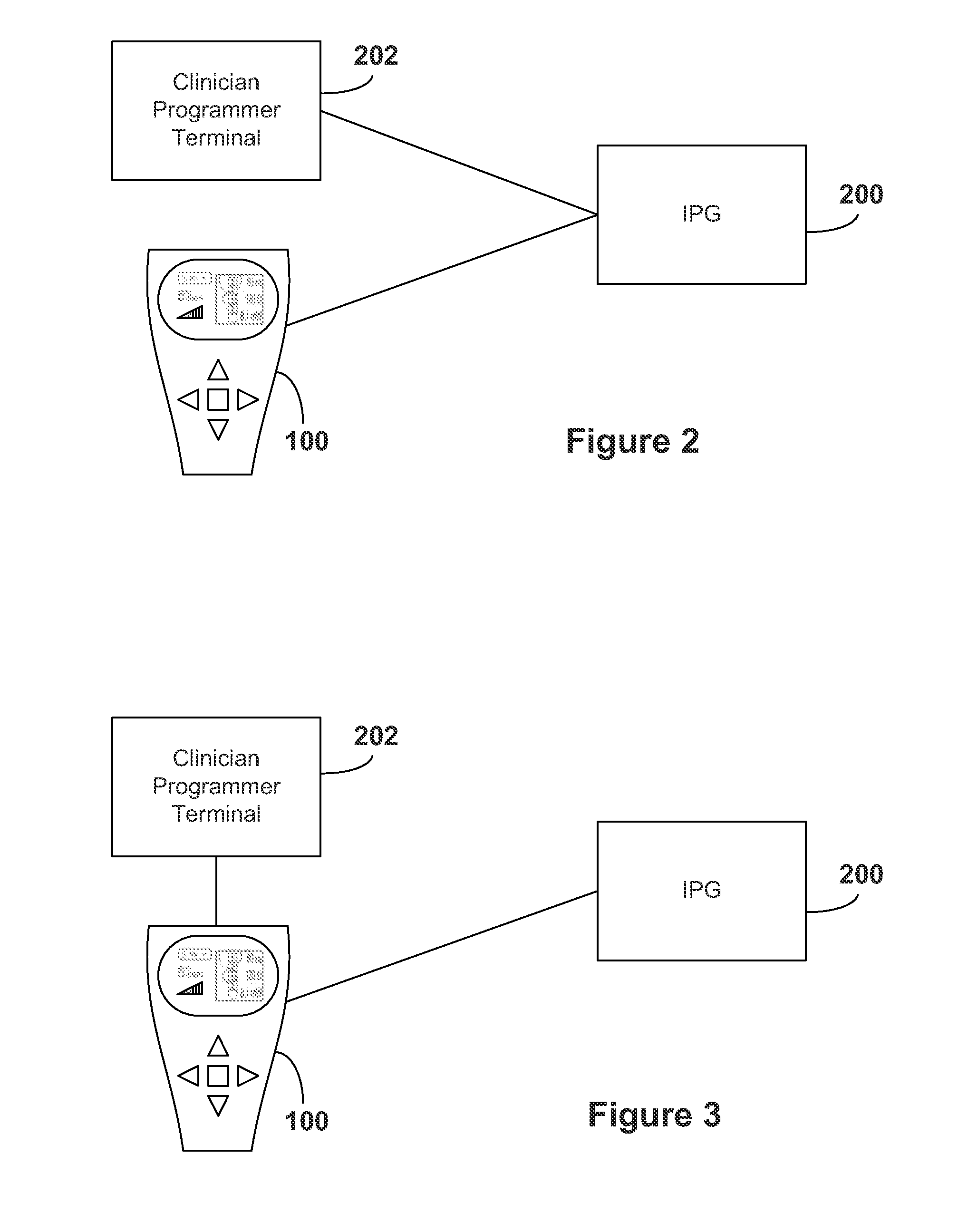

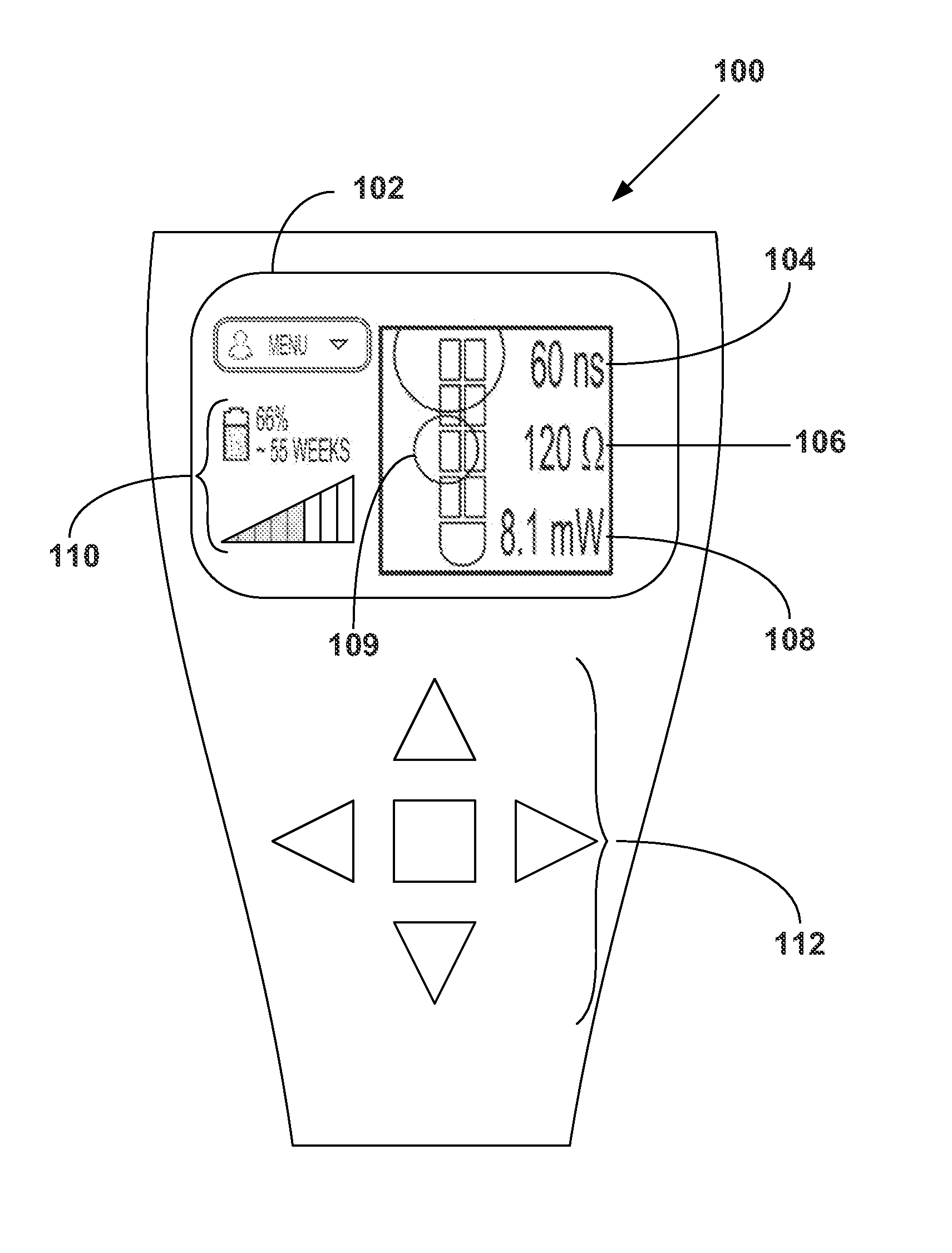

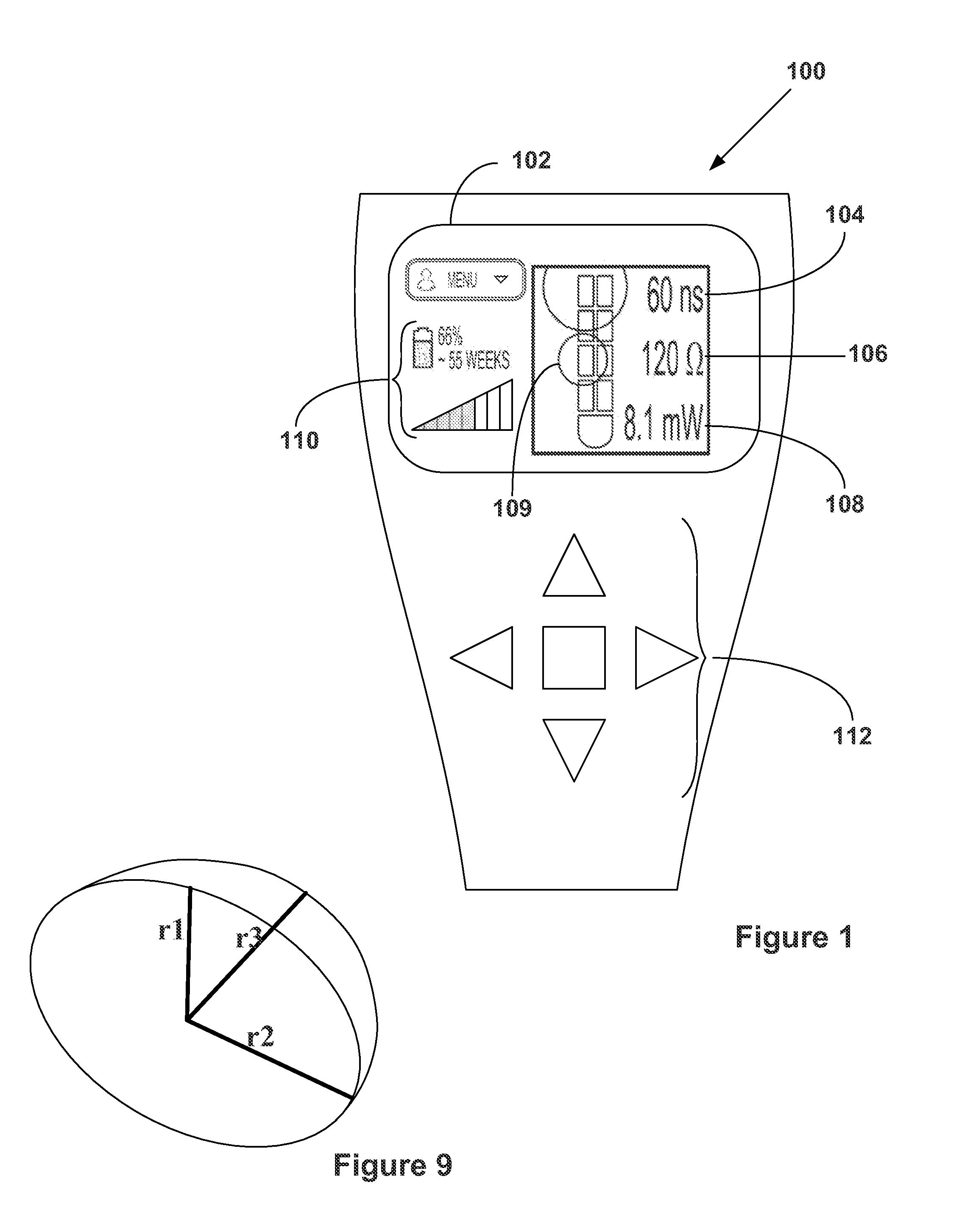

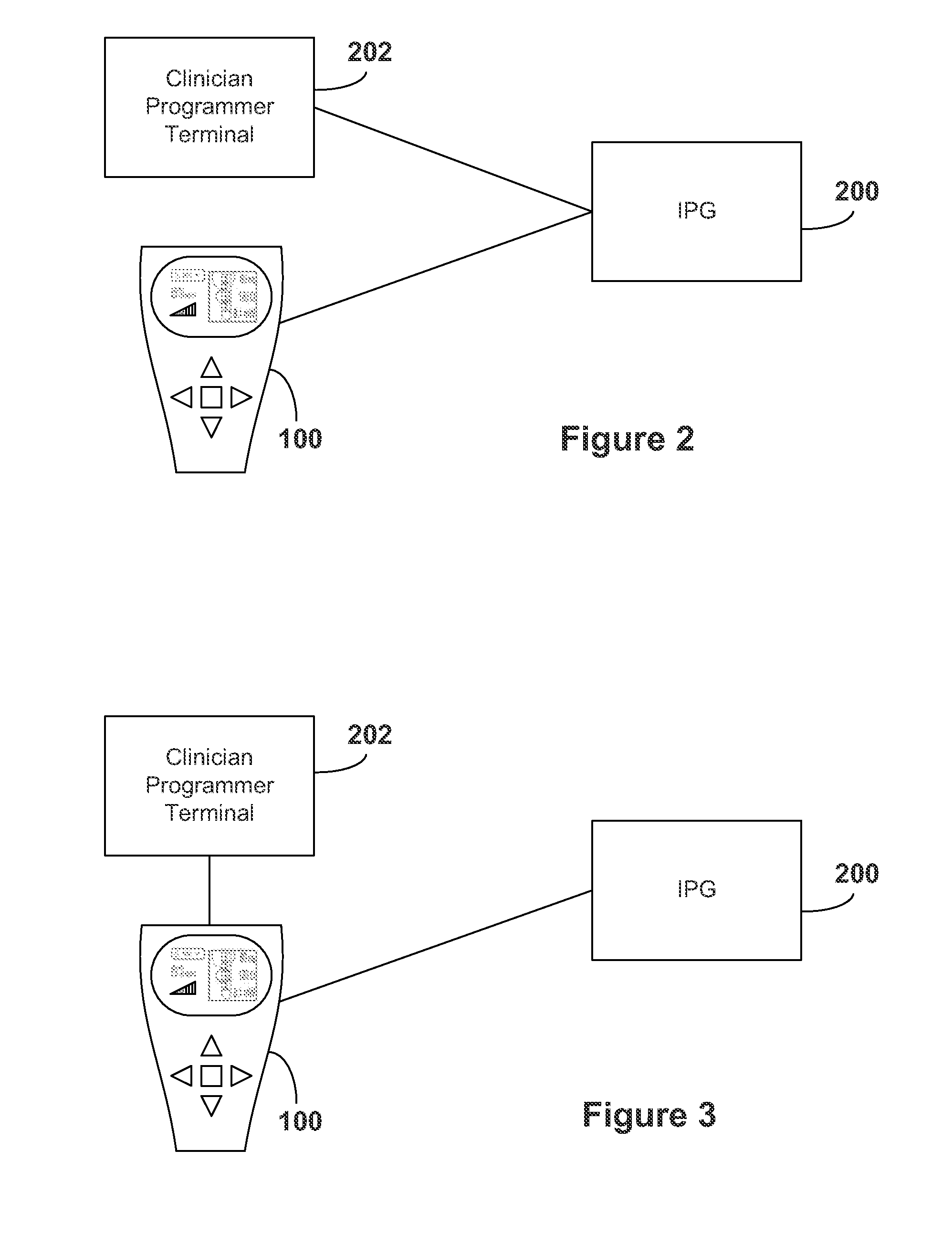

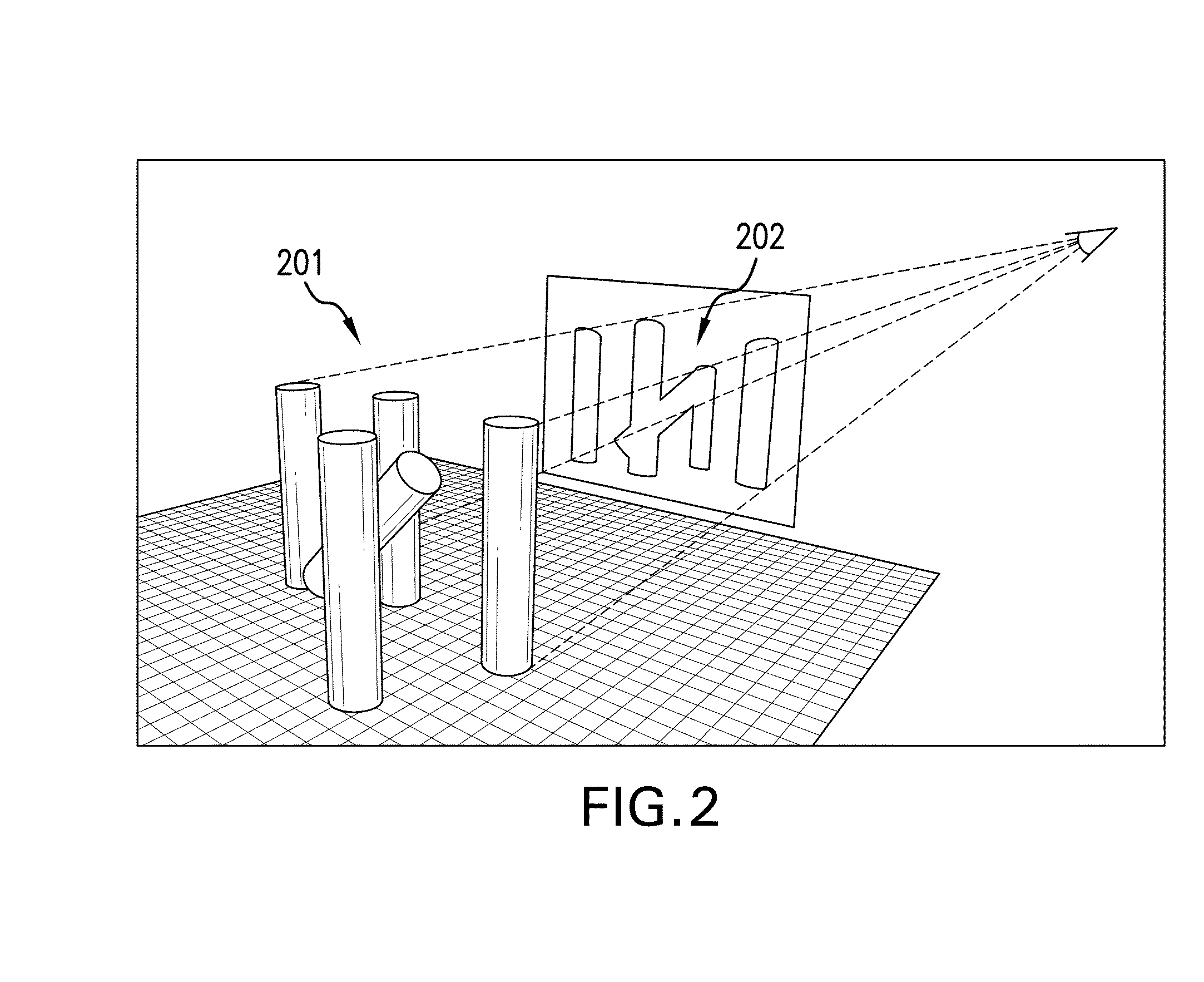

Systems and methods for stimulation-related volume analysis, creation, and sharing

ActiveUS20130116929A1Quality improvementMaximize usePhysical therapies and activitiesElectrotherapySide effectMedicine

A computer implemented system and method facilitates a cycle of generation, sharing, and refinement of volumes related to stimulation of anatomical tissue, such as brain or spinal cord stimulation. Such volumes can include target stimulation volumes, side effect volumes, and volumes of estimated activation. A computer system and method also facilitates analysis of groups of volumes, including analysis of differences and / or commonalities between different groups of volumes.

Owner:BOSTON SCI NEUROMODULATION CORP

Systems and methods for stimulation-related volume analysis, creation, and sharing

ActiveUS20130116749A1Quality improvementMaximize usePhysical therapies and activitiesElectrotherapySide effectMedicine

A computer implemented system and method facilitates a cycle of generation, sharing, and refinement of volumes related to stimulation of anatomical tissue, such as brain or spinal cord stimulation. Such volumes can include target stimulation volumes, side effect volumes, and volumes of estimated activation. A computer system and method also facilitates analysis of groups of volumes, including analysis of differences and / or commonalities between different groups of volumes.

Owner:BOSTON SCI NEUROMODULATION CORP

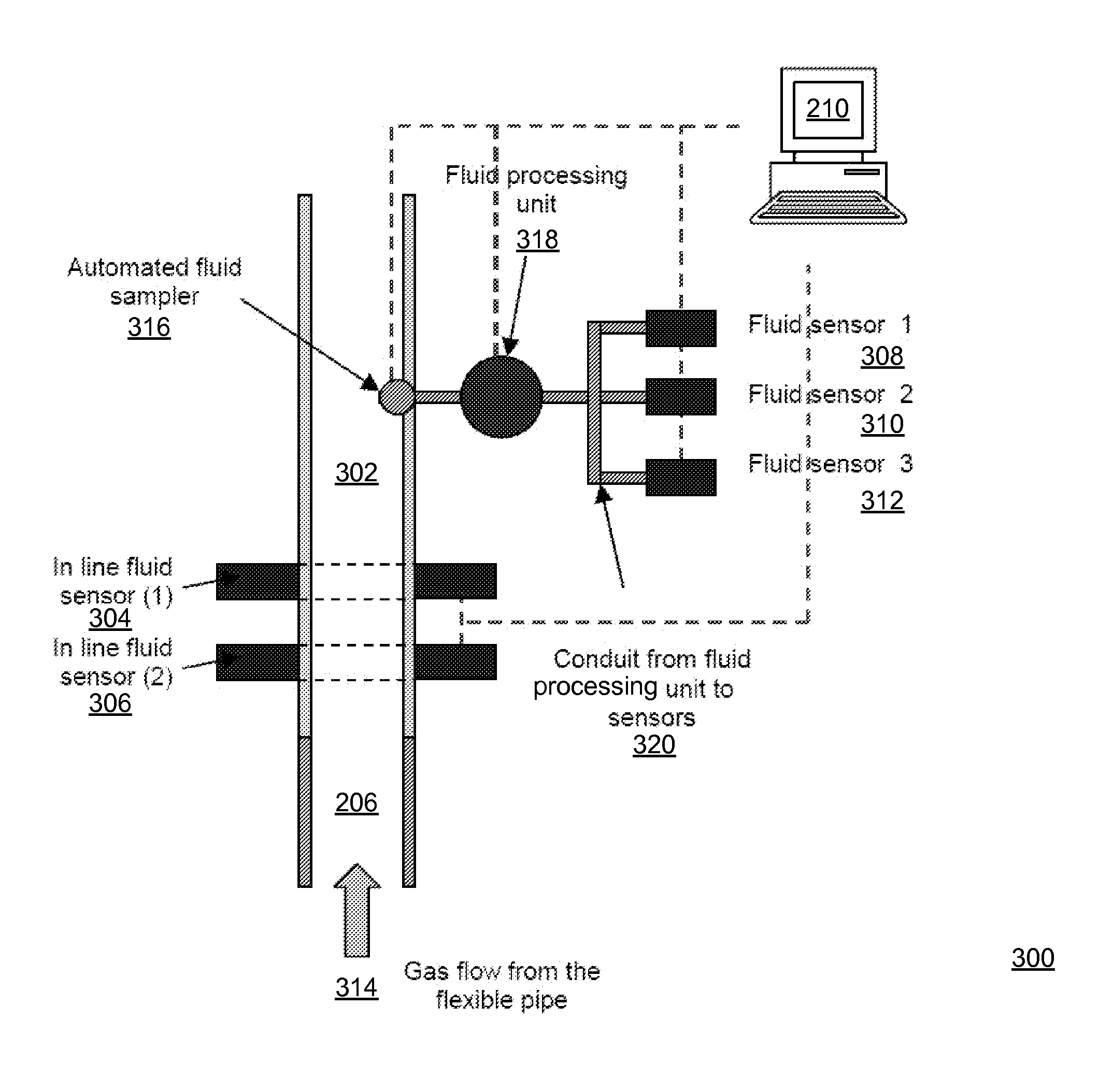

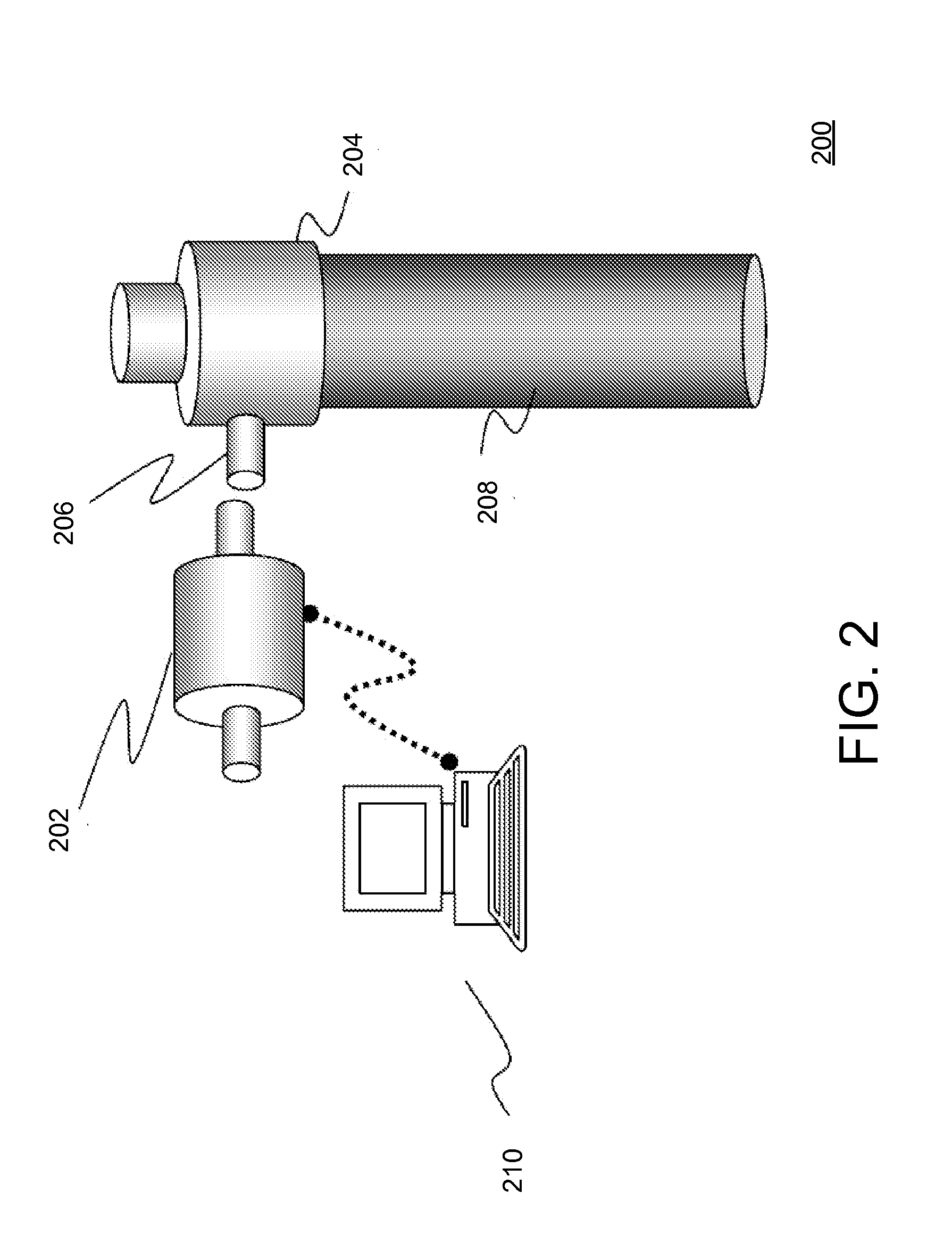

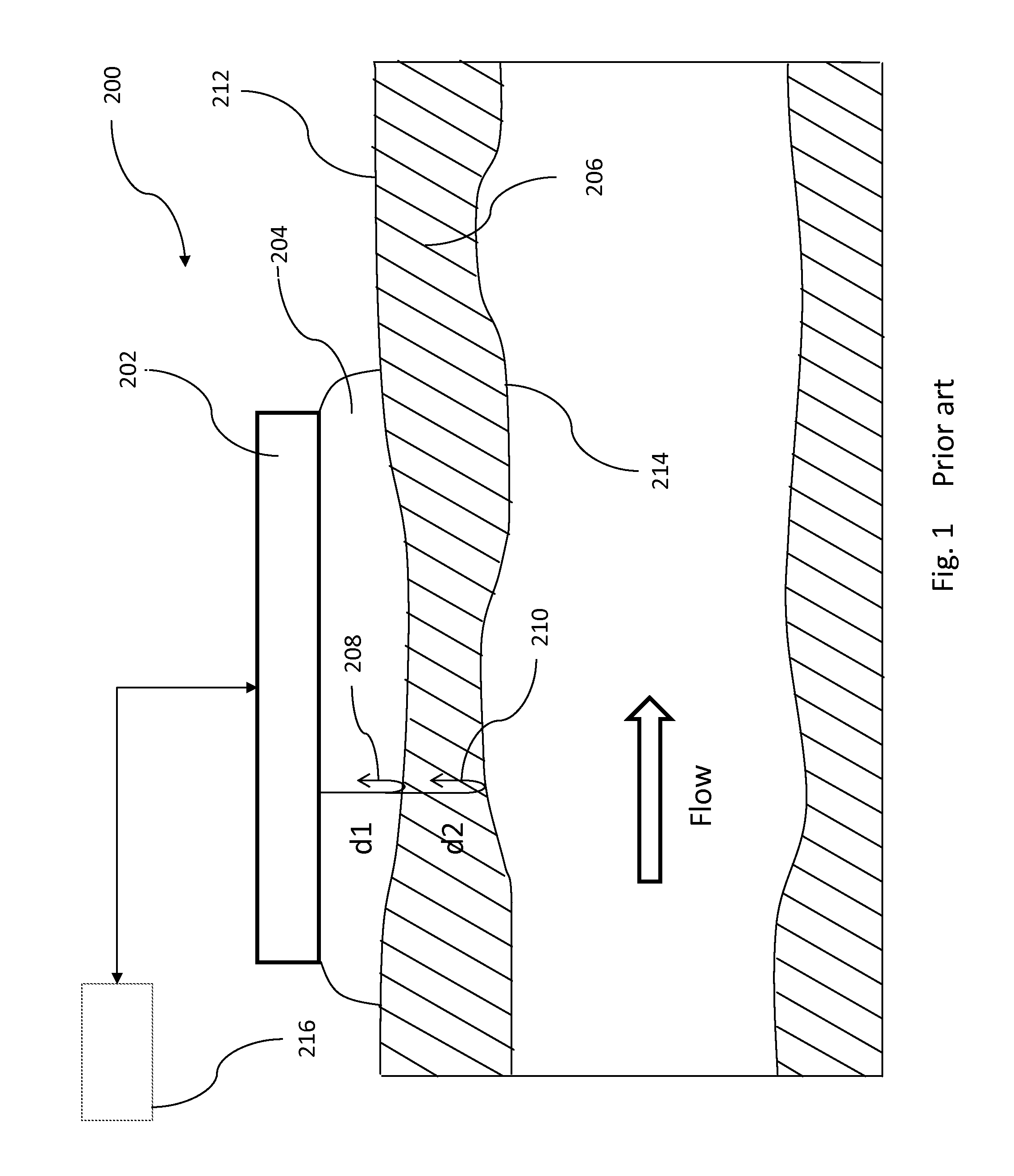

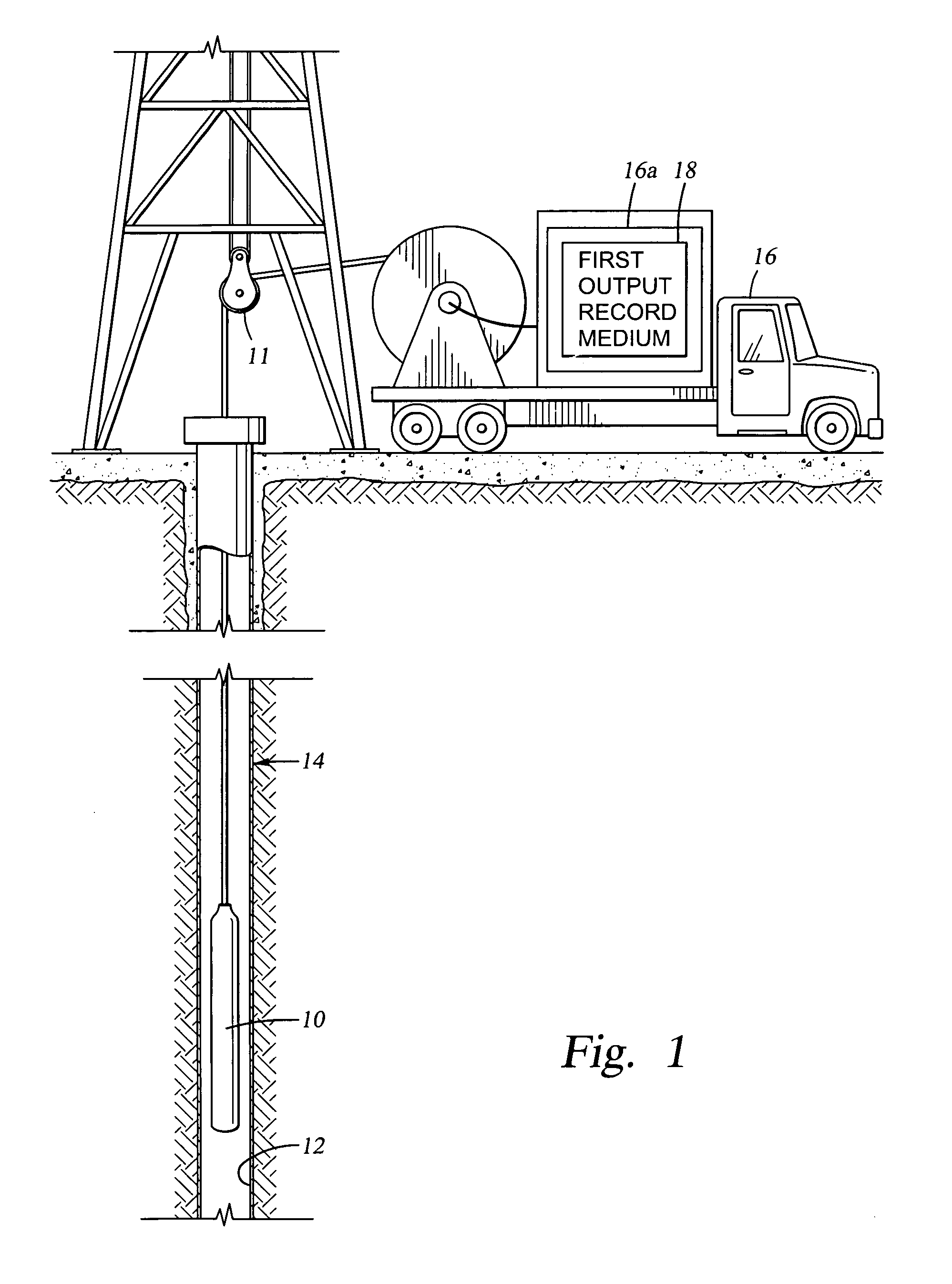

In-line composition and volumetric analysis of vent gases and flooding of the annular space of flexible pipe

InactiveUS20110153225A1High frequencyReduce in quantityPlug gaugesDrilling rodsExhaust valveVolume analysis

A method and system for monitoring a flexible pipe, including an inline sensor system coupled to the annulus of the flexible pipe to detect corrosion of the flexible pipe. Also disclosed are method and system for monitoring an amount of water being accumulated in an annulus of a flexible pipe, including locating a pressure measurement system proximate to the annulus for measuring pressure of gas inside the annulus; controlling a flow of vent gas with a vent gas valve; positioning a flow measurement system upstream or downstream of the vent gas valve for measuring the flow of the vent gas when the vent gas valve is opened; and collecting with a microprocessor pressure and flow measurement data from the pressure and the flow measurement systems for determining the amount of water accumulated in the annulus based on the collected pressure and flow measurement data.

Owner:SCHLUMBERGER TECH CORP

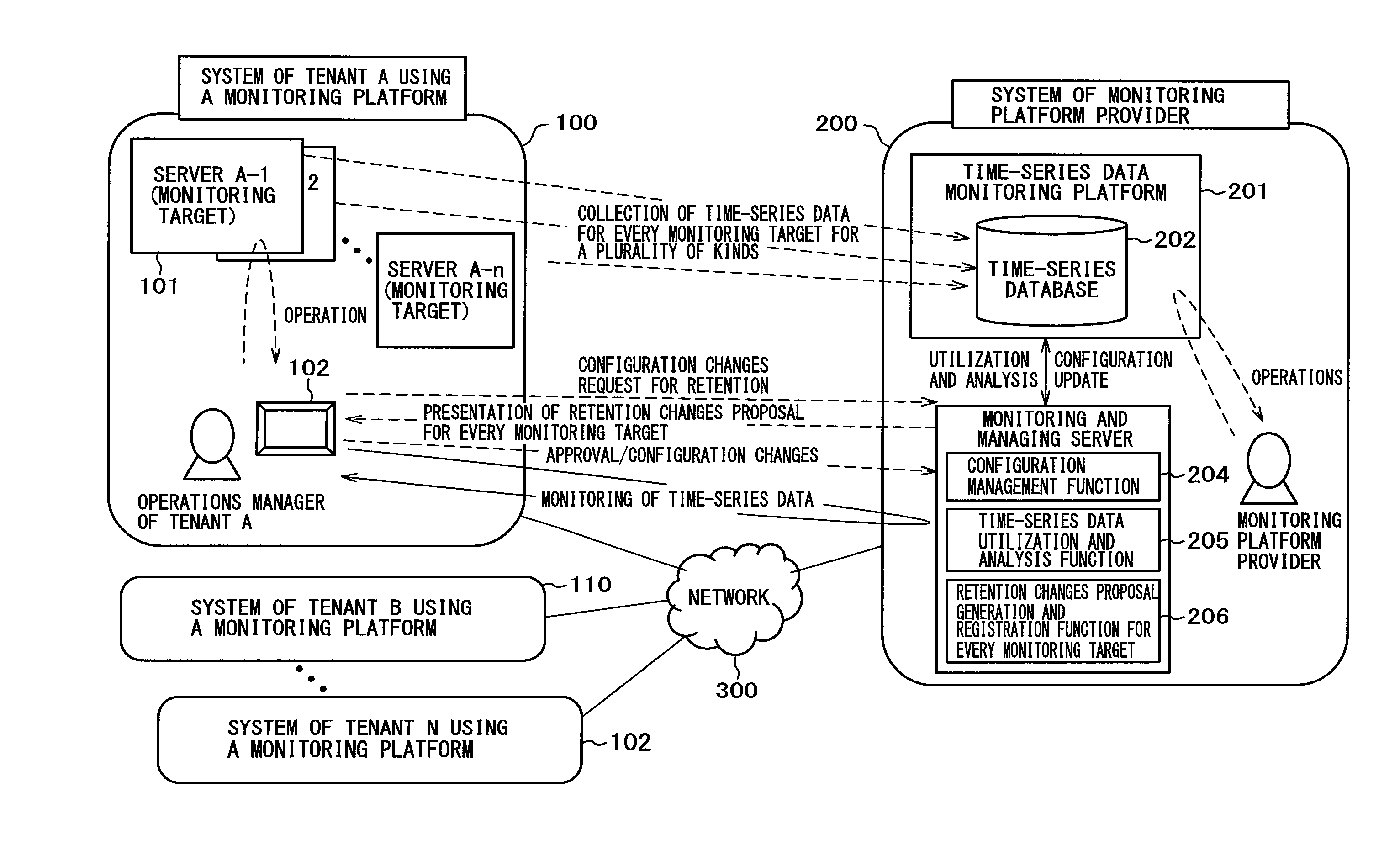

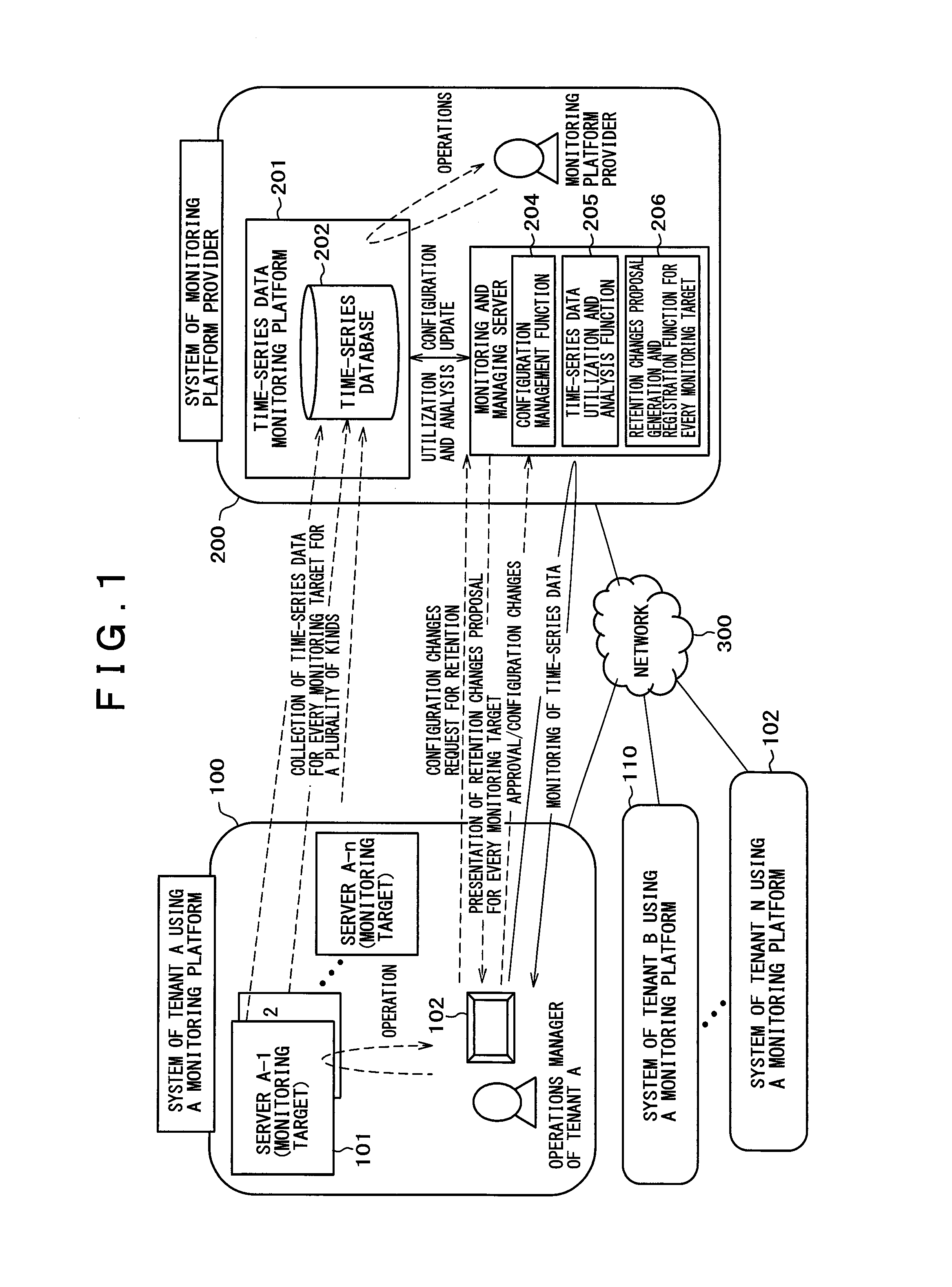

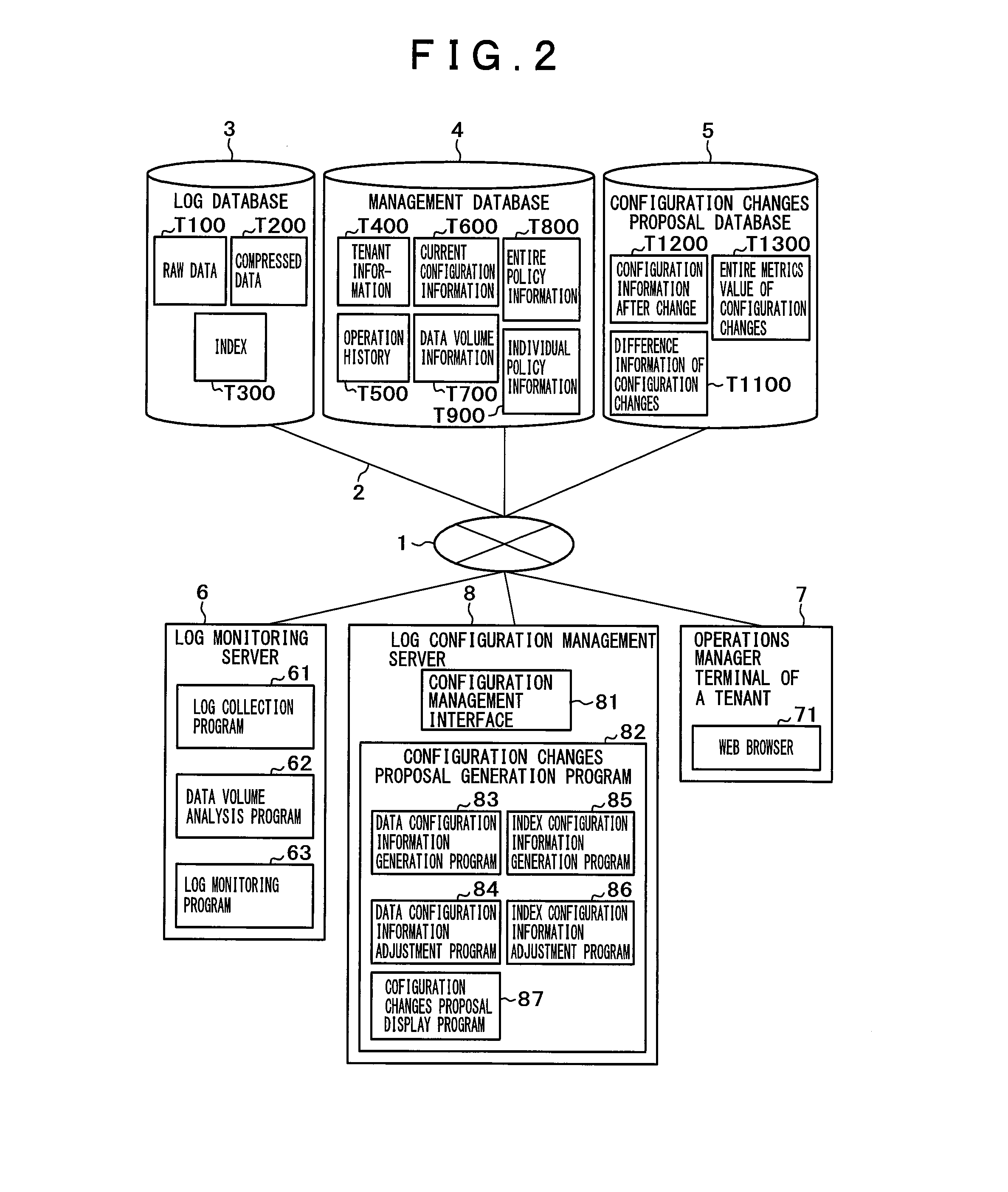

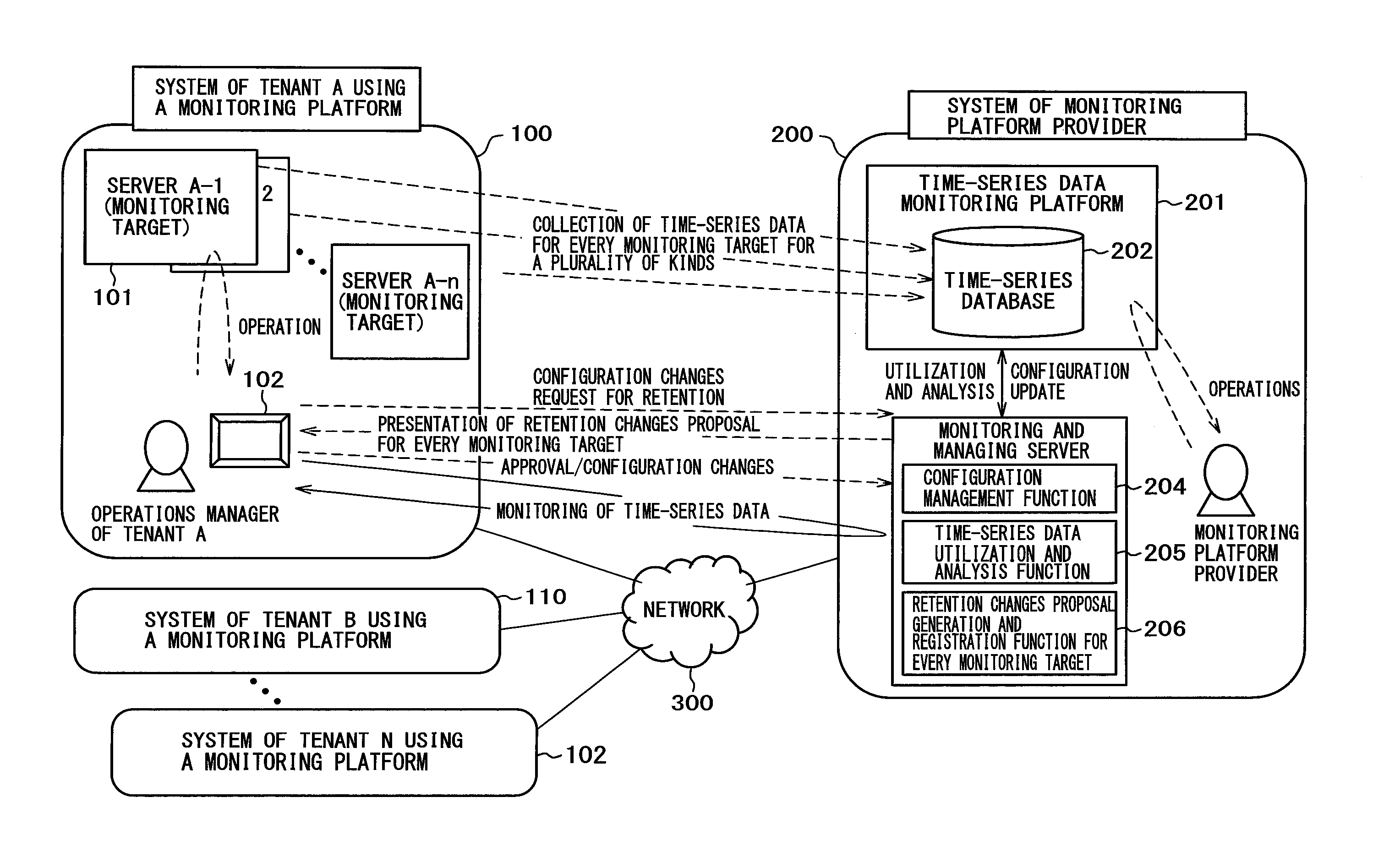

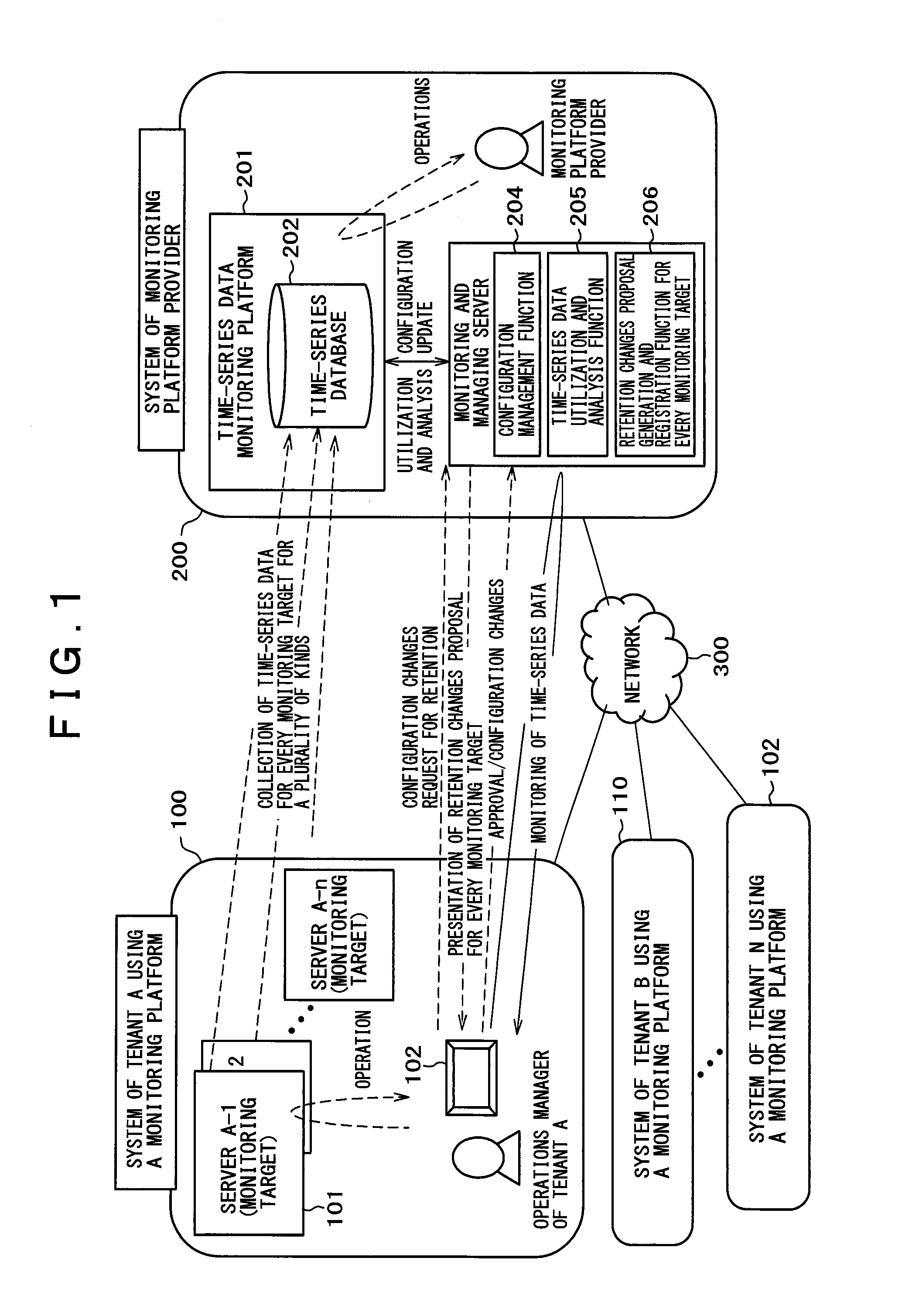

Time-series database setup automatic generation method, setup automatic generation system and monitoring server

InactiveUS20140149466A1Difficult to generateLow costError detection/correctionDigital data processing detailsVolume analysisData mining

If the operations manager makes configuration changes of the log database through configuration management interface, the configuration management interface records configuration information thereof on an management database. Furthermore, when log data of a monitoring target device are collected in a log collection unit through the log database, a log data volume analysis unit reads utilization information of data volume of the log database, and records the reading on a management database. A configuration changes proposal generating unit automatically generates configuration changes proposal of the log database based on the information recorded on the management database. Moreover, a metrics value for evaluating time required for configuration changes, a metrics value for evaluating performance in connection with the configuration changes, and a metrics value for evaluating the data volume in connection with the configuration changes are calculated, and an effect and an influence of changes proposal are presented to the operations manager.

Owner:HITACHI LTD

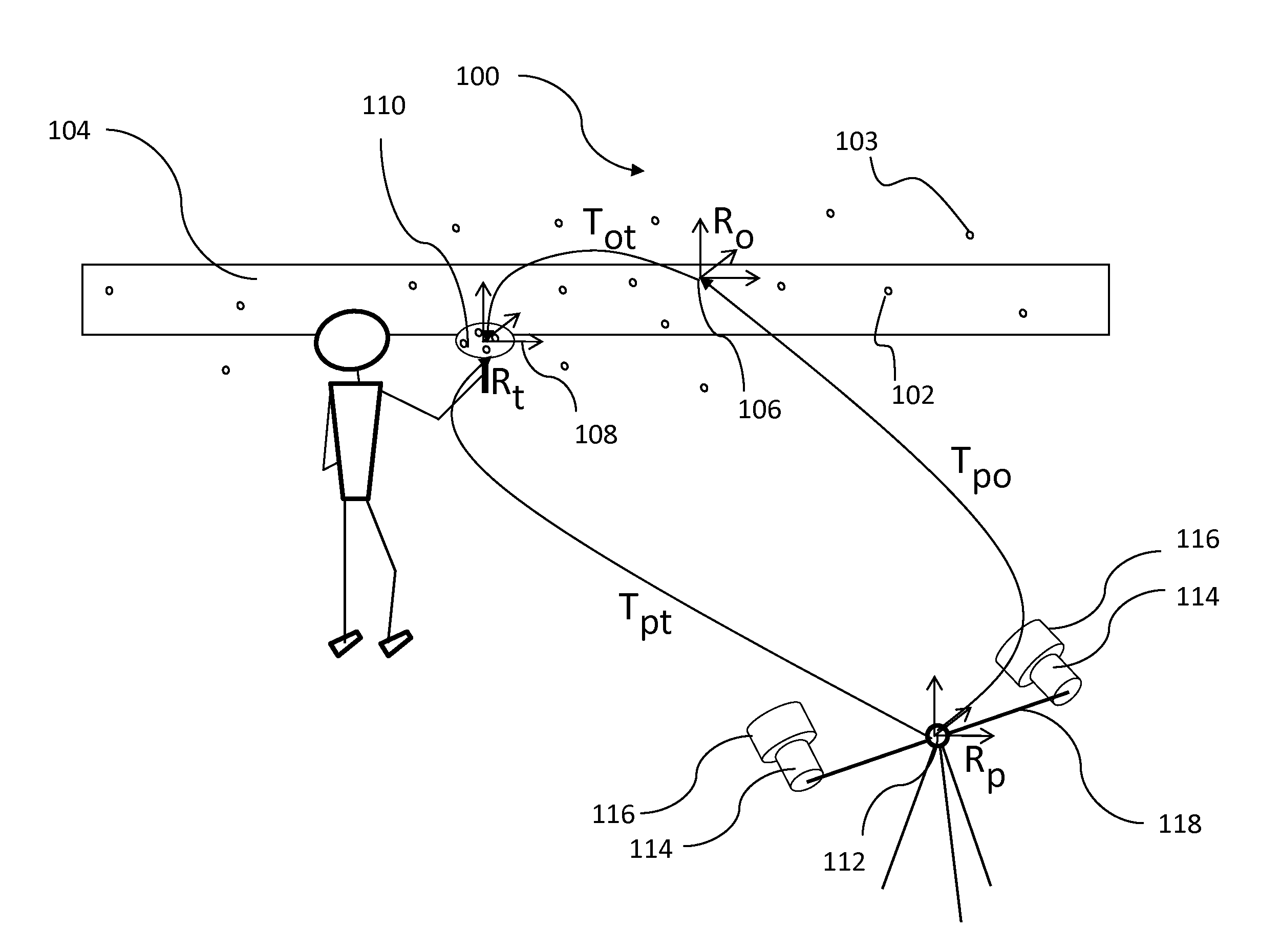

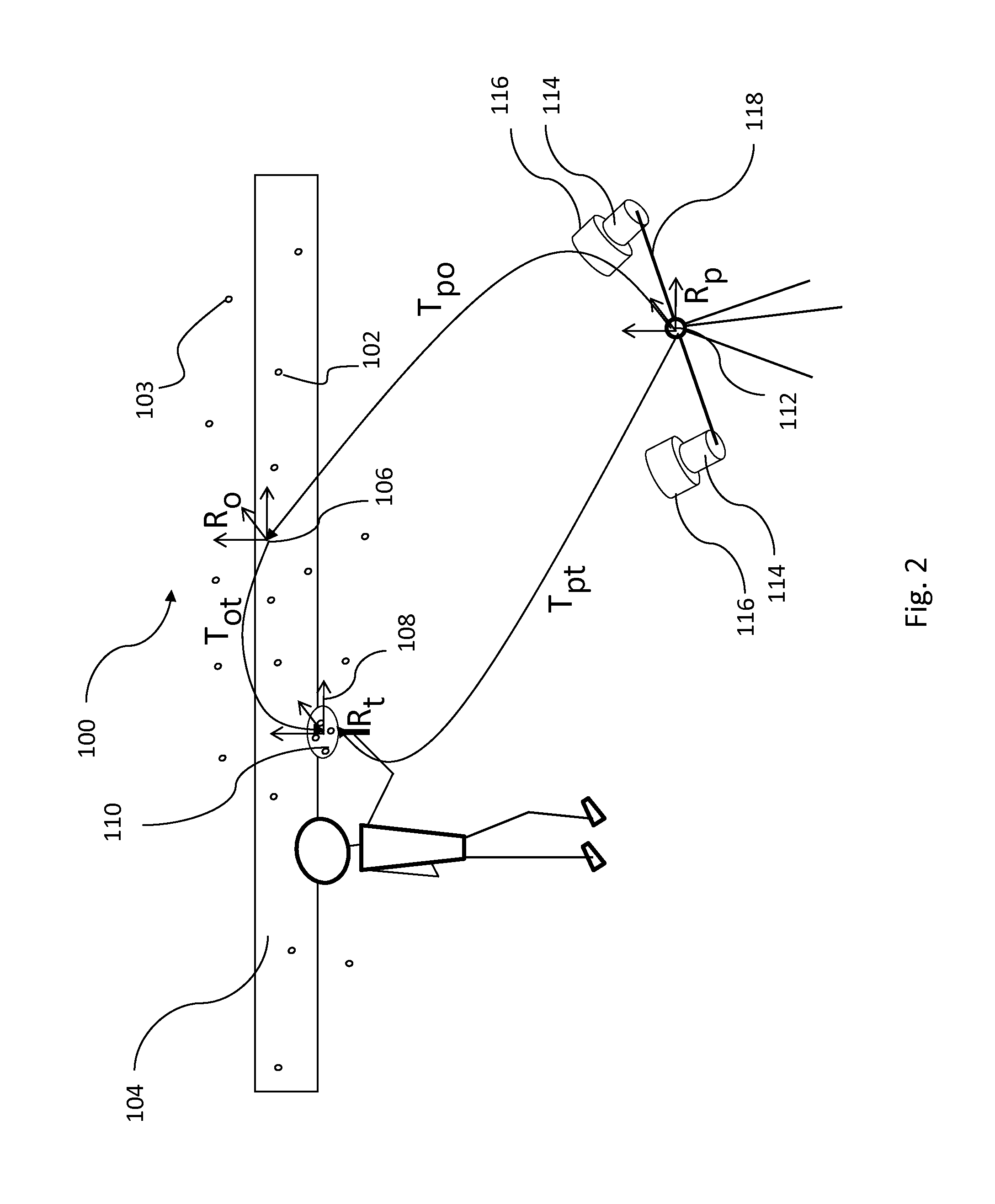

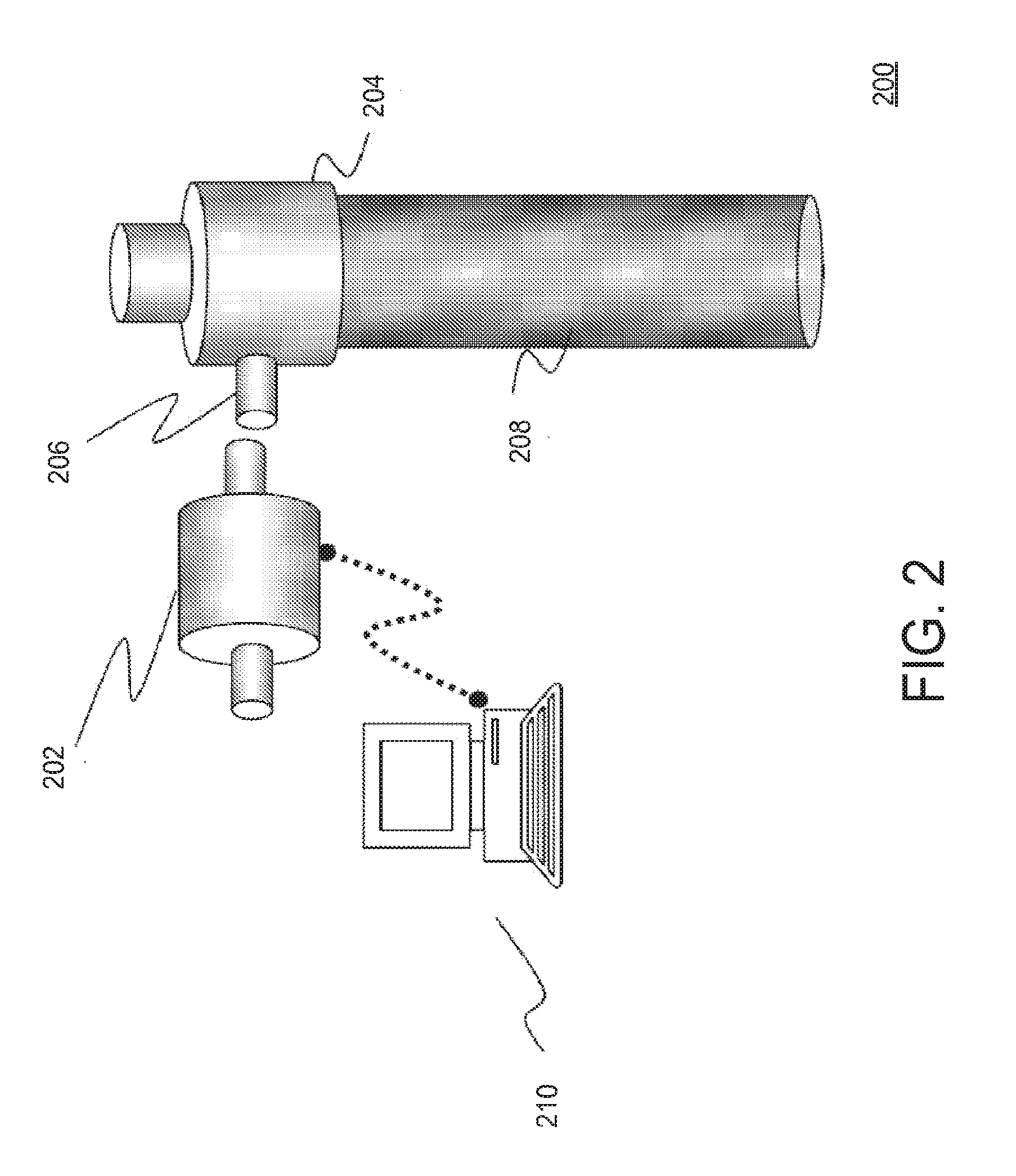

Object inspection with referenced volumetric analysis sensor

InactiveUS20130028478A1Using subsonic/sonic/ultrasonic vibration meansCharacter and pattern recognitionNon destructiveVolume analysis

A positioning method and system for non-destructive inspection of an object include providing at least one volumetric analysis sensor having sensor reference targets; providing a sensor model of a pattern of at least some of the sensor reference targets; providing object reference targets on at least one of the object and an environment of the object; providing an object model of a pattern of at least some of the object reference targets; providing a photogrammetric system including at least one camera and capturing at least one image in a field of view, at least a portion of the sensor reference and the object reference targets being apparent on the image; determining a sensor spatial relationship and an object spatial relationship; determining a sensor-to-object spatial relationship of the at I act one volumetric analysis sensor with respect to the object; repeating the steps and tracking a displacement of the volumetric analysis sensor and the object.

Owner:CREAFORM INC

Volume analysis and display of information in optical coherence tomography angiography

ActiveUS20160228000A1Solve the slow scanning speedHigh transparencyImage enhancementImage analysisData setVoxel

Computer aided visualization and diagnosis by volume analysis of optical coherence tomography (OCT) angiographic data. In one embodiment, such analysis comprises acquiring an OCT dataset using a processor in conjunction with an imaging system; evaluating the dataset, with the processor, for flow information using amplitude or phase information; generating a matrix of voxel values, with the processor, representing flow occurring in vessels in the volume of tissue; performing volume rendering of these values, the volume rendering comprising deriving three dimensional position and vector information of the vessels with the processor; displaying the volume rendering information on a computer monitor; and assessing the vascularity, vascular density, and vascular flow parameters as derived from the volume rendered images.

Owner:SPAIDE RICHARD F

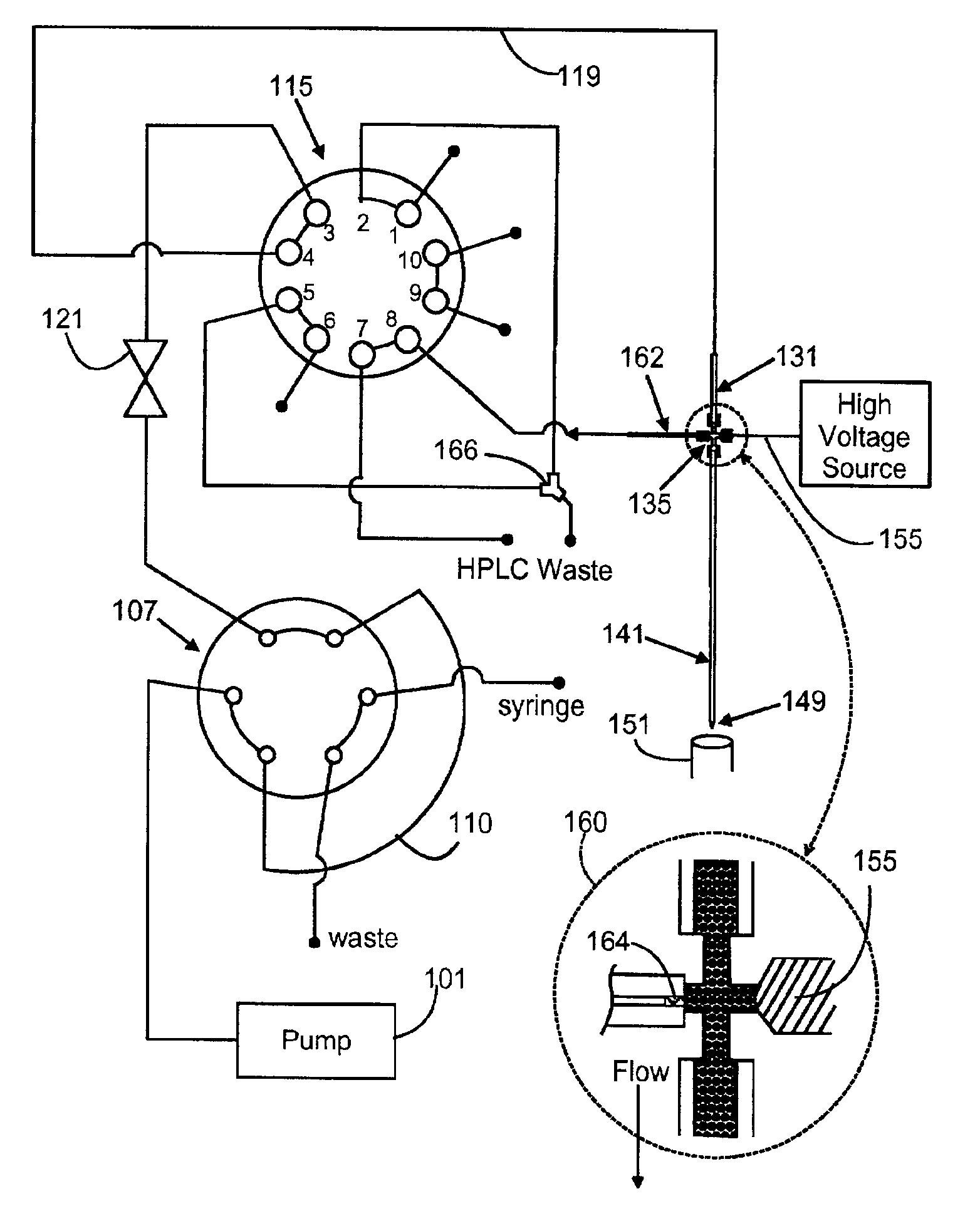

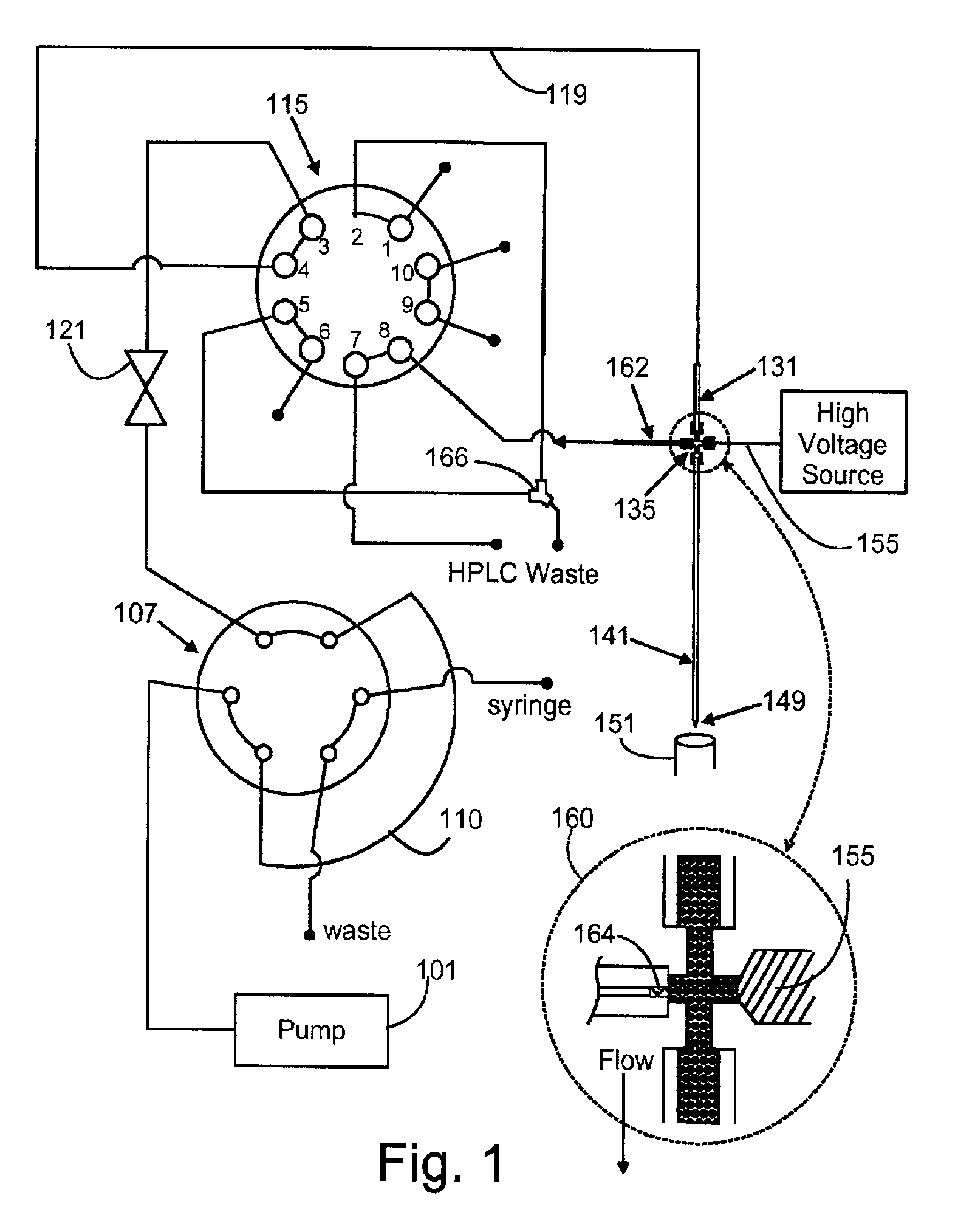

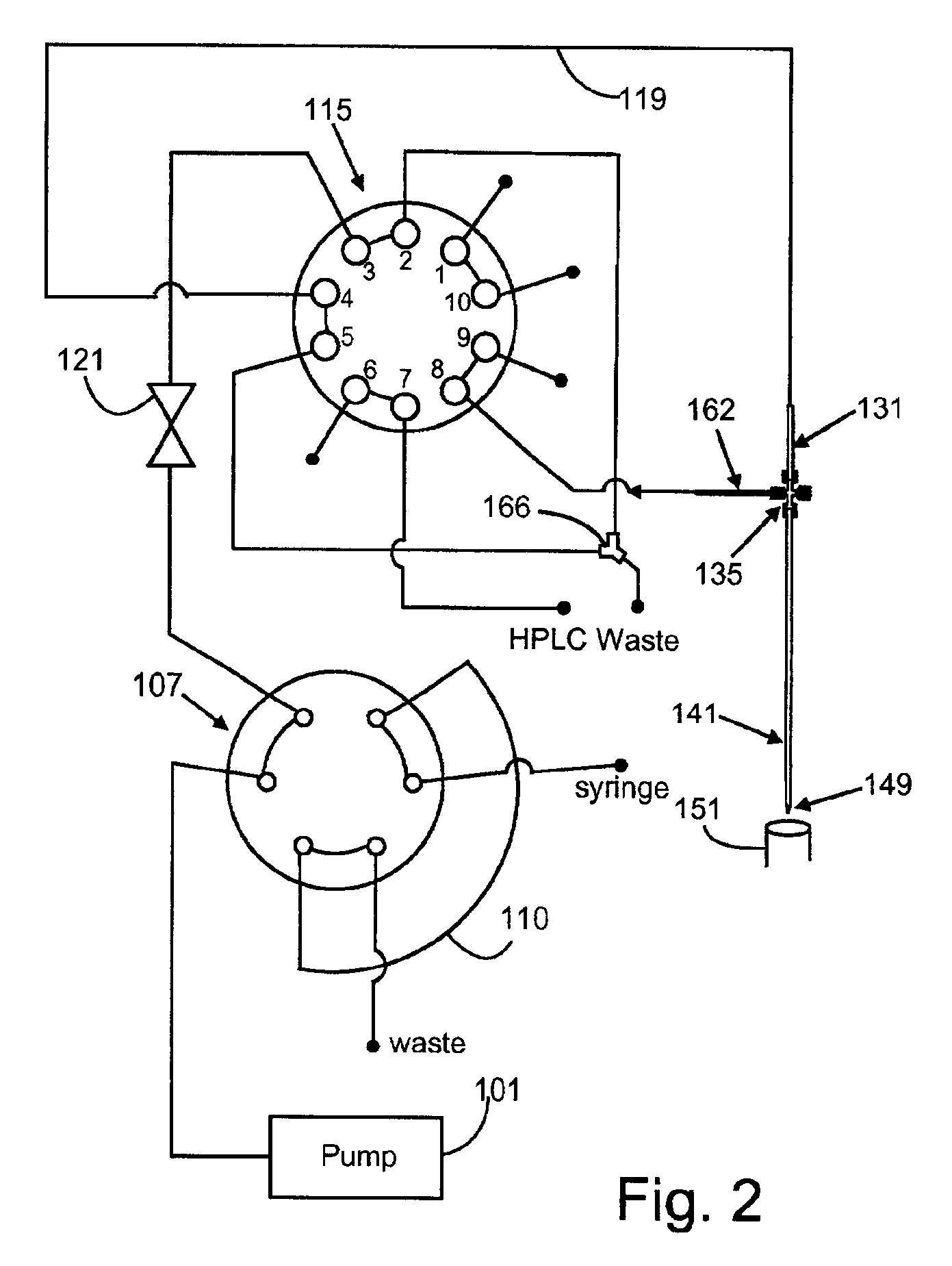

Automated capillary liquid chromatography small volume analysis system

InactiveUS6989129B2Reduce flow rateImprove performanceSamplingComponent separationChromatographic separationAutosampler

A system for automatically performing liquid chromatography analysis of low volume liquid chemical samples at nanosecond flow rates using an analysis column that integrates a pre-concentration trapping column and a chromatography separation column terminating at an electrospray nozzle of an online mass spectrometer. The analysis column consists of a capillary having an inside diameter of between 75 and 125 microns packed throughout with a porous bed of micron particles. A branch outlet positioned 10 to 16 centimeters upstream from the nozzle divides the analysis column into an upstream pre-concentration trap and a downstream separation column. An autosampler delivers low volume liquid samples to the upstream inlet via a two-position valve. Feed connections couple the autosampler to upstream inlet when the valve is open to inject a liquid sample into the pre-concentration trap at a maximum loading flow rate in the range from 0.5 to 50 microliters / minute. Thereafter, when the valve closes, it terminates the further injection the sample, and a concentrated portion of the sample then passes though the chromatography separation column at a much slower flow rate between 10 and 1,000 nanoliters per minute. Throughput can be doubled by coupling two such analysis columns to a single autosampler using a ten-port, two position valve. A single column can be supplied through a six port two-position valve.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

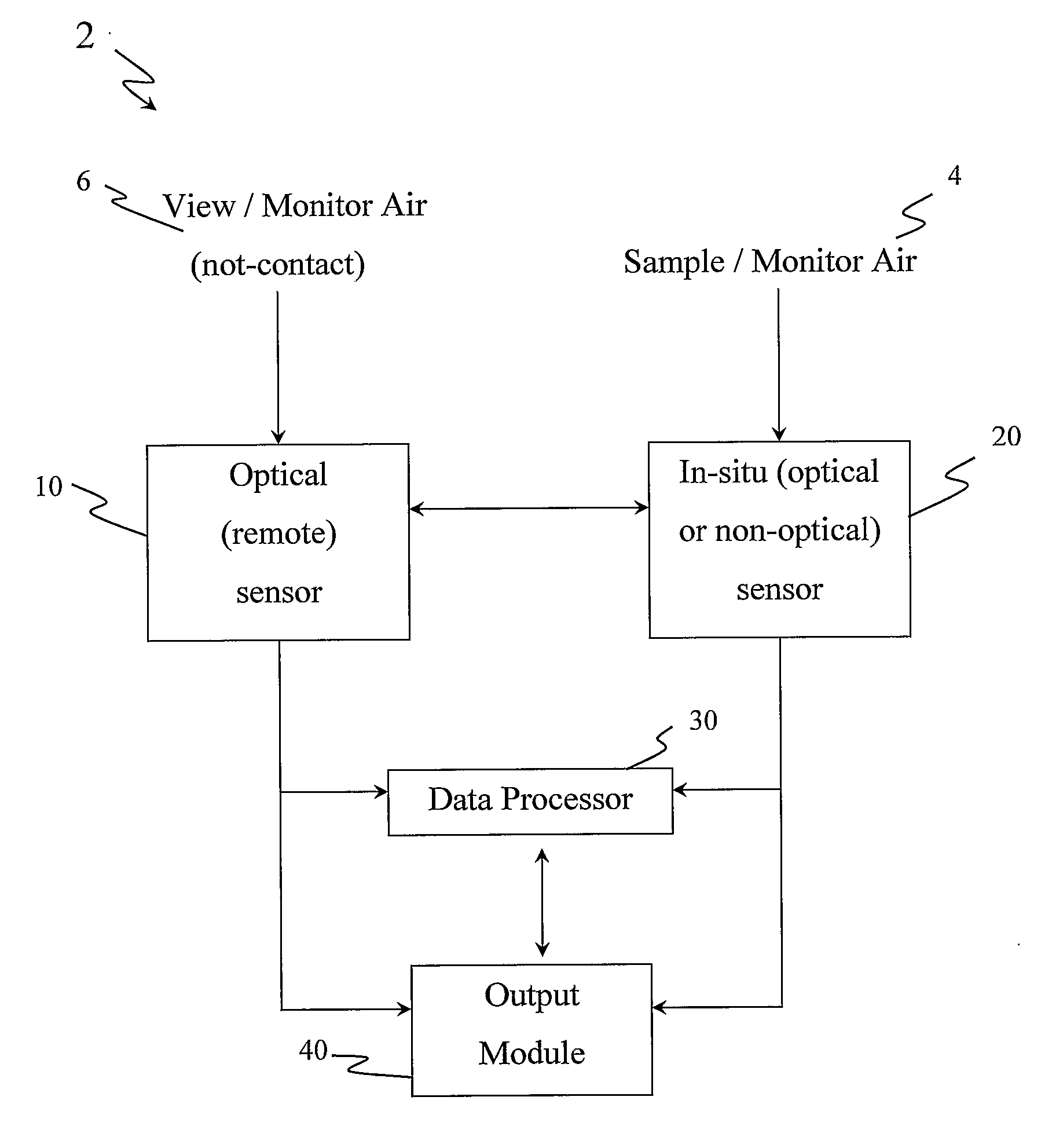

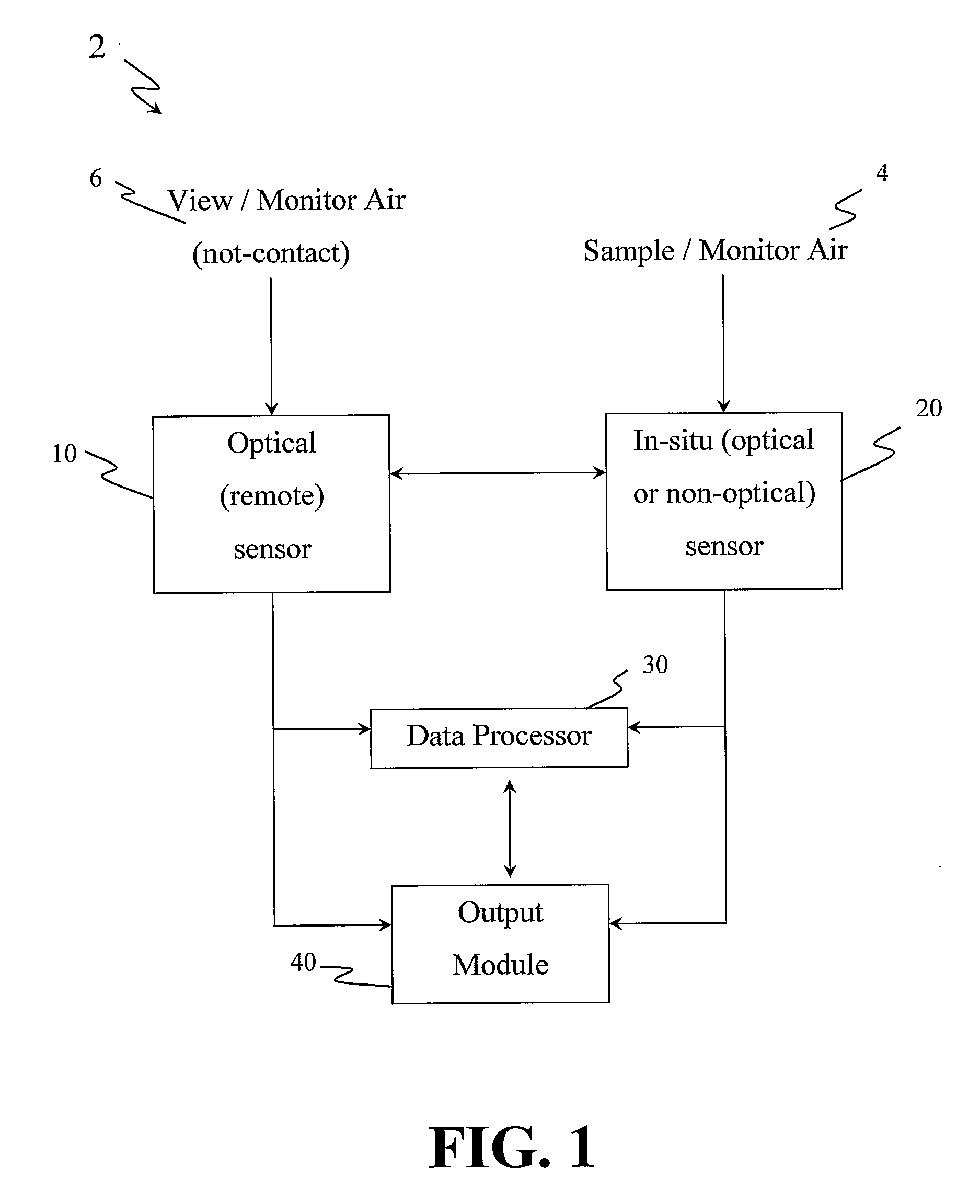

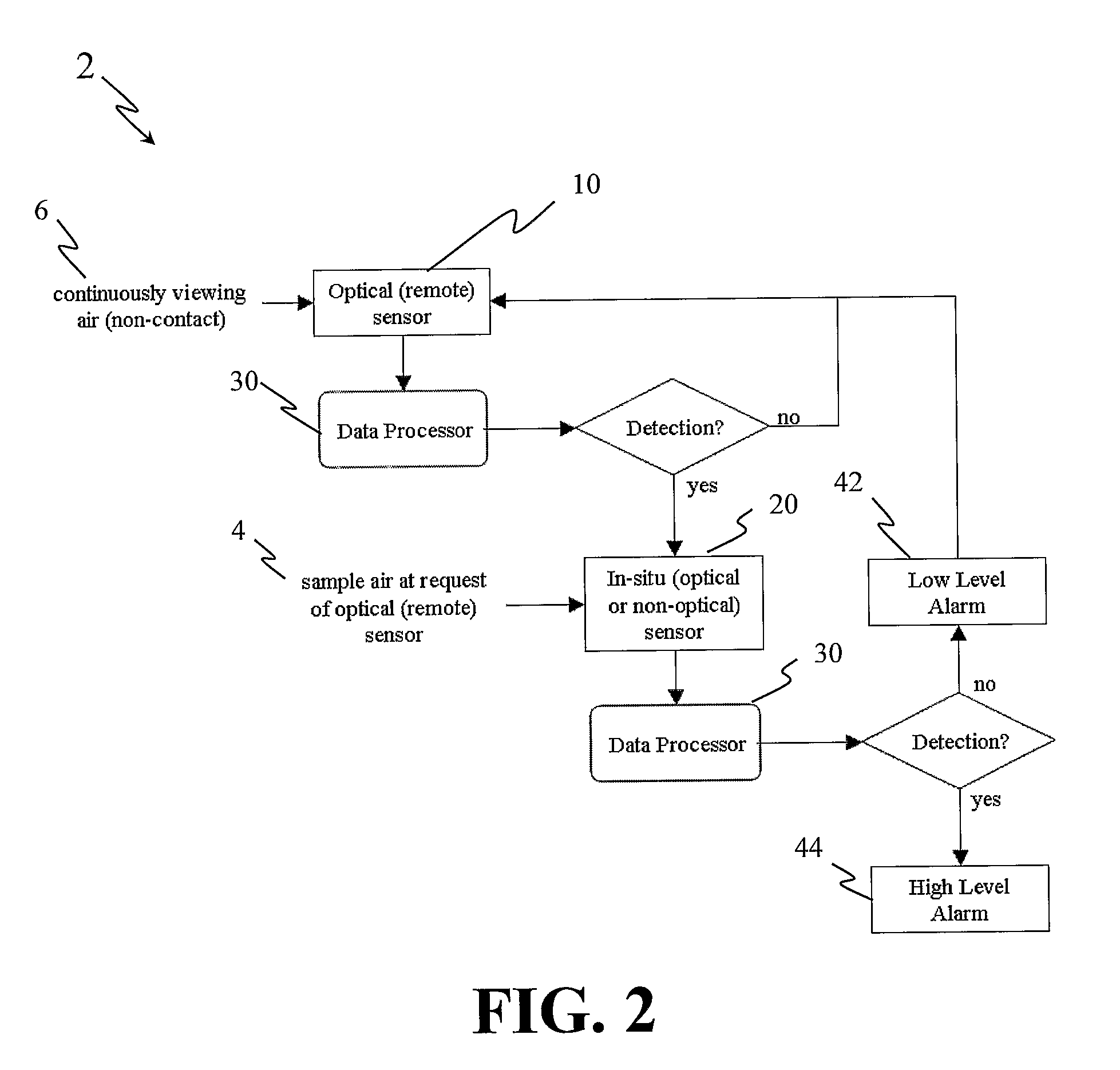

Remote sensor and in-situ sensor system for improved detection of chemicals in the atmosphere and related method thereof

InactiveUS20090055102A1Weaken energyReduce maintenanceSamplingError detection/correctionVolume analysisEngineering

A system having an optical remote sensor where sensing can be achieved from distance, and therefore without necessarily making contact with the threat chemical, with one or more in-situ sensors where sampling of air is required, and where at least one sensor is cross-reactive. Aspects of some of the various systems capable of achieving, but not limited to thereto, the following advantages: (a) by the optical sensor: long range advanced warning, rapid large volume analysis, fast response continuous monitoring for protection against bursts, safety to the operator, (b) by the in-situ sensor: high sensitivity, (c) by the combination of sensors, high specificity, better avoidance of interferences by chemicals and (d) by the inclusion of cross reactive characteristics, the ability to learn response to new chemicals.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

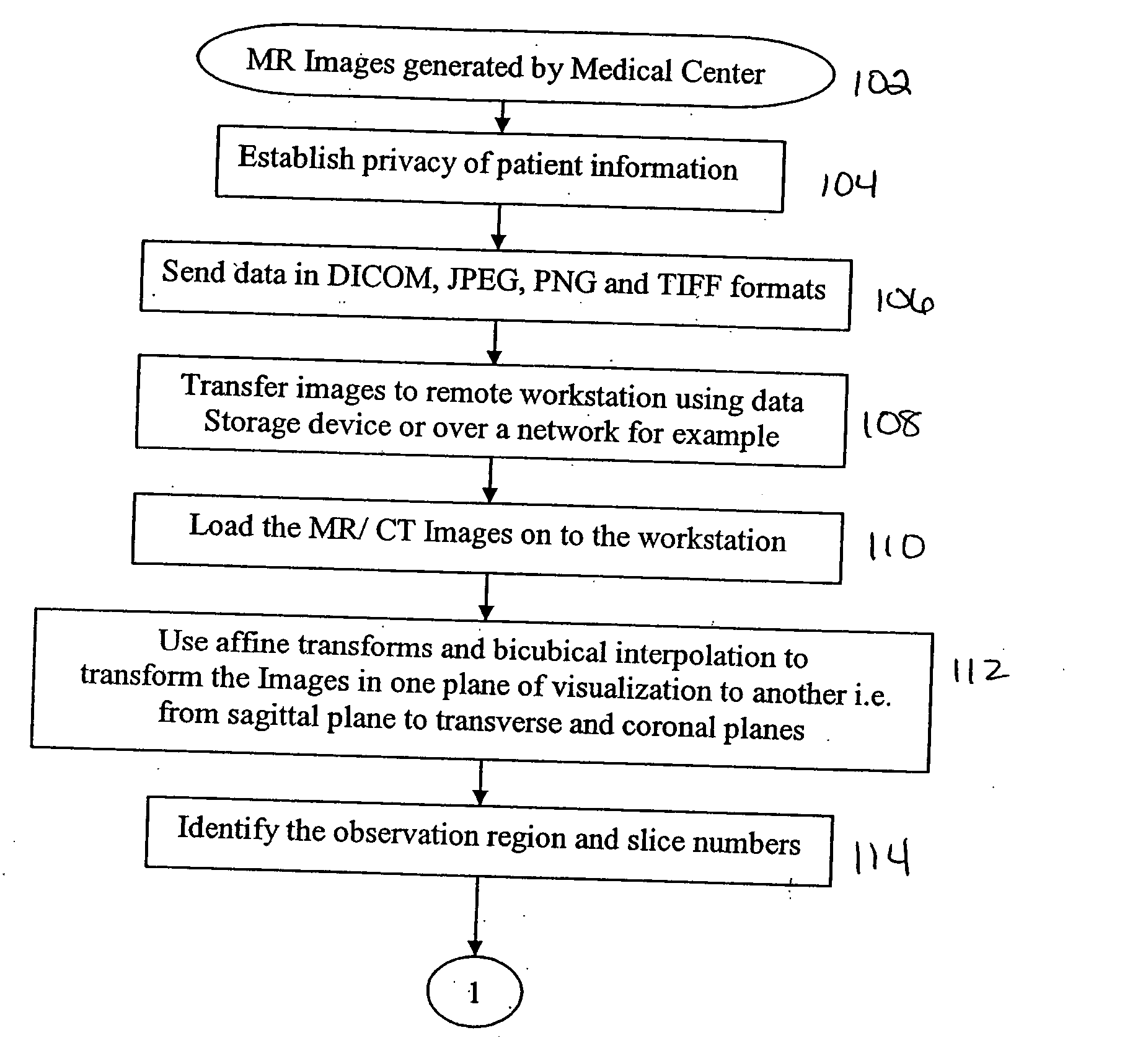

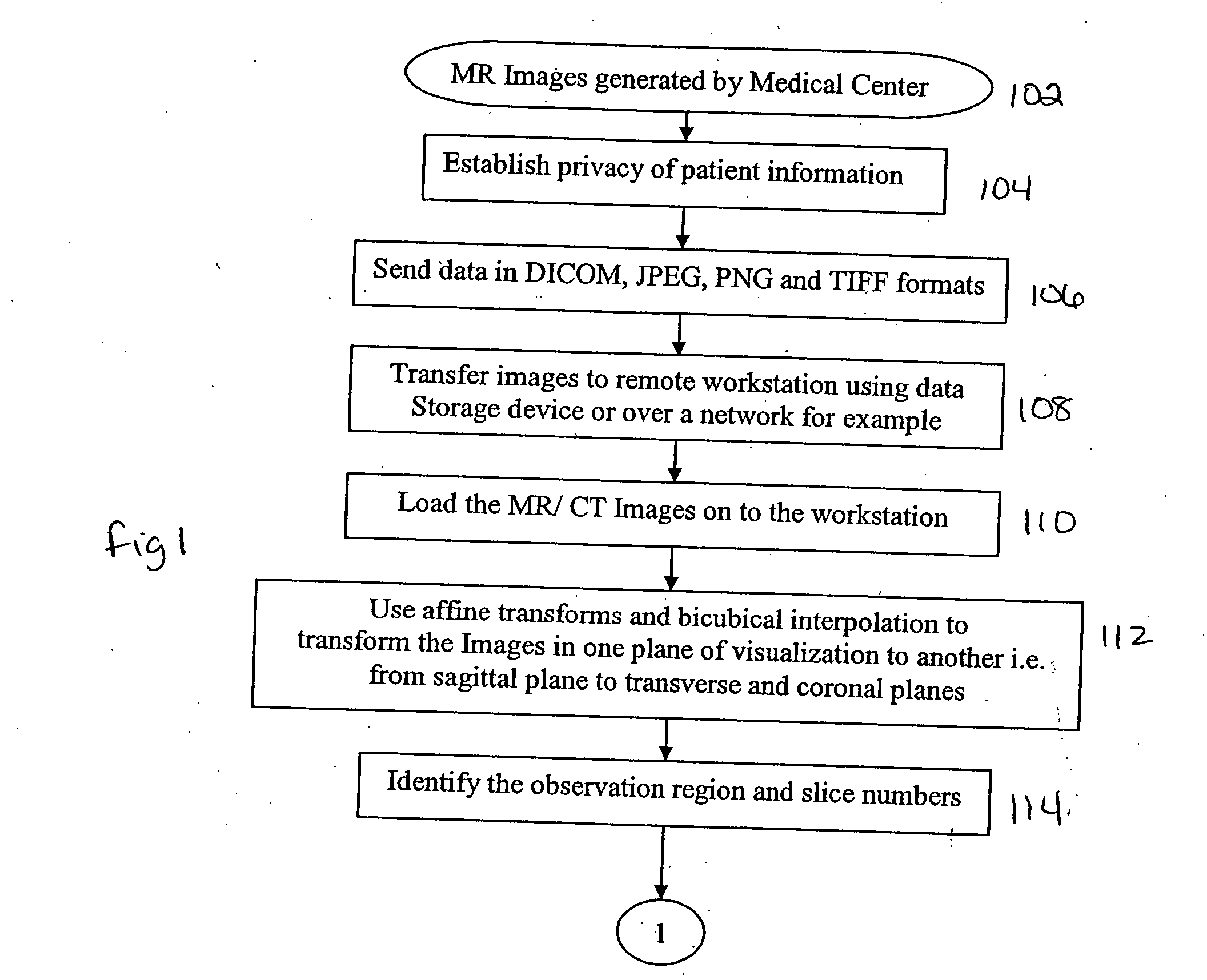

Radiographic imaging display apparatus and method

ActiveUS20060239523A1Character and pattern recognitionDiagnostic recording/measuringData setVolume analysis

The present invention is an anatomy display method for radiographically obtained data. The anatomy display method comprises obtaining an anatomy dataset comprised of pixels, each of the pixels having a luminance, and the pixels being arranged in slices. A portion of the anatomy dataset is selected. A representative slice of the portion of the anatomy dataset is used to establish a threshold pixel luminance within the entire selected portion of the anatomical dataset. All pixels in the selected portion of the anatomy dataset below the threshold are set to zero luminance. A selected organ in the selected portion is isolated by volumetric analysis. A volumetric matrix of the pixels corresponding to the selected organ is saved. The matrix may be further manipulated for examination by rotating it, tracking it, rendering it transparent and enlarging subvolumes.

Owner:BRADLEY UNIVERSITY

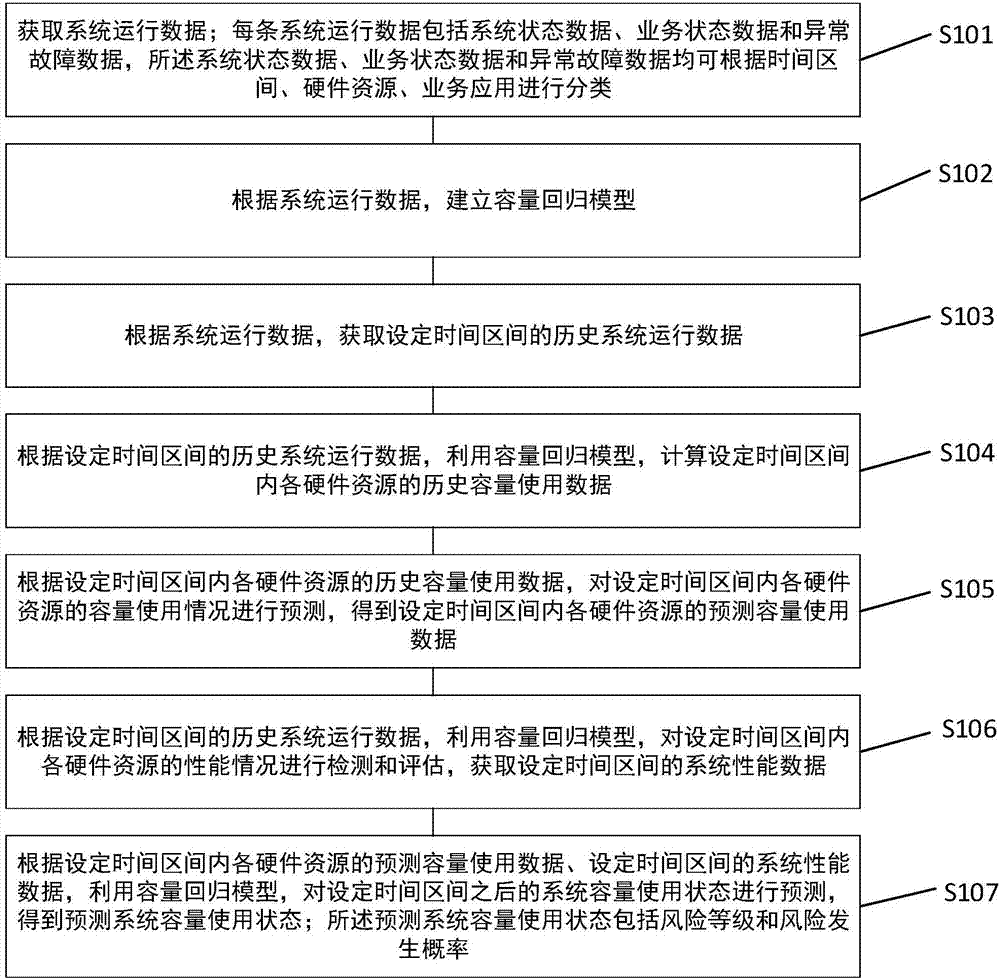

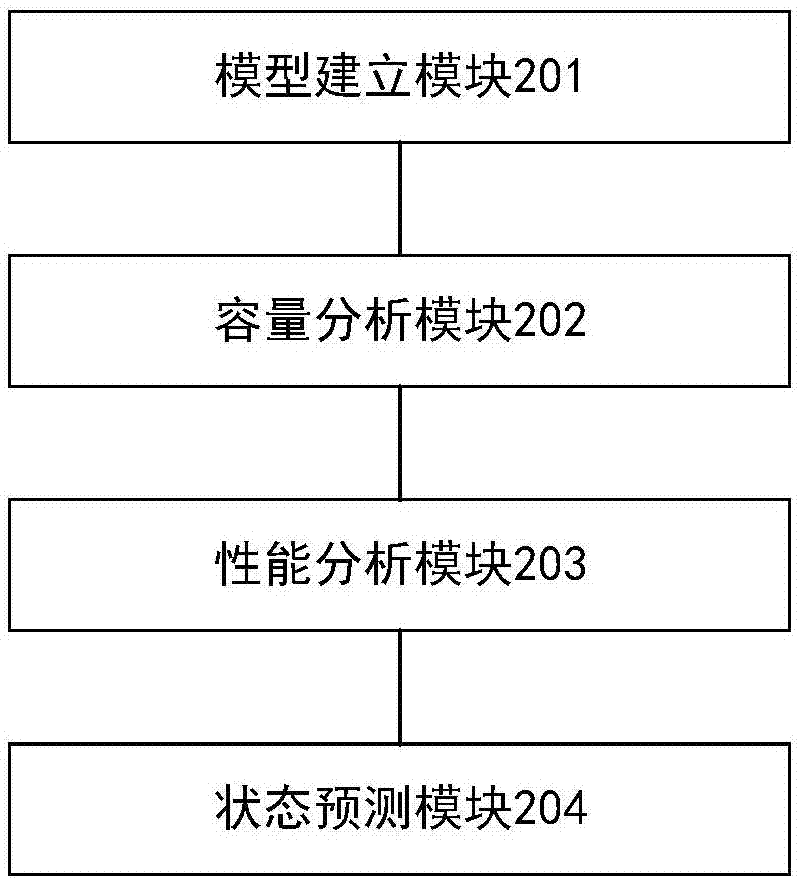

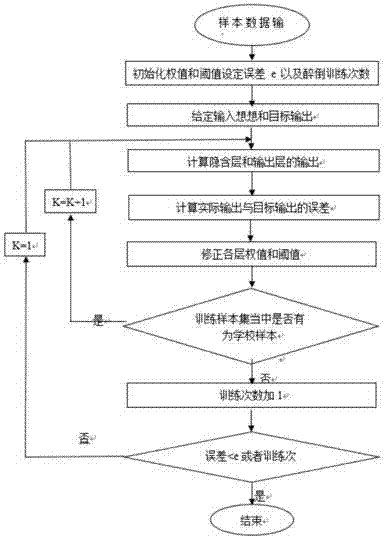

System volume analysis and prediction method and device

The invention provides a system volume analysis and prediction method and device. The method comprises the steps of obtaining system operation data, establishing a relationship between system condition data, business state data and abnormal fault data, and using the data as the foundation to establish a volume regression model, and on the basis of the volume regression model, calculating predictive volume use data of all hardware resources in a designated time and system performance data in the designated time, based on the two types of data, referring to the volume regression model, giving the prediction to the subsequent hardware resource volume, therefore through the comprehensive analysis of historic operation state data, analyzing the volume use conditions of all key resources of all stages, predetermining whether the volume of the hardware resources such as servers reaches a bottleneck, and giving warnings to potential volume risks to avoid the situation that the repair is only implemented after a hardware resource fault occurs. Therefore, the system safety is enhanced.

Owner:SHENZHEN AUDAQUE DATA TECH

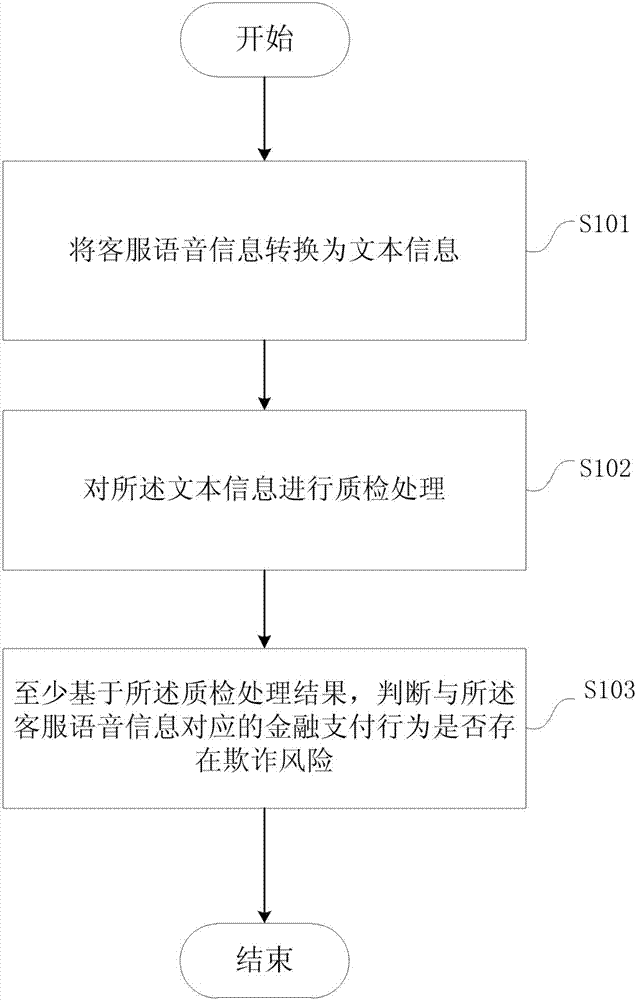

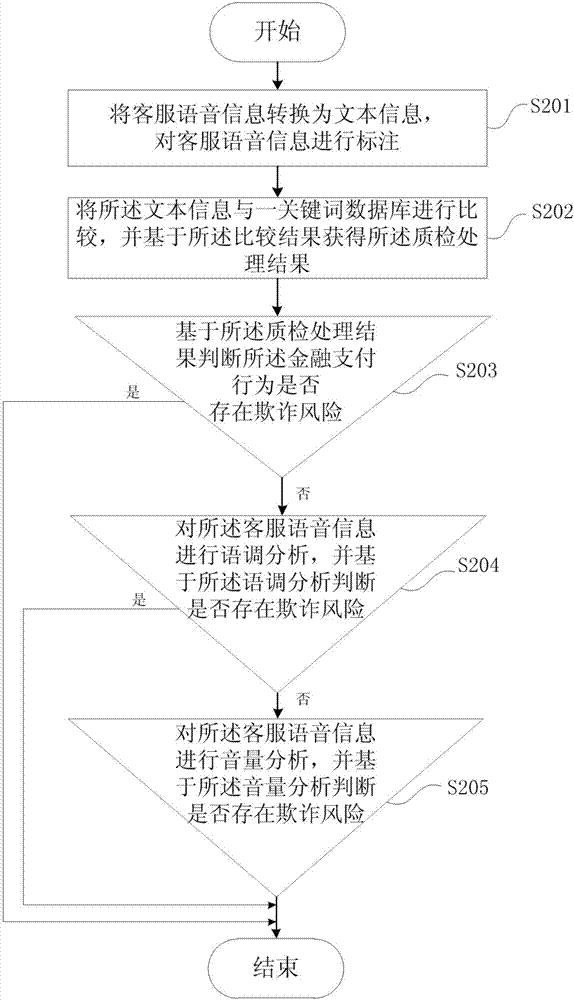

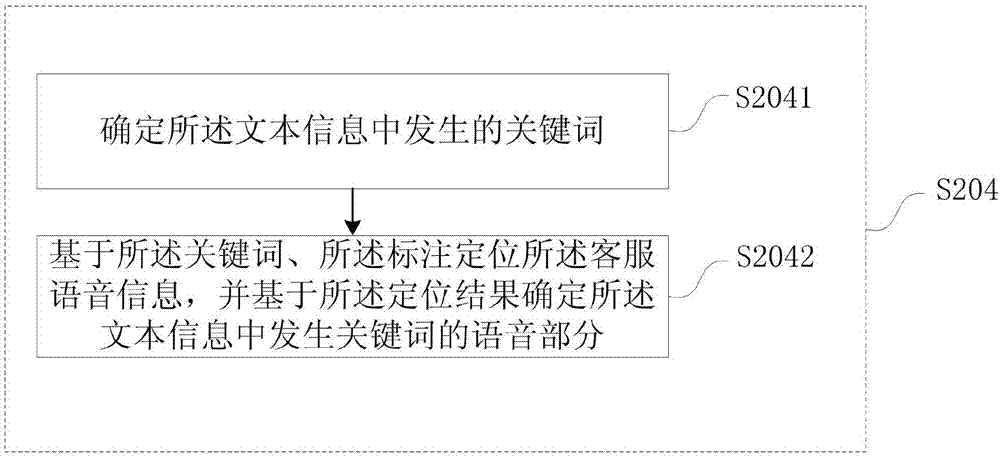

Voice quality-control financial security control system and method

The invention provides a voice quality-control financial security control method. The voice quality-control financial security control method is used for performing cheat-proof check based on customerservice voice information in a financial security control system. The voice quality-control financial security control method comprises the steps of: a, converting the customer service voice information into text information; b, performing quality control of the text information; and c, judging whether a financial payment behaviour corresponding to the customer service voice information has a cheat risk or not at least based on a quality-control processing result. According to the voice quality-control financial security control method provided by the invention, quality control of the text information is carried out; whether the financial payment behaviour corresponding to the customer service voice information has the cheat risk or not is judged based on the quality-control processing result; furthermore, tone or volume analysis of the customer service voice information is carried out; whether the financial payment behaviour corresponding to the customer service voice information hasthe cheat risk or not is further judged; and the voice quality-control financial security control method provided by the invention is powerful in function, high in practicability and simple to operate, and has high commercial value.

Owner:上海洪昇智能科技有限公司

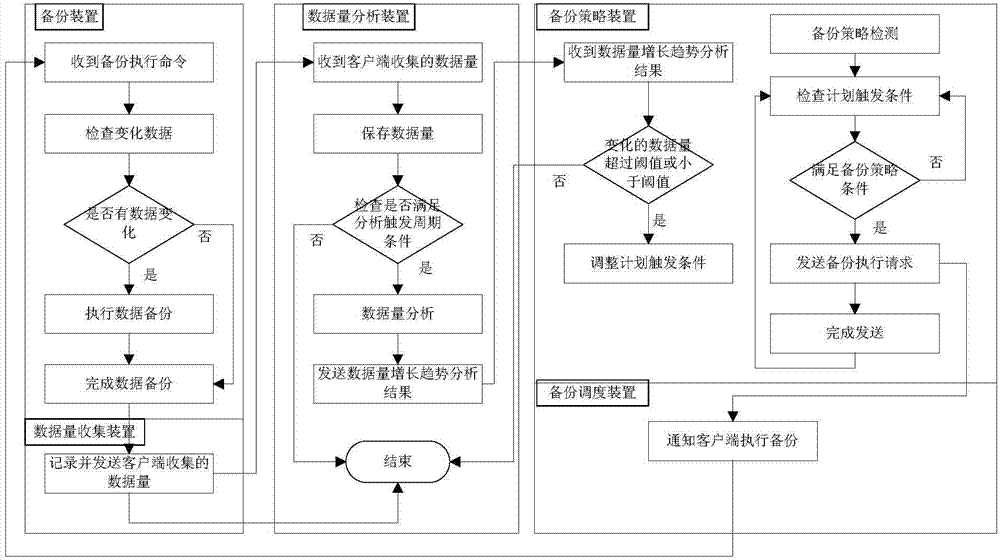

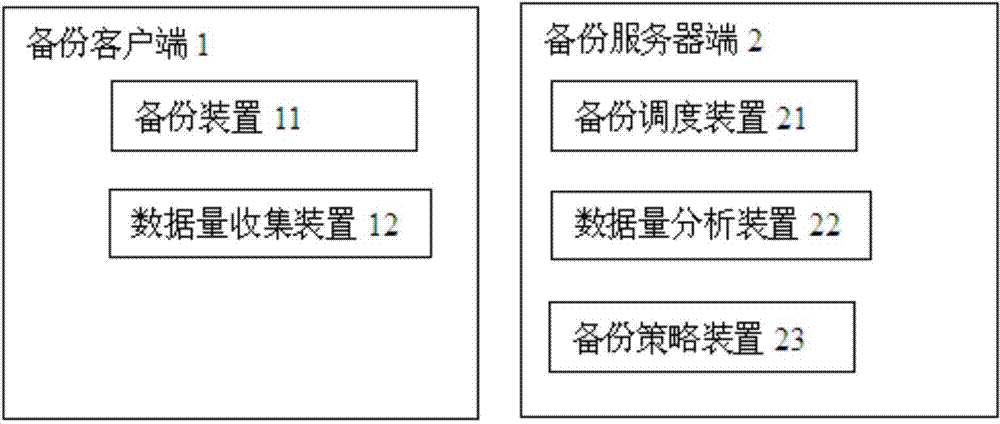

Intelligent backup method and system based on data changes

ActiveCN103617098AThe effect of smart backupTimely backup protectionRedundant operation error correctionVolume analysisClient-side

The invention relates to an intelligent backup method and system based on data changes. The intelligent backup system comprises a backup client and a backup server, the backup client comprises a backup device and a data volume collecting device, and the backup server comprises a backup dispatching device, a data volume analysis device and a backup strategy device. The backup strategy device, the backup dispatching device, the backup device, the data volume collecting device, the data volume analysis device and the backup strategy device are connected in sequence. Compared with the prior art, the intelligent backup method and system based on the data changes have the advantages that backup time is automatically adjusted, so that data backup can be performed more frequently when data increase becomes quick so as to improve data safety.

Owner:EISOO SOFTWARE

Time-series database setup automatic generation method, setup automatic generation system and monitoring server

InactiveUS9317539B2Low costReduce waste of resourcesError detection/correctionDigital data processing detailsVolume analysisData mining

If the operations manager makes configuration changes of the log database through configuration management interface, the configuration management interface records configuration information thereof on an management database. Furthermore, when log data of a monitoring target device are collected in a log collection unit through the log database, a log data volume analysis unit reads utilization information of data volume of the log database, and records the reading on a management database. A configuration changes proposal generating unit automatically generates configuration changes proposal of the log database based on the information recorded on the management database. Moreover, a metrics value for evaluating time required for configuration changes, a metrics value for evaluating performance in connection with the configuration changes, and a metrics value for evaluating the data volume in connection with the configuration changes are calculated, and an effect and an influence of changes proposal are presented to the operations manager.

Owner:HITACHI LTD

Image processing method

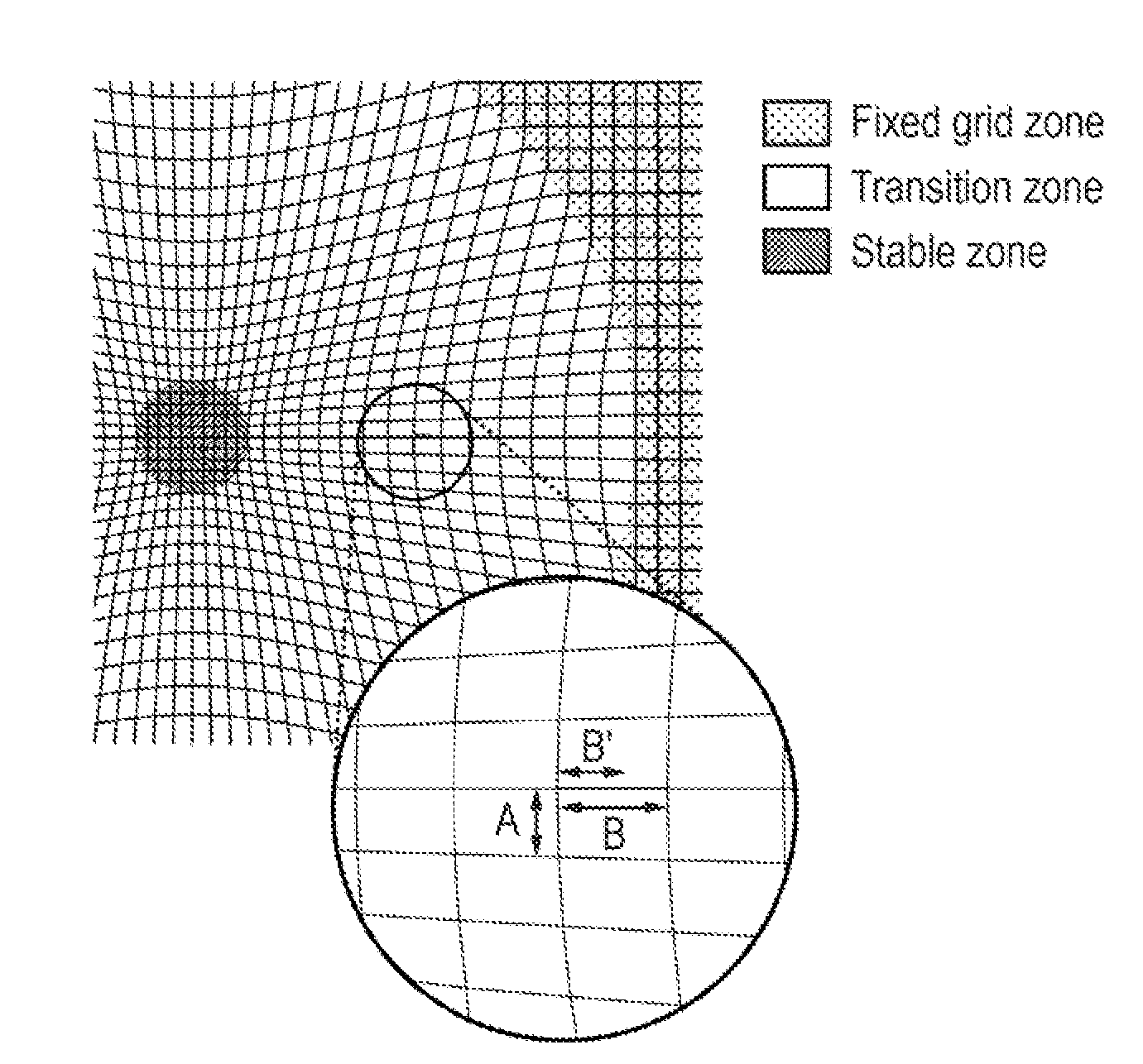

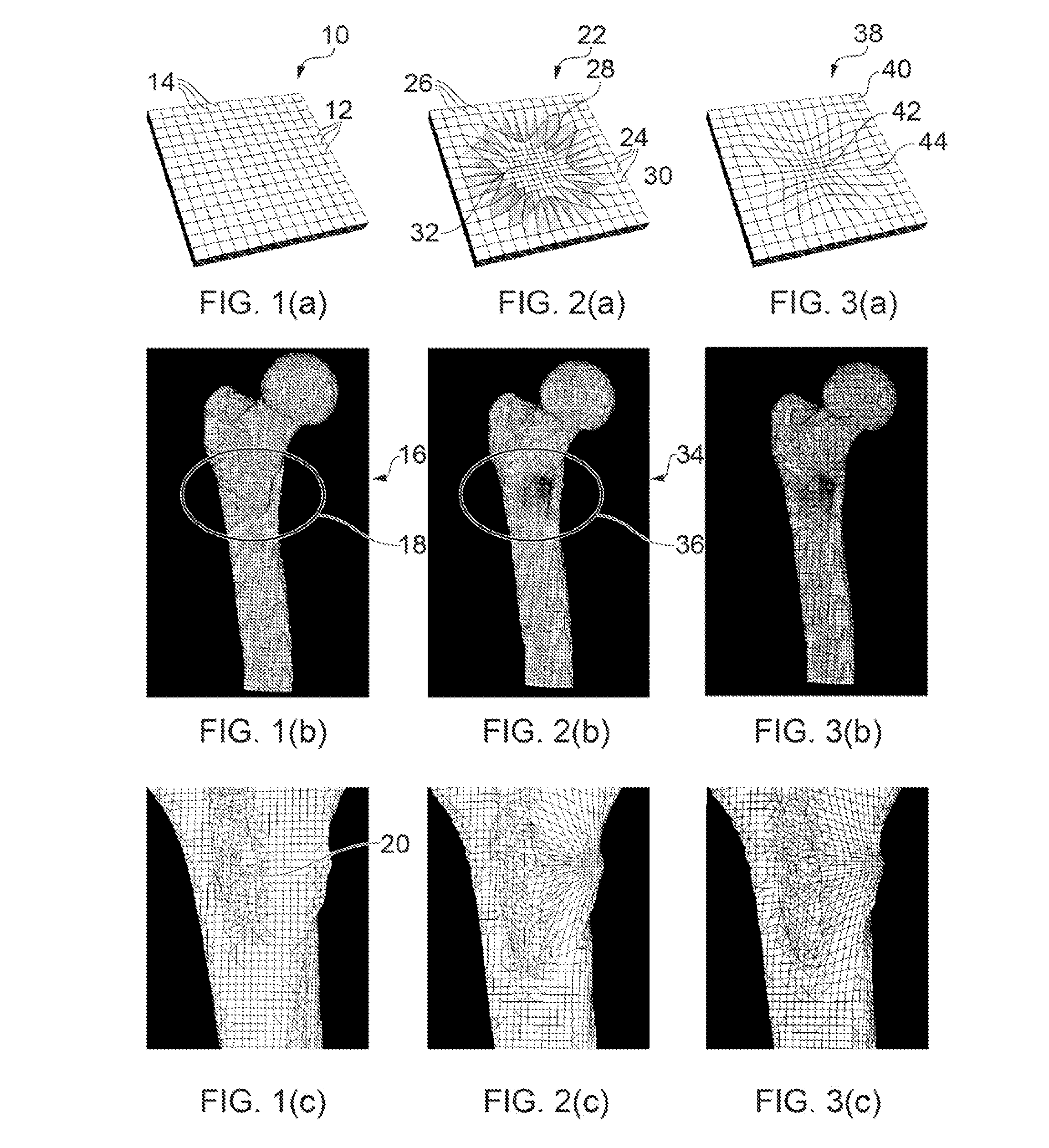

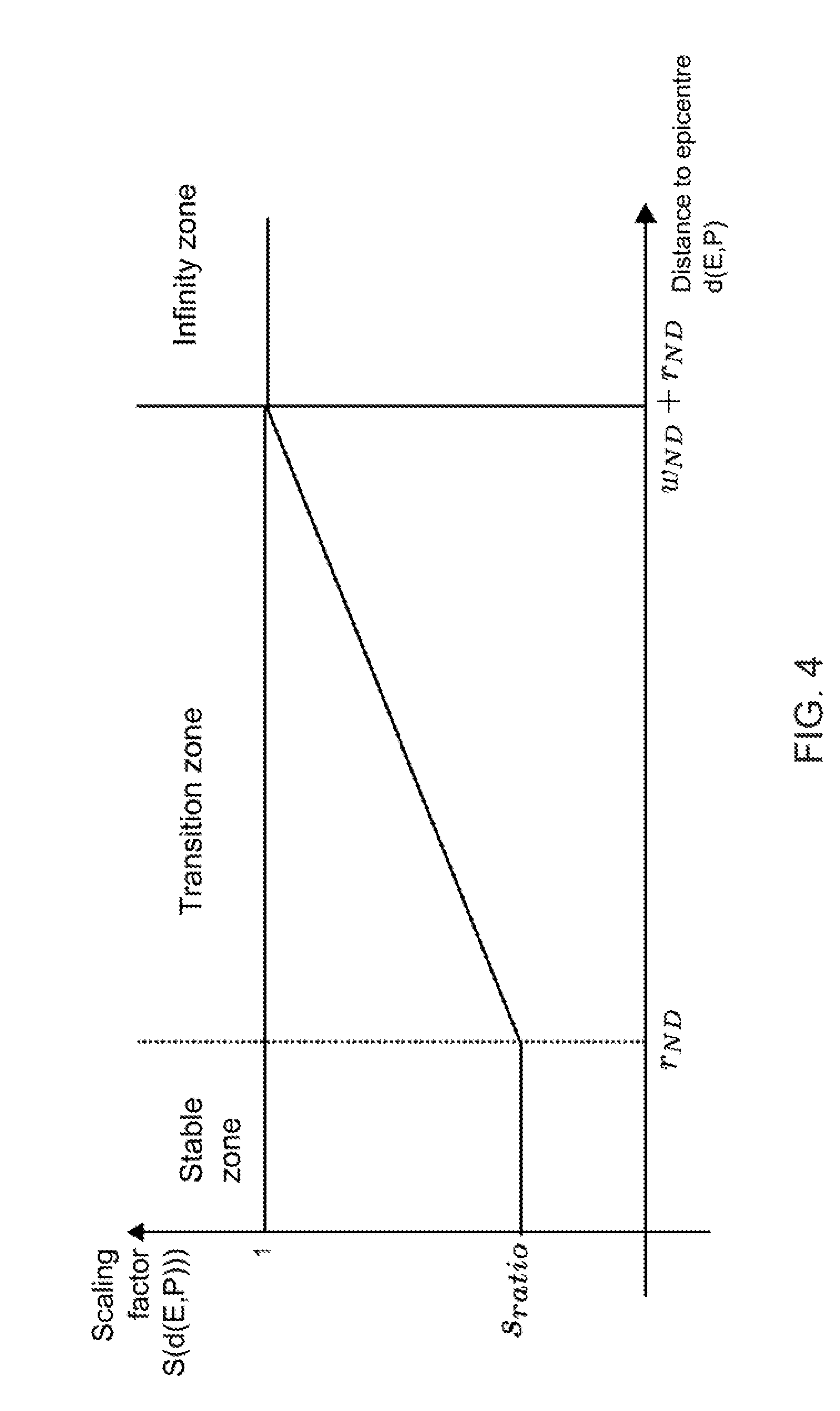

ActiveUS20090295803A1Maintain suitabilityBetter system responseGeometric image transformation3D-image renderingImaging processingData space

A modified VOMAC mesh generation method for image data sampled from an actual object in which mesh resolution can vary locally within the mesh whilst permitting control of the distortion of cells in the mesh to maintain suitability for performing finite element (or finite volume) analysis on a representation of the object.The method includes computer-implemented instructions that calculate a variable sampling point distribution (SPD) in image data space, the variable SPD having localized variations in SPD within the image data space, and the distribution of sampling points having the same topology as a uniform SPD suitable for obtaining a regular structured is mesh. The method includes generating an indication of the magnitude of cell distortion between the generated mesh and the regular structured meshVarying the mesh resolution may enable smaller elements to be located in regions of particular interest or activity when subsequently performing analysis using the mesh model.

Owner:SYNOPSYS INC

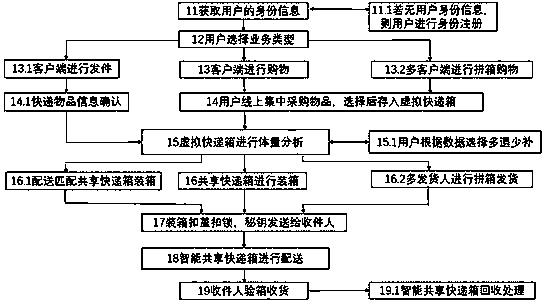

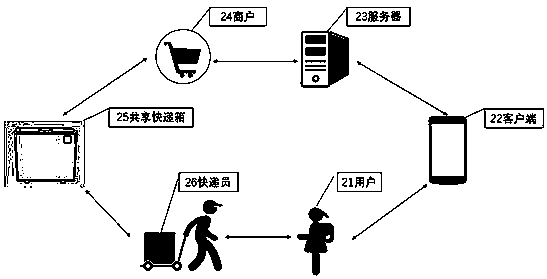

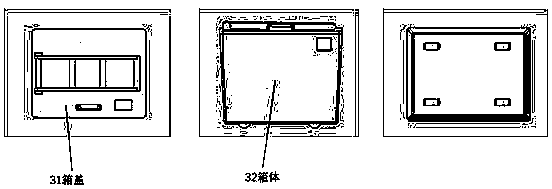

Method using smart share express box to receive and deliver express parcels and smart share express box

InactiveCN107767096ASpend lessImprove work efficiencyClosure with auxillary devicesCo-operative working arrangementsThe InternetVolume analysis

The invention provides a method using smart share express box based on internet technology to receive and deliver express parcels and the smart share express box. One concrete implementation method includes identify information of a user is acquired; if no user identity information is in presence, the user performs identity registration; the user selects a service type; shopping is performed at aclient terminal; the client terminal performs good delivery; box share shopping is performed at multiple client terminals; the user purchases goods online in a centralized manner, selects the items and stores the items into a virtual express box; express item information is confirmed; volume analysis is performed on the virtual express box; the user reduces or increases items according to the data; the share express box packing is performed; the matched share express box is delivered for packing; box share delivery is performed by multiple consigners; the box is covered and locked and a secrete key is sent to a recipient; the smart share express box is delivered; the recipient checks the box and receives the goods; the smart share express box is recycled.

Owner:田庆

Combined determination method for main components in high-carbon ferrochrome slag

InactiveCN104897661AReduce preprocessingTime consumingMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationDecompositionMolybdenum blue

A combined determination method for main components in high-carbon ferrochrome slag. The method is characterized by comprising the steps of: melting a high-carbon ferrochrome sample by a iron crucible; carrying out high-temperature melting decomposition by sodium peroxide; leaching in a 250ml plastic cup filled with water; acidifying and clarifying with sulfuric acid; placing at room temperature to obtain a high-carbon ferrochrome sample mother liquor; conducting constant volume analysis on the high-carbon ferrochrome mother liquor; decomposing the sample at one time; and respectively measuring the chemical composition of SiO2, Al2O3, MgO, CaO and Cr2O3 by 1) determination of Cr2O3 by potassium permanganate oxidation and ammonium ferrous sulfate titration method, 2) determination of SiO2 by a silicon molybdenum blue spectrophotometric method, and 3) determination of Al2O3, MgO and CaO by an EDTA volumetric method. The method greatly reduces the analysis time (determination of SiO2, Al2O3, MgO, CaO and Cr2O3 within four hours), while omits weighing and analysis of Al2O3 by a nickel crucible, and saves a lot of cost analysis.

Owner:HENAN AOXIN ALLOY

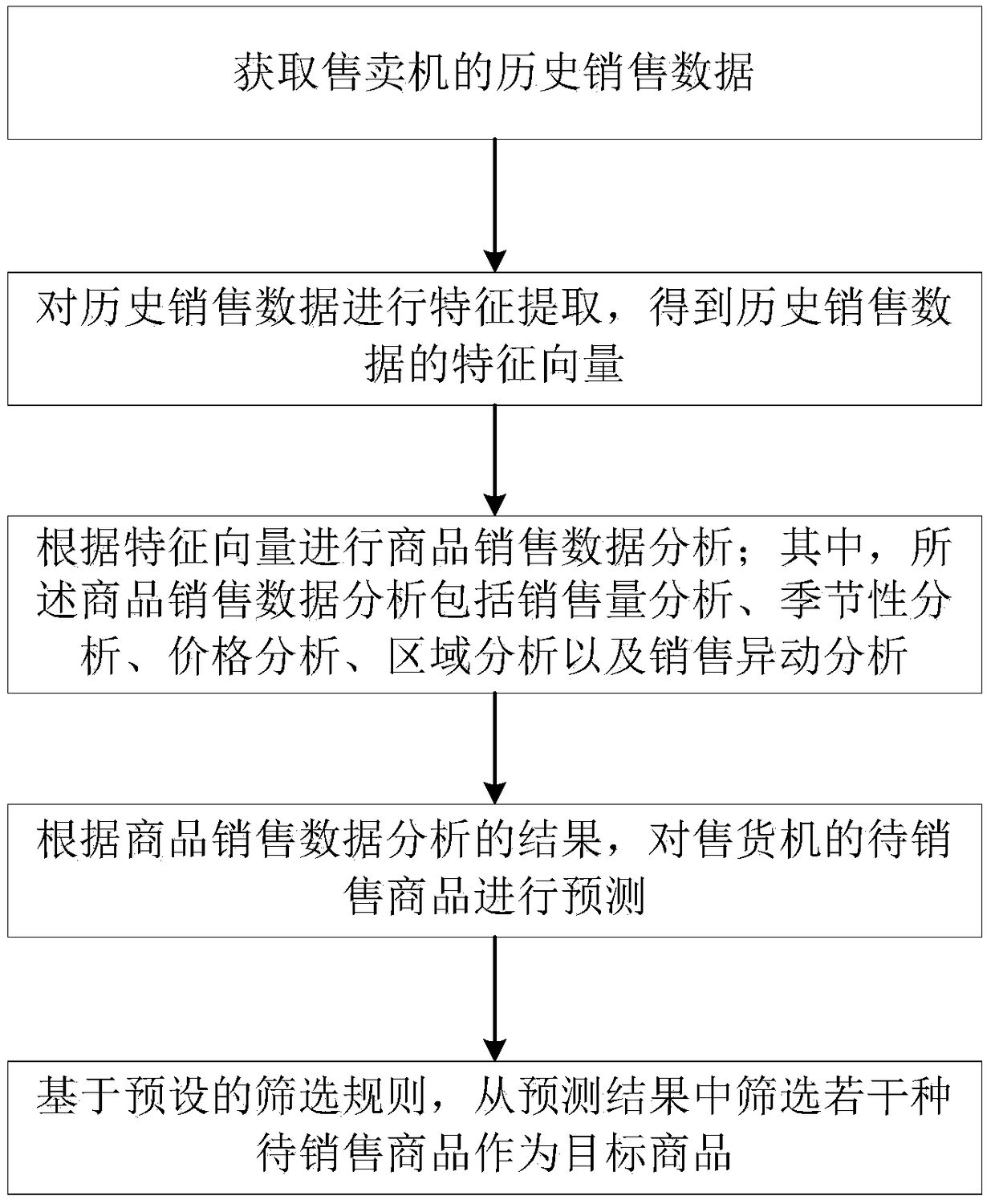

Method, system and storage medium for statistical analysis of sales data of vending machine

PendingCN109509037AImprove real-time performanceImprove accuracyMarket data gatheringFeature vectorFeature extraction

The invention discloses a sales data statistical analysis method, a system and a storage medium of a vending machine. The method comprises the following steps: obtaining the historical sales data of the vending machine; performing Feature extraction of historical sales data to obtain the feature vector of historical sales data; Analyzing the commodity sales data according to the eigenvector; Wherein, the commodity sales data analysis includes sales volume analysis, seasonal analysis, price analysis, regional analysis and sales change analysis; According to the result of the analysis of the commodity sales data, forcasting the merchandise to be sold of the vending machine. Based on the preset screening rules, selecting several kinds of merchandise to be sold as the target merchandise from the forecasting results. The invention can provide real-time merchandise sales suggestions for merchants according to the screened target merchandise, improves the real-time property and accuracy of data analysis, can fully excavate consumer preferences, has higher pertinence, and can be widely applied in the technical field of data analysis.

Owner:广州联业商用机器人科技股份有限公司

In-Line Composition and Volumetric Analysis of Vent Gases and Flooding of the Annular Space of Flexible Pipe

InactiveUS20170023435A1High frequencyReduce in quantityMeasurement of fluid loss/gain rateDrilling rodsLine sensorExhaust valve

A method and system for monitoring a flexible pipe, including an inline sensor system coupled to the annulus of the flexible pipe to detect corrosion of the flexible pipe. Also disclosed are method and system for monitoring an amount of water being accumulated in an annulus of a flexible pipe, including locating a pressure measurement system proximate to the annulus for measuring pressure of gas inside the annulus; controlling a flow of vent gas with a vent gas valve; positioning a flow measurement system upstream or downstream of the vent gas valve for measuring the flow of the vent gas when the vent gas valve is opened; and collecting with a microprocessor pressure and flow measurement data from the pressure and the flow measurement systems for determining the amount of water accumulated in the annulus based on the collected pressure and flow measurement data.

Owner:SCHLUMBERGER TECH CORP

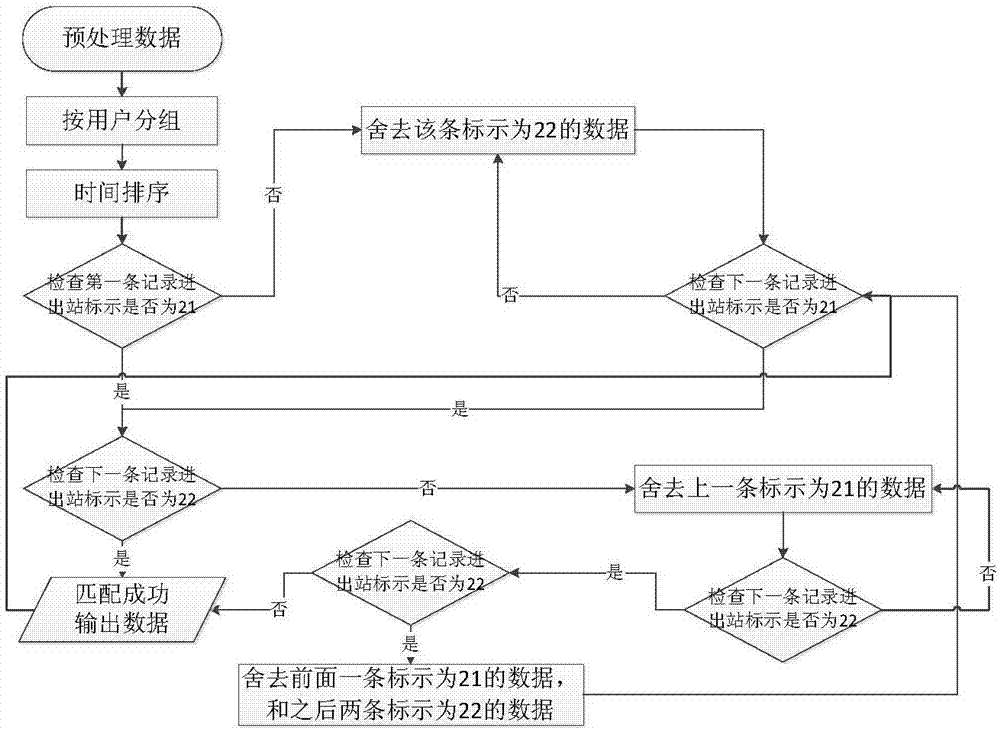

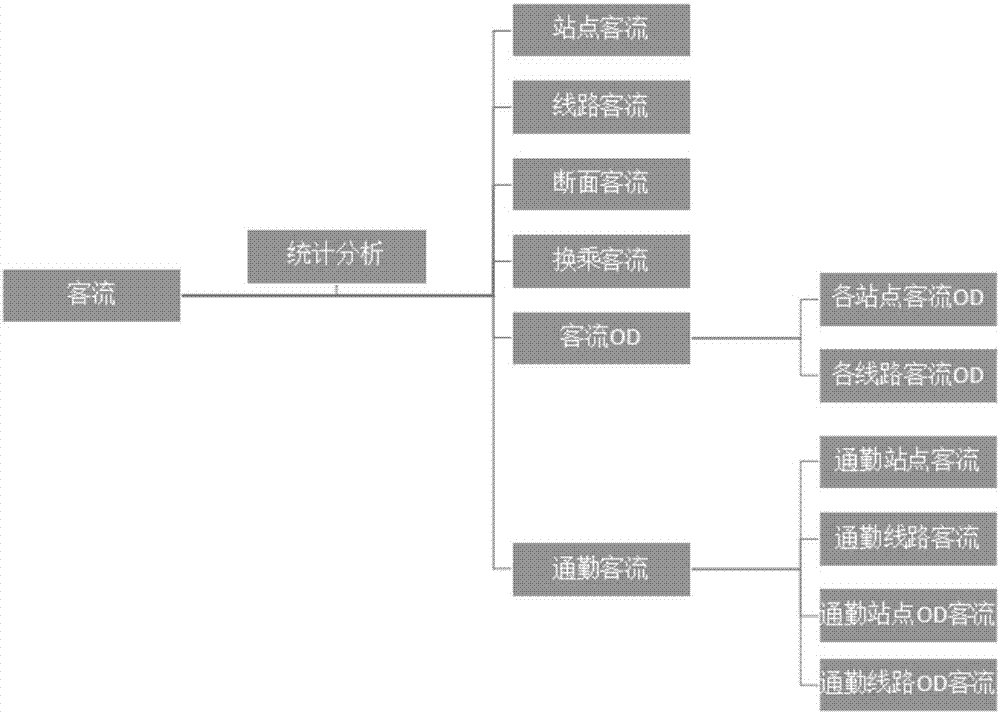

Rail transport passenger flow prediction method based on rail IC card and mobile phone signaling data

The invention relates to a rail transport passenger flow prediction method based on a rail IC card and mobile phone signaling data. The method comprises the following steps of S1, collecting rail transport passenger IC card data information and carrying out OD matching on pretreatment data; S2, carrying out commuting identification, inputting data of working days, grouping according to users, and determining a commuting rule of each user in the working days: when same inbound site and outbound site days of the user reach 50% of total days, determining that a trip is a commuting trip of the user; S3, calculating a rail transport passenger flow, wherein statistics indexes include a site passenger flow, a line passenger flow, a section passenger flow, a transfer passenger flow, a passenger flow OD, a commuting site passenger flow, a commuting line passenger flow, a commuting site OD passenger flow and a commuting line OD passenger flow; S4, carrying out normal state passenger flow volume analysis and holiday passenger flow volume analysis; and S5, carrying out normal state passenger flow volume prediction and holiday passenger flow volume prediction. By using the method, a rail transport passenger flow volume can be accurately predicted, and the method has an important effect on a reasonable compiling transport power configuration scheme, a passenger flow organization scheme and the like.

Owner:CHONGQING UNIV OF POSTS & TELECOMM +1

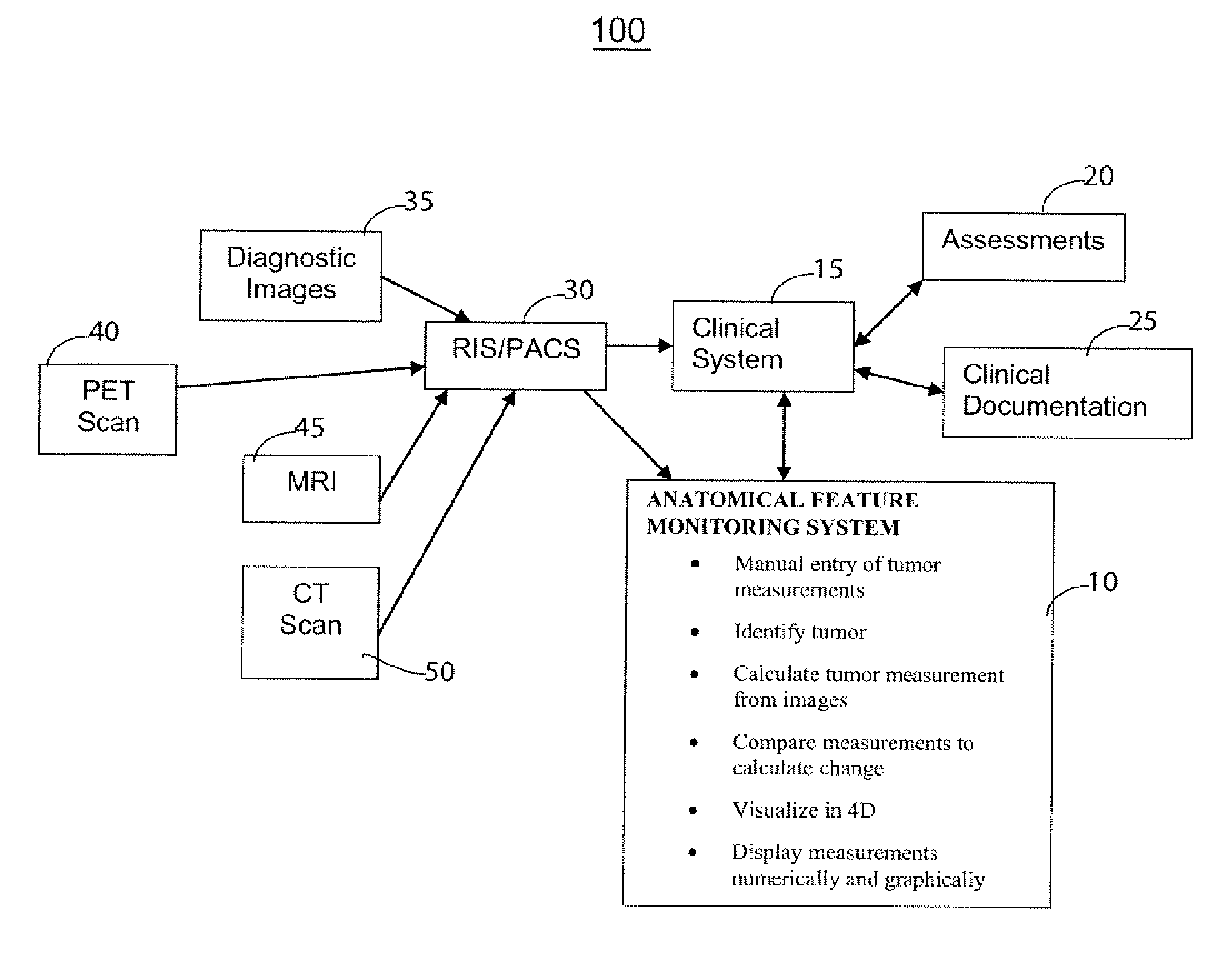

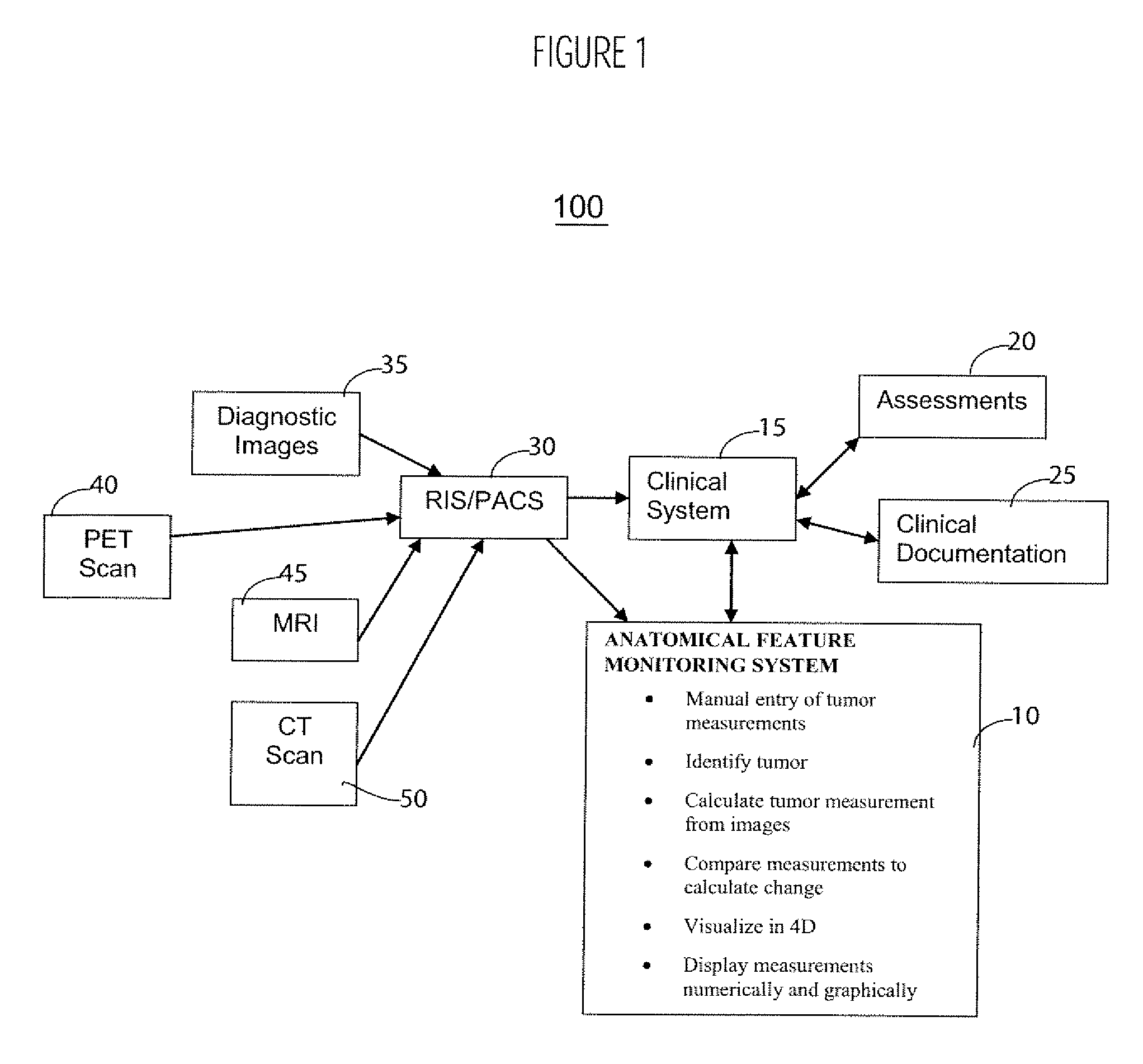

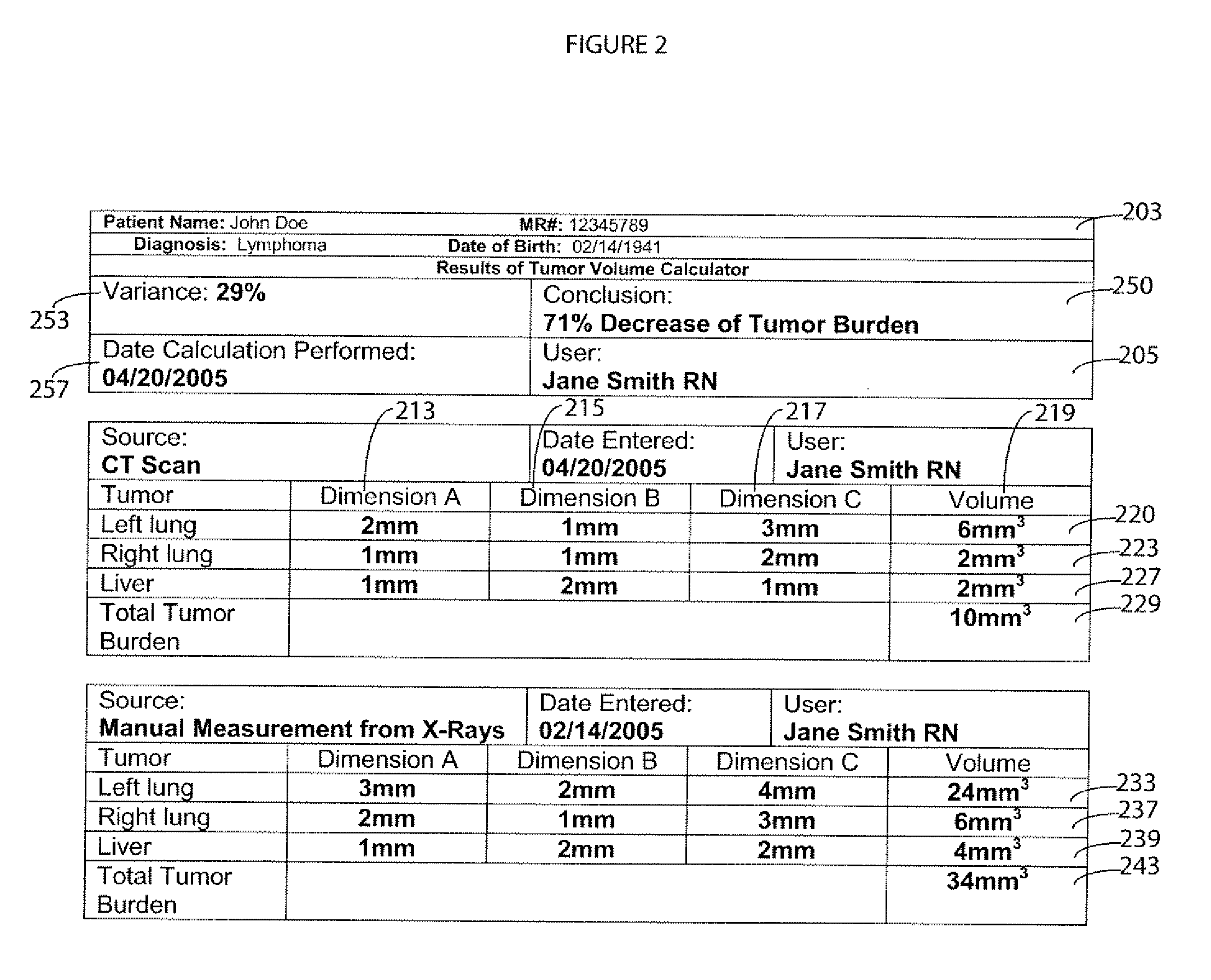

Anatomical Feature Tracking and Monitoring System

InactiveUS20070027408A1Person identificationMedical report generationAbnormal tissue growthTumor response

A system according to invention principles automatically calculates anatomical feature (e.g., tumor, body part, organ) size electronically to provide a clinician with useful information when assessing the tumor response during treatment. A system for monitoring change in patient anatomical features, includes a volumetric analyzer for automatically analyzing data derived from an imaging unit that represents a three dimensional view of a patient anatomical feature in order to determine spatial characteristics of the anatomical feature. A comparison processor automatically compares a first set of spatial characteristics of a patient anatomical feature derived at a first time with a second set of corresponding spatial characteristics of the patient anatomical feature derived at a subsequent second time, to provide change data representing change in spatial characteristics of the patient anatomical feature over a period of time. A repository stores change data for access by a user.

Owner:SIEMENS MEDICAL SOLUTIONS HEALTH SERVICES CORPORAT

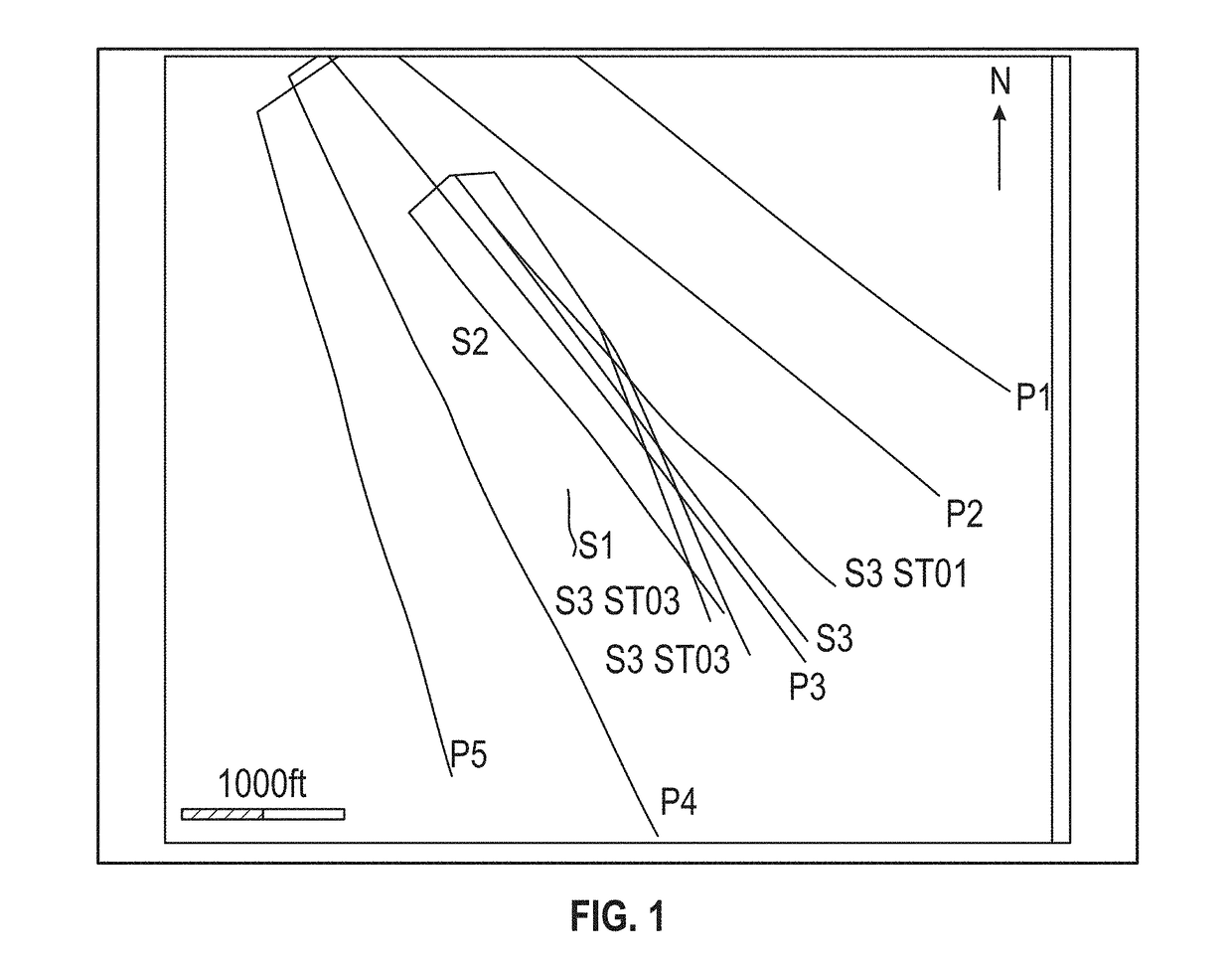

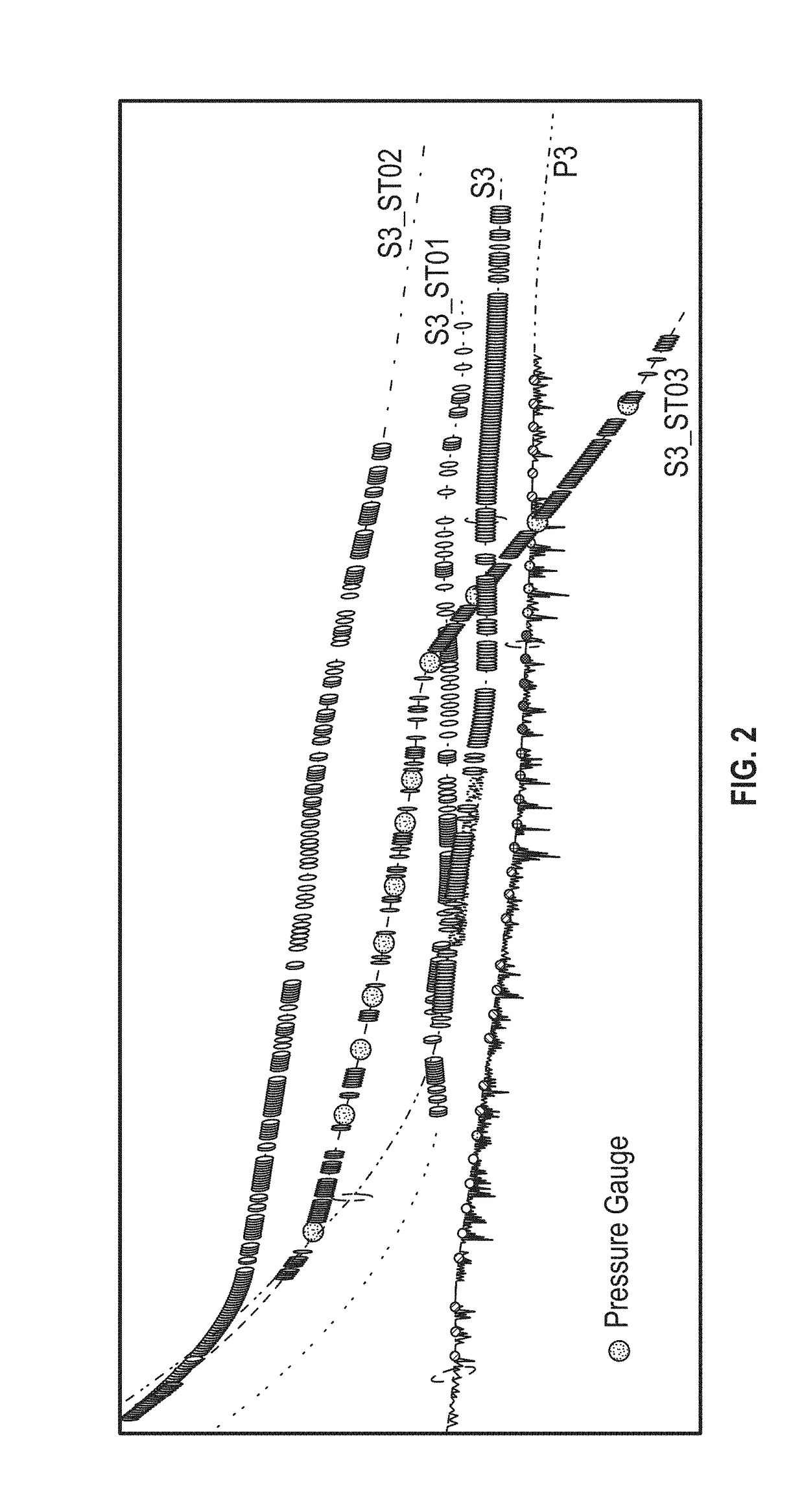

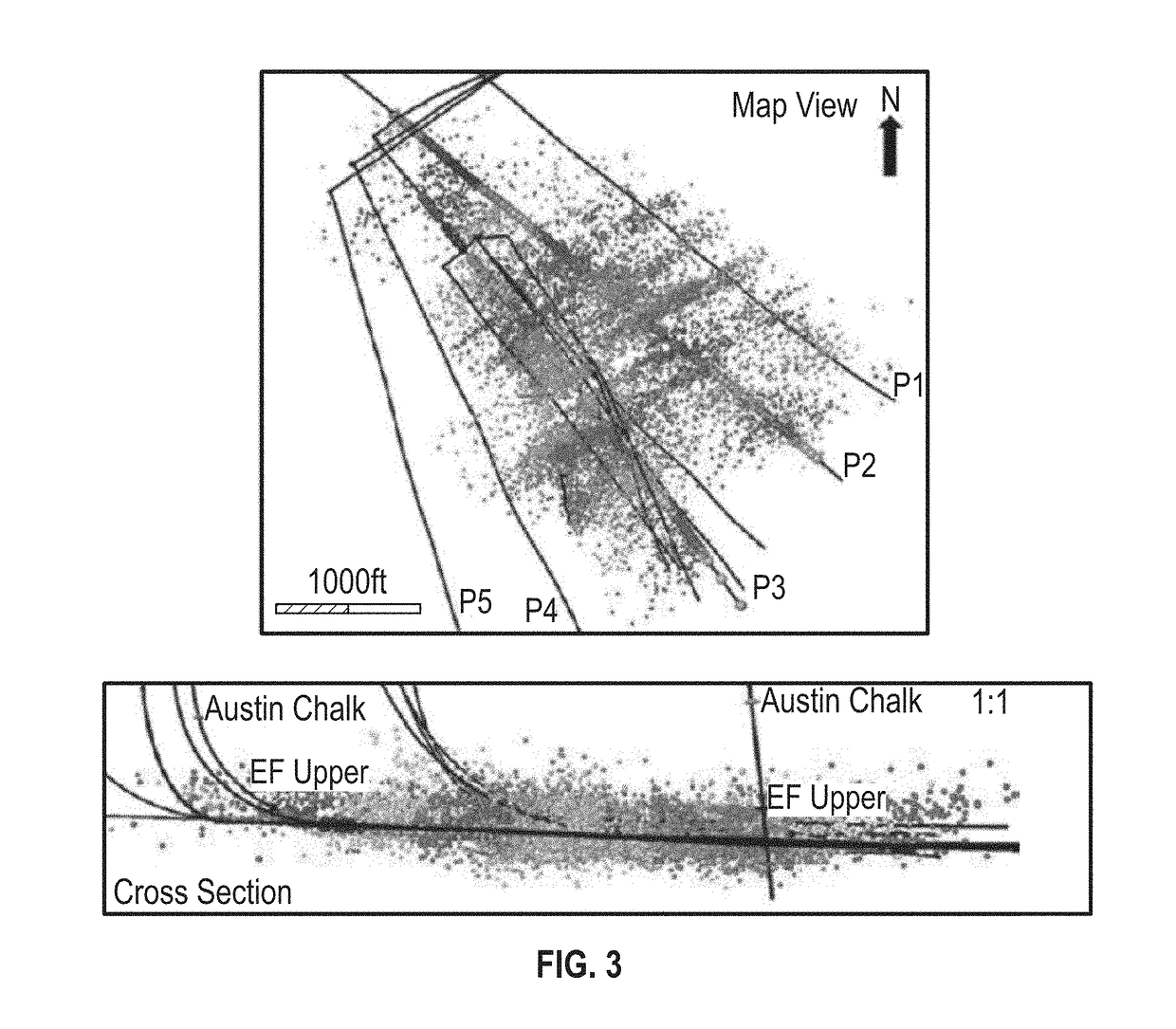

Stimulated rock volume analysis

ActiveUS20180364381A1Increase stimulationWell representedSurveyConstructionsComputational scienceRock core

A data acquisition program, which includes core, image log, microseismic, DAS, DTS, and pressure data, is described. This program can be used in conjunction with a variety of techniques to accurately monitor and conduct well stimulation.

Owner:CONOCOPHILLIPS CO

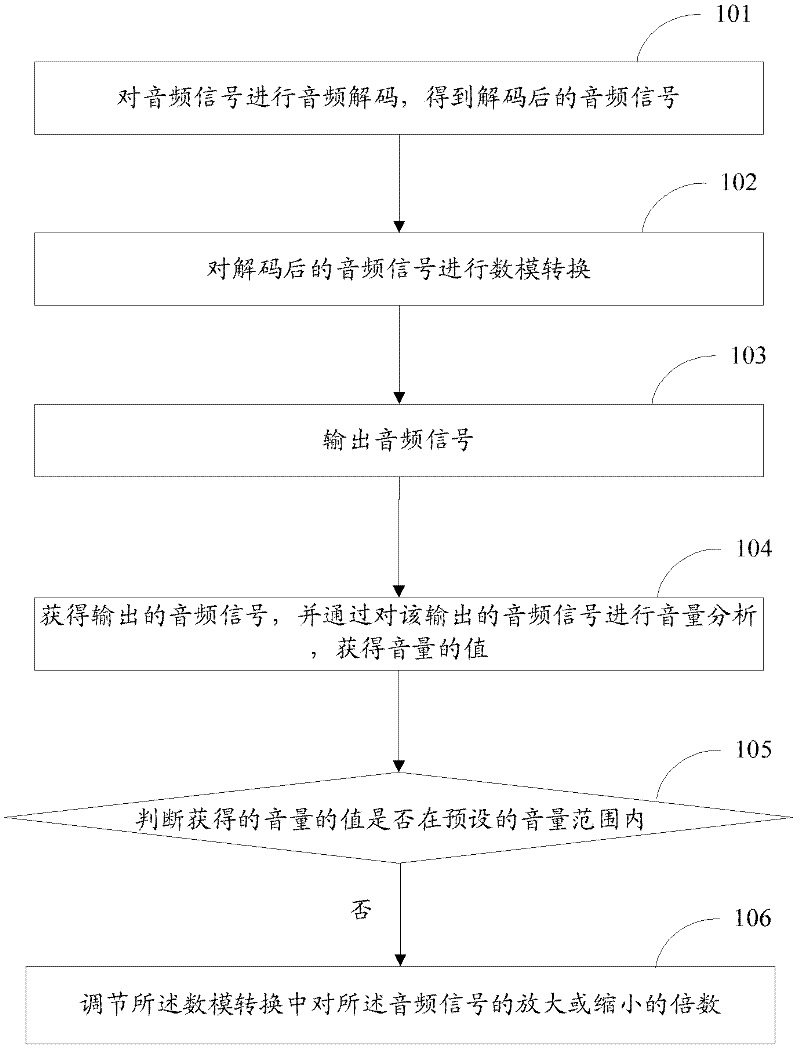

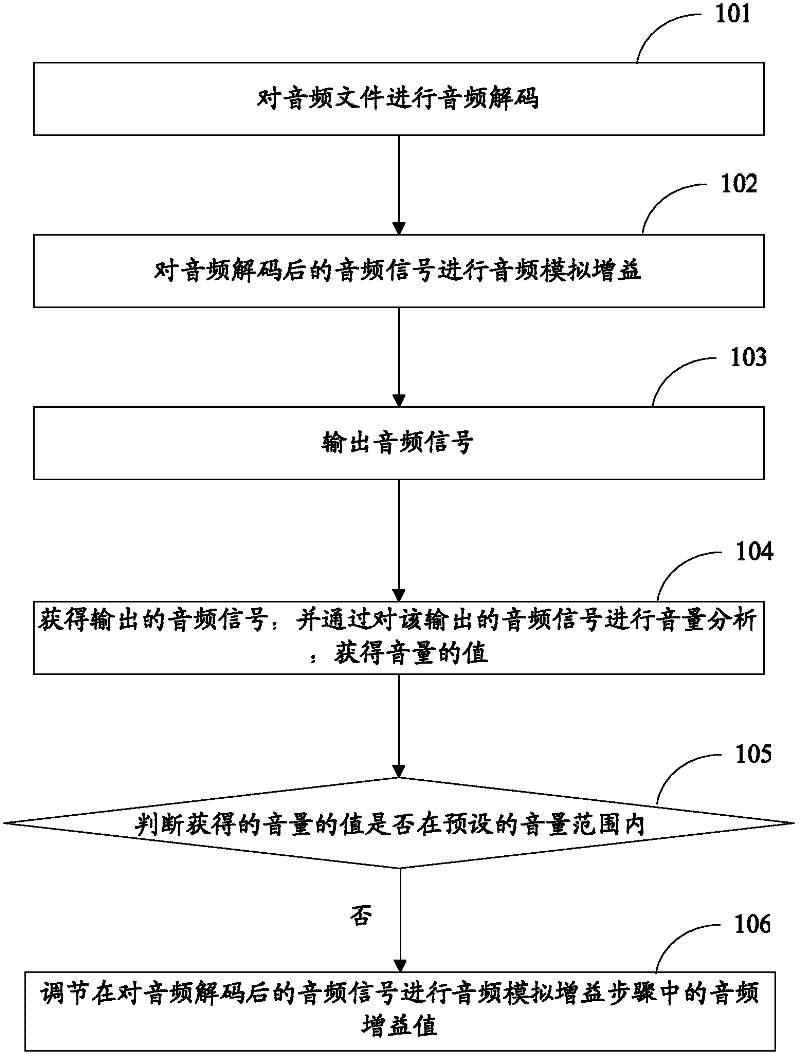

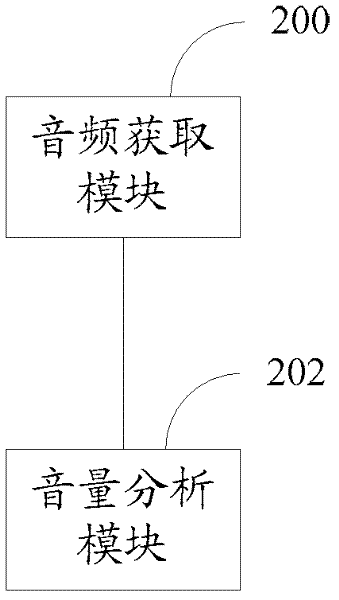

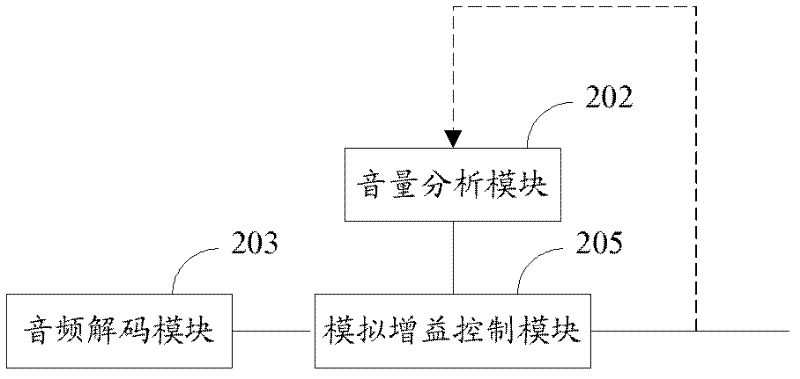

Volume adjusting method and device

InactiveCN102547523AAchieve regulationImprove comfortTransducer circuitsVolume analysisComputer science

The invention discloses a volume adjusting method, which is used for realizing adjustment of volume to improve the listening comfort. The method comprises the following steps of: performing audio decoding on an audio signal to obtain a decoded audio signal; performing digital-to-analog conversion on the decoded audio signal; outputting the audio signal; performing volume analysis on the output audio signal to obtain the value of the volume; judging whether the obtained value of the volume is in a preset volume range; and when the value of the volume is not in the preset volume range, adjusting the amplifying or reducing times of the audio signal in the digital-to-analog conversion. The invention further discloses a device for implementing the method.

Owner:WUXI ZGMICRO ELECTRONICS CO LTD

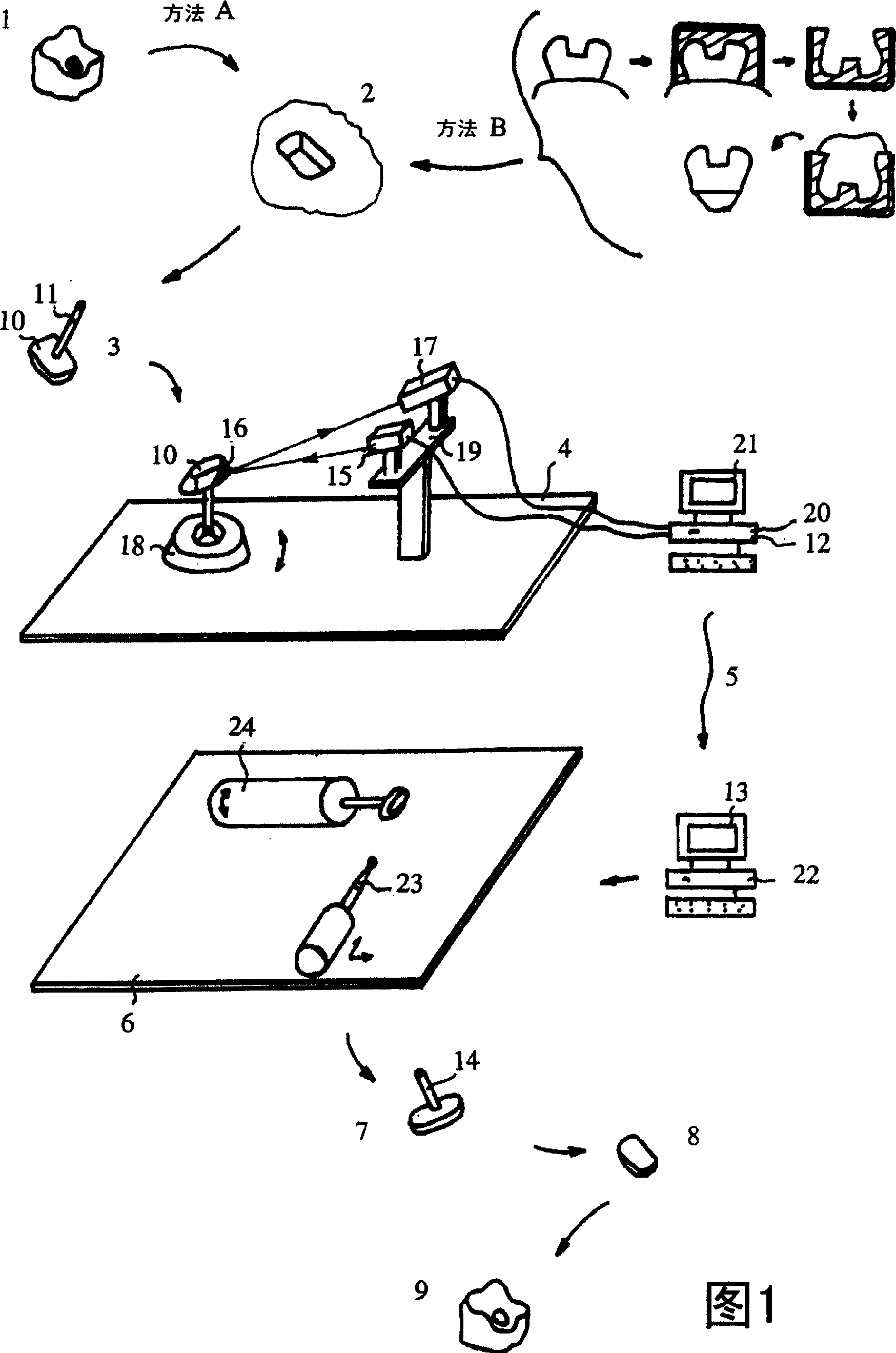

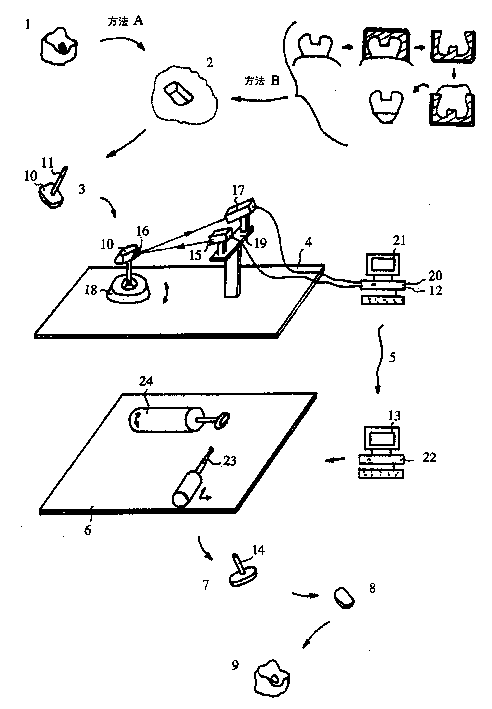

Method for producing dental restoration elements

The invention relates to a method for producing high-geometric precision elements made from a neutral material. Using different types of prosthetic restoration, said elements are intended to fill the damage caused in teeth by dental caries or tissue alteration having other causes. The inventive elements are also intended to be used to produce high-precision dental crowns or other related dental devices. The method is characterised in that: a model (10), which is designed to fill the missing dental tissue that has been destroyed, is made either in vivo, updating and defining a new volume (2) that is bordered by healthy tissue and having a tapered wall, or in vitro, taking an impression in the mouth of a dental preparation using an impression compound, said impression then being cast in plaster, and updating and defining a new volume (2) using said positive plaster model; the measurements of said model (10) are then taken in 3D using a three-dimensional measuring apparatus (4, 15, 17) with light wavefront analysis and volume analysis which is carried out using shots, a projector (15) being positioned at an angle to a camera (17) and said projector (15) and camera (17) being mechanically and geometrically linked to a revolving platform (18) that is used to support the model by means of a frame (19) in order to obtain good triangulation; the data are processed electronically (12) to remodel the morsels of volume; the files are subsequently modified electronically to determine exactly the desired profile; and the final element to be implanted is machined with a digitally-controlled machine (6, 23, 24, 22).

Owner:米歇尔·瓦莱里 +1

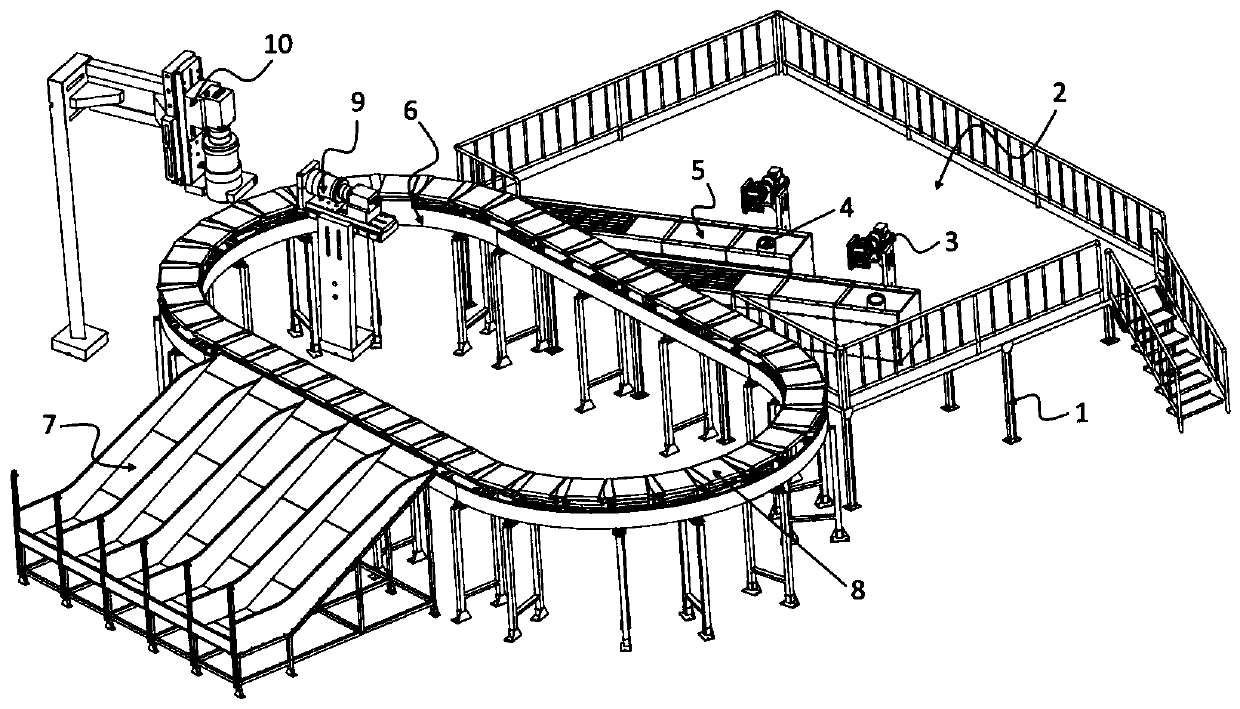

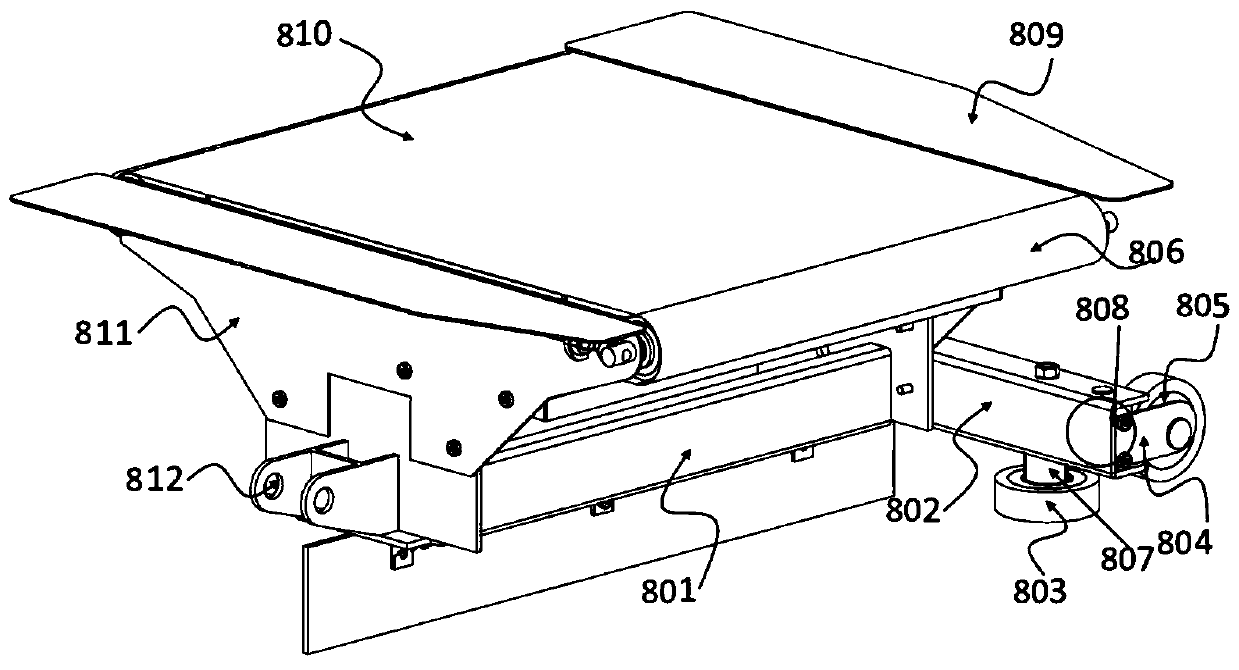

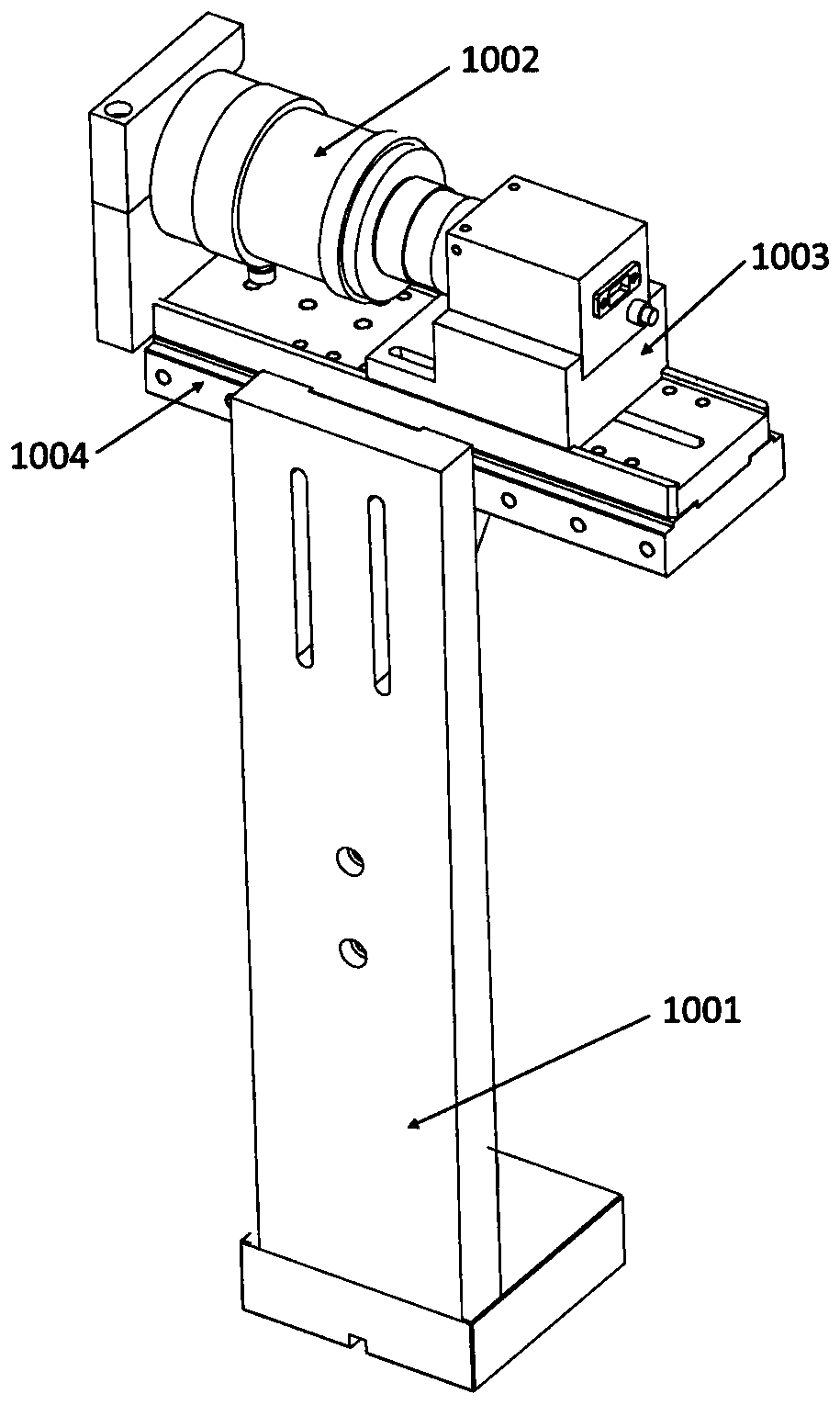

Sorting and tracing system based on Internet of Things for logistics and sorting method thereof

InactiveCN110180792AGuaranteed accuracyReduce areaCo-operative working arrangementsLogisticsInformation processingLogistics management

The invention relates to a sorting and tracing system based on Internet of Things for logistics and a sorting method thereof. The sorting and tracing system comprises a workbench assembly, a circulating transmission assembly, a visual analysis assembly, a discharging assembly and an information processing assembly, wherein the workbench assembly is used for feeding packages; the visual analysis assembly is used for bar code scanning and tracing, X-ray security scanning and volume analyzing of the packages; the visual analysis assembly sends scanned data of the packages to a server; the data are processed by the server and then pushed to a user terminal; compared with a linear transmission assembly, the circulating transmission assembly can greatly save the area of a storehouse; and the packages are laterally conveyed by a lateral conveying trolley which is in communication with the server, so that the packages are sorted out by selecting preset discharging slides according to destinations. According to the sorting and tracing system, the whole process is networked while high-efficiency and automatic sorting is achieved, the correct rate of package sorting is guaranteed, and the packages can be tracked in real time by users.

Owner:NANJING YUZHI INTELLIGENT TECH CO LTD

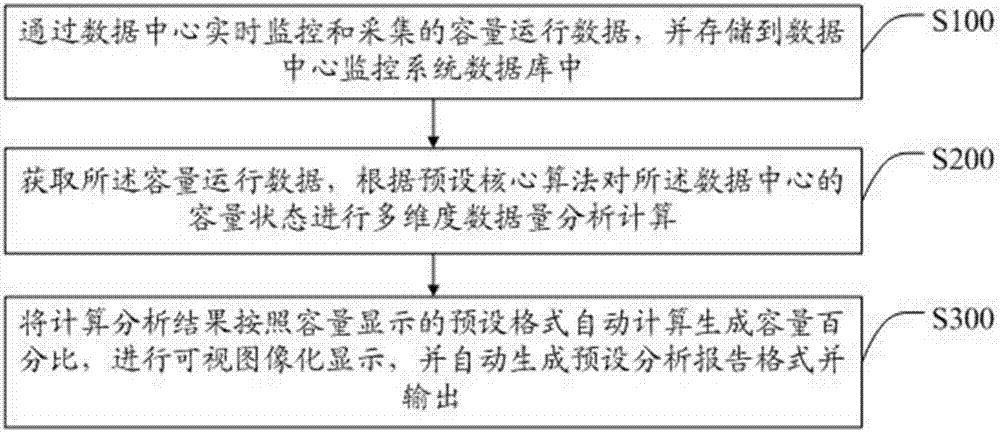

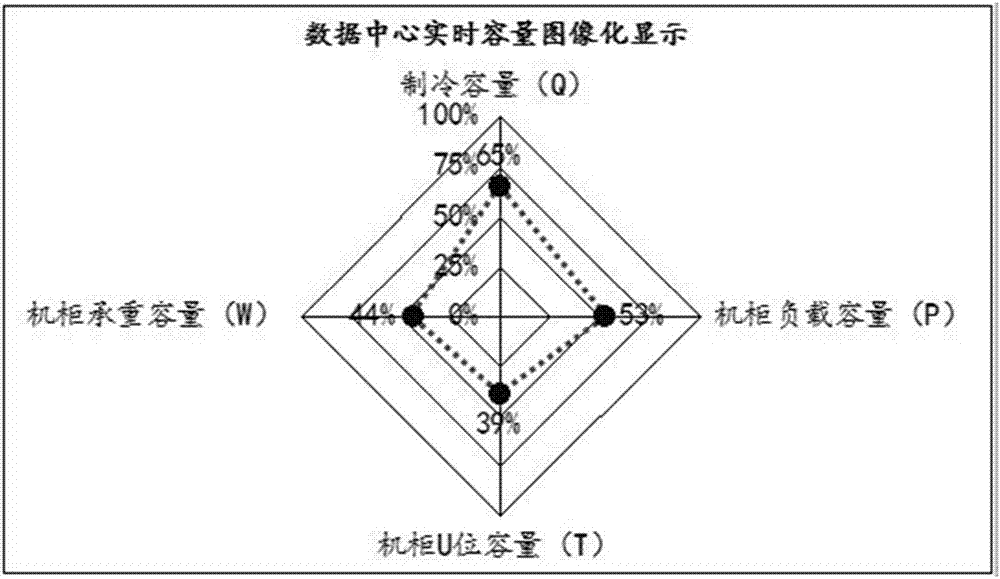

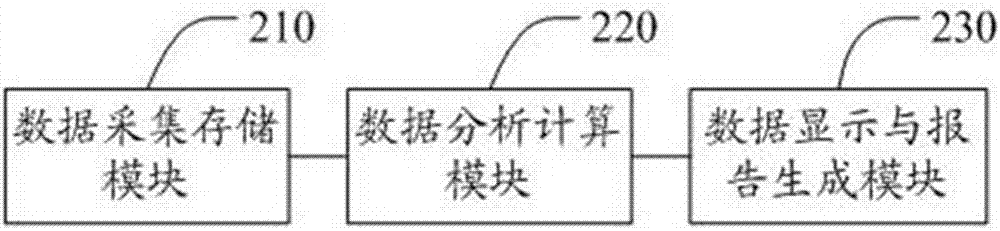

Display method and system for real-time capacity of data center

ActiveCN107038100AImprove operational management efficiencyLow operating and maintenance costsHardware monitoringData centerMonitoring system

The invention discloses a display method and system for real-time capacity of a data center. The method comprises the steps that capacity operating data is monitored and collected in real time through the data center and stored into a data center monitoring system database; the capacity operating data is acquired, and the capacity state of the data center is subjected to multi-dimensional data volume analysis and calculation according to a preset core algorithm; and the calculation and analysis result is automatically calculated to generate a capacity percent according to a preset format of capacity display, visual graphic display is performed, and a preset analysis report format is automatically generated and output. According to the method, the real-time operating data of the data center is subjected to calculation, analysis and summarization, therefore, graphic display of the capacity percent is automatically completed, guidance suggestions about transformation, expansion, etc. of the data center are given, operation management efficiency of the data center is effectively improved, operation and maintenance cost of the data center is lowered, and great convenience is brought to operation management of the data center by a user.

Owner:SHENZHEN XBROTHER TECH

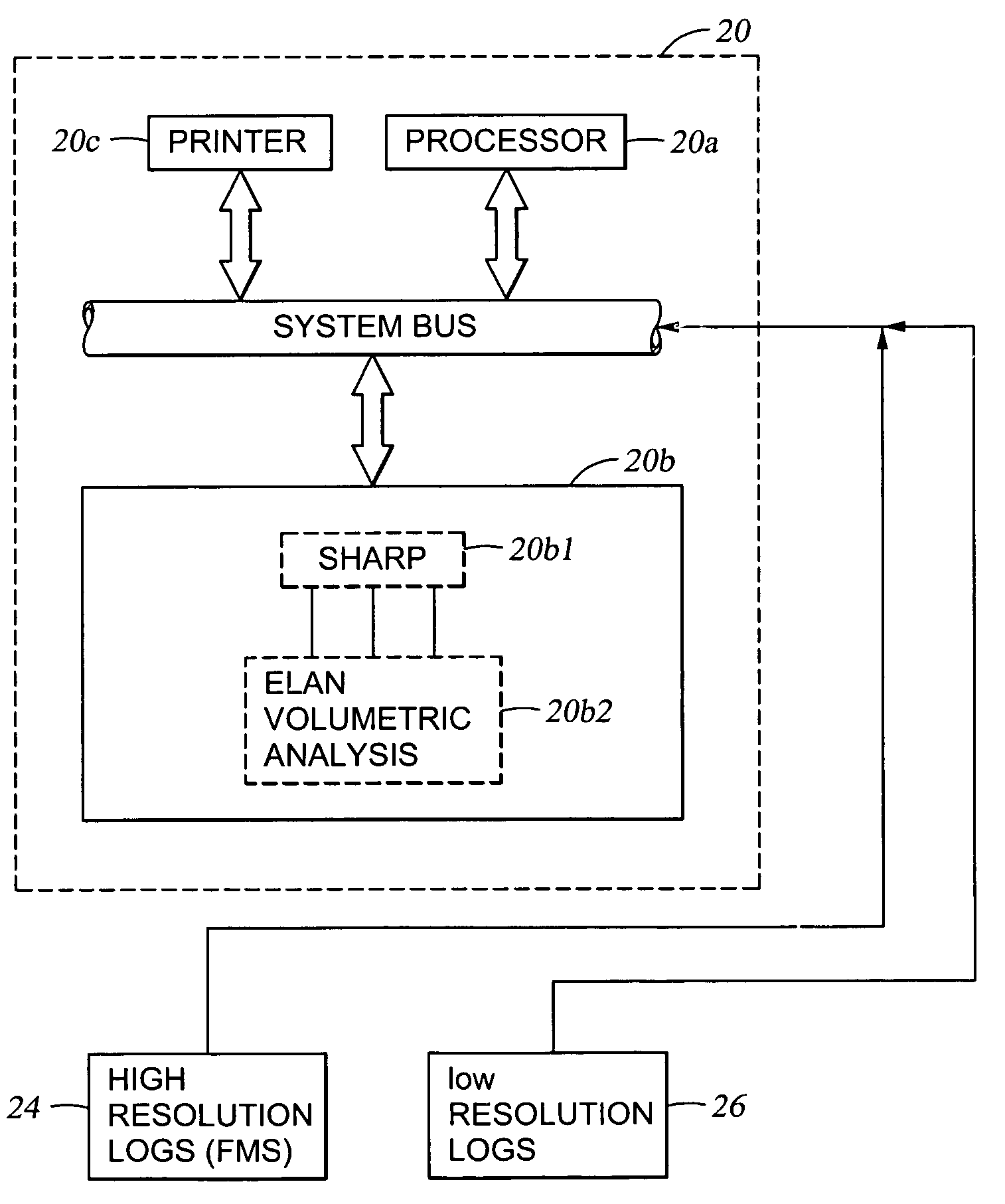

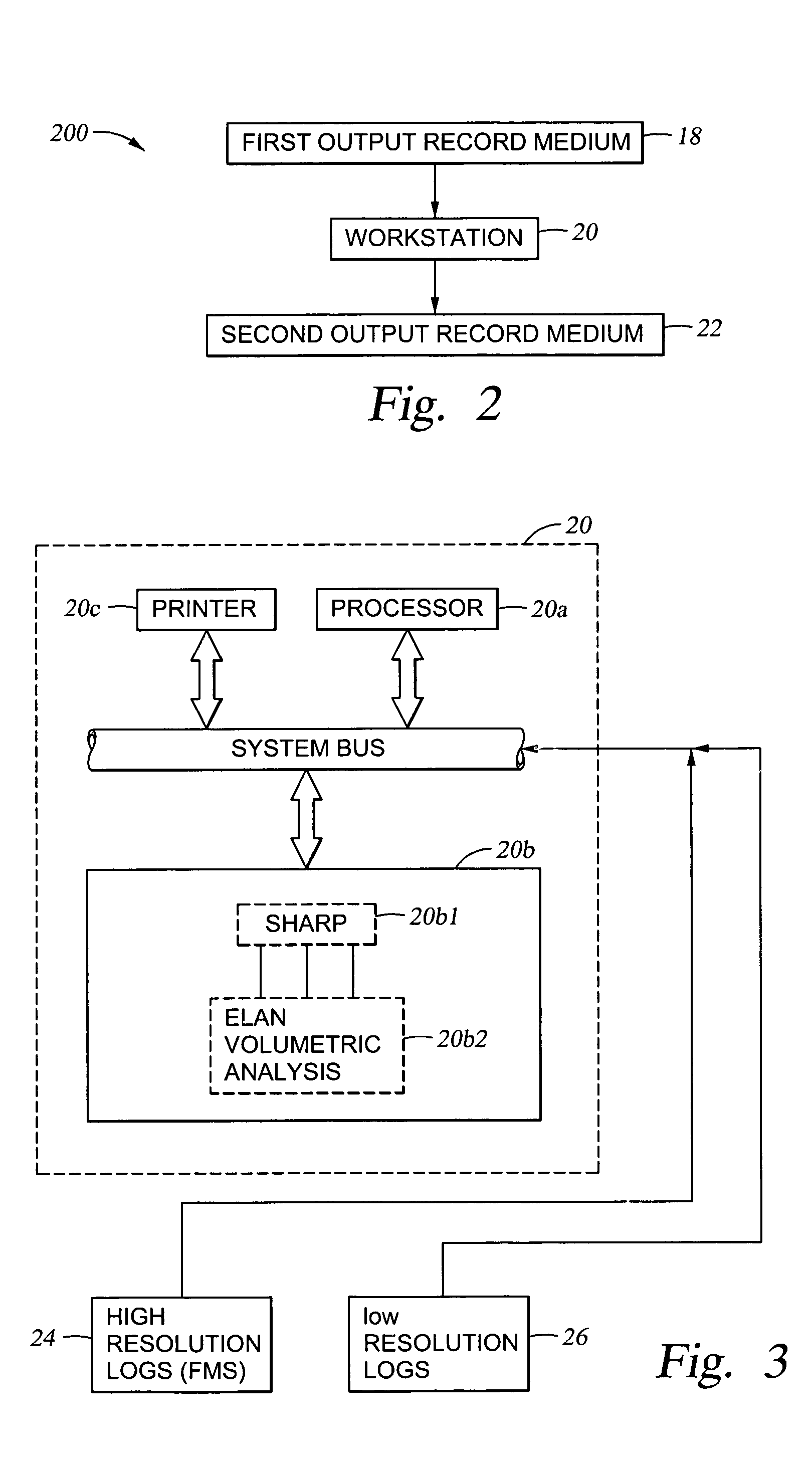

System and method for analyzing a thin bed formation

InactiveUS6963803B2Electric/magnetic detection for well-loggingSeismology for water-loggingSoil scienceImage resolution

One or more high resolution logs of a formation property having thin beds is provided for the laminated formation. From this log, the bed boundaries are detected and the facies for each of the beds detected is identified, using one or more high resolution logs of the laminated formation. Each of the identified facies is then defined. One or more squared logs for formation property is then generated by using the imported volumetric descriptions of the facies to generate a value of the formation property for each of the beds. A reconstructed log is generated and compared with a low resolution log of the formation property for laminated formation. By adjusting the values of the squared log the difference between the reconstructed log and the squared log may be minimized. An optimized squared log is output as having the square log and the volumetric analyses thereon.

Owner:SCHLUMBERGER TECH CORP

Method and device for adjusting sound volume

The invention discloses a method for adjusting sound volume. The method is used for adjusting the sound volume to improve the auditory comfort level. The method comprises the following steps: carrying out audio decoding on audio files; carrying out audio analog gain on audio signals obtained after audio decoding; outputting the audio signals; obtaining the output audio signals and obtaining the values of the sound volume by carrying out sound volume analysis on the output audio signals; judging whether the obtained values of the sound volume are in a preset sound volume range; and adjusting the audio gain value in the step for carrying out audio analog gain on the audio signals obtained after audio decoding when the values of the sound volume are not in the preset sound volume range. The invention also discloses a device for realizing the method.

Owner:WUXI ZGMICRO ELECTRONICS CO LTD

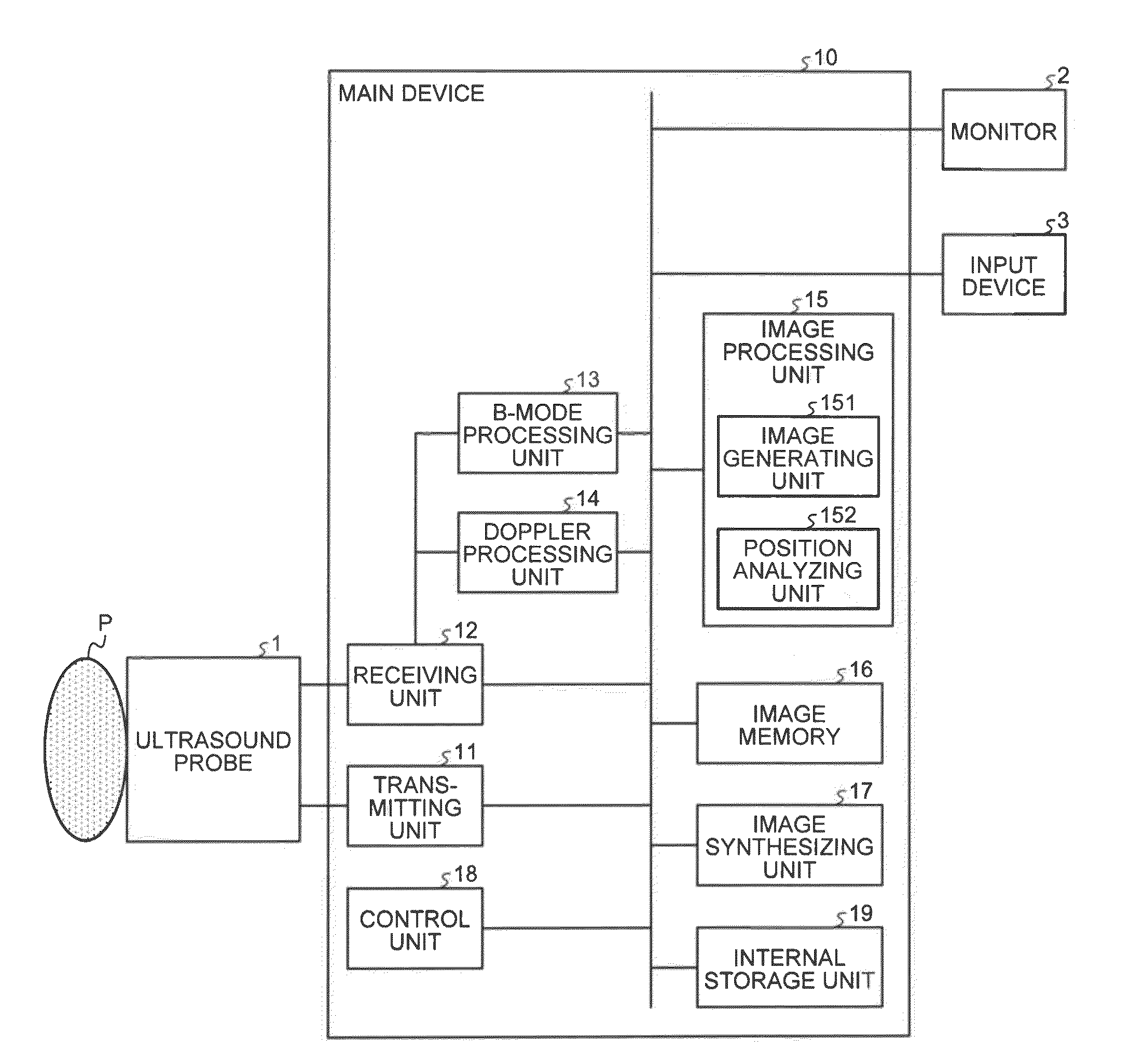

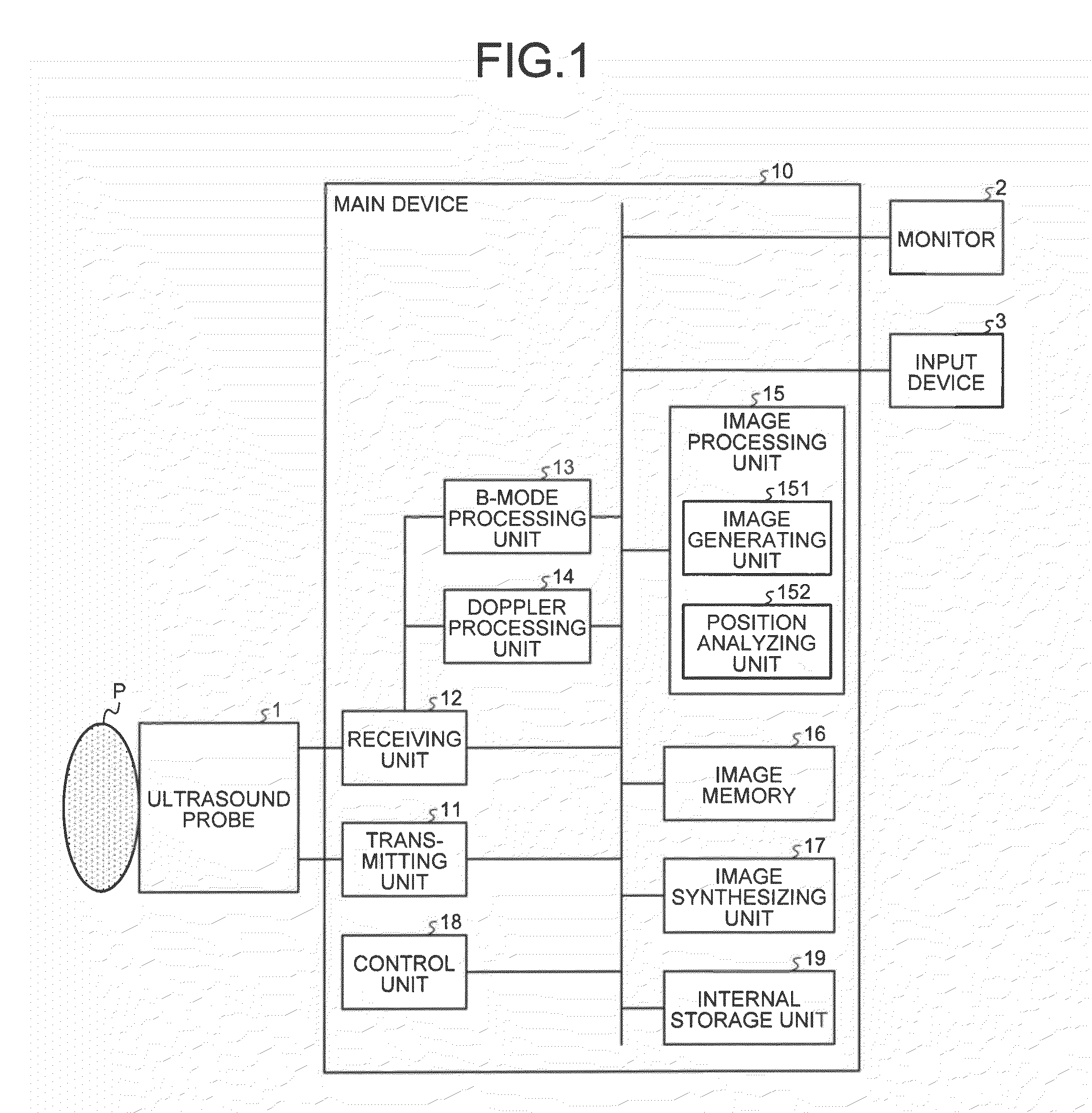

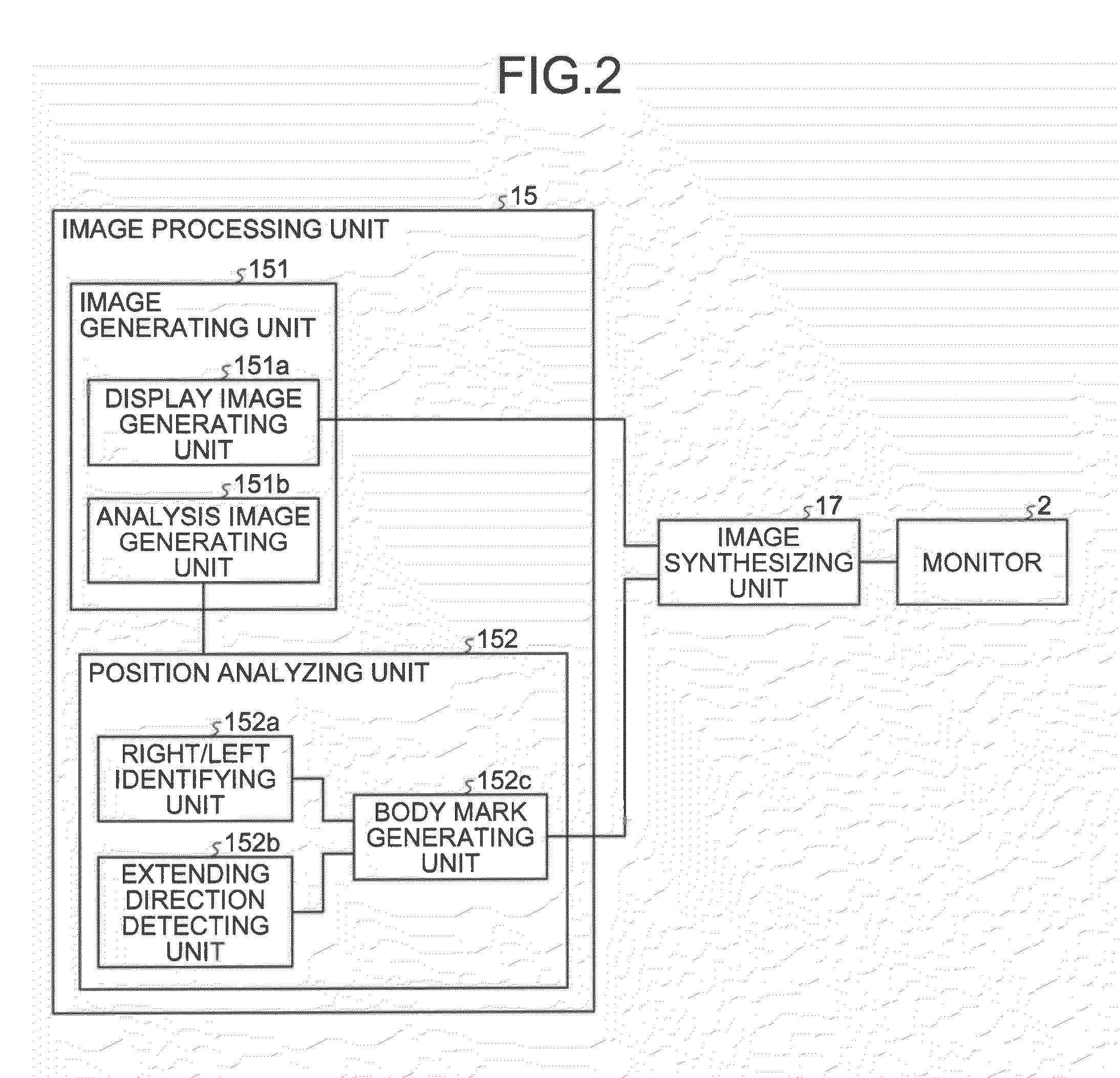

Ultrasonic diagnostic apparatus, positional information acquiring method, and computer program product

The analysis image generating unit generates section images from volume analysis data that is collected by sending an ultrasound wave down to a region under the ribs. The right / left identifying unit identifies the right or left breast from cyclic motion components in the section images. The extending direction detecting unit analyzes plane-A images or plane-B images generated from the same volume analysis data, or a plane-C thickness-added MIP image, and detects the rib extending direction. The extending direction detecting unit also determines the position of the ultrasound probe based on the relative displacement of the extending direction. The body mark generating unit generates a body mark from the analysis results obtained by the right / left identifying unit and the extending direction detecting unit. The image synthesizing unit integrates the display image generated by the display image generating unit and the body mark, and displays it on the monitor.

Owner:TOSHIBA MEDICAL SYST CORP

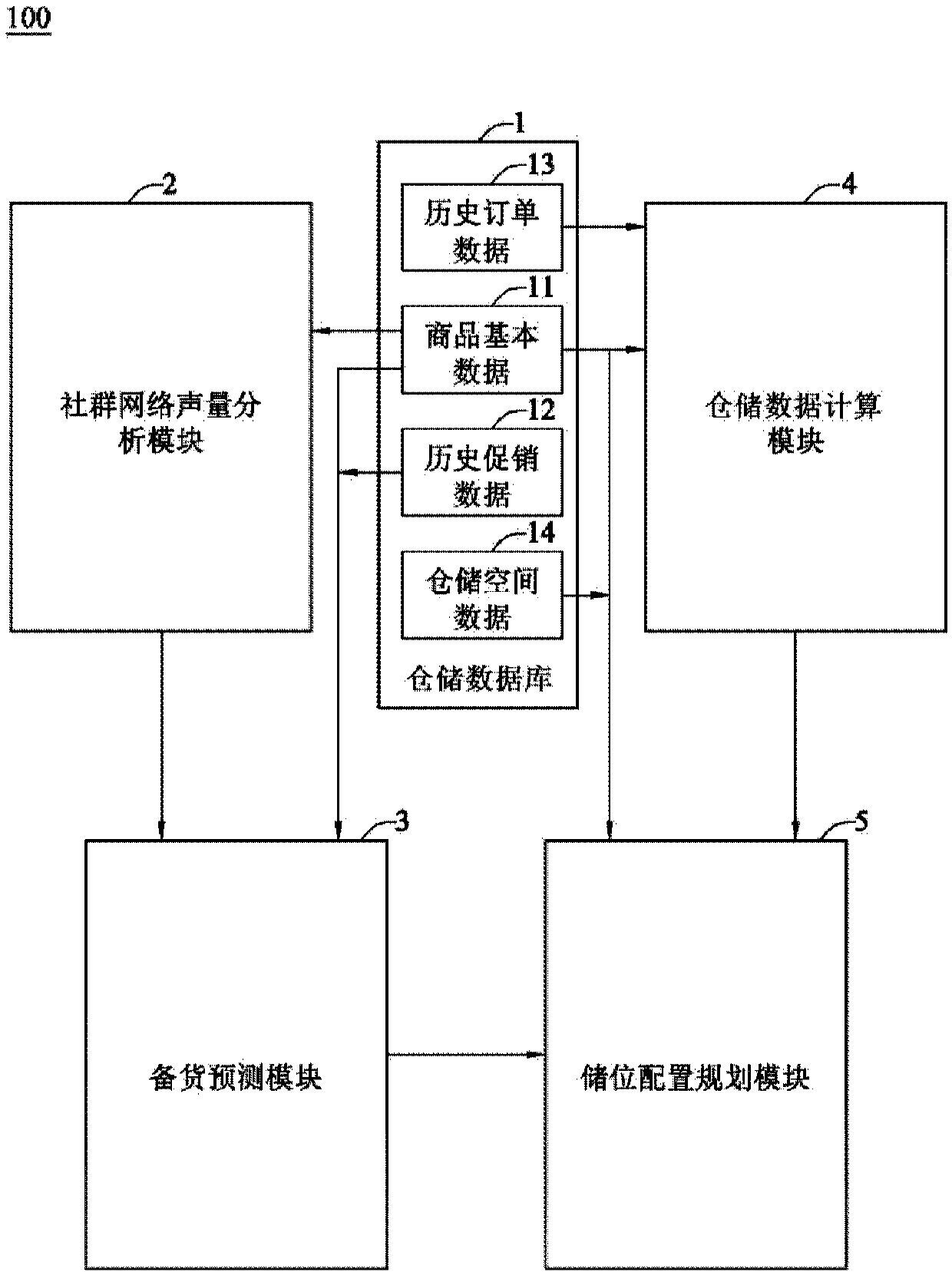

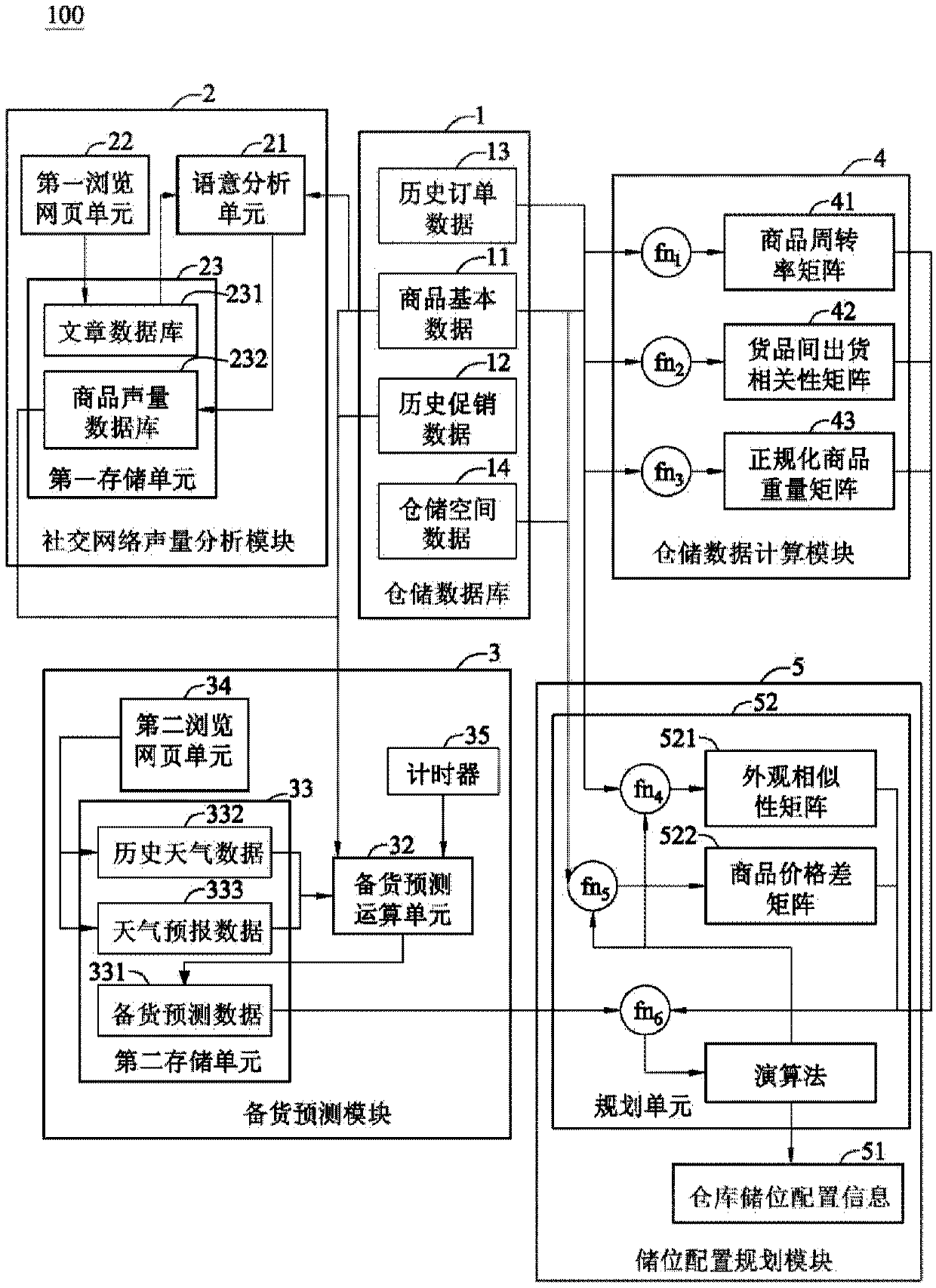

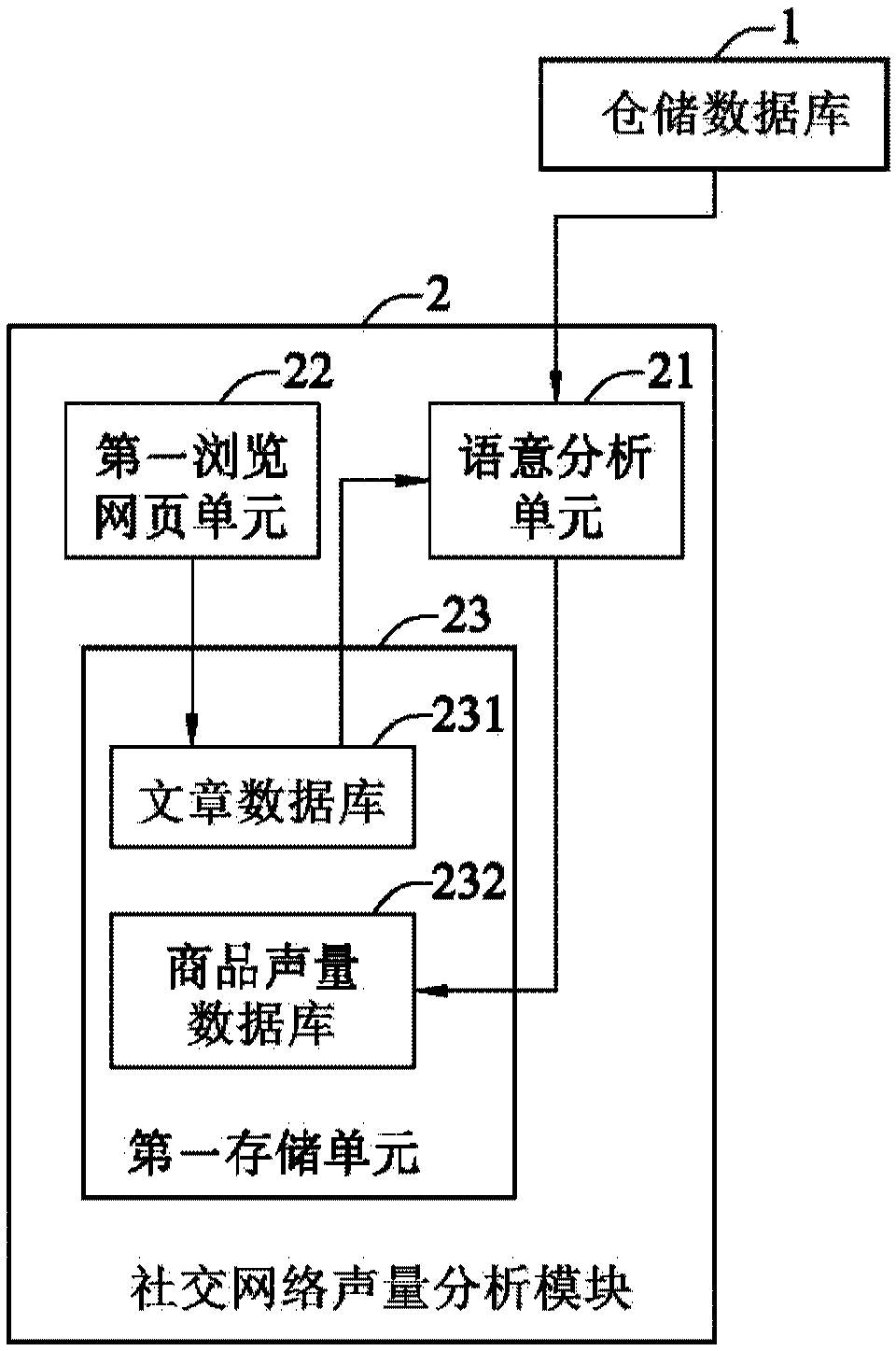

Warehousing storage location configuration system

ActiveCN110874670AEfficiently manage configurationDecrease stockForecastingLogisticsVolume analysisData mining

The invention discloses a warehousing storage location configuration system. The system comprises a warehousing database, a social network sound volume analysis module, a stock prediction module, a warehousing data calculation module and a warehousing location configuration planning module. The social network sound volume analysis module provides commodity sound volume data related to an externalsocial network; the stock prediction module provides stock prediction data; and the warehousing data calculation module provides a commodity data matrix related to the state of the goods in the warehouse, so that the warehousing location configuration planning module comprehensively considers the data provided by the warehousing database, the stock prediction module and the warehousing data calculation module to generate warehousing warehousing location configuration information, and the purpose of optimizing the warehousing location configuration is achieved.

Owner:IND TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com