Method for producing dental restoration elements

A manufacturing method, technology of teeth, applied in the field of manufacturing dental restoration elements, capable of solving problems such as not taking into account contours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

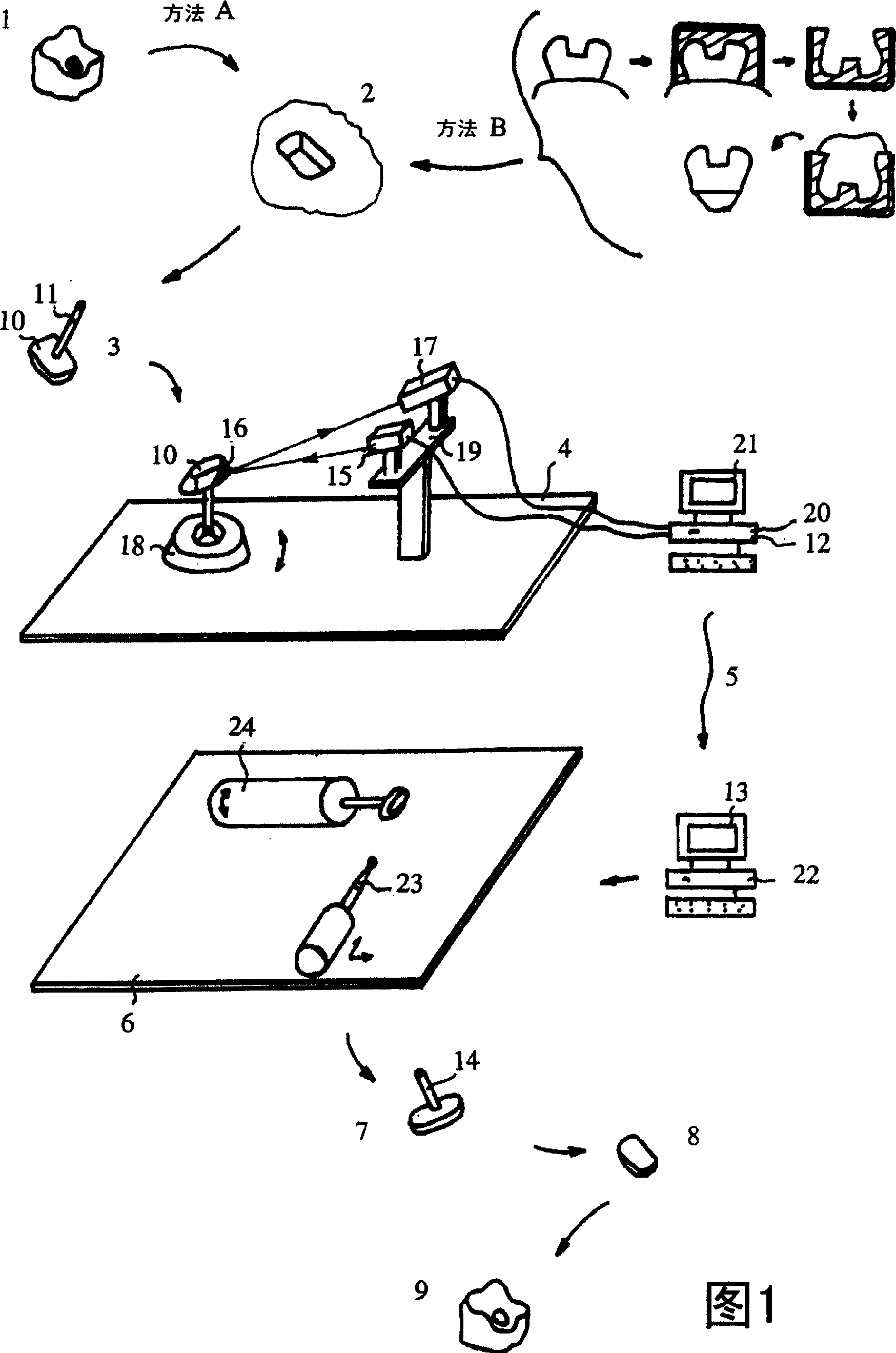

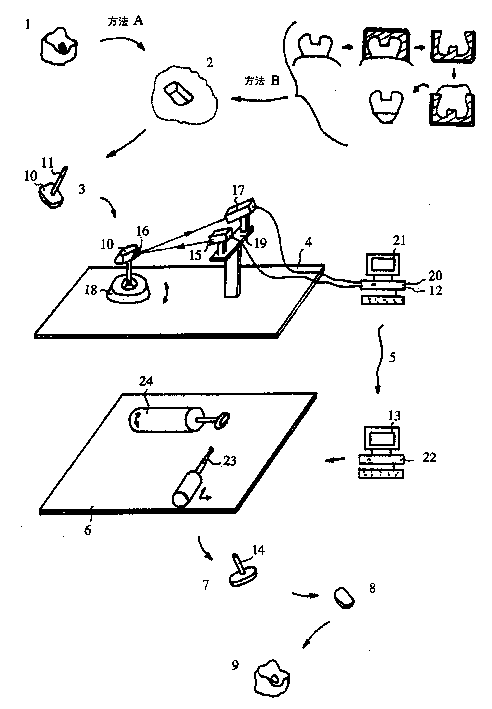

[0017] Referring to Fig. 1, this method is generally suitable for manufacturing multiple elements for filling damaged parts of mammalian teeth.

[0018] In order to implement this method, a model for filling one or more defective parts of one or more dental organs must first be constructed. This model can be realized by two methods, which can be made directly in the mouth, namely Method A; it can also be used by conventional materials (alginate, silicone or other materials) to create a dental model for the defect part in the denture maker’s Manufactured in the laboratory, method B. This dental model will be processed in the laboratory of the denture maker in order to obtain a positive model.

[0019] In the first method A, the dentist uses a grinder or a hole punch to remove the insufficient tooth tissue in operation step 1 in order to repair and define a new solid 2 defined by healthy tissue, which has a dial out oblique Degrees of wall shape. So far, what needs to be done is to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com