Drum brake module which can be operated by electric motor

A braking module and drum type technology, which is applied in the direction of mechanically driven drum brakes, drum brakes, brakes, etc., can solve the problems of not allowing deformation, etc., and achieve electric adjustment and adjustment process improvement, low friction loss, tension avoidance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

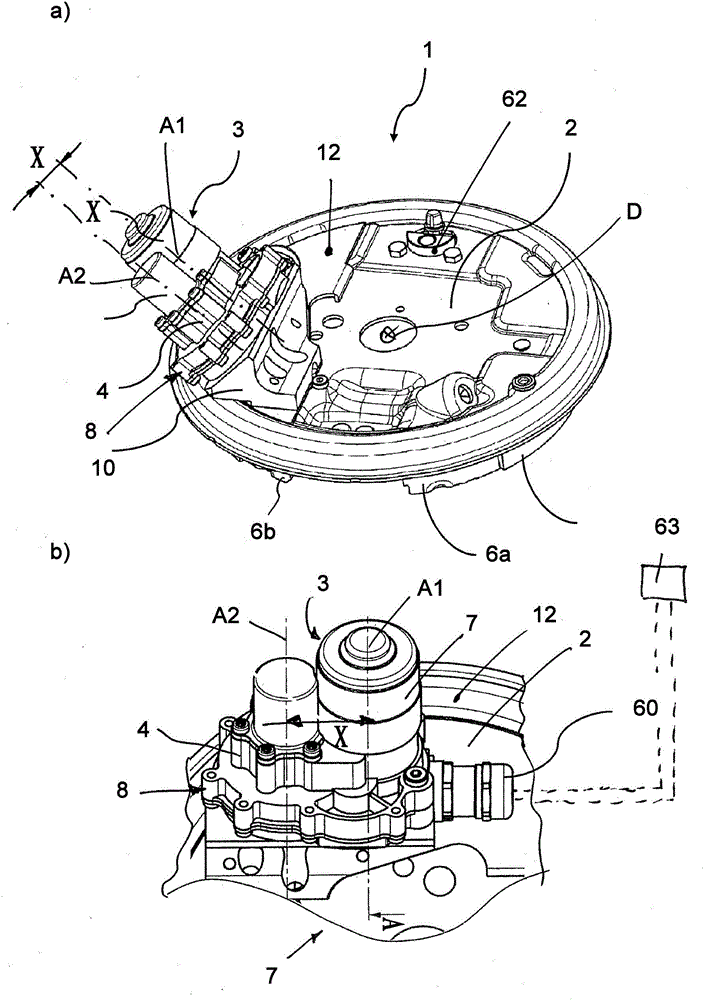

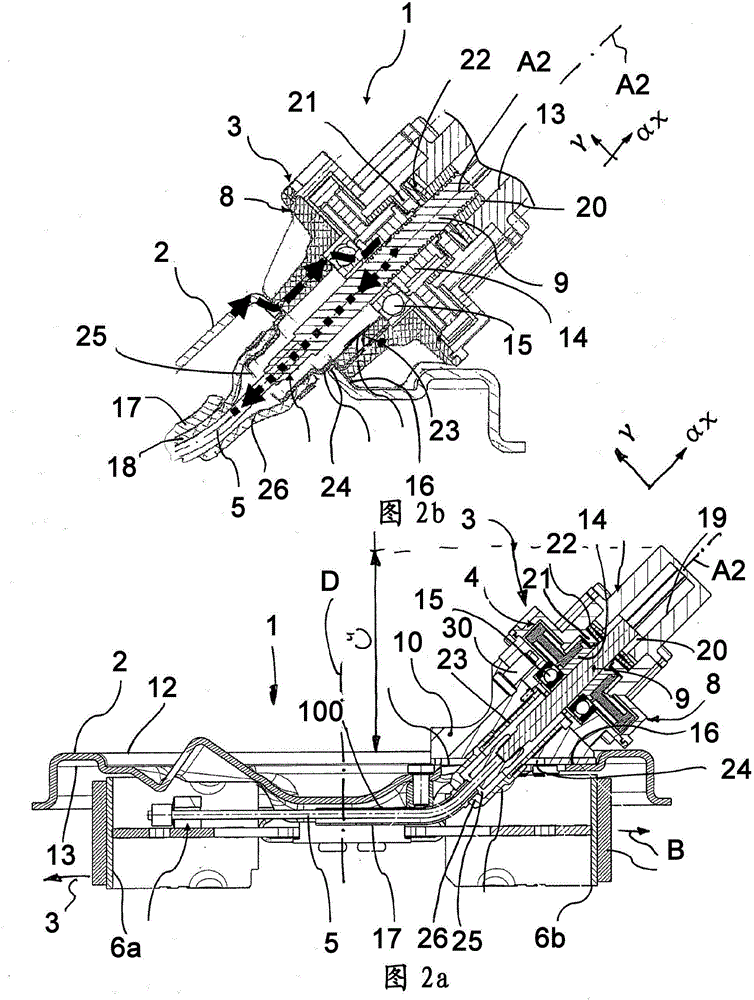

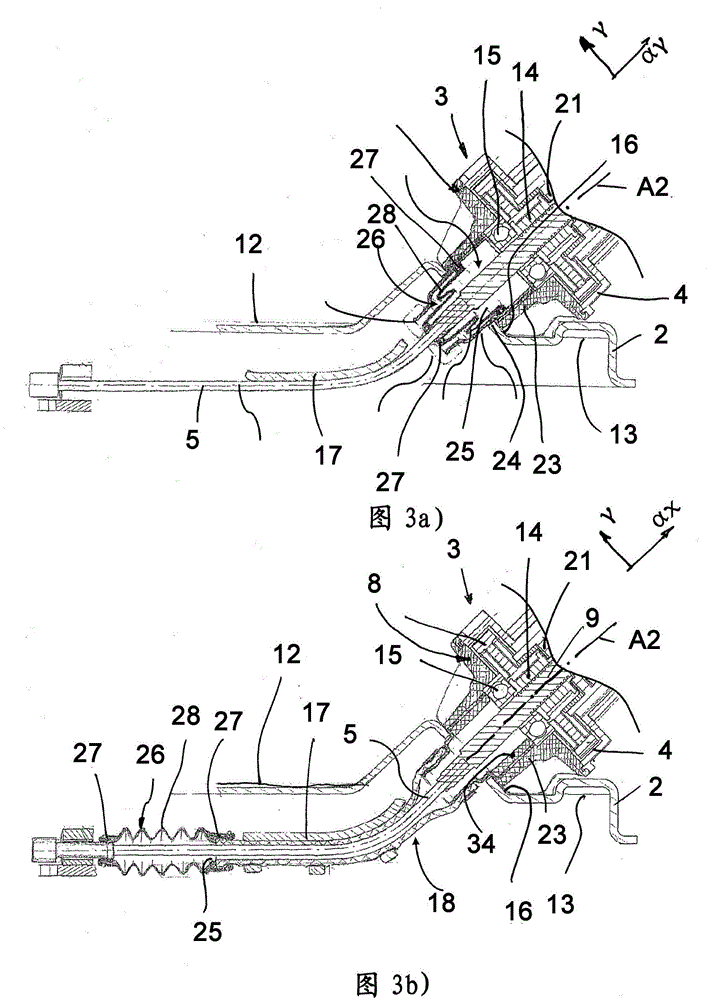

[0028] Features that correspond to each other are provided with mutually consistent reference numerals in the figures.

[0029] An electrically operable drum brake module 1 for arrangement on an axle component of a motor vehicle comprises an anchor plate 2 having brake shoes 6 a, b bearing thereon, the brake shoes Located inside the brake drum not shown. On the opposite side of the anchor plate 2 is fastened an electrically driven actuator 3 , which acts on the brake shoe 6 a via a transmission 4 and a downstream actuating pull 5 . , b, so that the brake shoe 6a, b can perform an operating movement B in the direction of the brake drum, so as to implement the service and / or parking brake function. A supporting device 11 may be arranged between the brake shoes 6a, b. The transmission 4 comprises a transmission housing 8 which receives the electric motor 7 or at least carries the electric motor 7 . The motor 7 uses direct current, which is rectified mechanically or electronica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com