A glass fiber fully wound aluminum liner composite gas cylinder and its manufacturing process

A manufacturing process and glass fiber technology, which is applied in the field of glass fiber full-wound aluminum liner composite gas cylinder and its manufacturing process, can solve the problems of high price and complicated molding process, and achieve the improvement of the play coefficient, the reduction of the void ratio, and the avoidance of the product. Effects of scrap and defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

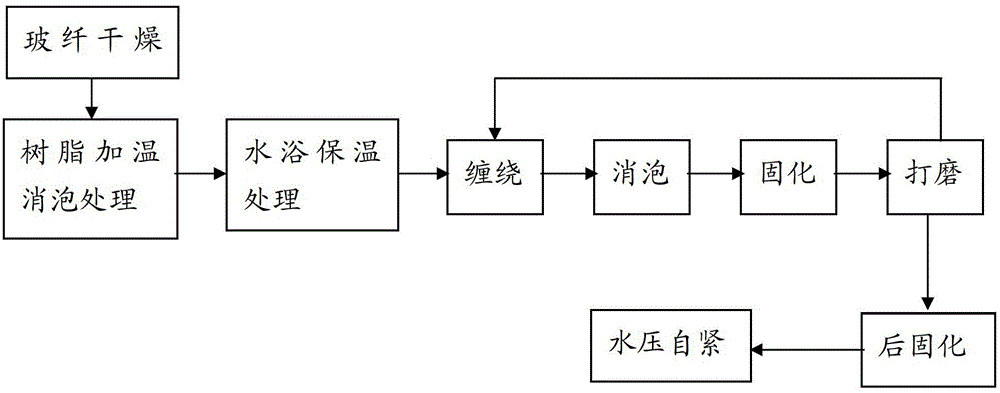

[0039] 1) Dry the high-strength glass fiber in an oven at 80°C for 4 hours;

[0040] 2) Use a 20 kg metal bucket to open the epoxy resin matrix, and bake it in an oven at 40°C for 2 hours for defoaming treatment;

[0041] 3) Take the epoxy resin (Dow Chemical der331) that has undergone defoaming treatment and mix it with the curing agent (Italy Pauline MMHPA), and stir it for 10 minutes at the speed of 90r / min in a pneumatic mixer;

[0042] 4) Pour the stirred resin matrix into the glue tank, and the dried glass fiber soaks the resin from the glue tank. The resin needs to be kept warm in a 40°C water bath to ensure a good wetting effect under low viscosity;

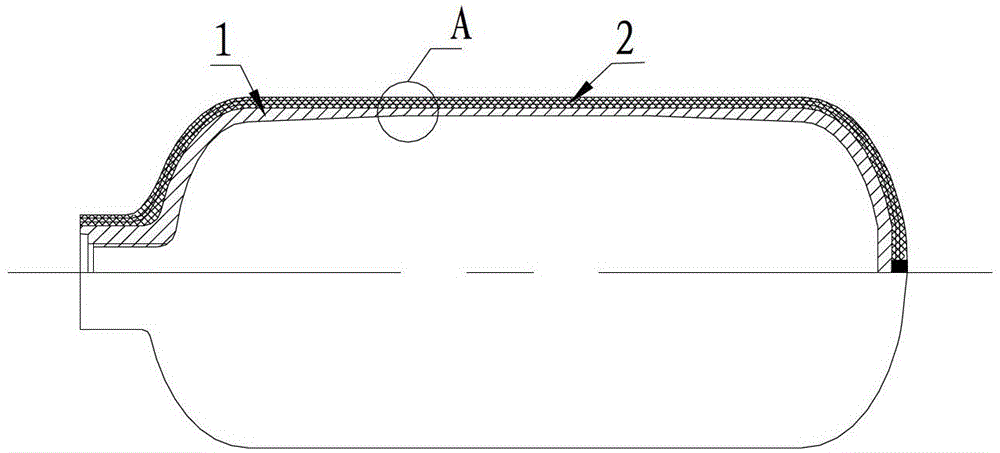

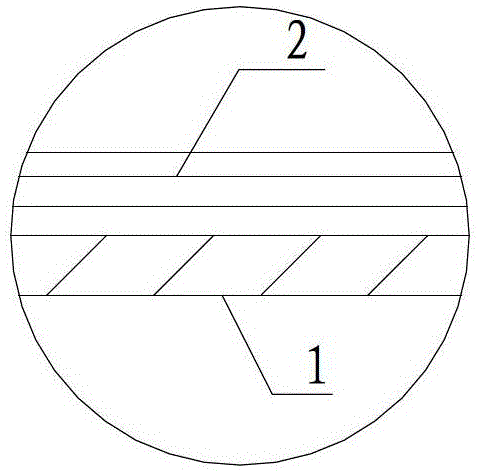

[0043] 5) The aluminum alloy liner is used as the inner lining. Since the glass fiber reinforced resin matrix composite material is an insulating material, the glass fiber reinforced resin matrix composite material is directly wound after the process top block is installed on the winding machine;

[0044] 6) The winding ...

Embodiment 2

[0054] 1) Dry the high-strength glass fiber in an oven at 75°C for 8 hours;

[0055] 2) Use a 20 kg metal bucket to open the epoxy resin matrix, and bake it in an oven at 35°C for 4 hours for defoaming treatment;

[0056] 3) Take the epoxy resin (Dow Chemical der331) that has undergone defoaming treatment and mix it with the curing agent (Italy Pauline MMHPA), and stir it for 10 minutes at the speed of 90r / min in a pneumatic mixer;

[0057] 4) Pour the stirred resin matrix into the glue tank, and the dried glass fiber soaks the resin from the glue tank. The resin needs to be kept warm in a 35°C water bath to ensure a good wetting effect under low viscosity;

[0058] 5) The aluminum alloy liner is used as the inner lining. Since the glass fiber reinforced resin matrix composite material is an insulating material, the glass fiber reinforced resin matrix composite material is directly wound after the process top block is installed on the winding machine;

[0059] 6) The winding ...

Embodiment 3

[0069] 1) Dry the high-strength glass fiber in an oven at 85°C for 4 hours;

[0070] 2) Use a 20 kg metal bucket to open the epoxy resin matrix, and bake it in an oven at 45°C for 4 hours for defoaming treatment;

[0071] 3) Take the epoxy resin (Dow Chemical der331) that has undergone defoaming treatment and mix it with the curing agent (Italy Pauline MMHPA), and stir it for 10 minutes at the speed of 90r / min in a pneumatic mixer;

[0072] 4) Pour the stirred resin matrix into the glue tank, and the dried glass fiber soaks the resin from the glue tank. The resin needs to be kept warm in a 45°C water bath to ensure a good wetting effect under low viscosity;

[0073] 5) The aluminum alloy liner is used as the inner lining. Since the glass fiber reinforced resin matrix composite material is an insulating material, the glass fiber reinforced resin matrix composite material is directly wound after the process top block is installed on the winding machine;

[0074] 6) The winding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com