Patents

Literature

48results about How to "Reduce material weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

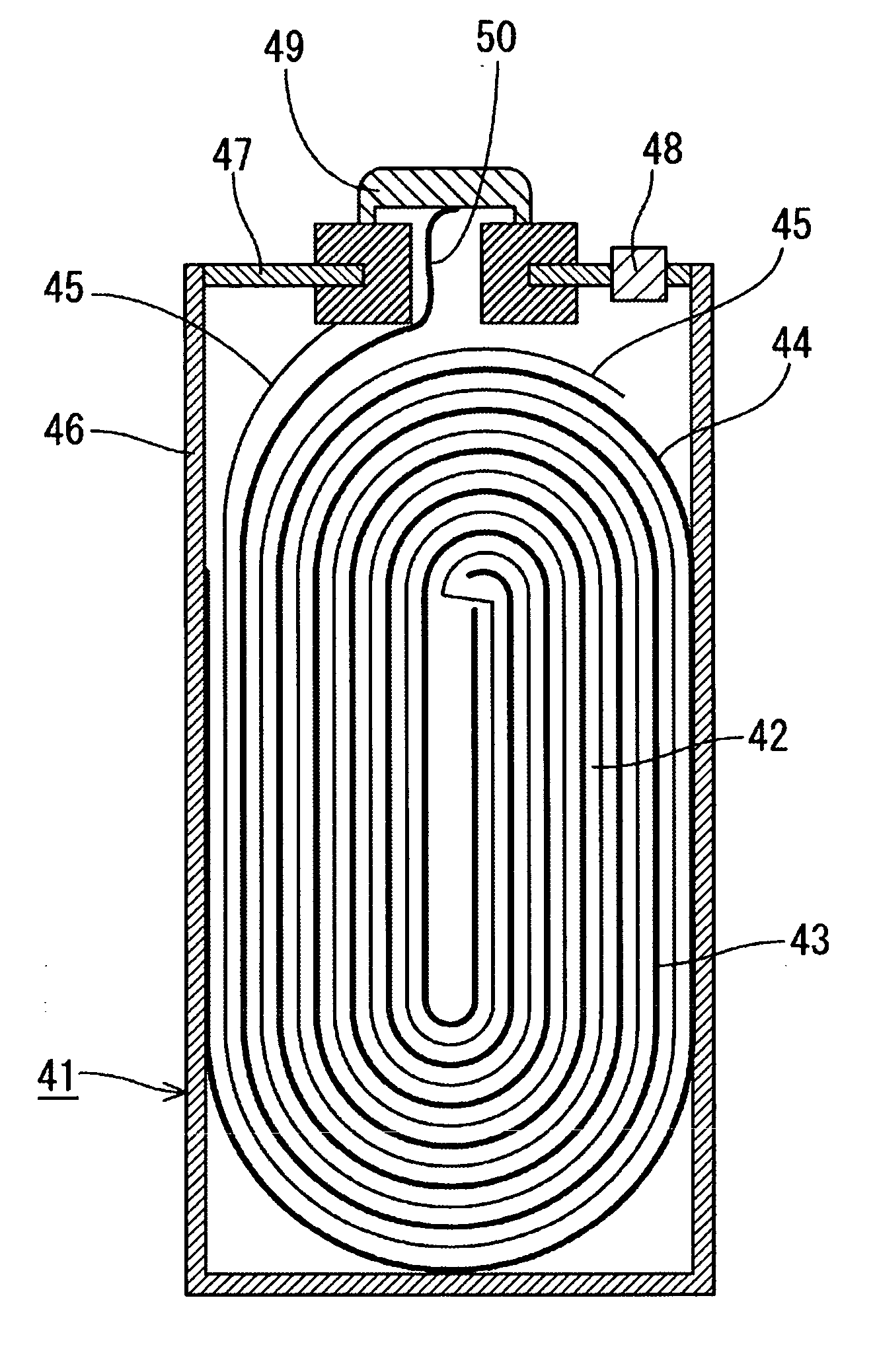

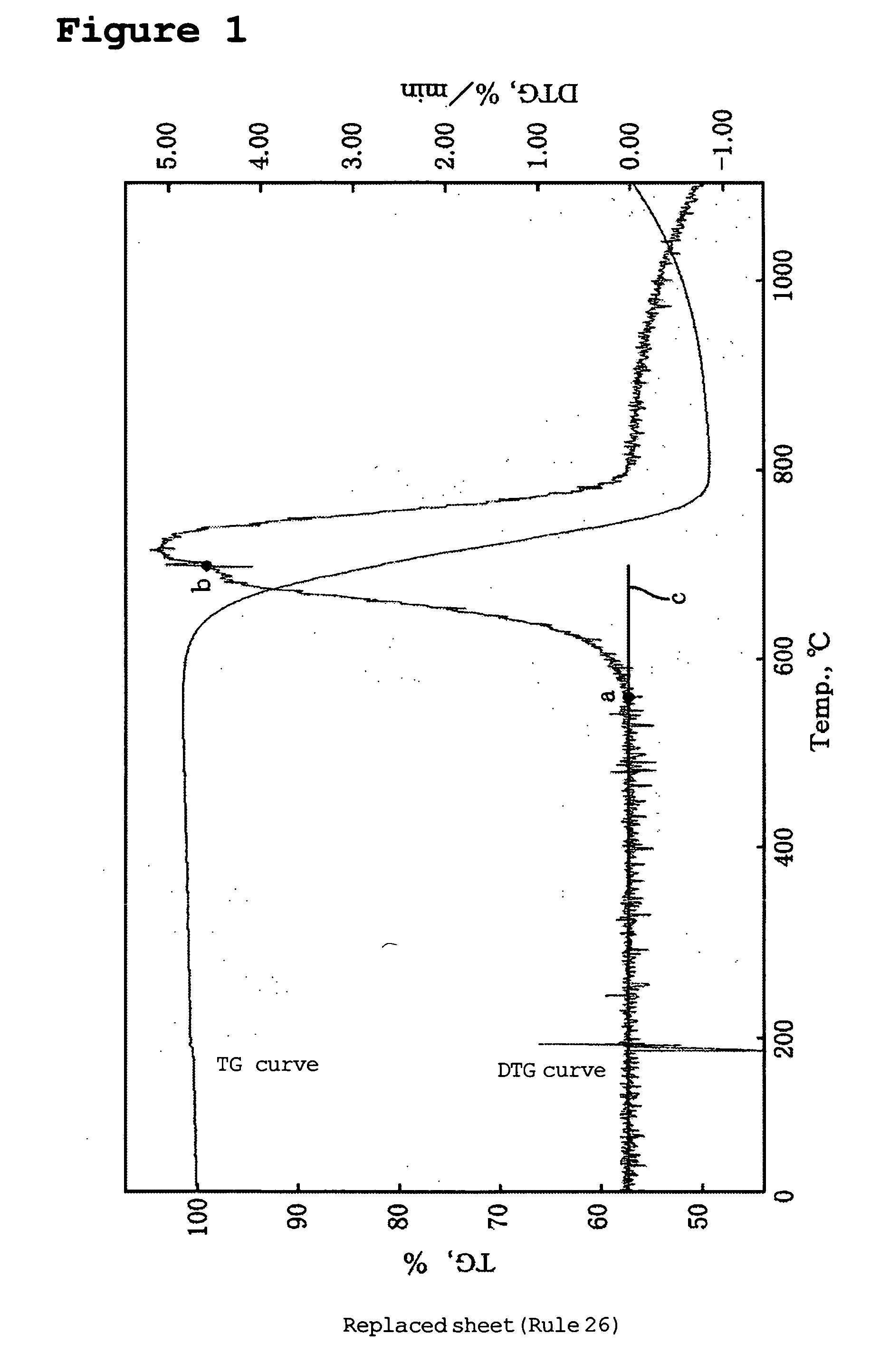

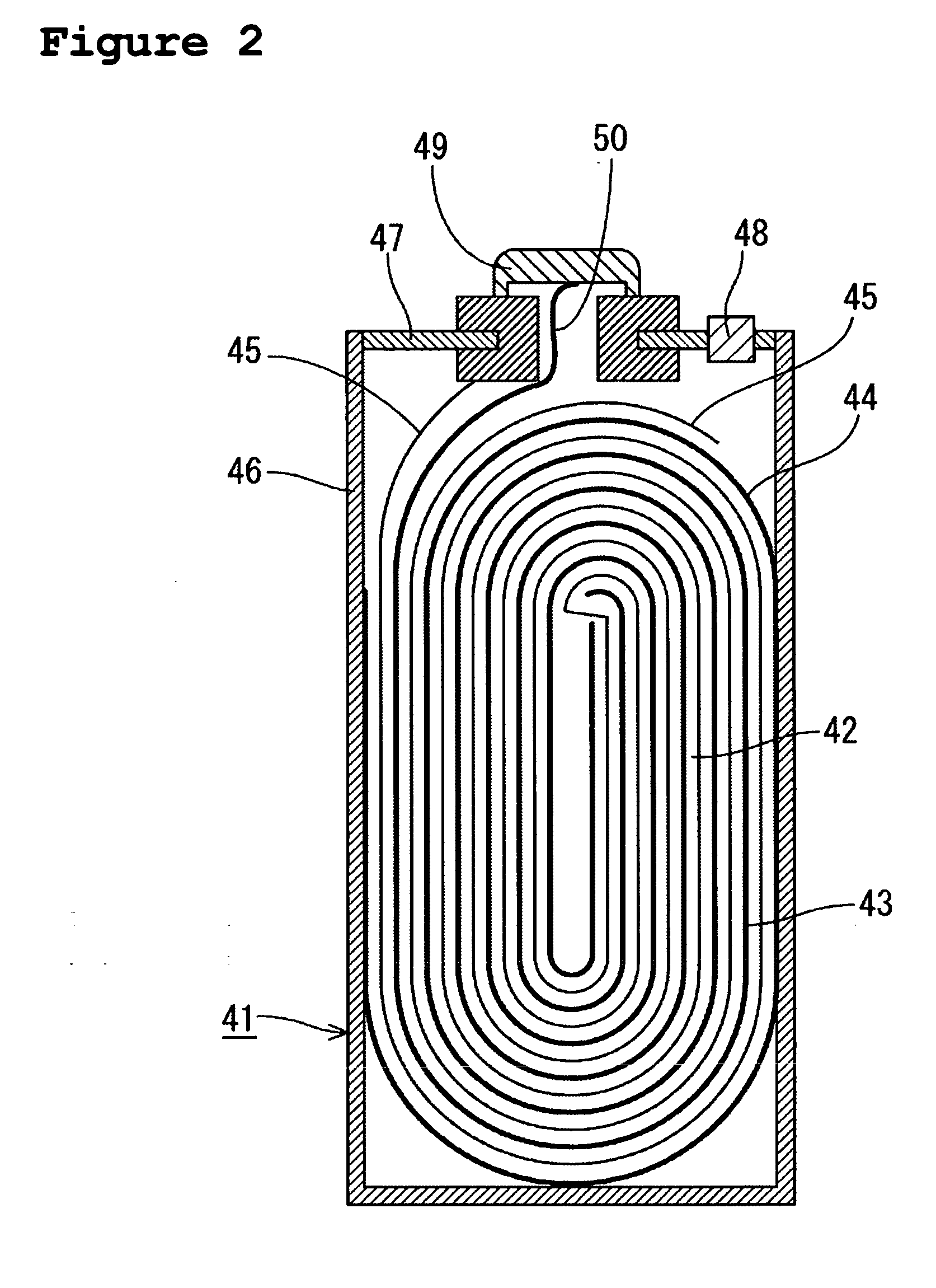

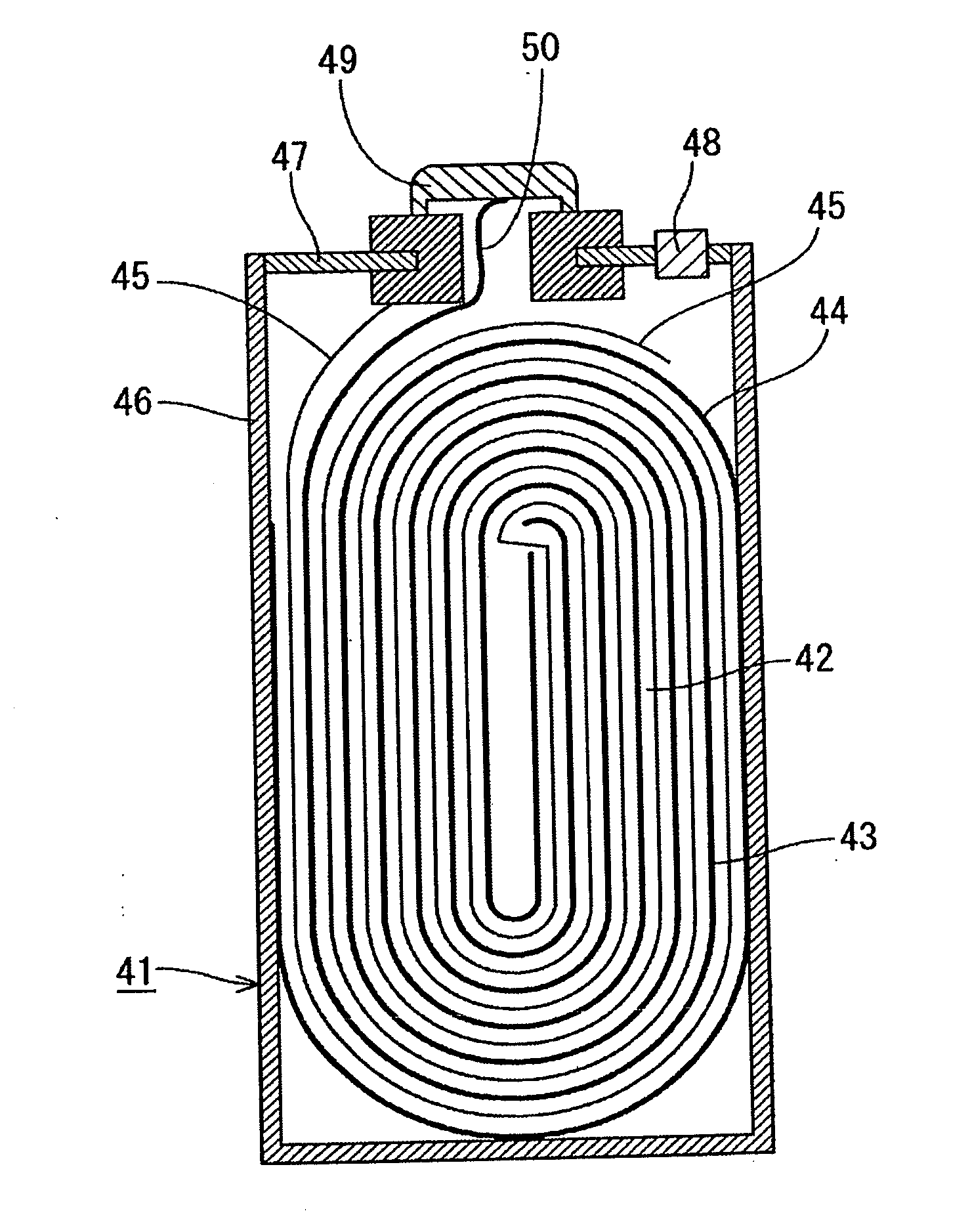

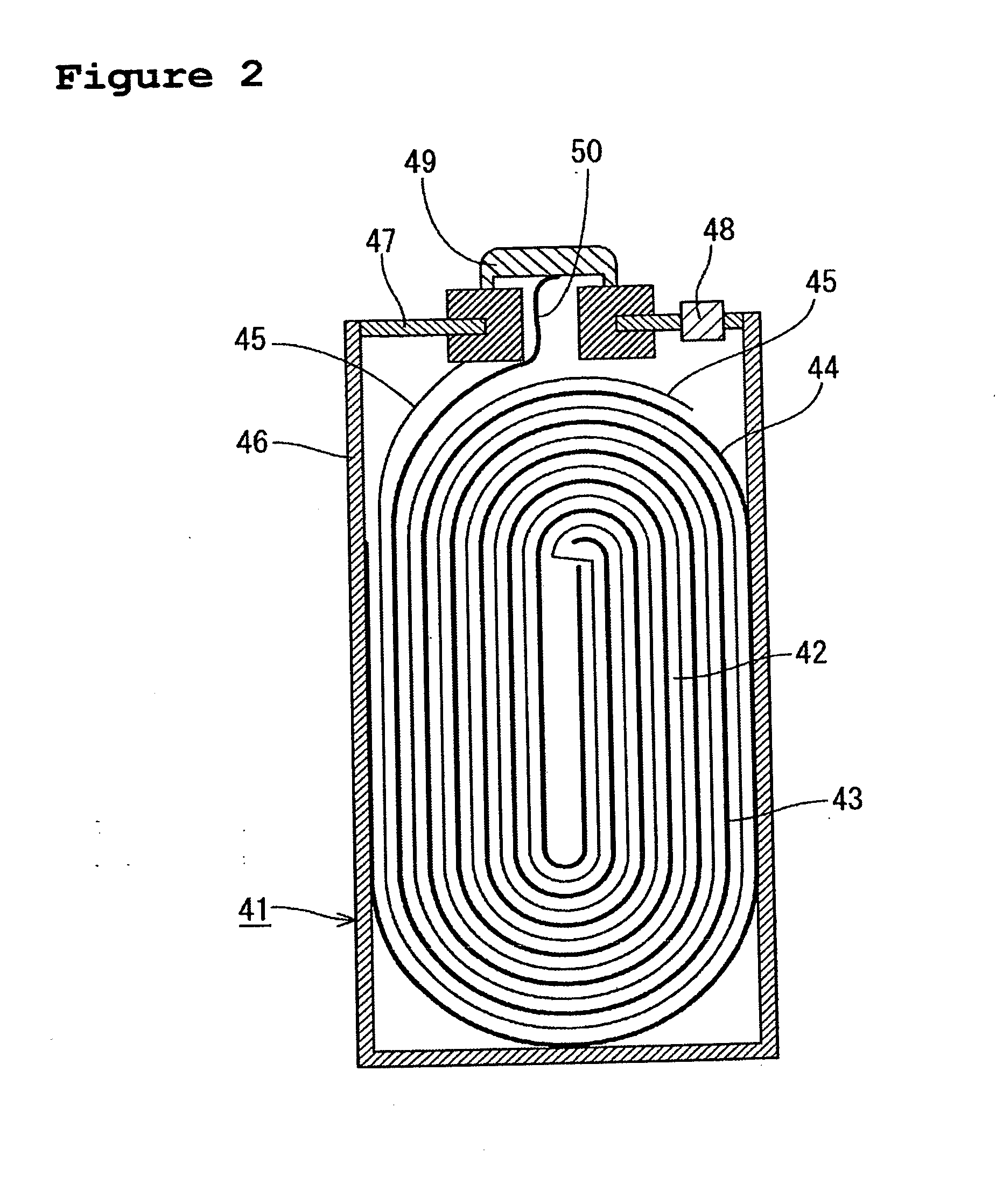

Nonaqueous electrolyte secondary cell

ActiveUS20060166098A1Improve cycle performanceImprove cycle lifeSecondary cellsNegative electrodesSiliconMaterials science

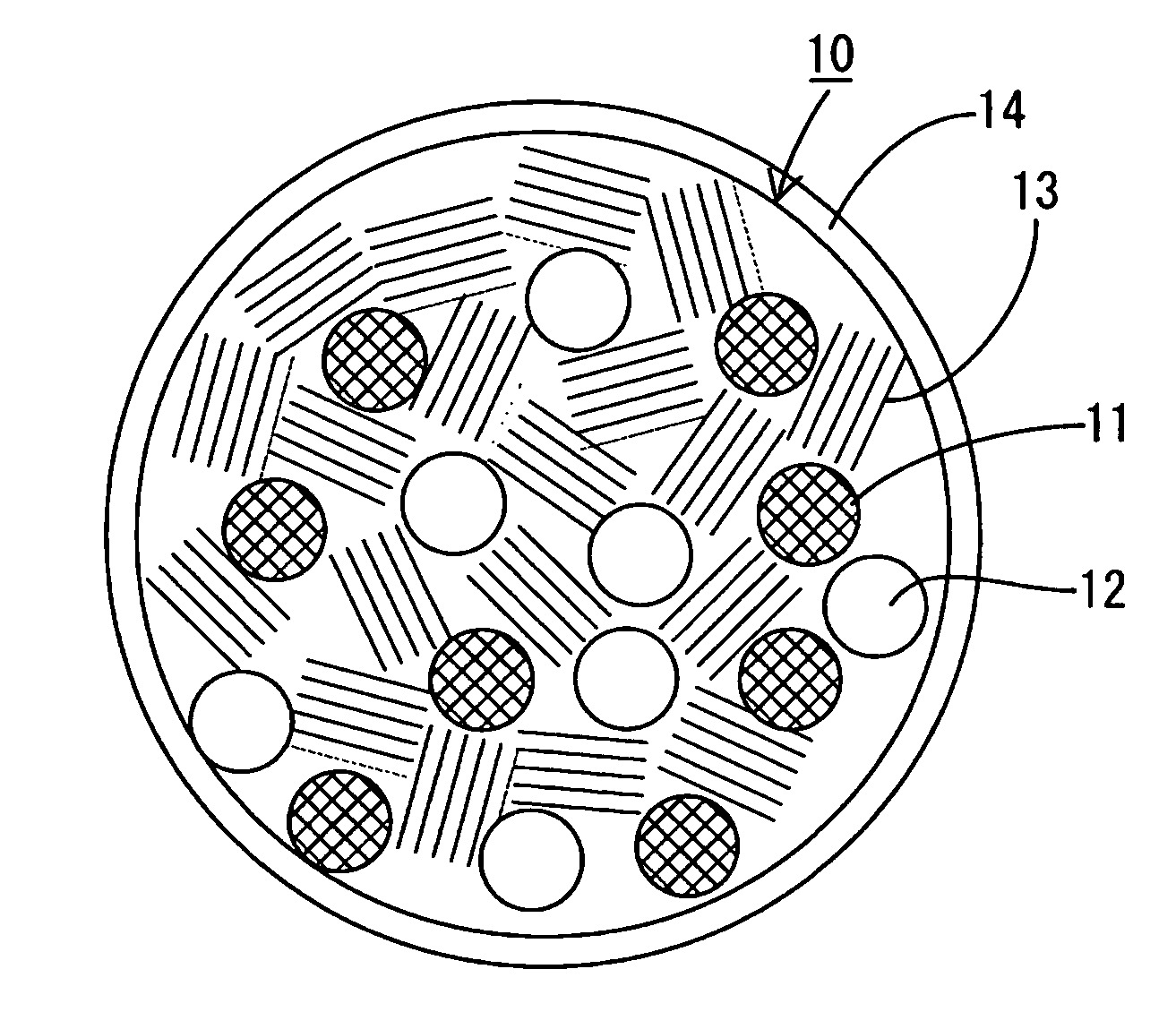

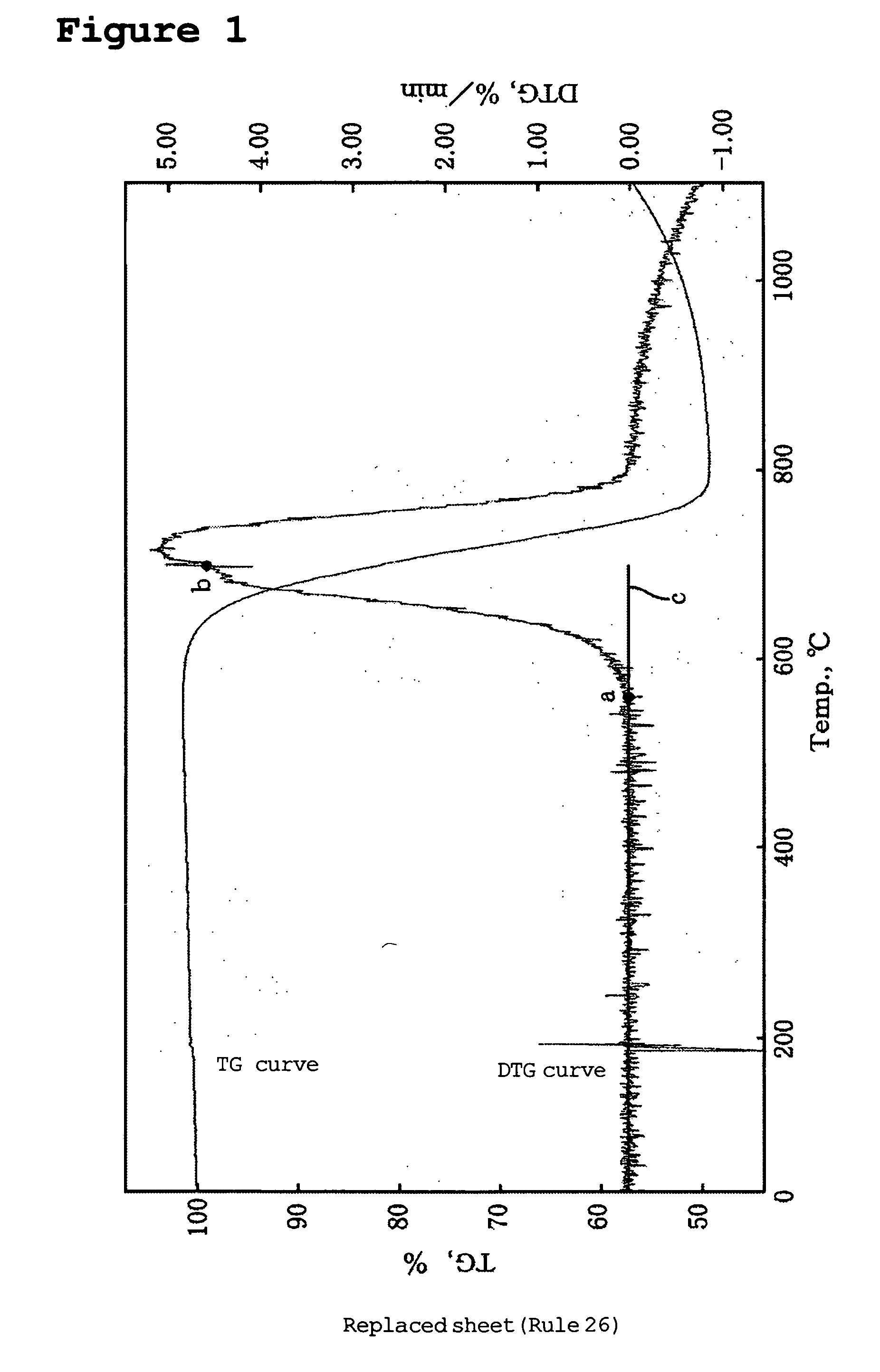

The present invention provides a non-aqueous electrolyte secondary battery comprising a positive electrode, a negative electrode having a negative active material, and a non-aqueous electrolyte; characterized in that said negative active material contains composite particle (C), which has silicon-containing particle (A) and electronic conductive additive (B), and carbon material (D), wherein the weight of said electronic conductive additive (B) falls within the range of 0.5 wt. % to 60 wt. % to the weight of said composite particle (C). The negative active material contains silicon which is capable of performing high discharge capacity, so that a non-aqueous electrolyte secondary battery having a large discharge capacity can be obtained. In addition, since the negative active material contains the electronic conductive additive (B) and the carbon material (D), the contact conductivity between the silicon-containing particle (A) or between the negative active material improves and, as a result, a non-aqueous electrolyte secondary battery having satisfactory cycle performance can be attained.

Owner:GS YUASA INT LTD

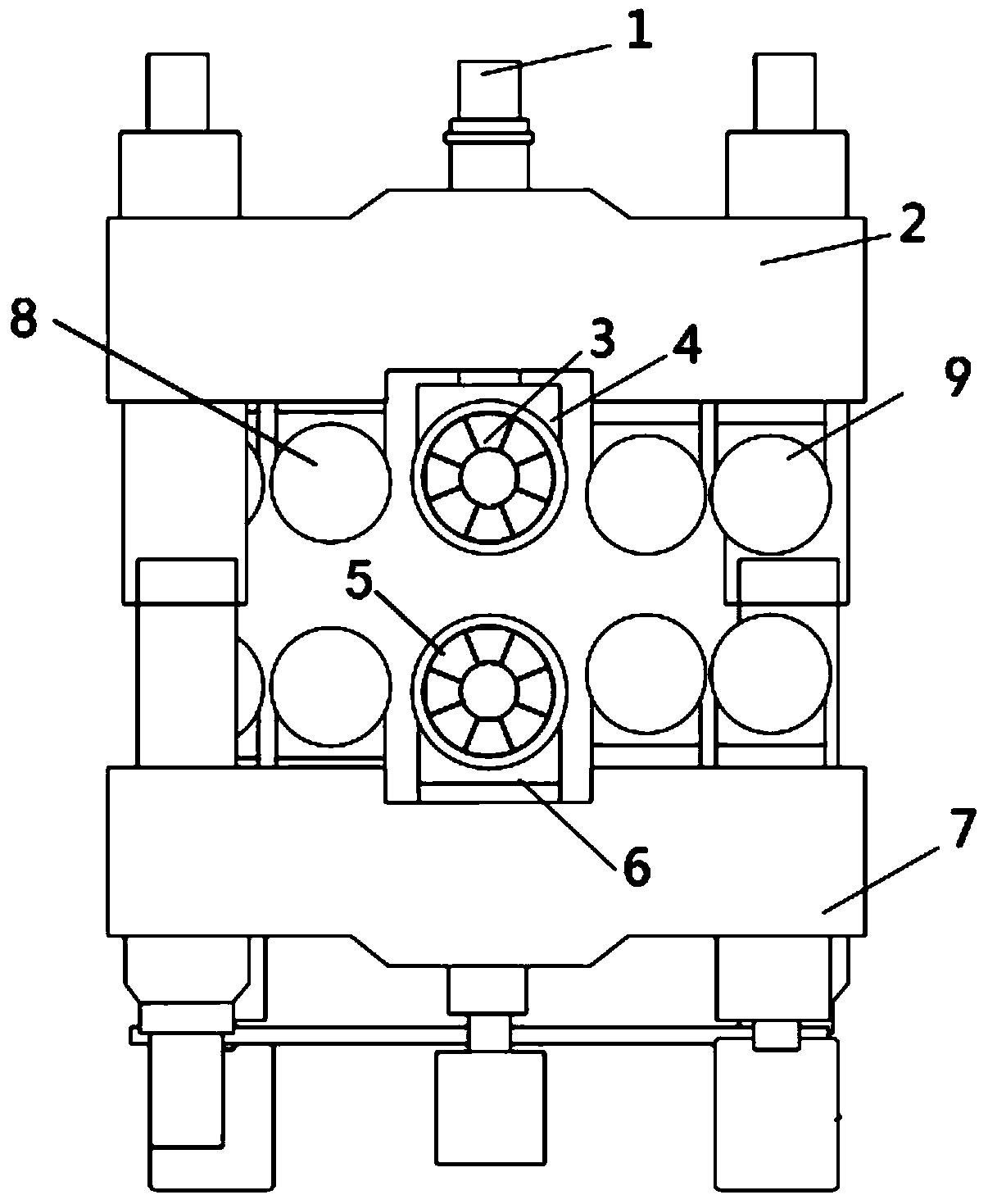

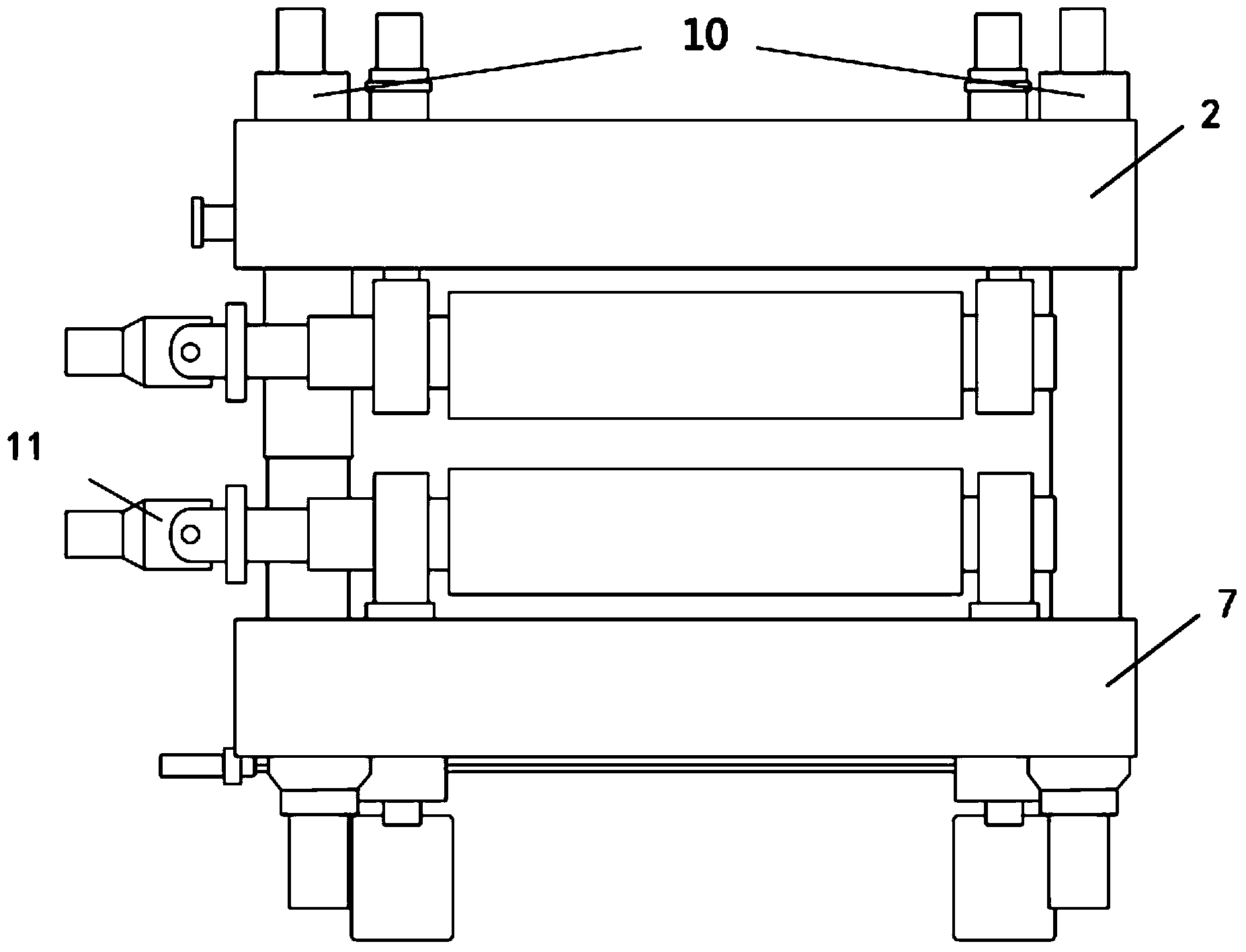

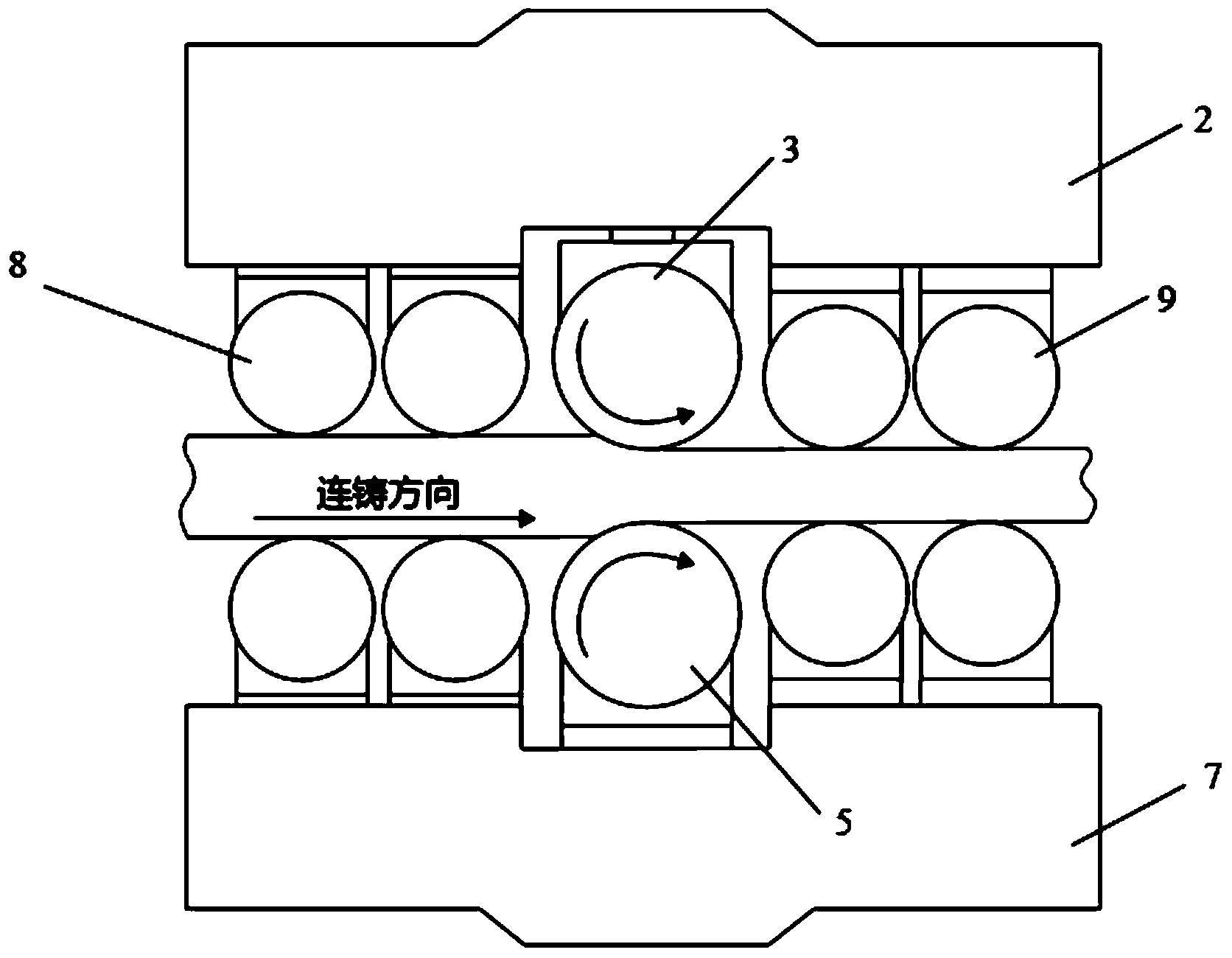

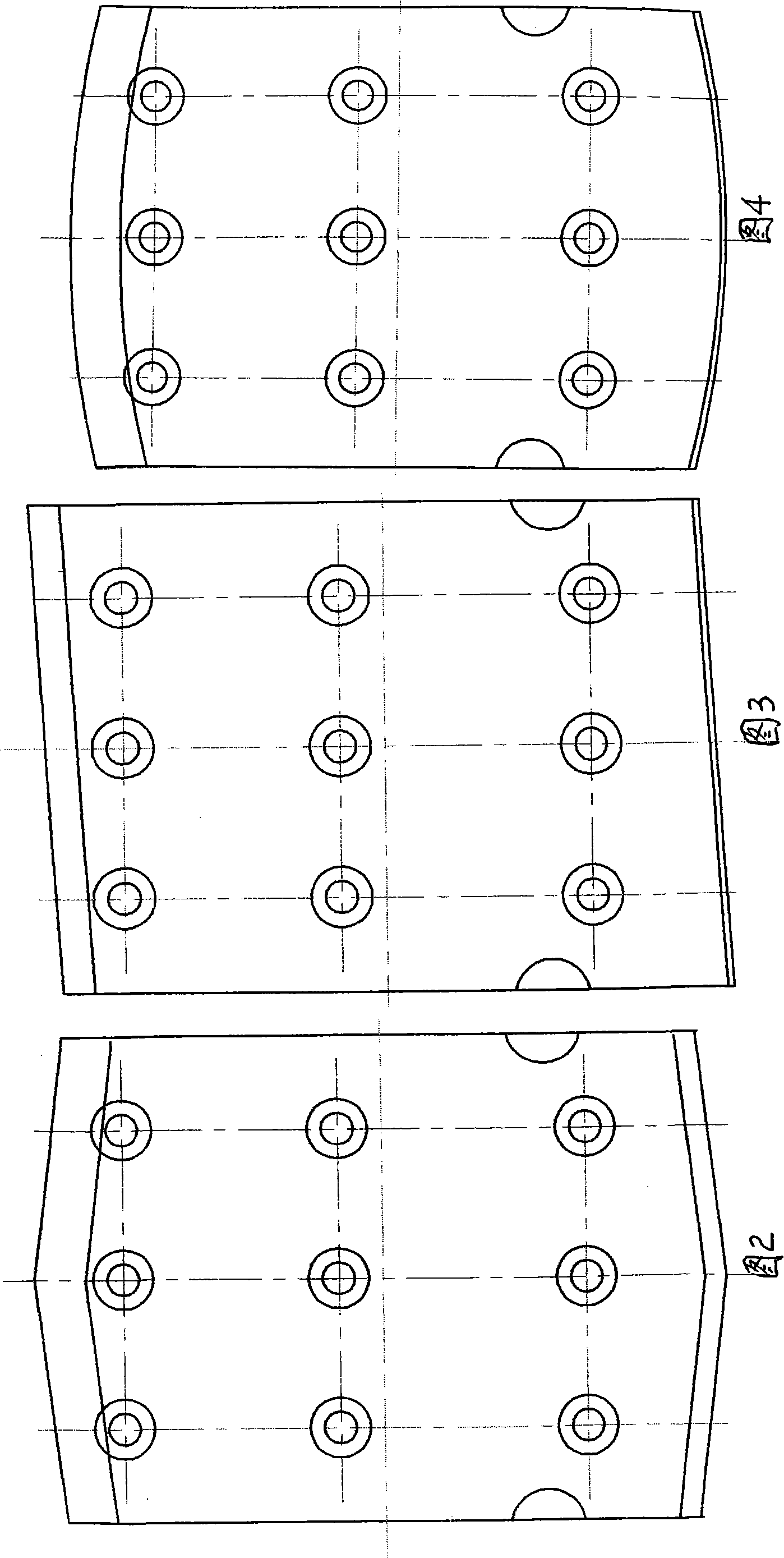

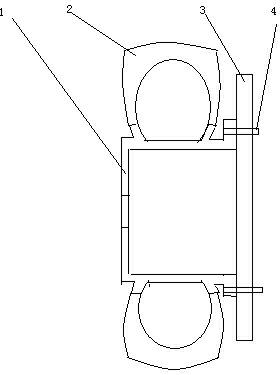

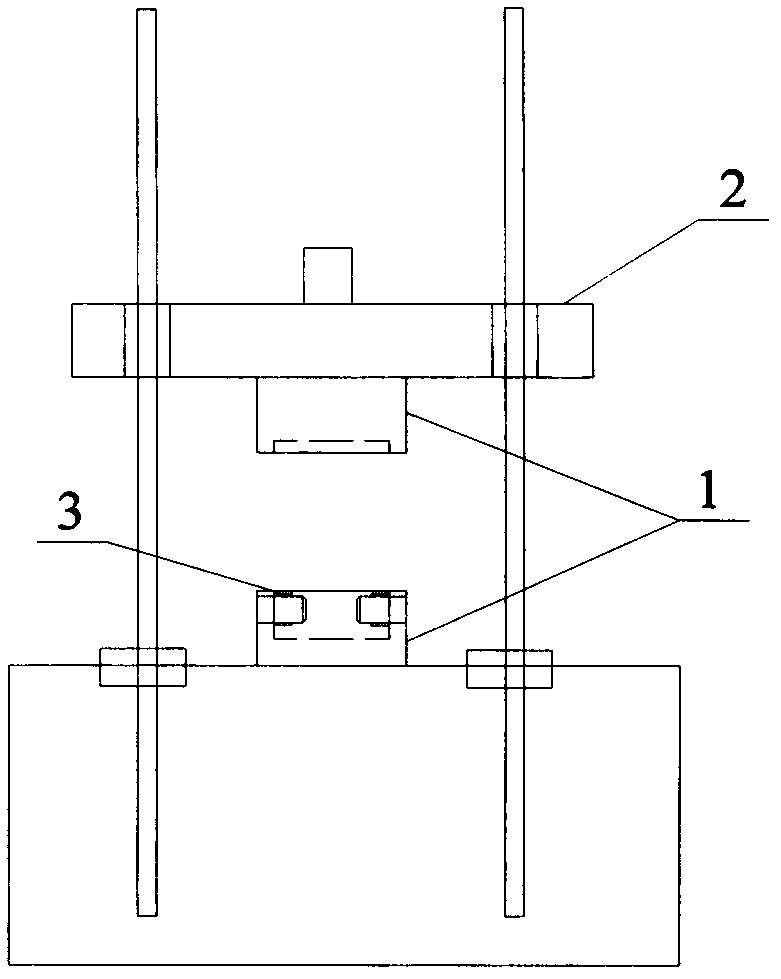

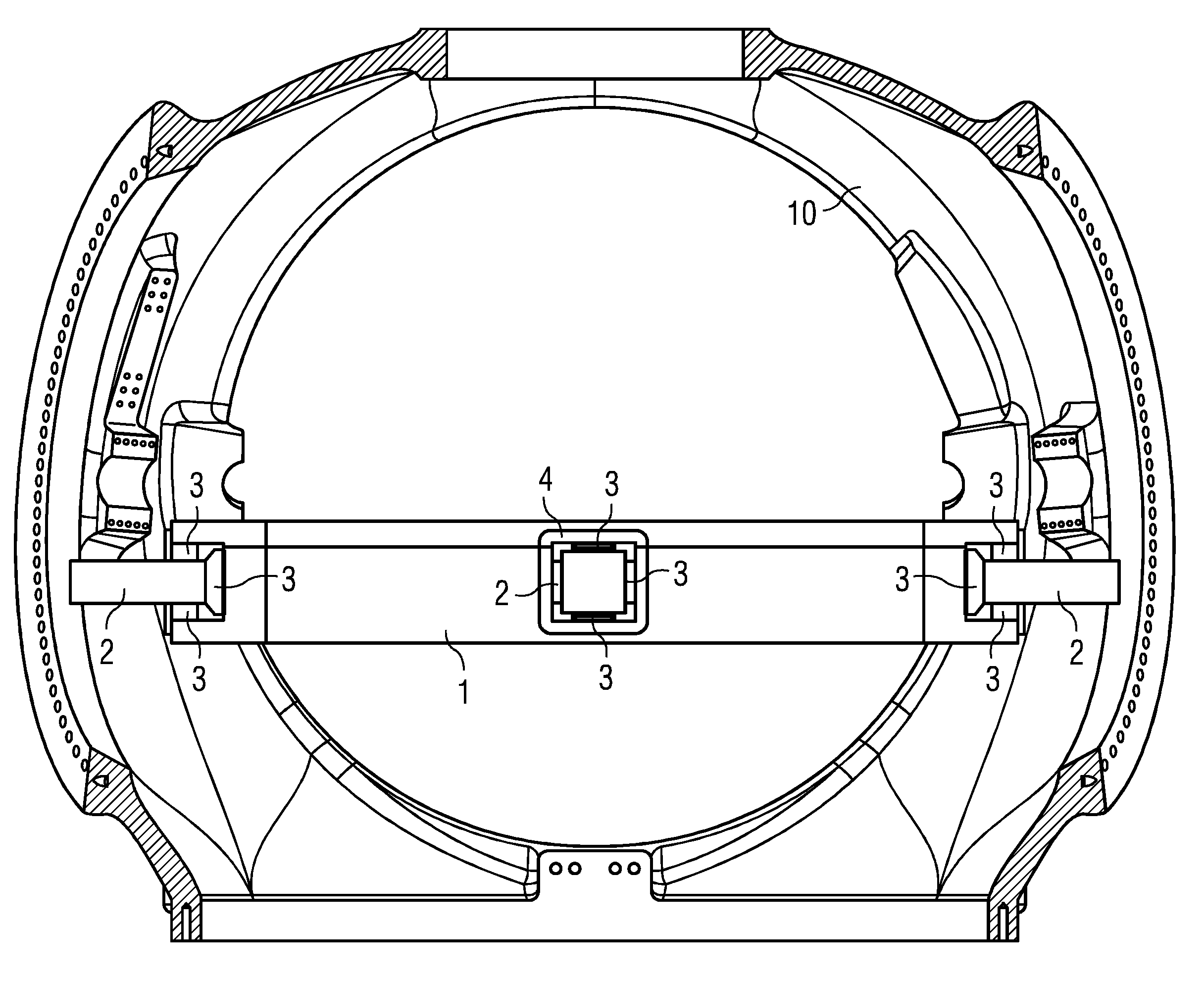

Continuous casting machine sector section for deep pressing of continuous casting blank solidification tail end and deep pressing method of continuous casting machine sector section

ActiveCN104057049AReduced plastic deformation contact areaTotal Deformation Force ReductionMaterials scienceContinuous casting

The invention provides a continuous casting machine sector section for deep pressing of the continuous casting blank solidification tail end and a deep pressing method of the continuous casting machine sector section. The continuous casting machine sector section comprises an upper frame, a lower frame, an upper driving roll, a lower driving roll, a left driven roll set, a right driven roll set, a pressing device and a clamping cylinder, wherein the upper frame, the lower frame, the upper driving roll, the lower driving roll, the left driven roll set, the right driven roll set, the pressing device and the clamping cylinder are arranged on the sector section; the clamping cylinder is used for clamping the upper frame and the lower frame to be kept in a certain set gap; the upper driving roll is connected with the pressing device and connected to the upper frame through a bearing base, the lower driving roll is connected to the lower frame through a bearing base, the left driven roll set and the right driven roll set are located on the two sides of the driving rolls respectively, the left driven roll set is used for clamping a casting blank before pressing, the right driven roll set is used for clamping the casting blank after pressing, and the radio of the diameter of each driving roll to the diameter of each driven roll is 1.1:1 to 2:1. According to the continuous casting machine sector section for deep pressing of the continuous casting solidification tail end and the deep pressing method of the continuous casting machine sector section, the deformation permeability is improved, deformation achieved through the continuous casting machine sector section is equivalent to that achieved by one rolling pass of a twin rolling mill with the large rolling diameter, and the improvement in loosening and segregating of a central zone of the casting blank is facilitated.

Owner:UNIV OF SCI & TECH BEIJING

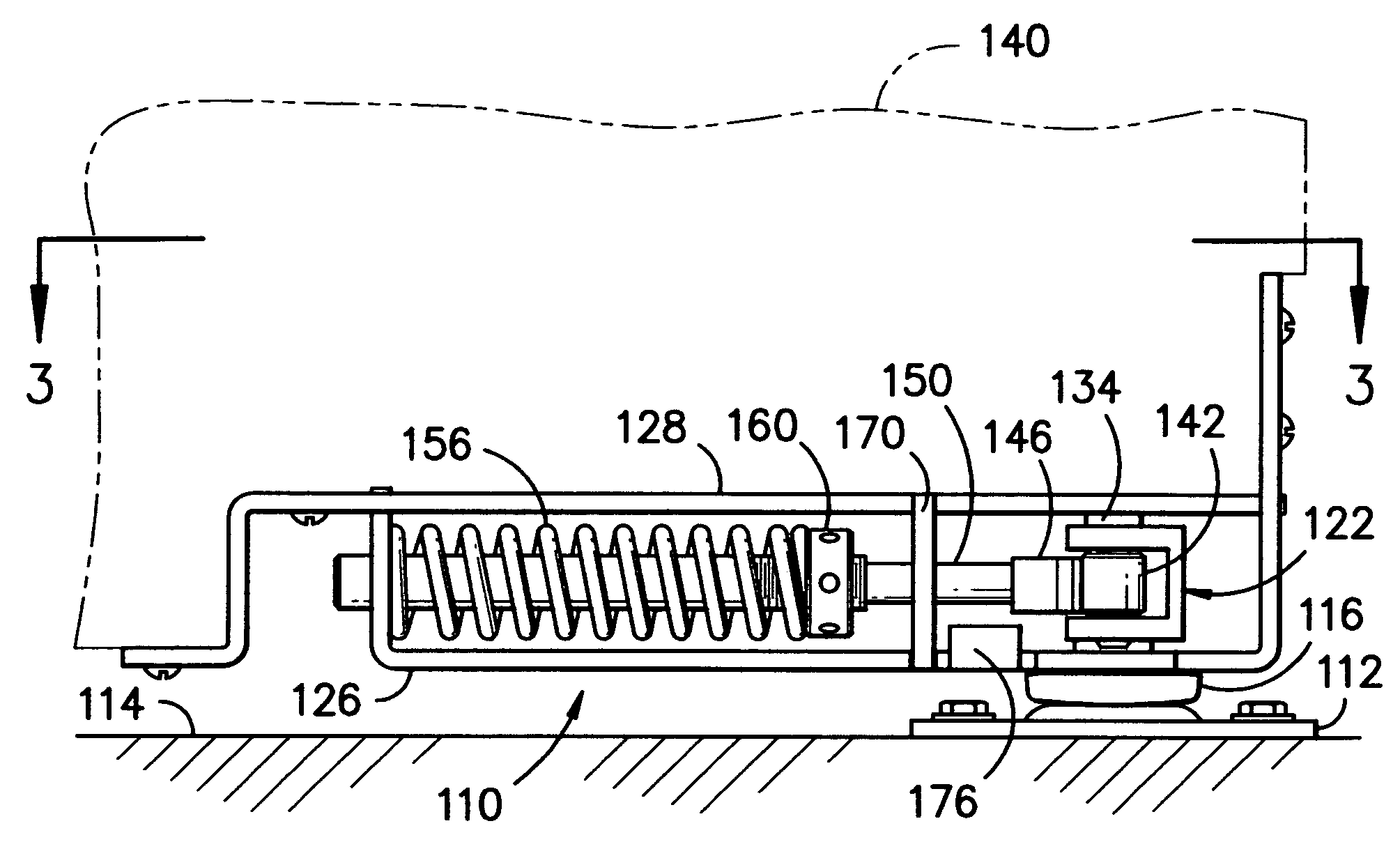

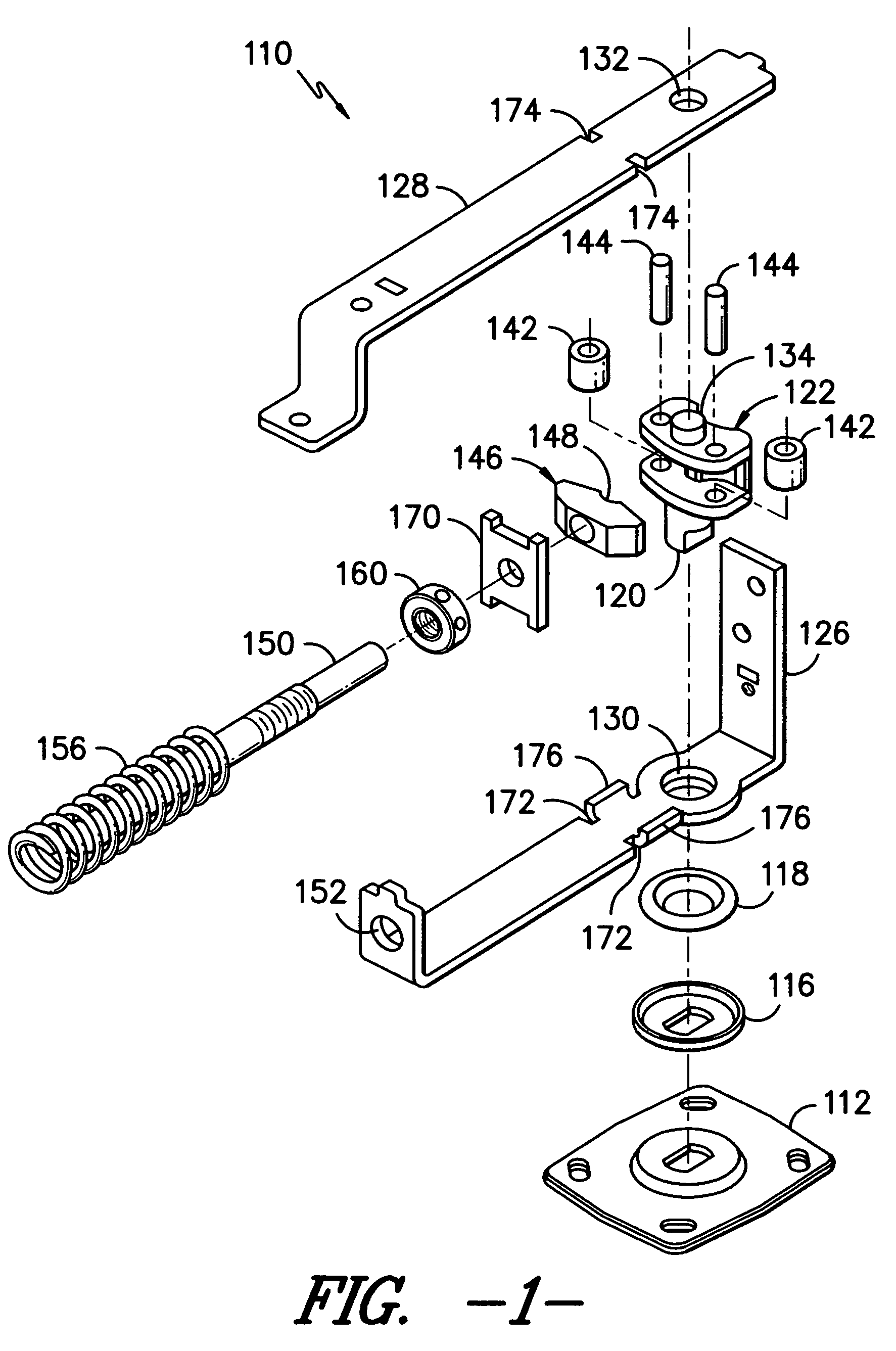

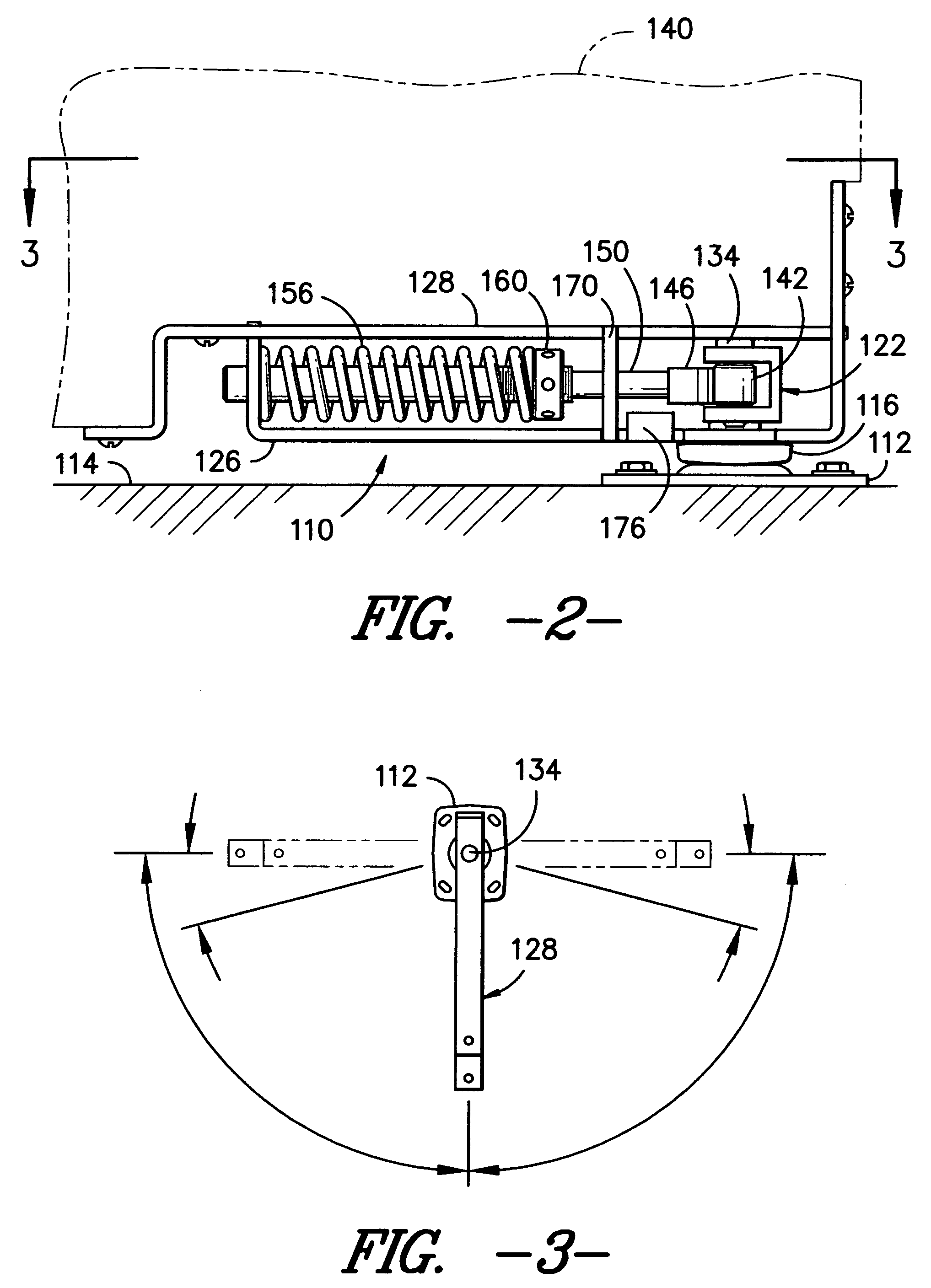

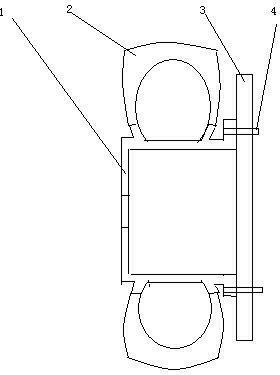

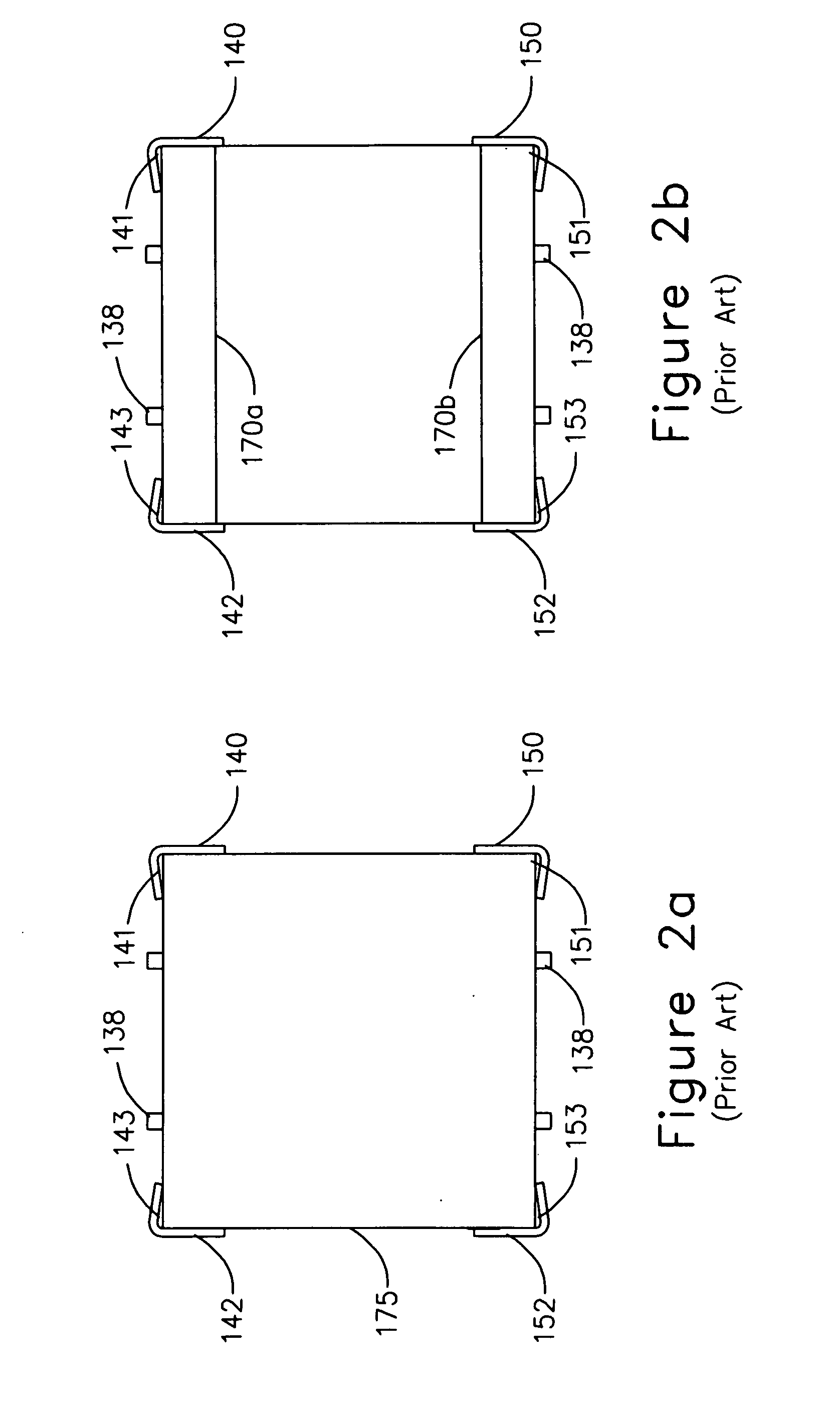

Floor hinge assembly

InactiveUS20080127452A1Reduce material weightReduce machining requirementsBuilding braking devicesPin hingesBraced frameEngineering

An improved self returning floor mounted hinge assembly for a door. The hinge assembly includes a guide plate affixed to a support frame and having an opening substantially surrounding a linearly displaceable guide shaft. The opening in the guide plate is substantially aligned with an opening in the frame structure supporting the end of the guide shaft.

Owner:BOMMER INDS

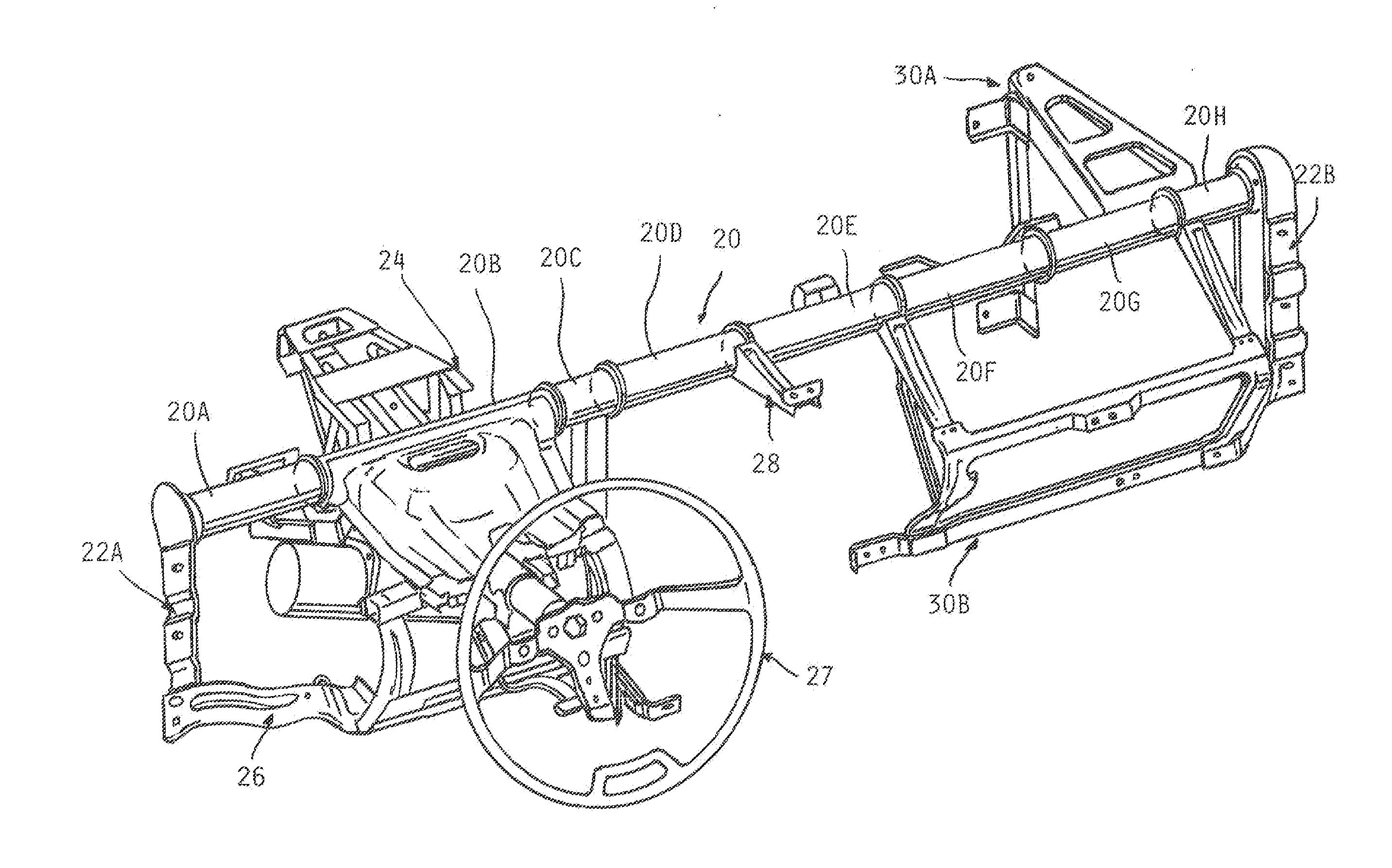

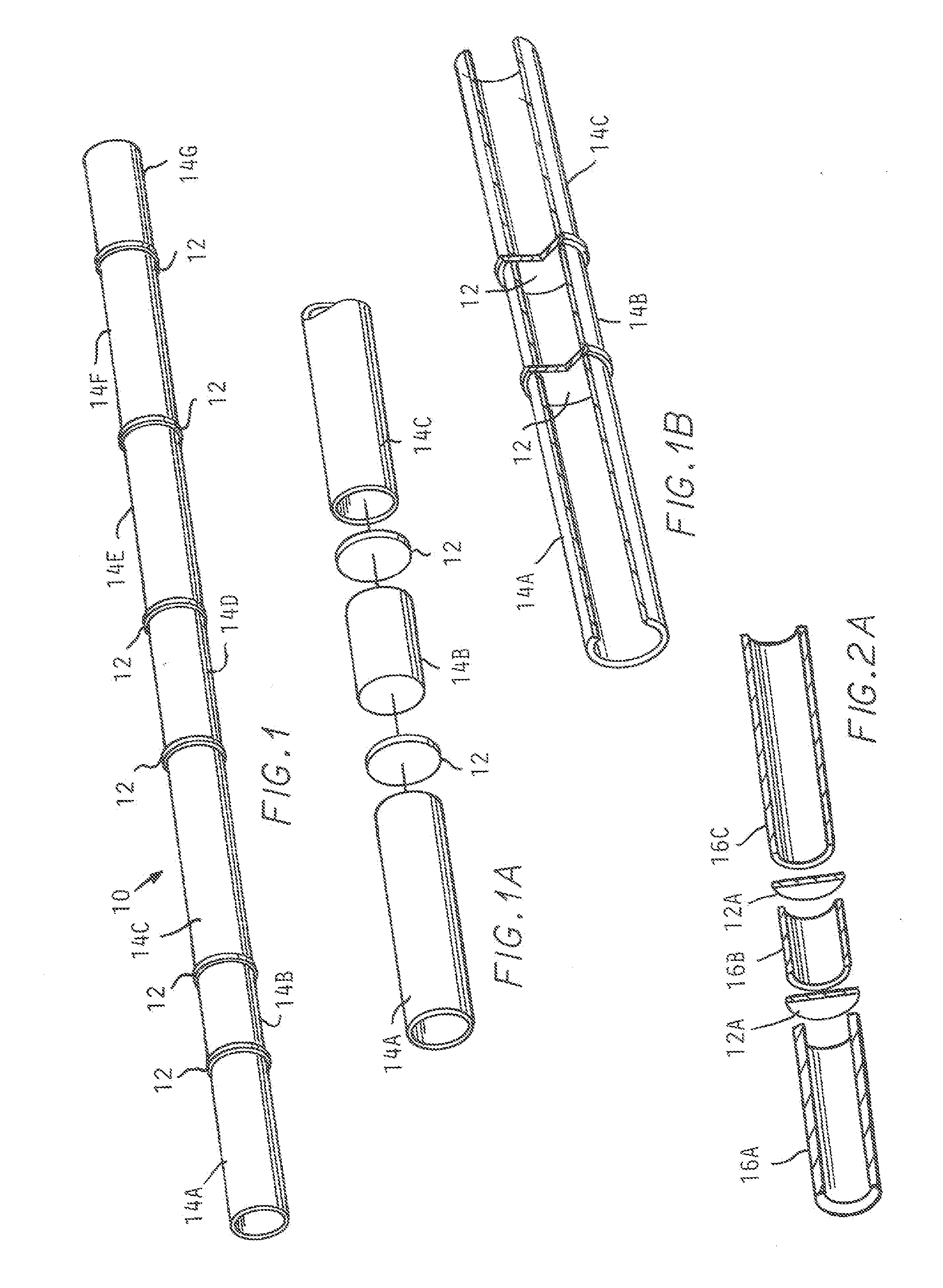

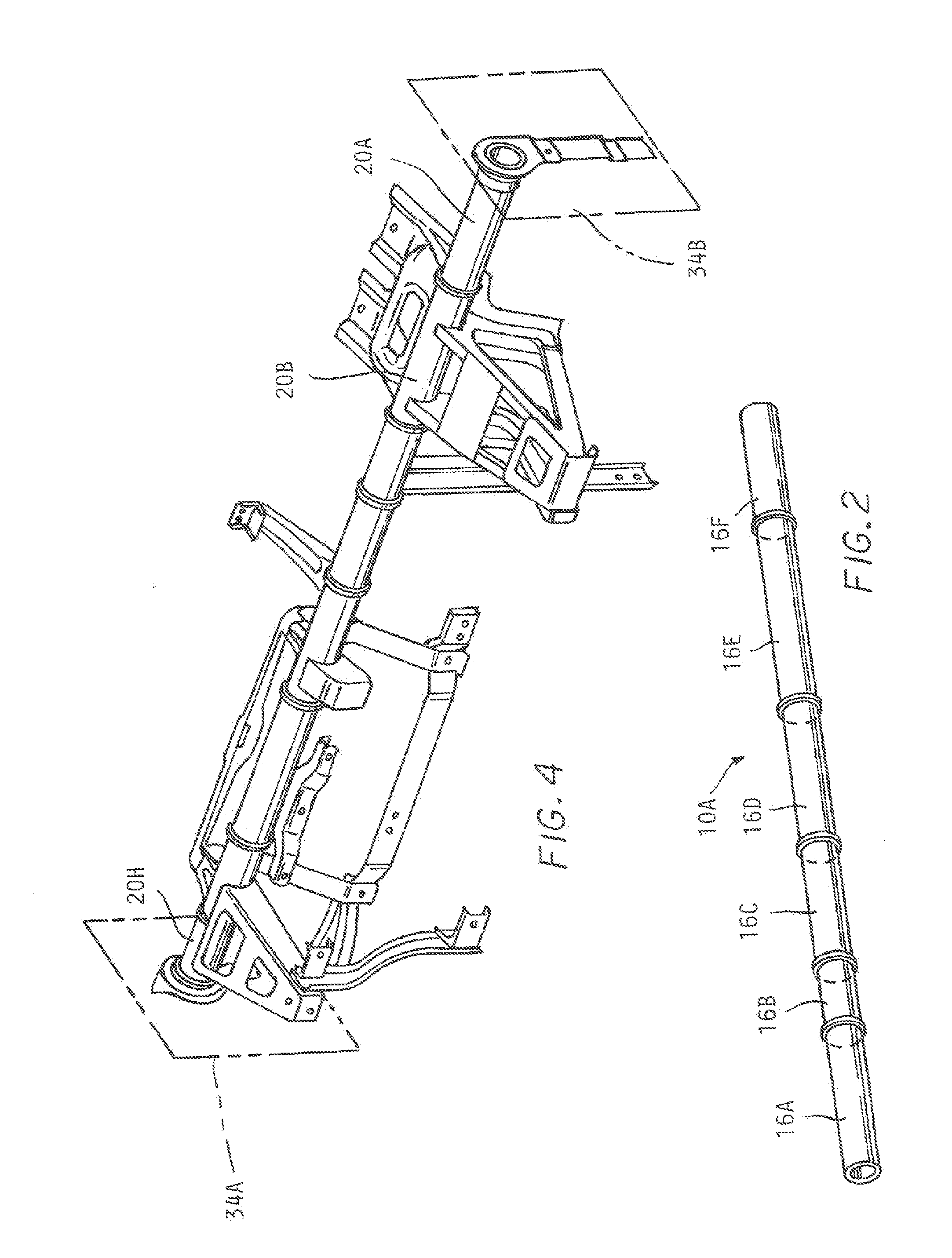

Lightweight Cross-Car Beam and Method of Construction

InactiveUS20140103685A1Efficiently strengthensReduce material weightVehicle seatsMetal-working apparatusEngineeringUltimate tensile strength

Owner:MANI AYYAKANNU

Non-aqueous electrolyte secondary battery

ActiveUS8092940B2Improve cycle lifeImprove contact conductivityNegative electrodesSecondary cellsSiliconMaterials science

Owner:GS YUASA INT LTD

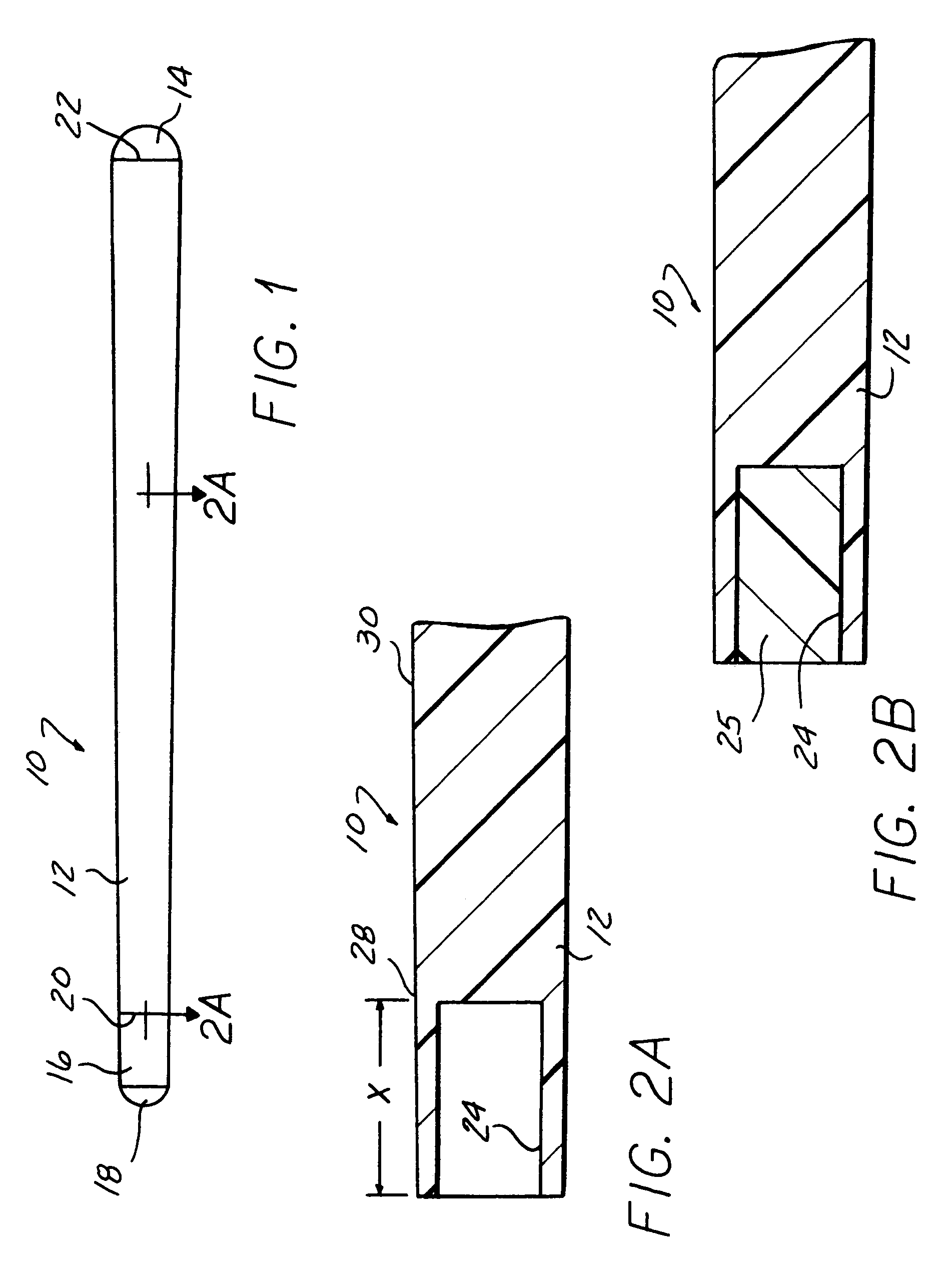

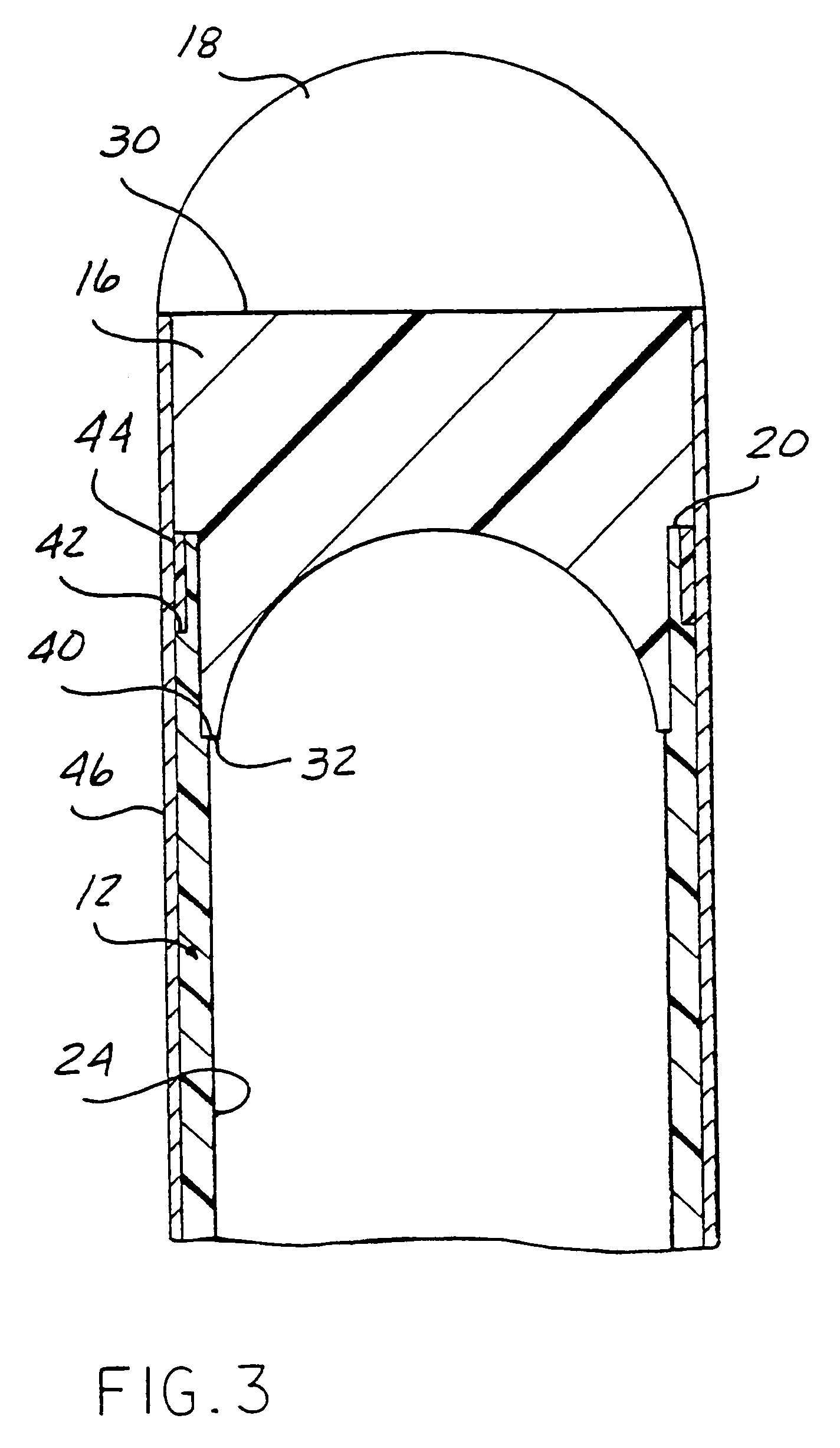

Billiard cue

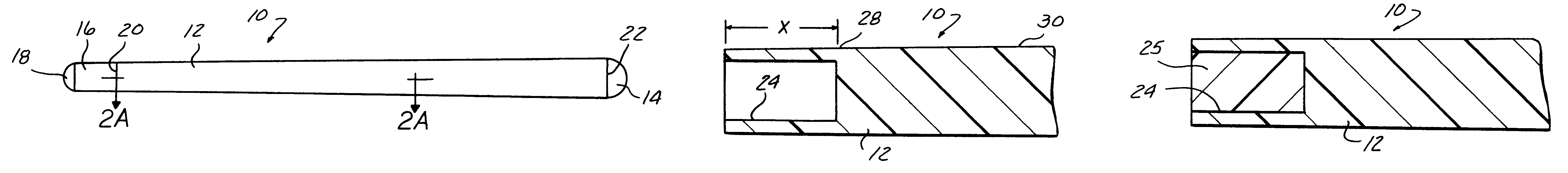

A billiard cue includes a shaft having a hollow bore extending for a predetermined distance from a first end of the shaft to reduce the tip end weight of the shaft. In one aspect, where the shaft is formed of a composite material consisting of fibers in a binder, such as carbon fibers in an epoxy resin, the bore forms an outer wall in the tip end of the shaft having a thickness between about 0.005 and about 0.05 inches The shaft material has a modulus of elasticity of at least 4.3×106 psi. The bore extending from the first end of the shaft, the thin wall thickness of the tip end of the shaft and the material forming the shaft combine to decrease the mass of the tip end of the shaft while maintaining substantially all of the stiffness of a conventional solid wood shaft formed of a hard maple to minimize buckling of the tip end of the shaft and thereby substantially decrease deflection of the cue ball from its intended path of movement along a path parallel to the stroke axis of the shaft. The tip end bore may be left hollow or filled with a light weight, non-structural material. The hollow bore is equally applicable to shafts formed of wood.

Owner:CLAWSON CUSTOM CUES

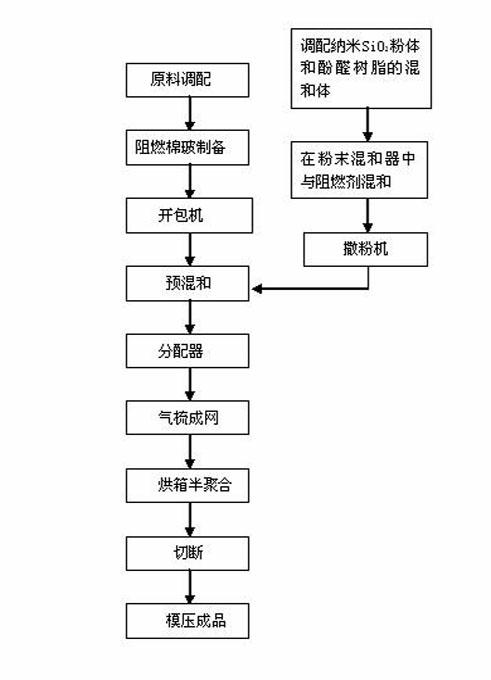

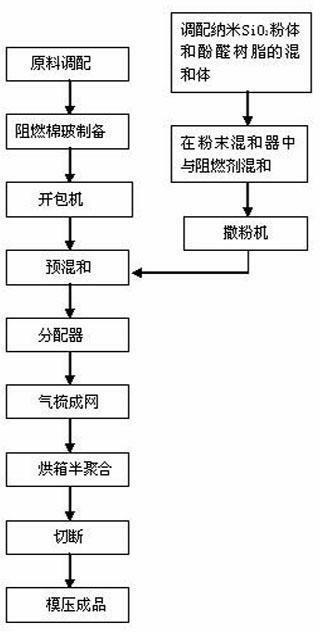

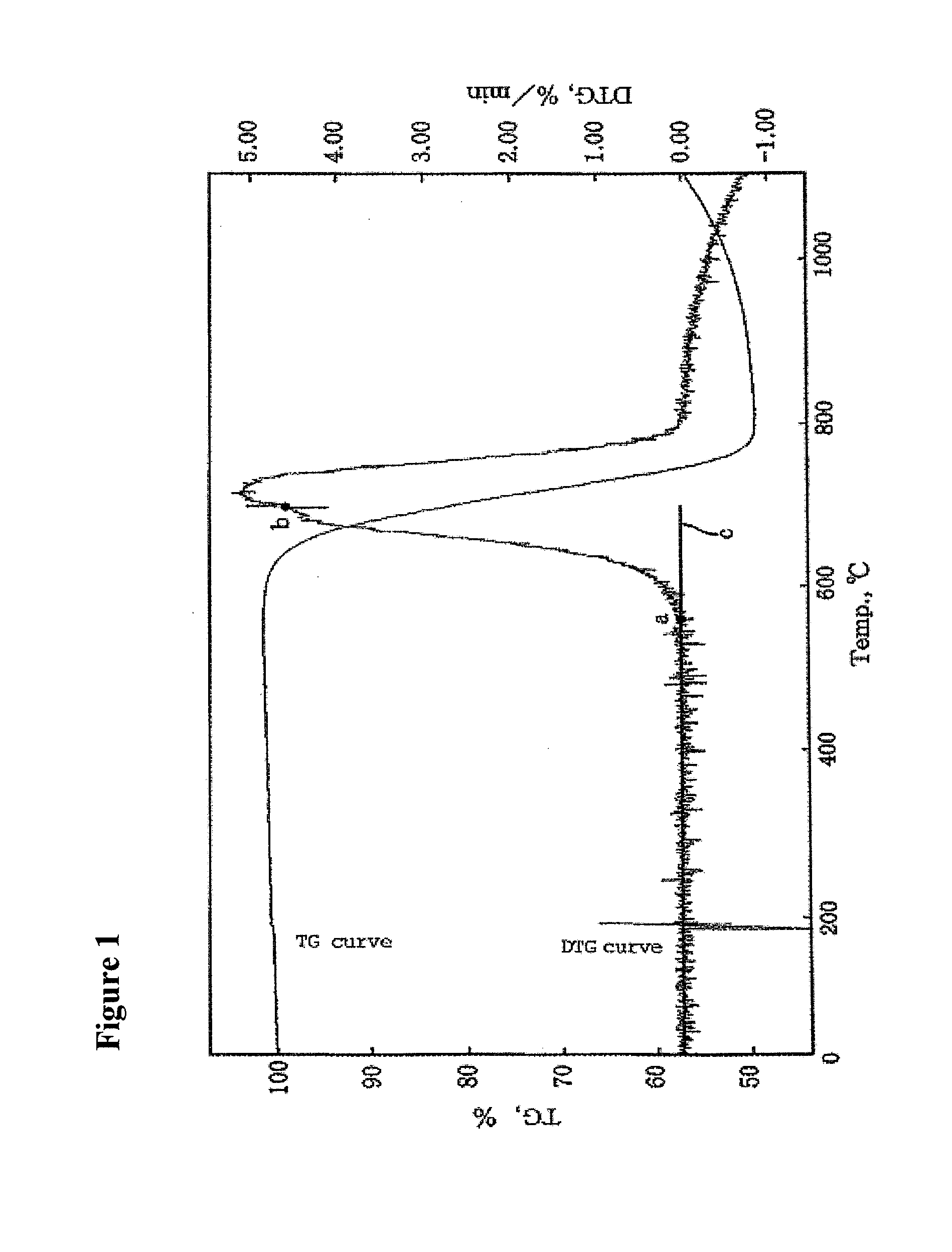

A kind of high flame retardant felt for automobile engine compartment and its manufacturing method

ActiveCN102277686AReduce material weightSmall difference in strengthFibre treatmentNon-woven fabricsChemistryPhenol formaldehyde resin

The invention discloses a highly flame-retardant felt used for automobile engine compartments and a manufacturing method thereof. The highly flame-retardant felt is a mixture of the following materials (accounting for the total weights of raw materials): 44 to 48 percent of blend of regenerated glass fibers and flame-retardant loosened cotton, 39 to 42 percent of blend of nano-sized SiO2 powders and phenolic resin, and 13 to 14 percent of a flame retardant agent. The method comprises the following steps: firstly, preparing an aqueous solution (30 to 35% concentration) of powdery polyammonium phosphate which is used as flame retardant agent and water, uniformly spraying the solution to loosened cotton, and loosening while adding regenerated glass fibers; then, mixing nano-sized SiO2 powders with phenolic resin such that nano-sized SiO2 powders are uniformly dispersed in phenolic resin, and adding the flame retardant agent and thoroughly mixing; and finally, simultaneously feeding the two powdery mixtures to an air-laid netting machine by use of a distributor. By virtue of the process of phenolic resin modification with nanopowders and the special process of fiber flame-retardant treatment, and the composition of flame-retardant loosened cotton, regenerated glass fibers and modified phenolic resin, in addition with an appropriate proportion of flame retardant agent, the best results of being both economic and flame-retardant and satisfying the need for performance improvement are achieved.

Owner:镇江立达纤维工业有限责任公司

Non-aqueous electrolyte secondary battery

InactiveUS20120021286A1Improve cycle lifeImprove contact conductivitySecondary cellsNegative electrodesSiliconMaterials science

The present invention provides a non-aqueous electrolyte secondary battery including a positive electrode, a negative electrode having a negative active material, and a non-aqueous electrolyte; characterized in that the negative active material contains composite particle (C), which has silicon-containing particle (A) and electronic conductive additive (B), and carbon material (D), wherein the weight of the electronic conductive additive (B) falls within the range of 0.5 wt. % to 60 wt. % to the weight of the composite particle (C). The negative active material contains silicon which is capable of performing high discharge capacity, so that a non-aqueous electrolyte secondary battery having a large discharge capacity can be obtained. In addition, since the negative active material contains the electronic conductive additive (B) and the carbon material (D), the contact conductivity between the silicon-containing particle (A) or between the negative active material improves and, as a result, a non-aqueous electrolyte secondary battery having satisfactory cycle performance can be attained.

Owner:GS YUASA INT LTD

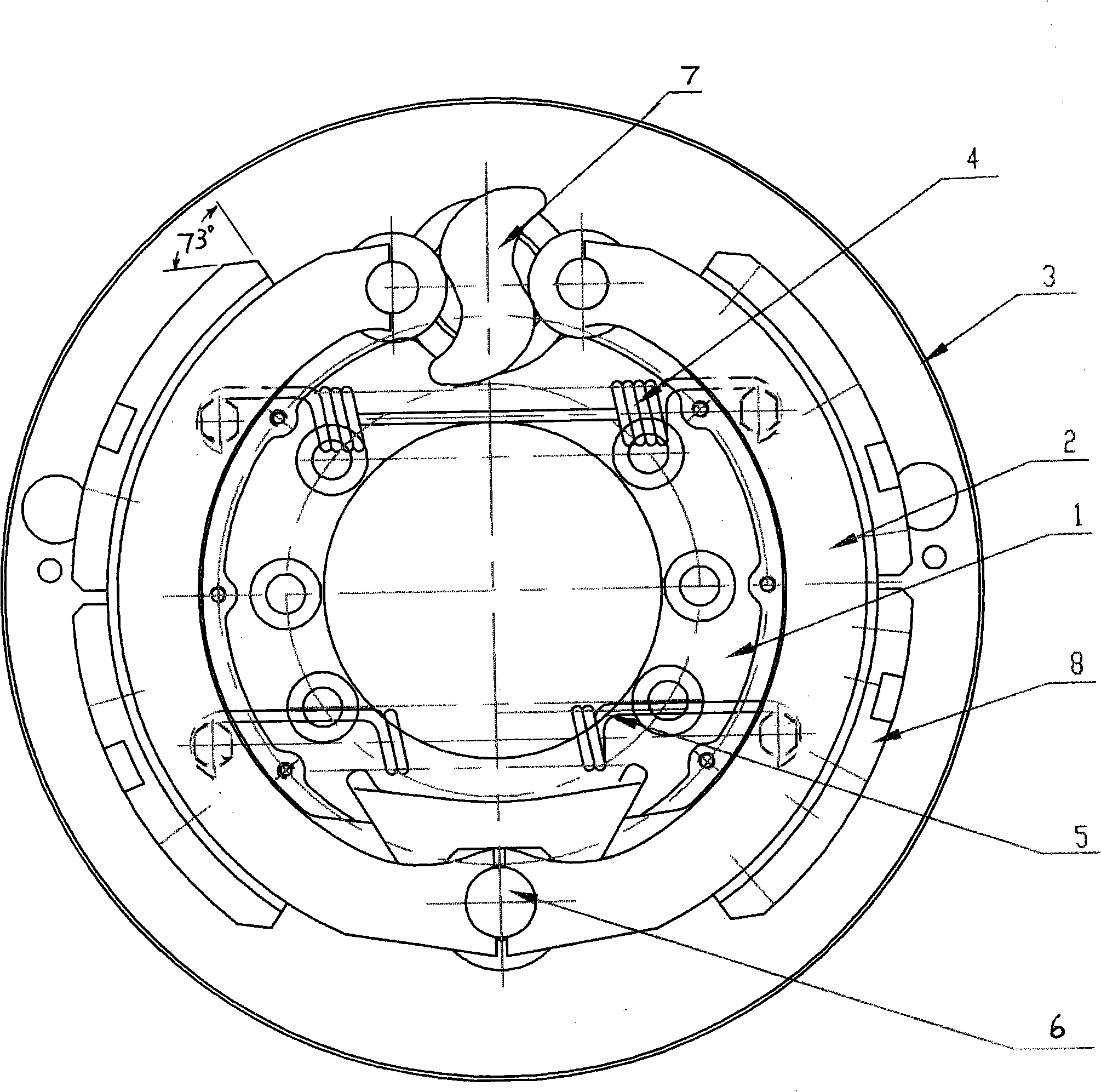

Single-anchor pin cam drum type brake

InactiveCN101493124AImprove performance factorReduce manufacturing costBraking membersMechanically actuated drum brakesHelical lineEngineering

A single rest pin cam drum brake mainly comprises a bottom plate of the brake, two brake shoes, a dust cover, a return spring, a fixed spring, a rest pin and a camshaft. The center of the rest pin is arranged on the extension line of the line of centers of the camshaft and the bottom plate of the brake. The supported end of the brake shoe adopts a double subplate riding tractor single rest pin structure. One end of the brake shoe is supported on the rest pin in a semicircle and nick way. The two brake shoes share one rest pin. The other end of the brake shoe is provided with a roller which is connected with the cam. The excircle of every brake shoe is fixed with two friction liners. The single rest pin drum brake has the advantages that the two brake shoes share one rest pin, which reduces the quantity of parts and the material weight of the bottom plate of the brake and the brake shoes and simplifies the processing technique of the bottom plate of the brake; in addition, the shape of the friction liners is optimized to cause the contact line of the friction liners and the cylindrical surface in the brake drum to be a cylindrical helix, thus brake being more stable and difficult to off tracking.

Owner:HUNAN YUNDA MACHINERY MFG

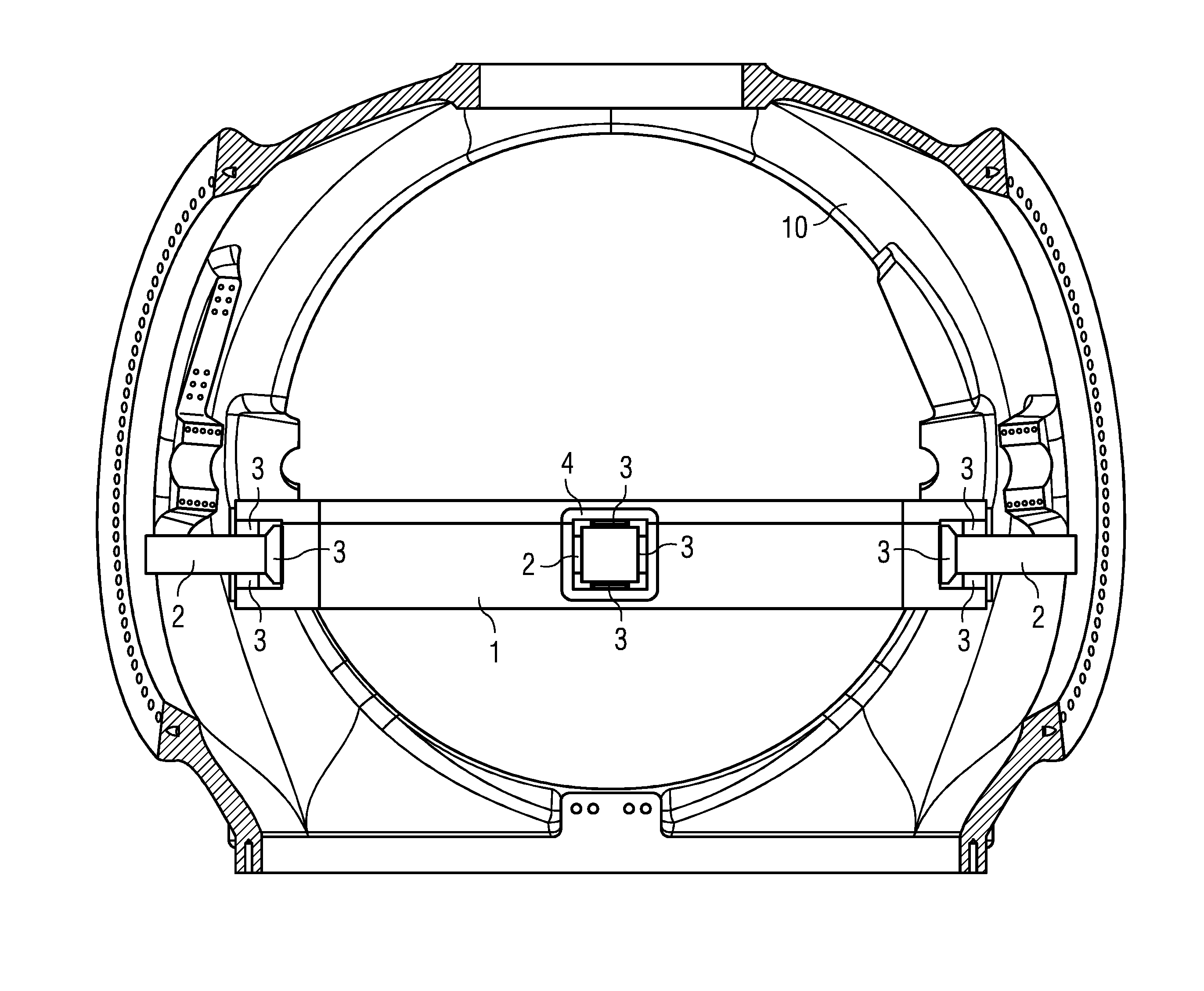

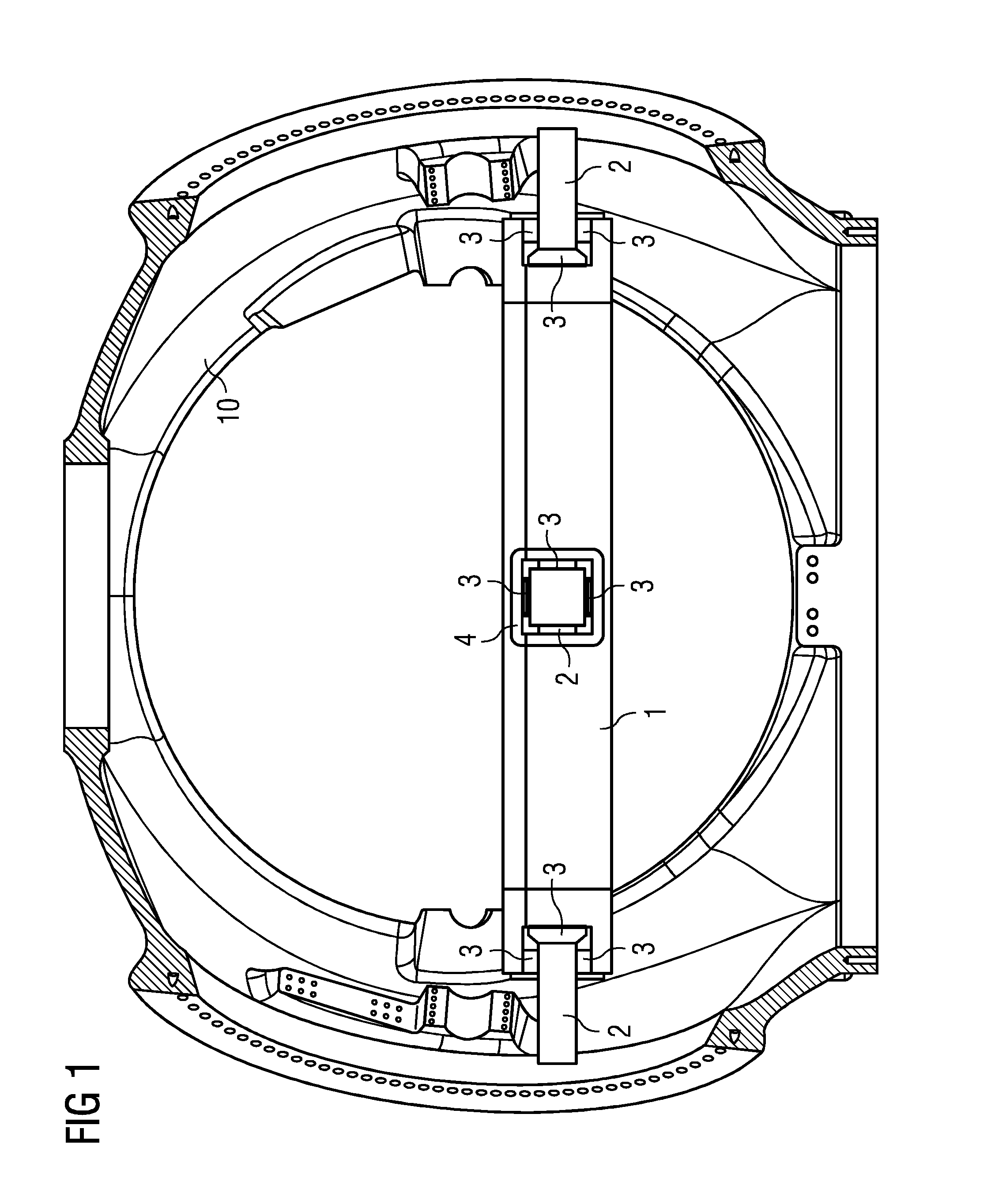

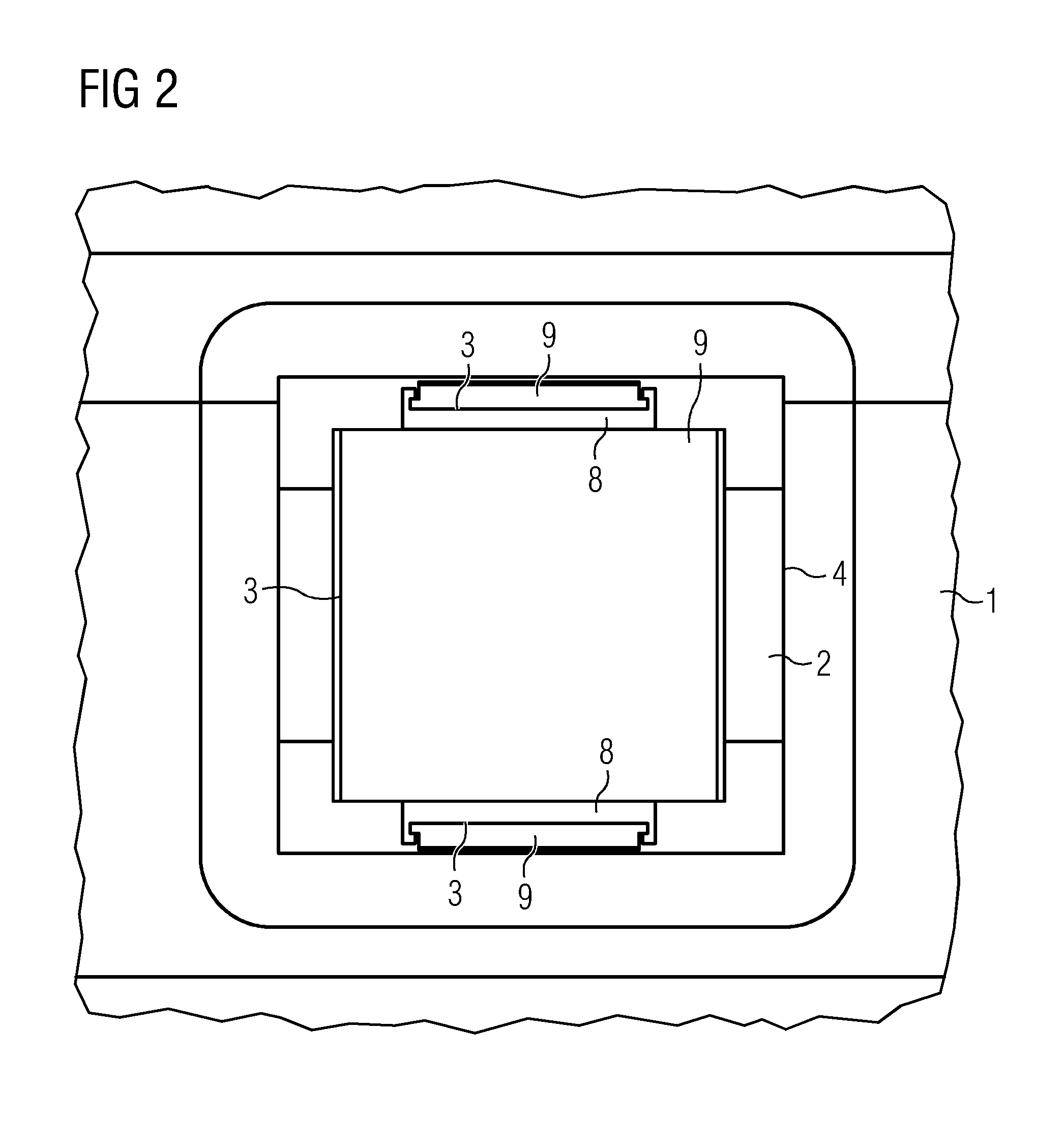

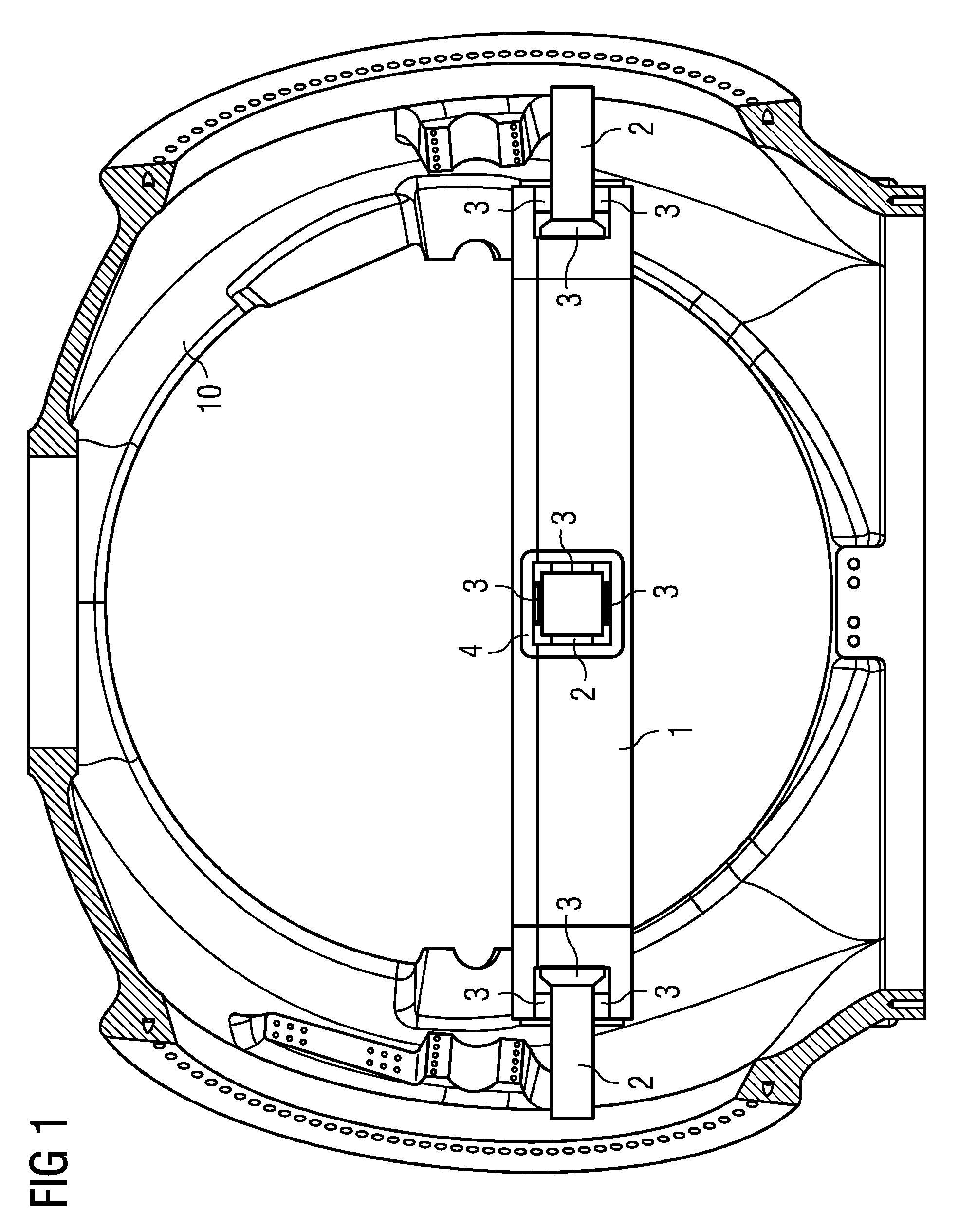

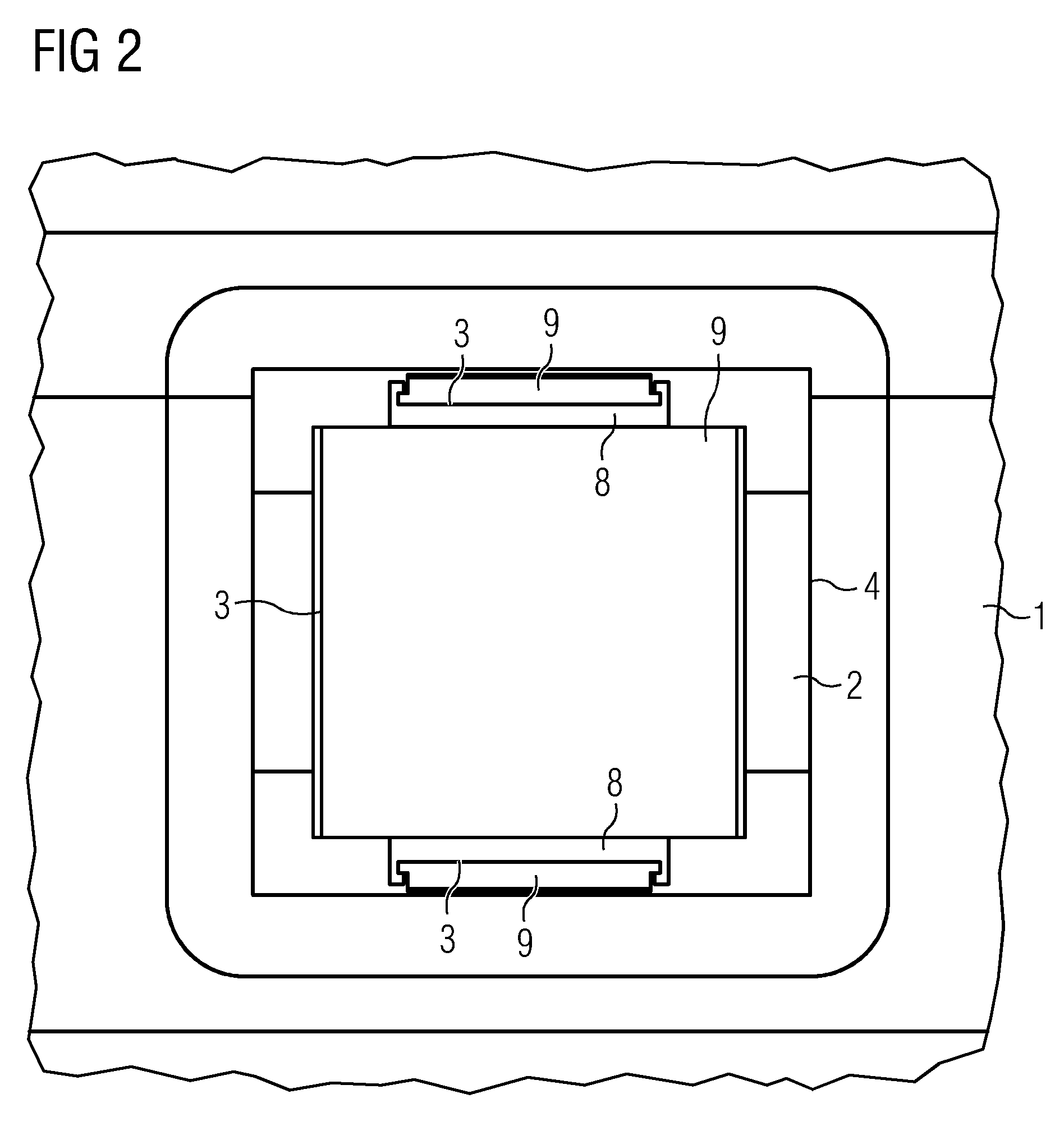

Slide bearing and method to perform service at the sliding bearing

ActiveUS20140086516A1Risk minimizationReduce risk of damageBearing repair/replacementRolling contact bearingsEngineeringMechanical engineering

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

Backup board for machining process

InactiveUS20070193680A1Less abrasionSacrificing their functionThread cutting machinesWood working apparatusAdhesiveKenaf

A backup board for use in a machining process includes a fibrous layer, at least one side of the fibrous layer being provided with a surface layer adhered and laminated thereon, wherein the surface layer is made of a cured paper impregnated with a thermosetting resin. The fibrous layer has a density of about 600˜900 kg / m3 and includes kenaf fibers adhered together by impregnating a thermosetting adhesive into a fibrous mat of the kenaf fibers, the kenaf fibers having an average length of about 10˜200 mm and an average diameter of about 10˜300 μm.

Owner:MATSUSHITA ELECTRIC WORKS LTD

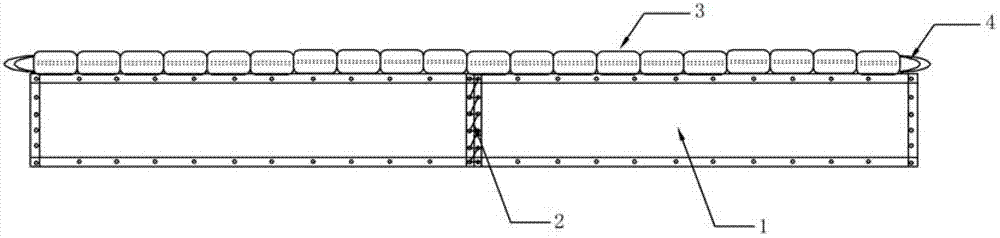

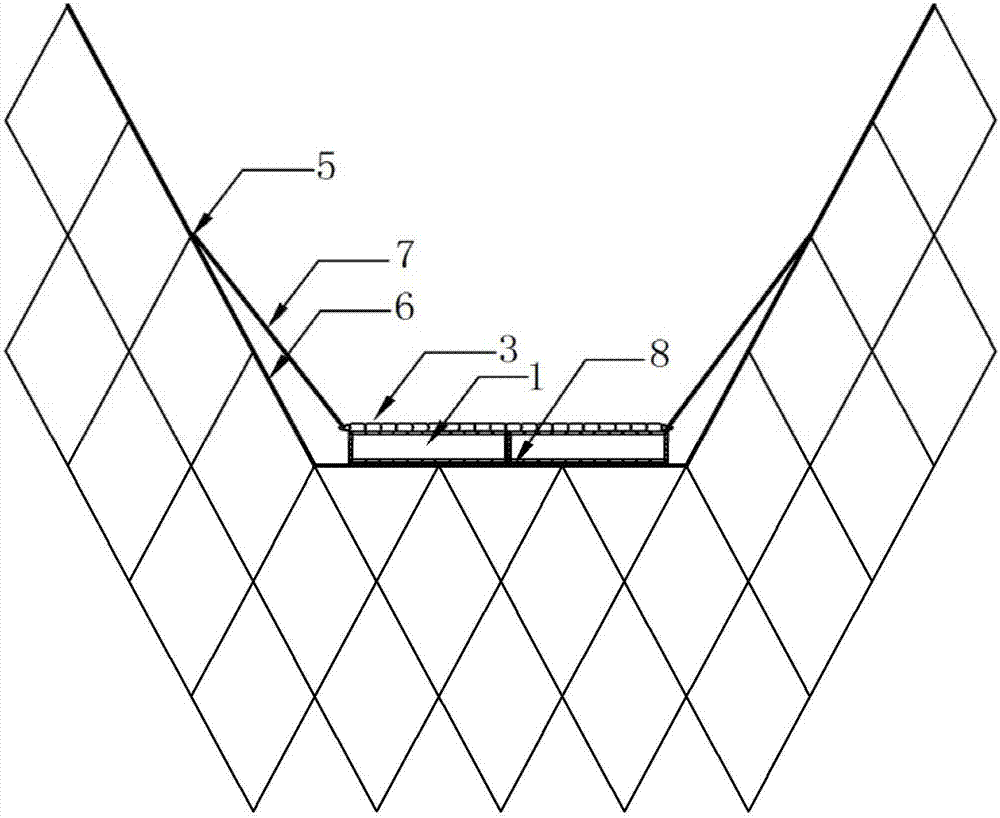

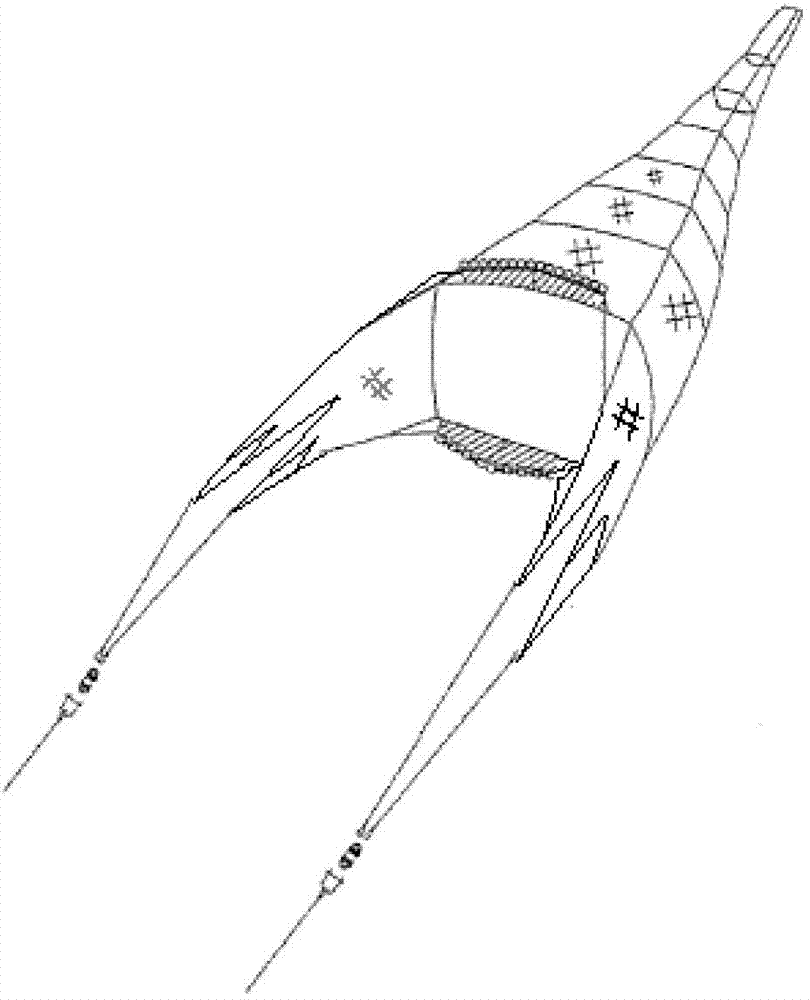

Method enabling trawl net to vertically expand

Disclosed is a method enabling a trawl net to vertically expand. Canvas is utilized for manufacturing flexible expanders. The method is characterized in that the flexible expander is made to be rectangular, the periphery of the expander is sewed with edges, and stamping eyelet rings are evenly distributed on a center line of each sewing edge; the flexible expander is tied on a middle position of an upper line or flexible expanders are respectively tied at the middle position of the upper line and the middle position of a lower line, the flexible expander tied on the middle position of the upper line is connected with a string of cork wire ropes of a deepwater trawl net, a rope ring at each of both ends of each cork wire rope is provided with an attack angle control line, two attack angle control lines of the flexible expander which is at the middle position of the upper line are respectively connected with the upper line on two sides of the flexible expander, the flexible expander which is tied on the middle position of the lower line is connected with a string of iron chains, an attack control line is installed at each of both ends of each iron chain, and two attack control lines of the flexible expander which is at the middle position of the lower line are respectively connected with the lower line on two sides of the flexible expander; and flexible expanders adjust an attack angle through adjustment to the lengths of the attack angle control lines. The method is suitable for the deepwater trawl net and a termocline trawl net.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Main and auxiliary double-wheel device of automobile

InactiveCN102582374AAvoid accidentsHigh strengthTyre partsMultiple wheel assemblyAutomotive engineeringLow speed

The invention discloses a main and auxiliary double-wheel device of an automobile. The main and auxiliary double-wheel device comprises a wheel hub and a tire arranged on the periphery of the wheel hub, wherein a rigid auxiliary wheel is arranged in parallel outside the tire; the outer diameter of the rigid auxiliary wheel is greater than that of the wheel hub and is smaller than that of the tire; and the rigid auxiliary wheel is fixedly connected to the outer side of the wheel hub by a bolt. For the automobile using the main and auxiliary double-wheel device, an accident can be effectively prevented being happened when one tire is punctured in a running process; the automobile can be enabled to run to the road side or a repair shop at a low speed in a short distance when the tire leaks air in a parking process; the rigid auxiliary wheel is fixedly connected to the outer side of the wheel hub by the bolt, so that the wheel hub forms a cylindrical cavity structure, therefore, the strength and the supporting force of the wheel hub are enhanced; and compared with the prior art, under the same supporting force, the material thickness and the material weight of the wheel hub can be reduced.

Owner:SHAOXING UNIVERSITY

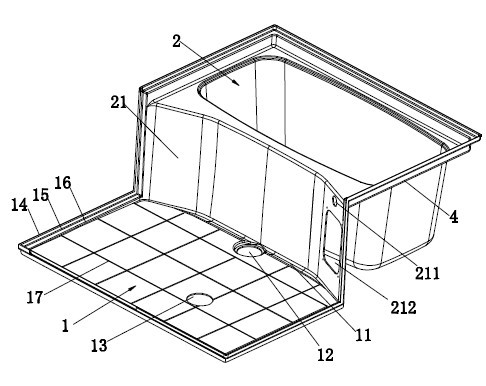

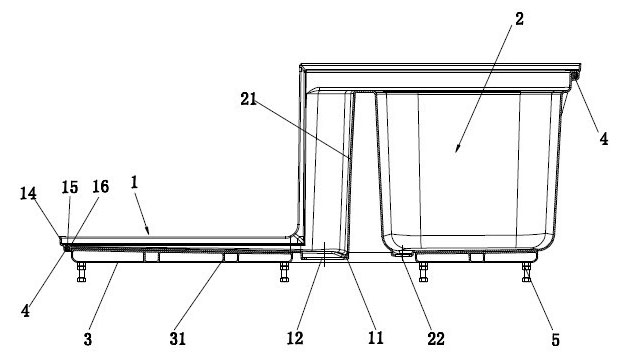

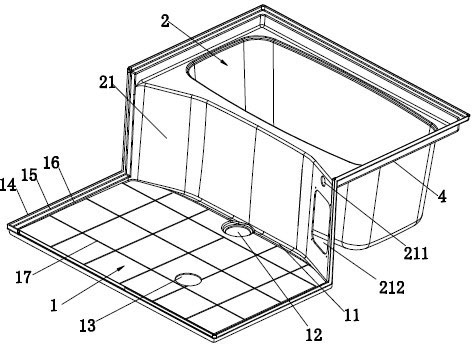

Bathtub-floor integrated super multi-coating (SMC) floor

ActiveCN102071726AHigh mechanical strengthReduce material weightDomestic plumbingFlooringBathtubEnvironmental geology

The invention discloses a bathtub-floor integrated super multi-coating (SMC) floor, which comprises a floor main body and a bathtub which are integrally arranged, wherein a bathtub drain hole is arranged at the bottom surface of the inner side of the bathtub, the edge of the bathtub extends downwards to form the skirt of the bathtub, a repair and maintain hole and the drain hole of a wash basin are arranged on the side edge of the skirt of the bathtub, the bottom of the bathtub is connected with the floor main body which is integrally arranged with the bathtub, and a drain ditch is arranged at the connection part of the bathtub and the floor main body, a floor drain hole and a defection hole are arranged on the floor main body, a shoulder step is arranged at the edge of the floor main body, a watertight shutter is arranged on the lateral straight edge of the shoulder step, and the bottoms of the floor main body and the bathtub are pneumatically reinforced, and are provided with adjustment bolts. The bathtub-floor integrated super multi-coating floor arranges the floor, the bathtub and the skirt of the bathtub into a whole body, so the bathtub and the skirt of the bathtub are parts of the floor, no splicing seam is generated, so the water leakage problem caused by the splicing seam of the conventional integral bathroom is solved, and the floor has an attractive and elegant overall appearance, and is easy to clean; and according to the floor, the repair and maintain hole and the drain hole of the wash basin are arranged on the skirt of the bathtub, so the subsequent fault maintenance is facilitated.

Owner:SUZHOU COZY HOUSE EQUIP

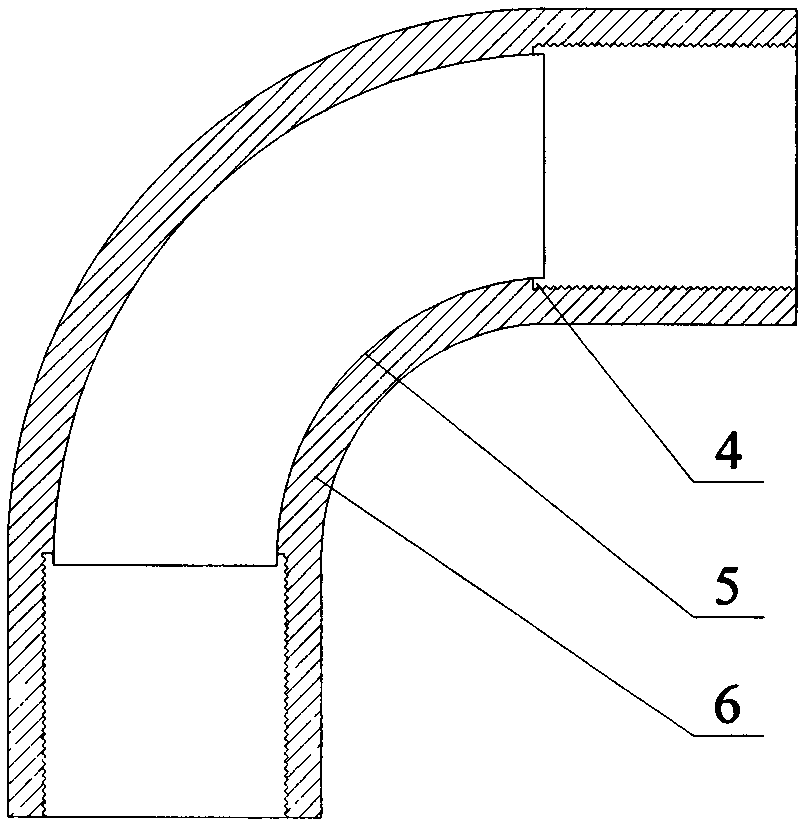

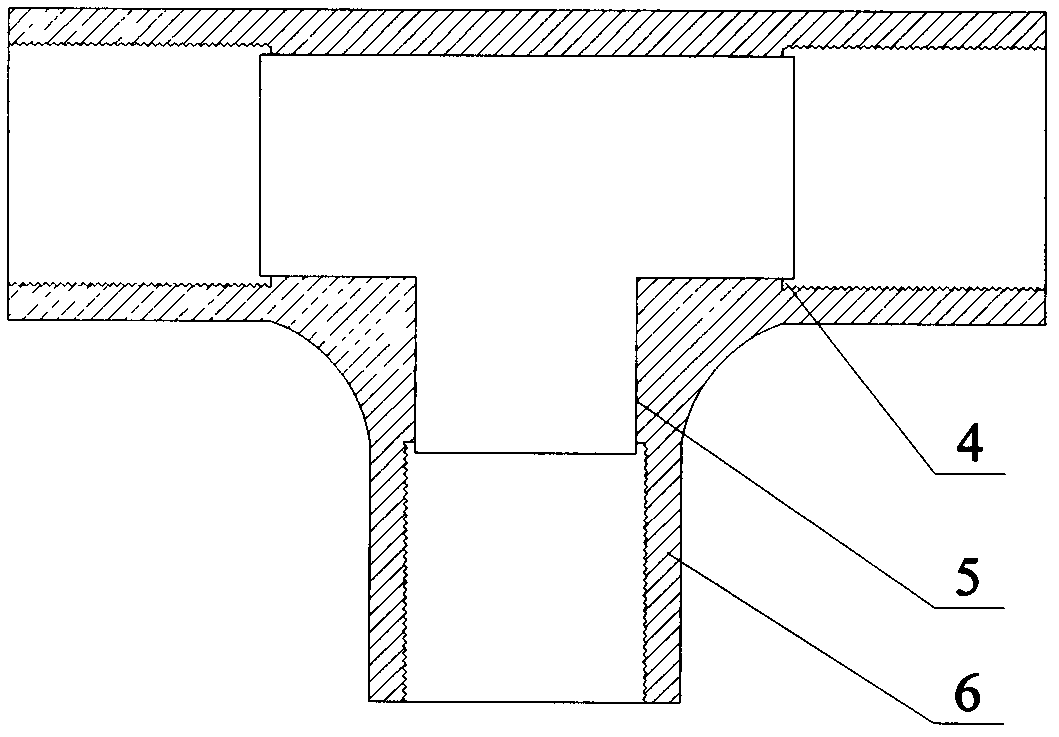

Pipe connector and manufacture method thereof

The invention provides a pipe connector and a manufacture method thereof. The pipe connector comprises a casing pipe and fiber reinforce plastic (FRP) materials, wherein the FRP materials are fastened on the outer surface of the casing pipe. The manufacture method of the pipe connector comprises a first step of placing and positioning the casing pipe in a die, a second step of placing the FRP materials into the die, a third step of extrusion forming, a fourth step of releasing the die and taking out the pipe connector, and a fifth step of trimming rough selvedges to form a pipe connector end product. Under a situation that all performance indexes of the pipe connector are guaranteed, the wall thickness of the casing pipe is effectively reduced, and material cost and weight are reduced. The FRP materials are adopted to conform to the developing demands of environmental protection and a resource-conserving society.

Owner:SHANGHAI KNP CHEM +3

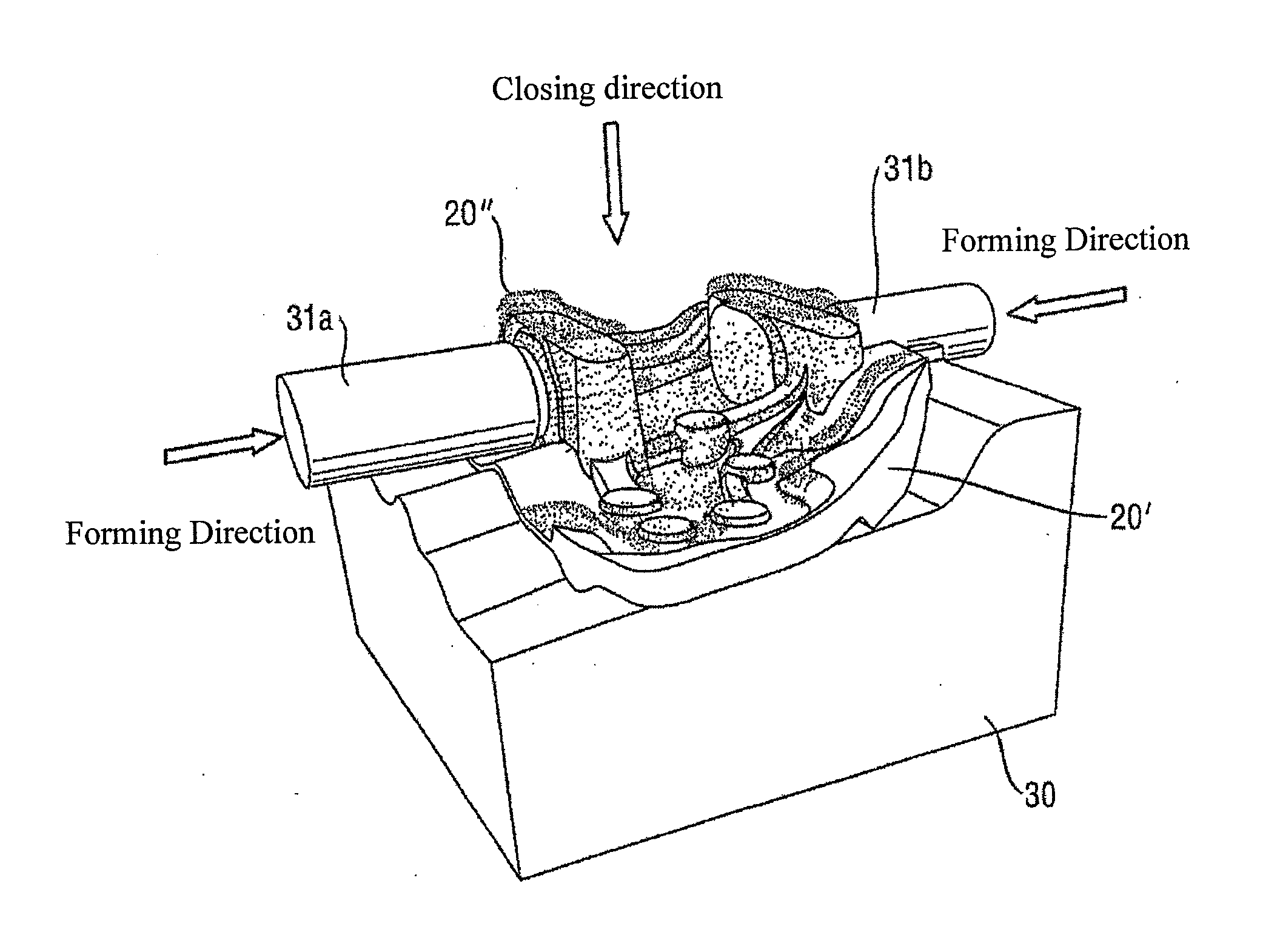

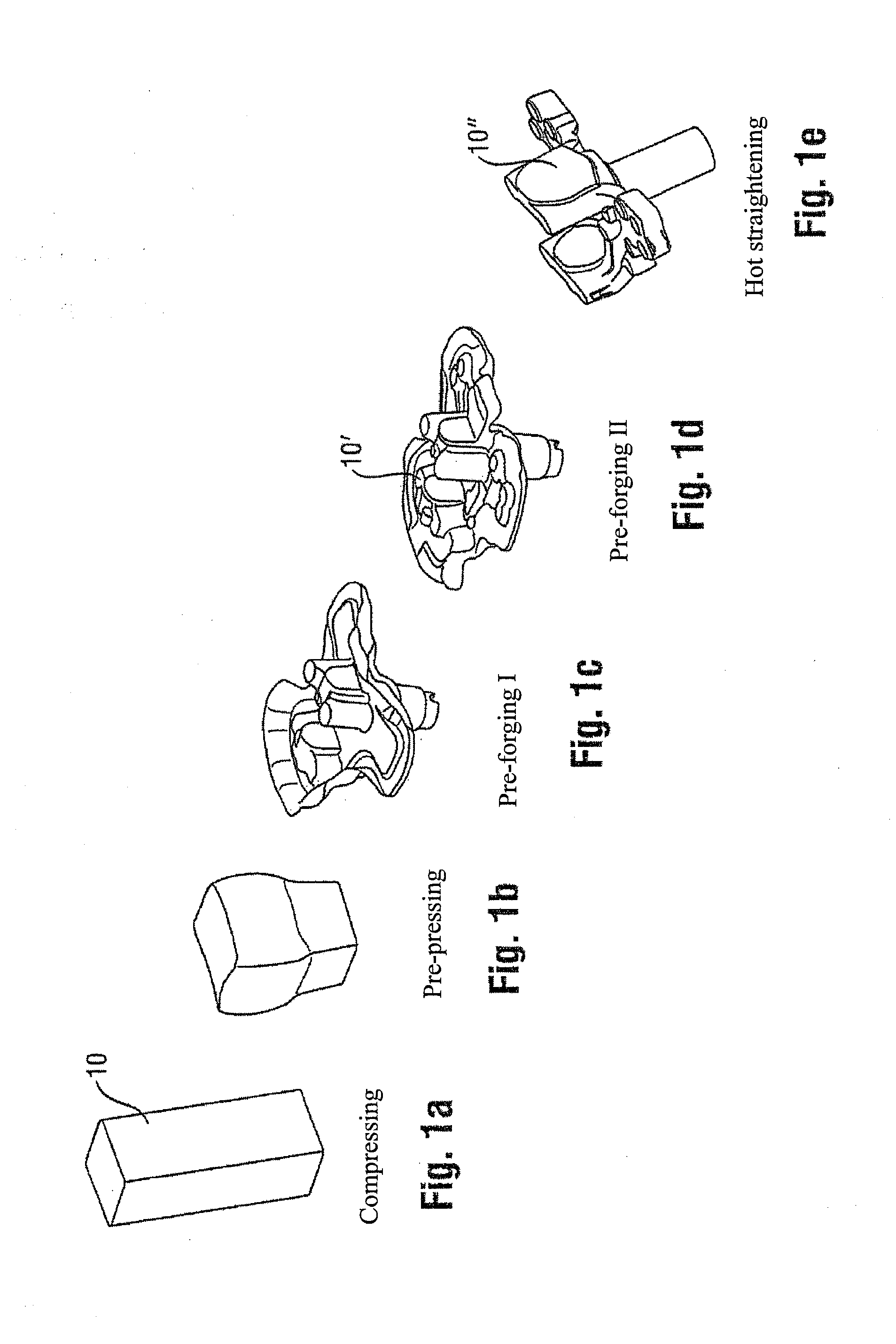

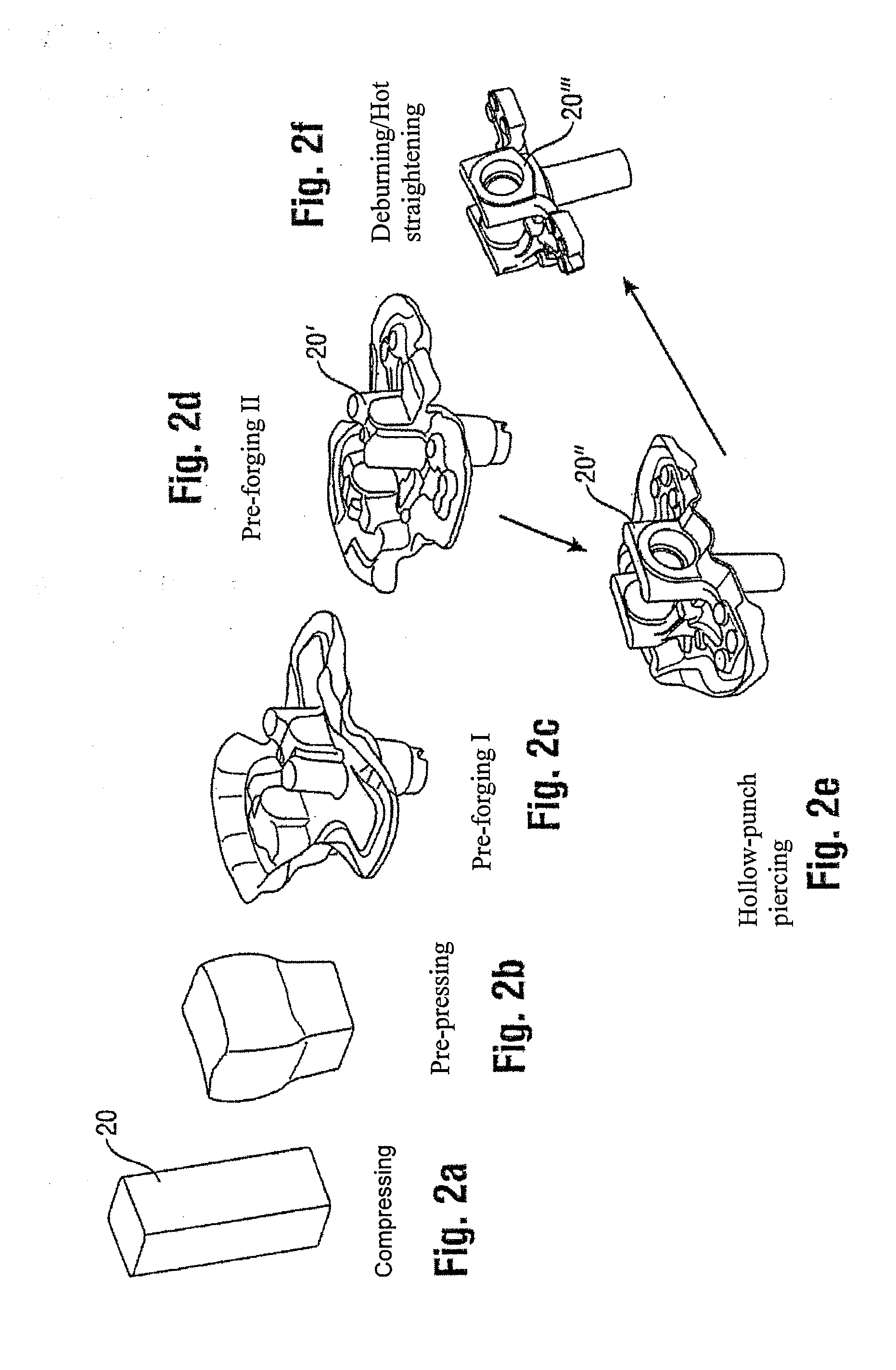

Method for forming forged parts

ActiveUS20150013408A1High forming forceEfficient material displacementWork treatment devicesForging/hammering/pressing machinesMaterials science

A method according to the invention for producing forged parts with a prescribed end contour comprises the following steps: pre-forging of a blank in order to obtain a forged part and subsequent reshaping of the forged part in a die, wherein one or a plurality of tools are inserted into the forged part during the reshaping and, in the process, the material of the forged part is displaced in a manner such that the specified end contour is obtained.

Owner:CARL DAN PEDDINGHAUS

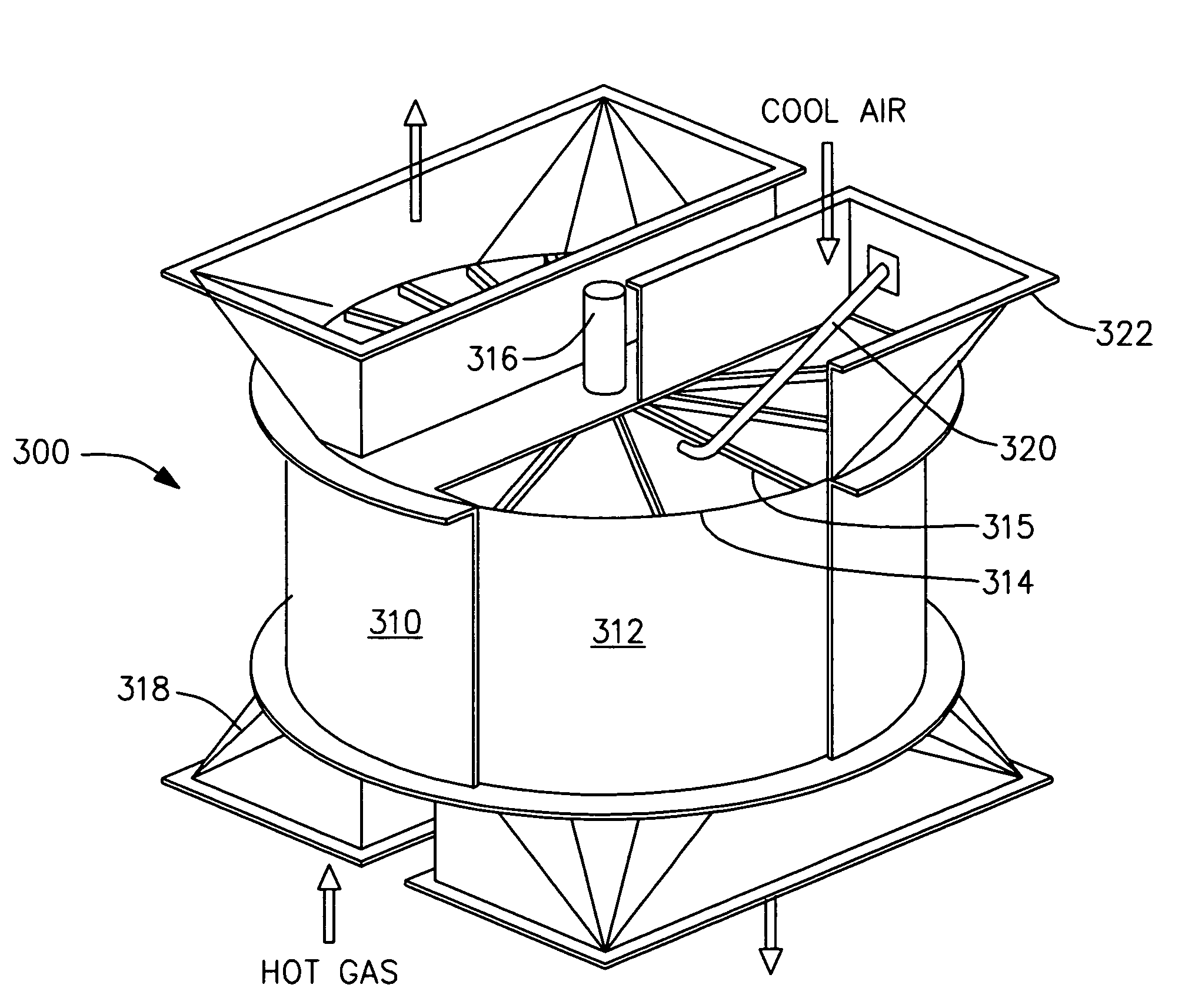

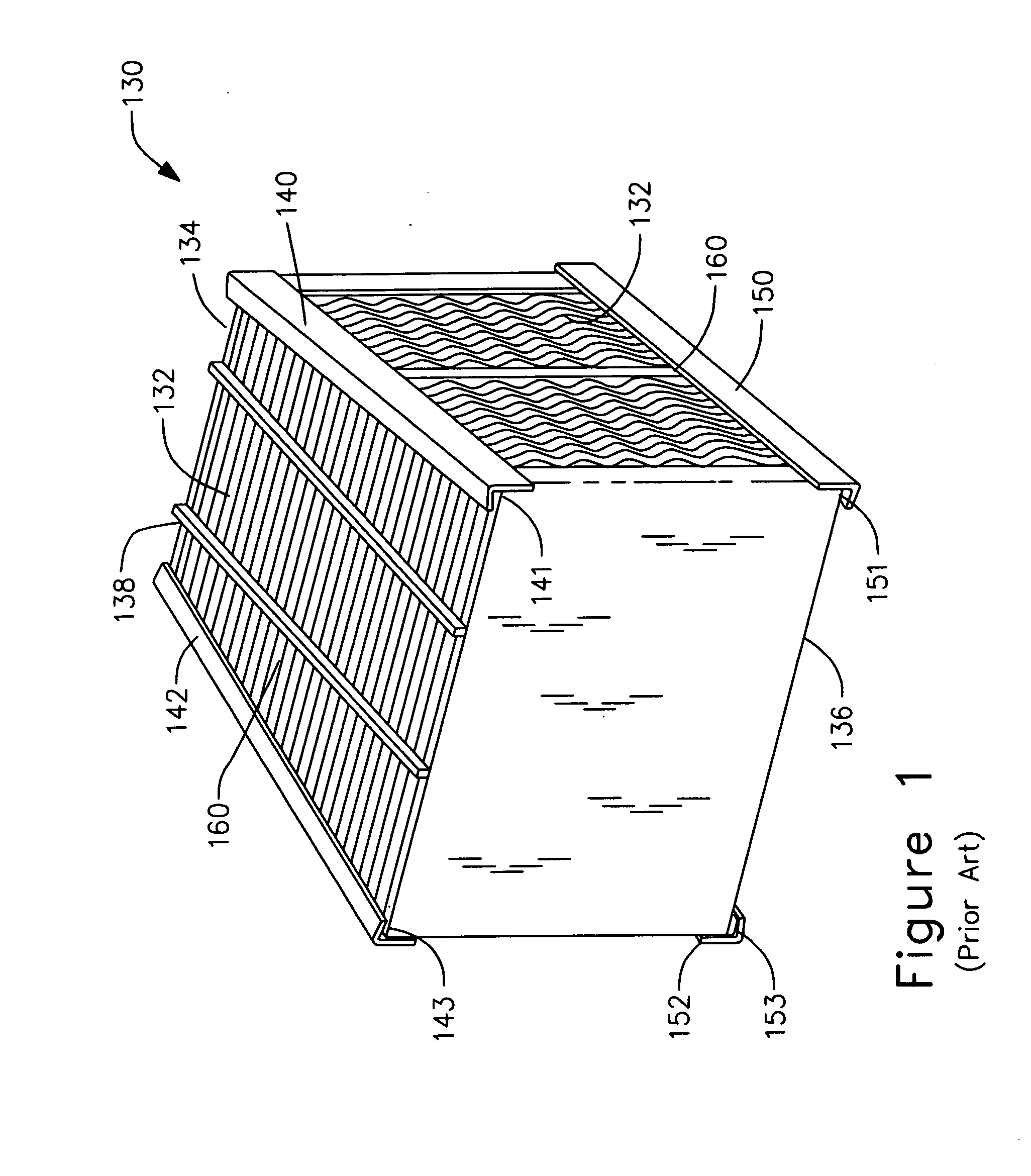

Reversible heat transfer element basket assembly with integrated frame for use in a heat exchanger

ActiveUS20080245500A1Loss in structural integrityMaterial weightCombustion processRegenerative heat exchangersPlate heat exchangerEngineering

A heat exchanger heat transfer element basket assembly (500) for receiving heat transfer element plates (850) therein. The heat exchanger heat transfer element basket assembly (500) includes first and second one-piece side straps (520a, 520b), a pair of inboard corner flanges (528a, 528b), an I-shaped splitter plate (530), a pair of outboard corner flanges (522a, 522b), first and second end straps (526a, 526b), and a cap. Each of the first and second one-piece side straps (520a, 520b) includes a center portion (625), a first extension (630), and a second extension (635). Each of the first and second extensions (630, 635) includes a flange portion that is folded over across the heat transfer element plates (850) so as to be operative to retain the heat transfer element plates (850) in the heat exchanger heat transfer element basket assembly (500).

Owner:ARVOS LJUNGSTROM LLC

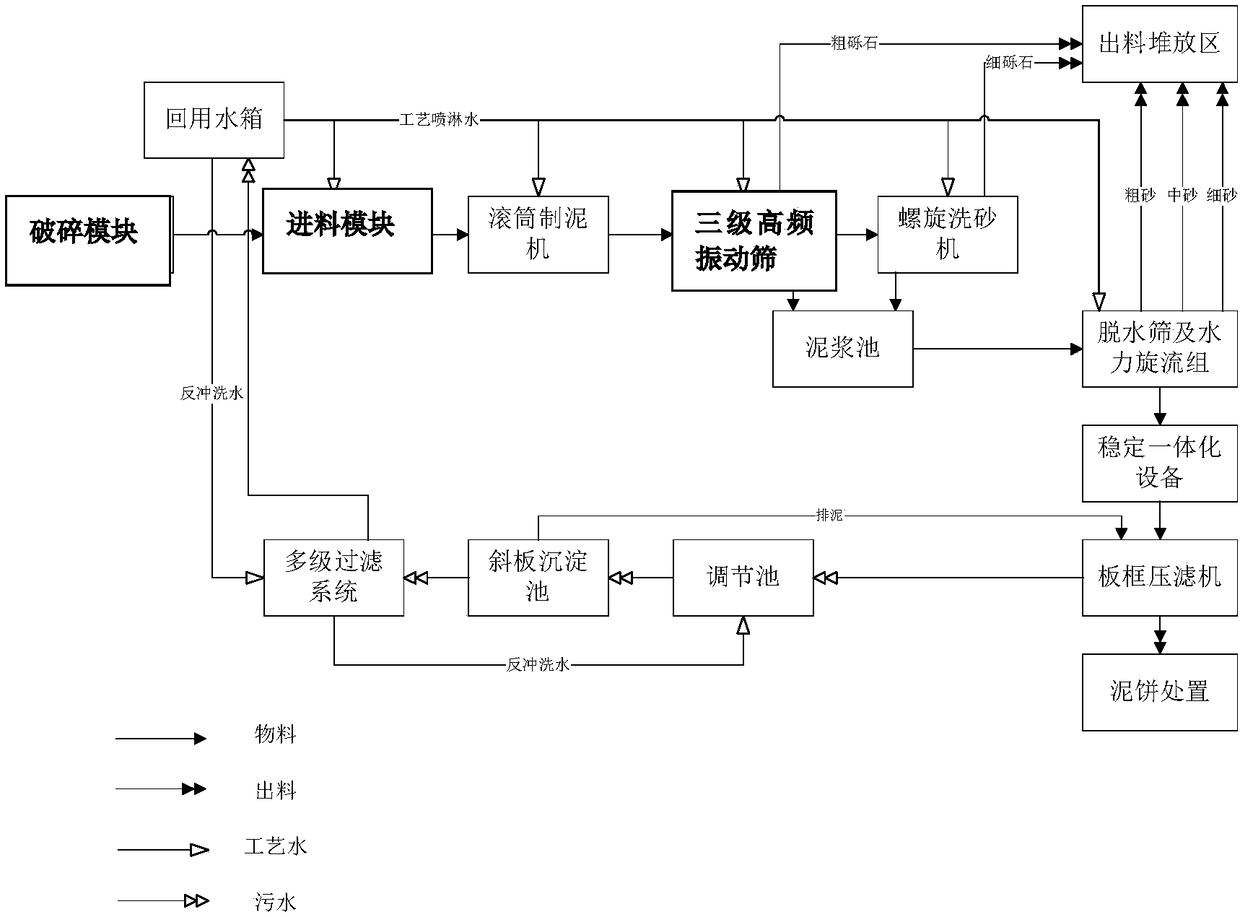

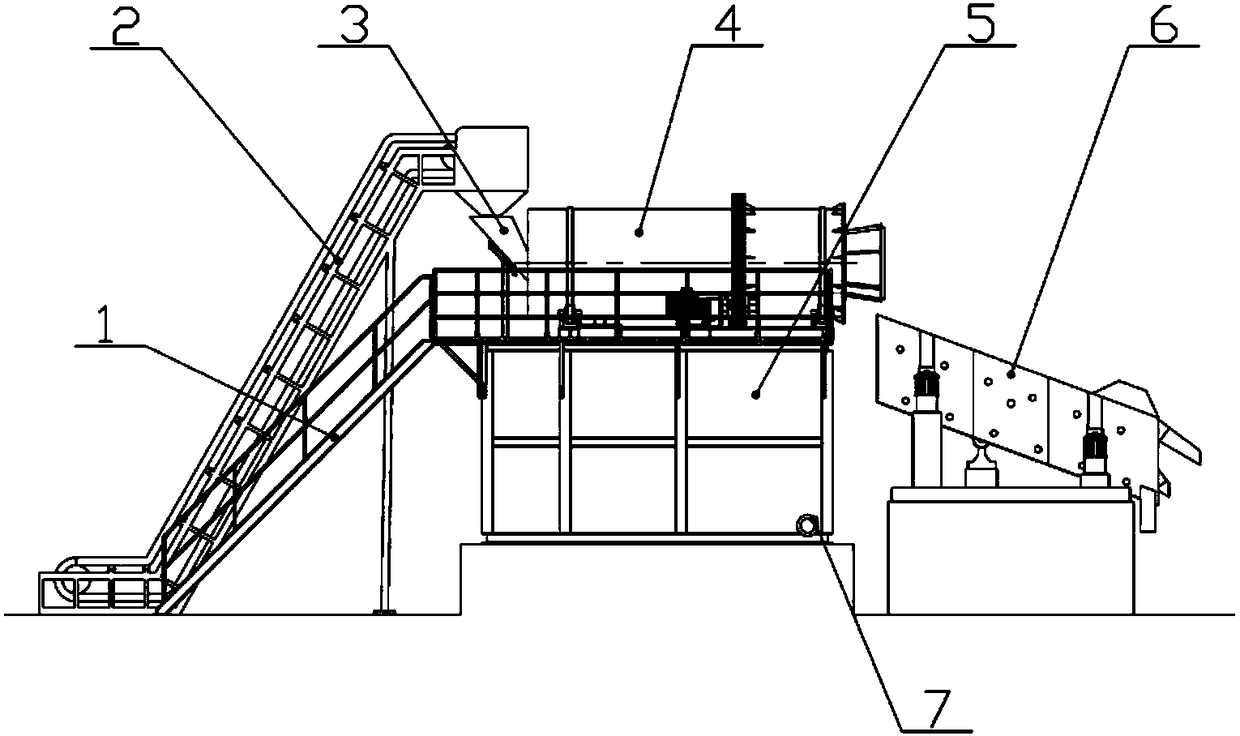

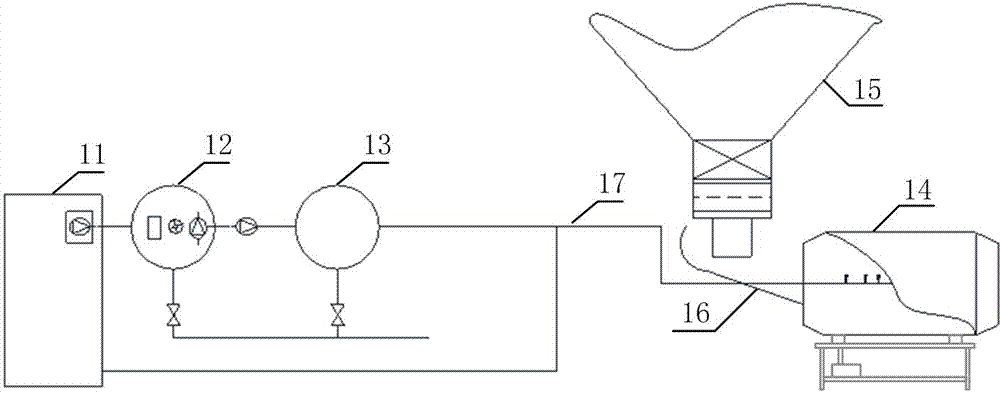

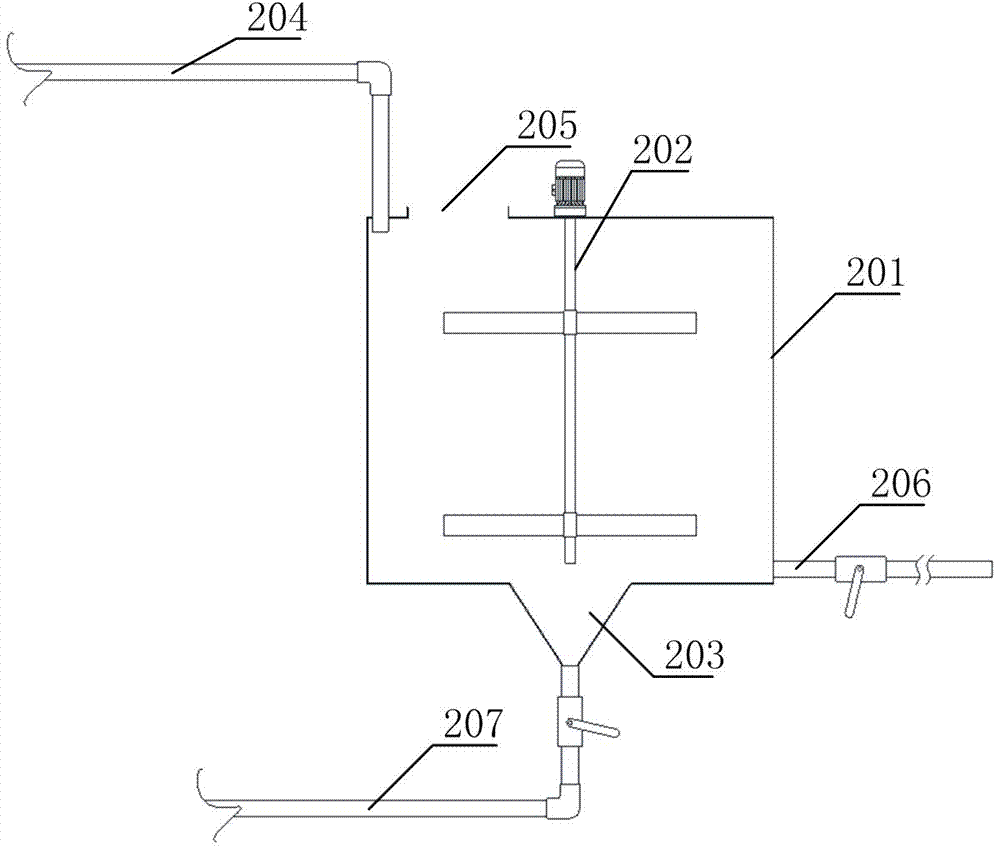

Remedying system for non-hazardous waste buildings and remedying method

InactiveCN108405563AReduce material weightReduce processing costsSludge treatment by de-watering/drying/thickeningSolid waste disposalEngineeringHigh pressure

The invention discloses a remedying system for non-hazardous waste buildings and a remedying method, and belongs to the technical field of remediation of contaminated sites. The remedying system for the non-hazardous waste buildings provided by the invention sequentially comprises the following modules: a crushing module for crushing and processing dismantled contaminated buildings, a feeding module including a material conveyor belt and a vibrating screen which is used for feeding and provided with a high-pressure spraying system, a roller mud-making module including a roller mud-making machine provided with the high-pressure spraying system, a multi-stage screening module for screening mud slurry materials discharged by the roller mud-making module, and a mud slurry dehydration and mud cake stabilizing module which is used for stabilizing integrated equipment and a plate and frame filter press to realize separation of mud and water, wherein the vibrating screen is used for screeningthe contaminated buildings processed by the crushing module, and after mud cakes are concentrated, stabilizing treatment is further adopted so as to realize non-hazardous treatment. According to the remedying system disclosed by the invention, remediation engineering on the contaminated buildings can be realized.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

Slide bearing and method to perform service at the sliding bearing

ActiveUS8974120B2Limit wearReduce material weightBearing repair/replacementRolling contact bearingsEngineeringMechanical engineering

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

Polypropylene and carbon nano-tube composite type foam material

The invention discloses a polypropylene and carbon nano-tube composite type foam material, and belongs to the technical field of foam materials. The polypropylene and carbon nano-tube composite type foam material comprises polypropylene materials and modified sodium bicarbonate. Carbon nano-tubes are added into the polypropylene materials to form carbon nano-tube reinforcement polypropylene composite materials. The polypropylene and carbon nano-tube composite type foam material comprises, by weight, 85-90 parts of polypropylene, 2-8 parts of compatibilizers, 0.5-10 parts of carbon nano-tubes and 0.5-2 parts of other additives. A weight ratio of the modified sodium bicarbonate to the carbon nano-tube reinforcement polypropylene composite materials is 0.5-5:95-99.5. The polypropylene and carbon nano-tube composite type foam material has the advantages that the raw material cost can be saved, and the polypropylene and carbon nano-tube composite type foam material which is a uniform and compact polypropylene micro-foam composite material with tiny cells and good mechanical properties further can be obtained.

Owner:陈阿珍

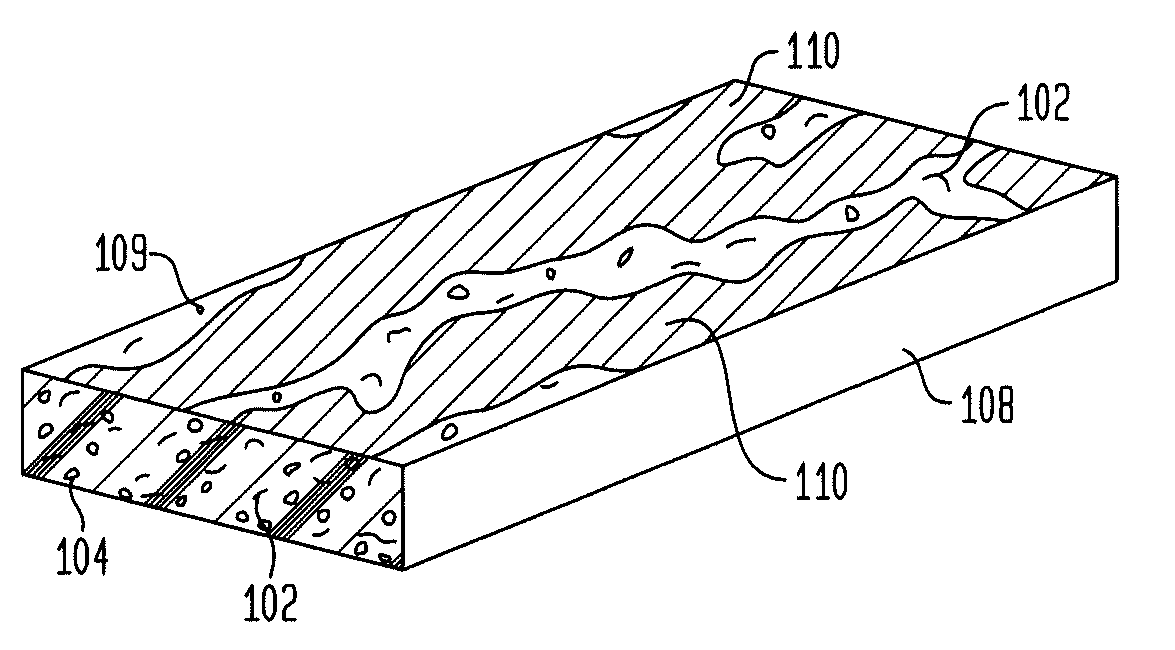

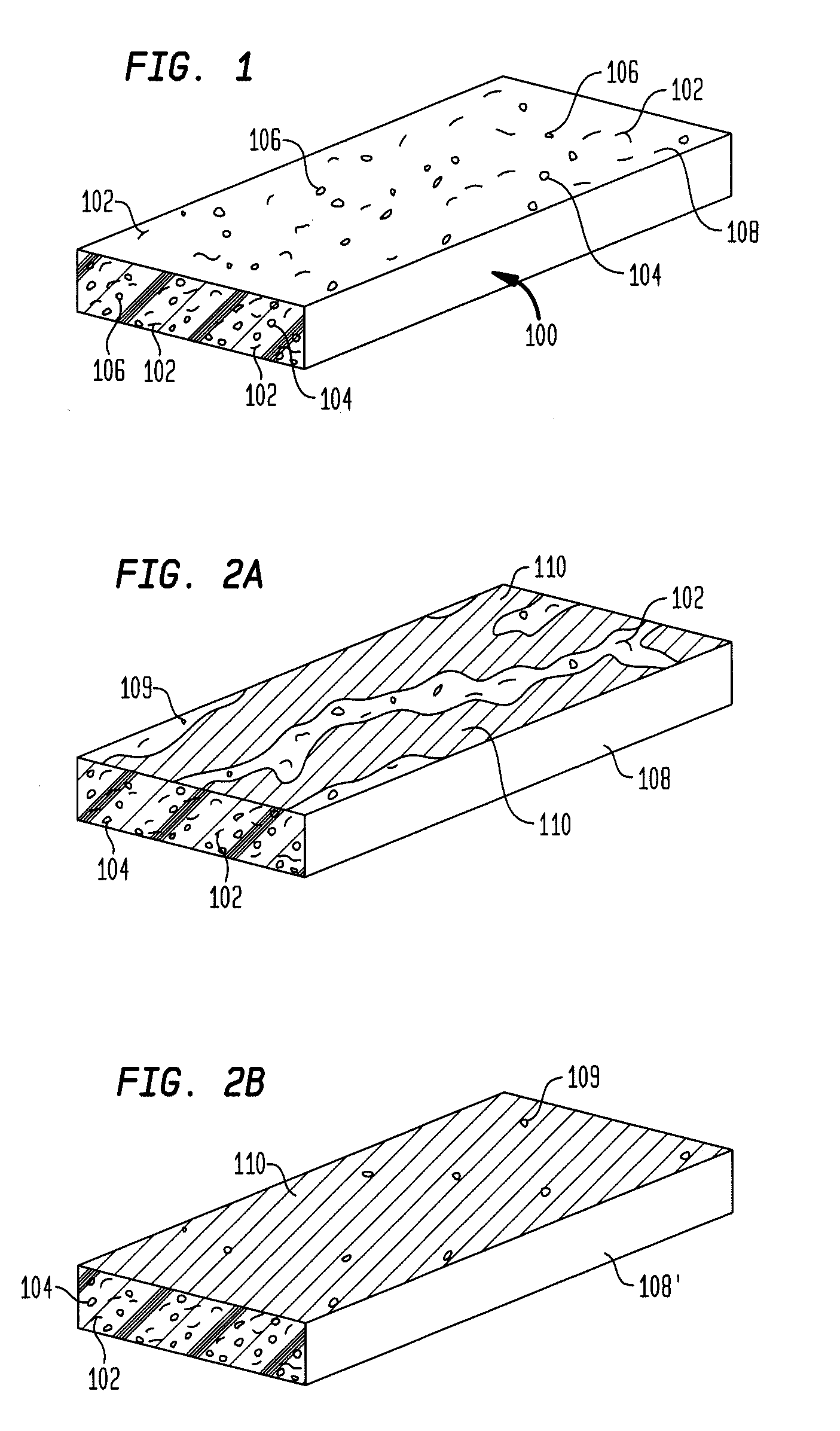

Faux wood building materials and articles therefrom

InactiveUS20110049959A1High mechanical strengthReduce material weightVehicle seatsLayered productsFiberPolymer chemistry

Building materials formed from synthetic polymer materials have an appearance which simulates natural woods. The building materials may be used in the construction of fences, sheds, decking materials, indoor / outdoor furniture, railings and numerous other products. The faux wood material is constructed to include reinforcing fibers and voids for weight reduction. The aesthetic appearance of the finished product can be enhanced by applying a color wash which includes a polymer component and a color component adhering to the surface of the material.

Owner:ENVIO PRODS

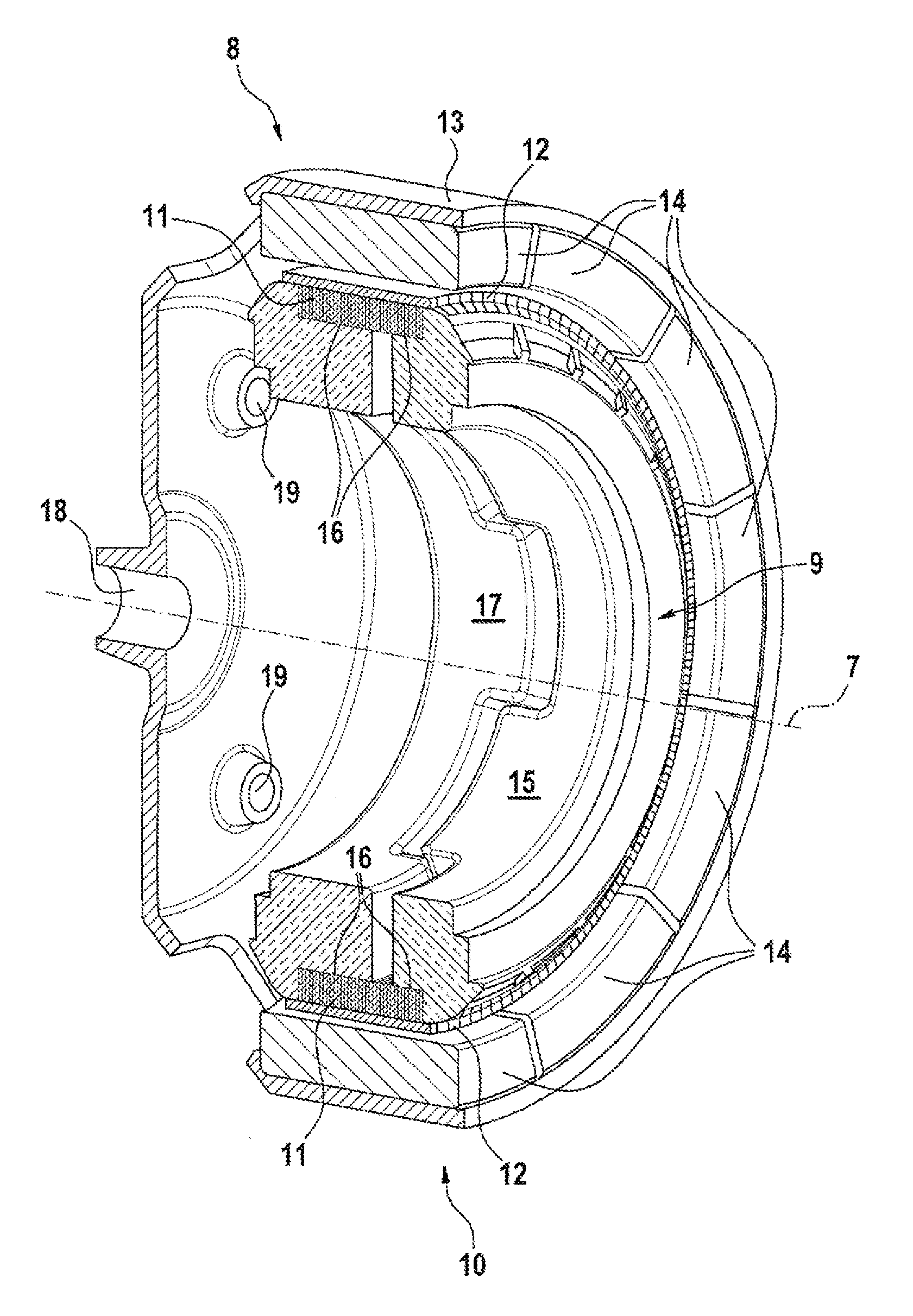

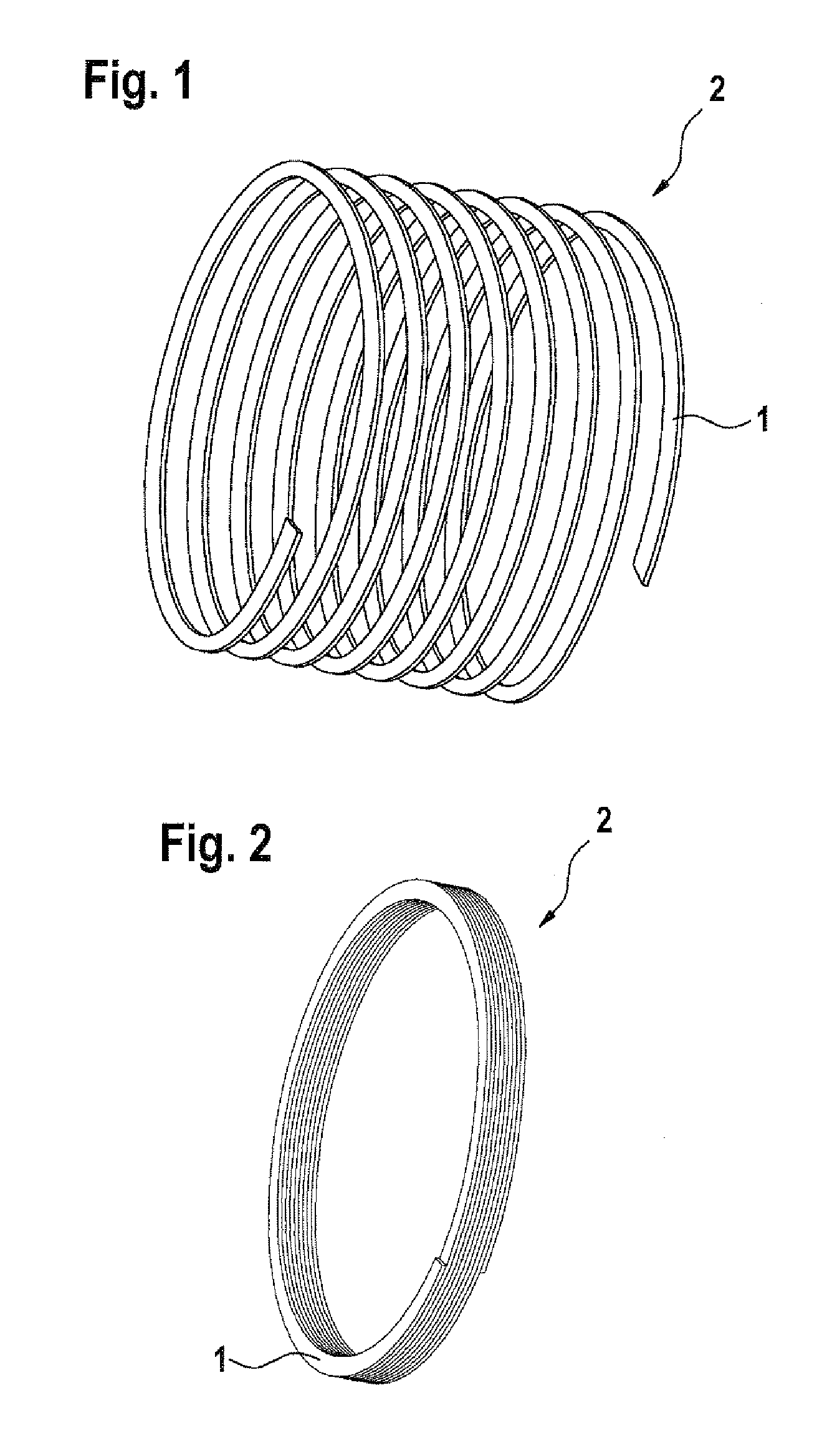

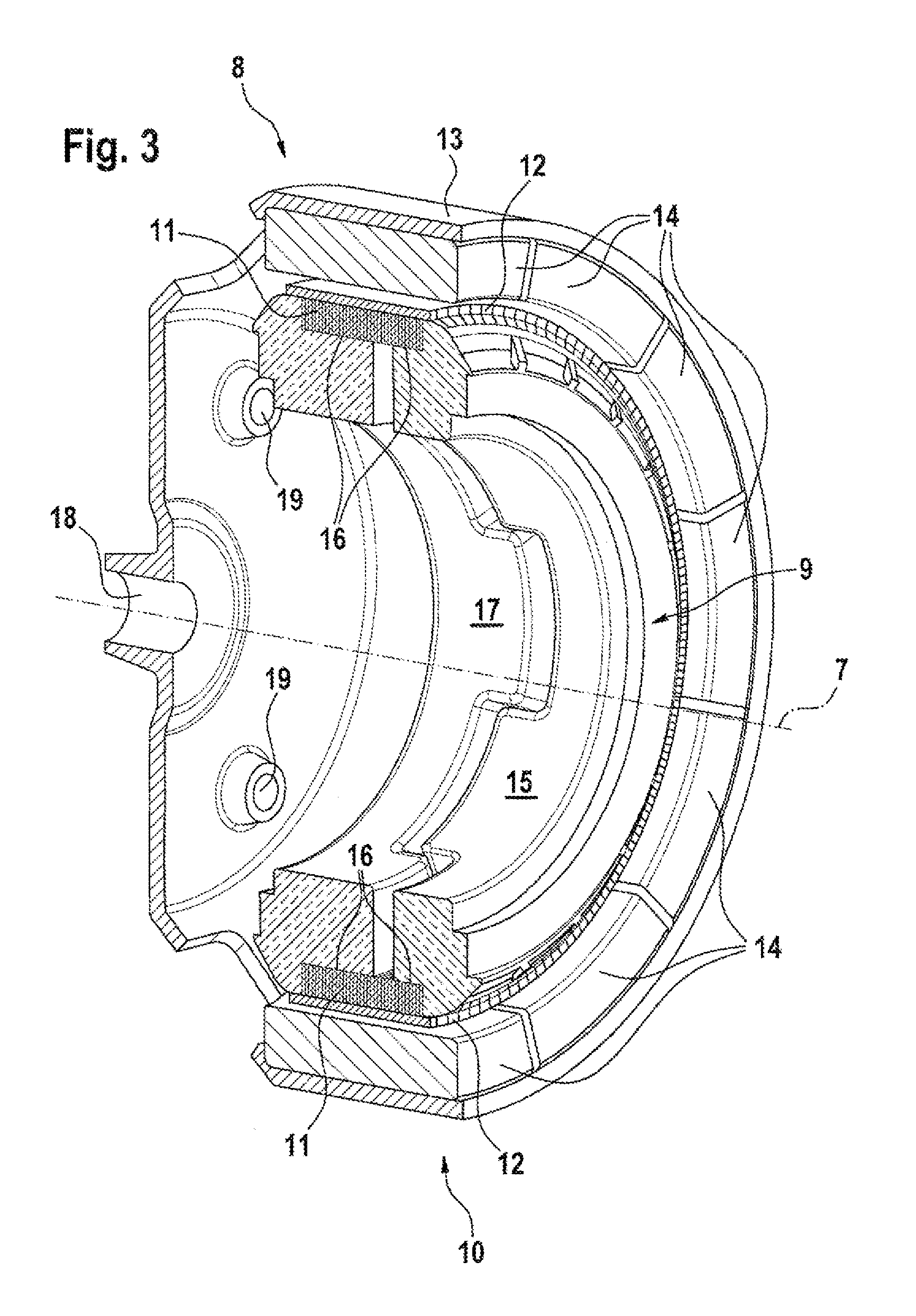

Electrical machine

ActiveUS20120091852A1Reduce wasteEasy to installMagnetic circuit rotating partsMagnetic circuit stationary partsMetal stripsElectric machine

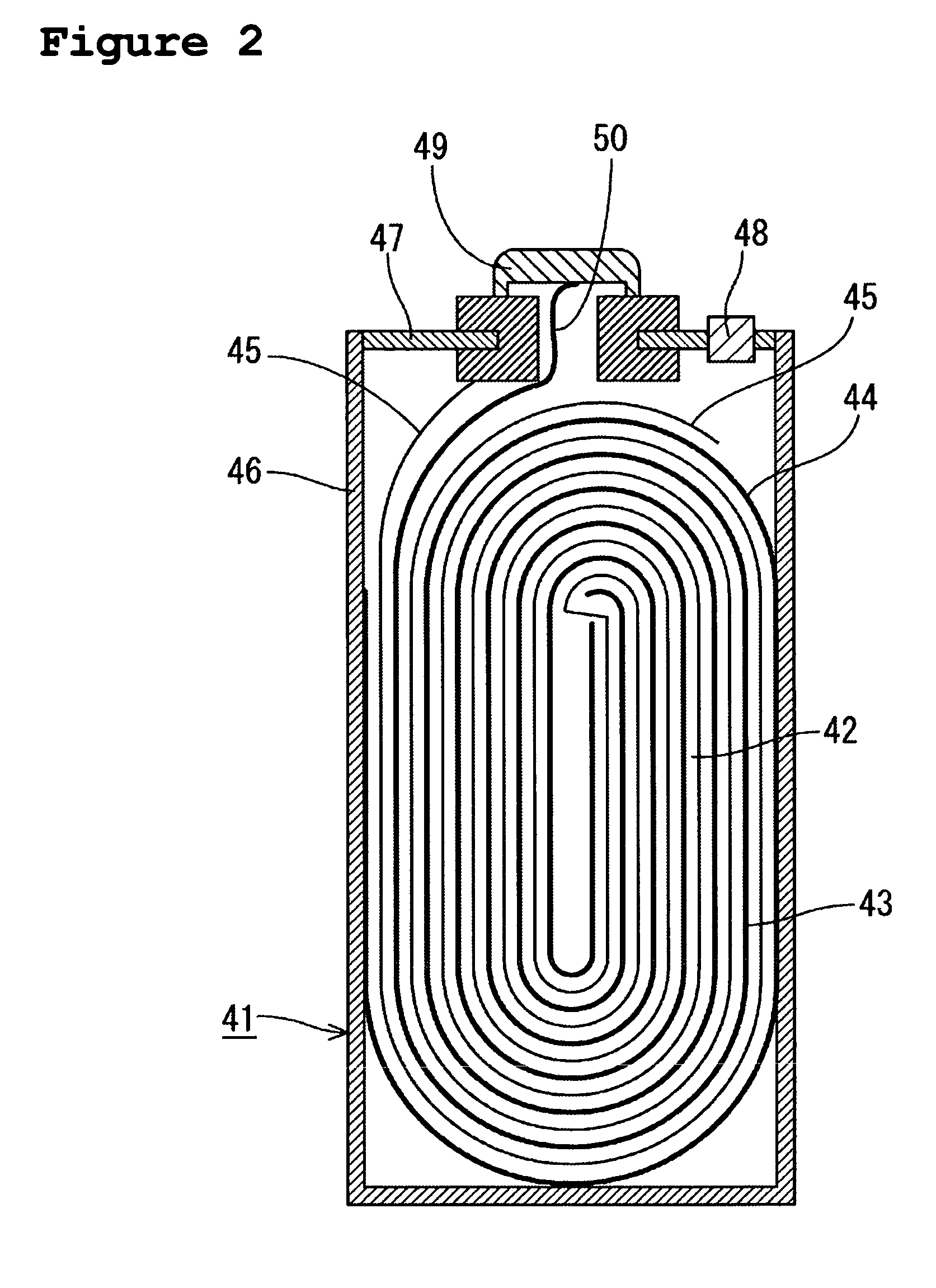

The invention relates to an electric machine, comprising a rotor (8; 50; 76) and a stator (9; 29; 77), wherein the rotor (8; 50; 76) and / or the stator (9; 29; 77) comprise at least one laminated core (2; 11; 32; 72) having a substantially rectangular cross-section, wherein the laminated core (2; 11; 32; 72) comprises a sheet metal strip (1), wherein the sheet metal strip (1) is wound in a coil shape.

Owner:ROBERT BOSCH GMBH

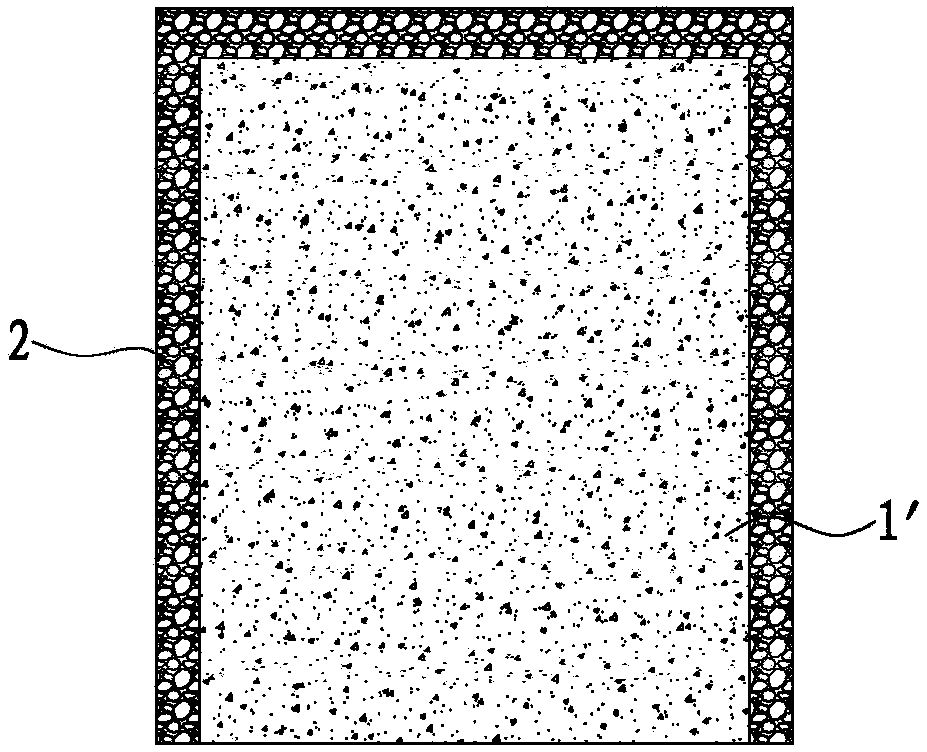

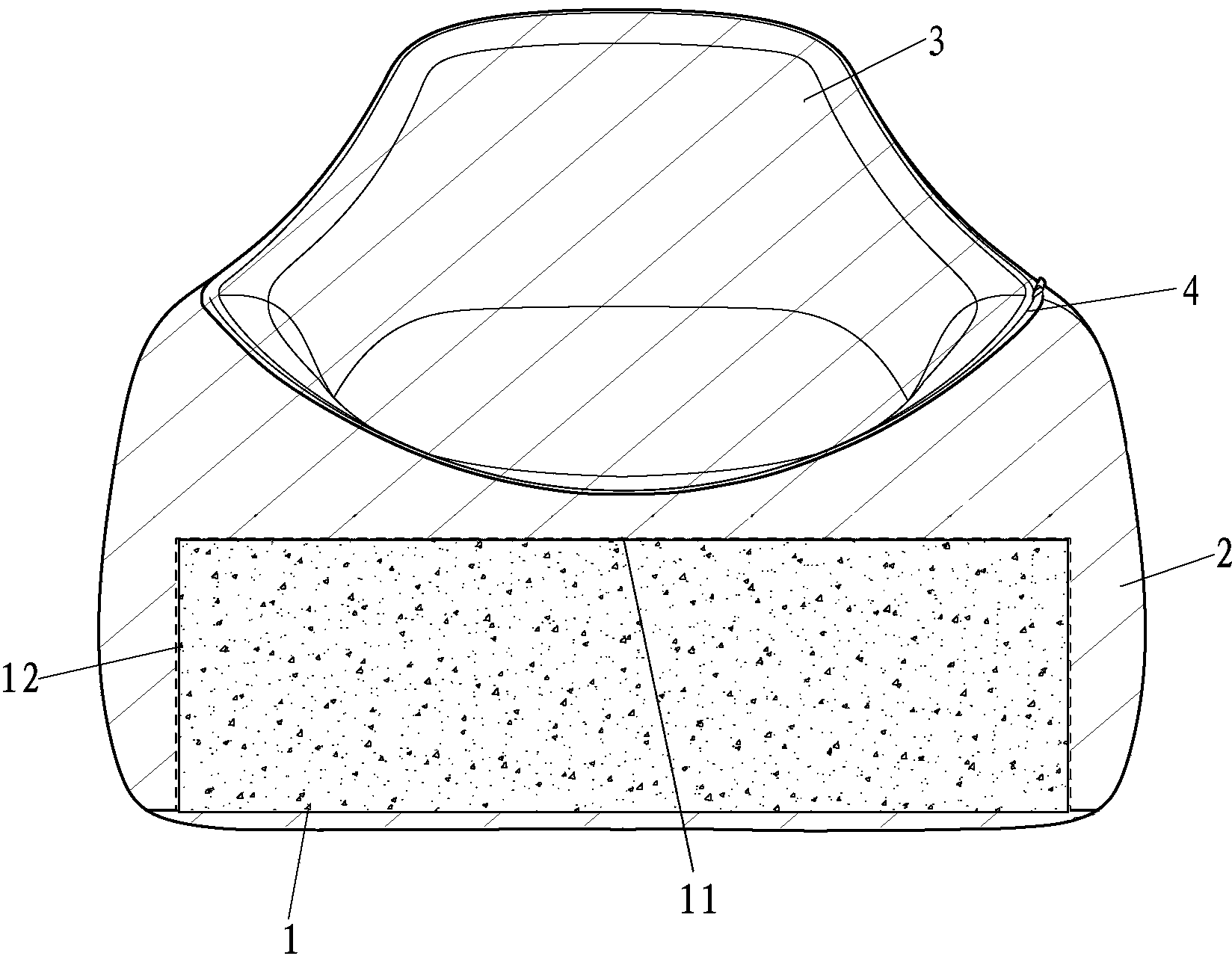

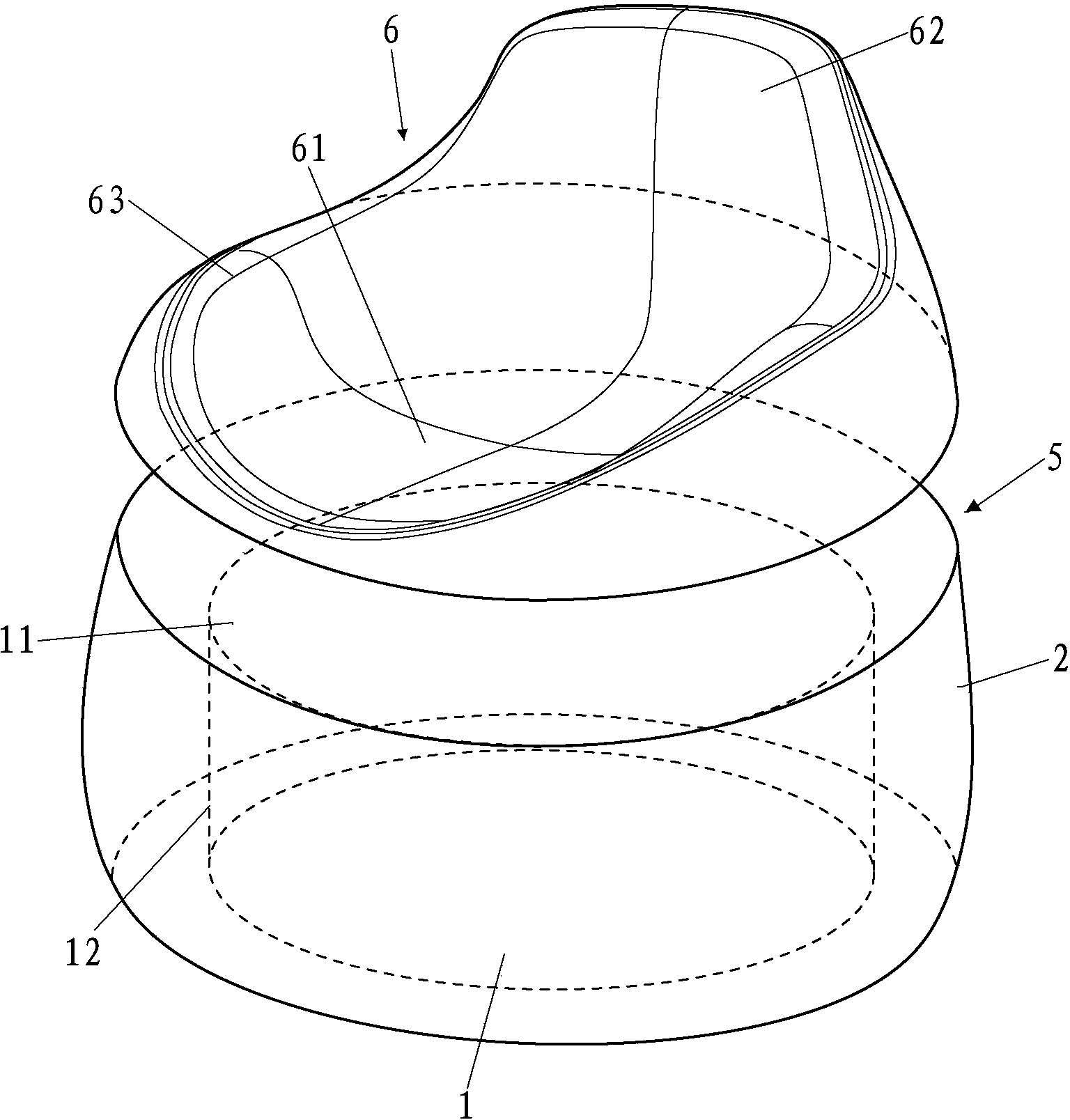

Sponge sofa or sponge stool structure

The invention discloses a sponge sofa or sponge stool structure which comprises a low-density sponge foaming forming sofa base or low-density sponge foaming forming stool base with the foaming density of 10-35 kg / m<3>, wherein a high-density sponge cladding layer with the foaming density of 35-60 kg / m<3> is integrally foamed on the outer surface of the base; the hardness of the sponge sofa base or the sponge stool base is Share A 20+; the hardness of the sponge cladding layer is 30-80 Kgf. The sponge sofa structure has the characteristics of simple manufacturing process, shape controllability, high production efficiency and low manufacturing cost. In addition, a low-density sponge of the sponge sofa base or the sponge stool base is relatively low in price and light in weight and has certain supporting strength and supporting toughness. Therefore, the consumption of a high-density sponge can be reduced, and the material cost and weight of a whole sponge sofa or stool can be further reduced. Moreover, the sponge cladding layer is integrally foamed on the outer surface of the sponge sofa base or the sponge stool base, is firmly attached to the surface of the base and is unlikely to loosen, and thus the service life of the sponge sofa or stool is guaranteed.

Owner:ZINUS (XIAMEN) INC

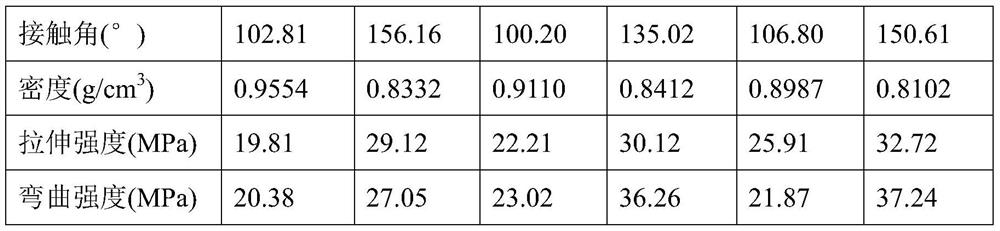

Super-hydrophobic material and preparation method thereof

The invention discloses a super-hydrophobic material and a preparation method thereof. The method includes: mixing expandable microspheres or a mixture of the expandable microspheres and modified silicon dioxide with EVA, and uniformly mixing the substances; carrying out hot cutting by using a single-screw extruder in a temperature range of 70-90DEG C by using an extrusion method to obtain expandable microsphere composite master batch; adding the expandable microsphere composite master batch into plastic resin, and conducting extrusion, injection molding, calendering or blow molding to obtainthe super-hydrophobic material. The surface of the prepared super-hydrophobic material has high hydrophobicity and high durability, and meanwhile, the weight of the material can be greatly reduced. The master batch prepared by the method can be used for improving the hydrophobic property of a material, and is specifically shown in the fields of pollution prevention, water prevention, fog prevention, freezing prevention, self-cleaning, lossless transmission of liquid and the like.

Owner:快思瑞科技(上海)有限公司

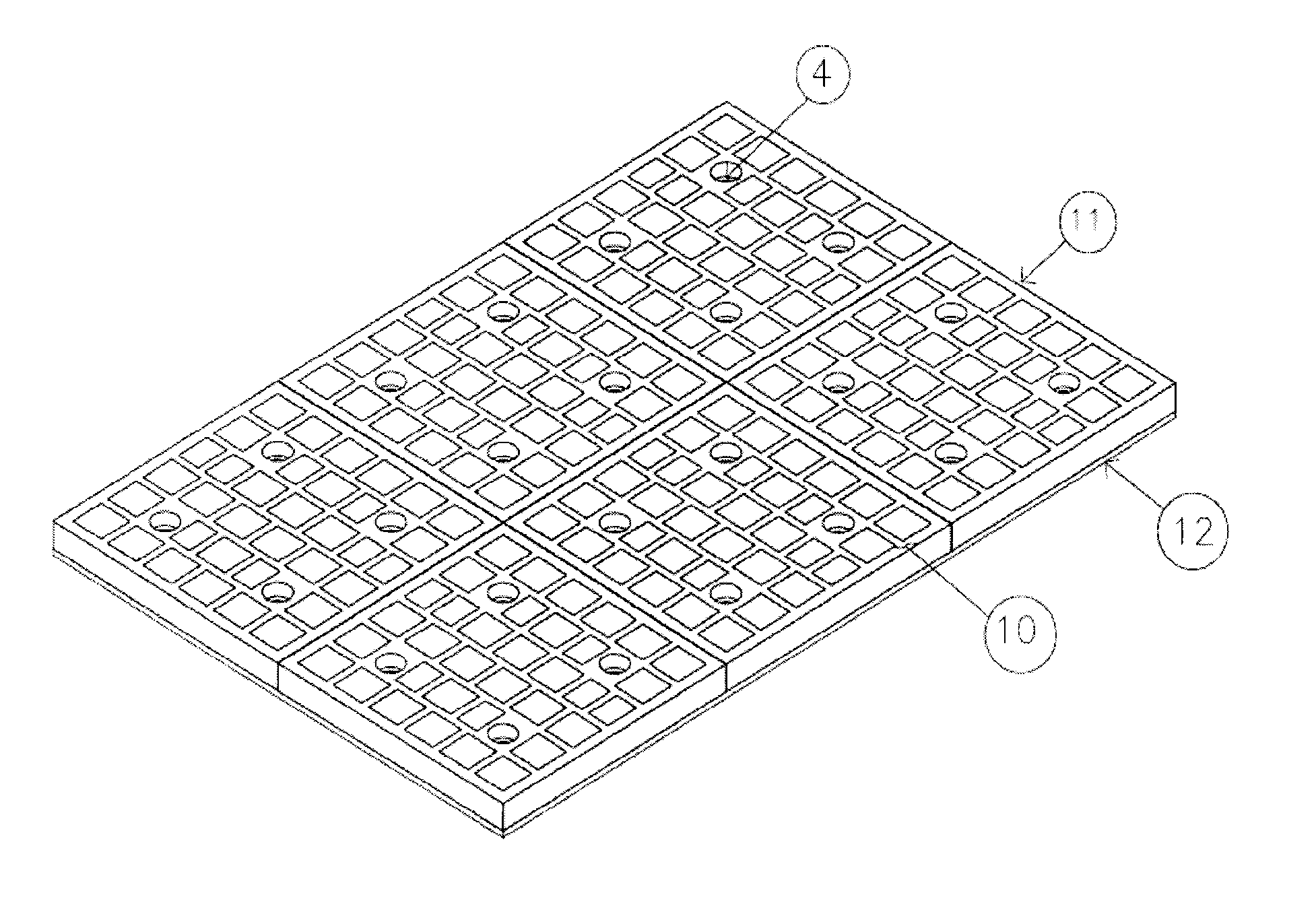

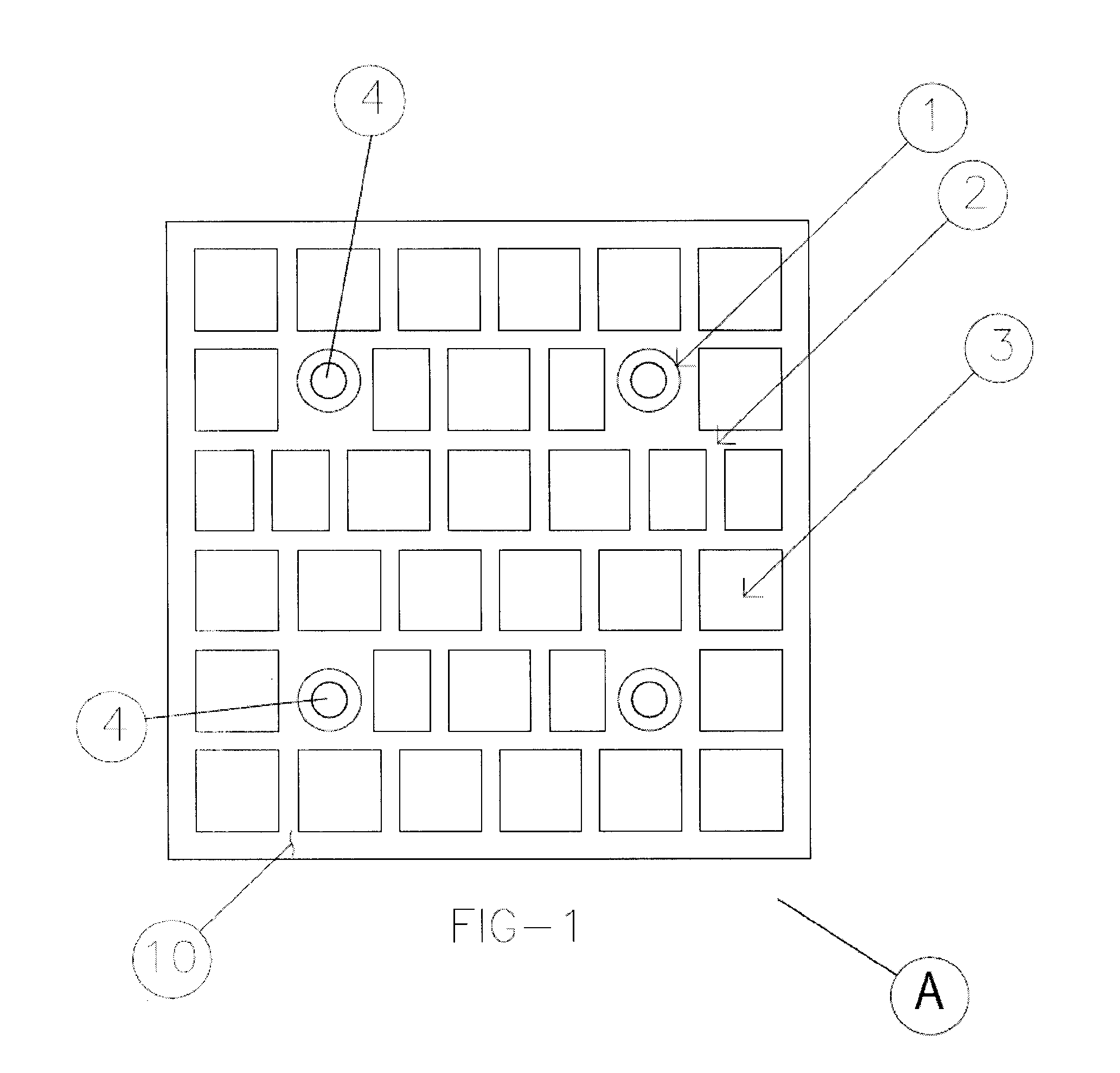

Mosaic liner for chute/hopper lining

A mosaic liner unit (A) for chute / hopper lining comprises of a body having a front face (10) and a rear face (11). Each of the front face (10) and the rear face (11) are made of an elastomeric material (2). Within the elastomeric material is embedded a plurality of high hardness steel units (3). The front face (10) is adapted to take the impact load of material falling on the chute / hopper and the rear face (11) is fixed to chute / hopper wall (12).

Owner:TEGA IND LTD

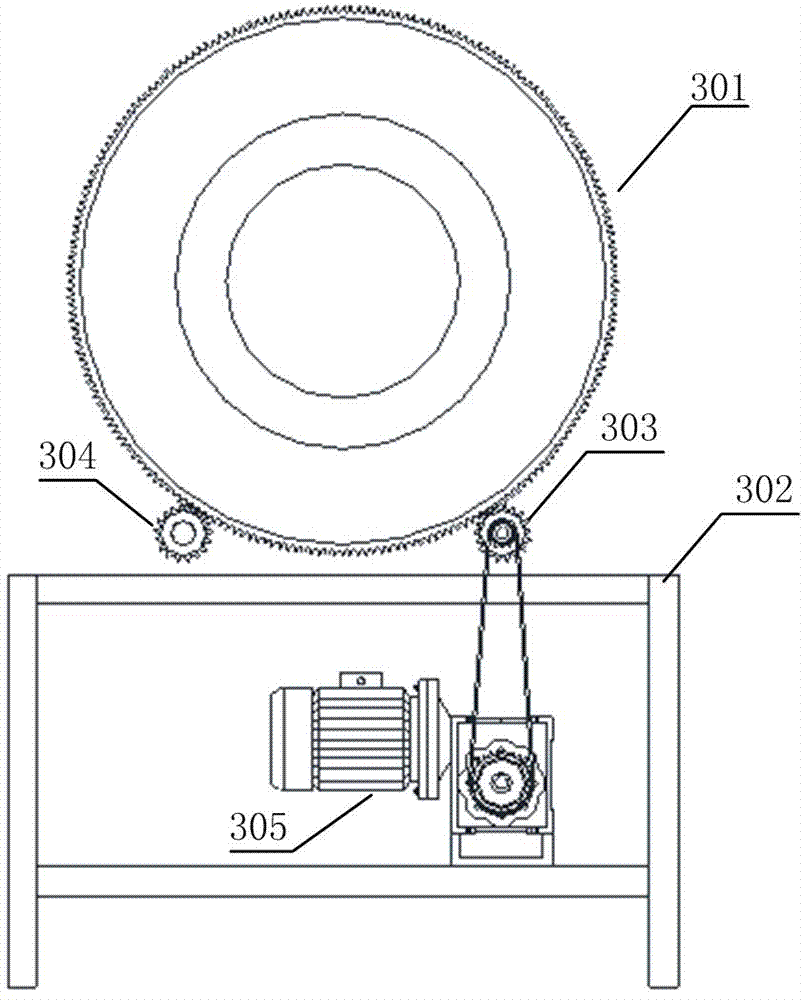

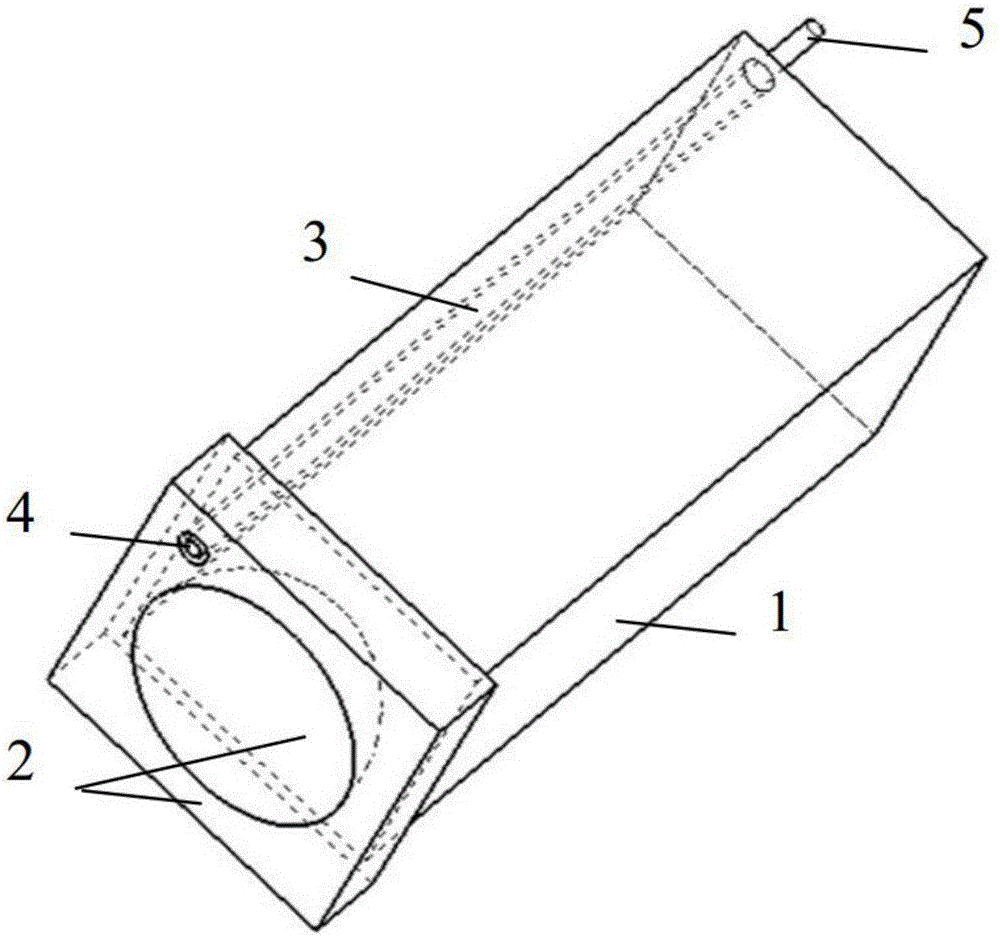

System and method for mixing expanded perlite plate raw materials

ActiveCN103786260AReduce material weightStable productionMixing operation control apparatusCement mixing apparatusPerliteAdhesive

The invention relates to a system for mixing expanded perlite plate raw materials. The system comprises an adhesive storage pool, a dosing tank, a feeding tank, a mixer, an expanded perlite chamber, a baffle plate and an adhesive pipeline, wherein the adhesive storage pool is connected with the dosing tank which is connected with the feeding tank, and the feeding tank is connected with the mixer; an impurity outlet of the dosing tank and an impurity outlet of the feeding tank are connected with the adhesive storage pool; the expanded perlite chamber is positioned above the mixer, and provides expanded perlite for the mixer through the baffle plate. According to the method, adhesive and liquid materials are subjected to liquid-liquid phase mixing; impurities are removed; expanded perlite and the adhesive mixed solution are subjected to solid-liquid mixing. Based on the system and the method provided by the invention, the consumption amount of the adhesive is effectively reduced, damage of materials is avoided, the quality of products is improved, and the production efficiency is also improved.

Owner:CHIFENG HUIYUAN BUILDING MATERIAL CO

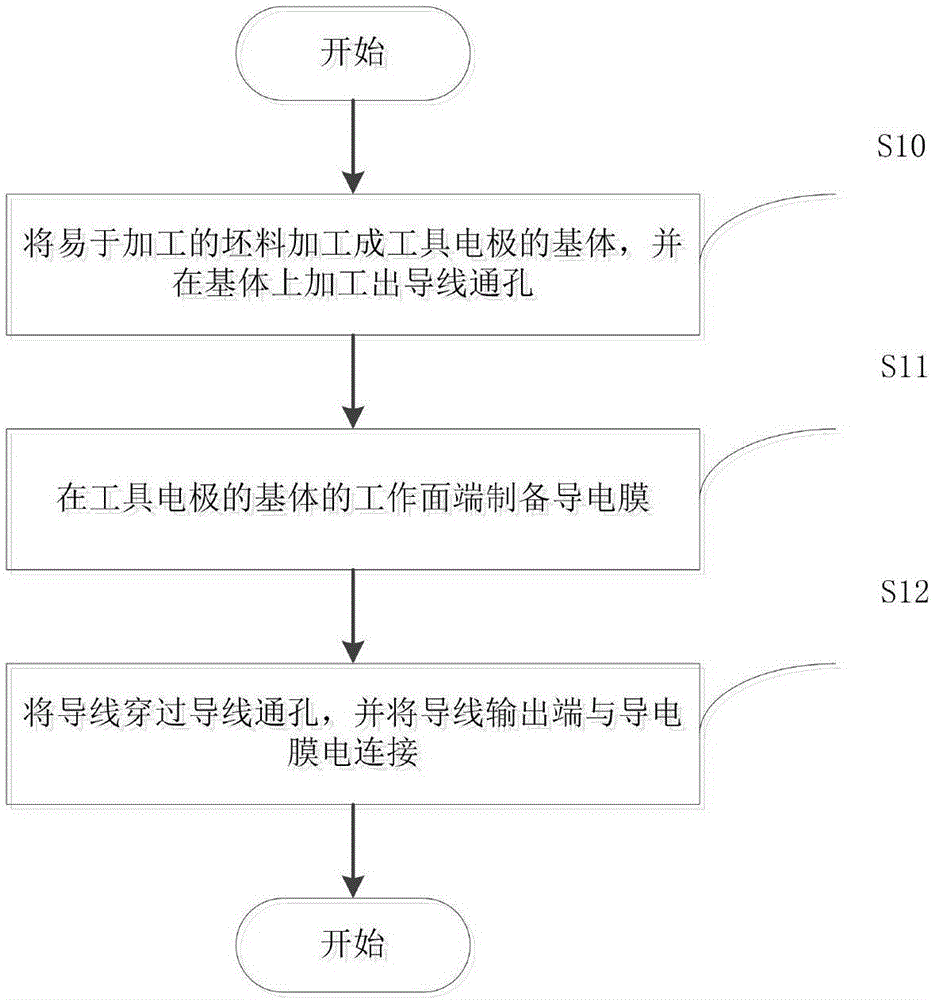

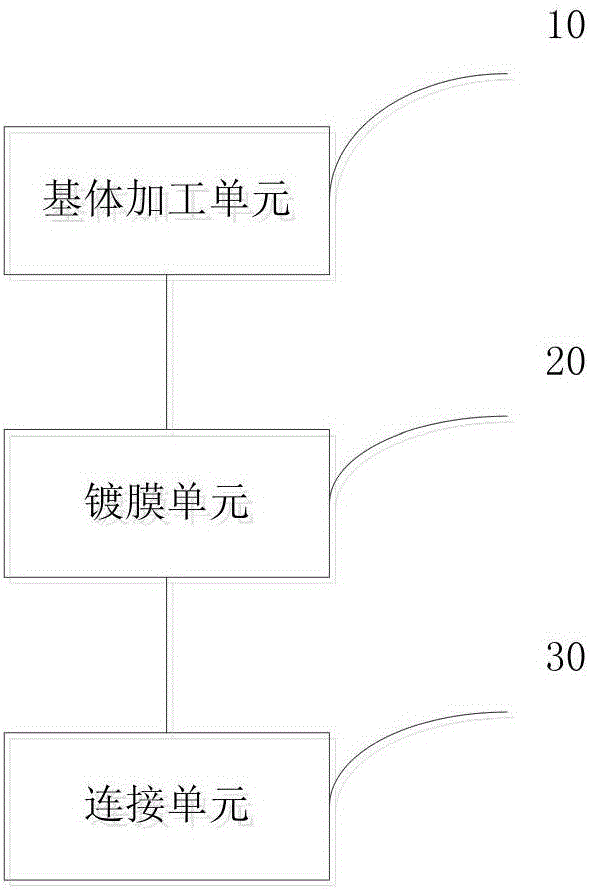

Conductive film electrochemical machining tool electrode and manufacturing method and device thereof

InactiveCN106825801AHigh current field concentrationImproving the precision of electrolytic machiningMachining electrodesElectrical-based machining electrodesEngineeringMaterials processing

The invention discloses a conductive film electrochemical machining tool electrode and a manufacturing method and device thereof. The tool electrode comprises a base and is characterized in that the base is machined by insulating materials, one end of the base is a working face, a conductive film closely attaches to the working face, the base is further provided with a wire, and the wire is electrically connected with the conductive film. The conductive film electrochemical machining tool electrode has the advantages that the insulating materials replace conductive metal to serve as the base of the tool electrode, the machining efficiency of the base of the tool electrode is increased greatly, machining difficulty, machining cost, material cost and electrode weight are lowered greatly, the loss of cutting equipment and cutting tools are is reduced greatly, and the electrochemical machining cost of enterprises is reduced.

Owner:SHENZHEN UNIV

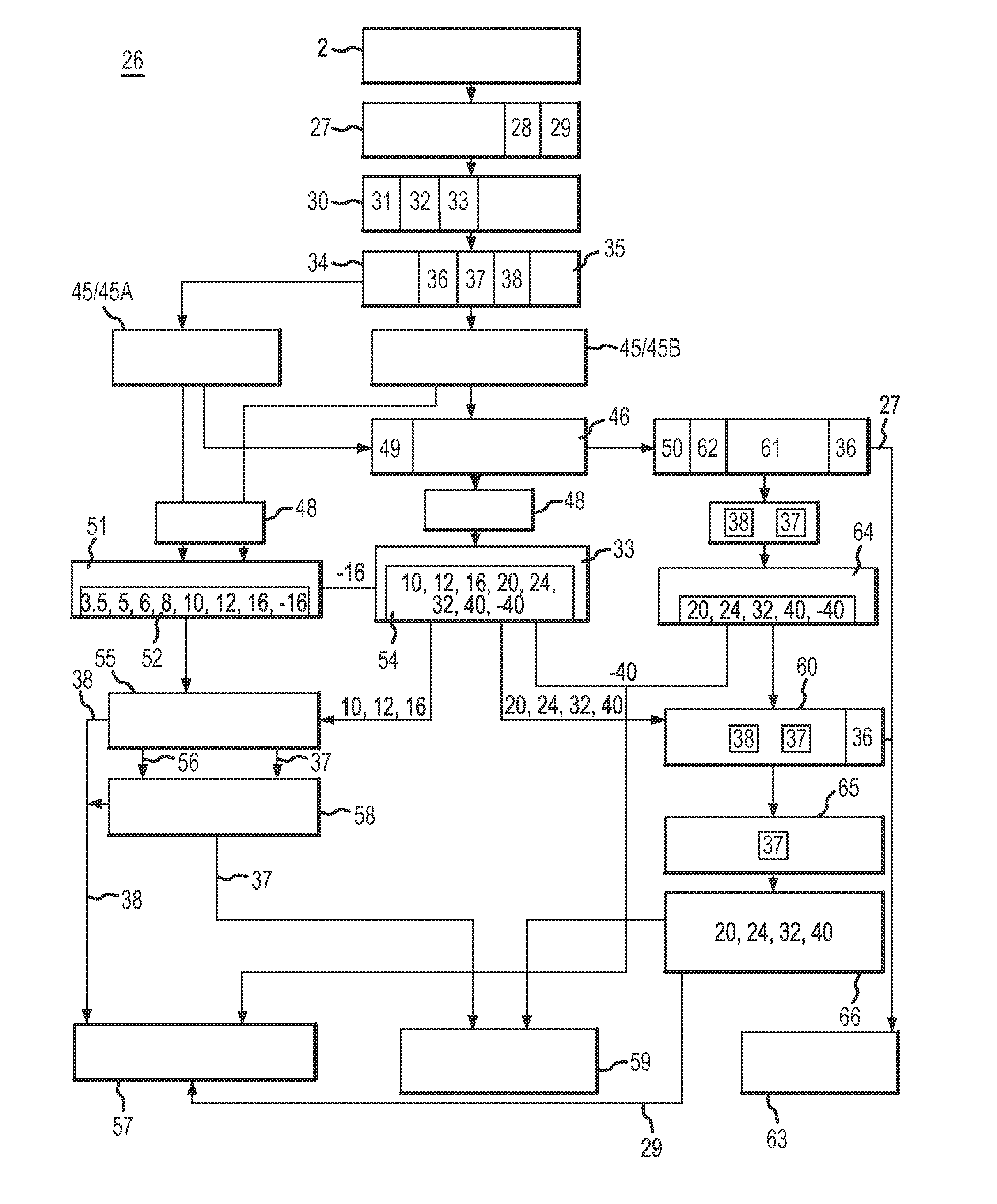

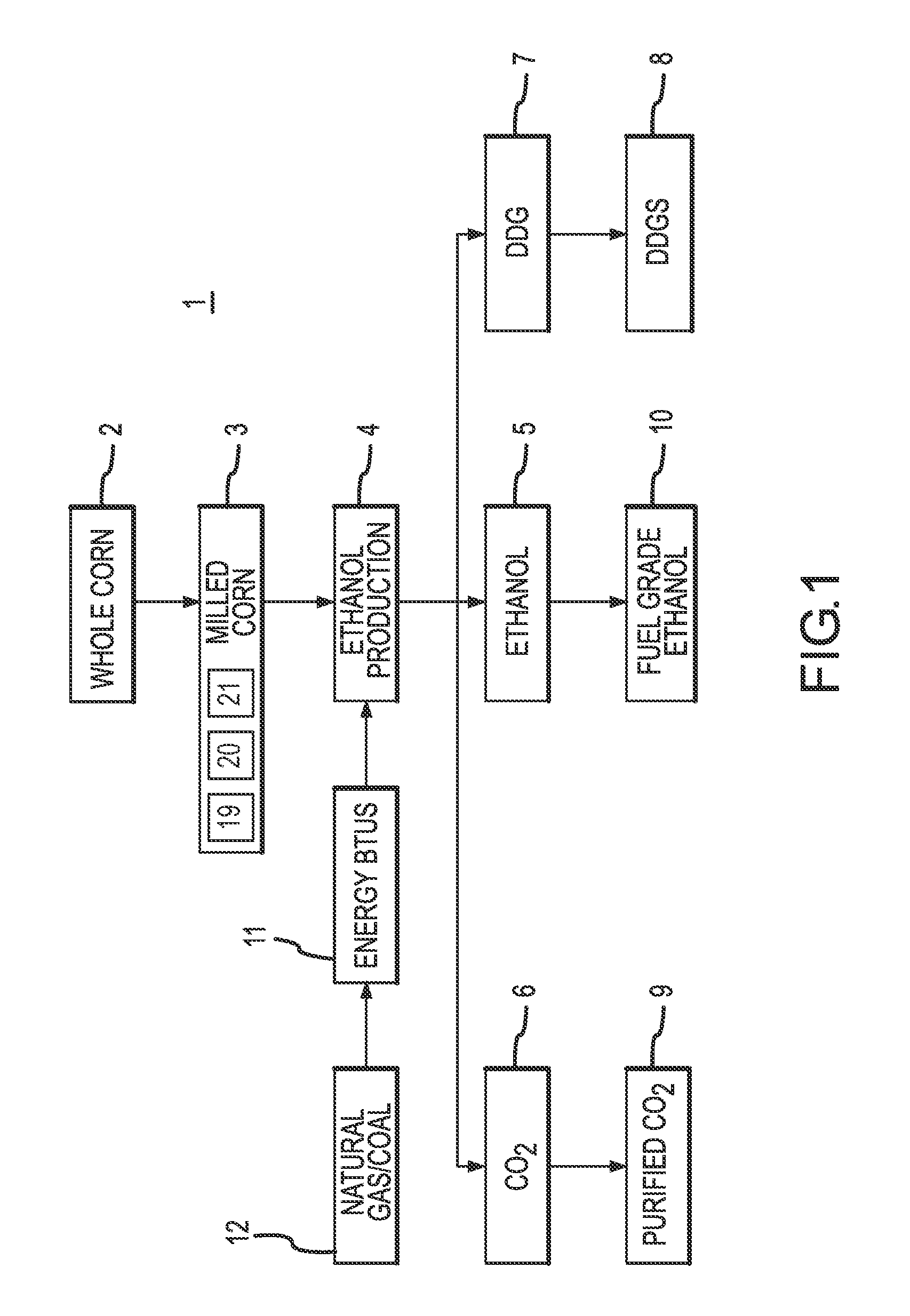

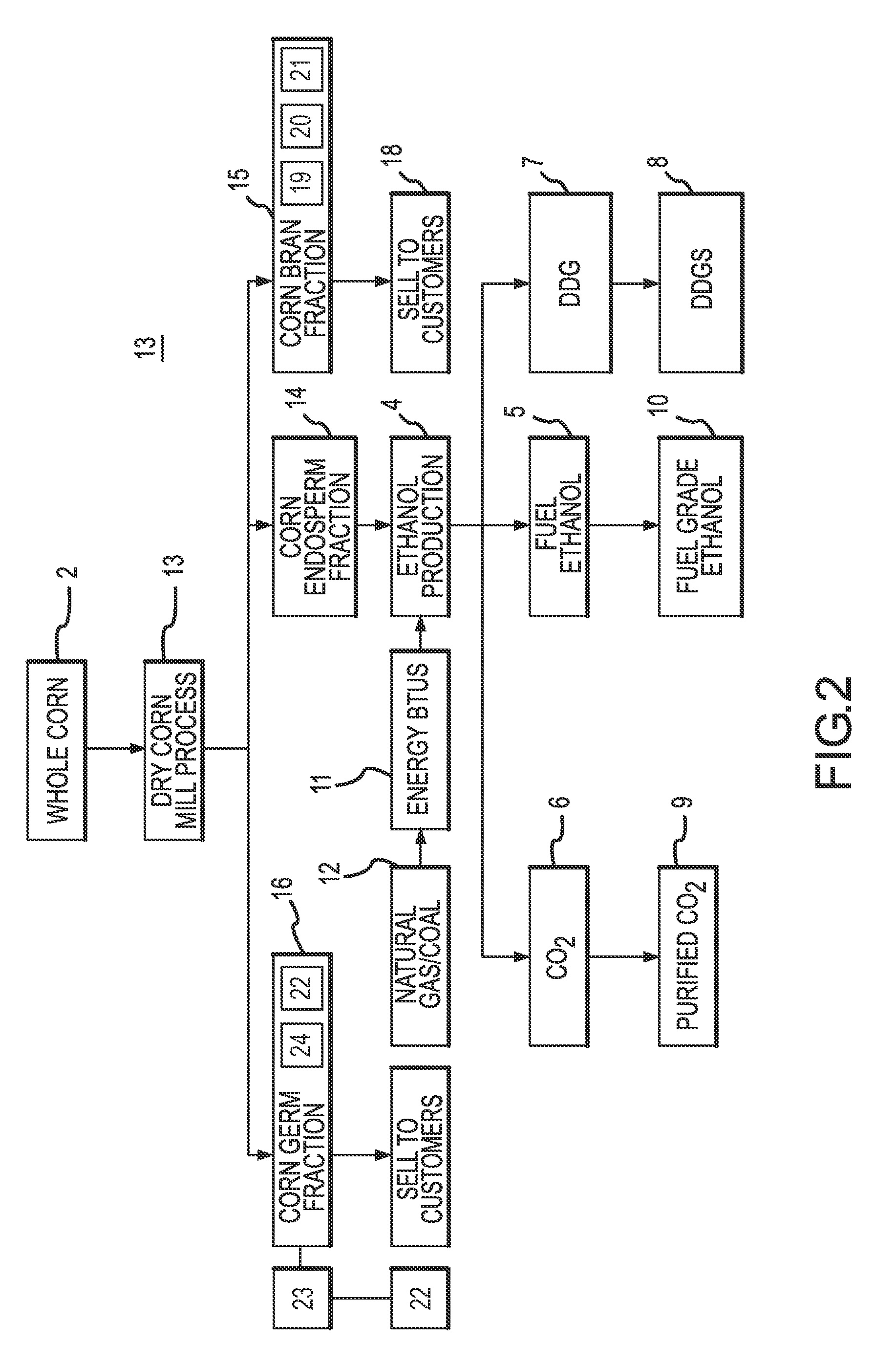

Grain fraction endosperm recovery system

Generally, a dry-wet grain fractionation system which provides a dry mill process (26) for the production of grain fractions (14) (15) (16) and a wet mill process (18) for the production of purified bran (19), endosperm (20) and germ (21) from the mixture of grain particles in a grain fraction (14) (15) or (16) or combinations thereof. Specifically, a dry-wet grain fractionation system for production of corn germ (21) having increased protein and oil content and an endosperm (20) having increased starch and sugar content.

Owner:MOR TECH

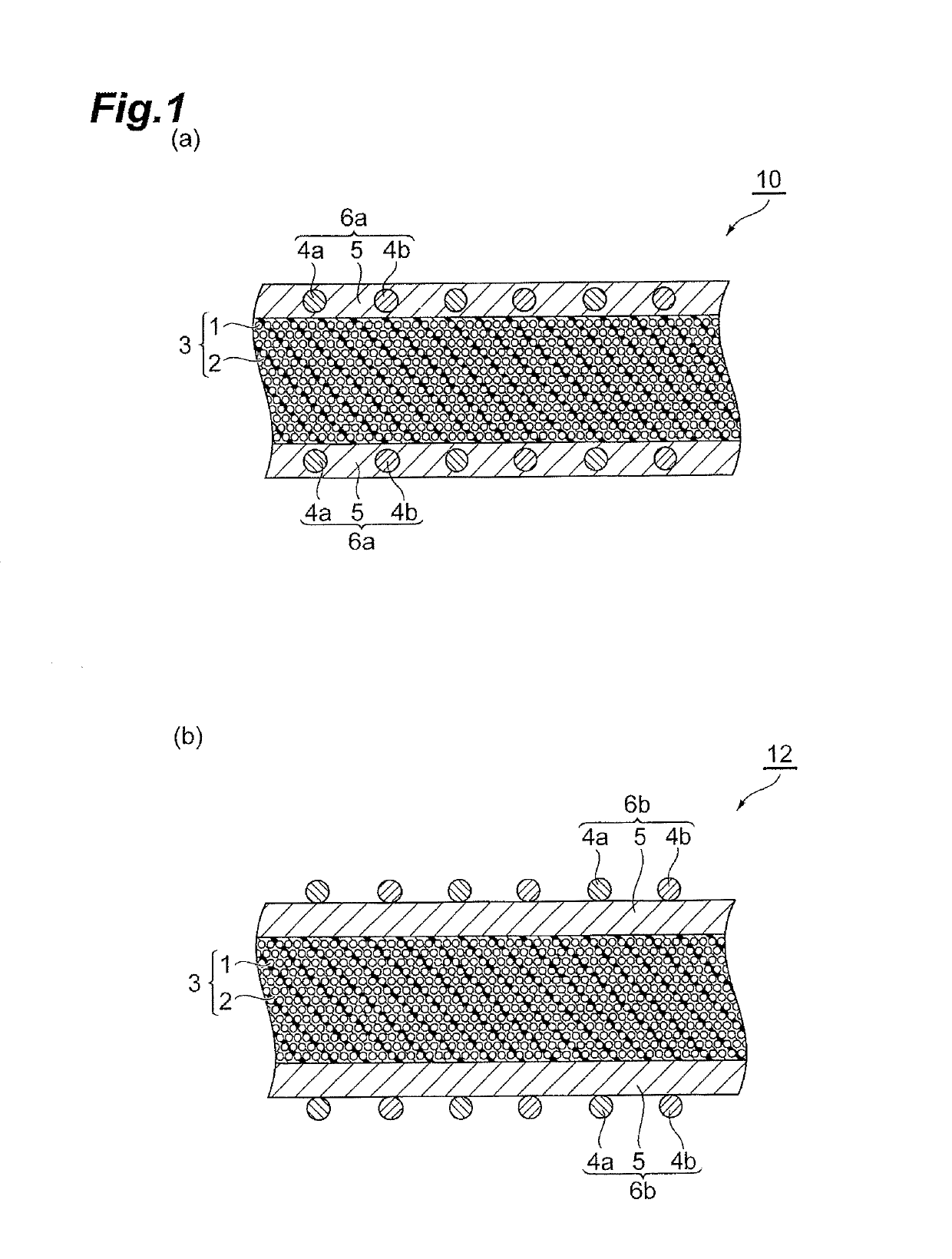

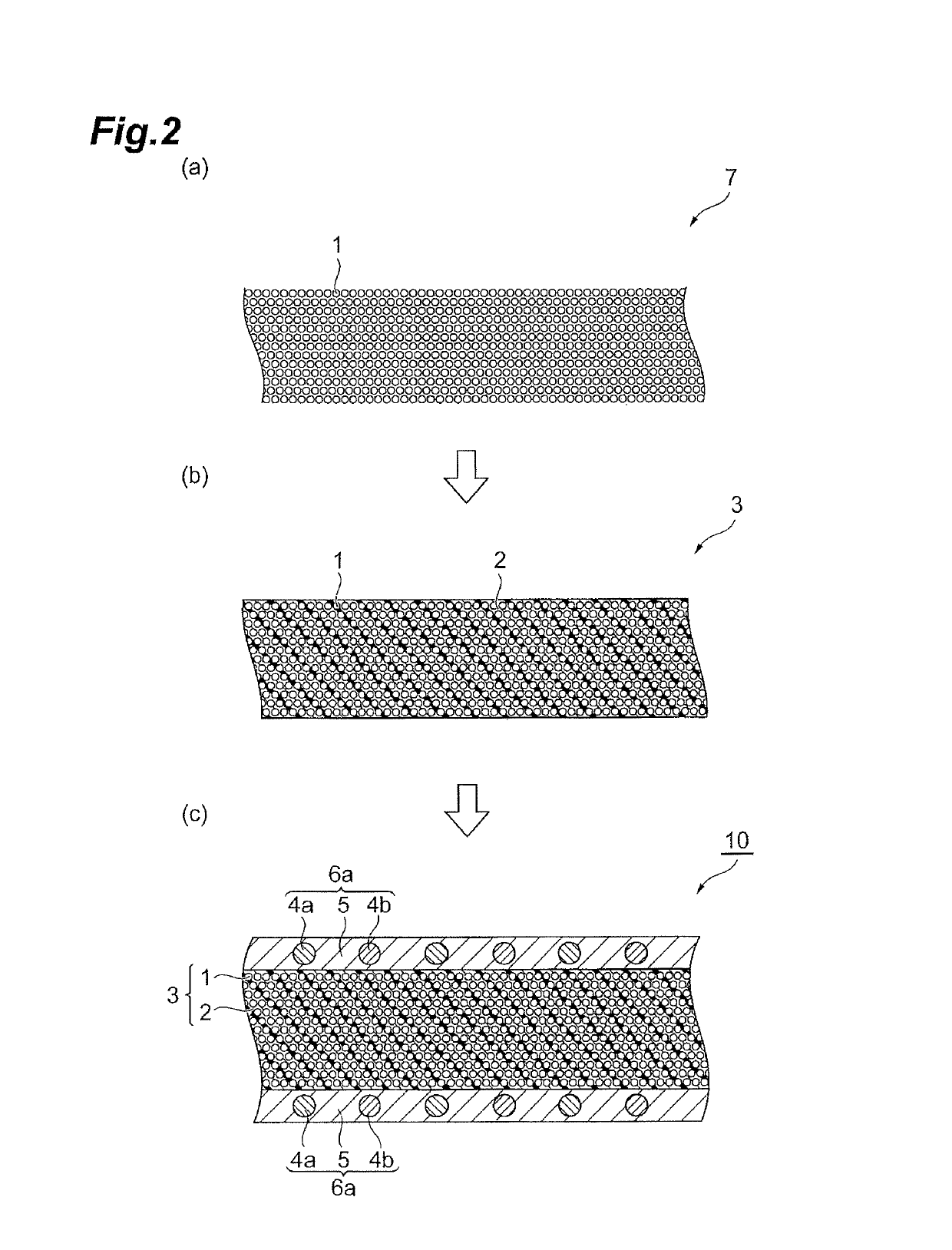

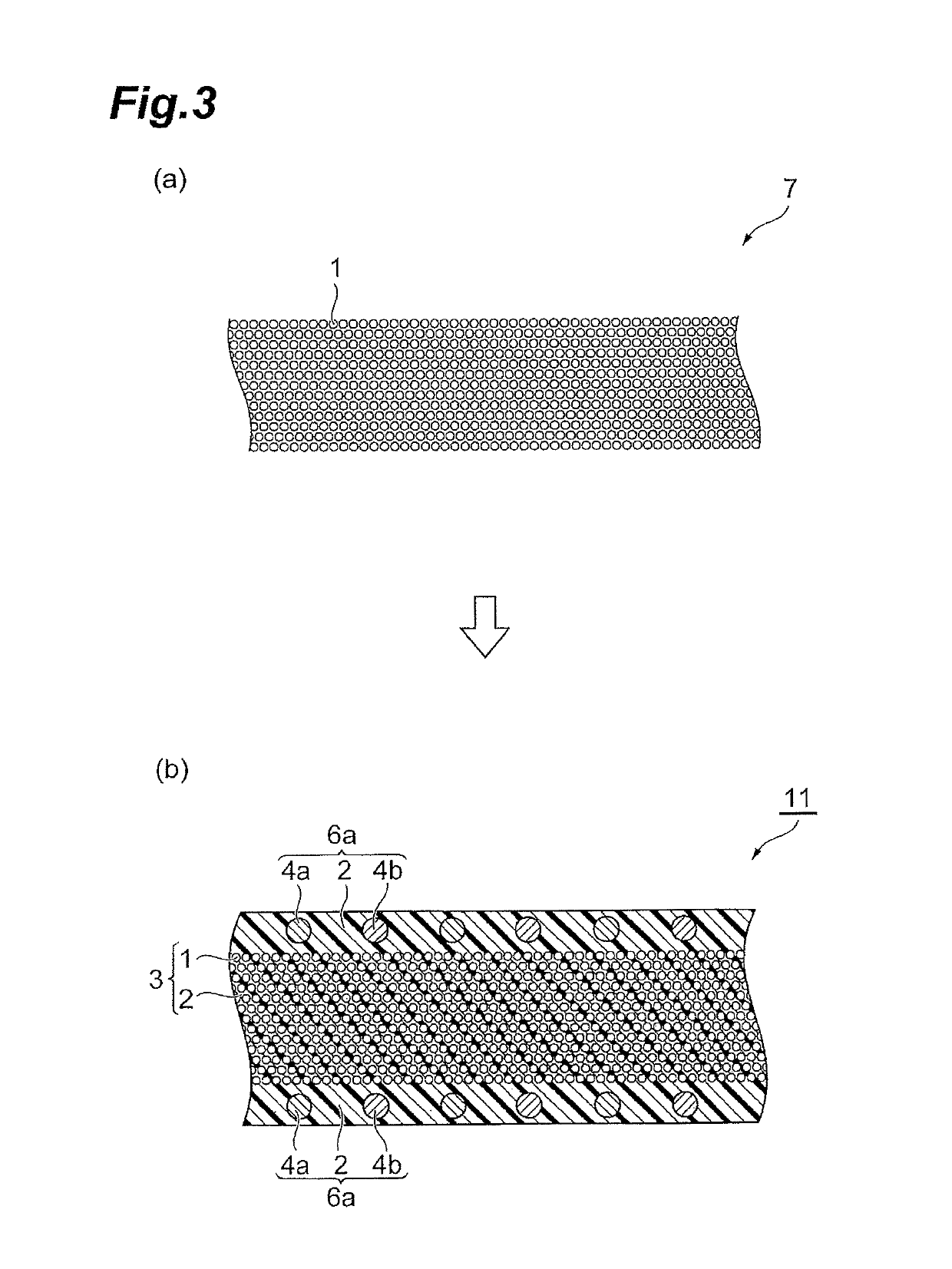

Production method for fibre-reinforced composite material, prepreg, particle-containing resin composition, and fibre-reinforced composite material

ActiveUS10316158B2Good moisture and heat resistanceHigh glass transition temperatureSynthetic resin layered productsVehicle componentsSurface layerPolyamide

A production method for a fiber-reinforced composite material comprises: a step of stacking a prepreg plurally to obtain a prepreg-stacked body; and a step of heating the prepreg-stacked body to cure a resin, wherein the prepreg comprises: a reinforcing fiber layer including reinforcing fibers and a resin composition with which the space between fibers of the reinforcing fibers is impregnated and which contains (A) a benzoxazine resin, (B) an epoxy resin, and (C) a curing agent having 2 or more phenolic hydroxy groups in a molecule; and a surface layer provided on at least one surface of the reinforcing fiber layer and containing (A) to (C) components, and (D) polyamide resin particles having an average particle size of 5 to 50 μm.

Owner:SUBARU CORP +1

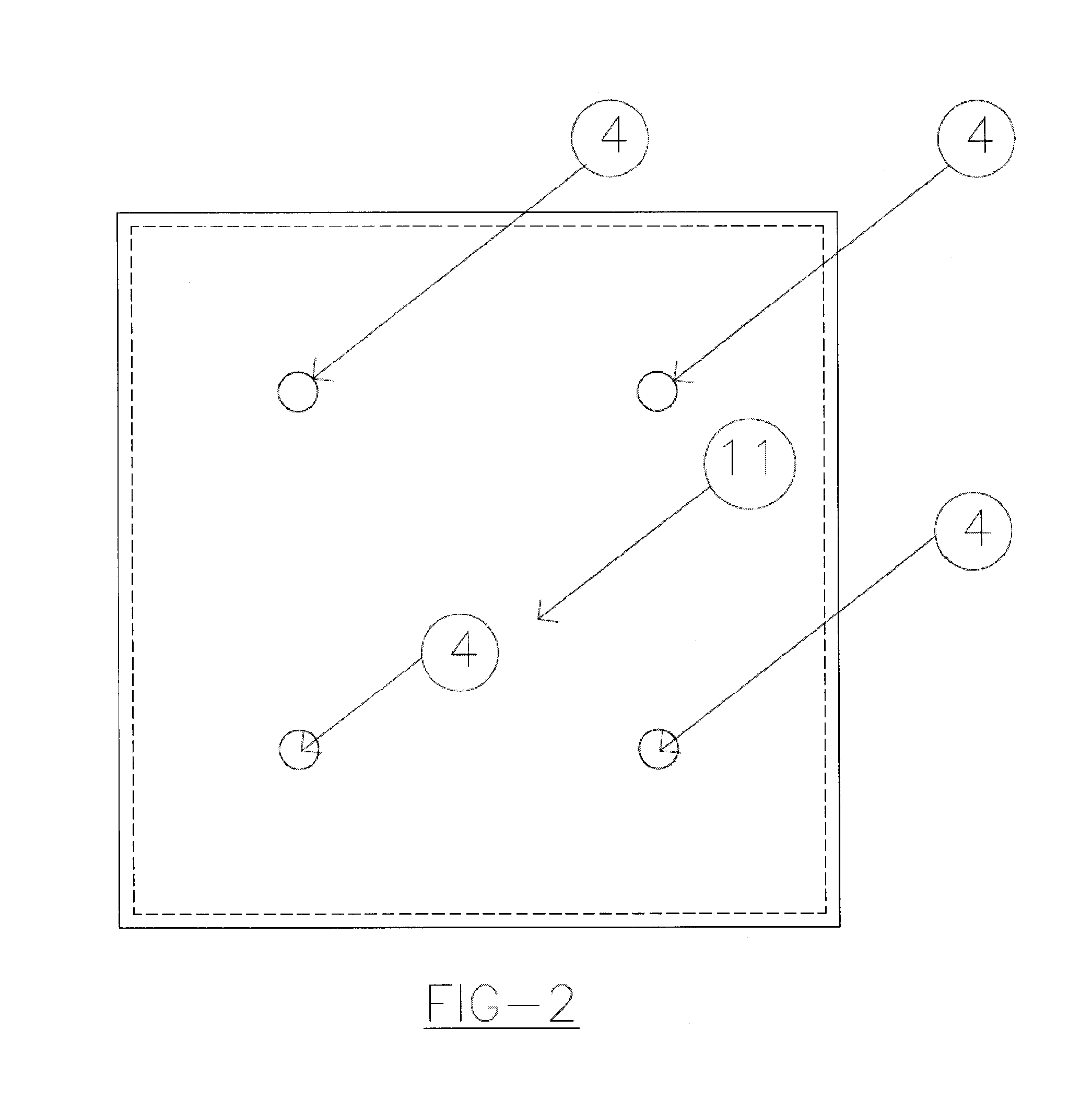

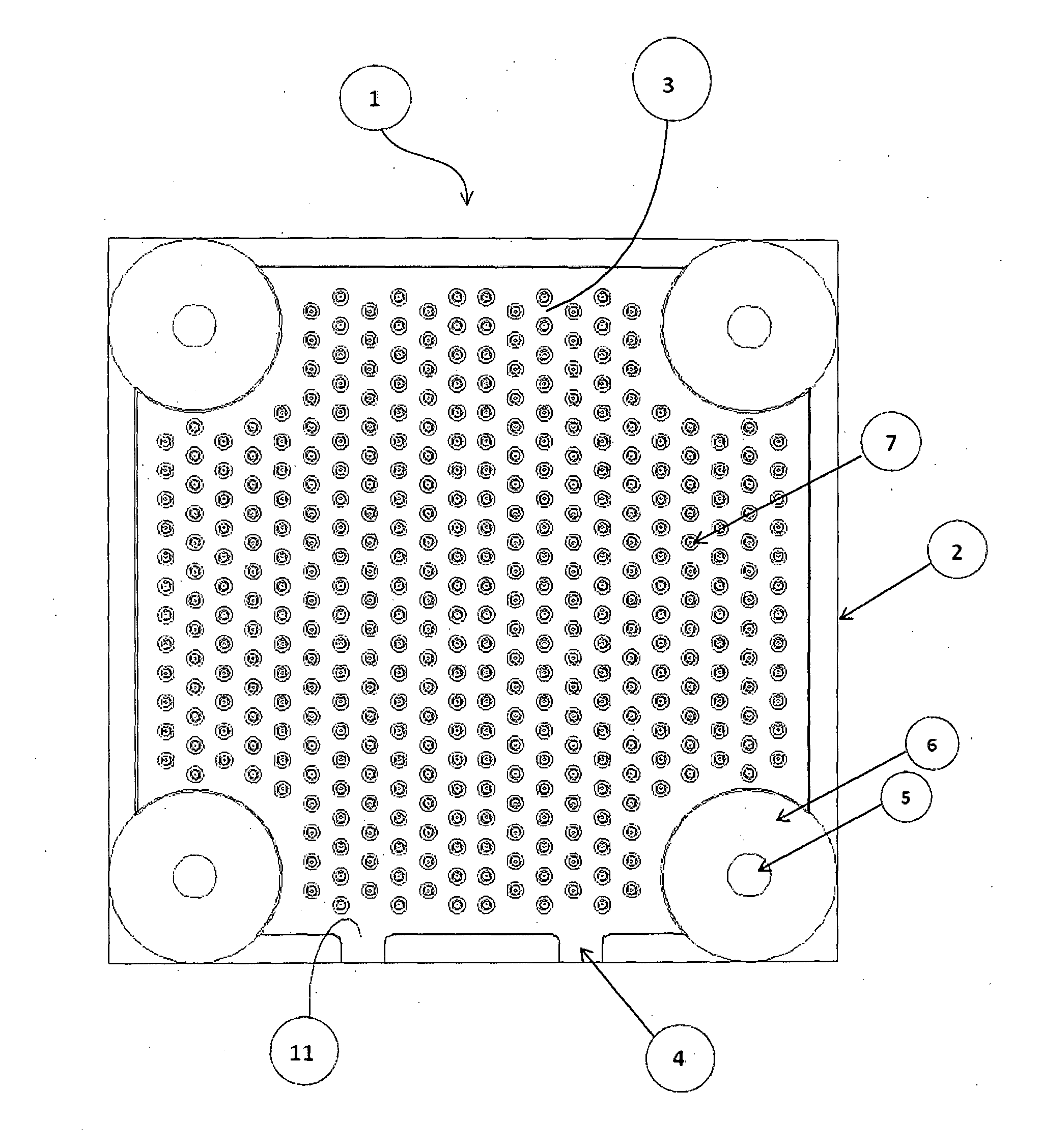

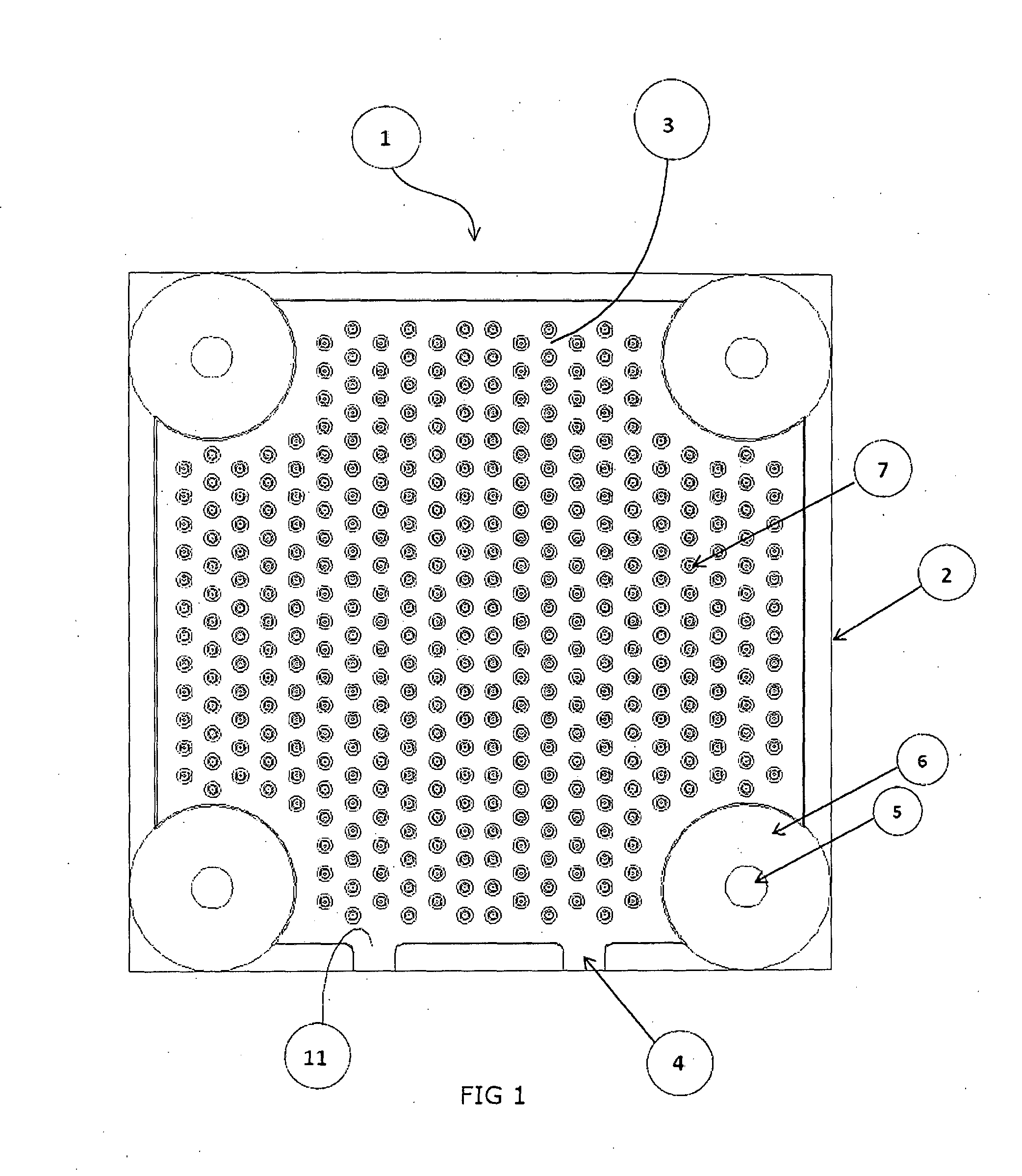

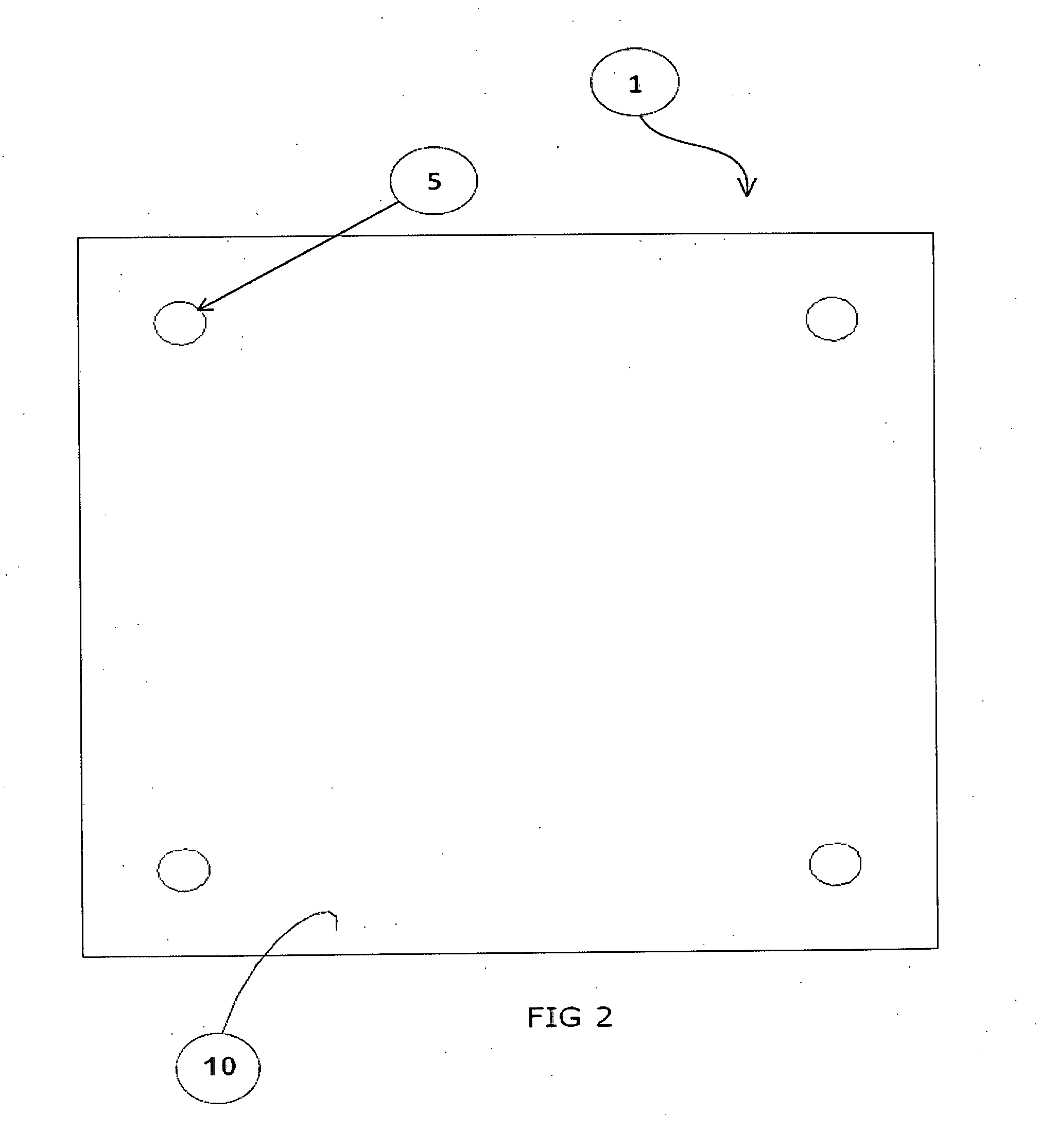

Liner Unit for Chute Wall

A liner unit (1) adapted to be detachably attached on a chute wall (12) comprises a liner base enclosed within an integrally formed frame (2) and having a front (10) and a back face (11), said liner unit (1) is adapted to be affixed with the said chute wall (12) through bolt holes (5) by means of fastening means (8), said liner base being provided with pockets on the surface thereof providing cushioning effect in the event of the liner base being impacted with a load during operation.

Owner:TEGA IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com