Remedying system for non-hazardous waste buildings and remedying method

A technology for repairing systems and buildings, which is applied in the field of leaching and repairing engineering polluted buildings, which can solve the problems of lack of efficient repair methods, etc., and achieve the effects of efficient operation, low processing cost, and reduced processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

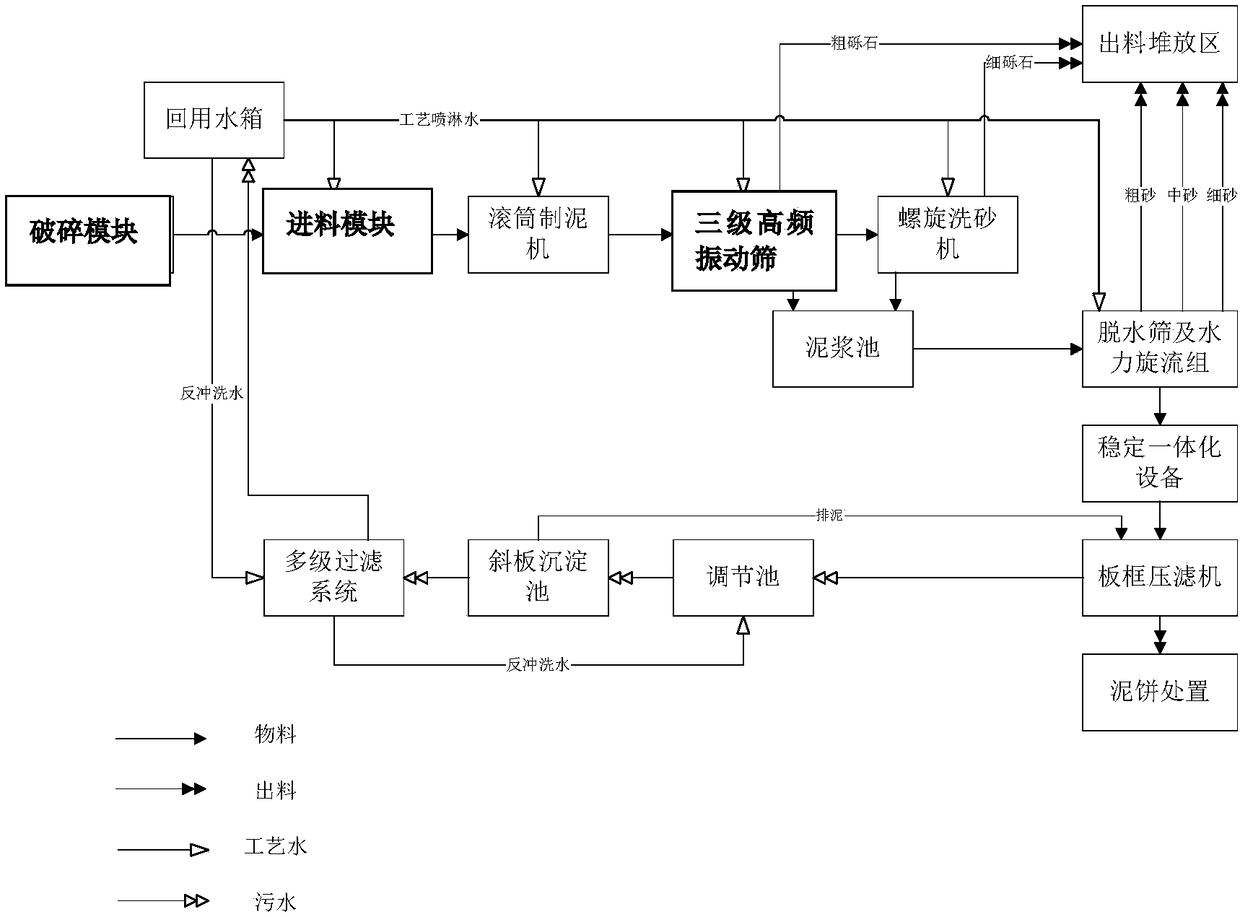

[0051] like figure 1 As shown, the restoration method for non-hazardous waste polluted buildings involved in this embodiment includes the following steps:

[0052] 1) Demolition and crushing: Demolition of polluted buildings and crushing;

[0053] 2) Feeding: Feed the crushed material in step 1) through a vibrating screen

[0054] 3) Sludge: make the material fed in step 2) spray the high-pressure cleaning liquid in the drum mud making machine, and discharge the slurried material after uniform dispersion

[0055] 4) Multi-stage screening: in step 3) the processed material is screened by multi-stage weight reduction; 5) mud dehydration and mud cake stabilization: the material treated by step 4) weight reduction treatment is added with medicine to obtain a mixed liquid, and then The mud is pumped into the plate and frame filter press through the mud pump to dewater the mud; after the mud and water are separated, the mud cake is further stabilized to complete the harmless dispo...

Embodiment 2

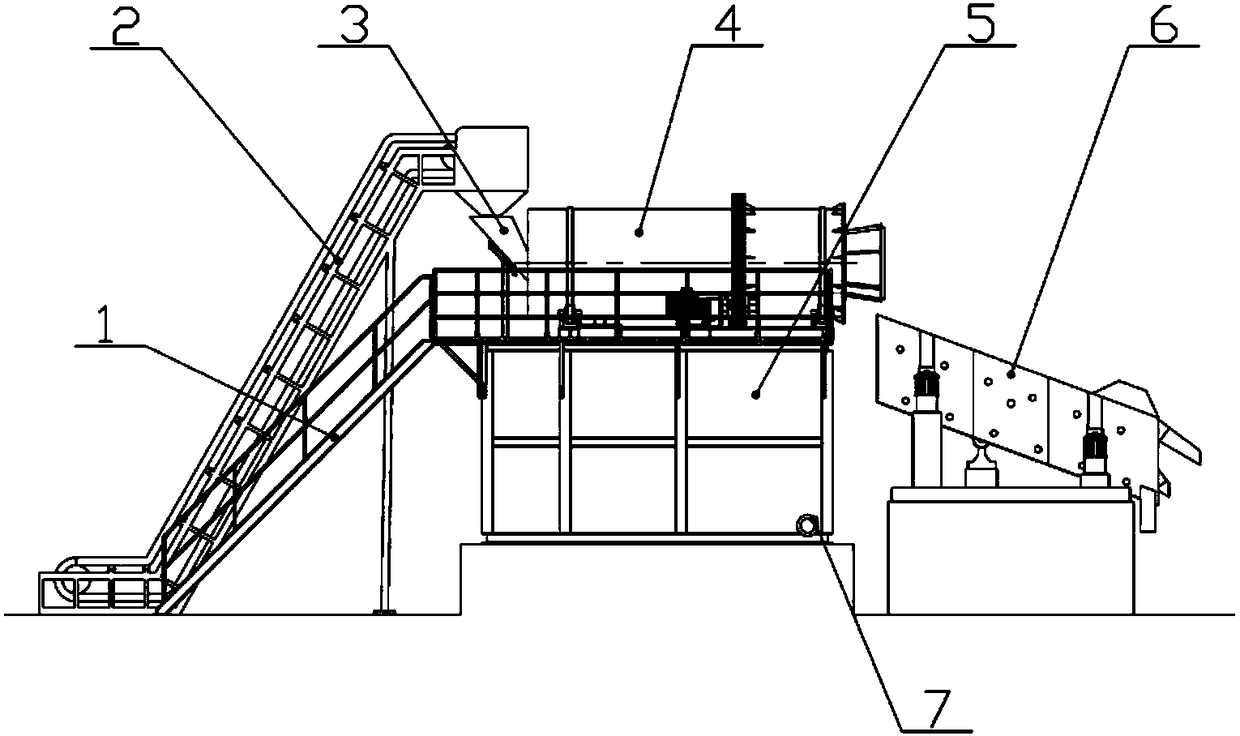

[0069] like Figure 1-2 As shown, this embodiment provides a repair system for non-hazardous waste polluted buildings, which includes the following modules in sequence:

[0070] A crushing module for crushing and dismantling polluted buildings;

[0071] A feeding module, including a vibrating screen for feeding and provided with a high-pressure spray system, and a material conveying belt, the vibrating screen is used for screening the polluted buildings treated by the crushing module;

[0072] A drum mud making module, including a drum mud making machine 4 with a high-pressure spray system;

[0073] Multi-stage screening module for screening the mud discharged from the drum mud making module;

[0074] Mud dehydration and mud cake stabilization module, including stabilization integrated equipment and plate and frame filter press to realize the separation of mud and water, after the separation of mud and water, the mud cake is further stabilized to complete harmless disposal; ...

Embodiment 3

[0085] Taking the polluted buildings in a historically polluted site of a chemical factory in western China as the treatment target, the main pollutant is hexavalent chromium. The part of the polluted building which is identified as non-hazardous waste shall be treated by the leaching technology of the present invention. The rinsing process uses clean water or reducing agents as the eluent. The rinsing system is based on the basic design concept of "reduction" and "concentration and final disposal", which realizes the pollution-containing fine particles and stones, gravel, etc. in the feed material. Effective separation of coarse particles, and elution, transfer and concentration of contaminants on the surface of coarse particles into the mud cake after pressure filtration.

[0086] 1. Demolition and crushing: Demolish polluted buildings and use crushers for crushing. After crushing, the particle size of the building is less than 100mm.

[0087] 2. Feeding system: The crushe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com