System and method for mixing expanded perlite plate raw materials

A technology for expanding perlite and mixing materials, which is applied to chemical instruments and methods, mixing operation control, mixing operation control devices, etc. On-site environment and complex processing work, reduce material weight, and achieve the effect of zero discharge of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

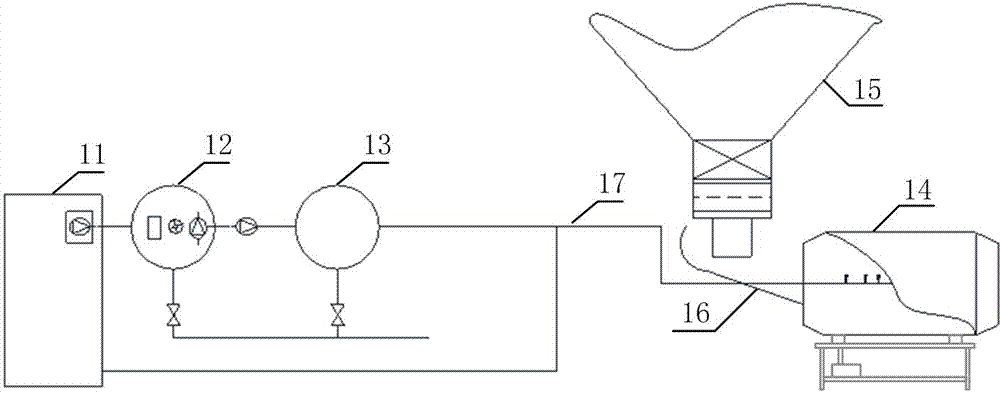

[0036] figure 1 It is a schematic diagram of the overall structure of the mixing system according to the present invention, such as figure 1 As shown, the mixing system of the present invention of the present invention comprises, binder storage tank 11, batching tank 12, feed tank 13, mixer 14, expanded perlite silo 15, deflector 16, and adhesive Binder pipeline 17, wherein,

[0037] Adhesive storage pool 11, which is used to store the adhesive solution, is connected to the batching tank 12 through pipelines, and the binder solution is pumped into the batching tank 12 by a pump, and the pipelines at the front and rear ends of the pump are respectively A filtering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com