Sponge sofa or sponge stool structure

A technology of sponge and sofa, applied in the field of sponge stool structure and sponge sofa, can solve the problems of large weight of sponge sofa or sponge stool, difficulty in guaranteeing the uniformity of product shape, and change of product shape, etc., so as to reduce material cost, weight and light weight. , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

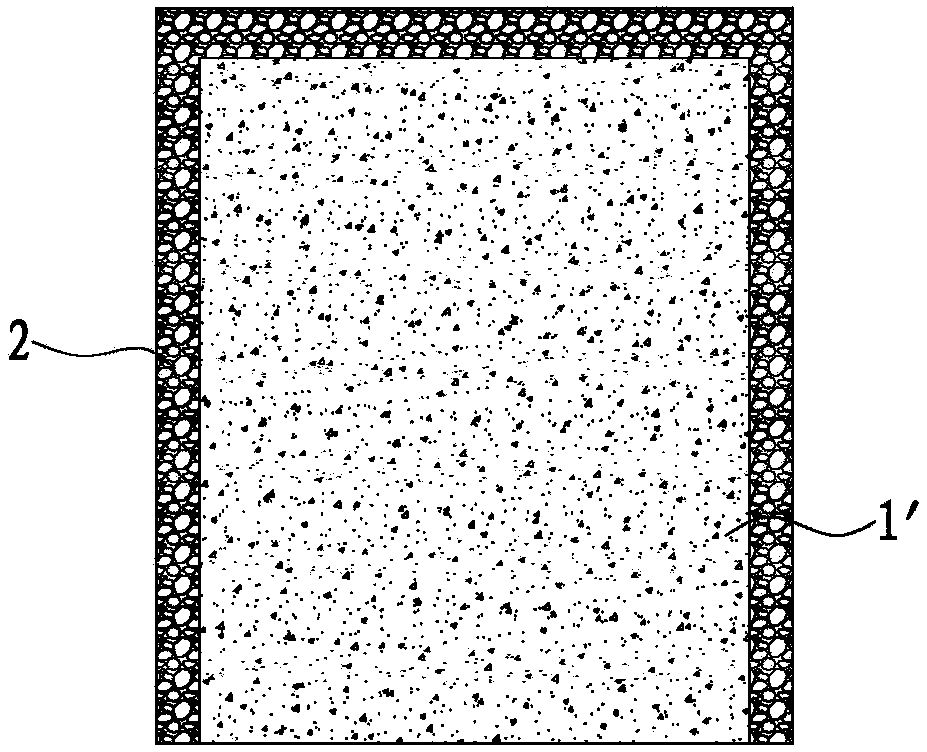

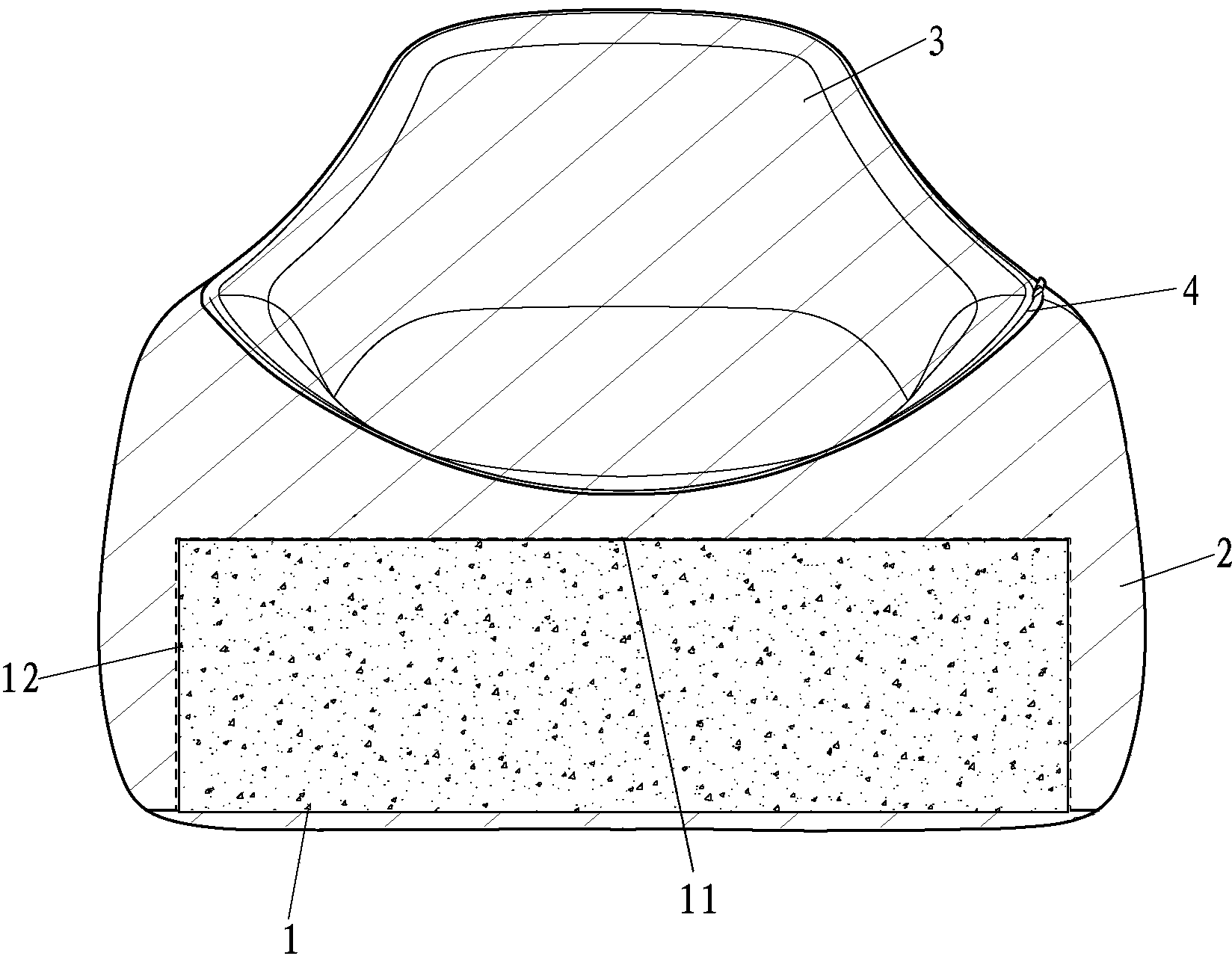

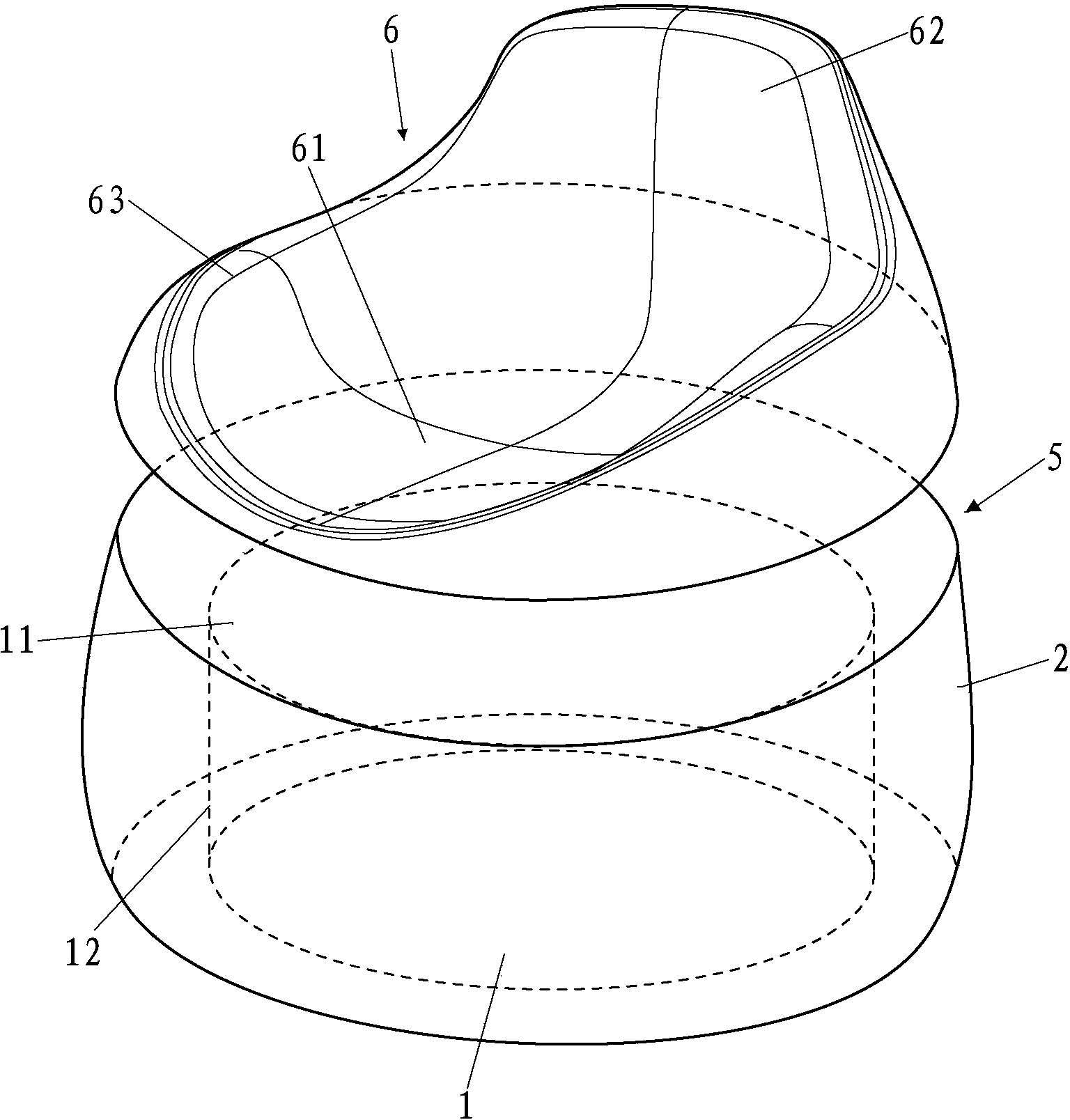

[0027] Such as Figure 1 to Figure 11 Shown, the present invention discloses a kind of sponge sofa, sponge stool structure, and it comprises a foaming density is 10~35kg / m 3 Sponge sofa base 1 and sponge stool base 1' are formed by low-foam foaming, and the outer surfaces of sponge sofa base 1 and sponge stool base 1' are integrally foamed with a foaming density of 35-60 kg / m 3 The sponge covering layer 2 of the high-density sponge, wherein the hardness of the sponge sofa base 1 and the sponge stool base 1' is Share A 20+, and the hardness of the sponge covering layer 2 is 30~80Kgf. The thickness of the sponge covering layer 2 at the seat of the sponge sofa base 1 and the sponge stool base 1' is 10-100 mm.

[0028] Such as figure 1 As shown, the sponge stool base 1' includes a seating surface 11' and a surrounding surface 12' supporting the seating surface 11', and the sponge covering layer 2 is directly integrally foamed on the seating surface 11' and the surrounding surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com