Freezer foaming layer

A foamed layer and freezer technology, applied in the field of freezer manufacturing, can solve the problems of high cost of foaming system, inability to meet energy conservation and environmental protection and excellent performance, insufficient foam fluidity, etc. Affected, low foam density effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The invention relates to a foaming layer of a freezer, which is prepared by reacting a high-viscosity black material, a combination polyether and a foaming agent;

[0020] The viscosity of the high-viscosity black material at 25°C is 300-700mPa·s; the high-viscosity black material is a mixture of isocyanate with higher functionality and diphenylmethane diisocyanate.

[0021] Among them, the viscosity value of the high-viscosity black material is 350-550 mPa·s.

[0022] Among them, the average viscosity functionality of high-viscosity black material is 2.8-3.0;

[0023] The commercial grades of high-viscosity black materials can be selected as PM-400, PM-4010, and M50.

[0024] Wherein, the foaming agent is one or more of pentane, butane, 1,1,1,3,3-pentafluoropropane or trans-1-chloro-3,3,3-trifluoropropene.

[0025] Wherein, pentane is one or both of cyclopentane and isopentane.

[0026] Wherein, butane is one or both of n-butane and isobutane.

Embodiment 2

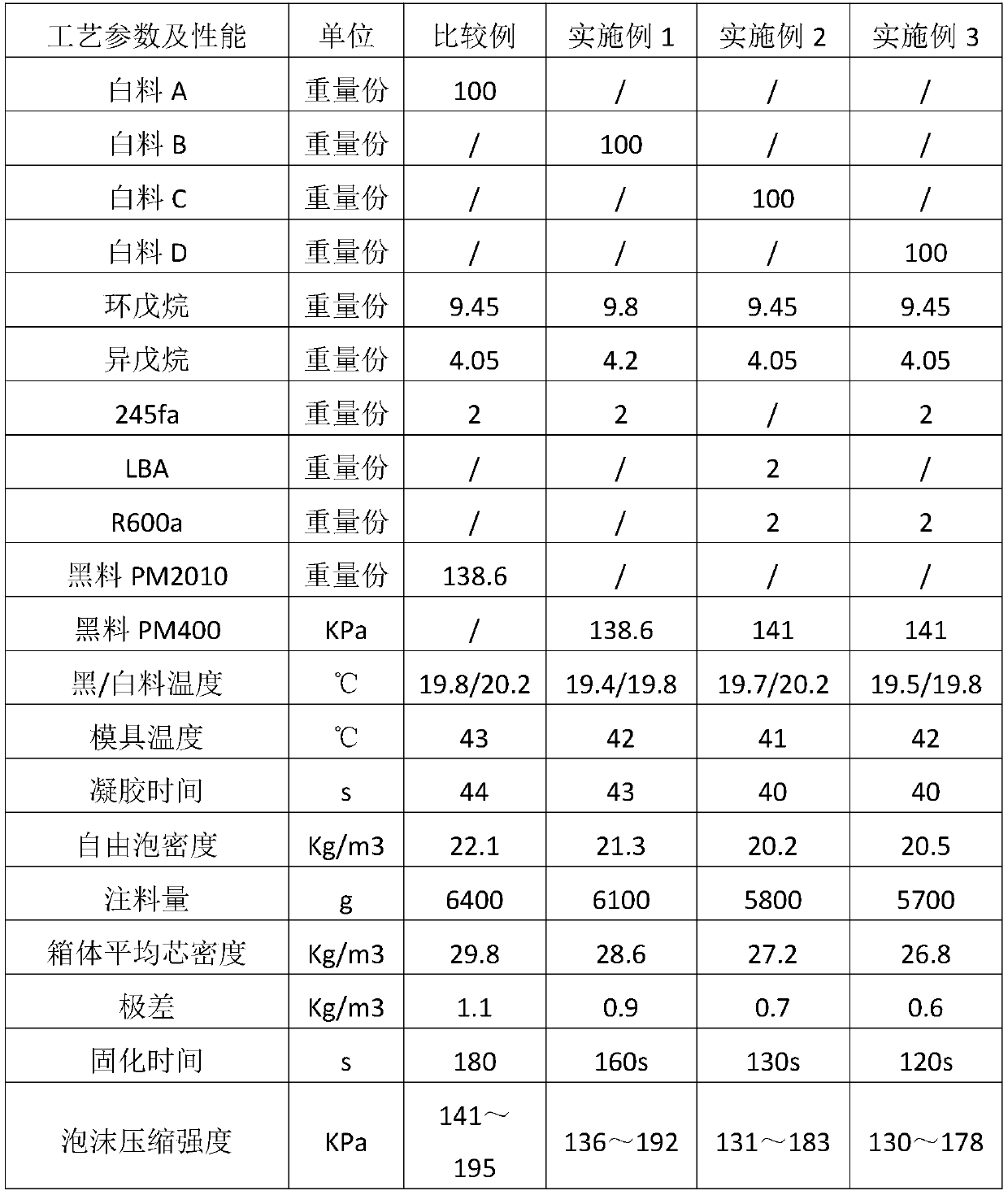

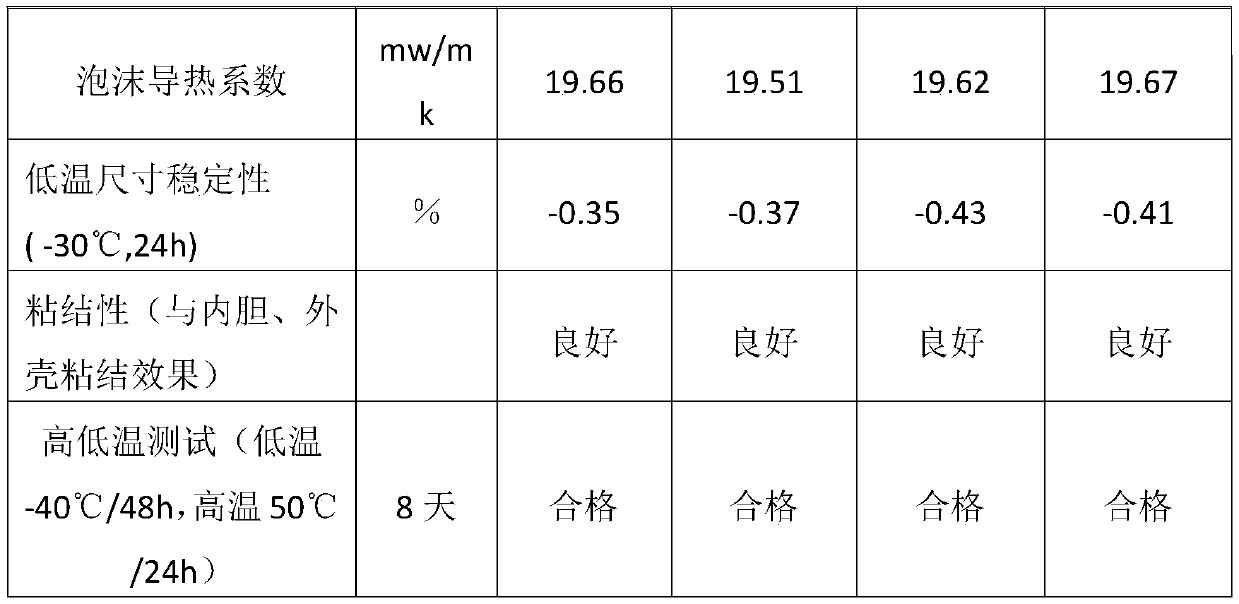

[0028] In a specific embodiment, taking the BCD-278 freezer as an example, according to the different components of cycloisopentane, 245fa, LBA and R600a blowing agent, develop different formulations of white material A, white material B, white material C, and white material D , corresponding to comparative example, embodiment 1, embodiment 2 and embodiment 3 respectively, process parameter and performance are shown in Table 1:

[0029]

[0030]

[0031] Table 1

[0032] As can be seen from the above table, compared with the comparative example in Example 1, Example 2 and Example 3, the amount of foaming material in Example 1 is reduced by 4.7%, the curing time is reduced by 20s, the thermal conductivity of the foam is slightly reduced, and the compressive strength is Basically the same; the amount of foaming material in Example 2 is reduced by 9.4%, the curing time is reduced by 50s, the thermal conductivity of the foam is basically the same, and the compressive strengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity value | aaaaa | aaaaa |

| Curing time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com