High-frequency vibration laser self-wire-fusing welding method

A high-frequency vibration and welding method technology, which is applied in welding equipment, tin feeding devices, metal processing equipment, etc., can solve the problems of complex control of welding parameters, high requirements for wire feeding accuracy, and poor stability of welding wire, and achieve accurate and flexible state control , Improve the solidification and crystallization process, and increase the effect of tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

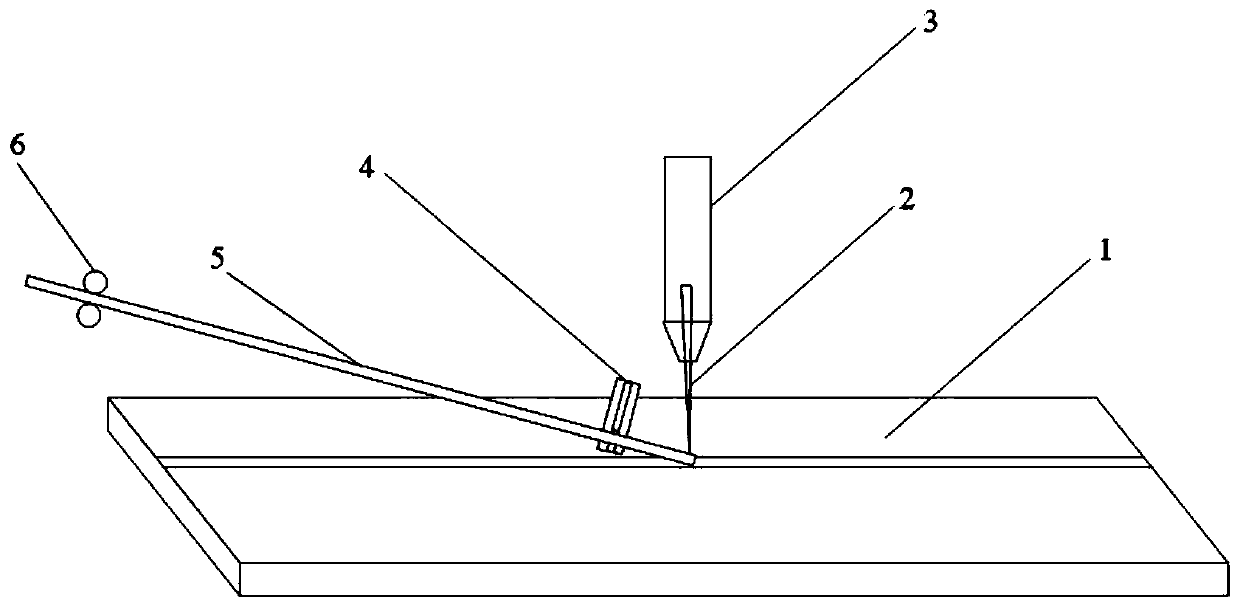

[0020] Specific embodiment 1: The high frequency vibration laser self-fuse welding method of this embodiment is carried out according to the following steps: 1. Focus the laser spot on the welding wire, and install the piezoelectric ceramic brake at the end of the welding wire; 2. Pass in shielding gas, Start the laser and piezoelectric ceramic brake, and the wire feeding speed is 5-10m / min, so that the laser beam is always focused on the welding wire, so as to realize the laser self-fuse welding.

[0021] The material and thickness of the workpiece to be welded suitable for the traditional laser fuse welding method are applicable to the method of this embodiment. It needs to be pointed out that the parameters involved in this method include gap width, wire feeding speed, laser power, welding speed, shielding gas composition and flow rate. These main process parameters should be adjusted according to the actual material type, size and joint form, gap size, etc. To optimize the sy...

specific Embodiment approach 2

[0022] Specific embodiment two: this embodiment is different from specific embodiment one in that the flow rate of the protective gas in step two is 15-25L / min. Others are the same as the first embodiment.

specific Embodiment approach 3

[0023] Specific embodiment three: This embodiment of the wire is different from specific embodiment one or two in that the welding speed in step two is 5-10m / min. Others are the same as the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com