Patents

Literature

190results about How to "Reduce assembly accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

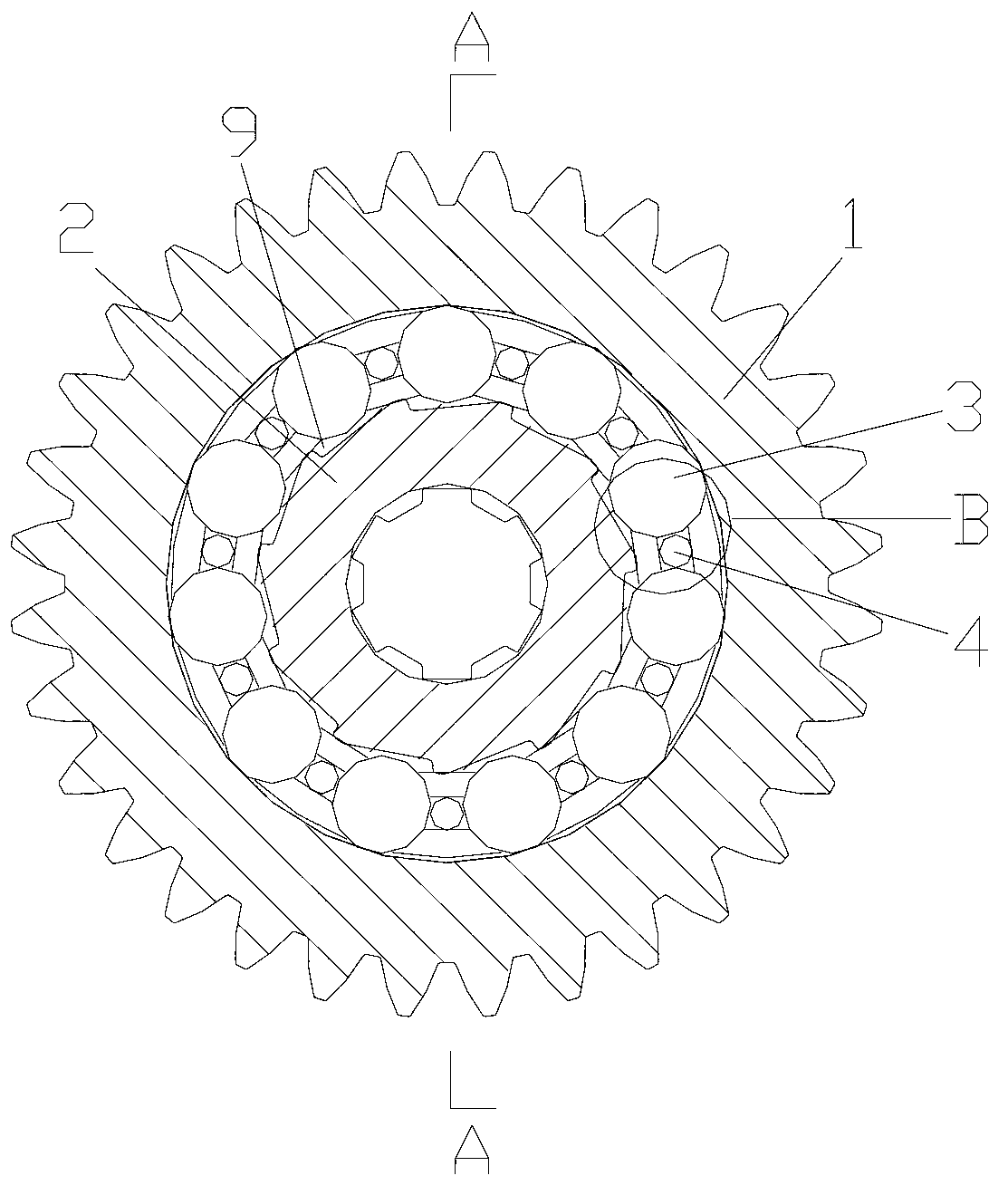

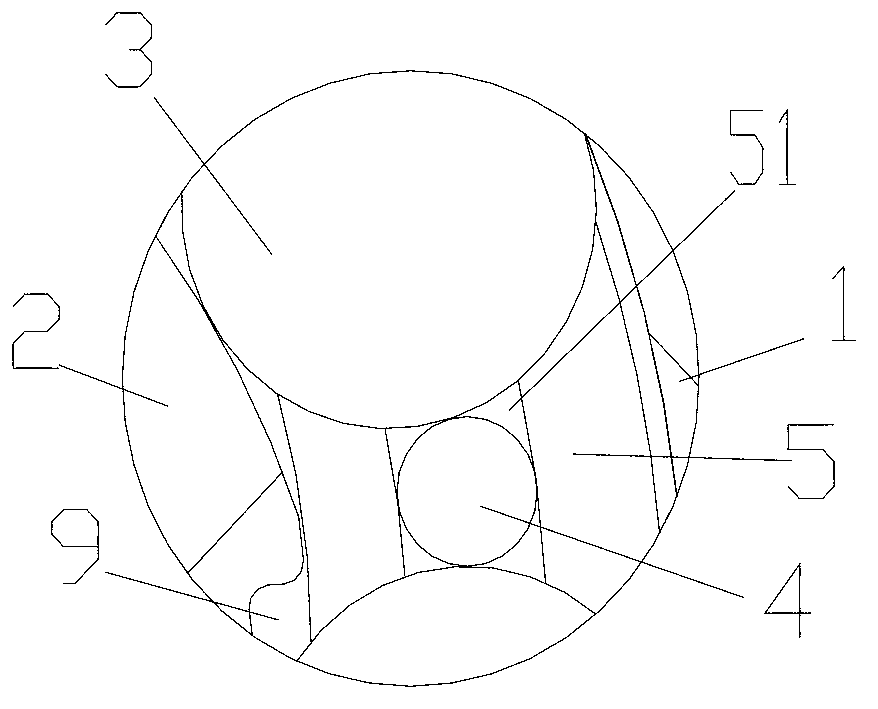

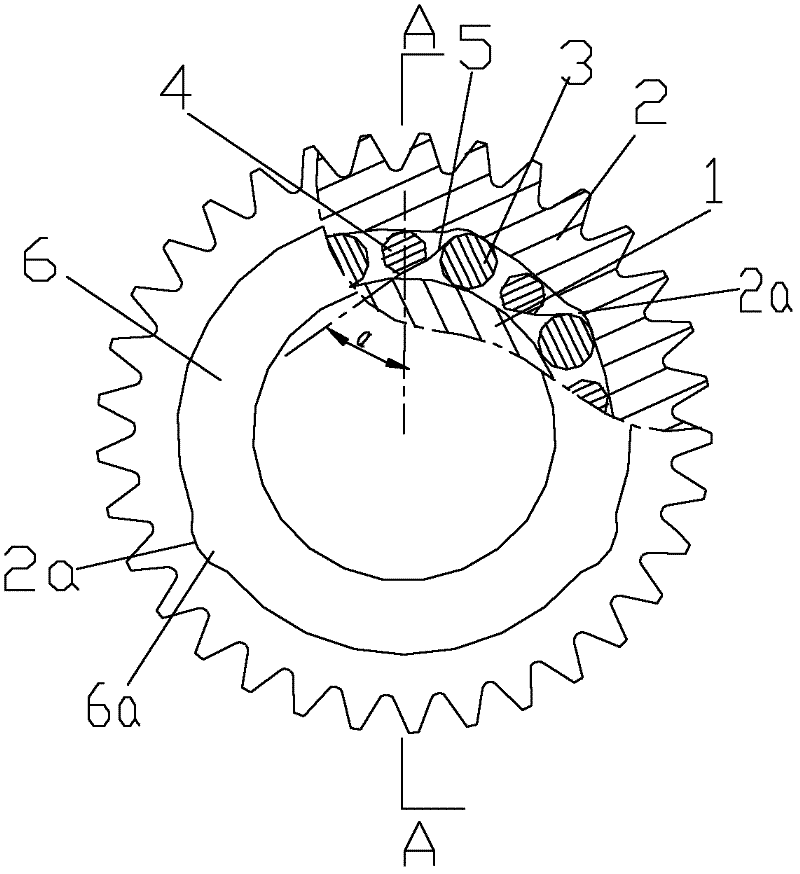

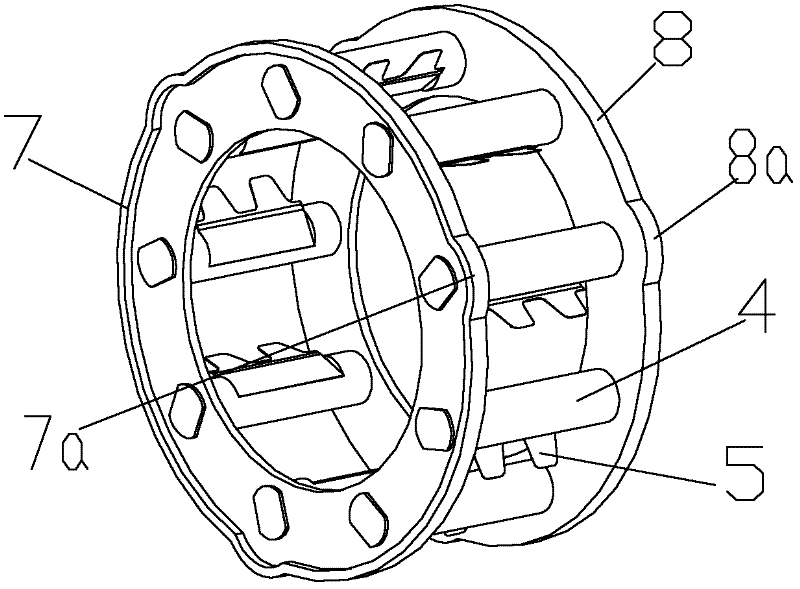

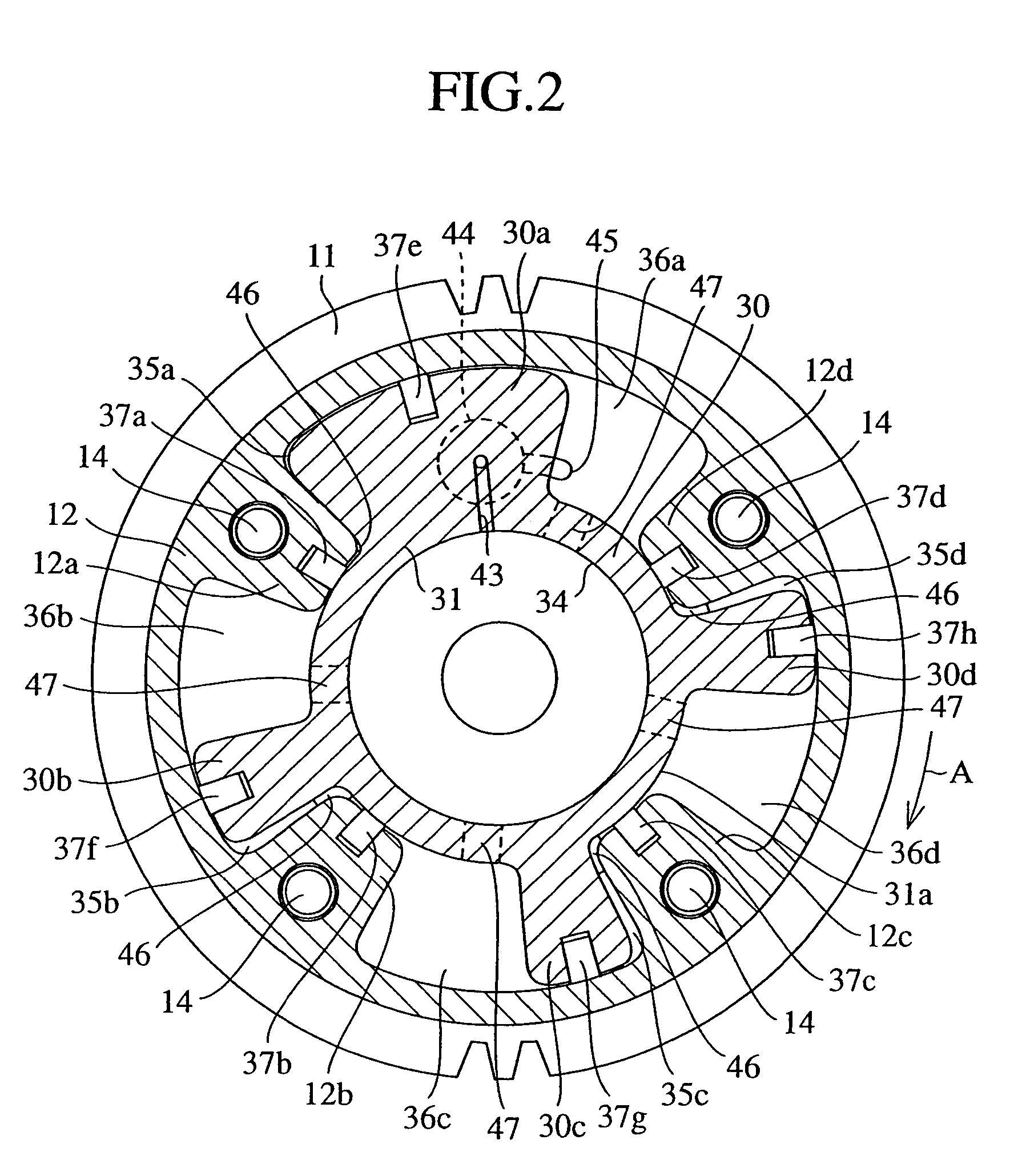

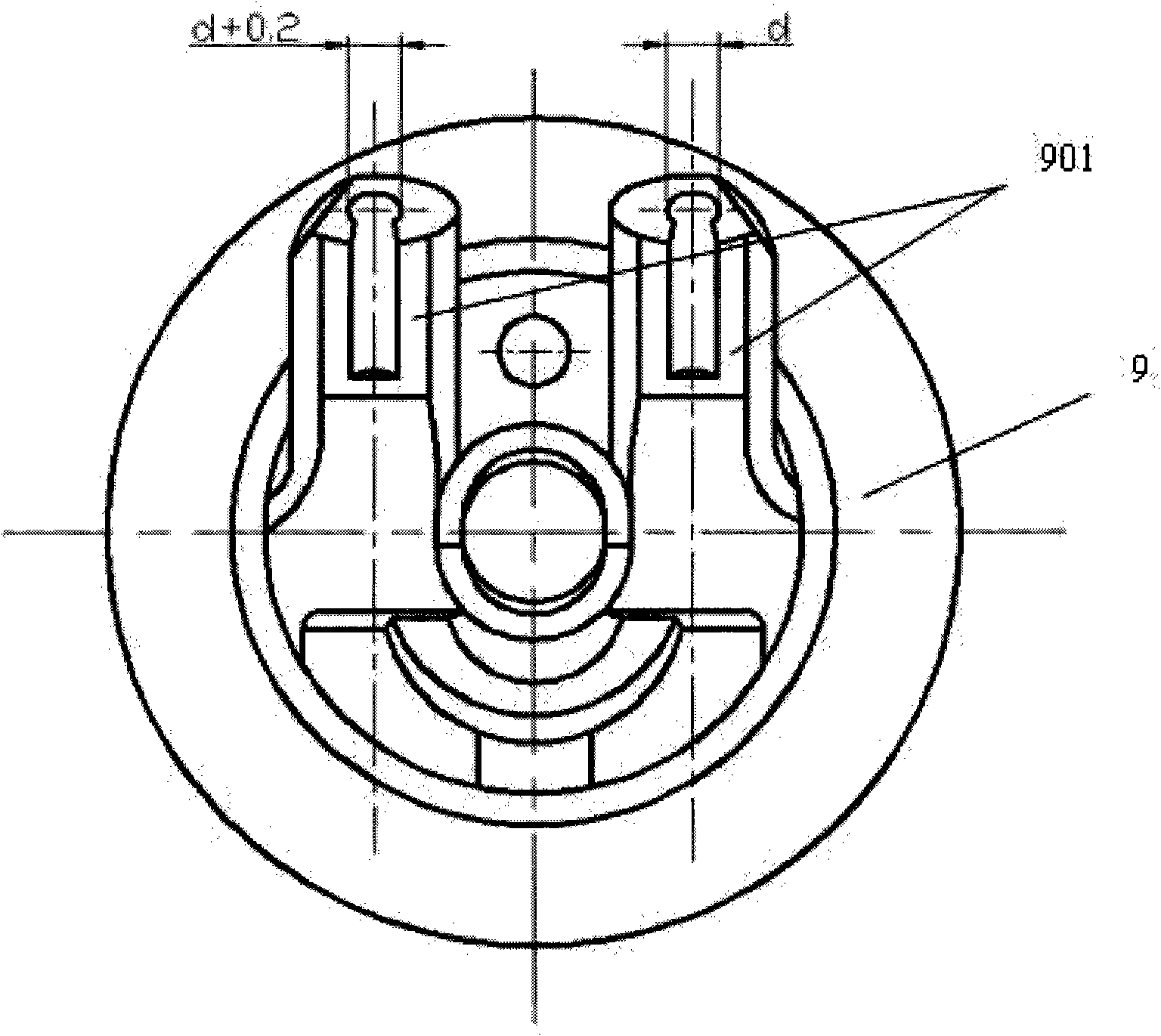

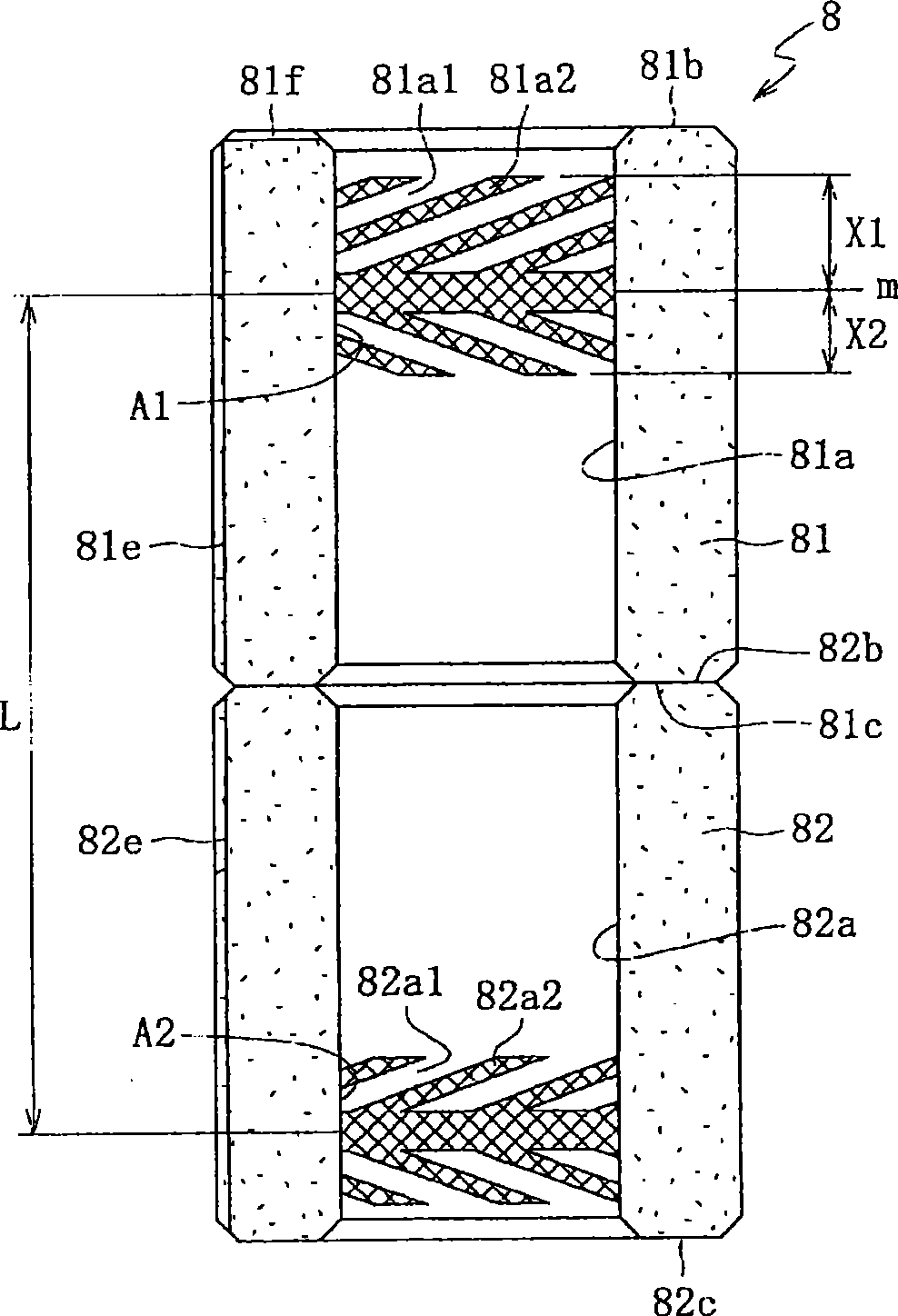

Floating auxiliary roller type overrun clutch

InactiveCN103307140AIncrease axial lengthIncrease the lengthFreewheel clutchesEngineeringMachining process

The invention discloses a floating auxiliary roller type overrun clutch which comprises an outer ring, an inner ring, rolling bodies and auxiliary rollers, wherein engagement spaces used for being engaged with or separated from the rolling bodies are formed between the outer ring and the inner ring; the auxiliary rollers are parallel to an axial line of the overrun clutch and are spaced from the rolling bodies; and the auxiliary rollers are arranged between the rolling bodies in such a way that the auxiliary rollers can move in a circumferential direction of the overrun clutch. According to the floating auxiliary roller type overrun clutch, the processing of a limiting seat is avoided, the processing process is simplified, the working efficiency is improved, and the processing cost is reduced; as the auxiliary roller structure is adopted, the axial length of the overrun clutch and the rolling bodies can be theoretically infinitely prolonged, the engagement length is prolonged, the bearing capacity of the overrun clutch is increased, the radial size of the overrun clutch under higher bearing capacity is reduced, and the service life of the overrun clutch is prolonged; and meanwhile, the probability of imbalance caused by application of a pretension force to point contact of each roller in the prior art is removed, thereby enabling each roller to keep parallel to the axial line of the inner ring.

Owner:SOUTHWEST UNIVERSITY

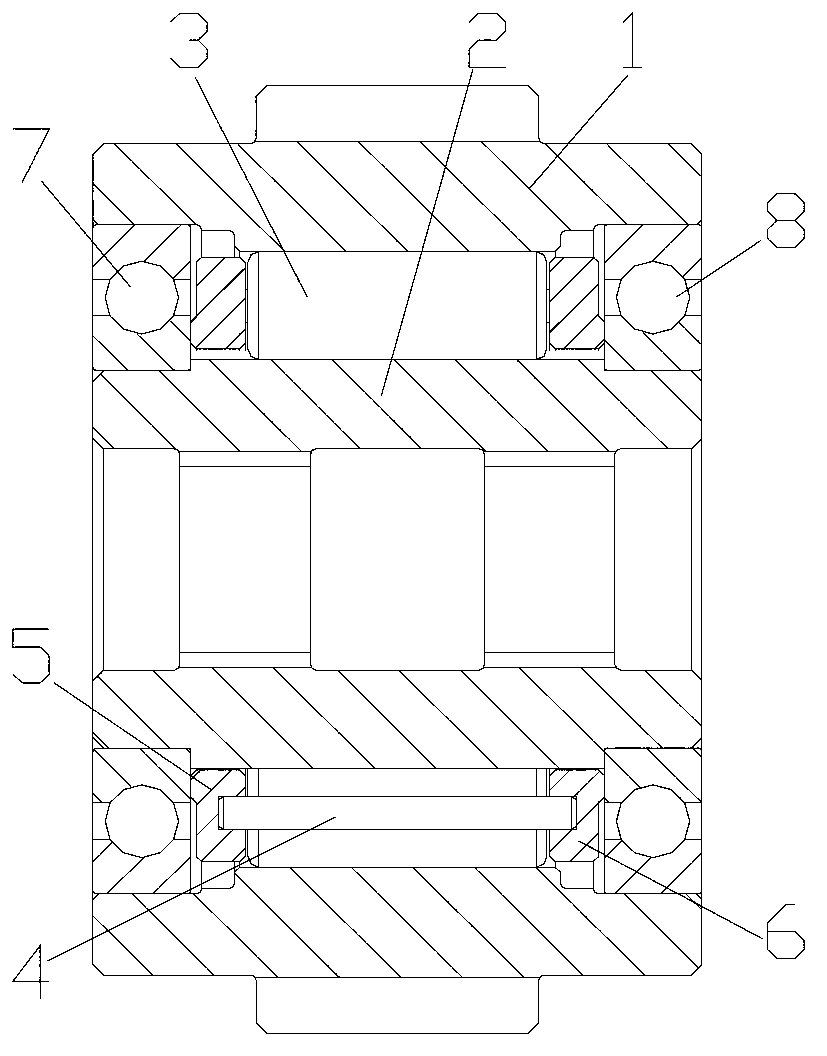

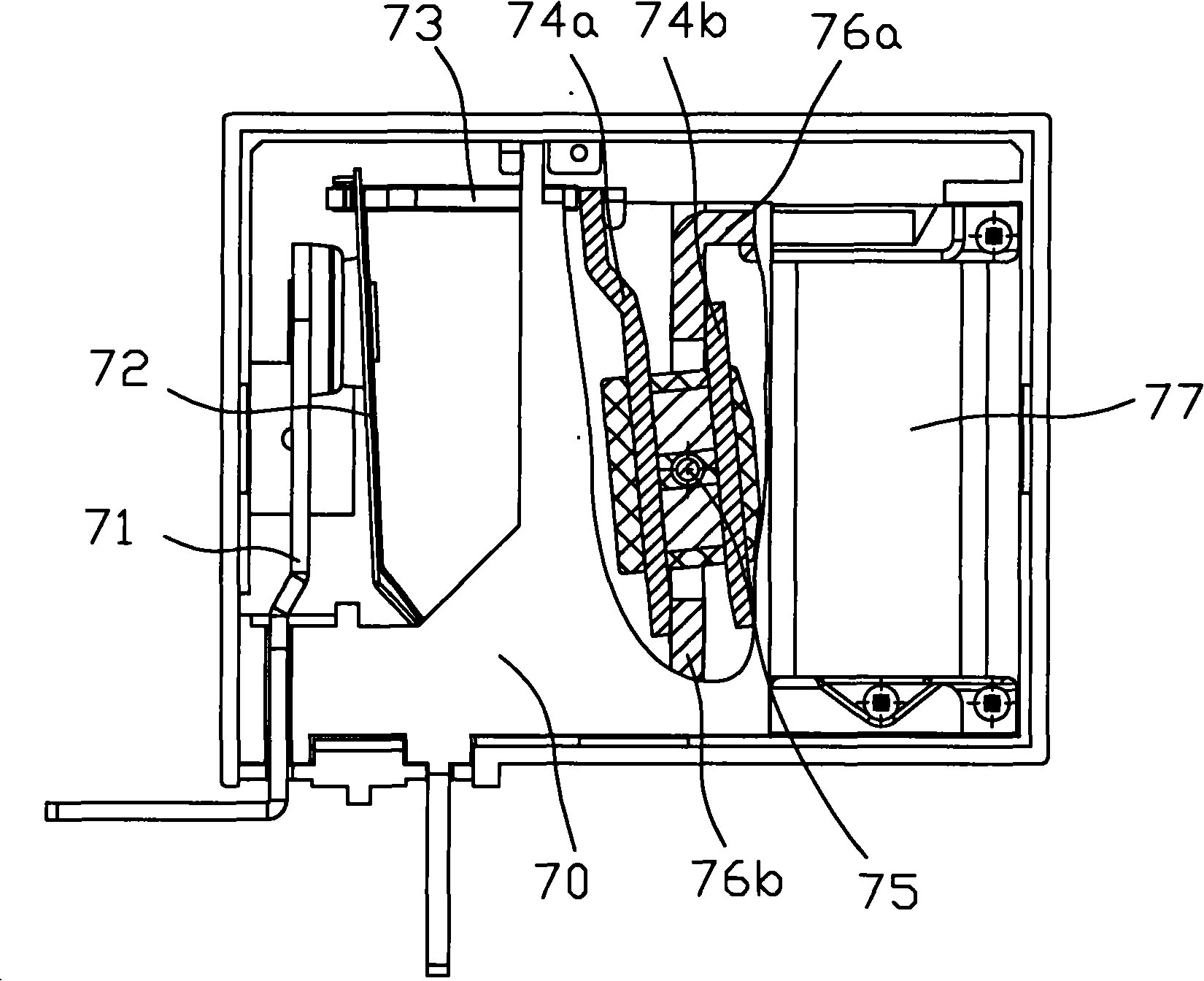

Piston-free Stirling engine system

InactiveCN101619687AReduce machining accuracyReduce assembly accuracyHot gas positive displacement engine plantsRoom temperatureEngineering

The invention discloses a piston-free Stirling engine system comprising a power driving device and a power transmission device, wherein the power driving device comprises an air cylinder and a thermoacoustic converter, and the thermoacoustic converter comprises a high-temperature end heat exchanger, a heat accumulator and a first room-temperature end heat exchanger; the power transmission device comprises an active piston and a first elastic piece far away from one end of the power driving device; the power driving device also comprises a heat buffer tube and an ejector which are sequentially arranged in the air cylinder, wherein the heat buffer tube is positioned on a position corresponding to the high-temperature end heat exchanger which is wrapped on the outer wall of the air cylinder and the heat accumulator; and the ejector is positioned on a position corresponding to the first room-temperature end heat exchanger which is wrapped on the outer wall of the air cylinder in the air cylinder. The invention replaces a part of the ejector, which is higher than a room-temperature end, with the heat buffer tube so that the ejector works in a room-temperature state, thereby enhancing the processing and assembling precision of the ejector and effectively prolonging the service life of the ejector.

Owner:LIHAN THERMOACOUSTIC TECH SHENZHEN

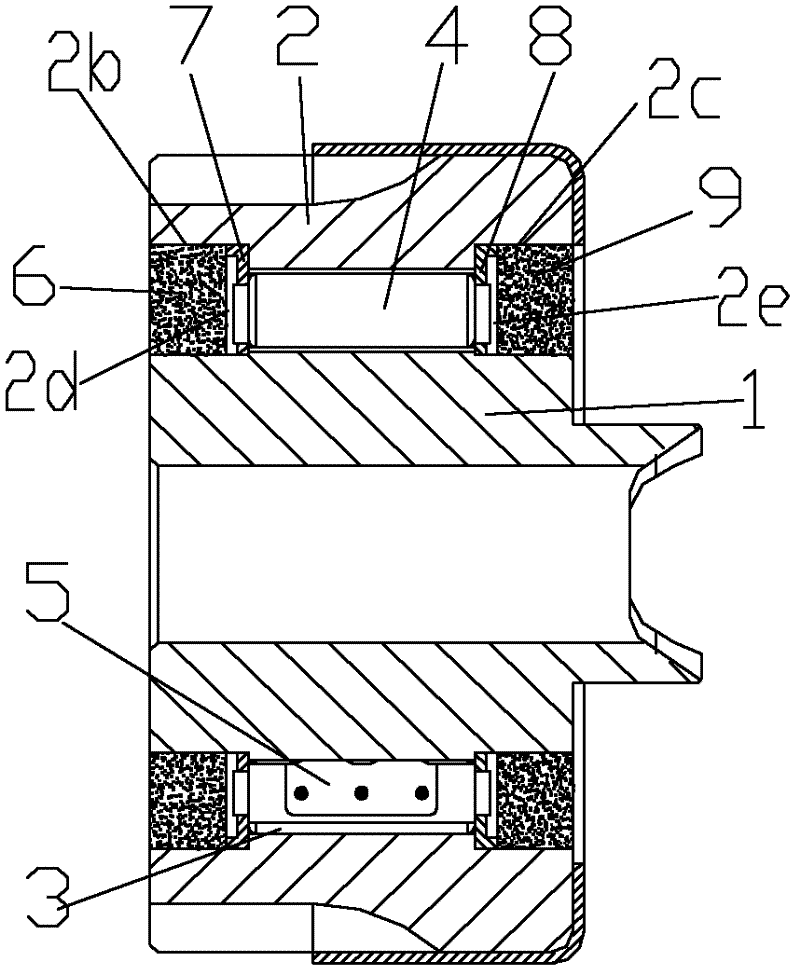

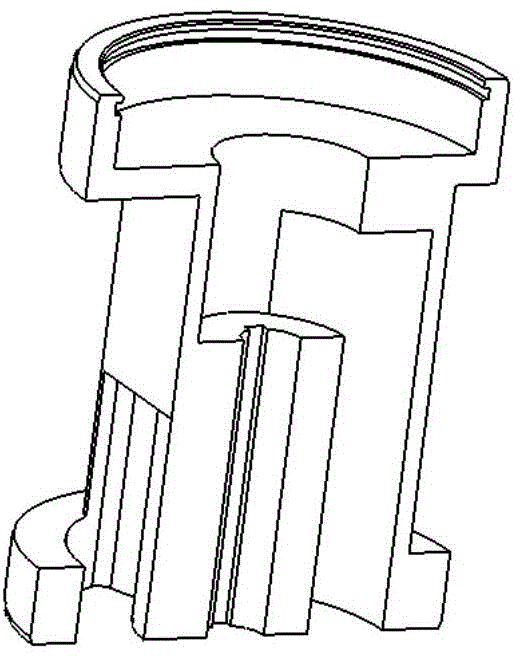

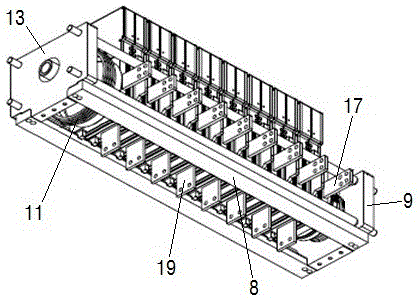

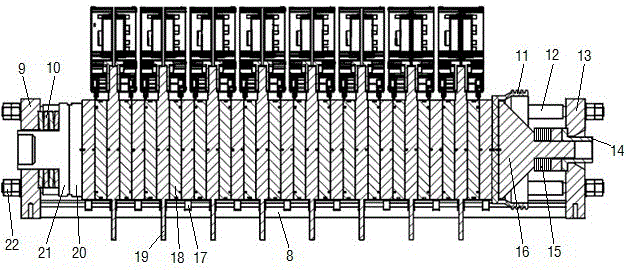

Heavy Duty Overrunning Clutch

The invention discloses a heavy-duty overrunning clutch, which comprises an outer ring, an inner ring, a plurality of rollers and a retaining frame. The retaining frame comprises a support ring I, a support ring II and a plurality of support columns corresponding to the rollers. Spring plates are fixedly arranged on the support columns along the axial direction and are used for applying pre-tightening force on the rollers along the engagement direction of an engagement slot. The direct processing of a limit seat on the outer ring can be avoided, the working efficiency can be increased, the processing cost can be reduced, the service life can be prolonged, and the transmission effect can be guaranteed. Moreover, relevant components can be replaced easily after being damaged, the outer ringneeds not to be rejected as a whole, and the cost of maintenance and use can be reduced. The axial length of the overrunning clutch and the rollers can be increased theoretically indefinitely, the engagement length can be increased, and thus the bearing capacity of the overrunning clutch can be improved. Meanwhile, the pre-tightening force can be applied at multiple points of the rollers according to needs, and the limiting balance for the rollers can be guaranteed while the axial length is ensured, so that the rollers cannot deviate from the axial line of the inner ring. Therefore, the stable operation of the overrunning clutch can be ensured, and mechanical failure can be avoided.

Owner:SOUTHWEST UNIVERSITY

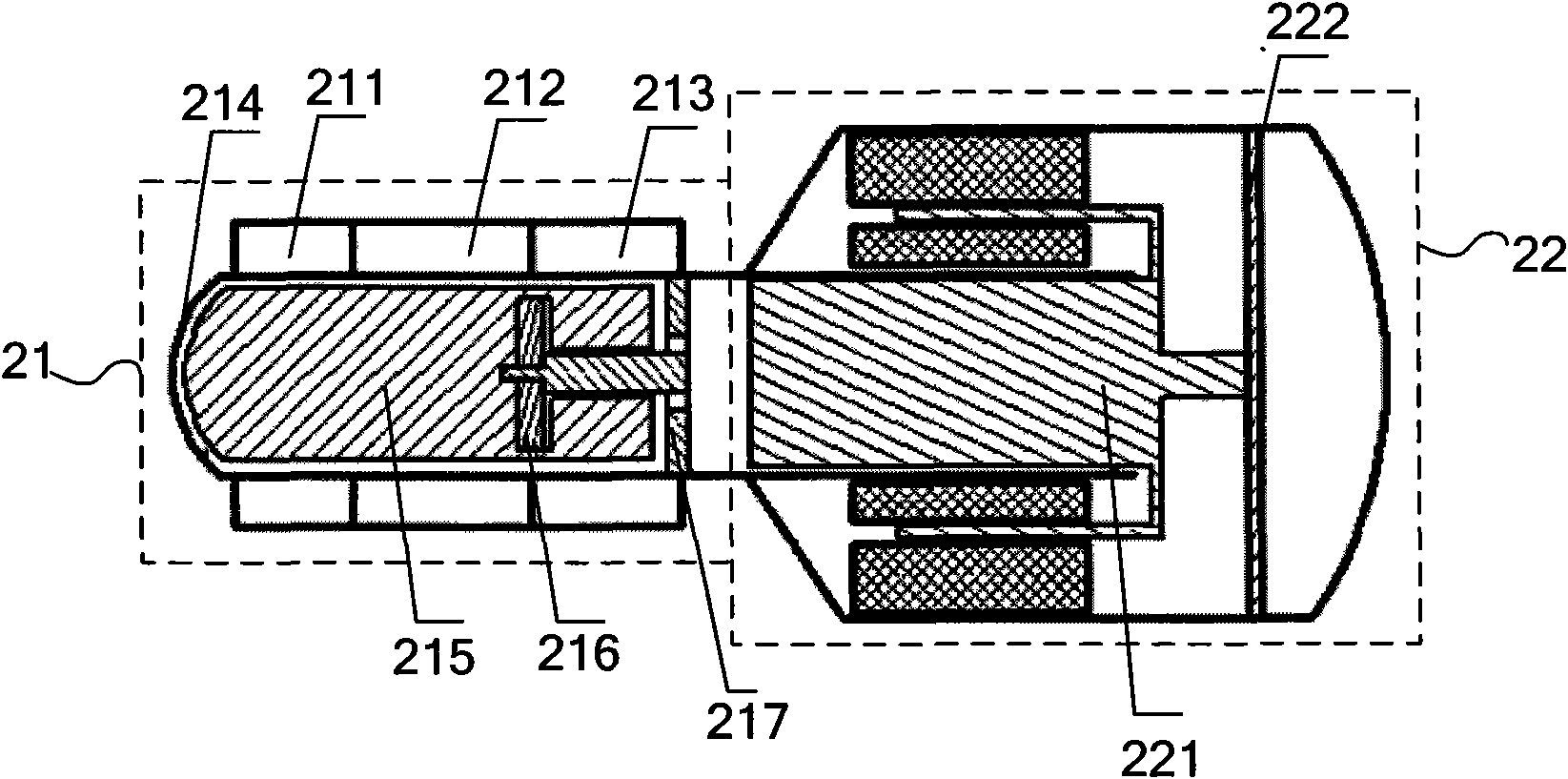

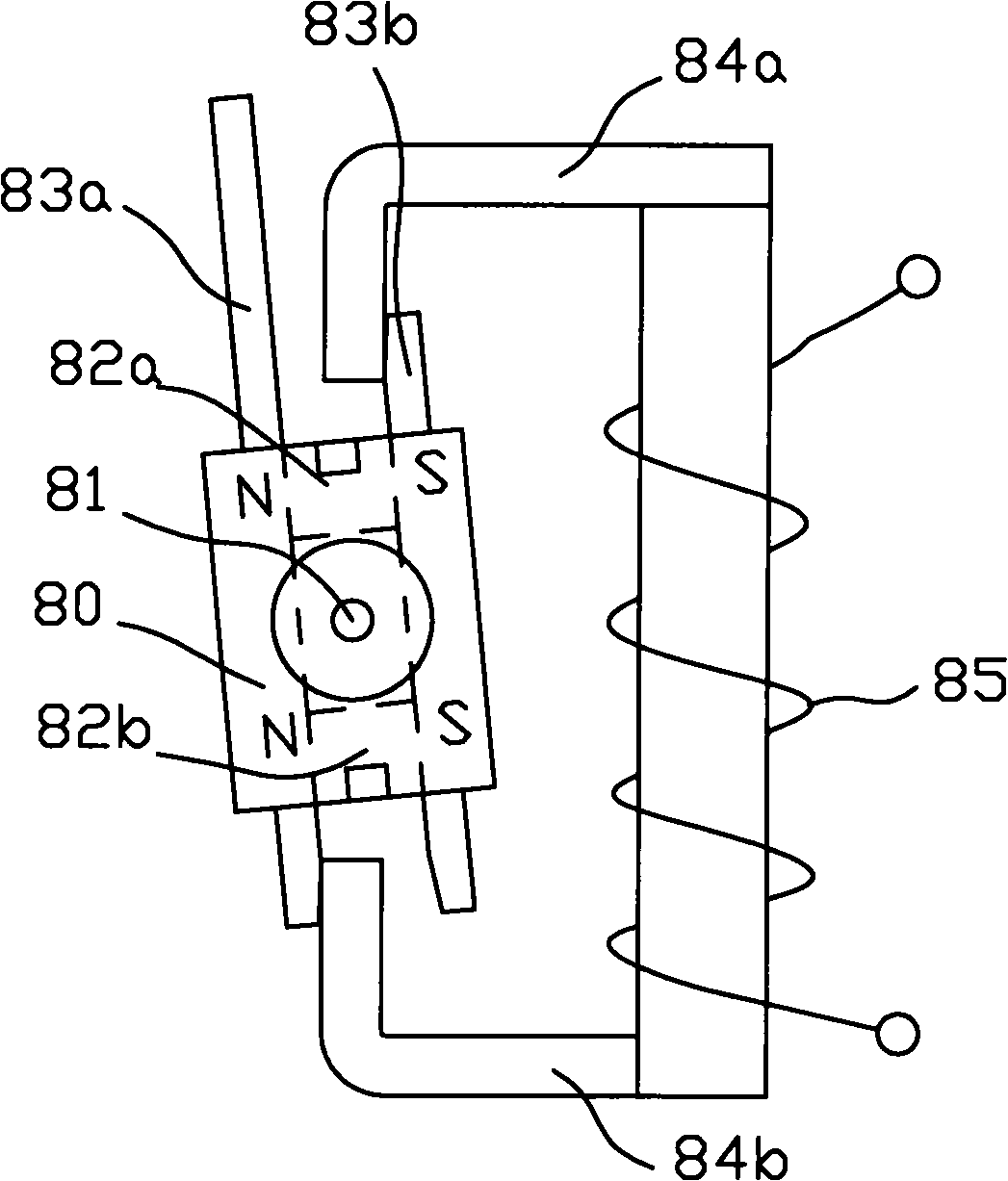

Magnet retaining relay

InactiveCN101335156AImprove stabilityReduce manufacturing difficultyElectromagnetic relay detailsNon-polarised relaysCounterforceRelay

The invention discloses a magnetic latching relay comprising a magnetic circuit part, a contact part and a counterforce reed. The magnetic circuit part is composed of a coil, an E-shaped static magnetizer component and a moveable magnetizer component; the coil is wound on the static magnetizer component and a movable magnetizer component comprises a magnetic steel and a movable magnetizer arranged at the both sides of the magnetic steel with the same structure, the E-shaped static magnetizer component is formed by connecting two magnetizers and at lease one magnetizer is provided with a U-shaped structure. The magnetic circuit takes the shape of 'two squares stacked vertically', solves the problem of unevenness of magnetic circuit contact surface and enhances the stability of product performance; the static magnetizer of the magnetic circuit part adopts the U-shaped structure, and the movable magnetizer adopts two same U-shaped or similar structures; therefore, the manufacture difficulty of parts and assemble difficulty and precision of components are reduced, the counterforce reed causes the absorbing counterforce of the relay in working state to be balanced, thus enhancing the reliability.

Owner:XIAMEN HONGFA ELECTROACOUSTIC CO LTD

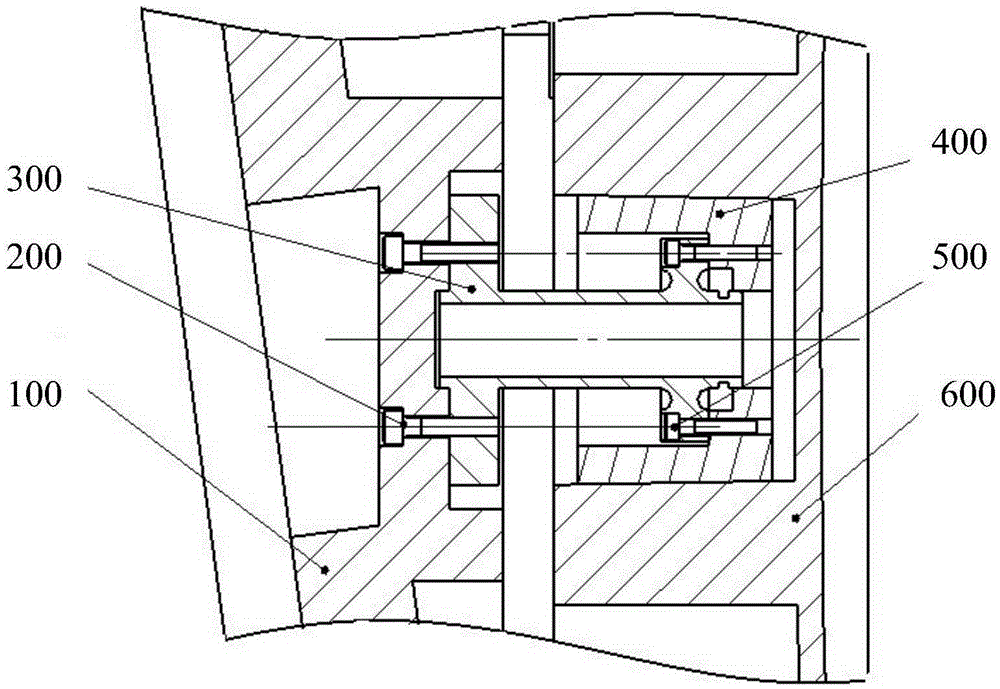

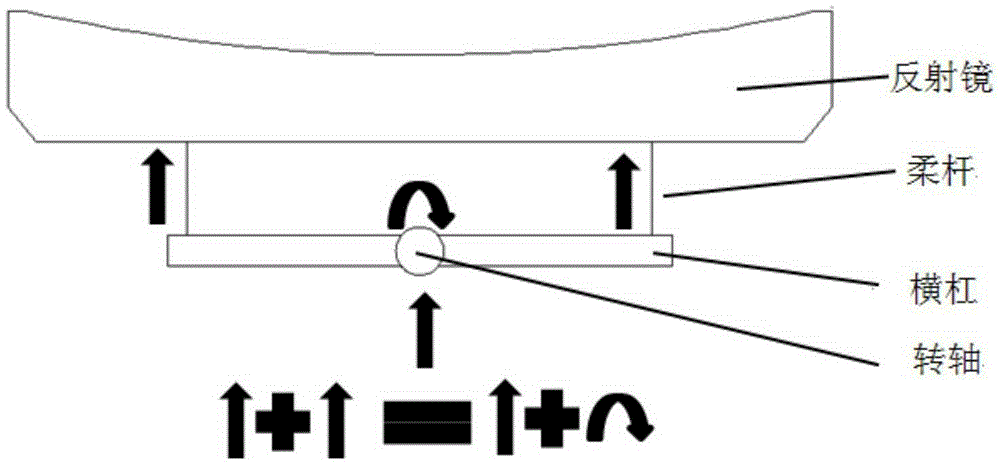

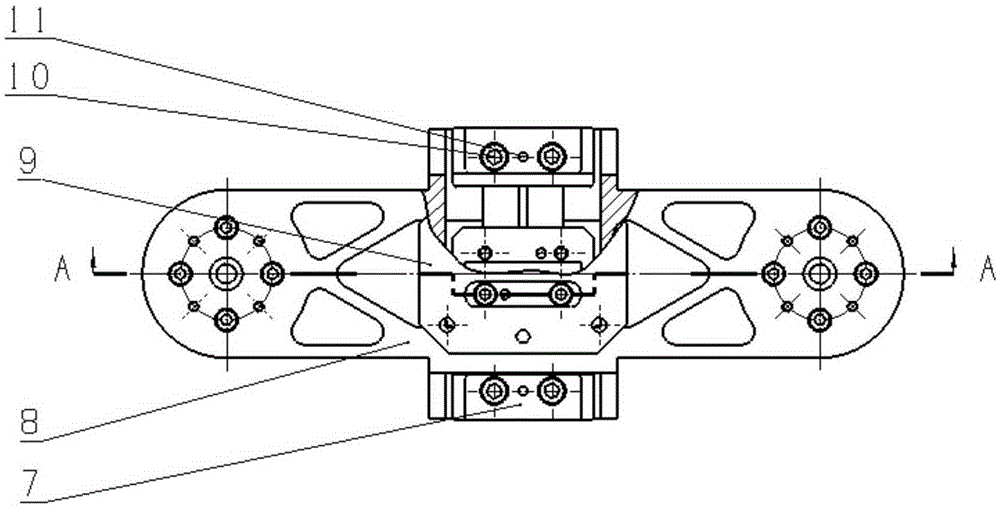

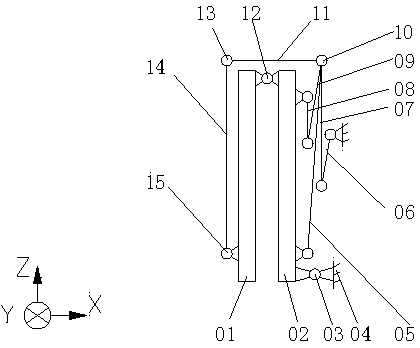

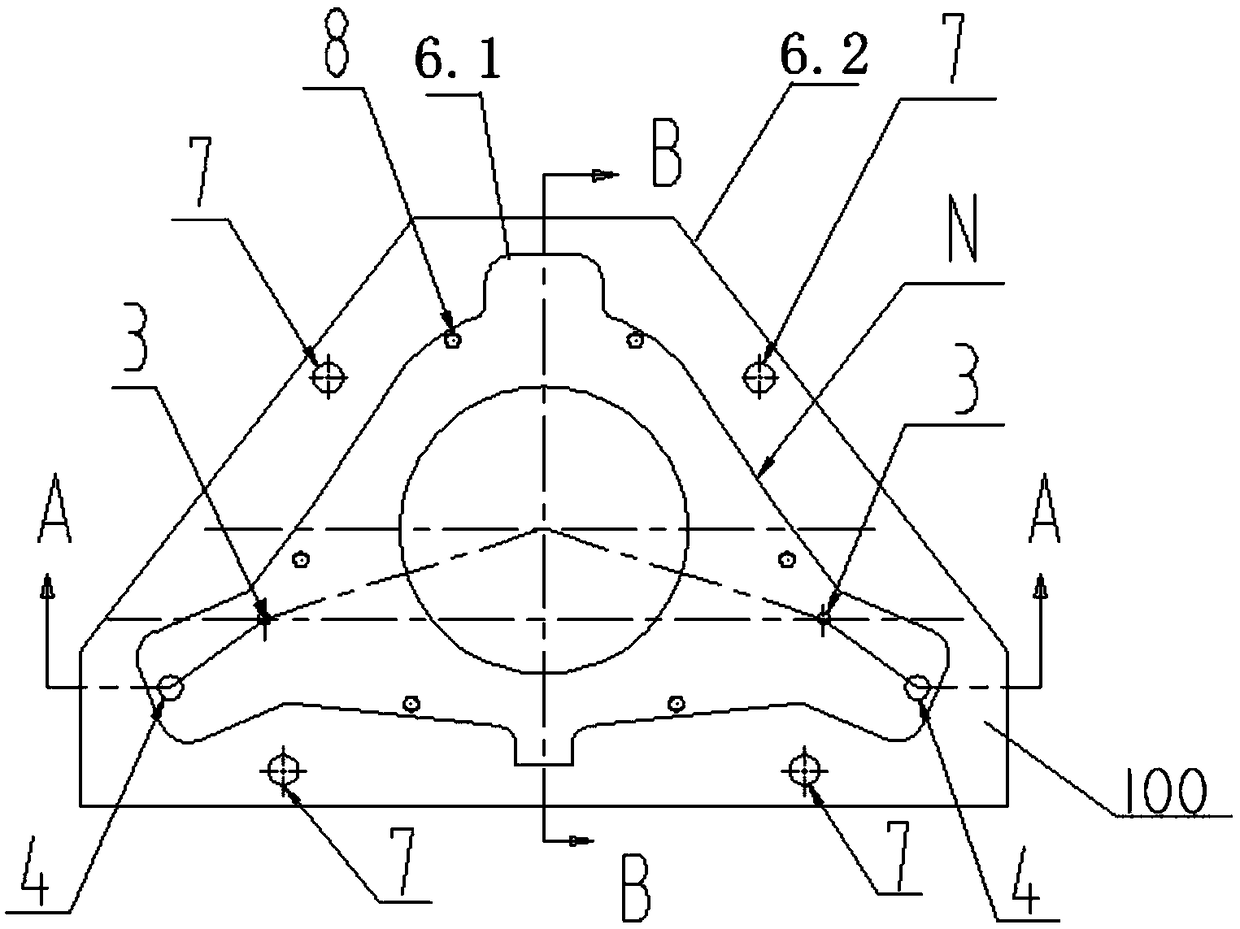

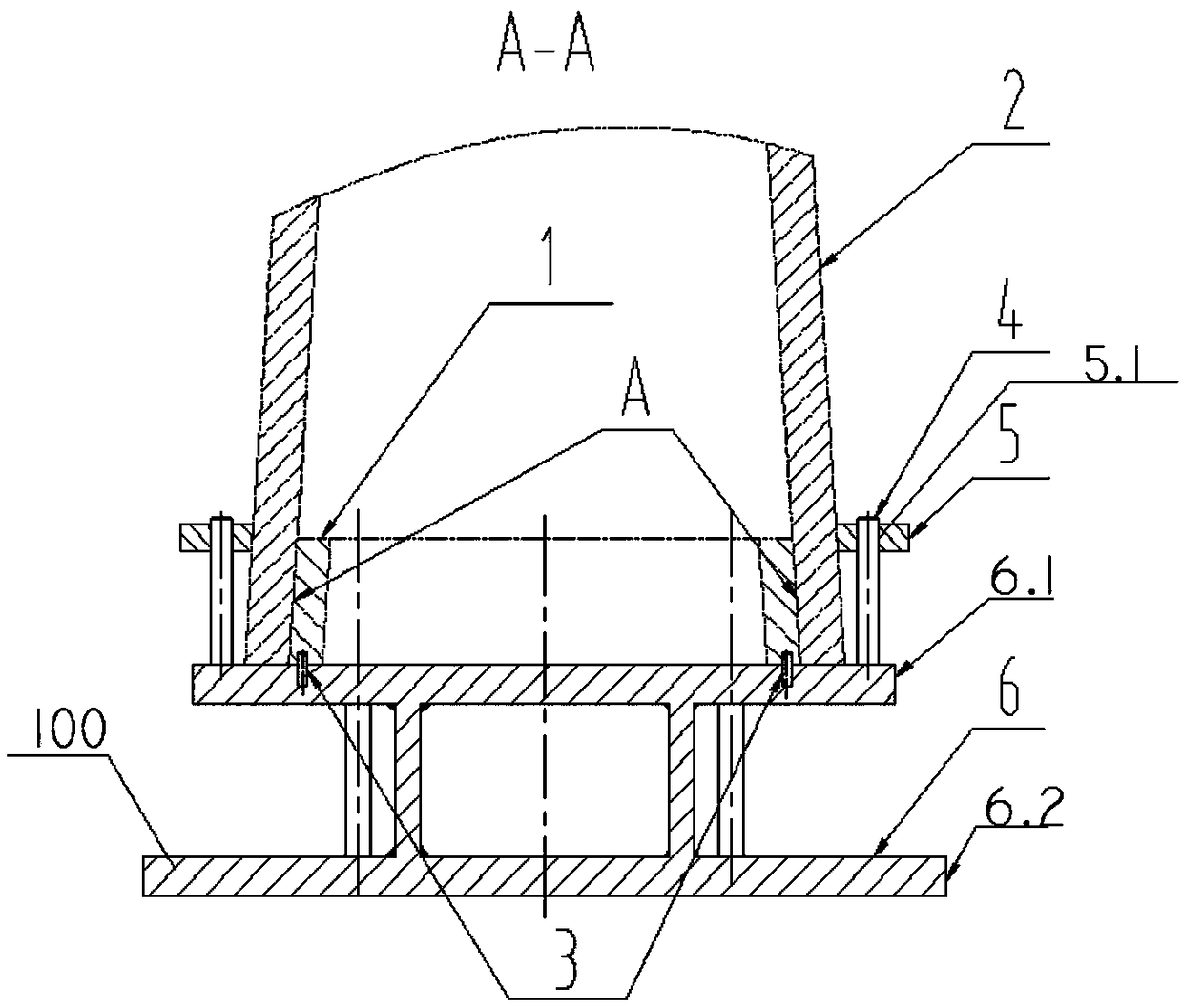

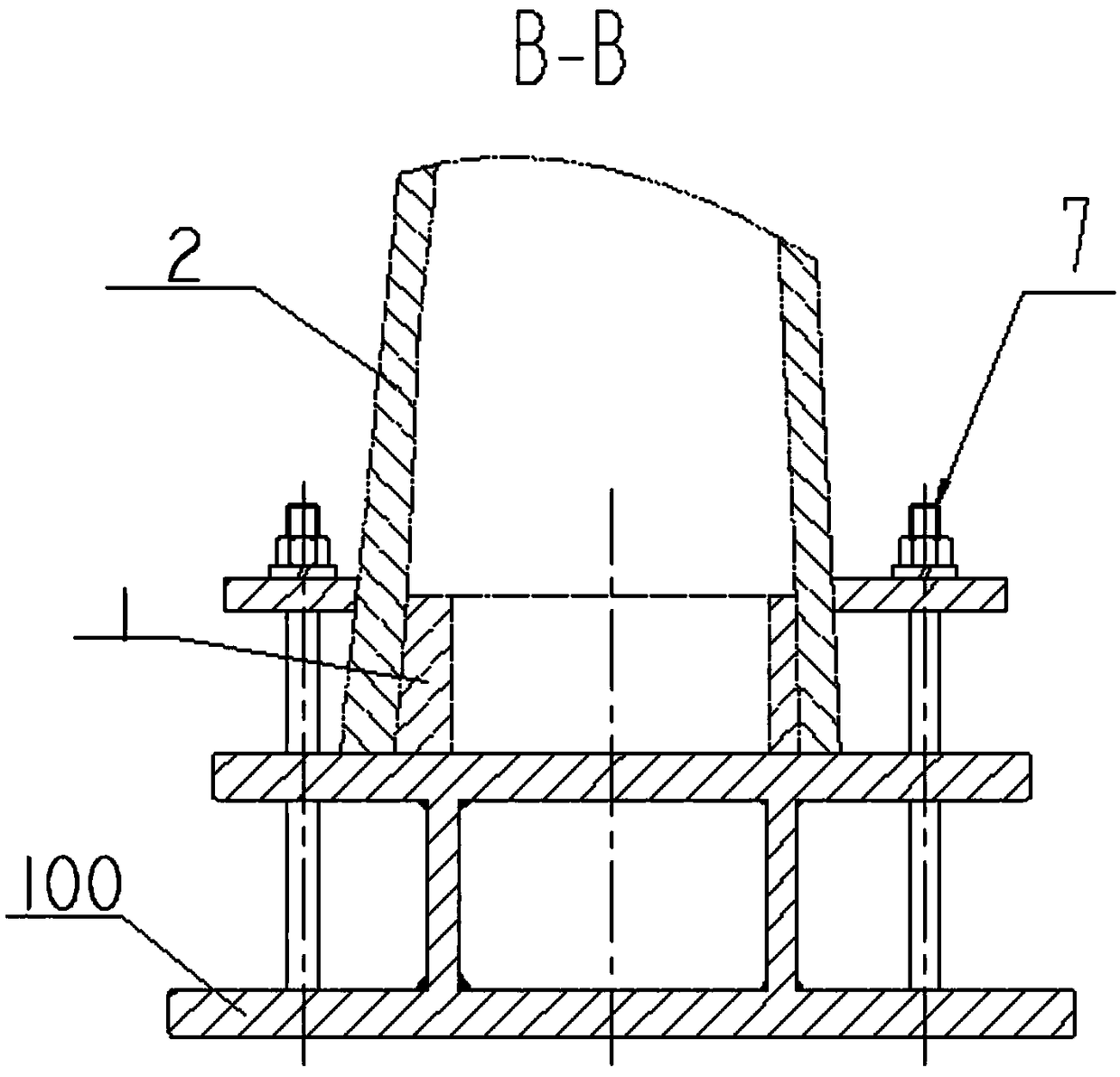

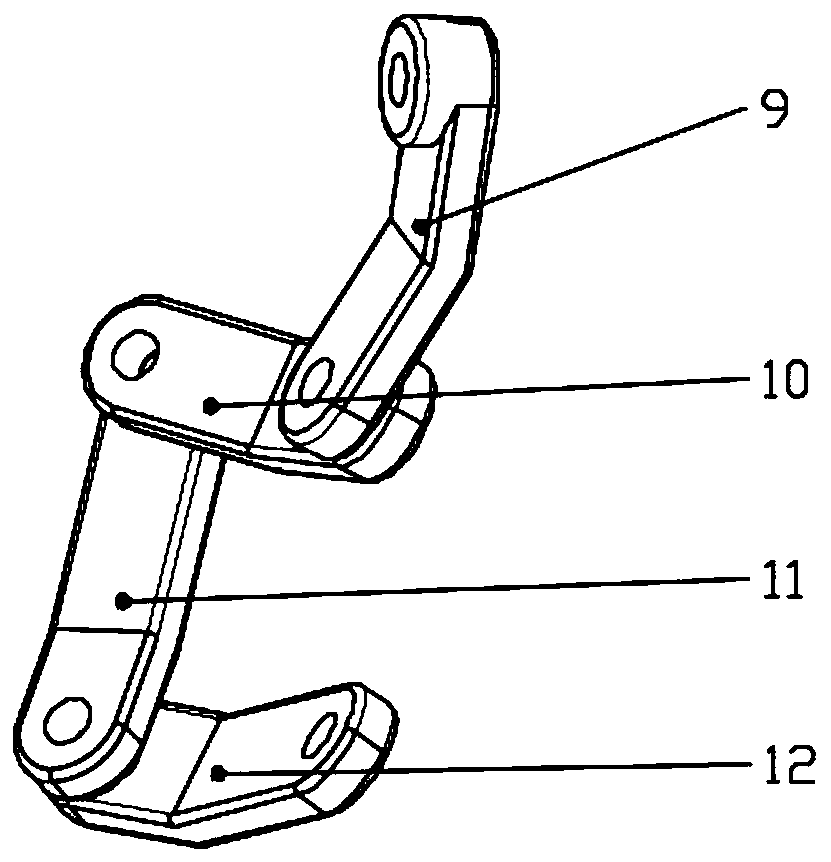

Whiffletree support structure applied to statically determined support of large-aperture reflector

InactiveCN105259635AIncrease the number of support pointsImproved ability to resist deformation due to gravityMountingsOptical axisEngineering

The invention relates to a whiffletree support structure applied to the statically determined support of a large-aperture reflector. The whiffletree support structure comprises a rotary shaft, a cross bar, a polishing pad, a rotary shaft and cross bar connection screw, a rotary shaft and cross bar positioning pin, a lens body back bonding part, a flexible rod and lens back bonding part connection screw, a flexible rod and lens back bonding part positioning pin, two flexible rods, a cross bar and flexible rod connection screw, a cross bar and flexible rod positioning pin, a polishing pad and rotary shaft connection screw, and a polishing pad and rotary shaft positioning pin. According to the invention, the number of support points of a reflector is increased on the condition that no extra-constraint is adopted. In this way, the resistance of the reflector to the gravity-caused deformation is effectively improved and the accuracy of the mirror surface of the reflector is also increased. The rotary shaft and the flexible rods are embedded into the design of the cross bar, so that the problem that the Whiffletree support structure is overlarge in dimension along the optical axis direction of the reflector can be effectively solved. The engineering implementation is facilitated.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

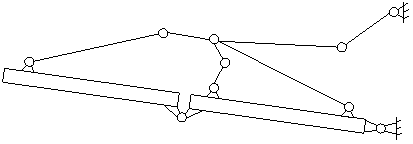

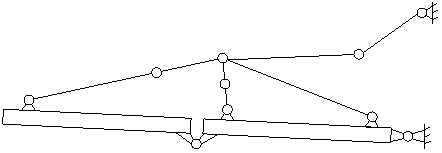

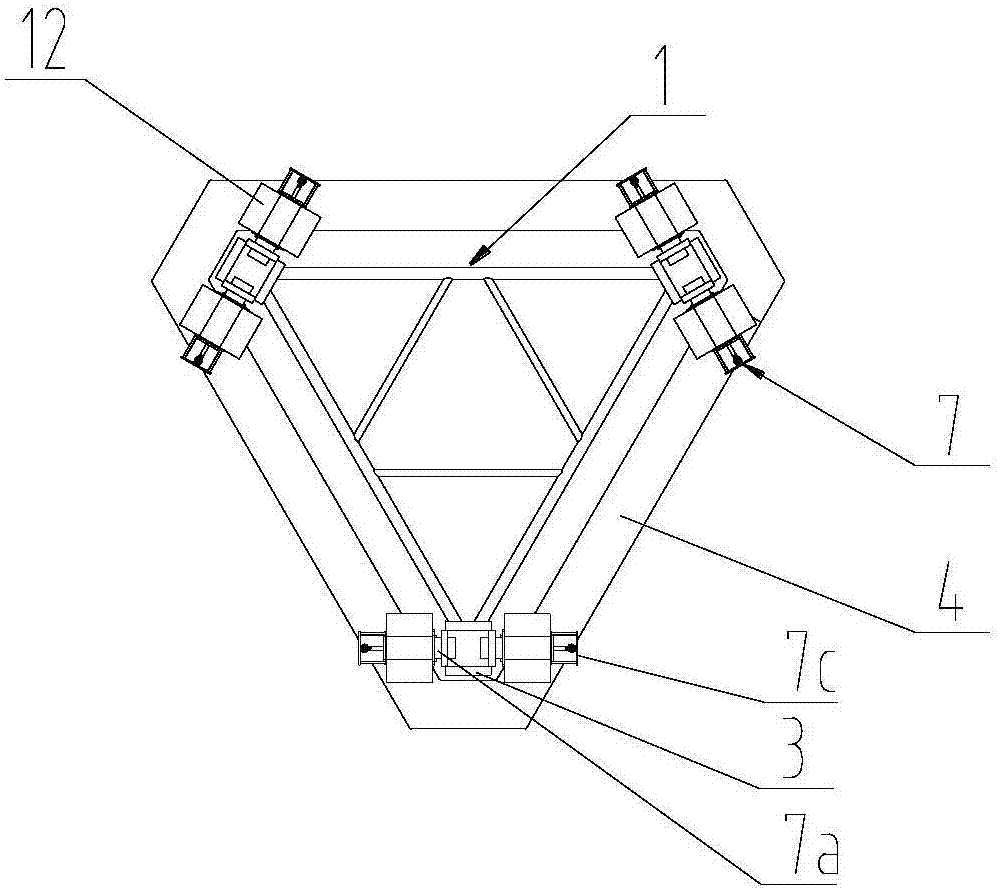

Planar unfoldable truss and stepwise unfolding method thereof

ActiveCN103840245AEnsure coordinationUniqueness guaranteedCollapsable antennas meansStructural engineeringControl theory

The invention discloses a planar unfoldable truss which includes a planar-antenna external board, a planar-antenna internal board, a first hinging chain, a spacecraft platform, an internal-board rod piece, a first platform rod piece, a second platform rod piece, a first internal-board oblique-support rod piece, a second internal-board oblique-support rod piece, a central hinging chain, a connection rod piece, a second hinging chain, an inter-rod hinging chain, an external-board rod piece and a joint bearing. The whole planar unfoldable truss is formed through mobile connection so that a ten-rod closed-loop three-freedom-degree rod system is formed. At the same time, the invention also discloses a stepwise unfolding method for the planar unfoldable truss and the method realizes the change of the truss structure and freedom degree from 3 to 2, to 1 and then to 0 through sequential locking of different hinging chains in the whole unfolding process so that unfolding and locking of the planar unfoldable truss are completed and the planar unfoldable truss can be used for unfolding of two planar antennae of a single wing of a spacecraft.

Owner:SHANGHAI AEROSPACE SYST ENG INST

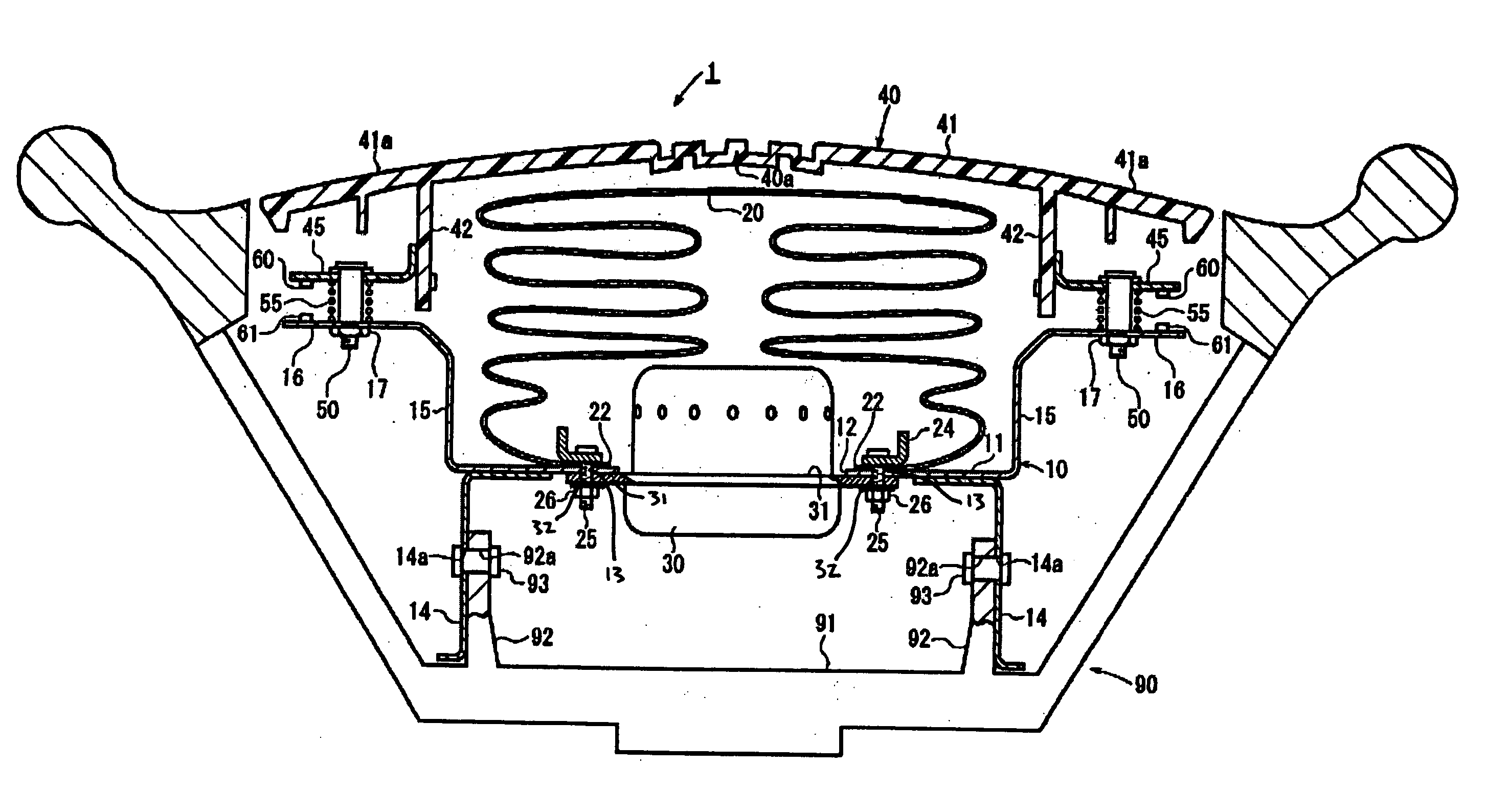

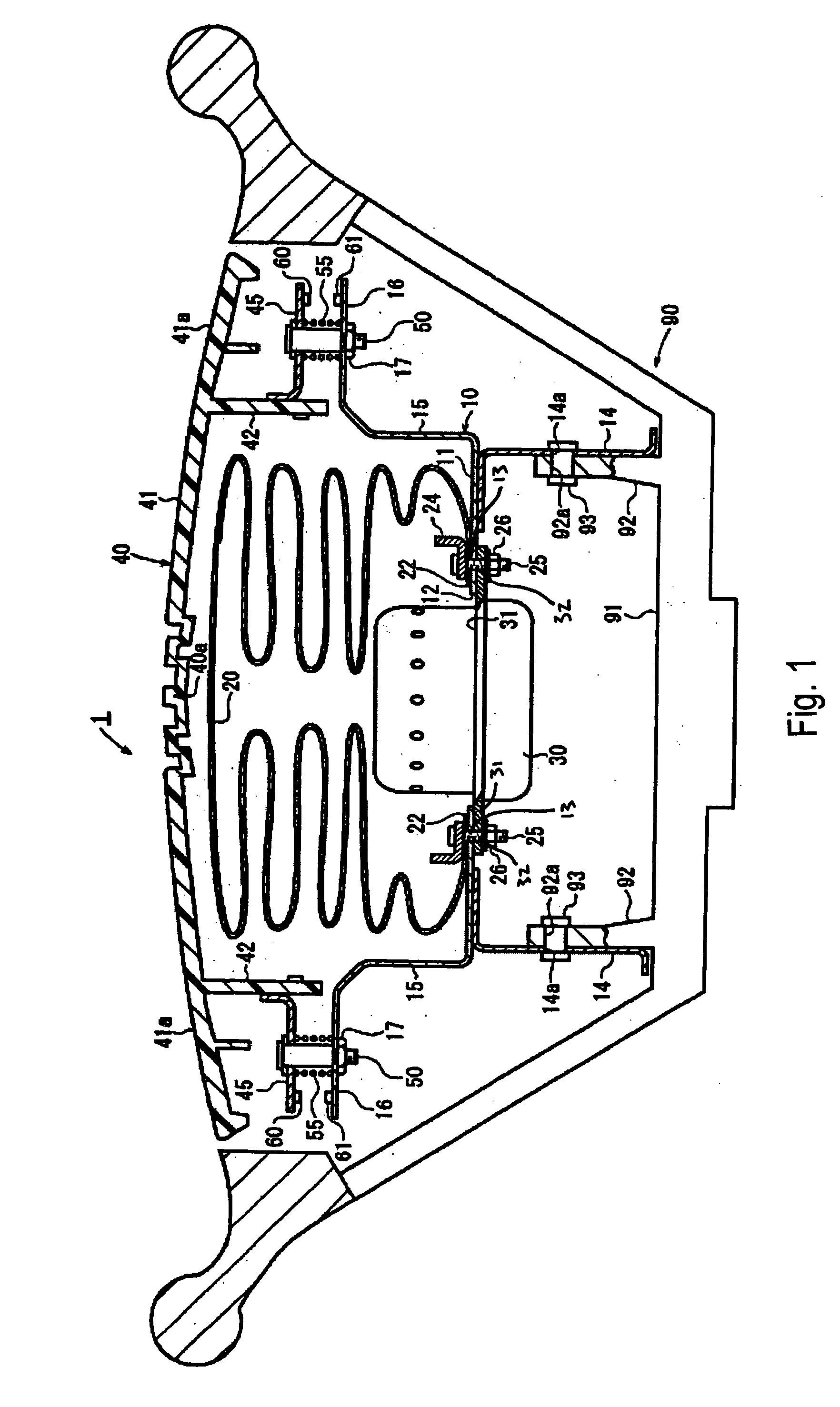

Horn switch gear, airbag system, and steering wheel

InactiveUS20060028002A1Increased durabilityNot affect operating characteristicAcoustic signal devicesPedestrian/occupant safety arrangementSteering wheelProximity sensor

A horn switch gear includes a proximity sensor that is mounted on a first surface and a magnet that is mounted on a second surface, at a position facing the first surface. When a module cover is depressed, the first surface moves downward together with the module cover, thereby bringing the sensor close to the magnet. When the distance between the sensor and the magnet becomes less than a specified value, a voltage greater than a threshold is generated. In response to this above-threshold voltage, the sensor generates a horn blowing signal that sounds the horn. Another horn switch gear has a structure in which a horn is activated by depression of the module cover, which depression generates an induced current by the relative movement of a magnet and a magnetic coil.

Owner:TAKATA CORPORATION

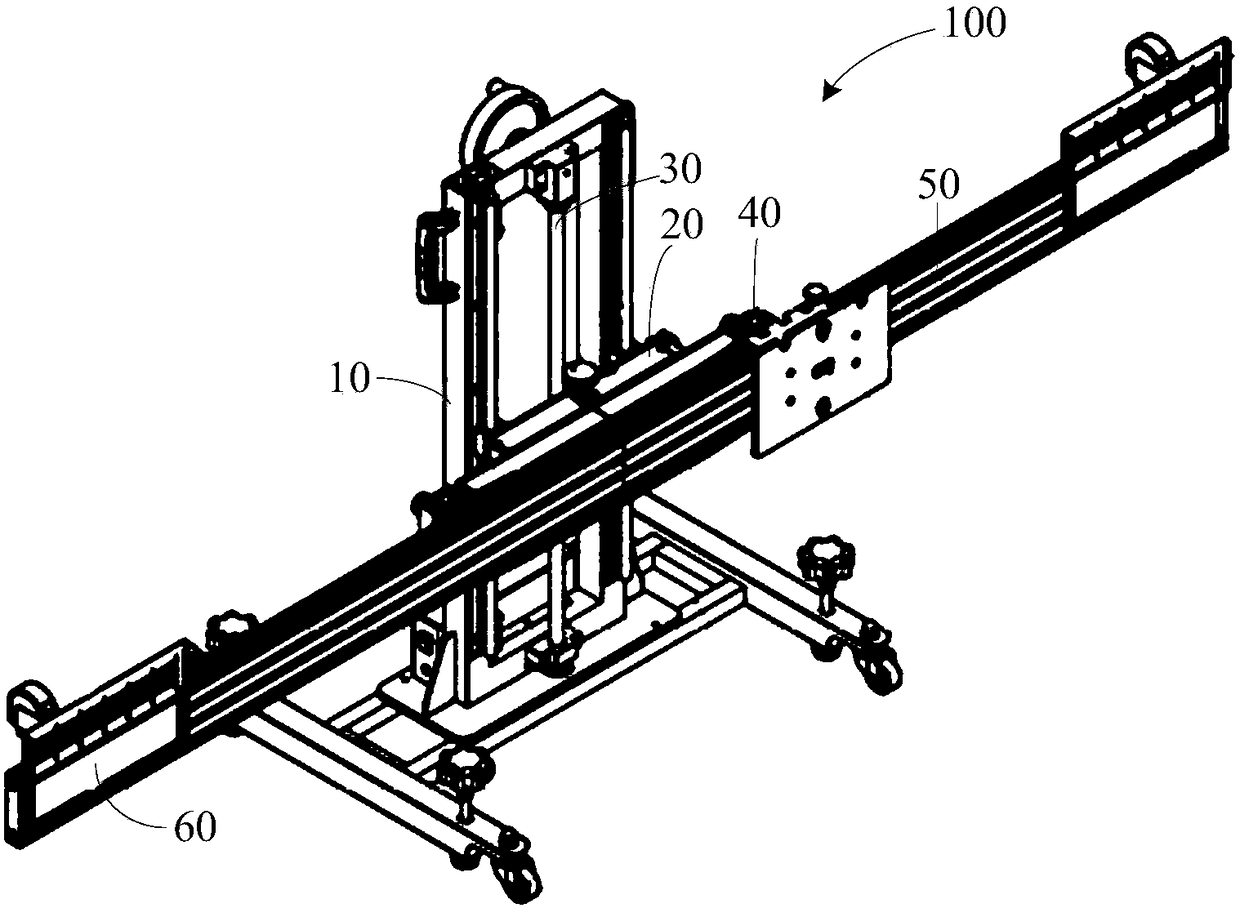

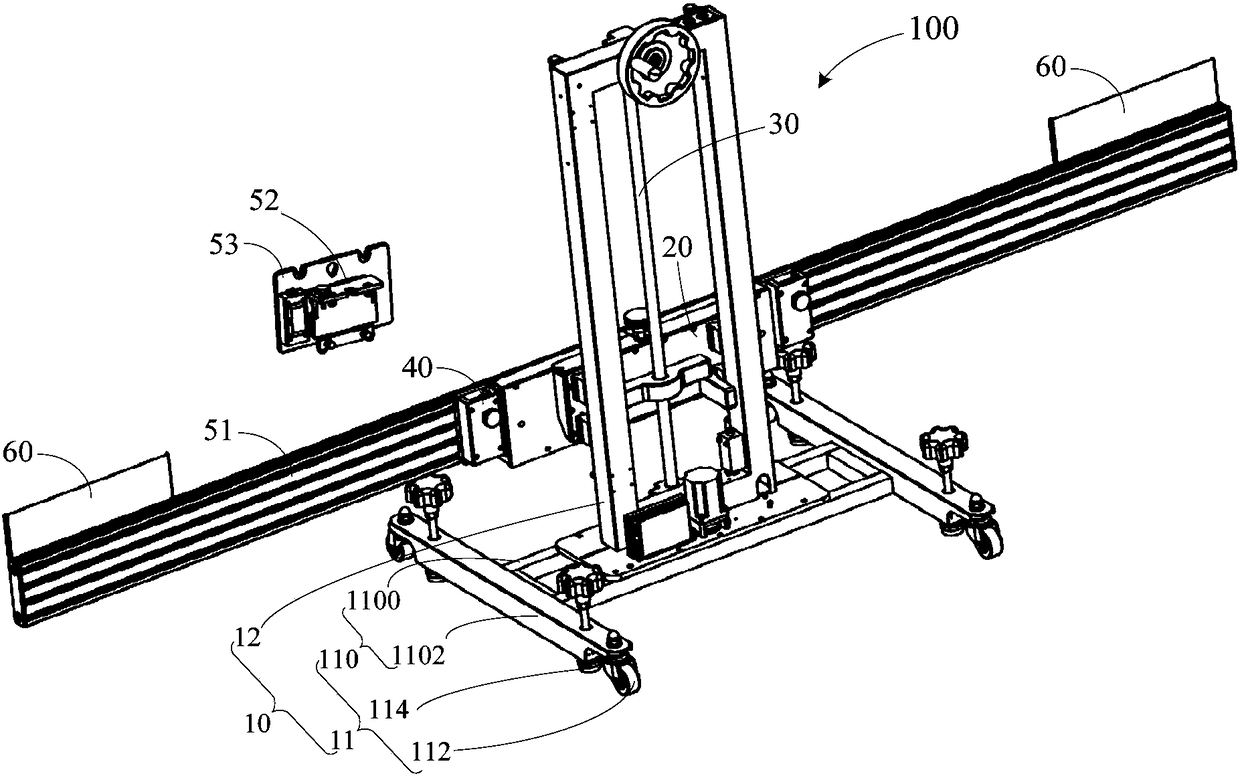

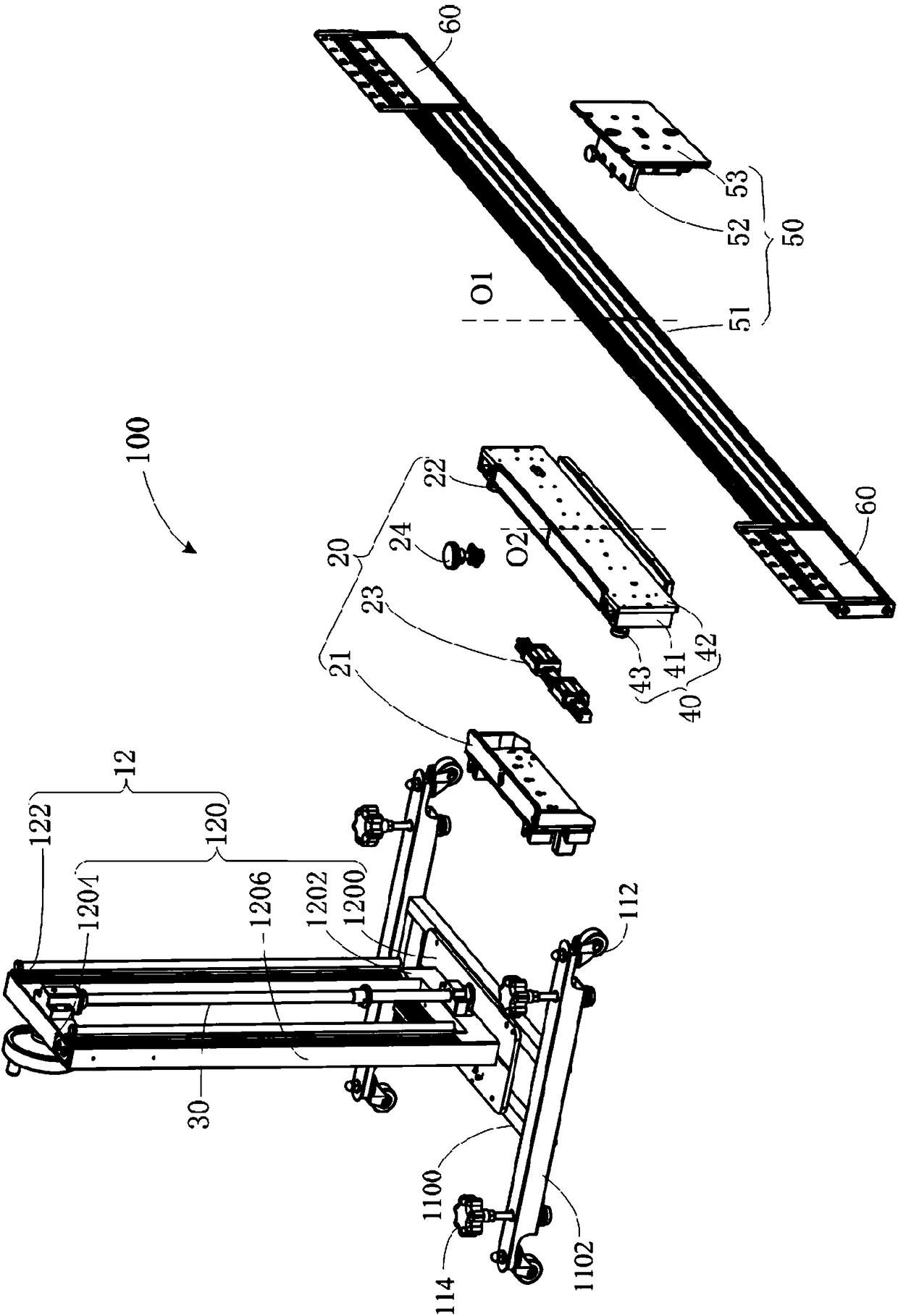

Clamping device and vehicle calibrating equipment

PendingCN108453646AQuick assemblyIncrease frictionWave based measurement systemsWork holdersEngineeringFriction force

The invention relates to the technical field of vehicle maintenance and equipment calibration, and discloses a clamping device and vehicle calibrating equipment. The clamping device comprises a fixedplate, a fixed block and an elastic knob. The fixed block comprises a fixed block body and a locking elastic piece; the fixed block body is mounted on the fixed plate; the fixed block body and the fixed plate surround an accommodating cavity; and the locking elastic piece is positioned in the accommodating cavity. The elastic knob is mounted on the fixed block body, and can be rotated relative tothe fixed block body to extend into the accommodating cavity to butt against the locking elastic piece. When a calibrating device needing to be clamped is inserted in the accommodating cavity, the elastic knob can push the locking elastic piece to butt against the calibrating device needing to be clamped. As the locking elastic piece and the calibrating device needing to be clamped are in surfacecontact, the friction force between the locking elastic piece and the calibrating device needing to be clamped is increased, and the locking elastic piece can firmly butt against the calibrating device needing to be clamped.

Owner:AUTEL INTELLIGENT TECHNOLOGY CORP LTD

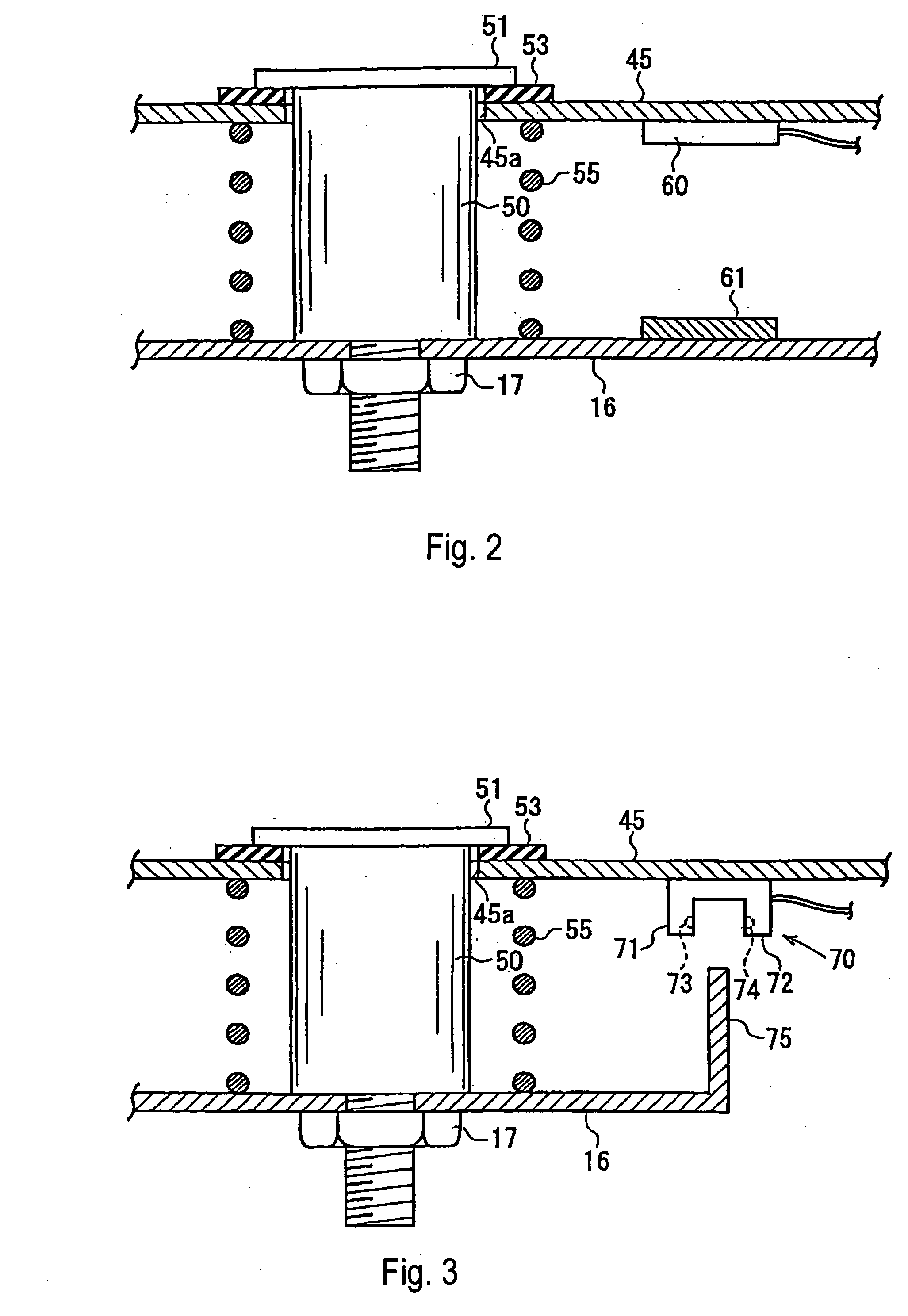

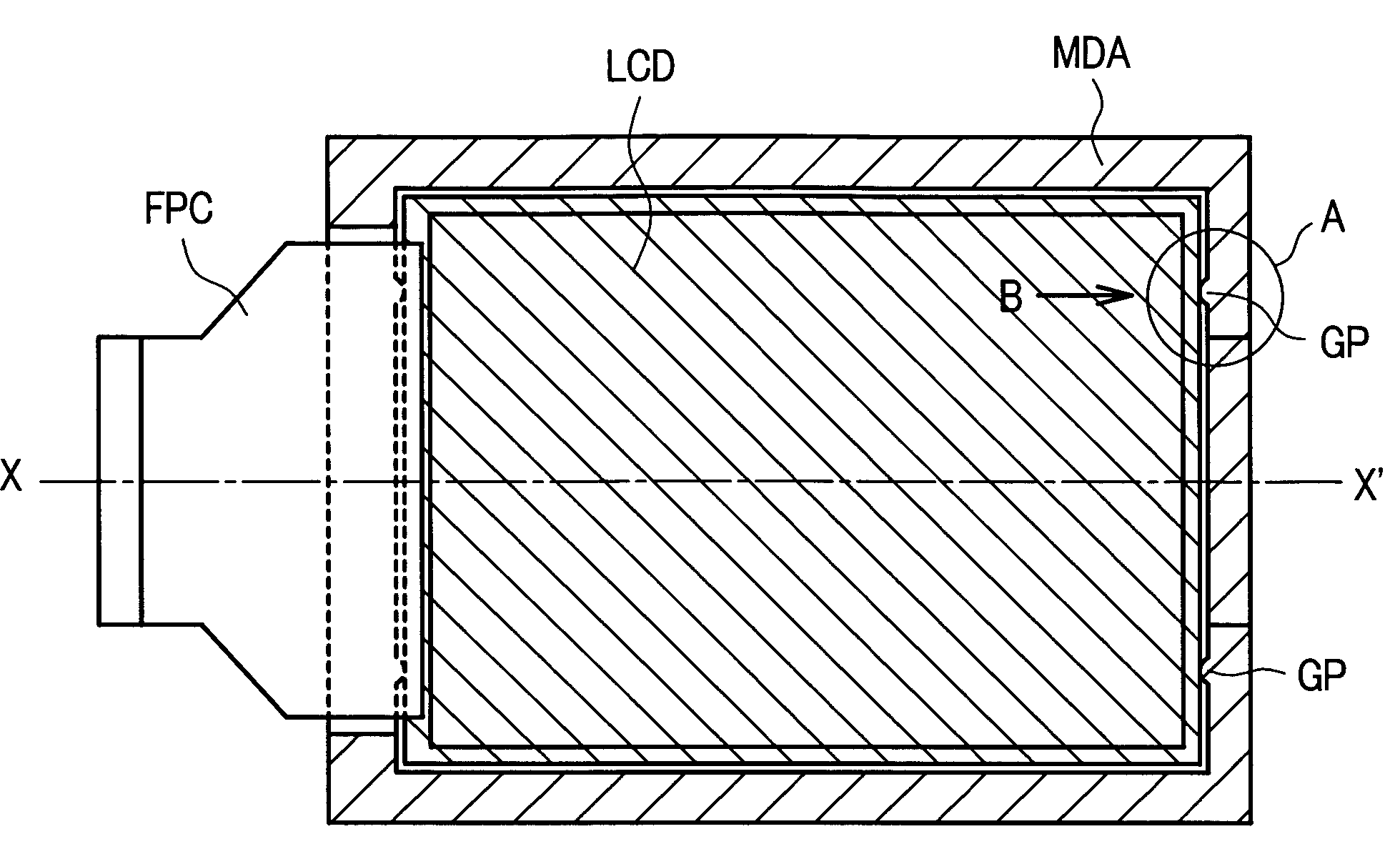

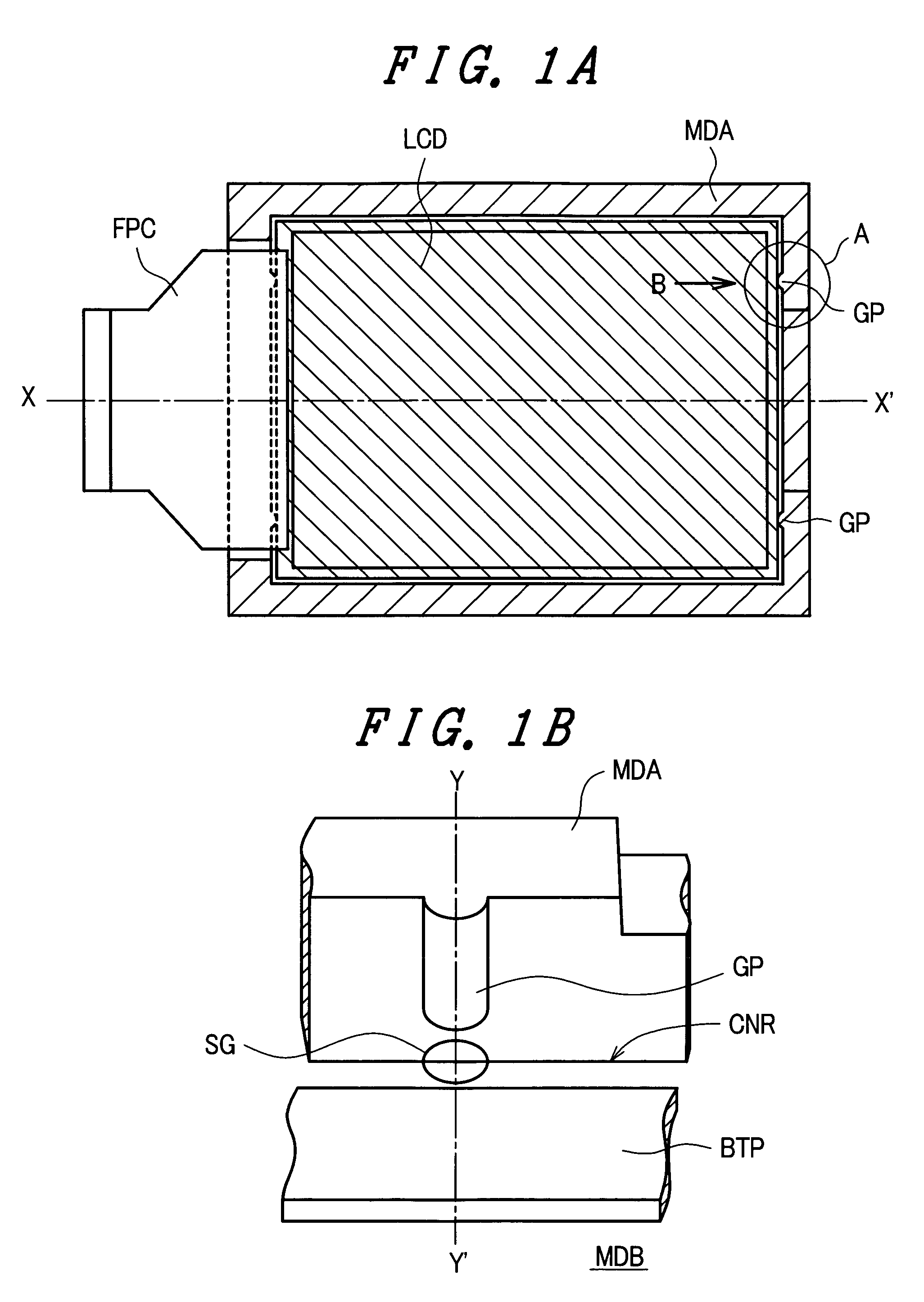

Display device

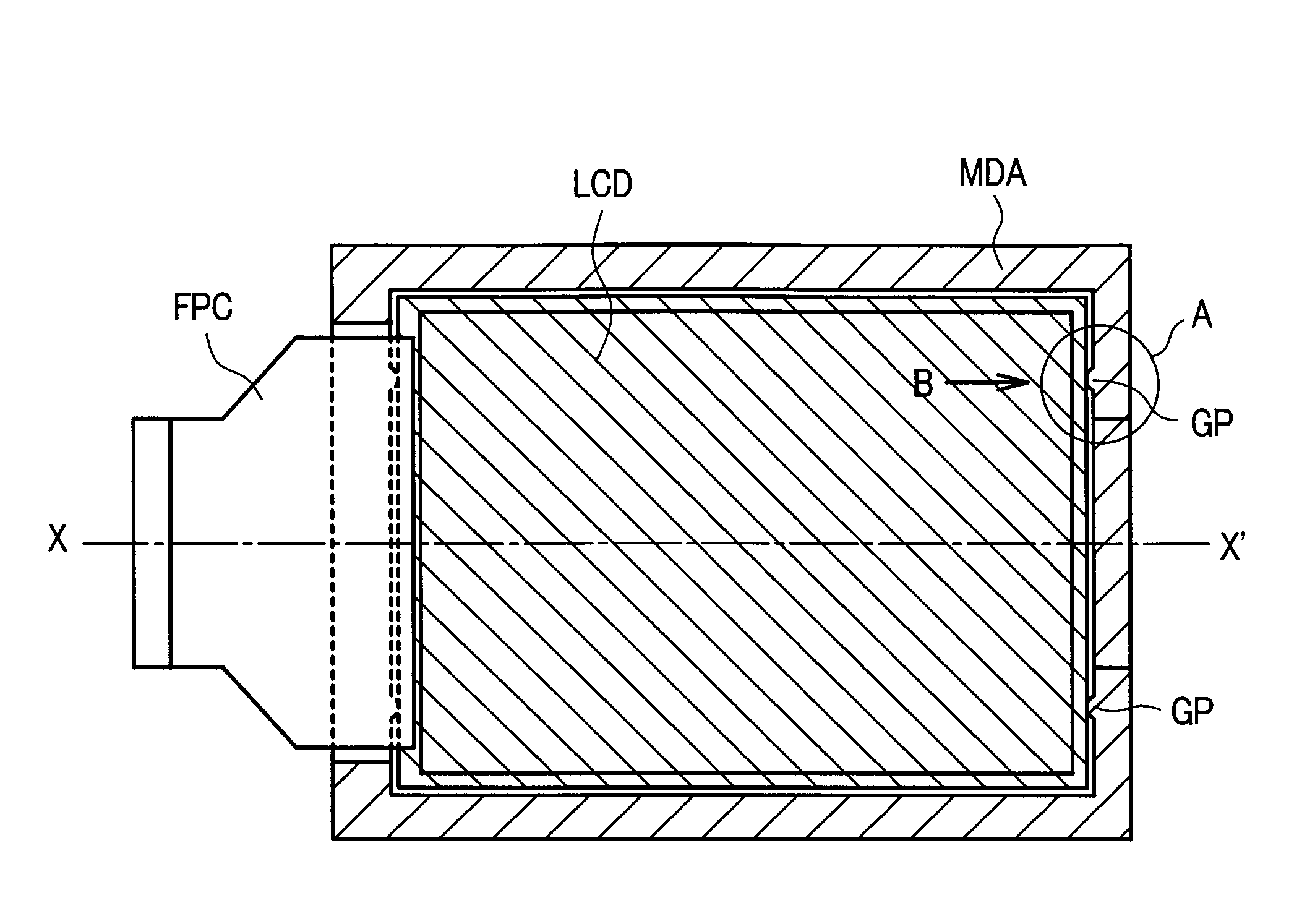

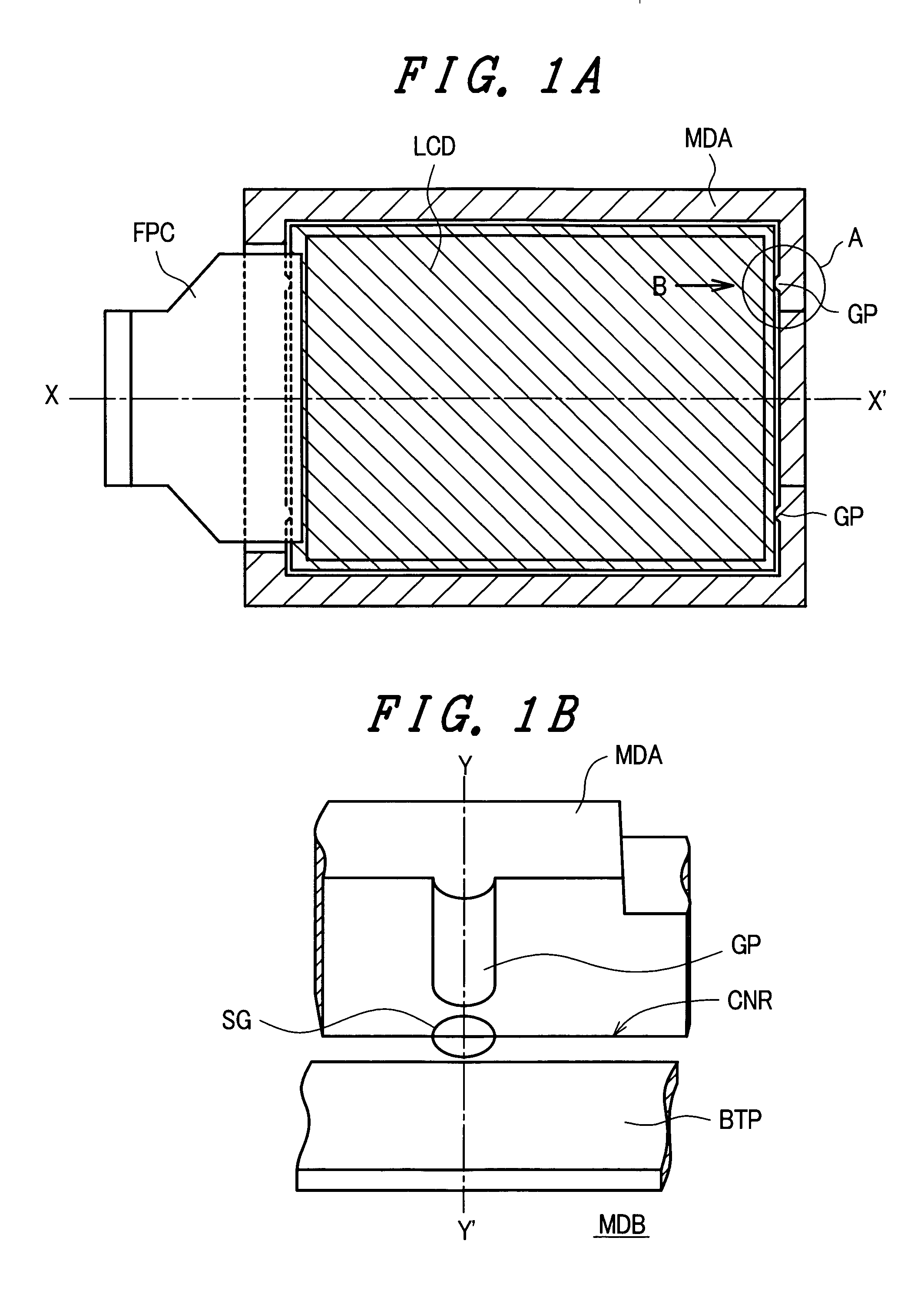

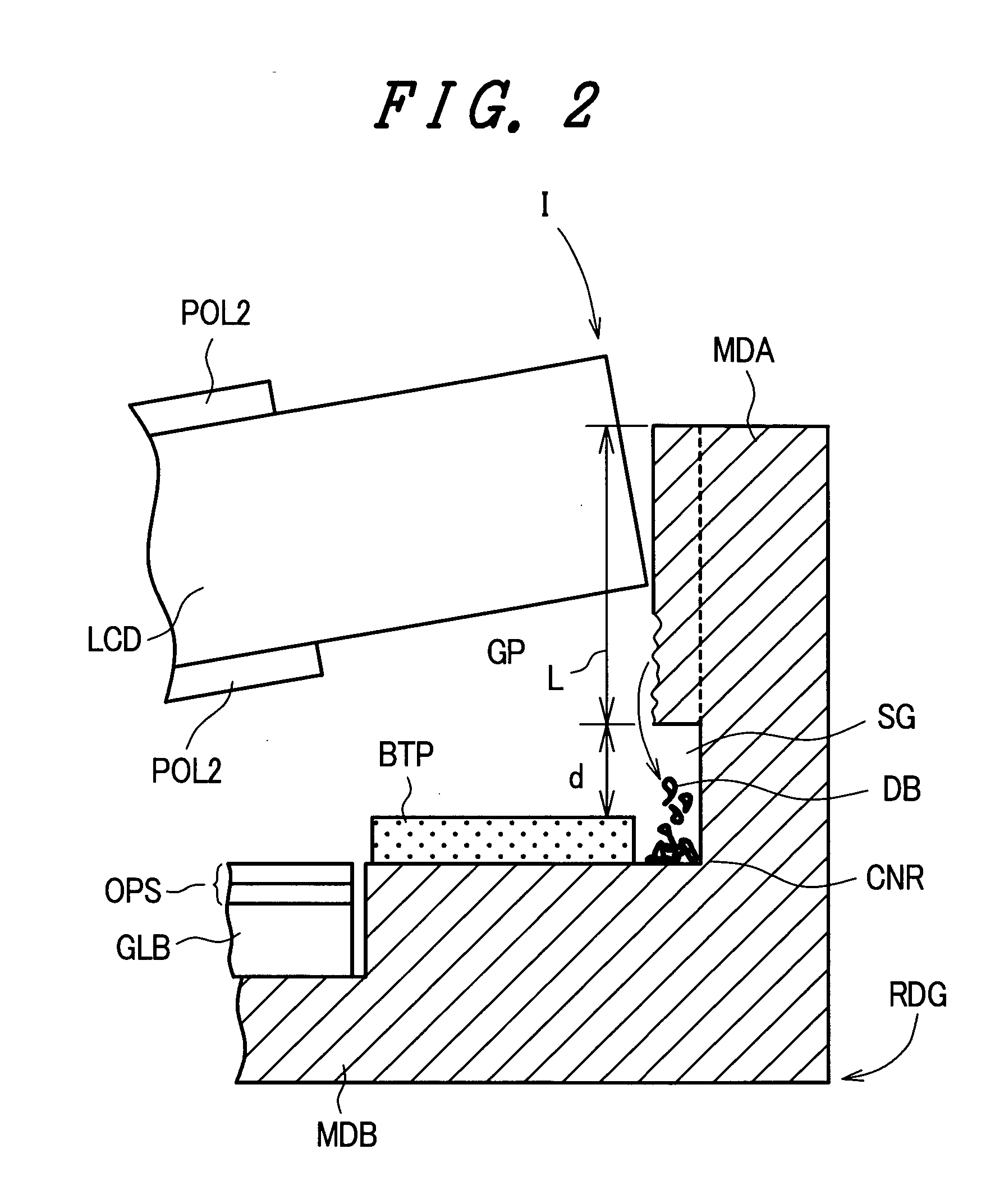

ActiveUS20050036335A1Improve adhesionPrevent floatingAircraft componentsIlluminated signsDisplay deviceEngineering

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD

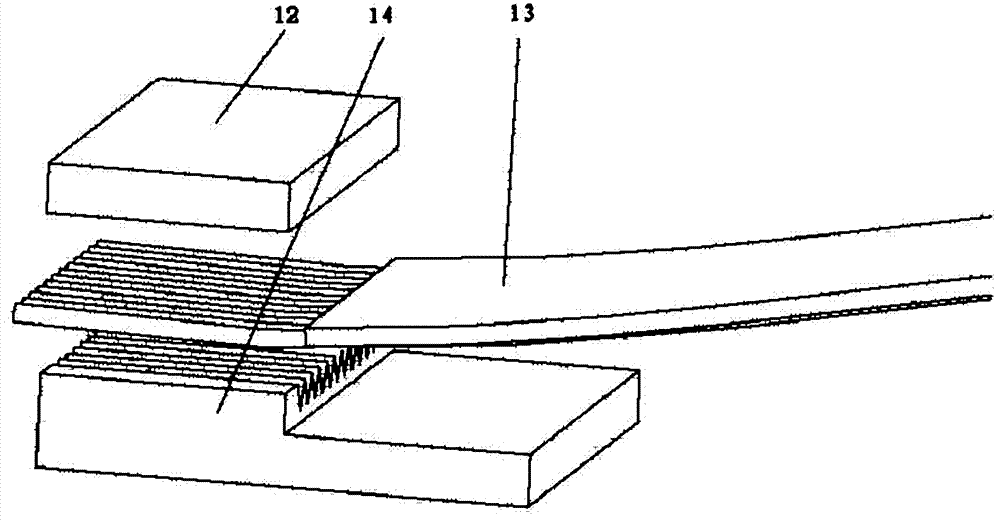

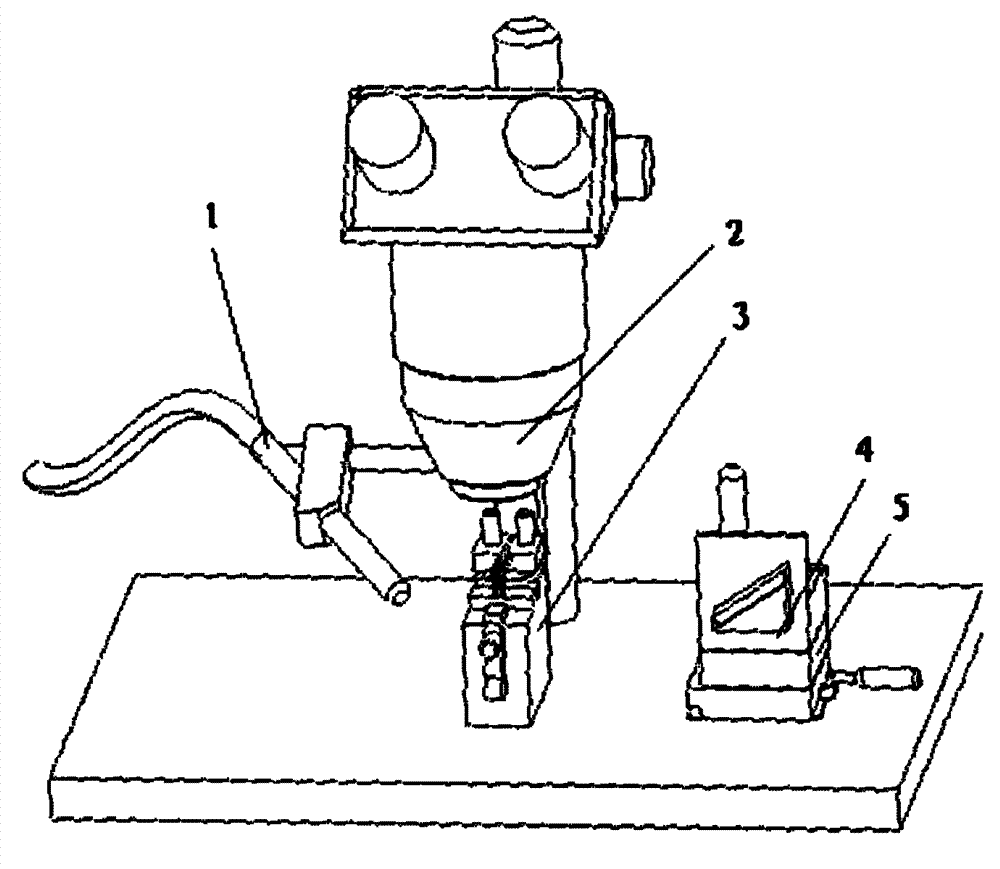

Fiber array board assembly device and fiber array board assembly platform using same

ActiveCN103358249AImprove assembly qualityIncrease profitWork holdersFastening meansFiber arrayMechanical engineering

The invention relates to a fiber array board assembly device and a fiber array board assembly platform using the same. The fiber array board assembly device comprises an L-shaped positioning base and a clamp component. The L-shaped positioning base comprises a side wall and a base. A positioning block is fixedly connected to the inner side of the side wall. A pressure block parallel to the positioning block is also movably connected to the inner side of the side wall. The pressure block can horizontally move along the inner side of the side wall. The inner side of the side wall is further provided with a clamp groove. The base is provided with a through hole. A lifting member and a support member are disposed in the through hole. A U-shaped support is disposed on two side walls of the clamp component. An elastic member is arranged between the bottom of the U-shaped support and the bottom of the clamp component. A glass pressure block is arranged between two ends of the U-shaped support. One end of the clamp component is provided with a protrusion which is clamped in the clamp groove. The lifting member controls the U-shaped support to ascend and descend through the support member.

Owner:广东安捷康光通科技有限公司

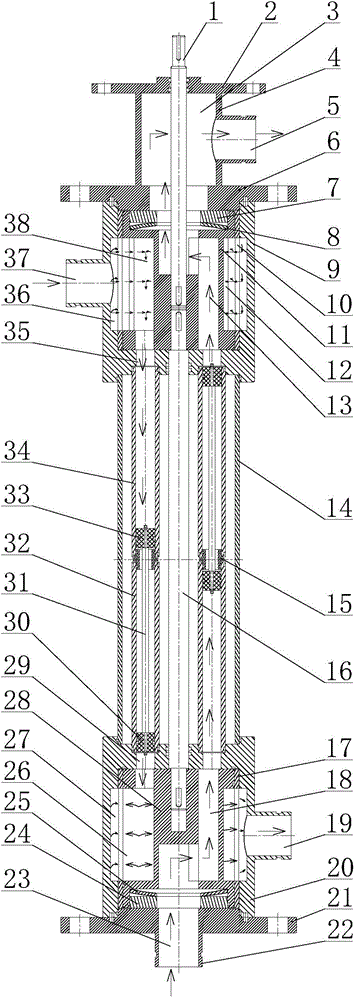

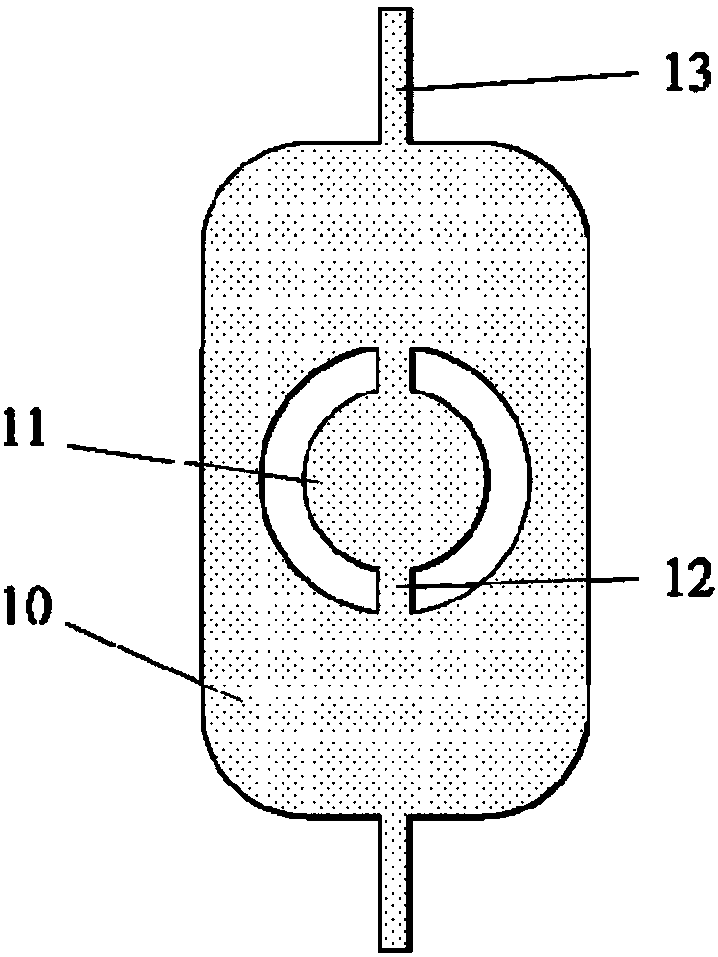

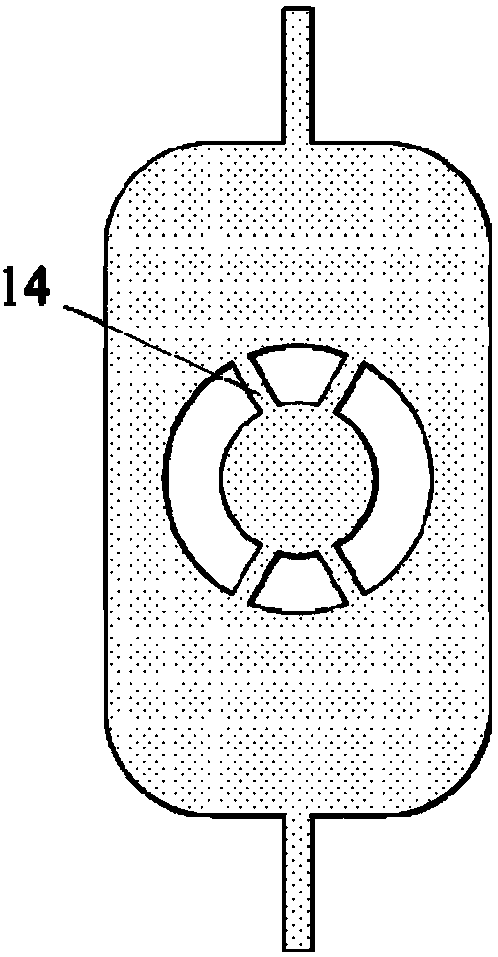

Electric-driven self-pressurization rotor-type energy recovery apparatus

ActiveCN103977708ASimple processPrevents mixing with overcurrent and overshoot phenomenaSeawater treatmentReverse osmosisElectric driveSeawater

The invention discloses an electric-driven self-pressurization rotor-type energy recovery apparatus which includes a pressure relieving part shell body, a brine end shell body, a support cylinder body, a seawater end shell body and a low-pressure seawater interface which are successively fixed to each other. A brine distribution rotating disk which is disposed in the brine end shell body and a seawater distribution rotating disk which is disposed in the seawater end shell body are connected to each other through a central shaft. A plurality of water pressure cylinder sets are arranged in the support cylinder body, wherein each water pressure cylinder set is composed of a large-diameter water pressure cylinder and a small-diameter water pressure cylinder which are connected to each other in series. The large-diameter water pressure cylinder is fixedly connected to the brine end shell body and the small-diameter water pressure cylinder is fixedly connected to the seawater end shell body. One piston is disposed in the large-diameter water pressure cylinder and the other piston is disposed in the small-diameter water pressure cylinder. Two pistons, which are disposed in the same water pressure cylinder set, are connected to each other through a piston rod. The brine distribution rotating disk and the seawater distribution rotating disk are driven by a motor. With energy of residual pressure of high-pressure brine, the pressure of raw material seawater can be increased to a level required by a membrane assembly without additionally increasing the pressure by a booster pump.

Owner:TIANJIN UNIV

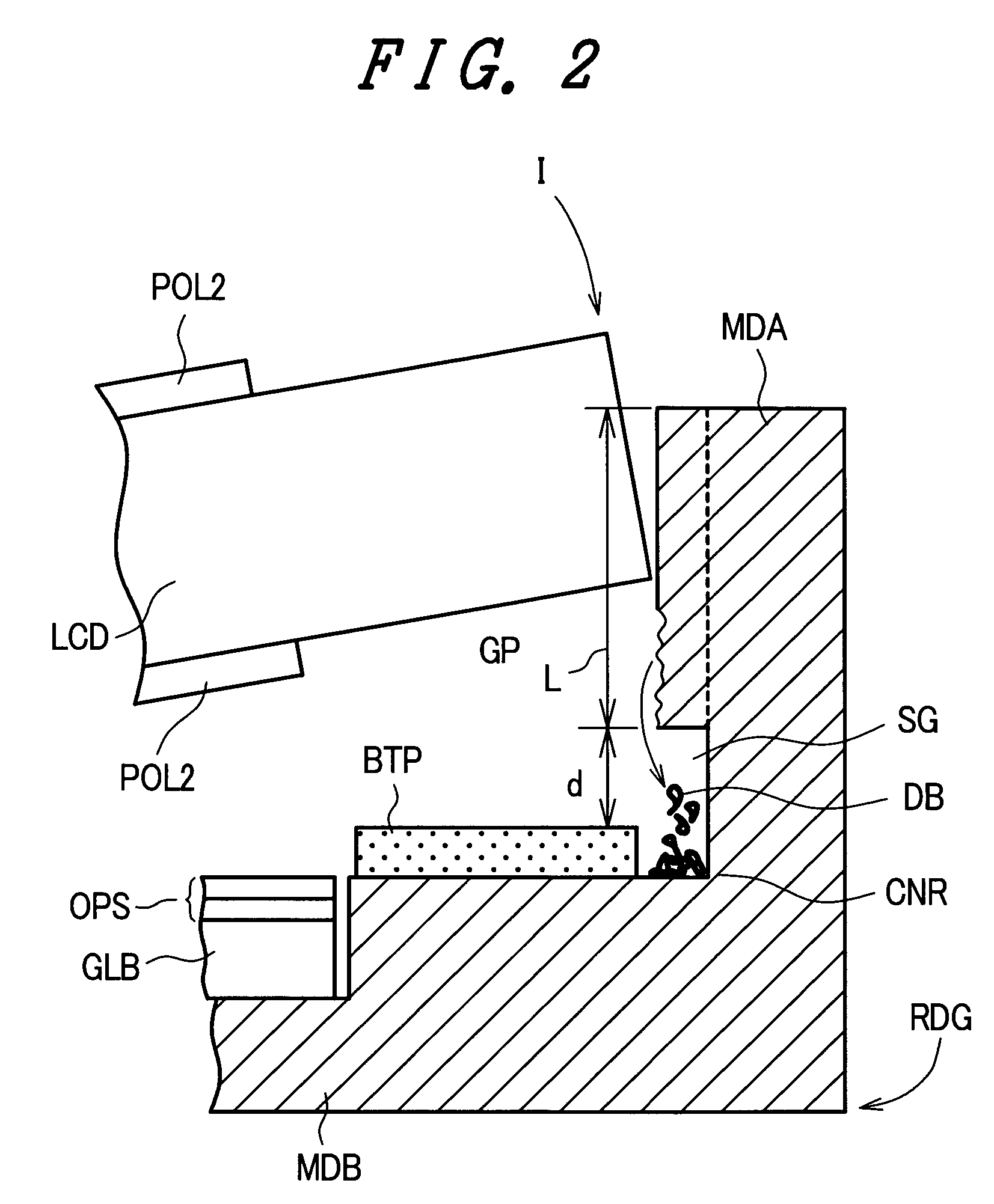

Display device

ActiveUS7165875B2Reduce assembly accuracyImprove suppression propertiesAircraft componentsIlluminated signsDisplay deviceMechanical engineering

Owner:JAPAN DISPLAY INC +1

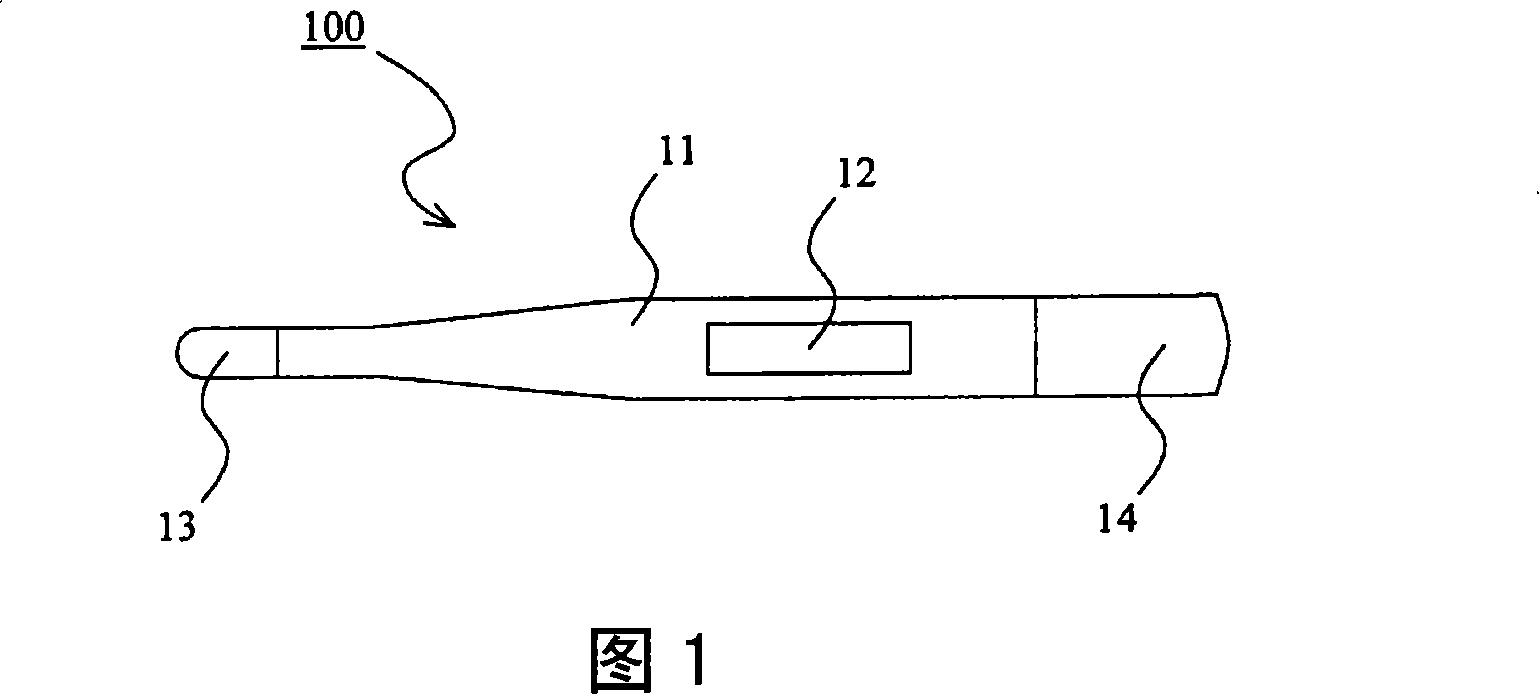

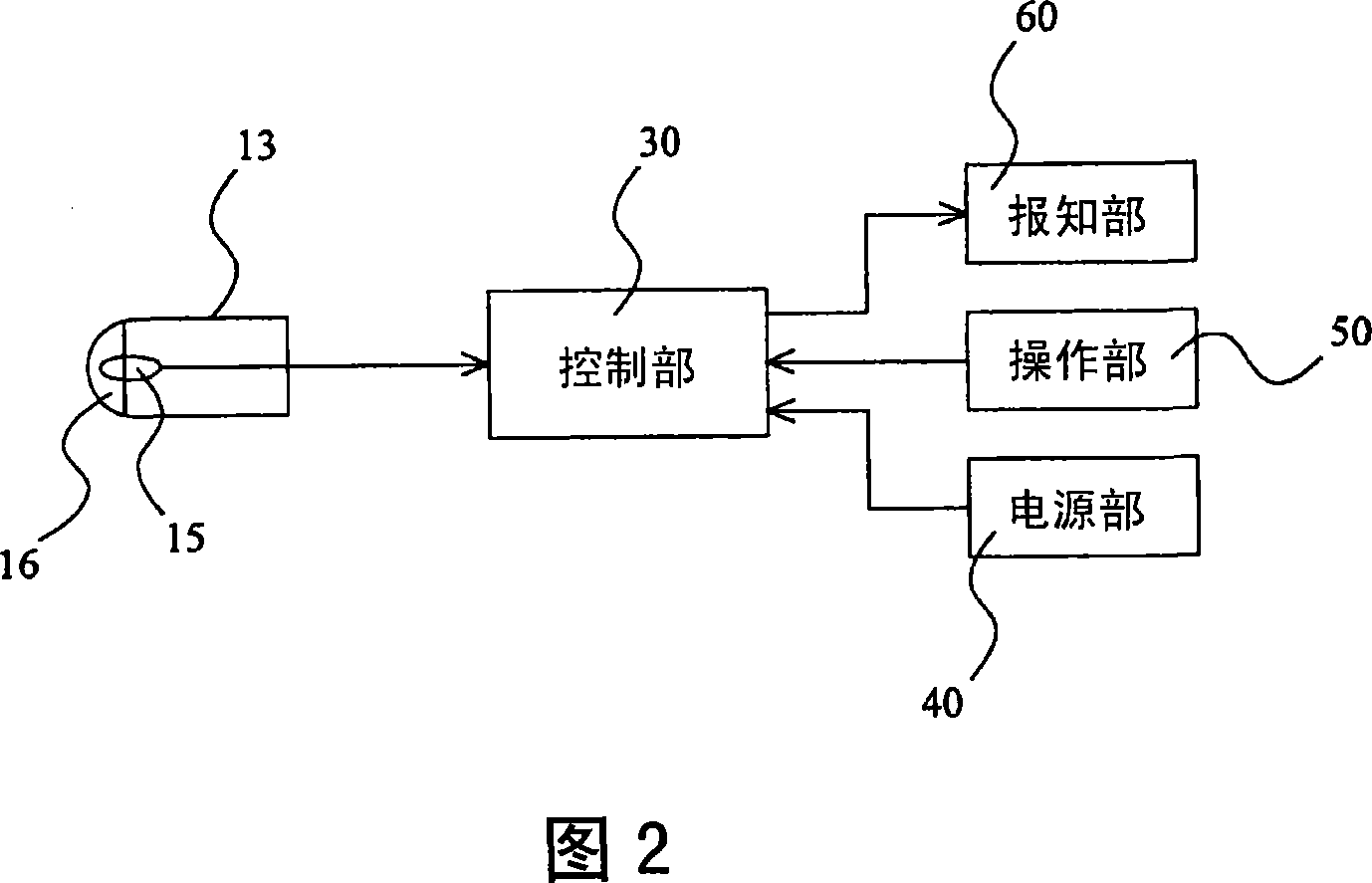

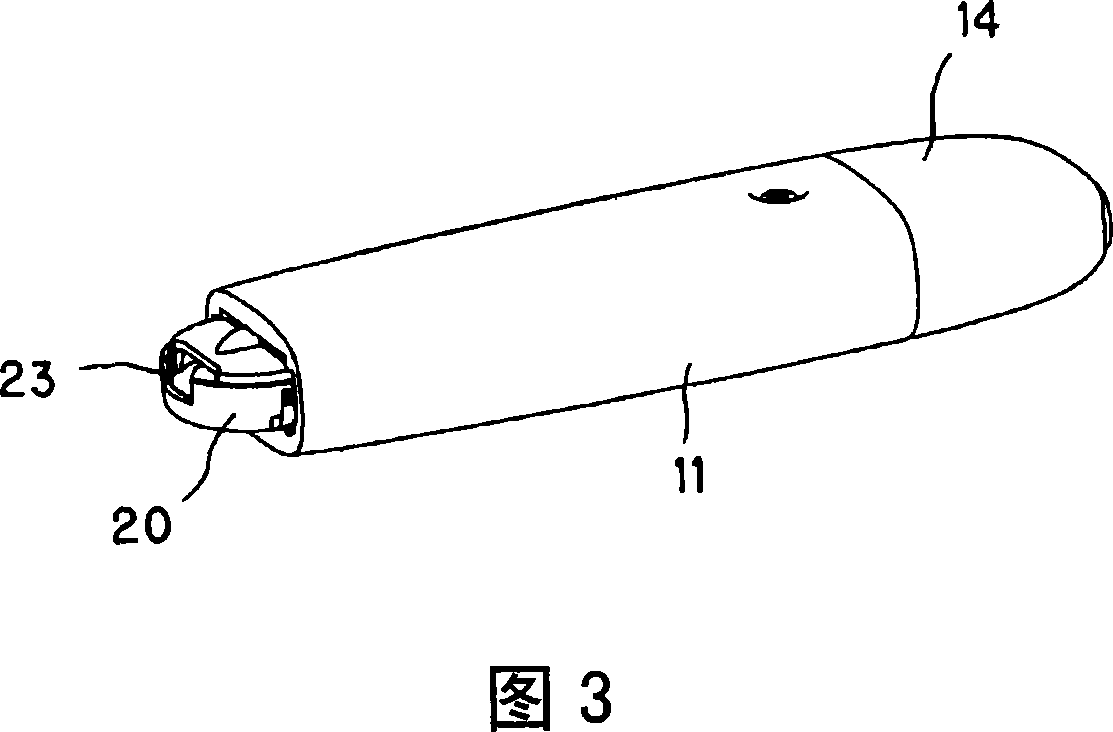

Electronic thermometer

ActiveCN101074893AReduced dimensional accuracyReduce assembly accuracyThermometer detailsThermometers using electric/magnetic elementsMechanical engineeringElectronic thermometers

The electronic thermometer of this invention includes a supporting portion which supports the vicinity of the periphery on one face of a vibration plate, and a buzzer cover having plasticity of pressing the vibration plate against the supporting portion by pressing the vicinity of the periphery of the other face of the vibration plate and further includes a mechanism which presses the vicinity of the center of the buzzer cover on an opposite side to a side provided with the vibration plate in the buzzer cover so as to flex the buzzer cover, thereby pressing the vicinity of the periphery on the other face of the vibration plate with elastic reaction force of the buzzer cover.

Owner:OMRON HEALTHCARE CO LTD

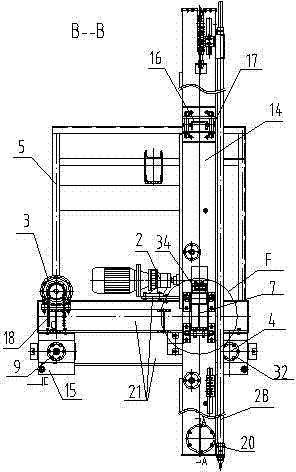

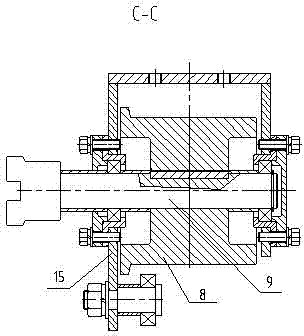

Press mounting apparatus and press mounting method of semiconductor valve string

ActiveCN106298594AImprove press stabilityGuaranteed assembly accuracySemiconductor/solid-state device detailsSolid-state devicesEngineeringPlacement method

The invention provides a press mounting apparatus and press mounting method of a semiconductor valve string. The press mounting apparatus comprises a horizontal workbench arranged on a frame, the horizontal workbench is provided with a guiding support mechanism used for guiding and supporting each device in a semiconductor valve string to be press-mounted, a force application mechanism is arranged at the end of a guiding direction on the frame, and the force application direction of the force application mechanism is the same as the guiding direction. The advantages are as follows: each device in the semiconductor valve string is horizontally placed on the guiding support mechanism for assembling, compared to a conventional vertical accumulation placement method, the method reduces transport paths, and therefore, the labor intensity is low and the assembling efficiency is high. Besides, the semiconductor valve string does not have to be hoisted and moved after being assembled, pressure loading can be carried out directly by use of the force application mechanism, the press-mounting efficiency and the automation degree of the whole press-mounting operation are improved, and the press-mounting precision is effectively guaranteed. At the same time, the height of the horizontally arranged semiconductor valve string is greatly reduced, and the press-mounting stability of the semiconductor valve string is improved.

Owner:PINGGAO GRP +3

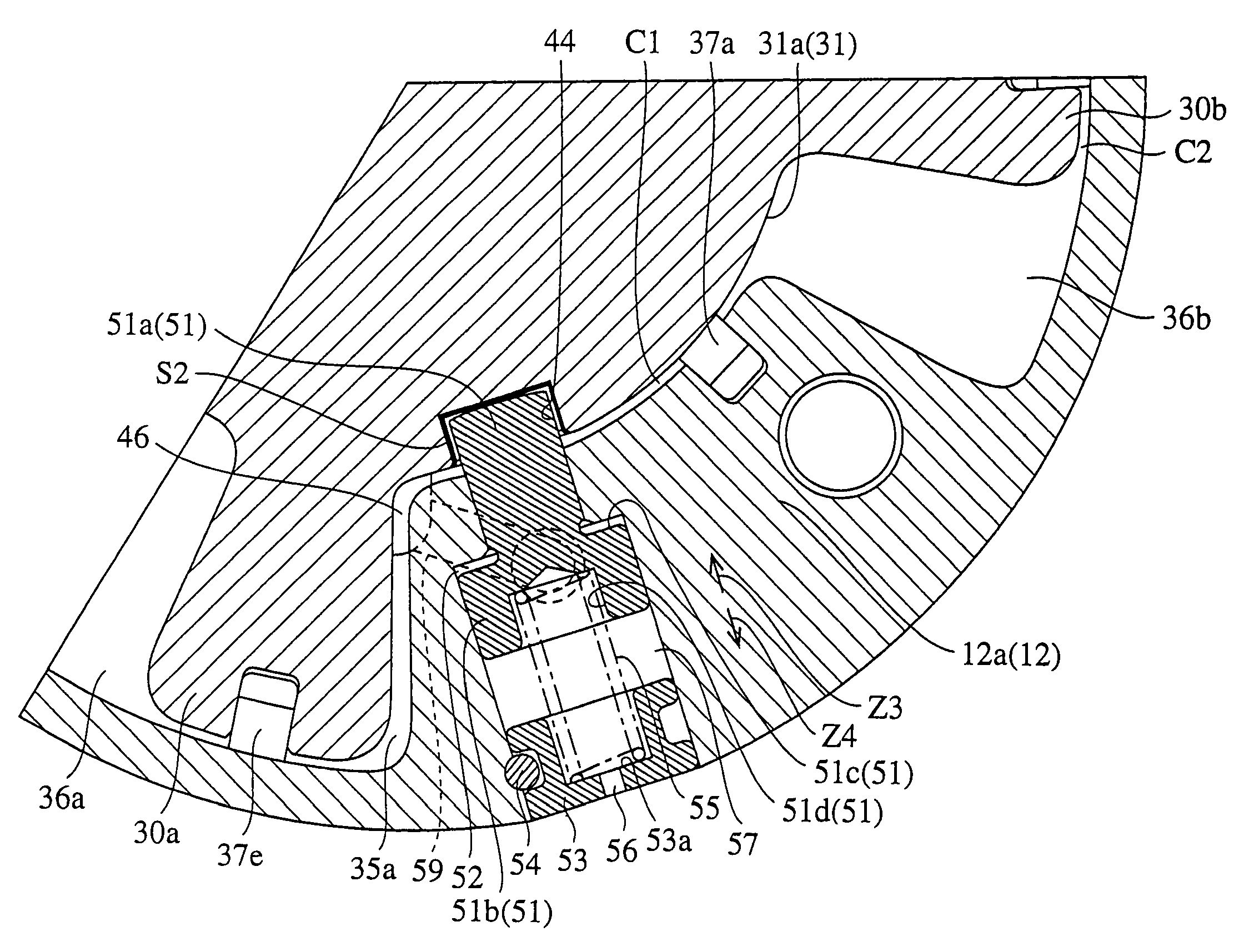

Valve timing adjusting device

ActiveUS6971351B2Manufacturing cost be increaseEnhance reliabilityValve arrangementsYielding couplingSurface finishingHardness

A region including an engaging hole is given surface treatment such as partial quench hardening by induction hardening for improving surface hardness of the region. The partial quench hardening by induction hardening provides the region with satisfactory mechanical strength or surface hardness enough for resisting deformation of the engaging hole and wear-out of an edge of opening of the engaging hole caused by putting in and out of the lock pin.

Owner:MITSUBISHI ELECTRIC CORP

Method for assembling special-shaped curved radome cover body and connecting ring

ActiveCN108994360ARealize the assemblySolving Assembly ChallengesMaterial gluingMilling equipment detailsAdhesiveEngineering

The invention discloses a method for assembling a special-shaped curved radome cover body and a connecting ring. The method comprises the following steps: 1) matching the connecting ring with a milling: fixing the connecting ring on an assembly fixture and positioning, matching a milling according to the actual size of the inner curved surface of the cover body, and machining the outer curved surface of the connecting ring, in which the cover body and the connecting ring are subjected to trial assembly until the outer curved surface of the connecting ring meets the fit clearance requirements;2) radome assembly: uniformly brushing and applying an adhesive onto the assembly surface of the outer curved surface of the connecting ring and the inner curved surface of the cover body, lifting thecover body with a cover body spreader, aligning an open end of the cover body with the connecting ring, slowly loading the cover body onto the connecting ring, and then fixing the cover body and positioning to fit the cover body in place. By adopting the method, not only is the assembly precision of the cover body and the connecting ring is ensured, but also the difficulty of matching milling andmachining on the assembly surface of the cover body and the connecting ring is reduced.

Owner:湖北三江航天江北机械工程有限公司

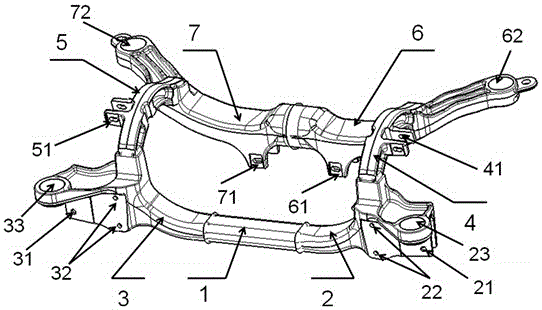

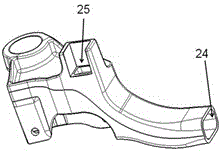

Environment-friendly aluminum alloy automobile sub-frame

The invention relates to an environment-friendly aluminum alloy automobile sub-frame. The environment-friendly aluminum alloy automobile sub-frame is of a bilaterally symmetrical structure, is made of aluminum alloy, and comprises a front cross beam, a front automobile body left installing part, a front automobile body right installing part, a rear automobile body left installing part, a rear automobile body right installing part, a left longitudinal beam and a right longitudinal beam, wherein the front automobile body left installing part and the front automobile body right installing part are welded and connected through the front cross beam; the rear automobile body left installing part and the rear automobile body right installing part are connected in a butt welding mode; the front automobile body left installing part and the rear automobile body left installing part are welded and connected through the left longitudinal beam; and the front automobile body right installing part and the rear automobile body right installing part are welded and connected through the right longitudinal beam. All use performance indexes such as the strength and the rigidity of the sub-frame can be effectively ensured. The environment-friendly aluminum alloy automobile sub-frame has the advantages that parts are few; the manufacturing process is simple; and the light-weight effect is obvious. On one hand, the workload is greatly reduced; on the other hand, the assembly precision problem due to welding deformation can be reduced; and in addition, the projection area of a single part is not large, so that the goal can be achieved by an ordinary extrusion casting machine.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

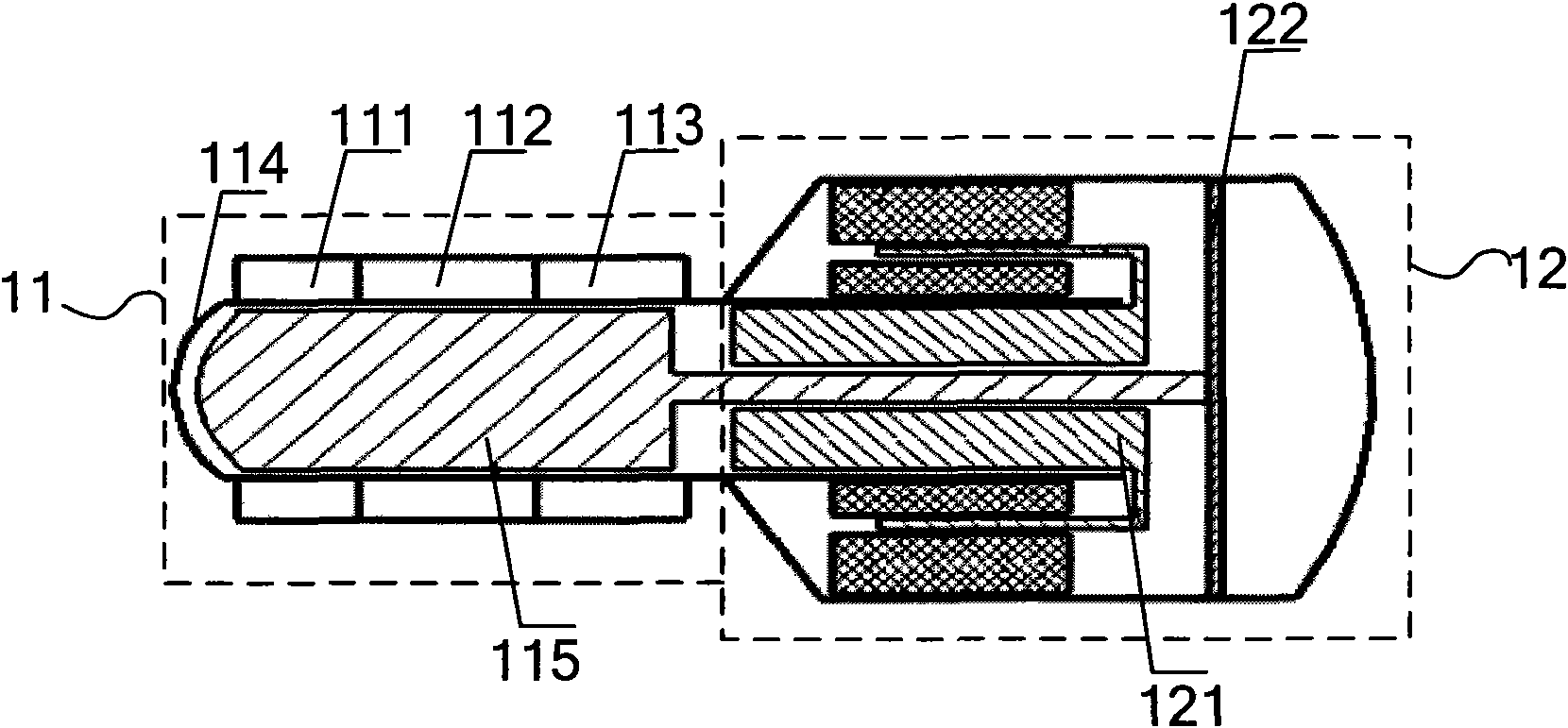

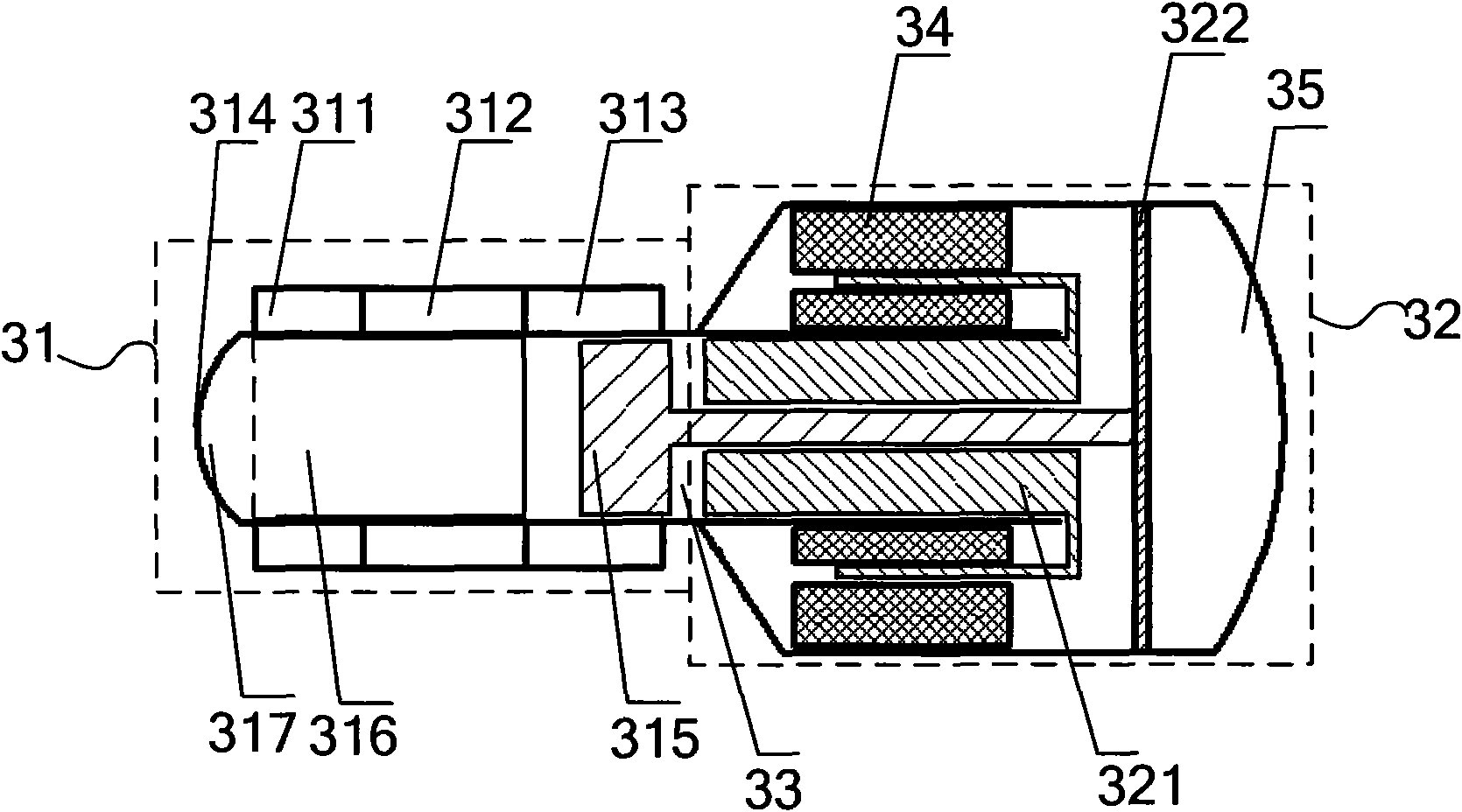

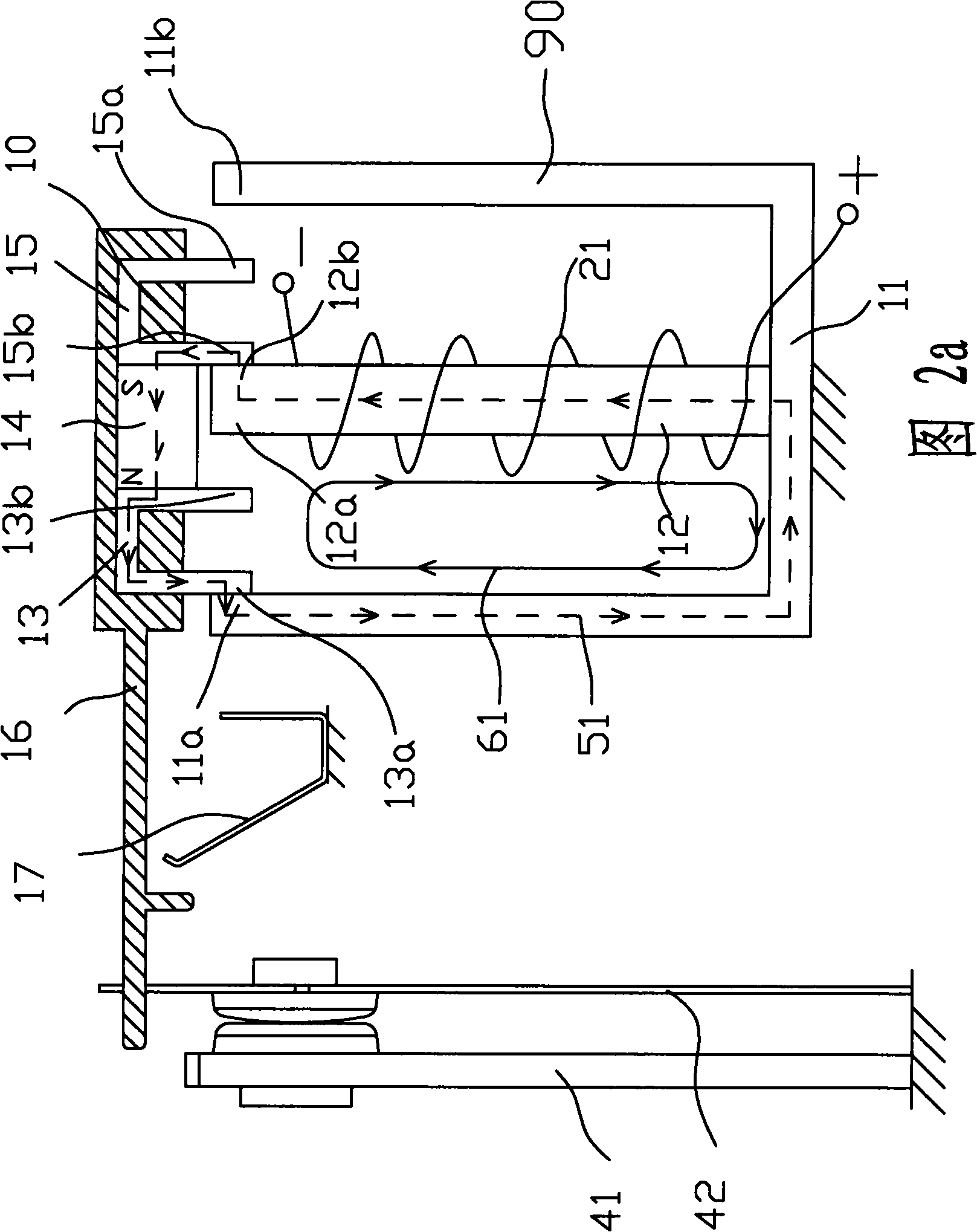

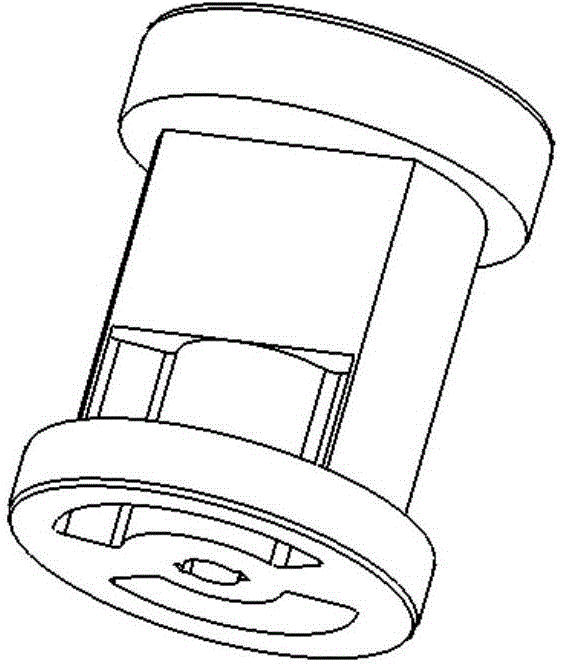

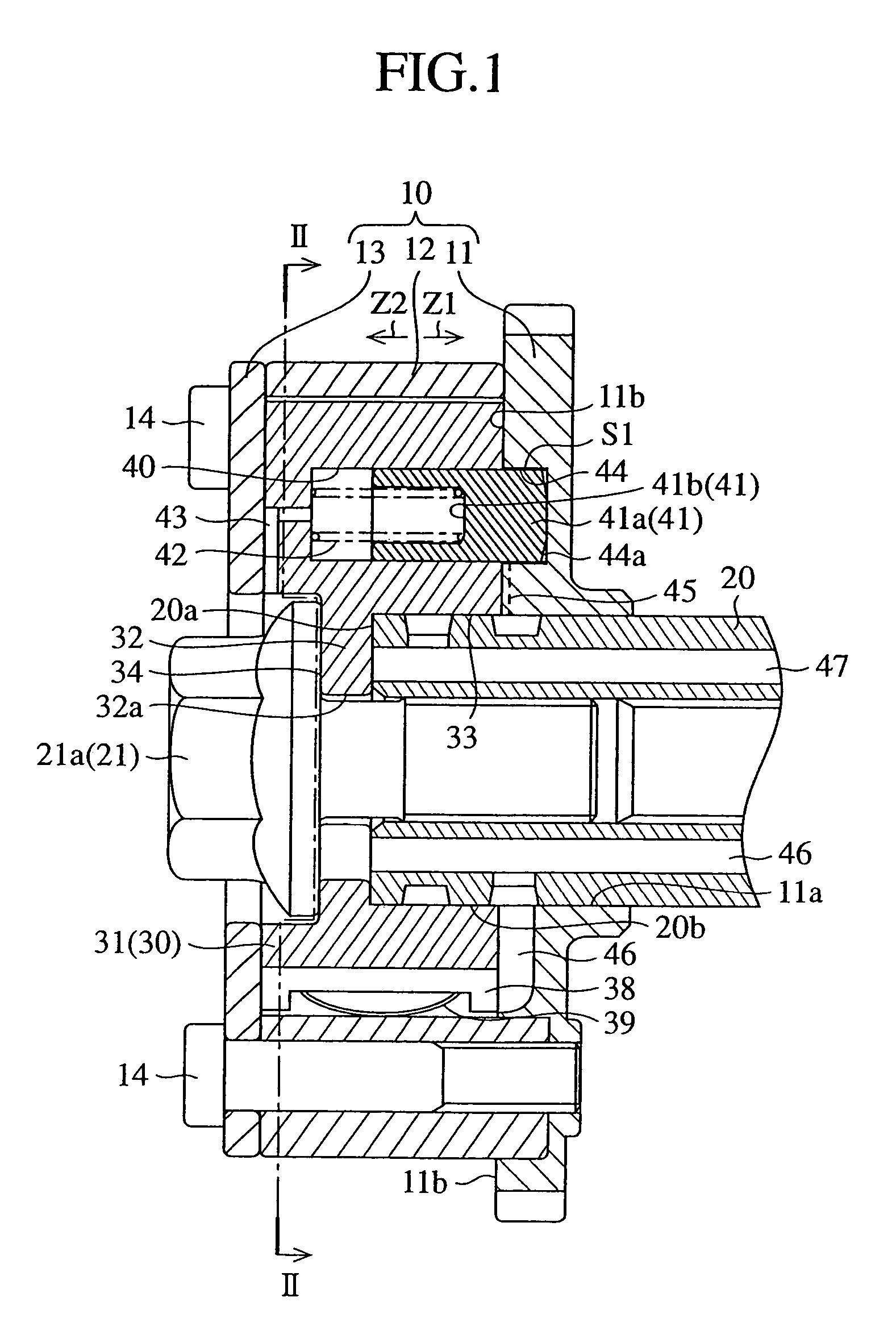

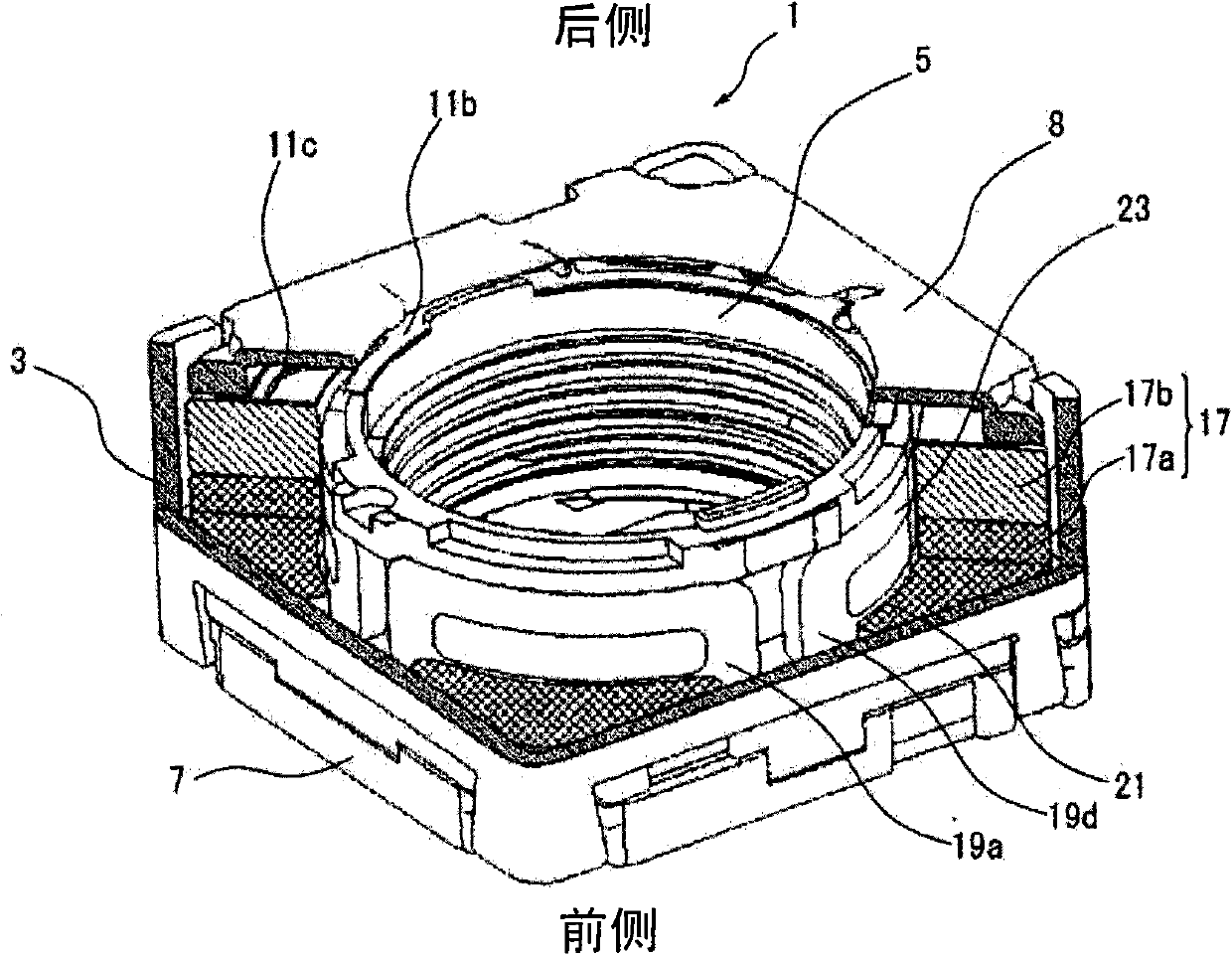

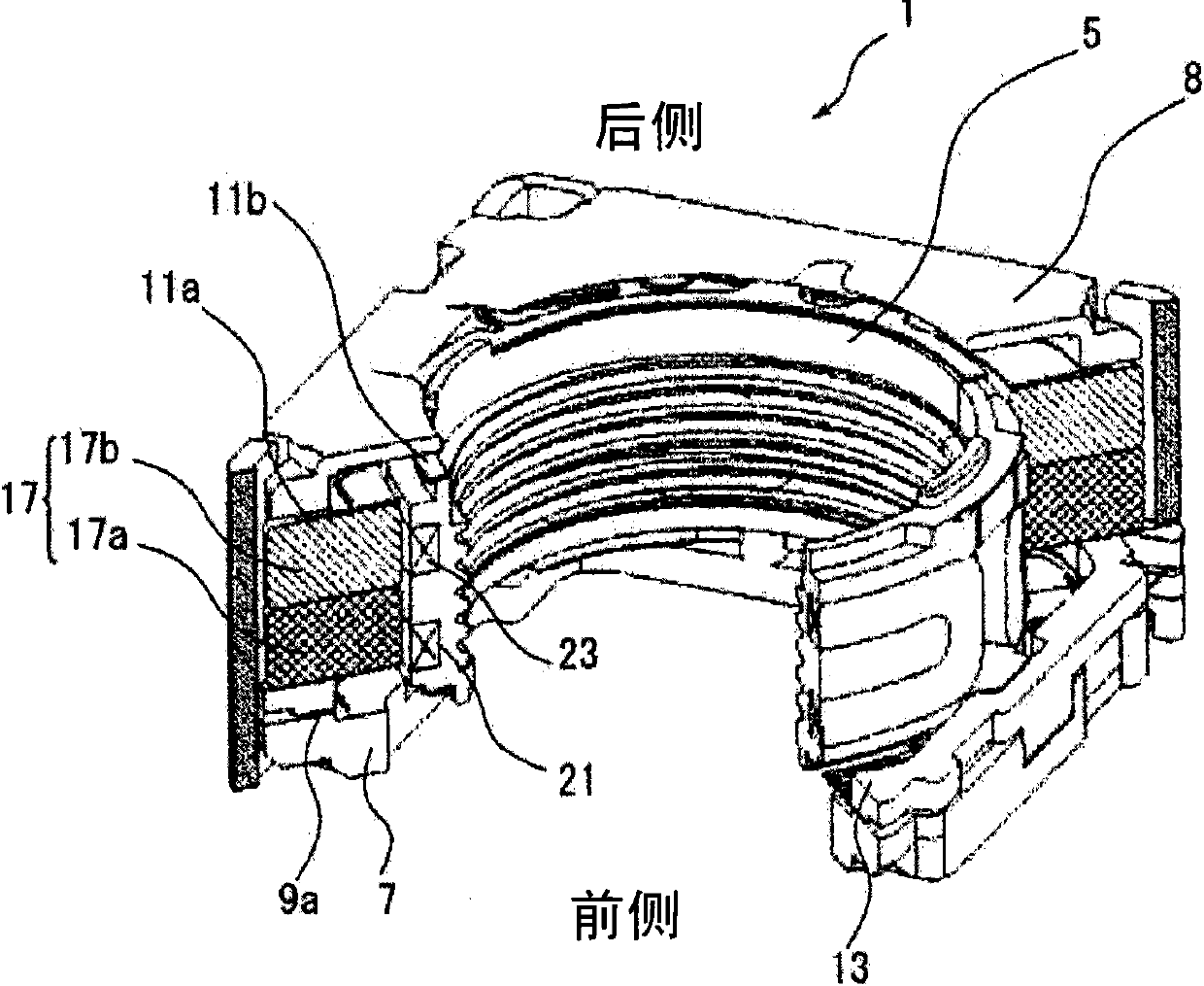

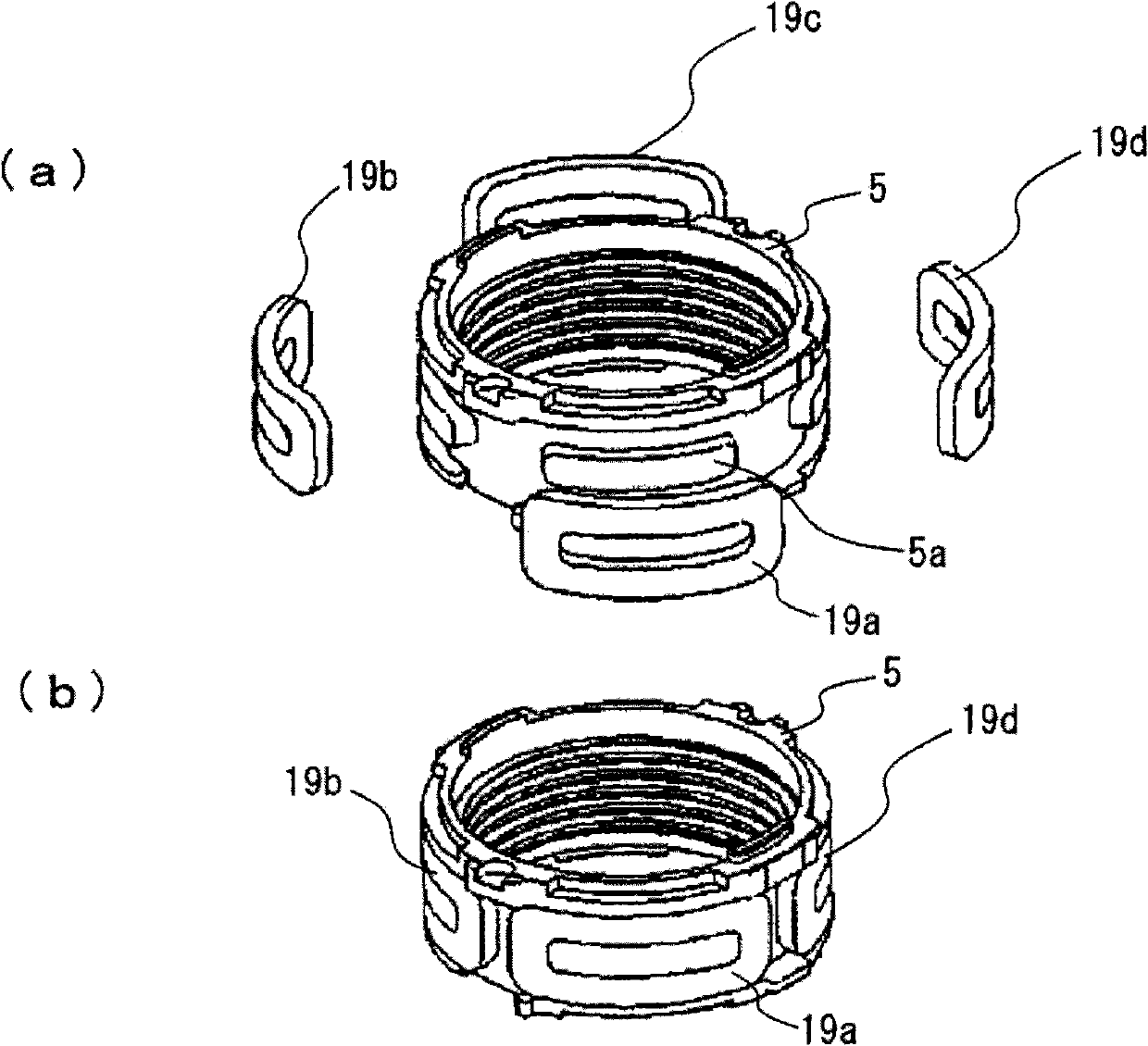

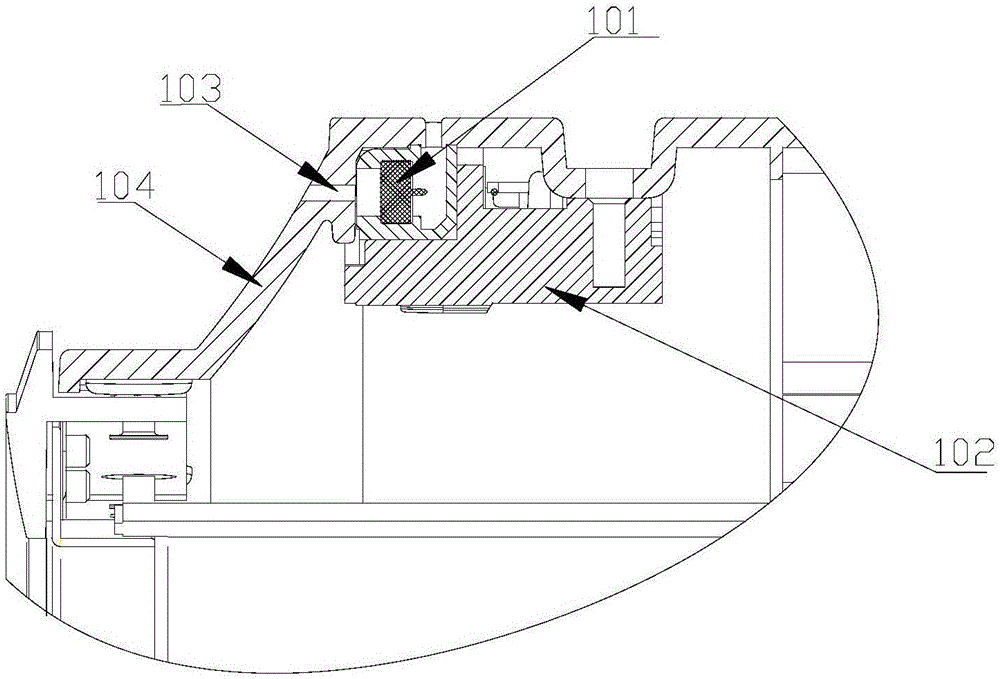

Lens driving device, autofocus camera, and camera-equipped mobile terminal

InactiveCN101995734ASmall sizeReduce precisionDynamo-electric machinesMountingsPower flowOptical axis

A lens driving device, an autofocus camera and a camera-equipped mobile terminal are provided that can correct movement of a lens in an optical axis direction and tilt of an optical axis, and reduce the dimension thereof in the optical axis direction. The device includes: a lens support 5 for supporting a lens at an inner circumference; a plurality of coils 19a to 19d disposed at regular intervals in a circumferential direction on an outer periphery of the lens support 5; a base 8 that supports the lens support 5 so as to move freely in an optical axis direction of the lens; and a magnet portion 17 arranged on the base 8 and facing each of the coils 19a to 19d, in which an electric current of equal current value is applied to each of the coils 19a to 19d when moving the lens support 5 in the optical axis direction, and current values of the electric current applied to predetermined coils 19a to 19d are varied when correcting tilt of the optical axis of the lens.

Owner:SHICOH MOTOR (SHANGHAI) CO LTD

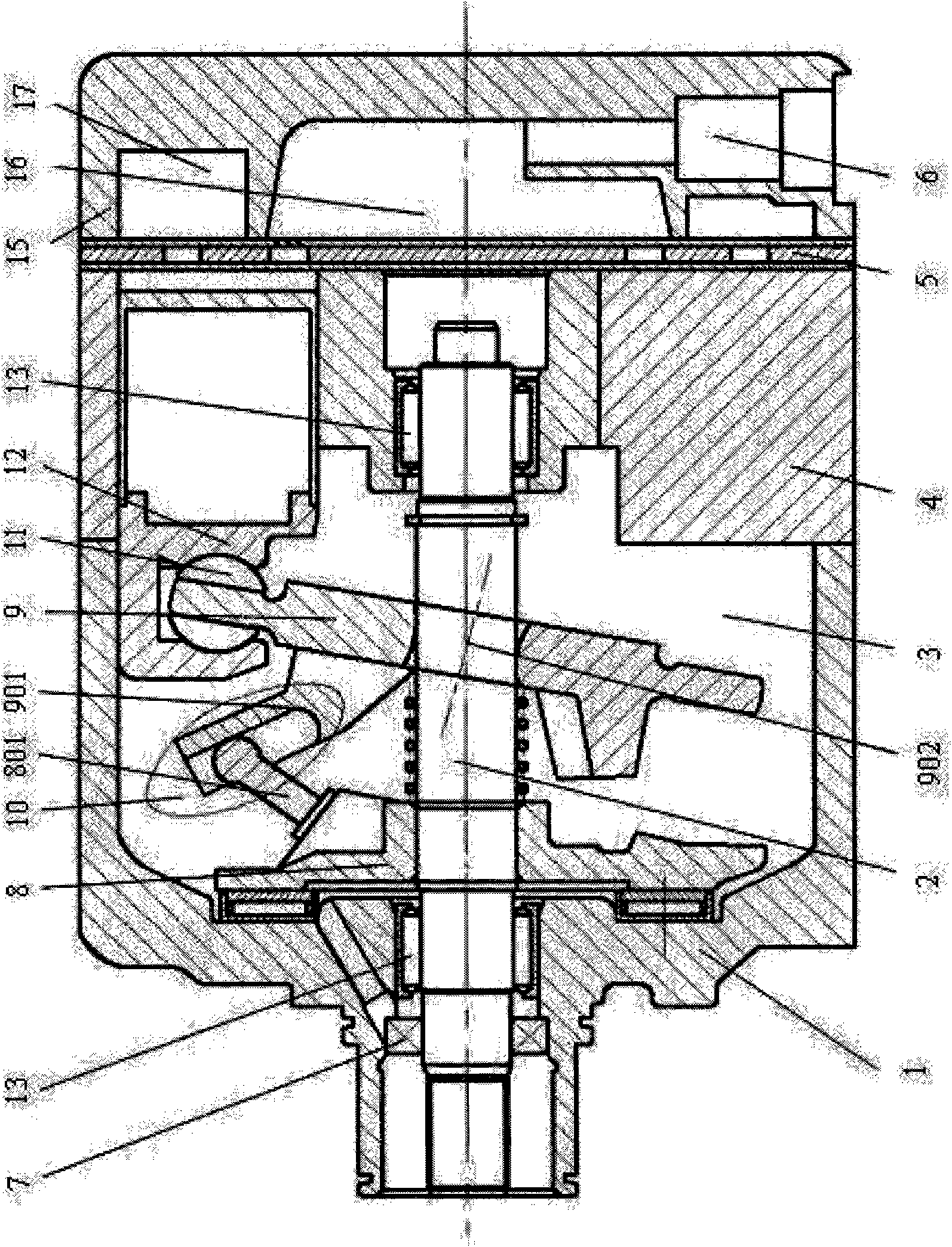

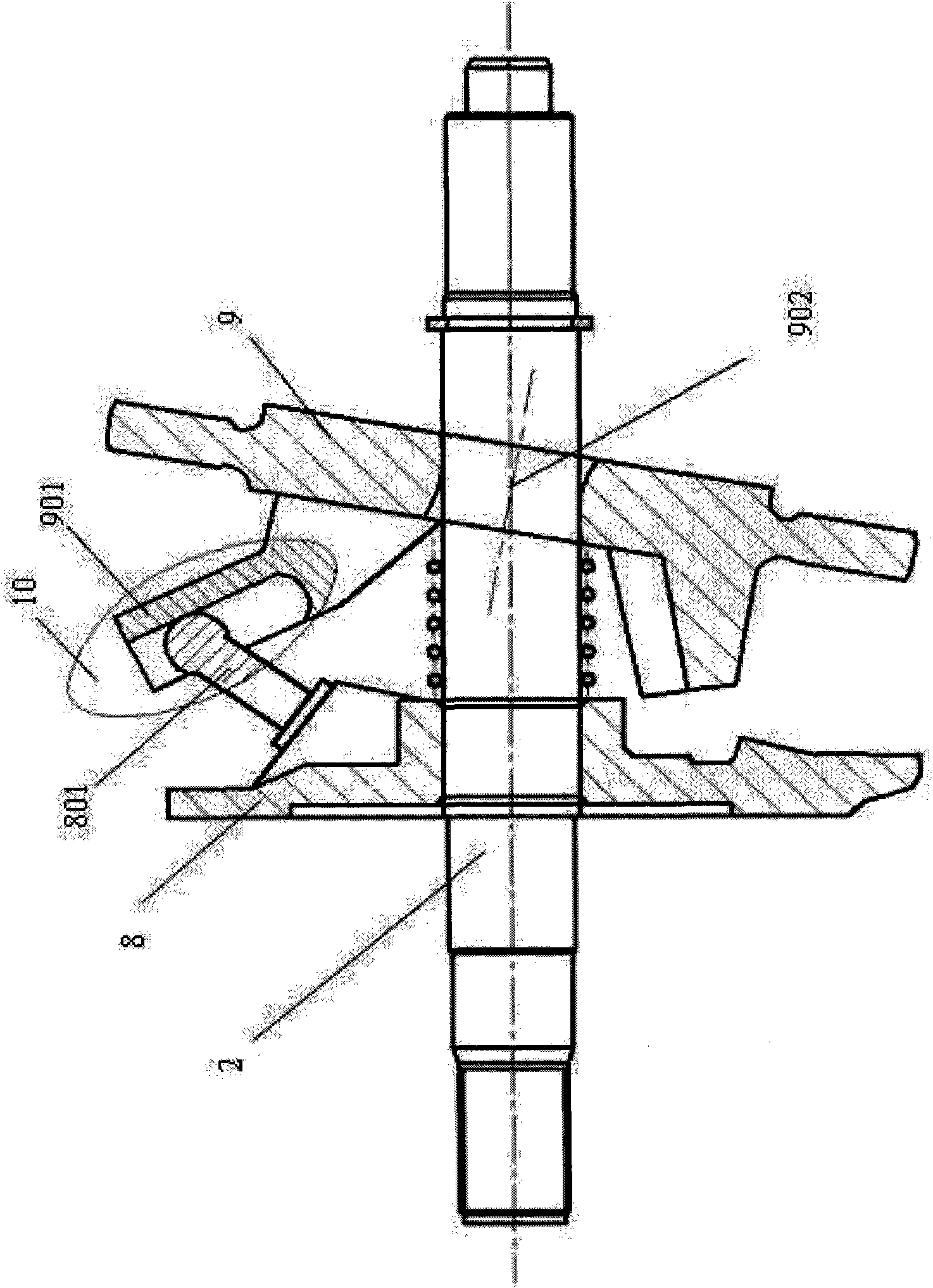

Variable displacement swash plate compressor

InactiveCN102011721AAppropriate amount of flexibilityReduce machining accuracyPositive displacement pump componentsMulti-stage pumpsReciprocating motionKinematic pair

The invention relates to a variable displacement swash plate compressor. A swash plate driving mechanisms with a flexible driving balance design is provided, has proper flexibility during work, overcomes unbalanced force and moment acting on the swash plate, improves vibration, noise, kinematic pair blockage and excessive wear caused by the unbalanced force and moment, and reduces machining and assembly precision of related workpieces; a piston with a spiral linear oil groove is provided and stores oil, and through the reciprocation of the piston and the acceleration change of the piston, lubricating oil flows reasonably between the kinematic pair and is uniformly distributed on the cylindrical surface of the piston and the peripheral surface of the cylinder to improve the sealing and lubricating properties between the piston and the peripheral surface of the cylinder, improve the performance of the compressor and prolong the service life of the piston; and a cylinder cover capable of being formed at one time through die casting and having simple process is provided, and suction and discharge channels adopt a single-section or multi-section expansion chamber-type cavity consisting of alternate contraction sections and expansion sections to improve the vibration and air flow noise caused by suction and discharge pulsation.

Owner:ZHEJIANG LONGDIAN AUTOMOTIVE PARTS MFG

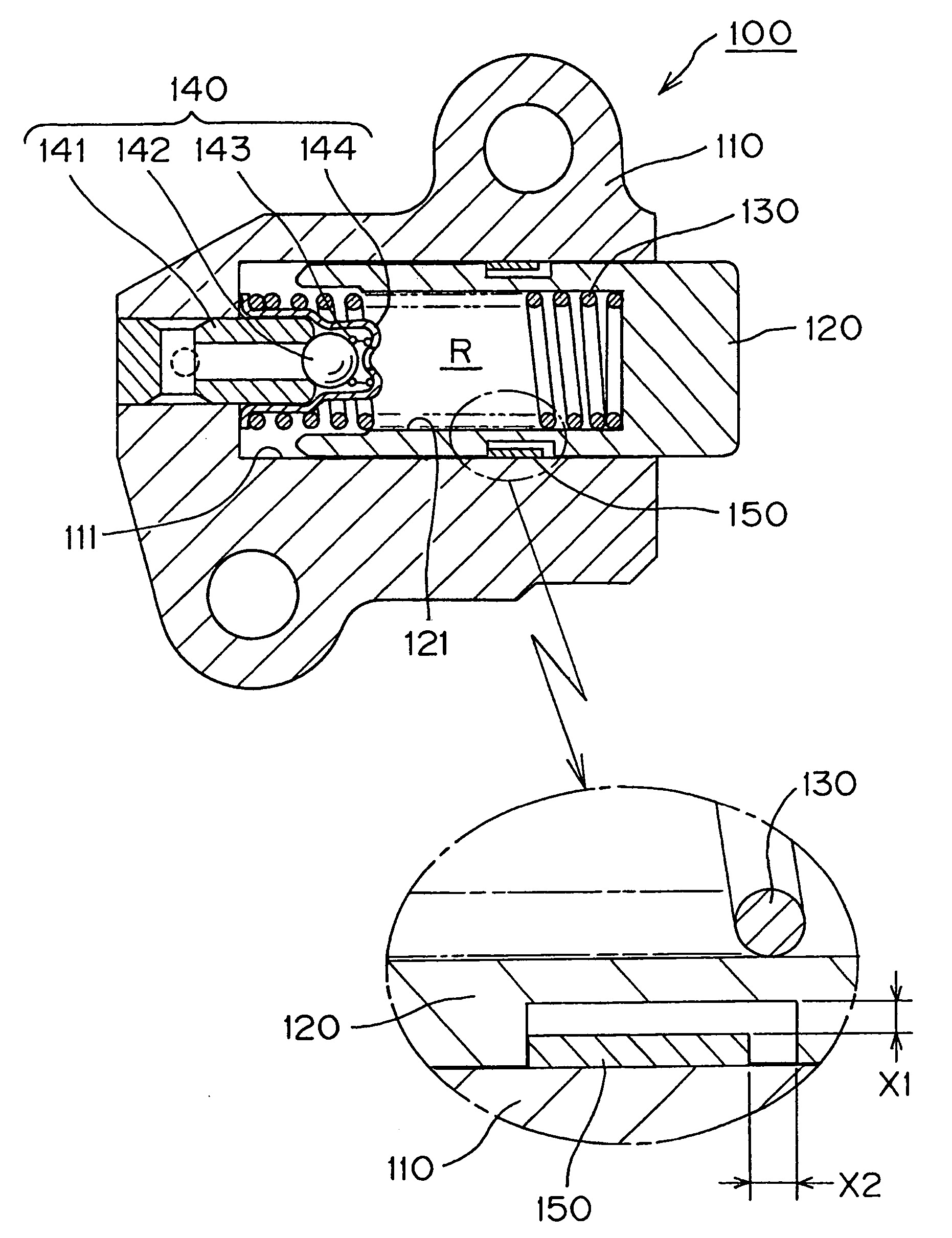

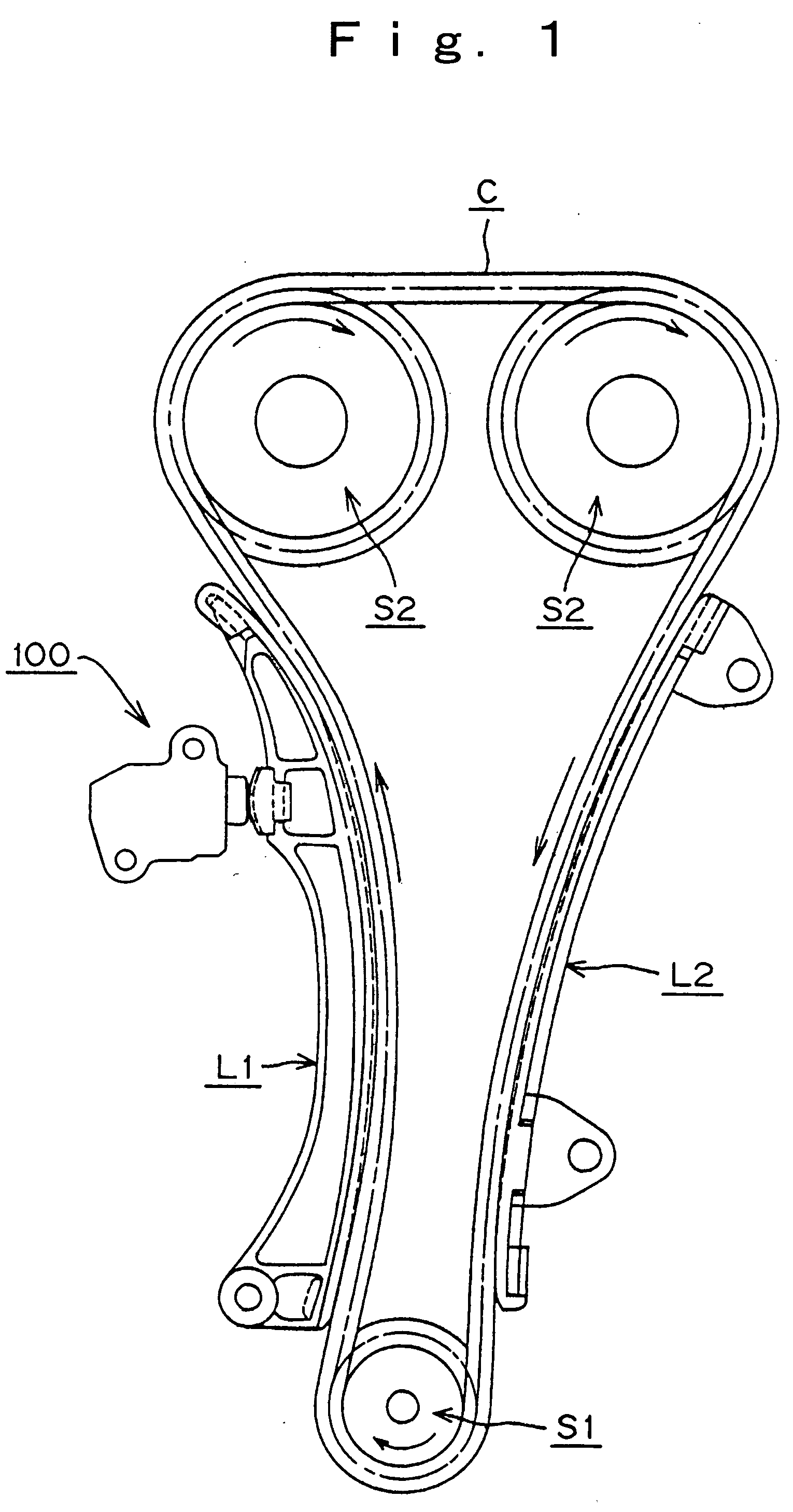

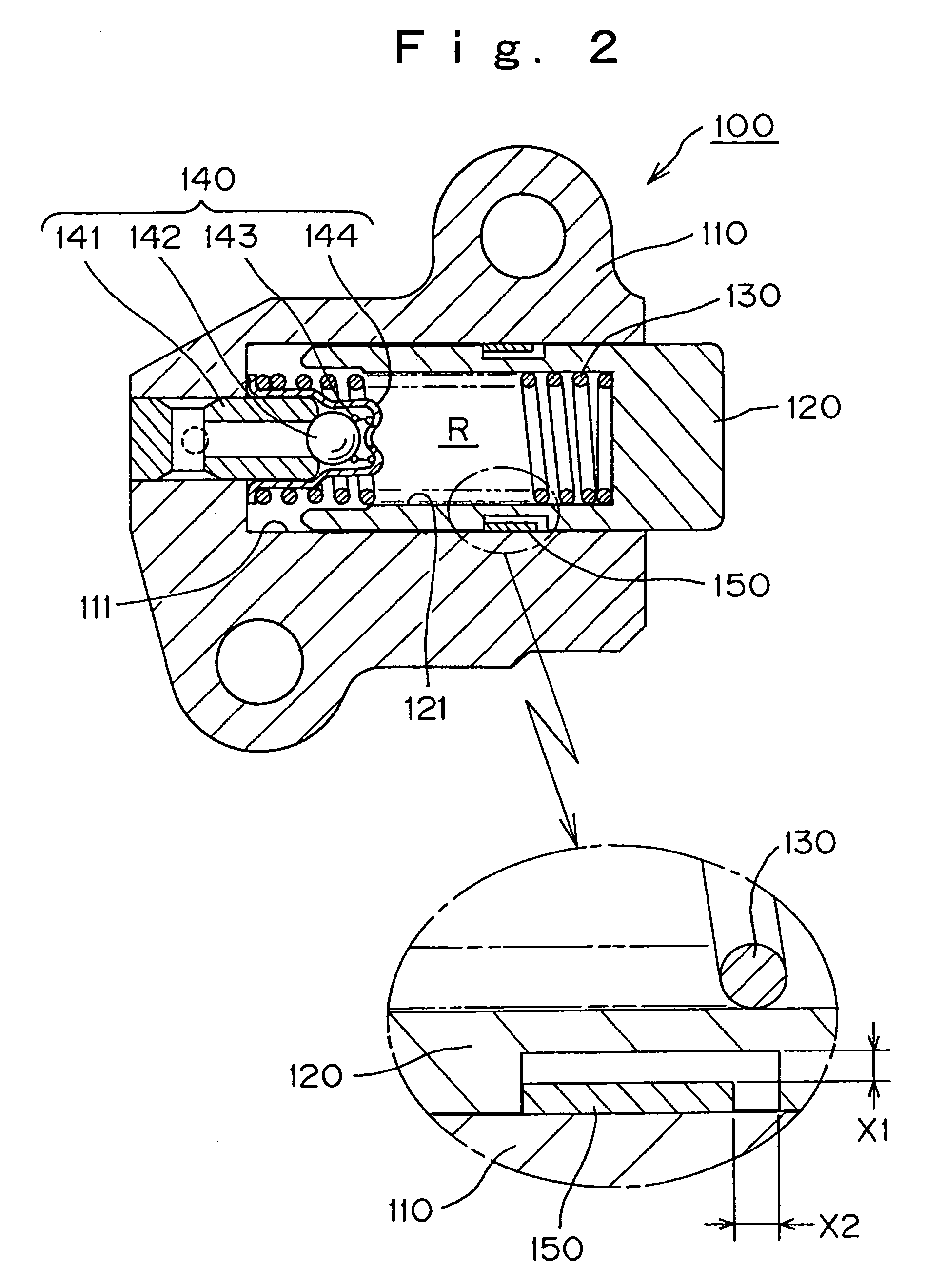

Ring type hydraulic tensioner

InactiveUS20050272542A1Quick retractPreventing backlash noiseGearingValve drivesRing typeHigh pressure chamber

In a hydraulic tensioner a cylindrical plunger slidably protrudes from a plunger-accommodating hole in a tensioner housing. A check valve unit allows oil to flow under pressure into a high pressure chamber formed by the plunger and the housing, but blocks reverse flow. The plunger is biased in the protruding direction by a spring located in the high pressure chamber. The plunger has an annular groove in its outer circumferential surface, and a C-shaped ring disposed in the groove is resiliently biased radially outwardly against the inner circumferential wall of the plunger-accommodating hole. A radial clearances is provided between the ring and the bottom of the groove, and the ring also fits into the groove with an axial clearance.

Owner:TSUBAKIMOTO CHAIN CO

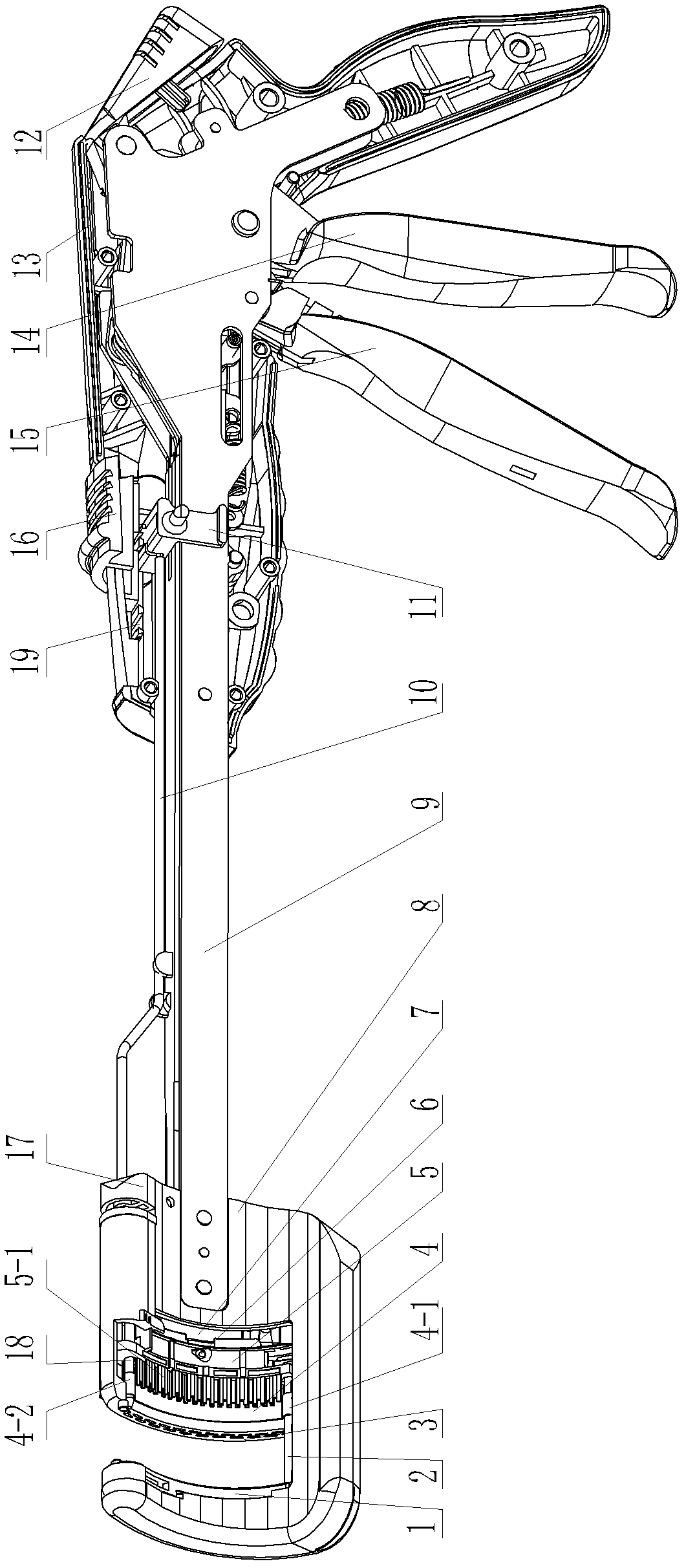

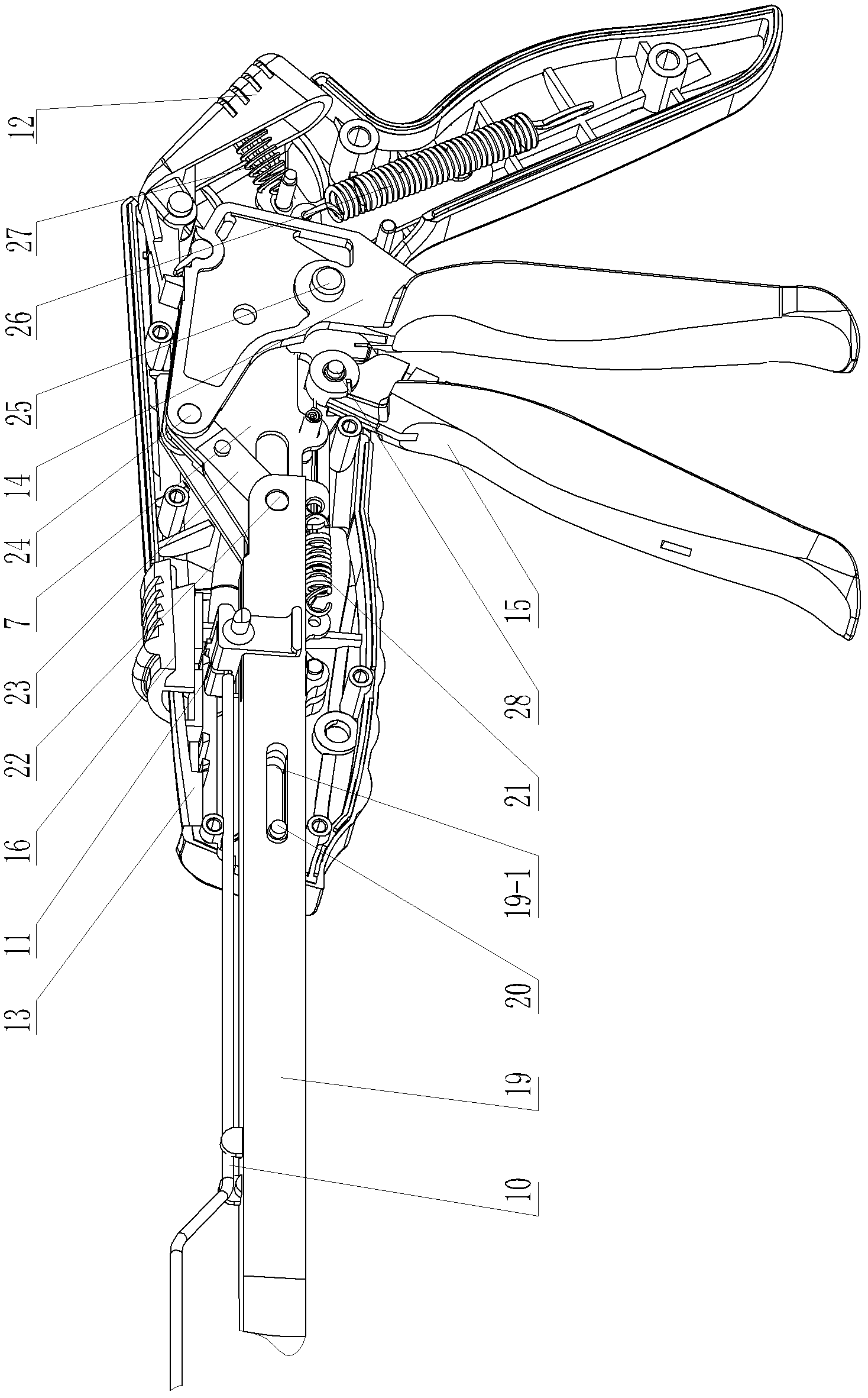

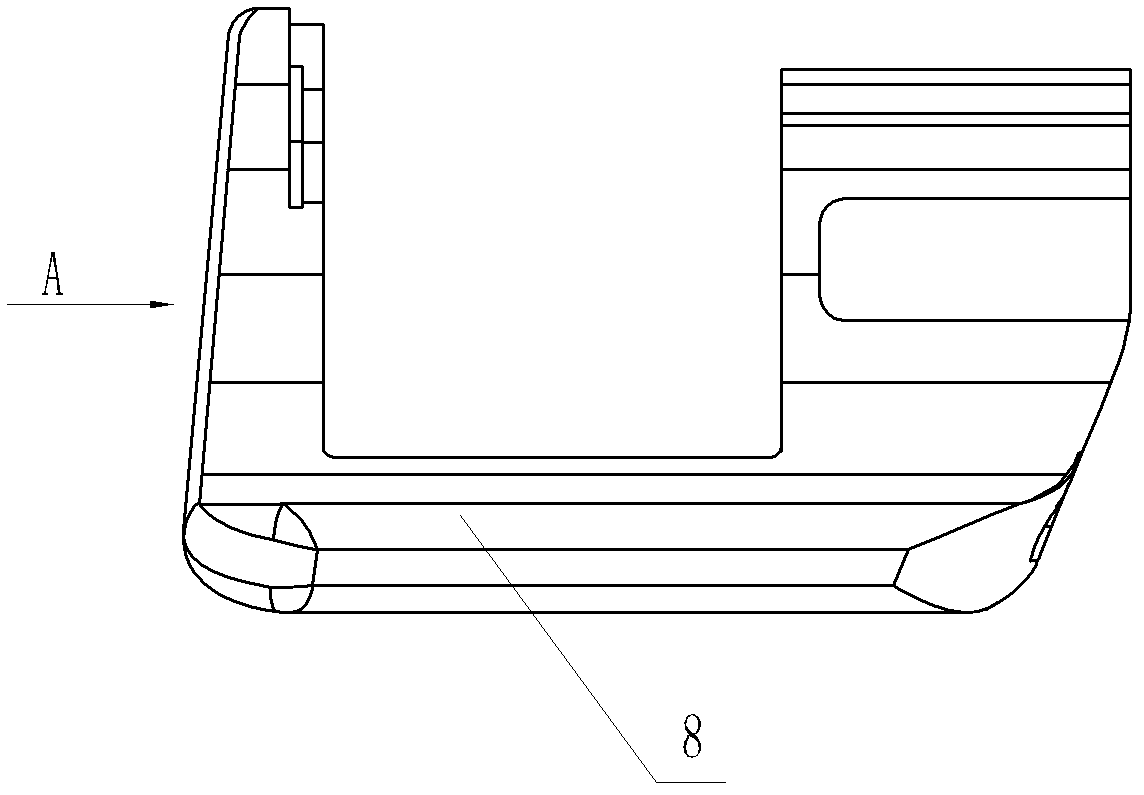

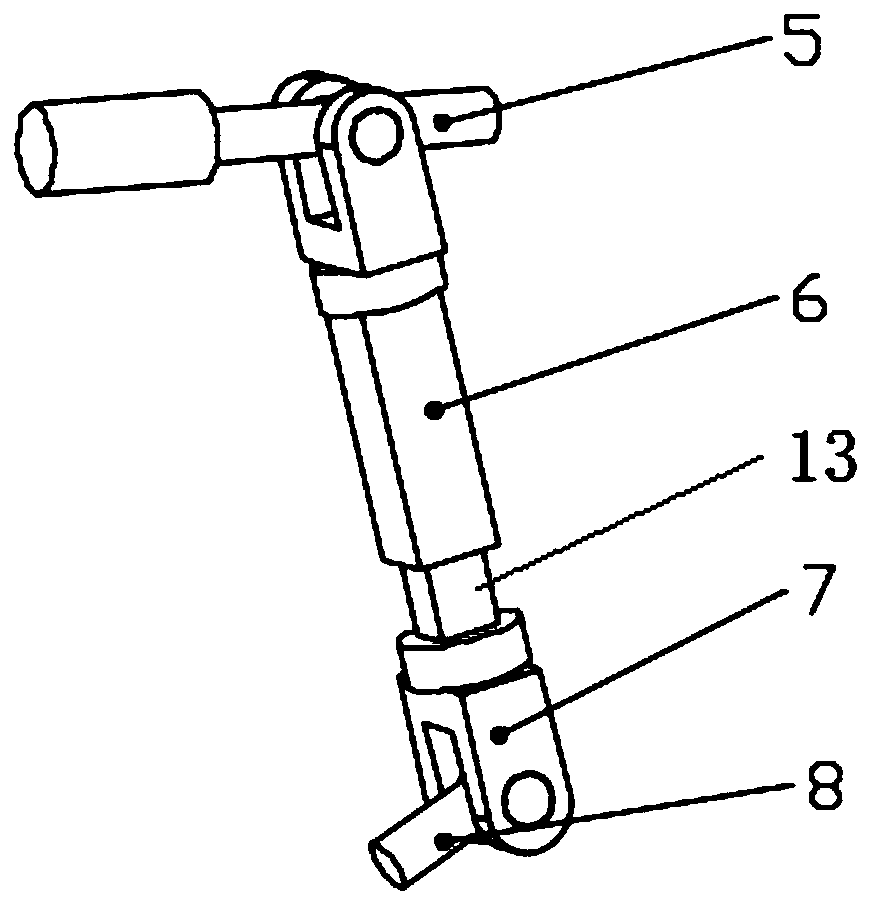

Surgical incision stitching instrument

InactiveCN102579095AImprove assembly efficiencyReduce machining and assembly accuracySurgical staplesEngineeringKnife holder

The invention relates to a surgical incision stitching instrument, comprising a support rod, a nail propping seat component, a nail pushing mechanism and a limit mechanism, wherein a cover with handles, the nail pushing mechanism and the limit mechanism are fixed at the rear part of the support rod; the nail propping mechanism is connected at the front part of the support rod and comprises a nail propping seat with an opening on one side, an anvil block fixed at the front part of the nail propping seat, and a nail bin and a knife holder arranged at the rear part of the nail propping seat; a blade fixed on the knife holder penetrates through the nail bin and is positioned in the middle of nail lines; each nail pushing piece on the knife holder is arranged in each nail line of the nail bin; the sections of the nail propping seat, the anvil block, the nail bin, the knife holder and the blade are arranged to be in the shape of a polygon with more than three sides; two ends of an internal locating pin on the closed side of the nail propping seat are respectively arranged on the nail bin and the anvil block; an external locating pin is arranged on the nail bin in a penetrating way, the rear end of the external locating pin is connected with a sliding seat, and the front end of the external locating pin corresponds to a location hole on the anvil block; and an internal guide sleeve and an external guide sleeve are respectively arranged on the internal locating pin and the external locating pin and can move front and back relatively. The surgical incision stitching instrument has a simple structure and can enhance assembly efficiency and reduce manufacturing cost.

Owner:CHANGZHOU ZHIYE MEDICAL DEVICES INST

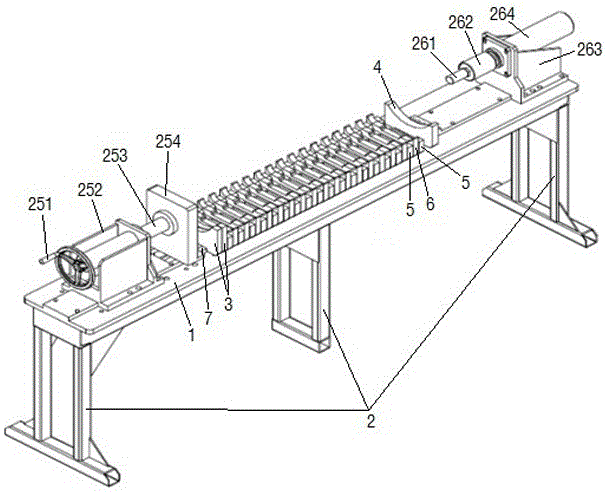

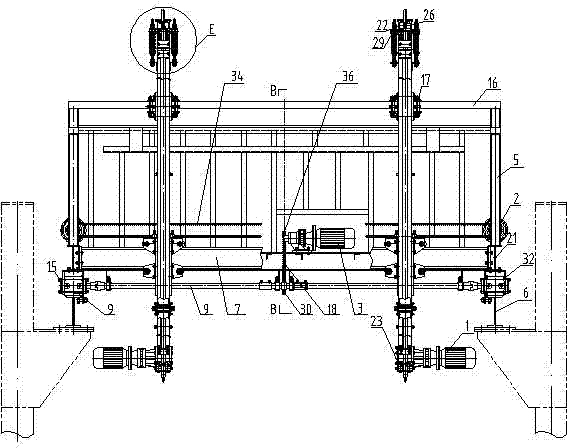

Automatic grain sampler

InactiveCN102305726AGuaranteed uptimeAvoid out of syncWithdrawing sample devicesMotor driveDrive shaft

The invention discloses an automatic grain sampler. The automatic grain sampler comprises a longitudinal traveling cart which is arranged on longitudinal traveling tracks, two transverse traveling trolleys which are arranged on transverse traveling tracks of the longitudinal traveling cart, and fiche chain transmission lifting mechanisms which are arranged on the transverse traveling trolleys. The automatic grain sampler is characterized in that: a longitudinal traveling cart reducing motor drives a driving shaft of the cart by a chain wheel, and traveling wheels of the cart which are positioned at both ends of the driving shaft and a driven shaft of the cart are arranged on the longitudinal traveling tracks; the two transverse traveling trolleys have the same structure, a driving sprocket of a transverse traveling reducing motor shaft of one trolley is connected with a driven sprocket of a transverse traveling reducing motor shaft of the other trolley through a trolley chain, and moving rollers of the trolleys are arranged on the transverse traveling tracks; and driving sprockets of fiche lifting reducing motor shafts of the fiche chain transmission lifting mechanisms are connected with driven sprockets of sprocket adjustment shafts of the trolleys through fiche chains, and the fiche chains are fixedly connected with fiches. The automatic grain sampler has the advantages of simple structure, high manufacturing and assembly processability, low cost, high performance-price ratio and the like, and can be operated stably.

Owner:吉林三豪自动化机械有限责任公司

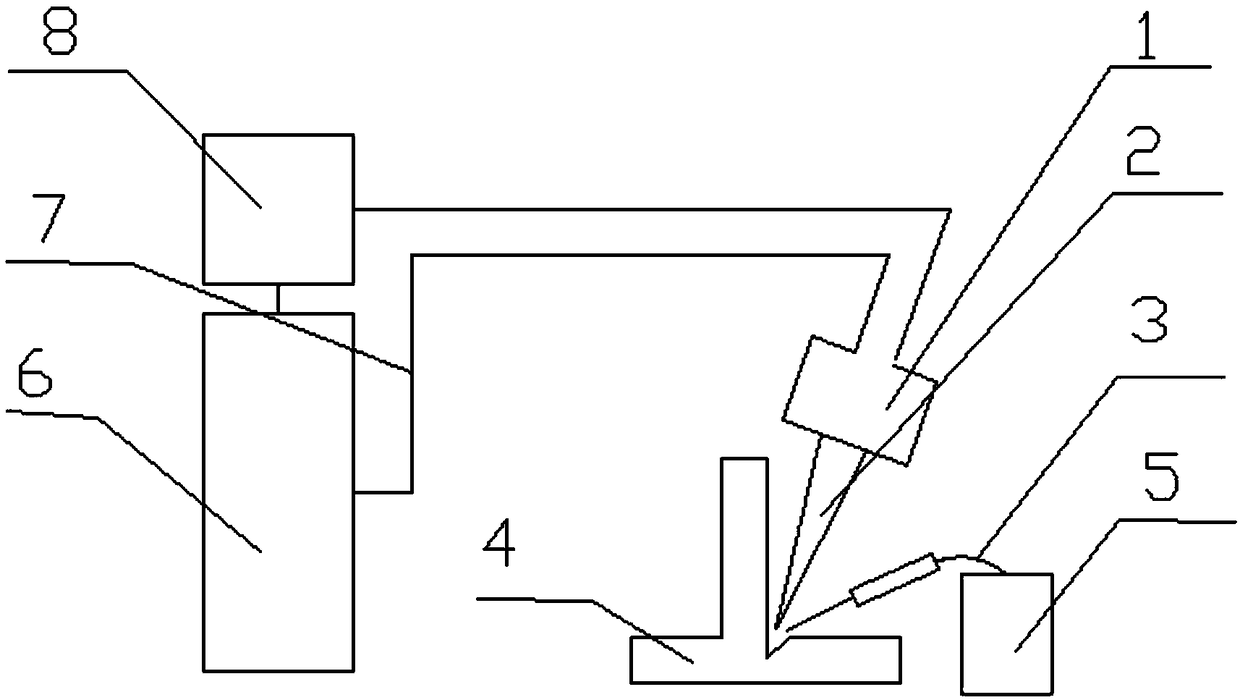

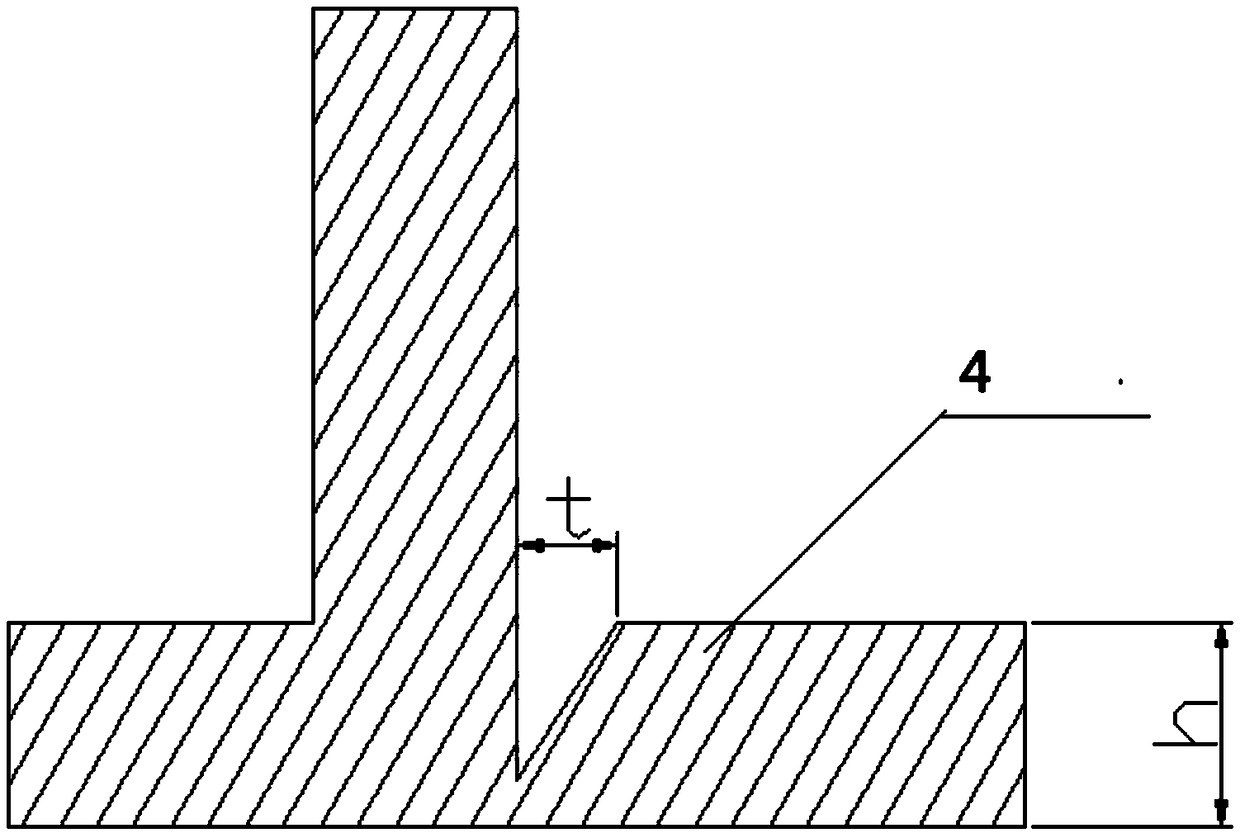

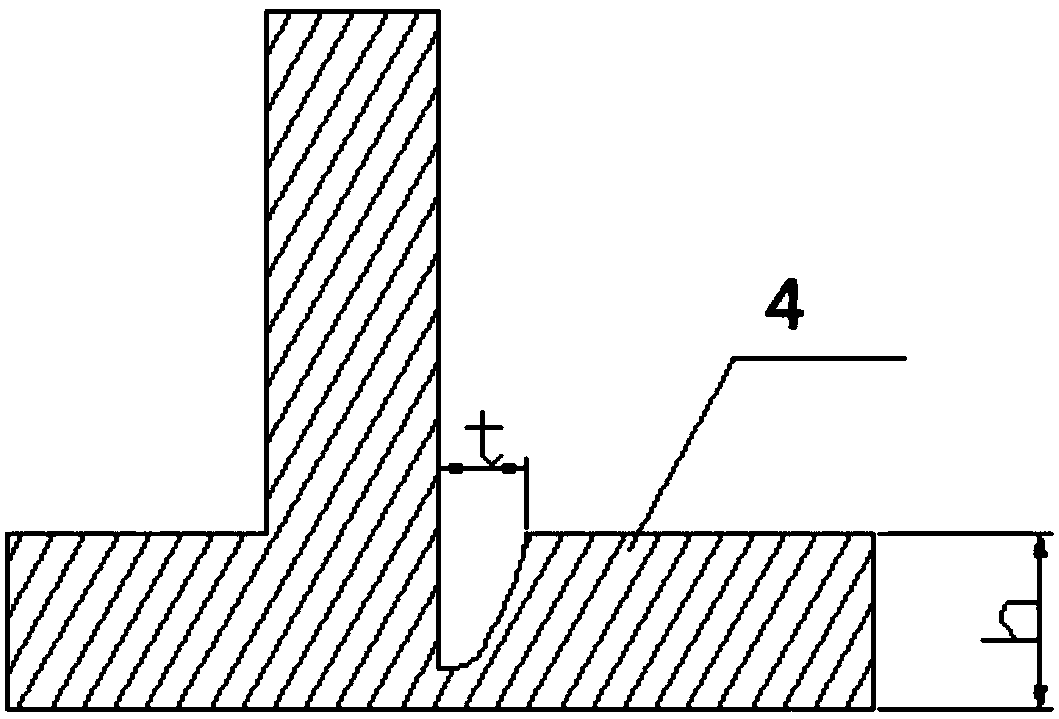

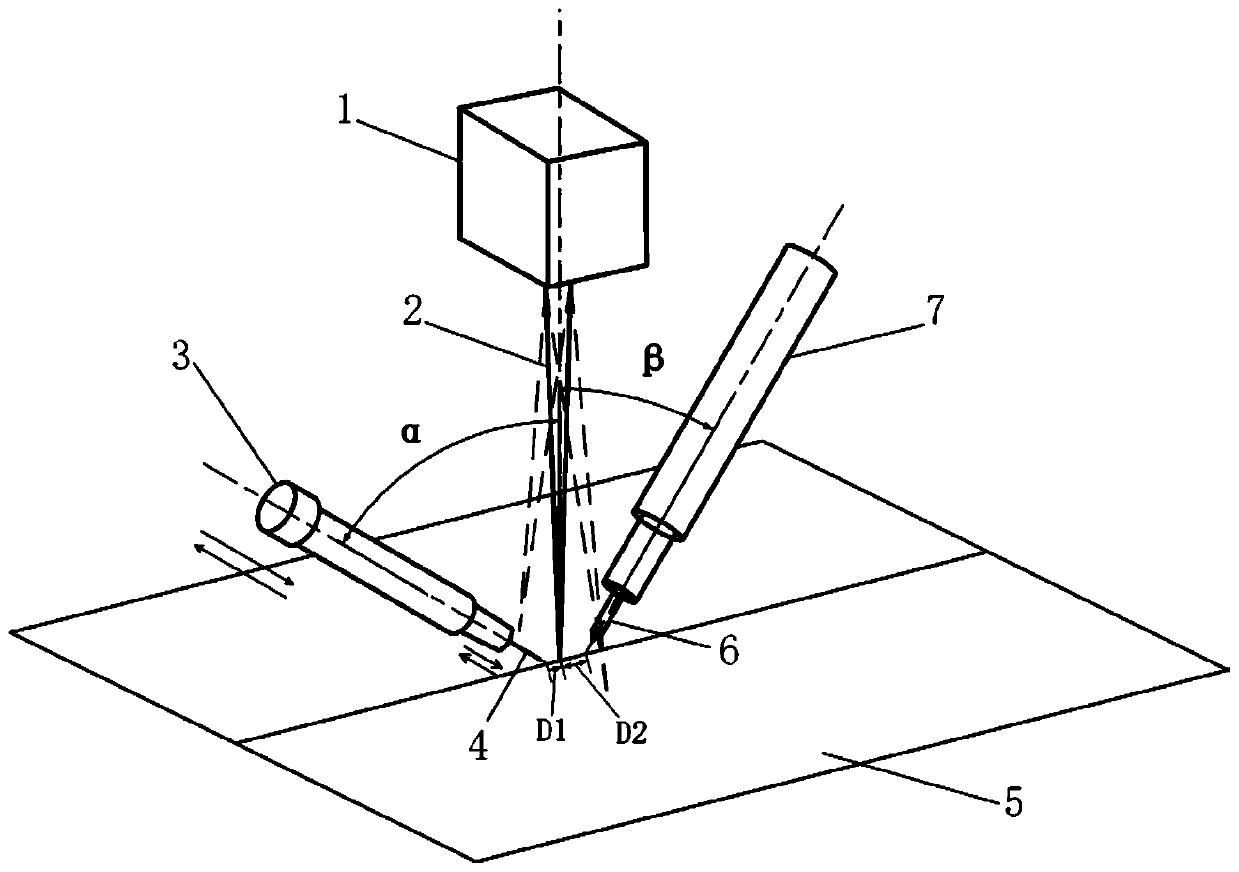

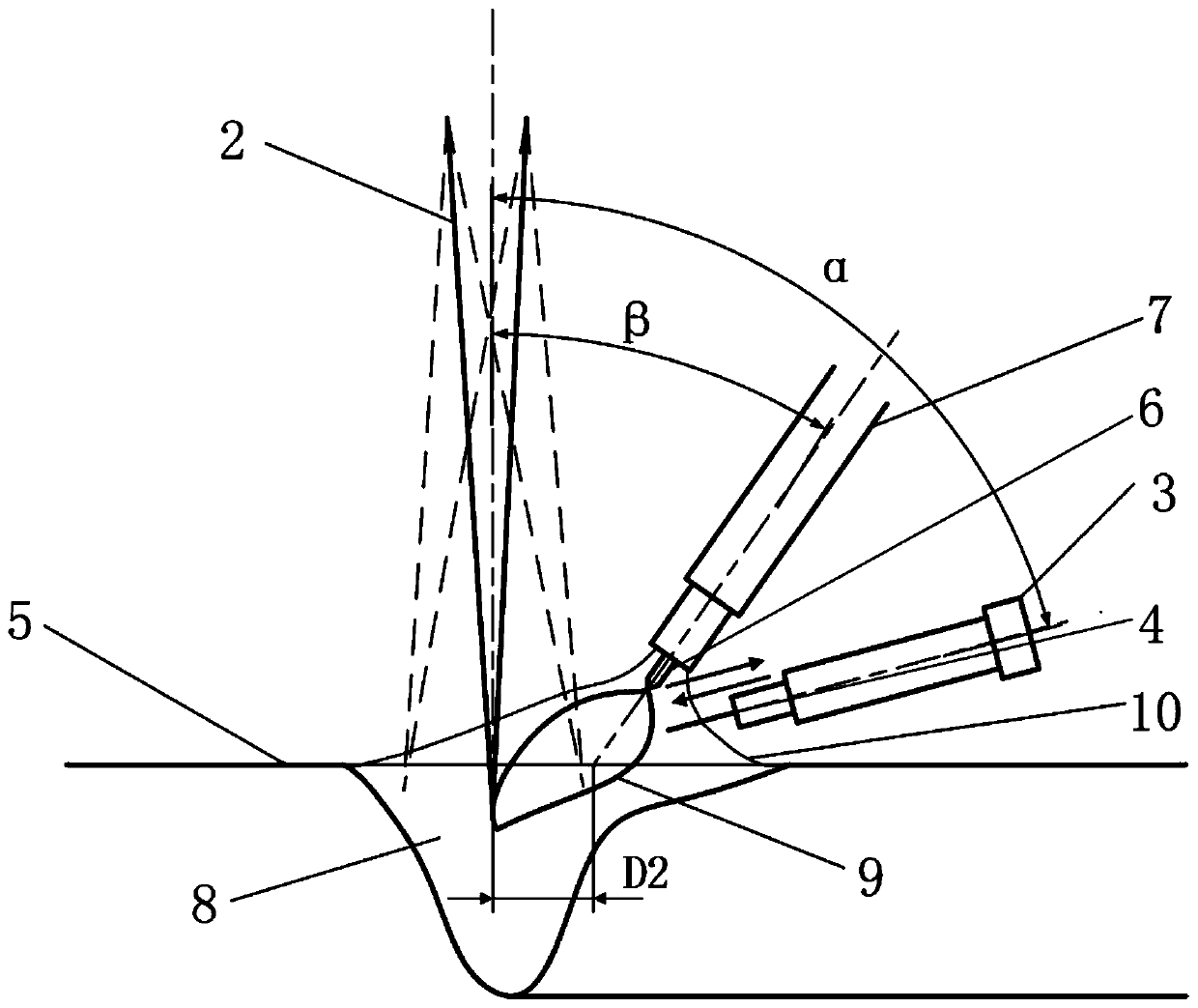

Sheet laser scanning filler wire welding method

ActiveCN109048059AReduce assembly accuracyReduce melt spatterLaser beam welding apparatusLaser scanningWelding deformation

The invention discloses a sheet laser scanning filler wire welding method. The method comprises the following steps that S1, before welding, a semi-V-shaped or semi-U-shaped groove is machined in a bottom plate of a to-be-welded right-angled structure of a to-be-welded workpiece; S2, welding wires are fed into the groove, and laser beams are focused to the welding wires; and S3, required laser welding technological parameters are set, and laser scanning filler wire welding is performed under protective gas. According to the sheet laser scanning filler wire welding method provided by the invention, on the basis of the regular T-shaped or L-shaped right-angled welding structure, the semi-V-shaped or semi-U-shaped groove is formed, the assembly precision of the right-angled structure can be greatly reduced, stacking and sinking of weld joints are effectively controlled, splashing on the surfaces of the weld joints is reduced, and the surfaces of the weld joints are smother; welding deformation of the sheet right-angled structure can be reduced while heat input is reduced, and the porosity rate is decreased; and metallurgical bonding of the welding wires and a base can be promoted, thesheet welding efficiency is improved, and the weld joints with the good quality are formed.

Owner:JIANGSU UNIV

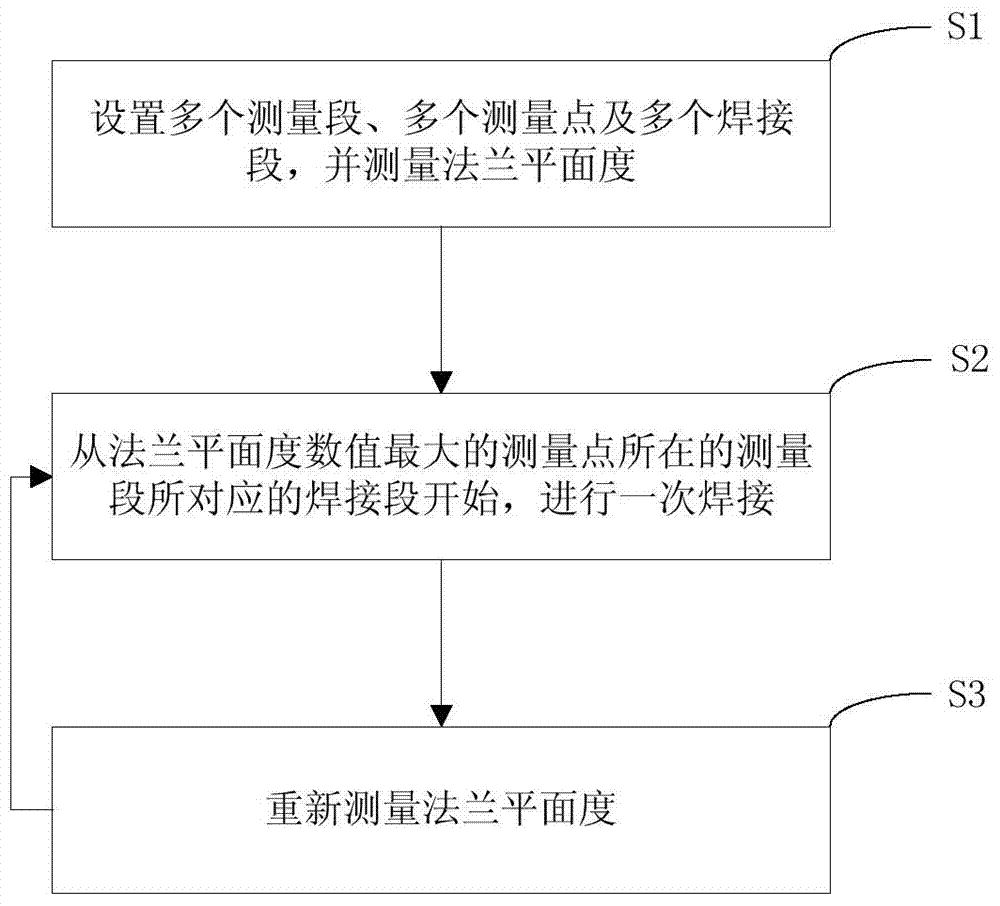

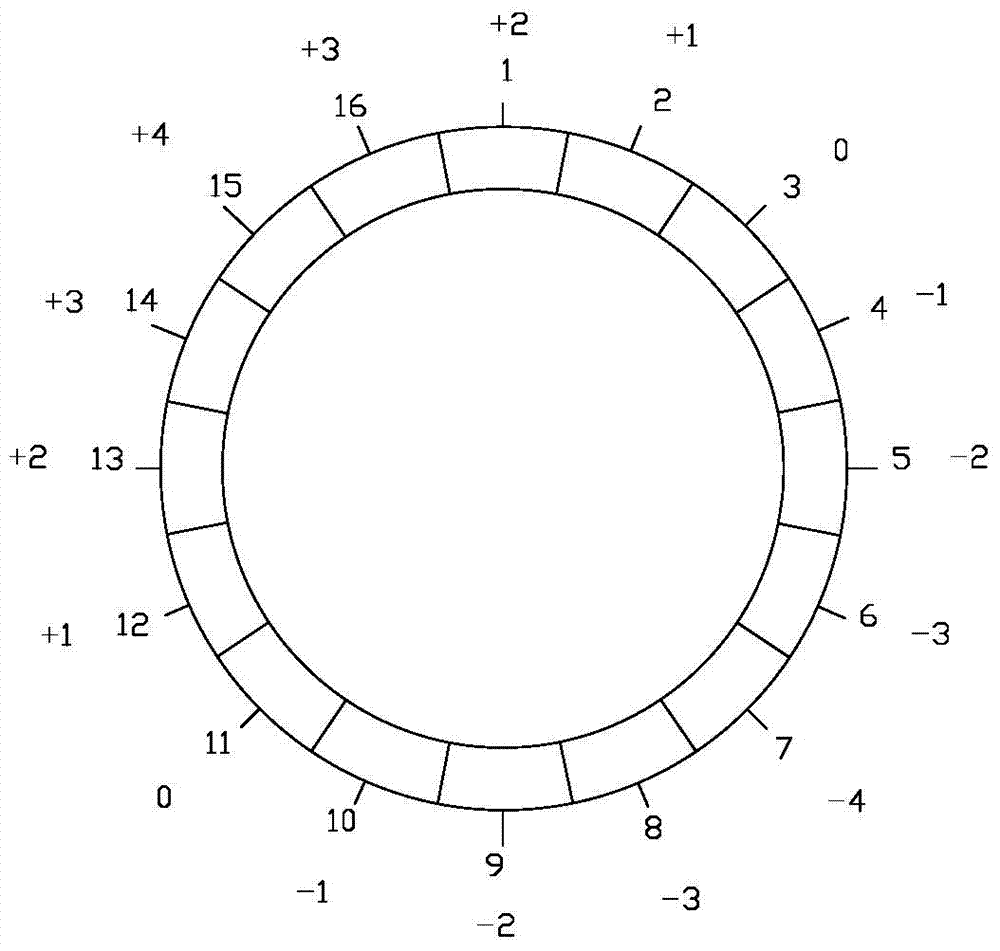

Method for controlling welding deformation of telescopic steering oar base seat barrel

ActiveCN103753034AReduce assembly accuracyReduce construction difficultyUsing optical meansWelding apparatusEngineeringWelding deformation

The invention discloses a method for controlling welding deformation of a telescopic steering oar base seat barrel, and relates to the material molding and controlling filed. The method for controlling the welding deformation of the telescopic steering oar base seat barrel includes steps: S1, equally dividing the outer perimeter of the top of the barrel into a plurality of measurement segments, setting a measurement point in the middle position of each measurement segment, arranging a plurality of welding segments which are in one to one correspondence with the plurality of the measurement segments on the outer perimeter of the bottom of the barrel, and measuring flatness of a flange through each measurement point; S2, starting from the welding segment corresponding to the measurement segment where the measurement point with the maximal flatness value of the flange is located to perform welding once, and welding at least one welding segment every time; S3, after welding once, re-measuring the flatness of the flange, moving to the step S2 to perform welding once again, and repeating the step 2 and the step 3 until welding of all the welding segments are finished. The method for controlling the welding deformation of the telescopic steering oar base seat barrel reduces assembly accuracy of the barrel, improves production efficiency, and effectively controls the flatness of the flange.

Owner:QINGDAO WUCHUAN HEAVY IND CO LTD

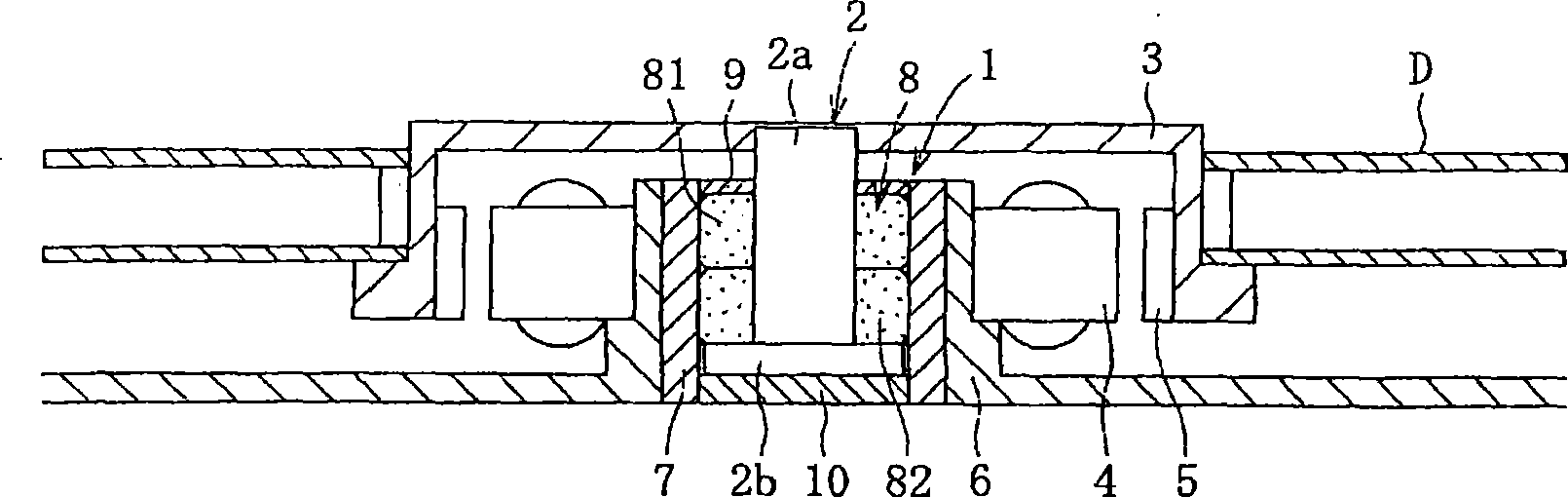

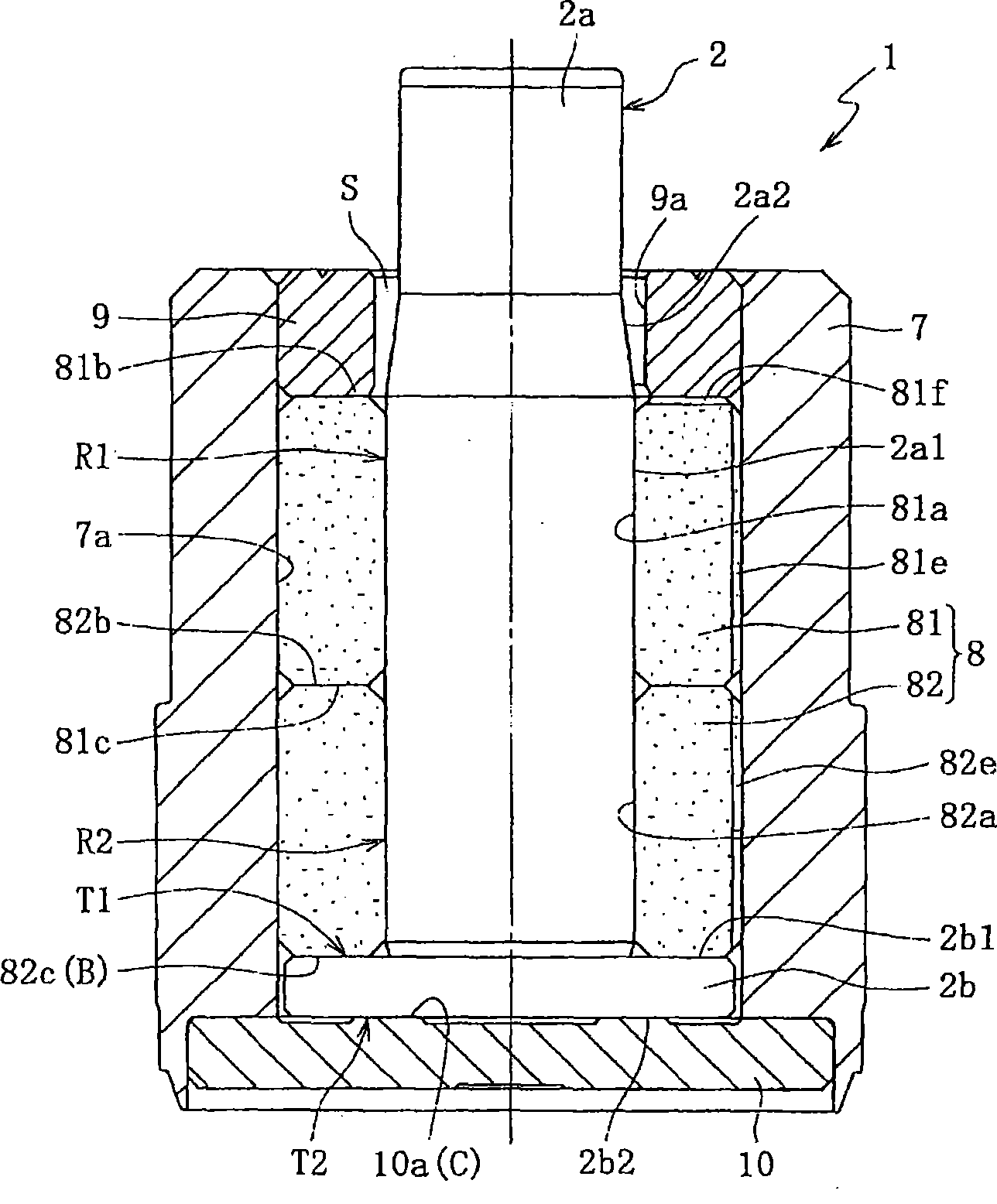

Fluid dynamic pressure bearing device and method of producing the same

InactiveCN101400904AAvoid bendingReduce assembly accuracyBearing componentsSliding contact bearingsEngineeringBearing surface

A fluid dynamic pressure bearing device that achieves high rigidity against moment without a reduction in assembly accuracy and bearing performance. In the bearing device, bearing sleeves are arranged in the axial direction and coaxiality of radial bearing surfaces formed on the inner peripheral surfaces of the bearing sleeves is set to 3 [mu]m or less. This secures width accuracy between the radial bearing gaps to prevent a reduction in bearing performance and a failure such as wear etc. caused by contact between a shaft member and the bearing sleeves. Further, a first radial bearing surface and a second radial bearing surface are provided on at least one sleeve, and this allows a sleeve assembly constructed from bearing sleeves to be supported at least three positions in the axial direction in a process of assembling the sleeve assembly. As a result, assembly work can be carried out with two bearing sleeves prevented from being bent in the middle and highly accurate coaxiality between both bearing sleeves secured.

Owner:NTN CORP

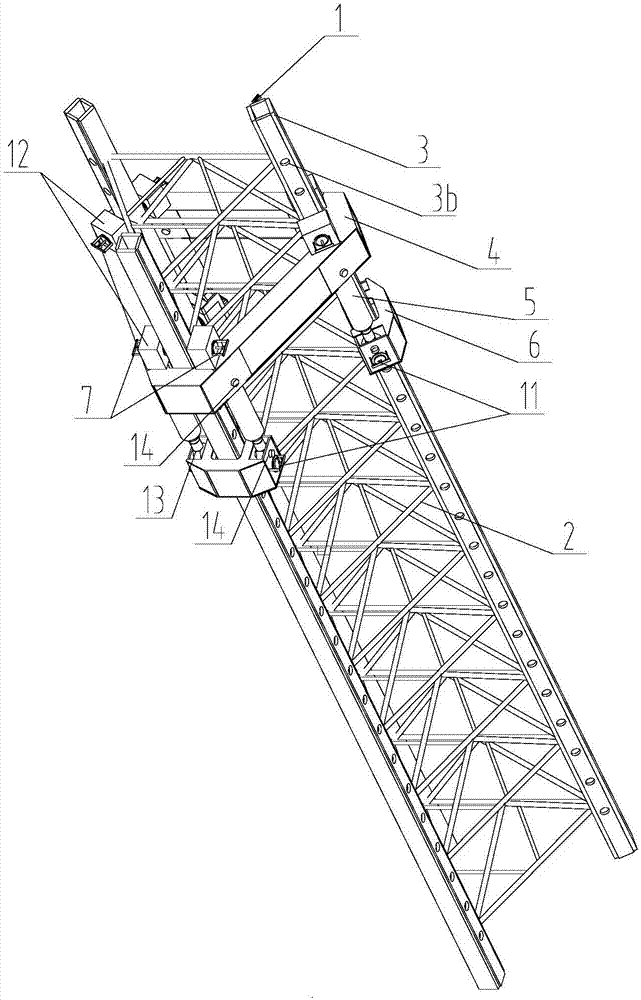

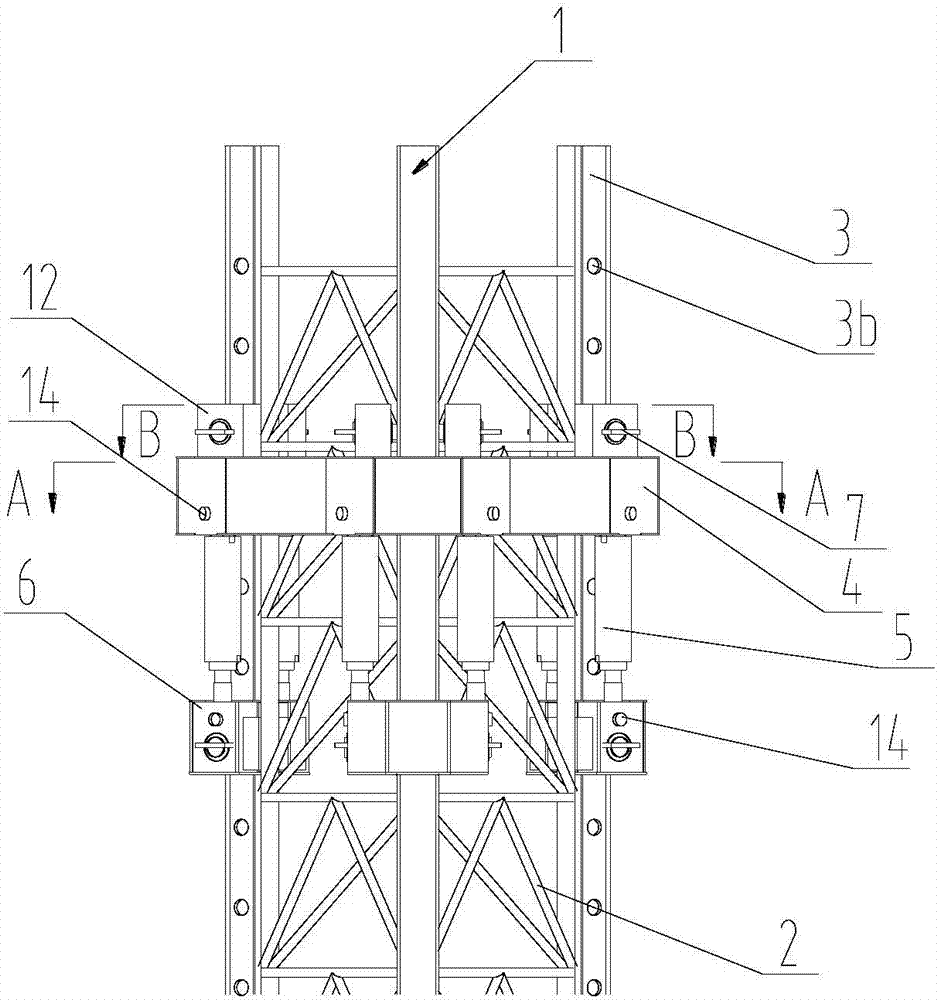

Hydraulic plug pin ascending device and descending device

ActiveCN107227726AAchieve liftingReduce assembly accuracyArtificial islandsUnderwater structuresEngineeringMechanical engineering

The invention discloses a hydraulic plug pin ascending and descending device, and belongs to the field of self-ascending type ocean platform accessories. The hydraulic plug pin ascending and descending device comprises truss type pile legs, a ring beam, a lifting oil cylinder, a sliding beam, plug pin assemblies and plug pin mounting blocks; a plurality of plug pin holes which are matched with plug pin assemblies are uniformly formed in each chord rod; the plurality of plug pin holes are arranged in the length direction of each chord rod; the ring bean is arranged on the truss type pile legs in a sliding and sleeving manner; the plurality of the plug pin mounting blocks are respectively mounted on the ring beam; the plurality of the plug pin assemblies are respectively mounted on the respective corresponding plug pin mounting blocks; the plug pin assemblies and the plug pin holes are oppositely arranged at intervals; a plurality of sliding beams are respectively arranged on the respective corresponding chord rod in a sliding manner; one end of the lifting oil cylinder is mounted on the ring beam; the other end of the lifting oil cylinder is mounted on the sliding beam. The hydraulic plug pin ascending and descending device is low in assembling precision; the manufacturing cost is reduced.

Owner:WUHAN MARINE MACHINERY PLANT

Laser scanning-vibration hot wire TIG hybrid welding method

InactiveCN110961789AWide heating rangeReduce assembly accuracyLaser beam welding apparatusLaser scanningDeposition rate

The invention relates to a laser scanning-vibration hot wire TIG hybrid welding method. The method is mainly formed by compounding laser scanning welding and vibration hot wire TIG welding. During welding, a welding heat source is formed by combining a scanning laser and a TIG electric arc, a welding wire is heated and vibrated in a reciprocating mode at the same time so as to generate a vibrationhot wire, and laser scanning-vibration hot wire TIG hybrid welding is jointly formed by the vibration hot wire and a hybrid heat source. According to the method, on one hand, the laser scanning welding can reduce an assembling precision requirement of a workpiece before welding; and on the other hand, a stirring effect on a molten pool can reduce a porosity and refine a structure; and heat inputduring welding can be reduced by preheating the welding wire, and a deposition rate and welding efficiency are improved. Under a condition that the hot wire is vibrated, on one hand, a molten pool canbe stirred to refine the structure; and on the other hand, a molten drop transition frequency can be increased, and the welding efficiency is improved.

Owner:HARBIN INST OF TECH AT WEIHAI

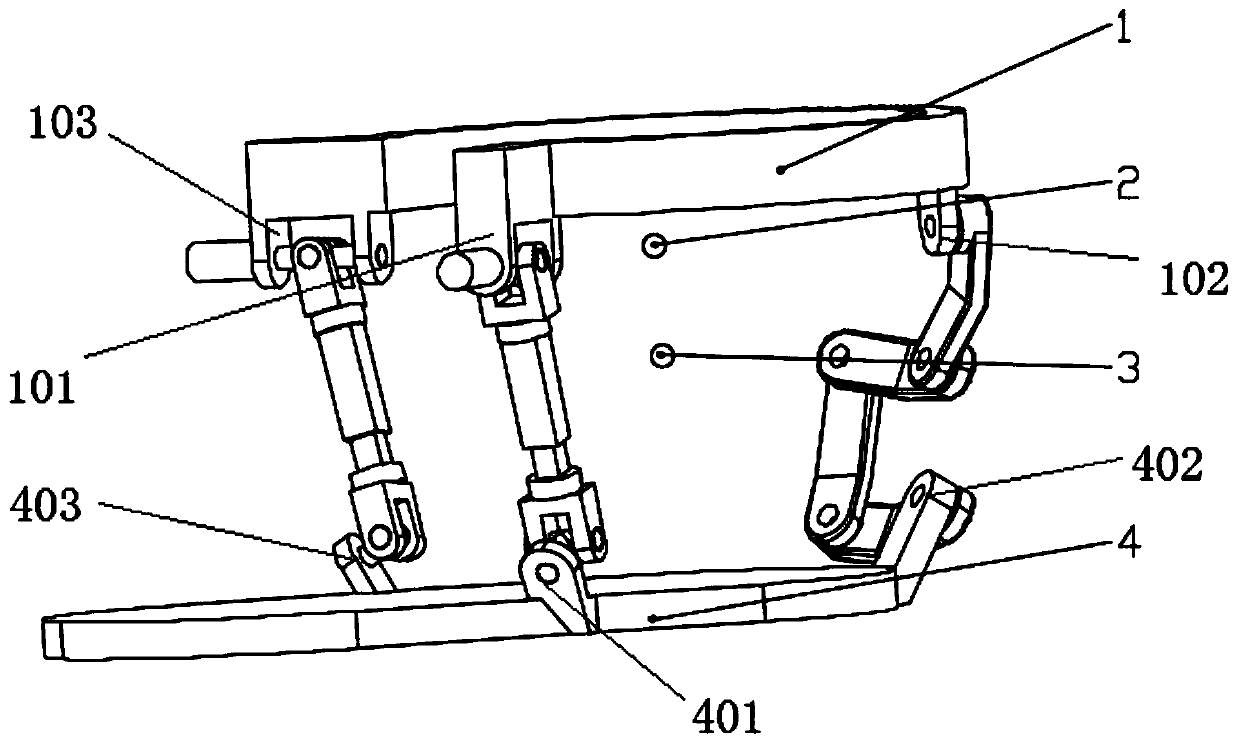

Novel ankle joint rehabilitation parallel mechanism

PendingCN111419634ADoes not affect mobilityReduce precisionChiropractic devicesPivotal connectionsPhysical medicine and rehabilitationEngineering

The invention discloses a novel ankle joint rehabilitation parallel mechanism. The mechanism comprises a static platform, a movable platform, two UPU branched chains and an AABA-type branched chain; the parallel mechanism is provided with two non-coincident rotary spherical centers which are respectively a fixed spherical center and a movable spherical center; the whole parallel mechanism is regarded as that the movable spherical center performs spherical motion with two degrees of freedom around the fixed spherical center, and the movable platform performs spherical motion with one degree offreedom around the movable spherical center under the constraint of the three branched chains; rotation axes of rotary pairs respectively between the three branched chains and the static platform meetat a point which is the fixed spherical center of the parallel mechanism; rotation axes of rotary pairs respectively between the three branched chains and the movable platform meet at a point which is the movable spherical center of the parallel mechanism; each UPU branched chain is provided with a moving pair along the length direction of the UPU branched chain; the two UPU branched chains control the positions of the fixed spherical center and the movable spherical center in space; and a B-type connecting rod in the AABA-type branched chain controls the distance between the fixed sphericalcenter and the movable spherical center. The parallel mechanism has the advantages of lower manufacturing, processing and assembling precision, simpler and more compact structure and lower cost.

Owner:HEBEI UNIV OF TECH

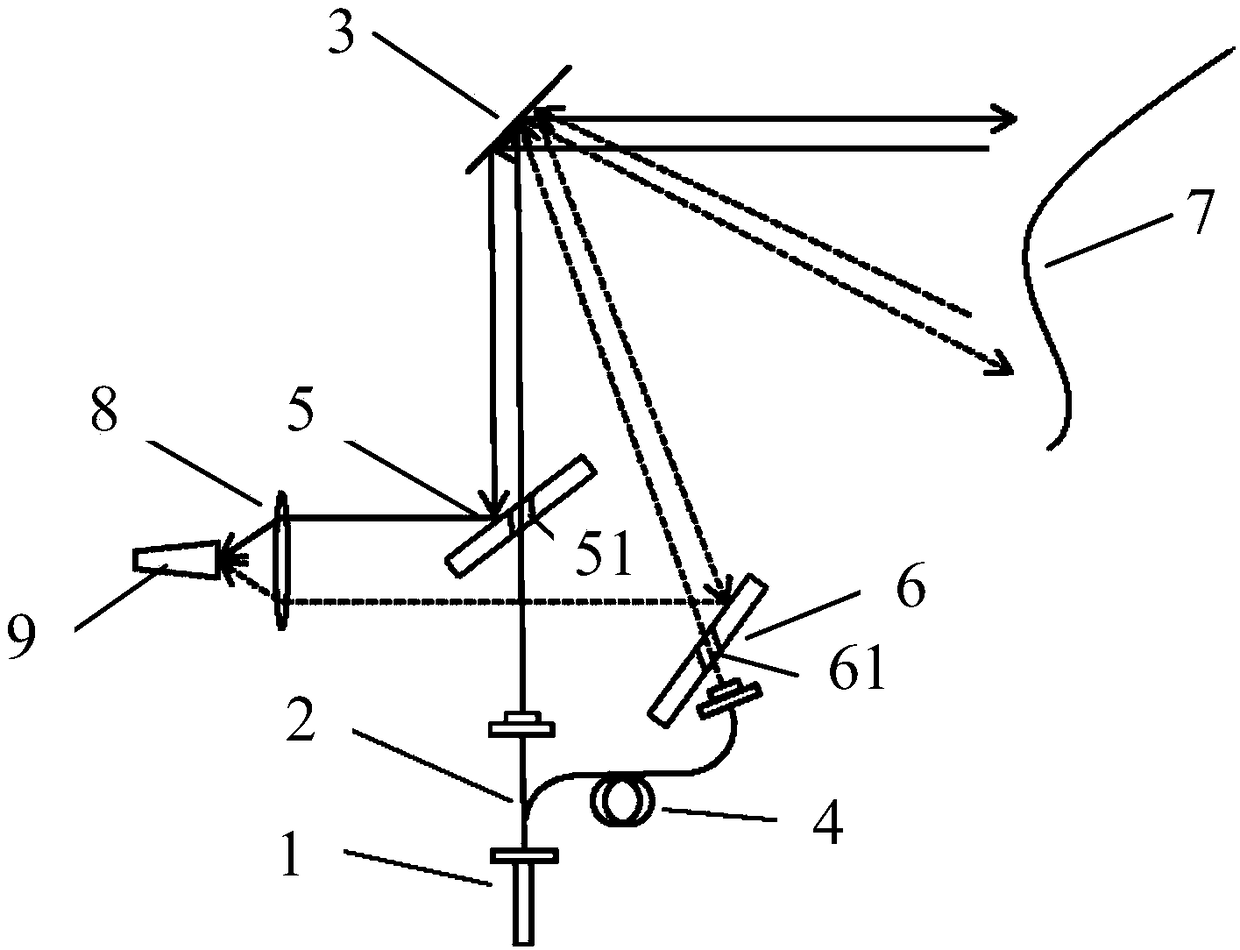

Micromirror-based time division shared window laser radar system

ActiveCN108226936AReduce in quantitySimple structureElectromagnetic wave reradiationTime domainRadar systems

The invention discloses a micromirror-based time division shared window laser radar system. A first through hole is formed in a single-face reflector; a second through hole is formed in a second single-face reflector; a laser beam generated by a laser is divided into two paths; one path of laser beam is emitted to a micromirror through the first through hole and then is emitted to a detection target through the micromirror; the other path of laser beam is emitted to the second single-face reflector after passing through delay optical fiber, is emitted to the micromirror through the second through hole and is emitted to the detection target through the micromirror; and an echo light beam reflected by the detection target is reflected to the first single-face reflector and the second single-face mirror by the micromirror and then is converged to a light detector through a converging lens. The echo light beams of two beams of emergent laser are separated in a time domain by the delay optical fiber, so that two paths of echo light beams can be detected simultaneously by one group of detector, the system structure is further simplified, the volume of the system and the number of parts are reduced, the cost is saved and the assembling precision of the system is reduced.

Owner:WUXI INFISENSE PERCEPTION TECH CO LTD

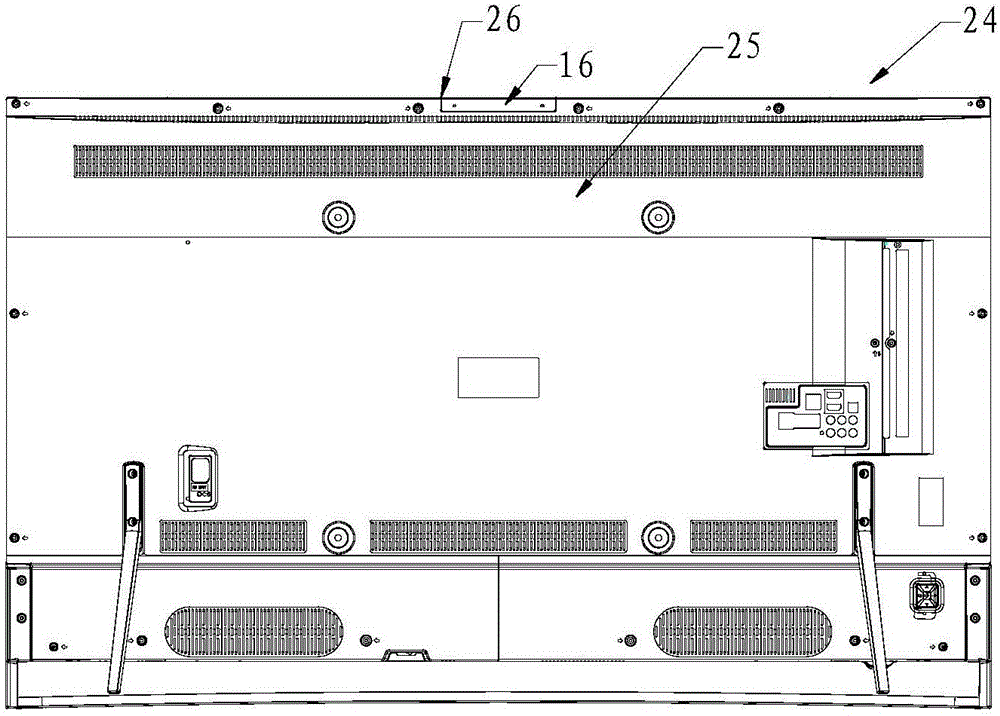

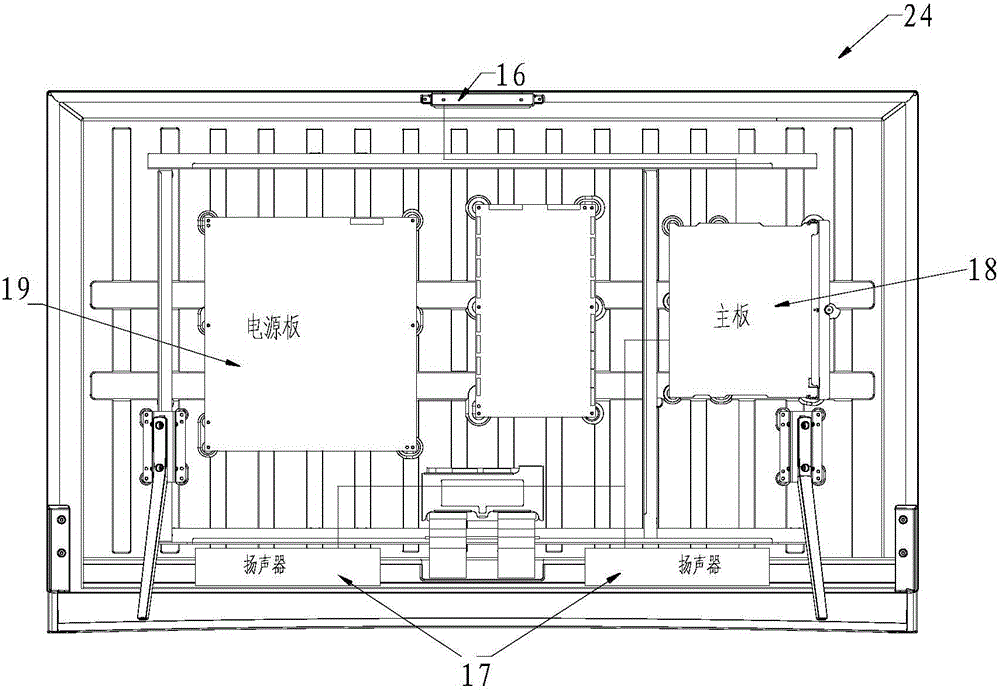

TV set

ActiveCN105163050AImprove recognition rateAvoiding the problems of forming a pickup cavityTelevision system detailsColor television detailsSpeech soundSize matching

Owner:HISENSE VISUAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com