Method for controlling welding deformation of telescopic steering oar base seat barrel

A welding deformation and telescopic technology, applied in welding equipment, manufacturing tools, instruments, etc., can solve the problems of affecting the flatness of flanges, rework of base installation, and difficulty in controlling welding deformation of cylinders, so as to reduce assembly accuracy and reduce The difficulty of construction and the effect of shortening the cycle in the dock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

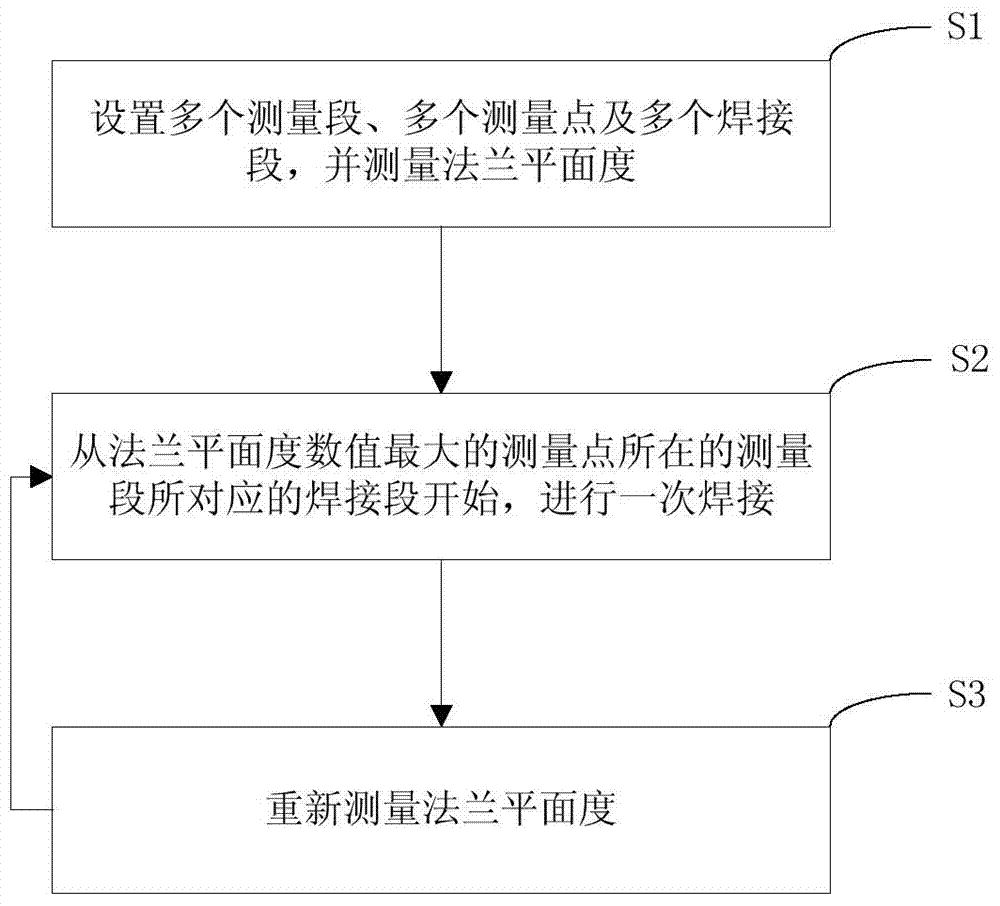

[0021] Such as figure 1 As shown, the present invention is a method for controlling the welding deformation of the telescopic rudder oar base cylinder, the telescopic rudder oar base includes a cylinder and a flange, the flange is horizontally arranged on the top of the cylinder, and the cylinder The bottom end of the body is welded to the hull, and when the bottom end of the cylinder body is welded to the hull, it specifically includes the following steps:

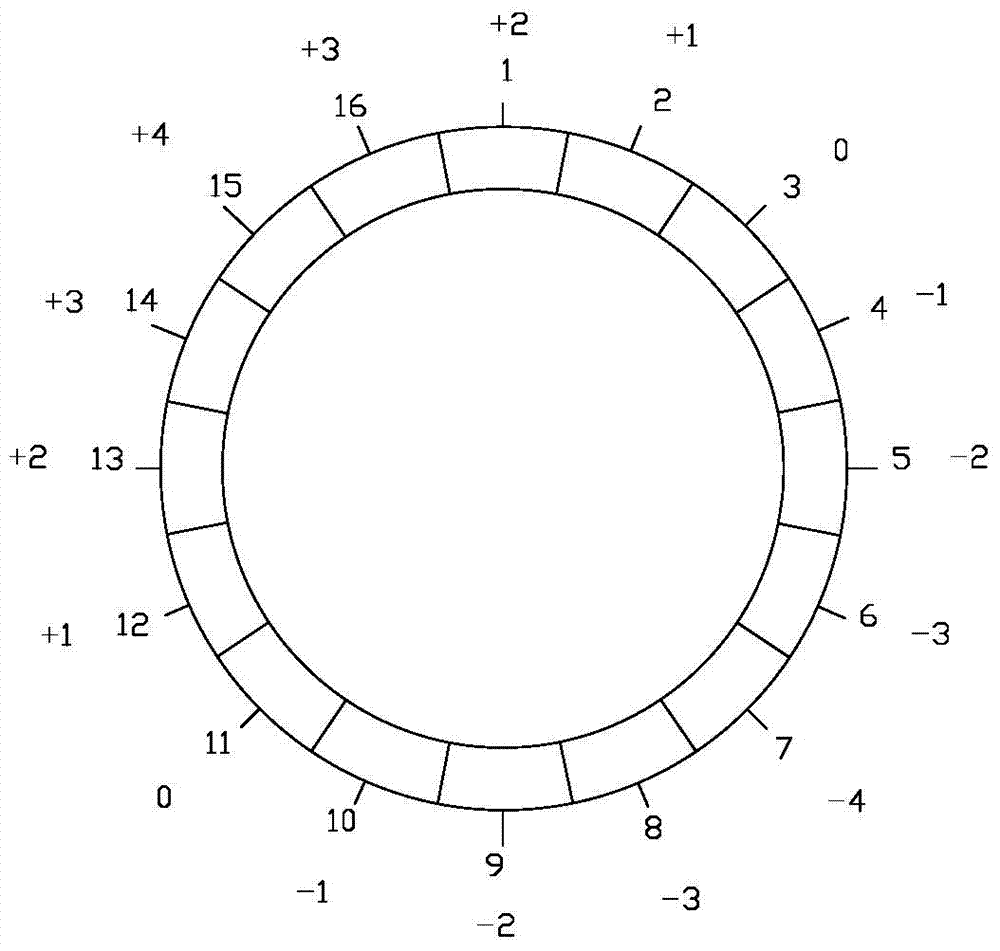

[0022] S1. Divide the outer perimeter of the top of the cylinder into multiple measuring sections. The number of measuring sections increases according to the diameter of the cylinder. A measuring point is set in the middle of each measuring section. The outer perimeter of the bottom of the cylinder is the same as A plurality of welding sections are set corresponding to the plurality of measuring sections one by one, and each measuring point has a corresponding projection point on the welding section, and the flatness of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com