Novel ankle joint rehabilitation parallel mechanism

A technology of ankle joints and parallel connection, which is applied in the direction of pivot connection, passive exercise equipment, physical therapy, etc., can solve the problems of difficult processing accuracy and loss of freedom, etc., and achieve low manufacturing processing accuracy, easy realization, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

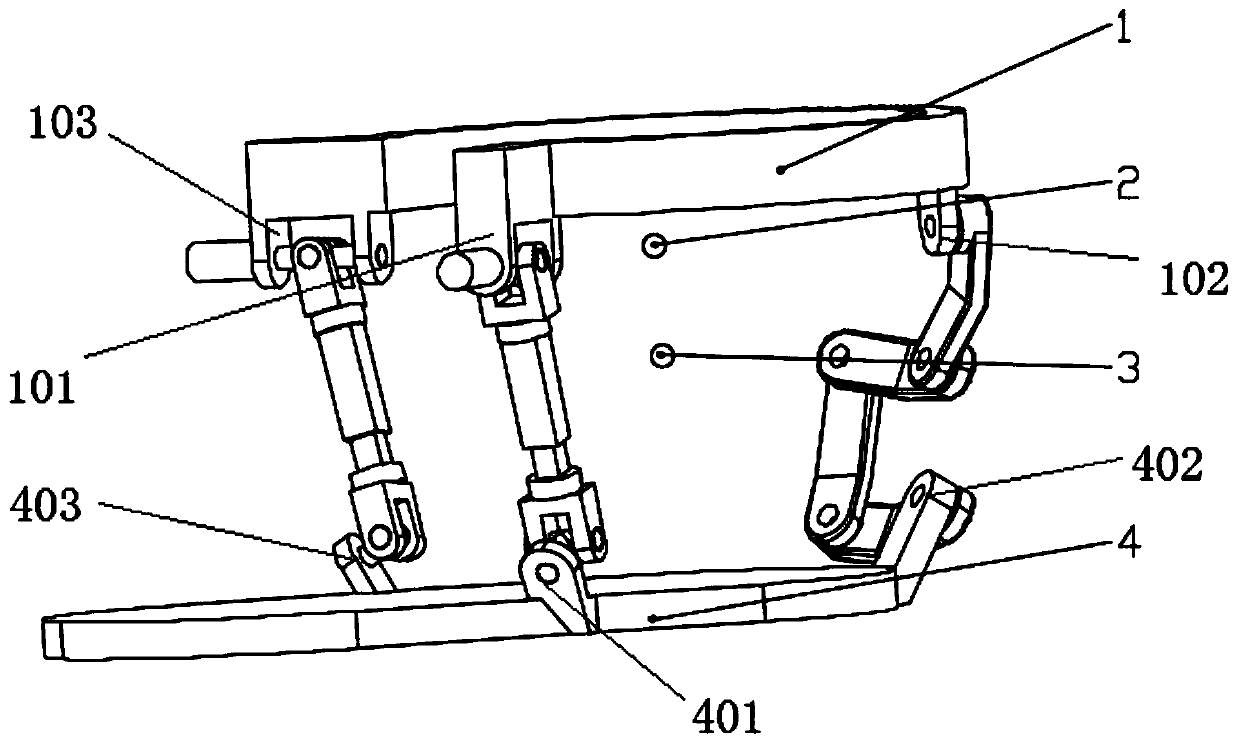

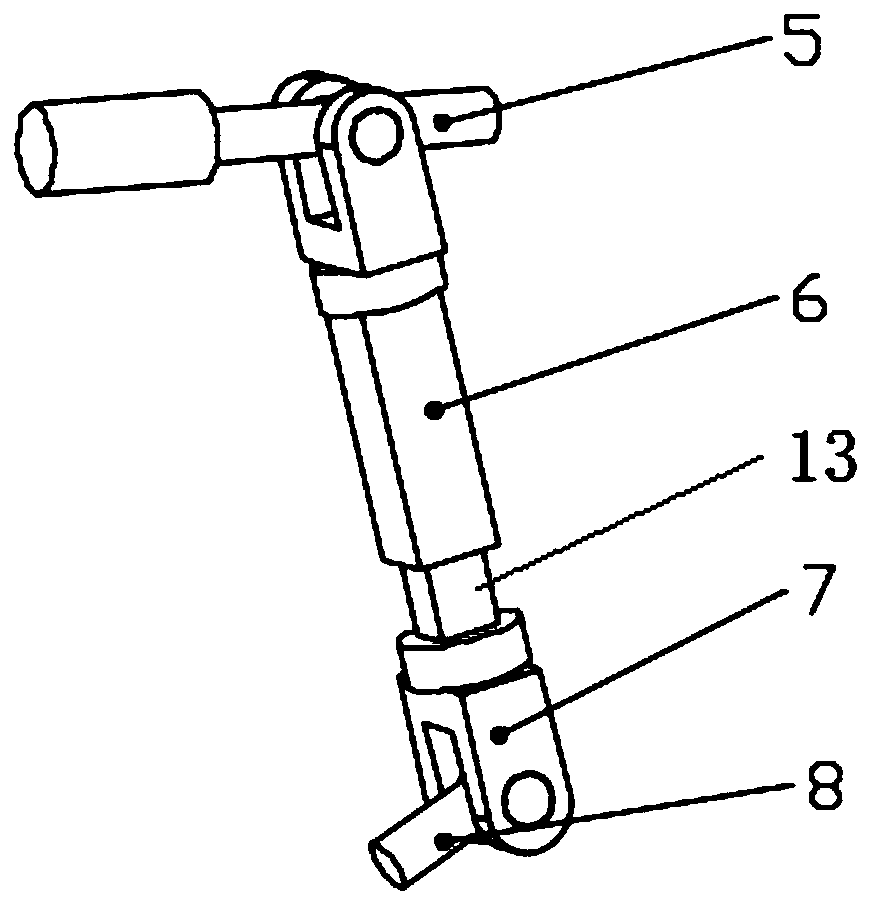

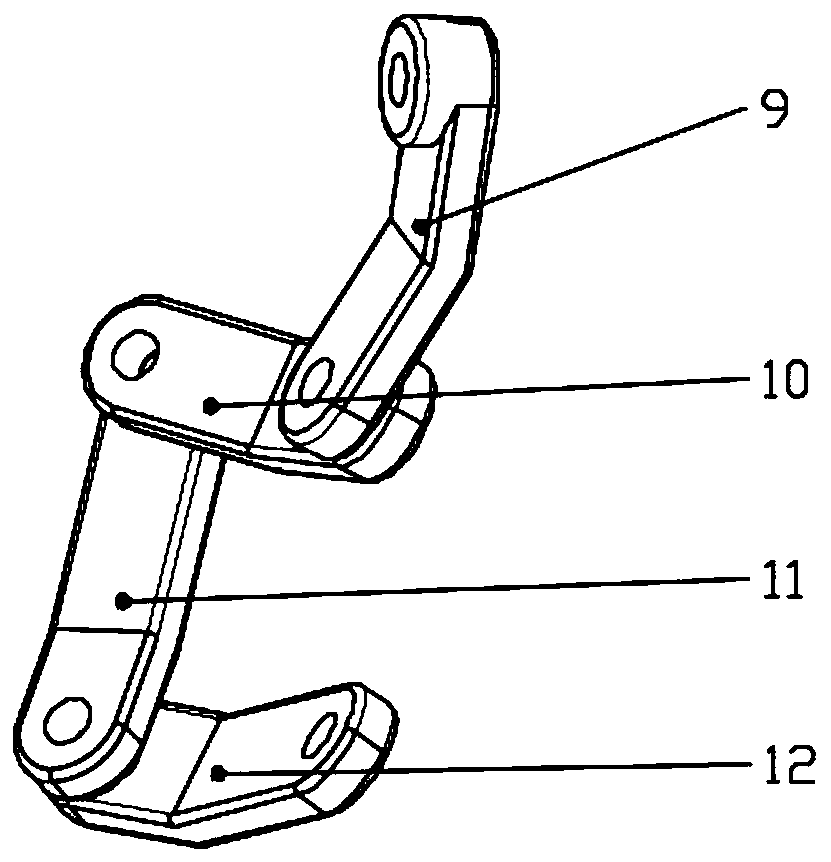

[0031] A kind of novel ankle joint rehabilitation parallel mechanism of this embodiment (referring to Figure 1-3 ), including static platform 1, dynamic platform 4, two UPU branch chains and one AABA branch chain;

[0032] The static platform 1 is evenly distributed on the circumference with the No. 1 hinge support 101 of the static platform, the No. 2 hinge support 102 of the static platform, and the No. 3 hinge support 103 of the static platform. The axes of the hinge holes of the three static platform hinge supports Converge at one point, this point is the fixed ball center 2 of the parallel mechanism;

[0033] On the moving platform 4, the No. 1 hinge support 401 of the moving platform, the No. 2 hinge support 402 of the moving platform and the No. 3 hinge support 403 of the moving platform are evenly distributed on the circumference, and the axes of the hinge holes of the three moving platform hinge supports Converge at one point, this point is the moving ball center 3 ...

Embodiment 2

[0042] A kind of novel ankle joint rehabilitation parallel mechanism of this embodiment (referring to Figure 1-3 ), including static platform 1, dynamic platform 4, two UPU branch chains and one AABA branch chain;

[0043] The static platform 1 is evenly distributed on the circumference with the No. 1 hinge support 101 of the static platform, the No. 2 hinge support 102 of the static platform, and the No. 3 hinge support 103 of the static platform. The axes of the hinge holes of the three static platform hinge supports Converge at one point, this point is the fixed ball center 2 of the parallel mechanism;

[0044] On the moving platform 4, the No. 1 hinge support 401 of the moving platform, the No. 2 hinge support 402 of the moving platform and the No. 3 hinge support 403 of the moving platform are evenly distributed on the circumference, and the axes of the hinge holes of the three moving platform hinge supports Converge at one point, this point is the moving ball center 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com