Hydraulic plug pin ascending device and descending device

A lifting device and hydraulic technology, applied in the field of self-elevating offshore platform accessories, can solve the problems of high manufacturing cost of the truss-type lifting device, and achieve the effects of low assembly accuracy, reduced manufacturing cost, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

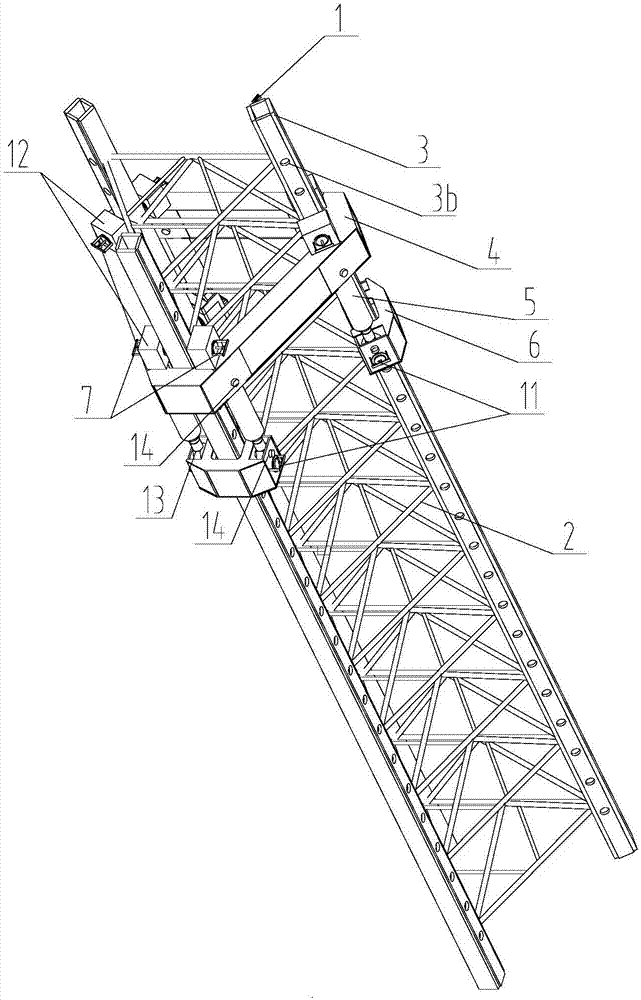

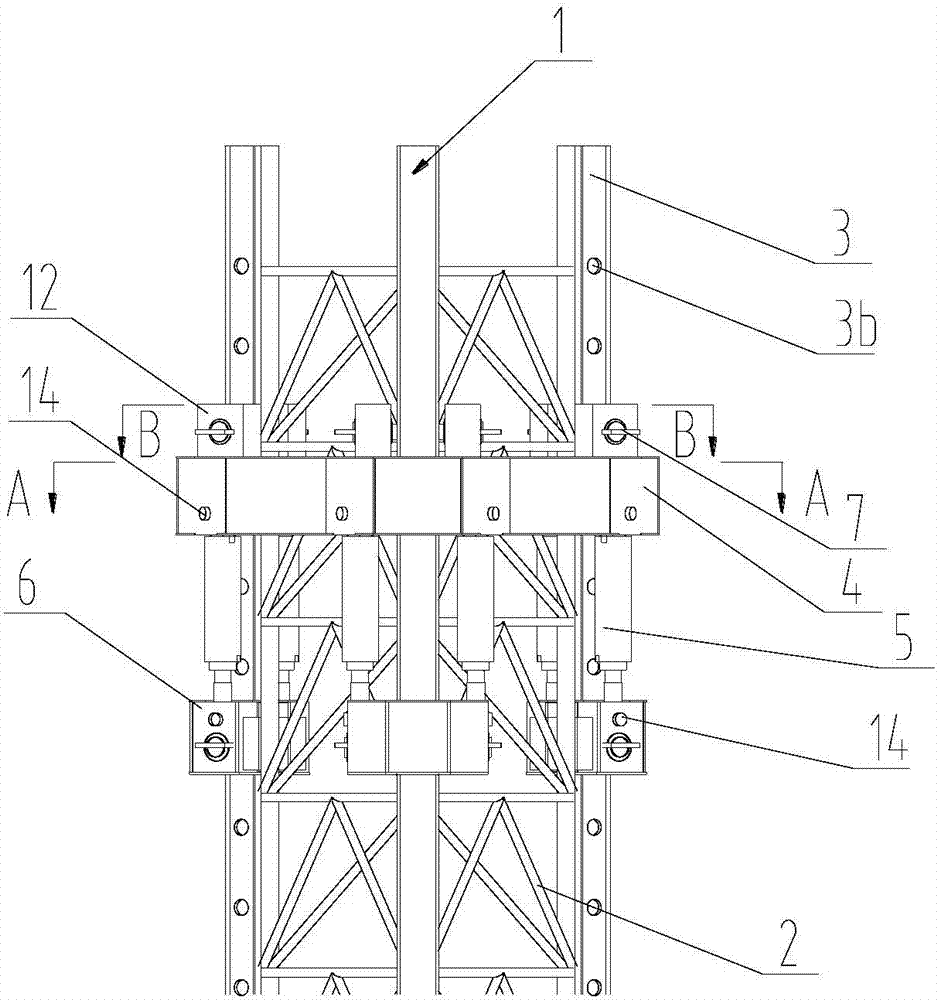

[0026] The embodiment of the present invention provides a hydraulic bolt lifting device, such as figure 1 and figure 2 As shown, the hydraulic bolt lifting device includes a truss-type leg 1. The truss-type leg 1 includes a truss structure 2 and three chords 3. The three chords 3 are not on the same plane and are arranged parallel to each other. The truss structure 2 is arranged on the three chords. Between 3, the hydraulic bolt lifting device also includes: a ring beam 4, a lifting cylinder 5, a sliding beam 6, a bolt assembly 7 and a bolt installation block 12.

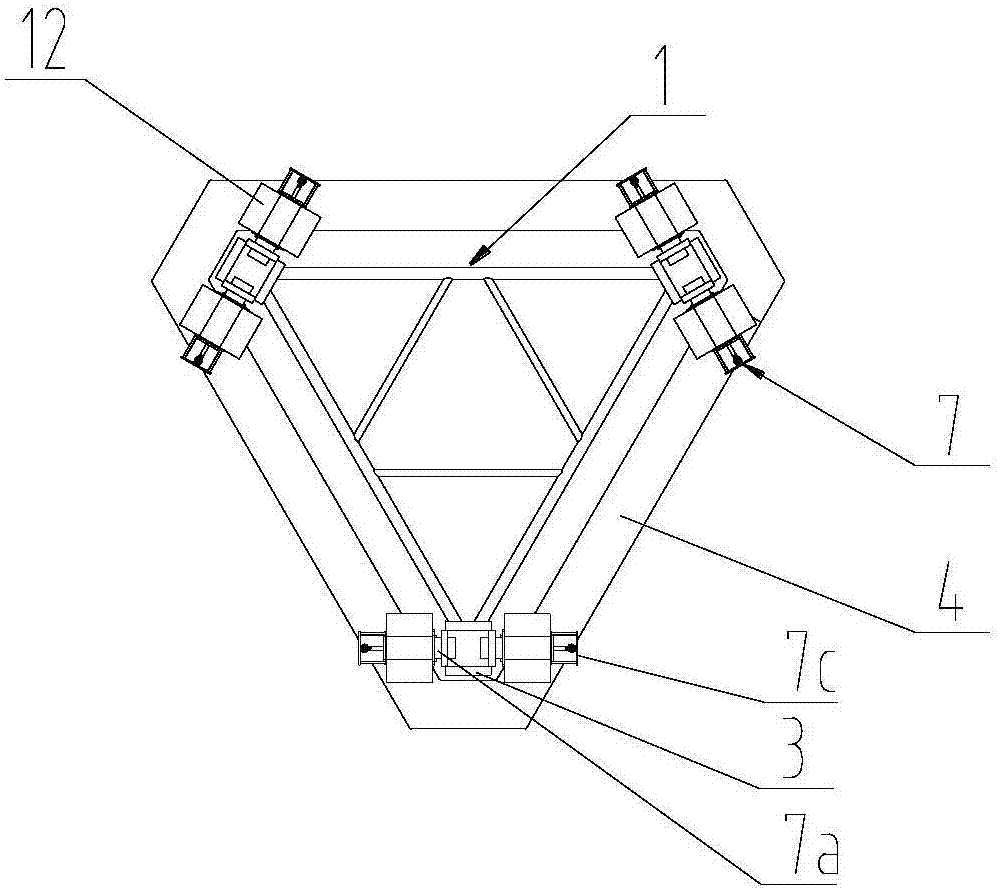

[0027] Each chord 3 is provided with a plurality of pin holes 3b matched with the pin assembly 7, and the multiple pin holes 3b are arranged along the length direction of the chord 3, and the ring beam 4 is slidably sleeved on the truss-type pile legs. 1 on. image 3 is a schematic diagram of the top view structure of the ring beam, combined with image 3 , a plurality of bolt mounting blocks 12 are installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com