Laser scanning-vibration hot wire TIG hybrid welding method

A technology of laser scanning and composite welding, which is applied in the field of welding processing, can solve the problems of low deposition rate and welding efficiency, high requirements for welding and assembly precision, and low requirements for assembly precision, so as to reduce the solidification speed, reduce the assembly precision, and reduce the heating range. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

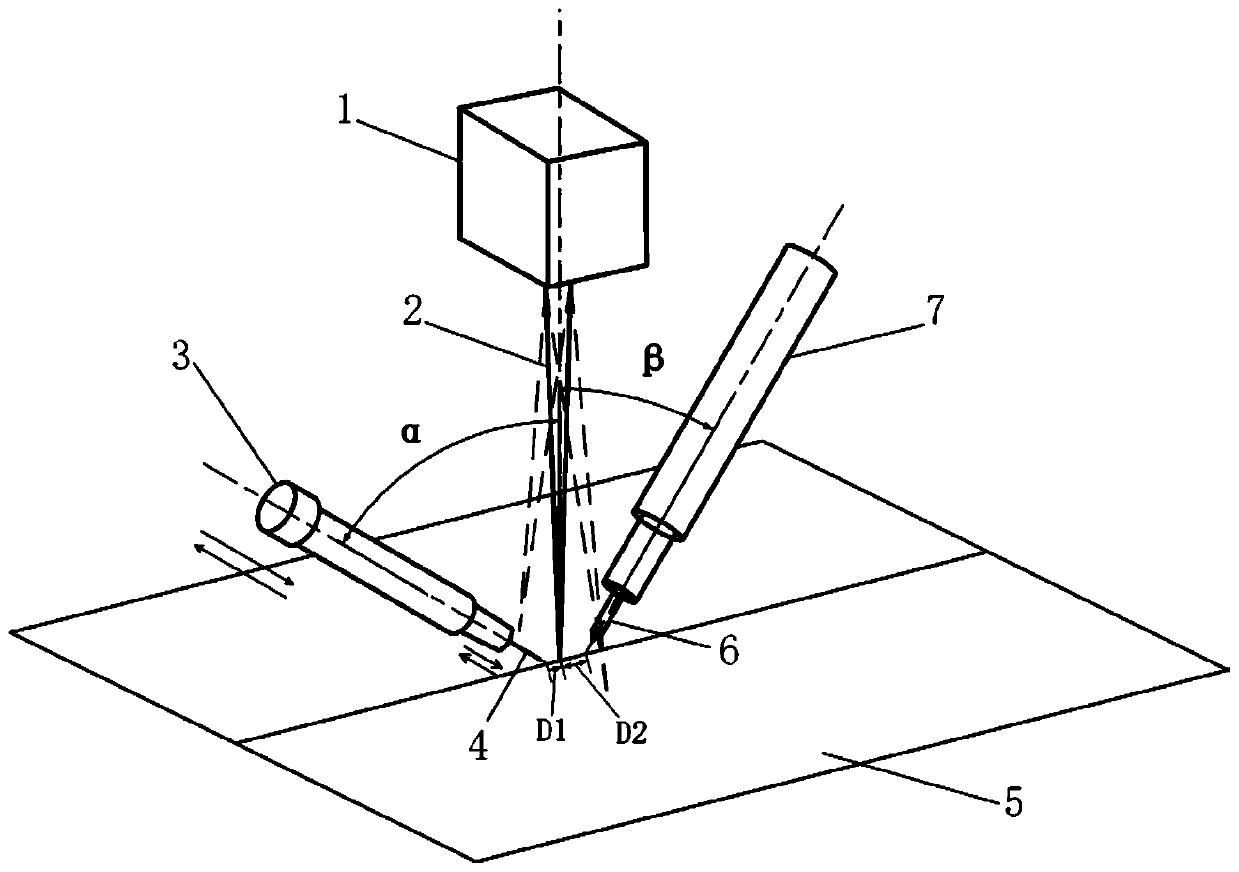

[0027] Such as figure 1 As shown, the scanning laser beam 2 is perpendicular to the welding plate, the wire feed gun 3 and the TIG welding gun 7 are located on both sides of the scanning laser beam 2, and the angle α between the wire feed gun 3 and the scanning laser beam 2 is 15°~75°, TIG The angle β between the welding gun 7 and the scanning laser beam 2 is 15°-60°, and the distances D1 and D2 between the scanning laser beam 2 and the heating wire 4 and the tungsten electrode 6 are 0-8mm and 0-10mm, respectively. Taking the X axis parallel to the welding seam direction as the Y axis perpendicular to the welding seam direction, the scanning laser beam 2 swings from -5mm to +5mm along the X axis and from -5mm to +5mm along the Y axis. The swing frequency is 10~1500Hz. The laser power can be 50 to 10000W, and the arc power can be 10 to 12000W. The current of the hot wire 4 is 0-180A, the wire feeding speed is 0-10m / min, the amplitude of the hot wire 4 along the wire direction i...

Embodiment 2

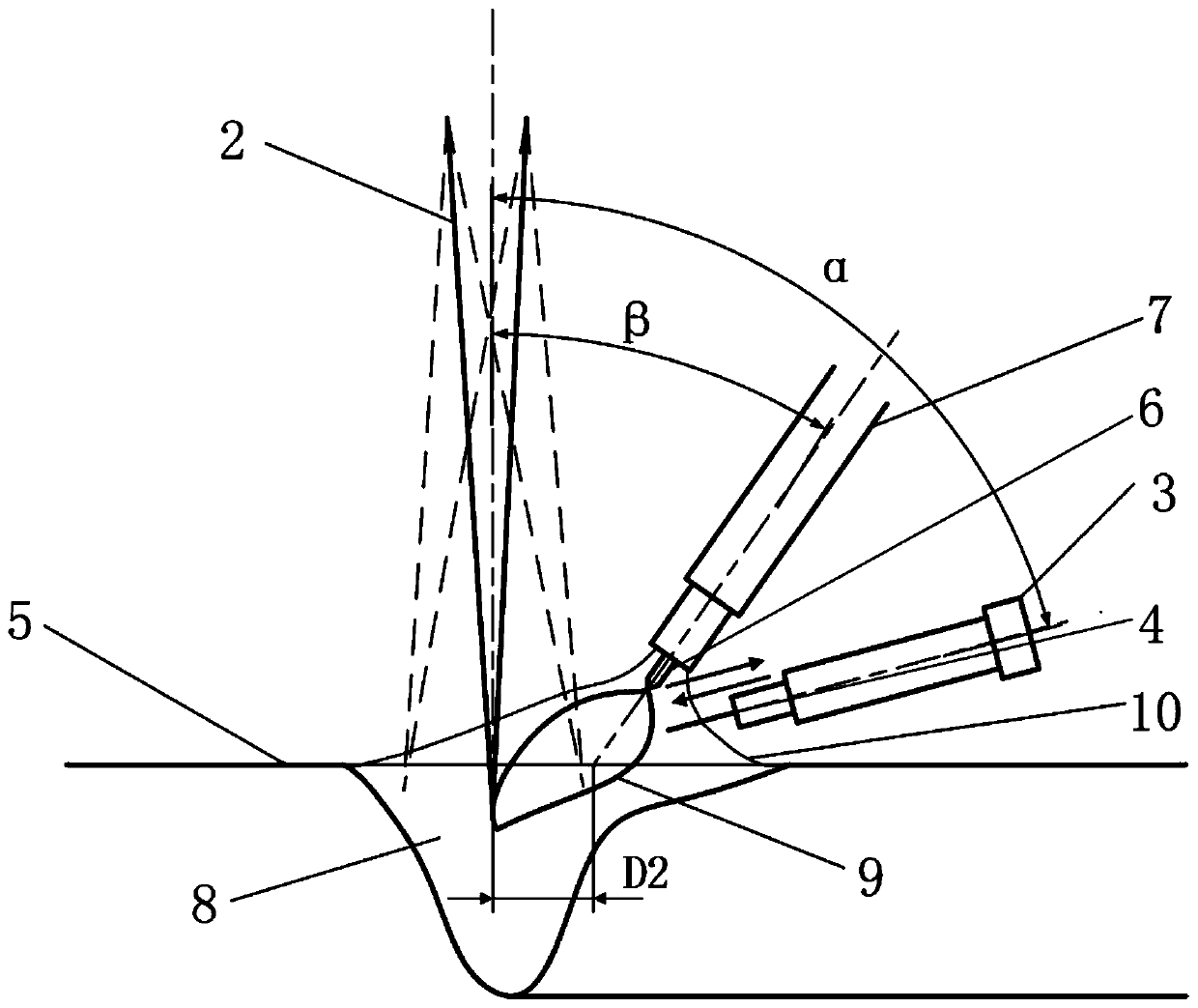

[0030] Such as figure 2 As shown, the scanning laser beam 2 is perpendicular to the welding plate, the wire feed gun 3 and the TIG welding torch 7 are respectively located on the same side of the scanning laser beam 2, the angle α between the wire feed gun 3 and the scanning laser beam 2 is 15°~75°, TIG The angle β between the welding gun 7 and the scanning laser beam 2 is 15°-60°, and the distances D1 and D2 between the scanning laser beam 2 and the heating wire 4 and the tungsten electrode 6 are 0-8mm and 0-10mm, respectively. Taking the X axis parallel to the welding seam direction as the Y axis perpendicular to the welding seam direction, the scanning laser beam 2 swings from -5mm to +5mm along the X axis and from -5mm to +5mm along the Y axis. The swing frequency is 10~1500Hz. The laser power can be 50 to 10000W, and the arc power can be 10 to 12000W. The current of the hot wire 4 is 0-180A, the wire feeding speed is 0-10m / min, the amplitude of the hot wire 4 along the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| laser power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com