Patents

Literature

47results about How to "Improve the billet rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing low-carbon high-sulfur (sulfur-phosphorous) easy-to-cut structural steel continuous casting billet

A continuous casting billet of low-carbon and high-sulphur free-cutting constructional steel production method with the following properties: (1) primary smelting: tapping with degree of oxygen activity of 700ppm, adding right amount Al when tapping of 20% and refinery cinder when tapping of 90%; (2) molten steel refining in LF refined-smelting ladle furnace: (A) deoxidising on top of the slag: agitating and blowing argon from bottom with pressure of 0.5MPa and analyzing sample and adjusting components after energizing for 10 minutes; (B) slag refining: adding 58%CaO,11%Al2O3, 9%SiO2 and 8 %MgO to get degree of oxygen activity of 60ppm; (C) closing argon from bottom when temperature of molten steel is 90 Deg.C more than liquidus line temperature, and feeding sulfur core-spun yarn rapidly. (3) continuous casting: (A) casting rate rationally, such as square continuous casting billet with casting rate of 2m / min; (B) roller pressure of every sedan at the end of conticaster is different from that of 10Bar; (C) setting rational continuous casting technical parameter. Continuous casting billet, which is made by steel of many pattern numbers such as 1213 and 1215, possesses the properties of high stabilization of component, good continuous casting, low cost of manufacture, high quality of casting blank (which meets the rolling request of subsequent heat working) and profound economic benefit.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

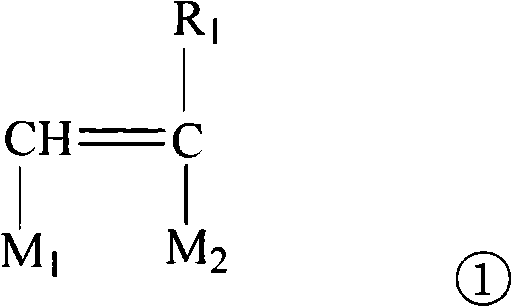

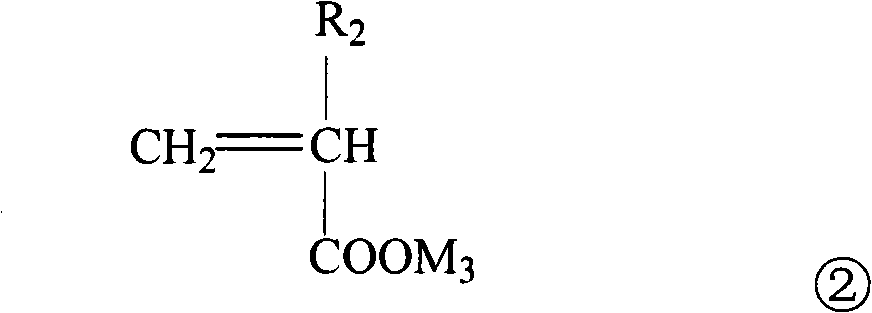

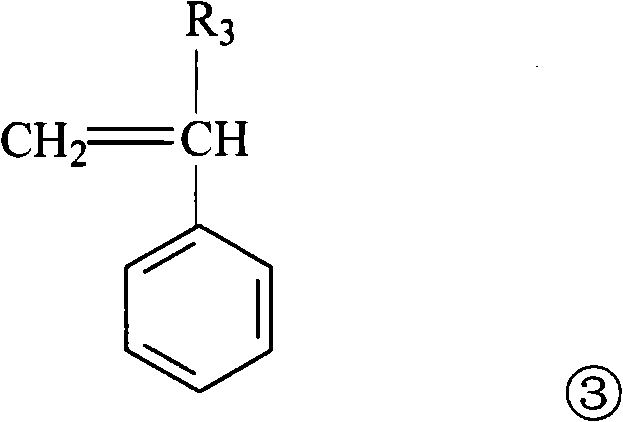

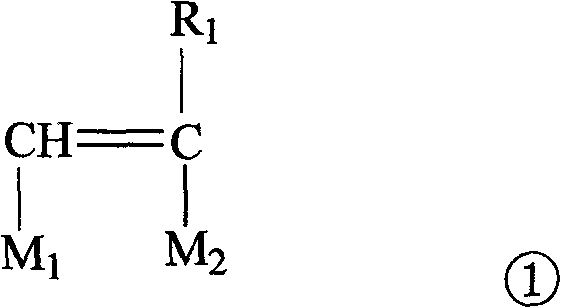

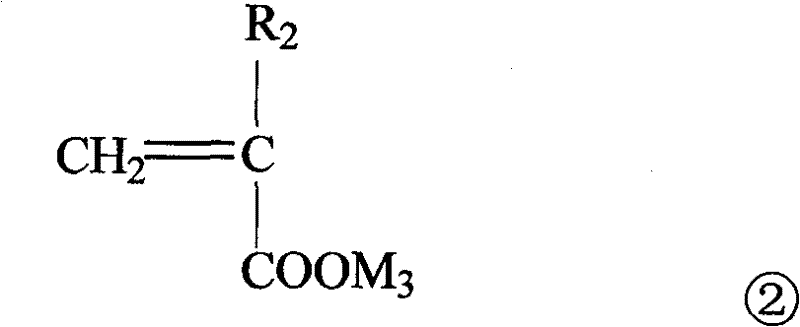

Method for preparing polymer ceramic dispersants

InactiveCN101274242AAppropriate viscosityImprove liquidityTransportation and packagingMixingPolymer sciencePolyethylene glycol

The invention discloses a preparation method of a polymer ceramic dispersant, which is characterized in that polyethylene glycol and maleic anhydride are uniformly mixed and polymerized to obtain a semi-esterification product; the semi-esterification product, vinyl monomer and water are uniformly mixed to carry out free radical polymerization under the inducement of initiating agent so as to obtain the polymer ceramic dispersant. The product prepared by adopting the invention has excellent dispersion dilution effect and grinding-aid effect on the ceramic slurry, improves the billet strength and the billet yield, thus reducing the production cost; meanwhile, the indexes such as the density and the folding resistance strength, etc. of the ceramic product are greatly reinforced. Furthermore, the product can be also used for the dispersion of dye and coating, etc.

Owner:SHAANXI UNIV OF SCI & TECH

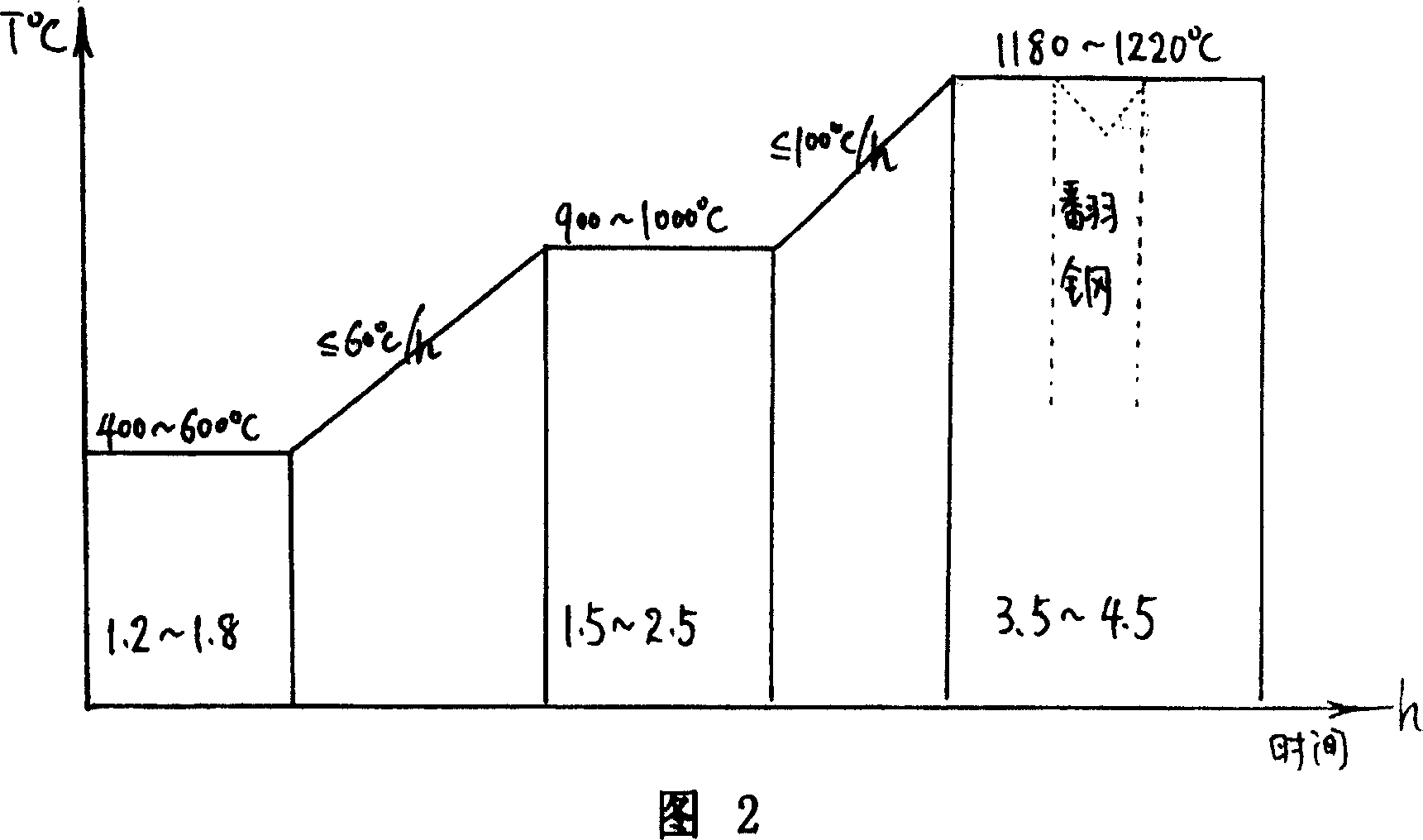

Rolling cogging production method of Cr4Mo4V electroslag steel ingot

InactiveCN1586749AThe process is reasonable and simpleEasy to operateMetal rolling arrangementsCarbideTemperature difference

The production process of rolling cogging Cr4Mo4V electroslag steel ingot features the heating in pit heating furnace and cogging in blooming mill to produce 100 mm square bloom. The production process includes heating Cr4Mo4V electroslag steel ingot at 630 deg.c for 90 min, 900 deg.c for 60 min, and 1190 deg.c for 210 min while turning the ingot to make the temperature difference between two opposite sides less than 20 deg.c; and cogging at initial temperature over 1130 deg.c and finishing temperature over 1000 deg.c through 44 gates and final annealing in annealing furnace to eliminate stress. The said production process is simple and has high product quality, raised bloom yield and lowered cost.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

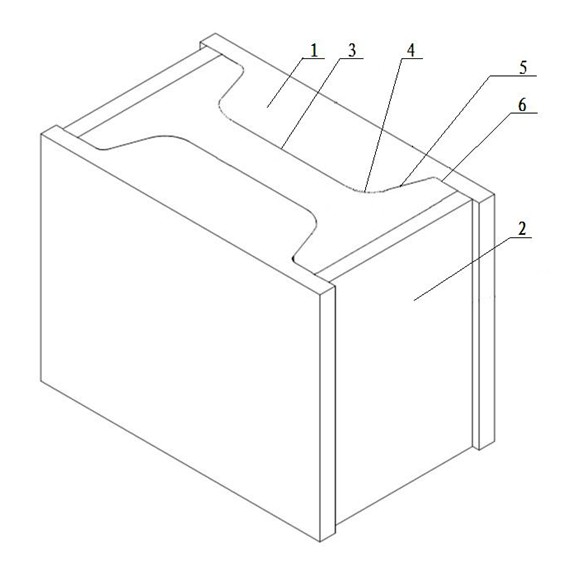

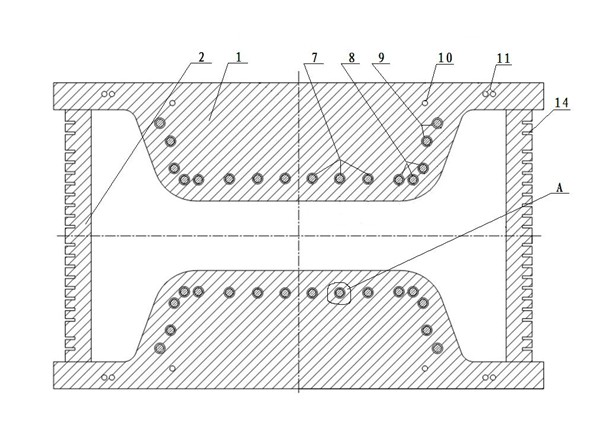

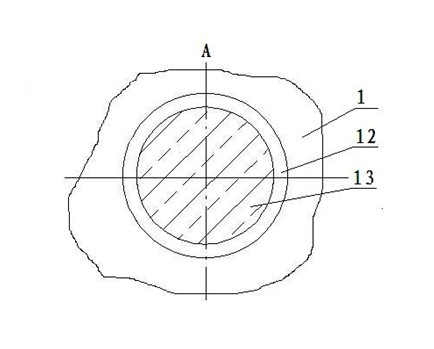

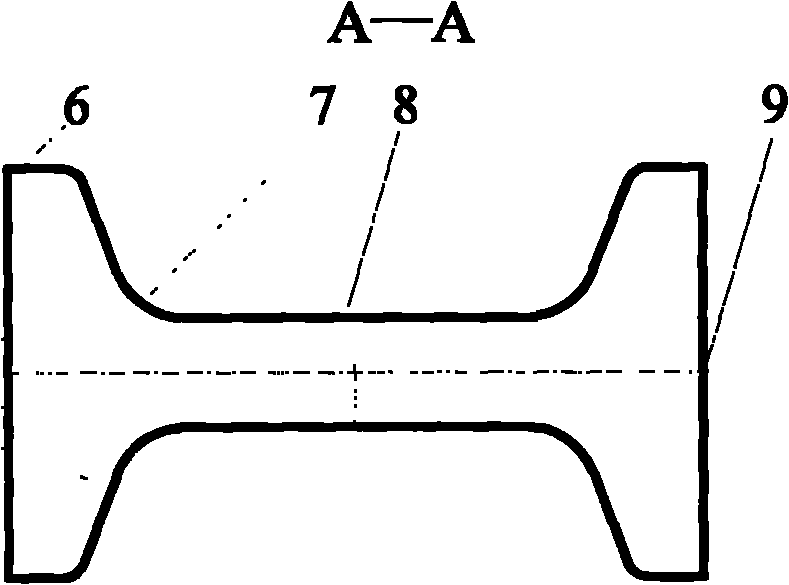

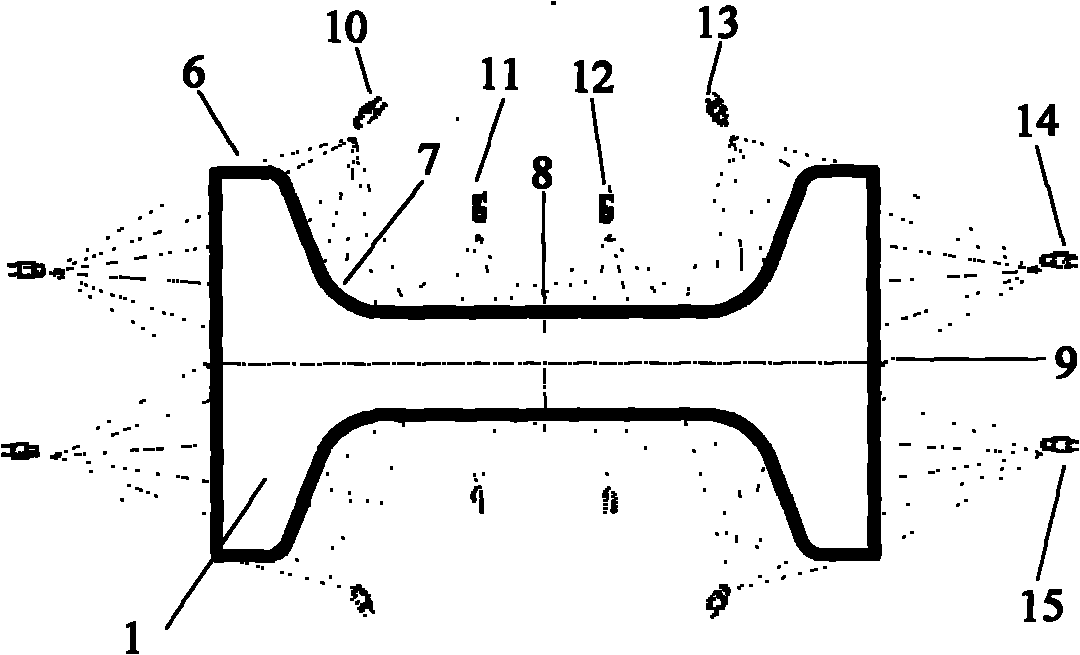

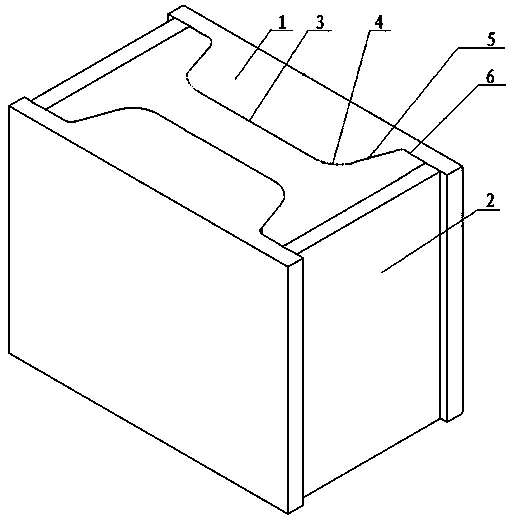

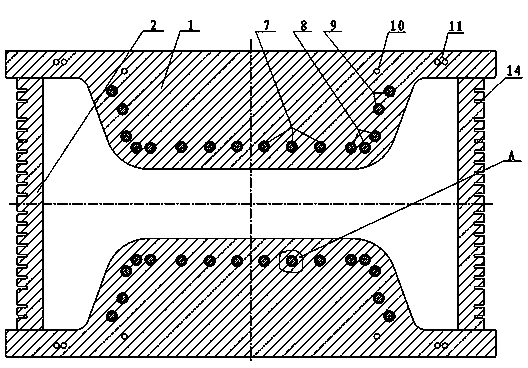

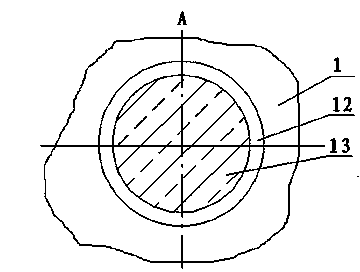

Water cooling channel for large beam blank continuous casting crystallizer

The invention belongs to a cooling casting blank or casting mould device and relates to a water cooling channel for a large beam blank continuous casting crystallizer,,and particularly to a copper plate cooling device for a beam blank continuous casting crystallizer. The copper plate cooling channel is characterized in that: a web water gap, a R angle water gap, a bevel water gap, a flange inner angle water hole and a flange top water hole are formed on a broadside copper plate according to the characteristics of the copper plate shape and heat face heat flux; the water gaps without corners are distributed uniformly, and the water gaps at R angle are dense, and few water holes are arranged at concave corners; and a cooling water tank is arranged outside a narrow side copper plate. The copper plate cooling channel has the advantages that cooling water channels are arranged in areas, the number of cooling water channels is reduced, water gap diameter is reduced, and processing quantity is reduced; the water gaps are arranged reasonably, temperature peak value at the R angle is eliminated, the temperature gradient is reduced, the cooling strength of the flange top is weakened, the overall temperature of the copper plate tends to be uniform, the working environment of the copper plate and blank heat transmission condition are improved, the cooling effect is good, and water is saved; deformation and abrasion of the copper plate are reduced, and service life is prolonged; the surface quality of blanks is remarkably improved, the cogging yield is improved, and continuous casting production can be performed smoothly.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

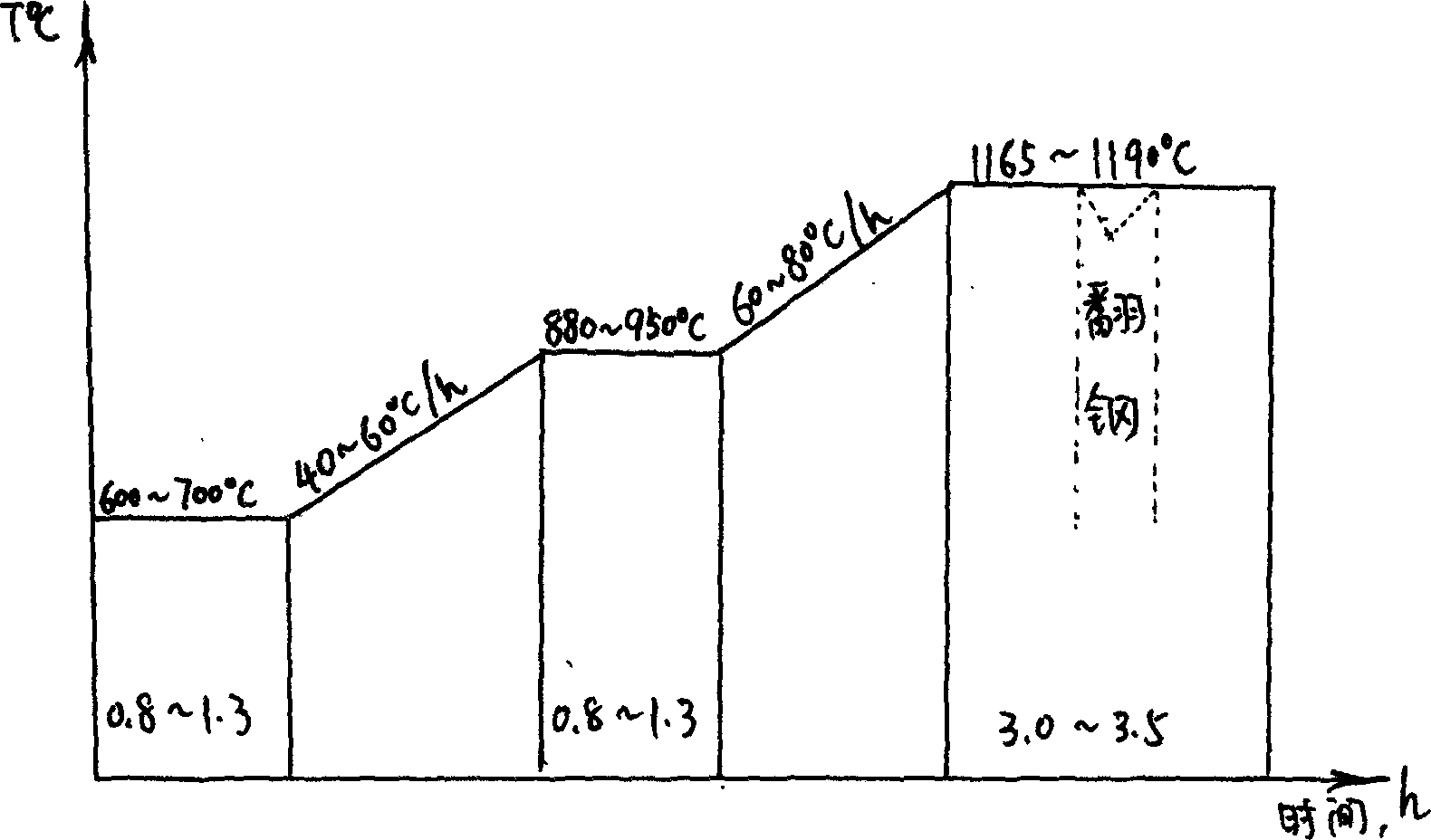

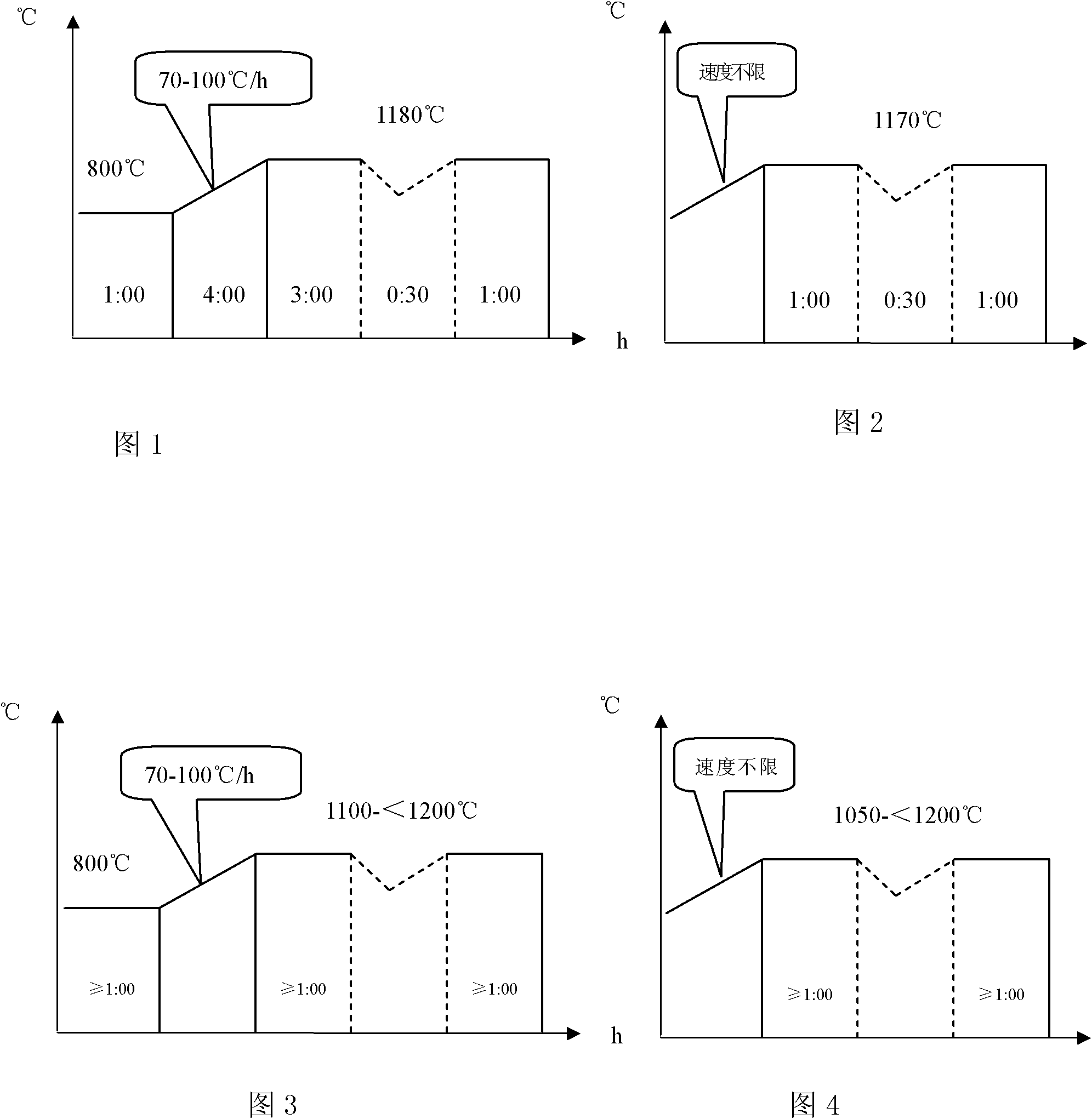

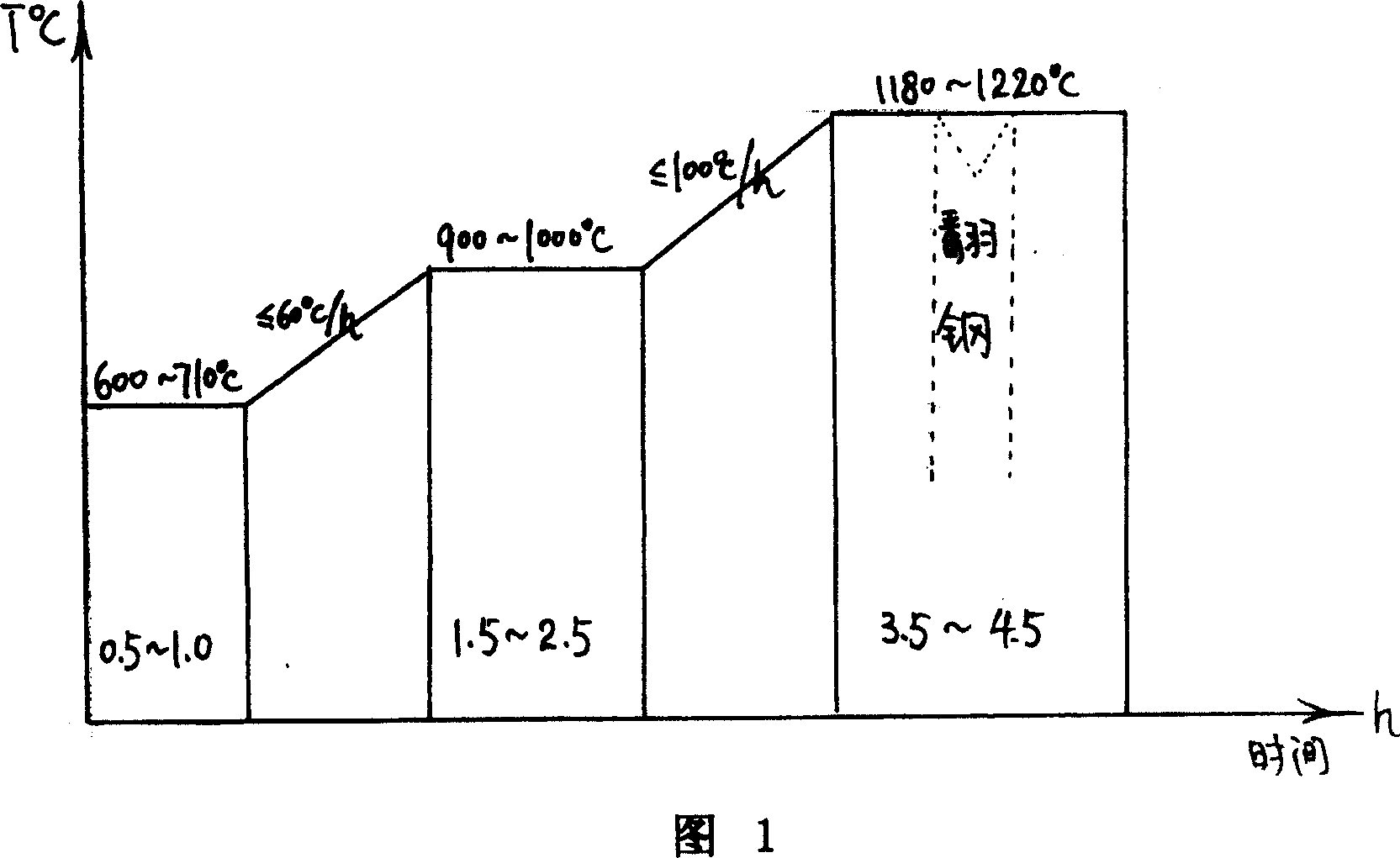

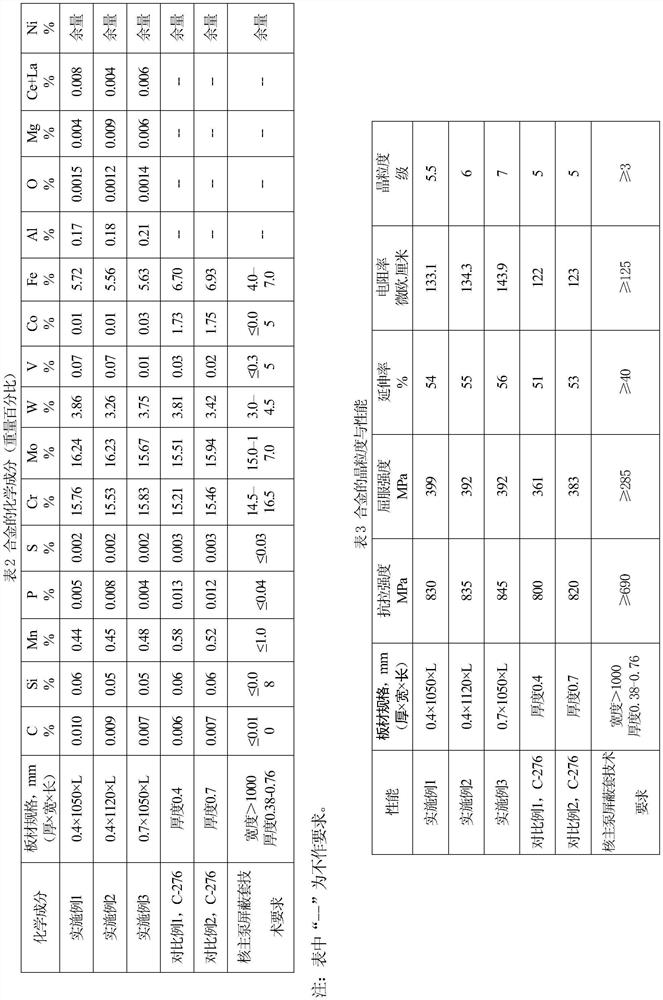

Rolling and cogging method for high-temperature alloy GH1015

InactiveCN1584066AInternal material quality is stableImprove production efficiencyMetal rolling arrangementsRolling speedAlloy

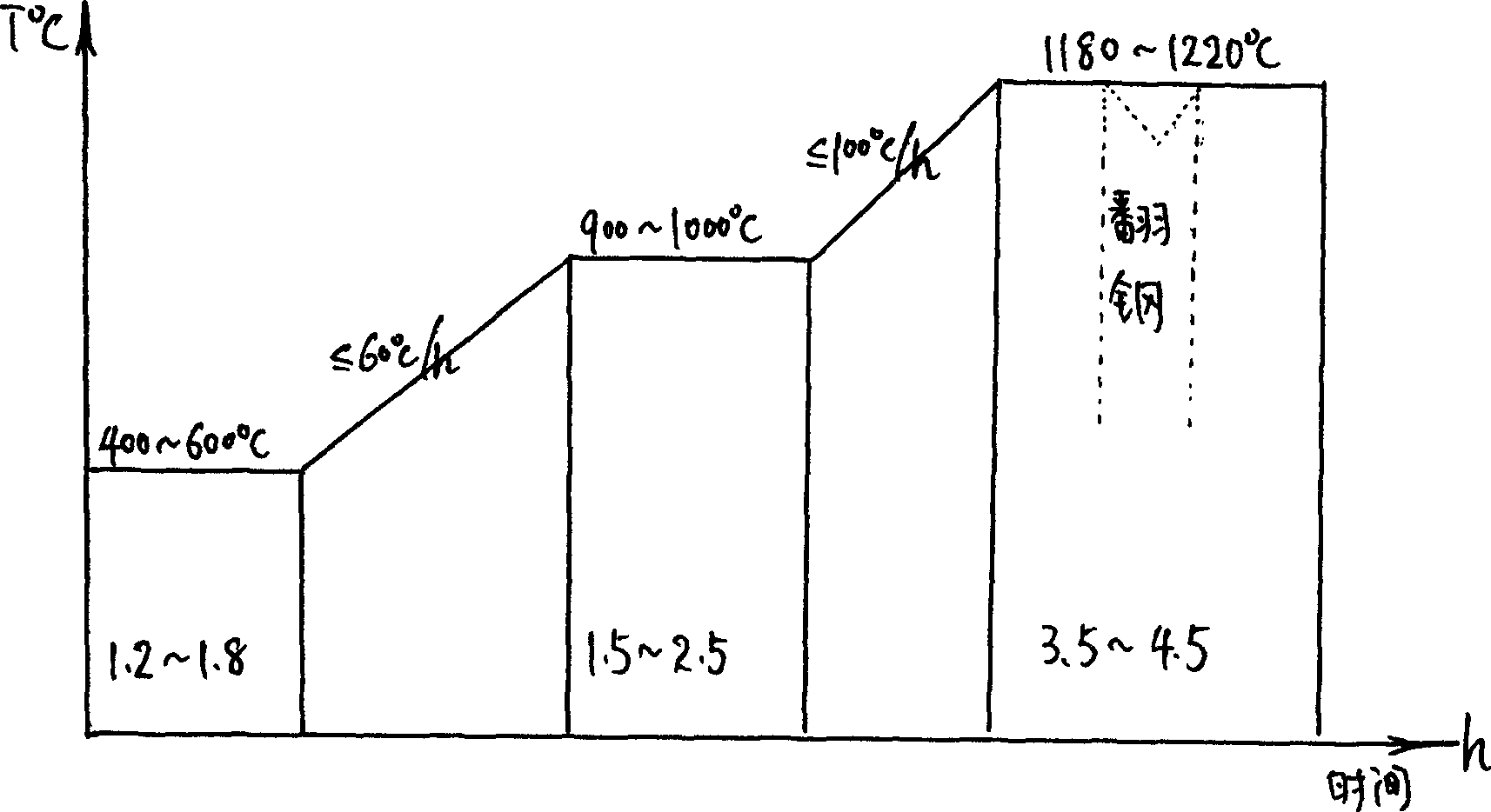

A rolling cogging manufacturing method for high temperature alloy GH1015 includes: 1) heating in one heat, electroslag ingot keeping temperature for 1 hr with entering furnace temperature is less than or equal to 700deg.C, keeping temperature for1 hr with is less than or equal to 60deg.C / h up to 900deg.C, keeping temperature for 3.5 hrs with is less than or equal to 80deg.C / h up to 1180deg.C and drawing charge with positive and negative face temperature differential is less than or equal to 20deg.C; 2) cogging in one heat with preheating temperature of roller 120deg.C and beginning temperature is greater than or equal to 1100deg.C, finishing temperature is greater than or equal to 1000deg.C, roller speed is less than or equal to 20 / min, drafts is less than or equal to 30mm and rolling passage is less than or equal to 15; 3) heating in second heat, keeping temperature for 80 mins at 1170deg.C and drawing charge with positive and negative face temperature differential is less than or equal to 20deg.C; 4) cogging in second heat and roller preheating with beginning temperature is greater than or equal to 1100deg.C, finishing temperature is greater than or equal to 1000deg.C, rolling speed is less than or equal to 20 / min, rolling speed of product passage is less than or equal to 10 / min and drafts 30mm. It achieves low cost, simple process and good quality.

Owner:宝钢特钢有限公司

Manufacturing method for Z210CrW12 ingots by rolling and cogging

InactiveCN1584065AReduce manufacturing costMeet user requirements and market needsMetal rolling arrangementsHeating furnaceHeat treating

A rolling cogging manufacturing method for X210CrW12 steel ingot includes: 1) heating by uniform heating furnace, keeping temperature for 150 mins with entering temperature of steel ingot is less than or equal to 450deg.C, heating to 1170deg.C and keeping temperature for 4.5 hrs with speed is less than or equal to 80deg.C / h, turning over steel ingot and drawing charge with positive and negative face temperature differential is less than or equal to 25deg.C; 2) rolling by rolling mill, closing cooled water of roller before rolling and roller preheating; first rolling with roller speed is less than or equal to 20 / min, beginning temperature is greater than or equal to 1130deg.C, finishing temperature is greater than or equal to 1060deg.C, rolling passage 40 and drafts is less than or equal to 30mm; billet melting down and distressing annealing heat treating. It achieves low cost, simple process and good quality.

Owner:SHANGHAI IRON & STEEL CO LTD NO 5 BAOSHAN IRON & STEEL GRP

Rolling and cogging method for OCr17Ni4Cu4Nb casting ingots

ActiveCN1584064AMetallurgical manufacturing cost reductionSimple processMetal rolling arrangementsIngot castingRolling speed

A rolling cogging manufacturing method for 0Cr17Ni4Cu4Nb ingot casting includes: 1) heating in one heat, cooling steel ingot and keeping temperature for 1.5 hr when entering furnace temperature is less than or equal to 600deg.C; heating steel ingot, keeping temperature for 1 hr when entering furnace temperature is less than or equal to 690deg.C and keeping temperature for 2 hrs with is less than or equal to 60deg.C / h up to 950deg.C, keeping temperature for 4 hrs with is less than or equal to 80deg.C / h up to 1180deg.C and drawing charge with positive and positive and negative face temperature differential is less than or equal to 30deg.C; 2) cogging in one heat, roller preheating with rolling speed is less than or equal to 10 / min, beginning temperature is greater than or equal to 1150deg.C, finishing temperature is greater than or equal to 1050deg.C, drafts is less than or equal to 40mm and rolling passage is less than or equal to 14; 3) heating in second heat and keeping temperature for 1 hr at 1180deg.C; 4) cogging in second heat with beginning temperature is greater than or equal to 1130deg.C, finishing temperature is greater than or equal to 1000deg.C and drafts is less than or equal to 50mm, rapid shearing billet and hot annealing. It achieves low cost, simple process and good quality.

Owner:宝武特种冶金有限公司

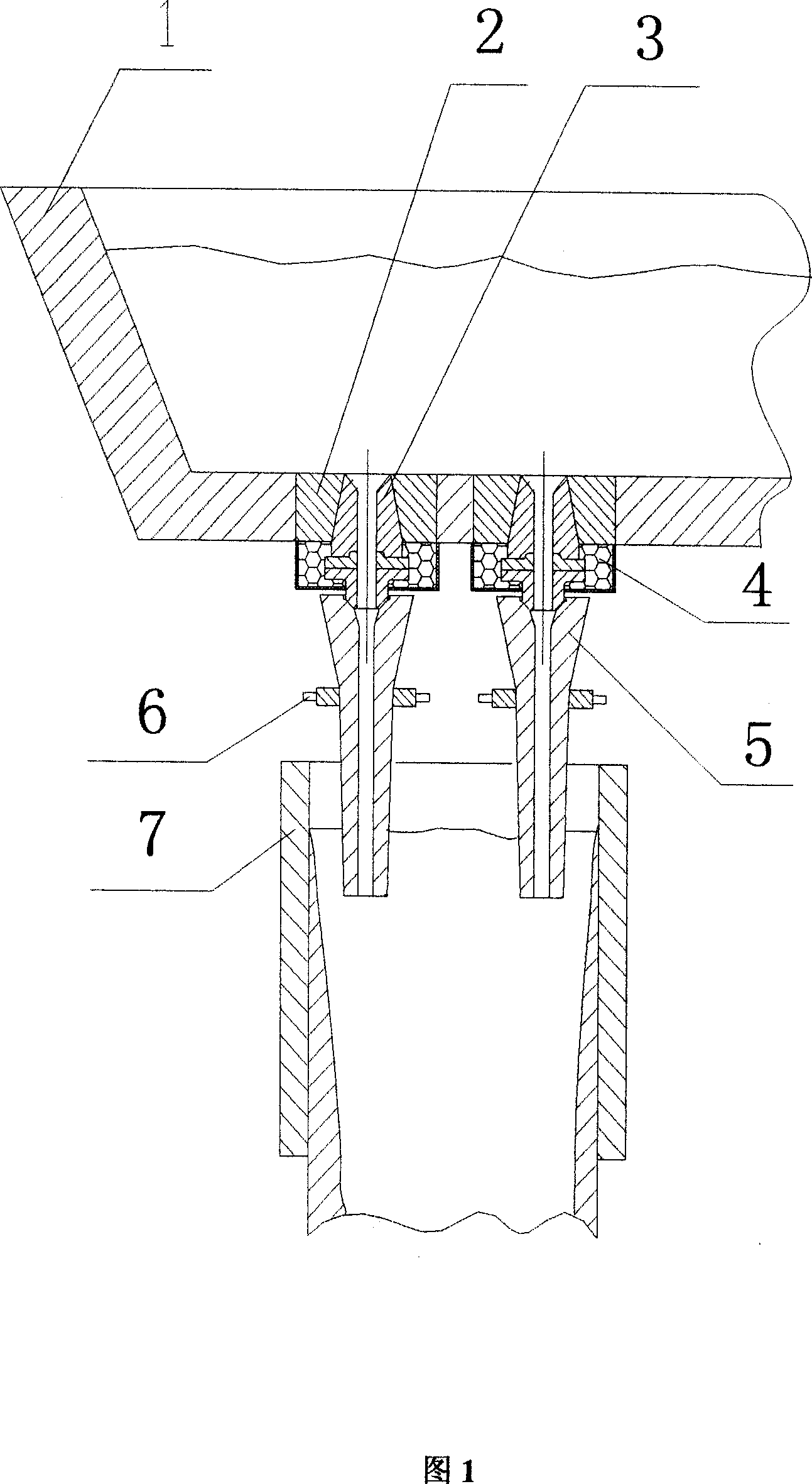

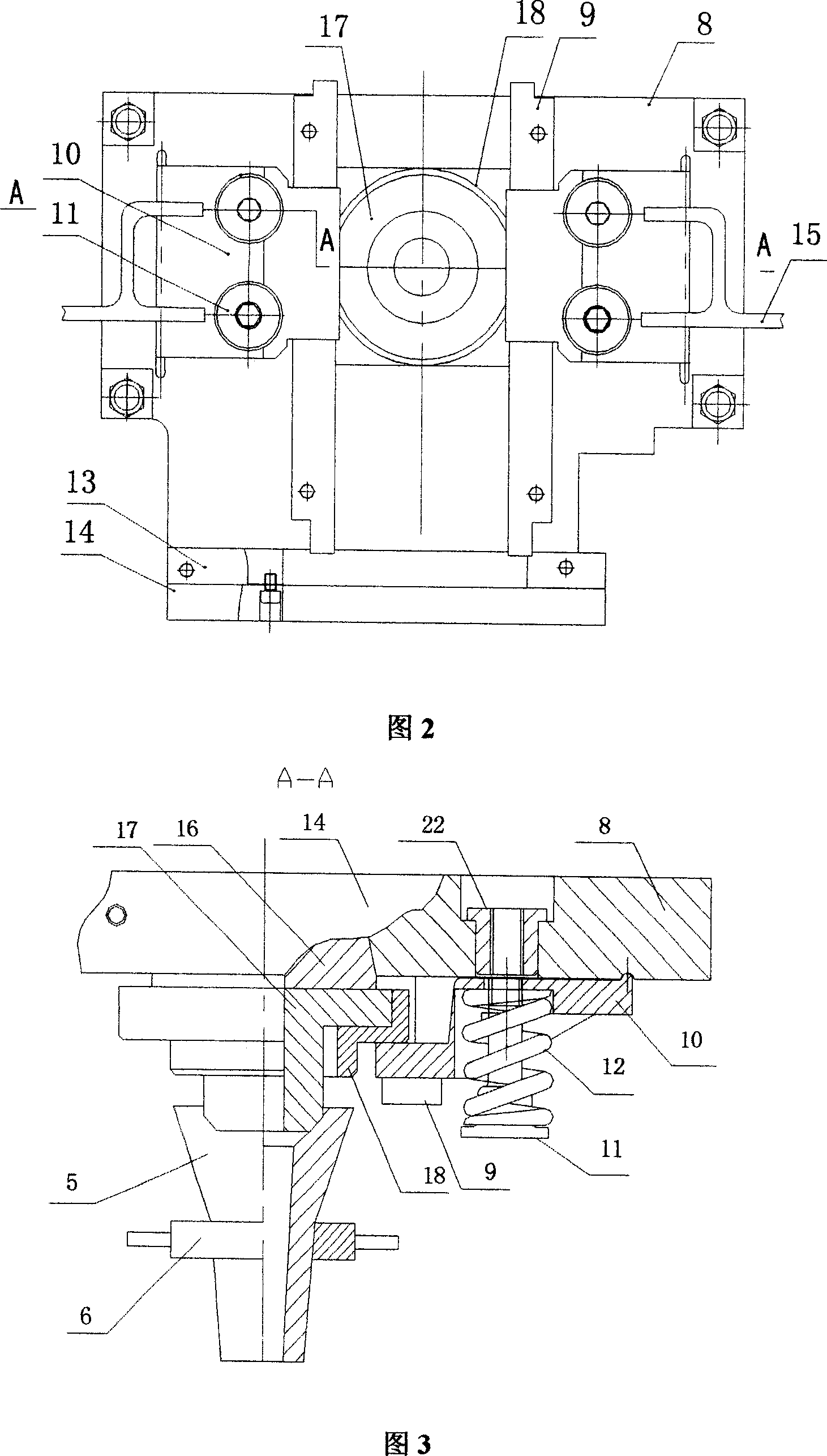

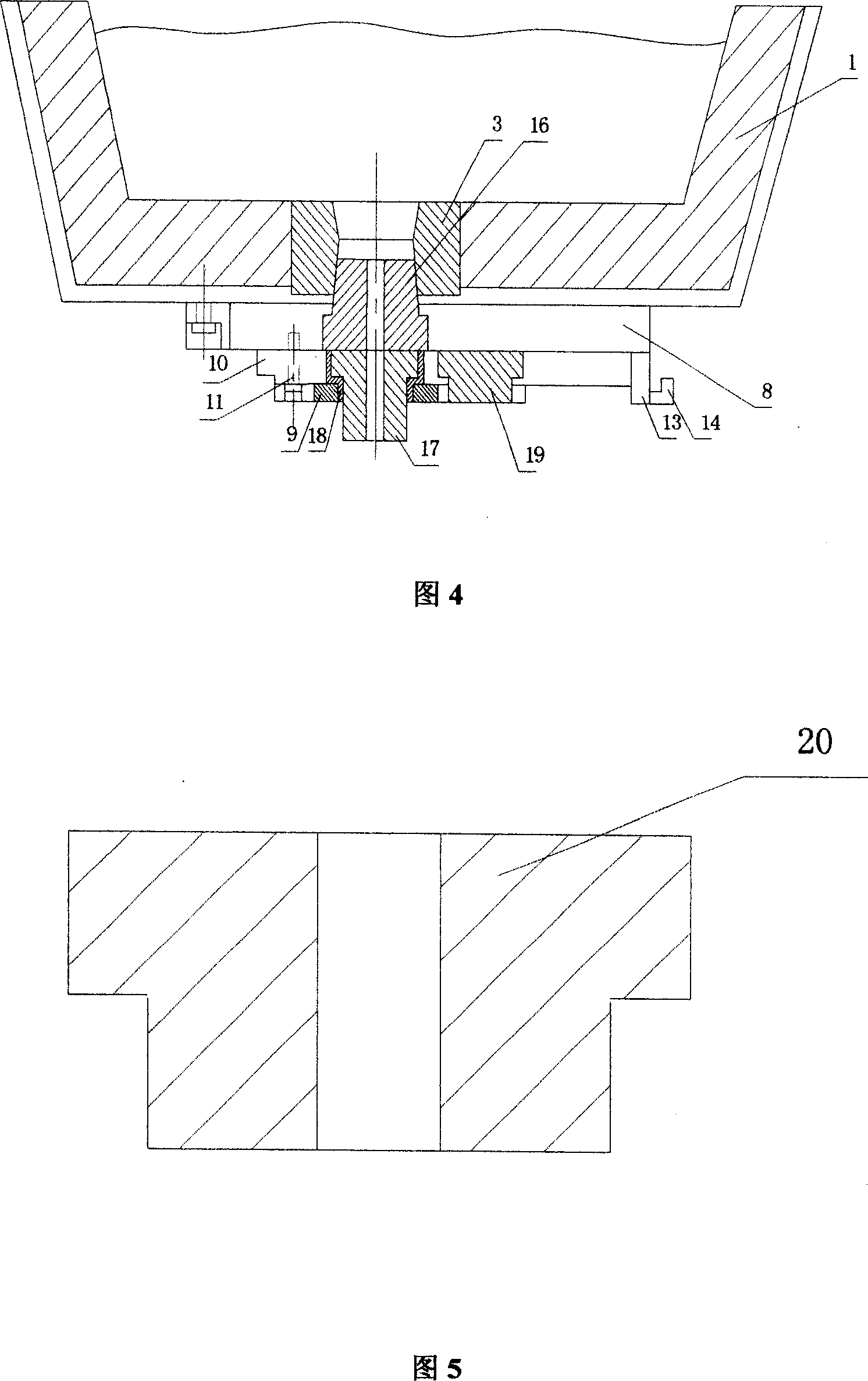

Fast sprue-replacing casting method and device for continuous irregular blank casting ladle

The present invention relates to continuous metal casting, and is especially special billet casting ladle and its casting process. The present invention includes one ladle and a crystallizer and features the ladle with at least two spouts with fast replacing mechanism including upper sliding spout and lower sliding spout and connected to the ladle spout and the immersed spout inserted into the crystallizer. During casting, molten steel flows through sealed channel to avoid secondary oxidation and improve billet quality. The fast spout replacing mechanism regulates the flow rate of molten steel and the level inside the crystallizer to reduce adhesion and leakage. The fast spout replacement can increase the continuous cast crystallizer number, reduce ladle number, lower consumption and raise billet quality.

Owner:MAANSHAN IRON & STEEL CO LTD

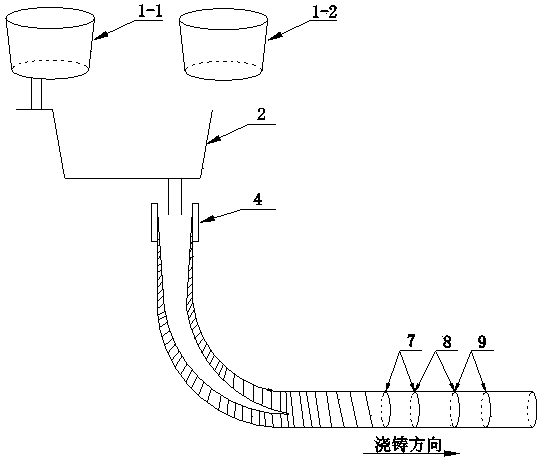

Continuous-casting big round billet dissimilar steel mixed casting production method

The invention discloses a continuous-casting big round billet dissimilar steel mixed casting production method. The method comprises the following steps that when molten steel of a prior melt is casted into a medium ladle, a certain amount of molten steel is left in a big ladle of the melt, and the casting speed is decreased; when the molten steel, left in the medium ladle, of the prior melt is decreased to a certain liquid level, casting is started on a big ladle of molten steel of a later melt, and a steel ladle covering agent in the medium ladle is replaced; after the big ladle of the latermelt is cast for a certain time, covering slag of a crystallizer is replaced; after the big ladle of the later melt is cast for 25 t, the liquid level of the medium ladle is kept, and the casting speed is increased; after the big ladle of the later melt is cast for 30 t, the liquid level of the medium ladle is slowly increased to the normal full liquid level, and then casting is conducted; and after the big ladle of the later melt is cast for 40 t, the casting speed is decreased to that corresponding to normal superheat degree, and then normal casting is conducted. According to the continuous-casting big round billet dissimilar steel mixed casting production method, when dissimilar steel is produced in the same medium ladle in a continuous casting manner, the thermal shutdown time can beshortened, the production efficiency of a continuous casting machine can be met, and the continuous casting billet yield can be increased.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

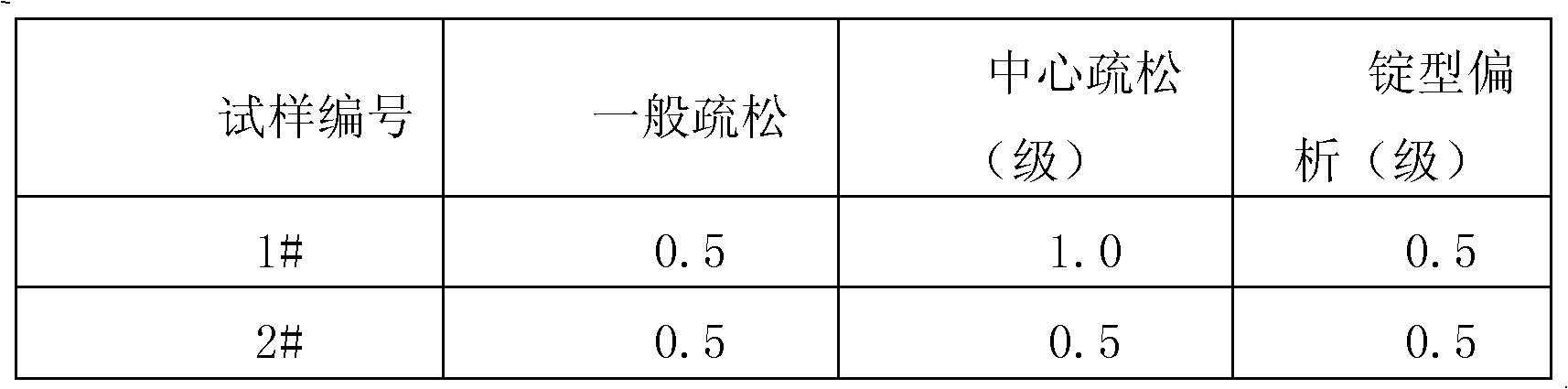

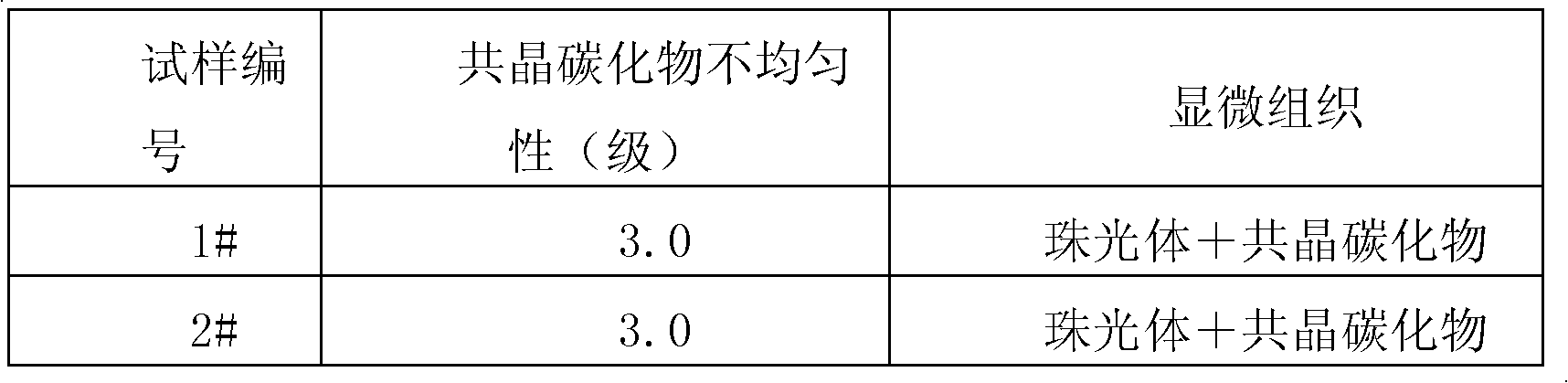

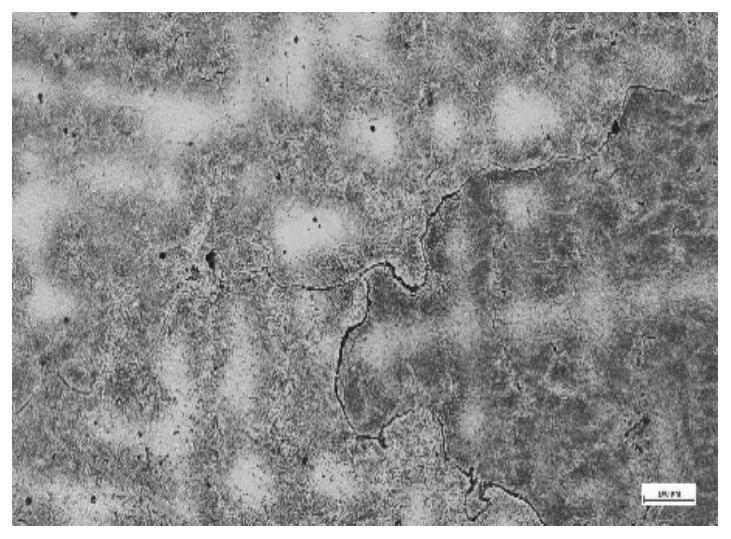

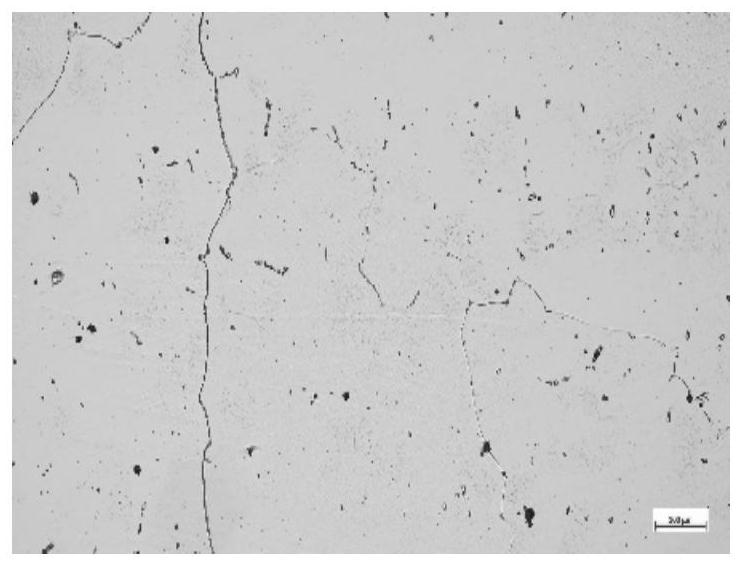

Production method for rolling and cogging big cast ingot of high-carbon high-alloy cold-working die steel

InactiveCN102581000ASimple processEasy to operateTemperature control deviceFurnace typesHigh carbonIngot

The invention relates to a production method for rolling and cogging a big cast ingot of high-carbon high-alloy cold-working die steel. The production method comprises 1) hot charging the cast ingot of high-carbon high-alloy cold-working die steel; 2) homogenizing in a soaking pit including a first fire cast ingot heating procedure, which comprises (A) charging the cast ingot at temperature of 600-800 DEG C, and keeping warm for 100-150 minutes; (B) raising the temperature to 1,100-lower than 1,200 DEG C; (C) at the temperature of 1,100-lower than 1,200 DEG C, incubating for 2-5 hours; and (D) keeping the temperature difference of the female face and male face of the cast ingot smaller than 50 DEG C; and a second fire rolled piece melt-down heating, which comprises (A) heating and raising the temperature to 1,100-lower than 1,200 DEG C, and incubating for 2-3 hours; (B) keeping the temperature difference of the female face and male face of the cast ingot smaller than 50 DEG C; and 3) after the two heating procedures, respectively carrying out rolling; wherein (A) the preheating temperature of a roller is 100-200 DEG C; (B) initial rolling temperature is 1,100- lower than 1,200 DEG C, and the final rolling temperature is higher than 900 DEG C; and (C) the biting speed of the roller is 10-40r / min. The production method has the advantages that the process is simple; the ingot mold of the cast ingot is enlarged, and the production cycle is greatly shortened; the energy consumption is greatly reduced; and the cogging yield is increased.

Owner:宝钢特钢有限公司

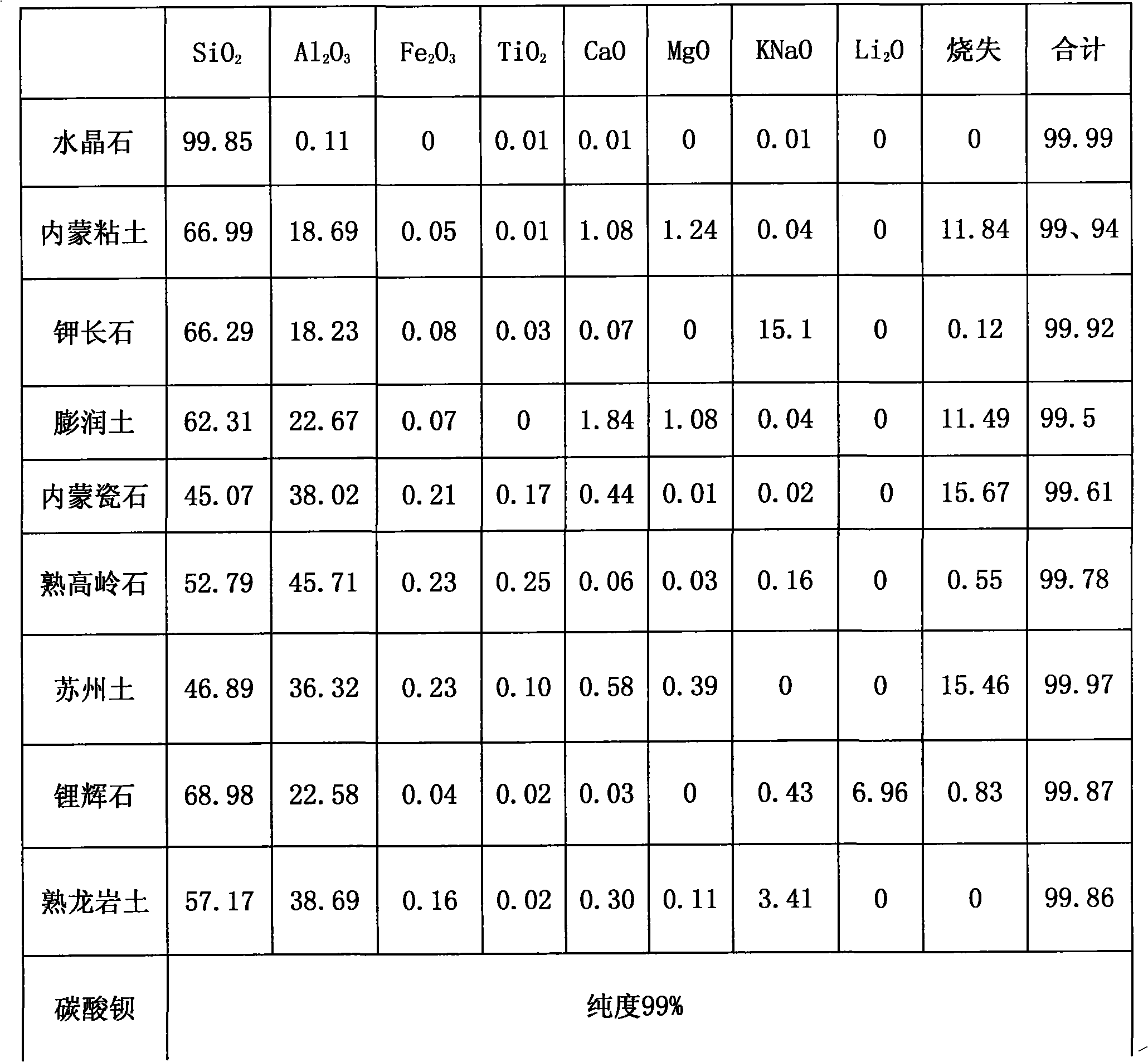

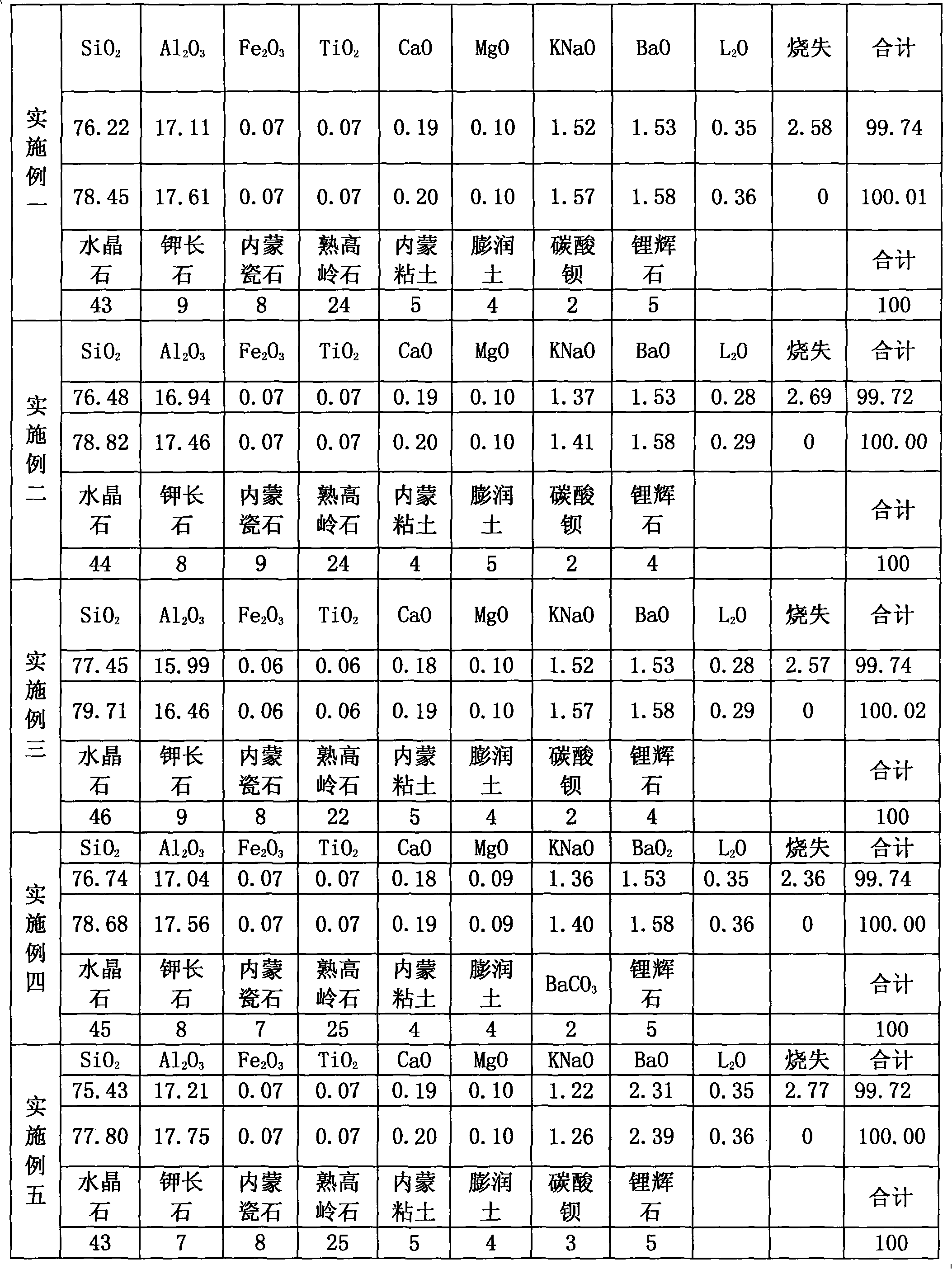

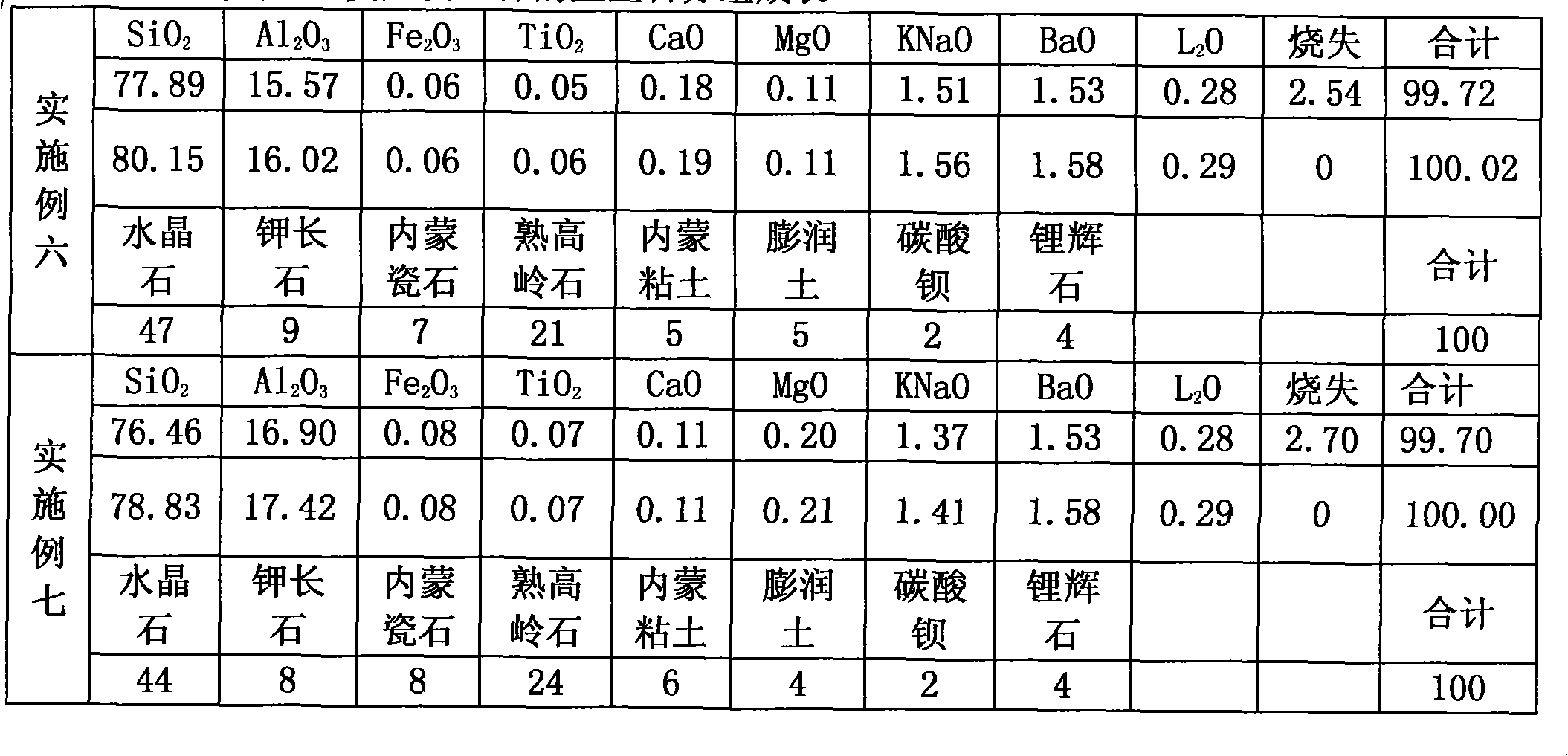

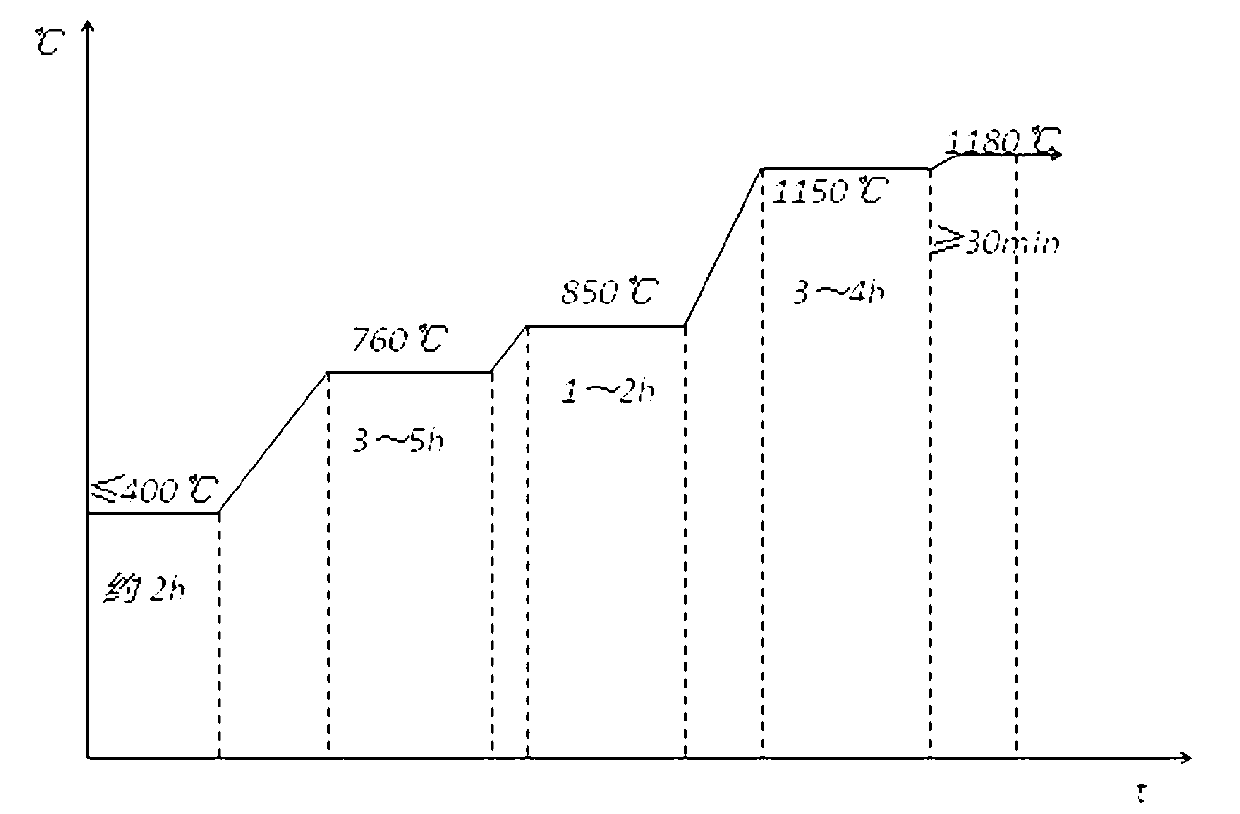

Crystal ceramic and preparation method thereof

The invention relates to a crystal ceramic which is a new product of ceramic products, or a new ceramic type. Glaze is coated on a green body which is prepared from the following components by weightpercent: 75-82 percent of SiO2, 15-21 percent of Al2O3, 0-0.1 percent of Fe2O3, 0-0.1 percent of TiO2, 0-0.5 percent of CaO, 0-0.9 percent of MgO, 0.5-2.6 percent of KNaO, 0.1-0.8 percent of Li2O and0.1-0.5 percent of BaO. The invention has the characteristics of wide range of firing temperature, easy firing control, high whiteness, favorable translucency, high mechanical strength and favorable thermal stability. The invention also provides a preparation method comprising the steps of preparing materials, dosing, molding, biscuiting, enamelling and glaze firing, wherein the crystal needs to be preprocessed, and the preprocessing comprises the steps of calcining at 1250-1300 DEG C, washing with acid, washing with water to neutrality and separately grinding and controlling the grain diameter ranges from 5 to 20 microns. The invention is scientific and reliable, is easy to implement and ensures the quality and qualification rate of products.

Owner:淄博泰山瓷业有限公司

1Cr10Co6MoVNb steel cogging and forging method

ActiveCN104084513AImprove plasticityReduce the difficulty of blankingMetal-working apparatusTime rangeIngot

The invention discloses a 1Cr10Co6MoVNb steel cogging and forging method. The method comprises the steps that a single 1Cr10Co6MoVNb steel cast ingot with the weight ranging from 1.2 tons to 1.8 tons is placed into a heating furnace, wherein the charging temperature ranges from 740 DEG C to 750 DEG C and is kept for 100 min to 120 min; the temperature is made to rise at the heating speed ranging from 60 DEG C / h to 80 DEG C / h to range from 940 DEG C to 950 DEG C, and the temperature is kept for 120 min to 150 min; then the temperature is made to rise at the heating speed ranging from 100 DEG C / h to 120 DEG C / h to range from 1140 DEG C to 1150 DEG C; one heating forging and cogging is carried out on the cast ingot, pressing upsetting is carried out three times to four times, and the pressing quantity for each time ranges from 30 mm to 40 mm; pressing and drawing-out are carried out six times to eight times, and the pressing quantity for each time ranges from 10 mm to 20 mm; finally, upsetting and rolling are carried out, wherein the initial forging temperature is larger than or equal to 1140 DEG C, and the final forging temperature is larger than or equal to 950 DEG C. According to the 1Cr10Co6MoVNb steel cogging and forging method, the cogging difficulty is reduced, the cogging yield is improved, the production cycle is shortened, and production efficiency is improved. The 1Cr10Co6MoVNb steel cogging and forging method is mainly used for cogging and forging forge pieces such as a high-pressure compressor disc and a rotor blade of an aero-engine.

Owner:GUIZHOU ANDA AVIATION FORGING

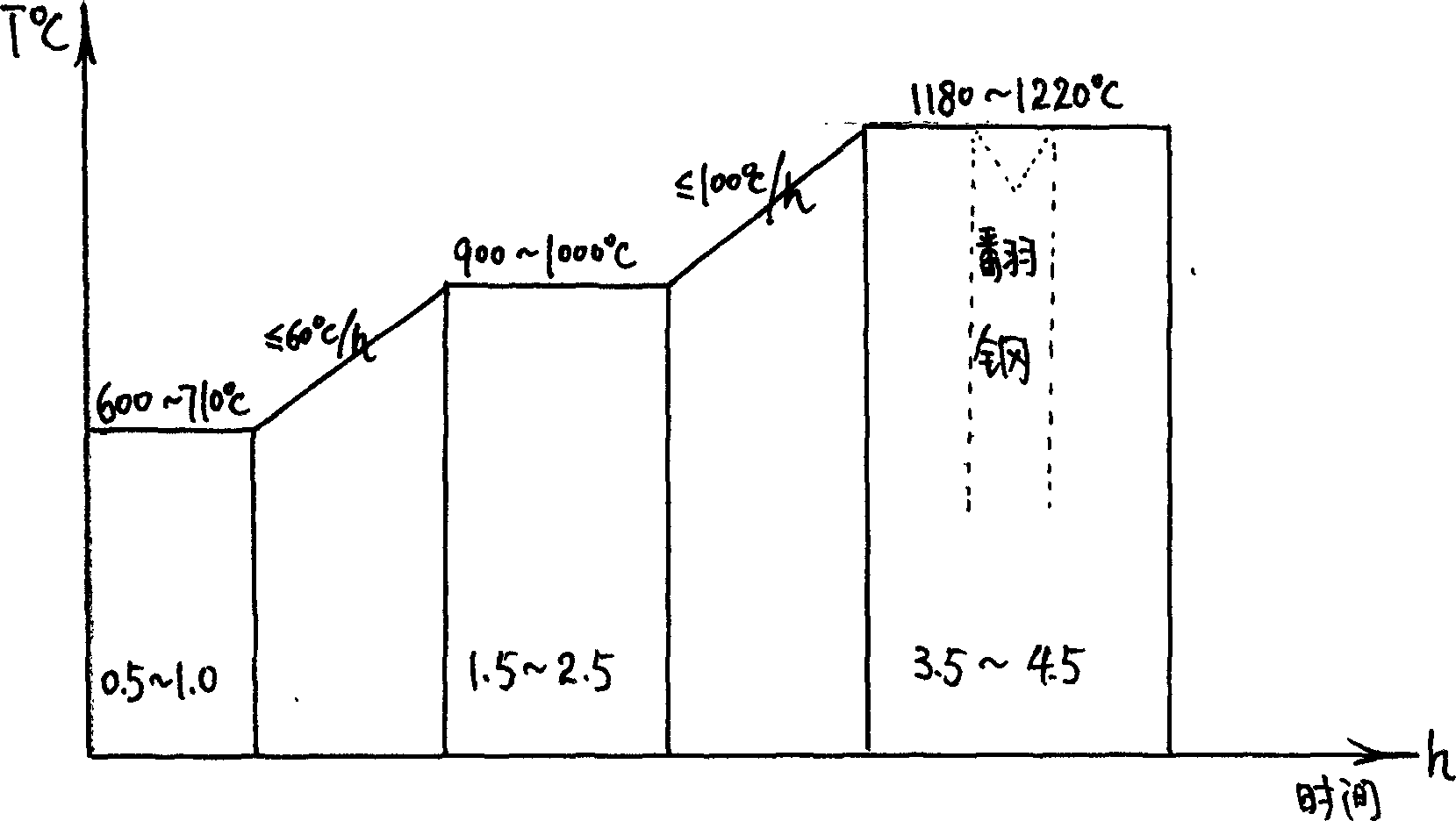

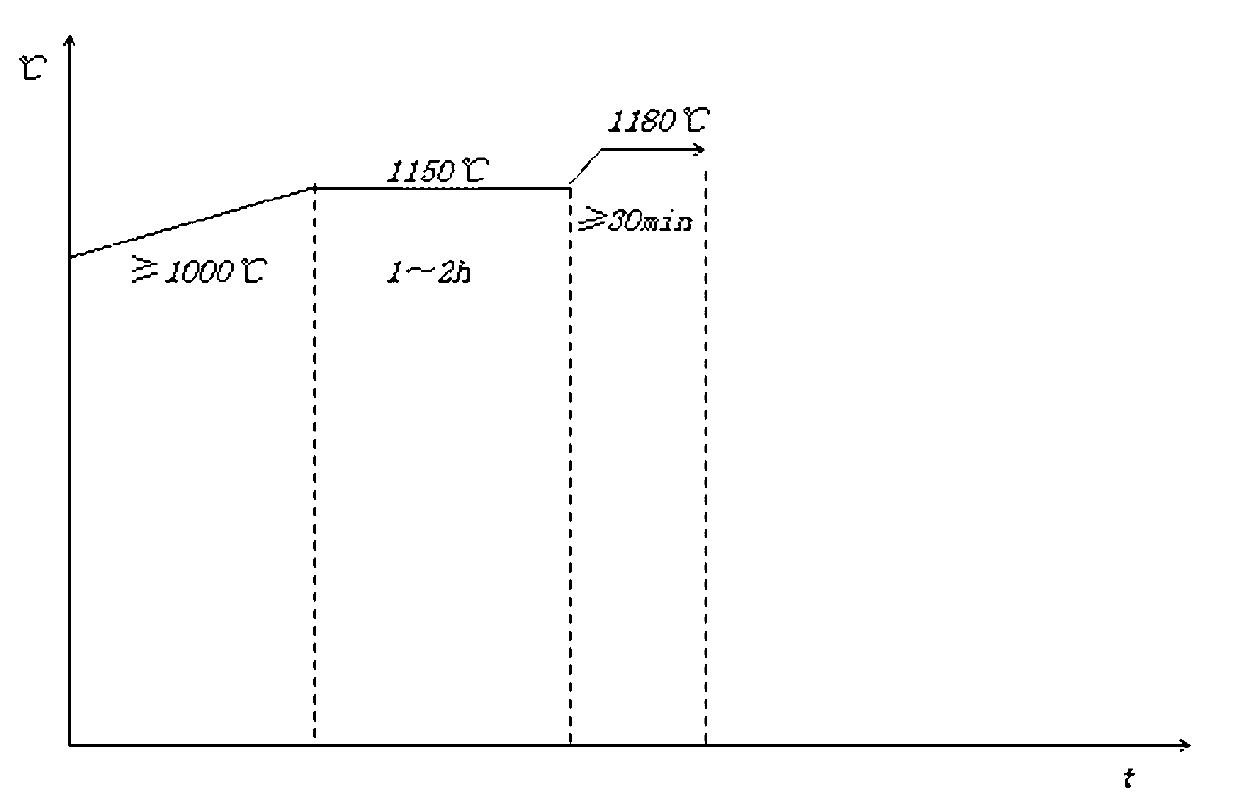

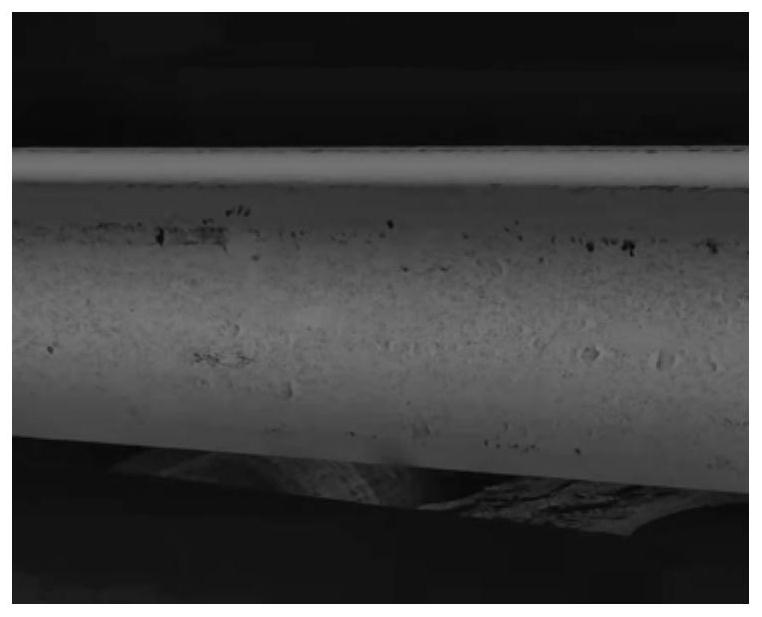

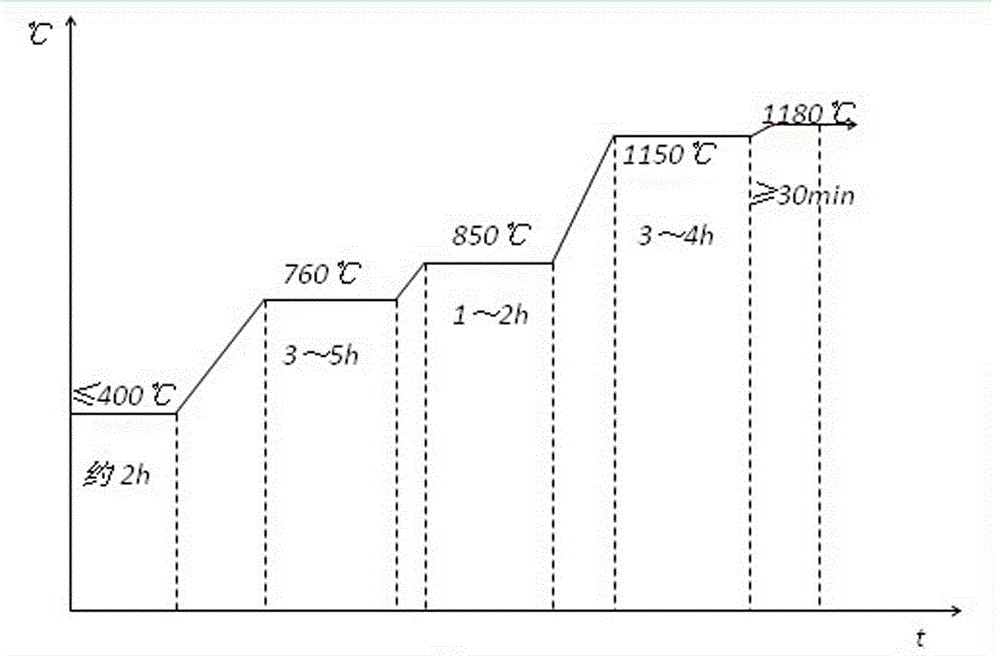

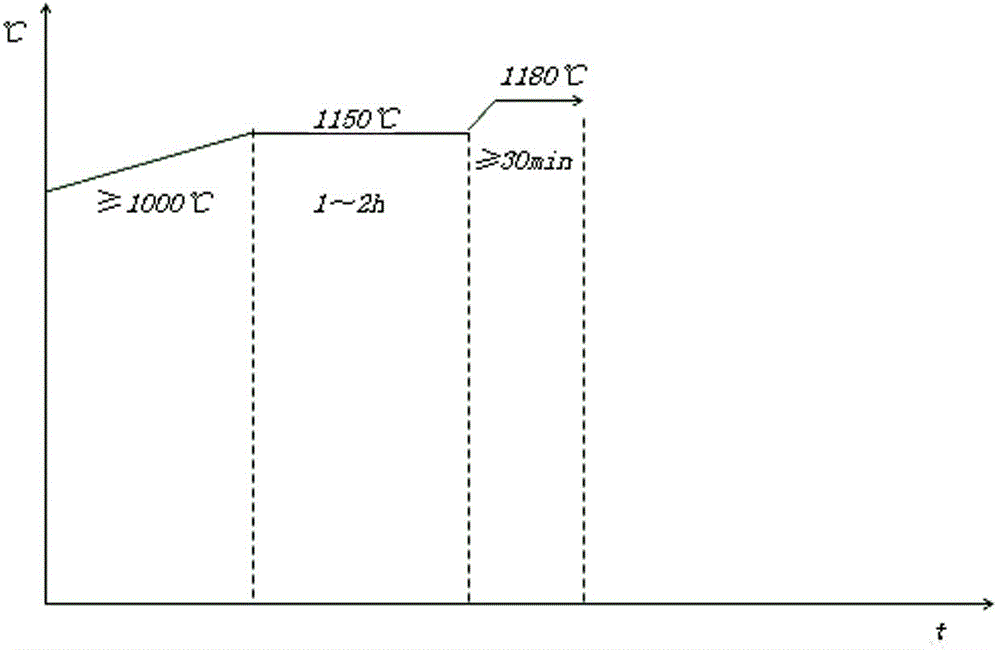

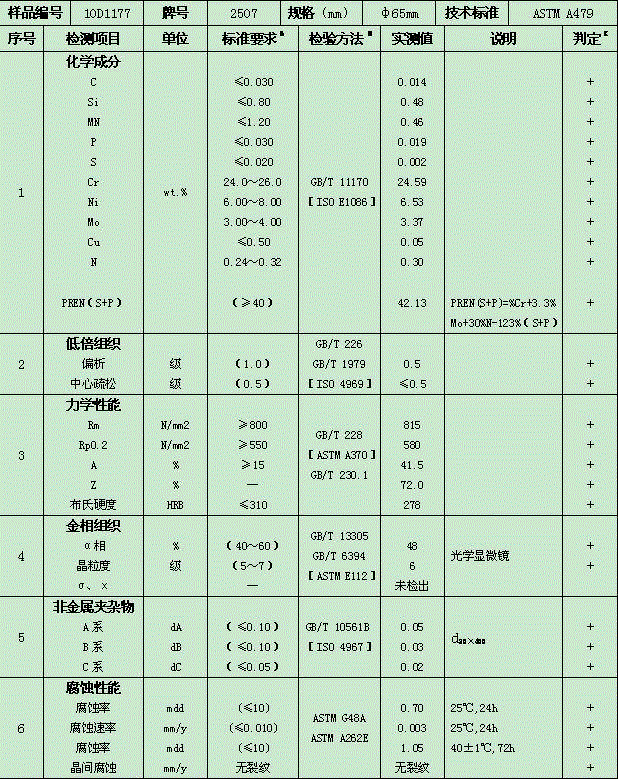

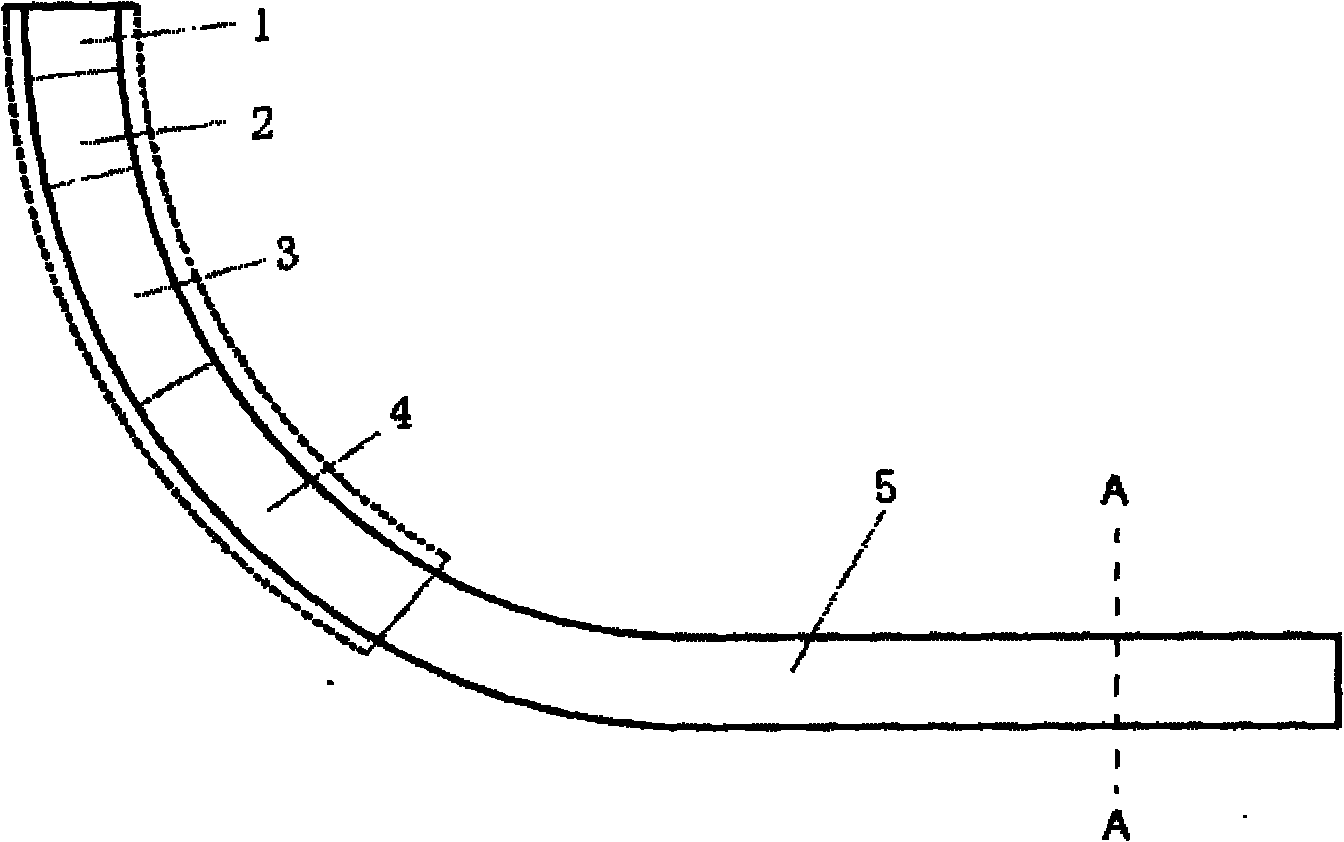

Super duplex stainless steel ingot hot working cogging method

ActiveCN103121034AReduce manufacturing costFulfil requirementsTemperature control deviceMetal rolling arrangementsIngotSS - Stainless steel

The invention belongs to the metallurgical industry, and particularly relates to a super duplex stainless steel ingot hot working cogging method. The methods comprises hot working cogging first fire rolling and hot working cogging second fire rolling. The method comprises the steps of heating a steel ingot with a soaking pit, hot working cogging with a blooming mill, heating a rolled piece with the soaking pit, and hot working second fire cogging with the blooming mill. According to the super duplex stainless steel ingot hot working cogging method, a forging press is replaced by the blooming mill for hot working cogging, a qualified 2507 billet is rolled for being further rolled into a seamless tube circular tube billet, the problems of long production period and low metal cogging yield are solved, production cost of metallurgy manufacturing is greatly reduced, and user requirements and market demands are met.

Owner:浙江青山钢铁有限公司

High-carbon high-chromium stainless steel and processing method thereof

The invention discloses high-carbon high-chromium stainless steel and a processing method thereof and relates to the technical field of stainless steel processing. The processing method of the high-carbon high-chromium stainless steel comprises the following steps: performing mold and cap red transferring on high-carbon high-chromium stainless steel ingots, performing mold and cap removal, puttinginto a furnace, heating, and performing primary rolling on the heated ingots, wherein different heating and heat-preservation processes are selected according to different temperatures of the ingotswhen the ingots are put into the furnace and heated. The processing method of the high-carbon high-chromium stainless steel, which is disclosed by the invention, has the advantages of being simple inprocess, low in production cost and high in blank rate, and the produced stainless steel is good in physical and chemical property. The invention further relates to the high-carbon high-chromium stainless steel produced by using the processing method.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

Method for producing cogging by air-valve steel rolling

ActiveCN101069894AResolution cycleSolve the problem of low metal forming rateRoll mill control devicesFurnace typesIngotHot working

The present invention discloses a production method of valve steel billet. It is characterized by that said production method adopts a hot-working cogging process of 'using continuous heating furnace to heat steel ingot and utilizing rolling mill to roll in one heat'.

Owner:JIANGSU SHENYUAN SPECIAL STEEL

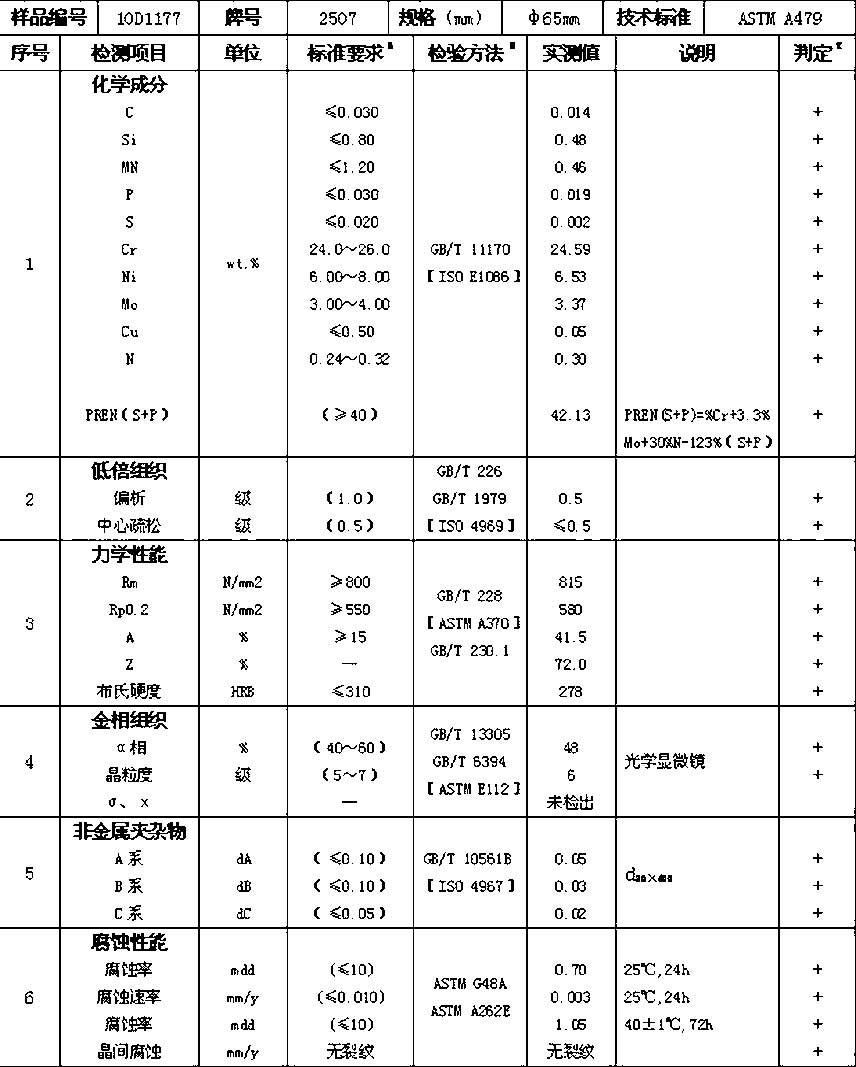

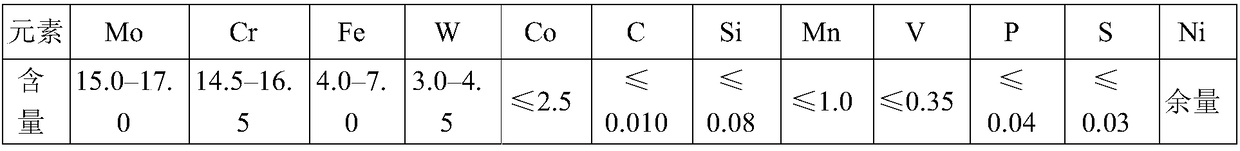

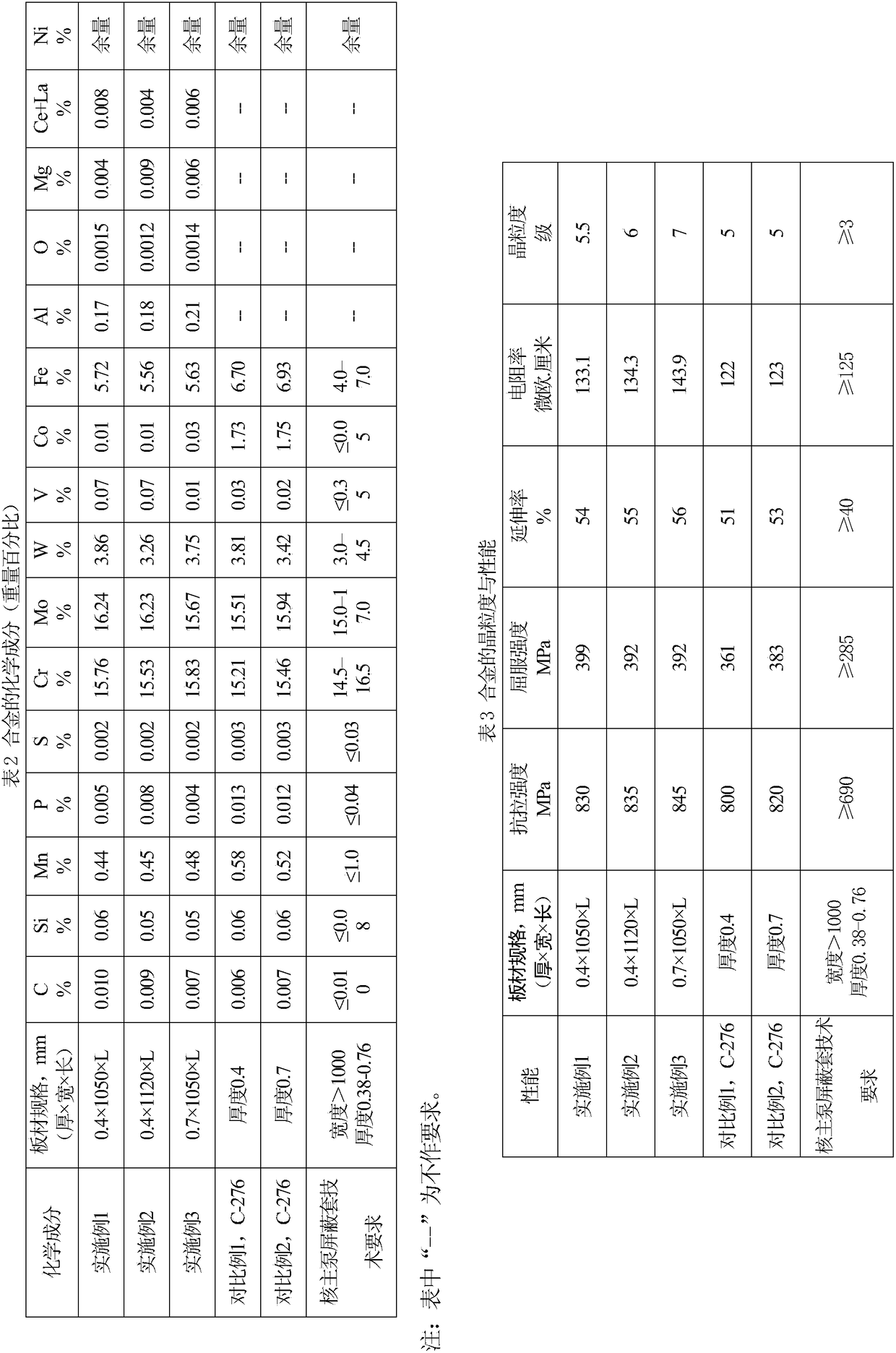

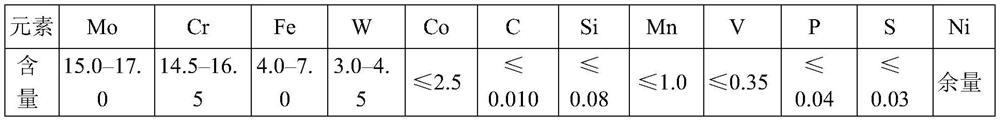

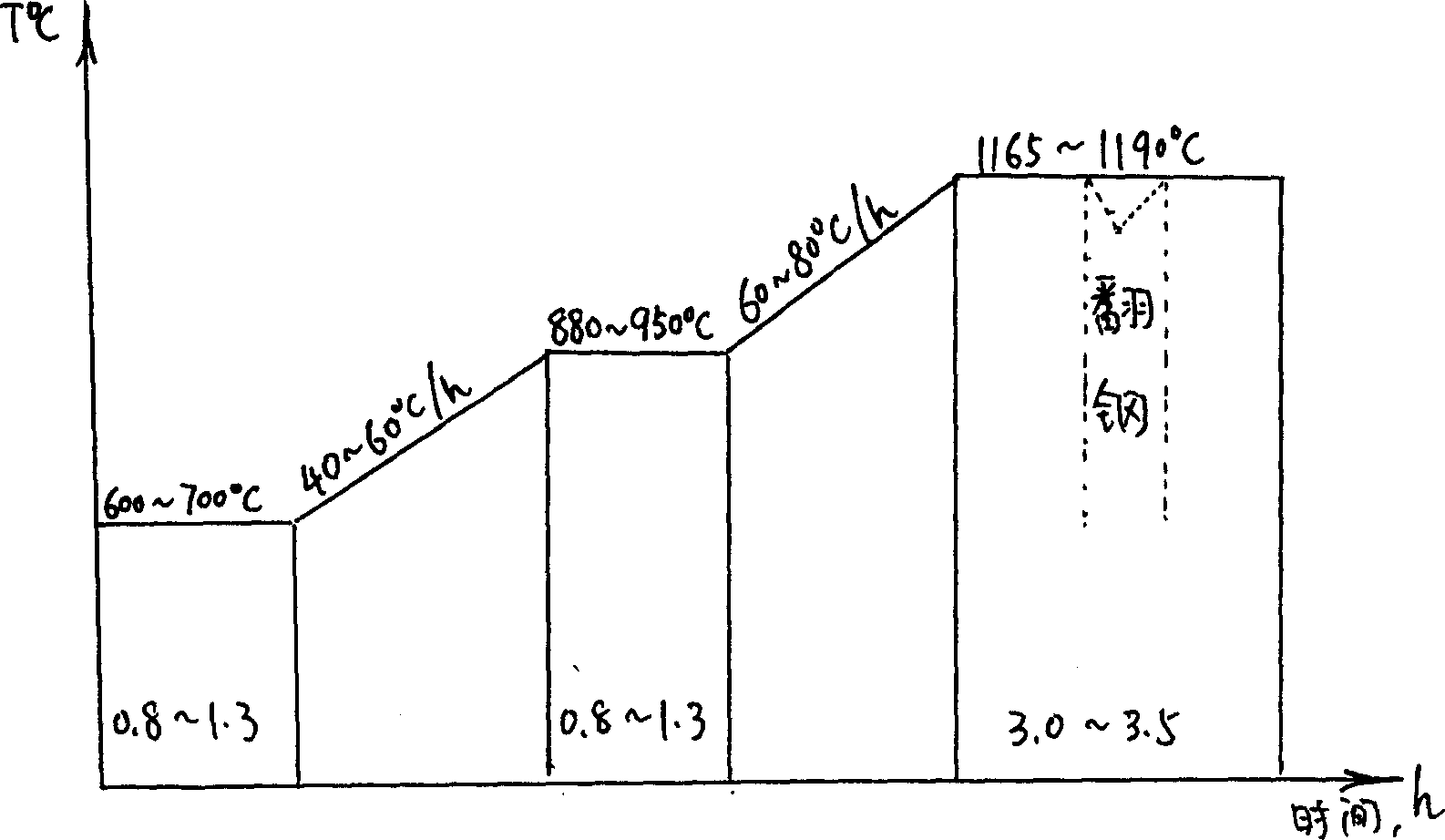

High-Mo Ni-based alloy sheet with width larger than or equal to 1000 mm, manufacturing method and application

The invention provides a high-Mo Ni-based alloy sheet with width larger than or equal to 1000 mm. The alloy comprises components in percentage by weight as follows: 0.006%-0.010% of C, 15.0%-16.5% ofMo, 15.0%-16.5% of Cr, 5.0%-7.0% of Fe, smaller than or equal to 0.05% of Co, 3.0%-4.0% of W, smaller than or equal to 0.10% of V, smaller than or equal to 0.08% of Si, smaller than or equal to 0.8% of Mn, smaller than or equal to 0.01% of P, smaller than or equal to 0.008% of S, 0.10%-0.30% of Al, smaller than or equal to 0.002% of O, 0.001%-0.010% of Mg, 0.001%-0.010% of Ce+La and the balance ofNi and inevitable impurities.

Owner:宝武特种冶金有限公司

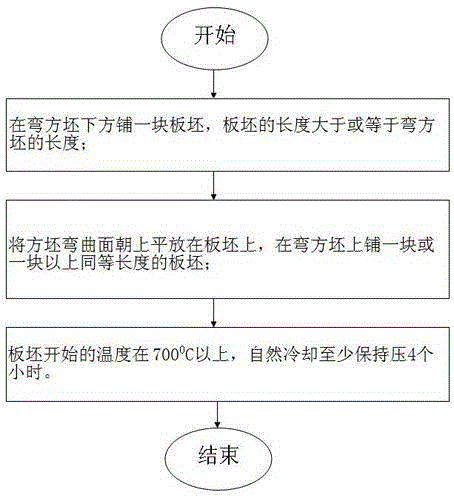

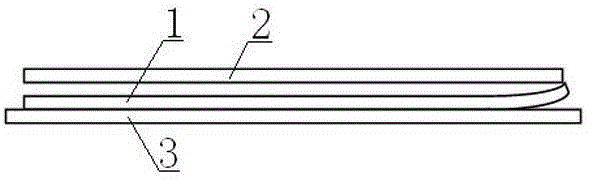

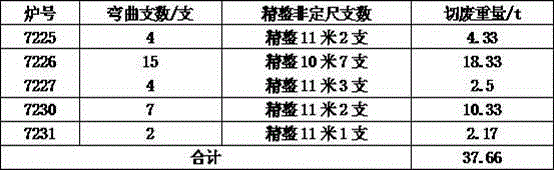

Method for straightening bent square billet

The invention relates to a method for straightening a bent and deformed square billet in the technical field of continuous casting, in particular to a method for straightening the bent square billet. The method includes the following steps that firstly, a plate billet is laid below the bent billet, and the length of the plate billet is larger than or equal to the length of the bent billet; secondly, the square billet is horizontally laid on the plate billet with the bent face facing upwards, and one or more plate billets with the same length are laid on the bent billet; thirdly, the starting temperature of the plate billets is more than 7000 DEG C, and the plate billets are naturally cooled, and pressing is kept for at least four hours. According to the method, operation is easy and convenient, the billet yield of the continuous billet is increased, and the production cost is saved.

Owner:ANYANG IRON & STEEL

New type bone china, and producing method

This invention relates to a method for manufacturing new type bone porcelain. The bone porcelain is composed of: SiO2 50-60 wt.%, Al2O3 20-30 wt.%, P2O5 1.8-3.5 wt.%, CaO 2-5 wt.%, MgO 0.2-0.5 wt.%, K2O and Na2O 3-5 wt.%. The crystal phase content is 50-70 wt. % in the porcelain body. The main crystal phase is mullite, and the minor crystal phases are beta-Ca3 (PO4)2 and anorthite. The bone porcelain is manufactured from: bone ashes 5-10 wt.%, Al powder 5-10 wt.%, kaolin 25-35 wt.%, and porcelain stone 45-60 wt.%. The bone porcelain has such advantages as good appearance, thin external wall, light weight, good light transmittance and good thermal stability. The title method has such advantages as low bon ashes addition, wide sintering range, high quality goods rate, low manufacturing cost and wide raw material resources, and is suitable for mass production.

Owner:HUNAN XIANFENG CERAMIC IND

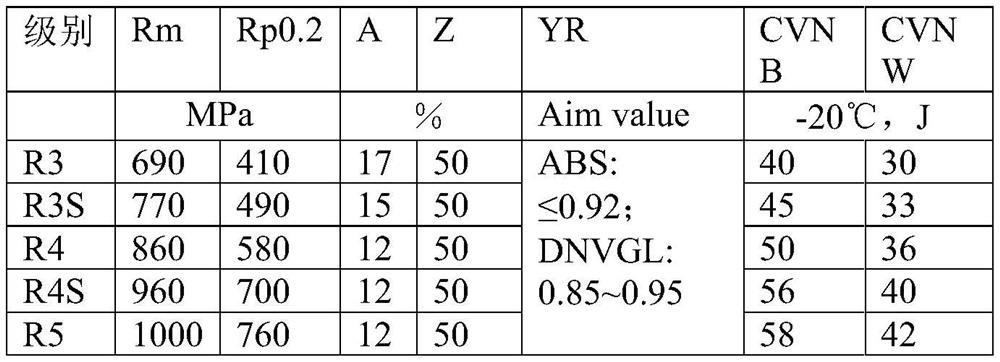

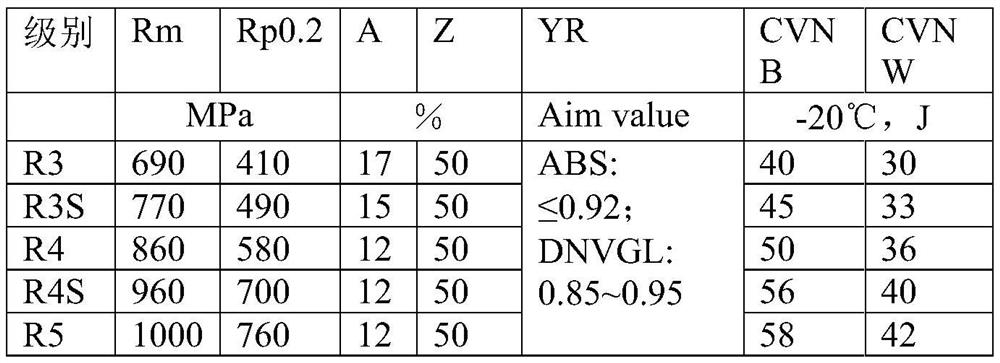

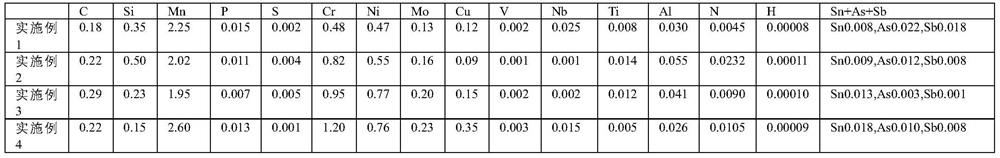

Mooring chain steel and production process thereof, and mooring chain and production process thereof

The mooring chain steel comprises the following components in percentage by mass: 0.18 to 0.32 percent of C, 1.95 to 2.60 percent of Mn, 0.15 to 0.50 percent of Si, 0.45 to 1.20 percent of Cr, 0.008 to 0.250 percent of Mo, 0.02 to 1.20 percent of Ni, less than or equal to 0.40 percent of Cu, less than or equal to 0.005 percent of S, 0.005 to 0.250 percent of Al, less than or equal to 0.35 percent of (V + Ti + Nb), less than or equal to 0.06 percent of (Sn + As + Sb), 0.0005 to 0.0040 percent of Ca, 0.010 to 0.025 percent of REM, 0.004 to 0.024 percent of N, less than or equal to 0.002 percent of O, less than or equal to 0.00015 percent of H and the balance of Fe and inevitable impurities. On the basis of improving the cost performance of R3, R4 and R4S grade mooring steel, by utilizing the river-bay effect of Mn influencing a continuous cooling curve of structural steel, namely similar to the influence rule of Mo, as the content of alloy Mn is increased to a certain amount, the continuous cooling curve of the steel begins to be bent, a component system for increasing cheap elements Mn and Al and reducing precious elements Mo and Ni is designed, and through trial production of the steel and a chain, the cost performance of the steel is improved. The effects of reducing the cost of the chain product and improving the obdurability of the chain product are achieved. The invention further relates to a mooring chain and a production process thereof.

Owner:SHANGHAI BAINITE CHAIN MATERIAL TECH CO LTD +1

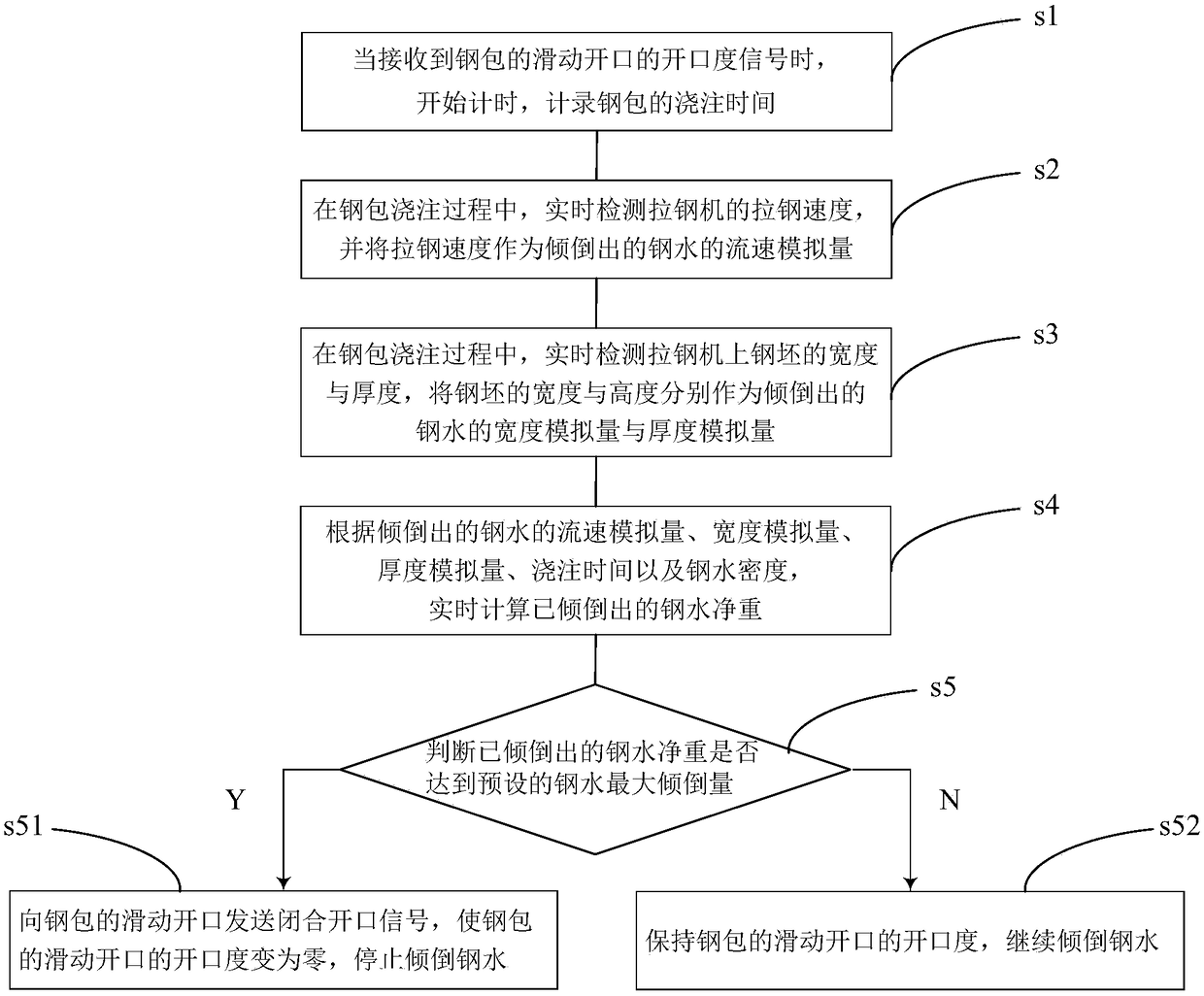

Method for measuring net weight of molten steel in steel ladle

The invention discloses a method for measuring the net weight of molten steel in a steel ladle. The method includes the steps that the pouring time of the steel ladle is recorded; the steel pulling speed of a steel pulling machine is detected to serve as the flow speed analog quantity of the poured molten steel; the width of a billet on the steel pulling machine is detected to serve as the width analog quantity of the poured molten steel, and the thickness of the billet on the steel pulling machine is detected to serve as the thickness analog quantity of the poured molten steel; and the net weight of the poured molten steel is calculated in real time according to the flow speed analog quantity, the width analog quantity and the thickness analog quantity of the poured molten steel, the pouring time and the density of the molten steel. By means of the method for measuring the net weight of the molten steel in the steel ladle, the problem that the net weight of the molten steel cannot beaccurately acquired under the condition that a weighing sensor is ineffective or the error is large is solved. Meanwhile, the method for measuring the net weight of the molten steel in the steel ladlemonitors the net weight of the poured molten steel in the steel ladle in real time, the accuracy of measured data of the net weight of the molten steel is guaranteed, stable operation of the site pouring technology is guaranteed, roughing slag of the molten steel is also avoided, the billet forming rate of the molten steel and the percent of pass of casting blanks are increased, and therefore economic benefits are increased.

Owner:SHANDONG IRON & STEEL CO LTD

Rolling and cogging method for OCr17Ni4Cu4Nb casting ingots

ActiveCN1302129CSimple processEasy to operateMetal rolling arrangementsFurnace temperatureIngot casting

A rolling cogging manufacturing method for 0Cr17Ni4Cu4Nb ingot casting includes: 1) heating in one heat, cooling steel ingot and keeping temperature for 1.5 hr when entering furnace temperature is less than or equal to 600deg.C; heating steel ingot, keeping temperature for 1 hr when entering furnace temperature is less than or equal to 690deg.C and keeping temperature for 2 hrs with is less than or equal to 60deg.C / h up to 950deg.C, keeping temperature for 4 hrs with is less than or equal to 80deg.C / h up to 1180deg.C and drawing charge with positive and positive and negative face temperature differential is less than or equal to 30deg.C; 2) cogging in one heat, roller preheating with rolling speed is less than or equal to 10 / min, beginning temperature is greater than or equal to 1150deg.C, finishing temperature is greater than or equal to 1050deg.C, drafts is less than or equal to 40mm and rolling passage is less than or equal to 14; 3) heating in second heat and keeping temperature for 1 hr at 1180deg.C; 4) cogging in second heat with beginning temperature is greater than or equal to 1130deg.C, finishing temperature is greater than or equal to 1000deg.C and drafts is less than or equal to 50mm, rapid shearing billet and hot annealing. It achieves low cost, simple process and good quality.

Owner:宝武特种冶金有限公司

Rolling cogging production method of Cr4Mo4V electroslag steel ingot

InactiveCN1247328CThe process is reasonable and simpleEasy to operateMetal rolling arrangementsCarbideTemperature difference

The production process of rolling cogging Cr4Mo4V electroslag steel ingot features the heating in pit heating furnace and cogging in blooming mill to produce 100 mm square bloom. The production process includes heating Cr4Mo4V electroslag steel ingot at 630 deg.c for 90 min, 900 deg.c for 60 min, and 1190 deg.c for 210 min while turning the ingot to make the temperature difference between two opposite sides less than 20 deg.c; and cogging at initial temperature over 1130 deg.c and finishing temperature over 1000 deg.c through 44 gates and final annealing in annealing furnace to eliminate stress. The said production process is simple and has high product quality, raised bloom yield and lowered cost.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Hot rolling method of niobium-containing austenitic stainless steel profile

ActiveCN114643280AImprove tissue uniformityGood thermal perforation performanceTemperature control deviceMetal rolling arrangementsNiobiumSS - Stainless steel

The invention discloses a hot rolling method of a niobium-containing austenitic stainless steel profile. The hot rolling method sequentially comprises the following steps: (1) casting refined molten steel into a steel ingot with a preset size; (2) heating the steel ingot and preserving heat for a certain time; and (3) cogging and rolling the steel ingot according to the set parameters. According to the hot rolling method, the cracking problem of the niobium-containing austenitic stainless steel profile is solved, the product quality and the production efficiency are improved, and the production cost is reduced.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Super duplex stainless steel ingot hot working cogging method

ActiveCN103121034BSimple processEasy to operateTemperature control deviceMetal rolling arrangementsIngotSS - Stainless steel

The invention belongs to the metallurgical industry, and particularly relates to a super duplex stainless steel ingot hot working cogging method. The methods comprises hot working cogging first fire rolling and hot working cogging second fire rolling. The method comprises the steps of heating a steel ingot with a soaking pit, hot working cogging with a blooming mill, heating a rolled piece with the soaking pit, and hot working second fire cogging with the blooming mill. According to the super duplex stainless steel ingot hot working cogging method, a forging press is replaced by the blooming mill for hot working cogging, a qualified 2507 billet is rolled for being further rolled into a seamless tube circular tube billet, the problems of long production period and low metal cogging yield are solved, production cost of metallurgy manufacturing is greatly reduced, and user requirements and market demands are met.

Owner:浙江青山钢铁有限公司

Beam blank continuous casting secondary cooling zone cooling device

The invention provides a beam blank continuous casting secondary cooling zone cooling device, relating to auxiliary device for carrying out cooling treatment on casting blank on the site. The cooling device is composed of a foot roller section cooling mechanism, a zone 1 section A cooling mechanism, a zone 1 section B cooling mechanism and a zone 2 cooling mechanism; wherein the foot roller section cooling mechanism is provided with four pairs of foot roller wide face nozzles and two pairs of foot roller narrow face nozzles, the zone 1 section A cooling mechanism is provided with two pairs of zone 1 section A wide face nozzles and one pair of foot roller narrow face nozzles, the zone 1 section B cooling mechanism is provided with two pairs of zone 1 section B wide face nozzles and one pair of zone 1 section B narrow face nozzles, and the zone 2 cooling mechanism is provided with two zone 2 section wide face nozzles and one pair of zone 2 section narrow face nozzles. The invention has the advantages of simple and reasonable structure and reliable use; casting blank surface heat transfer rule is followed, and utilization of water is reasonable and effective; temperature difference of different parts on cross section of casting blank is reduced, casting blank temperature and structural homogeneity are obviously improved, crack of casting blank can be effectively reduced, quality of casting blank is improved, blank yield is improved, and production is promoted.

Owner:MAANSHAN IRON & STEEL CO LTD

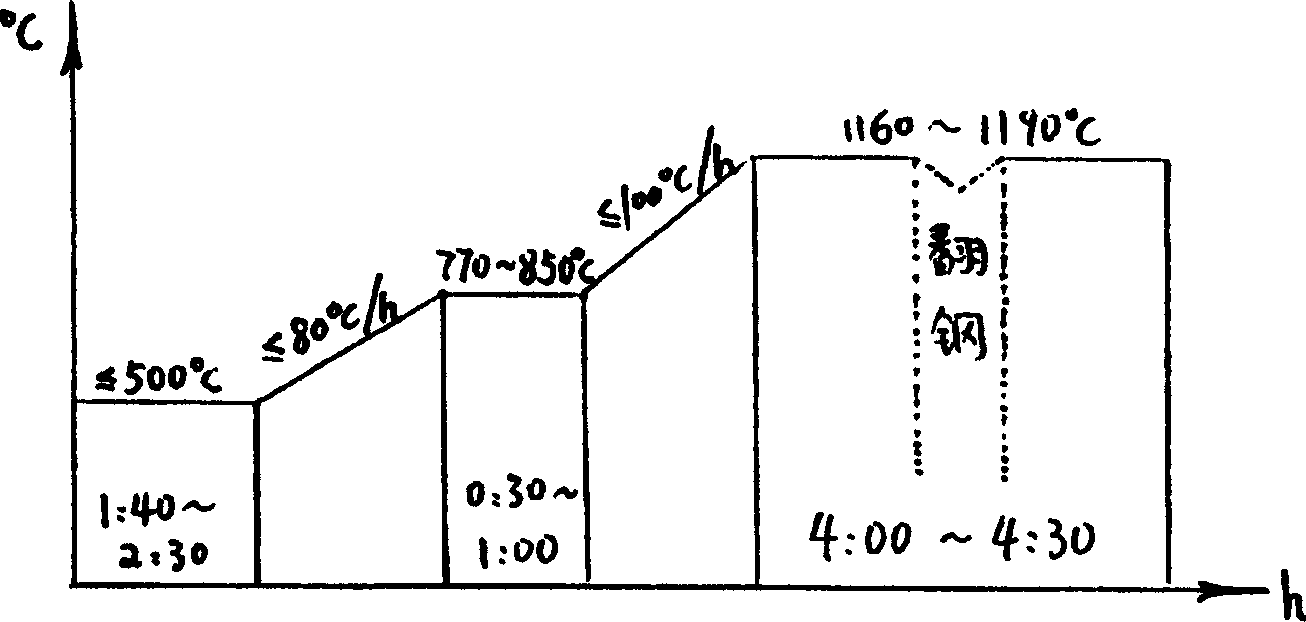

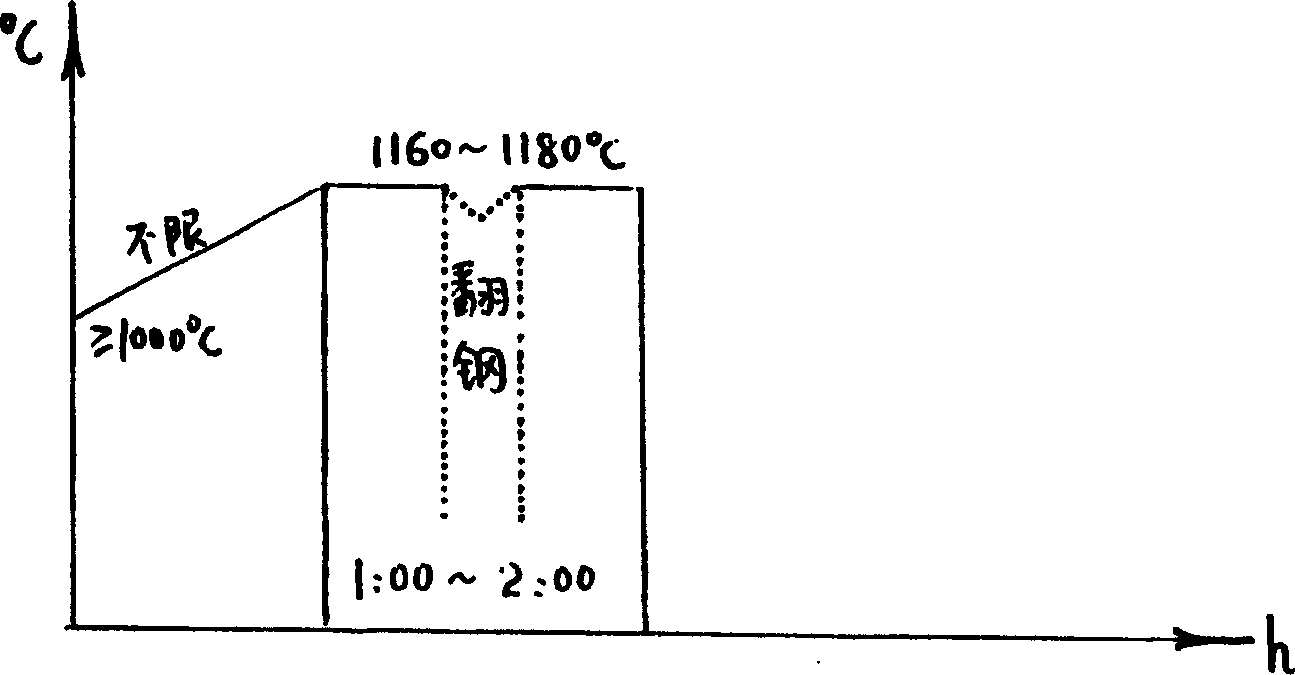

Productive method for cr 12 Mov rolling cogging

The production method of Cr12MoV cogged bloom is characterized by that it adopts the cogging process of "using soaking furnace to heat steel ingot and using cogging mill to roll in two heats": (1) using soaking furnace in one heat: steel ingot weight is less than or equal to 1.5 ton, furnace-feeding temp. is less than or equal to 500 deg.c, heat-insulating time is 2 hr., heating-up speed is less than or equal to 80 deg.C / h; heat-insulating for 4 hr. turning steel ingot and difference in temperature of heat side and cold side is less than or equal to 30 deg.C; (2). using cogging mill to cog in one heat; before rolling, closing cooling water for roll, preheating roll, temp. 150 deg.C, roll speed is less than or equal to 10 rpm; (3). heating in two heats, 1170 deg.C, heat-insulating for 1.5 hr; and (4) cogging in two heats, preheating roll, roll speed is less than and equal to 10 rpm.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

A high-molybdenum-nickel-based alloy thin plate with a width ≥ 1000 mm, its manufacturing method and application

The invention provides a high-Mo Ni-based alloy sheet with width larger than or equal to 1000 mm. The alloy comprises components in percentage by weight as follows: 0.006%-0.010% of C, 15.0%-16.5% ofMo, 15.0%-16.5% of Cr, 5.0%-7.0% of Fe, smaller than or equal to 0.05% of Co, 3.0%-4.0% of W, smaller than or equal to 0.10% of V, smaller than or equal to 0.08% of Si, smaller than or equal to 0.8% of Mn, smaller than or equal to 0.01% of P, smaller than or equal to 0.008% of S, 0.10%-0.30% of Al, smaller than or equal to 0.002% of O, 0.001%-0.010% of Mg, 0.001%-0.010% of Ce+La and the balance ofNi and inevitable impurities.

Owner:宝武特种冶金有限公司

Rolling and cogging method for high-temperature alloy GH1015

A rolling cogging manufacturing method for high temperature alloy GH1015 includes: 1) heating in one heat, electroslag ingot keeping temperature for 1 hr with entering furnace temperature is less than or equal to 700deg.C, keeping temperature for1 hr with is less than or equal to 60deg.C / h up to 900deg.C, keeping temperature for 3.5 hrs with is less than or equal to 80deg.C / h up to 1180deg.C and drawing charge with positive and negative face temperature differential is less than or equal to 20deg.C; 2) cogging in one heat with preheating temperature of roller 120deg.C and beginning temperature is greater than or equal to 1100deg.C, finishing temperature is greater than or equal to 1000deg.C, roller speed is less than or equal to 20 / min, drafts is less than or equal to 30mm and rolling passage is less than or equal to 15; 3) heating in second heat, keeping temperature for 80 mins at 1170deg.C and drawing charge with positive and negative face temperature differential is less than or equal to 20deg.C; 4) cogging in second heat and roller preheating with beginning temperature is greater than or equal to 1100deg.C, finishing temperature is greater than or equal to 1000deg.C, rolling speed is less than or equal to 20 / min, rolling speed of product passage is less than or equal to 10 / min and drafts 30mm. It achieves low cost, simple process and good quality.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Water cooling channel for large beam blank continuous casting crystallizer

The invention belongs to a cooling casting blank or casting mould device and relates to a water cooling channel for a large beam blank continuous casting crystallizer,,and particularly to a copper plate cooling device for a beam blank continuous casting crystallizer. The copper plate cooling channel is characterized in that: a web water gap, a R angle water gap, a bevel water gap, a flange inner angle water hole and a flange top water hole are formed on a broadside copper plate according to the characteristics of the copper plate shape and heat face heat flux; the water gaps without corners are distributed uniformly, and the water gaps at R angle are dense, and few water holes are arranged at concave corners; and a cooling water tank is arranged outside a narrow side copper plate. The copper plate cooling channel has the advantages that cooling water channels are arranged in areas, the number of cooling water channels is reduced, water gap diameter is reduced, and processing quantity is reduced; the water gaps are arranged reasonably, temperature peak value at the R angle is eliminated, the temperature gradient is reduced, the cooling strength of the flange top is weakened, the overall temperature of the copper plate tends to be uniform, the working environment of the copper plate and blank heat transmission condition are improved, the cooling effect is good, and water is saved; deformation and abrasion of the copper plate are reduced, and service life is prolonged; the surface quality of blanks is remarkably improved, the cogging yield is improved, and continuous casting production can be performed smoothly.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Method for preparing polymer ceramic dispersants

InactiveCN101274242BAppropriate viscosityImprove liquidityTransportation and packagingMixingPolymer sciencePolyethylene glycol

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com