Water cooling channel for large beam blank continuous casting crystallizer

A technology of cooling water channels and continuous casting of special-shaped billets, which is applied in the field of devices for cooling casting billets or molds, can solve problems such as wear and deformation, and achieve the effects of improving surface quality, reducing machining amount, and improving working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

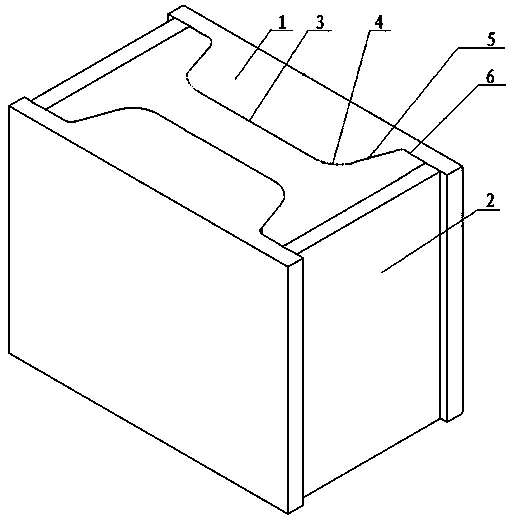

[0017] Depend on figure 1 It can be seen that the continuous casting crystallizer for large shaped billets is composed of two wide-faced copper plates 1 and two narrow-faced copper plates 2 connected. , R angle area 4, flange slope area 5, and flange top 6 areas, the molten steel flows into the "H"-shaped inner cavity, and is continuously cast into a billet.

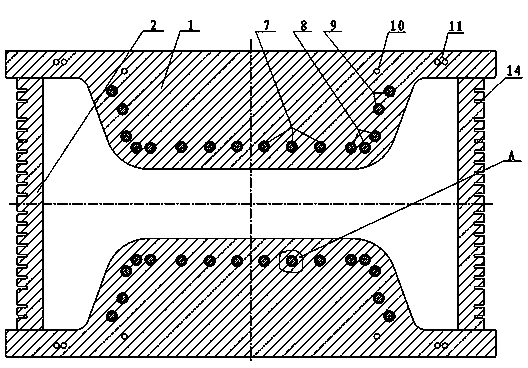

[0018] figure 2 It is a schematic diagram of the cross-section of the continuous casting crystallizer for large shaped billets, which is represented by figure 2 It can be seen that on the wide copper plate, the web water joint 7 set in the web 3 area is composed of 6-8 water joints; the R angle water joint 8 set in the R angle 4 area is composed of 6-8 water joints The slope water slot 9 provided in the flange slope 5 area is composed of 4-6 water slots; the flange top 6 area is provided with 2 flange inner corner cooling water holes 10 and 4 flange top cooling water holes 11, two pieces Wide-faced copper plates are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com