Method for measuring net weight of molten steel in steel ladle

A measurement method and technology for molten steel, applied in the field of steel industry control, can solve the problems of easy collision of load cells, affecting the accuracy of molten steel net weight measurement, and damage to load cell lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It is mentioned in the related technology that when using a load cell to weigh the net weight of molten steel, driving the ladle to release or lift the ladle is likely to collide with the load cell or the connection line of the load cell, causing the load cell or its connection line to be damaged. The damage of the load cell will affect the accuracy of the measurement data of the load cell itself, and then seriously affect the accuracy of the measured net weight of molten steel.

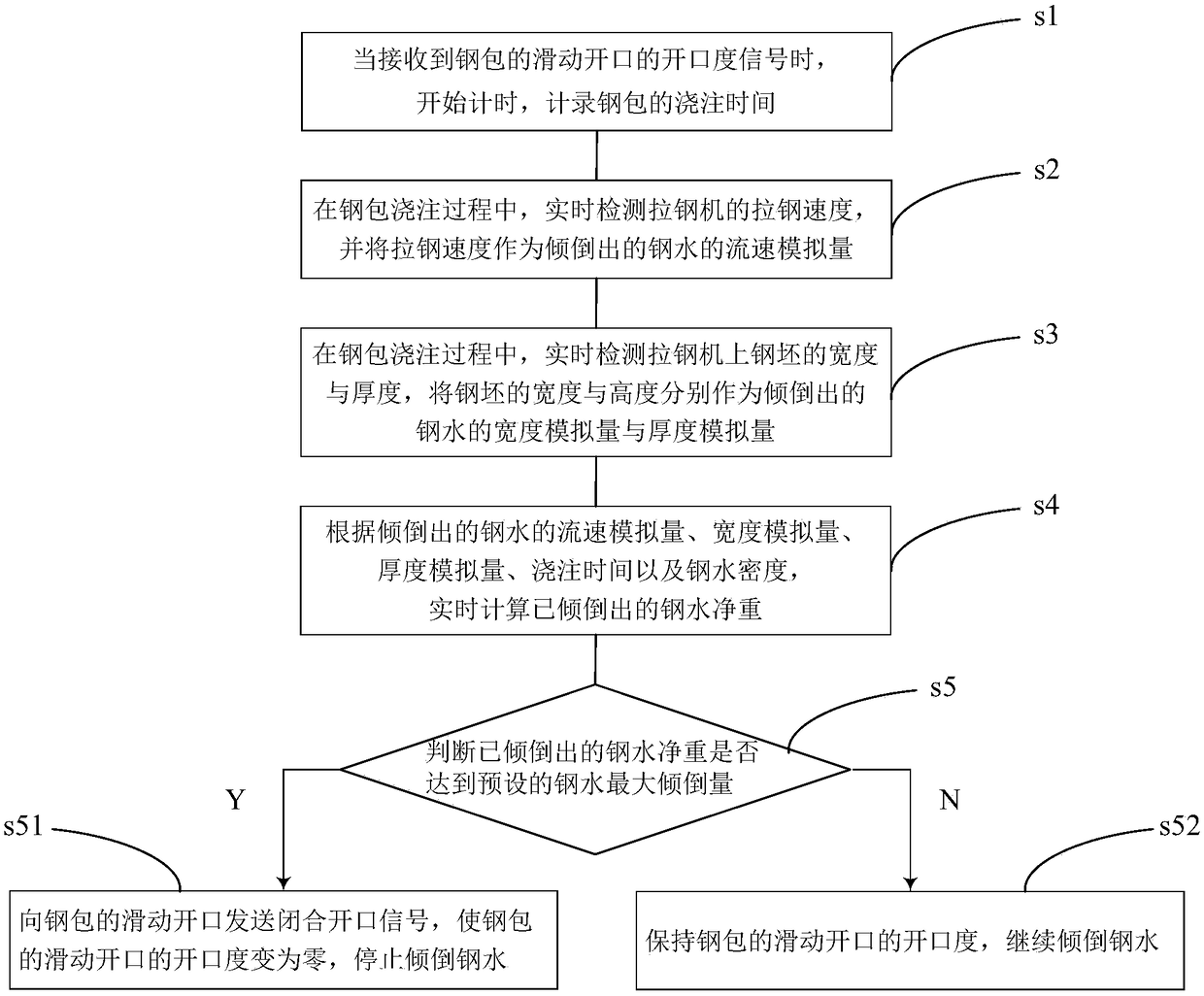

[0030] In order to solve the above technical problems, the present application provides a method for measuring the net weight of molten steel in a ladle. figure 1 For the flow chart of the net weight measurement method of molten steel in the ladle of this application, such as figure 1 As shown, the measurement method includes:

[0031] In step s1, when the opening degree signal of the sliding opening of the ladle is received, timing is started to record the pouring time of the ladle. In this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com