Double-cyclone cylinder burner W-shaped flame boiler capable of stably burning pulverized coal

A technology of pulverized coal combustion and double cyclone, which is applied in the combustion method, combustion equipment, transportation of non-flammable liquid/gas, etc., can solve the problems of difficulty in adding air, poor combustion stability under high load, stable combustion, and poor burnout performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

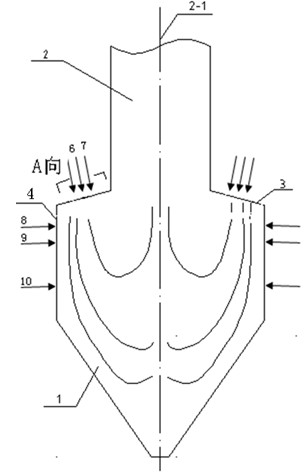

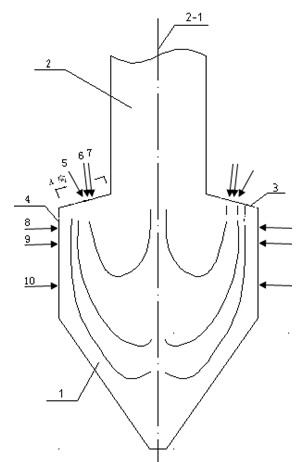

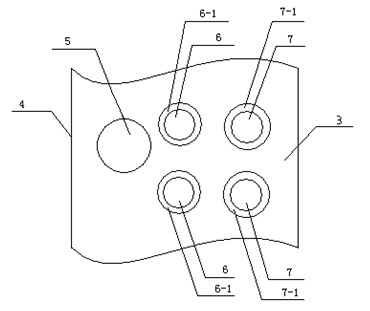

[0011] Embodiment: The structure of the double cyclone burner—W type flame boiler is as follows figure 1 and image 3 As shown, it is composed of lower furnace 1, upper furnace 2, front and rear arches 3 and front and rear wall water cooling walls 4. There are relatively symmetrical secondary air nozzles D8, E9 and F10 in the lower part of the front and rear wall water cooling walls 4, and the front and rear arches 3 has primary air nozzle 6, exhaust gas nozzle 7, secondary air C nozzle 5, secondary air B6-1 and secondary air A7-1; exhaust gas nozzle 7 is opened on the front and rear arches 3 near the center of the furnace The secondary air C nozzle is opened on the front and rear arches 3 near the front and rear walls, the primary air nozzle 6 is opened between the exhaust air nozzle 7 and the secondary air C nozzle 5 on the front and rear arch 3, the primary air nozzle 6 and the exhaust air nozzle 7 It is at an angle of 5° with the vertical. The air outlet of the secondar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com