Grate bar material and production method thereof as well as combined pouring unit of sintering machine

A production method and grate technology, which are applied in the field of sintering machine grate material and its production method and molds, can solve the problems of complex production process of high alloy grate, difficult control of casting defects, uneven performance, etc., and achieve improvement Casting process performance, improvement of casting quality, and effects of avoiding casting defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

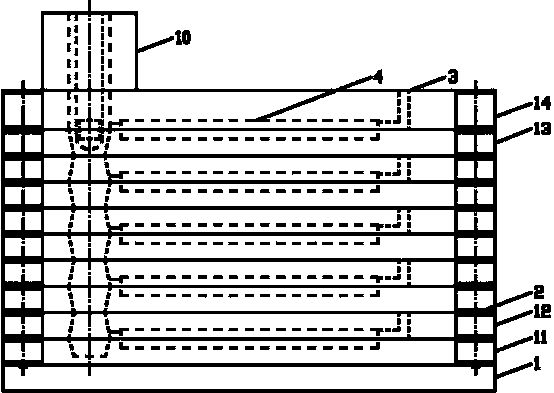

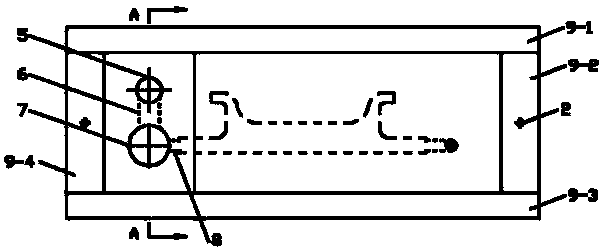

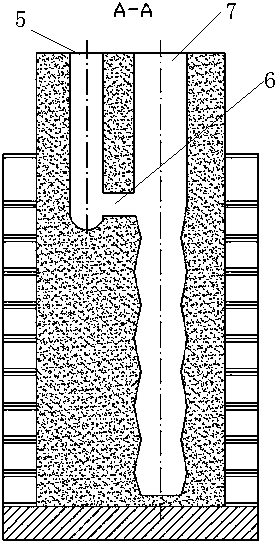

Image

Examples

Embodiment 1

[0027] The production method of embodiment 1 is as follows:

[0028] Mix scrap steel, foundry pig iron, ferromanganese, ferrosilicon, ferrochrome and other furnace materials according to the ratio, melt them in a 500kg medium-frequency induction furnace, heat and melt the furnace materials, measure the composition of the melt before the furnace, and adjust the addition of furnace materials according to the results until they meet the designed elements content, raise the temperature to 1590±10°C, remove slag, add silicon-calcium alloy for pre-deoxidation, insert a pure aluminum rod with a diameter of 15mm into the melt for final deoxidation, adjust the aluminum content of the melt, and add particulate ferroniobium and ferro-titanium to the melt liquid microalloying. The temperature of the furnace is controlled at 1470±10°C, and it is modified by the ladle method. First, one-third of the melt is poured into the ladle, and the rare earth ferrosilicon alloy preheated at 200~300°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com