Patents

Literature

54results about How to "Good casting process performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure casting aluminium aluminium alloy for cylinder of minicar engine

InactiveCN1483847AGood casting process performanceHigh leak inspection pass rateChemical compositionPressure casting

The present invention relates to a mnicar engine cylinder pressure casting aluminium alloy, and its chemical component composition includes (wt%) Cu 1.5-3.0%, Si 10.0-12.0%, Mg 0.15-0.35%, the rest is al and the other is impurity. Said alloy tensile strength Qb is greater than or equal to 300MP. Said alloy has enough strength and rigidity and good size stability. Said alloy can meet the requirements for minicar engine cylinder body high-pressure casting process and mechanical working process.

Owner:重庆长安汽车有限责任公司

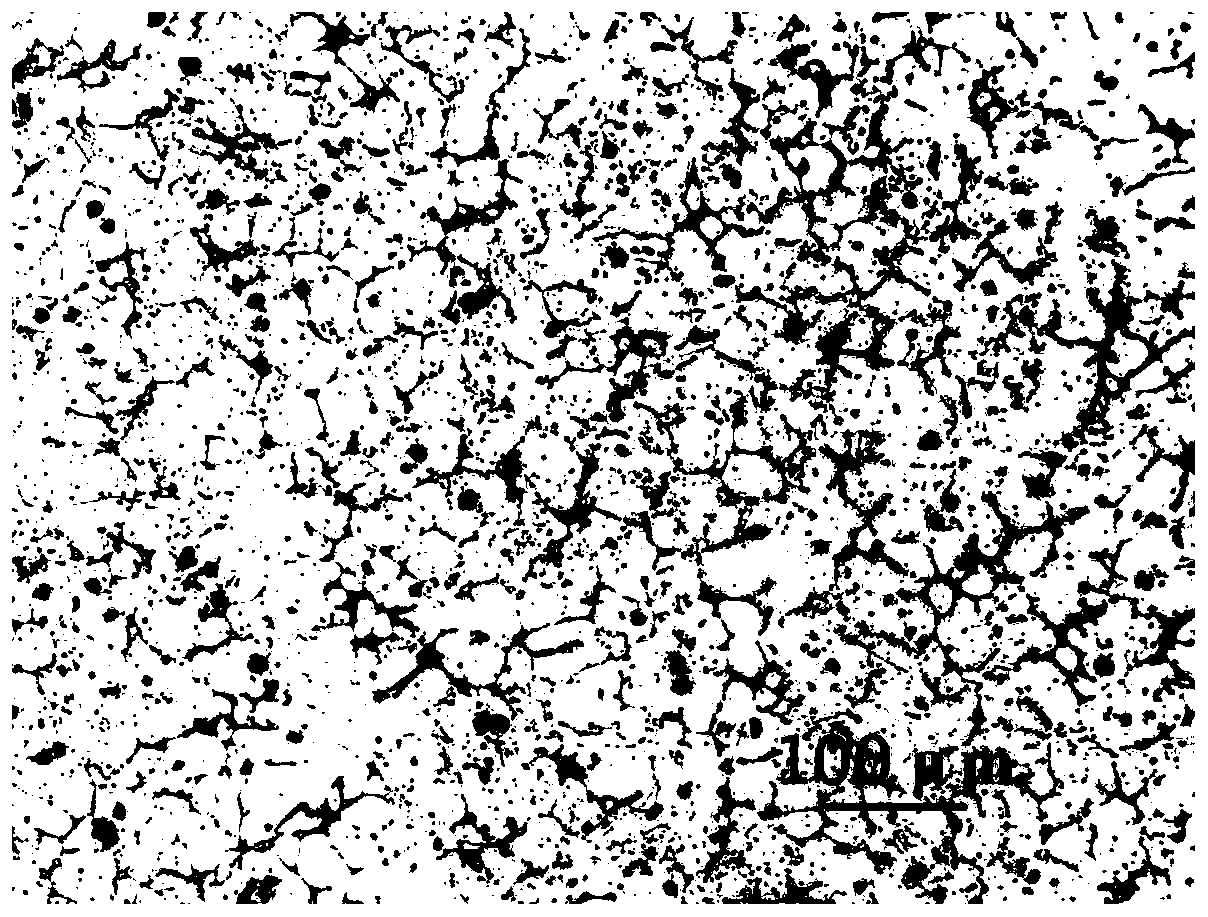

High strength and toughness rare earth magnesium alloy

The invention belongs to the magnesium alloy material field and particularly relates to a high strength and toughness rare earth magnesium alloy. The invention solves the defects of low strength and plasticity of the Mg-Al base alloy which is widely used now. The alloy comprises the following elemental compositions by weight percent: 3-9% of Al, 0.2-0.6% of Zn, 0.1-0.5% of Mn, 0.05-1.0% of Ce, 0.05-1.0% of La, 0.1-3.0% of Y, 0.1-2.0% of Er, 0.1-2.0% of Ho, 0.004% or less of impurity element Fe, 0.002% or less of impurity element Cu, 0.02% or less of impurity element Si, 0.001% or less of impurity element Ni and the balance Mg. Through combined action of the elements and proper homogenizing treatment, the comprehensive performance of the alloy is significantly improved.

Owner:TAIYUAN HUA YIN TAI ALLOY

Grate bar material and production method thereof as well as combined pouring unit of sintering machine

ActiveCN103849819AReduce contentHigh hardnessFoundry mouldsFurnace typesChemical compositionBar product

The invention relates to a production method of a grate bar material of a sintering machine. The production method mainly solves the problems that a high-alloy grate bar is complex in production process, relatively high in production cost, difficult in casting flaw control, non-uniform in performance and the like in the prior art. The technical scheme of the invention is as follows: the grate bar material of the sintering machine comprises the following chemical components in percentage by mass: 1-1.5% of C, 1.5-2.5% of Si, 1.2-2.2% of Al, 2.5-3% of Mn, 11-15% of Cr, 0.3-0.8% of Mo, 0.01-0.03% of Nb, 0.01-0.03% of Ti, 0.03-0.1% of Re, less than or equal to 0.06% of P, less than or equal to 0.06% of S, and the balance of Fe and inevitable impurity elements. A sand casting process of 'one pouring with more molds' is applied, so that the aluminum content and the casting flaws of a silicon grate bar are reduced, and the production cost is reduced. A heat treatment furnace provided with a flow guide circulating fan is applied to low-temperature uniform heat treatment on a cast so as to improve the performance uniformity of casts of the same batch. By adopting the production method disclosed by the invention, a grate bar product of the sintering machine, which is good in process stability, good in performance and relatively low in production cost, can be obtained.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

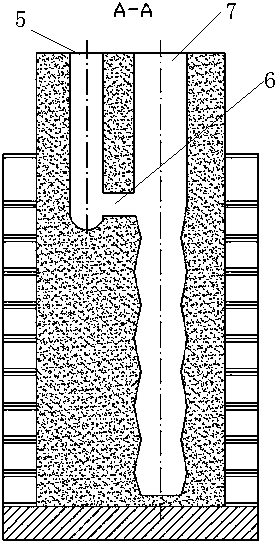

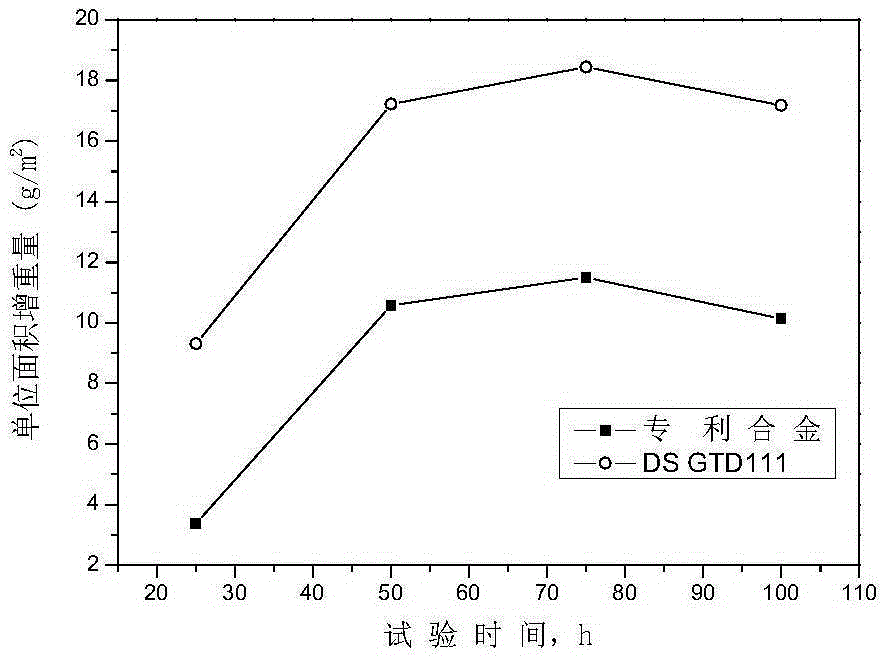

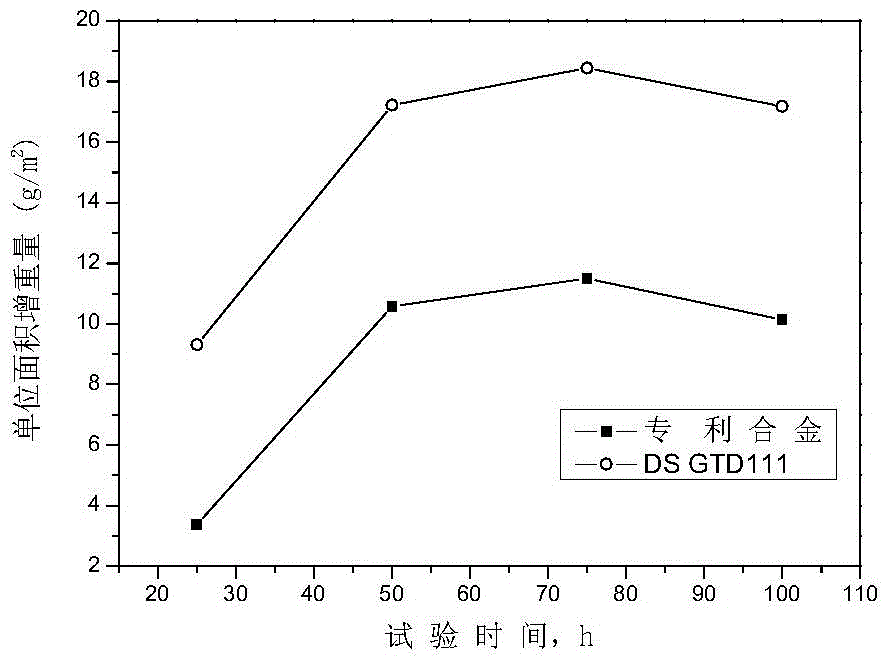

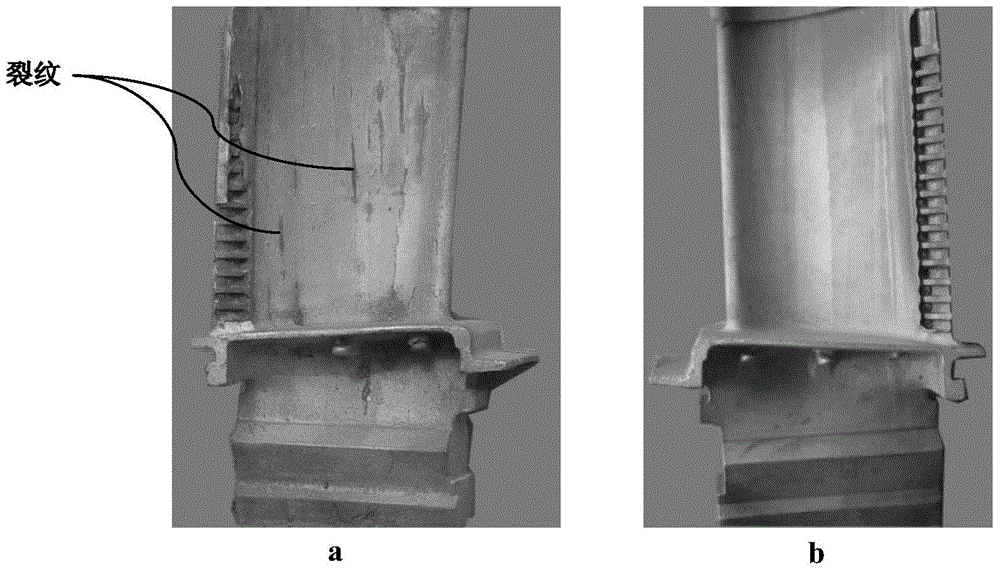

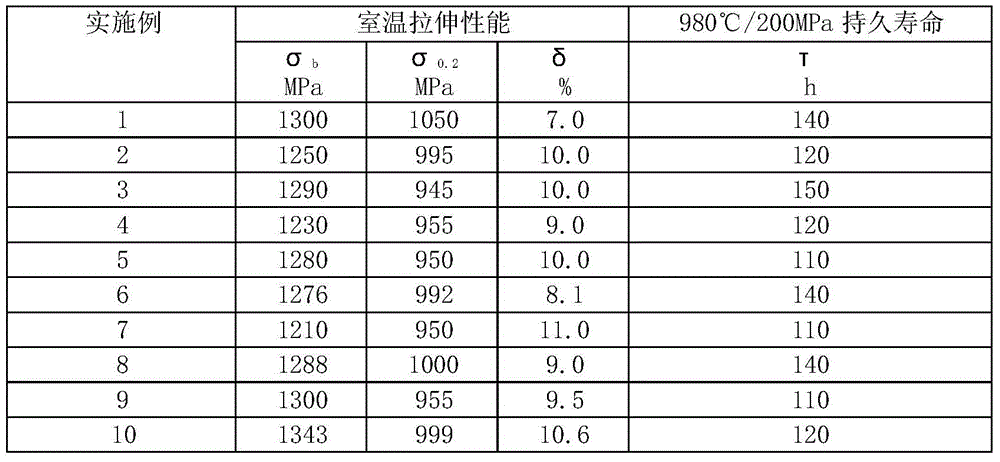

High-temperature alloy casting resistant to high-temperature hot corrosion

ActiveCN105349842AImprove mechanical propertiesGood long-term aging tissue stability at high temperatureFoundry mouldsFoundry coresMetallic materialsHigh-temperature corrosion

The invention belongs to the field of metal materials and relates to a high-temperature alloy casting which is resistant to high-temperature hot corrosion and is used for a part at the hot end of a gas turbine. Alloy comprises, by mass, 3.8%-6.0% of Al, 0.5%-3.5% of Ti, 10.0%-12.0% of Cr, 5.0%-7.0% of Ta, 8.0-10.0% of Co, 4.0%-7.0% of W, 1.0%-3.0% of Mo, 0-3.0% of Hf, 0-4% of Re, 0.02%-0.15% of C, 0.002-0.02% of B and the balance nickel. According to the high-temperature alloy casting resistant to high-temperature hot corrosion, the Al / Ti value, the content of Hf and the ratio of the content of Hf to the content of C and B are adjusted, so that the casting performance of the alloy is improved, and the high-temperature burning hot corrosion performance of the alloy is improved. Thus, the gas turbine high-temperature alloy more suitable for hollow blade casting is obtained.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

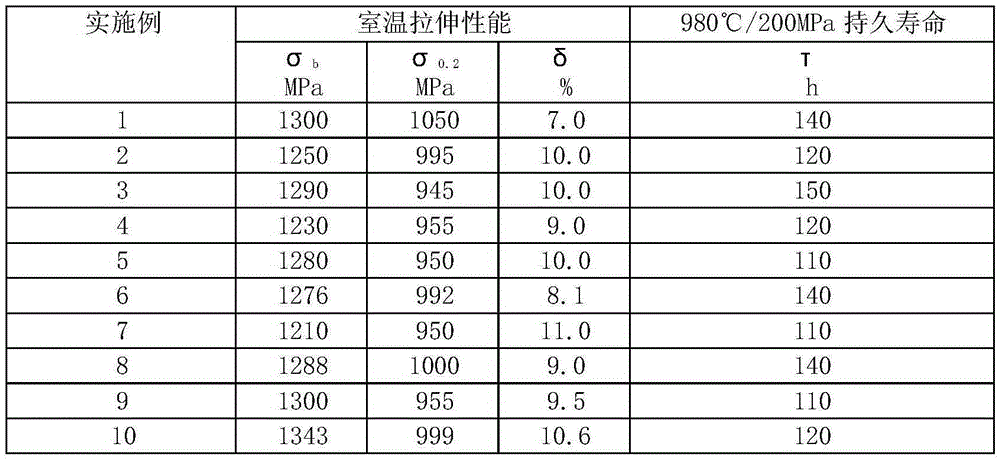

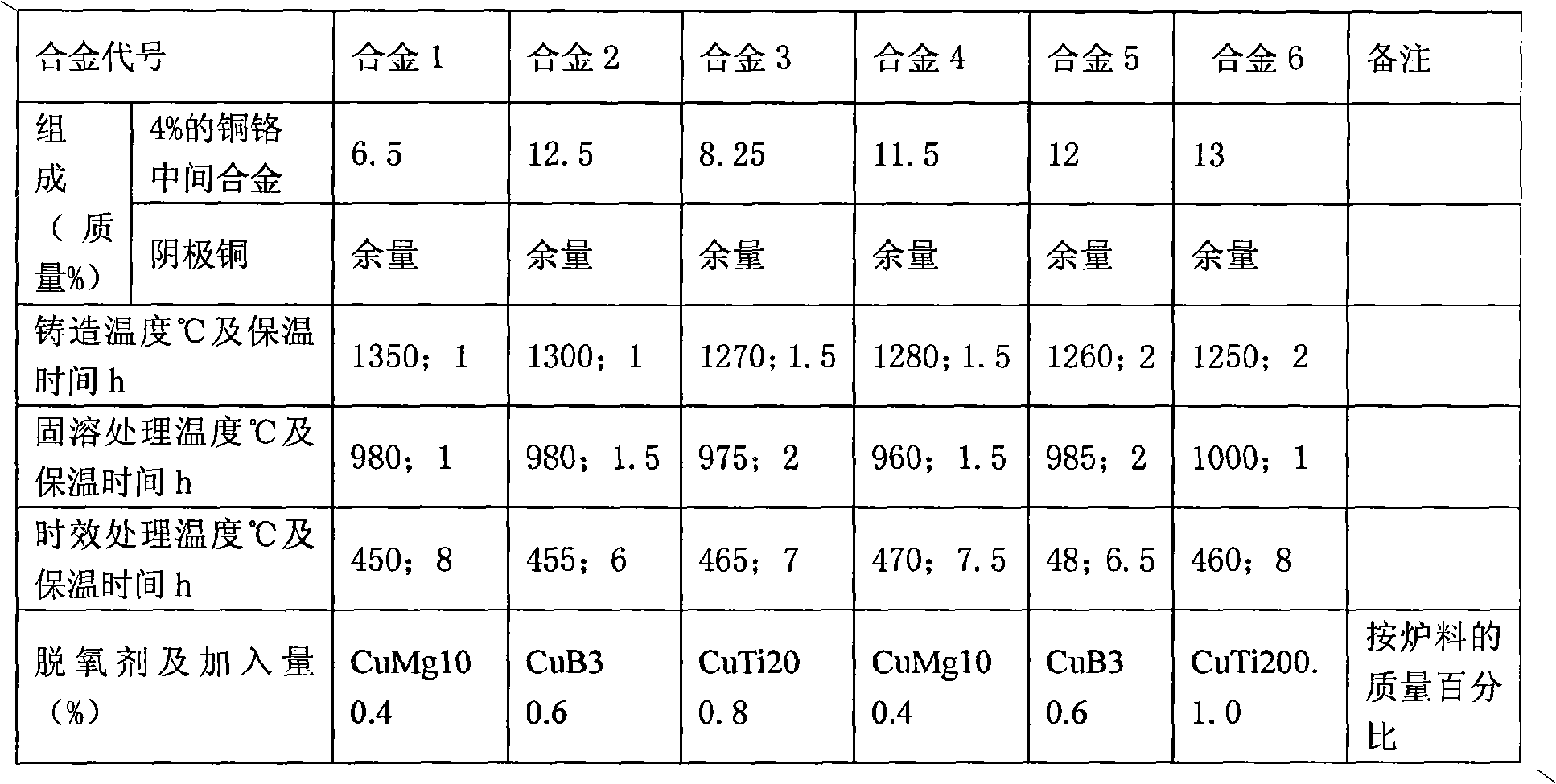

Casting copper-chromium alloy and preparation method thereof

ActiveCN101586200AMeet special performance needsGood casting process performanceHardnessHigh pressure

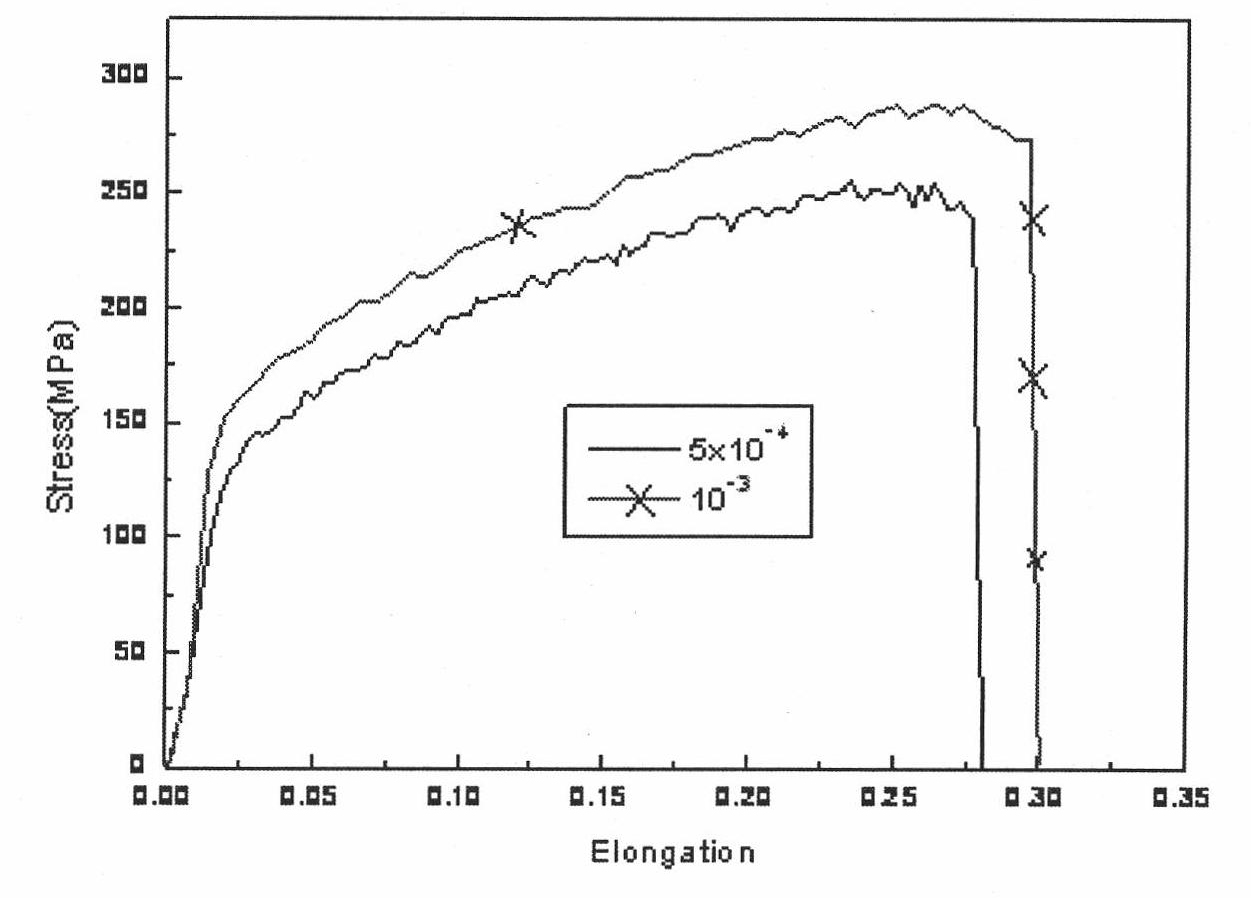

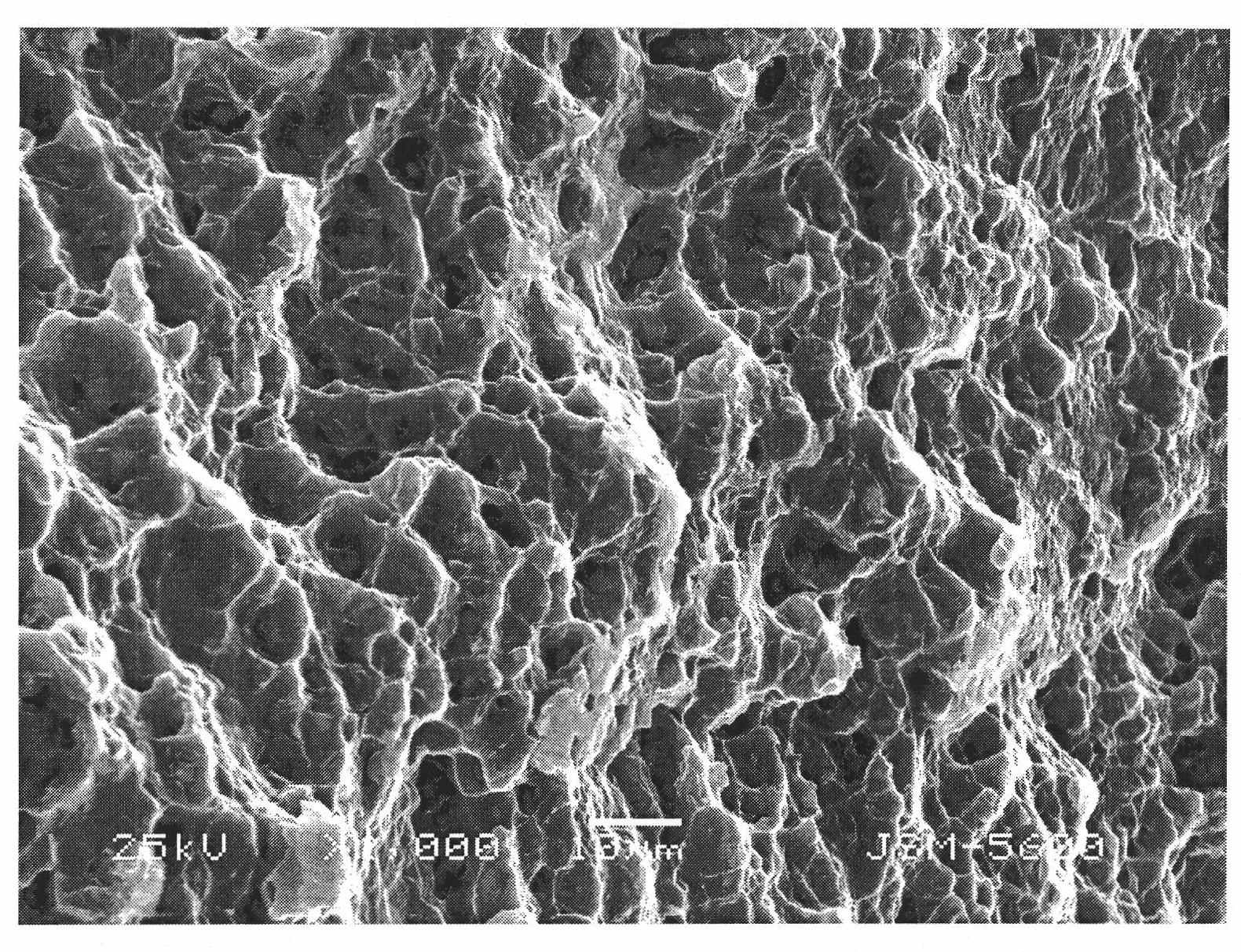

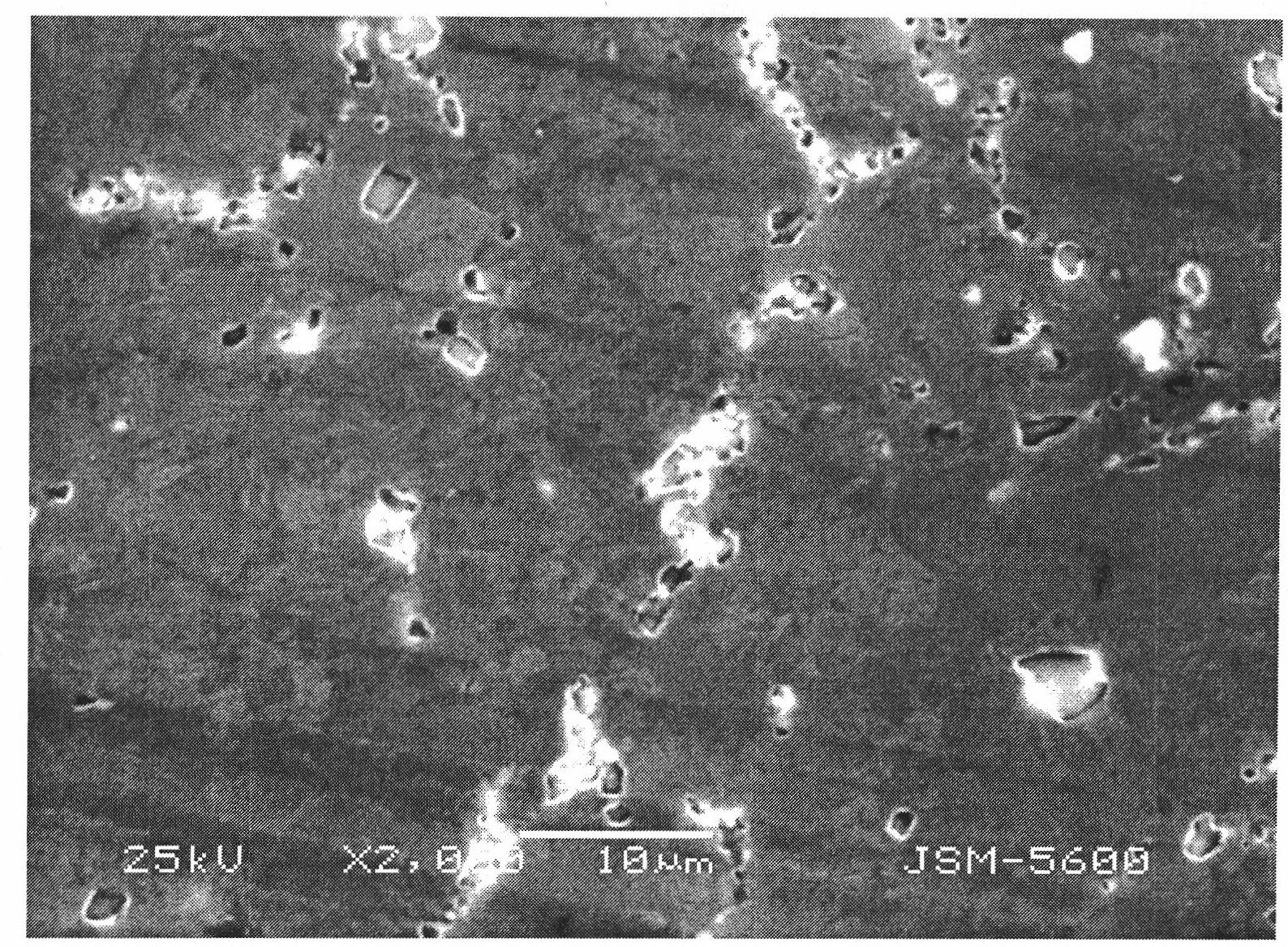

The invention discloses a casting copper-chromium alloy and a preparation method thereof. The alloy is characterized in that the alloy comprises the following components by weight percentage: 6.5 to 13 percent of copper-chromium master alloy, and the balance being copper, wherein the copper-chromium master alloy comprises 4 mass percent of chromium; the casting copper-chromium alloy has the following mechanical properties: tensile strength sigma b between 260 and 415 MPa, elongation delta between 20 and 37 percent, hardness HB between 93 and 130, and electrical conductivity IACS between 80 and 95 percent. The casting copper-chromium alloy is subjected to casting, melting, heat treatment and aging treatment. Compared with the prior casting copper chromium 0.3 / 0.5 alloy, the method of the invention has the advantages of obtaining the casting copper-chromium alloy with low chromium content between 0.28 and 0.52 percent by preparing the copper-chromium master alloy, increasing tensile strength by 21 percent, increasing electrical conductivity by 15 percent and meeting the requirement of high-voltage electrical products on special performance.

Owner:西安西开精密铸造有限责任公司 +1

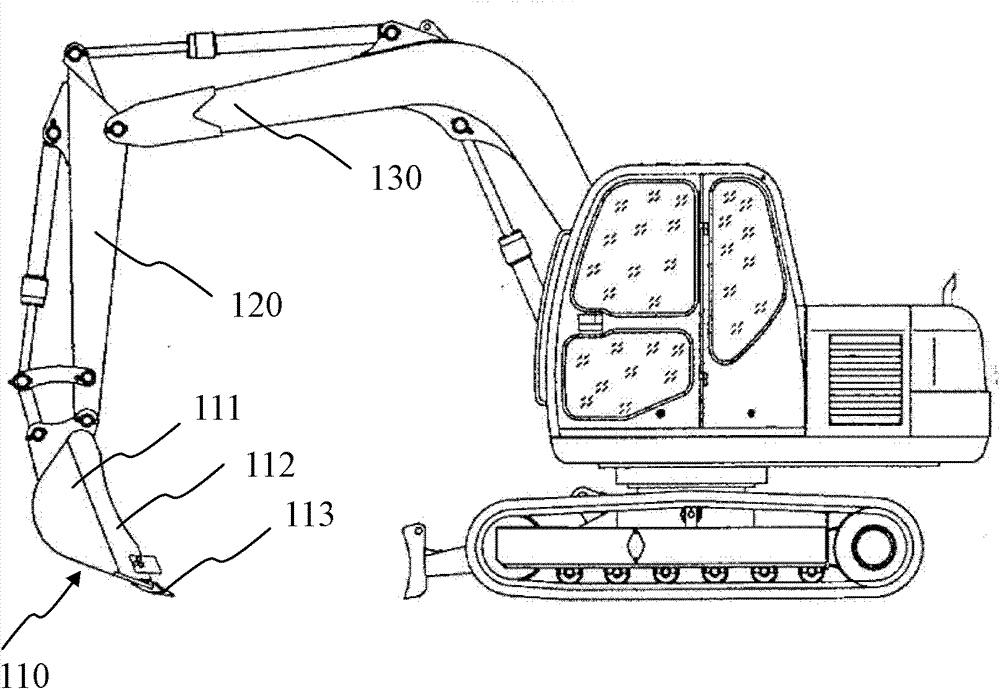

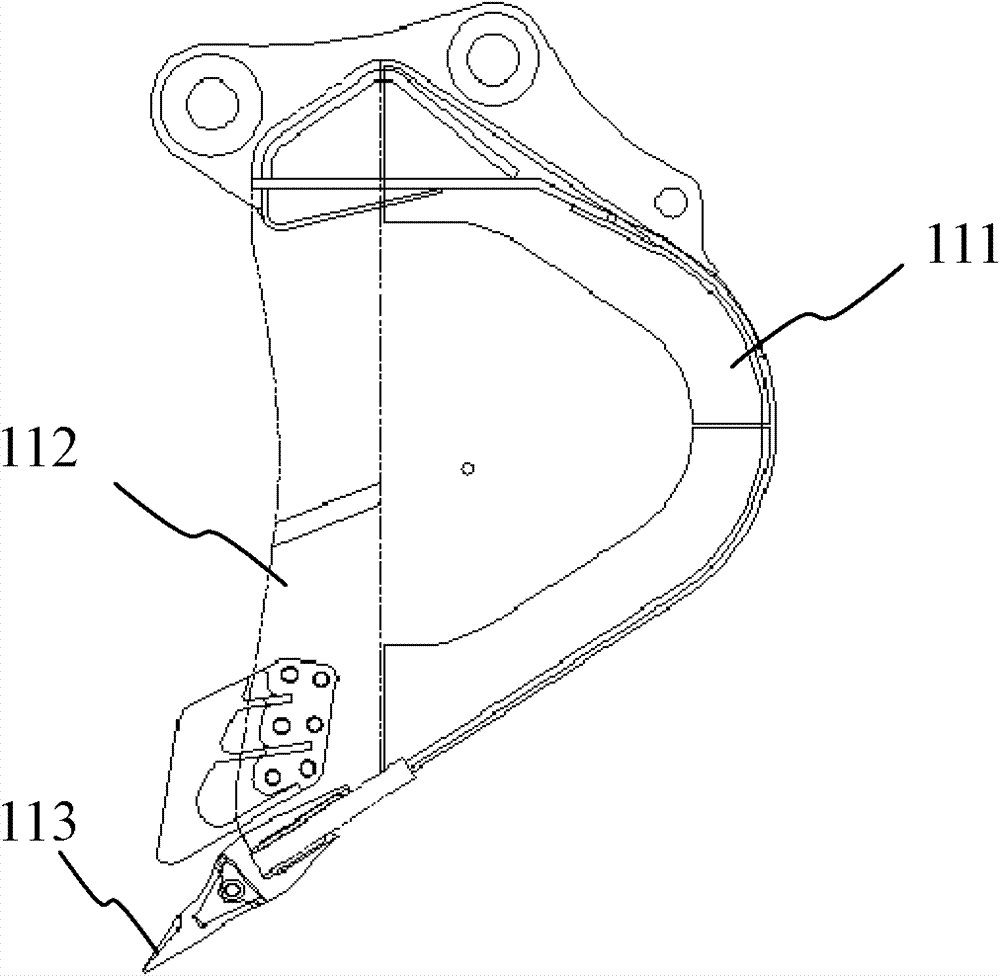

Digging bucket and bucket teeth thereof

InactiveCN102733446AEasy to uninstallExtended service lifeMechanical machines/dredgersVertical planeEngineering

The invention provides a digging bucket and bucket teeth of the digging bucket. Each of the bucket teeth comprises a wedge-shaped bucket tooth body, an upper thick tooth surface and an upper thin tooth surface, wherein the upper thick tooth surface is positioned at the upper surface of the wedge-shaped bucket tooth body; and the upper thin tooth surface is of a curved surface formed by downward depressing the upper surface of the wedge-shaped bucket tooth body, and is positioned at two sides of the upper thick tooth surface, and the projection of the curved surface, in the vertical plane, is of the projection region of a surrounding area. The strength and wear resistance of the bucket teeth can be improved, and the service lives of the bucket teeth can be prolonged.

Owner:DOOSAN INFRACORE CHINA

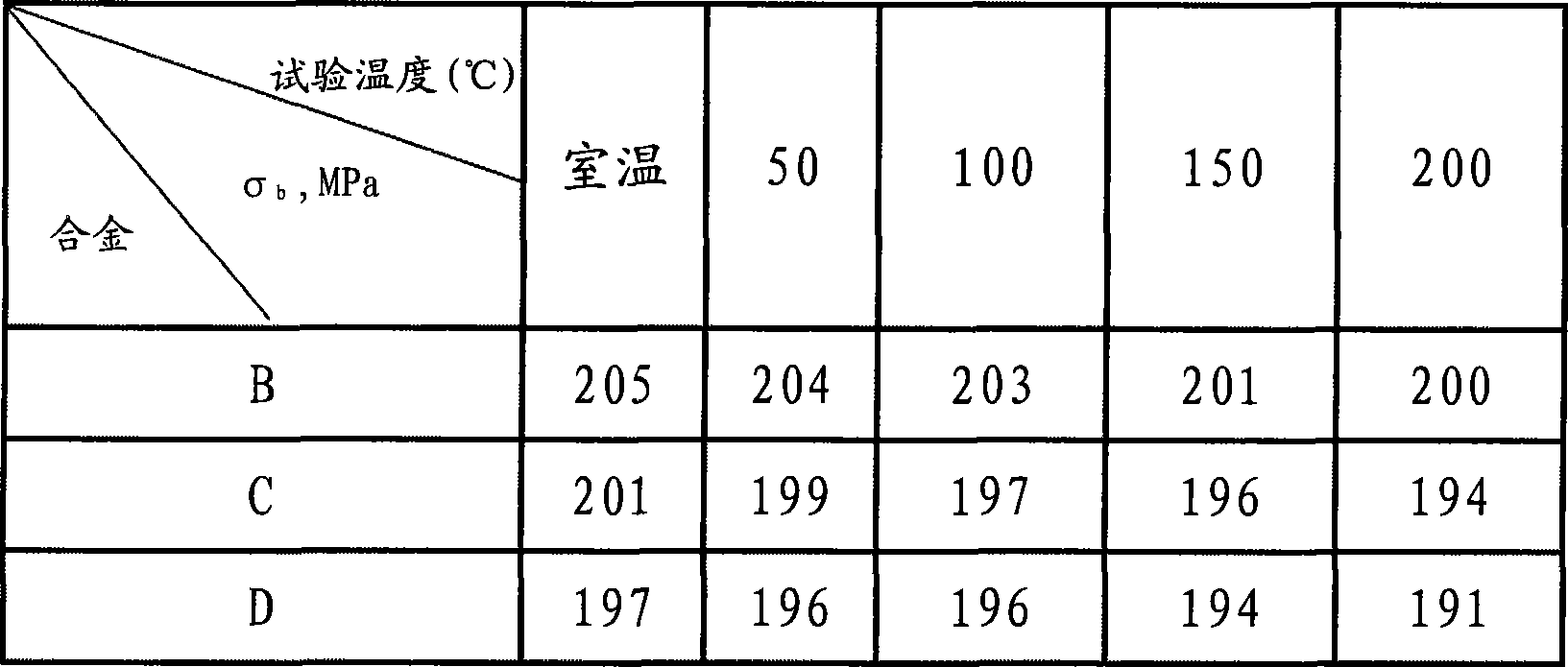

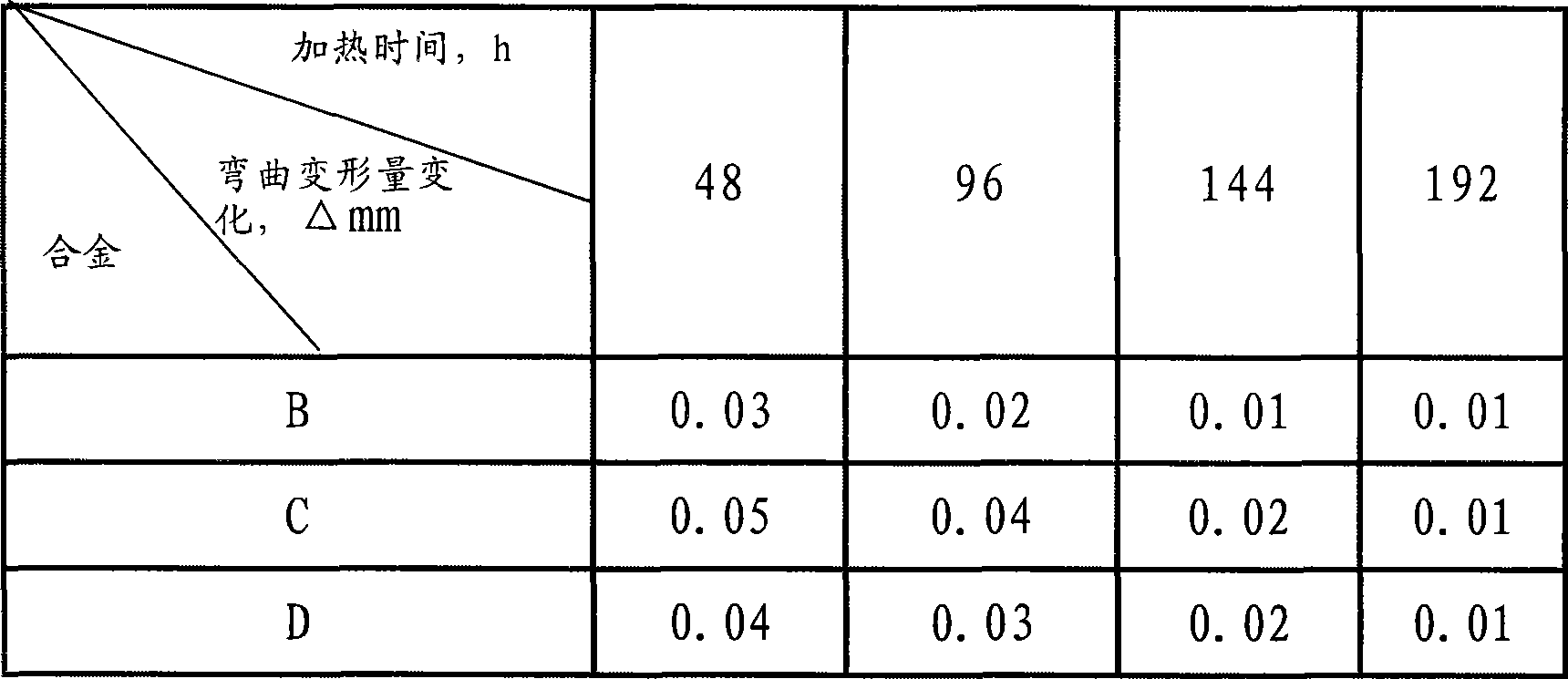

Al-Mn-Mg-Cu-Ni-Ce alloy and manufacturing method thereof

The invention relates to a novel aluminum alloy material, in particular to an aluminum-manganese-magnesium base alloy containing copper, nickel and cerium. The compositions in weight percentage of the aluminum-manganese-magnesium-copper-nickel-cerium alloy are 0.4 to 0.7 percent of copper, 0.2 to 0.7 percent of nickel, 0.02 to 0.05 percent of cerium, 0.8 to 1.3 percent of manganese, 0.6 to 1.2 percent of magnesium, and the balance being aluminum and inevitable impurity elements. The aluminum-manganese-magnesium-copper-nickel-cerium alloy has the advantages that the alloy can simultaneously have high strength and good thermal stability, thermal fatigue property and fluidity, and is suitable for manufacturing thin-wall pipe fittings after adoption of multicomponents of the copper, the nickel and the cerium for composite microalloying on the basis of the aluminum-manganese-magnesium base alloy. The invention also provides a method for manufacturing the aluminum-manganese-magnesium-copper-nickel-cerium alloy.

Owner:GUANGDONG HOSHION IND ALUMINUM CO LTD

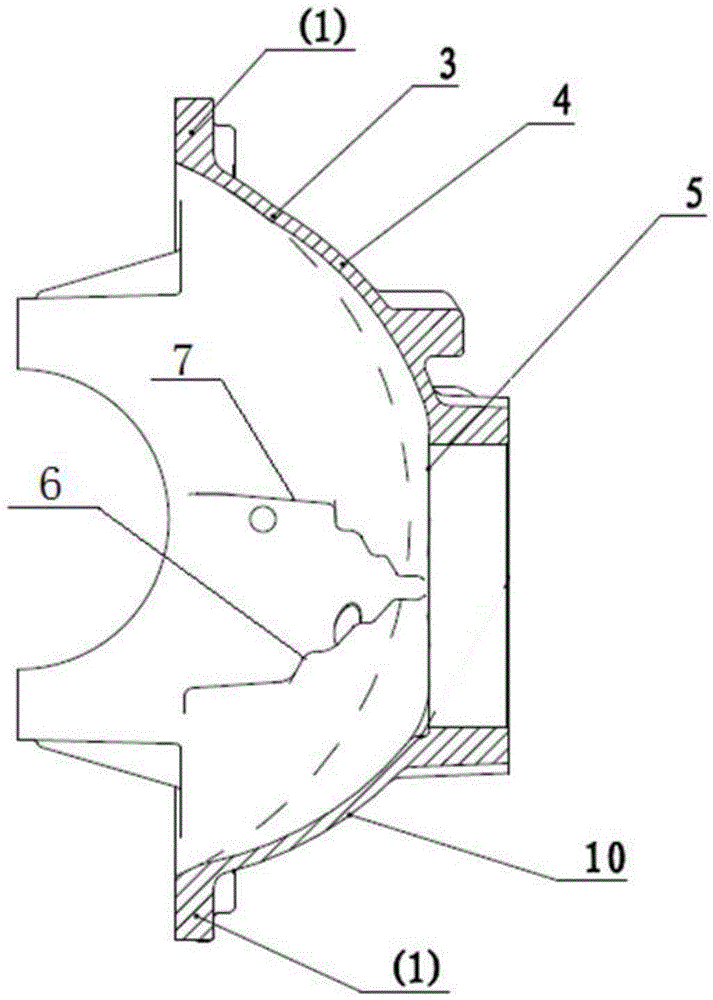

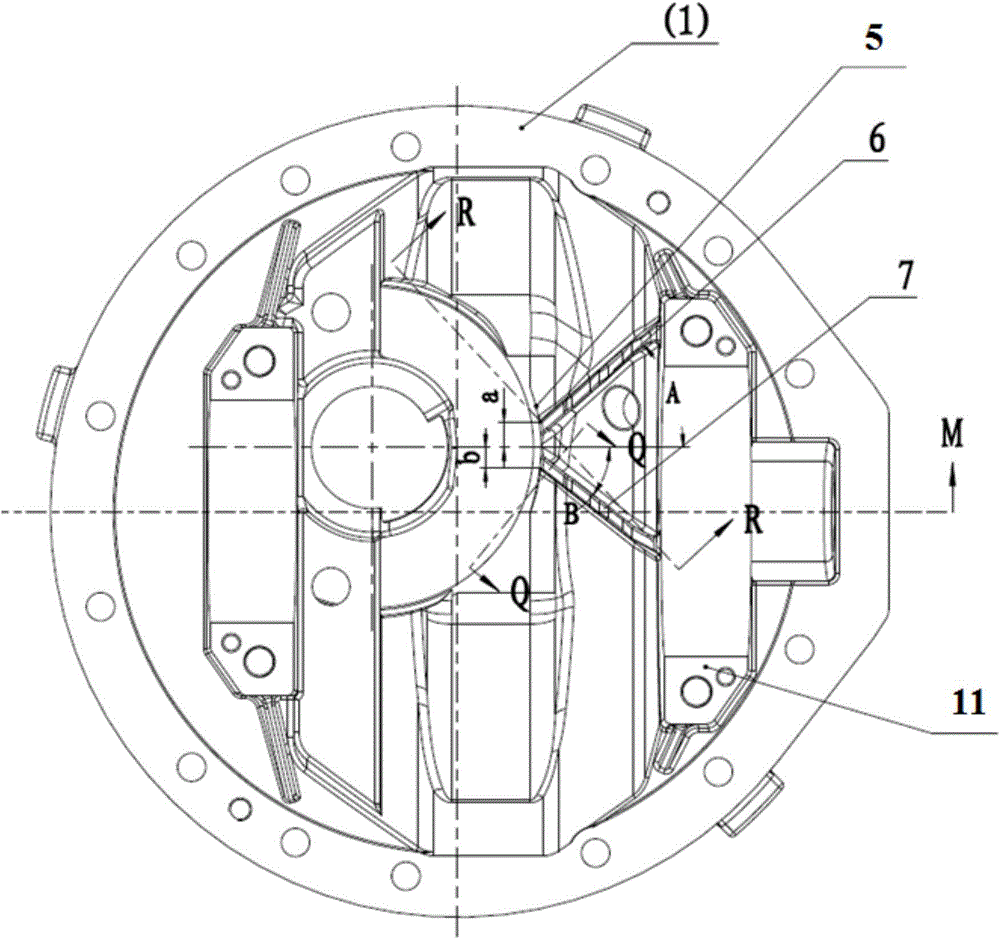

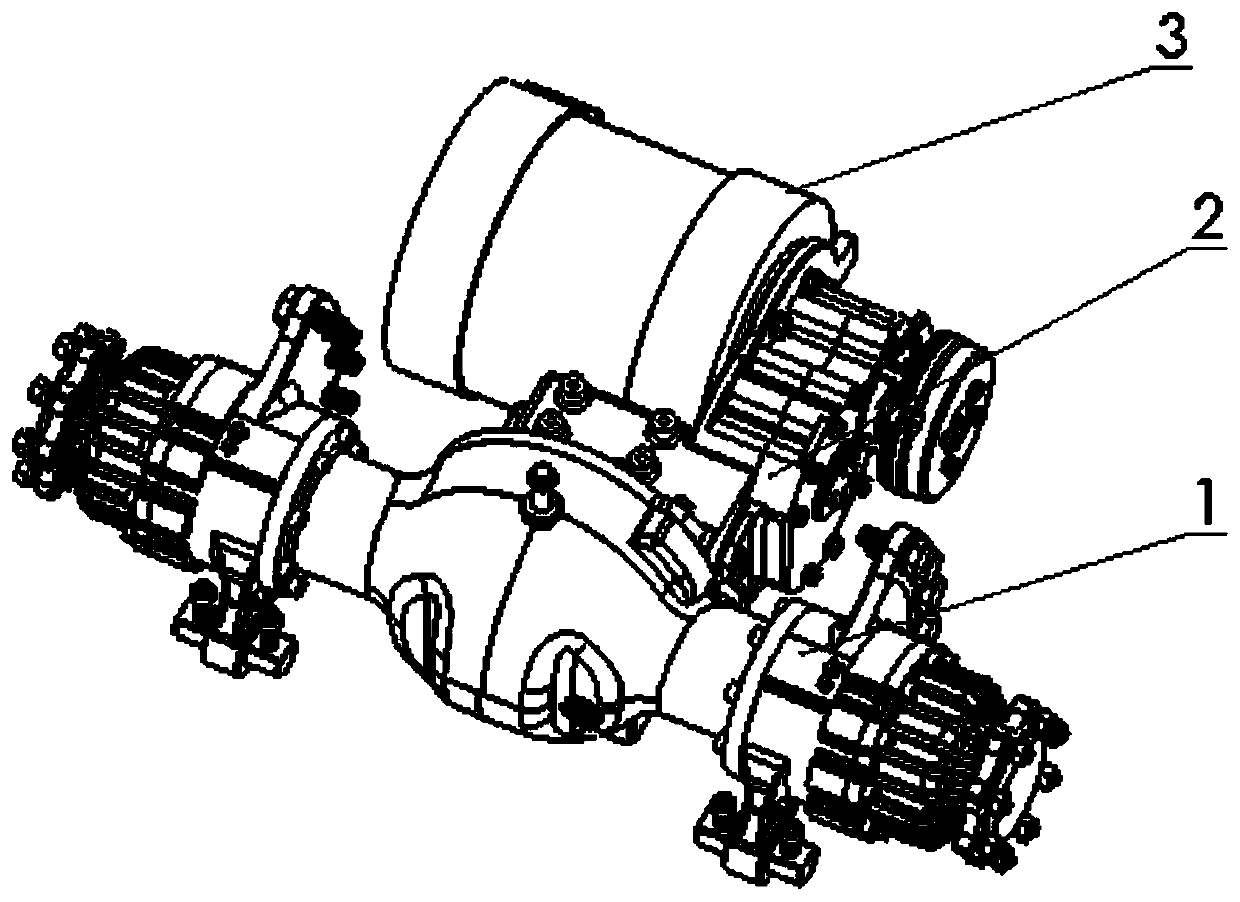

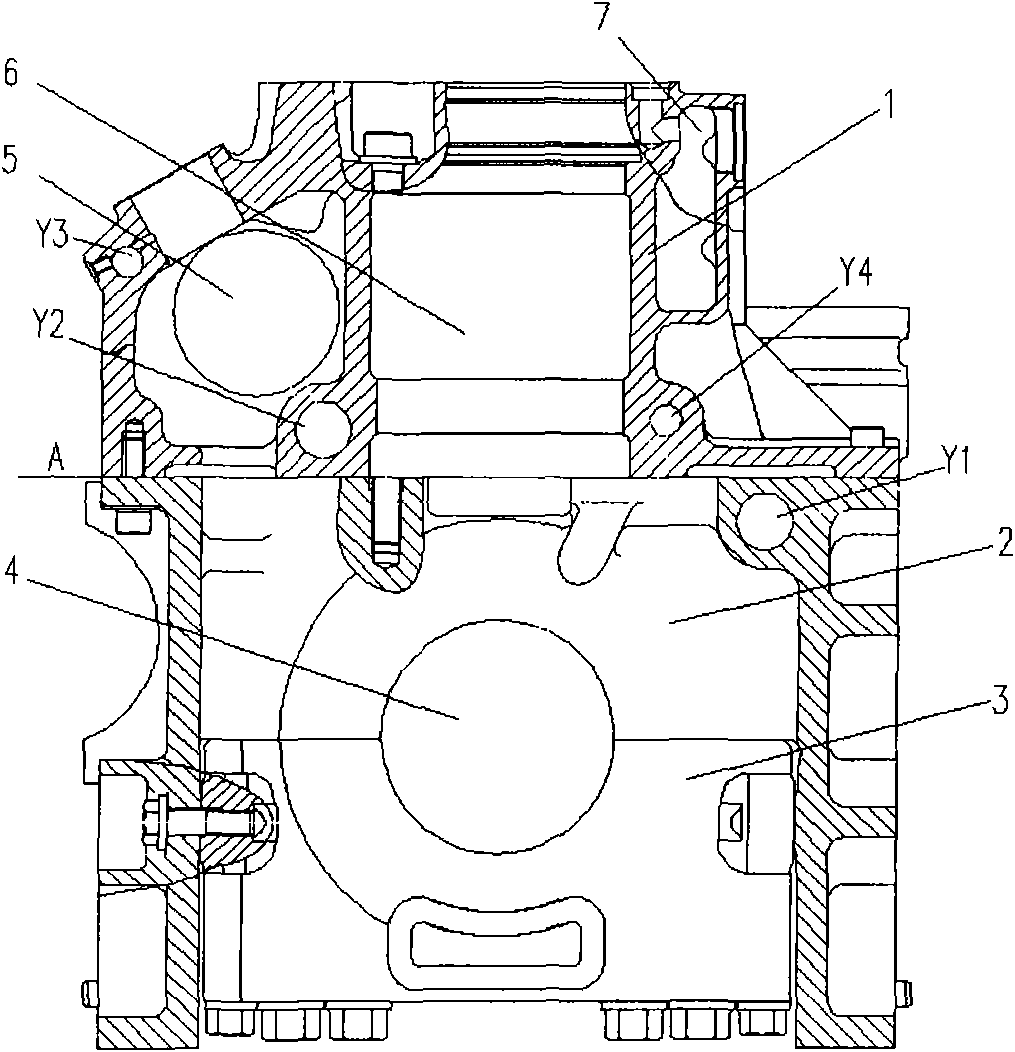

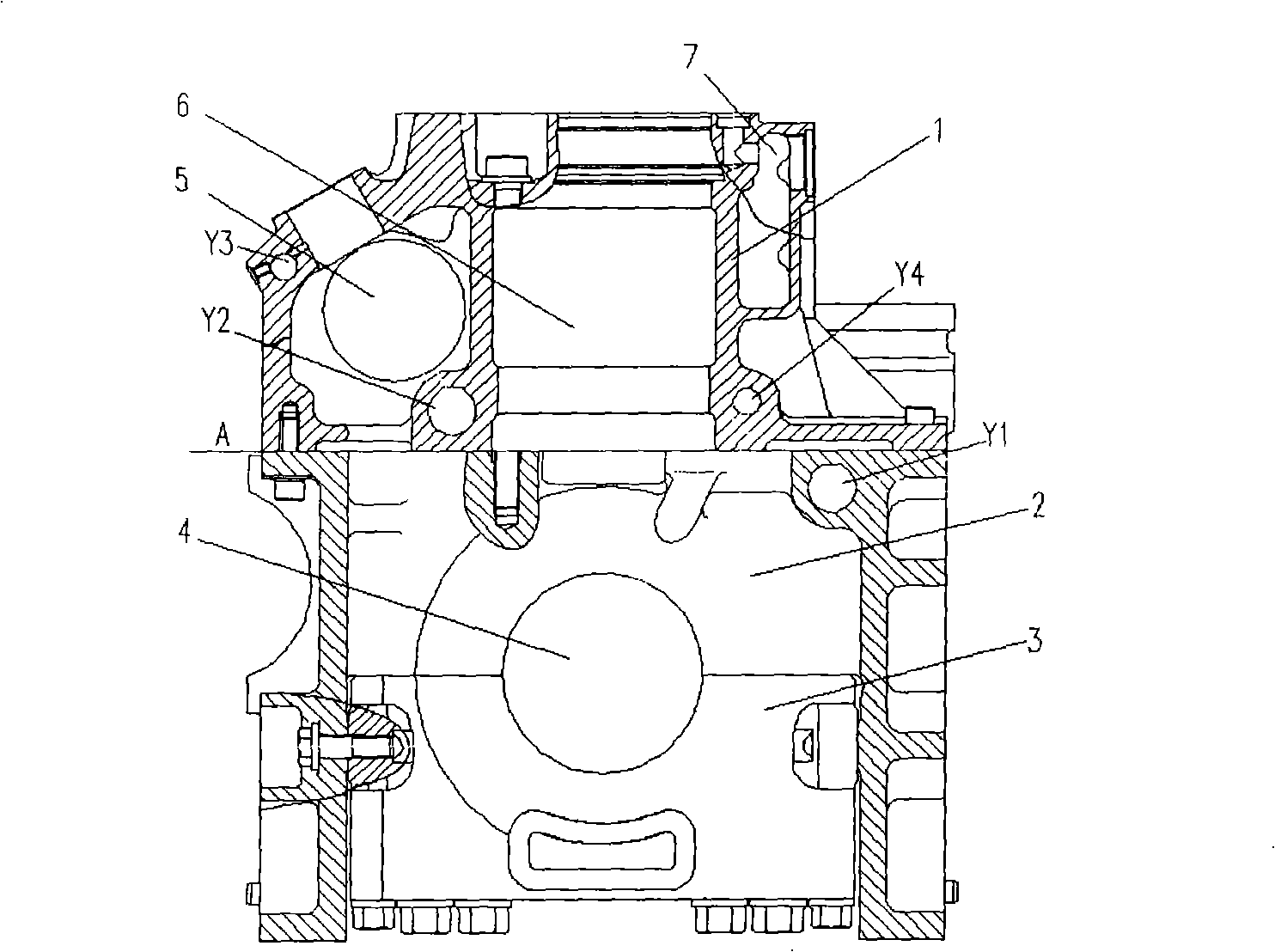

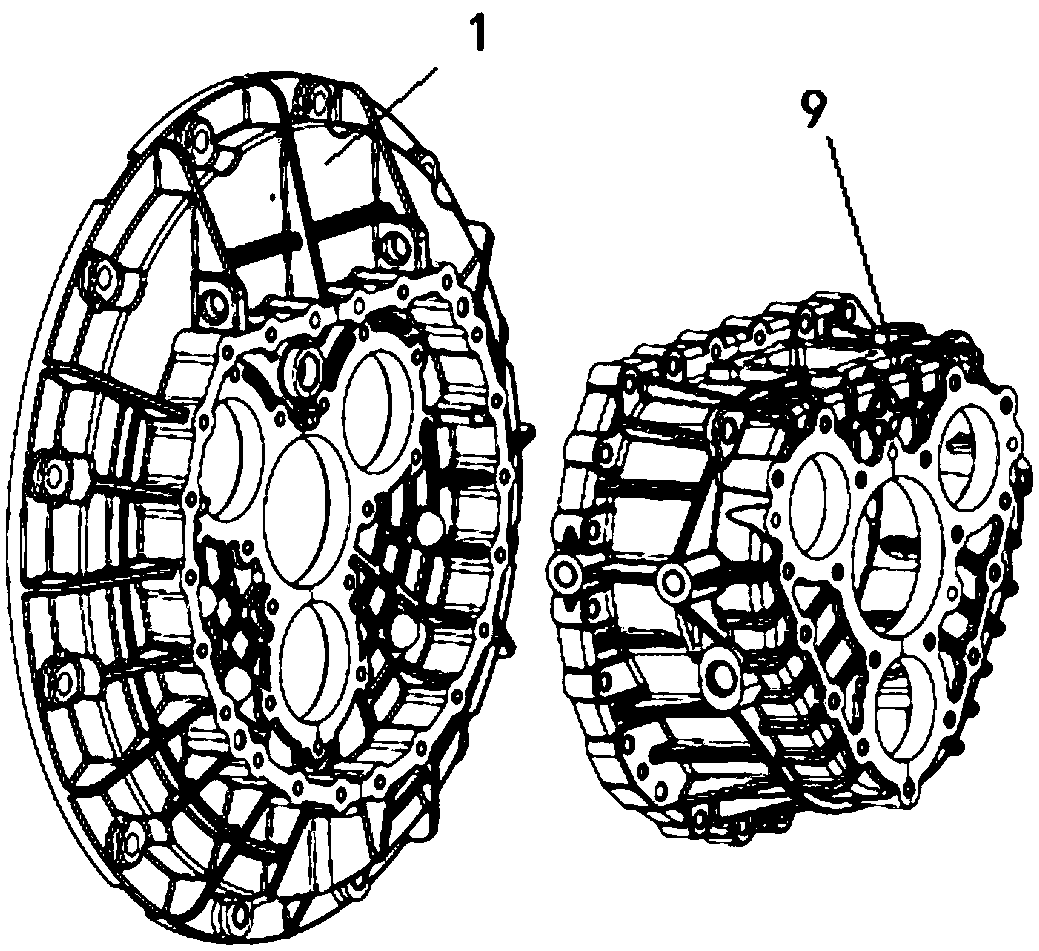

Main reducing gear shell and main reducing assembly

ActiveCN105003629AAchieve lubricationImprove versatilityGearboxesGear lubrication/coolingReduction driveLow offset

The invention provides a main reducing gear shell. The main reducing gear shell comprises a large reducing shell face, a rotating base body, a protruding circular arc and a bearing pedestal mounting hole. A circular arc face is formed by the rotating base body and the protruding circular arc, and a first oil stopping plate and a second oil stopping plate are arranged at the concave position of an inner cavity of the circular arc face, are distributed on the two sides of the mounting horizontal line of the bearing pedestal mounting hole and extend to the edge from the bearing pedestal mounting hole; a first oil adding hole boss and a second oil adding hole boss which can machine oil adding holes communicated with a lubricating oil cavity are cast on the outer surface of the rotating base body; the oil stopping plates of an innovative structure are arranged in the main reducing gear shell, and a protruding structure is innovatively designed on the shell, so that integration of an oil inlet way and an oil returning way is achieved; under the four states of forward rotation and reverse rotation of lower offset and forward rotation and reserve rotation of upper offset of a driving conical gear, a main reducing assembly supporting bearing is lubricated; and generality of the main reducing gear shell and a main reducing assembly is greatly improved, and the development cost of an axle is reduced.

Owner:SHAANXI HANDE AXLE CO LTD

Clay completely-regenerated sand modifier, modification method and application of modifier

ActiveCN103056284AReduce acid consumptionGood casting process performanceFoundry mouldsFoundry coresPhysical chemistryMineralogy

The invention discloses a clay completely regenerated sand modifier, a modification method and an application of the modifier, wherein the modifier is 0.05-5mol / L hydrochloric acid. The modification method comprises the following steps of: (1) adding the modifier into the clay completely-regenerated sand, wherein the modifier accounts for 2 to 10% of the total mass of the clay completely regenerated sand; (2) mixing the modifier and the clay completely-regenerated sand uniformly, then placing statically for 1 to 6 minutes; and (3) drying a mixture which is placed statically until the moisture content of the mixture is less than 0.2%. The modified clay completely-regenerated sand can be used for mixing coated sand, hot core-box sand and cold core-box sand. The modification method has the following advantages of having convenience in using, not only lowering the acid consumption value of the clay completely regenerated sand, but also enhancing the tensile strength of mixed sand by the modification method, and improving the casting process performances of the clay completely regenerated sand by adding the modifier.

Owner:SHANDONG JIANZHU UNIV

High-toughness heat-resistant Mg-Gd alloy suitable for gravity casting and preparation method thereof

The invention provides a high-toughness heat-resistant Mg-Gd alloy suitable for gravity casting and a preparation method thereof. The alloy comprises the following chemical components of, in percentage, 4.0-10.0% of Gd, 2.0-6.0% of Zn, 0.5-1.2% of Al, 0.1-0.3% of Mn, 0.01-0.08% of M, and the balance Mg, wherein the M is one or two elements of Ti and B; the preparation method comprises the following steps that (1) burdening is performed according to a Mg-Gd alloy component; (2) an industrial pure magnesium ingot is melted; (3) heating is performed to 700 DEG C, and industrial pure zinc, an Mg-Gd and Mg-Mn intermediate alloy are melted; (4) heating is performed to 730 DEG C, after an industrial pure aluminum ingot, Al-Ti, Al-Ti-B and Al-B intermediate alloys added are all melted, refining isperformed to obtain a magnesium alloy melt; (5) gravity casting is performed; and (6) secondary solid solution and artificial aging treatment are performed. According to the high-toughness heat-resistant Mg-Gd alloy and the preparation method, after the alloy is subjected to the gravity casting, the secondary solid solution treatment and the artificial aging heat treatment, the tensile strength at room temperature is 300 MPa, the elongation percentage is 15%, the high-temperature tensile strength at 200 DEG C is 218 MPa, the elongation percentage is 20%, and the high-end requirement for lightweight development in the industries of aerospace, automobiles, telecommunication and the like is met.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

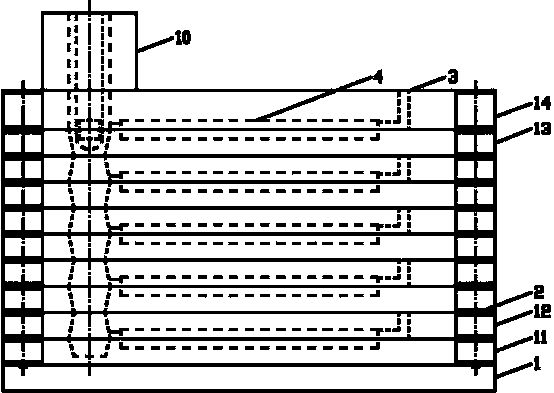

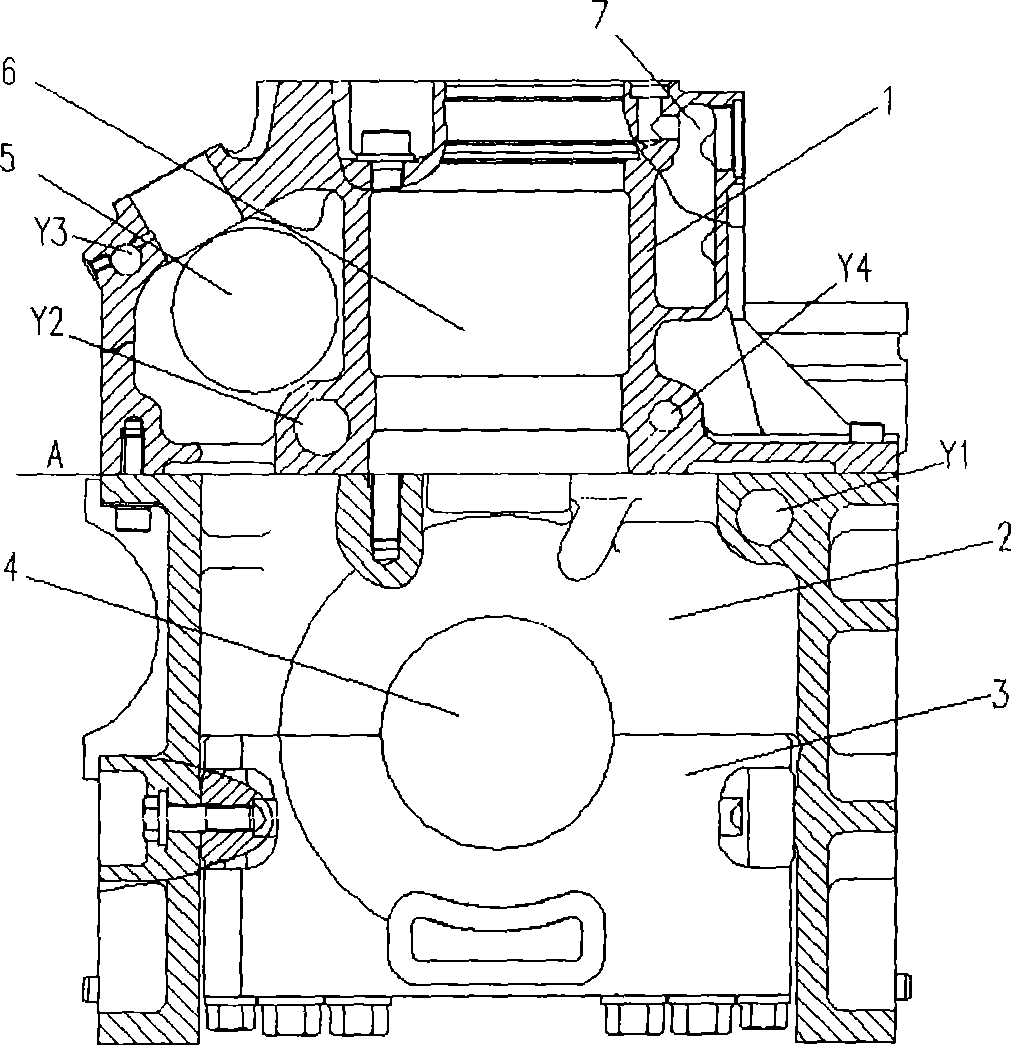

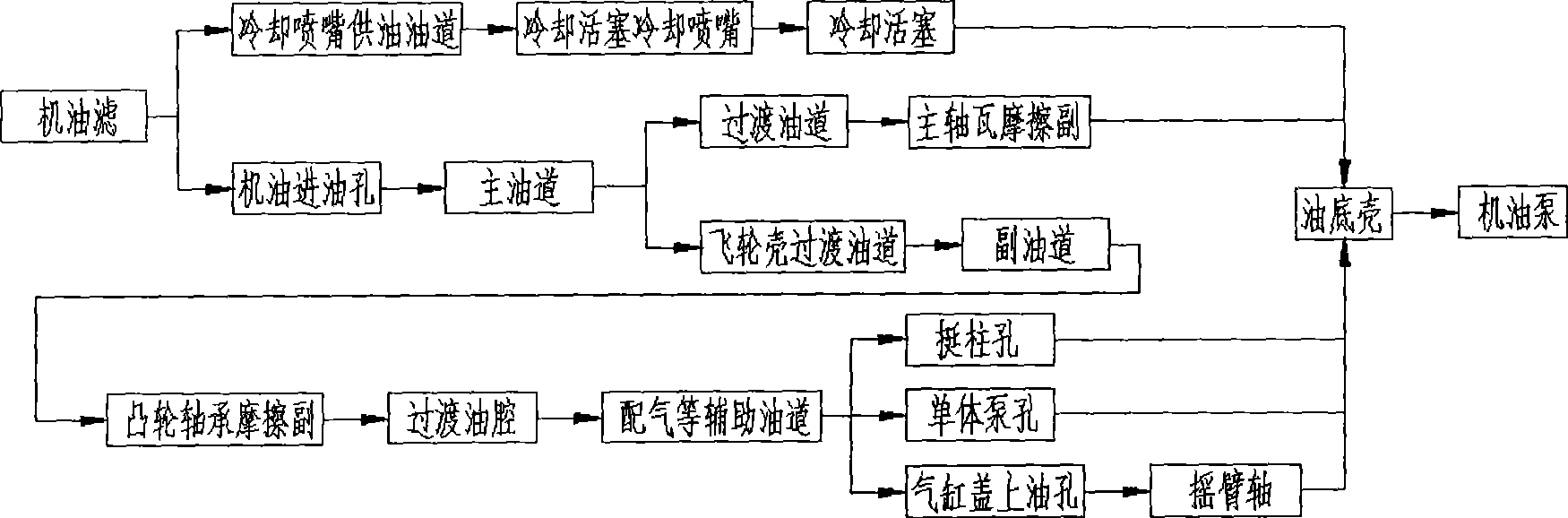

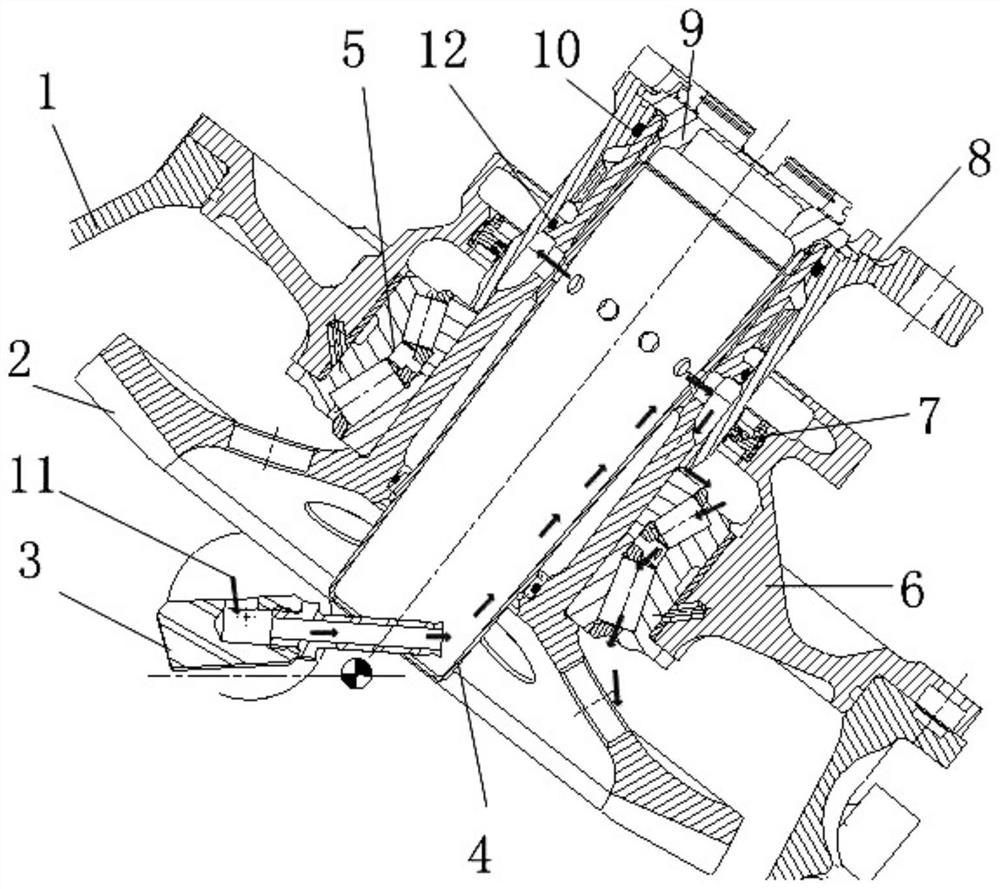

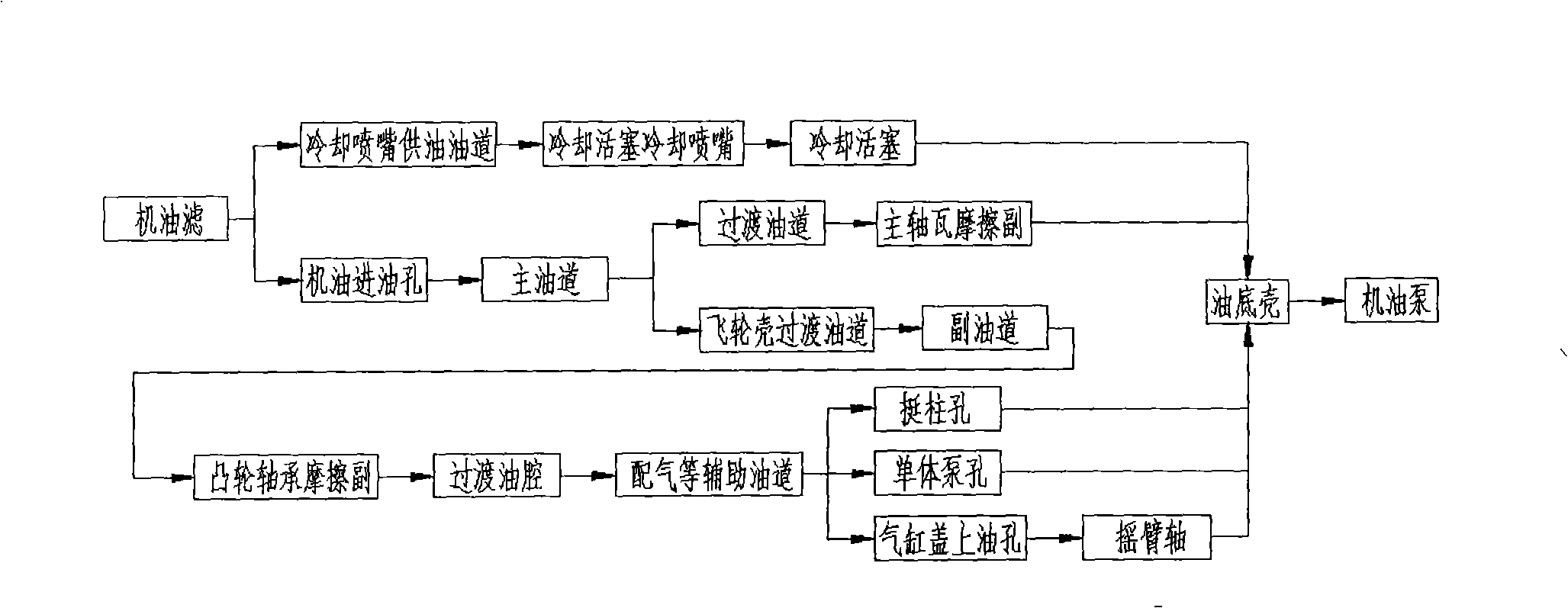

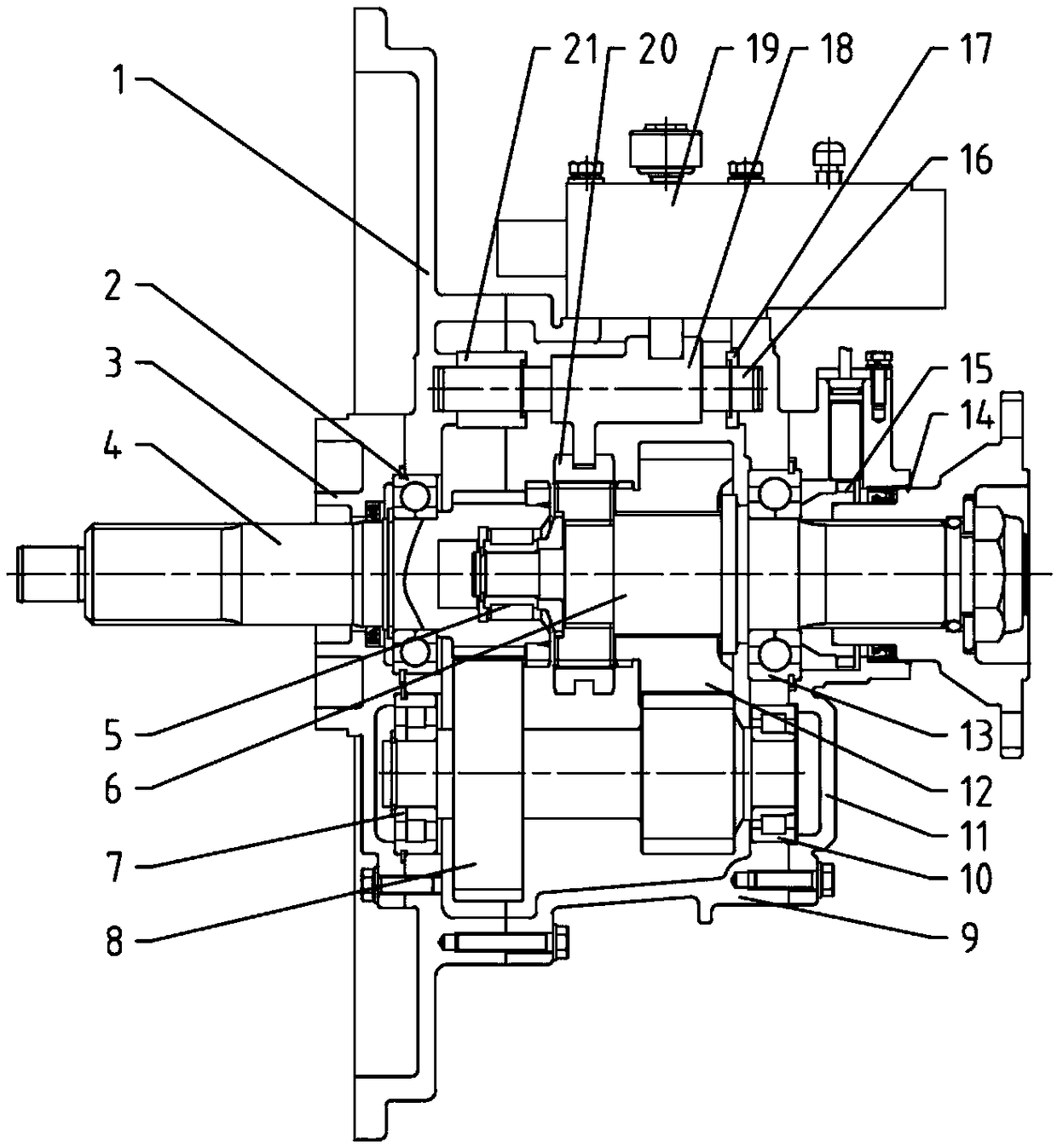

Engine multi-oil channel split type machine body structure

The invention belongs to engines technical field, particularly an engine multi-oil channel split type machine body structure, comprising a cylinder block, a crankshaft case and a bearing cap. The cylinder block and the crankshaft case are positioned by a cylindrical pin and connected by bolts. The crankshaft case and the bearing cap are positioned by a rabbet and connected by bolts. The cylinder block is an integral structure, including a distribution column compartment, a cylinder hole and a water chamber, which are linked by an integral casting mode. The crankshaft case is fastened at the support end A plane under the cylinder hole of the cylinder block. The bearing cap is connected with the crankshaft case. Three longitudinal oil passages including an auxiliary oil passage, a distribution auxiliary oil passage and a cooling jet oil supply passage are arranged on the cylinder block. The structure has small volume, good casting process and large material selectivity. The complete structure is with great stiffness; the cylinder sealing reliability is high; multi-oil channels have good lubrication and cooling effect.

Owner:CHINA NORTH IND GRP NO 70 RES INST

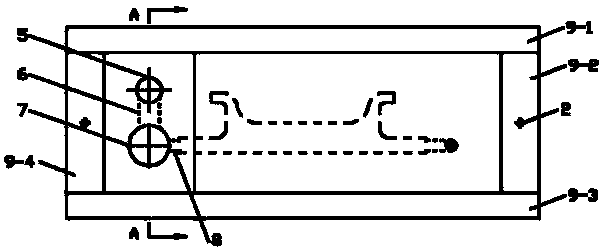

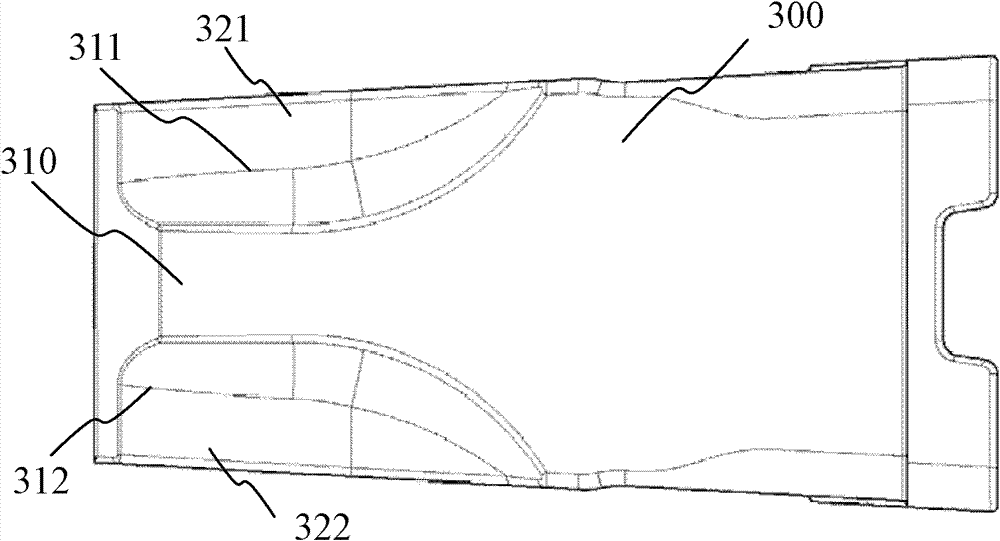

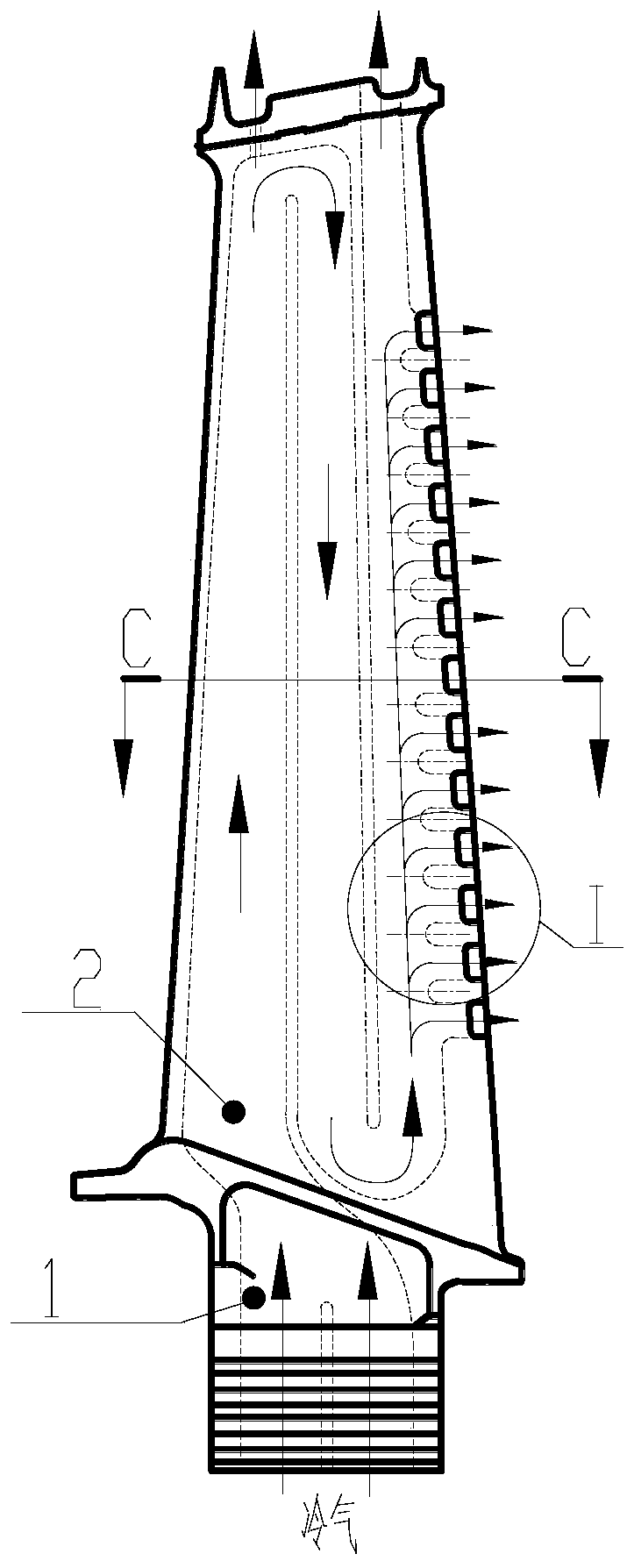

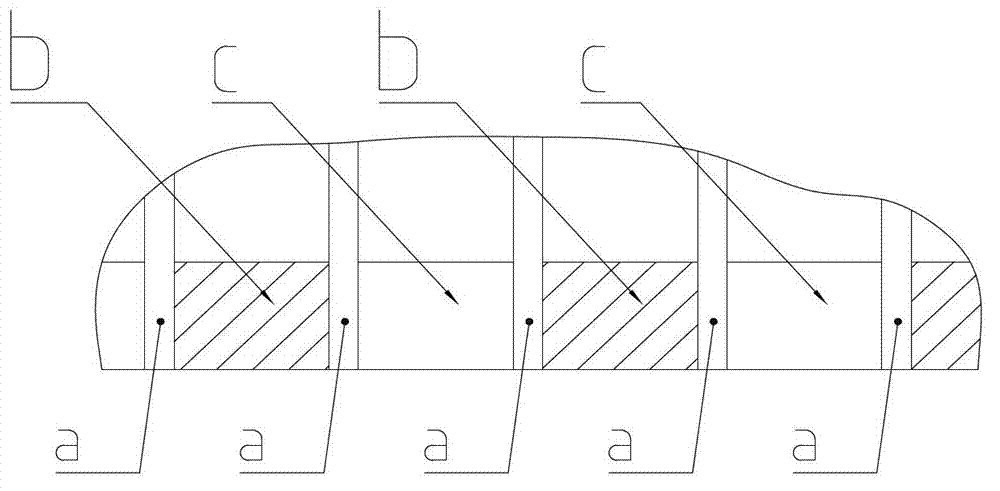

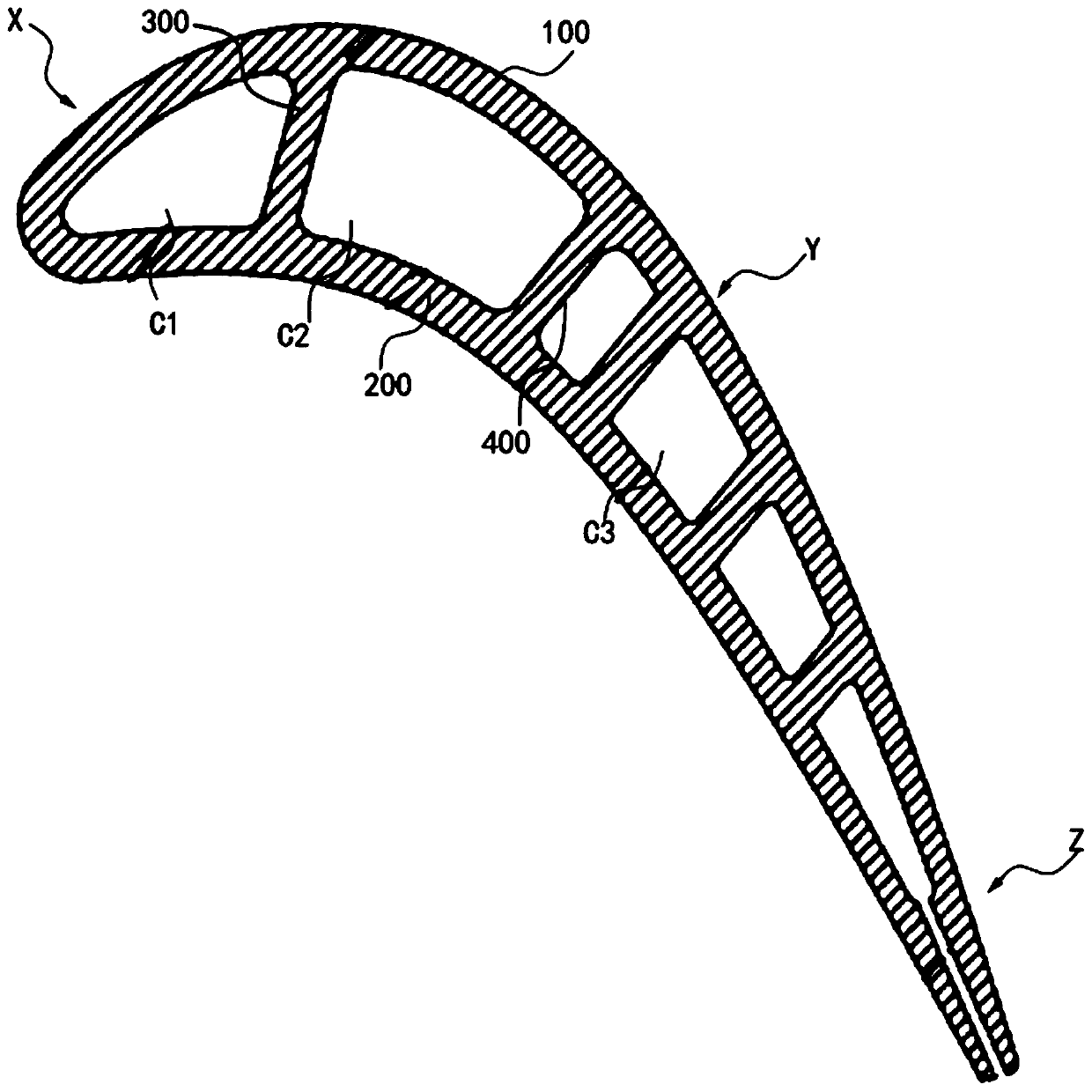

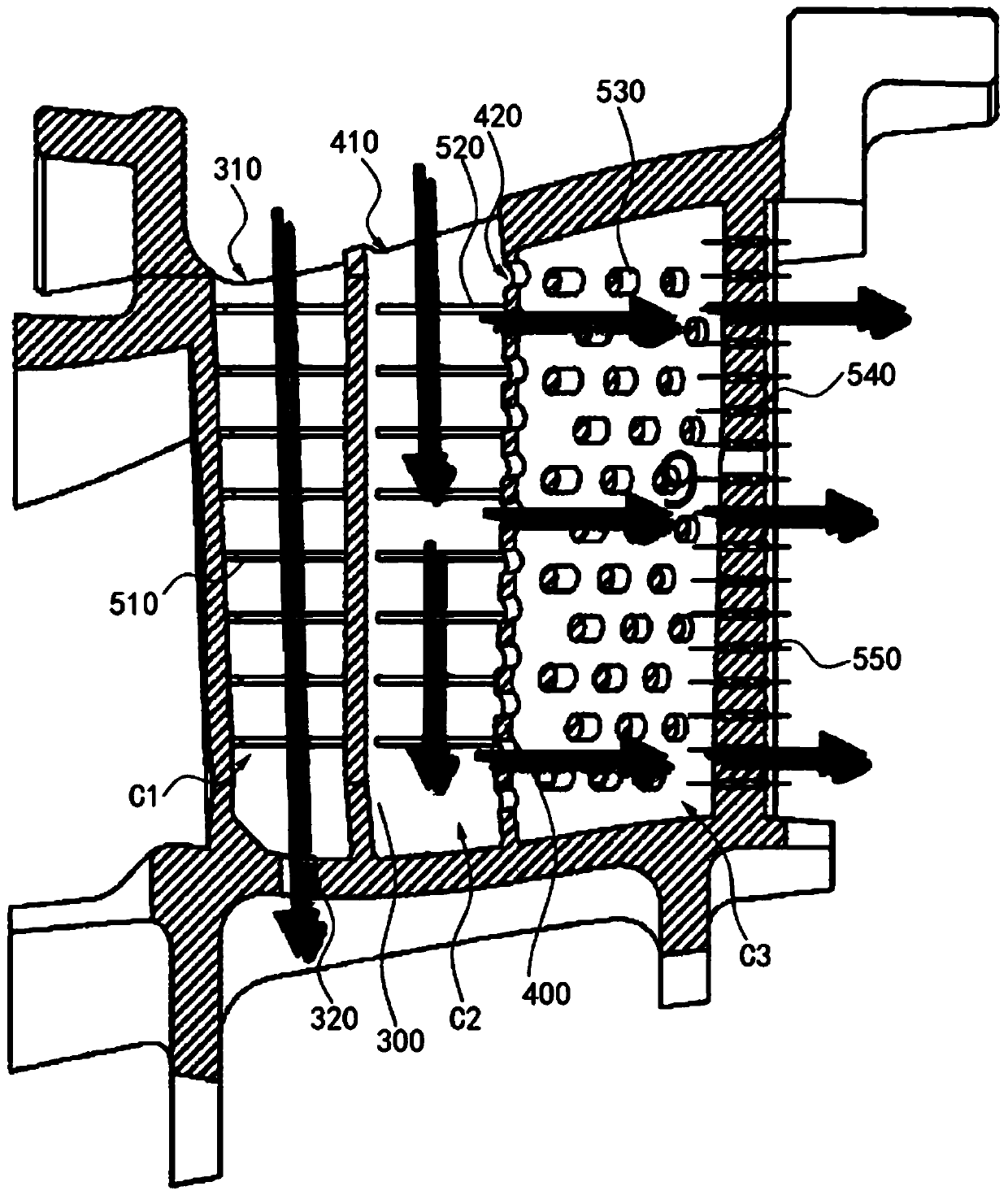

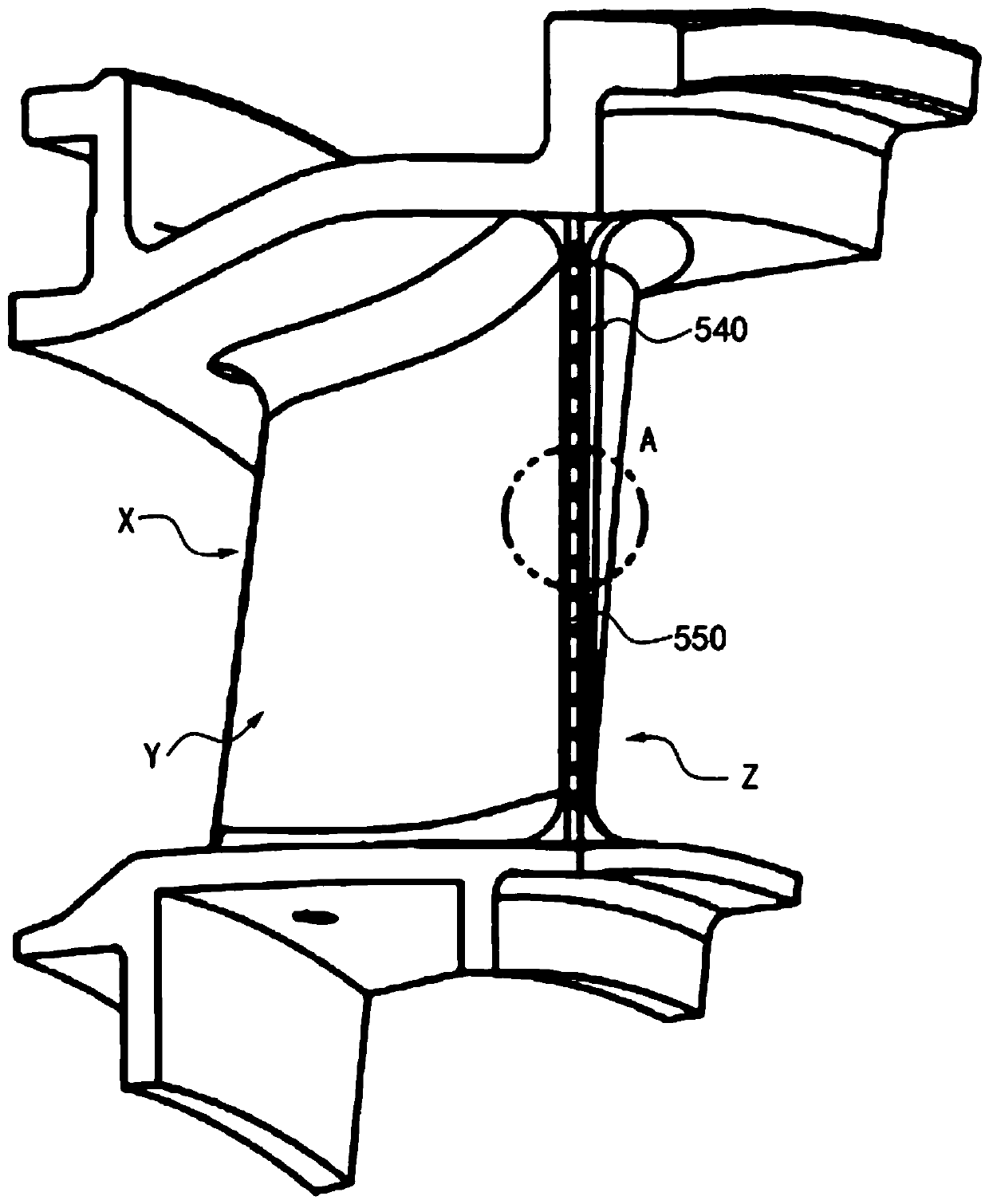

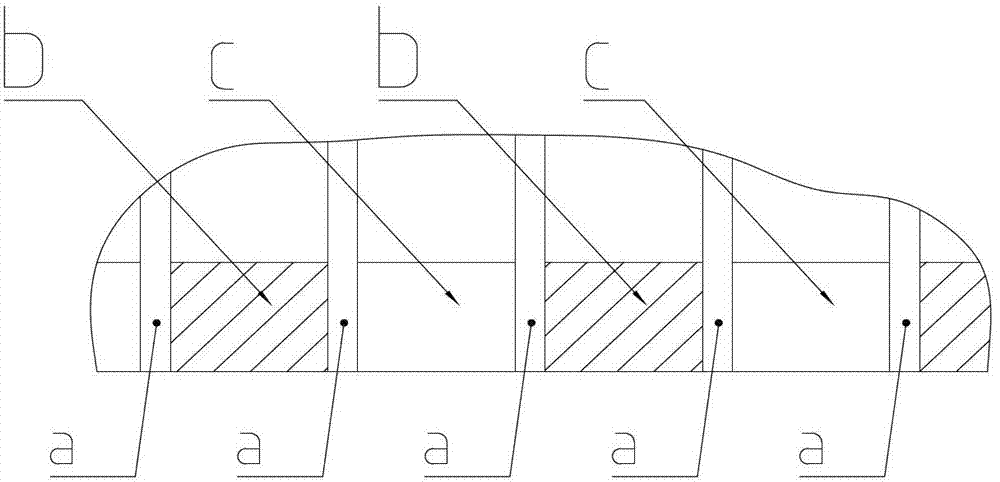

Turbine blade trailing edge fold line type exhaust split seam structure

ActiveCN110748384AIncrease widthLower temperature levelBlade accessoriesMachines/enginesCold airTurbine blade

The invention belongs to the technical field of aero-engine turbine cooling, and relates to a turbine blade trailing edge fold line type exhaust split seam structure. The turbine blade trailing edge fold line type exhaust split seam structure comprises a hollow turbine blade, an inner cavity cold air channel, a trailing edge exhaust split seam channel and trailing edge split seam partition ribs, wherein the inner cavity cold air channel is formed in the hollow turbine blade, and low-temperature cooling gas flows in the blade to cool the blade; the trailing edge split seam partition ribs arranged side by side are arranged on the trailing edge of the hollow turbine blade; and the trailing edge exhaust split seam channel is formed between the trailing edge split seam partition ribs arranged side by side. According to the turbine blade trailing edge fold line type exhaust split seam structure, a trailing edge exhaust split seam is designed into an inclined fold line type exhaust mode, theturning angle of the cooling gas in the split seam is reduced, and cold air is turned twice or multiple times instead of being turned once, so that the flow resistance and loss of the cold air in an inner cavity of the blade are reduced, and the flow resistance can be reduced by about 19%.

Owner:DALIAN UNIV OF TECH

High plasticity tin-based material for metal ornaments

The invention is about a tin-base alloy material which is composed of 1-15% Pb, 0.2-0.9% Bi, 0.1-0.5% Cu, 0.03-0.12% Ca, Sn: the residua. For all kinds meduim-height decorations and crafts. The product has the good plasticity tensile strength and stiffness, also it doesn't have the heat check and is easy to solder and galvanizer.

Owner:ZHEJIANG NEOGLORY JEWELRY CO LTD +1

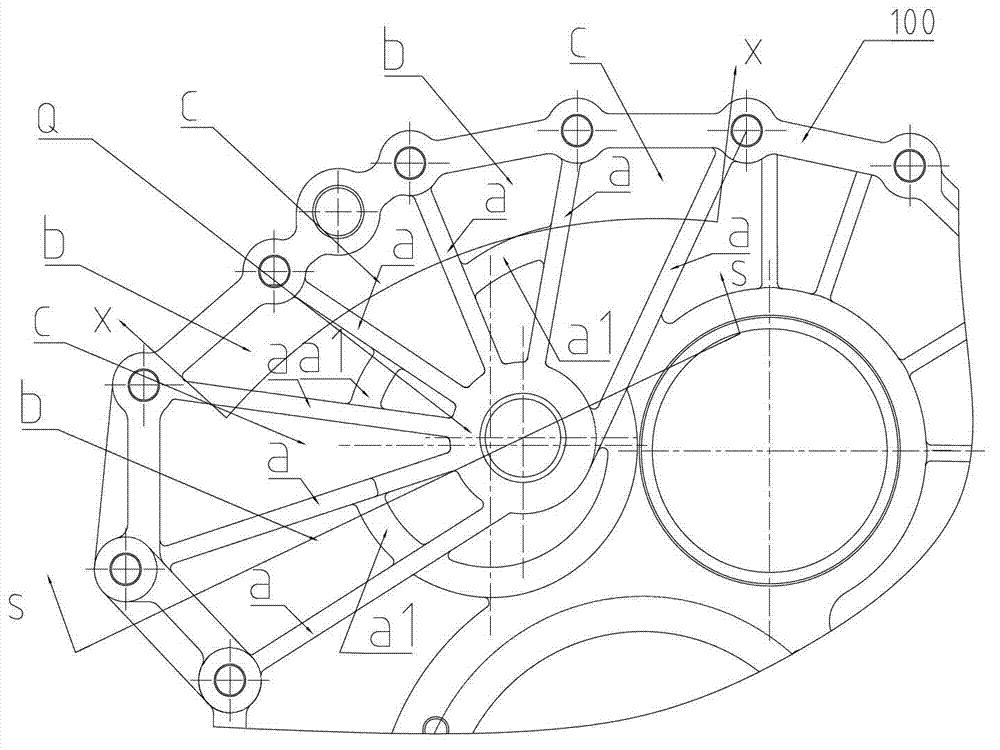

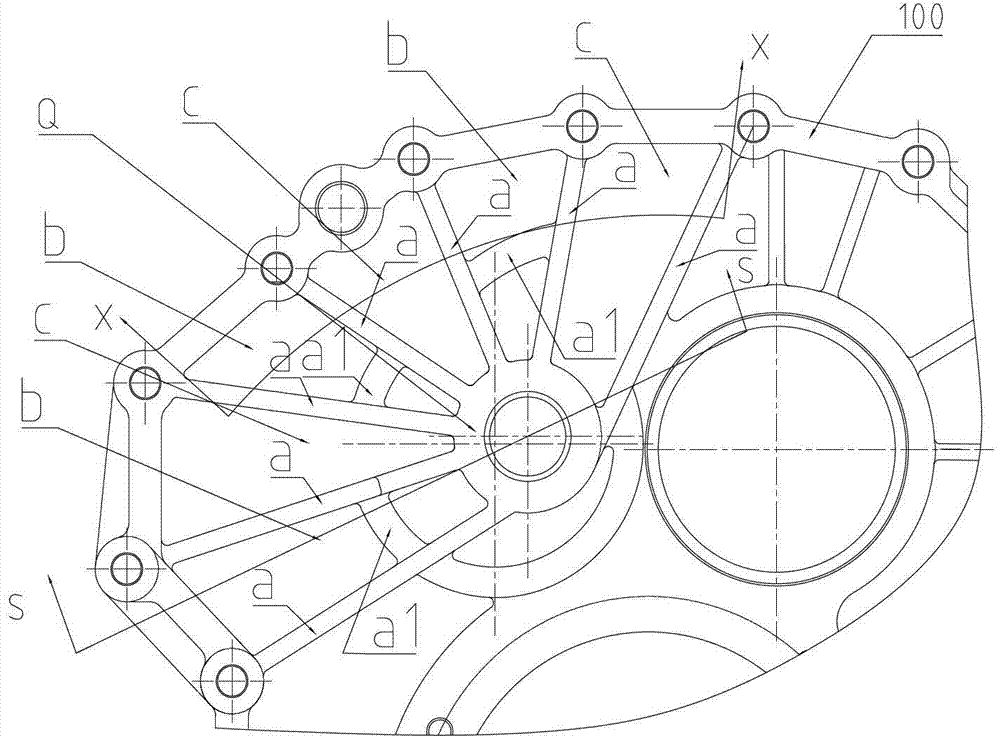

Support structure of reverse counter shaft of transmission

ActiveCN102878272AGood casting processImprove processing technologyGearing detailsEngineeringMilling cutter

The invention provides a support structure of a reverse counter shaft of a transmission. The support structure comprises a transmission housing, a partition and a boss. The transmission housing, the partition and the boss are integrated. Reverse idle gear mounting space is reserved between one side of a transmission main box, close to the partition, and the boss. The partition is provided with a second reverse counter shaft support hole and an auxiliary box counter shaft support hole, which are nonconcentric. One side of the boss, close to the transmission housing, is supported on the transmission housing through a plurality of ribs. Radial plates are disposed among the ribs. The reverse counter shaft boss is supported by the ribs in the support structure, and the reverse counter shaft boss with specific features is cast to reach a rear auxiliary box partition. By milling the reverse idle gear space with a disc milling cutter along with machining, casting of windows on two sides of the box is avoided effectively while fine casting manufacturability is guaranteed, casting manufacturability of the casing is improved, the parts such as window cover plates, spacers and bolts are omitted, and oil leakage spots are reduced effectively.

Owner:SHAANXI FAST GEAR CO

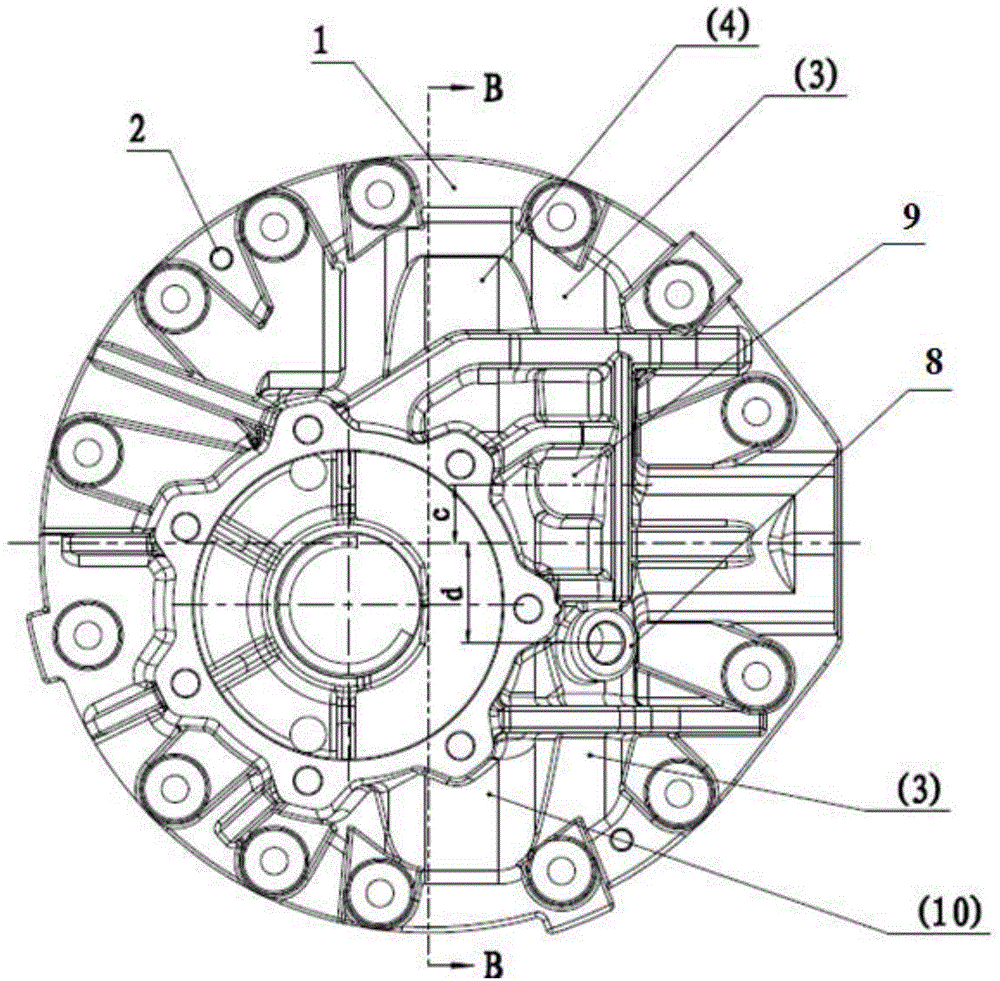

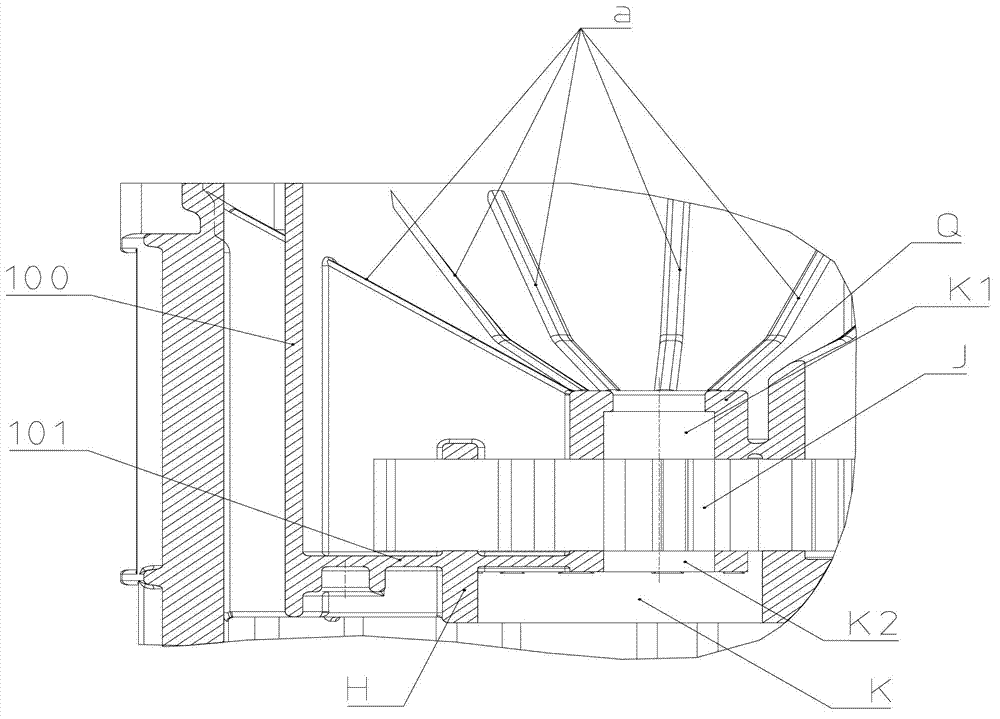

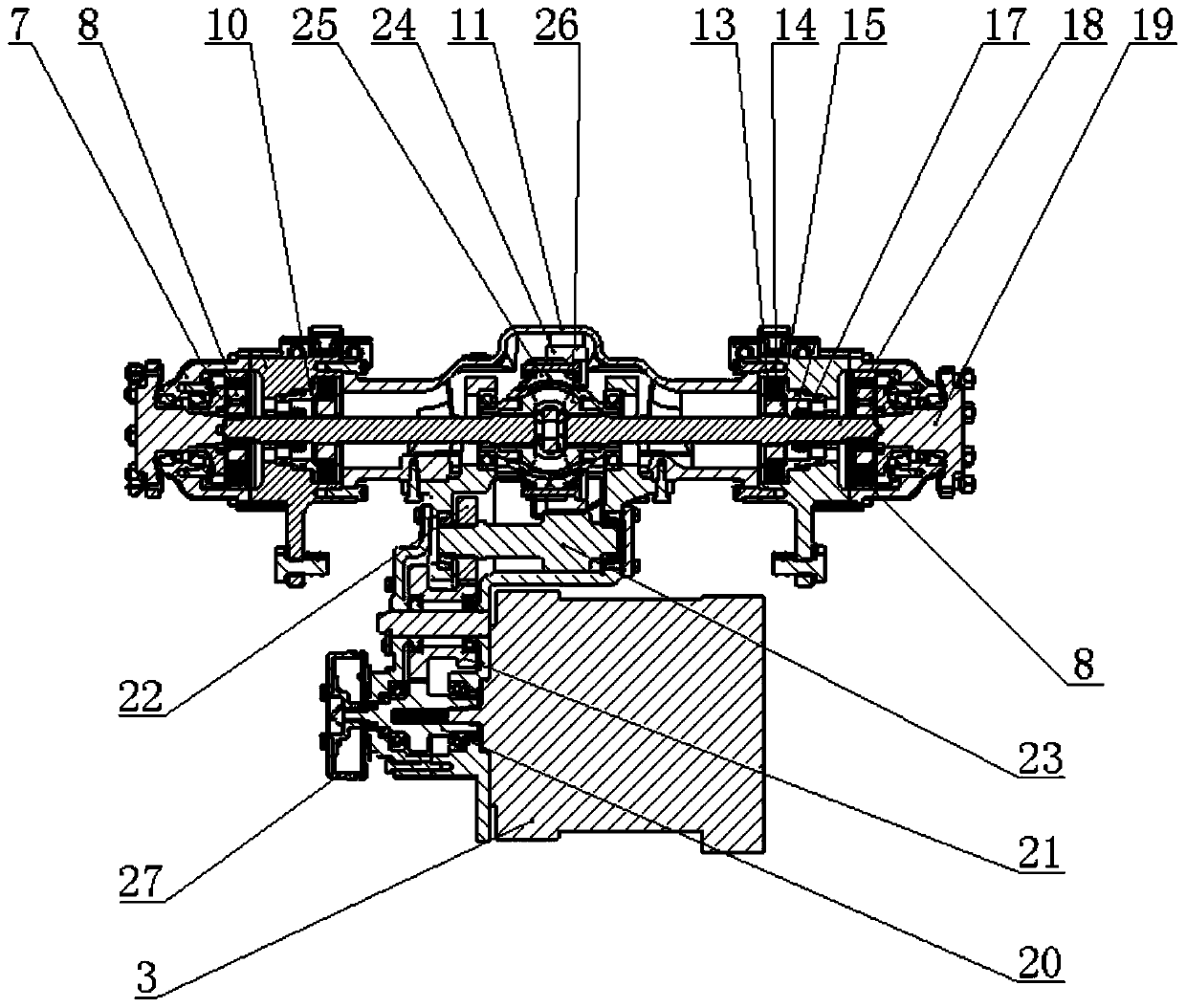

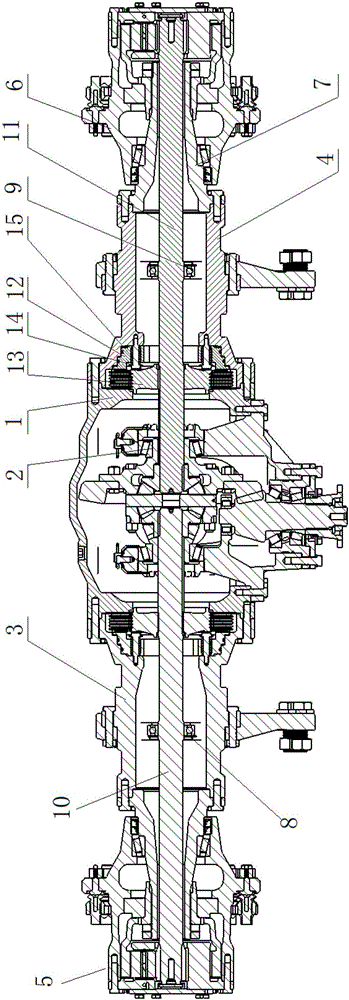

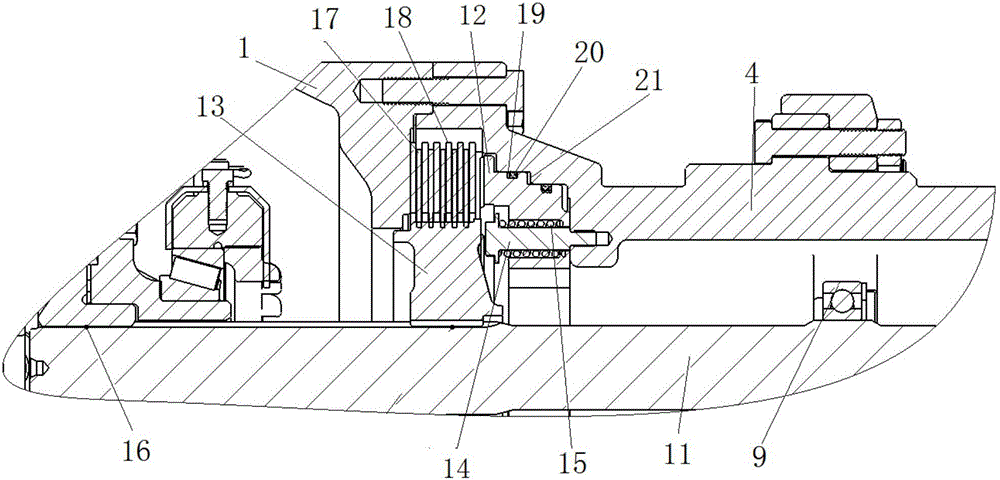

Electric forklift multifunctional wet drive system

PendingCN110239282ASmall sizeReduce gear ratioBraking element arrangementsElectric propulsion mountingPaper basedEngineering

The invention relates to an electric forklift multifunctional wet drive system which comprises a drive axle assembly, a reduction gearbox assembly and an alternating current motor. The drive axle assembly is of a three-section structure, and comprises a wheel edge wet brake system, a wheel edge planetary gear train deceleration system and an axle shell, wherein the axle shell is located in the middle section of the drive axle assembly, and the two ends of the axle shell are connected with the wheel edge wet brake system and the wheel edge planetary gear train deceleration system correspondingly. A wheel edge planetary deceleration structure design is adopted, the outer dimensions of a axle shell central drive axle are reduced, the ground clearance is increased, matching of small tires is ensured, and the speed ratio of a transmission system is increased, so that a whole vehicle can be better matched with the alternating current motor with high speed and low torque; a fully enclosed multi-disc self-cooling type wet brake is adopted, the structure is compact, large braking torque can be provided under smaller pressure, dustproof, waterproof effects are good, and service life is long; and friction plates of the brake is made from paper-based friction materials, and the characteristics of low brake noise, good thermal stability and good environmental protection are achieved.

Owner:LONKING SHANGHAI FORKELEVATOR

High-strength high-toughness heat-resistant Mg-Er alloy suitable for gravity casting and preparation method thereof

The invention provides a high-strength high-toughness heat-resistant Mg-Er alloy suitable for gravity casting and a preparation method thereof. The alloy is prepared from the following chemical components in percentage by mass: 4.0-10.0% of Er, 2.0-6.0% of Zn, 0.5-1.2% of Al, 0.1-0.3% of Mn, 0.01-0.08% of M, and the balance Mg, specifically, M is one or two elements of Ti and B. The preparation method comprises the following steps: (1) carrying out burdening according to the Mg-Er alloy components; (2) melting an industrial pure magnesium ingot; (3) rising the temperature to 700 DEG C to meltindustrial pure zinc, the Mg-Er intermediate alloy and a Mg-Mn intermediate alloy; (4) rising the temperature to 730 DEG C, and adding and melting an industrial pure aluminum ingot, an Al-Ti intermediate alloy, an Al-Ti-B intermediate alloy, and an Al-B intermediate alloy to obtain a magnesium alloy melt; (5) carrying out gravity casting; and (6) carrying out secondary solid solution and artificial aging treatment. After gravity casting, secondary solid solution treatment and artificial aging heat treatment, the alloy provided by the invention has tensile strength of 296 MPa and elongation rate of 18% at room temperature; while at high temperature of 200 DEG C, the tensile strength is 215 MPa and the elongation is 23%; and the requirements of aerospace, automobile, telecommunication and other industries for light weight are met.

Owner:FENGYANG L S NET FORMING CO LTD +1

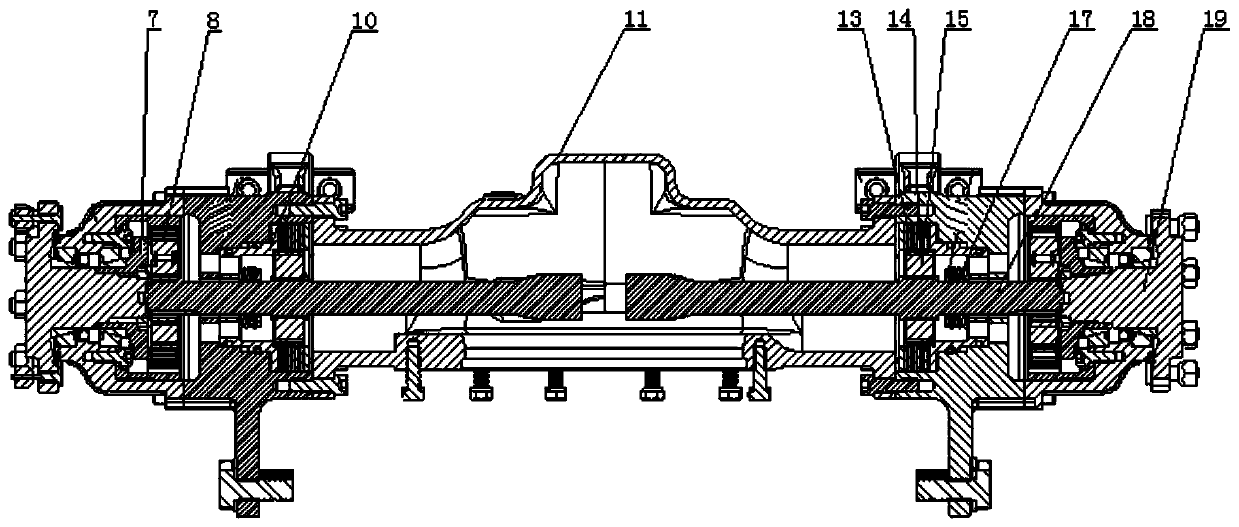

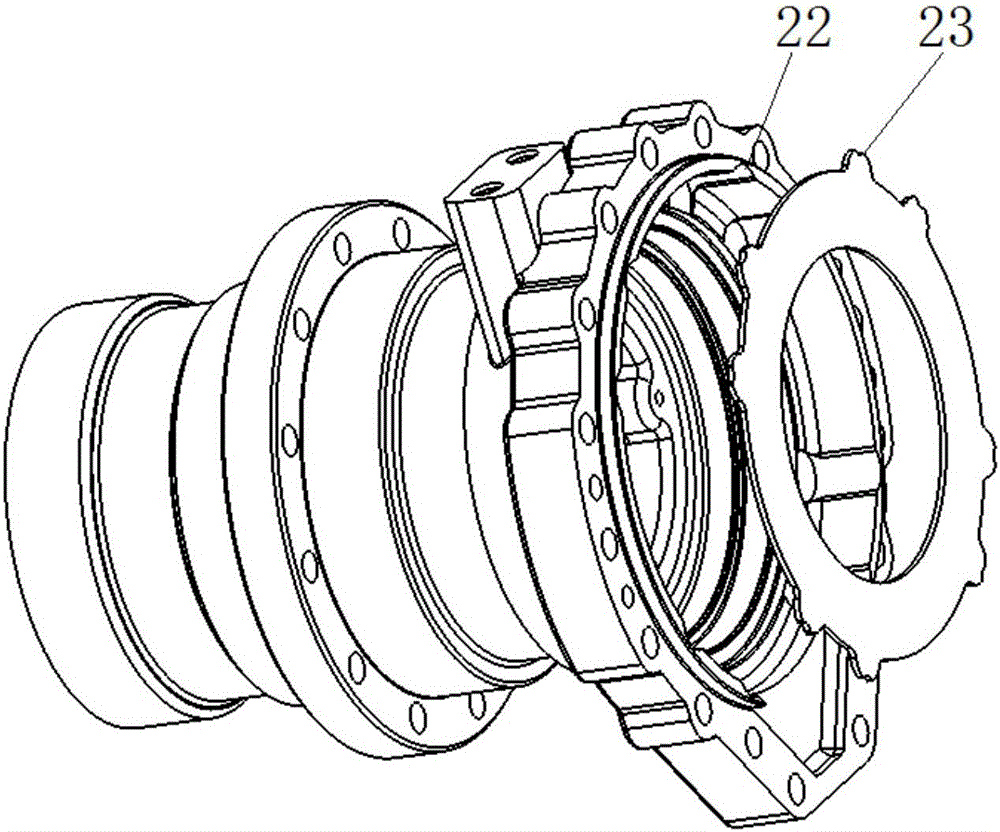

Drive axle with wet brakes and sectional axle housings

InactiveCN105752049ASimple structureGood casting process performanceBraking element arrangementsAxle unitsAutomotive engineeringRejection rate

The invention relates to a drive axle with wet brakes and sectional axle housings. The drive axle comprises an intermediate axle housing, a differential assembly, a left semi-axle, a right semi-axle, a left axle housing, a right axle housing, a left wheel side speed reducer assembly, a right wheel side speed reducer assembly, a left wet brake and a right wet brake, wherein the differential assembly is embedded and mounted into the intermediate axle housing; the left axle housing and the right axle housing, as well as the left wheel side speed reducer assembly and the right wheel side speed reducer assembly are sequentially and symmetrically arranged on the left side and the right side of the intermediate axle housing from inside to outside; the left wet brake and the right wet brake are symmetrically arranged and respectively located on the inner side of a joint between the intermediate axle housing and the left axle housing and on the inner side of a joint between the intermediate axle housing and the right axle housing; one end of the left semi-axle is connected with the differential assembly, and the other end penetrates the left wet brake and the left axle housing sequentially, and is then connected with the left wheel side speed reducer assembly; one end of the right semi-axle is connected with the differential assembly, and the other end penetrates the right wet brake and the right axle housing sequentially, and is then connected with the right wheel side speed reducer assembly. The drive axle has the characteristics of being stable in brake performance, uniform in stress to paired friction parts, convenient to machine, low in rejection rate and the like.

Owner:ANHUI HELI CO LTD

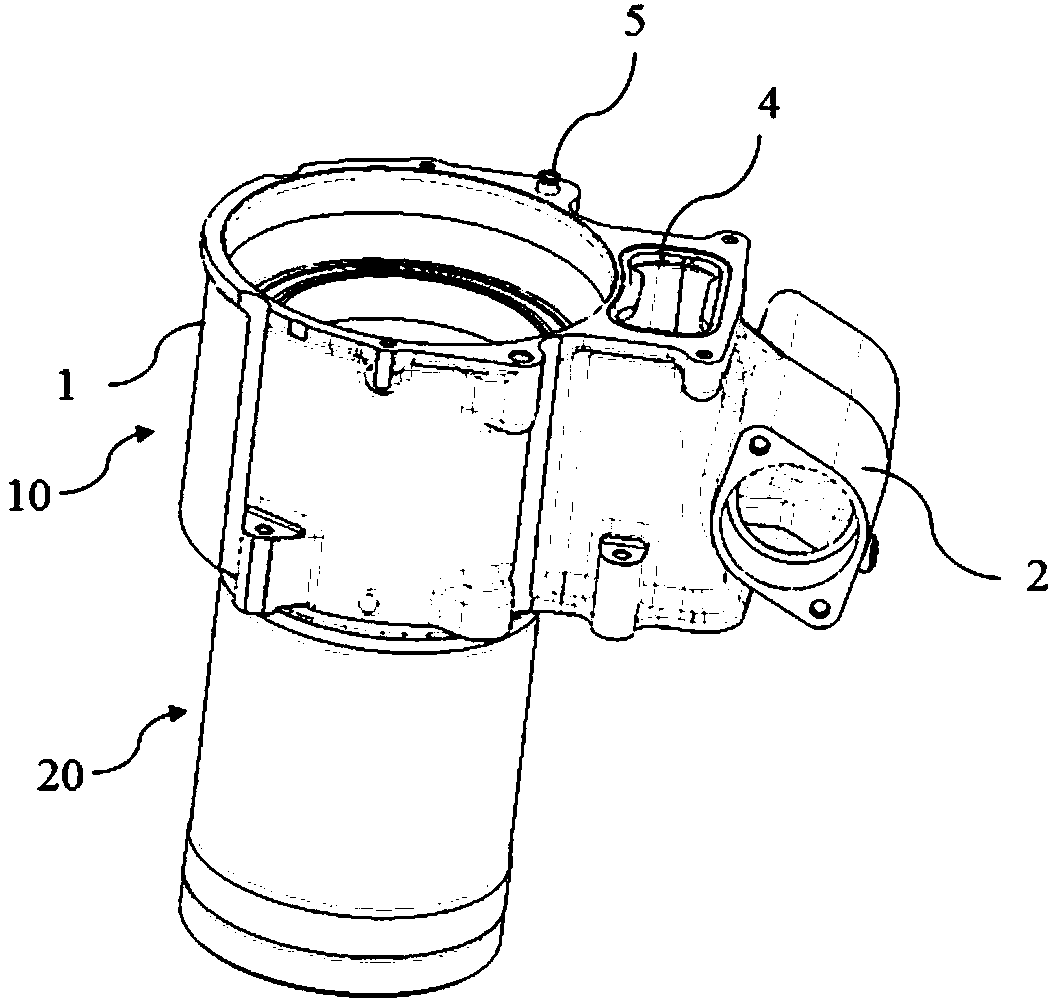

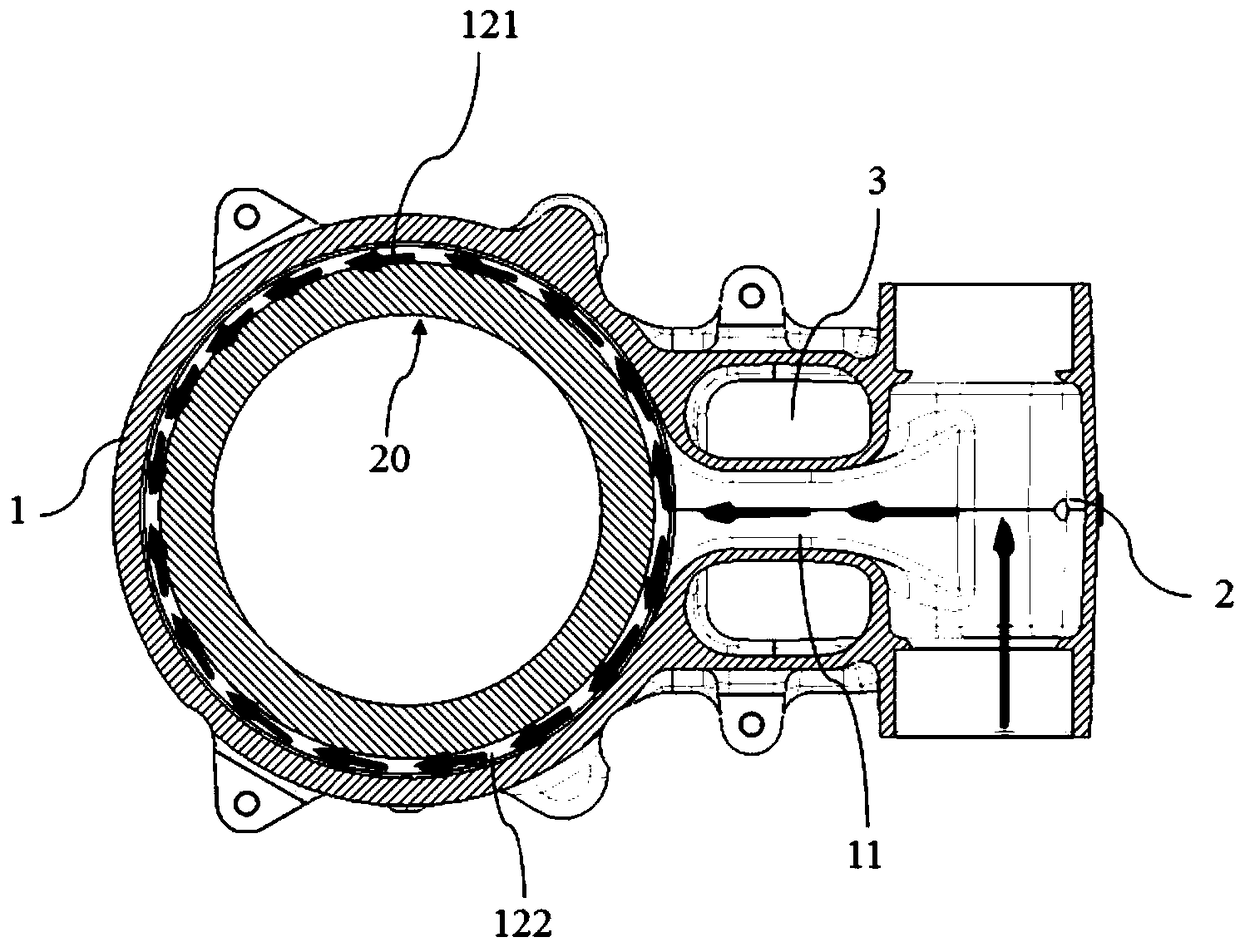

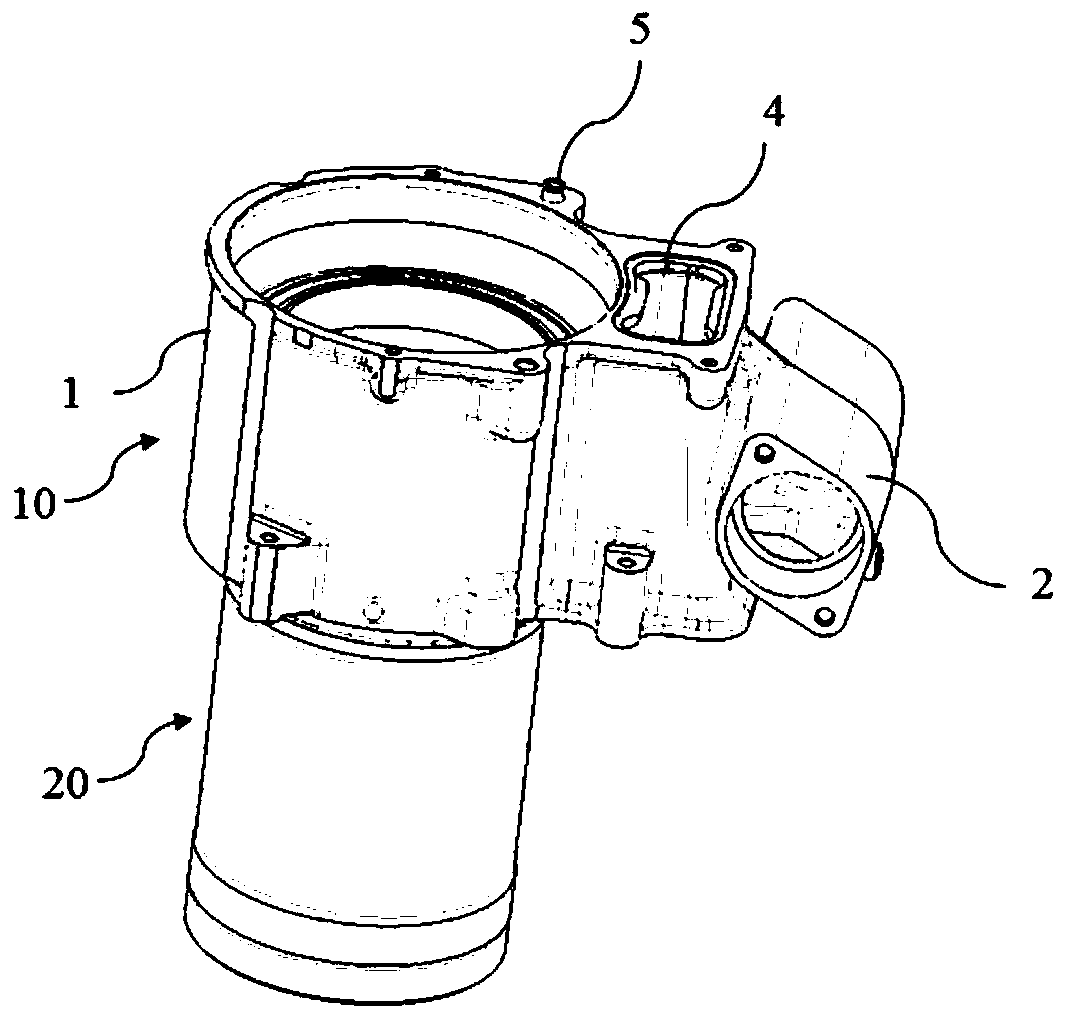

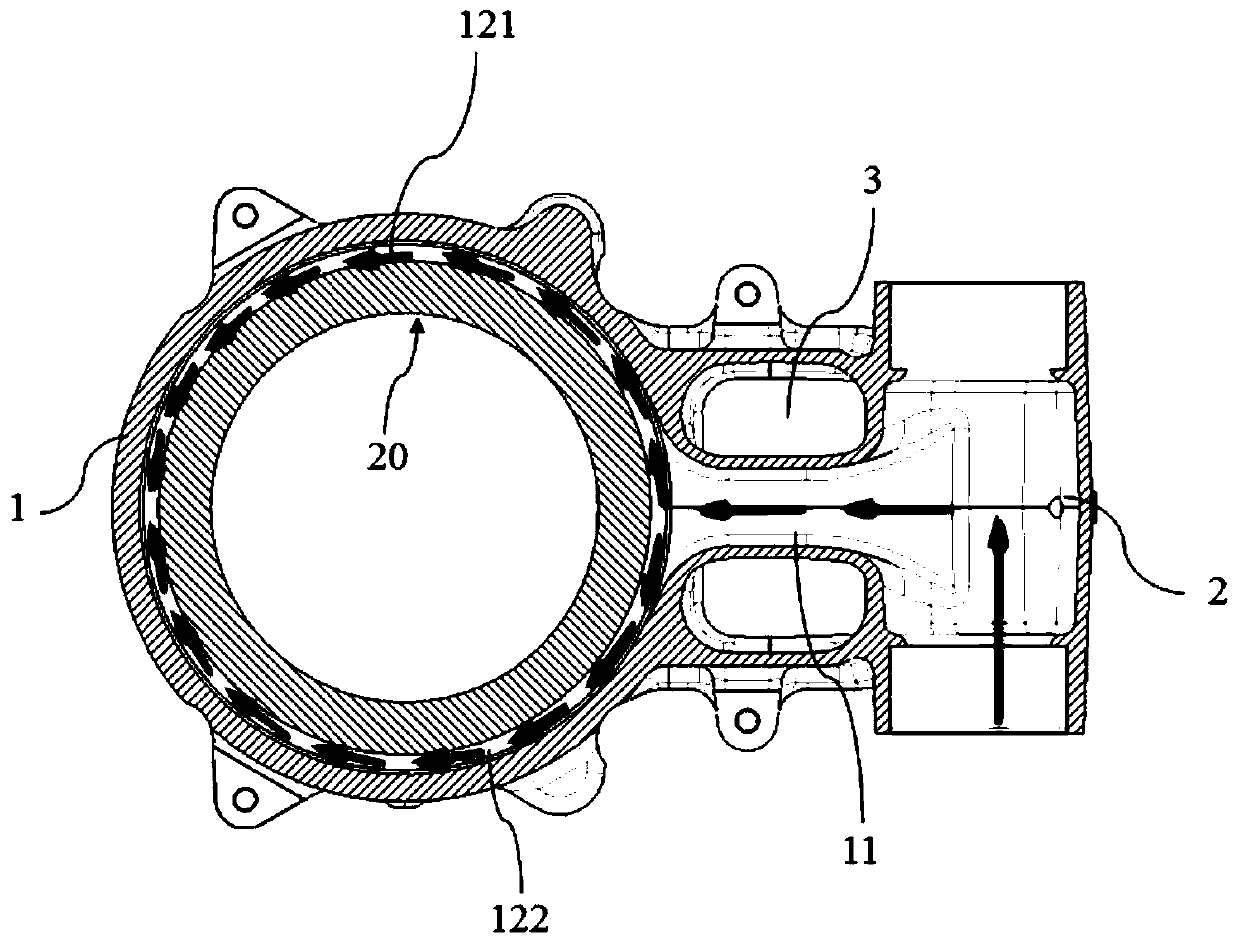

Engine cooling water jacket and engine

ActiveCN109441654AImprove casting processSimple body structureCylinder headsCylindersEngineeringWater jacket

The invention provides an engine cooling water jacket and an engine. The engine cooling water jacket comprises a water jacket body, and the water jacket body sleeves the outer circumference of one endof a cylinder sleeve of the engine so that a gap can be formed between the inner wall of the water jacket body and the outer wall of the cylinder sleeve to form an annular cooling water cavity. The engine cooling water jacket further includes a water inlet pipe disposed on one side of the water jacket body, the cooling water cavity communicates with the water inlet pipe, and cooling water can enter the cooling water cavity through the water inlet pipe to cool the cylinder sleeve. The cooling water jacket is a separate component independent of a machine body of the engine, a tappet cavity is integrally formed above the cooling water jacket, the casting processability of the machine body of the engine can be effectively improved, the structure of the machine body is simplified, and the height of the cooling water jacket is adjusted to control a cooling area of the cylinder sleeve.

Owner:WEICHAI POWER CO LTD

A resource utilization method for sludge produced by wet regeneration of clay old sand

ActiveCN108436027BEmission reductionMeet the process requirementsFoundry mouldsFoundry coresPolyethylene oxideSludge

Owner:SHANDONG JIANZHU UNIV

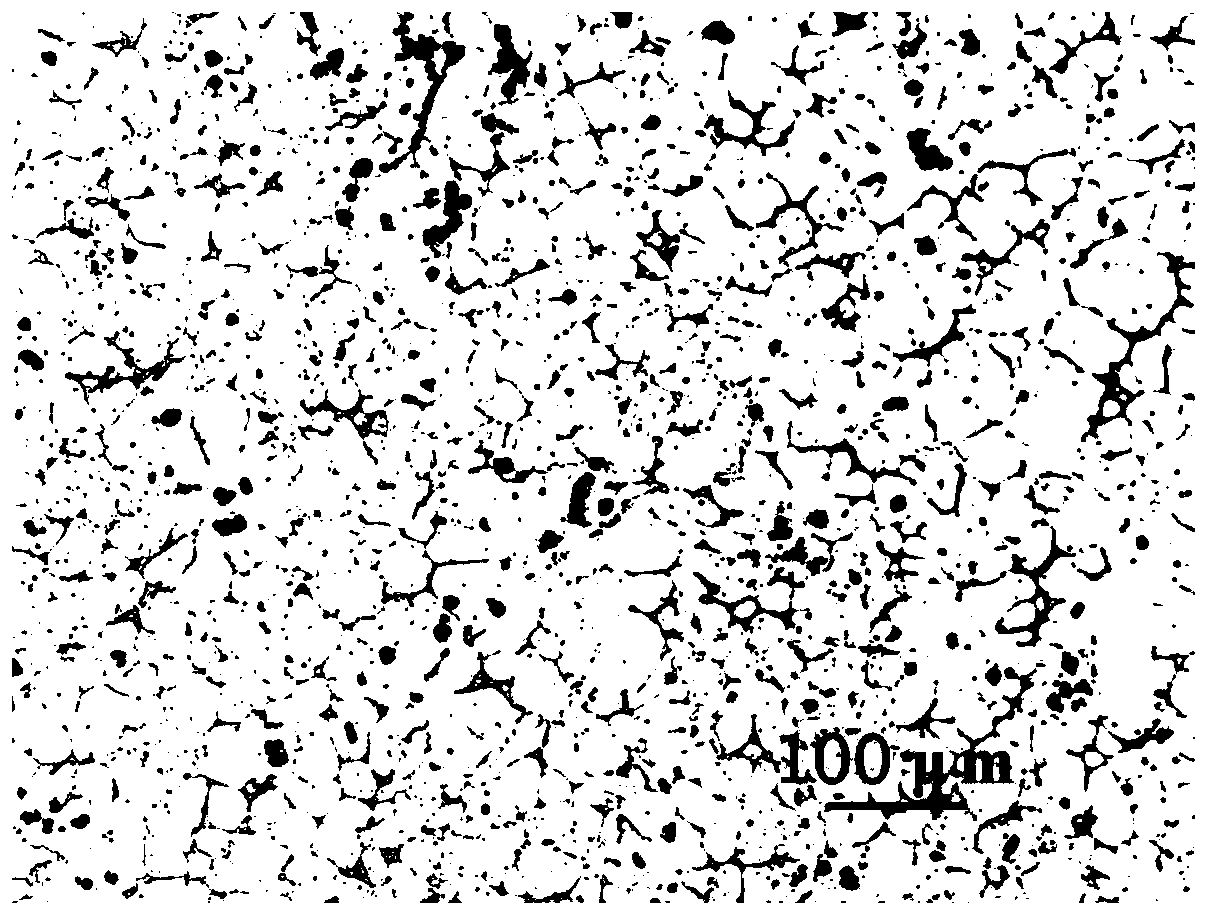

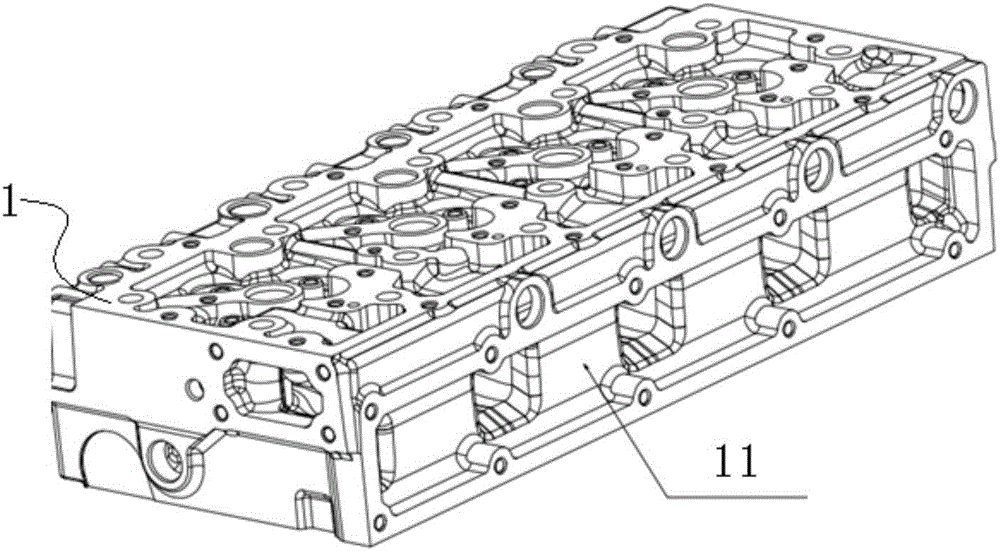

The production process of materials suitable for diesel engine cylinder blocks and cylinder heads

ActiveCN105755359BReduce dosageReduce manufacturing costCylinder headsCylindersFully developedChemical composition

The invention relates to a production process of materials suitable for diesel engine cylinder blocks and cylinder heads, and belongs to the technical field of casting. The process includes seven steps of equipment preparation, batching, feeding, melting, adjusting the chemical composition of molten iron, inoculating and pouring. The eutectic degree Sc of the diesel engine cylinder block and cylinder head material molten iron produced by the process of the present invention is controlled between 0.9-0.93, and the carbon equivalent CE is controlled between 3.95-4.1, which ensures the fluidity of molten iron and the casting process; at the same time, The maturity RG of molten iron can reach 113%, ensuring the inoculation effect, and the potential of the material itself has been fully utilized. The relative hardness RH of the prepared diesel engine cylinder block and cylinder head material can reach 0.84, and the cutting performance is excellent. This process has been applied for more than a year, and can reduce the cost of castings by 300 yuan per ton.

Owner:KUNMING YUNNEI POWER

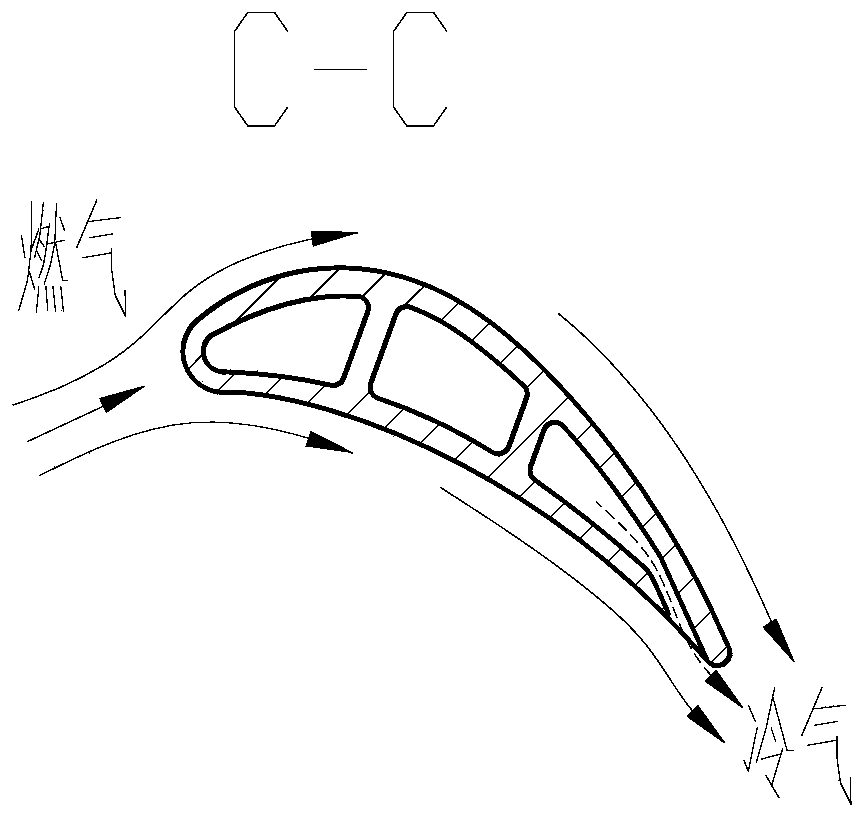

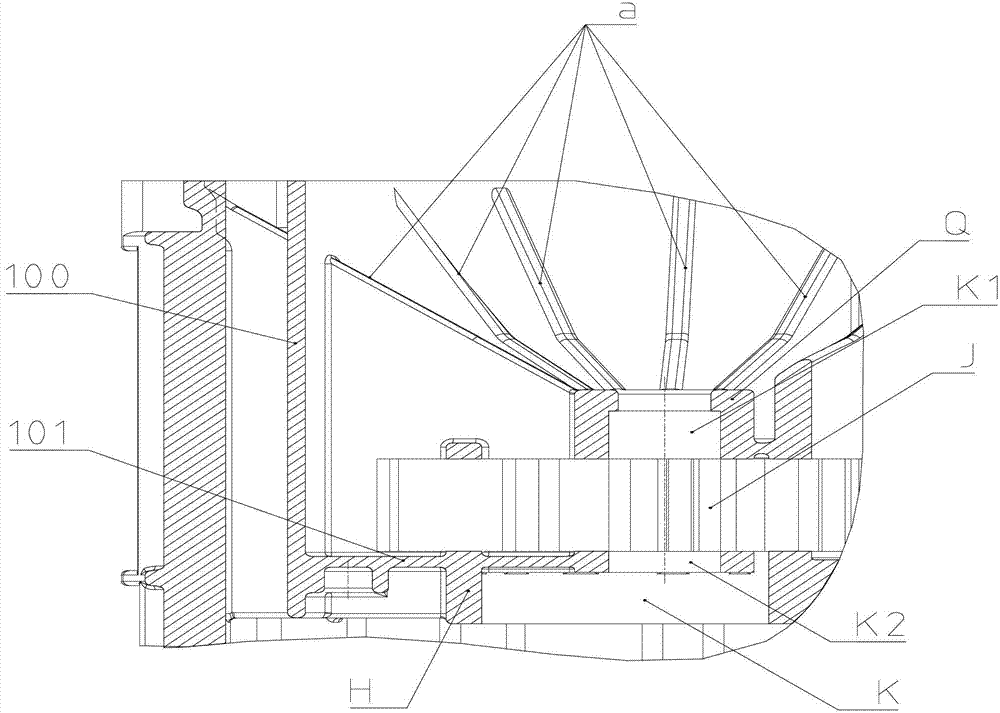

Turbine guide cooling blade

ActiveCN111485957AUniform temperature distributionReduce thermal stressBlade accessoriesEfficient propulsion technologiesTurbineMechanics

The invention provides a turbine guide cooling blade. The turbine guide cooling blade comprises a blade back and a blade basin, wherein a blade cavity is defined by the blade back and the blade basin,the turbine guide cooling blade further comprises a first partition plate and a second partition plate, the first partition plate and the second partition plate are connected between the blade back and the blade basin and sequentially arranged in the blade cavity in the radial direction, the blade cavity is divided into a first cavity, a second cavity and a third cavity which are sequentially arranged in the axial direction through the first partition plate and the second partition plate, the turbine guide cooling blade is provided with a first air inlet, a second air inlet and a first air outlet, the first air inlet and the first air outlet communicate with the radial upper side and the radial lower side of the first cavity respectively, the second air inlet communicates with the radialupper side of the second cavity, a plurality of through holes are formed in the second partition plate, the second cavity communicates with the third cavity through the plurality of through holes, a plurality of impact holes are formed in the blade tail edge of the turbine guide cooling blade, and the third cavity communicates with the outside of the turbine guide cooling blade through the impactholes.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

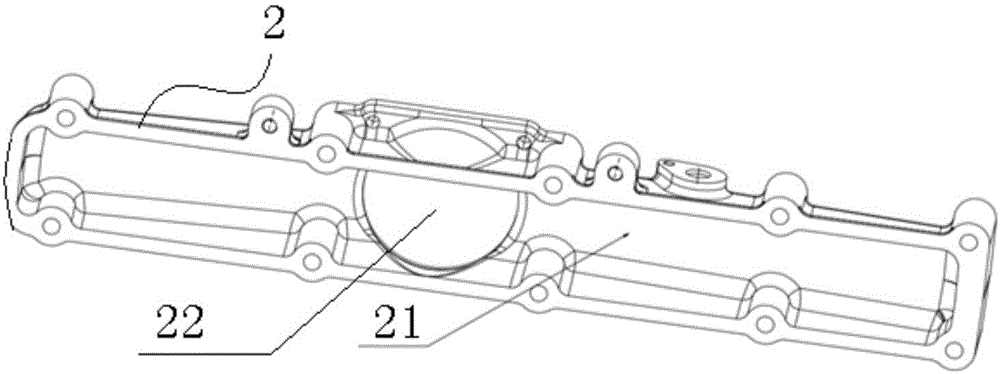

Cylinder cover assembly

InactiveCN106438089AGood casting process performanceReduce weightCombustion-air/fuel-air treatmentCylinder headsEngineeringInlet manifold

The invention discloses a cylinder cover assembly. The cylinder cover assembly comprises a cylinder cover body and an air inlet pipe hood, wherein a first open long cavity is integrally cast on the air inlet side of the cylinder cover body, and the first long cavity forms part of an air inlet pipe of an air inlet manifold; and the air inlet pipe hood is provided with a second open long cavity, and the first long cavity and the second long cavity are buckled to form an air inlet cavity of the air inlet manifold. According to the cylinder cover assembly, part of the structure of the air inlet manifold is integrated on a cylinder cover, and the independent air inlet pipe hood serves as the other part of the structure of the air inlet manifold so that integrated design can be guaranteed, system weight can be reduced, and the manufacturability of cylinder covers is optimized.

Owner:GUANGXI YUCHAI MASCH CO LTD

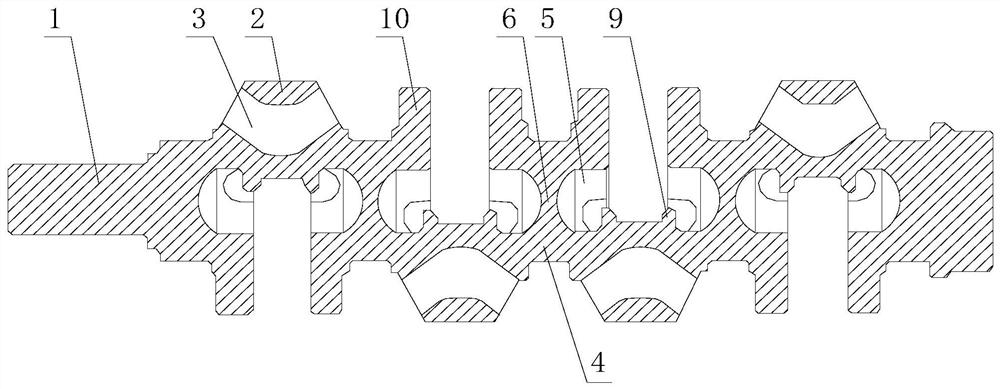

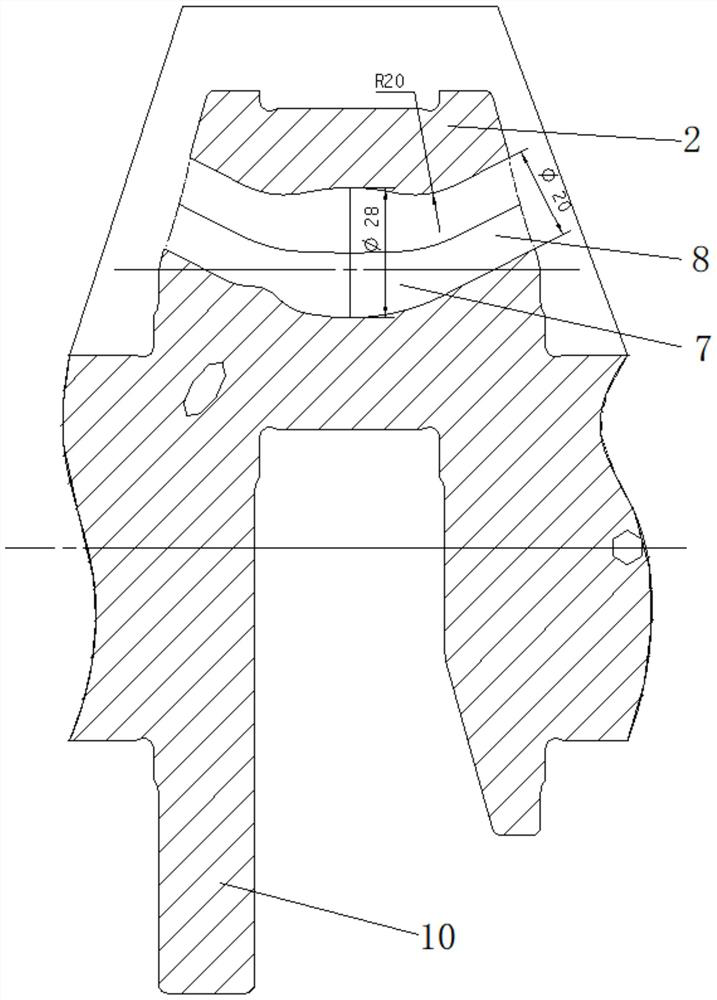

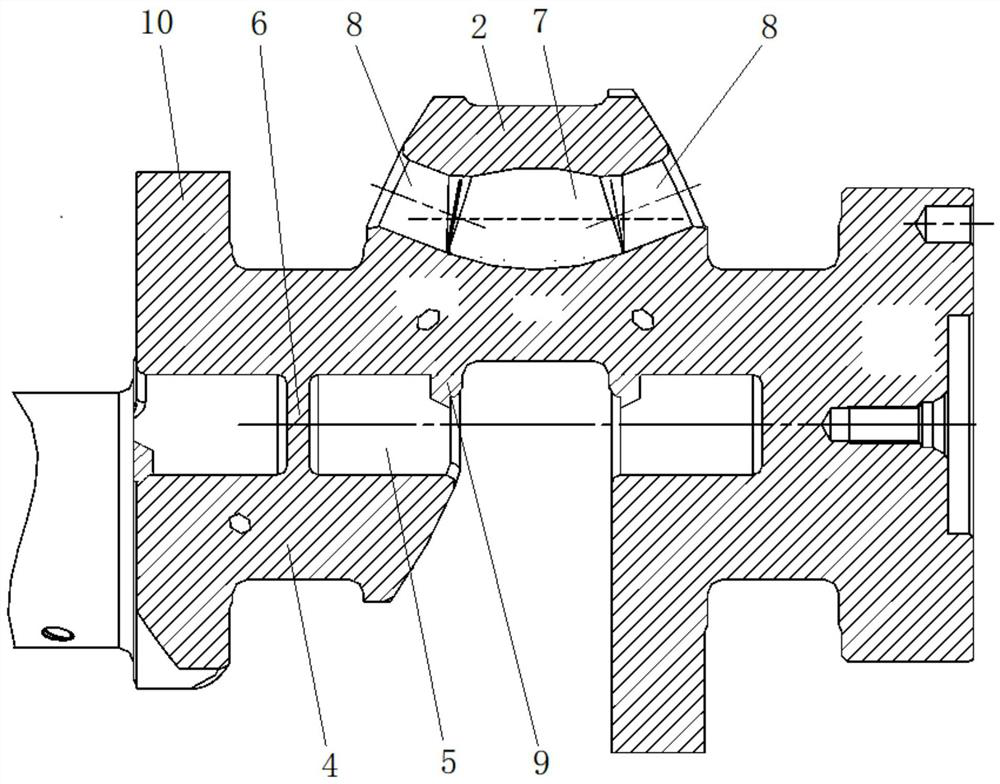

Weight-reduction cast iron crankshaft and casting method

PendingCN111637145AImprove stress distributionReduce thicknessCrankshaftsFoundry mouldsMechanical engineeringCrankshaft

The invention discloses a weight-reduction cast iron crankshaft, relates to an engine, and mainly solves the technical problems that an existing crankshaft is heavy and the reliability is influenced.The weight-reduction cast iron crankshaft comprises a crankshaft body, wherein a first weight-reduction cavity penetrating through the two ends of a connecting rod journal is formed in the connectingrod journal of the crankshaft body; a second weight-reduction cavity is formed in the end part of a main journal of the crankshaft body; a first reinforcing rib is arranged in the main journal betweentwo adjacent connecting rod journals; and the first reinforcing rib separates the second weight-reduction cavities in the two ends of the same main journal. The invention further discloses a castingmethod of the weight-reduction cast iron crankshaft. According to the weight-reduction cast iron crankshaft and the casting method, the first weight-reduction cavity is formed in the connecting rod journal, and the second weight-reduction cavity and the first reinforcing rib are arranged in the main journal, so that the thickness of a crankshaft solid is reduced, on one hand, the casting performance of the crankshaft can be improved, and the reliability is guaranteed, and on the other hand, the weight of the crankshaft can be reduced, the performance of the engine is improved, the rotating speed is increased, the friction work is reduced, the engine oil consumption is reduced, and the emission is better.

Owner:广西玉柴船电动力有限公司

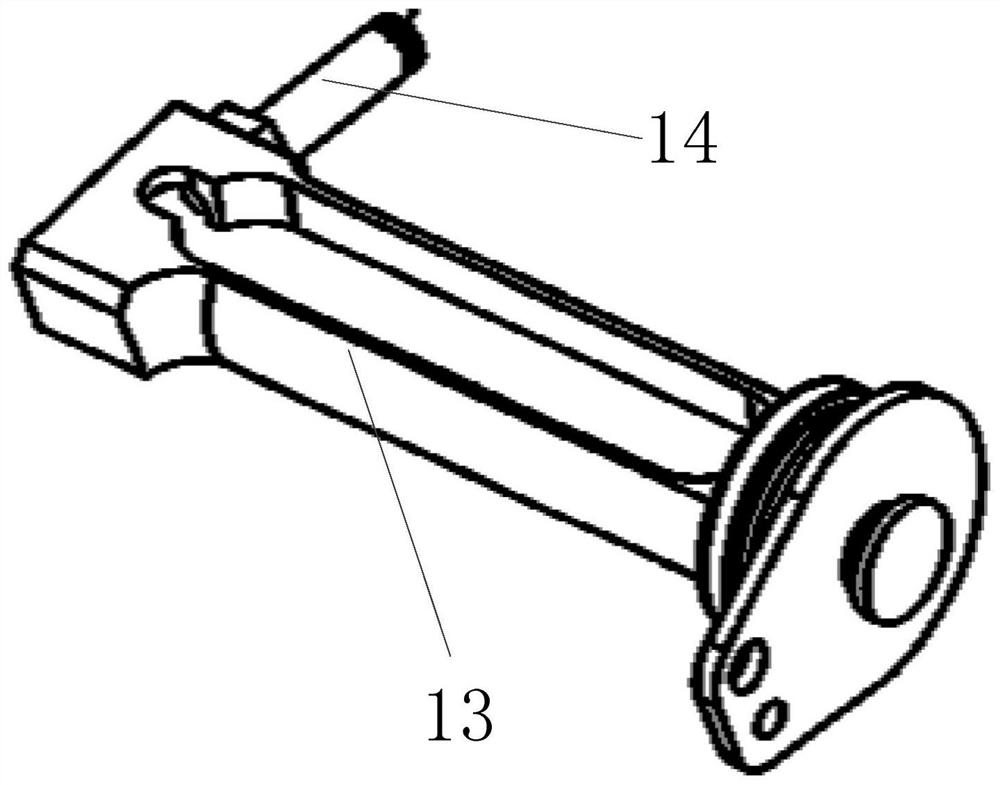

Output bearing oil delivery mechanism, intermediate reducer and helicopter

ActiveCN113431889BWeight increaseReduce weightGear lubrication/coolingMarine engineeringReduction drive

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

Engine multi-oil channel split type machine body structure

InactiveCN101545412BIndependent structure is smallGood casting process performanceCylinder headsCylindersCooling effectEngineering

Owner:CHINA NORTH IND GRP NO 70 RES INST

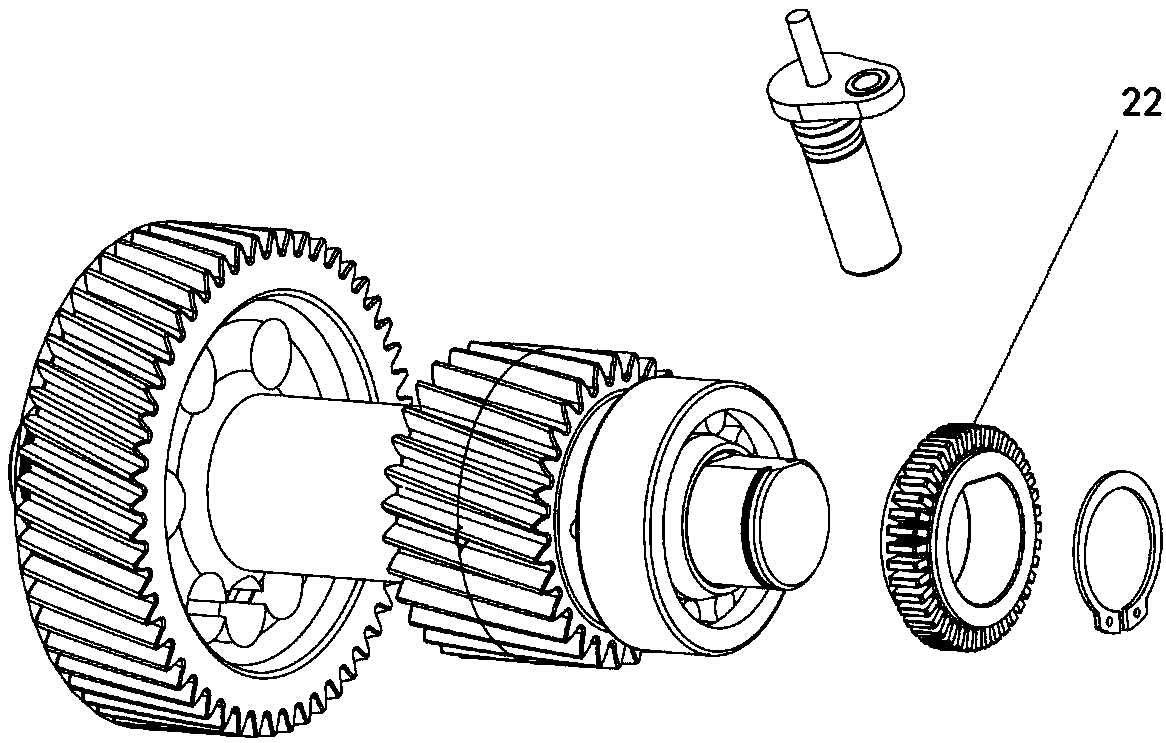

Two-speed pure electric transmission

The invention discloses a two-speed pure electric transmission. The transmission comprises a front shell, a front bearing cover connected with the front shell, an input shaft assembly, an output shaftassembly, a transmission shell and a rear bearing cover connected with the transmission shell. The input shaft assembly is supported on the front shell. The two ends of the output shaft assembly aresupported on an inner ring of the input shaft assembly and the transmission shell correspondingly. An output shaft first-speed gear is arranged on the output shaft assembly. A sliding sleeve is arranged between the output shaft first-speed gear and the input shaft assembly. A shifting fork is arranged above the sliding sleeve and sleeves a shift rail in an idling mode. A transmission control device is arranged above the shifting fork. Three counter shafts are uniformly distributed on the periphery of the output shaft assembly. The two ends of each counter shaft are supported on the front shelland the transmission shell correspondingly. According to the two-speed pure electric transmission, the technical route of the three counter shafts is adopted, the center-to-center distance is reduced, and the transmission is small in size, light in weight and compact in structure; and meanwhile, the three counter shafts adopt the symmetric distribution structure of two up and one down, lubrication is guaranteed, the churning loss can be further reduced as much as possible, and the transmission efficiency is improved.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

A method for completely regenerating sand from modified clay

ActiveCN107282866BHigh molecular weightImprove cohesionFoundry mouldsMould handling/dressing devicesFuranFluidized bed

The invention belongs to the technical field of reutilization of returned clay sand, and particularly relates to a method for modifying clay completely-reclaimed sand. The method for modifying the clay completely-reclaimed sand specifically comprises the steps that firstly, the clay completely-reclaimed sand is washed twice with non-ammonia water, then dried for four hours at the temperature of 140-160 DEG C, and naturally cooled for standby; secondly, the standby clay completely-reclaimed sand is added with a benzenesulfonic acid water solution with the weight being about 1.5-2% of the weight of the standby clay completely-reclaimed sand and dried till the weight of the standby clay completely-reclaimed sand is constant after heat preservation is conducted for 2-3 hours; and then the clay completely-reclaimed sand is mixed with a carbon nano tube with the weight being 3.5-4.5% of the weight of the clay completely-reclaimed sand, the mixture is placed in a grinding wheel type regenerator to be rubbed for five minutes and then winnowed for ten minutes in a negative-pressure fluidized bed, and thus modified clay completely-reclaimed sand is obtained. Compared with the prior art, the method for modifying the clay completely-reclaimed sand has the following advantages that by washing the clay completely-reclaimed sand with the non-ammonia water, the tensile strength of furan resin self-hardening sand mixed with the modified sand can reach about 1.45 MPa within 24 h, the usable time is prolonged by about 20% compared with fresh sand, and the casting manufacturability of the furan resin self-hardening sand is effectively improved.

Owner:HEFEI CITY TENVER PRECISION CASTING

A support structure for a reverse intermediate shaft of a transmission

ActiveCN102878272BGood casting processImprove support rigidityGearing detailsMilling cutterEngineering

The invention provides a support structure of a reverse counter shaft of a transmission. The support structure comprises a transmission housing, a partition and a boss. The transmission housing, the partition and the boss are integrated. Reverse idle gear mounting space is reserved between one side of a transmission main box, close to the partition, and the boss. The partition is provided with a second reverse counter shaft support hole and an auxiliary box counter shaft support hole, which are nonconcentric. One side of the boss, close to the transmission housing, is supported on the transmission housing through a plurality of ribs. Radial plates are disposed among the ribs. The reverse counter shaft boss is supported by the ribs in the support structure, and the reverse counter shaft boss with specific features is cast to reach a rear auxiliary box partition. By milling the reverse idle gear space with a disc milling cutter along with machining, casting of windows on two sides of the box is avoided effectively while fine casting manufacturability is guaranteed, casting manufacturability of the casing is improved, the parts such as window cover plates, spacers and bolts are omitted, and oil leakage spots are reduced effectively.

Owner:SHAANXI FAST GEAR CO

Engine cooling water jacket and engine

ActiveCN109441654BSimple structureGood casting process performanceCylinder headsCylindersEngineeringWater jacket

The invention provides an engine cooling water jacket and an engine. The engine cooling water jacket comprises a water jacket body, and the water jacket body sleeves the outer circumference of one endof a cylinder sleeve of the engine so that a gap can be formed between the inner wall of the water jacket body and the outer wall of the cylinder sleeve to form an annular cooling water cavity. The engine cooling water jacket further includes a water inlet pipe disposed on one side of the water jacket body, the cooling water cavity communicates with the water inlet pipe, and cooling water can enter the cooling water cavity through the water inlet pipe to cool the cylinder sleeve. The cooling water jacket is a separate component independent of a machine body of the engine, a tappet cavity is integrally formed above the cooling water jacket, the casting processability of the machine body of the engine can be effectively improved, the structure of the machine body is simplified, and the height of the cooling water jacket is adjusted to control a cooling area of the cylinder sleeve.

Owner:WEICHAI POWER CO LTD

A High Temperature Corrosion Resistant Superalloy Casting

ActiveCN105349842BImprove mechanical propertiesGood long-term aging tissue stability at high temperatureFoundry mouldsFoundry coresMetallic materialsSuperalloy

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com