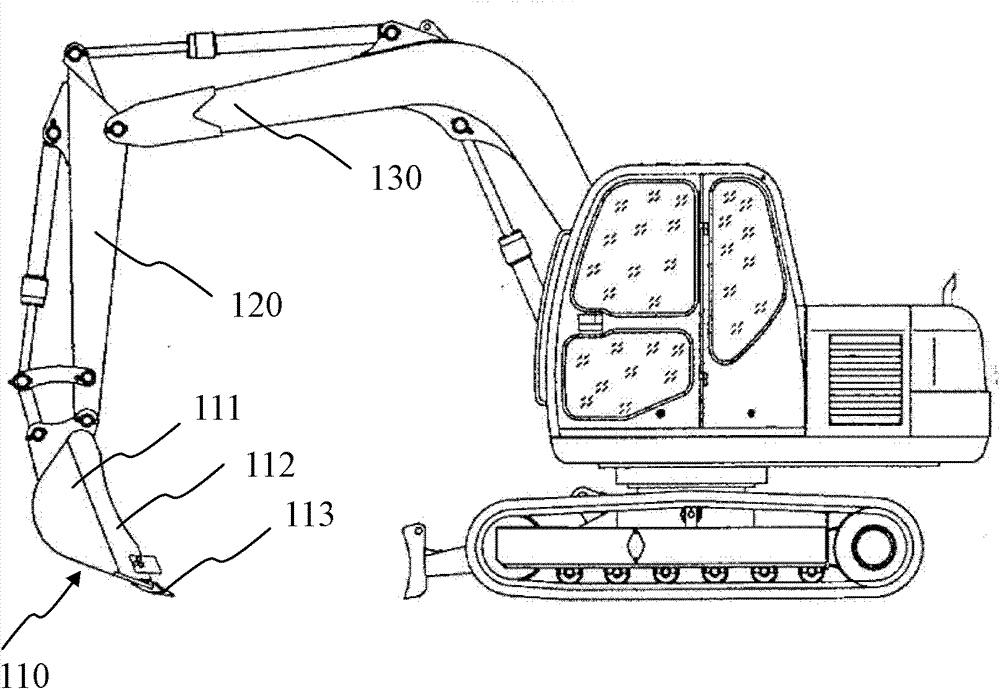

Digging bucket and bucket teeth thereof

A technology for excavators and bucket teeth, which is applied in the field of construction machinery, can solve problems that affect the working efficiency of excavators, are not suitable for stonework operations, and have poor wear resistance, so as to improve practicability, economy, and good wear resistance , The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, specific embodiments will be described in detail below with reference to the accompanying drawings.

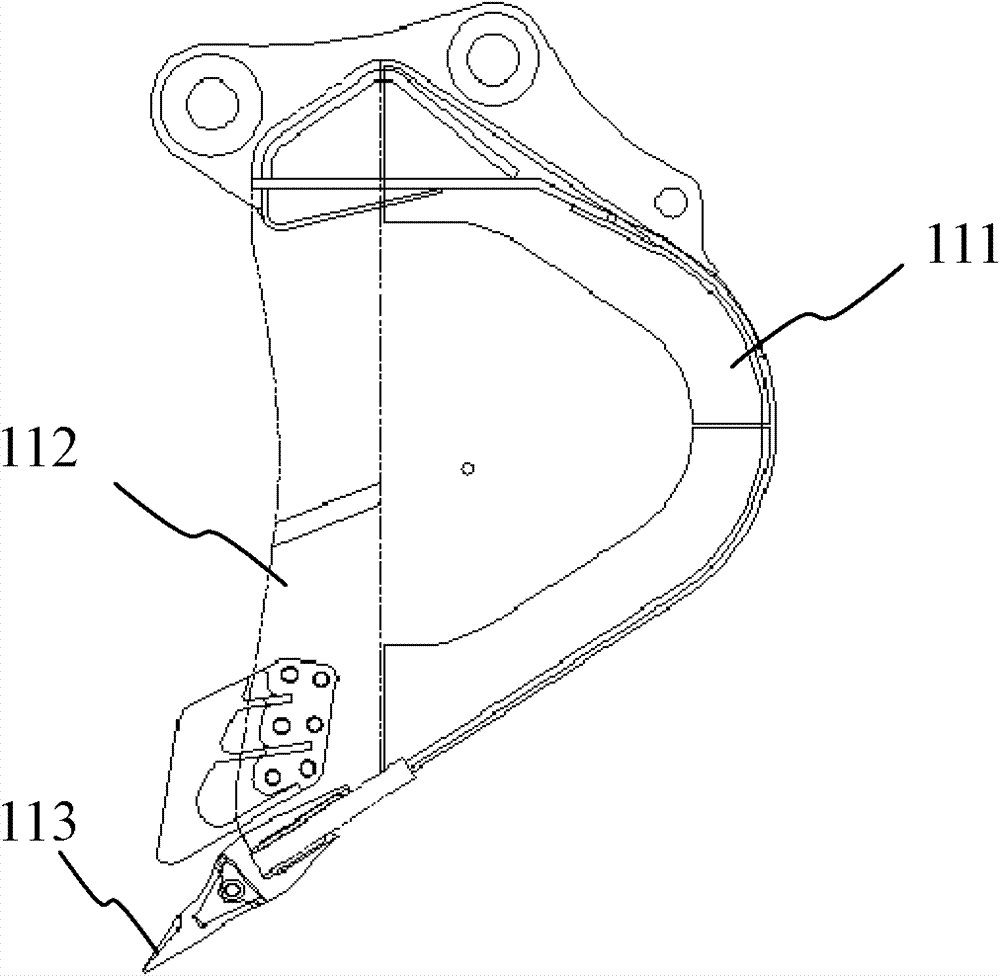

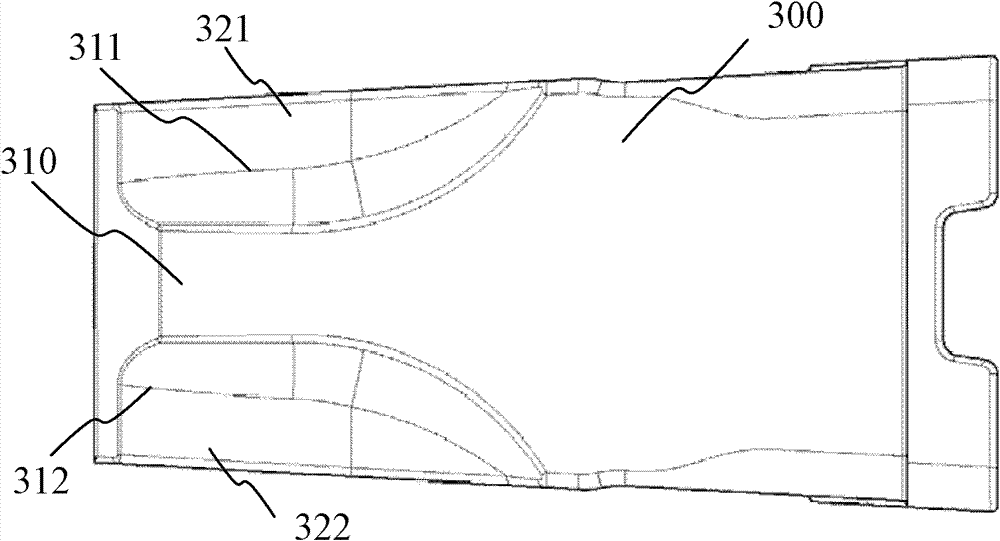

[0039] Figure 4 It is a three-dimensional view of a bucket tooth according to an embodiment of the present invention, Figure 5a , 5b , 5c, 5d, and 5e are the top view, front view, bottom view, left view and right view of the bucket teeth of the embodiment of the present invention, respectively. refer to Figure 4 As shown in Figure 5, the bucket teeth of the excavator bucket include:

[0040] Wedge tooth body 400;

[0041] The upper thick tooth surface 410 is located on the upper surface of the wedge-shaped bucket tooth body 400;

[0042] The upper thin tooth surface 421, 422 is a curved surface formed by the downward depression of the upper surface of the wedge-shaped body, and is located on both sides of the upper thick tooth surface 410. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com