Removable tower sleeve

A tower and sleeve technology, applied in the field of lifting platform, can solve the problems of impossible sleeve/tower structure, high cost, and inability to allow on-site installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Description of preferred embodiments

[0045] Preferred embodiments of the invention will now be described, schematically and not limitatively, with reference to the accompanying drawings.

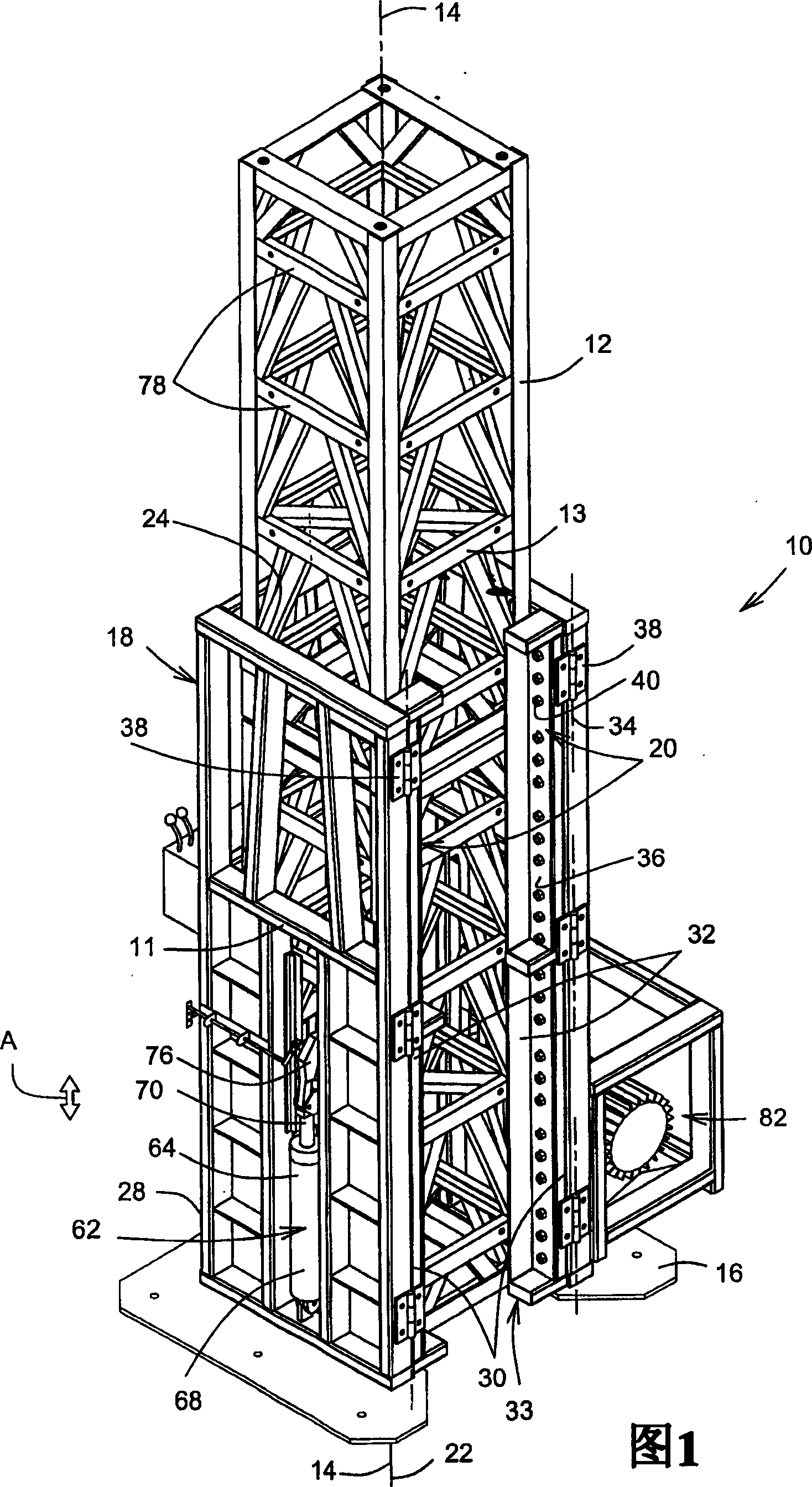

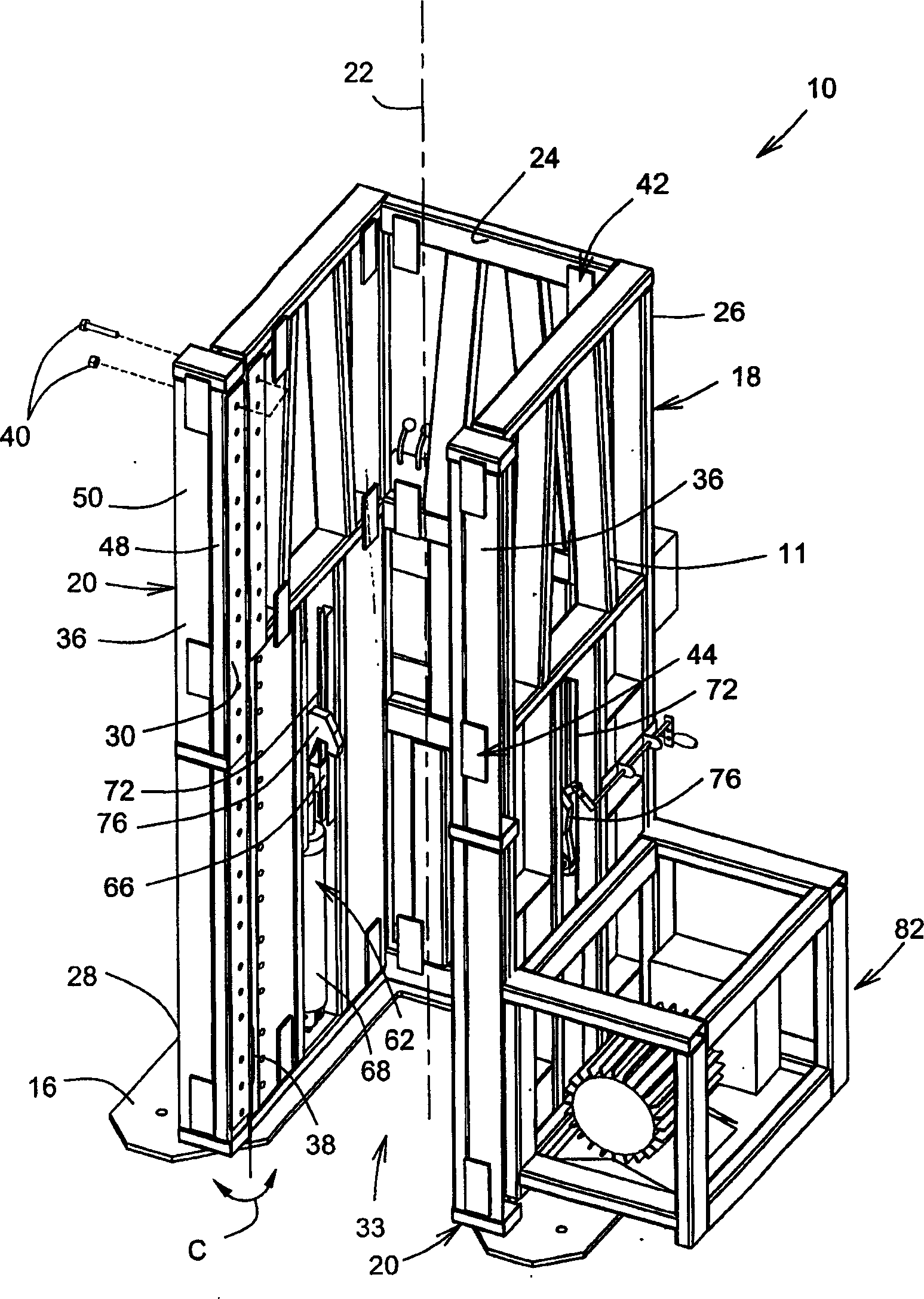

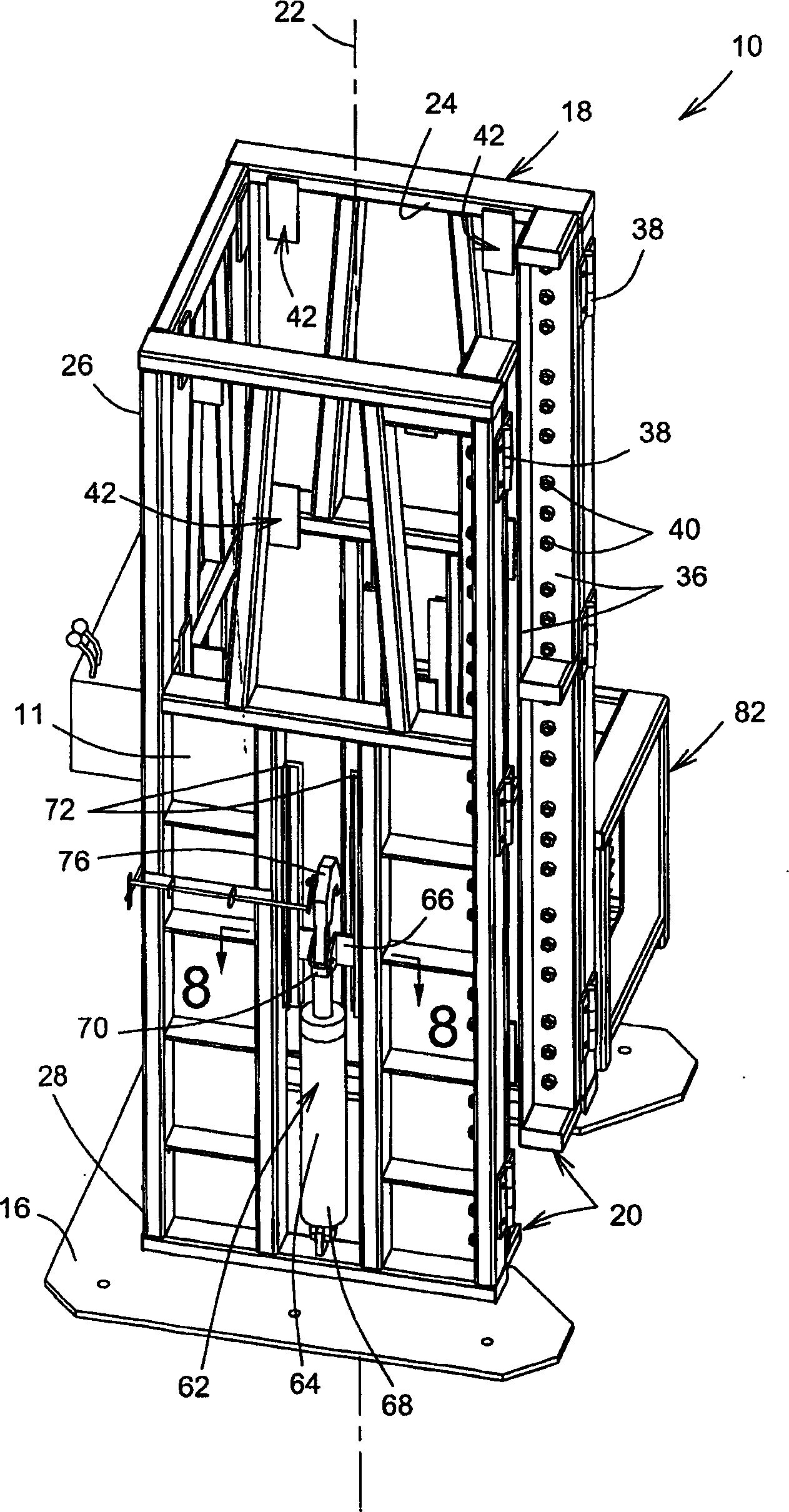

[0046]1 and 2, there is shown an embodiment of a tower sleeve 10 according to the present invention for sliding engagement with a conventional tower 12 or mast using scaffolding or the like, the tower 10 defining a tower longitudinal axis 14 and a A tower longitudinal side wall 13 substantially parallel to the tower longitudinal axis 14 . A tower sleeve 10 for guiding up and down movement along the tower 12 (as shown by the arrow in FIG. 1 ) is used to detachably and firmly support a platform (not shown) etc. on the interface plate structure 16, Such as US Patent No. 5,159,993 authorized to St-Germain on November 3, 1992, US Patent No. 5,746,290 authorized to St-Germain et al. on May 5, 1998, or authorized to St-Germain on November 6, 2001 shown in US Patent No. 6,311,800 to et al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com