Patents

Literature

48results about How to "Not easy to embed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

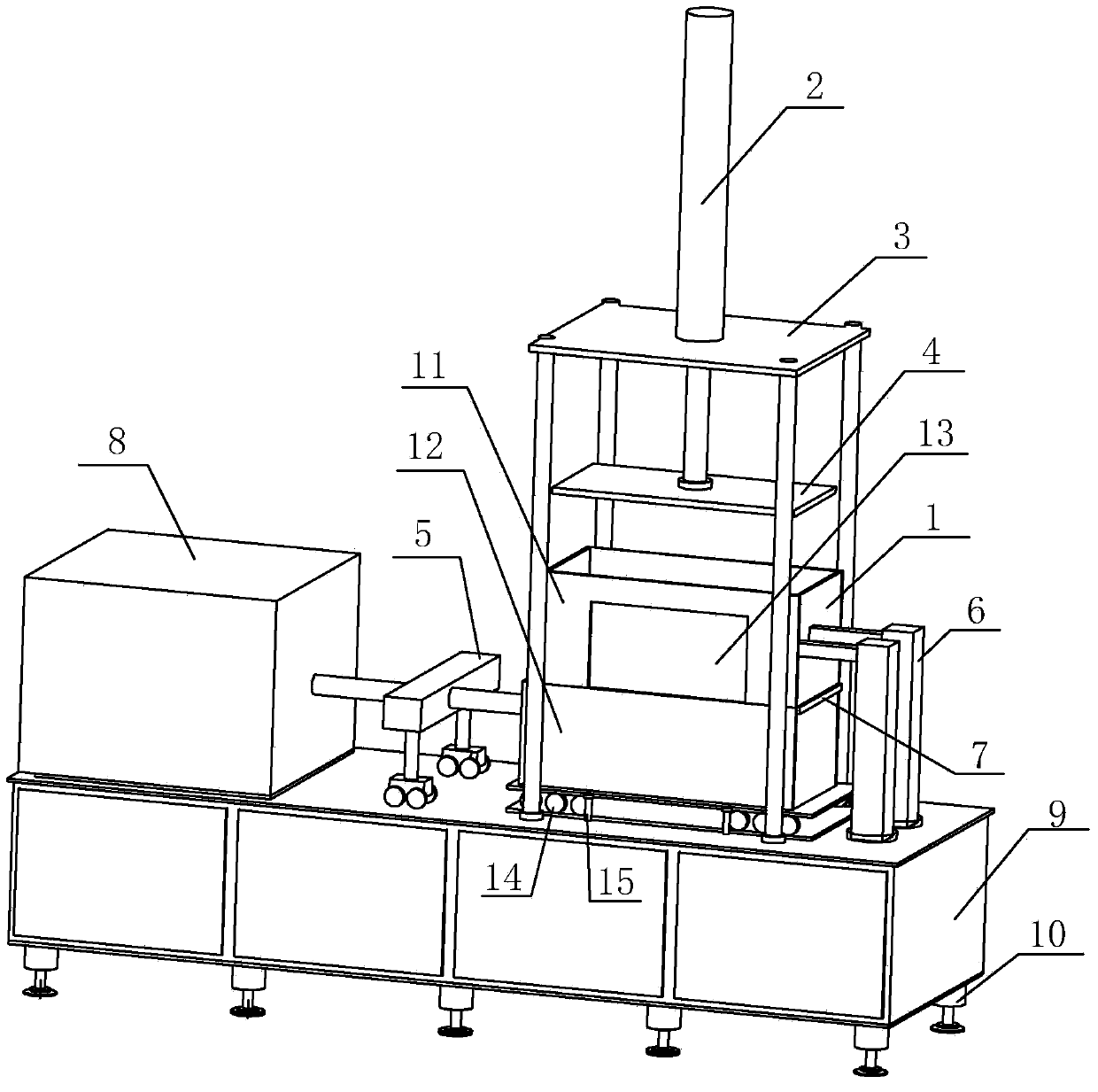

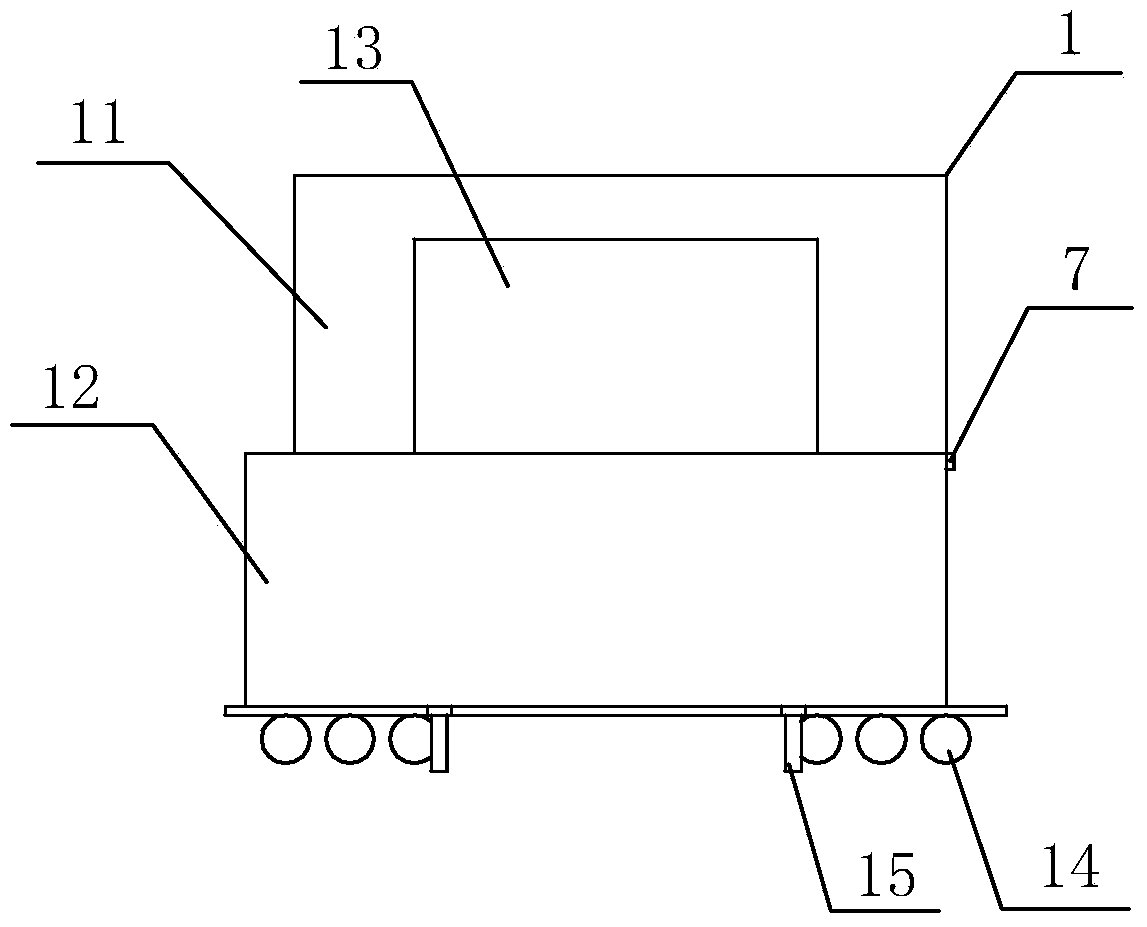

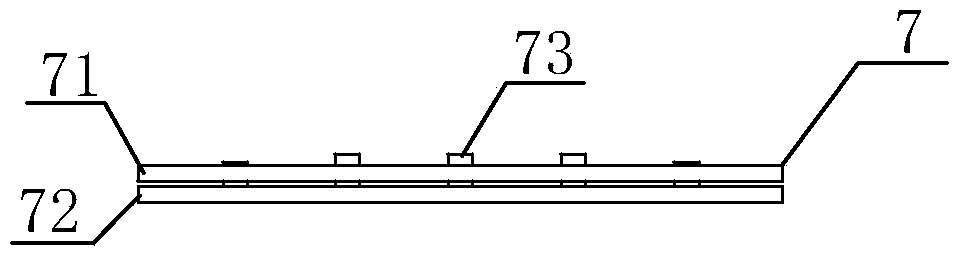

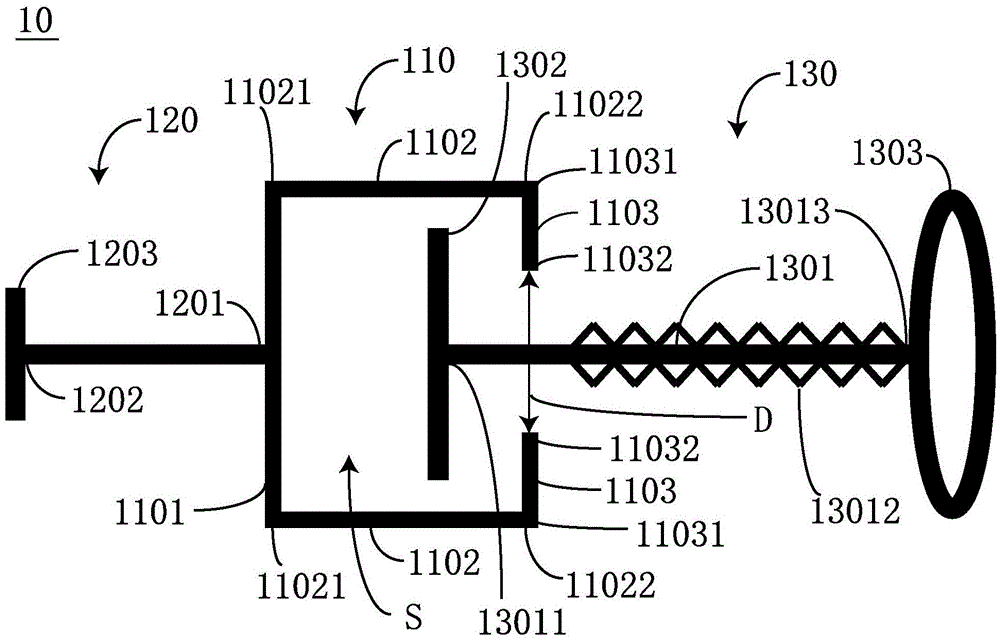

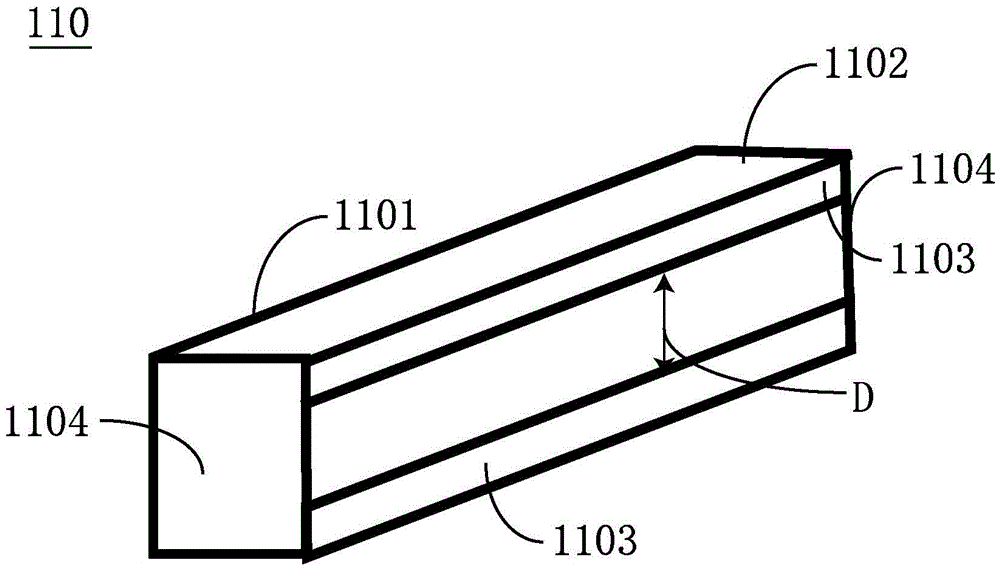

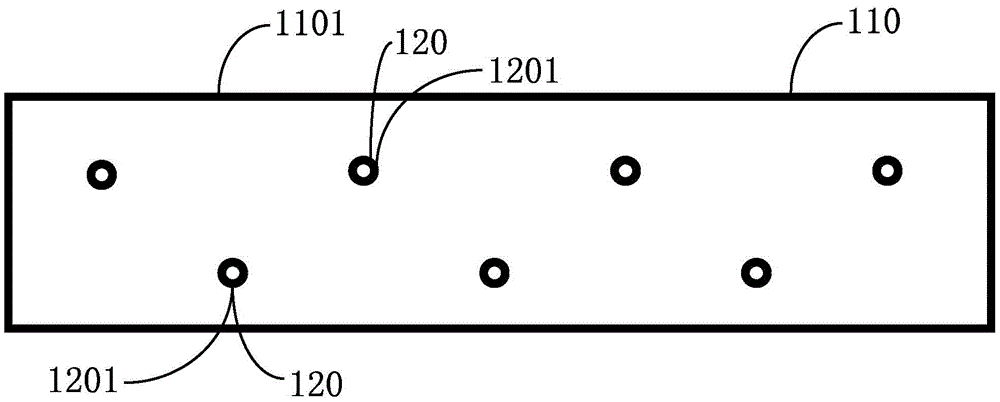

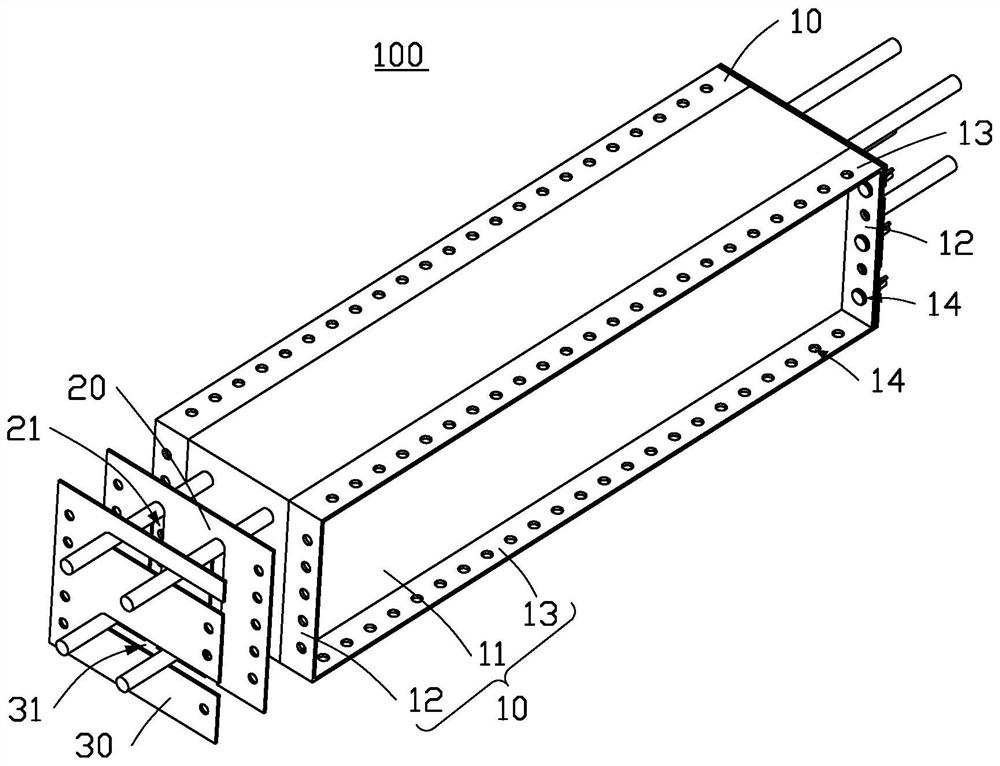

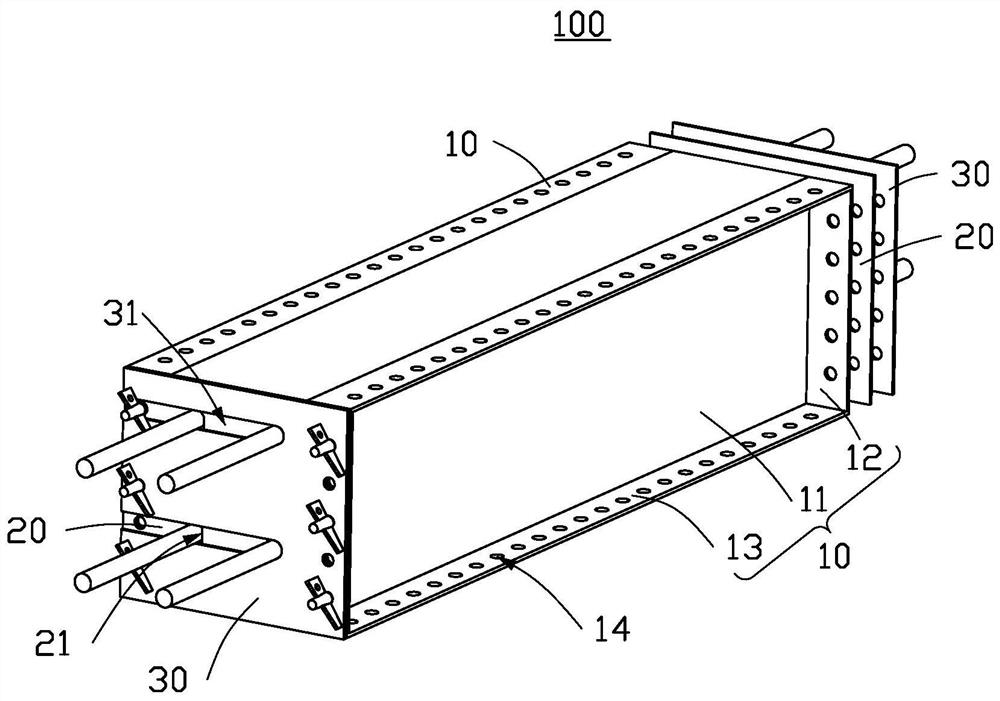

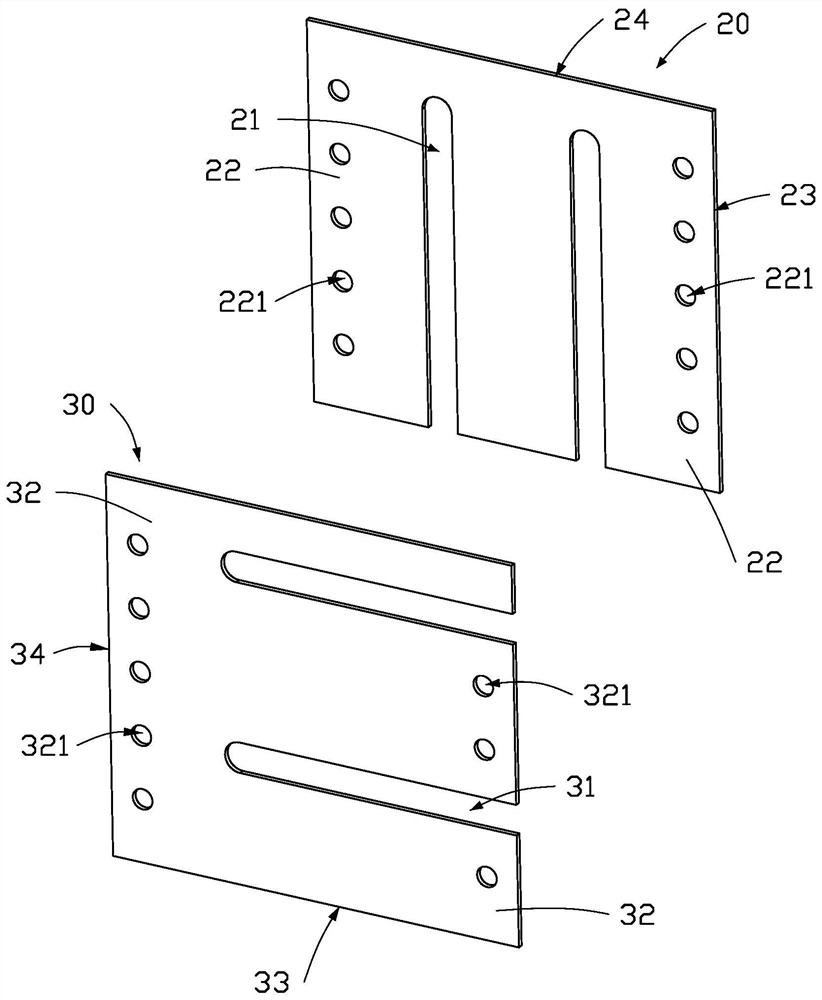

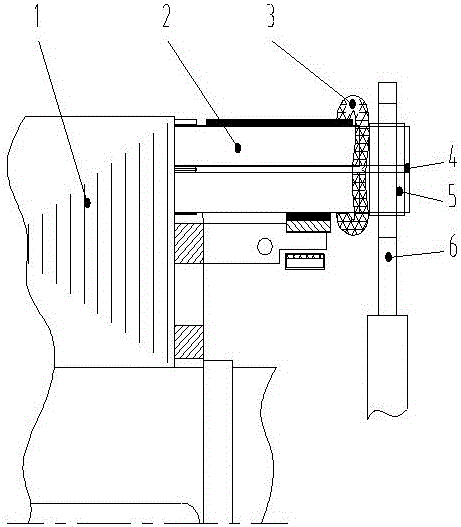

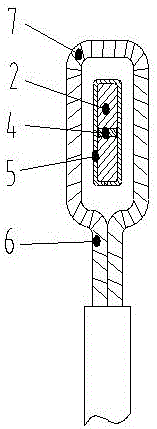

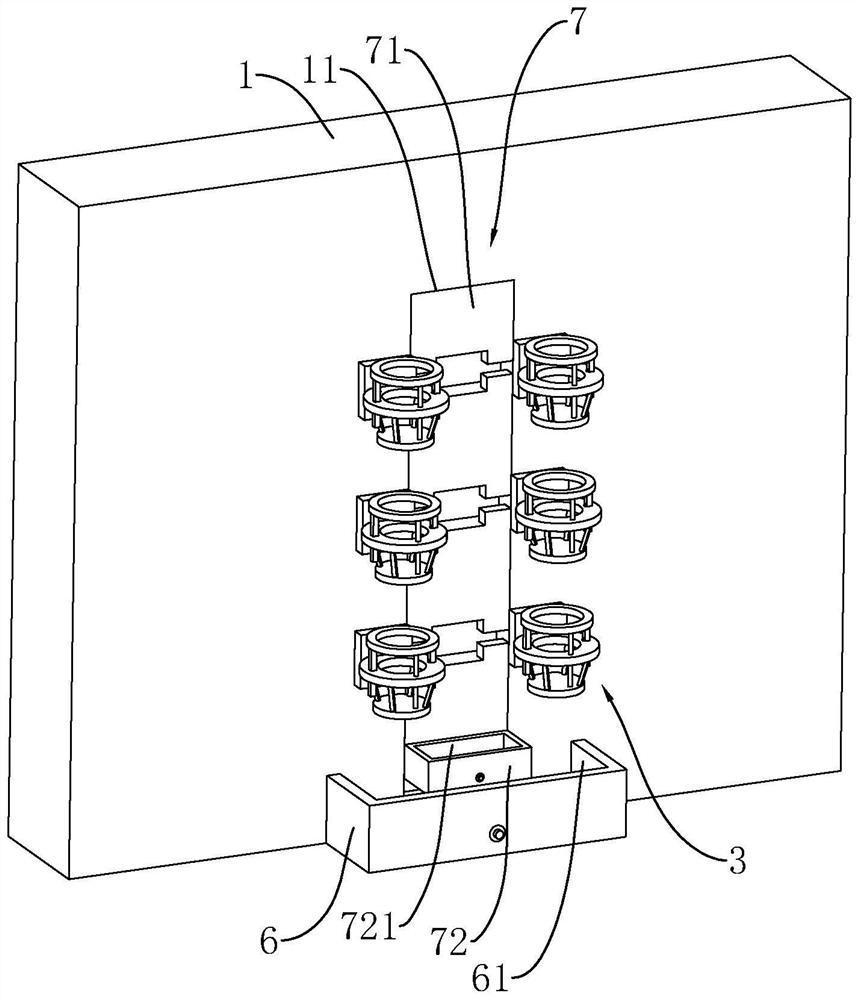

Direct shear test data acquisition instrument for big visual model of reinforced earth

ActiveCN104198301AImprove reliabilityNot easy to embedMaterial strength using steady shearing forcesDigital videoData acquisition

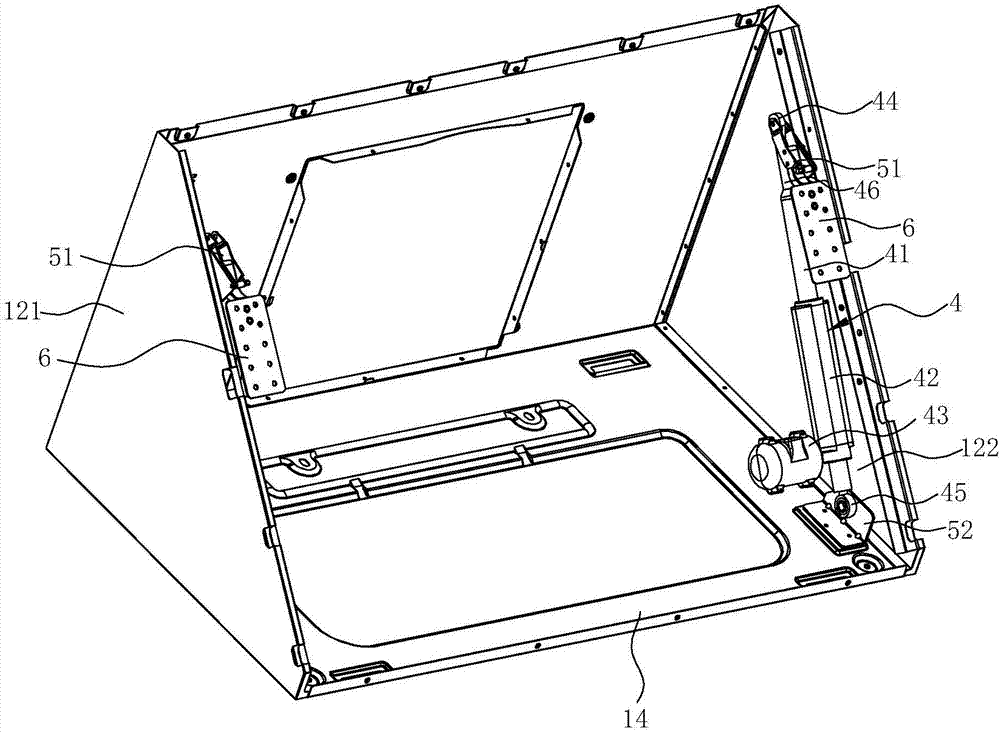

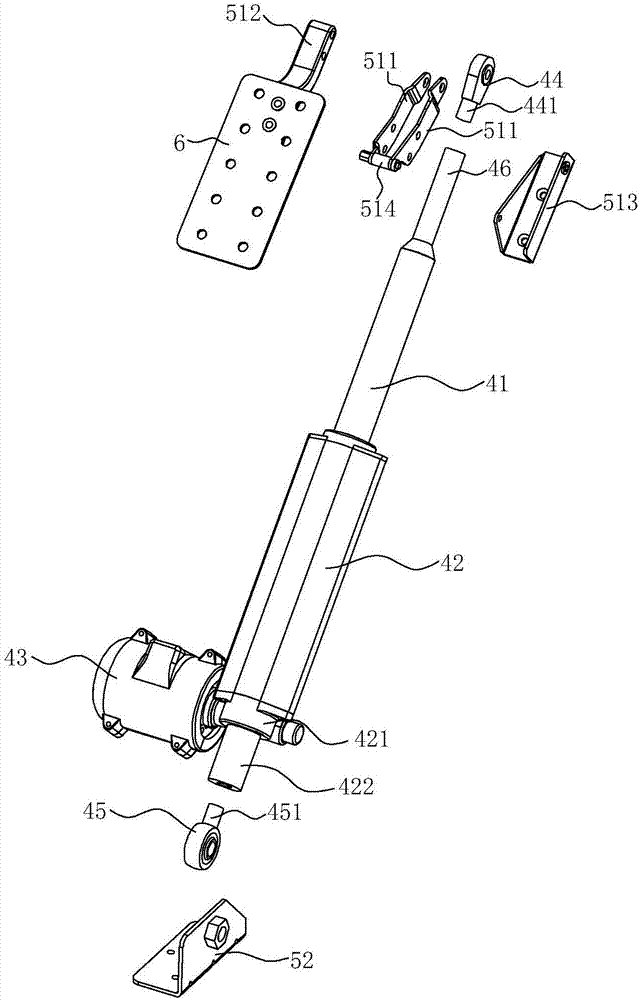

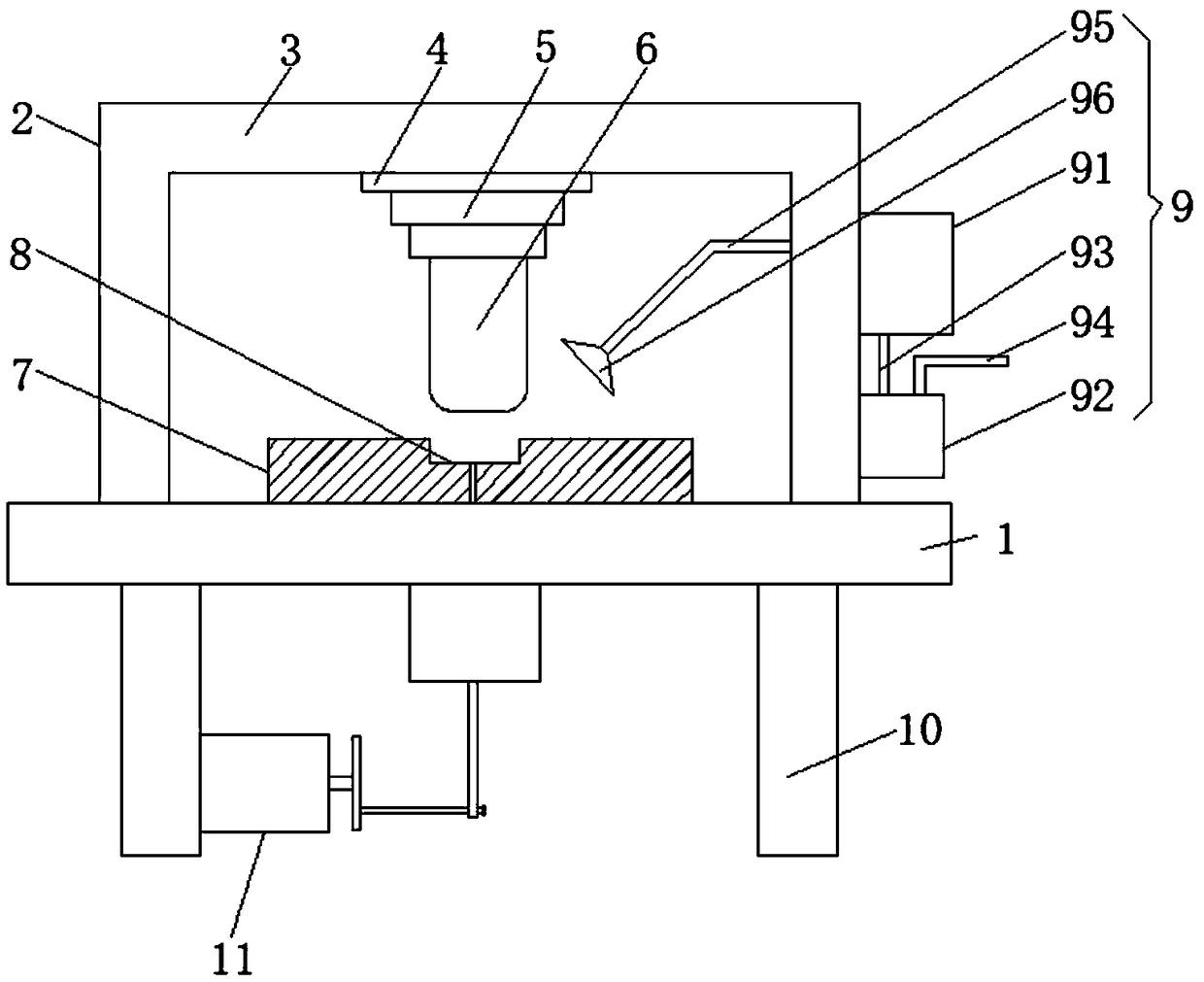

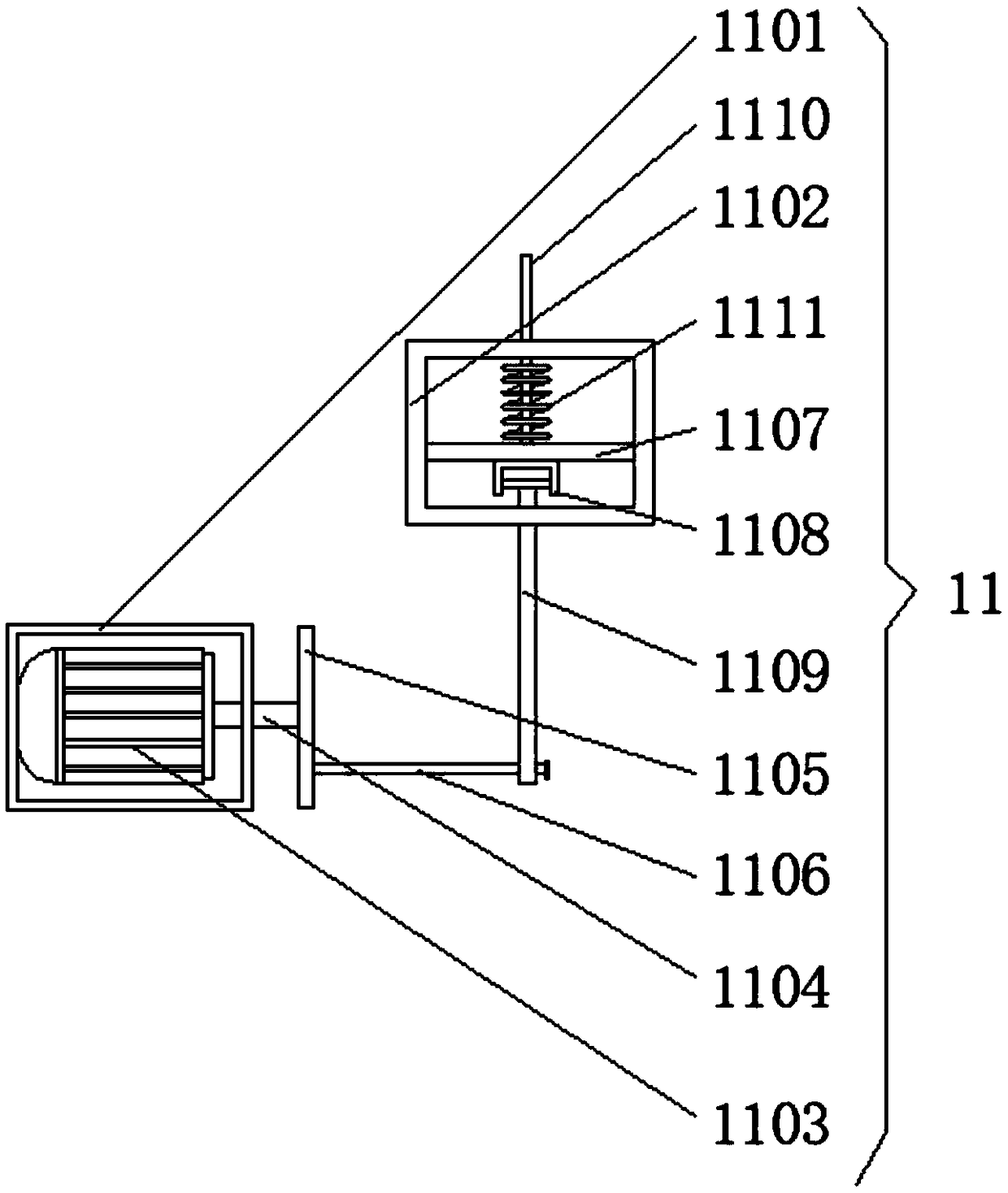

The invention relates to a direct shear test data acquisition instrument for a big visual model of reinforced earth. The direct shear test data acquisition instrument comprises a vertical loading system, a horizontal loading system and a shear box, wherein the shear box comprises an upper shear box and a lower shear box which are both filled with packing; the horizontal loading system comprises a push-pull electromotor and a sliding balanced pushing rod, and a displacement sensor and a pressure sensor are mounted on the push-pull electromotor; one end of the sliding balanced pushing rod is connected with the push-pull electromotor, and the other end of the sliding balanced pushing rod is connected with the lower shear box; a counterforce device is mounted on one side, far away from the sliding balanced pushing rod, of the lower shear box and connected with the upper shear box; transparent tempered glass is arranged on one side wall of the upper shear box in the shear direction, and a digital video camera is mounted in front of the tempered glass; a geotechnical material spring clip is mounted at one end of the lower shear box. The direct shear test data acquisition instrument is convenient to use, small in test error, precise test data and convenient to widely promote and use.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

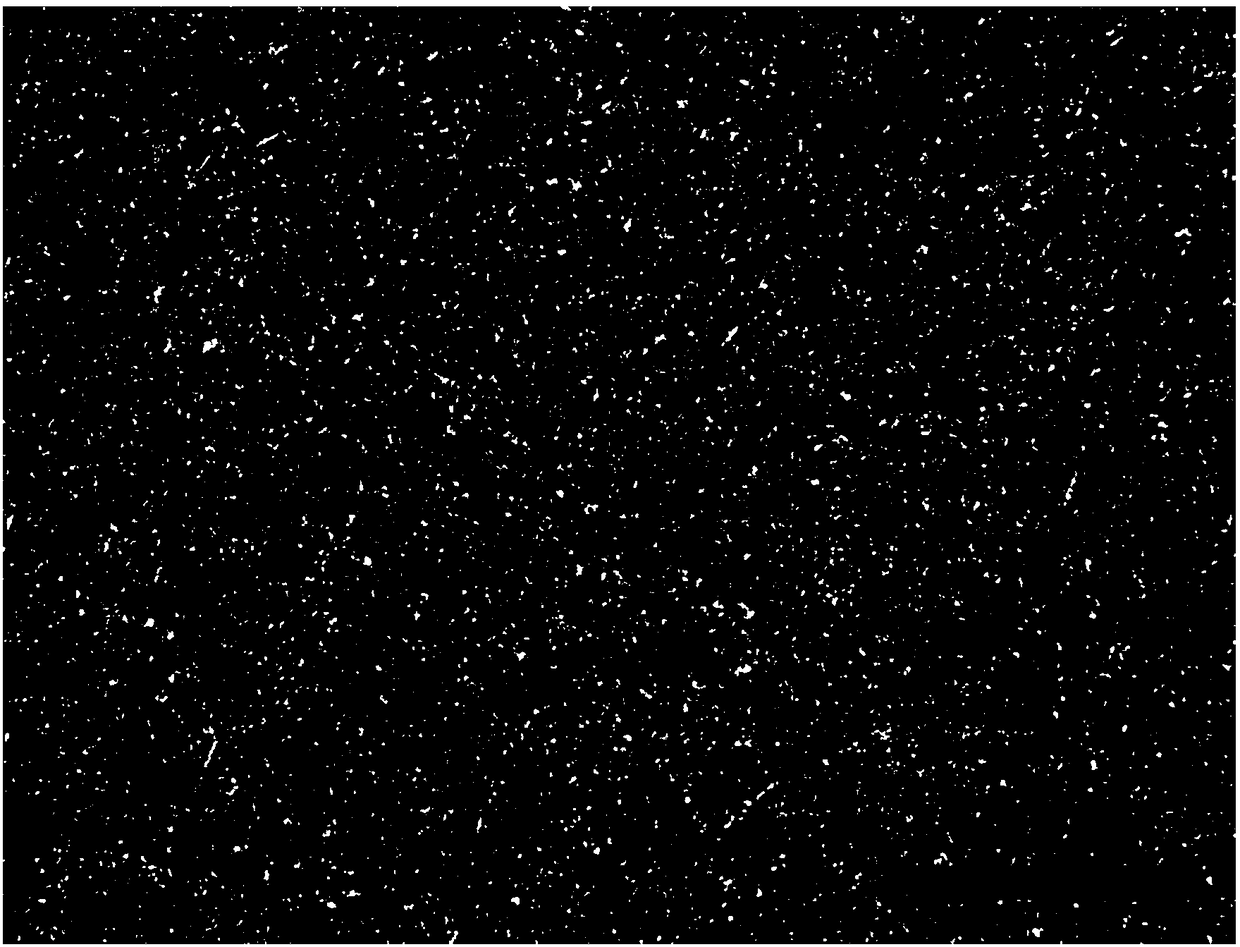

Method for preparing rubber powder-supported pavement automobile exhaust degrading composite

InactiveCN101703889ALarger than surfaceImprove adsorption capacityDispersed particle separationRolling resistanceRoad surface

The invention relates to a method for preparing a rubber powder-supported pavement automobile exhaust degrading composite, which is a method for compounding rubber powder, titanium oxide powder having a photocatalysis function and a coupling agent. Due to a characteristic of huge specific surface area, the rubber powder can be used to absorb and carry the titanium oxide powder to a maximum degree and fully absorb and collect automobile exhaust over pavements. Therefore, the method has the advantages that: the photocatalysis function of the titanium oxide is effectively protected and fully used and the efficiency of the pavement automobile exhaust degradation of the titanium oxide is improved; meanwhile, due to the high elasticity of the rubber powder and the action of the coupling agent, corresponding products have high wheel rolling resistance and rain washing resistance and the service life of the photocatalysis is prolonged. The composite can be used on surfaces of traffic facilities needing automobile exhaust degradation, such as asphalt concrete and cement concrete pavements, tunnels and culverts.

Owner:FUJIAN XINHAIWAN BUILDING MATERIALS TECH

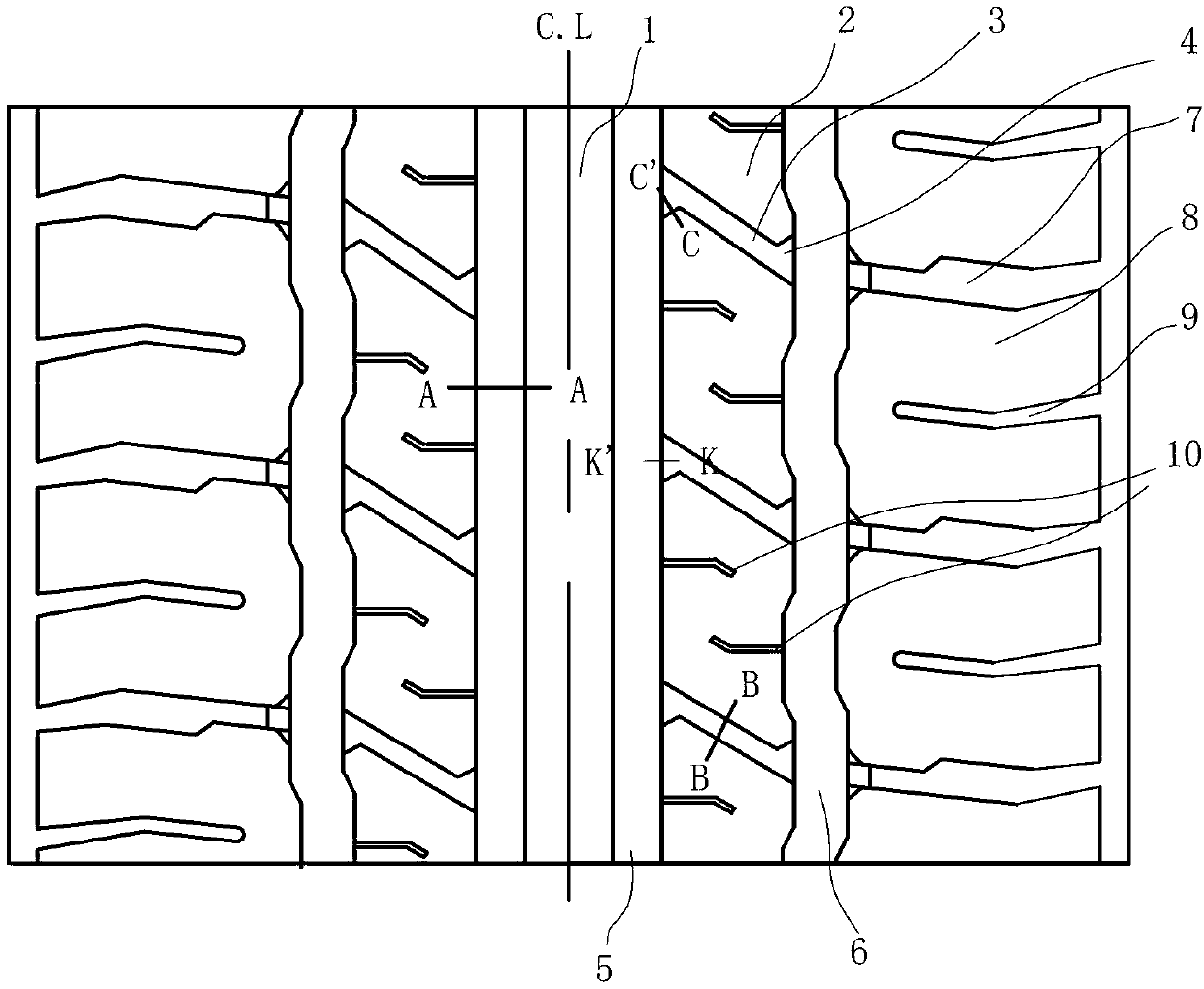

Stone-clamping preventing tyre

InactiveCN102887039AEasy to excludeImprove anti-rock performanceTyre tread bands/patternsSurface patternMain channel

Owner:CHENG SHIN RUBBER XIAMEN IND

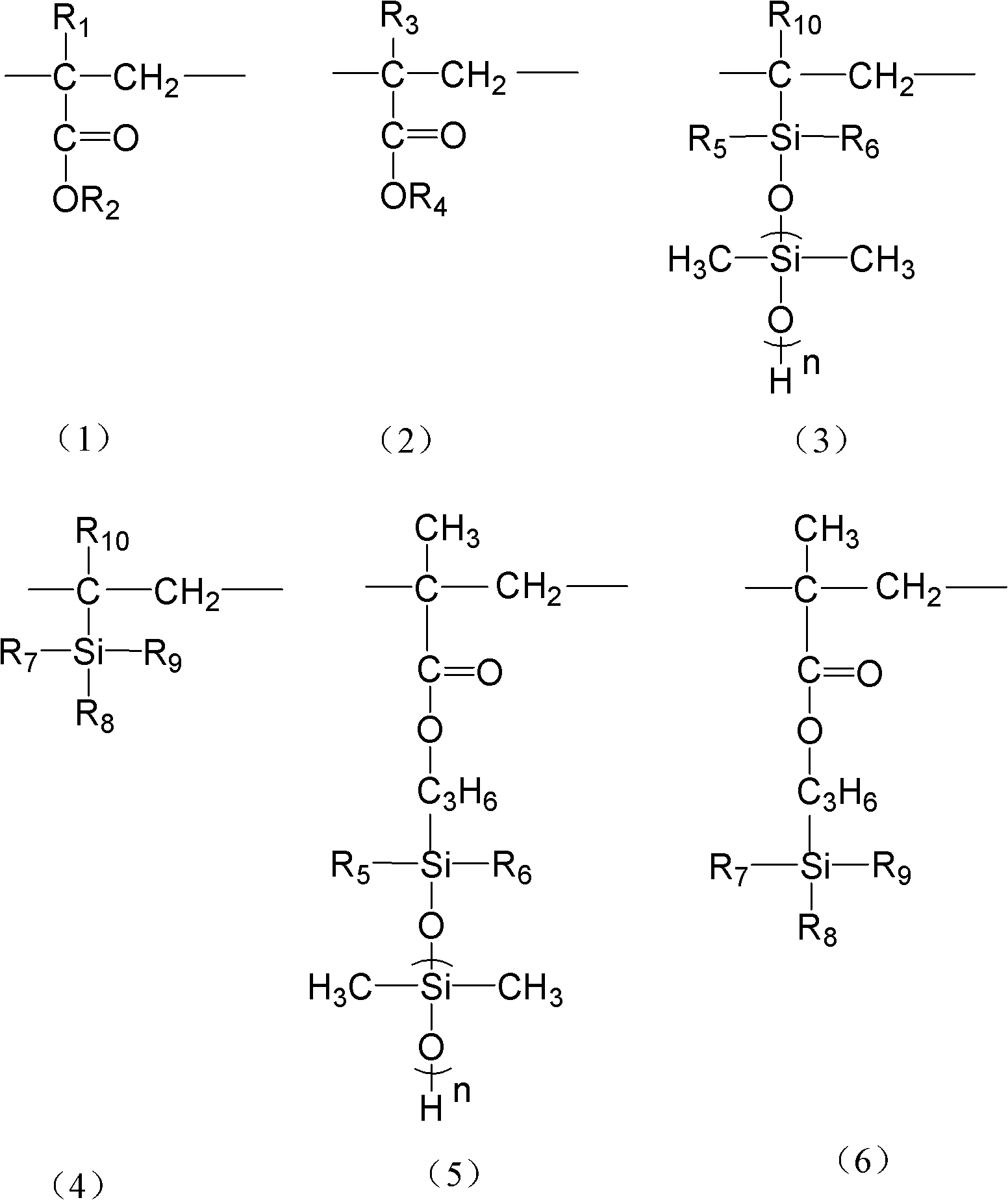

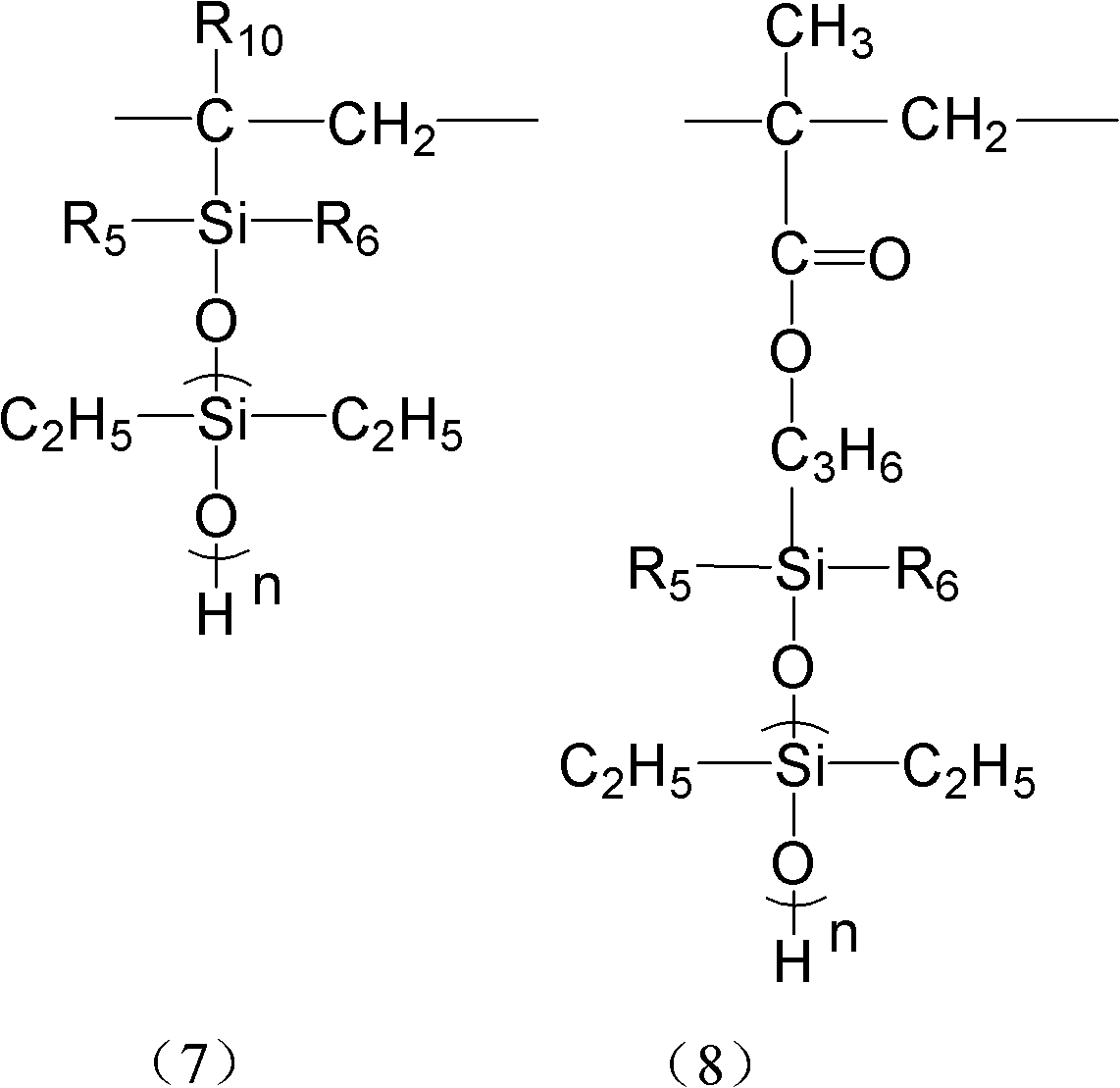

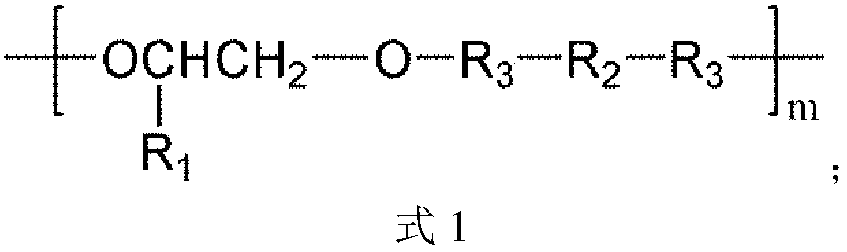

A kind of water-based organosilicon grafted (meth)acrylate polymer and its emulsion preparation method

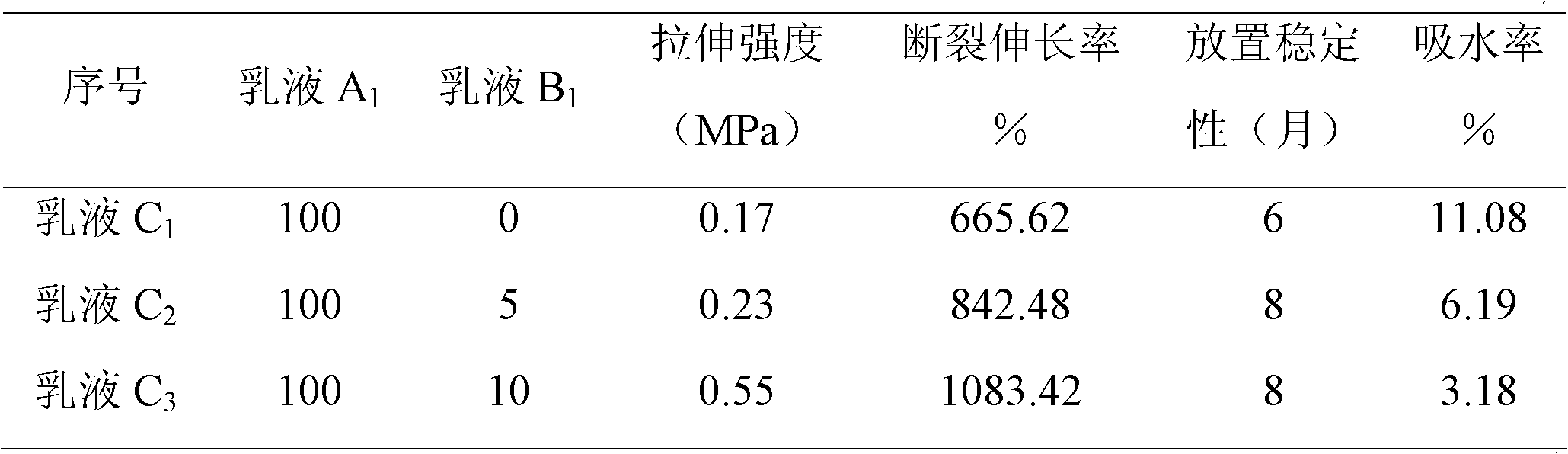

The invention discloses an aqueous organosilicon grafted (methyl) acrylic polymer and a preparation method of an emulsion thereof. The method comprises the following steps that 100 weight parts of poly(methyl)acrylate emulsion, 15-50 weight parts of polysiloxane cation emulsion and 0.1-0.5 weight part of catalyst react at 60-90 DEG C for 3-8h; and organic solvents are deprived to obtain the aqueous organosilicon grafted (methyl) acrylic polymer emulsion. The invention employs long-chain alkyl benzene sulfonic acid as a reactive emulsifier, so the emulsion has a good emulsification effect; meanwhile, an emulsion film has no residual emulsifier therein, so the emulsion has a better film performance. The final polymer emulsion has a high organosilicon content; and the grafted siloxane chain is long and is not easily embedded or covered by an acrylate main chain, so as to fully play a modification effect of the organosilicon. The operation method of the invention has low requirements of equipment and raw materials, and is beneficial for the realization of industrialized production.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

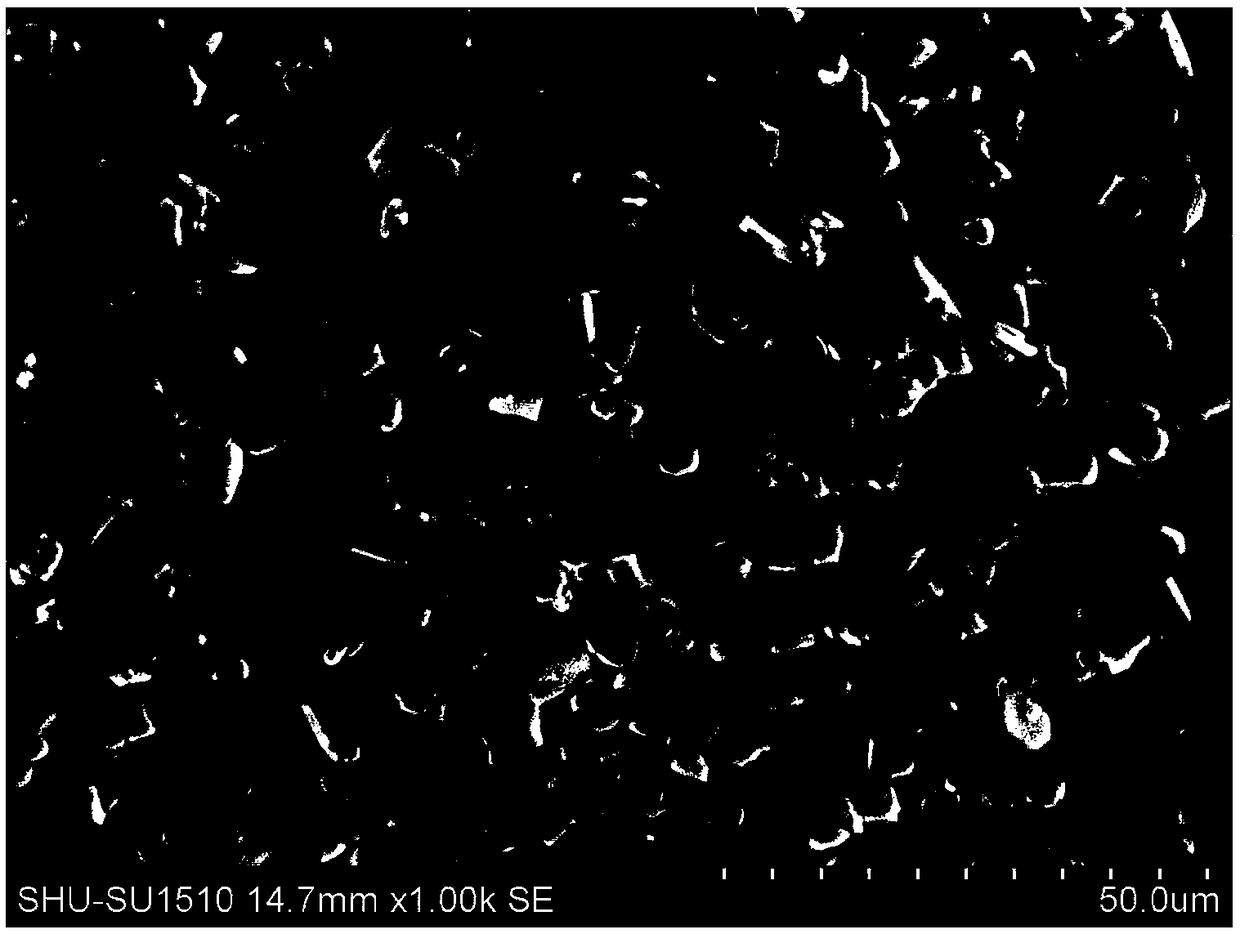

Ceramic diaphragm and preparation method and application thereof

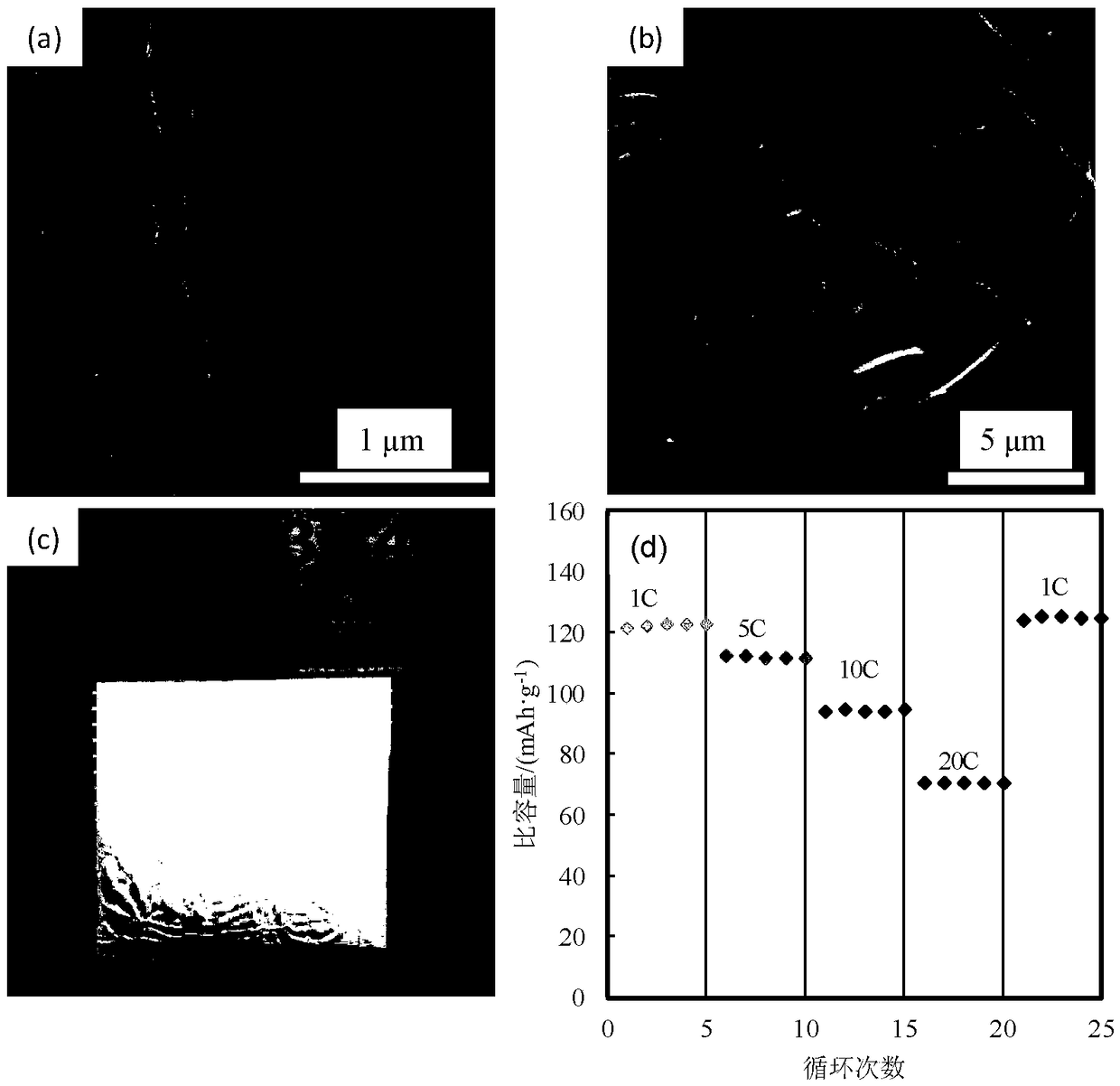

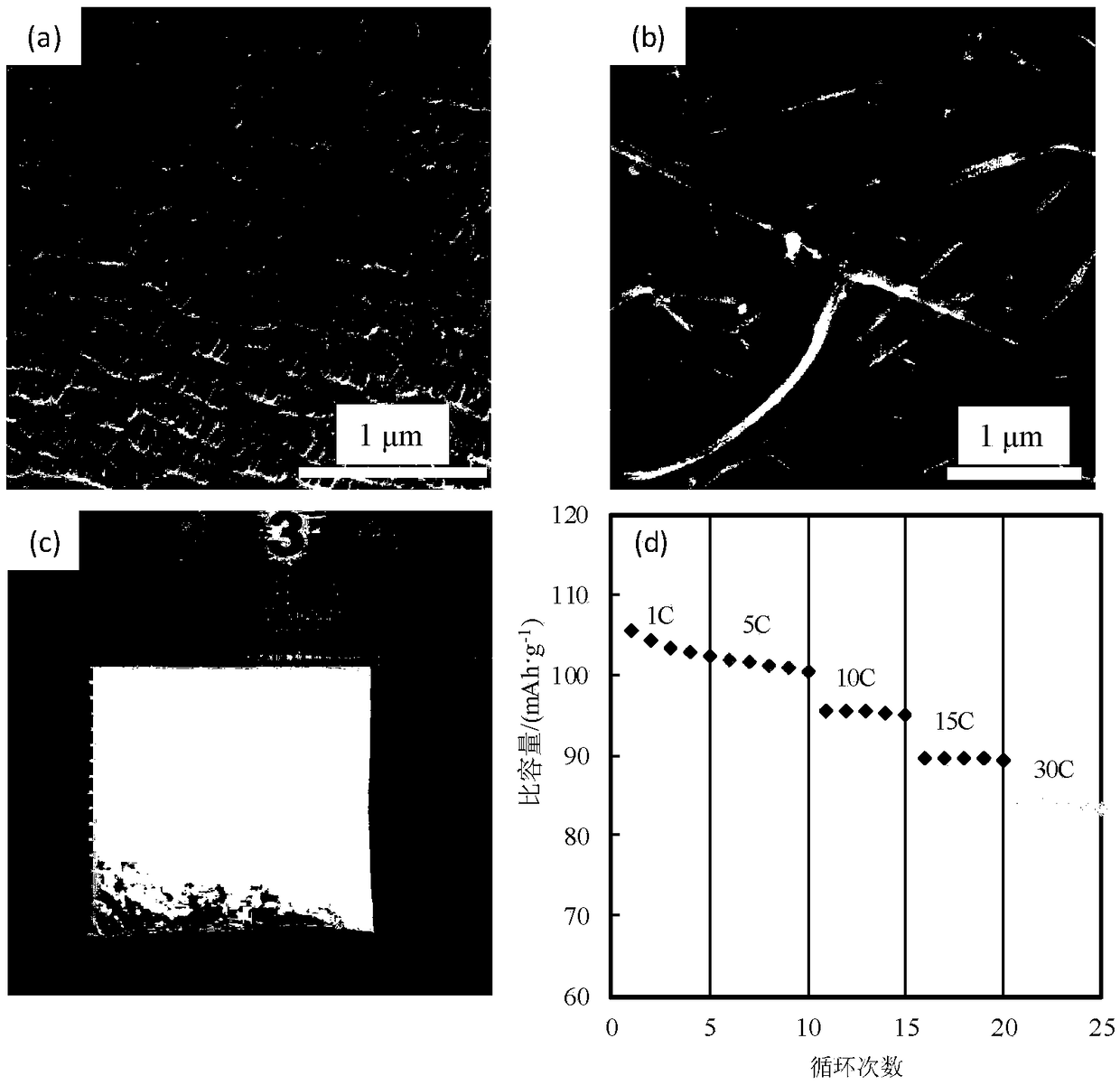

InactiveCN108695476AImprove thermal stabilityImprove heat shrink resistanceMaterial nanotechnologyCell seperators/membranes/diaphragms/spacersLithiumMetallurgy

The invention discloses a ceramic diaphragm and a preparation method and application thereof. The ceramic diaphragm comprises a substrate and a ceramic coating attached to at least one side surface ofthe substrate. The ceramic coating contains a one-dimensional nano-material and does not contain granular ceramic powder and / or ceramic powder. The one-dimensional nano-material has the diameter of 50 nm to 500 nm and the length of 100 nanometers to 100 micrometers. The surface of one side of the substrate is not coated with the ceramic coating. Each ceramic coating has thickness of 0.1 micrometers to 2 micrometers. The ceramic diaphragm contains the one-dimensional nano-material and is difficult to be inserted into micropores of the organic diaphragm substrate so that the micropore channelsare not blocked and the conduction of lithium ions of the battery in the organic diaphragm is not blocked. The one-dimensional nano-material significantly improves the thermal stability of the ceramicdiaphragm and can improve the heat shrinkage resistance of the ceramic diaphragm even in the case of coating a very thin ceramic coating.

Owner:HUNAN UNIV OF HUMANITIES SCI & TECH

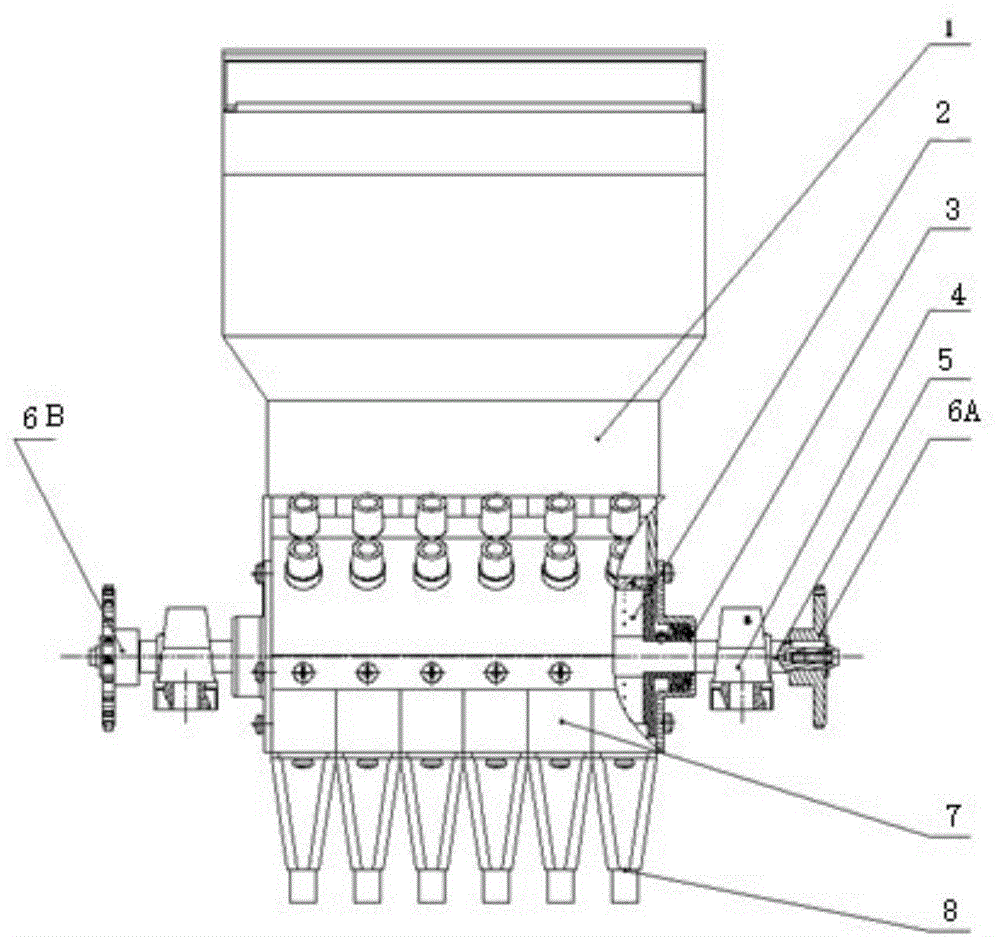

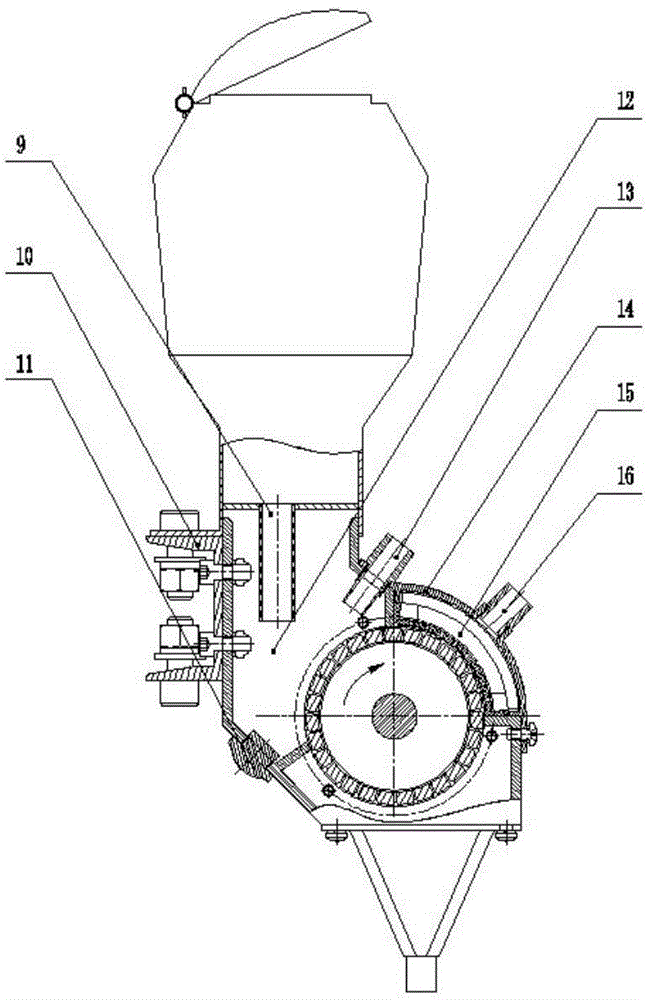

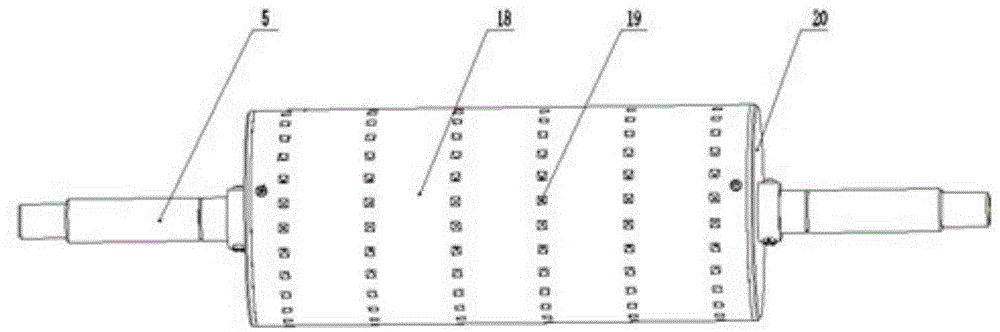

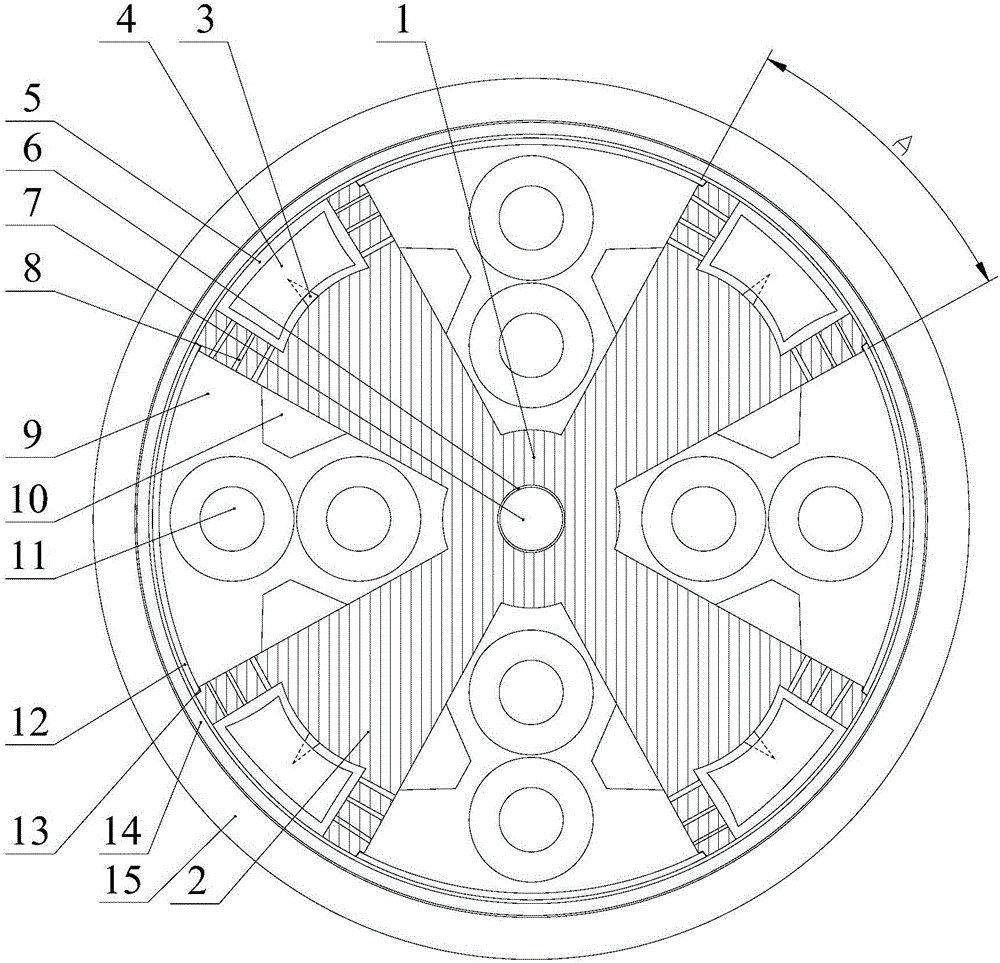

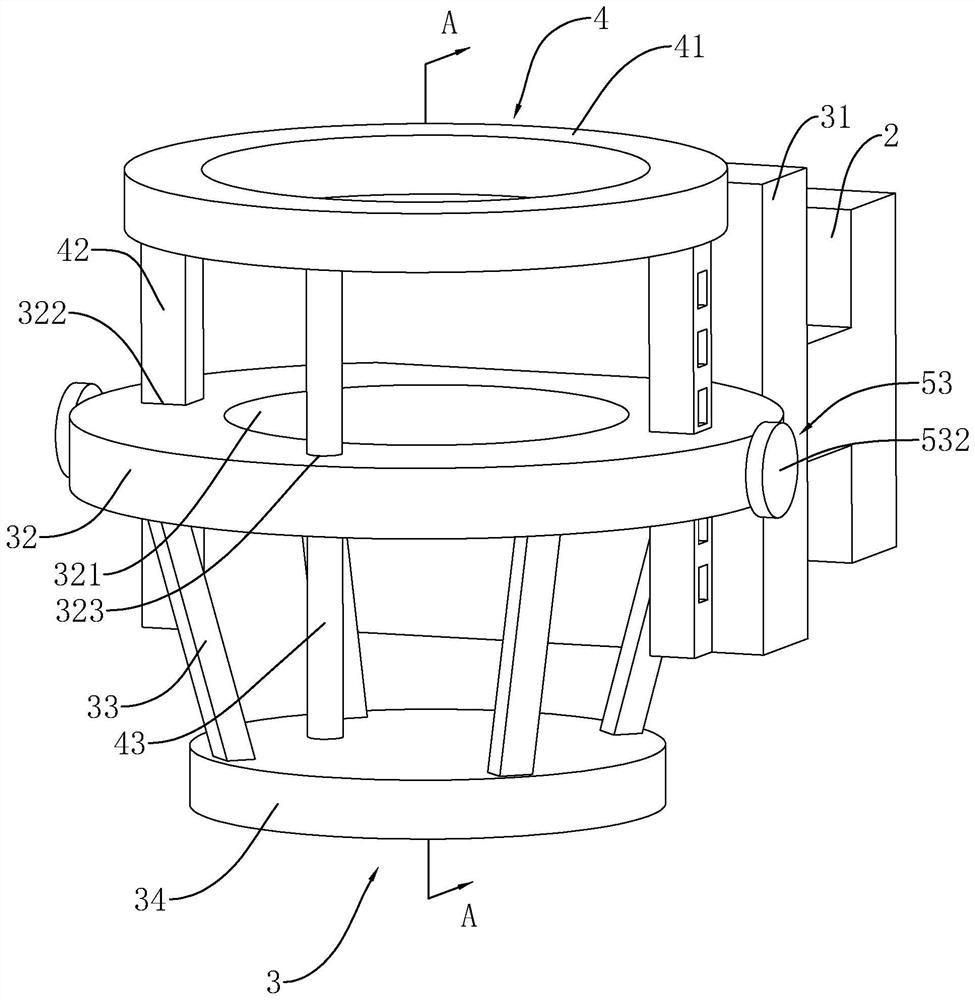

Pneumatic seed protection type precision concentrated seeding device

ActiveCN104303651AGood pickupEasy to embedSeed depositing seeder partsAgricultural engineeringAtmospheric pressure

The invention discloses a pneumatic seed protection type precision concentrated seeding device, including a seed box, a seeding roller assembly and a seed divider provided with a seed discharge plug, a seed guide tube, a shunt tube, a seed clearing mouth, a protection room plate and a pressure nozzle. The seeding roller assembly is installed in the seed divider, the seed box and the seed divider are connected through a connecting plate, the inlet of the shunt tube is located in the seed box, and a seed protective air cushion is arranged between the protection room plate and the seeding roller assembly. The invention adopts the "inverted cone" or "inverted rectangular cone" shaped hole for facilitating seed picking, at the same time when shaped hole carrying seeds passes through the pneumatic seed protection zone, the seeds are not easy to embed into the shaped hole.

Owner:HUAZHONG AGRI UNIV

Quasi-crystal abrasive paste applicable to surface mechanical finishing of soft metals

InactiveCN103242803AImprove smoothnessReduce wearOther chemical processesPolishing compositions with abrasivesSurface finishGranularity

The invention discloses a quasi-crystal abrasive paste applicable to the surface mechanical finishing of soft metals, and the adopted abrasive material thereof is a quasi-crystal alloy powder material. The quasi-crystal abrasive paste comprises a quasi-crystal alloy and related phase materials; the granularity of a powdered abrasive material is less than or equal to 50mu m; the mass percentage of the quasi-crystal powdered abrasive material in the abrasive paste is 1-90%, and the balance of the abrasive paste refers to abradant auxiliary materials such as oil-soluble or water-soluble pastes and the like. According to the invention, based on the unique grinding behavior and mechanism, the abrasive paste has an efficient mechanical finishing and defect repair capacity to the surfaces of soft metals / alloy specimens or workpieces; and compared with traditional abrasive materials, a surface finishing effect required by workpieces can be achieved efficiently, and the erosion amount is low, therefore, the abrasive paste is applicable to the surface finishing of high-precision workpieces, namely, the dimensional accuracy of workpieces can be kept while the surface quality of workpieces is satisfied. The abrasive paste disclosed by the invention has the characteristics of high stability, high liquidity, no adhesiveness and easiness for cleaning, therefore, the abrasive paste is an ideal grinding material for the mechanical finishing of soft materials.

Owner:DALIAN UNIV OF TECH

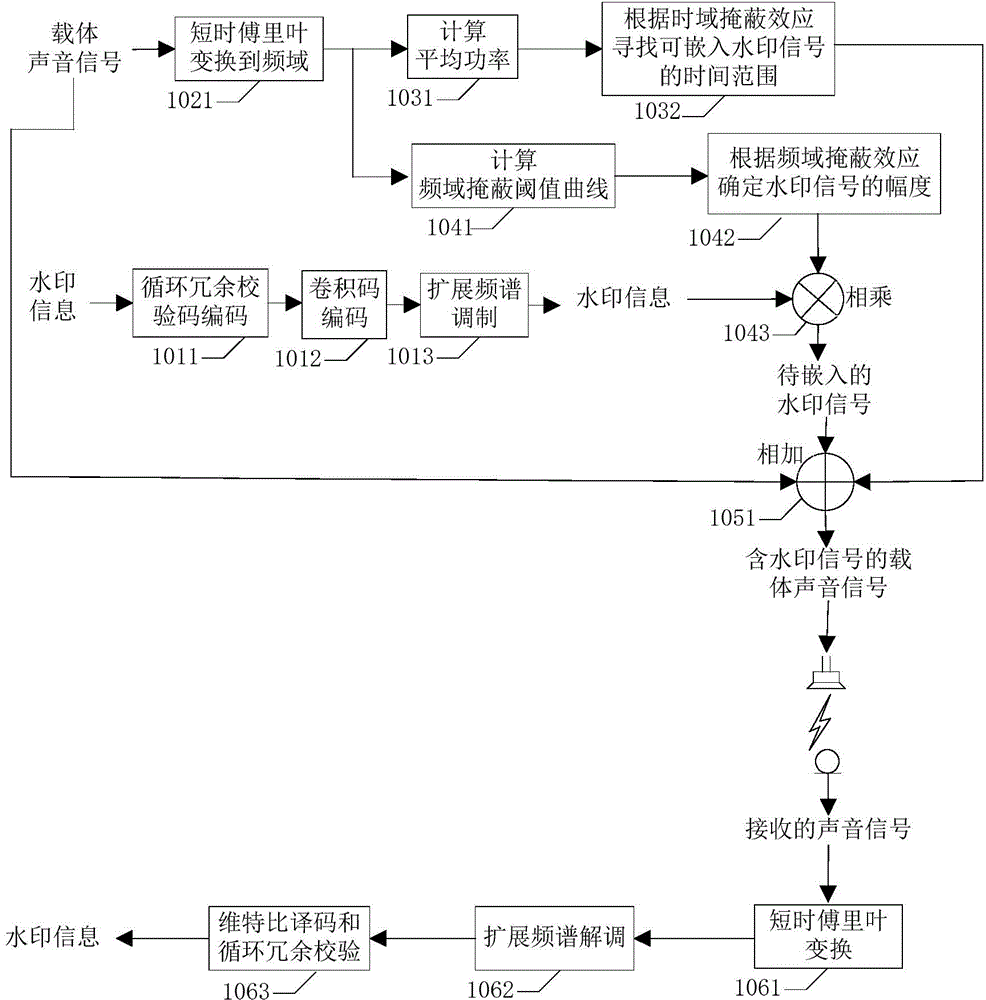

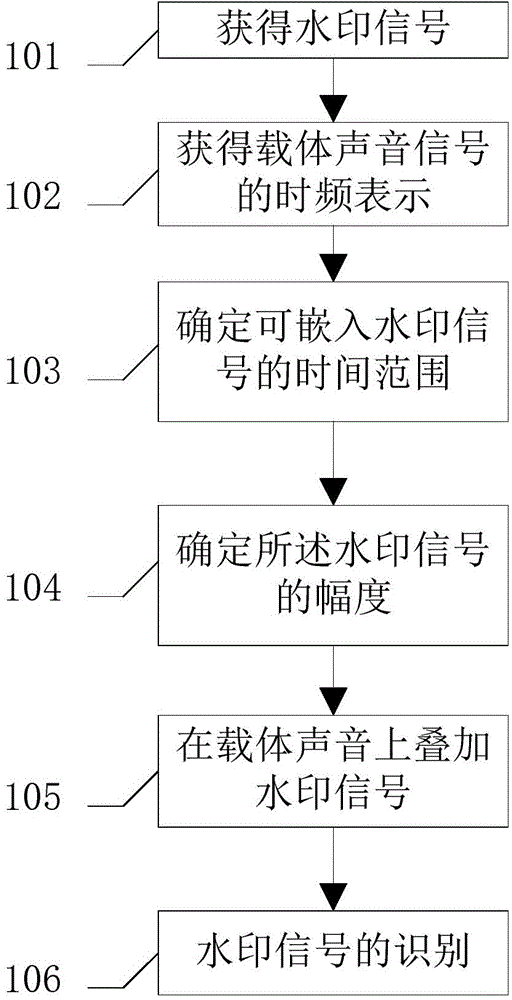

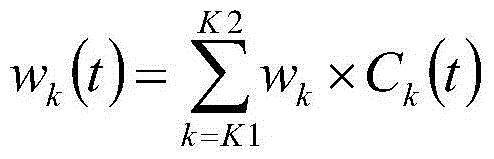

Method for embedding and recognizing broadcast audio watermark

InactiveCN104361890ASignificant watermark signal powerOccupies less frequency bandSpeech analysisTablet computerFrequency spectrum

The invention discloses a method for embedding and recognizing a broadcast audio watermark. The method includes determining a time range in which a watermark signal can be embedded according to time domain masking effect; determining amplitude of the watermark signal according to frequency domain masking effect. A microphone of wearable electronic equipment like a cellphone and a tablet computer which are portable equipment limited in operational capability and battery capacity can be used to receive voice, the watermark is restored through application software running on the wearable electronic equipment, and information can be extracted after the process of transmission with loss. The audio watermark is embedded in a frequency band audible for human ears and below 16000Hz according to the time domain masking effect and the frequency domain masking effect, in other words, the television media audio watermark technology the frequency band audible for the human ears and below 16000Hz is applied in a broadcast system. Carrier signal range for frequency spectrum modulation is expanded to be 4000-8000Hz.

Owner:江苏梦之音科技有限公司

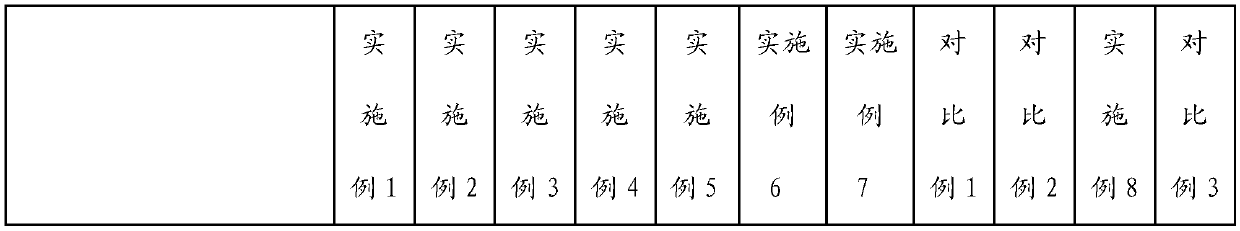

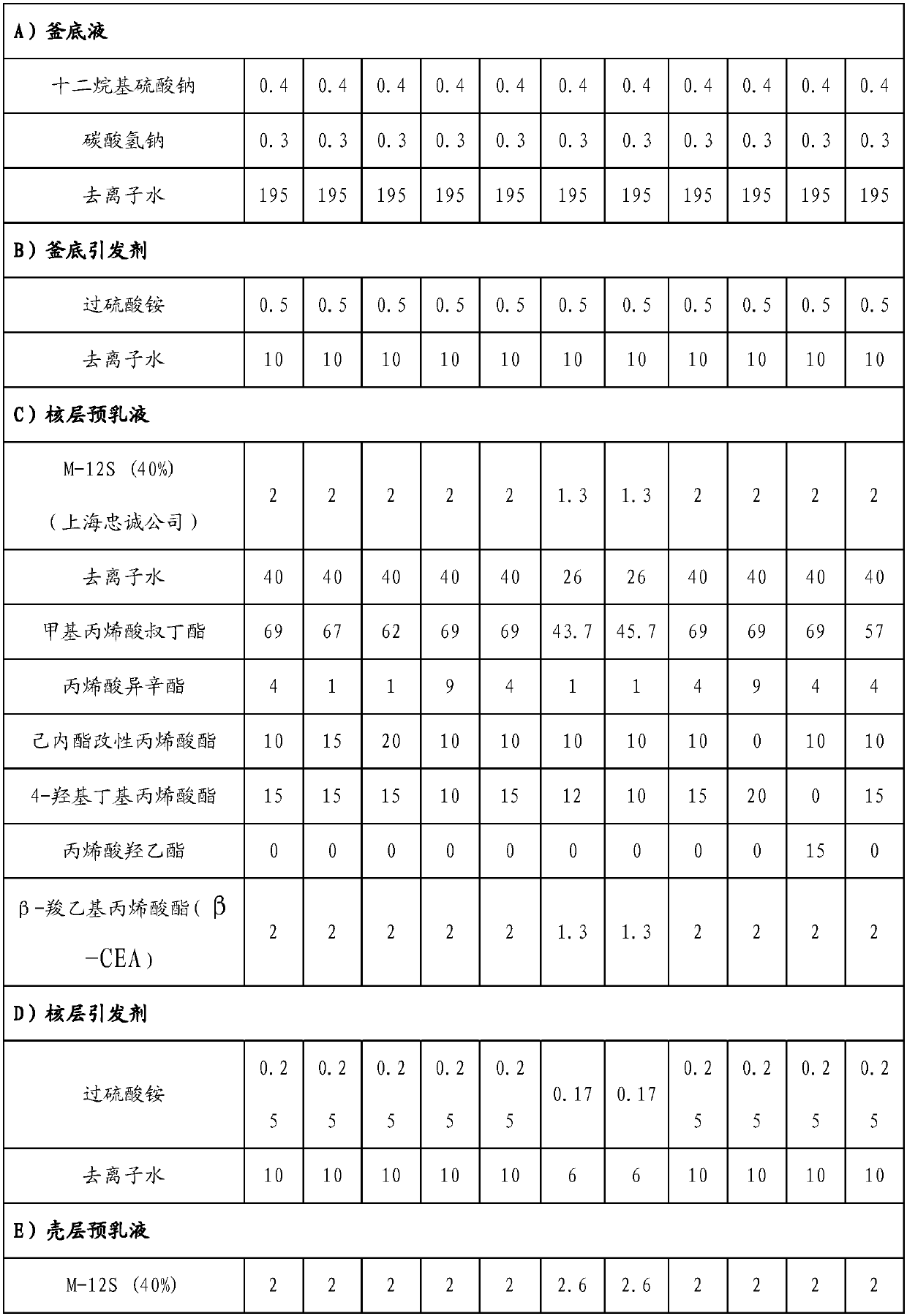

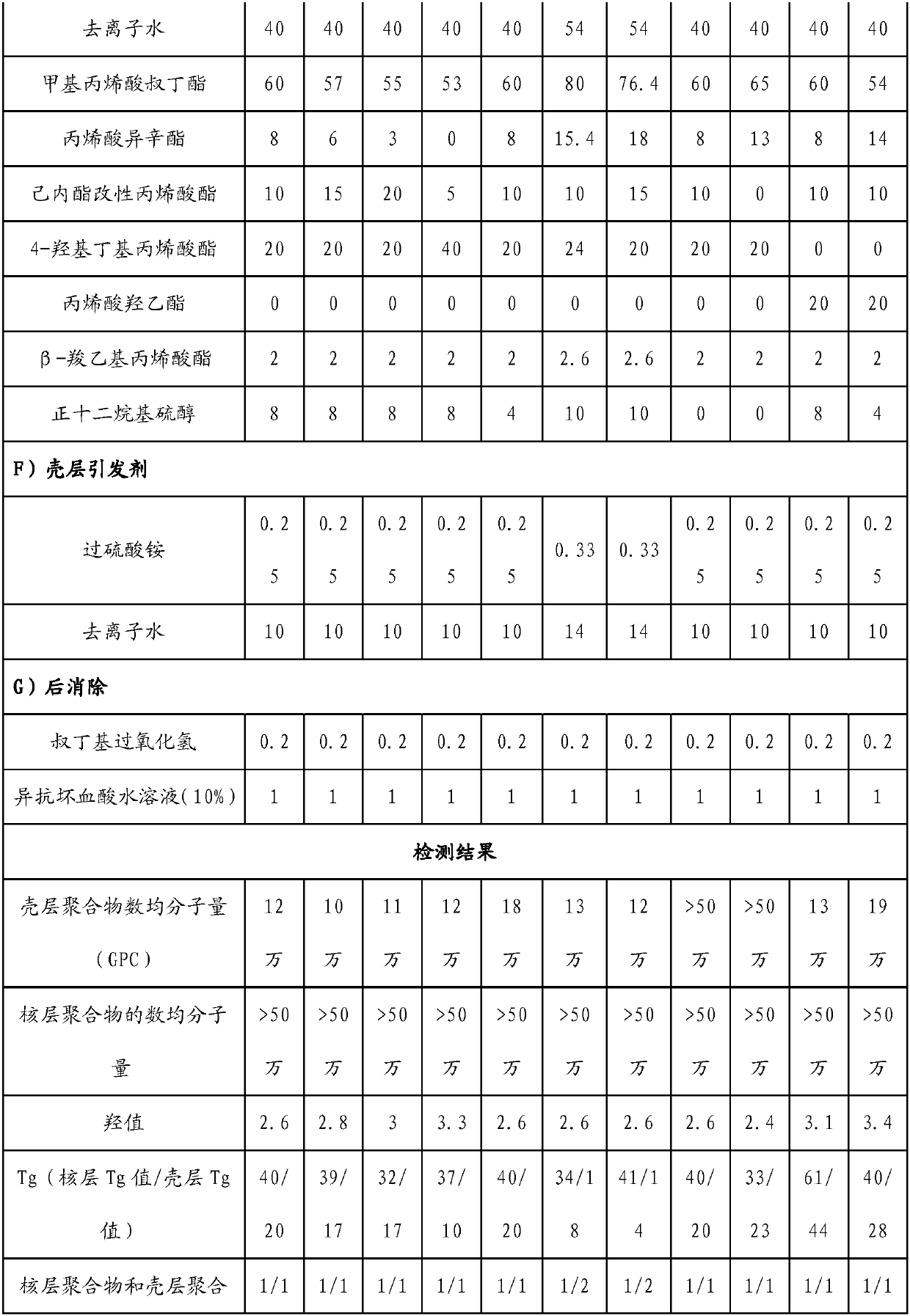

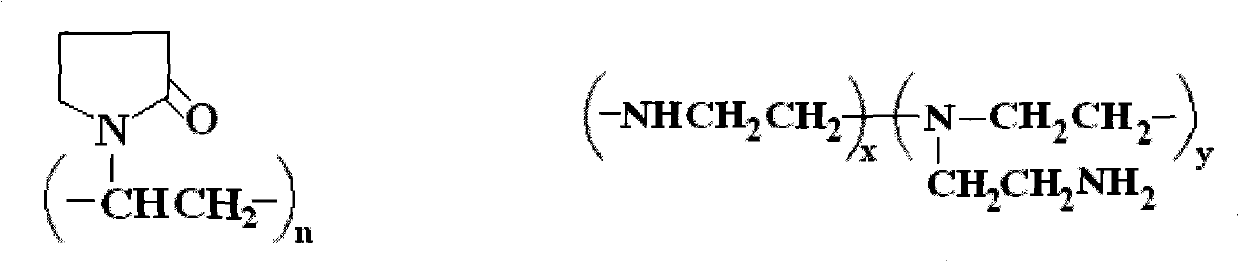

Core-shell structure acrylate emulsion, preparation method and applications thereof

ActiveCN109929067ANot easy to embedPromote mutual integrationAnti-corrosive paintsPolymer scienceEmulsion

The invention provides a core-shell structure acrylate emulsion, a preparation method and applications thereof, wherein the shell-layer polymer of the core-shell structure acrylate emulsion has a number average molecular weight of 50000-250000, the number average molecular weight of the core-layer polymer is greater than the number average molecular weight of the shell-layer polymer, the shell-layer polymer and / or the core-layer polymer has a hydroxyl functional group, and the shell-layer monomer for preparing the shell-layer polymer and the core-layer monomer for preparing the core-layer polymer respectively comprise a caprolactone-modified acrylate monomer. According to the present invention, the coating material prepared based on the core-shell structure acrylate emulsion has low VOC, and the paint film has characteristics of good gloss, chemical resistance, impact resistance and the like.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +2

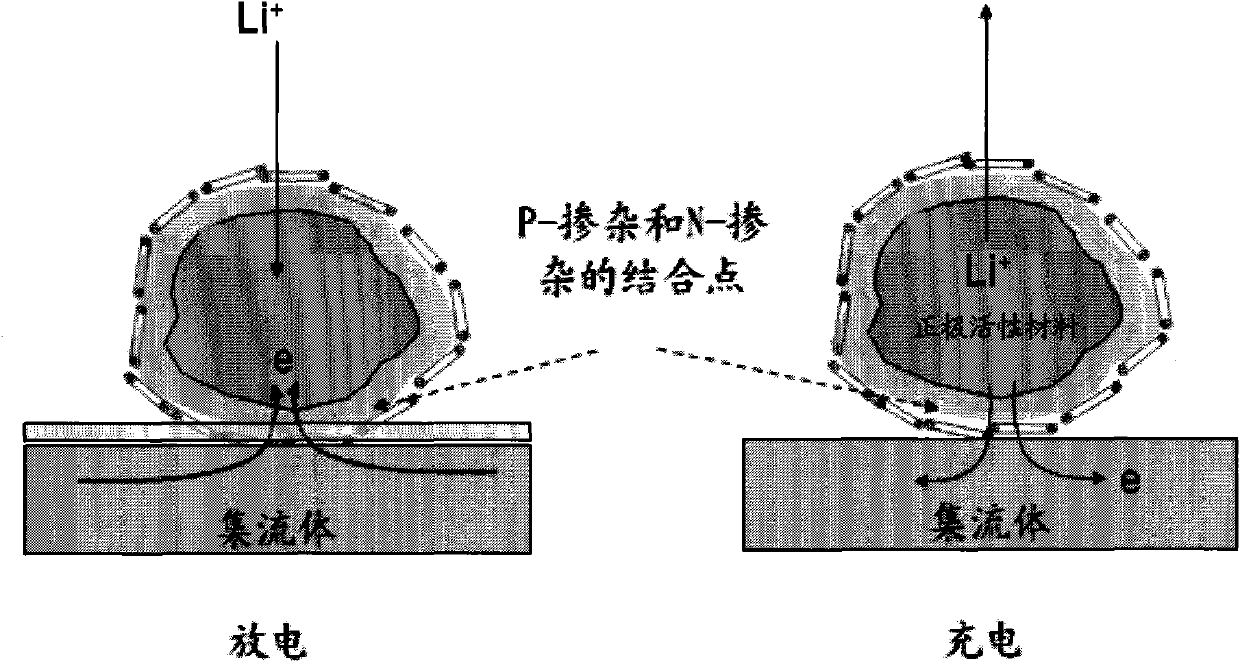

Lithium ion battery anode plate, preparation method thereof and lithium ion battery using lithium ion battery anode plate

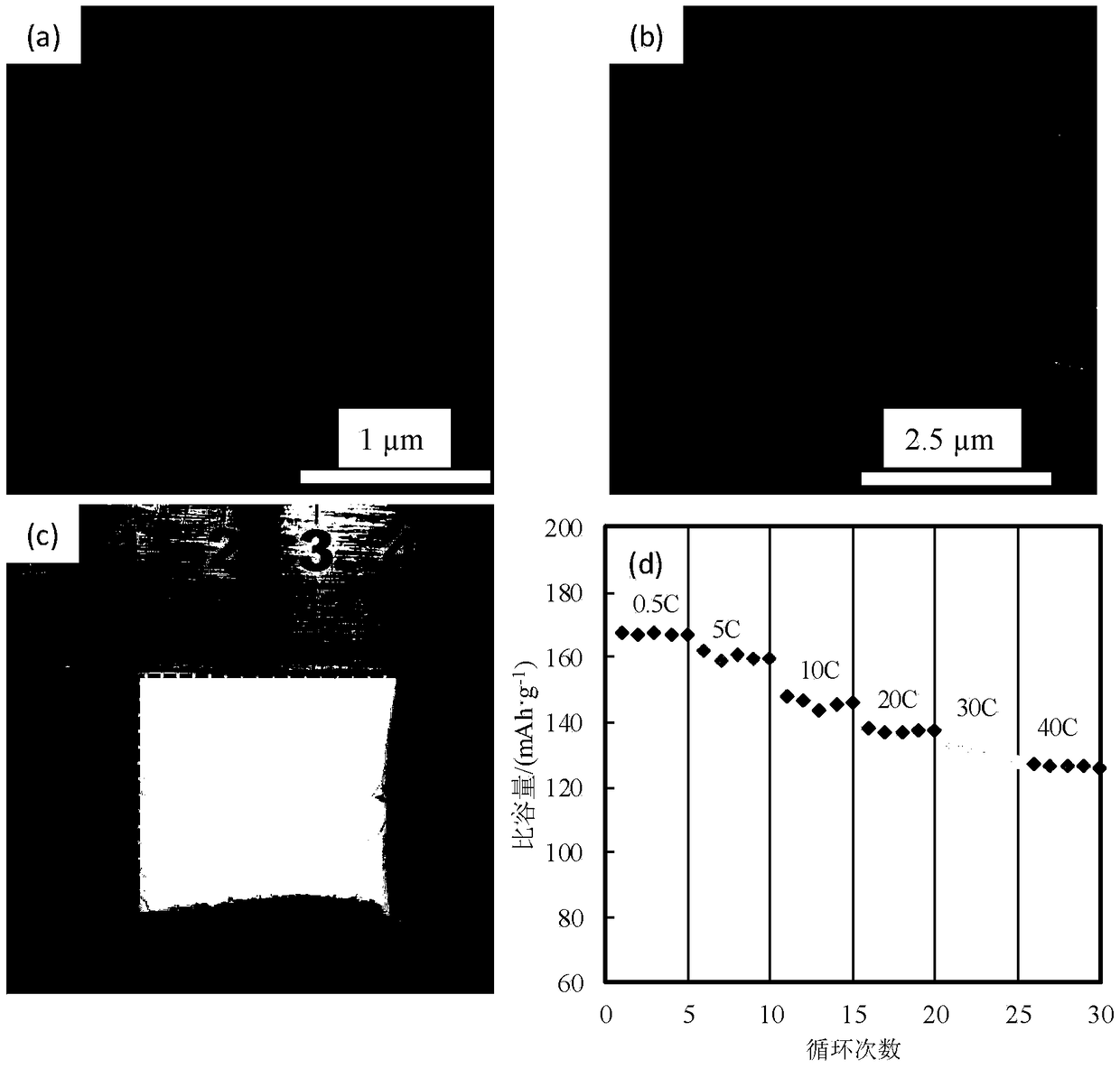

ActiveCN102024952AImprove securityRealize high current dischargeElectrode carriers/collectorsSecondary cellsElectrical batteryNano carbon

The invention discloses a lithium ion battery anode plate which comprises an anode current collector and anode active materials distributed on the anode current collector, wherein the anode active materials contain P-type doped nano carbon tubes and N-type doped nano carbon tubes. The P-type doped nano carbon tubes and N-type doped nano carbon tubes, which are added into the lithium ion battery anode plate, can improve the conductivity of the anode in the processes of charging and discharging, and enhance the safety of the lithium ion battery, thereby realizing heavy-current discharge of the lithium ion battery. In addition, the invention also discloses a preparation method of the lithium ion battery anode plate and a lithium ion battery using the lithium ion battery anode plate.

Owner:NINGDE AMPEREX TECH

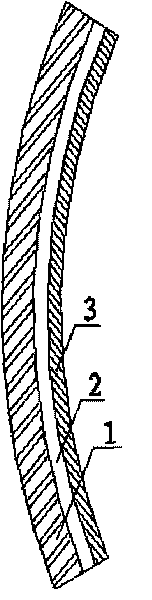

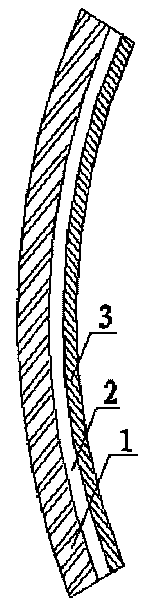

Retardation film, method for producing retardation film, polarizing plate, and liquid crystal display device

ActiveCN104040385AExcellent roll stabilityIncrease contrastSynthetic resin layered productsPolarising elementsLiquid-crystal displayPolarizer

The present invention addresses the problem of providing: a retardation film which has high contrast and exhibits excellent wound state stability during the production of a long laminated roll; a method for producing the retardation film; and a polarizing plate and a liquid crystal display device, each of which is provided with the retardation film. A retardation film of the present invention contains a cellulose acylate that has a degree of substitution of acetyl groups within the range of 2.0-2.5, and is characterized in that if one surface of the retardation film is referred to as surface A and the other surface of the retardation film is referred to as surface B, the Martens hardness of surface A and the Martens hardness of surface B are both within the range of 190-210 N / mm2, and the arithmetic mean roughness (Ra) of surface A and the arithmetic mean roughness (Ra) of the surface B are both within the range of 0.5-2.0 nm.

Owner:KONICA MINOLTA INC

Durable concrete tiles

The invention discloses durable concrete tiles. The durable concrete tiles are prepared from the raw materials in parts by weight: 100-200 parts of cement, 80-100 parts of natural river sand, 200-300 parts of limestone rubble, 10-35 parts of illite, 5-25 parts of chlorite, 2-10 parts of phosphorite powder, 10-25 parts of vitrified microbeads, 3-15 parts of pumice, 3-12 parts of fly ash, 2-10 parts of silicon micropowder, 10-30 parts of natural zeolite ultrafine powder, 1-5 parts of silicon carbide, 0.5-2 parts of water reducing agent, 0.1-0.5 part of alkyl glycoside, 0.1-0.3 part of rosin, 0.1-0.28 part of magnesium carbonate, 0.1-0.38 part of calcium sulfoaluminate, 0.5-2 parts of basalt fibers, 0.3-1.5 parts of polyvinyl alcohol fibers, 0.2-1.5 parts of steel fibers, 0.5-2.5 parts of methyltrichlorosilane and 30-50 parts of water.

Owner:安徽城洁环境科技有限公司

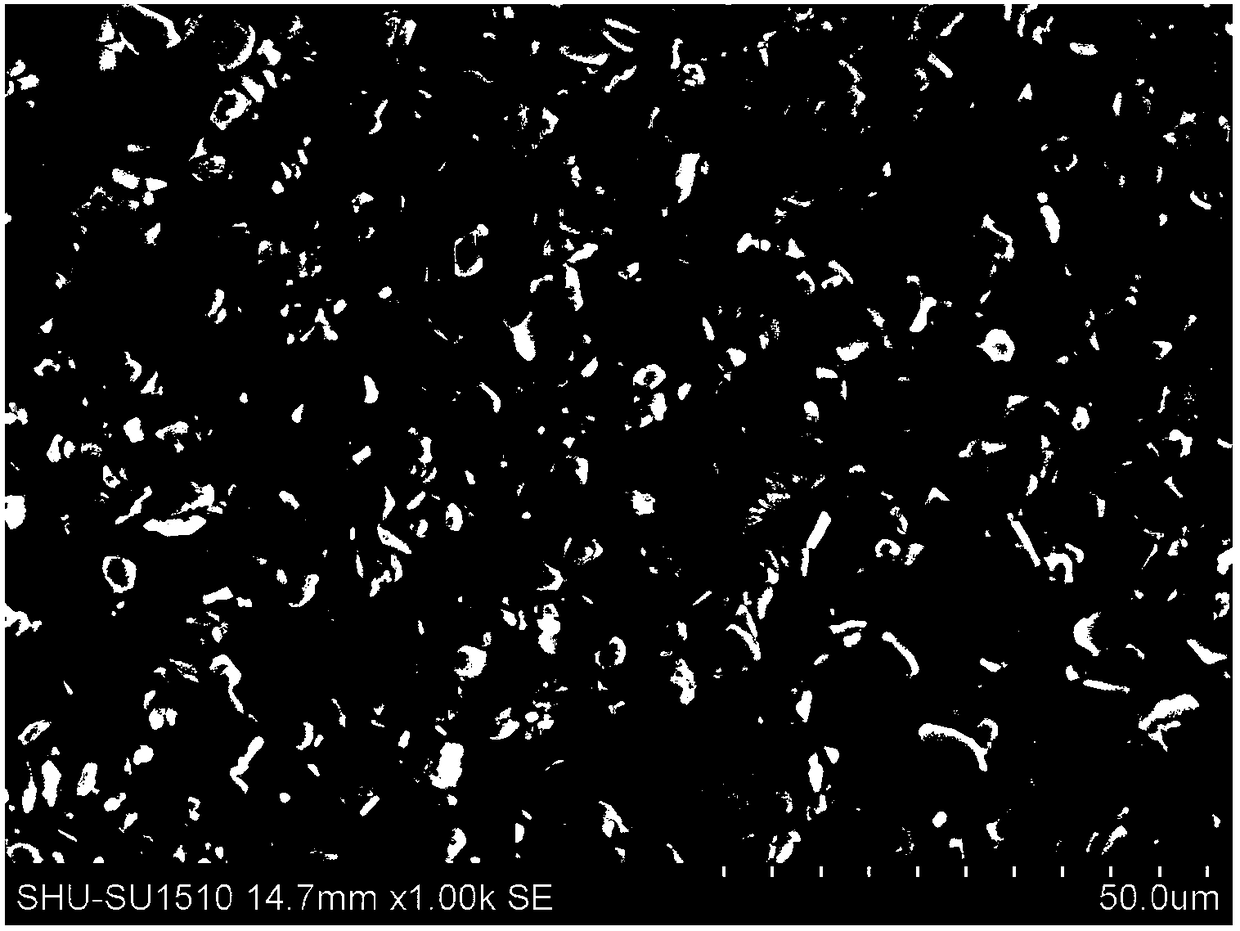

Abrasive for grinding and polishing of tellurium-zinc-cadmium soft and crispy wafers

InactiveCN108587567AGood chemical stabilitySuitable for precision grinding and polishing processOther chemical processesStrong acidsTe element

The invention brings forward an abrasive for grinding and polishing of tellurium-zinc-cadmium soft and crispy wafers. The crystal form of the abrasive is alpha-alumina, and particle shape is regular plate-like; particle size D50 is 2-9 microns, D90 is no higher than 10 microns, D10 is no lower than 1.5 microns, and plate thickness is 0.9-2.2 microns; and the abrasive will not be settled or flocculated in a suspension. In particular the abrasive has strong chemical stability, is suitable for a strong acid and strong alkali environment, is greatly suitable for precision grinding and polishing process of tellurium-zinc-cadmium soft and crispy wafers, is not easy to insert wafers, is not easy to cause scratches, and has high removal rate.

Owner:镇江爱豪科思电子科技有限公司

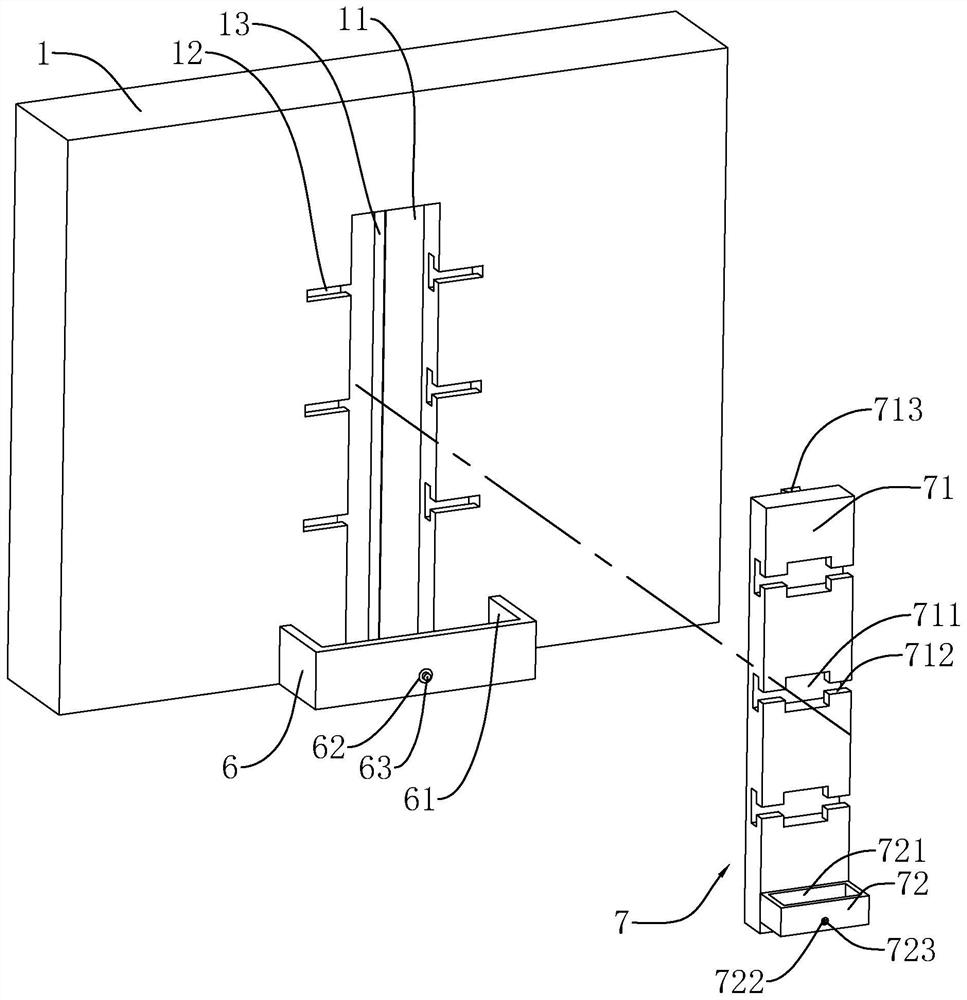

Slot-type embedded part and application node structure of same

The invention discloses a slot-type embedded part and an application node structure of the slot-type embedded part. The slot-type embedded part comprises a slot-type connecting portion, a plurality of anchor bars and a plurality of T-shaped bolts. The slot-type connecting portion comprises a waistline, two supporting legs, and two blocking portions. The first ends of the two supporting legs are connected with the top and the bottom of the waistline. The first ends of the two blocking portions are connected with the second ends of the two supporting legs. The second ends of the two blocking portions bend toward the middle part of the waistline, and a distance is between the second ends. The two supporting legs and the two blocking portions are on the same side of the waistline. The first end of the anchor bar is connected with a side of the waistline. The T-shaped bolt comprises a screw, an abutting and clamping portion, and a nut. The abutting and clamping portion is vertically connected with the first end of the screw. The length of the abutting and clamping portion is larger than the distance and smaller than the distance between the two supporting legs. The axial dimension of the abutting and clamping portion is smaller than the distance. The surface of the screw is provided with threads. The nut is sleeved on the screw from the second end of the screw through the threads.

Owner:DUOWEI UNION GRP

Method for manufacturing solar cell electrode

ActiveCN106549081AImprove photoelectric conversion efficiencyNot easy to embedPhotovoltaic energy generationSemiconductor devicesSlurryBiological activation

The invention relates to the field of a solar cell, and discloses a method for manufacturing a solar cell electrode. The method comprises the following steps of (1) coating the surface of a solar cell silicon wafer with metal slurry containing a transitional metal complex; (2) performing optical curing on a region, where an electrode needs to be formed, on the surface of the solar cell silicon wafer coated with the metal slurry, so as to enable the metal slurry on the region to be subjected to an optical curing reaction; (3) immersing the optically-cured solar cell silicon wafer by a developing medicinal liquid to dissolve the metal slurry on the non-optically-cured region in the developing medicinal liquid to form an electrode pattern; and (4) performing high-temperature sintering on the product obtained in the step (3), and carrying out surface activation and surface metallization on the electrode pattern in sequence. By adoption of the method provided by the invention, the cost is greatly lowered, the production efficiency is improved, and the photoelectric conversion efficiency of a solar cell corresponding to the obtained solar cell electrode is relatively high.

Owner:BYD CO LTD

Flashing formwork and formwork frame

PendingCN112252711ANot easy to embedPrevent leakageForms/shuttering/falseworksRebarMechanical engineering

Owner:SNTO TECH GRP

Data cable

ActiveCN106098200AImprove structural strengthAffect qualityQuad constructionsInsulated cablesEngineering

The invention discloses a data cable, which comprises a skeleton body, four groups of stranded wire pairs, solid rat expelling blocks, four covering plates, a waterproof layer and a sheath, wherein the skeleton body comprises four fan-shaped parts; an accommodating cavity is formed between two adjacent fan-shaped parts; an arc-shaped side wall of each fan-shaped part is provided with an installation groove; the four groups of stranded wire pairs are arranged in the corresponding accommodating cavities respectively; the solid rat expelling blocks are arranged in the corresponding installation grooves; the four covering plates cover the corresponding accommodating cavities respectively; the waterproof layer coats the outer sides of the skeleton body and the covering plates; and the sheath coats the outer side of the waterproof layer. The fan-shaped parts can be effectively utilized to form the installation grooves for arranging the solid rat expelling blocks, so that the space utilization rate can be effectively improved in comparison with independent arrangement of a rat expelling layer; and openings of the accommodating cavities are relatively large, and the condition that the quality of the data cable is affected because the waterproof layer is embedded in the accommodating cavities can be avoided through the arrangement of covering plates.

Owner:HANGZHOU FUTONG ELECTRIC WIRE & CABLE

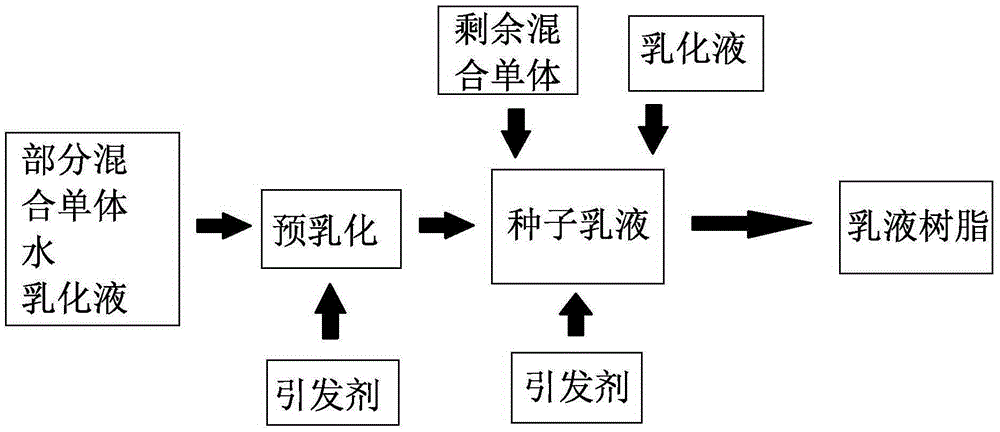

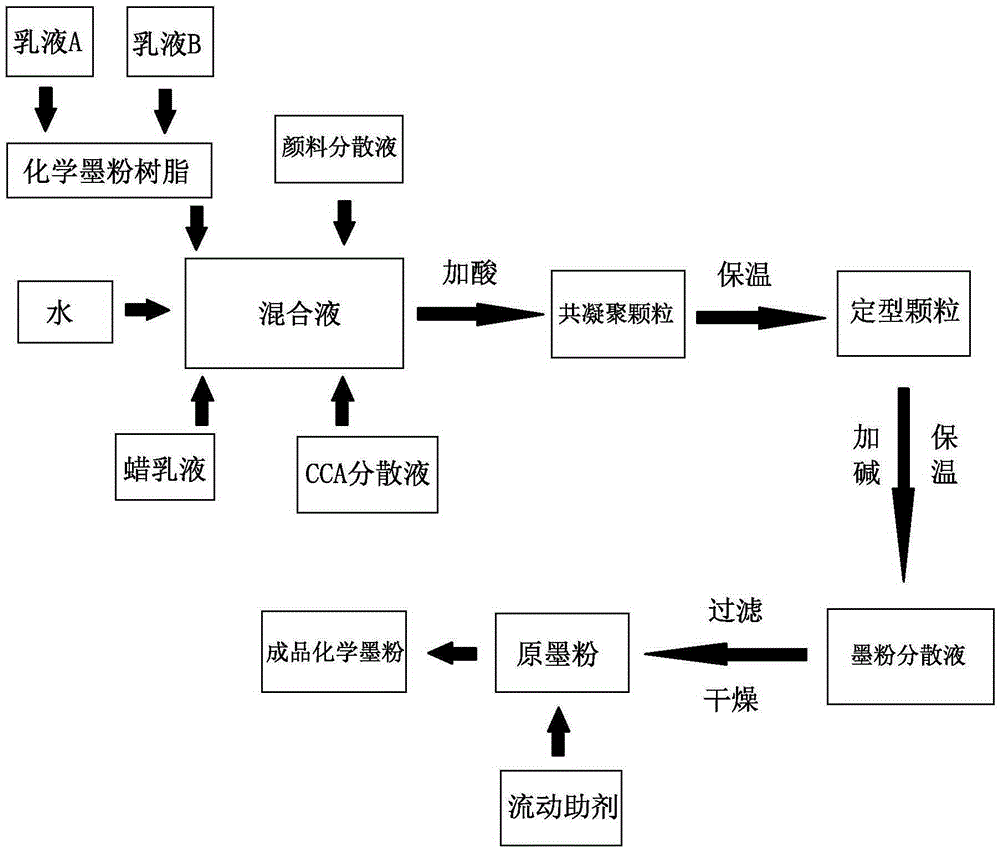

Preparation method for low-temperature fixing chemical ink powder resin and method for preparing ink powders

The invention belongs to the field of ink powders, and relates to a preparation method for low-temperature fixing chemical ink powder resin and a method for preparing ink powders. The preparation method for low-temperature fixing chemical ink powder resin comprises the steps of: 1, preparing a seed emulsion; 2, preparing low-molecular and high-molecular low-temperature fixing emulsion resin; and 3, proportioning the low-molecular and high-molecular low-temperature fixing emulsion resin and adjusting the solid content to 33.0% to obtain low-temperature fixing chemical link powder resin. The method for preparing ink powders comprises the steps of: taking 20-50% of low-temperature fixing chemical link powder resin, 1-5% of a pigment, 1-3% of a CCA dispersion liquid, 1-3% of a wax emulsion and 40-70% of water; adding dilute sulphuric acid; raising the temperature and keeping the temperature for 1-3 hours; adding sodium hydroxide to adjust the pH to 6-8; and then raising the temperature, keeping the temperature, reducing the temperature and drying the mixture to obtain finished product low-temperature fixing chemical ink powders. The preparation method provided by the invention is environmentally-friendly and pollution-free in production process and low in production cost, and is suitable for preparing the low-temperature fixing chemical ink powders; the prepared ink powders are suitable for a majority of low-temperature fixing energy-saving laser printers / copiers, and are good in fixing effect, high in transfer rate, excellent in color density and excellent in electrical property.

Owner:鼎龙(宁波)新材料有限公司

Method for preparing rubber powder-supported pavement automobile exhaust degrading composite

InactiveCN101703889BLarger than surfaceImprove adsorption capacityDispersed particle separationRolling resistanceRoad surface

The invention relates to a method for preparing a rubber powder-supported pavement automobile exhaust degrading composite, which is a method for compounding rubber powder, titanium oxide powder having a photocatalysis function and a coupling agent. Due to a characteristic of huge specific surface area, the rubber powder can be used to absorb and carry the titanium oxide powder to a maximum degreeand fully absorb and collect automobile exhaust over pavements. Therefore, the method has the advantages that: the photocatalysis function of the titanium oxide is effectively protected and fully used and the efficiency of the pavement automobile exhaust degradation of the titanium oxide is improved; meanwhile, due to the high elasticity of the rubber powder and the action of the coupling agent, corresponding products have high wheel rolling resistance and rain washing resistance and the service life of the photocatalysis is prolonged. The composite can be used on surfaces of traffic facilities needing automobile exhaust degradation, such as asphalt concrete and cement concrete pavements, tunnels and culverts.

Owner:FUJIAN XINHAIWAN BUILDING MATERIALS TECH

Welding method for winding rotors and head combining sleeve

The invention relates to a welding method for winding rotors and a head combining sleeve and belongs to the field of motor manufacturing processes. According to the welding method, motor rotor coils are embedded in a rotor iron core, end heads of the motor rotor coils are sleeved with a head combining sleeve; then the rotors are hoisted onto a welding workbench and horizontally placed; the insulating portions, close to the head combining sleeve, of the motor rotor coils are wrapped by a circle of waterishlogged asbestos rope; an electrode holder is wrapped by one to two layers of glass tapes; then the electrode holder clamps the head combining sleeve; welding is performed through a medium-frequency welding machine; before the head combining sleeve becomes completely red, a silver solder with the silver content being 15% is used for painting a gap between the head combining sleeve and the motor rotor coils one time; and after the head combining sleeve becomes completely red, the gap between the head combining sleeve and the motor rotor coils and the end faces of the head combining sleeve and the motor rotor coils are uniformly and smoothly painted with silver solder and soldering flux. The welding method achieves the purposes that the welding time is short, the work efficiency is high, insulating damage is small, welding is thorough, and process reliability is good.

Owner:NANTONG JINCHI MECHANICAL ELECTRIC

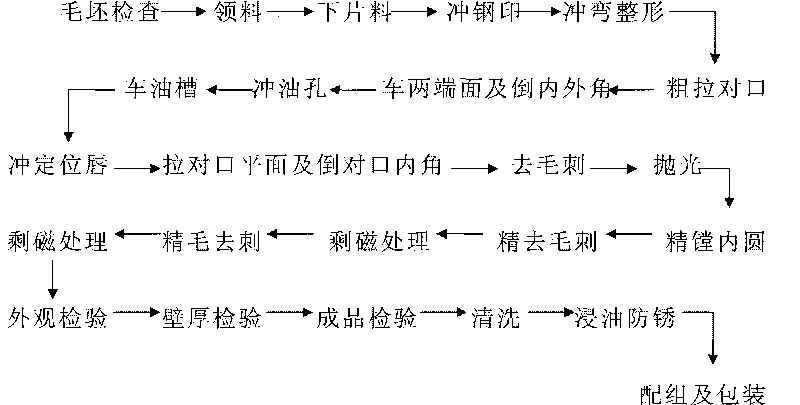

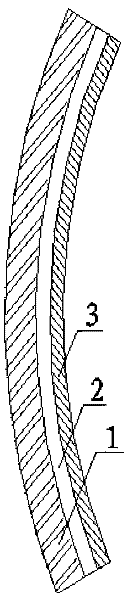

Sparingly soluble bearing of engine

InactiveCN101718303AChange wear resistanceImprove carrying capacityBearing componentsBiochemical engineeringLow emission

The invention relates to a bearing, in particular to a sparingly soluble bearing of an engine. The sparingly soluble bearing is characterized by comprising a steel back layer, a substrate layer and a sparingly soluble layer which are arranged from outside to inside, wherein the substrate layer is made of aluminum material; and the sparingly soluble layer is made of silicon-iron environment-friendly material. The invention saves energy in the manufacture process, has low cost and can satisfy the technical requirements of the engine, such as high voltage increase, great torque and low emission.

Owner:SHANDONG YUNCHENG HAORUN MACHINERY MFG

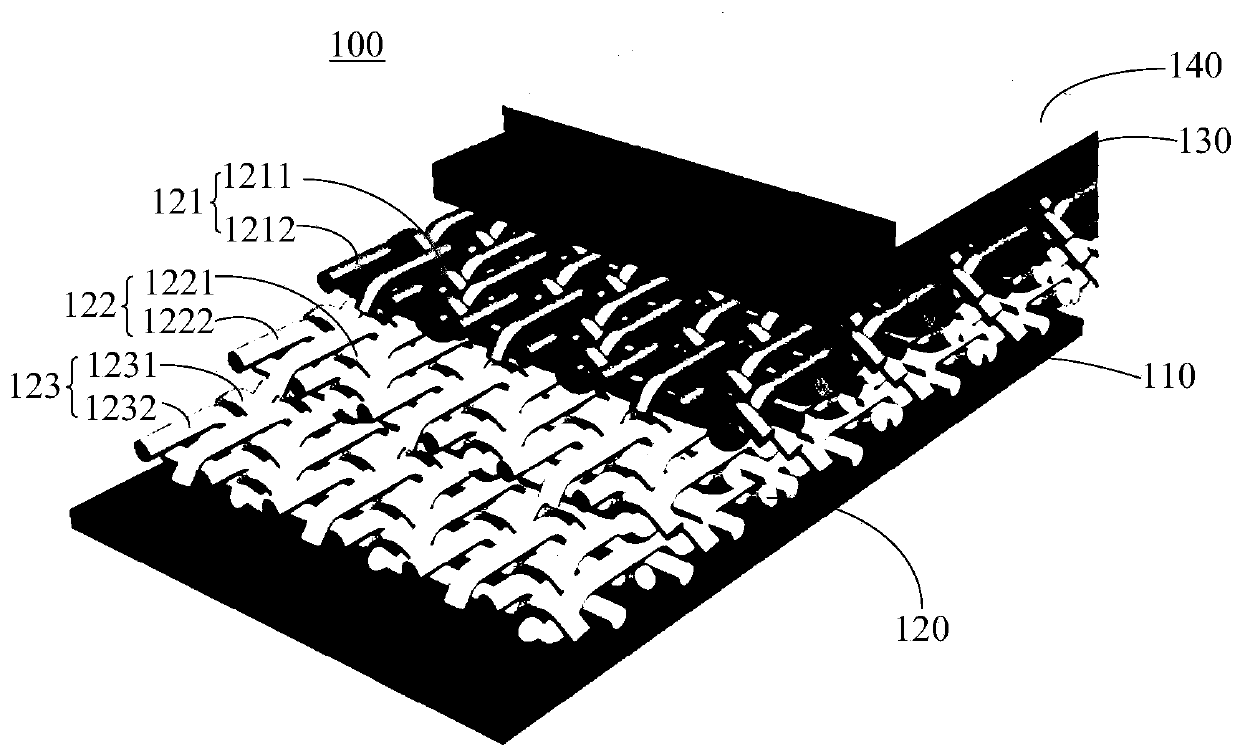

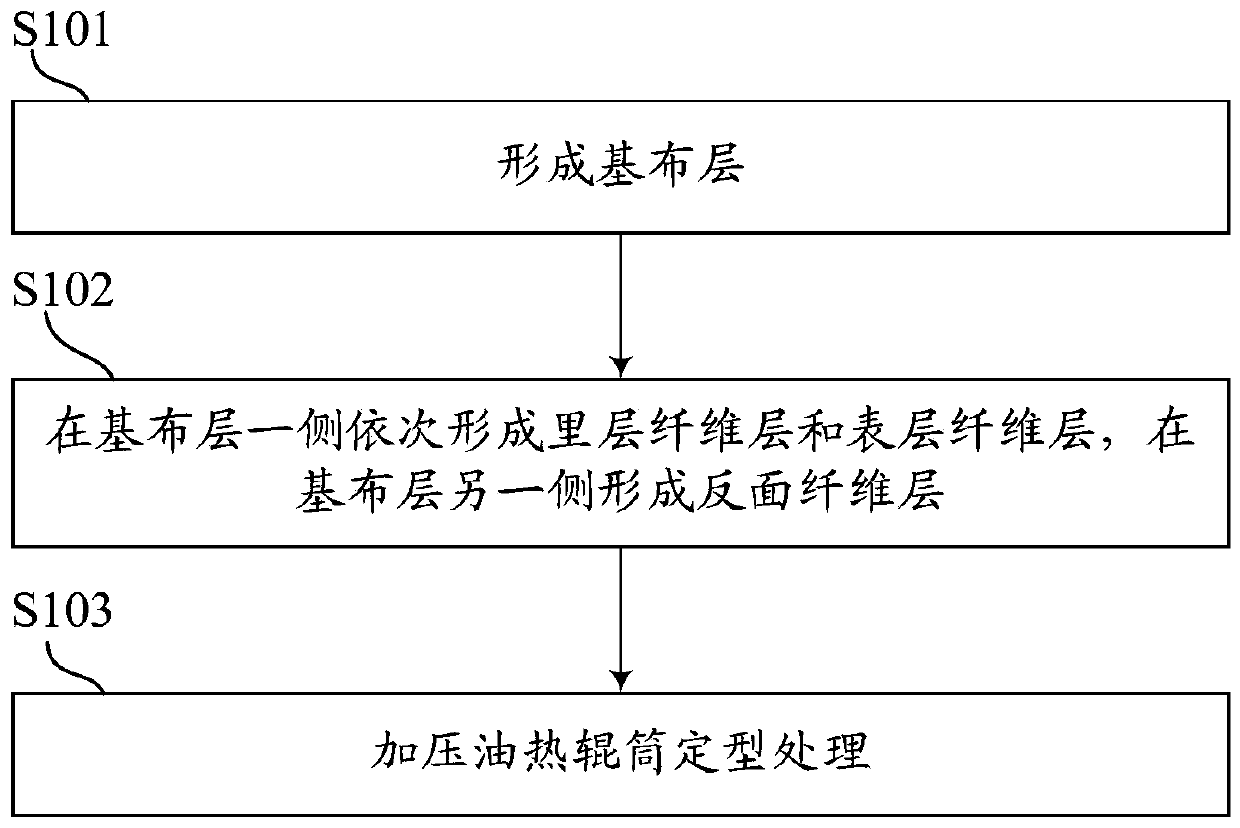

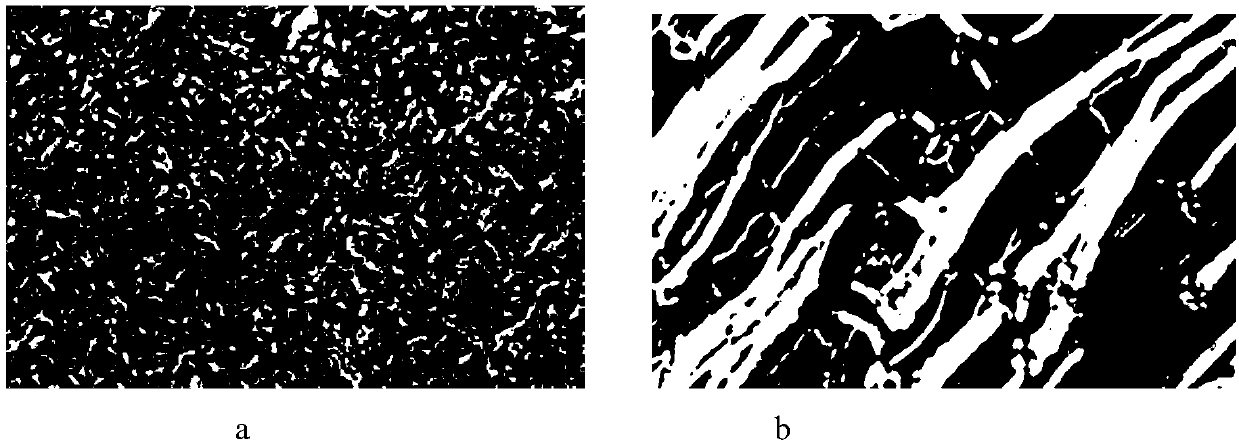

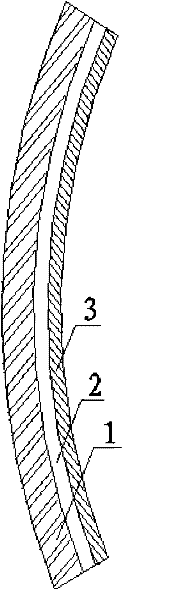

Multi-layer composite high-line-pressure-resistant papermaking felt and preparation method thereof

PendingCN111424459AMeet dehydration requirementsExtended service lifeLamination ancillary operationsSynthetic resin layered productsYarnFiber

The invention discloses a multi-layer composite high-line-pressure-resistant papermaking felt and a preparation method thereof. The multi-layer composite high-line-pressure-resistant papermaking feltcomprises a bottom fiber layer, a base cloth layer, an inner fiber layer and a surface fiber layer making contact with paper, wherein all of the layers are arranged in a stacked mode, and the base cloth layer comprises at least two layers of single-layer base cloth. The multi-layer composite papermaking felt is actually formed by compounding a plurality of pieces of single-layer base cloth with awarp and weft weave system, and warp yarns in an upper-layer weave are not easy to embed into gaps of warp yarns in lower-layer weave; after receiving high line pressure, the multi-layer composite papermaking felt is good in resilience, high in water containing space and not easy to deform, and does not lose water filtering performance; and the multi-layer composite papermaking felt facilitates quick transferring of moisture in paper sheets to the papermaking felt, meets the dehydration requirement of a high-speed high-line-pressure paper machine on the papermaking felt, and is prolonged in service life.

Owner:JIANGSU JINNI ENGINEERED FABRIC CO LTD

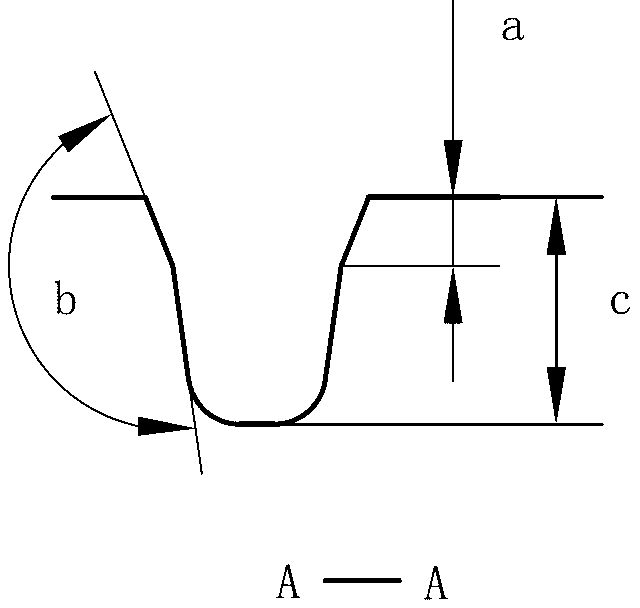

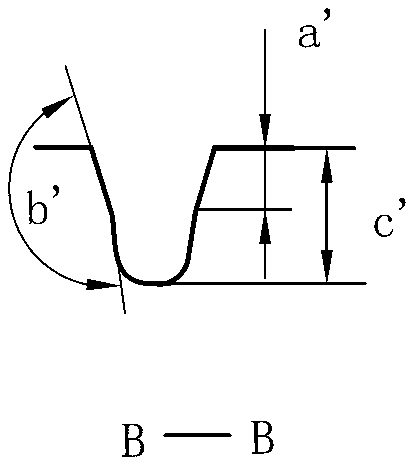

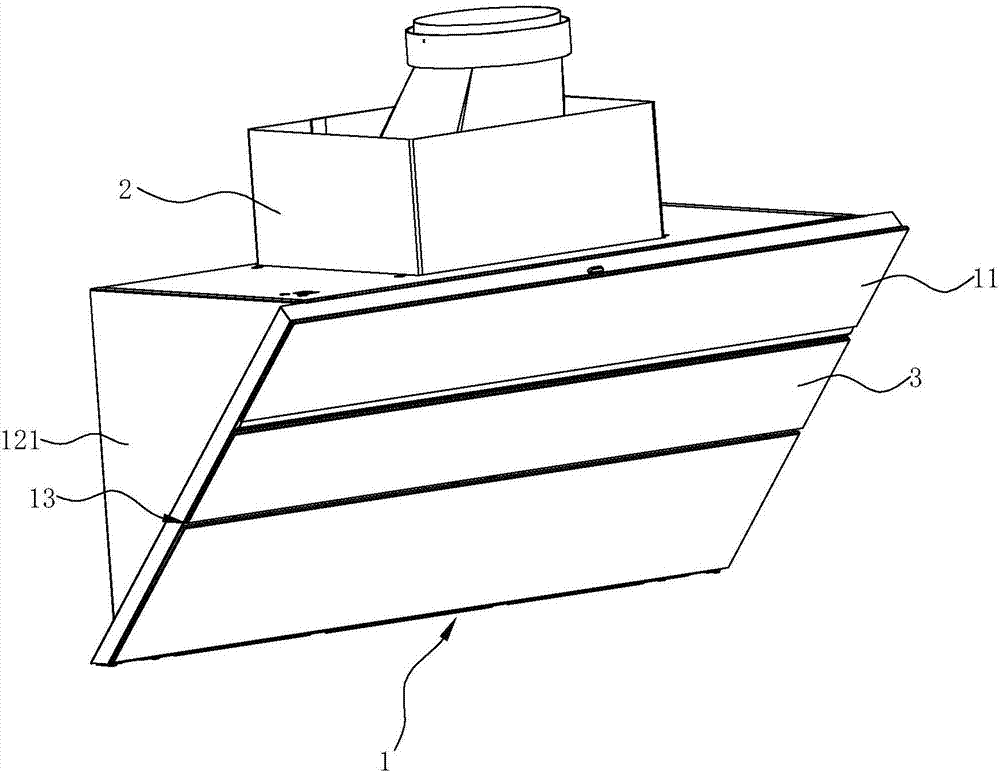

Side draught type extractor hood

PendingCN107975835AHigh precisionReduce gapDomestic stoves or rangesLighting and heating apparatusReciprocating motionEngineering

The invention discloses a side draught type extractor hood. The side draught type extractor hood includes a machine shell. The right front of the machine shell is provided with an air inlet. A smoke deflector is arranged in the air inlet. The machine shell is internally provided with an electric pushing rod mechanism used for driving the smoke deflector to overturn. The electric pushing rod mechanism includes a pushing rod outer shell and a pushing rod carrying out linear reciprocating motion relative to the pushing rod outer shell. The side draught type extractor hood is characterized in thatthe end, away from the pushing rod outer shell, of the pushing rod is connected with the smoke deflector through a first bearing. The end, away from the pushing rod, of the pushing rod outer shell isconnected with the machine shell through a second bearing. Through arranging the electric pushing rod mechanism into a double-bearing structure, the pushing rod can rotate around the bearing center,the pushing rod can be inclined to compensate disadvantages of low accuracy, when the centers of a rod end knuckle bearing and a mounted bearing are in misregistration, the straightness accuracy of the pushing rod can be ensured through a rotation shaft of the rod end knuckle bearing, and the radial force inside when the pushing rod moves can be eliminated.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Molding device of vibration mechanism of multifunctional fitness massager

InactiveCN108655236AImprove cleanlinessEasy to embedDirt cleaningEjection devicesPunchingElectric machinery

The invention provides a molding device of a vibration mechanism of a multifunctional fitness massager, and relates to the technical field of punching molding devices. The molding device of the vibration mechanism of the multifunctional fitness massager comprises a worktable; a punching device is fixedly mounted at the top of the worktable; the punching device comprises a frame; a mounting plate is fixedly mounted at the bottom of the inner wall of the frame; and a hydraulic extension device is fixedly mounted at the bottom of the mounting plate. The molding device of the vibration mechanism of the multifunctional fitness massager is provided with a demolding device; after the hydraulic extension device drives a punching head to downwards finish a punching procedure, a motor is started; under the linkage effect of a connecting rod, the connecting rod can drive an extension rod to move up and down in a demolding cylinder; meanwhile, the extension rod drives a demolding rod to move up and down through a slide plate; the demolding rod can eject out finished products in a molding cavity in the up-down moving process; and compared with a traditional manual demolding mode, the demoldingmode is fast and convenient to operate, and saves more time and power.

Owner:NINGBO HALTHMATE TECH DEV

Greening structure for house building

ActiveCN113530005AEasy to separateEasy to replaceRoof improvementSewerage structuresGreeningHouse building

The invention relates to the technical field of house building, and discloses a greening structure for a house building. The greening structure involves a wall body, a vertical groove and a horizontal groove are formed in the wall body, the horizontal groove communicates with the vertical groove, a bracket is arranged on the wall body, a potted plant can be placed on the bracket, the side, orienting the wall body, of the bracket is provided with an embedded block arranged in the horizontal groove in a sliding mode, and a blocking structure for blocking the horizontal groove is arranged in the vertical groove. According to the greening structure, the greening effect of the wall body is improved.

Owner:浙江可久建筑工程有限公司

Liquid crystal polyurethane urea material with cholesteric side chains and preparation method of liquid crystal polyurethane urea

ActiveCN108912305ALow biocompatibilityGood biocompatibilityLiquid crystal compositionsSide chainBiocompatibility Testing

The invention provides liquid crystal polyurethane urea with cholesteric side chains and a preparation method of the liquid crystal polyurethane urea. Cholesteric liquid crystal units are connected toa main chain through long flexible segments in a covalently mode, single-end dihydroxy cholesteric liquid crystal monomer (DAP) is mixed with double-end hydroxyl polyethylene glycol (PEG), chain extension is performed by using diisocyanate containing a urea-based structure, and the liquid crystal polyurethane urea with the cholesteric side chains is obtained through purification. The liquid crystal polyurethane has a number average molecular weight of 1.0*10<5>-5.0*10<5> and a dispersion coefficient of 1.20-1.51, the mass content of DAP in the liquid crystal polyurethane is 25-52%, and the mass content of PEG in the liquid crystal polyurethane is 12-52%. By combining a cholesteric liquid crystal into polyurethane through a condensation polymerization mode, not only can migration of the small molecule liquid crystal be avoided, but also the blood compatibility and biocompatibility of a polyurethane film can be improved; therefore, reference is provided for application of the modified polyurethane material in biomedical engineering, and good biodegradability can be obtained.

Owner:广州迈腾化工科技有限公司

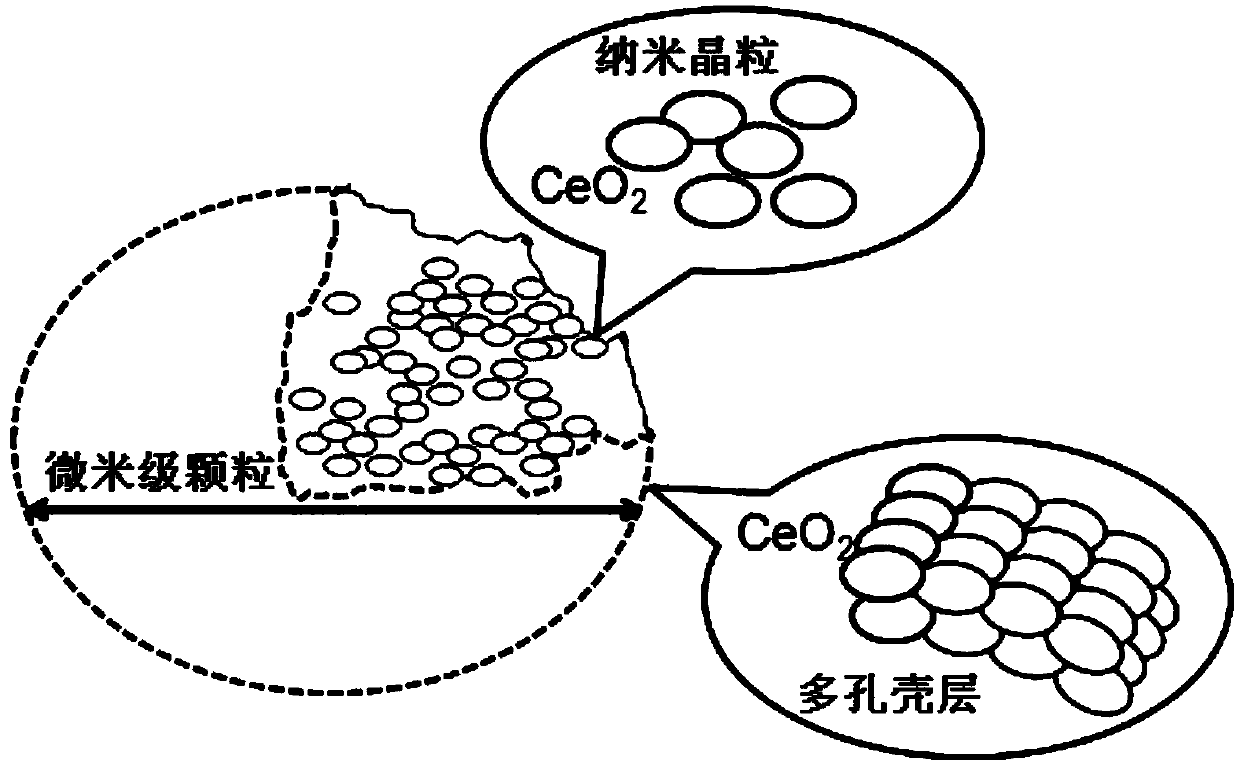

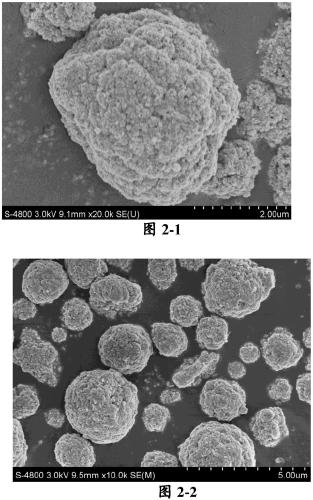

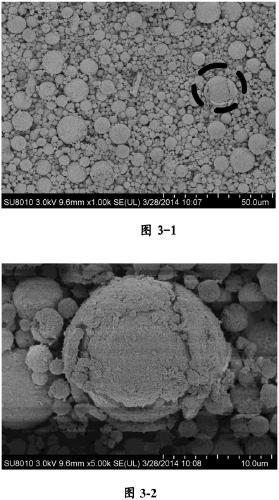

A kind of micron cerium oxide particles with multi-core co-shell structure and preparation method thereof

ActiveCN107207274BLarge specific surface areaHigh mechanical strengthHeterogenous catalyst chemical elementsDispersed particle separationCatalytic oxidationCerium oxide

The invention relates to a micron cerium oxide particle with a multi-core common-shell structure, which comprises: a cerium oxide shell layer, the shell layer is composed of crystalline and / or amorphous nano-cerium oxide particles; and a cerium oxide particle located inside the shell layer Numerous aggregates of nano-cerium oxide crystal grains. The invention also relates to a preparation method of micron cerium oxide particles with a multi-core common-shell structure. The supported catalyst based on the micron cerium oxide particles of the present invention has good hydrothermal stability, good sulfur resistance and the active component of the supported catalyst is not easy to be embedded. It has a good application prospect.

Owner:RARE EARTH CATALYSIS INNOVATION RES INST (DONGYING) CO LTD

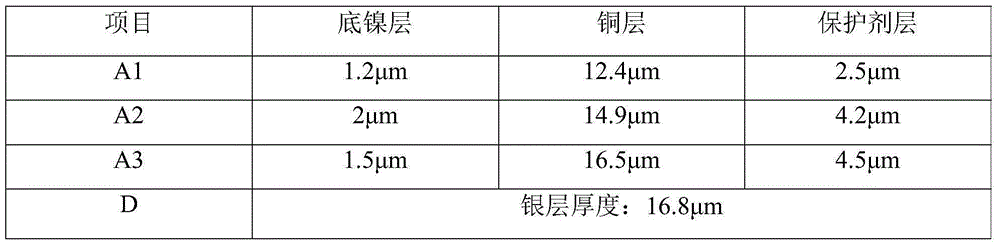

A kind of treatment fluid and its application and metallization product and method

ActiveCN106544654BEasy to embedNot easy to embedLiquid/solution decomposition chemical coatingCelluloseMetal coating

The invention relates to the field of substrate surface metallization, and provides a treating fluid and an application thereof as well as a metallized product and a method. The treating fluid contains titanate, silicate ester, cellulose and a complexing agent, wherein the complexing agent is a compound which contains at least one group of acetylacetonate, carboxylate radicals, carbonyl, alkoxy, azide groups, nitrato, amido and halogen. When the treating fluid provided by the invention is used for metallizing the substrate surface, the limit of the prior art to substrate materials can be eliminated, an integral metal coating can be formed, and the treating fluid has great industrial application prospects.

Owner:BYD CO LTD

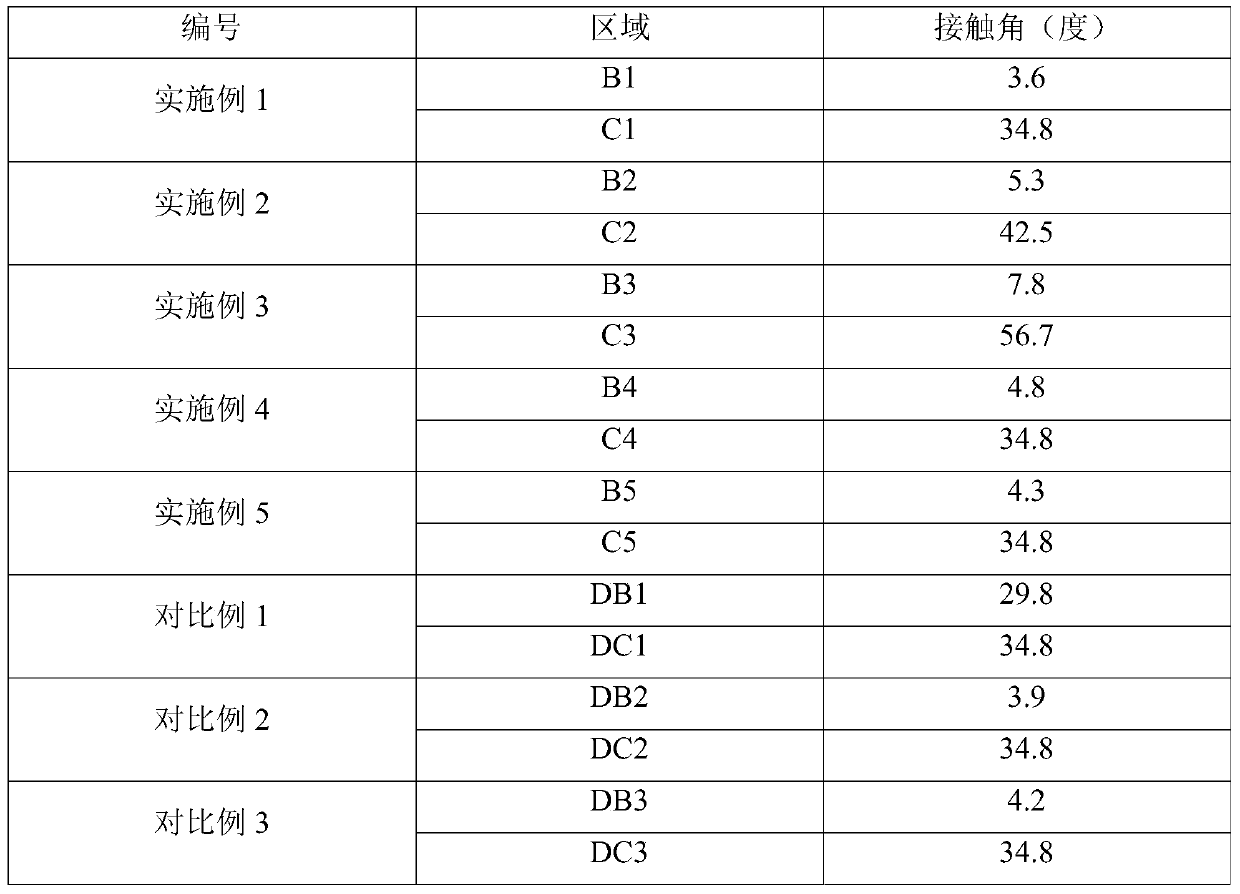

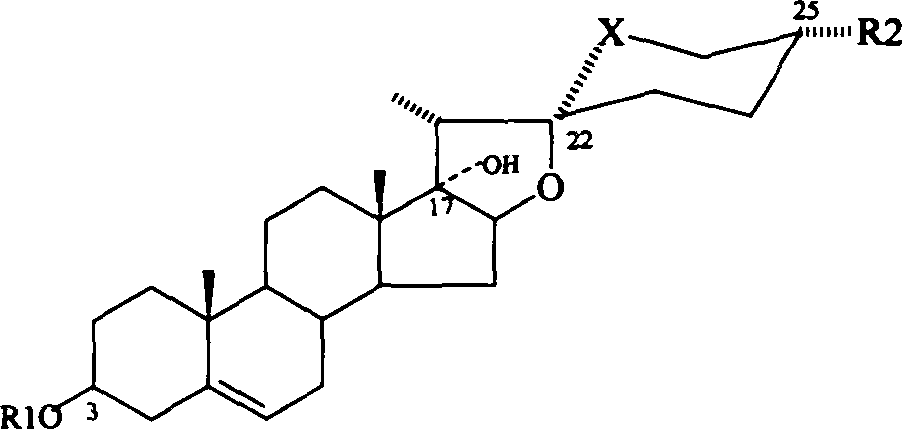

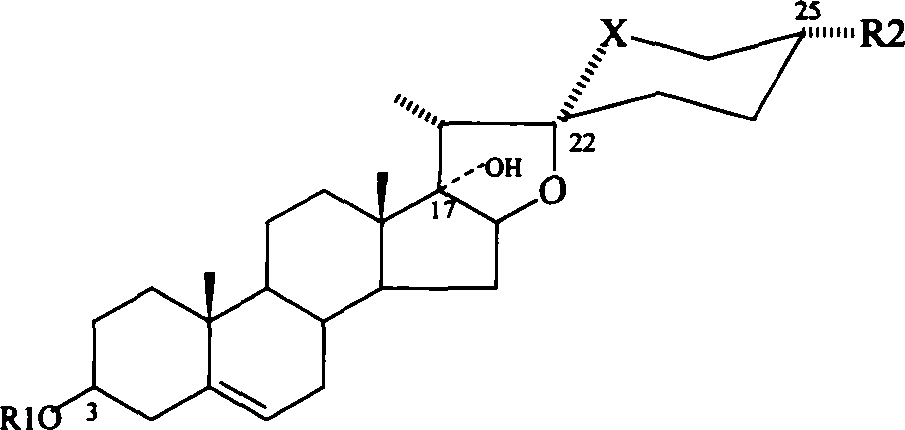

Solid-state molecular dispersible preparation of pennogenin compound

InactiveCN1883494ANot easy to embedOvercome the disadvantage of slow dissolution caused by easy agingOrganic active ingredientsPharmaceutical delivery mechanismAdditive ingredientCyclodextrin

The present invention relates to a special preparation form using pennogenin composite as an active constituent. Said pennogenin composite solid molecule dispersing preparation is formed by the mass percent of 0.5 to 40% pennogenin composite and 60 to 99.5% cyclodextrin. Composites with molecular weight over 1000 are generally supposed to be hard buried by cyclodextrin due to their big molecular space volume. The present invention is characterized in burying the pennogenin composite in cyclodextrin in a dispersing state in single molecule with the dispersing degree over ten times smaller than that of nanometer grains, which is quickly disintegrated and dispersed and absorbed by human body after entering into gastrointestinal tract, which as a result, improves the biological utility ratio by over two times. And the invention is also characterized in overcoming the shortcoming of PEG solid dispersant easily aging which results in slow dissolving-out speed. The present preparation is mainly used to cure gynecological blood diseases including hemostasis, hematopoiesis and gynecological inflammation.

Owner:YUNNAN BAIYAO GROUP

Sparingly soluble bearing of engine

InactiveCN101718303BHigh strengthExtended service lifeBearing componentsBiochemical engineeringLow emission

The invention relates to a bearing, in particular to a sparingly soluble bearing of an engine. The sparingly soluble bearing is characterized by comprising a steel back layer, a substrate layer and a sparingly soluble layer which are arranged from outside to inside, wherein the substrate layer is made of aluminum material; and the sparingly soluble layer is made of silicon-iron environment-friendly material. The invention saves energy in the manufacture process, has low cost and can satisfy the technical requirements of the engine, such as high voltage increase, great torque and low emission.

Owner:SHANDONG YUNCHENG HAORUN MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com