Ceramic diaphragm and preparation method and application thereof

A ceramic diaphragm and ceramic coating technology, applied in the direction of separator/film/diaphragm/spacer, nanotechnology for materials and surface science, nanotechnology, etc., can solve the adhesion between ceramic powder and diaphragm substrate The strength is not strong, the thermal shrinkage of the ceramic diaphragm cannot be reduced, and the ion conduction resistance of the ceramic coating is increased, so as to achieve the effect of improving thermal shrinkage resistance, excellent safety performance, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

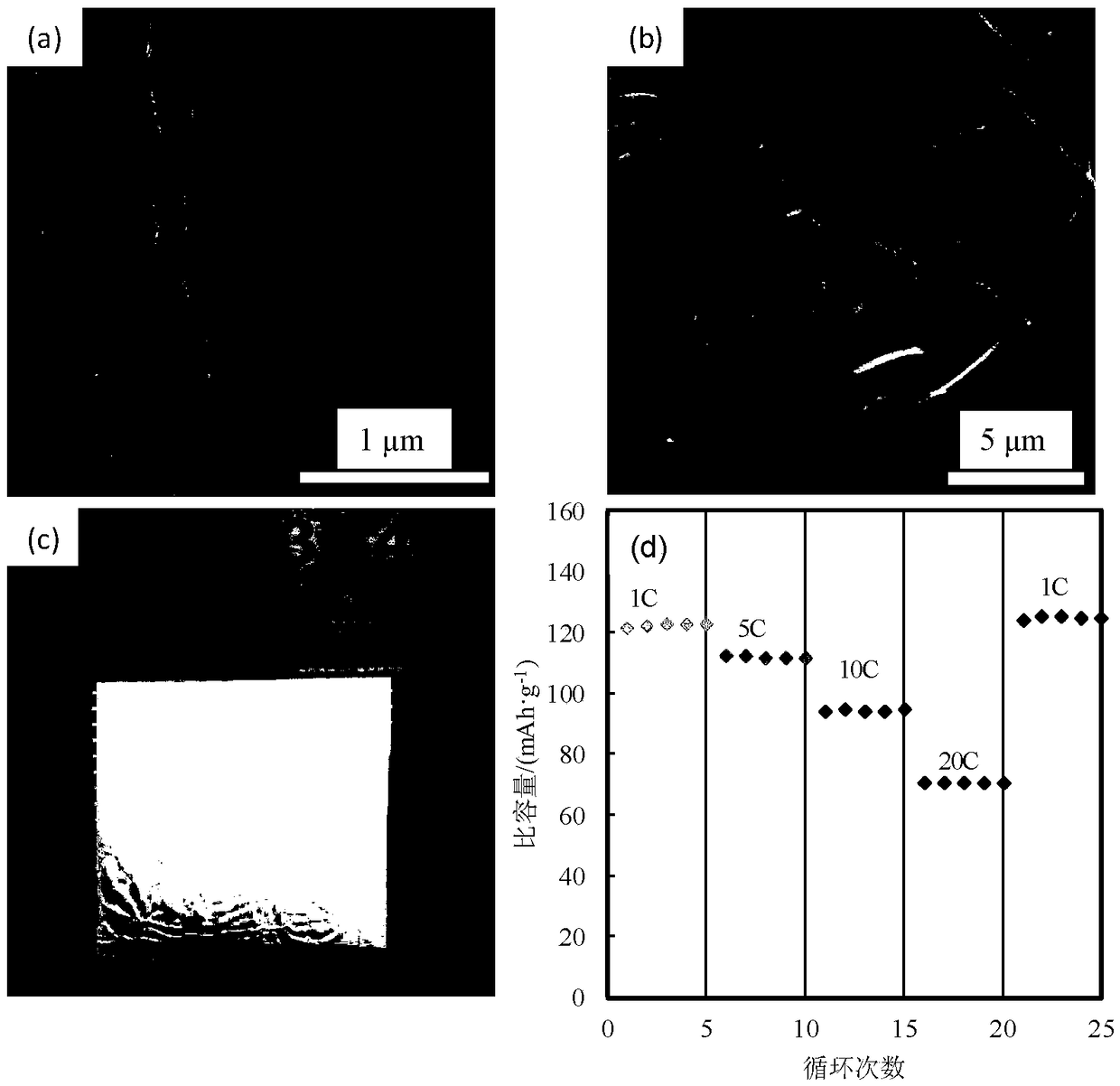

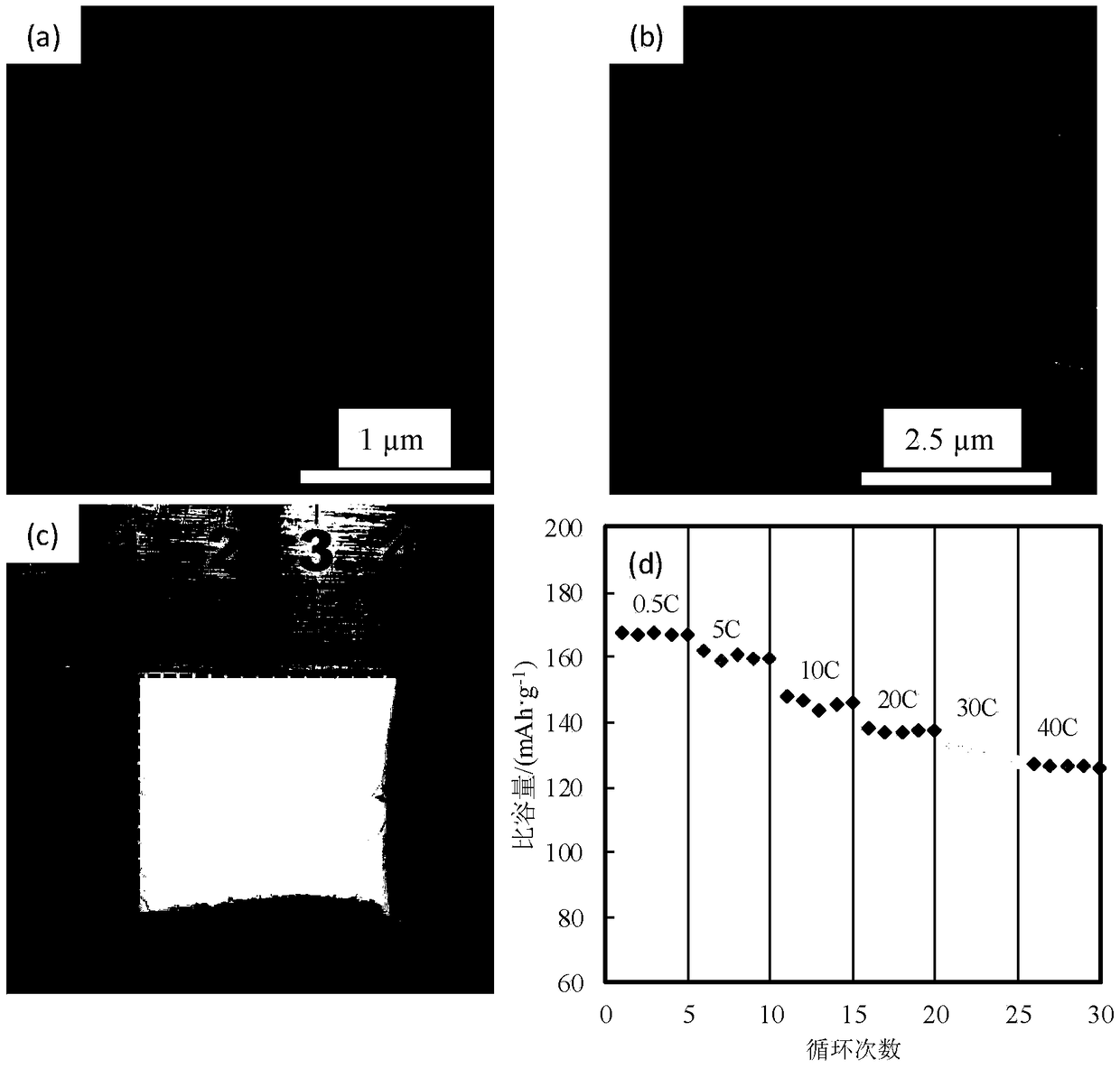

[0047] above Na 2 Ti 3 o 7 The preparation method of nanobelts is: after ultrasonically mixing titanium dioxide powder with 10mol / L alkaline solution such as sodium hydroxide or potassium hydroxide, react in a high-pressure reactor at 150°C to 180°C for 12h to 48h, and use deionized water to Wash to neutral, filter and dry to get Na 2 Ti 3 o 7 nanobelt. The Na prepared by the above method 2 Ti 3 o 7 The nanoribbons have a uniform width of about 800 nanometers and a length ranging from a few micrometers to tens of micrometers.

[0048] above H 2 Ti 3 o 7 The preparation method of nanowires is: use 0.1mol / L~0.5mol / L acidic solution to Na 2 Ti 3 o 7 Nanobelts were soaked for 10h to 24h, and then washed with deionized water until neutral to obtain H 2 Ti 3 o 7 Nanowires. The H prepared by the above method 2 Ti 3 o 7 Nanowires have a uniform diameter of about 100 nanometers and lengths ranging from hundreds of nanometers to tens of micrometers.

[0049] The ab...

Embodiment 1

[0065] The preparation method of the ceramic diaphragm in this embodiment is as follows:

[0066] After ultrasonically mixing titanium dioxide powder and 10mol / L sodium hydroxide solution, react in an autoclave at 170°C for 36 hours, wash with deionized water until neutral, filter, and dry to obtain Na 2 Ti 3 o 7 nanobelt. The Na prepared by the above method 2 Ti 3 o 7 The nanoribbons have a uniform width of about 800 nanometers and a length ranging from a few micrometers to tens of micrometers. Na 2 Ti 3 o 7 Nanobelts, poly(vinylidene fluoride-hexafluoropropylene) and carboxymethyl cellulose are mixed with N,N-dimethylformamide in a weight ratio of 10:4:0.4:85.6, and the mechanical ball mill is used at a speed of 500rpm Ceramic slurry was obtained after ball milling for 8 hours. The ceramic slurry was uniformly coated on both sides of the PP / PE separator, the coating thickness was controlled at 0.8 μm, and the ceramic separator for lithium batteries was obtained aft...

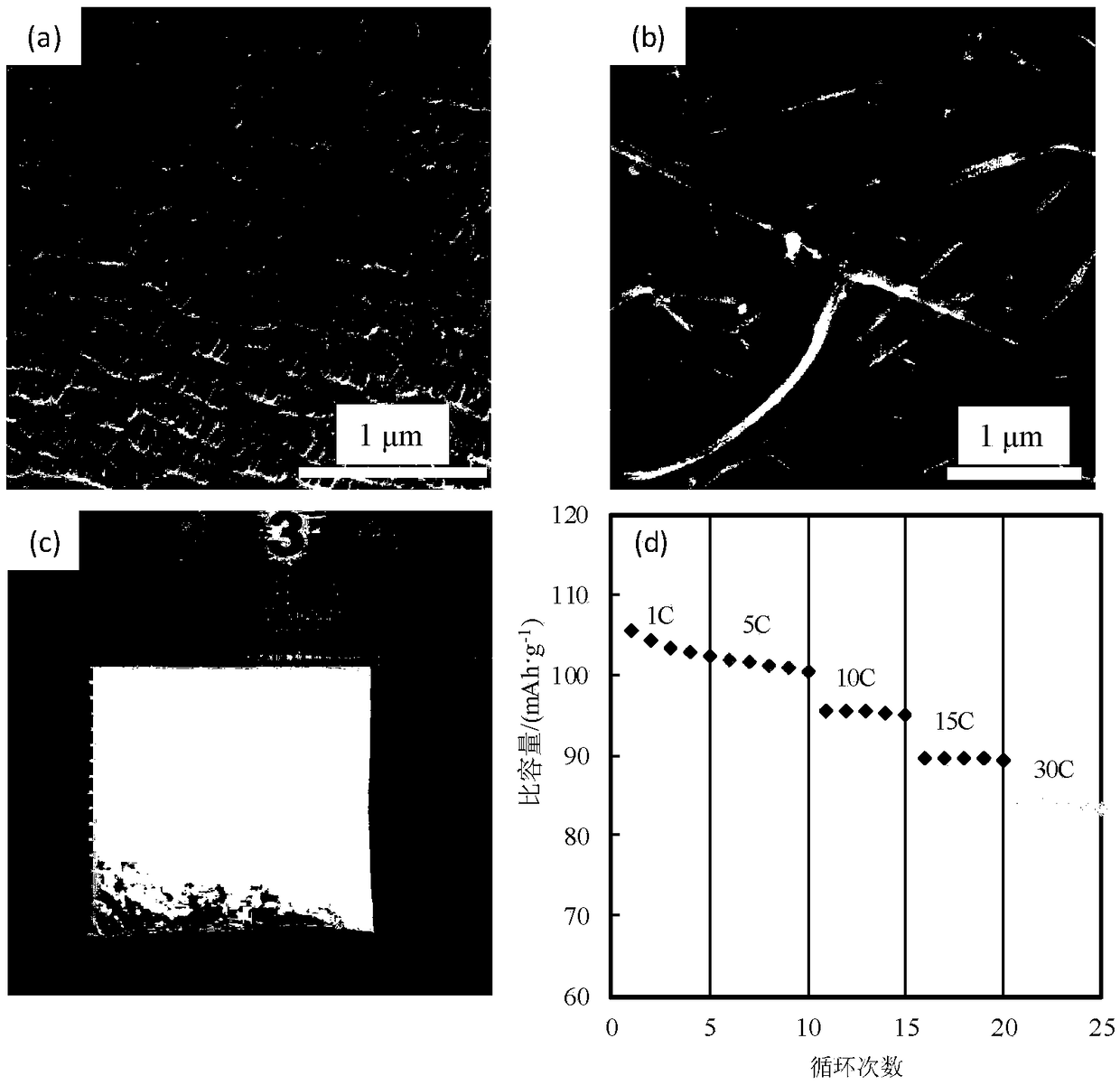

Embodiment 2

[0070] The preparation method of the ceramic diaphragm in this embodiment is as follows:

[0071] After ultrasonically mixing titanium dioxide powder and 10mol / L sodium hydroxide solution, react in an autoclave at 160°C for 20h, wash with deionized water until neutral, filter, and dry to obtain Na 2 Ti 3 o 7 nanobelts, and then use 0.4mol / L acid to the above-prepared Na 2 Ti 3 o 7 Nanobelts were soaked for 12 h, and then washed with deionized water until neutral to obtain H 2 Ti 3 o 7 Nanowires. The H prepared by the above method 2 Ti 3 o 7 Nanowires have a uniform diameter of about 100 nanometers and lengths ranging from hundreds of nanometers to tens of micrometers. H 2 Ti 3 o 7 Nanowires, polyvinylidene fluoride, polyvinylpyrrolidone and N-methylpyrrolidone were mixed in a weight ratio of 8:0.5:0.3:91.2, and ball milled with a mechanical ball mill at a speed of 400 rpm for 4 hours to obtain a ceramic slurry. The ceramic slurry was evenly coated on one side of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com