Patents

Literature

33results about How to "Improve heat shrink resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

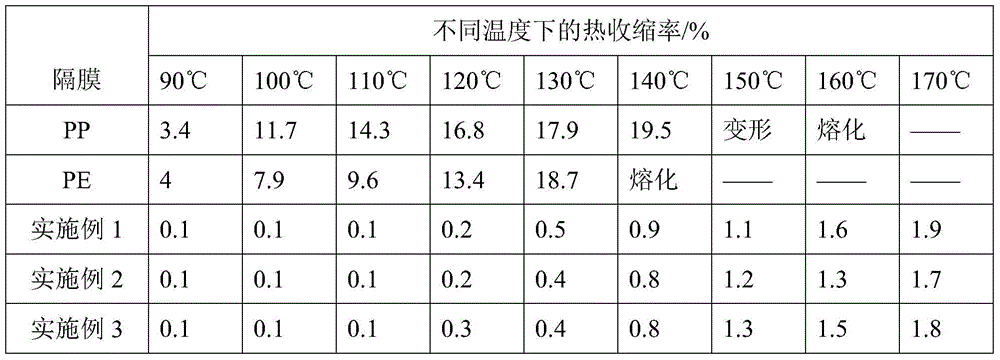

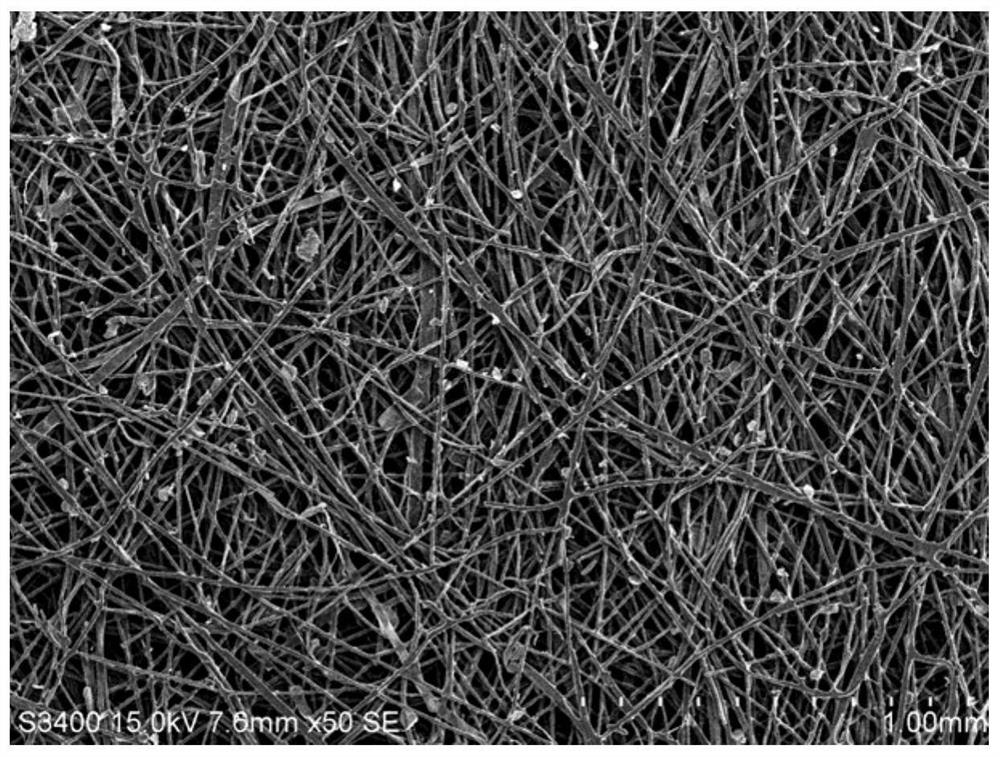

High-performance flexible composite nonwoven fabric membrane for lithium ion battery, as well as preparation method and application of membrane

InactiveCN103296240AGood flexibilityGood high current discharge performanceCell component detailsAdhesiveCharge discharge

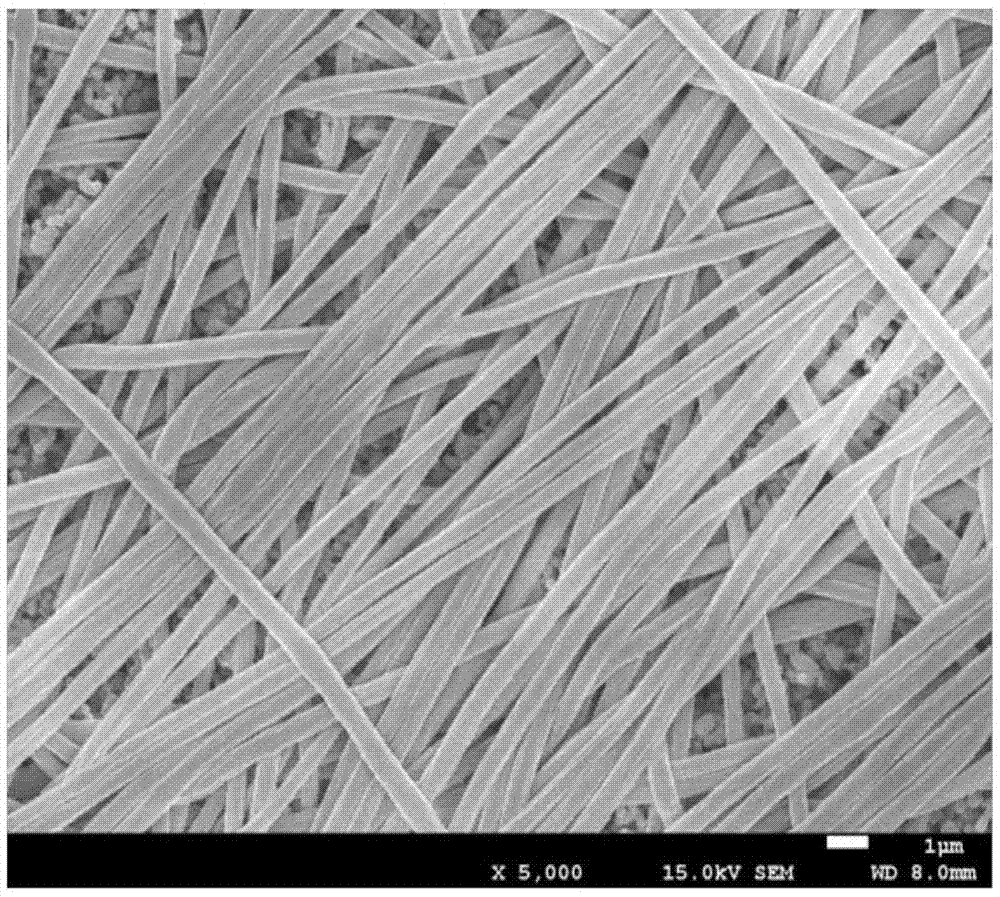

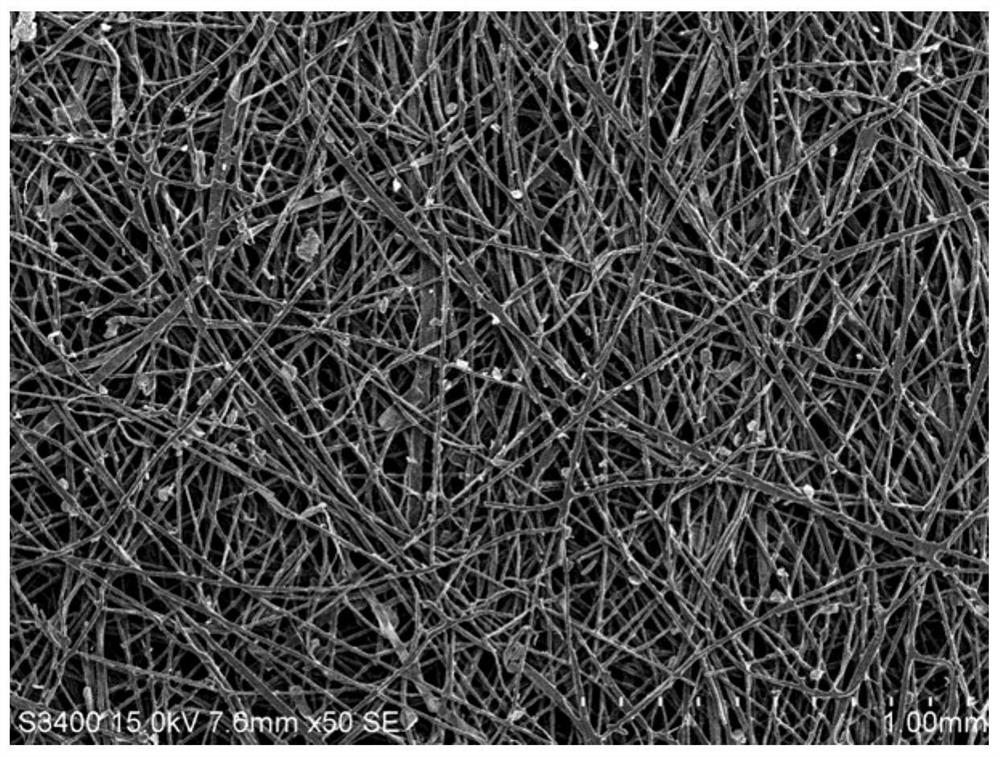

The invention discloses a high-performance flexible composite nonwoven fabric membrane for a lithium ion battery, as well as a preparation method and an application of the membrane, which belongs to the technical field of a lithium-ion battery membrane material. The prepared composite nonwoven fabric membrane is formed by coating functional serous fluid with thermally curable or optically curable functional groups onto a substrate membrane containing an active functional group, thermally curing or optically curing the substrate membrane, removing a pore-forming agent, and hot pressing and drying the substrate. The prepared composite nonwoven fabric membrane is good in flexibility. The composite nonwoven fabric membrane has good ion electric conductivity and hot shrinkage resistance, can bear the large-current discharge, and also can improve the safety performance of the battery. Since no fluorine-containing adhesive is used in a preparation process, nano particles or nano optical fibers are connected with the substrate membrane through a chemical key, the nano particles or the nano fibers are bonded together through the chemical key and free from dropping off in the charging-discharging cycle, the stability of the coating is enhanced, and the cycling performance of the battery can be improved. The prepared flexible composite nonwoven fabric membrane is used as a membrane assembly of the lithium ion battery.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

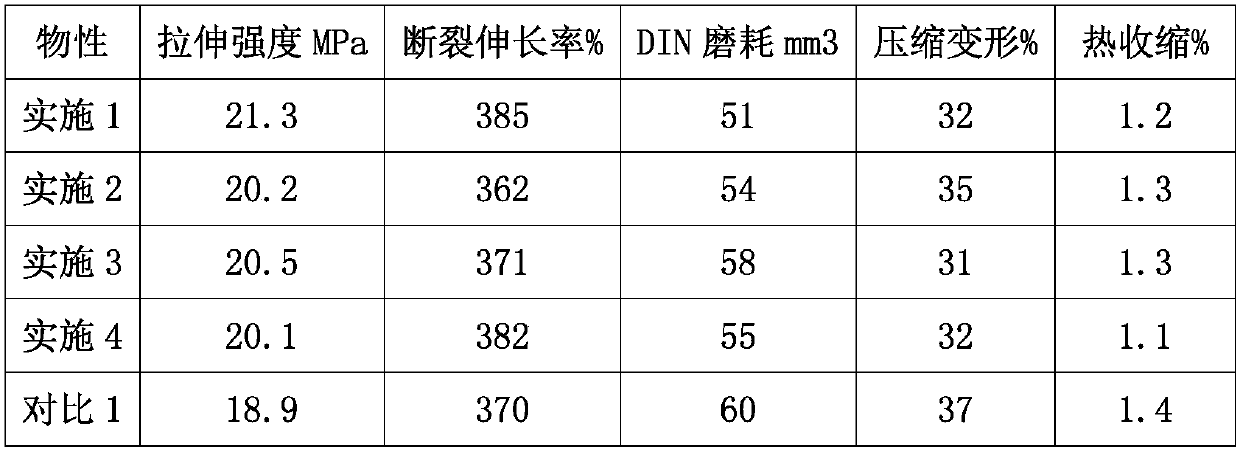

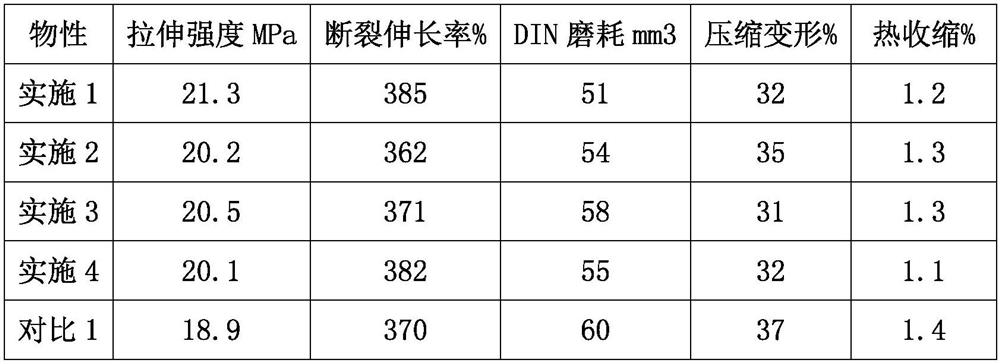

Ultralight graphene rubber foaming colloidal particles for shoe soles and preparation method thereof

InactiveCN109627512AImprove thermal stabilityImprove wear resistanceSolesRubber materialPolymer science

The invention relates to ultralight graphene rubber foaming colloidal particles for shoe soles. The colloidal particles are prepared from, by weight, 60-65 parts of natural rubber, 8-12 parts of isoprene rubber, 8-12 parts of butadiene rubber, 6-8 parts of butadiene styrene rubber, 0.8-1.0 part of modified graphene, 0.08-0.12 part of poly N-vinyl acetamide, 0.8-1.0 part of silicone oil, 3.0-3.5 parts of inorganic nanoparticles, 1.2-1.5 parts of activated zinc oxide, 0.8-1.0 part of zinc stearate, 1.0-1.2 part of stearic acid, 0.8-1.0 part of a cross-linking agent, 2.0-3.0 parts of a flow assistant and 1.5-1.8 parts of a foaming agent. By adopting the ultralight graphene rubber foaming colloidal particles, the modified graphene is uniformly dispersed in all rubber materials, the rubber foaming colloidal particles have good heat stability, good abrasive resistance performance and good stretching intensity, the permanent compression deformation performance and the heat resistance shrinkage performance are improved, and 50% or above weight can be reduced.

Owner:FUJIAN WUCHIHENG TECH DEV CO LTD

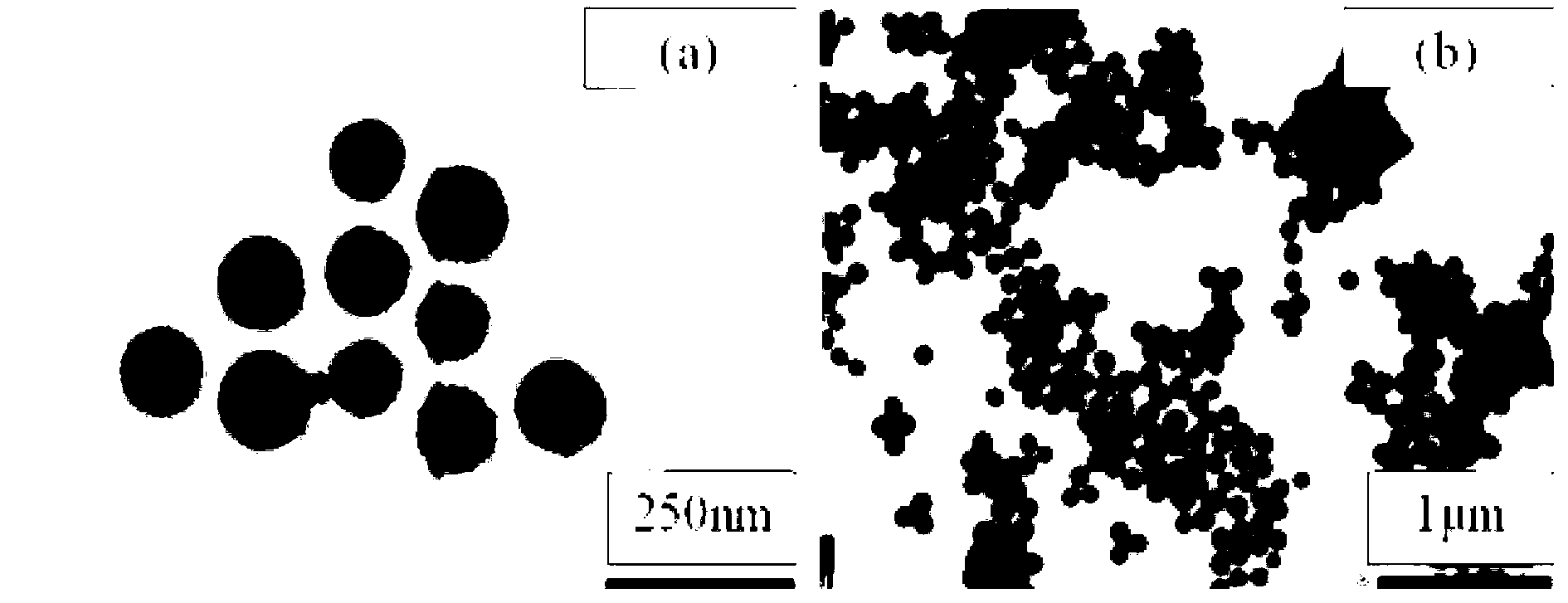

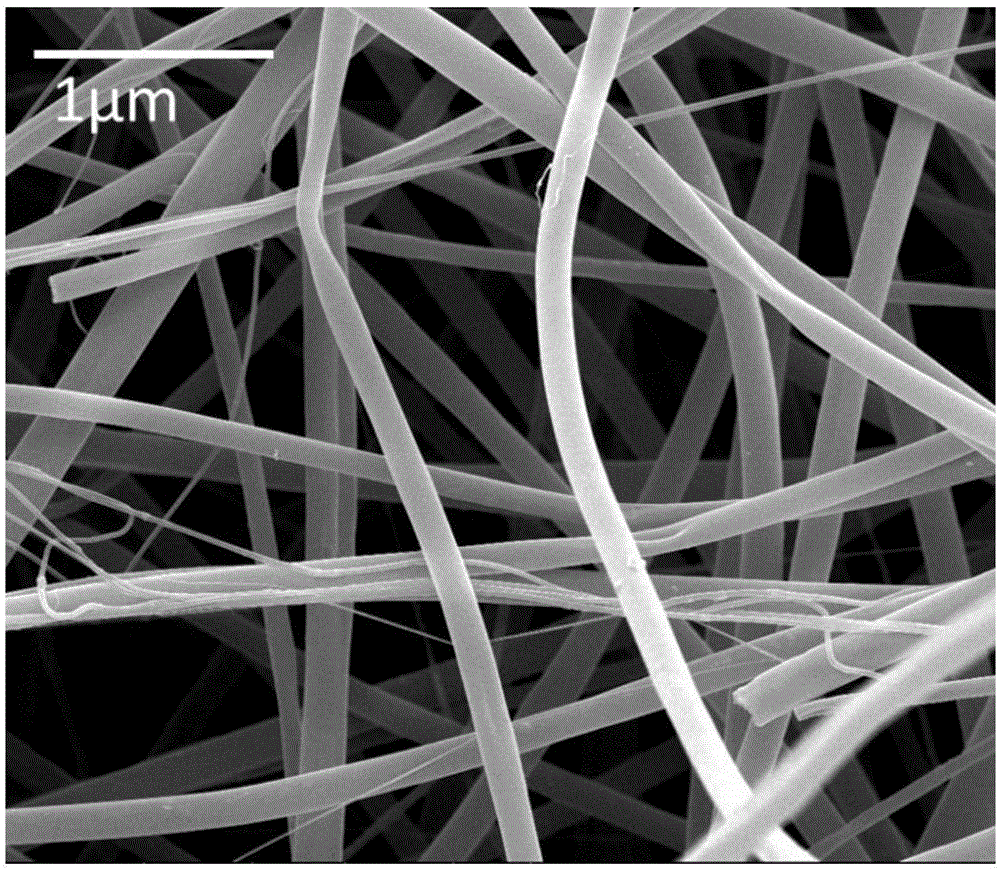

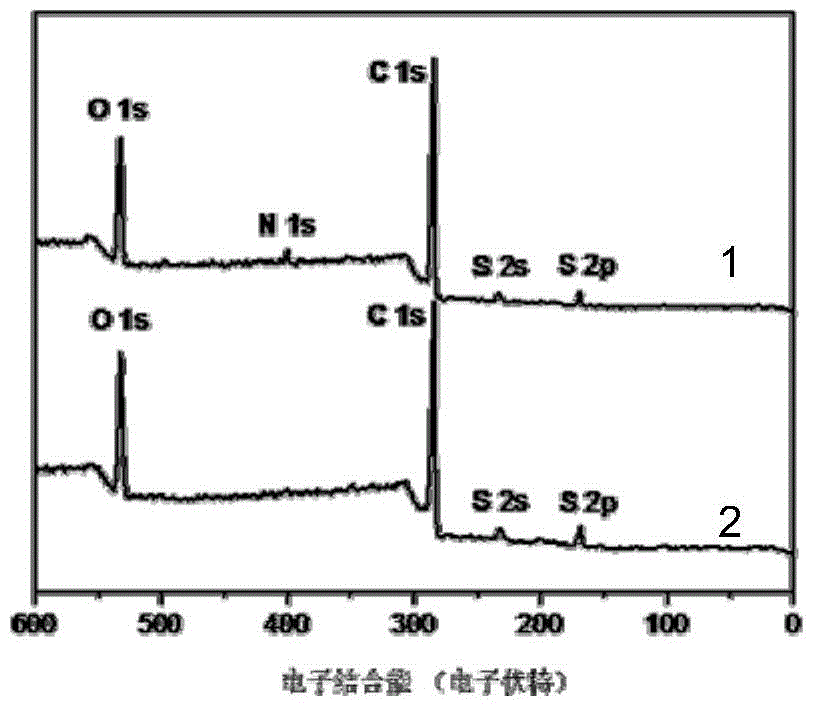

Li7La3Zr2O12 ion conductor ceramic fiber and preparation method thereof

ActiveCN106673651AImprove heat shrink resistanceReduce clogging rateInorganic material artificial filamentsWater soluble polymersWater soluble

The invention discloses Li7La3Zr2O12 ion conductor ceramic fiber. The material has the chemical composition of Li7La3Zr2O12, has the ion conductor ceramic fiber length of 1-2.5 mu m, the diameter of 80-120 nm and the lithium ion conductivity of 1.5*10<-4> S / cm-6*10<-3> S / cm. The invention further provides a method for preparing the ion conductor ceramic fiber. Lithium carbonate, lanthanum oxide, zirconyl nitrate, a nitric acid solution and absolute ethyl alcohol are mixed, heated and then mixed with citric acid and ethylene glycol, and the mixture is stirred at the constant temperature, and precursor sol is obtained; spinning sol is obtained by mixing a water-soluble polymer and the obtained precursor sol, spinning and calcination are performed sequentially, and ion conductor ceramic fiber with stable morphology and size is obtained. The method can improve the lithium ion conductivity significantly, adopts a simple process, is low in cost, has low requirements for equipment and environment and is suitable for industrial application.

Owner:QINGTAO KUNSHAN ENERGY DEV CO LTD

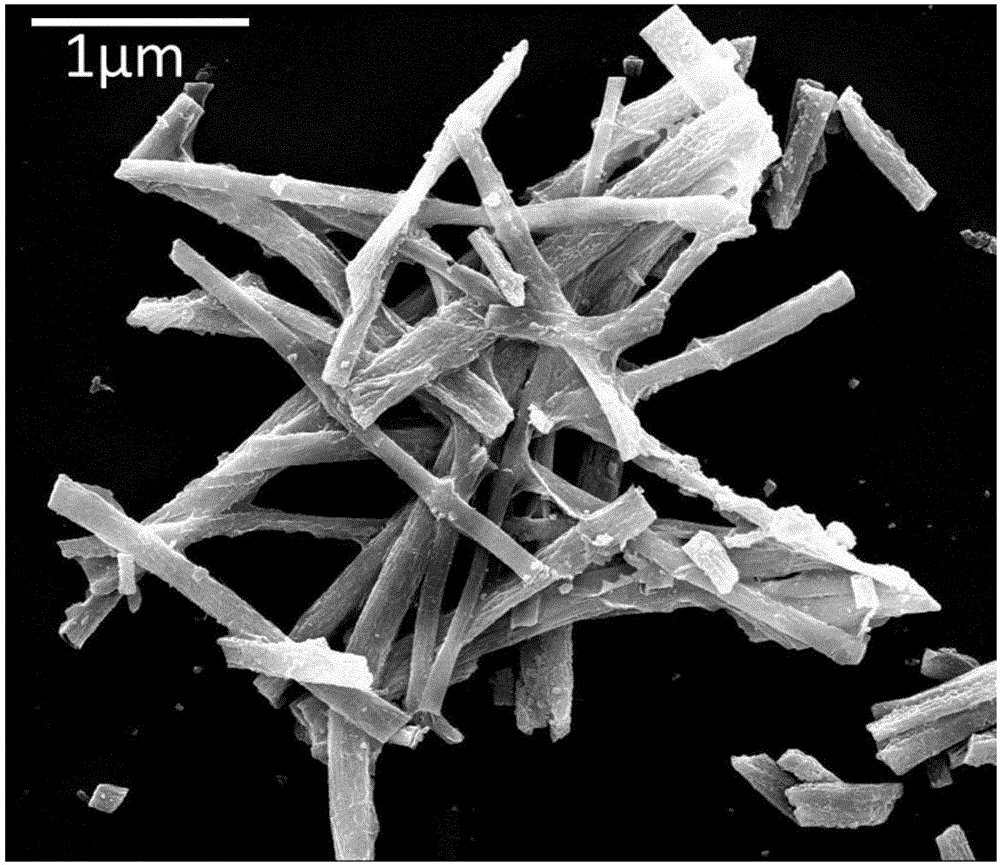

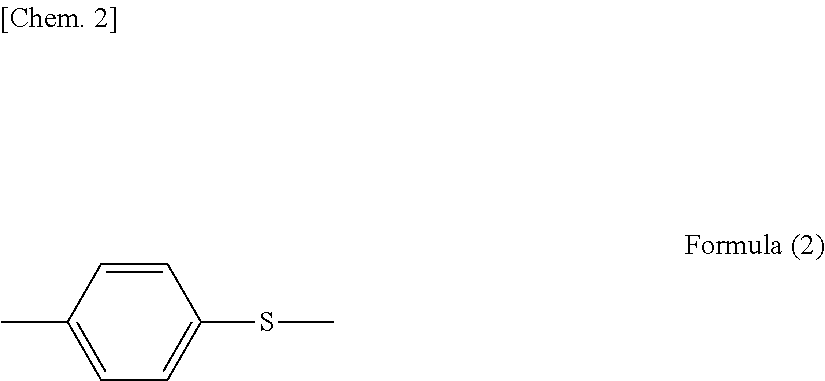

Microporous member, method for producing same, battery separator, and resin composition for nonaqueous electrolyte secondary battery separator

InactiveUS20150228948A1Improve heat shrink resistanceCell component detailsHigh resistancePolyolefin

Provided are a microporous membrane including a thermoplastic resin having a melting point of 220° C. or more and a polyolefin, the thermoplastic resin (a) having an acicular structure, and a method for producing the microporous membrane. The microporous membrane has high resistance to thermal shrinkage since it includes a polyolefin and a high-melting-point thermoplastic resin having an acicular structure. Thus, a battery separator for nonaqueous electrolyte secondary batteries and, in particular, a single-layer battery separator for nonaqueous electrolyte secondary batteries which have a good shut-down function and high resistance to thermal shrinkage may be produced.

Owner:DAINIPPON INK & CHEM INC

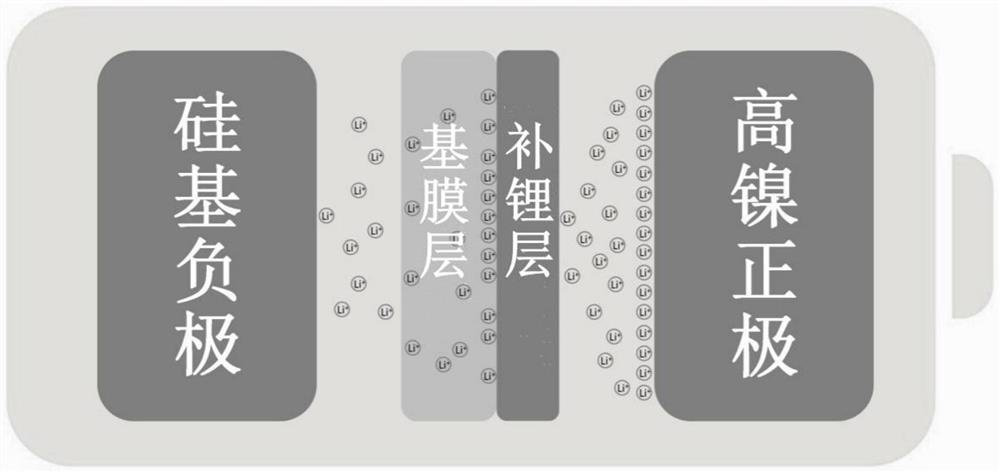

Functionalized lithium supplementing diaphragm and preparation method thereof

ActiveCN111816822AImprove performanceWill not harmSecondary cellsCell component detailsElectrolytic agentPolymer substrate

The invention provides a functionalized lithium supplementing diaphragm and a preparation method, the functionalized lithium supplementing diaphragm is composed of a lithium supplementing layer and abase film layer, and the lithium supplementing layer comprises a lithium-containing compound, a polymer substrate and a flexibilizer; the base film layer comprises a polymer base material; and the lithium supplementing layer and the base film layer are prepared through melting double-layer co-extrusion. The functionalized lithium supplementing diaphragm replaces a traditional lithium ion battery diaphragm, lithium ions can be supplemented for the first circle after the battery is assembled, the performance of the battery is improved, and the performance of the battery cannot be damaged after the charging of the first circle. The inventor unexpectedly finds that the lithium supplementing agent and the polymer base material are matched according to a proper ratio, and a proper thickness is extruded in a double-layer co-extrusion manner, so that the formed three-dimensional porous composite structure can realize good lithium supplementing, and can prevent the lithium supplementing agent from falling into an electrolyte to cause reduction of the lithium supplementing efficiency.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Graphene regenerated rubber and plastic foamed colloidal particle for soles and preparation method thereof

The invention relates to a graphene regenerated rubber and plastic foamed colloidal particle for soles. The graphene regenerated rubber and plastic foamed colloidal particle for soles is prepared fromthe following ingredients in parts by weight: 60 to 65 parts of EVA (Ethylene-vinyl acetate copolymer) waste materials, 23 to 25 parts of natural rubber, 4 to 6 parts of POE (Polyolefin elastomers),1 to 2 parts of modified graphene, 0.1 to 0.2 part of poly N-vinylacetamide, 2.0 to 2.3 parts of white mineral oil, 1.0 to 1.2 parts of silicone oil, 1.4 to 1.5 parts of active zinc oxide, 0.8 to 1.0part of zinc stearate, 0.8 to 1.0 part of stearic acid, 0.8 to 1.0 part of crosslinking agents, 2.0 to 3.0 parts of flow additives and 1.5 to 1.8 parts of foaming agents. According to the invention, the existing EVA waste materials are sufficiently utilized; resources are regenerated; and the foamed colloidal particle with the physical properties reaching a standard and the heat-shrinkage-resistant performance capable of being enhanced is obtained.

Owner:FUJIAN WUCHIHENG TECH DEV CO LTD

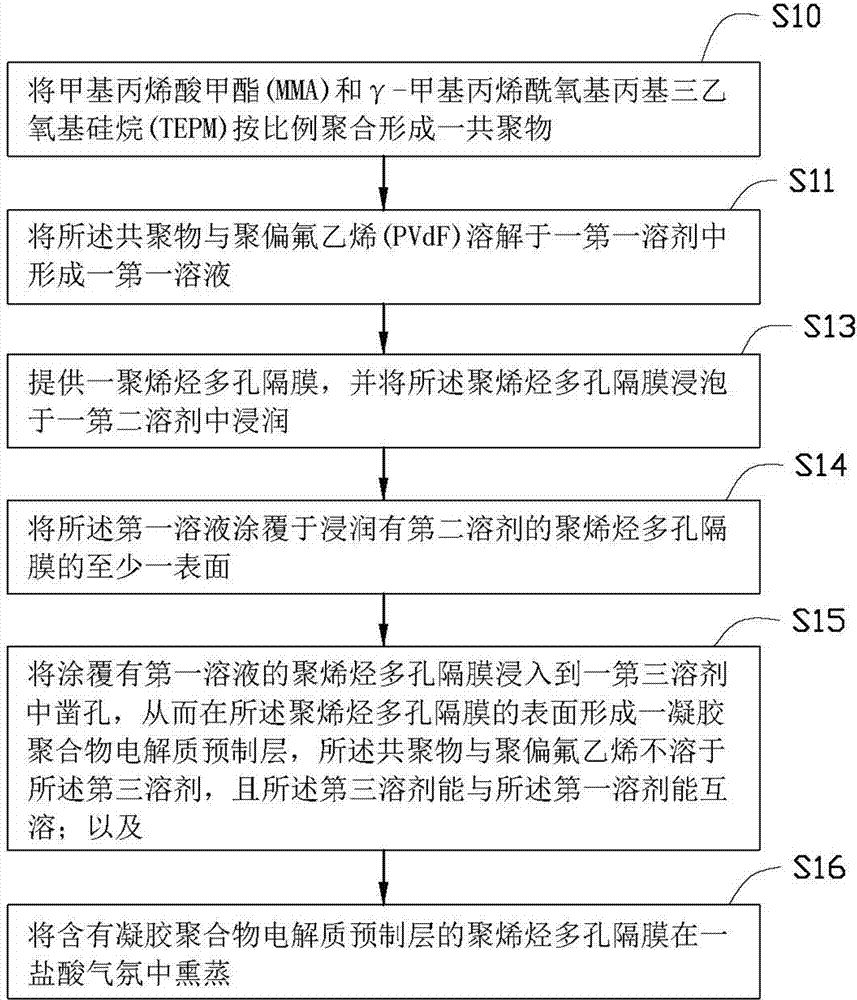

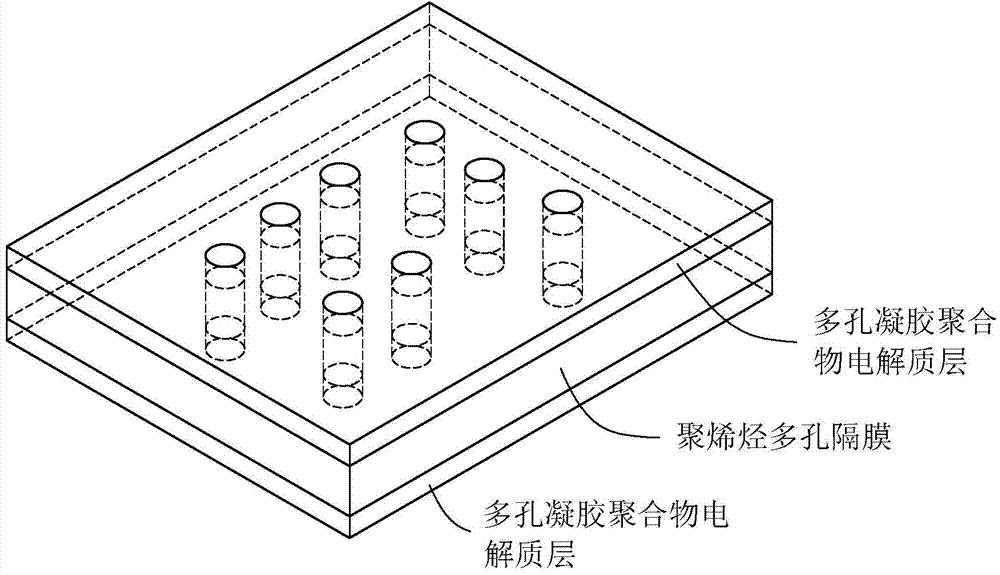

Polyolefin composite membrane and preparation method thereof as well as lithium ion battery

ActiveCN104124416AImprove surface wettabilityImprove performanceSynthetic resin layered productsSecondary cellsPolymer sciencePolyolefin

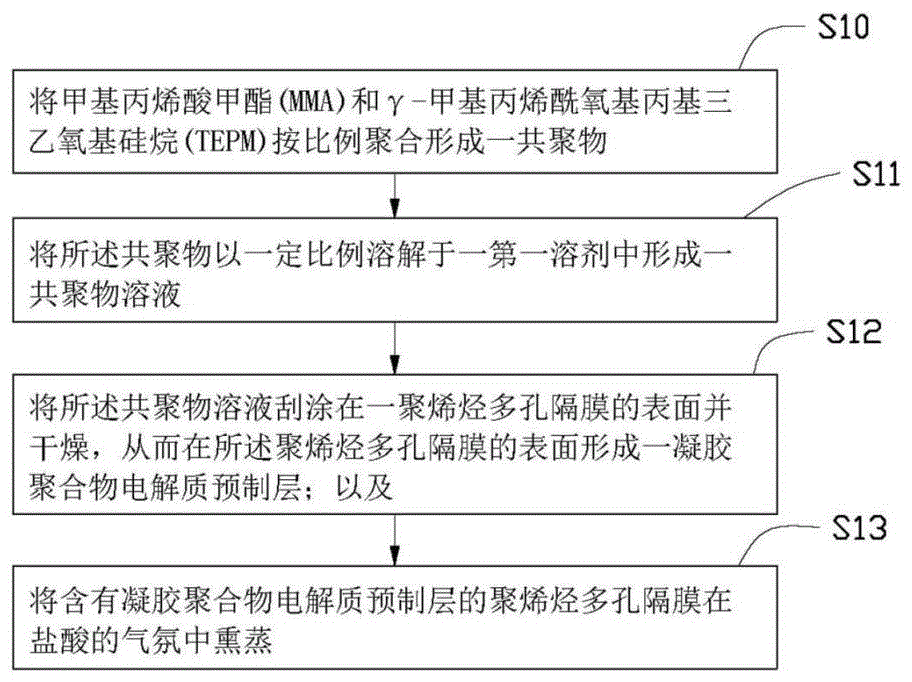

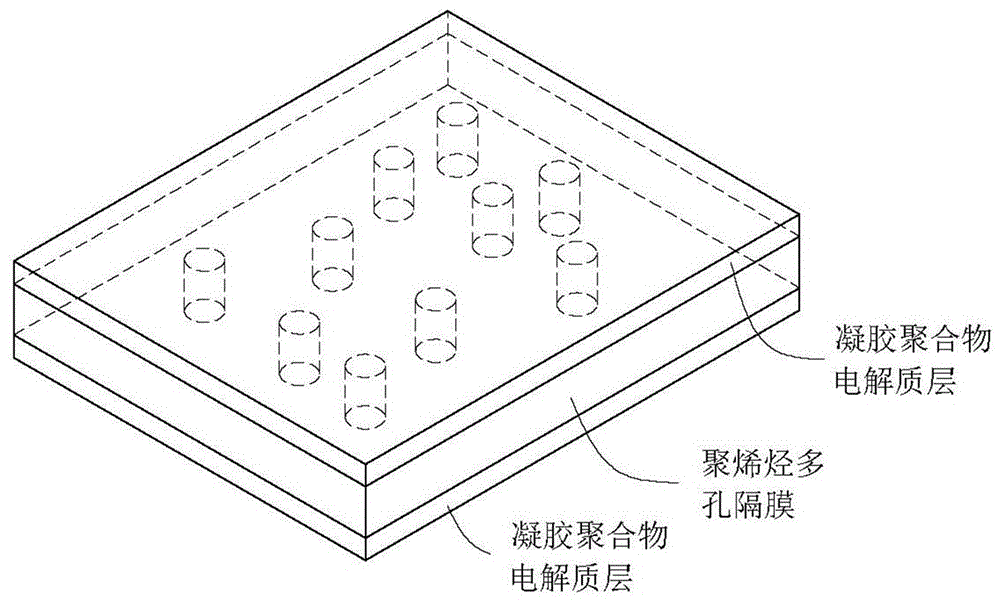

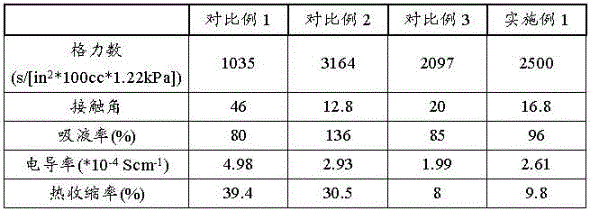

The invention relates to a preparation method of a polyolefin composite membrane. The method comprises the following steps of polymerizing methyl methacrylate and gamma-3-(Triethoxysilyl)propyl methacrylate in proportion to form a copolymer with the molecular formula shown in the description; dissolving the copolymer and polyvinylidene fluoride into a first solvent to form a first solution; soaking a perforated polyolefin membrane into a second solvent; coating at least one surface of the perforated polyolefin membrane (which is soaked in the second solvent) with the first solution; soaking the perforated polyolefin membrane coated with the first solution into a third solvent, and punching to form a gel polymer electrolyte prefabrication layer on the surface of the perforated polyolefin membrane; and performing fumigation on the perforated polyolefin membrane with the gel polymer electrolyte prefabrication layer in hydrochloric acid atmosphere. The invention also relates to the polyolefin composite membrane and a lithium ion battery.

Owner:JIANGSU HUADONG INST OF LI ION BATTERY +1

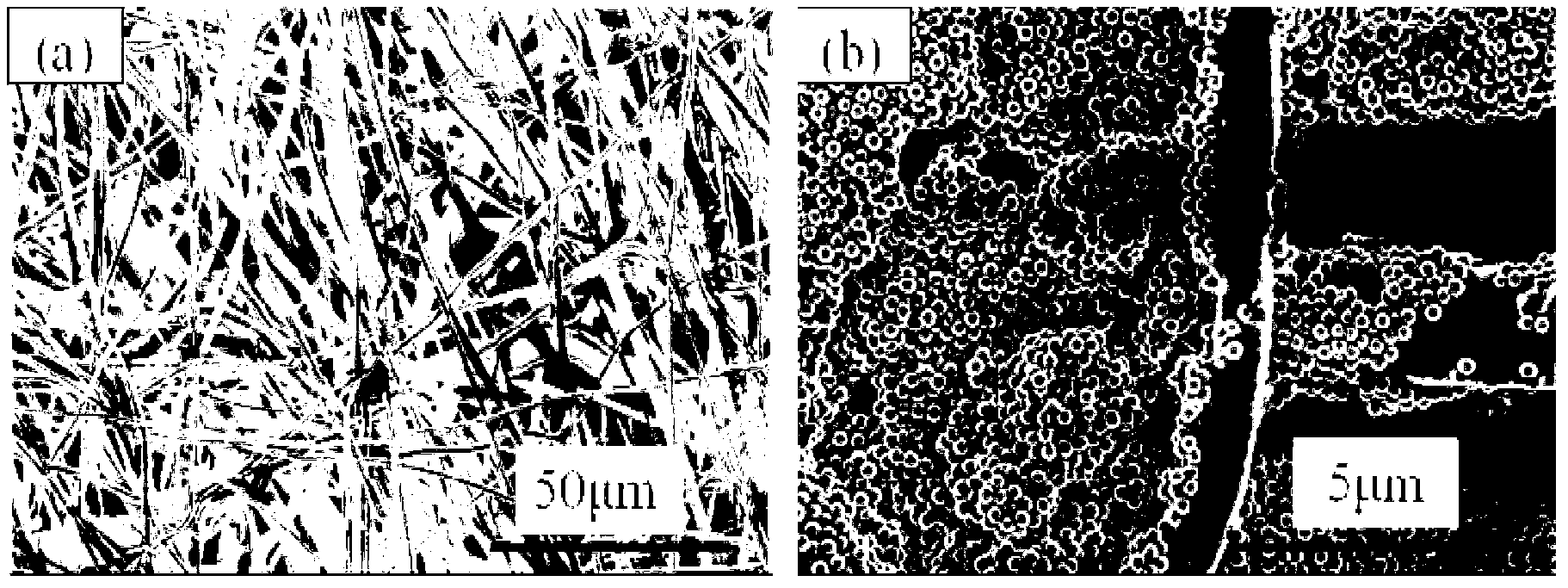

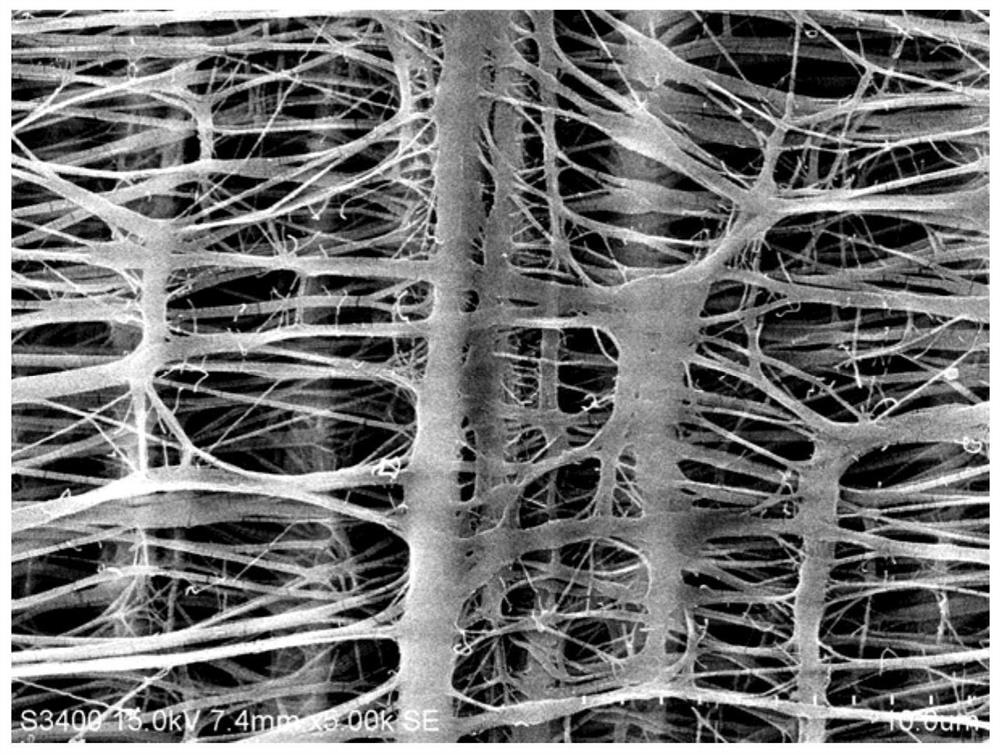

Polymer composite film and preparation method thereof, and lithium ion battery

ActiveCN106898814AHigh mechanical strengthImproved heat shrink resistance and mechanical strengthSolid electrolytesFilament/thread formingFiber layerPolymer composites

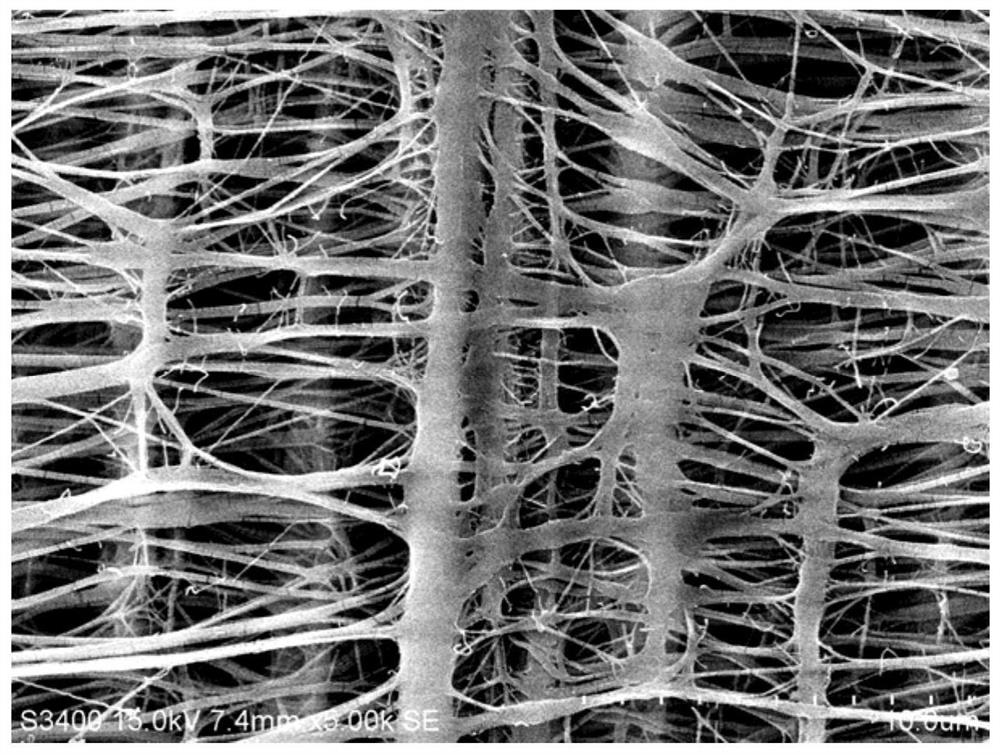

In order to solve the problem of poor mechanical strength of the polymer composite film in the prior art, the invention provides a polymer composite film which comprises a porous diaphragm and a fiber layer positioned on the diaphragm, wherein at least one fiber bundle is arranged in the fiber layer; and each fiber bundle comprises a plurality of fibers arranged in parallel. The invention also provides a preparation method of the polymer composite film and a lithium ion battery using the polymer composite film. The polymer composite film provided by the invention has favorable mechanical strength.

Owner:BYD CO LTD

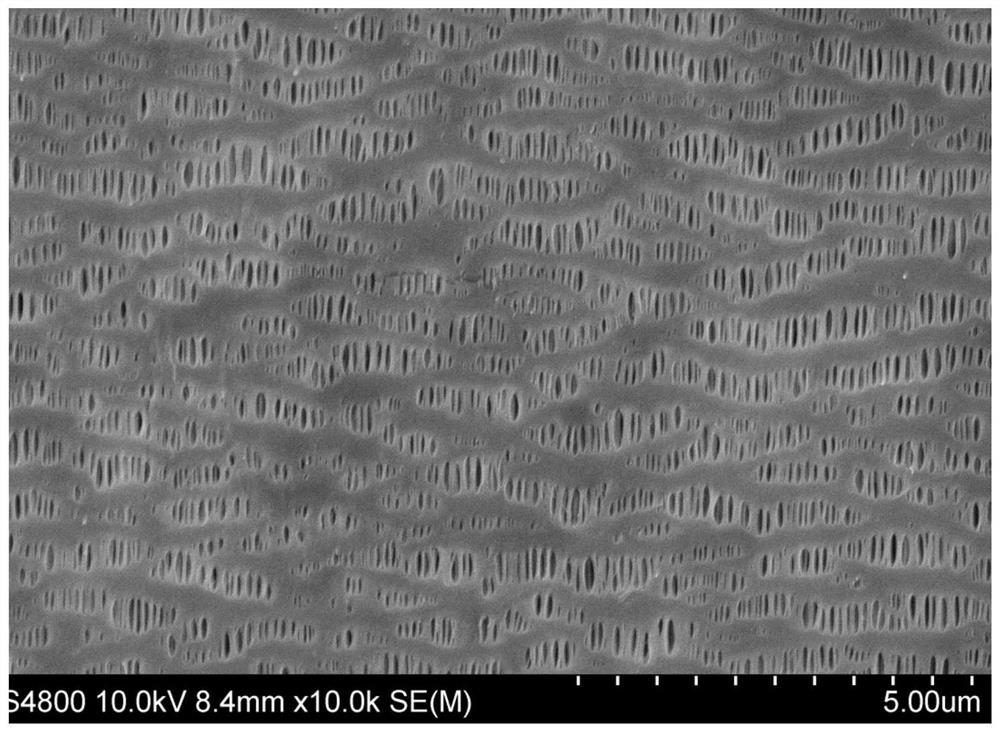

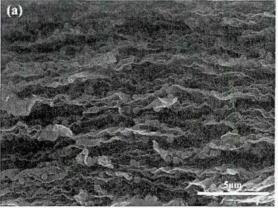

PI-AlN-PTFE ternary nano-composite multi-curve pore membrane material and preparing method and application thereof

ActiveCN105047847AImprove temperature resistanceHigh hardnessNon-aqueous electrolyte accumulatorsElectrolytic capacitorsPorosityFiber

The invention discloses a nano-composite multi-curve pore membrane material, polyimide (PI) nano-fiber non-woven fabric serves as the base material, and base material pores are filled with composite nano-particles. The nano-composite multi-curve pore membrane material is characterized in that the nano-particles are formed by mixing polytetrafluoroethylene nanoparticle (PTFE-NP) and aluminium nitride nanoparticle (AlN-NP) at the weight ratio of (7-12) / (8-13). The nano-composite multi-curve pore membrane material is resistant to high temperature, high in hardness, proper in porosity, proper in surface density, good in ion transmission performance and good in mechanical performance, when the nano-composite multi-curve pore membrane material is used in lithium-ion batteries, the problem of a battery micro short circuit due to the excessively-high porosity of a pure polyimide nano-fiber membrane can be solved, and the serious problem of thermal runaway caused by the mechanical collision of the power lithium-ion batteries can be solved.

Owner:JIANGXI NORMAL UNIV

Flat plate type denitrification membrane for wastewater treatment and preparation method thereof

ActiveCN111939767AHighly match the physical structureHighly Compatible FunctionSemi-permeable membranesWater contaminantsCarbon fibersCellulose fiber

The invention relates to a flat plate type denitrification membrane for wastewater treatment and a preparation method thereof, and belongs to the technical field of wastewater treatment. The membranecomprises a non-woven fabric base material layer and a gas permeation layer, wherein the non-woven fabric base material layer and the gas permeation layer are bonded into a whole; the non-woven fabricbase material comprises polypropylene fibers, cellulose fibers and carbon fibers, wherein the polypropylene fiber accounts for 60-90 wt%, the cellulose fiber accounts for 5-30 wt%, the carbon fiber accounts for 5-15 wt%, and the gas permeable layer is an expanded polytetrafluoroethylene film. The flat plate type denitrification membrane provided by the invention is an immersed flat plate membraneand has a large specific surface area, so that the membrane can be directly applied to ammonia-nitrogen wastewater, does not need to be additionally provided with a front filtering device, and is convenient to operate, easy to replace and convenient to clean and overhaul. The flat plate type denitrification membrane has a unique physical structure, the physical structure is highly matched with functionality, the denitrification performance is better, and index parameters such as a contact angle, a pore diameter and air permeability are reasonable.

Owner:CHINA HAISUM ENG

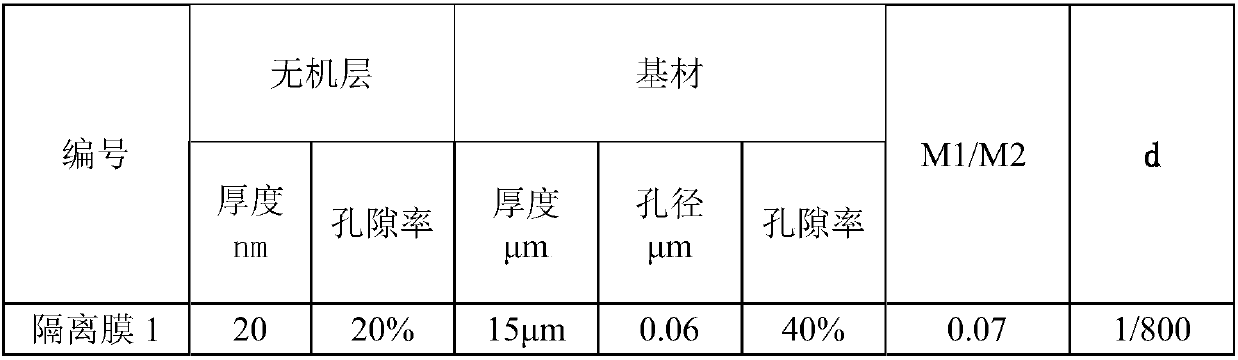

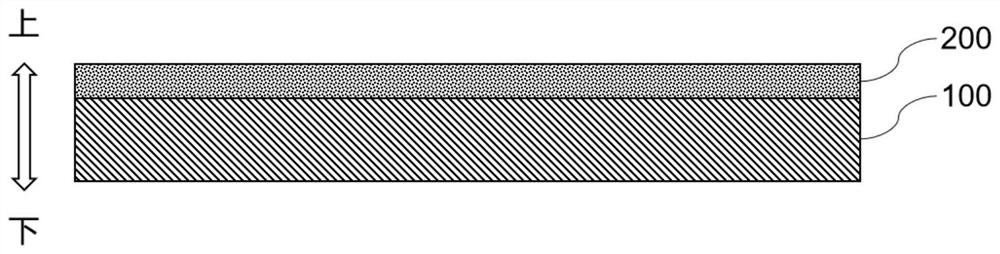

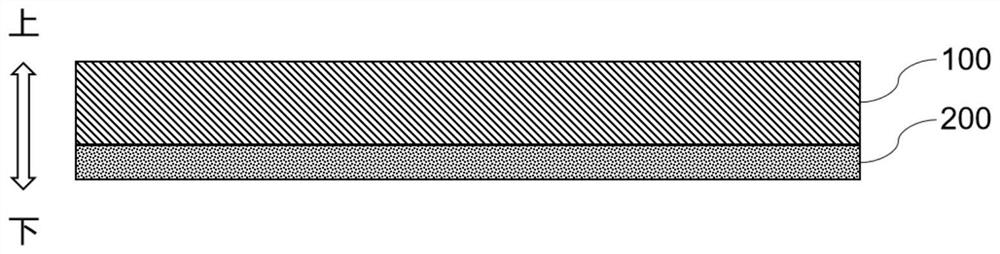

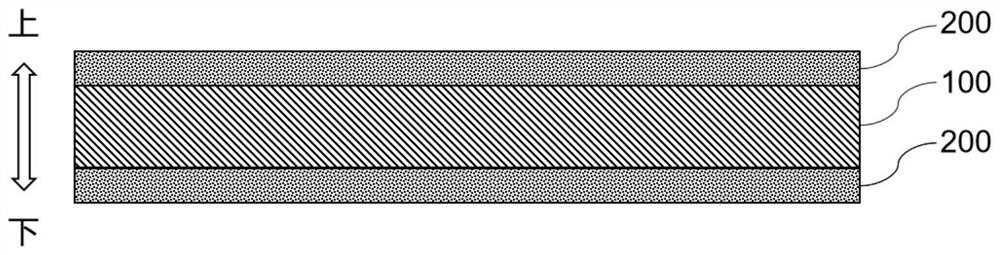

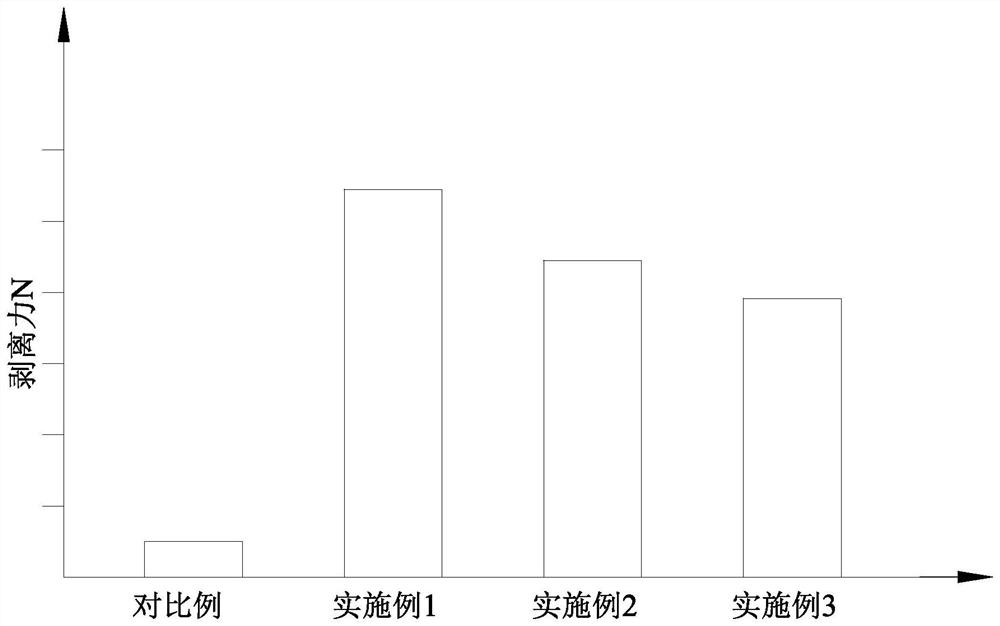

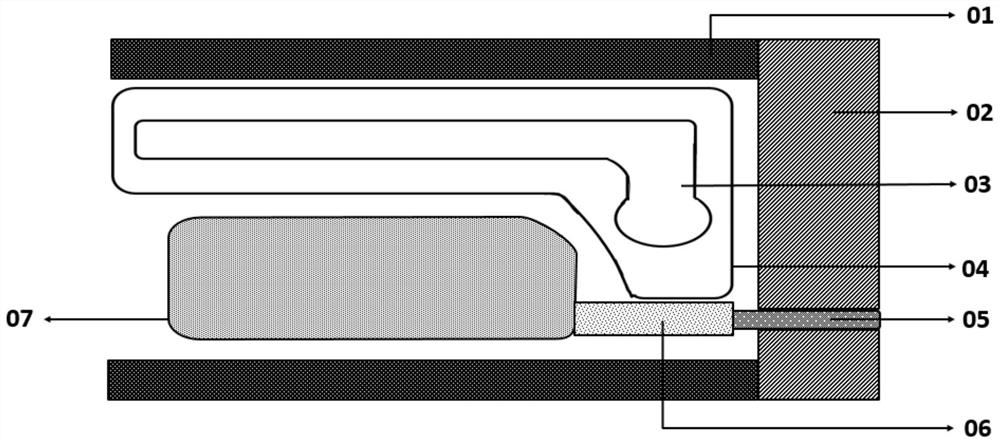

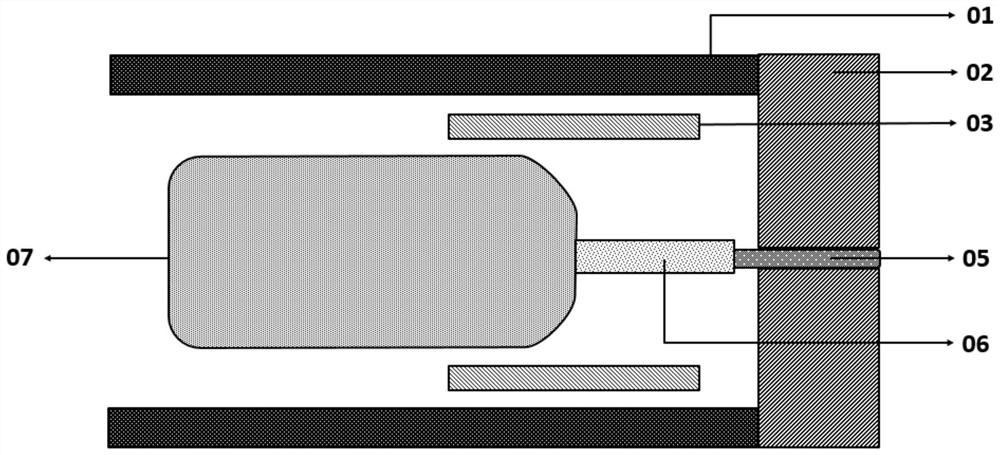

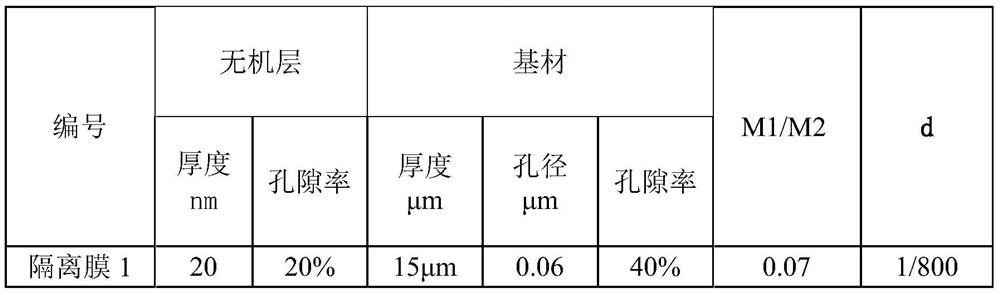

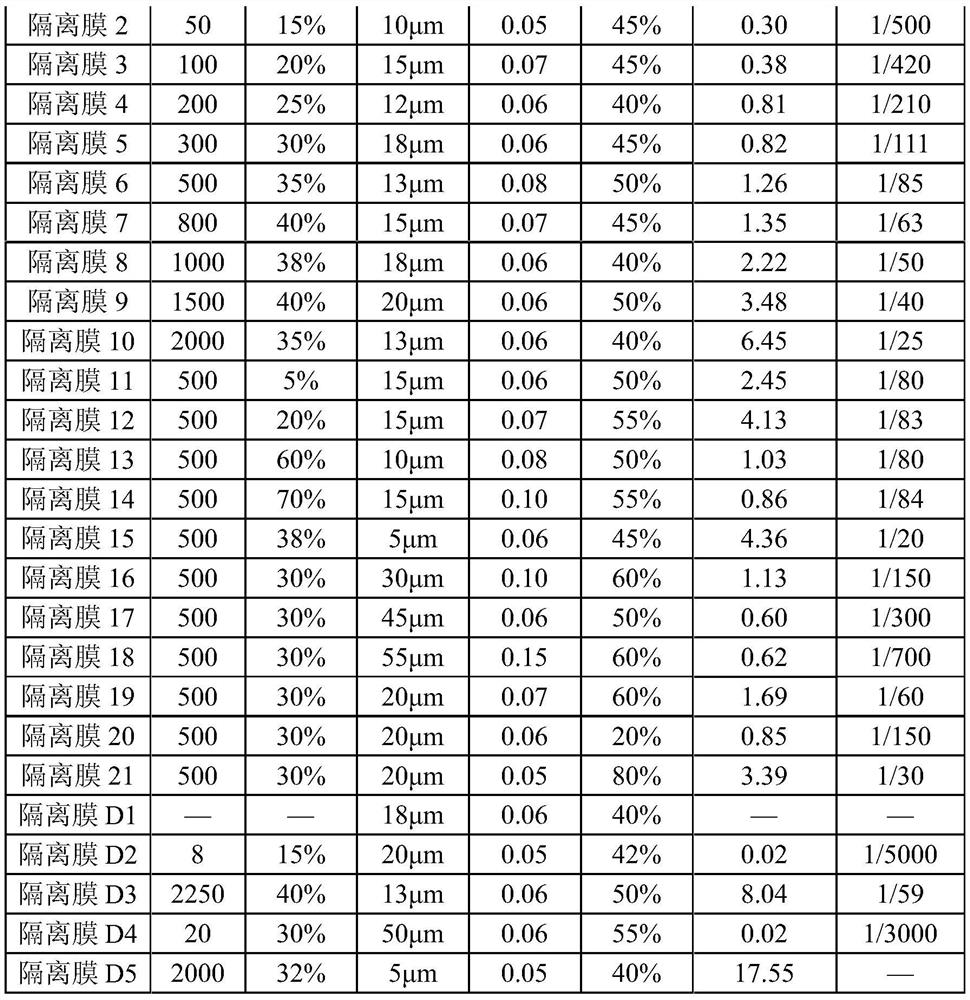

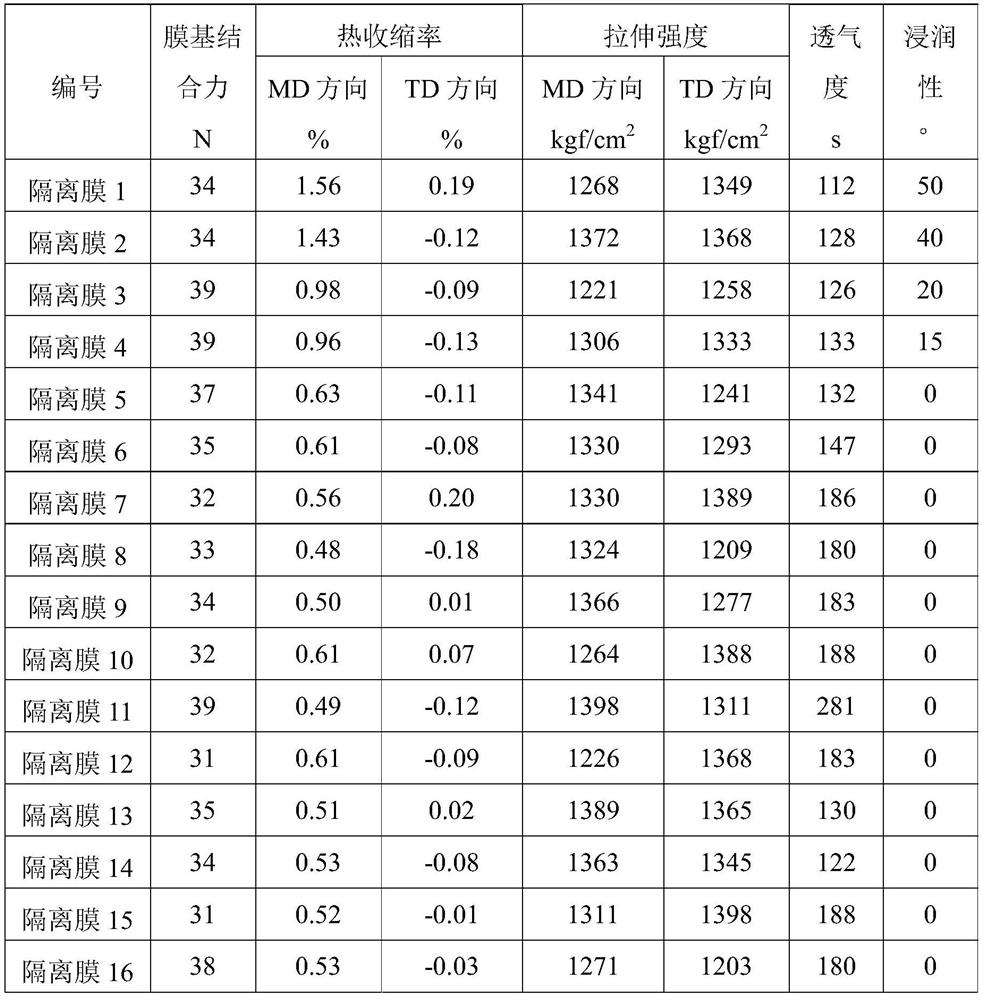

Isolating membrane, preparation method of isolating membrane, and electrochemical device comprising isolating membrane

ActiveCN109994691AGood interface wettabilityImprove heat shrink resistanceVacuum evaporation coatingSecondary cellsAdhesiveElectrochemistry

The invention relates to the field of energy storage materials, in particular to an isolating membrane, a preparation method of the isolating membrane and an electrochemical device comprising the isolating membrane. The isolating membrane comprises a base material and an inorganic layer at least arranged on one side of the base material, wherein the base material is a porous base material, and theinorganic layer is a dielectric layer which does not contain an adhesive; the thickness of the inorganic layer is 20-2000 nm; the ratio of the mass M1 of the inorganic layer to the mass M2 of the base material is M1 / M2, wherein M1 / M2 is greater than or equal to 0.05 and less than or equal to 7.5; and the interface stripping force of the inorganic layer and the base material is not lower than 30N / m. According to the isolating membrane disclosed by the invention, the ultrathin inorganic layer without the adhesive is arranged on the surface of the porous base material, so that the interface wettability and the thermal shrinkage resistance of the isolating membrane are effectively improved, certain mechanical strength is guaranteed, and the problem that the mechanical strength is lowered andthe base material is blocked caused by falling can be avoided, and the safety and the cycle life of the battery are improved and prolonged. By controlling the ranges of the M1 / M2 and the interface stripping force, the energy density is relatively high.

Owner:CONTEMPORARY AMPEREX TECH CO

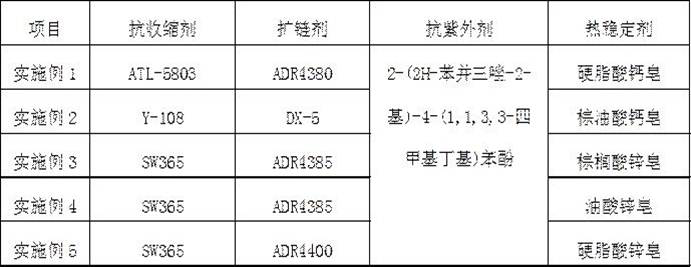

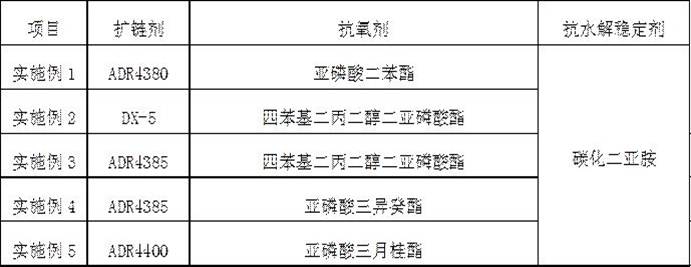

Polyester film with high barrier property and preparation and application thereof

InactiveCN114074469AImprove barrier propertiesImprove heat stabilityFlexible coversWrappersPolyesterPolymer science

The invention relates to a polyester film with high barrier property, wherein the polyester film comprises an outer surface layer, an inner surface layer and a middle core layer arranged between the outer surface layer and the inner surface layer, wherein the outer surface layer and the inner surface layer are prepared from the following raw materials in parts by weight: 70 to 85 parts of PET, 15 to 30 parts of PEN, 1 to 10 parts of PET-g-MAH, 2 to 5 parts aofn anti-shrinking agent, 1 to 3 parts of a chain extender, 0.1 to 0.6 part of an anti-ultraviolet agent and 0.2 to 0.8 part of a heat stabilizer; and the middle core layer is prepared from the following raw materials in parts by weight: 60 to 80 parts of PET, 20 to 40 parts of PMMA, 1 to 10 parts of PET-g-MAH, 5 to 20 parts of starch modified superfine montmorillonite, 2 to 8 parts of a chain extender, 0.1 to 1 part of an antioxidant and 0.2 to 0.5 part of a hydrolysis-resistant stabilizer. Compared with the prior art, the polyester film provided by the invention has excellent water vapor barrier property and thermal shrinkage resistance, good flexibility and weather resistance, simple and efficient preparation process, and good application prospect.

Owner:河南源宏高分子新材料有限公司

Composite diaphragm and application thereof

InactiveCN112038554AImprove ionic conductivityImprove heat shrink resistanceLi-accumulatorsCell component detailsNano catalystPtru catalyst

The invention discloses a composite diaphragm and application thereof. The composite diaphragm comprises a diaphragm matrix and an active lithium source coating, wherein the active lithium source coating is arranged on the diaphragm matrix, and the active lithium source coating comprises a nano active lithium source, a nano catalyst, a ceramic electrolyte and a binder. Therefore, multiple effectsof improving the safety of the battery, supplementing lithium and improving the conductivity of the diaphragm are achieved.

Owner:KUNSHAN BAOTRON NEW ENERGY TECH CO LTD

High-cohesiveness ceramic coating slurry and preparation method thereof

PendingCN113611982AGood thermal supportImprove heat shrink resistanceSecondary cellsMacromolecular adhesive additivesAdhesive glueCeramic coating

The invention relates to high-cohesiveness ceramic coating slurry and a preparation method thereof. The method comprises the steps that: PVDF glue and a kneading agent are added into deionized water to be stirred, the PVDF glueand the kneading agent are combined to form large-particle PVDF micelle, and large-particle PVDF micelle primary slurry is obtained; and ceramic powder, glue, a dispersing agent and a wetting agent are added into the large-particle PVDF micelle primary slurry to be stirred, large-particle PVDF micelle slurry is obtained, and the large-particle PVDF micelle slurry is prepared from, by weight, 20-40 parts of large-particle PVDF primary slurry, 50-70 parts of ceramic powder and 5-15 parts of glue, and the large-particle PVDF micelle primary slurry comprises the following raw materials in parts by weight: 5-7 parts of PVDF glue, 1-3 parts of kneading agent and 1-3 parts of deionized water. According to the preparation method, the kneading agent and the PVDF glueare subjected to kneading pretreatment, so that the PVDF glue forms the large-particle PVDF micelle primary slurry, the large-particle PVDF micelle primary slurry can be highlighted on the surface of the ceramic after being mixed with the ceramic, a corresponding pole piece bonding effect is achieved, and meanwhile, the heat-resistant shrinkage performance of a film is improved.

Owner:DONGGUAN ADVANCED ELECTRONICS TECH

Binder for lithium-ion battery separator, preparation method and separator using the binder

ActiveCN104140502BImprove high temperature resistanceImprove overcharge resistanceCell component detailsCoatingsHigh diaphragmElectrical battery

The invention discloses a binder for a lithium ion battery diaphragm, a preparation method and a diaphragm using the same. The binder comprises the following raw materials by weight: 0.5-1 part of a water-soluble polymer, 1-10 parts of a flexible segment monomer, 1-10 parts of a rigid segment monomer, 0.01-0.05 part of an initiator, and 1-10 parts of a plasticizer. The binder for the lithium ion battery diaphragm provided by the invention can be mixed with an inorganic matter to serve as a coating material of the lithium ion battery diaphragm, and the thermal stability and anti-thermal shrinkage performance of the diaphragm can be improved, so that the likely internal short circuit problem caused by poor thermal stability of the existing lithium ion battery diaphragms can be solved, and the diaphragm can have good safety and overcharge tolerance. At the same time, the binder contains polar groups, which can closely bonds with the inorganic matter to improve the wettability and liquid retention of the diaphragm. The flexible segment is introduced while the rigid segment exists, thereby improving the mechanical properties of the binder and guaranteeing the bonding force and the flexibility of the diaphragm.

Owner:SHANGHAI FANNENG NEW MATERIAL TECH CO LTD

Graphene recycled rubber and plastic foam particles for shoe soles and preparation method thereof

The invention relates to graphene regenerated rubber and plastic foam particles for shoe soles, comprising the following components by weight: 60-65 parts of EVA waste; 23-25 parts of natural rubber; 4-6 parts of POE elastomer; modified graphene 1-2 parts; 0.1-0.2 parts of poly N-vinyl acetamide; 2.0-2.3 parts of white mineral oil; 1.0-1.2 parts of silicone oil; 1.4-1.5 parts of active zinc oxide; 0.8-1.0 parts of zinc stearate; 0.8-1.0 parts of stearic acid; 0.8-1.0 parts of crosslinking agent; 2.0-3.0 parts of flow aid; 1.5-1.8 parts of foaming agent. The present invention makes full use of existing EVA waste materials, regenerates resources, and obtains foam rubber particles with up to standard physical properties and enhanced thermal shrinkage resistance.

Owner:FUJIAN WUCHIHENG TECH DEV CO LTD

A flat-plate denitrification membrane for wastewater treatment and preparation method thereof

ActiveCN111939767BEasy to replaceEasy to clean and maintainSemi-permeable membranesWater contaminantsAmmoniacal nitrogenCarbon fibers

The invention relates to a flat-plate denitrification membrane for wastewater treatment and a preparation method thereof, belonging to the technical field of wastewater treatment; comprising a non-woven substrate layer and a gas permeable layer; the non-woven substrate layer and the gas permeable layer are bonded In one piece; the non-woven base material includes polypropylene fiber, cellulose fiber and carbon fiber; wherein polypropylene fiber accounts for 60-90wt%, cellulose fiber accounts for 5-30wt%, carbon fiber accounts for 5-15wt%, gas permeability The layer is an expanded polytetrafluoroethylene film. The flat-plate denitrification membrane provided by the invention is a submerged flat-plate membrane with a large specific surface area, which can be directly applied in ammonia nitrogen wastewater without adding a pre-filtering device, and is easy to operate, the membrane is easy to replace, and the cleaning and maintenance are convenient. The flat-plate denitrification membrane of the present invention has a unique physical structure, and the physical structure and functionality are highly matched, the denitrification performance is good, and the index parameters such as contact angle, pore diameter and air permeability are reasonable.

Owner:CHINA HAISUM ENG

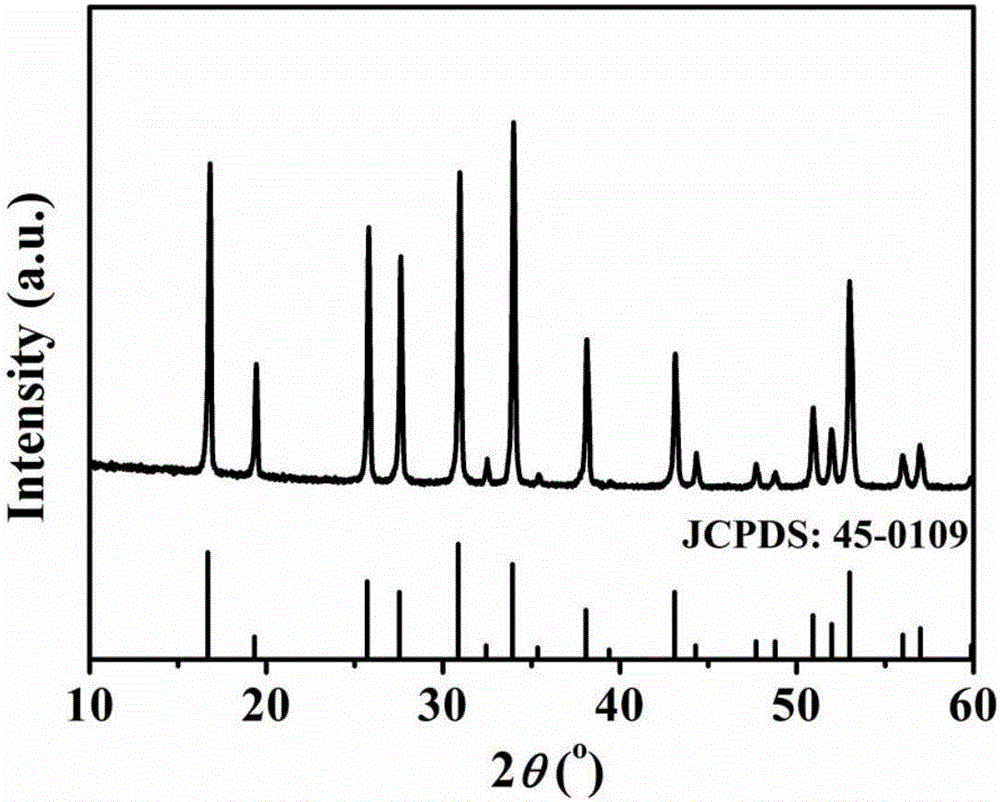

pi‑aln‑ptfe ternary nanocomposite porous membrane material and its preparation method and application

ActiveCN105047847BImprove temperature resistanceHigh hardnessNon-aqueous electrolyte accumulatorsElectrolytic capacitorsFiberElectrical battery

The invention discloses a nanocomposite multi-porous membrane material, which uses polyimide (PI) nanofiber non-woven fabric as a base material, and the pores of the base material are filled with composite nanoparticles; it is characterized in that: the composite The nanoparticles are composed of polytetrafluoroethylene nanospheres (PTFE-NP) and aluminum nitride nanoparticles (AlN-NP) mixed in a weight ratio of (7-12) / (8-13). The nanocomposite multi-porous membrane material provided by the invention has high temperature resistance, high hardness, moderate porosity, moderate areal density, good ion transport and excellent mechanical properties. The imide nanofiber diaphragm causes the problem of micro-short circuit of the battery due to high porosity; it can solve the serious problem of thermal runaway caused by mechanical collision of power lithium-ion batteries.

Owner:JIANGXI NORMAL UNIV

Flared steel strip reinforced polyethylene spiral corrugated pipe and preparation method thereof

ActiveCN112694657AEasy to stretchPrevent lateral slippageRigid pipesPipe protection against damage/wearPolymer scienceCrazing

The invention relates to the technical field of pipes, and particularly discloses a flared steel strip reinforced polyethylene spiral corrugated pipe and a preparation method thereof. The corrugated pipe comprises an inner pipe, a steel strip and an outer pipe, wherein the outer pipe and the inner pipe are prepared from the following raw materials by weight: 85-105 parts of high-density polyethylene, 25-45 parts of polyether polyurethane, 15-25 parts of maleic anhydride grafted polyethylene, 15-30 parts of filler, 5-10 parts of color master batch, 15-25 parts of a flame retardant, 4-8 parts of a dispersing agent and 2-6 parts of a coupling agent. The corrugated pipe provided by the invention has excellent tensile property and impact resistance, and has the effect of improving the defect that the flared steel strip reinforced polyethylene spiral corrugated pipe is easy to generate chronic cracks.

Owner:四川兰晨管业有限公司

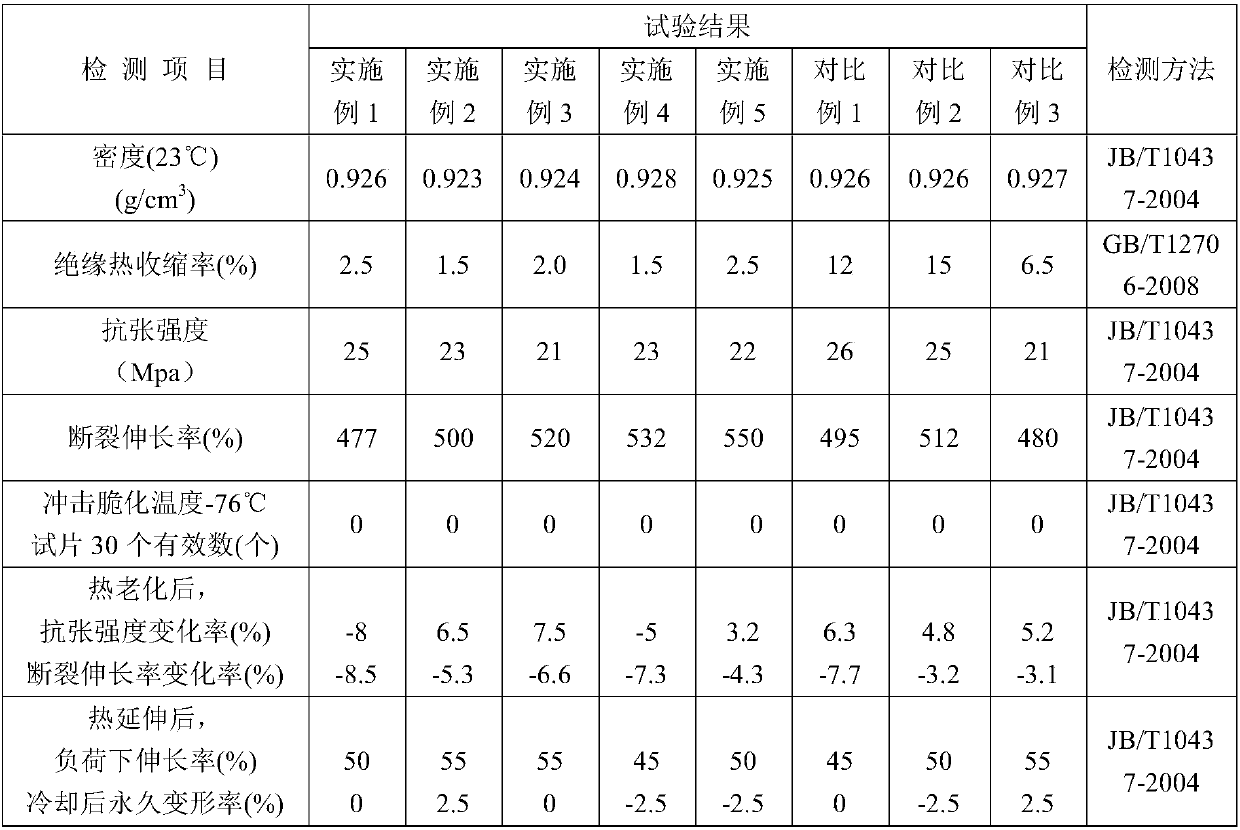

Polyolefin resin composition, preparation method thereof, insulating material for cable, cable

ActiveCN106397960BExcellent thermal shrinkage performanceExtended service lifePlastic/resin/waxes insulatorsElectrical conductorPolyolefin

Owner:ZHEJIANG WANMA MACROMOLECULE MATERIAL

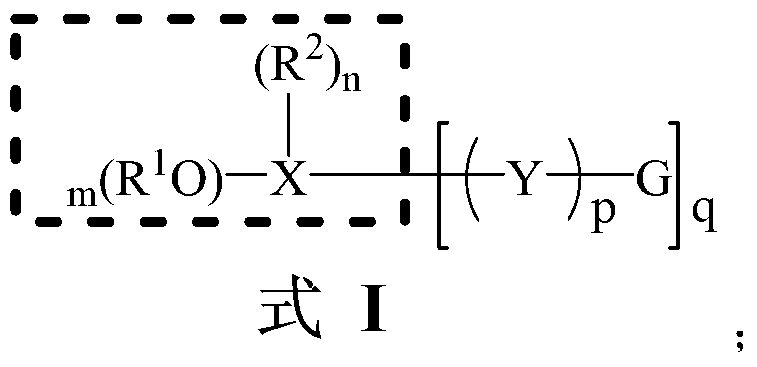

Polyolefin composite separator, preparation method thereof, and lithium-ion battery

ActiveCN104031289BHigh liquid absorptionImprove permeabilitySolid electrolytesLi-accumulatorsPolyolefinPolymer science

A method for preparing a polyolefin composite diaphragm, comprising: polymerizing methyl methacrylate and γ-methacryloxypropyltriethoxysilane in proportion to form a copolymer, the molecular formula of the copolymer is:, Wherein, m and n are integers; the copolymer is dissolved in the first solvent to form a copolymer solution; the copolymer solution is scraped on the surface of the polyolefin porous membrane and dried, so that the polyolefin porous A gel polymer electrolyte prefabricated layer is formed on the surface and inner pore walls of the diaphragm; and the polyolefin porous diaphragm containing the gel polymer electrolyte prefabricated layer is fumigated in an atmosphere of hydrochloric acid. The invention also relates to a polyolefin composite diaphragm and a lithium ion battery.

Owner:JIANGSU HUADONG INST OF LI ION BATTERY +1

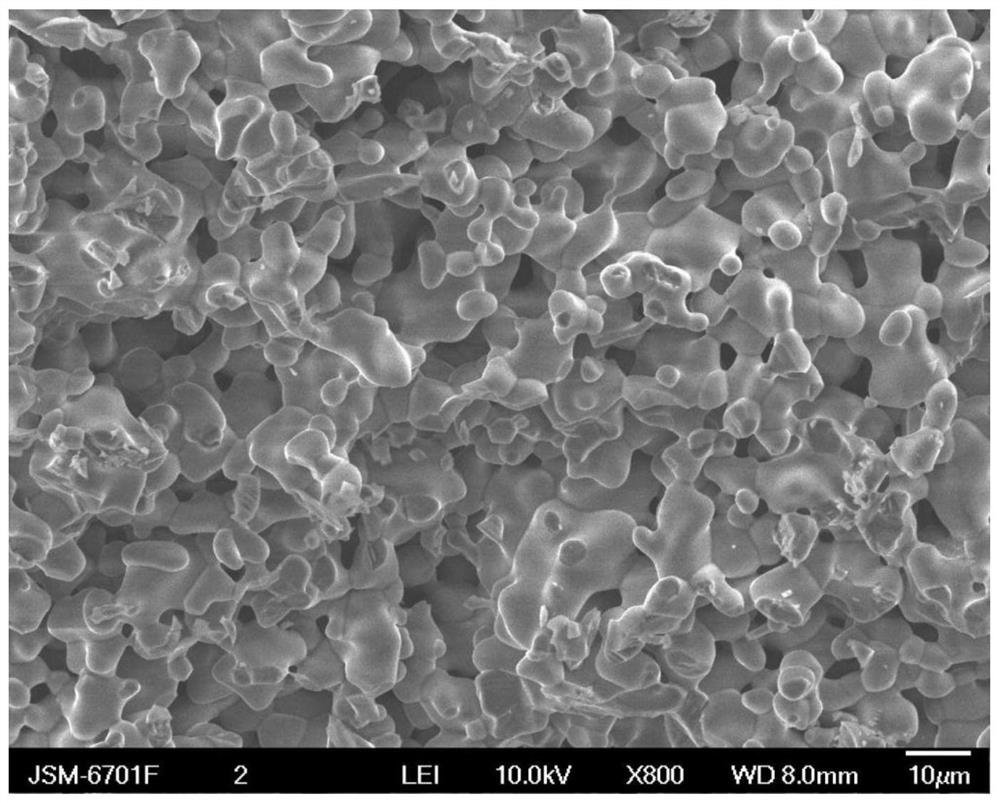

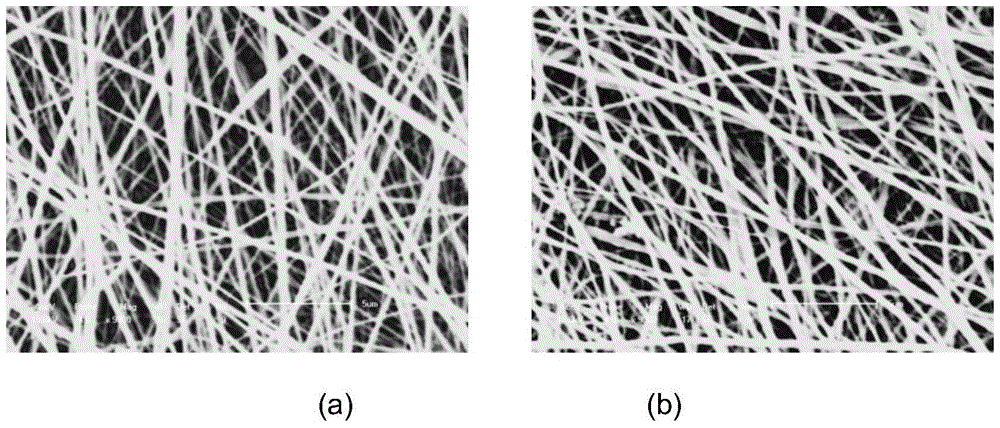

Polydopamine surface-modified polyethersulfone nanofiber composite diaphragm, preparation method and application

ActiveCN104466063BHigh porosityHigh temperature resistantSecondary cellsCell component detailsPolymer scienceIn situ polymerization

A novel polydopamine surface-modified polyethersulfone nanofiber composite membrane for lithium-ion batteries, a preparation method and its application in lithium-ion batteries belong to the technical field of lithium-ion battery materials. The present invention mainly adopts electrospinning method to prepare polyethersulfone nanofiber membrane with high porosity, and then uniformly coats polydopamine on the surface of nanofiber through in-situ polymerization method to prepare polydopamine surface-modified polyethersulfone nanofiber Composite diaphragm. As a result, the composite separator has both structural and performance advantages such as excellent heat resistance, wetting performance, and high porosity. From the perspective of lithium battery separators, the performance of lithium-ion batteries can be improved.

Owner:吉林省聚科高新材料有限公司

Shrinkage-resistant graphene oxide-based porous battery diaphragm and preparation method thereof

InactiveCN113410578AFacilitate the grafting reactionRich pore structureLi-accumulatorsCell component detailsElectrical batteryGraphene flake

The invention discloses an anti-shrinkage graphene oxide-based porous battery diaphragm and a preparation method thereof. The porous battery diaphragm is a diaphragm taking graphene oxide as a matrix. The porous battery diaphragm has the beneficial effects that (1) the graphene oxide has good thermal stability, electrochemical inertness and self-film-forming property, and the polyether polyol is grafted, so that the thermal shrinkage resistance of the diaphragm is effectively enhanced, and the size integrity of the diaphragm at 200 DEG C is ensured; (2) the liquid absorption rate of the diaphragm is obviously increased by utilizing the good compatibility between polyether bonds in the polyether polyol and electrolyte; (3) gaps between graphene oxide sheet layers are combined with pores generated between the sheet layers by the PS microspheres, so that the diaphragm generates a rich pore structure, and an adsorption space is provided for liquid absorption of the diaphragm; and (4) the graphene oxide is grafted by using polyether polyol, so that the graphene oxide is inhibited from being reduced into conductive graphene at high temperature, and the thermal stability and safety of the diaphragm are improved.

Owner:JIANGSU HORIZON NEW ENERGY TECH CO LTD

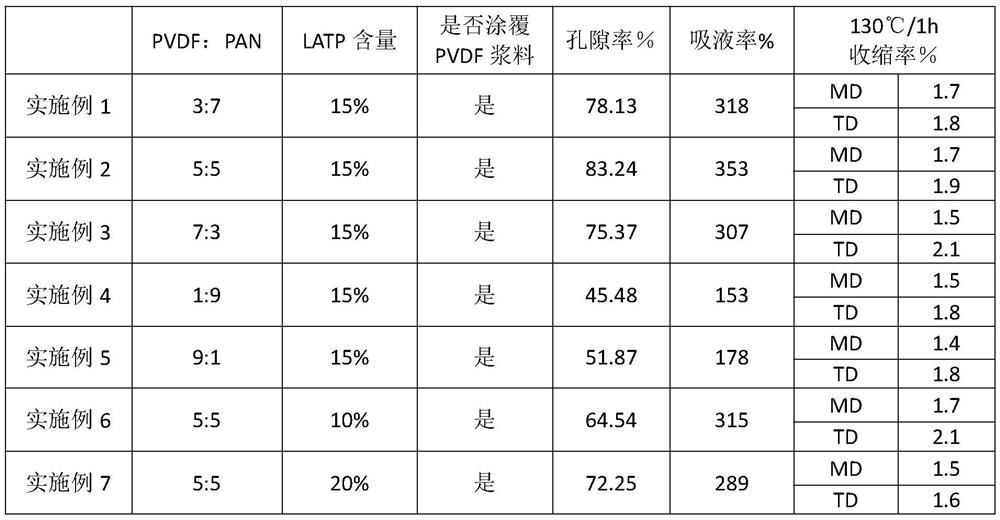

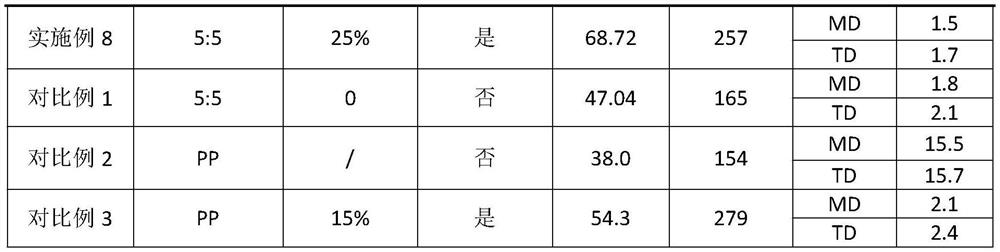

Composite diaphragm and preparation method thereof as well as battery and object with composite diaphragm

PendingCN114374050AGood hydrophilicityHigh surface energyCell seperators/membranes/diaphragms/spacersElectro conductivityElectrospinning

The invention discloses a composite diaphragm and a preparation method thereof, and relates to the technical field of secondary batteries. The electrostatic spinning thin film is used as the base film, the electrostatic spinning thin film is subjected to electrostatic spinning in a mixing and dissolving mode, the polymer mixture has the advantages of being good in hydrophilicity and high in surface energy, and the affinity of the lithium battery diaphragm to electrolyte can be improved. Besides, one side of the electrostatic spinning film is coated with a nano material, the nano material has the characteristic of high room-temperature ionic conductivity, the conductivity of the lithium battery diaphragm can be improved, and meanwhile, the other side of the base film is coated with PVDF slurry, so that the liquid absorption performance and the heat shrinkage resistance of the composite diaphragm are improved.

Owner:NINGDE ZHUOGAO NEW MATERIAL TECH CO LTD

pi‑sio 2 ‑PTFE ternary nanocomposite porous membrane material and its preparation method and application

ActiveCN105064007BImprove temperature resistanceSmall surface pore sizeFibre typesCell component detailsPorosityFiber

The invention discloses a nanocomposite multi-porous membrane material, which uses polyimide (PI) nanofiber non-woven fabric as a base material, and the pores of the base material are filled with composite nanoparticles; it is characterized in that: the composite Nanoparticles are composed of polytetrafluoroethylene nanospheres (PTFE‑NP) and silica nanoparticles (SiO 2 ‑NP) mixed in a weight ratio of (7‑12) / (8‑13). The nanocomposite multi-porous membrane material provided by the invention has high temperature resistance, moderate porosity, moderate areal density, good ion transport and excellent mechanical properties, and can overcome pure polyimide when used in lithium ion batteries. The nanofiber diaphragm causes the problem of micro-short circuit of the battery due to too high porosity; it can solve the serious problem of thermal runaway of the power lithium-ion battery due to mechanical collision.

Owner:JIANGXI NORMAL UNIV

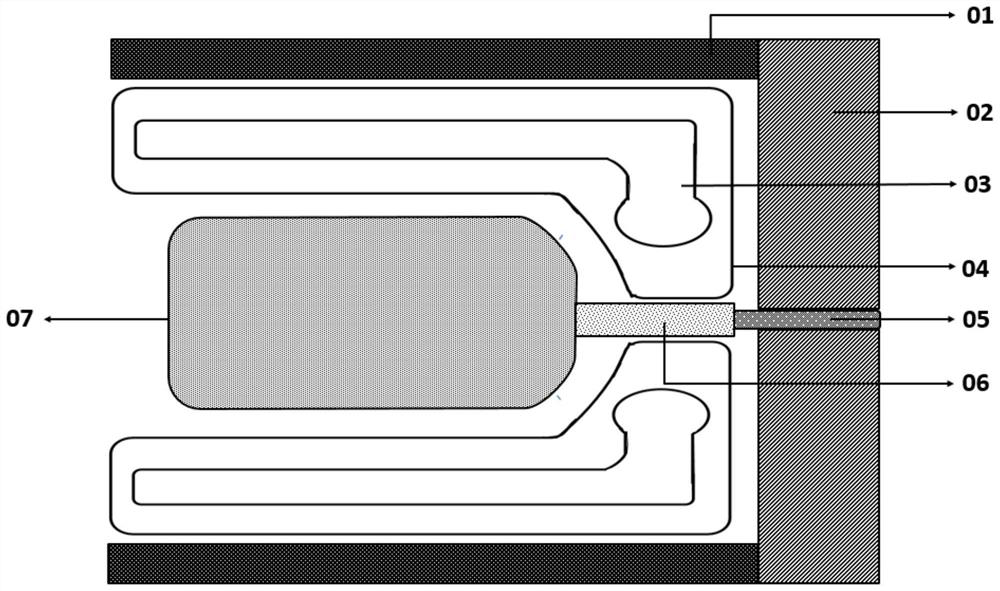

A kind of silica gel pad and its application in the preparation of lithium ion battery

ActiveCN109560327BShorten the transmission pathTight bondFinal product manufactureSecondary cells charging/dischargingPhysical chemistryStructural engineering

The invention discloses a silica gel pad. The silica gel pad has an L-shaped board surface structure, an angle is formed between two board surfaces of the silica gel pad, and an airtight hollow chamber is arranged inside the silica gel pad. In the formation process of preparing lithium-ion batteries, the silica gel gasket of the present invention is used to buckle the deep pit surface of the battery cell, so that the hollow chamber in the long side plate surface of the silica gel pad covers the main part of the battery cell, so that the silica gel pad The short side of the board is fastened to the head of the cell, and the bottom of the short side of the board is against the top sealing edge. The diaphragm of the battery cell adopts a rubber-coated diaphragm, combined with high-temperature fixture formation, which can form the cell head and the cell body without pressure difference. After formation, the diaphragm of the cell head can be tightly bonded to the pole piece. In this way, the transmission path of lithium ions during the charging and discharging process is reduced to ensure that lithium precipitation will not occur after multiple charging and discharging. The silica gel pad of the invention has simple structure, simple and feasible application method, and is convenient for realizing mass production. The invention is applied in the field of battery technology.

Owner:余姚市海泰贸易有限公司

A separator, its preparation method and an electrochemical device comprising the separator

ActiveCN109994691BGood interface wettabilityImprove heat shrink resistanceVacuum evaporation coatingSputtering coatingPorous substrateElectrical battery

The present application relates to the field of energy storage materials, and specifically relates to an isolation film, its preparation method and an electrochemical device including the isolation film. An isolation film includes a base material and an inorganic layer provided on at least one side of the base material. The base material is a porous base material. The inorganic layer is a dielectric layer that does not contain a binder. The thickness of the inorganic layer is 20nm ~ 2000nm, the ratio M1 / M2 of the mass M1 of the inorganic layer to the mass M2 of the substrate satisfies 0.05≤M1 / M2≤7.5, and the interface peeling force between the inorganic layer and the substrate is not less than 30N / m. The isolation film of this application effectively improves the interfacial wettability and thermal shrinkage resistance of the isolation film by arranging an ultra-thin inorganic layer without binder on the surface of the porous substrate, and ensures that it has a certain mechanical strength and avoids the problem of The problem of reduced mechanical strength and clogging of the pores of the substrate caused by falling off improves the safety and cycle life of the battery. By controlling the range of M1 / M2 and interface peeling force, the energy density is also higher.

Owner:CONTEMPORARY AMPEREX TECH CO

Pi-bn-ptfe ternary nanocomposite porous membrane material and its preparation method and application

ActiveCN105070869BImprove temperature resistanceHigh hardnessHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersFiberElectrical battery

The invention discloses a nanocomposite multi-porous membrane material, which uses polyimide (PI) nanofiber non-woven fabric as a base material, and the pores of the base material are filled with composite nanoparticles; it is characterized in that: the composite The nanoparticles are composed of polytetrafluoroethylene nanospheres (PTFE‑NP) and boron nitride nanoparticles (BN‑NP) in a weight ratio of (7‑12) / (8‑13). The nanocomposite multi-porous membrane material provided by the invention has high temperature resistance, high hardness, moderate porosity, moderate areal density, good ion transport and excellent mechanical properties. The imide nanofiber diaphragm causes the problem of micro-short circuit of the battery due to high porosity; it can solve the serious problem of thermal runaway caused by mechanical collision of power lithium-ion batteries.

Owner:JIANGXI NORMAL UNIV

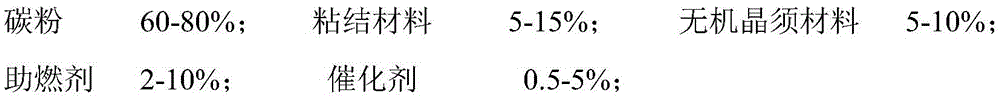

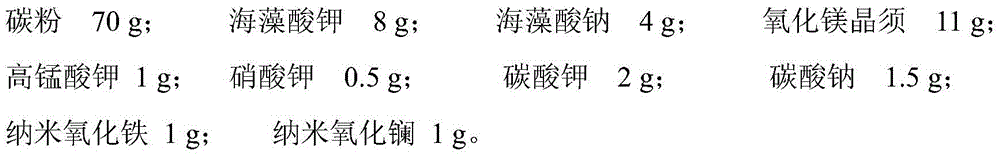

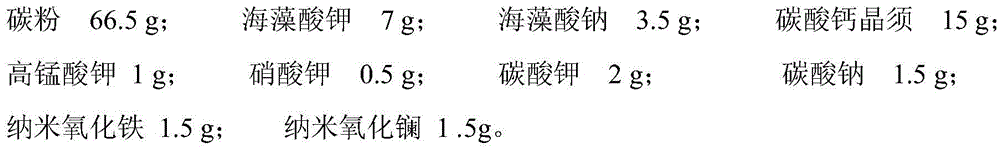

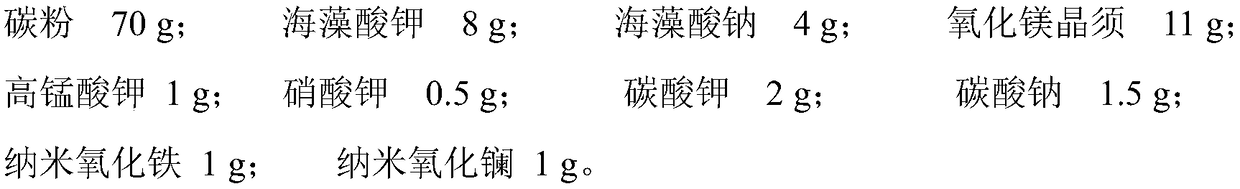

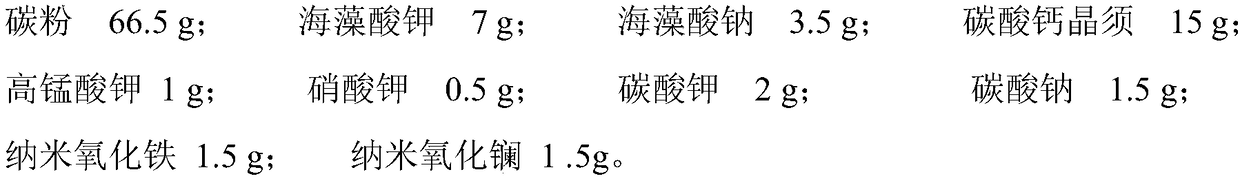

Method for preparing porous carbon heat source material

The invention discloses a method for preparing a porous carbon heat source material. The method includes the steps that all components and water are primarily mixed through a mixing machine, and then are fed into a screw extruder to continue to be mixed; meanwhile, a foaming agent CO2 is injected into the screw extruder, extrusion molding is conducted after foaming, then drying and cutting are conducted, and the porous carbon heat source material is obtained. According to the method, due to the porous characteristic of a porous carbon heat source, the porous carbon heat source is easy to ignite, full in burning and smooth in thermal flow transferring, and the difficulty, caused by the complex-longitudinal-channel design, of processing molding and reduction, caused by the complex-longitudinal-channel design, of mechanical strength are avoided.

Owner:CHINA TOBACCO ANHUI IND CO LTD

A kind of preparation method of porous carbonaceous heat source material

The invention discloses a method for preparing a porous carbon heat source material. The method includes the steps that all components and water are primarily mixed through a mixing machine, and then are fed into a screw extruder to continue to be mixed; meanwhile, a foaming agent CO2 is injected into the screw extruder, extrusion molding is conducted after foaming, then drying and cutting are conducted, and the porous carbon heat source material is obtained. According to the method, due to the porous characteristic of a porous carbon heat source, the porous carbon heat source is easy to ignite, full in burning and smooth in thermal flow transferring, and the difficulty, caused by the complex-longitudinal-channel design, of processing molding and reduction, caused by the complex-longitudinal-channel design, of mechanical strength are avoided.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com