Polymer composite film and preparation method thereof, and lithium ion battery

A polymer and composite film technology, used in secondary batteries, circuits, electrical components, etc., can solve problems such as poor mechanical strength, improve heat shrinkage resistance and mechanical strength, improve heat shrinkage resistance and mechanical strength, The effect of improving the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The present invention also provides a preparation method of the above-mentioned polymer composite membrane,

[0055] Including the following steps:

[0056] S1, provide diaphragm;

[0057] S2, providing a spinning solution; the spinning solution includes a solvent and a spinning polymer dissolved in the solvent;

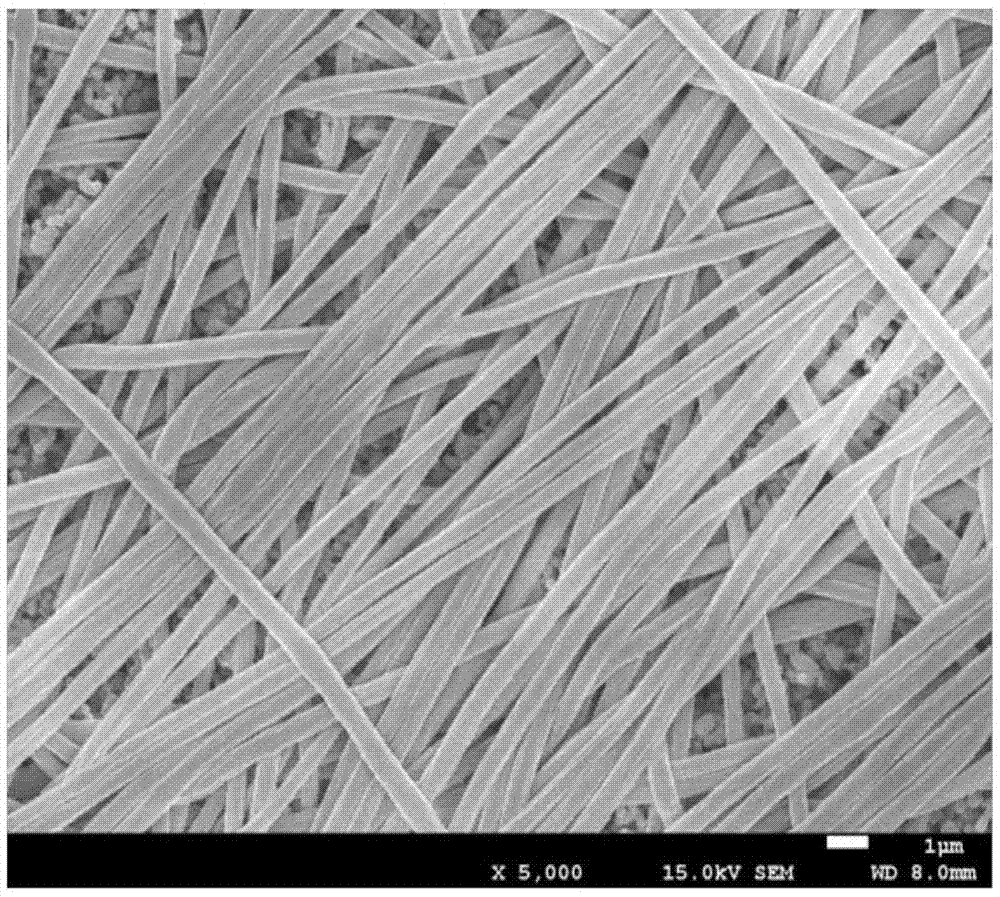

[0058] S3, using the spinning solution to prepare a fiber layer on the diaphragm, and obtain a polymer composite membrane with a fiber layer on the diaphragm after drying;

[0059] The method for preparing the fiber layer is high-speed electrospinning or auxiliary electric field electrospinning;

[0060] The high-speed electrospinning method is as follows: electrospinning is performed under the condition that the rotating speed of the collection device for collecting fibers is 1000-6000 rpm;

[0061] The method of described auxiliary electric field electrospinning is:

[0062] An auxiliary electrode is provided on the side of the collection device away fro...

Embodiment 1

[0112] This example is used to illustrate the polymer composite membrane disclosed in the present invention and its preparation method.

[0113] 1. Preparation of diaphragm

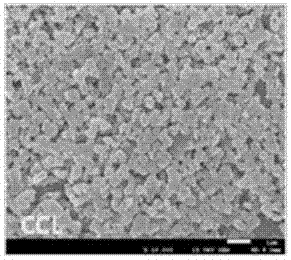

[0114] Al with an average particle size of 615nm 2 o 3 Granules, binder (PEO) and coating solvent (deionized water) are mixed into a slurry at a weight ratio of 24:1:500, and the surface of a 12 μm thick PE film is coated with Al 2 o 3 The granular layer, after drying, forms a double-layer film A1 with a thickness of 15 μm (its surface structure is as figure 1 shown), where the thickness of the PE film is 12 μm, and the surface of the PE film has Al with a thickness of 3 μm 2 o 3 Inorganic particle layer.

[0115] 2. Preparation of spinning solution

[0116] Spinning polymer (polyacrylonitrile) was added to the solvent NMP, and magnetically stirred under a water bath at 50° C. to fully dissolve to form a spinning solution with a concentration of 5 wt%.

[0117] 3. Preparation of polymer composite ...

Embodiment 2

[0132] This example is used to illustrate the polymer composite membrane disclosed in the present invention and its preparation method.

[0133] 1. Preparation of diaphragm

[0134] Al with an average particle size of 615nm 2 o 3 The particles, binder (PEO) and coating solvent (deionized water) were mixed into a slurry at a weight ratio of 24:1:500, and both surfaces of the 11 μm thick PE film were coated with Al 2 o 3 Particle layer, dried to form a three-layer film A2 with a thickness of 15 μm, in which the thickness of the PE film is 11 μm, and both surfaces of the PE film have Al with a thickness of 2 μm 2 o 3 Inorganic particle layer.

[0135] 2. Preparation of spinning solution

[0136] Spinning polymers polyetherimide and polyacrylonitrile were respectively added to two parts of solvent NMP, fully dissolved by magnetic stirring in a water bath at 50° C. to form two parts of spinning solutions with concentrations of 20 wt % and 10 wt % respectively.

[0137] 3. Pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com