Patents

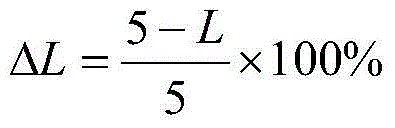

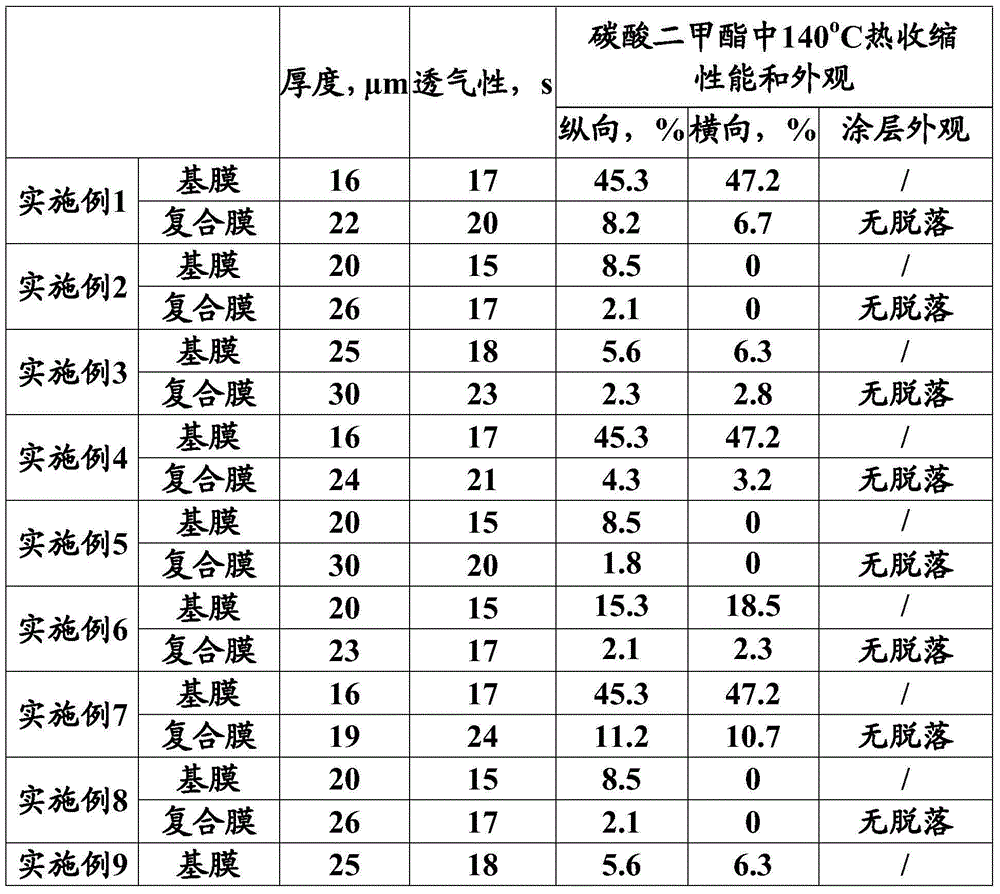

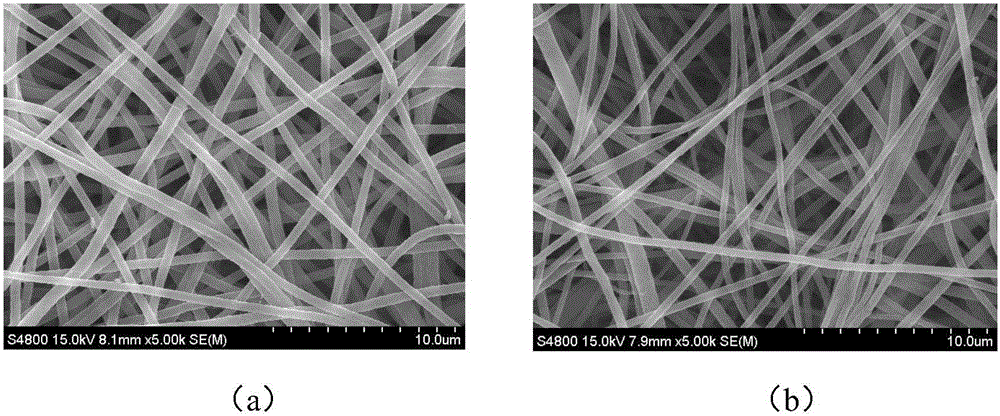

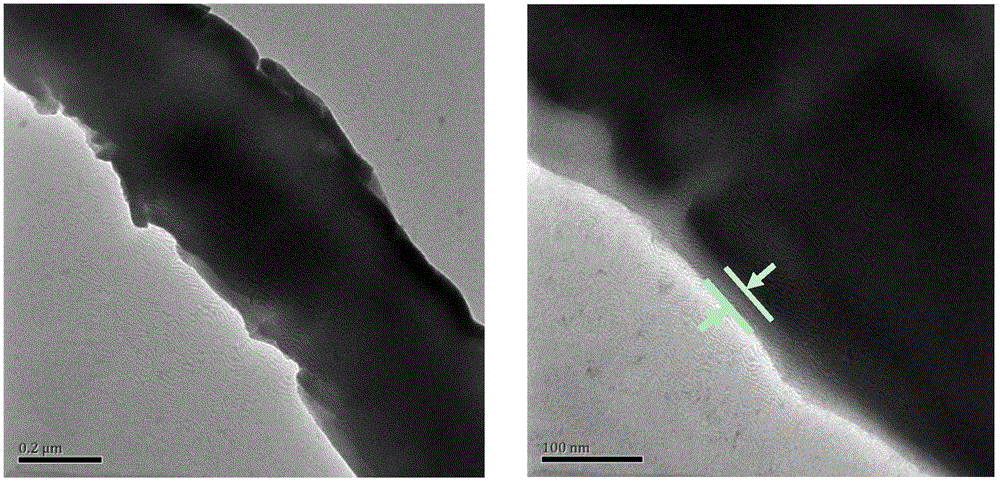

Literature

51results about How to "Improved resistance to heat shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance flexible composite nonwoven fabric membrane for lithium ion battery, as well as preparation method and application of membrane

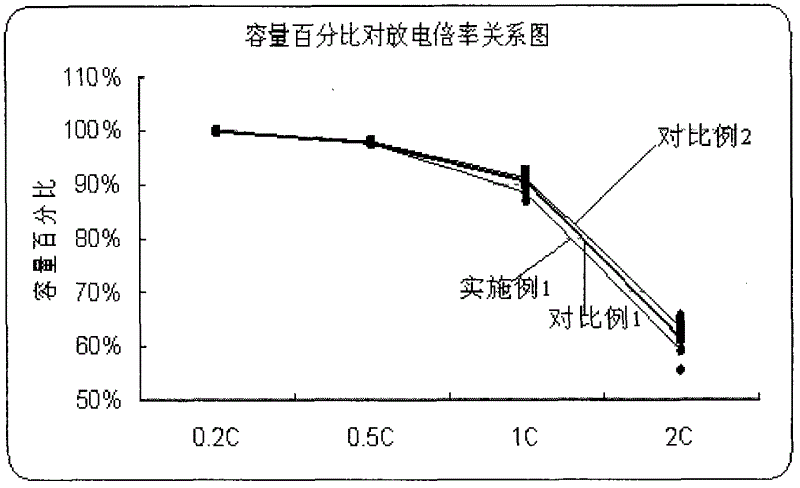

InactiveCN103296240AGood flexibilityGood high current discharge performanceCell component detailsAdhesiveCharge discharge

The invention discloses a high-performance flexible composite nonwoven fabric membrane for a lithium ion battery, as well as a preparation method and an application of the membrane, which belongs to the technical field of a lithium-ion battery membrane material. The prepared composite nonwoven fabric membrane is formed by coating functional serous fluid with thermally curable or optically curable functional groups onto a substrate membrane containing an active functional group, thermally curing or optically curing the substrate membrane, removing a pore-forming agent, and hot pressing and drying the substrate. The prepared composite nonwoven fabric membrane is good in flexibility. The composite nonwoven fabric membrane has good ion electric conductivity and hot shrinkage resistance, can bear the large-current discharge, and also can improve the safety performance of the battery. Since no fluorine-containing adhesive is used in a preparation process, nano particles or nano optical fibers are connected with the substrate membrane through a chemical key, the nano particles or the nano fibers are bonded together through the chemical key and free from dropping off in the charging-discharging cycle, the stability of the coating is enhanced, and the cycling performance of the battery can be improved. The prepared flexible composite nonwoven fabric membrane is used as a membrane assembly of the lithium ion battery.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Diaphragm and preparation method thereof, and lithium ion battery

ActiveCN102623658AThe absolute value of the surface potential is largeEvenly distributedSecondary cellsCell component detailsHexafluoropropyleneLithium-ion battery

The invention belongs to the technical field of lithium ion batteries, and particularly relates to an inorganic and organic composite multihole diaphragm. The diaphragm comprises a multihole diaphragm base material and an active coating layer attached to at least one surface of the multihole diaphragm base material, wherein the active coating layer comprises inorganic particles, vinylidene fluoride and hexafluoropropylene copolymer, cellulose based polymer with the molecular weight of 100,000 to 1,000,000 and at least one of polyacrylic acid and polyacrylate. Compared with the prior art, the diaphragm keeps relatively high air permeability and lithium ion transmission capacity; the active coating layer and the multihole diaphragm base material are well bonded; and the overheating contraction performance and the puncture strength of a diaphragm base can be improved remarkably. Furthermore, the invention also discloses a preparation method for the diaphragm and a lithium ion battery with the diaphragm.

Owner:NINGDE AMPEREX TECH +1

Inorganic/organic composite porous isolating membrane, preparation method and lithium-ion battery thereof

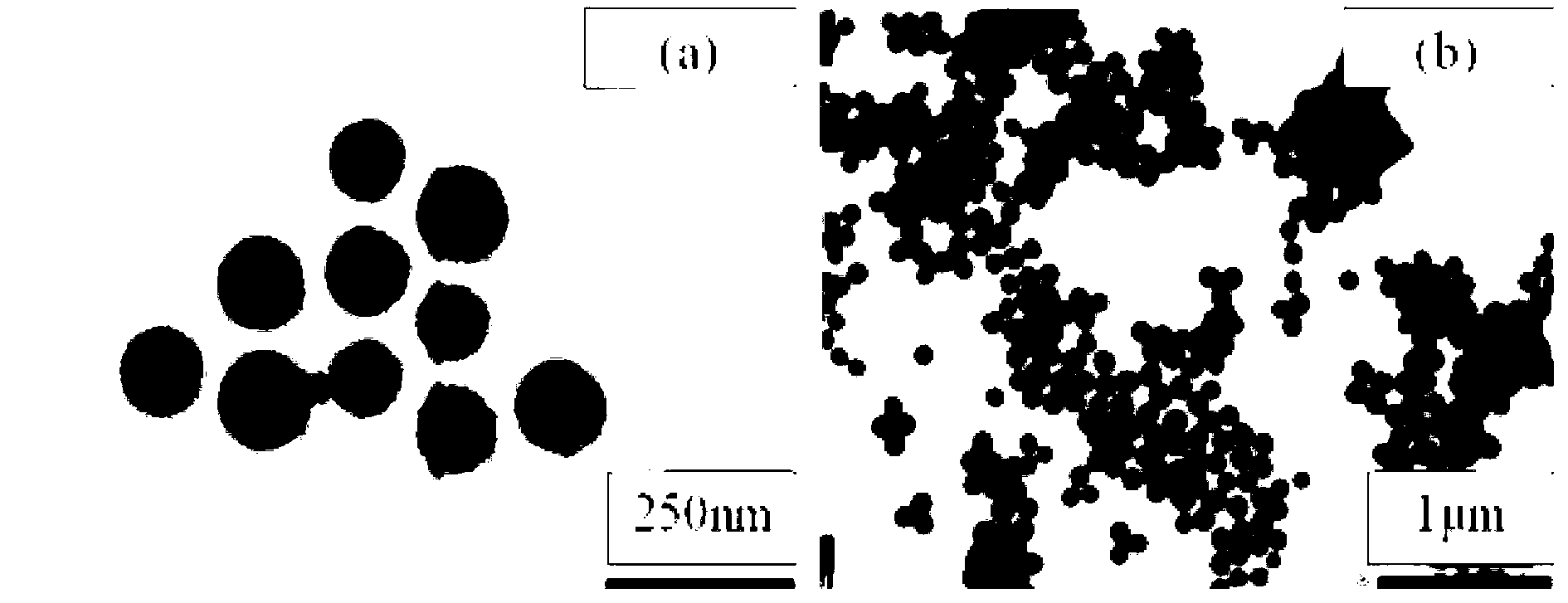

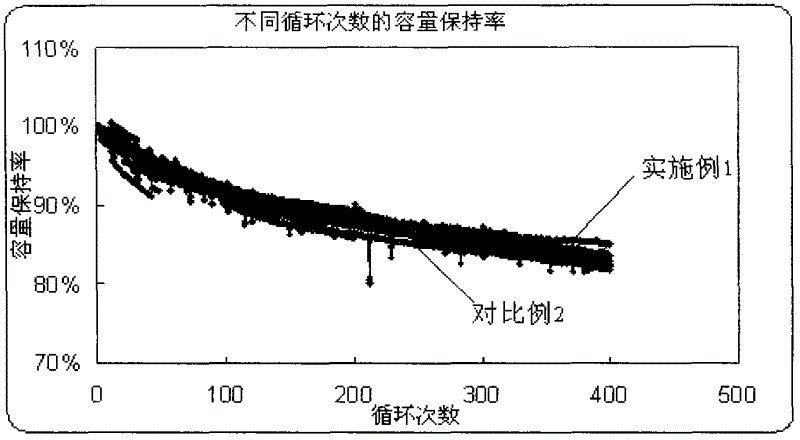

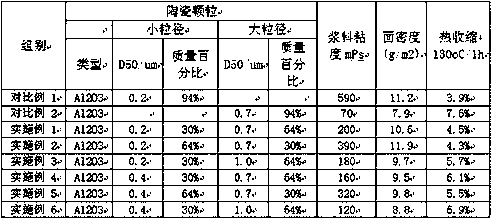

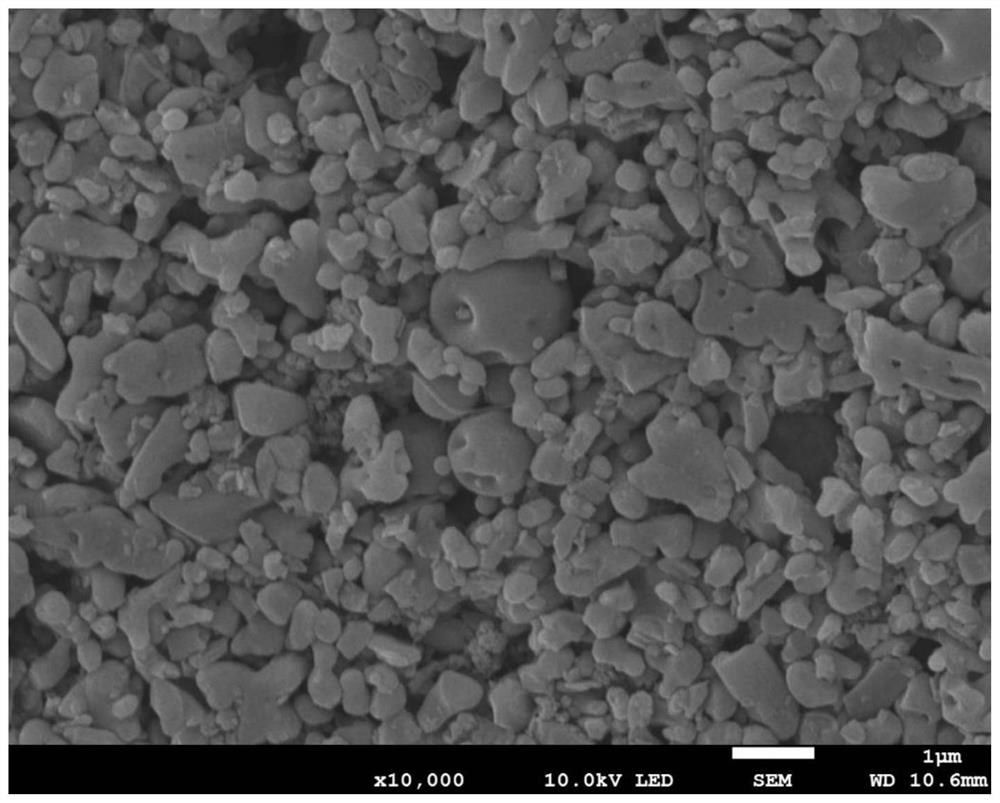

InactiveCN107895765AHigh mechanical strengthImprove reliabilityCell component detailsSecondary cells servicing/maintenancePolymer adhesiveSlurry

The invention discloses an inorganic / organic composite functional porous isolating membrane. The isolating membrane comprises porous base material and at least one inorganic functional coating adhering to the surface of the porous base material, and aqueous slurry prepared for the inorganic functional coatings is prepared from inorganic ceramic particles, water-soluble polymer thickener and aqueous polymer adhesive; the inorganic ceramic particles comprise the same substance in two types of particle sizes, wherein the average particle size (D50) of the smaller inorganic ceramic particles is 0.2-0.5 micrometer, and the average particle size (D50) of the larger inorganic ceramic particles is 0.6-1.0 micrometer; the aqueous polymer adhesive is a hydrophobic high-molecular polymer with the water drop contact angle of the dry adhesive of the aqueous polymer adhesive 110-140 degrees; the solid content of the aqueous slurry is 40-60%. According to the inorganic / organic composite functional porous isolating membrane, the high-temperature thermal stability of the isolating membrane can be effectively improved by means of the inorganic functional coatings, and the water content of the inorganic coatings is effectively reduced, so that the safe performance of a battery and the stability of long-term circulation are improved.

Owner:深圳市旭然电子有限公司

Lithium ion battery composite separation membrane and lithium ion battery containing lithium ion battery composite separation membrane

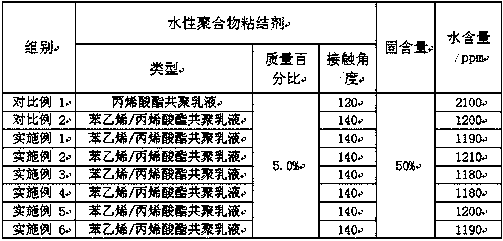

InactiveCN105390643AEnsure safetyImproved resistance to heat shrinkageSecondary cellsCell component detailsPorous substratePolyetherimide

The present invention relates to a lithium ion battery composite separation membrane, which comprises: (a) a porous substrate having pores; and (b) an organic / inorganic composite layer formed by coating at least a surface of the porous substrate or partial surface area of the porous substrate with a mixture containing inorganic particles, one or a plurality of polymer binders selected from polyetherimide, polyetherketoneketone and polyisophthaloyl metaphenylene diamine, and an optional high temperature closed-cell material, wherein the inorganic particles are connected and are fixed with the polymer binder, and the gap between the inorganic particles forms the pore. According to the present invention, the organic / inorganic composite layer on the separation membrane is firmly bonded onto the porous substrate, and the polymer binder in the organic / inorganic composite layer substantially does not swell in the electrolyte, and further has good heat-shrinkage resistance so as to ensure the safety performance of the lithium ion battery. The present invention further relates to a method for preparing the composite separation membrane and an ion battery containing the composite separation membrane.

Owner:BEIJING NORMAL UNIVERSITY

Nonwoven fabric ceramic separator, and preparation method and application thereof

InactiveCN106784539AImprove liquid absorption and retention capacityHigh porosityCell seperators/membranes/diaphragms/spacersSecondary cellsLayer thicknessNonwoven fabric

The invention provides a nonwoven fabric ceramic separator, and a preparation method and application thereof. The preparation method specifically comprises the following steps: preparing a nonwoven fabric fiber base membrane through an electrostatic spinning method; and performing atomic layer deposition on the surface through a plasma enhanced atomic layer deposition technology, so that inorganic matters are uniformly coated on the surface of the polymer fiber to form a core-shell structure taking the one-dimensional polymer fiber as the core and the inorganic matters as the shell. The nonwoven fabric ceramic separator is used in a secondary battery. The separator can be further endowed with a thermal shutdown function through a polymer layer compounding method. The nonwoven fabric ceramic separator obtained by the invention has high thermal shrinkage resistance, enhanced mechanical strength, small membrane ceramic layer thickness and favorable uniformity; and an assembled battery has high mass and volume specific energy and high safety. Thus, the separator provided by the invention can be used as a high safety separator material for lithium ion batteries and other secondary batteries.

Owner:XIAMEN UNIV

Inorganic/organic compound functional porous isolating membrane and preparation method as well as lithium ion battery adopting inorganic/organic compound functional porous isolating membrane

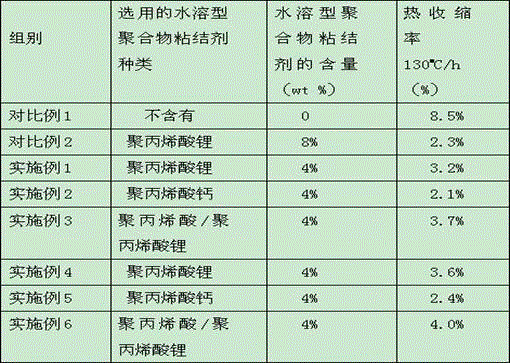

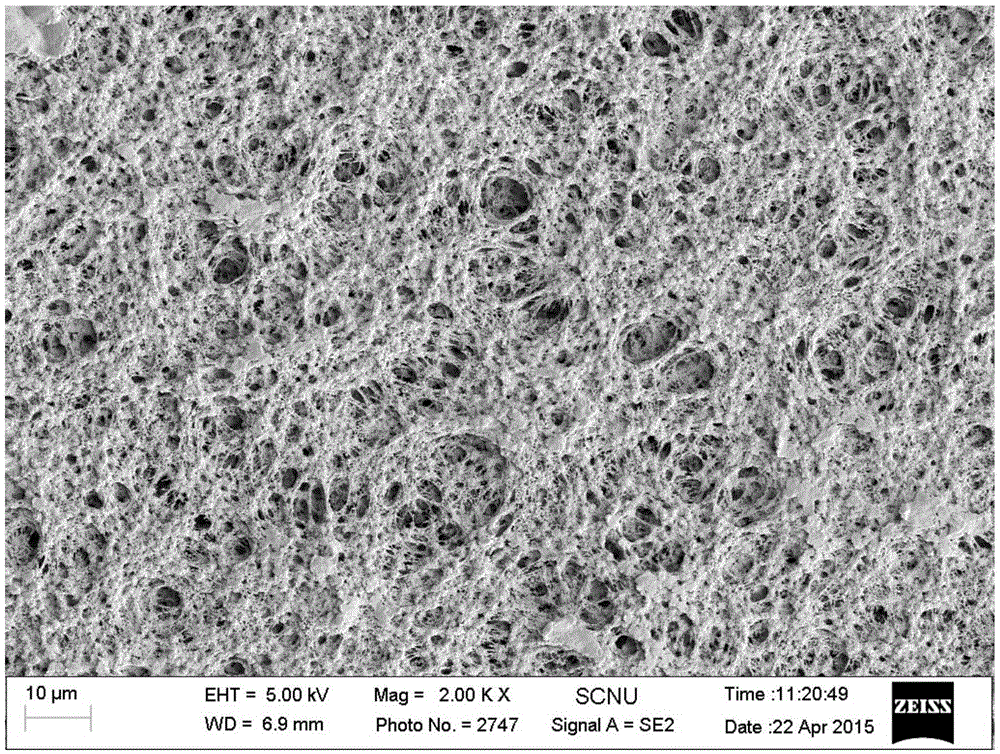

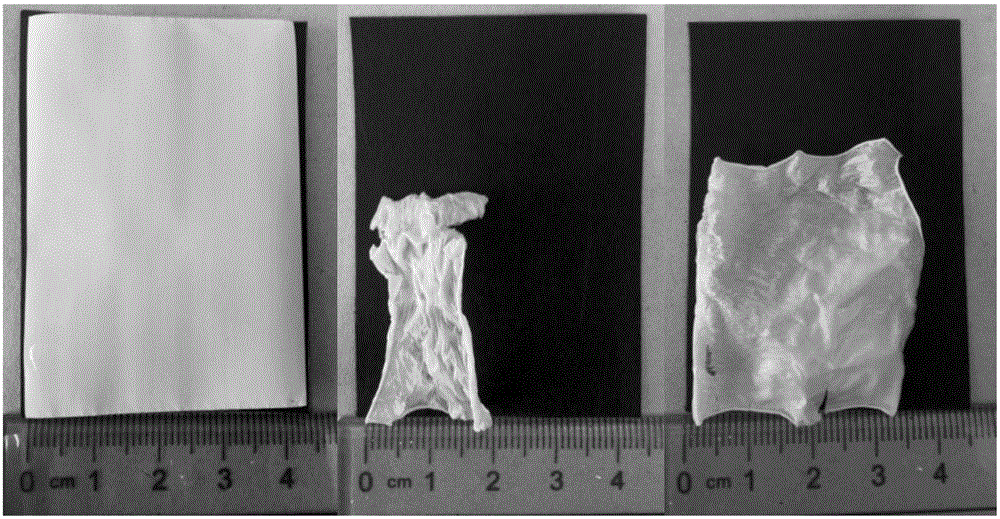

ActiveCN105789523AGood dispersionImproved high temperature thermal stabilitySecondary cellsCell component detailsPorous substrateOrganic compound

The invention provides an inorganic / organic compound functional porous isolating membrane. The inorganic / organic compound functional porous isolating membrane comprises a porous substrate and an inorganic functional coating which is adhered to at least one surface of the porous substrate, wherein the inorganic functional coating is prepared from inorganic ceramic particles, a water-soluble macromolecular thickening agent, a water emulsion type polymer binding agent and a water soluble type polymer binding agent; the water emulsion type polymer binding agent is a macromolecular polymer with the surface tensile force of 40dyne / cm to 50dyne / cm, and a water drip contact angle of water emulsion type polymer binding agent dry glue is 100 degrees to 130 degrees; the water emulsion type polymer binding agent is a polar macromolecular polymer with the glass transition temperature of 100 DEG C to 150 DEG C. Therefore, the inorganic / organic compound functional porous isolating membrane has the advantages that the heat stability of the isolating membrane can be effectively improved, and the moisture content of the inorganic coating can also be reduced, so that the safety performance of a battery and the stability of long-period cycle are improved.

Owner:深圳市旭然电子有限公司

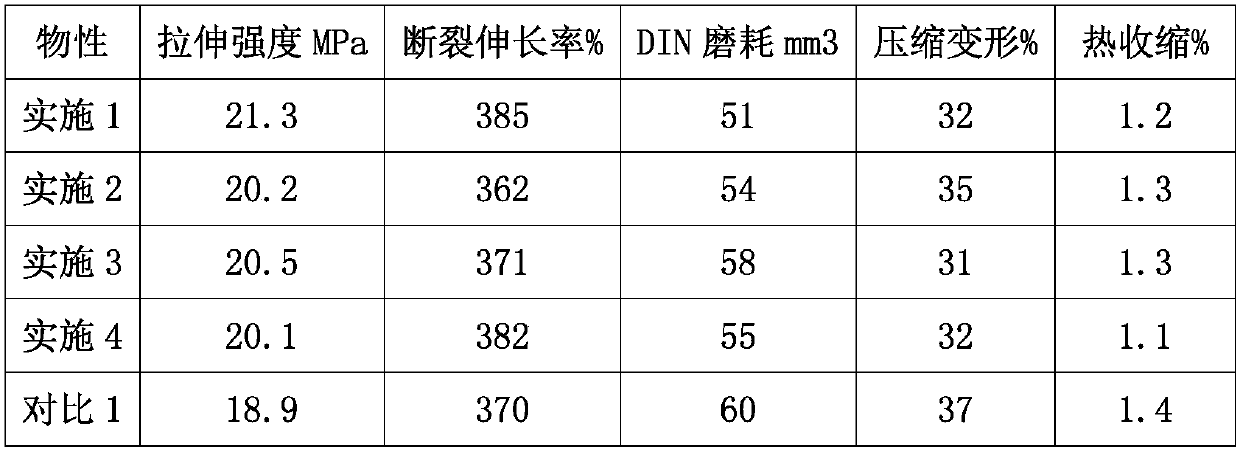

Ultralight graphene rubber foaming colloidal particles for shoe soles and preparation method thereof

InactiveCN109627512AImprove thermal stabilityImprove wear resistanceSolesRubber materialPolymer science

The invention relates to ultralight graphene rubber foaming colloidal particles for shoe soles. The colloidal particles are prepared from, by weight, 60-65 parts of natural rubber, 8-12 parts of isoprene rubber, 8-12 parts of butadiene rubber, 6-8 parts of butadiene styrene rubber, 0.8-1.0 part of modified graphene, 0.08-0.12 part of poly N-vinyl acetamide, 0.8-1.0 part of silicone oil, 3.0-3.5 parts of inorganic nanoparticles, 1.2-1.5 parts of activated zinc oxide, 0.8-1.0 part of zinc stearate, 1.0-1.2 part of stearic acid, 0.8-1.0 part of a cross-linking agent, 2.0-3.0 parts of a flow assistant and 1.5-1.8 parts of a foaming agent. By adopting the ultralight graphene rubber foaming colloidal particles, the modified graphene is uniformly dispersed in all rubber materials, the rubber foaming colloidal particles have good heat stability, good abrasive resistance performance and good stretching intensity, the permanent compression deformation performance and the heat resistance shrinkage performance are improved, and 50% or above weight can be reduced.

Owner:FUJIAN WUCHIHENG TECH DEV CO LTD

Alumina particle-filled composite multi-arc hole membrane material and preparation method and application thereof

ActiveCN105098125AHigh electrical breakdown strengthImprove heat resistanceHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersMicro nanoShock resistance

The invention discloses an alumina particle-filled composite multi-arc hole membrane material. With polyimide (PI) nanofiber nonwoven fabric as a base material, holes of the base material are filled with micro-nano Al2O3 particles; the diameters of the micro-nano Al2O3 particles are 50-800nm; and the micro-nano Al2O3 particles account for 20%-50% of total weight of the composite multi-arc hole membrane material. According to the micro-nano composite multi-arc hole membrane material, the porosity is 30%-60%; the surface mean pore size is 50-800nm; and the thicknesses are 10-40 microns. The micro-nano composite multi-arc hole membrane material disclosed by the invention has high-temperature resistance, heat shrinkage resistance, high-voltage and high-current shock resistance and mechanical impact resistance, and is suitable for manufacturing various high-capacity and high-power lithium batteries or super-capacitors as a safety battery diaphragm and a safety super-capacitor diaphragm. The invention further provides a preparation method of the nano composite multi-arc hole membrane material, and an application of the nano composite multi-arc hole membrane material as the battery diaphragm.

Owner:JIANGXI XIAN CAI NANOFIBERS TECH

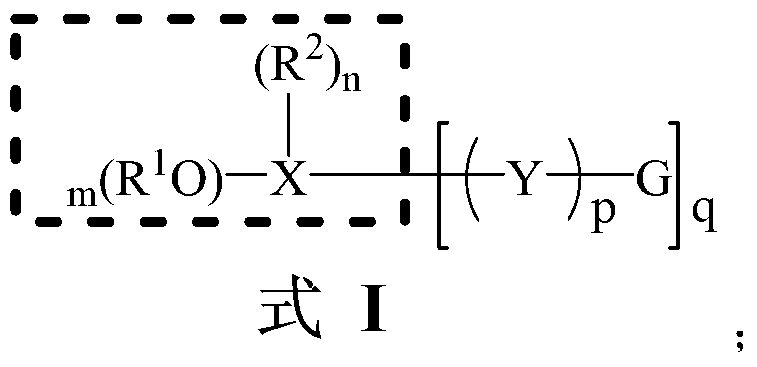

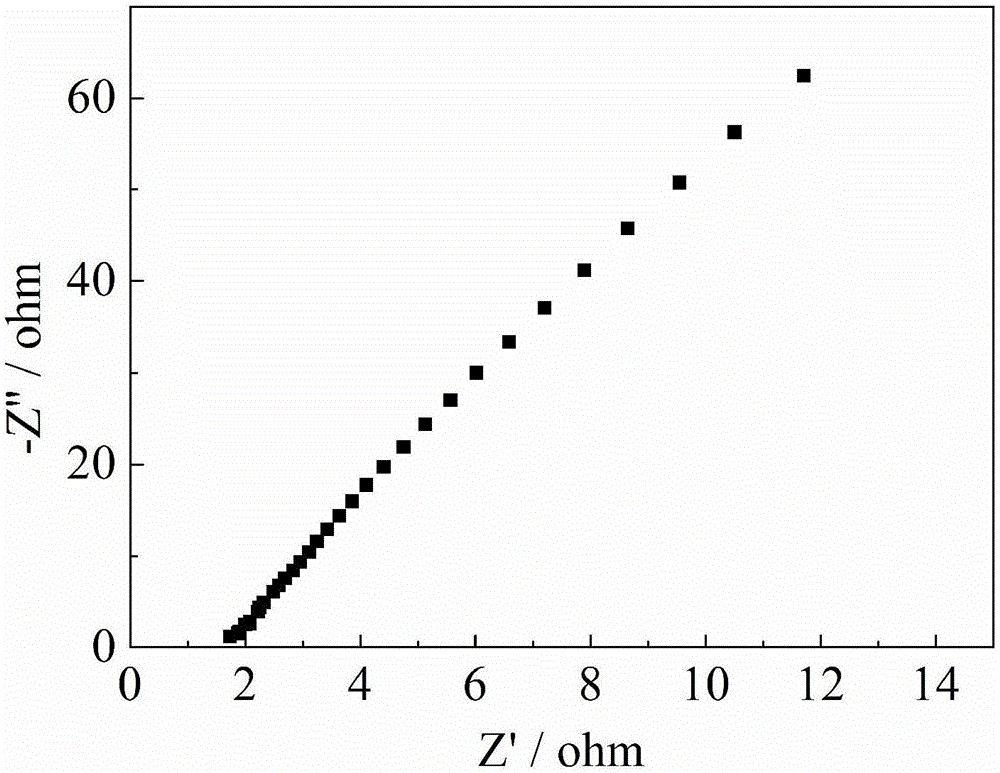

Gel polymer electrolyte for lithium ion battery, and preparation method thereof

InactiveCN105119012AImproved resistance to heat shrinkageImprove conductivitySolid electrolytesSecondary cellsPolymer sciencePolyolefin

The invention discloses a gel polymer electrolyte for a lithium ion battery, and a preparation method thereof. The gel polymer electrode is composed of a polymer film as a substrate, and an electrolyte adsorbed to the polymer film; and the polymer film is made through the following steps: co-dissolving Carbomer resin, polyvinylidene fluoride and cellulose acetate butyrate in a solvent, mechanically stirring to form a liquid, coating the liquid, and solidifying the coated liquid on a polyolefin micro-porous film. The preparation method of the gel polymer electrolyte comprises the following steps: co-dissolving polyvinylidene fluoride and cellulose acetate butyrate in the solvent to prepare a liquid 1, adding the Carbomer resin to the liquid, fully stirring to form a liquid 2, immersing the polyolefin micro-porous film in the liquid 2, drying, immersing the dried polymer film in the electrolyte, and taking out the immersed film. The polymer lithium ion battery comprises the gel polymer electrolyte, a positive electrode and a negative electrode. The gel polymer electrolyte has the advantages of thermal contraction resistance, high conductivity and high electrochemical stability.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Graphene regenerated rubber and plastic foamed colloidal particle for soles and preparation method thereof

The invention relates to a graphene regenerated rubber and plastic foamed colloidal particle for soles. The graphene regenerated rubber and plastic foamed colloidal particle for soles is prepared fromthe following ingredients in parts by weight: 60 to 65 parts of EVA (Ethylene-vinyl acetate copolymer) waste materials, 23 to 25 parts of natural rubber, 4 to 6 parts of POE (Polyolefin elastomers),1 to 2 parts of modified graphene, 0.1 to 0.2 part of poly N-vinylacetamide, 2.0 to 2.3 parts of white mineral oil, 1.0 to 1.2 parts of silicone oil, 1.4 to 1.5 parts of active zinc oxide, 0.8 to 1.0part of zinc stearate, 0.8 to 1.0 part of stearic acid, 0.8 to 1.0 part of crosslinking agents, 2.0 to 3.0 parts of flow additives and 1.5 to 1.8 parts of foaming agents. According to the invention, the existing EVA waste materials are sufficiently utilized; resources are regenerated; and the foamed colloidal particle with the physical properties reaching a standard and the heat-shrinkage-resistant performance capable of being enhanced is obtained.

Owner:FUJIAN WUCHIHENG TECH DEV CO LTD

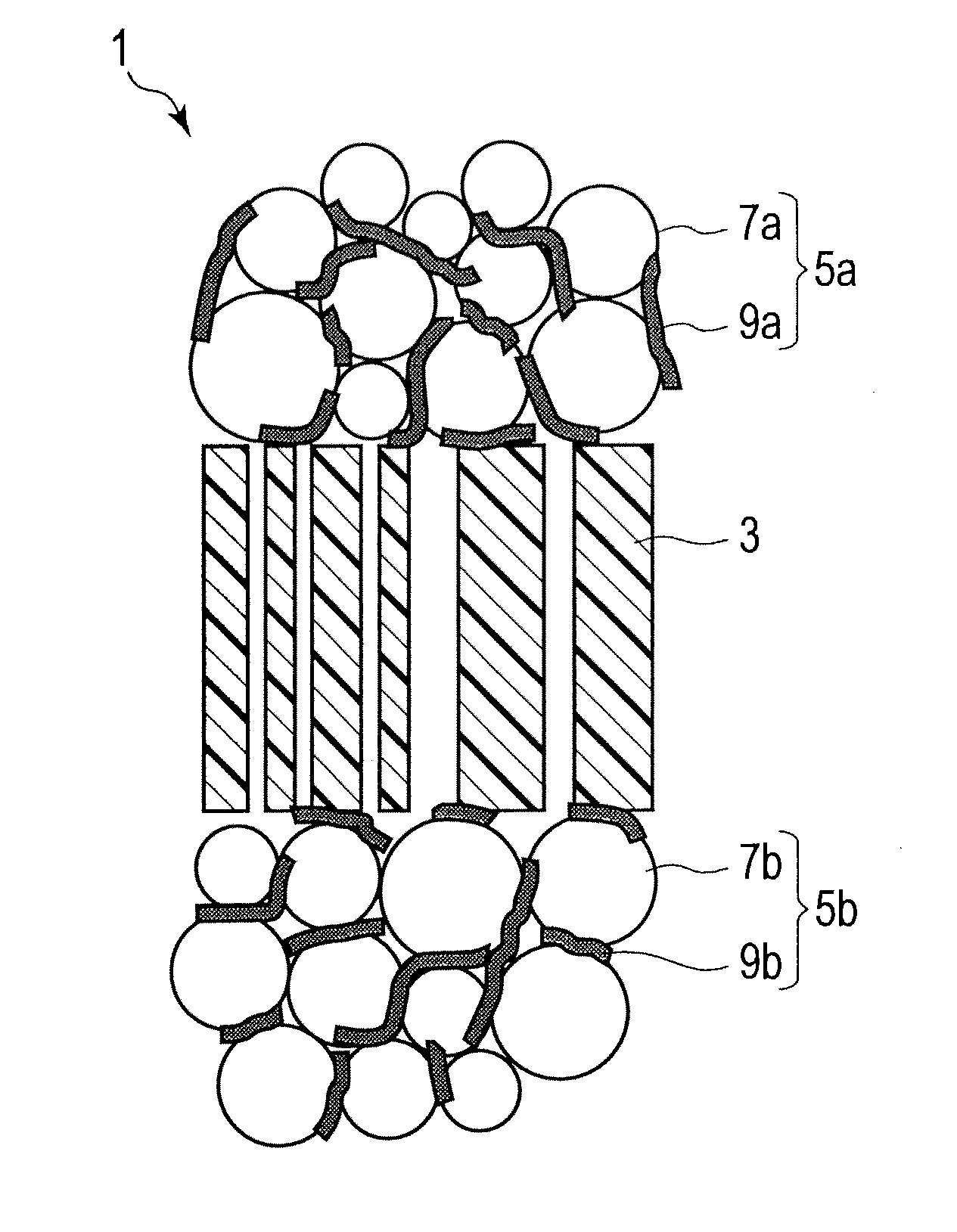

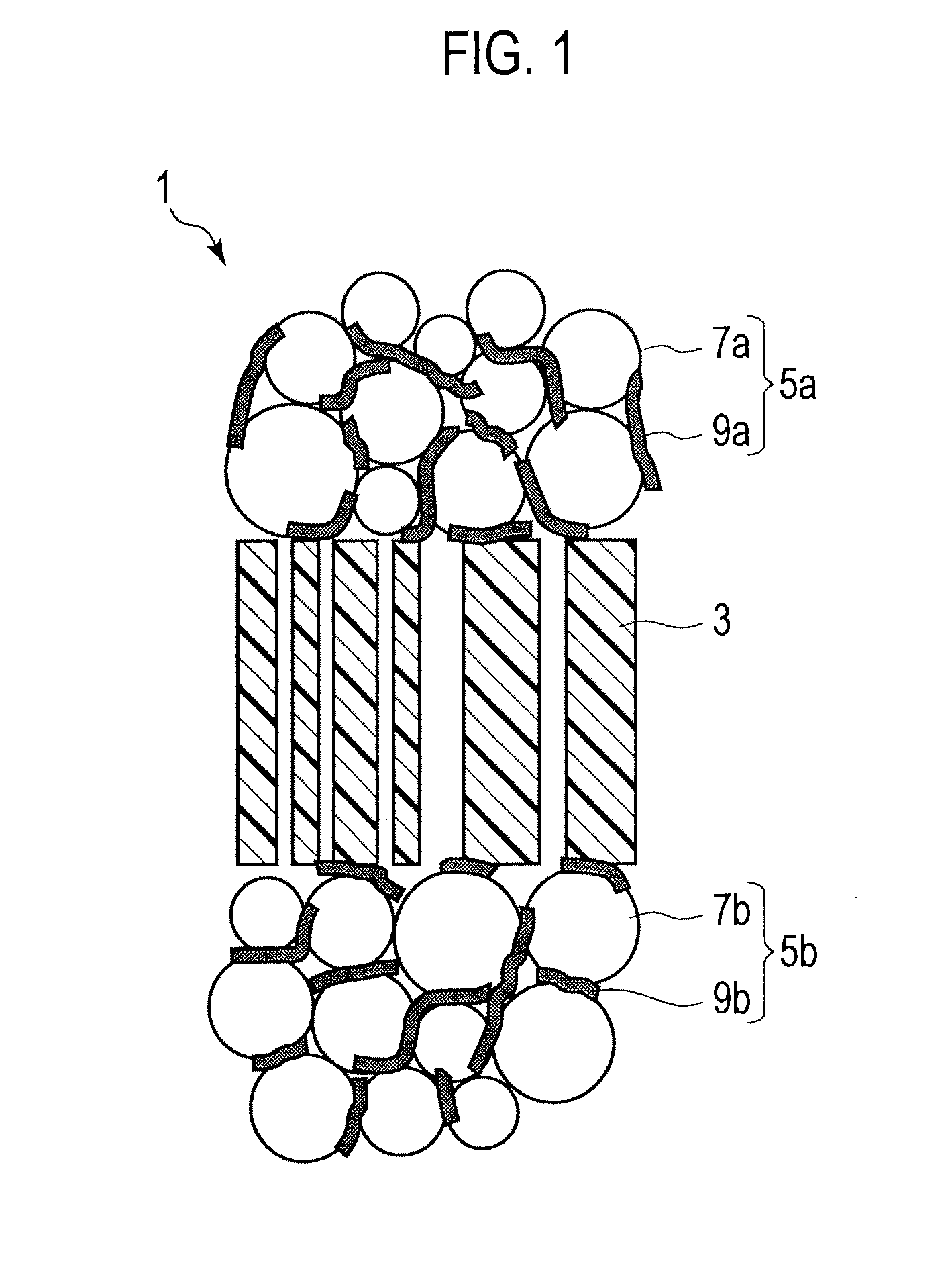

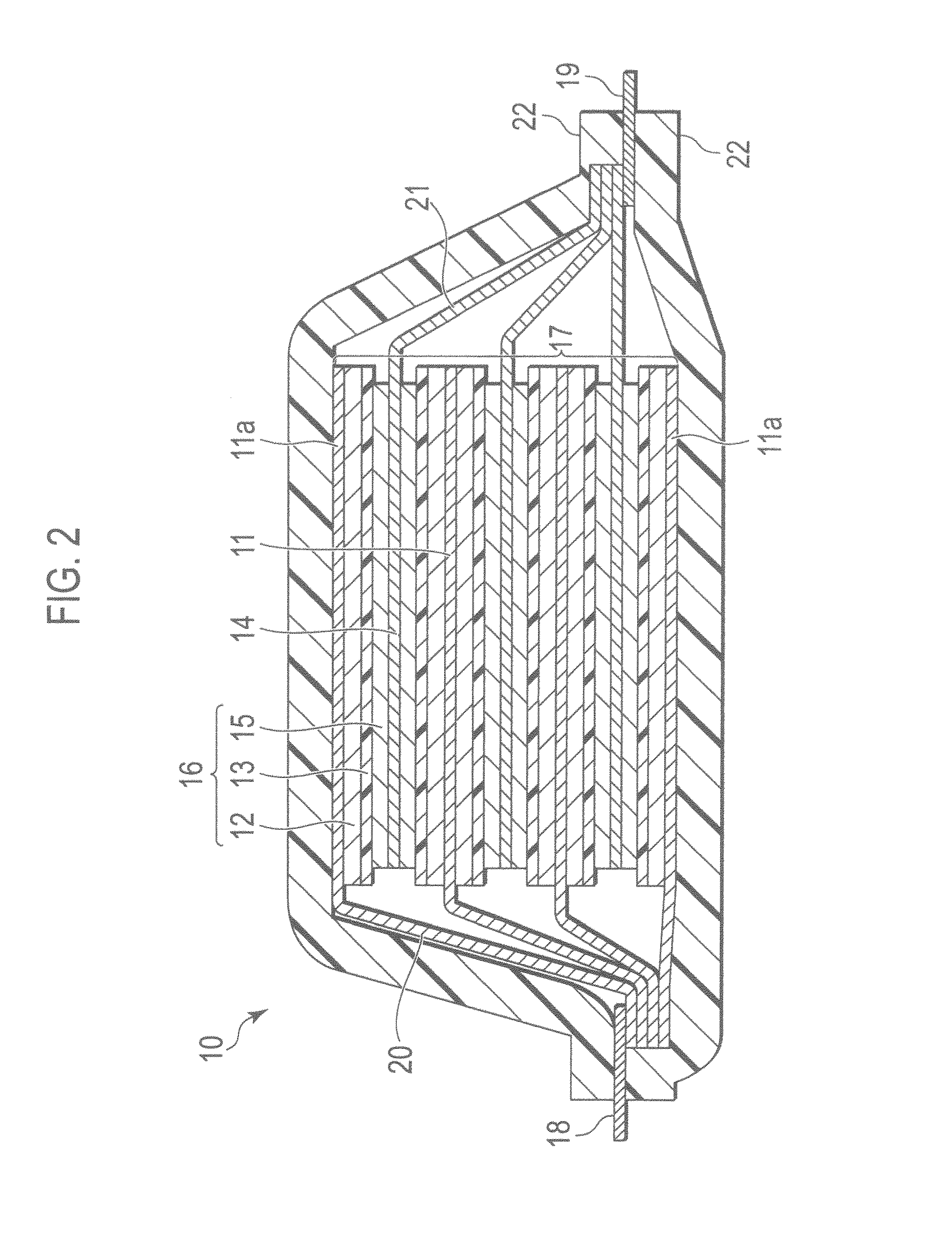

Separator having heat-resistant insulating layer and electric device comprising the same

ActiveUS20140113173A1Reducing thermal shrinkageIncrease powerHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersInorganic particleInorganic particles

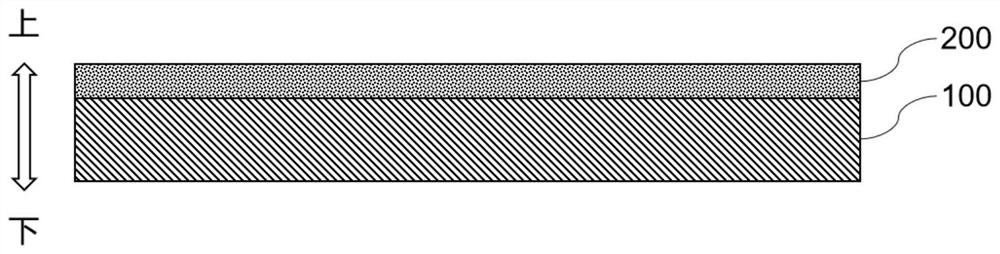

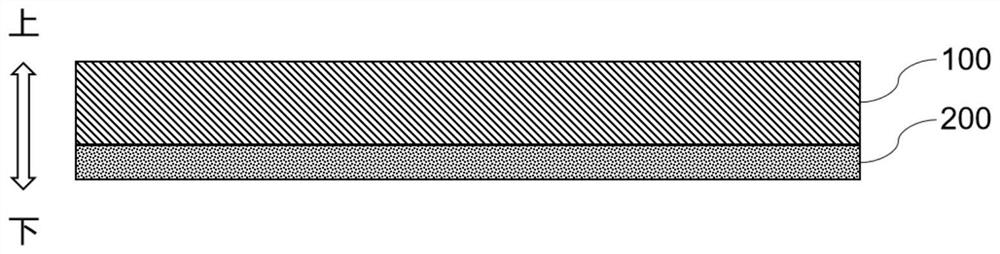

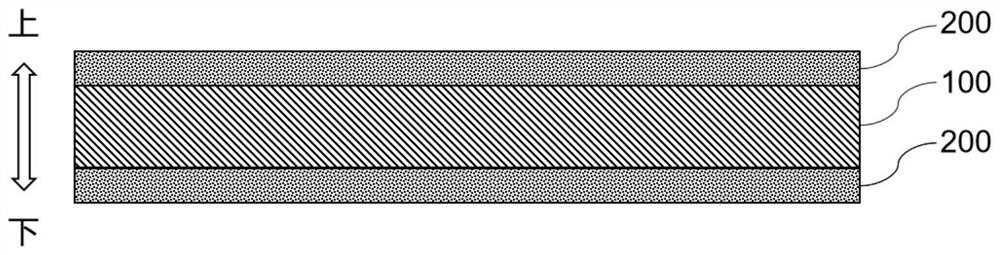

A separator having a heat-resistant insulating layer of the present invention includes a porous resin base layer and a heat-resistant insulating layer which is formed on one or both sides of the porous resin base layer and contains inorganic particles and a binder. The porous resin base layer contains a resin having a melting temperature of 120° C. to 200° C. The separator is configured so that the ratio of the basis weight of the heat-resistant insulating layer to the basis weight of the porous resin base layer is not less than 0.5. Accordingly, the separator having a heat-resistant insulating layer of the present invention exhibits excellent thermal shrinkage resistance while ensuring a shutdown function.

Owner:ENVISION AESC JAPAN LTD

Polymer composite film and preparation method thereof, and lithium ion battery

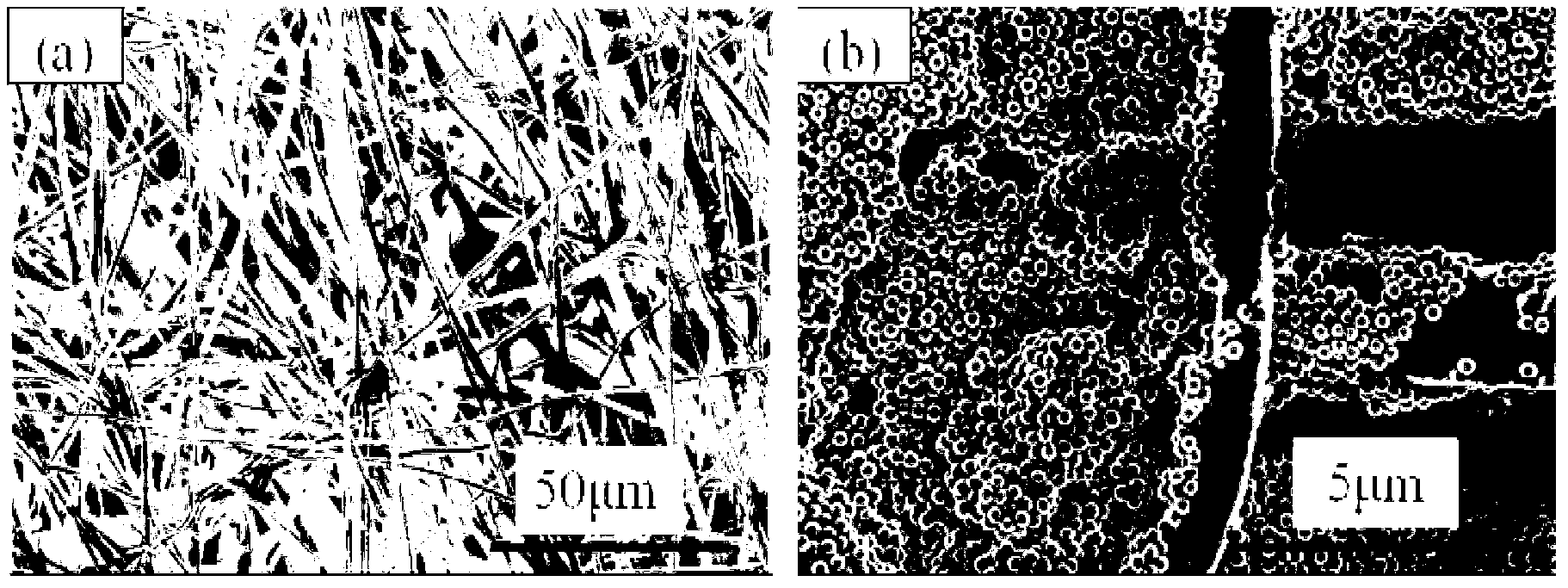

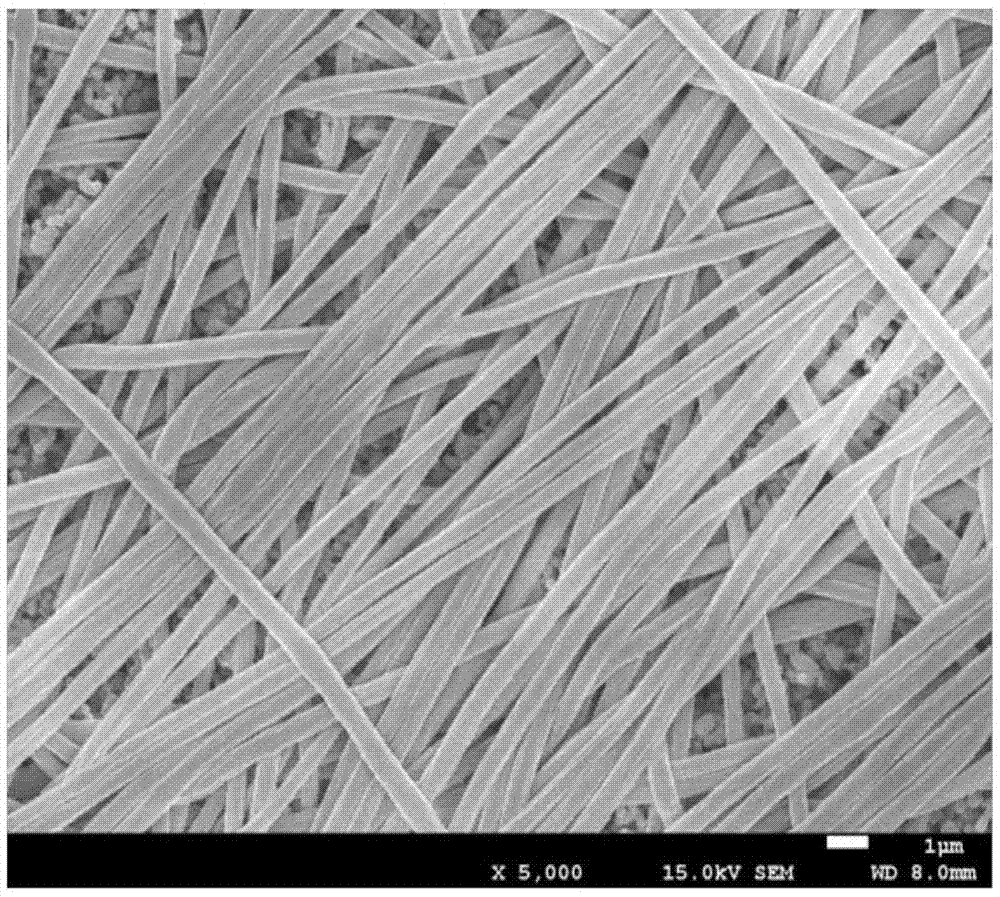

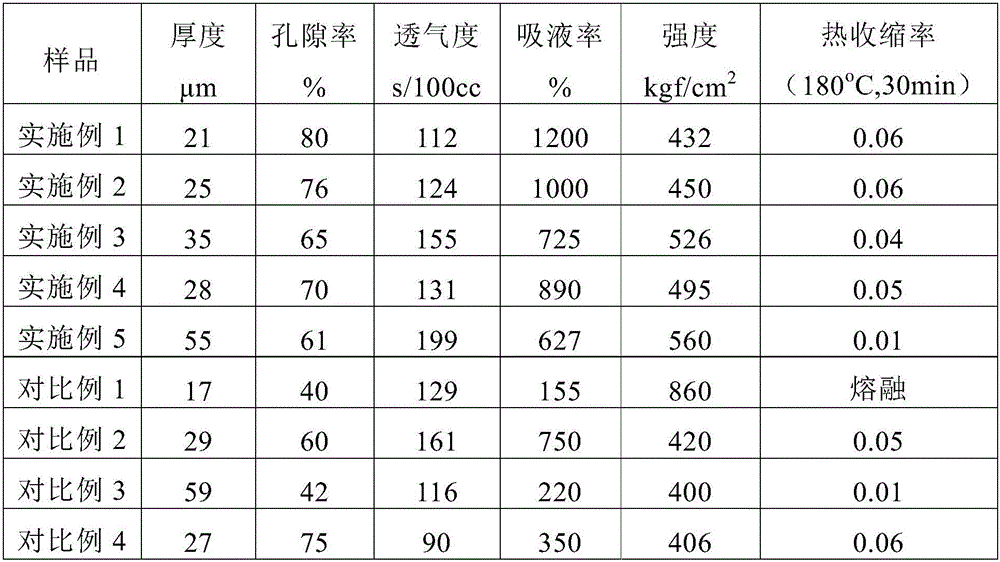

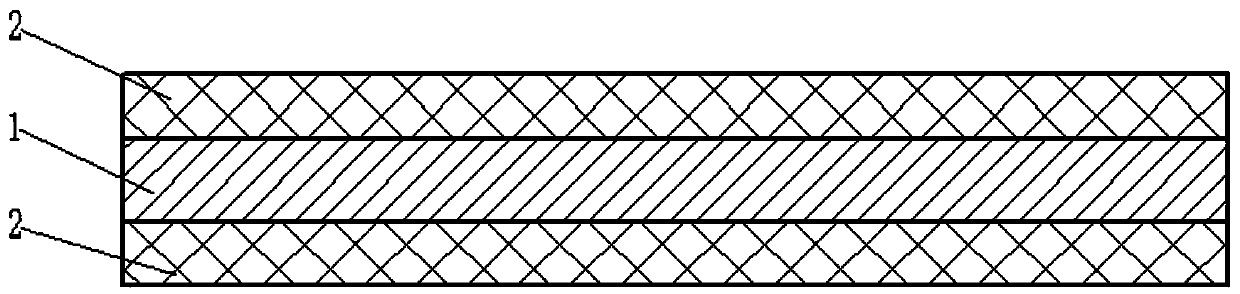

ActiveCN106898814AHigh mechanical strengthImproved heat shrink resistance and mechanical strengthSolid electrolytesFilament/thread formingFiber layerPolymer composites

In order to solve the problem of poor mechanical strength of the polymer composite film in the prior art, the invention provides a polymer composite film which comprises a porous diaphragm and a fiber layer positioned on the diaphragm, wherein at least one fiber bundle is arranged in the fiber layer; and each fiber bundle comprises a plurality of fibers arranged in parallel. The invention also provides a preparation method of the polymer composite film and a lithium ion battery using the polymer composite film. The polymer composite film provided by the invention has favorable mechanical strength.

Owner:BYD CO LTD

Lithium battery separator and preparation method and application thereof

InactiveCN107437630AUniform structure distributionGood electrolyte wetting propertiesSecondary cellsCell component detailsCelluloseSilicon dioxide

The invention discloses a lithium battery separator and a preparation method and application thereof. Cellulose and inorganic matter particles are contained in raw materials of the separator, wherein the inorganic matter particles are selected from more than one of silicon dioxide, aluminum oxide, boehmite, titanium oxide, zirconium oxide, tin oxide, magnesium oxide and silicon carbide.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

Polytetrafluoroethylene nanoparticle-filled composite tortuous porous membrane material and preparation method and application thereof

ActiveCN105161659AIncrease capacitySmall surface pore sizeCell component detailsSecondary cells servicing/maintenancePorosityMicrosphere

The invention discloses a polytetrafluoroethylene nanoparticle (PTFE-NP)-filled composite tortuous porous membrane material. With polyimide (PI) nanofiber nonwoven fabric as a base material, holes of the base materials are filled with polytetrafluoroethylene nanoparticles (PTFE-NPs); the PTFE-NPs are 100-300nm in diameter and account for 30%-60% of total weight of the composite tortuous porous membrane material; and the PI nanofiber nonwoven fabric is electrospinning PI nanofiber nonwoven fabric of which the thickness is 9-38 microns, the porosity is 60%-80% and the fiber diameters are less than 0.5 micron. The nano composite tortuous porous membrane material disclosed by the invention has the advantages of high temperature resistance, heat shrinkage resistance, high voltage impact resistance, high current impact resistance and mechanical impact resistance, and is suitable for manufacturing various high-capacity and high-power lithium batteries or super capacitors as a safe battery diaphragm and a safe super capacitor diaphragm. The invention further provides a preparation method of the nano composite tortuous porous membrane material and an application of the composite tortuous porous membrane material as a battery diaphragm.

Owner:JIANGXI NORMAL UNIV

Functional coating material component of isolating membrane for power battery and preparation method thereof

InactiveCN107641460AIncrease aramidGood pore uniformityPolyurea/polyurethane coatingsPolyamide coatingsAramidDiatom

The invention discloses a functional coating material component of an isolating membrane for a power battery. The functional coating material component of the isolating membrane for the power batterycomprises a base film and a coating layer; the coating layer comprises the following materials taken as components calculated in parts by mass: 30-40 parts of nano-scale aluminum oxide, 30-40 parts ofaramid fibers, 10-20 parts of polymer emulsion, 5 to 10 parts of porous polyimide nanofibers, 5-10 parts of nano-porous shell powder and diatom mud, 5-10 parts of a crosslinking agent, 1-5 parts of an aqueous fluorine leveling agent, 2-5 parts of a dispersant and 1-3 parts of a stabilizer. The isolating membrane is added with the aramid fibers to improve the porosity uniformity of the isolating membrane and increase the puncture resistance strength of the isolating membrane, and has good heat shrinkage resistance to improve the practical life of the battery, in addition, the isolating membrane is added with the porous polyimide nanofibers and the nano-porous shell powder and the diatom mud, and the porous material structure has excellent liquid absorption to greatly improve the performance of ions passing through the isolating membrane and the conductive capability so as to further improve use performances of the battery.

Owner:HUIZHOU JIAHENENG NEW ENERGY TECH CO LTD

Composite multi-curved-pore membrane material filled by silicon dioxide particles, and preparation method and application therefor

The invention discloses a micro-nano composite multi-curved-pore membrane material. The polyimide (PI) nanofiber non-woven fabric is taken as the base material; the pores of the base material are filled by silicon dioxide particles; the diameter of the micro-nano silicon dioxide particles is 50-800 nm, accounting for 20-50% of the total weight of the micro-nano composite multi-curved-pore membrane material; and the PI nanofiber non-woven fabric is 9-38 um in thickness, and 60-80% in the porosity. The micro-nano composite multi-curved-pore membrane material prepared by the invention is high temperature resistant, thermal shrinkage resistant, high voltage resistant, high current impact resistant, and mechanical collision resistant, and suitable for being used as safe battery membranes and safe supercapacitor membranes for manufacturing various high-capacity and high-power lithium ion batteries or supercapacitors. The invention also provides a preparation method for the micro-nano composite multi-curved-pore membrane material, and application of the membrane material in being used as the battery membranes.

Owner:JIANGXI XIAN CAI NANOFIBERS TECH

Porous polyvinylidene fluoride lithium ion battery diaphragm and preparation method thereof

InactiveCN107845758AImproved resistance to heat shrinkageImprove heat resistanceCell seperators/membranes/diaphragms/spacersSecondary cellsLithium-ion batteryThermal contraction

The invention discloses a porous polyvinylidene fluoride diaphragm used for a lithium ion battery and a preparation method thereof. The porous polyvinylidene fluoride lithium ion battery diaphragm comprises the following components in parts by weight: 20-70 parts of one type of polyvinylidene fluoride resin or at least more than two of a polyvinylidene fluoride resin mixture, and 30-80 parts of adiluent. The preparation method comprises the following steps: 1) raw material pretreatment; 2) mixing; 3) granulation; 4) drying; 5) dried particles casting through a casting line for film forming; 6) transverse stretching or vertical stretching or transverse and vertical stretching on a film; and 7) extraction on the stretched film through an extractant to obtain the porous polyvinylidene fluoride lithium ion battery diaphragm. The porous polyvinylidene fluoride lithium ion battery diaphragm can resist acid-base solutions with pH values from 1 to 14, and cannot be dissolved in an organic solvent such as alcohol, aldehyde and benzene; wettability of an electrolyte is good, and thermal contraction resistance is good. The preparation method has the advantages of simple process, environmental protection, and high production efficiency.

Owner:ZHEJIANG GREEN NEW MATERIALS

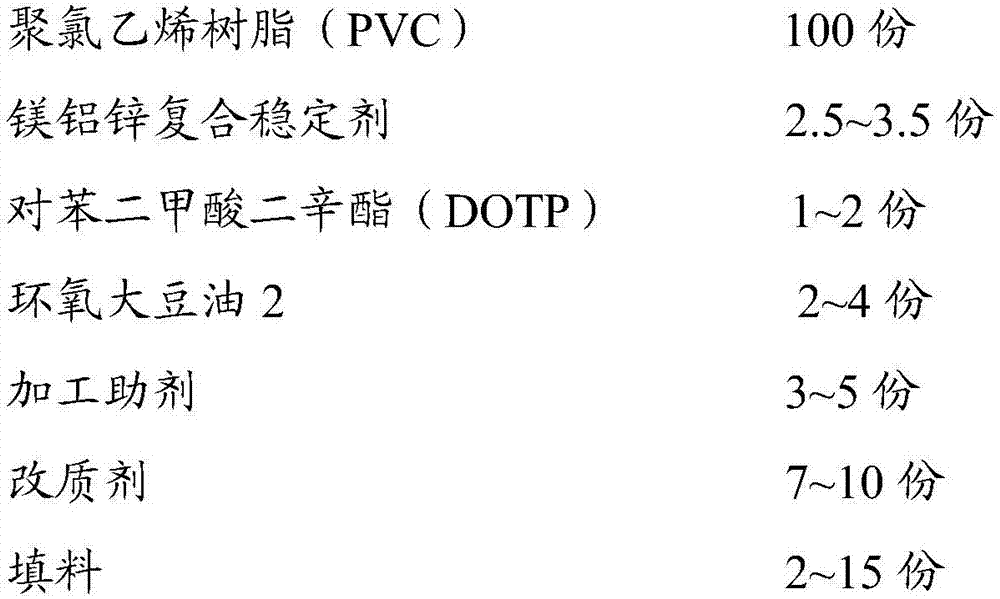

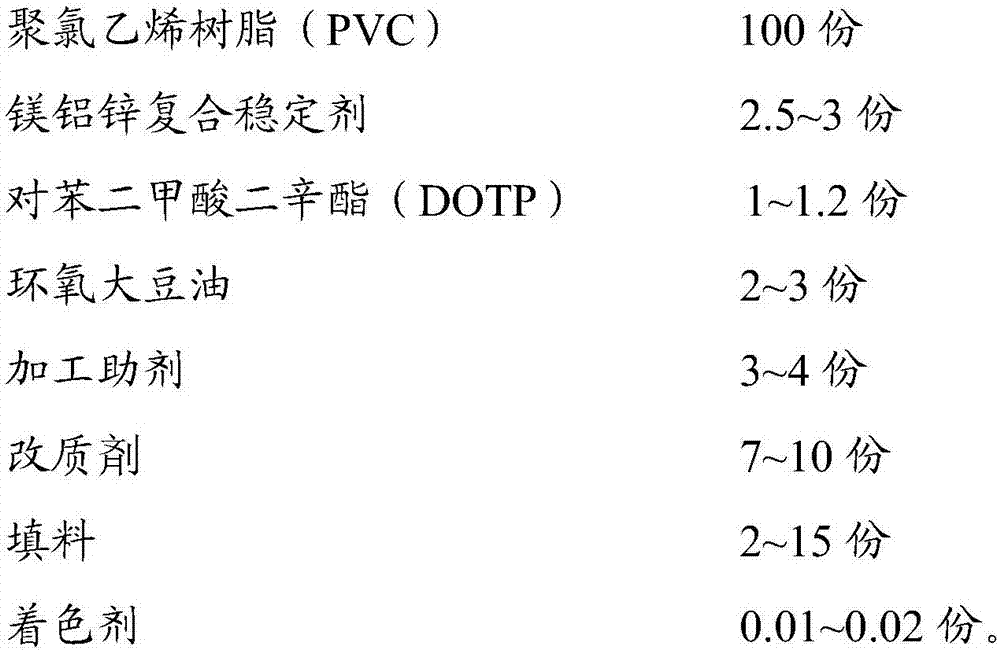

Environment-friendly polyvinyl chloride material composition as well as preparation method and application thereof

The invention relates to an environment-friendly polyvinyl chloride material composition as well as a preparation method and application thereof. The environment-friendly polyvinyl chloride material composition is prepared from the following raw material components in parts by weight: 100 parts of polyvinyl chloride resin, 2.5 to 3.5 parts of magnesium aluminum zinc composite stabilizer, 1 to 2 parts of dioctyl terephthalate, 2 to 4 parts of epoxy soybean oil, 3 to 5 parts of processing aid, 7 to 10 parts of modifier, 2 to 15 parts of filler, and 0.01 to 0.02 part of coloring agent. The environment-friendly polyvinyl chloride material composition is environment-friendly; the physical performance of the environment-friendly polyvinyl chloride material composition is ensured, the impact resistance is excellent, and the heat shrinkable property can be improved; and the polyvinyl chloride material composition is high in smoothness, excellent in gloss, high in product quality and low in cost.

Owner:无锡宏义高分子材料科技有限公司

PI-AlN-PTFE ternary nano-composite multi-curve pore membrane material and preparing method and application thereof

ActiveCN105047847AImprove temperature resistanceHigh hardnessNon-aqueous electrolyte accumulatorsElectrolytic capacitorsPorosityFiber

The invention discloses a nano-composite multi-curve pore membrane material, polyimide (PI) nano-fiber non-woven fabric serves as the base material, and base material pores are filled with composite nano-particles. The nano-composite multi-curve pore membrane material is characterized in that the nano-particles are formed by mixing polytetrafluoroethylene nanoparticle (PTFE-NP) and aluminium nitride nanoparticle (AlN-NP) at the weight ratio of (7-12) / (8-13). The nano-composite multi-curve pore membrane material is resistant to high temperature, high in hardness, proper in porosity, proper in surface density, good in ion transmission performance and good in mechanical performance, when the nano-composite multi-curve pore membrane material is used in lithium-ion batteries, the problem of a battery micro short circuit due to the excessively-high porosity of a pure polyimide nano-fiber membrane can be solved, and the serious problem of thermal runaway caused by the mechanical collision of the power lithium-ion batteries can be solved.

Owner:JIANGXI NORMAL UNIV

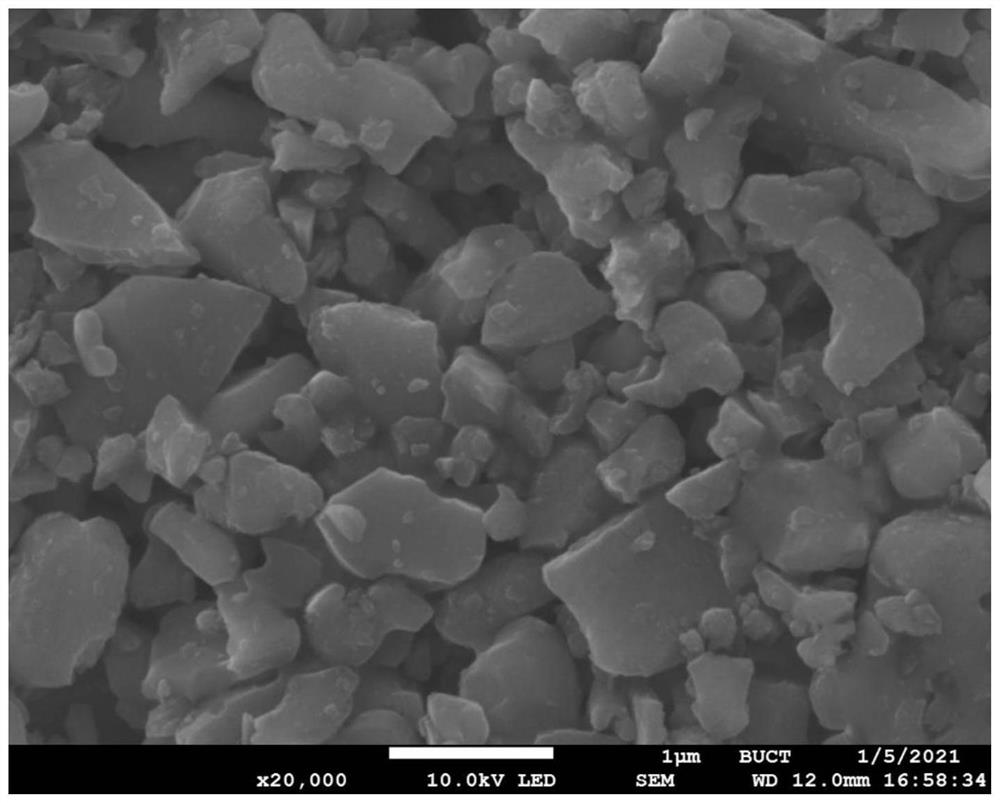

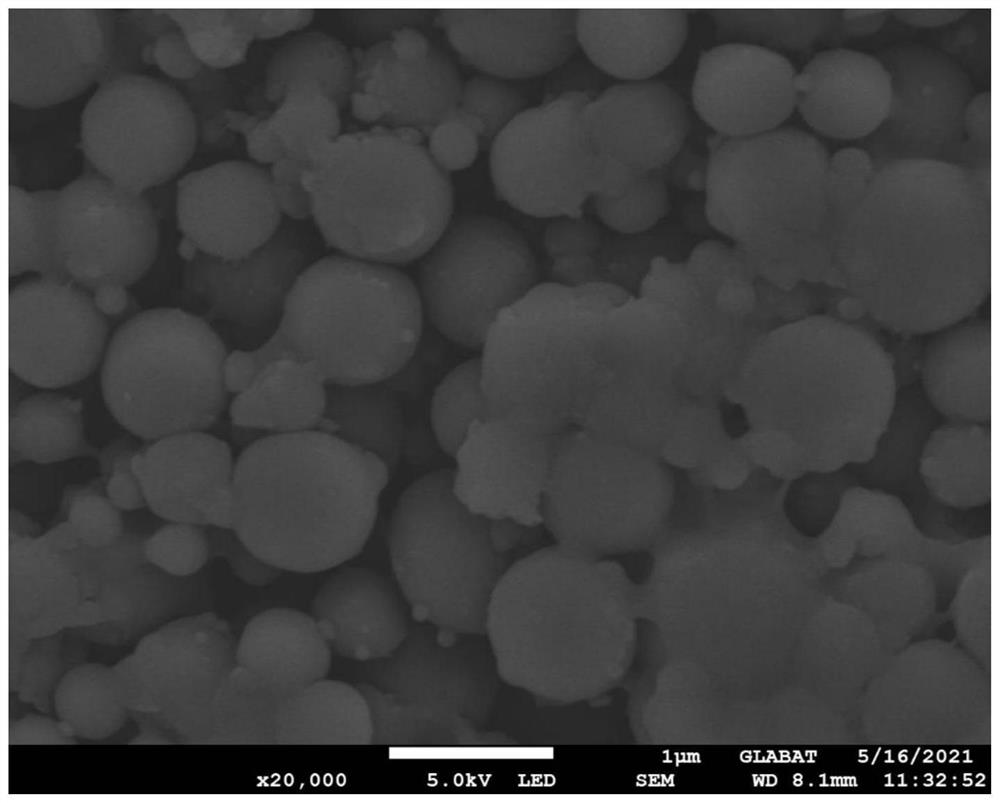

Novel polyimide microsphere slurry and coated diaphragm thereof

The invention discloses novel polyimide microsphere slurry and a coated diaphragm thereof, and is applied to the field of lithium ion batteries. The slurry is composed of polyimide microspheres, inorganic particles, a binder, a surfactant, a dispersant and a solvent. The coating diaphragm is obtained by coating the slurry on the surface of at least one side of a porous base membrane in a manner of micro-concave coating, extrusion coating, transfer coating, dip coating or bar coating and then drying, and the coating diaphragm has excellent lithium dendrite puncture resistance and an effect of preventing short circuit in a battery by high-temperature hole closing. Compared with a common ceramic diaphragm, the novel polyimide microsphere slurry coated diaphragm provided by the invention has more excellent cohesiveness and thermal shrinkage resistance. The novel polyimide coated diaphragm has lower surface density than a ceramic coated diaphragm, and the energy density of the lithium ion battery is remarkably improved. The slurry and the diaphragm provided by the invention are adaptive to the existing mature diaphragm coating process, and have great application prospects.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

Aramid UV coating for battery isolation membrane and preparation method of aramid UV coating

InactiveCN106601963AOptimal ThicknessGood heat shrink resistanceCell component detailsWater contentChemistry

The invention provides an aramid UV coating for a battery isolation membrane. The aramid UV coating comprises the following components in parts by weight: 70-80 parts of aramid, 2-8 parts of a resin binder, 1-5 parts of an initiator, 0.1-2 parts of a dispersing agent and 0.5-1 part of a stabilizer. According to the aramid UV coating for the battery isolation membrane, the thickness and hole uniformity is improved, the puncture strength of the isolation membrane is improved, the water content is reduced, the aramid UV coating has good thermal shrinkage resistance and the service life of a battery is effectively prolonged.

Owner:HUIZHOU JIAHENENG NEW ENERGY TECH CO LTD

Polyester film with high barrier property and preparation and application thereof

InactiveCN114074469AImprove barrier propertiesImprove heat stabilityFlexible coversWrappersPolyesterPolymer science

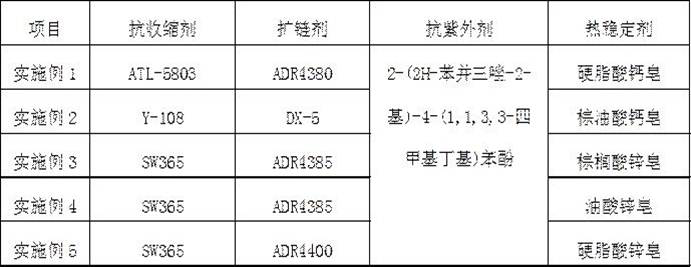

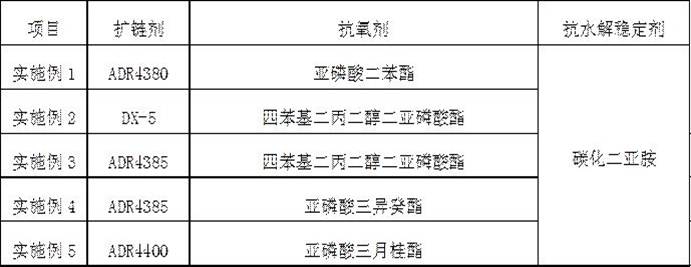

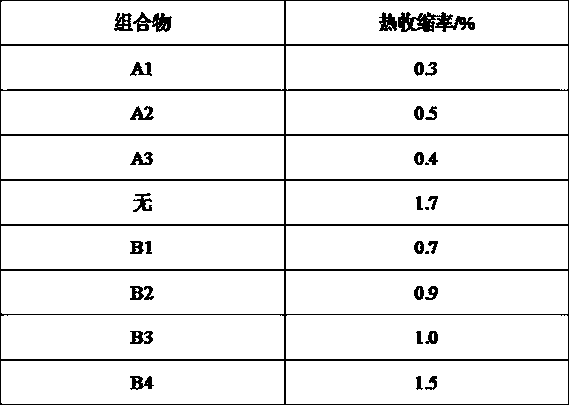

The invention relates to a polyester film with high barrier property, wherein the polyester film comprises an outer surface layer, an inner surface layer and a middle core layer arranged between the outer surface layer and the inner surface layer, wherein the outer surface layer and the inner surface layer are prepared from the following raw materials in parts by weight: 70 to 85 parts of PET, 15 to 30 parts of PEN, 1 to 10 parts of PET-g-MAH, 2 to 5 parts aofn anti-shrinking agent, 1 to 3 parts of a chain extender, 0.1 to 0.6 part of an anti-ultraviolet agent and 0.2 to 0.8 part of a heat stabilizer; and the middle core layer is prepared from the following raw materials in parts by weight: 60 to 80 parts of PET, 20 to 40 parts of PMMA, 1 to 10 parts of PET-g-MAH, 5 to 20 parts of starch modified superfine montmorillonite, 2 to 8 parts of a chain extender, 0.1 to 1 part of an antioxidant and 0.2 to 0.5 part of a hydrolysis-resistant stabilizer. Compared with the prior art, the polyester film provided by the invention has excellent water vapor barrier property and thermal shrinkage resistance, good flexibility and weather resistance, simple and efficient preparation process, and good application prospect.

Owner:河南源宏高分子新材料有限公司

Modified composition for thermal-contraction-resistant seal rings and preparation method of modified composition for thermal-contraction-resistant seal rings

InactiveCN108707260AImproved resistance to heat shrinkageSimple processFibre typesCyclodextrinRare earth

The invention discloses a modified composition for thermal-contraction-resistant seal rings and a preparation method of the modified composition for the thermal-contraction-resistant seal rings. The preparation method includes: 1) subjecting polyamide fibers, cyclodextrin, a silane coupling agent and water to contact reaction, filtering, taking a filter cake, and drying to obtain modified polyamide fibers; 2) subjecting the modified polyamide fibers, cobalt salt, alkali, urea and ethyl alcohol to solvothermal reaction, filtering, taking a filter cake, and calcining in existence of shielding gas to obtain composite polyamide fibers; 3) mixing the composite polyamide fibers, shell powder, attapulgite, barium sulfate whiskers and rare earth oxides to obtain the modified composition for the thermal-contraction-resistant seal rings. The modified composition prepared according to the method is capable of greatly improving thermal contraction resistance of the seal rings. The preparation method has advantages of simple procedures and easiness in raw material acquisition.

Owner:芜湖瑞德机械科技有限公司

Composite diaphragm and application thereof

InactiveCN112038554AImprove ionic conductivityImprove heat shrink resistanceLi-accumulatorsCell component detailsNano catalystPtru catalyst

The invention discloses a composite diaphragm and application thereof. The composite diaphragm comprises a diaphragm matrix and an active lithium source coating, wherein the active lithium source coating is arranged on the diaphragm matrix, and the active lithium source coating comprises a nano active lithium source, a nano catalyst, a ceramic electrolyte and a binder. Therefore, multiple effectsof improving the safety of the battery, supplementing lithium and improving the conductivity of the diaphragm are achieved.

Owner:KUNSHAN BAOTRON NEW ENERGY TECH CO LTD

Composite multi-arc-hole membrane material filled with boric nitride particles as well as preparation method and application thereof

ActiveCN105206783AImprove heat resistanceImprove mechanical propertiesCell component detailsPorosityBoron nitride

The invention discloses a nano composite multi-arc-hole membrane material. The nano composite multi-arc-hole membrane material is characterized in that a polyimide (PI) nano fiber nonwoven fabric is used as a base material, and pores of the base material are filled with nano boric nitride particles; the diameter of the nano boric nitride particles falls in a range of 50nm to 100nm, and the nano boric nitride particles account for 30 to 60 percent in the total weight of the nano composite multi-arc-hole membrane material; the thickness of the PI nano fiber nonwoven fabric is ranged from 9 micrometers to 38 micrometers, and the porosity is ranged from 60 percent to 80 percent. The nano composite multi-arc-hole membrane material is resistant to high temperature, heat shrinkage, high voltage, high current impact and mechanical collision, suitable for being used as a safety cell diaphragm and a safety super capacitor diaphragm and suitable for manufacturing various high-capacity and high-power lithium cells or super capacitors. The invention also provides a preparation method of the nano composite multi-arc-hole membrane material and an application of the nano composite multi-arc-hole membrane material as a cell diaphragm.

Owner:JIANGXI NORMAL UNIV

Lithium ion battery, isolation membrane utilized by same and preparation method of isolation membrane

InactiveCN103855351AImprove high temperature internal short circuit performanceGood continuitySecondary cellsCell component detailsPhysical chemistryLithium-ion battery

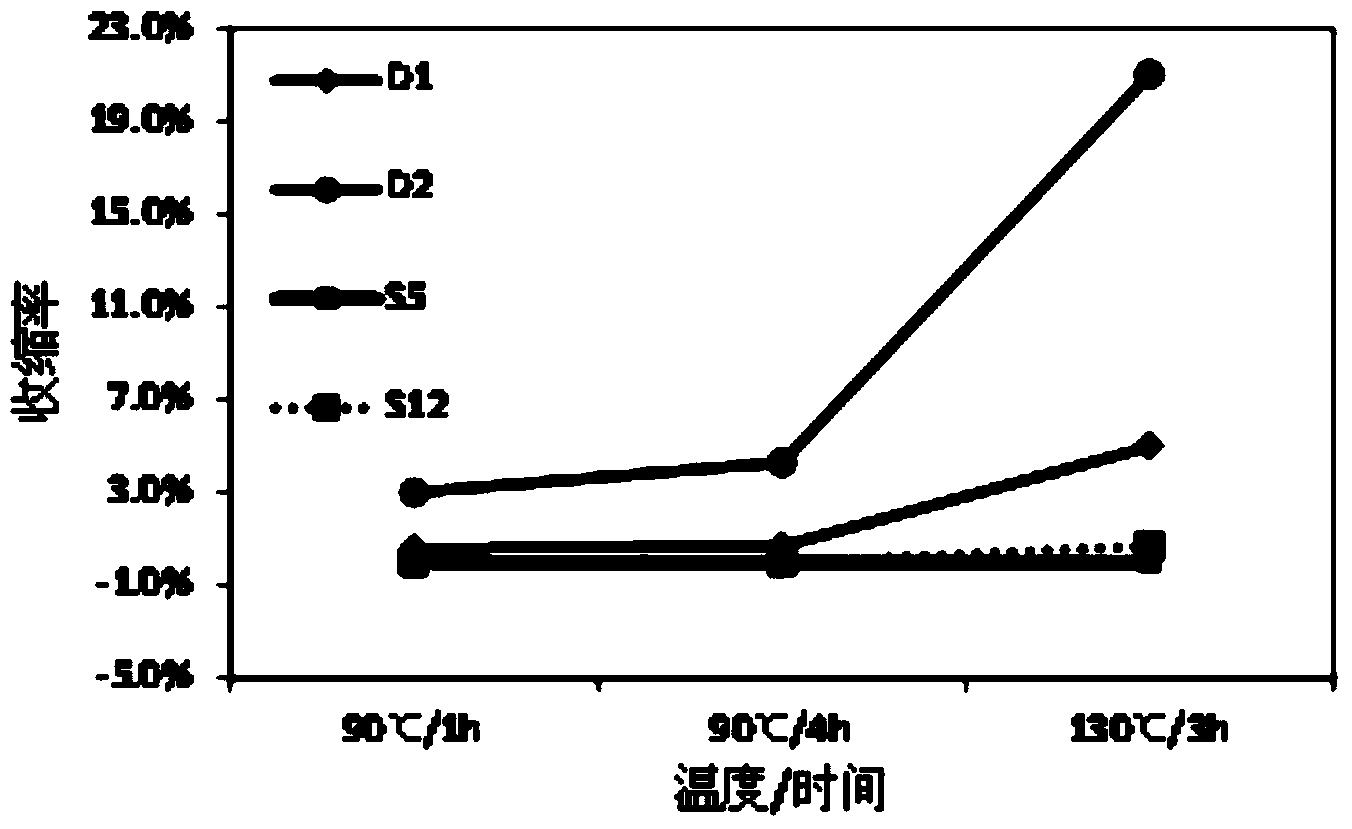

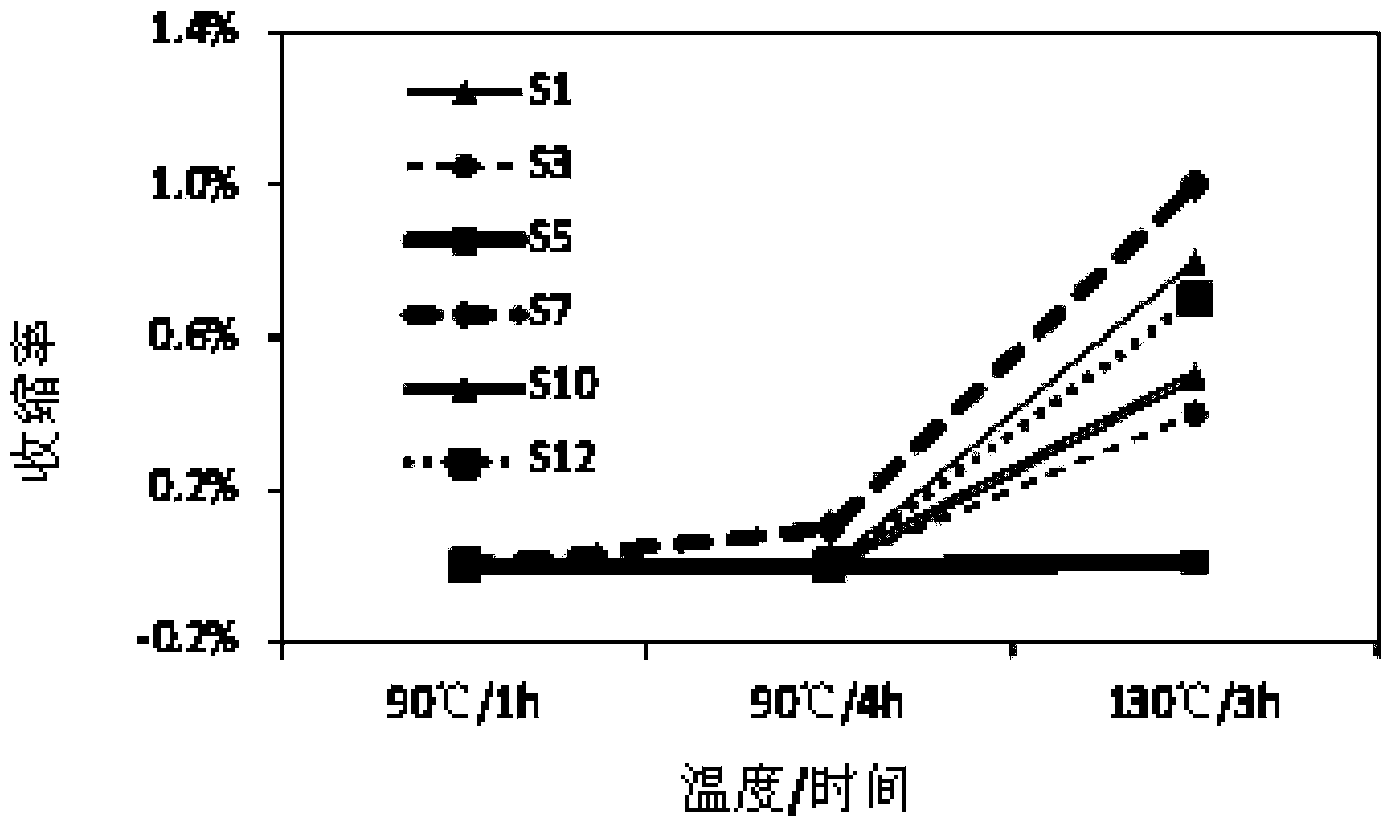

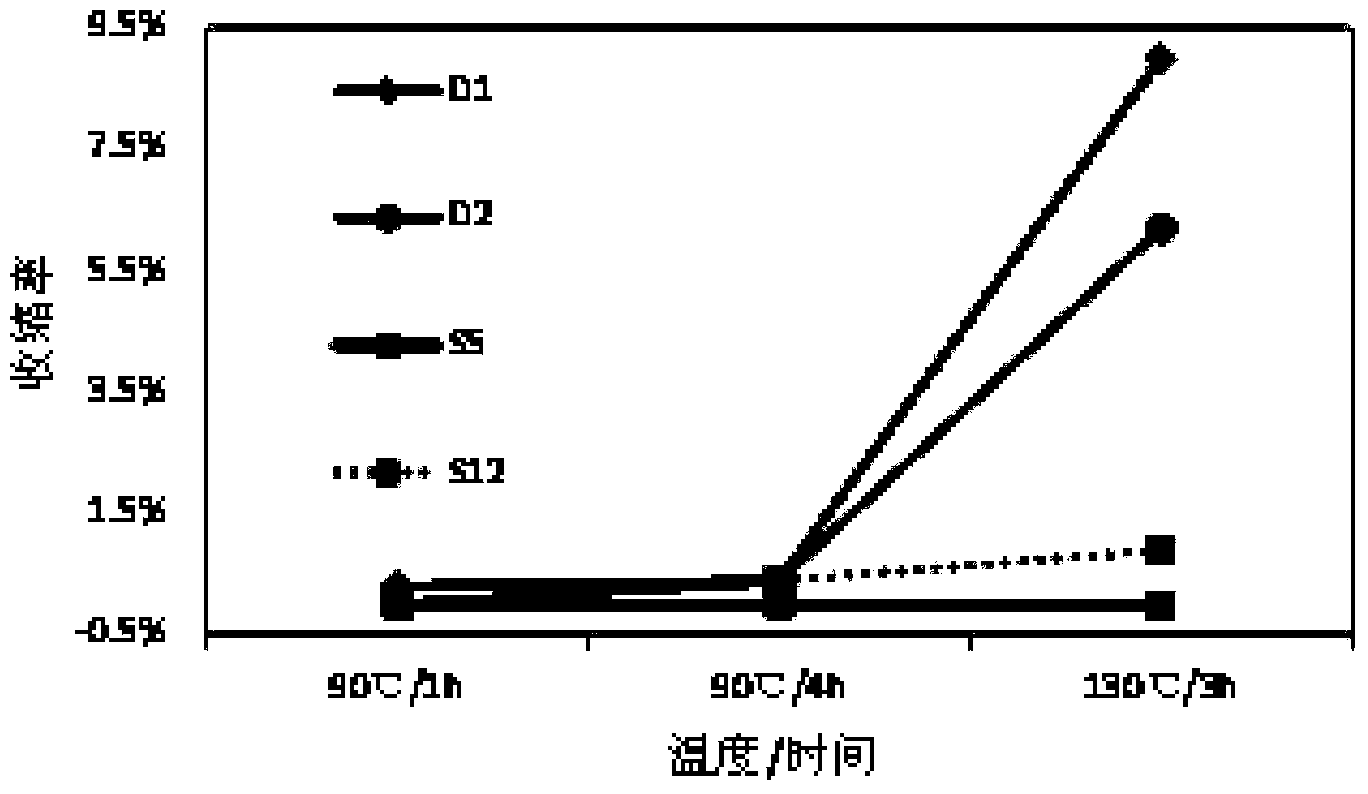

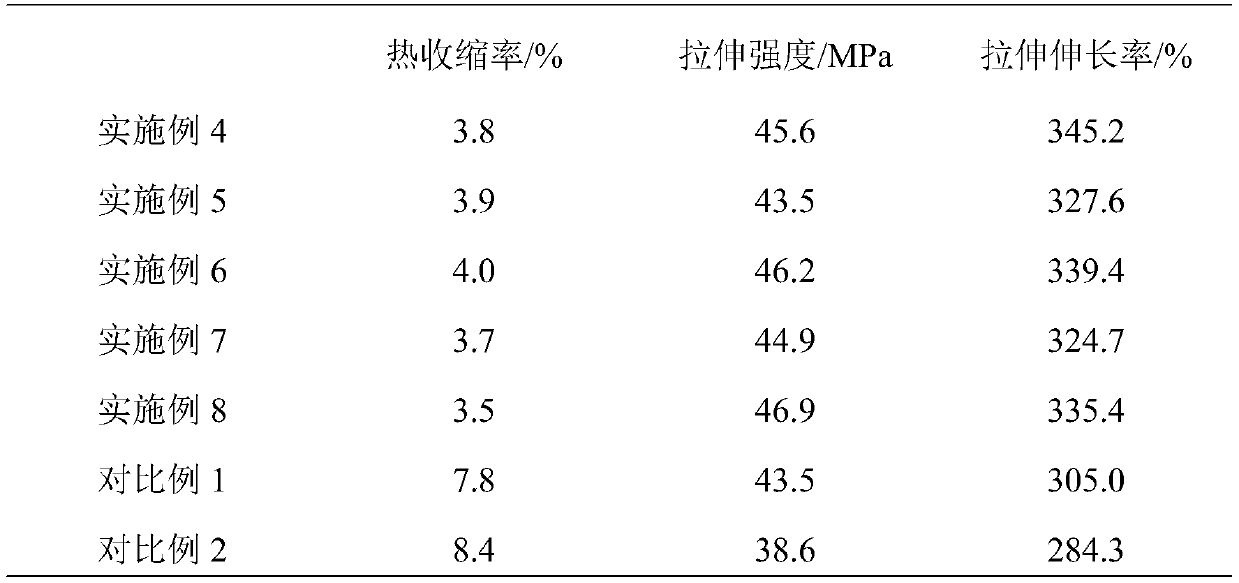

The invention discloses a lithium ion battery, an isolation membrane of the lithium ion battery and a preparation method of the isolation membrane. The isolation membrane comprises embedded copolymer resin which is formed by copolymerizing a monomer A and a monomer B, wherein the monomer A is selected from cyanate ester and derivatives of cyanate ester, and the monomer B is selected from olefin and derivatives of olefin; the thermal shrinkage of the embedded copolymer resin is smaller than 3 percent at the condition of 130DEG C / 3h. Compared with the prior art, the isolation membrane of the lithium ion battery is excellent in thermal shrinkage performance, so that the short circuit of the lithium ion battery at the high temperature can be effectively improved, and the rate performance and the cycling performance of the battery also can be improved.

Owner:DONGGUAN AMPEREX TECH

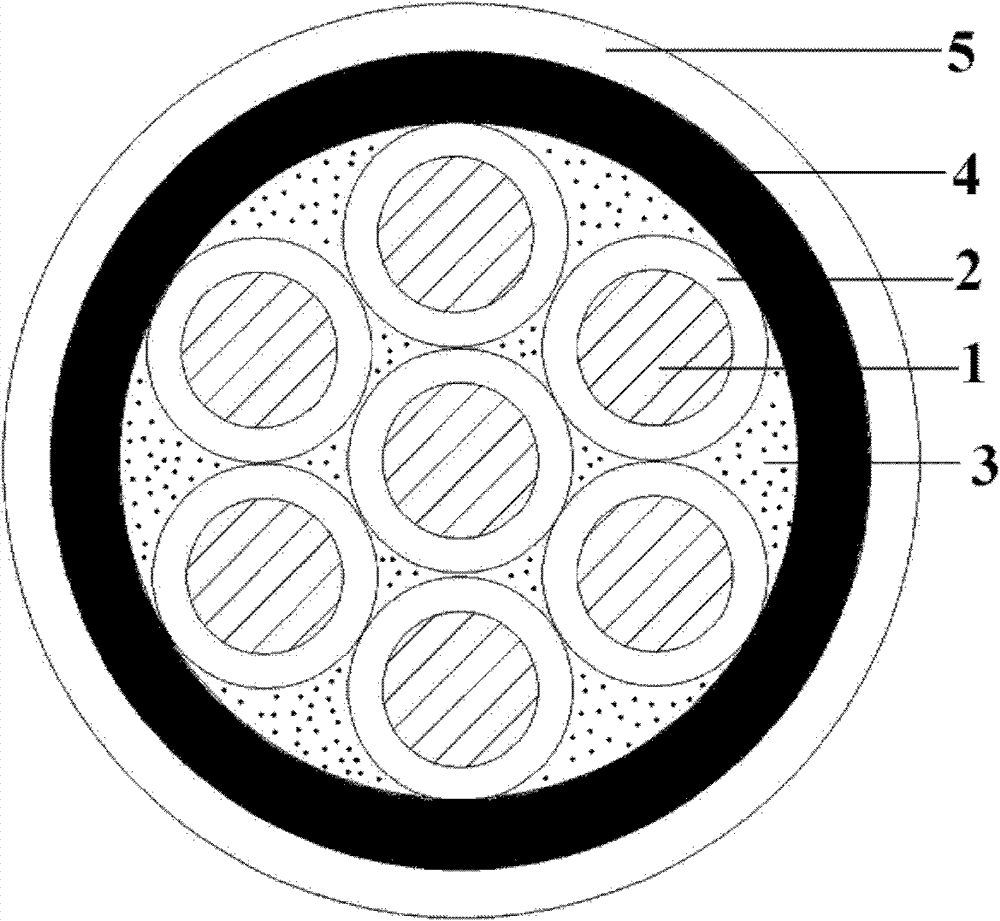

Elastic body polrvinyl chloride nylon sheathed cable

InactiveCN102956307AReduce coefficient of frictionEasy to wear tubeInsulated cablesInsulated conductorsElastomerElectrical conductor

The invention discloses an elastic body polrvinyl chloride nylon sheathed cable. The elastic body polrvinyl chloride nylon sheathed cable comprises a plurality of cable cores and sheathes, wherein the cable cores consists of conductors and insulated layers packaged at the exteriors of the conductors, and the cable cores and filling ropes are twisted to form the cable cores; and inner sheathes are pressed and packaged outside the cable cores, and outer sheathes are pressed and packaged outside the inner sheathes. According to the cable, the structure is simple, proper materials are selected, the environmental pollution is avoided, the friction coefficient of the cable is small, the tube penetration is convenient, the chemical resistance is good, and the cable has the functions of defending mice and ants; and better mechanical property can be still maintained under a rugged environment, and the service life can be up to 40 years.

Owner:江苏兴海线缆有限公司

Heat shrinkage-resistant sealing ring and preparation method thereof

The invention discloses a heat shrinkage-resistant sealing ring and a preparation method thereof. The preparation method comprises the following steps: 1) performing contact reaction on polyamide fibers, cyclodextrin, a silane coupling agent and water, then filtering, taking a filter cake and drying to prepare modified polyamide fibers; 2) performing a solvo-thermal reaction on the modified polyamide fibers, cobalt salt, alkali, urea and ethanol, then filtering, taking a filter cake and finally calcining in the presence of protective gas to prepare composite polyamide fibers; 3) mixing the composite polyamide fibers, a shell powder, attapulgite, barium sulfate whiskers and rare earth oxide to prepare a modified composition; 4) mixing styrene butadiene rubber, ethylene-propylene-diene monomer rubber, a talcum powder, zinc borate, white carbon black, white oil, aluminum hydroxide and the modified composition and forming to prepare the heat shrinkage-resistant sealing ring. The sealing ring prepared by the preparation method disclosed by the invention has excellent thermal shrinkage resistance; moreover, the preparation method has the advantages of being simple in process and easily-available in raw materials.

Owner:芜湖瑞德机械科技有限公司

Heat-shrinkage-resistant sealing ring and preparation method thereof

InactiveCN111117121AImproved resistance to heat shrinkageImprove mechanical propertiesFibre typesFiberPolymer science

The invention provides a heat-shrinkage-resistant sealing ring and a preparation method thereof. Fluoroether rubber and polyacrylate rubber are adopted as main materials and have excellent high-temperature resistance and aging resistance, so that the sealing ring has good high-temperature resistance, and it can be guaranteed that the sealing ring still has good mechanical properties after being subjected to high-temperature treatment; sodium gluconate can improve the size stability of the sealing ring; a modified fiber is used for improving the dimensional stability of the sealing ring and improving the shrinkage resistance of the sealing ring; double-vinyl-terminated silicone oil is used for improving the toughness of the rubber and improving the sealing performance of the sealing ring; and polyallylamine hydrochloride can improve the mechanical stability of the sealing ring, so that the sealing ring has excellent shrinkage resistance. Experimental results show that the heat-resistantand oil-resistant sealing ring has excellent shrinkage resistance, mechanical properties and the like. The preparation method is simple, and the prepared heat-shrinkage-resistant sealing ring has excellent heat shrinkage resistance and mechanical properties.

Owner:河北新尔特橡塑密封有限公司

Composite porous membrane material filled with alumina particles and its preparation method and application

ActiveCN105098125BSmall surface pore sizeReduce porosityHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersMicro nanoFiber

The invention discloses a micro-nano composite multi-curvature membrane material, which uses polyimide (PI) nanofiber non-woven fabric as a base material, and the pores of the base material are filled with micro-nano Al2O3 particles; the micro-nano Al2O3 The particles have a diameter between 50-800nm and account for 20-50% of the total weight of the micro-nano composite multi-curved pore membrane material; the micro-nano composite multi-curved pore membrane material has a porosity between 30-60% , the average surface pore diameter is between 50-800nm, and the thickness is between 10-40μm. The micro-nano composite multi-curved hole membrane material provided by the invention is resistant to high temperature, thermal shrinkage, high voltage and high current impact, and mechanical impact resistance, and is suitable for use as a safety battery separator and a safety supercapacitor separator to manufacture various high-capacity and High power lithium battery or supercapacitor. The invention also provides a preparation method of the nanocomposite multi-curvature membrane material and its application as a battery separator.

Owner:JIANGXI ADVANCED NANOFIBER S&T CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com