Functional coating material component of isolating membrane for power battery and preparation method thereof

A coating material and power battery technology, applied in coatings, polyamide coatings, polyurea/polyurethane coatings, etc., can solve the problem of battery life and safety reduction, poor thermal shrinkage resistance of the isolation film, and poor electrical conductivity of the isolation film and other issues, to achieve the effect of improving performance, good heat shrinkage resistance, and improving puncture strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

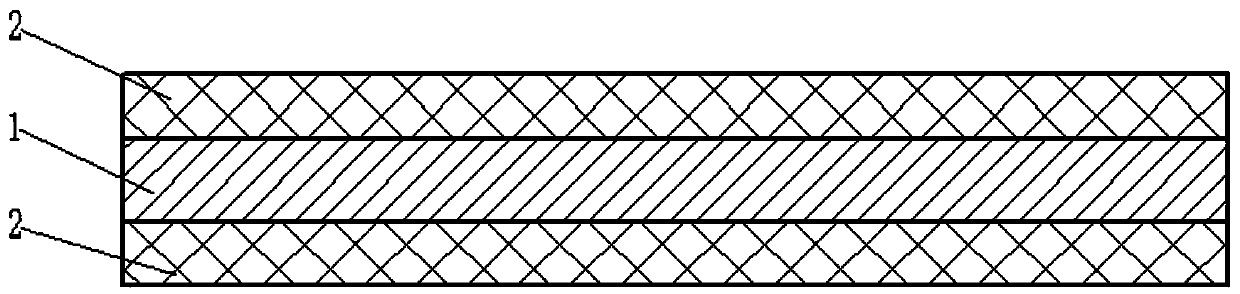

[0028] see figure 1 , a functional coating material assembly for a power battery separator, comprising a base film 1 and a coating layer 2; the coating layer material is composed of the following components, in parts by mass: nano-scale aluminum oxide 30 parts; 30 parts of aramid fiber; 10 parts of polymer emulsion; 5 parts of porous polyimide nanofiber; 5 parts of nanoporous shell powder and diatom mud; 5 parts of crosslinking agent; 1 part of water-based fluorine leveling agent; 2 parts of agent; 1 part of stabilizer.

[0029] The base film 1 adopts an ethylene-propylene copolymerized polymer membrane with micropores evenly arranged on the surface;

[0030] The polymer emulsion is selected as one or more of polyacrylate silicone acrylic emulsion or polyurethane;

[0031] The crosslinking agent is one or more of divinylbenzene, diisocyanate, acrylamide, aziridine crosslinking agent or peroxide crosslinking agent;

[0032] Described water-based fluorine leveling agent is a ...

Embodiment 2

[0041] see figure 1 , a functional coating material assembly for a power battery separator, comprising a base film 1 and a coating layer 2; the coating layer material is composed of the following components, in parts by mass: nano-scale aluminum oxide 35 parts; 35 parts of aramid fiber; 15 parts of polymer emulsion; 8 parts of porous polyimide amine nanofiber; 8 parts of nanoporous shell powder and diatom mud; 8 parts of crosslinking agent; 2 parts of water-based fluorine leveling agent; 4 parts of dispersant; 2 parts of stabilizer.

[0042] The base film 1 adopts an ethylene-propylene copolymerized polymer membrane with micropores evenly arranged on the surface;

[0043] The material used in the polymer emulsion is one or more of polyacrylate silicone acrylic emulsion or polyurethane;

[0044] The crosslinking agent is one or more of divinylbenzene, diisocyanate, acrylamide, aziridine crosslinking agent or peroxide crosslinking agent;

[0045] Described water-based fluorin...

Embodiment 3

[0054] see figure 1, a functional coating material assembly for a power battery separator, comprising a base film 1 and a coating layer 2; the coating layer material is composed of the following components, in parts by mass: nano-scale aluminum oxide 40 parts; 40 parts of aramid fiber; 20 parts of polymer emulsion; 10 parts of porous polyimide nanofiber; 10 parts of nanoporous shell powder and diatom mud; 10 parts of crosslinking agent; 5 parts of water-based fluorine leveling agent; 5 parts of agent; 3 parts of stabilizer.

[0055] The base film 1 adopts an ethylene-propylene copolymerized polymer membrane with micropores evenly arranged on the surface;

[0056] The polymer emulsion is selected as one or more of polyacrylate silicone acrylic emulsion or polyurethane;

[0057] The crosslinking agent is one or more of divinylbenzene, diisocyanate, acrylamide, aziridine crosslinking agent or peroxide crosslinking agent;

[0058] Described water-based fluorine leveling agent i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com