Natural fiber woven environment-friendly sun-shading fabric and production process thereof

A natural fiber and production process technology, applied in textile and papermaking, fabric surface trimming, heating/cooling fabrics, etc., can solve the problems of cumbersome production process of sunshade fabrics, lower limit oxygen index, poor fabric degradation ability, etc., and achieve excellent environmental protection. The effect of flame retardant performance, smooth hand feeling, and antibacterial ability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

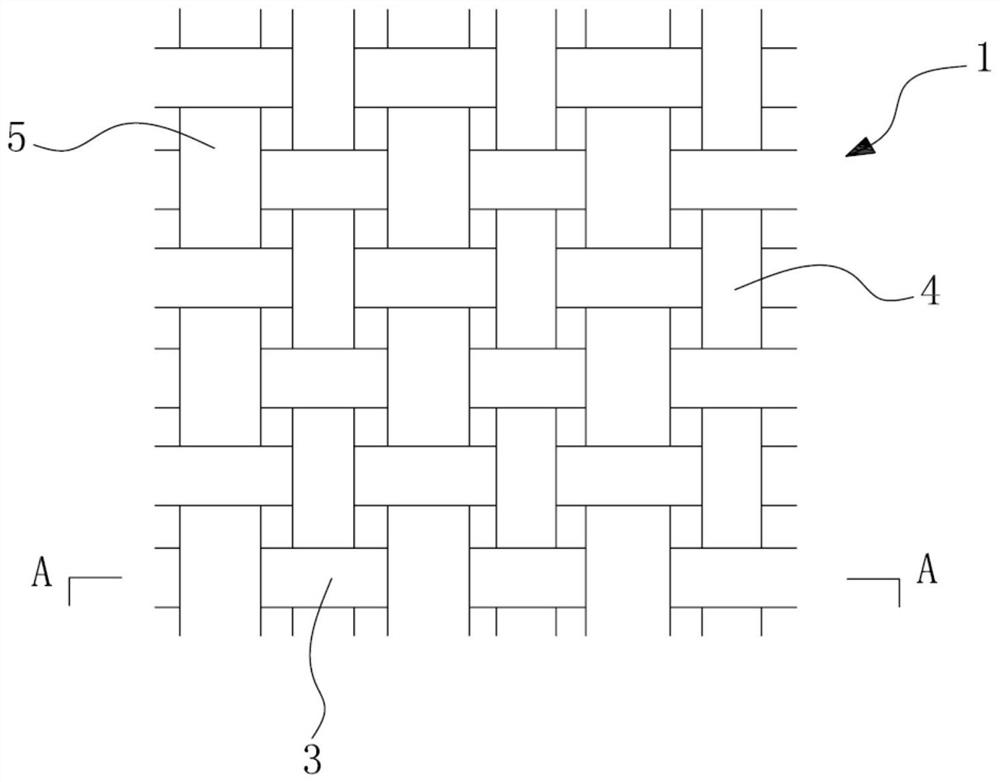

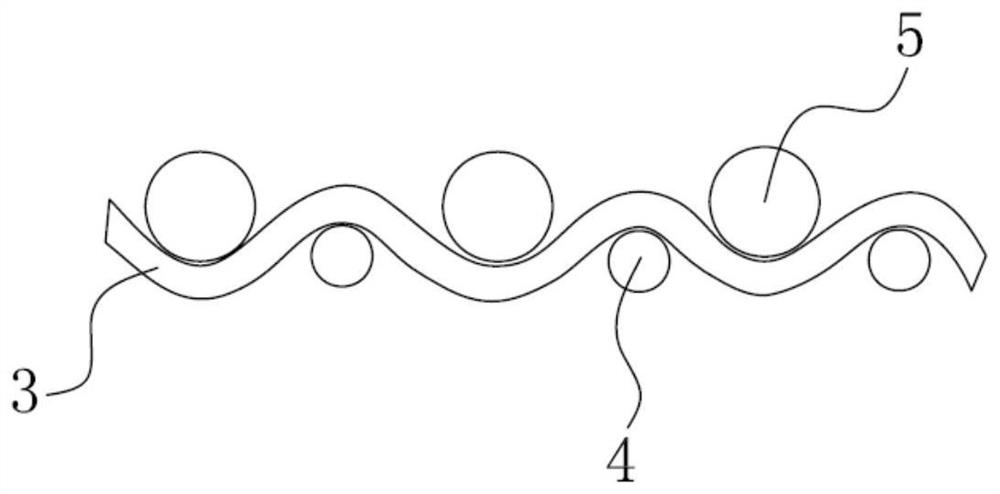

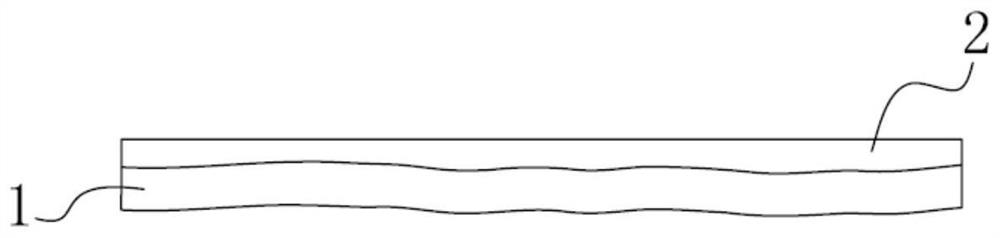

[0040] like figure 1 , 2 , 3, a natural fiber weaving environment-friendly sunshade fabric, the fabric includes a weaving layer 1 woven from warp yarns and weft yarns, at least one surface of the weaving layer 1 is coated with a transparent and flame-retardant coating Layer 2, weaving layer 1 is a plain weave structure with a three-dimensional structure composed of warp yarns 3 and weft yarns interwoven with warp yarns 3. The warp yarns are low-fusible yarns, and the weft yarns include low-fusible yarns. Hemp fiber yarn 5 for alternate weaving. In this embodiment, the warp yarn and the weft yarn have the same low fuse fineness, and the fineness is 50D. The hemp fiber yarn adopts hemp yarn, and the wire diameter of the hemp yarn is 0.32mm. Set the density of the weft yarn to 65 yarns / inch, and the density of the warp yarn to 100 yarns / inch, and the final weight of the fabric is 152g / m 2 , the thickness is 0.38-0.56mm, and the opening rate of the control fabric is 5%. The l...

Embodiment 2

[0052] The similarities with Embodiment 1 will not be repeated, but the difference is that in this embodiment, flax yarn is used as the hemp fiber yarn; the fineness of the low-fuse filament is 70D, and the diameter of the flax yarn is 0.5mm. The density of the warp yarn is 90 threads / inch, and the weight of the obtained fabric is 168g / m 2 , the thickness is 0.38-0.56mm, and the opening rate of the fabric is 3%. The low fuse in this embodiment uses polyamide (PA).

[0053] In this embodiment, the coating of the coating layer is prepared from the following components by weight percentage: 6.32% of acrylic emulsion with a concentration of 45% by mass; 20.51% of acrylic emulsion with a concentration of 50% by mass; flame retardant 60.68% %; Wetting agent 3.81%; Defoamer 0.52%; Thickener 3.48%; Ammonia 2.79%;

[0054] The preparation method of the coating is first to mix the acrylic emulsion with a concentration of 45% by mass, the acrylic emulsion with a concentration of 50% by...

Embodiment 3

[0057] The similarities with Embodiment 1 will not be repeated, the difference is that the diameter of the hemp yarn in this embodiment is 0.6mm. Set the density of the weft yarn to 65 yarns / inch, and the density of the warp yarn to 110 yarns / inch, and the final weight of the fabric is 165g / m 2 , The low fuse adopts polyamide (PA).

[0058]In this embodiment, the coating of the coating layer is prepared from the following components by weight percentage: 8.18% of acrylic emulsion with a concentration of 45% by mass; 24.1% of acrylic emulsion with a concentration of 50% by mass; flame retardant 55.86% %; Wetting agent 3.38%; Defoamer 0.29%; Thickener 1.23%; Ammonia 3.56%;

[0059] The preparation method of the coating is first to mix the acrylic emulsion with a concentration of 45% by mass, the acrylic emulsion with a concentration of 50% by mass, a flame retardant, a wetting agent, a defoamer, 0.56% by weight of water, a thickener , the weight percent is 2.84% water, and amm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com